Patents

Literature

645results about How to "Improve heat utilization efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Enclosed multi-chamber fluidized bed drying method for sludge

InactiveCN101186422AUniform humidityReduce breakageSludge treatment by de-watering/drying/thickeningLiquid wasteFluidized bed drying

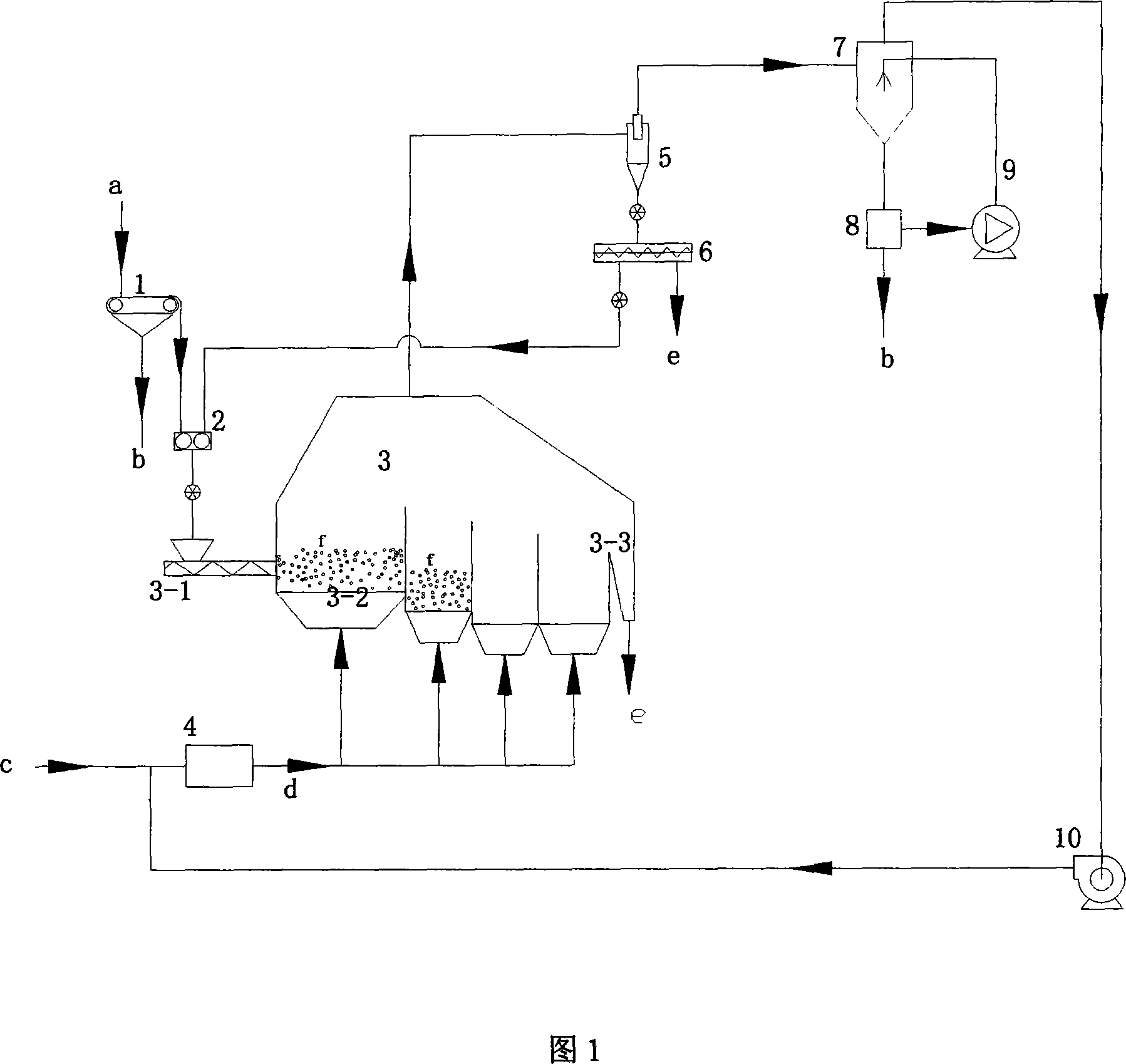

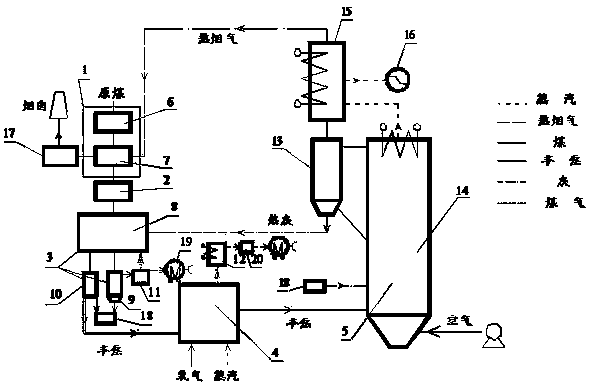

A closed multi-room fluidized bed sludge drying method is provided, which is a sludge drying method having the advantages of simple equipment structure, convenient operation, strong sludge adaptability, high thermal efficiency, safety, continuity, stability, etc. After the mechanically dewatered sludge is mixed with the back-mixed sludge, the mixture is dried room by room in an inert particles multi-room fluidized bed dryer (3). The first room and the second room of the inert particles multi-room fluidized bed dryer (3) adopt inert particles (f) as heat storage medium. Gas from a cyclone separator (5) goes through a spray tower (7) and returns into an air heating unit (4) through a circulating fan (10). Part of dried sludge (e) at the lower part of the cyclone separator (5) enters the inert particles multi-room fluidized bed dryer (3) through the back-mixing in a mixer (2). Waste liquid from the bottom of the spray tower (7) enters a waste liquid circulating pool (8), with part of waste liquid circulating into the spray tower (7) and part into a sewage treatment system.

Owner:SOUTHEAST UNIV

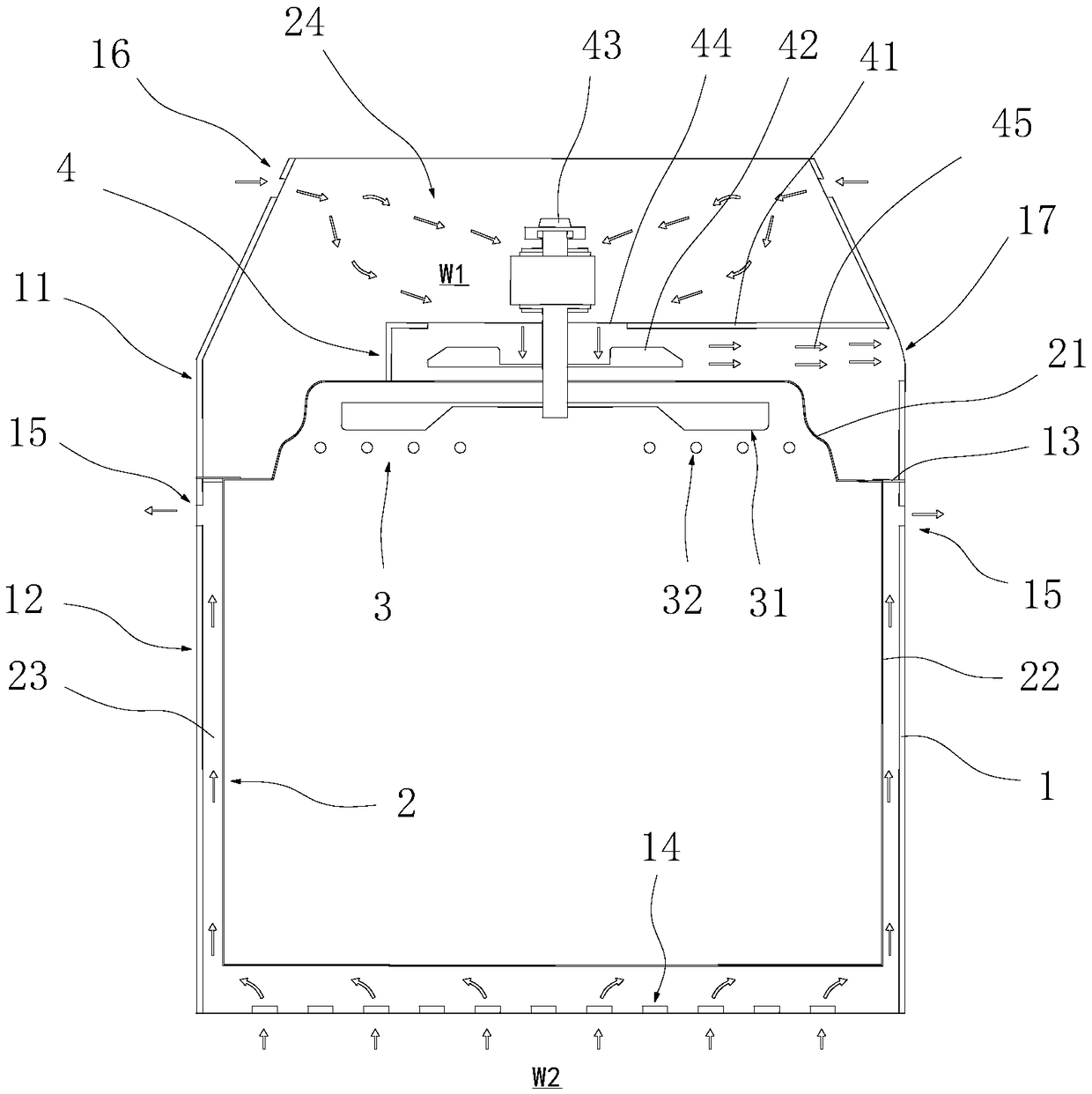

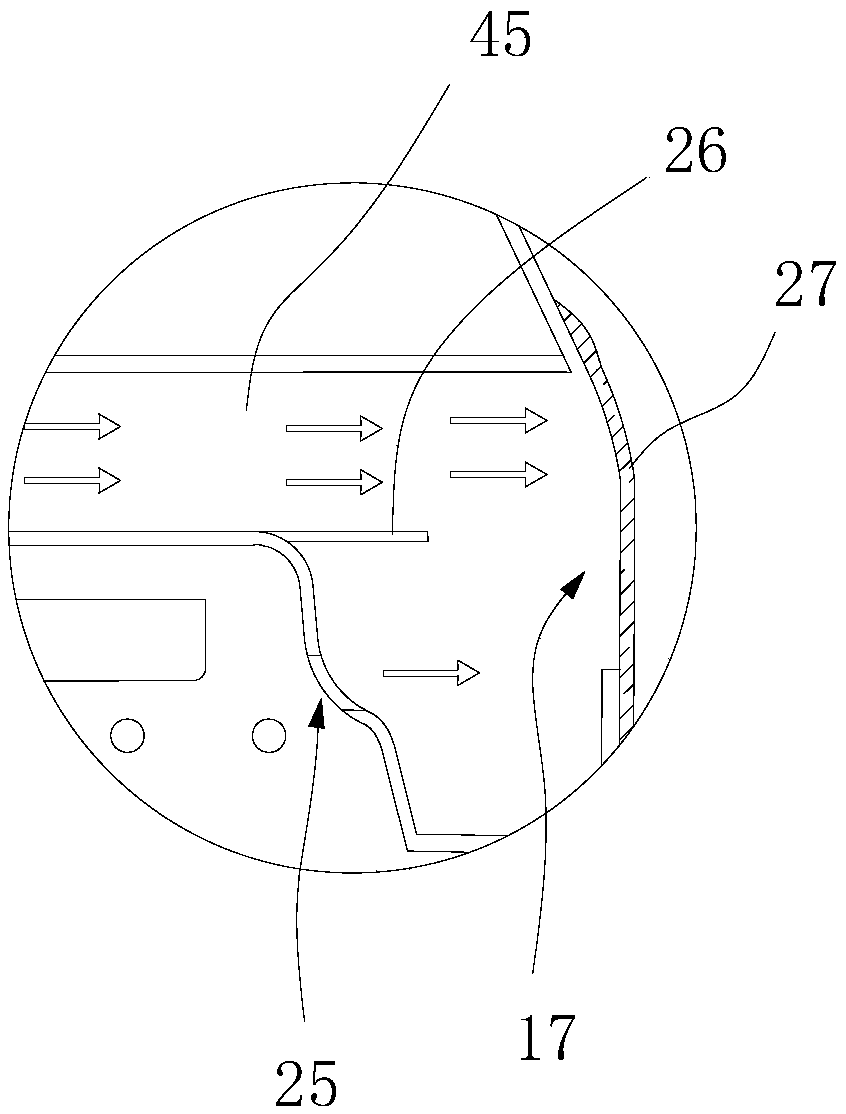

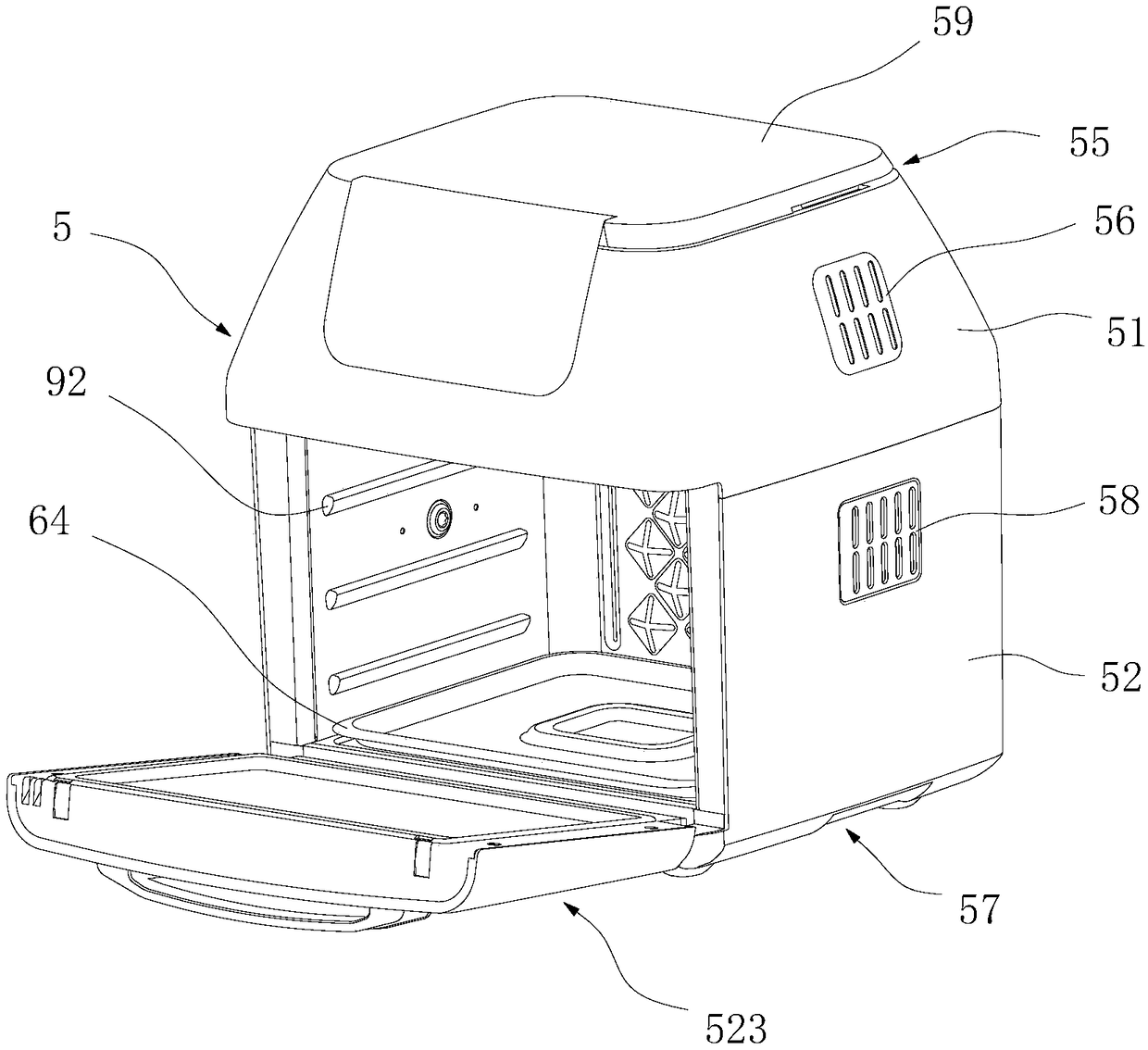

Cooking device

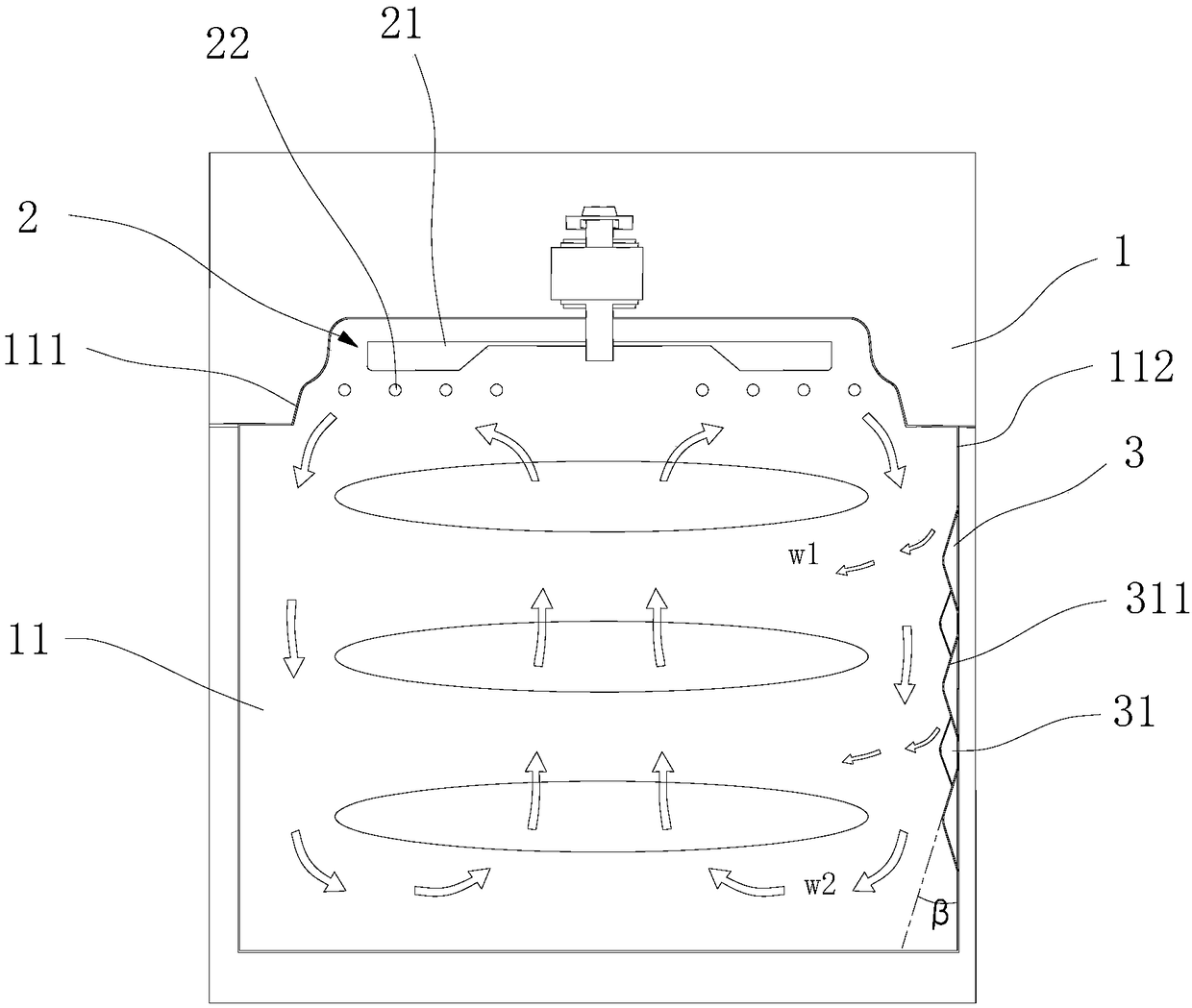

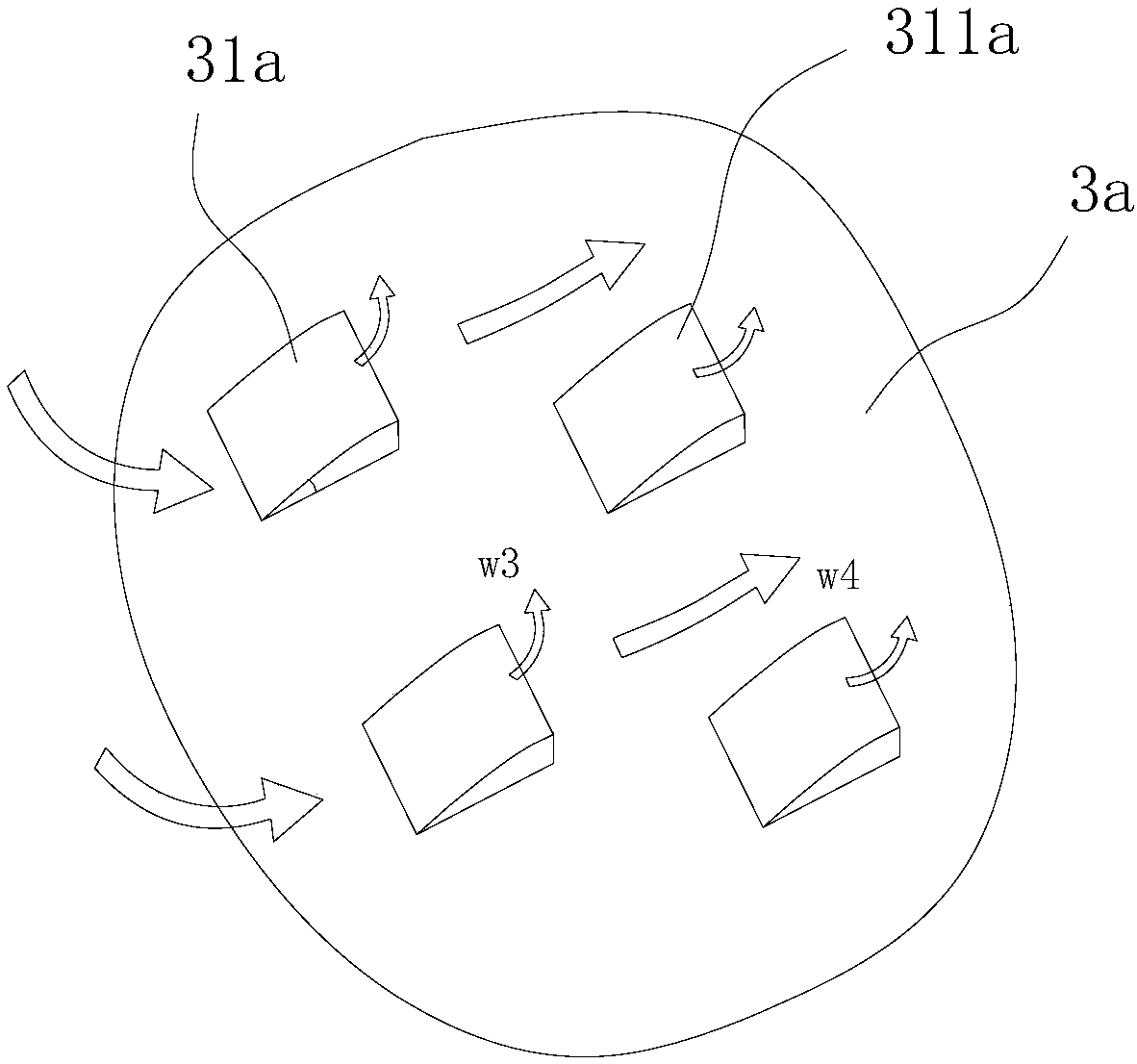

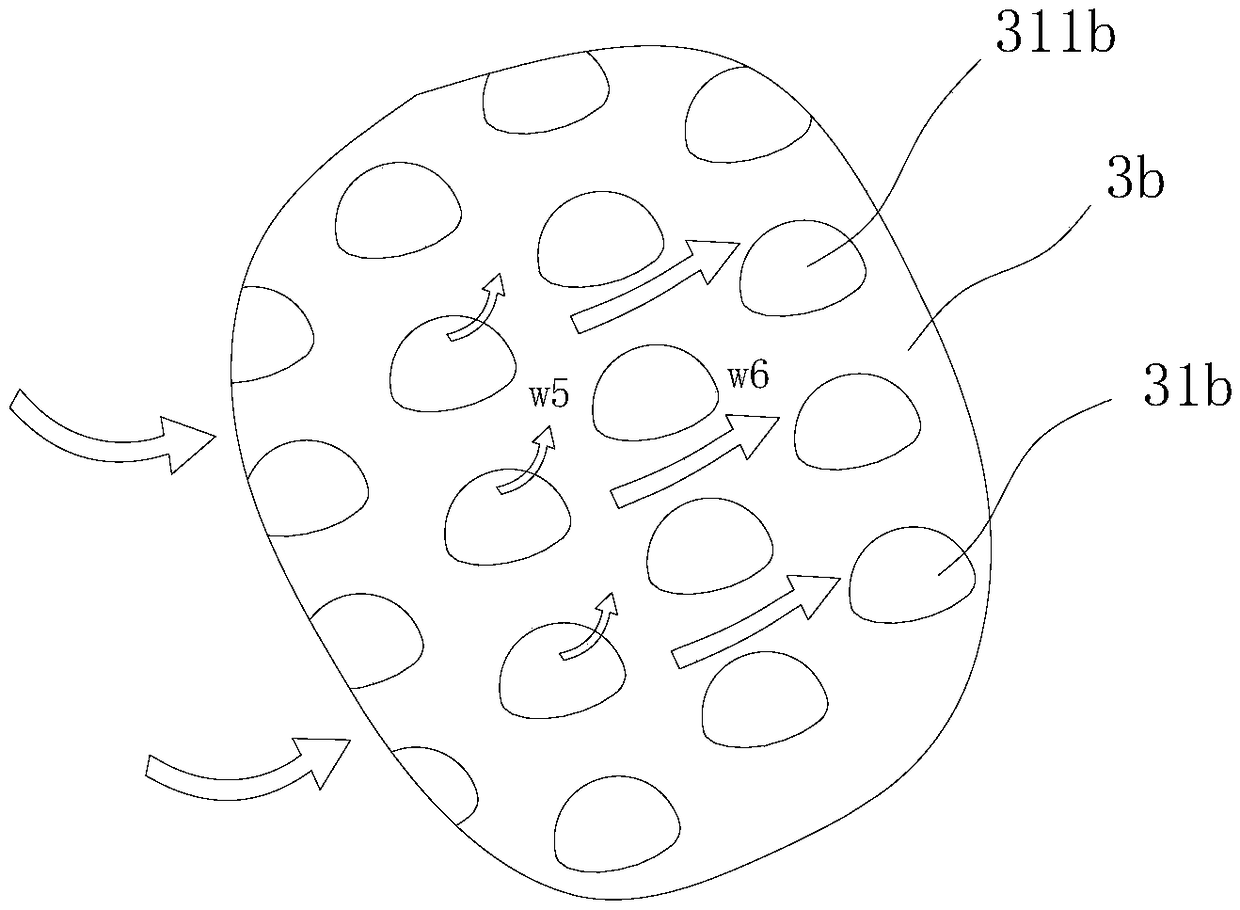

PendingCN108703675AFully heatedImprove cooking resultsRoasting apparatusRoasters/grillsProcess engineeringAirflow

Owner:FOSHAN SHUNDE KUFU ELECTRIC APPLIANCES CO LTD

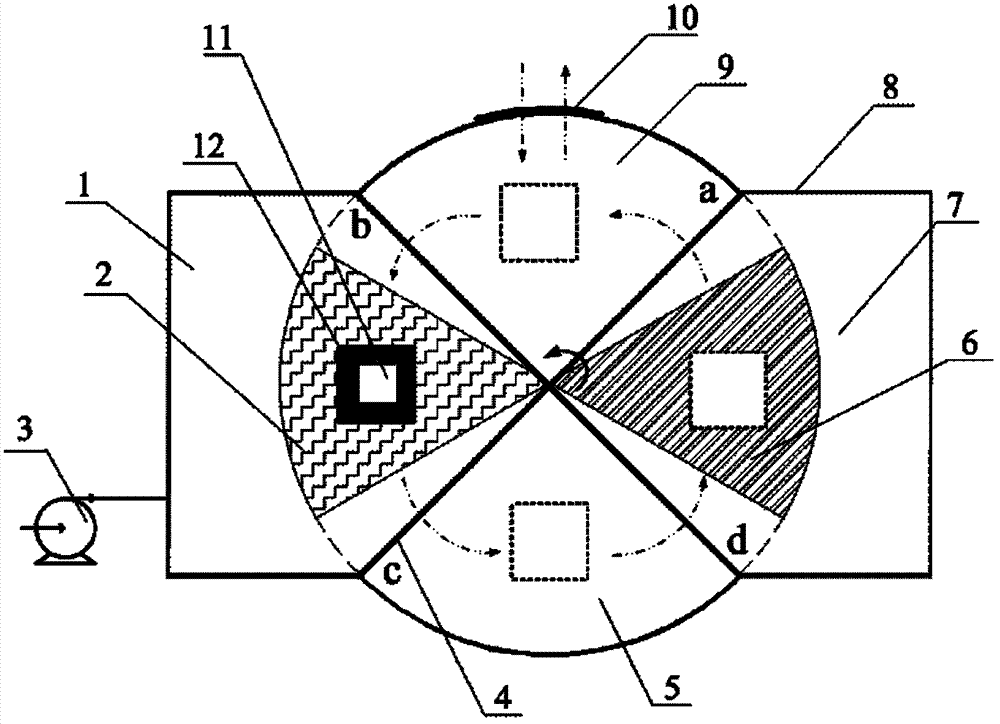

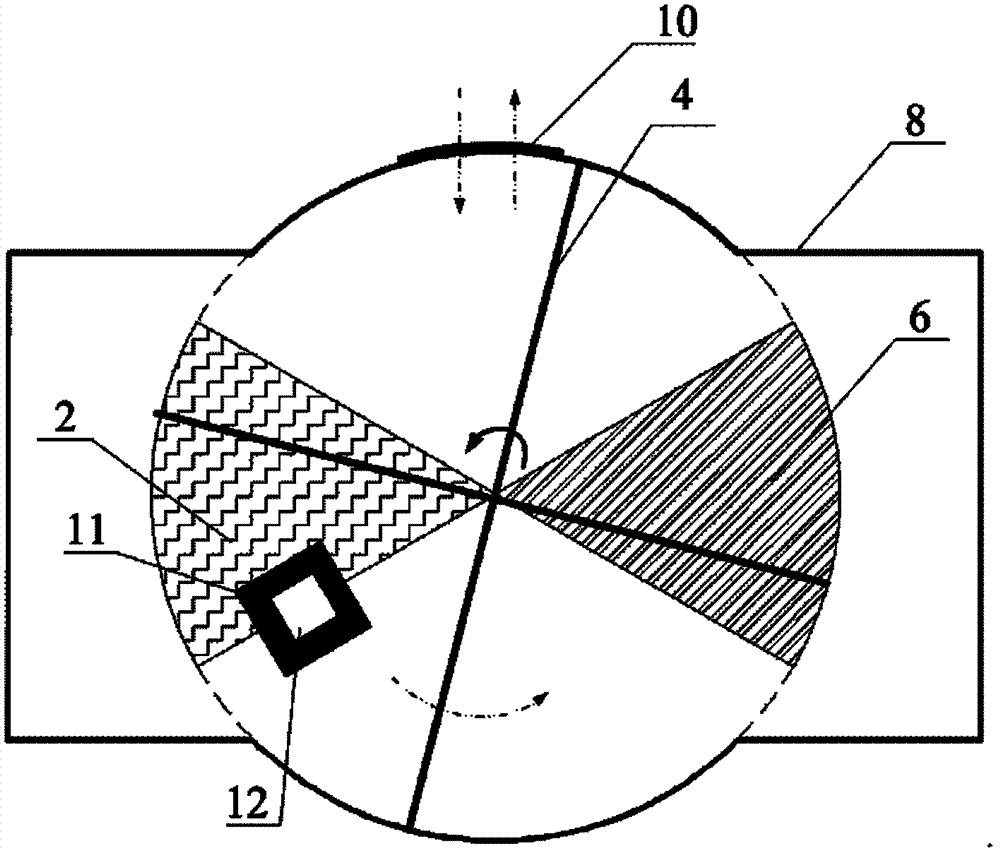

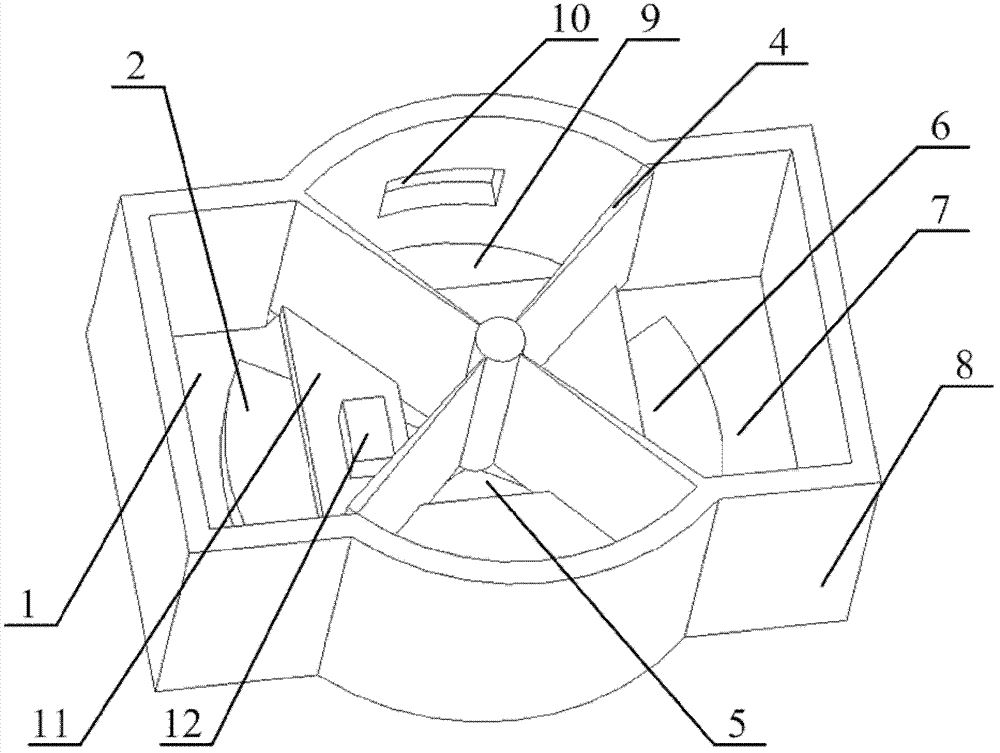

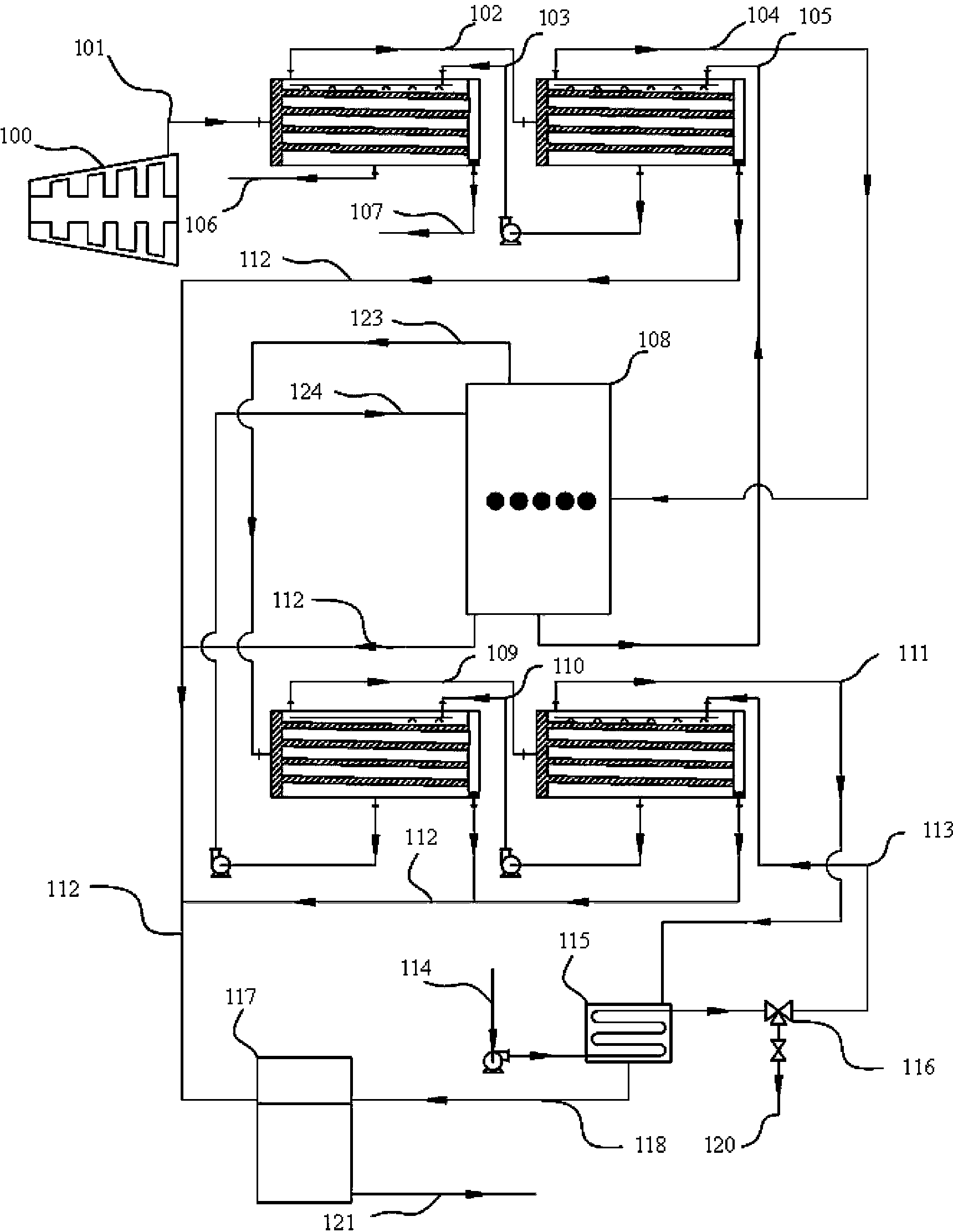

Latent heat recoverable multi-phase change sludge drying method and device

ActiveCN101774743AReduce drying costsEnergy balanceSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningThermal energyBrick

The invention discloses a latent heat recoverable multi-phase change sludge drying method and a latent heat recoverable multi-phase change sludge drying device, which are designed for solving the technical problems that the energy consumption is high, the latent heat of the sludge vapor cannot be recovered and reused, the dried tail gas pollutes the environment, the operating cost is high and the like in the conventional sludge drying technology. Due to the combination of a low-temperature vapor turntable dryer, a sludge waste vapor latent heat recover heat pump and a tail gas purification device, and the use of indirect phase change heat exchange for low-temperature vapor, the heat exchange is improved, and the loss of organic components of the sludge is low. The latent heat of the sludge drying tail gas is recovered by using the latent heat recover heat pump, and the recovered heat energy is reused for sludge drying. Therefore, the heat efficiency is improved, the operating cost is reduced, and the problems that the heat utilization ratio is low, the operating cost is high and the like in the sludge drying process are better solved. The dried products meet the requirement of baking light and energy-saving bricks and producing cement laminated products, and over 90 percent of heat value of the original sludge is maintained. Therefore, the resource utilization value of the sludge is maximized.

Owner:SHENYANG INST OF AERONAUTICAL ENG

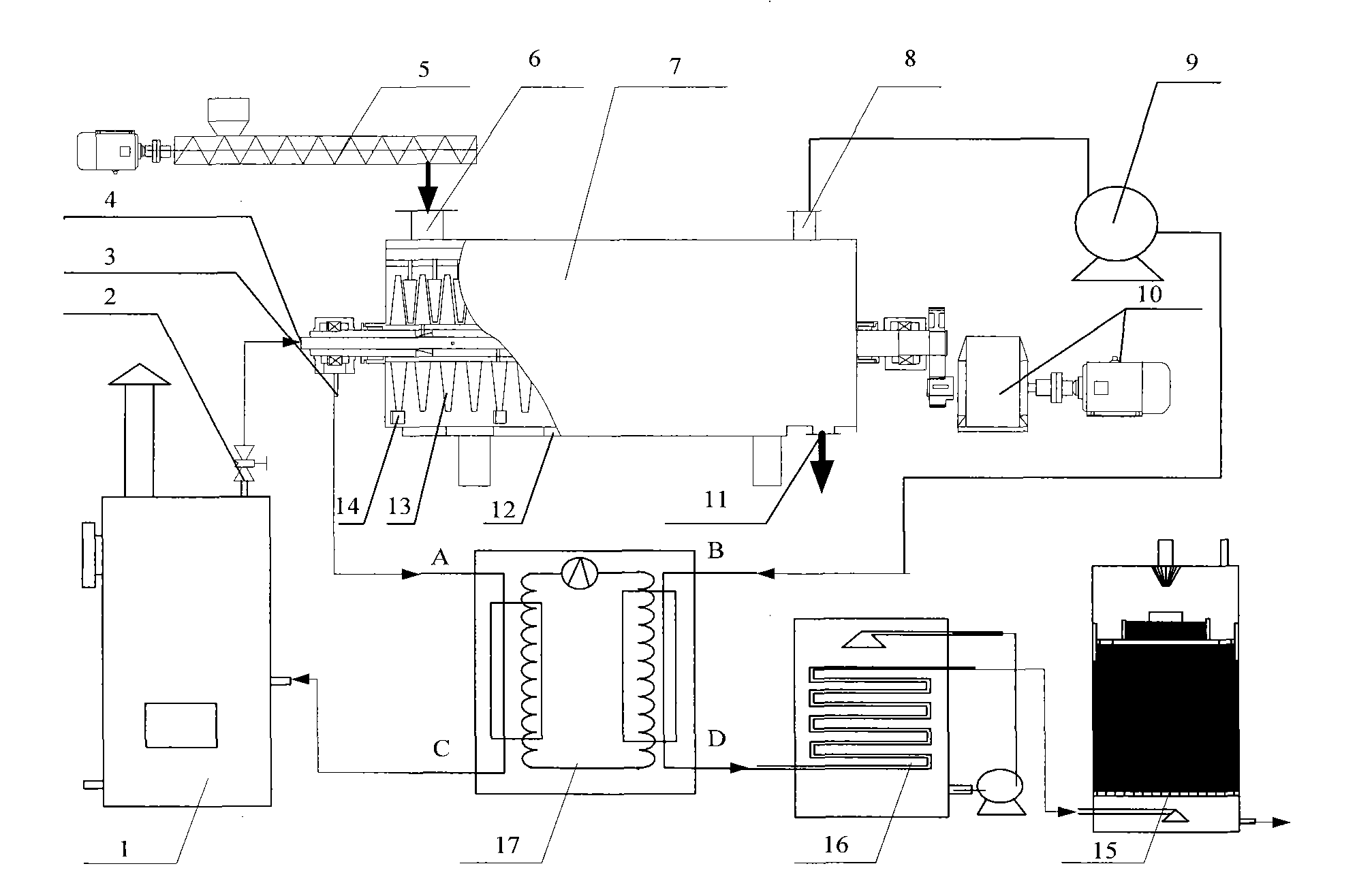

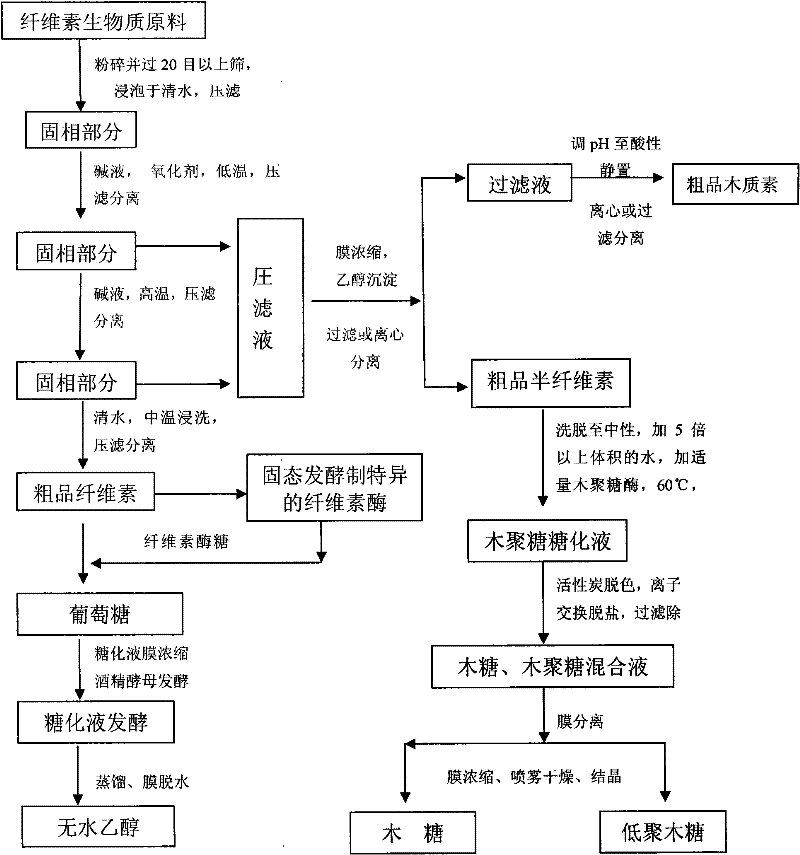

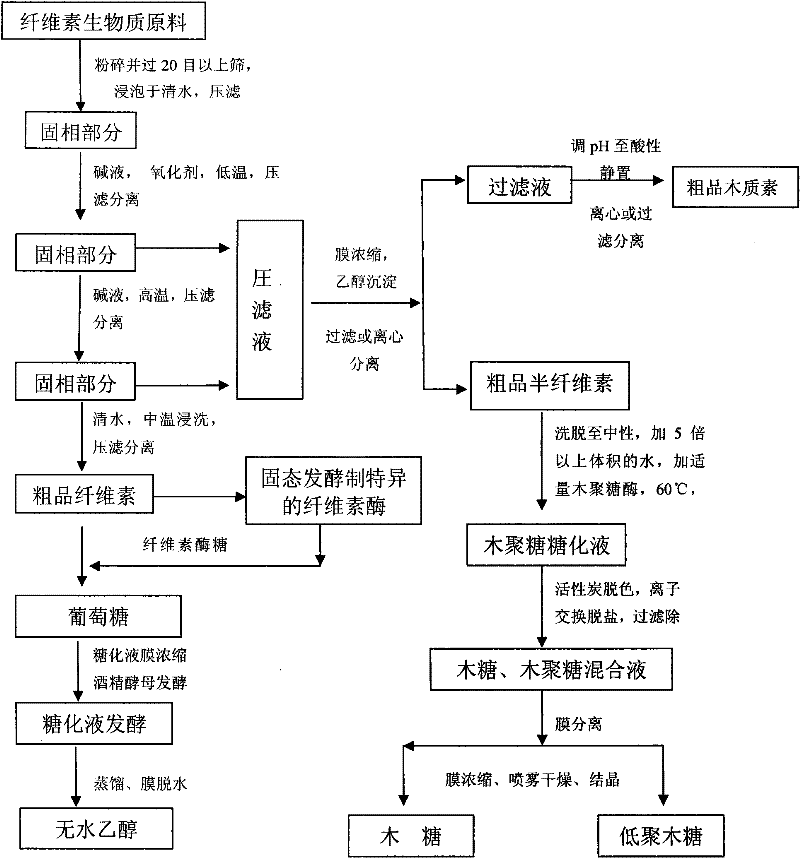

A method for fractional separation of full components of agricultural and forestry cellulose biomass and preparation of fuel alcohol and xylooligosaccharides by using the separated components

InactiveCN102261007AHigh extraction rateImprove heat utilization efficiencyPretreatment with alkaline reacting compoundsBiofuelsChemical industryFiltration membrane

The invention discloses grading and separating of all components of forestry cellulose biomass and preparing of fuel alcohol and xylo-oligosaccharide by utilizing the separated components. The method comprises the following steps of: (a) crushing, immersing and filter pressing dry substances of the forestry cellulose biomass; (b) immersing the filter pressed solid phase part using an alkaline solution, adding an oxidizing agent, extracting and solidifying phase to form a cellulose crude product; (c) concentrating pressure filtrate through a nano-filtration membrane, adding alcohol with the final concentration of above 50% to the concentrated solution, filtering or centrifugally separating after standing to obtain precipitate and supernatant, wherein the precipitate is a hemi-cellulose crude product; and (d) adjusting the supernatant obtained in the step (c) to be acid, and filtering, separating and precipitating to obtain a lignin crude product. According to the method disclosed by the invention, the resource utilization is maximized; the independence on imported oil in our country can be reduced; the environment pollution is reduced; establishment of a new energy industry and a biological chemical industry can also be promoted; the economic growth pattern in our country is changed; and social and economic sustainable development can be realized.

Owner:陈方和

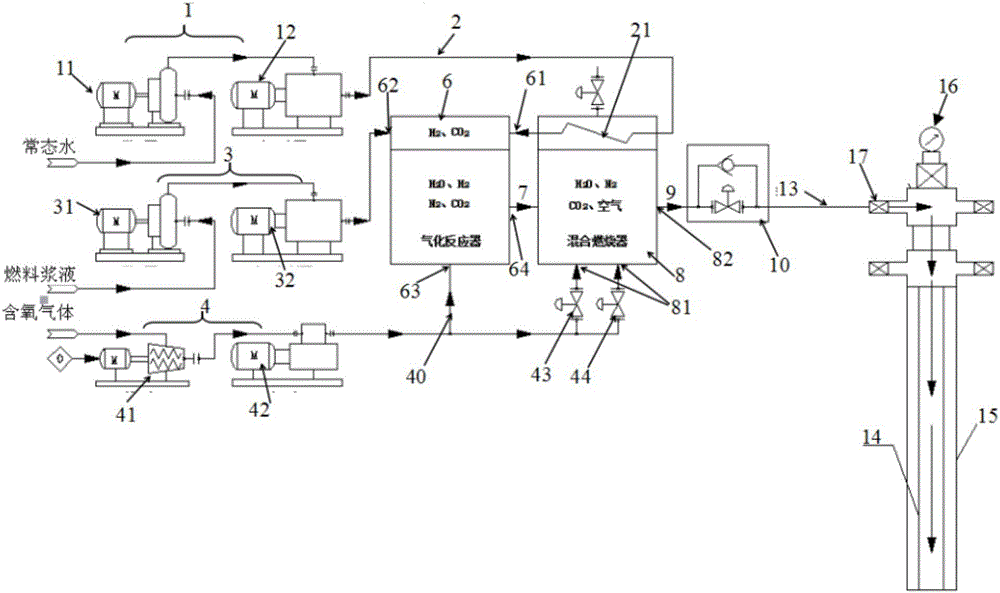

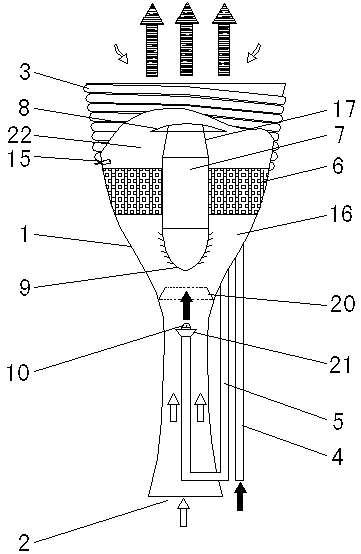

Supercritical multisource multielement thermal fluid injection-production system and injection-production method

InactiveCN106640008AImprove insulation effectLow thermal conductivityLiquid fuel feeder/distributionFluid removalCombustionProduct gas

The invention discloses a supercritical multisource multielement thermal fluid injection-production system and injection-production method. The system comprises a supercritical multisource multielement thermal fluid generating system and an oil tube. The oil tube is arranged in an exploiting shaft; the supercritical multisource multielement thermal fluid generating system comprises a supercritical gasification reactor and a supercritical mixed combustion reactor; in the presence of supercritical water, a gasification reaction is performed on fuel slurry in the supercritical gasification reactor, and the gasification product of the reaction and oxygen-containing gas dissolved in the supercritical water combust in the supercritical mixed combustion reactor to form a supercritical multisource multielement thermal fluid containing supercritical water and carbon dioxide; the supercritical mixed combustion reactor is connected to the oil tube. The supercritical multisource multielement thermal fluid injection-production system provided by the invention has the effects that thermal efficiency is high, the viscosity of thickened oil is reduced, the flowability of the thickened oil is improved and the recovery efficiency is increased.

Owner:CHINA NAT OFFSHORE OIL CORP +1

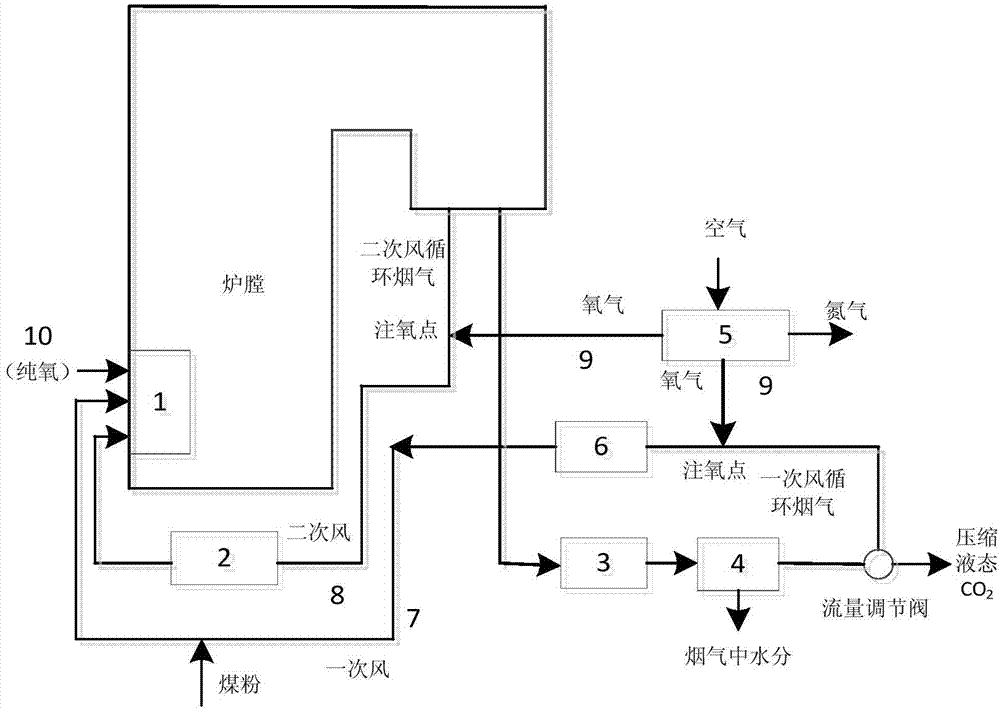

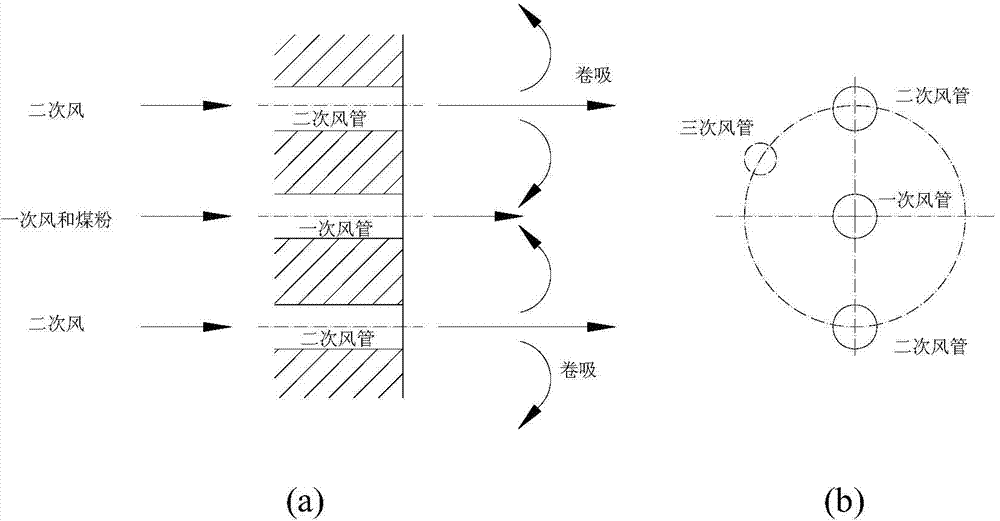

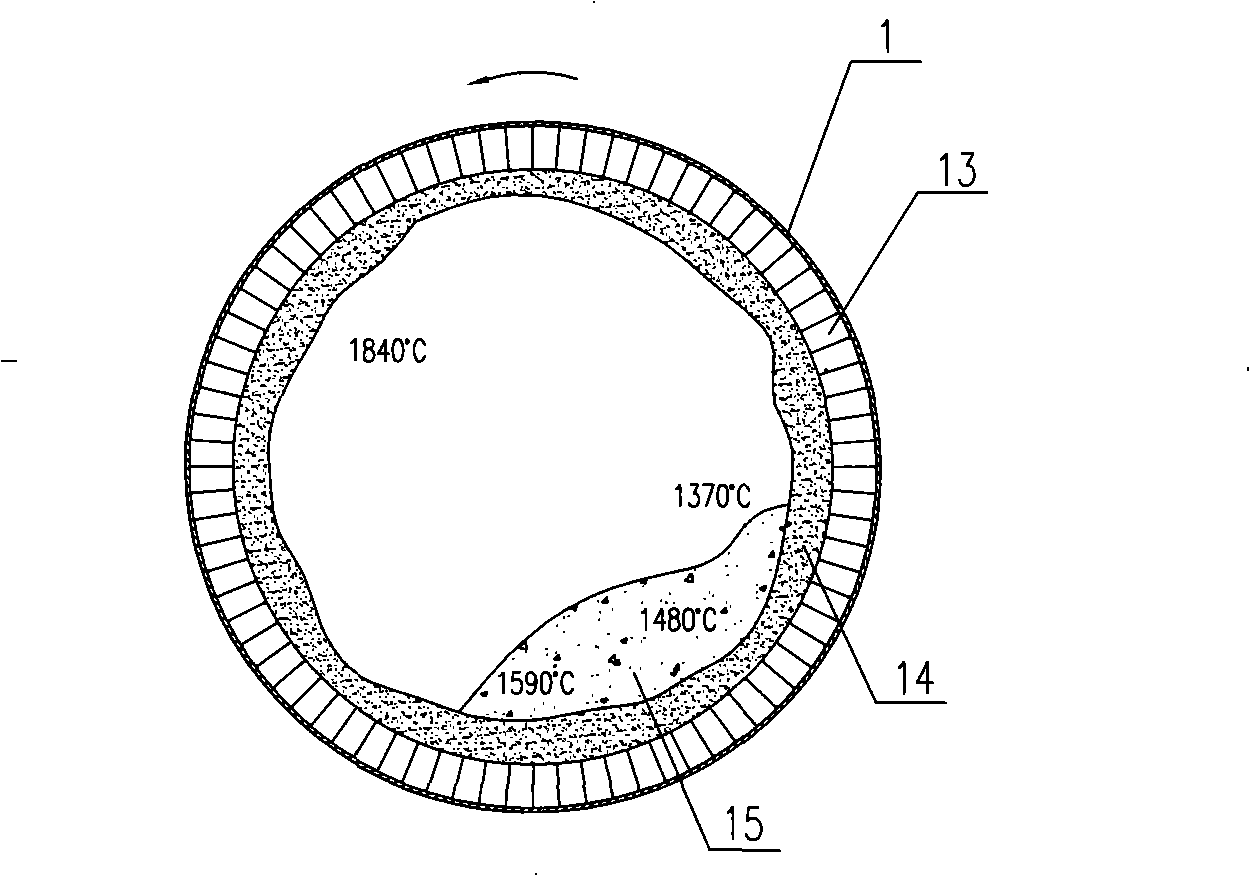

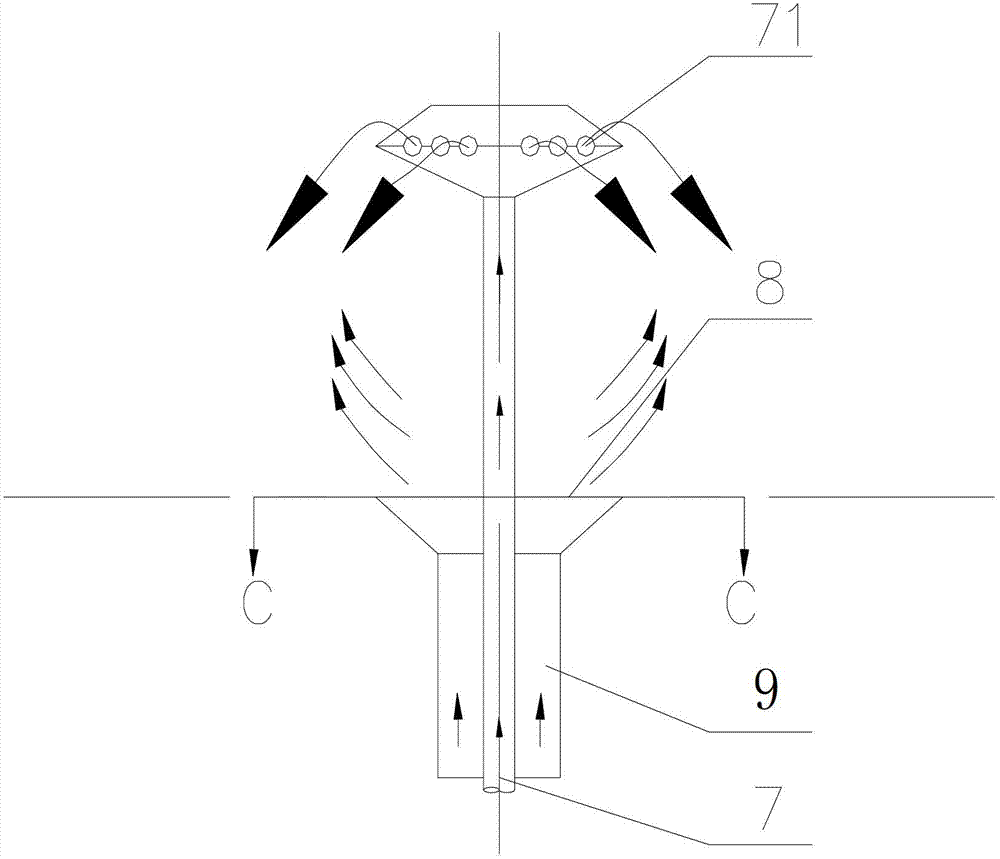

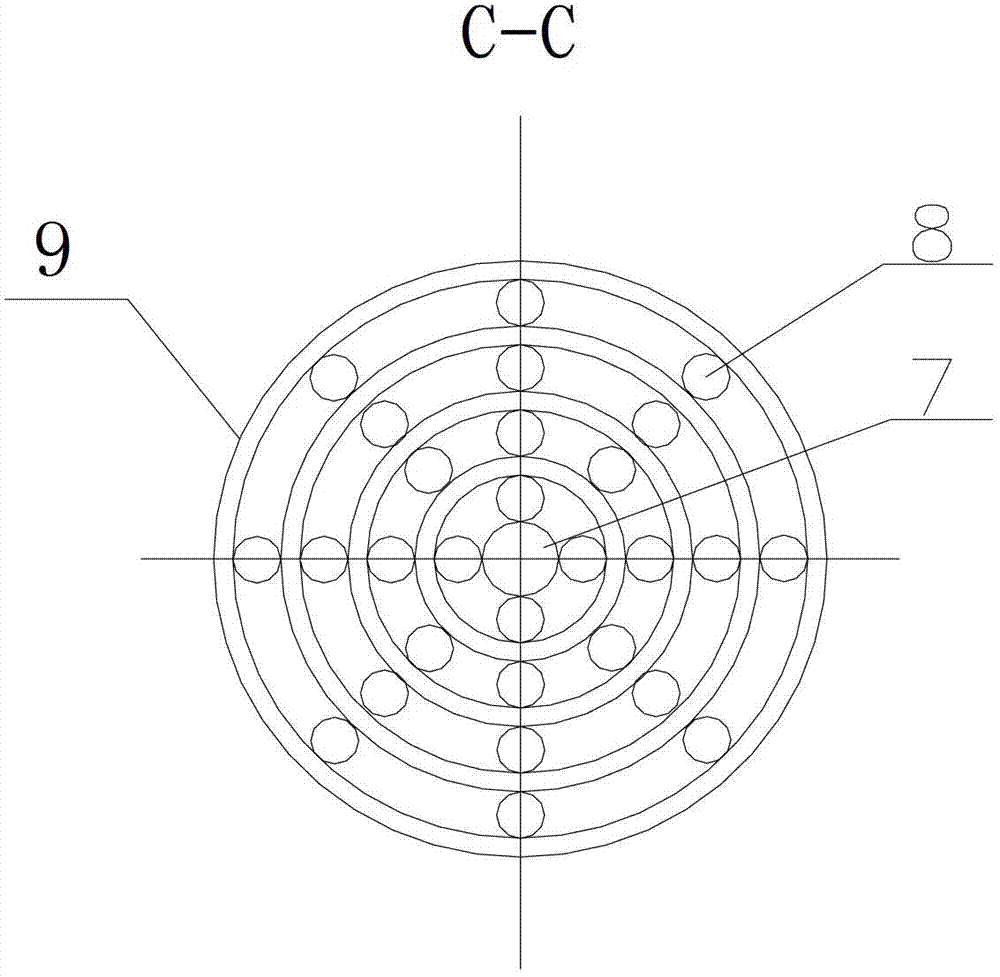

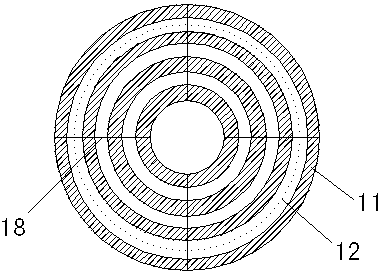

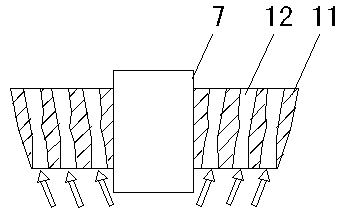

Method and system thereof for oxygen-enriched flameless combustion of coal powder

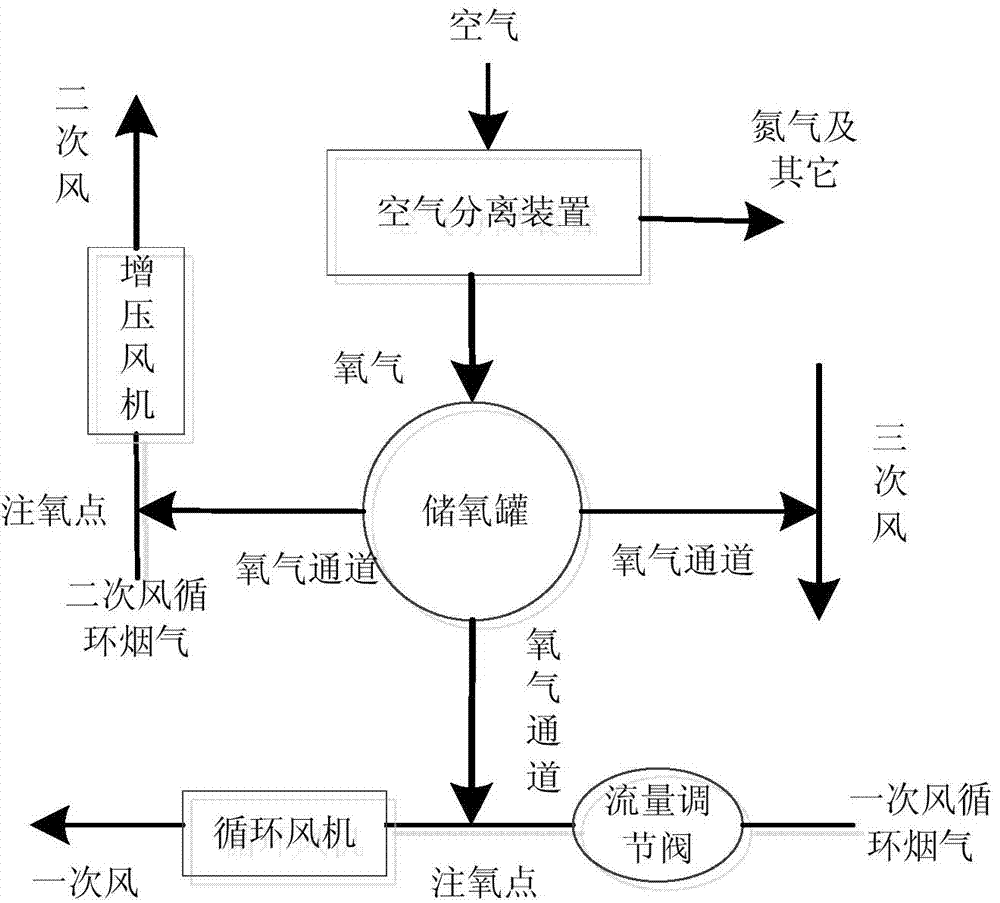

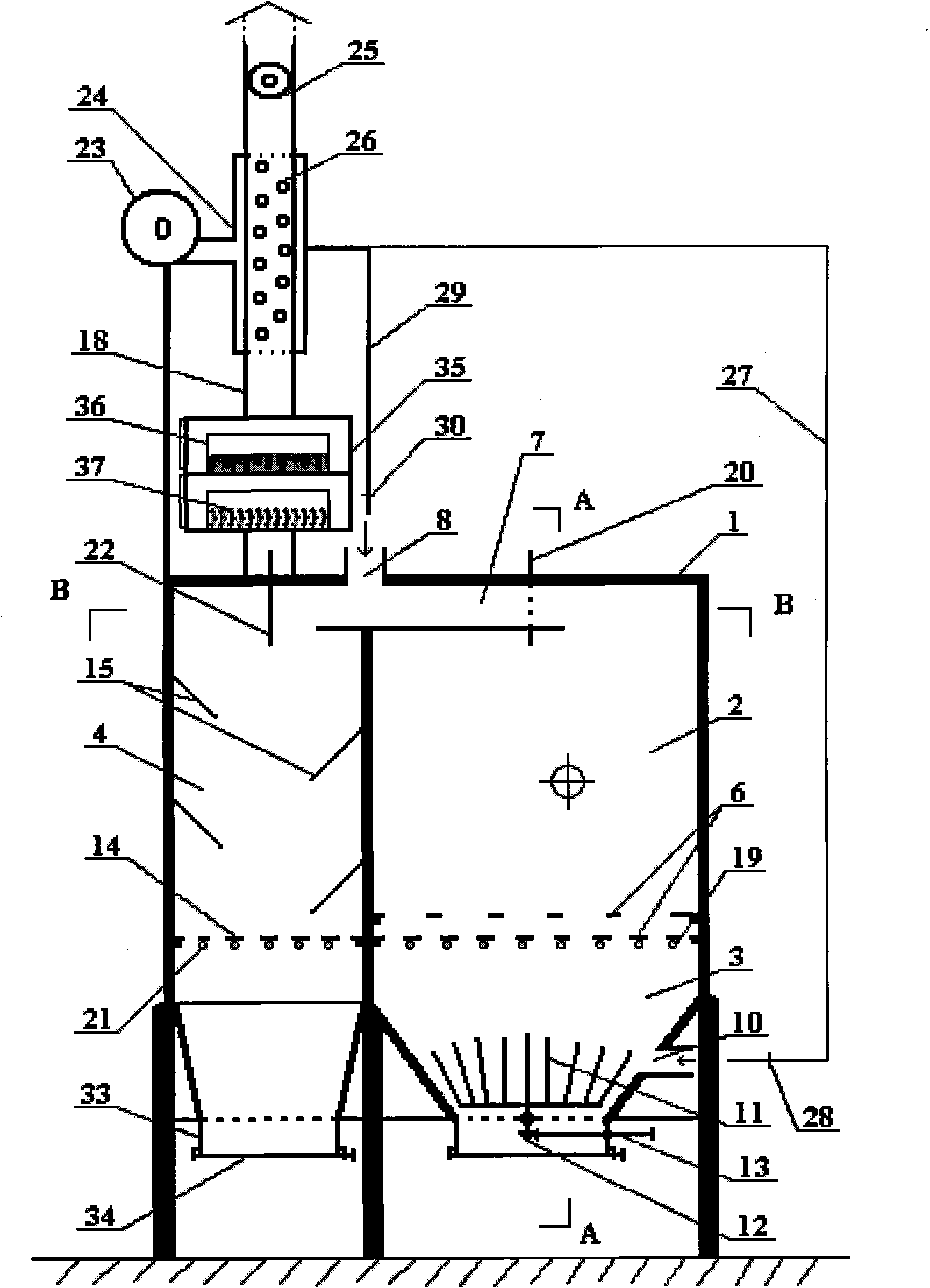

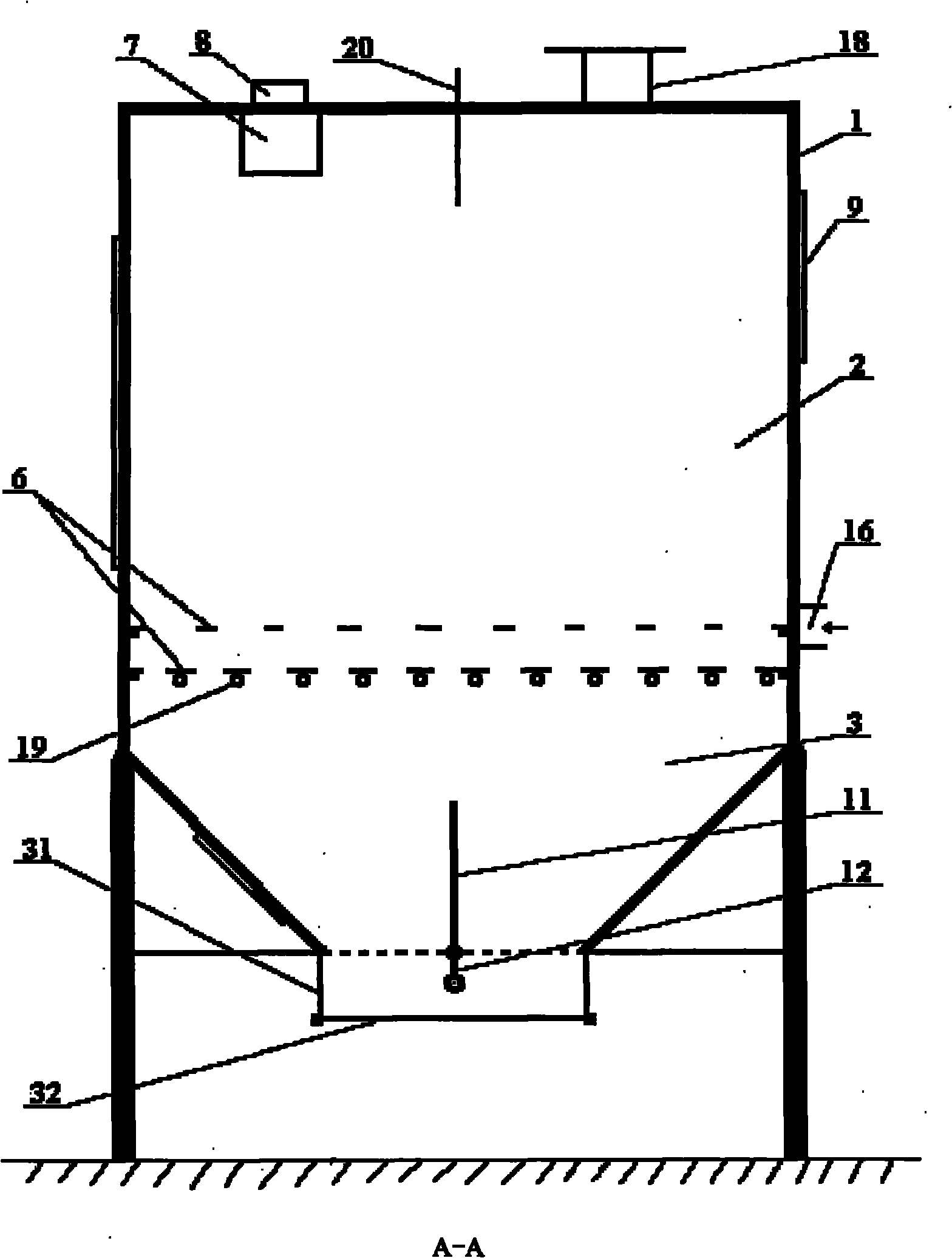

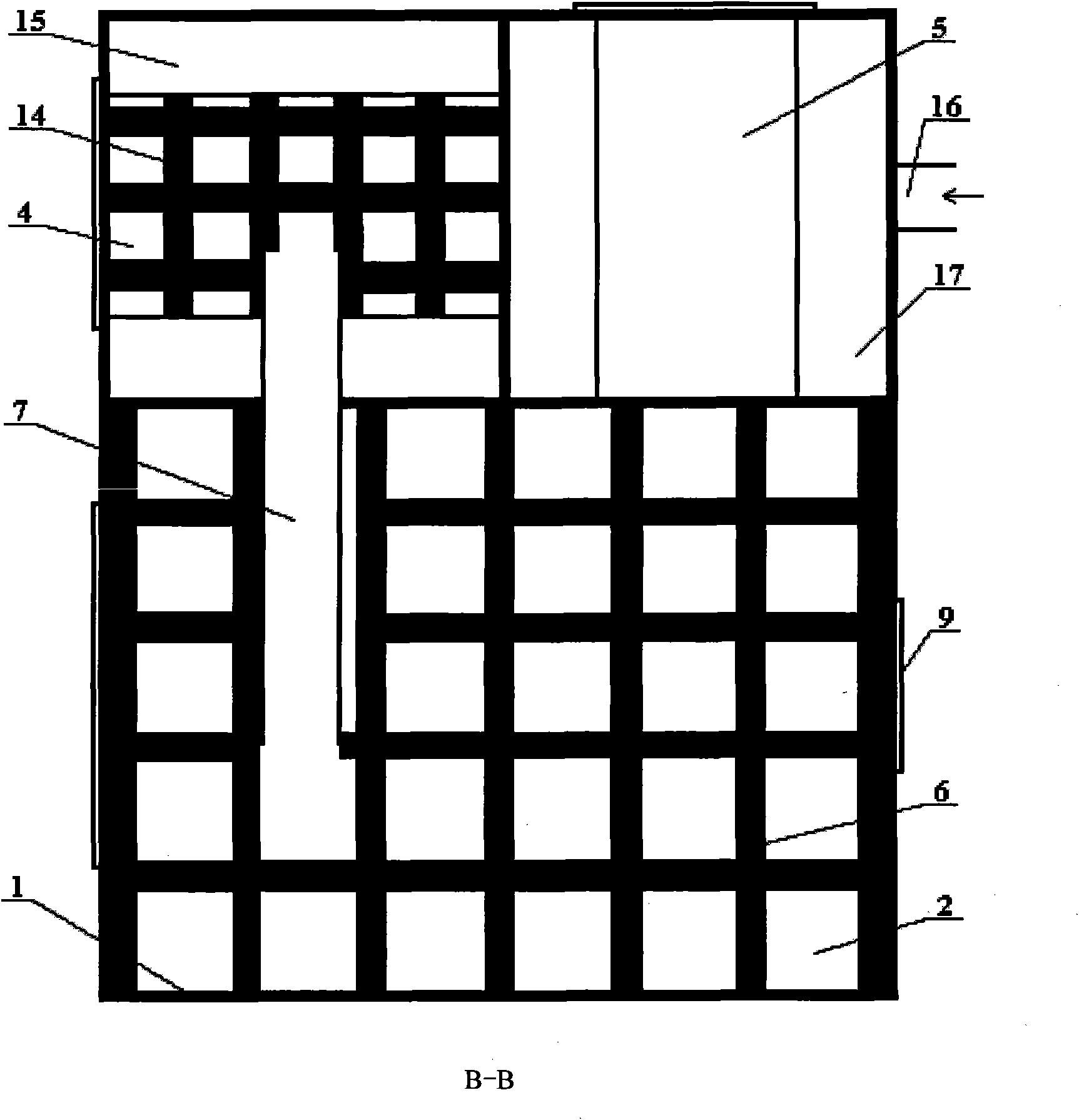

ActiveCN103615713AIncrease temperatureImprove heat utilization efficiencyDirect carbon-dioxide mitigationIndirect carbon-dioxide mitigationFlue gasInjection point

The invention discloses a method and a system thereof for oxygen-enriched flameless combustion of coal powder. By adopting the method, the stability, burn-off rate and radiative heat transfer of combustion can be improved through flameless combustion on the basis of enriching CO2 during oxygen-enriched combustion. High-temperature flue gas generated by the oxygen-enriched combustion is injected into a hearth in the form of high-speed jet flow through a direct-current flameless burner, and quick and uniform mixing of heat and quality in the hearth can be realized through high-speed jet flow entrainment. The system comprises an oxygen injection system, and a primary air oxygen-injection point is positioned between a circulating fan and a flow regulating valve; a secondary air oxygen-injection point is positioned between a booster fan and a hearth outlet; a primary air pipe of the direct-current flameless burner is positioned in the center, and a secondary air pipe is parallel to the primary air pipe and is circularly arranged around the primary air pipe; the booster fan with a high-pressure head is arranged on a secondary air duct, and secondary air is boosted and speeded up and then enters the hearth in the form of the high-speed jet flow. The heat utilization ratio of the method and the system can be improved by 10-25%, and the generation of NOX can be reduced by 15-40%.

Owner:HUAZHONG UNIV OF SCI & TECH

Small efficient medicinal rubbish pyrolysis incinerator

InactiveCN102042601AProblem Solving Using Unitary Furnace StructureLarge capacity reduction ratioIndirect carbon-dioxide mitigationIncinerator apparatusCombustion chamberGas phase

The invention discloses a small efficient medicinal rubbish pyrolysis incinerator, which belongs to rubbish burning treatment equipment and solves the problems that a gas combustion chamber has simple structure, an auxiliary fuel is needed, the temperature cannot be accurately measured or controlled, and defects are produced in cloth bag dust removal and the like. The hearth of the incinerator consists of a pyrolysis and gasification chamber, a solid-phase burn-out chamber, a gas-phase combustion chamber and a flue gas treatment chamber; the solid-phase burn-out chamber is positioned below the pyrolysis and gasification chamber and communicated through a netlike fire grate; the gas-phase combustion chamber is arranged in parallel to the pyrolysis and gasification chamber, and the top of the gas-phase combustion chamber is communicated with a flue; the flue gas treatment chamber is arranged in parallel to the gas-phase combustion chamber and the pyrolysis and gasification chamber; and the gas-phase combustion chamber is communicated with the lower part of the flue gas treatment chamber, the gas-phase combustion chamber and the flue gas treatment chamber are provided with a fireproof baffle plate respectively, and the lower part of the gas-phase combustion chamber is provided with the netlike fire grate. The temperature in the incinerator is measured and controlled in real time through an electric heating and automatic temperature measurement and control system. A high-temperature granule dust removal and filter device avoids regeneration of dioxin, and the cost is reduced. The incinerator effectively and cleanly burns the medicinal rubbish on the aspects of incinerator shape design, ignition and combustion modes, temperature measurement and control, high-temperature flue gas treatment and the like.

Owner:杨显志

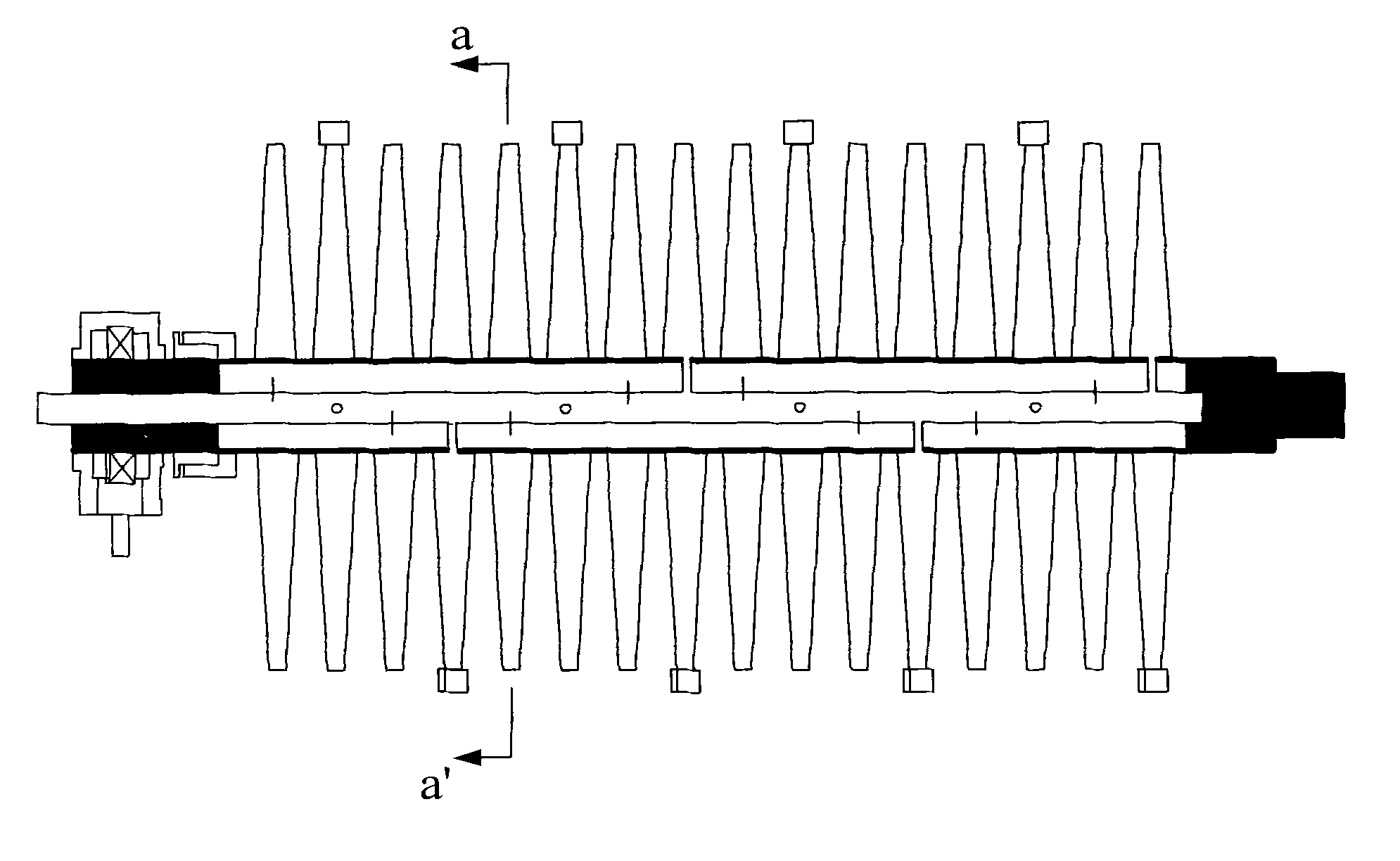

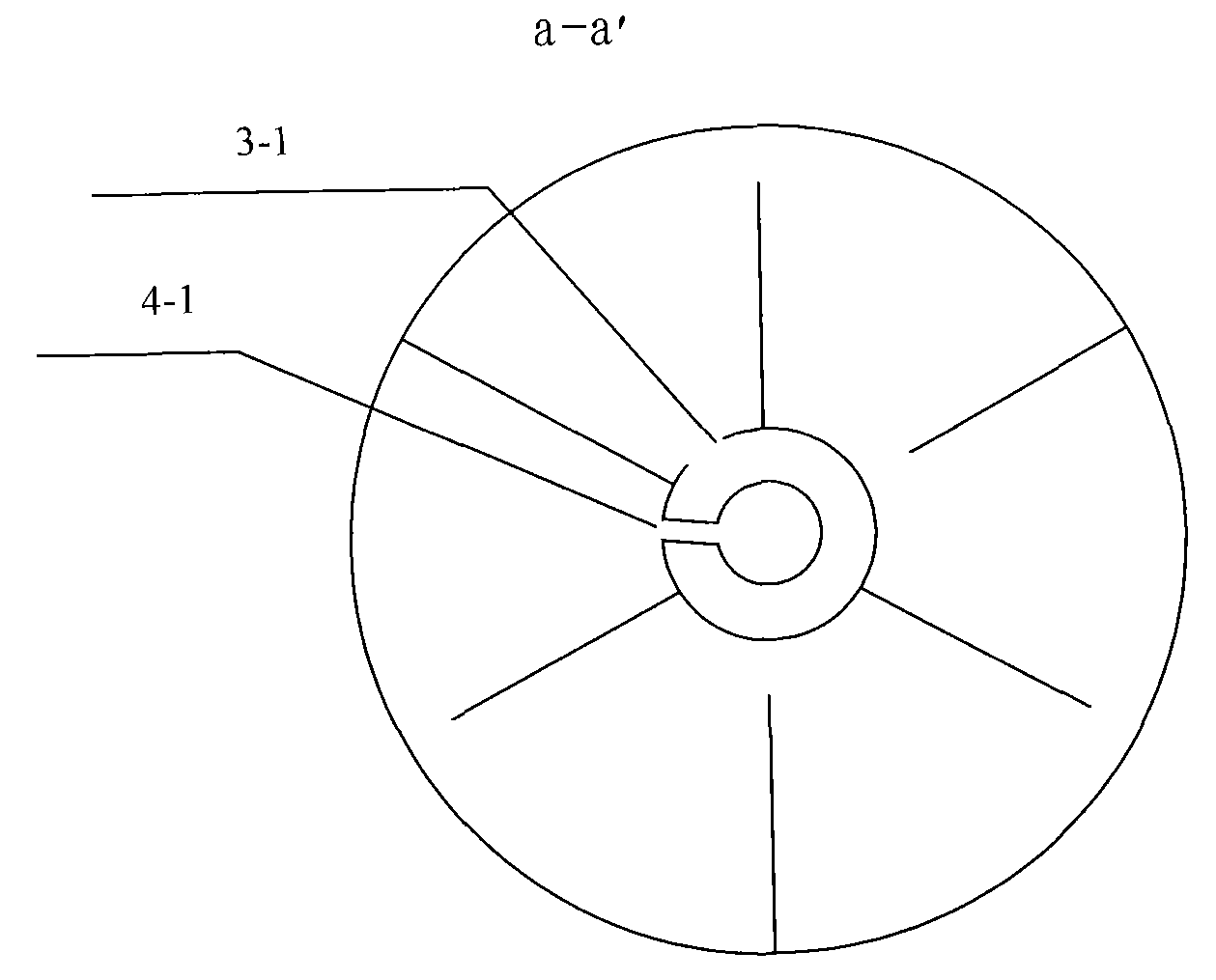

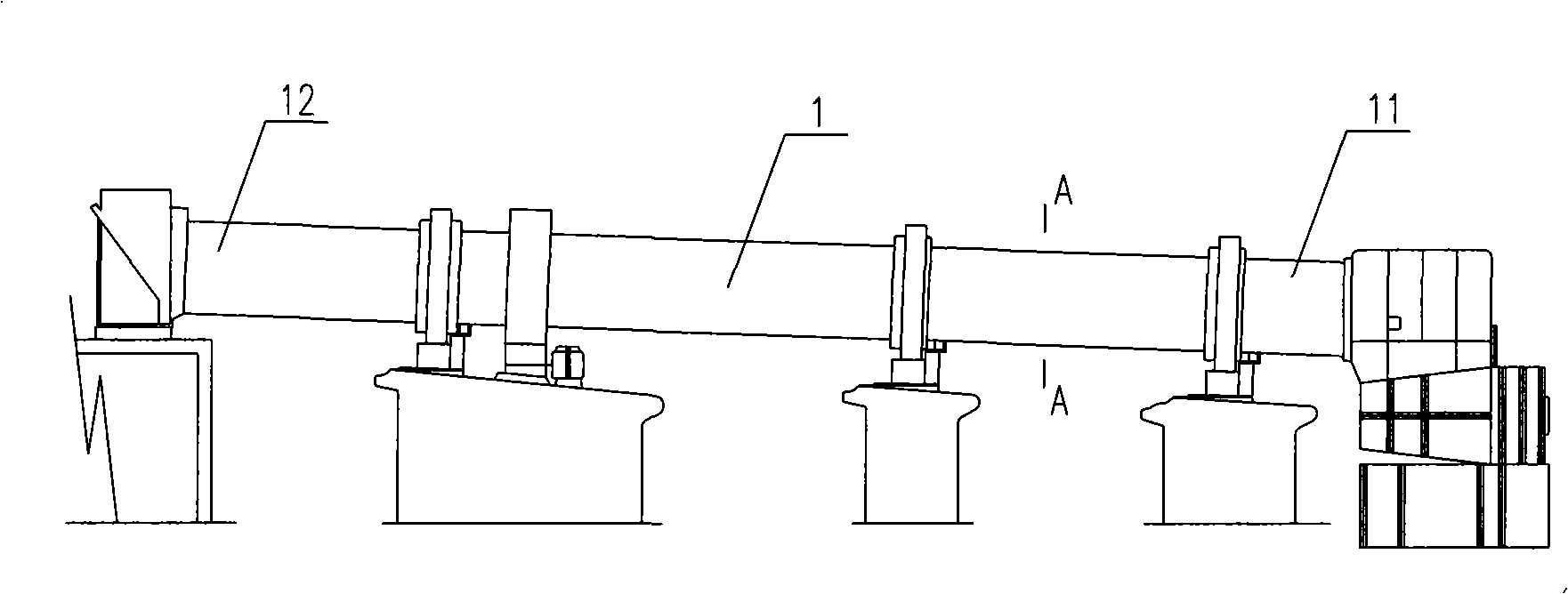

Device and method for continuously preparing active carbon by biomass in bulk

InactiveCN101885487ASolve for uniformityAvoid intermediate manual linksCarbon compoundsEnergy inputCombustionCarbonization

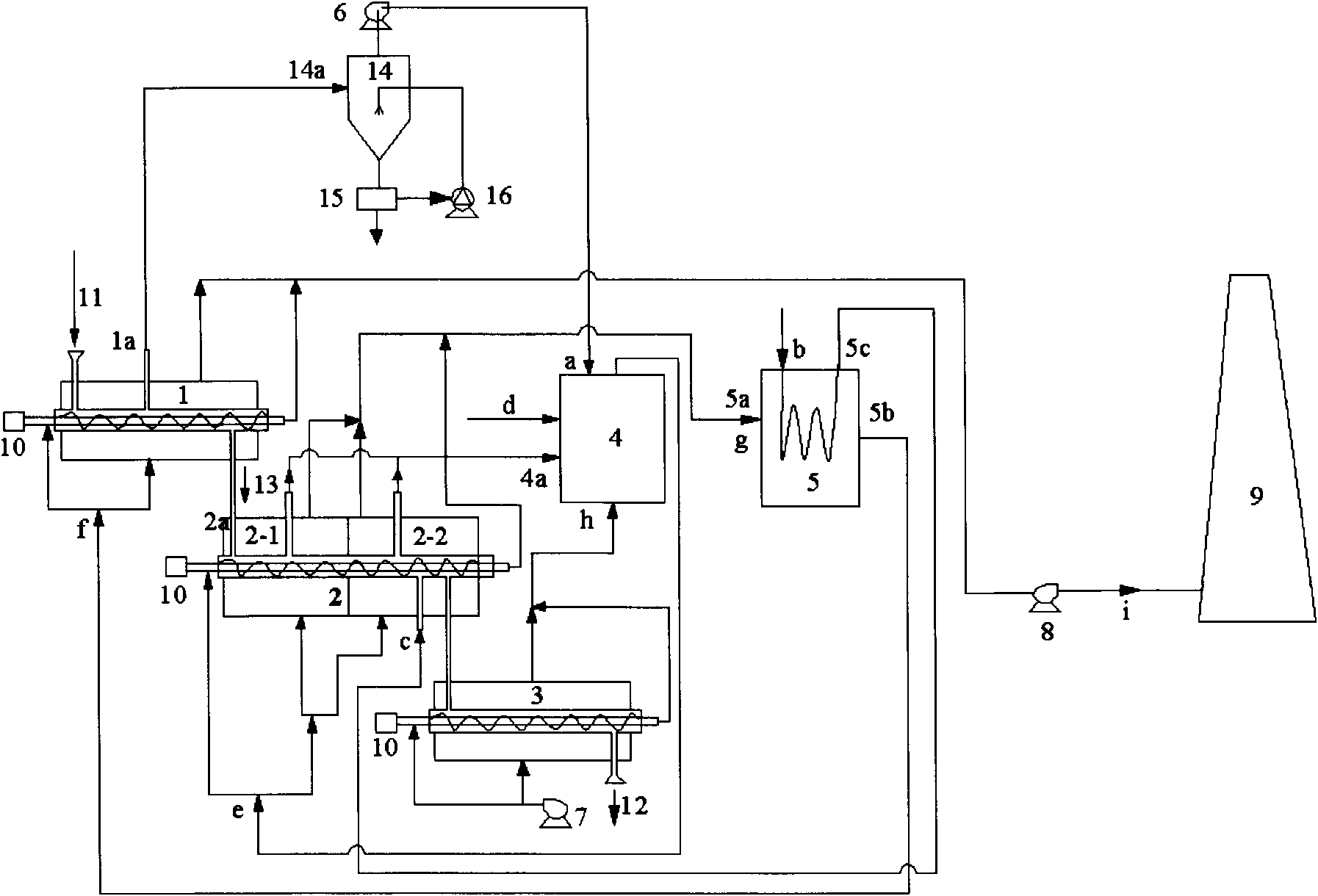

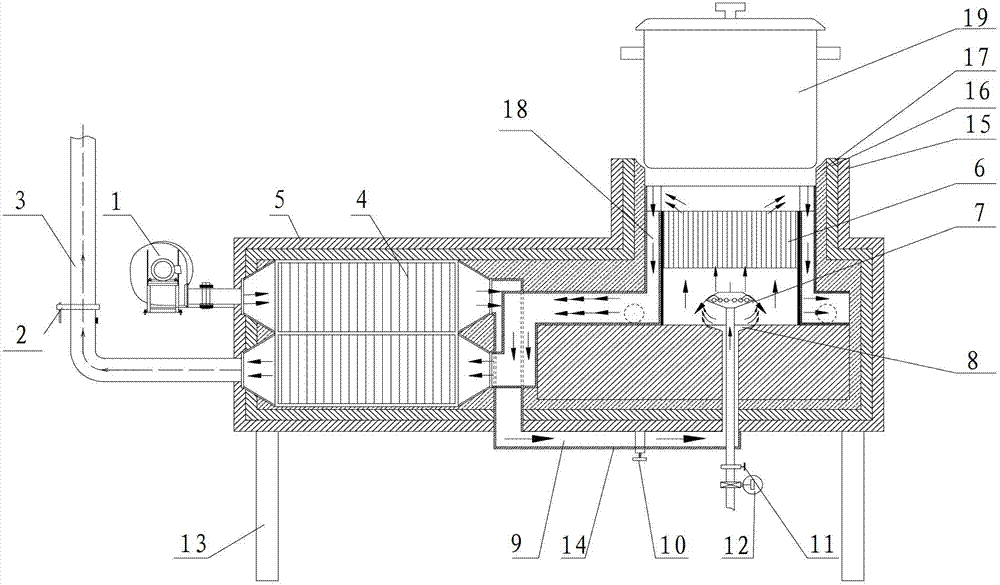

The invention relates to a device and a method for continuously preparing active carbon by a biomass in bulk. The invention is characterized in that the device comprises a spiral dryer (1), a spiral carbonization activation device (2), a spiral cooling device (3), a combustion furnace (4), a waste heat boiler (5), a circulating fan (6), a blower (7), an induced fan (8), a chimney (9), a velocity modulation motor (10), a spray tower (14), a waste liquor circulation pool (15), and a circulation water pump (16), wherein the spiral dryer (1) is provided with a feed port (11), a waste air outlet(1a), a material outlet after drying (13), a coil and a sleeve; and the spiral carbonization activation device (2) comprises a carbonization section (2-1) and an activation section (2-2) communicated with the carbonization section (2-1). By using the invention, the defects of low heat utilization efficiency, low drying / carbonization / activation efficiencies, discontinuous production course and the like in the existing active carbon preparation technology are overcome.

Owner:SOUTHEAST UNIV

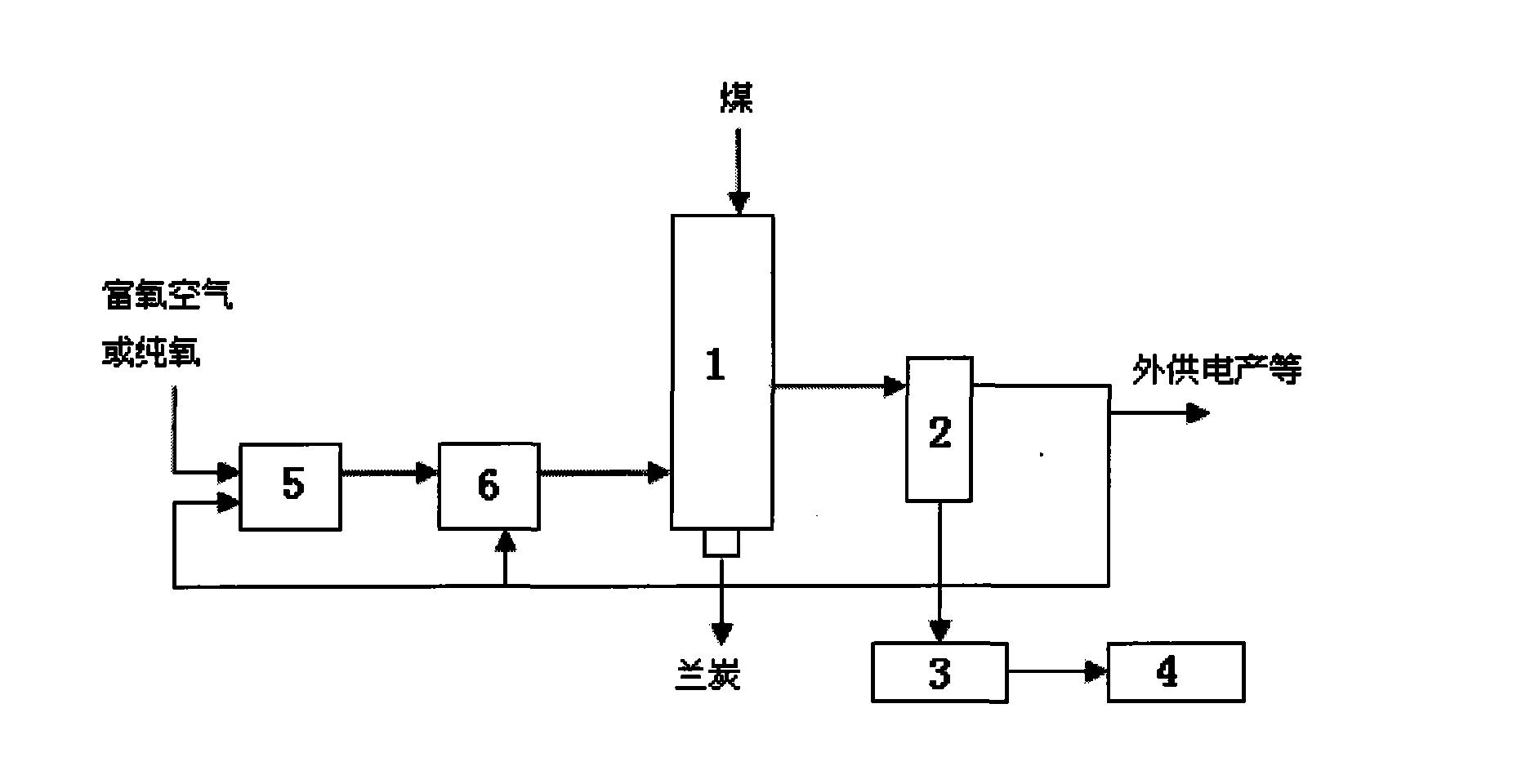

Method for coke dry quenching by coal internal heat smouldering

InactiveCN101514291ATake advantage ofImprove heat utilization efficiencyCoke quenchingIndirect heating destructive distillationCarbonizationQuenching

The invention discloses a method coke dry quenching by coal internal heat smouldering. In the method, high temperature carbonized coal gas produced by carbonized dry quenched coke is made into cool coal gas by washing and collecting tar; after the cool coal gas passes a circulating fan, part of the coal gas is introduced into a burner to be synthesized with high temperature waste gas into high temperature mixed gas satisfying the coal smouldering requirement; the high temperature mixed gas enters into a carbonization section of a coke oven to be used as a carbonization heat source; the other part of pure coal gas passing the circulating fan is introduced to a coke quenching and cooling section of a carbonization furnace by a booster fan to be used as an inertia medium of Ramsbottom coke and quenched coke; the cool coal gas passing the coke quenching and cooling section of the carbonization furnace absorbs the heat and then passes the carbonization section of the coke oven to carry out nonoxidation heating or weak-oxidation heating towards the coal together with the carbonization heat source to realize combustion-free circulation. The method simplifies the coke dry quenching technology, reduces the water content of the Ramsbottom coke, uses the heat of the Ramsbottom coke before coke quenching effectively, improves the utilization rate of the pure coal gas, reduces the use of combustion-supporting gas and accordingly reduces the energy consumption of the burner.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

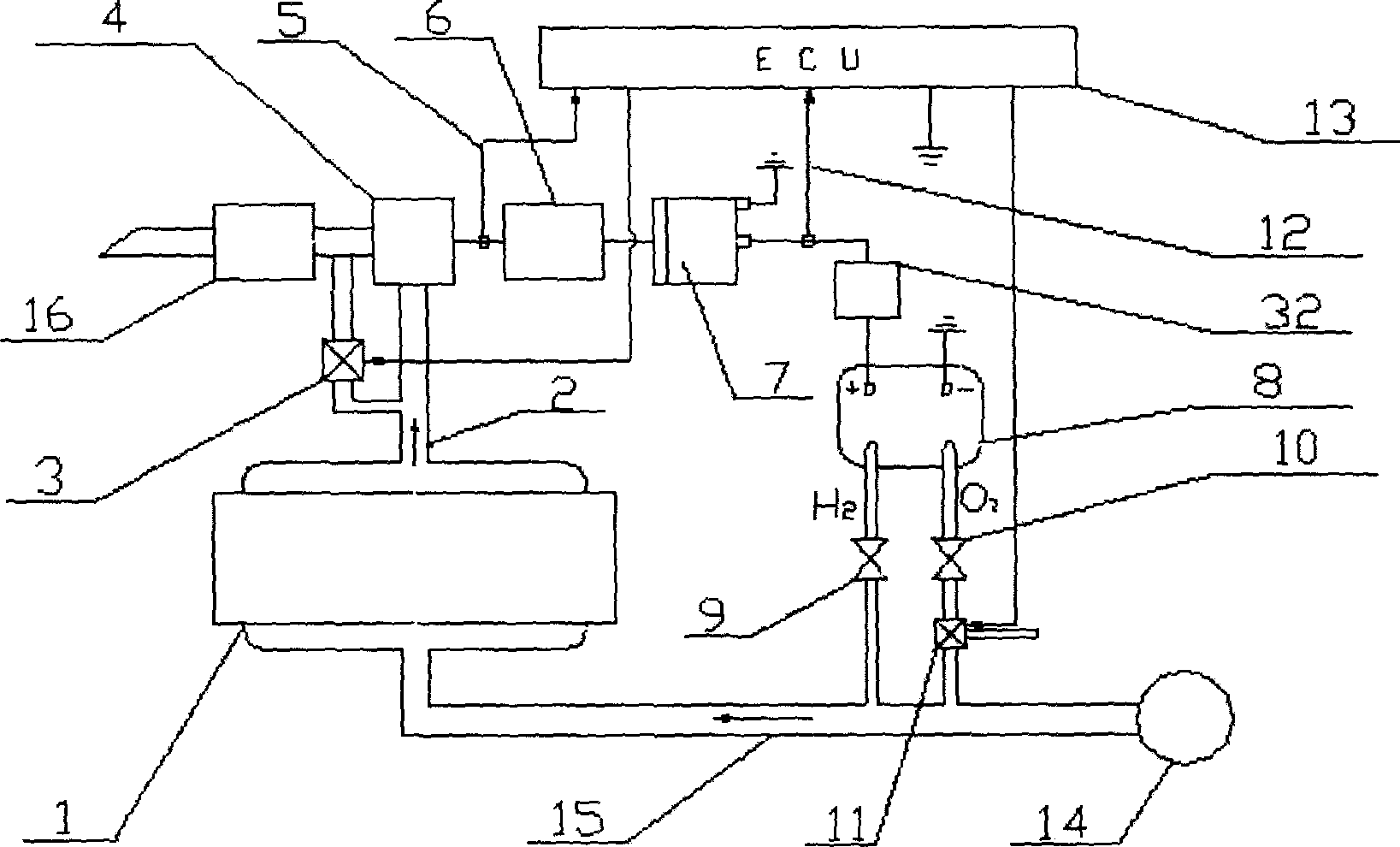

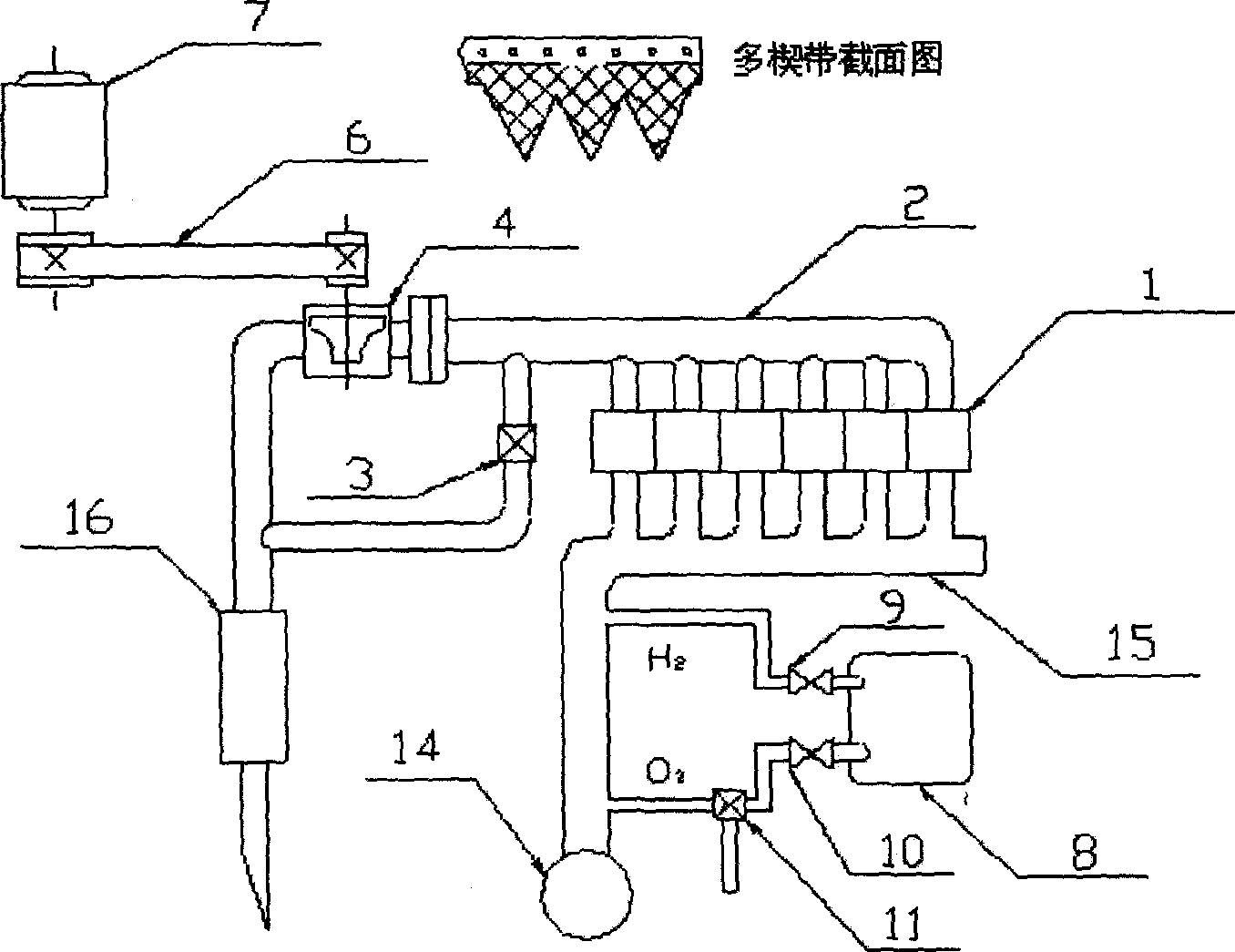

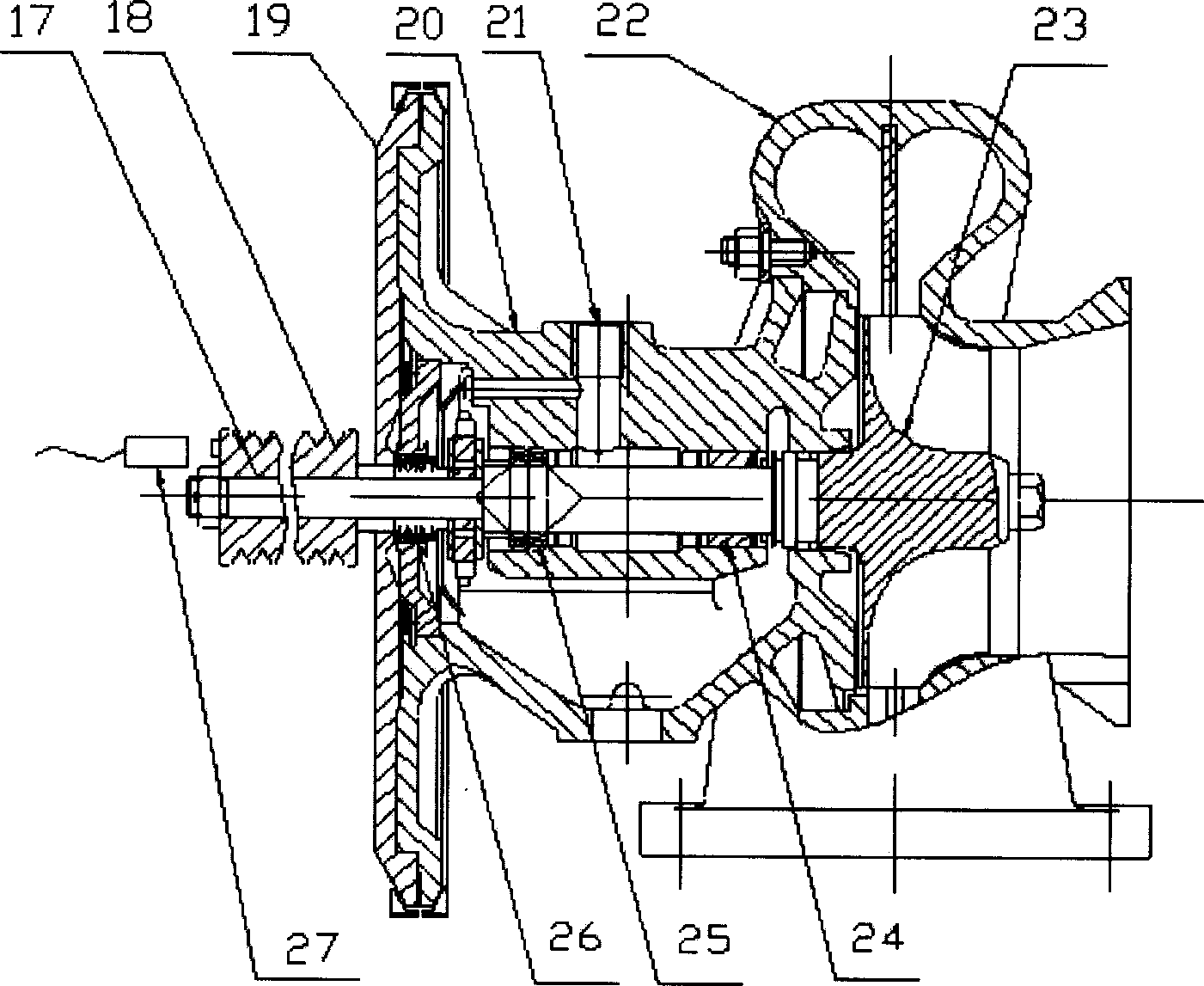

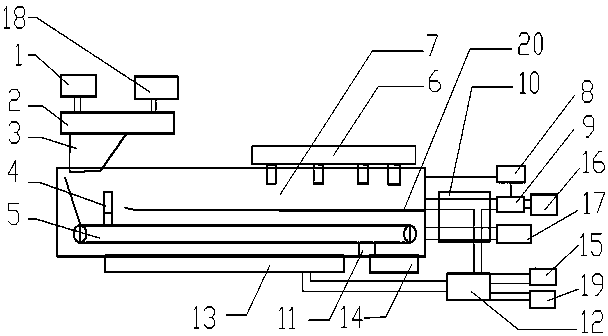

Power generating and hydrogen producing method and unit utilizing waste gas of internal combustion engine

InactiveCN1388308AAvoid storage hazardsSolve the problem of high cost of hydrogen productionElectrolysis componentsInternal combustion piston enginesExternal combustion engineMechanical energy

The present invention relates to the method and unit to utilize the energy of waste gas of internal combustion engine to generate hydrogen and oxygen and to improve burning state of internal combustion engine. The electricity generating and hydrogen generating unit consists of waste gas turbine converting the energy in waste gas into mechanical energy, electricity generator converting the mechanical energy into electrical energy, water electrolyzer utilizing the electrical energy to electrolyze water into hydrogen and oxygen and electric controller. The hydrogen and oxygen are fed to the internal combustion engine for catalyzing hydrocarbon fuel inside the internal combustion engine to improve burning, increase power output and reduce exhaust.

Owner:姜伟

Consecutive reaction apparatus for moisture sludge through anhydration and pyrolysis under microwave irradiation as well as method thereof

ActiveCN104163555AGood heating selectivityRapid pyrolysisSludge treatment by pyrolysisByproduct vaporizationRadiation lossNitrogen generator

The invention discloses a consecutive reaction apparatus for moisture sludge through anhydration and pyrolysis under microwave irradiation as well as a method thereof. The condensation comprises a sludge warehouse, a stirrer, a hopper feeder, a sludge-shaped controller, a belt sender, a power control microwave irradiation device, a microwave pyrolysis reaction chamber, a pressure sensing controller, a blower fan, a condensation heat exchanger, a scraper plate separator, an oil-water separating device, a liquid dredging groove, a coke storage tank, a product oil tank, a product gas tank, a nitrogen generator, a coke crusher, a sludge water pot and a gas shunting plate. According to the invention, microwave material internal heating characteristic can be fully used for reducing heat radiation loss, moisture sludge is directly performed with anhydration and pyrolysis to obtain the cracking oil, combustible gas and solid coke; heat recovery of the product gas and auxiliary microwave heating characteristic of the products residue are fully used for reducing the operation cost, and sludge pyrolysis efficiency and products quality can be increased. The apparatus has the advantages of simple structure, small volume, reasonable design and convenient market popularization, and is suitable for industrial application of microwave sludge continuous pyrolysis.

Owner:ZHEJIANG UNIV

System for preparing hydrogen from methanol and fuel battery device containing the same

A hydrogen production by methanol system includes a methanol supplying device, a water supplying device and a hydrogen production by methanol device. The methanol supplying device and the water supplying device communicate with an inlet of the hydrogen production by methanol device including a hydrogen production activator, a selective oxidation reactor of carbon monoxide and an oxidative gas supplying device. An outlet of the hydrogen production by methanol device and the oxidative gas supplying device both communicate with the inlet of the selective oxidation reactor of carbon monoxide including a selective oxidation activator of carbon monoxide which comprises the alloy of a platinum or the platinum and a palladium andor a rhodium. The hydrogen production by methanol system provided bythe present invention can produce the mixed gas of hydrogen, in which the concentration of the carbon monoxide is less than 50 parts per million and does not cause an oxidation or a blast of the hydrogen.

Owner:BYD CO LTD

Method for preparing nano fluid for heat transfer medium of solar heat exchange system

InactiveCN101735775AImprove heat collection efficiencyFast heatingHeat-exchange elementsNanoparticleSURFACTANT BLEND

The invention relates to a method for preparing nano fluid for a heat transfer medium of a solar heat exchange system, which comprises the following steps: selecting one of Al2O3, TiO2, ZnO, Ni and Cu nano grains with the grain diameter of 5 to 100 nanometers as additive, selecting water or water / ethylene glycol or water / propylene glycol mixture as base solution, adding surfactant into the solution, and strongly stirring and ultrasonically oscillating to form the nano fluid which is used for the heat transfer medium of the solar heat exchange system, wherein the Al2O3, TiO2, ZnO, Ni or Cu nano grains account for 0.1 to 3 volume percent of the volume of the nano fluid. The practical detection result for placing the solar heat exchange system on the roof shows that the nano fluid can remarkably improve the heat collecting efficiency of the solar heat exchange system, has the advantages of high heating speed, low cooling speed, low cost and simple preparation process and can remarkably improve the heat collection and heat utilization efficiencies of the existing solar heat collecting system.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

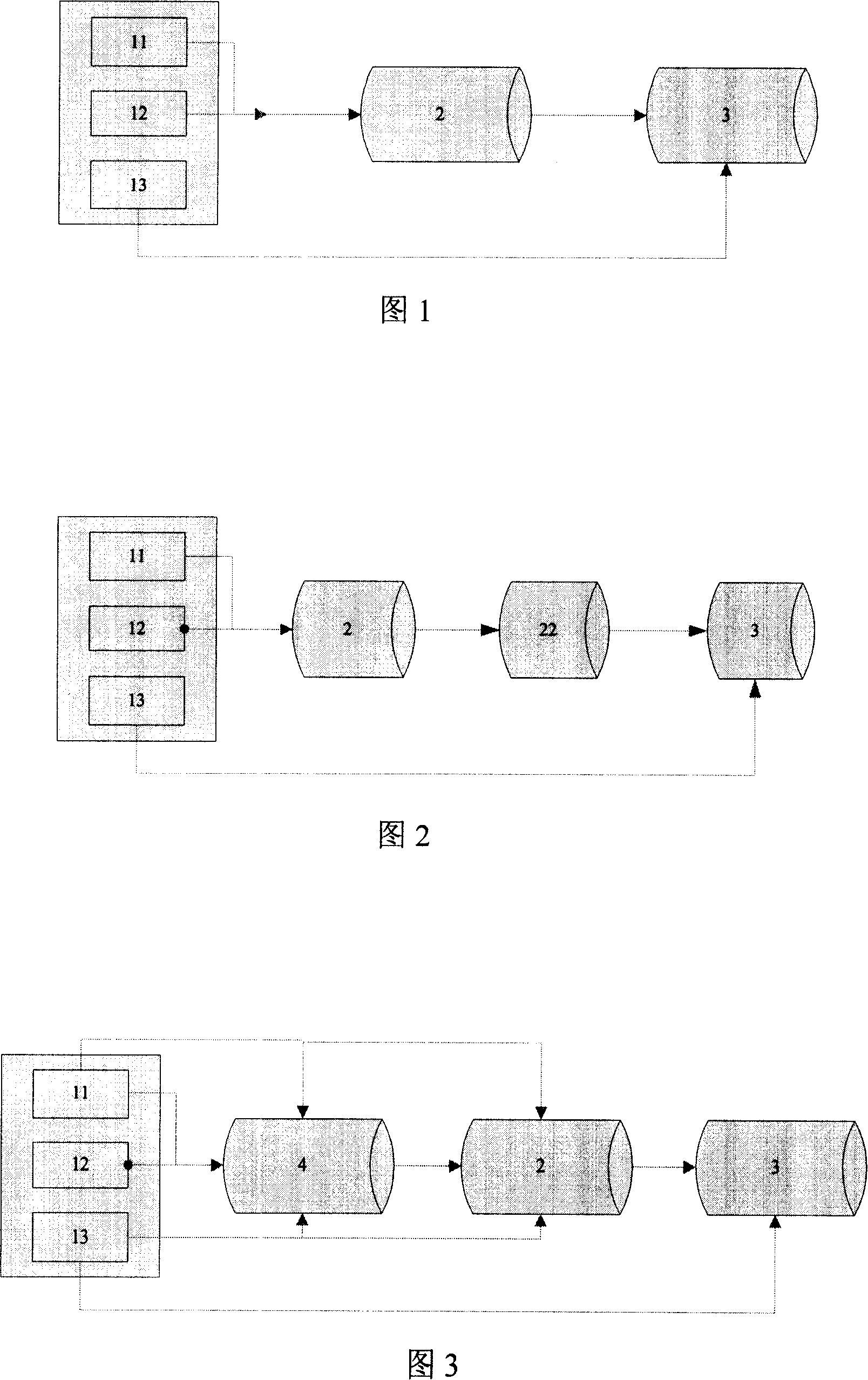

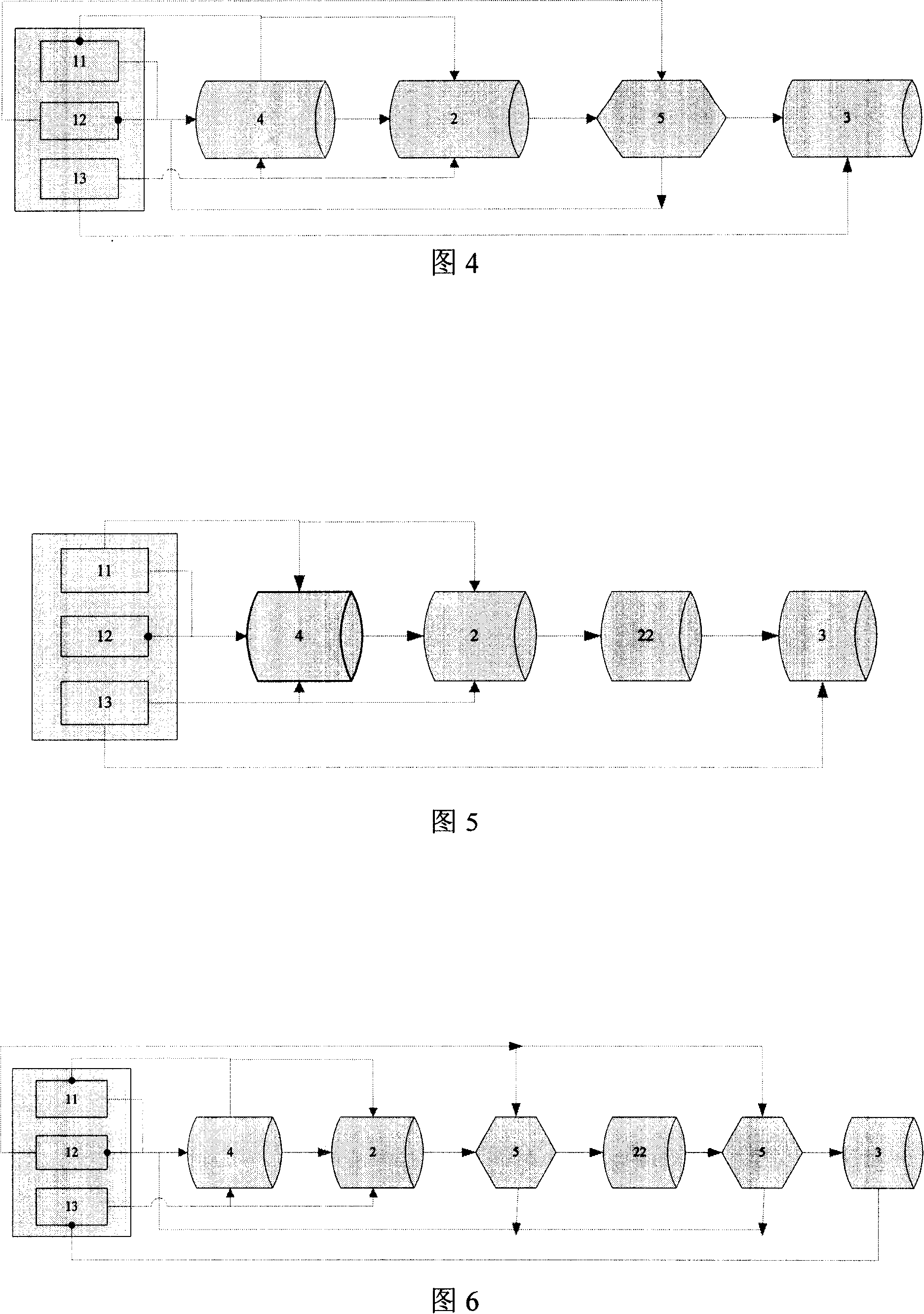

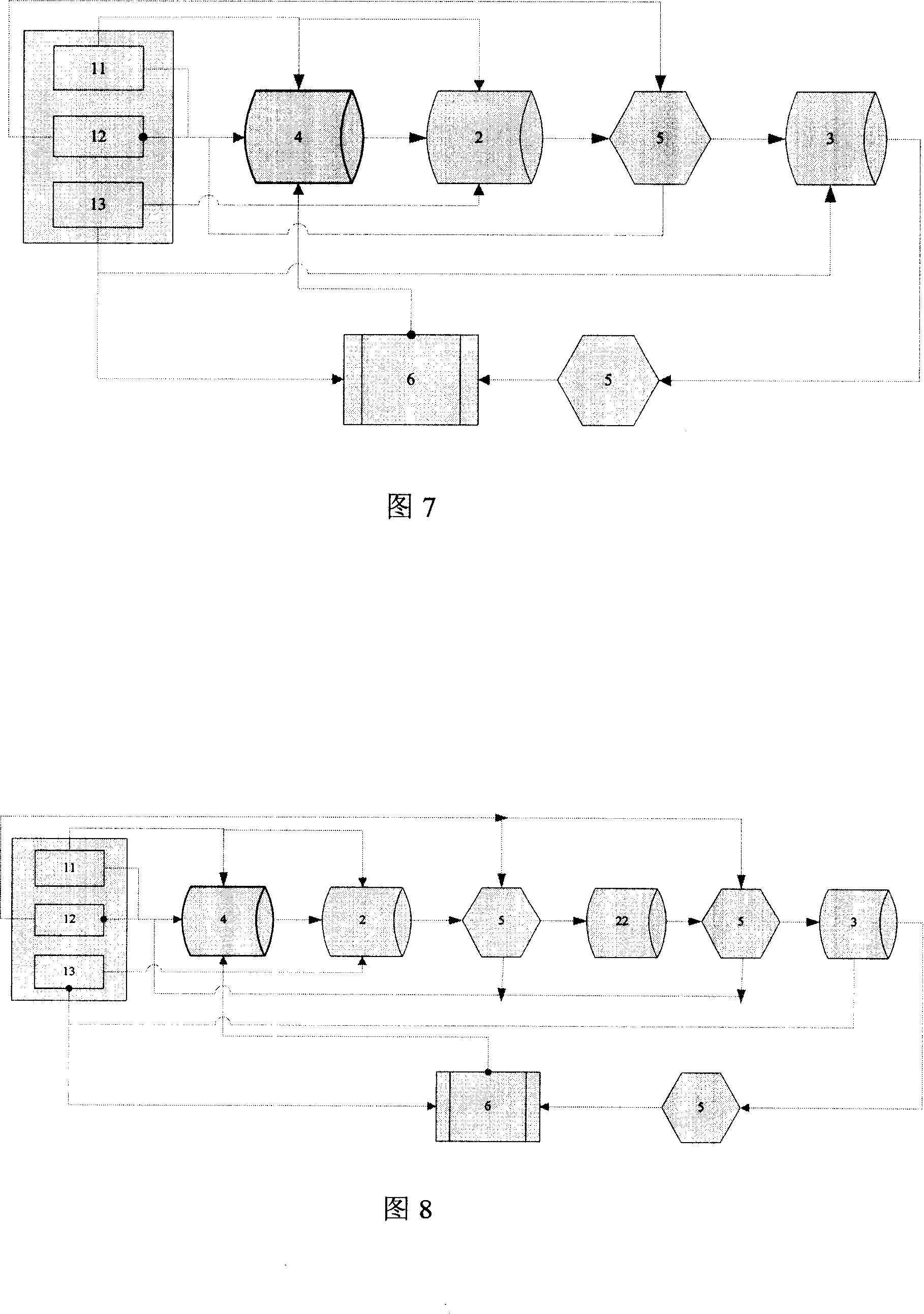

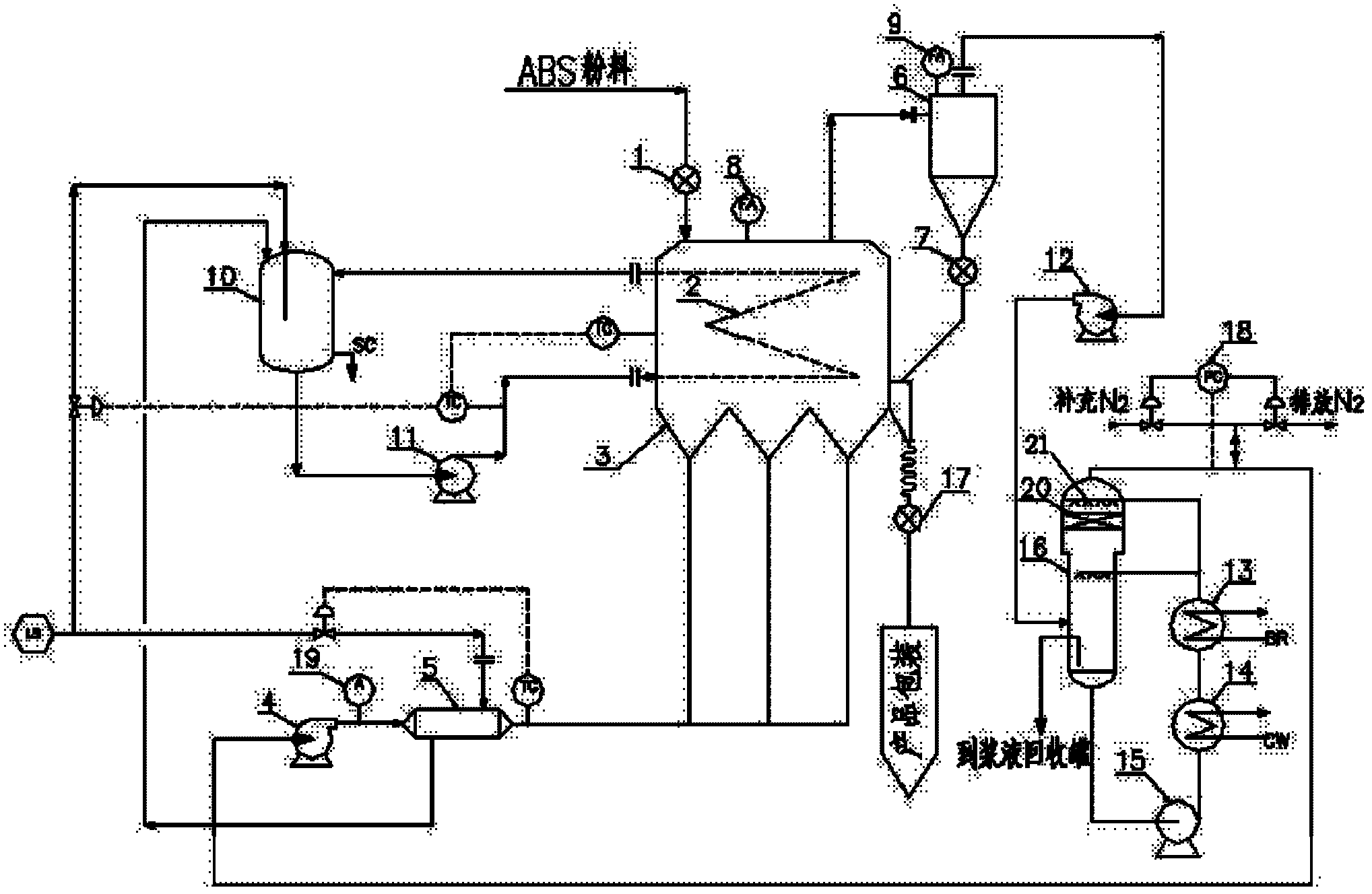

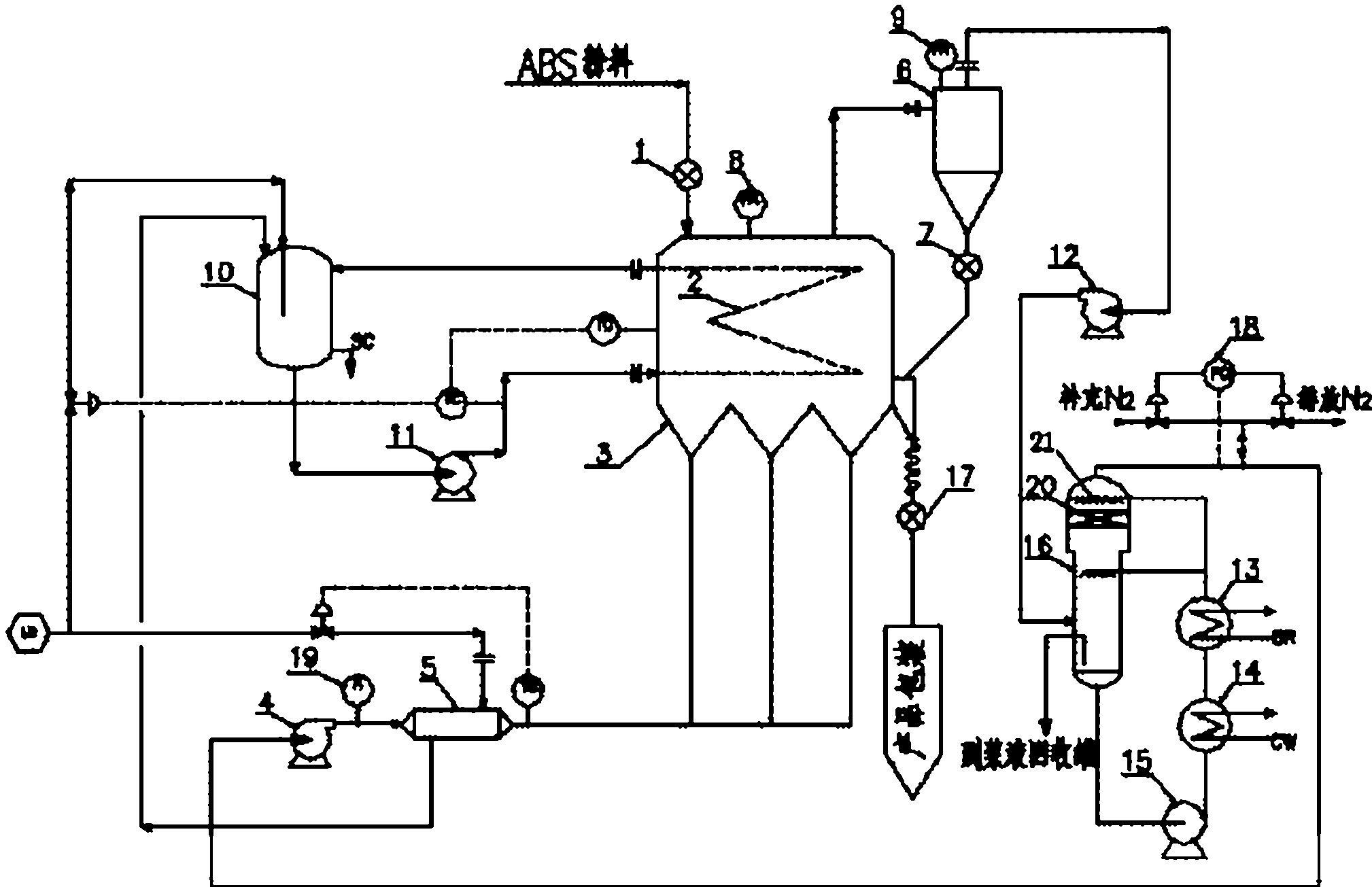

ABS powder drying method

ActiveCN102626965AEasy to separateImprove securityDrying solid materials with heatDrying gas arrangementsFluidized bed dryingNitrogen

The invention provides an ABS powder drying method, comprising a step of powder drying and a step of powder recovery. In the step of powder drying the technology of utilization of waste heat of condensed water comprises conveying the steam condensed water in a nitrogen heater to a buffer hot water tank as heating medium hot water in a heater. A slurry recovery tank is connected to a bottom portion of a washing tower. The upper portion diameter of the washing tower is slightly bigger than the bottom portion diameter. No filling material and no tray floor are arranged inside the washing tower. The washing tower is provided with a demister, and second spray water in the upper portion of the washing tower. A split-range controller is arranged on the top portion of the washing tower. A first fire extinguishing device is installed in a fluidized bed dryer. A second fire extinguishing device is installed at the exit port of a cyclone separator. An oxygen detector is installed at a nitrogen inlet side of the nitrogen heater. The method of the invention has the advantages of full utilization of the waste heat, energy saving and consumption reduction, heat utilization efficiency improvement, short process flow, reduction of powder loss, reduction of equipment investment, high operation flexibility and stability in the whole technology process, a good ABS separating effect, and good safety performance.

Owner:CHINA TIANCHEN ENG +3

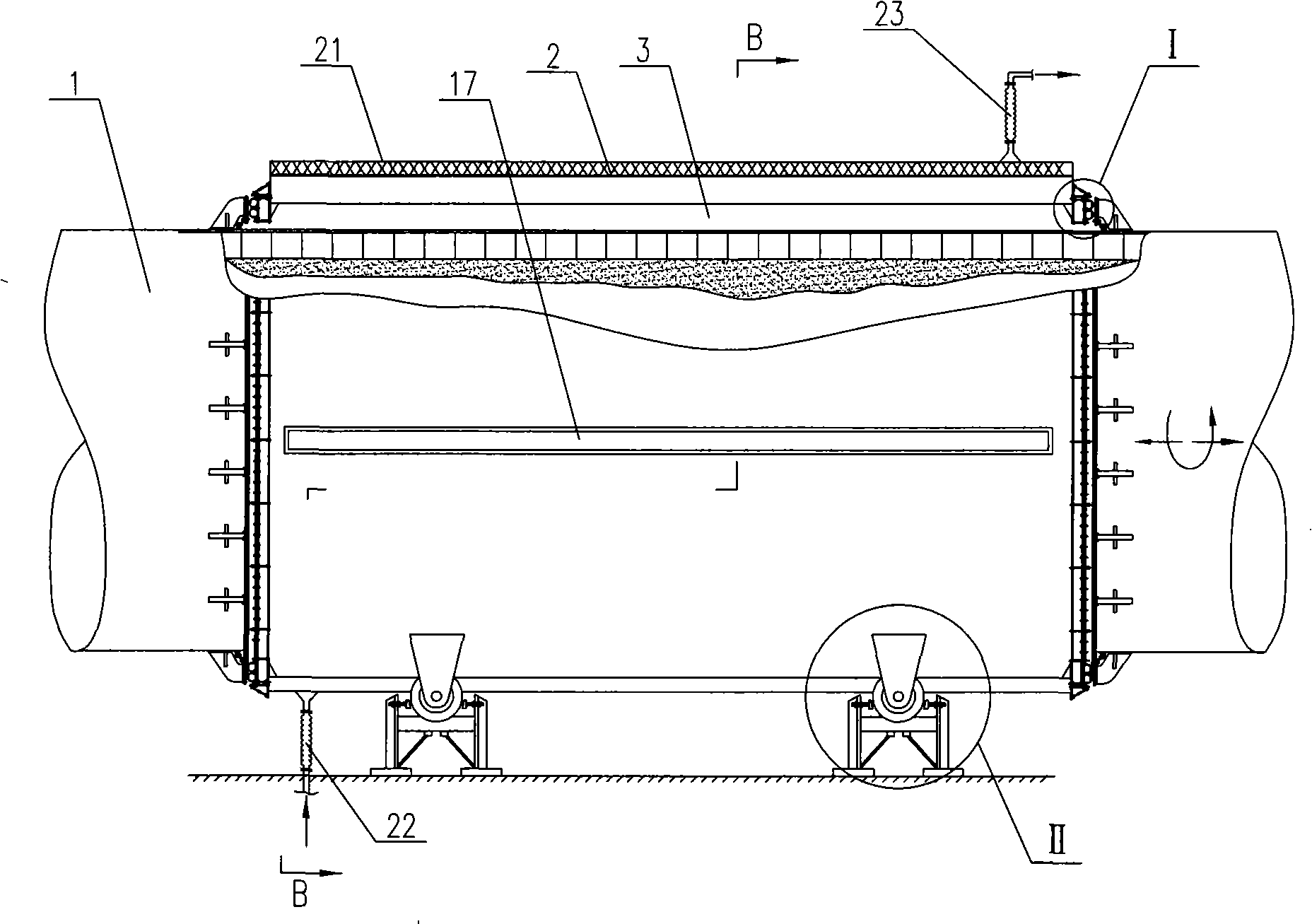

Cement rotary kiln barrel radiation, reclaiming and utilizing device

ActiveCN101290190APracticalSignificant energy saving and economic benefitsRotary drum furnacesIncreasing energy efficiencyCement kilnEngineering

The invention discloses a device for recycling heat radiated from a rotary cement kiln shell body, comprising a plurality of heat transfer covers arranged on the upper section of the rotary cement kiln shell body. Each of the external surfaces of the heat transfer covers is provided with an insulating layer, sealing equipment is arranged between the two ends of the heat transfer covers and the rotary cement kiln shell body, a sealing heat transfer cavity is formed by the inner surfaces of the heat transfer covers and the external surface of the rotary kiln shell body via the sealing equipment, the bottom of the heat transfer covers is provided with an inlet which is communicated with the heat transfer cavity, the top of the heat transfer covers is provided with an outlet which is communicated with the heat transfer cavity, the bottom of the heat transfer covers is connected to a slip fitting so as to realize the axial displacement. The sealing equipment comprises a permanent seat on the external surface of the rotary cement kiln shell body, and one side of the permanent seat is provided with a dynamic sealing ring; the bottom of the dynamic seal ring is hermetically connected to the rotary cement kiln shell body by a temperature resistant rubber I, and a self-propelling stationary seal ring is arranged between the dynamic seal ring and the head face of the heat transfer cover; the top of the self-propelling stationary seal ring is hermetically connected to the head face of the heat transfer cover by a temperature resistant rubber II, the self-propelling stationary seal ring is connected to an elastic stationary seal ring, and a sealing gland is arranged between the elastic stationary seal ring and the dynamic seal ring.

Owner:天津健威泽节能环保科技股份有限公司

Waste salt treating device and process

ActiveCN104310434AImprove heat utilization efficiencyEnergy inputAlkali metal halide purificationProcess systemsHeat conducting

The invention discloses a waste salt treating device. The waste salt treating device structurally comprises an industrial feeder, a multi-stage indirect heating furnace, a heat-conducting oil circulating system, a molten salt circulating system, an organic waste gas conveyor and a waste salt afterheat recycler. The invention further discloses a waste salt treating process. The waste salt treating process comprises the following steps: treating waste salt, circulating a heat-conducting oil working medium, circulating a hot-molten salt working medium, and treating hot air and tail gas. The waste salt treating device and the waste salt treating process can effectively meet an industrial waste salt refining requirement and solve the problem of tail gas emission; the whole process system is high in energy utilization efficiency and small in secondary pollution.

Owner:SHANGHAI LYMAX ENVIRONMENTAL TECH CO LTD

Steam drive exploitation method for heavy oil reservoir

The invention belongs to the field of oil exploitation, and relates to a steam drive exploitation method for a heavy oil reservoir, in particular to a steam drive exploitation method of intermediate-deep layer heavy oil aided by injecting air. The method comprises the following steps of synchronously and continuously injecting steam and air in a steam injection well according to a certain mass ratio in the process of intermediate-deep layer heavy oil steam drive production, and performing a low-temperature oxidation reaction between crude oil and oxygen. According to the method disclosed by the invention, heat utilization and recovery ratio of intermediate-deep layer heavy oil steam drive can be improved; a problem of steam channeling among injection and exploitation wells can be eased, and development effect of steam drive can be improved.

Owner:PETROCHINA CO LTD

Process for processing smoke

InactiveCN101893387AHigh recovery rateReduce processingEnergy industryIncreasing energy efficiencyCombustionProcess engineering

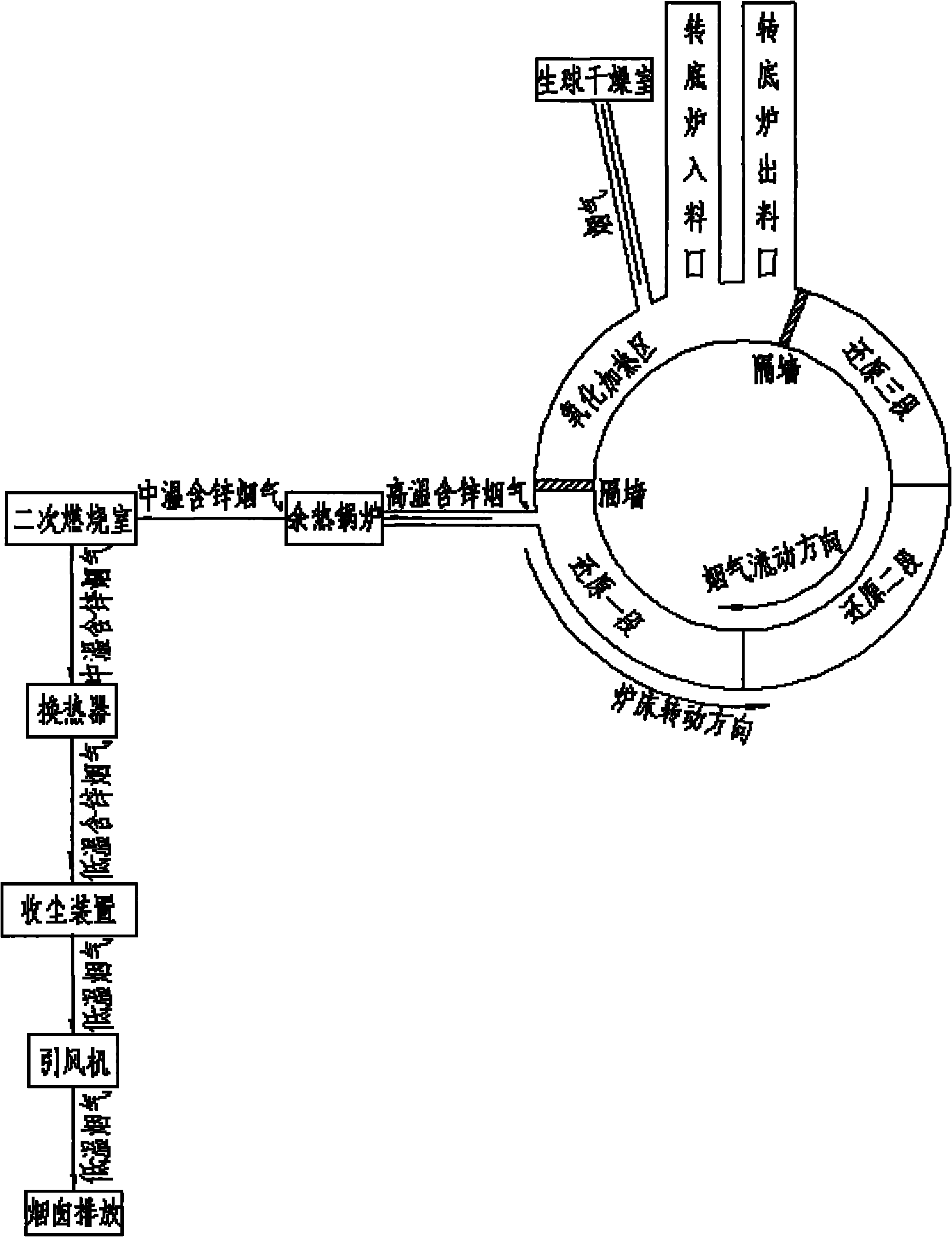

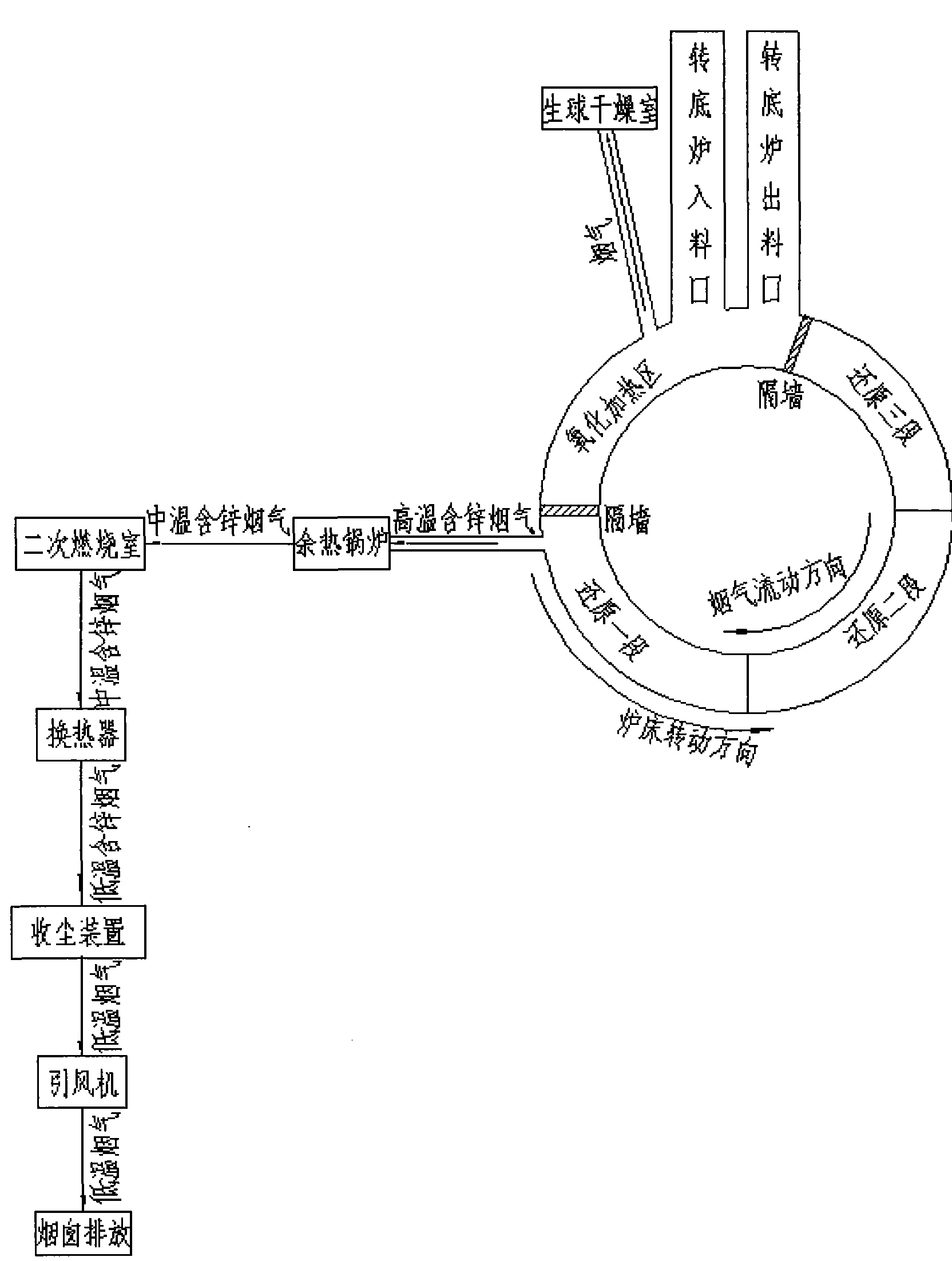

The invention relates to a process for processing smoke, which is characterized in that: in the process, the smoke generated by a rotary hearth furnace is subjected to segmental processing. In the process for processing the smoke, the segmental processing is performed on the smoke generated by the rotary hearth furnace, and the low zinc content smoke in an oxidation heating region is used for drying a preheated green ball, so the waste heat of the smoke can be completely recycled, unburned gas can also be combusted completely to recycle usable waste heat further; the smoke in a high-temperature reducing region where the zinc is gasified and volatilized intensively is subjected to dust removal and zinc recycling after waste heat recycling and secondary combustion, and the amount of the smoke which needs to perform zinc recycling is reduced, so the equipment investment and operation cost of a smoke processing system are reduced; and due to the secondary waste heat recycling and the secondary combustion of the smoke in the high-temperature reducing region, the waste heat of the smoke in the region can be completely recycled, the recovery rate of the zinc is improved, and the environmental pollution is reduced.

Owner:CISDI ENG CO LTD

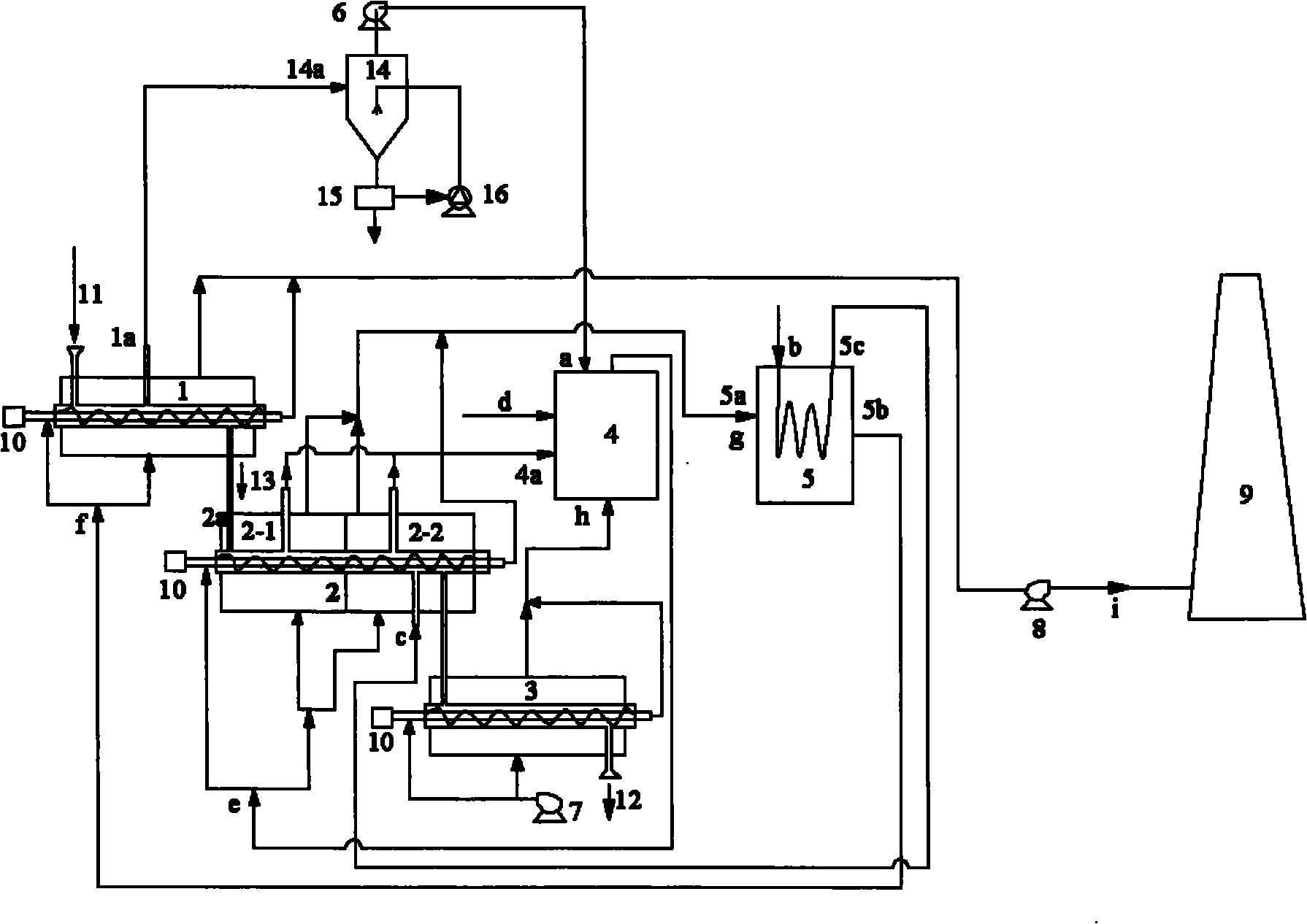

Polygeneration technology for gradient utilization of low-rank coal

InactiveCN103740389AIncrease added valueEmission reductionDirect heating destructive distillationSpecial form destructive distillationWaxBrown coal

The invention discloses a polygeneration technology for gradient utilization of low-rank coal. According to the polygeneration technology, a circulating fluidized bed combustion boiler, a circulating fluidized bed dry distillation reactor and a circulating fluidized bed gasification reactor are taken as cores; series power generation equipment achieves gradient cyclic utilization of low metamorphic coals; the low-rank coal is firstly subjected to lignite wax extraction after crushing and drying, and then enters a brown coal pyrolysis reactor; a raw gas of the gasification reactor is adopted as a fluidizing agent; tar and the raw gas are obtained after dry distillation; semicoke enters the gasification reactor to carry out partial gasification; a part of coal gas is generated as a fluidizing agent of a dry distillation reactor; incompletely gasified semicoke enters the combustion boiler as a fuel; heat and steam generated by combustion are applied to power generation; a by-product low-pressure steam can be used as a raw material of the gasification reactor; the high-temperature semi-coke and hot ashes obtained by combustion enter the dry distillation reactor and the gasification reactor as heat carriers, so as to finish a cycle. By adopting the polygeneration technology, the economic value of the low-rank coal can be obviously improved, emission of pollutants can be significantly reduced by gradient cyclic utilization, and the technology is safe and reliable.

Owner:BEIJING TIANSU SUNLIGHT LOW CARBON TECH

Cold trap for radiosodium on-line purifying

ActiveCN101231898ASuitable for in-line purificationImprove heat utilization efficiencyNuclear energy generationReactor fuel elementsWire gauzeEngineering

The invention discloses a cold trap used for on-line purification of radiosodium, which comprises an outer cylinder body. A wire gauze arranged in the outer cylinder body. A sodium inlet and a sodium outlet are arranged on the upper part of the outer cylinder body. A central return conduit is arranged inside the outer cylinder body communicating with the sodium outlet through a heat saving unit coil. The technical proposal provided by the invention makes the best of the temperature difference between the inlet and the outlet for heat exchange, thus improving the efficiency of heat utilization. On the premise that a reactor is not stopped, liquid sodium of high temperature is cooled, separated out, filtered, heated and so on. The invention can process a great deal of sodium and is applicable for on-line purification of a great deal of sodium.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

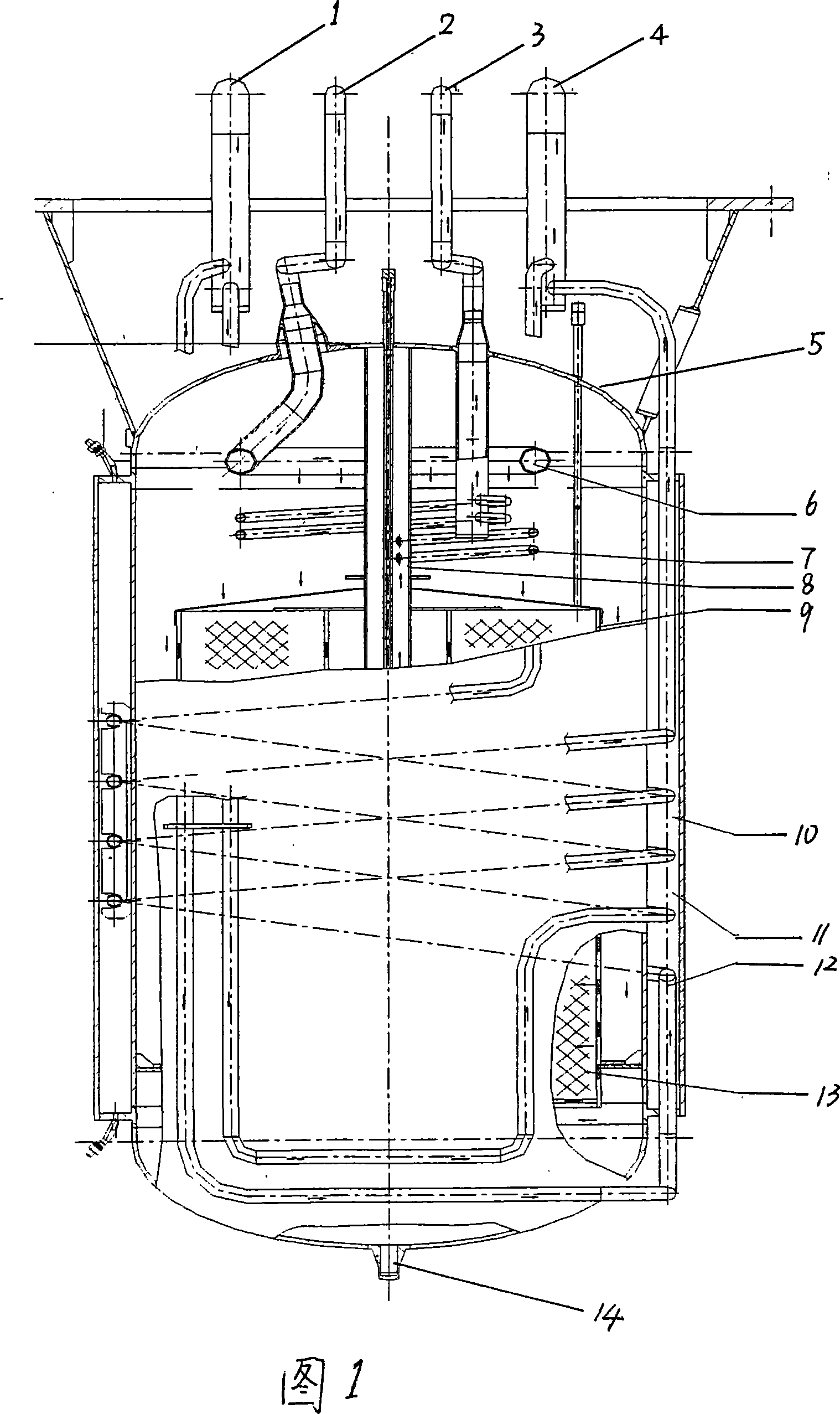

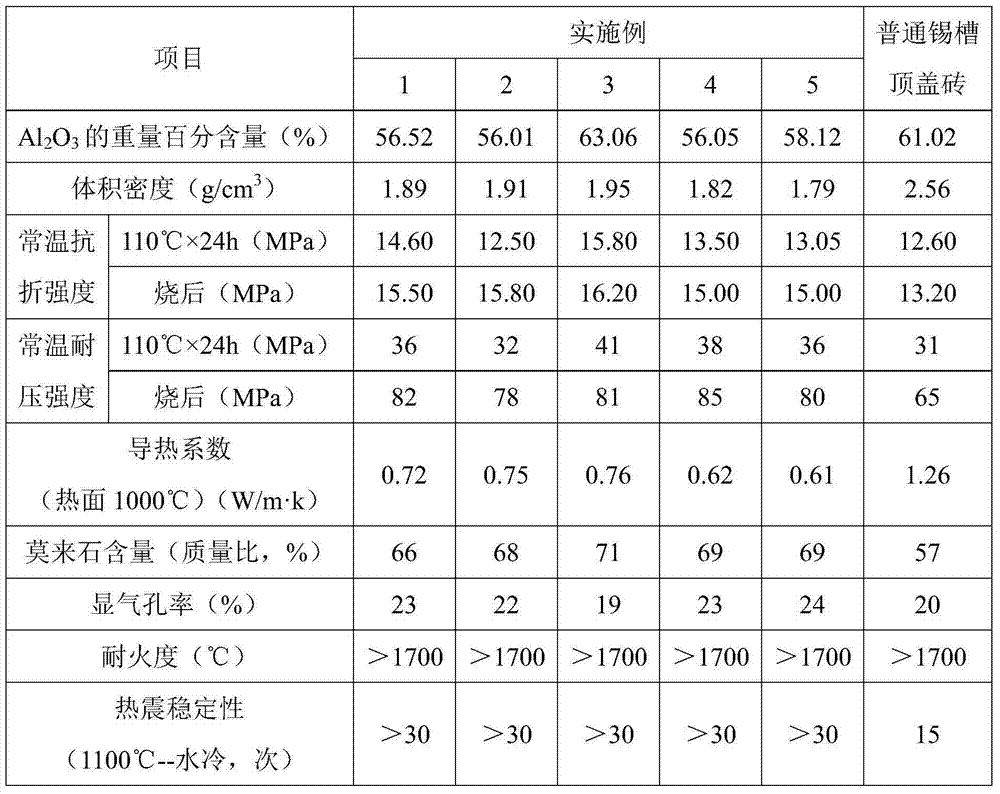

Low-thermal-conductivity mullite tin bath combined top cover brick

The invention discloses a low-thermal-conductivity mullite tin bath combined top cover brick prepared from the following raw materials by the mass percentage: 40.5%-65% of a mullite aggregate, 8%-15% of calcium aluminate cement, 4%-10% of a silica micropowder, 10%-18% of an alumina micropowder, 5%-13% of a mullite fine powder, 2%-3% of a mineralizing agent, and 0.1%-0.5% of a water reducing agent. The low-thermal-conductivity mullite tin bath combined top covering brick has the advantages of small thermal conductivity coefficient, small proportion, light weight, high strength, good thermal shock resistance, high refractoriness (greater than 1700 DEG C) and the like; the tin bath combined top cover brick is used in a top cover of a tin bath, greatly reduces the kiln body weight, and reduces the kiln body heat capacity while saving cost; the tin bath combined top cover brick has good thermal shock resistance, and has the service life of a kiln improved greatly; and the tin bath combined top cover brick has the advantages of small thermal conductivity coefficient, good thermal insulation effect and little heat loss, significantly improves the thermal utilization efficiency, saves energy, greatly reduces the energy consumption, and is suitable for popularization and application.

Owner:HENAN ZHONGYUAN SPECIAL REFRACTORY

Waste heat recovering efficient gas stove

InactiveCN102759130ALower exhaust gas temperatureCompact structureDomestic stoves or rangesCombustion processCombustion chamberEngineering

The invention discloses a waste heat recovering efficient gas stove. A hot air tube (9) for supplying air and matched with a gas tube (7) is arranged on a stove body (5), a hearth of the stove body (5) is provided with a porous ceramic medium (6) covering the gas tube (7) and the hot air tube (9) to form a combustion chamber, a smoke recovering channel (18) is formed between a side wall of the porous ceramic medium (6) and a hearth side wall of the stove body (5), a cooker can seal a hearth port when placed on the hearth port, a heat exchange tube (4) is arranged in the stove body (5), an air blower (1) is connected with an air inlet of the heat exchange tube (4), an air outlet of the heat exchange tube (4) is connected with the hot air tube (9), a smoke inlet of the heat exchange tube (4) is connected with a smoke recovering channel (18), and a smoke outlet of the heat exchange tube (4) is connected with a chimney (3). The waste heat recovering efficient gas stove can effectively improve heat efficiency, reduce pollutant discharge and improve chef working environment.

Owner:HUNAN HANLON ENERGY TECH +1

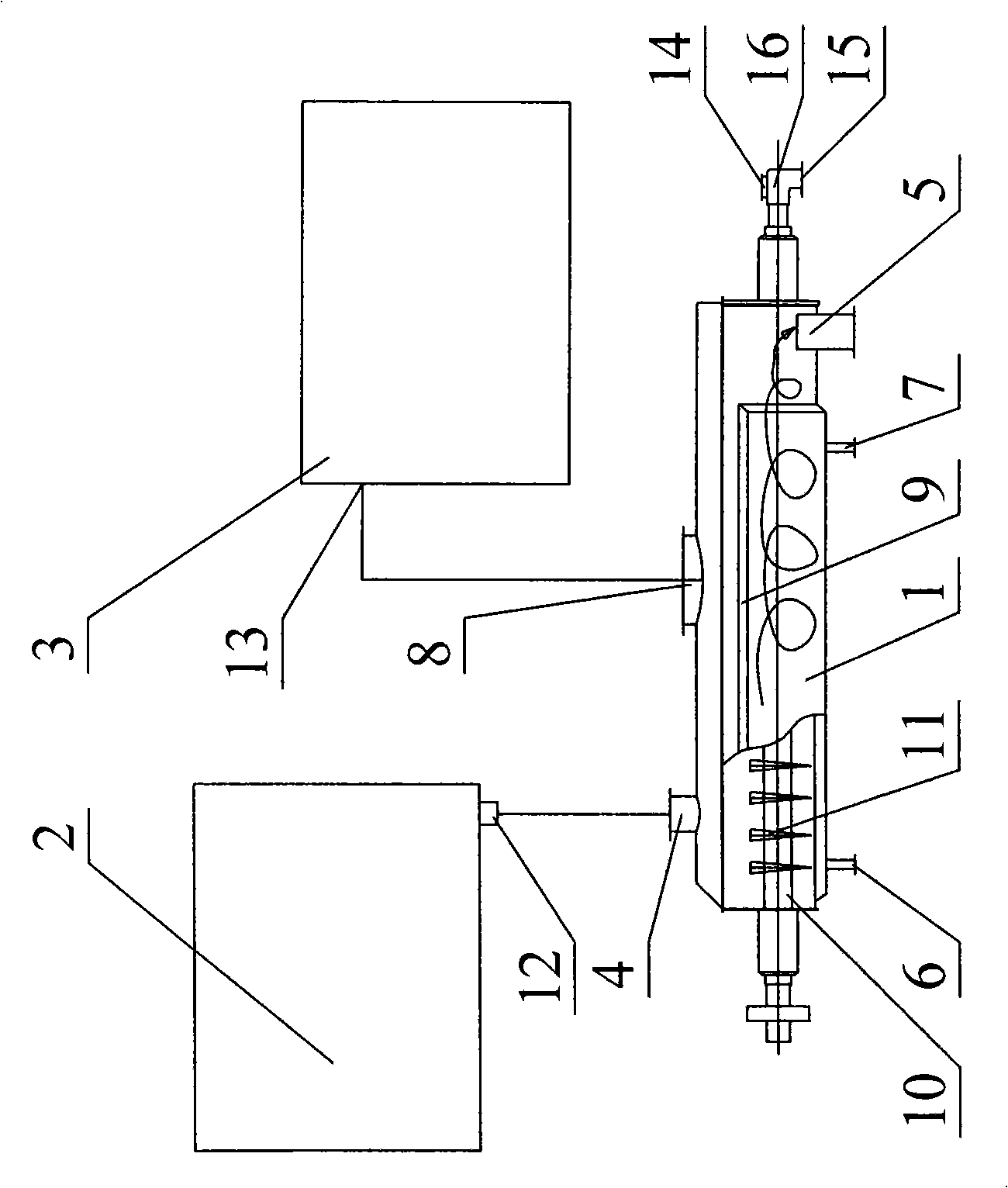

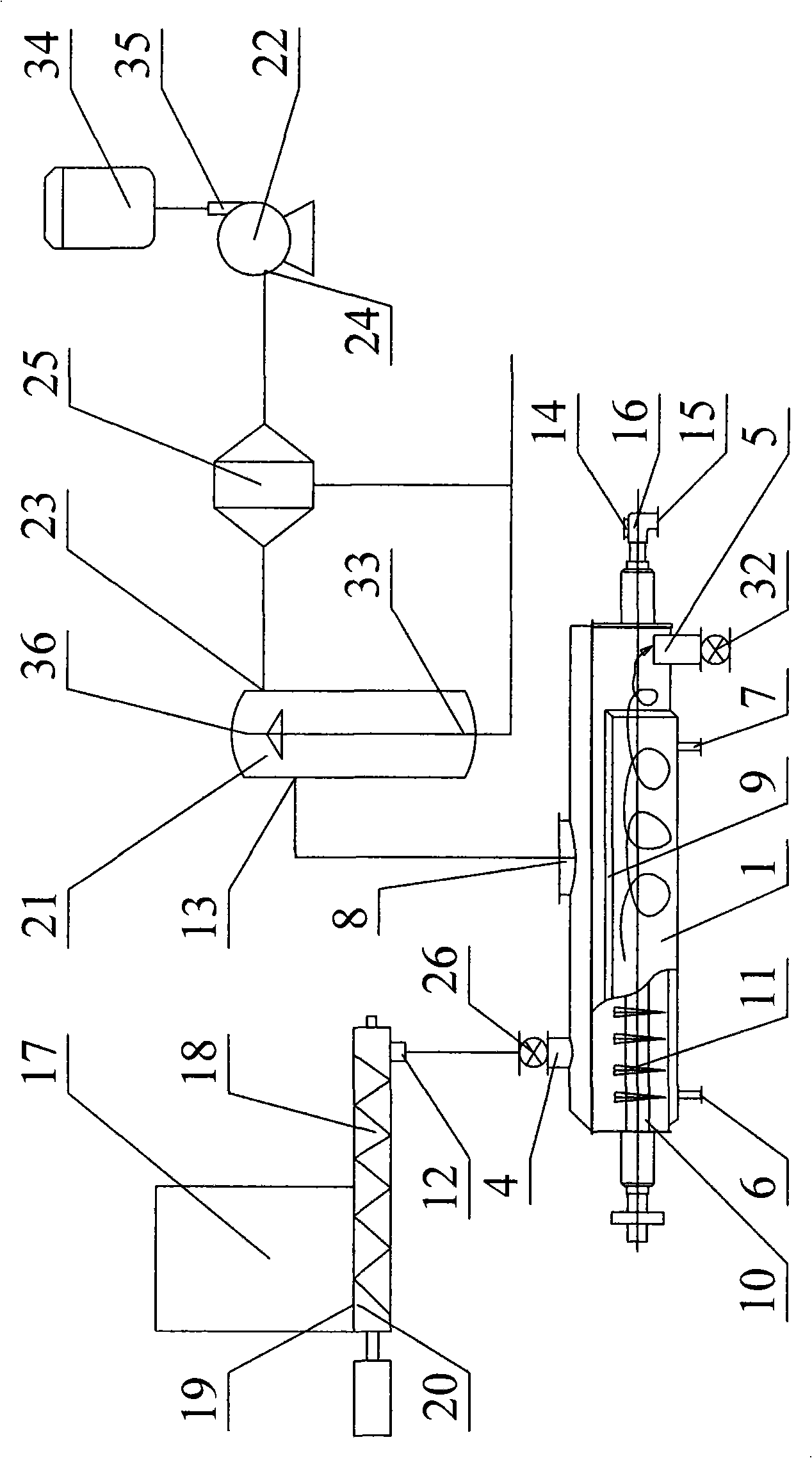

Set treatment device of sludge drying

InactiveCN101549945AIncrease flow rateLow costSludge treatment by de-watering/drying/thickeningSludgeExhaust gas

The invention relates to a treatment device of sludge drying in the field of environmental protection, in particular to a set treatment device of sludge drying, comprising a paddle sludge drier (1) with a feeding inlet (4), a discharging hole (5), a steam inlet pipe (6), a water outlet pipe (7), a tail gas outlet (8), a cylinder (9), a hollow shaft (10) and hollow paddles (11); the hollow paddles (11) are arranged on the hollow shaft (10); the set treatment device of sludge drying also comprises a storing and feeding device (2) and a tail gas purifying processing device (3); the discharging hole (12) of the storing and feeding device (2) and the feeding inlet (4) of the paddle sludge drier (1) are connected; and the tail gas outlet (8) of the paddle sludge drier (1) and the gas inlet (13) of the tail gas purifying processing device (3) are connected. The treatment device has the advantages of simple structure, good drying effect, low cost, environmental protection, high cost performance, continuous drying and realization of sludge integrated treatment.

Owner:史少军

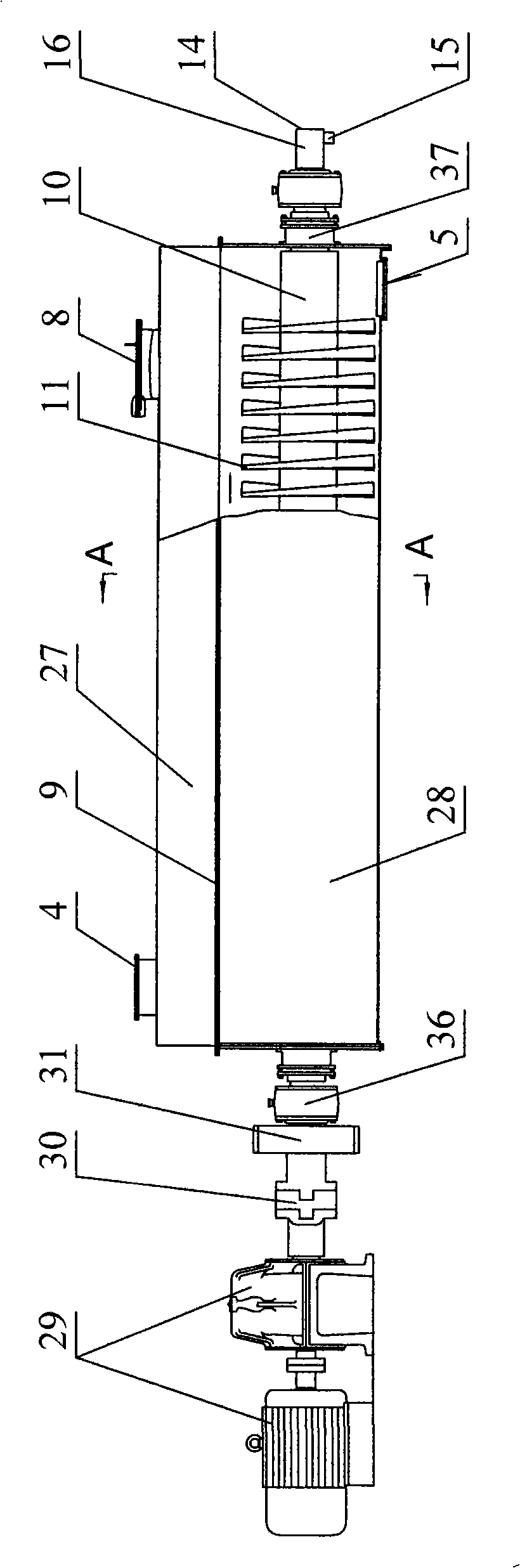

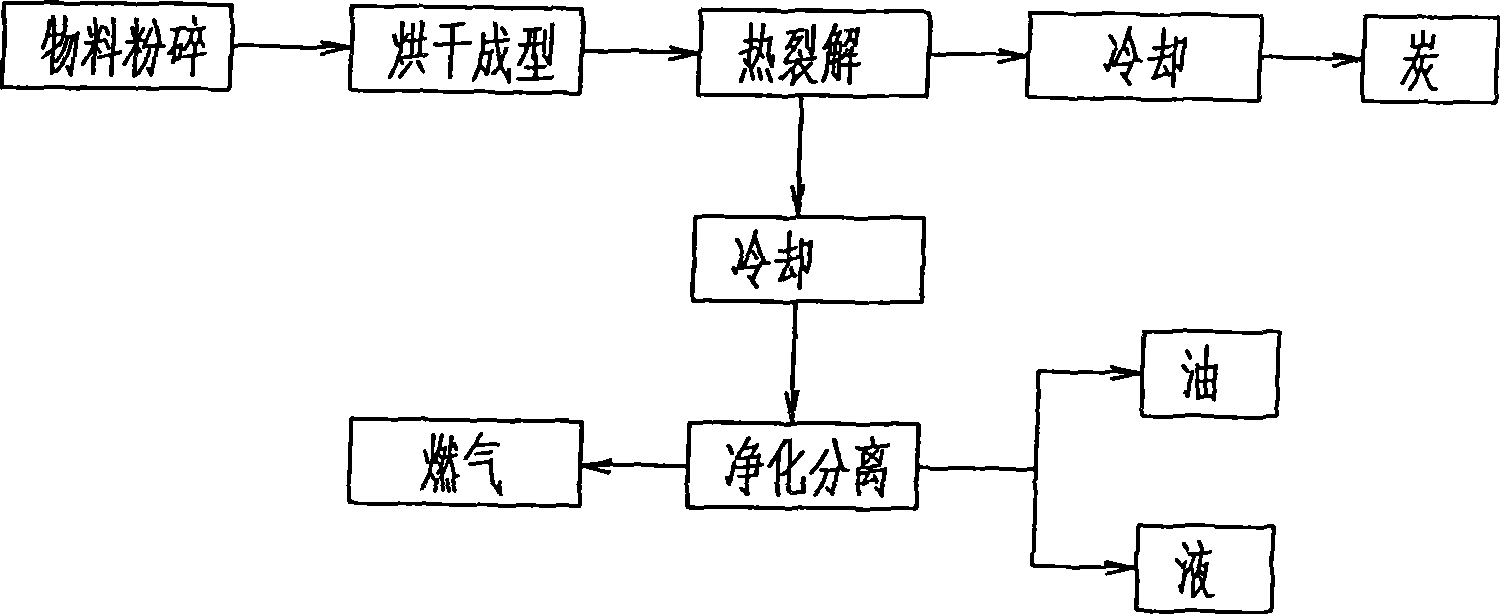

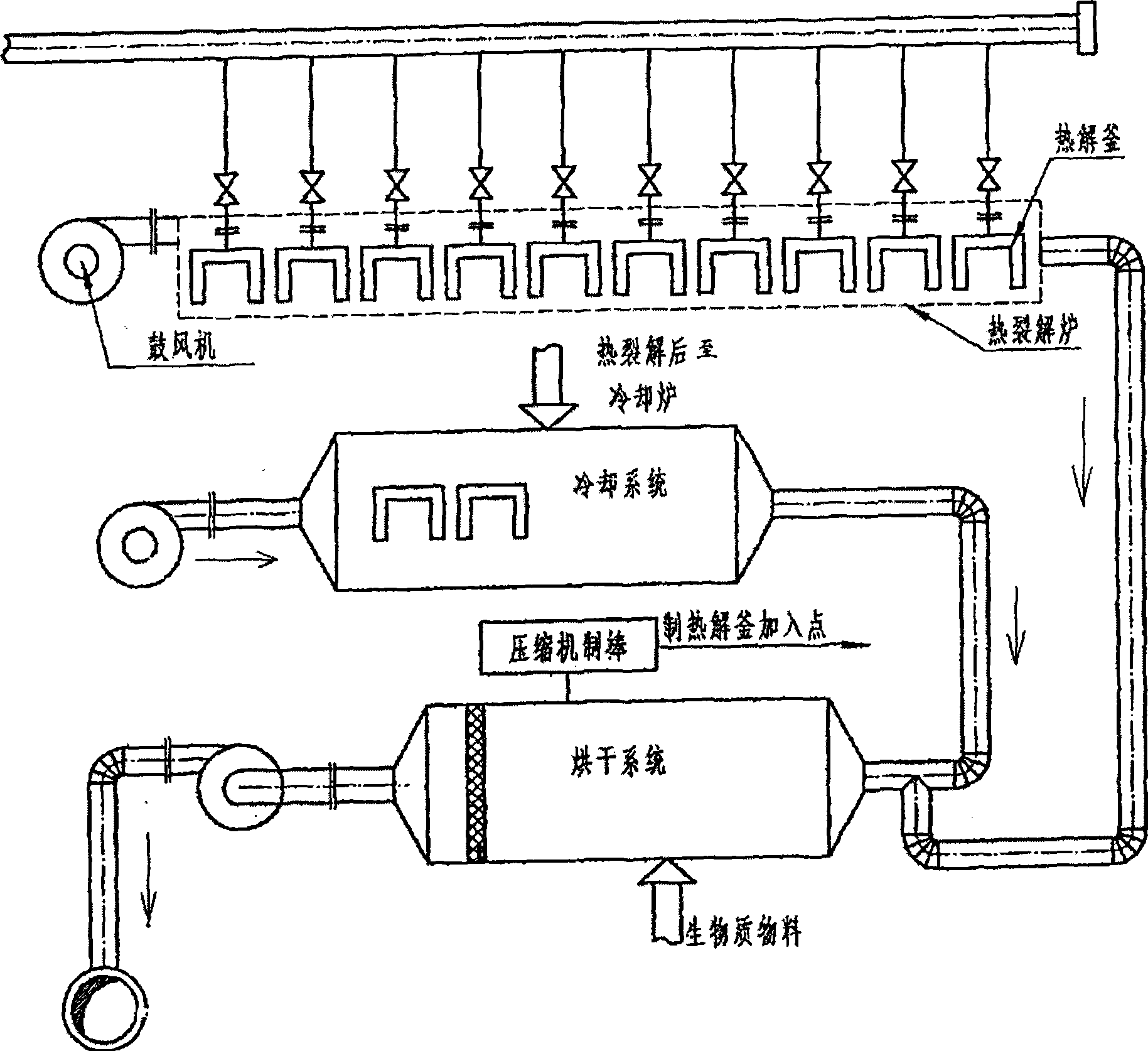

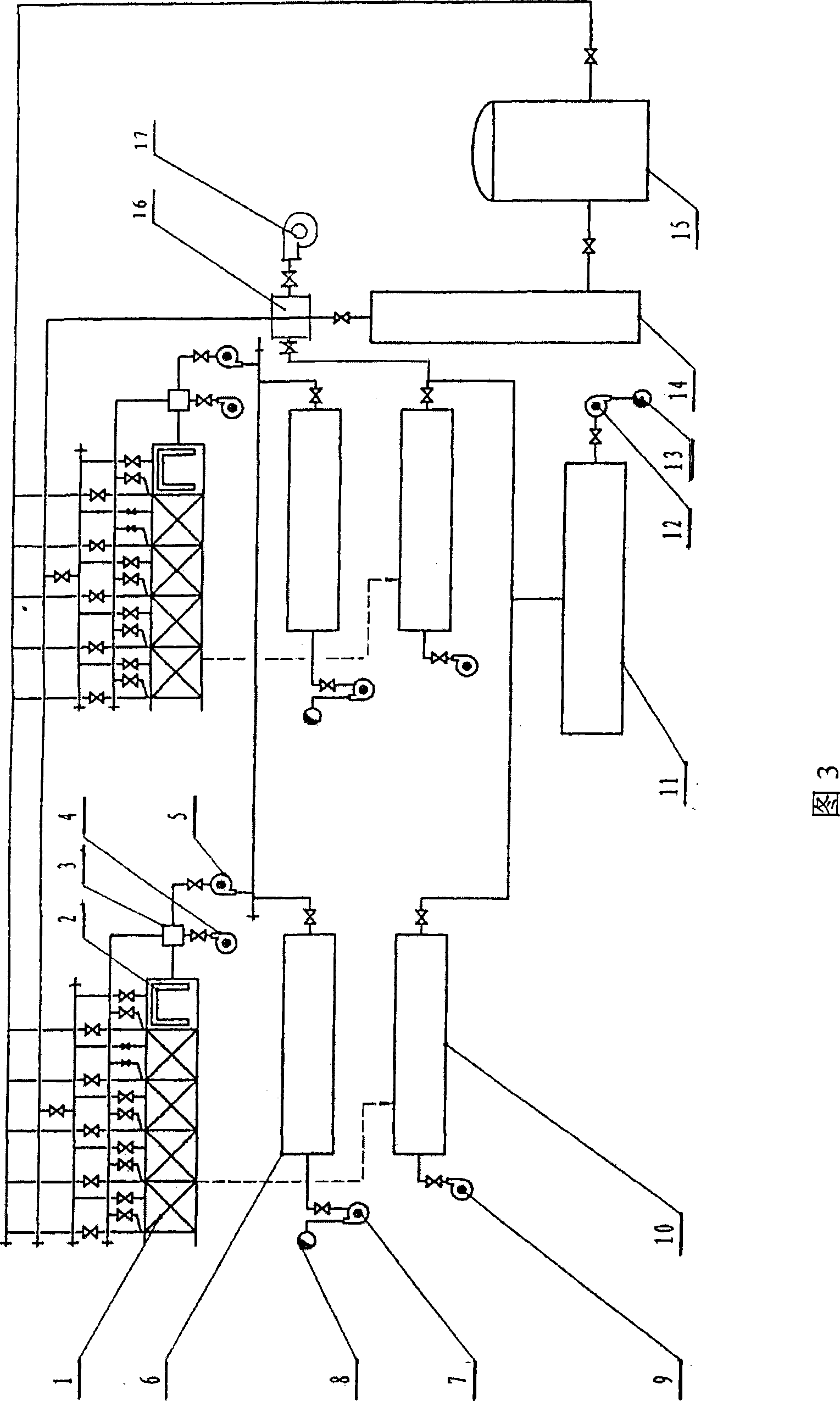

Method for preparing carbon, gas, oil and solution in scale by thermally cracking biomass material

InactiveCN101372624AImprove comprehensive heat utilization efficiencyReduce unit energy consumptionBiofuelsEnergy inputBiomassProcess engineering

The invention discloses a method for large-scale preparation of carbon, gas, oil and liquid by thermal cracking of biomass materials; the method includes the following production steps: material pulverization-drying and molding-thermal cracking-cooling and separation; in the invention, waste heat in a cooling system and a thermal cracking system is induced into a drying and molding system for drying materials, biomass fuel gas obtained by cooling and separation is burned to provide heat for thermal cracking, surplus biomass fuel gas is stored and used as industrial or domestic fuel. In thermal cracking, a plurality of thermal cracking reactors are taken as one batch to form one row which is positioned in a thermal cracking furnace. The method can raise comprehensive heat utilization efficiency of the system, greatly reduce unit energy consumption of products, improve the operating efficiency of the system, achieve outstanding energy-saving effect, shorten molding time of products, reduce heat emission and effectively control thermal pollution, thus achieving significant environmental production benefits. The method can realize large-scale production and has the capacity of treating tens of thousands of tons of raw materials every year.

Owner:熊晓明

Smoke reflux vaporized alcohol-based fuel burner

InactiveCN103196139AImprove heat utilization efficiencyReduce the temperatureBurnersIndirect carbon-dioxide mitigationRefluxAlcohol

The invention discloses a smoke reflux vaporized alcohol-based fuel burner which comprises a shell, wherein the top of the shell is provided with a fuel pipeline, a catalytic reaction body is arranged in the shell, a smoke reflux passage is vertically arranged in the shell, the smoke reflux passage penetrates through the catalytic reaction body, a top cover is arranged above the smoke reflux passage, and a bottom cover is arranged at the bottom of the smoke reflux passage; and an outlet section of a fuel output pipe vertically extends upwards to a throat part of the shell from the lower part of the shell, and an igniter is arranged on the inner wall of the shell. Before the fuel is atomized, the alcohol-based fuel is heated by utilizing the heat produced by the burner, so that the tension of the alcohol-based fuel is reduced, and the atomizing effect is better; and when the smoke returns to a gas atomizing mixing area, not only the air can be preheated and the comprehensive utilization efficiency of the burner be increased, but also the heat in a flame burning area transfers towards a mixing space due to the refluxing of the smoke, the temperature in the flame burning area is reduced, the temperature of the entire burner is more uniform, and the carbon deposition produced by the liquid fuel due to the over-high temperature of the flame can be reduced.

Owner:CHONGQING UNIV

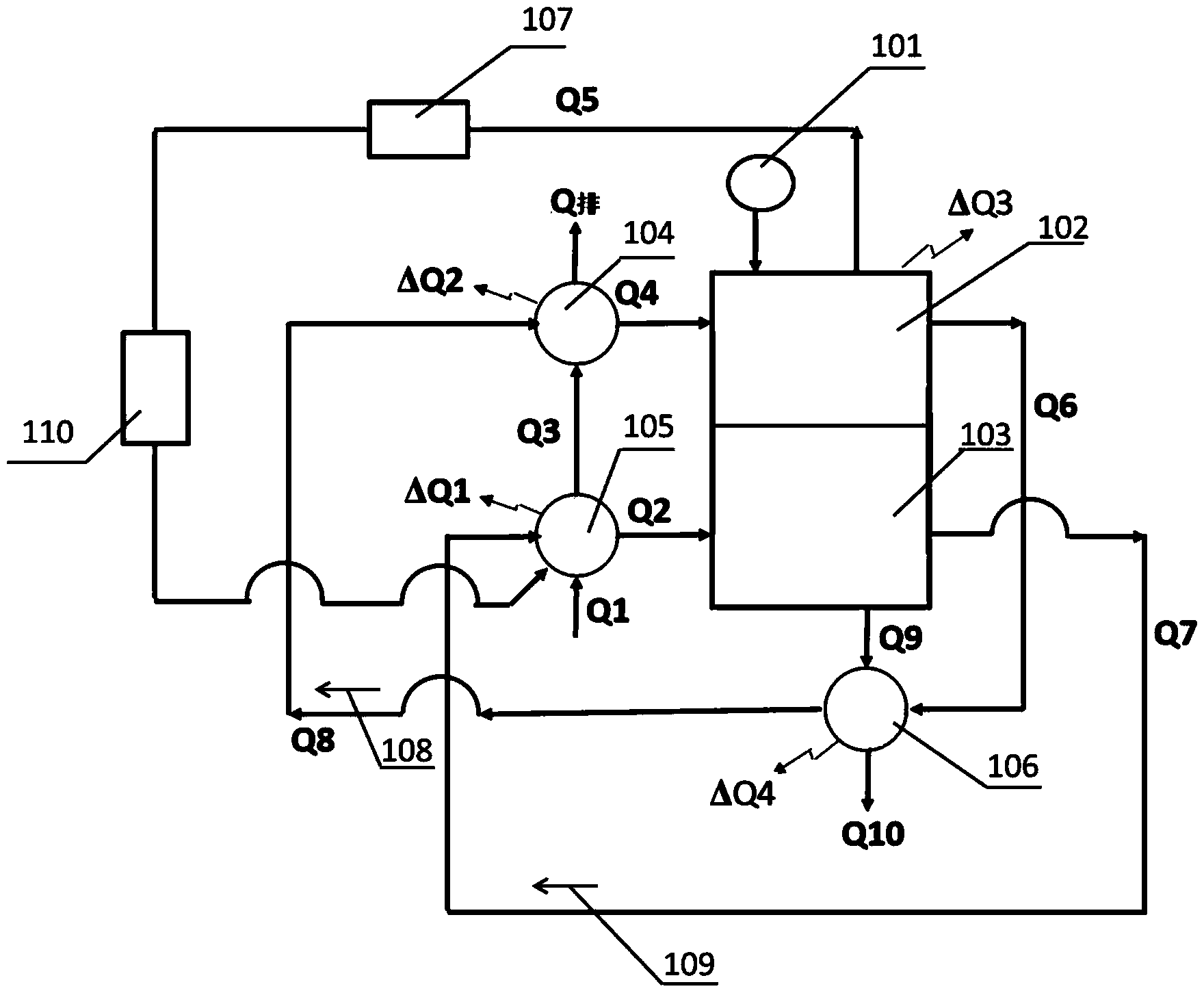

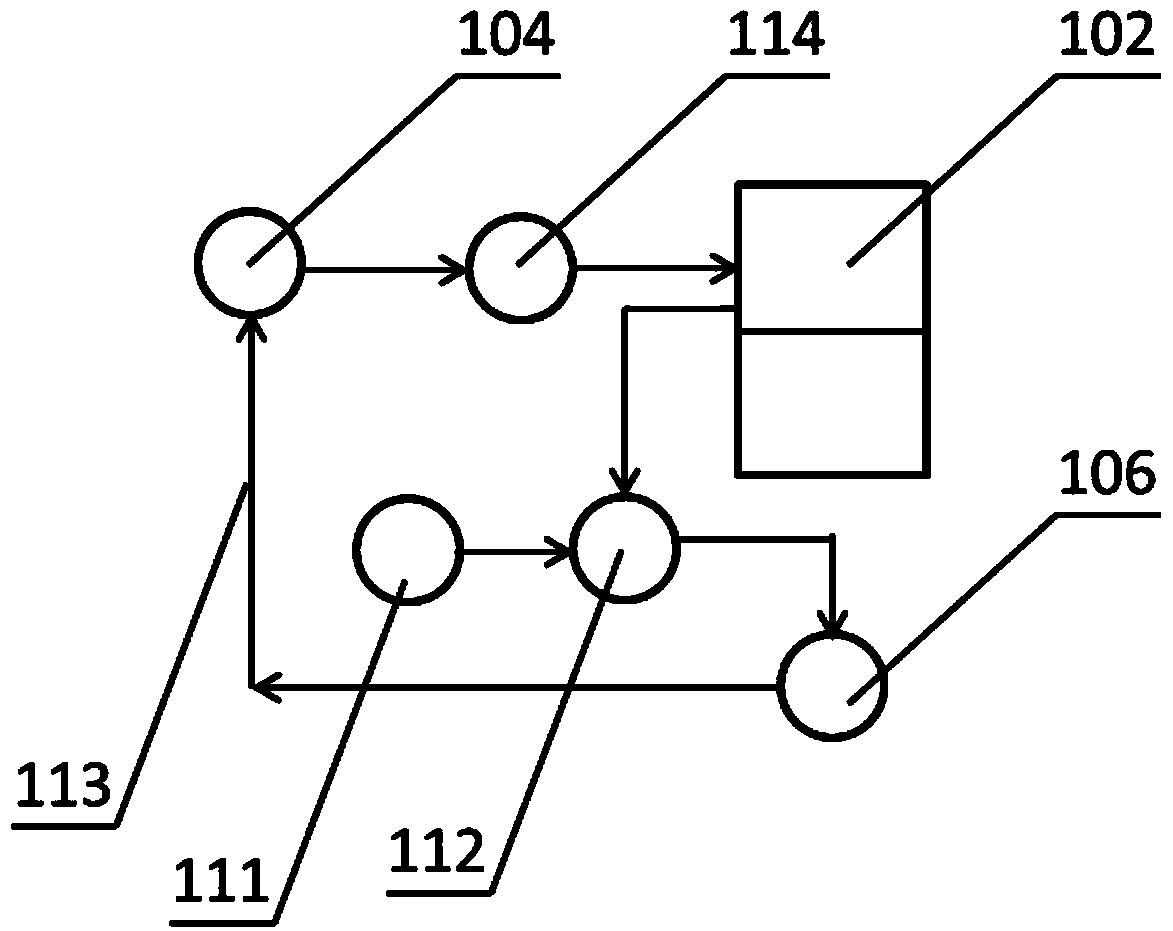

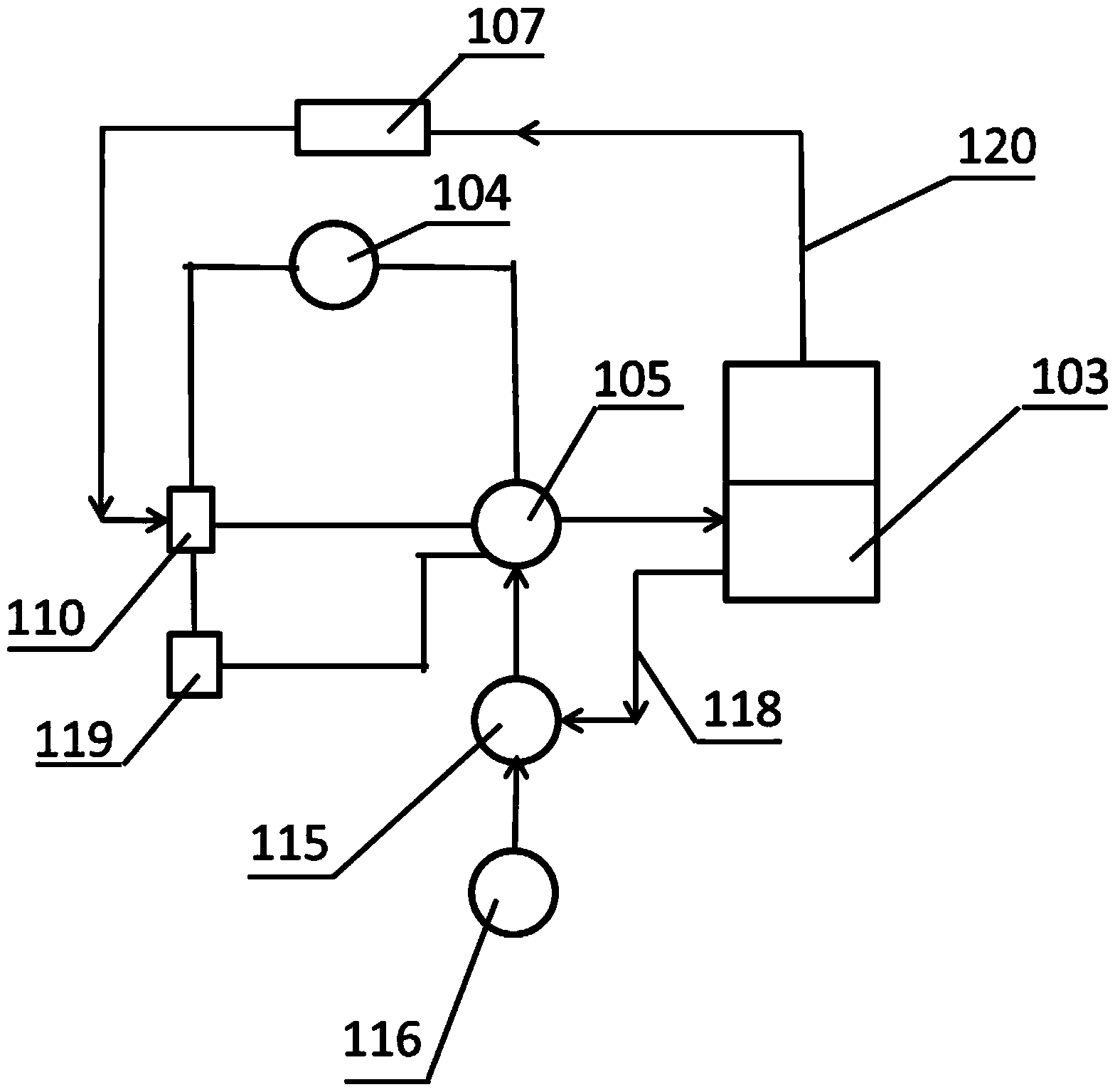

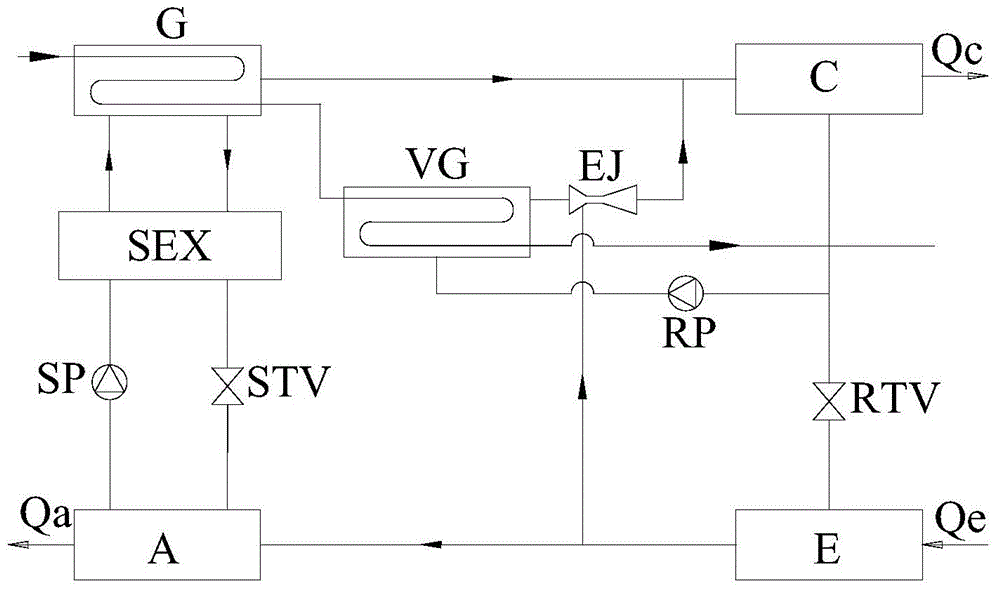

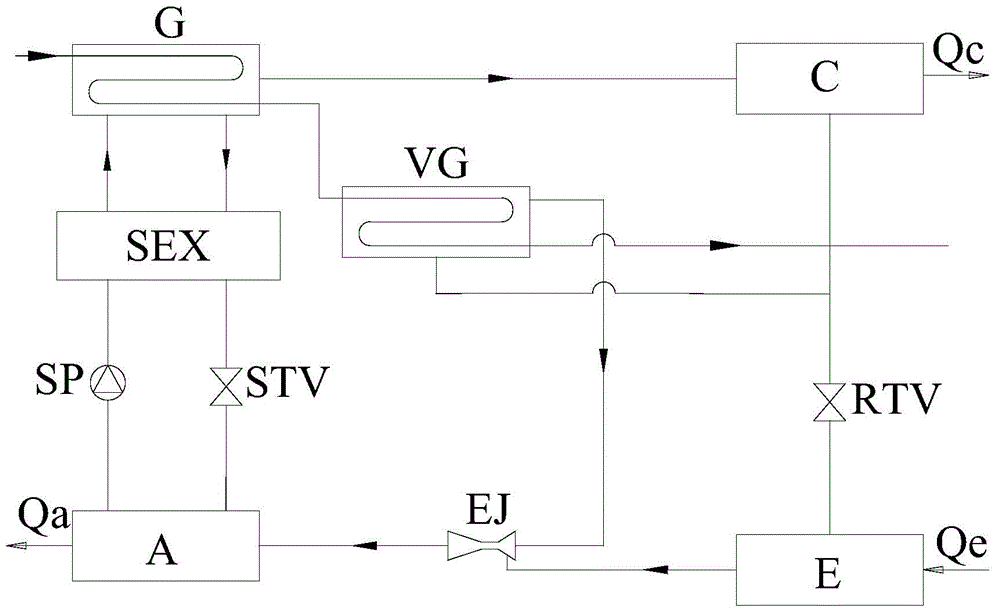

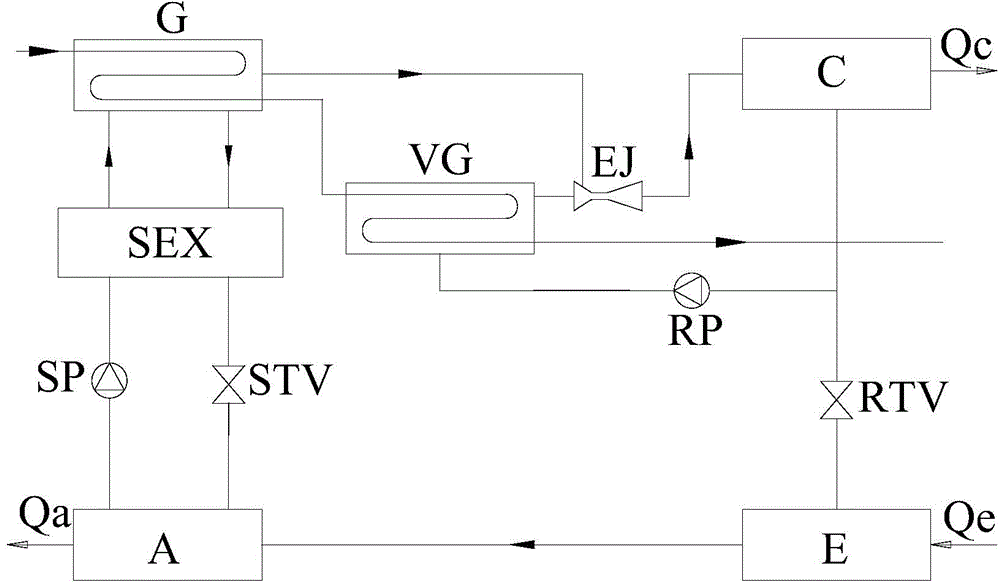

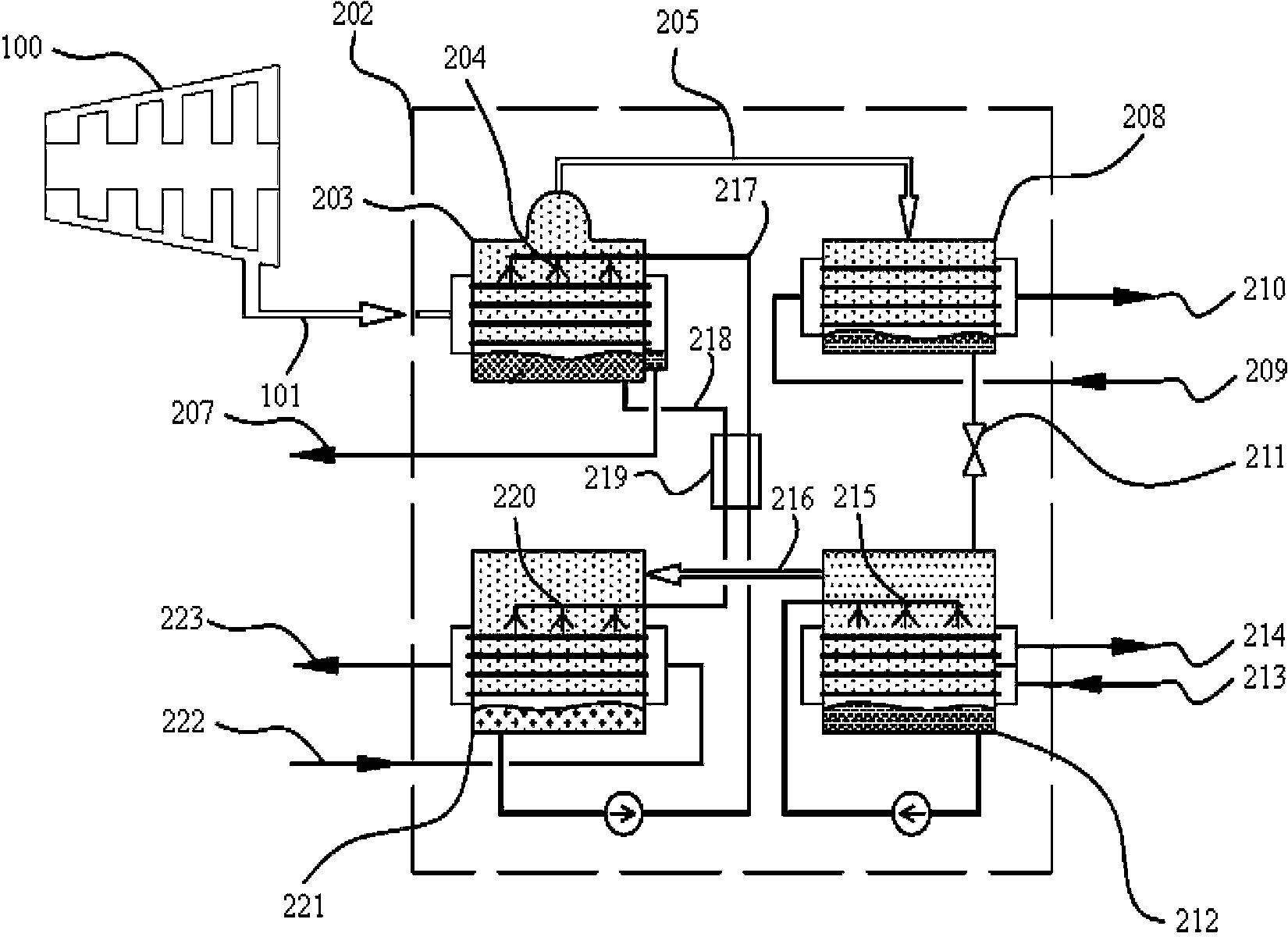

Ejection-absorbing hybrid refrigerating and heat pump unit and operating method thereof

InactiveCN104676958ALower outlet temperatureRaise the outlet temperatureHeat pumpsSteam generation plantsSteam pressureEngineering

The invention belongs to the technical field of refrigerating and heat pumps and particularly relates to an ejection-absorbing hybrid refrigerating and heat pump unit and an operating method thereof. The unit comprises generators, a condenser, an evaporator, an absorber, a solution heat exchanger, a solution pump, a solution throttle valve, a coolant throttle valve, a steam generator and a gas ejector. By providing one or multiple steam generators, outlet temperature of a high-level drive heat source of the unit can be decreased, utilization efficiency of heat and hierarchy of coolant steam pressure are increased, and the gas ejector can be conveniently set according to different pressure level; high-temperature high-pressure steam generated by the steam generator allow coolant steam to be ejected from outlets of the generators to the condenser, thereby decreasing the high-level heat source temperature of the generators; the coolant steam from an outlet of the evaporator can also be ejected to the absorber so as to enhance absorbing pressure of the absorber and reduce the size of the absorber; the coolant steam from the outlet of the evaporator can also be ejected to the condenser to increase refrigerating and heating quantity of the unit and improve comprehensive thermal performance of the unit.

Owner:BEIJING UNIV OF CIVIL ENG & ARCHITECTURE

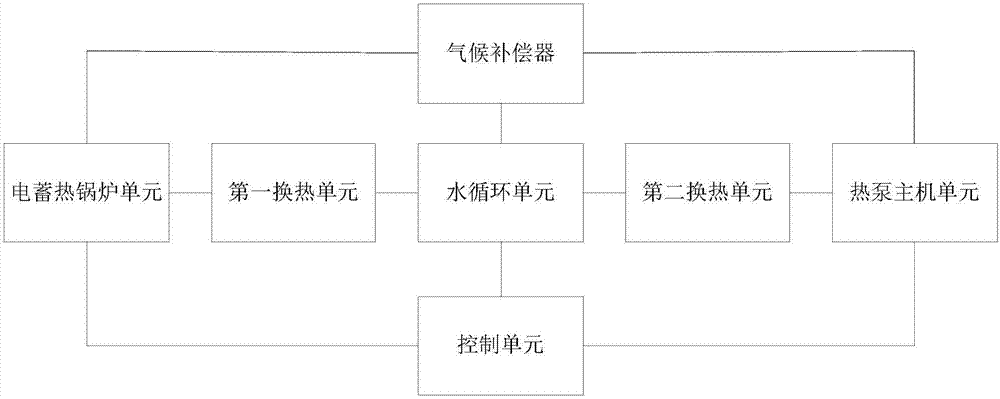

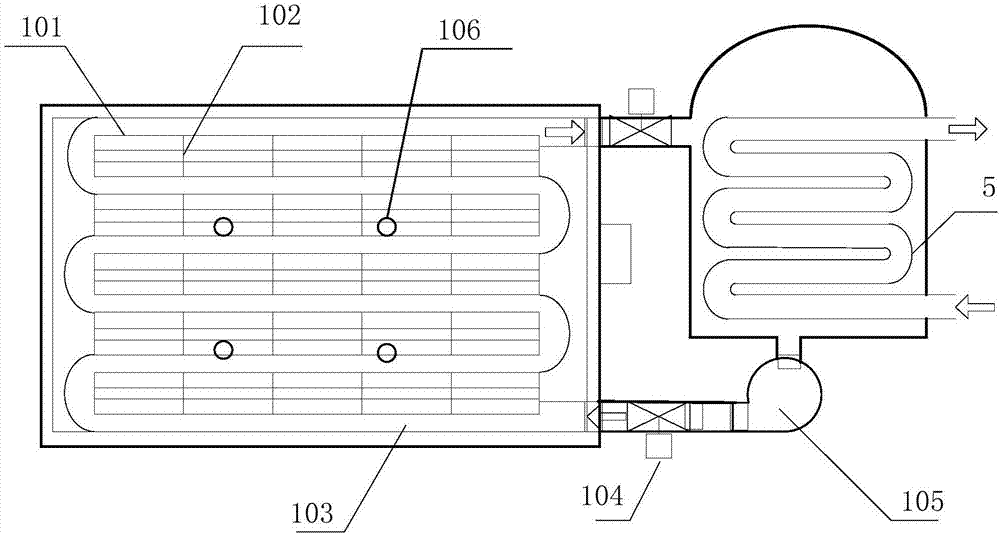

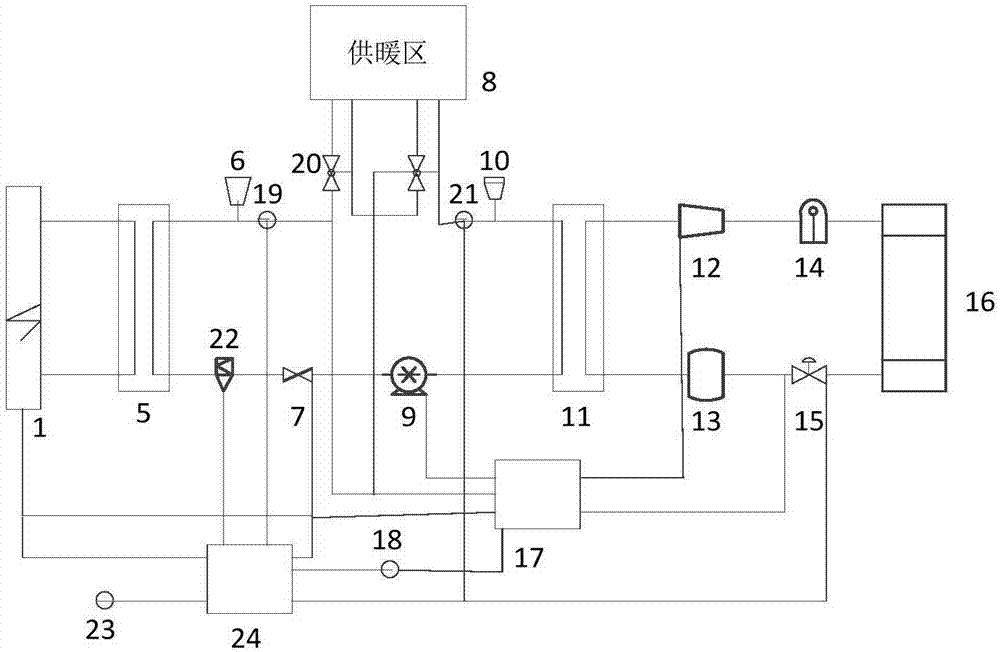

Electric heating system and control method thereof

ActiveCN106885289AAlleviate the peak-to-valley differenceIncrease profitHeating fuelCentral heating with accumulated heatThermal energyElectricity

The invention relates to an electric heating system and a control method thereof. The electric heating system comprises an electric heat storage boiler unit, a water circulation unit, a heat pump main body unit, a climate compensator and a control unit, wherein the electric heat storage boiler unit is connected with the water circulation unit connected with a heat supply zone through an inner circulation pipe of a first heat exchange unit; the heat pump main body unit is connected with the water circulation unit connected with the heat supply zone through an inner circulation pipe of a second heat exchange unit; and the climate compensator and the control unit are separately connected with the electric heat storage boiler unit, the heat pump main body unit and the water circulation unit. According to the technical scheme provided by the invention, when electricity usage is at a low trough, circulating water can be independently or simultaneously heated by the heat pump and the electric heat storage boiler, so that the problem that the temperature rise of the heat pump is limited is solved, the heat utilizing efficiency is increased, and the energy source is saved; and at the same time, electric energy is converted to heat energy and stored in a heat storing body by the electric heat storage boiler, and when electricity usage is at a high peak, the heat can be released by the electric heat storage boiler through the heat storing body to heat the circulating water and realize indoor heating, so that the electricity usage pressure of a power grid is relieved, and electricity fees are saved for a user.

Owner:CHINA ELECTRIC POWER RES INST +2

Rotation type reflow soldering furnace and soldering method thereof

InactiveCN103357981AReduce generationShorten welding timeHeating appliancesMetal working apparatusImpellerEngineering

A rotation type reflow soldering furnace comprises a furnace body, a furnace door, an impeller, a rotation control device, a tray, a tray position adjusting device, a vacuum pump and a temperature controller. The rotation type reflow soldering furnace is characterized in that the furnace body is formed by intersection of a cylinder and a cuboid equal in height, the furnace door is arranged on the wall of the furnace body, the furnace body is divided into a loading zone, a heating zone, a buffering zone and a cooling zone, a hot plate is arranged in the heating zone, a cold plate is arranged in the cooling zone, the impeller is arranged in the furnace body and connected with the rotation control device in a circuit manner, a to-be-soldered electronic component and a solder tray are placed between two blades, a vacuum pipe is connected with the heating zone via a pipeline, and the temperature controller is connected with the hot plate and the cold plate via circuits. The rotation type reflow soldering furnace has the advantages that the rotation type reflow soldering furnace has an independent heating system and an independent cooling system, and can perform non-interfering heating and cooling processes in a vacuum or protective atmosphere, repeated heating and cooling is not needed, and accordingly soldering time can be saved, power consumption is reduced, and working efficiency and soldering quality are improved.

Owner:WUHAN FINEMEMS

Method and system for comprehensively utilizing steam turbine dead steam latent heat

InactiveCN103806964AImprove power generation efficiencyLatent heat effectiveGeneral water supply conservationSeawater treatmentThermal energyLithium bromide

The invention belongs to the technical field of heat energy comprehensive utilization, and particularly relates to a method and system for comprehensively utilizing steam turbine dead steam latent heat. The method comprises the steps that dead steam is exhausted through a steam turbine, and the dead steam exhausted through the steam turbine is transmitted to a waste-heat utilization condensation system which carries out latent heat and condensate the dead steam into water through the dead steam to finish the Rankine cycle. The system comprises the steam turbine and the waste-heat utilization condensation system which is connected with the steam turbine to carry out latent heat and condensate the dead steam through the dead steam to finish the Rankine cycle. A condenser utilizing the waste heat can be a specially-designed low-temperature and multi-effect evaporation sea water desalting plant and can also be a single-effect lithium bromide absorption air conditioner unit. According to the method and system, the low-pressure dead steam latent heat can be efficiently utilized under the condition that the generating efficiency of a turboset is high.

Owner:BLUELAGOON TECH

Electric cookware with efficient heat dissipation function

Owner:FOSHAN SHUNDE KUFU ELECTRIC APPLIANCES CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com