Ethylene glycol hydrofining method

A technology of hydrofining and ethylene glycol, applied in chemical instruments and methods, preparation of hydroxyl compounds, preparation of organic compounds, etc., can solve the problems of few catalytic active sites, difficult control of the preparation process, inactivity, etc., and achieve catalyst particles Good strength, improved UV transmittance, simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

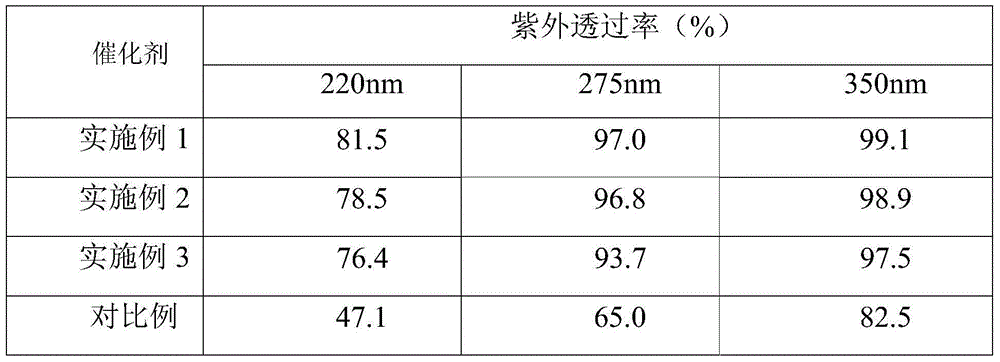

Examples

Embodiment 1

[0036] (1) 100 parts by mass of liquid epoxy resin (Baling Petrochemical, CYD-128), 85 parts by mass of curing agent methyltetrahydrophthalic anhydride (MeTHPA) (Guangdong Shengshida Technology and Trade Co., Ltd.), curing accelerator triethanolamine (TEA) (Tianjin Chemical Reagent No. 1 Factory) 1.5 parts by mass and stirred evenly.

[0037] (2) Weigh 40g of the epoxy system prepared in step (1) and 180g of nickel-aluminum alloy powder and mix them thoroughly. The Ni content in the nickel-aluminum alloy is 48% (by weight), and the aluminum content is 52% (by weight). Take an appropriate amount Put the mixture into a cylindrical mold, mold it with a flat vulcanizer at a temperature of 120°C and a pressure of 7MPa for 30mins, and use a flat vulcanizer at a temperature of 150°C and a pressure of 7MPa for 90mins, and take it out after cooling to obtain granules Catalyst precursor;

[0038] (3) Measure 100ml of catalyst precursor, put it into a tube-type high-temperature electric...

Embodiment 2

[0041] (1) 100 parts by mass of liquid epoxy resin (Baling Petrochemical, CYD-128), 85 parts by mass of curing agent methyltetrahydrophthalic anhydride (MeTHPA) (Guangdong Shengshida Technology and Trade Co., Ltd.), curing accelerator triethanolamine (TEA) (Tianjin Chemical Reagent No. 1 Factory) 1.5 parts by mass and stirred evenly.

[0042] (2) Weigh 50g of the epoxy system prepared in step (1) and 150g of nickel-aluminum alloy powder and mix them thoroughly. The Ni content in the nickel-aluminum alloy is 48% (by weight), and the aluminum content is 52% (by weight). Take an appropriate amount Put the mixture into a cylindrical mold, mold it with a flat vulcanizer at a temperature of 120°C and a pressure of 7MPa for 30mins, and use a flat vulcanizer at a temperature of 150°C and a pressure of 7MPa for 90mins, and take it out after cooling to obtain granules Catalyst precursor;

[0043] (3) Measure 100ml of catalyst precursor, put it into a tube-type high-temperature electric...

Embodiment 3

[0046] (1) Fully mix powdered phenolic resin and curing agent hexamethylenetetramine with a high-speed mixer, the weight ratio of hexamethylenetetramine to phenolic resin is 12 / 100; mix 100 grams of mixture with 350 grams of nickel aluminum alloy The powder is fully mixed with a high-speed mixer, and the Ni content in the nickel-aluminum alloy powder is 48% (weight), and the aluminum content is 52% (weight);

[0047] (2) Raise the temperature of the tablet press to 90°C, put the above materials into the mold and press on the tablet press to form a sheet with a thickness of 2mm; raise the temperature of the tablet press to 150°C, and refill the formed sheet Put it into the mold and solidify under the pressure of 5MPa on the tablet press for 10min; cut the cured 2mm thick sheet into small particles;

[0048] (3) Take 100ml of small particles and carbonize them in a tube-type high-temperature electric furnace with a heating rate of 10°C / min, a furnace temperature of 600°C, and ke...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com