Method for processing complex joint part of aircraft

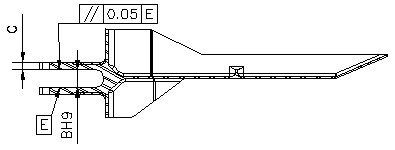

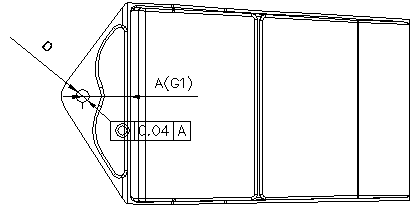

A processing method and part processing technology, applied in the field of parts processing, can solve the problems of difficult to guarantee the hole spacing A of the key elements of processing, easy deformation of parts, and difficult to guarantee the size of the width of the ear groove BH9, so as to ensure the consistency of manufacturing quality and reduce the Tool error, the effect of increasing the calibration edge and the calibration hole process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

[0024] A processing method for aircraft complex joint parts, the specific steps are as follows:

[0025] 1) Prepare the blank for processing;

[0026] 2) Mill the hexagon on the prepared blank to get the first part;

[0027] 3) Drill process holes on the original parts;

[0028] 4) Roughly mill the front and back sides of the primary parts drilled with process holes to obtain rough machined parts;

[0029] 5) Heat treatment of rough processed parts;

[0030] 6) Flatten the rough-worked parts after heat treatment;

[0031] 7) Carry out semi-finish milling on the front and back of the rough machined parts after flattening. In order to effectively release the processing stress of the parts and reduce the deformation of the parts, arrange 72 hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com