System for preparing hydrogen from methanol and fuel battery device containing the same

A methanol-to-hydrogen and methanol-to-methanol technology is applied in the field of fuel cell devices and methanol-to-hydrogen systems to achieve the effects of reducing volume, increasing conversion rate, and improving resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

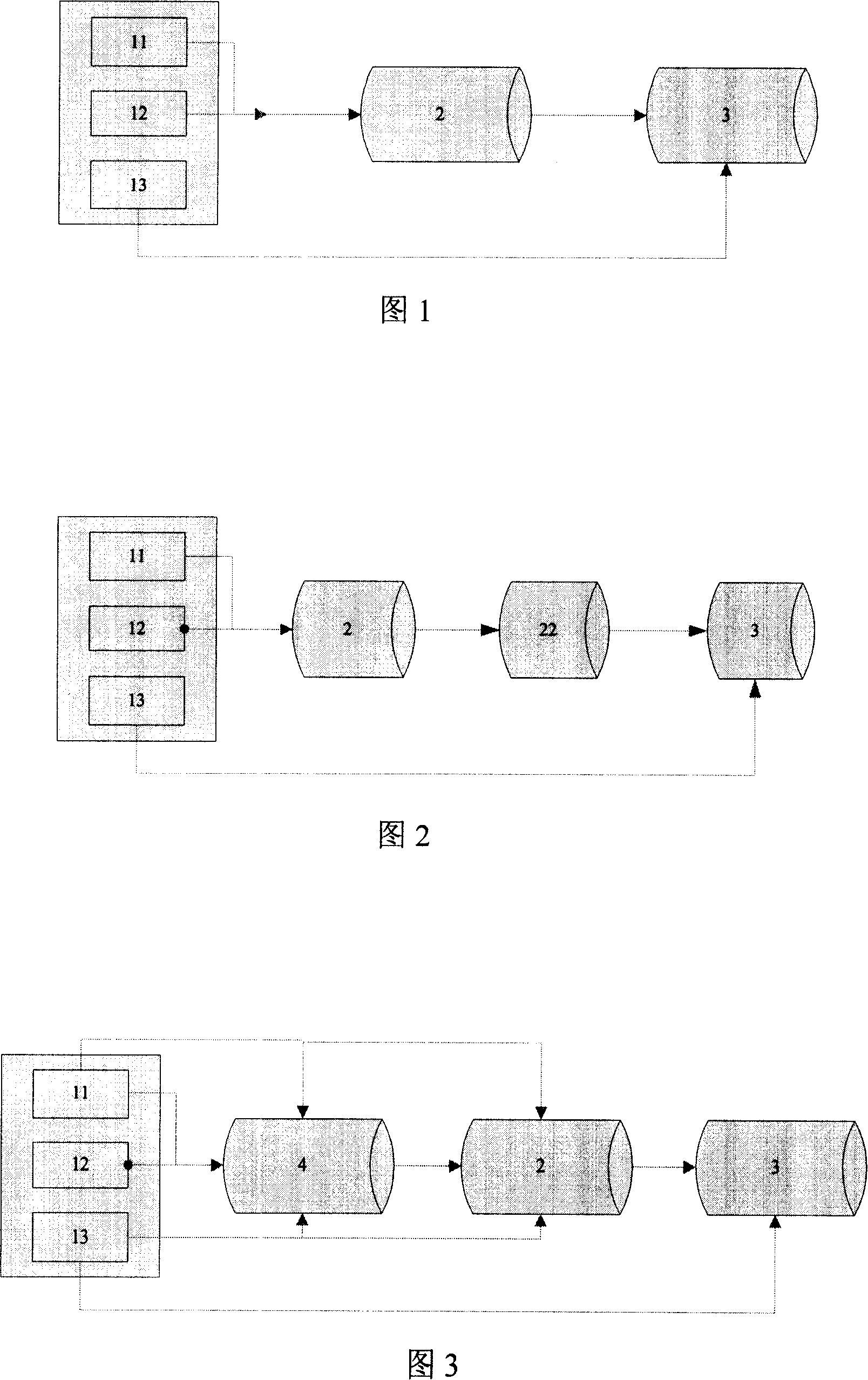

[0018] According to the first embodiment of the present invention, as shown in Figure 1, the methanol hydrogen production system provided by the present invention includes a methanol supply device 11, a water supply device 12, an oxidizing gas supply device 13 and a methanol hydrogen production device 2, the The methanol supply unit 11 and the water supply unit 12 are all communicated with the inlet of the methanol hydrogen production unit 2, and the outlet of the methanol hydrogen production unit 2 and the oxidizing gas supply unit 13 are all communicated with the entrance of the carbon monoxide selective oxidation reactor 3, so The methanol hydrogen production unit 2 includes a hydrogen production catalyst, the carbon monoxide selective oxidation reactor 3 includes a carbon monoxide selective oxidation catalyst, and the carbon monoxide selective oxidation catalyst contains platinum or an alloy of platinum, palladium and / or rhodium.

[0019] When using the methanol hydrogen pr...

Embodiment 1

[0078] This embodiment is used to illustrate the methanol-hydrogen production system and fuel cell device provided by the present invention.

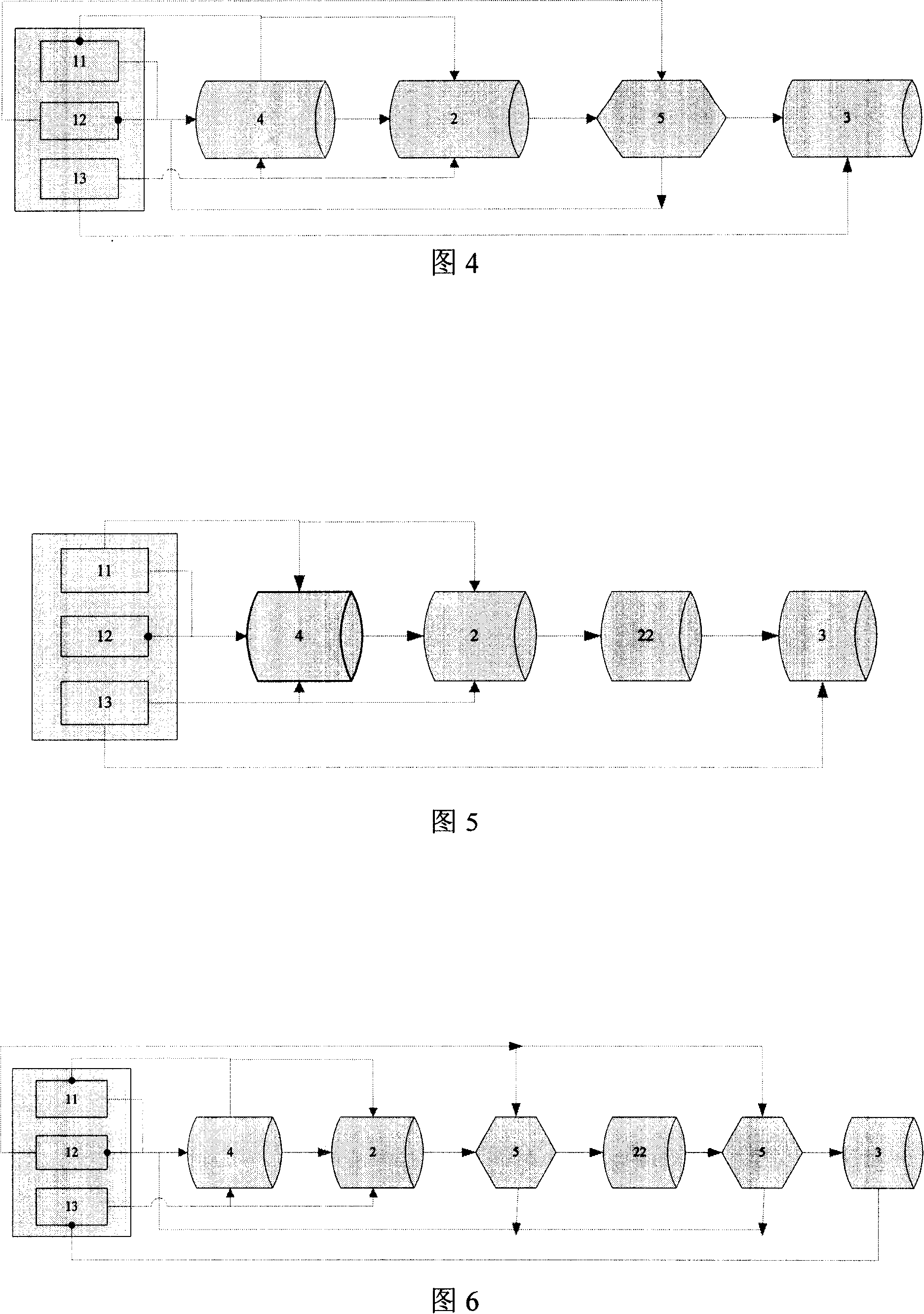

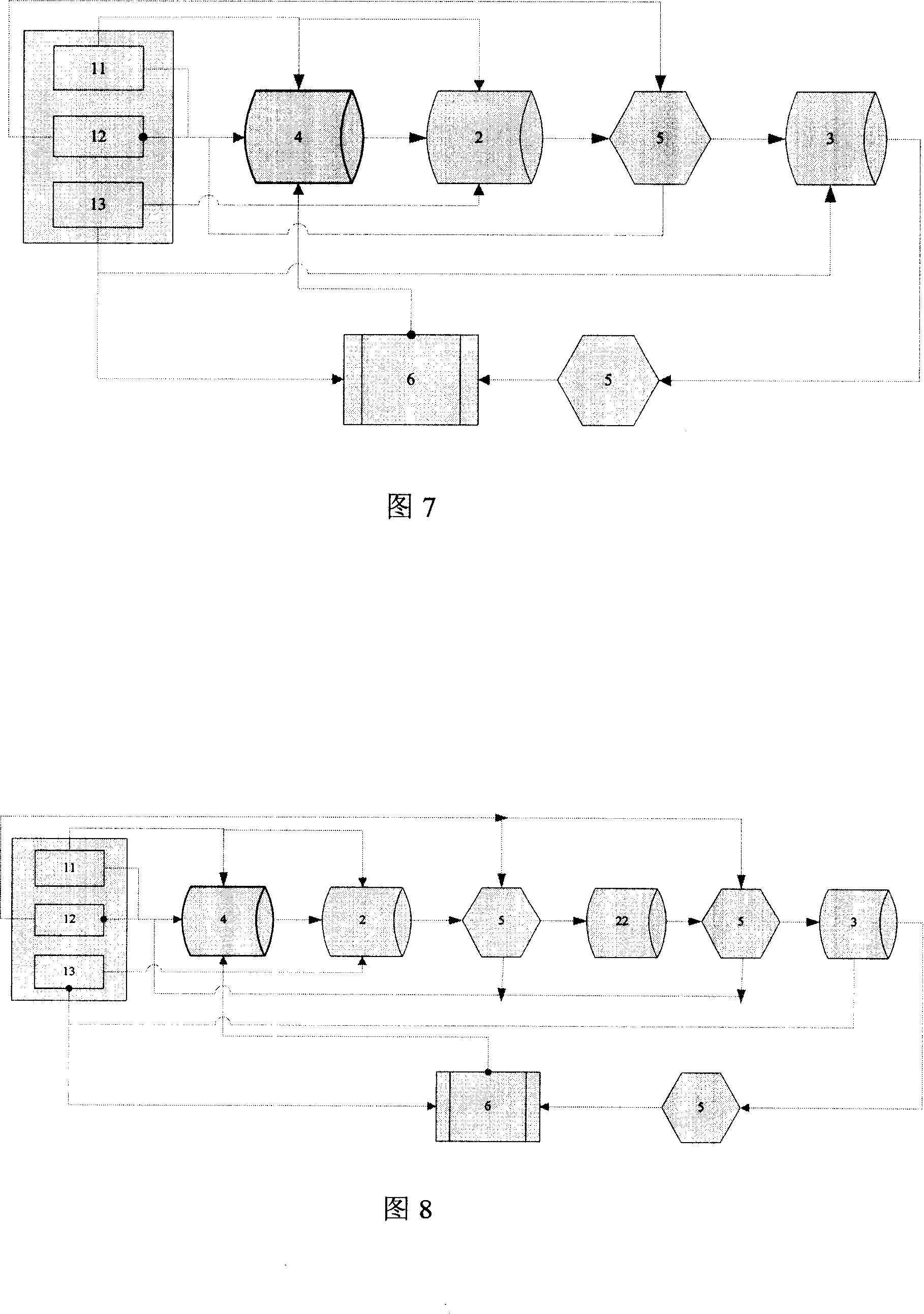

[0079] The methanol hydrogen production system shown in Figure 3 and the fuel cell device shown in Figure 7 were prepared.

[0080] Wherein, the methanol supply device 11 and the water supply device 12 are cuboid storage tanks of 150 mm * 150 mm * 200 mm made of stainless steel; the oxidizing gas supply device 13 is compressed air; the methanol hydrogen production device 2 is made of The tubular reactor of 1.4 liters of volume that 0.3 millimeters of stainless steel 316 is made, comprises inner channel and outer channel; Described carbon monoxide selective oxidation reactor 3 is the tubular reactor of 0.06 liters of volumes that stainless steel 316 is made; The gas The carburetor 4 is a plate-fin heat exchanger with an inner channel and an outer channel made of stainless steel with a heat exchange area of 0.8 square meters. The inlet ...

Embodiment 2

[0085] This embodiment is used to illustrate the methanol-hydrogen production system and fuel cell device provided by the present invention.

[0086] The methanol hydrogen production system as shown in Figure 3 and the fuel cell device as shown in Figure 7 are prepared using the same device, material and connection method as in Example 1, the difference is that the carbon monoxide selective oxidation catalyst is a Pt-Ce alloy (20% by weight of Pt80% by weight of Ce) (Selectra (TM) catalyst produced by Yingge Chemical Company), Pt-Ce alloy is supported on Al 2 o 3 On the coating, the coating density is 20 g / cm2, Al 2 o 3 The coating is coated on a 300-mesh cordierite honeycomb carrier, and the coating thickness is 20 microns; the hydrogen production catalyst is supported on Al 2 o 3Cu-Zn alloy (50% by weight Cu50% by weight Zn) on the coating, coating density 30 g / cm2, Al 2 o 3 Coated on a 300-mesh FeCrAl alloy honeycomb carrier, the thickness of the coating is 30 microns...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com