Copper and copper alloy casting equipment under protection of nitrogen

A technology of nitrogen protection and ingot casting equipment, which is applied in the field of copper and copper alloy ingot casting equipment, copper and copper alloy ingot casting, and can solve problems such as high temperature in the core of the ingot and oxidation of copper ingots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

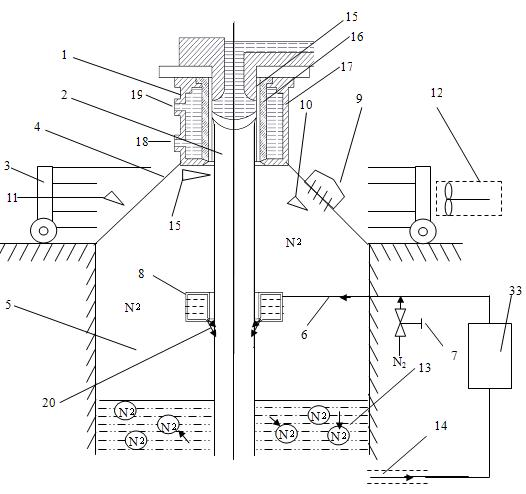

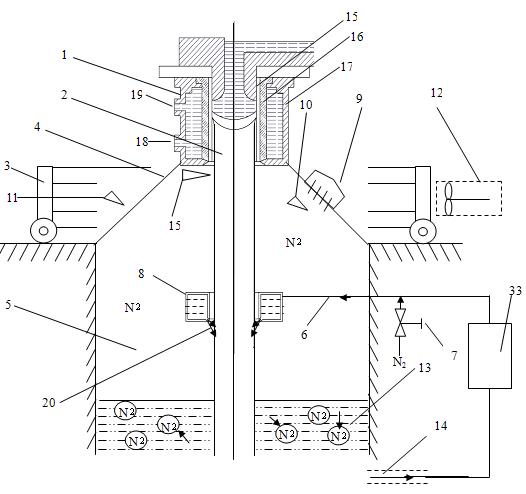

[0026] The structure and working principle of the present invention will be described in detail below through specific embodiments.

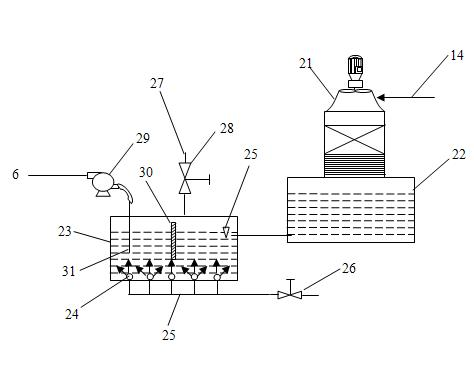

[0027] see figure 1 , the copper and copper alloy ingot casting equipment with nitrogen protection of the present invention, it comprises crystallizer assembly 1, the secondary water cooling device 8 that is positioned at the bottom of described crystallizer assembly 1 and ingot well 5, and crystallizer assembly 1 An airtight protective cover 4 is provided between the ingot well 5; the secondary water cooling device 8 is connected to the water outlet of the secondary water cooling-deoxidation device 33 through the secondary cooling water pipe 6, and connected to the secondary cooling water pipe 6 There are nitrogen injection pipes and valves 7; the bottom of the casting well 5 is provided with a tertiary cooling water return pipe 14, which is connected to the water inlet of the secondary water cooling-deoxidation device 33.

[0028] The crystal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com