Preparation method of spherical molecular sieve catalyst

A spherical molecular sieve, molecular sieve technology, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as the inability to meet the needs of catalyst particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

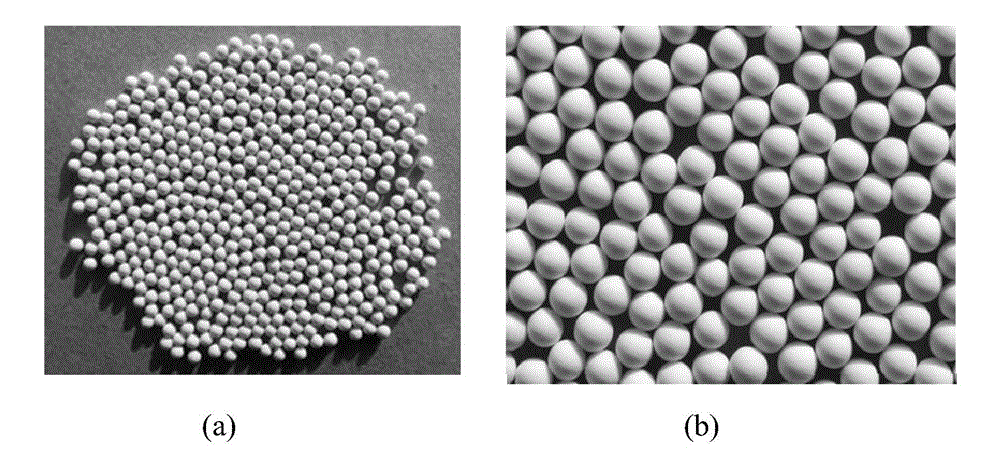

[0039] Add 2.25g of aluminum powder with an average particle size of 50μm to 15.2g of hydrochloric acid with a concentration of 15% by weight, and prepare a salt-aluminum glue with an aluminum content of 12.9% by weight at 90°C; add to the salt-aluminum glue first and then 50g of water and 2.83g of H-ZSM-5 molecular sieve were stirred for 30 minutes to fully mix the salt-aluminum glue and the molecular sieve to form a mixed slurry; add 2.7g of hexamethylenetetramine to the mixed slurry and put it in an ice bath, fully mix to obtain a slurry, and then Use a 0.8mm needle to drop the slurry into a stator oil column with an oil temperature of 85°C and a height of 2500mm (purchased from Beijing Sifang Special Oil Factory, brand GS-1, with a viscosity of 263mPa·S at 40°C) for molding ; Separate the formed gel balls from the oil column, age at 130°C for 4 hours, then wash the aged balls, dry at 120°C for 4 hours, and roast at 500°C for 4 hours to obtain spherical H- ZSM-5 molecular s...

Embodiment 2

[0043] The spherical molecular sieve catalyst was prepared by the method of Example 1, except that the amount of H-ZSM-5 molecular sieve added was 4.25 g.

[0044] The H-ZSM-5 molecular sieve content in the obtained spherical H-ZSM-5 molecular sieve catalyst was 50% by weight. The physical properties of the spherical H-ZSM-5 molecular sieve catalyst are shown in Table 1.

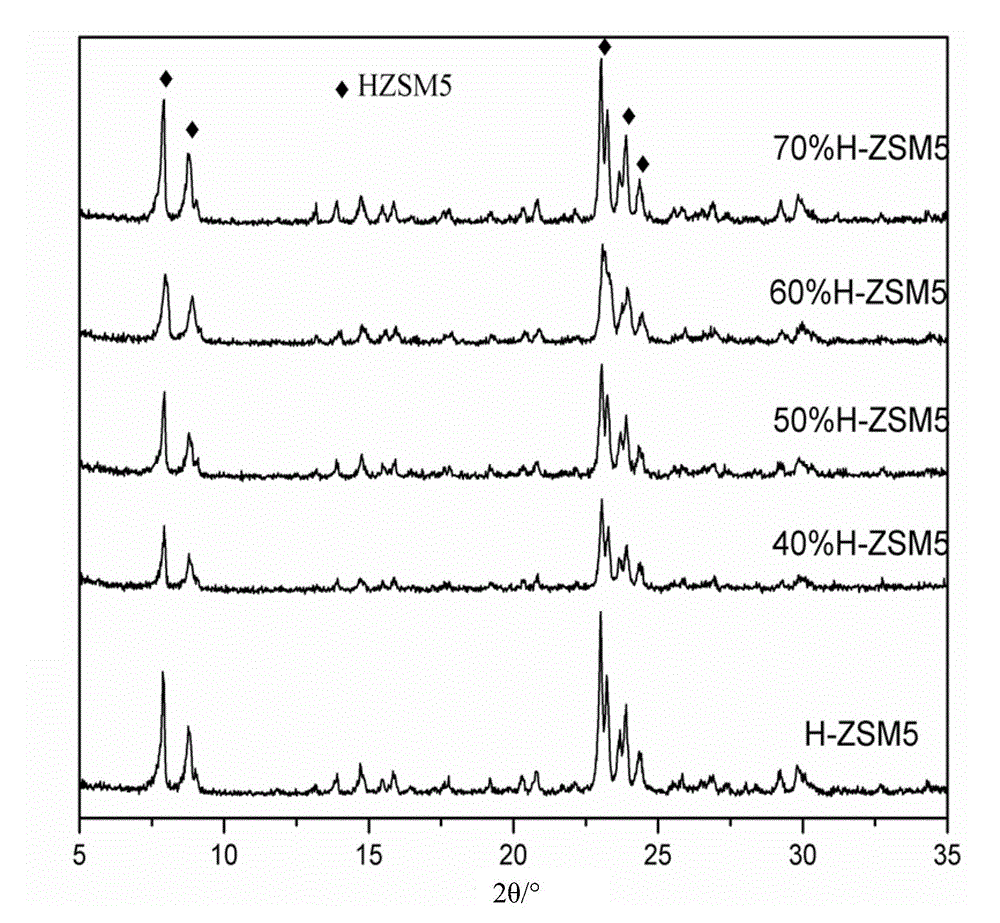

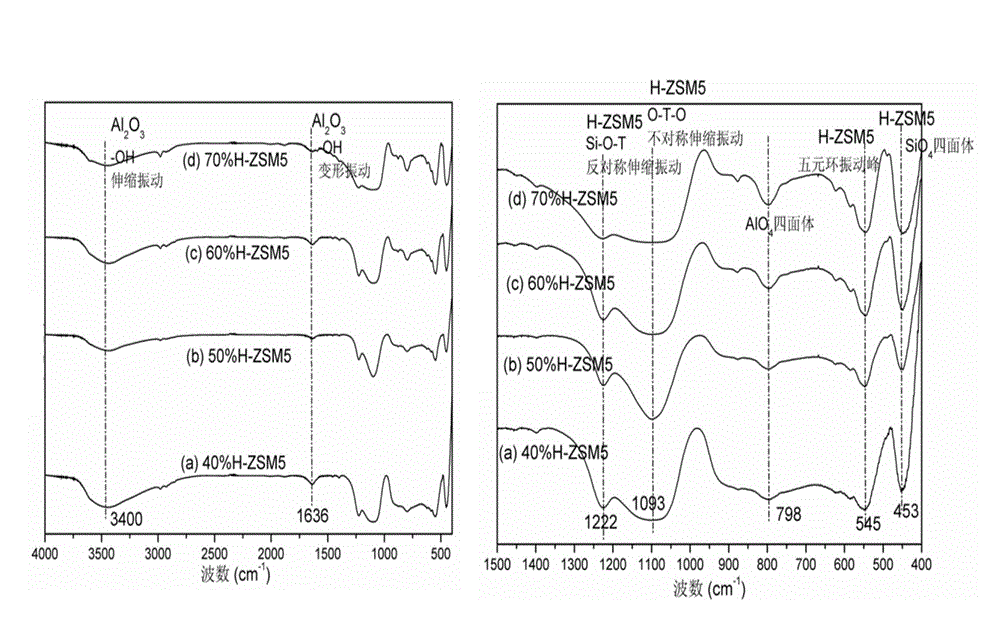

[0045] The appearance of gained spherical H-ZSM-5 molecular sieve catalyst and figure 1 Similar, the XRD spectrum is as figure 2 As shown, the IR spectrum is as image 3 shown.

Embodiment 3

[0047] The spherical molecular sieve catalyst was prepared by the method of Example 1, except that the amount of H-ZSM-5 molecular sieve added was 6.38 g.

[0048] The H-ZSM-5 molecular sieve content in the obtained spherical H-ZSM-5 molecular sieve catalyst was 60% by weight. The physical properties of the spherical H-ZSM-5 molecular sieve catalyst are shown in Table 1.

[0049] The appearance of gained spherical H-ZSM-5 molecular sieve catalyst and figure 1 Similar, the XRD spectrum is as figure 2 As shown, the IR spectrum is as image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com