Solar energy electric heat utilization device and utilization method thereof

A solar energy and electric heating technology, applied in the field of solar energy utilization, can solve the problems of unreasonable structure, single solar energy utilization mode, and low efficiency, and achieve the effects of low manufacturing cost, simple structure principle, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

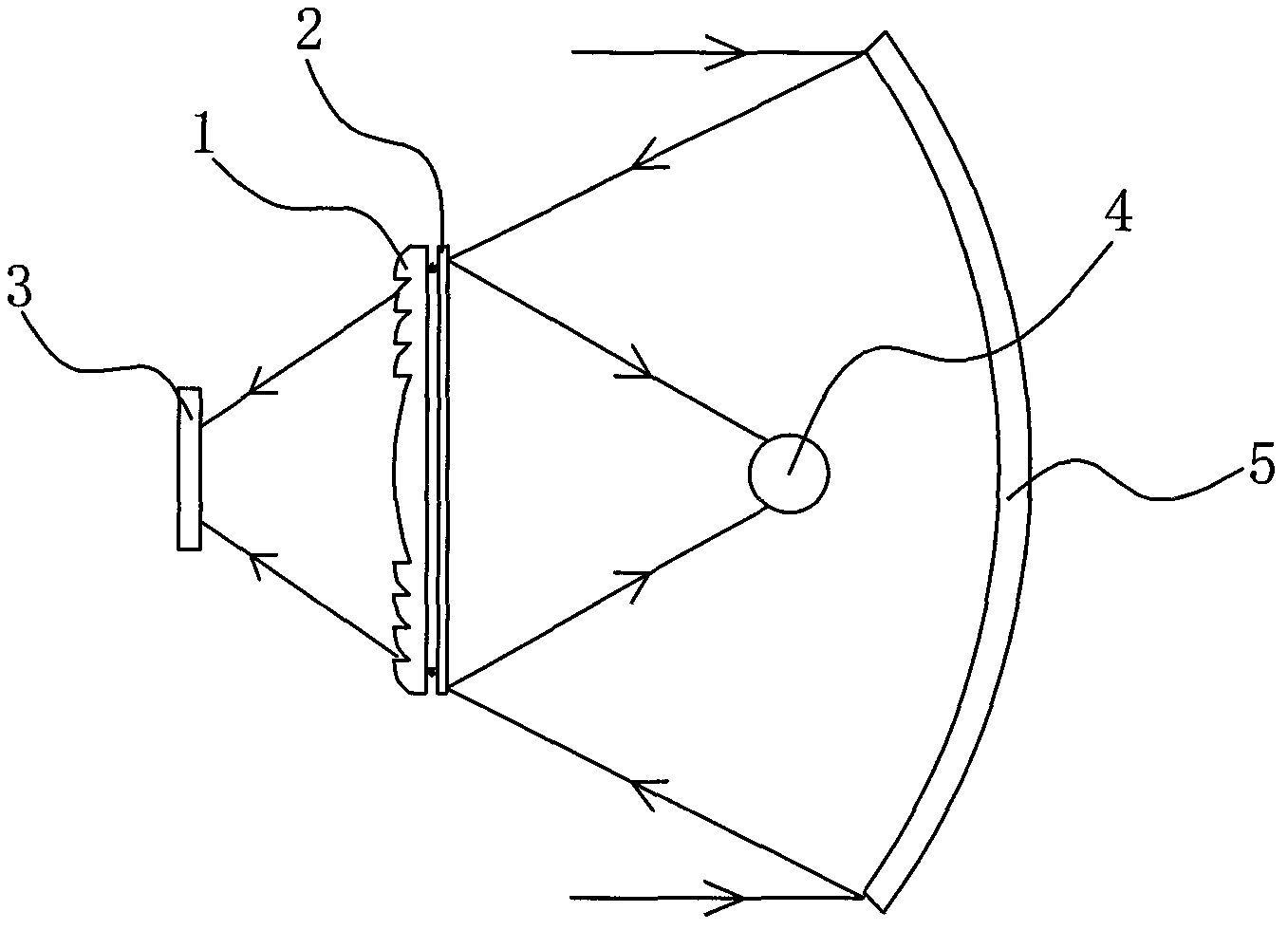

[0028] Embodiment one: if figure 1 As shown, the coated frequency divider is attached to the surface of one side of the Fresnel lens, and the coated frequency divider transmits short-wave light and reflects long-wave light. The coated frequency divider and the Fresnel lens are located between the photovoltaic cell and the heat receiver, and the coated frequency divider and the Fresnel lens receive the condensed beam of the condensing reflector. In the figure, the photovoltaic cell is located at the focus of the Fresnel lens, and the thermal receiver is located at the focus of the concentrated beam reflected by the coated frequency divider. The principle of this scheme is: the first time the sunlight is concentrated by the concentrating reflector to form a concentrating beam, and the concentrating beam is directed to the coated frequency dividing mirror and the Fresnel lens. Because the coated frequency-dividing mirror transmits short-wave light and reflects long-wave light, t...

Embodiment 2

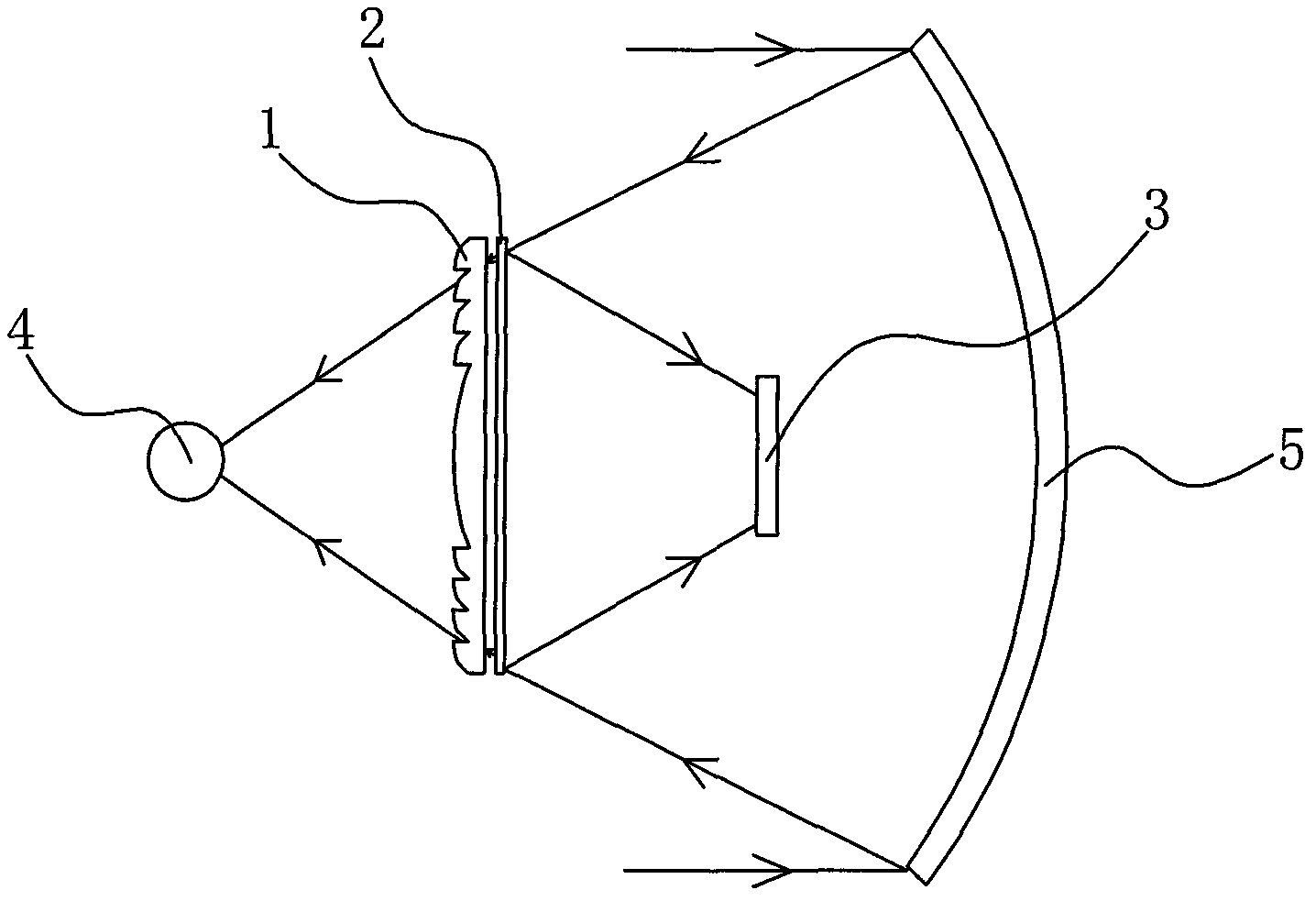

[0029] Embodiment two: if figure 2As shown, change the filter characteristics of the coated frequency-dividing mirror in Embodiment 1, set the coated frequency-dividing mirror to transmit long-wave light and reflect short-wave light, and exchange the positions of the photovoltaic cell and the heat receiver in Embodiment 1, That is, the thermal receiver is located at the focus of the Fresnel lens, and the photovoltaic cell is located at the focus of the concentrated beam reflected by the coated frequency divider. The principle of this scheme is: the first time the sunlight is concentrated by the concentrating reflector to form a concentrating beam, and the concentrating beam is directed to the coated frequency dividing mirror and the Fresnel lens. Because the coated frequency-dividing mirror transmits long-wave light and reflects short-wave light, the long-wave light in the concentrated beam will pass through the coated frequency-dividing mirror and be condensed twice by the F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com