Patents

Literature

37 results about "Complex joint" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Complex joint. a joint composed of three or more skeletal elements, or in which two anatomically separate joints function as a unit. For example, the talonavicular and calcaneocuboid joints act together as the compound transverse tarsal joint.

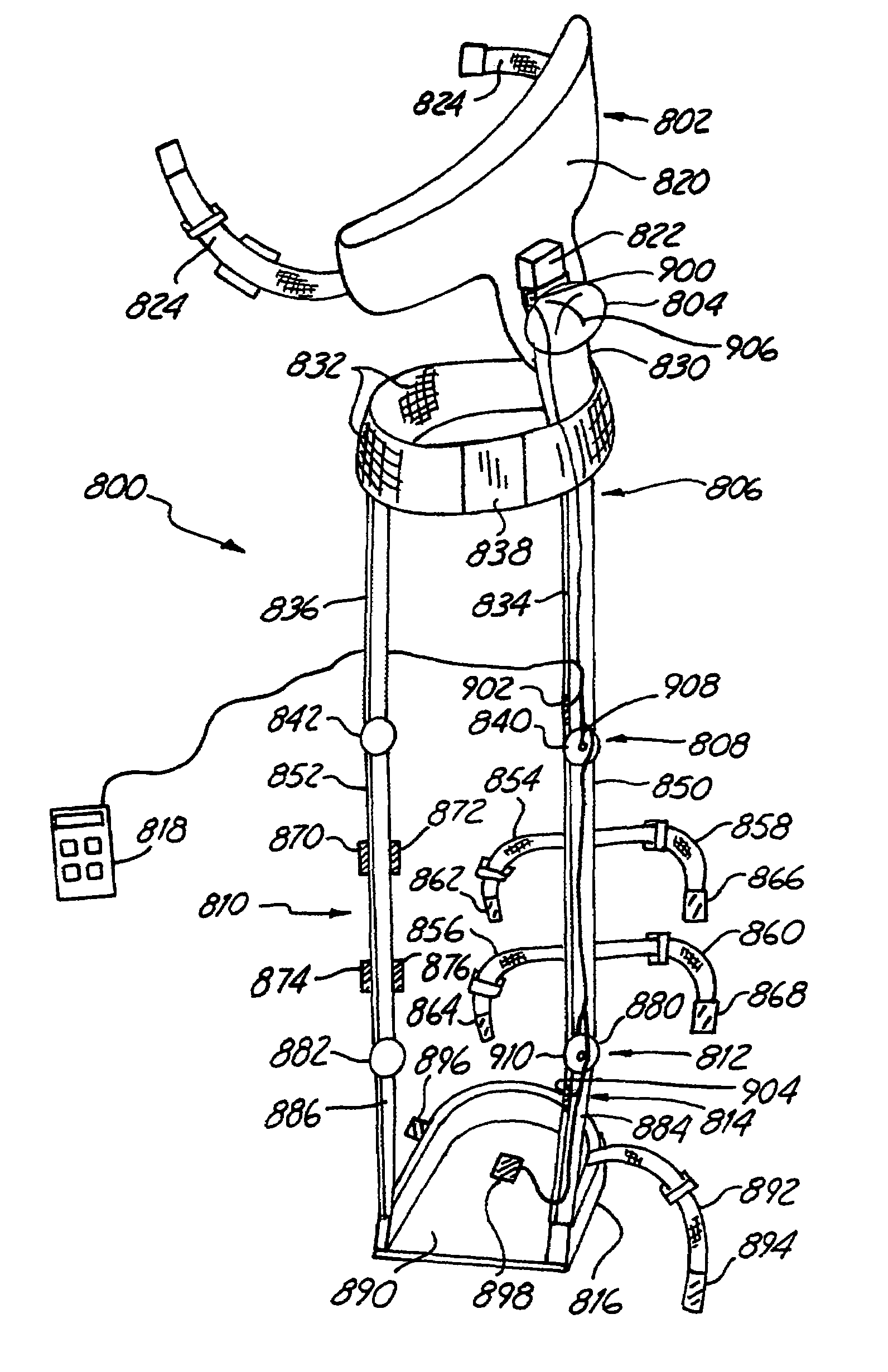

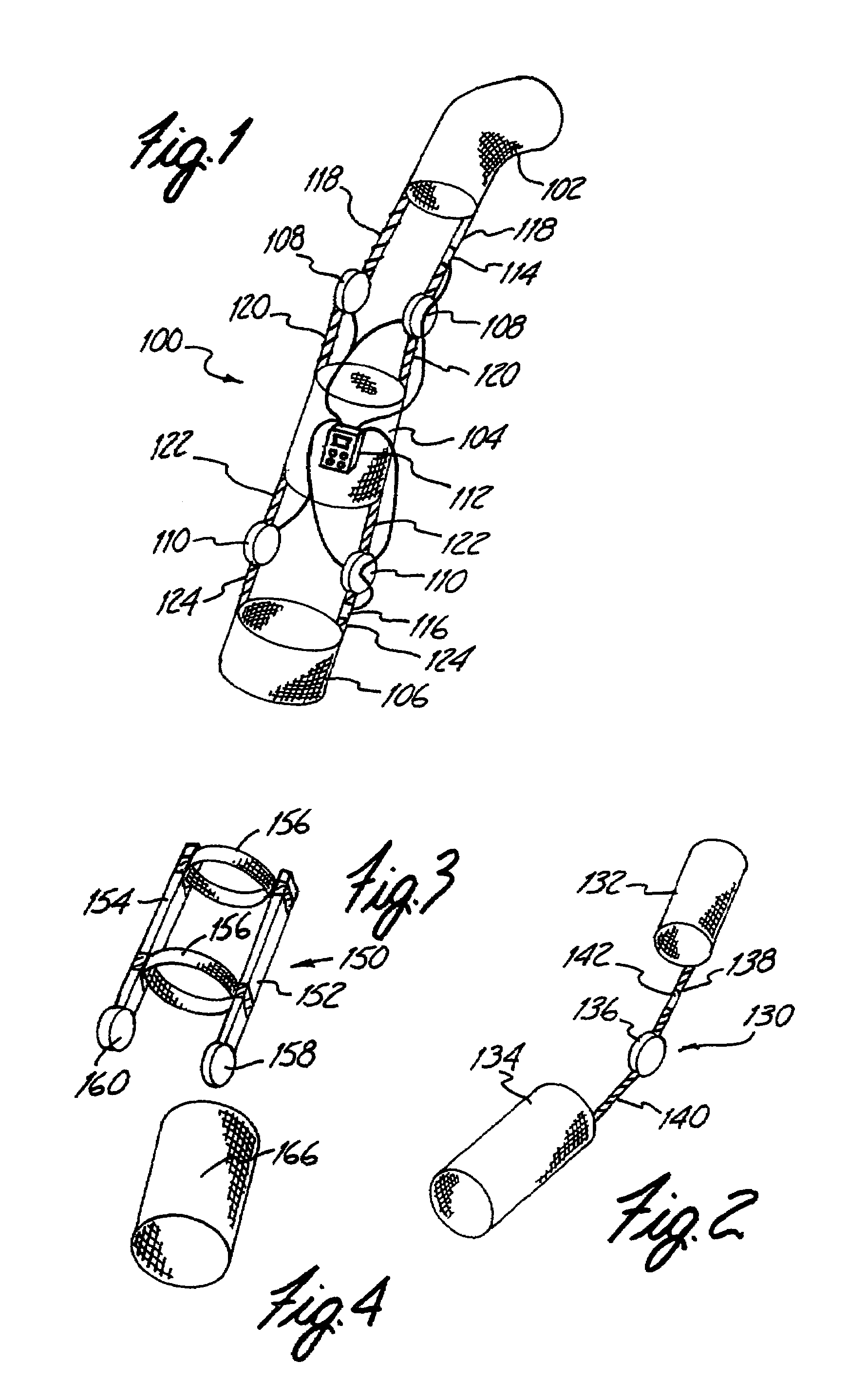

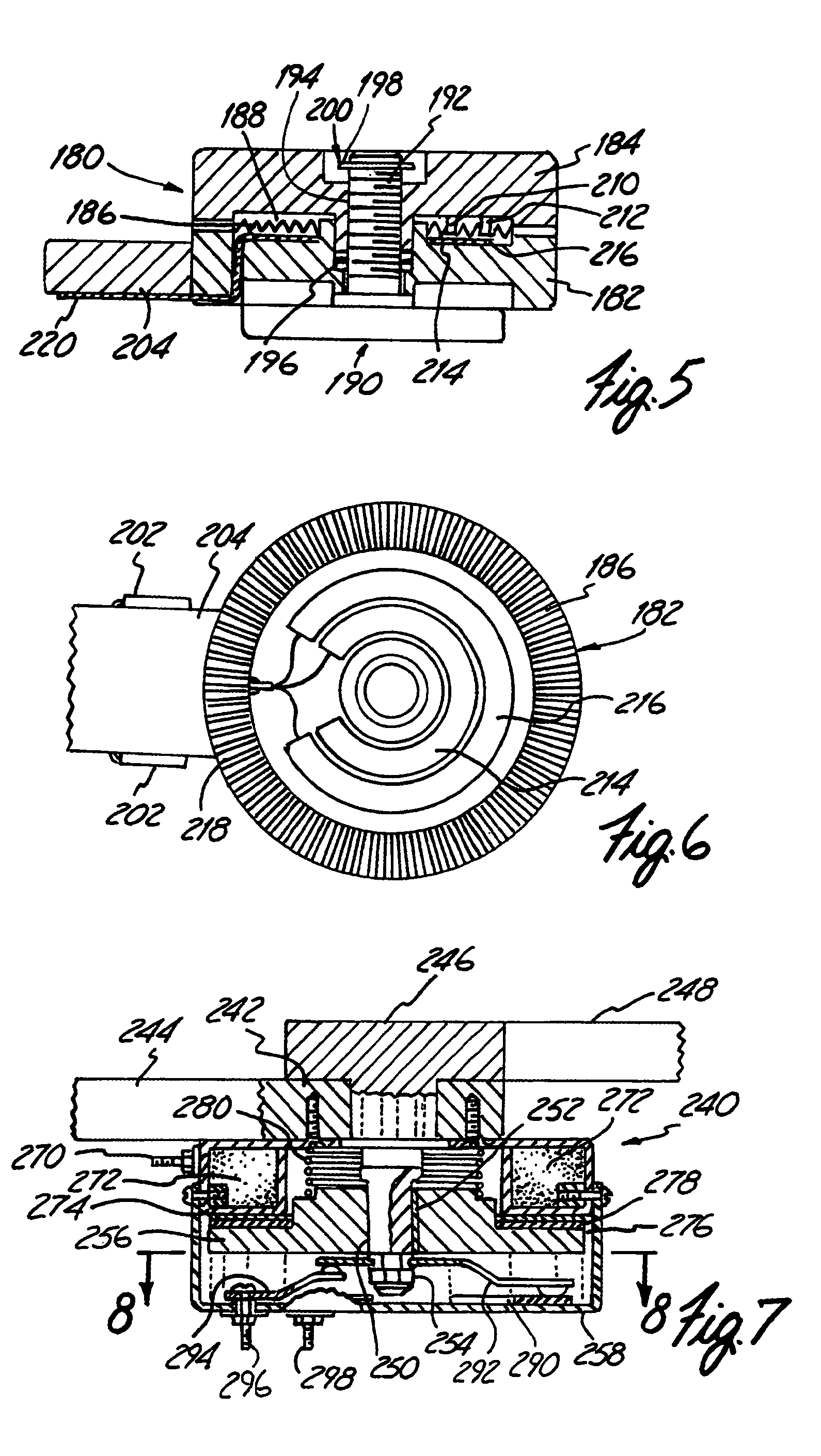

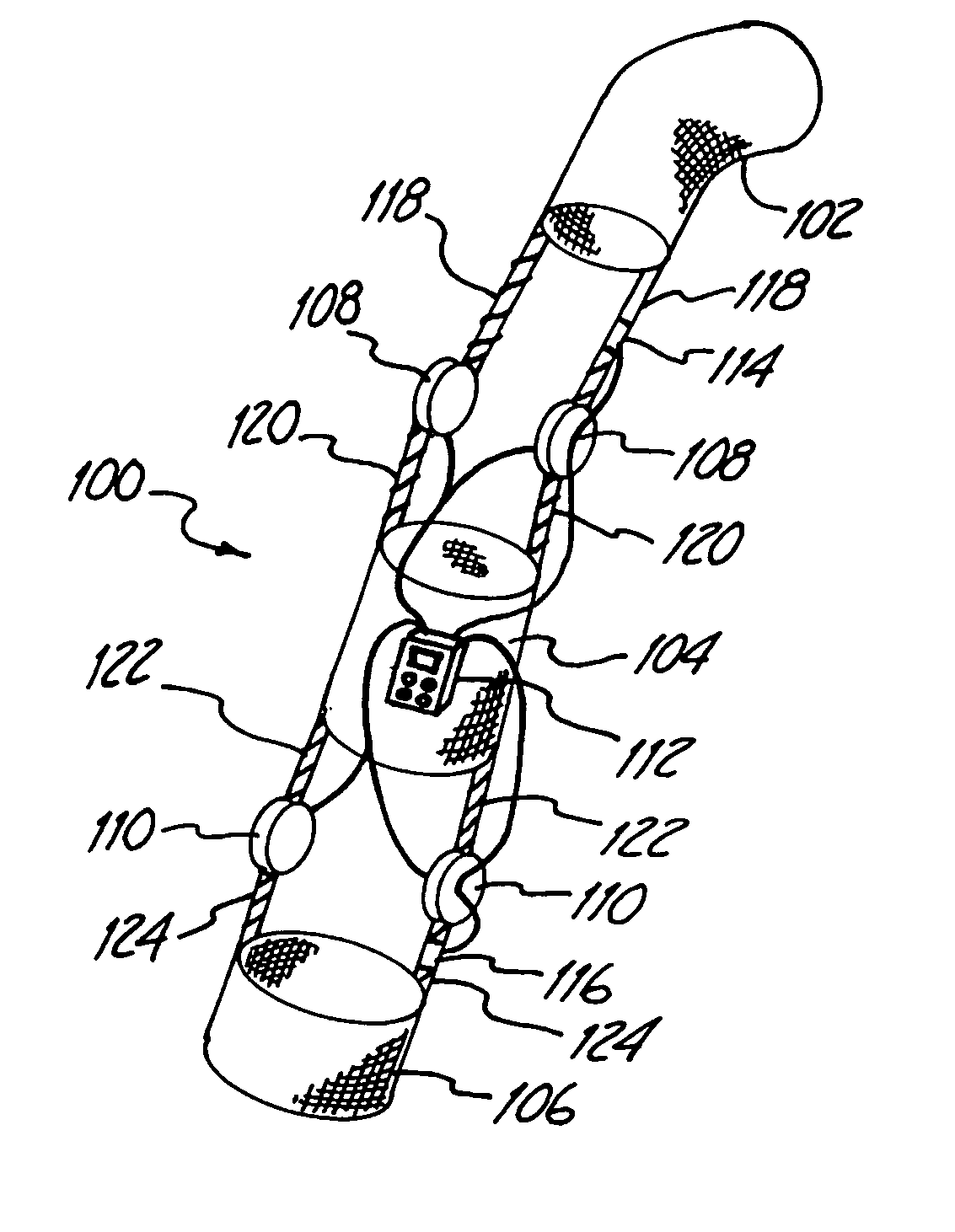

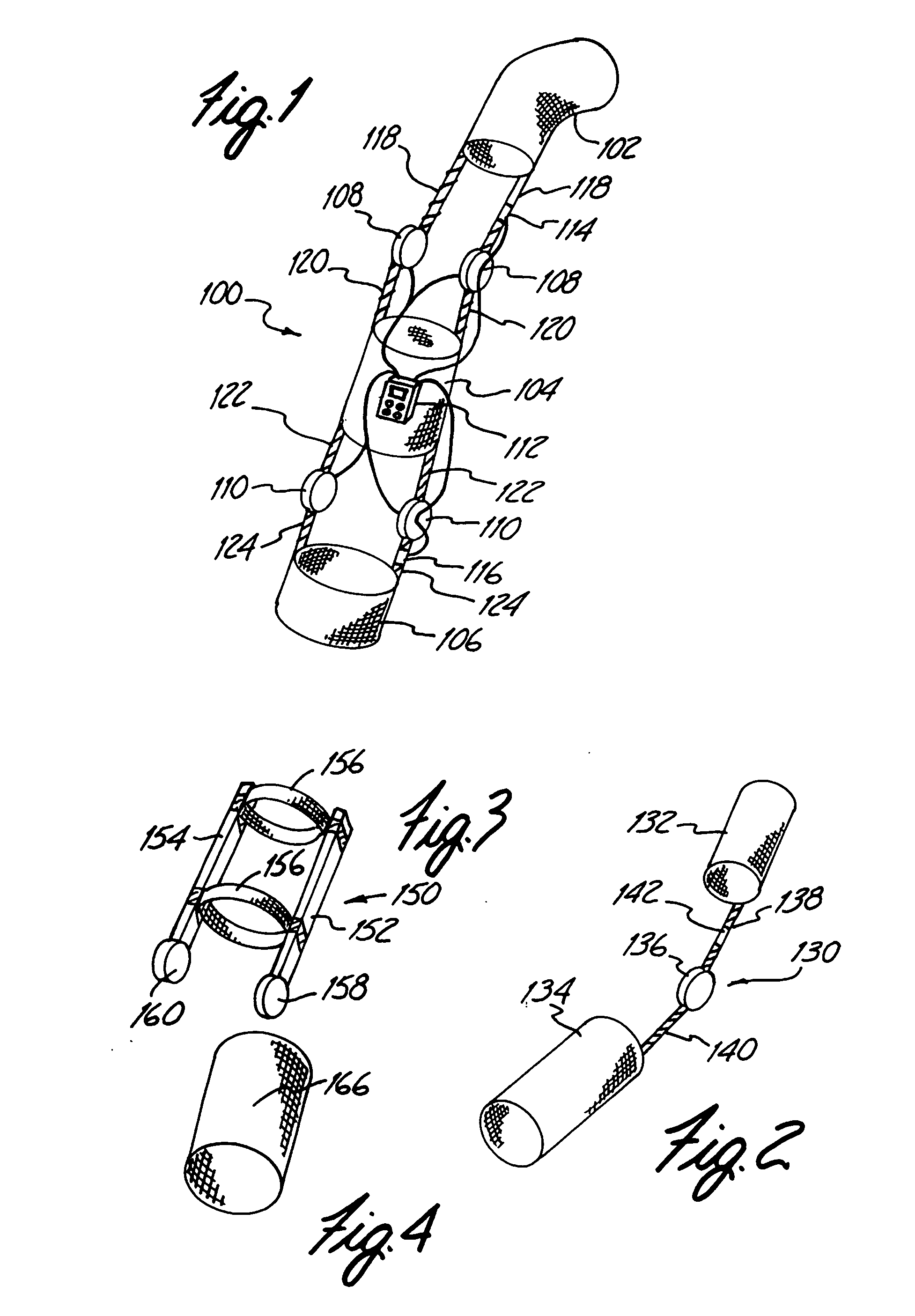

Rehabilitative orthoses

Instrumented orthoses with more sophisticated structures provide for coordinated support and rehabilitation of complex joints and multiple injured joints. Improved instrumented orthoses can include hinges that can rotate in multiple different planes. Particularly preferred embodiments include a shoulder brace with a hand hold and a lower extremities brace. Preferably, a control unit monitors the output of transducers used to instrument the brace. A patient can be prompted by the control unit for the performance of a variety of different monitored exercises.

Owner:IZEX TECH

Remote psychological evaluation

Instrumented orthoses with more sophisticated structures provide for coordinated support and rehabilitation of complex joints and multiple injured joints. Improved instrumented orthoses can include hinges that can rotate in multiple different planes. Particularly preferred embodiments include a shoulder brace with a hand hold and a lower extremities brace. Preferably, a control unit monitors the output of transducers used to instrument the brace. A patient can be prompted by the control unit for the performance of a variety of different monitored exercises.

Owner:IZEX TECH

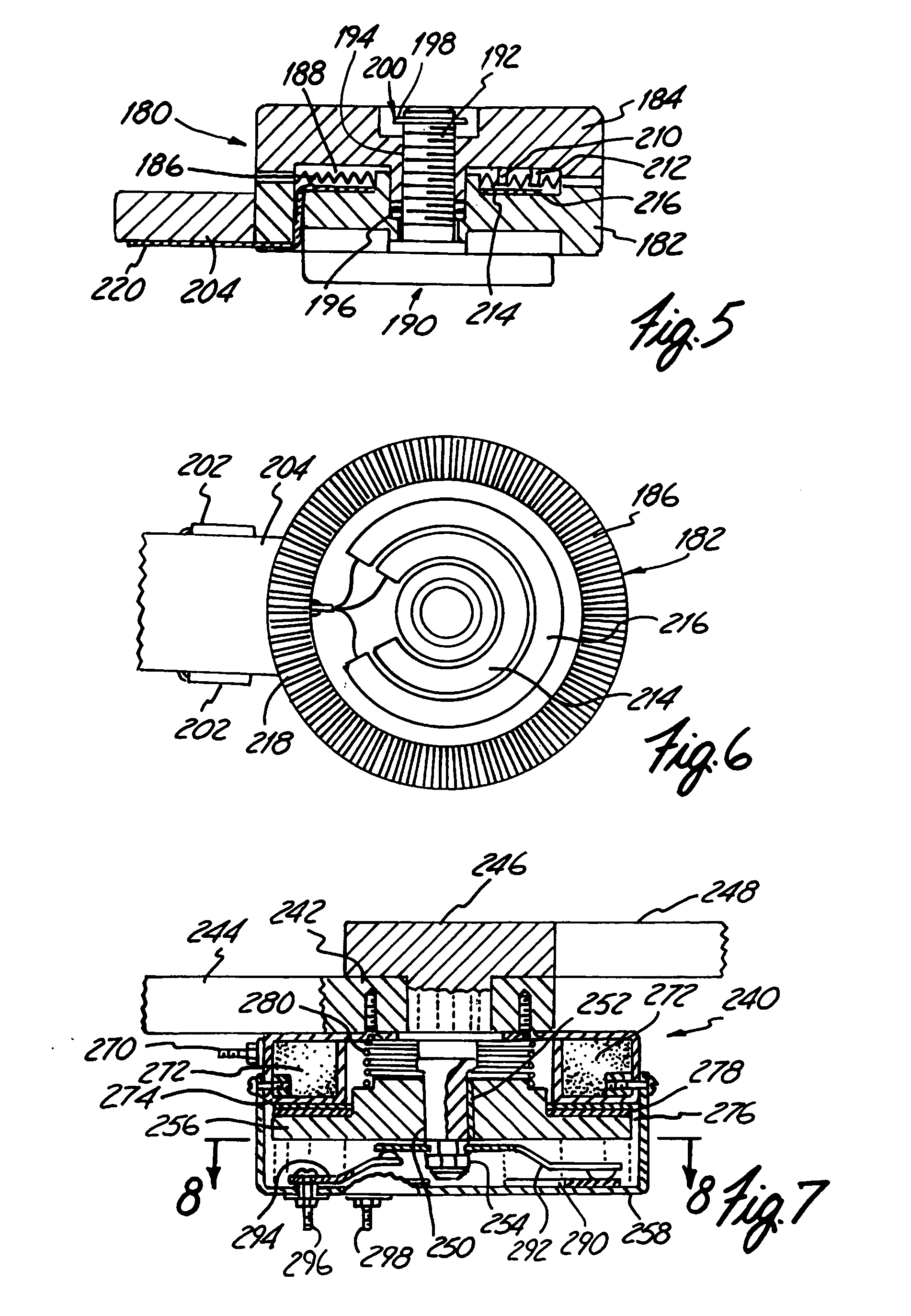

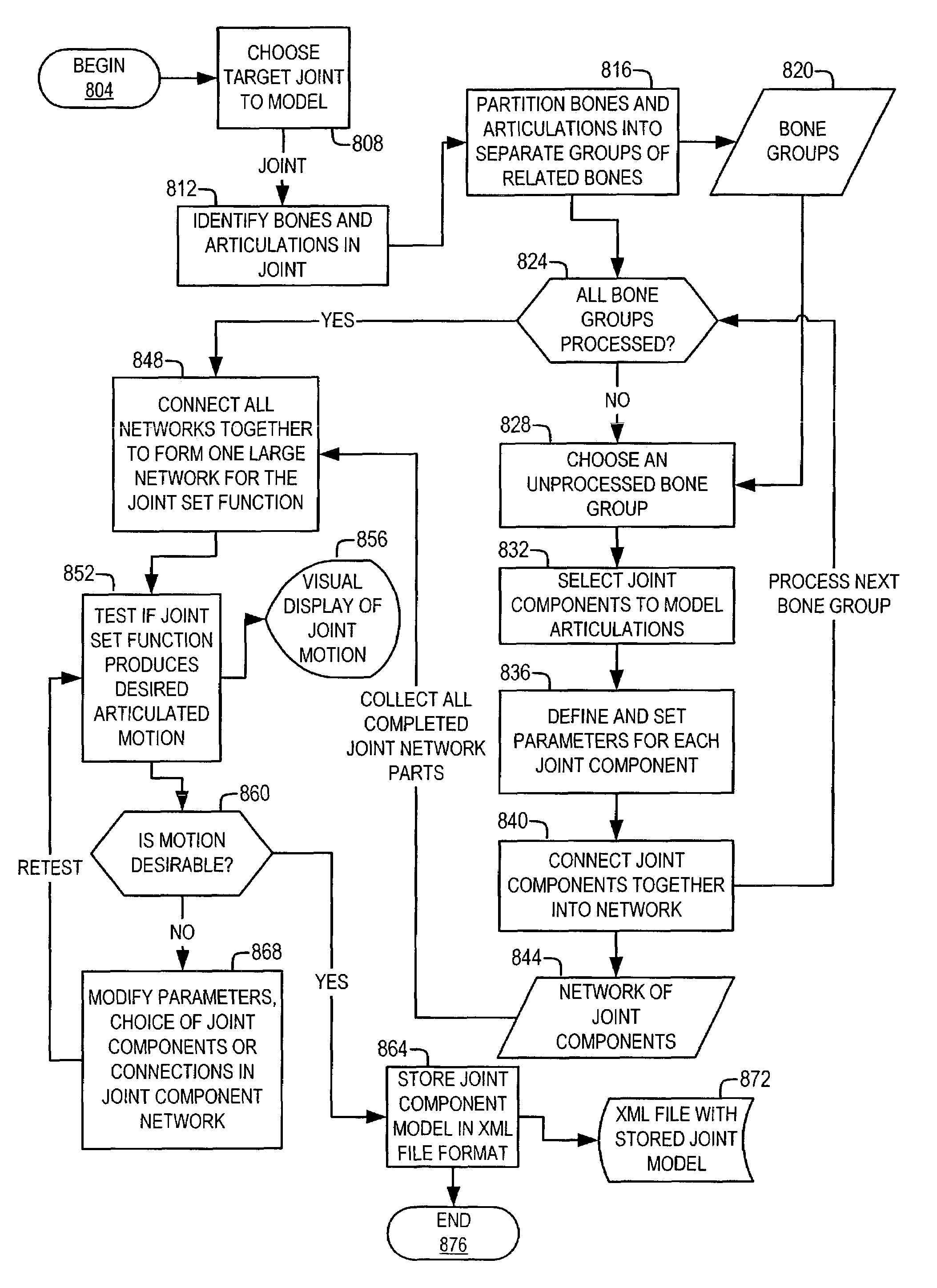

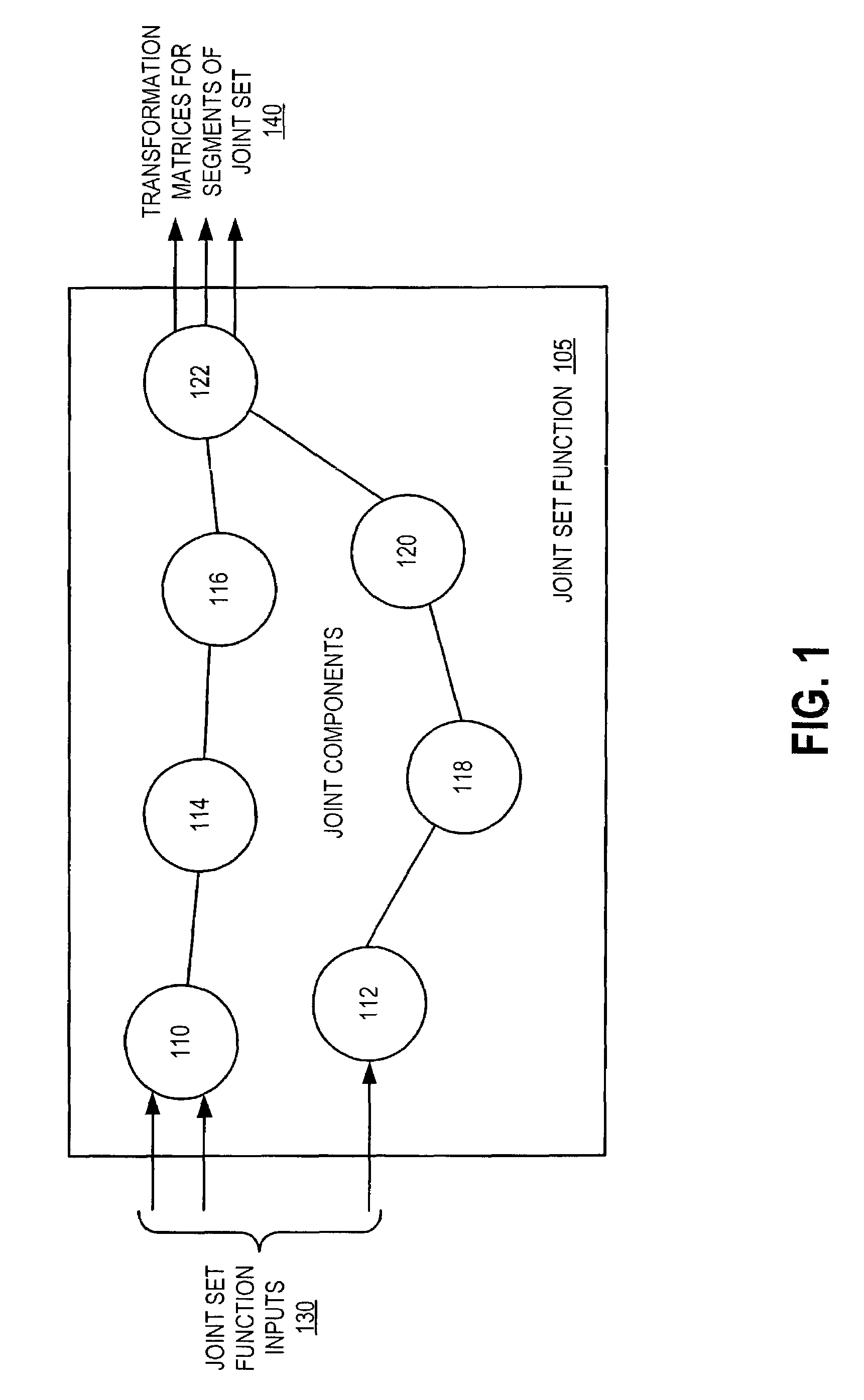

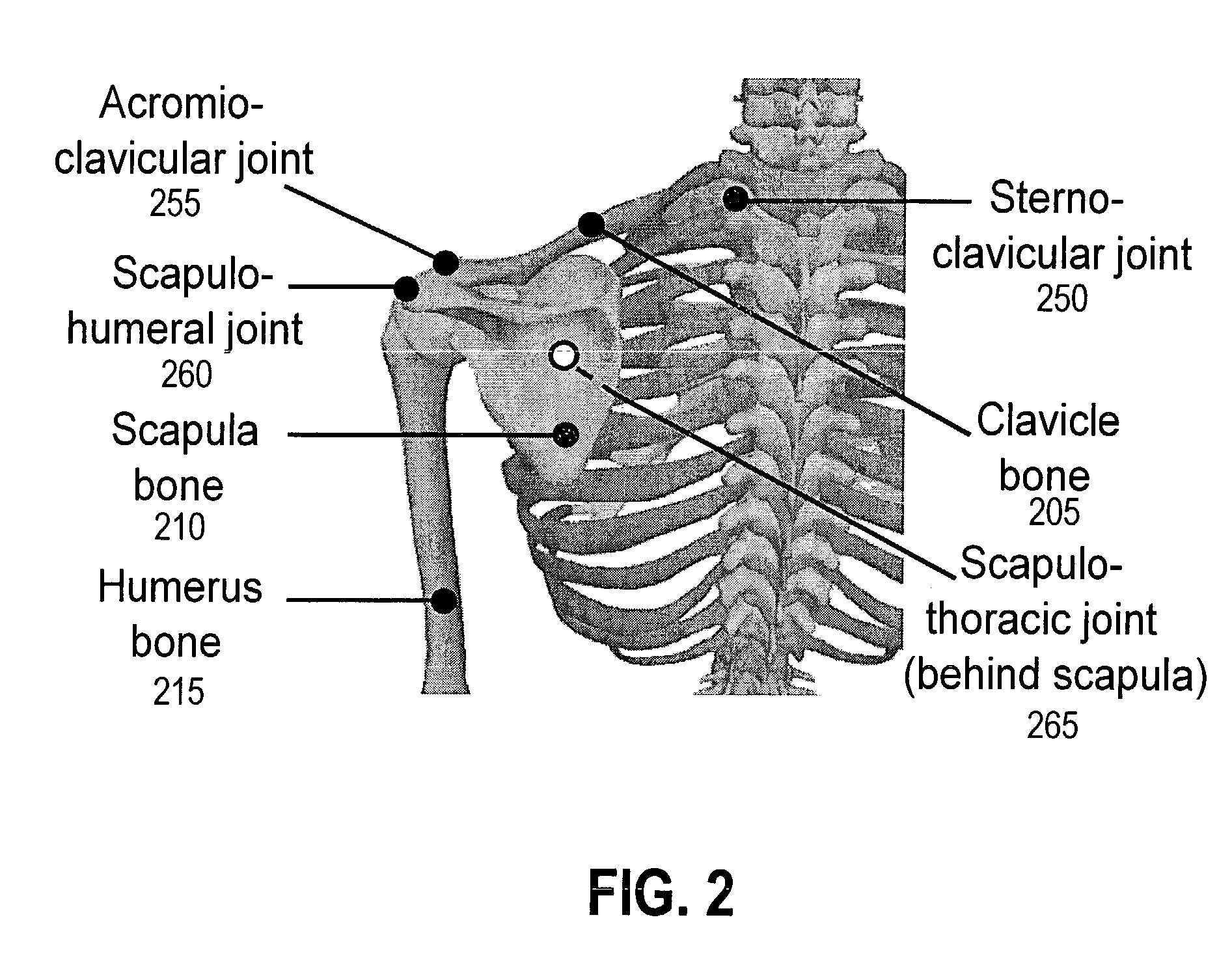

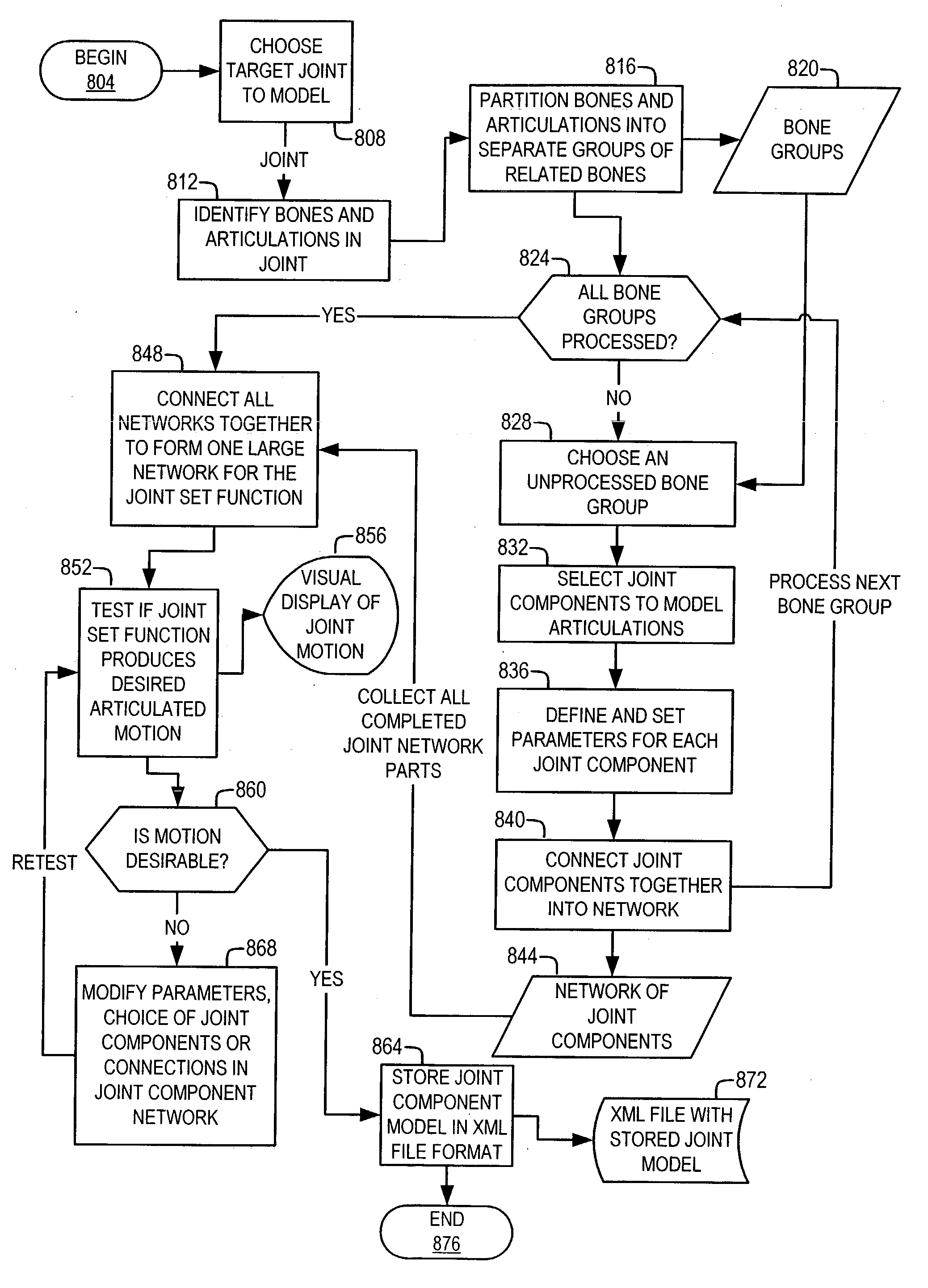

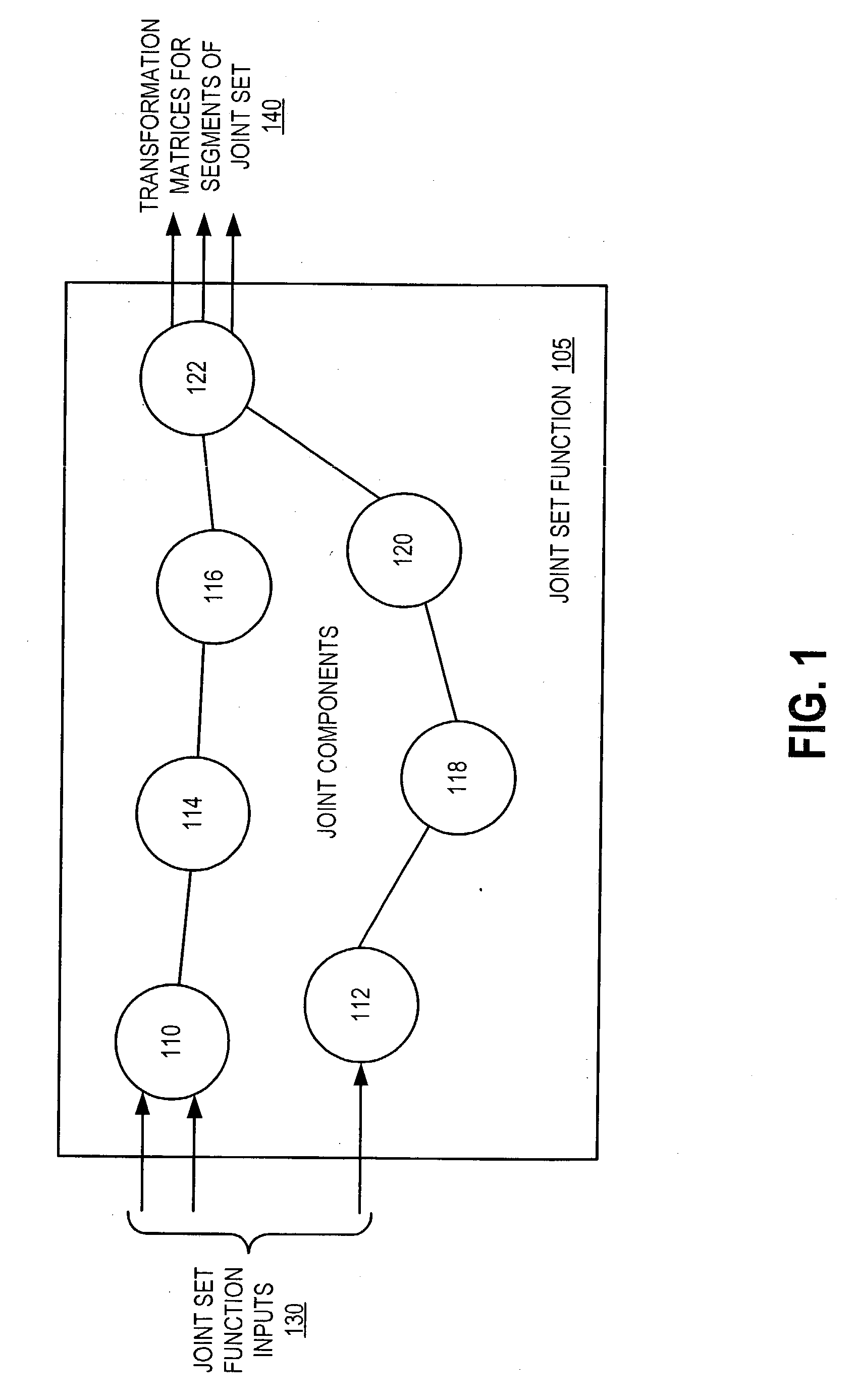

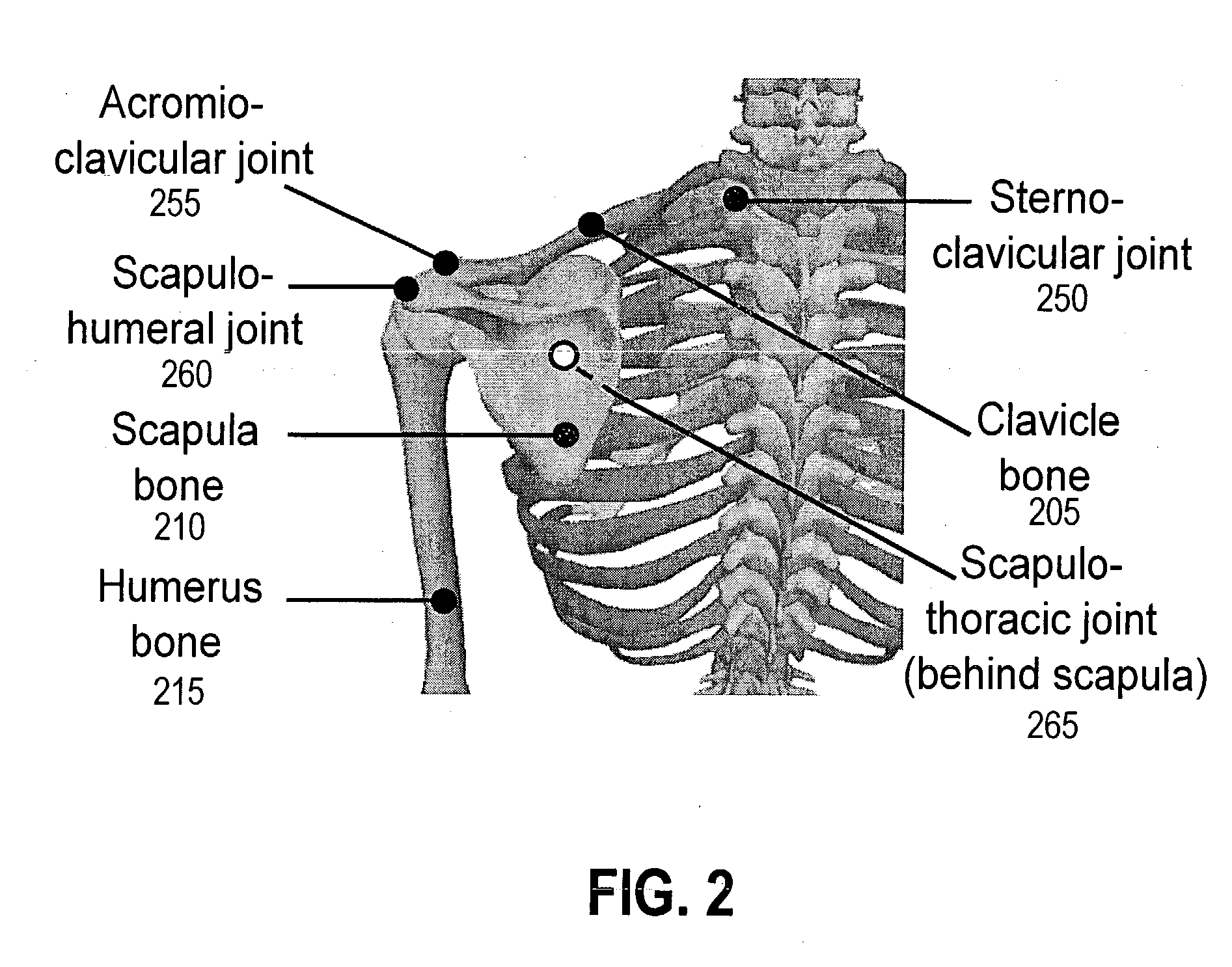

Joint component framework for modeling complex joint behavior

ActiveUS7333111B2Improve accuracySufficiently compactAnimationImage generationJoint componentKinematics

A general joint component framework that is capable of exhibiting complex behaviors of joints in articulated figures is provided. A network of joint components is used to model the kinematics of a joint. A joint builder can specify parameters for each of the joint components and join the joint components to form a joint set function that captures the biomechanical dependencies between the components. The joint function has fewer inputs than the total number of possible articulations yielding both simple control and biomechanically accurate joint movement.

Owner:HONDA MOTOR CO LTD

Joint component framework for modeling complex joint behavior

ActiveUS20060061574A1Improve accuracySufficiently compactAnimationImage generationJoint componentKinematics

A general joint component framework that is capable of exhibiting complex behaviors of joints in articulated figures is provided. A network of joint components is used to model the kinematics of a joint. A joint builder can specify parameters for each of the joint components and join the joint components to form a joint set function that captures the biomechanical dependencies between the components. The joint function has fewer inputs than the total number of possible articulations yielding both simple control and biomechanically accurate joint movement.

Owner:HONDA MOTOR CO LTD

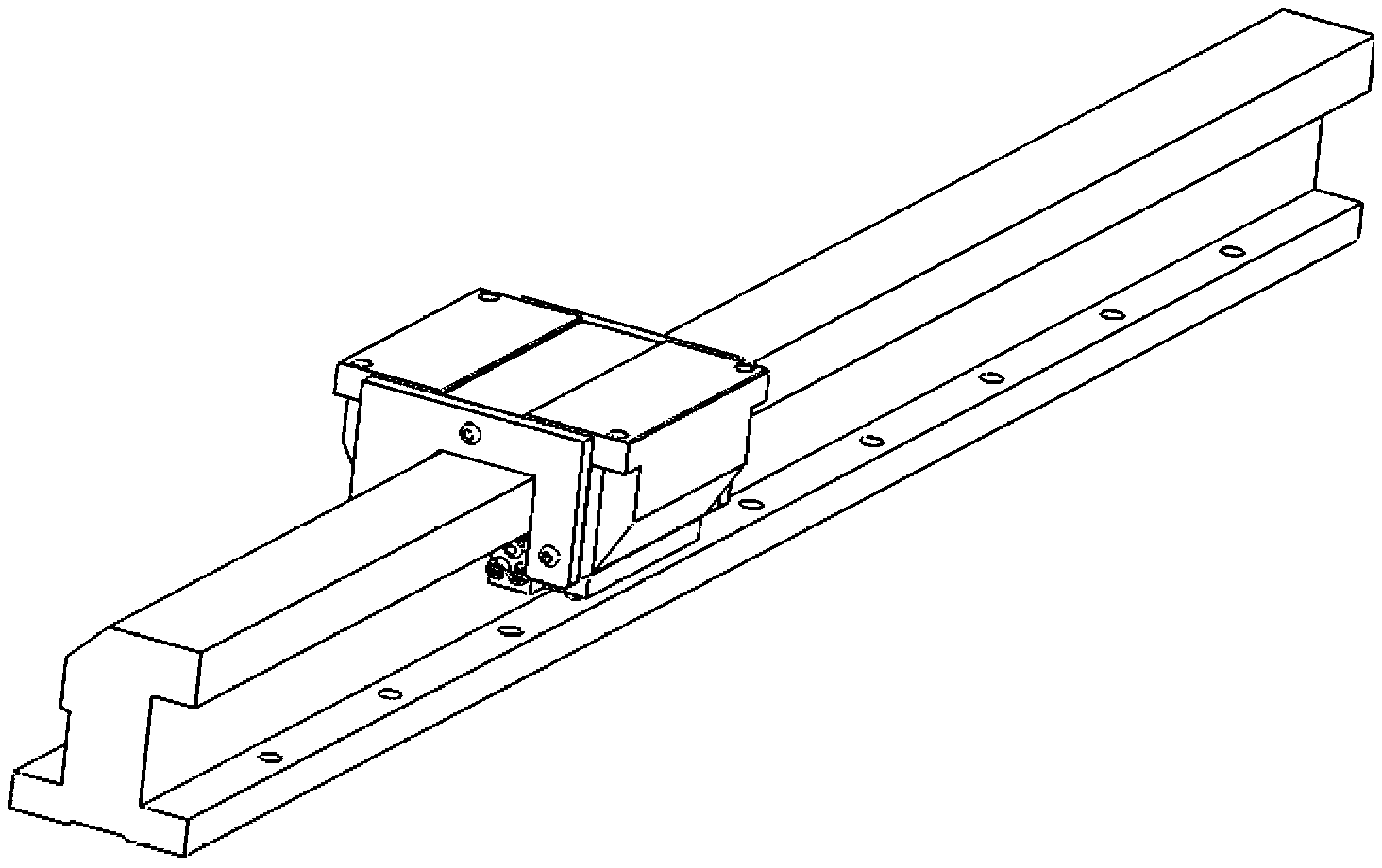

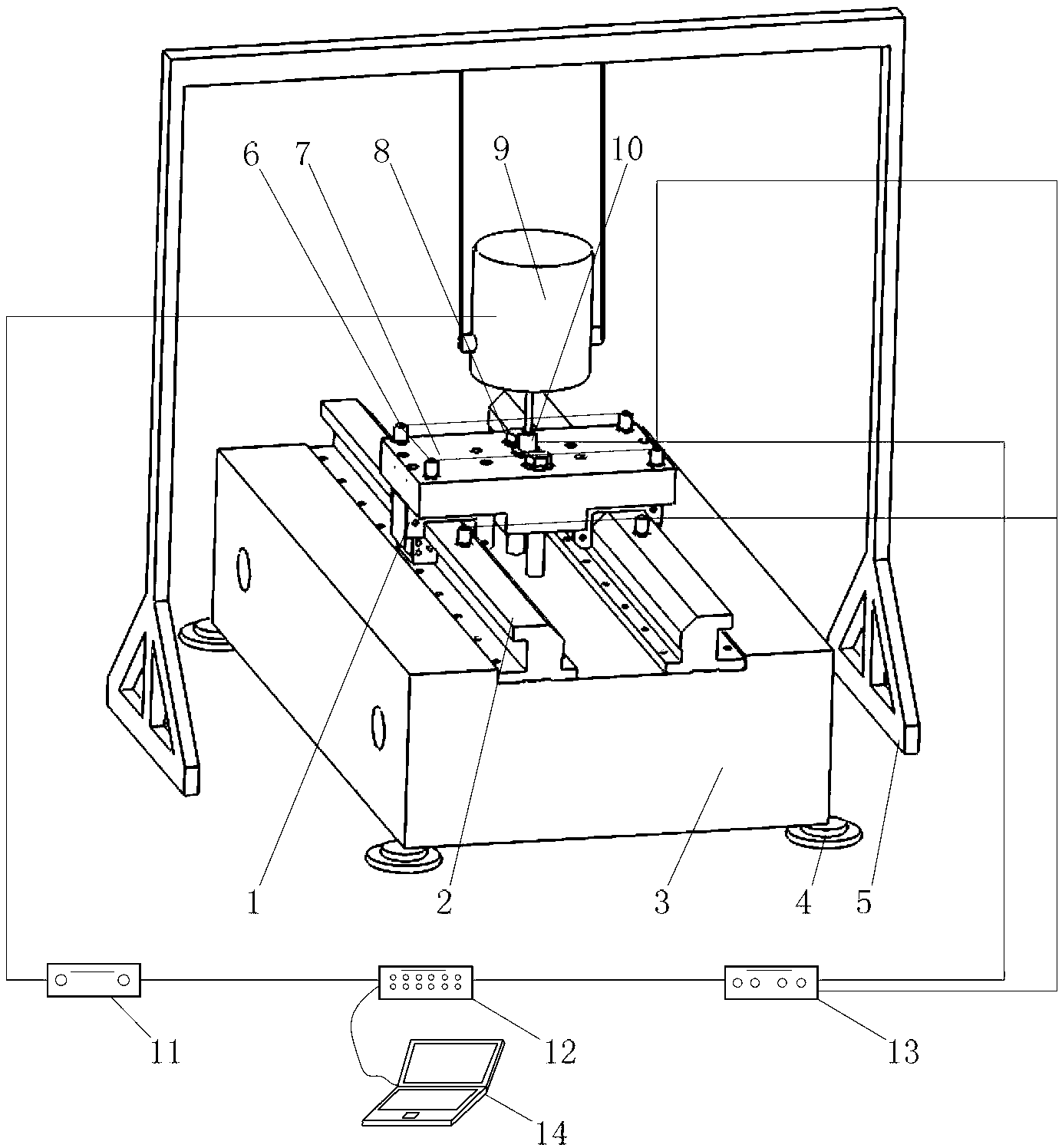

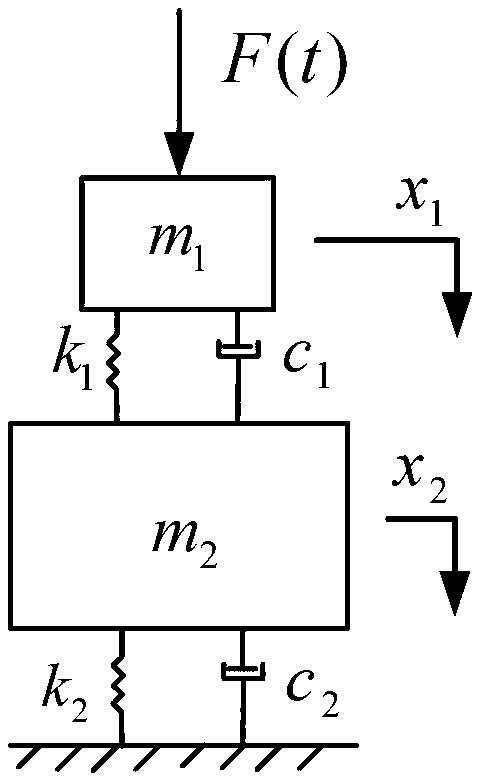

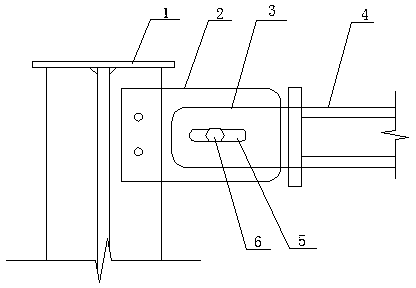

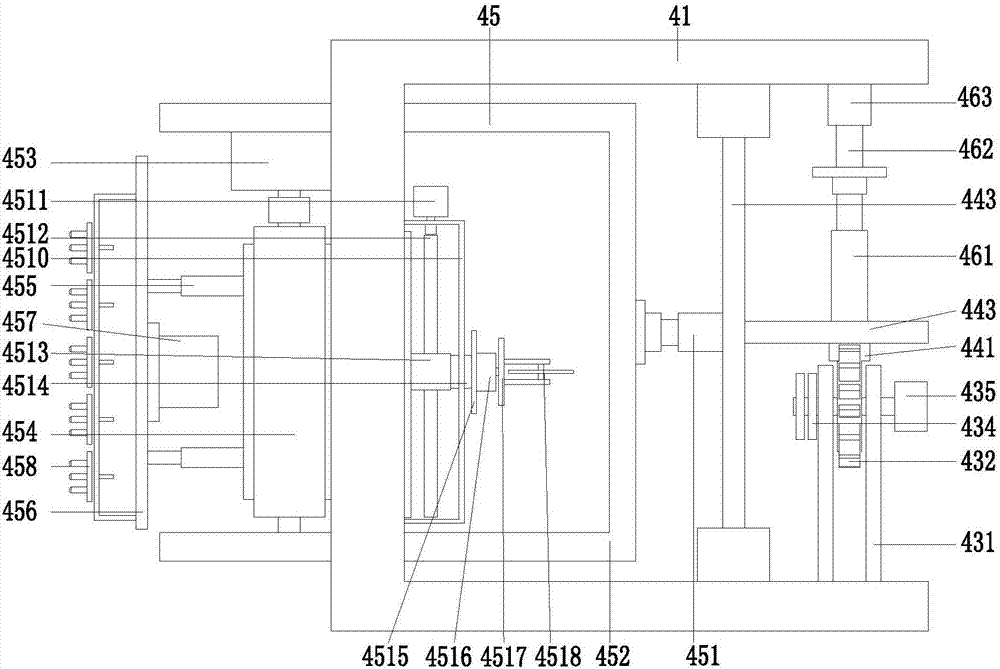

Device and method for testing dynamic characteristics parameters of joint part of rolling-sliding combined guide rail

InactiveCN103217267AIncrease the number of degrees of freedomImprove test accuracyVibration testingDirect testData acquisition

The invention discloses a device and a method for testing dynamic characteristics parameters of a joint part of a rolling-sliding combined guide rail based on a two-degree-of-freedom system. The test device comprises a test platform and a data collection and analysis system. Compared with the prior art, the device has the obvious advantages that the test platform is simplified as a system with two degrees of freedom so as to be more approximate to the self degree of freedom of the test platform, the theory error is reduced, the test complexity degree is reduced, and dynamic characteristic test signals of a movable component and a foundation can be acquired more easily and accurately; the influence of the foundation displacement is taken into consideration, four sizing blocks are arranged so as to regulate the stability of the test platform, so that the influence of external environment excitation on the test device is further eliminated, and the test accuracy is improved; by virtue of directly testing the dynamic characteristic parameters of the joint part of the rolling-sliding combined guide rail, the influence of a complex joint surface in the joint part is reduced, and the parameter testing accuracy is improved.

Owner:NANJING UNIV OF SCI & TECH

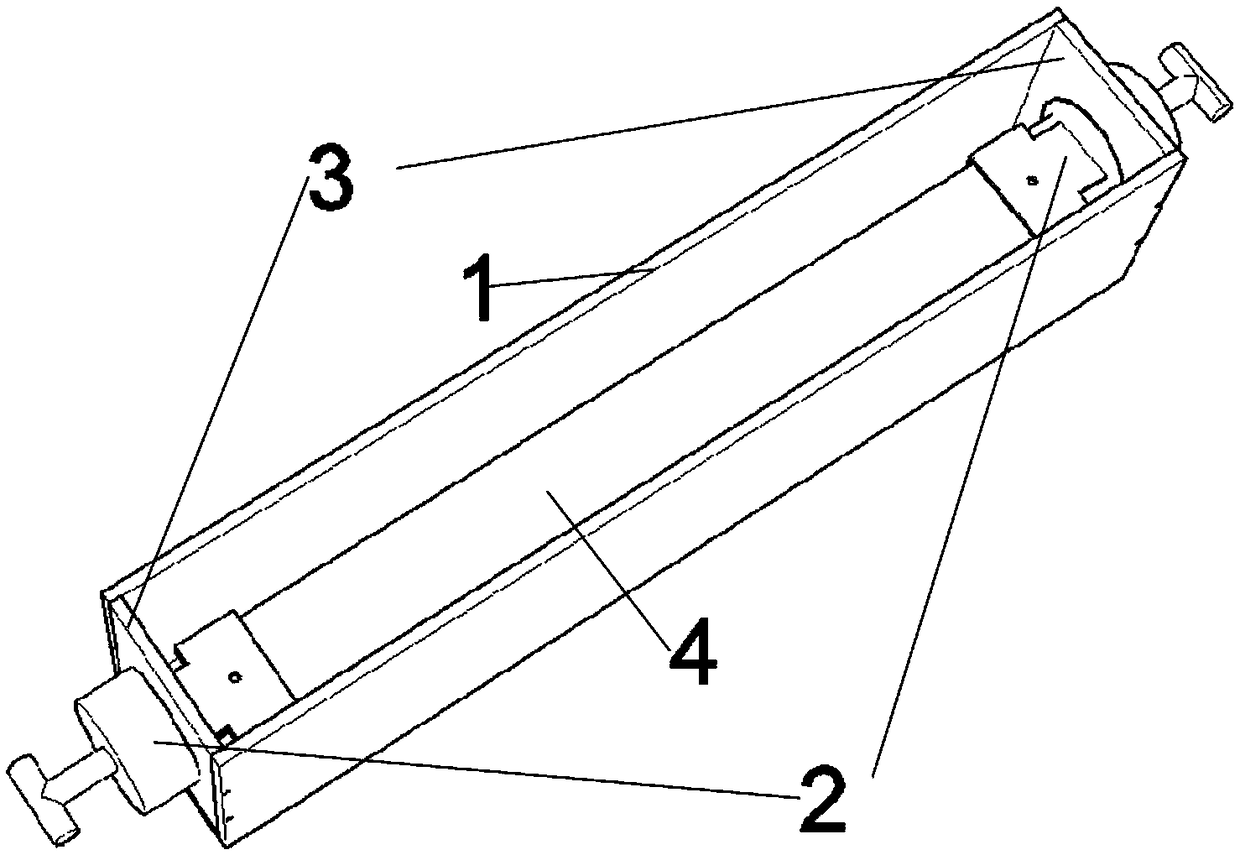

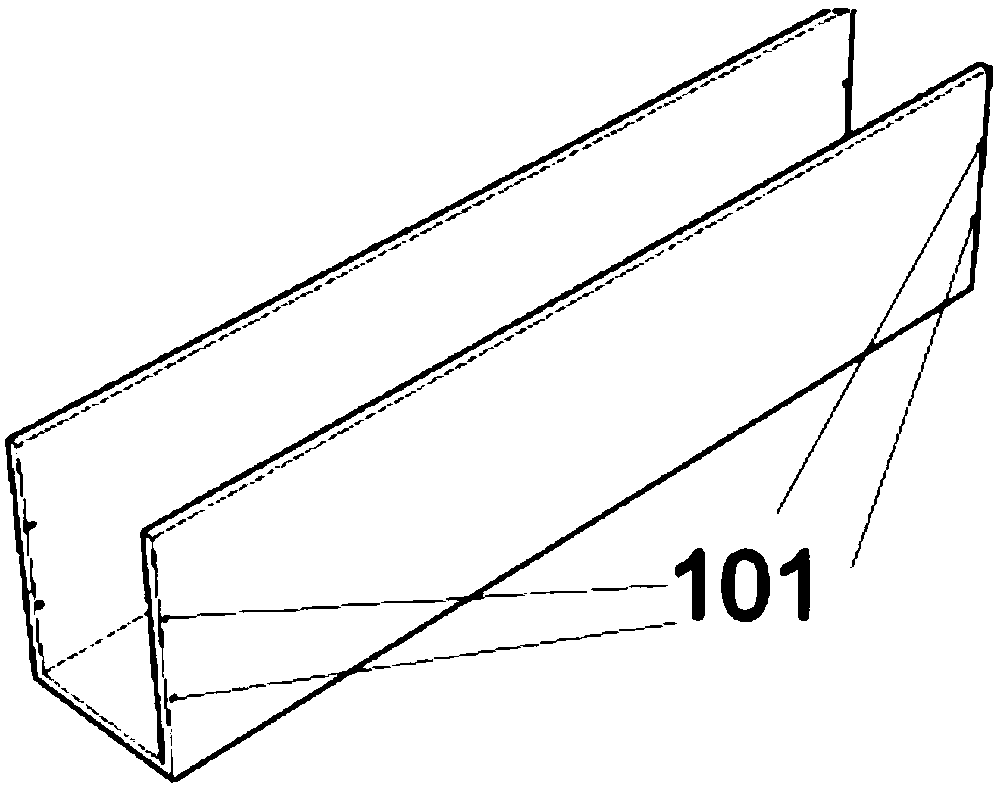

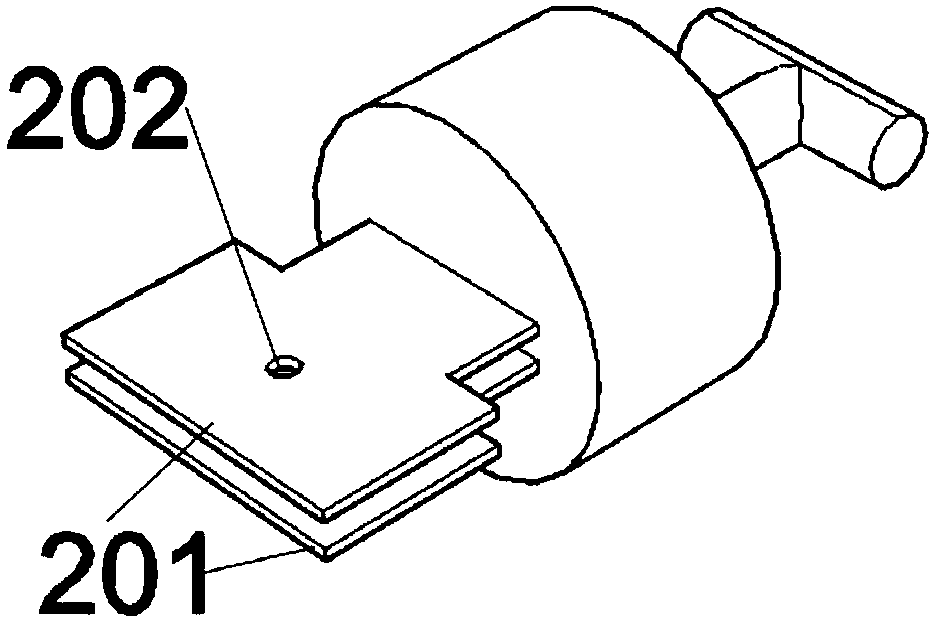

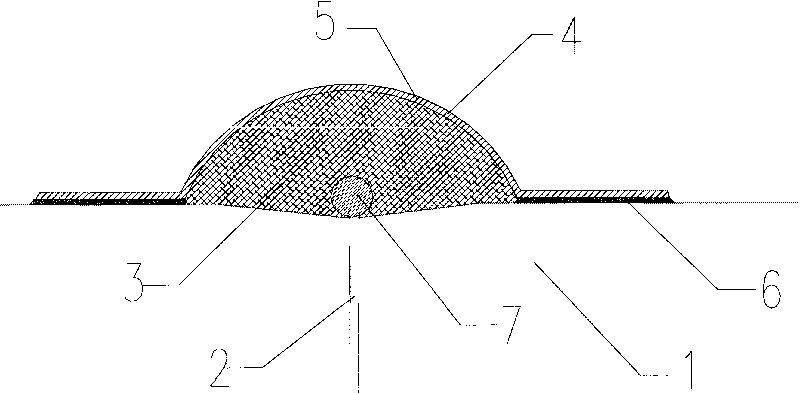

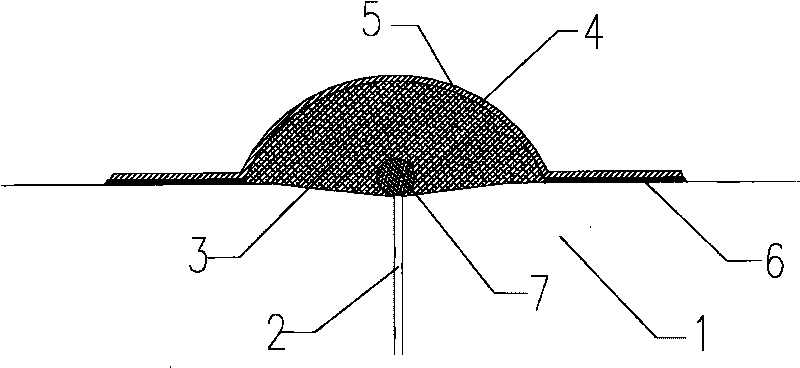

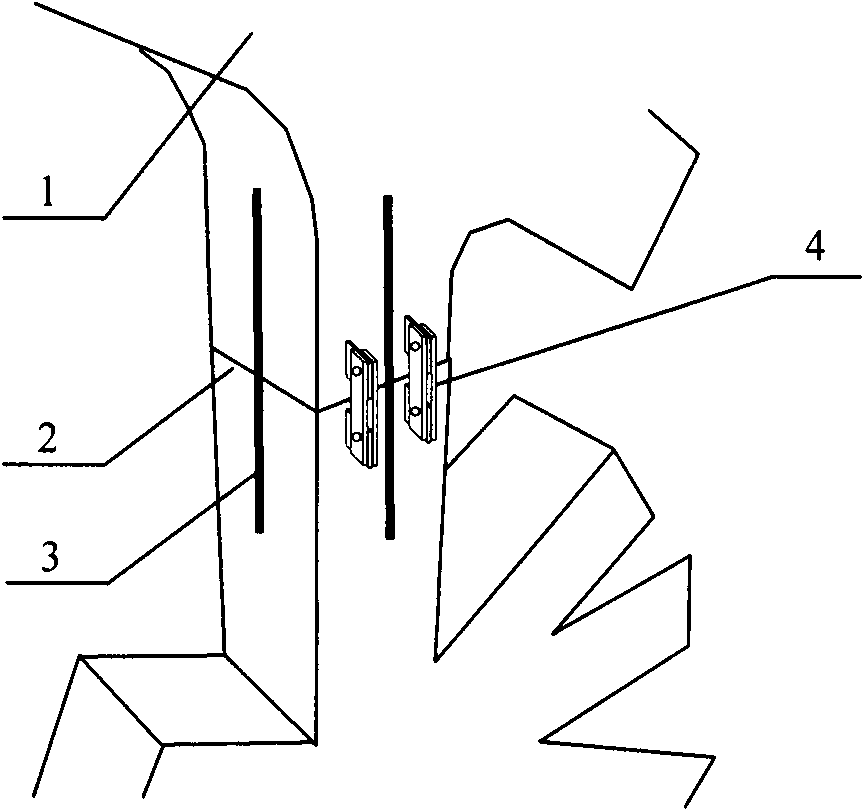

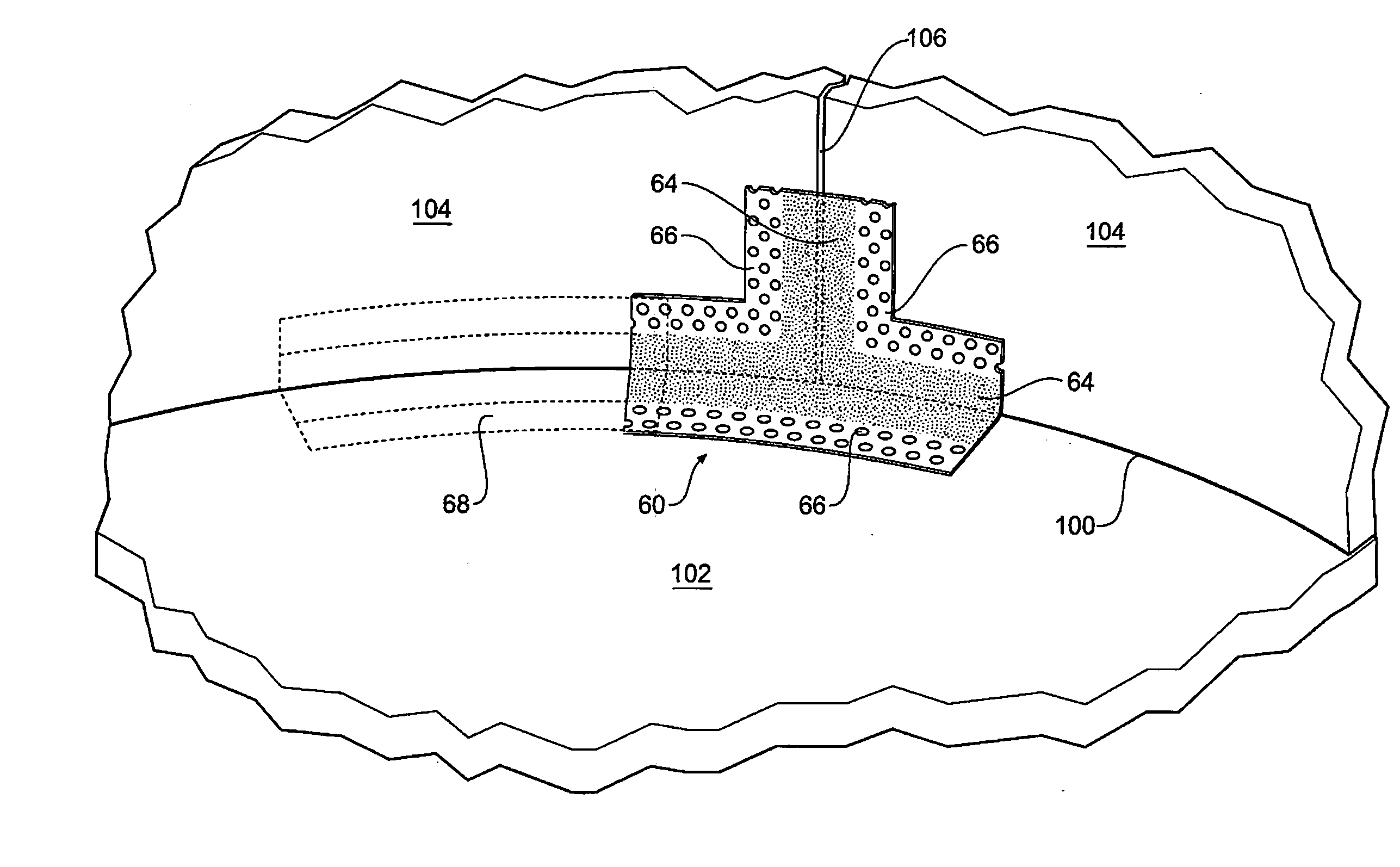

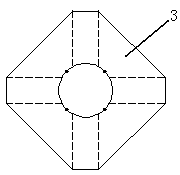

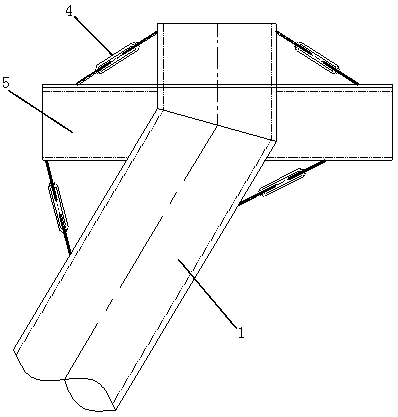

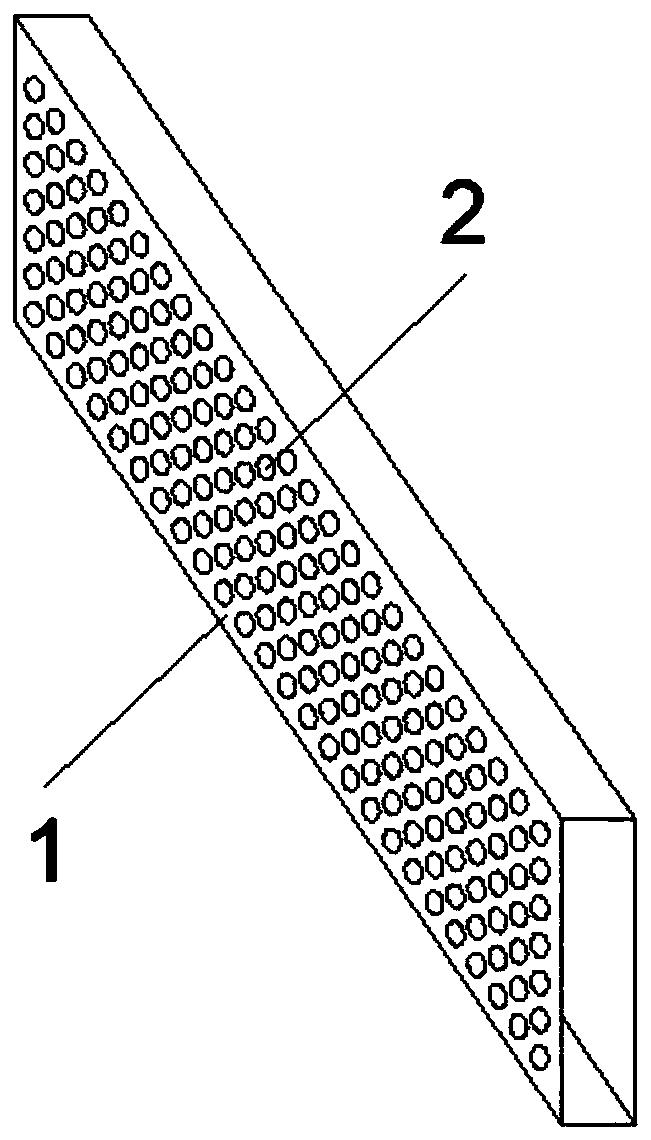

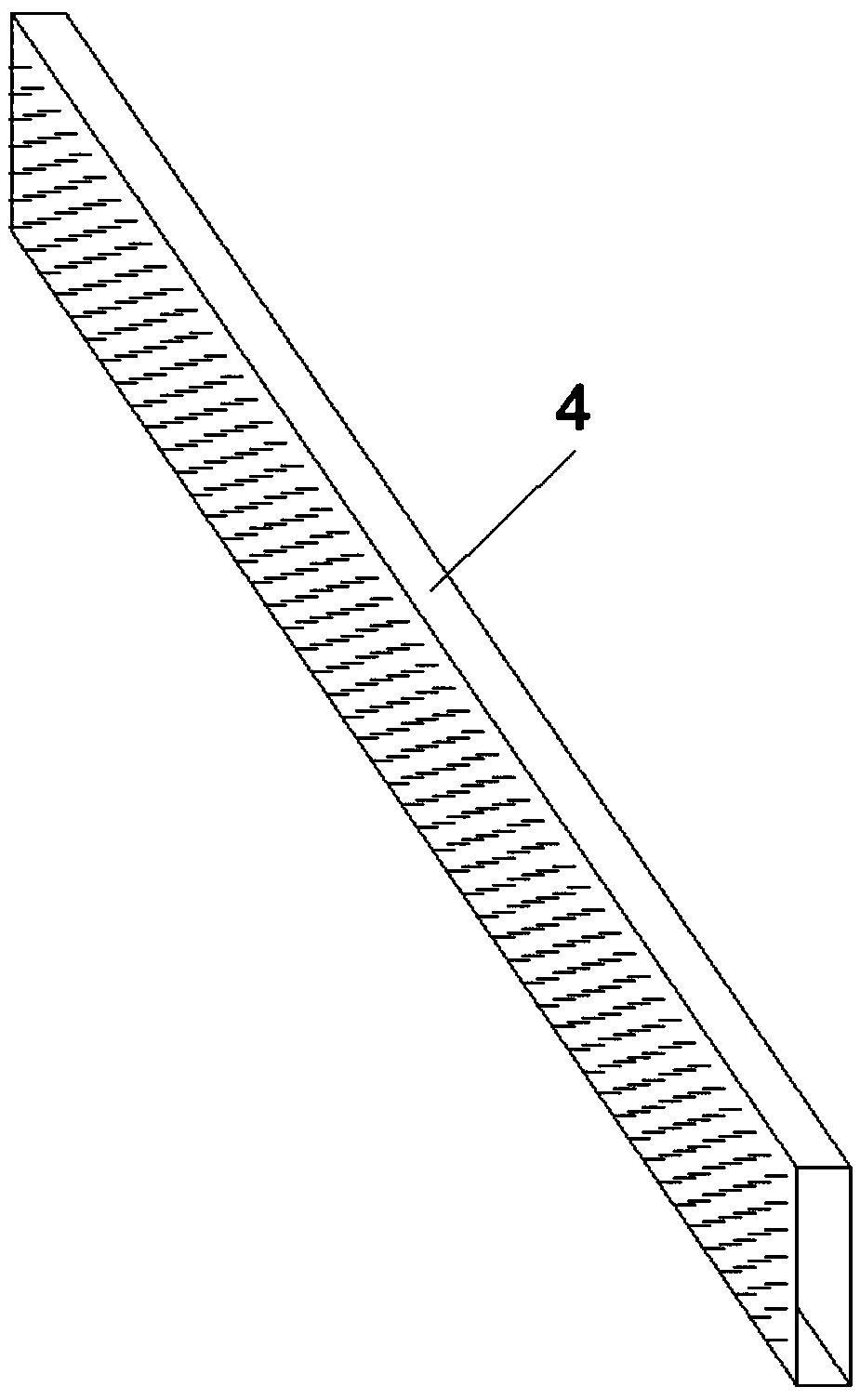

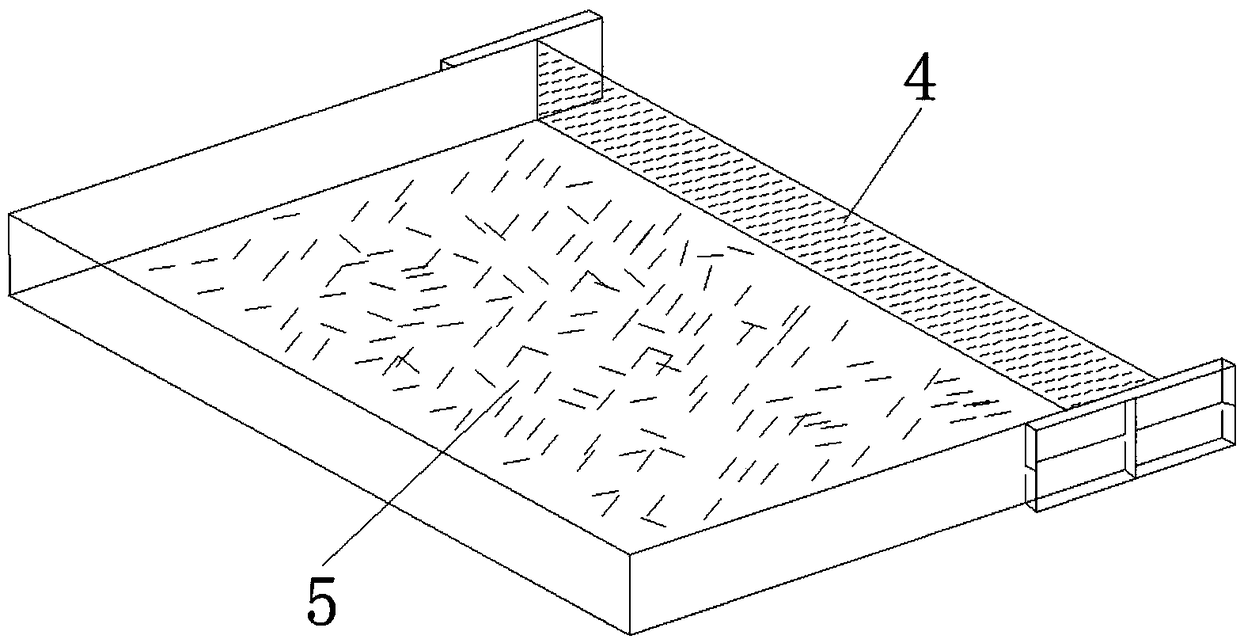

Mold for rock-like sample containing complex joints and sample preparing method

InactiveCN108827729AControl joint inclinationImprove production efficiencyPreparing sample for investigationComplex jointPenetration rate

The invention discloses a mold for a rock-like sample containing complex joints and a sample preparing method. The mold comprises a frame, a drawable rotating disc, thin embedded sheets and a joint insert sheet, wherein the frame comprises a bottom plate and two side plates vertically fixed on two long sides of the bottom plate; the two thin embedded sheets are perpendicular to two short sides ofthe bottom plate and connected with the side plates, and five faces of a cuboid are formed by the thin embedded sheets and the frame; round holes are formed in the thin embedded sheets; the drawable rotating disc comprises a rotating body, a handle and an insert plate, the diameter of the rotating body is equal to that of each round hole, one end of the rotating body is connected with the handle,the other end of the rotating body is connected with the insert plate, and the insert plate penetrates the round holes and is located in the frame; the joint insert sheet is connected with the insertplate and has different shapes. Rock-like material samples with different penetration rates, different inclinations and different fracture shapes can be prepared with the mold.

Owner:HOHAI UNIV

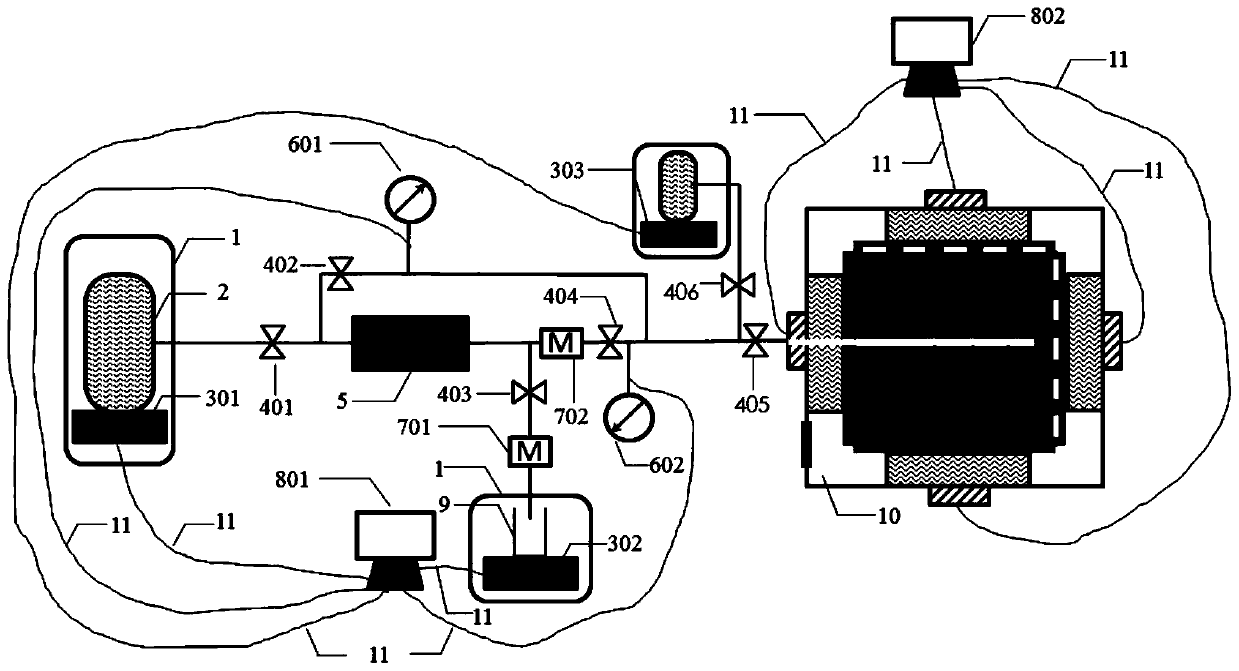

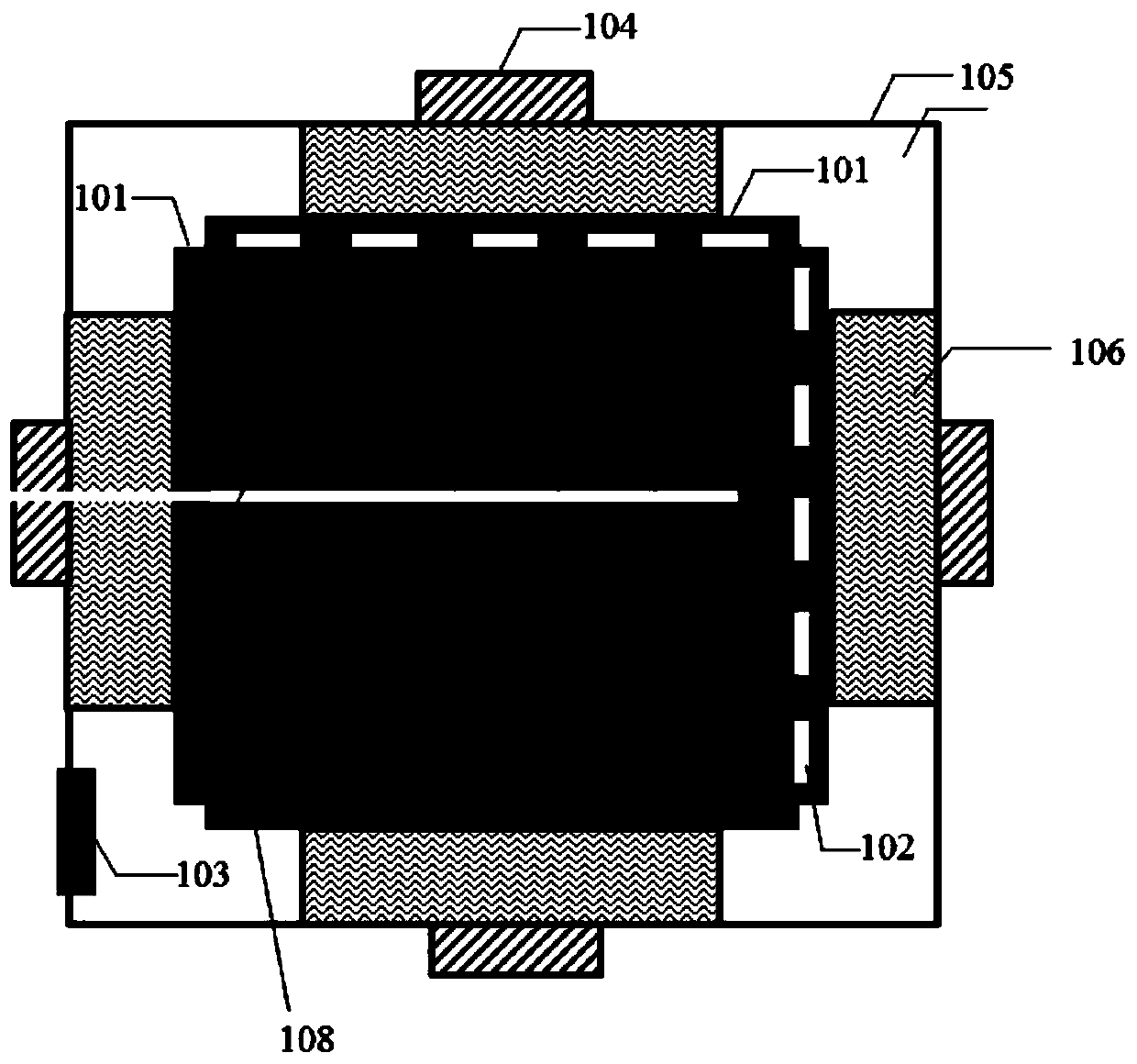

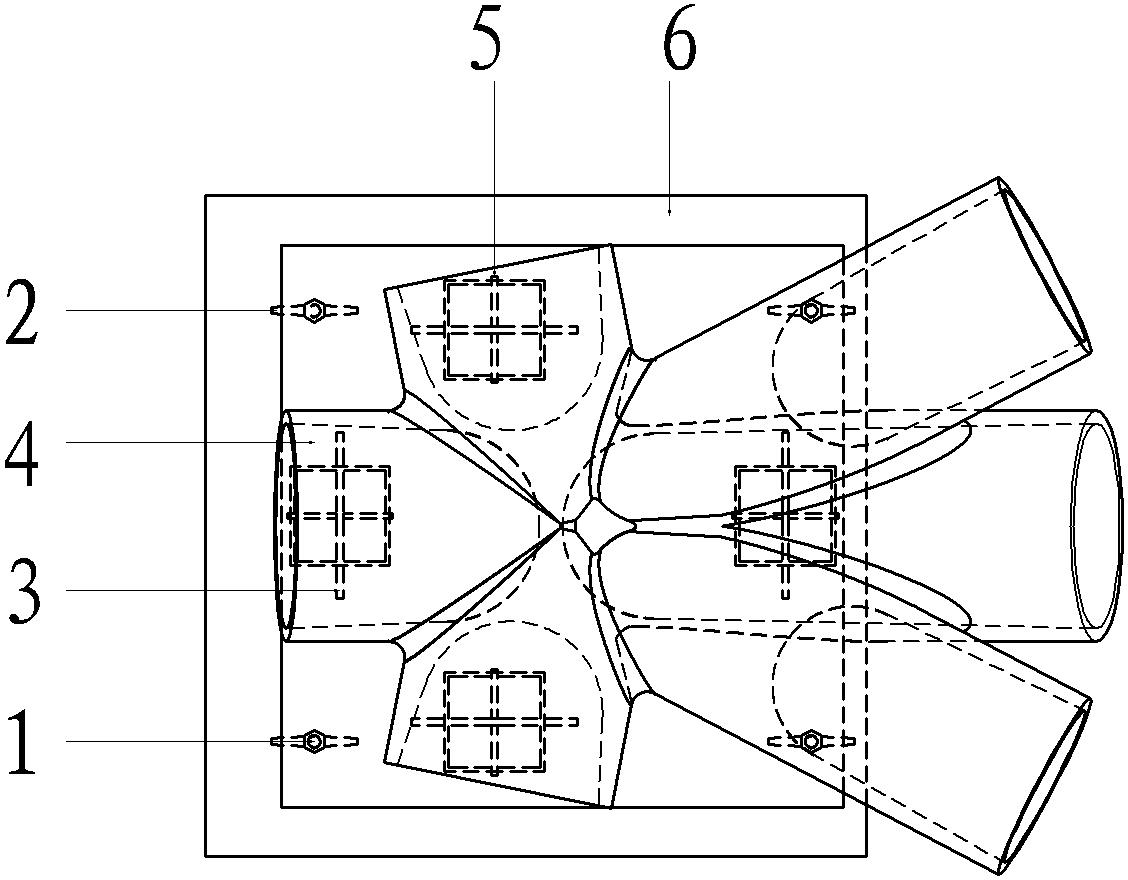

Testing device and method for simulating flowback performance of well soaking of fracturing well

ActiveCN110219631AFlowback capacity QuantificationSurveyAnalysing solids using sonic/ultrasonic/infrasonic wavesTemperature controlFracturing fluid

The invention discloses a testing device and method for simulating the flowback performance of well soaking of a fracturing well. The testing device includes a fracturing fluid tank, a flowback fracturing fluid tank, a hydraulic fracturing pump, a flowback fluid collection beaker and a well soaking flowback testing system, the well soaking flowback testing system includes a box body, and an acoustic wave testing device, a temperature control device, a fracturing string and a square rock block which are arranged in the box body, a tress loading plate and a hydraulic block are arranged successively between the four surfaces of the square rock block and the inner wall of the box body, the acoustic wave testing device includes an acoustic wave transmitting probe and an acoustic wave receivingprobe, and hydraulic grooves are formed in the four outer surfaces of the box body. According to the testing device and method for simulating the flowback performance of well soaking of the fracturingwell, the situation and temperature of original crustal stress are considered, simulation of the rule of well soaking and flowback can be closer to the real situation, the flowback performance of shale under the complex joint net situation during volume transformation is further considered, and through a passive acoustic monitoring system, the flowback performance of fracturing fluid under different joint net complexity can be evaluated.

Owner:SOUTHWEST PETROLEUM UNIV

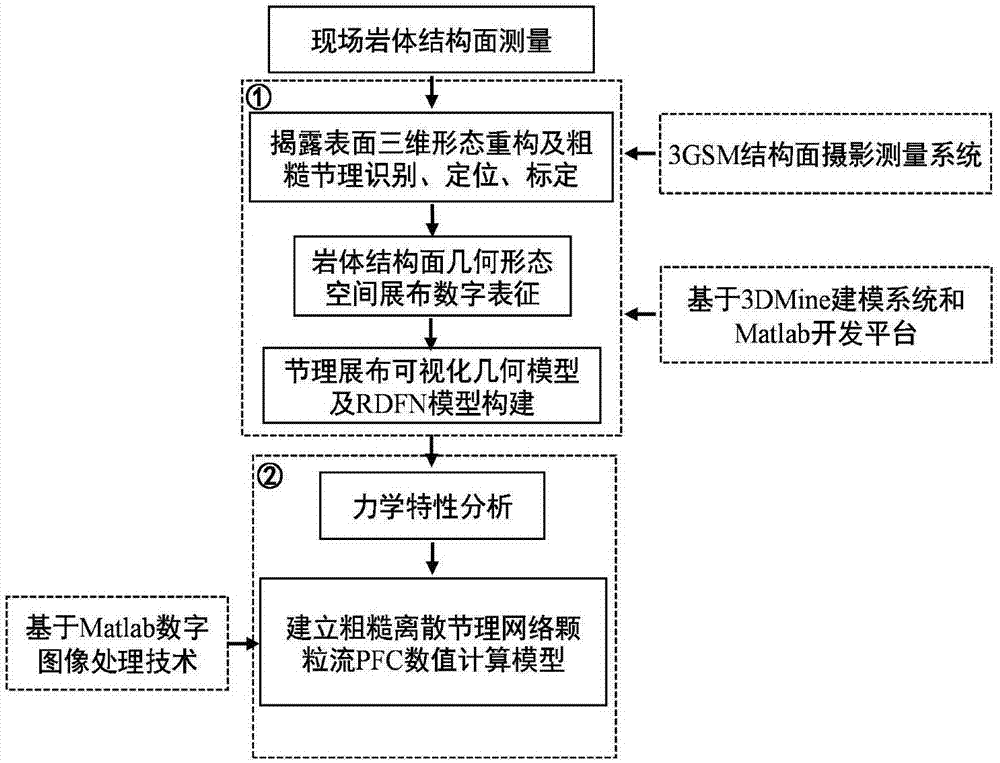

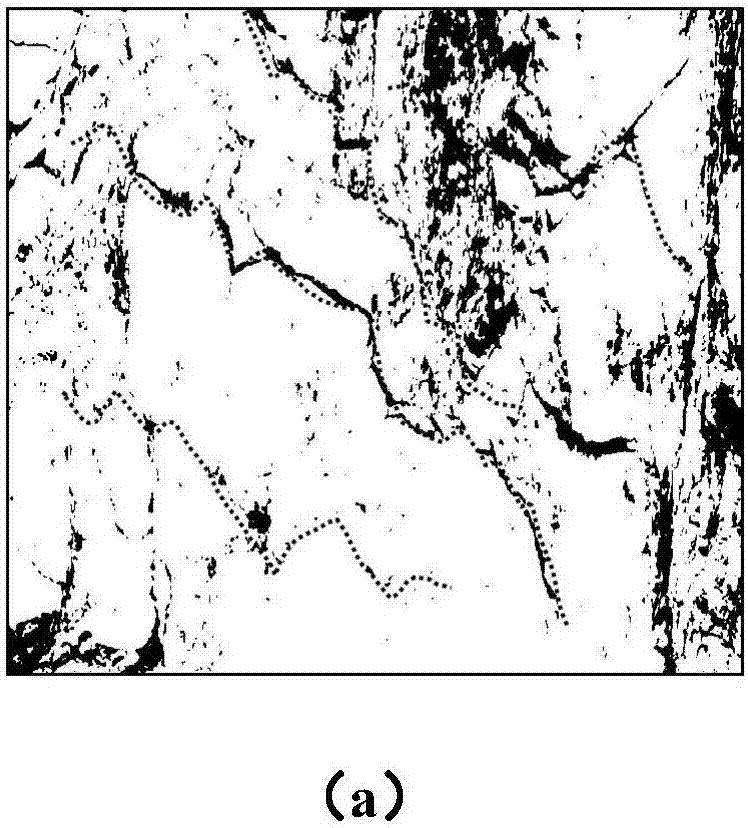

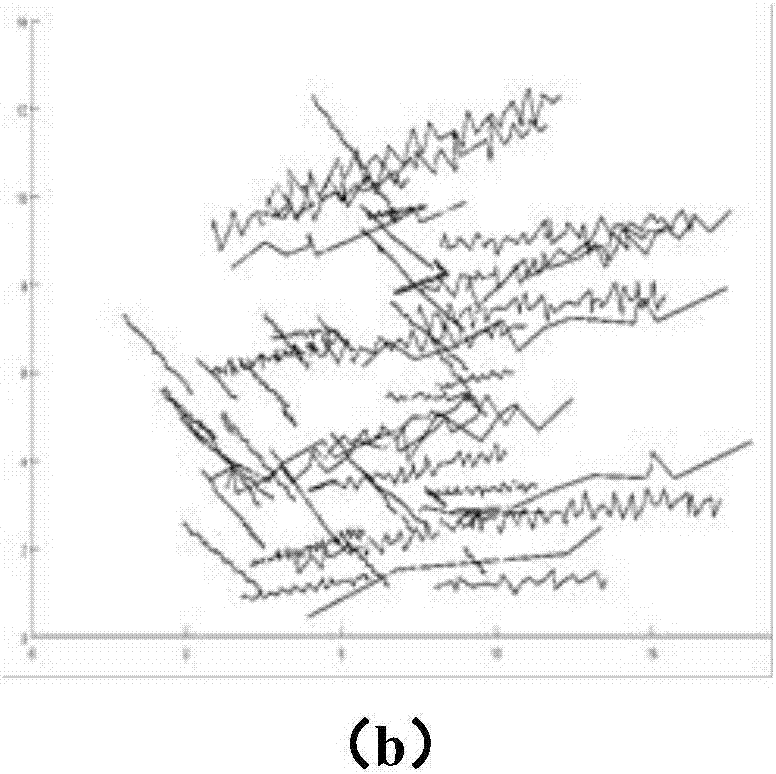

Method for building rough stochastic discrete joint network models

ActiveCN107203670AAchieve convergencePreparing sample for investigationDesign optimisation/simulationStatistical analysisNetwork model

The invention provides a method for building rough stochastic discrete joint network models, and belongs to the field of technologies for modeling complex joint rock mass. The method includes surveying rock mass structural planes and identifying information; digitally representing spatial distribution of geometric morphology of the rick mass structural planes; statistically analyzing probability models of geometric occurrence information of the structural planes; creating stochastic rough geometric joint curves corresponding to the geometric morphology; creating model interfaces of Matlab and mechanical analysis software PFC by the aid of digital image processing technologies; physically modeling built RDFN models by the aid of 3D (three-dimensional) printers to provide the models for indoor similarity tests. The method has the advantages that representation processes and model bases can be provided for reasonable research on mechanical characteristics of joint rock mass, and scientific bases can be provided for guiding rock and soil engineering construction, support designs and the like by achievement.

Owner:UNIV OF SCI & TECH BEIJING

Temperature stress releasing structure of large-size steel structure building

InactiveCN103132603AEasy to makeEasy to installBuilding constructionsTemperature stressExpansion joint

The invention relates to a large-size steel structure building, in particular to a temperature stress releasing structure of a large-size steel structure building. Members of the structure comprise a steel beam, and a longitudinal member. A connected node between the longitudinal member and the steel beam is a slidable slotted hole structure node. Under the condition that a temperature expansion joint is not arranged, a slotted hole variant high strength bolt node is utilized to effectively release the temperature stress of a steel structure system. The problem of brittle failure of a large number of beam-column nodes of the steel structure is avoided. A door type steel beam and corresponding foundation are reduced and a complex joint structure is avoided. Slotted hole technology is simple in manufacture in a factory, and convenient to assemble, an opening is in the shape of a long circle. Bolt is hardly in need of repair after slide deformation.

Owner:TANGSHAN COLLEGE

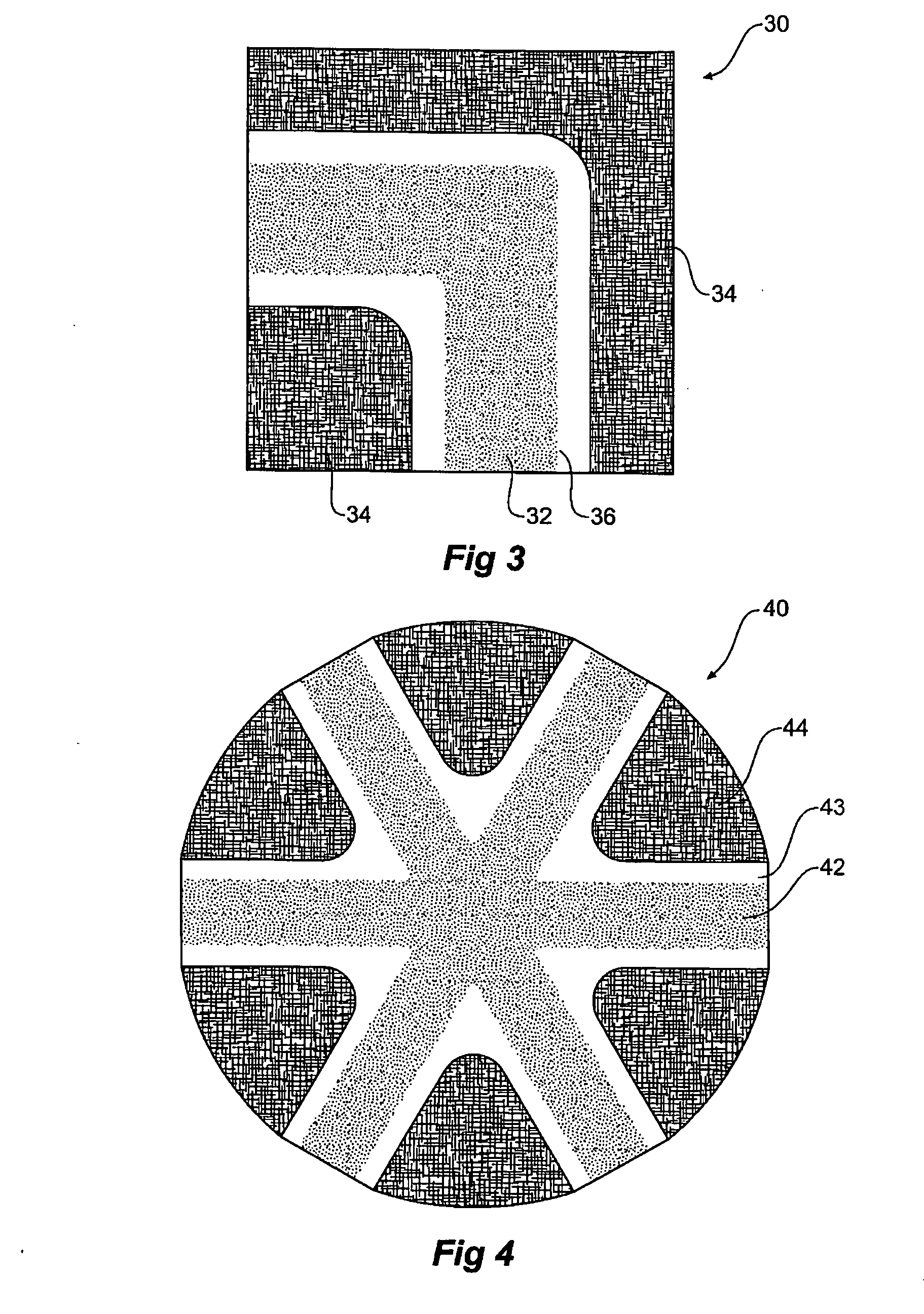

Anticorrosion cladding method of complex joint of ocean platform

The invention discloses an anticorrosion cladding method of a complex joint of an ocean platform, which comprises the following steps of: (1) carrying out manual rust removal / or blast sanding on a to-be-processed steel structure of the complex joint of the ocean platform; (2) coating corrosion inhibition repair cream on the surface of the steel structure which is subjected to the processing in the step (1); (3) sticking a mineral oil anti-corrosion band on the corrosion inhibition repair cream; and (4) coating unsaturated polyester resin on the mineral oil anti-corrosion band, sticking the glass wool cloth on the unsaturated polyester resin, coating the unsaturated polyester resin on the glass wool cloth, and rolling. The invention has the beneficial effects that the construction is convenient, the surface processing is simple, and the anticorrosion cladding method is suitable for an object with any shape and any structure; and by adopting the method, the complex joint of the ocean platform has good sealability, impact resistance and excellent anticorrosion effect, is environmental-friendly, and has no toxicity or pollution. The anticorrosion cladding method can be suitable for the cladding corrosion resistance of any complex joint of the ocean platform.

Owner:CHINA NAT OFFSHORE OIL CORP +1

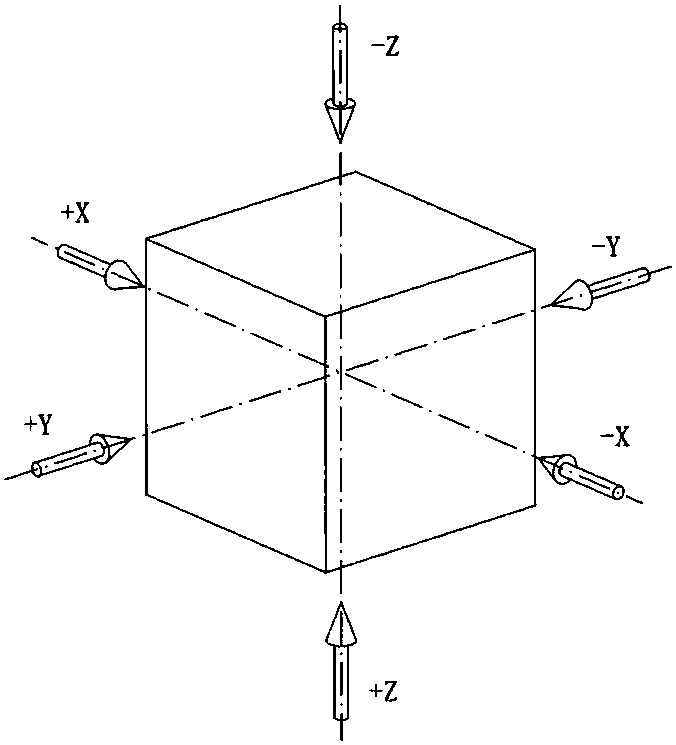

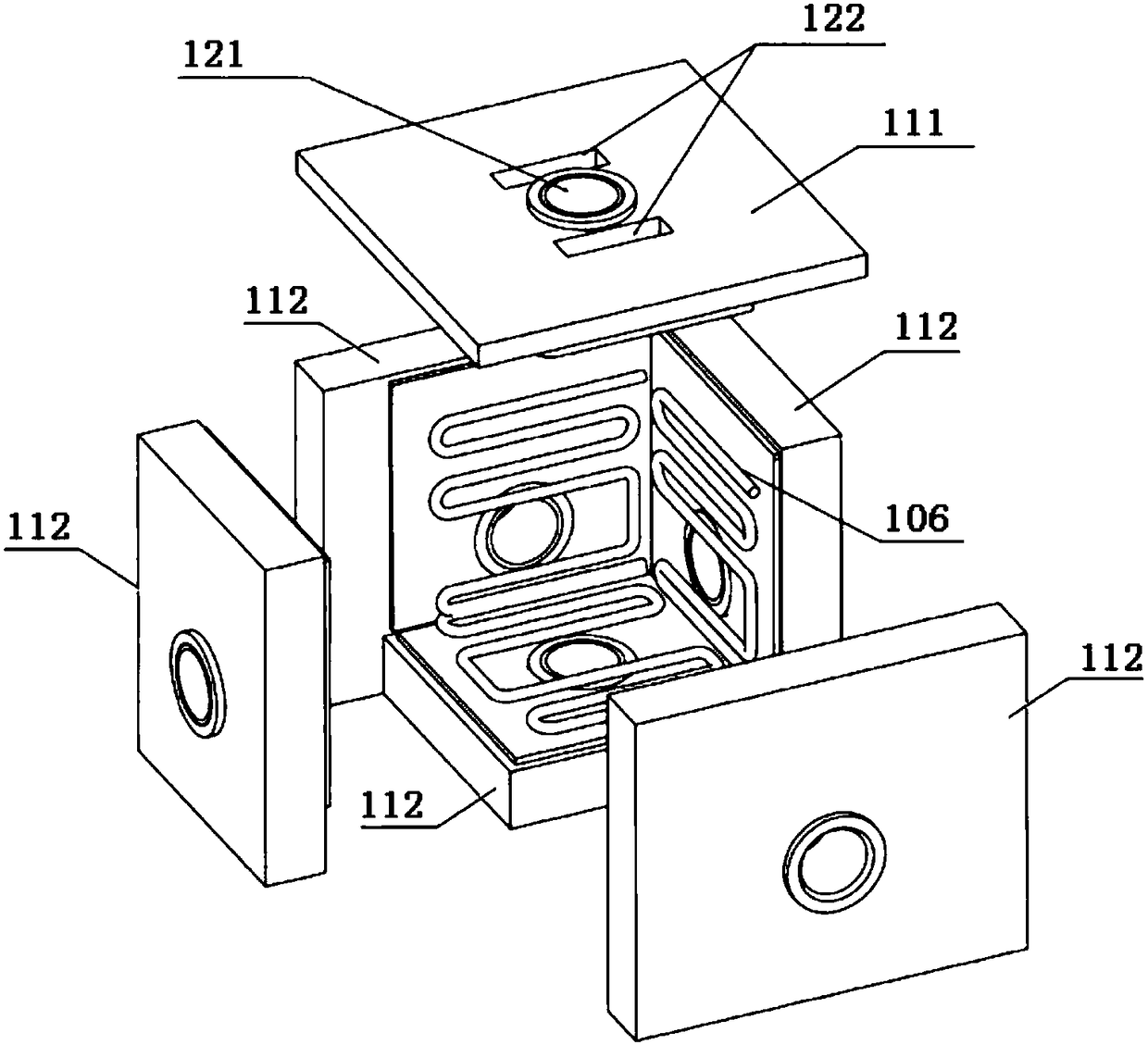

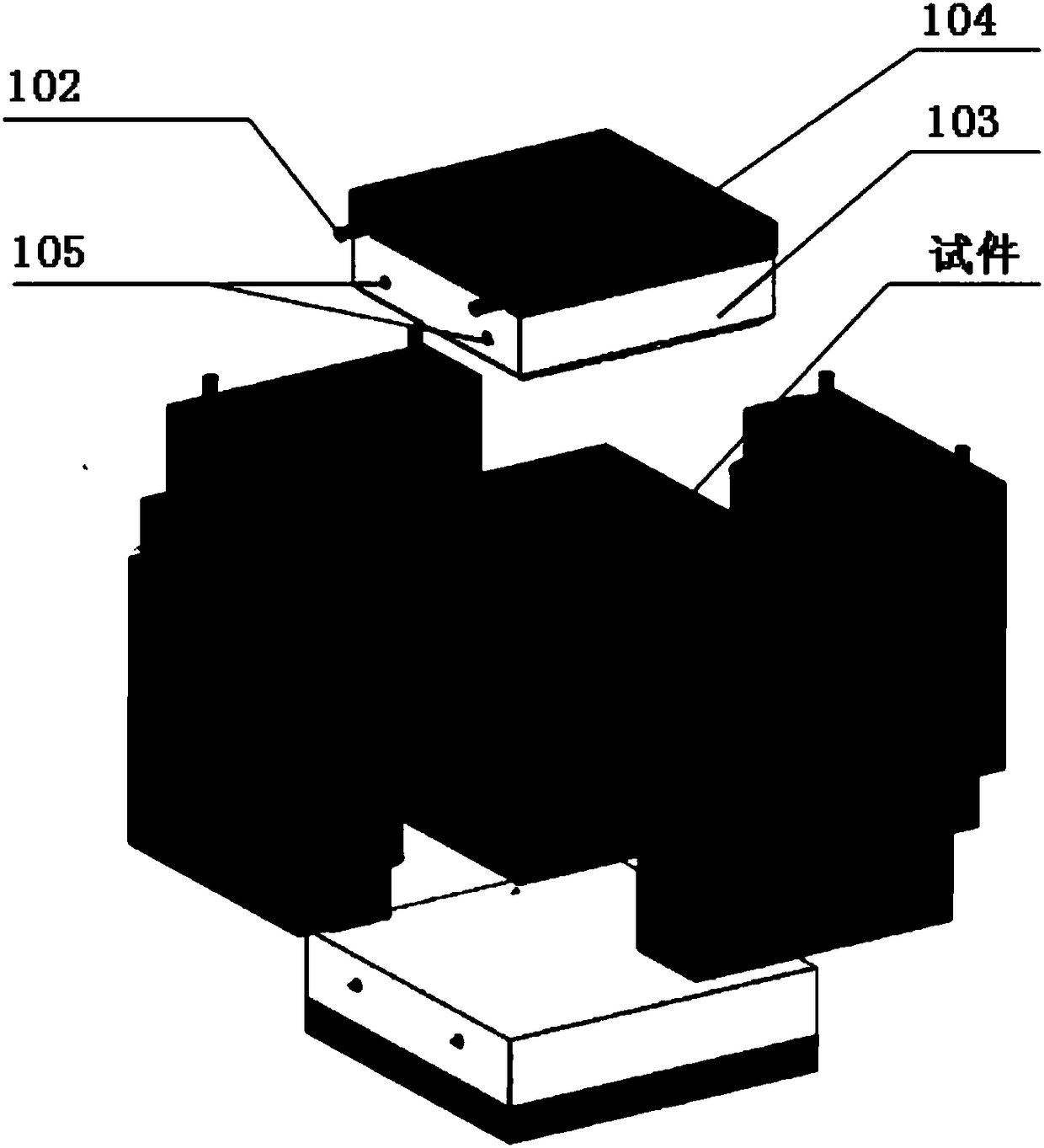

Experimental device for stress freezing during fracturing

PendingCN108871968AStress freeze implementationRealize intuitive observationMaterial strength using tensile/compressive forcesIncreasing energy efficiencyEngineeringThermostat

The invention provides an experimental device for stress freezing during fracturing. A test piece arranged in a thermostat of a temperature control system is heated and cooled under the correspondingtemperature control by means of the temperature control system according to a photosensitive curve and a preset temperature gradient, so that the stress freezing of the test piece is realized; the test piece is fixed and applied with corresponding pressure by means of a true triaxial servo loading system; a fracturing body pumping system, having an output end arranged in the thermostat, is used for performing a corresponding fracturing test on the test piece; since the test piece is a transparent photosensitive model printed by means of a 3D printer, by combining the stress loading of the truetriaxial servo loading system, a stress freezing experiment under the precise temperature control of the temperature control system and a fracturing experiment of the fracturing body pumping system,visual observation and transparent display of the evolution law of a crack tip stress field can be realized during the crack initiation of a complex joint in the fracturing process.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Water conservancy project concrete member expansion joint or crack sealing-up and seepage-proofing method

InactiveCN101701456AImprove sealingNo connection problemsMarine site engineeringFlexible fiberComplex joint

The invention relates to a water conservancy project concrete member expansion joint or crack sealing-up and seepage-proofing method. The invention uses a material combination of flexible filleting material and on-site coated flexible film. First, the flexible filleting material is used for sealing the surface of concrete member expansion joint or crack, then the filleting material and the member of certain width at two sides of the joint or crack are coated to form flexible film material on site, the on-site coated flexible film can be flowing liquid and change into flexible solid film after being coated on the object surface, the strength of the on-site coated flexible film can be reinforced by adding flexible fiber and / or fiber fabric, adhesive material is arranged between the filming material and the surface of the member to ensure the filming material and the member to be tightly bonded. The method improves water pressure resisting capacity of the entire seepage-proofing structure, and enhances the capacity thereof adapting to change of joint / crack opening, thus being suitable for various complex joint / crack surface with ideal sealing effect and no joint problem.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES +1

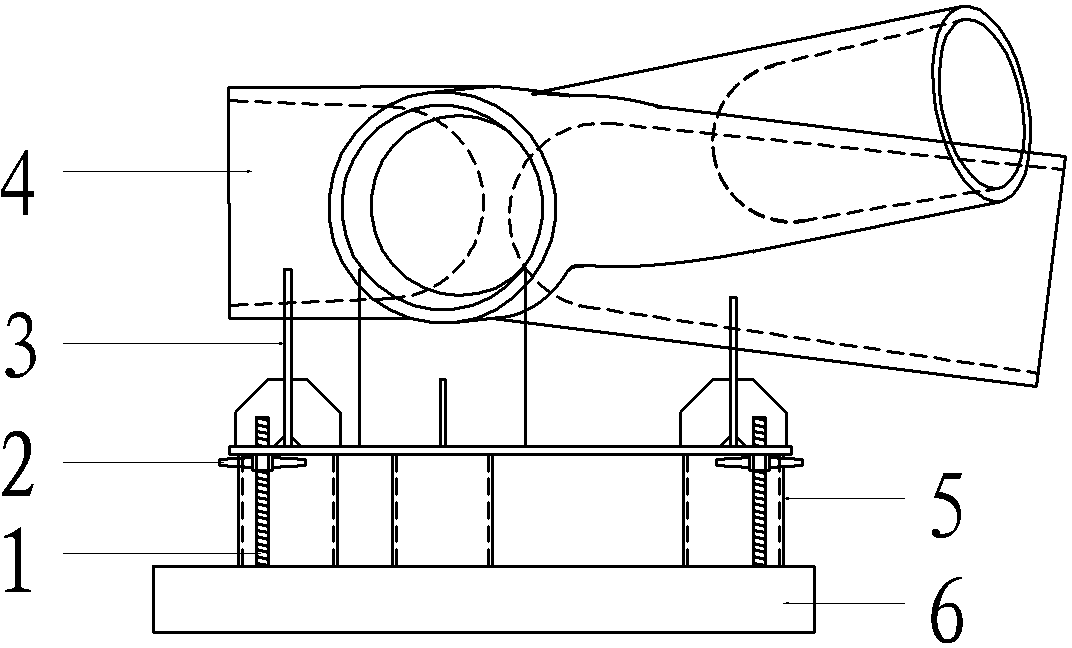

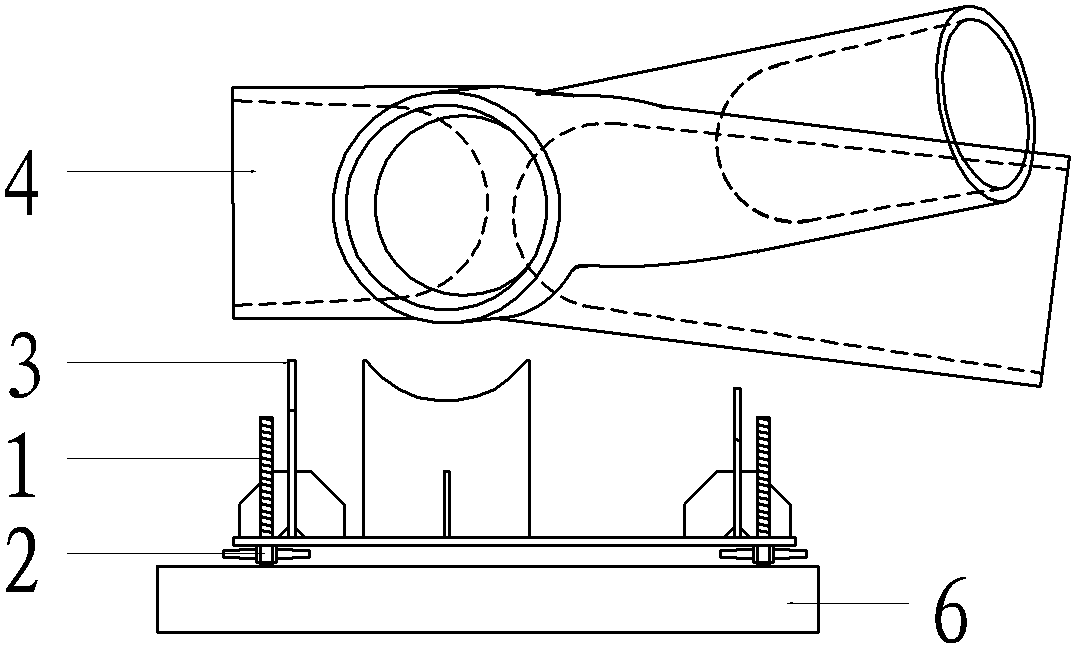

Movable copying positioning frame of steel structure complex joint

ActiveCN103061524ASolve the problem of repeated disassembly and assemblyBuilding material handlingHeavy dutyPositioning system

The invention aims to provide a movable copying positioning frame of a steel structure complex joint to solve the problem that a complex joint positioning device needs to be demounted and mounted repeatedly in multi-joint construction in the prior art. The movable copying positioning frame comprises an underframe, wherein a copying positioning plate is arranged on the underframe; the upper opening profile of the copying positioning plate is matched with the support surface of a support joint in shape; and a height adjusting element is arranged in the underframe. Compared with a traditional fixed copying positioning method, the method of the movable copying positioning frame provided by the invention has the advantages that the demounting and mounting time of the copying positioning frame is saved, and simultaneously, accurate positioning can be achieved by using a line hammer only; and therefore, the use of a heavy-duty crane is reduced, the construction procedure is simplified, and the goals of simplicity, reliability, good quality and high efficiency are achieved.

Owner:GUANGDONG IND EQUIP INSTALLATION

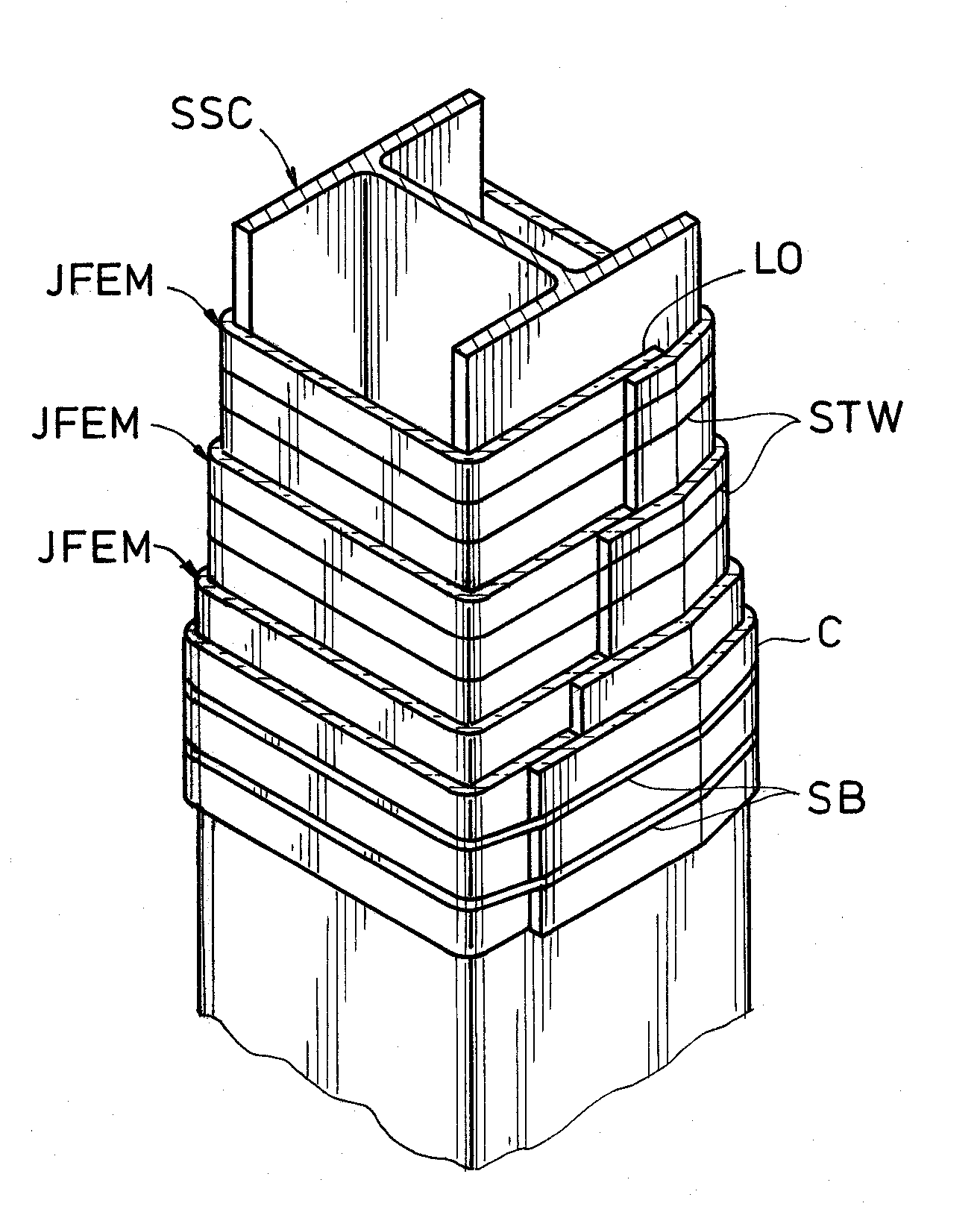

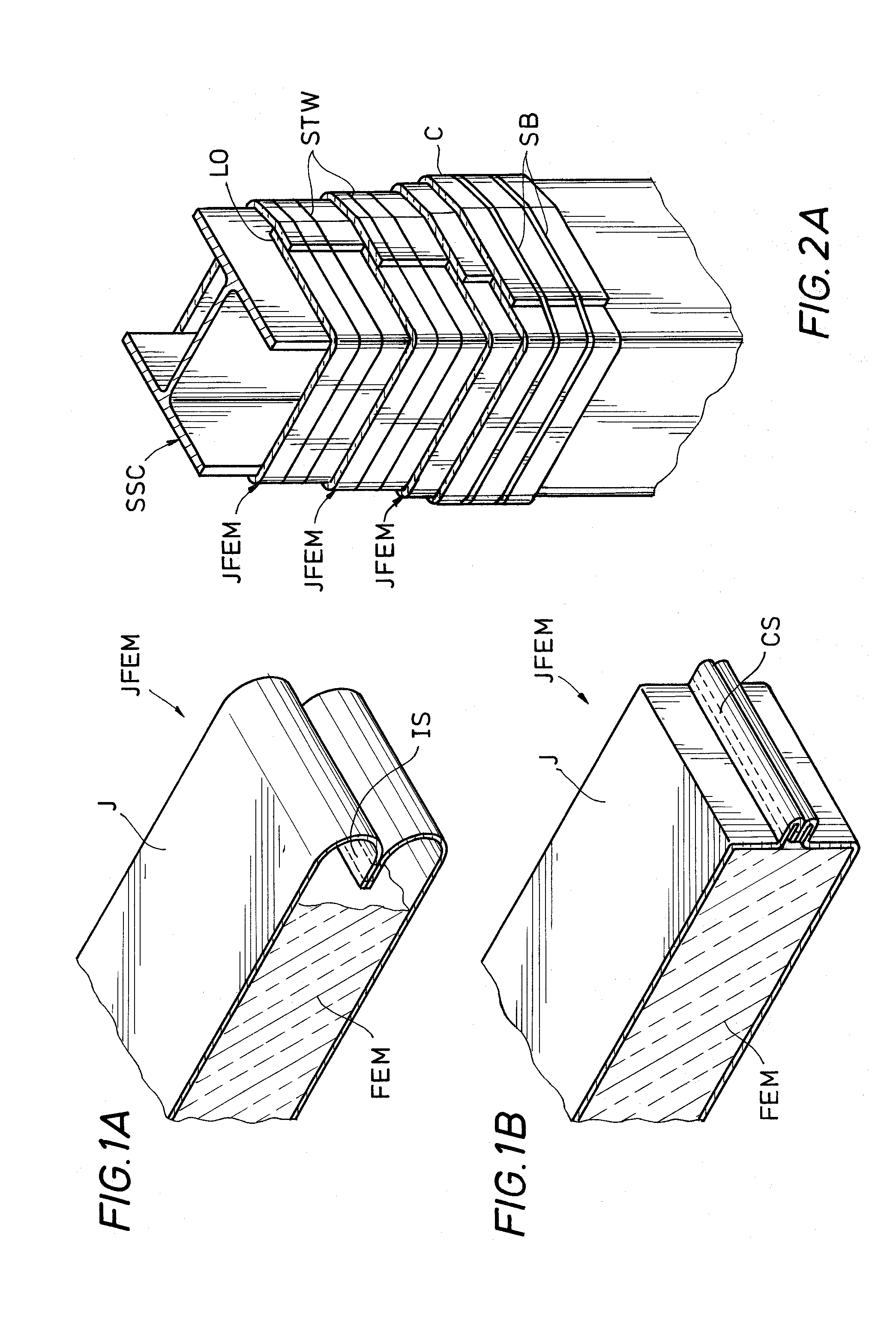

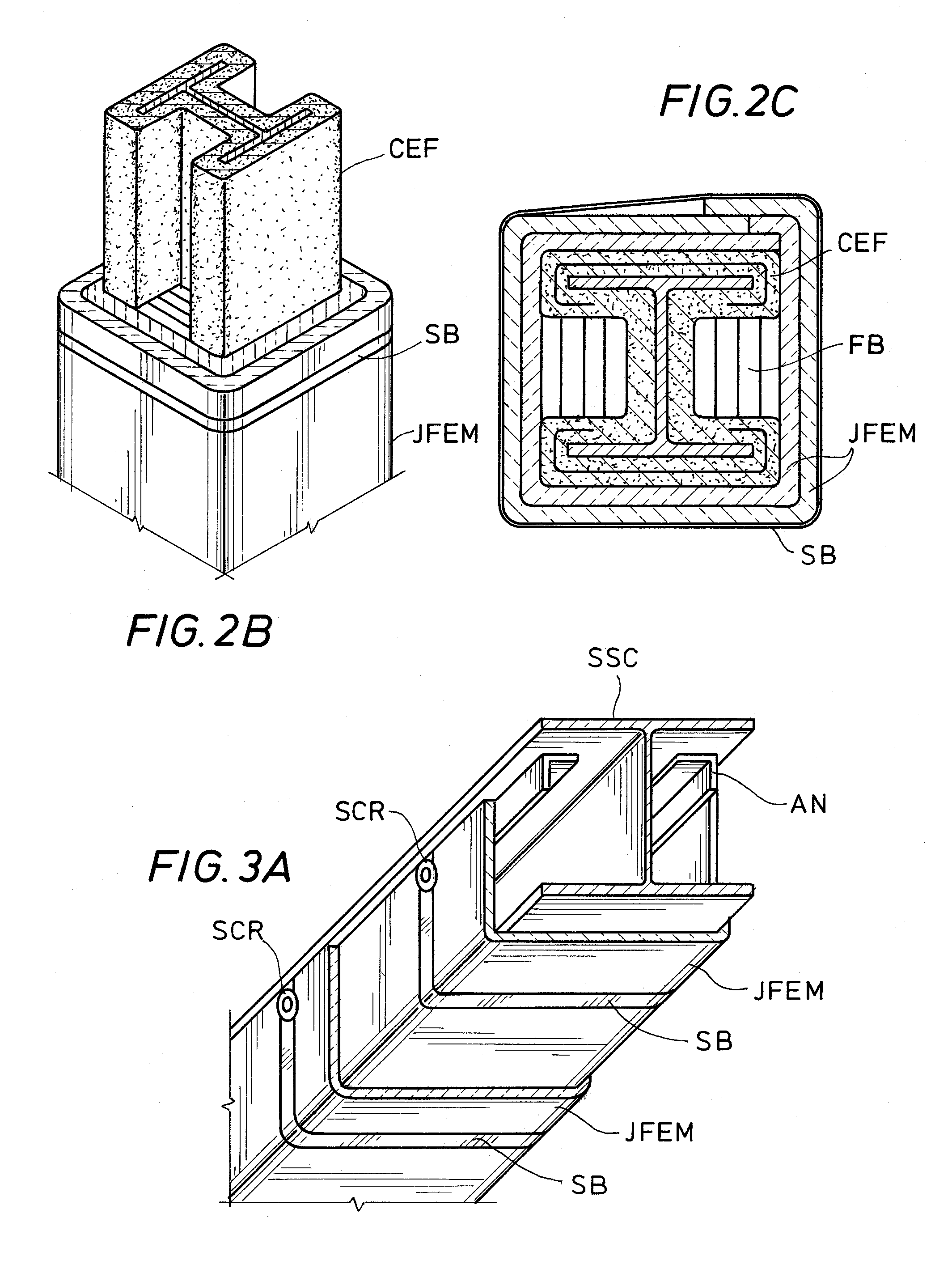

Fireproof System Using Jacketed Fibrous Endothermic Mats

InactiveUS20140076482A1Glass/slag layered productsPipe protection against damage/wearFiberGlass fiber

A fire protective composite comprising a jacketed fibrous endothermic mat and method of wrapping thereof, the jacket material preferably including impregnated fiberglass fabric, the composite designed for fire protection of structural elements such as steel I-beams and complex joints, electrical conduits and cable trays, LP-gas container and vessel skirts and valves.

Owner:KUNK BRANDON ALOYS +3

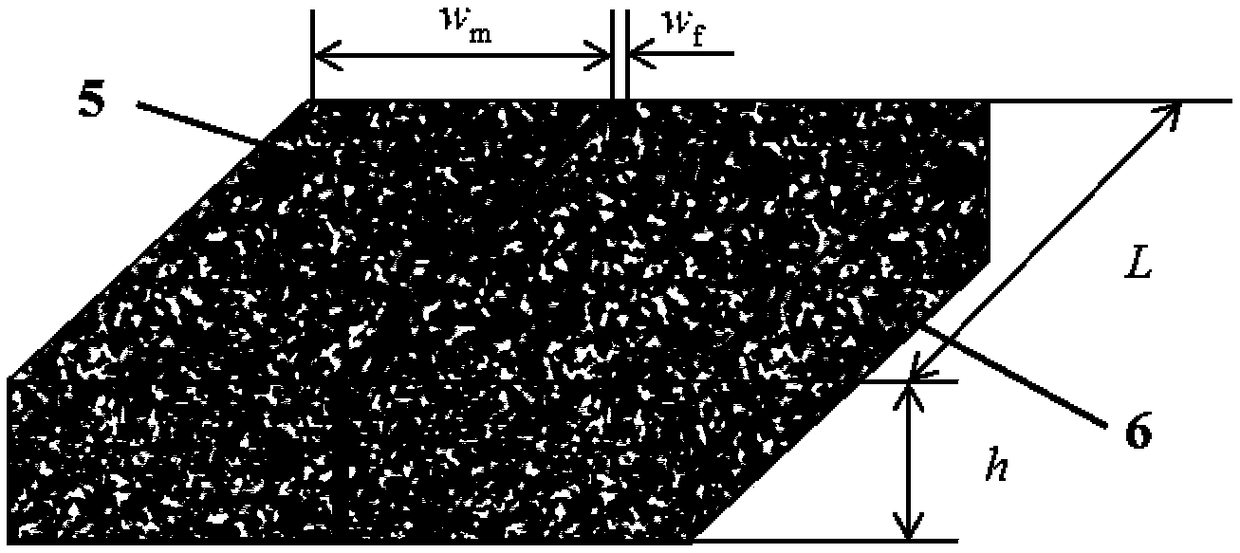

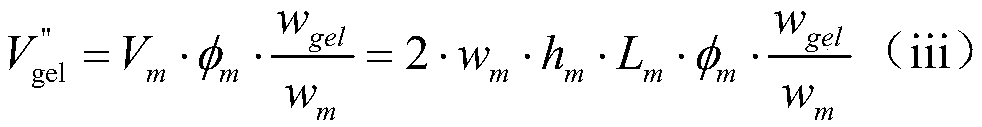

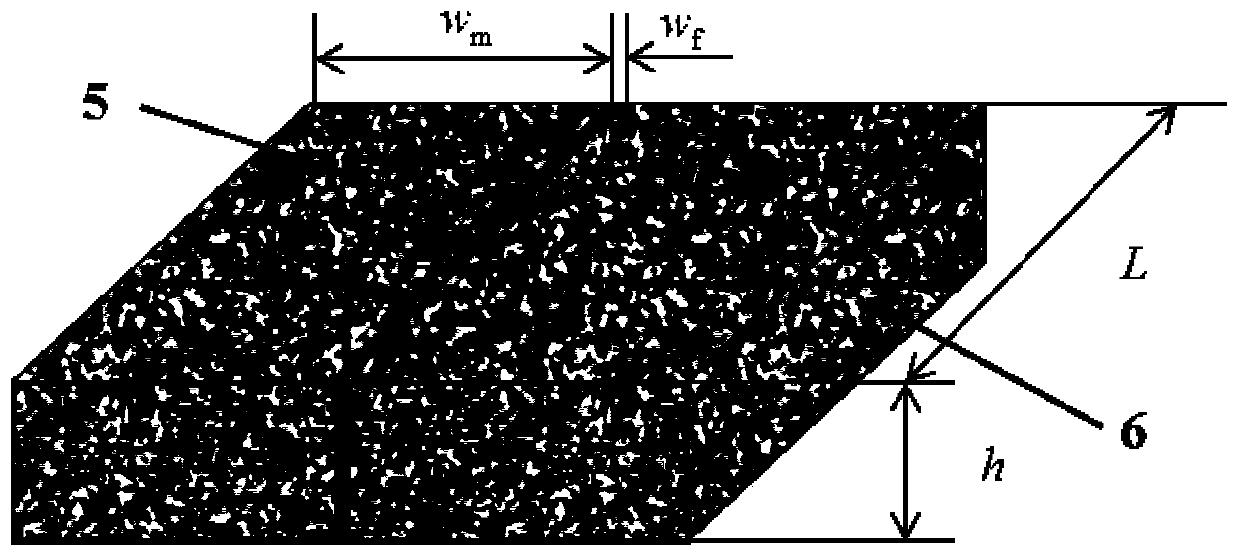

A method for calculating the dosage of water plugging agent for hydraulic fractures in horizontal wells

ActiveCN109145497AIncrease reflectionTypical representativeDesign optimisation/simulationSpecial data processing applicationsFiltrationHorizontal wells

The invention provides a method for calculating the dosage of water plugging agent for hydraulic fractures in horizontal wells, which comprises the following steps: (1) designing an equivalent calculation model, simplifying a single section complex fracture network formed by hydraulic fracturing of the horizontal wells into an equivalent calculation model composed of a single macrofracture and a high permeability matrix; the macrofracture penetrating the high permeability matrix from the middle; (2) determining the physical parameters of the equivalent calculation model; (3) calculating the filling volume of plugging agent for single section complex joint net; (4) calculation of a total dosage of plugging agent. The calculation method of the invention can realize the quantitative calculation of the required plugging agent dosage, fully considers the plugging agent filtration loss and the filling effect of the plugging agent on the fracture, is accurate and simple and easy to operate, avoids the cost caused by the general injection of the plugging agent in large dosage, ensures the effective plugging of the plugging agent on the fracture, and improves the oil production quality of the oil well.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Improved construction method for hoisting and welding large-tonnage cast steel component complex joints

InactiveCN103495793AReduce workloadHarm reductionArc welding apparatusWelding/soldering/cutting articlesCarrying capacityElectroslag welding

The invention provides an improved construction method for hoisting and welding large-tonnage cast steel component complex joints. Through studying the welding technology of cast steel joints and section steel dissimilar steel, cracks are not prone to being generated by welding in a low-temperature state, welding quality is good, and using requirements are satisfied; the welding quality of electroslag welding is guaranteed without weakening carrying capacity, and a theoretical basis is provided for welding of cast steel and section steel dissimilar materials; the improved construction method has important theoretical value and application value and provides a basis for welding of similar structures of engineering or the same industry; integrality is good, force transmission is smooth, anti-fatigue performance is good, force application to a steel structure is more reasonable, the overall structure is more stable, the workload of aerial operation is reduced, the quality of the overall engineering is improved, construction cost is lowered, and hazards of the aerial operation to constructors are lowered; besides, the technological process of the improved construction method is simple, and operating is convenient.

Owner:YONGSHENG CONSTR GRP

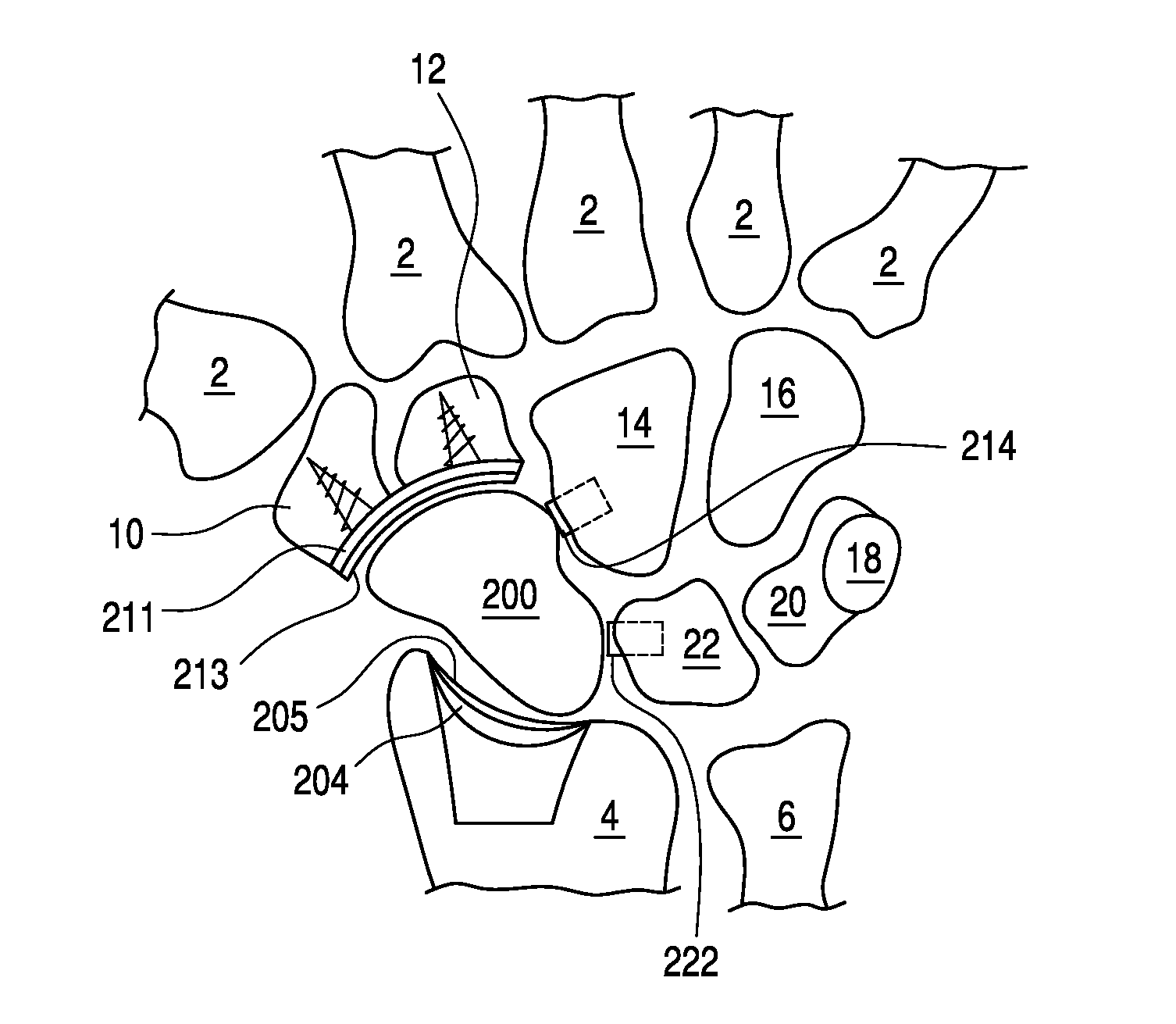

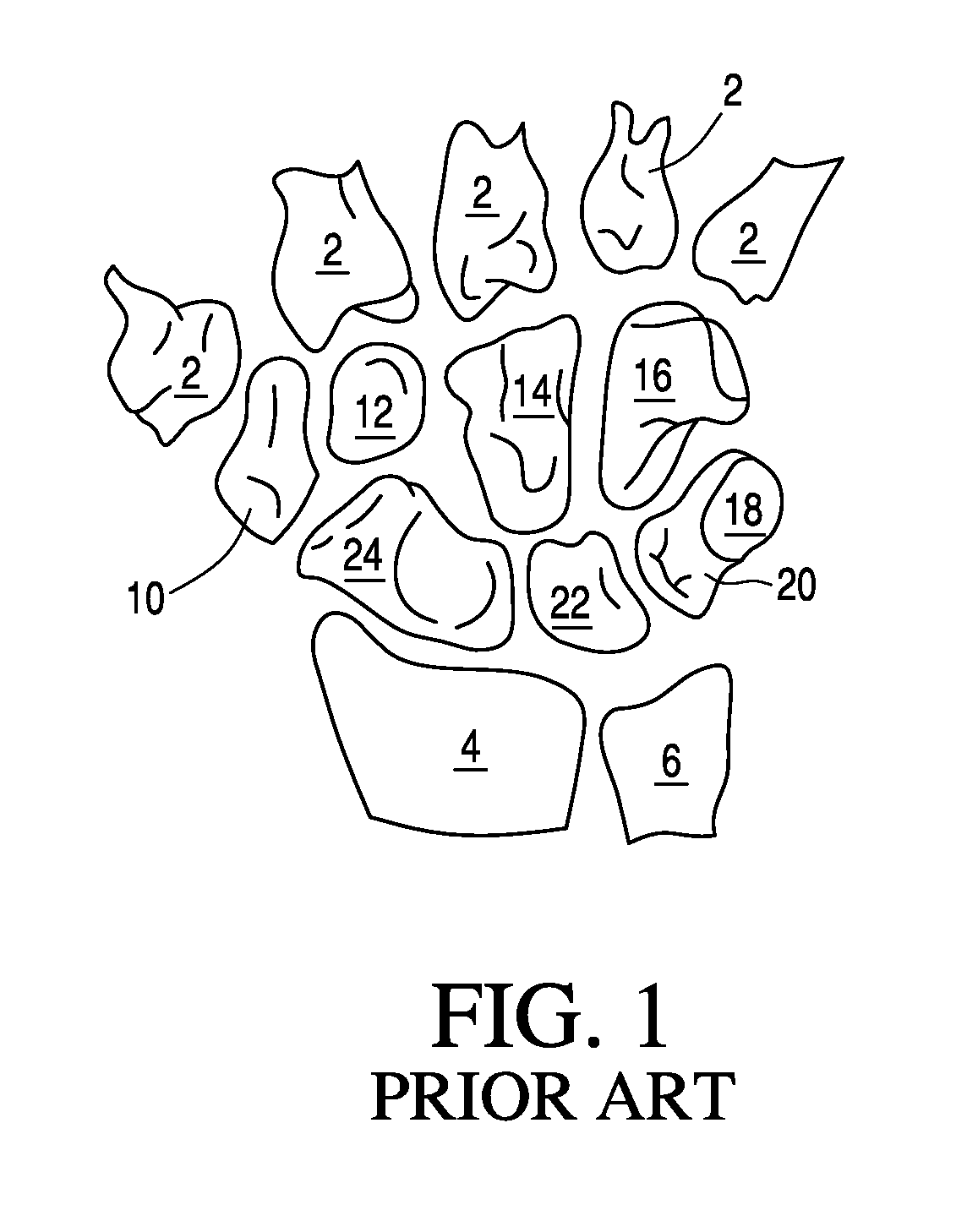

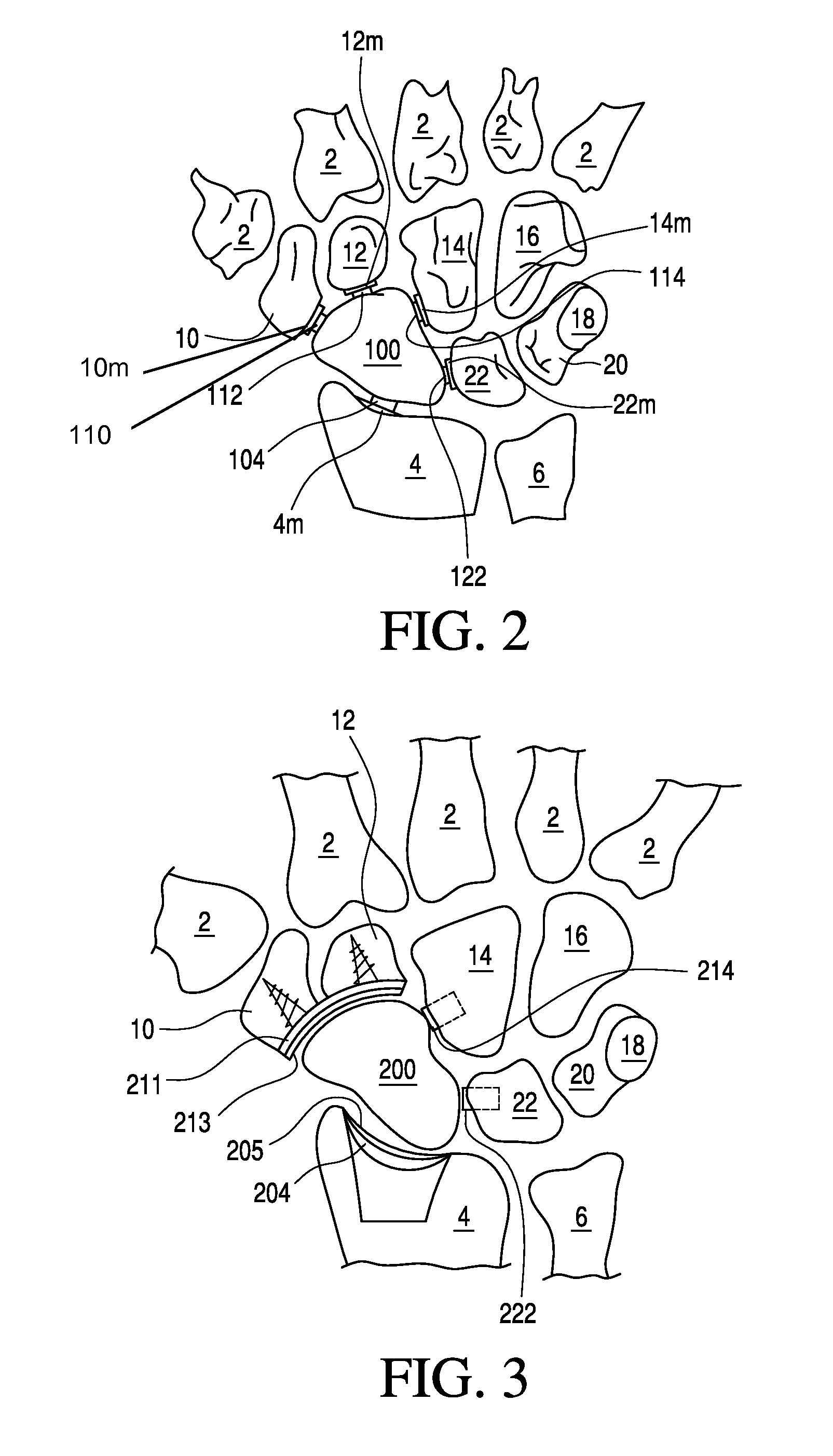

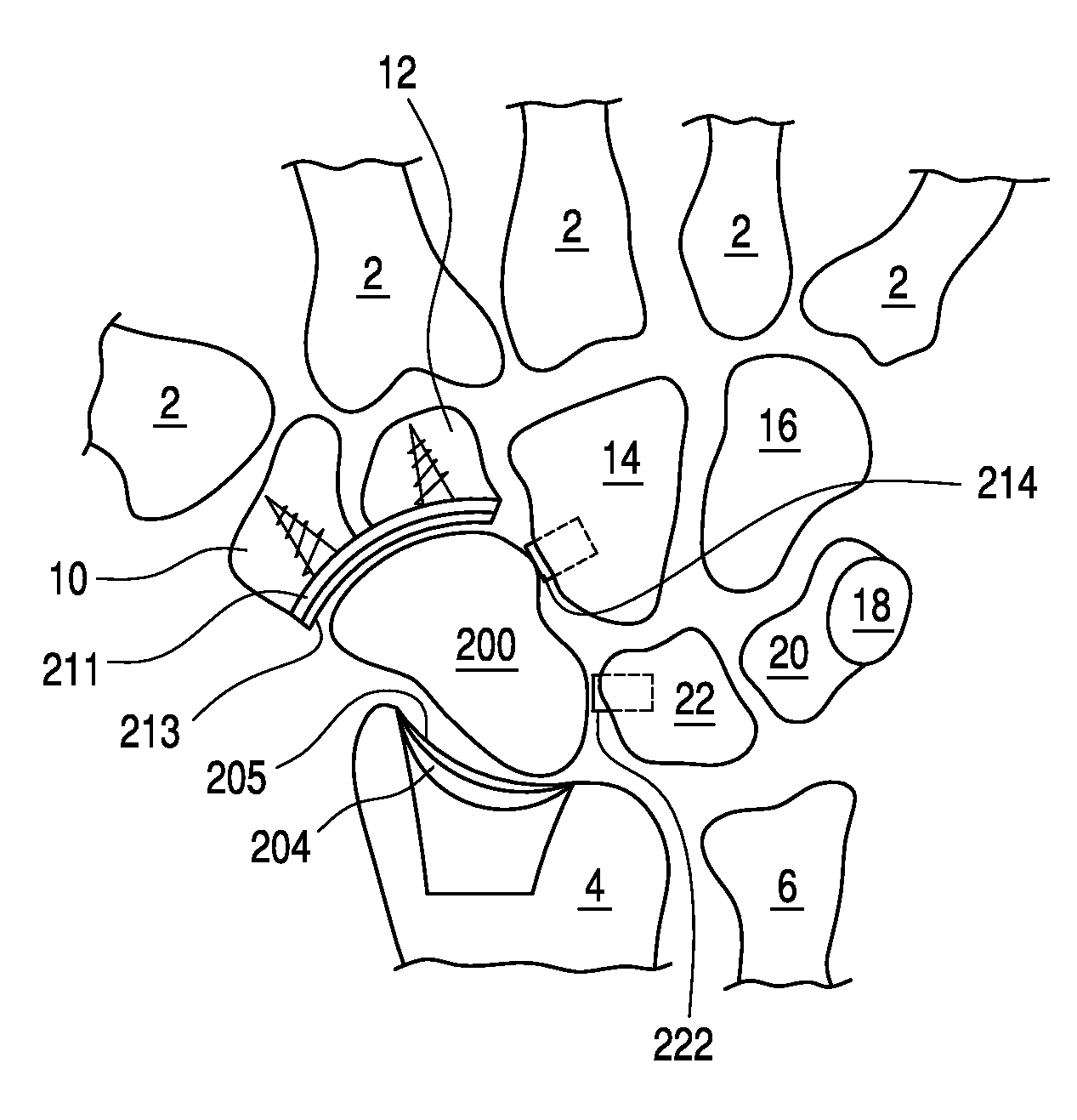

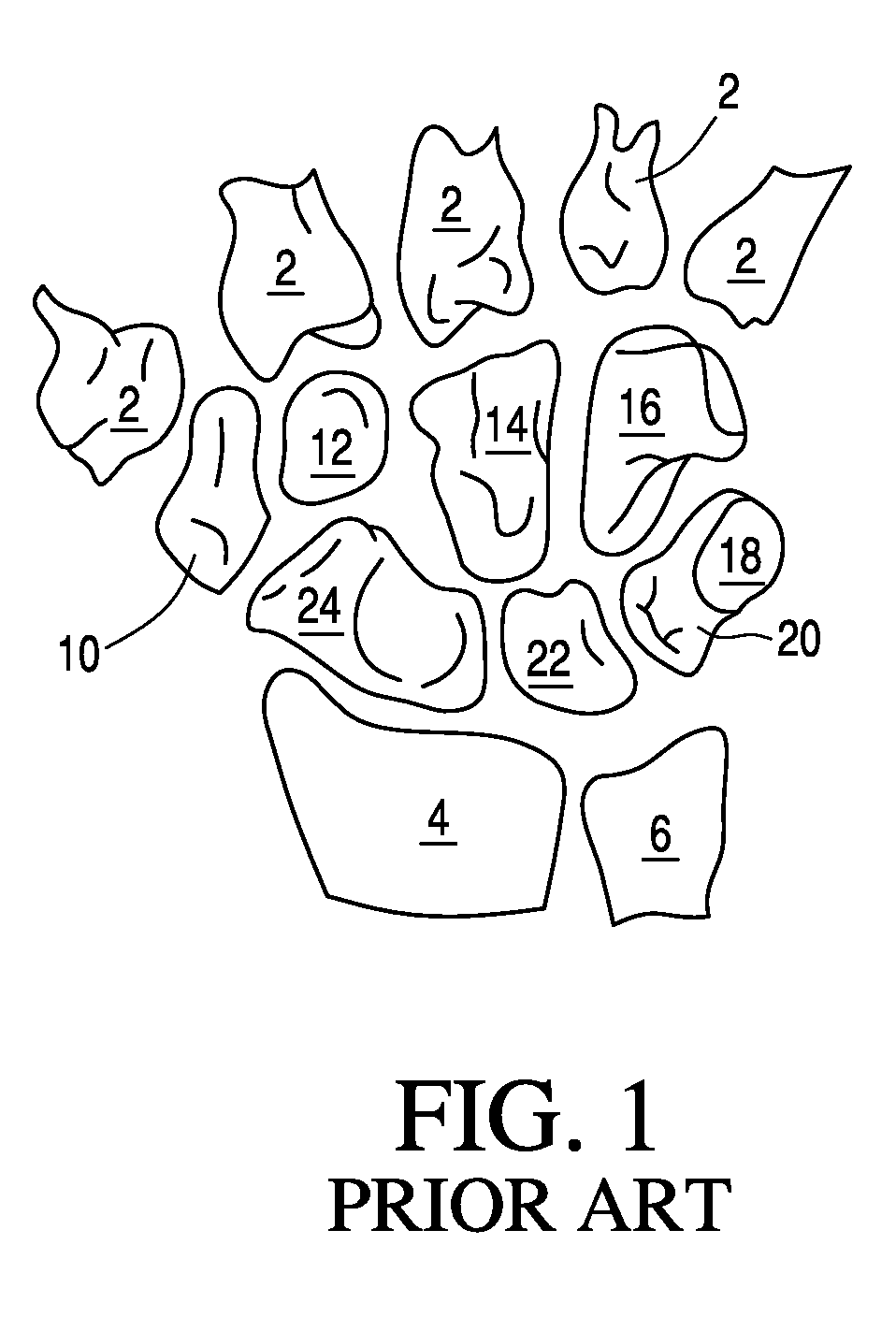

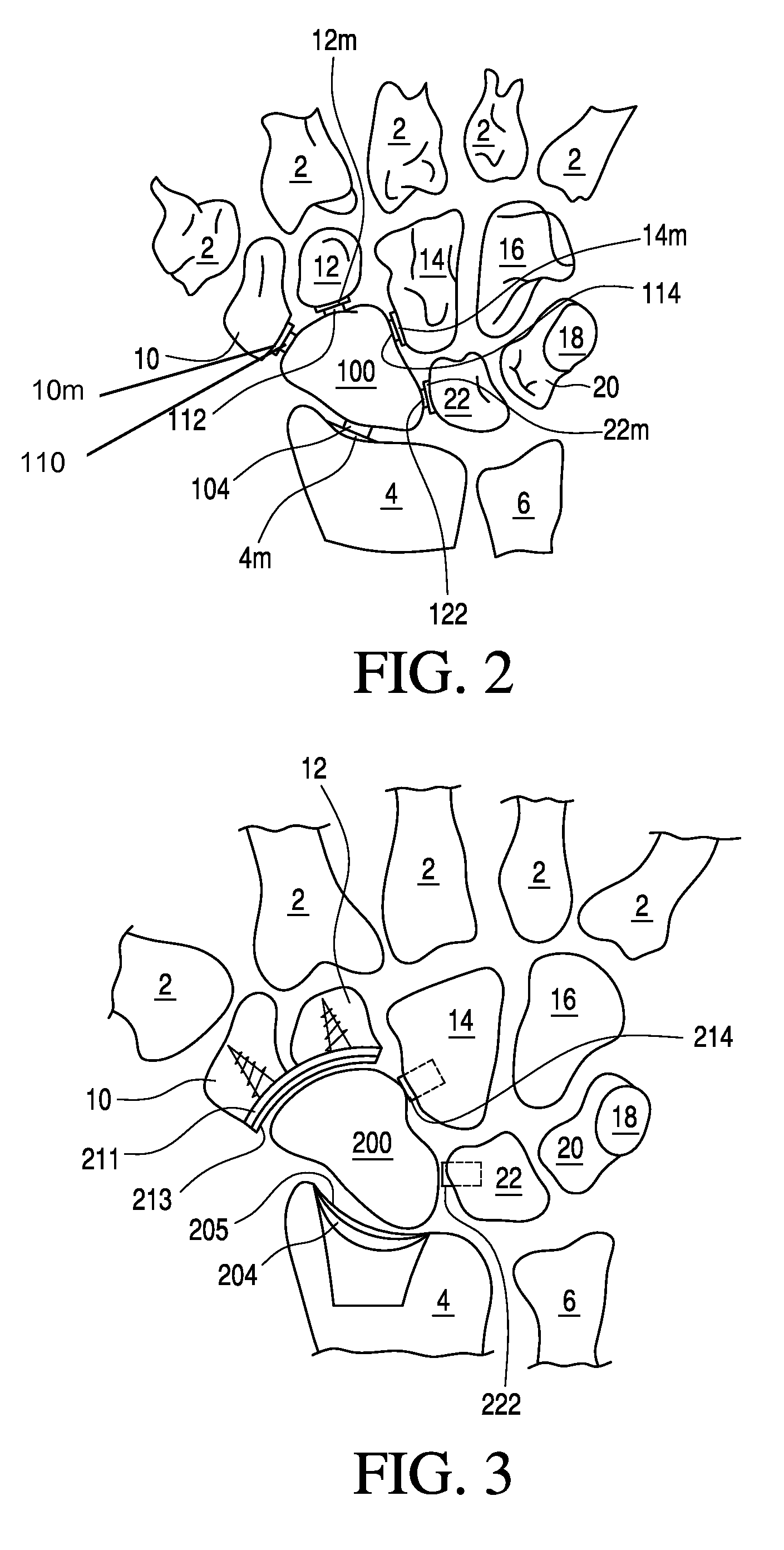

Bone prosthesis for maintaining joint operation in complex joints

A prosthesis for reconstructing a multibone joint such as a wrist. A patient's scaphoid is removed to create a void. The scaphoid has a plurality of adjacent bones, each of the adjacent bones comprising a surface generally facing the void. The surface of at least two of the adjacent bones is prepared by affixing a magnetic element thereto and a magnetic scaphoid implant is inserted into the void. A magnetic relationship exists between the magnetic elements and the magnetic scaphoid implant.

Owner:ROGACHEFSKY RICHARD A

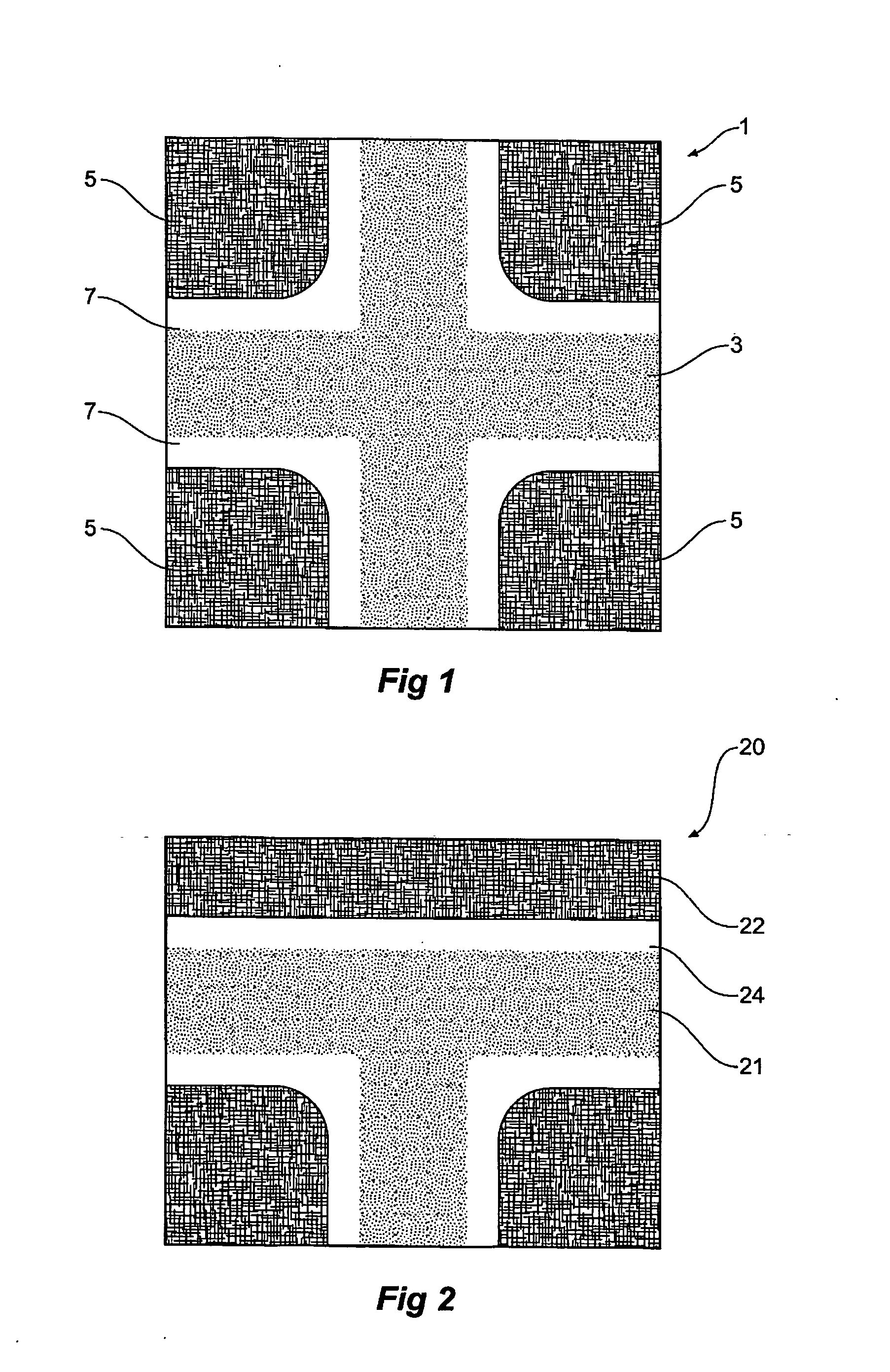

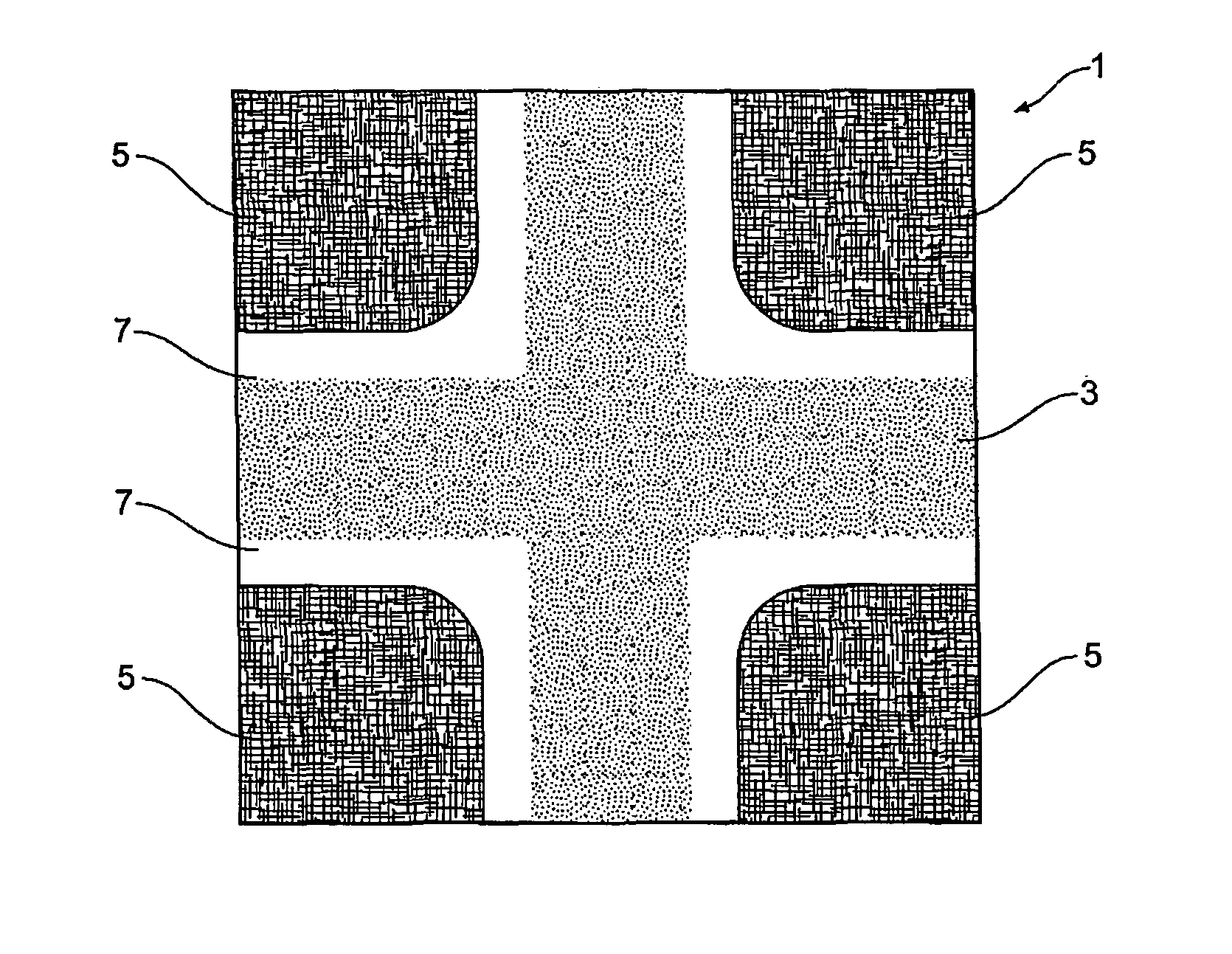

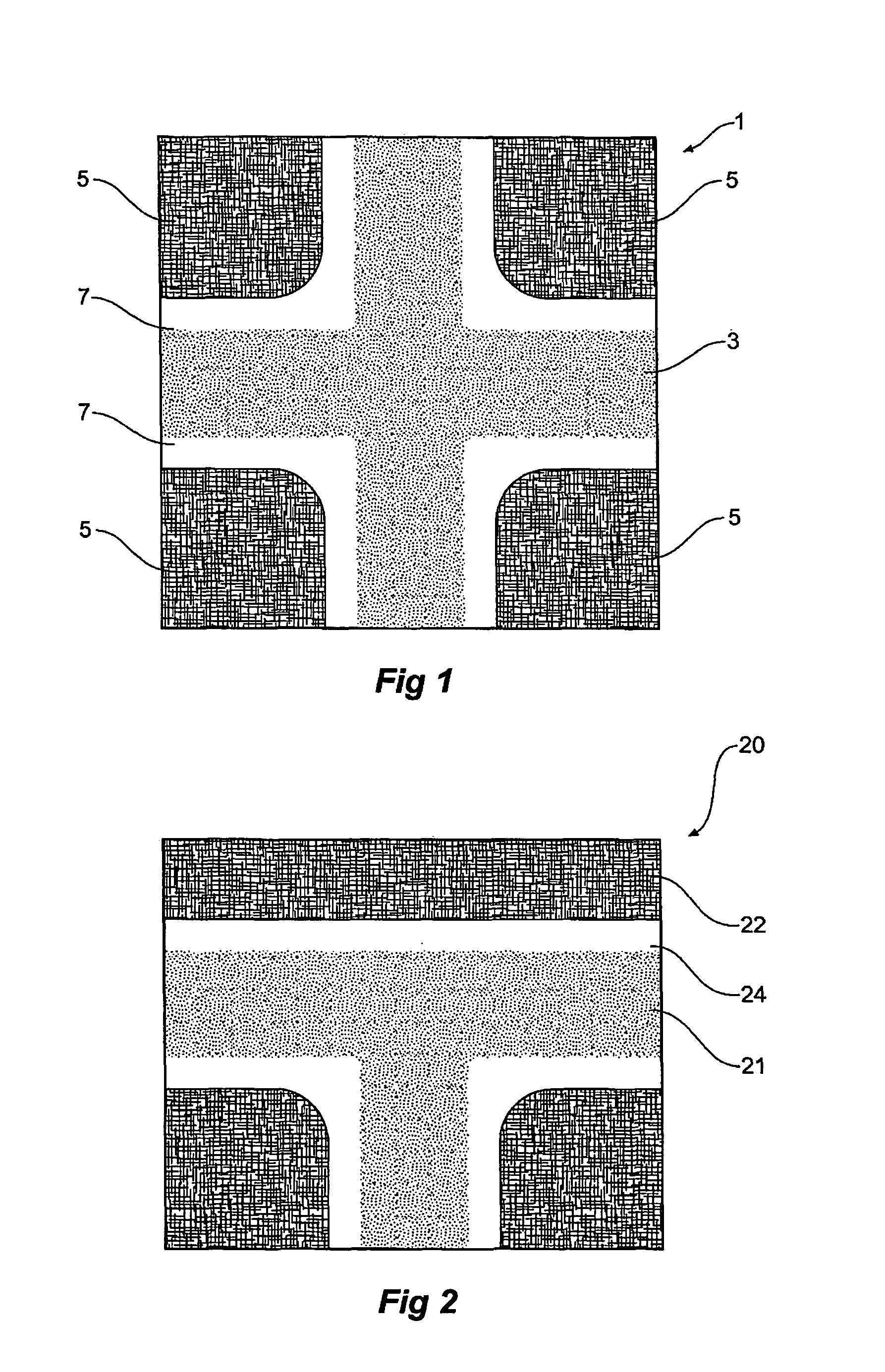

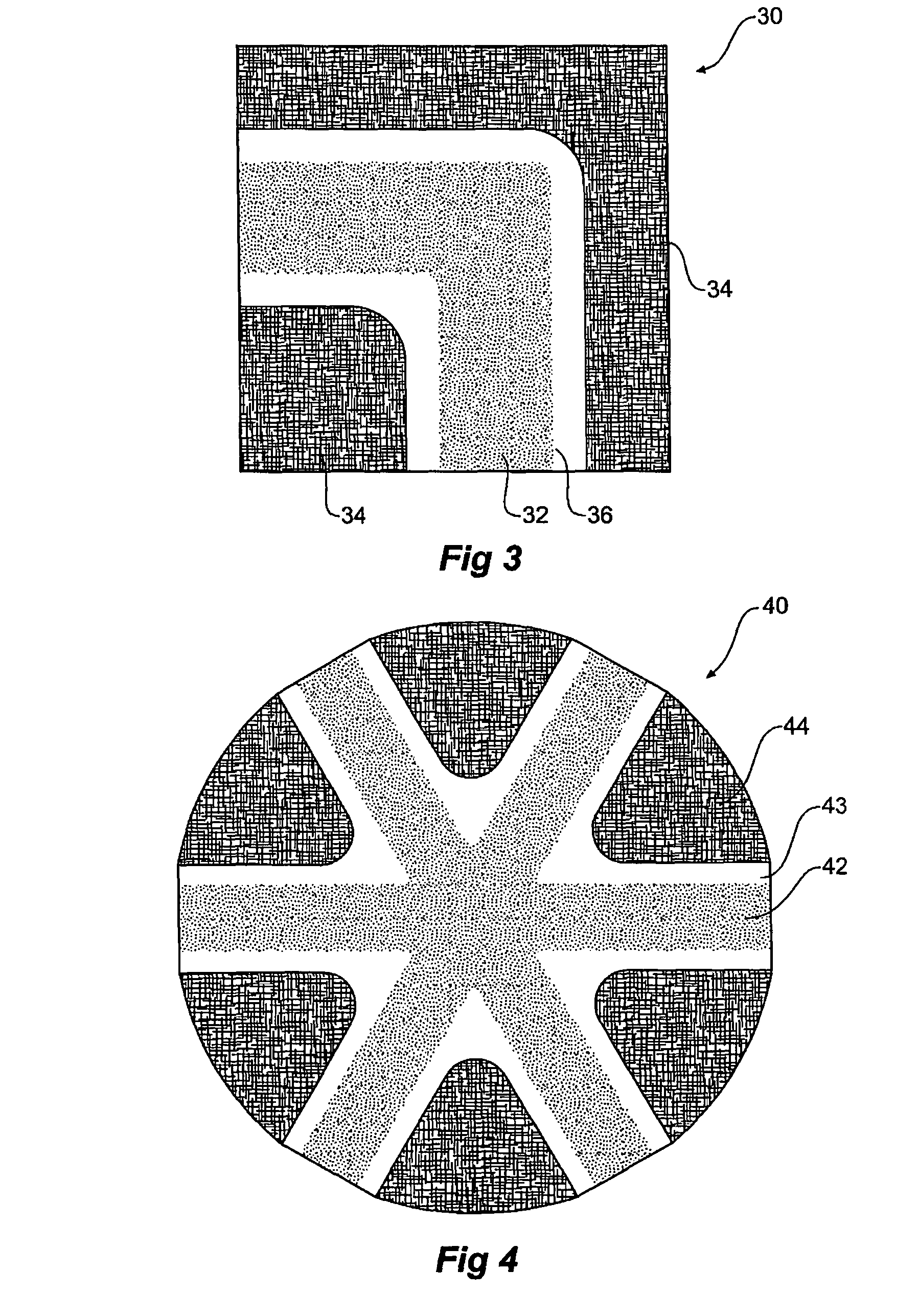

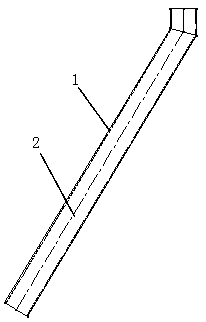

Prefabricated complex joint sealer

A sealing member for sealing over a structural joint or compound expansion joint. The sealing member has an elastomeric portion to overlie the lines of the joint and an adhesive receiving region to the sides of the elastomeric portion. The adhesive receiving region is adapted to be adhered to material adjacent to the structural joint. The elastomeric portion extends along each line of the structural joint in use to allow relative movement along each joint to be absorbed by the elastomeric portion.

Owner:SCARDIGNO PHILIP ANTHONY

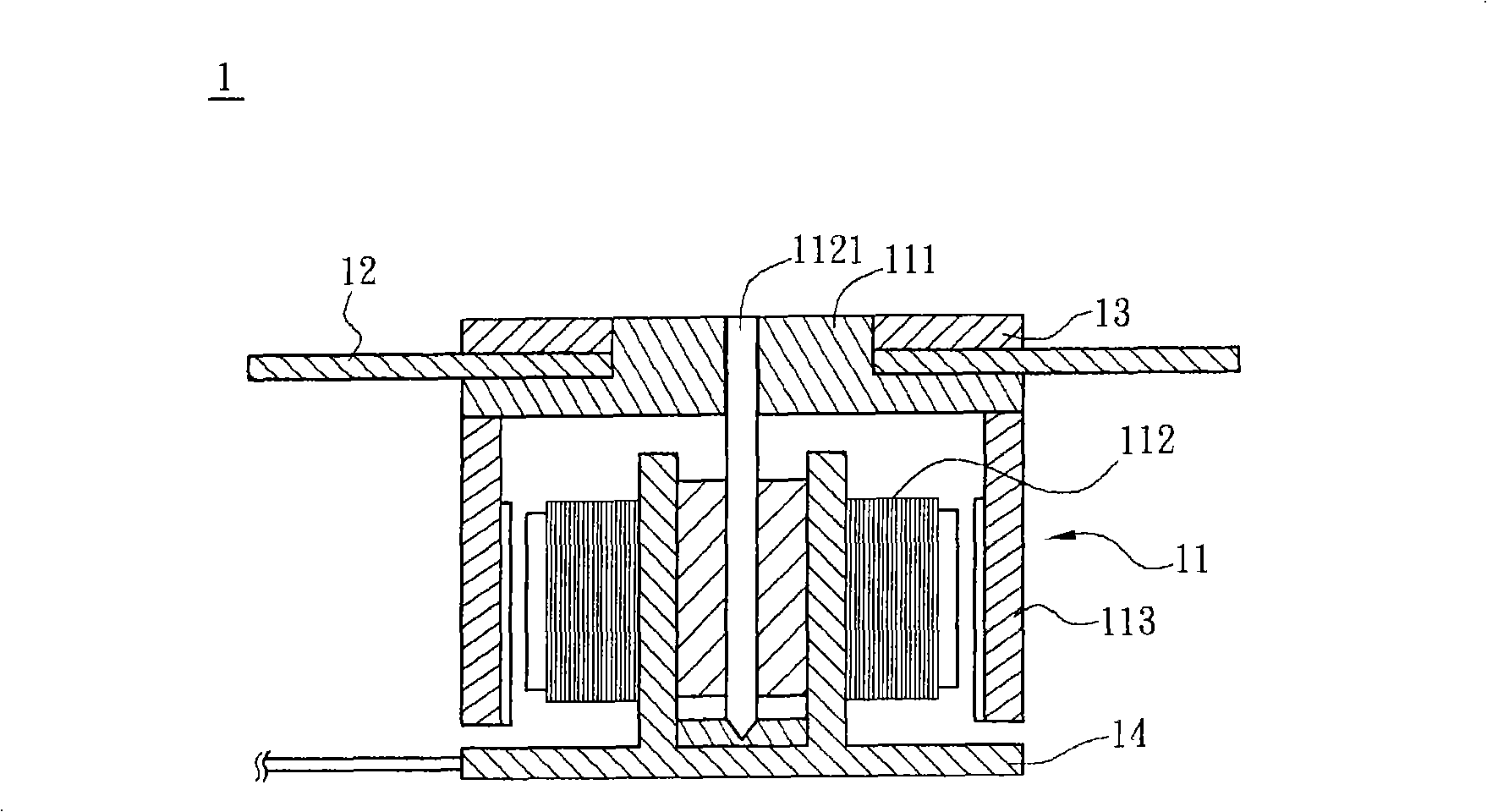

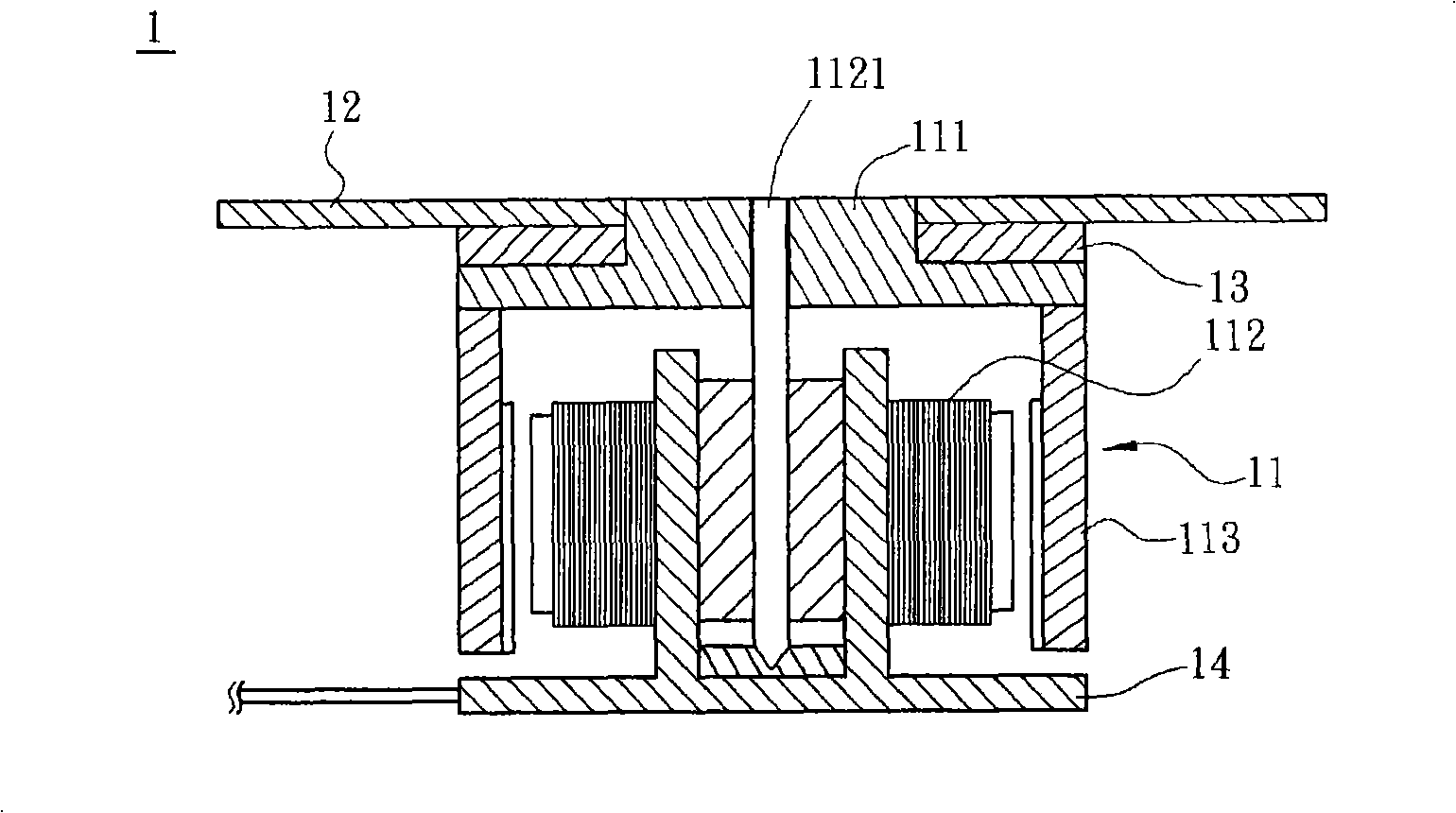

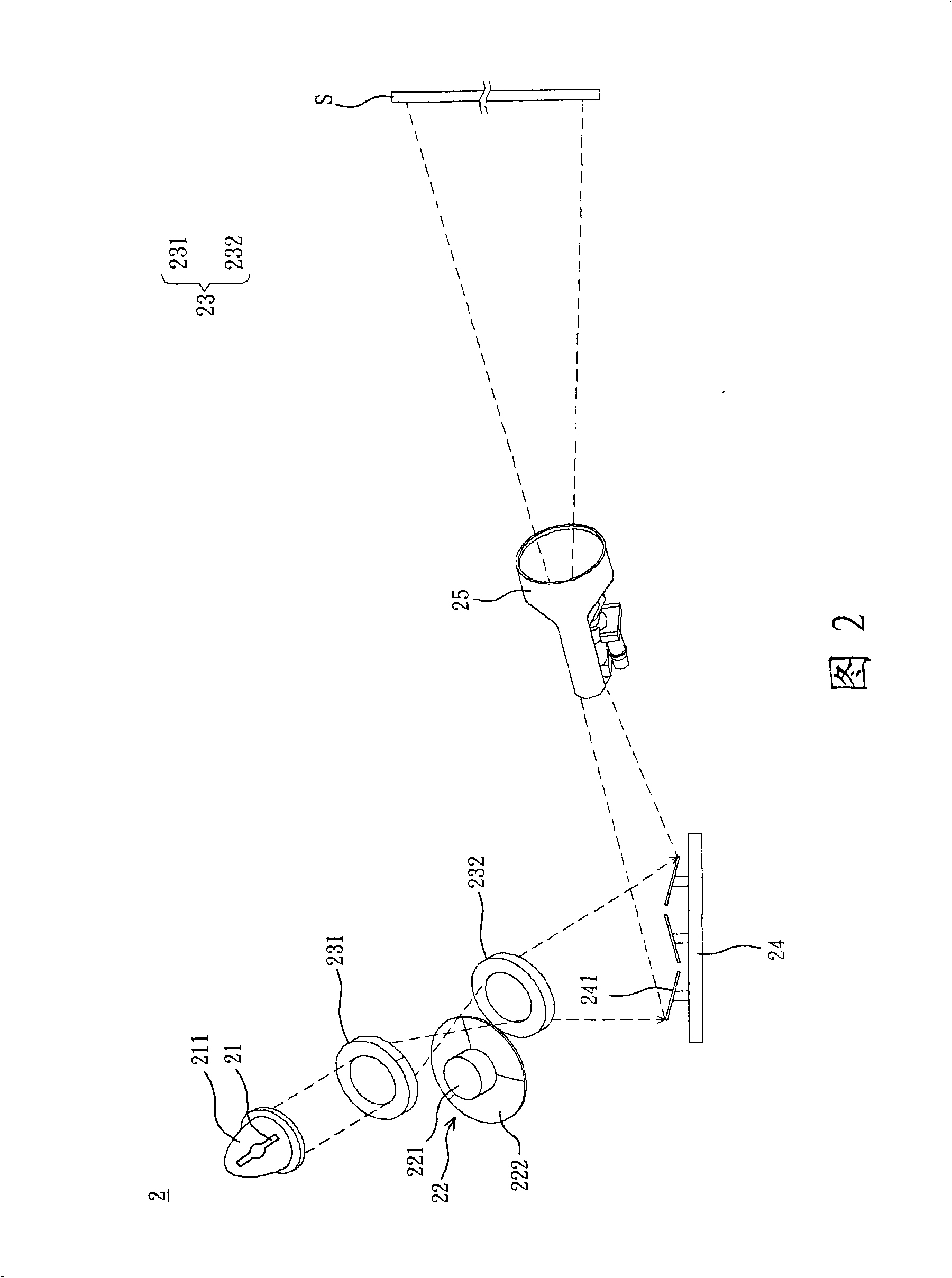

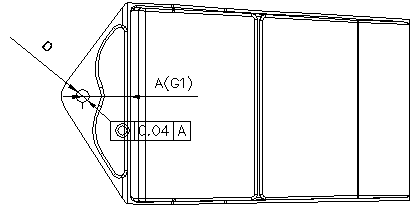

Color wheel component

InactiveCN101276133AAccelerated dissipationAvoid damageOptical filtersProjectorsEngineeringElectronic component

The present invention provides a color wheel component, including a motor, a gasket and a color wheel. The gasket is mounted on one surface of the motor and having complex joint parts, the color wheel is mounted on the gasket and having complex filters, the filters are mounted on the joint parts respectively, and each filter has an angle with the surface of the motor. The invention makes the filter drive the surrounding air flow to form a color wheel similar to a fan by utilizing the angle formed between the filter of the motor and the surface of the motor, the heat energy is preferably dispersed by mode of air convection, and assisting air flow, capable of avoiding the damage case of the color wheel component or other electronic elements in the projection system caused by the high temperature, very pleasant to the use.

Owner:PRODISC TECH INC

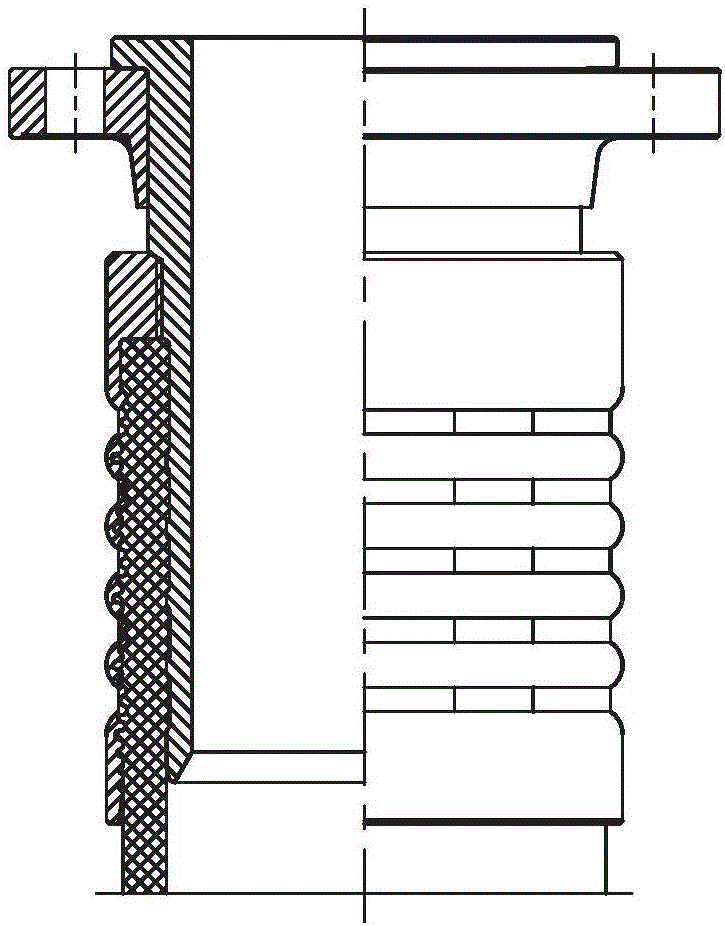

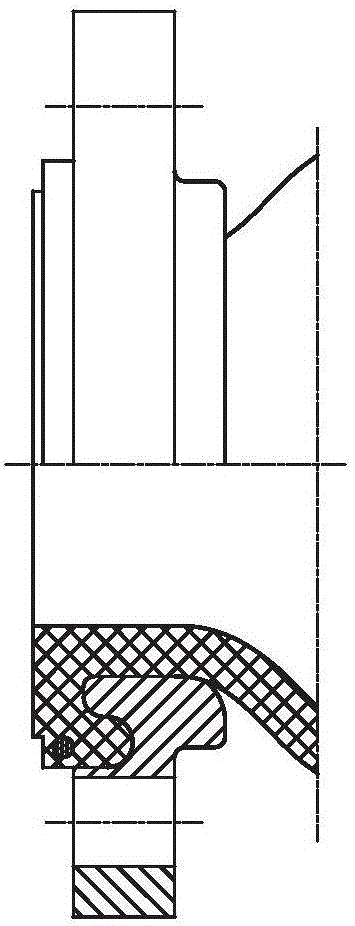

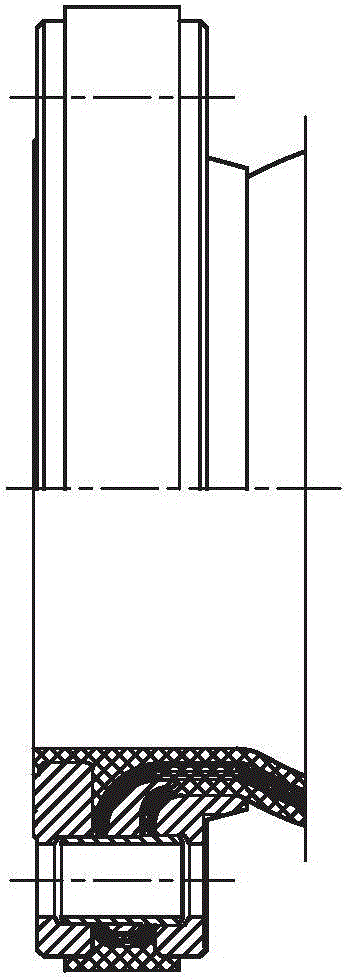

Large-diameter low-rigidity balancing flexible connecting tube for moveable flange and self-locking joint

The invention relates to a large-diameter low-rigidity balancing flexible connecting tube for a moveable flange and a self-locking joint. The connecting tube comprises a flexible tube body and buckling joints, wherein an inner glue layer, a skeleton layer and an outer glue layer are successively arranged in the flexible tube body from inner to outer; the buckling joints are symmetrically arranged at the two ends of the flexible tube body; each of the buckling joints comprises an outer pressing ring and an inner pressing ring; the outer pressing ring is arranged on the exterior of the inner glue layer at the end part of the flexible tube body in a sleeving manner; the front end of the skeleton layer is outward back turned and reversely wrapped on the front end face and the side wall of an annular plate; the inner glue layer, the skeleton layer, the outer glue layer, the outer pressing ring and the inner pressing ring are vulcanized and integrally formed. Through the symmetrical structures at the two ends of the tube body and the structure of the buckling joints, the technical problems of the traditional connecting tube of easiness in creeping, aging and losing efficacy, falling risk, complex joint structure, high dead weight, low flexibility, inferior vibration-reducing noise-attenuating effect, insufficient displacement compensation performance and easiness in cracking of welding joint are solved.

Owner:NAVAL UNIV OF ENG PLA +1

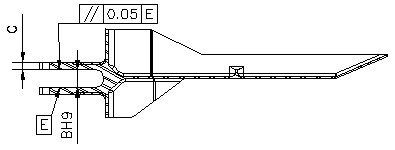

Method for processing complex joint part of aircraft

A method for processing a complex joint part of an aircraft comprises the steps of first milling a hexagonal part on a prepared blank to obtain a preliminary part, performing rough milling on the front and reverse side of the preliminary part with a drilled process hole to obtain a roughly processed part; performing heat treatment on the roughly processed part and then forming a plane, and then perform half finish-milling processing to obtain a processed half finish-milling part; after fine plane processing is performed on the processed half finish-milling part, performing finish-milling on the front and the reverse side, adopting a phi12R3 cutter to perform high-speed hole milling on the part, performing hole processing on the surface of a finish-milling lug piece and a recession, and processing a lug groove in two steps to obtain a processed finish-milling part; metering the appearance of the processed finish-milling part, and selecting the qualified processed finish-milling part toremove a process supplementing block to obtain a joint part. By reasonable selection of the cutter and optimized processing of process parameters, high-speed and high-efficiency processing of the joint part is achieved; meanwhile, a lug groove front and reverse side verification edge and verification hole process is added, and the front and reverse side butt joint errors are effectively reduced.

Owner:JIANGXI HONGDU AVIATION IND GRP

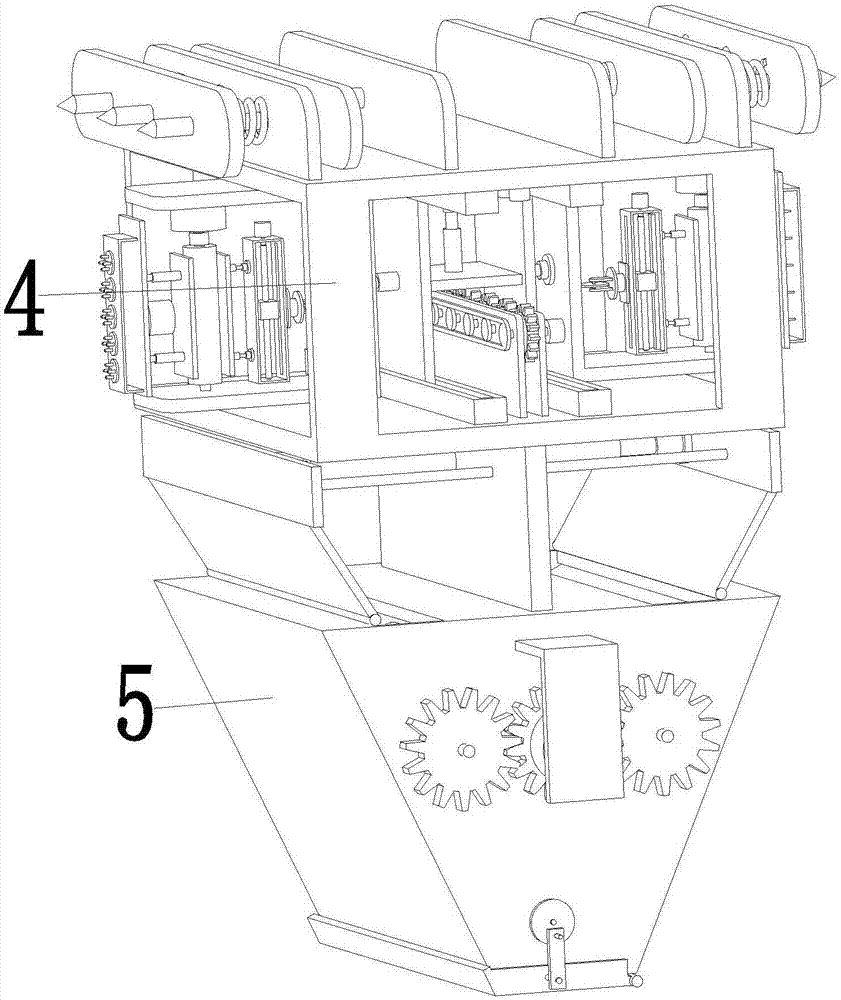

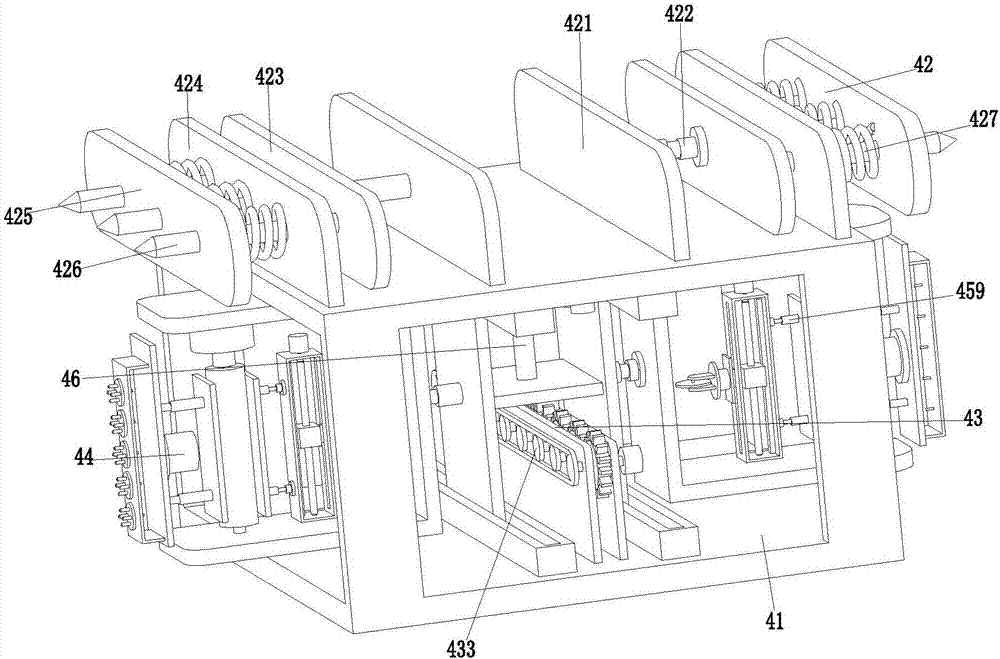

Efficient dabbing and grooving type pre-stressed concrete beam wet joint construction equipment

InactiveCN107988912AGood effectReduce labor intensityBridge erection/assemblyPrestressed concrete beamConcrete beams

The invention relates to efficient dabbing and grooving type pre-stressed concrete beam wet joint construction equipment which comprises a dabbing and grooving device. A crushing recovery device is arranged at the lower end of the dabbing and grooving device and comprises a dabbing support plate mounted at the lower end of a dabbing and grooving frame, the lower end of the dabbing support plate ismounted on a crushing recovery bucket, two crushing guide mechanisms are symmetrically arranged on the dabbing support plate, a crushing mechanism is arranged in the crushing recovery bucket, and a crushing retaining mechanism is arranged at the lower end of the crushing recovery bucket. By the efficient dabbing and grooving type pre-stressed concrete beam wet joint construction equipment, problems of manual construction with existing dabbing equipment, repeated dabbing at complex joint positions, treatment incompleteness in manual control of the dabbing equipment, complexity in operation, human health hazards and environmental pollution caused by impurities and dust in a construction process, potential safety hazards caused by arbitrary throwing of wastes generated in construction, and the like in an existing wet joint dabbing and grooving process can be solved.

Owner:范满香

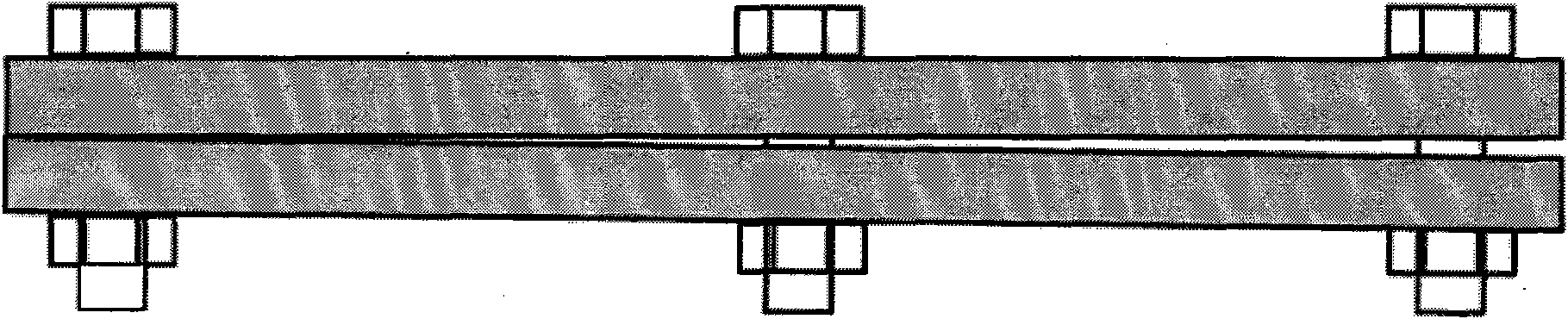

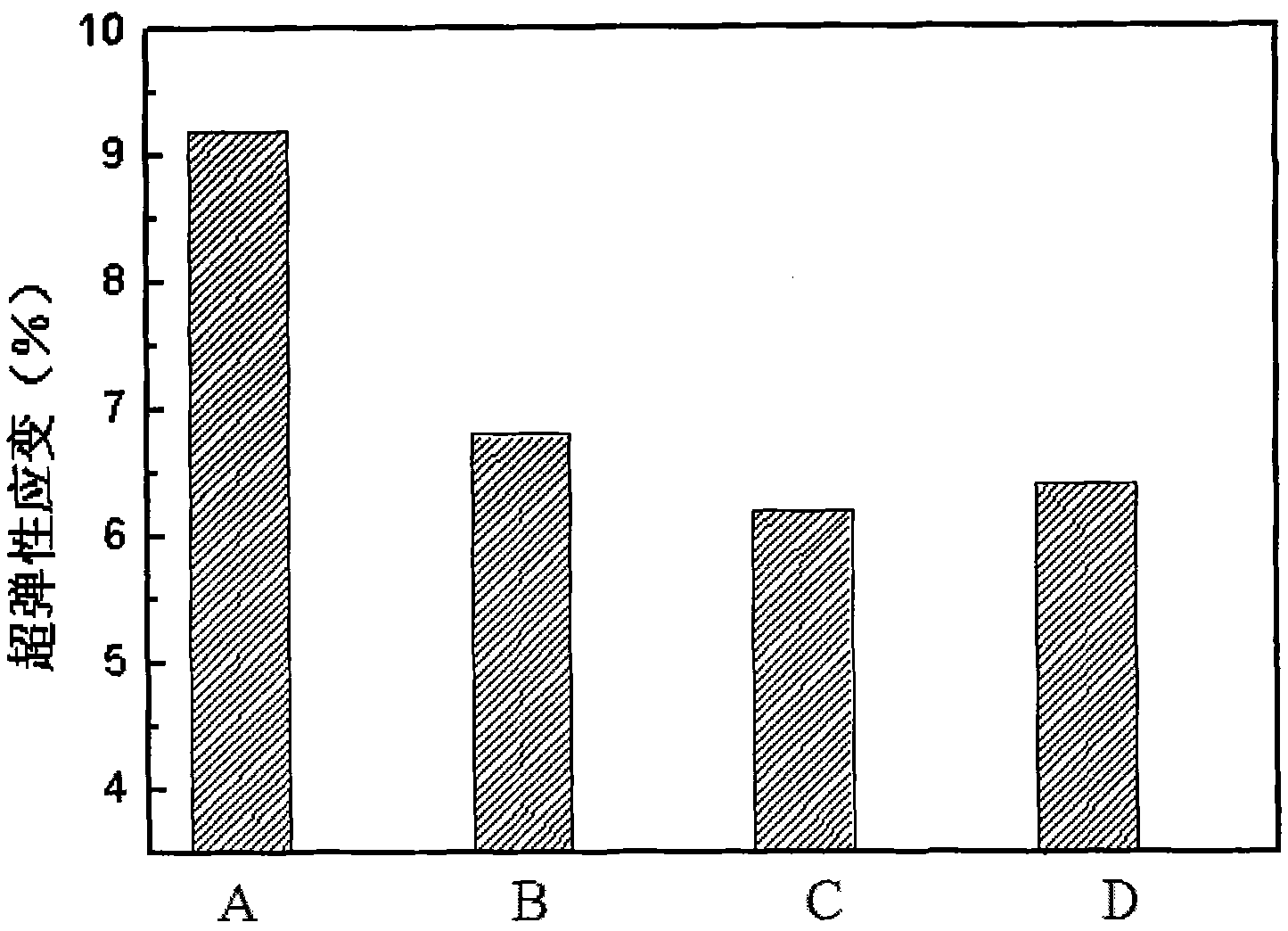

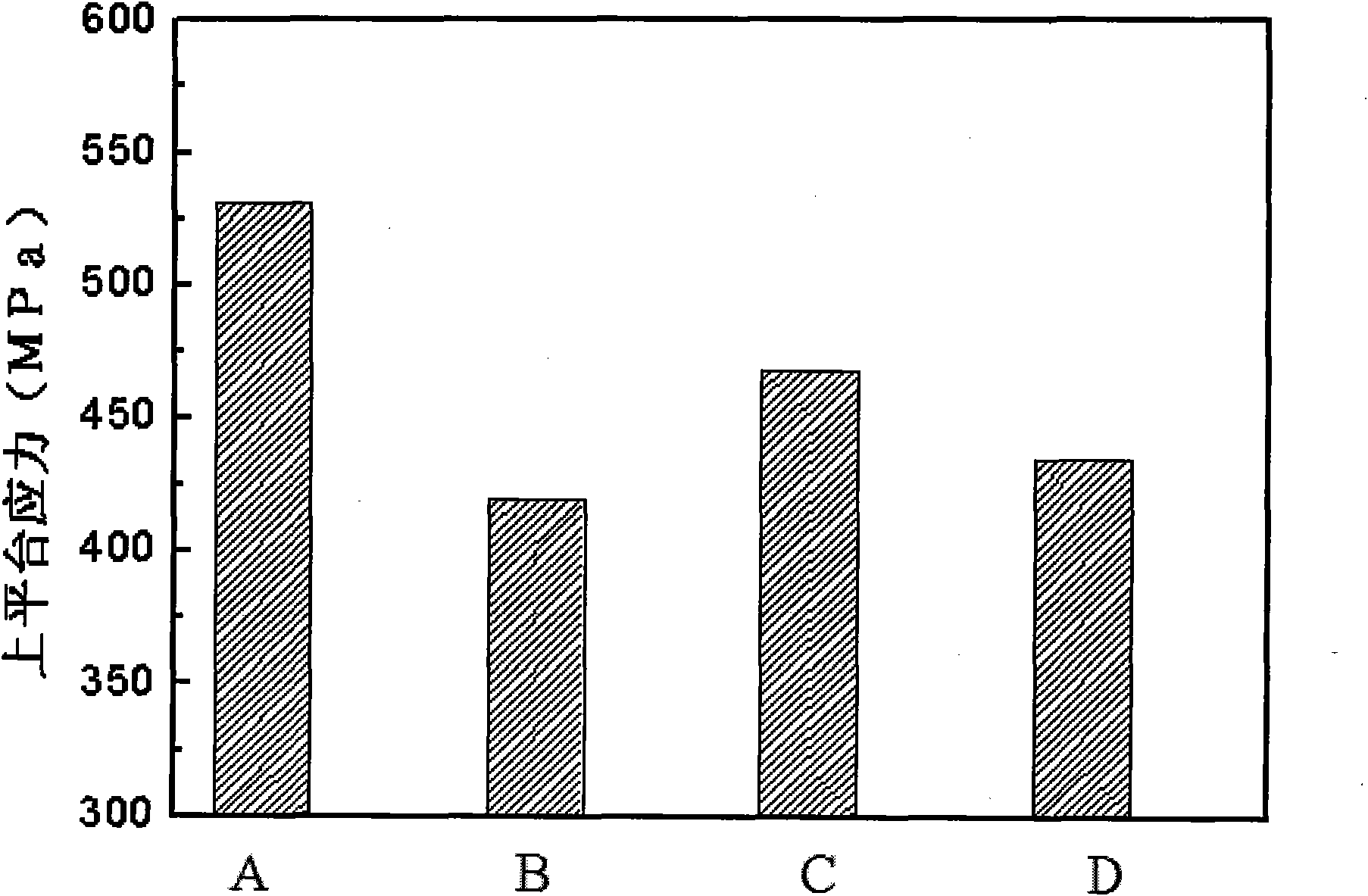

Manufacturing method of memory alloy balanced-load connecting damping element

InactiveCN101982290AImprove performanceGood damping propertiesStress concentrationShape-memory alloy

The invention discloses a manufacturing method of a memory alloy balanced-load connecting damping element, which relates to a manufacturing method of a damping element. The invention solves the problems that the current composite materials have high brittleness, performance anisotropy, easy lamination in mechanical processing, poor local strength and complex joint stressing, and once a component is overloaded locally, the whole component can be quickly damaged due to stress concentration. The manufacturing method comprises the following steps: (1) carrying out cold rolling to deform TiNi memory alloy by more than 20%, then annealing at 300DEG C-550DEG C for 1 hour, then mechanically processing, and then carrying out constraint aging to obtain the element; and (2) putting the element into liquid nitrogen and then putting into boiled water repeatedly for 20-100 times to obtain the memory alloy balanced-load connecting damping element. The balanced-load connecting damping element prepared by the method of the invention simultaneously has superior super-elasticity (the constant elasticity strain can reach 8% and the high upper plateau stress is greater than 490MPa) and excellent damping behavior, can realize perfect balanced-load connection, and avoids the problem of failure breakage caused by local stress concentration.

Owner:HARBIN INST OF TECH

Bone prosthesis for maintaining joint operation in complex joints

A prosthesis for reconstructing a multibone joint such as a wrist. A patient's scaphoid is removed to create a void. The scaphoid has a plurality of adjacent bones, each of the adjacent bones comprising a surface generally facing the void. The surface of at least two of the adjacent bones is prepared by affixing a magnetic element thereto and a magnetic scaphoid implant is inserted into the void. A magnetic relationship exists between the magnetic elements and the magnetic scaphoid implant.

Owner:ROGACHEFSKY RICHARD A

A Calculation Method of Water Plugging Agent Dosage for Hydraulic Fractures in Horizontal Wells

ActiveCN109145497BIncrease reflectionTypical representativeDesign optimisation/simulationSpecial data processing applicationsFiltrationHorizontal wells

The invention provides a method for calculating the dosage of water plugging agent for hydraulic fractures in horizontal wells, which comprises the following steps: (1) designing an equivalent calculation model, simplifying a single section complex fracture network formed by hydraulic fracturing of the horizontal wells into an equivalent calculation model composed of a single macrofracture and a high permeability matrix; the macrofracture penetrating the high permeability matrix from the middle; (2) determining the physical parameters of the equivalent calculation model; (3) calculating the filling volume of plugging agent for single section complex joint net; (4) calculation of a total dosage of plugging agent. The calculation method of the invention can realize the quantitative calculation of the required plugging agent dosage, fully considers the plugging agent filtration loss and the filling effect of the plugging agent on the fracture, is accurate and simple and easy to operate, avoids the cost caused by the general injection of the plugging agent in large dosage, ensures the effective plugging of the plugging agent on the fracture, and improves the oil production quality of the oil well.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Prefabricated complex joint sealer

A sealing member for sealing over a structural joint or compound expansion joint. The sealing member has an elastomeric portion to overlie the lines of the joint and an adhesive receiving region to the sides of the elastomeric portion. The adhesive receiving region is adapted to be adhered to material adjacent to the structural joint. The elastomeric portion extends along each line of the structural joint in use to allow relative movement along each joint to be absorbed by the elastomeric portion.

Owner:SCARDIGNO PHILIP ANTHONY

Method for positioning multiple brackets

InactiveCN110043053ARapid positioningPrecise positioningBuilding material handlingStructural engineeringAngle gauge

The invention relates to a method for positioning multiple brackets. The method comprises the following steps that first, a broken line column is assembled; second, horizontal brackets are positioned,specifically, the distribution positions of the horizontal brackets are marked on a horizontal steel plate, the top of the broken column sleeves the horizontal steel plate, base points on the inner side of the broken column are aligned, thus the horizontal steel plate is located on the top faces of all the horizontal brackets, meanwhile, turn buckles are arranged between the horizontal steel plate and the top face of the broken column to adjust the horizontal steel plate, and the horizontal brackets start to be mounted; and third, oblique brackets are positioned, specifically, after the horizontal brackets are welded, the horizontal steel plate is detached, the oblique brackets start to be mounted, the horizontal brackets are taken as the datum during positioning of the oblique brackets,the angles of the brackets are controlled through an angle-controllable angle gauge, and the angle of the angle gauge is consistent with the angles between the oblique brackets and the horizontal brackets. The method is mainly applied to machining of a complex joint of the broken line column with the multiple brackets, by using a device, the brackets at different angles can be positioned rapidly and precisely, and the mounting precision of on-site members is guaranteed.

Owner:SHANGHAI BAOYE GRP CORP

Construction method for realizing fiber continuity at joints of concrete structure through molds

The invention discloses a construction method for realizing fiber continuity at joints of a concrete structure through molds. The concrete joints are connected through fibers in a bridging mode, mechanical properties of the joints do not need to be improved through complex joint modes such as changing of the shapes of the joints and density increasing of reinforcing bars or special-shaped steel plates, and thus the problem of fiber incontinuity at the joints of the concrete structure is solved fundamentally; by manufacturing the fine-hole molds, the work that fibers are inserted into connecting plates is easy to realize, construction is quick, position inserting of the fibers is precise, the spacing of fine holes is manufactured according to the designed fiber spacing, the molds can be reused, and the construction cost is greatly saved; different types of fibers can be considered to be inserted into the manufactured molds, and the manufactured molds are suitable for various concrete structure joints; and in addition, the method is fast in construction, the project cost can be reduced, and good promotion prospects are achieved.

Owner:FUZHOU UNIV

Construction method for beam column joint core area rigid steel structure

InactiveCN105735490AGuaranteed StrengthThe effect of weakening intensity changesBuilding constructionsSteel barSteel columns

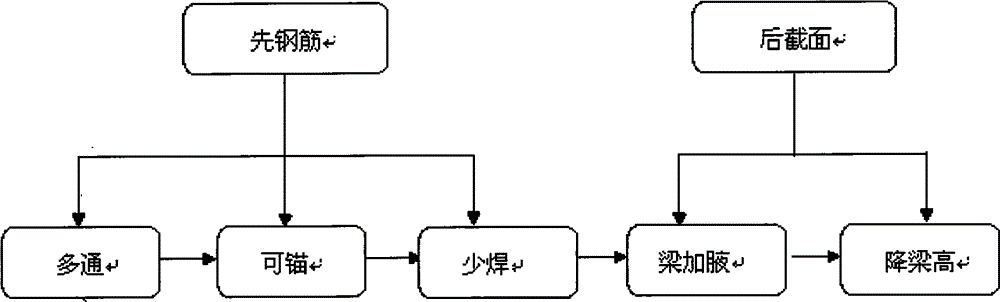

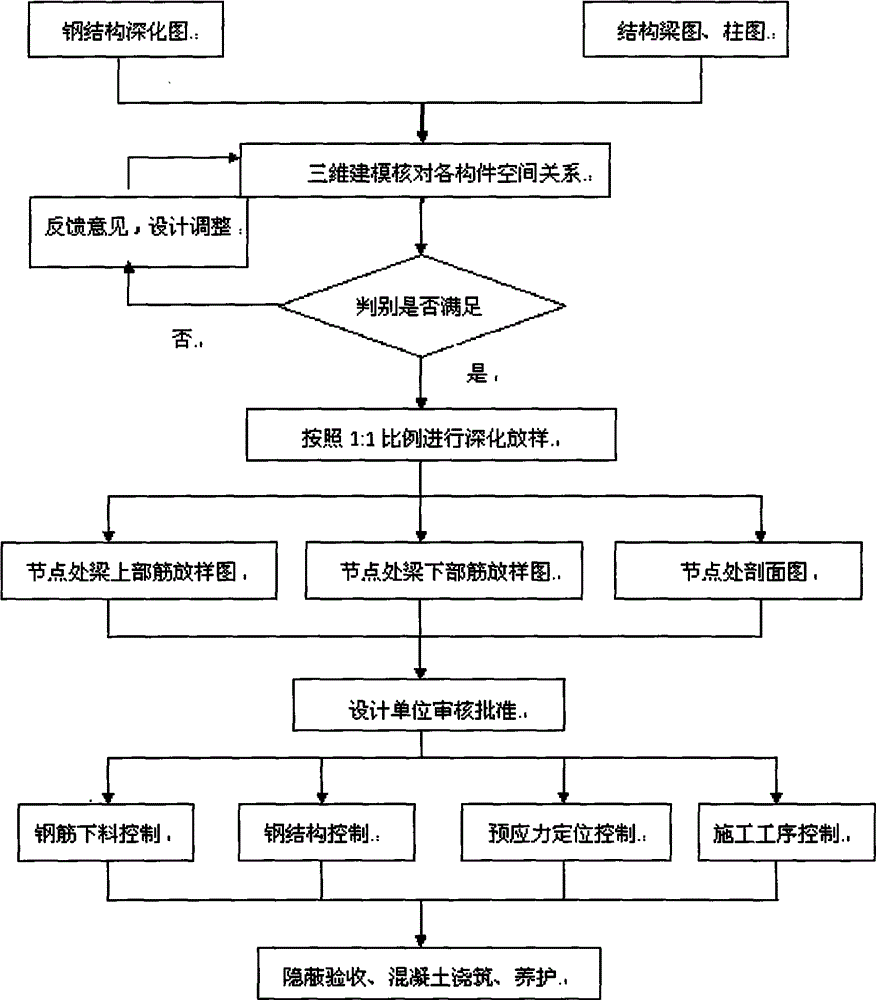

The construction method of the steel structure in the core area of the beam-column joint is to firstly carry out multi-pass, anchorage and less welding operations on the steel structure, and then carry out beam addition and beam height reduction operations on the section; multi-pass means that on both sides of the support For the upper steel bars with different reinforcement values, it is advisable to choose steel bars with the same diameter as much as possible so that they can pass through the support and avoid anchoring at the support separately; when the beam reinforcement cannot meet the conditions for penetrating joints, it can be selected in the core area of the joint Carry out anchoring; less welding means that when the beam reinforcement cannot meet the conditions of penetration joints and anchorage, you can choose to weld the reinforcement to the section steel reinforcement plate; the beam is added with axillary, that is, the stressed reinforcement at the edge of the beam can bypass the section steel column to penetrate or directly anchor; Lowering the height of the beam is to reduce the elevation of the top of the beam. In multi-beams and multiple rows of steel bars, it may lead to complex nodes with super high slab surface after pouring, and reduce the elevation of the top of the beam. Guaranteeing the strength of the node area also weakens the impact of concrete strength changes, and the bearing capacity can be increased by 20%-30%, reducing construction costs.

Owner:YONGSHENG CONSTR GRP +1

Anticorrosion cladding method of complex joint of ocean platform

The invention discloses an anticorrosion cladding method of a complex joint of an ocean platform, which comprises the following steps of: (1) carrying out manual rust removal / or blast sanding on a to-be-processed steel structure of the complex joint of the ocean platform; (2) coating corrosion inhibition repair cream on the surface of the steel structure which is subjected to the processing in the step (1); (3) sticking a mineral oil anti-corrosion band on the corrosion inhibition repair cream; and (4) coating unsaturated polyester resin on the mineral oil anti-corrosion band, sticking the glass wool cloth on the unsaturated polyester resin, coating the unsaturated polyester resin on the glass wool cloth, and rolling. The invention has the beneficial effects that the construction is convenient, the surface processing is simple, and the anticorrosion cladding method is suitable for an object with any shape and any structure; and by adopting the method, the complex joint of the ocean platform has good sealability, impact resistance and excellent anticorrosion effect, is environmental-friendly, and has no toxicity or pollution. The anticorrosion cladding method can be suitable for the cladding corrosion resistance of any complex joint of the ocean platform.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com