Patents

Literature

344results about How to "High particle strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

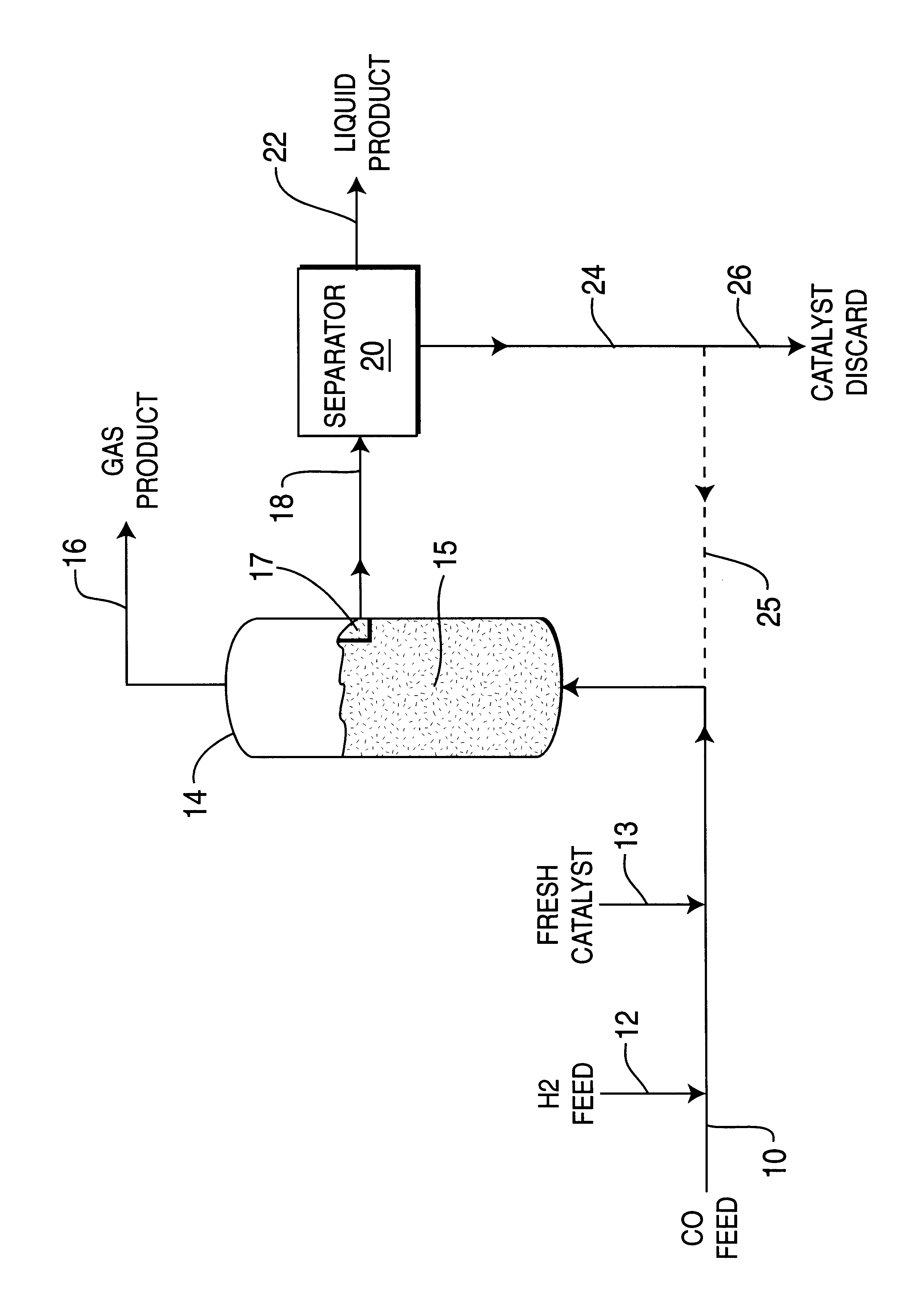

Skeletal iron catalyst having improved attrition resistance and product selectivity in slurry-phase synthesis processes

InactiveUS6277895B1High particle strengthGood attristion resistanceHydrocarbon from carbon oxidesOrganic compound preparationFixed bedSlurry

Particulate skeletal iron catalyst is provided which contain at least about 50 wt. % iron with the remainder being a minor portion of a suitable non-ferrous metal and having characteristics of 0.062-1.0 mm particle size, 20-100 m2 / g surface area, and 10-40 nm average pore diameter. Such skeletal iron catalysts are prepared and utilized for producing synthetic hydrocarbon products from CO and H2 feeds by Fischer-Tropsch synthesis process. Iron powder is mixed with non-ferrous powder selected from aluminum, antimony, silicon, tin or zinc powder to provide 20-80 wt. % iron content and melted together to form an iron alloy, then cooled to room temperature and pulverized to provide 0.1-10 mm iron alloy catalyst precursor particles. The iron alloy pulverized particles are treated with NaOH or KOH caustic solution at 30-95° C. temperature to extract and / or leach out most of the non-ferrous metal portion, and then screened and treated by drying and reducing with hydrogen and to provide the smaller size skeletal iron catalyst material. Such skeletal iron catalyst is utilized with CO+H2 feedstream for Fischer-Tropsch reactions in either a fixed bed or slurry bed type reactor at 180-350° C. temperature, 0.5-3.0 mPa pressure and gas hourly space velocity of 0.5-3.0 L / g Fe / hr to produce desired hydrocarbon products.

Owner:INST OF COAL CHEM ICCCHINESE ACADEMY OF SCI +1

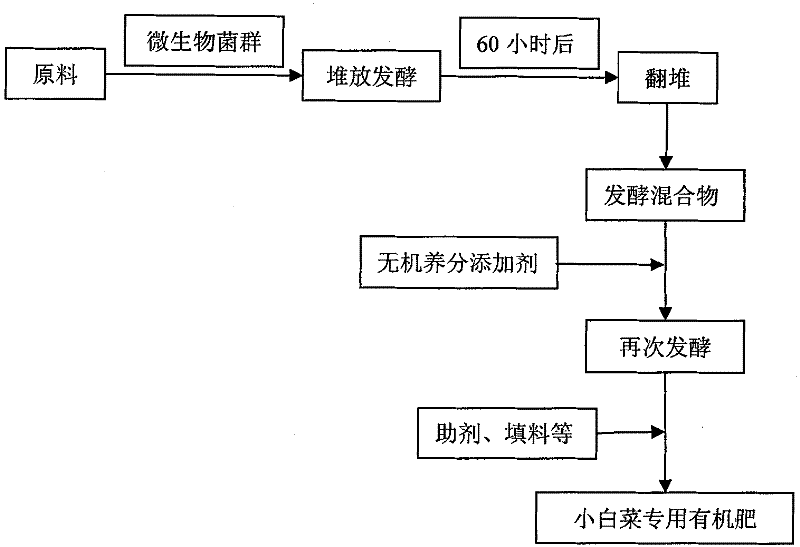

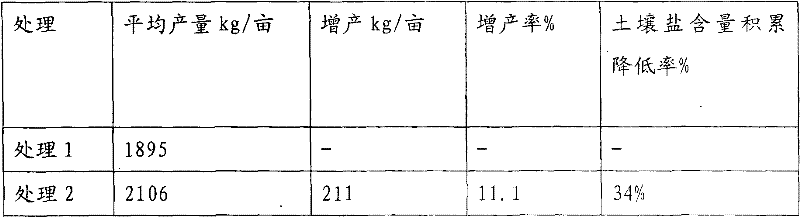

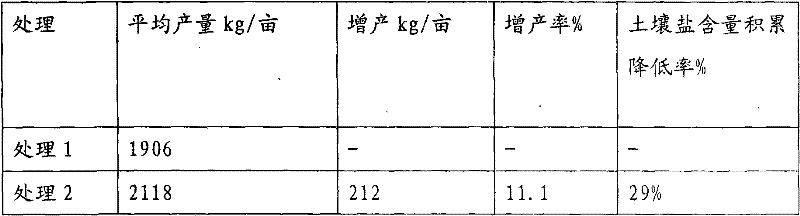

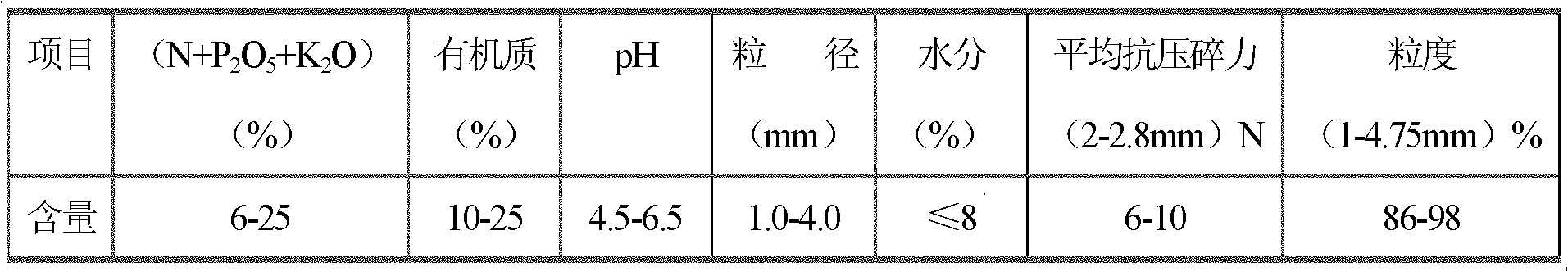

Pakchoi organic composite fertilizer

ActiveCN102351596AReasonable ratioFully absorb and utilizeBio-organic fraction processingOrganic fertiliser preparationSoil typeEffective microorganism

The invention relates to pakchoi organic composite fertilizer. The pakchoi organic composite fertilizer is characterized in that medium and trace elements needed by multiple plants are mixed with inorganic fertilizer and organic fertilizer; and simultaneously, auxiliary agents capable of improving an absorption and utilization rate for a plant and increasing fertilizer slow-release performances and effective microorganisms are added into the mixture to be prepared into specialized composite fertilizer particles through proper fermentation and processing. The pakchoi organic composite fertilizer has the advantages that scopes of suitable regions and soil types are wide; base fertilizer one-step application can be realized in fertilizer application and topdressing can be carried out later according to needs; pakchoi growth needs are satisfies; and effects of yield increase and harvest increase are realized.

Owner:SHANDONG BAOYUAN BIOTECH CO LTD

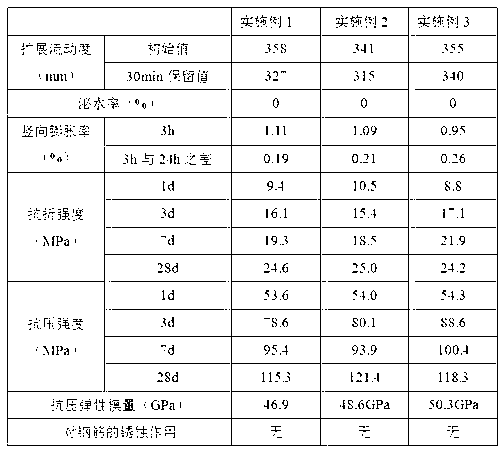

Ultrahigh-strength grouting material based on iron tailing sand and cement and preparation method of grouting material

InactiveCN102992722AGood dispersionImprove liquiditySolid waste managementCompressive strengthUltimate tensile strength

The invention relates to an ultrahigh-strength grouting material based on iron tailing sand and cement and a preparation method of the grouting material. The ultrahigh-strength grouting material is composed of the following components in proportion by weight: 30%-45% of cement, 45%-55% of iron tailing sand, 6%-15% of multielement mineral admixtures, 0.35%-1% of water reducing agent, 0.1%-1% of plastic retaining agent, 0.01%-0.1% of plastic expanding agent, and 2%-6% of shrinkage-compensating expanding agent. The preparation method comprises the steps of uniformly mixing all the components and then uniformly stirring the mixed components in water, wherein the ratio of the water to the materials is 0.09-0.11. The grouting material is good in flowability, is good in stability in a plastic stage, is free from shrinkage in the whole course from the plastic stage to a later hardening stage, and is ultrahigh in early strength, final strength and elasticity modulus, the 1d compressive strength of the material reaches up to 50MPa, the 28d compressive strength of the material can exceed 110MPa, and the 28d elasticity modulus of the material exceeds 45GPa, and therefore, the ultrahigh-strength grouting material is suitable for grouting of various important parts or areas with requirements on high strength and high modulus.

Owner:WUHAN UNIV OF TECH

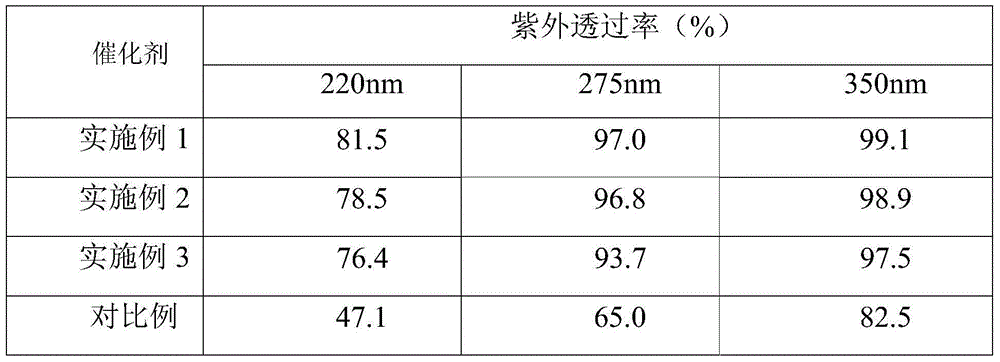

Ethylene glycol hydrofining method

ActiveCN104945227AEasy to makeLow costOrganic compound preparationHydroxy compound preparationTransmittanceAlloy

The invention discloses an ethylene glycol hydrofining method which adopts a composite hydrogenation catalyst. The catalyst comprises continuous-phase carbon and disperse-phase Raney alloy particles, wherein the disperse-phase Raney alloy particles are uniformly or nonuniformly dispersed in the continuous-phase carbon. The catalyst particles have high strength and high catalytic activity, and obviously enhance the ultraviolet transmittance of the hydrogenated ethylene glycol.

Owner:CHINA PETROLEUM & CHEM CORP +1

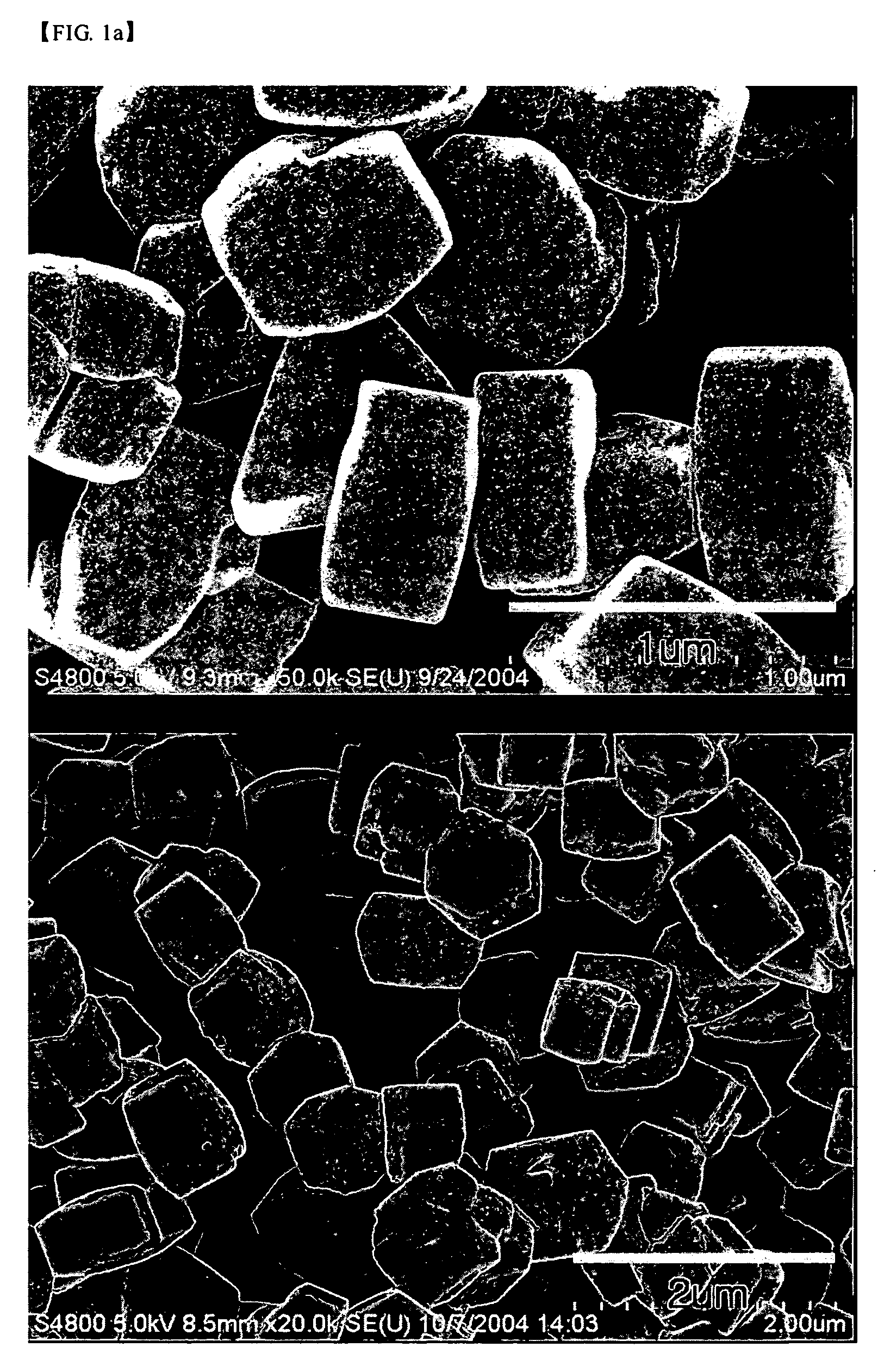

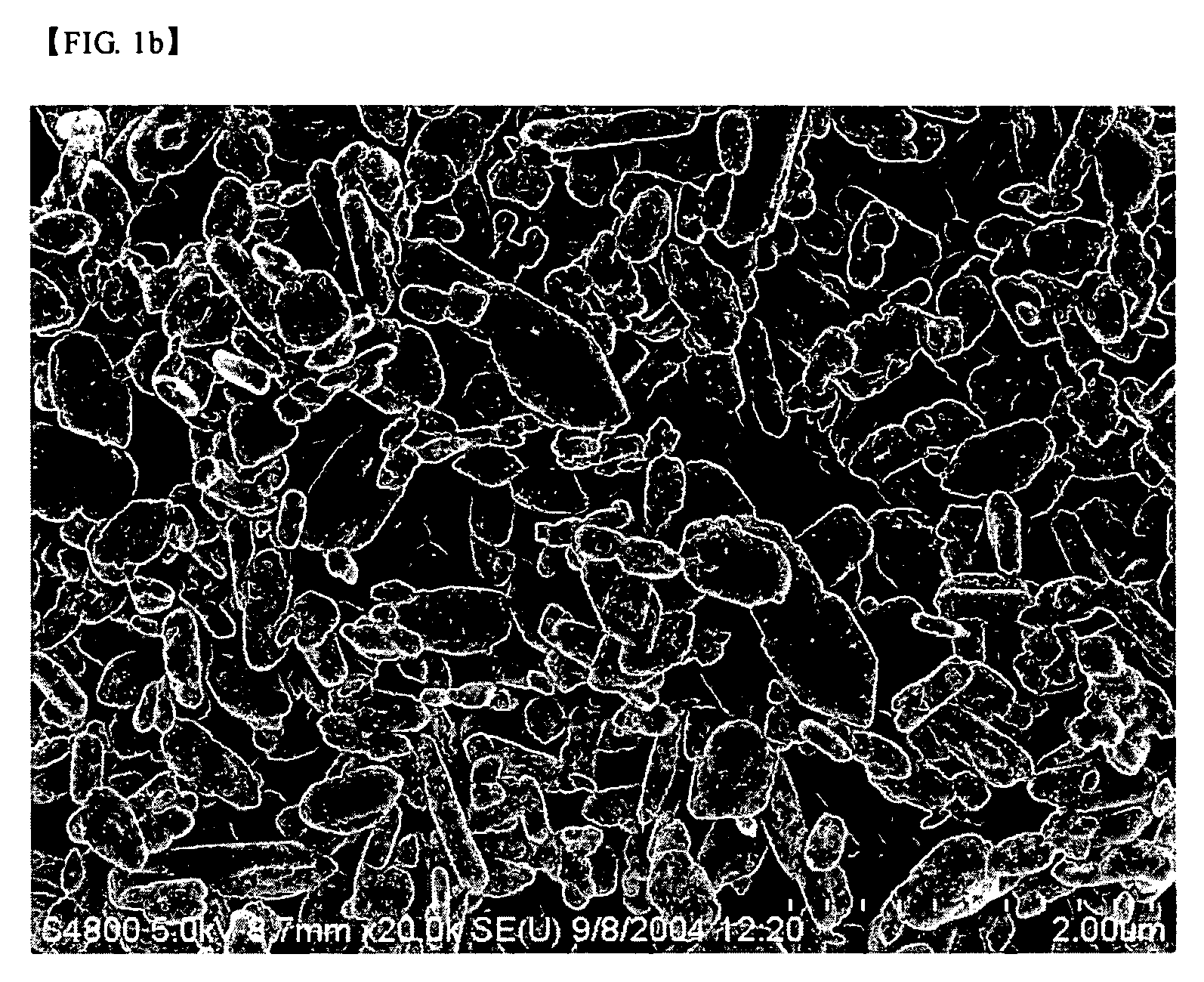

Cerium oxide abrasive and slurry containing the same

InactiveUS20060162260A1Dispersion force can be reducedSlow polishing rateMaterial nanotechnologyPigmenting treatmentCeriumCrystal structure

Disclosed are a cerium oxide abrasive for selectively polishing various SiO2 films and SiO2—Si3N4 films; and a slurry containing the same. The cerium oxide abrasive and the polishing slurry of the present invention have a high polishing rate and are also free from microscratches in a polished surface upon polishing since polycrystalline cerium oxide having a mean crystalline particle size of 5 nm or less is synthesized by using hexagonal cerium carbonate having a hexagonal crystal structure as a raw material of cerium.

Owner:LG CHEM LTD

Preparation method of naturally-degradable compound fertilizer anti-blocking agent and application thereof

The invention discloses a preparation method of a naturally-degradable compound fertilizer anti-blocking agent and an application thereof. The naturally-degradable compound fertilizer anti-blocking agent comprises the following components in percentage by mass: 10-20 percent of fatty amine or salt thereof, 20-25 percent of stearic acid, 15-20 percent of oleic acid, 5-15 percent of refined glycerin and 20-50 percent of waste edible oil and fat, and the sum of all the components is 100 percent according to the percentage. The preparation method comprises the following steps of: mixing all the components according to the proportion, heating to be 70 DEG C -85 DEG C, and stirring and reacting for 15 minutes-30 minutes. The used amount of the compound fertilizer anti-blocking agent is 05-2.0kg / t (compound fertilizer), and a granulation mode of a high air-cooling crystallization tower of an all-molten compound fertilizer is adopted to mix the naturally-degradable compound fertilizer anti-blocking agent with the compound fertilizer. In the preparation method and the application thereof, the processing is simple, the use cost is low, the anti-blocking performance is good, the purely natural and environmentally-friendly performances are achieved, the absorption of crops is convenient, the fertilizer effect is enhanced, and the soil is protected.

Owner:福建达安能源实业有限责任公司

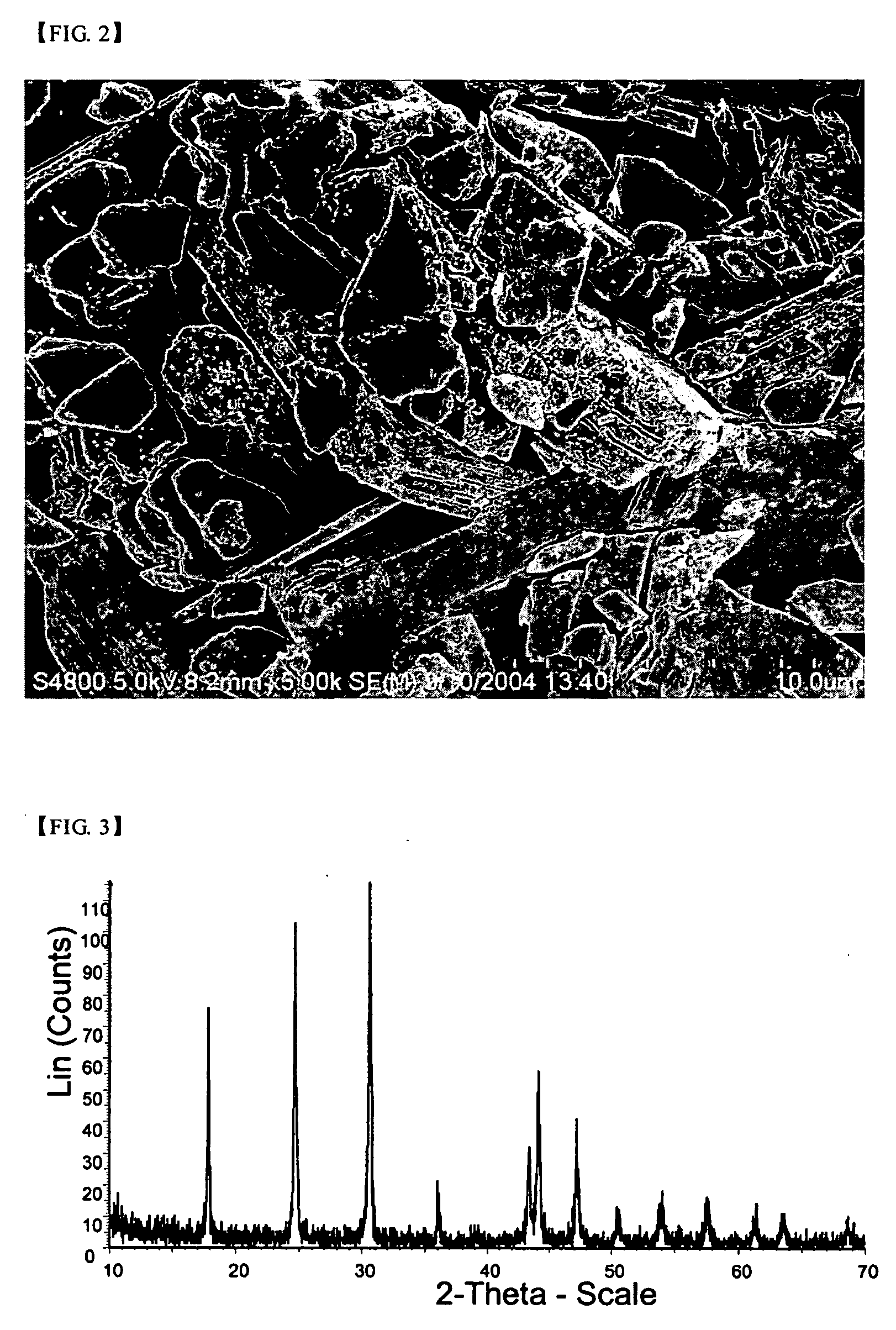

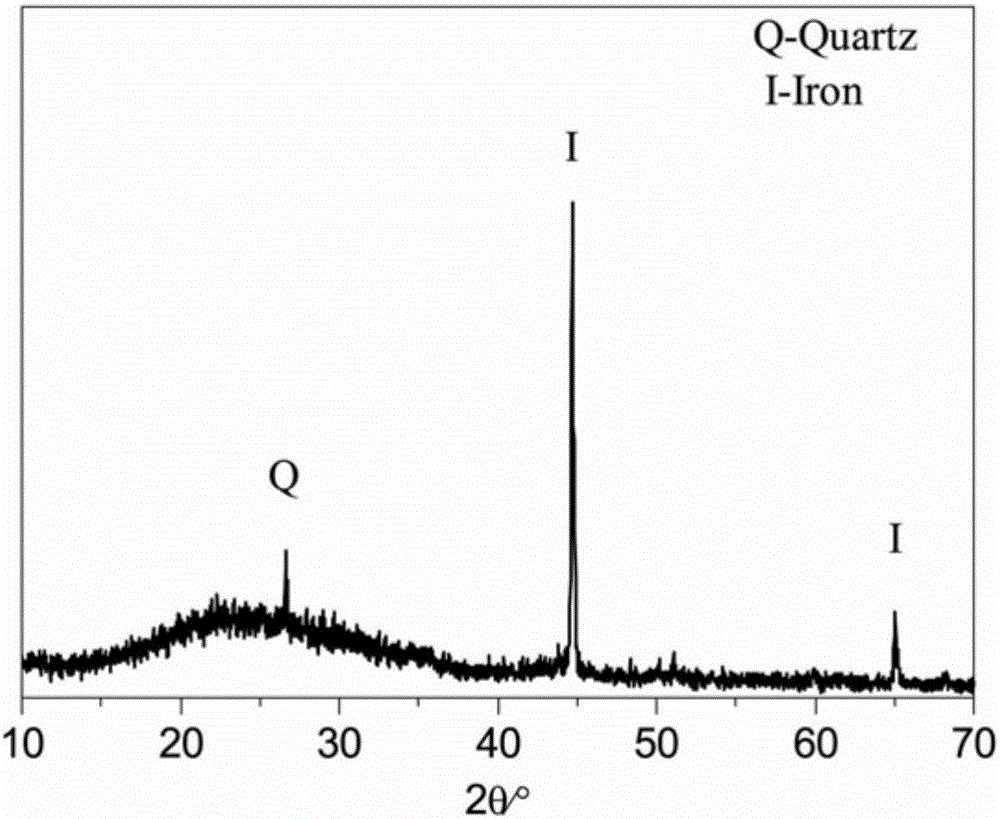

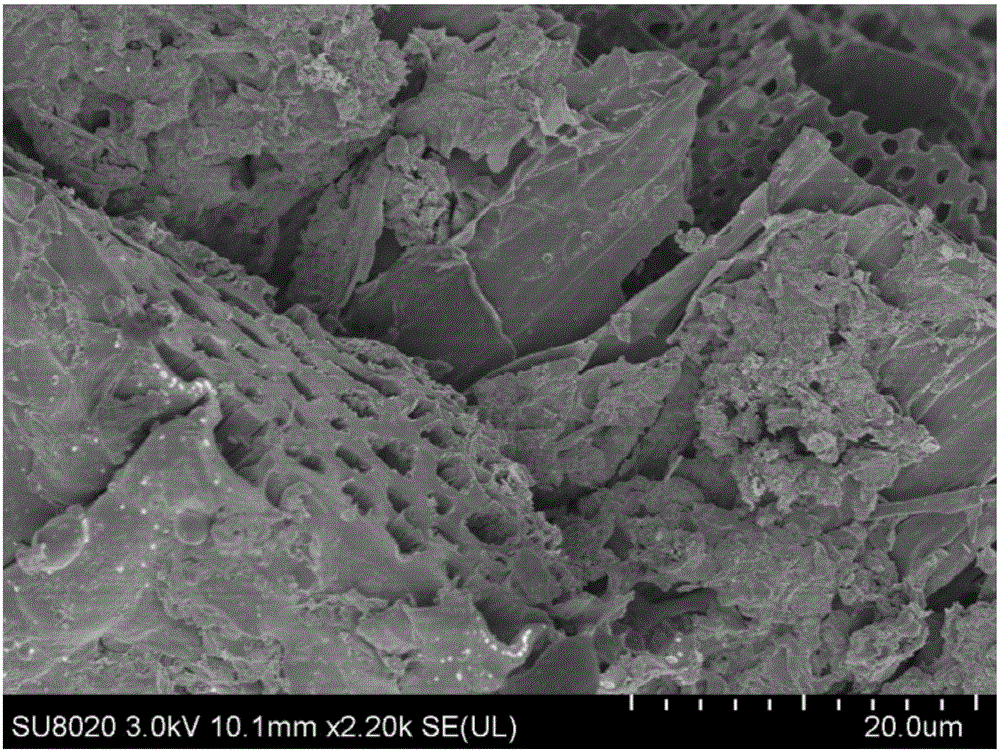

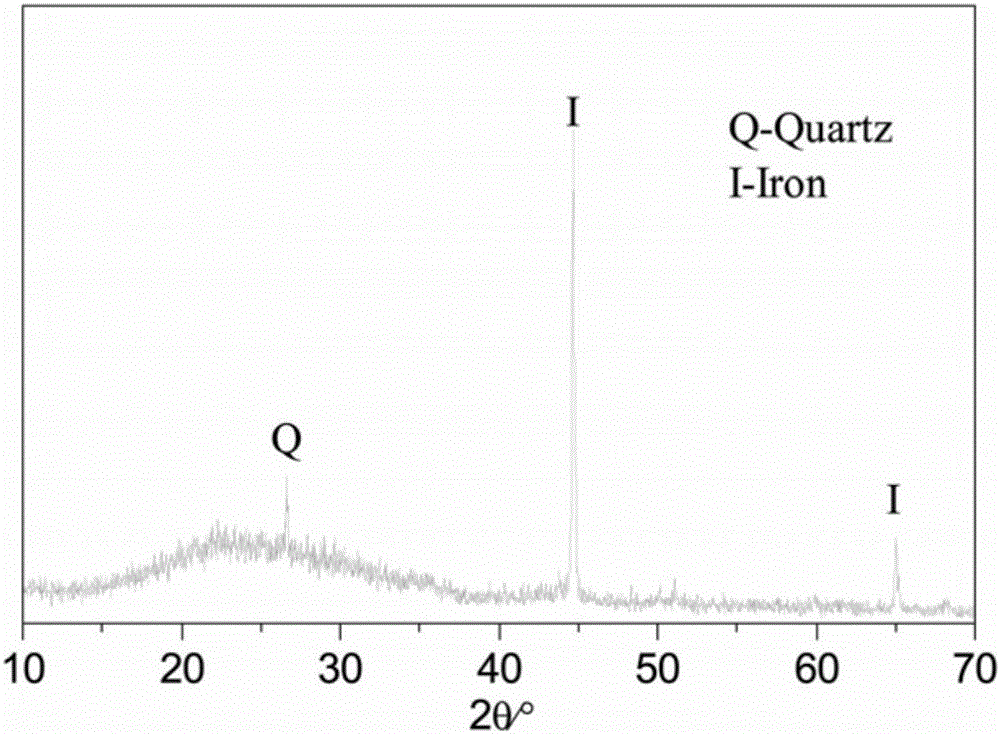

Fe/C composite porous structure material as well as preparation method and application thereof

ActiveCN105776506AHigh particle strengthHas a bonding effectTreatment using aerobic processesContaminated soil reclamationPorosityMagnetic susceptibility

The invention discloses a Fe / C composite porous structure material as well as a preparation method and application thereof. The Fe / C composite porous structure material is characterized by being prepared from low-grade sedimentary iron ore and biomass as raw materials in manners of crushing, mixing, extrusion molding and pyrolysis and reduction reaction in the presence of hydrogen atmosphere at 650-900 DEG C, wherein the main phase composition comprises biomass carbon and zero-valent iron. The Fe / C composite porous structure material disclosed by the invention is high in opening porosity, magnetic susceptibility, adsorbability and biological chemical activity, can be used for treating eutrophicated river water, living sewage and landscape water bodies, or can be used for mediation of underground water pollution and polluted soil.

Owner:HEFEI UNIV OF TECH

Double chelate compound fertilizer

InactiveCN101333131AImprove utilization efficiencySolve physiological diseasesOrganic fertilisersUrea compound fertilisersNutrientUrea

The invention discloses a two-chelating compound fertilizer, which is composed of chelates, potash fertilizer, urea and clay, and also can be joined with monoammonium phosphate based on needs. The two-chelating compound fertilizer of the invention has rational compatibility, simple process, low cost, high efficiency, good particle strength and balanced nutrients, which improves the soil and stimulates the development of plant roots to prevent disease in the process of crop growth due to lack of trace elements; the two-chelating compound fertilizer adds trace elements to the soil and has good organic matter effects, which is a novel efficient compound fertilizer.

Owner:SHANDONG CHUNYU FERTILIZER IND

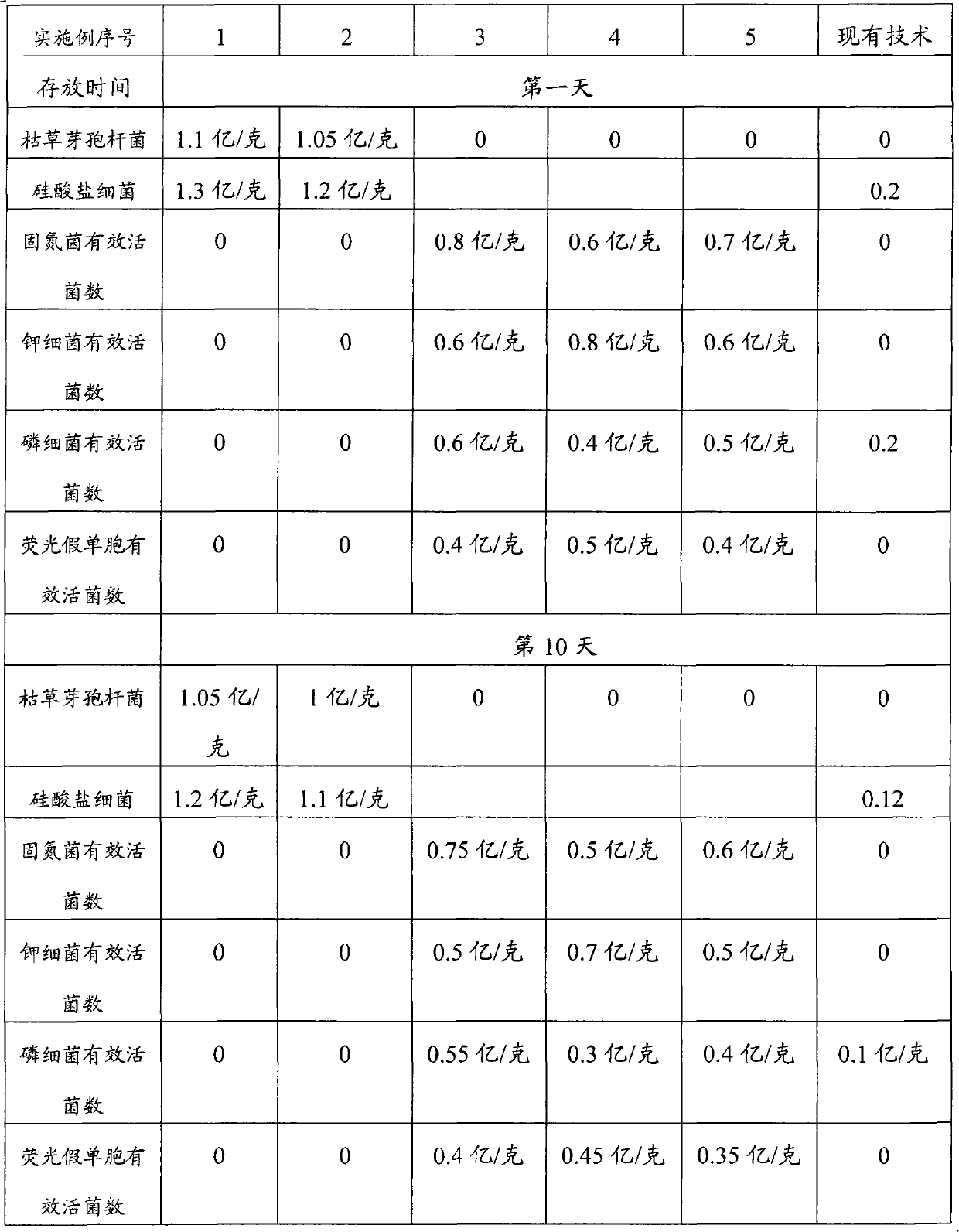

Composite microbial agent and production method thereof

ActiveCN101993305AImprove performanceIncrease productivityFertilizer mixturesMicrobial agentEffective microorganism

The invention relates to a composite microbial agent and a production method thereof. The composite microbial agent consists of a granular material core, a paraffin protective coating and a microbial agent coating layer between the core and the protective layer. The excellent product structure can ensure that the effective microbe content in the composite microbial agent is high, and the product has stable properties and high fertilizer efficiency and meets the requirements of various crops; and compared with the conventional biofertilizer, the composite microbial agent can improve the yield of food crops by 10 to 15 percent, improve the yield of cash crops by 8 to 14 percent, improve the yield of vegetables by 15 to 20 percent, and improve the yield of fruits by 15 to 25 percent. Throughthe production method, the granulation rate of the product is 95 percent, the granule strength of the product is high, and because the water content of the granular material is low, the energy consumption in the energy process is reduced, the production efficiency of drying equipment is improved and the investment of the drying equipment is reduced.

Owner:领先生物农业股份有限公司

Large-scale brown coal quality-improving process and apparatus

InactiveCN102757833AImprove utilizationComprehensive utilization of product quality improvementSolid fuelsSpecial form destructive distillationBrown coalMicrowave

The invention belongs to the technical field of brown coal quality improving, and relates to a large-scale brown coal quality-improving process and a large-scale brown coal quality-improving apparatus. According to the invention, an interrelated large-scale continuous brown coal quality-improving system is composed of three modules which are a tunnel internal-heat drying module, an external-heating microwave destructive distillation module, and a powdery brown coal molding and drying module. Because of large-amount water discharging, a brown coal block large-capillary framework is collapsed, so that the brown coal is naturally broken into small blocks and powder without mechanical disruption. The small-block brown coal is subjected to destructive distillation under high-temperature hot wind external heating and microwave coupling, until the blocks turn into semi-coke; water-containing coal gas, water-containing coal tar, anhydrous gas, and anhydrous coal tar are respectively obtained by destructive distillation. With a binder of the water-containing coal tar and coal tar pitch (one or a mixture thereof), the powdery brown coal is subjected to kneading and aging; the material is processed into granules by using a vacuum extrusion granulator; and the particles are processed by using a low-temperature microwave drying device, so that high-quality brown coal particles with high strength, low moisture absorption, and high heat value are obtained. The brown coal particles can endure long-distance transportation.

Owner:周灿旭

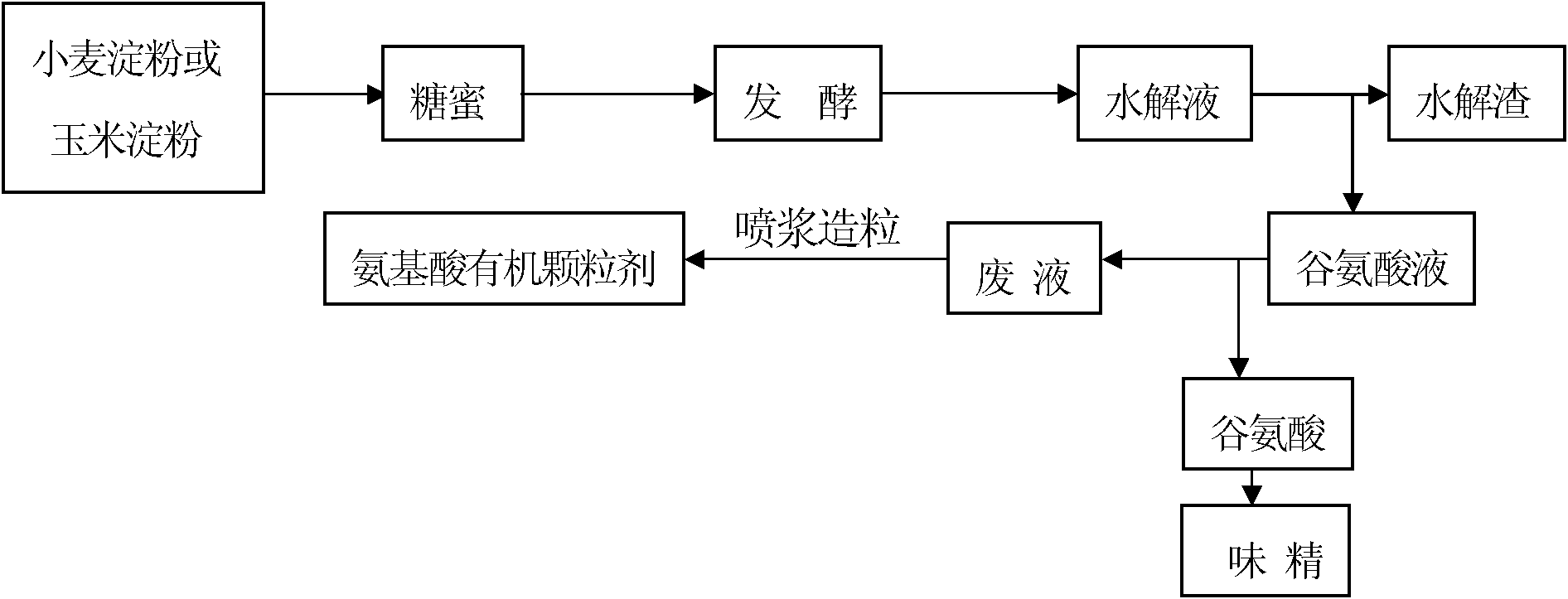

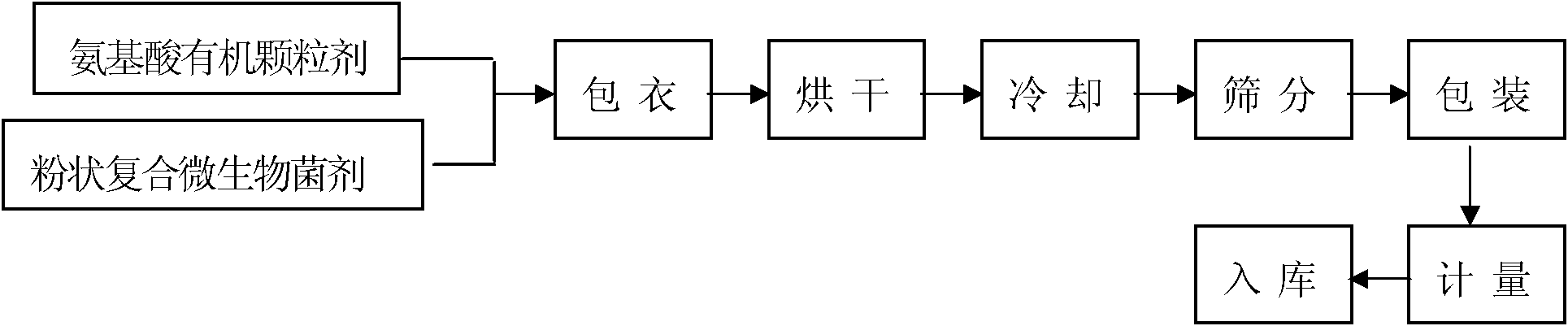

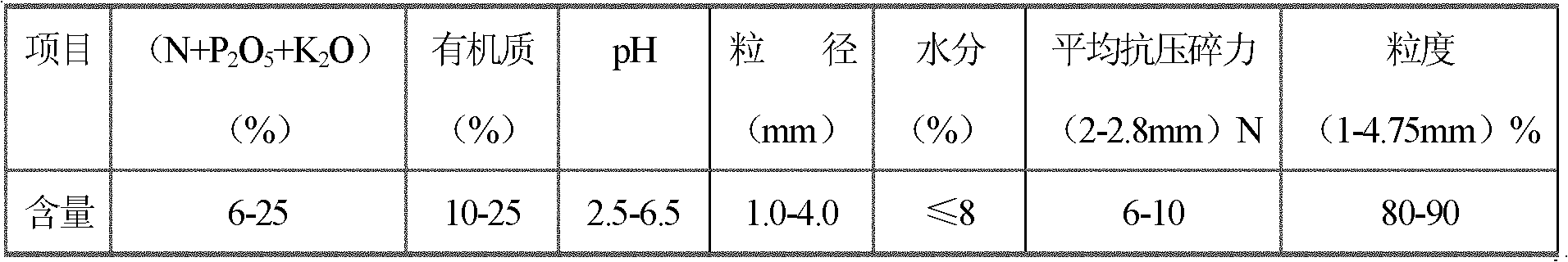

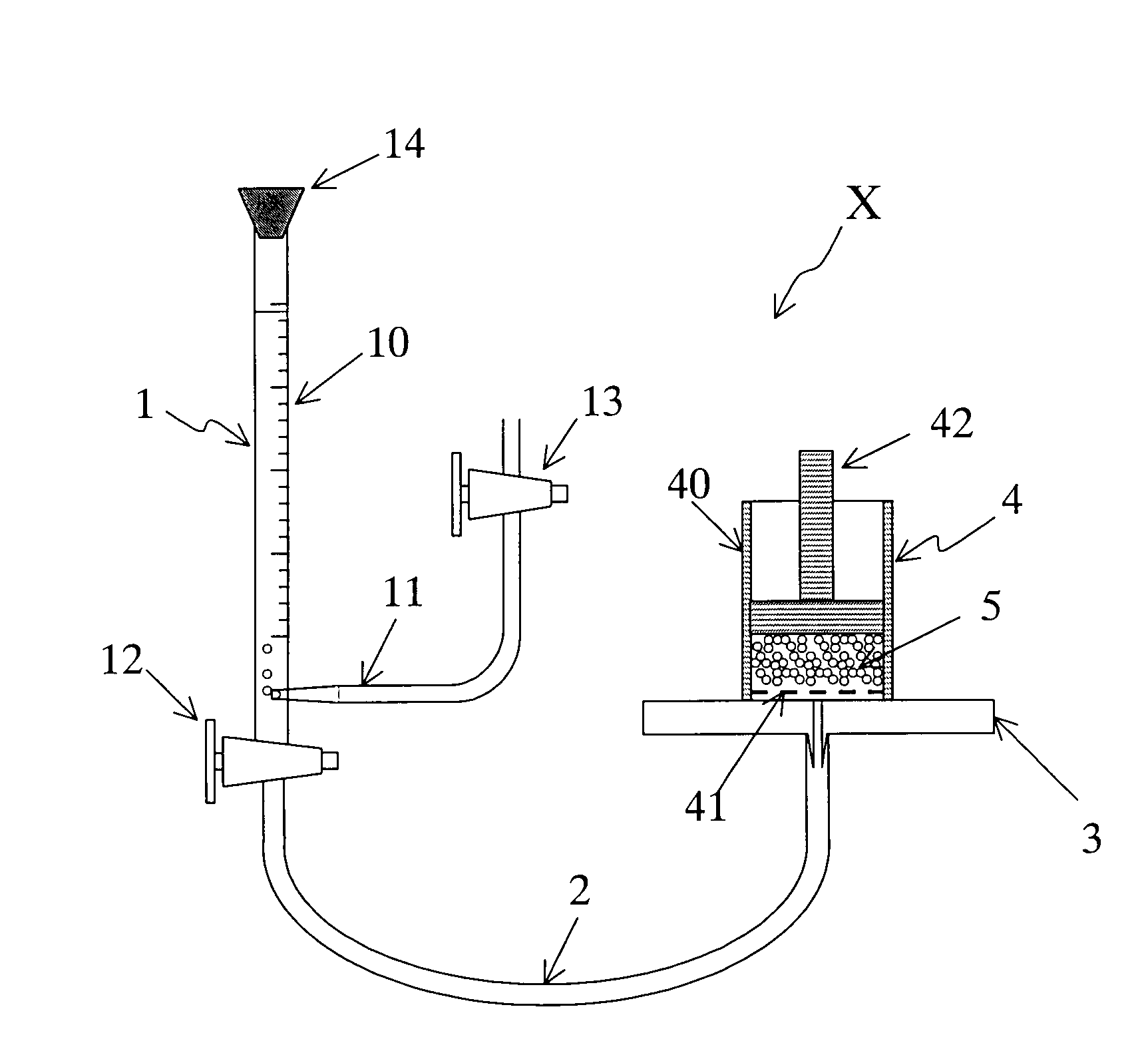

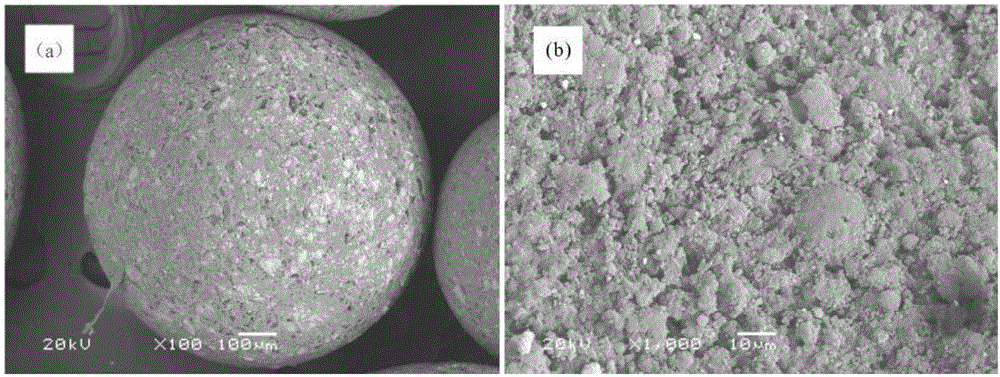

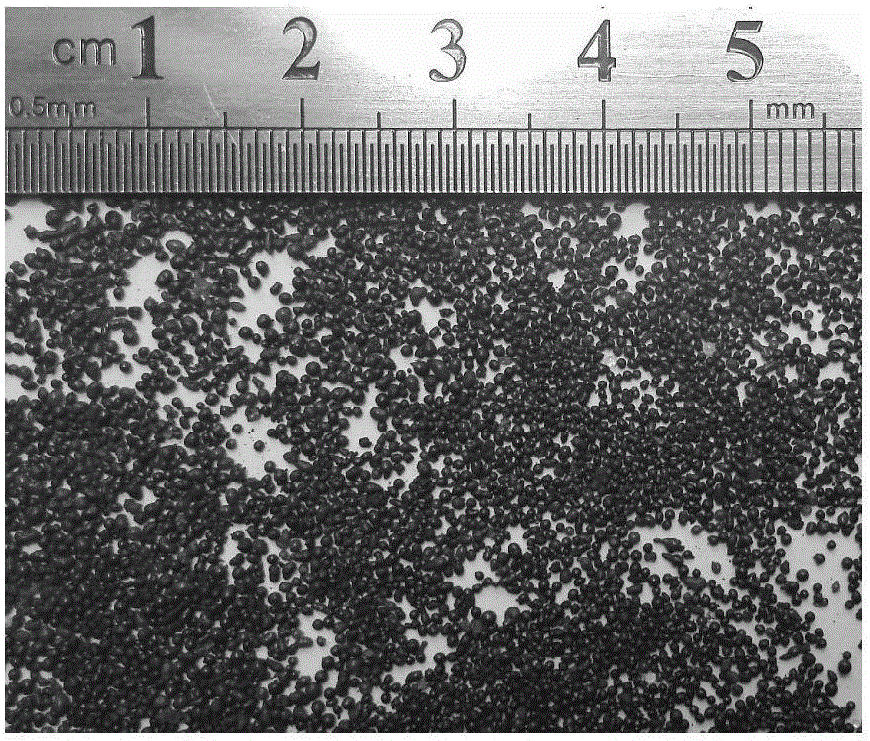

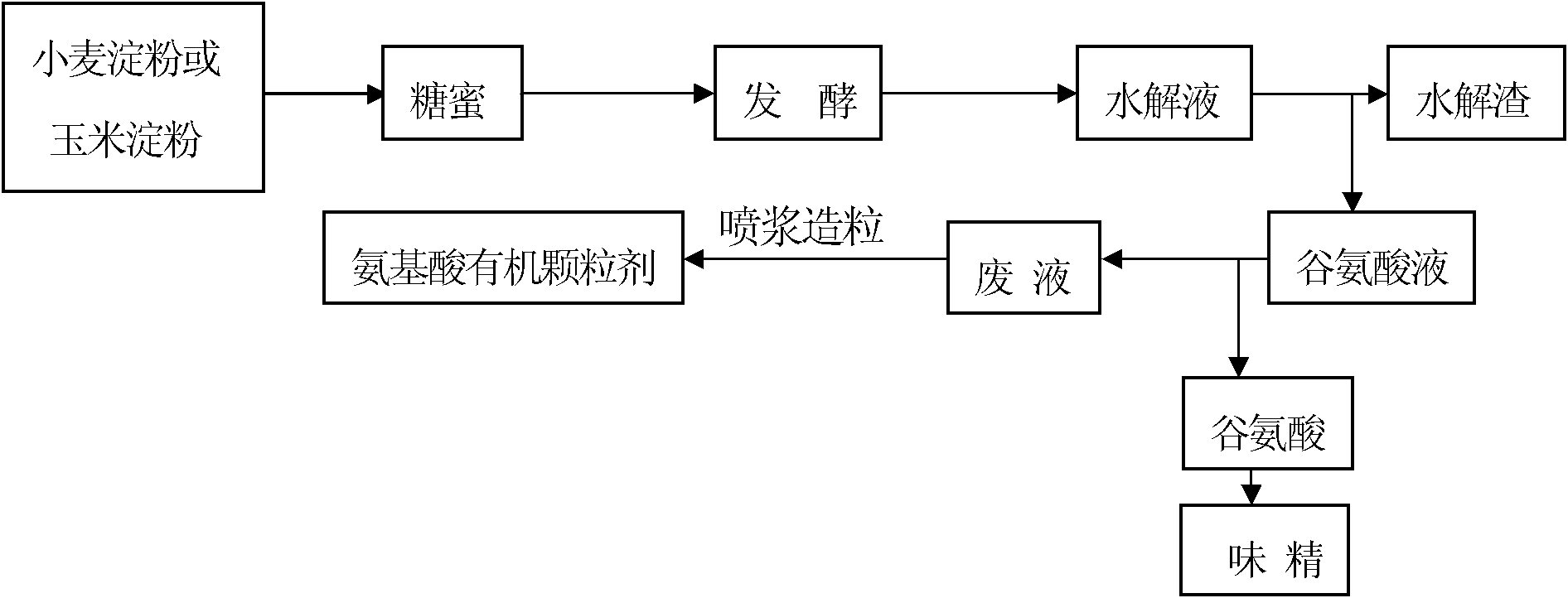

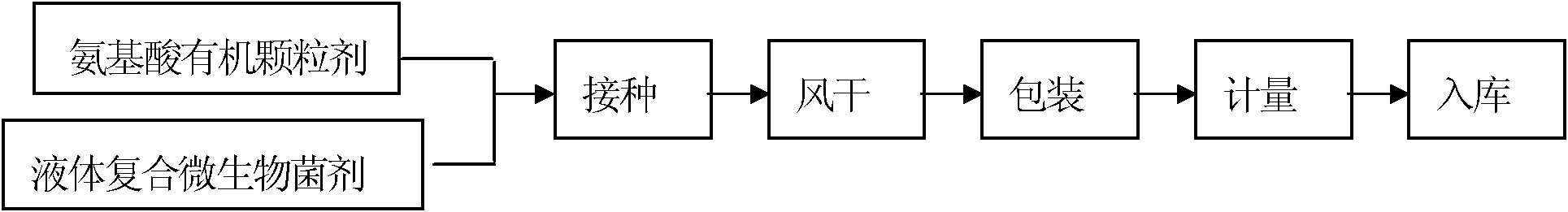

Production method of amino acid complex microorganism fertilizer

ActiveCN102040407ASolve ball problemSolve solubilityOrganic fertilisersSpray GranulationMicroorganism

The invention provides a production method of an amino acid complex microorganism fertilizer, in particular to a method for producing an amino acid complex microorganism fertilizer by using amino acid organic granules. The method comprises the following steps: preparing solid inoculant; pelleting amino acida liquid waste into organic granules; compounding the organic granules with solid powders; when compounding, adding powdery inoculant which accounts for 5-15% of the finished product complex microorganism fertilizer at weight ratio; and mixing, pelleting and drying, wherein the material temperature in a drying cylinder is not higher than 80 DEG C. The production method provided by the invention breaks the normal procedure and is divided into two steps of pelleting of the organic granules and the package of the organic granules, as well as ensures viable count in the complex microorganism fertilizer. The production method of the complex microorganism fertilizer provides a new process which realizes the breakthrough of the process from powder pelleting by a disc and a roller to spraying granulation, thus improving commodity and effectiveness of the complex microorganism fertilizer and laying a foundation for popularization.

Owner:SHANGHAI NUOTONG INFORMATION TECH CO LTD

High-strength ceramic granule filter material for treating water and its preparation method

The present invention relates to a high-intensity earthen granular filter material for water treatment and its production method. It includes base body and additive, in which said base body can adoptany one of kaoline, wheat-ball stone, bentonite, shale rock and flyash or mixture of more than two materials of them, and the described additive can adopt any one of iron ore, saw dust, coal powder, heavy oil, furfural dregs or polyvinyl glycol or mixture of more than two materials of them. Its production method includes the processes of granulation and sintering.

Owner:上海申威陶粒制品有限公司

Hollow glass mineral agent

InactiveCN1736554AReduce manufacturing costHigh particle strengthDispersed particle separationSilicon compoundsAbsorption ratioDesiccant

The invention discloses a glazing glass mineral desiccant, the technique highlight of which is that, the glazing glass mineral desiccant comprises warp clay, sodium-hydroxide, calcium oxide, diatom earth, and high-alumina earth, and the product is prepared after milling, granulating, drying, sifting, and packing. It has a good stability, a high wet absorption ratio, and a strong intensity. And it can apply to glazing glass devices and other location needing to keep dry.

Owner:许盛英

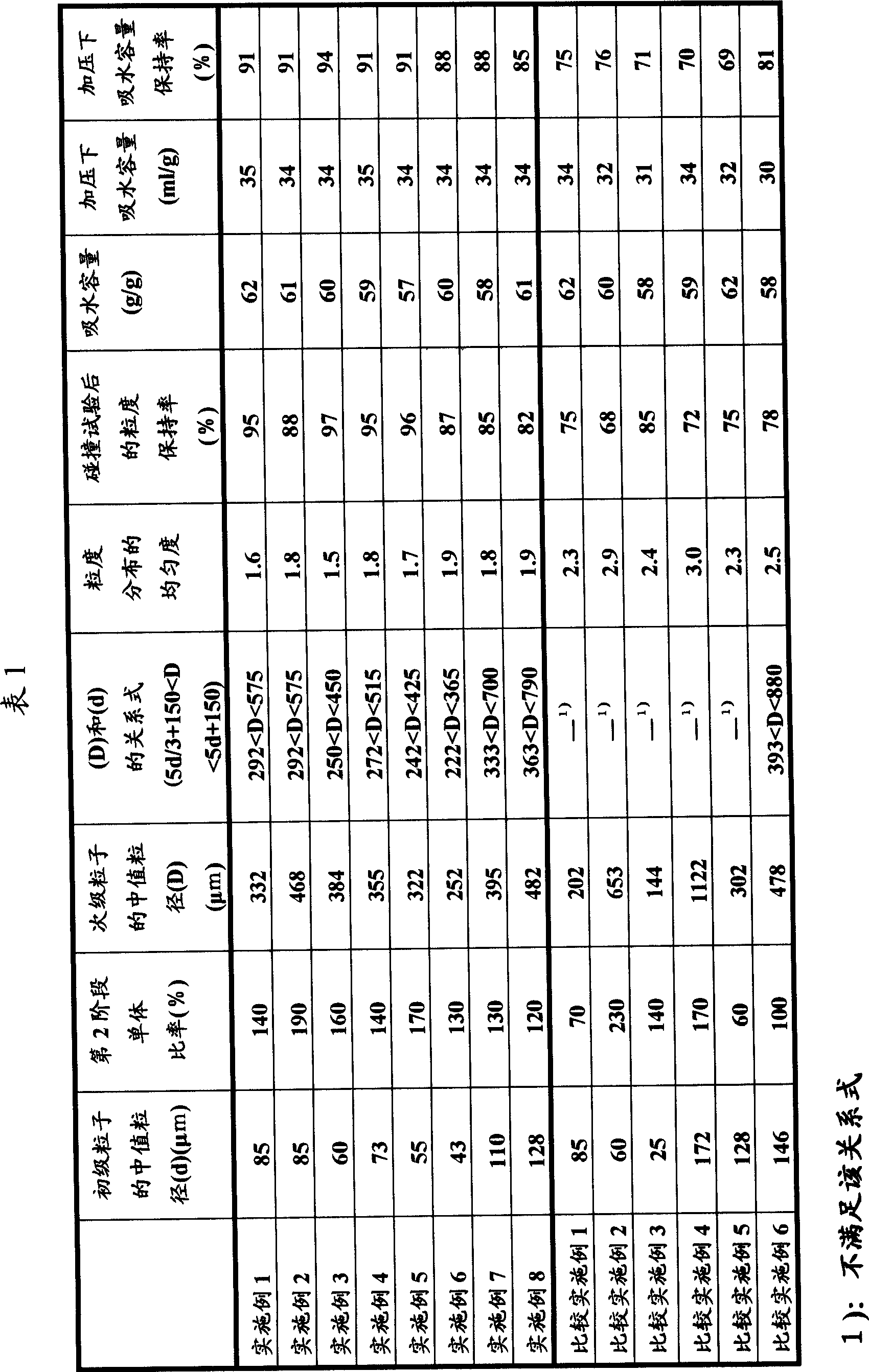

Process for production of water-absorbable resin particle, and water-absorbable resin particle produced by the process

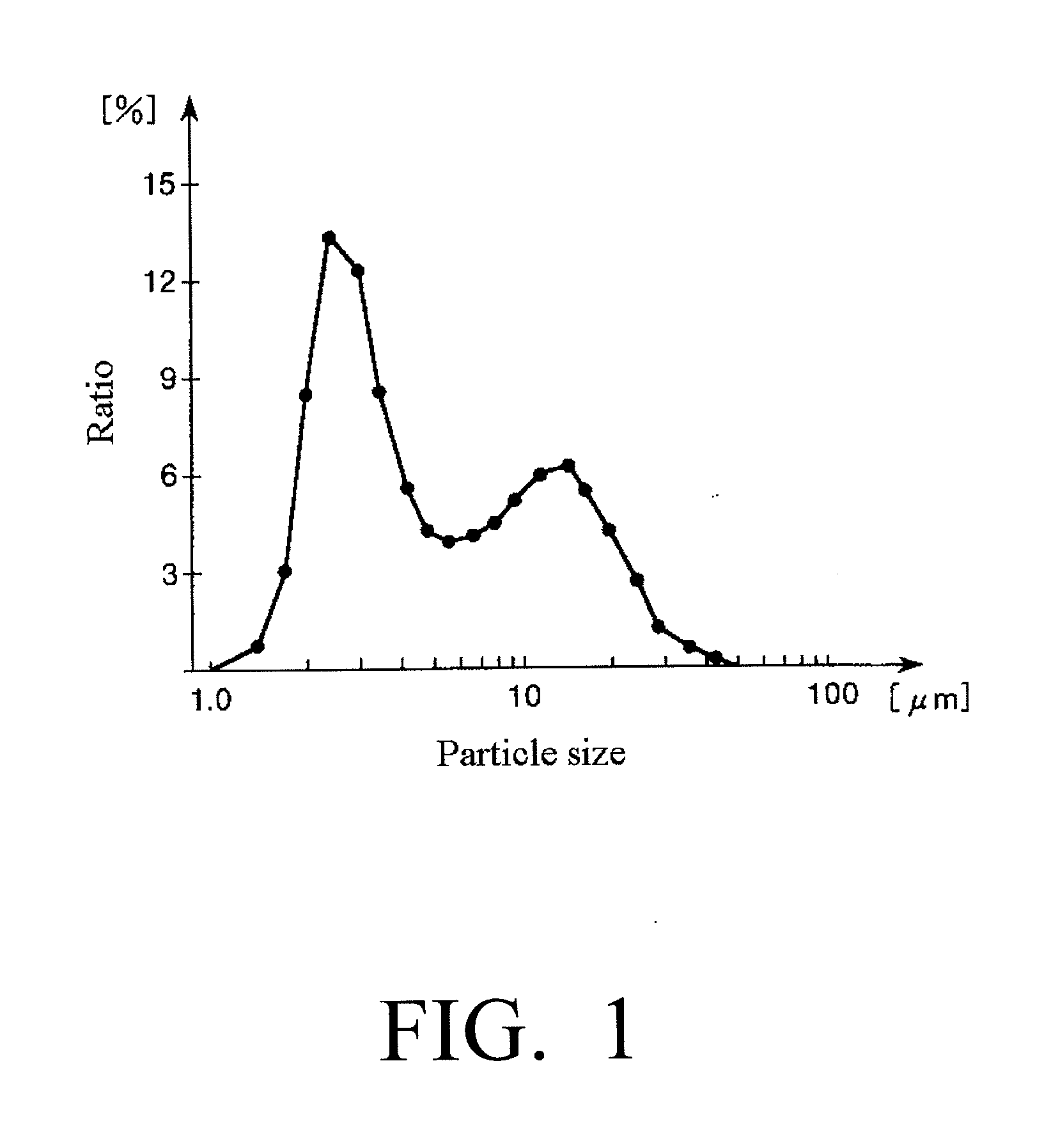

ActiveUS20090281247A1High particle strengthImprove water absorptionSynthetic resin layered productsCellulosic plastic layered productsHydrocarbon solventsWater soluble

The present invention relates to a method of producing water-absorbent resin particles in which a median particle size of primary particles (d) and a median particle size of secondary particles (D) satisfy the relationship of the formula, 5d / 3+150<D<5d+150, comprising the steps of: (1) subjecting a water-soluble ethylenically unsaturated monomer to a first-step reversed phase suspension polymerization reaction, in a petroleum hydrocarbon solvent, in the presence of a dispersion stabilizer, to give spherical primary particles having a median particle size (d) of from 30 to 130 mum; (2) cooling the polymerization reaction solution, to precipitate the dispersion stabilizer; and (3) carrying out a second-step reversed phase suspension polymerization reaction by adding the water-soluble ethylenically unsaturated monomer for the second step to the polymerization reaction solution to agglomerate the primary particles, to give secondary particles having a median particle size (D) of from 200 to 500 mum.

Owner:SUMITOMO SEIKA CHEM CO LTD

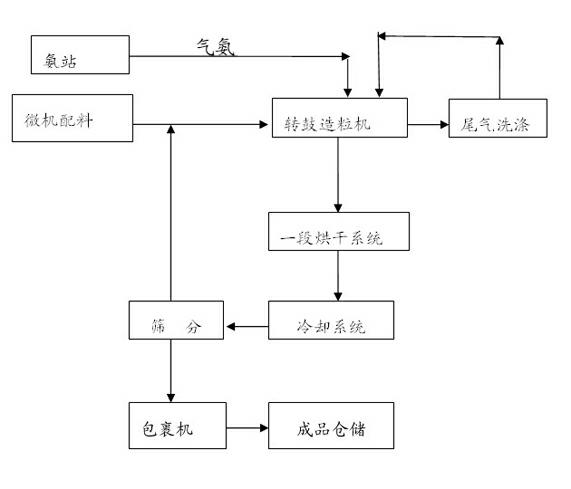

Production method of readily available and controlled release composite fertilizer containing three nitrogen elements

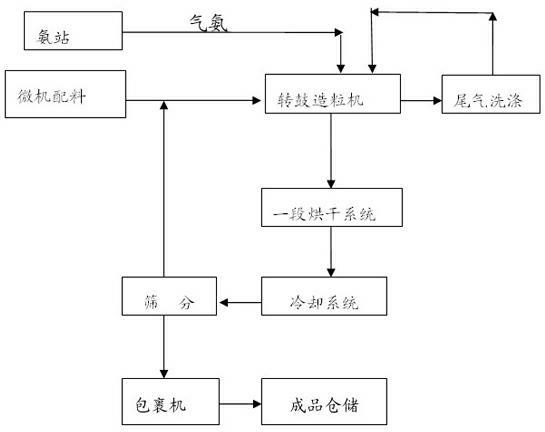

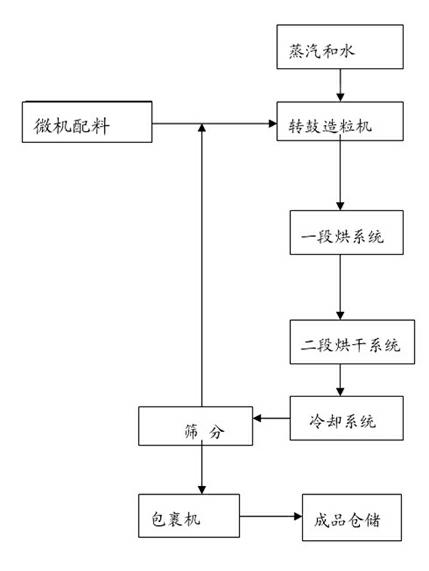

The invention discloses a production method of a readily available and controlled release composite fertilizer containing three nitrogen elements. The production method is as follows: raw materials containing nitric nitrogen, ammonium nitrogen and amido nitrogen are added in materials; in order to prevent that urea reacts with nitro phosphate fertilizer to generate too much urea nitrate and the production can not performed, ammonia gas is introduced in the granulation process according to different proportions to ammonify nitro phosphate fertilizer, reduce the generation of urea nitrate and increase the neutralization degree of monoammonium phosphate; and powdery fundamental fertilizers containing nitrogen, phosphorous and potassium are added to granulate, and then the composite fertilizer can be obtained through drying, cooling, screening and coating. In the production method of the invention, a lot of heat generated in the thermolysis of the nitro phosphate fertilizer and the neutralization heat of the reaction of ammonia gas and monoammonium phosphate are fully utilized to heat materials and increase the granulation temperature; and the viscosity of urea nitrate is utilized, the solubility of ammonium phosphate salt is increased, the quantity of the liquid phase for granulation can be satisfied, higher granulation rate can be realized without using other adhesive, the cost is reduced, the water content of the granulation material is significantly reduced, the drying energy consumption can be reduced and a large amount of energy consumption can be saved.

Owner:天津芦阳肥业股份有限公司

Control method for preventing caking and chalking of high-tower nitro-sulfenyl compound fertilizer

ActiveCN102875216AHigh particle strengthHigh glossFertilizer mixturesPhosphoric acidAmmonium nitrate

The invention discloses a control method for preventing caking and chalking of high-tower nitro-sulfenyl compound fertilizer. The method comprises steps as follows: adding ammonium nitrate and / or nitro-phosphorus compound fertilizer and ammonium phosphate to a melting groove to be molten, so as to obtain co-melting size; transferring the co-melting size into a mixing system; and adding phosphatic fertilizer, potash fertilizer, medium trace element, magnesium sulfate monohydrate and filling materials to be uniformly mixed to obtain the mixing size; transferring the mixing size into an emulsifying system to be broken, diffused and homogenized, so as to obtain emulsion size; transferring the emulsion size into a granulation system for granulation; and then carrying out steps of heat exchange through a tower body, cooling, sieving and surface treatment and the like. According to the control method disclosed by the invention, the magnesium sulfate monohydrate is added to the mixing size, so that the particle strength of the product is averagely increased by 4 to 12N by being compared with the particle strength of the product without adding the magnesium sulfate monohydrate or without improving the melting or mixing temperature, and the free water is reduced by 0.2 to 0.4%, and the caking and chalking of the stocked product are effectively prevented, and the time of the chalking can be prolonged.

Owner:GUIGANG BATIAN ECOLOGY

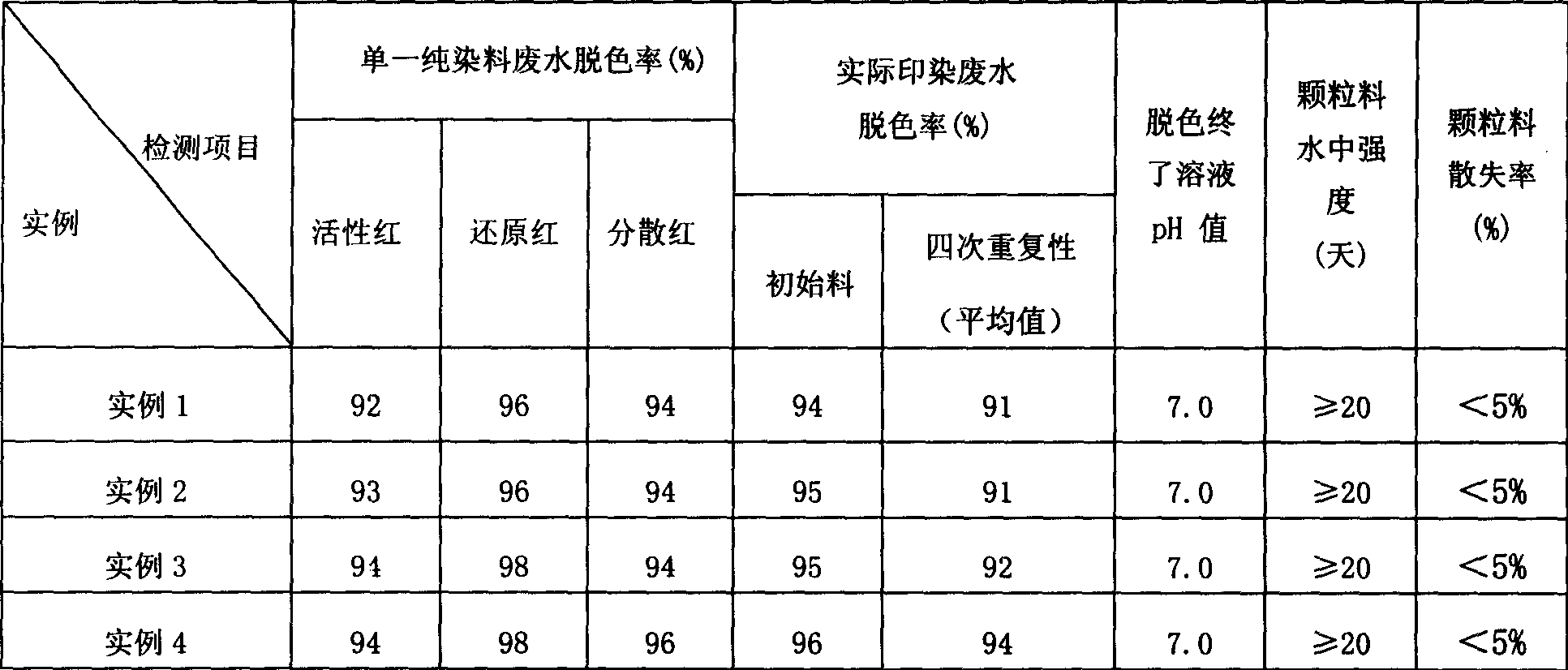

Method for preparing decoloring material of dyeing waste water by attapulgite ore

InactiveCN1843950AWith physical adsorptionExcellent chemical flocculation and decolorizationWater/sewage treatment by flocculation/precipitationWater/sewage treatment by sorptionManganeseRoom temperature

The invention relates to method for preparing decolouring material for printing and dyeing wastewater, which employs concave-convex stick mineral as main raw material (80-100 mu), mixing with sulfuric acid of 1.5-3.0 mol / l, the ratio between solid and liquid is 1:2-3, activating under room temperature for 1-2 hours; adding 0-5% of metallic sulphate such as iron, manganese and alumium (weight by metallic oxide); neutralizing with basic solution of 3-6 mol / l to make pH be about 7-8; solid-liquid separating, granulating (3-5 mm), drying, calcining under 700 Deg. C for 0.5-2 hours, and getting product. The invention can get side product of Na2SO4 10H2O or (NH4)2SO4 from filtering liquor; the decoloring material can be reused for more than four times after being immersed with ammonia sulfate of 1.5-6.0 mol / l for 2-5 minutes and calcined under 300 Deg.C for 5-25 minutes; the decoloration rate is over 94%, and decoloration rate with reused decoloraing material is over 91%. The invention is characterized by simple producing process, low cost and no pollution.

Owner:SICHUAN UNIV

Process for production of water-absorbable resin particle, and water-absorbable resin particle produced by the process

ActiveCN101466740AHigh particle strengthImprove water absorptionOther chemical processesThin material handlingHydrocarbon solventsWater soluble

Owner:SUMITOMO SEIKA CHEM CO LTD

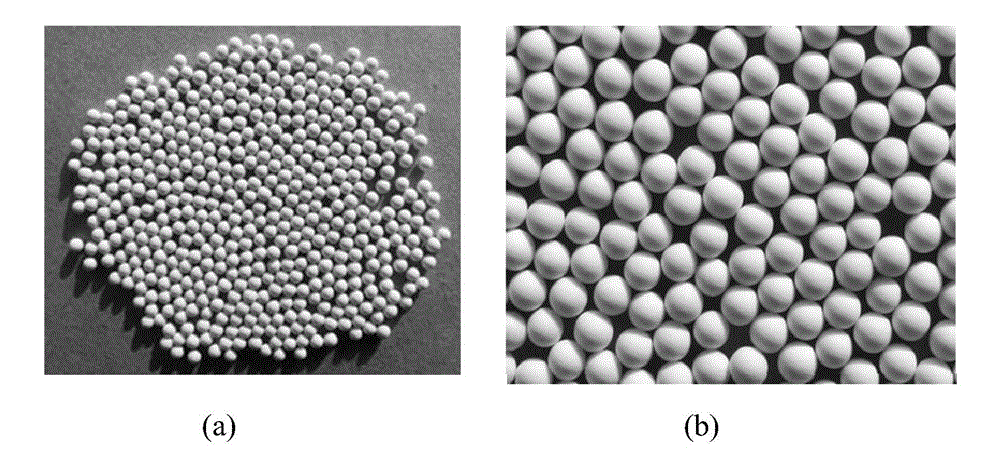

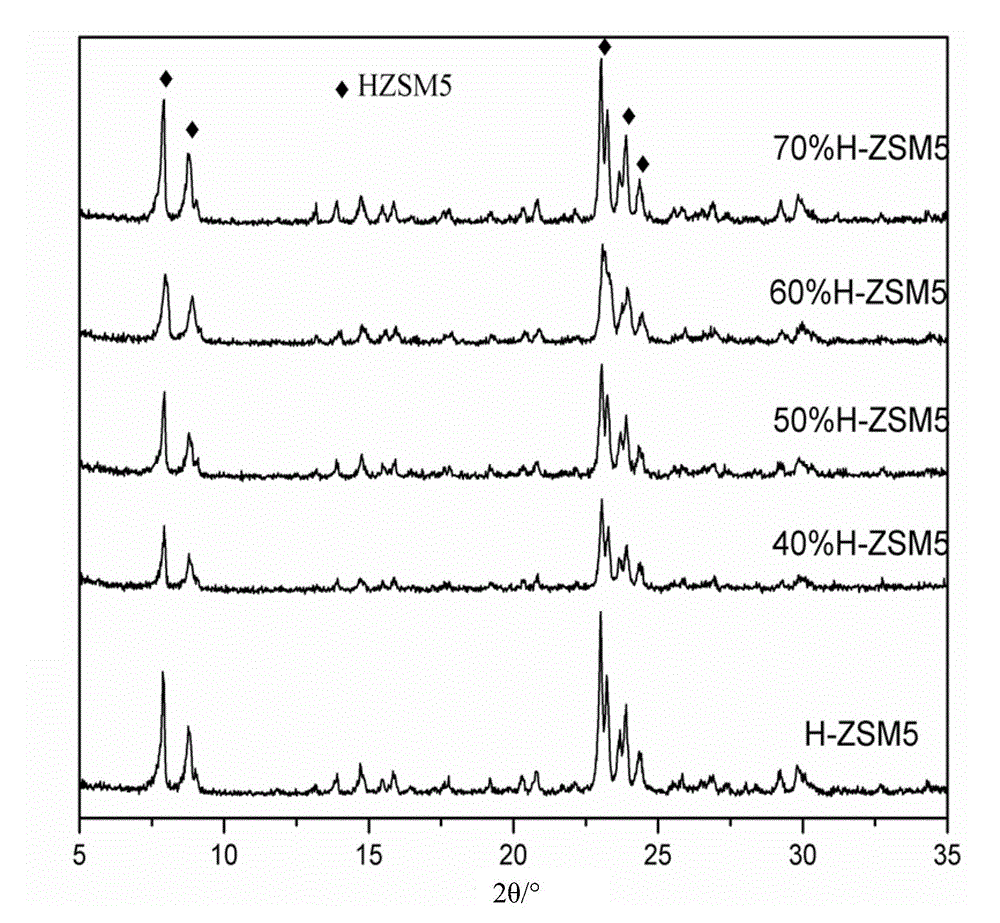

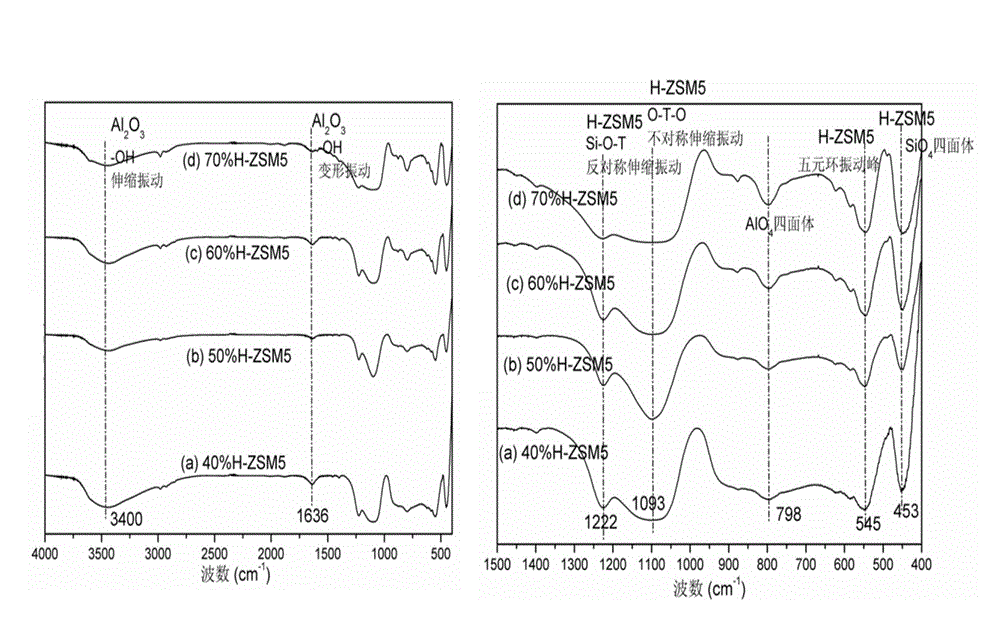

Preparation method of spherical molecular sieve catalyst

InactiveCN104549553AUniform particle sizeThe size is easy to controlMolecular sieve catalystsMolecular sieveSlurry

The invention provides a preparation method of a spherical molecular sieve catalyst. The method comprises the following steps of mixing alumina sol, a molecular sieve and organic amine so as to obtain slurry, molding the slurry by an oil column molding method, then aging, drying and roasting sequentially. The method provided by the invention can be used for preparing spherical molecular sieve catalyst which is uniform in particle size and controllable in size, and moreover, the prepared spherical molecular sieve catalyst has relatively high particle intensity.

Owner:CHINA PETROLEUM & CHEM CORP

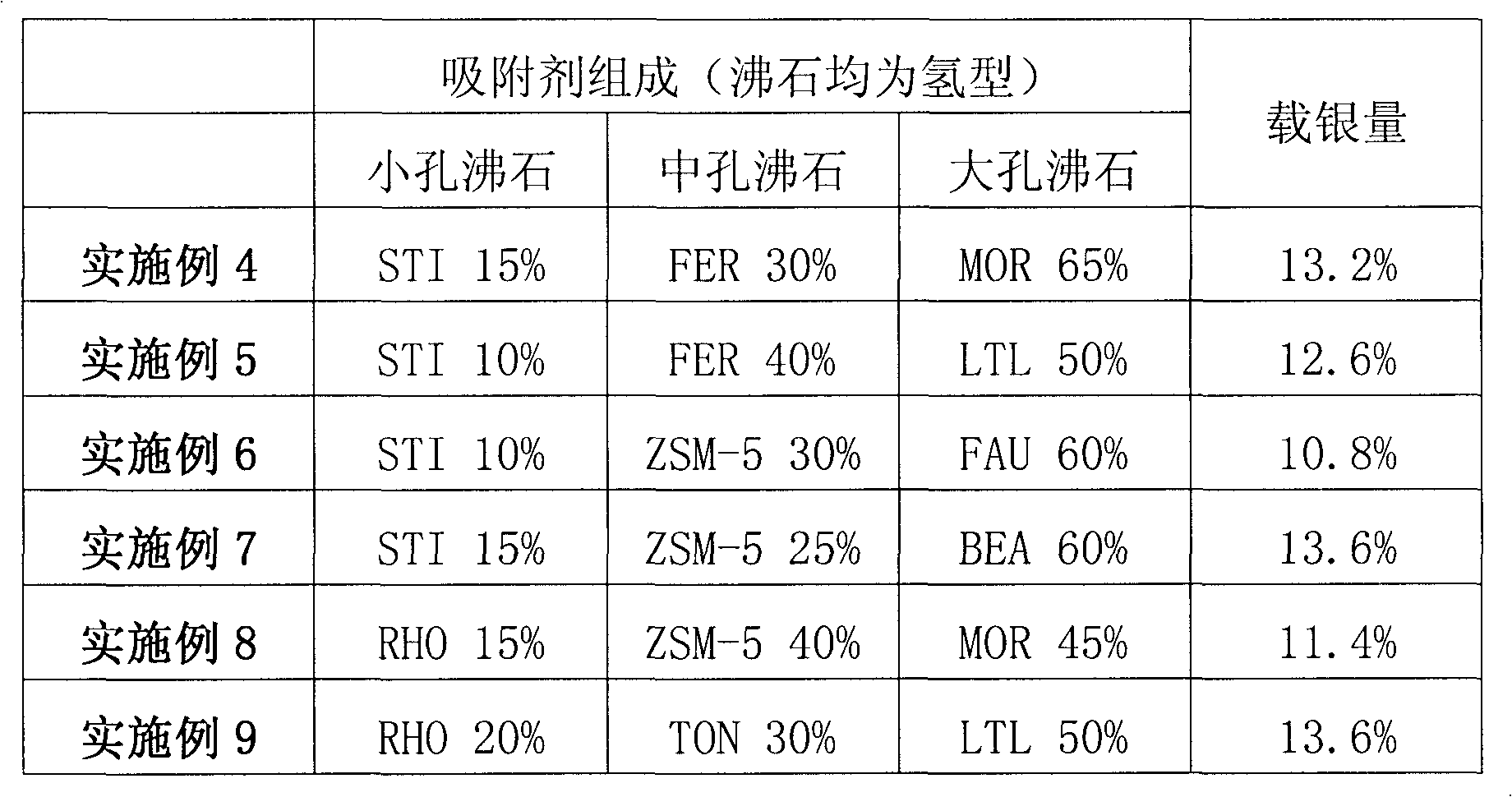

Preparation method, product and applications thereof of acetate deep deiodination adsorbent

InactiveCN101811023AHigh degree of crystallinityHigh particle strengthOther chemical processesCarboxylic compound separation/purificationAdhesiveSorbent

The invention relates to preparation method, product and applications thereof of an acetate deep deiodination adsorbent. The method comprises the following steps of: mixing small-pore, medium-pore and large-pore zeolite molecular sieves with different structures; forming by using an adhesive; generating chemical bonds by hydrothermal strengthening treatment; removing sodium and loading silver by ion exchange to prepare the product. The adsorbent is prepared from the following components in percentage by weight: 10-30% of small-pore zeolite, 20-50% of medium-pore zeolite and 20-70% of large-pore zeolite, and the adhesive accounts for 10-30% of the total weight of the adsorbent. The invention has the advantage that the adsorbent has strong adsorption capability on organic iodide, inorganic iodide and molecular iodine with different sizes in the strong acid medium, the total iodine content in the deep deiodination product is less than 5*10<-9>, and the adsorbent is suitable for being used as raw materials which are used for synthesizing vinyl acetate.

Owner:SHANGHAI FUXU MOLECULAR SIEVE

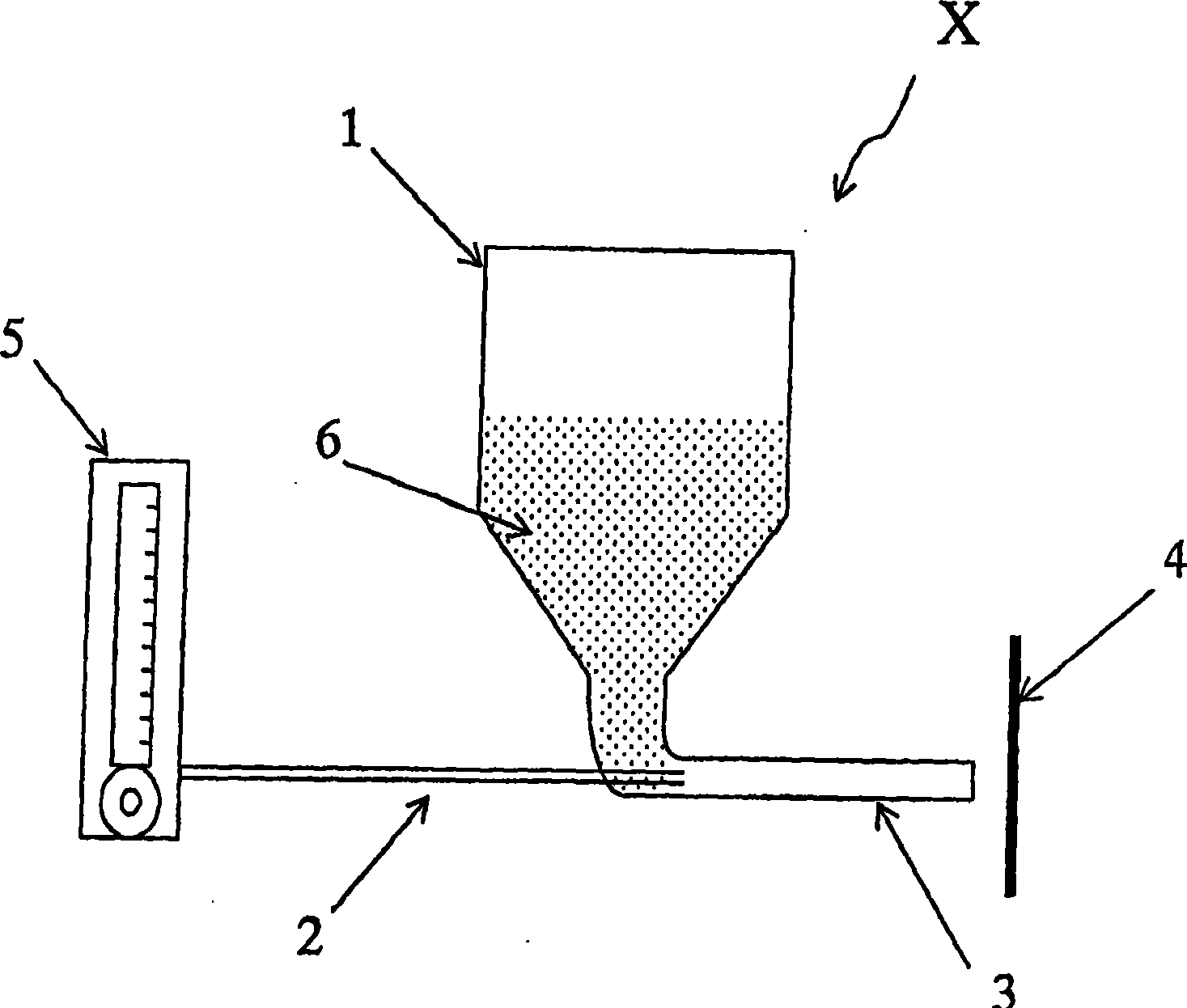

Preparation method of novel granular potassium chloride fertilizer

ActiveCN103819271AImprove granulation performanceHigh particle strengthFertilizer mixturesFertilizerNutrient

The invention discloses a preparation method of a novel granular potassium chloride fertilizer. The preparation method is characterized by comprising the following steps: adding a granular-making additive which accounts for 1%-20% of the total material amount into a raw material potassium chloride, uniformly mixing and putting the mixture into an agglomeration granulator, drying, cooling, and screening to obtain the novel epigranular pellet-shaped potassium chloride. The granular-making additive is powdery magnesium oxide. According to the invention, magnesium oxide is added into powdery potassium chloride. The powdery magnesium oxide plays a role in bonding and granulation and also plays a role in providing the nutrient element Mg required by crops. Diameter of the prepared novel granular potassium chloride fertilizer is 2-4 mm, and its granular strength is 40-60 N.

Owner:HUBEI FORBON TECH

Method for preparing vermicompost activated carbon by utilizing vermicompost

InactiveCN102688745AImprove qualityReduce energy consumptionOther chemical processesEnvironmental resistanceHigh absorption

The invention relates to the technical field of the preparation of novel environment-friendly absorbing agents, and in particular relates to a method for preparing vermicompost activated carbon by utilizing vermicompost. The method comprises the following steps of: airing and drying vermicompost; then crashing, grinding and screening; then immersing by a composite activated agent water solution; then filtering; putting a solid obtained through filtering into an activating oven; heating, preserving the temperature and activating, and then taking out; then immersing by diluted hydrochloric acid; then filtering; washing a filtered cake in an ultrasonic reactor, and then rinsing by deionized water to be neutral; and then drying, crashing and screening, thereby obtaining the vermicompost activated carbon. The vermicompost activated carbon prepared by the method provided by the invention has high absorption capability, has high particle intensity, has a good effect for removing pollutants, is a favorable absorbing agent and a favorable deordorant, and has favorable absorption effect for waste water, heavy metal and foul gases. The method for preparing vermicompost activated carbon by utilizing vermicompost provided by the invention has dual beneficial effects of environment friendliness and economy.

Owner:HENAN UNIV OF SCI & TECH

Slowly/control released fertilizer special for field and its production process

InactiveCN1974493AGood effectImprove nitrogen use efficiencyAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersFertilizerRosin

The present invention discloses one kind of slowly / control released fertilizer specially for field and its production process. The fertilizer consists of urea 30-45 weight portions, monoammoium phosphate 10-45 weight portions, mixture of calcium oxide and magnesium oxide as the coating material 20-45 weight portions, mixture of phosphoric acid and sulfuric acid as the adhesive 10-15 weight portions, and industrial alcohol solution of rosin as the sealant 3-5 weight portions. The fertilizer is produced with the materials and through pelletizing, stoving, cooling and sieving and has granularity of 2-4 mm. The slowly / control released fertilizer has obvious slowly / control releasing effect, high nitrogen fertilizer utilizing rate and other advantages.

Owner:HENAN AGRICULTURAL UNIVERSITY

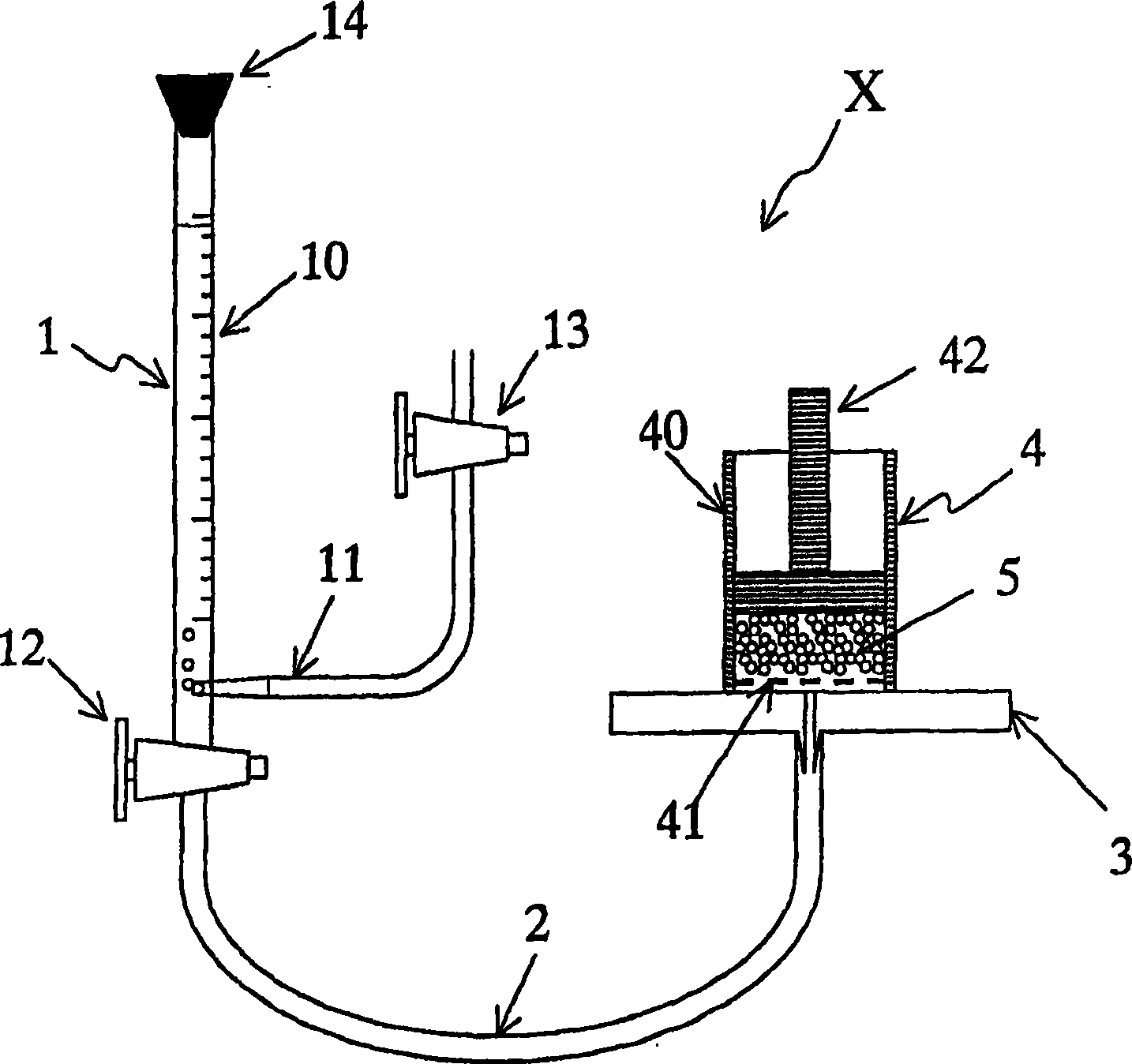

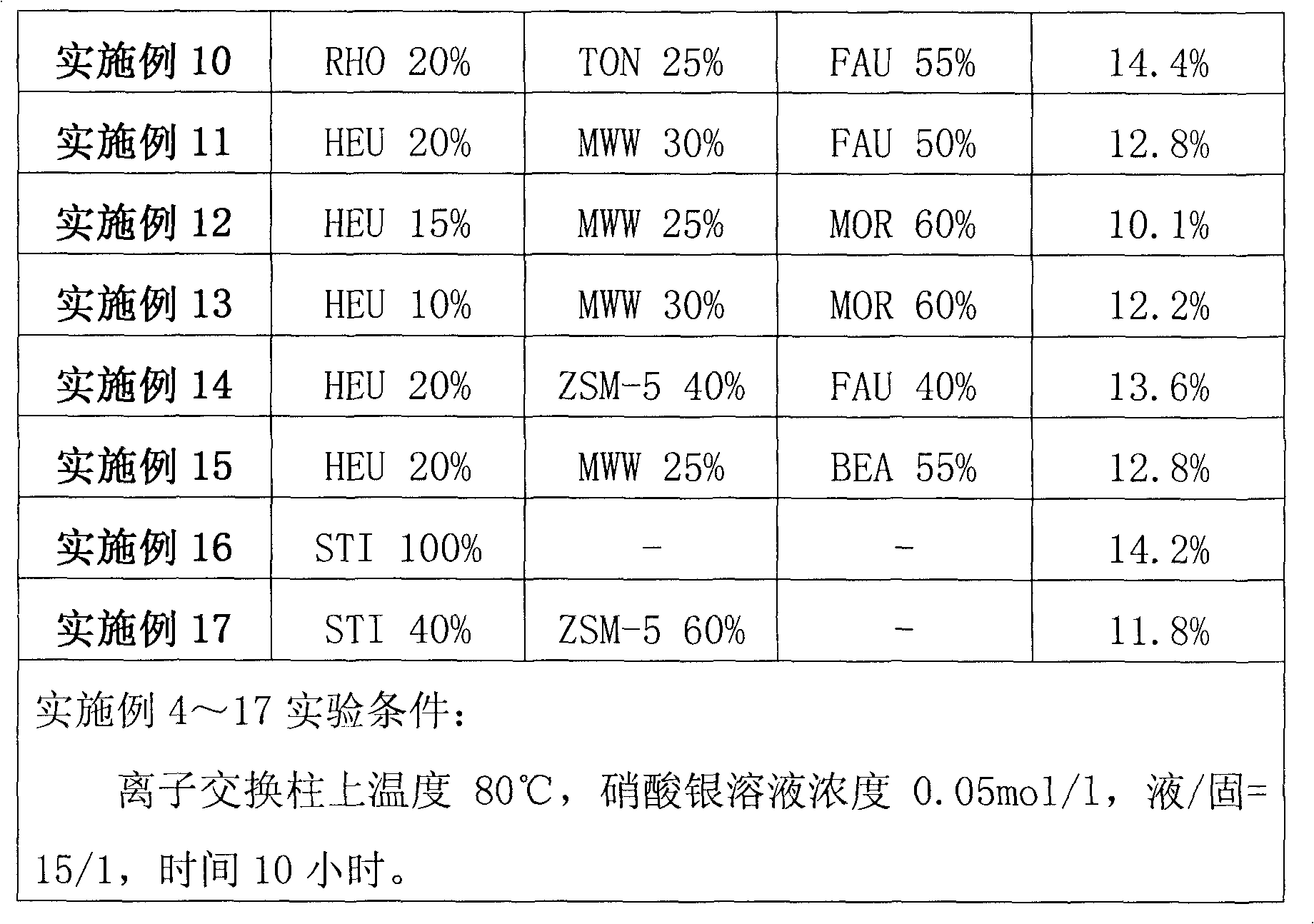

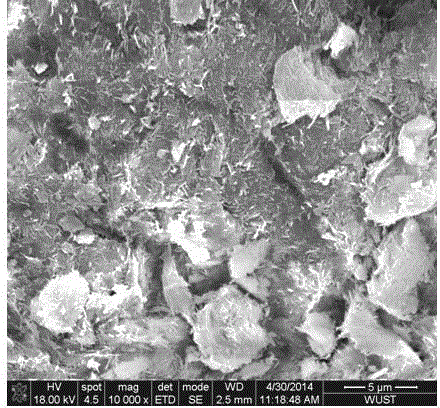

Particulate attapulgite adsorbent and preparation method thereof

InactiveCN104014299AWell mixedSimple processOther chemical processesWater contaminantsSorbentPhysical chemistry

The invention relates to a particulate attapulgite adsorbent and a preparation method thereof. According to the technical scheme, the preparation method comprises the following steps: uniformly mixing water and attapulgite powder to obtain mud attapulgite, wherein are in the mass ratio of the water to the attapulgite powder is 1 to (0.5-1); drying the prepared mud attapulgite for 8 to 16 hours at 90 to 110 DEG C; crushing dried mud attapulgite to the particulate attapulgite with the particle size being 0.045 to 1.25 mm; calcining the prepared particulate attapulgite for 2 to 3 hours at 650 to 750 DEG C in a Muffle furnace to prepare the particulate attapulgite adsorbent. According to the particulate attapulgite adsorbent and the preparation method thereof, the process is simple; secondary pollution is avoided; the prepared particulate attapulgite adsorbent has the characteristics of large particle, easiness in sedimentation, easiness in recycling and high adsorption performance, and is applicable to industrial heavy metal cationic wastewater treatment.

Owner:WUHAN UNIV OF SCI & TECH

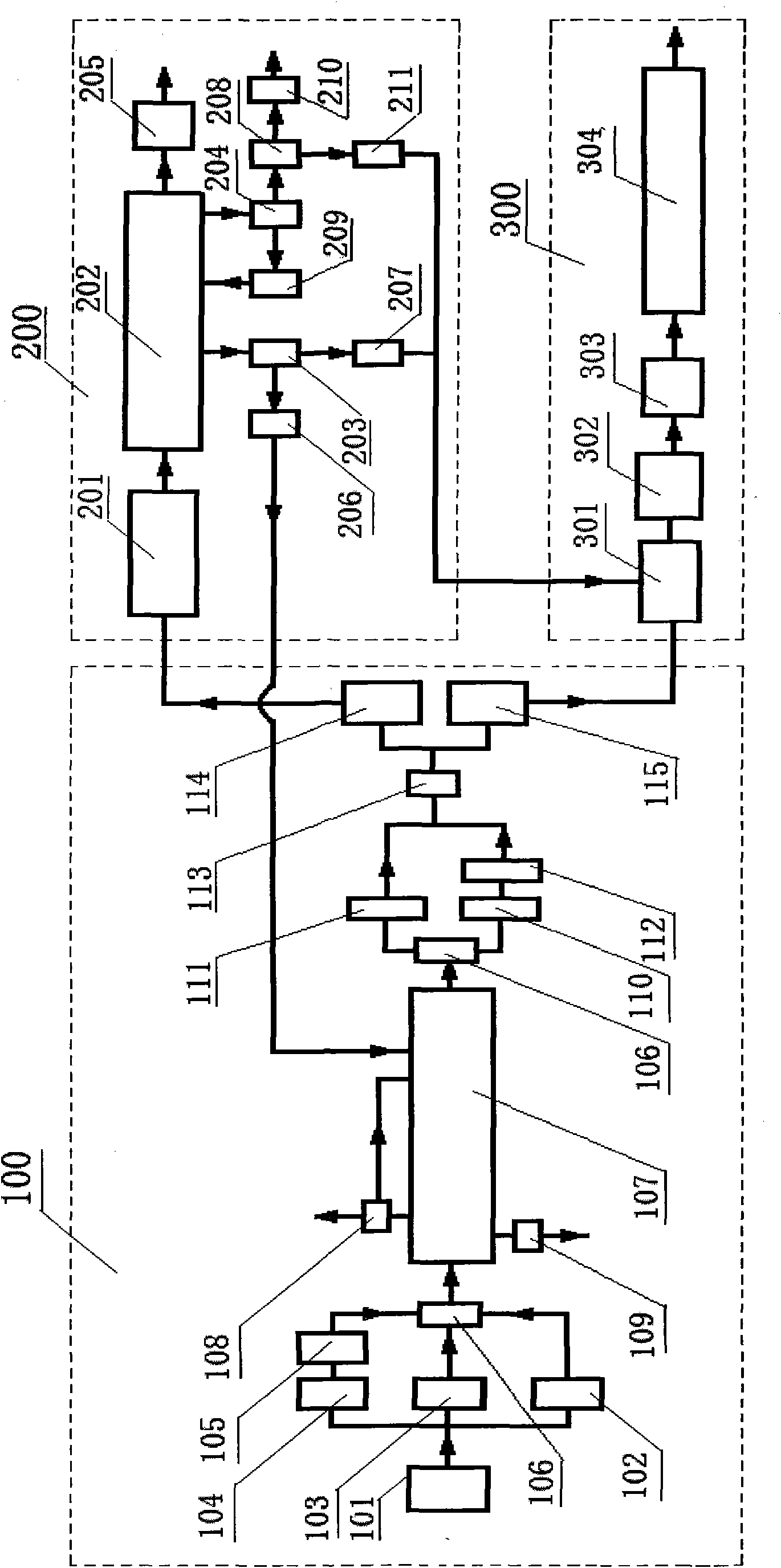

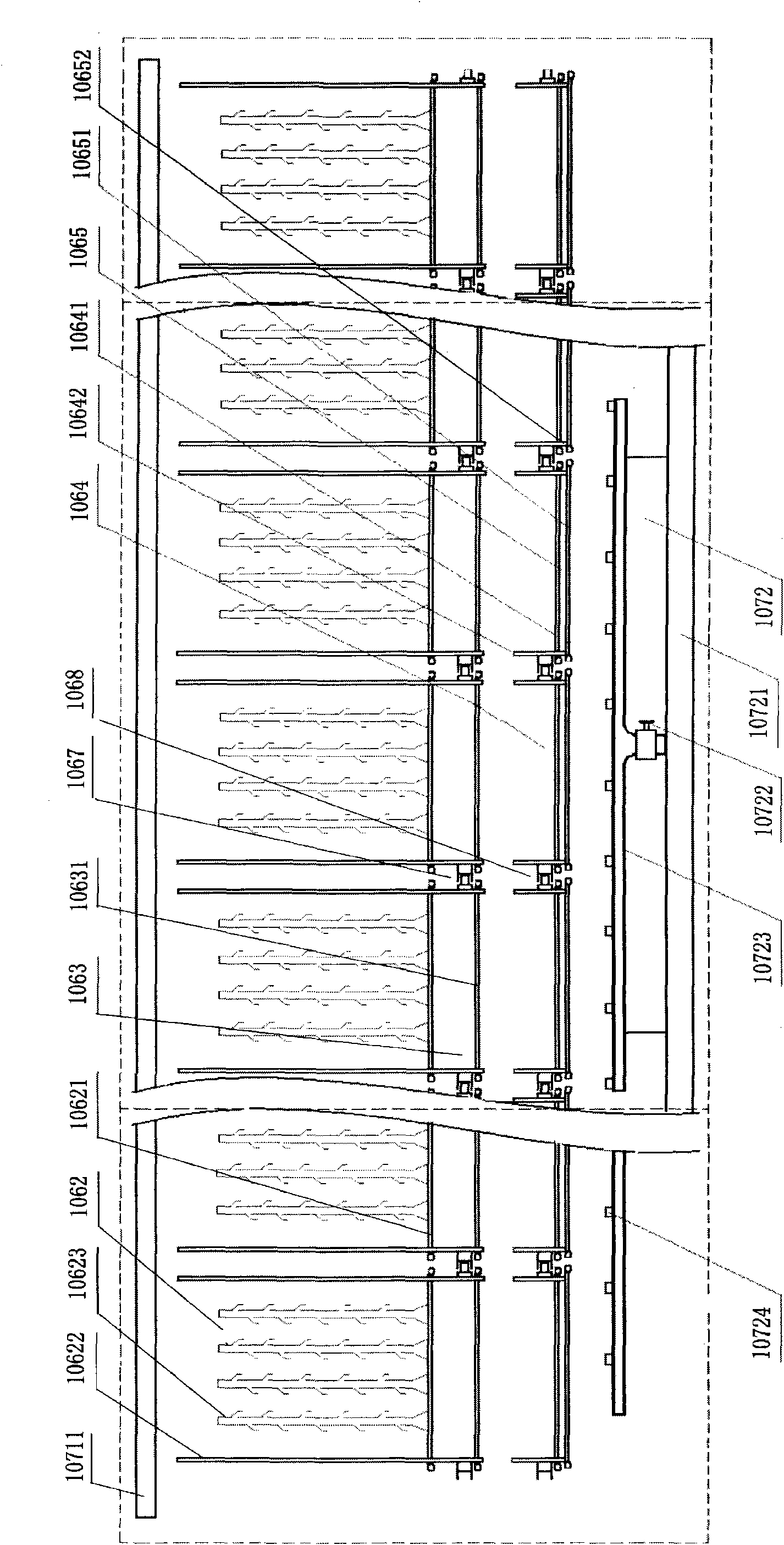

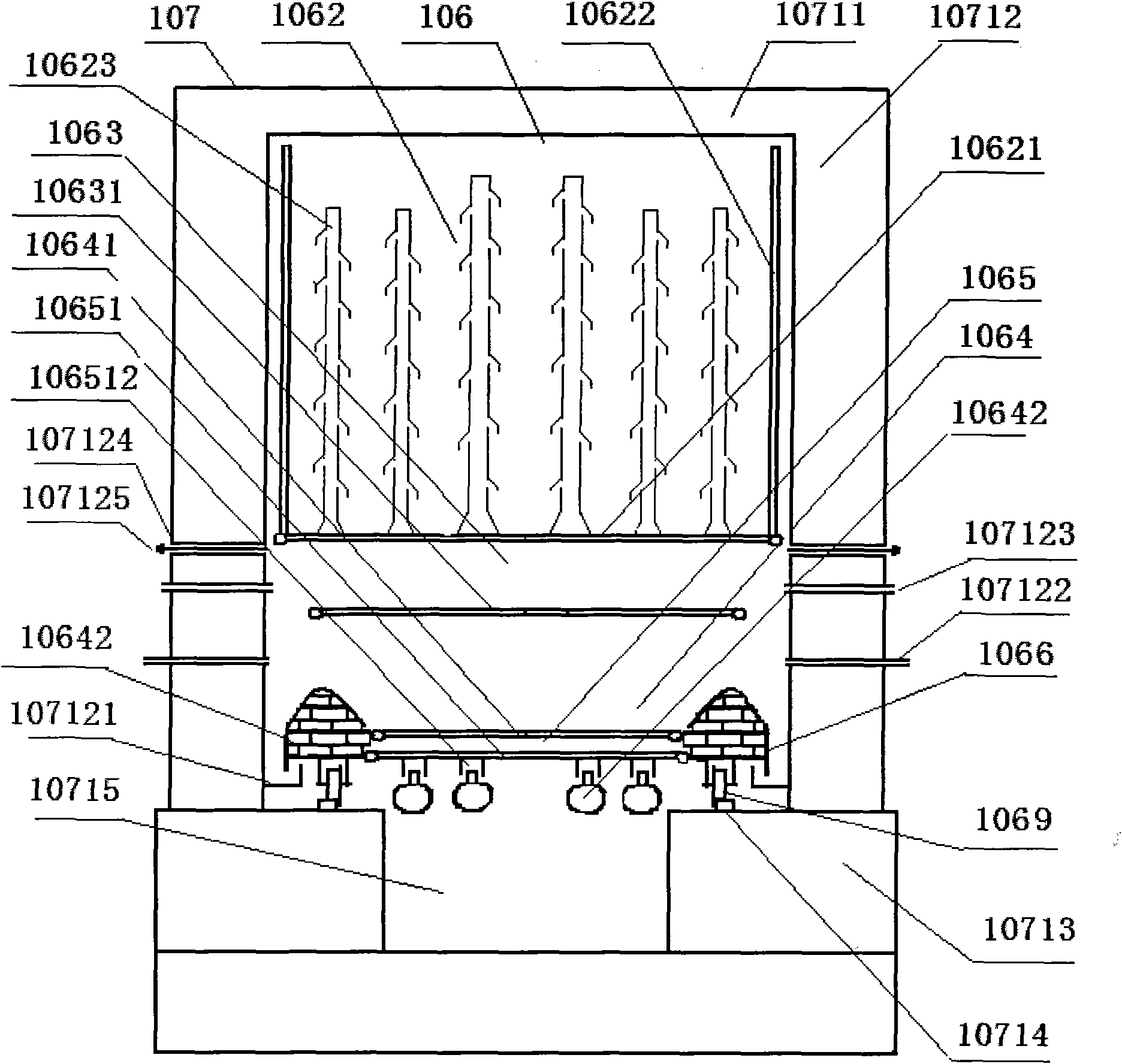

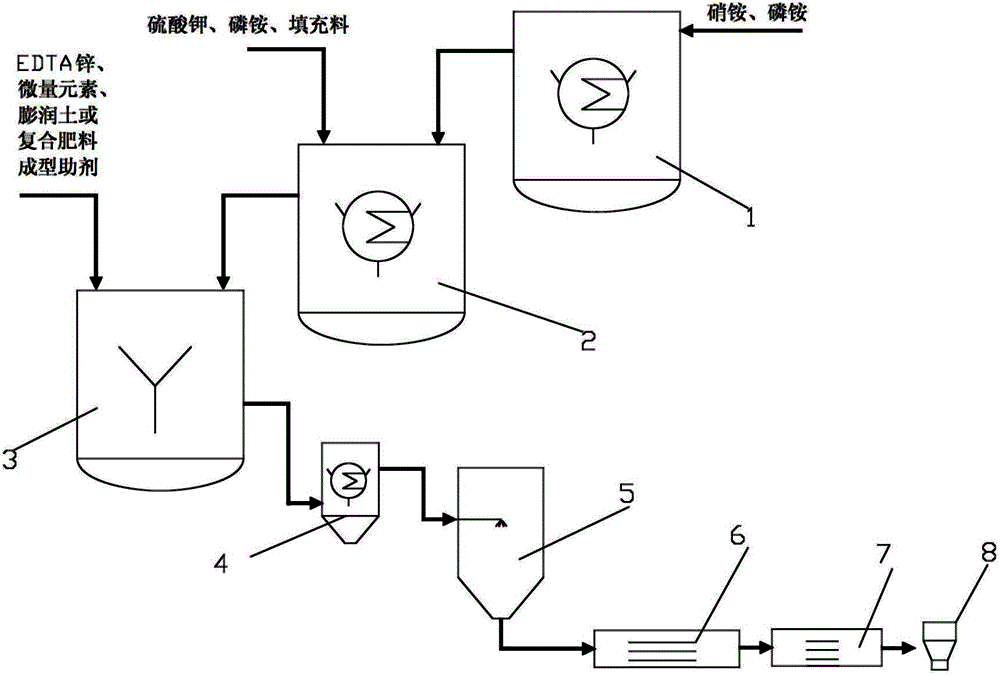

Method for producing high-tower nitro-sulfenyl compound fertilizer and production system applying method

The invention discloses a method for producing a high-tower nitro-sulfenyl compound fertilizer and a production system applying the method. According to the method, one or more mineral raw materials and a forming aid for granulating the compound fertilizer are added into a mixer of a high-tower molten heating system according to the proportioning requirement and are mixed with nitrogen-phosphorus-potassium fertilizers and secondary trace element fertilizers to form a granular compound fertilizer by using a high-efficiency chelation technology and an emulsification granulating technology. According to the nitro-sulfenyl compound fertilizer produced by the method, the strength of granules of which the diameters are between 2.0 and 3.0 millimeters is over 40 N, so that the nitro-sulfenyl compound fertilizer is pressure-resistant and convenient to transport and store, is prevented from agglomerating and pulverizing, and is suitable for the mechanical fertilization of field crops; and after being dissolved in water, the nitro-sulfenyl compound fertilizer can be quickly disintegrated to form powder, suspensions and a few dregs, is suitable for the spraying, drop irrigation and spray irrigation of shed crops and commercial crops, and belongs to the popularization category of national water-saving agriculture industrialization.

Owner:徐州市芭田生态有限公司

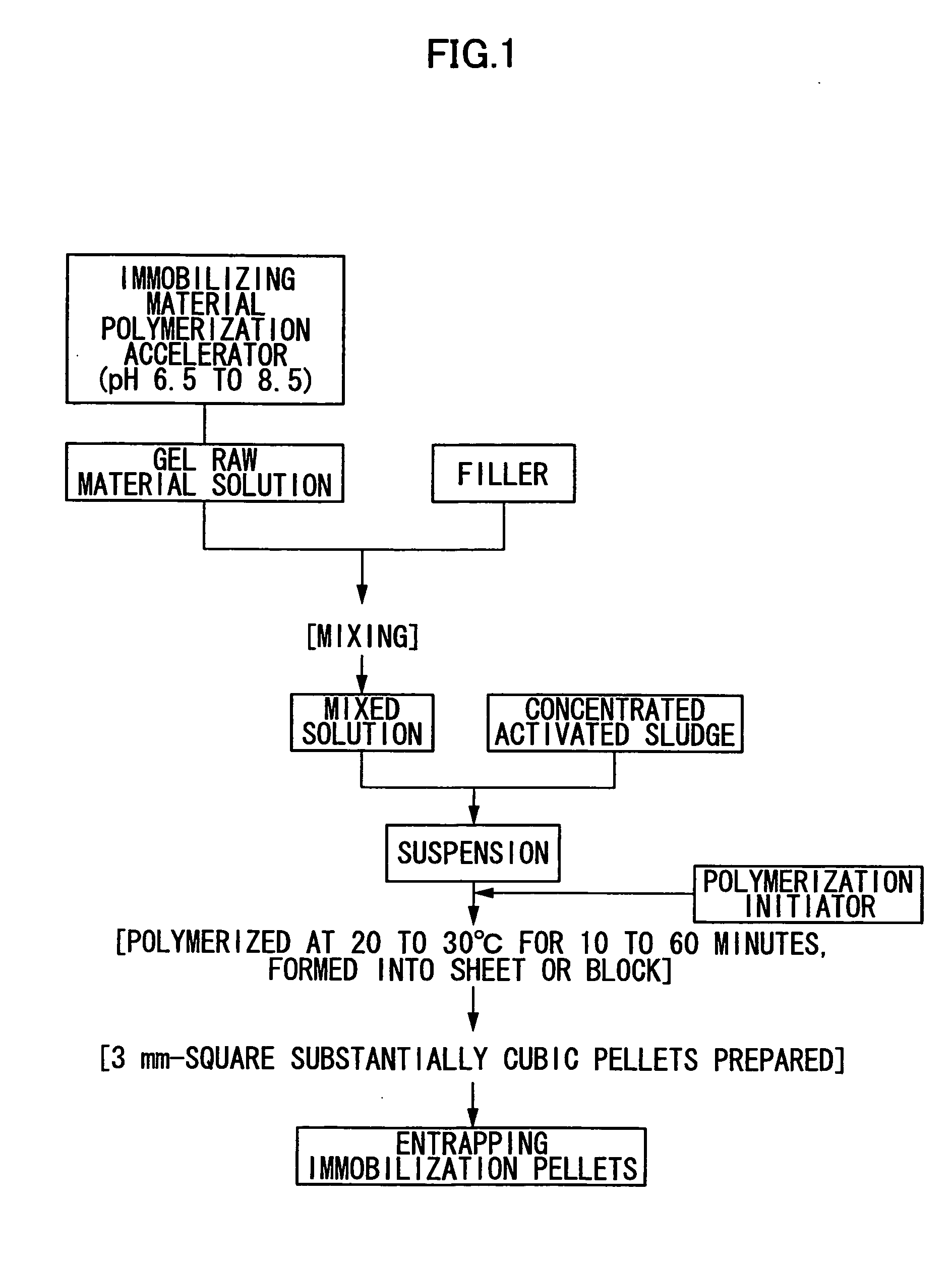

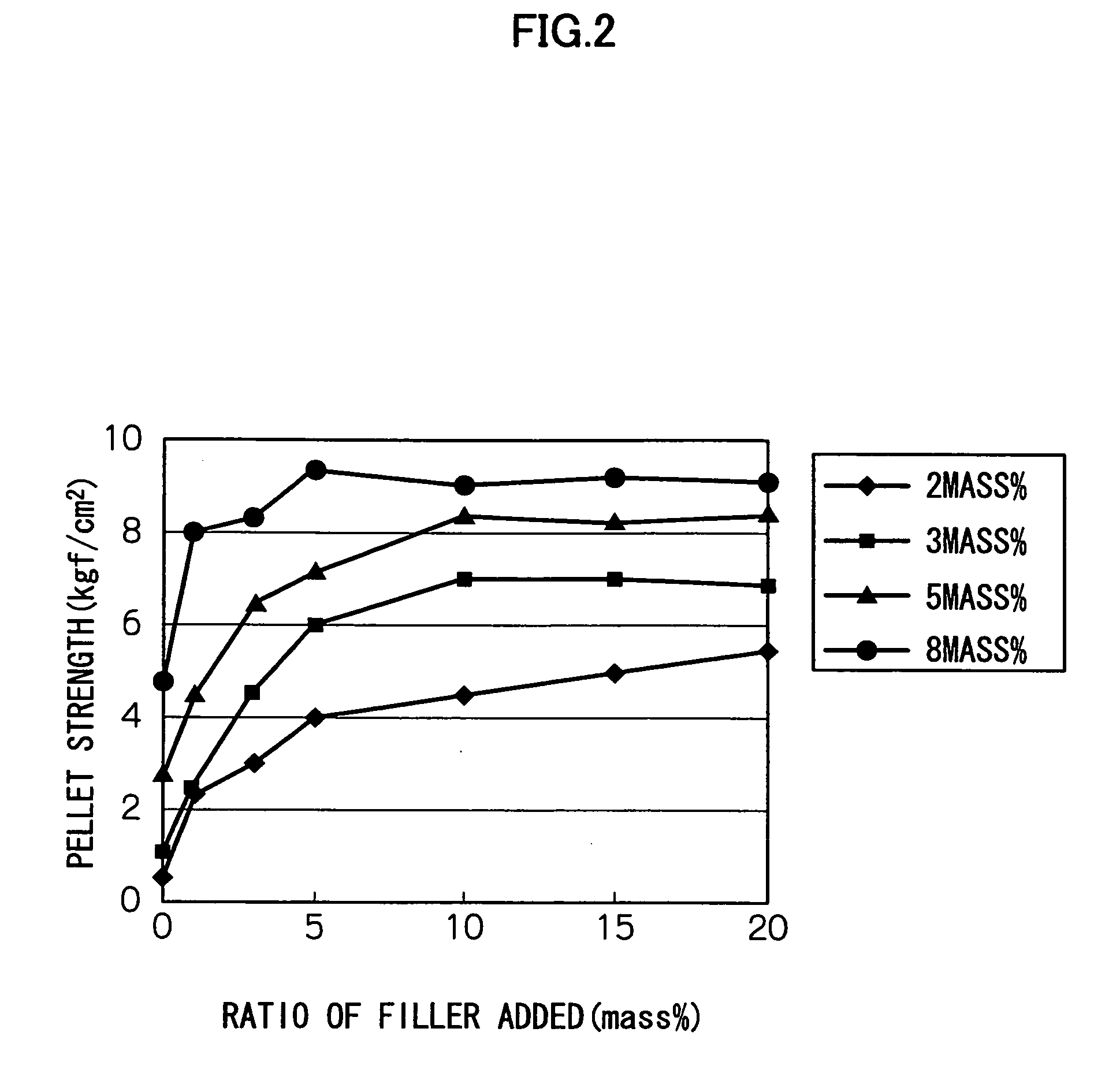

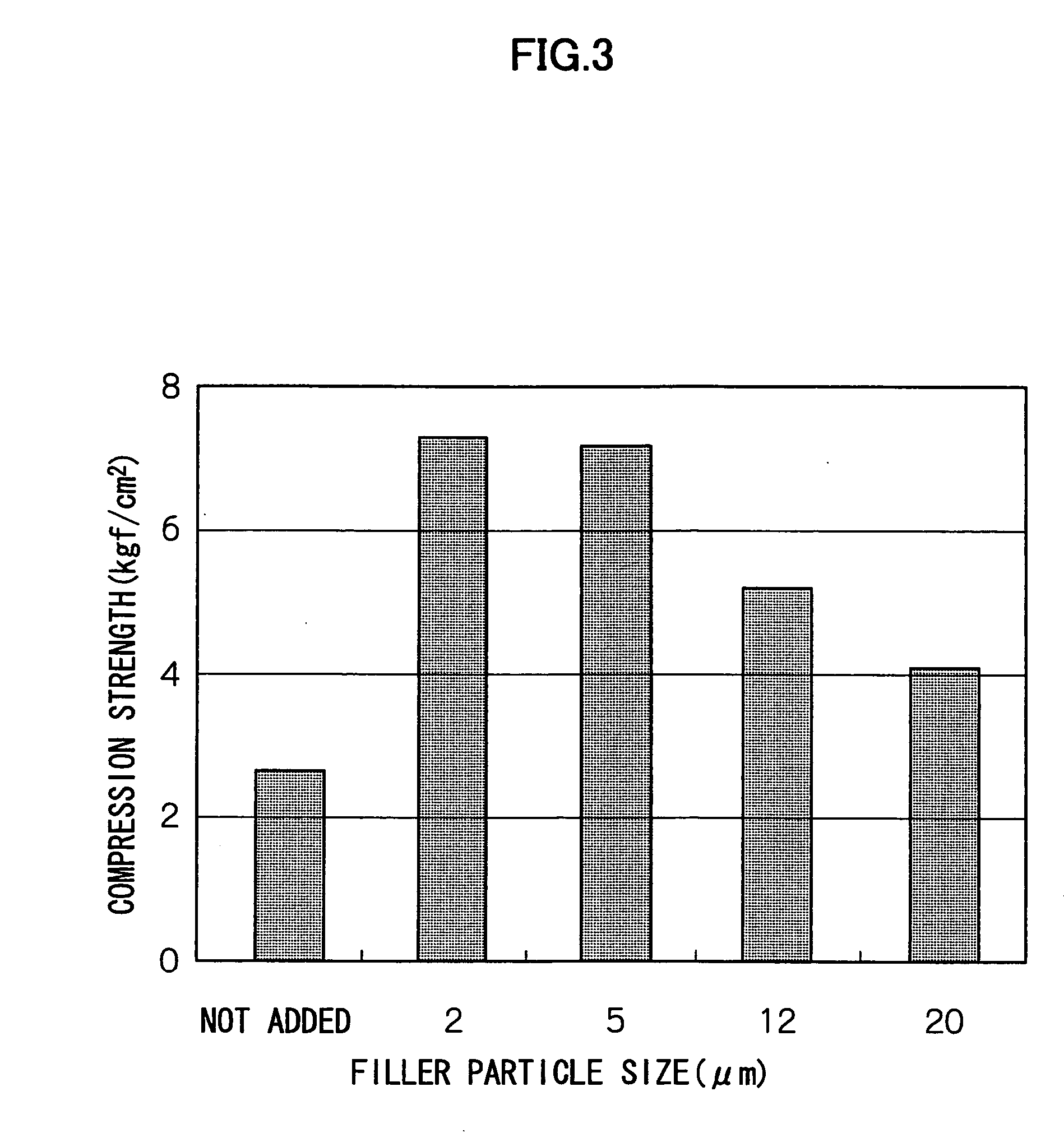

Entrapping immobilization pellets and process for producing the same

InactiveUS20070015268A1Reduced activityHigh shape accuracyBacteriaUnicellular algaeCrystal structureUltimate tensile strength

The present invention produces entrapping immobilization pellets which have high pellet strength and retain high and stable microbial activity (nitrification activity) even if a low concentration of a material involved in immobilization (such as an immobilizing material or polymerization initiator) used. The entrapping immobilization pellets in which microorganisms are entrapped and immobilized in an immobilizing material comprise a filler having a plate-like and / or needle-like crystal structure in the immobilizing material.

Owner:HITACHI PLANT TECH LTD

Method of producing powder, powder, and adsorption apparatus

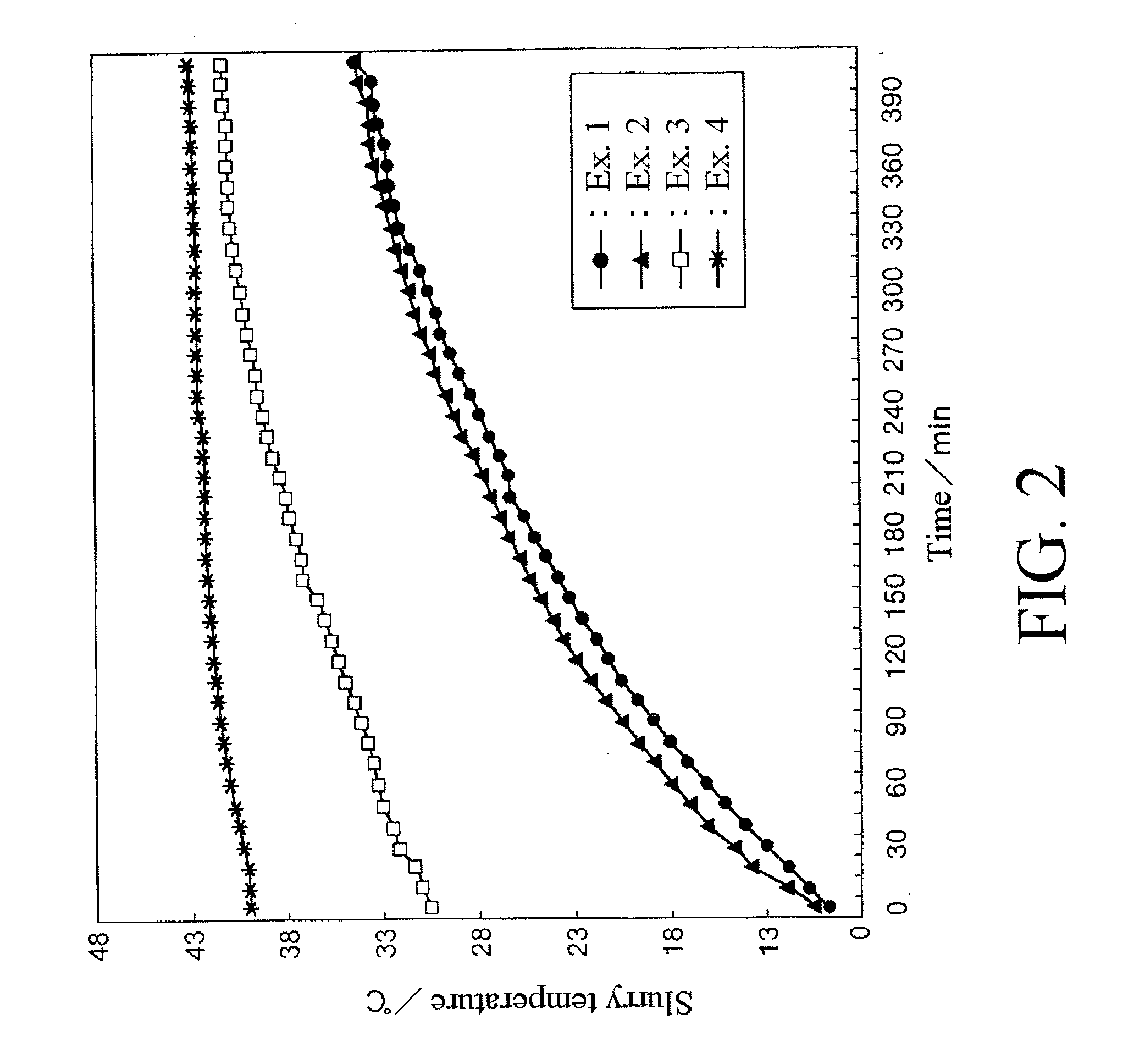

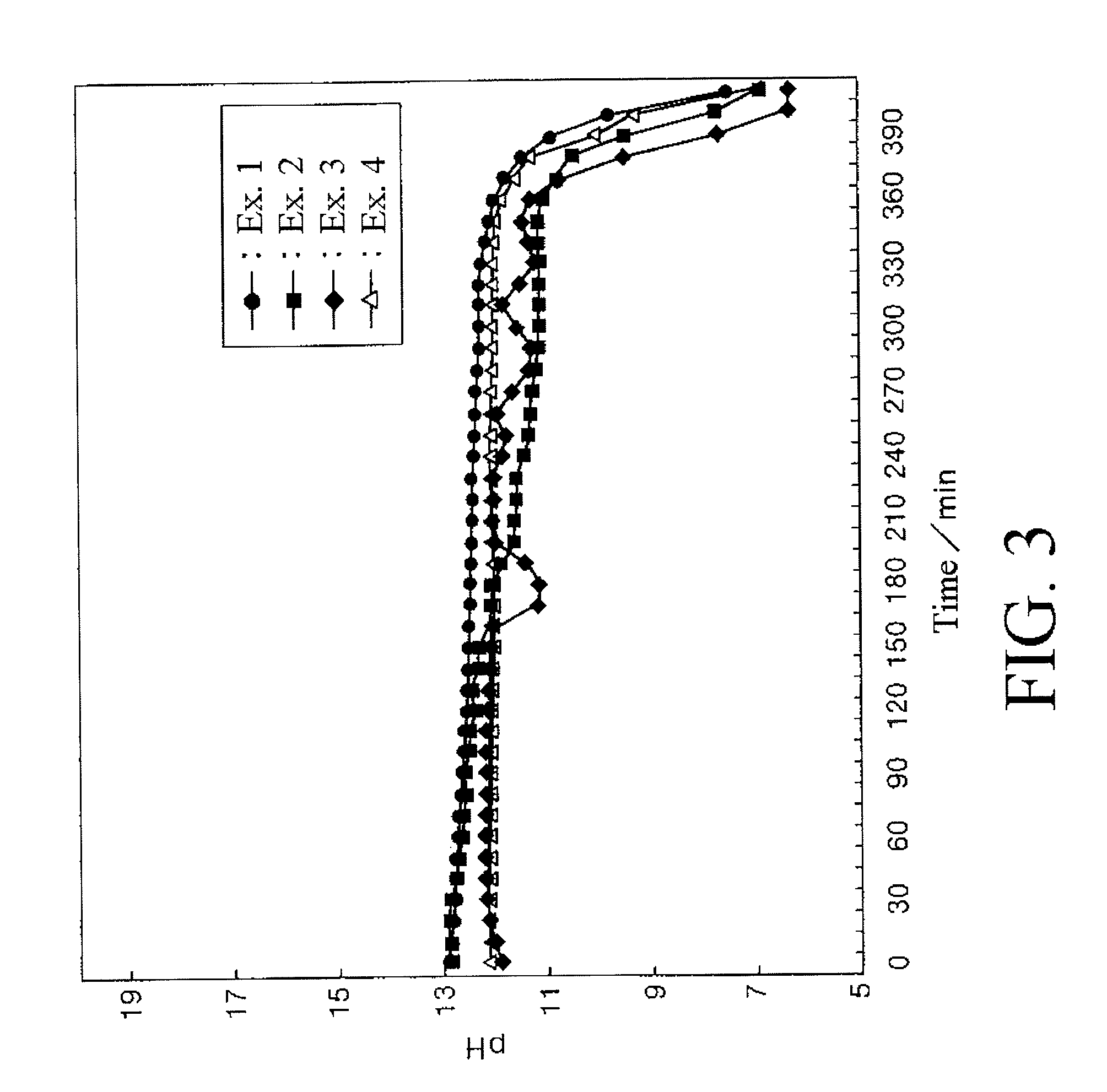

InactiveUS20100303702A1High particle strengthSufficient and uniform strengthPhosphatesOther chemical processesSynthetic materialsSlurry

A method of producing powder by using a first liquid and a second liquid to be mixed with the first liquid, the first liquid containing a first raw material and the second liquid containing a second raw material. The method comprises: mixing the first liquid and the second liquid to obtain a mixture; stirring the mixture for reacting the first raw material and the second raw material to thereby obtain a synthetic material and a slurry containing aggregates of the synthetic material; and drying the slurry to obtain powder of the synthetic material. In the mixing the first liquid and the second liquid, particle strength of the powder is adjusted by setting an initial temperature of mixing the first liquid with the second liquid.

Owner:HOYA CORP

Preparation method of catalyst for sintering flue gas and desulfurizing and denitrifying

ActiveCN101507923AHigh particle strengthTolerance to interferenceDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsMaterials preparationActivated carbon

The invention provides a method for preparing a catalyst which can realize desulphurization and denitration of sintered fume at the same time, and belongs to the technical field of material preparation and waste gas treatment. In the method, chromium and cerium are taken as main components, active carbon or active coke is taken as a carrier, and the materials are soaked and burned in the atmosphere of inert gas to obtain the catalyst which can effectively catalyze NH3 and reduce NOx into N2 at a low temperature; the catalyst has high low-temperature activity, and can tolerate the interference of as high as 6 percent of CO in the system; and simultaneously, the catalyst can also catalyze and oxidize SO2 into SO3 and store the SO3 in the form of (NH4)2SO4, so that the reutilization of the SO2 in the waste gas is realized, and the catalyst has wider application prospect in the desulphurization and denitration operation of the sintered fume.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

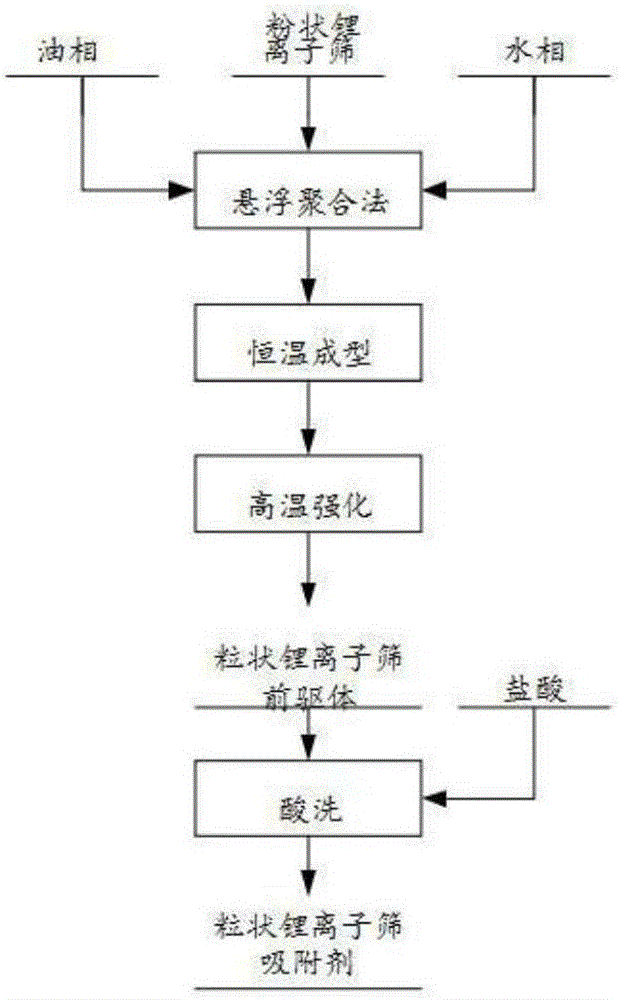

Method for preparing spherical granular lithium ion sieve

The invention discloses a method for preparing a spherical granular lithium ion sieve. The method comprises the following steps: 1) mixing a dispersant and water, dissolving the materials to obtain a water phase; 2) adding a powder lithium ion sieve in the water phase obtained in the step 1), stirring the materials, heating the materials, adding an oil phase containing a monomer and an initiator for performing a suspension polymerisation reaction; wherein the monomer comprises styrene; and 3) after the reaction in the step 2) is complete, continuously heating the materials, hardening the spherical particles prepared by the suspension polymerisation reaction, washing the hardened particles, drying, pickling, and drying the materials to obtain the spherical lithium ion sieve. The prepared spherical granular lithium ion sieve has the advantages of uniform granularity and high intensity, the oil phase recovery rate is greater than 95%, and the powder ion sieve recovery rate is 100%.

Owner:CENT SOUTH UNIV

Method for producing compound microbial fertilizer from amino acid organic granules

InactiveCN102040406ASimplify the steps of dryingSolve ball problemOrganic fertilisersFertilizer mixturesMicrobial agentSlurry

The invention provides a method for producing compound microbial fertilizer from amino acid organic granules, in particular to a method for producing compound microbial fertilizer by adopting slurry spraying and granulating processes, comprising the following steps: preparing liquid microbial agent, granulating waste amino acid solution into organic granules, and compounding the organic granules with the liquid compound microbial agent, wherein the liquid compound microbial agent is uniformly absorbed on the surfaces of the amino acid organic granules, and fermentation liquid accounts for 0.5-1.5wt% of the finished product of the compound microbial fertilizer. According to the invention, the normal method for producing the compound microbial fertilizer is improved, a novel method for producing the granular compound microbial fertilizer by two steps of granulating waste amino acid solution into organic granules and absorbing the liquid compound microbial agent by the amino acid organic granules is provided, and the number of viable bacteria in the compound microbial fertilizer is ensured. The production of the compound microbial fertilizer by the slurry spraying and granulating processes breaks through the production of the powdery compound microbial fertilizer by the disc and roller granulating process, thus a good foundation is laid for improving the commodity value, effectiveness and large-area popularization of the compound microbial fertilizer.

Owner:SHANGHAI NUOTONG INFORMATION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com