Patents

Literature

39results about How to "Does not cause oxidation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

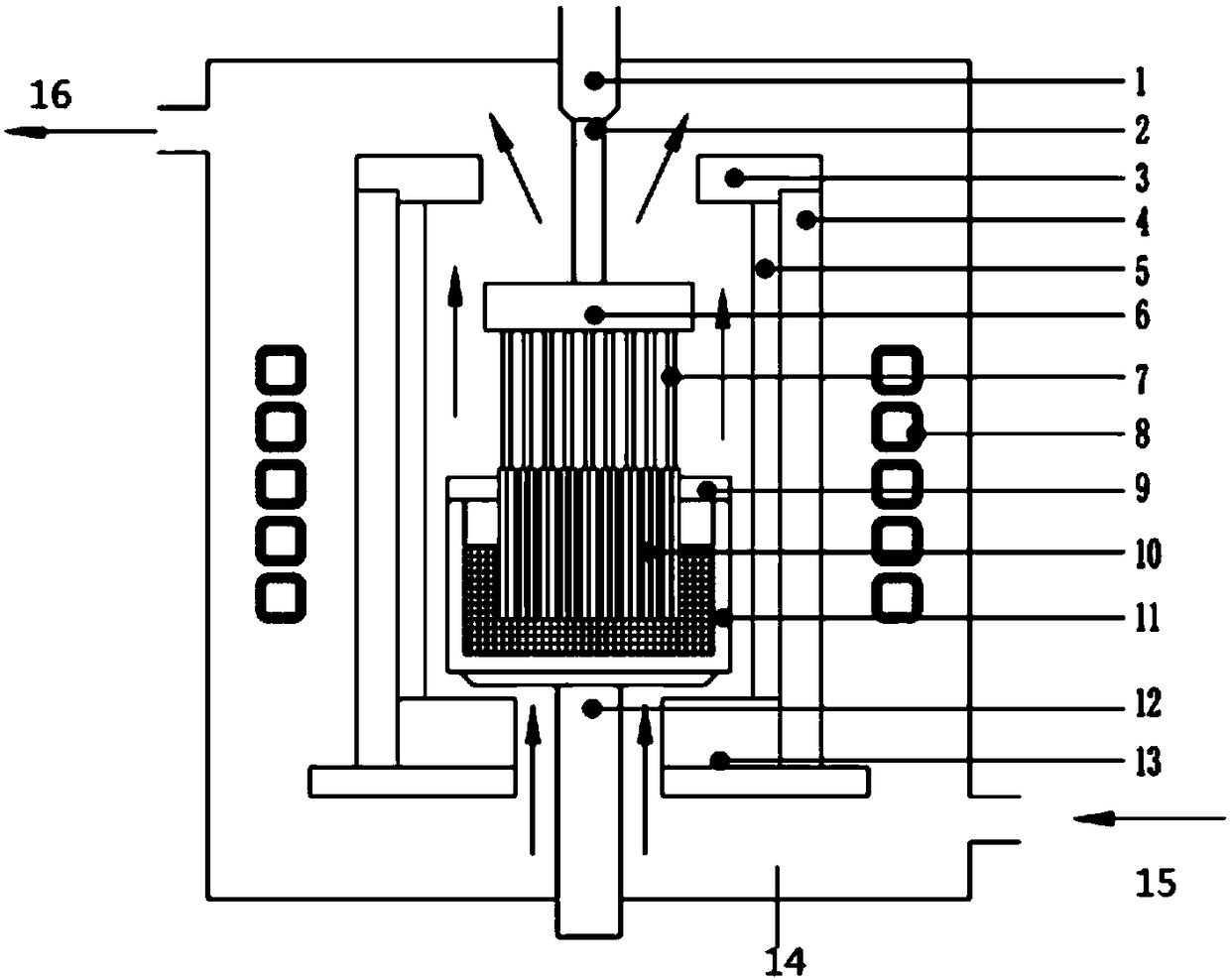

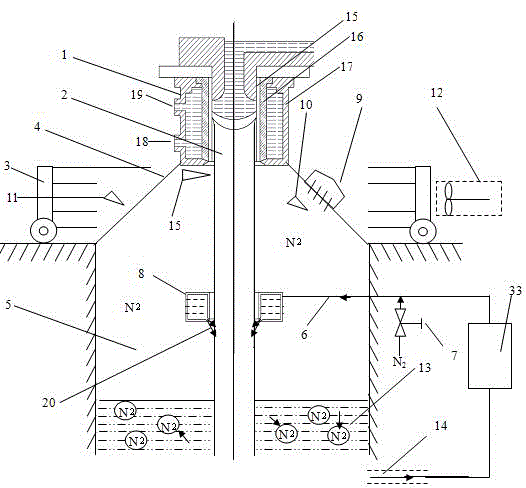

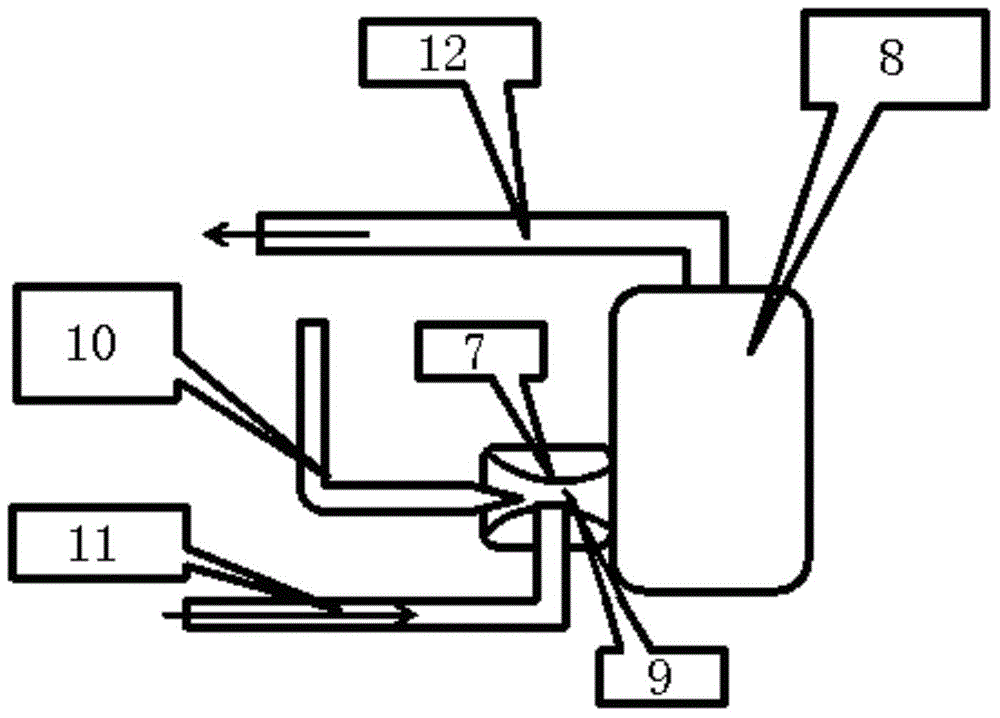

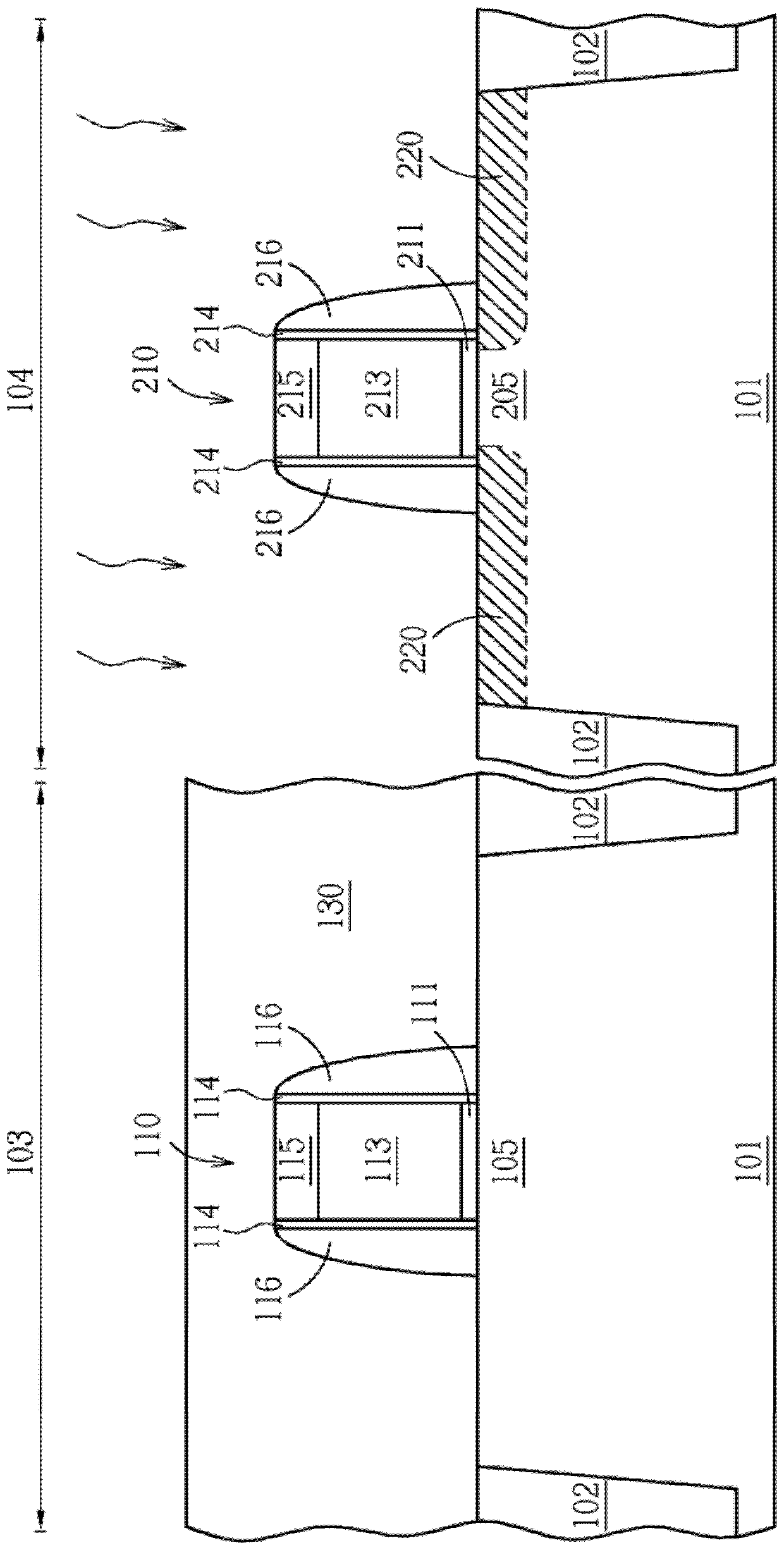

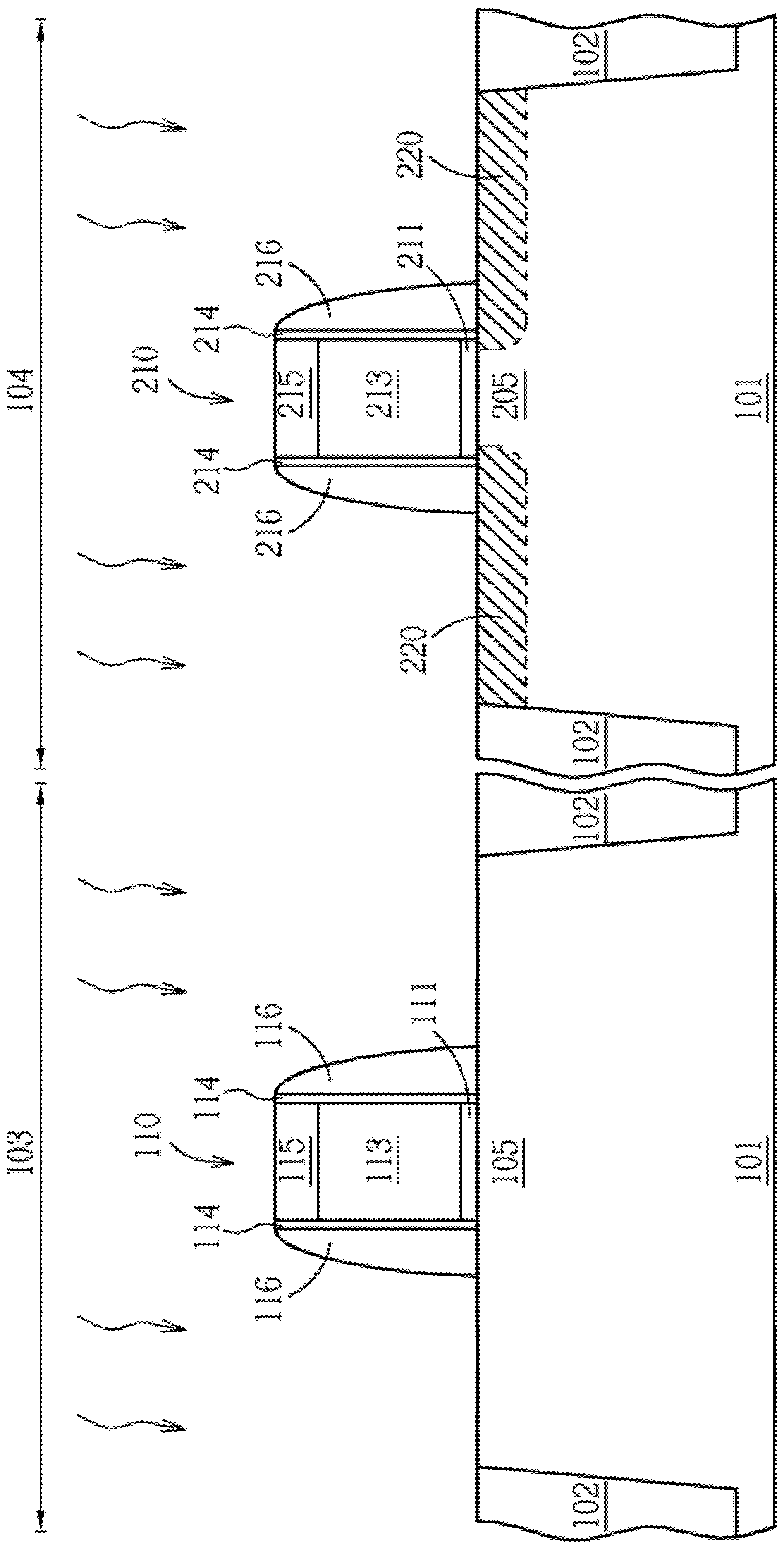

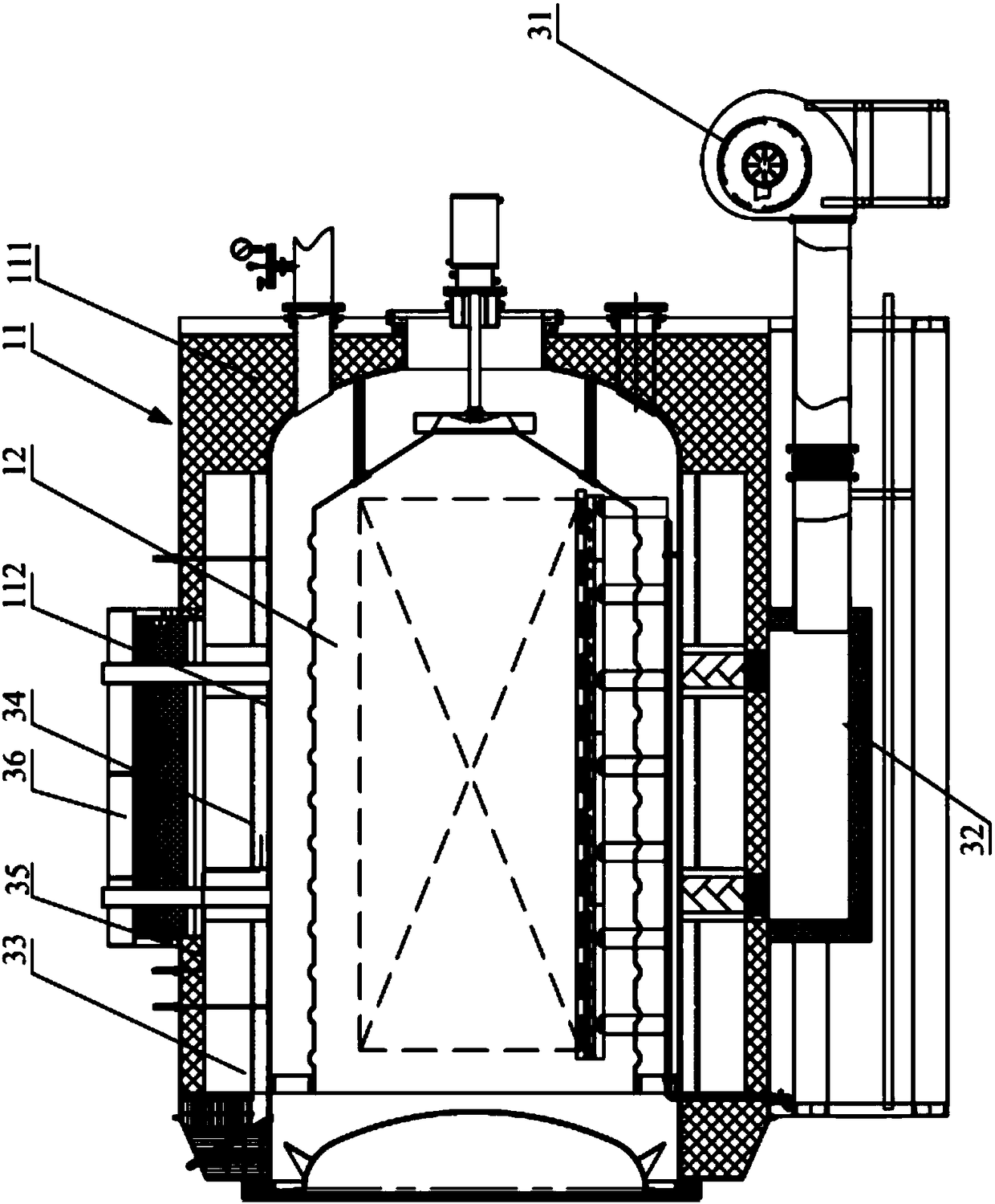

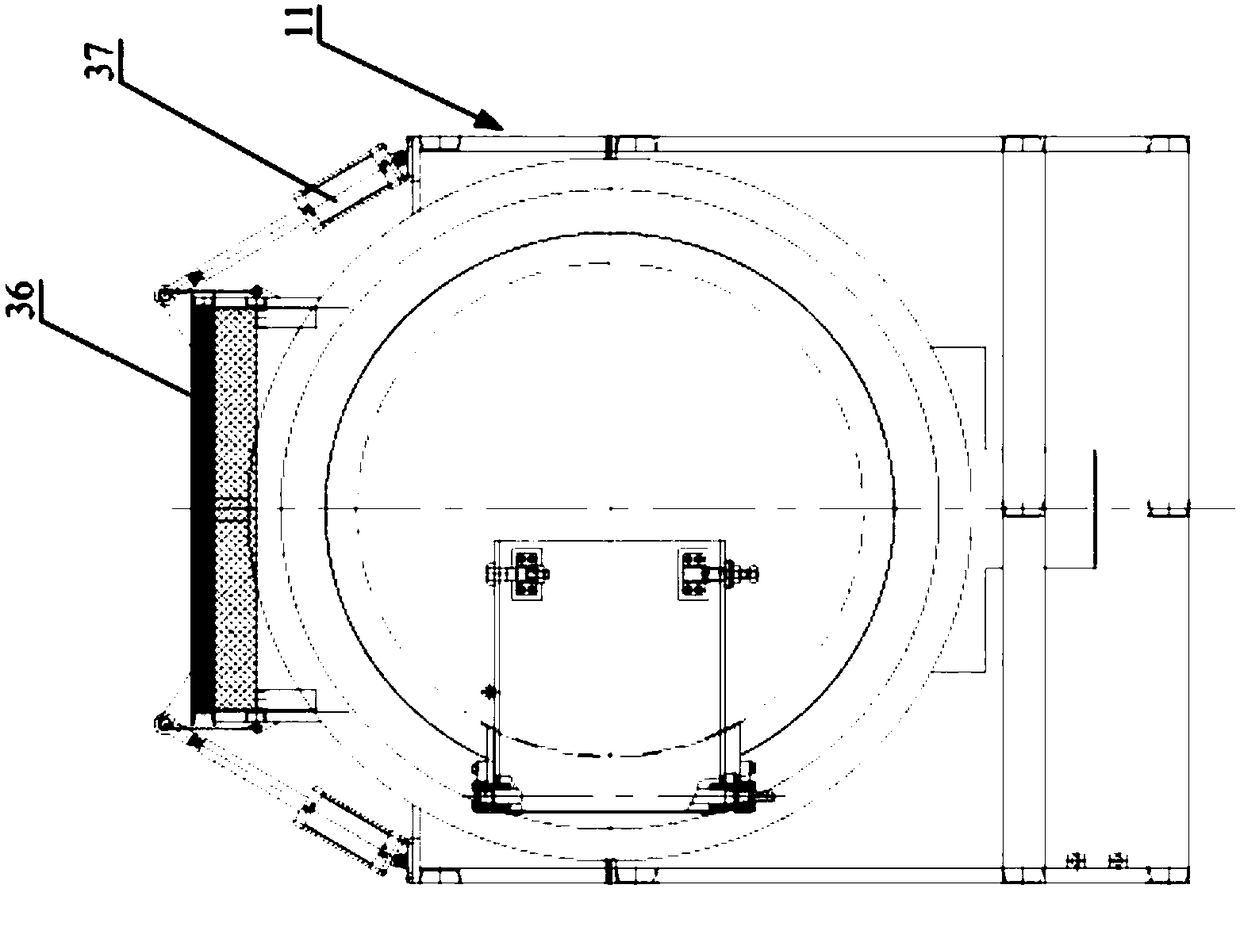

Flowing atmosphere edge-defined film-fed crystal growth multi-chip sapphire crystal growth device and method

InactiveCN108411367ASolve the problem of inconsistency in growing crystalsSolve the problem of overheatingPolycrystalline material growthBy pulling from meltInsulation layerCrucible

The invention relates to a flowing atmosphere edge-defined film-fed crystal growth multi-chip sapphire crystal growth device and method. The device comprises a smelting furnace and an atmosphere device, the smelting furnace is placed into the atmosphere device, inert gas with an up-out and down-in flowing direction is fed into the atmosphere device, the smelting furnace comprises a tray, a heat insulation cylinder (4), an induction coil (8), a bottom heat insulation layer (13), a crucible (11), a growth mould unit (10), a seed crystal (6) and a seed rod (1), the heat insulation cylinder (4) isarranged on the tray, the induction coil (8) sleeves the heat insulation cylinder (4), the bottom heat insulation layer (13), the crucible (11), the growth mould unit (10), the seed crystal (6) and the seed rod (1) are sequentially arranged in the heat insulation cylinder (4) from bottom to top, and the seed crystal (6) is fixed to the bottom end of the seed rod (1) and arranged right above the growth mould unit (10) in a vertically movable manner through the seed rod (1). Compared with the prior art, the device has the advantages that gradient temperature distribution of a sapphire crystal growth interface area can be effectively controlled, synchronous consistency of 20 whole sapphire crystals is realized, the growth process is visible and controllable, and crystal quality is high.

Owner:TONGJI UNIV

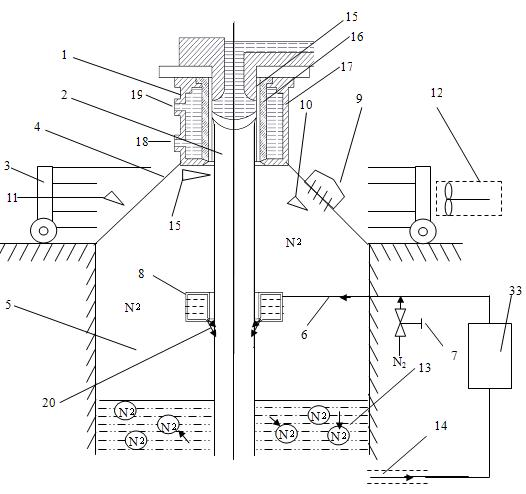

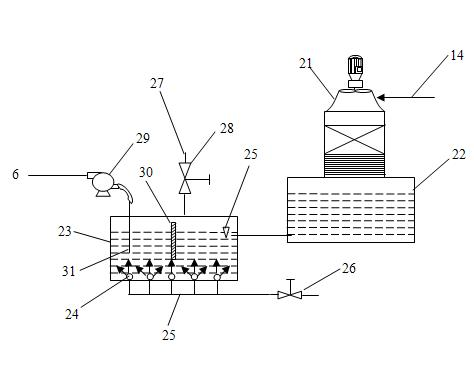

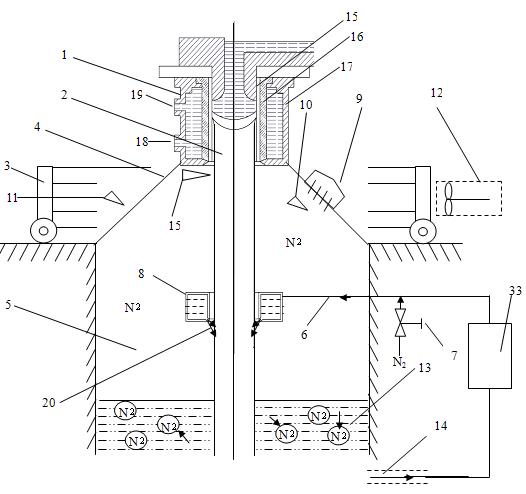

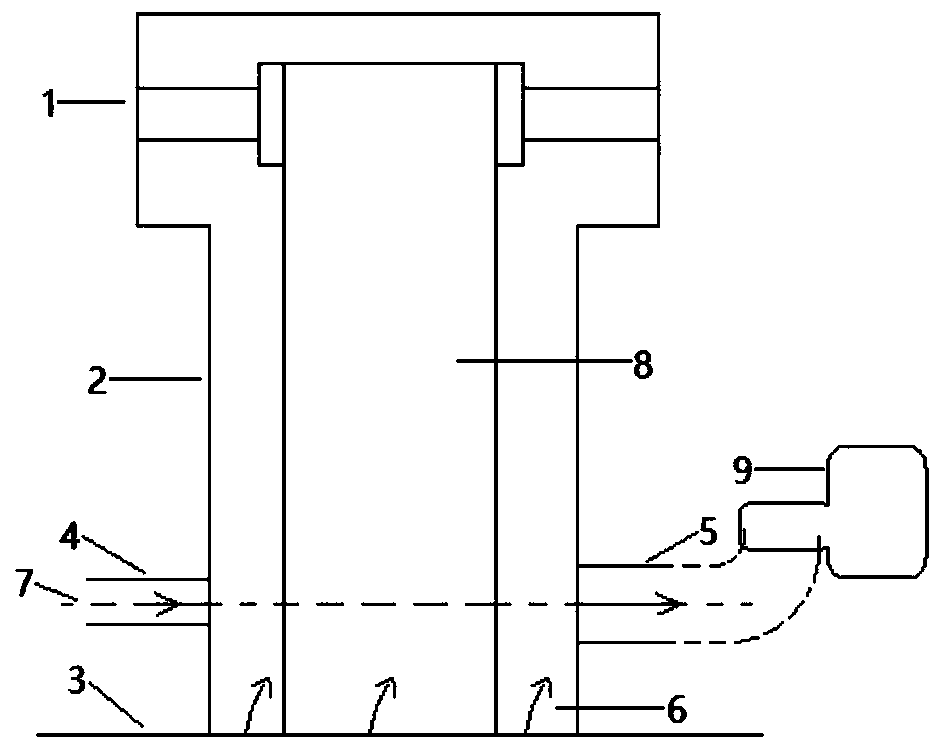

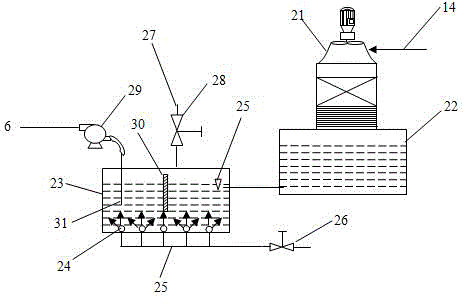

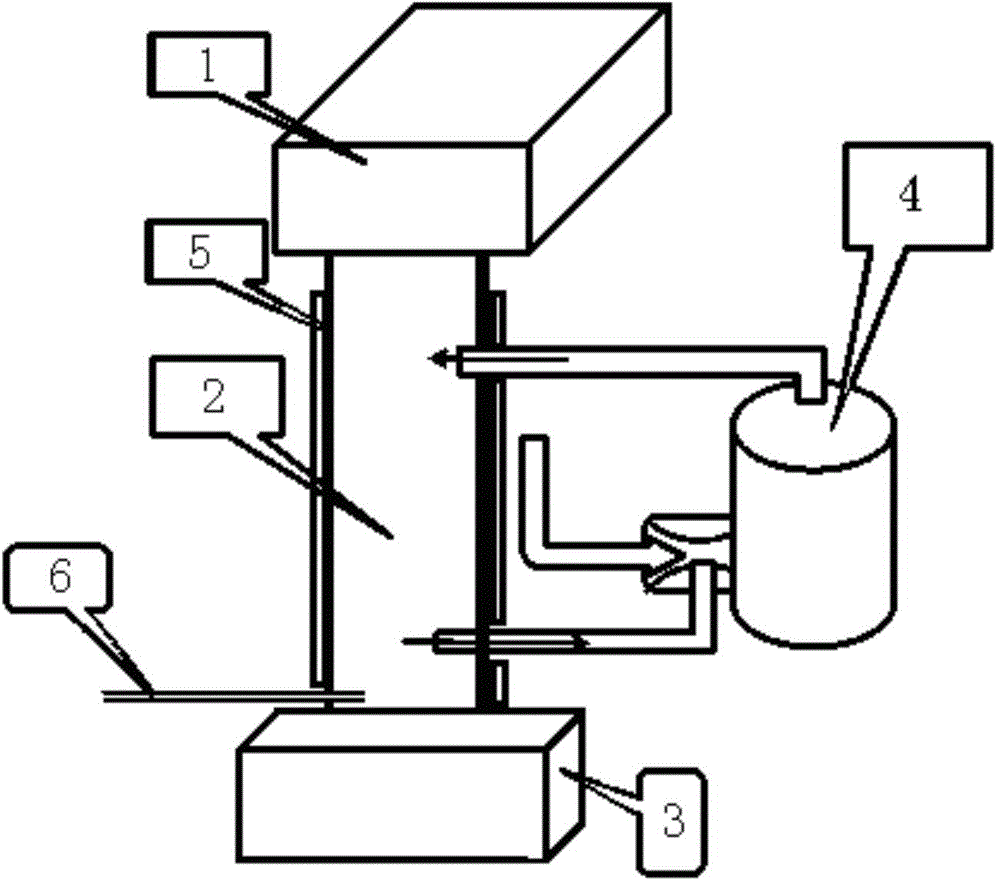

Copper and copper alloy casting equipment under protection of nitrogen

The invention discloses copper and copper alloy casting equipment under the protection of nitrogen. The equipment comprises a crystallizer assembly, and a secondary water cooling device and a casting well which are positioned below the crystallizer assembly. The equipment is characterized in that: an airtight protective cover is arranged between the crystallizer assembly and the casting well; the secondary water cooling device is connected to a secondary water cooling-deoxidizing device through a secondary cooling water pipe which is connected with a nitrogen injection pipe and a valve; and the bottom of the casting well is provided with a cooling water return pipe. Under the sealing protection of the nitrogen, outside air is prevented from entering the casting well so as not to contact high-temperature copper ingots in the casting process, the copper ingots are prevented from being oxidized by the air, the surface non-oxidation casting of industrial pure copper, high copper and a white copper alloy is realized, and the aims of reducing the oxidation loss of copper metal and production cost are fulfilled.

Owner:JINCHUAN GROUP LIMITED

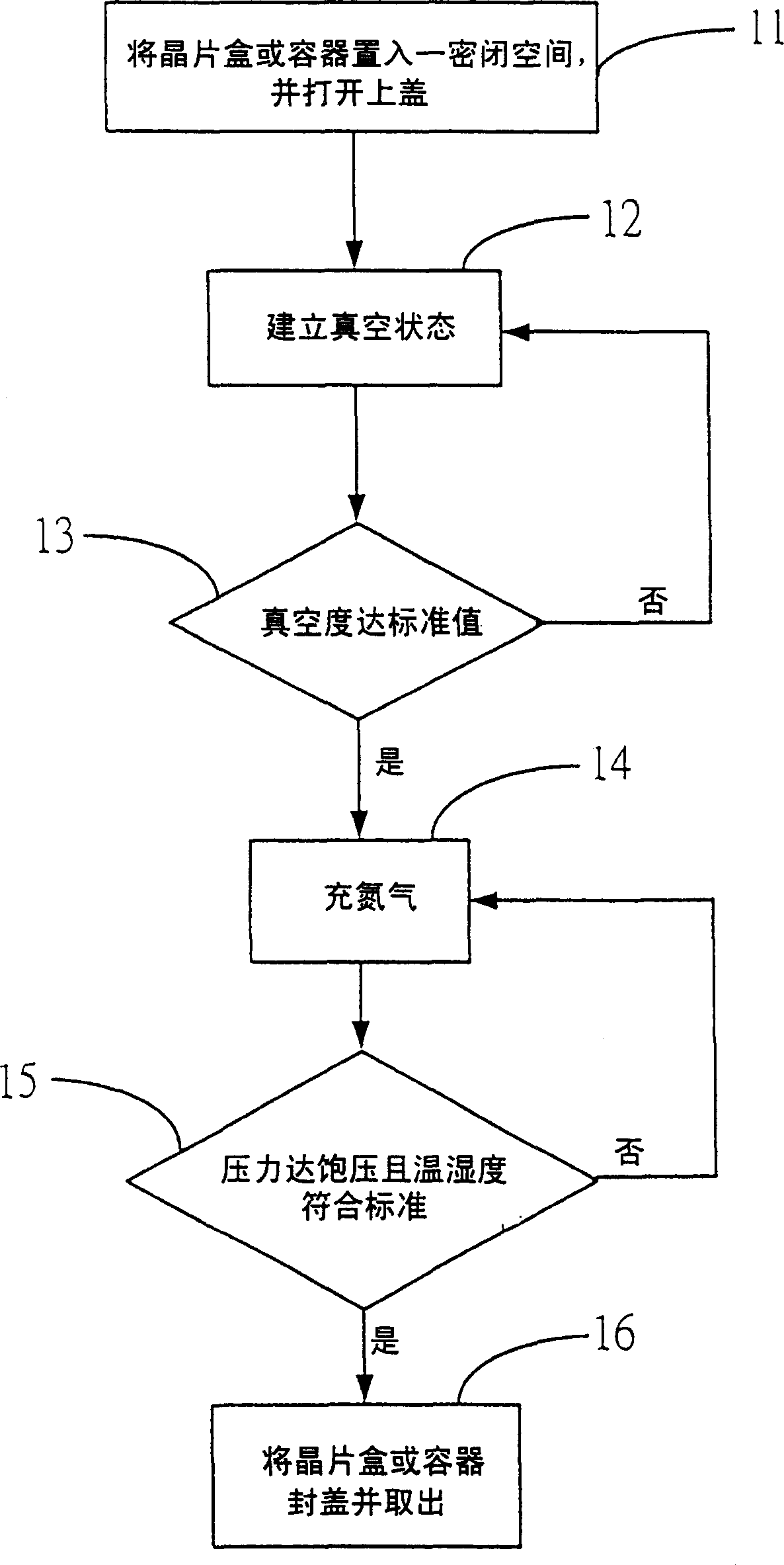

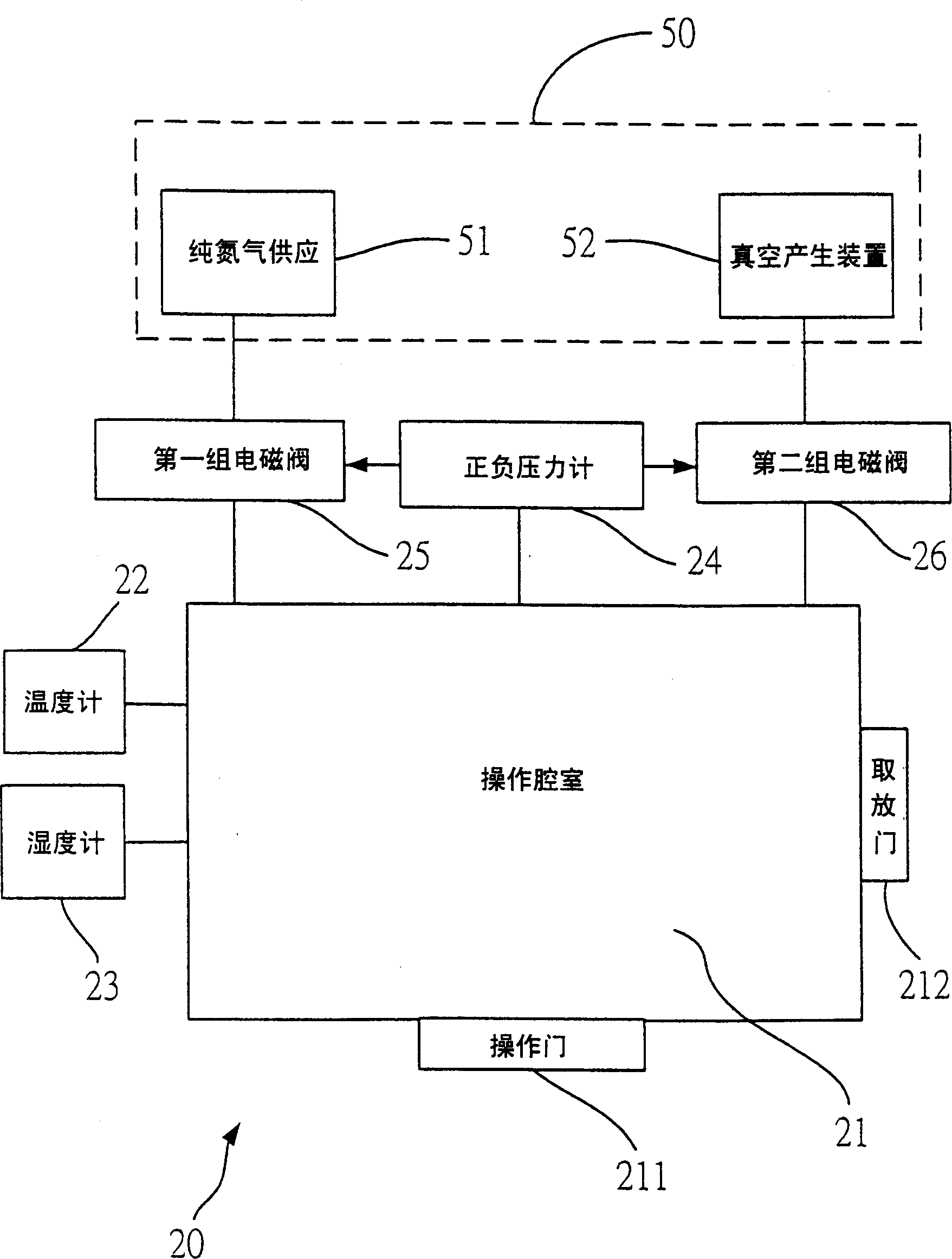

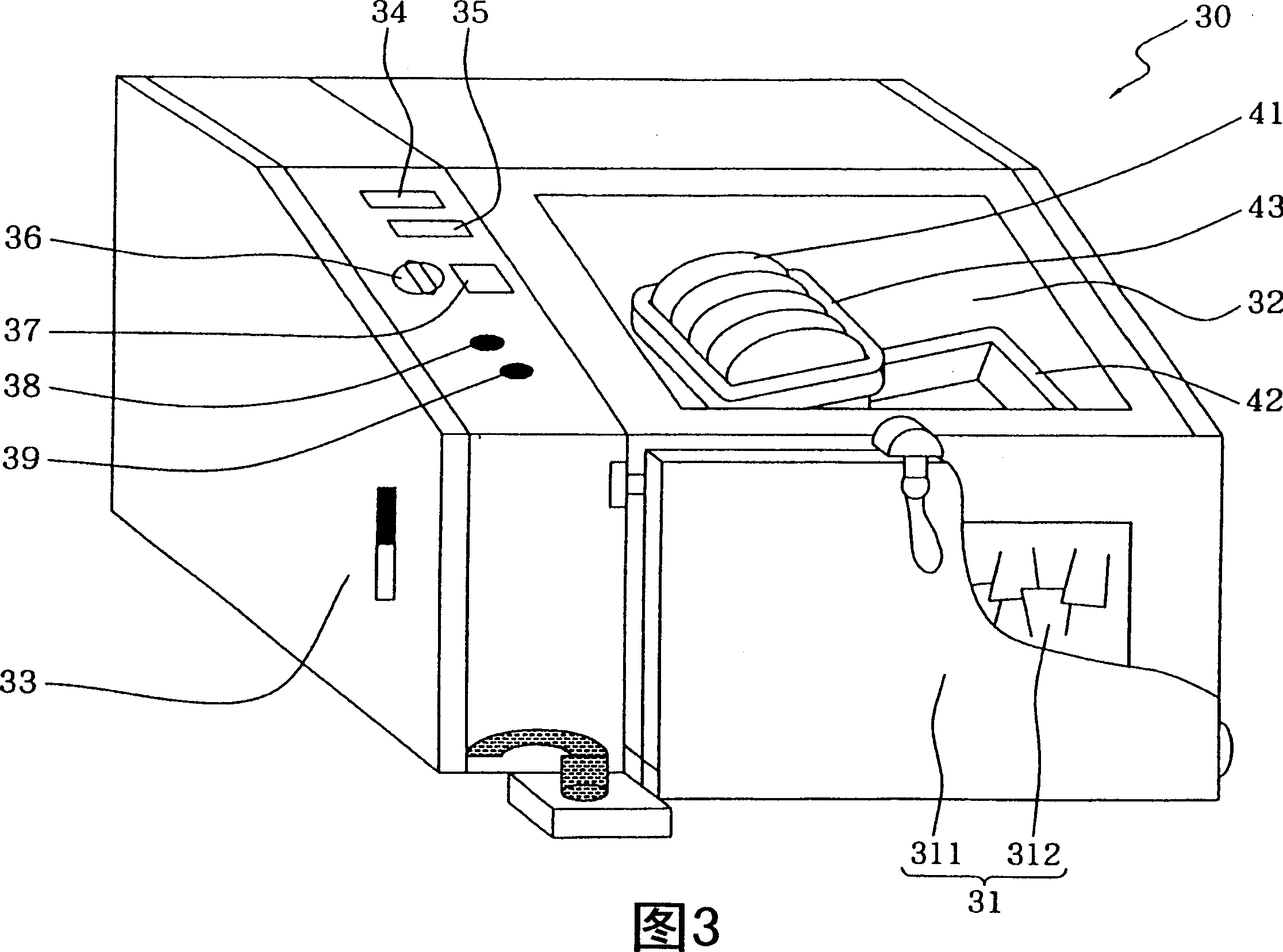

Process and apparatus for low oxygen and low moistness packing

InactiveCN1464543ADoes not cause oxidationSemiconductor/solid-state device manufacturingPackagingNitrogenNitrogen gas

The invention discloses a low oxygen content and low humidity process and apparatus for long term storage of oxidizing article and precision instrument, characterized by exhausting the air in the article storing container and filling with nitrogen of over 99% concentration, thus resulting the low oxygen content and low humidity in the storage space, preventing the metal portion of the protected article from the oxidizing corrosion.

Owner:KING YUAN ELECTRONICS +1

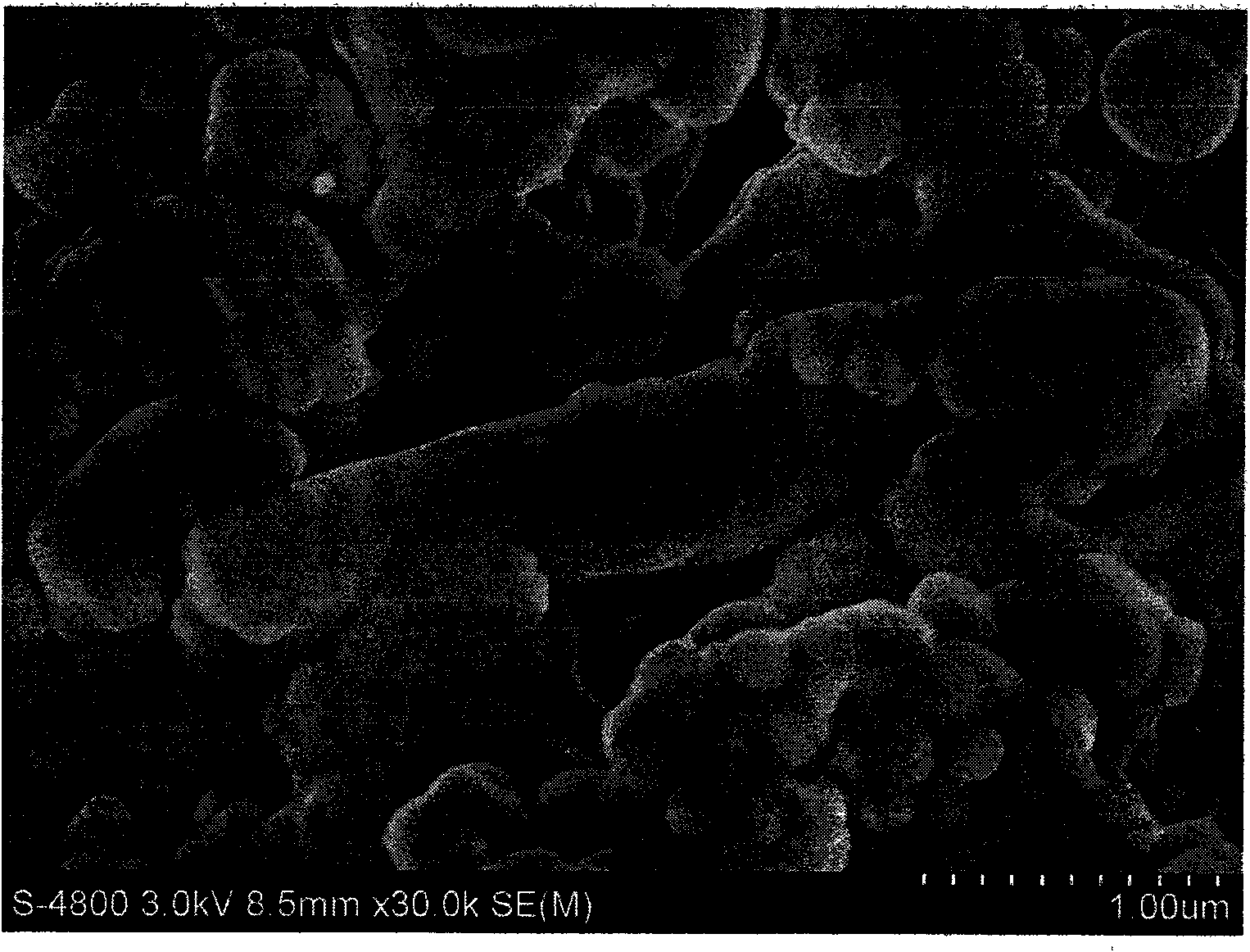

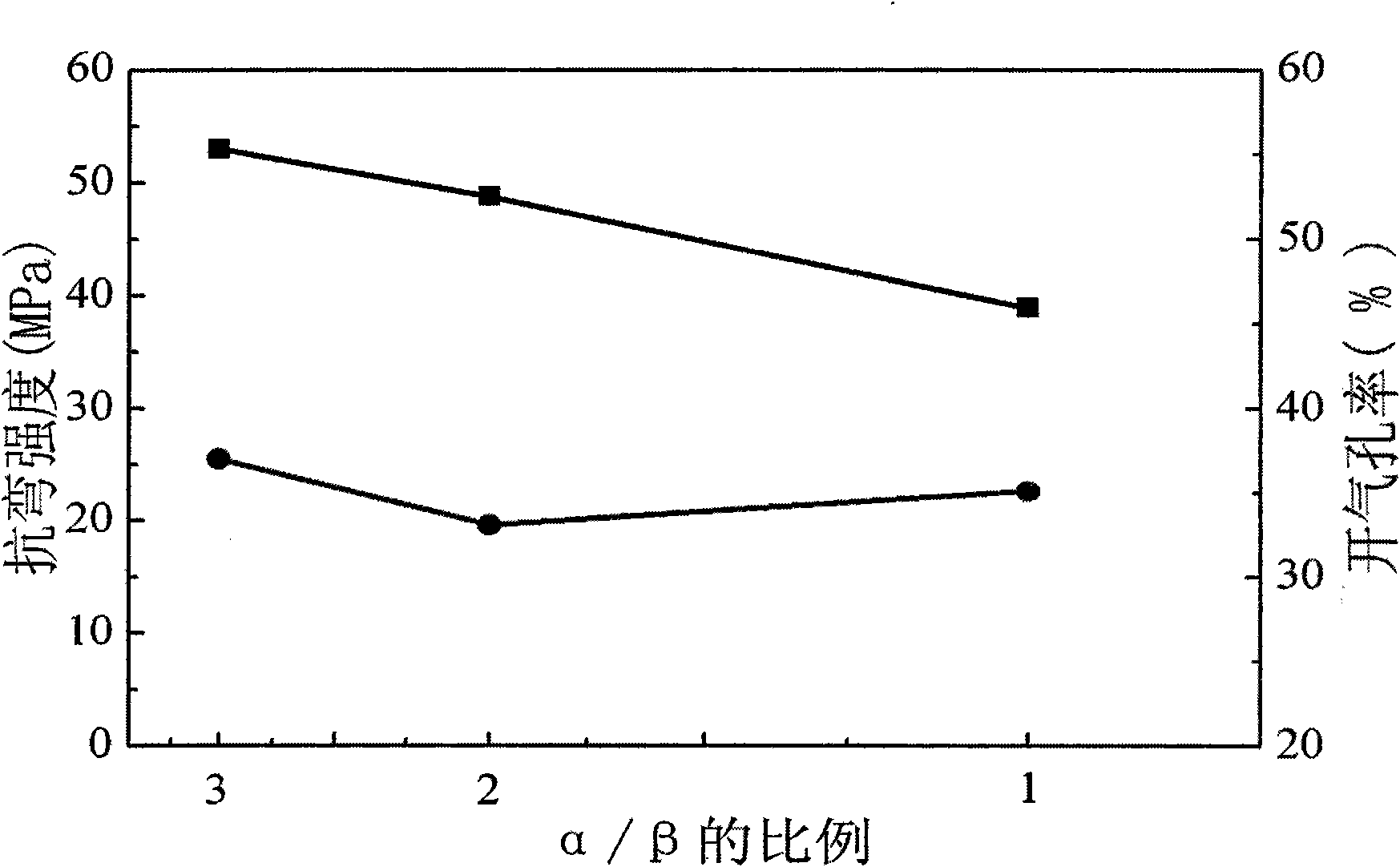

Method for producing porous ceramic materials by adopting low-temperature hydrothermal method

InactiveCN101570436ANo reduction in dielectric propertiesDoes not cause oxidationCeramicwareSilica particleNon oxide ceramics

The invention discloses a method for producing porous ceramic materials by adopting the low-temperature hydrothermal method. The method utilizes the hydrothermal reaction to immerse a ceramic formed body in silicon dioxide sol; according to the dissolution-precipitation mechanism, part of silicon dioxide particles can be precipitated on the surfaces of ceramic grains to play a bonding role, thereby producing the porous ceramic materials. The hydrothermal temperature in the preparation method is lower and can not cause the oxidation of non-oxide ceramics during the sintering process.

Owner:BEIHANG UNIV

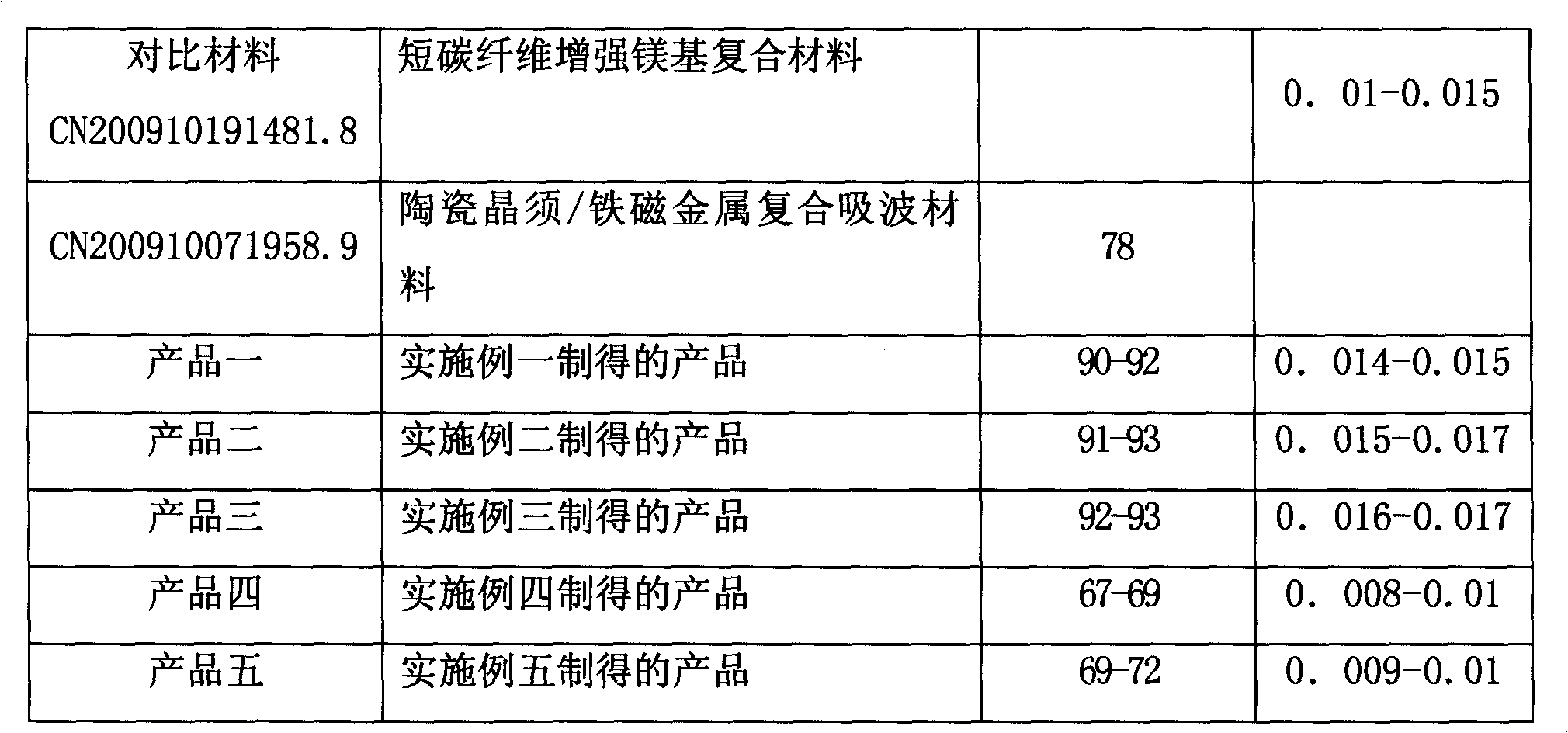

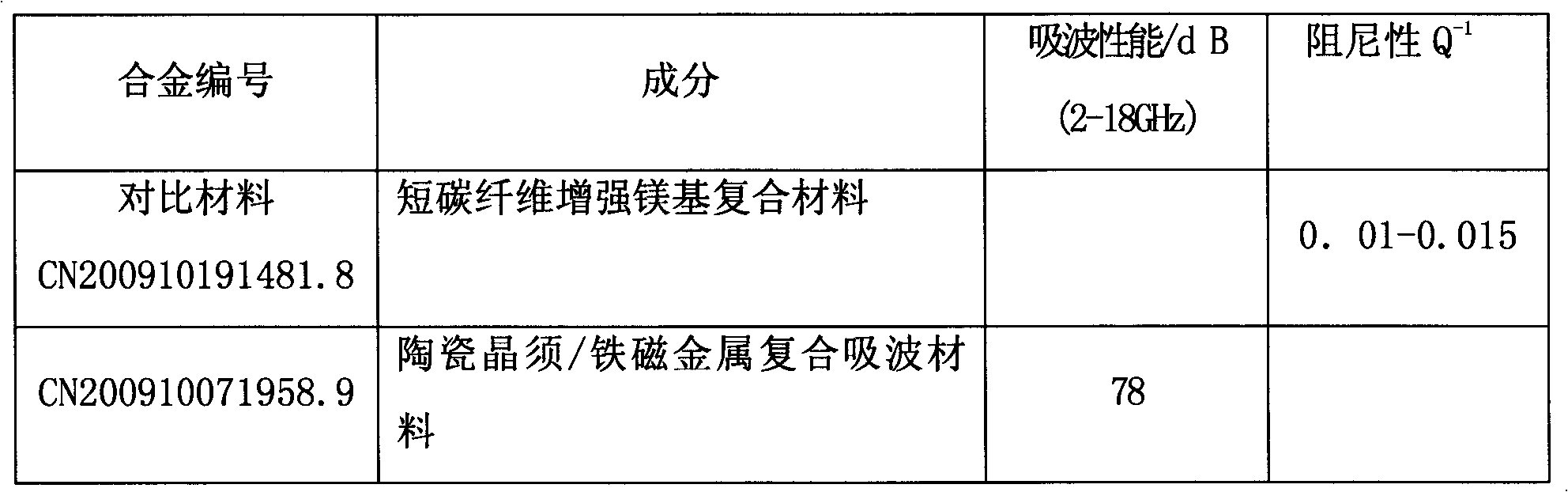

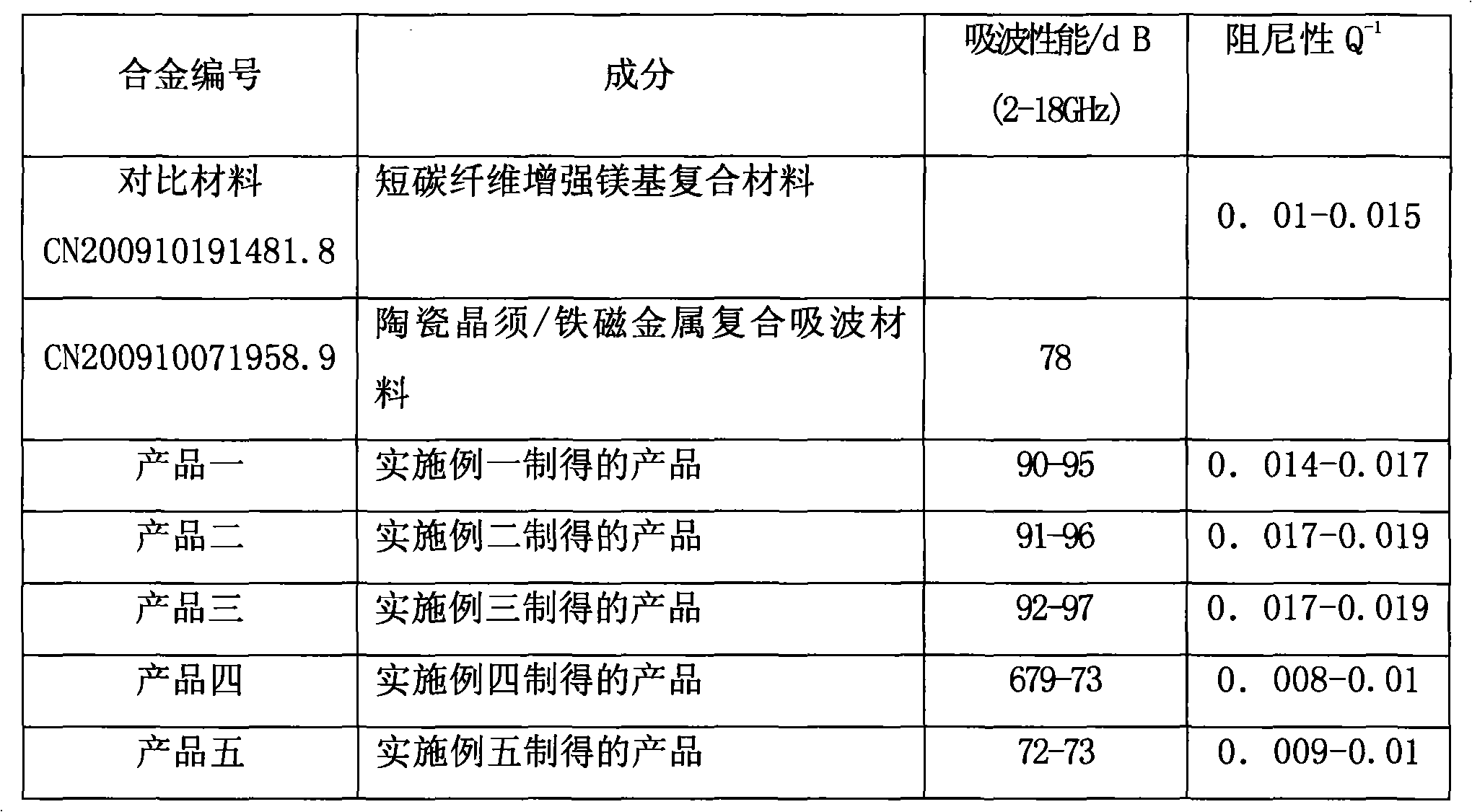

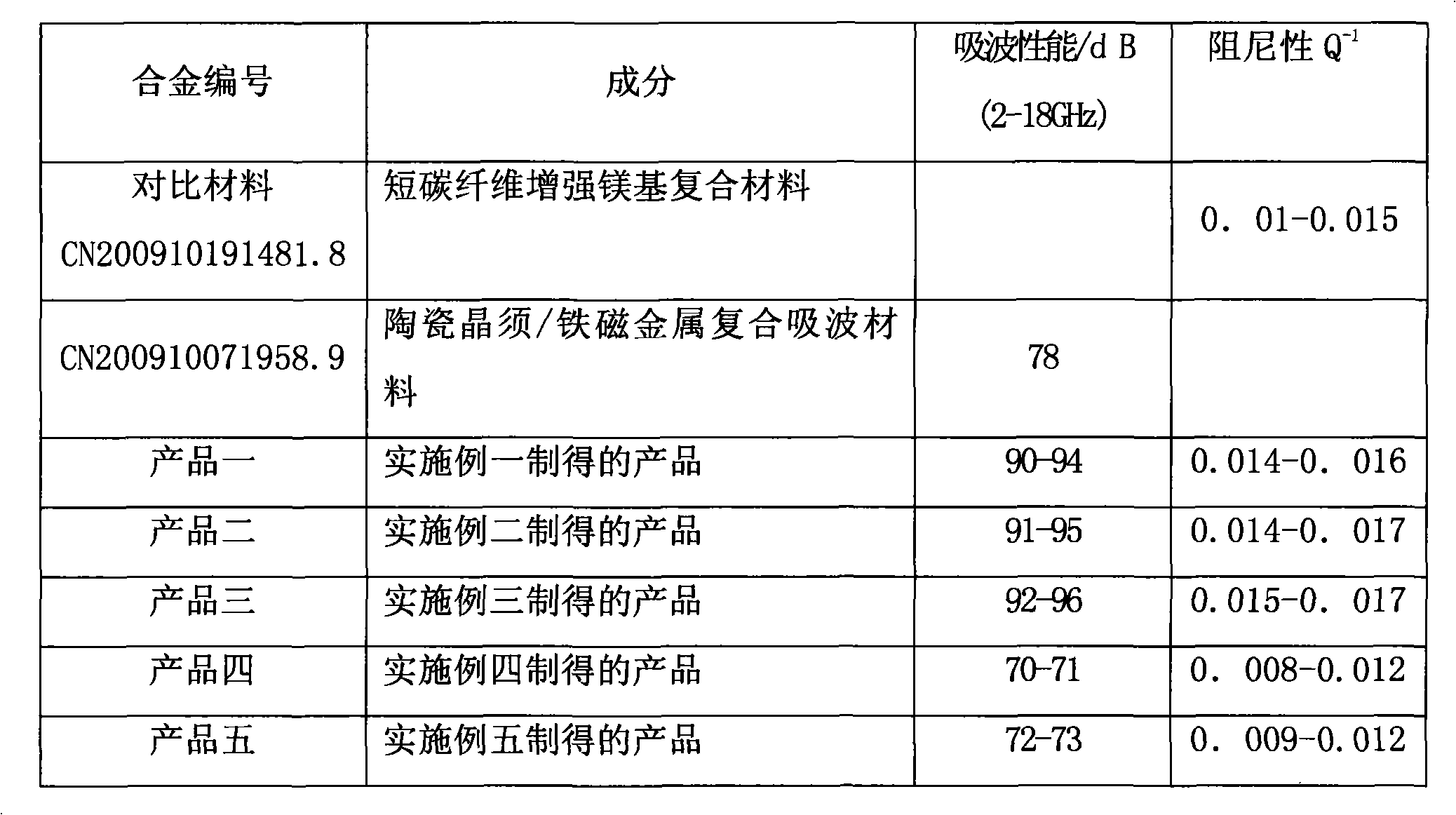

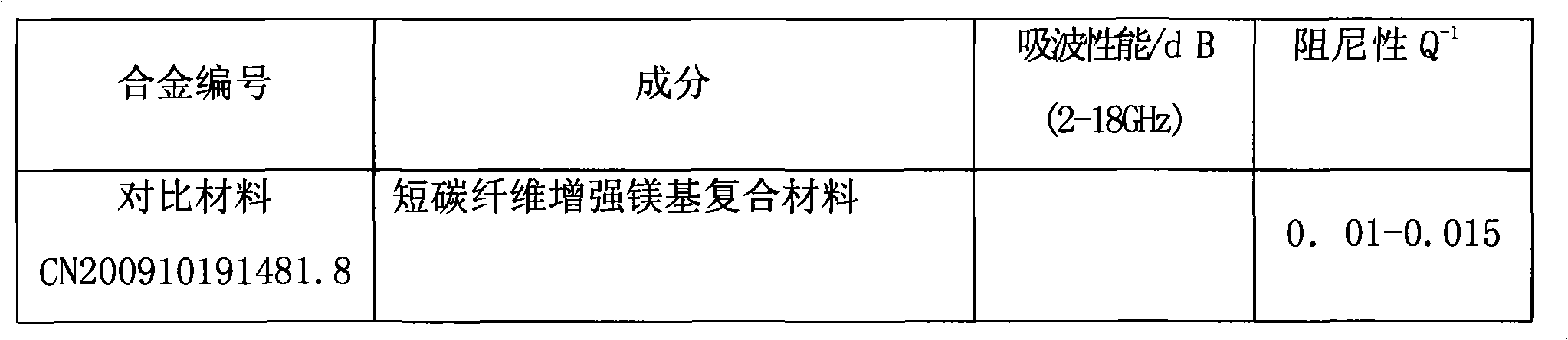

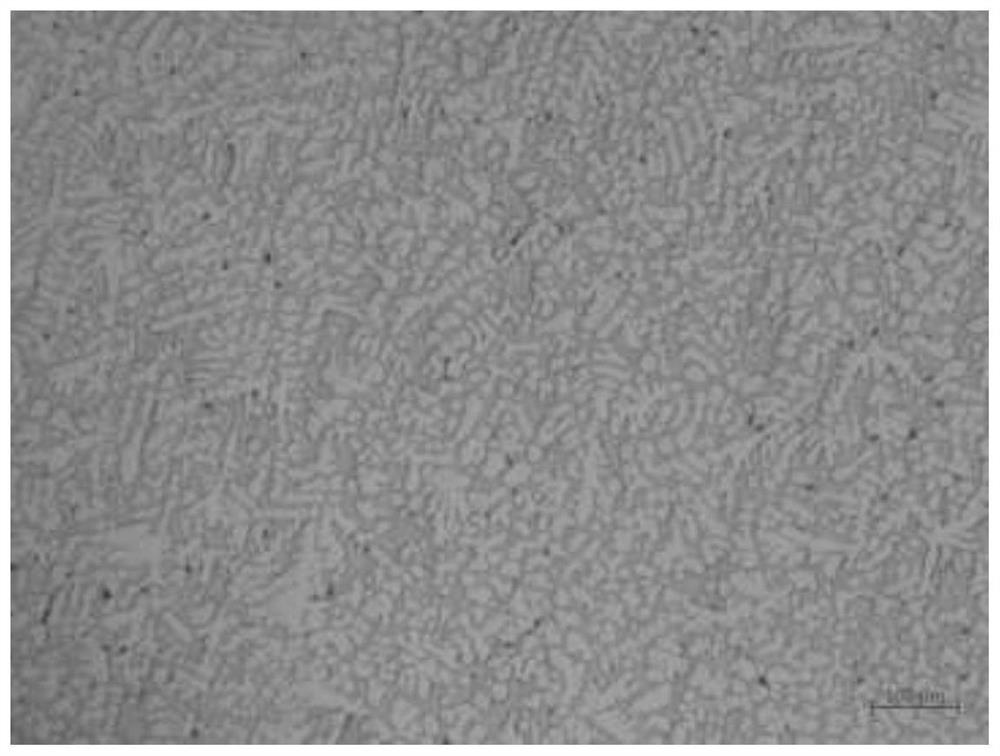

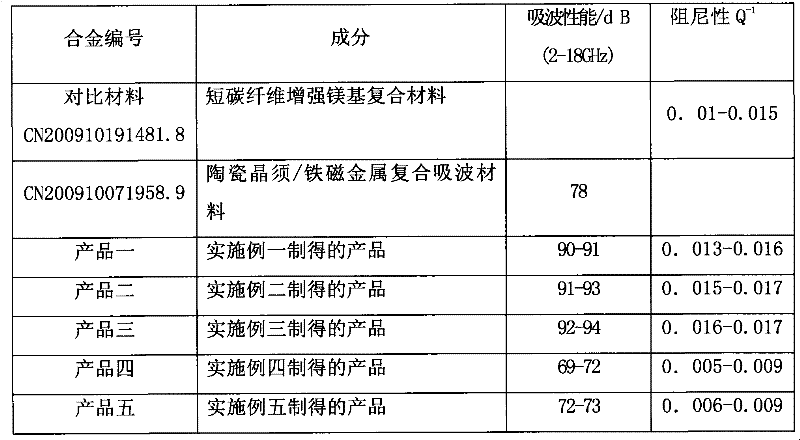

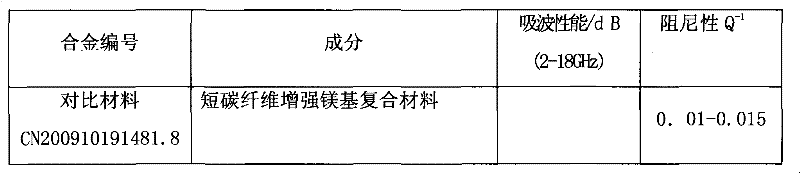

Magnesium alloy pumice ferric oxide cobalt composite material and preparation method thereof

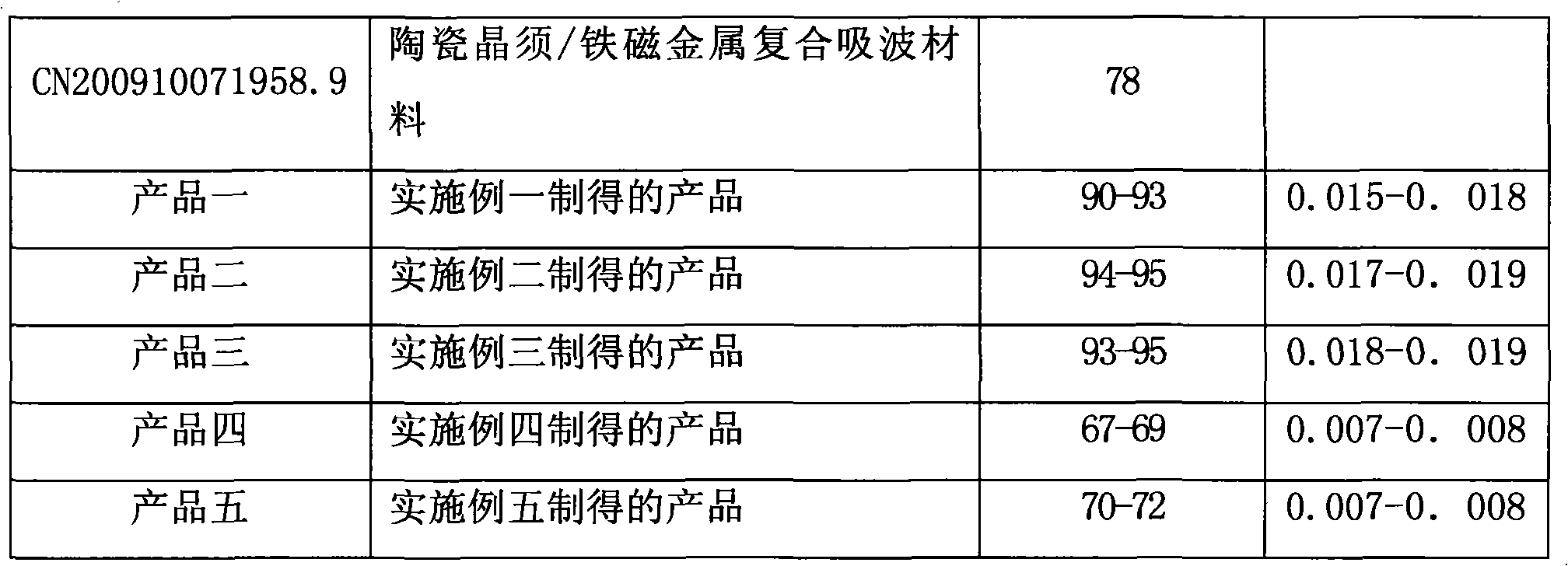

The invention provides a magnesium alloy pumice ferric oxide cobalt composite material and a preparation method thereof. The composite material has high absorbing properties and excellent damping performance. The method of the invention has simple process and low production cost, and is suitable for industrialized production. The composite material takes magnesium alloy as a matrix; pumice ferric oxide cobalt composite material and dolomite granule are distributed on the matrix; the volume percent of the pumice ferric oxide cobalt composite material and the dolomite granule accounts for 40-45% of the composite material; the size of the composite granule is 0.5-1mm; and the magnesium alloy base body comprises the following chemical composition by weight percent: 4-8% of Al, 0.01-0.05% of Th, 0.5-1% of Si, 0.001-0.005% of Bi and the balance of Mg.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

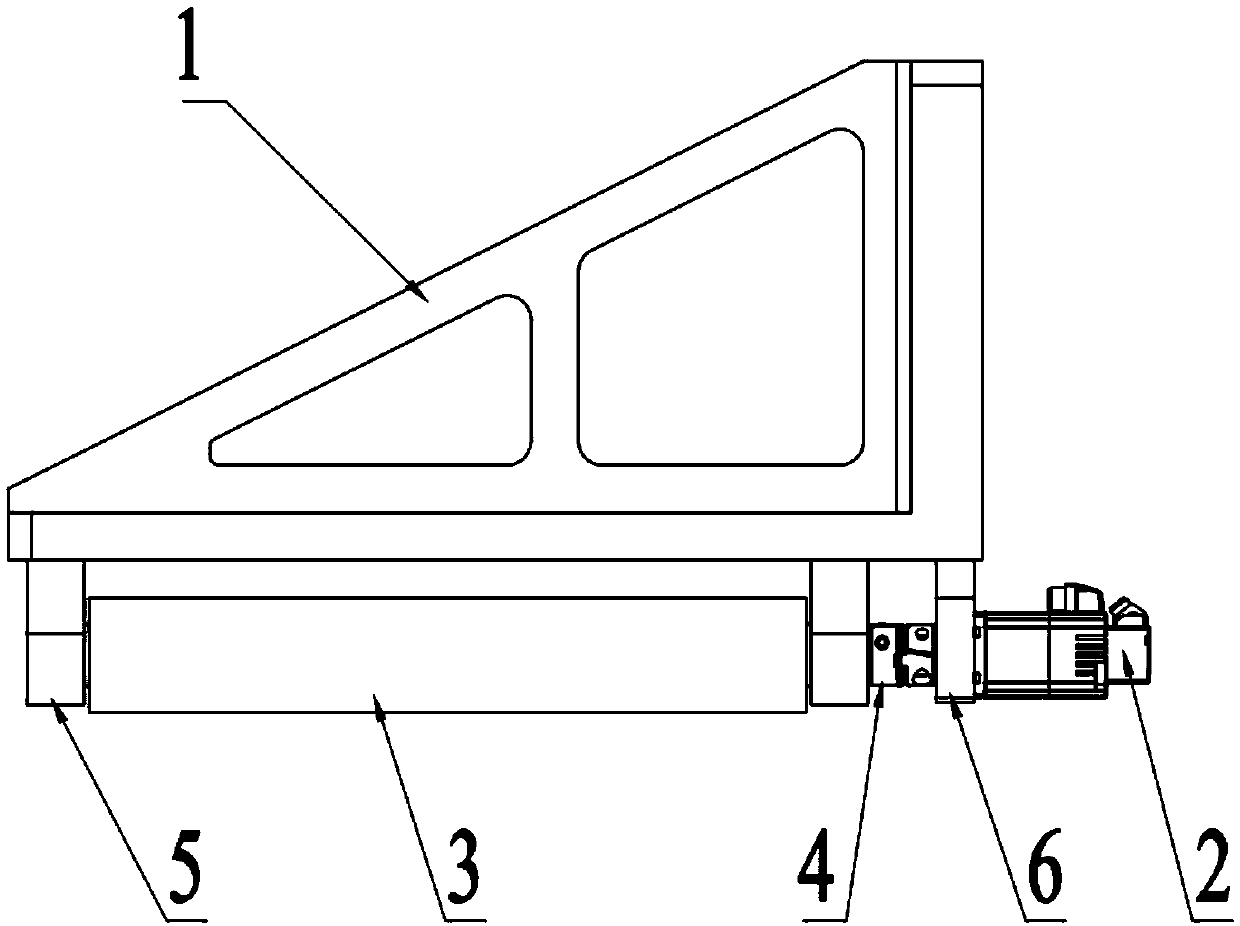

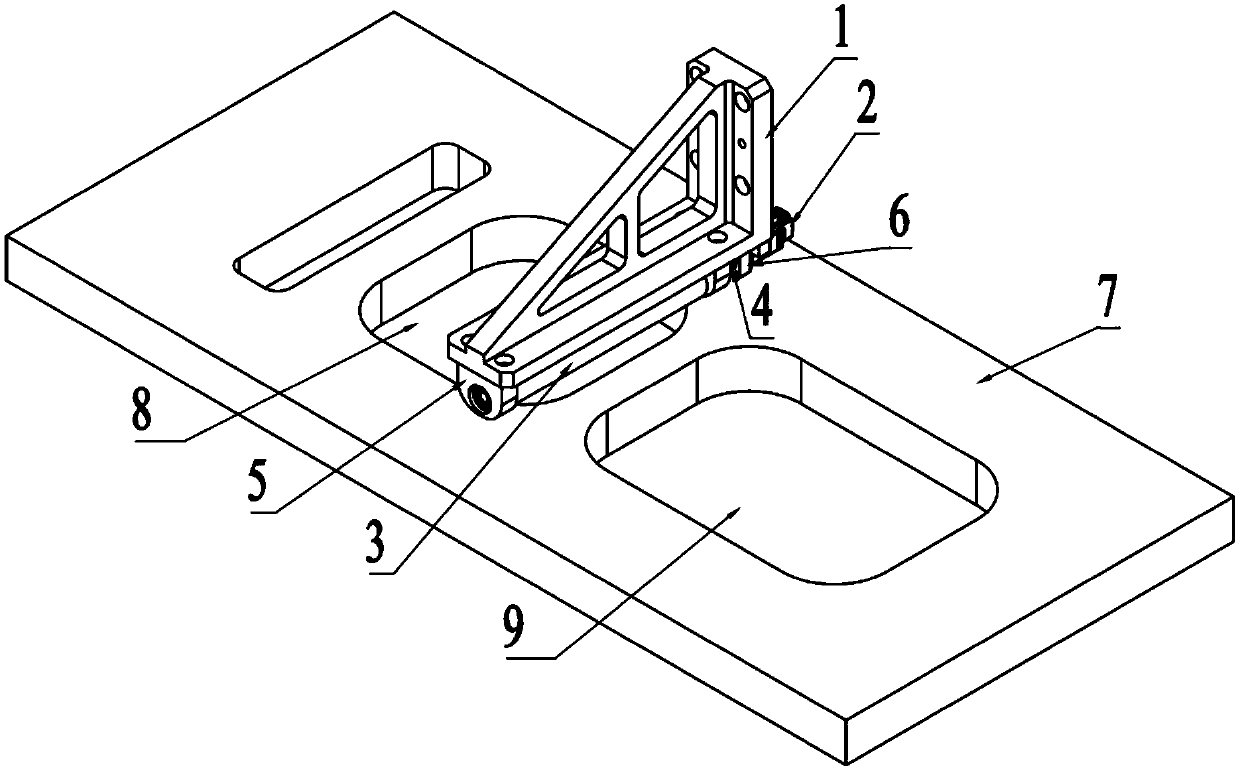

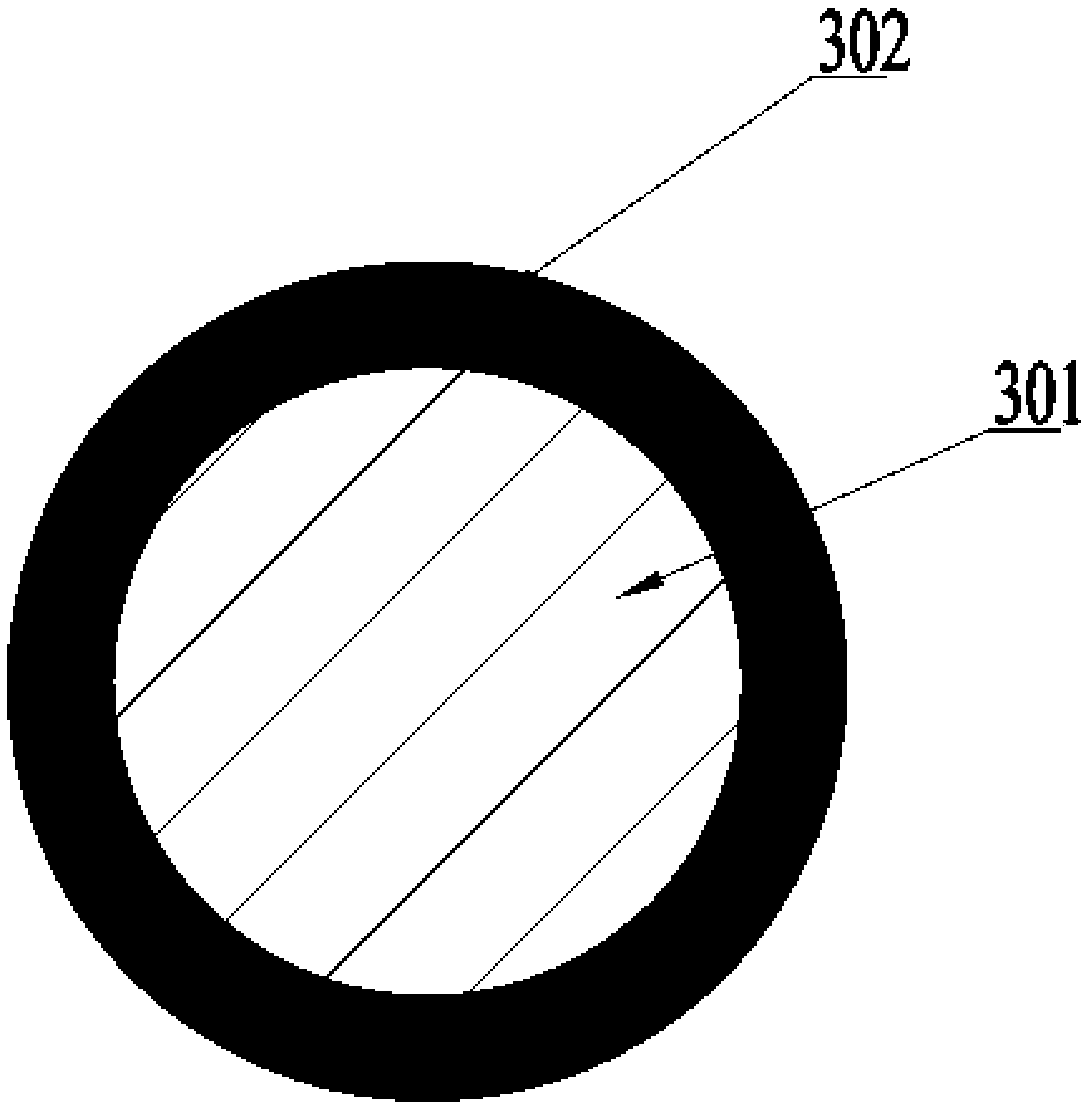

Powder spreading device

InactiveCN109570503AIncrease profitDoes not cause oxidationAdditive manufacturing apparatusIncreasing energy efficiencyCouplingDrive motor

The invention discloses a powder spreading device, and relates to the technical field of additive manufacturing. The powder spreading device comprises a scraper frame, a drive motor, a flexible scraper and a coupler. The flexible scraper comprises a scraper core and a scraper sleeve; the scraper core is of a cylinder structure; the scraper sleeve is of a hollow cylinder structure; the scraper coreis sleeved with the scraper sleeve; the flexible scraper and the drive motor are installed on the scraper frame; and a rotary shaft of the drive motor is connected with one end of the flexible scraper through the coupler. The drive motor is connected with the flexible scraper. after the part of the flexible scraper is abraded, the drive motor can drive the flexible scraper to be rotated by any angle, the contact position of the flexible scraper and powder is adjusted again, the part, not abraded, of the flexible scraper makes contact with the powder, the flexible scraper can be continue to beused, the utilization rate of the scraper is improved, the drive motor controls the position of the scraper, a cabin door does not need to be opened, formed parts are not oxidized, and the printing quality is ensured.

Owner:HANS LASER TECH IND GRP CO LTD +1

Magnesium-base copper-fiber pumice iron-barium oxide composite and preparation method thereof

The invention discloses a magnesium-base copper-fiber pumice iron-barium oxide composite and a preparation method thereof. The composite has a high wave-absorbing property and a high damping property. The preparation method is simple in process, in low production cost and suitable for industrial production. In the composite, magnesium alloy is used as a matrix, and pumice iron-barium oxide complex and copper alloy fibers are distributed on the matrix and account for 45 to 55 percent of the volume of the composite; the grain size of the pumice iron-barium oxide complex ranges from 0.5 to 1mm; and the magnesium alloy matrix comprises the following chemical components in percentage by weight: 3 to 6 percent of Al, 0.005 to 0.01 percent of Pb, 0.001 to 0.005 percent of Ta, 0.5 to 1 percent of Si, 0.005 to 0.01 percent of Te and the balance of Mg.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

Active lilium extract, and preparation method and application of active lilium extract

InactiveCN103417819AReduce hydrophobicityKeep aliveImmunological disordersAntineoplastic agentsNicotiana tabacumBULK ACTIVE INGREDIENT

The invention relates to an active lilium extract, and a preparation method and application of the active lilium extract. The active lilium extract comprises, by mass, 22-35% of proteins, 18-32% of polysaccharide, 20-32% of amino acid and 0.005-0.01% of alkaloid. The preparation method includes a cleaning procedure, a smashing processing procedure, an ultrasonic low-temperature extracting procedure, a microwave intermediate-temperature extracting and a concentrating and drying procedure. The active lilium extract is applied to manufacturing human immunity improving and anti-cancer healthcare products and can be used as an additive of food, wine, tobacco and cosmetics. The active lilium extract, the preparation method and the application have the advantages that active ingredients are prevented from being damaged, and the active component extraction efficiency is high.

Owner:NANJING BIAOKE BIO TECH

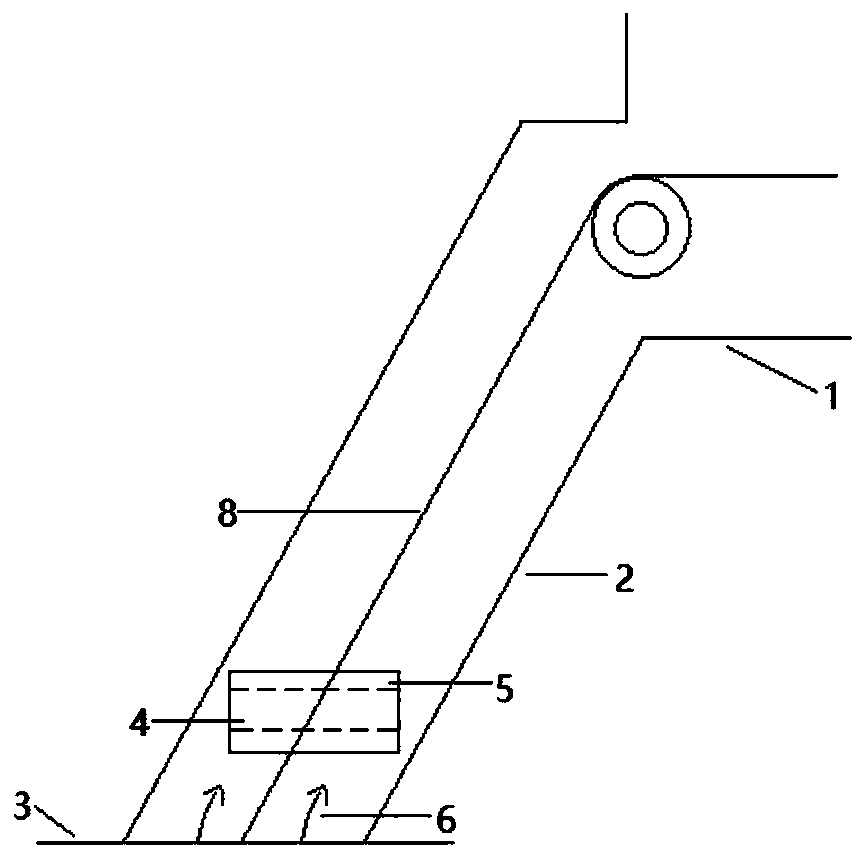

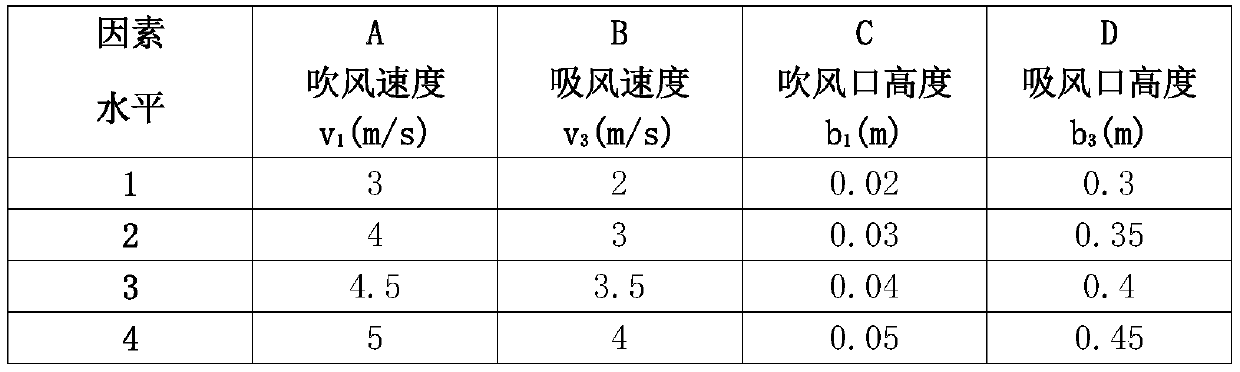

Method for inhibiting zinc steam diffusion in galvanized wire furnace nose

The invention provides a method for inhibiting zinc steam diffusion in a galvanized wire furnace nose. An air blowing opening and an air suction opening are formed in the two sides of the furnace nosecorrespondingly, the air blowing opening is used for sucking in dry nitrogen, the air suction opening sucks the gas continuously, and the rear portion of the air suction opening is connected with a steam collecting and treating device. The dry nitrogen brings away zinc steam generated by evaporation on the surface of zinc liquid in the furnace nose, the airflow is parallel to the surface of beltsteel and moves towards the air suction opening so that the zinc steam above the zinc liquid can be brought away continuously, and the zinc steam cannot be accumulated on the inner wall of the furnacenose to form zinc dust. Compared with the prior art, the method has the beneficial effects that due to the fact that the zinc steam in an area above the zinc liquid face is sucked away, zinc dust cannot be precipitated, and wet nitrogen does not need to be adopted for controlling zinc steam any more; the reducing atmosphere in the area above the zinc liquid in the furnace nose is high so that oxidation of sensitive elements cannot be avoided; and meanwhile, the airflow is parallel to the surface of the belt steel, and extra influences cannot be generated on the belt steel galvanizing quality.

Owner:WUHAN UNIV OF SCI & TECH

Copper alloy based sepiolite, ferric oxide, vermiculite and barium ferric oxide composite material and preparation method thereof

The invention provides a copper alloy based sepiolite, ferric oxide, vermiculite and barium ferric oxide composite material and a preparation method thereof. The composite material has high absorbing property and excellent damping property. The preparation method is simple in process, low in production cost and suitable for industrialized production. The composite material takes the copper alloy as the matrix and the sepiolite and ferric oxide compounds and the vermiculite and barium ferric oxide compounds are distributed on the matrix. The two kinds of compounds account for 40-50% of the composite material by volume. The copper alloy matrix comprises the following chemical components in percentage by weight: 3-5% of Al, 0.05-0.1% of Te, 0.05-0.1% of Co, 0.005-0.01% of Pr and the balance Cu.

Owner:常熟紫金知识产权服务有限公司

Zinc alloys, sepiolite-ferric oxide and vermiculite-barium ferrate composite material and preparation method thereof

The invention provides a zinc alloys, sepiolite-ferric oxide and vermiculite-barium ferrate composite material and a preparation method thereof. The composite material has high absorbing property and excellent damping property. The preparation method is simple in process, low in production cost and suitable for industrialized production. The composite material takes the zinc alloys as the matrices and the sepiolite-ferric oxide and vermiculite-barium ferrate compounds and titanium fibers are distributed on the matrices. The zinc alloys, the sepiolite-ferric oxide and the vermiculite-barium ferrate account for 40-50% of the composite material by volume. The titanium fibers comprise the following components in percentage by weight: 0.2-0.4% of V, 0.003-0.09% of Pr and the balance Ti. The zinc alloy matrices comprise the following chemical components in percentage by weight: 13-18% of Al, 0.05-0.1% of Te, 0.05-0.1% of Co, 0.005-0.01% of Pr and the balance Zn.

Owner:高满华

Copper and copper alloy casting equipment under protection of nitrogen

The invention discloses copper and copper alloy casting equipment under the protection of nitrogen. The equipment comprises a crystallizer assembly, and a secondary water cooling device and a casting well which are positioned below the crystallizer assembly. The equipment is characterized in that: an airtight protective cover is arranged between the crystallizer assembly and the casting well; thesecondary water cooling device is connected to a secondary water cooling-deoxidizing device through a secondary cooling water pipe which is connected with a nitrogen injection pipe and a valve; and the bottom of the casting well is provided with a cooling water return pipe. Under the sealing protection of the nitrogen, outside air is prevented from entering the casting well so as not to contact high-temperature copper ingots in the casting process, the copper ingots are prevented from being oxidized by the air, the surface non-oxidation casting of industrial pure copper, high copper and a white copper alloy is realized, and the aims of reducing the oxidation loss of copper metal and production cost are fulfilled.

Owner:JINCHUAN GROUP LIMITED

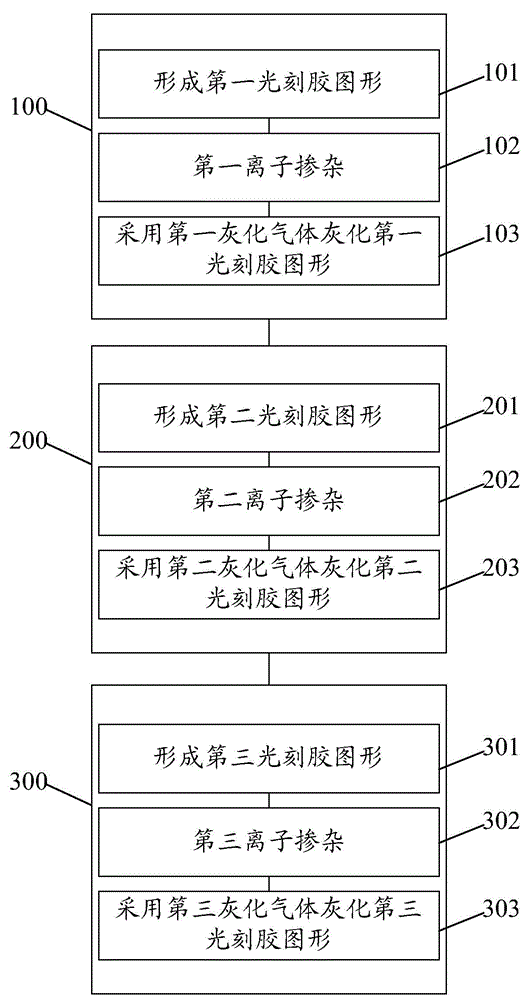

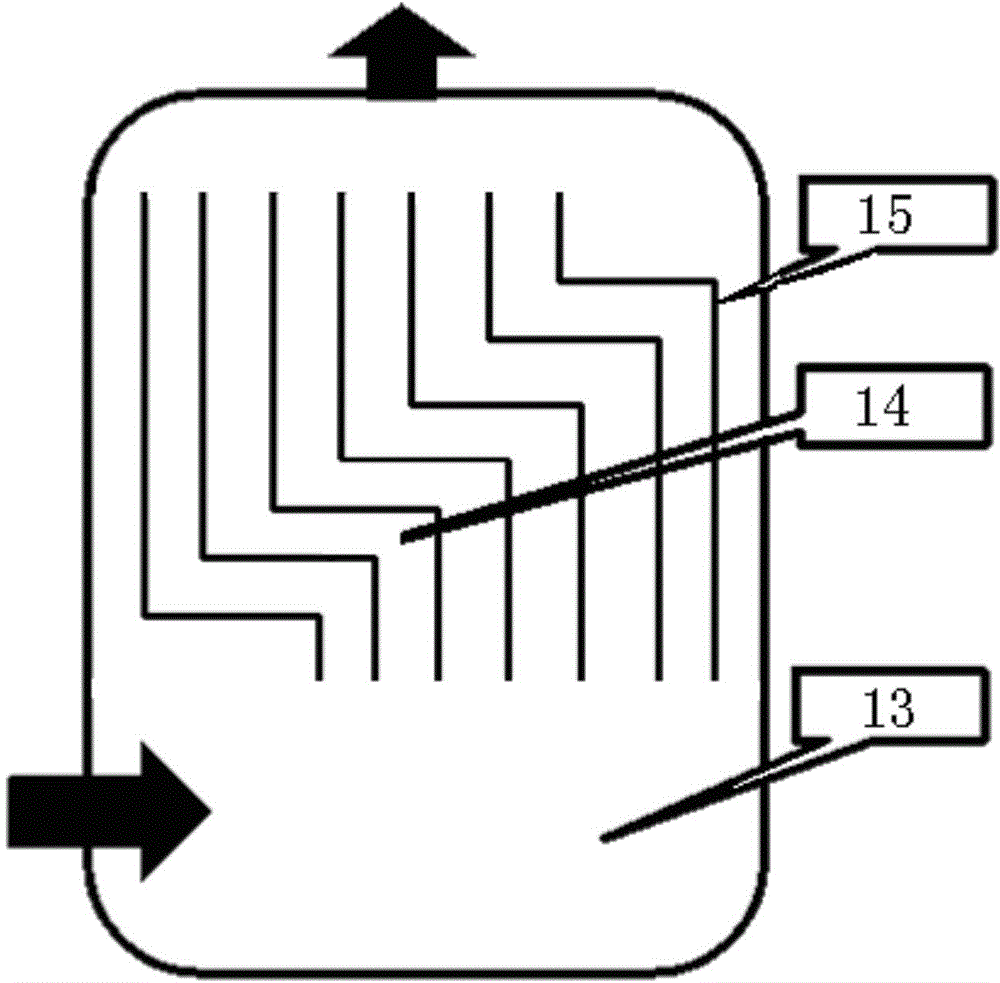

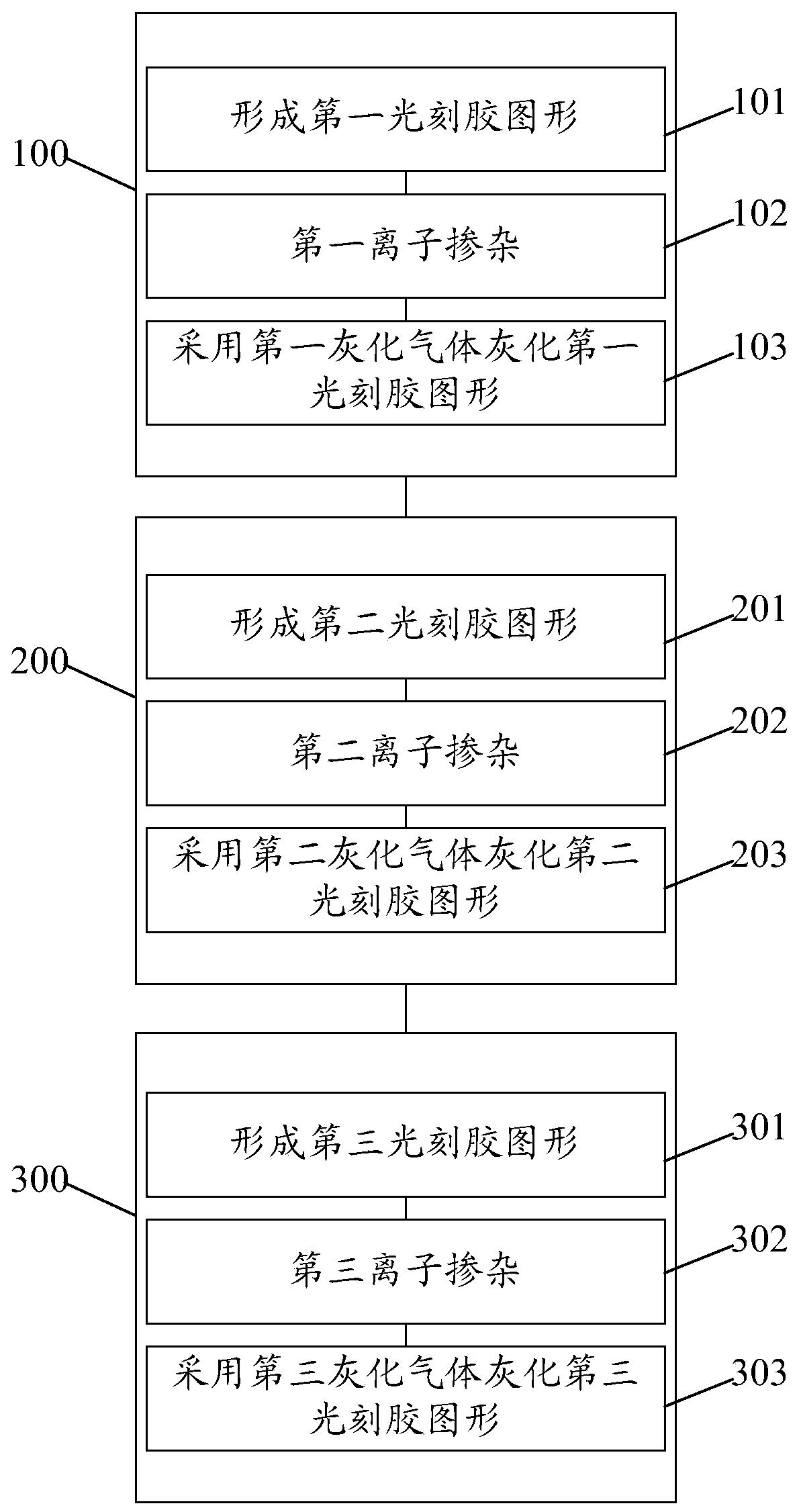

Ashing method for photoresist patterns

ActiveCN105223787AIncrease flexibilityAvoid damagePhotosensitive material processingHydrogen contentPhotoresist

The invention provides an ashing method for photoresist patterns. The ashing method comprises the following steps: providing a substrate; sequentially forming photoresist patterns on the substrate at least twice; after forming the photoresist pattern each time, with the corresponding photoresist pattern as a corresponding mask, carrying out ion doping on the substrate, and doping doped ions with different contents into the corresponding photoresist pattern; and after ion doping, ashing the corresponding photoresist pattern with corresponding ashing gas containing hydrogen, wherein the ashing gases adopted for the photoresist patterns doped with the ions with different content are different in hydrogen content. The ashing method has the beneficial effects that the effects on the substrate can be reduced; the ashing rate on the photoresist patterns is also relatively high; and in addition, the control flexibility of photoresist pattern ashing is increased and the rate of ashing the photoresist patterns and the thoroughness degrees of ashing the photoresist patternscan be adjusted.

Owner:SEMICON MFG INT (SHANGHAI) CORP

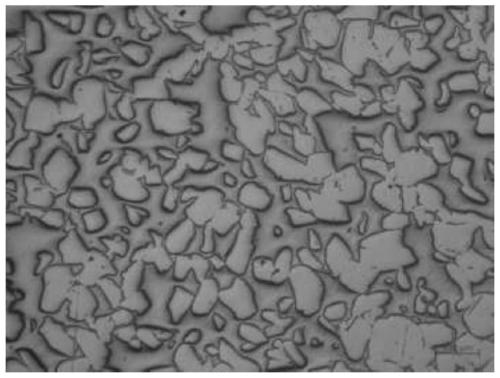

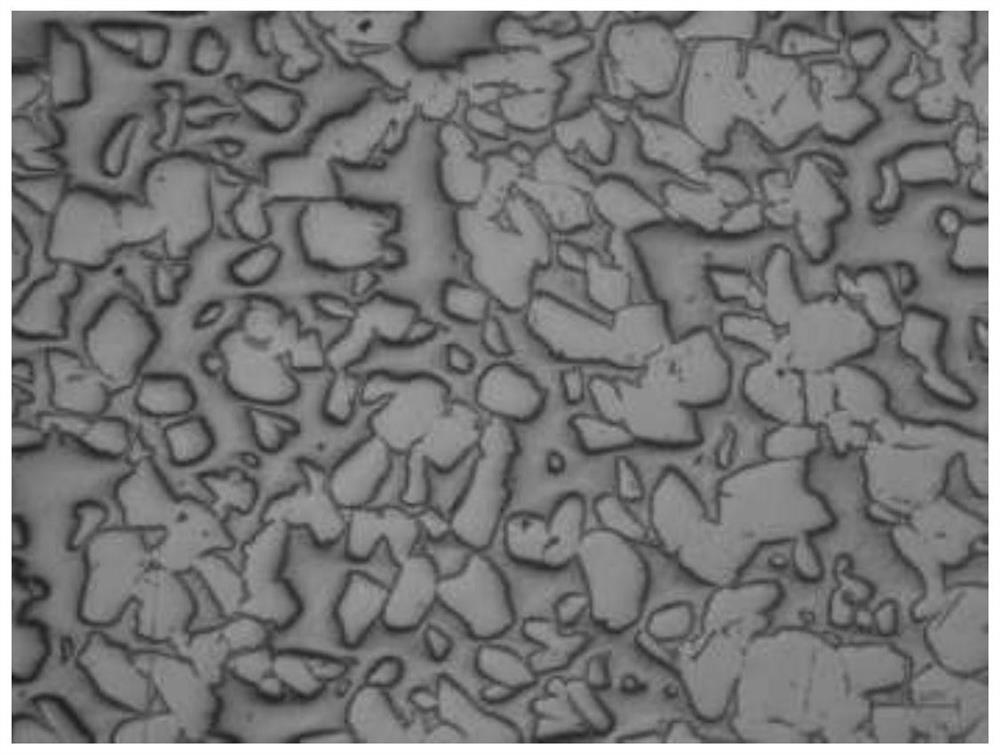

Preparation method of consumable electrode bar for copper-chromium electric arc melting

ActiveCN111593224AFully integratedHigh internal densityIncreasing energy efficiencyHeat inorganic powder coatingArc stabilityIngot casting

The invention discloses a preparation method of a consumable electrode bar for copper-chromium electric arc melting, and belongs to the technical field of metal processing. The method comprises the steps of burdening, ingot casting, powder making, blank making, degassing and hot isostatic pressing, wherein in the blank making step, spherical copper-chromium alloy powder with the particle size of 5-15 micrometers is selected to be made into a copper-chromium alloy blank bar in a cold static pressure pressing or cold spraying deposition mode, the density of the consumable electrode bar is remarkably improved by combining a hot isostatic pressing process, the density is improved to about 99% from previous 75%-85%, the arc stability of the consumable electrode bar in the smelting process is improved favorably, the gas content of the consumable electrode bar is remarkably reduced from previous 600-800 ppm to 210-400 ppm, and the voltage fluctuation in the electrode bar smelting procedure isreduced.

Owner:SHAANXI SIRUI ADVANCED MATERIALS CO LTD

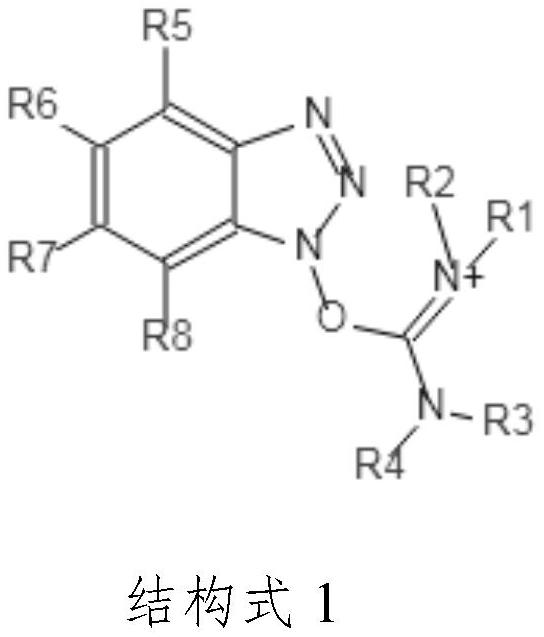

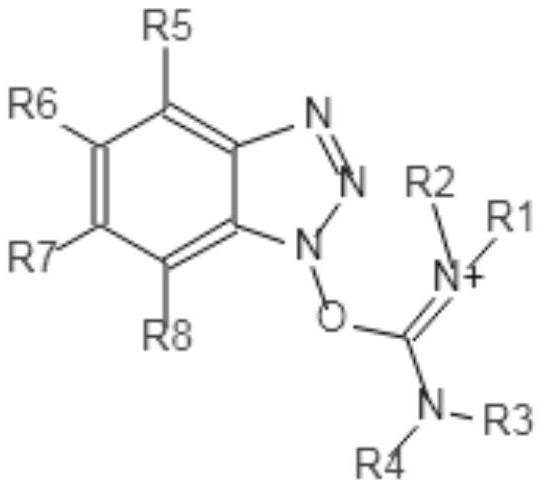

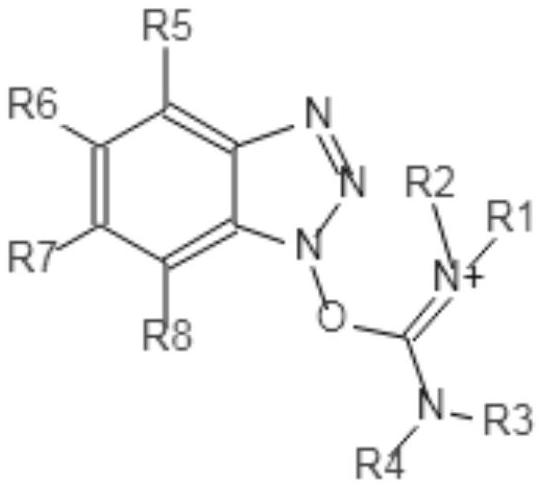

Lithium iron phosphate battery

PendingCN113871715ALower impedanceImprove low temperature performanceSecondary cellsOrganic electrolytesElectrolytic agentNitroso

In order to solve the problem that an electrolyte in the existing lithium iron phosphate battery is difficult to meet the low-temperature performance requirement, the invention provides a lithium iron phosphate battery which comprises a positive electrode, a negative electrode and the electrolyte, wherein the positive electrode comprises a positive electrode active material, and the positive electrode active material is selected from lithium iron phosphate; the electrolyte comprises a solvent, a lithium salt and an additive A, the additive A comprises anions and cations shown in a structural formula 1 in the description, R1, R2, R3, R4, R5, R6, R7 and R8 are independently selected from hydrogen, cyano, nitroso, aldehyde, acyl, halogen, substituted or unsubstituted alkyl with the carbon atom number of 1-8 and substituted or unsubstituted aryl with the carbon atom number of 6-12, and the anions are acid radical ions containing phosphorus, boron or aluminum. The lithium iron phosphate battery provided by the invention has relatively low impedance and relatively good low-temperature performance.

Owner:BASF BATTERY MATERIALS SUZHOU

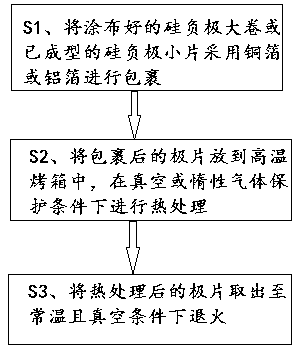

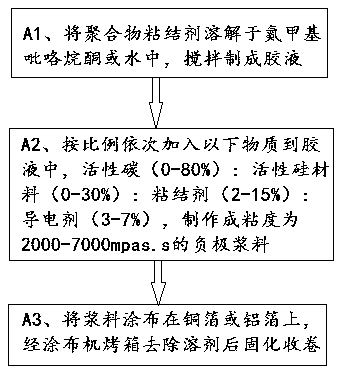

Thermal treatment preparation method of silicon negative electrode plate

InactiveCN108511688APromote expansionImprove cycle performanceCell electrodesPolymer adhesiveRoom temperature

The invention relates to the technical field of preparation of a silicon negative electrode plate, and specifically provides a thermal treatment preparation method of the silicon negative electrode plate. The thermal treatment preparation method comprises the following steps: S1, coating a coated big silicon negative electrode roll or a formed small silicon negative electrode plate by adopting a copper foil or an aluminum foil; S2, putting the coated plate in a high-temperature baking oven, and carrying out thermal treatment under a vacuum or inert gas protection condition; S3, taking out theplate after thermal treatment, cooling to room temperature, and annealing under a vacuum condition. According to the thermal treatment preparation method provided by the invention, a negative electrode after the thermal treatment requires not to be cooled in the high-temperature baking oven, and can be directly taken out and transferred to a normal temperature baking oven for cooling; the purposeof thermal polymerization of a polymer adhesive can be achieved, oxidation of the silicon negative electrode cannot be caused; the thermal treatment preparation method provided by the invention is simple in operation and short in time, and is beneficial for industrial production.

Owner:FULLYMAX BATTERY CO LTD

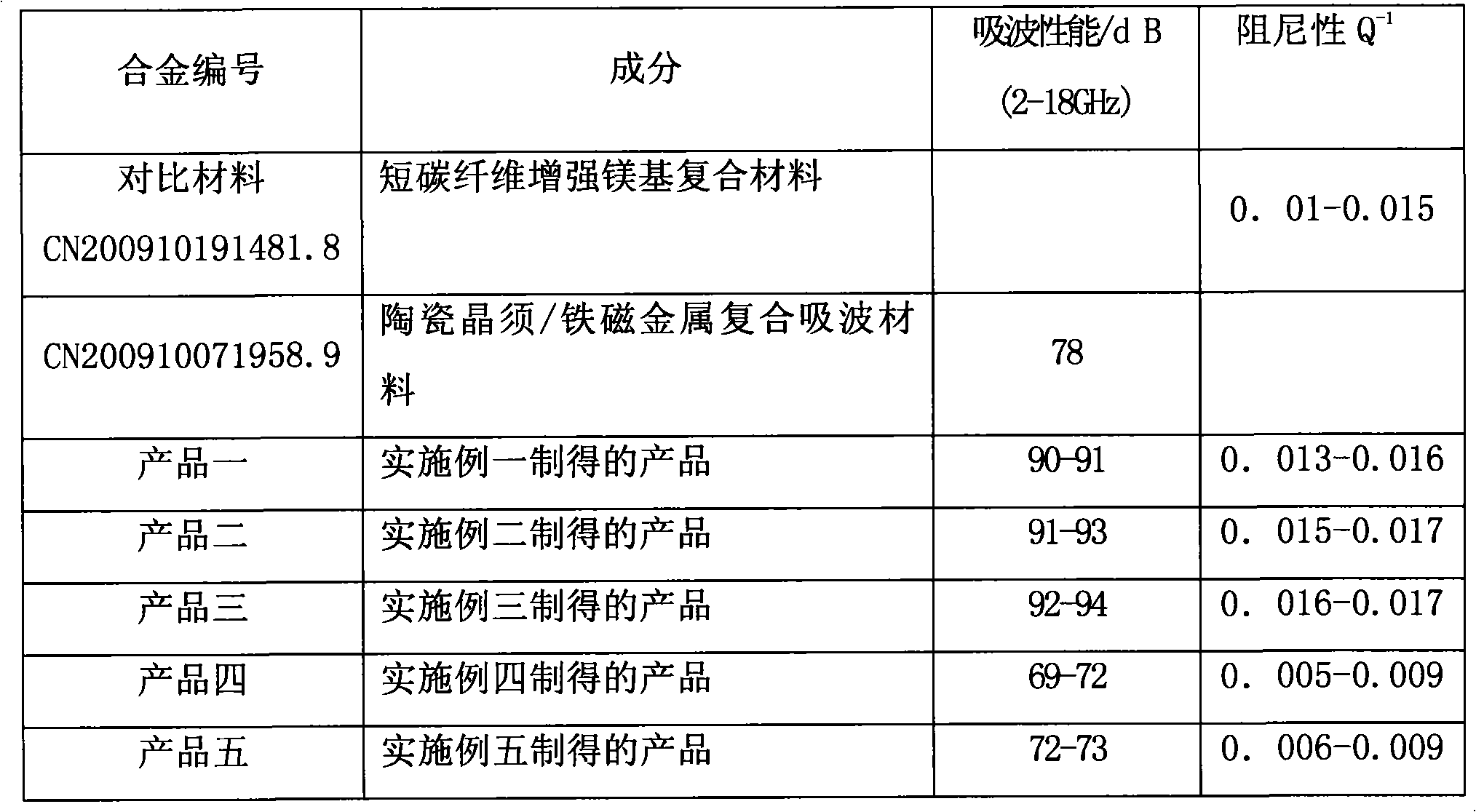

Titanium alloy, diatomite and barium ferric oxide composite material and preparation method thereof

The invention provides a titanium alloy, diatomite and barium ferric oxide composite material and a preparation method thereof. The composite material has high absorbing property and excellent damping property. The preparation method is simple in process, low in production cost and suitable for industrialized production. The composite material takes the titanium alloy as the matrix and diatomite and barium ferric oxide compounds are distributed on the matrix. The diatomite and barium ferric oxide compounds account for 45-55% of the composite material by volume. The particle size of the diatomite and barium ferric oxide compounds is 0.5-1mm. The titanium alloy matrix comprises the following chemical components in percentage by weight: 3-8% of Al, 0.001-0.005% of Ta, 0.5-1% of Si and the balance Ti. The diatomite and barium ferric oxide compounds are formed in such a manner that barium ferric oxide penetrates into the pores of the diatomite and a layer of film is formed on the wall surfaces of the pores.

Owner:常熟紫金知识产权服务有限公司

Aluminium alloys, pumice-ferric oxide and vermiculite-barium ferrate composite material and preparation method thereof

InactiveCN101942594ASimple preparation processIncrease dampingChemical compositionBlack ferric oxide

The invention provides an aluminium alloys, pumice-ferric oxide and vermiculite-barium ferrate composite material and a preparation method thereof. The composite material has high absorbing property and excellent damping property. The preparation method is simple in process, low in production cost and suitable for industrialized production. The composite material takes the aluminium alloys as the matrices and the pumice-ferric oxide and vermiculite-barium ferrate compounds are distributed on the matrices. The pumice-ferric oxide and vermiculite-barium ferrate compounds account for 40-50% of the composite material by volume. The aluminium alloy matrices comprise the following chemical components in percentage by weight: 3-6% of Mg, 0.005-0.01% of Pb, 0.001-0.005% of Ta, 0.001-0.005% of Ga, 0.5-1% of Si and the balance Al.

Owner:许少文

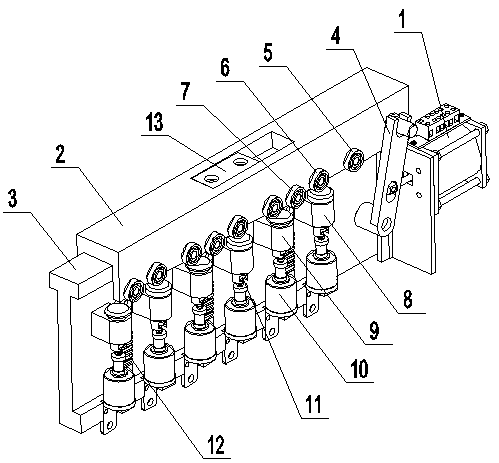

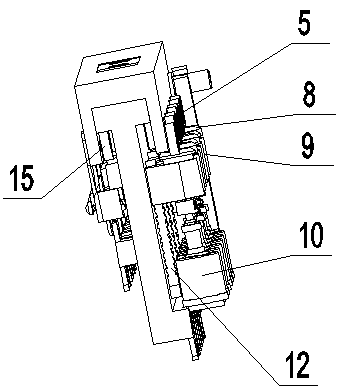

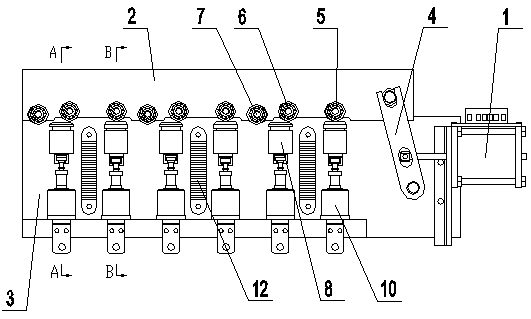

Linear vacuum on-load dual-position switch

The invention provides a linear vacuum on-load dual-gear selector switch. A sliding block is in sliding connection with the top of a base. A limit limiting mechanism is arranged on the sliding block. The sliding block is connected with a permanent magnet mechanism. One side of the sliding block is provided with a roller, and the other side of the sliding block is provided with a movable contact mounting base. One side of the base, relative to the roller, is provided with a vacuum tube buffer, a main vacuum tube, an auxiliary vacuum tube and a transition resistor. The other side of the base, relative to the movable contact mounting base, is provided with a static contact set of the selector switch. The static contact set comprises two static contacts, and a neutral position gear is arranged between the two static contacts. By the selector switch, the gear switching function and the vacuum arc extinguishing function of the selector switch can be completed at the same time. Meanwhile, during the switching process, the circuit is continuously powered on. By adopting the linear switching mode, the installation volume of the selector switch can be reduced, and the switching speed of the selector switch is high. Meanwhile, the selector switch is high in reliability, and long in service life.

Owner:宁波安德奥电力设备有限公司

A method for manufacturing hot-dip galvanized steel sheet without strip zinc dust and bright spot defects on the surface

ActiveCN103556095BEnhanced reducing atmosphereDoes not cause oxidationHot-dipping/immersion processesSheet steelHydrogen

The invention relates to the technical field of hot galvanized steel sheet manufacturing, particularly to a manufacturing method for a hot galvanized steel sheet without strip zinc ash and bright spot defects on the surface. The method is characterized by: installing a condensation precipitation device outside a furnace nose to form negative pressure at a zinc pot side in the furnace nose, at the same time, heating a furnace nose side wall to raise the temperature to 450-550DEG C, making the zinc vapor over the zinc pot sucked away continuously and unable to accumulate on the side wall in the region, keeping the dew point of the nitrogen and hydrogen protective gases in the furnace nose in the range from -70DEG C to -20DEG C without additional humidification, cooling the zinc vapor in the condensation precipitation device, and precipitating and depositing zinc powder. Compared with the prior art, according to the method provided by the invention, the zinc vapor over the zinc pot is sucked away, and no zinc powder precipitates out, so that a high dew point method is no longer needed to inhibit the zinc vapor. Therefore, the strip zinc ash and bright spot defects are maximumly controlled.

Owner:ANSC TKS GALVANIZING

Ashing method of photoresist pattern

ActiveCN105223787BIncrease flexibilityAvoid damagePhotosensitive material processingHydrogen contentPhotoresist

The invention provides an ashing method for photoresist patterns. The ashing method comprises the following steps: providing a substrate; sequentially forming photoresist patterns on the substrate at least twice; after forming the photoresist pattern each time, with the corresponding photoresist pattern as a corresponding mask, carrying out ion doping on the substrate, and doping doped ions with different contents into the corresponding photoresist pattern; and after ion doping, ashing the corresponding photoresist pattern with corresponding ashing gas containing hydrogen, wherein the ashing gases adopted for the photoresist patterns doped with the ions with different content are different in hydrogen content. The ashing method has the beneficial effects that the effects on the substrate can be reduced; the ashing rate on the photoresist patterns is also relatively high; and in addition, the control flexibility of photoresist pattern ashing is increased and the rate of ashing the photoresist patterns and the thoroughness degrees of ashing the photoresist patternscan be adjusted.

Owner:SEMICON MFG INT (SHANGHAI) CORP

A preparation method of consumable electrode rod for copper chromium arc smelting

ActiveCN111593224BFully integratedHigh internal densityIncreasing energy efficiencyHeat inorganic powder coatingArc stabilitySmelting process

Owner:SHAANXI SIRUI ADVANCED MATERIALS CO LTD

Titanium alloy, diatomite and barium ferric oxide composite material and preparation method thereof

The invention provides a titanium alloy, diatomite and barium ferric oxide composite material and a preparation method thereof. The composite material has high absorbing property and excellent damping property. The preparation method is simple in process, low in production cost and suitable for industrialized production. The composite material takes the titanium alloy as the matrix and diatomite and barium ferric oxide compounds are distributed on the matrix. The diatomite and barium ferric oxide compounds account for 45-55% of the composite material by volume. The particle size of the diatomite and barium ferric oxide compounds is 0.5-1mm. The titanium alloy matrix comprises the following chemical components in percentage by weight: 3-8% of Al, 0.001-0.005% of Ta, 0.5-1% of Si and the balance Ti. The diatomite and barium ferric oxide compounds are formed in such a manner that barium ferric oxide penetrates into the pores of the diatomite and a layer of film is formed on the wall surfaces of the pores.

Owner:常熟紫金知识产权服务有限公司

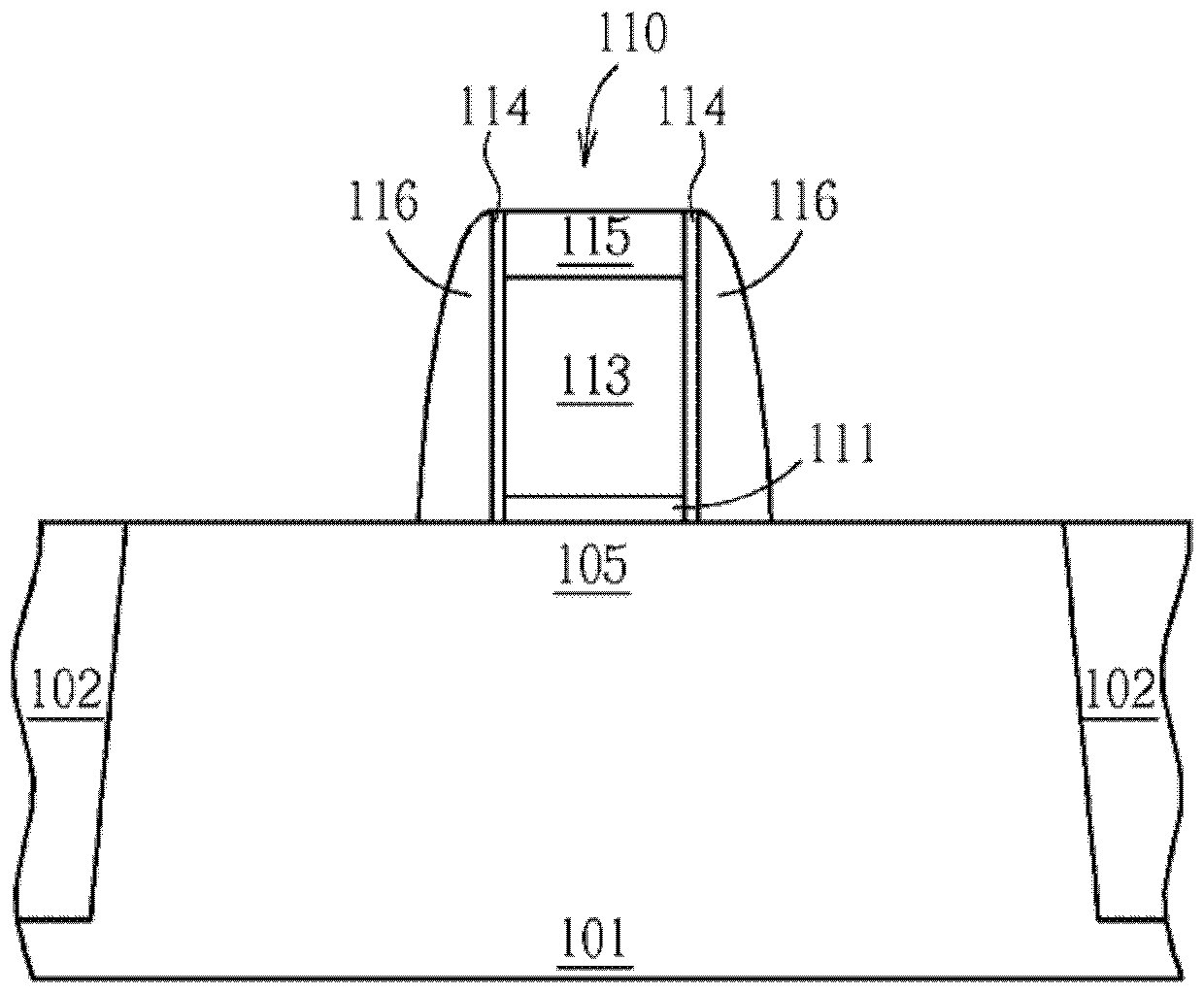

Manufacturing method of semiconductor element

ActiveCN103378007BDoes not cause oxidationAvoid cutsSemiconductor/solid-state device manufacturingOxygenNitride

The invention discloses a method for manufacturing a semiconductor element. First, a gate structure on a substrate and a first nitride material layer on the gate structure are provided. Secondly, a protection step is performed to modify the first nitride material layer in an oxygen-containing environment. Then, a second material layer is formed on the substrate. Continuing, a removal step is performed after the protection step to remove the second nitride material layer without substantially reducing the modified first nitride material layer.

Owner:UNITED MICROELECTRONICS CORP

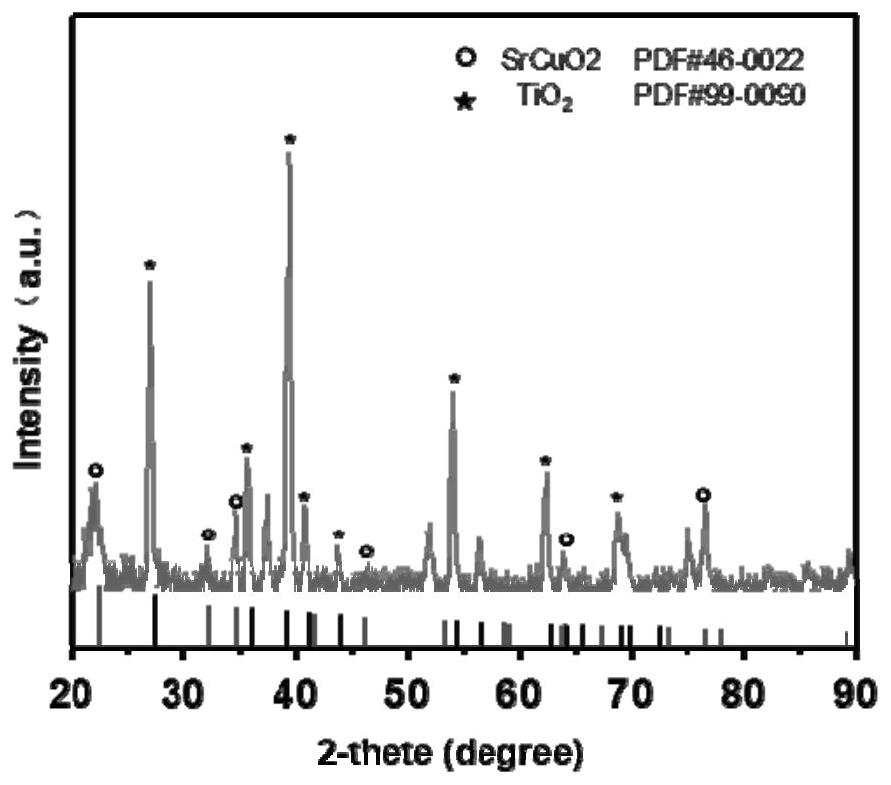

Preparation method and application of strontium perovskite catalytic cathode

PendingCN114054032AImprove removal efficiencyHigh selectivityWater contaminantsWater/sewage treatmentAmmoniacal nitrogenNitrate salts

The invention discloses a preparation method and application of a strontium perovskite catalytic cathode. The electrode comprises a porous titanium sheet electrode and a catalyst layer, the catalyst layer is a perovskite catalyst layer generated on the porous titanium sheet electrode in situ, the catalyst layer is SrMO3, and M is one or more of Cu, Fe and Co. The preparation method comprises the following steps: S1, mixing Sr(NO3)2 and M(NO3)2.6H2O with sodium citrate monohydrate and ethylene glycol, and evaporating the solution to dryness to obtain gel; s2, pretreating the porous titanium sheet electrode; s3, soaking the pretreated porous titanium sheet electrode in the gel until no bubble is generated; s4, drying and calcining the soaked porous titanium sheet electrode, and generating a catalyst layer on the surface of the porous titanium sheet electrode; s5, repeating the soaking, drying andcalcining steps to obtain the SrMO3 catalytic electrode. The SrMO3 catalytic cathode prepared through the method is simple in preparation method and high in ammonia nitrogen selectivity and can be used for sewage treatment, nitrate nitrogen is converted into ammonia nitrogen, and a foundation is laid for nitrate sewage recycling.

Owner:DONGGUAN UNIV OF TECH

A kind of L-ascorbyl palmitate-based baking oil and preparation method thereof

ActiveCN110637893BLow in saturated fatty acidsCatering to the needs of low oil contentEdible oils/fatsModified nutritive productsBiotechnologyHigh oleic acid

The invention discloses an L-ascorbyl palmitate-based baking oil and a preparation method thereof, belonging to the field of baking oil production. The present invention uses high oleic acid sunflower seeds as base oil, and adds L-ascorbyl palmitate to construct a gel network, firstly dissolves L-ascorbyl palmitate in ethanol, and then adds high oleic acid sunflower seeds In oils, gel oil networks can be formed at lower temperatures. While reducing trans-fatty acids and unsaturated fatty acids, it can bring nutrition and health to consumers, and the method of the invention can save energy and reduce costs.

Owner:JIANGNAN UNIV

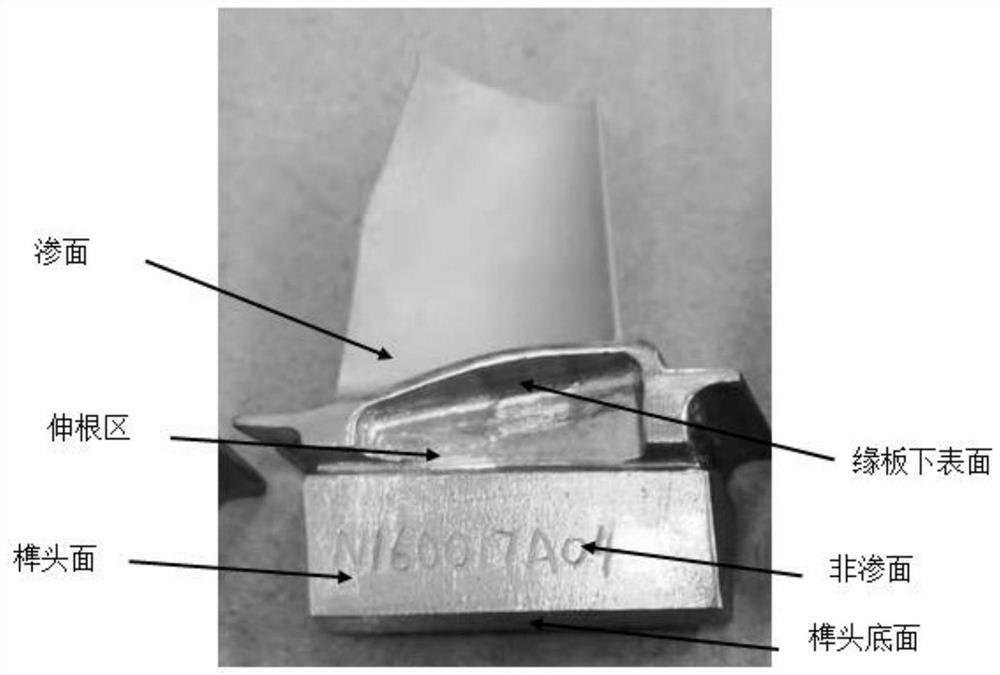

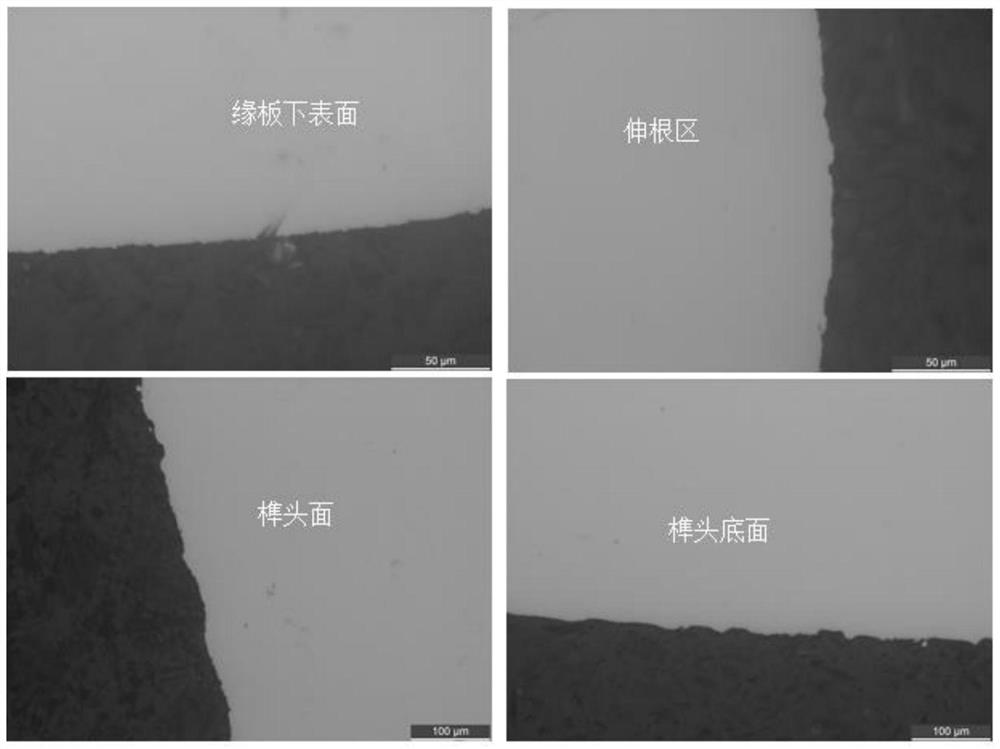

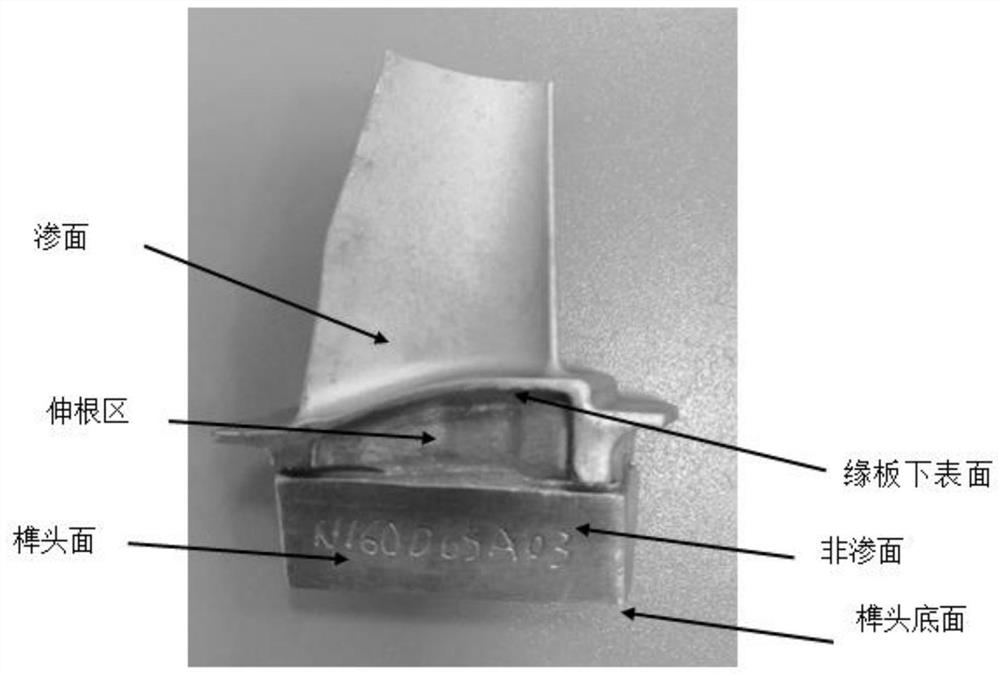

Ceramic slurry for aluminizing protection and preparation method and application of ceramic slurry

PendingCN112853350AWide range of temperatureDoes not cause oxidationTransportation and packagingMetal-working apparatusMetal powderZirconium oxide

The invention belongs to the field of chemical heat treatment, and particularly relates to ceramic slurry for aluminizing protection and a preparation method and application of the ceramic slurry. According to the ceramic slurry for aluminizing protection and the preparation method and application of the ceramic slurry, the ceramic slurry for aluminizing protection forms a stable and non-falling aluminizing protective layer after being sintered, has a good shielding effect, and does not react with a matrix. The ceramic slurry for aluminizing protection comprises the following components of zirconium oxide, a binder and metal, wherein the mass ratio of the zirconium oxide to the binder to the metal is (0.8-3): (0.5-1.5): (0.8-1.5). According to the ceramic slurry for aluminizing protection, zirconium oxide powder, the binder and metal powder are mixed and then coat a tenon of a turbine blade, and the ceramic slurry is used for protection during aluminizing of solid powder at the aluminizing temperature of 600-1,100 DEG C.

Owner:成都航宇超合金技术有限公司

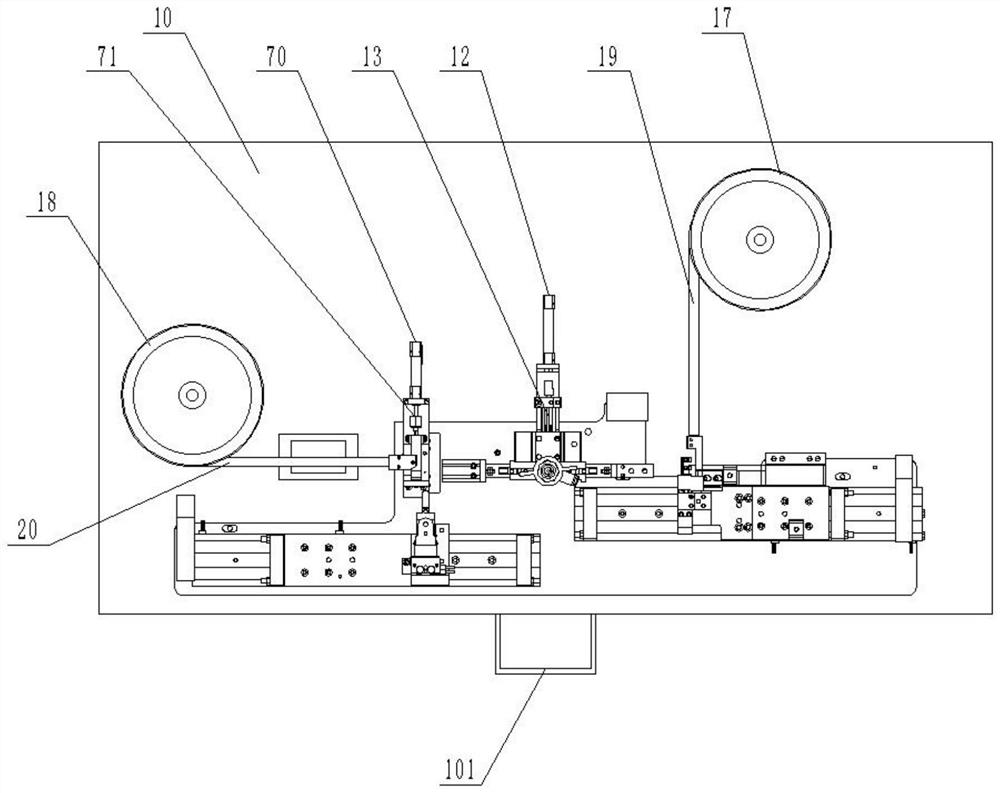

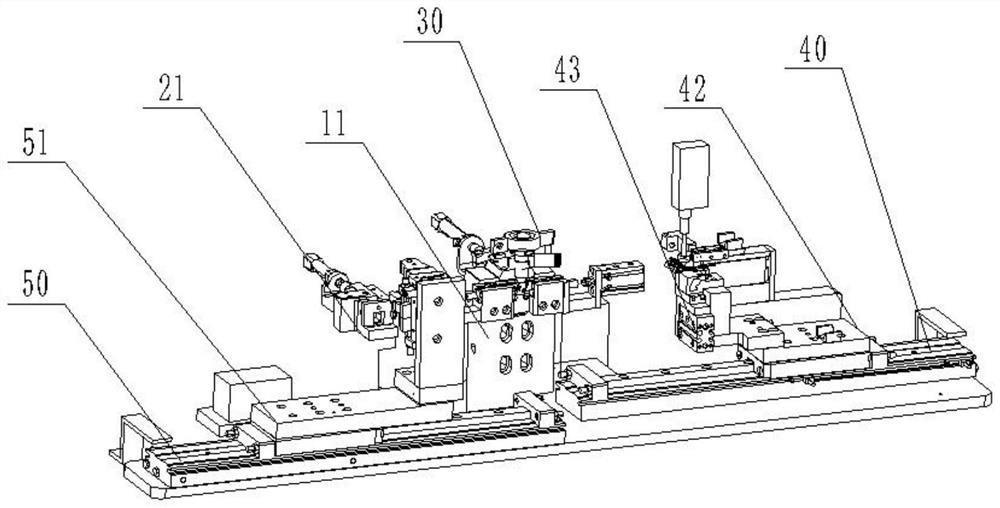

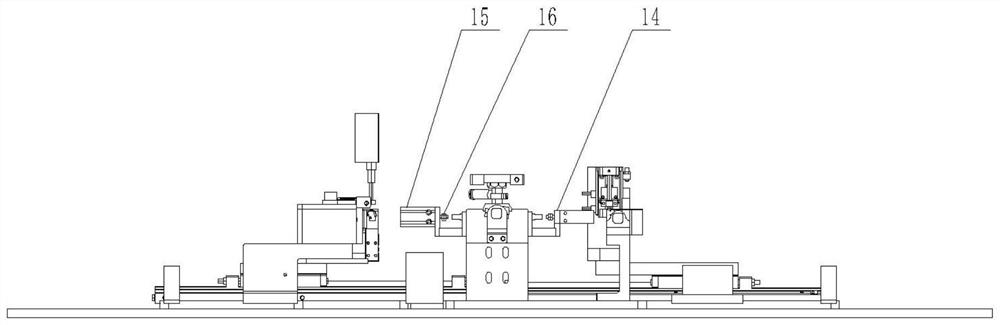

Contact terminal automatic welding machine

PendingCN113675692ADoes not cause oxidationImprove production and processing efficiencyLine/current collector detailsEngineeringWorkbench

The invention discloses a contact terminal automatic welding machine which comprises a workbench, wherein a fixing block is arranged on the workbench, a material pushing air cylinder is arranged on one side of the fixing block, a material pushing rod is arranged at the output end of the material pushing air cylinder, a welding assembly is arranged above the material pushing rod, a feeding assembly is arranged at the end, away from the material pushing air cylinder, of the material pushing rod, a first clamping air cylinder and a second clamping air cylinder are arranged on the two sides of the material pushing rod correspondingly, and fixing rods are arranged at the output end of the first clamping air cylinder and the output end of the second clamping air cylinder correspondingly; and the feeding assembly comprises a first vibration feeding disc and a second vibration feeding disc, a first feeding groove is formed in the output end of the first vibration feeding disc, a first feeding mechanism is arranged at the output end of the first feeding groove, a second feeding groove is formed in the output end of the second vibration feeding disc, and a storage table, a second feeding mechanism and a feeding mechanism are arranged at the output end of the second feeding groove. According to the contact terminal automatic welding machine, small parts needing to be welded can be precisely carried to the designated positions, the carrying speed is high, the welding precision is high, and the stability is high.

Owner:ZHEJIANG JIAXING JINRONG AUTO PARTS CO LTD

Quick cooling system and intermittent carbide furnace

The embodiment of the invention discloses a quick cooling system. The quick cooling system is applied to an intermittent carbide furnace and comprises an air blower and a cooling air duct, wherein thecooling air duct is arranged outside a Muffle vacuum tank of the intermittent carbide furnace and communicates with the air blower. In the quick cooling stage, external air is used as a cooling medium to be injected into the furnace from the bottom of the furnace through the centrifugal air blower, the cooling medium takes out heat in the furnace through the air duct and then is subjected to high-altitude exhaust through an air exhaust device, the air blower conducts continuous blowing, and quick cooling is achieved. The quick cooling system directly cools a sealed furnace body, the cooling medium does not make contact with a product, product oxidization is avoided, and the quality stability of the product is ensured. In addition, air serves as the cooling medium, so that the cost is reduced; and the structure is simple, operation is convenient, and the safety is good. The embodiment of the invention further discloses the intermittent carbide furnace.

Owner:JIANGSU MINHE MACHINERY MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com