Patents

Literature

68 results about "Ruthenium tetroxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ruthenium tetroxide is the inorganic compound with the formula RuO₄. It is a yellow volatile solid that melts near room temperature. Samples are typically black due to impurities. The analogous OsO₄ is more widely used and better known. One of the few solvents in which RuO₄ forms stable solutions is CCl₄.

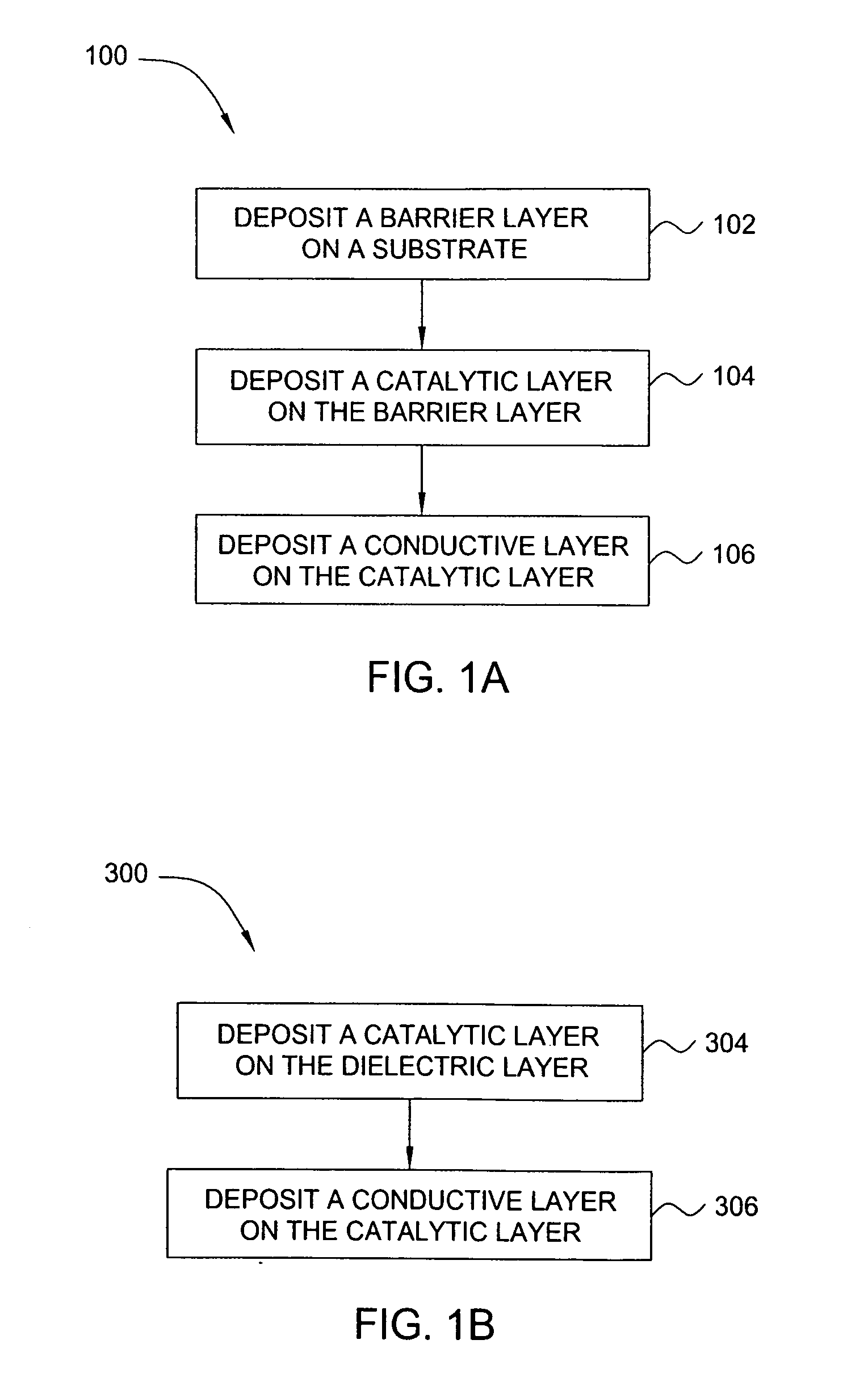

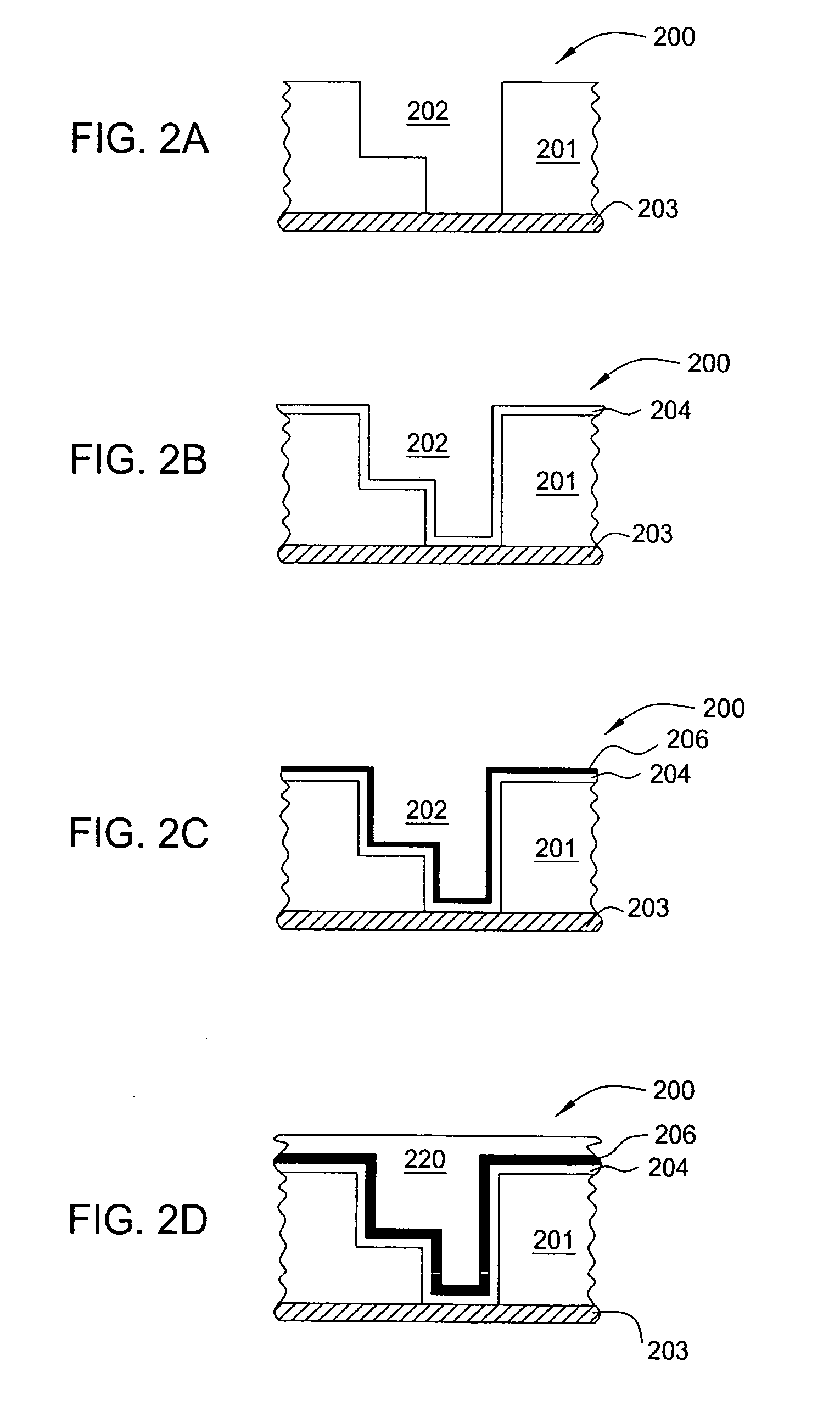

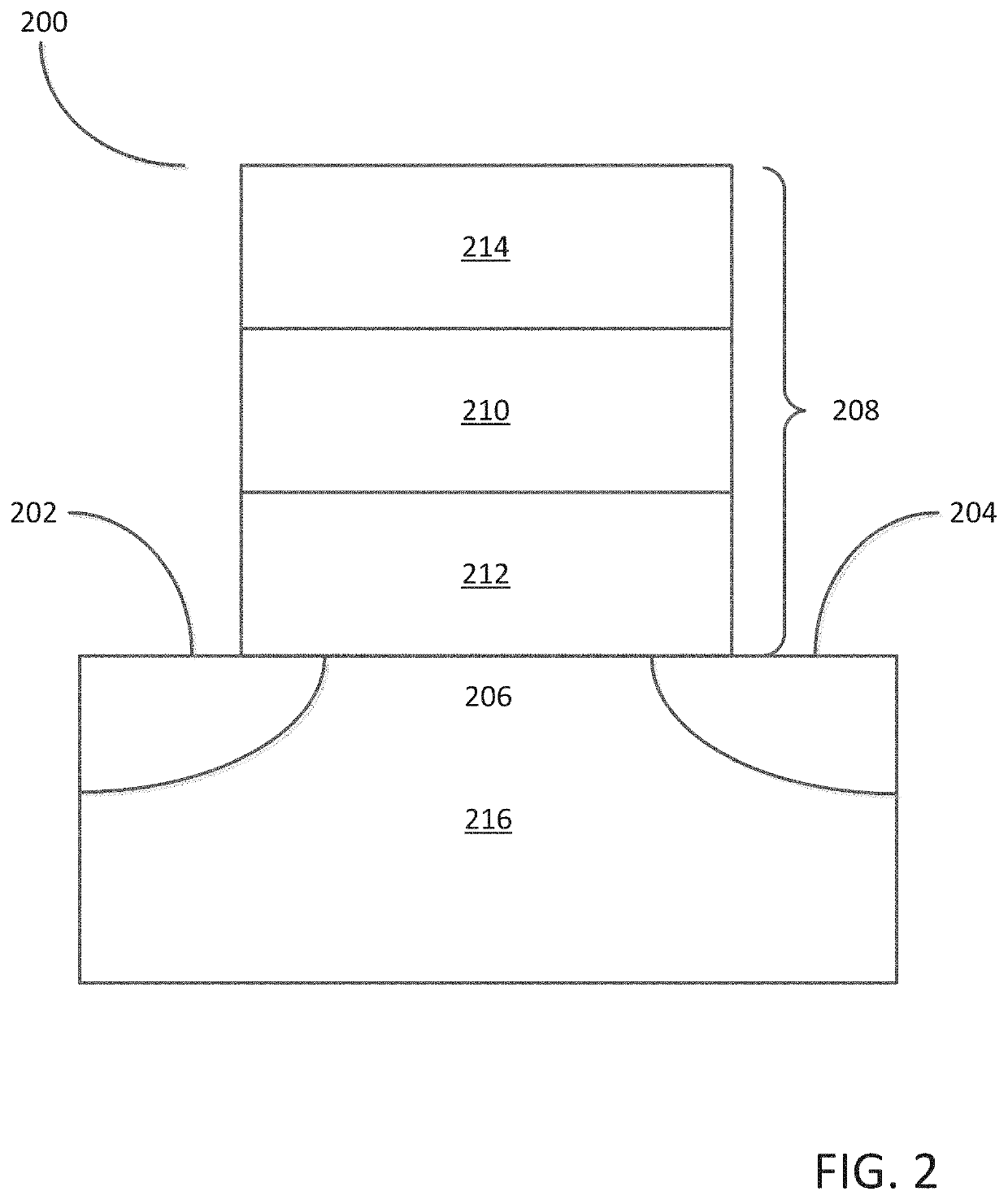

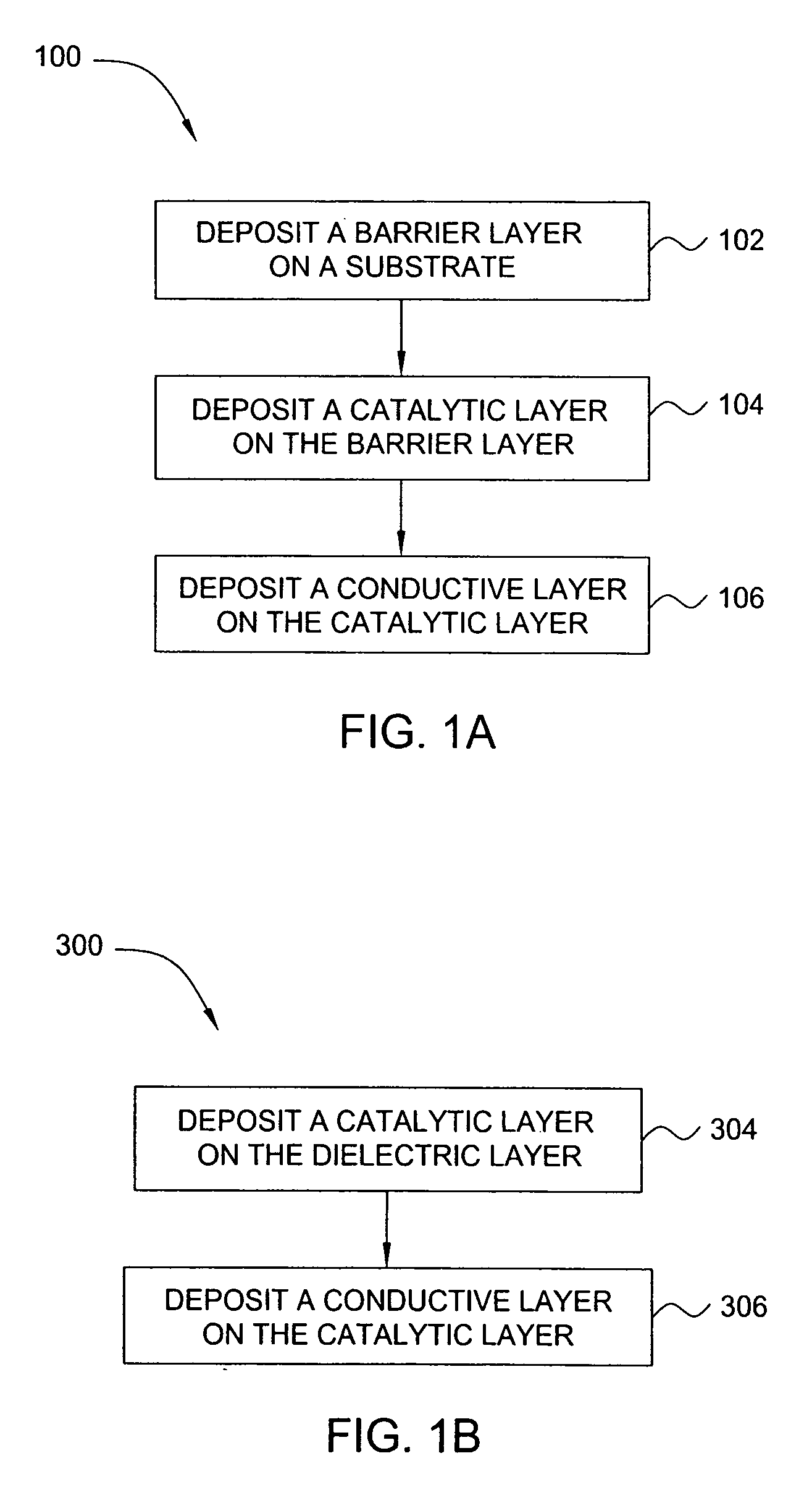

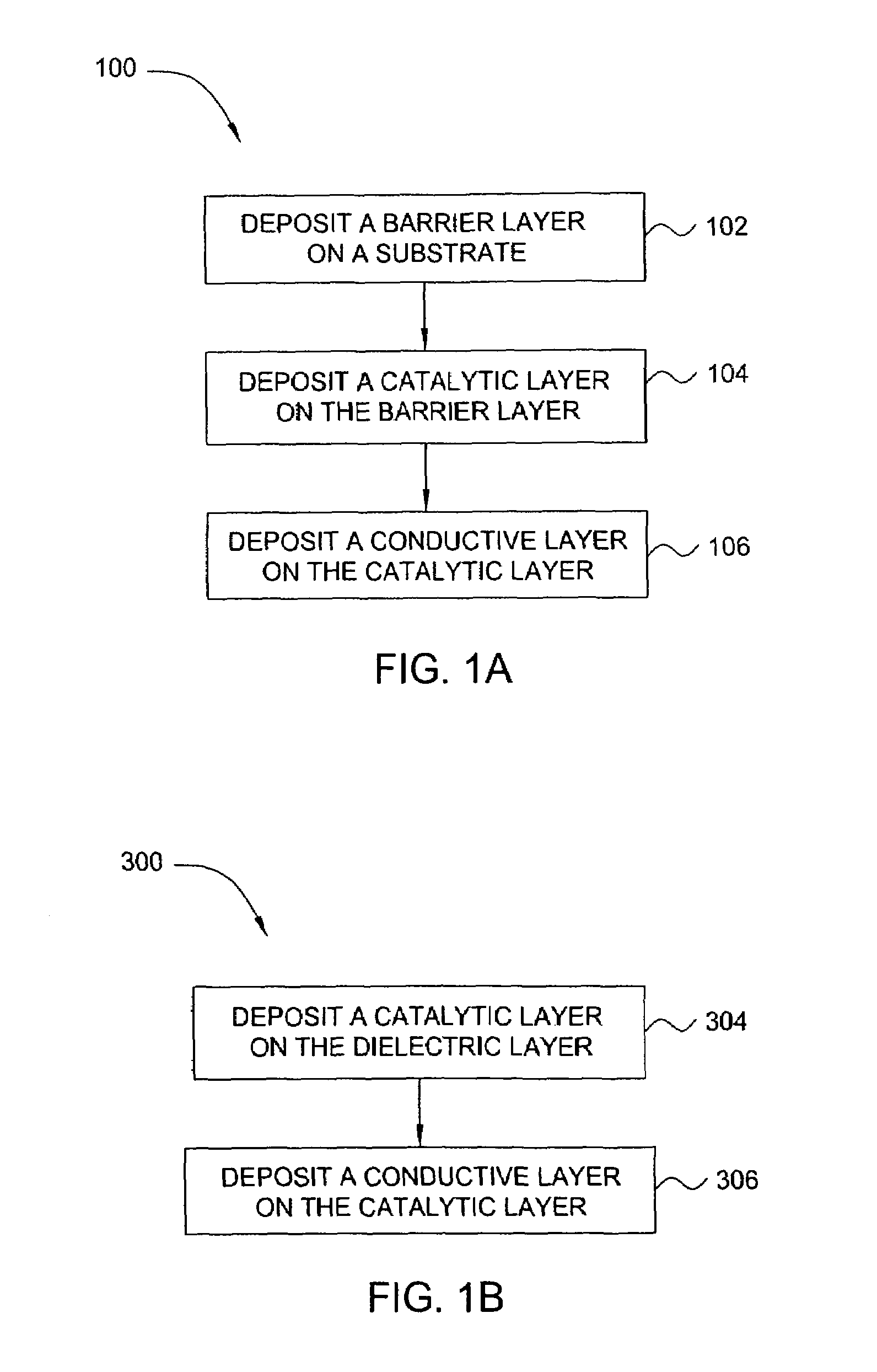

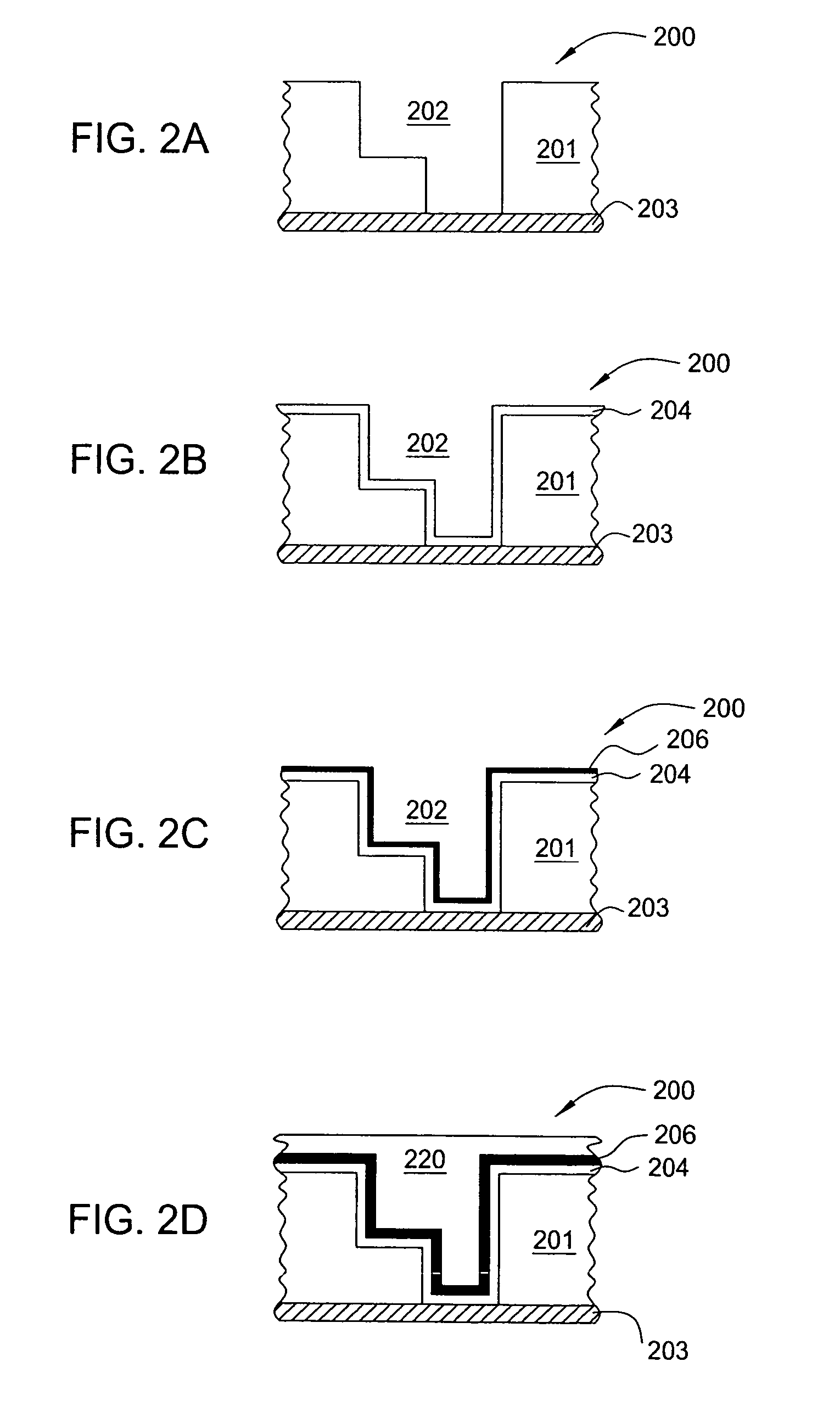

Deposition of an intermediate catalytic layer on a barrier layer for copper metallization

InactiveUS20060240187A1Solid-state devicesSemiconductor/solid-state device manufacturingIridiumSilanes

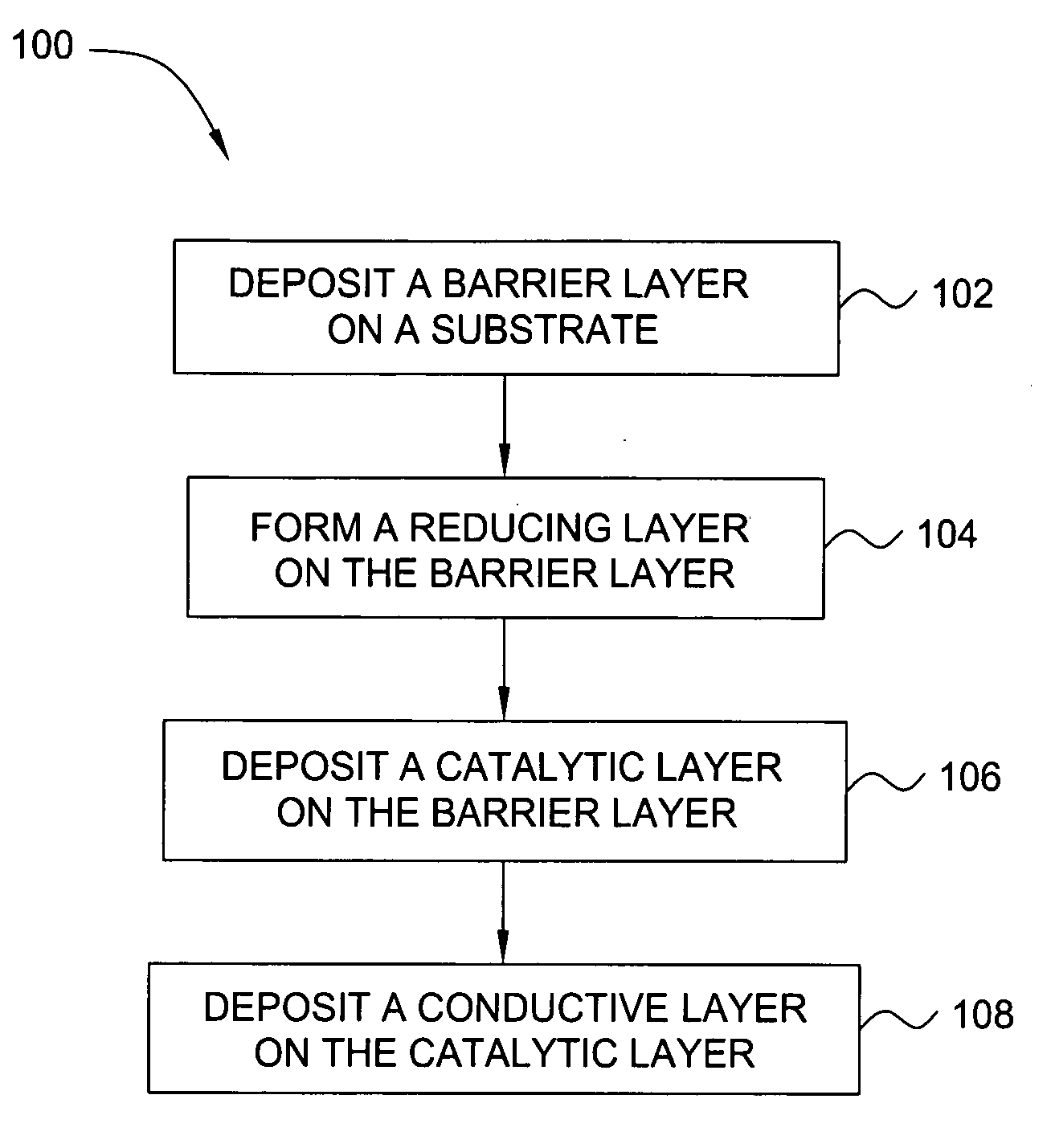

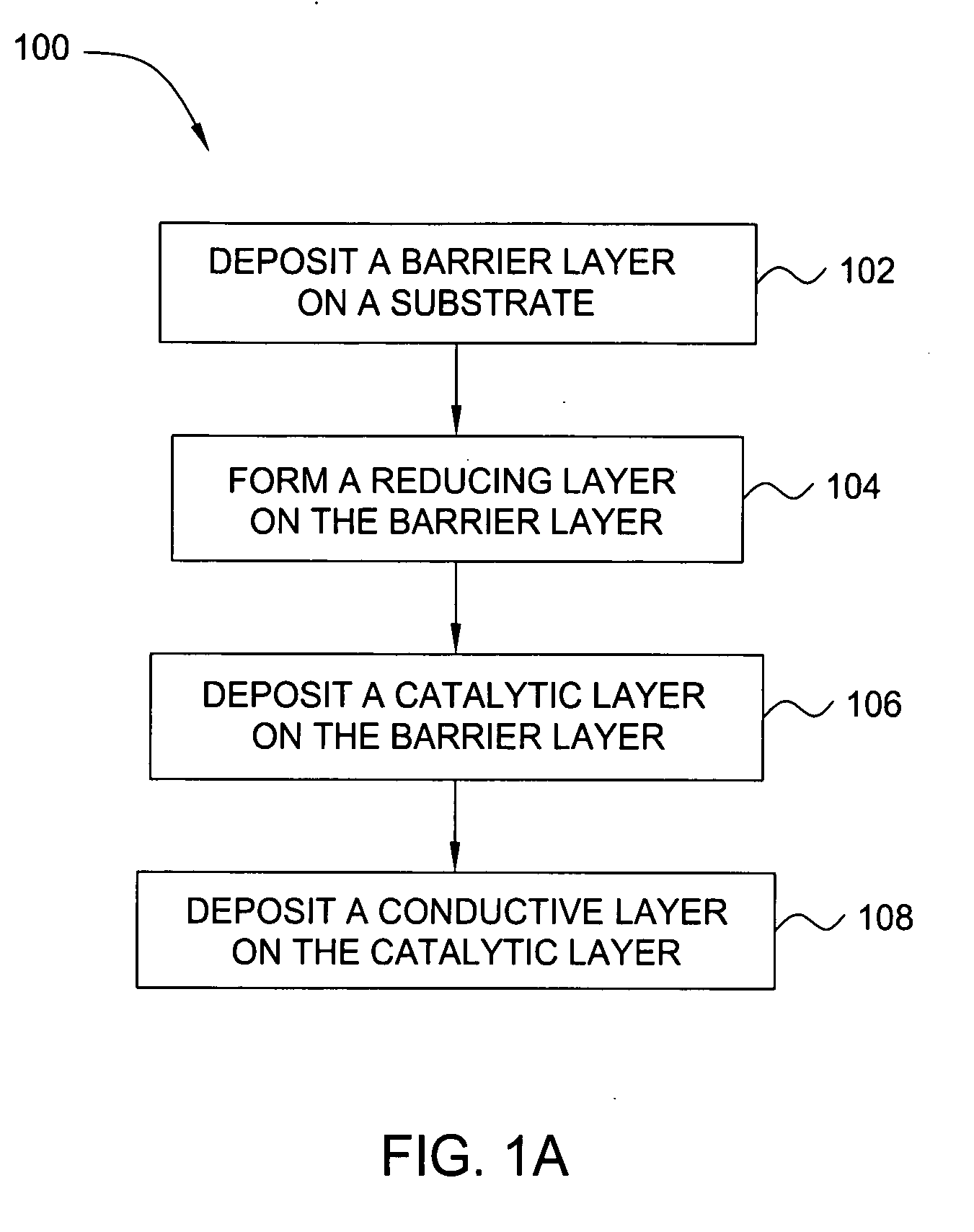

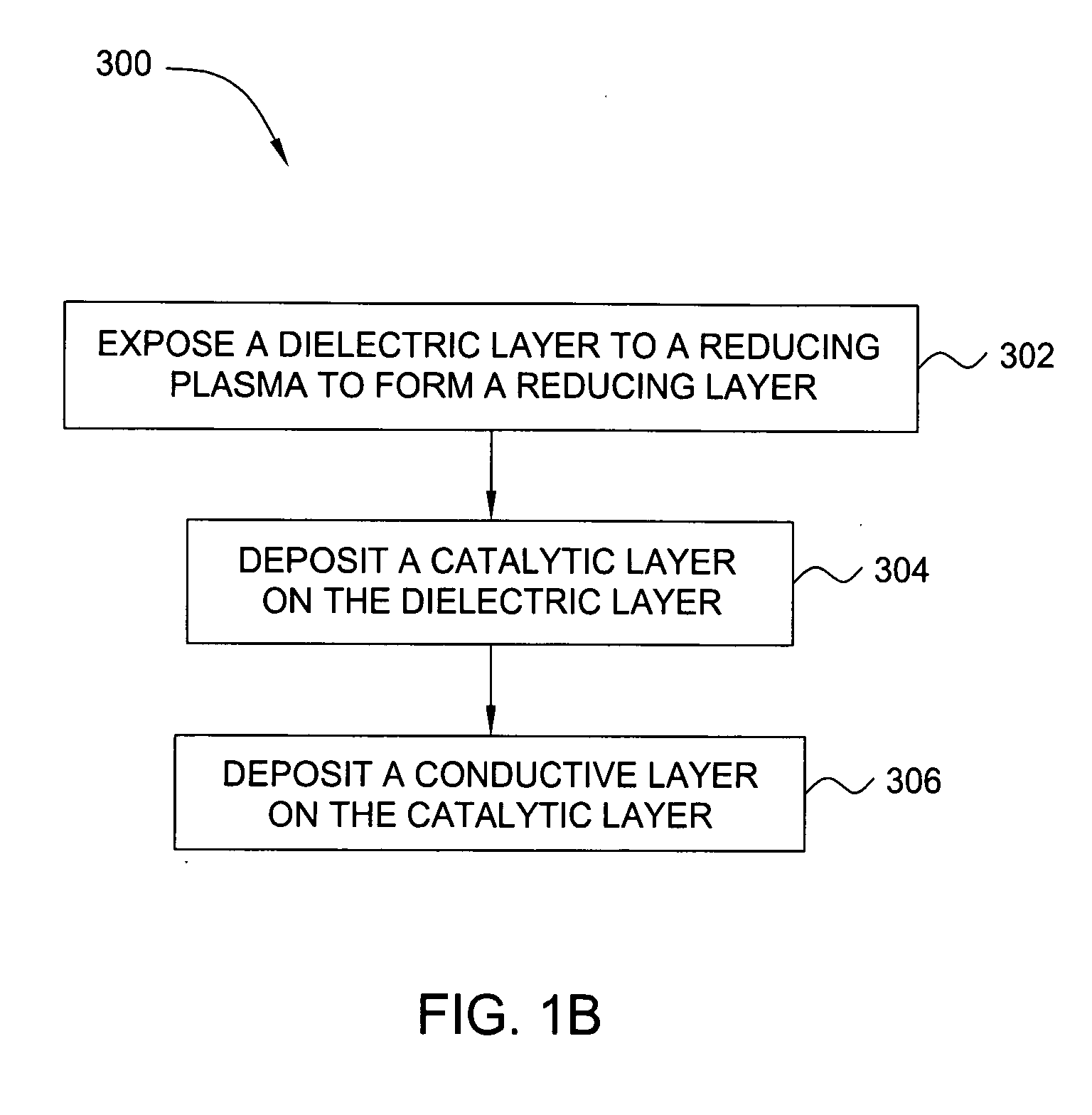

In one embodiment, a method for depositing a conductive material on a substrate is provided which includes exposing a substrate containing a barrier layer to a volatile reducing precursor to form a reducing layer during a soak process, exposing the reducing layer to a catalytic-metal precursor to deposit a catalytic metal-containing layer on the barrier layer, and depositing a conductive layer (e.g., copper) on the catalytic metal-containing layer. The volatile reducing precursor may include phosphine, diborane, silane, a plasma thereof, or a combination thereof and be exposed to the substrate for a time period within a range from about 1 second to about 30 seconds during the soak process. The catalytic metal-containing layer may contain ruthenium, cobalt, rhodium, iridium, nickel, palladium, platinum, silver, or copper. In one example, the catalytic metal-containing layer is deposited by a vapor deposition process utilizing ruthenium tetroxide formed by an in situ process.

Owner:APPLIED MATERIALS INC

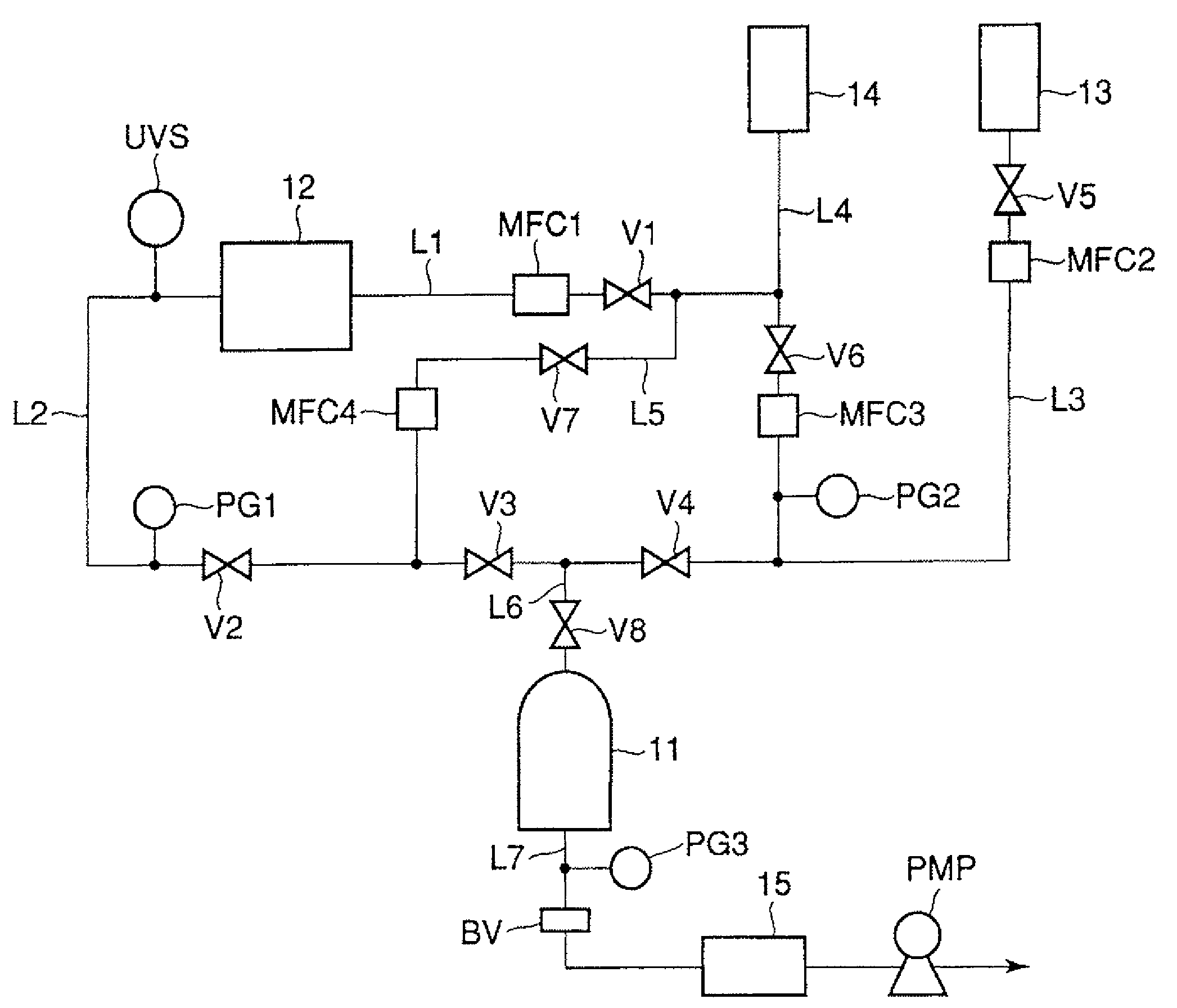

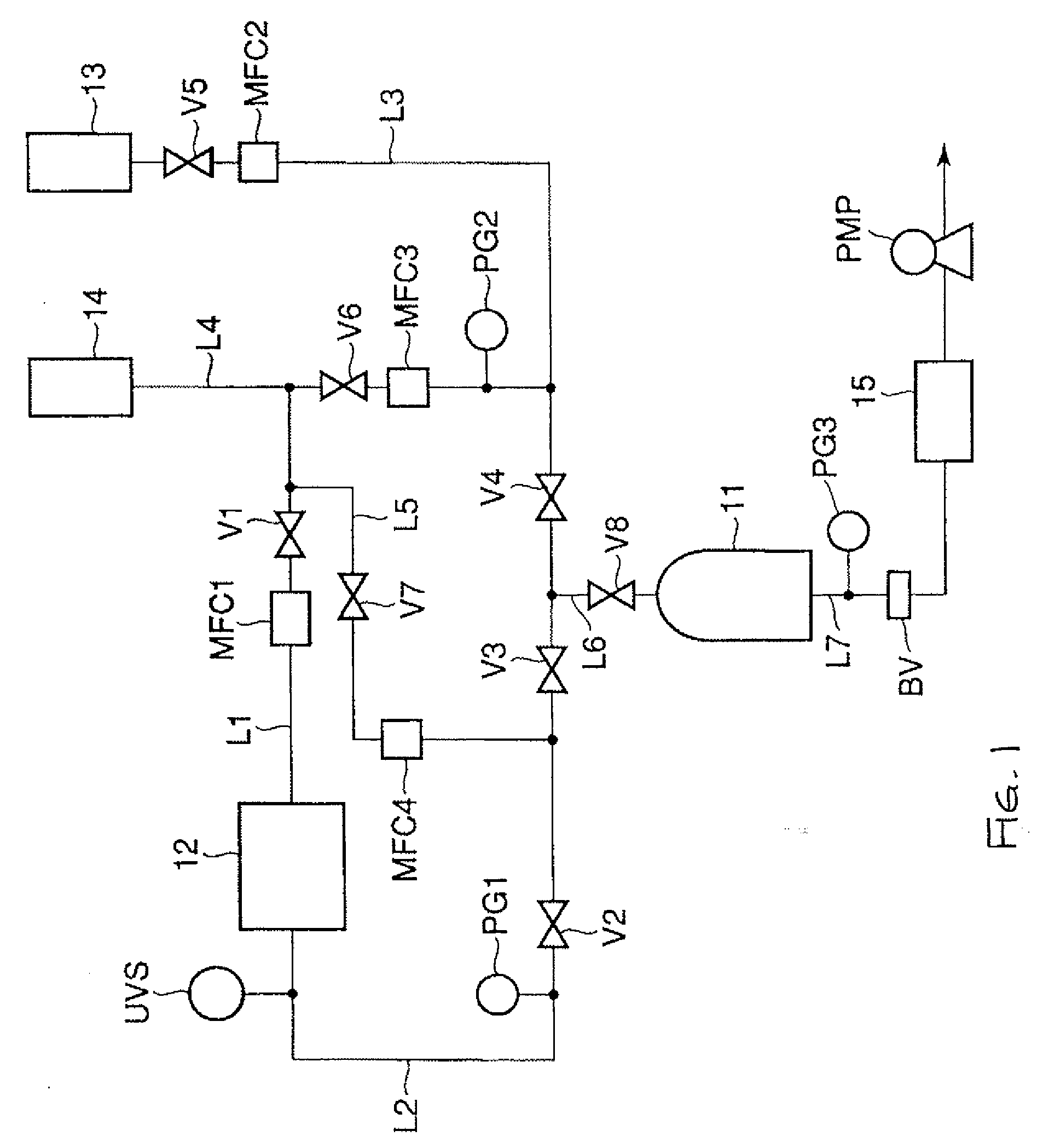

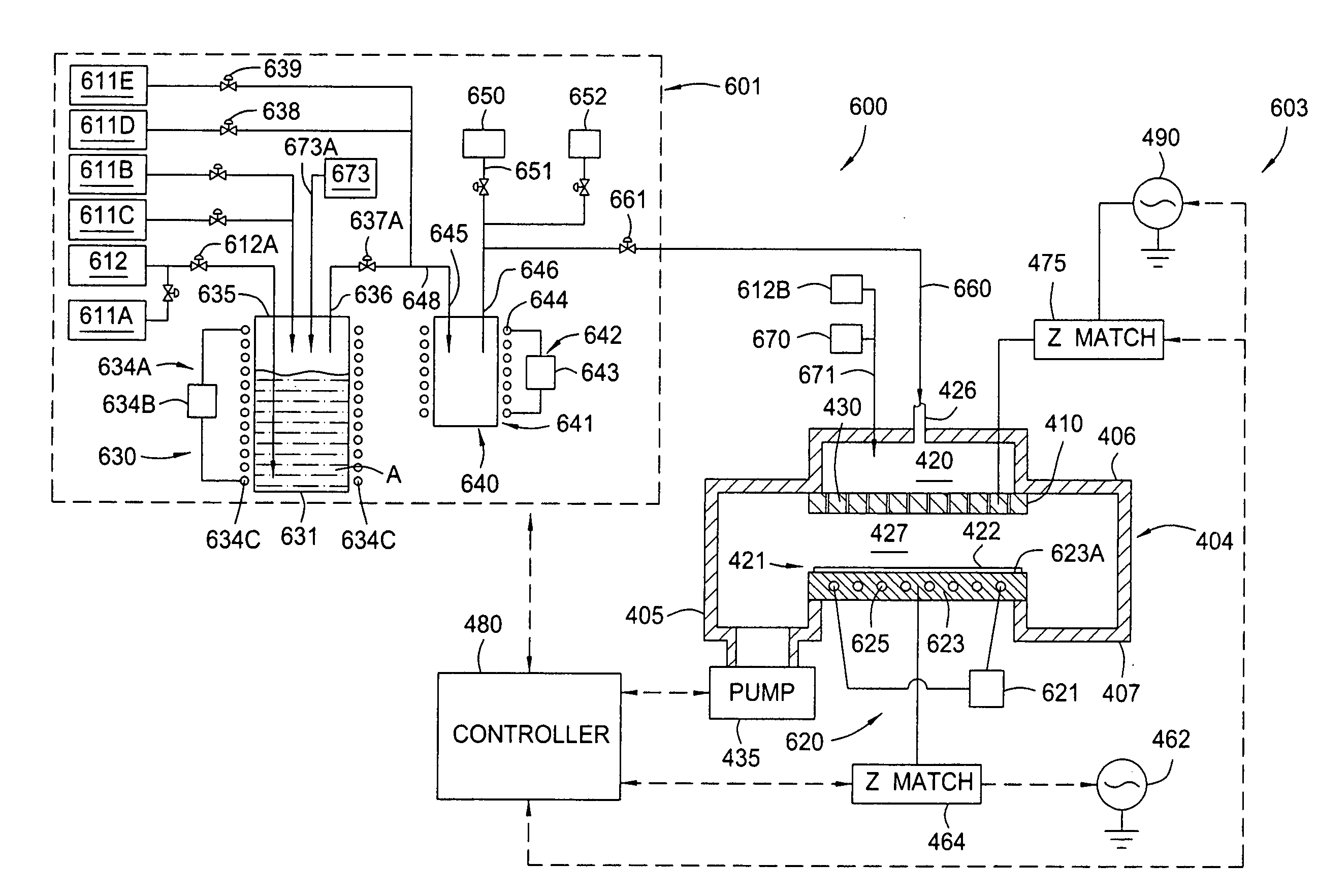

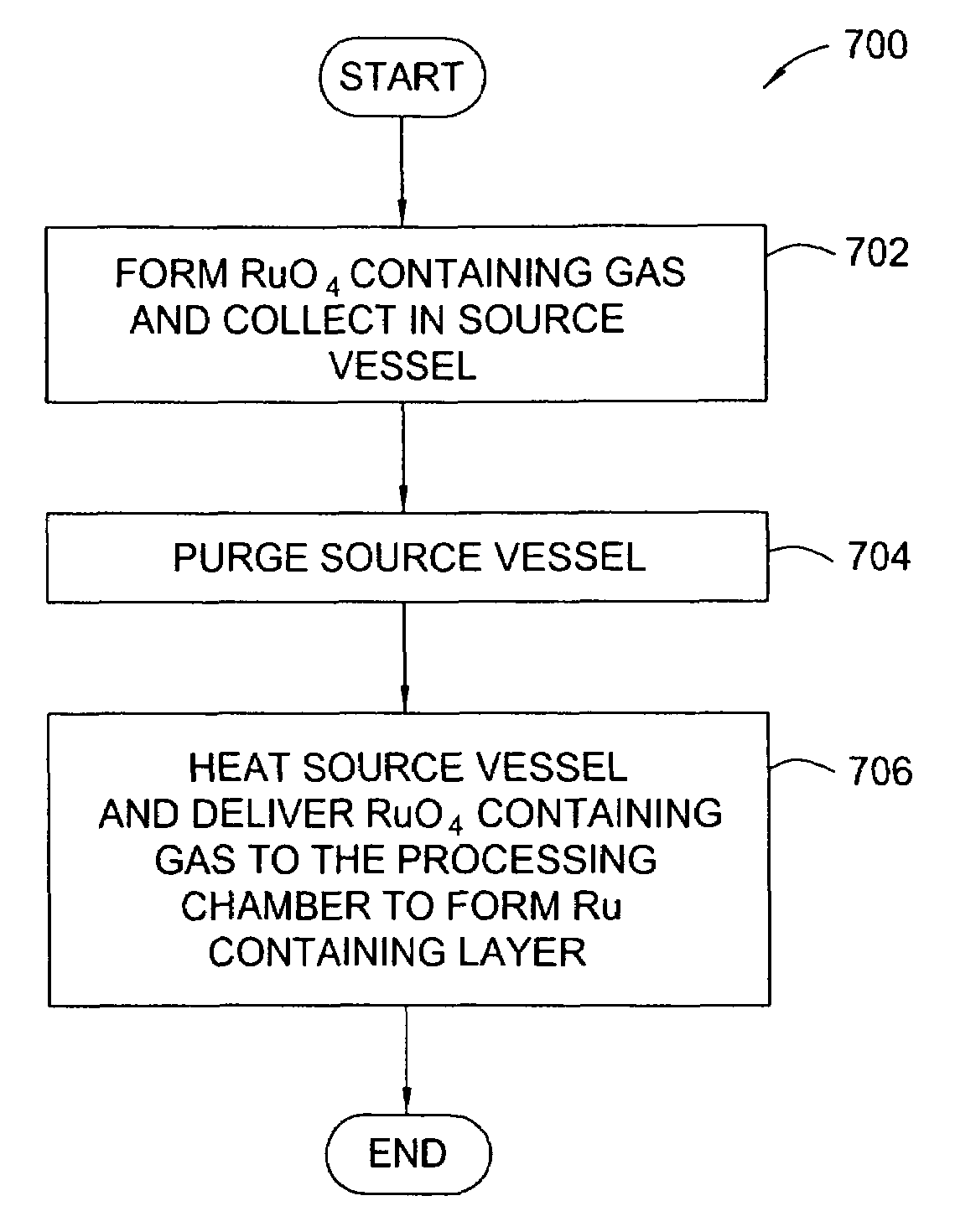

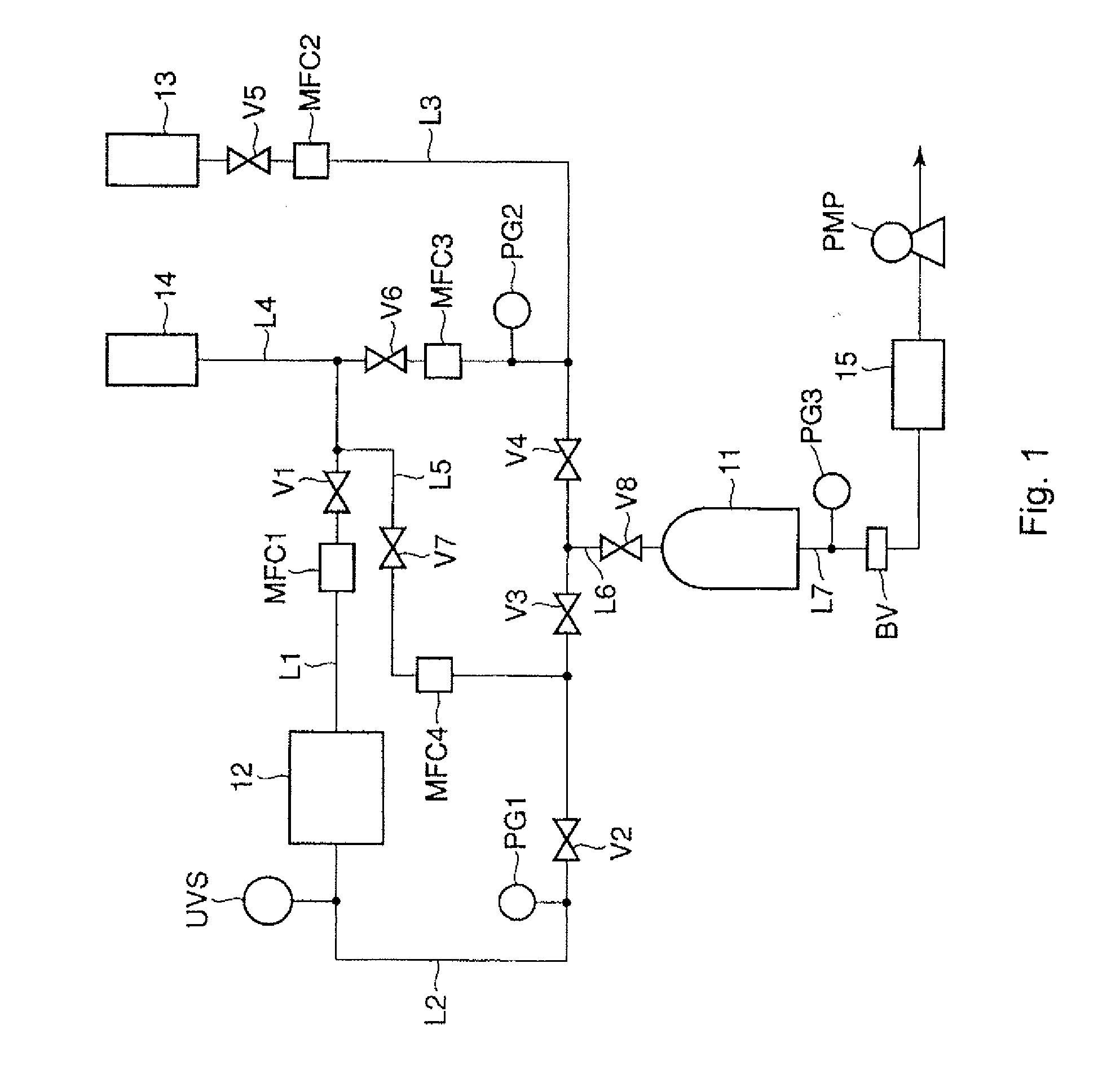

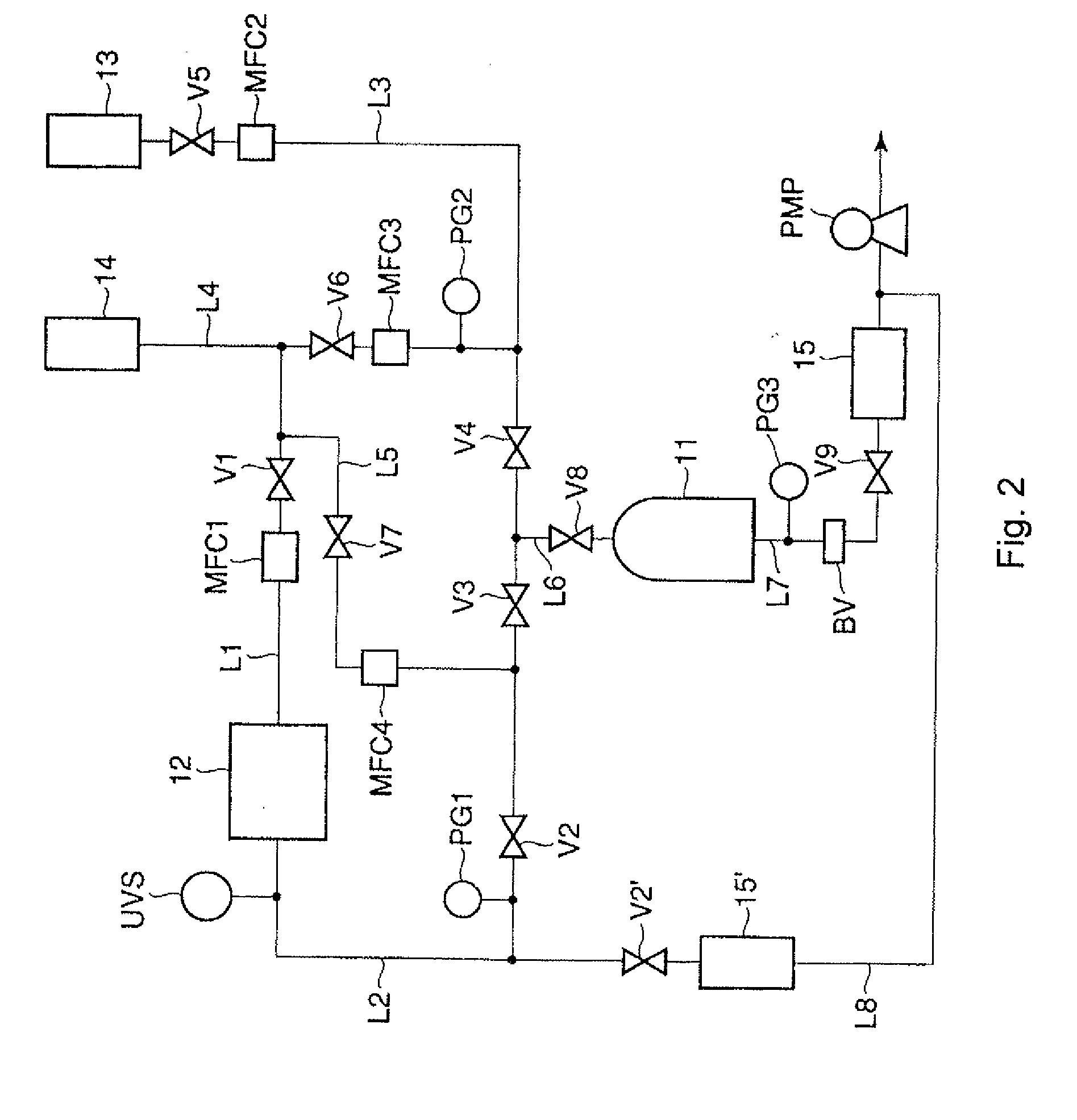

Ruthenium containing layer deposition method

ActiveUS20060165892A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingTemperature controlSource material

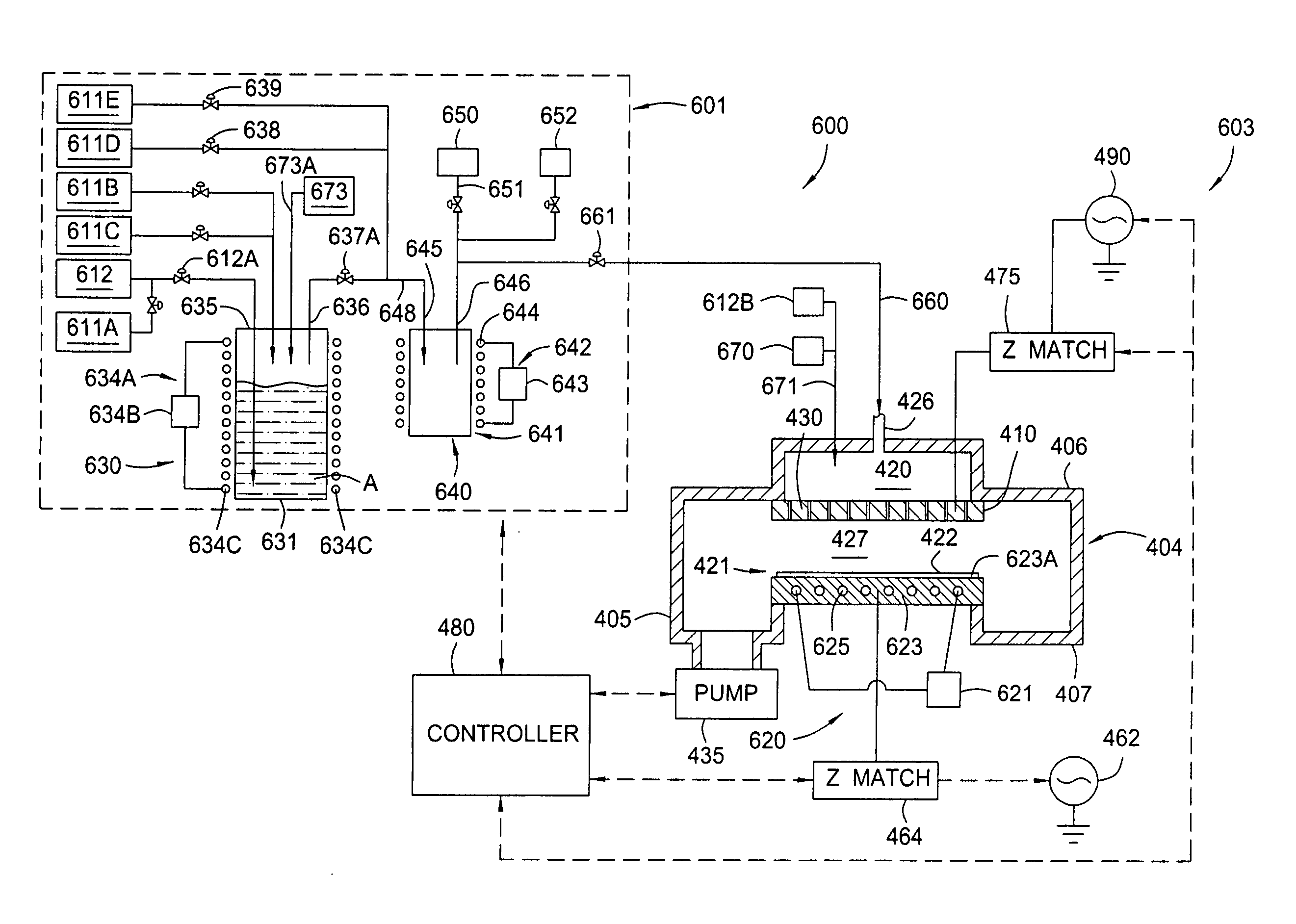

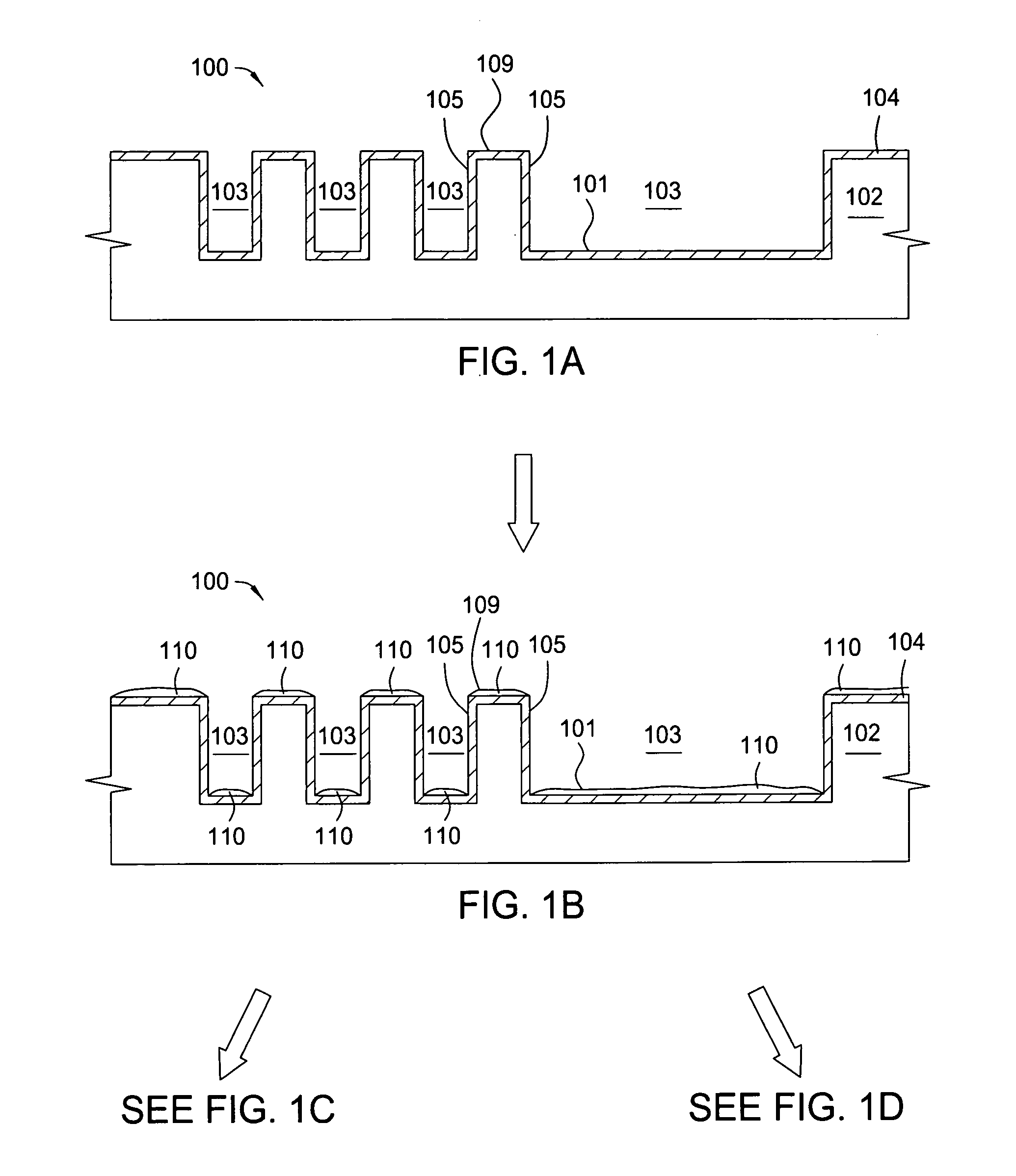

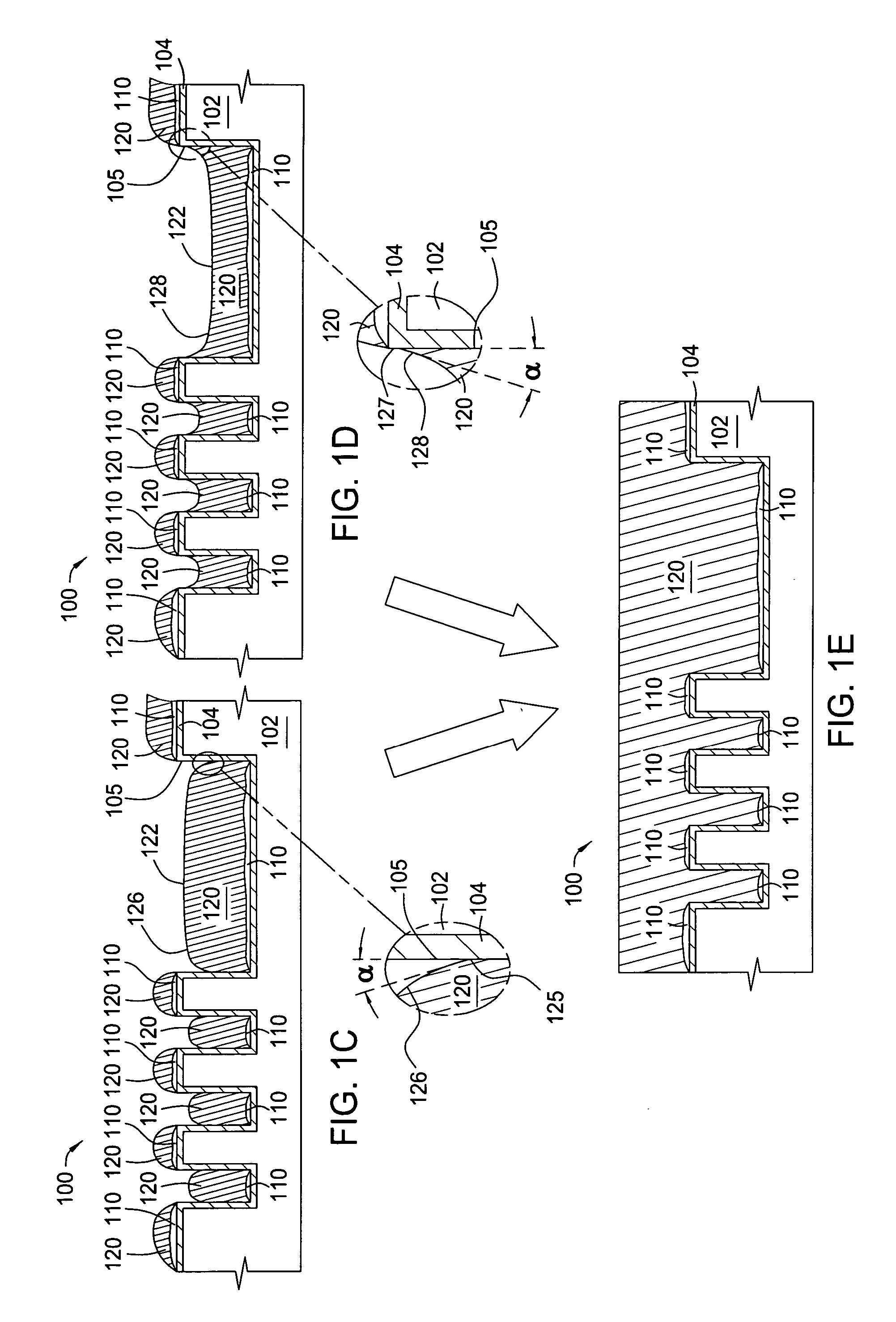

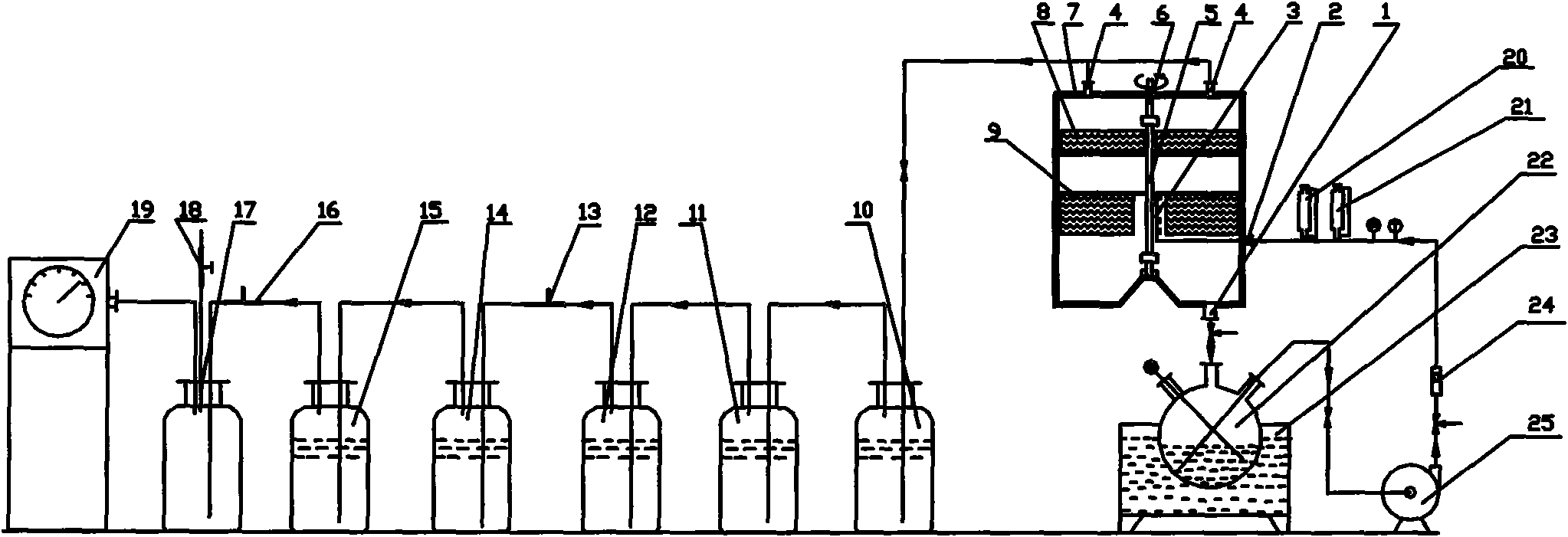

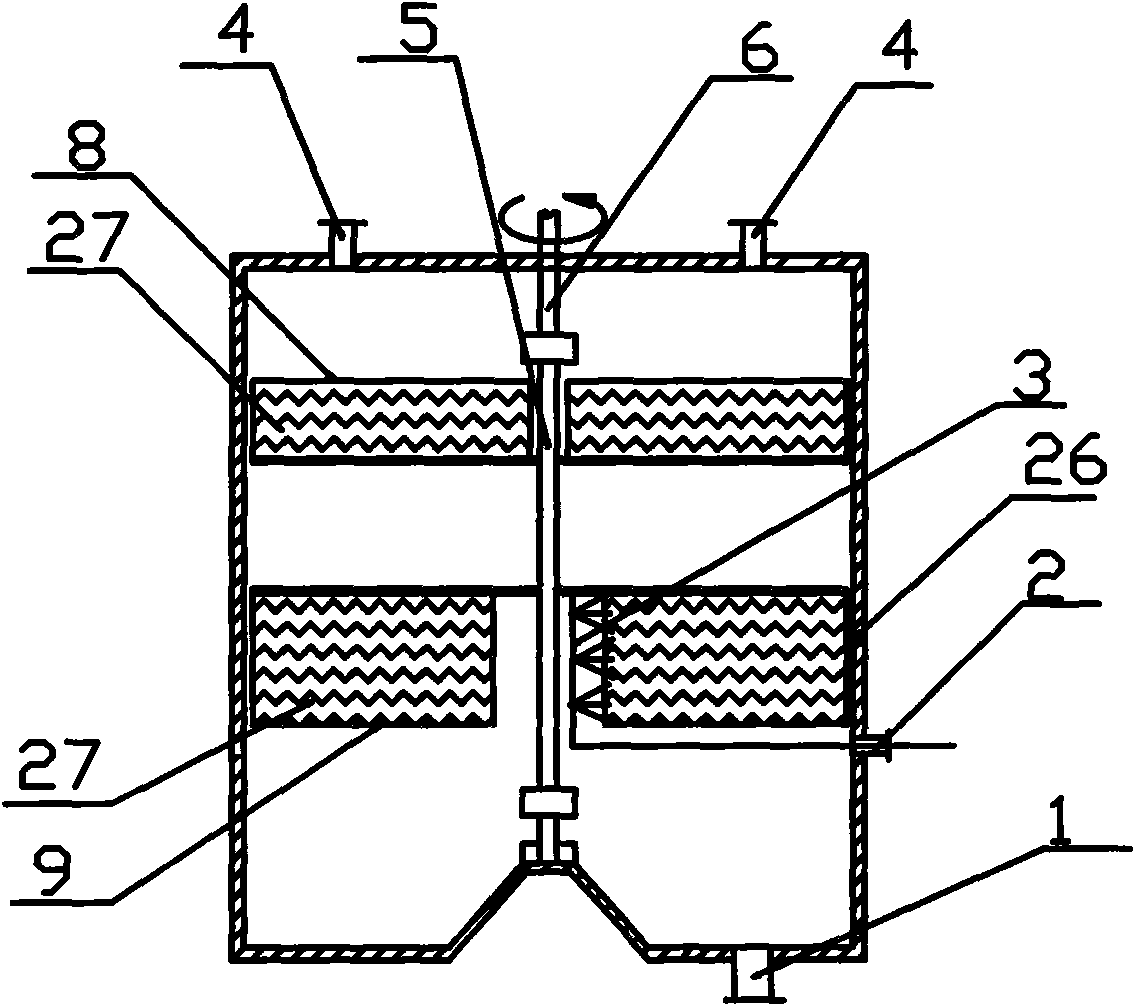

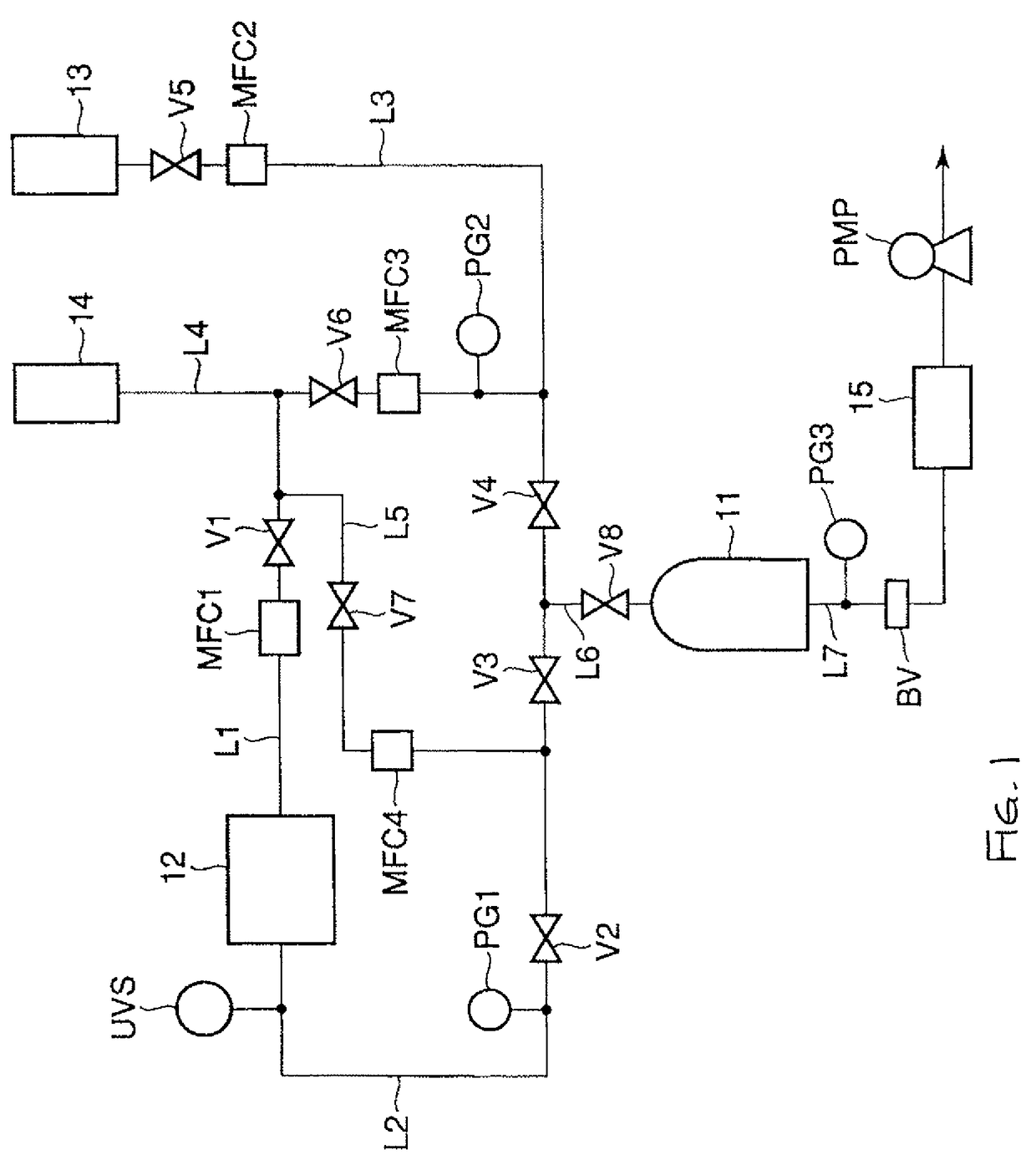

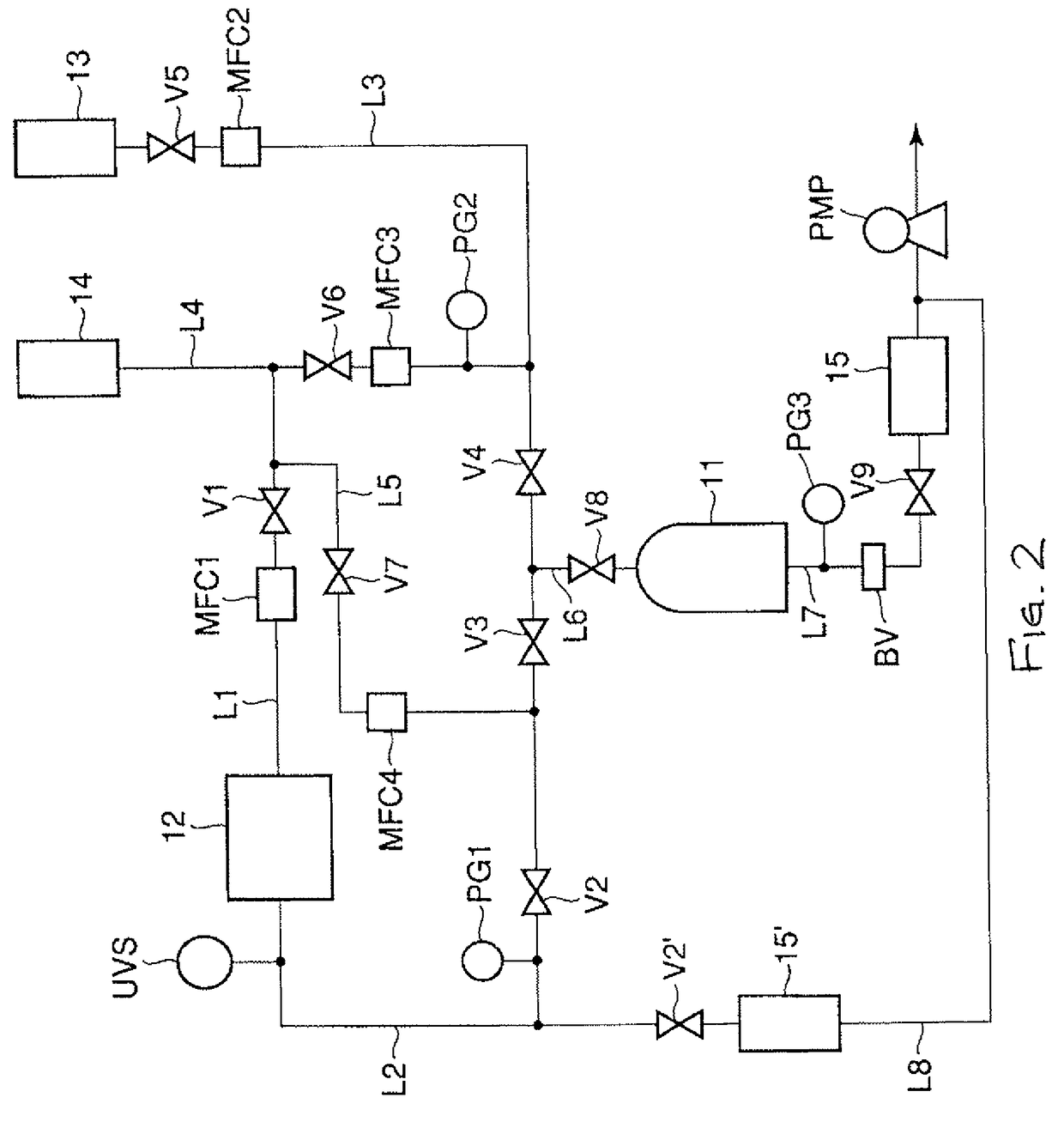

An exemplary apparatus and method of forming a ruthenium tetroxide containing gas to form a ruthenium containing layer on a surface of a substrate is described herein. The method and apparatus described herein may be especially useful for fabricating electronic devices that are formed on a surface of the substrate or wafer. Generally, the method includes exposing a surface of a substrate to a ruthenium tetroxide vapor to form a catalytic layer on the surface of a substrate and then filling the device structures by an electroless, electroplating, physical vapor deposition (PVD), chemical vapor deposition (CVD), plasma enhanced CVD (PECVD), atomic layer deposition (ALD) or plasma enhanced ALD (PE-ALD) processes. In one embodiment, the ruthenium containing layer is formed on a surface of a substrate by creating ruthenium tetroxide in an external vessel and then delivering the generated ruthenium tetroxide gas to a surface of a temperature controlled substrate positioned in a processing chamber. In one embodiment, a ruthenium tetroxide containing solvent formation process is used to form ruthenium tetroxide using a ruthenium tetroxide containing source material. In one embodiment, of a ruthenium containing layer is formed on a surface of a substrate, using the ruthenium tetroxide containing solvent. In another embodiment, the solvent is separated from the ruthenium tetroxide containing solvent mixture and the remaining ruthenium tetroxide is used to form a ruthenium containing layer on the surface of a substrate.

Owner:APPLIED MATERIALS INC

Methods for forming a ruthenium-based film on a substrate

ActiveUS20080214003A1Without riskStable long-term holding (storage)Semiconductor/solid-state device manufacturingChemical vapor deposition coatingSolventSemiconductor

Methods for forming a film on a substrate in a semiconductor manufacturing process A reaction chamber a substrate in the chamber are provided. A ruthenium based precursor, which includes ruthenium tetroxide dissolved in a mixture of at least two non-flammable fluorinated solvents, is provided and a ruthenium containing film is produced on the substrate.

Owner:AIR LIQUIDE ELECTRONICS US LP

Use of ruthenium tetroxide as a precursor and reactant for thin film depositions

ActiveUS20130059078A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingAtomic layer depositionSemiconductor

Disclosed are atomic layer deposition methods using ruthenium-containing precursors to form ruthenium-containing films for use in the manufacture of semiconductor, photovoltaic, LCD-TFT, or flat panel type devices.

Owner:AIR LIQUIDE AMERICA INC +1

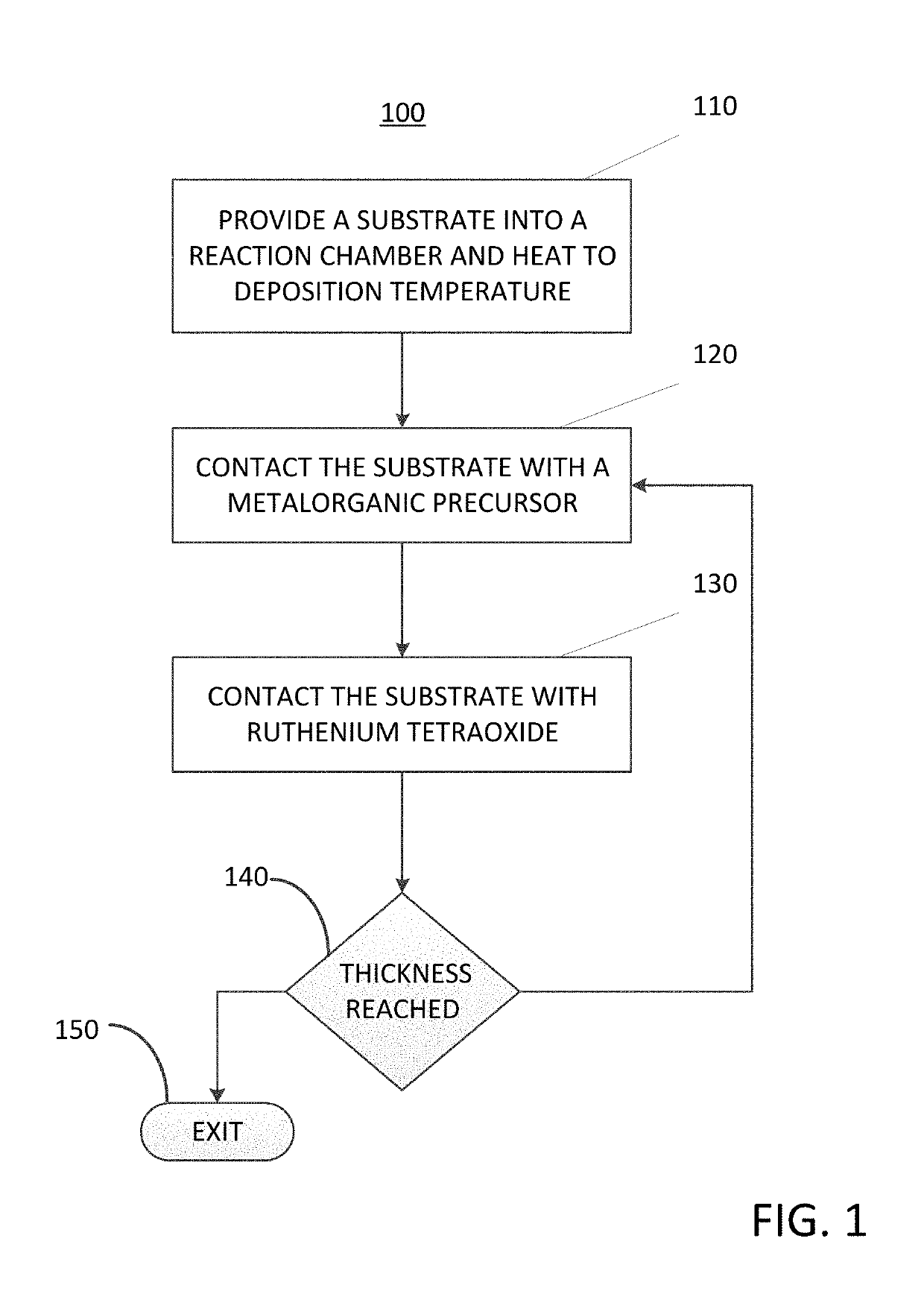

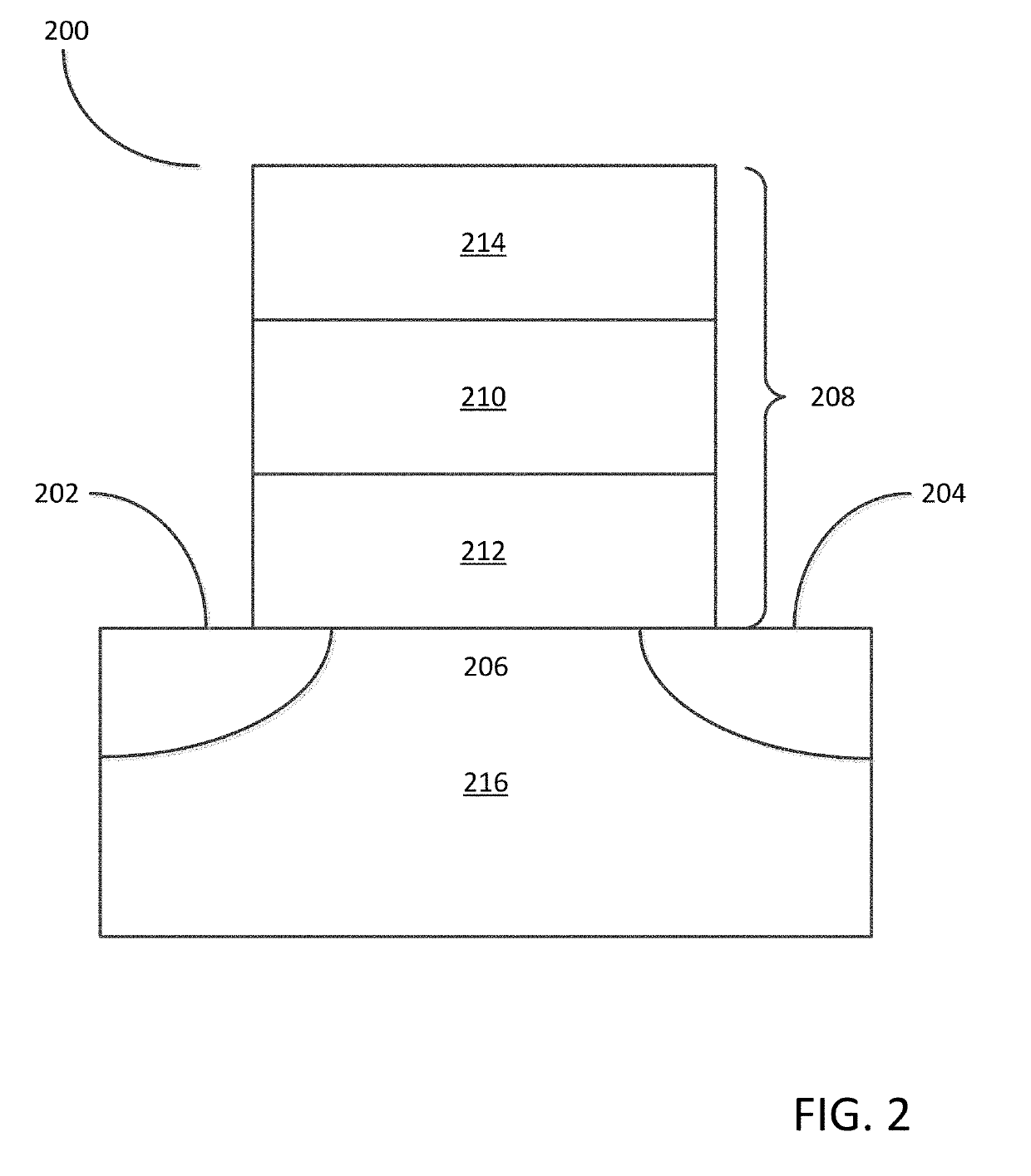

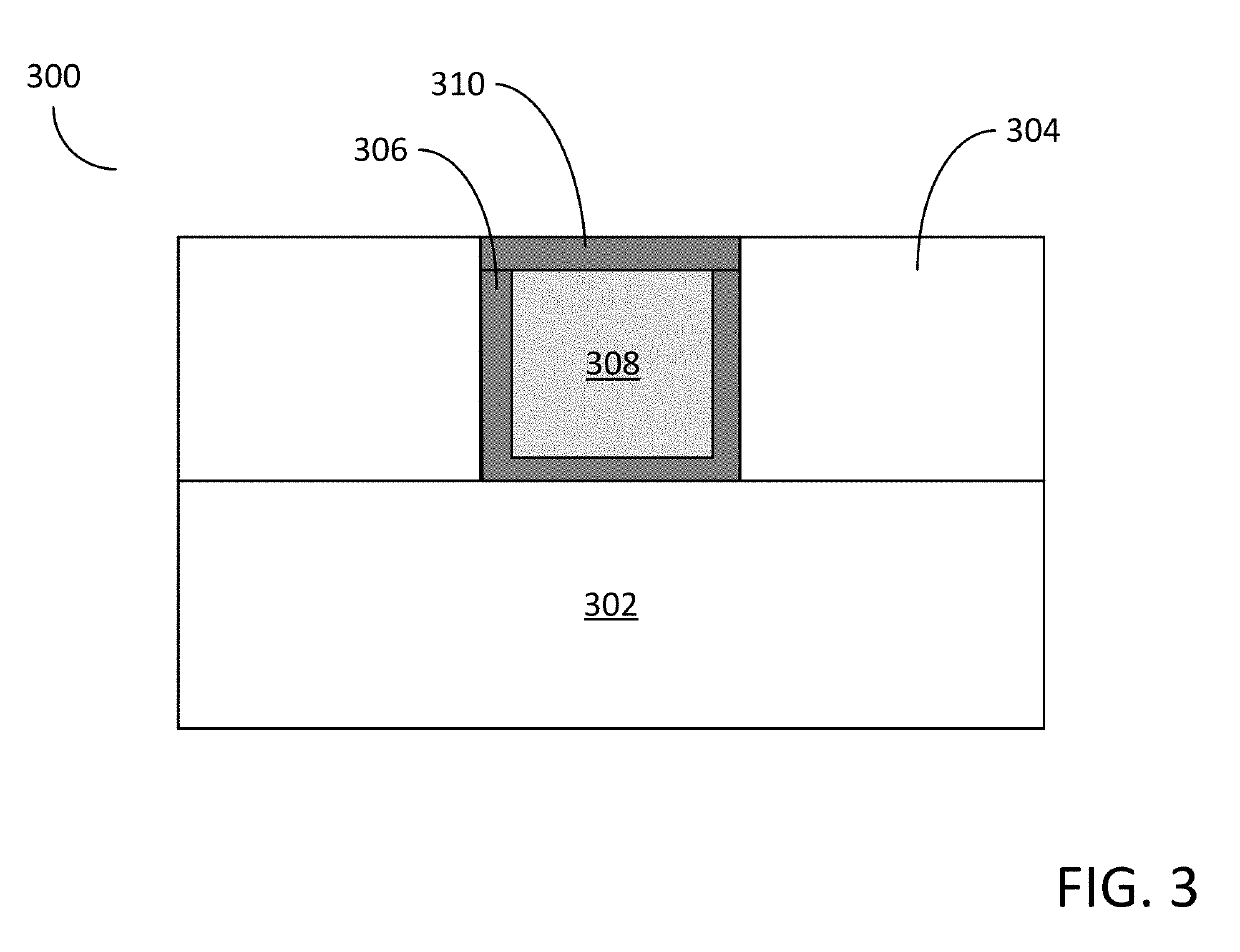

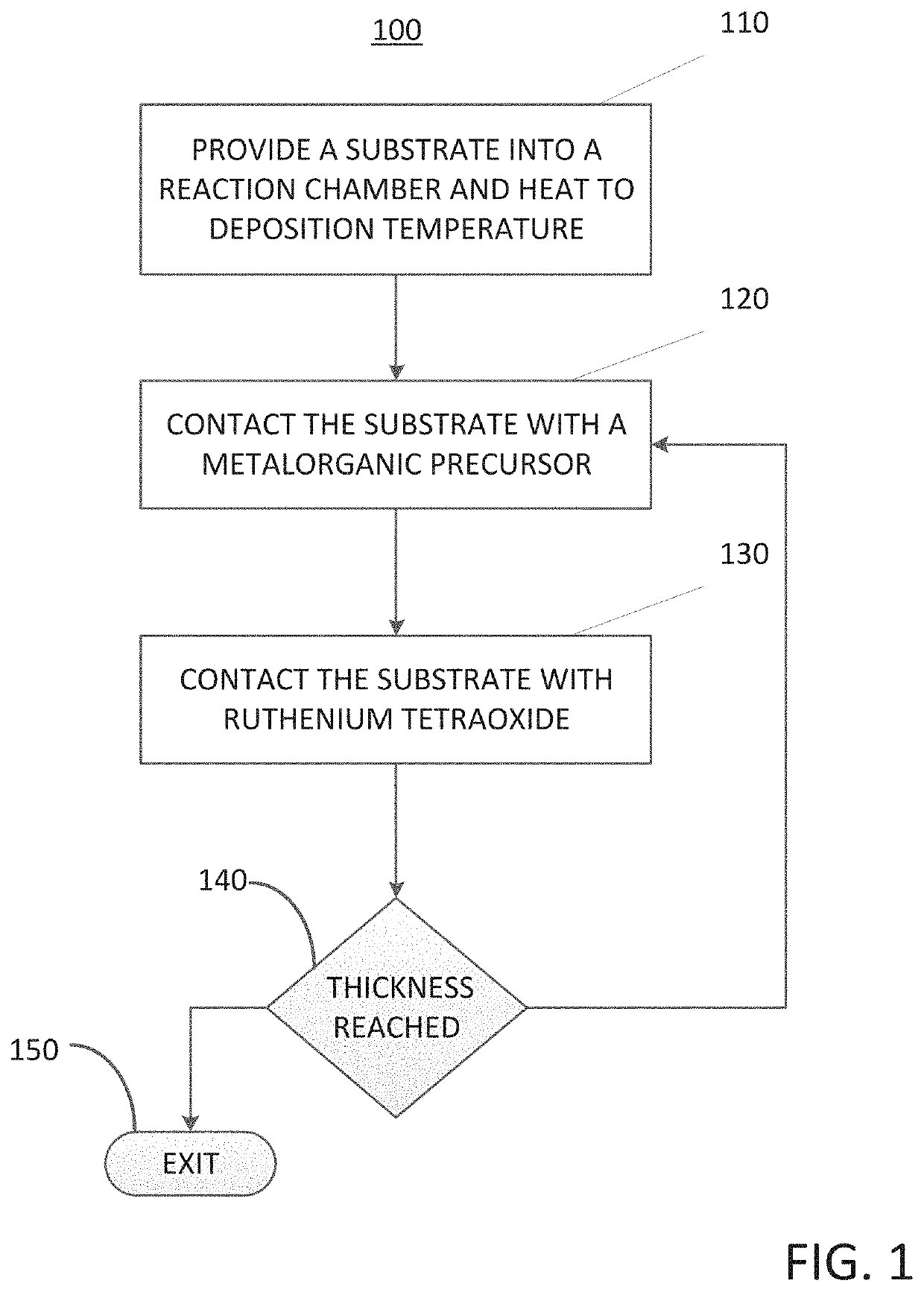

Method for depositing a ruthenium-containing film on a substrate by a cyclical deposition process

A method for depositing a ruthenium-containing film on a substrate by a cyclical deposition process is disclosed. The method may include: contacting the substrate with a first vapor phase reactant comprising a metalorganic precursor, the metalorganic precursor comprising a metal selected from the group consisting of a cobalt, nickel, tungsten, molybdenum, manganese, iron, and combinations thereof. The method may also include; contacting the substrate with a second vapor phase reactant comprising ruthenium tetroxide (RuO4); wherein the ruthenium-containing film comprises a ruthenium-metal alloy. Semiconductor device structures including ruthenium-metal alloys deposited by the methods of the disclosure are also disclosed.

Owner:ASM IP HLDG BV

Method for depositing a ruthenium-containing film on a substrate by a cyclical deposition process

A method for depositing a ruthenium-containing film on a substrate by a cyclical deposition process is disclosed. The method may include: contacting the substrate with a first vapor phase reactant comprising a metalorganic precursor, the metalorganic precursor comprising a metal selected from the group consisting of a cobalt, nickel, tungsten, molybdenum, manganese, iron, and combinations thereof. The method may also include; contacting the substrate with a second vapor phase reactant comprising ruthenium tetroxide (RuO4); wherein the ruthenium-containing film comprises a ruthenium-metal alloy. Semiconductor device structures including ruthenium-metal alloys deposited by the methods of the disclosure are also disclosed.

Owner:ASM IP HLDG BV

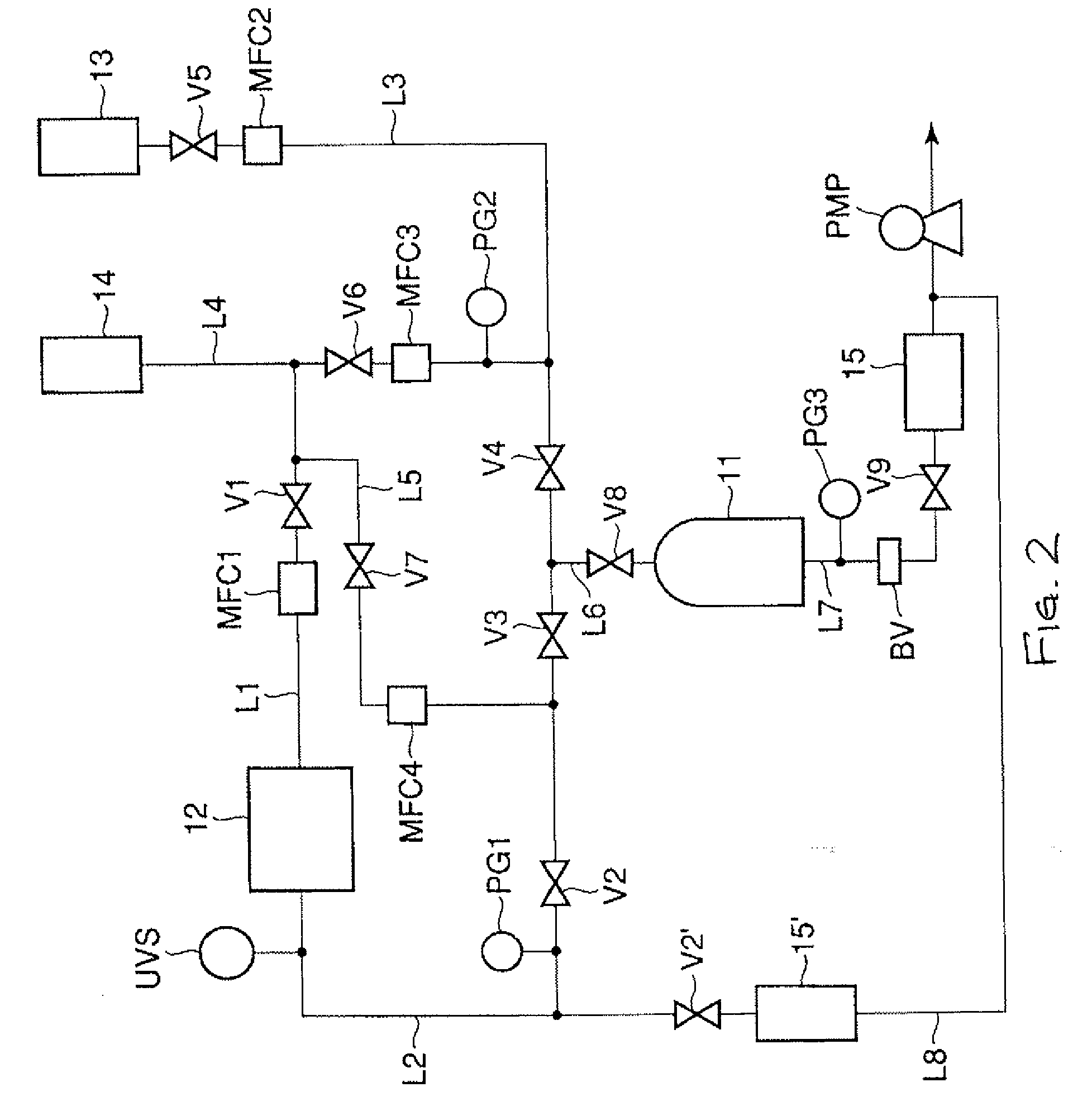

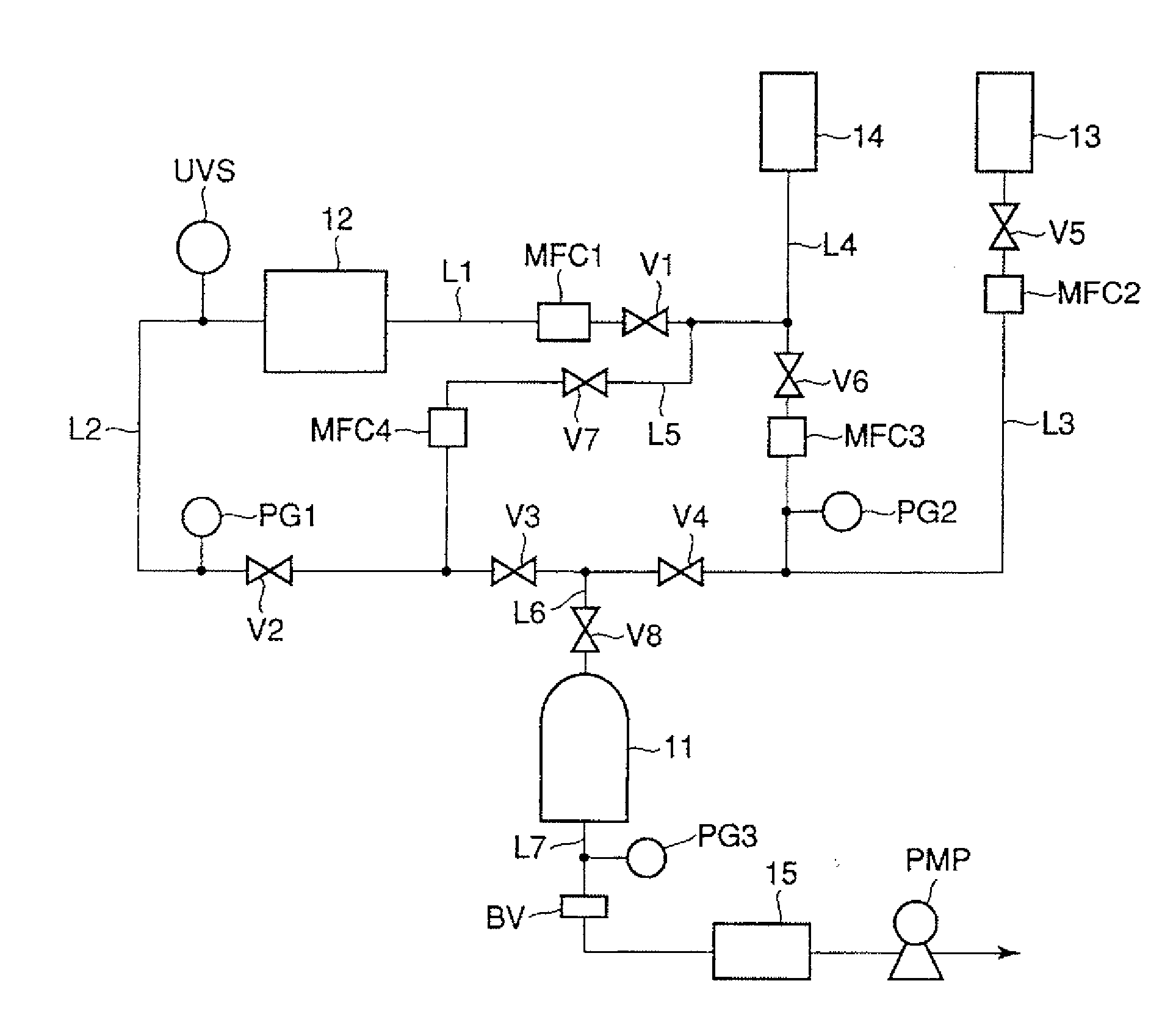

Ruthenium layer deposition apparatus and method

InactiveUS20060162658A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingTemperature controlSource material

An exemplary apparatus and method of forming a ruthenium tetroxide containing gas to form a ruthenium containing layer on a surface of a substrate is described herein. The method and apparatus described herein may be especially useful for fabricating electronic devices that are formed on a surface of the substrate or wafer. Generally, the method includes exposing a surface of a substrate to a ruthenium tetroxide vapor to form a catalytic layer on the surface of a substrate and then filling the device structures by an electroless, electroplating, physical vapor deposition (PVD), chemical vapor deposition (CVD), plasma enhanced CVD (PECVD), atomic layer deposition (ALD) or plasma enhanced ALD (PE-ALD) processes. In one embodiment, the ruthenium containing layer is formed on a surface of a substrate by creating ruthenium tetroxide in an external vessel and then delivering the generated ruthenium tetroxide gas to a surface of a temperature controlled substrate positioned in a processing chamber. In one embodiment, a ruthenium tetroxide containing solvent formation process is used to form ruthenium tetroxide using a ruthenium tetroxide containing source material. In one embodiment, of a ruthenium containing layer is formed on a surface of a substrate, using the ruthenium tetroxide containing solvent. In another embodiment, the solvent is separated from the ruthenium tetroxide containing solvent mixture and the remaining ruthenium tetroxide is used to form a ruthenium containing layer on the surface of a substrate.

Owner:APPLIED MATERIALS INC

Process for producing high-purity ruthenium

InactiveUS6036741AReduce Particle GenerationVacuum evaporation coatingSolid-state devicesAlkaline earth metalHydrogen atmosphere

A process comprises forming ruthenium tetroxide by blowing ozone-containing gas into crude ruthenium powder while hypochlorous acid is being added to the powder, allowing a hydrochloric acid solution to absorb the ruthenium tetroxide, evaporating the solution to dryness, and roasting the RuOCl3 crystals thus obtained in a hydrogen atmosphere. Thus a high-purity ruthenium material for thin film deposition, typically sputtering targey, is obtained which contains less than 1 ppm each of alkali metal elements, less than 1 ppm each of alkaline earth metal elements, less than 1 ppm each of transition metal elements, less than 10 ppb each of radioactive elements, a total of less than 500 ppm of carbon and gaseous ingredient elements, the material having a purity of ruthenium of at least 99.995% excluding the gaseous ingredient elements.

Owner:JAPAN ENERGY CORP

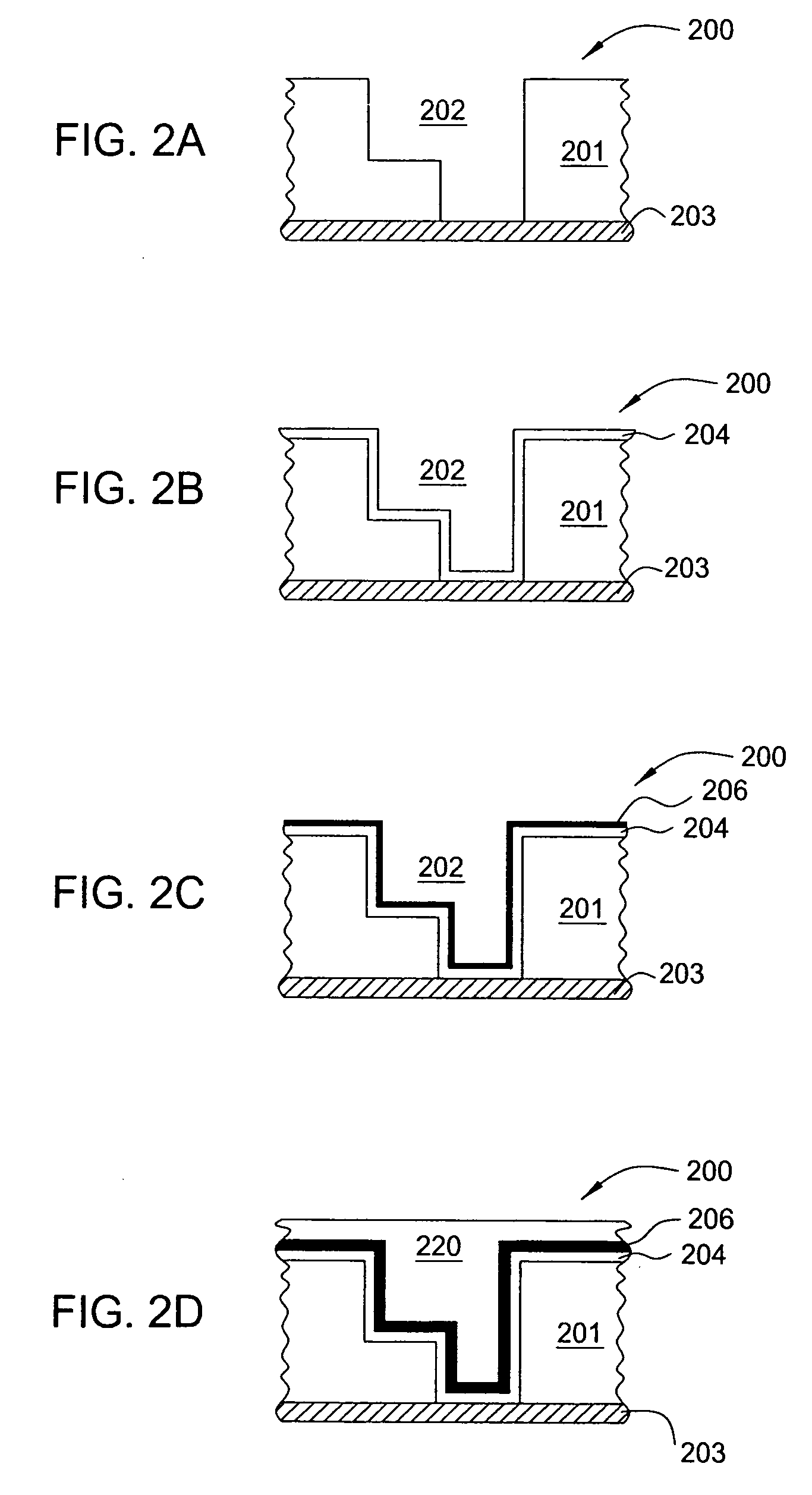

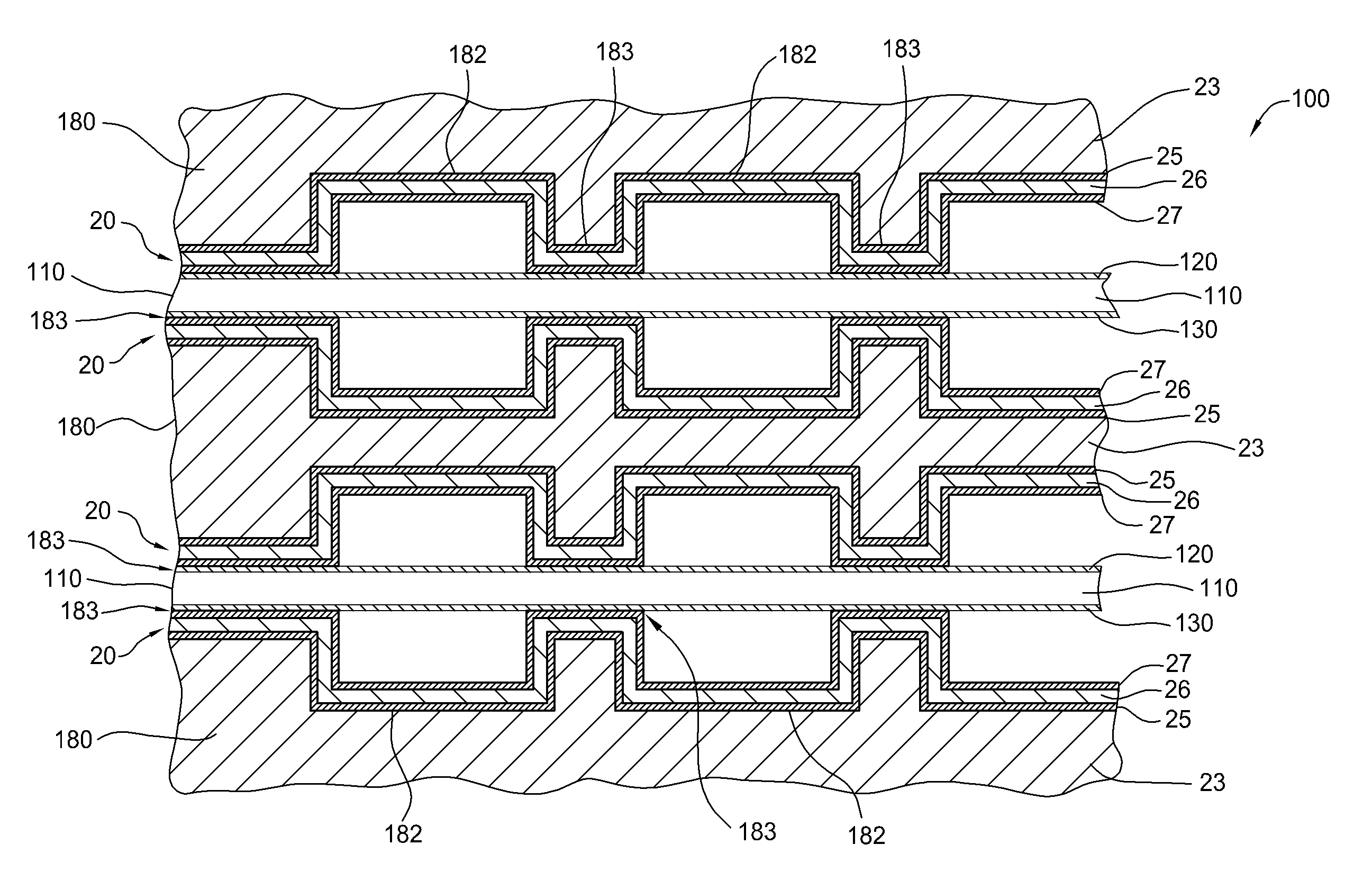

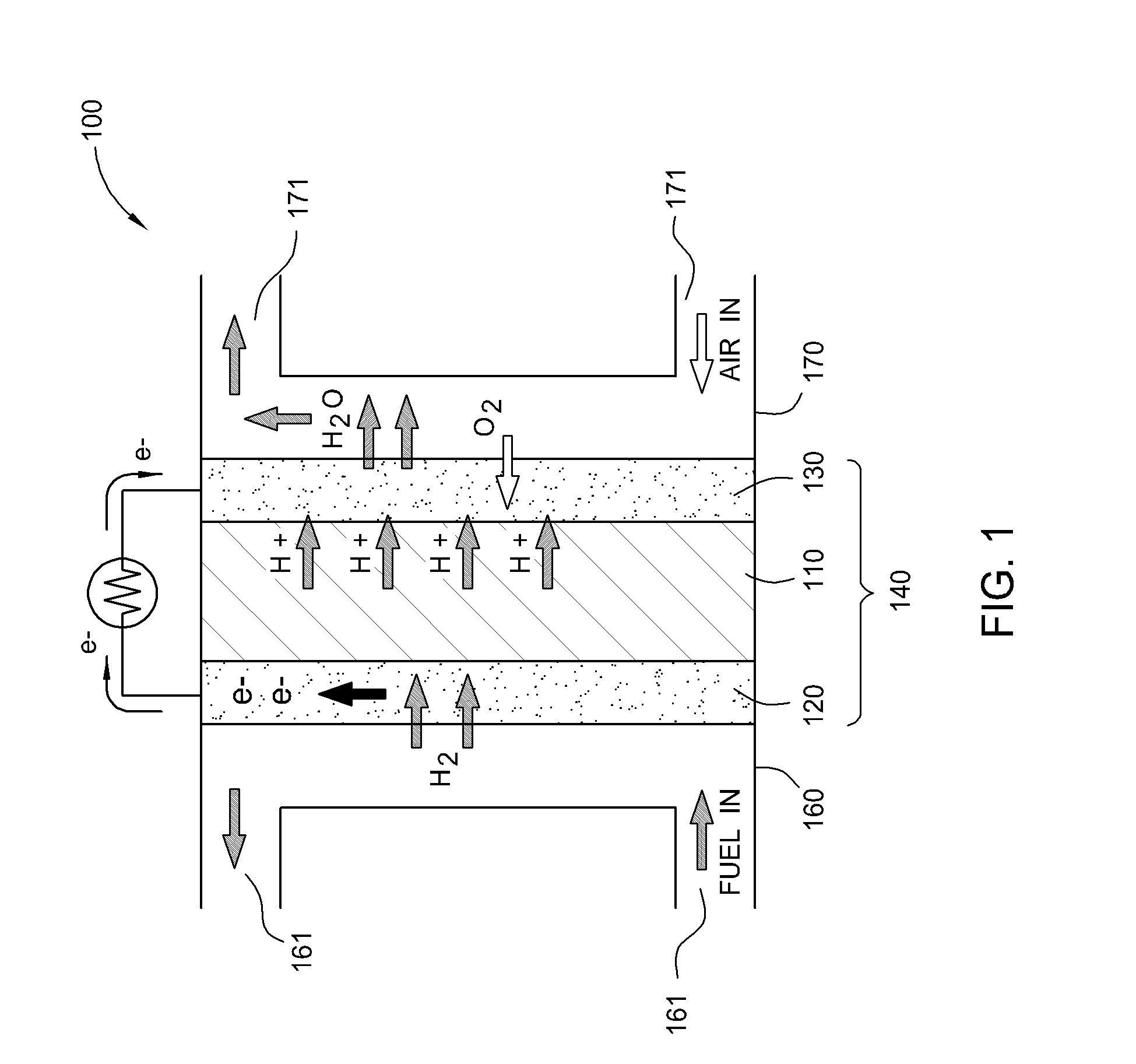

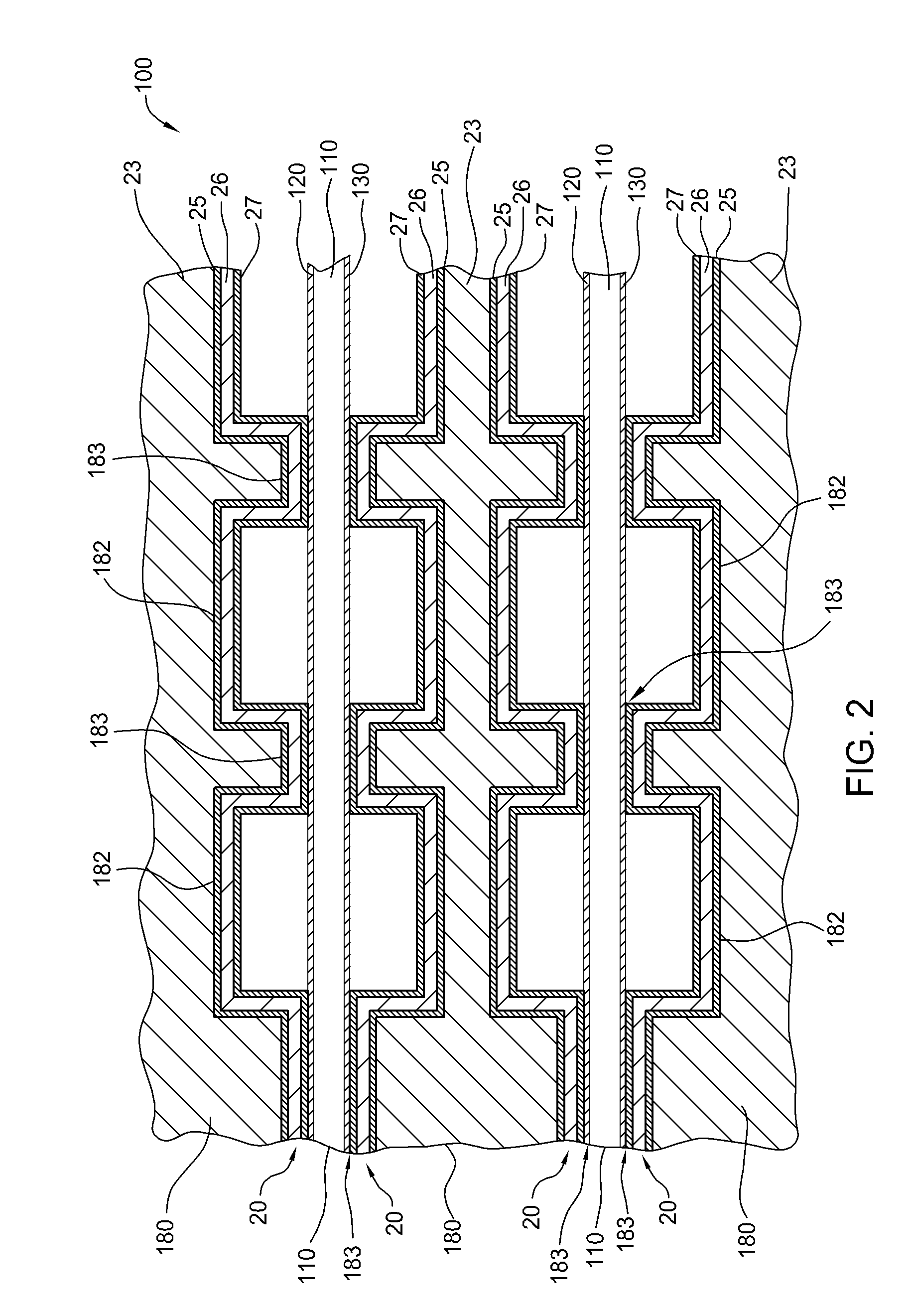

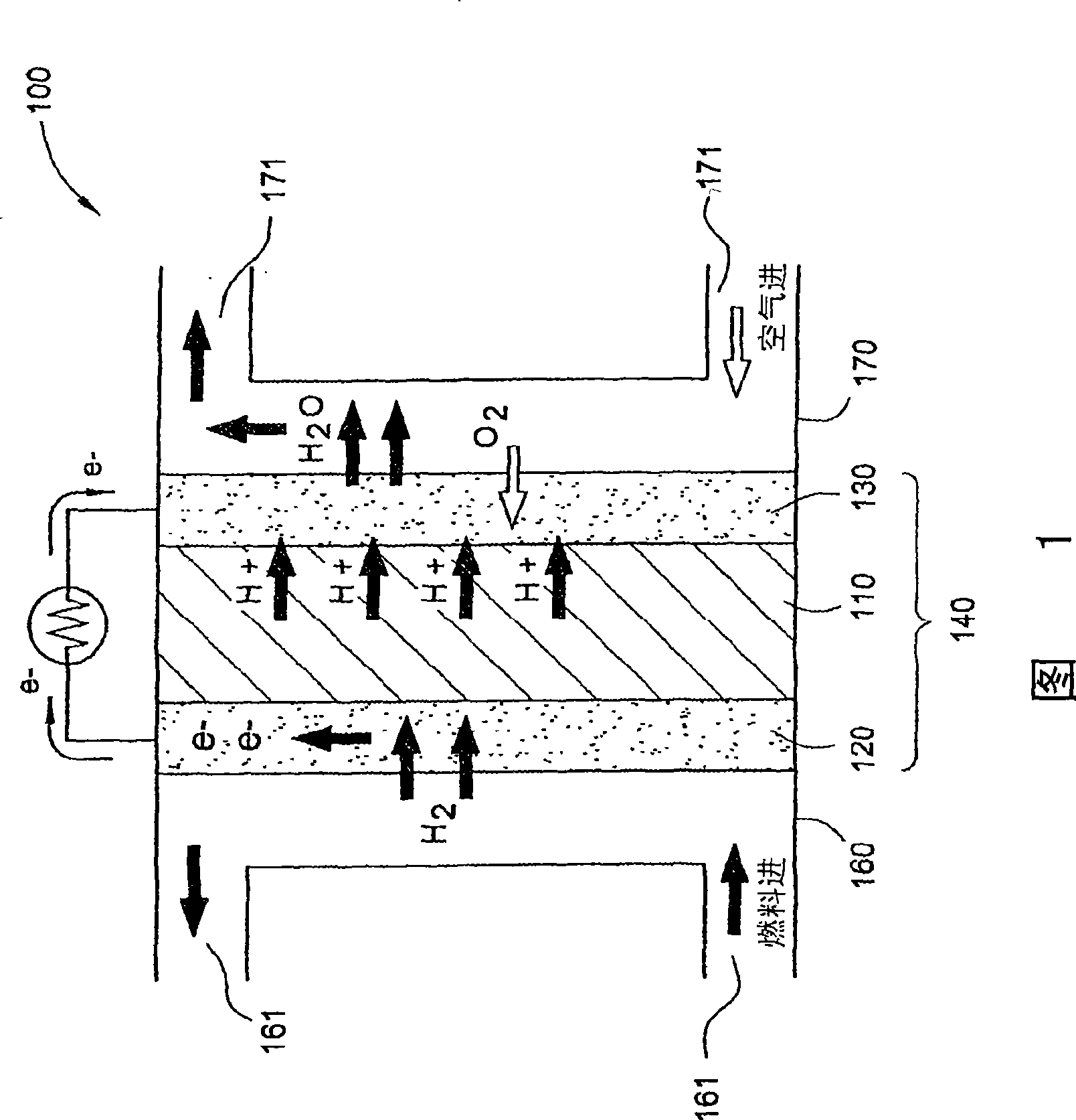

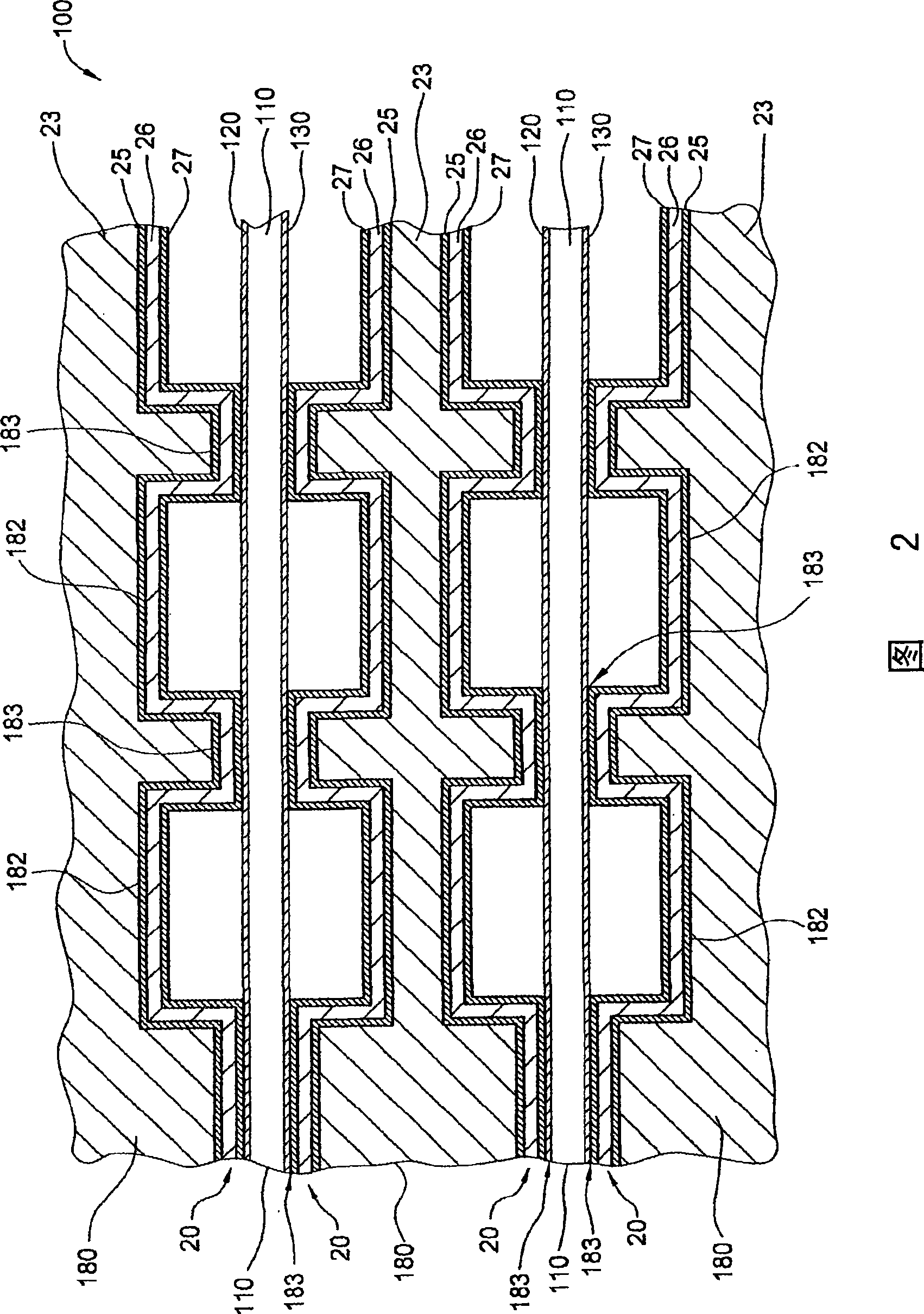

Reliable fuel cell electrode design

InactiveUS20070243452A1Avoid Surface CorrosionAvoid corrosionFinal product manufactureFuel cell auxillariesFuel cellsEngineering

The present invention generally relates to the creation of fuel cell components and the method of forming the various fuel cell components that have an improved lifetime, lower production cost and improved process performance. The invention generally includes treating or conditioning a substrate surface by depositing a material layer, or layers, having good adhesion to the substrate, low electrical resistivity (high conductivity) and has good resistance to chemical attack during the operation of fuel cell. The substrate may be, for example, a fuel cell part, a conductive plate, a separator plate, a bipolar plate or an end plate, among others. In one embodiment, the substrate surface is treated or conditioned by exposing at least a portion of it to a gas or liquid comprising ruthenium tetroxide.

Owner:APPLIED MATERIALS INC

Ruthenium containing layer deposition method

ActiveUS7438949B2Semiconductor/solid-state device manufacturingChemical vapor deposition coatingTemperature controlSource material

An exemplary apparatus and method of forming a ruthenium tetroxide containing gas to form a ruthenium containing layer on a surface of a substrate is described herein. The method and apparatus described herein may be especially useful for fabricating electronic devices that are formed on a surface of the substrate or wafer. Generally, the method includes exposing a surface of a substrate to a ruthenium tetroxide vapor to form a catalytic layer on the surface of a substrate and then filling the device structures by an electroless, electroplating, physical vapor deposition (PVD), chemical vapor deposition (CVD), plasma enhanced CVD (PECVD), atomic layer deposition (ALD) or plasma enhanced ALD (PE-ALD) processes. In one embodiment, the ruthenium containing layer is formed on a surface of a substrate by creating ruthenium tetroxide in an external vessel and then delivering the generated ruthenium tetroxide gas to a surface of a temperature controlled substrate positioned in a processing chamber. In one embodiment, a ruthenium tetroxide containing solvent formation process is used to form ruthenium tetroxide using a ruthenium tetroxide containing source material. In one embodiment, of a ruthenium containing layer is formed on a surface of a substrate, using the ruthenium tetroxide containing solvent. In another embodiment, the solvent is separated from the ruthenium tetroxide containing solvent mixture and the remaining ruthenium tetroxide is used to form a ruthenium containing layer on the surface of a substrate.

Owner:APPLIED MATERIALS INC

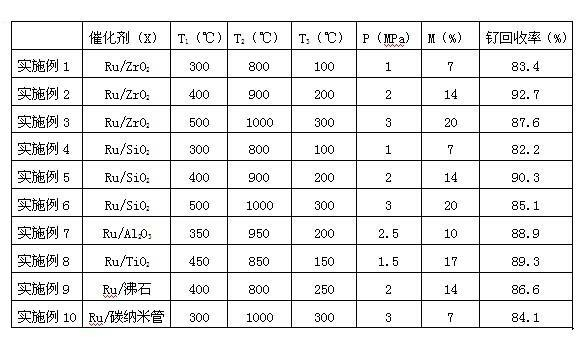

Method for recycling ruthenium in supported type ruthenium catalyst

ActiveCN102108444AReduce recycling stepsEasy to recycleProcess efficiency improvementEconomic benefitsNitrogen

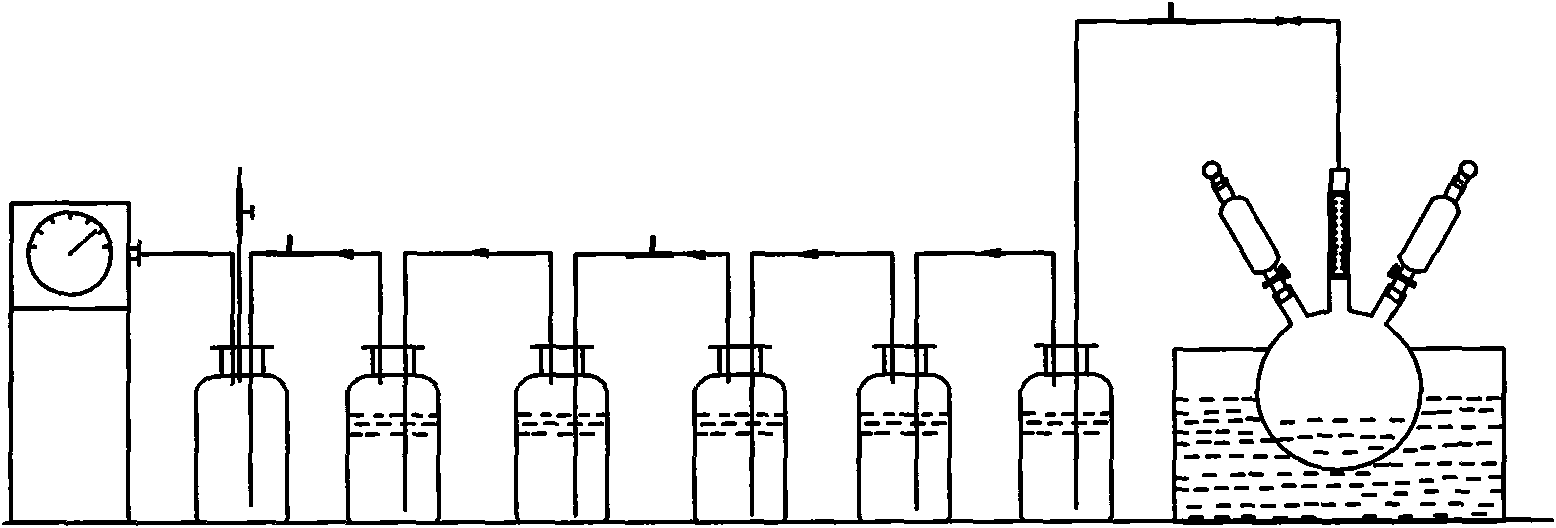

The invention discloses a method for recycling ruthenium in a supported type ruthenium or ruthenium oxide catalyst. The method comprises the following technological steps: (1) placing a supported type ruthenium catalyst or a supported type ruthenium oxide catalyst in an airtight container, heating to 300-500 DEG C, and roasting for 1-2 hours; and feeding nitrogen for protection during roasting process; (2) stopping the feeding of nitrogen stream in the step (1), continuing to heat to 800-1000 DEG C, and roasting for 2-10 hours; and obtaining black solids after cooling; (3) grinding black solids into powder, placing in the airtight container, and heating to 100-300 DEG C; and feeding oxygen / ozone to oxidize solid powder and generate ruthenium tetroxide gas; and (4) feeding the ruthenium tetroxide gas into diluted hydrochloric acid, and restoring the acid combined with the gas into a red and brown ruthenium trichloride solution. According to the device, the step of recycling the catalyst is reduced; not only is the cost reduced during the recycling process of ruthenium catalyst, but also the recycling process is simplified; and economic benefit and the environment benefit are greatly improved.

Owner:KAILUAN ENERGY CHEM

Methods for forming a ruthenium-based film on a substrate

ActiveUS20110171836A1Conductive materialSemiconductor/solid-state device manufacturingSolventSemiconductor

Owner:AIR LIQUIDE ELECTRONICS US LP

Method for preparing high-purity ruthenium sputtering target and high-purity ruthenium sputtering target

InactiveUS6284013B1Minimize formation of particleSolve the large leakage currentTransportation and packagingRuthenium/rhodium/palladium/osmium/iridium/platinum compoundsHydrogen atmosphereImpurity

There is provided a high-purity ruthenium sputtering target with a low impurity content, in particular producing extremely few particles, which is suitable for applications such as the formation of semiconductor thin films. The high-purity ruthenium sputtering target is manufactured by feeding crude ruthenium powder into a sodium hydroxide solution; blowing an ozone-containing gas while or after blowing chlorine gas into the solution to form ruthenium tetroxide; absorbing the ruthenium tetroxide in a hydrochloric acid solution or a mixed solution of hydrochloric acid and ammonium chloride, and evaporating the solution to dryness; sintering the resultant ruthenium salt in a hydrogen atmosphere to form high-purity ruthenium powder; and hot-pressing the ruthenium powder into a sputtering target.

Owner:NIKKO MATERIALS CO LTD

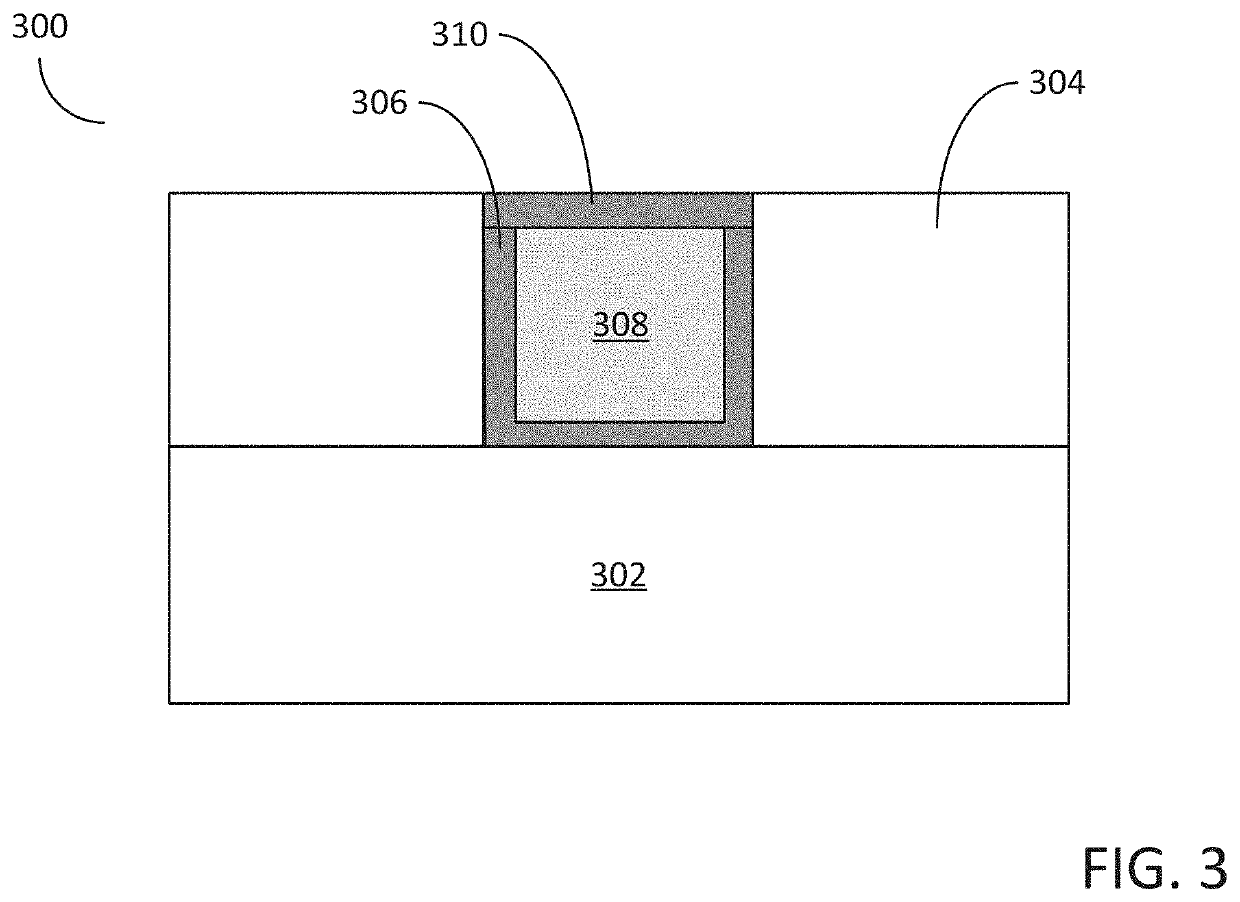

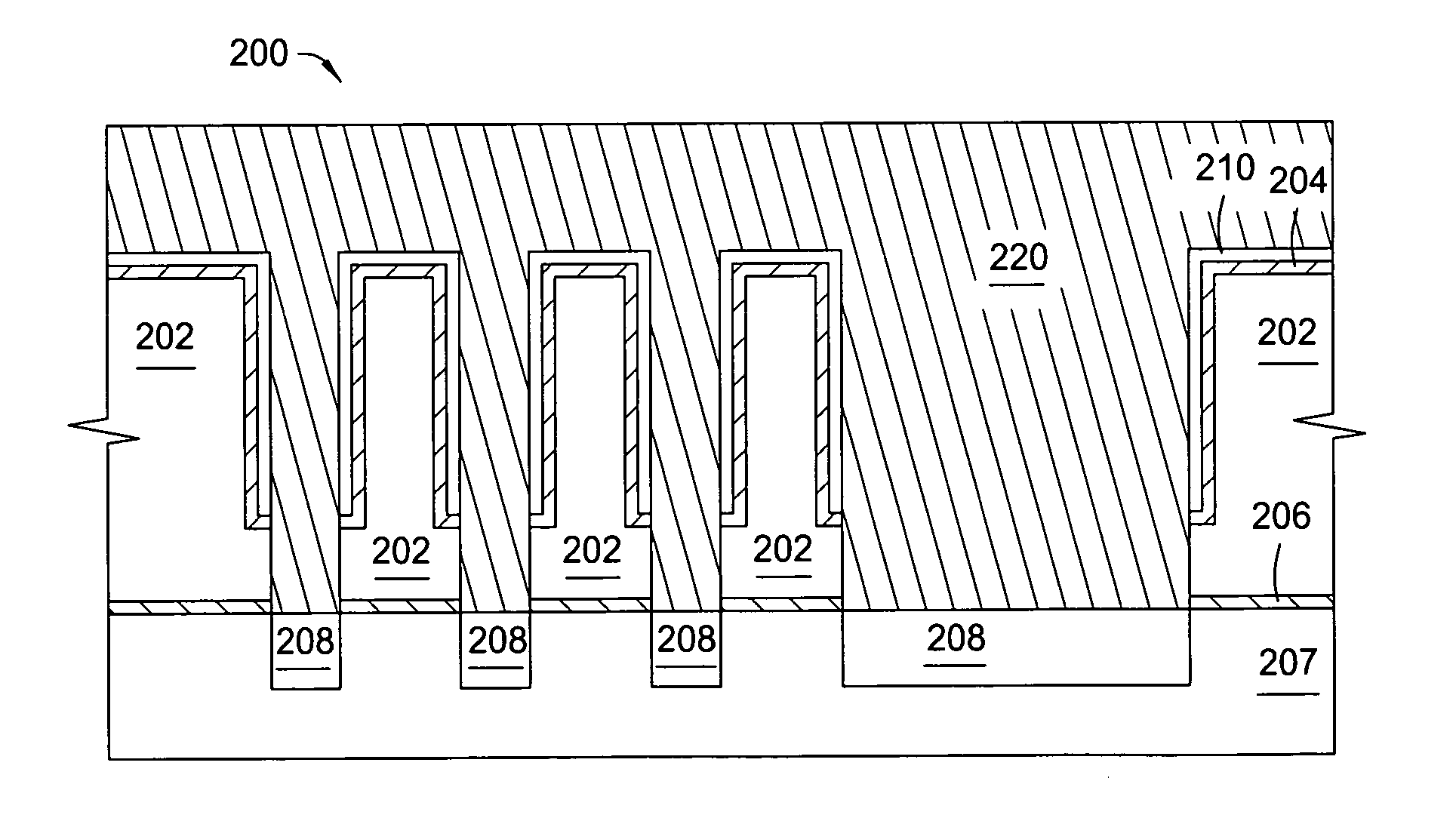

Process for electroless copper deposition

ActiveUS20070004201A1Semiconductor/solid-state device manufacturingLiquid/solution decomposition chemical coatingCompound (substance)Conductive materials

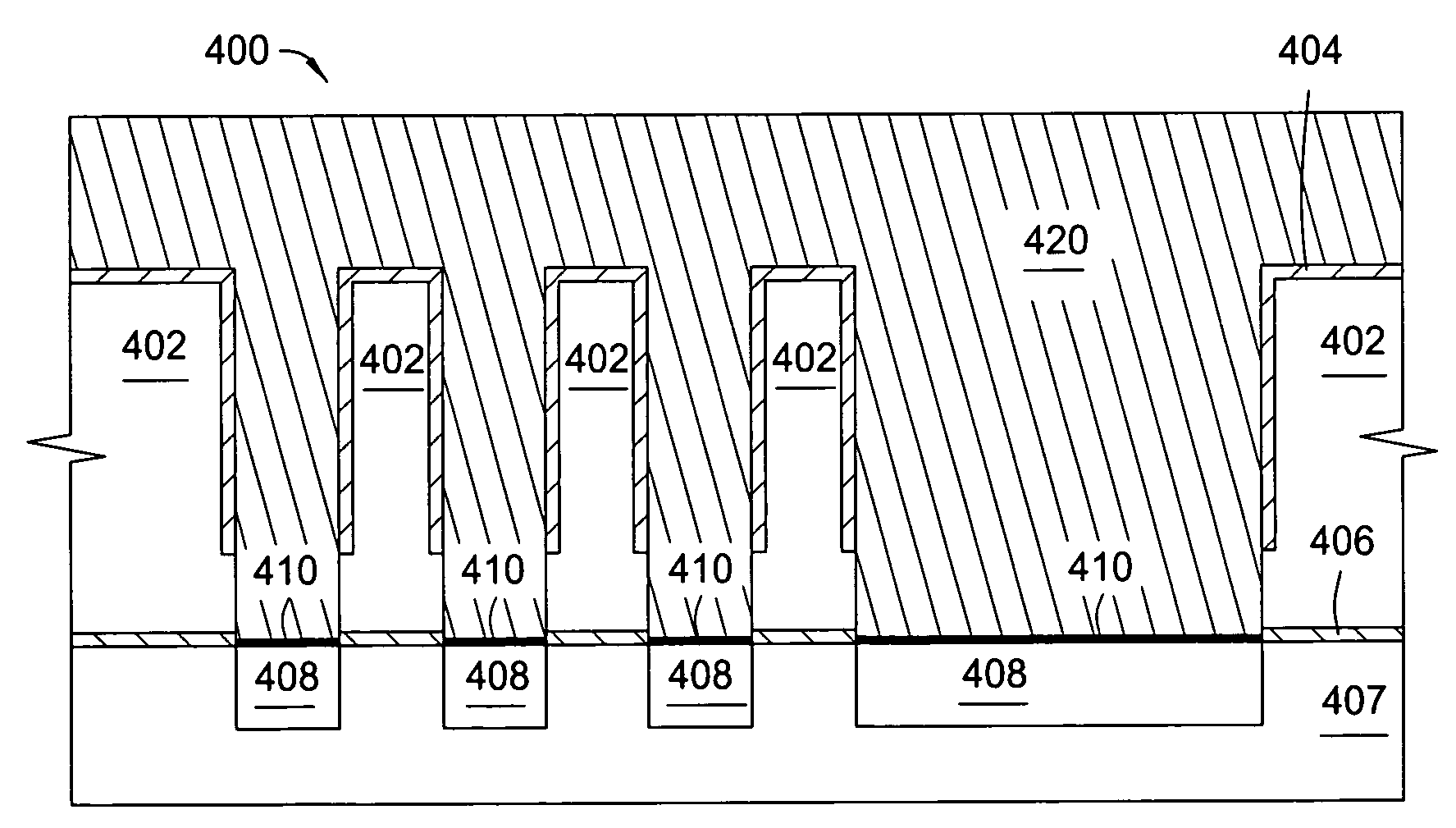

Embodiments of the invention provide methods for forming conductive materials within contact features on a substrate by depositing a seed layer within a feature and subsequently filling the feature with a copper-containing material during an electroless deposition process. In one example, a copper electroless deposition solution contains levelers to form convexed or concaved copper surfaces. In another example, a seed layer is selectively deposited on the bottom surface of the aperture while leaving the sidewalls substantially free of the seed material during a collimated PVD process. In another example, the seed layer is conformably deposited by a PVD process and subsequently, a portion of the seed layer and the underlayer are plasma etched to expose an underlying contact surface. In another example, a ruthenium seed layer is formed on an exposed contact surface by an ALD process utilizing the chemical precursor ruthenium tetroxide.

Owner:APPLIED MATERIALS INC

Process for electroless copper deposition

ActiveUS7651934B2Semiconductor/solid-state device manufacturingLiquid/solution decomposition chemical coatingCompound (substance)Electroless deposition

Owner:APPLIED MATERIALS INC

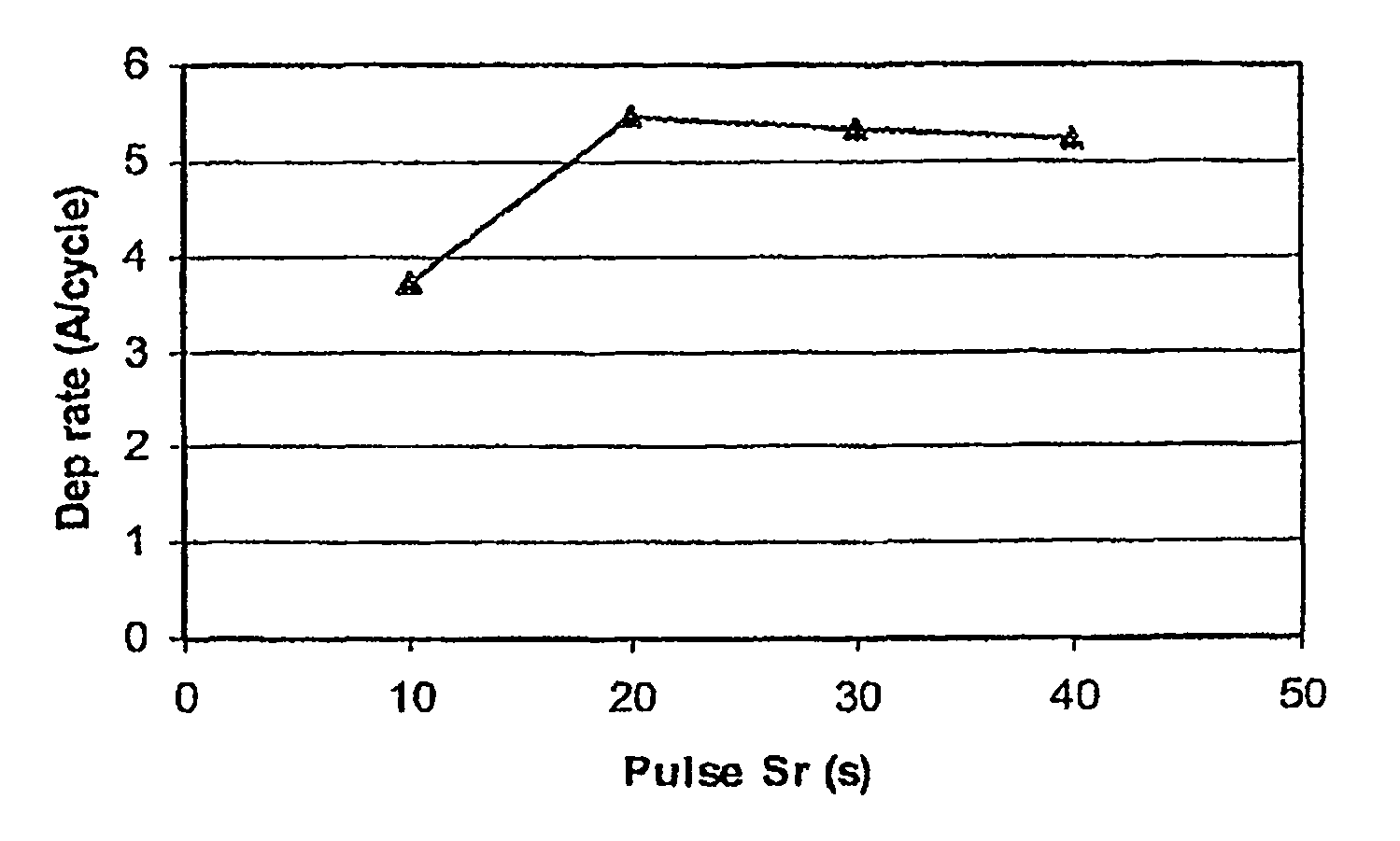

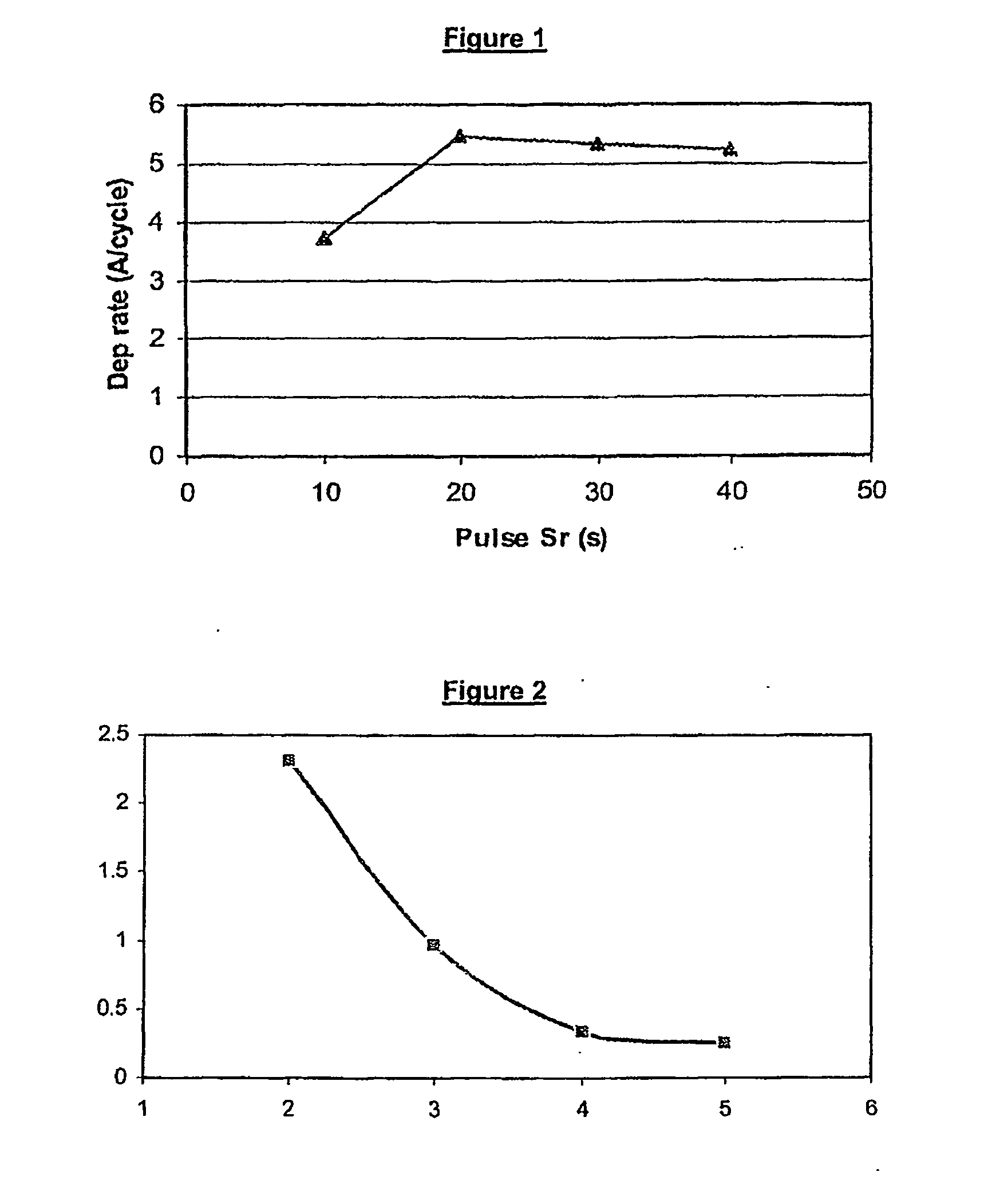

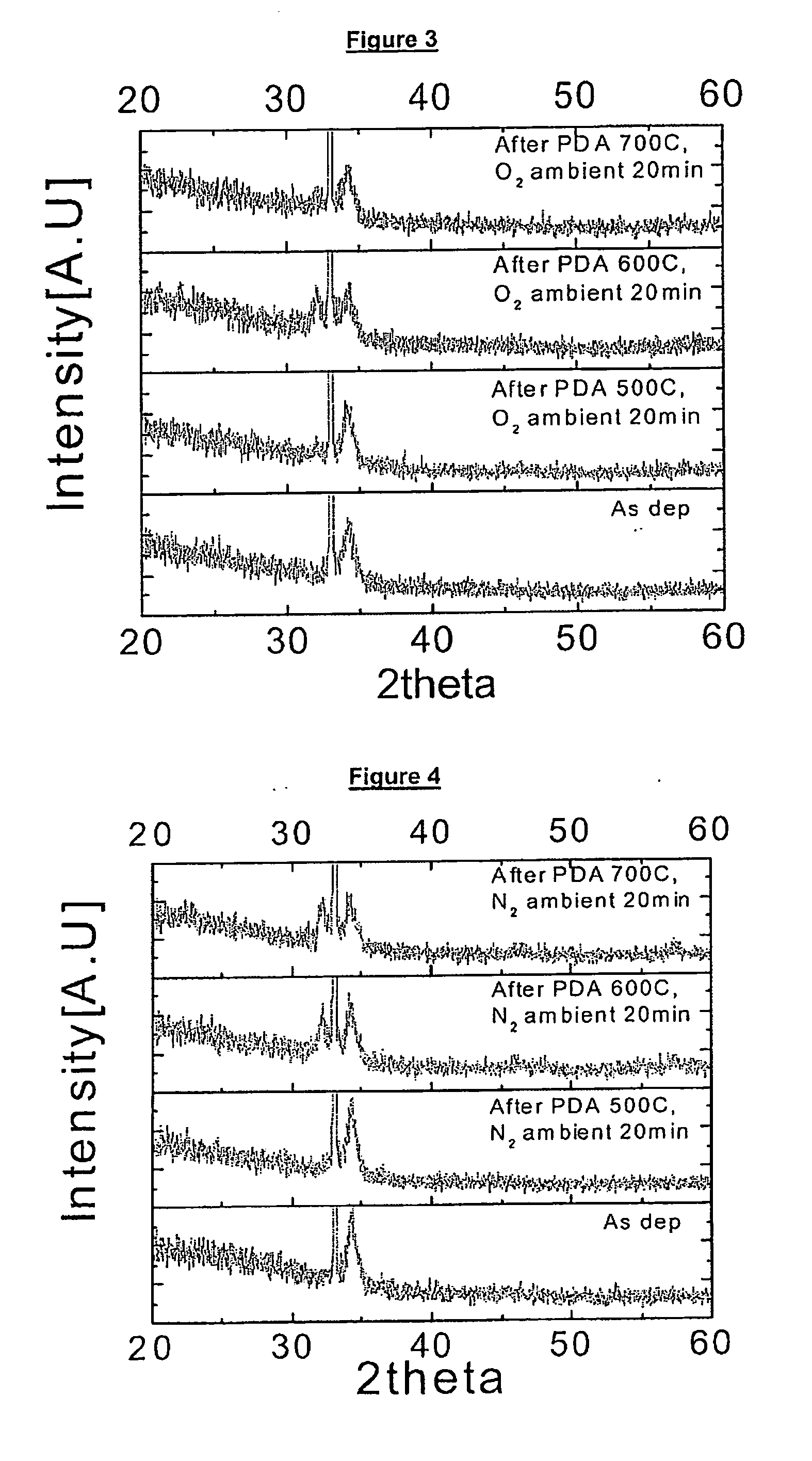

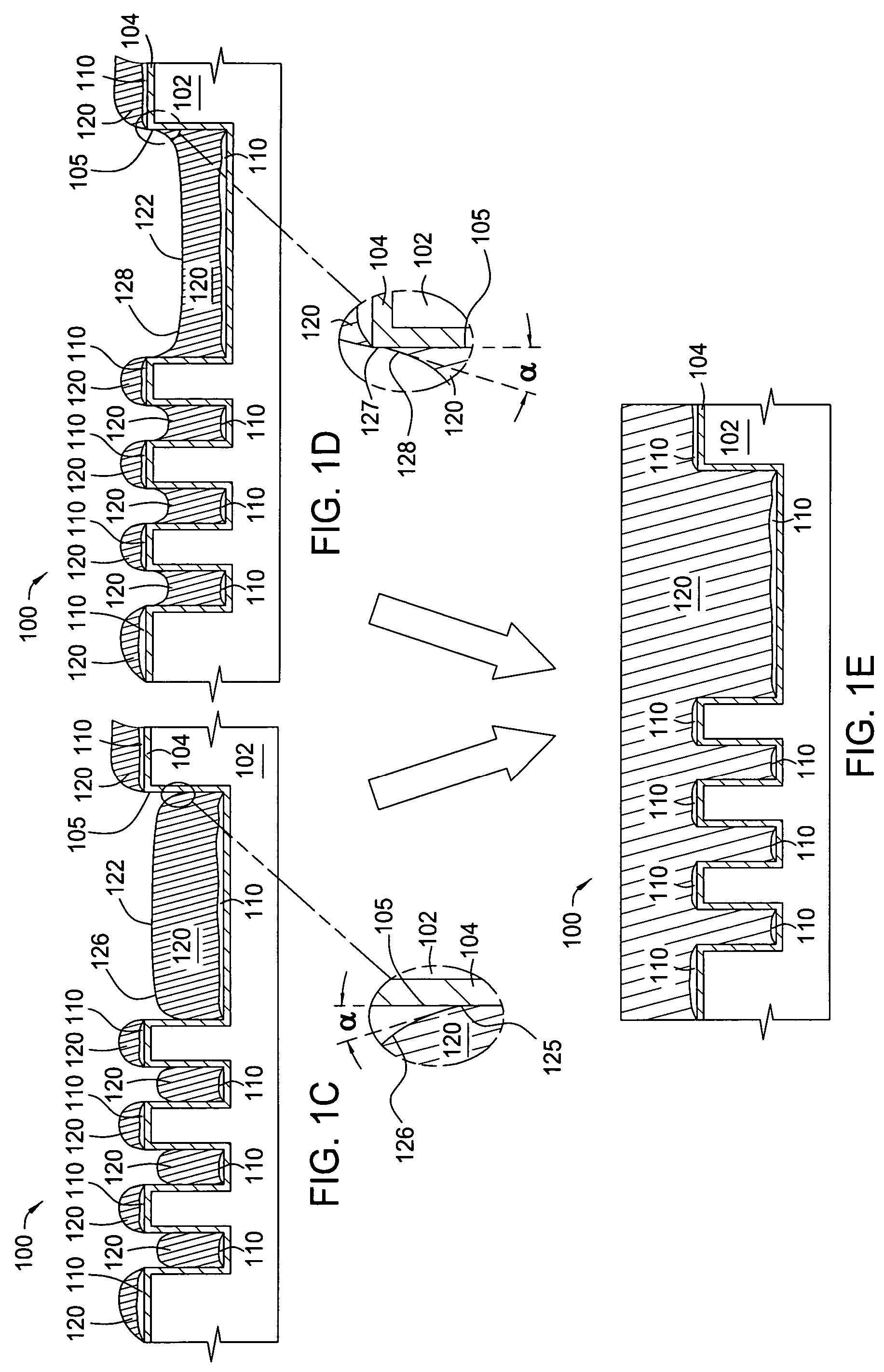

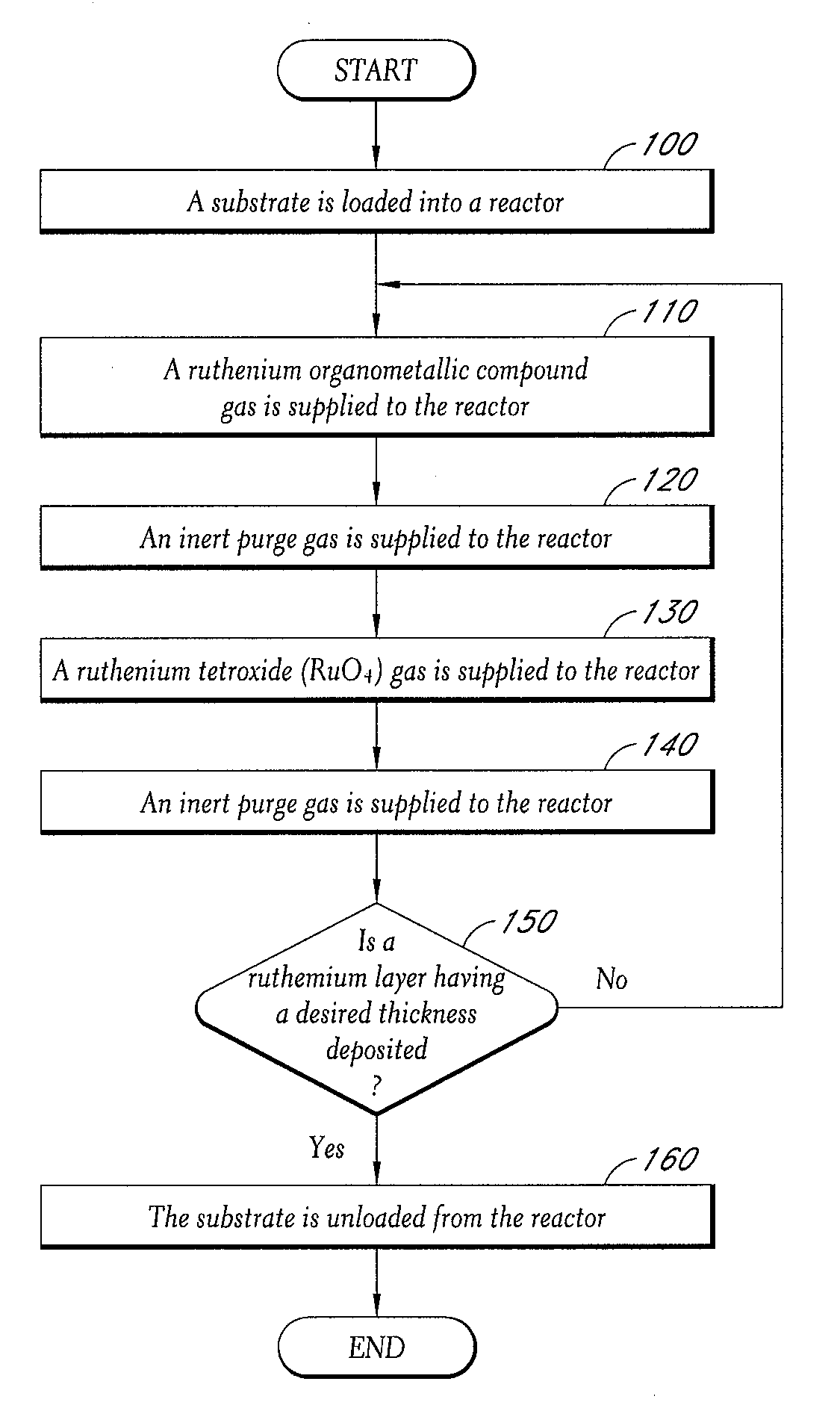

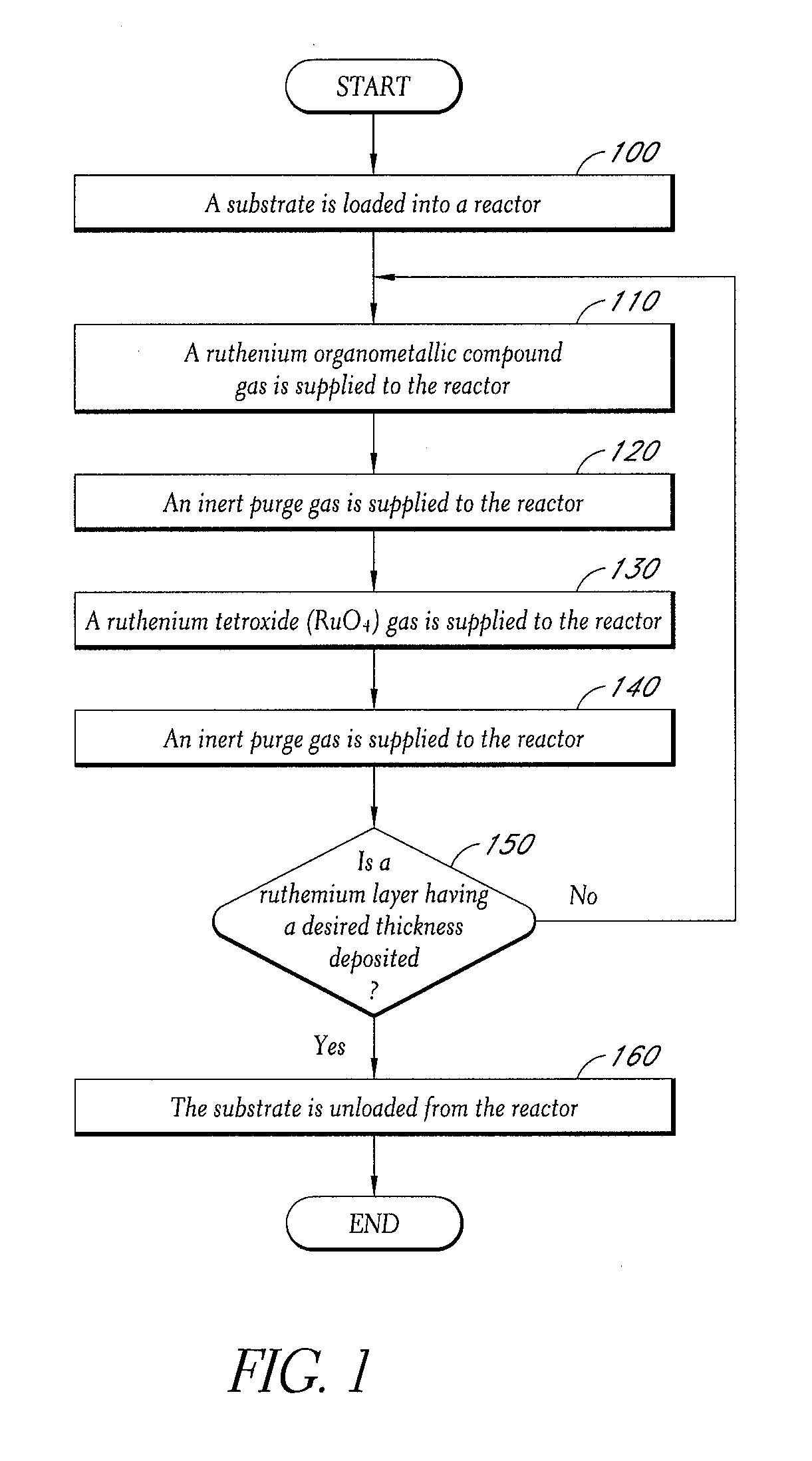

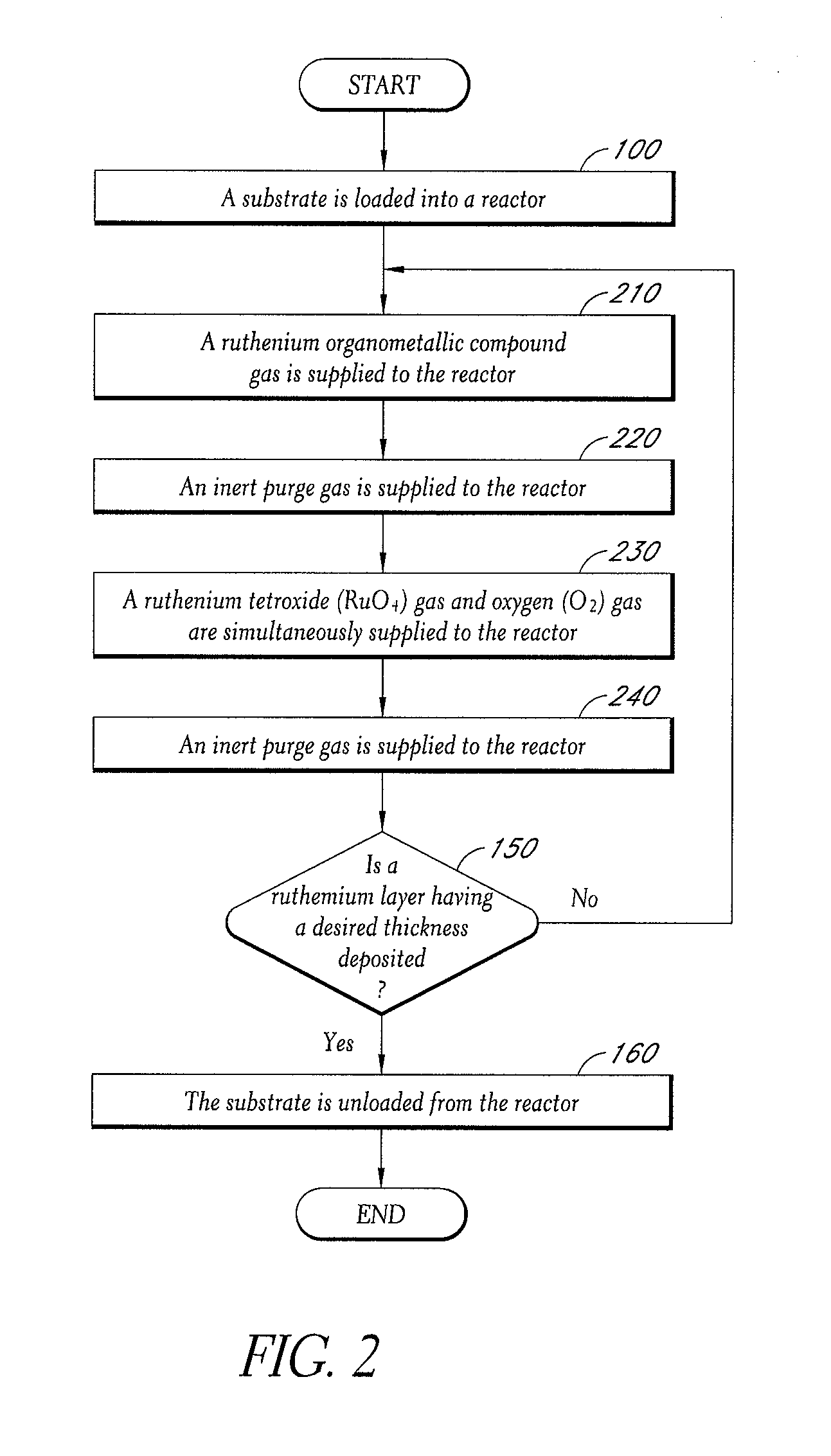

Methods of depositing a ruthenium film

InactiveUS20080171436A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingMetalReducing agent

Cyclical methods of depositing a ruthenium film on a substrate are provided. In one process, each cycle includes supplying a ruthenium organometallic compound gas to the reactor; purging the reactor; supplying a ruthenium tetroxide (RuO4) gas to the reactor; and purging the reactor. In another process, each cycle includes simultaneously supplying RuO4 and a reducing agent gas; purging; and supplying a reducing agent gas. The methods provide a high deposition rate while providing good step coverage over structures having a high aspect ratio.

Owner:ASM GENITECH KOREA

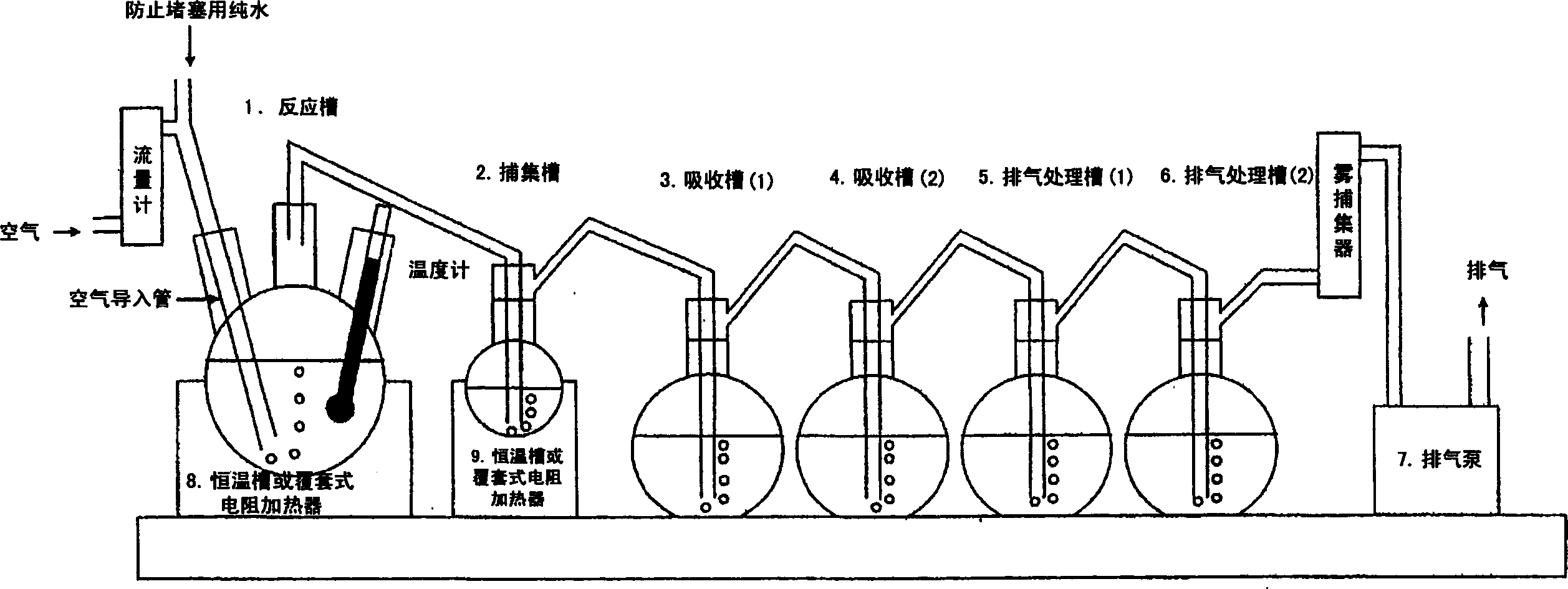

Method and device for preparing high-purity ruthenium

InactiveCN101797649ASolve the sintered very hardSolve the problem of high chlorine and oxygen contentVacuum evaporation coatingSputtering coatingHydrofluoric acidHydrogen

The invention relates to a method and a device for preparing high-purity ruthenium. The method comprises the following steps that: hydrogen dioxide is added into ruthenium hydrochloride solution to be undertaken one section of oxidation distillation reaction, then oxidant is added into the liquid to be undertaken a second section of adequate oxidation distillation reaction, then the oxidation distillation is repeatedly performed to extract the ruthenium, ruthenium tetroxide gas which is discharged from the second section of oxidation reaction is adequately collected, the ruthenium tetroxide gas is transformed to ruthenium hydrochloride absorption liquid, ammonium chloride is added into the ruthenium hydrochloride absorption liquid to be crystallized and precipitated, and the prepared ammonium chloride ruthenium precipitant is calcined and reduced to sponge ruthenium under the atmosphere of hydrogen; and the prepared sponge ruthenium is dried under the atmosphere of the hydrogen after being boiled and washed by mixed acid of aqua regia and hydrofluoric acid to obtain the high-purity ruthenium.

Owner:LANZHOU UNIVERSITY

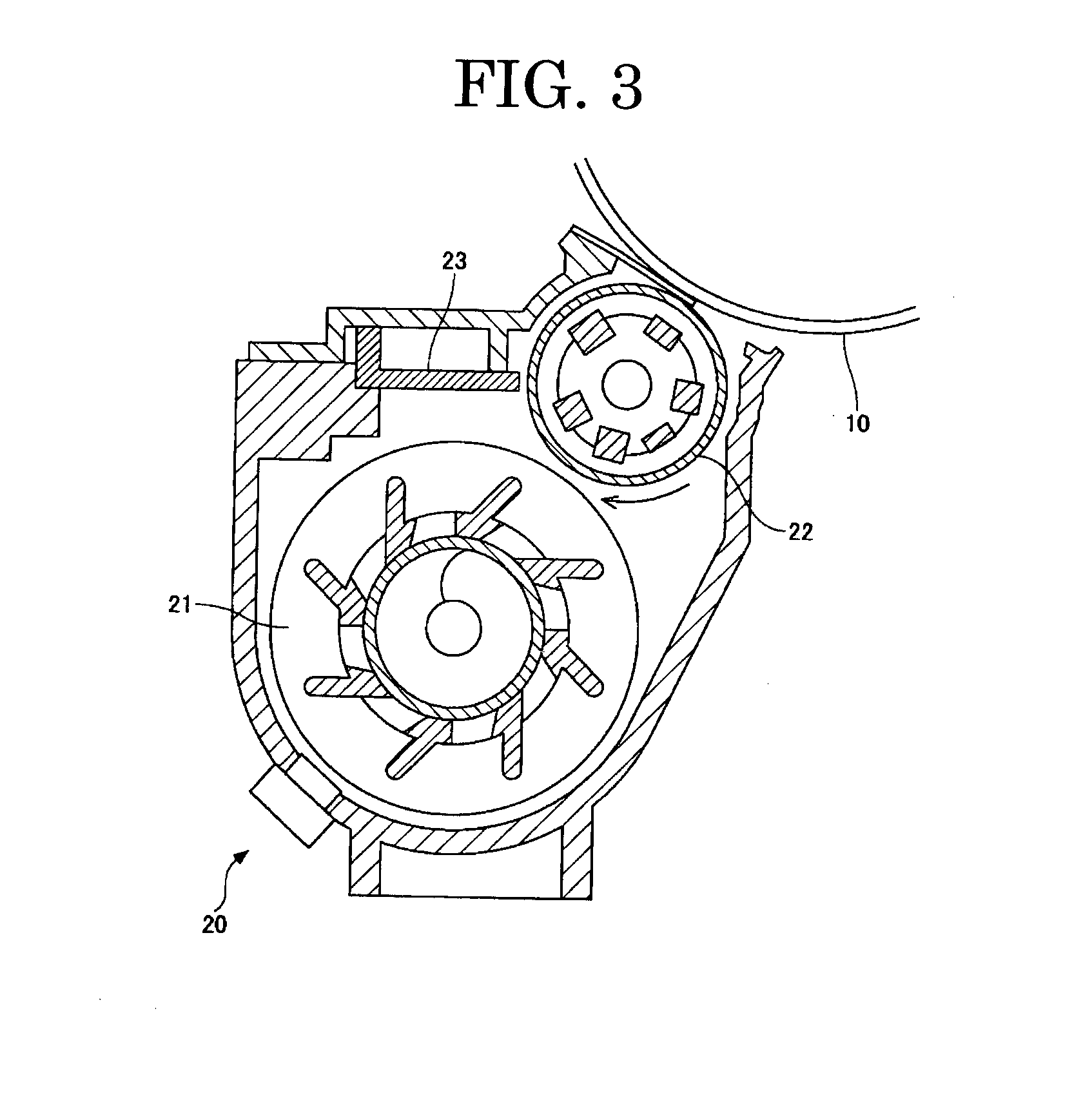

Methods for osmylating and ruthenylating single-walled carbon nanotubes

The present invention provides a method of differentiating metallic carbon nanotubes from semiconducting carbon nanotubes. The method comprising providing a nanotube dispersion, wherein the nanotube dispersion comprises a plurality of carbon nanotubes, osmium tetroxide, or ruthenium tetroxide, and a solvent; and irradiating the nanotube dispersion with ultraviolet light, wherein the metallic carbon nanotubes are osmylated, or ruthenylated, thereby differentiating the metallic carbon nanotubes from the semiconducting carbon nanotubes.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

Reliable fuel cell electrode design

InactiveCN101432908AFinal product manufactureCell electrodesElectrical resistance and conductanceFuel cells

The present invention generally relates to the creation of fuel cell components and the method of forming the various fuel cell components that have an improved lifetime, lower production cost and improved process performance. The invention generally includes treating or conditioning a substrate surface by depositing a material layer, or layers, having good adhesion to the substrate, low electrical resistivity (high conductivity) and has good resistance to chemical attack during the operation of fuel cell. The substrate may be, for example, a fuel cell part, a conductive plate, a separator plate, a bipolar plate or an end plate, among others. In one embodiment, the substrate surface is treated or conditioned by exposing at least a portion of it to a gas or liquid comprising ruthenium tetroxide.

Owner:APPLIED MATERIALS INC

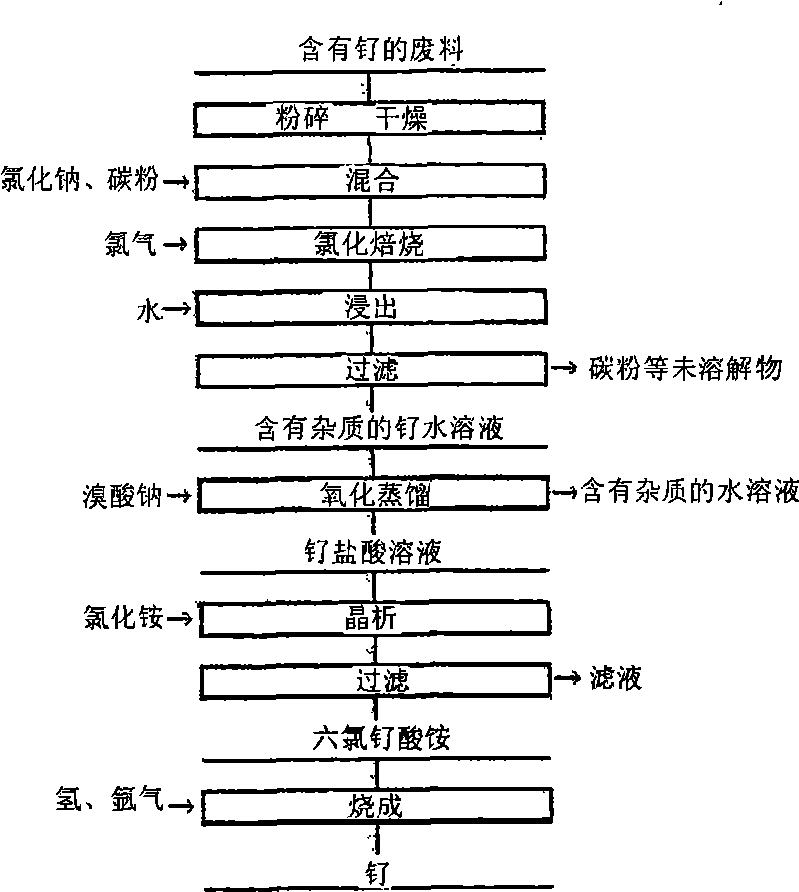

Method for recycling ruthenium from ruthenium-containing waste

InactiveCN101519732AEfficient separationEfficient recyclingProcess efficiency improvementChloride sodiumSodium bromate

The present invention provides a method for efficiently separating and recycling ruthenium from ruthenium-containing waste. The method comprises the steps of mixing sodium chloride and powdered carbon in powdered waste, wherein the amount of sodium chloride is 1 to 7 times of the amount needed in soluble chlorination reaction of ruthenium, and the amount of powdered carbon is 0.5 to 12 times of the needed amount; heating in chlorine atmosphere at 700 to 850 DEG C, thus obtaining soluble ruthenium salt; dissolving the ruthenium salt in water, changing ruthenium into ruthenium tetroxide by using oxidizer sodium bromate, oxidizing and distillating, and then purifying and recycling ruthenium in hydrochloric acid solution.

Owner:JX NIPPON MINING & METALS CO LTD

Process for recovery of ruthenium from a ruthenium-containing supported catalyst material

InactiveUS20080287282A1High purityHigh purity gradeCell electrodesFinal product manufactureHydrogen halideRuthenium Compounds

Process to recover ruthenium in the form of ruthenium halide, particularly ruthenium chloride, from a ruthenium-containing supported catalyst material comprising:a) chemically decomposing the ruthenium-containing supported catalyst material;b) producing a raw ruthenium salt solution;c) purifying the raw ruthenium salt solution and optionally stripping gaseous ruthenium tetroxide from the raw ruthenium salt solution; andd) treating the purified ruthenium compound obtained in c), particularly the ruthenium tetroxide, with hydrogen halide or hydrohalic acid to obtain ruthenium halide, particularly with hydrogen chloride or hydrochloric acid to obtain ruthenium chloride.

Owner:BAYER MATERIALSCIENCE AG

Method for extracting noble metal ruthenium from mixed oxide containing ruthenium, iridium, titanium, tin, zirconium and palladium

The method discloses a method for extracting noble metal ruthenium from a mixed oxide containing ruthenium, iridium, titanium, tin, zirconium and palladium. The method comprises the following steps: firstly, placing a mixed metal oxide containing noble metal ruthenium in a KOH and KNO3 mixed molten salt for dissolving; secondly, cooling the molten salt, immersing and dissolving the molten salt in water, and filtering and separating the solution; thirdly, adding the filtrate into a reaction bottle, adding sodium hypochlorite and sulfuric acid in the reaction bottle, and generating ruthenium tetroxide gas from the reaction; and fourthly, leading the ruthenium tetroxide gas into an absorption device, adding hydrochloric acid in the absorption device, and generating ruthenium trichloride from the reaction. The method can separate and extract the noble metal ruthenium from a waste electrode coating and a waste electrode cladding and achieving the aim of conserving and reutilizing energy; and the method is also applicable to ruthenium extraction in ruthenium catalyst in the pharmaceutical industry.

Owner:CHINA NAT BLUESTAR GRP CO LTD +1

Method for separating and recovering Ru from solution containing pt family

InactiveCN1786224AAvoid decompositionEfficient recyclingProcess efficiency improvementDistillationEquivalent weight

PROBLEM TO BE SOLVED: To provide a method for efficiently separating Ru from a solution containing a platinum group element by oxidation distillation. SOLUTION: The method for separating and collecting Ru from the solution containing the platinum group element includes adjusting the pH of the solution containing one or more platinum group elements among Ru, Pt, Pd, Rh and Ir to 0.5 to 2.5, converting Ru to ruthenium tetroxide through oxidation with the use of sodium bromate as an oxidizing agent, and distilling the solution, wherein sodium bromate is excessively added in an amount of 1 equivalent weight required for oxidizing Ru into ruthenium tetroxide and further an amount required for adjusting the concentration of sodium bromate to 80 g / L or higher. COPYRIGHT: (C)2006,JPO&NCIPI

Owner:JX NIPPON MINING & METALS CO LTD

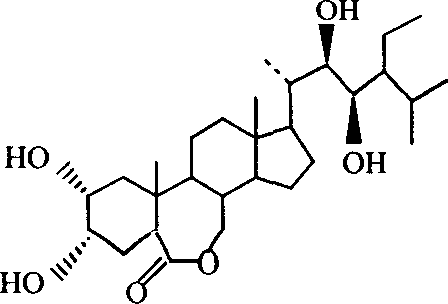

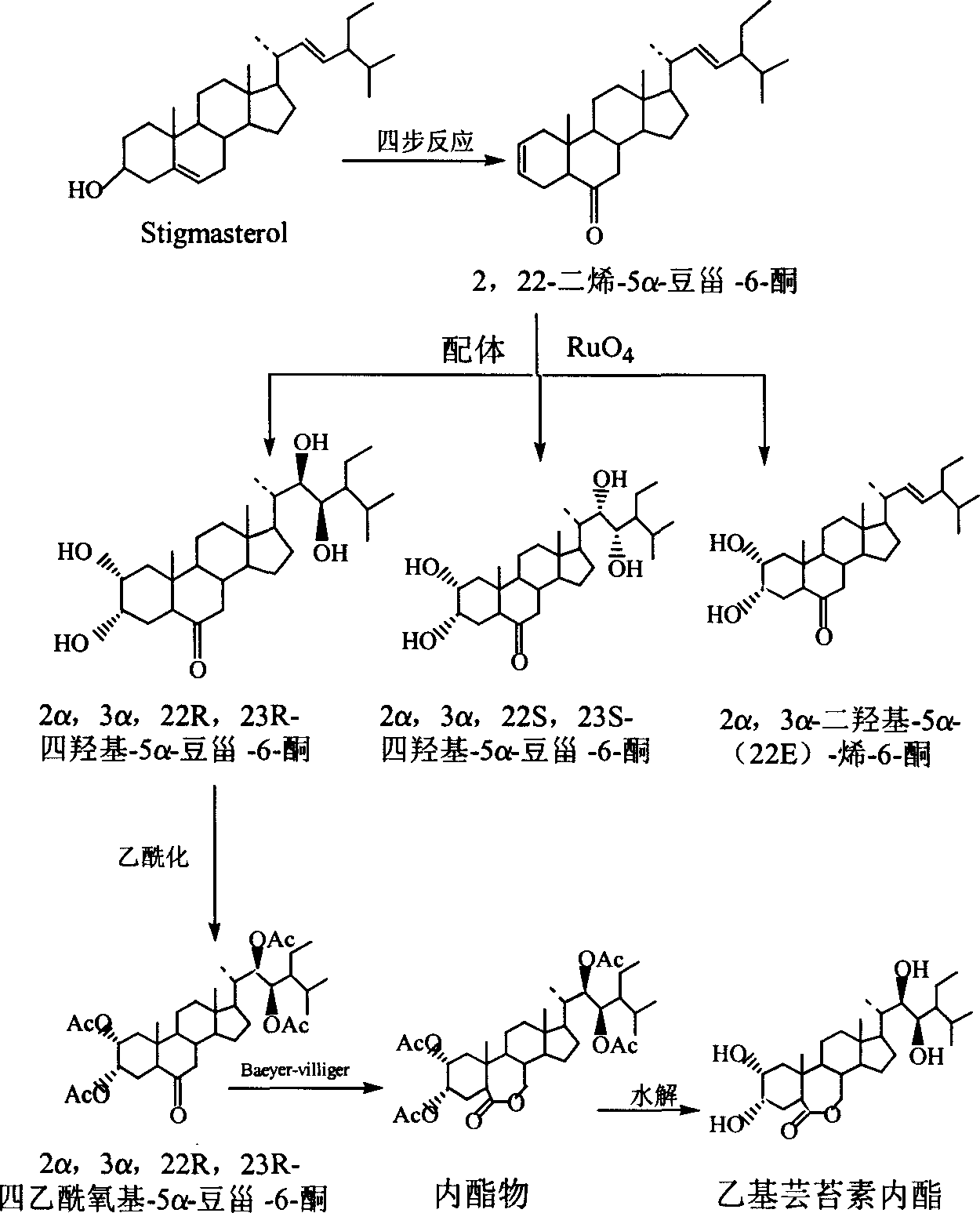

Manufacture method of ethyl brassinolide

The invention discloses a new preparing method of ethyl brassin lactone, which comprises the following steps: 1) preparing intermediate compound of 2, 22- diene -5a-stigma-6-ketone according to present technology; 2) adopting ruthenium tetroxide as oxidant, phenanthrene dihydrochinidin ether as ligand to control stereoscopic structure; proceeding asymmetric double-hydroxide for 2, 22-diene-5a- stigma-6-ketone to generate 2a, 3a, 22R, 23R-tetrahydroxy-5a- stigma-6-ketone; 3) making 2a, 3a, 22R, 23R-tetrahydroxy-5a- stigma-6-ketone to produce acetylate through acetylate protection; 4) using peroxyformic acid as agent to proceed Baeyer-Villiger reaction; lactonizing the acetylate to produce lactone: 2a, 3a, 22R, 23R-tetraace oxygen base-24S- ethyl group-B-high-7- oxa-5a-cholester-6-ketone; hydrolyzing the lactone to produce ethyl brassin lactone.

Owner:浙江来益生物技术有限公司 +1

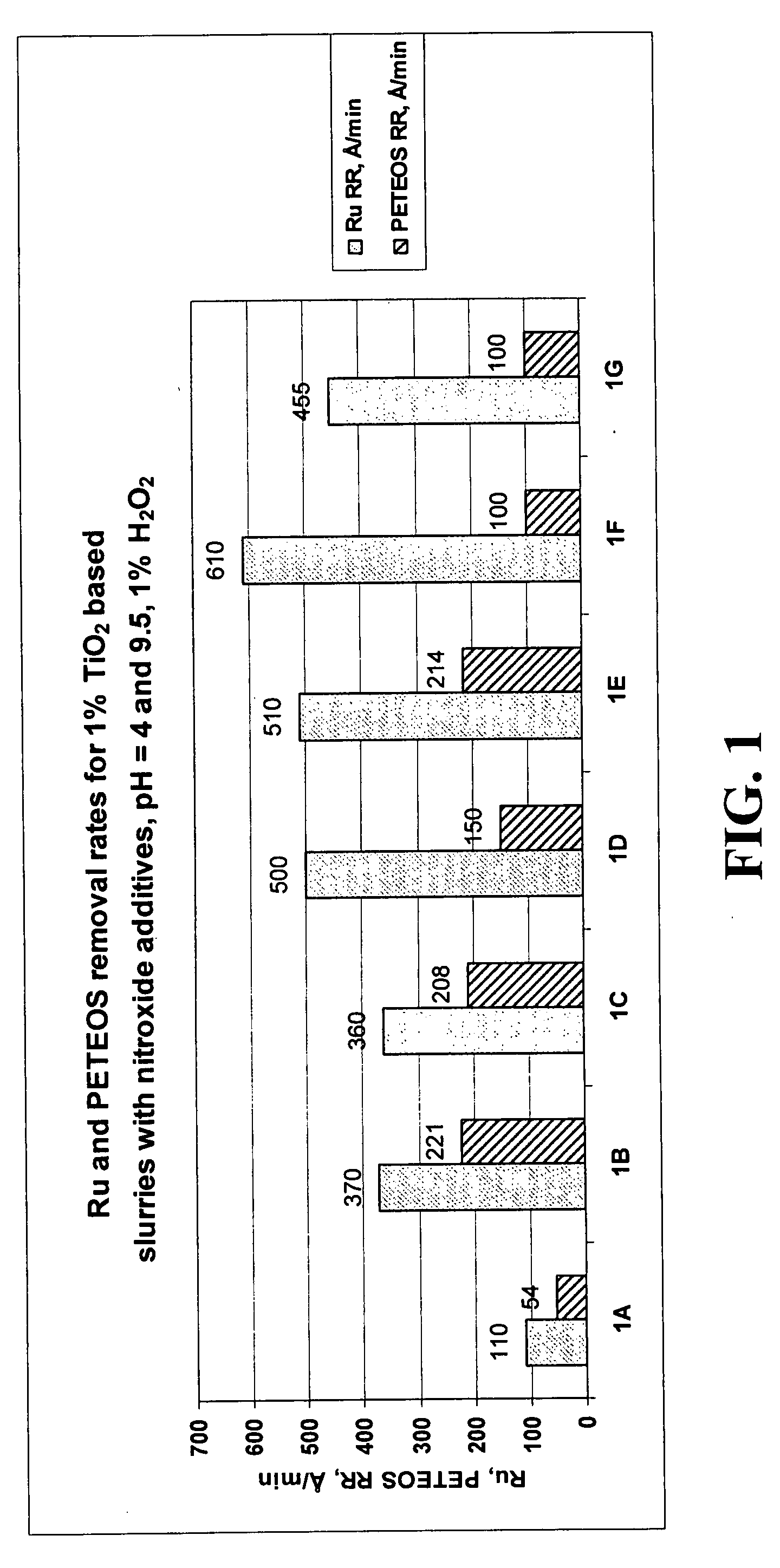

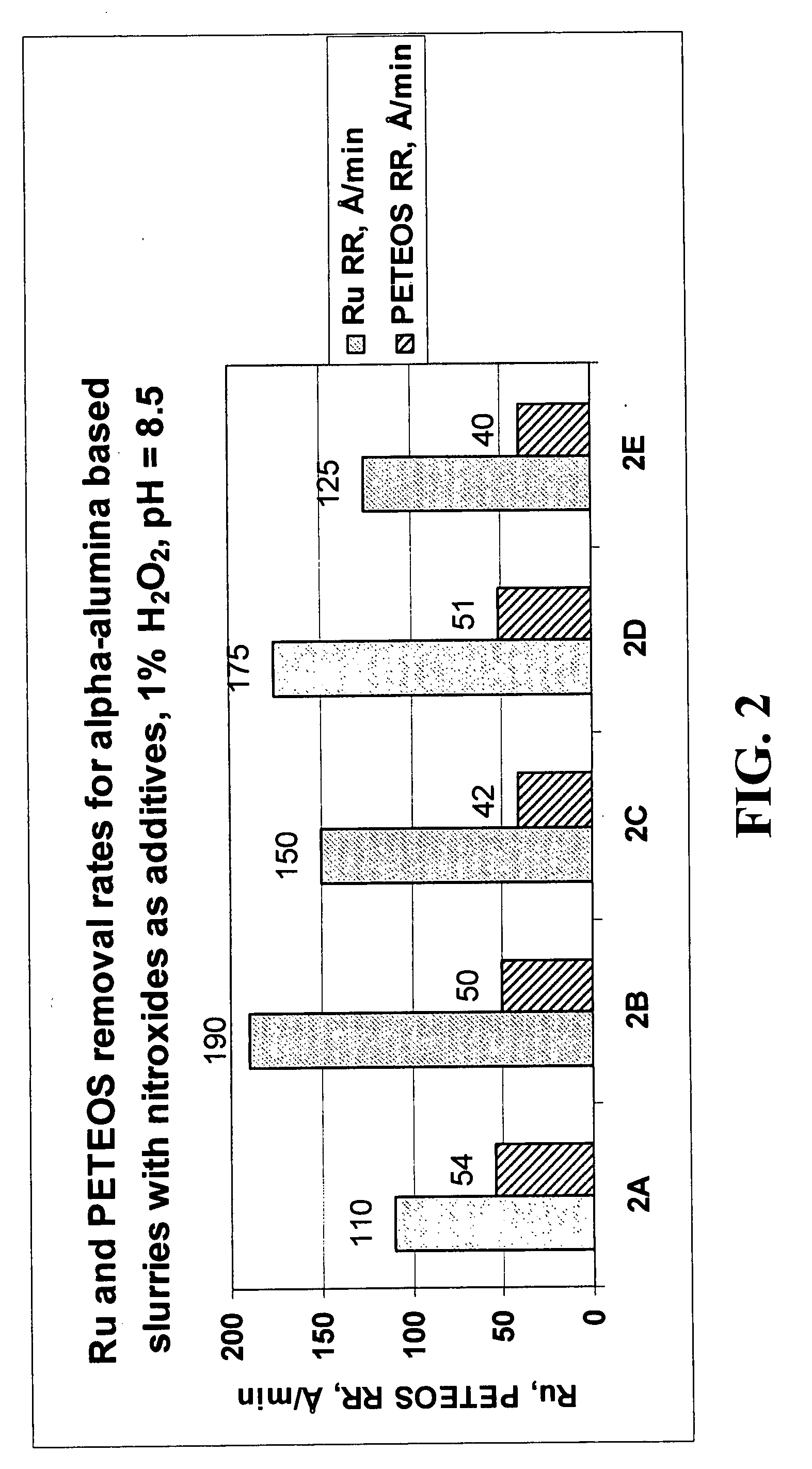

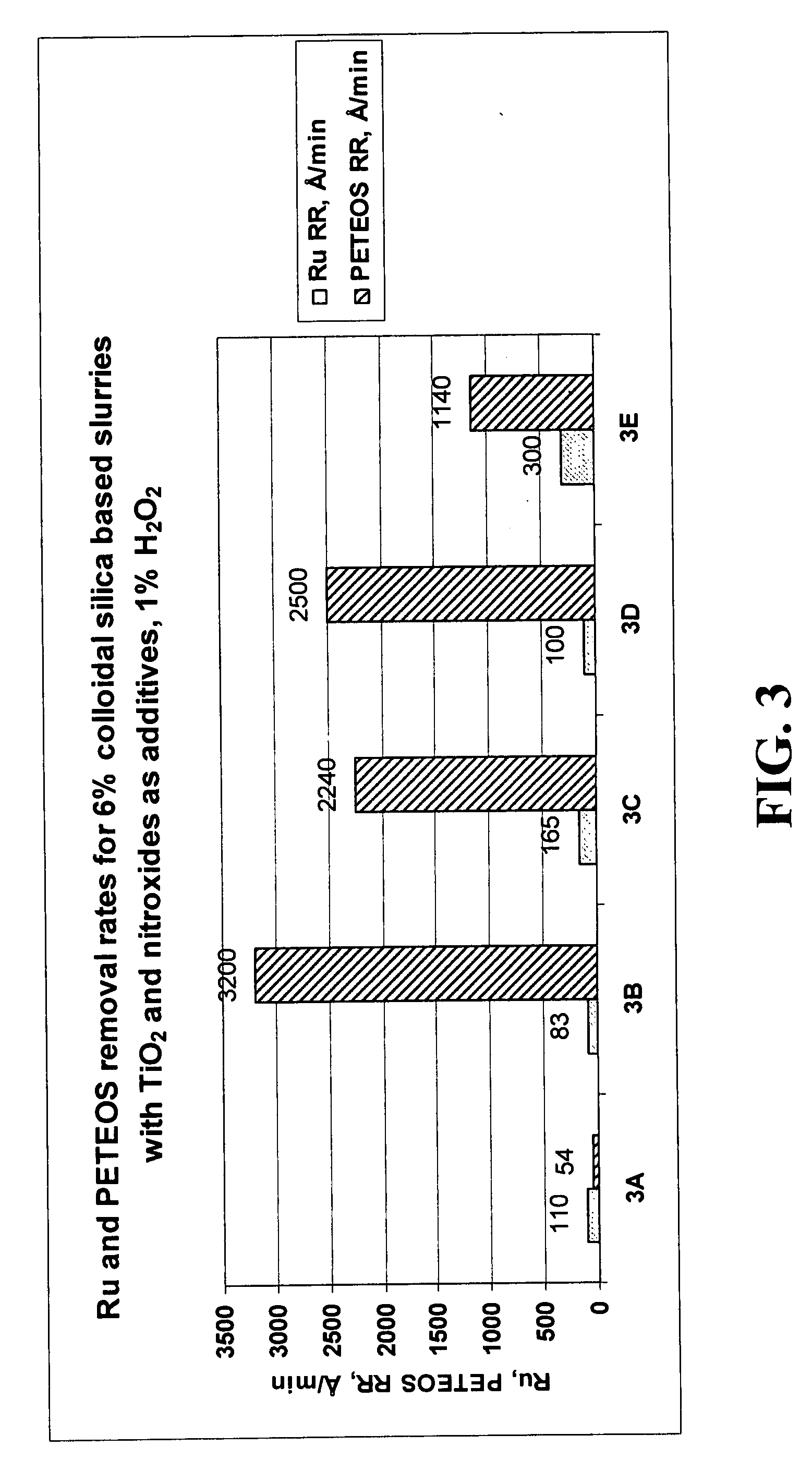

Ruthenium CMP compositions and methods

InactiveUS20090035942A1High ruthenium removal rateAdequate ruthenium removal ratePigmenting treatmentOther chemical processesParticulatesOxidation state

The present invention provides a chemical-mechanical polishing (CMP) composition for polishing a ruthenium-containing substrate in the presence of an oxidizing agent such as hydrogen peroxide without forming a toxic level of ruthenium tetroxide during the polishing process. The composition comprises a particulate abrasive (e.g., silica, alumina, and / or titania) suspended in an aqueous carrier containing a ruthenium-coordinating oxidized nitrogen ligand (N—O ligand), such as a nitroxide (e.g., 4-hydroxy-TEMPO). In the presence of the oxidizing agent, the N—O ligand prevents the deposition of ruthenium species having an oxidation state of IV or higher on the surface of the substrate, and concomitantly forms a soluble Ru(II) N—O coordination complex with oxidized ruthenium formed during CMP of the substrate. CMP methods for polishing ruthenium-containing surfaces with the CMP composition are also provided.

Owner:CABOT MICROELECTRONICS CORP

Method for recovering ruthenium from benzene hydrogenation prepared cyclohexene catalyst

InactiveCN108396145ASimple preparation processEasy to operateProcess efficiency improvementHypochloriteDistillation

The invention discloses a method for recovering ruthenium from a benzene hydrogenation prepared cyclohexene catalyst. The method comprises the following steps that alkali fusion treatment is carried out on the catalyst by adopting a conventional method, and thermal dissolution by adopting water is carried out; then an oxidizing agent is added to carry out distillation reaction, and the generated ruthenium tetroxide gas is absorbed by an acidic solution; and the absorption liquid is subjected to concentrated and drying to obtain a ruthenium trichloride product. According to the method, the distillation reaction liquid is returned and used for the alkali fusion heat treatment step without wastewater discharge; and excessive chlorine generated in the distillation reaction is recovered by adopting a dilute alkali liquid, and the generated hypochlorite is returned and used for distillation reaction, so that the utilization rate of raw materials is improved.

Owner:LUXI CATALYST

Methods for osmylating and ruthenylating single-walled carbon nanotubes

The present invention provides a method of differentiating metallic carbon nanotubes from semiconducting carbon nanotubes. The method comprising providing a nanotube dispersion, wherein the nanotube dispersion comprises a plurality of carbon nanotubes, osmium tetroxide, or ruthenium tetroxide, and a solvent; and irradiating the nanotube dispersion with ultraviolet light, wherein the metallic carbon nanotubes are osmylated, or ruthenylated, thereby differentiating the metallic carbon nanotubes from the semiconducting carbon nanotubes.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

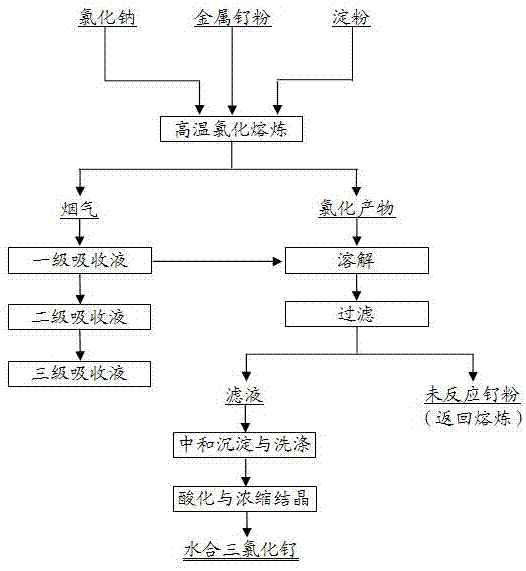

Ruthenium trichloride hydrate preparation method

ActiveCN107540025APromote conversionControl early oxidation reaction speedRuthenium/rhodium/palladium/osmium/iridium/platinum compoundsReaction rateDissolution

The invention discloses a ruthenium trichloride hydrate preparation method. Metallic ruthenium powder and sodium chloride are mixed for melting at a high temperature at first, and a trace amount of starch is added for maintaining a weak reducing atmosphere at the early heating stage; chlorine is introduced into the molten melt, so that most of the ruthenium powder is converted to sodium chlororuthenate; ruthenium tetroxide gas generated in the melting process is absorbed by a mixed solution of diluted hydrochloric acid and ethyl alcohol; after the sodium chlororuthenate obtained by melting andthe diluted hydrochloric acid solution with the absorbed ruthenium tetroxide are combined, black ruthenium hydroxide or ruthenium dioxide hydrate is generated after sodium hydroxide is added for neutralization, and after a product is filtered and washed for multiple times for removing sodium ions, dissolution with hydrochloric acid is conducted for concentration and crystallization to generate ruthenium trichloride hydrate crystals for preparation. According to the method, the chlorine is introduced into the melt for thorough stirring, and ruthenium conversion is efficiently promoted throughbath smelting, so that the reaction rate is fast, and the reaction efficiency is high; a trace amount of the starch is added into the material to control the early stage oxidation reaction rate of theruthenium powder, so that the production cycle is short, and the labor intensity is low.

Owner:CENT SOUTH UNIV

Methods for forming a ruthenium-based film on a substrate

ActiveUS7906175B2Without riskStable long-term holding (storage)Semiconductor/solid-state device manufacturingChemical vapor deposition coatingSolventSemiconductor

Methods for forming a film on a substrate in a semiconductor manufacturing process. A reaction chamber a substrate in the chamber are provided. A ruthenium based precursor, which includes ruthenium tetroxide dissolved in a mixture of at least two non-flammable fluorinated solvents, is provided and a ruthenium containing film is produced on the substrate.

Owner:AIR LIQUIDE ELECTRONICS US LP

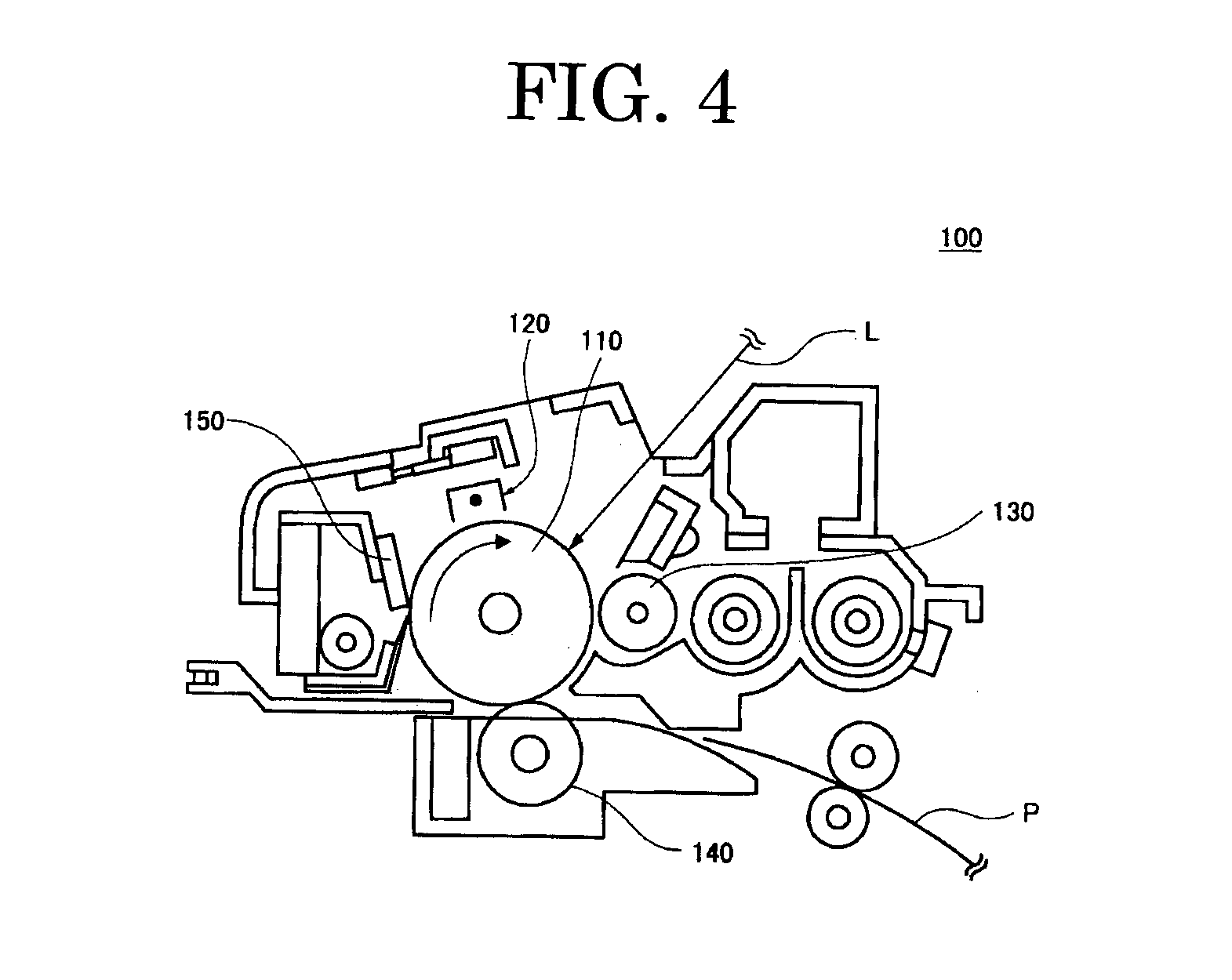

Toner, developer, image forming apparatus, and process cartridge

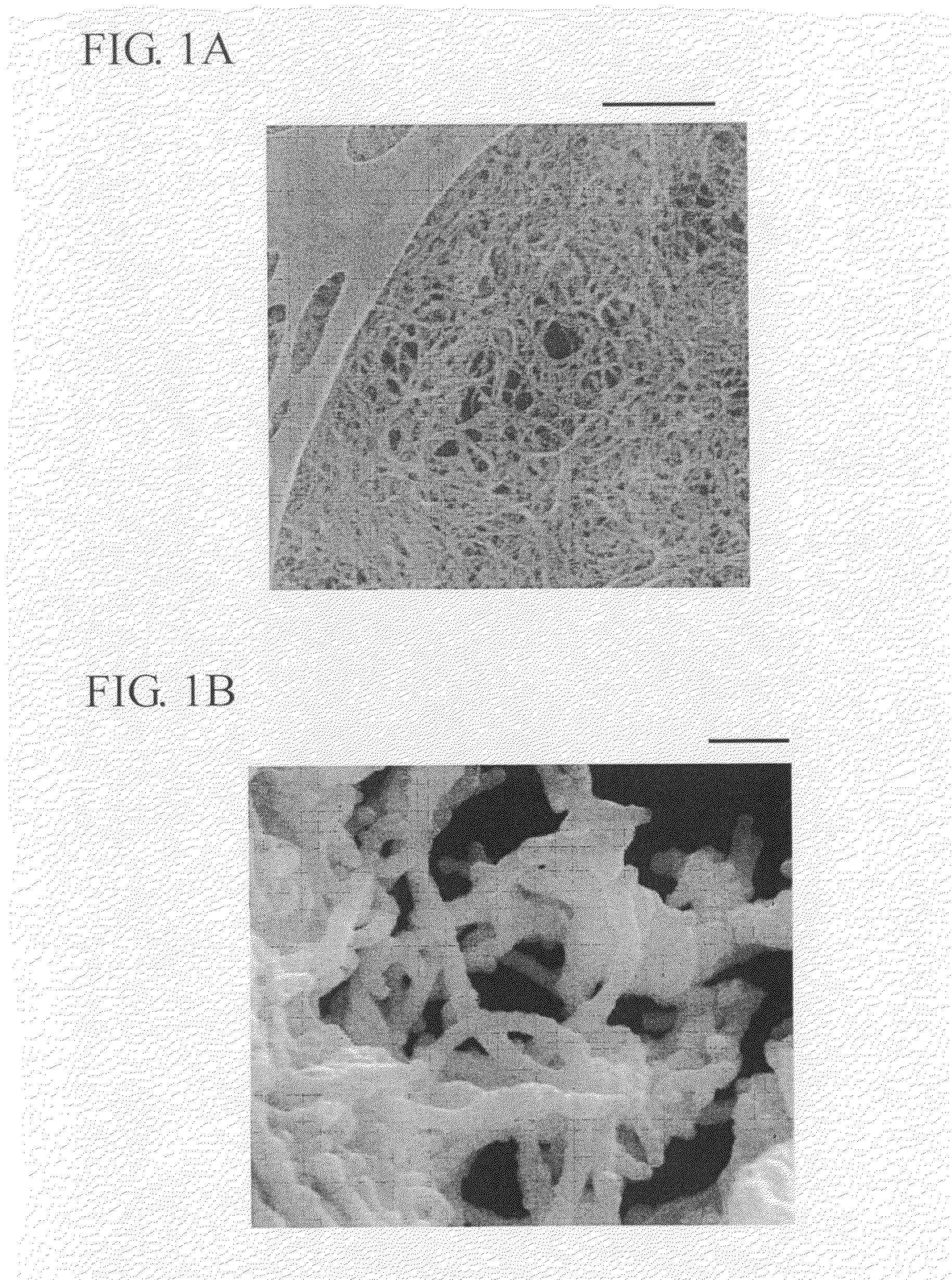

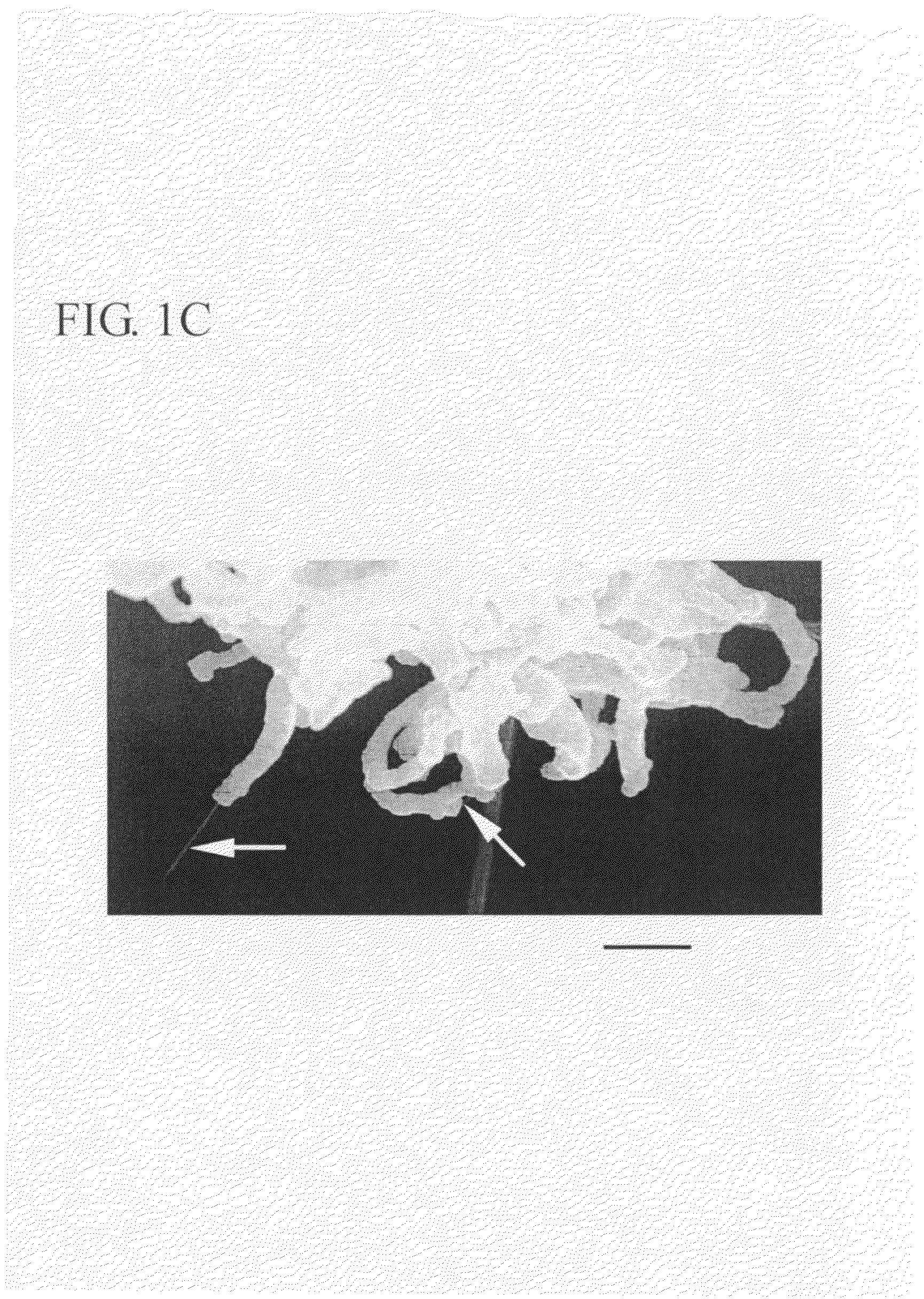

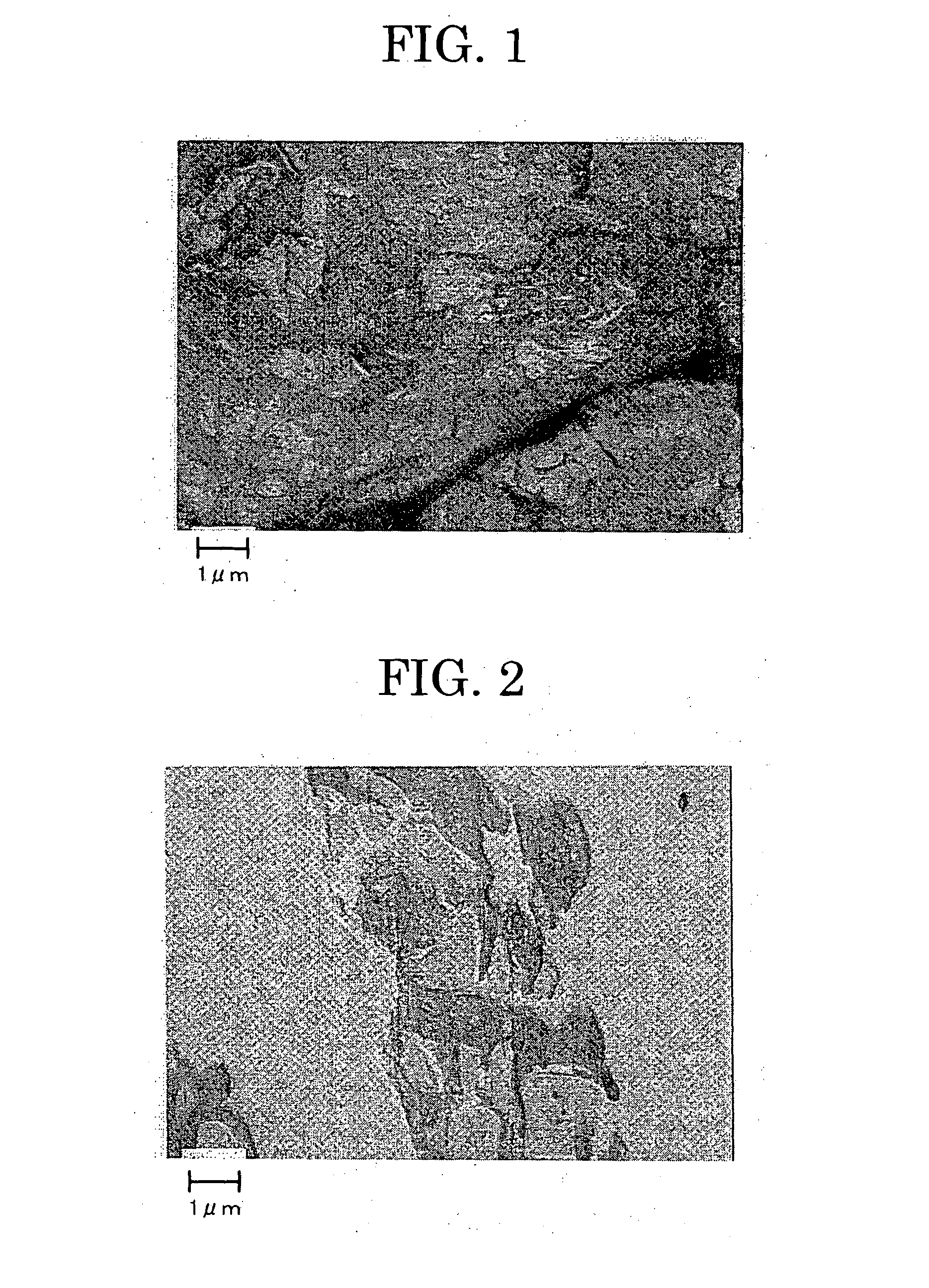

ActiveUS20150212444A1Excellent low temperature fixabilityAvoid it happening againElectrographic process apparatusDevelopersScanning electron microscopeElectron microscope

Provided is a toner including a crystalline resin and a non-crystalline resin. In a reflected electron image of a cross-section of the toner stained by ruthenium tetroxide captured by a scanning electron microscope, the ratio of regions stained by ruthenium tetroxide is from 50 area % to 80 area %. In a reflected electron image of the surface of the toner stained by ruthenium tetroxide captured by a scanning electron microscope, the ratio of regions stained by ruthenium tetroxide is from 10 area % to 40 area %.

Owner:RICOH KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com