Patents

Literature

120results about How to "Not oxidized" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

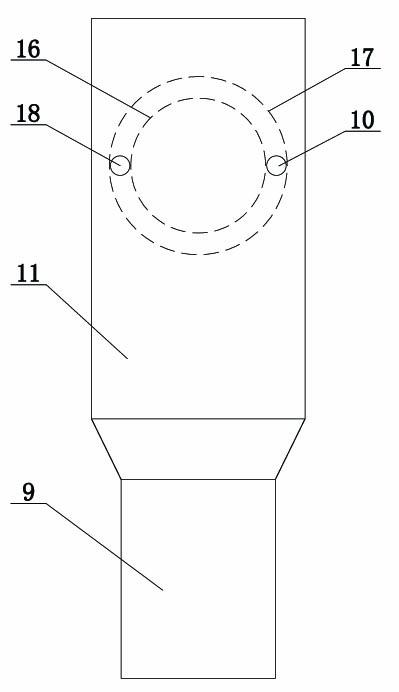

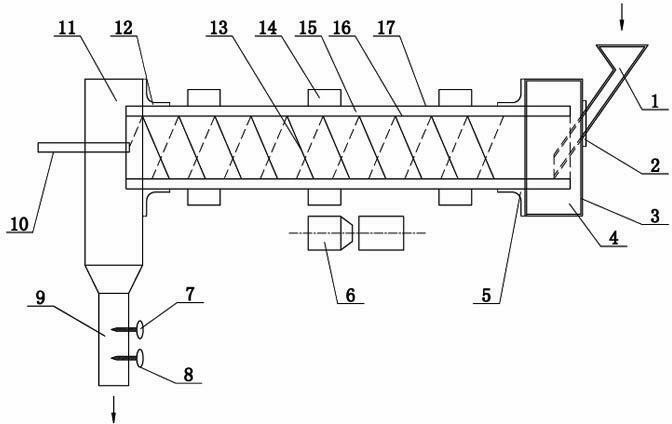

Method and device for light, powder and gas coaxial transmission laser cladding forming manufacturing

InactiveCN101774084AGood rigidityReduce divergenceMetallic material coating processesLaser beam welding apparatusOptical pathCircular section

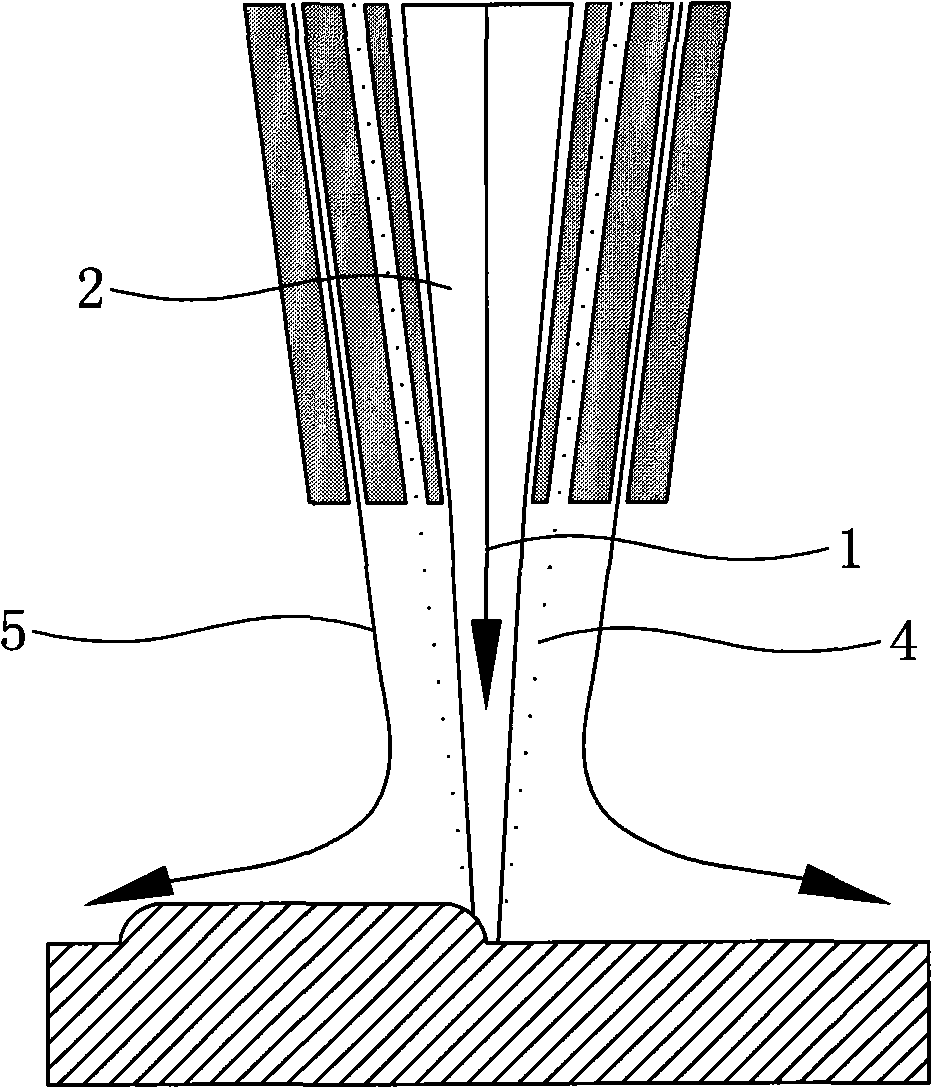

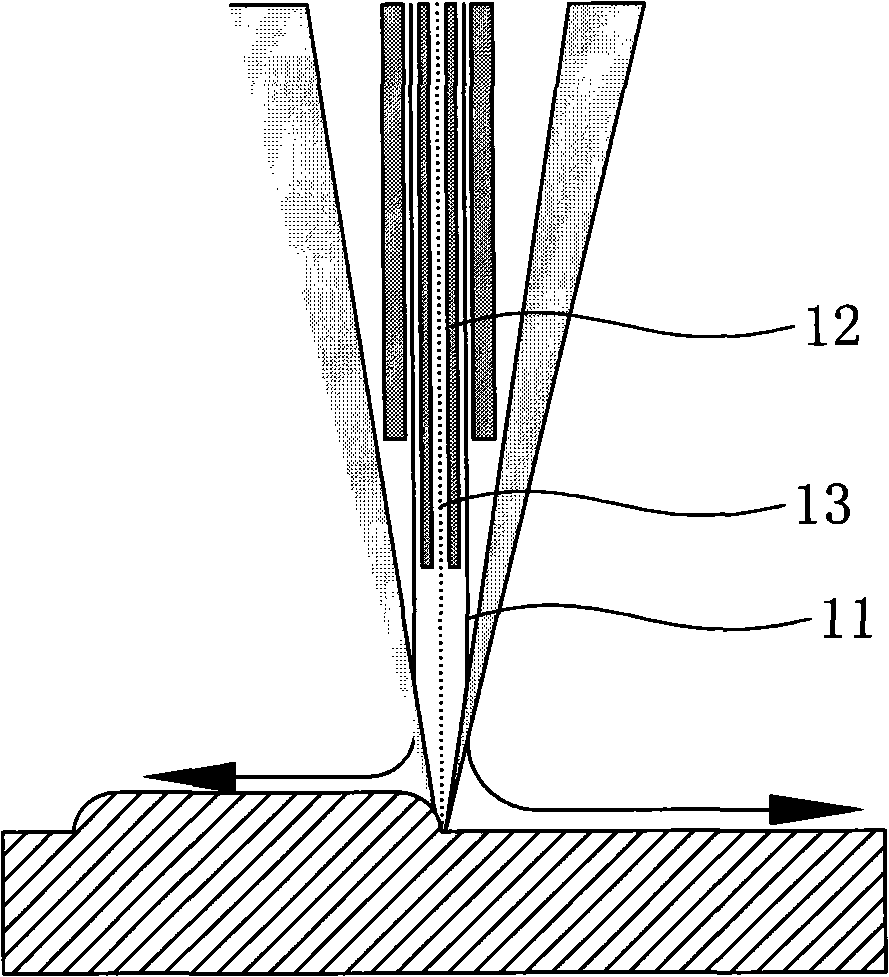

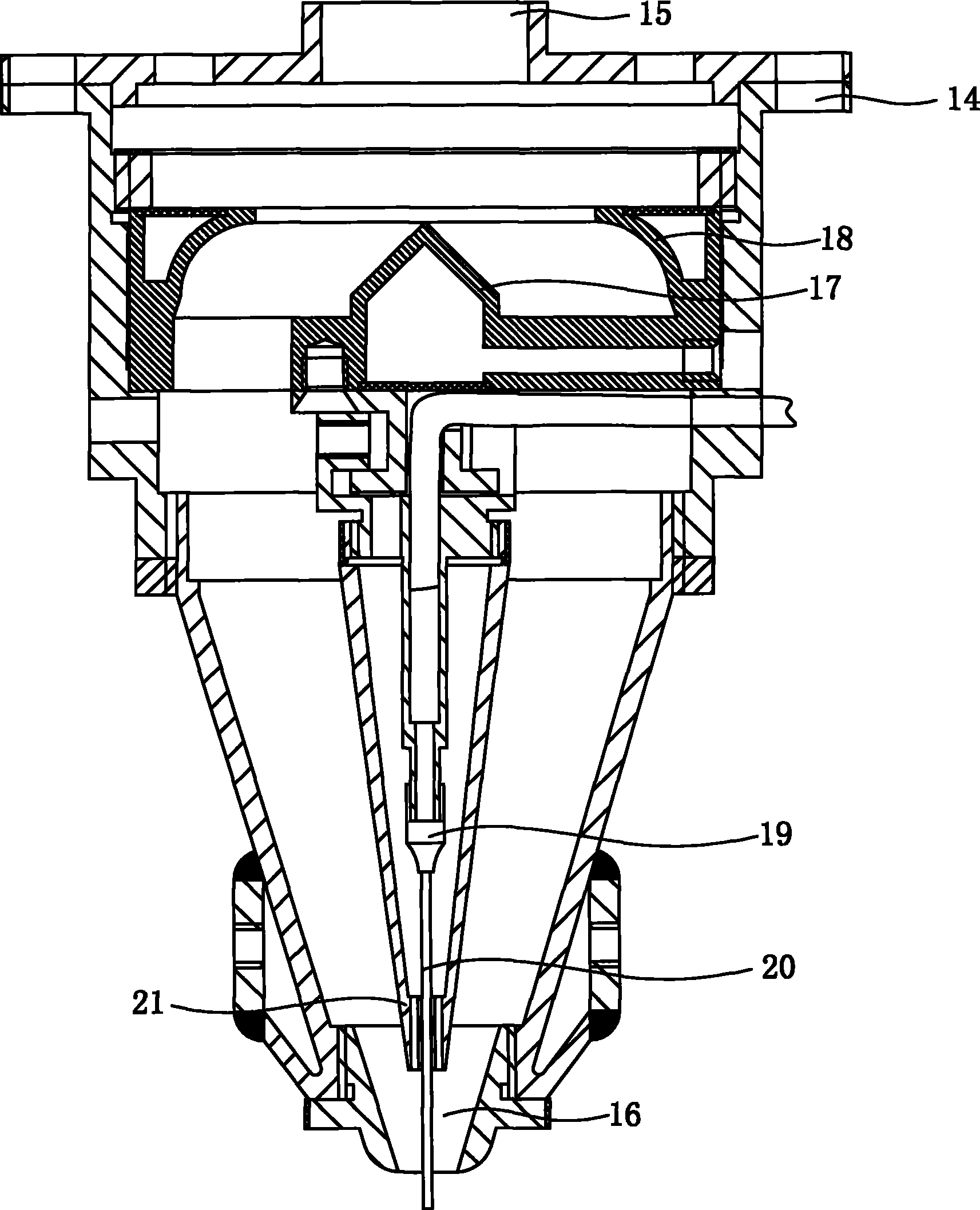

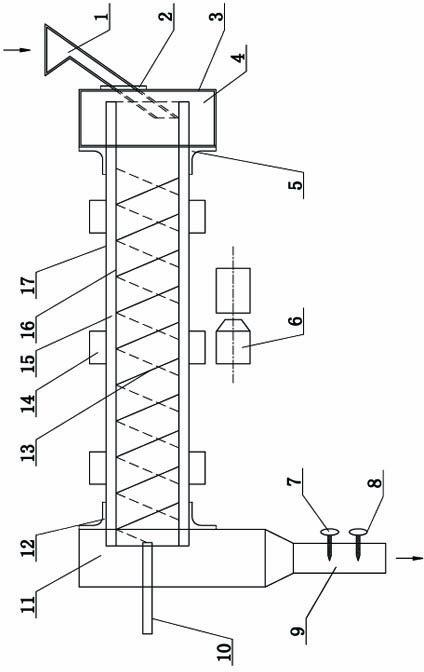

The invention discloses a method for light, powder and gas co-axial transmission laser cladding forming manufacturing, which is characterized in that: a circular section solid laser beam emitted by a laser is subjected to transformation and beam expansion by the optical path transformation to become a circular laser beam; the circular laser beam is focused to become a hollow circular cone focused laser beam; a powder spraying nozzle is arranged on the hollow part of the circular cone focused laser beam; the powder spraying nozzle and the circular cone focused laser beam are coaxial; the periphery of a single powder beam sprayed by the powder spraying nozzle is provided with a circle of collimation shielding gas curtain; and the collimation shielding gas curtain, the circular cone focused laser beam and the single powder beam sprayed by the powder spraying nozzle are coaxial. By arranging the collimation shielding gas curtain on the periphery of the powder beam, the method realizes the coaxial transmission of light, powders and gas and solves the defects in the prior art.

Owner:SUZHOU UNIV

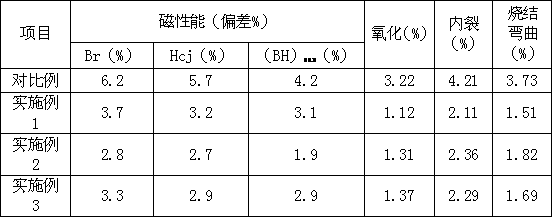

Partial pressure sintering method for sintering neodymium-iron-boron magnet

ActiveCN103000363AEnsure consistencyGuaranteed uniformityInductances/transformers/magnets manufactureMagnetic materialsMetallurgyVacuum pump

The invention relates to a partial pressure sintering method for sintering a neodymium-iron-boron magnet. Certain inert gases Ar are filled into various deflation sections in the sintering process, the pressure of the Ar gases inside a furnace is regulated according to blank deflation velocity and vacuum pump system exhaust velocity through vacuum degree control, so that heating sintering is carried out by uniformly deflating under different partial pressures of the Ar gases, and negative pressure is still kept. The partial pressure sintering method disclosed by the invention ensures the consistency and uniformity of magnetic property and saves the sintering time.

Owner:宁波永久磁业有限公司

Manufacturing method of copper-clad aluminum busbar

InactiveCN101060025ANot oxidizedAchieve oxidation-free recombinationOther manufacturing equipments/toolsCable/conductor manufactureBusbarMelting temperature

The disclosed manufacture method for Cu-covered-Al pipeline product comprises: 1. pre-preparing the copper into pipe with uniform wall thickness; 2. cleaning the pipe inner wall to remove its oil pollution and oxidation layer; 3. coating a protective layer on the inner wall of copper pipe; 4. heating to 500-700Deg for pre-processing; 5. with the protection of inert gas, casting molten Al into the pipe inside; and 6. rolling and drawing. This invention overcomes the defects in traditional techniques, and improves product stability.

Owner:ZIRUIDA NEW MATERIAL SCI TECH DEV DALIAN

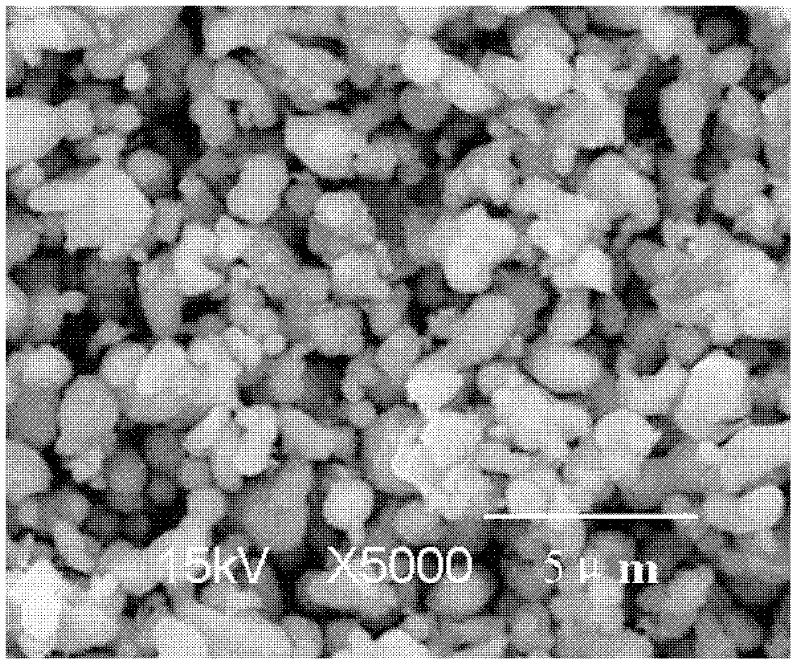

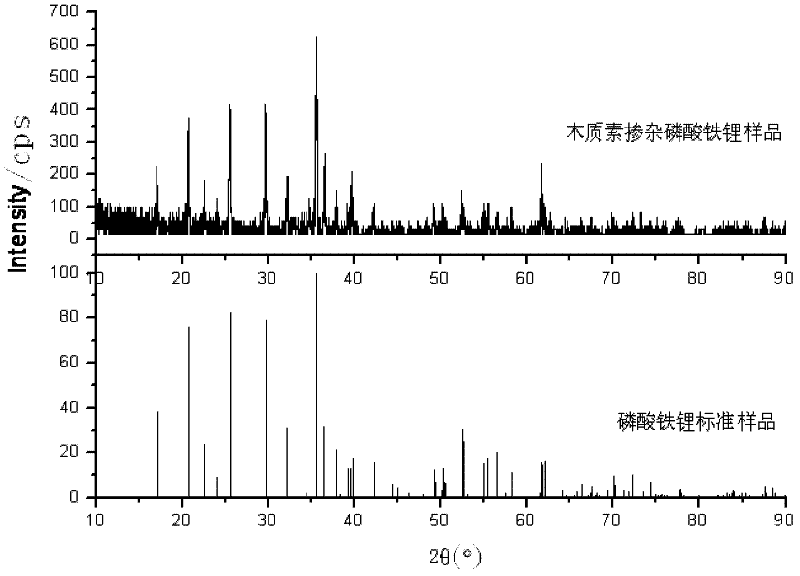

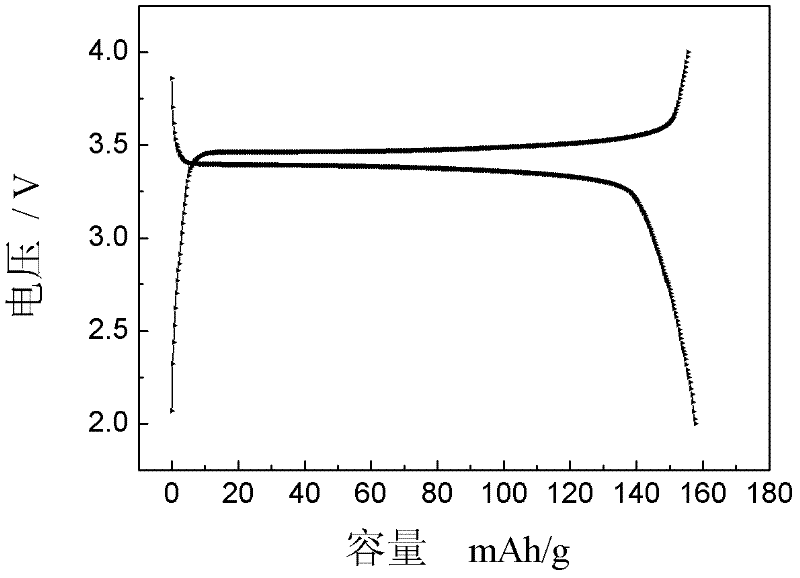

Preparation method for modified LiFePO4 lithium ion battery anode material

InactiveCN102361071ARich sourcesImprove electrochemical performanceCell electrodesCharge dischargeCellulose fiber

The invention relates to a preparation method for a modified LiFePO4 lithium ion battery anode material, which belongs to the field of lithium ion battery materials. In the process of preparing a LiFePO4 lithium ion battery cathode material, a modifier is added, and the modifier is cellulose fiber, a lignin salt or a mixture of the two. According to the invention, cheap lignin, a renewable natural high-molecular material, is used as a carbon source precursor for the LiFePO4 lithium ion battery anode material, and lignin is widely available and easy to well mix with lithium source compounds, iron source compounds and phosphor source compounds once and for all; the prepared LiFePO4 lithium ion battery anode material has high purity and good electrochemical performance; a process for the anode material is simple and is easy to control; low production cost is obtained; a lithium ion battery made of the cathode material has a stable quality and 0.2C charge-discharge reversible specific capacity higher than 157 mAh / g, and battery capacity of the prepared lithium ion battery does not attenuate after 50 times of cycle; the method is applicable to large scale industrial production.

Owner:HUNAN ZHONGTIAN NEW ENERGY

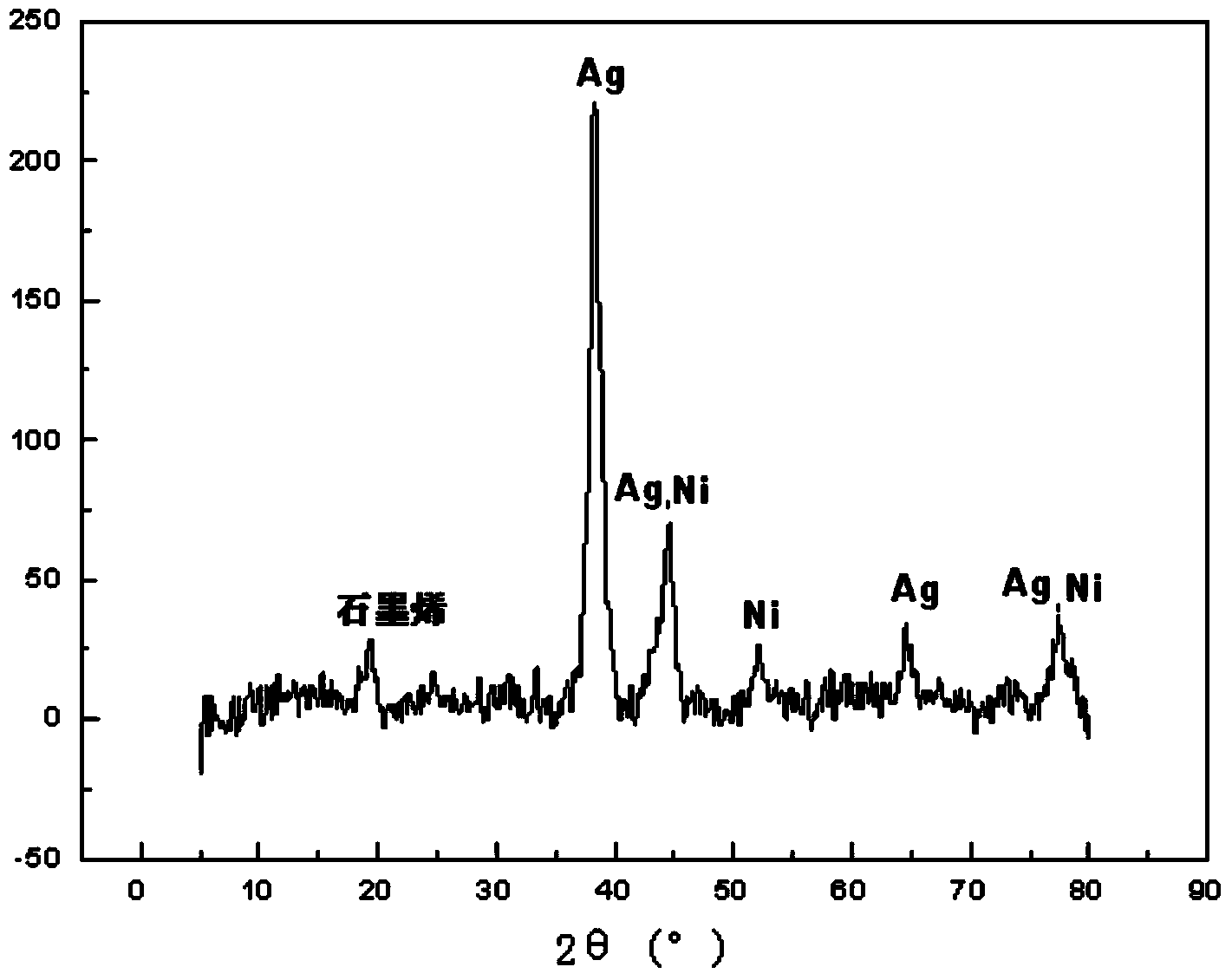

Method for preparing graphene load nano silver-nickel alloy composite powder materials

InactiveCN103466611ASimple methodWell dispersedMaterial nanotechnologyGrapheneCvd grapheneOxidation reduction

The invention relates to a method for preparing graphene load nano silver-nickel alloy composite powder materials. The method aims to solve the problems that graphene load nano silver-nickel alloy composite materials prepared in the prior art are nonuniform in scattering and poor in chemical stability. The method comprises the first step of intercalation and expansion, the second step of stripping and the third step of the preparation of the graphene load nano silver-nickel alloy composite powder materials. Oxidized graphene is prepared through an oxidation-reduction method, then the oxidized graphene, silver ions and nickel ions are mixed and restored through reducing agents to obtain the graphene nano silver-nickel alloy composite materials, the method is simple and fast, any surface dressing agent does not need to be added, and alloy particles on the surface of the graphene are uniform in distribution and stable in chemical performance. The method is used for preparing the graphene load nano silver-nickel alloy composite powder materials.

Owner:HEILONGJIANG UNIV

Method for extracting pleurotus eryngii polysaccharide from pleurotus eryngii leftover by using subcritical water

InactiveCN103130911ATo achieve the purpose of comprehensive utilization of resourcesRich sourcesOrganic solventPolymeric adsorbent

The invention provides a method for extracting pleurotus eryngii polysaccharide from pleurotus eryngii leftovers by using subcritical water. The method comprises the following steps of: feeding the pleurotus eryngii leftovers into an extraction kettle; feeding deoxidized deionized water according to a material-liquid mass volume ratio of 1:(5-30); controlling the extraction pressure to be 3-10MPa, the temperature to be 100-250 DEG C and the extraction time to be 10-60min; filtering, cooling and centrifuging; carrying out ultrafiltration by using an ultrafiltration film of which the molecular weight cut-off is 100-300kD; cutting off the filtrate by using an ultrafiltration film of which the molecular weight cut-off is 3-10kD; feeding the crude polysaccharide cut-off liquid into an anion exchange resin column; and eluting by using deionized water; and concentrating under reduced pressure and drying the collected polysaccharide eluate so as to obtain a pleurotus eryngii polysaccharide product. According to the method, a subcritical water extraction technique is combined with the separation means of ultrafiltration edulcoration and resin absorption decoloration, no organic solvents are used in the whole process, the extraction process is green and environment-friendly, and the pleurotus eryngii polysaccharide is high in purity and is applicable to industrial production.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY +1

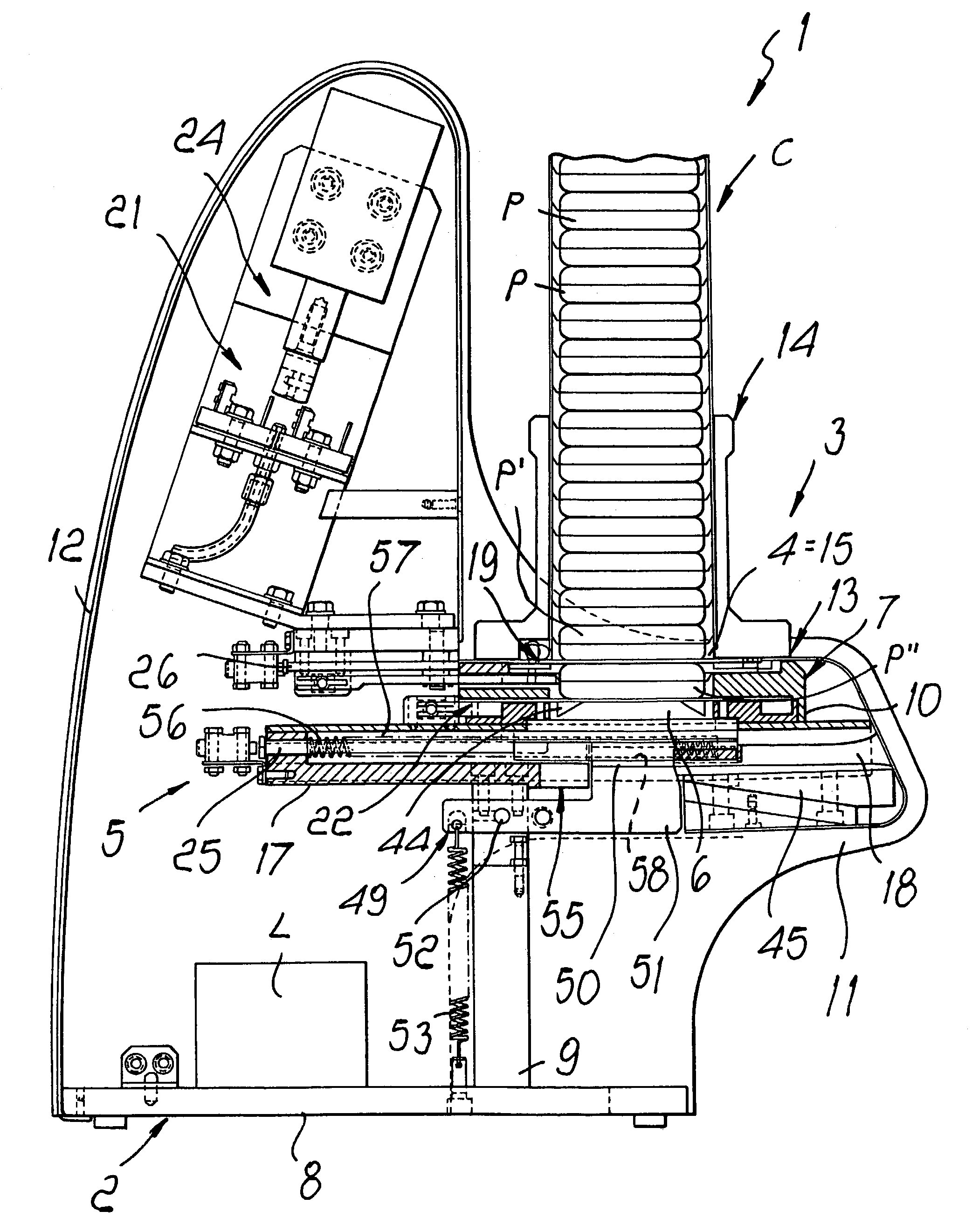

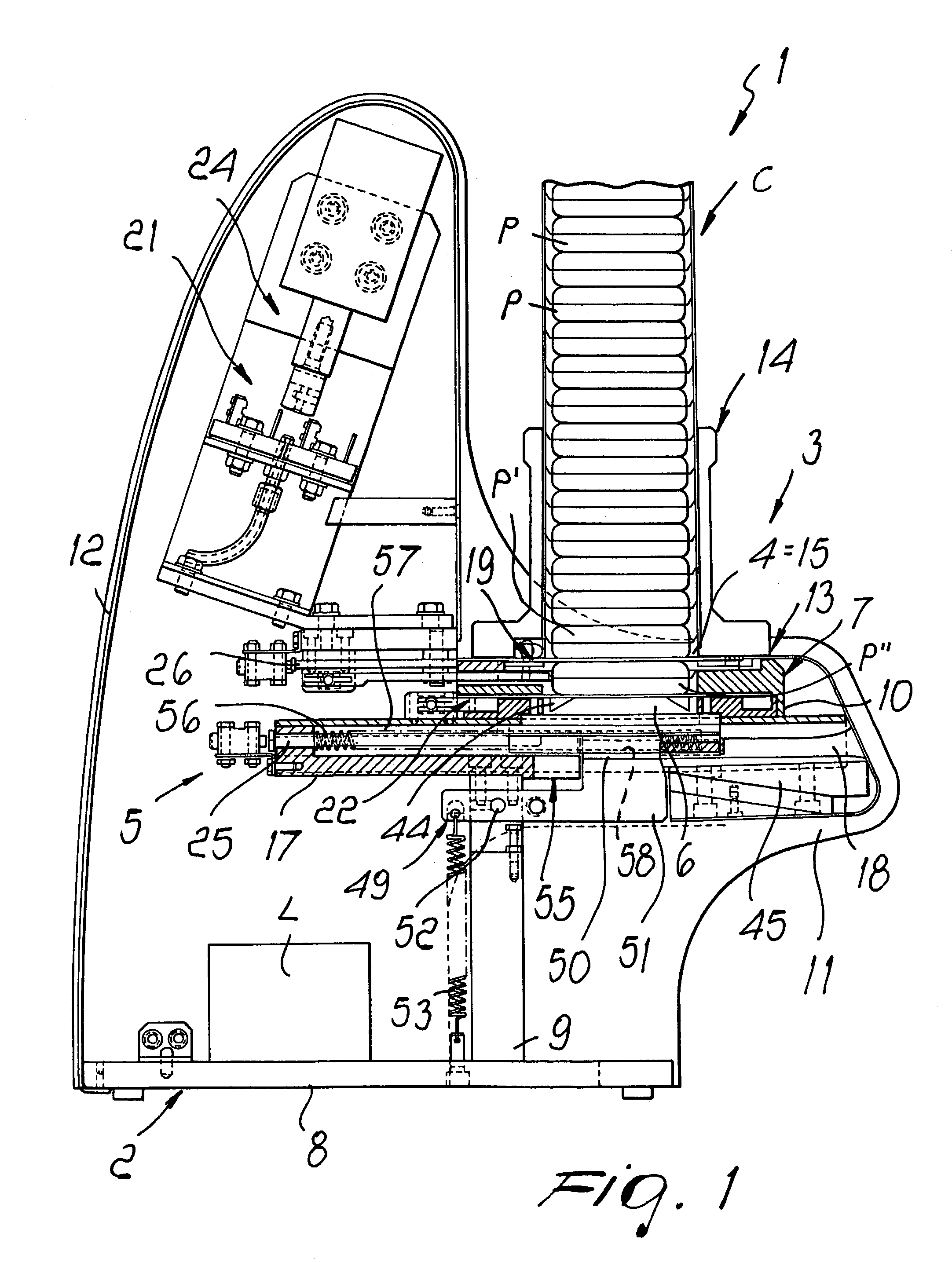

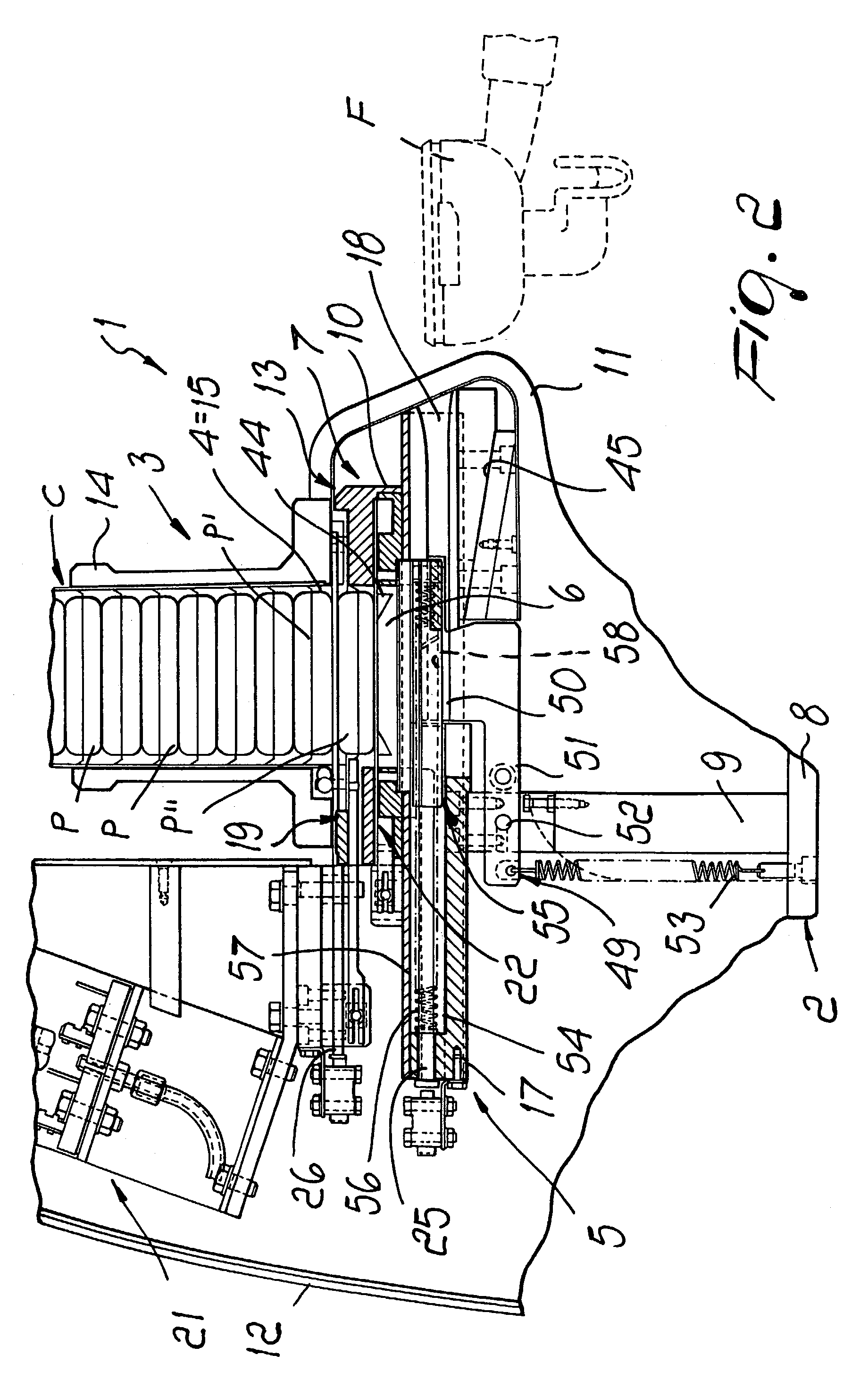

Dispenser of single-use portions of preparations for beverages, particularly coffee or the like

InactiveUS6971546B2Easy to storeLose aromaCoin-freed apparatus detailsBeverage vesselsSingle useWaste management

A dispenser of single-use portions of preparations for beverages, comprising a structure that supports at least one storage assembly for single-use portions provided with a discharge outlet for the discharge of the portions, at least one distribution assembly for the portions which is provided with an outlet for dispensing said portions and with a device for transferring the portions from the discharge outlet to the dispensing outlet, which are interposed between the storage assembly and the distribution assembly.

Owner:COSTA MARC ROBERT

Large-size high-density tungsten crucible and preparation method thereof

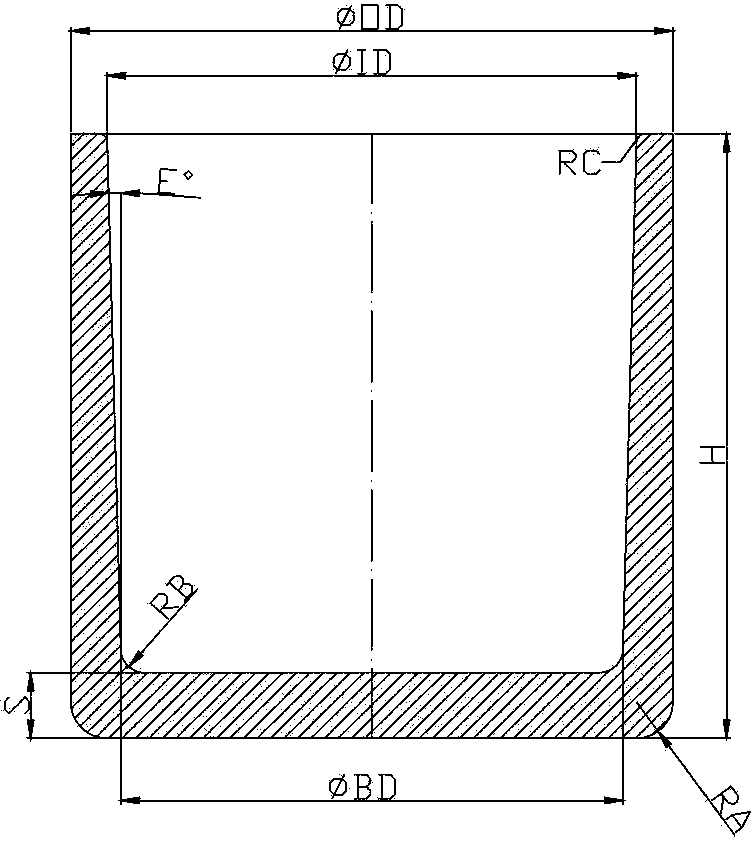

The invention provides a large-size high-density tungsten crucible which is mainly used for sapphire crystal growth industry, and particularly provides a preparation method for the large-size high-density tungsten crucible. The method comprises the following steps: raw materials processing, mould core manufacturing, mould setting and forming, high-temperature sintering and mechanical processing. Compared with the prior art, the produced crucible is large in size range and suitable for mass production. Moreover, no binding agent is added in the production process, and impurity content of the product is low; the finished product has the advantages of being high in density, large in size (maximal external diameter of phi 650 mm and maximal height of 800 mm), good in size adaptability and consistency, and high in yield and surface finish, can bear 2000-2300 DEG C high temperature under the protective atmosphere, and can not react with sapphire raw materials under the high temperature.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

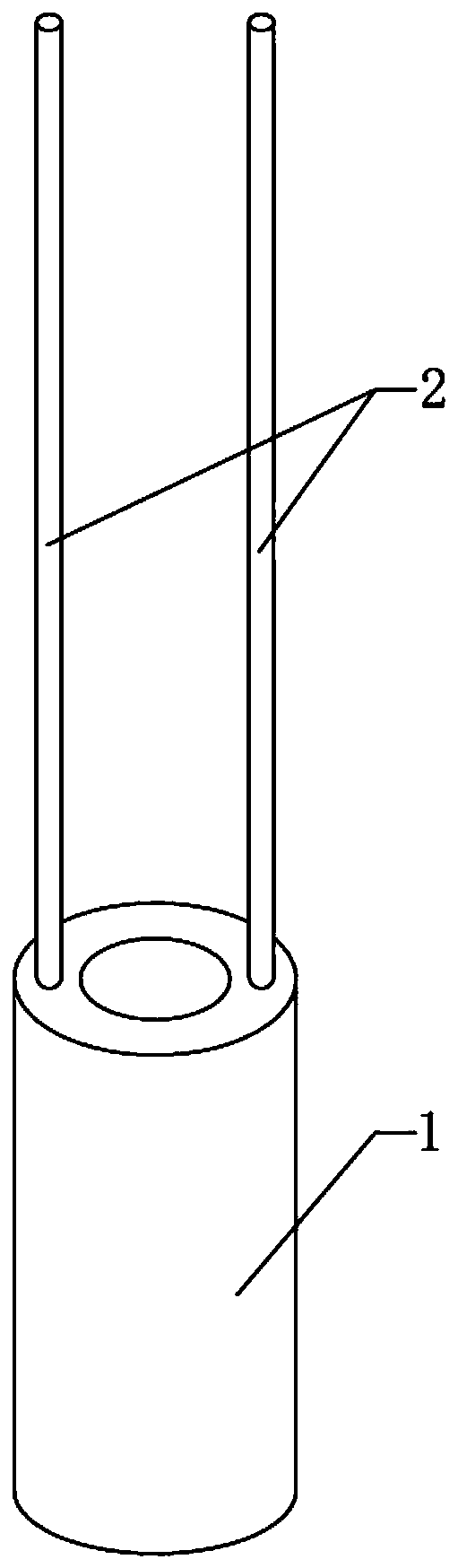

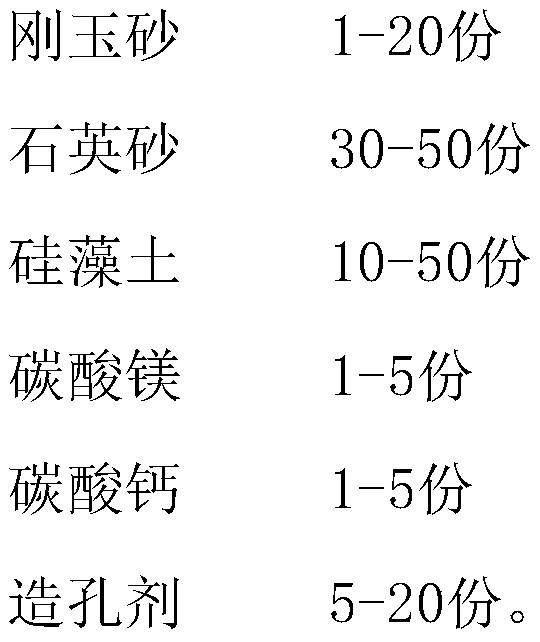

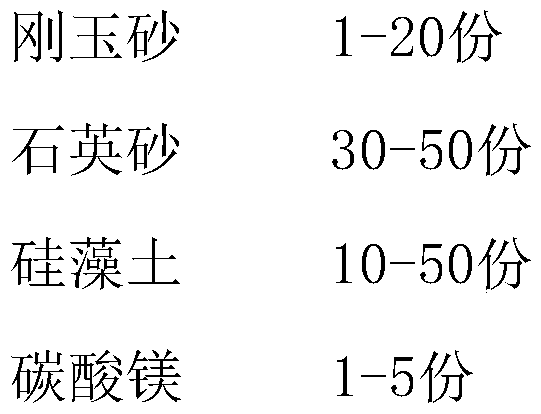

Porous ceramic heating body and preparation method thereof

InactiveCN110981454AHigh strengthImprove performanceTobaccoCeramicwareElectronic cigaretteSilicon dioxide

The invention relates to the technical field of electronic cigarettes, in particular to a porous ceramic heating body and a preparation method thereof. The porous ceramic heating body comprises a porous ceramic matrix and a metal heating element. The porous ceramic matrix comprises the following raw materials in parts by weight: 1-20 parts of emery, 30-50 parts of quartz sand, 10-50 parts of diatomite, 1-5 parts of magnesium carbonate, 1-5 parts of calcium carbonate and 5-20 parts of a pore forming agent. The porous ceramic heating body is novel in structure, high in product porosity and highin strength; the metal heating element is not oxidized; the diatomite forms gaps under the action of the pore forming agent, so the porosity of the produced porous ceramic heating body is guaranteed;magnesium carbonate and calcium carbonate can decompose a part of carbon dioxide gas under a high-temperature condition, so porosity is improved; and magnesium oxide and calcium oxide generated afterhigh-temperature decomposition form aluminosilicate together with silicon dioxide and aluminum oxide, so the inter-binding property of material particles is improved, and the structural stability andstrength of the porous ceramic matrix are improved.

Owner:KEY MATERIAL

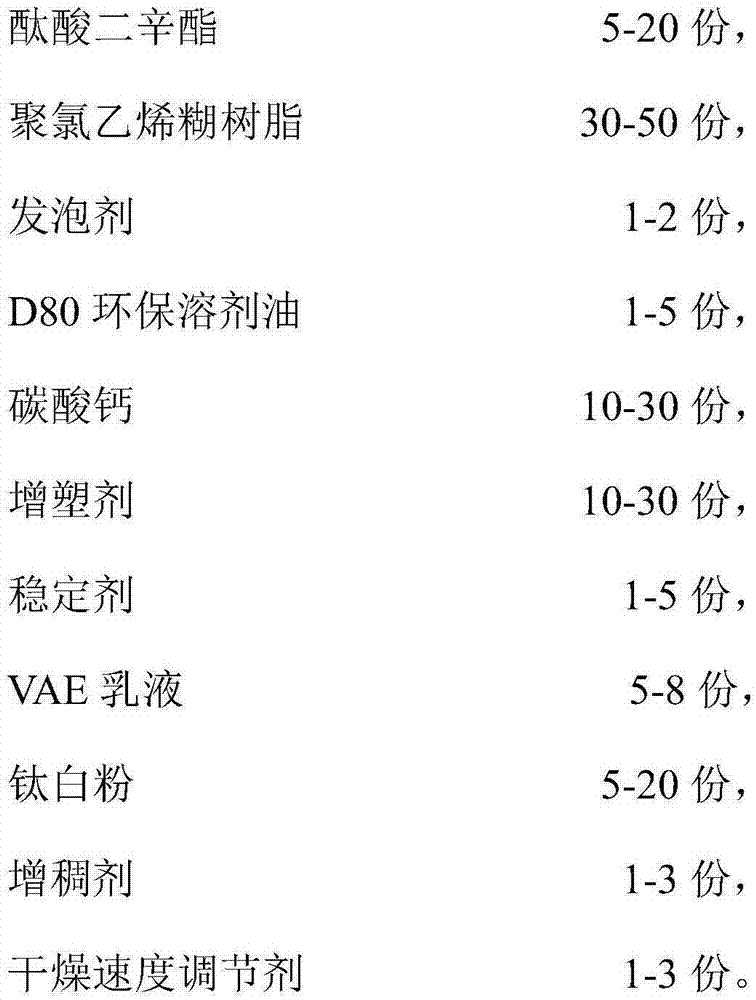

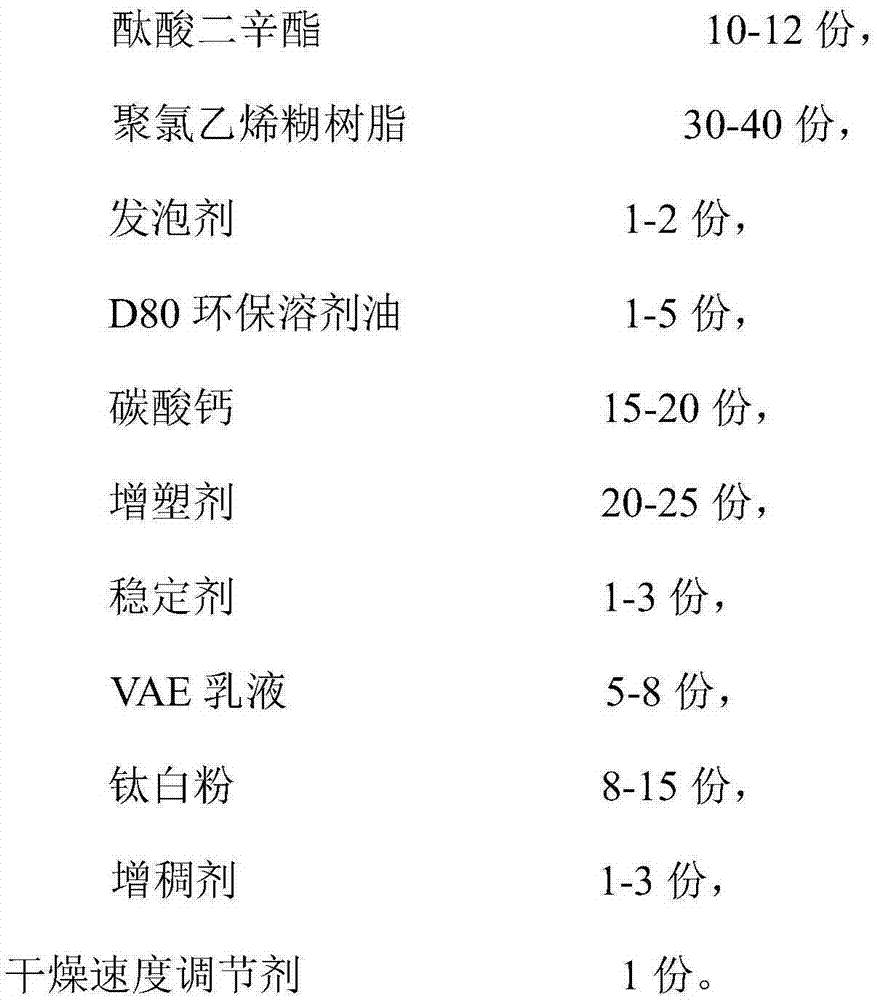

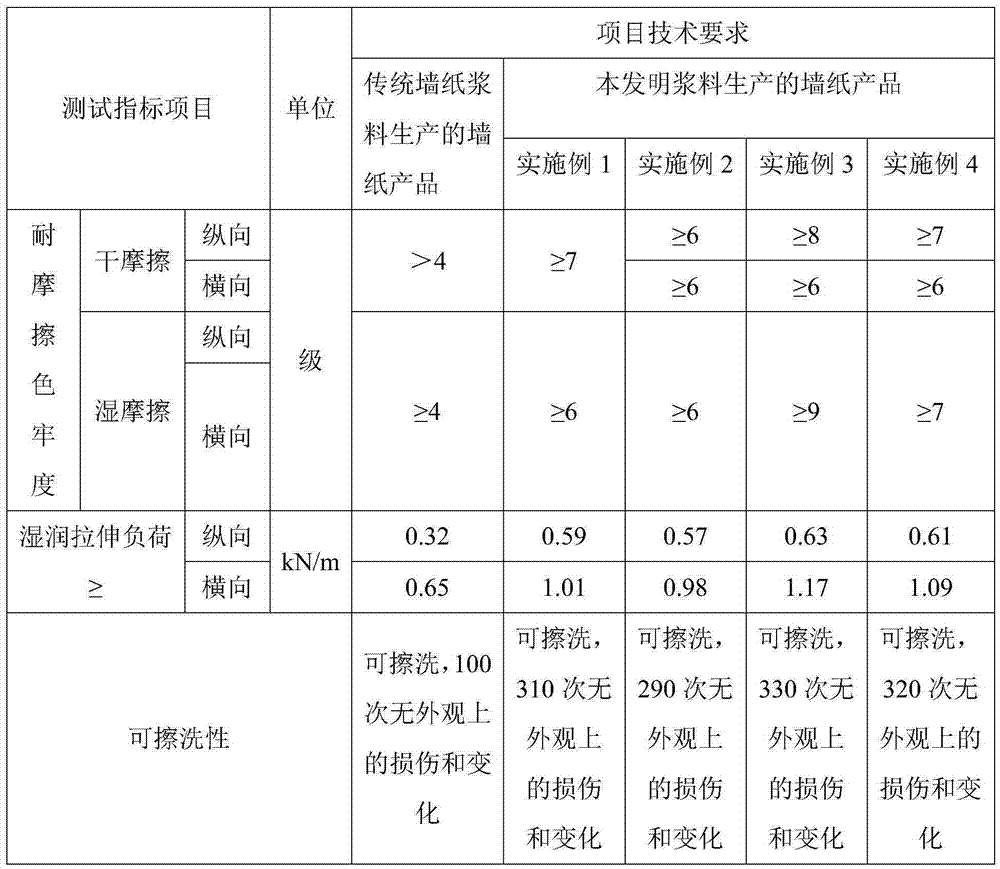

Special slurry for printing wallpaper having 3D stereo transparent streamer effect and preparation method for special slurry

The present invention relates to slurry for printing wallpaper, and in particular to special slurry for printing wallpaper having a 3D stereo transparent streamer effect and a preparation method for the special slurry. The present invention provides special slurry for printing wallpaper having the 3D stereo transparent streamer effect. The slurry is mainly prepared by the following raw materials in parts by weight: 5-20 parts of dioctyl phthalate, 30-50 parts of polyvinyl chloride paste resins, 1-2 parts of a foaming agent, 1-5 parts of D80 environmental-friendly solvent oil, 10-30 parts of calcium carbonate, 10-30 parts of a plasticizer, 1-5 parts of a stabilizer, 5-8 parts of a VAE emulsion, 5-20 parts of titanium dioxide, 1-3 parts of a thickener and 1-3 parts of a drying speed regulator. The adhesive force of the slurry provided by the present invention is strong; meanwhile, the transparency effect can be displayed. The slurry is suitable for performing an embedding process on gold powder, silver powder and pearl powder in a gold spraying process, and can wrap up the gold powder, silver powder and pearl powder to promote the level of the wallpaper and prolong the service life of the wallpaper.

Owner:GAREFU TECH CO LTD

Method for producing reduced coenzyme Q10

InactiveCN101967499ANot oxidizedNo immunogenic responseMicroorganism based processesFermentationAntioxidantOxygen

The invention relates to a method for producing a reduced coenzyme Q10. The method is characterized by comprising the following steps of: adopting cell lines or cell strains of all people and animals as female parents for producing the reduced coenzyme Q10; performing cell culture in biological culture agent DMEM-1 culture solution to obtain cell sap containing a great deal of the reduced coenzyme Q10; and obtaining a final product of the reduced coenzyme Q10 by a method of centrifugal separation and concentration or a method in which ethanol extraction and concentration is performed first and then cooling crystallization is performed. Compared with the conventional disclosed method for producing the reduced coenzyme Q10, the reduced coenzyme produced by the method is stable and is not oxidized by oxygen in the air, not only has no residue of a reducing agent but also has no chemical residues of any antioxidant, protective agent and the like, can be used for foods, medicaments, cosmetics or injections for infusion, and has no immunogenicity reaction to a human body.

Owner:河南东都生物科技有限公司

Cooling device for direct reduction iron

InactiveCN102435075AImprove cooling effectExtend walking timeHandling discharged materialThermodynamicsWater flow

The invention relates to a cooling device for direct reduction iron. The cooling device comprises a cooling cylinder, wherein a gear ring is fixed on the outer circumference of the cooling cylinder; a transmission device is used for driving the gear ring to rotate; one end of the cooling cylinder is connected with a feeding hopper, and the other end of the cooling cylinder is connected with a kiln tail box; the lower end of the kiln tail box is provided with a discharging pipe; a water sleeve is fixed on the inner wall of the cooling cylinder; the discharging end of the feeding hopper is arranged in the water sleeve; a cooling water channel is formed between the outer wall of the water sleeve and the inner wall of the cooling cylinder; one end of the cooling water channel is provided a water inlet and a water outlet; and the inner wall of the water sleeve is provided with spiral fins. In the invention, a cooling cylinder shell is forcedly cooled by adopting water sleeve type high-speed water current, and the walking path of the direct reduction iron in the cylinder is controlled by using the spiral fins, so that the walking time of the direct reduction iron in the cylinder is prolonged, the cooling efficiency is greatly increased, the diameter and the length of the cooling cylinder are reduced, the equipment weight is greatly reduced, and the transmission power and power consumption of the equipment are lowered; and meanwhile, no steam is dissipated, so that the environmental pollution is improved greatly.

Owner:李世杰 +1

Back surface field aluminum conductive slurry used for preparing silicon solar battery, and manufacturing method thereof

InactiveCN102737751AEasy to makeImprove photoelectric conversion efficiencyNon-conductive material with dispersed conductive materialCable/conductor manufactureBack surface fieldAlloy

The invention provides back surface field aluminum conductive slurry used for preparing a silicon solar battery, and a manufacturing method thereof. The back surface field aluminum conductive slurry has a formula by mass percentage: 65-80% of aluminum powder, 10-19% of organic modifying solvent, 1-5% of lead-free glass powder, 0.1-8% of infiltration dispersant, and 0.1-3% of modifying nanometer level silicon powder, with the total amount being 100%. According to the back surface field aluminum conductive slurry obtained from the above formula, a sintered silicon chip and the aluminum powder and the nanometer level silicon powder in the slurry can form a silicon-aluminum alloy with a firm contact, thereby improving the electrical property and the photoelectric conversion efficiency of the battery, and the sintered silicon chip is required to be non-curved, have no aluminum bead, have a smooth surface, have no spot, have no lead, and meet environmental protection requirements.

Owner:SHANGHAI NEW TIANHE ELECTRONICS MATERIAL

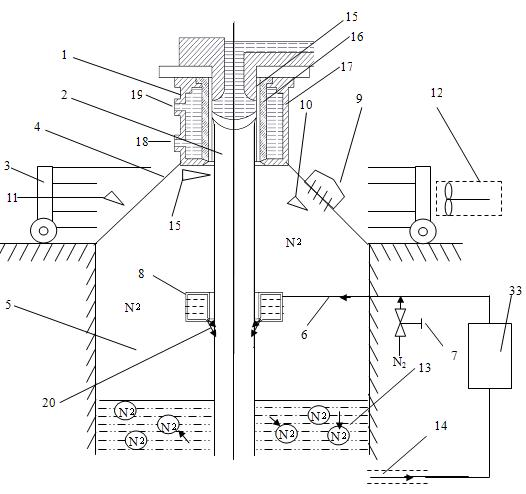

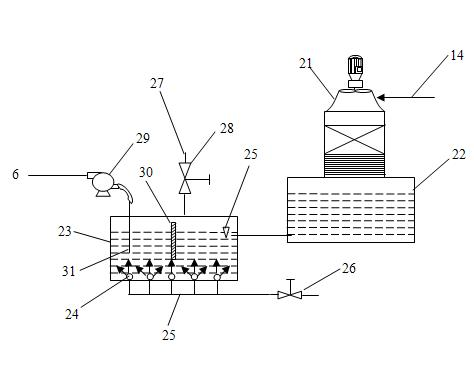

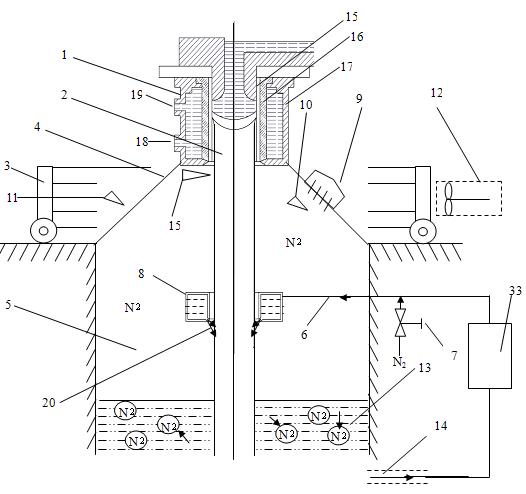

Copper and copper alloy casting equipment under protection of nitrogen

The invention discloses copper and copper alloy casting equipment under the protection of nitrogen. The equipment comprises a crystallizer assembly, and a secondary water cooling device and a casting well which are positioned below the crystallizer assembly. The equipment is characterized in that: an airtight protective cover is arranged between the crystallizer assembly and the casting well; the secondary water cooling device is connected to a secondary water cooling-deoxidizing device through a secondary cooling water pipe which is connected with a nitrogen injection pipe and a valve; and the bottom of the casting well is provided with a cooling water return pipe. Under the sealing protection of the nitrogen, outside air is prevented from entering the casting well so as not to contact high-temperature copper ingots in the casting process, the copper ingots are prevented from being oxidized by the air, the surface non-oxidation casting of industrial pure copper, high copper and a white copper alloy is realized, and the aims of reducing the oxidation loss of copper metal and production cost are fulfilled.

Owner:JINCHUAN GROUP LIMITED

Method for preparing carbon-coated LiFePO4 for lithium ion batteries

InactiveCN101764205AGuaranteed reducibilityNot oxidizedElectrode manufacturing processesNew energyPhosphate ion

The invention relates to a method for preparing carbon-coated LiFePO4 (lithium iron phosphate) for lithium ion batteries, belonging to the technical field of new energy materials. The synthesis process of the invention comprises the following steps: mixing and drying ultra-fine iron powder, phosphoric acid, simple organic matter and doping element compounds with the molar ratio of phosphate ions, iron ions and doping element ions being 1:y:z, wherein y is larger than or equal to 0.95 and smaller than or equal to 1, and the sum of y and z is 1; adding lithium-source compounds and water to the mixture in sequence, remixing and drying, wherein the molar ratio between the lithium ions and the phosphate ions is x:1, and x is larger than or equal to 0.95 and smaller than or equal to 1.05; and sintering the mixture on a microwave temperature at 500 to 950 DEG C for 5 to 40 minutes in the vacuum atmosphere or the non-oxidizing atmosphere. The ultra-fine iron powder is used as microwave absorption media and iron source materials, so as to the iron powder is capable of rapidly absorbing the microwave energy to cause the solid-phase reaction to be rapidly conducted. Compared with the prior art, the invention has the advantages of simple technological process and easily controllable operation; and the final product has the advantages of high purity, complete crystallization, high capacity and good cycle stability.

Owner:孙琦

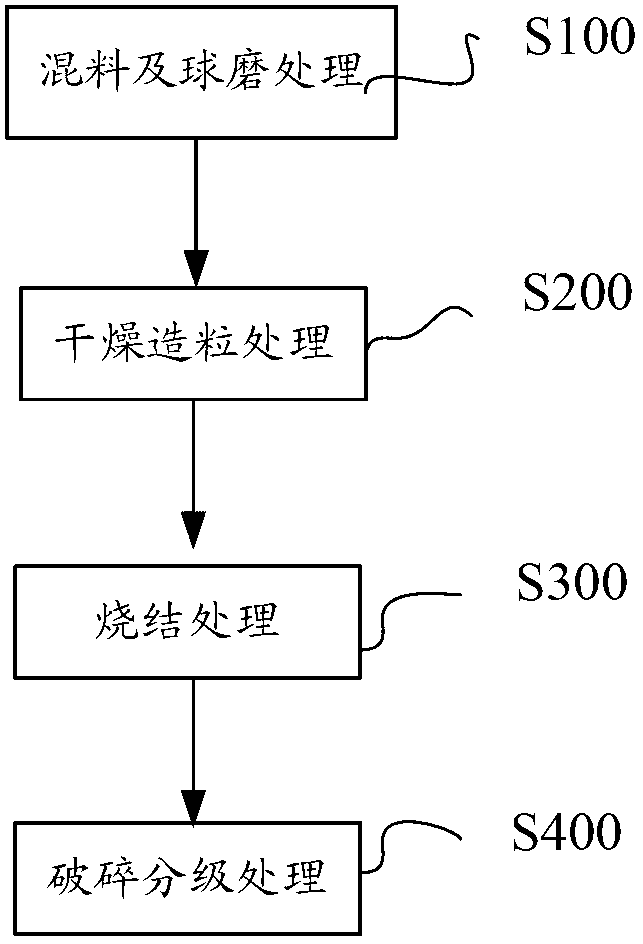

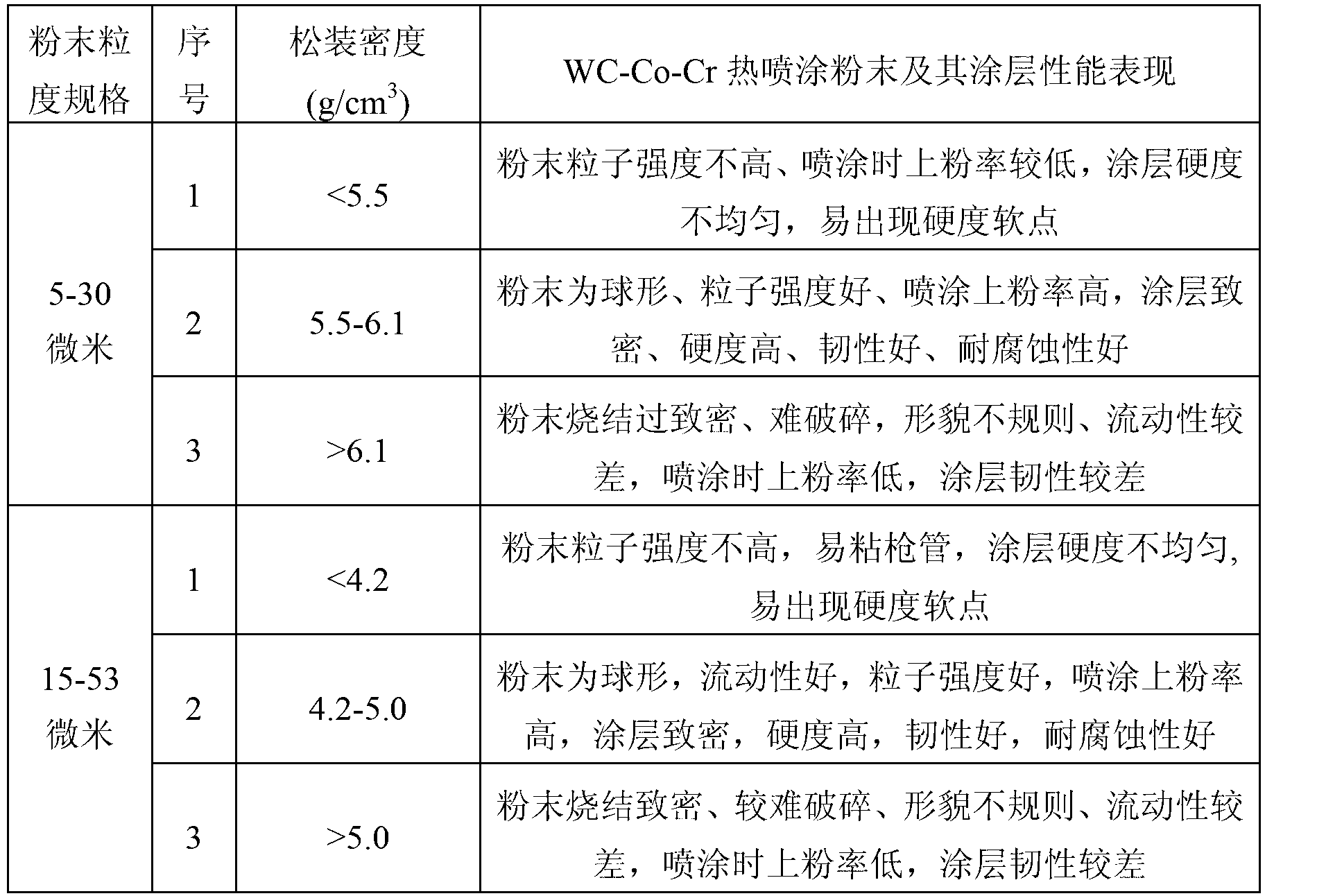

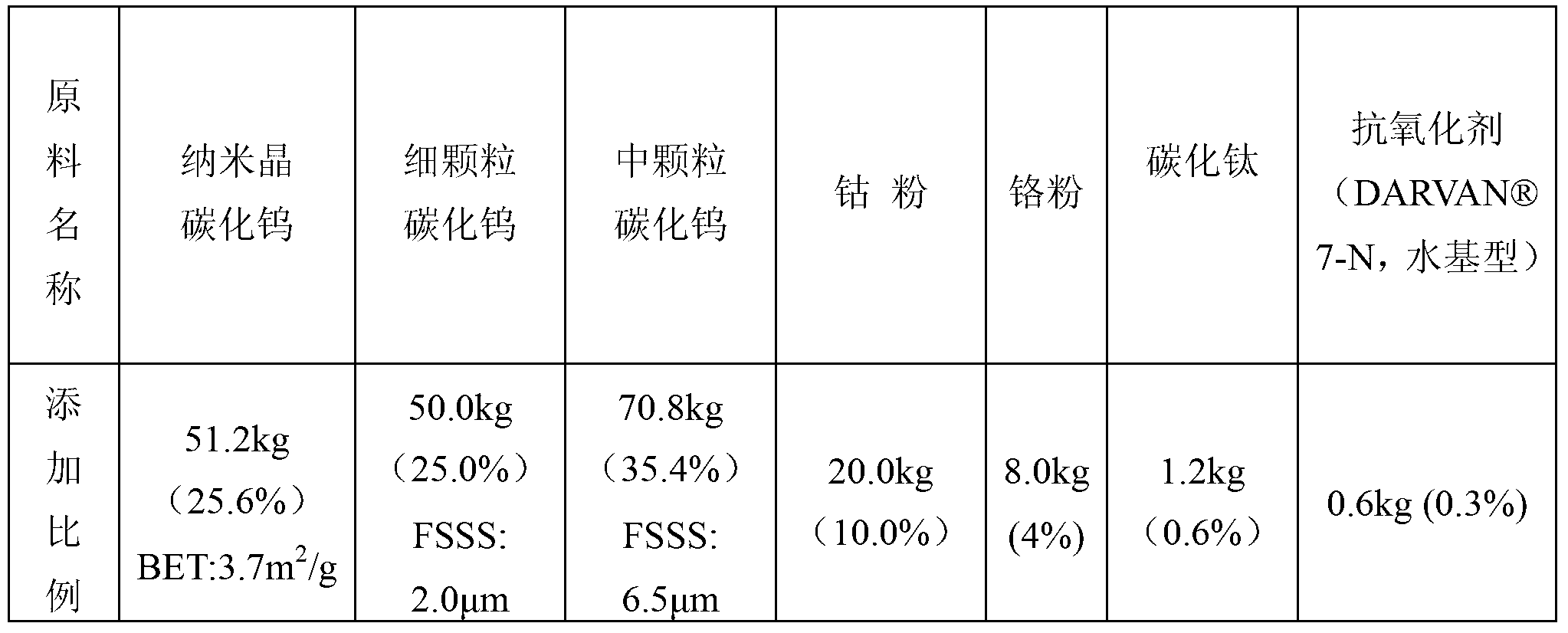

WC-Co-Cr thermal spraying powder and its preparation method and application

ActiveCN103225053AImprove corrosion resistanceImprove toughnessMolten spray coatingThermal sprayingTitanium carbide

The utility model discloses a WC-Co-Cr thermal spraying powder and its preparation method and an application thereof. The WC-Co-Cr thermal spraying powder comprises: by weight, 86 parts of a tungsten carbide mixture, 9.8-10.2 parts of cobalt, 4.0 parts of chromium, 0.3-0.6 parts of titanium carbide and 0.3 parts of an anti-oxidant, wherein the tungsten carbide mixture comprises: by weight, 13.2-25.6 parts of tungsten carbide with the granularity of 0.05-0.2 micrometer, 15.0-31.5 parts of tungsten carbide with the granularity of 1.0-2.5 micrometer and 24.5-65 parts of tungsten carbide with the granularity of 4.5-9.0. The WC-Co-Cr thermal spraying powder provided by the invention has excellent toughness and corrosion resistance and can be used to effectively improve compactness of a coating which has been undergone thermal spraying. Thus, the WC-Co-Cr thermal spraying powder can be effectively used in preparation of a super-high pressure sealing and corrosion-resistant coating.

Owner:GANZHOU ACHTECK TOOL TECH +1

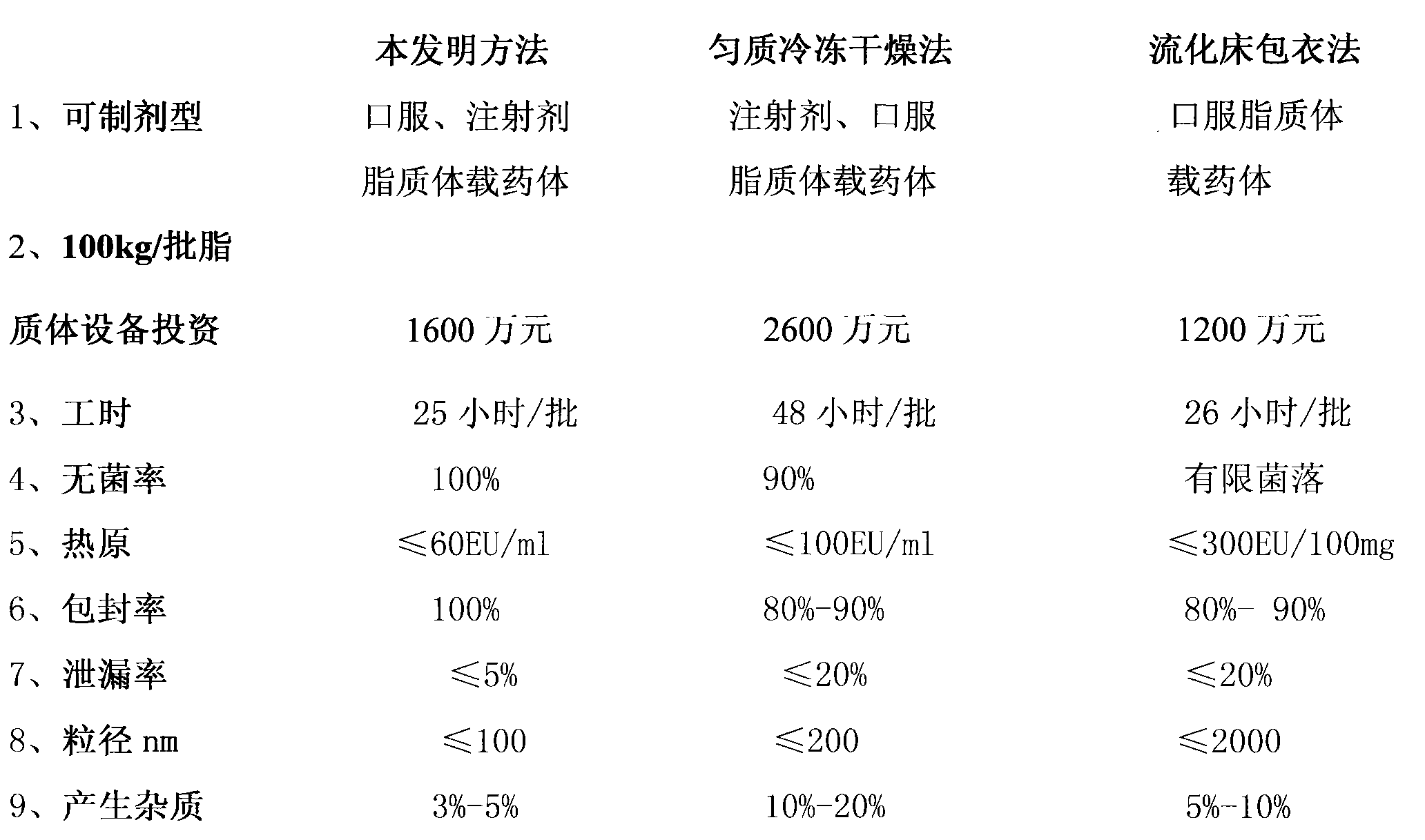

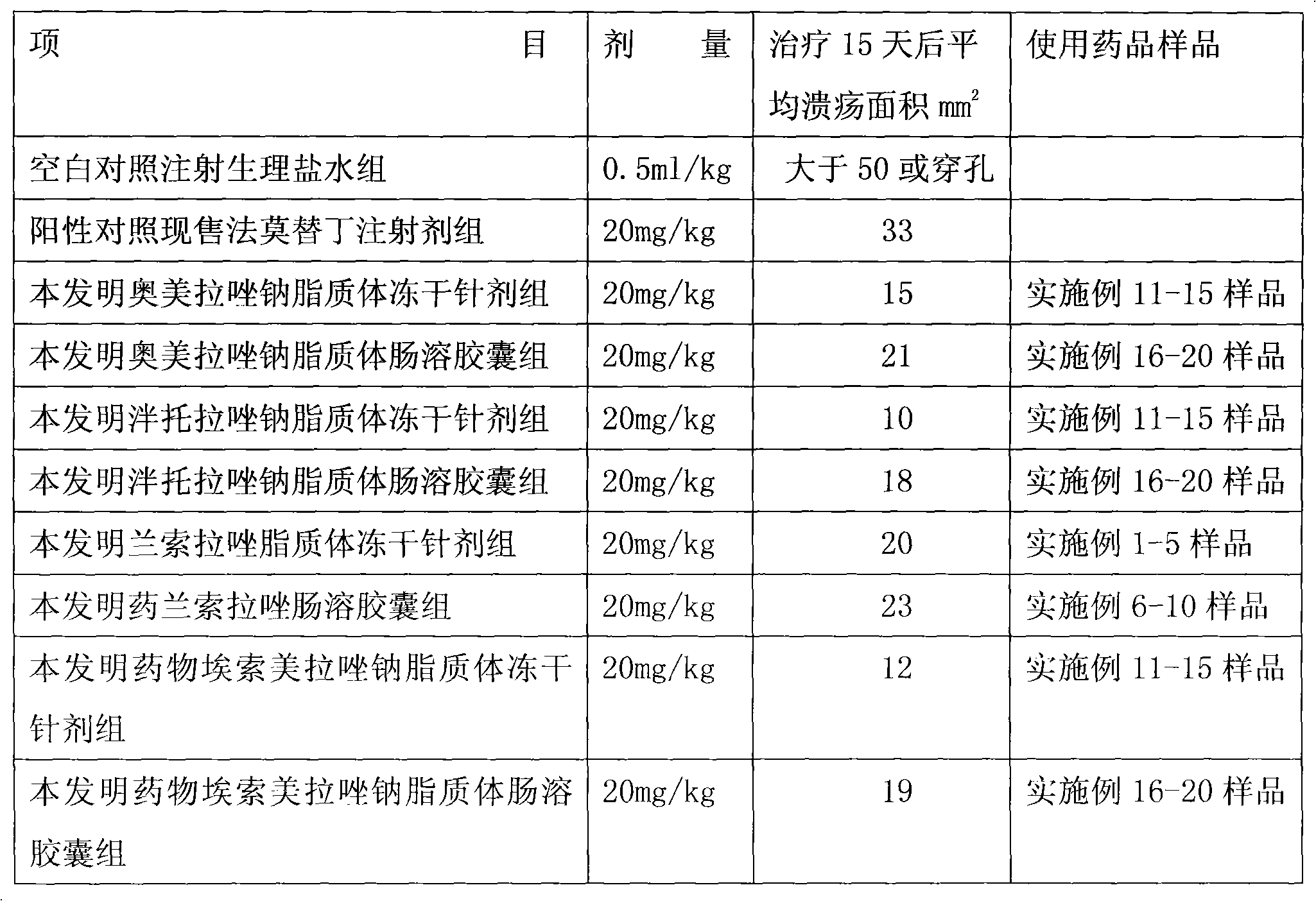

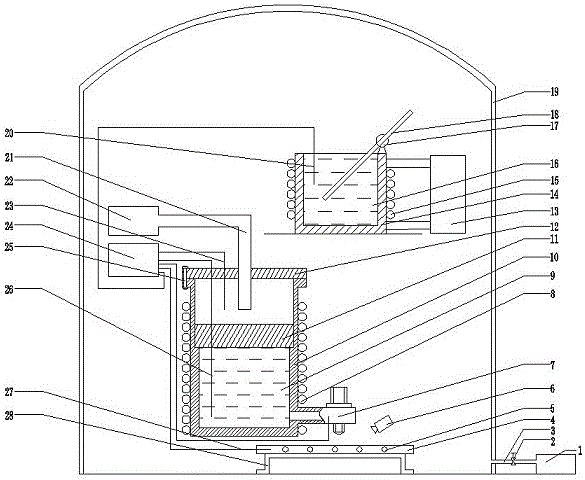

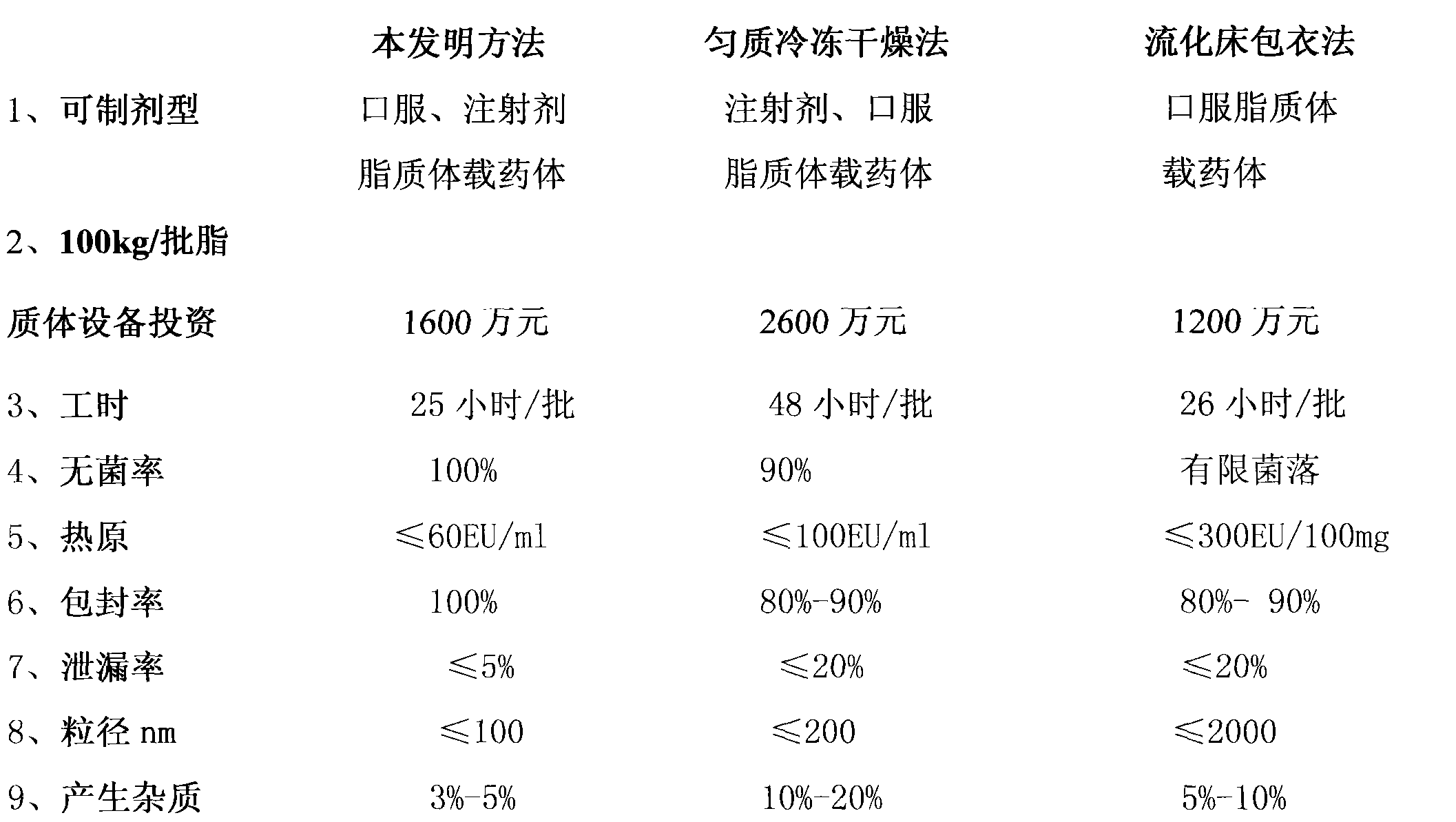

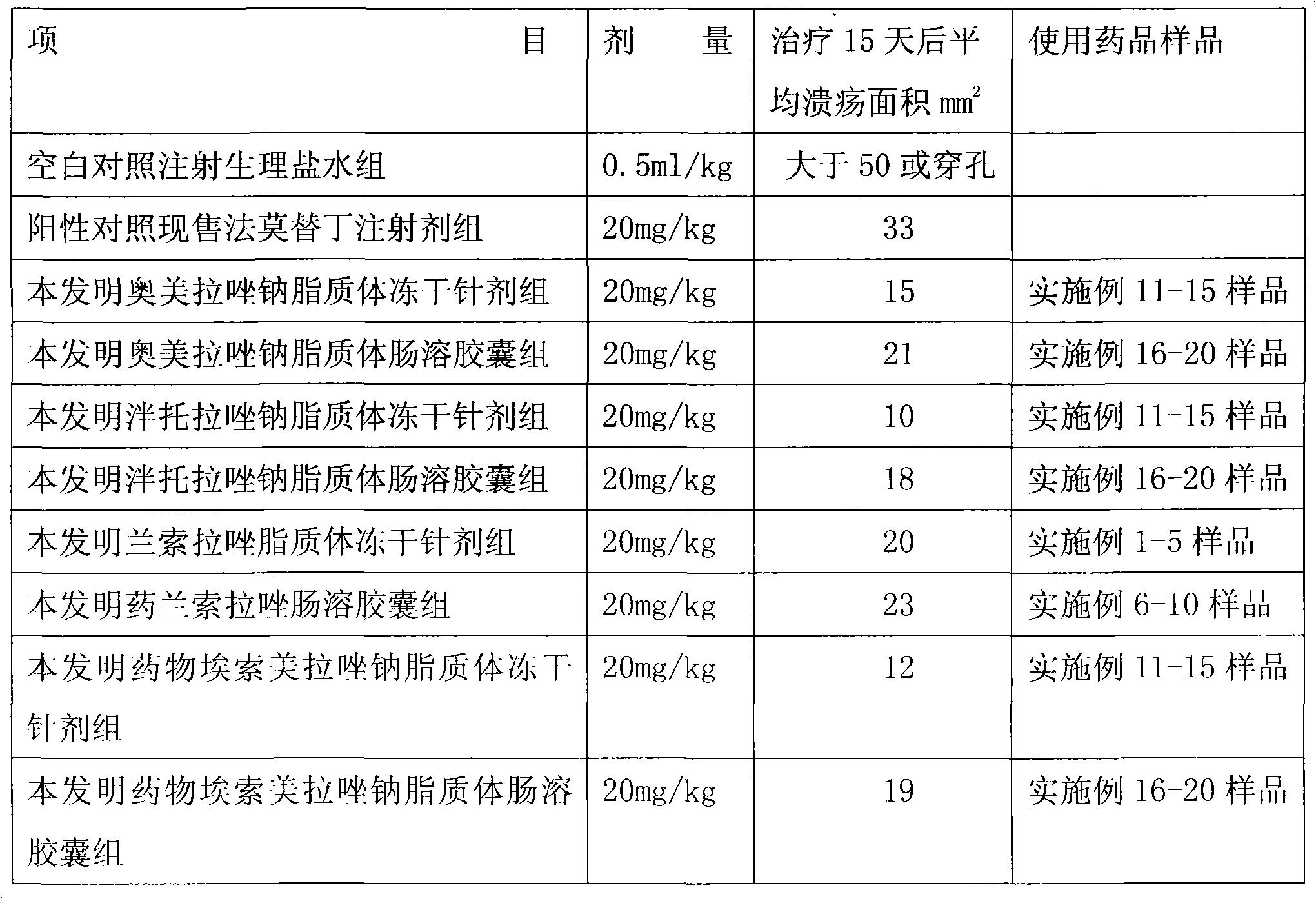

Ginkgolide B liposome medicinal composition

InactiveCN101912364AImprove therapeutic indexEvenly dispersedOrganic active ingredientsPharmaceutical product form changeVascular diseaseFreeze-drying

The invention aims to industrially produce ginkgolide B liposome medicinal composition injection and ginkgolide B liposome medicinal composition oral preparations through uniform formula, process and equipment by a molecule dispersing method. The invention provides a molar ratio formula of the component raw materials for preparing the ginkgolide B liposome medicinal composition, steps and method for preparing ginkgolide B liposome medicinal composition freeze-dried injection and oral preparations, and embodiments for preparation. The ginkgolide B liposome medicinal composition is used for treating cerebral and vascular diseases.

Owner:刘会梅

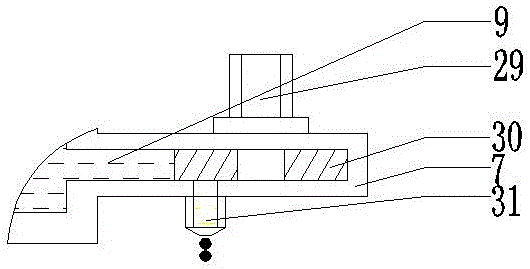

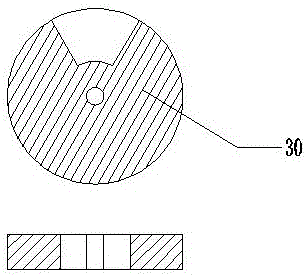

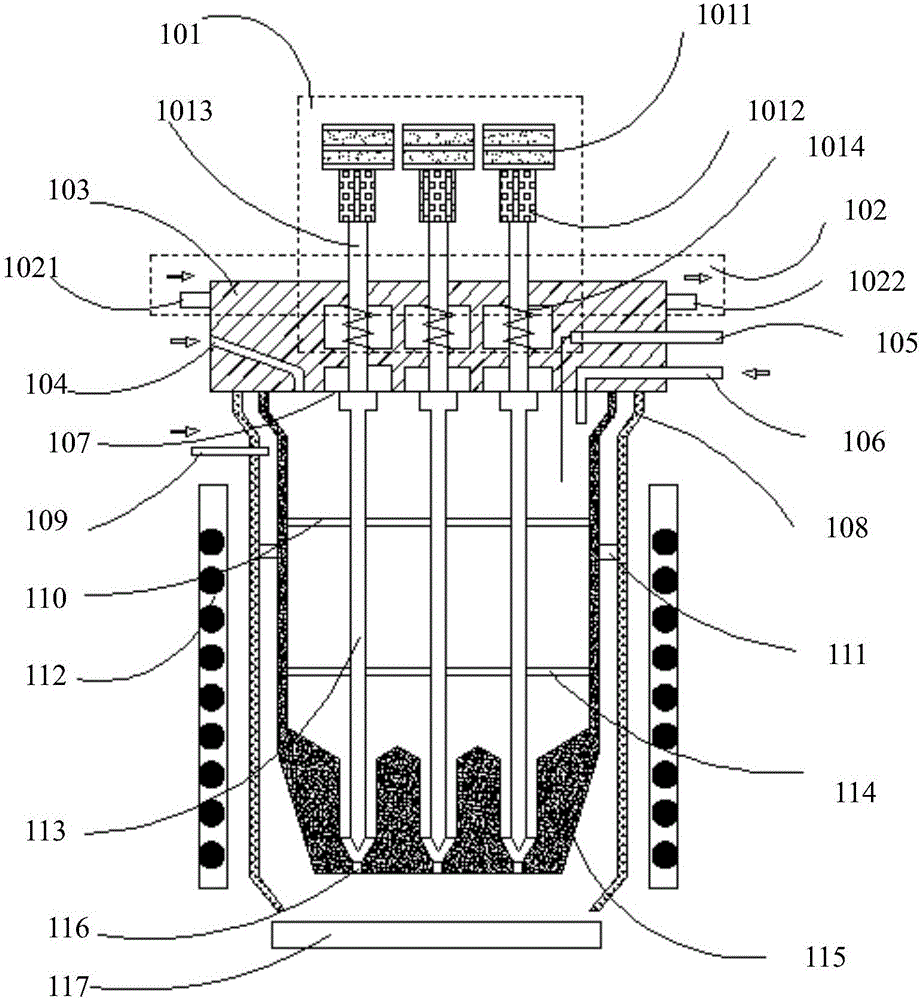

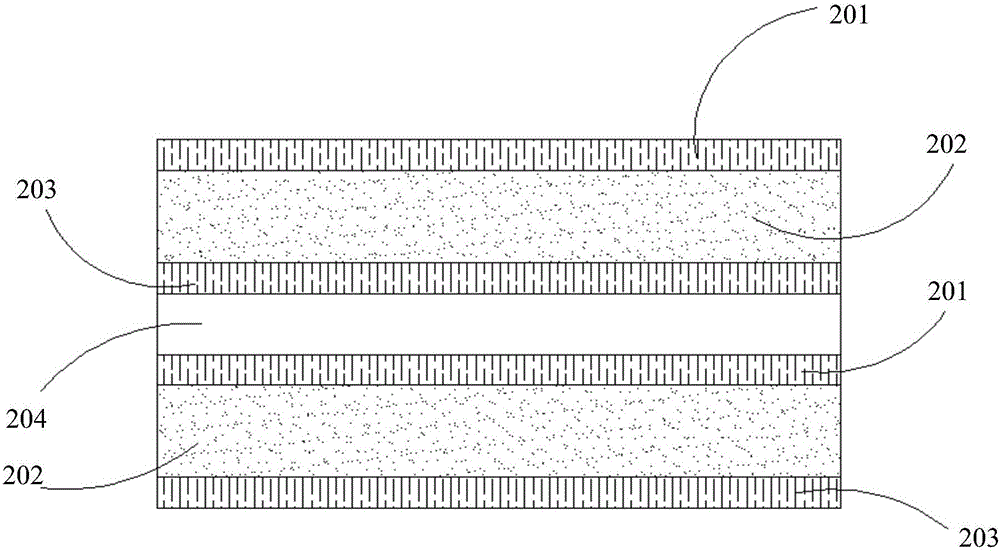

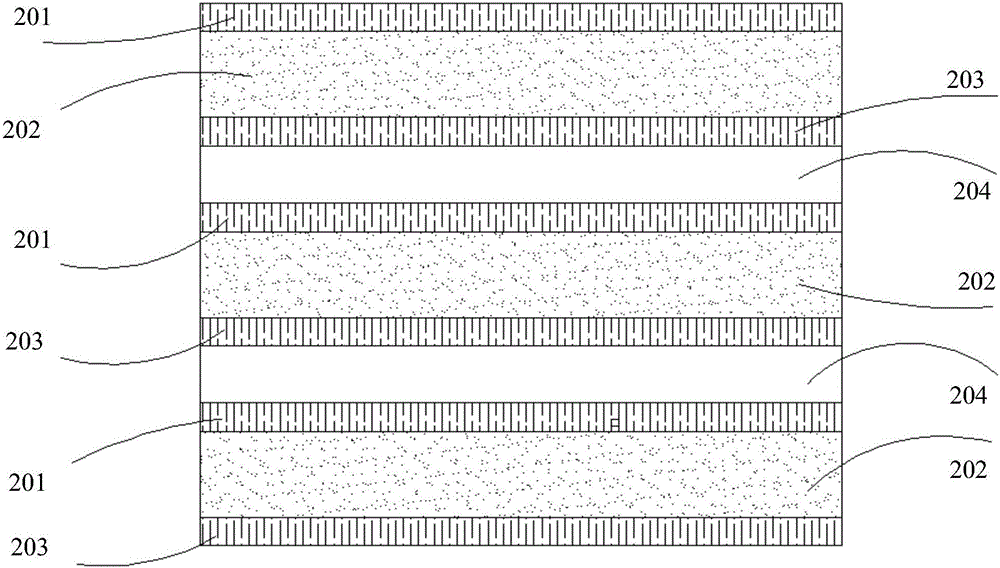

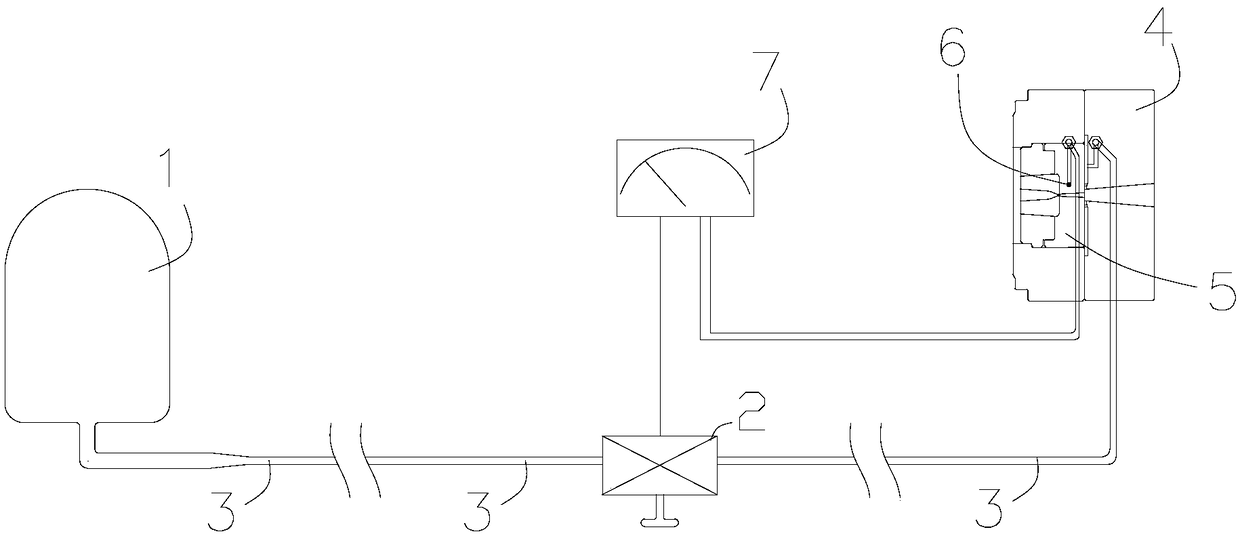

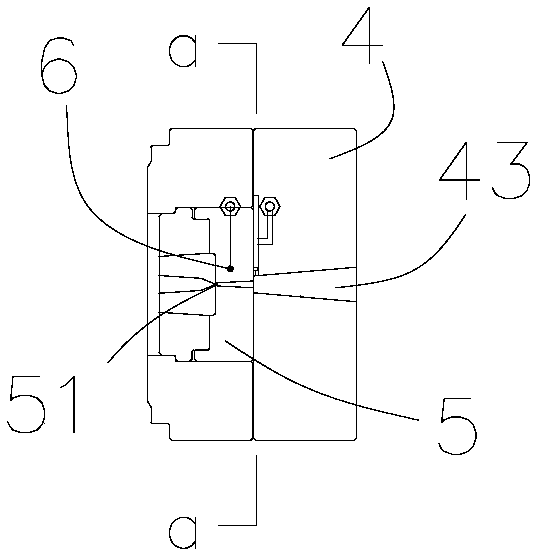

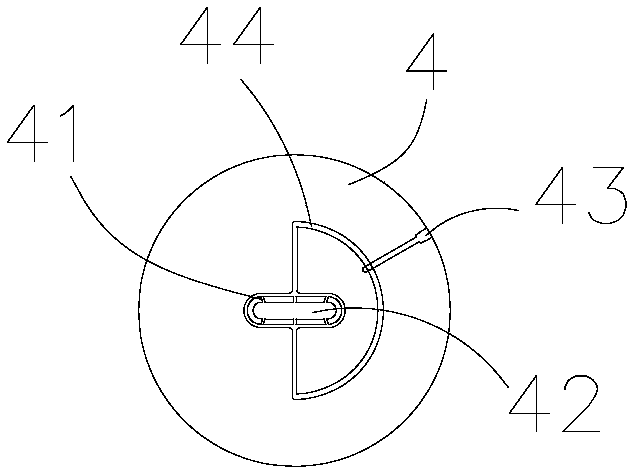

Pulse on-off valve type metal 3D printing device

ActiveCN106378454AReal-time monitoring of melt temperature changesAdjust heating powerAdditive manufacturing apparatusIncreasing energy efficiencyMolten metalMaterials science

The invention discloses a pulse on-off valve type metal 3D printing device capable of realizing precise spray-deposition 3D printing formation of molten metal under the control of a pulse on-off valve. More specifically, the pulse on-off valve type metal 3D printing device is characterized in that a metal liquid is purified through melting and filtering, the precise controllable continuous spray of the molten metal is realized through controlling the pulse on-off of a rotating blade-shaped valve at a printing spray head, the movement of the spray head is controlled through a three-dimensional coordinate platform, a forming platform is provided with stable temperature by a printing substrate, and low-cost additive manufacturing equipment capable of realizing rapid metal melting, multistage purification and precise controllable spray deposition is finally designed.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH

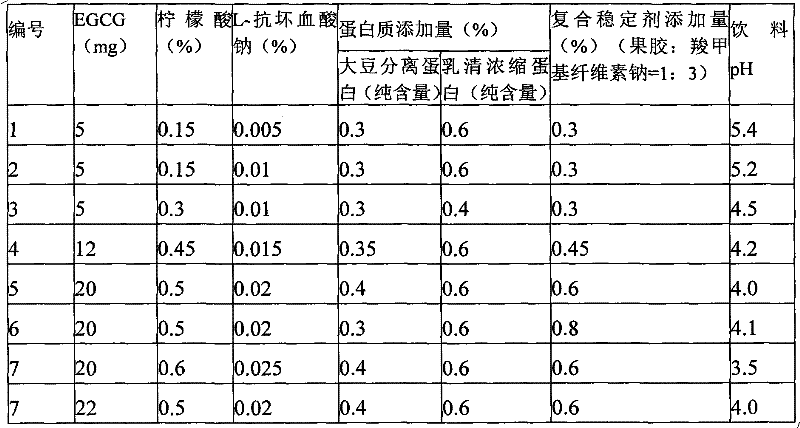

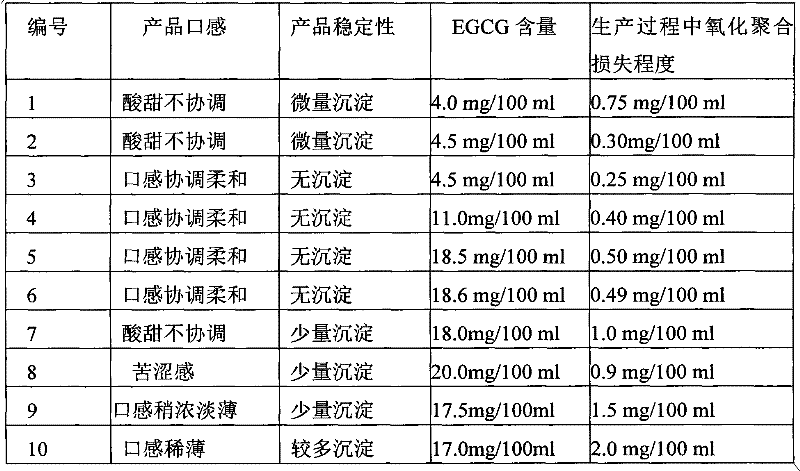

EGCG (Epigallocatechin Gallate)-added compound protein acidic beverage and preparation method thereof

The invention relates to the field of beverage processing, in particular to EGCG (Epigallocatechin Gallate)-added compound protein acidic beverage and a preparation method thereof. According to the EGCG-added compound protein acidic beverage provided by the invention, the EGCG-added compound protein acidic beverage contains 0.7-1.0 part of protein, 0.3-0.6 part of stabilizer, 5*10<-3> to 20*10<-3> part of EGCG, 0.3-0.5 part of citric acid and 0.01-0.02 part of sodium L-ascorbate, based on 100 parts by weight of raw materials. According to the EGCG-added compound protein acidic beverage and the preparation method of the EGCG-added compound protein acidic beverage, the acidity is adjusted by adding the citric acid into the beverage, so that the pH value of the beverage can be in the range of 4.0 to 4.5, the EGCG can be stably present at the acidity, and soybean protein isolate and whey protein concentrate which are simultaneously added can also be stably present without flocculation; and bee honey, polydextrose and oligosaccharides are further added into the beverage, so that the EGCG-added compound protein acidic beverage has the advantages of comprehensive regulation and improvement on human metabolic function, excellent mouth feel and healthcare function.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

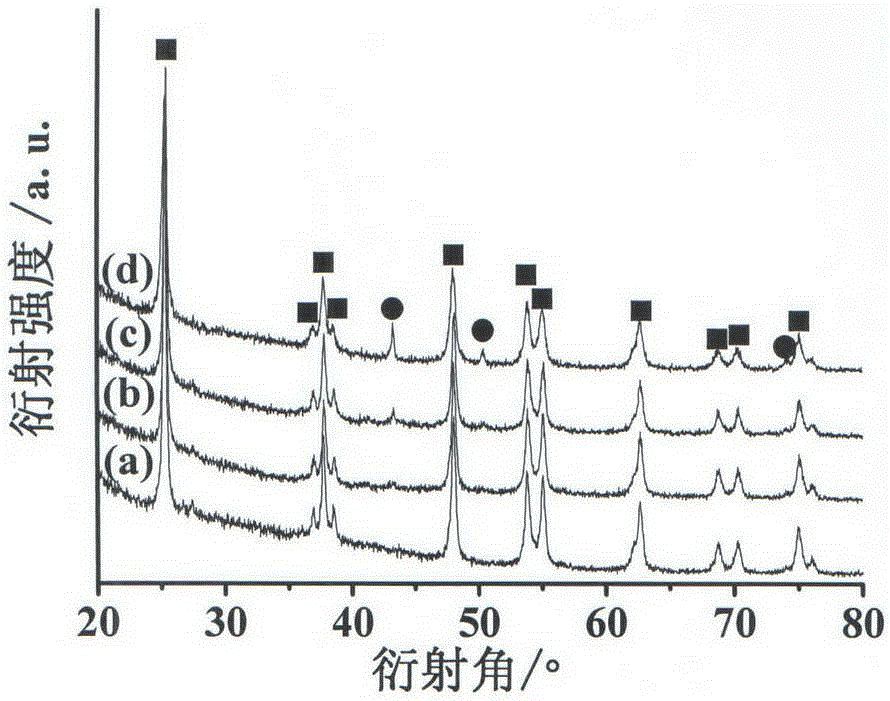

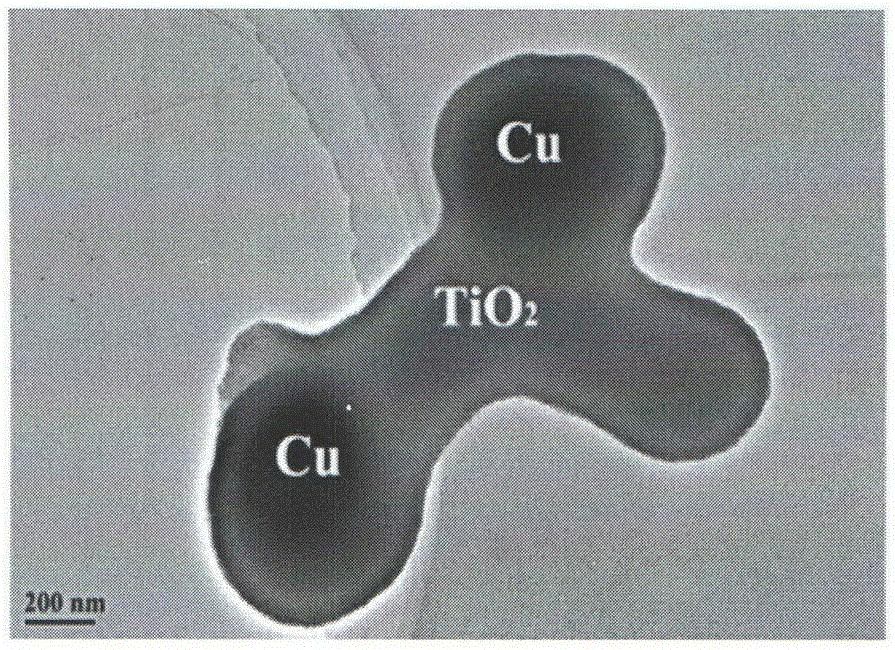

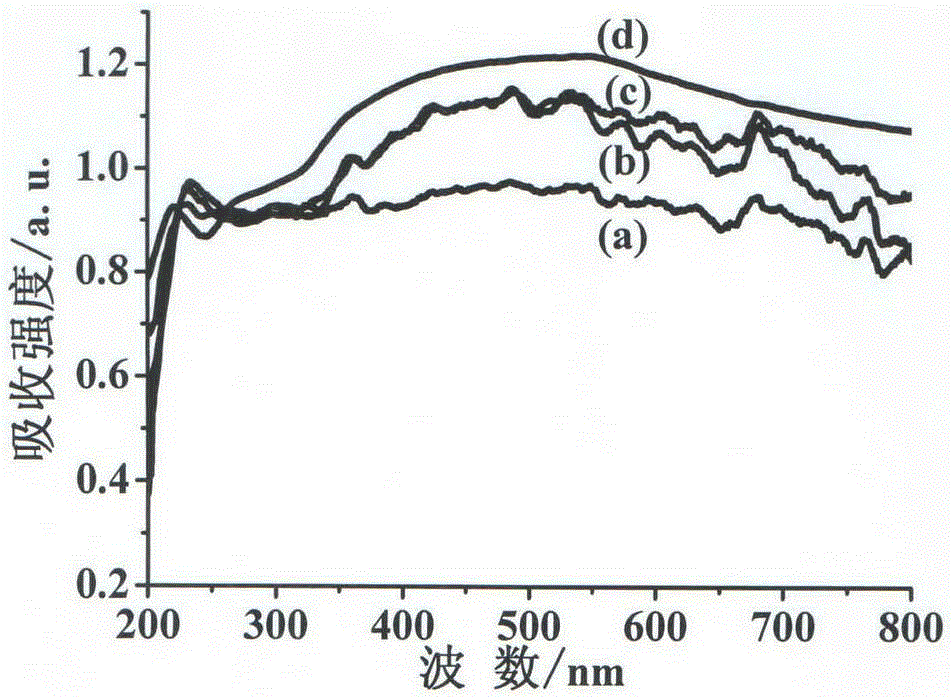

Preparation method and application of black TiO2 clad metal copper nanometer photocatalyst

InactiveCN105195146ACatalytic reduction of CO under strong visible light

<sub>2</sub>

abilityNot oxidizedHydrocarbon from carbon oxidesCarbon monoxideNano catalystPhotocatalytic reaction

The invention relates to a preparation method and application of a black TiO2 clad metal copper nanometer photocatalyst. The preparation method comprises the following two steps of firstly, preparation of nanocrystalline metal copper particles: synthesizing copper oxide-aluminum oxide compound, removing aluminum oxide and reducing nanometer copper oxide; and secondly, performing hydrolysis precipitation on a titanium source on surfaces of metallic copper nano particles under the protection of an inert or hydrogen atmosphere, and drying and performing vacuum roasting to obtain the black TiO2 clad metal copper nanometer photocatalyst. The preparation method has the advantages that nanocrystalline metal copper particles can be obtained without surfactant, and preparation cost is low. The photocatalyst prepared by the method is high in visible light region full-color response and high in photo-induced carrier separating efficiency, and good photo-reduction CO2 activity can be shown in visible light. Moreover, the metallic copper nano particles in the photocatalyst are not oxidized in a light-catalyzed reaction process.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

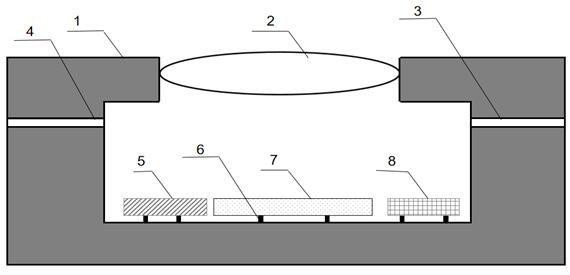

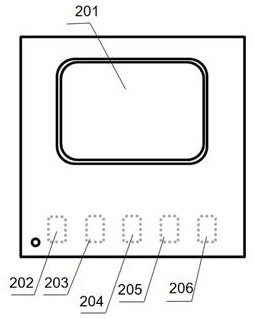

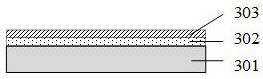

DFN packaged digital infrared temperature sensor

InactiveCN111637978AMiniaturizationMiniaturization hasVacuum evaporation coatingSputtering coatingThermopileMiniaturization

The invention discloses a DFN packaged digital infrared temperature sensor. The sensor comprises a DFN packaging shell with a window in the top, a thermopile, a TC template and an ASIC module are arranged in the DFN packaging shell, an infrared optical filter is arranged at the window of the DFN packaging shell, and a closed space is defined by the infrared optical filter and the DFN packaging shell; the DFN packaging shell is provided with an air guide hole and an exhaust hole, the bottom of the DFN packaging shell is provided with a pin, and the inner wall of the DFN packaging shell is provided with a metal shielding layer and a SiO2 film. The DFN packaged digital infrared temperature sensor has the advantages of miniaturization, low cost, high electromagnetic shielding efficiency, highmeasurement precision, high readability, simple forming process, suitability for large-scale production and wide application.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

Ceramic support for microwave magnetron and preparation method of ceramic support

The invention discloses a ceramic support for a microwave magnetron and a preparation method of the ceramic support, and relates to the technical field of metalized ceramic processing. The ceramic support for a microwave magnetron comprises a ceramic matrix and a metalized layer. The ceramic matrix is prepared from raw materials such as a silicon carbide-triazole silane-aluminum nitride net-shapedmatrix, blast furnace slag, a dispersing agent and a defoaming agent through the steps of preparation of the silicon carbide-triazole silane-aluminum nitride net-shaped film coating matrix, mixing, granulation, sintering and the like. Raw materials of the metalized layer comprise titanium powder, copper powder, clay and a binder. The invention further discloses a preparation method of the ceramicsupport composed of the metalized layer and the ceramic matrix. The ceramic support for a microwave magnetron provided by the invention has high density and tensile strength, excellent tensile strength, toughness, high temperature resistance and thermal conductivity, the cost of raw materials can be reduced, and the purposes of energy conservation and environmental protection can be achieved.

Owner:HUNAN MEICHENG CERAMIC TECH

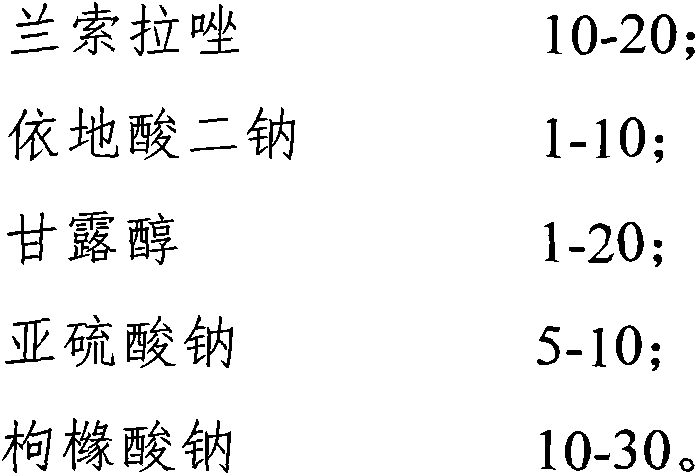

Drug composition containing lansoprazole compound and preparation method of drug composition

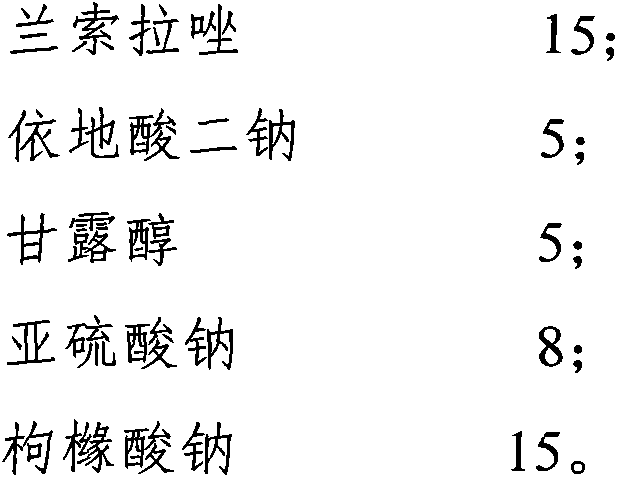

ActiveCN103040737ASignificant synergyImprove solubilityPowder deliveryOrganic active ingredientsSolubilityDisodium Edetate

The invention discloses a drug composition containing a lansoprazole compound, which comprises the following raw materials in parts by weight: 10-20 parts of lansoprazole, 1-10 parts of edetate disodium, 1-20 parts of mannitol, 5-10 parts of sodium sulfite and 10-30 parts of sodium citrate. According to the drug composition, a pH regulator sodium citrate is screened out by a large number of tests and compounded with a stabilizing agent edetate disodium, the synergistic interaction is obvious; decrease of a pH value of strongly basic lansoprazole solution during production or a lyophilized agent during storage can be avoided well; therefore, re-dissolution of the lansoprazole lyophilized agent can be well avoided; and the solubility is good. The drug composition does not go bad and is not oxidized in a storage process, and the administration safety is ensured.

Owner:罗诚

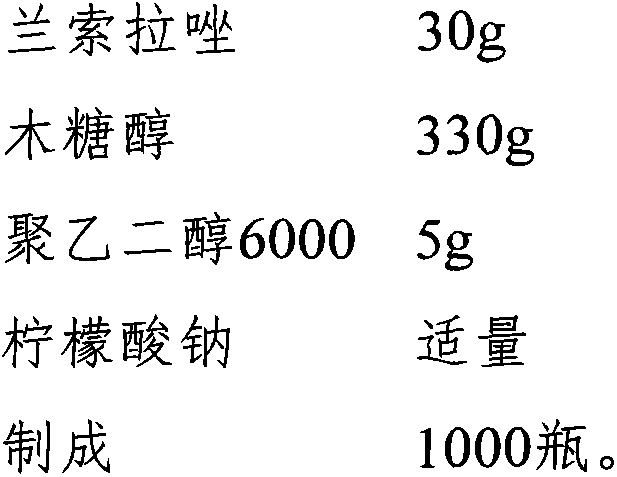

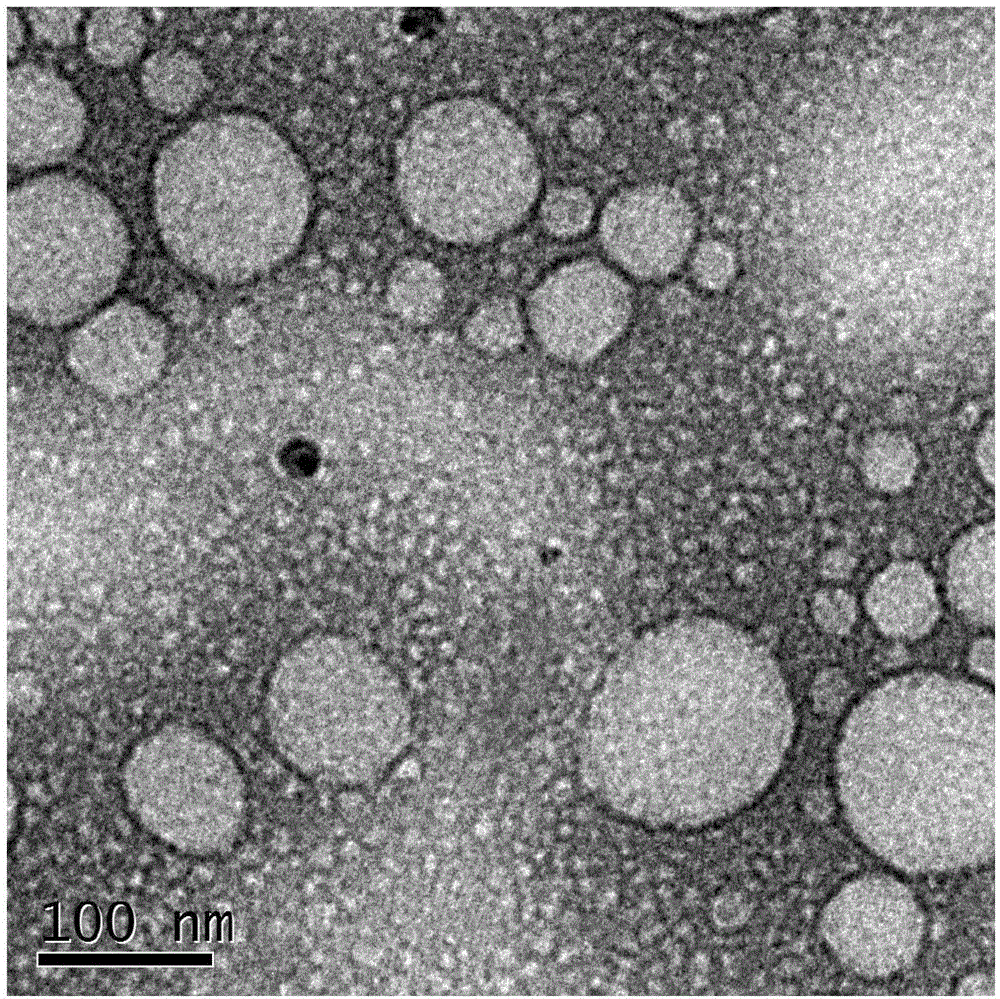

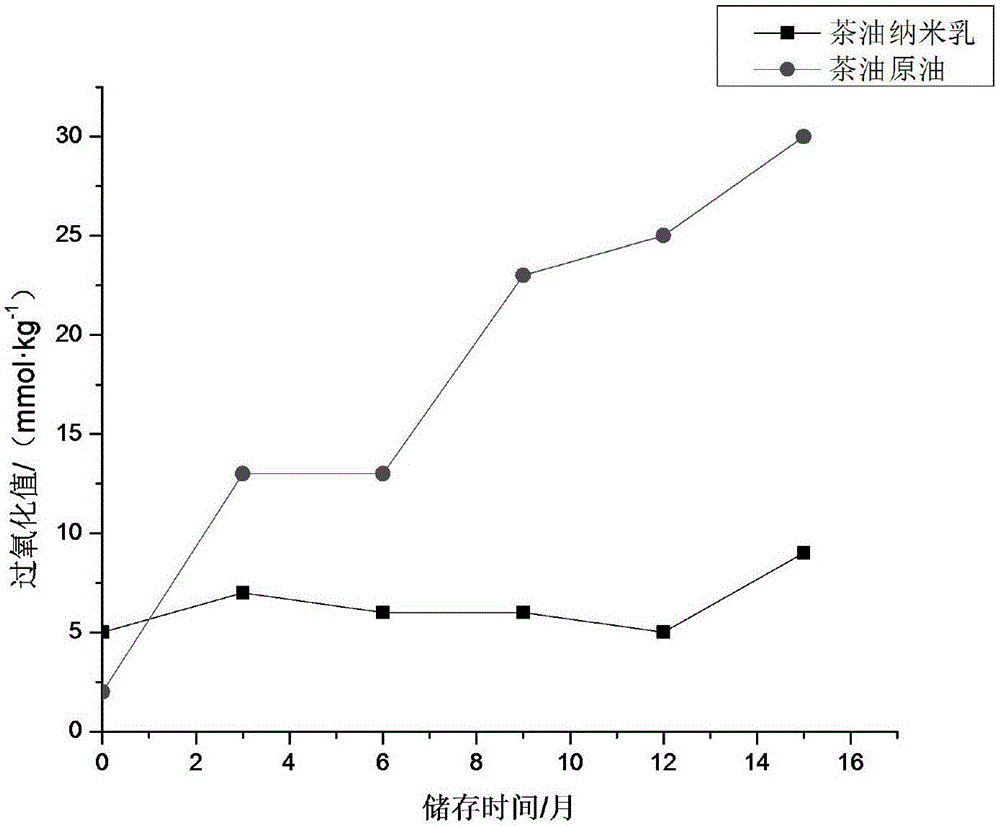

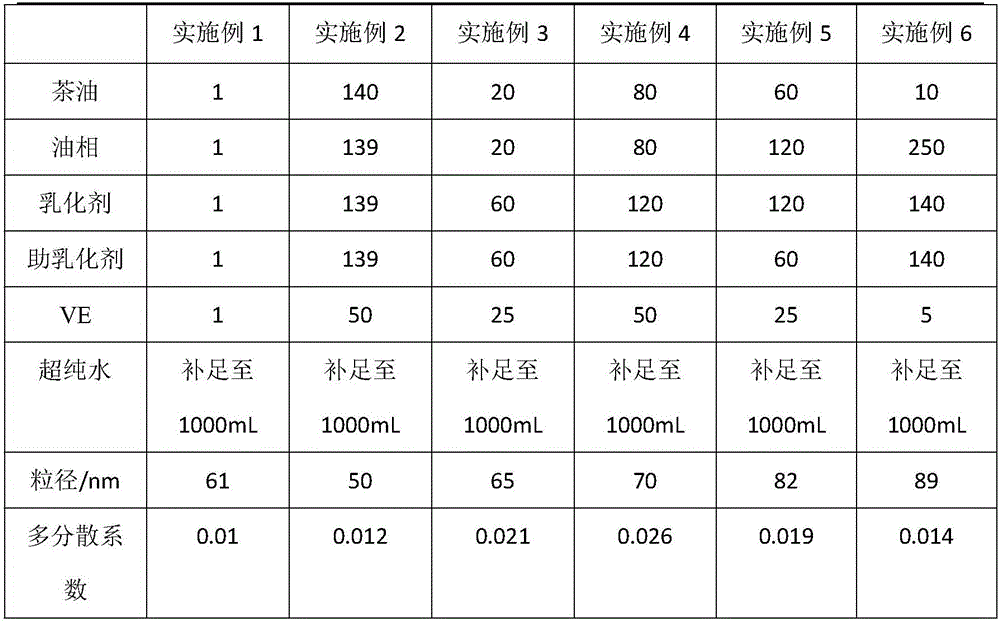

Camellia oil nano-emulsion and preparation method thereof

InactiveCN106821977AImprove bioavailabilityReduce incidenceEmulsion deliveryDermatological disorderAntioxidantCurative effect

The invention relates to camellia oil nano-emulsion and a preparation method thereof. Each 1000 mL of camellia oil nano-emulsion comprises the following components: 1 to 140 g of camellia oil, 1 to 250 g of oil phase, 1 to 140 g of an emulsifier, 1 to 140 g of a co-emulsifier, 1 to 50 g of an antioxidant and the balance of ultrapure water, wherein the total volume is 1000 mL and the average grain size is less than 100 nanometers. The preparation method comprises the following steps: (1) preparation of the oil phase: weighing the camellia oil, the emulsifier, the oil phase and the antioxidant, mixing, and heating and stirring at 37+ / -3 DEG C to obtain the oil phase; and (2) preparation of the camellia oil nano-emulsion: under the condition of continuously heating, dropwise adding the ultrapure water into the oil phase while stirring until the oil phase is clear and transparent or blue opalescence occurs to obtain nano-emulsion. After the camellia oil nano-emulsionis prepared, the mechanical stability of the camellia oil is improved, the bioavailability of the camellia oil is improved and the curative effect is enhanced.

Owner:FUJIAN MEDICAL UNIV

High-efficiency high-temperature print head supporting multiple printing materials

InactiveCN105772725AStrong oxidation and corrosion resistanceImprove work efficiencyAdditive manufacturing apparatusEngineeringHigh pressure

The invention discloses a high-efficiency high-temperature print head supporting multiple printing materials. The print head comprises a driving device, a circular water-cooling system, a material inlet, a high-pressure protection gas inlet pipe, a high-temperature liquid cavity and a heating device; the high-temperature liquid cavity is formed by a crucible; two filter layers are arranged in the high-temperature liquid cavity; multiple spraying holes are formed in the bottom of the high-temperature liquid cavity; a coaxial protection gas shield is arranged outside the high-temperature liquid cavity; a gas uniformizing sheet is arranged between the coaxial protection gas shield and the high-temperature liquid cavity; the heating device is arranged on the outer part of the coaxial protection gas shield; protection gas is introduced into the coaxial protection gas shield; and the material inlet is used for injection printing materials. The print head can be used for printing of metal or other materials which need to be molten at high temperature; the print head is provided with multiple spraying holes; the structure is compact; and the working efficiency can be improved. Different driving positions can be provided by the print head, so that the print head can be applicable to printing of different materials, and meanwhile, the print head is also applicable to printing of the same material with different liquid drop sizes.

Owner:XI AN JIAOTONG UNIV

Device and method for accurately controlling local temperature of aluminum profile hot extrusion die

PendingCN108500076APrecise temperature controlOvercome inconsistencyExtrusion control devicesHysteresisLiquid nitrogen container

The invention provides a device for accurately controlling the local temperature of an aluminum profile hot extrusion die. The device comprises a liquid nitrogen container, a low temperature control valve, a liquid nitrogen pipeline, a die cushion, the die and a temperature controller. The die is installed in the die cushion, the liquid nitrogen pipeline is connected between the liquid nitrogen container and the die cushion and used for delivering liquid nitrogen into the die cushion, and the low temperature control valve is arranged on the liquid nitrogen pipeline and controls the flow of theliquid nitrogen. A contact type thermocouple is arranged in the die, the contact type thermocouple is connected with the temperature controller through a compensating lead, and the temperature controller is electrically connected with the low temperature control valve and transmits a direct current electric control signal to the low temperature control valve. The invention further provides a method for accurately controlling the local temperature of the aluminum profile hot extrusion die. A feedback signal is provided for the low temperature liquid nitrogen control valve by directly measuringthe temperature of the die, so that the temperature of the die is accurately controlled, and the changing hysteresis quality and inconsistency of the high temperature of a profile and the temperatureof the die at an outlet of a pressing machine in the aluminum extrusion process are overcome.

Owner:浙江海亮新材料有限公司 +1

6000-series high-performance aluminum alloy plate for automobile panel and manufacturing method thereof

The invention relates to a 6000-series high-performance aluminum alloy plate for an automobile panel and a manufacturing method thereof. The 6000-series high-performance aluminum alloy plate contains Si, Fe, Cu, Mn and Mg and comprises a 6016 high-performance aluminum alloy plate, a 6022 high-performance aluminum alloy plate and a 6111 high-performance aluminum alloy plate. The manufacturing method comprises the following steps: adding an alloy, determining a metallographical refinement level, casting an aluminum plate ingot of a certain thickness, carrying out mechanical cold working to a certain process dimension, determining gate arrangements, rolling reductions and front and back tensile forces for hot rolling and cold rolling, carrying out recrystallization annealing at 370-390 DEG C for 10-20 minutes, thereby manufacturing the 6000-series high-performance aluminum alloy plate for an automobile panel. Thus, the invention achieves the purposes of automobile weight reduction, energy conservation and emission reduction.

Owner:JIANGSU CAIFA ALUMINUM

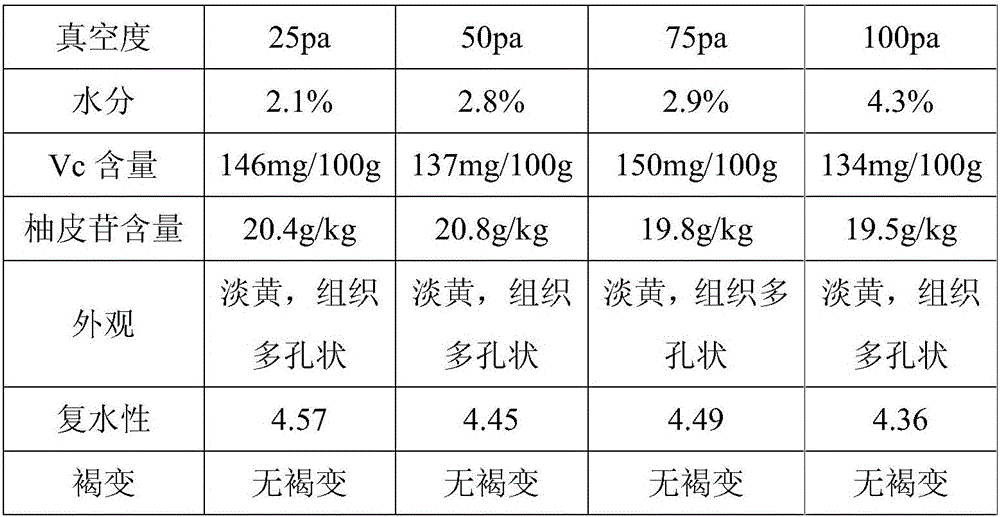

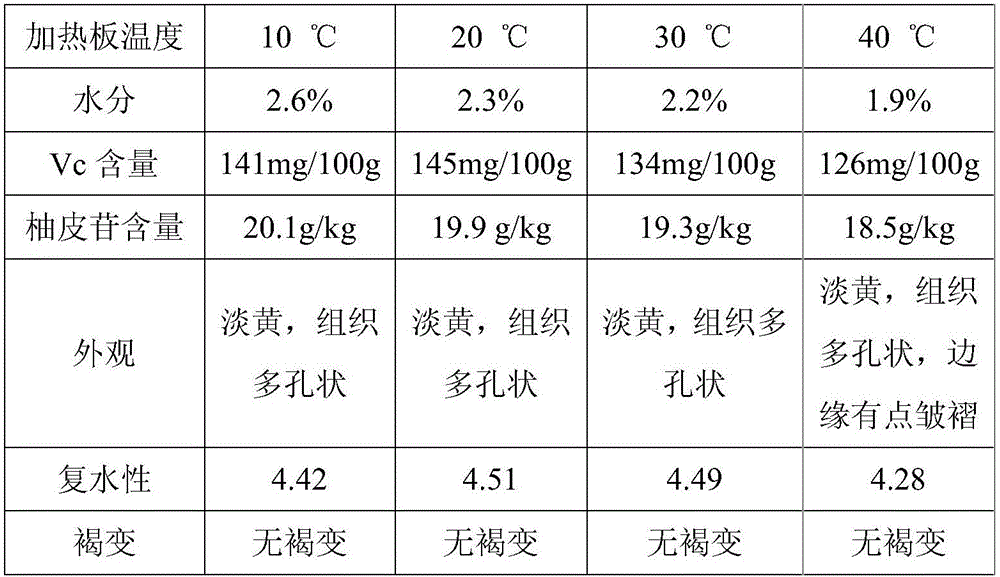

Lime slices and preparation method thereof

InactiveCN105685881APrevent browningFast drying efficiencyFruits/vegetable preservation by freezing/coolingNitrogenMoisture

The invention relates to the technical field of food, and particularly discloses lime slices and a preparation method thereof. The preparation method comprises the following steps that a lime is cut into slices along the transverse diameter to obtain lime slices; the lime slices are prefrozen; the prefrozen lime slices are frozen and dried on the vacuum condition till the moisture of the lime slices is lower than 3%, and nitrogen-filled packing is performed. The lime slices obtained through the preparation method are good in appearance, color and fragrance and good in rehydration property, and Vc and naringin content in the lime slices can be well protected.

Owner:HUNAN AGRI PRODS PROCESSING INST

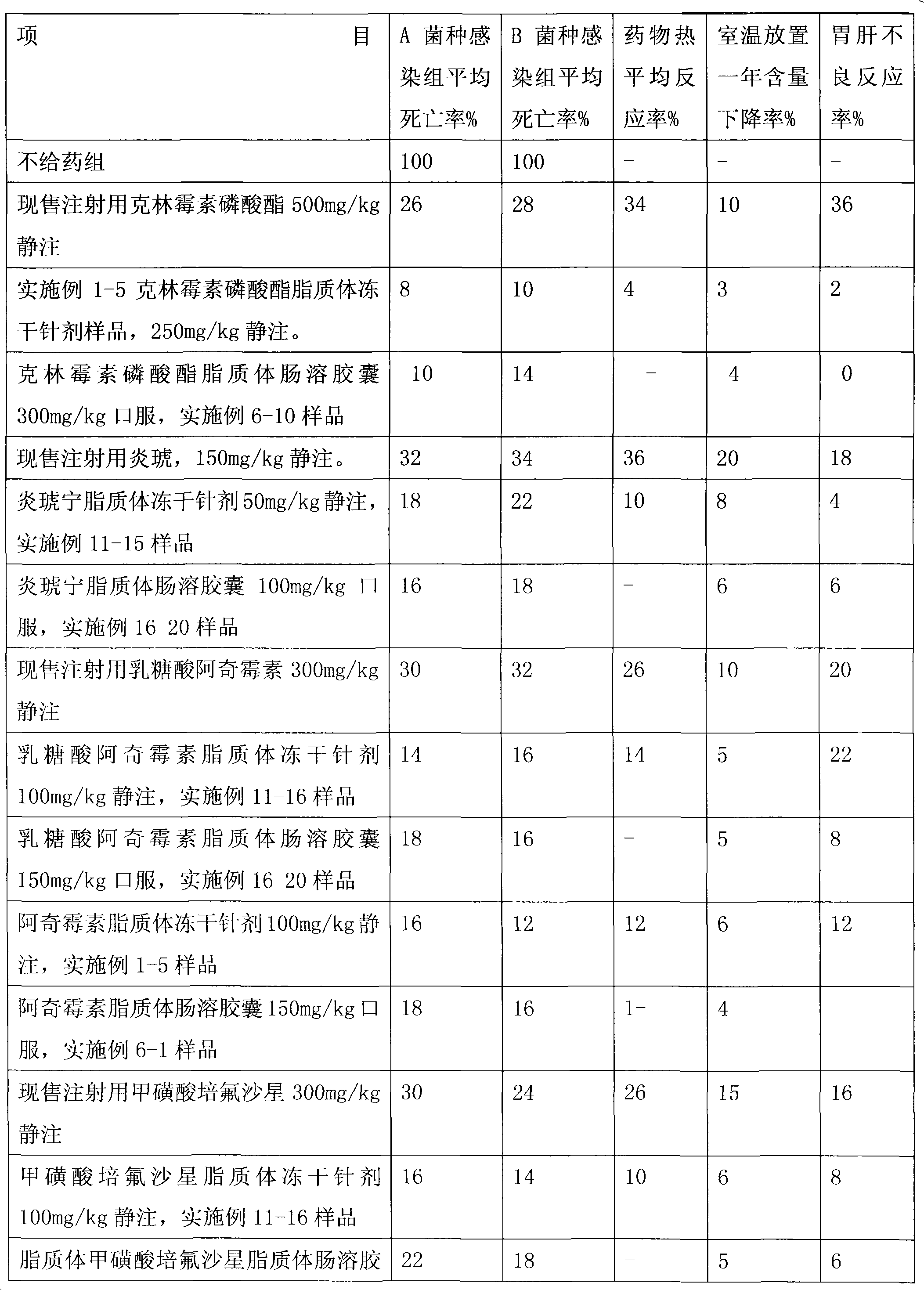

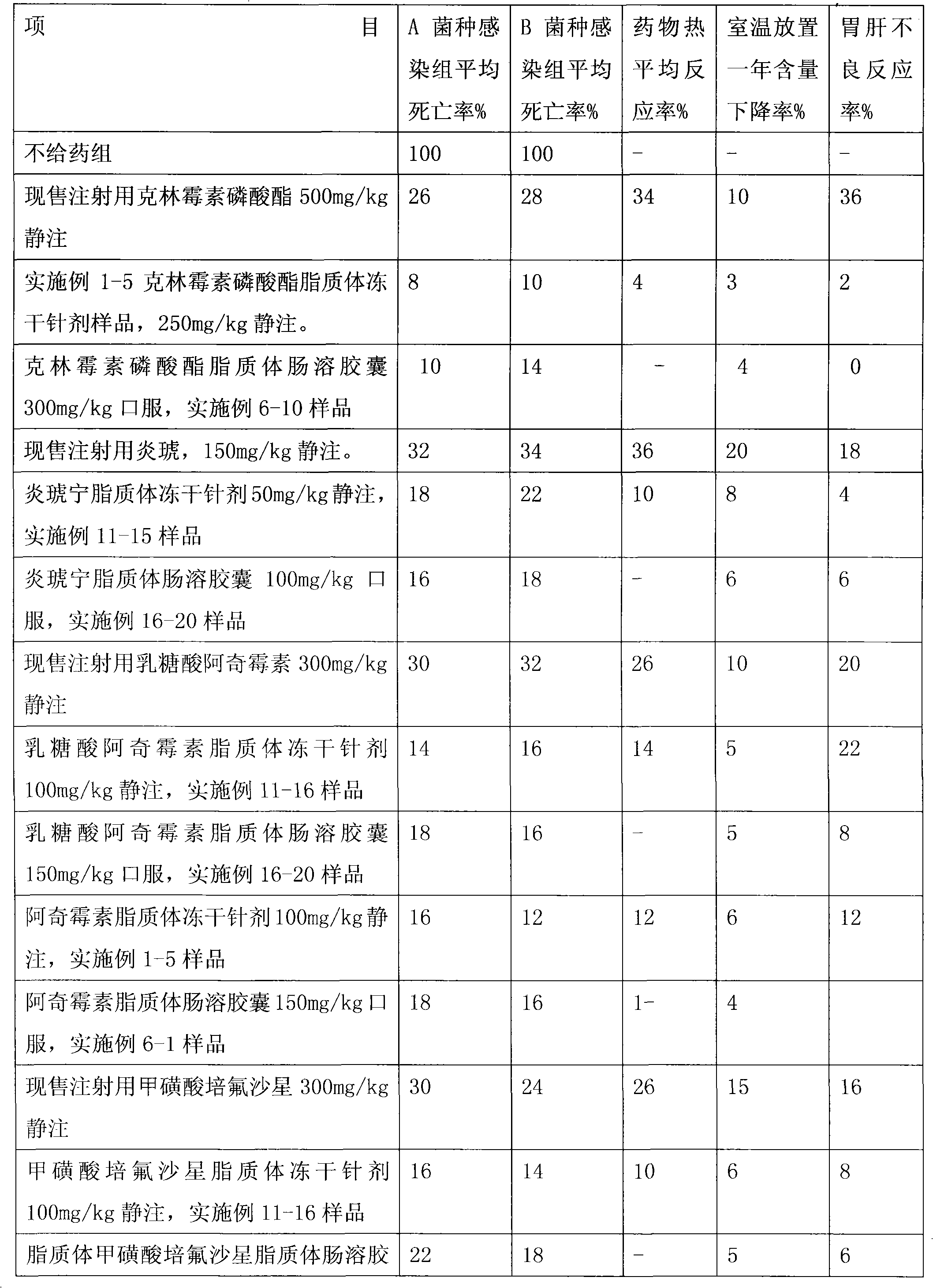

Pefloxacin mesilate liposome medicine composition

InactiveCN102091035AImprove therapeutic indexEvenly dispersedAntibacterial agentsOrganic active ingredientsPefloxacinMedicine

The invention is characterized in that uniform formula, process and equipment are used for industrial production of pefloxacin mesilate liposome medicine composition in the forms of injection and oral preparation by using a molecular dispersion method. The invention provides the mole ratio of the components in a formula of the pefloxacin mesilate liposome medicine composition. The invention also provides steps, methods and specific embodiments for preparing the pefloxacin mesilate liposome medicine composition in the forms of lyophilized injection and oral preparation. The pefloxacin mesilate liposome medicine composition can be used for resisting bacteria.

Owner:邓学峰

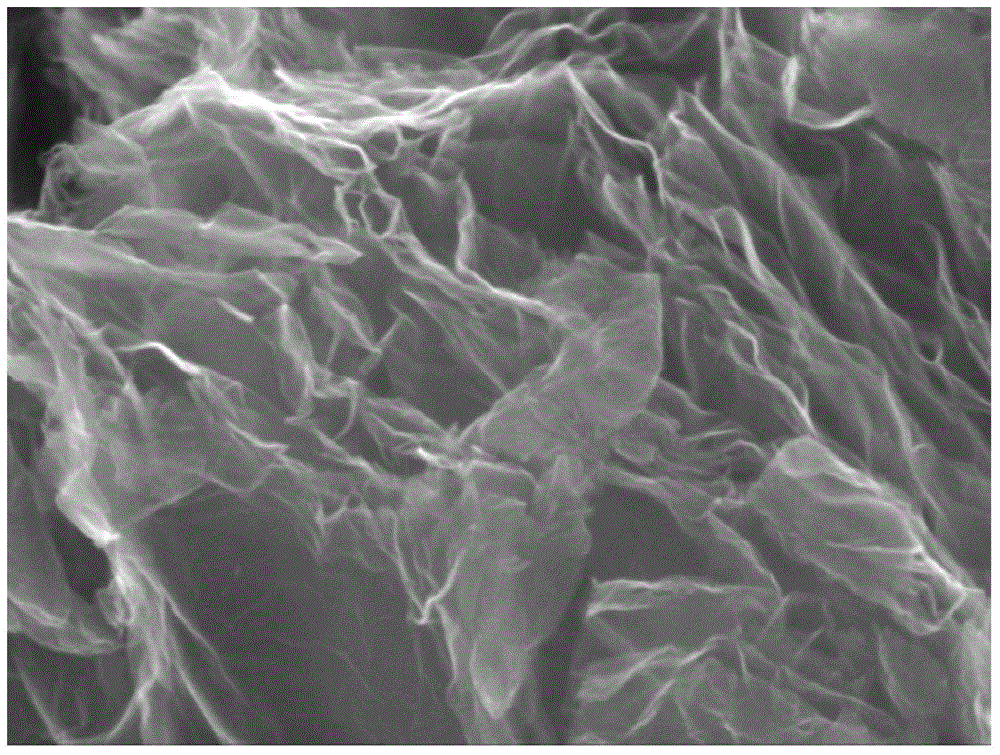

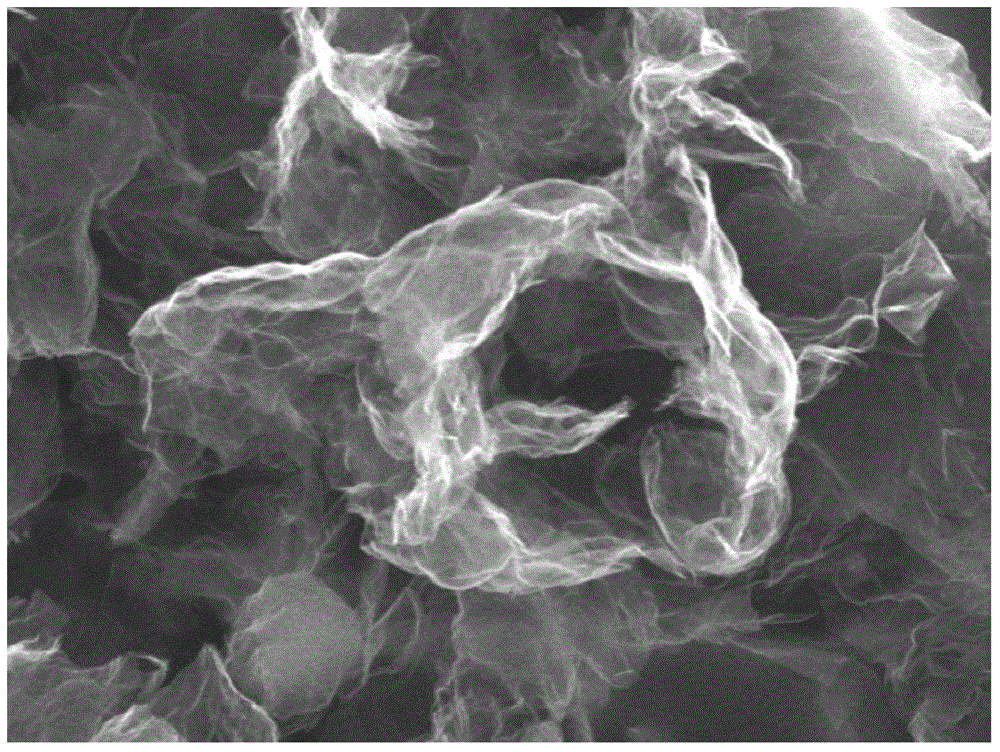

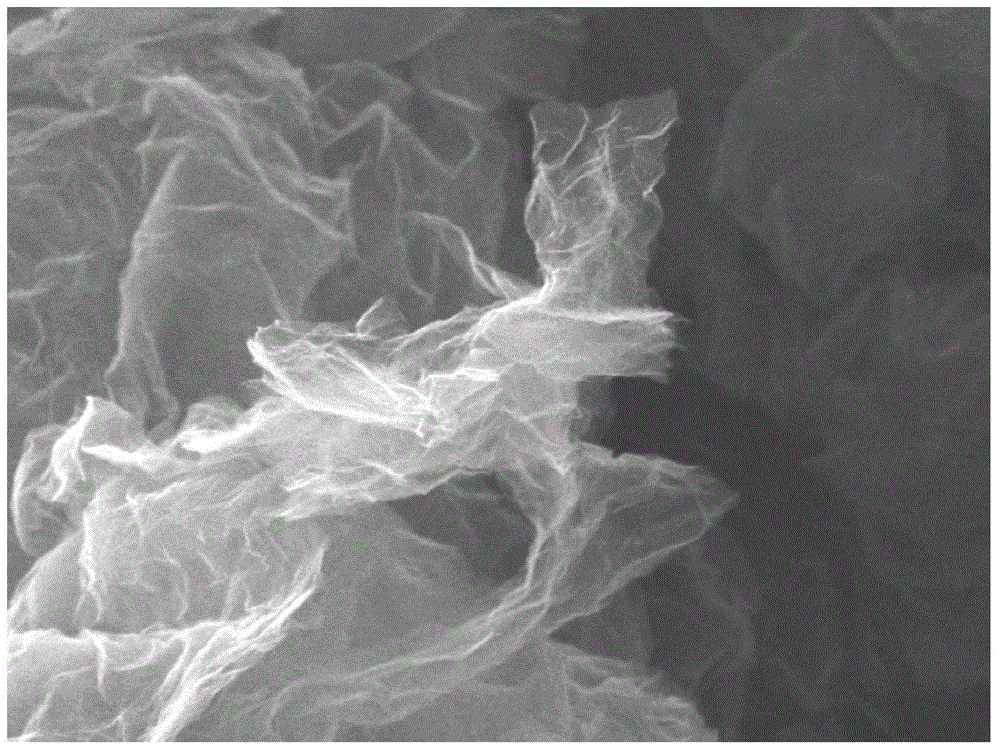

Method for quickly preparing high-performance graphene

The invention discloses a method for quickly preparing high-performance graphene. The method comprises the steps of putting graphite oxide into a reactor, vacuumizing the reactor, treating the graphite oxide by three-stage gradient microwave radiation, and peeling off the graphite oxide expanded with heat, thus obtaining high-performance graphene. The method has the advantages of high production efficiency, low production cost, high safety and reliability in the operation process and high product quality.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com