WC-Co-Cr thermal spraying powder and its preparation method and application

A technology of thermal spraying powder, wc-co-cr, applied in the direction of coating, molten spraying, metal material coating process, etc., can solve the problem of low product qualification rate, no reliable guarantee of sealing surface safety, and dense coating The properties, toughness and corrosion resistance indicators are not easy to meet the requirements, so as to achieve the effect of good particle strength, good fluidity and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

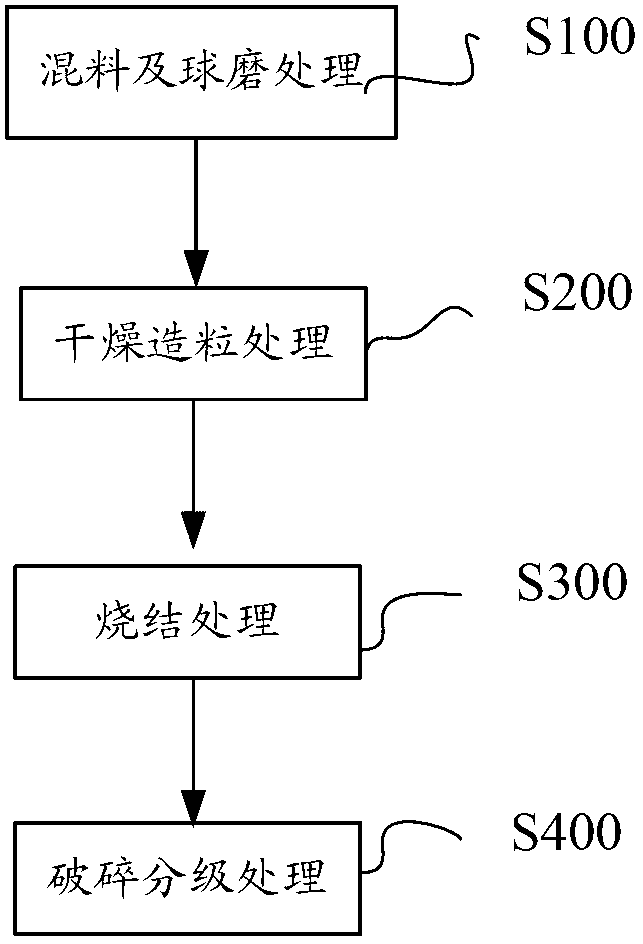

Method used

Image

Examples

Embodiment 1

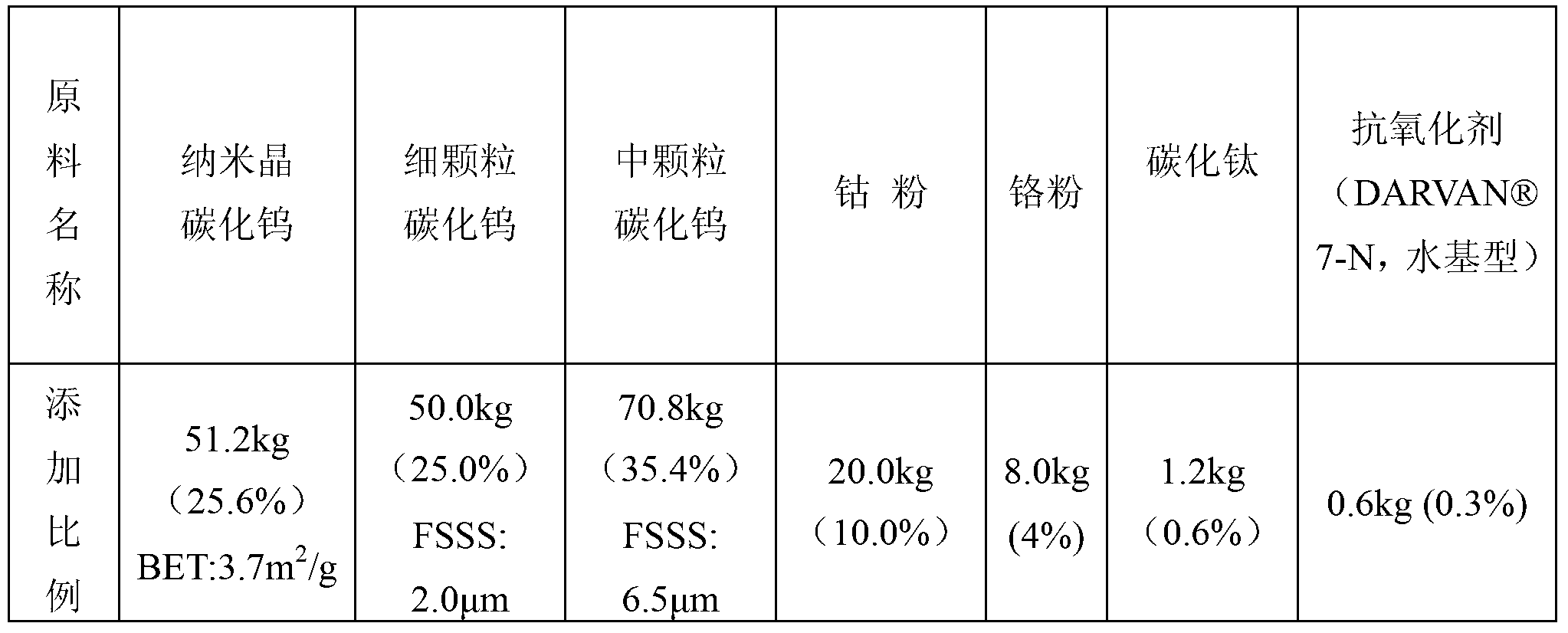

[0052] With reference to the above-mentioned general method in this embodiment, taking the production of 200kg spray powder as an example, the WC-Co-Cr thermal spray powder of the present invention is prepared according to the following process steps:

[0053] Among them, the ratio of raw materials and corresponding parameters are shown in the table below.

[0054]

[0055] Note: BET: refers to the BET test method, that is, the BET specific surface area test method, where the specific surface area refers to the total area of a unit mass of material. In the above table, the BET value measured by the BET test method is used to characterize the particle size of the nano-tungsten carbide with spherical porous structure used in the present invention.

[0056] FSSS: The abbreviation of Fischer particle size test, the basic method is the steady flow air permeation method, that is, the specific surface area and average particle size are measured under the condition of constant ai...

Embodiment 2

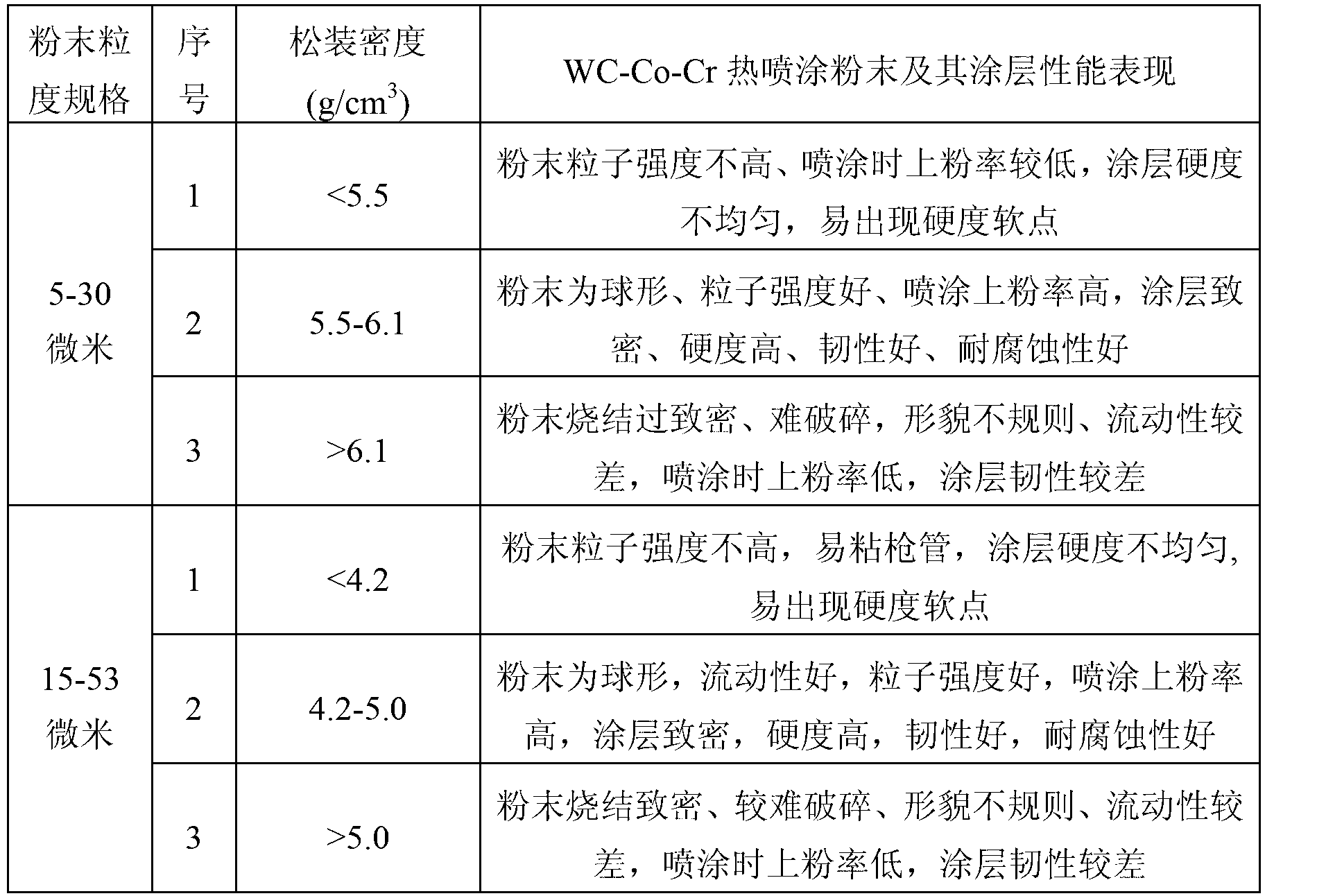

[0093] Taking the production of 200kg spray powder as an example, prepare the WC-Co-Cr thermal spray powder of the present invention according to the method described in Example 1, wherein the difference from Example 1 is that it has the raw material ratio shown in the following table And the corresponding parameters; the sintering temperature is 1150°C (one zone), 1200°C (two and three zones). In this way, the final product WC-Co-Cr thermal spraying powder is prepared, and the particle size specification is 55kg of 5-30 microns, 140kg of 15-53 microns, and the metal loss is about 5kg (2.5%) during the production process. The bulk density of the powder Respectively: 5-30 micron WC-Co-Cr thermal spray powder, 5.5-6.0g / cm 3 ; 15-53 micron WC-Co-Cr thermal spray powder, 4.2-4.7g / cm 3 .

[0094]

[0095] Then, the performance of the new WC-Co-Cr thermal spray powder prepared above was tested and evaluated in combination with the visual observation and the performance test aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| bulk density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com