Patents

Literature

674 results about "Catalytic metal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

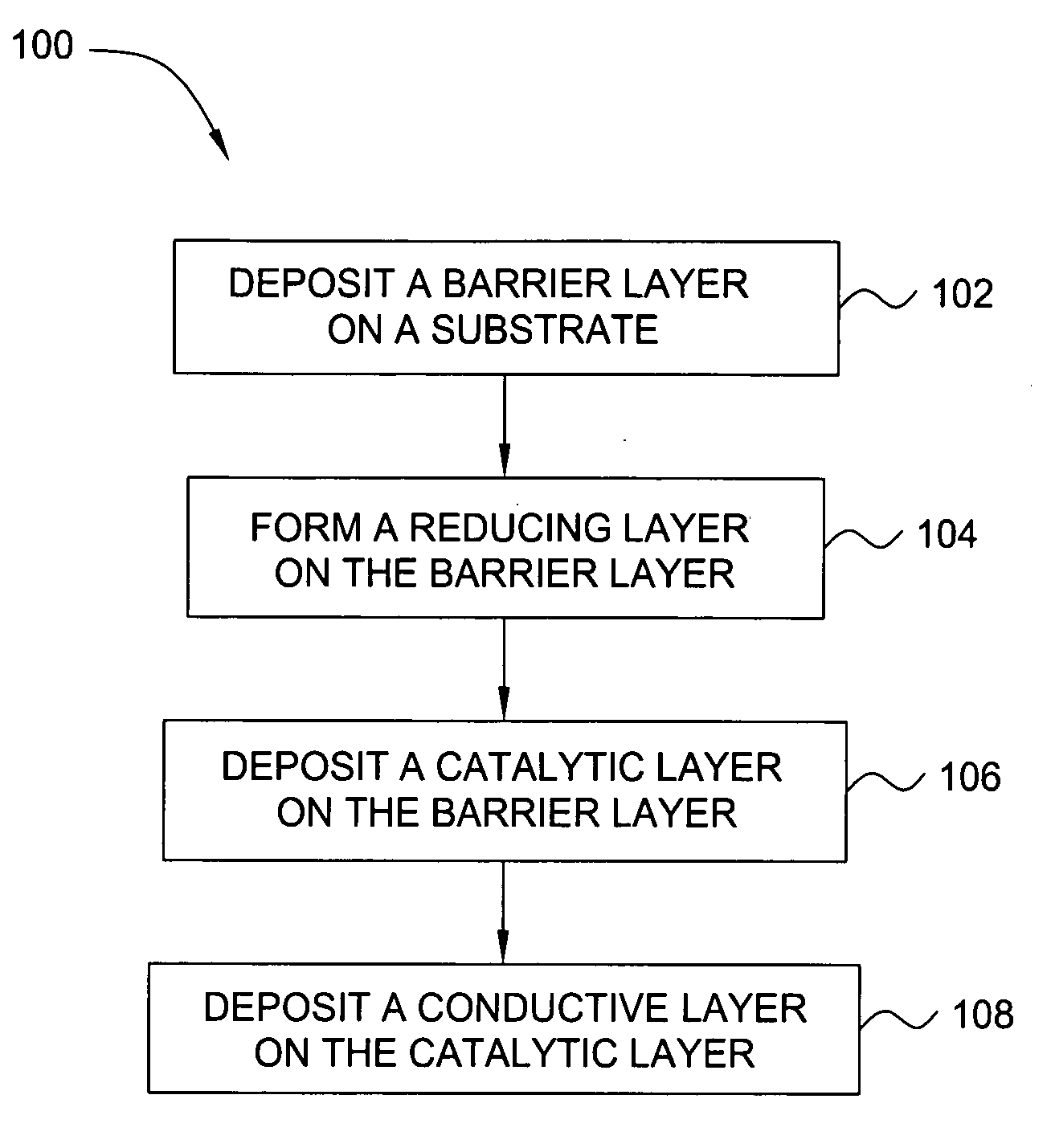

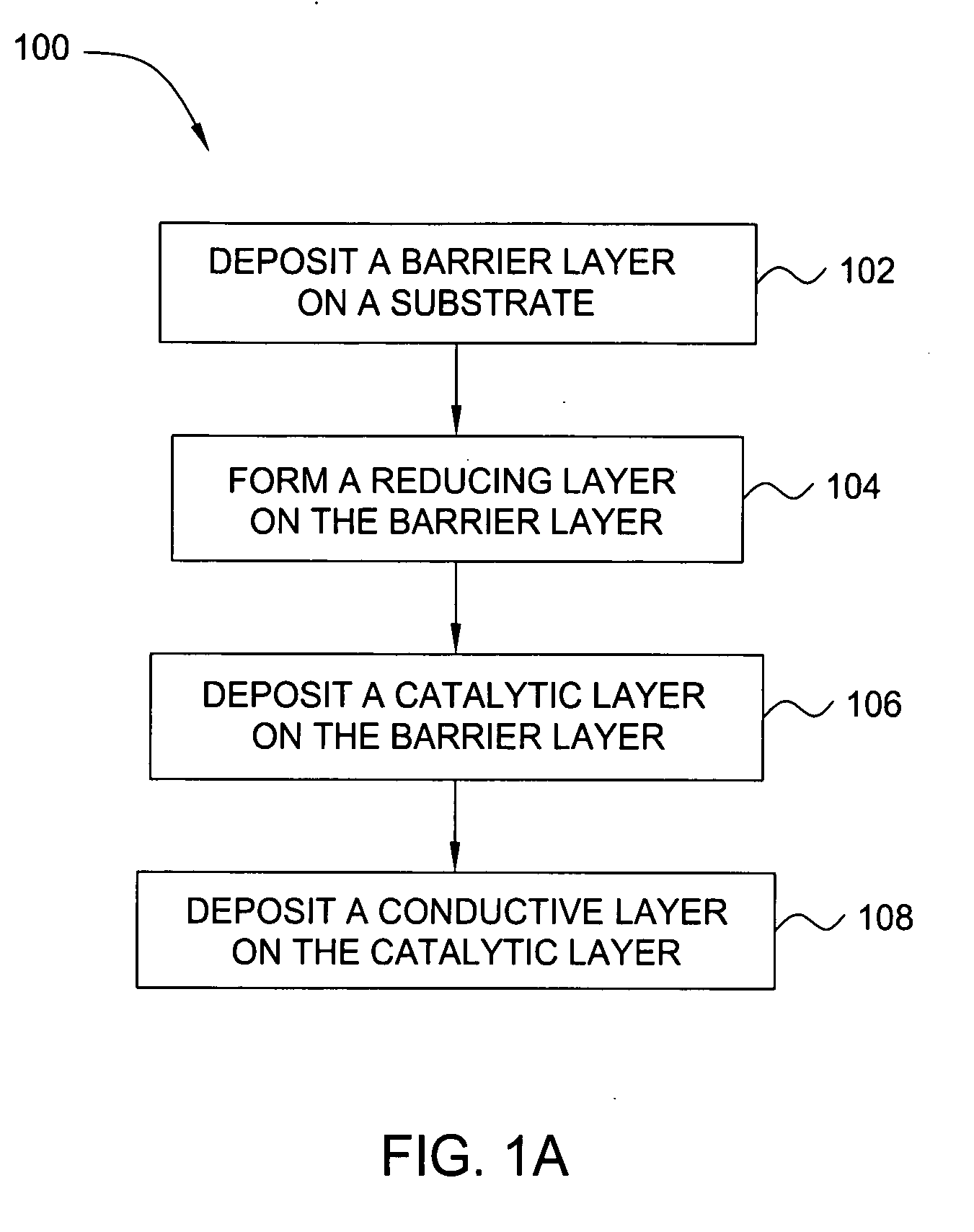

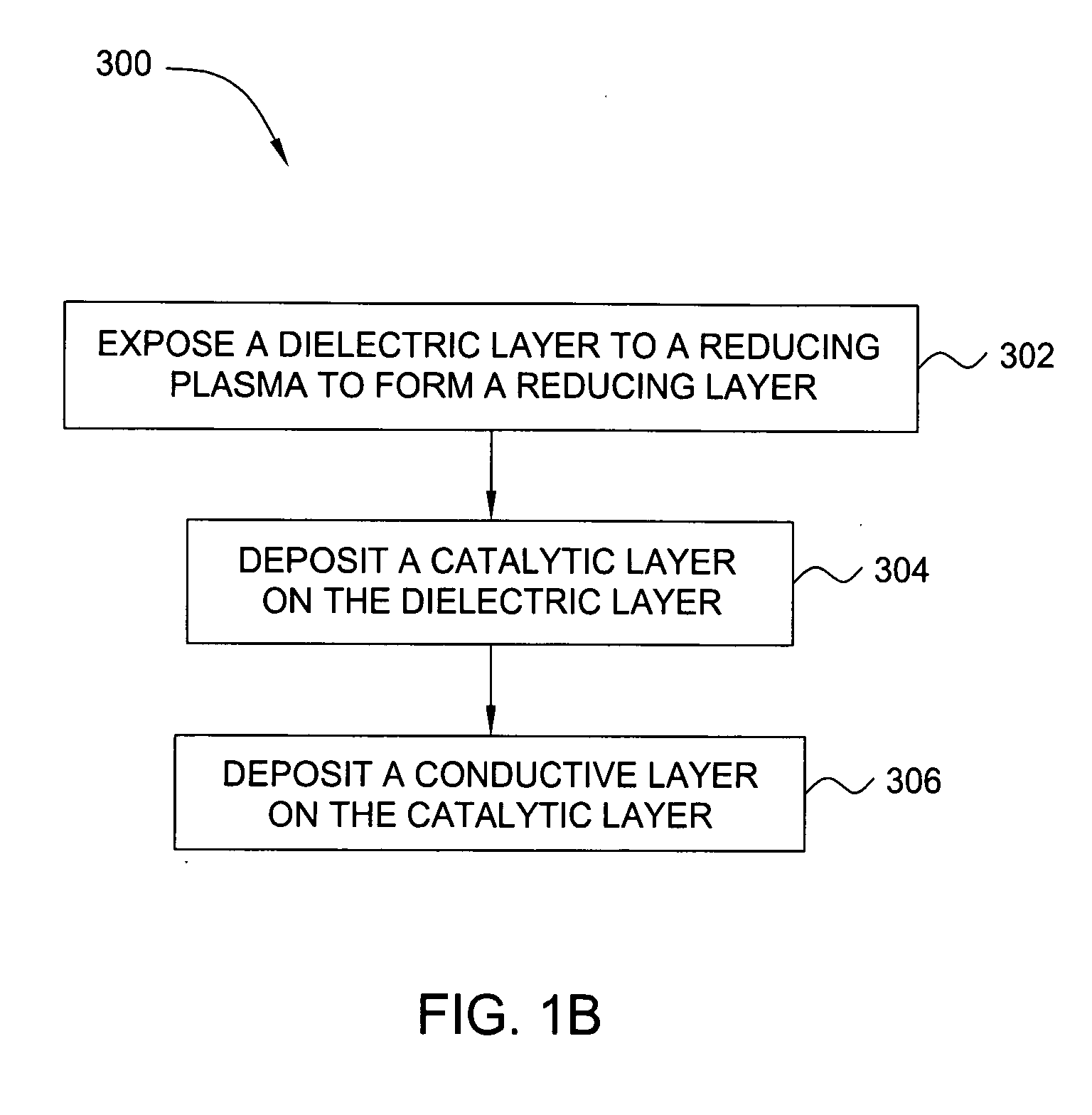

Deposition of an intermediate catalytic layer on a barrier layer for copper metallization

InactiveUS20060240187A1Solid-state devicesSemiconductor/solid-state device manufacturingIridiumSilanes

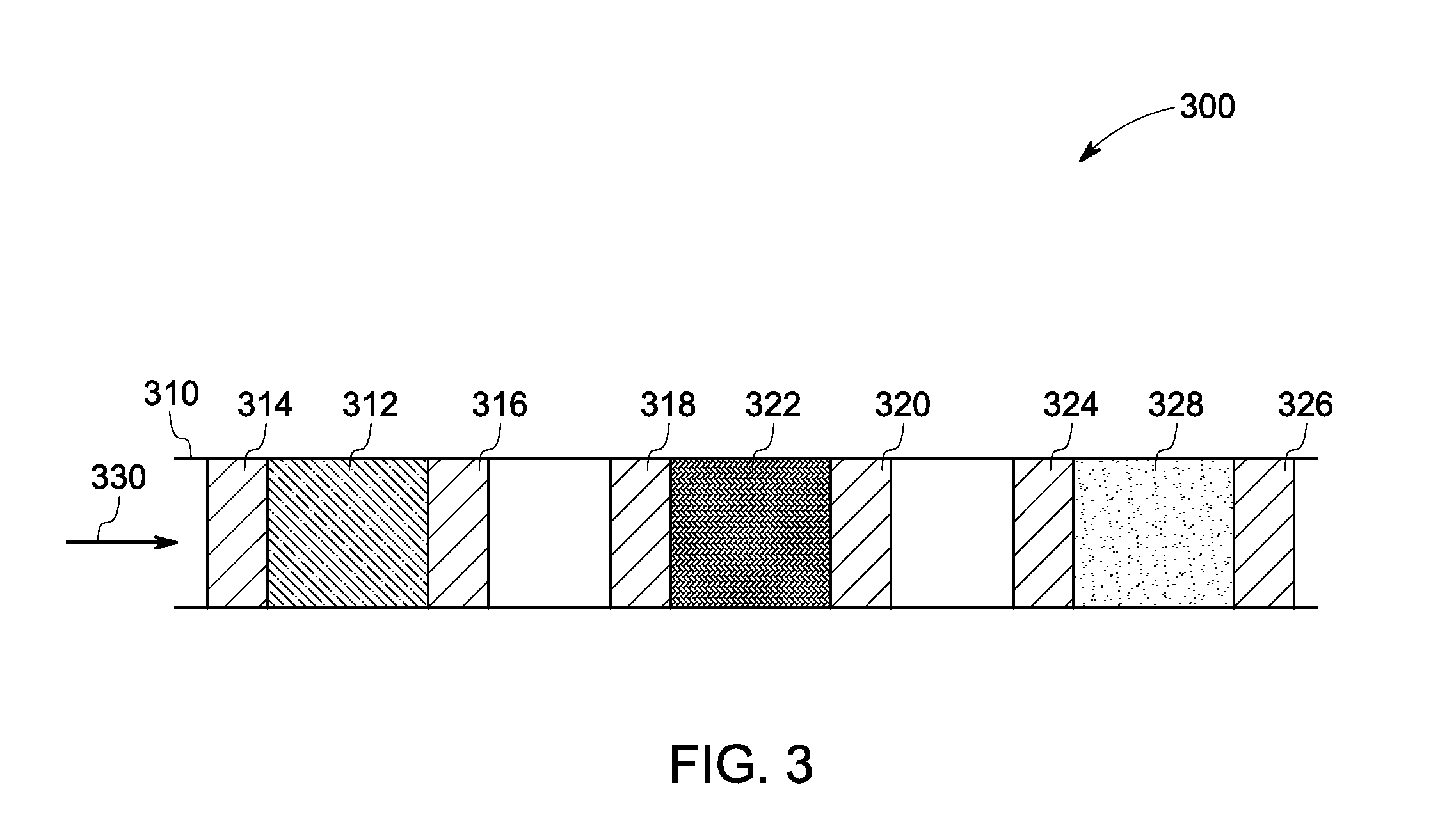

In one embodiment, a method for depositing a conductive material on a substrate is provided which includes exposing a substrate containing a barrier layer to a volatile reducing precursor to form a reducing layer during a soak process, exposing the reducing layer to a catalytic-metal precursor to deposit a catalytic metal-containing layer on the barrier layer, and depositing a conductive layer (e.g., copper) on the catalytic metal-containing layer. The volatile reducing precursor may include phosphine, diborane, silane, a plasma thereof, or a combination thereof and be exposed to the substrate for a time period within a range from about 1 second to about 30 seconds during the soak process. The catalytic metal-containing layer may contain ruthenium, cobalt, rhodium, iridium, nickel, palladium, platinum, silver, or copper. In one example, the catalytic metal-containing layer is deposited by a vapor deposition process utilizing ruthenium tetroxide formed by an in situ process.

Owner:APPLIED MATERIALS INC

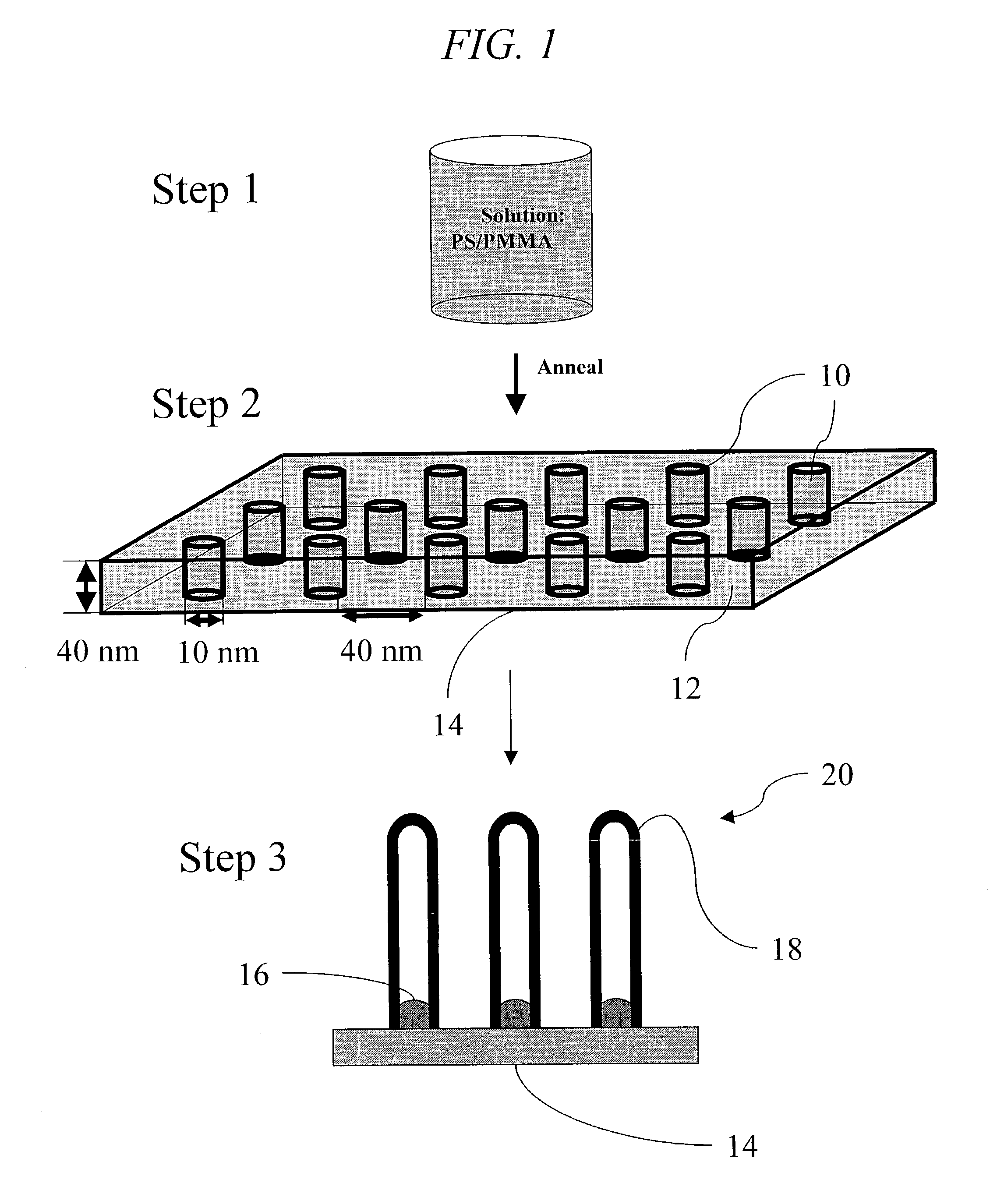

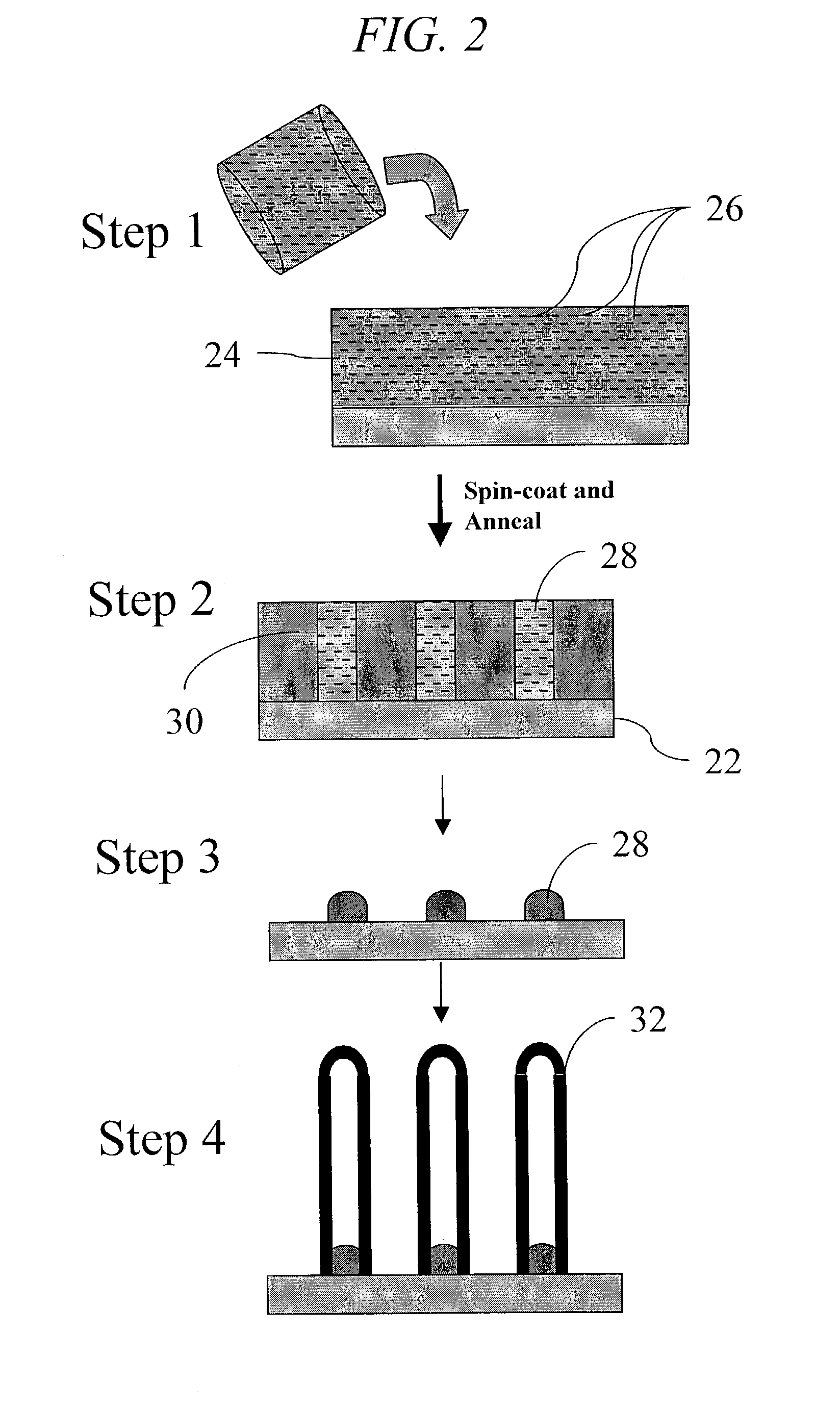

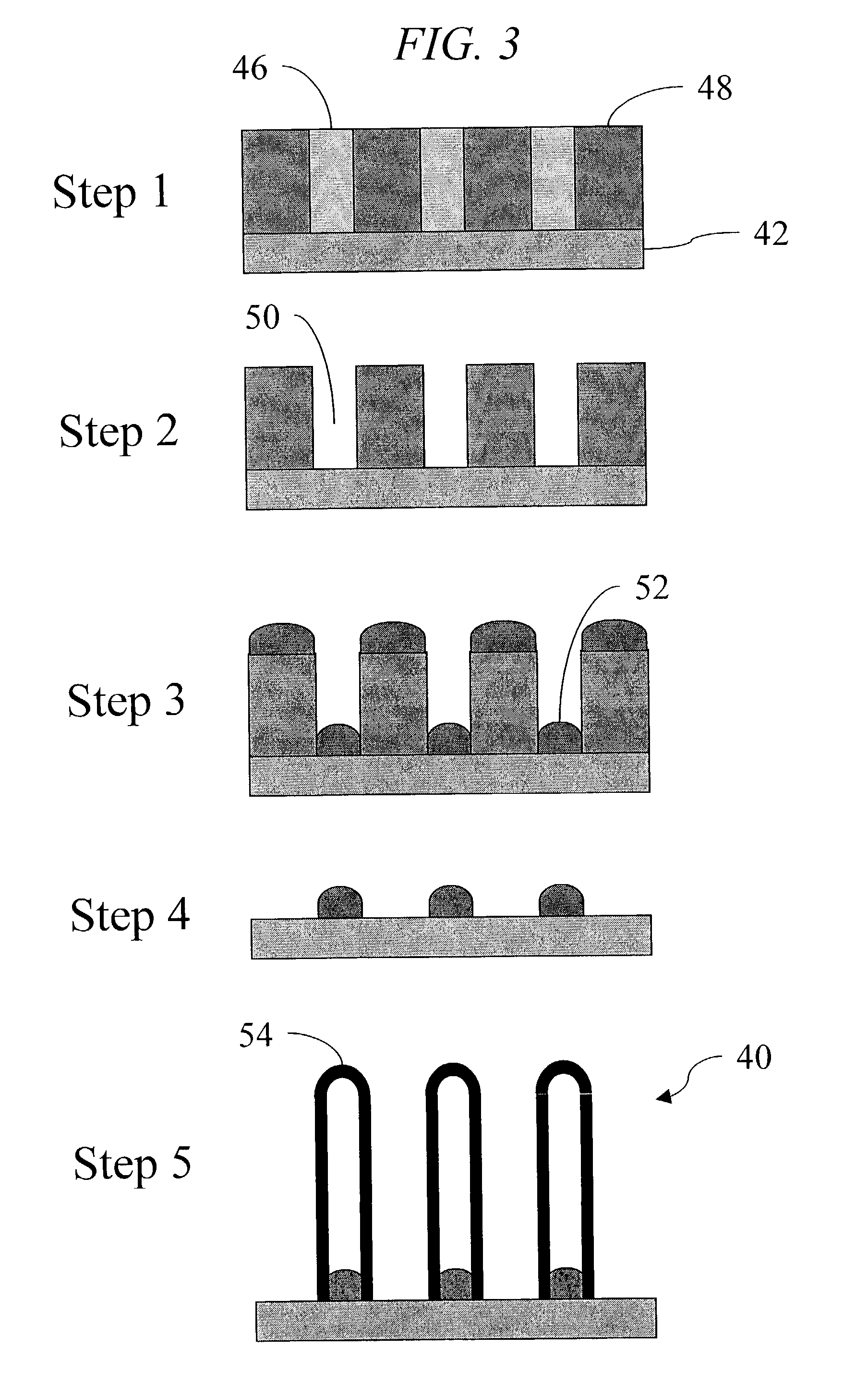

Method of producing regular arrays of nano-scale objects using nano-structured block-copolymeric materials

A method of forming a periodic array of nano-scale objects using a block copolymer, and nano-scale object arrays formed from the method are provided. The method for forming the arrays generally includes the steps of depositing a block copolymer of at least two blocks on a substrate to form an ordered meso-scale structured array of the polymer materials, forming catalytic metal dots based on the meso-scale structure, and growing nano-scale objects on the catalytic dots to form an ordered array of nano-scale objects.

Owner:CALIFORNIA INST OF TECH

Method of preparing catalyst for manufacturing carbon nanotubes

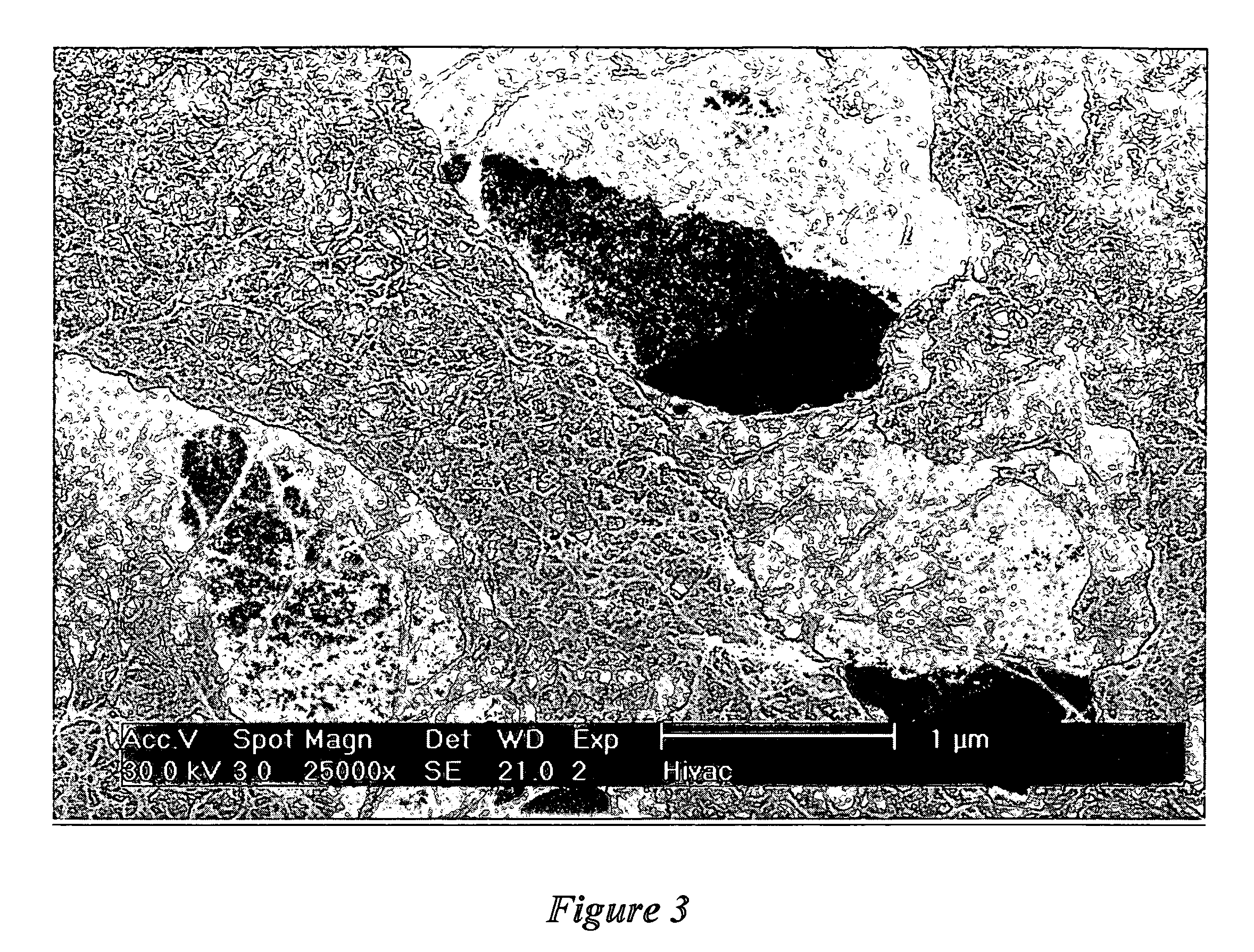

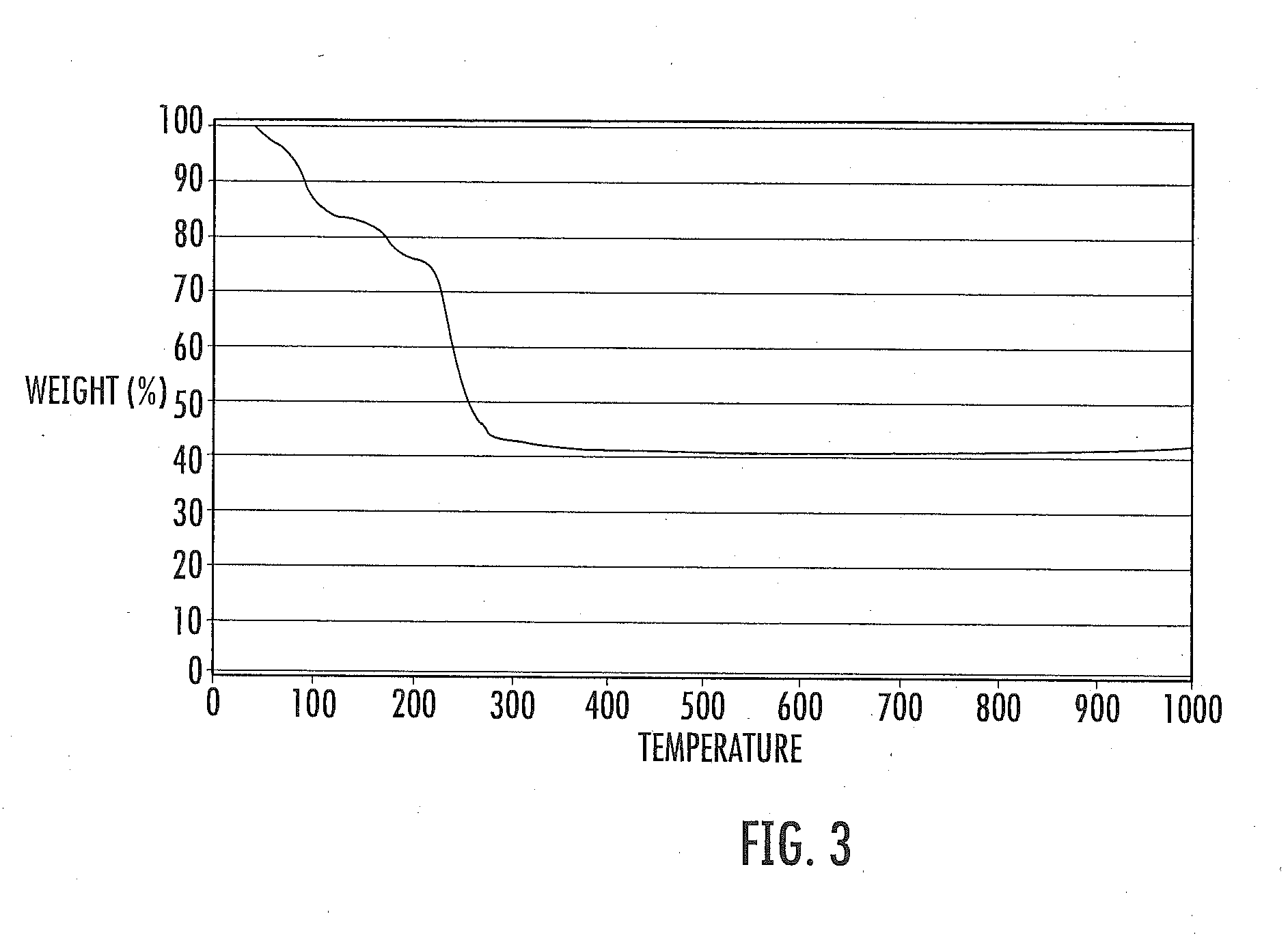

InactiveUS20070020167A1Improve uniformityMinimize agglomerationMaterial nanotechnologyNanostructure manufactureFreeze-dryingCarbon nanotube

A novel method of forming catalyst particles, on which carbon nanotubes grow based, on a substrate with increased uniformity, and a method of synthesizing carbon nanotubes having improved uniformity are provided. A catalytic metal precursor solution is applied to a substrate. The applied catalytic metal precursor solution is freeze-dried, and then reduced to catalytic metal. The method of forming catalyst particles can minimize agglomeration and / or recrystallization of catalyst particles when forming the catalyst particles by freeze-drying the catalyst metal precursor solution. The catalyst particles formed by the method has a very uniform particle size and are very uniformly distributed on the substrate.

Owner:SAMSUNG SDI CO LTD

Method for Preparing Fuel Element For Smoking Article

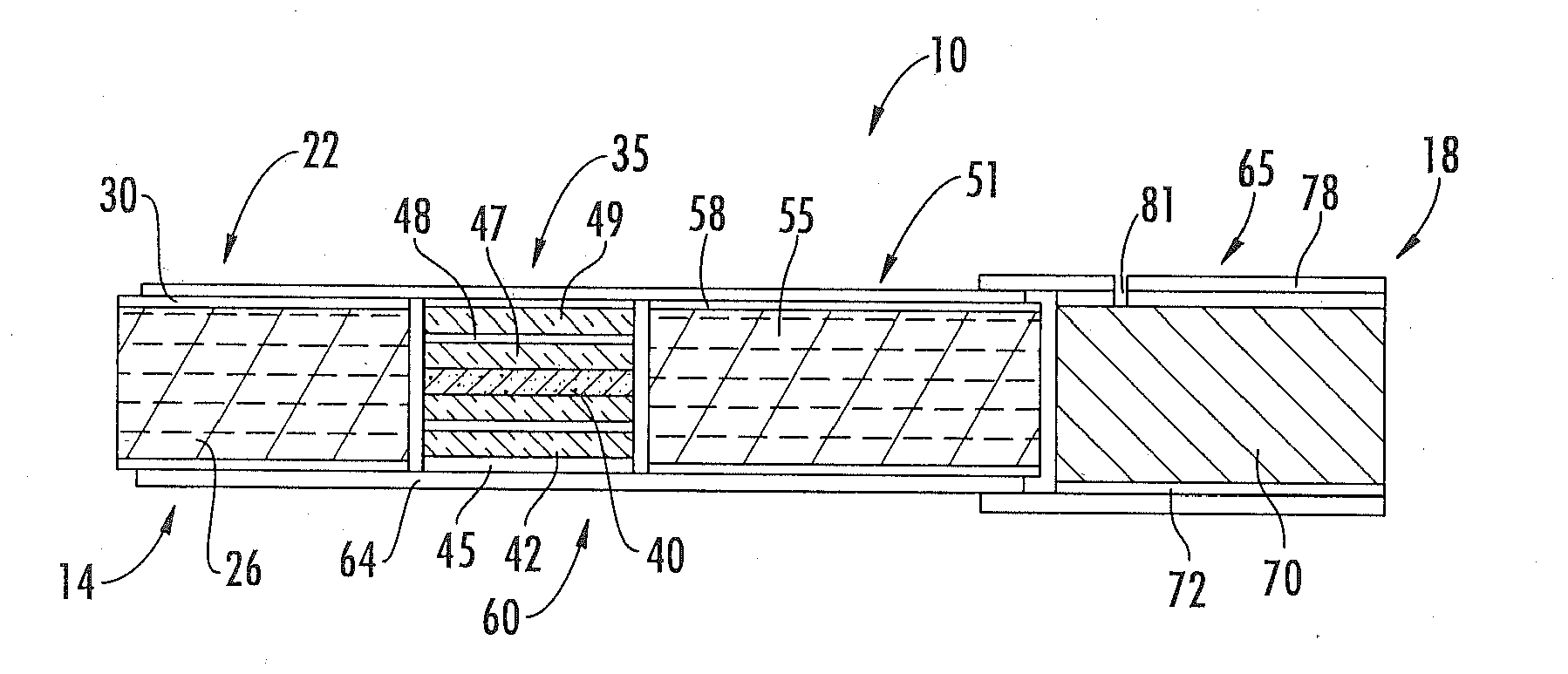

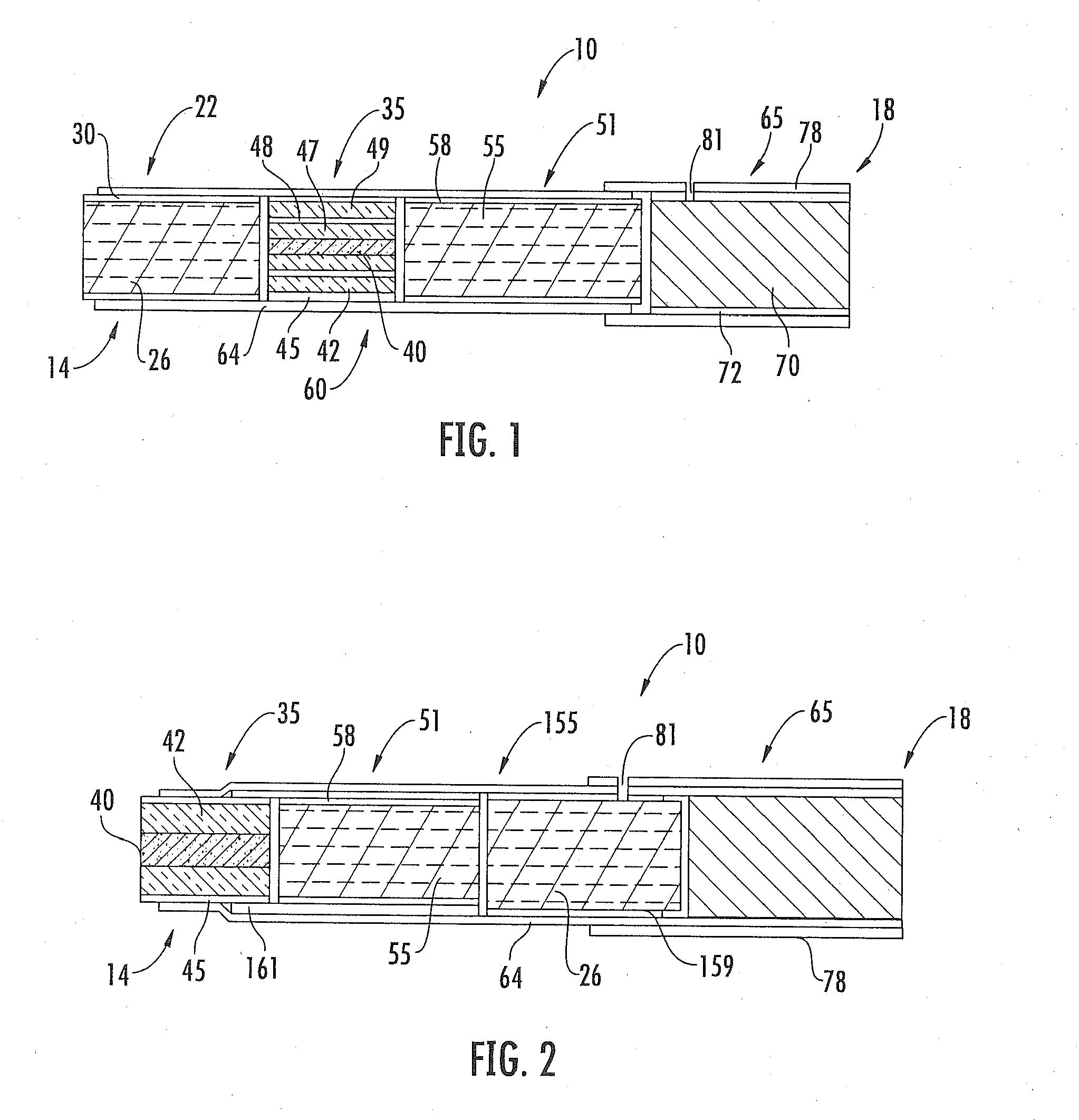

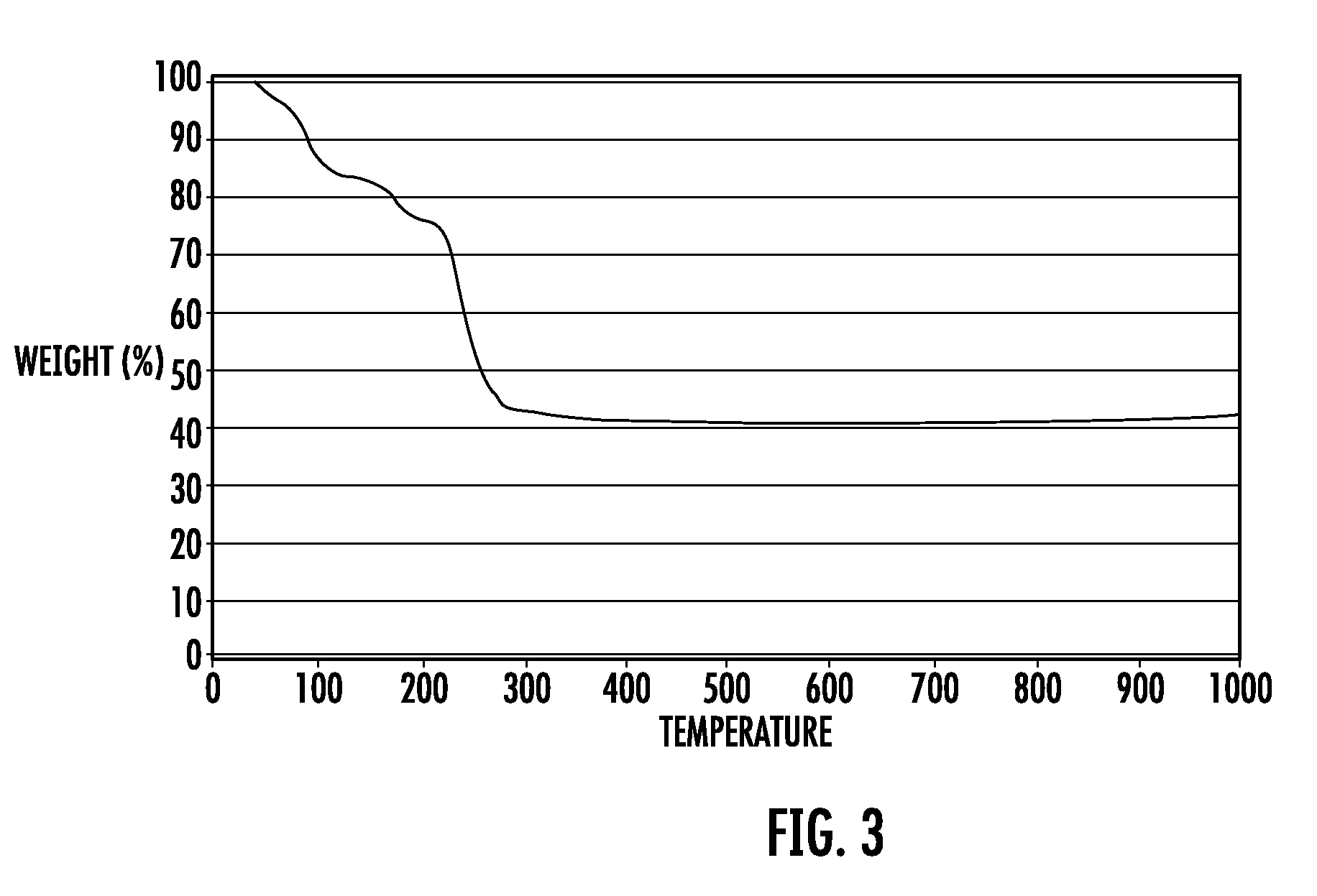

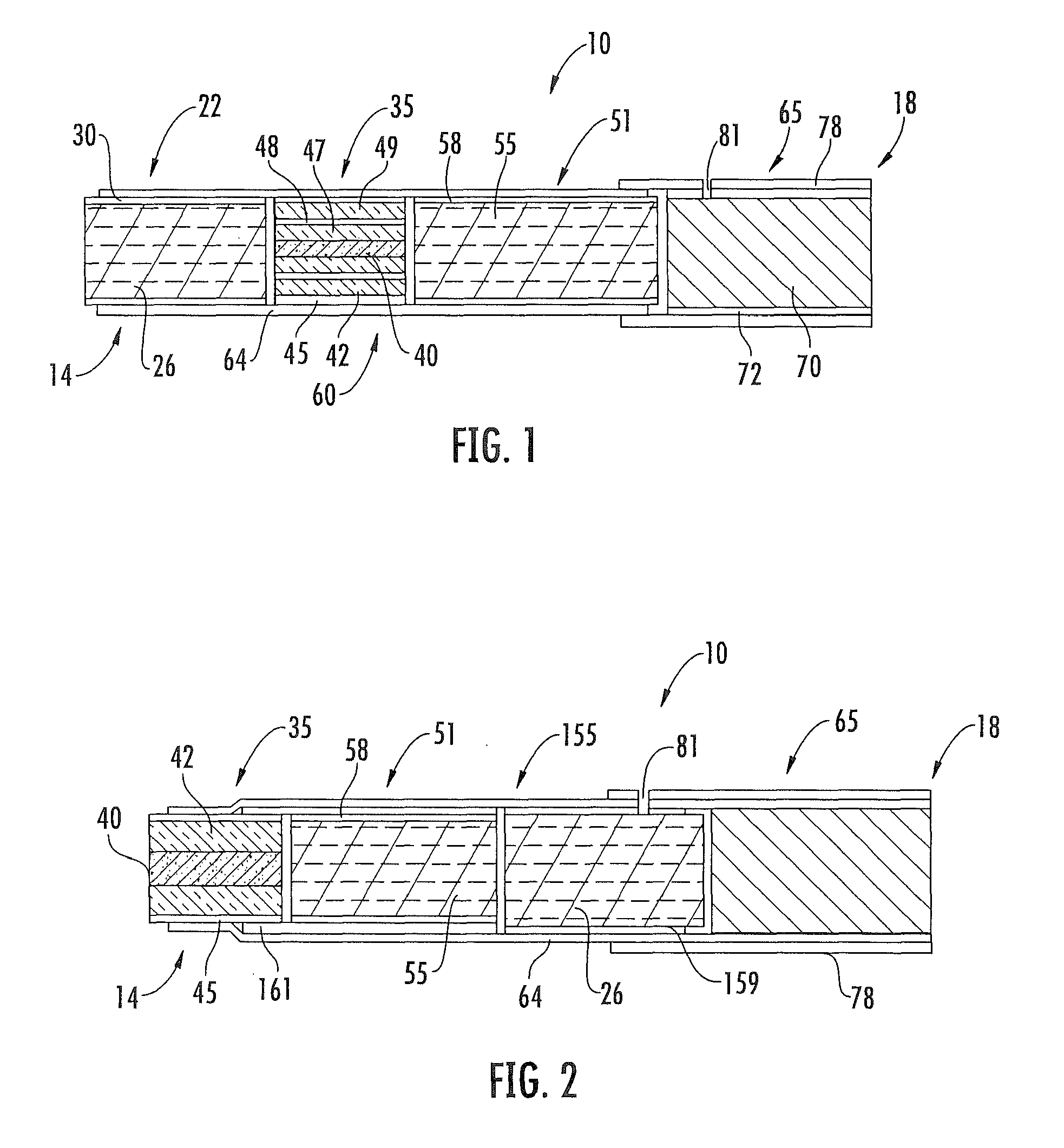

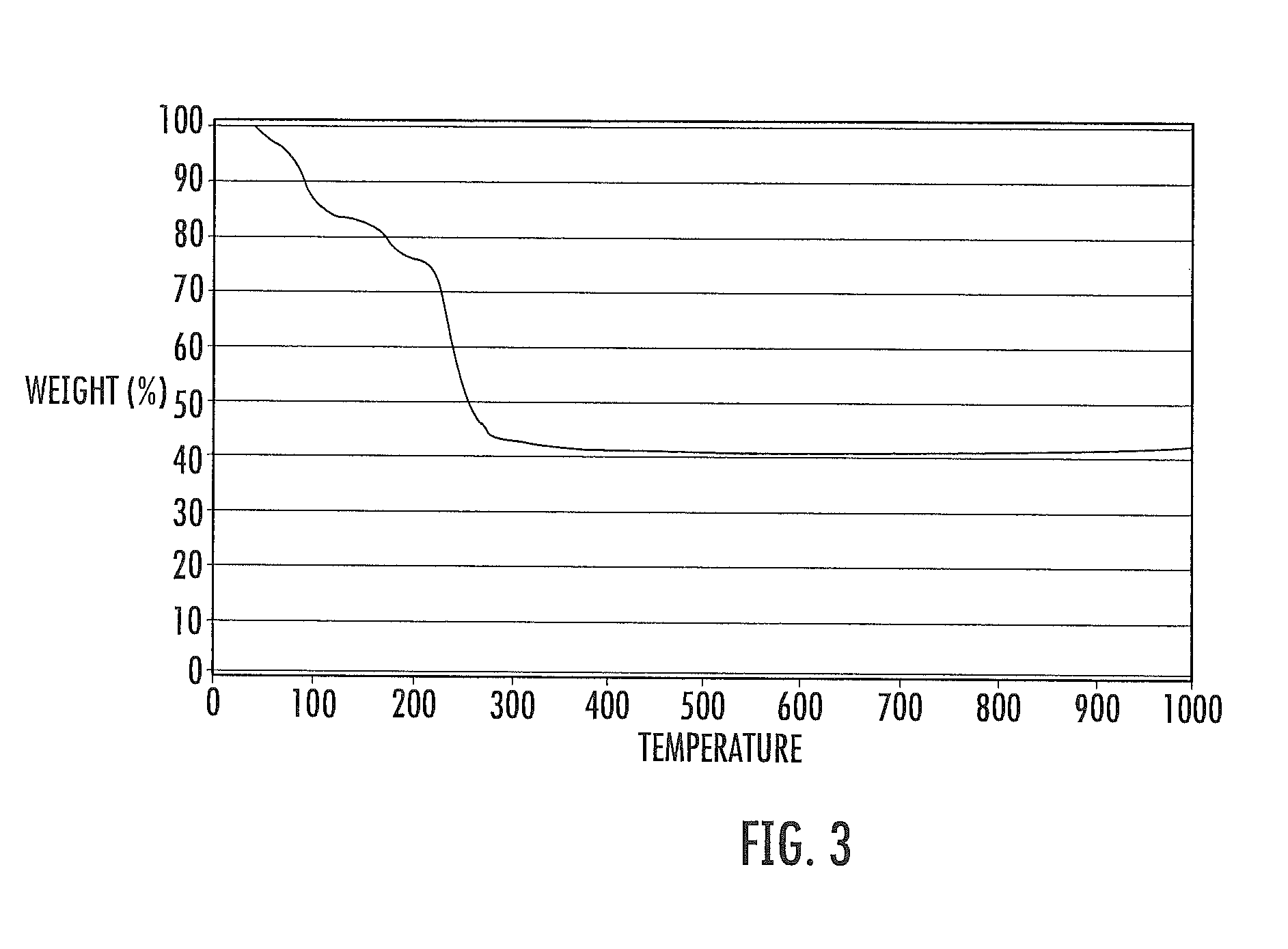

ActiveUS20100065075A1Good water solubilityTobacco treatmentTobacco smoke filtersCerium nitrateCopper nitrate

The invention provides a method for making a fuel element for a smoking article comprising forming a combustible carbonaceous material into a fuel element adapted for use in a smoking article; incorporating a metal-containing catalyst precursor into the fuel element or onto the surface thereof to form a treated fuel element, the incorporating step occurring before, during, or after said forming step; and optionally heating or irradiating the treated fuel element at a temperature and for a time sufficient to convert the catalyst precursor to a catalytic metal compound. Examples of metal-containing catalyst precursors include iron nitrate, copper nitrate, cerium nitrate, cerium ammonium nitrate, manganese nitrate, magnesium nitrate, and zinc nitrate. Fuel elements treated according to the invention, and smoking articles including such fuel elements, are also provided.

Owner:R J REYNOLDS TOBACCO COMPANY

Reclamation of a Titanosilicate, and Reconstitution of an Active Oxidation Catalyst

InactiveUS20080064591A1Acceptable product selectivityAcceptable selectivityMolecular sieve catalystsOther chemical processesCatalytic metalTitanium

A method of reclaiming a titanosilicate from a deactivated or spent oxidation catalyst containing a titanosilicate having deposited thereon one or more catalytic metals, such as gold, and optionally, one or more promoter metals, the method involving treating the deactivated catalyst with an oxidant; contacting the oxidant-treated catalyst with acid, preferably aqua regia; washing the titanosilicate to remove residual acid; and optionally drying and / or calcining. A method of reconstituting an active oxidation catalyst from a spent or deactivated oxidation catalyst, the method involving reclaiming the titanosilicate as noted above, and then depositing one or more catalytic metals and, optionally, one or more promoter metals onto the reclaimed titanosilicate.

Owner:DOW GLOBAL TECH LLC

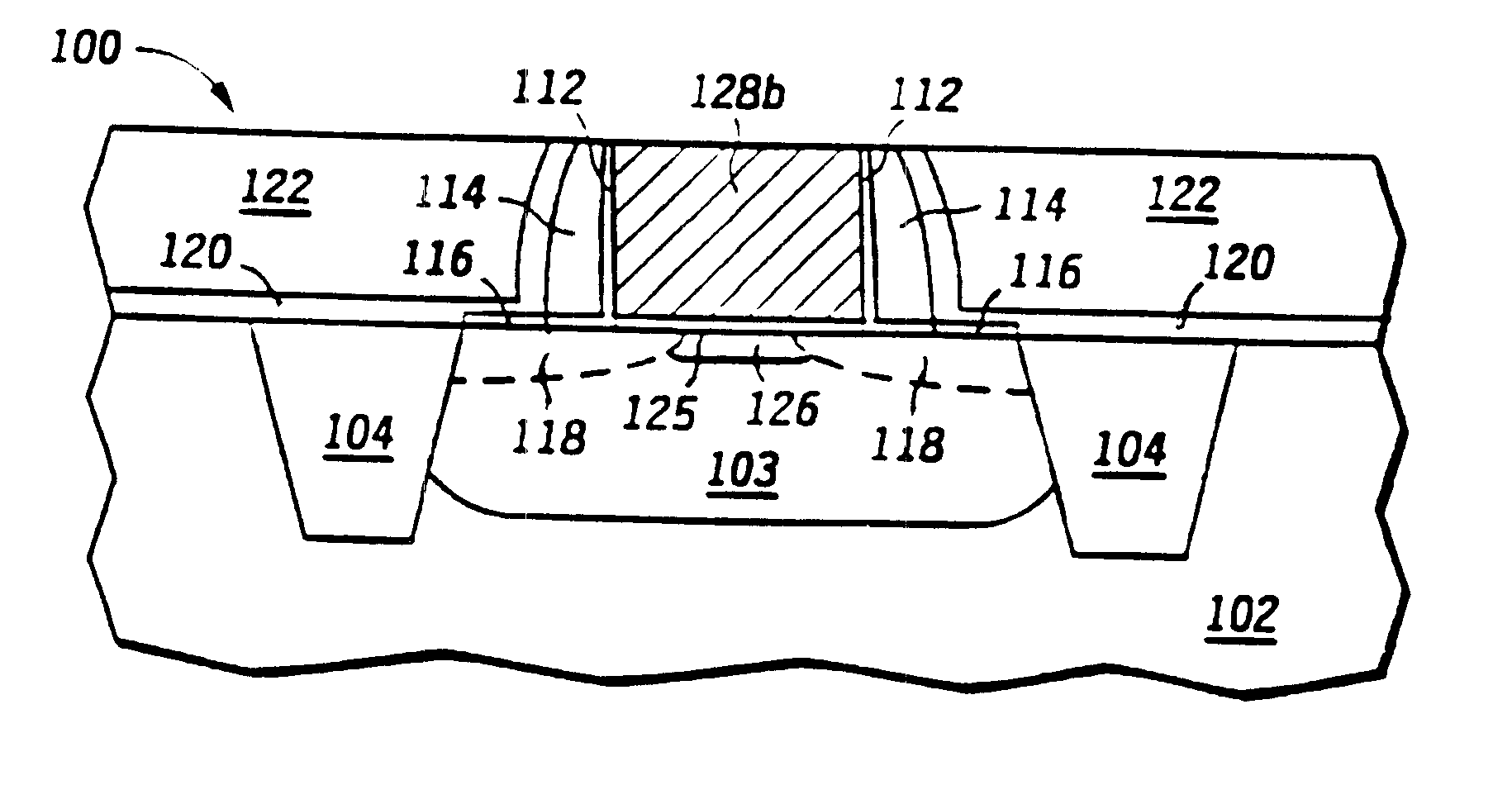

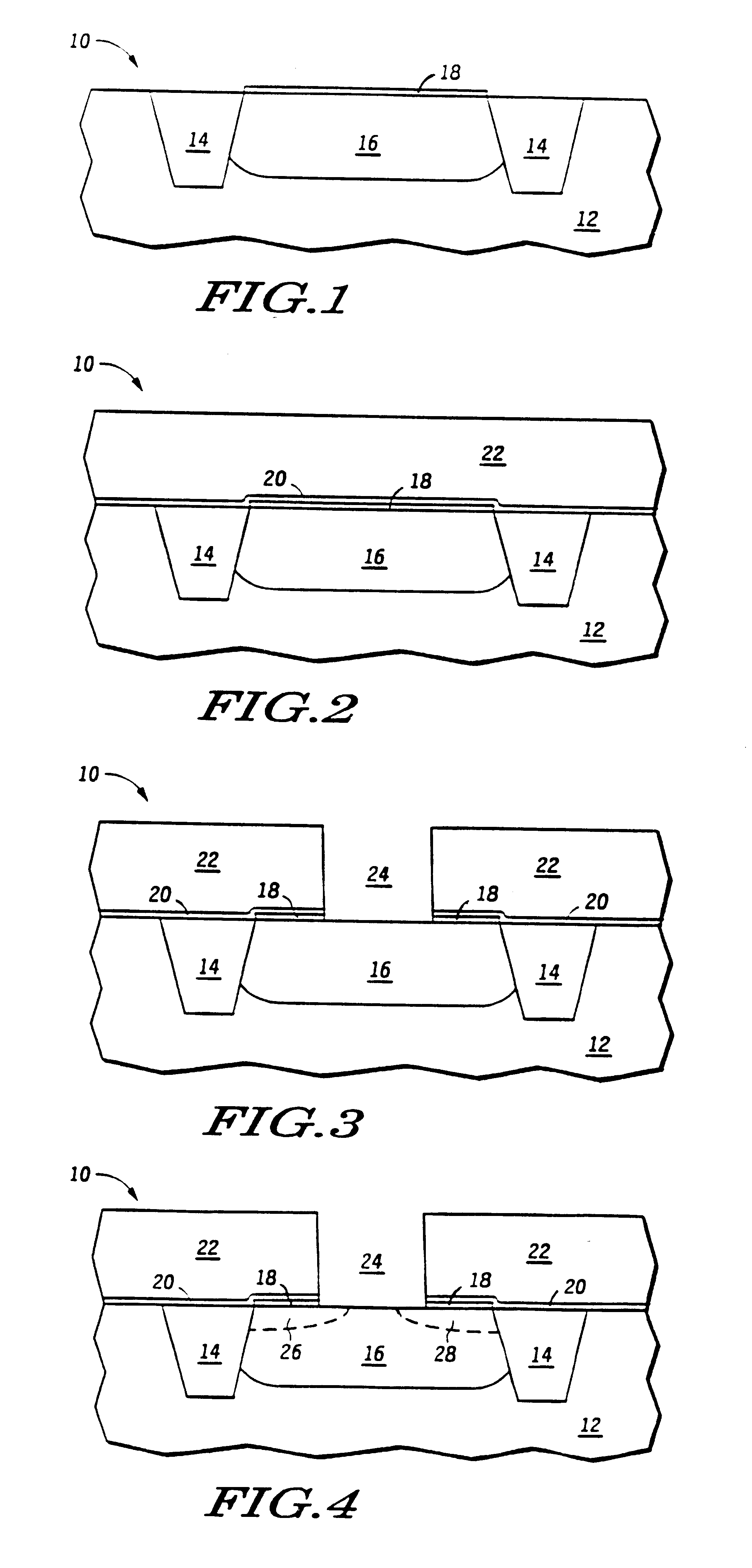

Enhanced electroless deposition of dielectric precursor materials for use in in-laid gate MOS transistors

InactiveUS6465334B1Semiconductor/solid-state device manufacturingSemiconductor devicesElectroless depositionOxygen

High quality dielectric layers, e.g., high-k dielectric layers comprised of at least one refractory or lanthanum series transition metal oxide or silicate, for use as gate insulator layers in in-laid metal gate MOS transistors and CMOS devices, are fabricated by forming an ultra-thin catalytic metal layer, e.g., a monolayer thick layer of Pd or Pd, on a Si-based semiconductor substrate, electrolessly plating on the catalytic layer comprising at least one refractory or lanthanum series transition metal or metal-based dielectric precursor layer, such as of Zr and / or Hf, and then reacting the precursor layer with oxygen or with oxygen and the semiconductor substrate to form the at least one high-k metal oxide or silicate. The inventive methodology prevents, or at least substantially reduces, oxygen access to the substrate surface during at least the initial stage(s) of formation of the gate insulator layer, thereby minimizing deleterious formation of oxygen-induced surface states at the semiconductor substrate / gate insulator interface.

Owner:GLOBALFOUNDRIES US INC

High surface area sol-gel route prepared hydrogenation catalysts

InactiveUS6686310B1Good dispersionImprove uniformityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsRheniumSilicon oxide

This invention concerns novel compositions, useful as hydrogenation catalyst, said compositions comprising metals and metal ions such as ruthenium (Ru) or palladium (Pd) dispersed in and distributed throughout a matrix comprising an inorganic or silicon oxide network. The catalyst may be prepared by the sol-gel method; a solution of at least one catalytic metal compound is added to a solution of at least one metal alkoxide selected from Al, Ti, Nb, Zr, Ta, Si and other inorganic alkoxides, and then gelling the mixture. Promotors such as rhenium (Re), molybdenum (Mo) and tin (Sn) may be added. The catalyst may be used in the reduction of metallic acid or gamma-butyrolactone to tetrahydrofuran (THF) and 1,4-butanediol (BDO).

Owner:EI DU PONT DE NEMOURS & CO

Doped spherically-shaped supported catalyst and process for hydrotreating and hydroconverting metal-containing oil fractions

ActiveUS20050211603A1Catalytic crackingCatalyst activation/preparationCatalytic metalSilicon dioxide

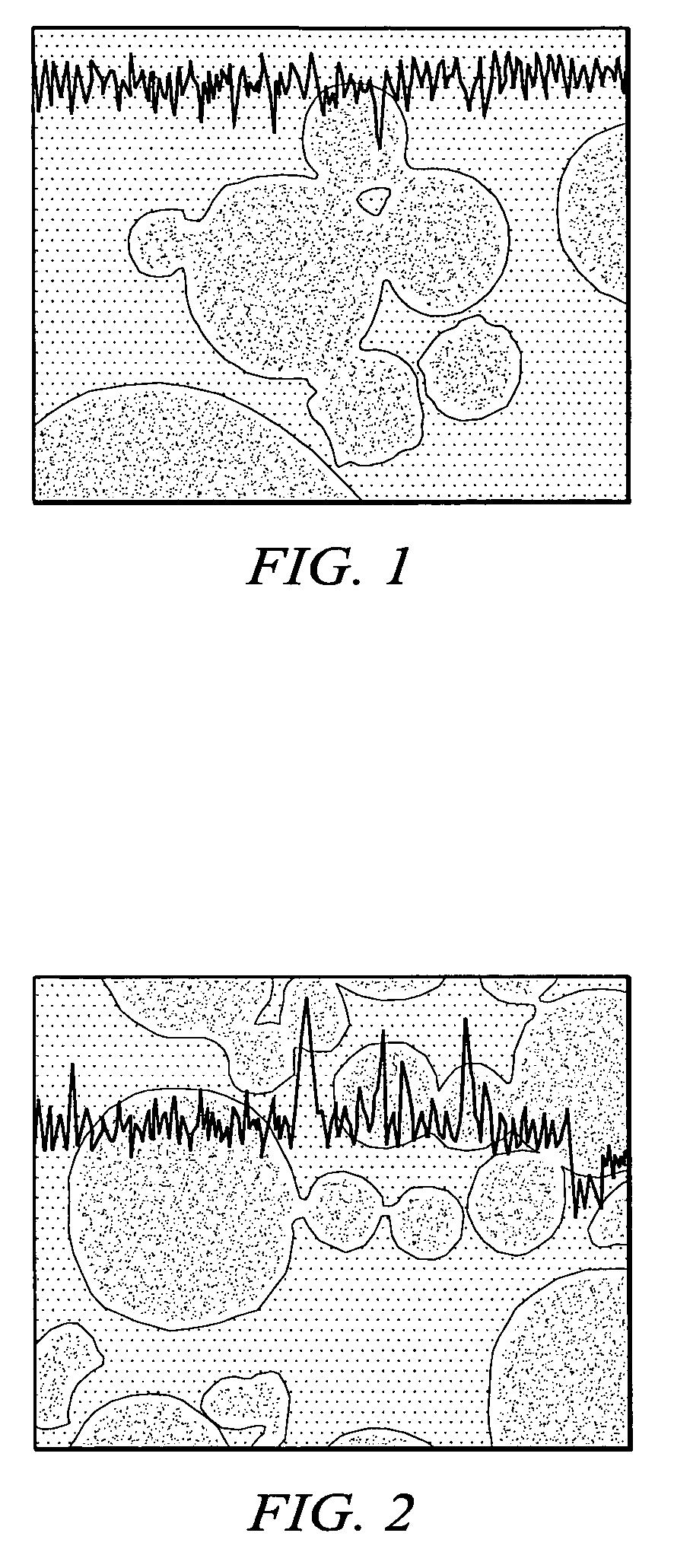

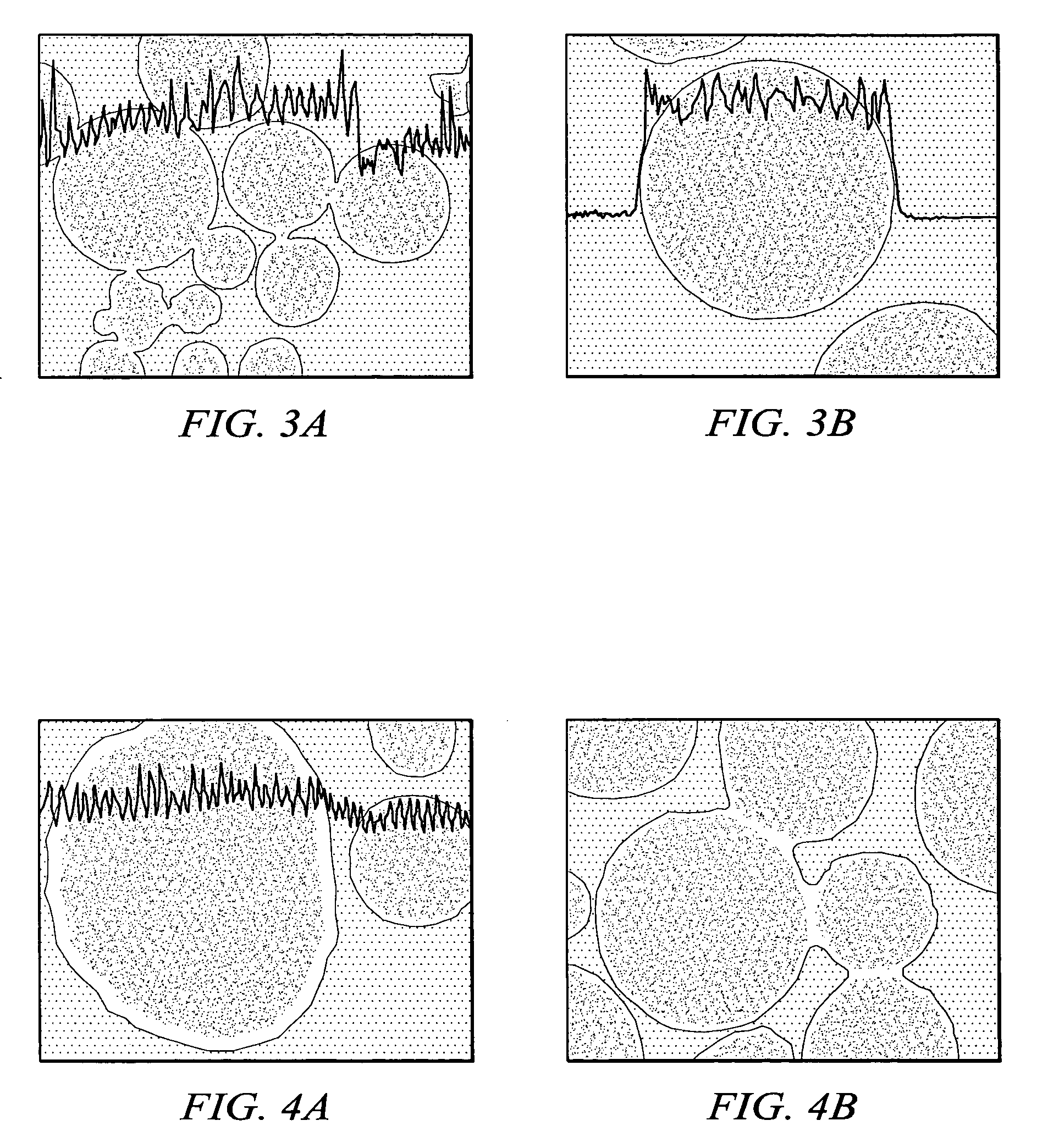

The present invention concerns a catalyst for hydrotreating and / or hydroconverting heavy metal-containing hydrocarbon feeds, said catalyst comprising a support in the form of beads based on alumina, at least one catalytic metal or a compound of a catalytic metal from group VIB (column 6 in the new periodic table notation), optionally at least one catalytic metal or compound of a catalytic metal from group VIII (columns 8, 9 and 10 of the new periodic table notation), with a pore structure composed of a plurality of juxtaposed agglomerates, each formed by a plurality of acicular platelets, the platelets of each agglomerate being generally radially orientated with respect to each other and with respect to the center of the agglomerate. The catalyst also comprises at least one doping element selected from the group constituted by phosphorus, boron, silicon (or silica which does not belong to that which could be contained in the selected support) and halogens. The invention also concerns the use of said catalyst in converting metal-containing feeds.

Owner:INST FR DU PETROLE

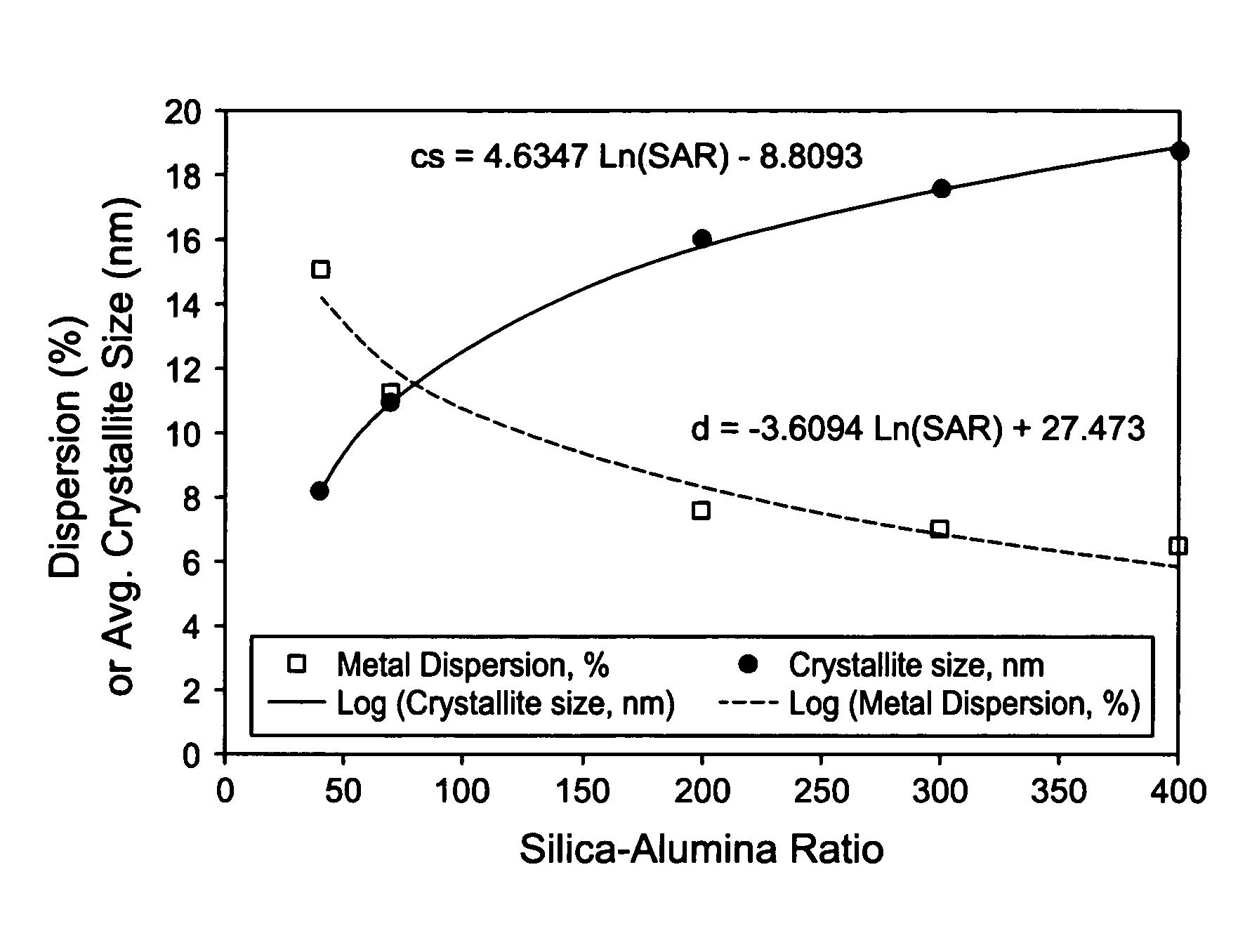

Silica-alumina catalyst support, catalysts made therefrom and methods of making and using same

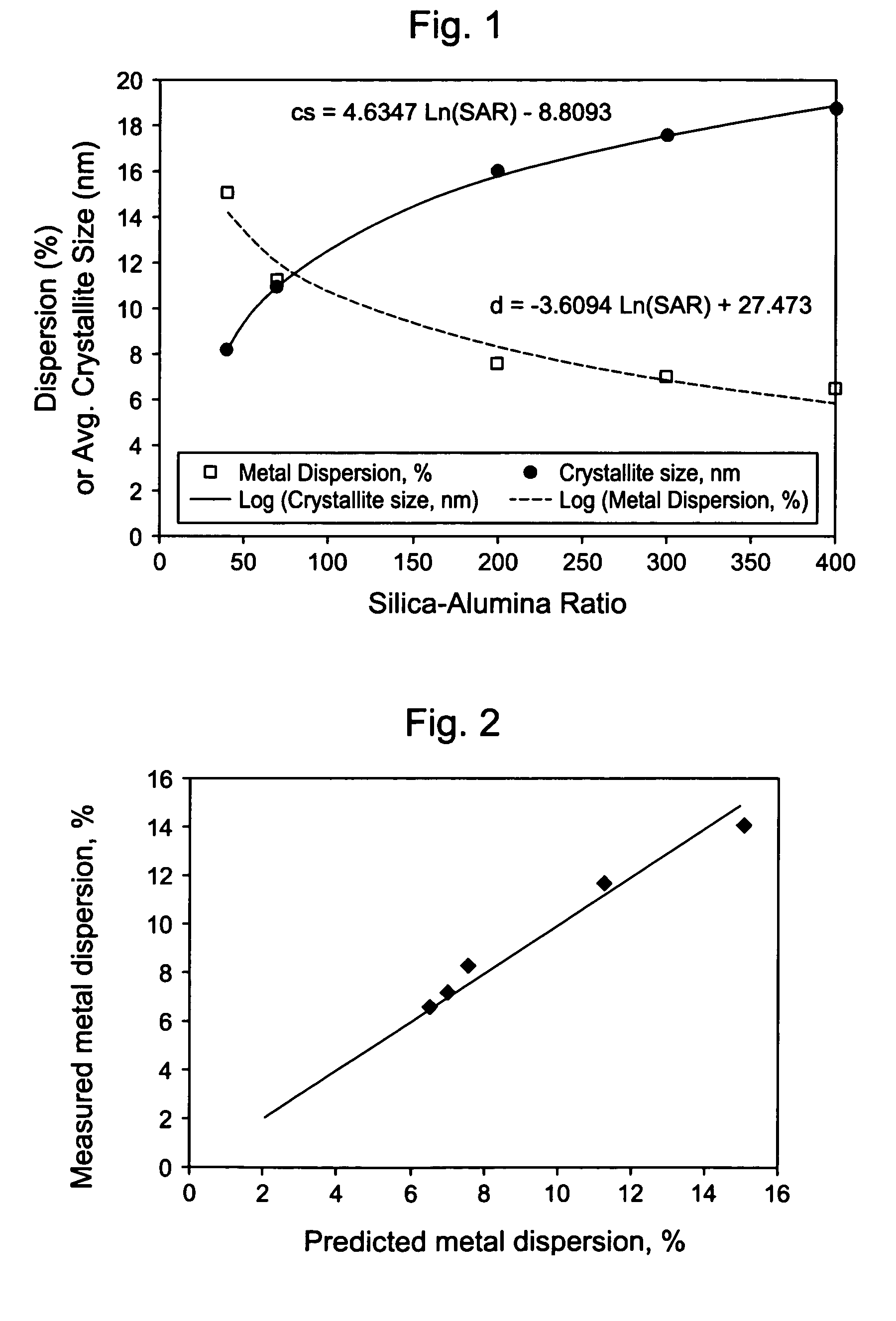

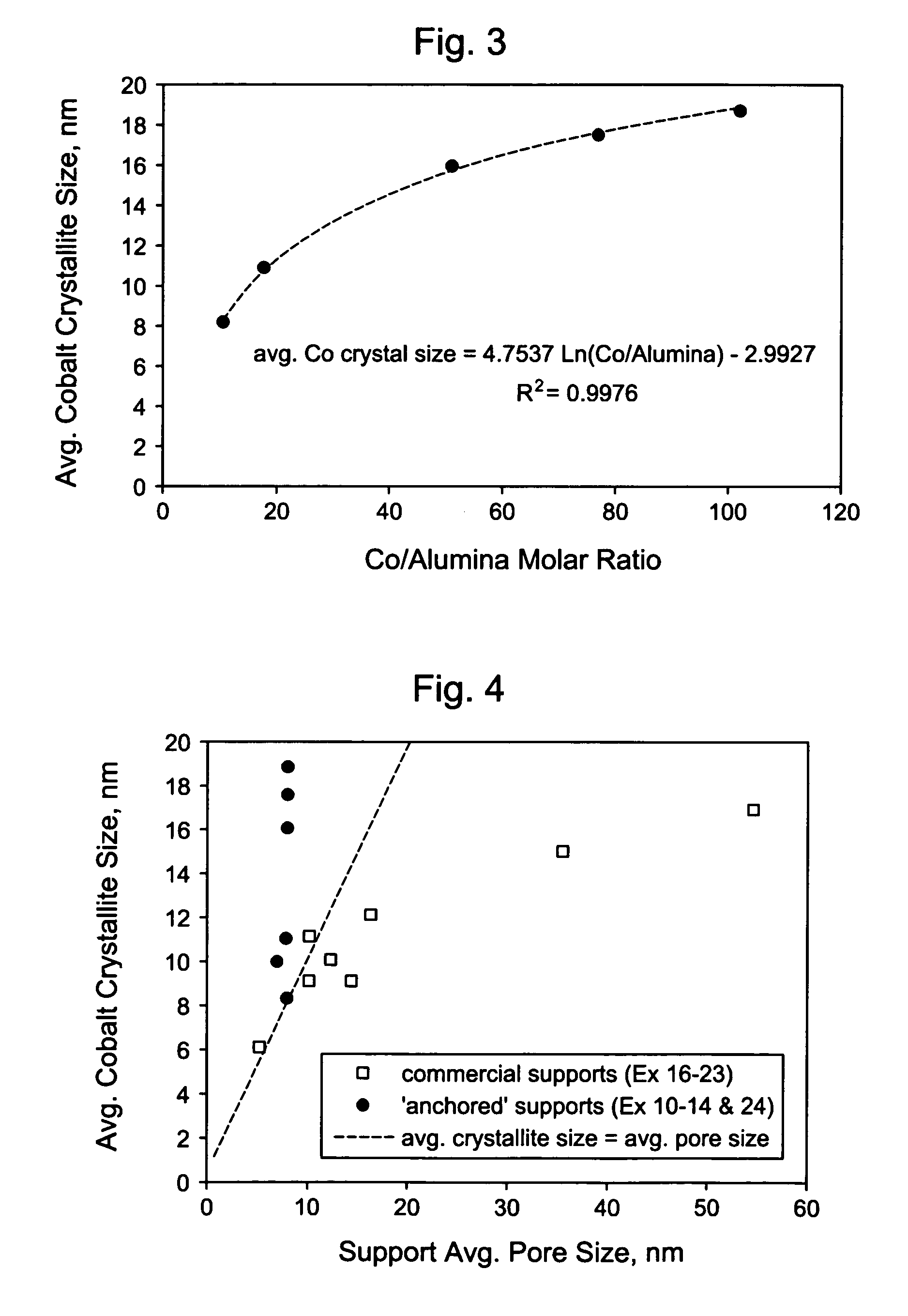

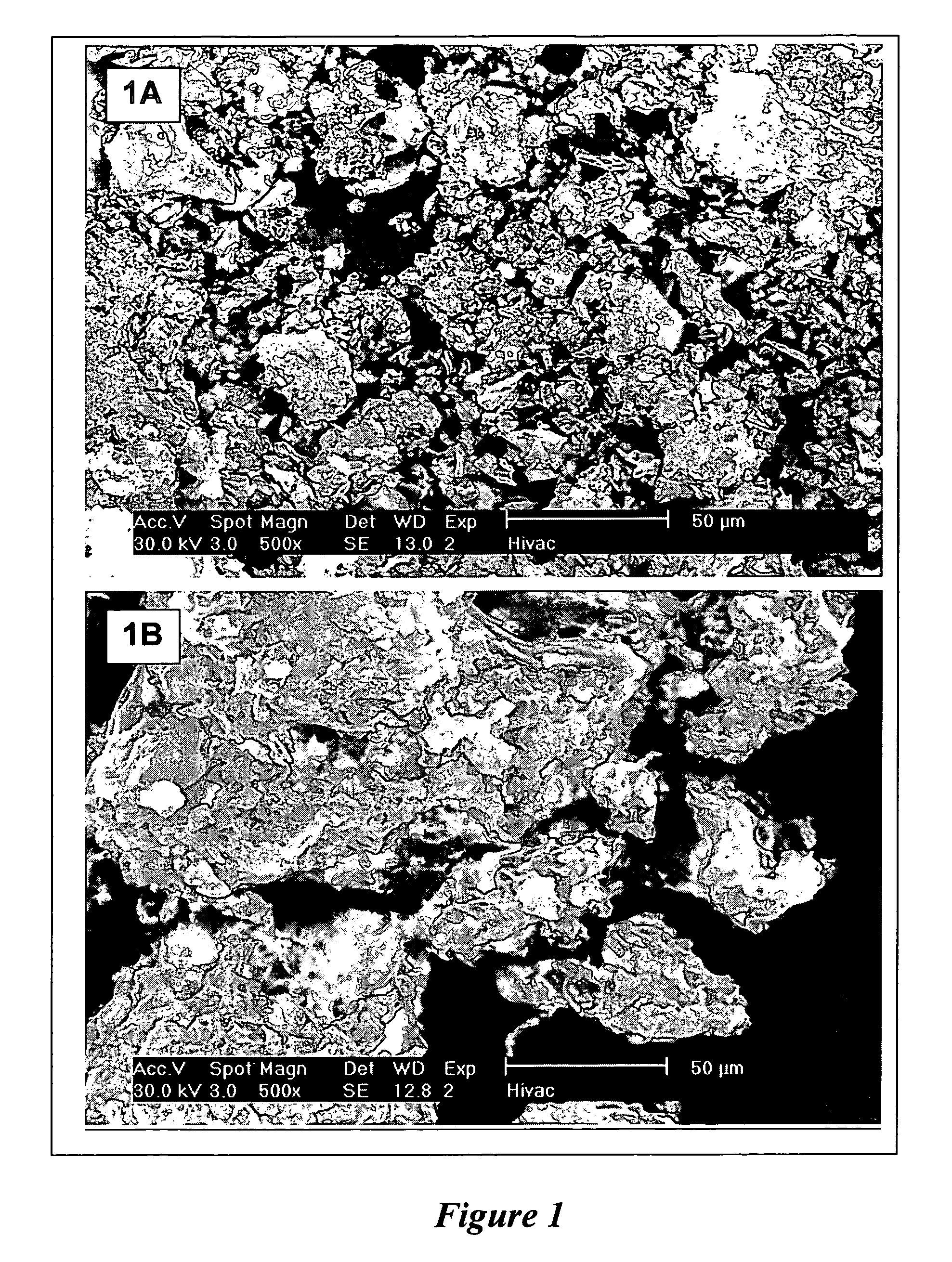

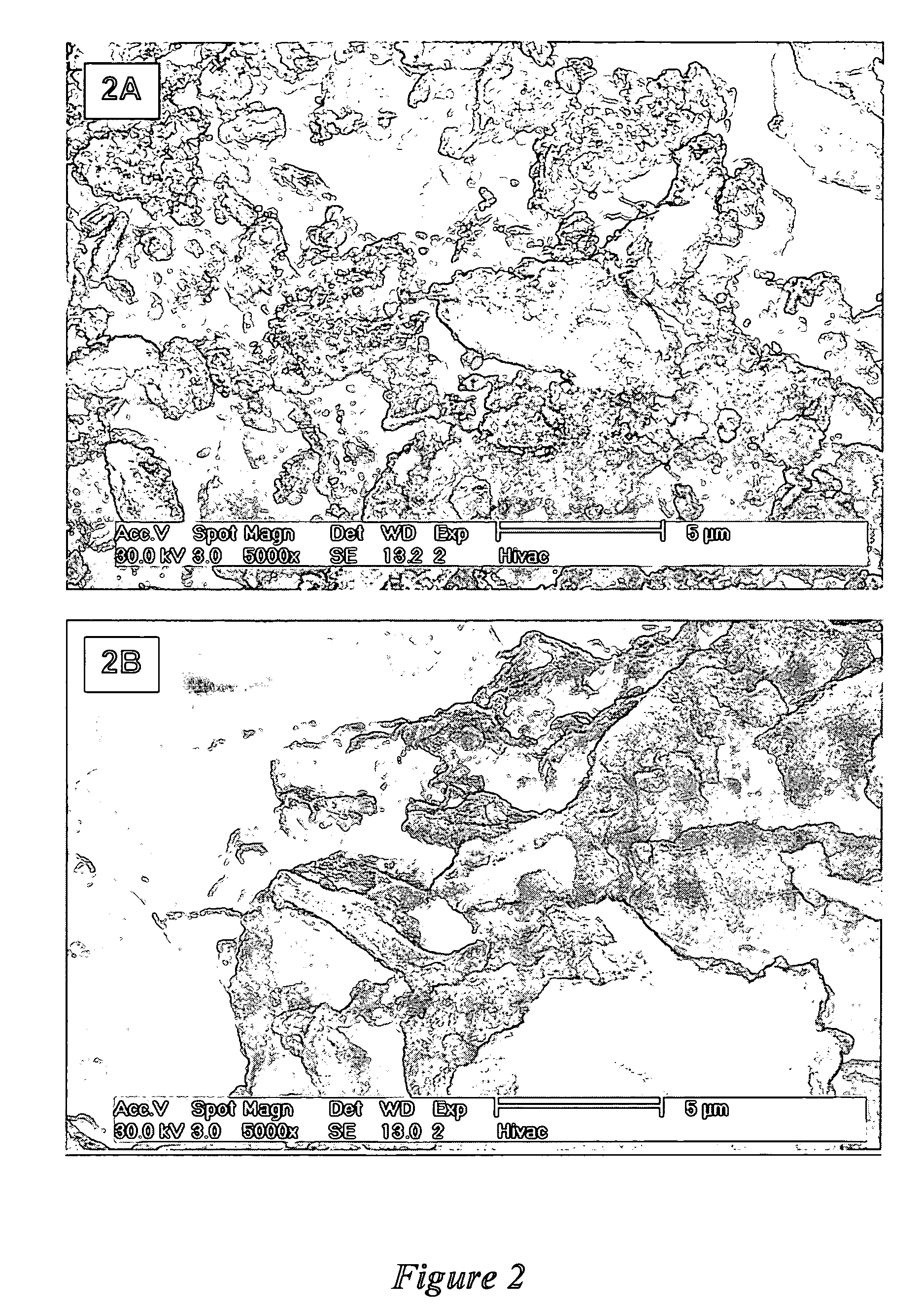

ActiveUS7541310B2High activityHydrocarbon from carbon oxidesMolecular sieve catalystsCompound (substance)Catalytic metal

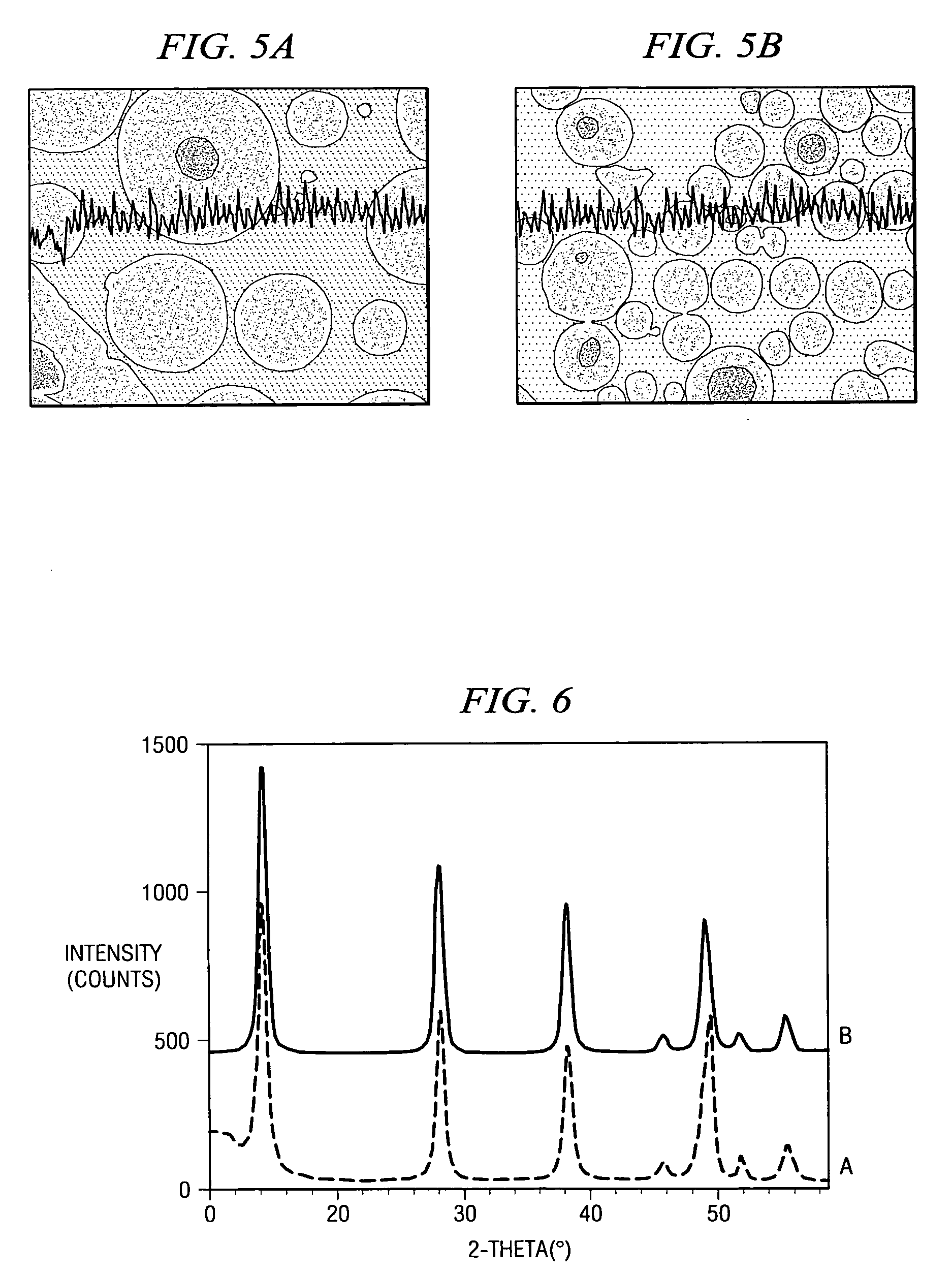

This invention relates to catalysts comprising a catalytic metal deposited on a composite support with well-dispersed chemical “anchor” species acting as nucleation centers for catalytic metal crystallites growth. The catalysts have the advantage that the average catalytic metal crystallite size can be controlled by the molar ratio of catalytic metal to chemical “anchor,” and is not limited by the porous structure of the support. A preferred embodiment comprises a cobalt-based catalyst on a silica-alumina support made by a co-gel method, wherein its average pore size can be controlled by the pH. The alumina species in the support most likely serve as chemical “anchors” to control the dispersion of cobalt species, such that the average cobalt crystallite size can be greater than the average pore size.

Owner:CLARIANT INT LTD

Carbon nanotube particulates, compositions and use thereof

InactiveUS20050002851A1Suitable for useMaterial nanotechnologyNanoinformaticsParticulatesContact time

A method for making carbon nanotube particulates involves providing a catalyst comprising catalytic metals, such as iron and molybdenum or metals from Group VIB or Group VIIIB elements, on a support material, such as magnesia, and contacting the catalyst with a gaseous carbon-containing feedstock, such as methane, at a sufficient temperature and for a sufficient contact time to make small-diameter carbon nanotubes having one or more walls and outer wall diameters of less than about 3 nm. Removal of the support material from the carbon nanotubes yields particulates of enmeshed carbon nanotubes that retain an approximate three-dimensional shape and size of the particulate support that was removed. The carbon nanotube particulates can comprise ropes of carbon nanotubes. The carbon nanotube particulates disperse well in polymers and show high conductivity in polymers at low loadings. As electrical emitters, the carbon nanotube particulates exhibit very low “turn on” emission field.

Owner:UNIDYM

Method for preparing fuel element for smoking article

The invention provides a method for making a fuel element for a smoking article including the steps of mixing a metal-containing catalyst precursor with a filler material or graphite or a combination thereof to form a pre-treated fuel element component; optionally calcining the pre-treated fuel element component in order to convert the catalyst precursor to a catalytic metal compound; after the optional calcining step, combining the pre-treated fuel element component with a carbonaceous material and a binder to produce a fuel element composition; and forming the fuel element composition into a fuel element adapted for use in a smoking article. Examples of metal-containing catalyst precursors include iron nitrate, copper nitrate, cerium nitrate, cerium ammonium nitrate, manganese nitrate, magnesium nitrate, and zinc nitrate. Fuel elements treated according to the invention, and smoking articles including such fuel elements, are also provided.

Owner:R J REYNOLDS TOBACCO COMPANY

Method for growing continuous fiber

This invention relates generally to a method for growing carbon fiber from single-wall carbon nanotube (SWNT) molecular arrays. In one embodiment, the present invention involves a macroscopic molecular array of at least about 106 tubular carbon molecules in generally parallel orientation and having substantially similar lengths in the range of from about 50 to about 500 nanometers. The hemispheric fullerene cap is removed from the upper ends of the tubular carbon molecules in the array. The upper ends of the tubular carbon molecules in the array are then contacted with a catalytic metal. A gaseous source of carbon is supplied to the end of the array while localized energy is applied to the end of the array in order to heat the end to a temperature in the range of about 500° C. to about 1300° C. The growing carbon fiber is continuously recovered.

Owner:RICE UNIV

Method for preparing fuel element for smoking article

The invention provides a method for making a fuel element for a smoking article comprising forming a combustible carbonaceous material into a fuel element adapted for use in a smoking article; incorporating a metal-containing catalyst precursor into the fuel element or onto the surface thereof to form a treated fuel element, the incorporating step occurring before, during, or after said forming step; and optionally heating or irradiating the treated fuel element at a temperature and for a time sufficient to convert the catalyst precursor to a catalytic metal compound. Examples of metal-containing catalyst precursors include iron nitrate, copper nitrate, cerium nitrate, cerium ammonium nitrate, manganese nitrate, magnesium nitrate, and zinc nitrate. Fuel elements treated according to the invention, and smoking articles including such fuel elements, are also provided.

Owner:R J REYNOLDS TOBACCO COMPANY

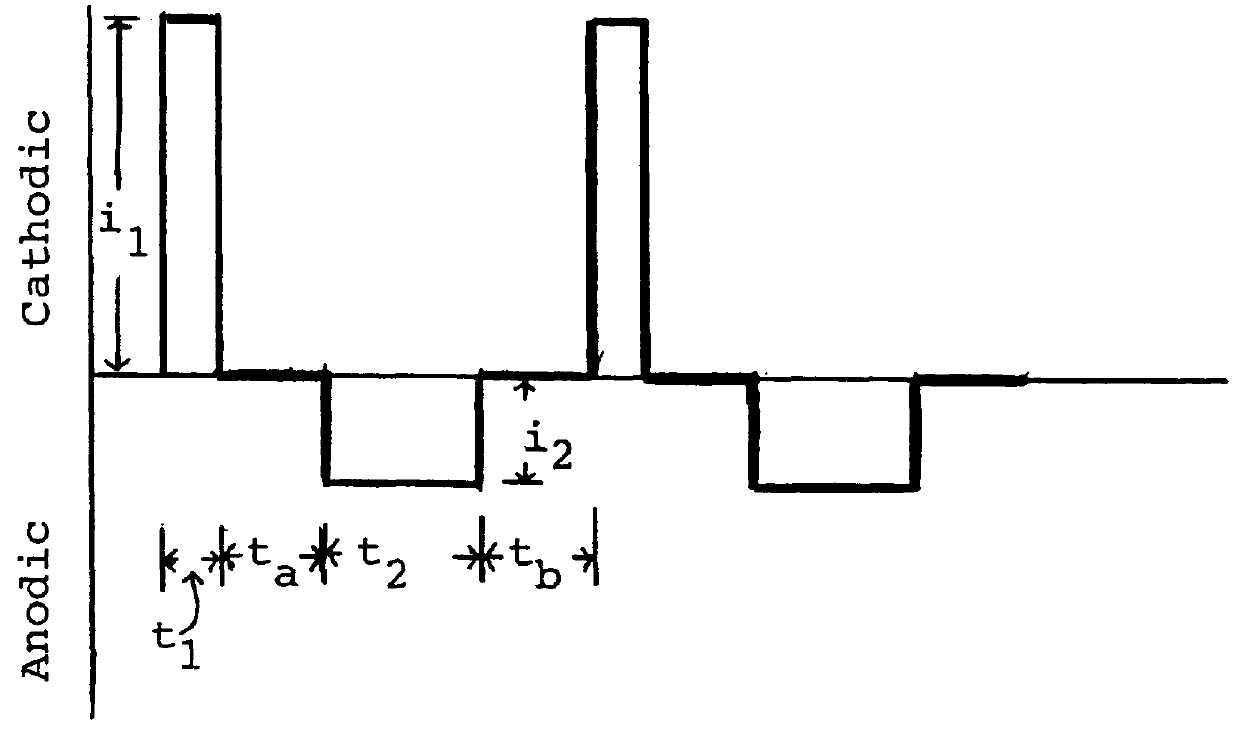

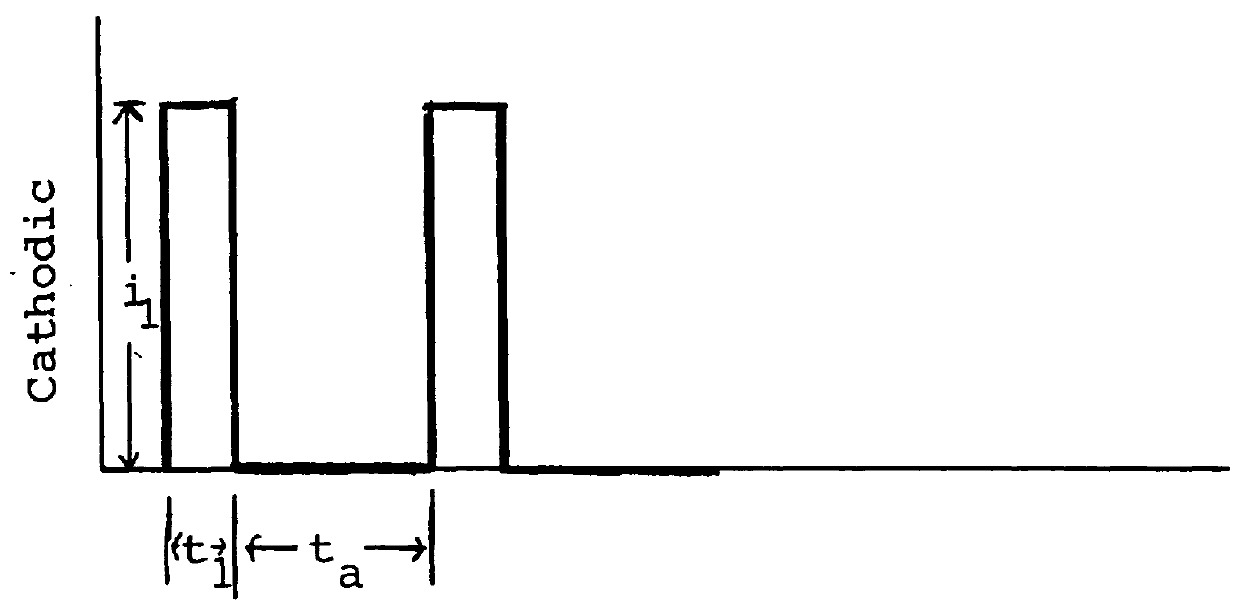

Electrodeposition of catalytic metals using pulsed electric fields

InactiveUS6080504AAdequate power densityEconomical catalyst loadingSolid electrolytesElectrolytic coatingsHertzPulse electric field

A gas diffusion electrode for a proton exchange membrane fuel cell is prepared by electrodeposition of a catalytic metal in nanocrystalline form on a substrate by contacting an electrically conductive substrate and a counterelectrode with a plating bath containing ions of a metal to be deposited on the substrate and passing a pulsed electric current between the substrate and counterelectrode having pulses that are cathodic with respect to the substrate and have a short on-time and / or a short duty cycle with a frequency from about 10 hertz to about 5000 hertz. In a preferred embodiment the electric current is a modulated reversing electric current having pulses that are cathodic with respect to the substrate and pulses that are anodic with respect to the substrate, the cathodic pulses having a short on-time and / or short duty cycle, the charge transfer ratio of the cathodic pulses to the anodic pulses being greater than one, and the frequency of the pulses ranging from about 10 hertz to about 5 kilohertz.

Owner:FARADAY TECH INC

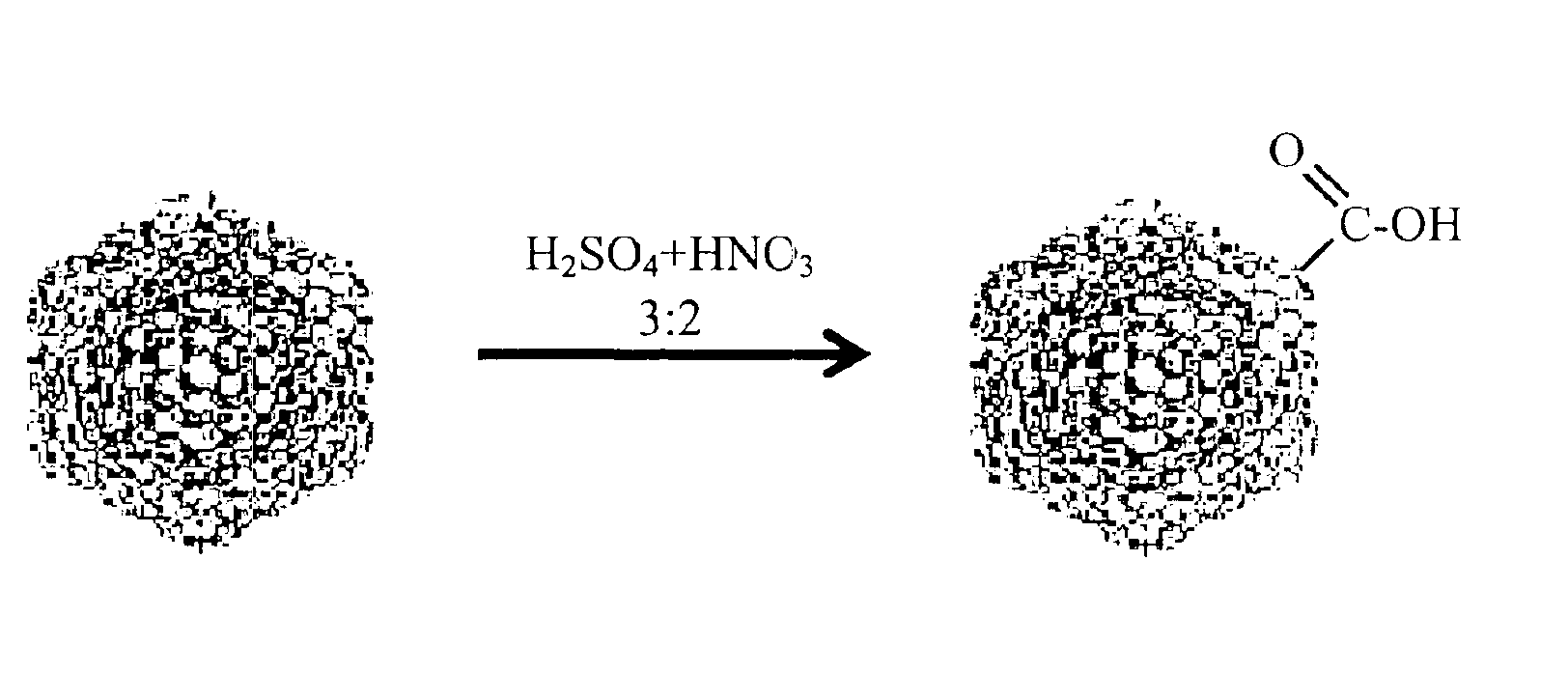

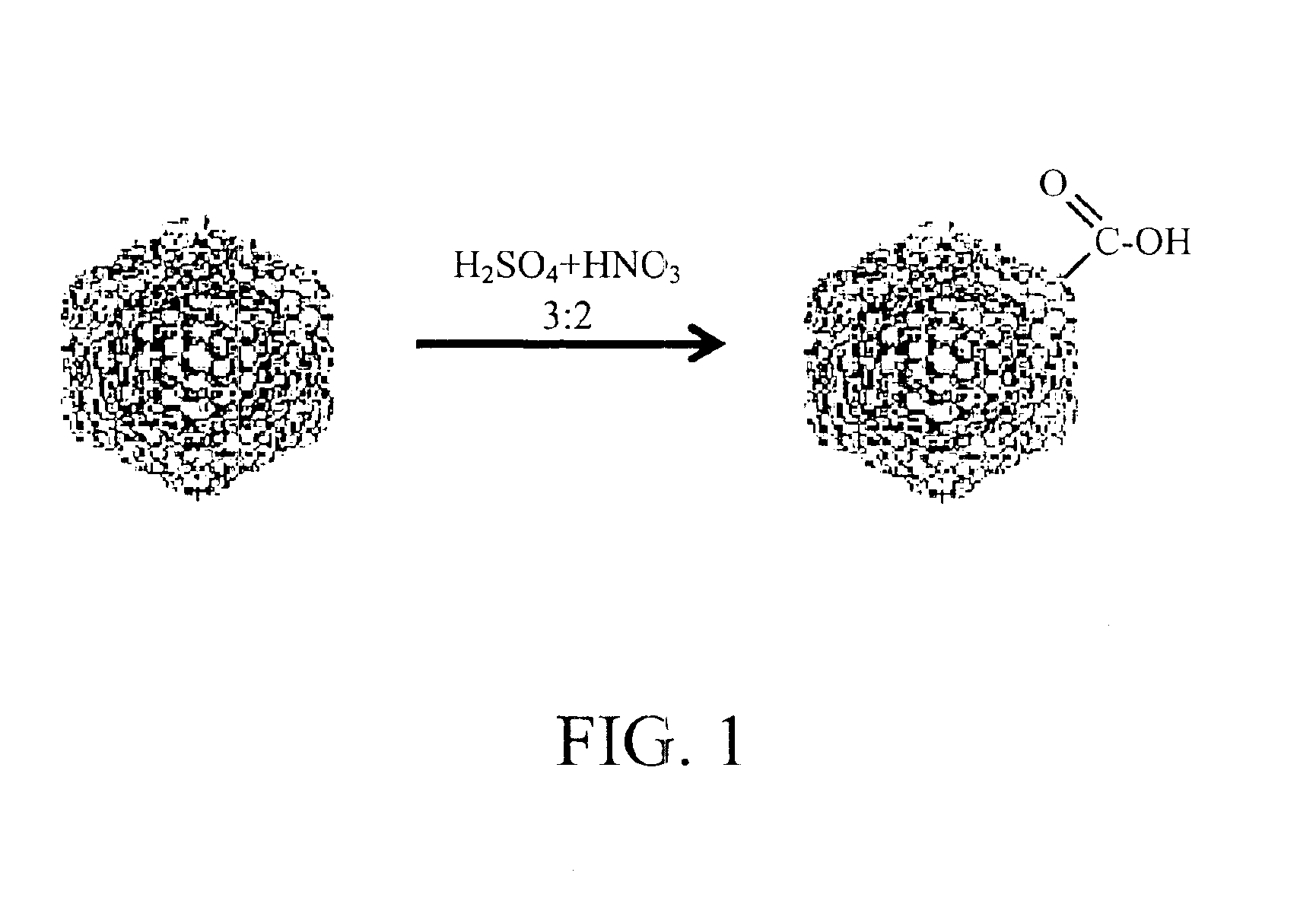

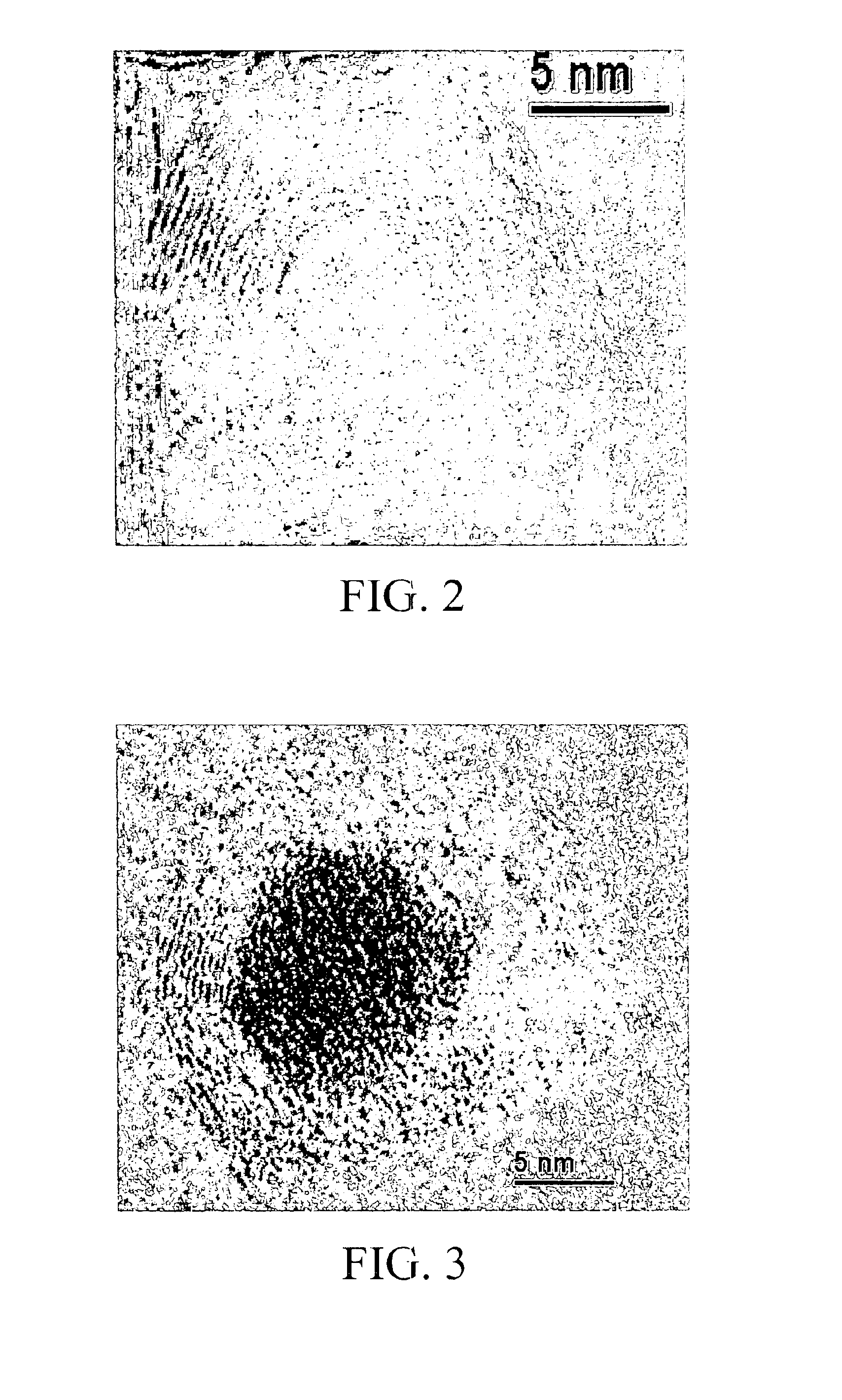

Carbon nanocapsule supported catalysts

ActiveUS6841509B1Improve developmentEasy to modifyNanotechSynthetic resin layered productsCatalytic metalCatalytic effect

A carbon nanocapsule supported catalysts. At least one kind of catalytic metal particle is deposited to a carbon nanocapsule, wherein the carbon nanocapsule has the following formula: F(−M)n, in which F is the carbon nanocapsule, M is the catalytic metal particle, and n is the number of the catalytic metal particle. By applying the carbon nanocapsule as a catalyst support, the catalytic behavior of the catalytic metal particle is specialized, the dispersion is improved, and the catalytic effect is enhanced.

Owner:IND TECH RES INST

Method for making single-wall carbon nanotubes using supported catalysts

InactiveUS7250148B2Suitable for growthAppropriate densityMaterial nanotechnologyFibre chemical featuresCarbon nanotubeMoving bed

A method for growing single-wall carbon nanotubes involves preparing a catalyst comprising catalytic metals, iron and molybdenum, and magnesium oxide support material and contacting the catalyst with a gaseous carbon-containing feedstock at a sufficient temperature and for a sufficient contact time to make single-wall carbon nanotubes. The weight ratio of iron and molybdenum can range from about 2 to 1 to about 10 to 1 and the metals loading up to about 10 wt % of the MgO. The catalyst can be sulfided. Methane is a suitable carbon-containing feedstock. The process can be conducted in batch, continuous or semi-continuous modes, in reactors, such as a transport reactor, fluidized bed reactor, moving bed reactors and combinations thereof. The process also includes making single-wall carbon nanotubes with catalysts comprising at least one Group VIB or Group VIIIB metal on supports such as magnesia, zirconia, silica, and alumina, where the catalyst is sulfided.

Owner:UNIDYM

Mercury-free catalyst with low bullion content for acetylene hydrochlorination and application thereof

InactiveCN101947465AThe content of precious metal elements is reducedLow content of precious metal elementsPhysical/chemical process catalystsPreparation by halogen halide additionPrecious metalNoble metal

The invention discloses a mercury-free catalyst with low bullion content for acetylene hydrochlorination and application thereof and belongs to the technical field of a catalyst for the acetylene hydrochlorination and a preparation technique and a reaction process thereof. The catalyst comprises a noble metal element which accounts for 0.05 to 0.5 weight percent of the total weight of the catalyst, a common metal element which accounts for 0.1 to 5 weight percent of the total weight of the catalyst, and a carrier, wherein the noble metal element and the noble metal element exist in the form of metallic compounds. The noble metal element content of the catalyst is reduced greatly, the loading amount of a cocatalyst metallic element is also low, and the cost of the catalyst is reduced greatly; and the catalyst can replace the highly toxic mercury catalyst and is applied to the industrial production of the acetylene hydrochlorination.

Owner:TSINGHUA UNIV

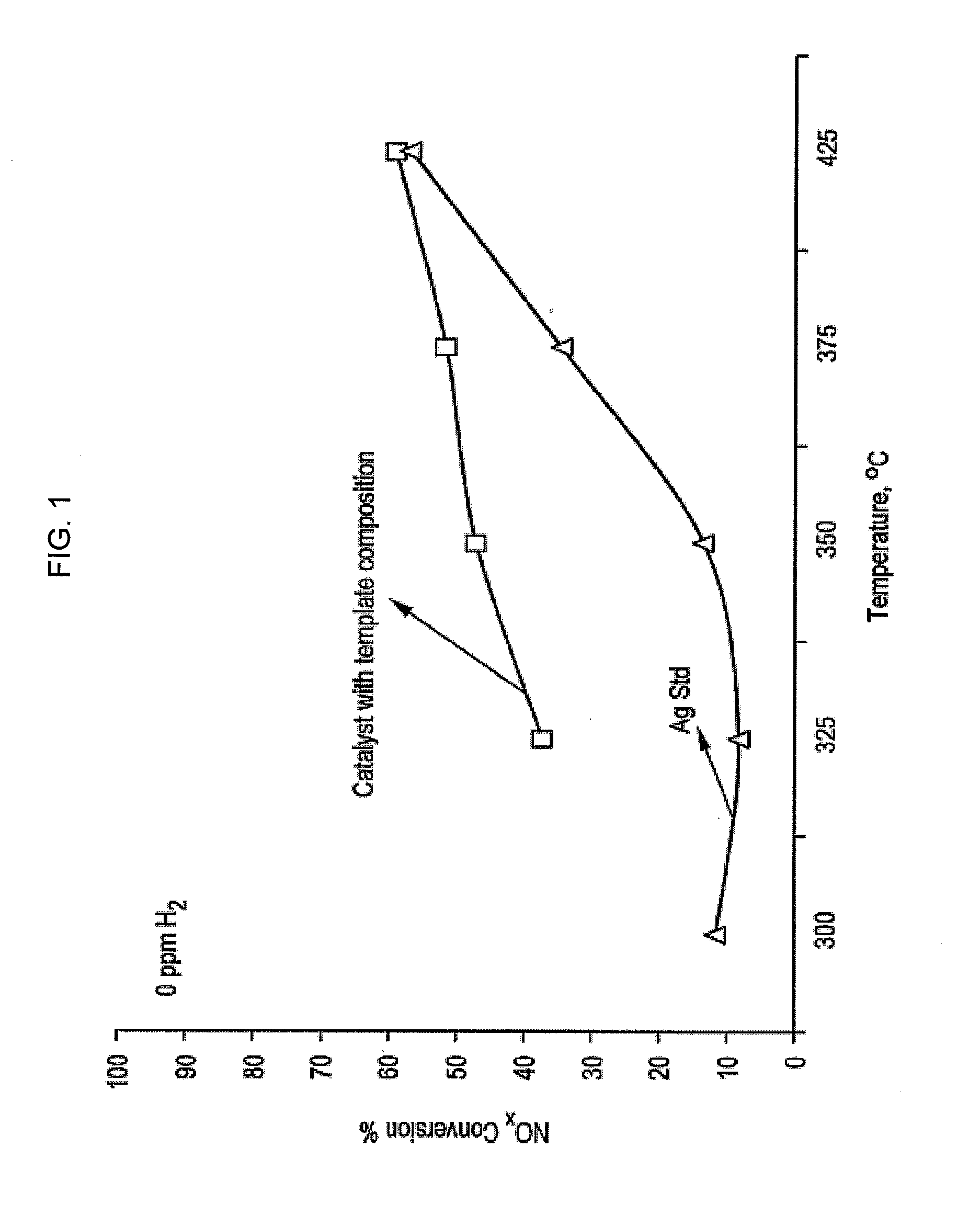

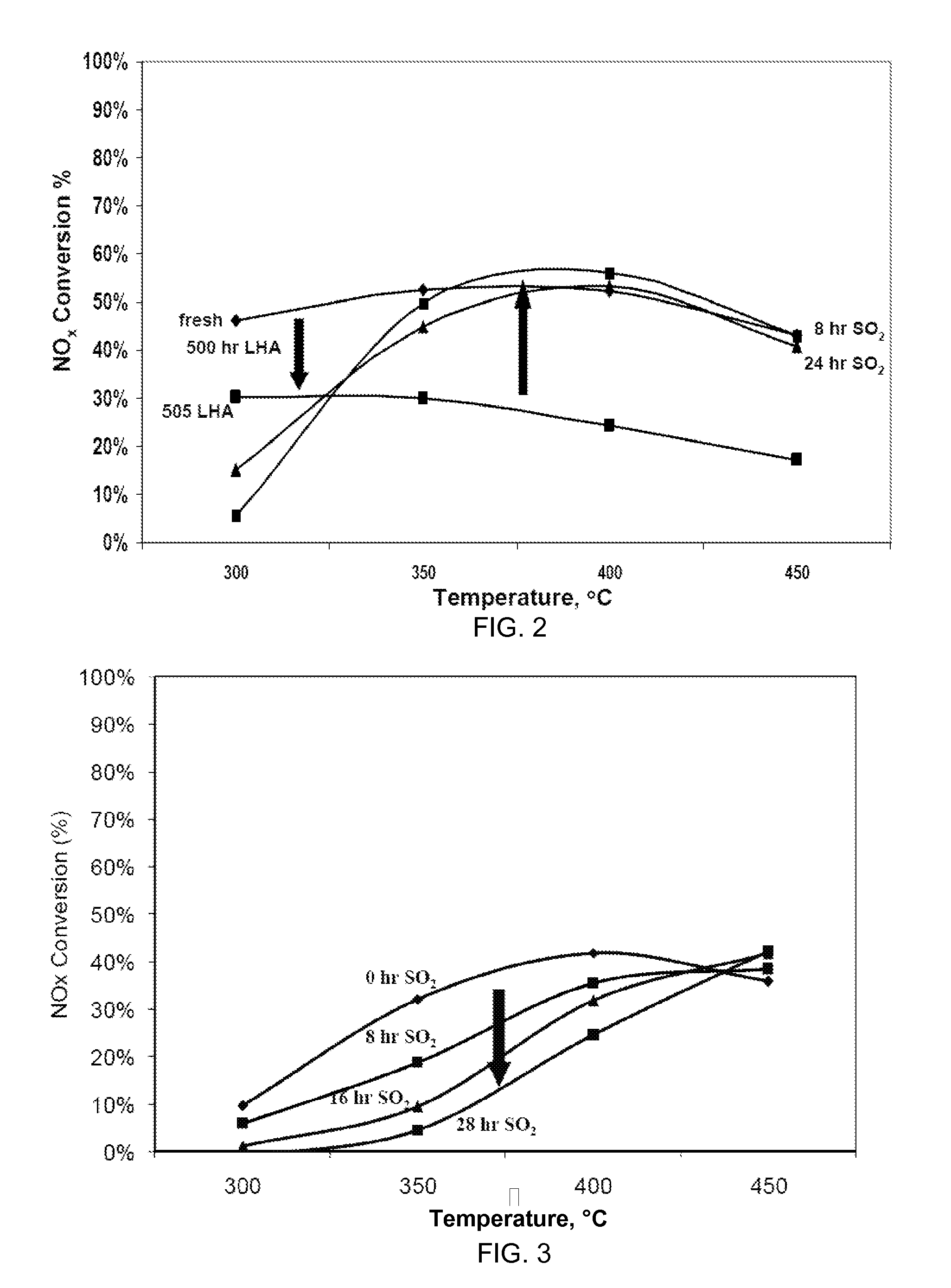

Catalyst and method of manufacture

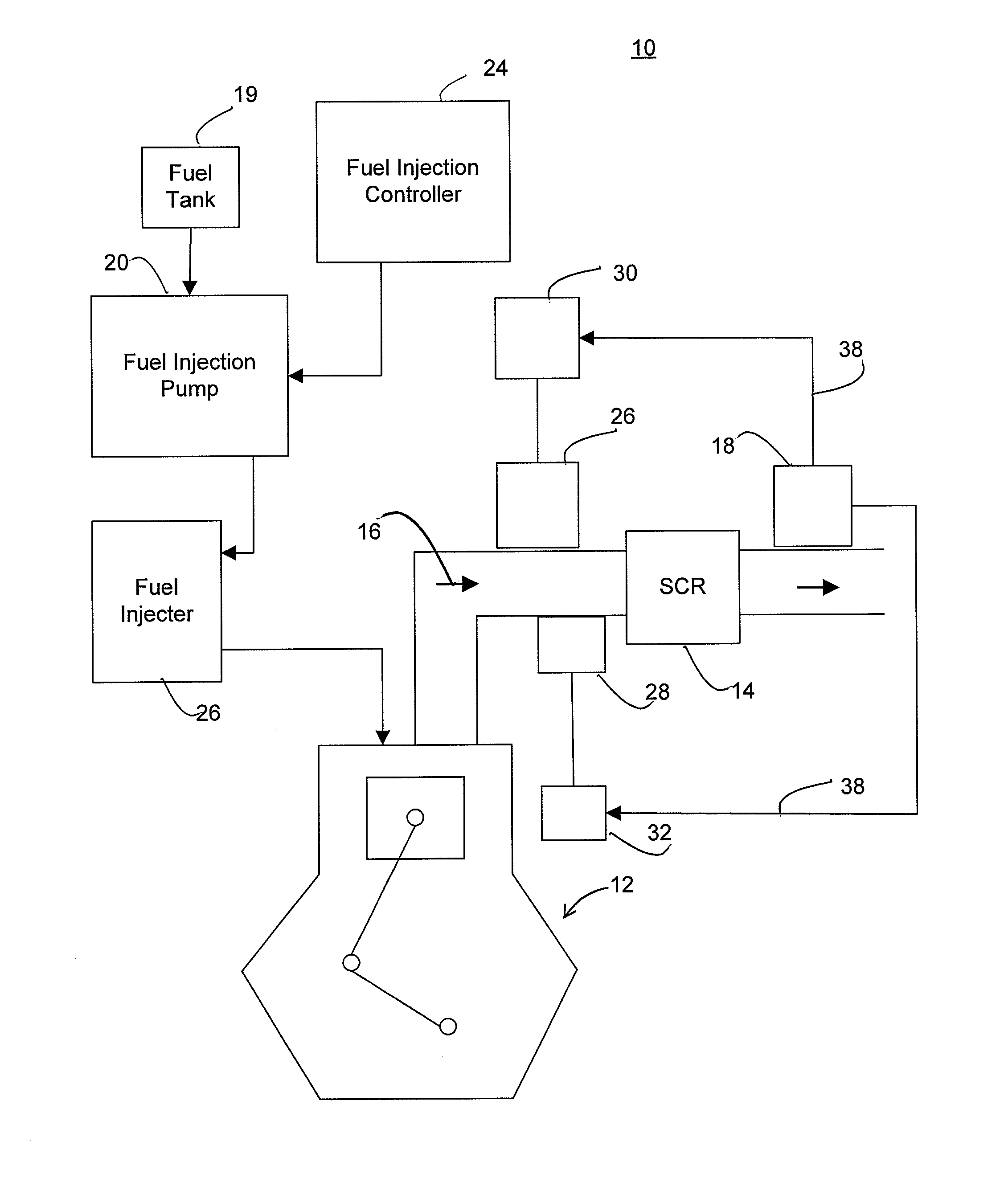

A catalyst composition is provided that includes a catalytic metal secured to a substrate, and the substrate is mesoporous and has pores that are templated. A catalyst composition includes a catalytic metal secured to a mesoporous substrate. The mesoporous substrate is a reaction product of a reactive solution, a solvent, a modifier, and a templating agent. A method includes reacting a reactive solution and a templating agent to form a gel; and calcining the gel to form a substrate having a mesoporous template that is capable to support a catalyst composition.

Owner:GENERAL ELECTRIC CO

High temperature naphtha desulfurization using a low metal and partially deactivated catalyst

InactiveUS6231754B1Catalyst regeneration/reactivationMetal/metal-oxides/metal-hydroxide catalystsNaphthaThiol

A high temperature naphtha desulfurization process with reduced olefin saturation employs a partially spent and low metals content hydrodesulfurization catalyst having from 2-40% the activity of a new catalyst. The catalytic metals preferably include Co and Mo in an atomic ratio of from 0.1 to 1. The catalyst is preferably at least partially regenerable, has less than 500 wppm of a total of one or more of nickel, iron and vanadium and preferably has no more than 12 wt. % catalytic metal calculated as the oxide. This permits selective deep desulfurization, with reduced olefin saturation, low product mercaptan levels and little or need for downstream mercaptan removal.

Owner:EXXON RES & ENG CO

Process for cognate nucleotide detection in a nucleic acid sequencing workflow

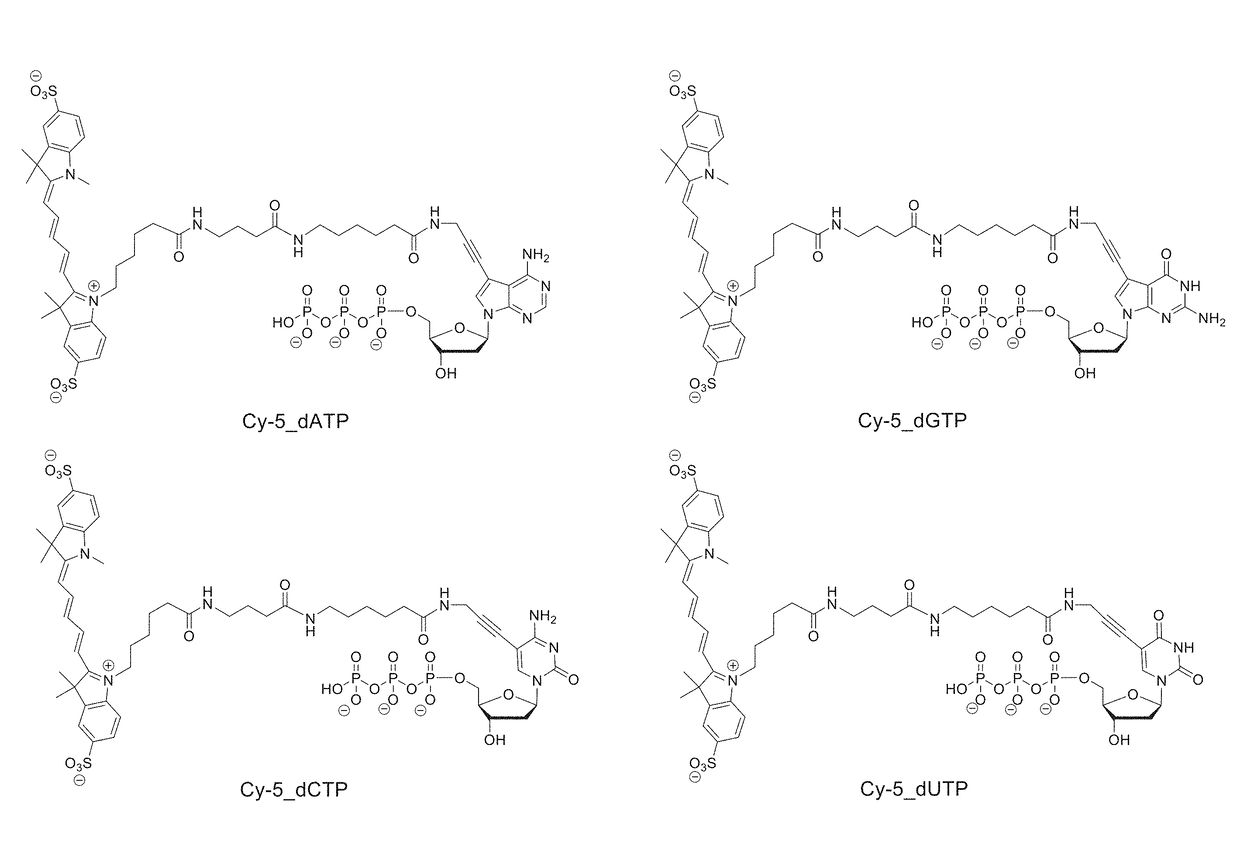

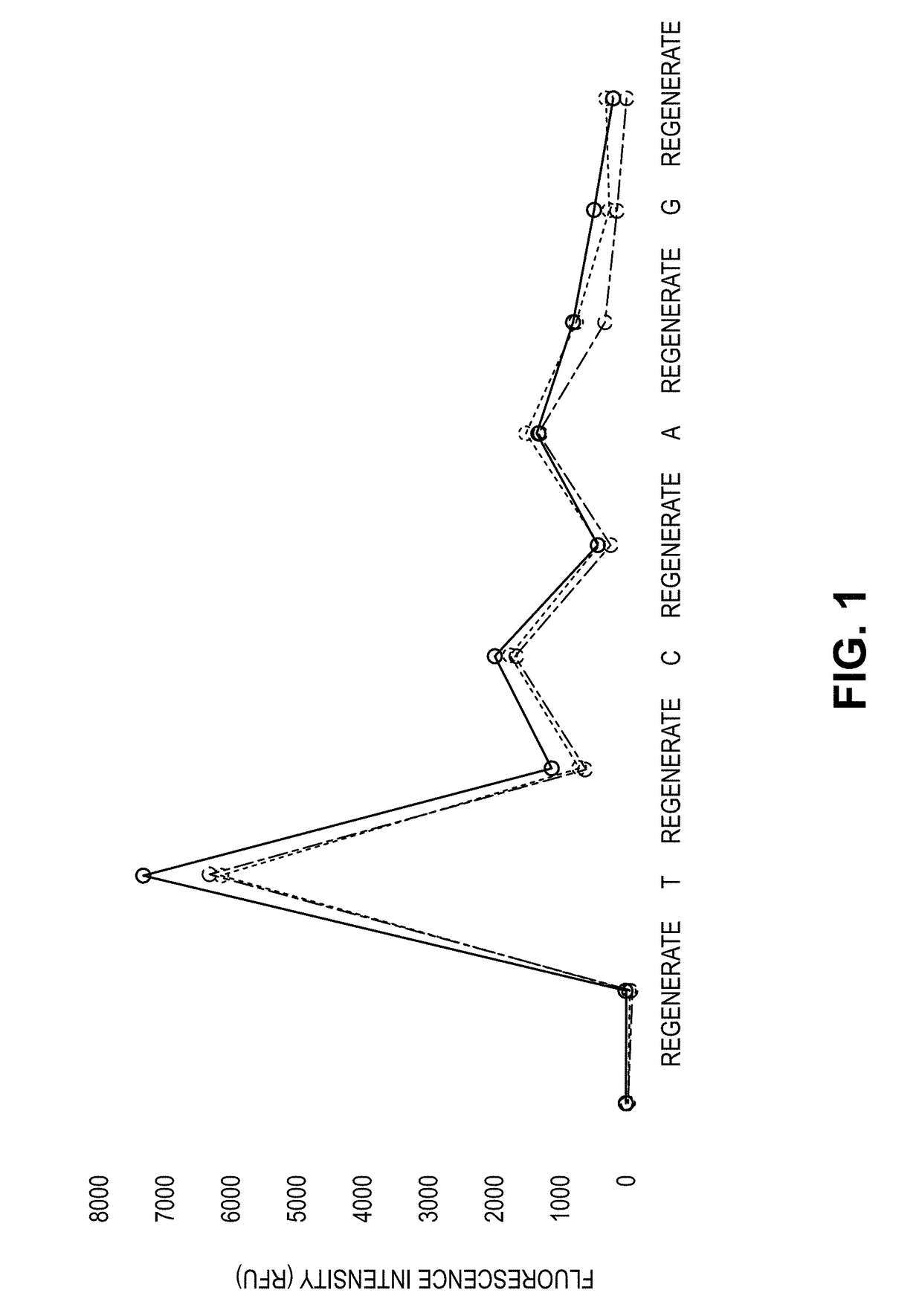

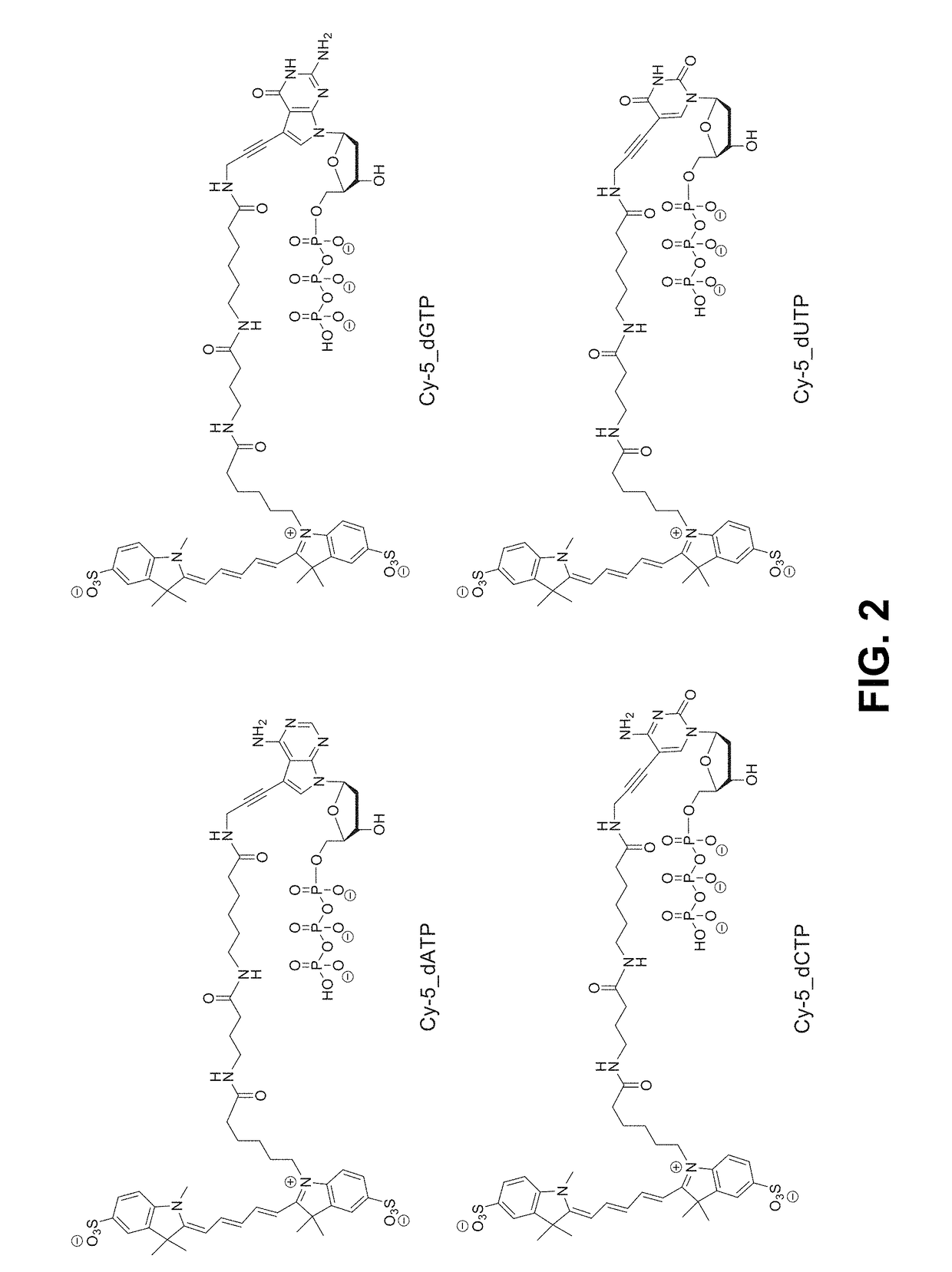

Method and composition for identifying cognate nucleotides in a Sequencing By Binding™ procedure, wherein one or more labeled nucleotides are detected in ternary complexes but never incorporated. Labeled nucleotides can be incorporable nucleotides that contact preformed blocked primed template nucleic acids. Alternatively, labeled nucleotides are labeled non-incorporable nucleotides. Labeled nucleotides, including labeled non-incorporable nucleotides, can be detected in ternary complexes in the same reaction mixture that incorporates a reversible terminator nucleotide to create a blocked primed template nucleic acid. Detection of ternary complexes can take place in the presence of a catalytic metal ion.

Owner:PACIFIC BIOSCIENCES

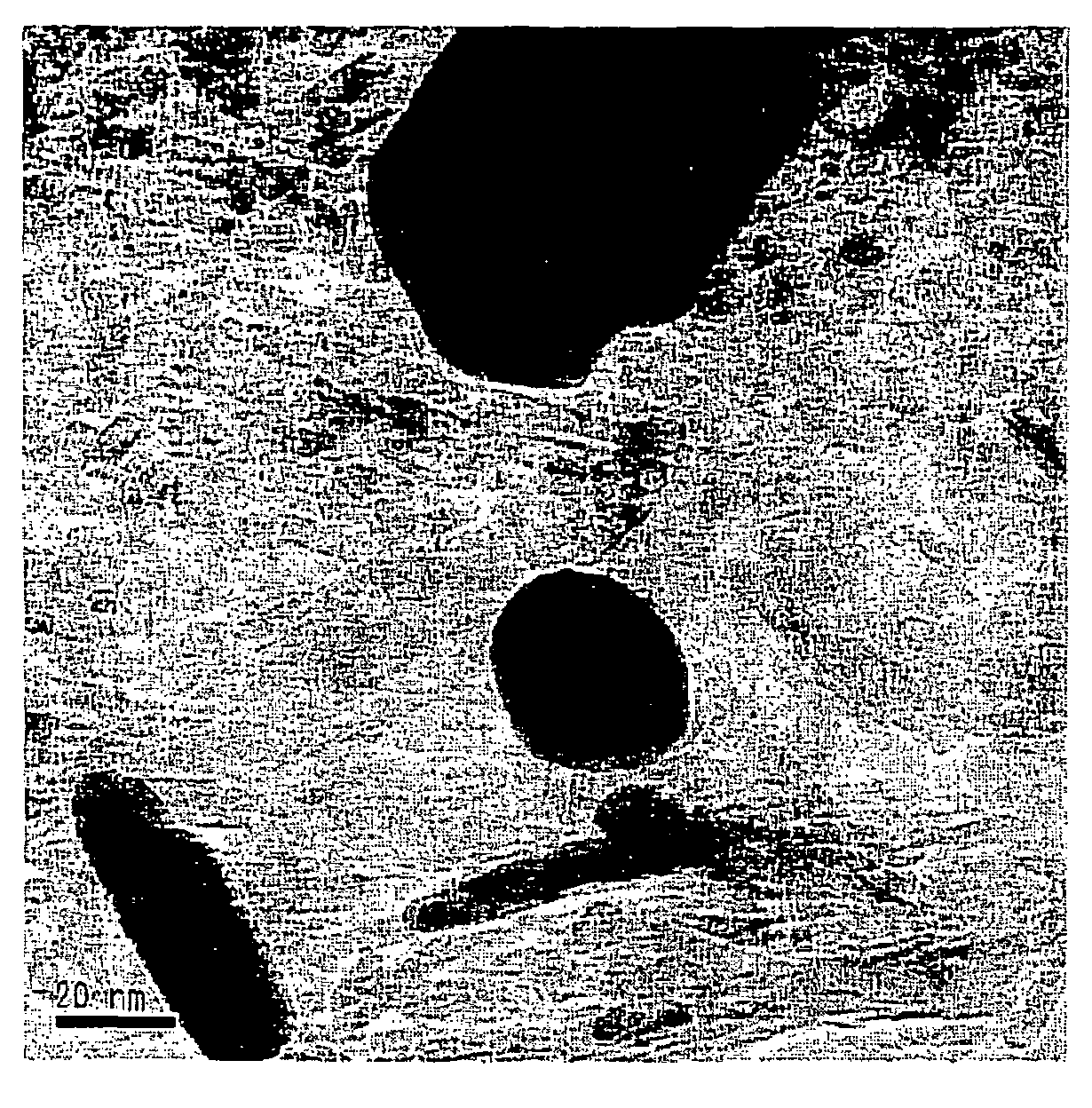

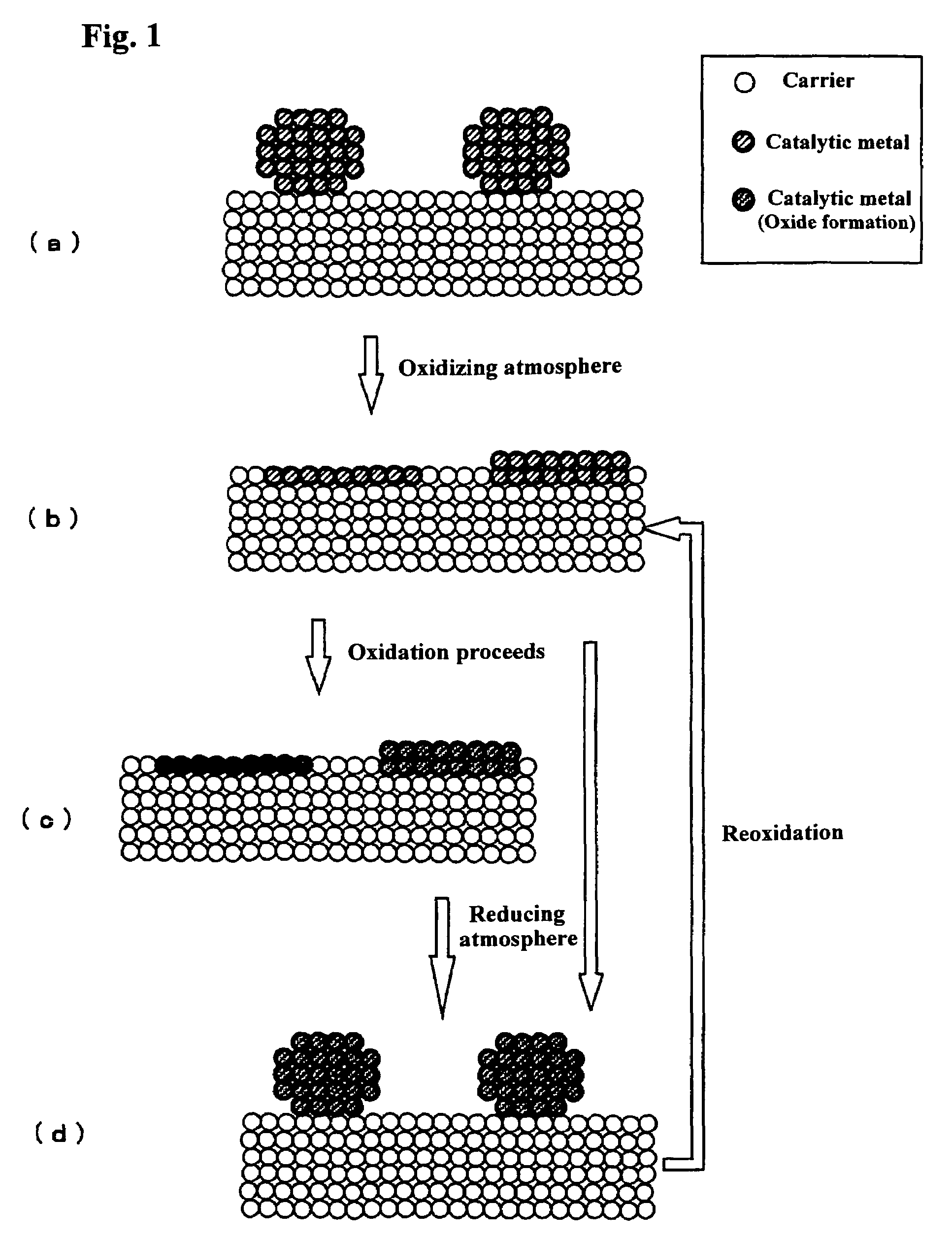

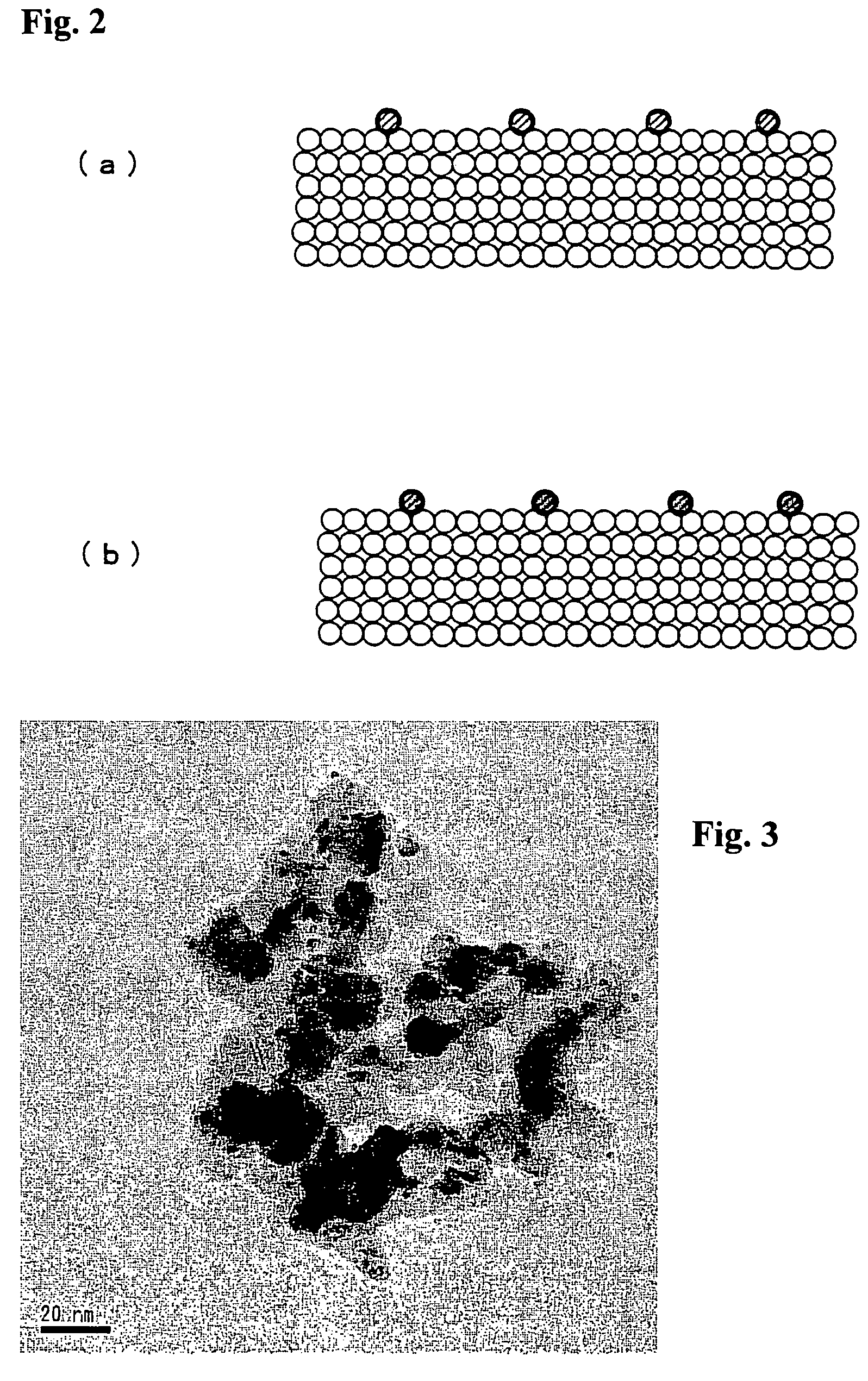

Catalyst

InactiveUS7576029B2Inhibit migrationLarge constraining forceGas treatmentInternal combustion piston enginesCatalytic metalRare earth

The present invention provides a catalyst comprising particles of one or more catalytic metals supported on a porous carrier made of one or more metal oxides, wherein the porous carrier is made of an oxide containing a rare earth oxide, and that the catalytic metal particles are made of one or more transition metals or transition metal oxides having 10 to 50000 atoms. In the present invention, cluster-like catalyst particles are supported on a specific carrier. The catalyst of the present invention maintains desirable activity while changing the morphology of catalyst particles by the atmosphere of the catalyst.

Owner:TANAKA PRECIOUS METAL IND

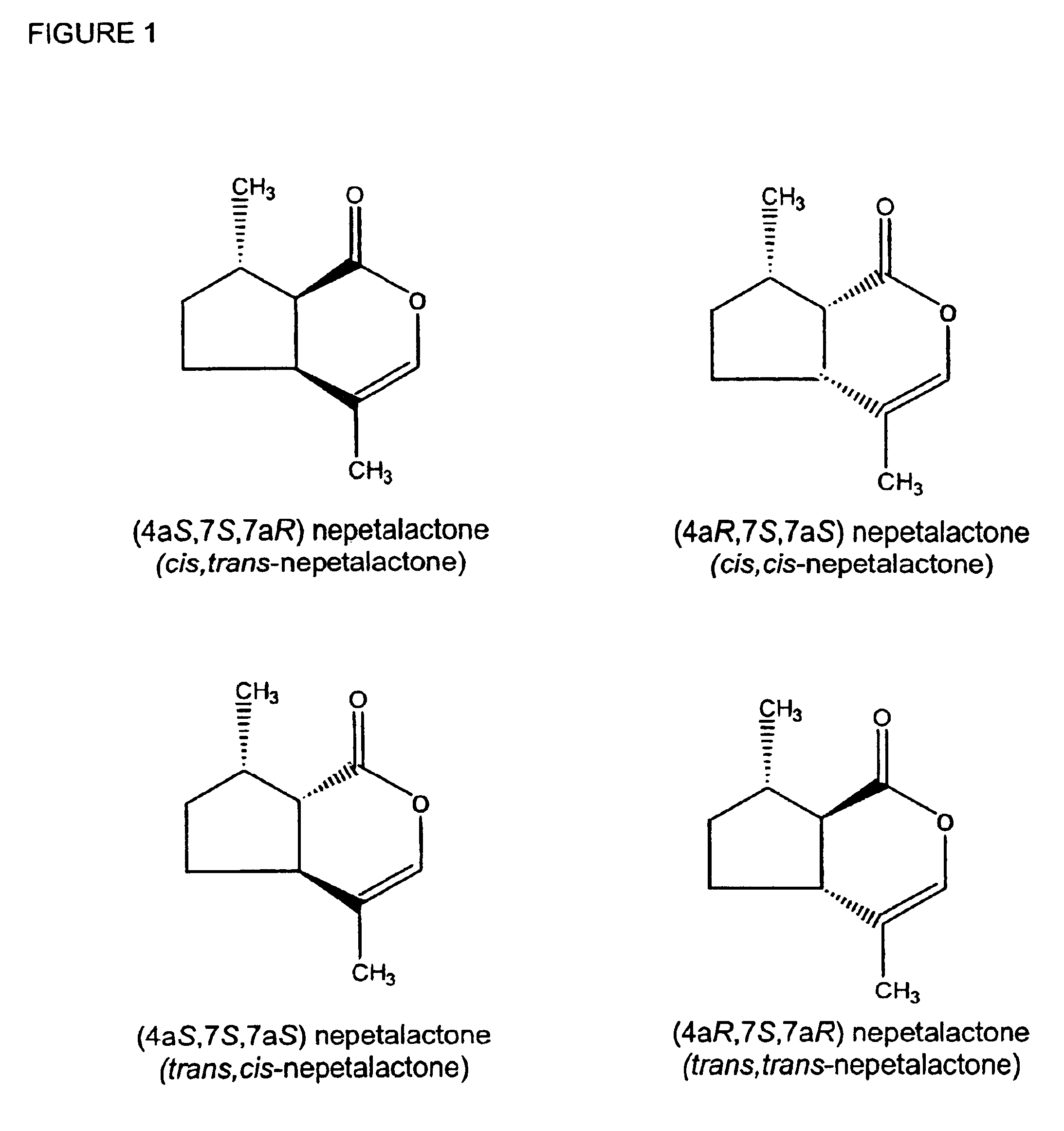

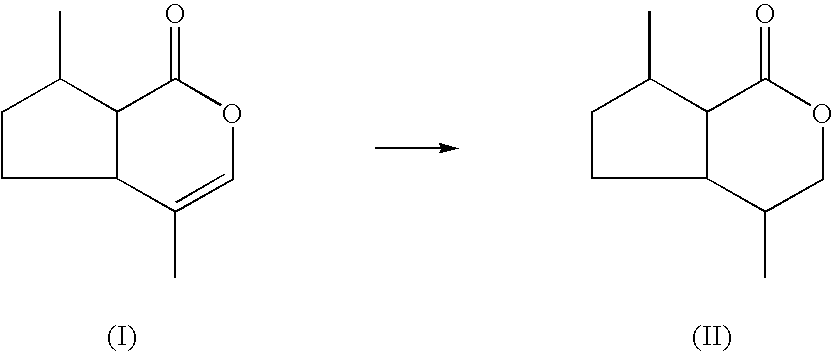

Production of dihydronepetalactone by hydrogenation of nepetalactone

InactiveUS7067677B2Organic chemistry methodsMetal/metal-oxides/metal-hydroxide catalystsMetal catalystCatalytic metal

This invention relates to a process for hydrogenating nepetalactone, utilizing a metal catalyst that is optionally supported, to yield dihydronepetalactone. A suite of supported catalytic metals lead to rapid hydrogenation and high selectivity for dihydronepetalactone.

Owner:DUPONT US HLDG LLC

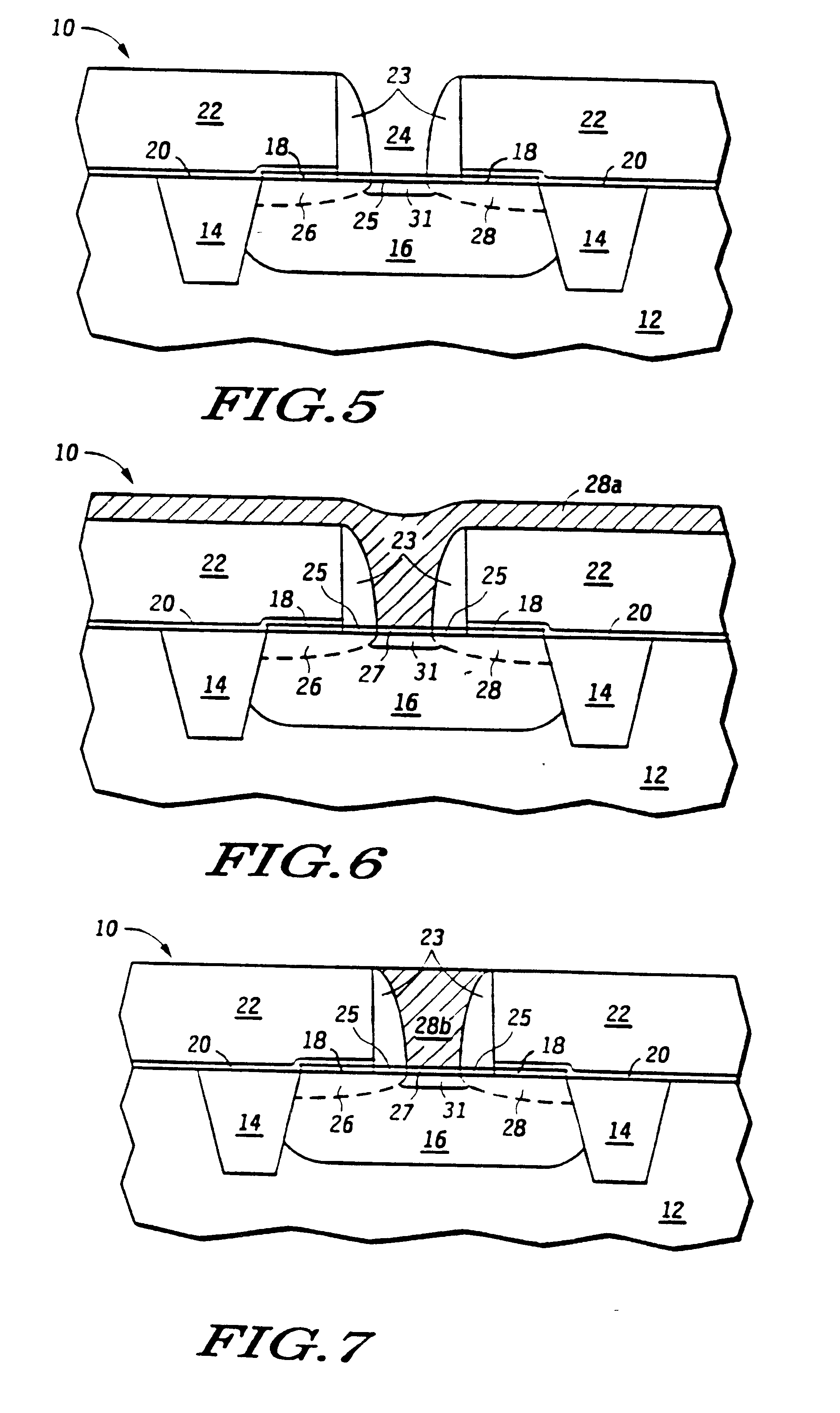

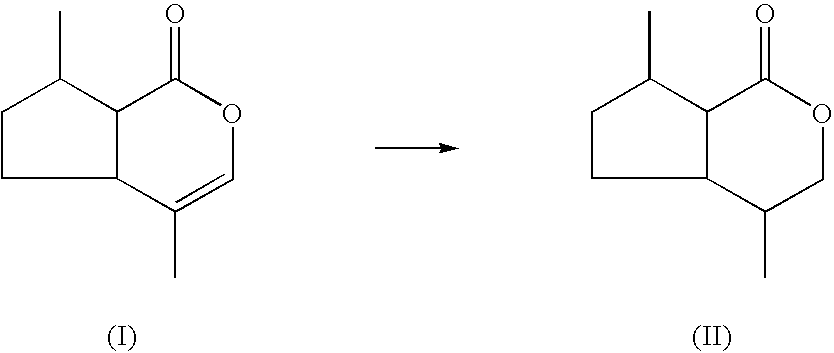

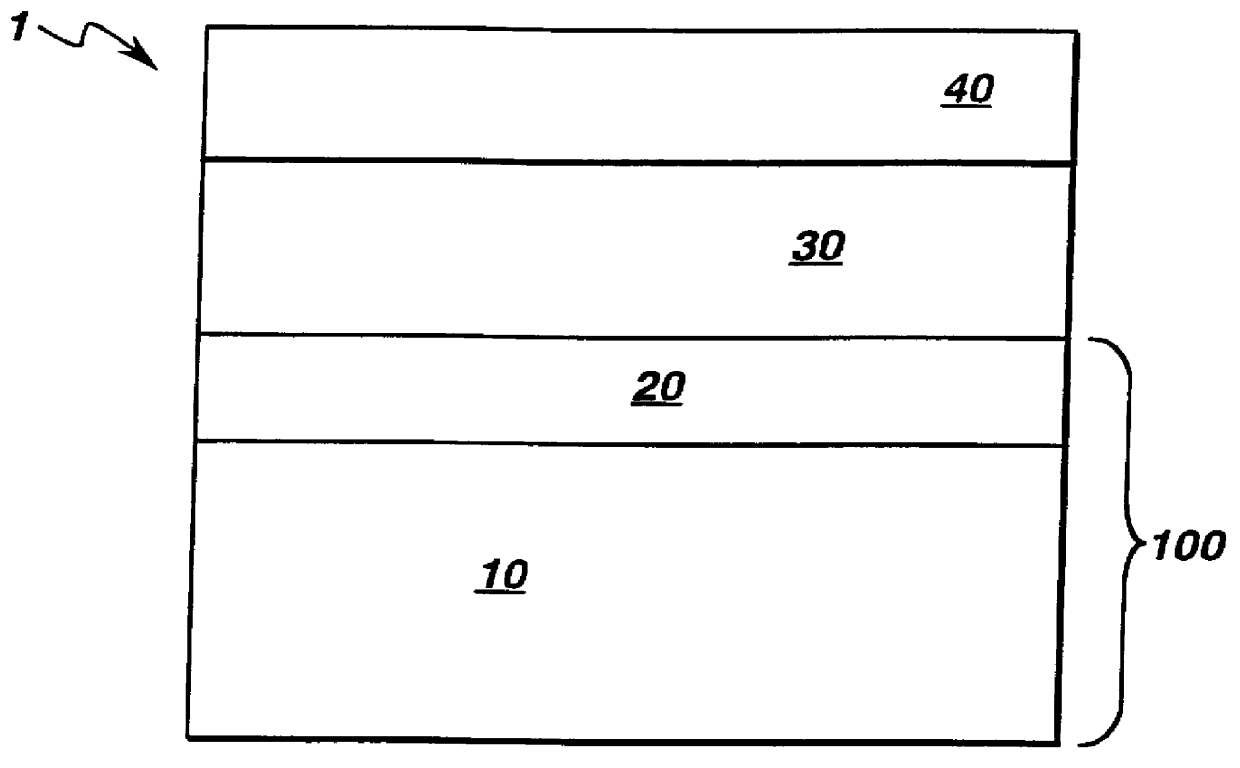

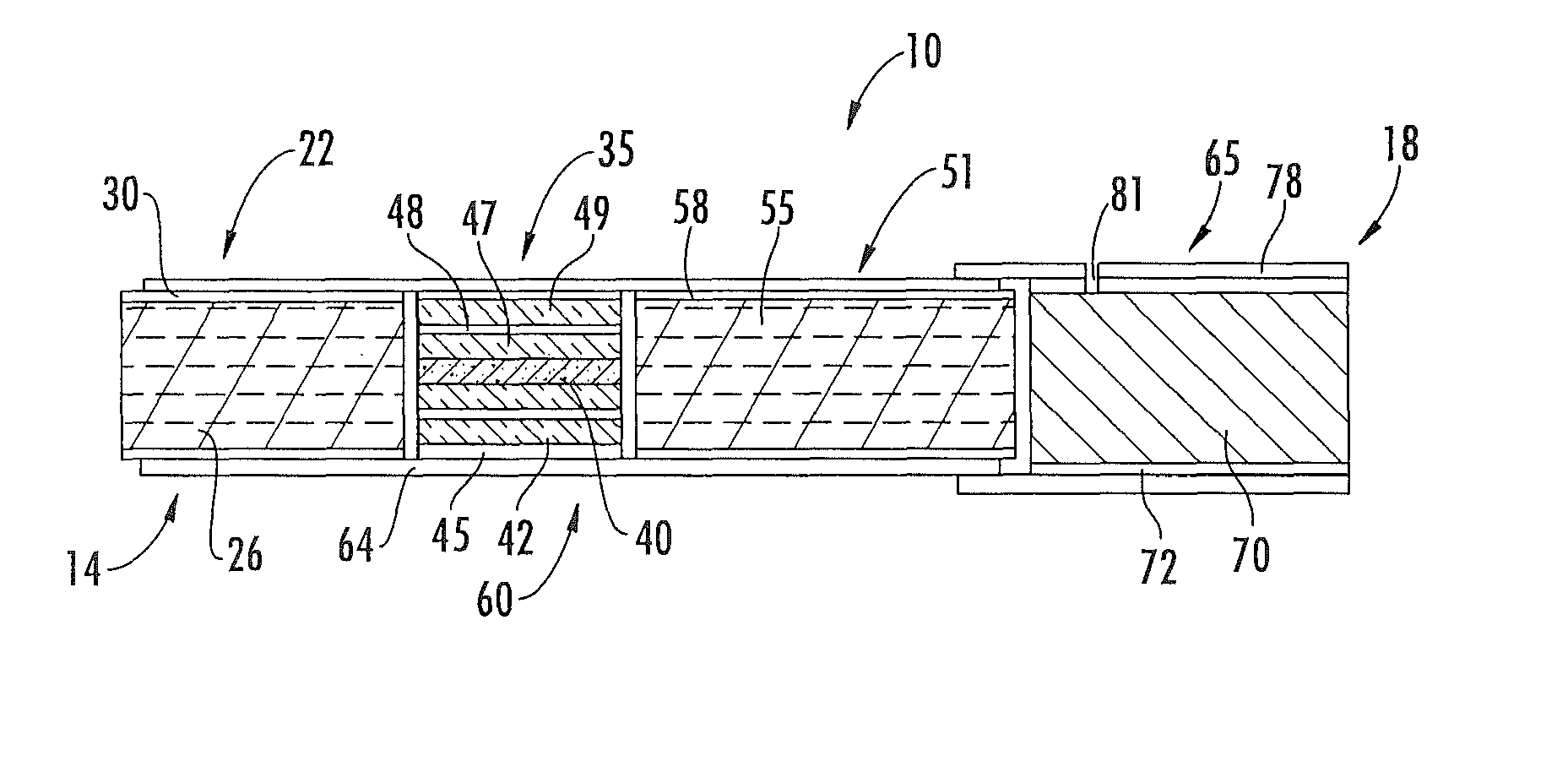

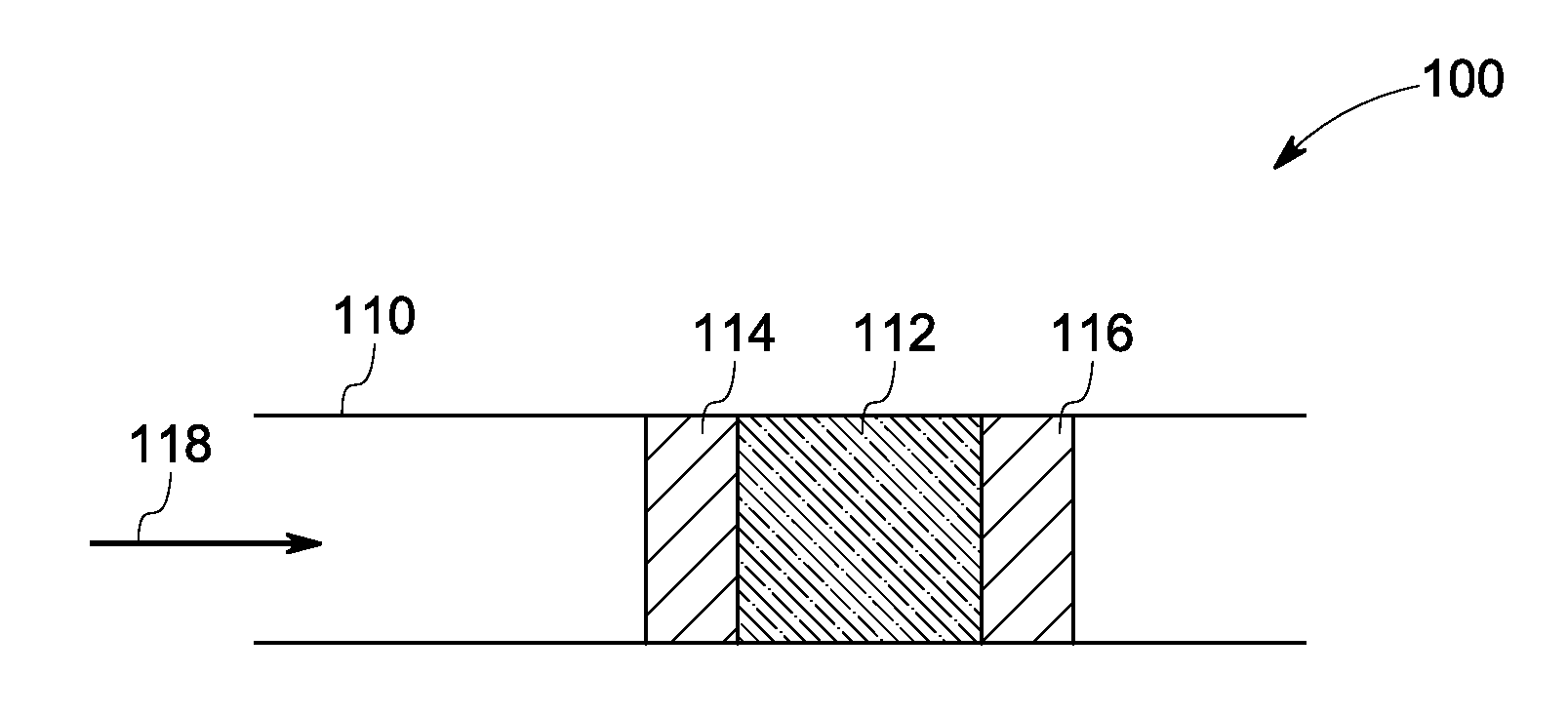

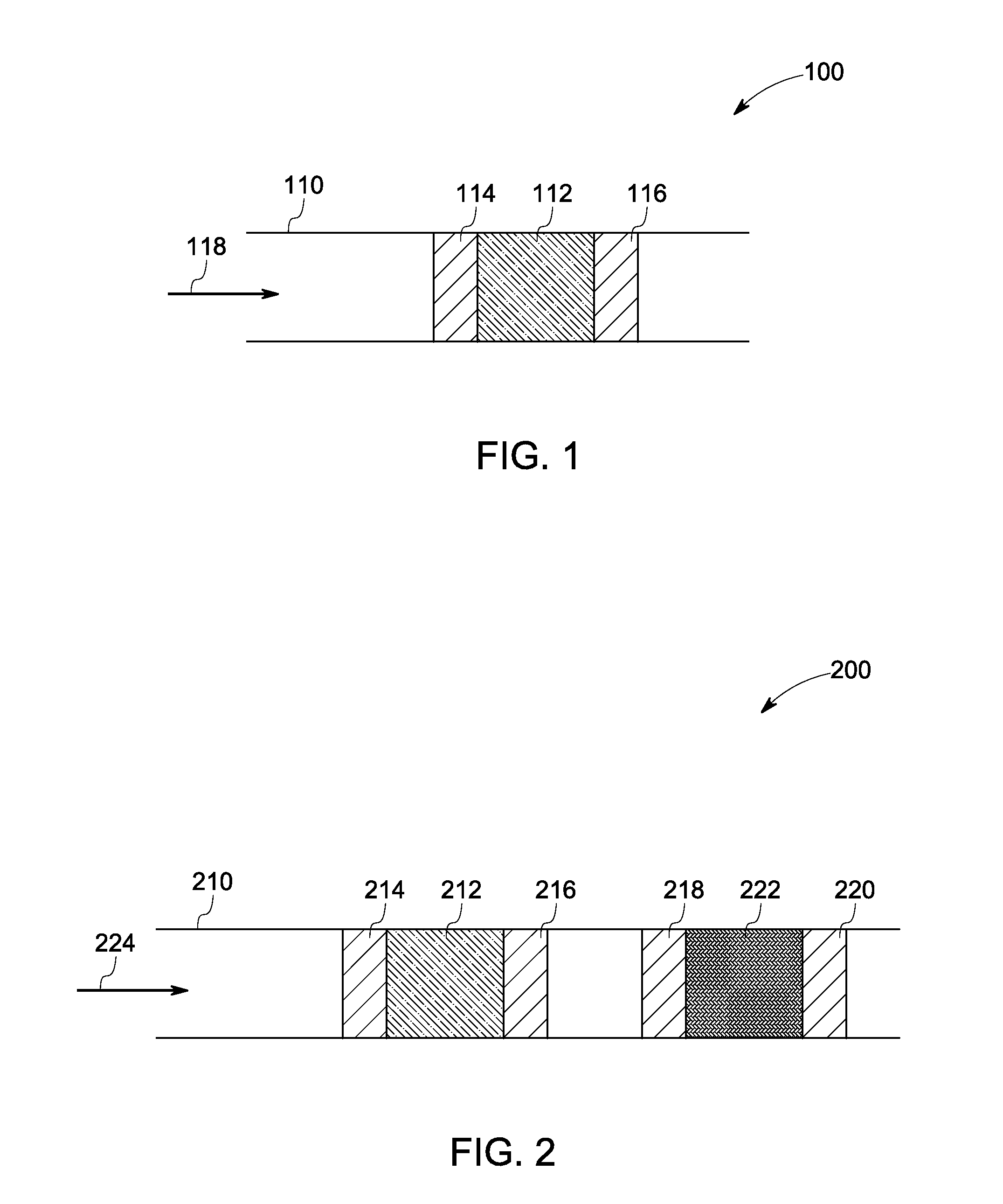

Gas sensor with protective gate, method of forming the sensor, and method of sensing

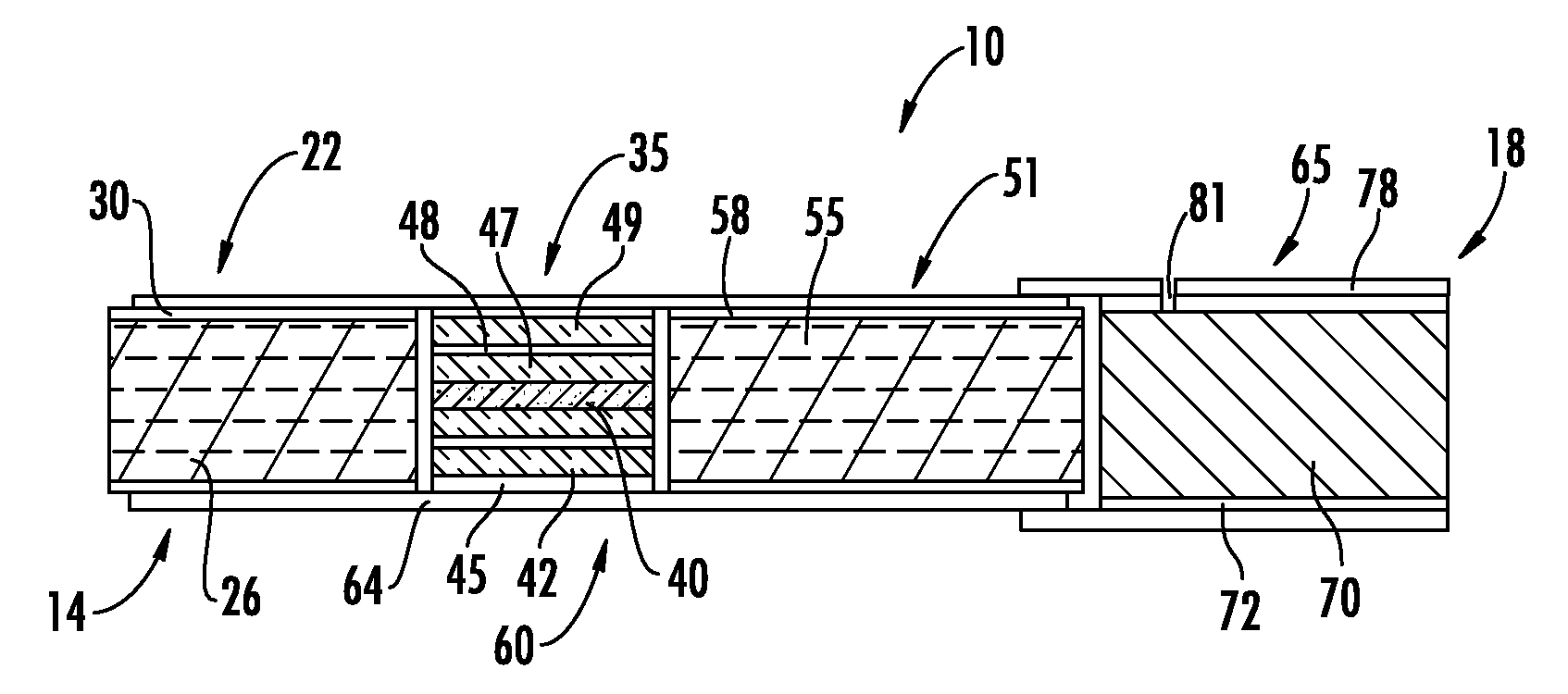

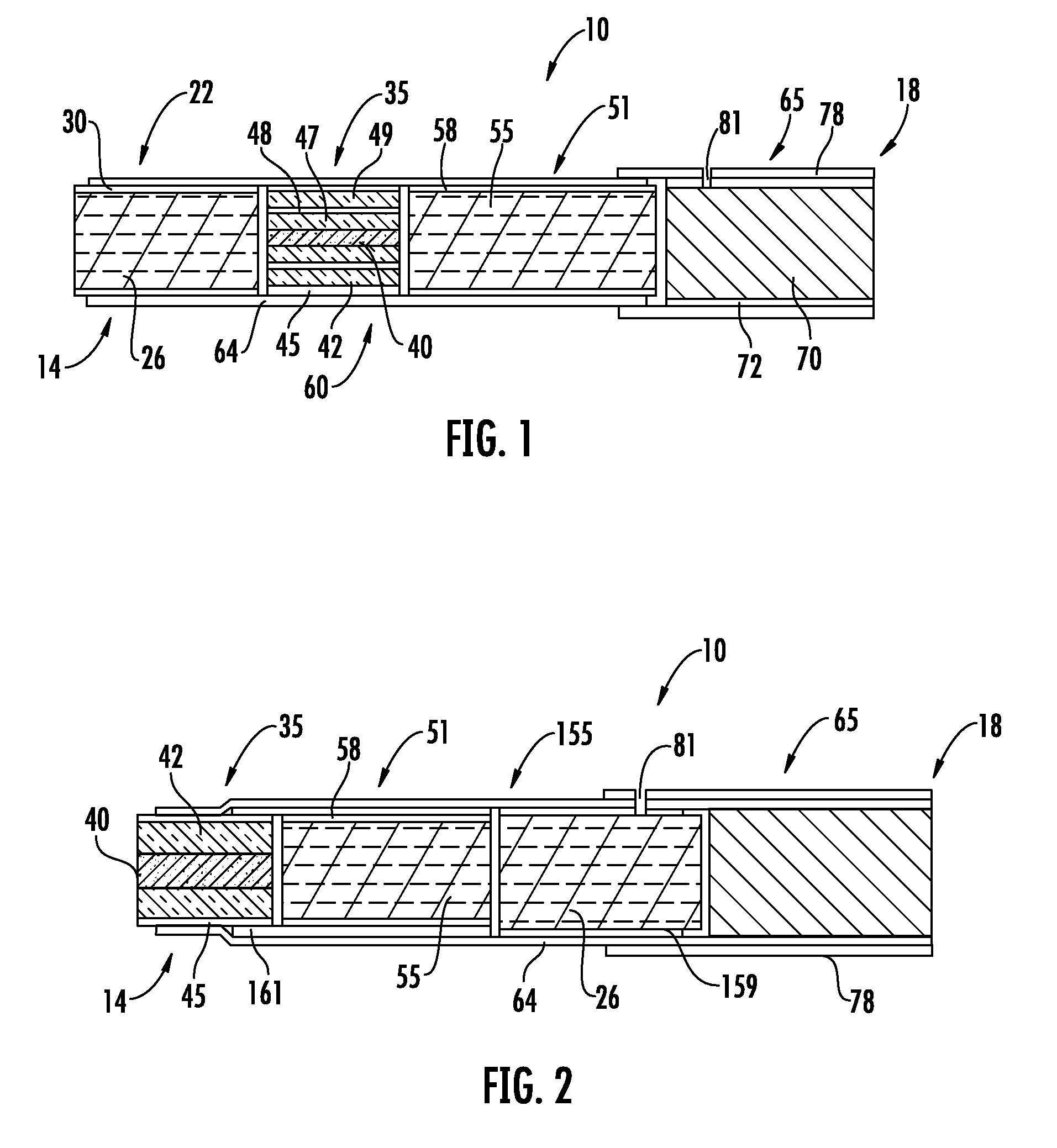

InactiveUS6041643AMaterial testing goodsGas analyser construction detailsForeign matterCatalytic metal

A gas sensor determines the presence of at least one designated gas in a gaseous environment. The gas sensor comprises a semiconductor substrate; a thin insulator layer disposed on the semiconductor substrate; a catalytic metallic gate disposed on the thin insulator layer; and a chemically modified layer disposed on the catalytic metal gate. The chemically modified layer comprises a material that protects the sensor from corrosive gases and interference from at least one foreign matter and water, alters at least one of surface chemical properties and surface physical properties of the sensor, and passes only the designated gas therethrough.

Owner:GENERAL ELECTRIC CO

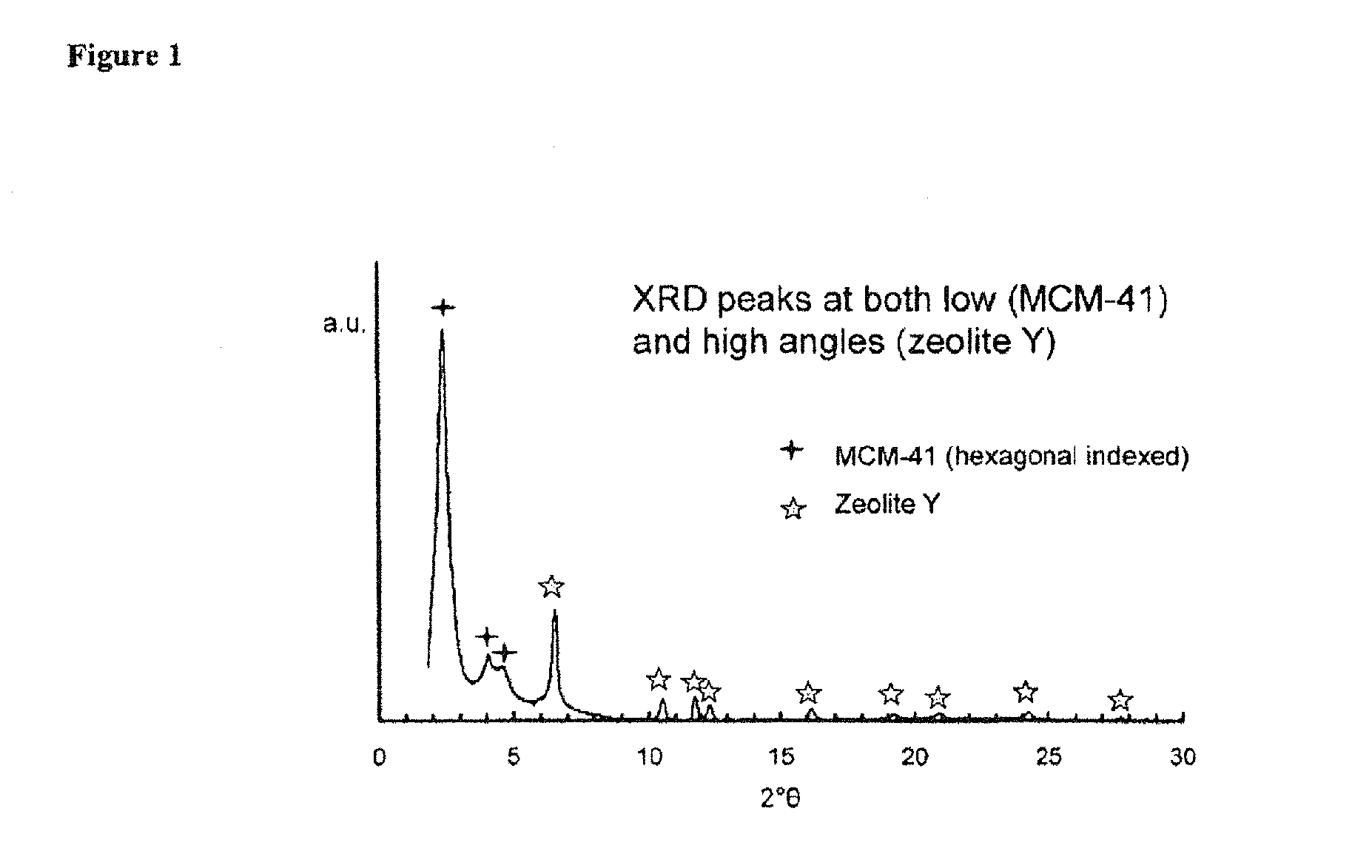

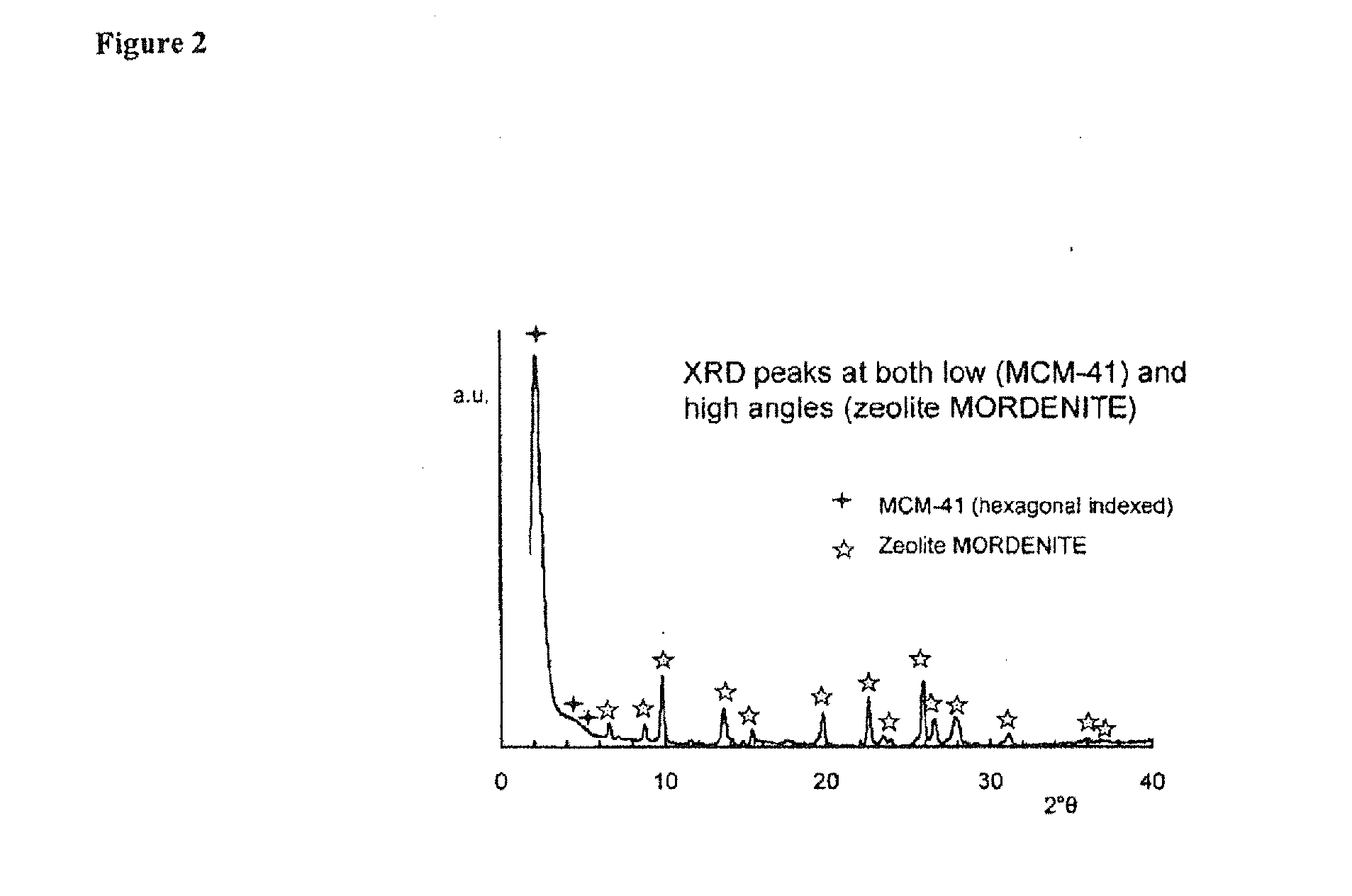

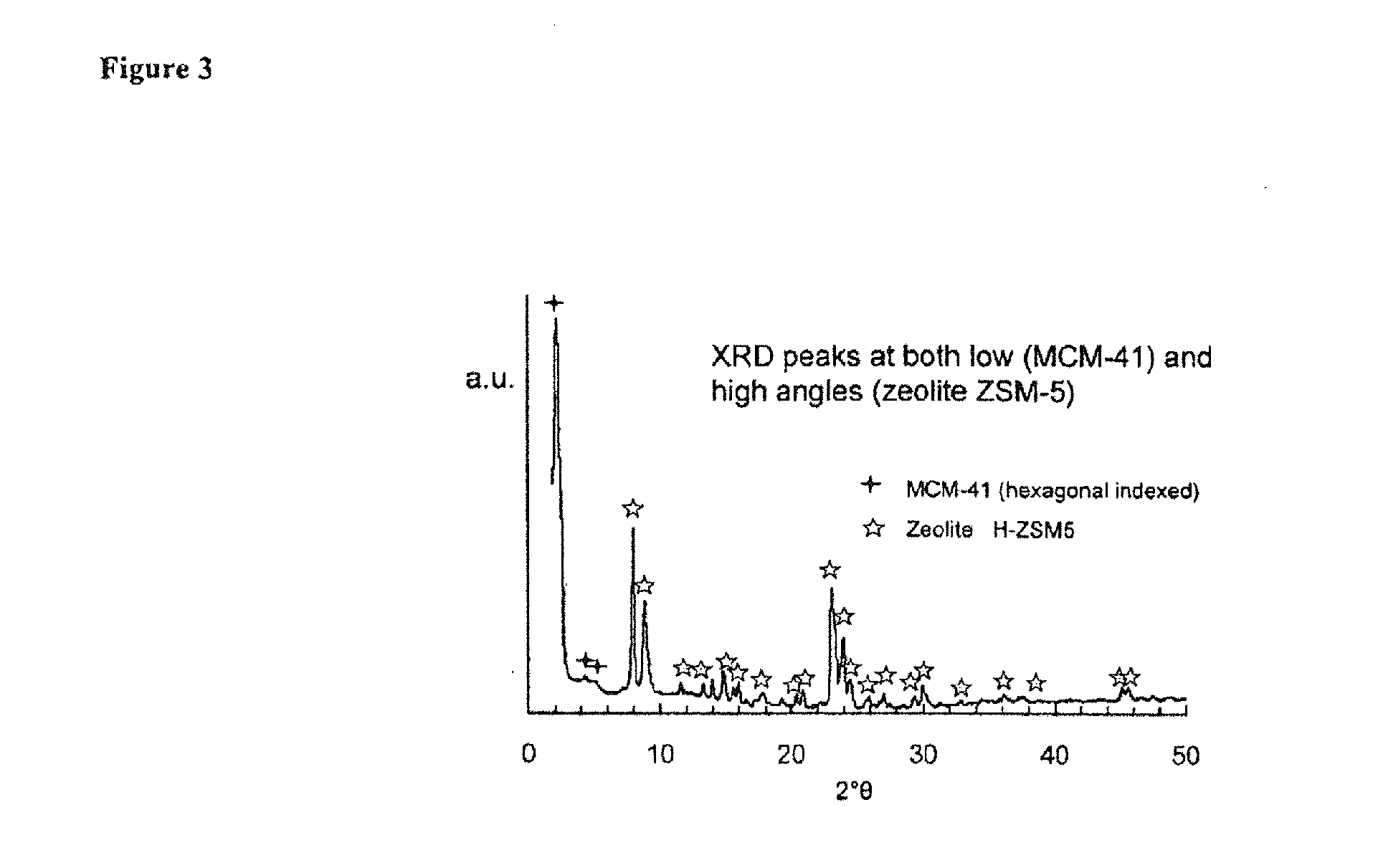

Mesostructured zeolitic materials suitable for use in hydrocracking catalyst compositions and methods of making and using the same

InactiveUS20130292300A1Increase productionConvenient lightingMaterial nanotechnologyCatalytic crackingCatalytic metalCrystallinity

Hydrocracking processes and catalyst composition for use therein are provided. The catalyst compositions described herein include a mesoporous support material and at least one catalytic metal supported thereon. The mesoporous support material may comprise a single-phase crystalline mesostructured zeolite. Additionally, the mesoporous structure may exhibit long range crystallinity and include a plurality of mesopores defined within of the volume of the crystalline mesostructure. Suitable feedstocks for the hydrocracking processes according to embodiments of the present invention crude oil, a gas oil fraction, vacuum gas oil, and combinations thereof.

Owner:MASSACHUSETTS INST OF TECH

Method for preparing fuel element for smoking article

The invention provides a method for making a fuel element for a smoking article including the steps of mixing a metal-containing catalyst precursor with a filler material or graphite or a combination thereof to form a pre-treated fuel element component; optionally calcining the pre-treated fuel element component in order to convert the catalyst precursor to a catalytic metal compound; after the optional calcining step, combining the pre-treated fuel element component with a carbonaceous material and a binder to produce a fuel element composition; and forming the fuel element composition into a fuel element adapted for use in a smoking article. Examples of metal-containing catalyst precursors include iron nitrate, copper nitrate, cerium nitrate, cerium ammonium nitrate, manganese nitrate, magnesium nitrate, and zinc nitrate. Fuel elements treated according to the invention, and smoking articles including such fuel elements, are also provided.

Owner:R J REYNOLDS TOBACCO COMPANY

Catalyst and method of manufacture

InactiveUS20110120100A1Internal combustion piston enginesMolecular sieve catalystsCatalytic metalNanocrystal

A catalyst system comprising a first catalytic composition comprising a homogeneous solid mixture containing at least one catalytic metal and at least one metal inorganic support. The pores of the solid mixture have an average diameter in a range of about 1 nanometer to about 15 nanometers. The catalytic metal comprises nanocrystals.

Owner:GENERAL ELECTRIC CO

Contaminant removal from natural resources

InactiveUS7008964B2Increase chanceEasy to degradeTransportation and packagingSolid waste disposalNatural resourceEmulsion

A zero-valent metal emulsion containing zero-valent metal particles is used to remediate contaminated natural resources, such as groundwater and soil. In a preferred embodiment, the zero-valent metal emulsion removes heavy metals, such as lead (Pb), from contaminated natural resources. In another preferred embodiment, the zero-valent metal emulsion is a bimetallic emulsion containing zero-valent metal particles doped with a catalytic metal to remediate halogenated aromatic compounds, such as polychlorinated biphenyls (PCBs), from natural resources.

Owner:NASA +1

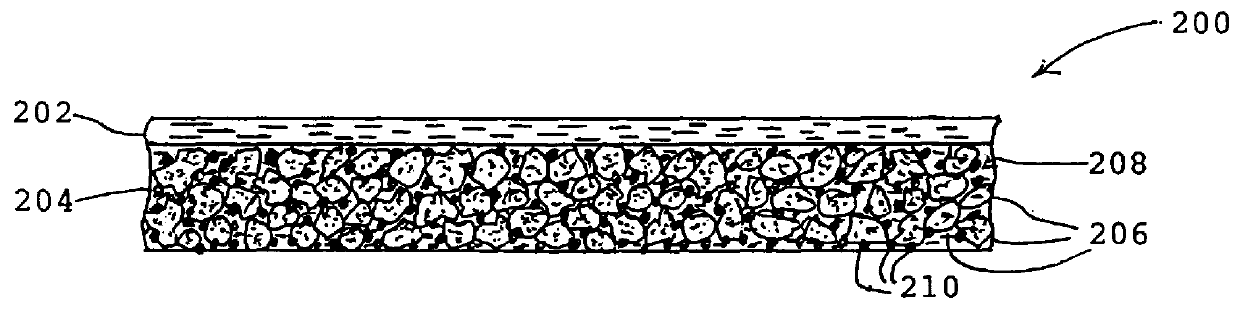

Fischer-Tropsch processes and catalysts made from a material comprising boehmite

ActiveUS7012104B2Improve performanceOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsPseudoboehmiteCatalytic metal

A hydrothermally-stable catalyst, method for making the same, and process for producing hydrocarbon, wherein the catalyst is used in synthesis gas conversion to hydrocarbons. In one embodiment, the method comprises depositing a compound of a catalytic metal selected from Groups 8, 9, and 10 of the Periodic Table on a support material comprising boehmite to form a composite material; and calcining the composite material to form the catalyst. In other embodiments, the support material comprises synthetic boehmite, natural boehmite, pseudo-boehmite, or combinations thereof.

Owner:CLARIANT INT LTD

System and Method for Controlling Nitrous Oxide Emissions of an Internal Combustion Engine and Regeneration of an Exhaust Treatment Device

ActiveUS20110209459A1Internal combustion piston enginesExhaust apparatusExhaust fumesCatalytic metal

A catalyst composition is provided that includes a catalytic metal secured to a substrate, and the substrate is mesoporous and has pores that are templated. A catalyst composition includes a catalytic metal secured to a mesoporous substrate. The mesoporous substrate is a reaction product of a reactive solution, a solvent, a modifier, and a templating agent. A method for controlling nitrous oxide emissions including the catalyst composition comprising introducing a regeneration fuel into an exhaust stream upstream relative to the catalyst composition and heating the exhaust stream upstream relative to the catalyst composition. When the regeneration fuel is introduced the air λ of an air / fuel mixture of a lean burn exhaust does not exceed 1.

Owner:GE GLOBAL SOURCING LLC

Process for slurry phase hydroconversion of heavy hydrocarbon feeds and/or coal using a supported catalyst

InactiveUS20080149531A1Catalyst activation/preparationHydrocarbon oil crackingSlurry reactorSpherical shaped

The invention concerns a process for converting heavy feeds carried out in a slurry reactor in the presence of hydrogen and in the presence of a catalyst comprising at least one catalytic metal or a compound of a catalytic metal from group VIB and / or VIII supported on alumina, the pore structure of which is composed of a plurality of juxtaposed agglomerates each formed by a plurality of acicular platelets, the platelets of each agglomerate being generally radially oriented with respect to the others and with respect to the centre of the agglomerate, said catalyst having an irregular and non-spherical shape and being mainly in the form of fragments, obtained using a process including the following steps:a) granulation starting from an active alumina powder having a low crystallinity and / or amorphous structure, to obtain agglomerates in the form of beads;b) maturing in a moist atmosphere between 60° C. and 100° C. then drying said beads;c) sieving to recover a fraction of said beads;d) crushing said fraction;e) calcining at least a portion of said crushed fraction at a temperature in the range 250° C. to 900° C.;f) impregnating with acid and hydrothermal treatment at a temperature in the range 80° C. to 250° C.;g) drying then calcining at a temperature in the range 500° C. to 1100° C.h) depositing at least one catalytic metal or compound of a catalytic metal from group VIB and / or group VIII by impregnation.The process of the invention employs a catalyst with a specific pore texture, shape and granulometry, resulting in improved performances.

Owner:INST FR DU PETROLE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com