Patents

Literature

1148results about "Raney catalysts" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing alcohols by hydrogenation of carbonyl compounds

InactiveUS6486366B1Less amountHigh strengthSugar derivativesOrganic compound preparationCobaltPt element

A method for preparation of alcohols by catalytic hydrogenation of carbonyl compounds with hydrogen or hydrogen-containing gases in the presence of a hydrogenation catalyst of Raney type, where the catalyst is used in the form of hollow bodies, Preferred as catalytically active components are nickel, cobalt, copper, iron, platinum, palladium or ruthenium.

Owner:DEGUSSA AG

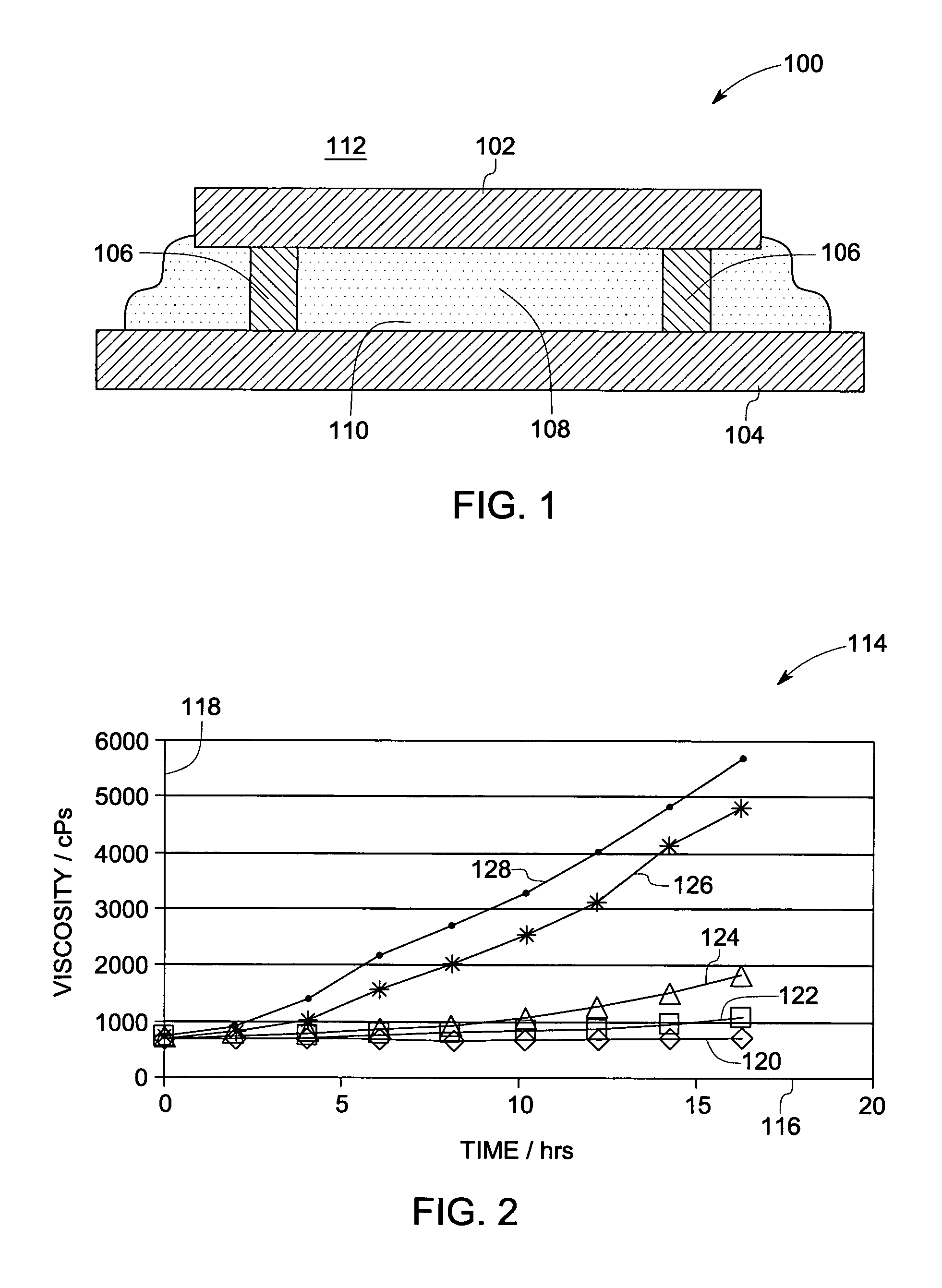

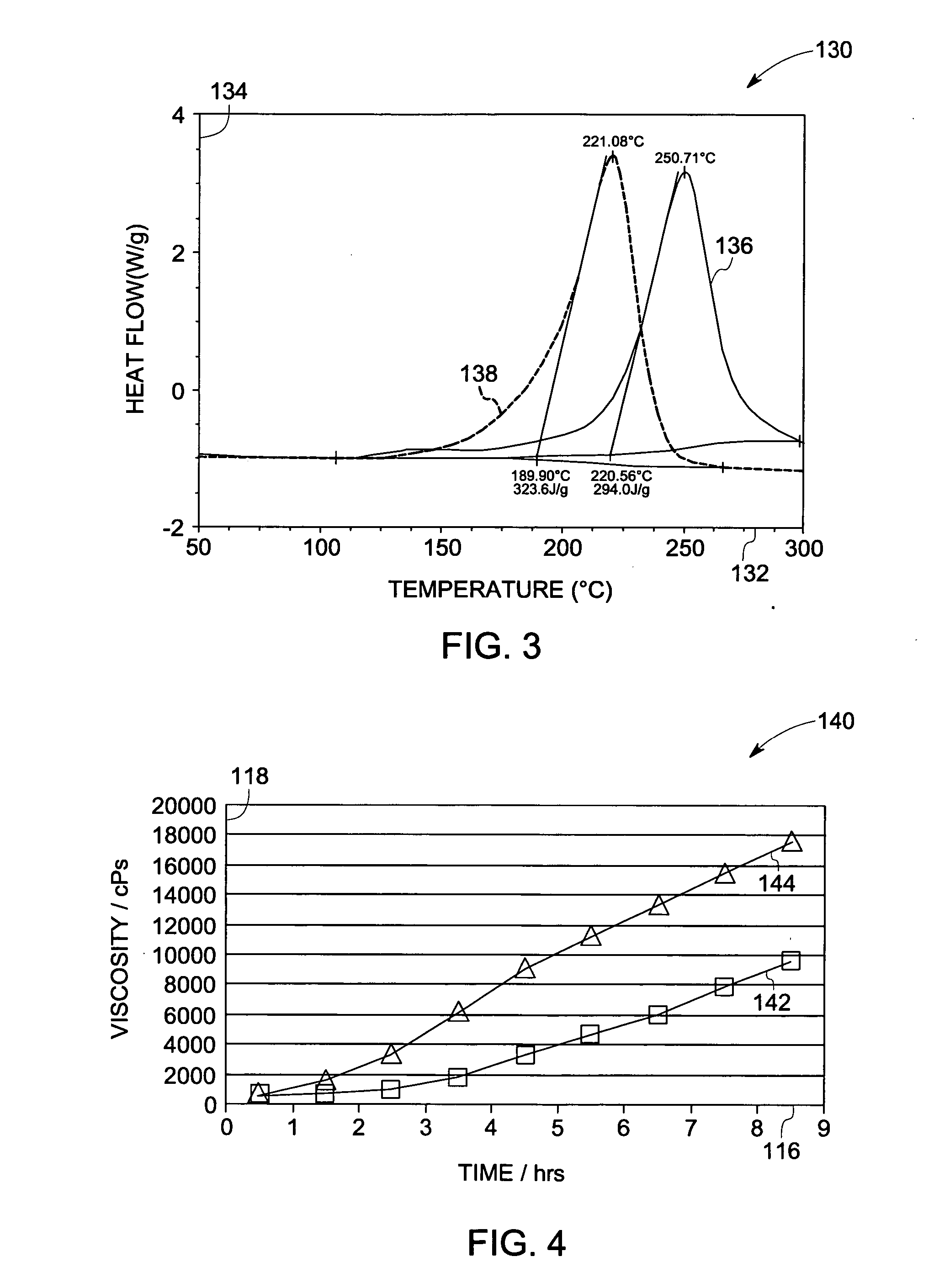

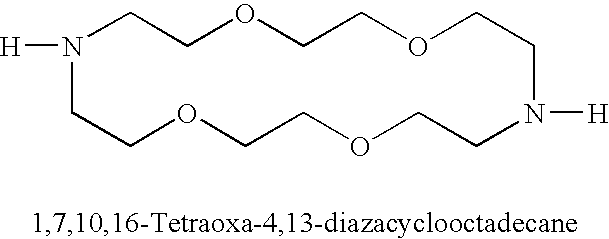

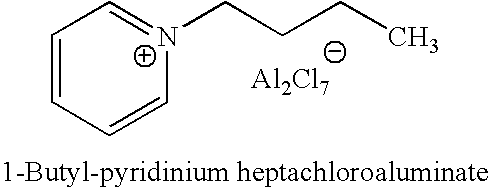

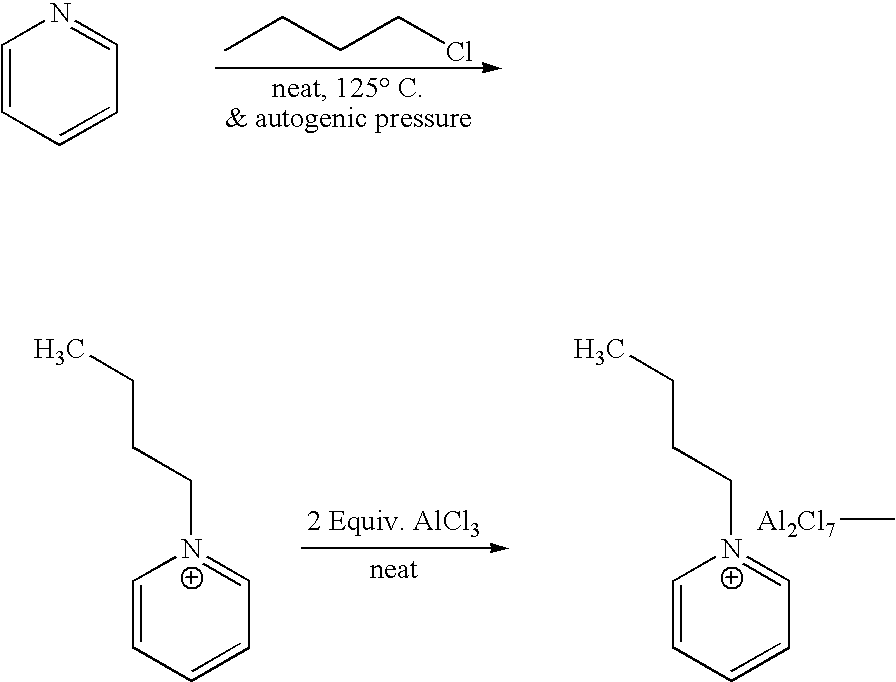

Cure catalyst, composition, electronic device and associated method

InactiveUS20060293172A1Molecular sieve catalystsOrganic-compounds/hydrides/coordination-complexes catalystsSimple Organic CompoundsNitrogen

A cure catalyst is provided. The cure catalyst may include a Lewis acid and one or both of a nitrogen-containing molecule or a non-tertiary phosphine. The nitrogen-containing molecule may include a mono amine or a heterocyclic aromatic organic compound. A curable composition may include the cure catalyst. An electronic device may include the curable composition. Methods associated with the foregoing are provided also.

Owner:MOMENTIVE PERFORMANCE MATERIALS INC

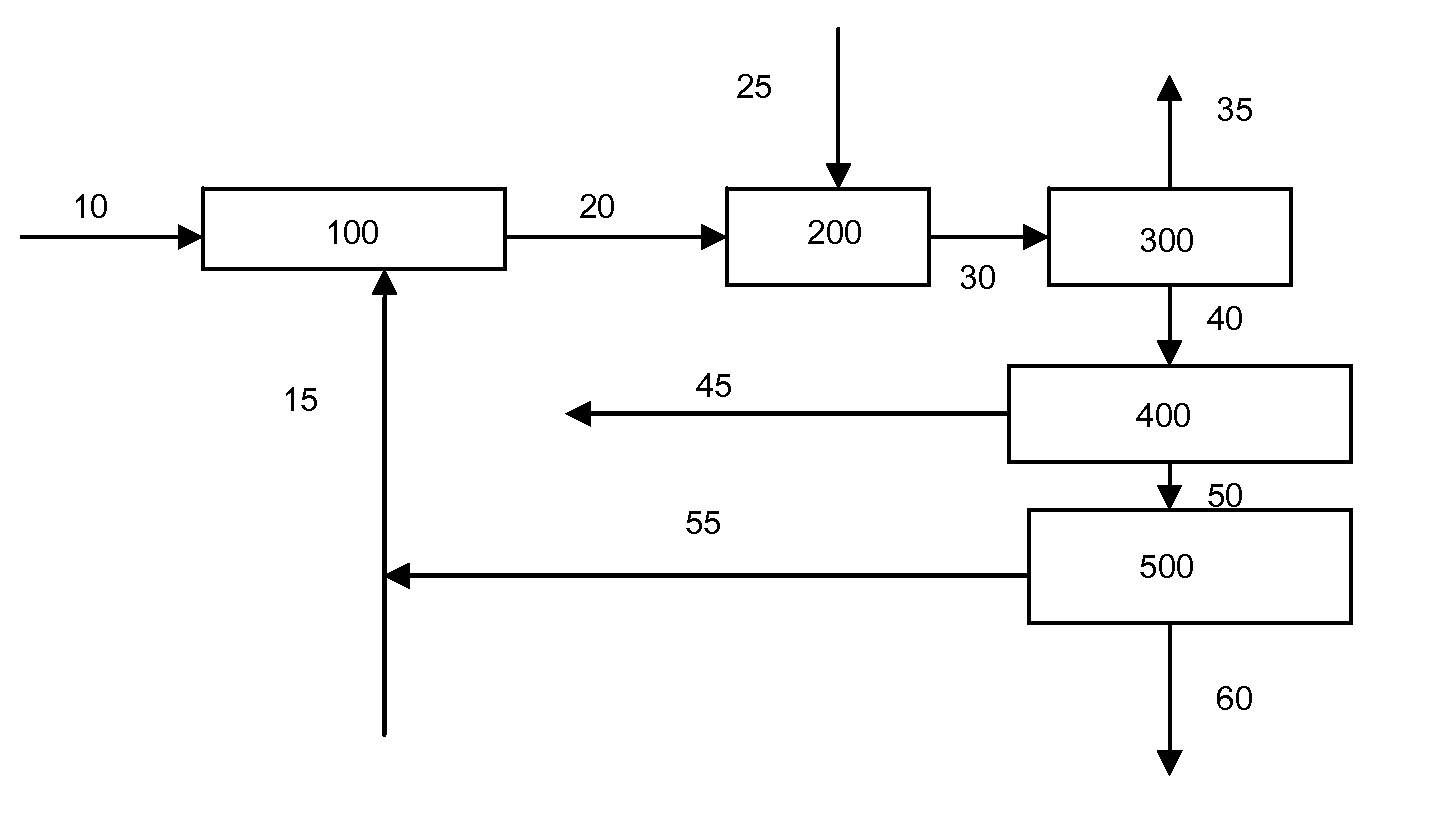

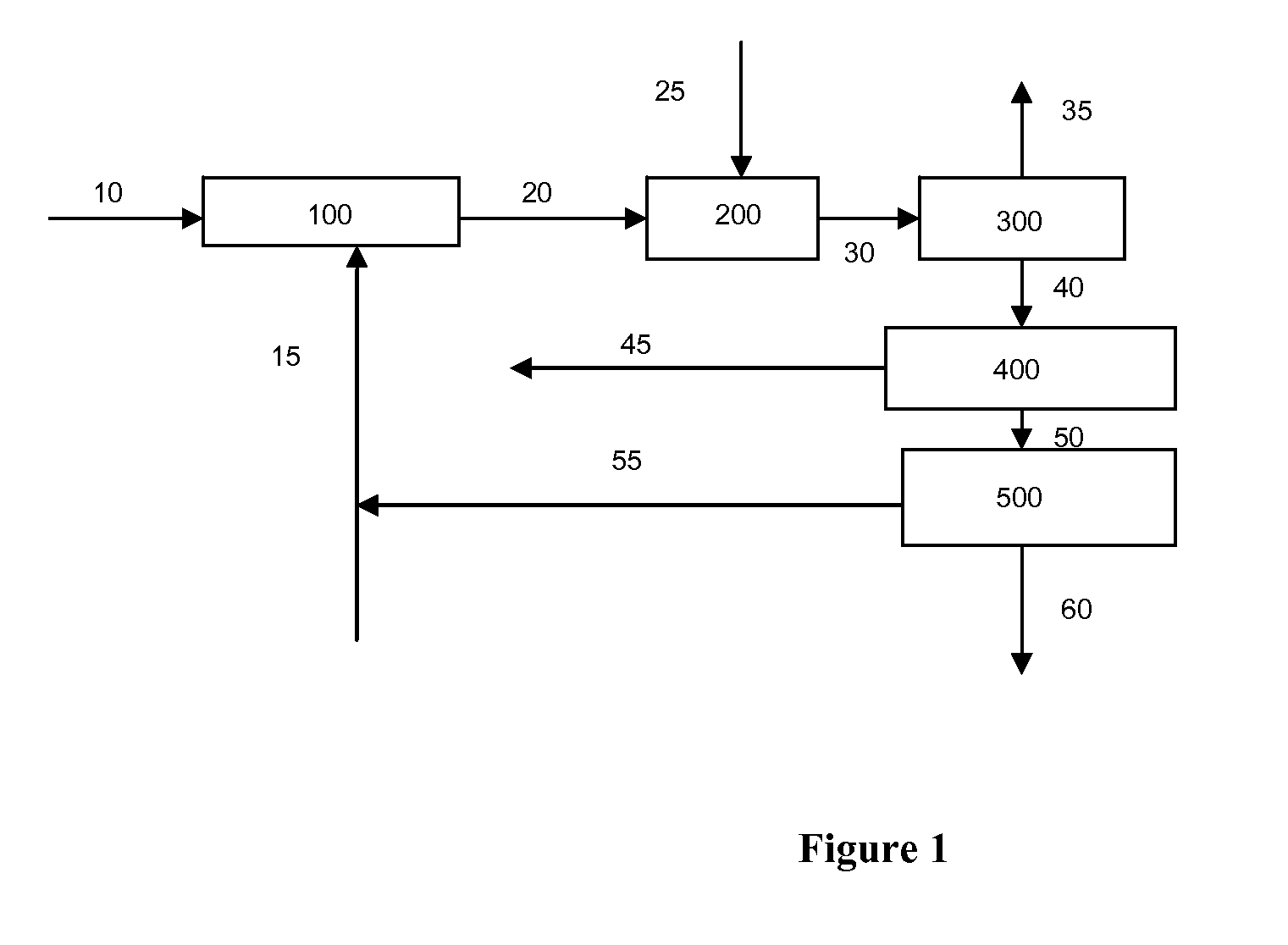

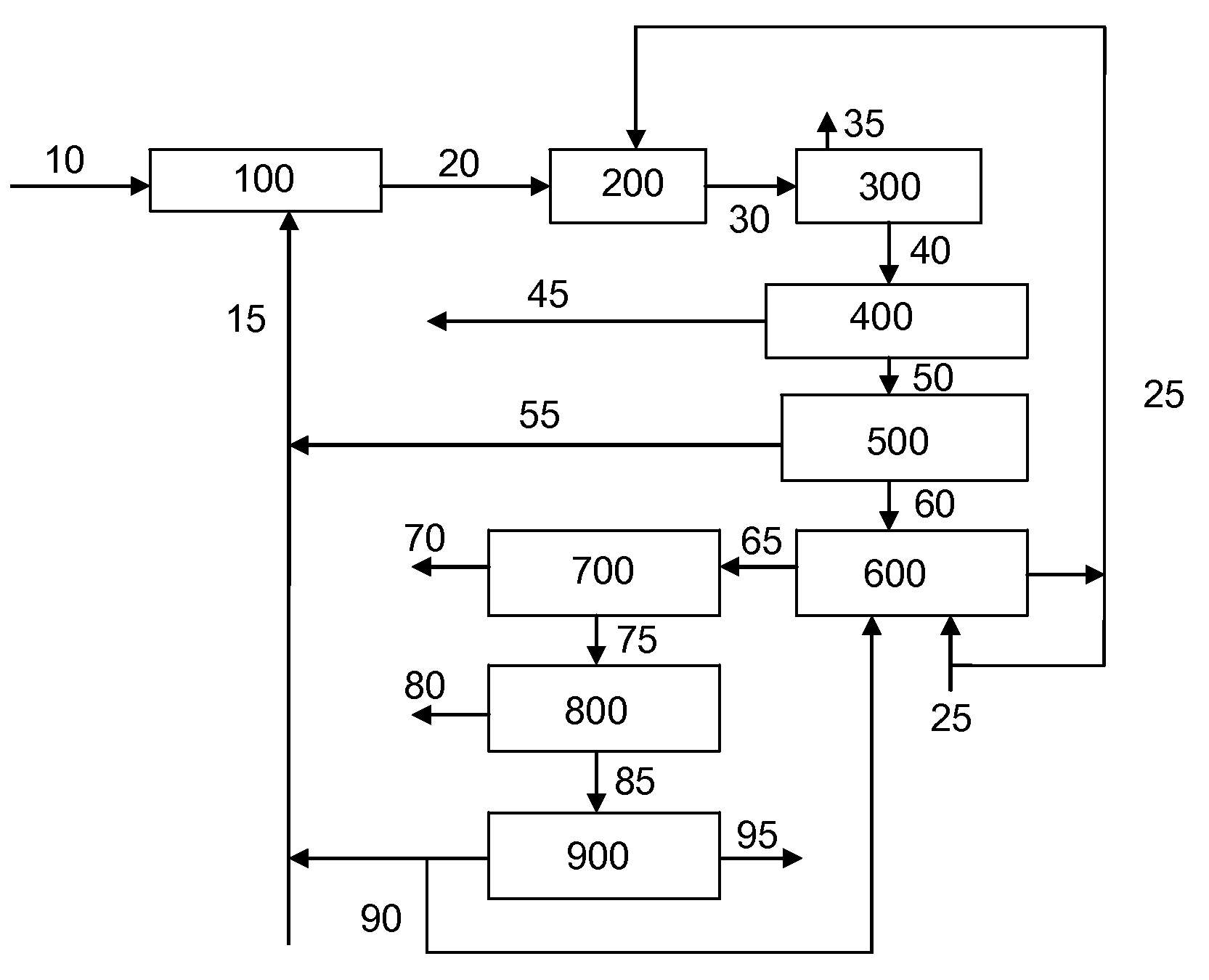

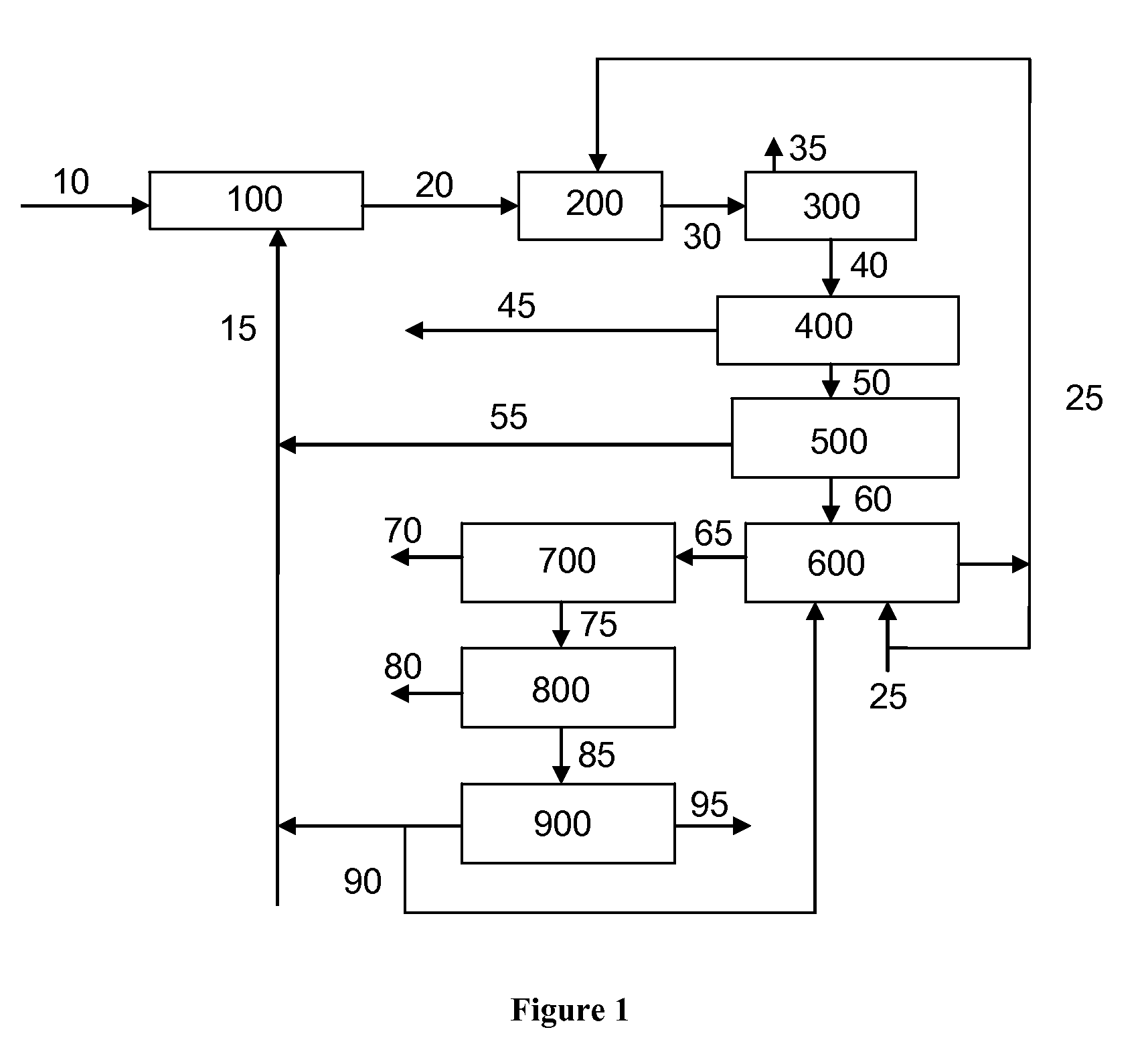

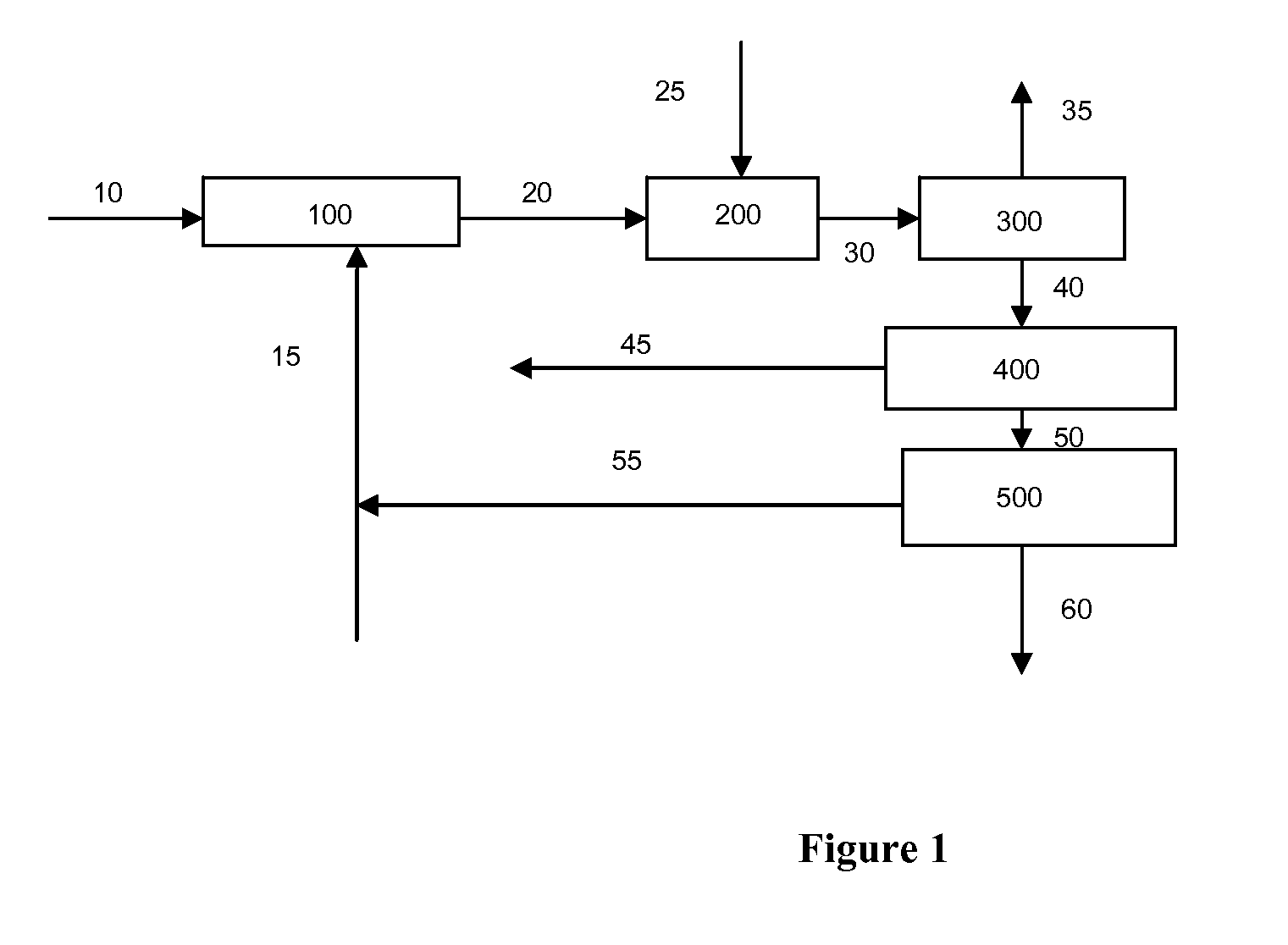

Catalytic Gasification Process with Recovery of Alkali Metal from Char

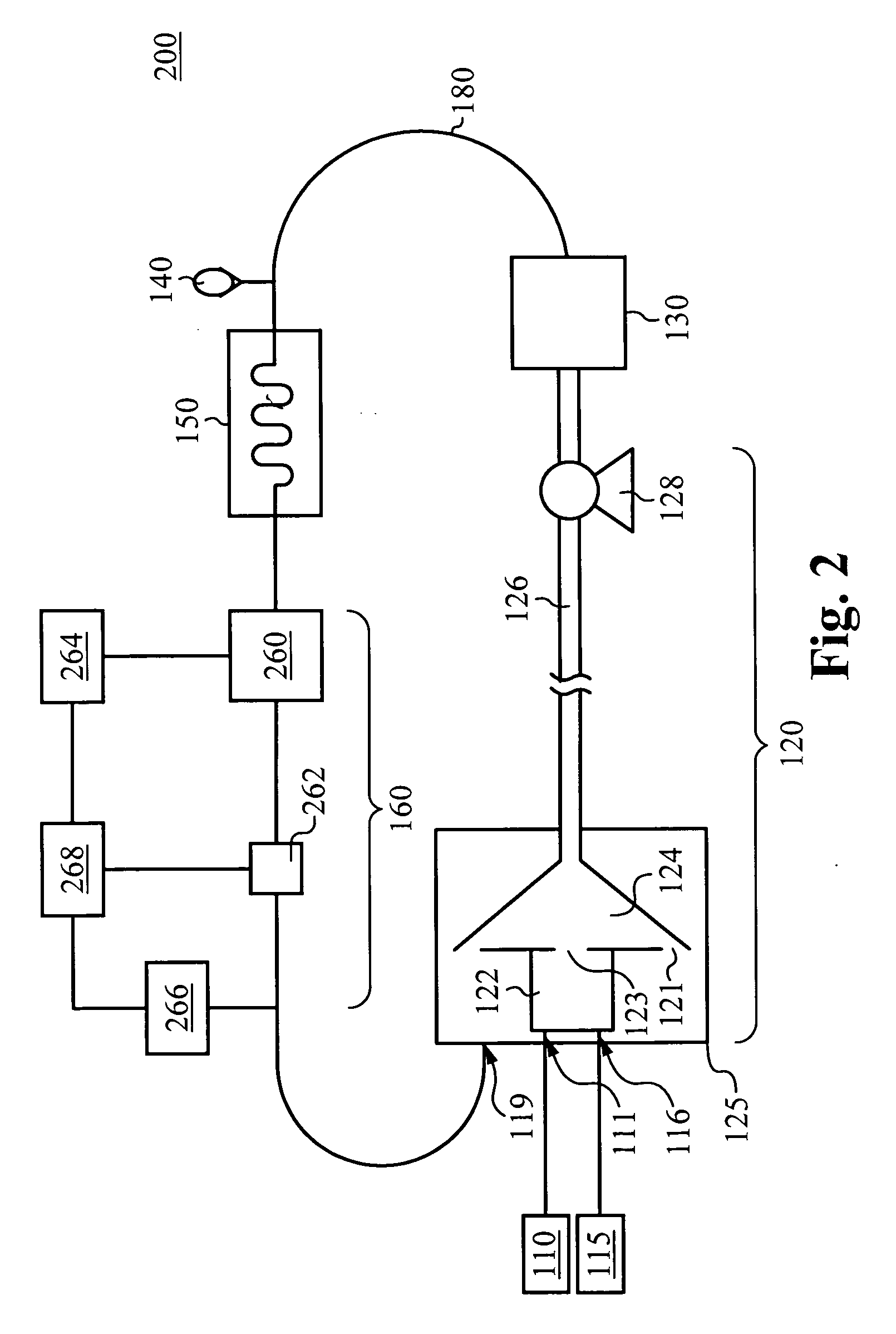

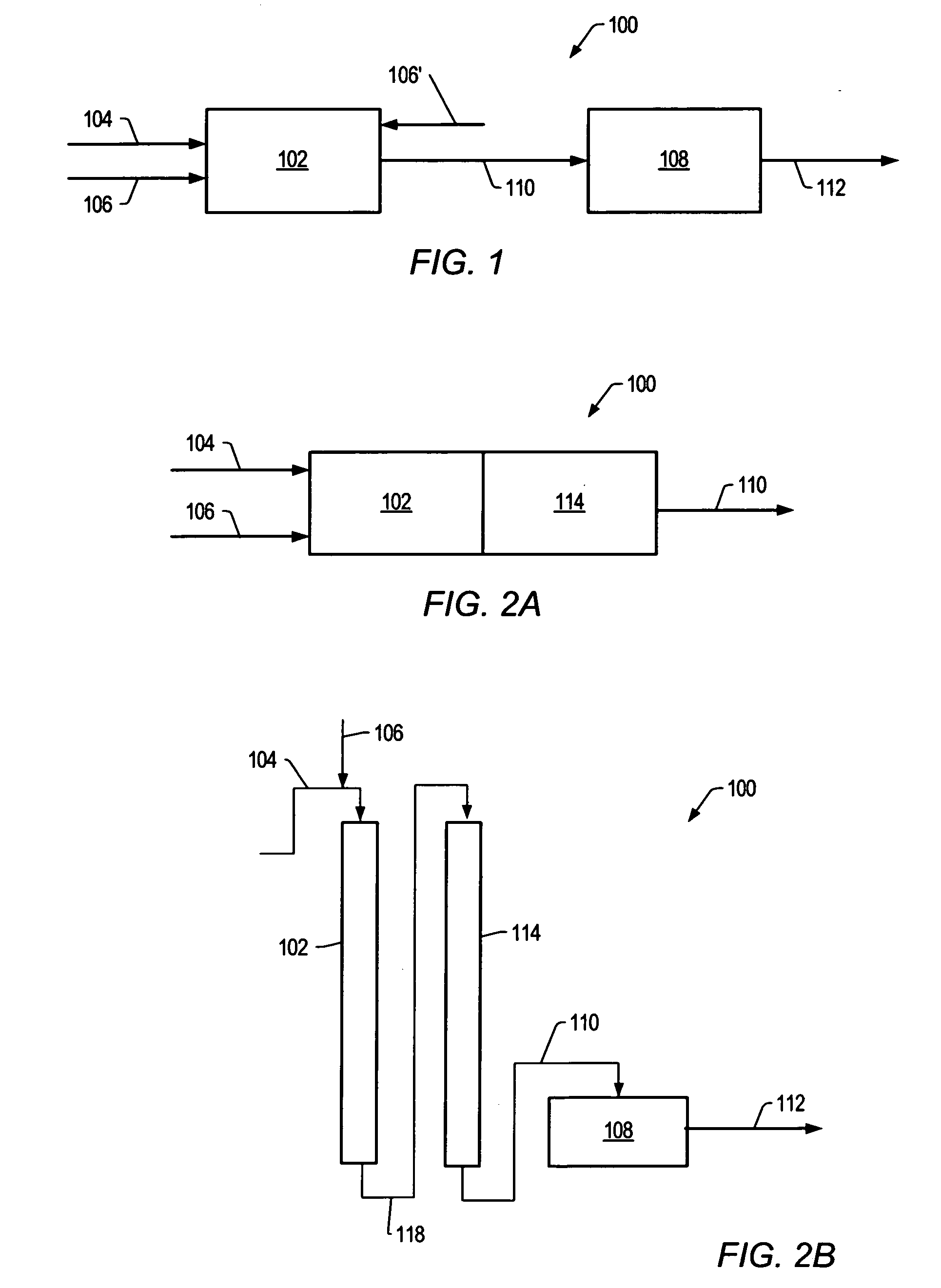

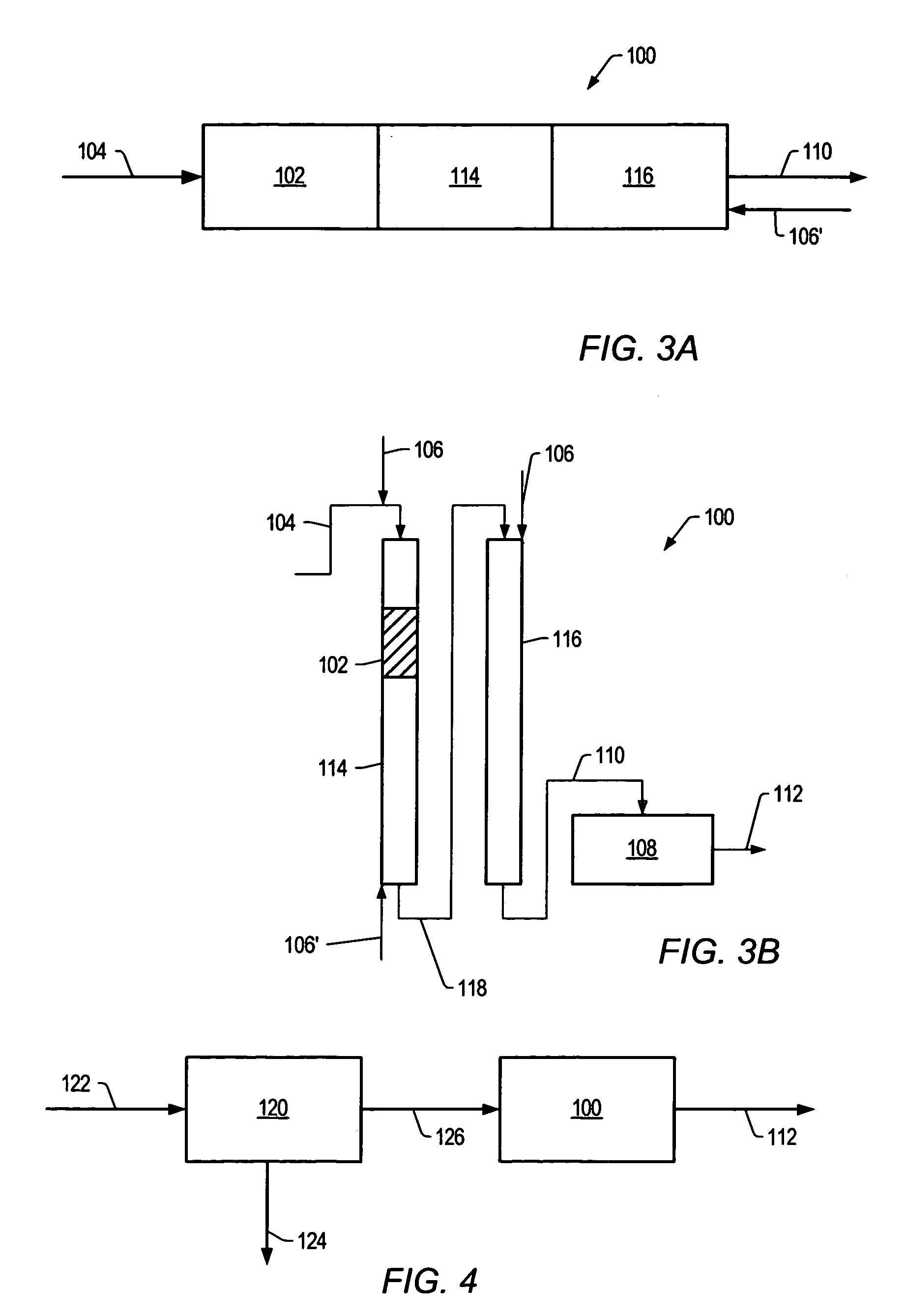

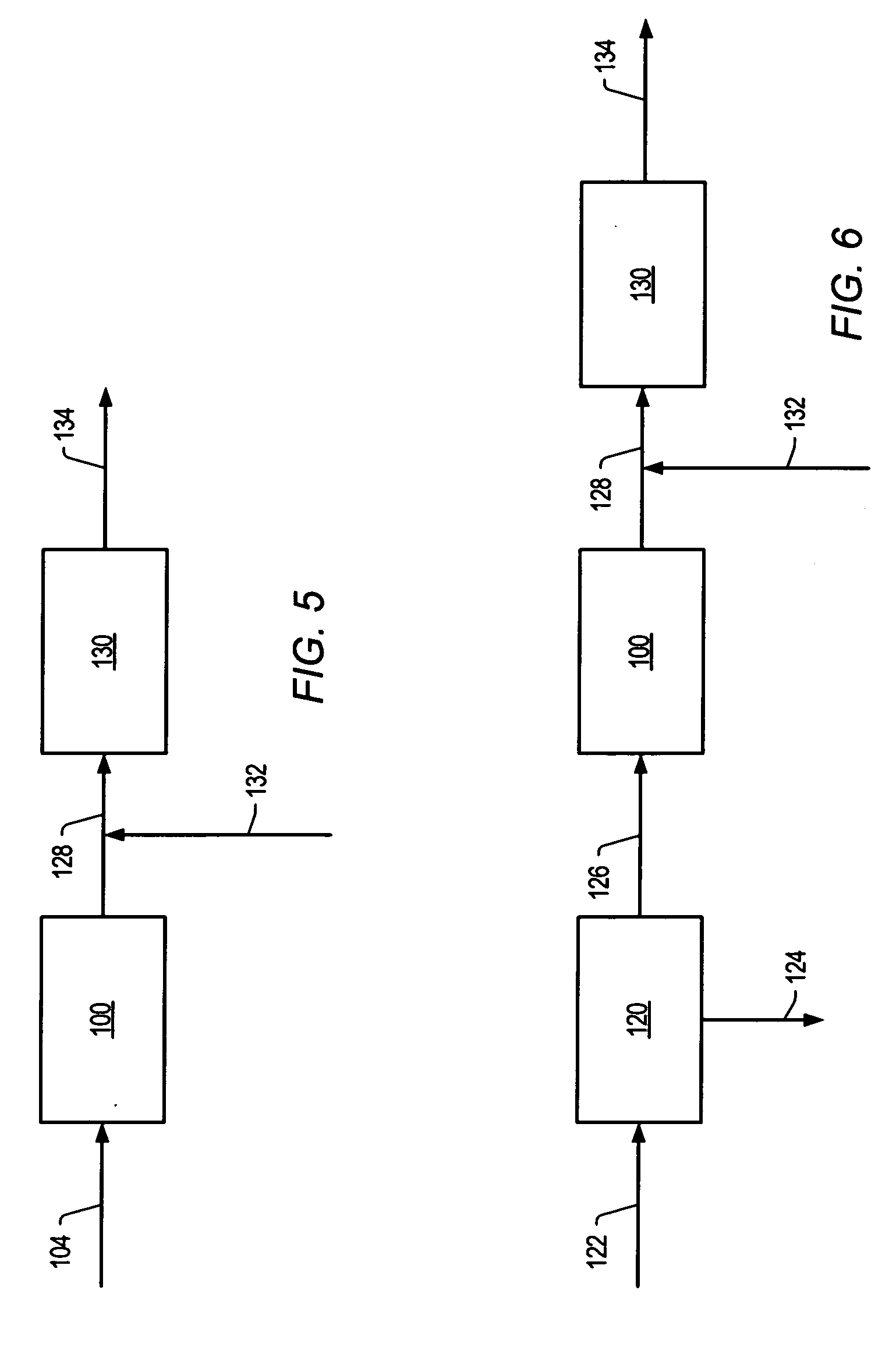

ActiveUS20090169448A1Quantity minimizationThermal non-catalytic crackingMuffle furnacesPhysical chemistryAlkali metal

Processes are described for the extraction and recovery of alkali metal from the char that results from catalytic gasification of a carbonaceous material. Among other steps, the processes of the invention include a hydrothermal leaching step in which a slurry of insoluble particulate comprising insoluble alkali metal compounds is treated with carbon dioxide and steam at elevated temperatures and pressures to effect the conversion of insoluble alkali metal compounds to soluble alkali metal compounds. Further, processes are described for the catalytic gasification of a carbonaceous material where a substantial portion of alkali metal is extracted and recovered from the char that results from the catalytic gasification process.

Owner:SURE CHAMPION INVESTMENT LTD

Catalytic Gasification Process with Recovery of Alkali Metal from Char

ActiveUS20090169449A1Quantity minimizationThermal non-catalytic crackingMuffle furnacesParticulatesSlurry

Processes are described for the extraction and recovery of alkali metal from the char that results from catalytic gasification of a carbonaceous material. Among other steps, the processes of the invention include a hydrothermal leaching step in which a slurry of insoluble particulate comprising insoluble alkali metal compounds is treated with carbon dioxide and steam at elevated temperatures and pressures to effect the conversion of insoluble alkali metal compounds to soluble alkali metal compounds. Further, processes are described for the catalytic gasification of a carbonaceous material where a substantial portion of alkali metal is extracted and recovered from the char that results from the catalytic gasification process.

Owner:SURE CHAMPION INVESTMENT LTD

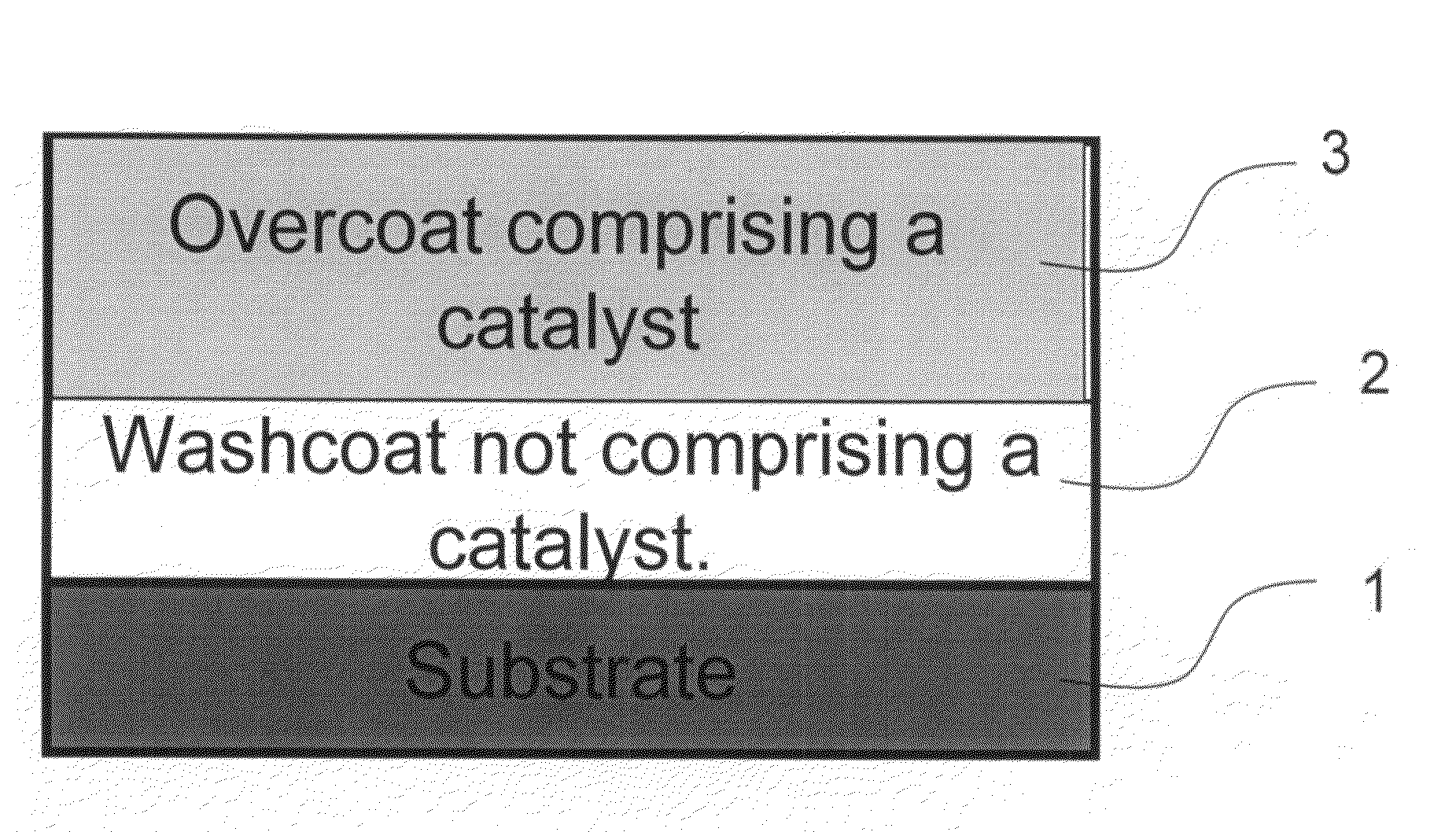

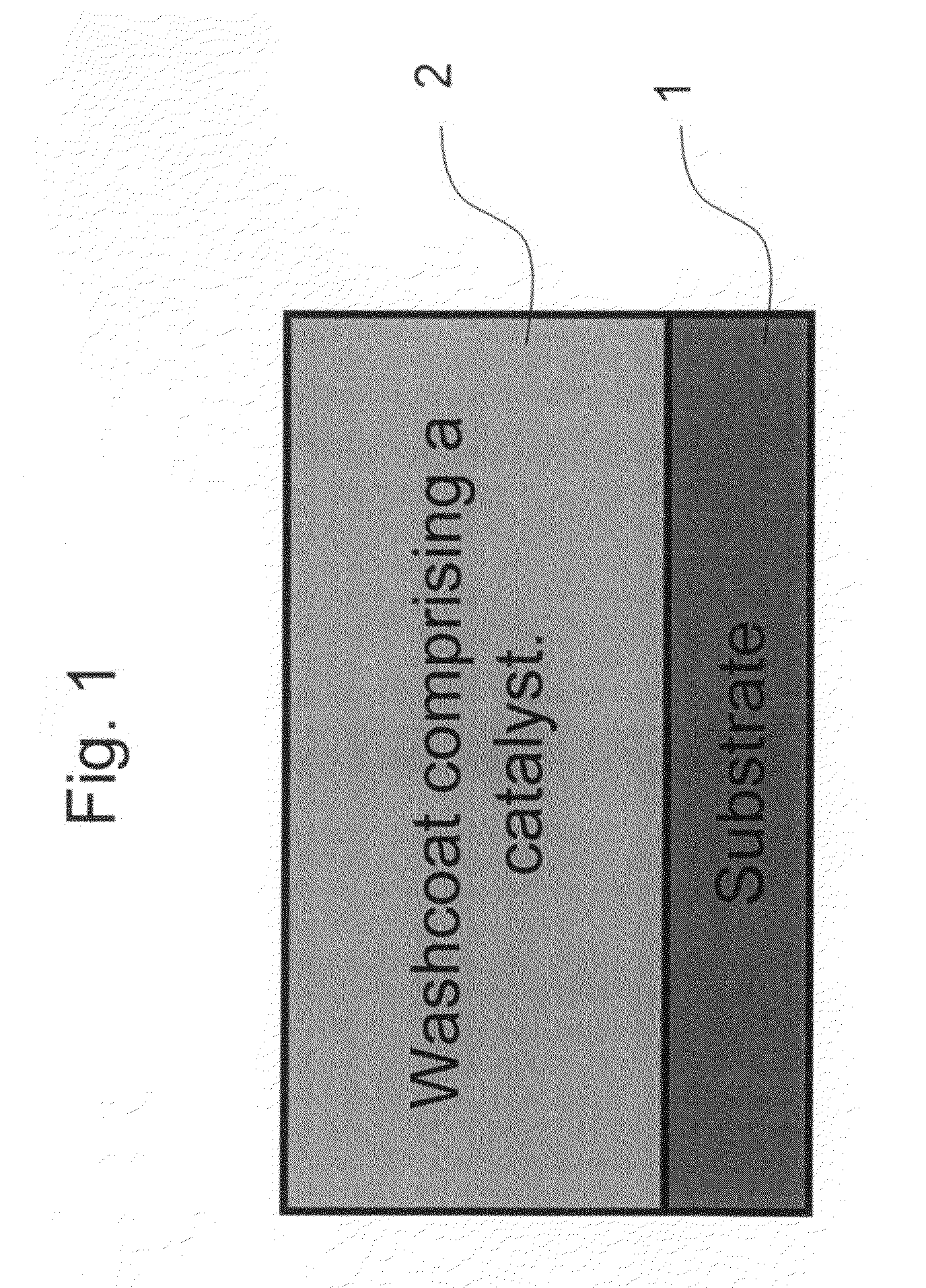

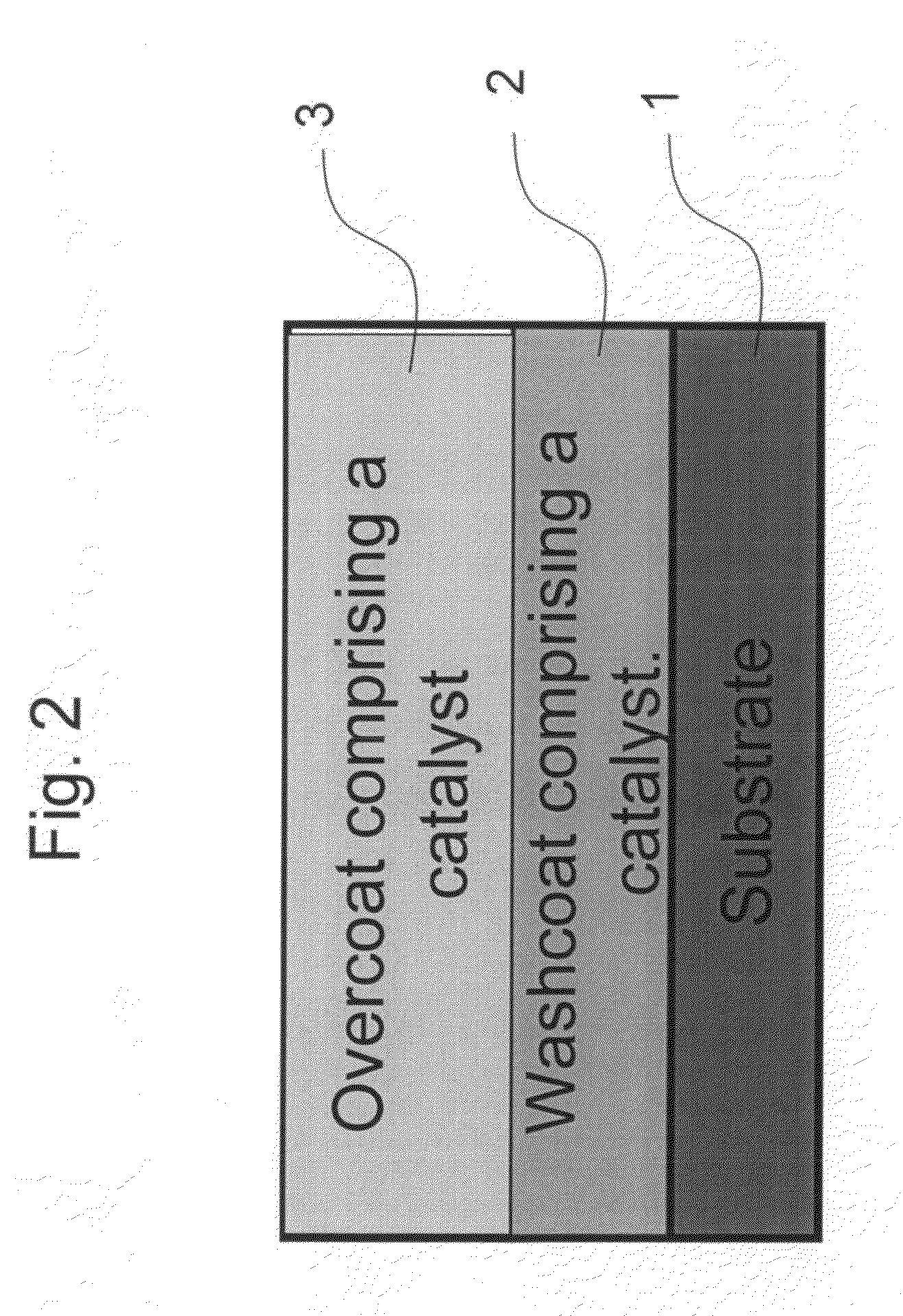

Zero platinum group metal catalysts

The present invention pertains to catalyst systems for nitrogen oxide, carbon monoxide, hydrocarbon, and sulfur reactions that are free or substantially free of platinum group metals. The catalyst system of the present invention comprise a substrate and a washcoat, wherein the washcoat comprises at least one oxide solid, wherein the oxide solid comprises one or more selected from the group consisting of a carrier material oxide, a catalyst, and mixtures thereof. The catalyst system may optionally have an overcoat, wherein the overcoat comprises at least one oxide solid, wherein the oxide solid comprises one or more selected from the group consisting of a carrier material oxide, a catalyst, and mixtures thereof. The catalyst comprises one or more selected from the group consisting of a ZPGM transition metal catalyst, a mixed metal oxide catalyst, a zeolite catalysts, or mixtures thereof.

Owner:CATALYTIC SOLUTIONS INC

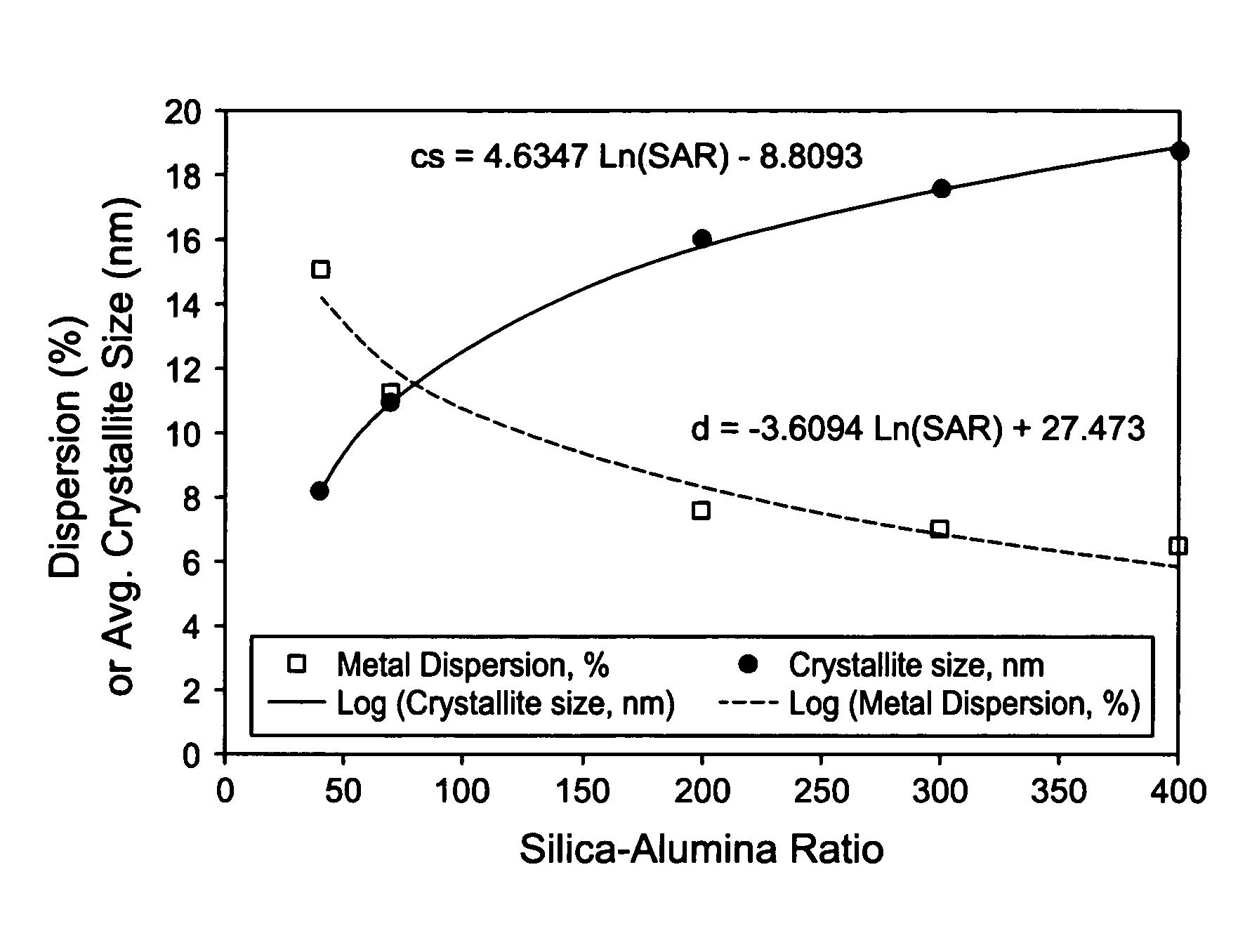

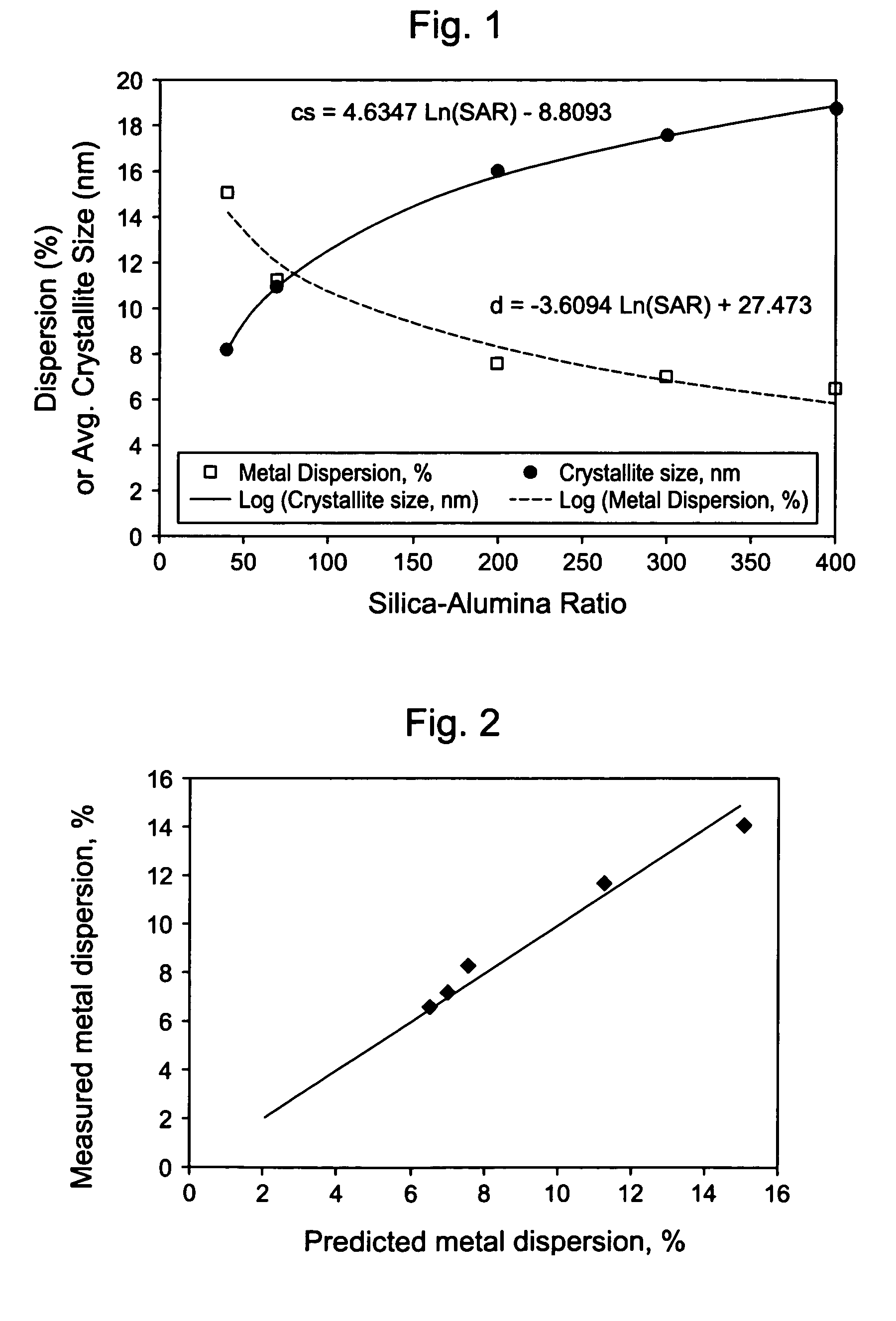

Silica-alumina catalyst support, catalysts made therefrom and methods of making and using same

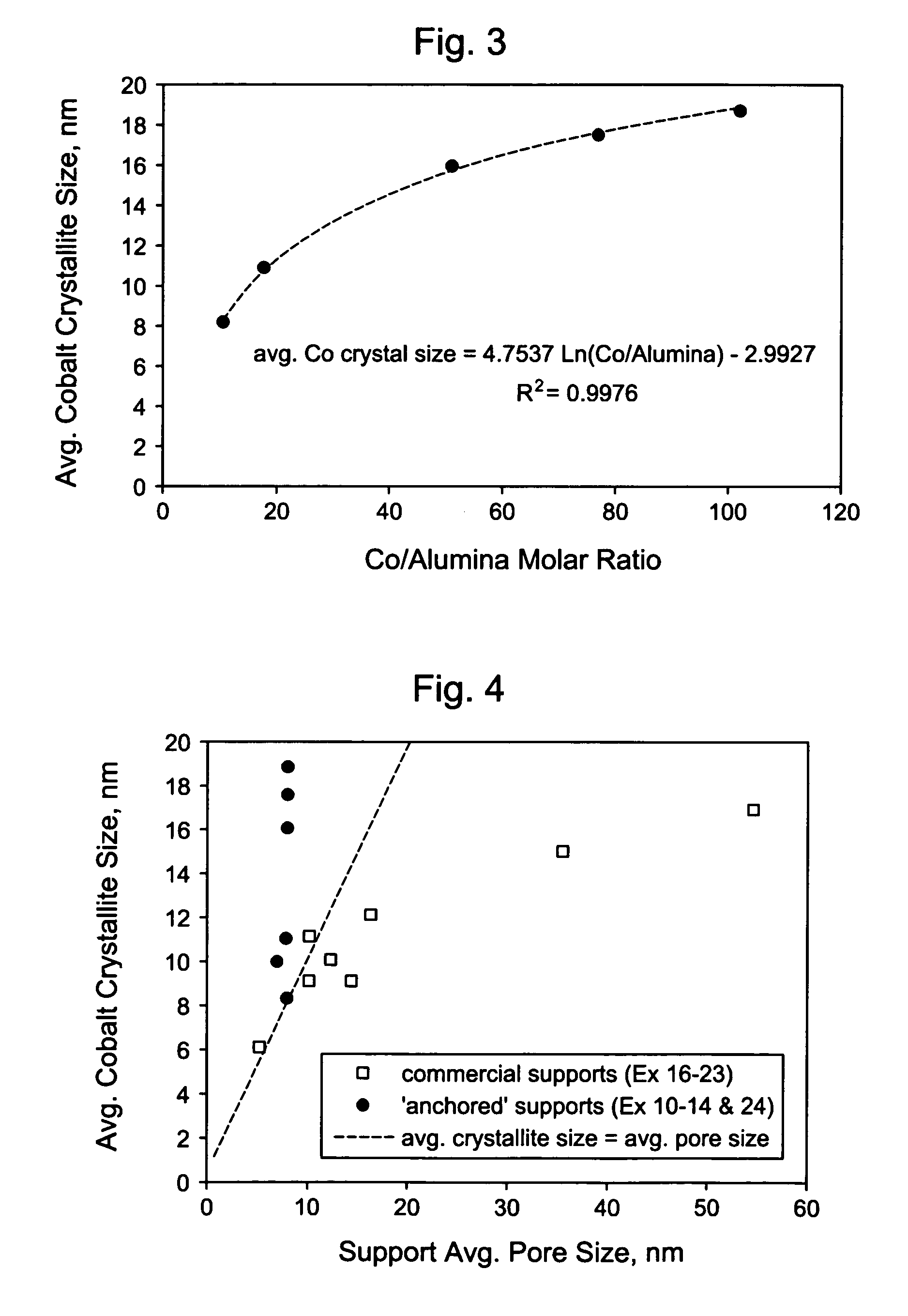

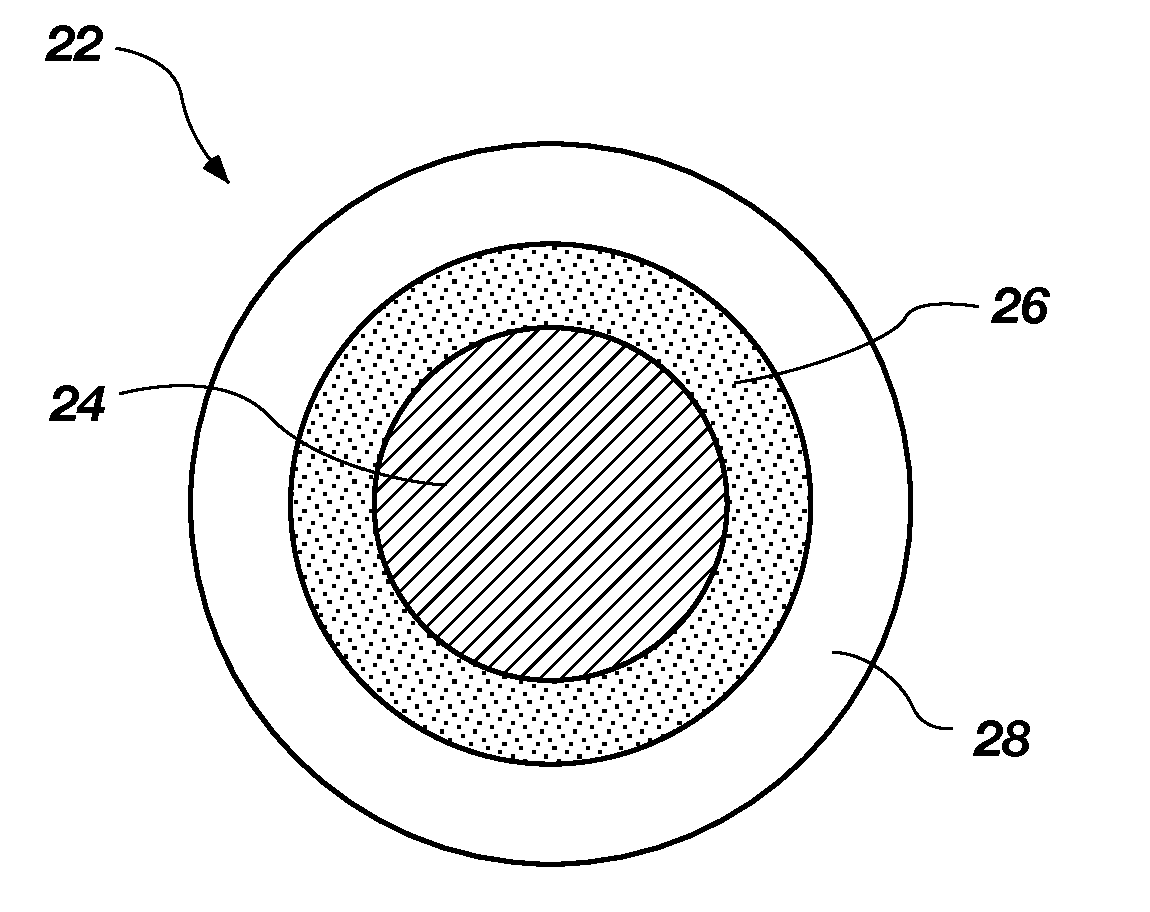

ActiveUS7541310B2High activityHydrocarbon from carbon oxidesMolecular sieve catalystsCompound (substance)Catalytic metal

This invention relates to catalysts comprising a catalytic metal deposited on a composite support with well-dispersed chemical “anchor” species acting as nucleation centers for catalytic metal crystallites growth. The catalysts have the advantage that the average catalytic metal crystallite size can be controlled by the molar ratio of catalytic metal to chemical “anchor,” and is not limited by the porous structure of the support. A preferred embodiment comprises a cobalt-based catalyst on a silica-alumina support made by a co-gel method, wherein its average pore size can be controlled by the pH. The alumina species in the support most likely serve as chemical “anchors” to control the dispersion of cobalt species, such that the average cobalt crystallite size can be greater than the average pore size.

Owner:CLARIANT INT LTD

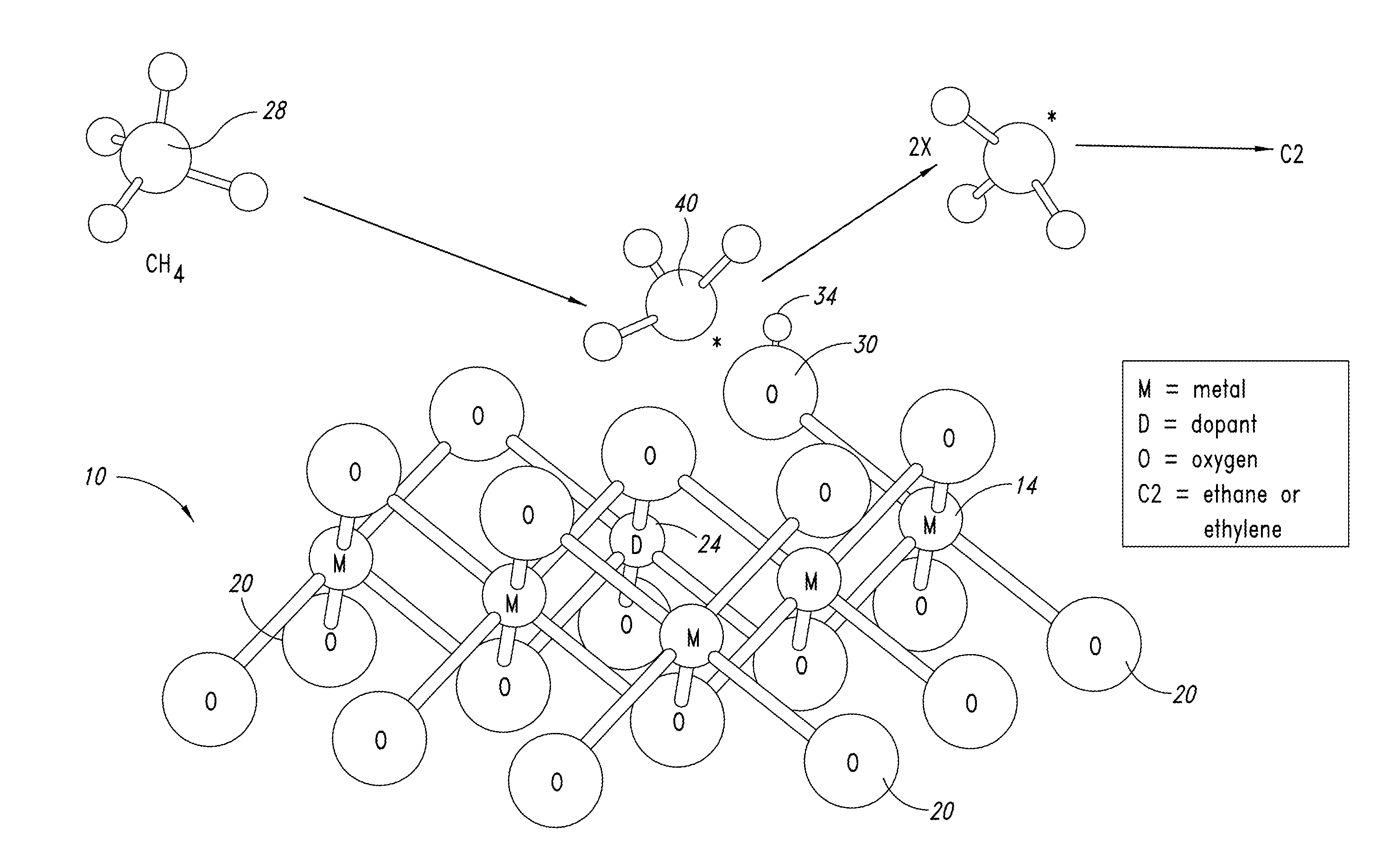

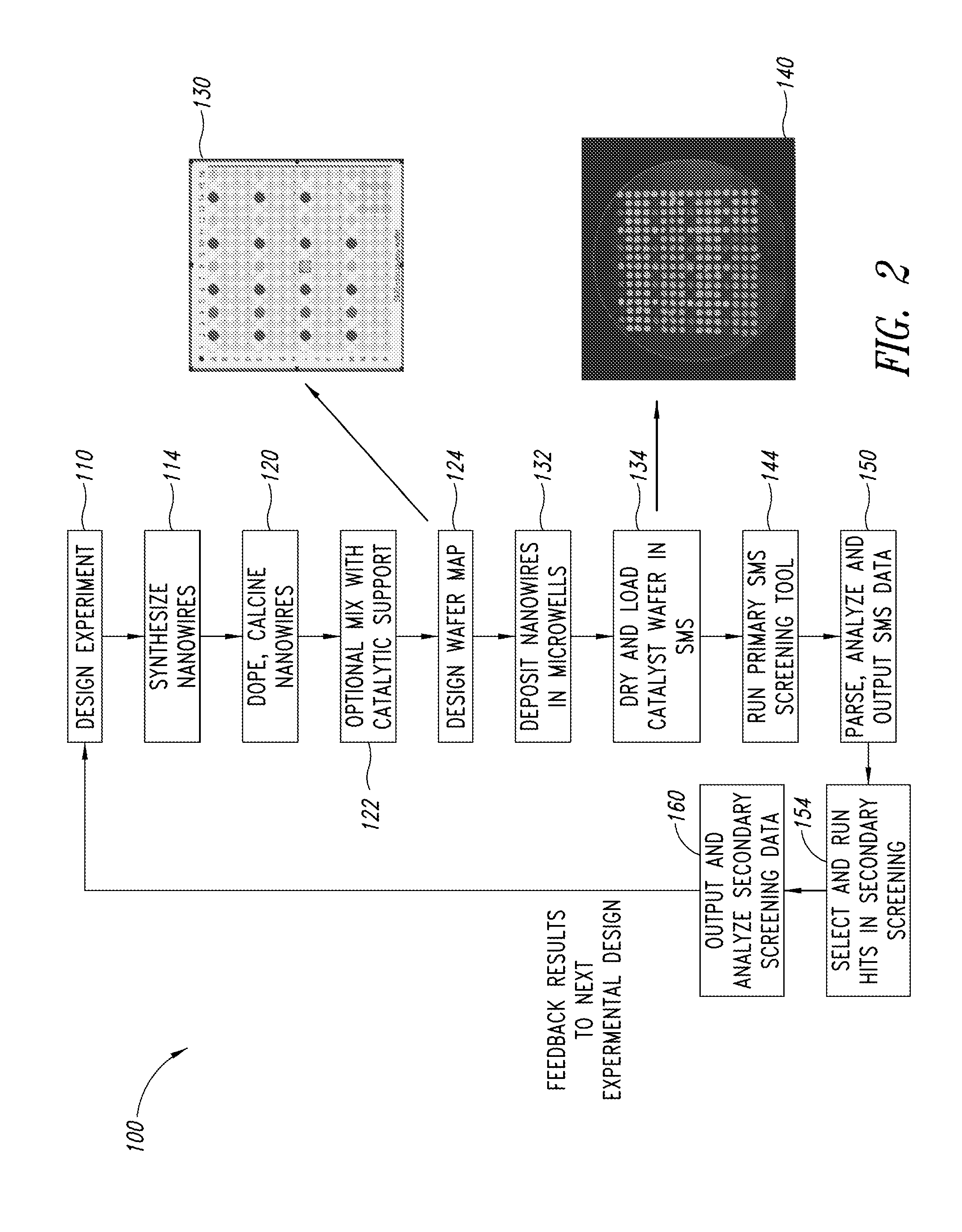

Catalytic forms and formulations

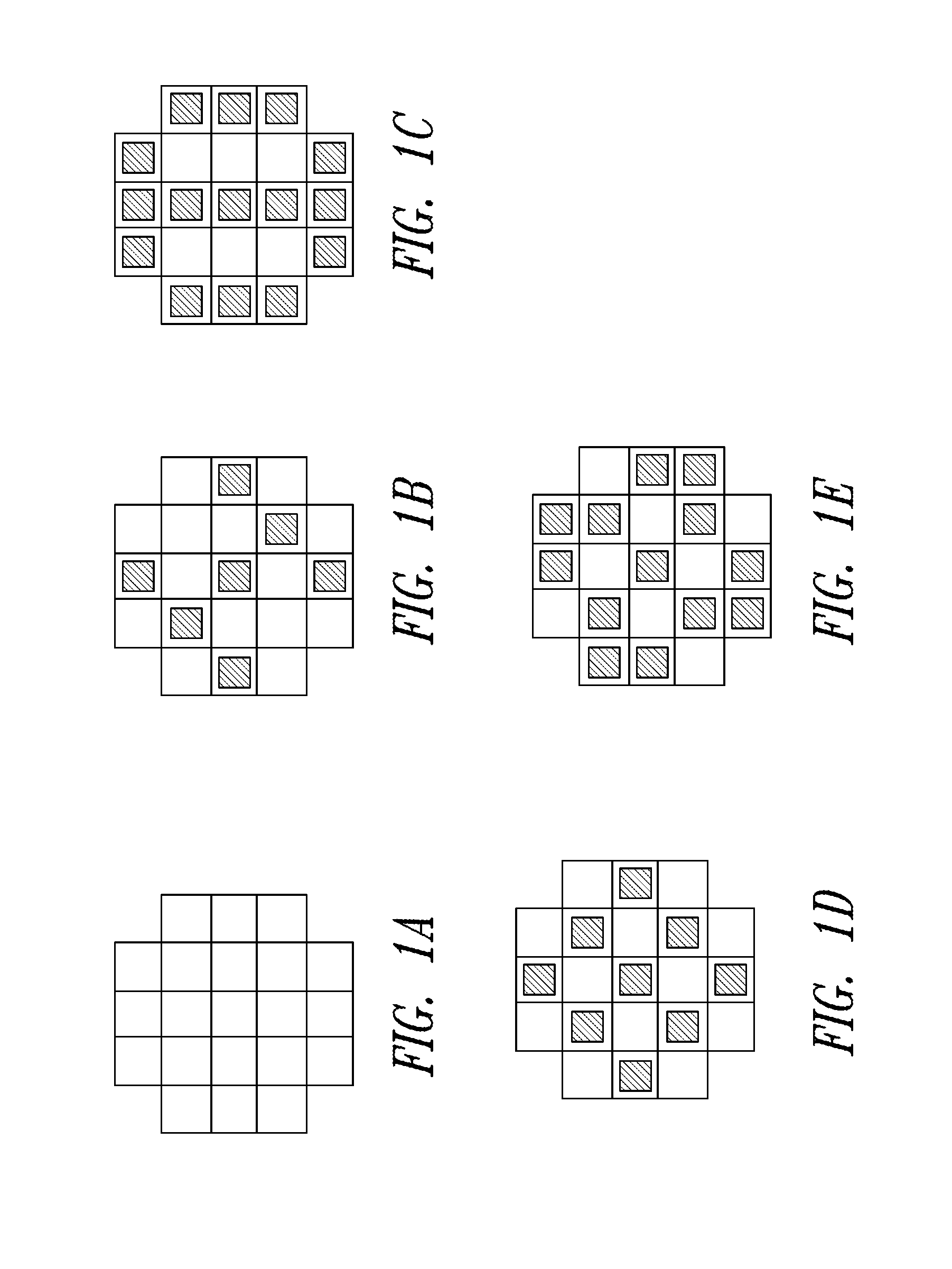

InactiveUS20140121433A1Material nanotechnologyMolecular sieve catalystsOxidative coupling of methaneChemistry

Catalytic forms and formulations are provided. The catalytic forms and formulations are useful in a variety of catalytic reactions, for example, the oxidative coupling of methane. Related methods for use and manufacture of the same are also disclosed.

Owner:SILURIA TECH INC

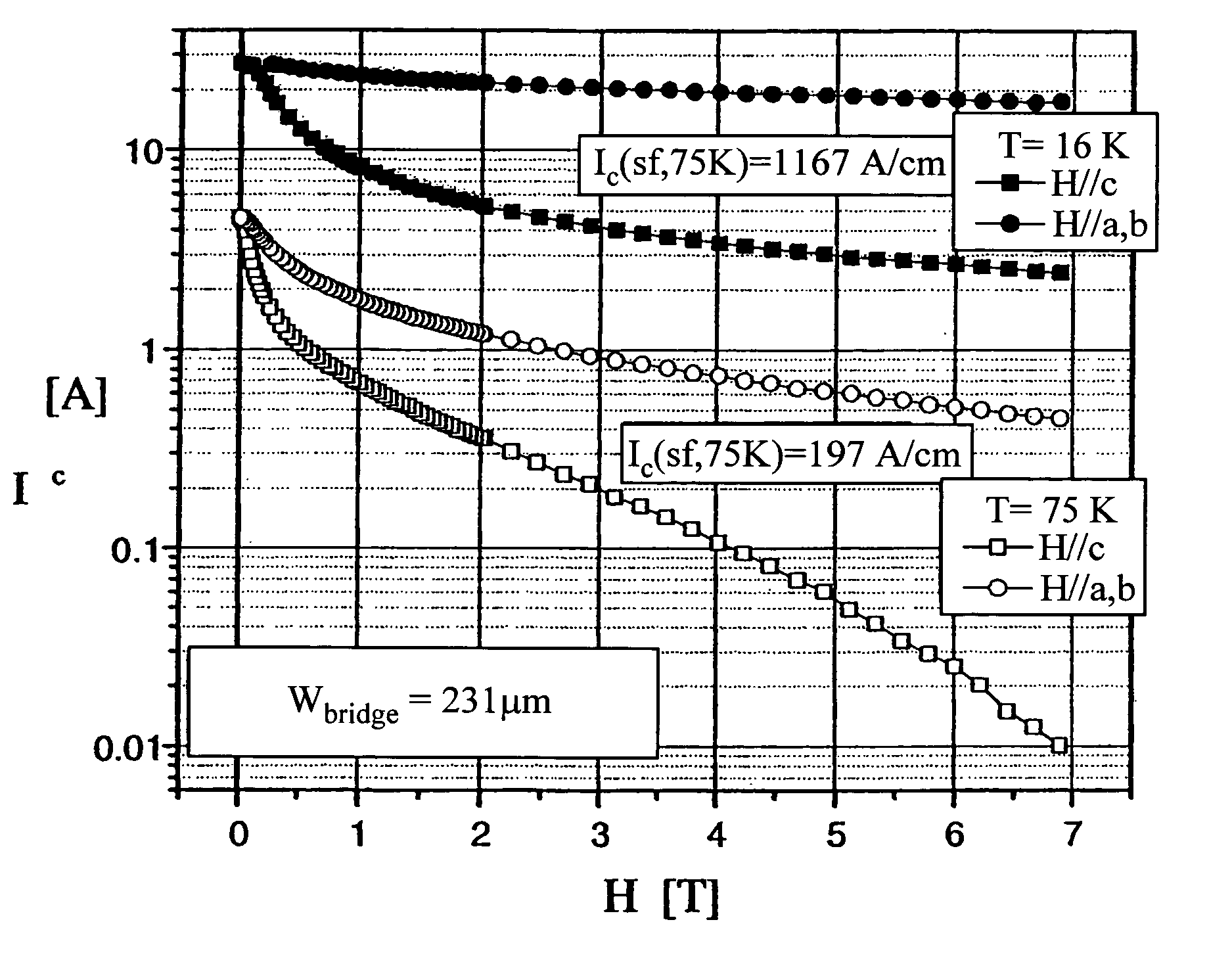

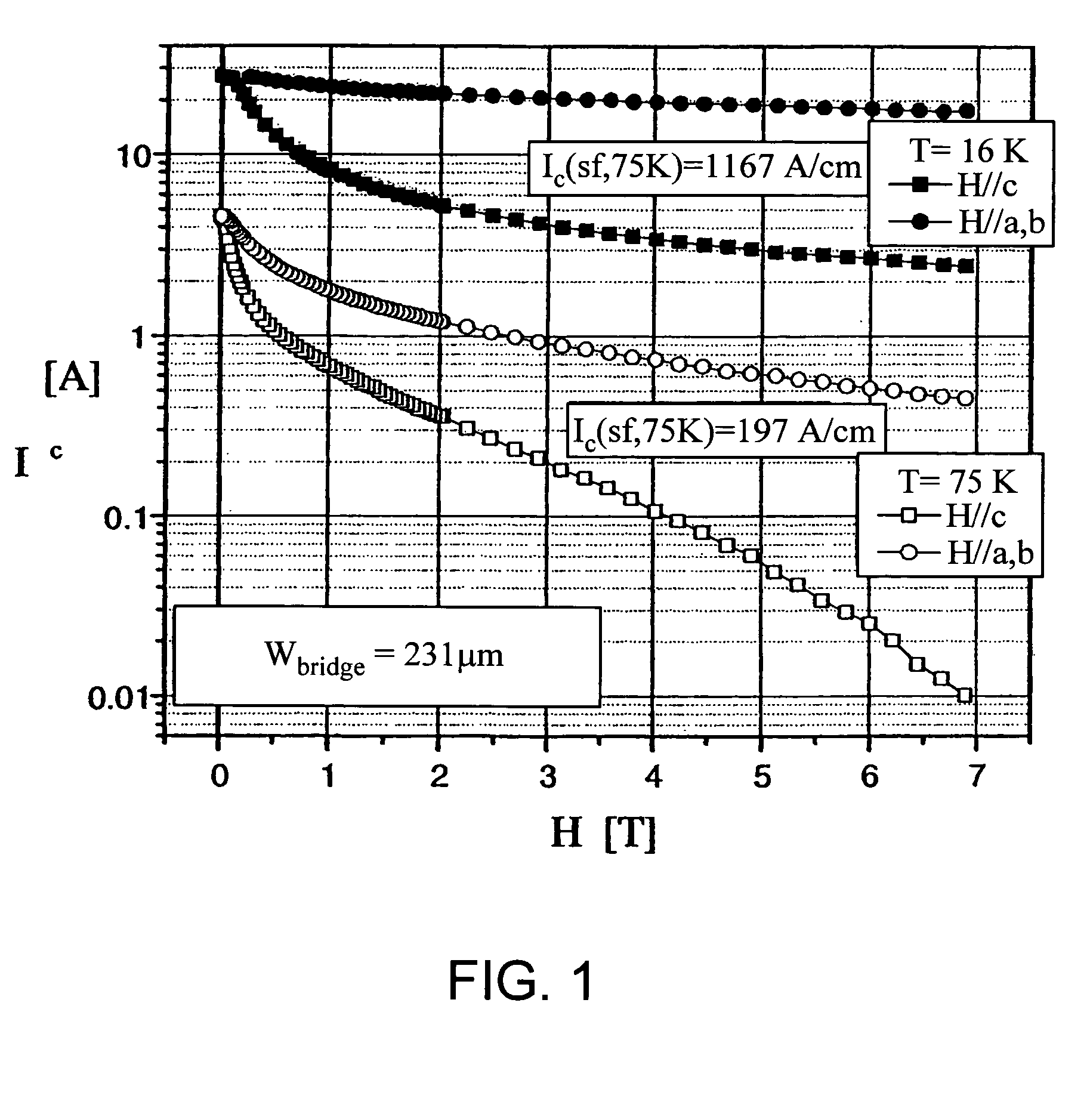

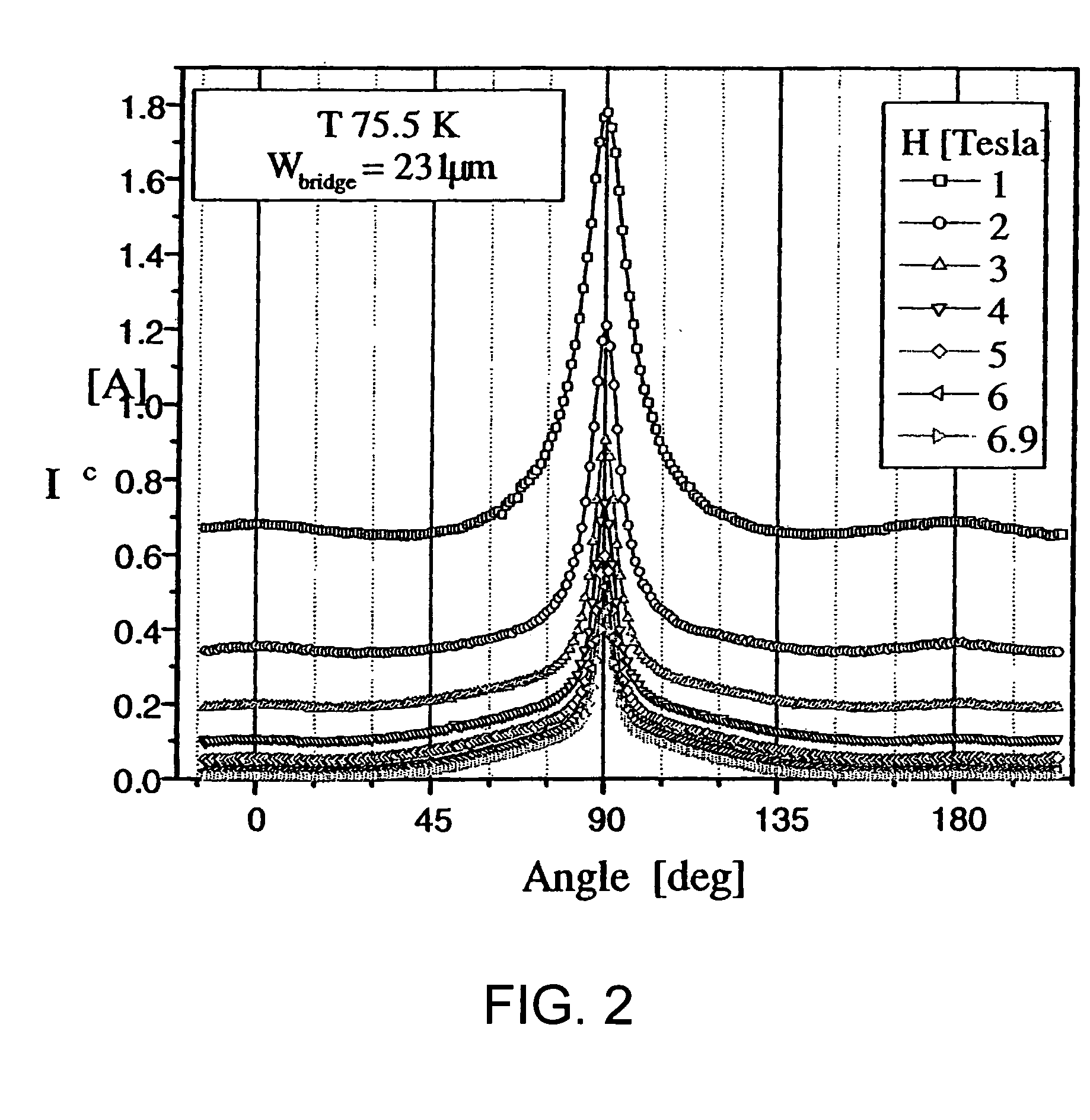

Oxide films with nanodot flux pinning centers

InactiveUS20050159298A1Increasing critical current densitySimple and versatileMaterial nanotechnologyMolecular sieve catalystsNanodotRare-earth element

A method for producing a thin film includes disposing a precursor solution onto a substrate to form a precursor film. The precursor solution contains precursor components to a rare-earth / alkaline-earth-metal / transition-metal oxide including a salt of a rare earth element, a salt of an alkaline earth metal, and a salt of a transition metal in one or more solvents, wherein at least one of the salts is a fluoride-containing salt. The precursor solution also contains an additive component comprising one or more metal compounds capable of forming a second phase nanoparticle, either alone or in combination with one or more of the precursor components of the precursor solution or a dopant component comprising one or more metal compounds capable of substituting for an element of the rare-earth / alkaline-earth-metal / transition-metal oxide, and treating the precursor film to form an intermediate metal oxyfluoride including the rare earth, the alkaline earth metal, the transition metal and the additive metal or dopant metal of the precursor solution.

Owner:AMERICAN SUPERCONDUCTOR

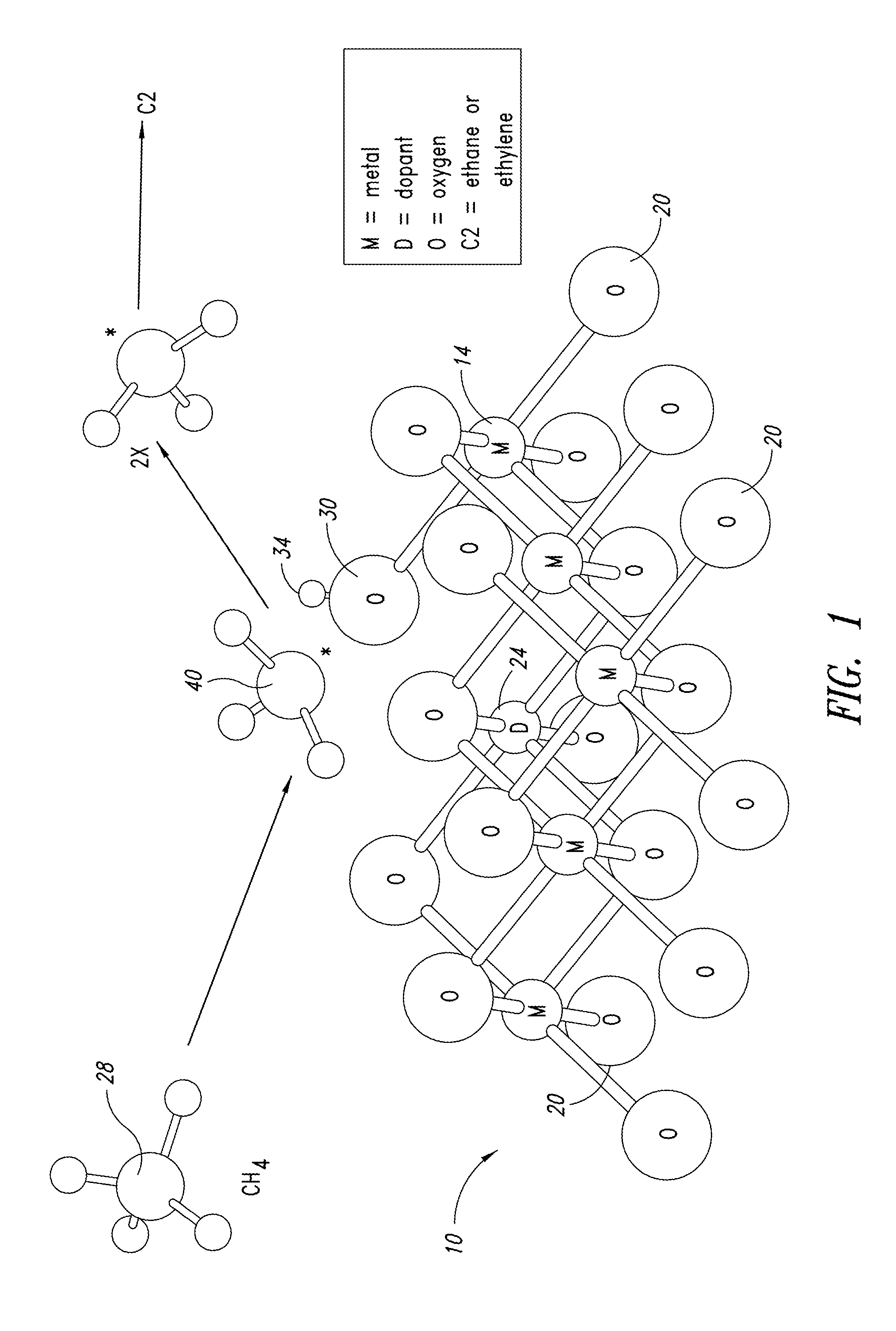

Nanowire catalysts and methods for their use and preparation

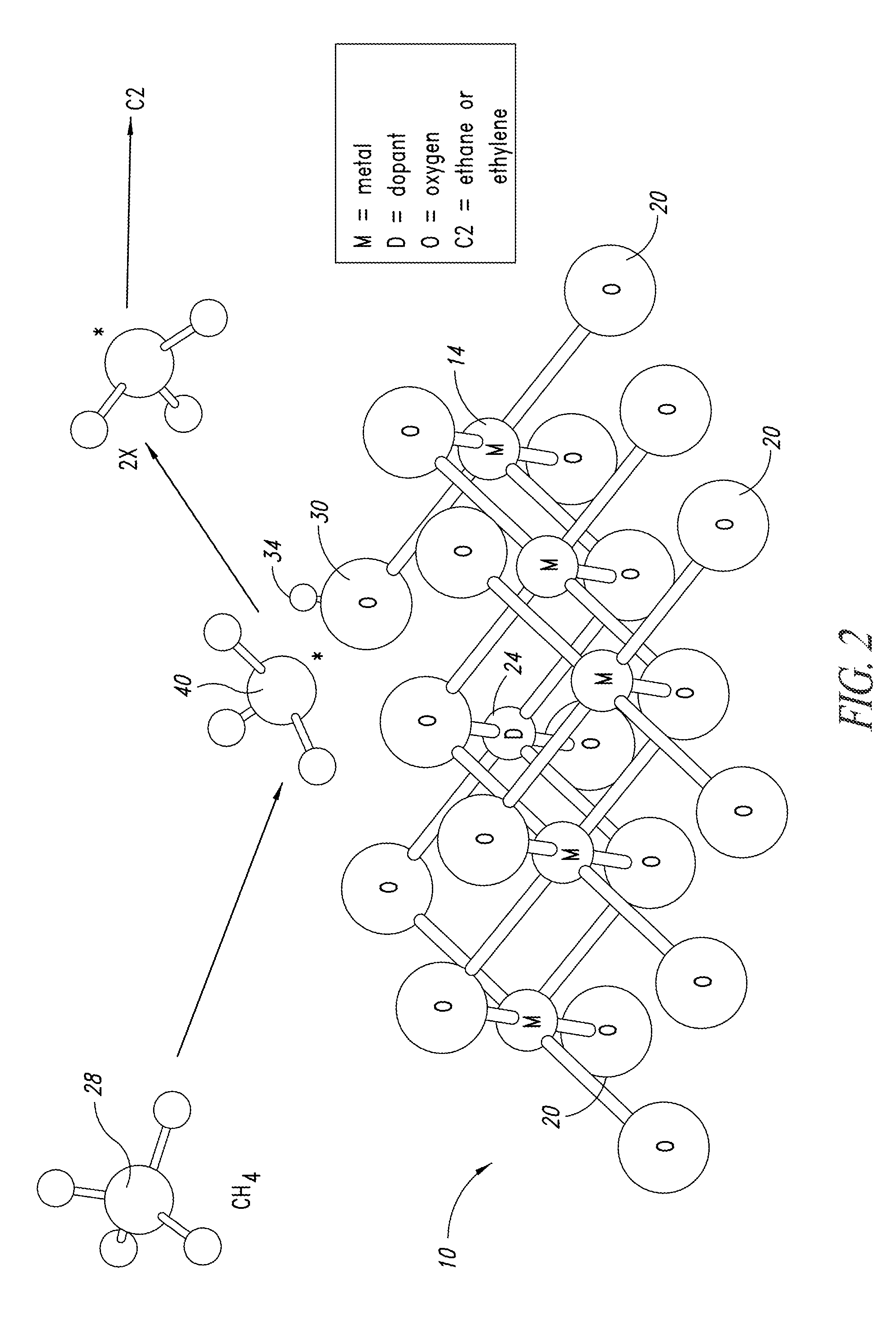

ActiveUS20130165728A1Material nanotechnologyManganese oxides/hydroxidesNanowireOxidative coupling of methane

Nanowires useful as heterogeneous catalysts are provided. The nanowire catalysts are useful in a variety of catalytic reactions, for example, the oxidative coupling of methane to C2 hydrocarbons. Related methods for use and manufacture of the same are also disclosed.

Owner:LUMMUS TECH LLC

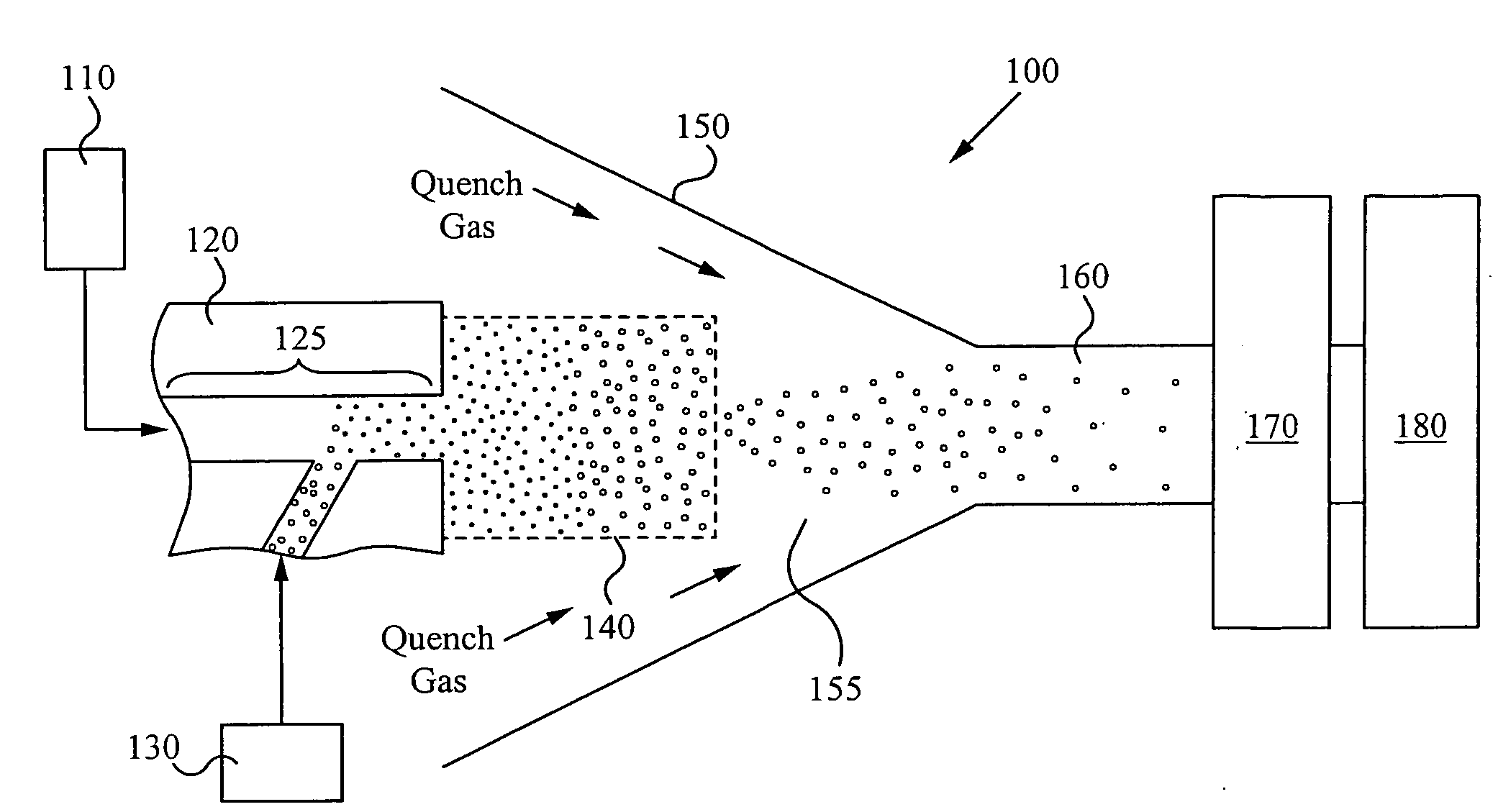

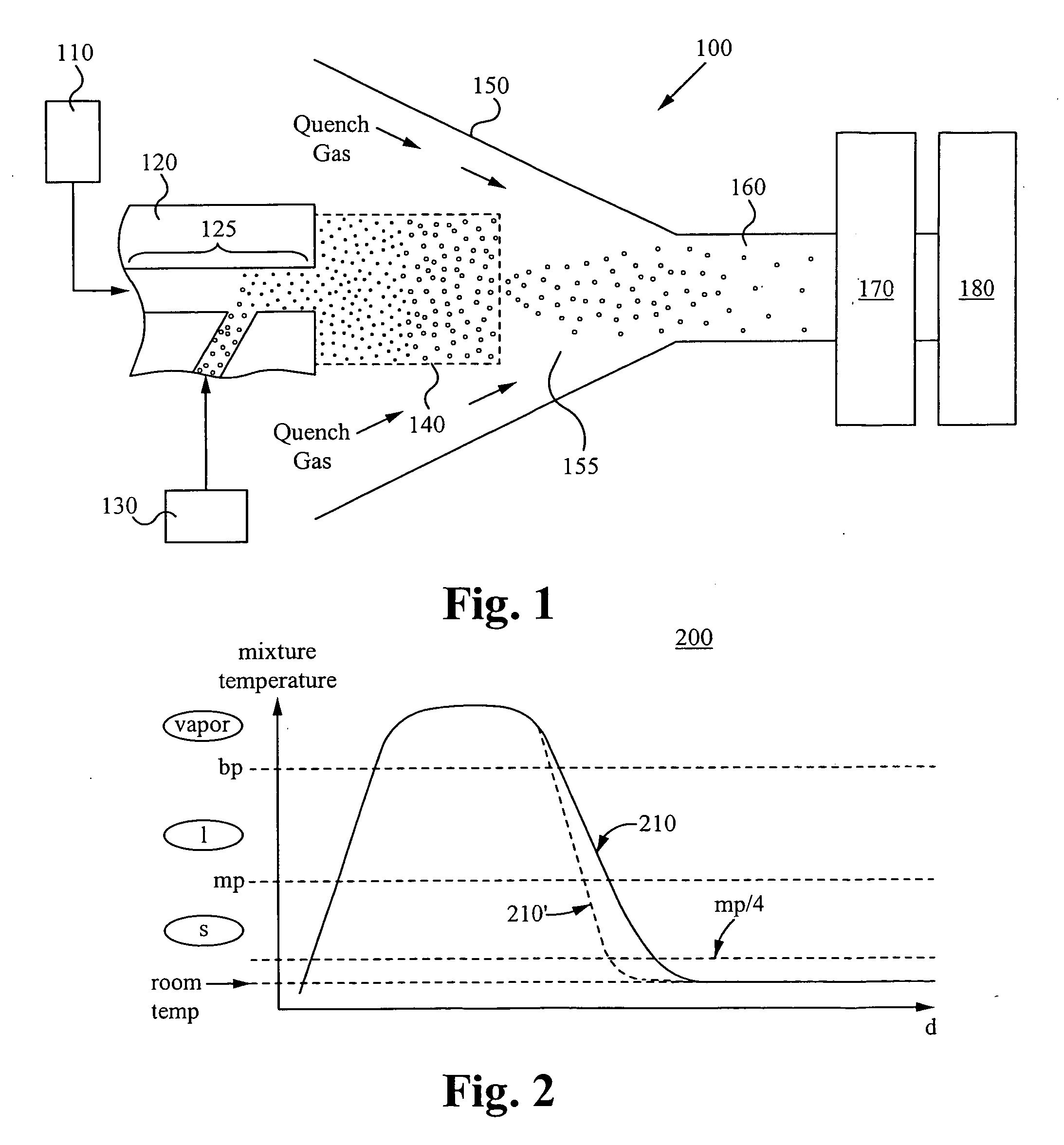

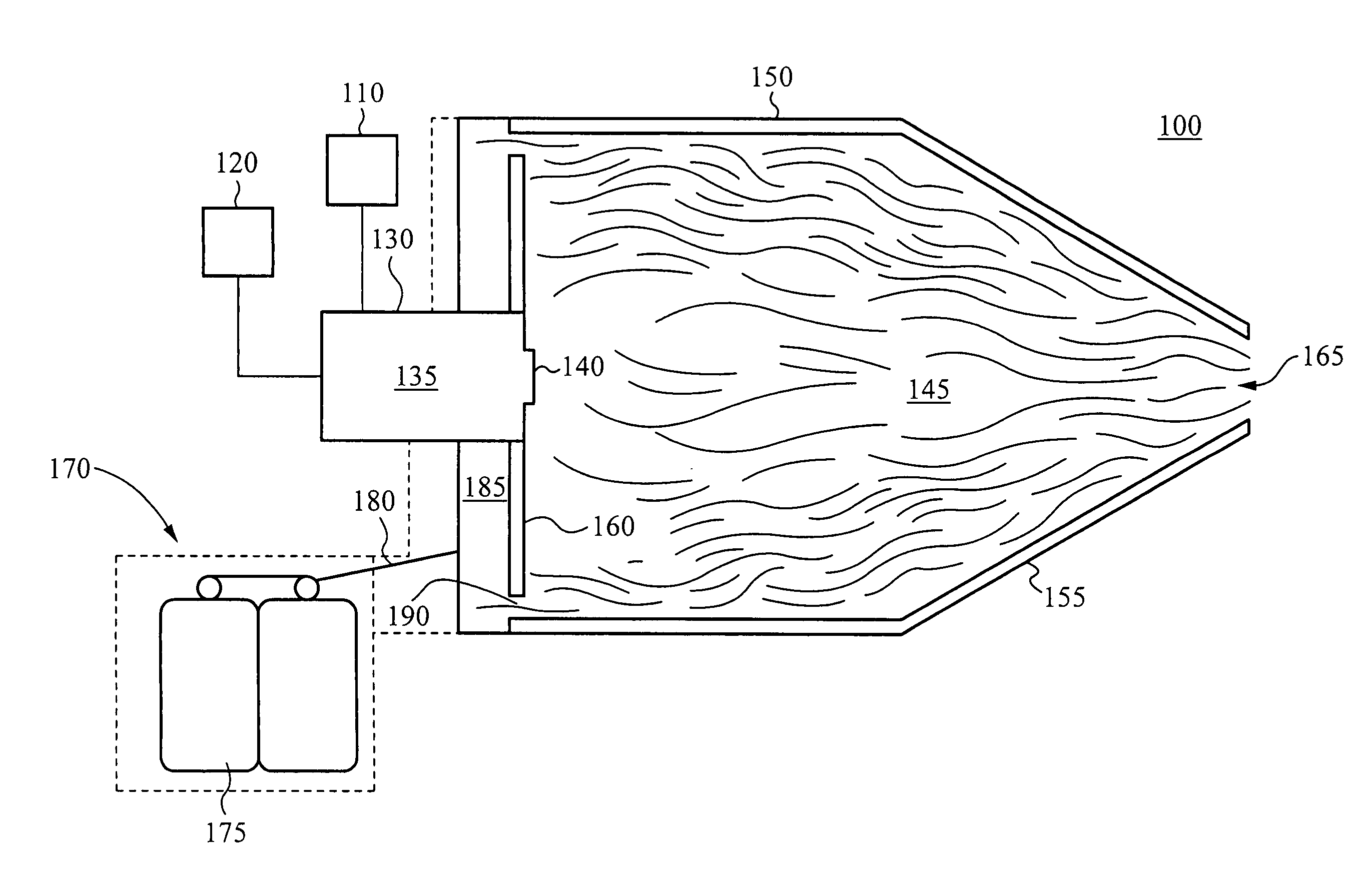

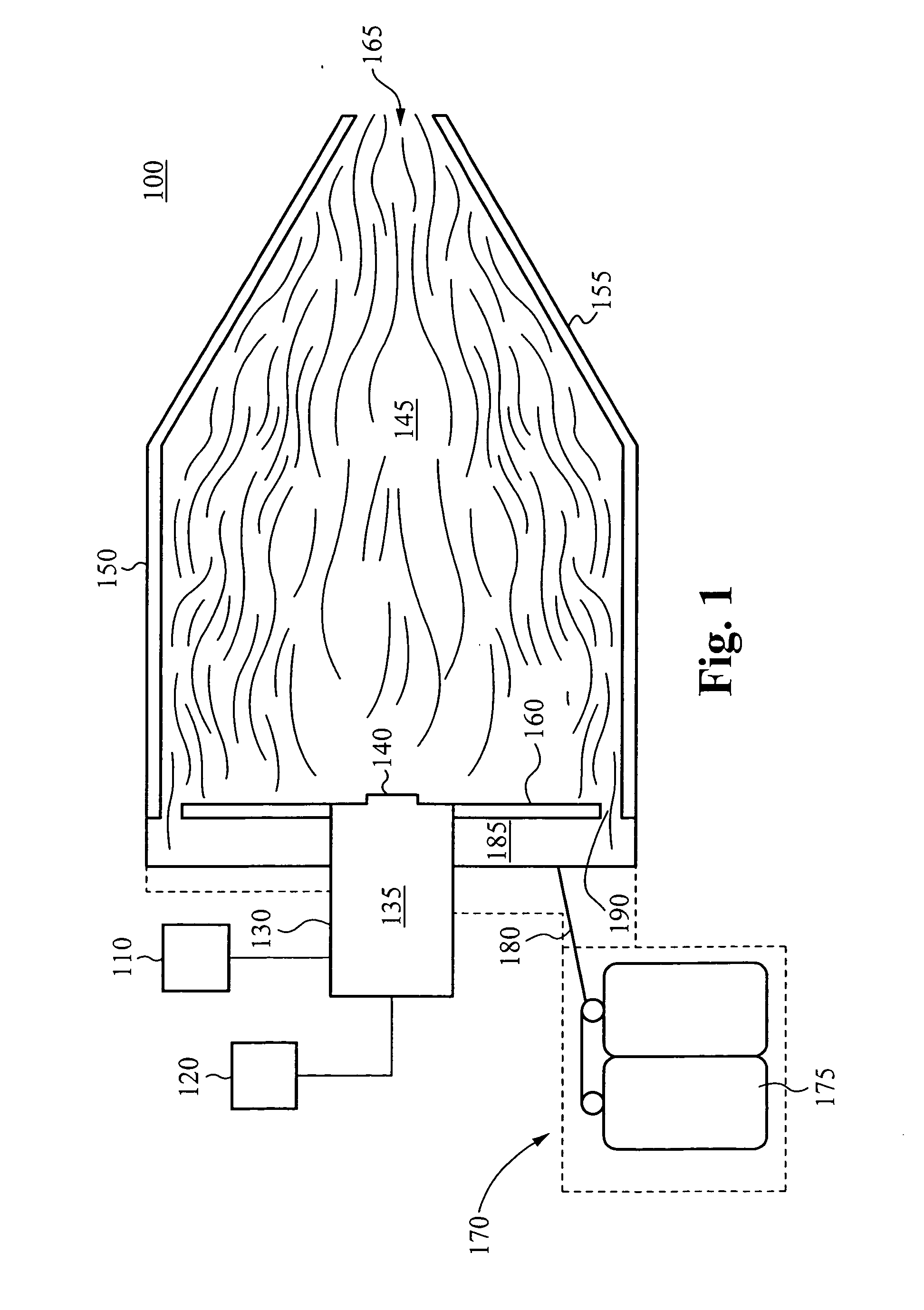

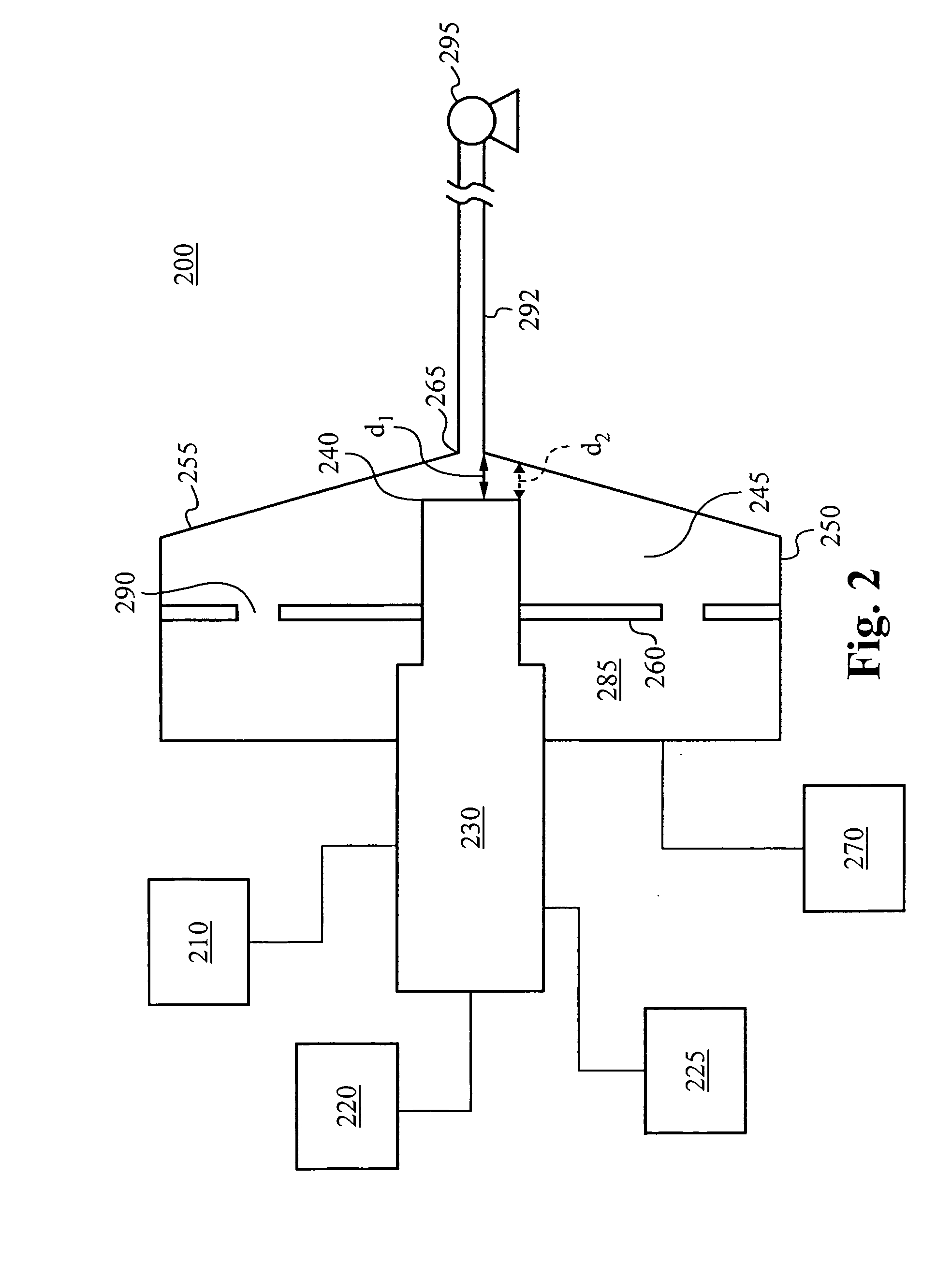

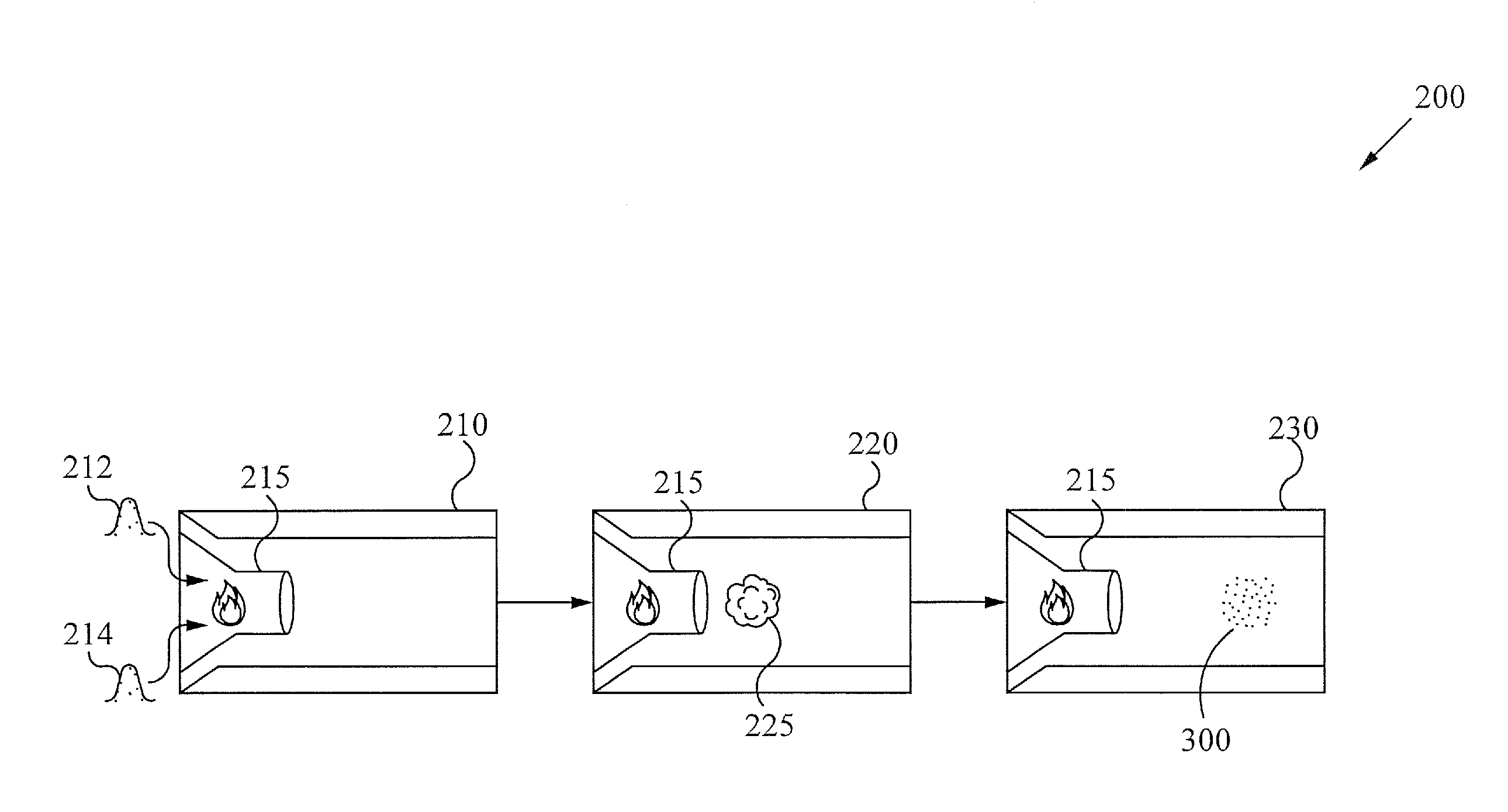

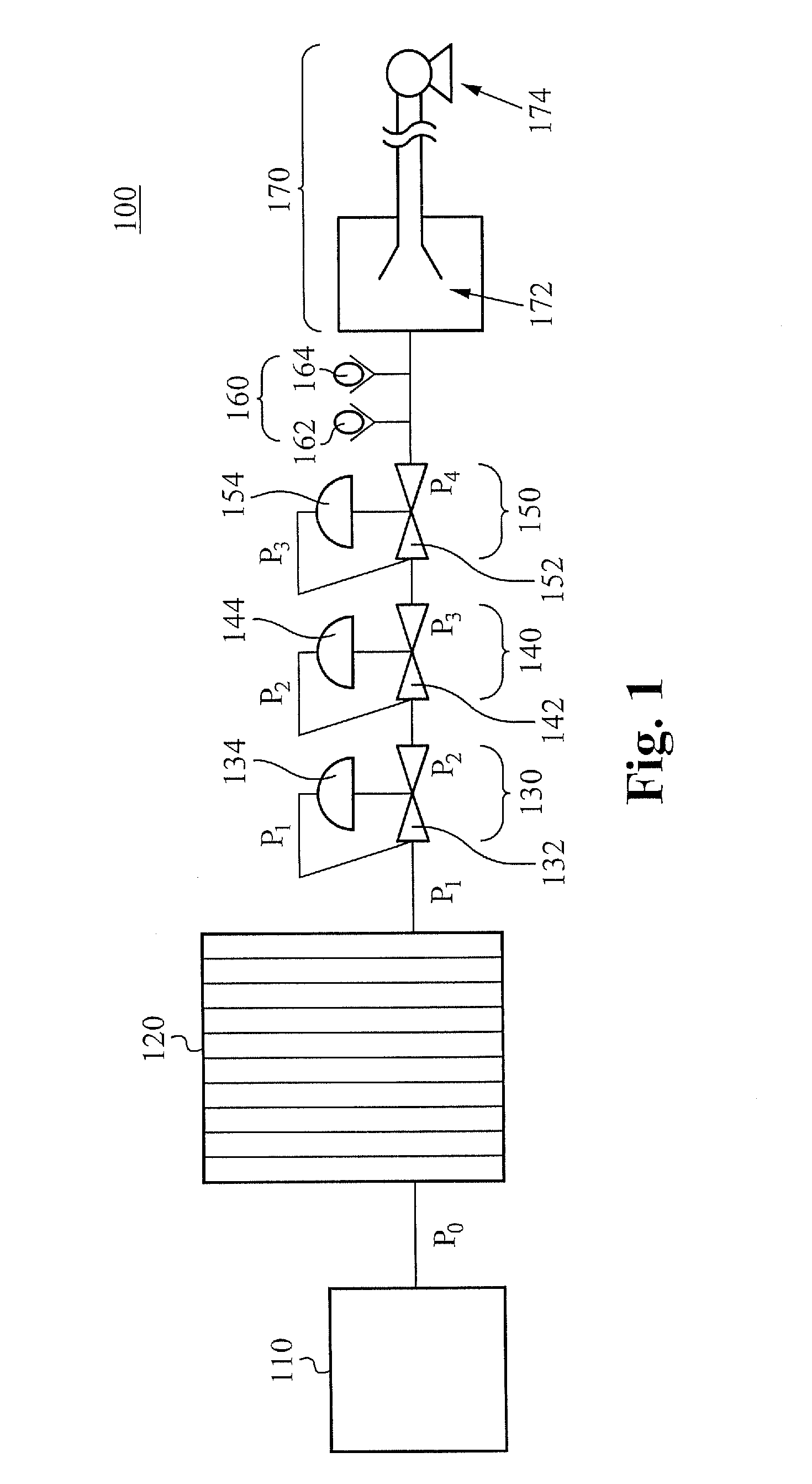

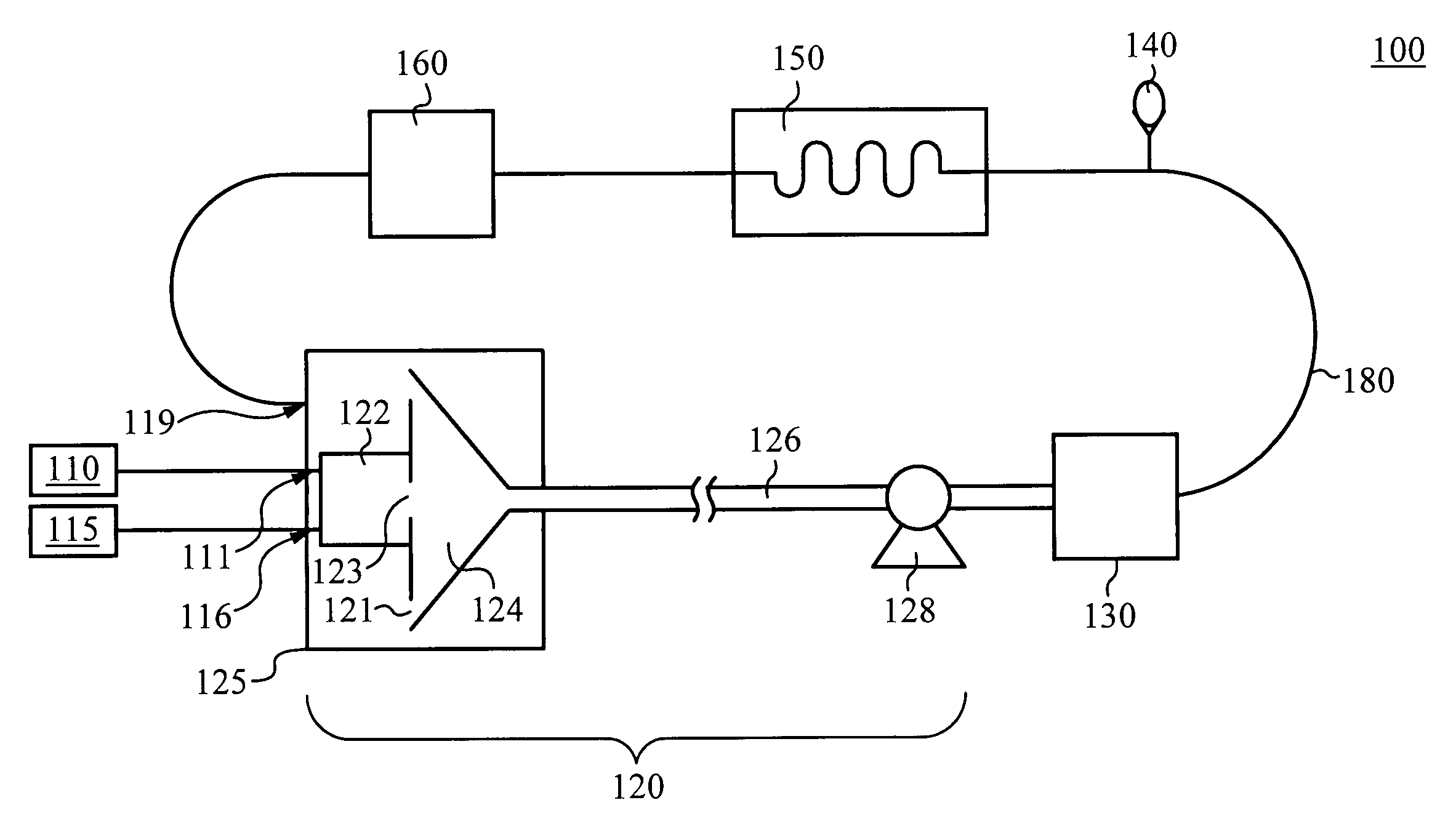

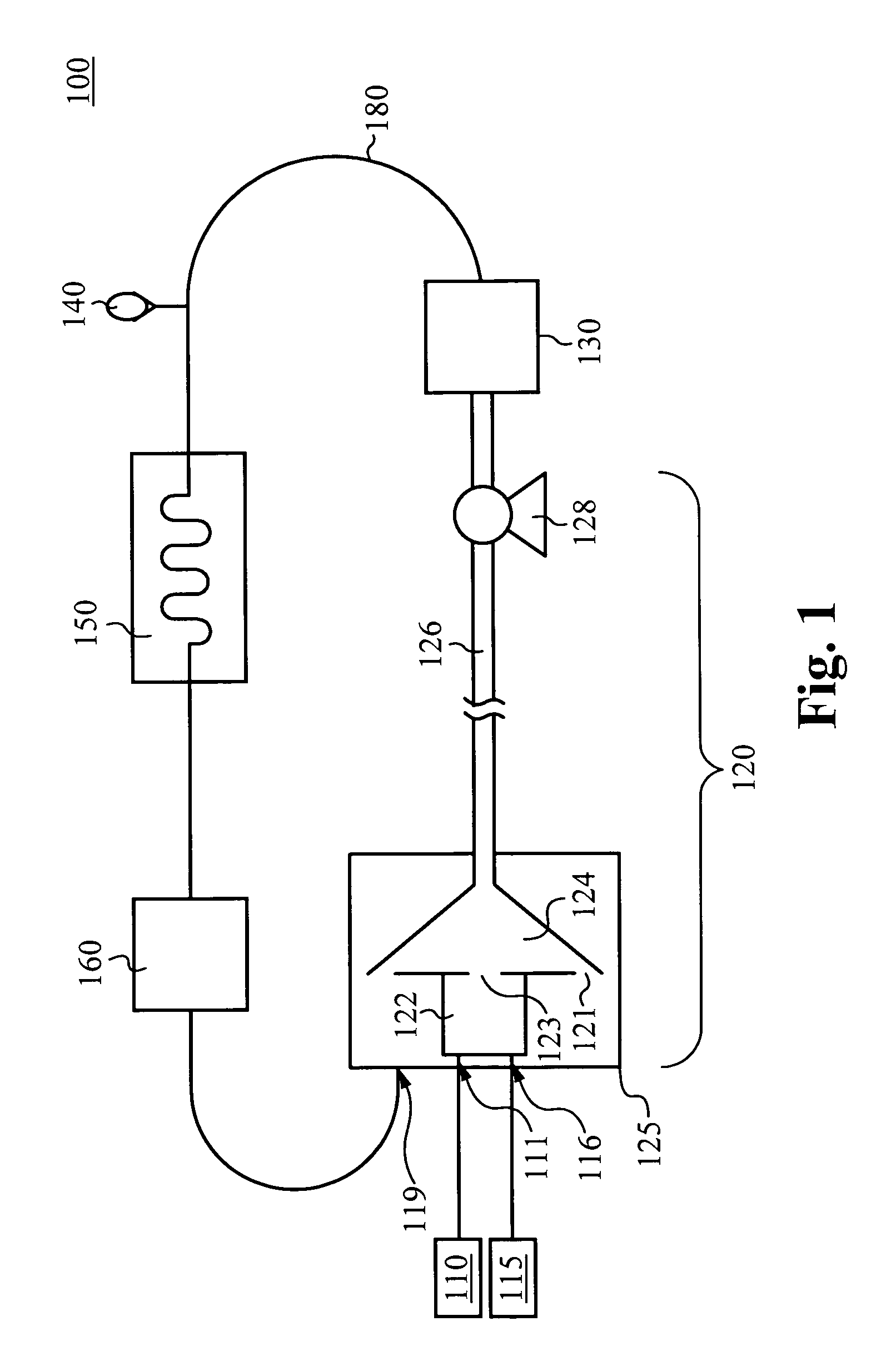

Method and apparatus for making uniform and ultrasmall nanoparticles

ActiveUS20080277270A1Catalyst activation/preparationDirect contact heat exchangersNanoparticleEngineering

A system comprising: a plasma production chamber configured to produce a plasma; a reaction chamber vaporize a precursor material with the plasma to form a reactive mixture; a quench chamber having a frusto-conical surface and a quench region formed within the quench chamber between an ejection port of the reaction chamber and a cooled mixture outlet, wherein the quench region configured to receive the reactive mixture from the ejection port, to cool the reactive mixture to form a cooled mixture, and to supply the cooled mixture to the cooled mixture outlet; and a conditioning fluid injection ring disposed at the ejection port and configured to flow a conditioning fluid directly into the reactive mixture as the reactive mixture flows through the ejection port, thereby disturbing the flow of the reactive mixture, creating turbulence within the quench region and cooling the reactive mixture to form a cooled mixture comprising condensed nanoparticles.

Owner:SDC MATERIALS +1

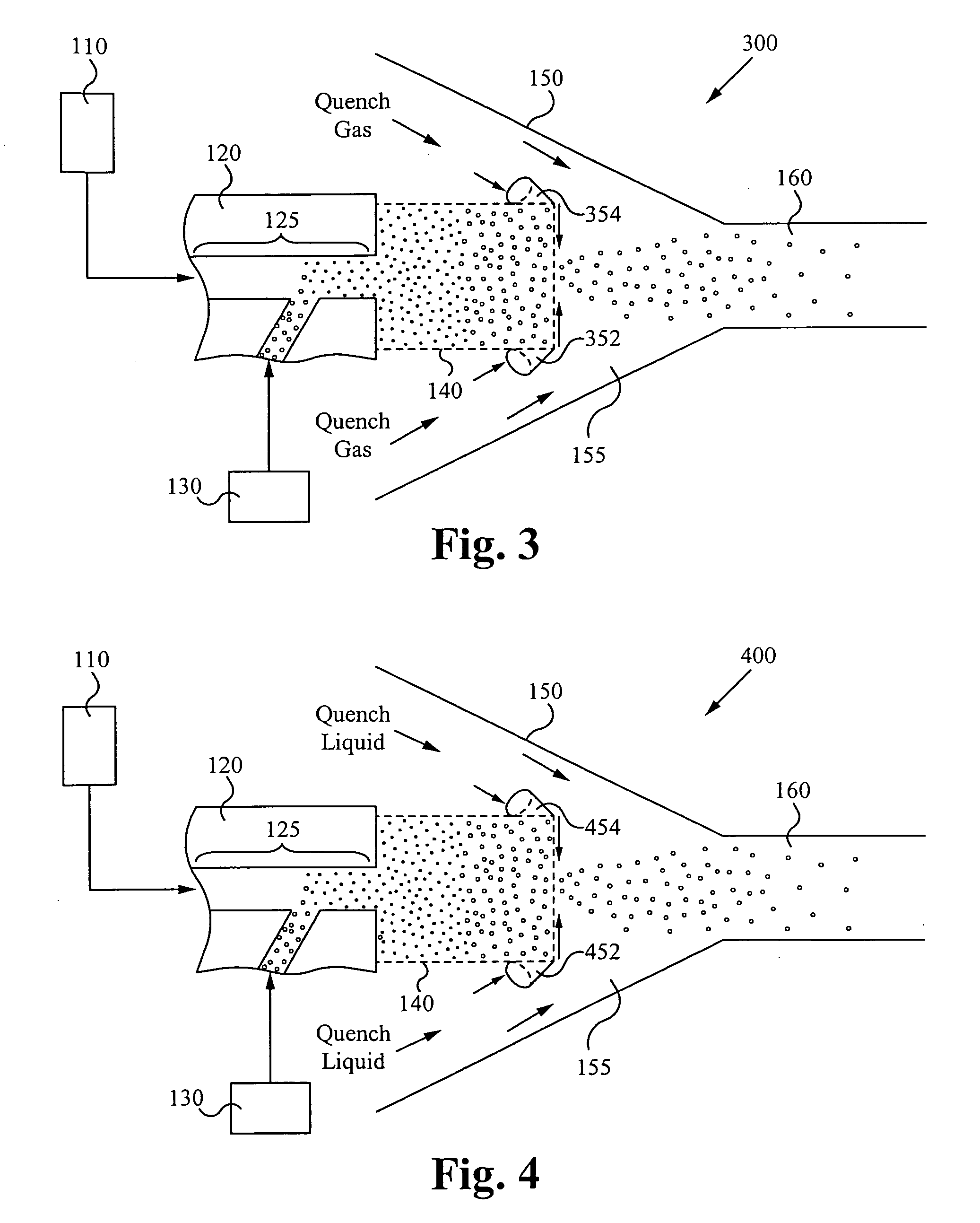

Highly turbulent quench chamber

ActiveUS20080277267A1Temperature controlDirect contact heat exchangersStationary tubular conduit assembliesEngineeringQuenching

An apparatus for cooling a reactive mixture, comprising: a reactor configured to form the reactive mixture; a quench chamber comprising a frusto-conical body having a wide end, a narrow end, and a quench region formed between the wide and narrow end, wherein the quench chamber is configured to receive the reactive mixture from the plasma reactor through a reactive mixture inlet into the quench region, to receive a conditioning fluid through at least one fluid inlet, and to flow the conditioning fluid into the quench region, wherein the frusto-conical body is configured to produce a turbulent flow within the quench region with the flow of the conditioning fluid into the quench region, thereby promoting the quenching of the reactive mixture to form a cooled gas-particle mixture; and a suction generator configured to force the cooled gas-particle mixture out of the quench chamber.

Owner:UMICORE AG & CO KG +1

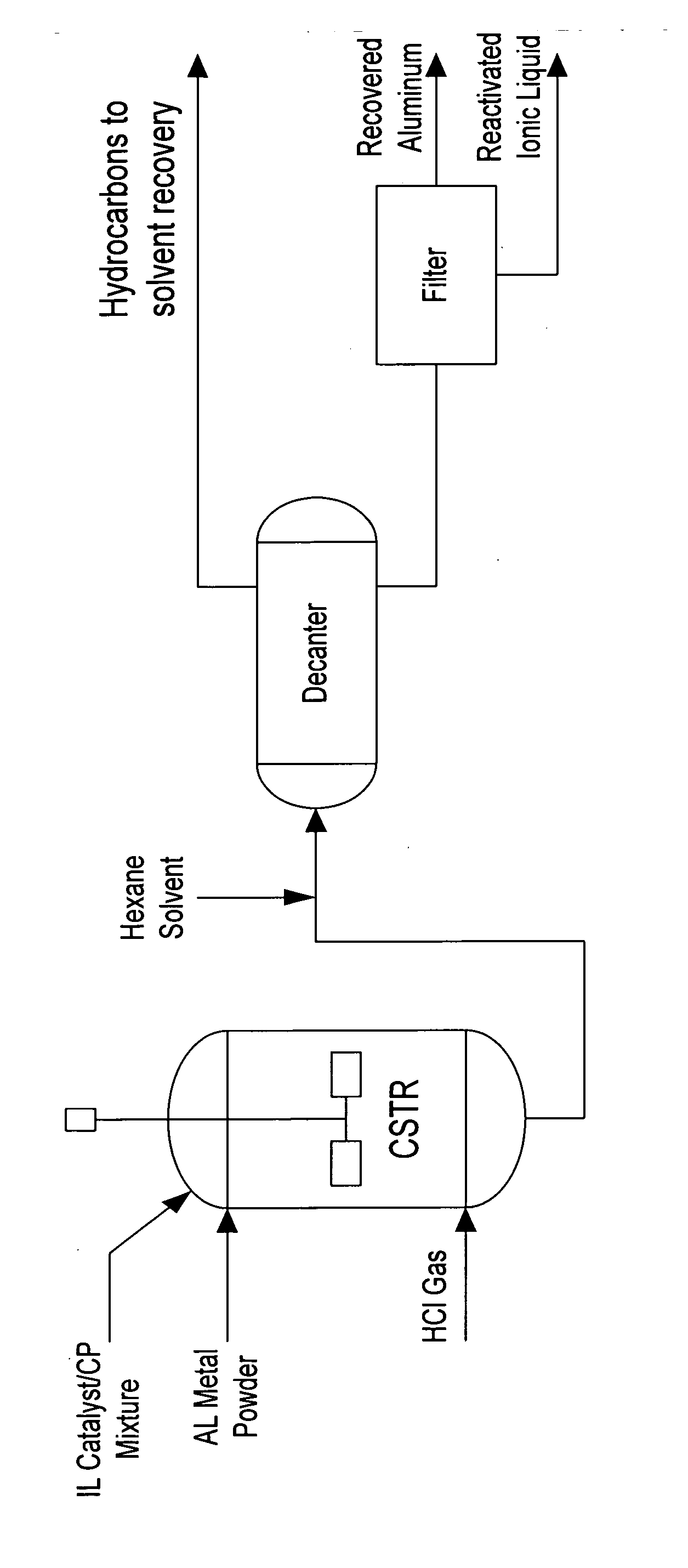

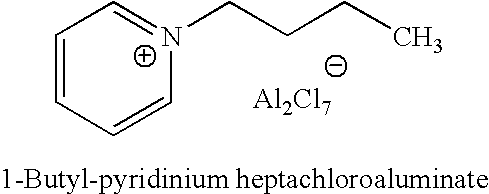

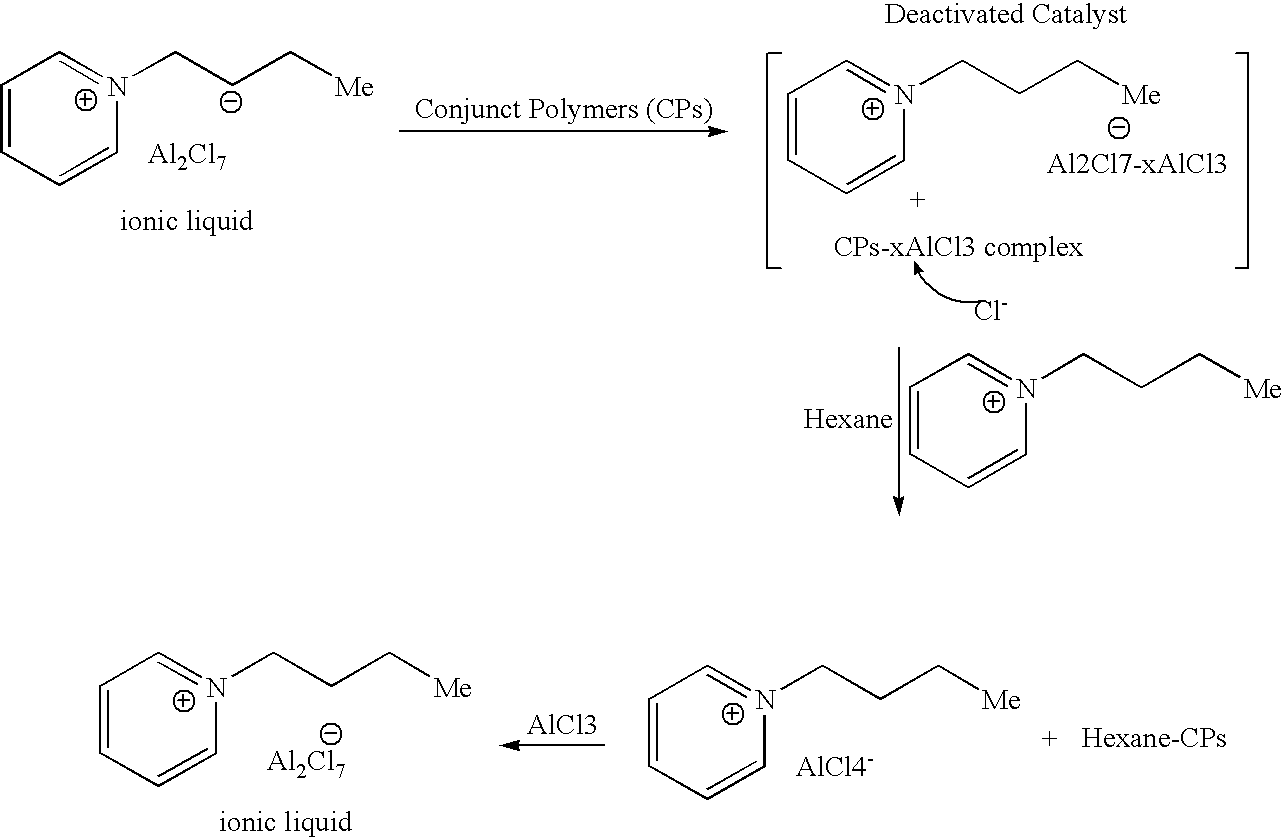

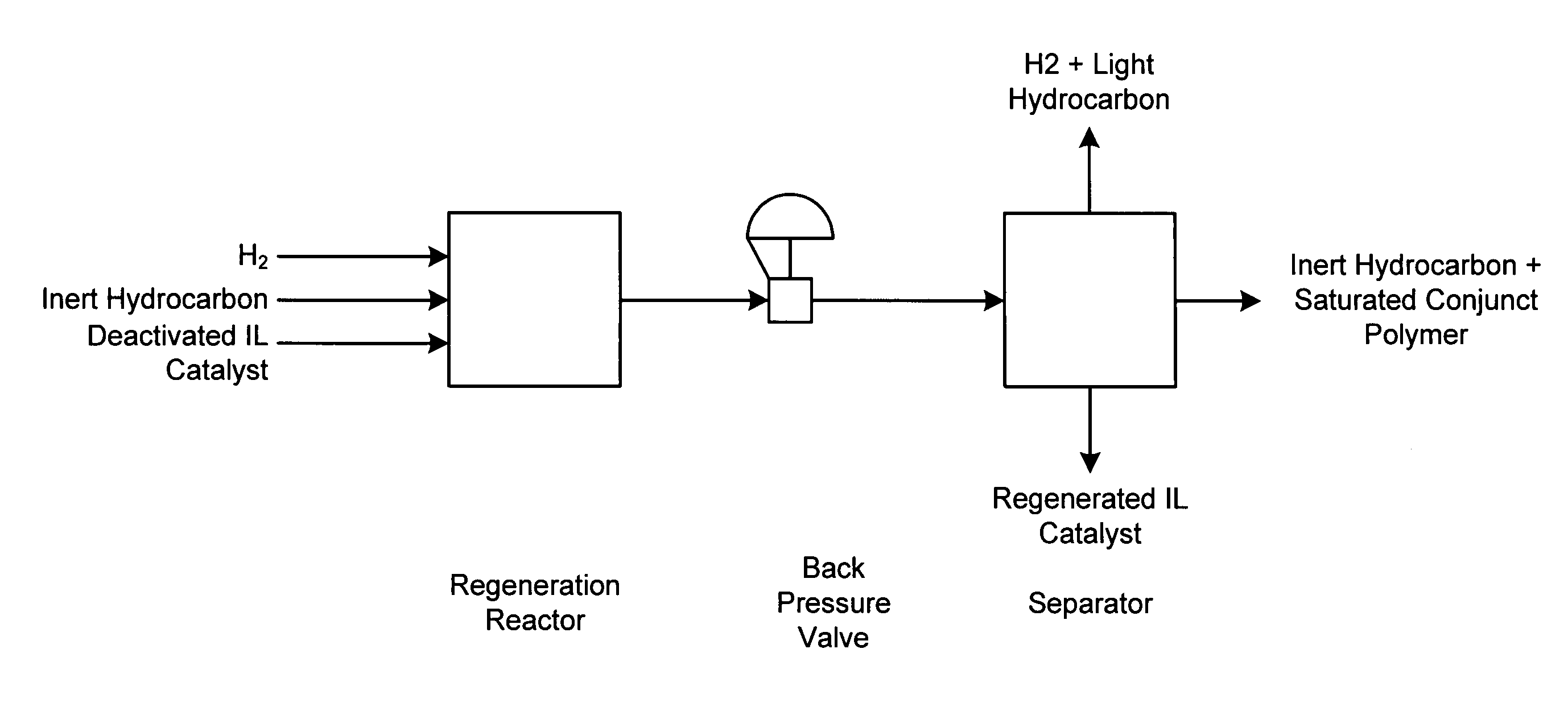

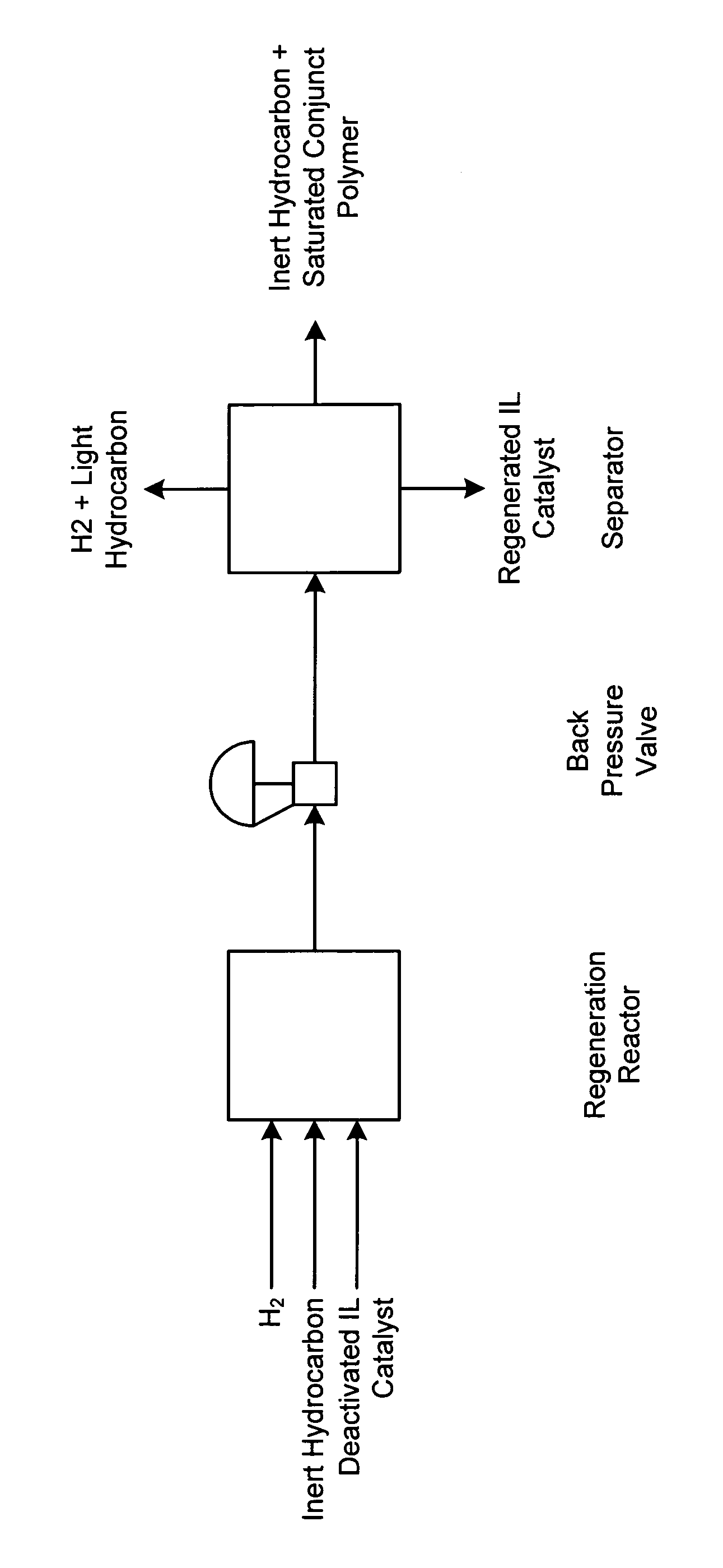

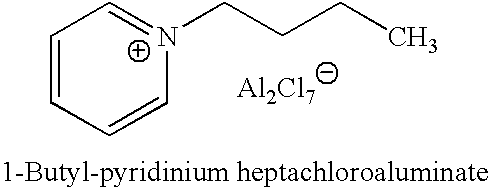

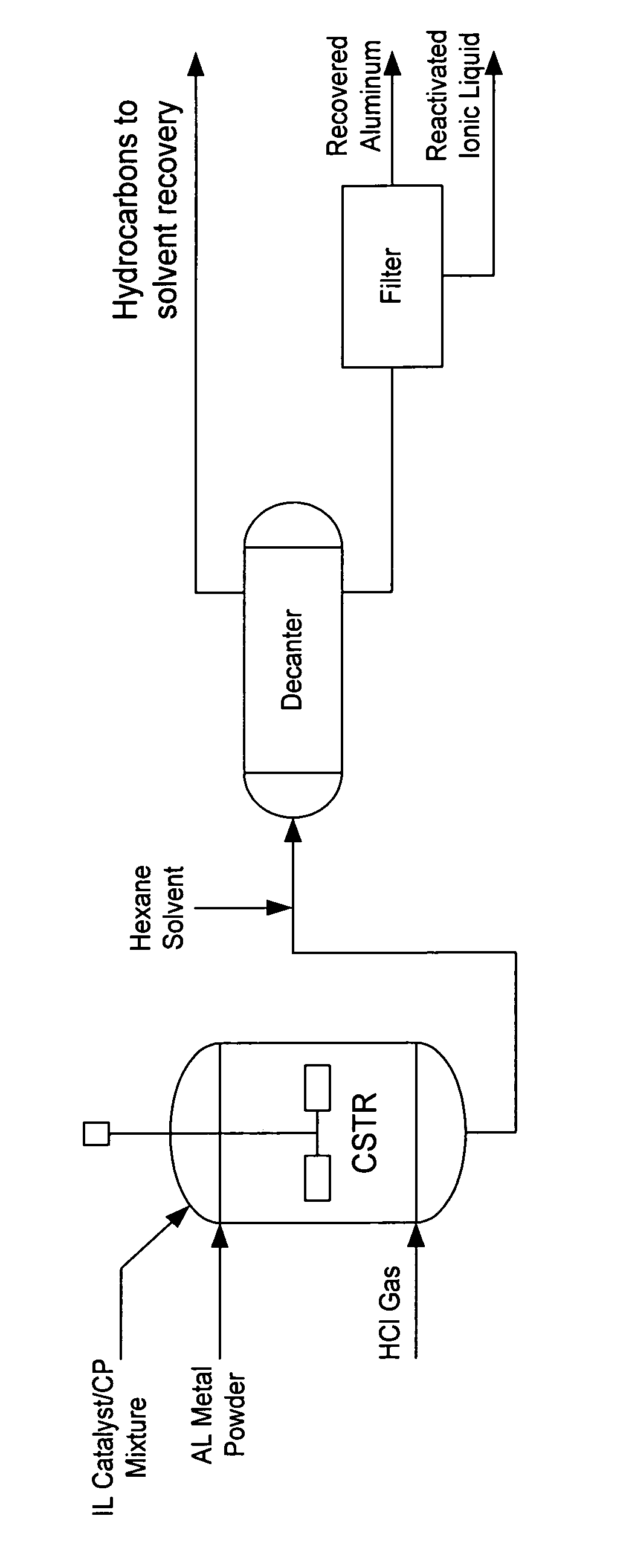

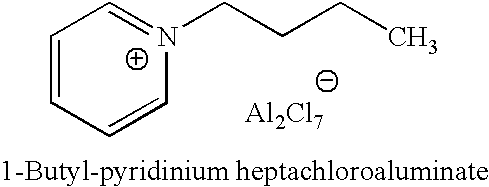

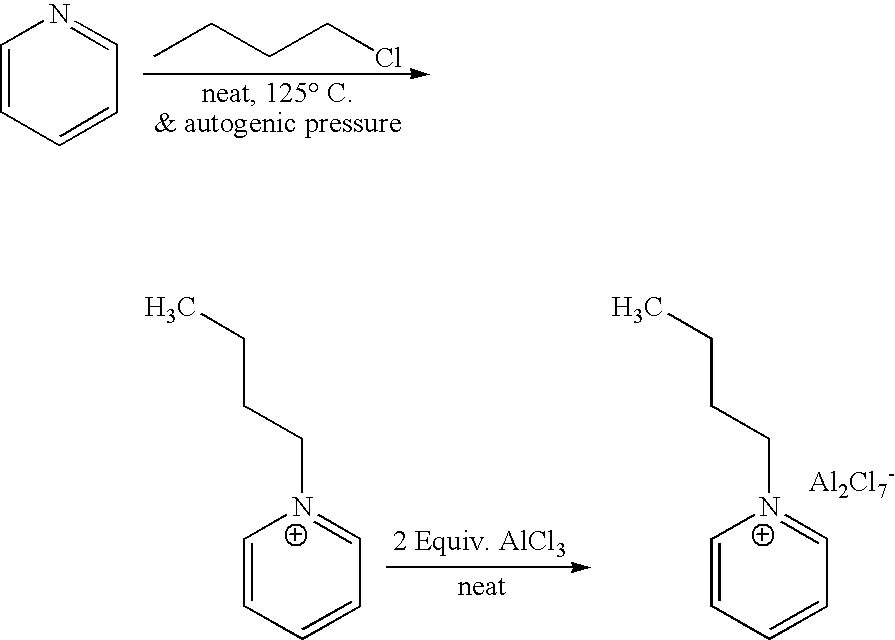

Regeneration of acidic catalysts

ActiveUS20070142213A1High activityChlorine/hydrogen-chloride purificationSulfur compoundsAlkyl transferIonic liquid

A process for regenerating a used acidic catalyst which has been deactivated by conjunct polymers by removing the conjunct polymers so as to increase the activity of the catalyst is disclosed. Methods for removing the conjunct polymers include hydrogenation, addition of a basic reagent and alkylation. The methods are applicable to all acidic catalysts and are described with reference to certain ionic liquid catalysts.

Owner:CHEVROU USA INC

Pinning and affixing nano-active material

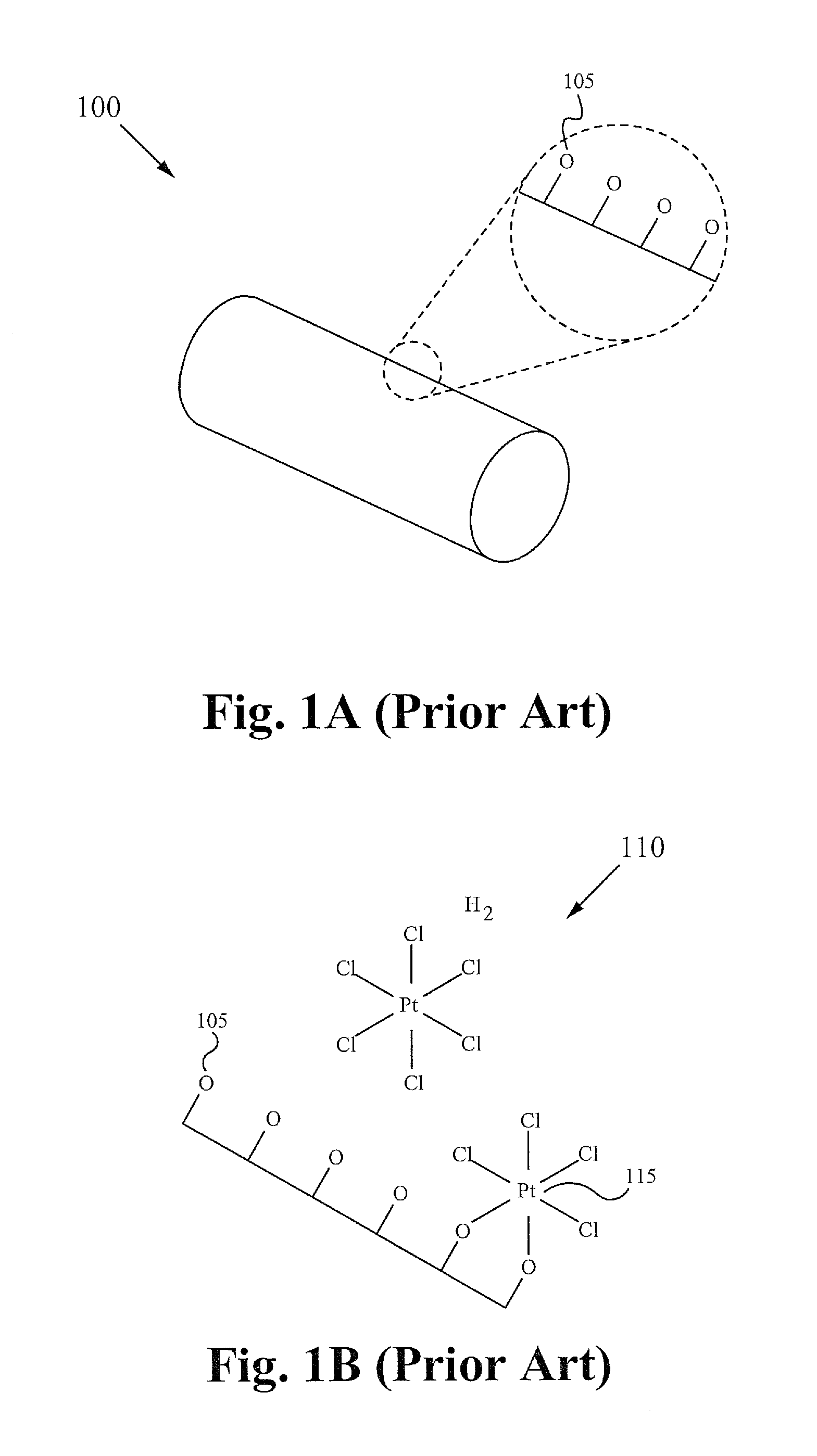

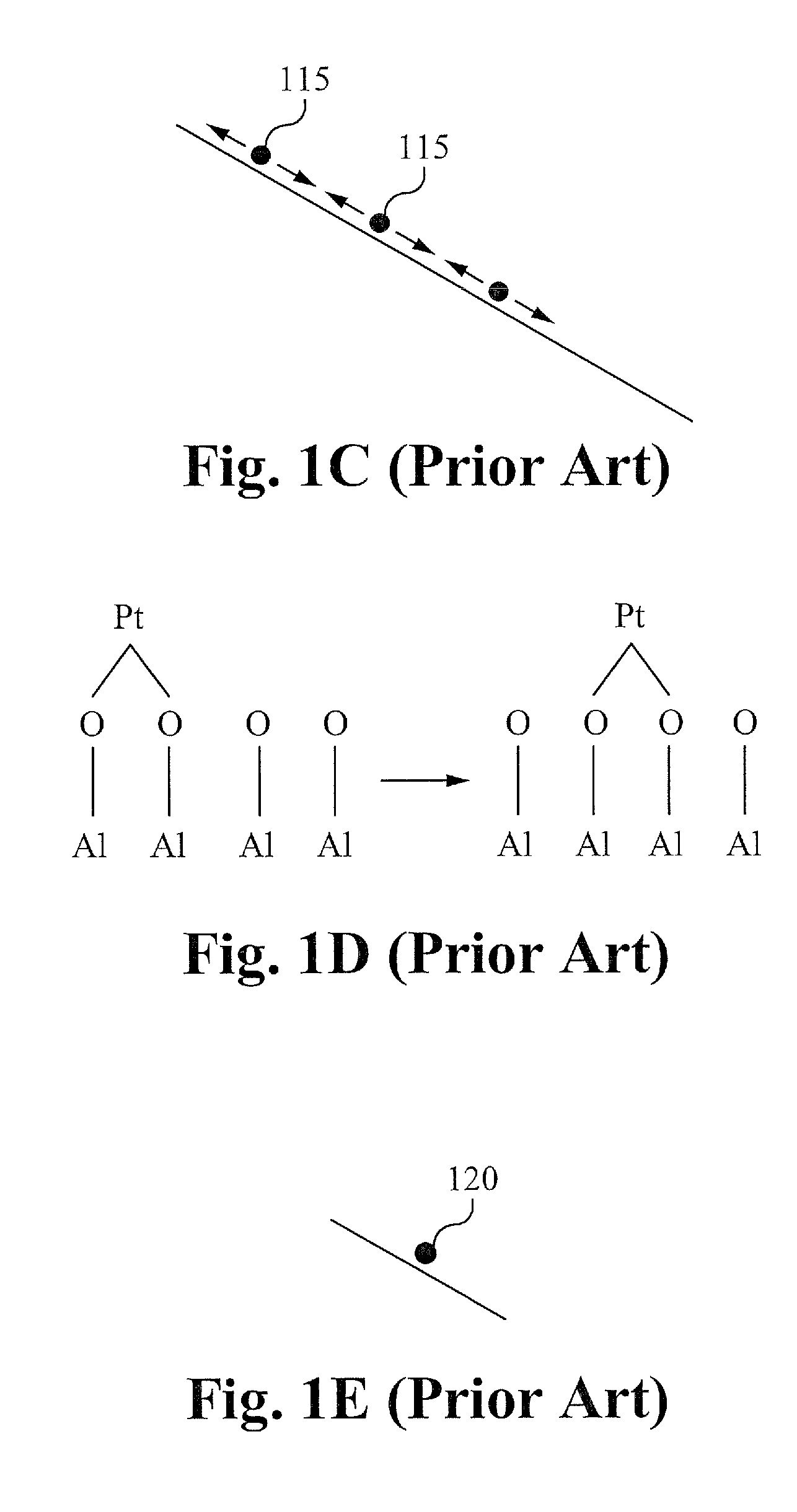

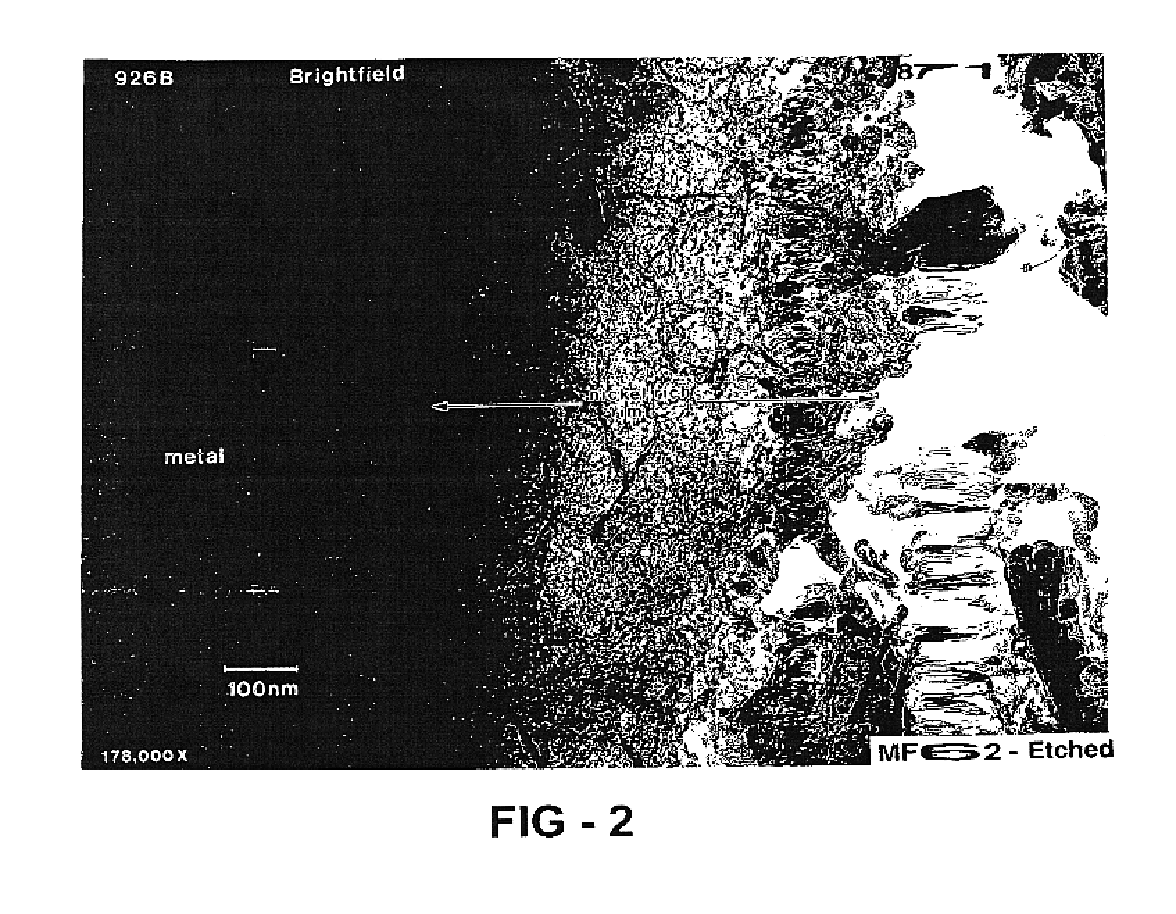

InactiveUS20110143915A1Improve propertiesRestrict movementMaterial nanotechnologyMolten spray coatingPlatinumNanoparticle

A nanoparticle comprises a nano-active material and a nano-support. In some embodiments, the nano-active material is platinum and the nano-support is alumina. Pinning and affixing the nano-active material to the nano-support is achieved by using a high temperature condensation technology. In some embodiments, the high temperature condensation technology is plasma. Typically, a quantity of platinum and a quantity of alumina are loaded into a plasma gun. When the nano-active material bonds with the nano-support, an interface between the nano-active material and the nano-support forms. The interface is a platinum alumina metallic compound, which dramatically changes an ability for the nano-active material to move around on the surface of the nano-support, providing a better bond than that of a wet catalyst. Alternatively, a quantity of carbon is also loaded into the plasma gun. When the nano-active material bonds with the nano-support, the interface formed comprises a platinum copper intermetallic compound, which provides an even stronger bond.

Owner:SDC MATERIALS +1

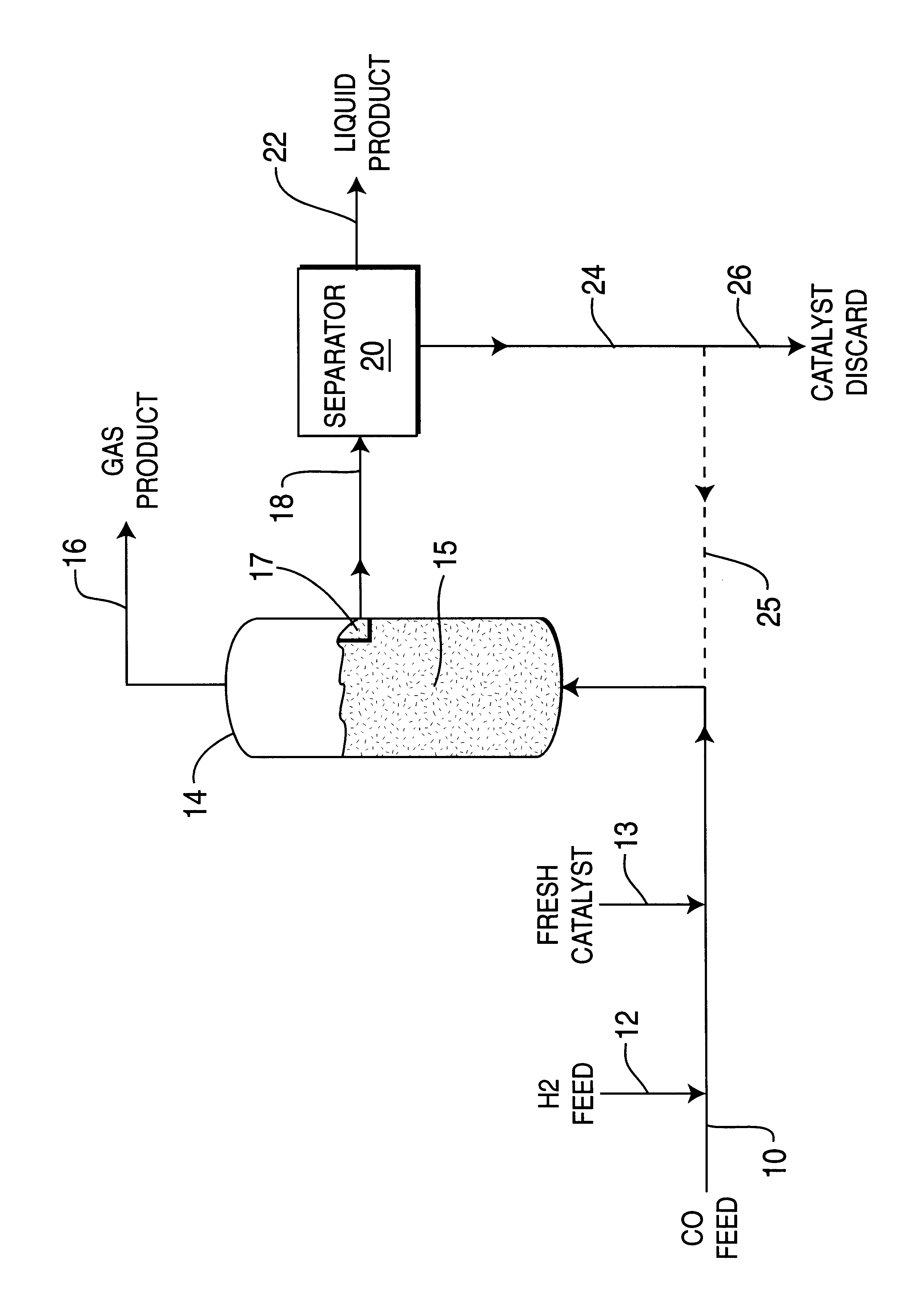

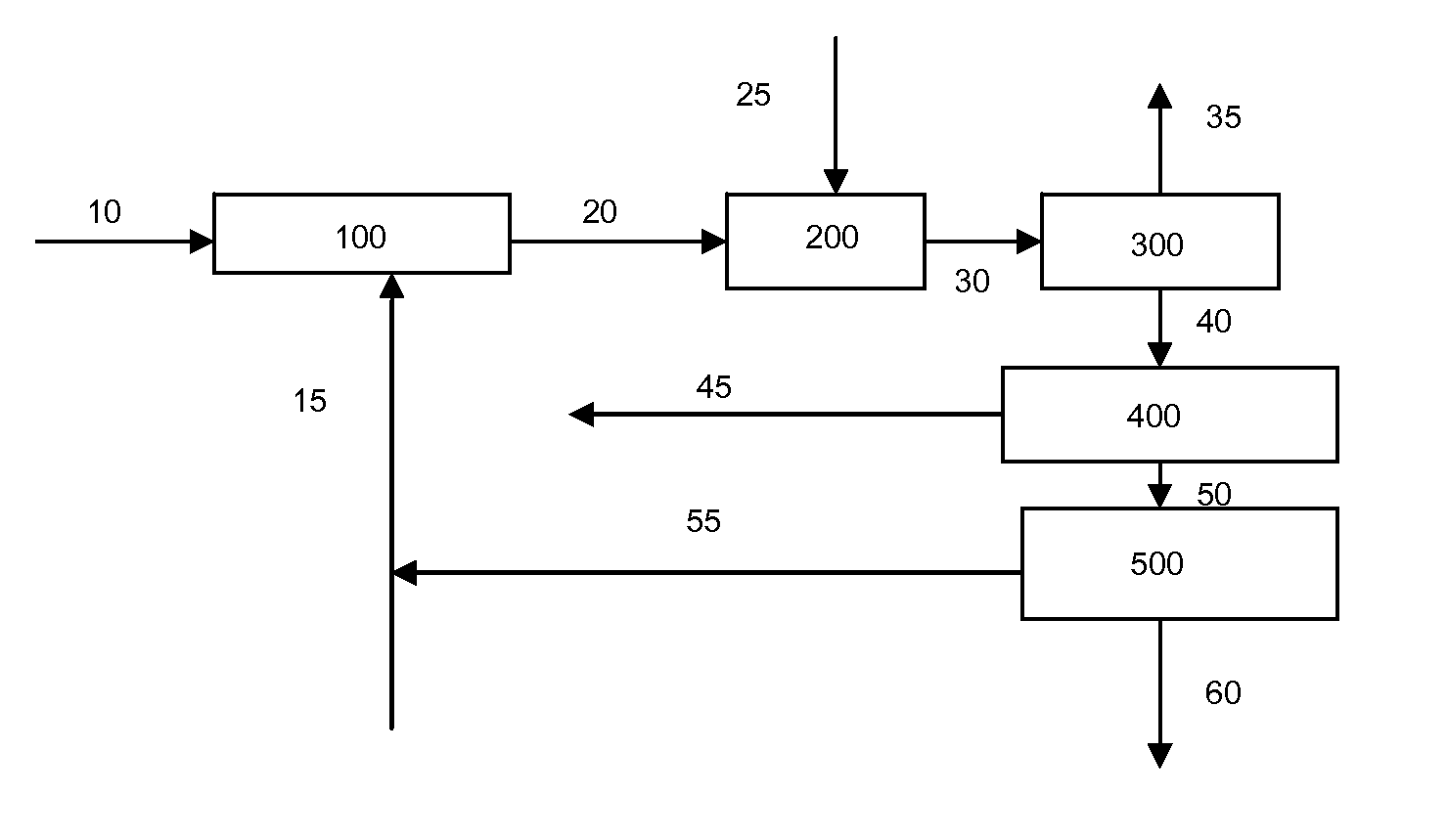

Skeletal iron catalyst having improved attrition resistance and product selectivity in slurry-phase synthesis processes

InactiveUS6277895B1High particle strengthGood attristion resistanceHydrocarbon from carbon oxidesOrganic compound preparationFixed bedSlurry

Particulate skeletal iron catalyst is provided which contain at least about 50 wt. % iron with the remainder being a minor portion of a suitable non-ferrous metal and having characteristics of 0.062-1.0 mm particle size, 20-100 m2 / g surface area, and 10-40 nm average pore diameter. Such skeletal iron catalysts are prepared and utilized for producing synthetic hydrocarbon products from CO and H2 feeds by Fischer-Tropsch synthesis process. Iron powder is mixed with non-ferrous powder selected from aluminum, antimony, silicon, tin or zinc powder to provide 20-80 wt. % iron content and melted together to form an iron alloy, then cooled to room temperature and pulverized to provide 0.1-10 mm iron alloy catalyst precursor particles. The iron alloy pulverized particles are treated with NaOH or KOH caustic solution at 30-95° C. temperature to extract and / or leach out most of the non-ferrous metal portion, and then screened and treated by drying and reducing with hydrogen and to provide the smaller size skeletal iron catalyst material. Such skeletal iron catalyst is utilized with CO+H2 feedstream for Fischer-Tropsch reactions in either a fixed bed or slurry bed type reactor at 180-350° C. temperature, 0.5-3.0 mPa pressure and gas hourly space velocity of 0.5-3.0 L / g Fe / hr to produce desired hydrocarbon products.

Owner:INST OF COAL CHEM ICCCHINESE ACADEMY OF SCI +1

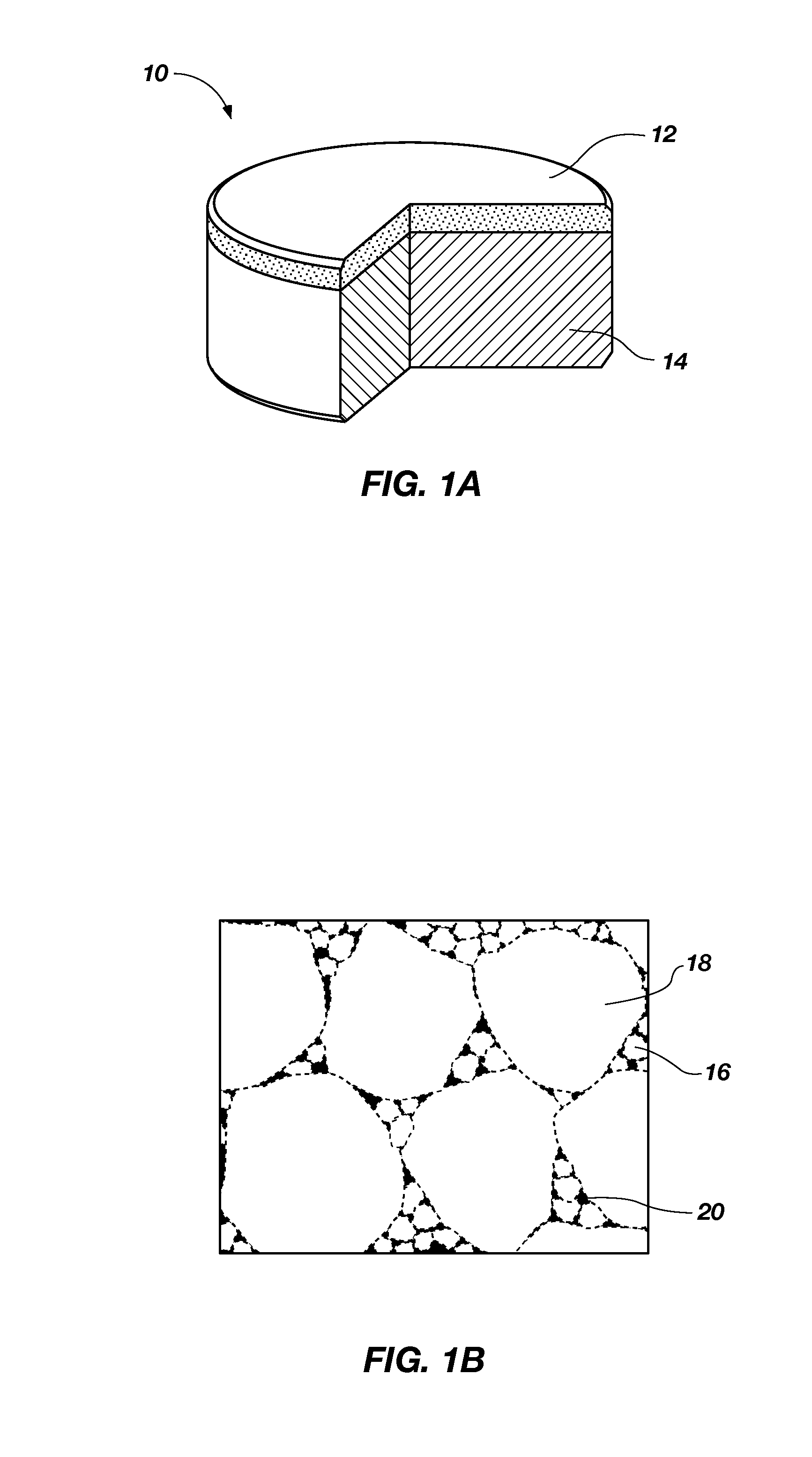

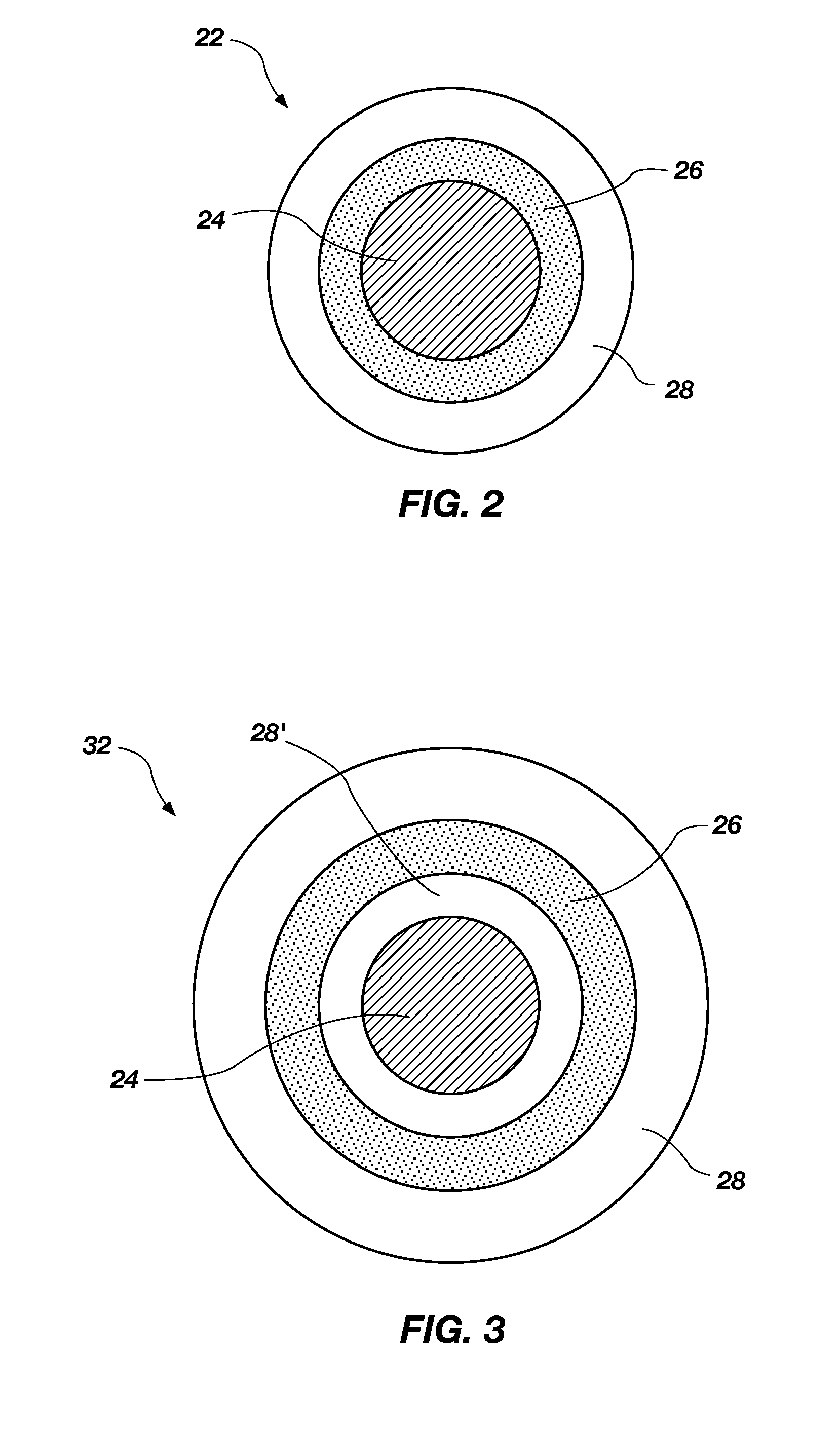

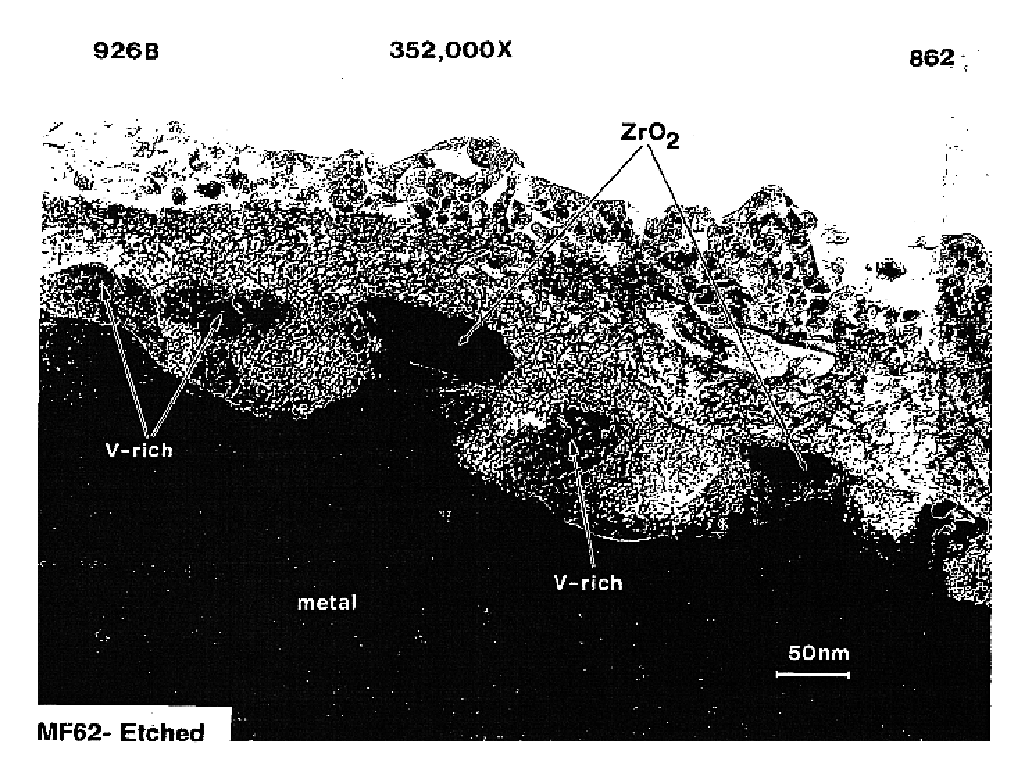

Polycrystalline compacts including in-situ nucleated grains, earth-boring tools including such compacts, and methods of forming such compacts and tools

Polycrystalline compacts include hard polycrystalline materials comprising in situ nucleated smaller grains of hard material interspersed and inter-bonded with larger grains of hard material. The average size of the larger grains may be at least about 250 times greater than the average size of the in situ nucleated smaller grains. Methods of forming polycrystalline compacts include nucleating and catalyzing the formation of smaller grains of hard material in the presence of larger grains of hard material, and catalyzing the formation of inter-granular bonds between the grains of hard material. For example, nucleation particles may be mixed with larger diamond grains, a carbon source, and a catalyst. The mixture may be subjected to high temperature and high pressure to form in smaller diamond grains using the nucleation particles, the carbon source, and the catalyst, and to catalyze formation of diamond-to-diamond bonds between the smaller and larger diamond grains.

Owner:BAKER HUGHES INC

Finely divided metal catalyst and method for making same

InactiveUS6841512B1Facilitating hydrogen consumptionSmall particle sizeReactant parameters controlReversible hydrogen uptakeParticulatesMetal catalyst

An inexpensive, highly catalytic material preferably formed by a leaching process. The catalyst comprises a finely divided metal particulate and a support. The active material may be a nickel and / or nickel nickel alloy particulate having a particle size less than about 100 Angstroms. The support may be one or more metal oxides.

Owner:CHEVRONTEXACO TECH VENTURES

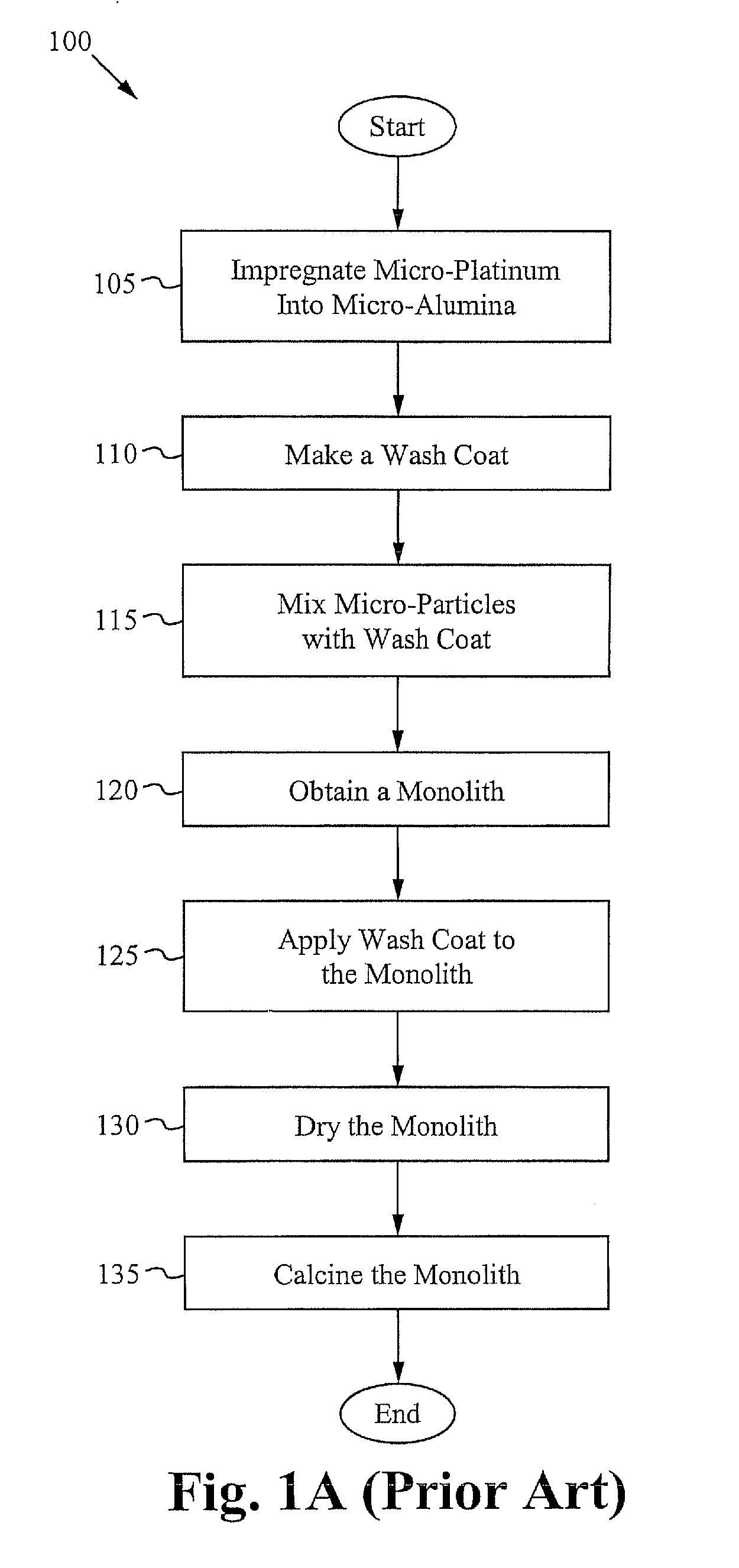

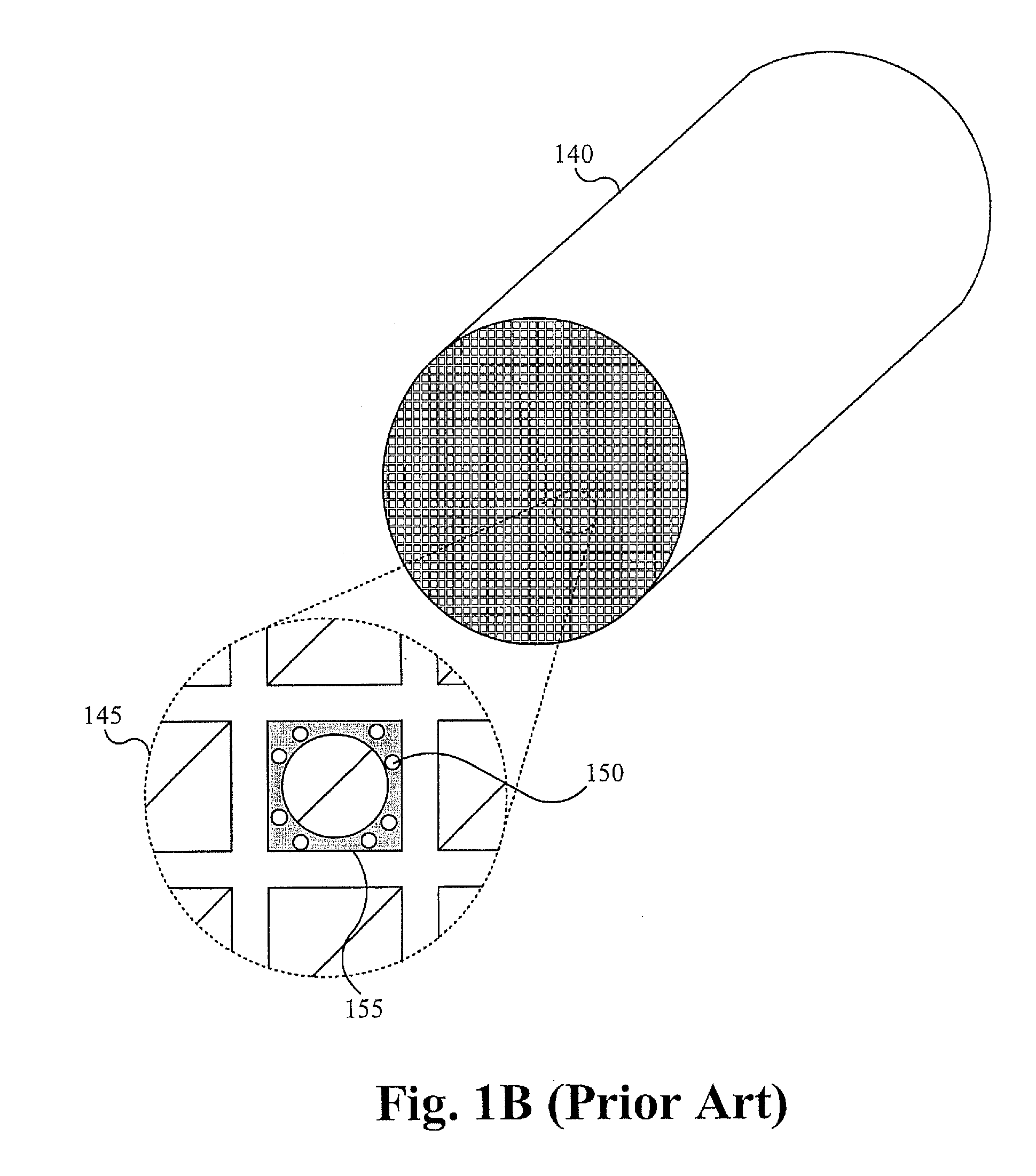

Advanced catalysts for automotive applications

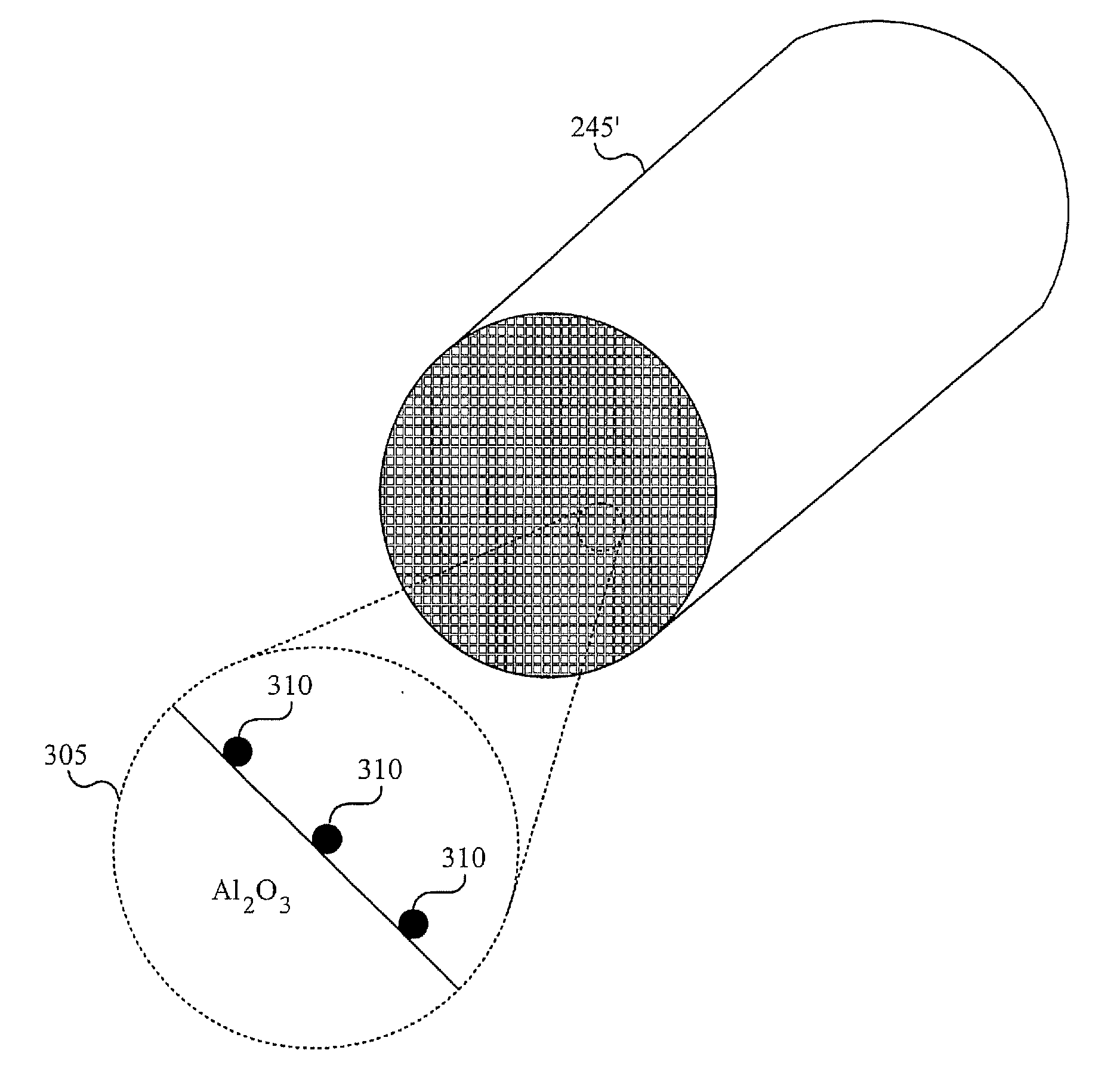

ActiveUS20110143933A1Restrict movementMaterial nanotechnologyMolten spray coatingPlatinumNanoparticle

Embodiments of present inventions are directed to an advanced catalyst. The advanced catalyst includes a honeycomb structure with an at least one nano-particle on the honeycomb structure. The advanced catalyst used in diesel engines is a two-way catalyst. The advanced catalyst used in gas engines is a three-way catalyst. In both the two-way catalyst and the three-way catalyst, the at least one nano-particle includes nano-active material and nano-support. The nano-support is typically alumina. In the two-way catalyst, the nano-active material is platinum. In the three-way catalyst, the nano-active material is platinum, palladium, rhodium, or an alloy. The alloy is of platinum, palladium, and rhodium.

Owner:UMICORE AG & CO KG +1

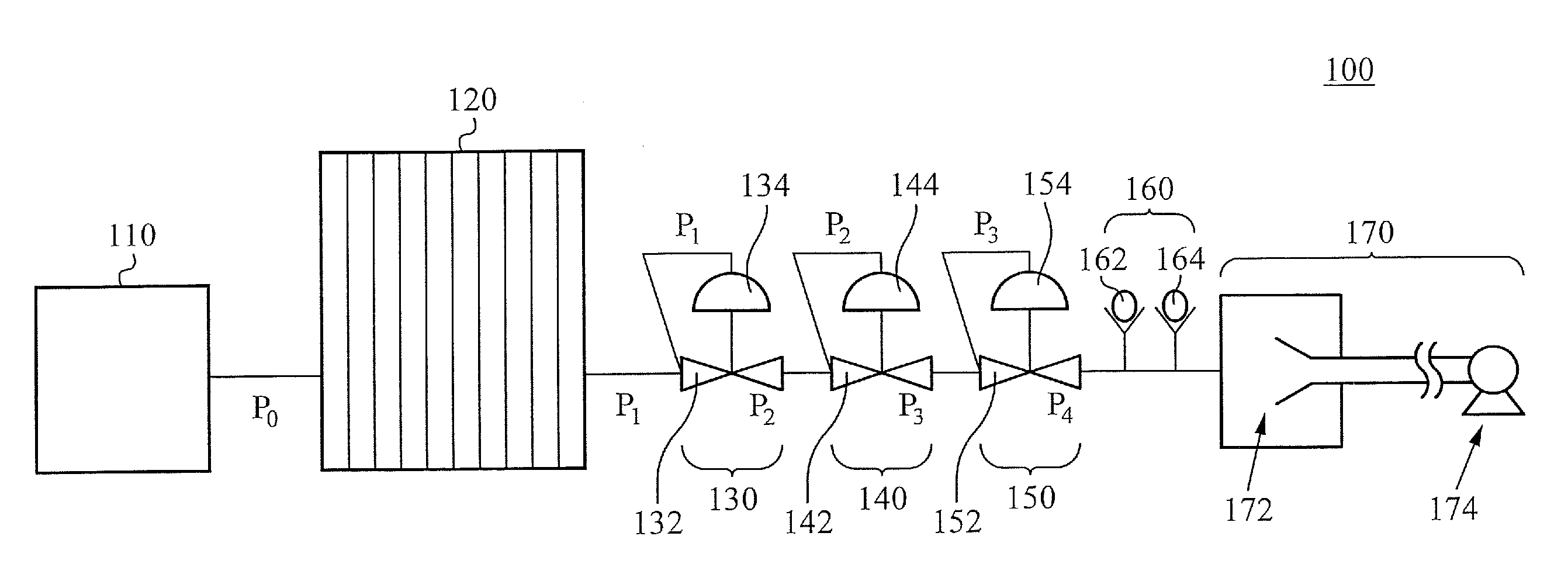

Gas delivery system with constant overpressure relative to ambient to system with varying vacuum suction

ActiveUS20110006463A1Reduce pressureMinimizes pressure differentialCatalyst activation/preparationDirect contact heat exchangersSuction forceComputer module

A system operating in an environment having an ambient pressure, the system comprising: a reactor configured to combine a plasma stream, powder particles and conditioning fluid to alter the powder particles and form a mixture stream; a supply chamber coupled to the reactor; a suction generator configured to generate a suction force at the outlet of the reactor; a fluid supply module configured to supply the conditioning fluid at an original pressure; and a pressure regulation module configured to: receive the conditioning fluid from the fluid supply module, reduce the pressure of the conditioning fluid from the original pressure to a selected pressure relative to the ambient pressure regardless of any changes in the suction force at the outlet of the reactor, and supply the conditioning fluid at the selected pressure to the supply chamber.

Owner:UMICORE AG & CO KG +1

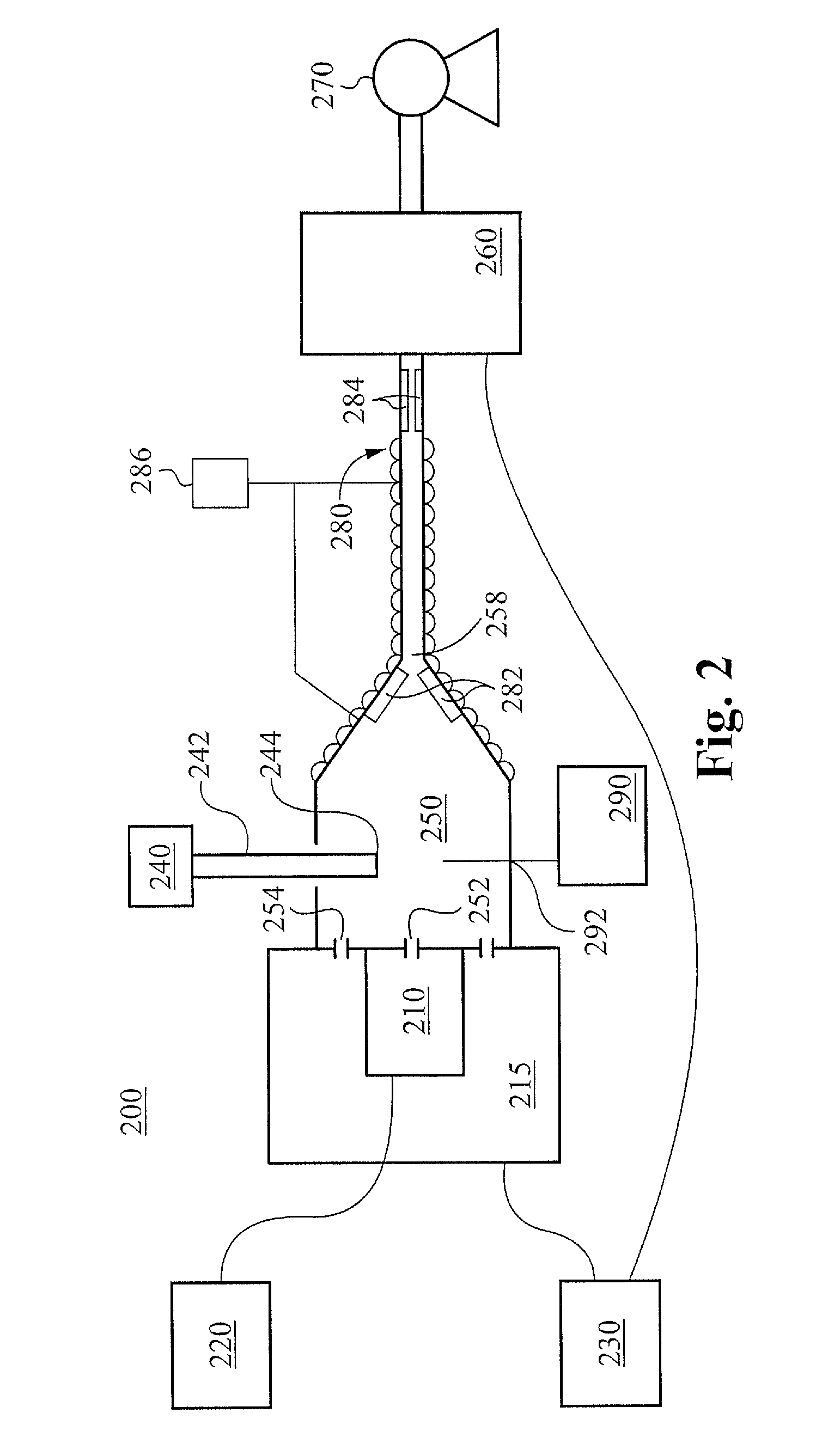

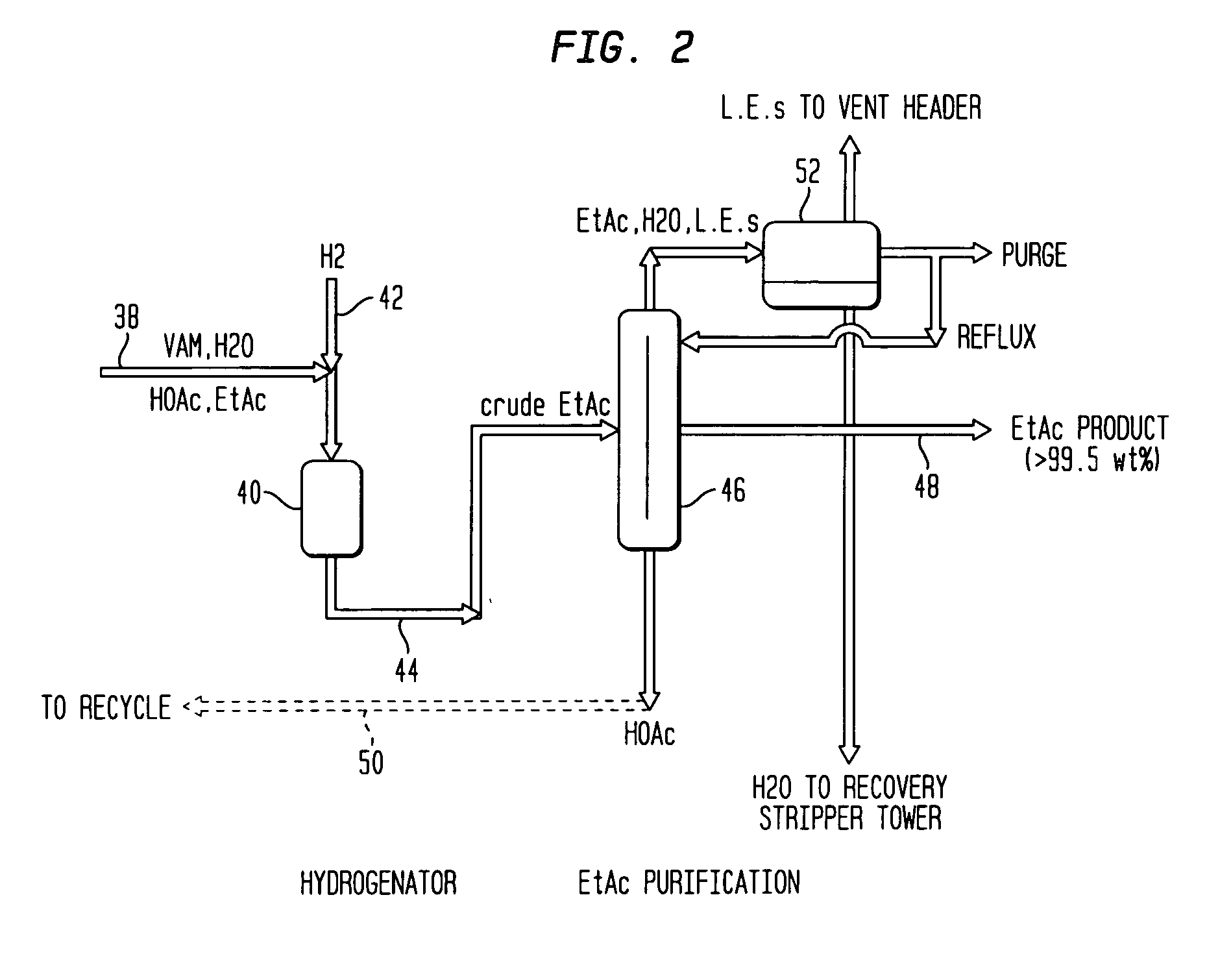

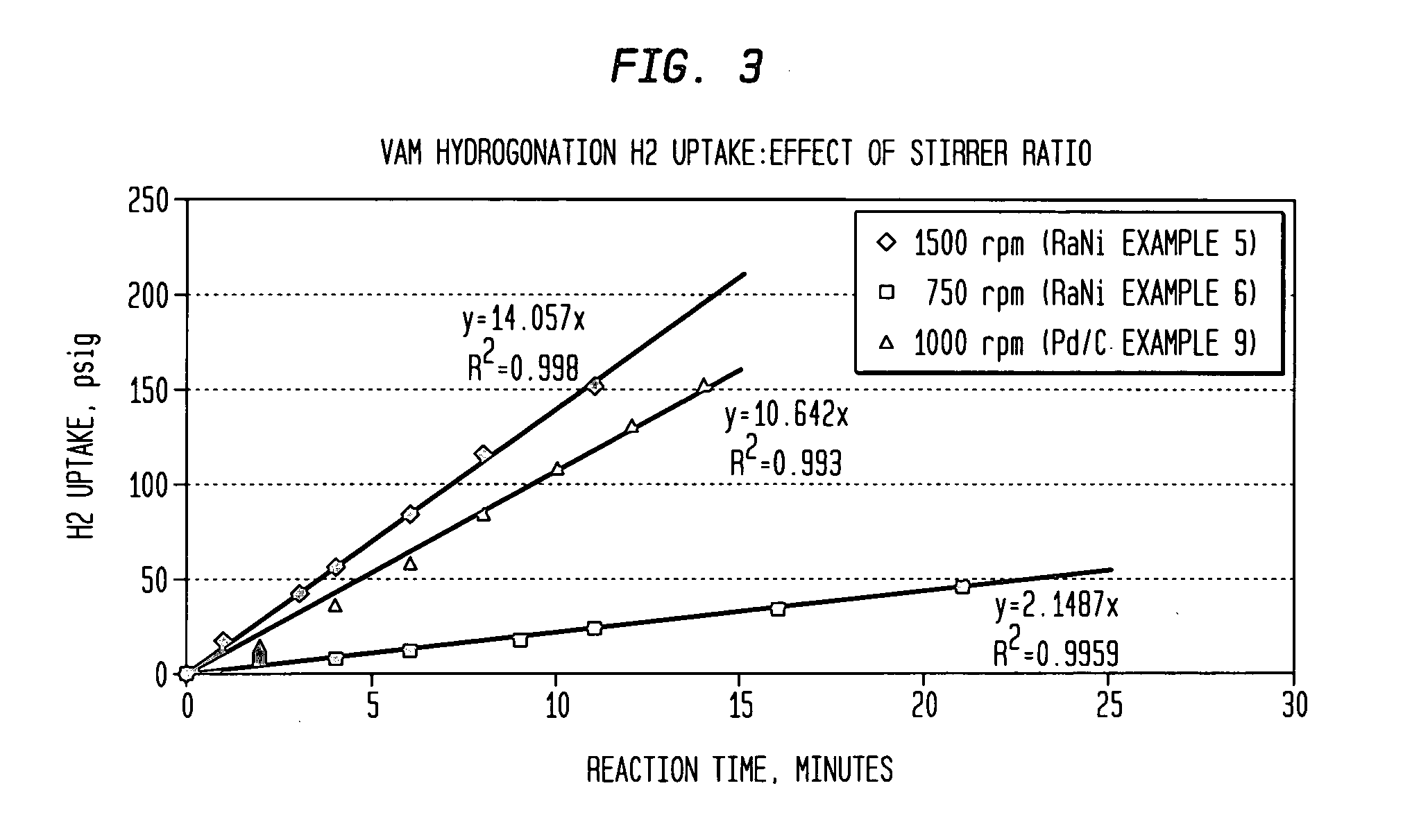

Co-production of vinyl acetate and ethyl acetate

InactiveUS20060106246A1Improve throughputReduce purification costsOrganic compound preparationCarboxylic acid esters preparationAcetic acidDistillation

A method of co-producing vinyl acetate and ethyl acetate includes: (a) reacting ethylene, acetic acid and oxygen to form vinyl acetate and at least a minor amount of ethyl acetate; (b) providing a crude product stream containing the vinyl acetate and ethyl acetate of step (a) and acetic acid to a distillation tower; (c) separating the crude product stream into: (i) a vinyl acetate product stream enriched in vinyl acetate with respect to the crude product stream; (ii) an acid recycle stream enriched in acetic acid with respect to the crude product stream; (iii) a mixed sidestream containing vinyl acetate and ethyl acetate, the mixed sidestream being enriched in ethyl acetate with respect to the vinyl acetate product stream; and (d) hydrogenating vinyl acetate in the mixed sidestream to provide an ethyl acetate product stream.

Owner:CELANESE INT CORP

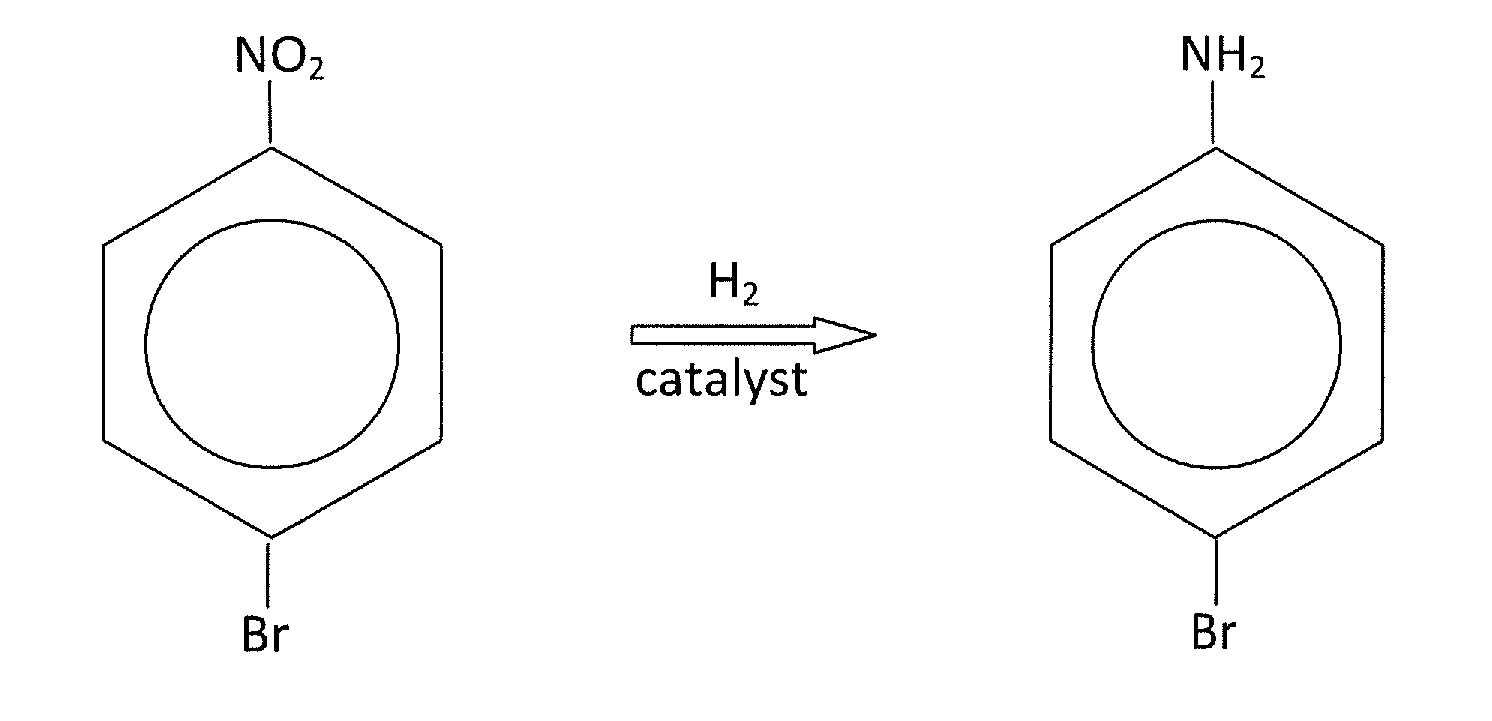

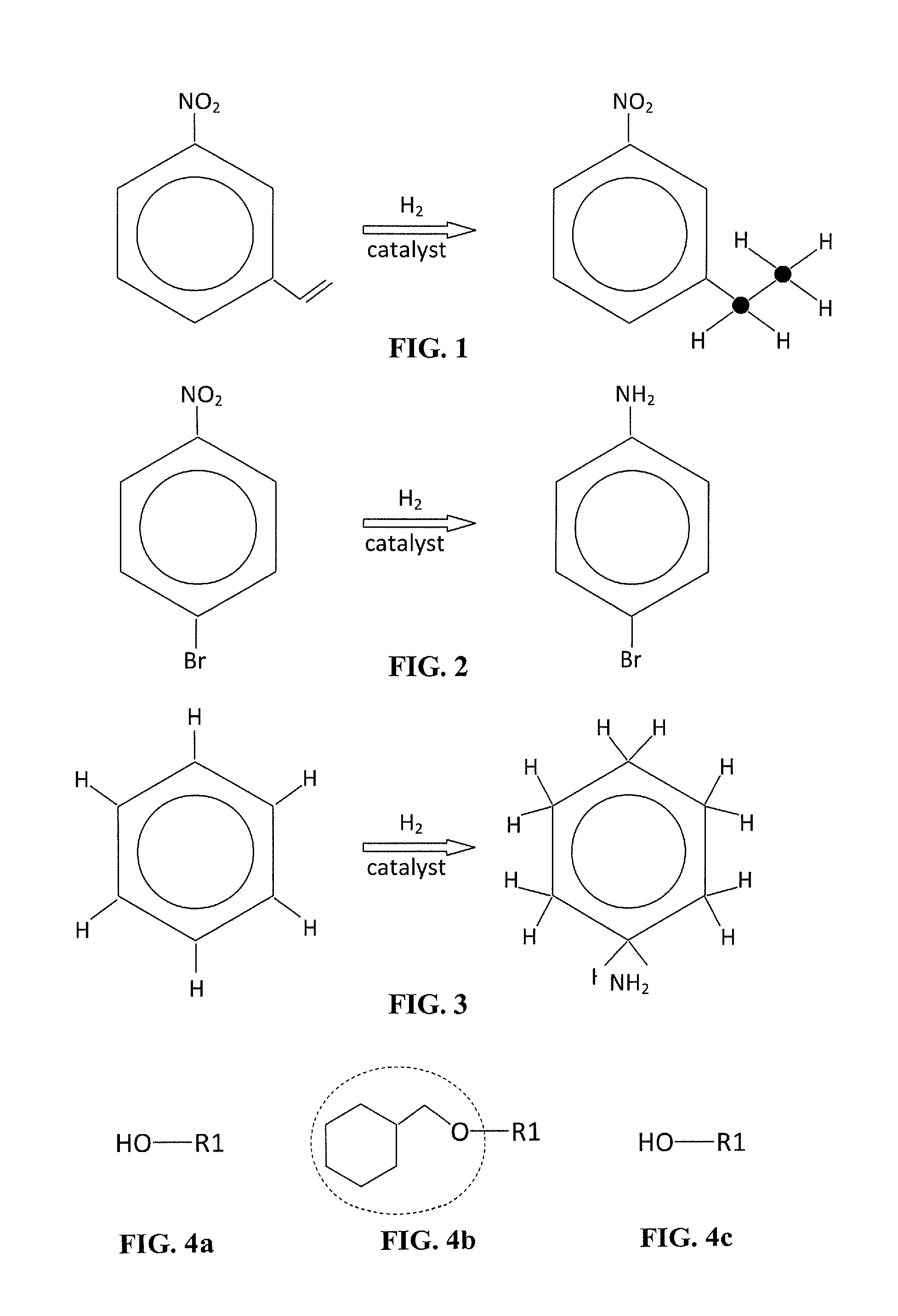

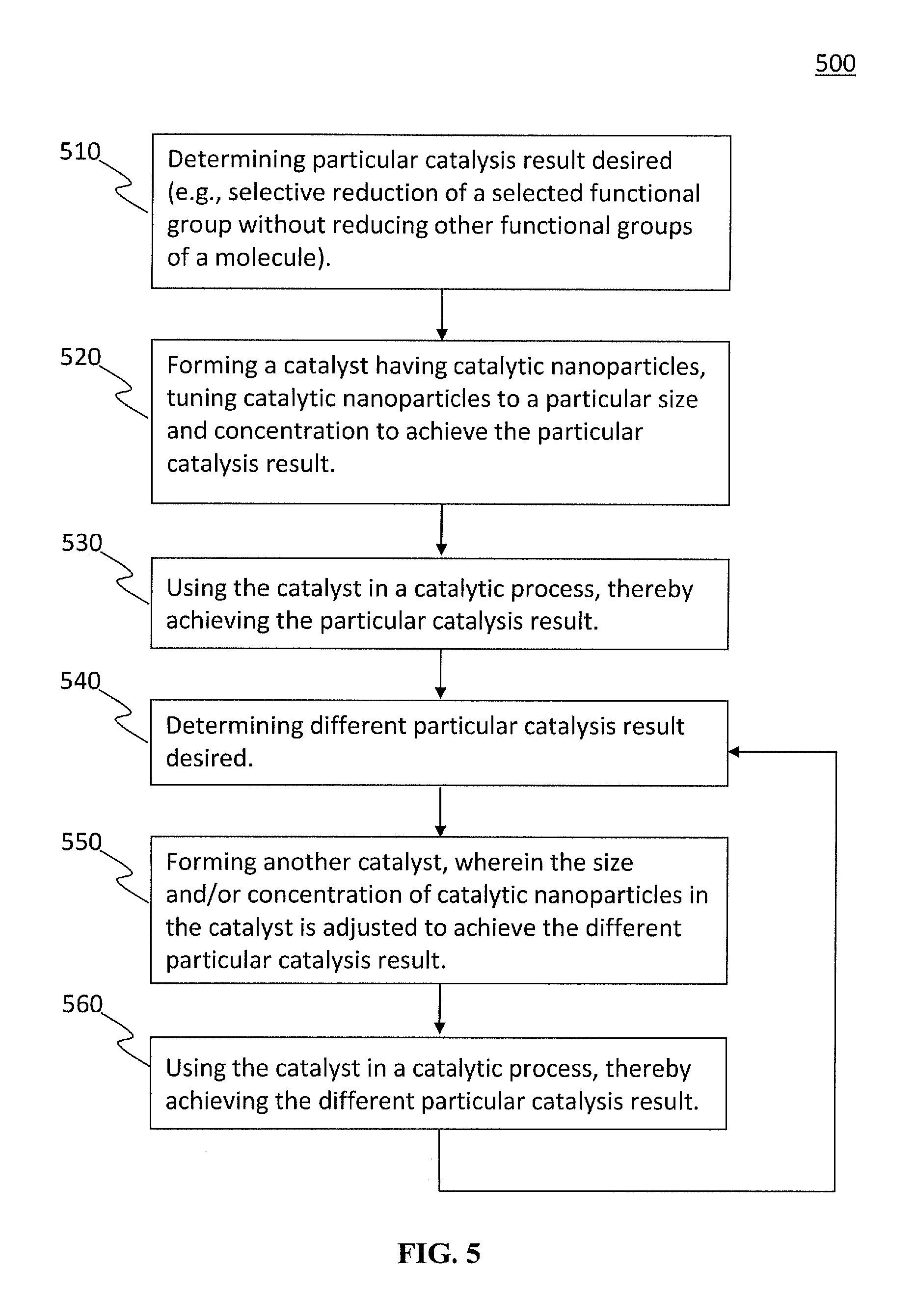

Advanced catalysts for fine chemical and pharmaceutical applications

A catalyst comprising a plurality of support nanoparticles and a plurality of catalytic nanoparticles. At least one catalytic nanoparticle is bonded to each support nanoparticle. The catalytic particles have a size and a concentration, wherein a first configuration of the size and the concentration of the catalytic nanoparticles enables a first catalysis result and a second configuration of the size and the concentration of the catalytic nanoparticles enables a second catalysis result, with the first and second configurations having a different size or concentration, and the first and second catalysis results being different. In some embodiments, the first catalysis result is a selective reduction of a first selected functional group without reducing one or more other functional groups, and the second catalysis result is a selective reduction of a second selected functional group without reducing one or more other functional groups.

Owner:SDC MATERIALS

Regeneration of ionic liquid catalyst by hydrogenation using a supported catalyst

A process for regenerating a used acidic ionic liquid catalyst comprising the steps of contacting the used ionic liquid catalyst and hydrogen with a supported hydrogenation catalyst comprising a hydrogenation component on a support in a reaction zone under hydrogenation conditions for a time sufficient to increase the activity of the used catalyst is disclosed.

Owner:CHEVROU USA INC

Regeneration of ionic liquid catalyst using a metal in the absence of added hydrogen

ActiveUS20070249485A1High activityMolecular sieve catalystsOther chemical processesHydrocarbon solventsHydrogen

A process for regenerating a used acidic ionic liquid catalyst comprising contacting the used ionic liquid catalyst with at least one metal in a regeneration zone in the absence of added hydrogen under regeneration conditions for a time sufficient to increase the activity of the ionic liquid catalyst is described. In one embodiment, regeneration is conducted in the presence of a hydrocarbon solvent.

Owner:CHEVROU USA INC

Fluid recirculation system for use in vapor phase particle production system

ActiveUS20080277268A1Reduce pressureDispersed particle filtrationDirect contact heat exchangersTemperature controlProduct gas

A method of and system for recirculating a fluid in a particle production system. A reactor produces a reactive particle-gas mixture. A quench chamber mixes a conditioning fluid with the reactive particle-gas mixture, producing a cooled particle-gas mixture that comprises a plurality of precursor material particles and an output fluid. A filter element filters the output fluid, producing a filtered output. A temperature control module controls the temperature of the filtered output, producing a temperature-controlled, filtered output. A content ratio control module modulates the content of the temperature-controlled, filtered output, thereby producing a content-controlled, temperature-controlled, filtered output. A channeling element supplies the content-controlled, temperature-controlled, filtered output to the quench chamber, wherein the content-controlled, filtered output is provided to the quench chamber as the conditioning fluid to be used in cooling the reactive particle-gas mixture.

Owner:SDC MATERIALS +1

Systems, methods, and catalysts for producing a crude product

InactiveUS20060231456A1Molecular sieve catalystsLiquid hydrocarbon mixture productionOrganic acidAlkaline earth metal

Methods and systems for contacting of a crude feed with one or more catalysts to produce a total product that includes a crude product are described. The crude product is a liquid mixture at 25° C. and 0.101 MPa. The crude product may have a total content of alkali metal and alkaline-earth metal in metal salts of organic acids of at most 90% of the total content of alkali metal and alkaline-earth metal in metal salts of organic acids of the crude feed. One or more other properties of the crude product may be changed by at least 10% relative to the respective properties of the crude feed.

Owner:SHELL OIL CO

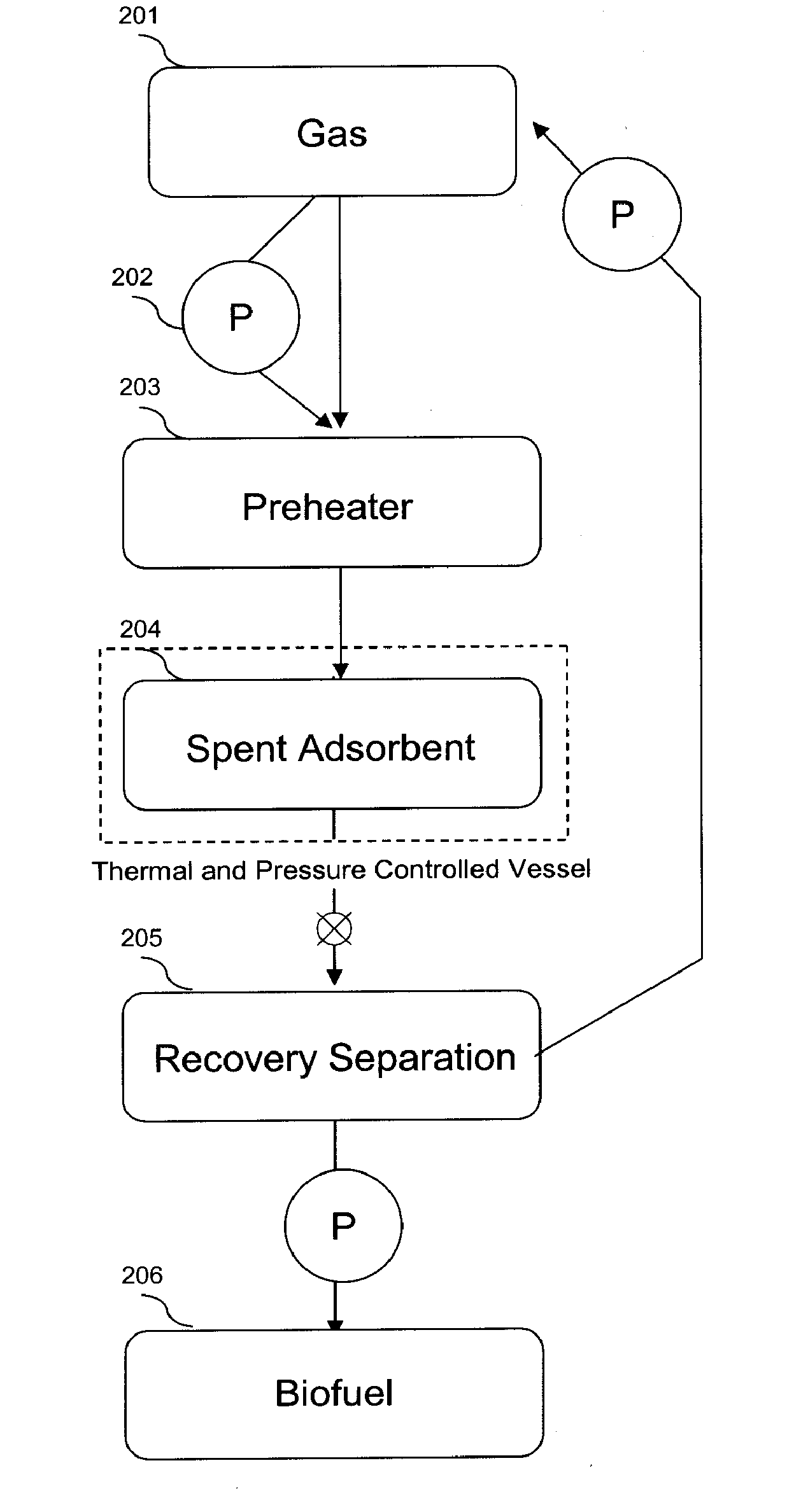

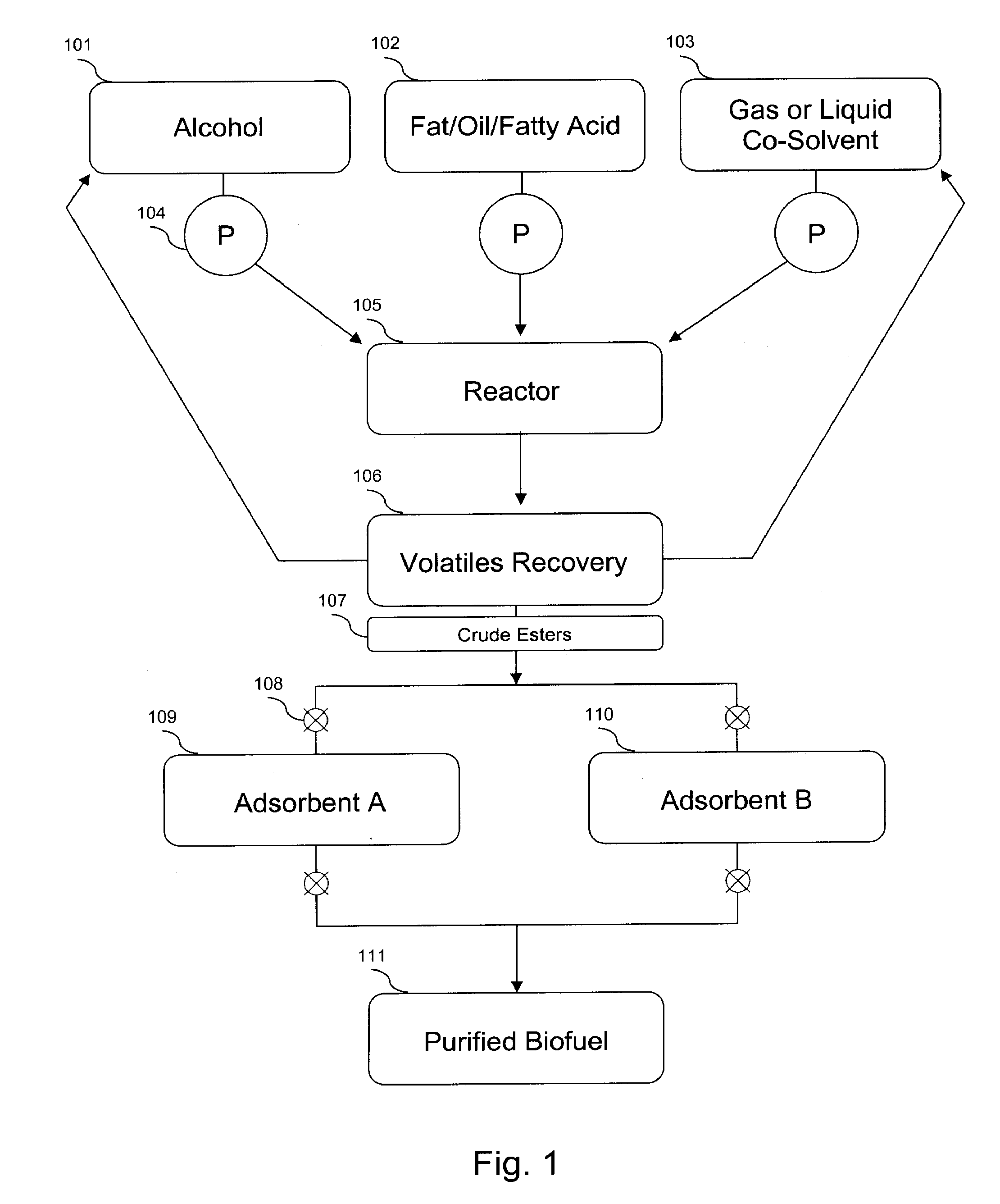

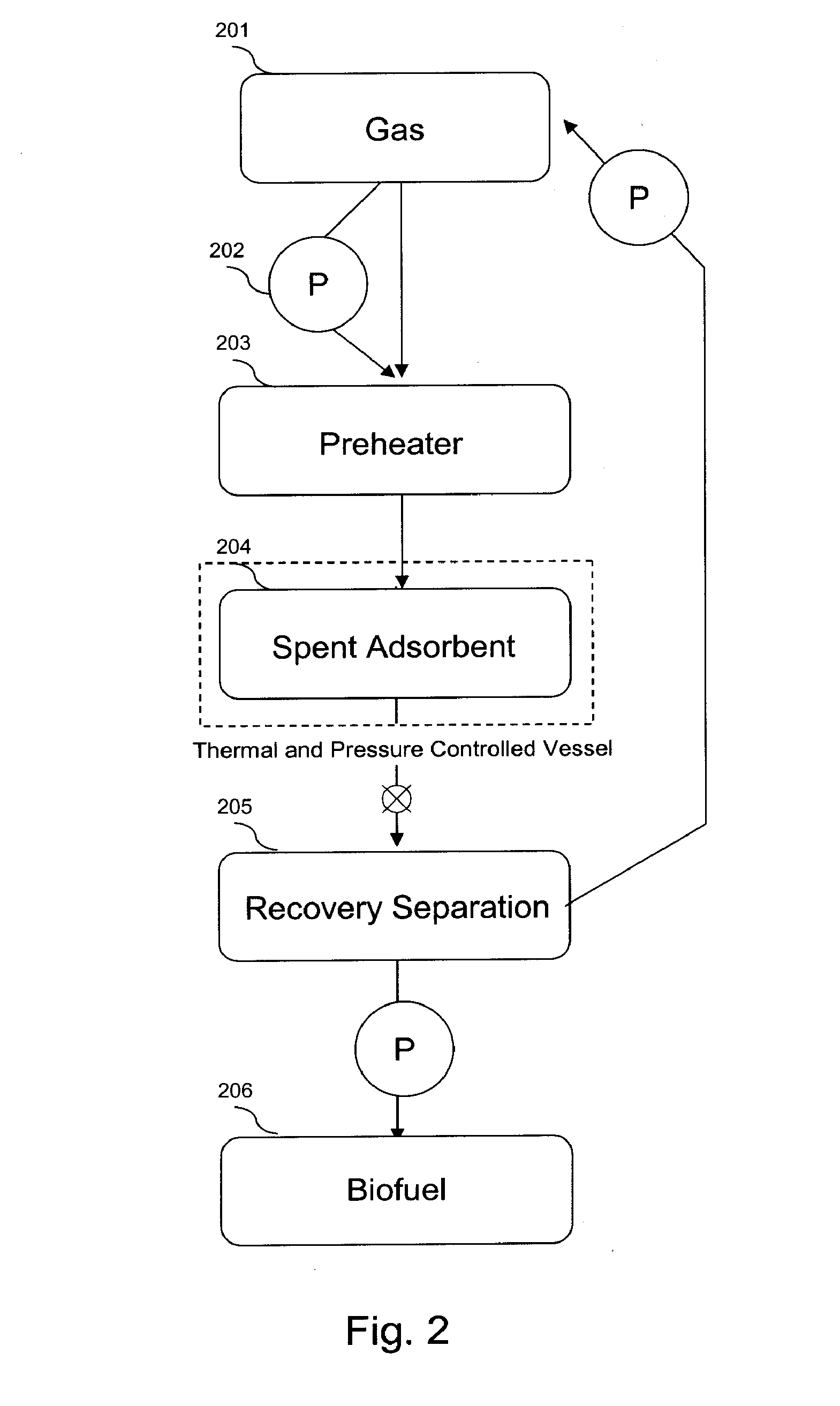

System for production and purification of biofuel

Systems and methods are provided for the regeneration of adsorbent medium and the production of additional fatty acid esters, i.e., biofuel, in particular, by means of discharging adsorbed contaminants from an adsorbent medium such as an inorganic catalytic medium by methods that convert the contaminants into additional biofuel or biofuel intermediates, thereby increasing production efficiency, conserving labor, and reducing material waste and environmental contamination.

Owner:BIOFUELBOX

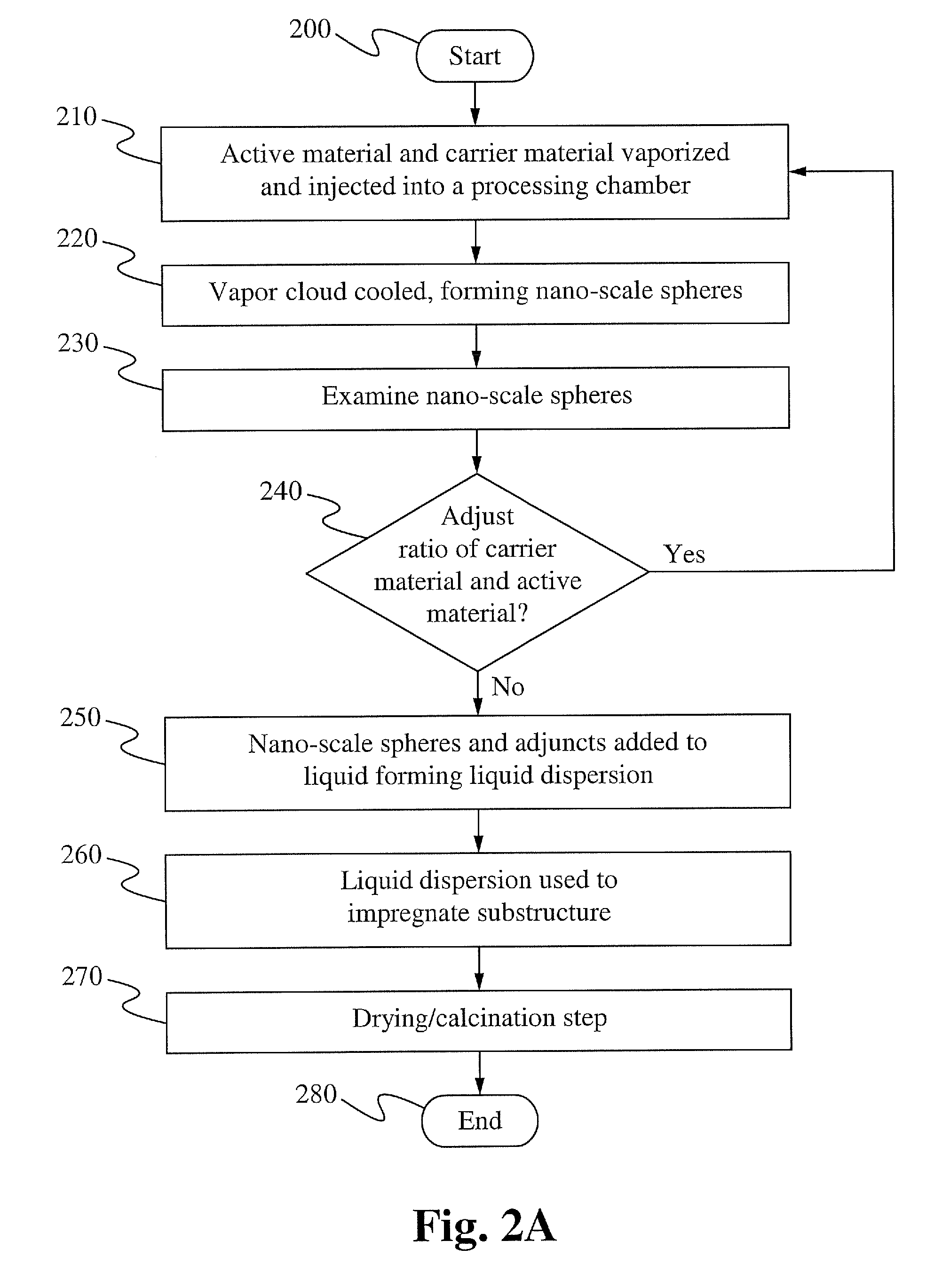

Tunable size of nano-active material on nano-support

InactiveUS20110143930A1Limited useful lifeSmall sizeMaterial nanotechnologyMolten spray coatingNanocarriersVapor phase

A method of tuning the size of an nano-active material on a nano-carrier material comprising: providing a starting portion of a carrier material and a starting portion of an active material in a first ratio; adjusting the first ratio, forming a second ratio, thereby tuning the ratio of active material and carrier material; combining the portion of the active material in a vapor phase and the portion of the carrier material in a vapor phase, forming a conglomerate in a vapor phase; and changing the phase of the conglomerate, thereby forming nano-spheres comprising a nano-carrier material decorated with a nano-active material, wherein the size of the nano-active material is dependent upon the second ratio.

Owner:SDC MATERIALS

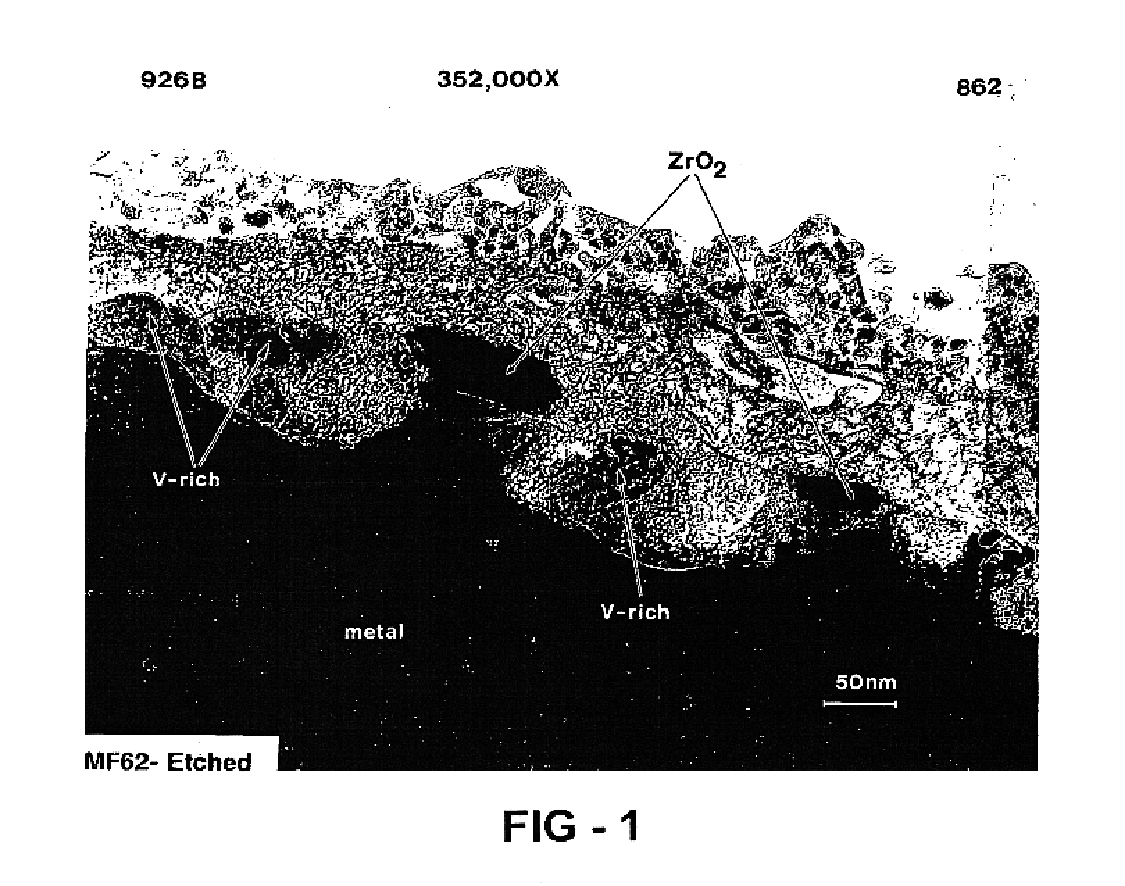

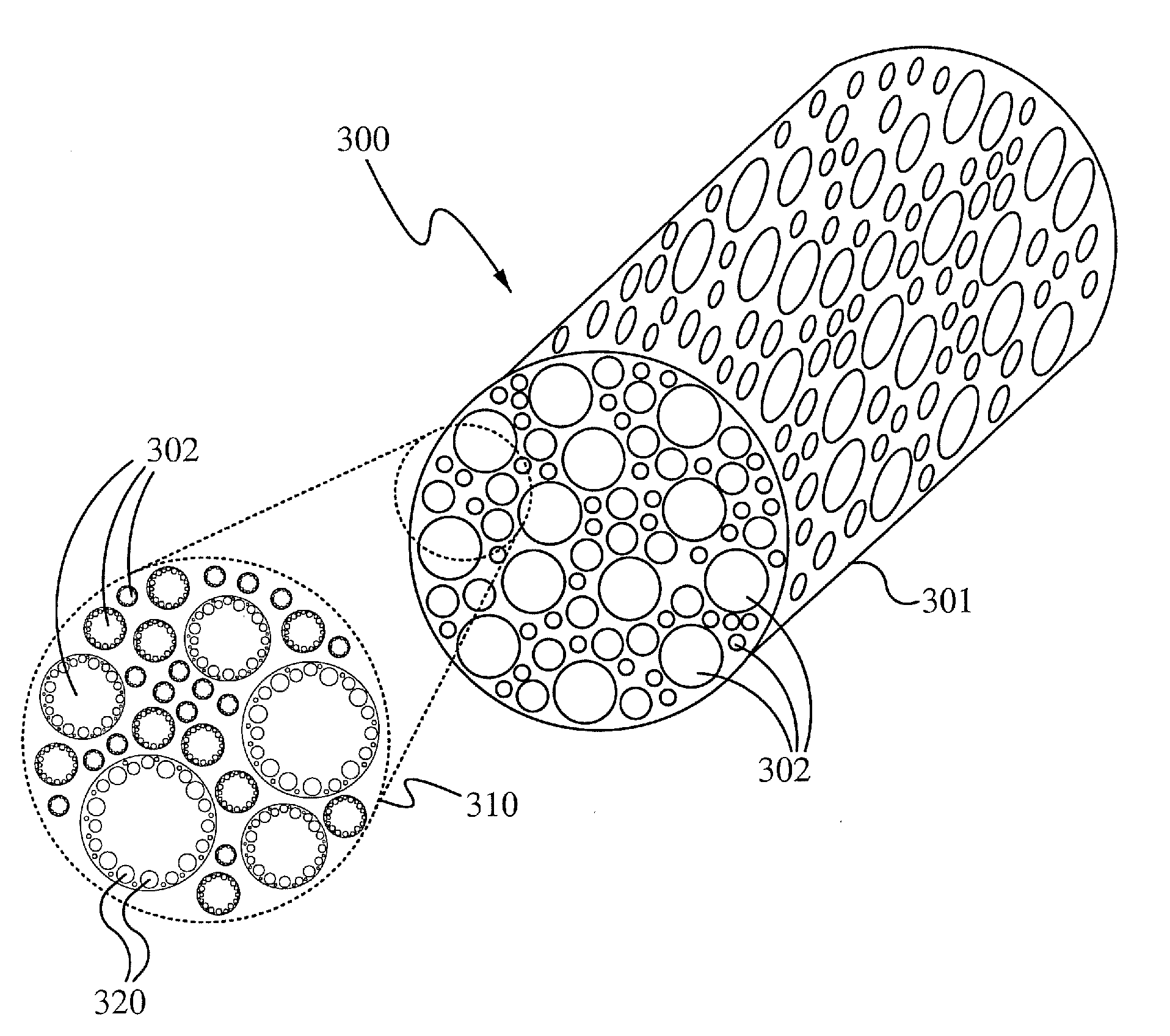

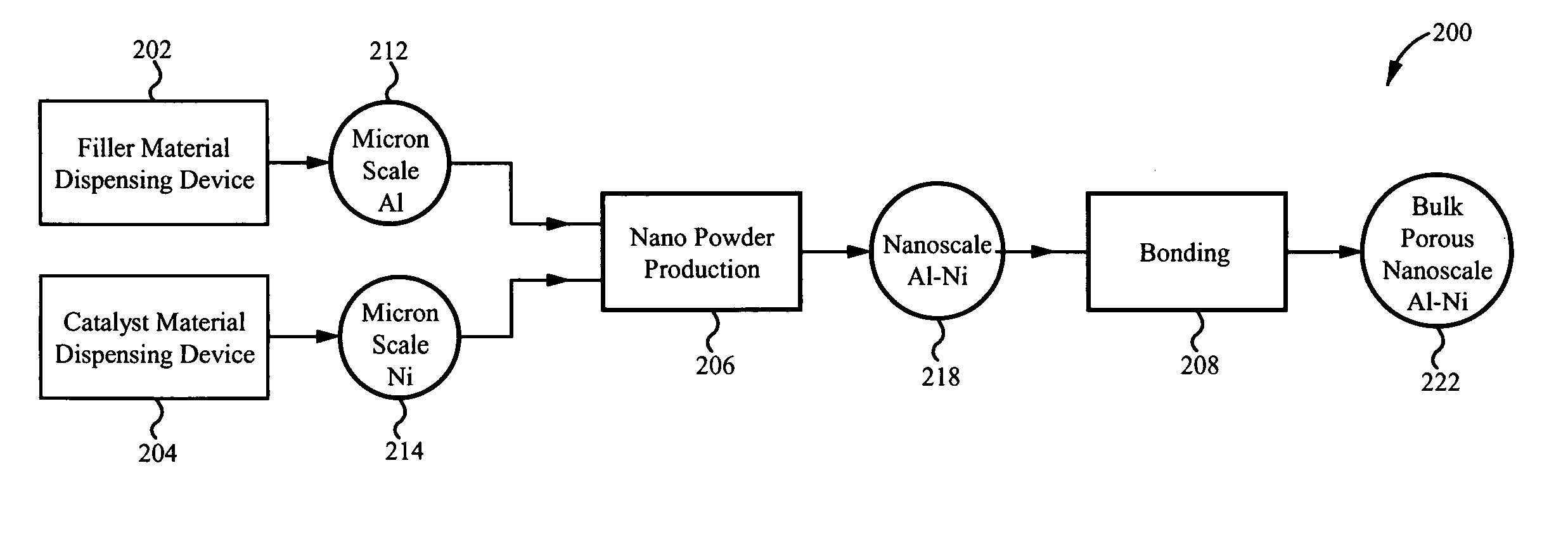

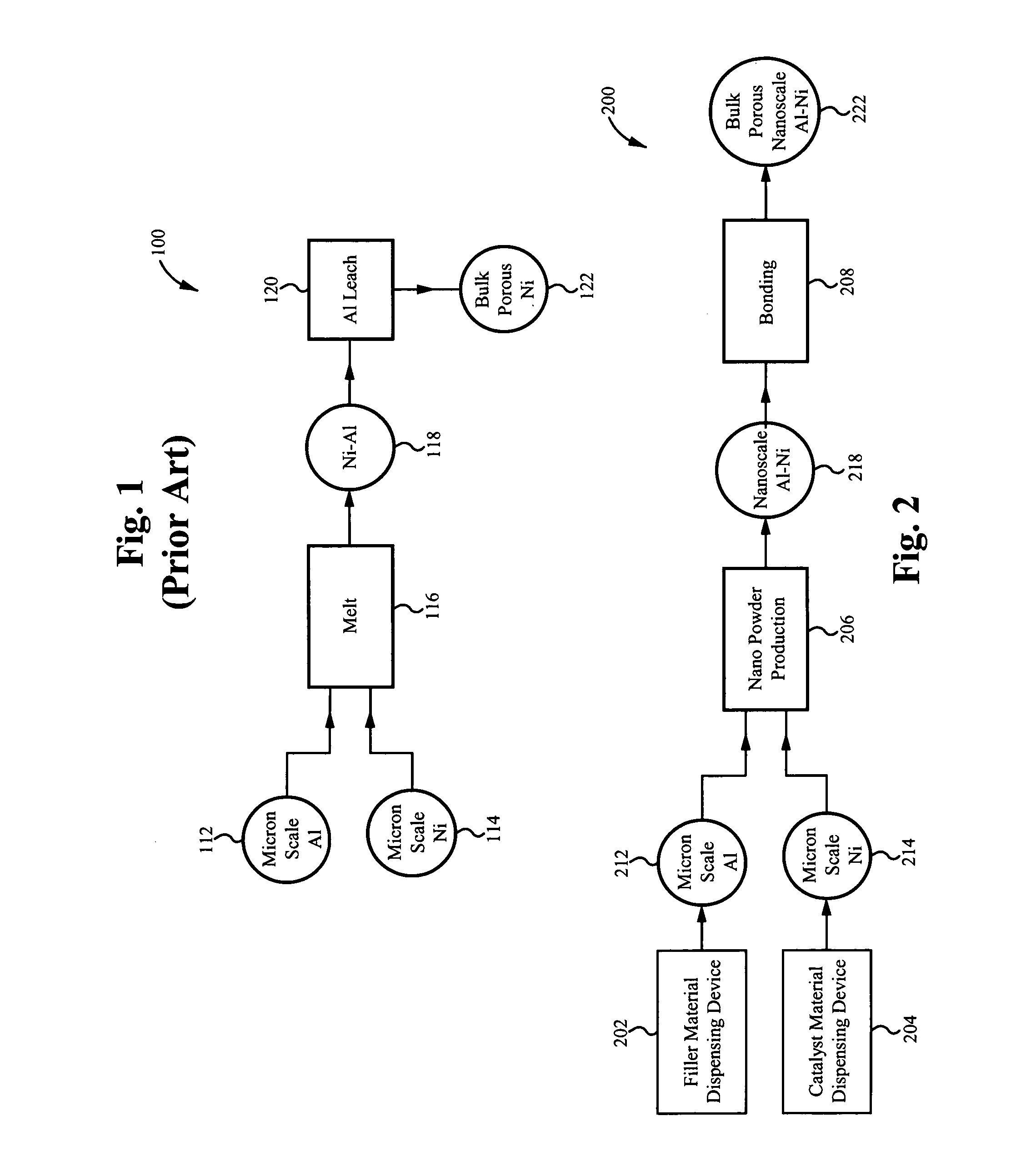

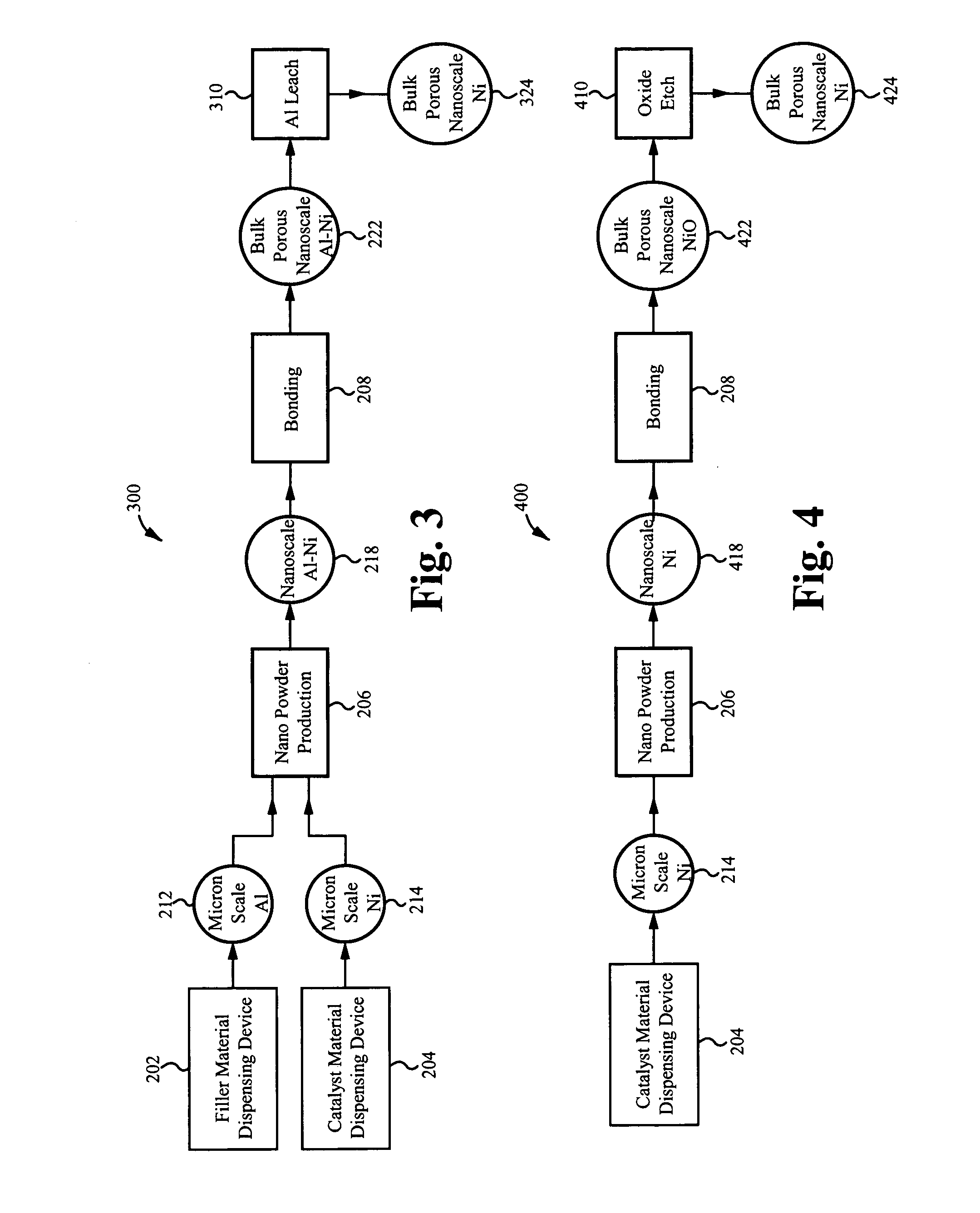

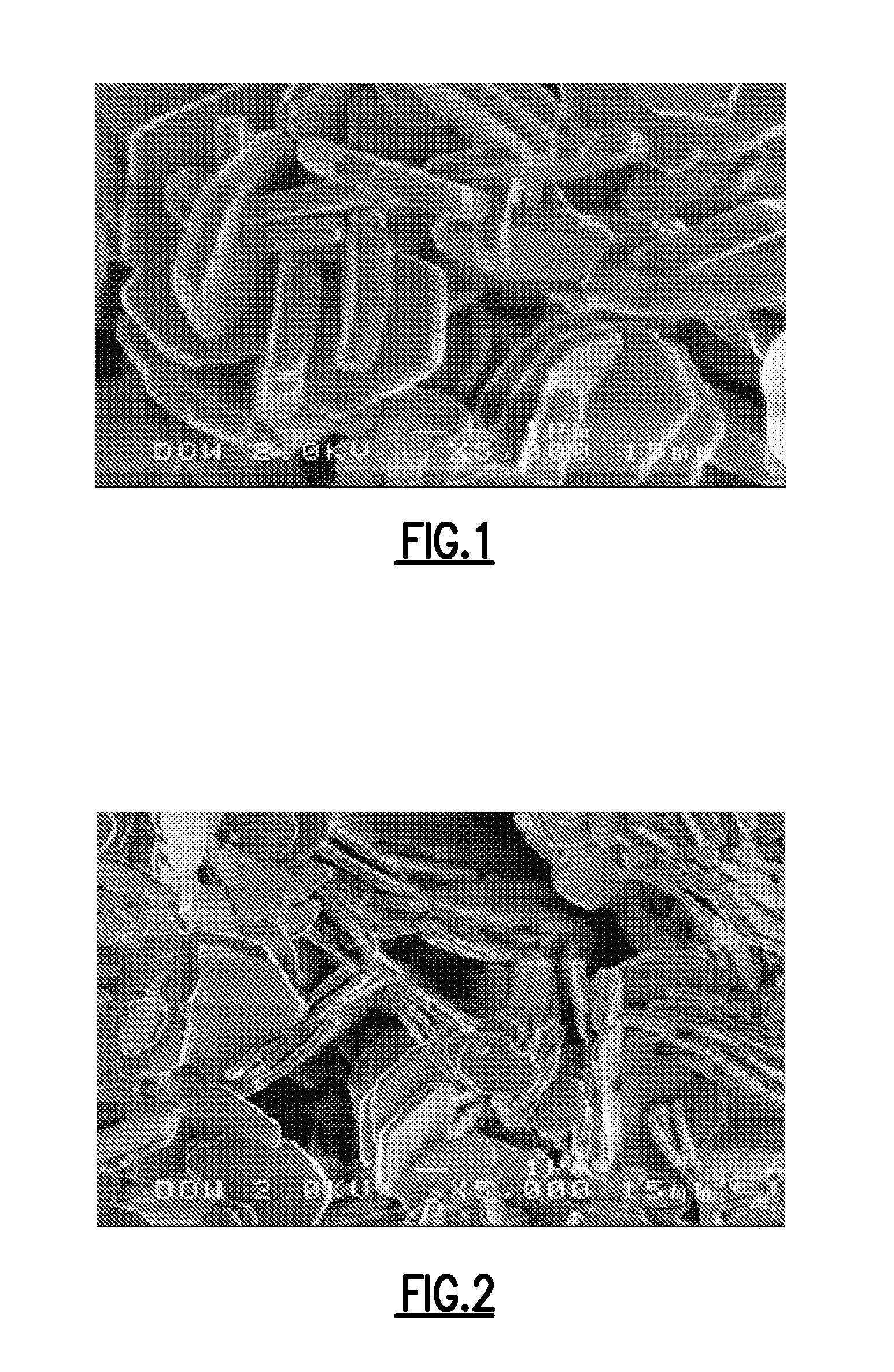

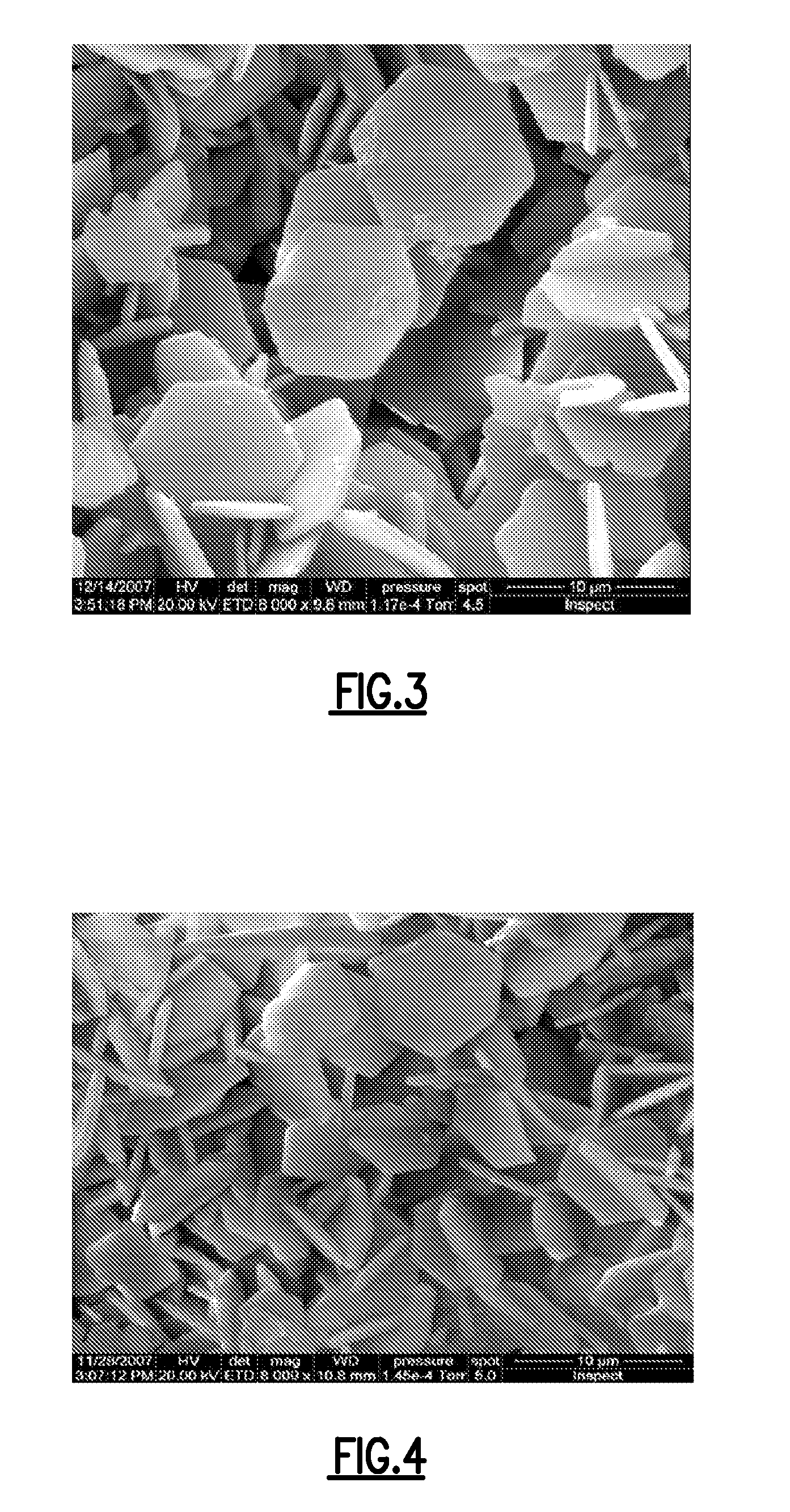

Nano-skeletal catalyst

ActiveUS20080280756A1Increase surface areaMassive costMechanical working/deformationSemiconductor/solid-state device manufacturingPolymer scienceScale structure

A method of producing a catalyst material with nano-scale structure, the method comprising: introducing a starting powder into a nano-powder production reactor, the starting powder comprising a catalyst material; the nano-powder production reactor nano-sizing the starting powder, thereby producing a nano-powder from the starting powder, the nano-powder comprising a plurality of nano-particles, each nano-particle comprising the catalyst material; and forming a catalyst precursor material from the nano-powder, wherein the catalyst precursor material is a densified bulk porous structure comprising the catalyst material, the catalyst material having a nano-scale structure.

Owner:SDC MATERIALS +1

Regeneration of ionic liquid catalyst by hydrogenation using metal and acid

A process for regenerating a used acidic ionic liquid catalyst which has been deactivated by conjunct polymers comprising combining the used catalyst, a metal and a Broensted acid which acts a source of hydrogen in a reaction zone under hydrogenation conditions for a time sufficient to hydrogenate at least a portion of the conjunct polymer is disclosed. An embodiment of a process for regenerating a used acidic ionic liquid catalyst which has been deactivated by conjunct polymers comprising the steps of combining the used ionic liquid catalyst, a metal and HCl in a reaction zone under hydrogenation conditions for a time sufficient to hydrogenate at least a portion of the conjunct polymer; removing reaction product from the reaction zone; mixing the removed reaction product with a hydrocarbon solvent in which the hydrogenated conjunct polymers are soluble; allowing the mixture to separate into two phases, a lighter phase which contains the hydrogenated conjunct polymers and a heavier phase which contains a regenerated ionic liquid catalyst; and recovering at least a portion of the heavier phase is also disclosed.

Owner:CHEVROU USA INC

Porous body precursors, shaped porous bodies, processes for making them, and end-use products based upon the same

ActiveUS20110136659A1Low costShorten the timeOrganic chemistryMolecular sieve catalystsPore diameterProduct base

The present invention provides porous body precursors and shaped porous bodies. Also included are catalysts and other end-use products based upon the shaped porous bodies and thus the porous body precursors. Finally, processes for making these are provided. The porous body precursors, comprise one or more topography-enhancing additives, i.e., additives that are capable of at least marginally enhancing one or more of surface area, aspect ratio, pore volume, median pore diameter, surface morphology, etc. Downstream products need not necessarily comprise the topography-enhancing additives in order to exhibit the benefits of their inclusion in the porous body precursors.

Owner:DOW TECH INVESTMENTS

Catalytic gasification process with recovery of alkali metal from char

ActiveUS7897126B2Quantity minimizationThermal non-catalytic crackingMuffle furnacesParticulatesSlurry

Processes are described for the extraction and recovery of alkali metal from the char that results from catalytic gasification of a carbonaceous material. Among other steps, the processes of the invention include a hydrothermal leaching step in which a slurry of insoluble particulate comprising insoluble alkali metal compounds is treated with carbon dioxide and steam at elevated temperatures and pressures to effect the conversion of insoluble alkali metal compounds to soluble alkali metal compounds. Further, processes are described for the catalytic gasification of a carbonaceous material where a substantial portion of alkali metal is extracted and recovered from the char that results from the catalytic gasification process.

Owner:SURE CHAMPION INVESTMENT LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com