Patents

Literature

57 results about "Osmium tetroxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Osmium tetroxide (also osmium(VIII) oxide) is the chemical compound with the formula OsO₄. The compound is noteworthy for its many uses, despite its toxicity and the rarity of osmium. It also has a number of unusual properties, one being that the solid is volatile. The compound is colourless, but most samples appear yellow. This is most likely due to the presence of the impurity OsO₂, which is yellow-brown in colour.

Methods for osmylating and ruthenylating single-walled carbon nanotubes

The present invention provides a method of differentiating metallic carbon nanotubes from semiconducting carbon nanotubes. The method comprising providing a nanotube dispersion, wherein the nanotube dispersion comprises a plurality of carbon nanotubes, osmium tetroxide, or ruthenium tetroxide, and a solvent; and irradiating the nanotube dispersion with ultraviolet light, wherein the metallic carbon nanotubes are osmylated, or ruthenylated, thereby differentiating the metallic carbon nanotubes from the semiconducting carbon nanotubes.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

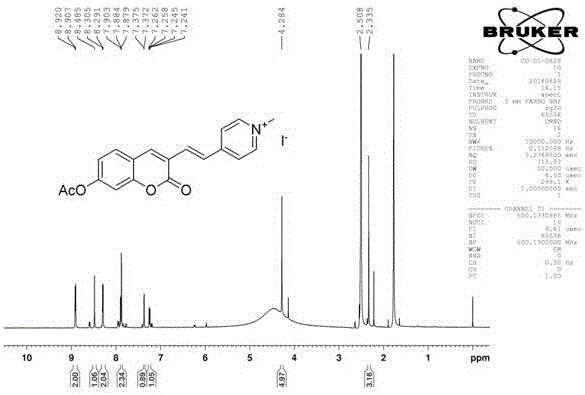

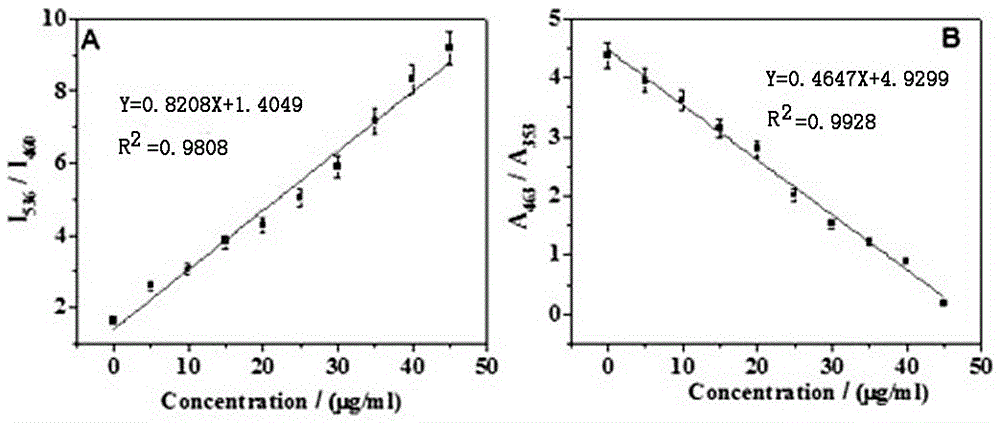

Preparation method and application of double-rate-type multifunctional high-sensitivity florescent probe for carboxylesterase detection

InactiveCN106588846ASensitive detectionAccurate detectionOrganic chemistryFluorescence/phosphorescenceOsmium tetroxideDisease

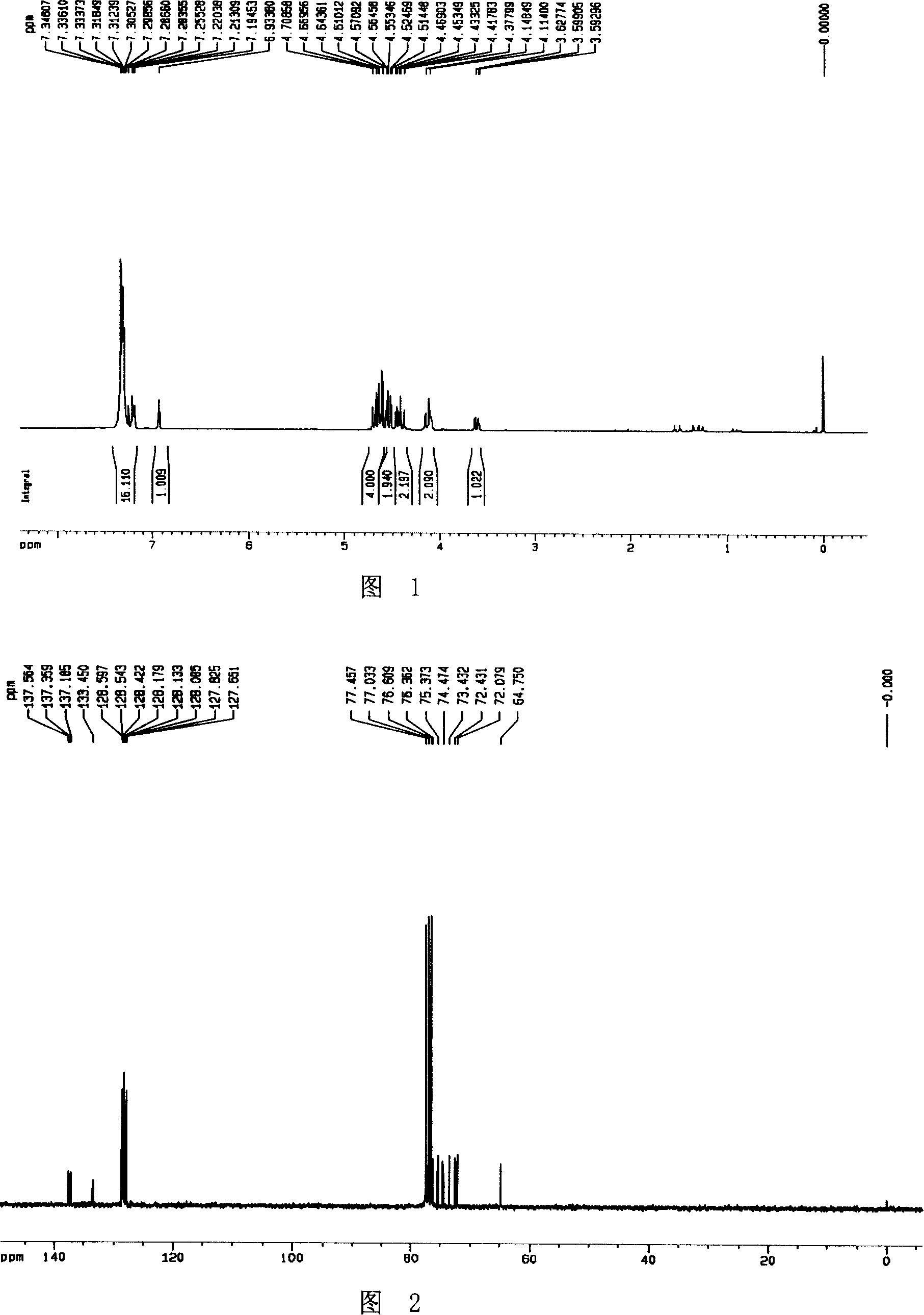

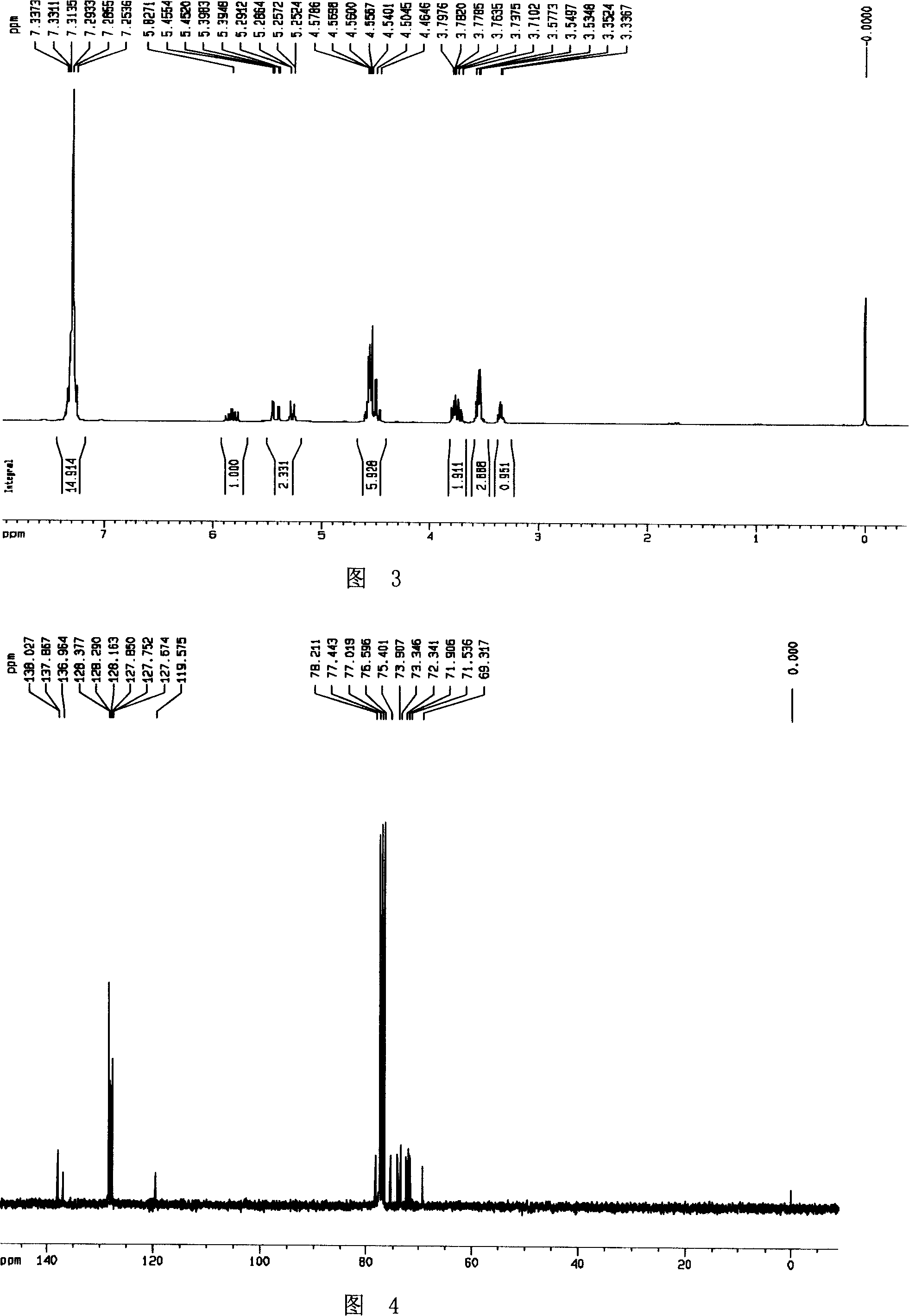

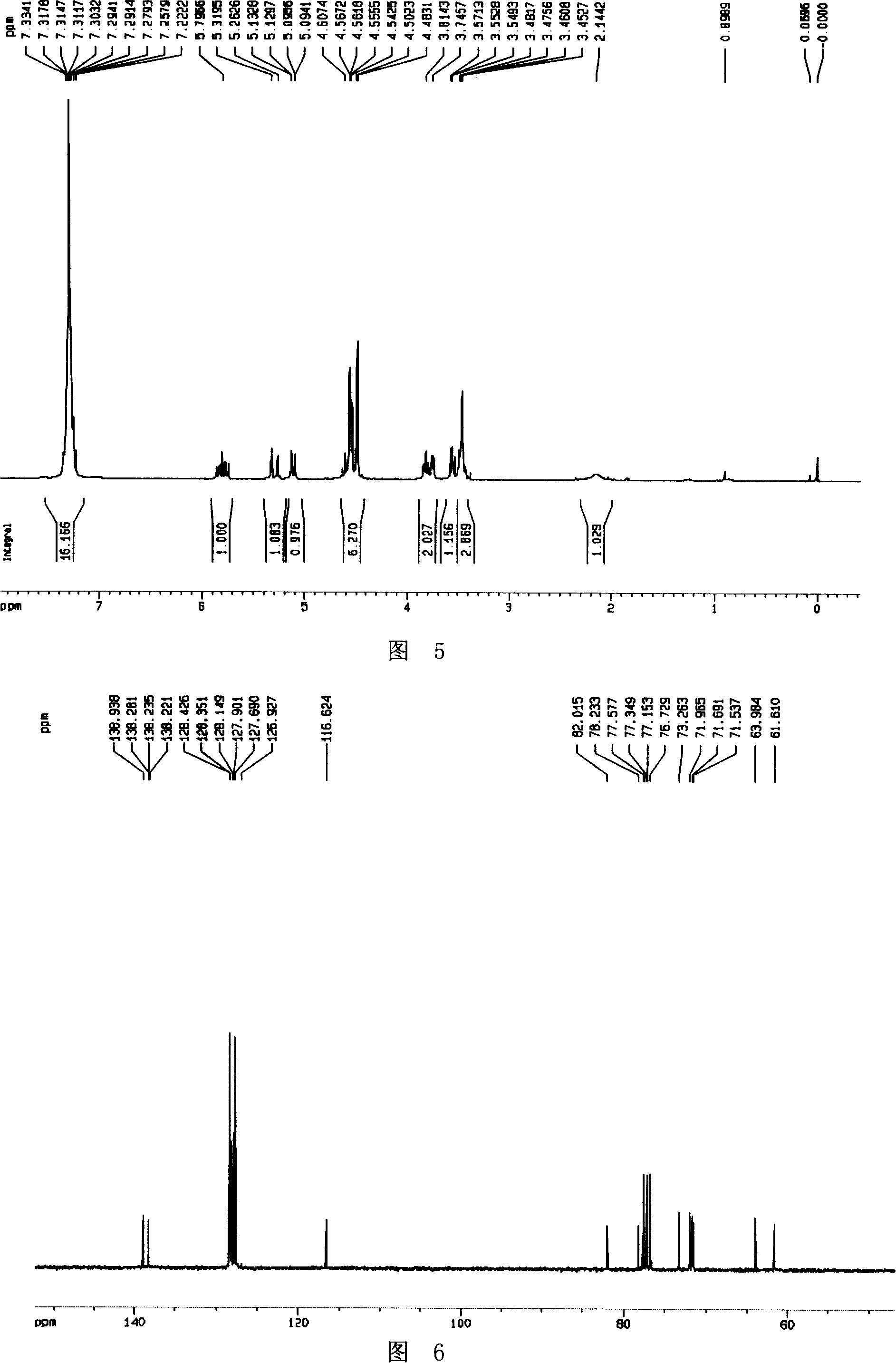

The invention relates to a preparation method and an application of a double-rate-type (ultraviolet / fluorescence) multifunctional (calorimetric / fluorescence / ultraviolet) high-sensitivity florescent probe for carboxylesterase detection. Firstly, 2,4-dihydroxybenzaldehyde, diethyl glutaconate and anhydrous piperidine react in ethyl alcohol to produce a product 1, the product 1 and acetic anhydride react in anhydrous pyridine to produce a product 2, the product 2 reacts with osmium tetroxide and sodium periodate in tetrahydrofuran to produce a product 3, and the product 3 reacts with anhydrous potassium carbonate in methyl alcohol to produce a product 4; then methylpyridine and methyl iodide react in absolute ether to produce a product 5; next, the product 4 and the product 5 are dissolved in absolute ethanol, piperidine is added for a reaction, and a product 6 is obtained; finally, the product 6 is dissolved in acetic anhydride, anhydrous sodium acetate is added, and the double-rate-type multifunctional florescent probe for carboxylesterase detection is obtained. The probe is applicable to qualitative and quantitative analysis of carboxylesterase in biological samples, is sensitive, accurate and quick in detection, and can be applied to related fields of analytical chemistry, life organic analytical chemistry, disease pre-diagnosis, clinical medical examination and the like.

Owner:QUFU NORMAL UNIV

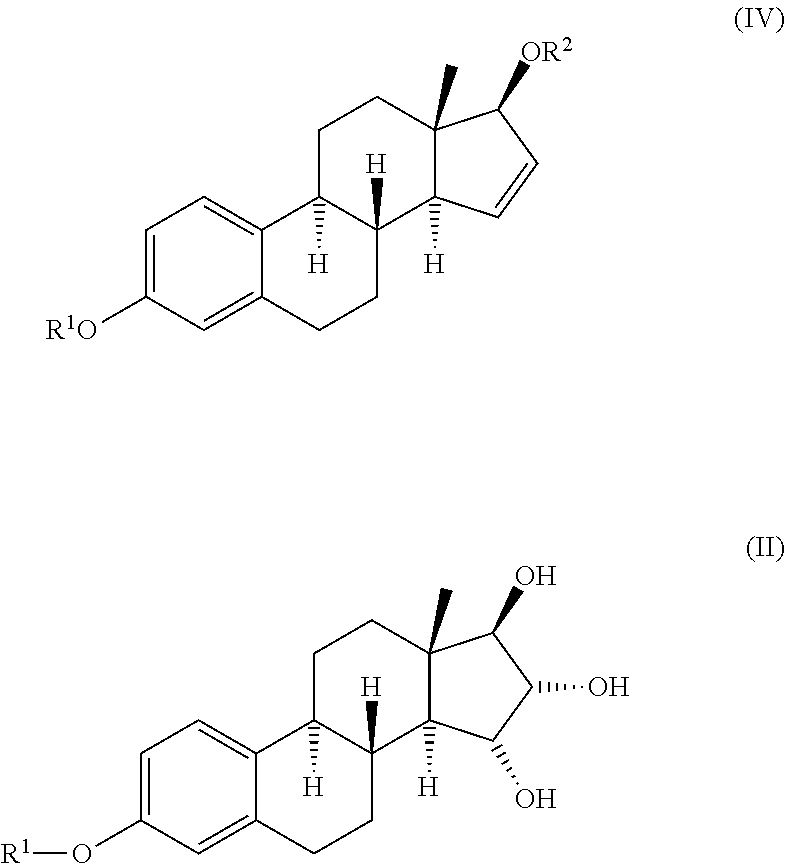

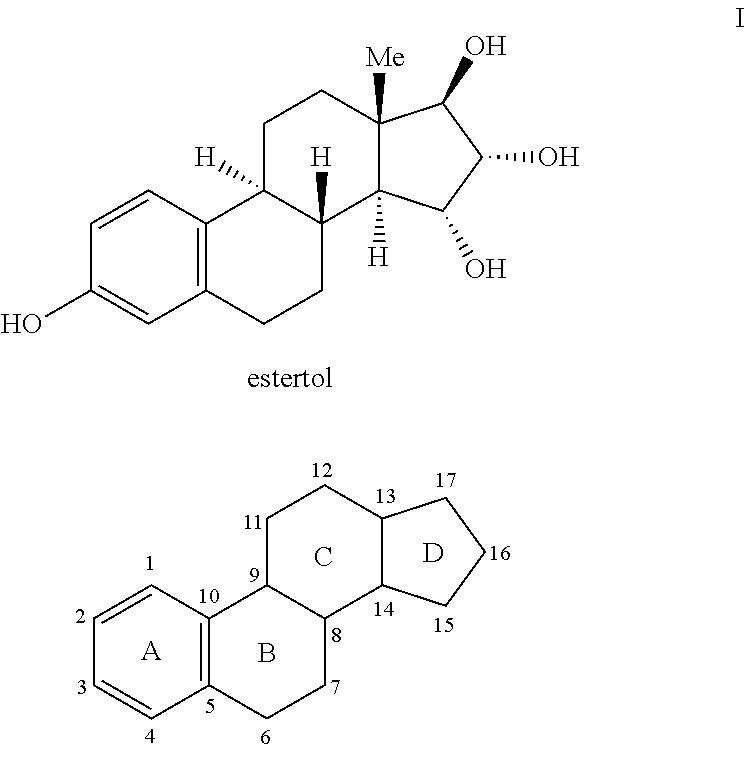

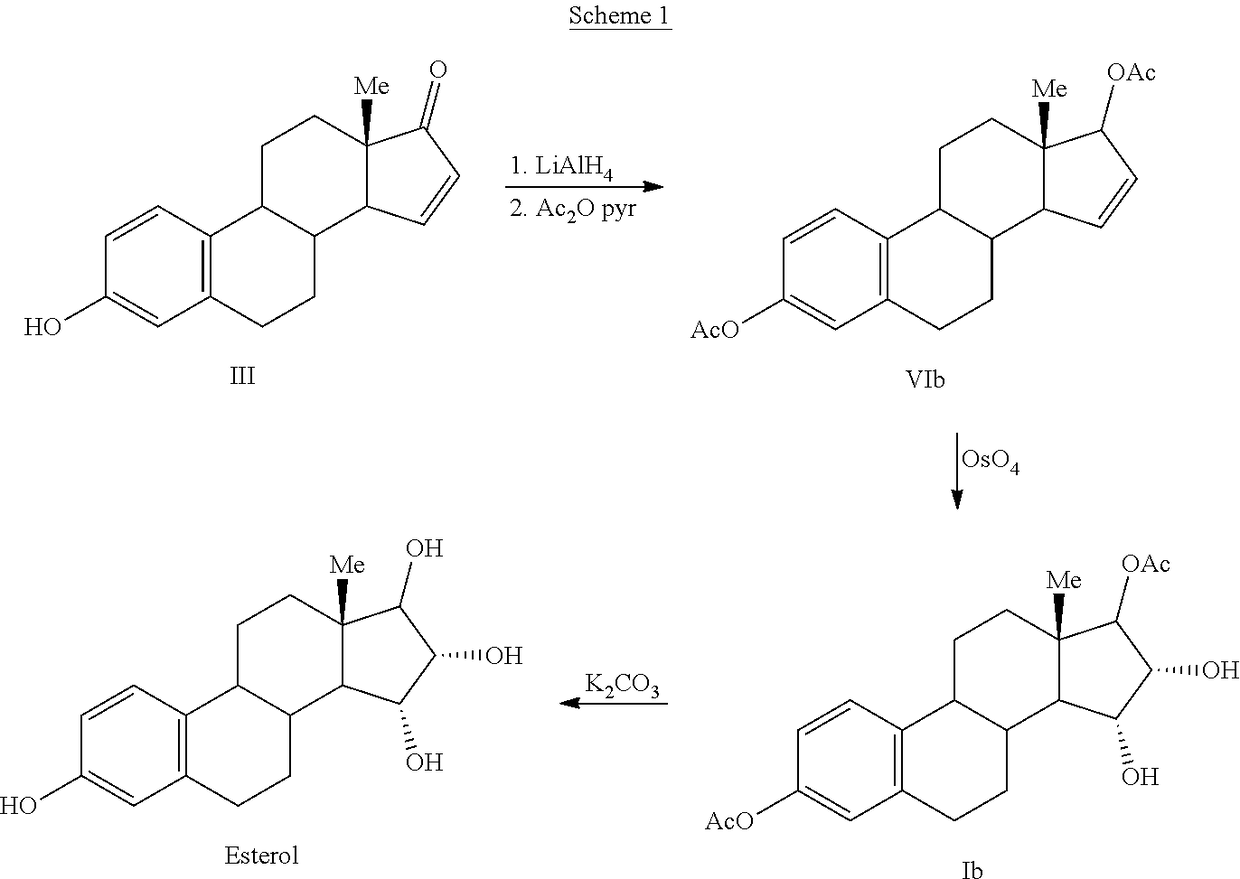

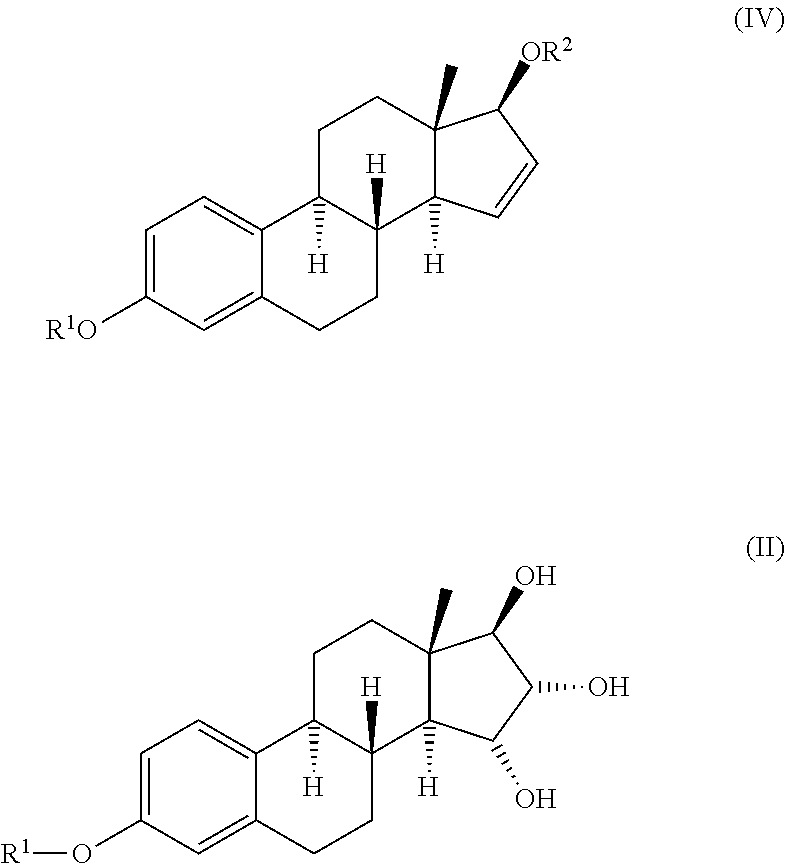

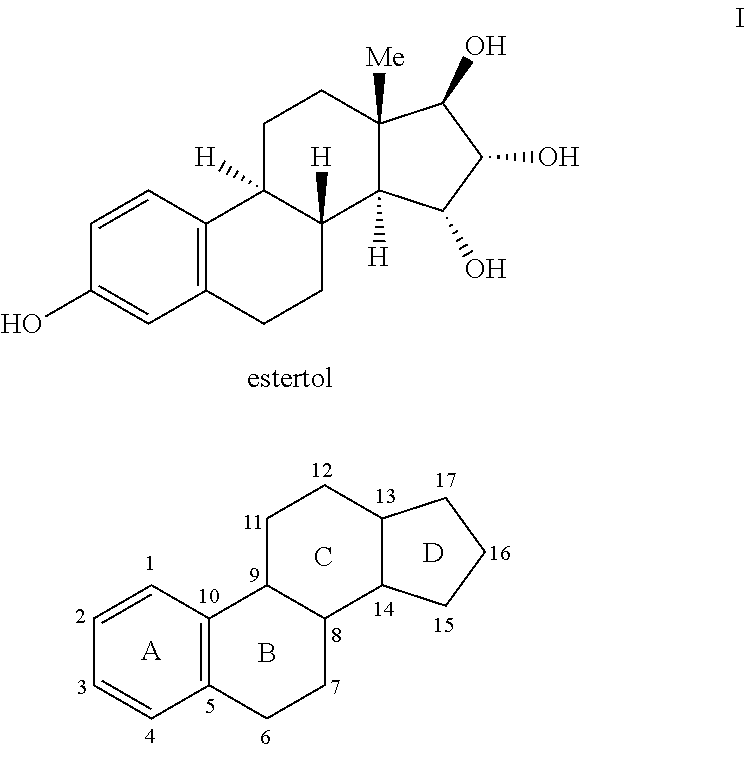

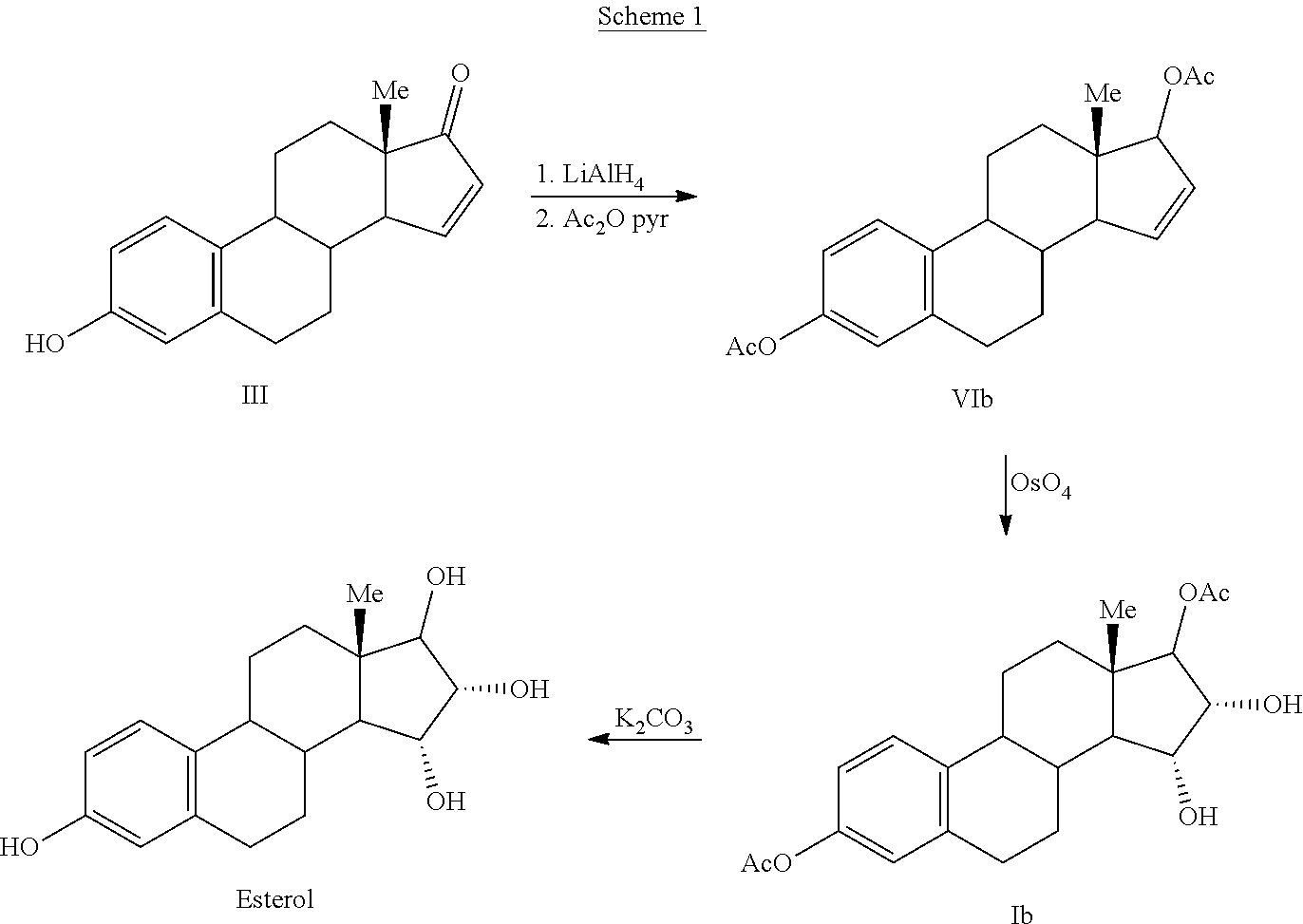

Process for the preparation of estetrol

The invention relates to a process for obtaining Estetrol or a salt or solvate thereof, the process comprising: a) reacting a compound of formula (IV) or a salt or solvate thereof, wherein R1 is a hydroxyl protecting group selected from a silyl ether, an ether, an ester, a carbamate and a carbonate, and R2 is a hydroxyl protecting group selected from an ether, with an oxidizing agent selected from OsO4 or a source of osmium tetroxide to produce Estetrol or a compound of formula (II) or a salt or solvate thereof wherein R1 is as defined previously; and b) if a compound of formula (II) is obtained in step a), deprotecting said compound to produce Estetrol.

Owner:CRYSTAL PHARMA SA

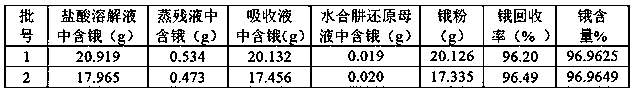

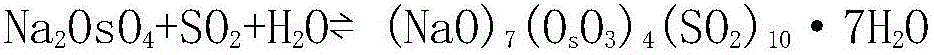

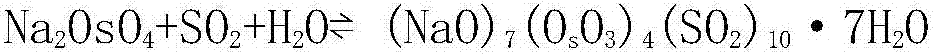

Method for recycling and utilizing precious metal in IrOsRu ore

The invention discloses a method for recycling and utilizing a precious metal in an IrOsRu ore, which comprises the following process steps: 1) blending and shredding raw materials: mixing and shredding IrOsRu ore, zinc and aluminum to form raw materials; 2) performing acid leaching to remove zinc and aluminum; 3) performing alkali dissolution and water leaching: melting the filter residue with asolid base, and performing water leaching; 4) performing oxidative distillation to remove cesium: adding nitric acid to produce and absorb osmium tetroxide vapor; 5) performing recovery of ruthenium:adding sodium chlorate to produce and recycle osmium tetroxide vapor, performing concentration and crystallization by rotary evaporation to obtain ruthenium trichloride; and 6) performing purificationof hydrazine, concentration of filtrate, etc., to obtain ammonium chloroiridate precipitation, and then filtering and drying the precipitation. According to the method for recycling and utilizing precious metal in IrOsRu ore, the IrOsRu ore, zinc and aluminum are shredded at high temperature in an intermediate frequency furnace to avoid the problems of high loss and difficult filtration caused bythe use of zinc or aluminum alone. The intermediate frequency furnace is provided with mixing, so the heating is fast, the efficiency is high and the energy is saved. Toxic gases are not used, so thesafety is high. The recovery rate is improved through recycling and multiple filtration. Other metal resources can be recycled again to avoid waste.

Owner:ZHEJIANG TELI RECYCLING RESOURCES

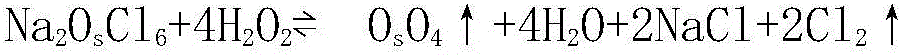

Method for rapidly extracting osmium from osmium-containing material

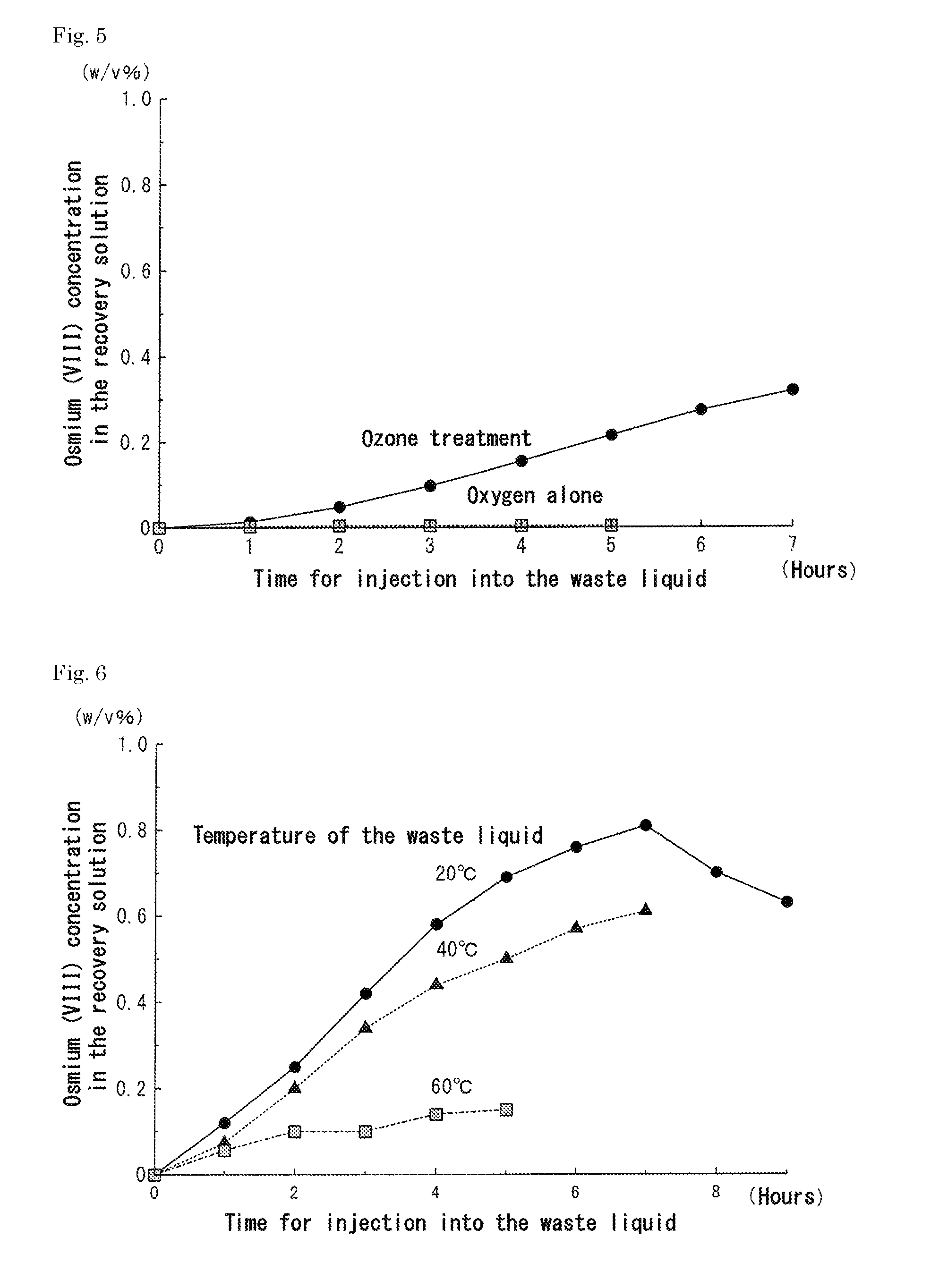

The invention discloses a method for rapidly extracting osmium from an osmium-containing material and belongs to the technical field of noble metal metallurgy. After the osmium-containing material isdissolved by hydrochloric acid, ozone is adopted to conduct selective distillation, two-grade absorption is conducted on the osmium tetroxide obtained after distillation by means of a mixed solution of sodium hydroxide and ethyl alcohol, the pH value of a solution is adjusted, osmium black is obtained through hydrazine hydrate reduction, after calcination and hydrogen reduction, metal osmium powder is obtained. The method for rapidly extracting the osmium from the osmium-containing material guarantees that the osmium tetroxide is not reduced, improves distillation efficiency and shortens the osmium distillation time to within 8 hours. The method for rapidly extracting the osmium from the osmium-containing material has the advantages of being simple in technology, short in technological process, convenient to operate, stable in product quality and the like.

Owner:JINCHUAN GROUP LIMITED

Methods for osmylating and ruthenylating single-walled carbon nanotubes

The present invention provides a method of differentiating metallic carbon nanotubes from semiconducting carbon nanotubes. The method comprising providing a nanotube dispersion, wherein the nanotube dispersion comprises a plurality of carbon nanotubes, osmium tetroxide, or ruthenium tetroxide, and a solvent; and irradiating the nanotube dispersion with ultraviolet light, wherein the metallic carbon nanotubes are osmylated, or ruthenylated, thereby differentiating the metallic carbon nanotubes from the semiconducting carbon nanotubes.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

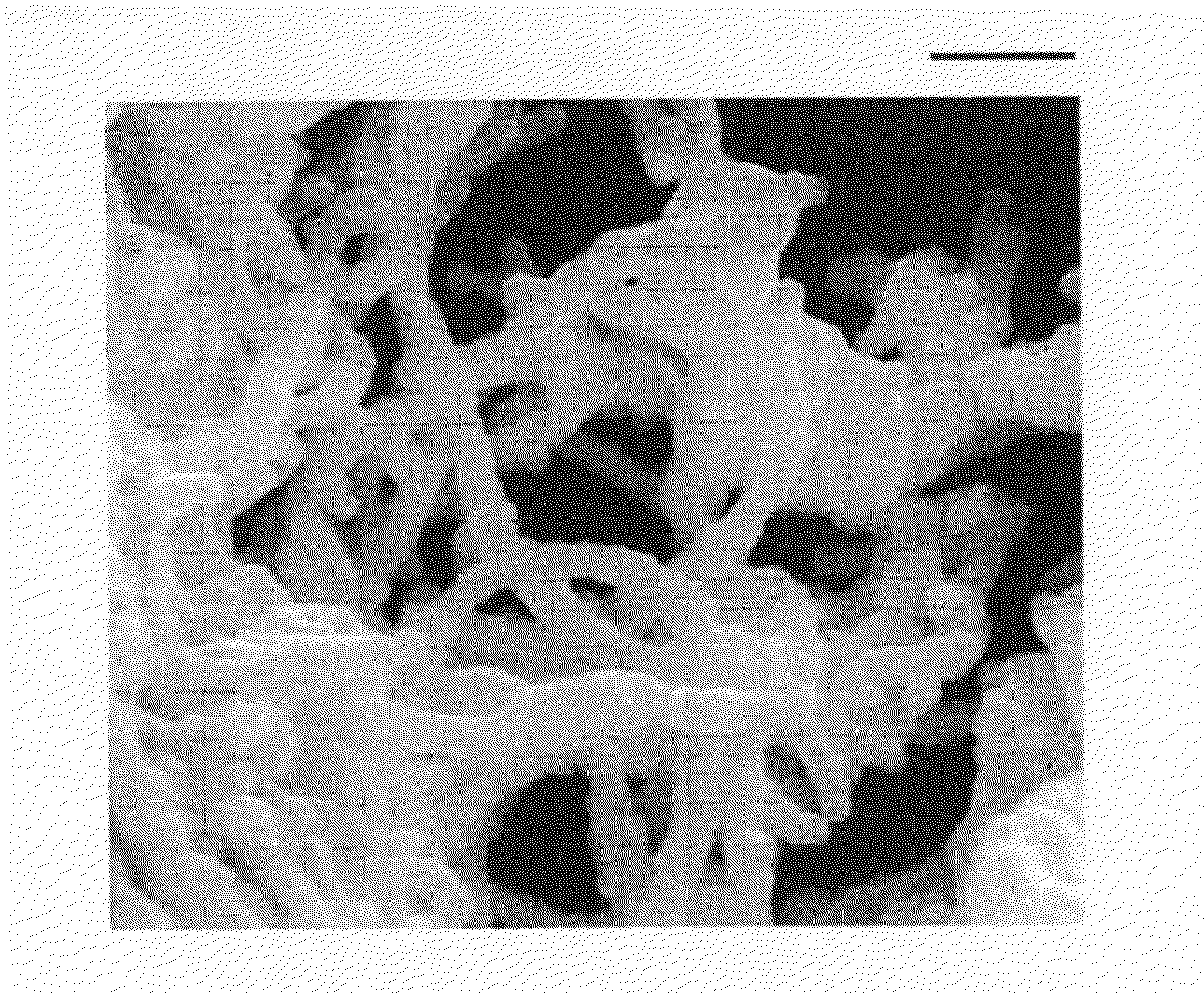

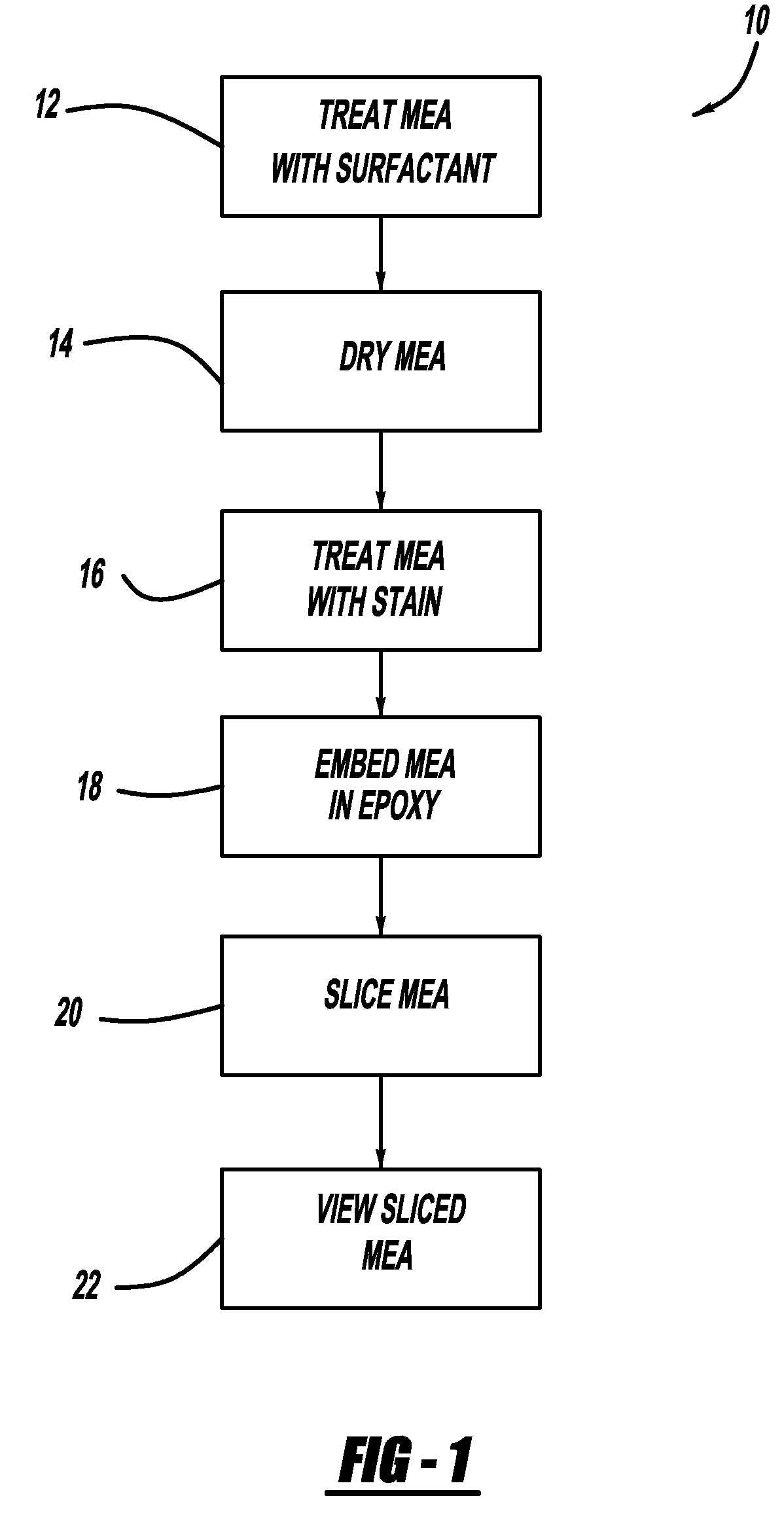

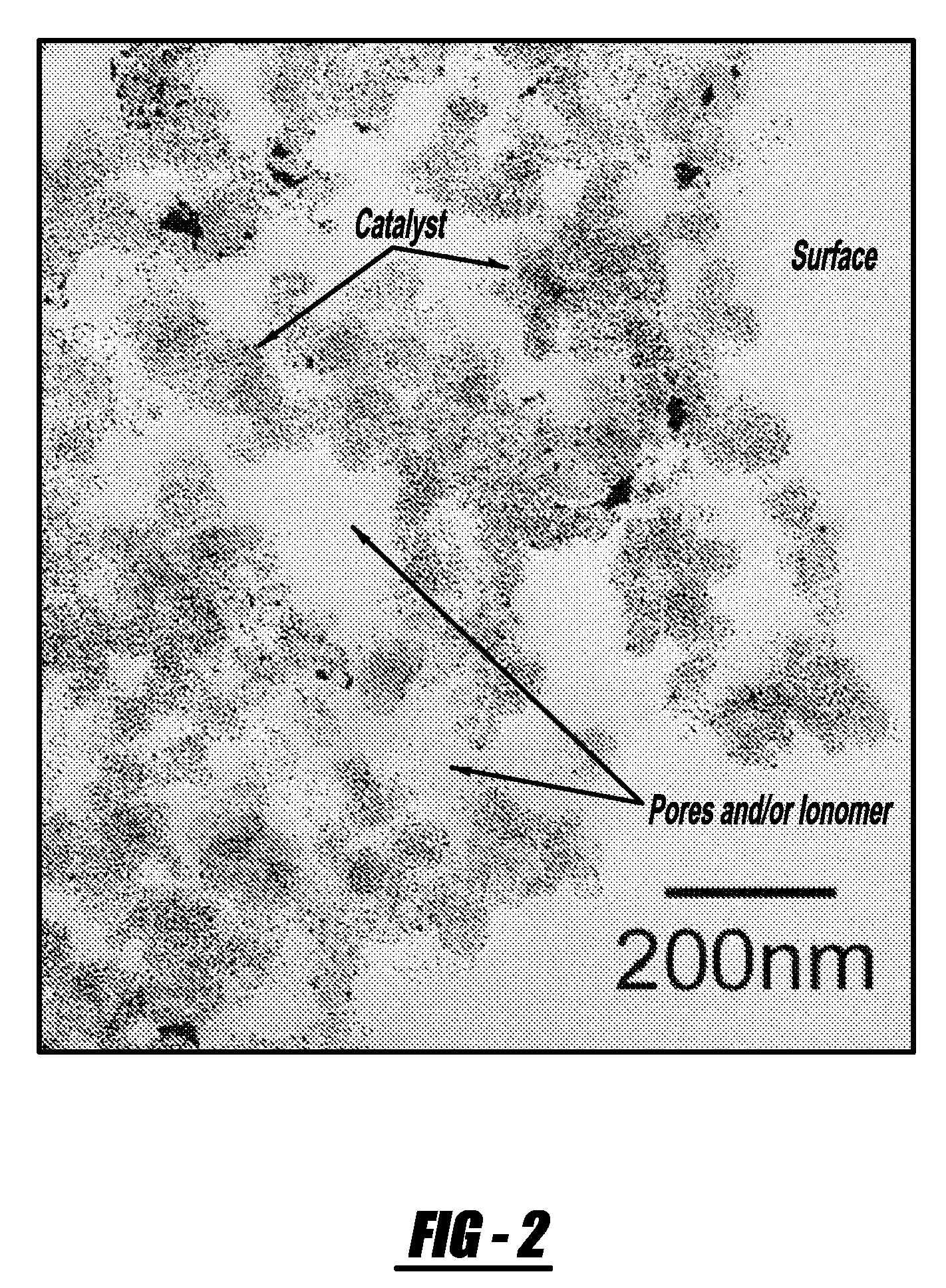

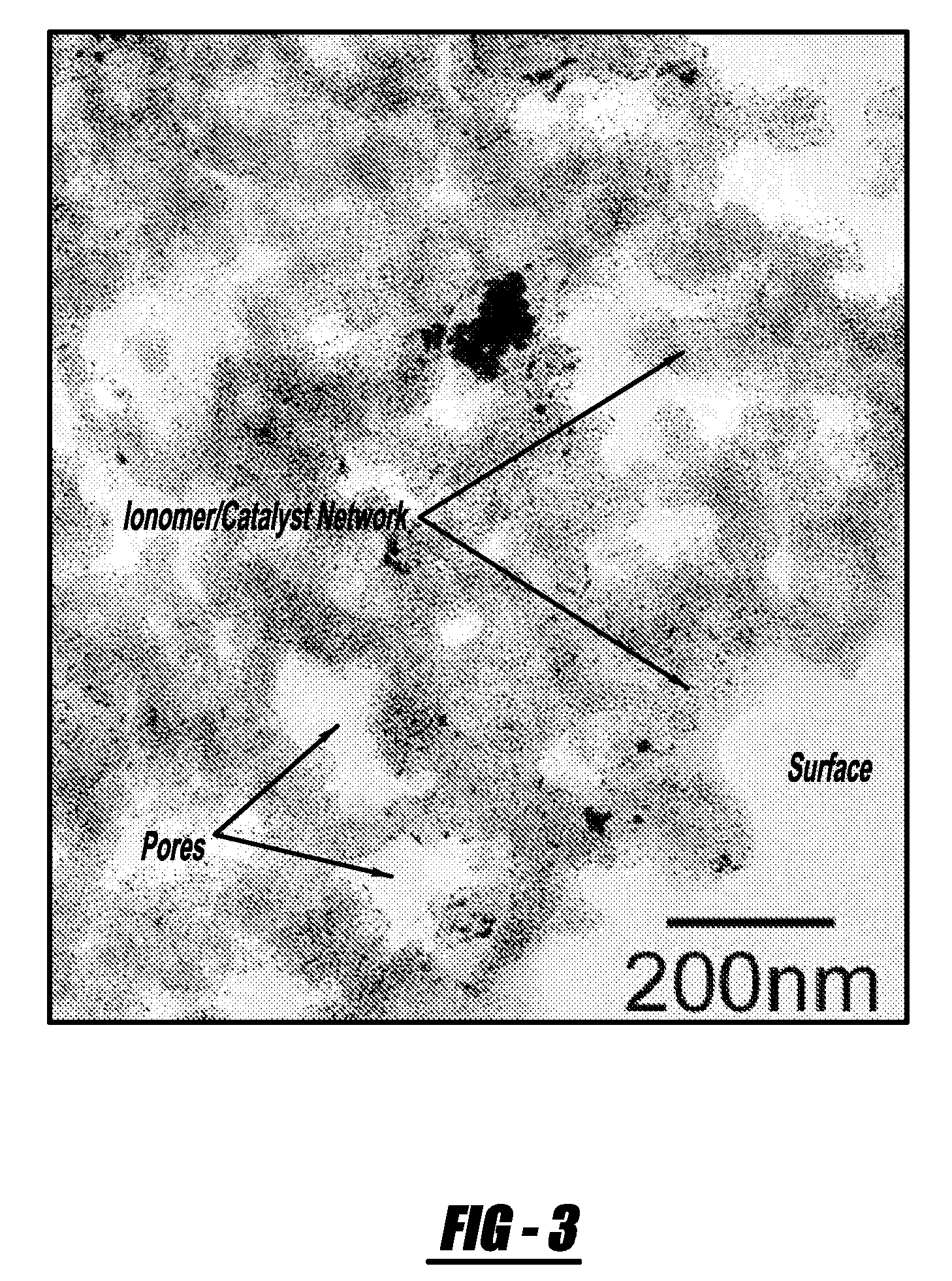

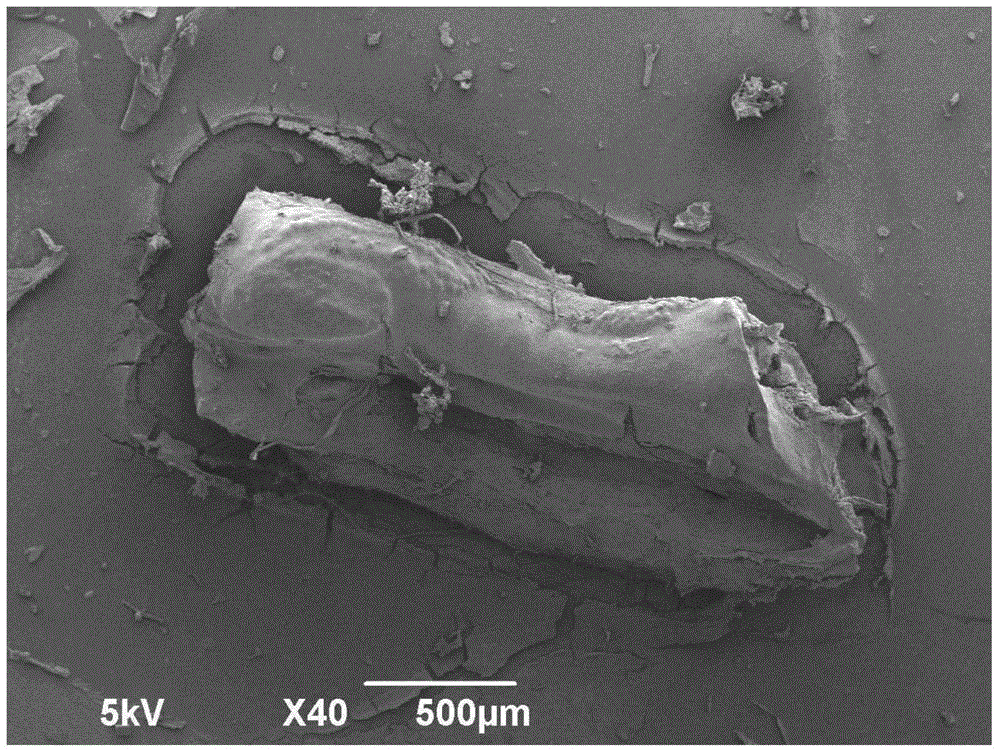

Method for Characterizing the Porosity in Fuel Cell Electrodes

A method for evaluating the composition of an MEA for a fuel cell. The method includes soaking the MEA in an unsaturated organic compound for a predetermined period of time, and then allowing the MEA to dry. The method then includes staining the MEA with osmium tetroxide (OsO4) in a closed container. The stained MEA is then encased in an epoxy. Thin sections of the encapsulated MEA are then prepared, and the sections are viewed through a transmission electron microscope. The stained MEA will show dark regions where the ionomer and carbon particles are located and lighter regions that are epoxy filled pores.

Owner:GM GLOBAL TECH OPERATIONS LLC

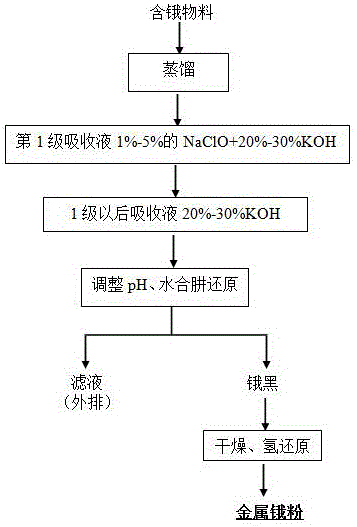

Method for extracting osmium from osmium-containing materials

The invention discloses a method for extracting osmium from osmium minerals or osmium-containing materials. The invention belongs to precious metal metallurgy. The method comprises the following steps: distilling the osmium-containing materials under a hydrochloric acid medium, wherein multi-stage absorption is used for distillation and absorption, 1-5% of sodium hypochlorite solution and 20-30% of potassium hydroxide solution are used as a first-stage absorption solution, and 20-30% of potassium hydroxide solution is used as an absorption solution for absorption after first-stage absorption; and combining the multiple stages of absorption solutions, adjusting a pH value by virtue of hydrochloric acid, reducing by virtue of hydrazine hydrate to obtain osmium black, and carrying out drying and hydrogen reduction to obtain a metal osmium powder. The method disclosed by the invention is capable of effectively absorbing an acid gas introduced during a secondary distillation process, and ensuring that osmium tetroxide has enough oxidizability for preventing reduction due to the addition of sodium hypochlorite. In addition, the method is capable of extracting osmium from the osmium minerals or the refractory osmium-containing materials, simple in process, convenient to operate, reasonable in procedures, and stable in product quality.

Owner:JINCHUAN GROUP LIMITED

Method for synthesizing polyhydroxy pyrroline acridine alkaloid

The present invention discloses a method of synthesizing multi-hydroxy pyrrolidine alkaloid. The present invention comprises the following steps: 1) the multi-hydroxy ring-shaped nitrone of the structure in formula II reacts to prepare Cbz-protected amide of the structure in formula III; 2) the amide of the structure in formula III is changed into an alpha, beta-unsaturated ketone of the structure IV; 3) the alpha, beta-unsaturated ketone of the structure IV and ketone do the dual-hydroxylation reaction with the influence of osmium tetroxide and NMO system to get a structure in formula V; 4) the formula V is catalyzed and hydrogenated to get the multi-hydroxy pyrrolidine alkaloid of the structure in formula I. The present invention startes from the low-cost and easily accessible raw materials; the sugar derived multi-hydroxy chiral nitrone is used as a key chiral intermediate; a set of simple, effective and practical methods of highly three-dimensional selectivity and high production rate to synthesize the multi-hydroxy pyrrolidine alkaloid of hyacinthacine C1 category is formed through the pro-nuclear addition, Wittig reaction, double-hydroxylation and reductive amination and other reactions.

Owner:INST OF CHEM CHINESE ACAD OF SCI

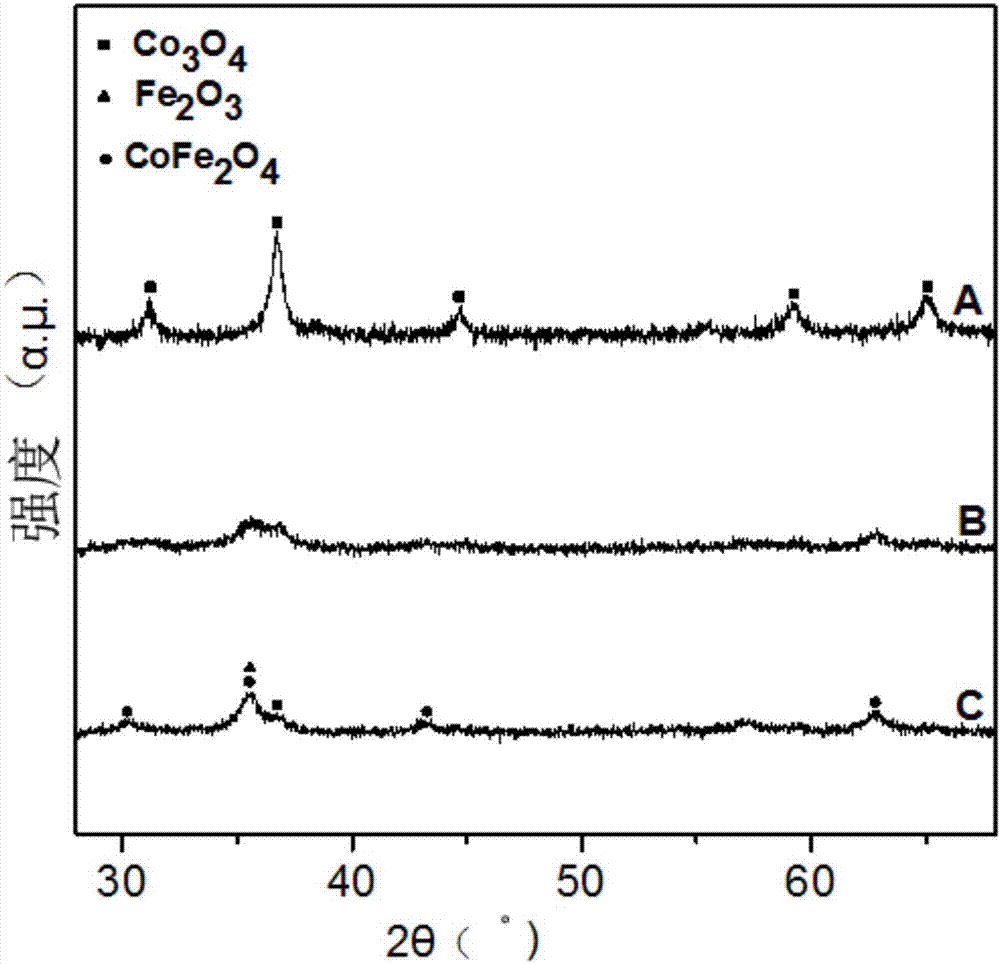

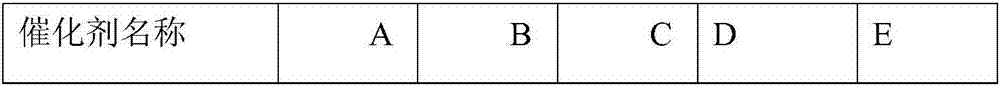

Catalyst for preparing glyoxylic acid from methyl glycolate, preparation method and application

ActiveCN107876055ASimple manufacturing processImprove conversion rateOxygen-containing compound preparationOrganic compound preparationOXALIC ACID DIHYDRATEOsmium tetroxide

The invention belongs to the technical field of organic chemical industry and particularly relates to a catalyst for preparing glyoxylic acid from methyl glycolate, a preparation method and an application. The catalyst is a composite oxide formed of ferric oxide and osmium tetroxide, or a mixture of one or two of cobalt ferrite, wherein the molar ratio of Fe to Co is between 1:8 and 2:1. The catalyst is prepared by a solid phase grinding method, that is, iron nitrate nonahydrate, cobalt nitrate hexahydrate, oxalic acid dihydrate and ethylene glycol are mixed and then ground, dried and baked. The method is simple and easy to implement. The catalyst is used in the preparation of the glyoxylic acid from the methyl glycolate, a fixed bed reactor is used, the reaction is performed under the conditions of the reaction temperature of 200 to 260 DEG C and the space velocity of gaseous methyl glycolate of 1740 ml / (h.g), the conversion rate of the methyl glycolate is 67% to 99%, and the selectivity of the glyoxylic acid is 55% to 100%.

Owner:SHANGHAI INST OF TECH

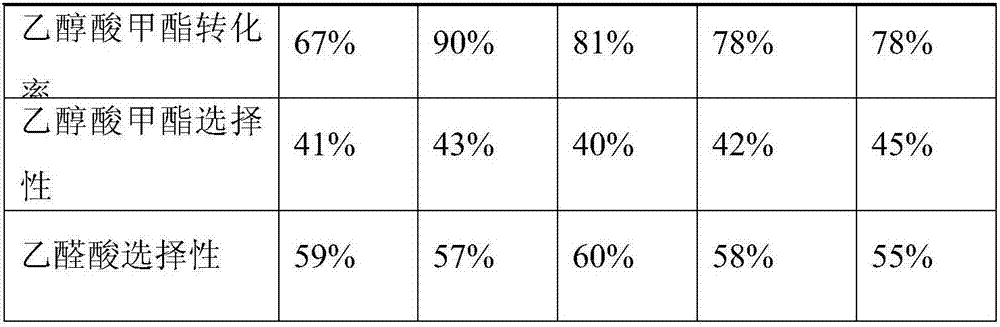

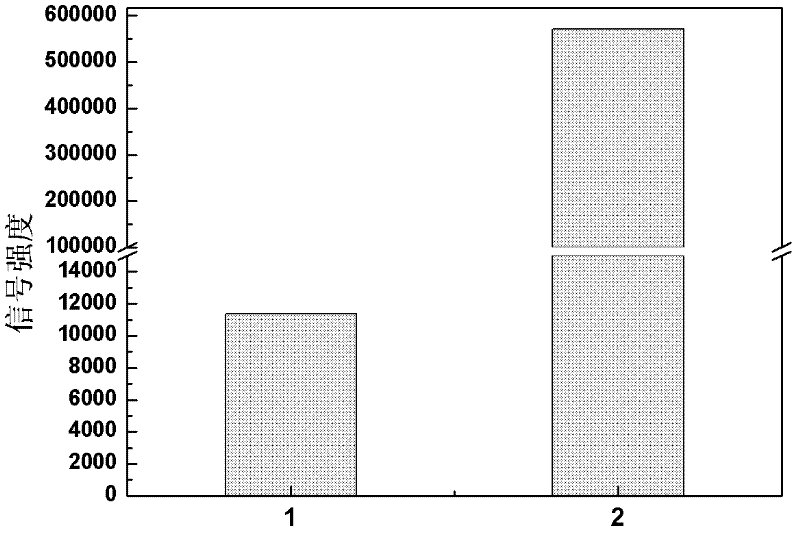

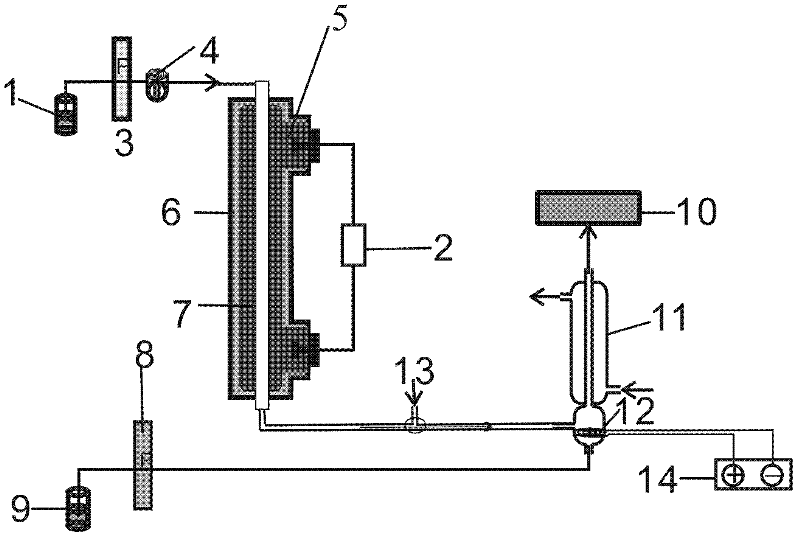

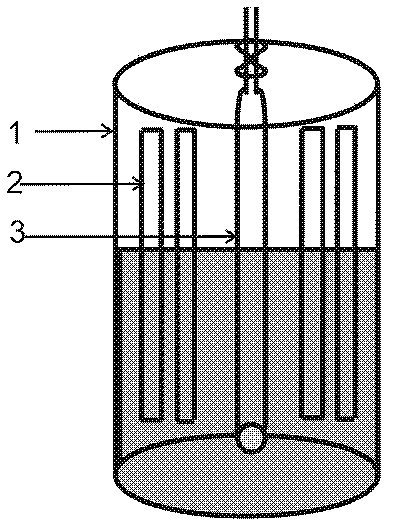

Mobile detection method and detection device for chemically inducing osmium to be oxidized by using ultraviolet light

InactiveCN102519766AReduce lossesReduce pollutionPreparing sample for investigationMaterial analysis by electric/magnetic meansOsmium tetroxideUltraviolet lights

The invention discloses a mobile detection method and a detection device for chemically inducing osmium to be oxidized by using ultraviolet light. The detection method comprises the following steps that: an osmium-containing solution sample to be detected is introduced into a sample reaction quartz tube, and is irradiated by the ultraviolet light to induce osmium in the sample to be oxidized into an osmium tetroxide solution; and the osmium tetroxide solution is introduced into a gas-liquid separator for gas-liquid separation to produce osmium tetroxide steam, and the osmium tetroxide steam is measured by ICP-OES or ICP-MS to obtain osmium signals. The detection device at least comprises the reaction quartz tube and an ultraviolet lamp, wherein the quartz tube is positioned inside or outside the ultraviolet lamp, and is communicated with the gas-liquid separator by a pipeline, and a gas carrier inlet is positioned in the middle of the reaction quartz tube and the gas-liquid separator through a three-way pipe; an upper section of the gas-liquid separator is a straight condenser pipe, and a lower section of the gas-liquid separator is provided with a coolant inlet; and the coolant inlet is wrapped with a metal wire or heating tape. The method provided by the invention is relatively simple, does not need any redox reagent, and reduces the loss of osmium in the sample and the pollution brought in the pretreatment process; and the sensitivity is higher, the sample can be introduced more effectively than the traditional nebulization sampling method, and the detection limit is lower.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

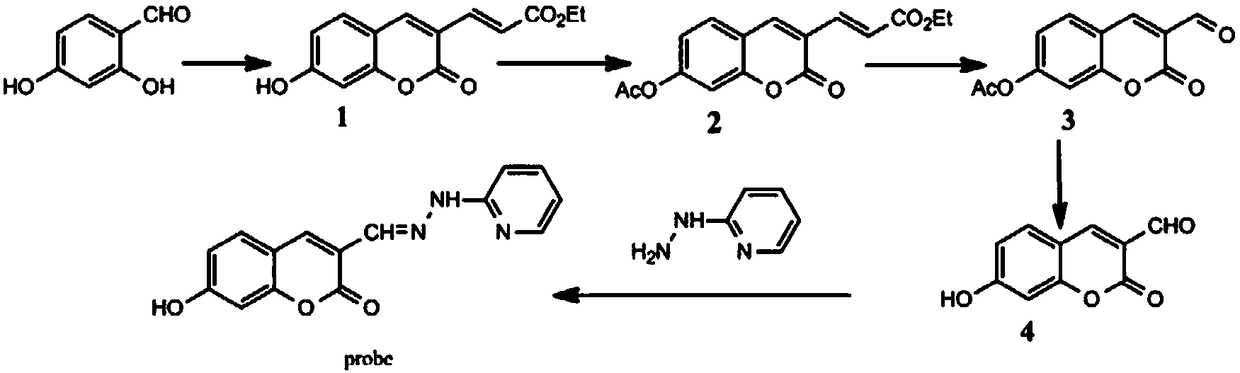

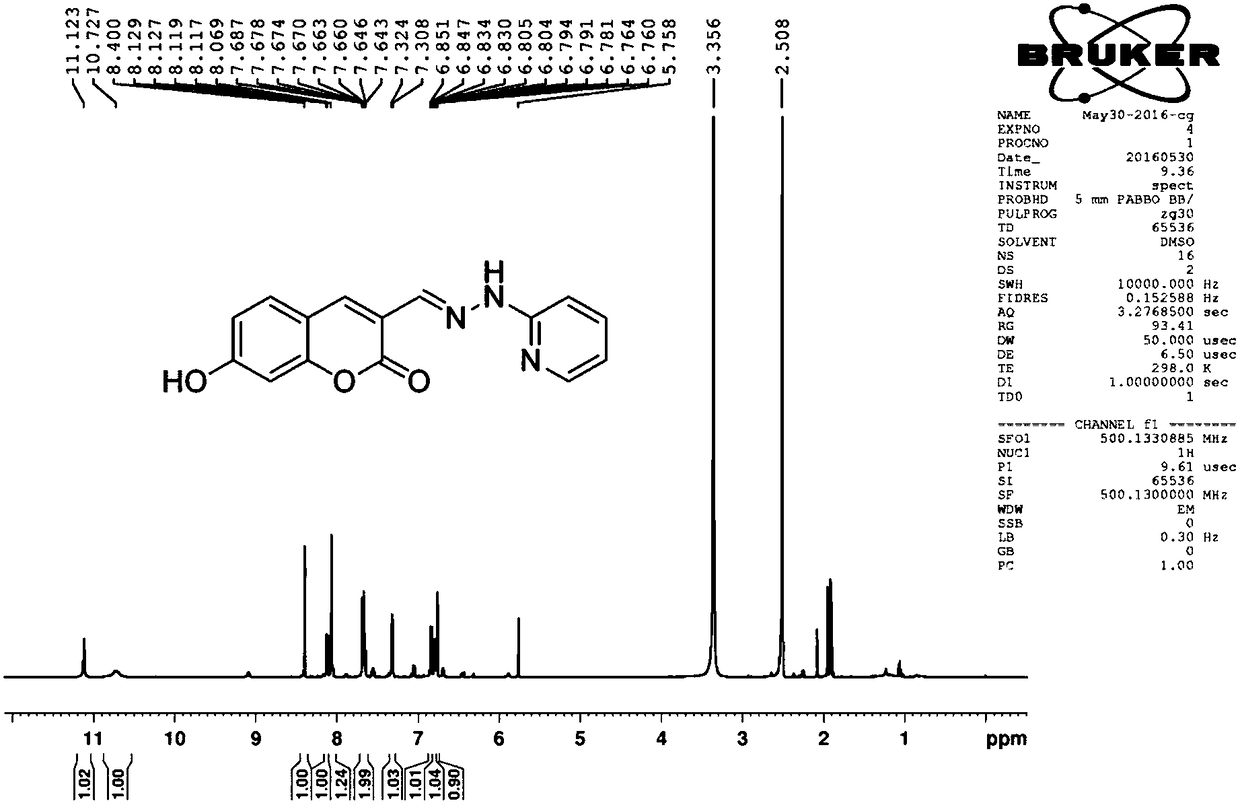

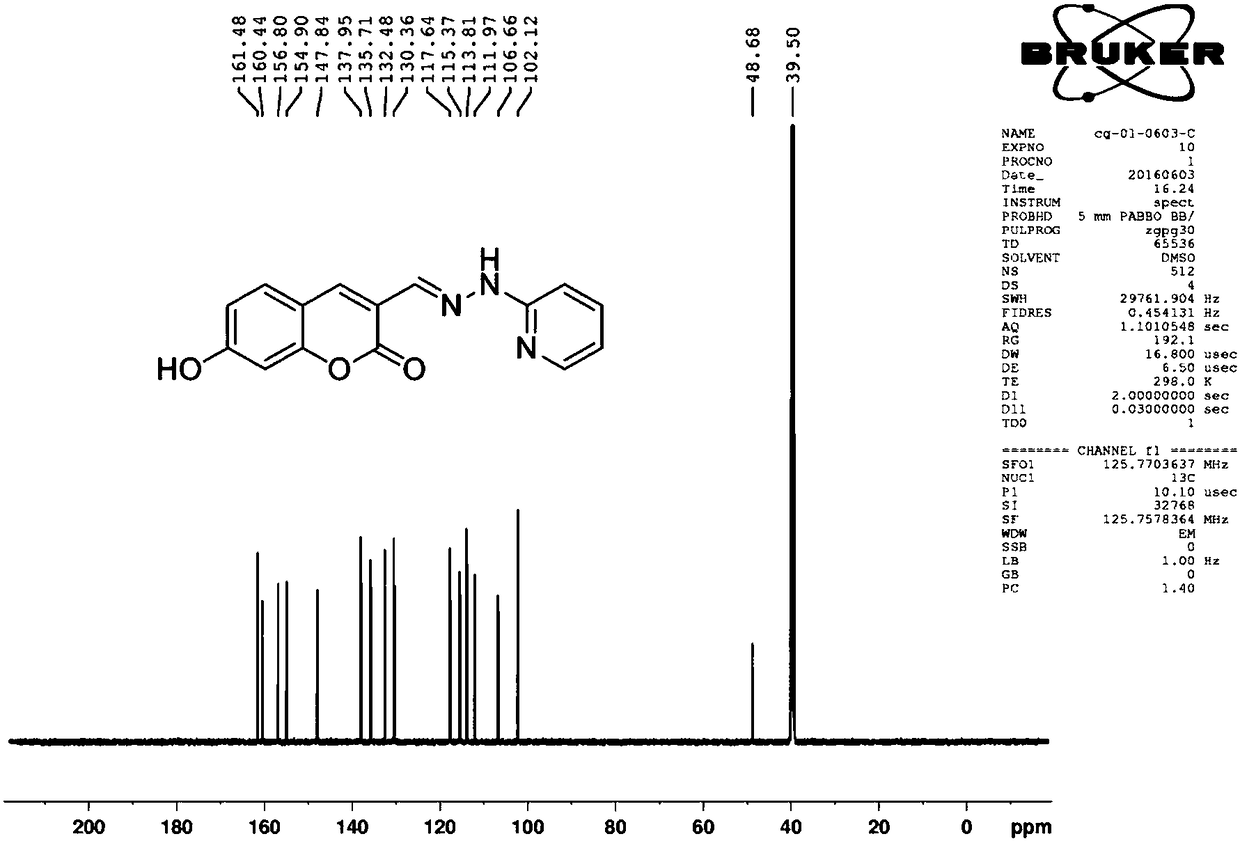

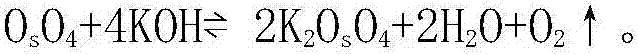

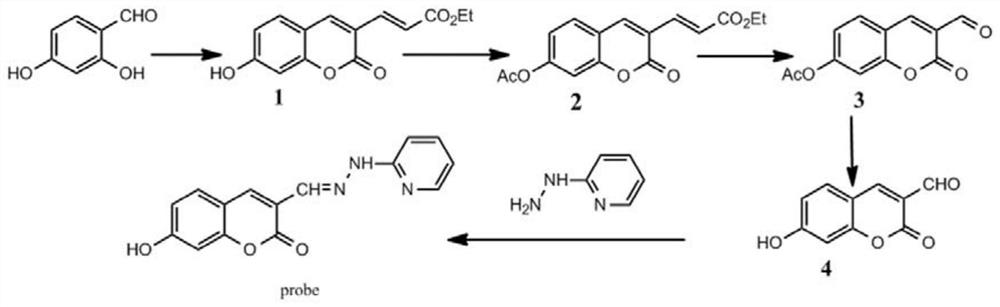

Preparation method and application of multifunctional super-sensitive Zn<2+> two-photon detection fluorescence molecular probe

ActiveCN108299402AImprove accuracyStrong specificityOrganic chemistryFluorescence/phosphorescenceOsmium tetroxideDisease

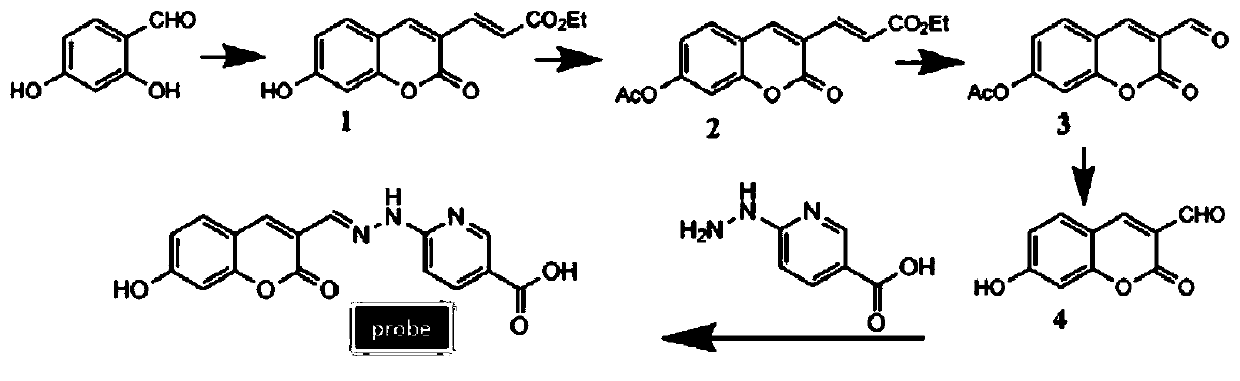

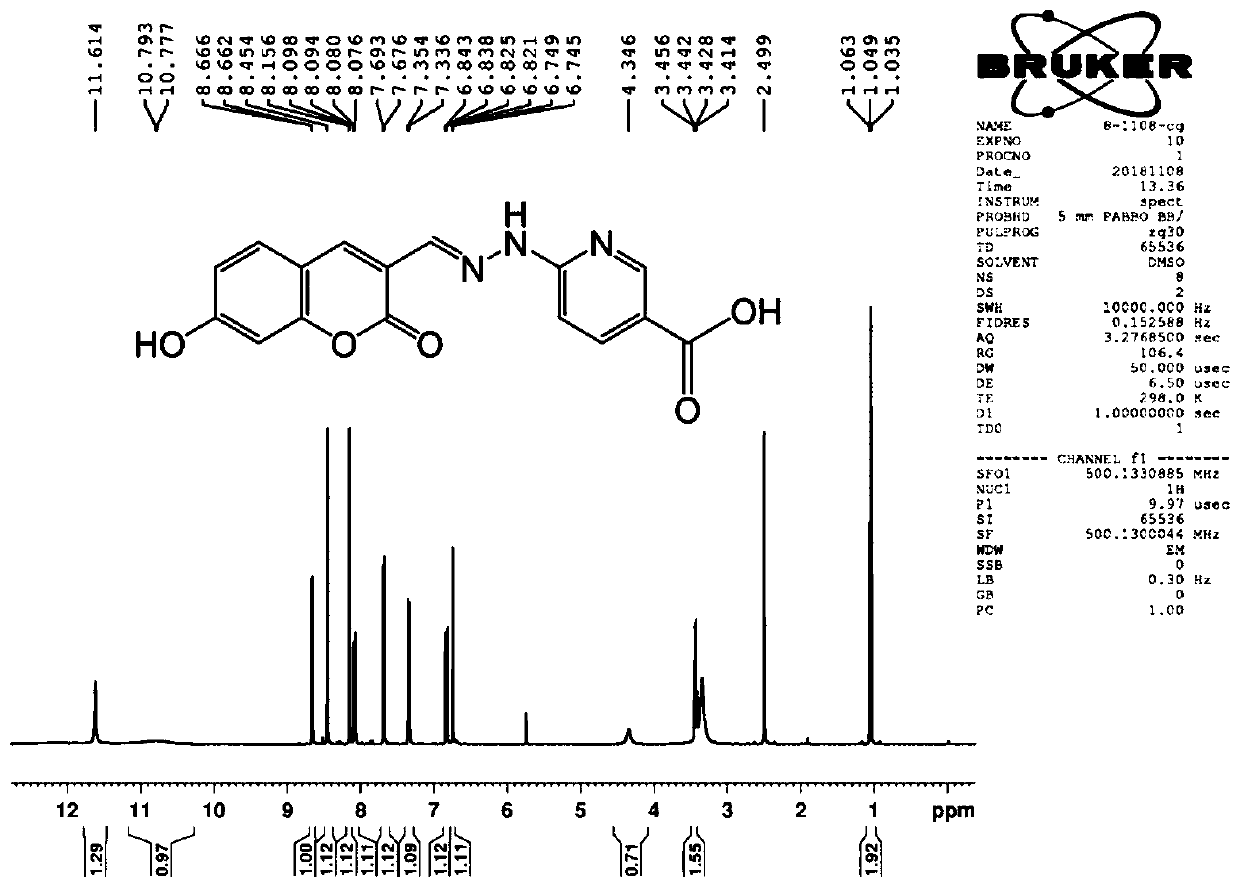

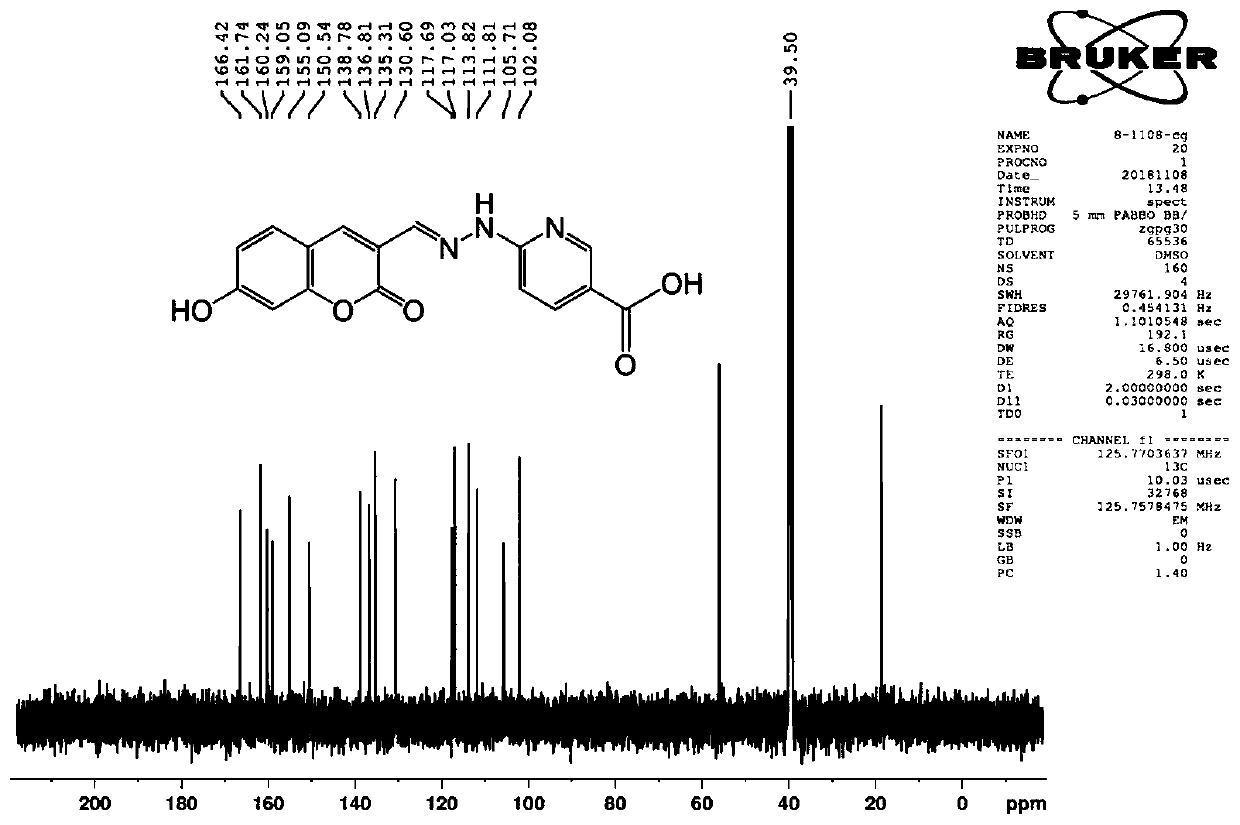

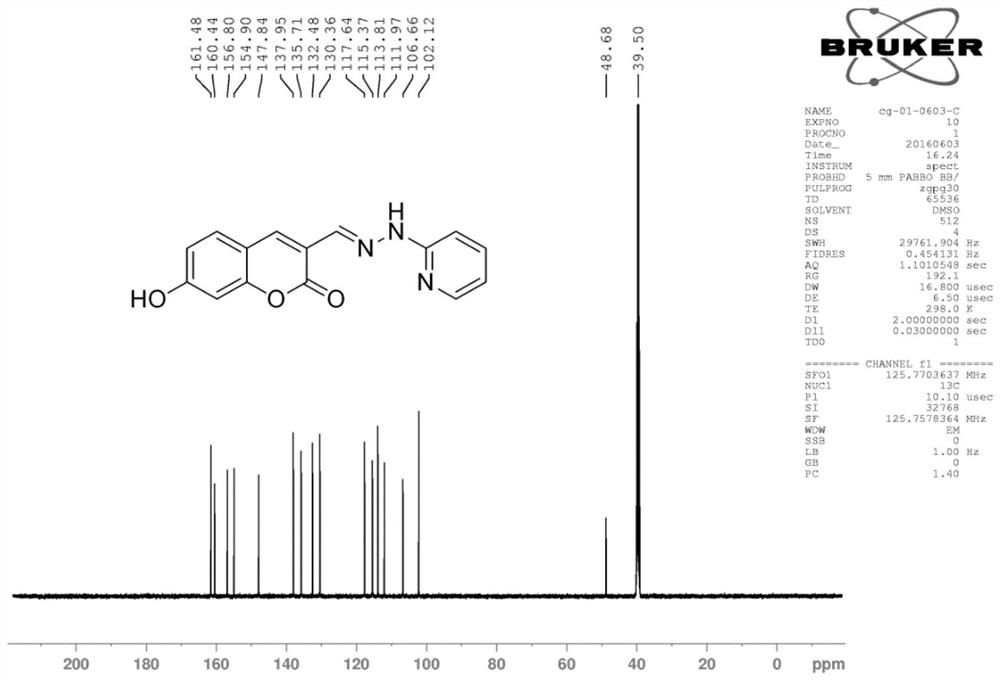

The invention relates to a preparation method and application of a multifunctional super-sensitive Zn<2+> two-photon detection fluorescence molecular probe. Firstly, 2,4-dihydroxy benzaldehyde, diethyl glutaconate and anhydrous piperidine react in ethanol to obtain a product 1; the product 1 and acetic anhydride react in anhydrous pyridine to obtain a product 2; the product 2, osmium tetroxide andsodium periodate react in tetrahydrofuran to obtain a product 3; the product 3 and anhydrous potassium carbonate react in methyl alcohol to obtain a product 4; finally, the product 4 id dissolved into the ethanol; 2-hydrazinopyridine and glacial acetic acid are added; the steps of backflow, recrystallization and the like are performed; the multifunctional super-sensitive Zn<2+> two-photon detection fluorescence molecular probe is obtained. The probe is applicable to the qualitative and quantitative analysis of Zn<2+> in a biological sample; the detection is sensitive, accurate and fast; the probe can be applied to the relevant fields of analytical chemistry, life organic analytical chemistry, disease advanced diagnosis, medical clinic detection and the like.

Owner:QUFU NORMAL UNIV

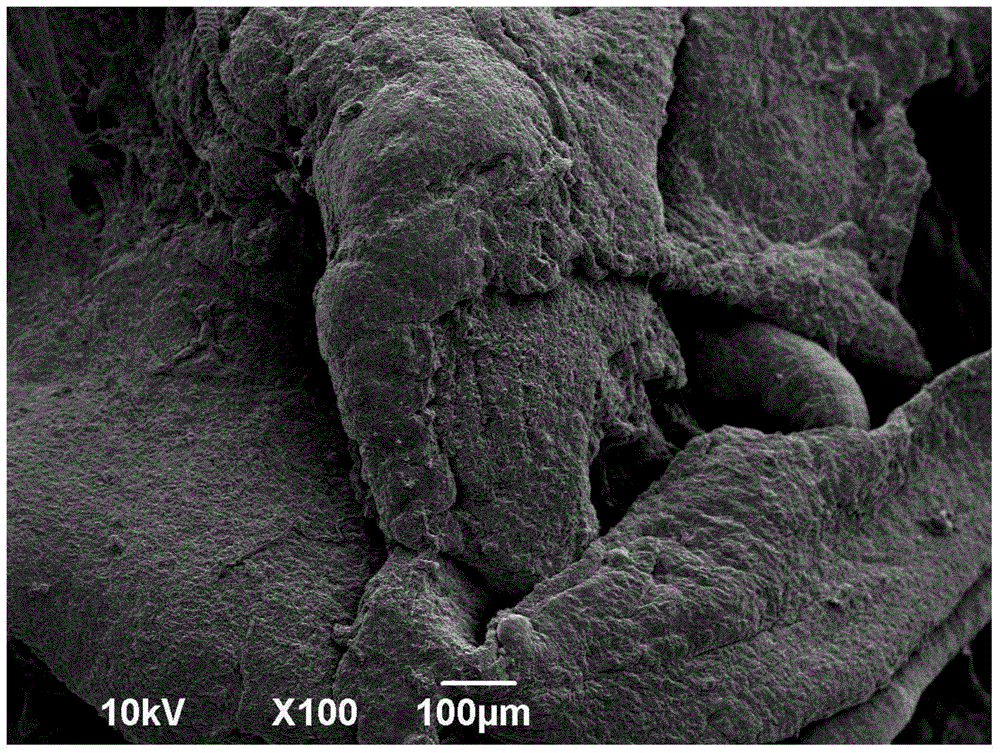

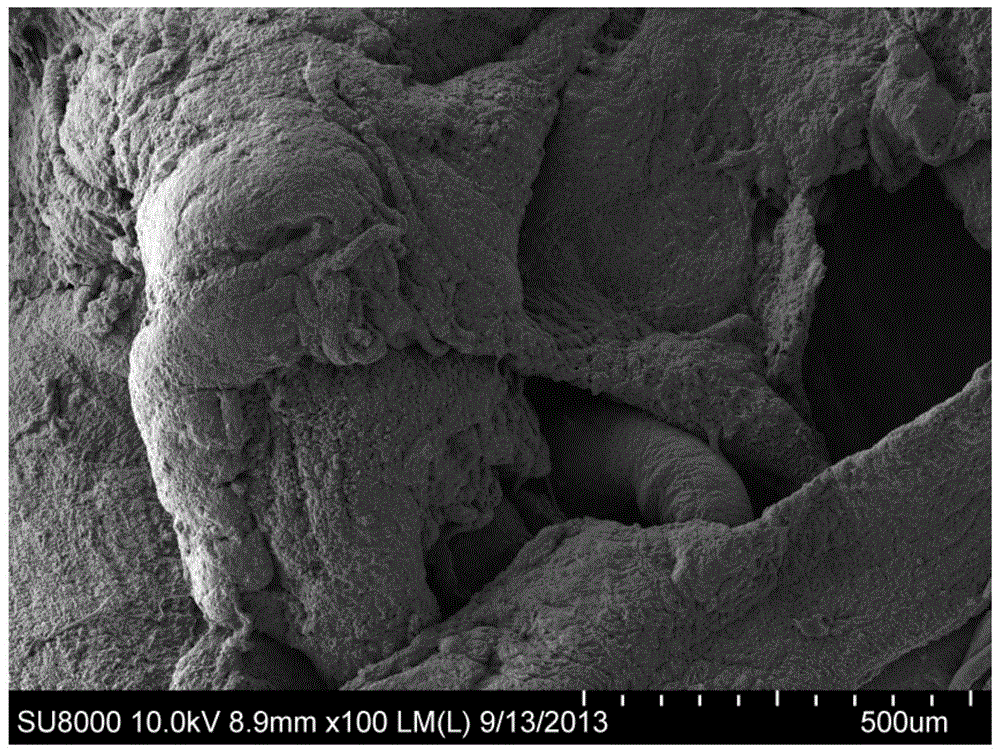

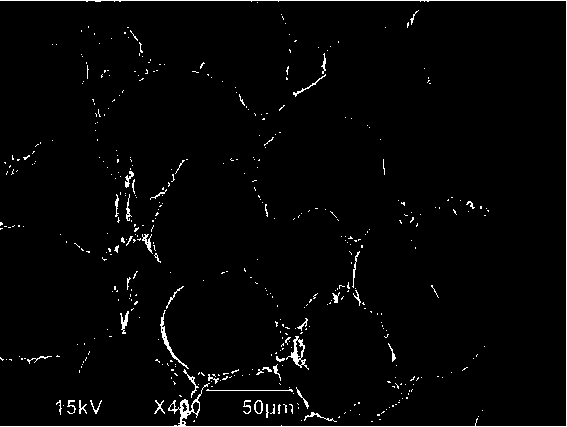

Biological electron microscope sample carbonization method

ActiveCN105021432AChemical physical shrinkage is smallPromote resultsPreparing sample for investigationOsmium tetroxideFine structure

The invention belongs to the field of biological sample preparation, and particularly relates to a biological electron microscope sample carbonization method. Volatile gas of 0.1 M osmium tetroxide liquid is adopted for conducting fumigation and burning on organic biological samples, so that the organic biological samples are completely carbonized to meet the requirement for scanning electron microscope observation. Biological electron microscope samples manufactured through the method have a better expression result and are environmentally friendly and low in carbon, operation is easy and convenient, the chemical and physical contraction rate of all the samples is small, the appearance structure is almost unchanged, and the fine structure is clear. The method breaks through the bottleneck of manufacturing of some electron microscope samples so that some transmission electron microscope samples and scanning electron microscope samples which can not be manufactured in the prior art can be smoothly manufactured and meet the requirement for electron microscope observation. The method can be used for biological electron microscope sample manufacturing of biological sample tissue, bacteria, organic macromolecule protein bodies or organic macromolecule substances.

Owner:FUDAN UNIV

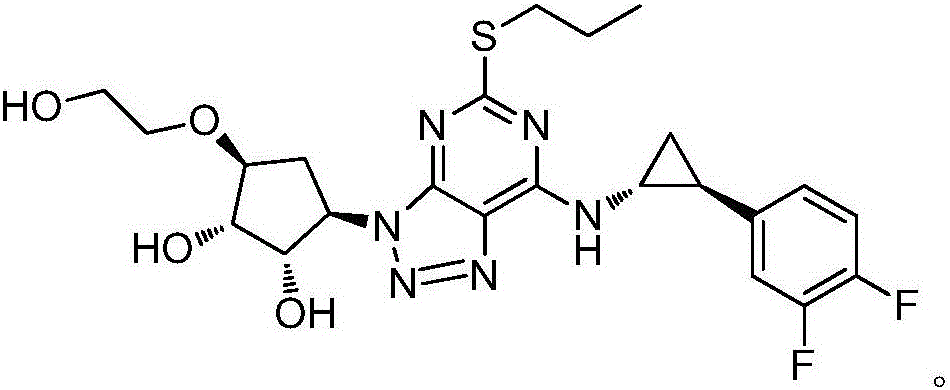

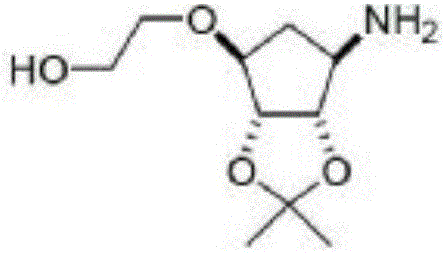

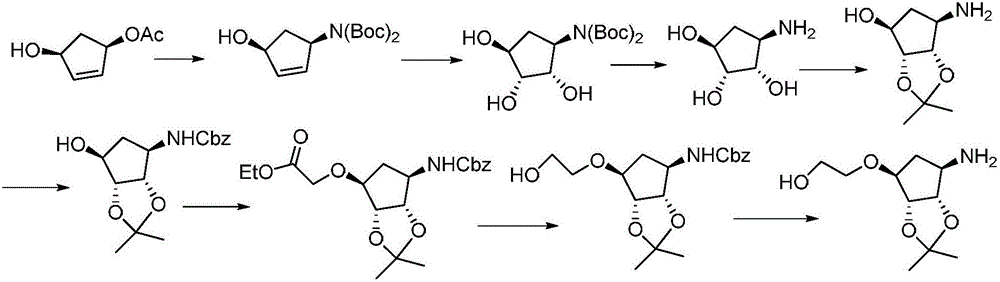

Synthesis process of ticagrelor intermediate

InactiveCN106496179ARaw materials are cheap and easy to getReduce manufacturing costOrganic compound preparationOrganic chemistry methodsOsmium tetroxideAlcohol

The invention discloses a synthesis process of a ticagrelor intermediate. The synthesis process of the ticagrelor intermediate is characterized by including the steps: 1) under acidic condition, contacting benzaldoxime with cyclopentadiene for reaction so as to obtain a compound shown in formula I; 2) under the catalysis of osmium tetroxide, using hydrogen peroxide to oxidize the compound shown in the formula I so as to obtain a compound shown in formula II; 3) under the catalysis of p-toluenesulfonic acid, reacting the compound shown in the formula II and acetone to obtain a compound shown in formula III; 4) in the presence of an alkali, reacting the compound shown in the formula III with 2-bromoethyl alcohol so as to obtain a compound shown in formula IV; 5) reducing the compound shown in the formula IV so as to obtain the ticagrelor intermediate. The raw materials used here in the method provided herein are low in cost and easy to obtain, so that production cost; the use of chiral materials is not required, a high stereoselectivity product can be acquired through cycloaddition reaction, the steps are short, the reaction yield is very high, and a new approach for the synthesis of ticagrelor is provided.

Owner:QINGDAO YUNTIAN BIOTECH

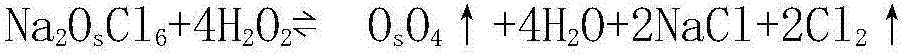

Production process of potassium osmate

ActiveCN106698530ARuthenium/rhodium/palladium/osmium/iridium/platinum compoundsOsmium tetroxideOsmium Compounds

The invention relates to a new synthetic process of potassium osmate, wherein the synthetic process comprises the steps of fire process, water immersion, neutralization, filtration and washing, distillation, crystallization and the like. A pure osmium powder is used as a raw material, osmium enters a solution by the way of fire-process smelting, and the compound potassium osmate is obtained by oxidation distillation, crystallization and other steps. The potassium osmate is a powder crystal at room temperature, has stable properties and more convenient storage, transport and use compared with osmium tetroxide, and solves the defects of fewer commonly used osmium compounds and troublesome osmium compound collection, packaging, storage and use in the prior art.

Owner:南京东锐铂业有限公司 +1

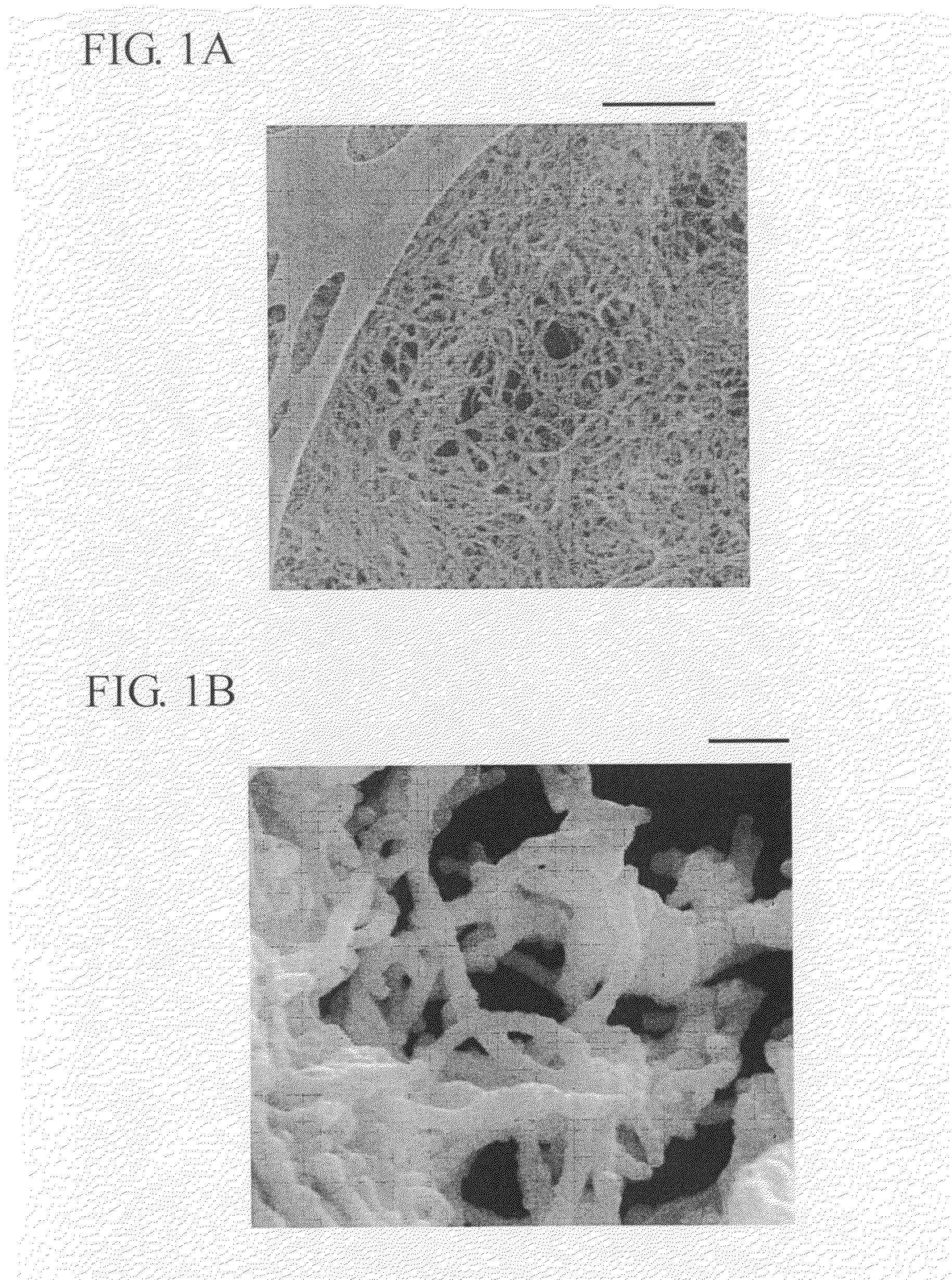

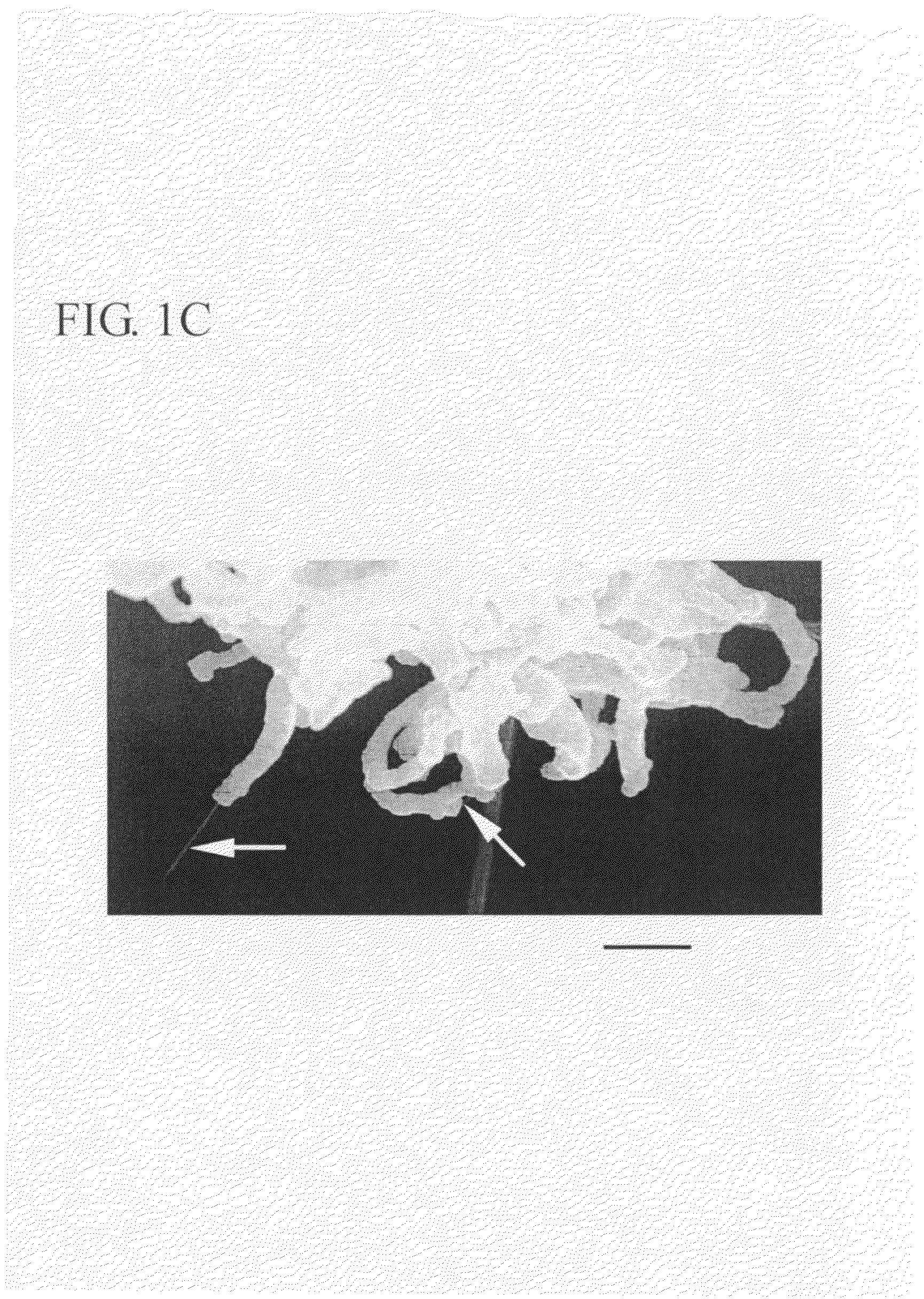

Method for preparing scanning electron microscope sample of carp muscle extracellular connective tissue

ActiveCN107843609AComplete structureClear structureMaterial analysis using wave/particle radiationMicro structureOsmium tetroxide

The invention discloses a method for preparing a scanning electron microscope sample of carp muscle extracellular connective tissue. The method comprises fixing muscle in a pre-fixation solution, sucking out the pre-fixation solution, adding a NaOH solution to the muscle, carrying out oscillation and cleaning, fixing a sample in a tannic acid solution, carrying out cleaning, fixing the sample through osmium tetroxide, carrying out cleaning, washing the sample through a cryoprotectant solution, orderly carrying out dehydration through methanol according to concentration gradient from low to high, putting the dehydrated sample into a methanol solution, carrying out quick-freezing through liquid nitrogen, slicing the sample, carrying out replacement through tertiary butanol, carrying out freeze drying on the sample, and recording the dried sample through photograph. The method can guarantee the complete structure of the sample subjected to cytoplasm removal, does not dissolve or partiallydissolve the connective tissue under action of cytoplasm and keeps the integrity of the connective tissue. Through the method, clear and strong three-dimensional effect images of the connective tissue under scanning electron microscope observation are obtained and the micro-structure characteristics can be well observed.

Owner:ZHEJIANG OCEAN UNIV

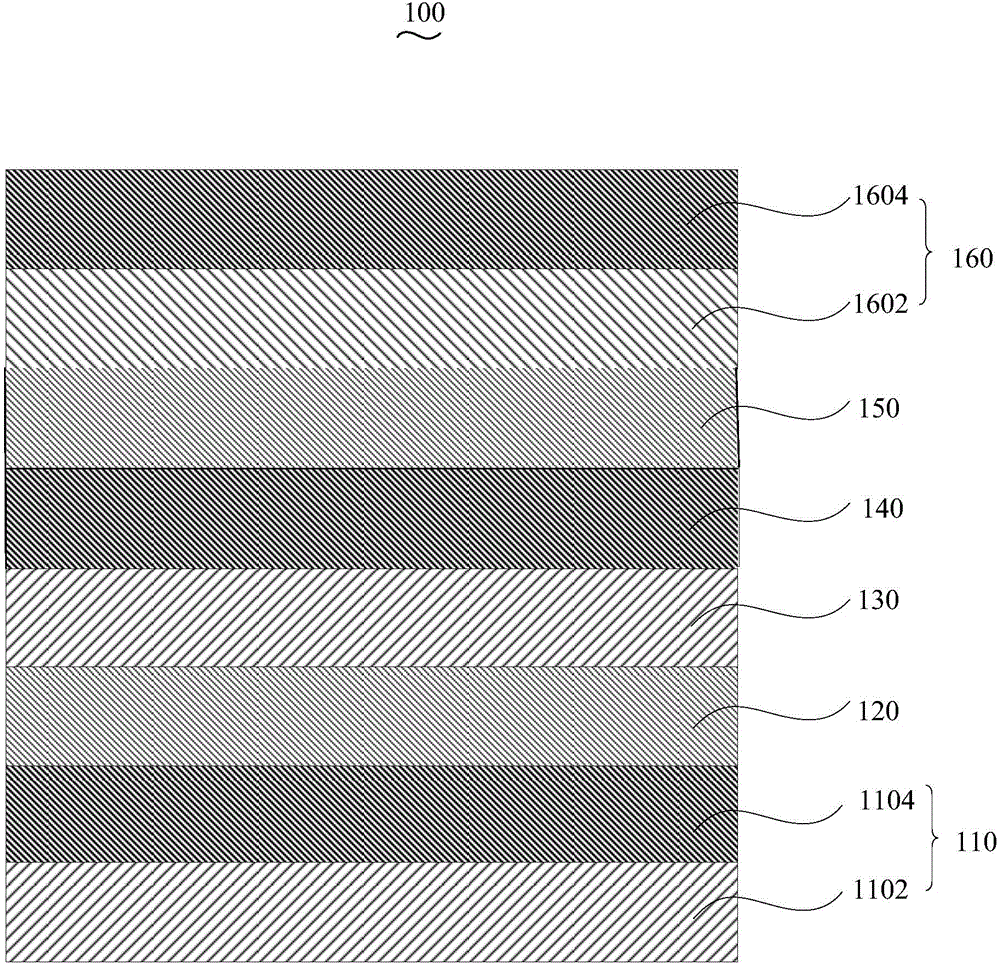

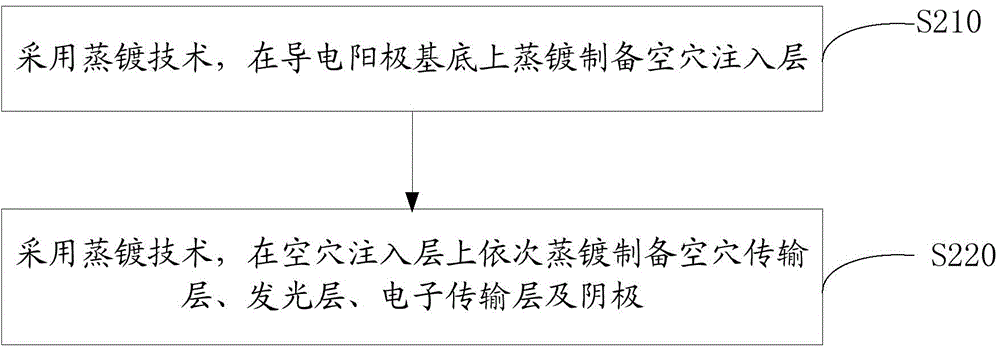

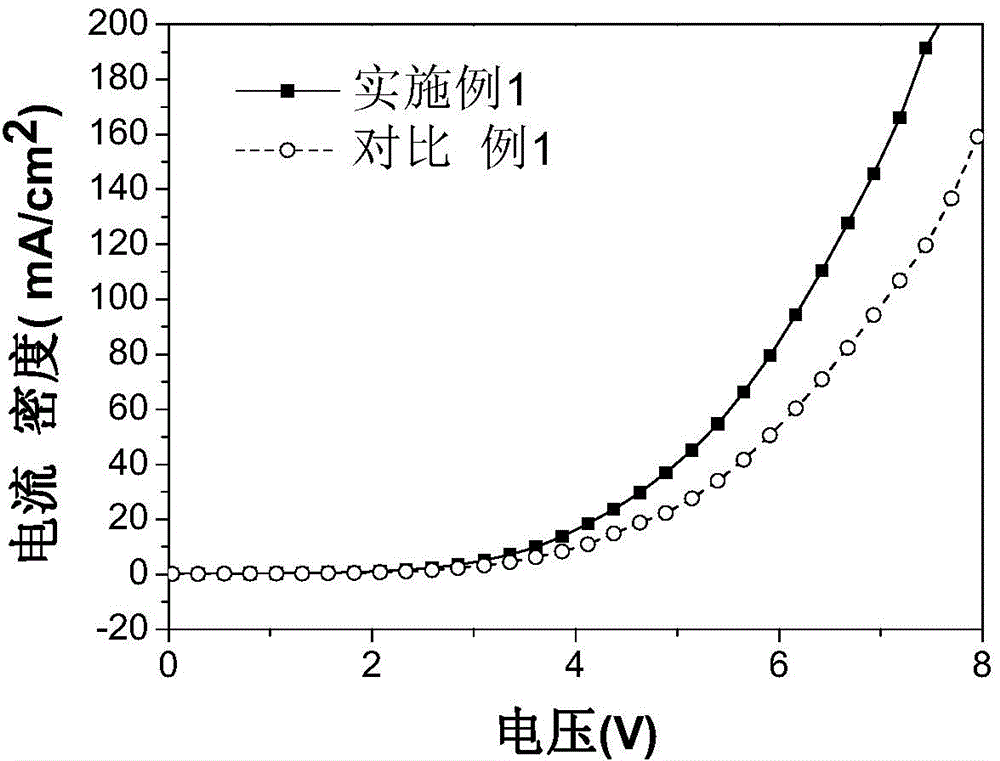

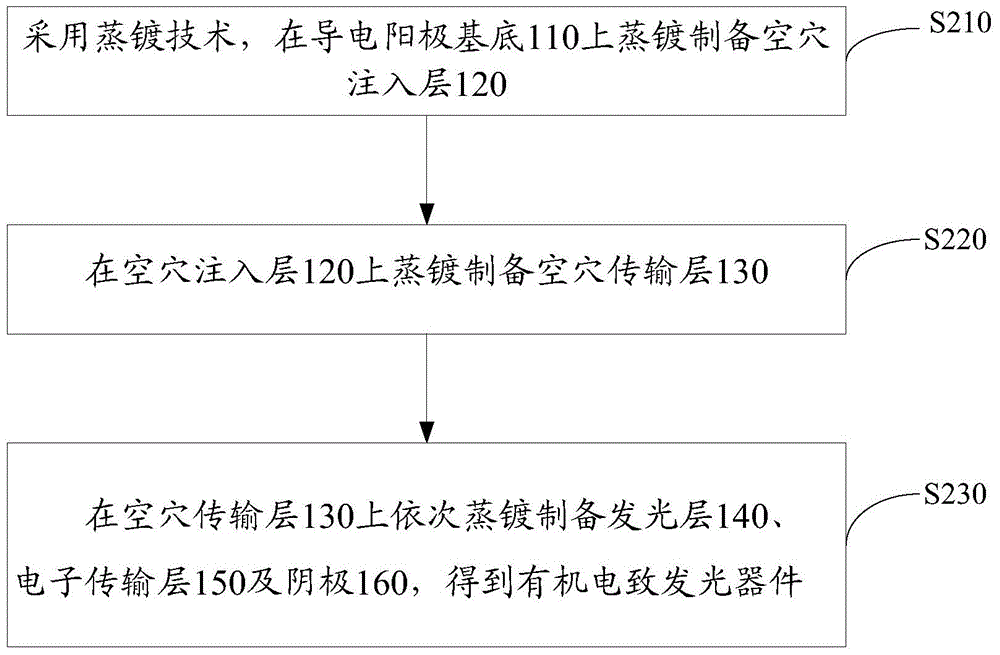

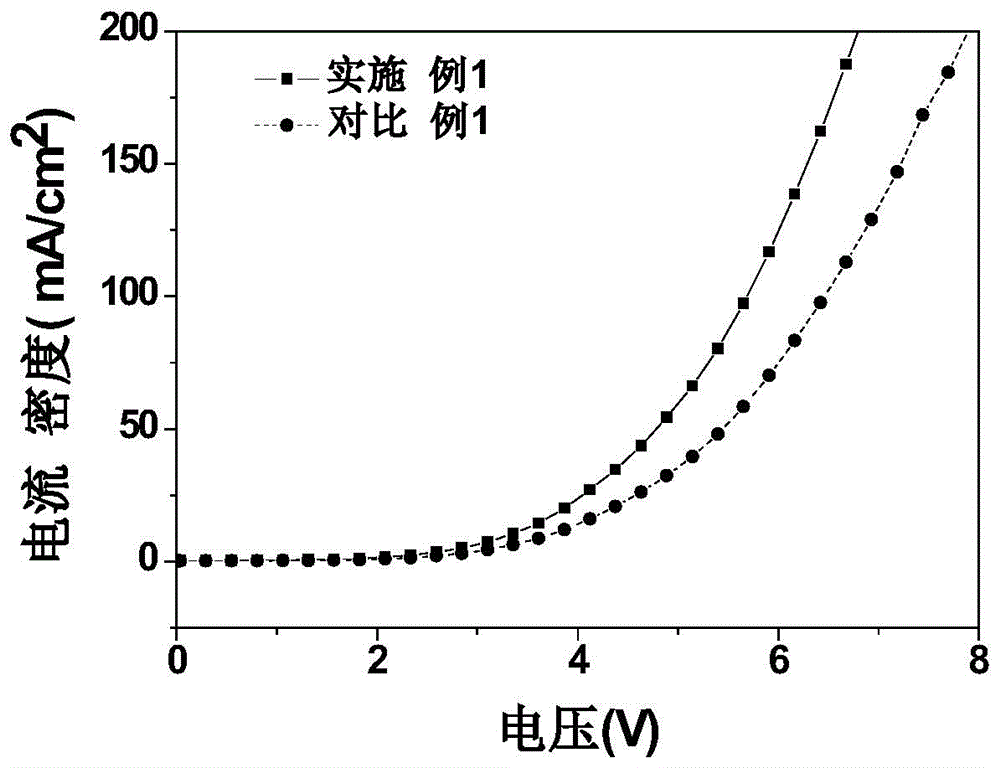

Organic electroluminescent component and manufacturing method thereof

InactiveCN104576949AImprove luminous efficiencyRaise the Fermi levelSolid-state devicesSemiconductor/solid-state device manufacturingOsmium tetroxideHole injection layer

An organic electroluminescent component comprises a conductive anode substrate, and a hole injection layer, a hole transmission layer, a luminescent layer, an electron transmission layer and a cathode which are sequentially laminated on an anode layer of the conductive anode substrate, wherein the anode layer is made of indium tin oxide; the hole injection layer is made of iron trifluoride, ruthenium trichloride, osmium trichloride or osmium tetroxide. The luminescent efficiency of the organic electroluminescent component is relatively high. The invention further provides a manufacturing method of the organic electroluminescent component.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

Process for the preparation of estetrol

The invention relates to a process for obtaining Estetrol or a salt or solvate thereof, the process comprising: a) reacting a compound of formula (IV) or a salt or solvate thereof, wherein R1 is a hydroxyl protecting group selected from a silyl ether, an ether, an ester, a carbamate and a carbonate, and R2 is a hydroxyl protecting group selected from an ether, with an oxidizing agent selected from OsO4 or a source of osmium tetroxide to produce Estetrol or a compound of formula (II) or a salt or solvate thereof wherein R1 is as defined previously; and b) if a compound of formula (II) is obtained in step a), deprotecting said compound to produce Estetrol.

Owner:CRYSTAL PHARMA SA

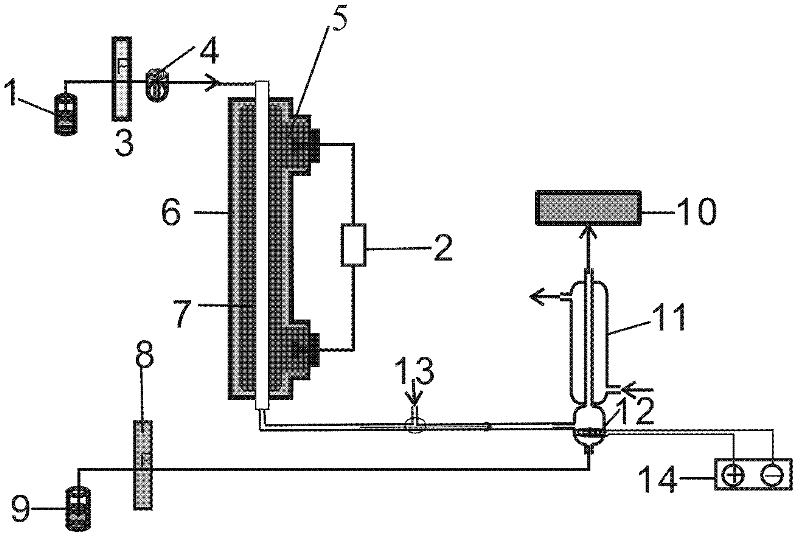

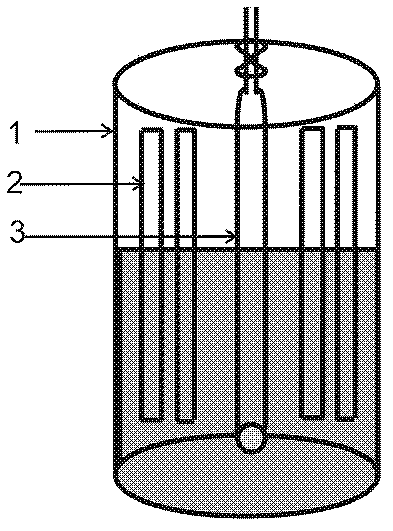

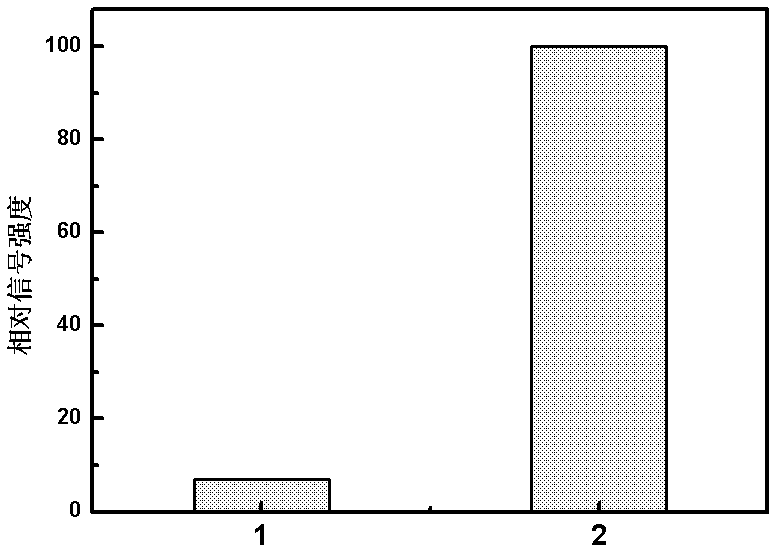

Method for chemically inducing osmium to be oxidized through static type ultraviolet light and reaction device

InactiveCN102519765ARealize analysisAvoid pollutionPreparing sample for investigationMaterial analysis by electric/magnetic meansOsmium tetroxideUltraviolet lights

The invention discloses a method for chemically inducing osmium to be oxidized through static type ultraviolet light and a reaction device. The method comprises the following steps of: introducing a to-be-detected solution sample containing osmium into a sample reaction quartz tube, irradiating the sample through ultraviolet light, and inducing osmium in the sample to be oxidized to generate osmium tetroxide, so as to form an osmium tetroxide solution. The osmium tetroxide solution obtained by using the method is measured by directly using ICP-OES (Inductively Coupled Plasma-Optical Emission Spectroscopy) or ICP-MS (Inductively Coupled Plasma-Mass Spectrometry), so that an osmium signal can be obtained; or osmium tetroxide is measured by using the ICP-MS or N-TIMS (Thermal Ionization Mass Spectrometry) after purifying osmium tetroxide in the solution by using an extraction or distillation method, so that the osmium signal can be obtained. The reaction device provided by the invention at least comprises a cylindrical reaction cavity body and the reaction quartz tube positioned in the middle part of the reaction cavity body. 2-8 ultraviolet lamps are arranged on the periphery of the reaction quartz tube in an encircling manner. The method and the reaction device disclosed by the invention have the advantages that: the method is simpler; any oxidization and reduction reagent is not required; loss of osmium in the sample and pollution caused by osmium in a pre-treatment process are reduced; the sensitivity is relatively higher; compared with the traditional atomization sample introduction, the sample can be introduced more effectively; and the detection limit is lower.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

In-situ detection method of honeysuckle flower tannin

InactiveCN105928942APrecise positioningShorten the timeInvestigation of vegetal materialPreparing sample for investigationOsmium tetroxideAlcohol

The invention provides an in-situ detection method of honeysuckle flower tannin. The method comprises the following steps: (1) a honeysuckle flower sample is immersed in a 2% glutaraldehyde solution for 12 hours; (2) extra glutaraldehyde in the sample is cleaned, and the sample is immersed in a 1% osmium tetroxide aqueous solution for 4 hours; (4) the sample is dehydrated by alcohol with gradient, and each alcohol gradient is used for 15 minutes; (4) the dehydrated sample is embedded in resin; (5) the sample is sliced, and the thickness is 1-2 micrometers; (6) tannin is observed by microscopic observation.

Owner:LINYI UNIVERSITY

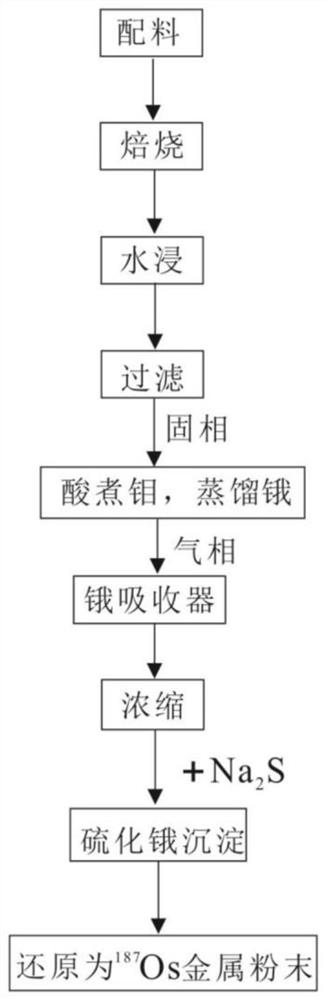

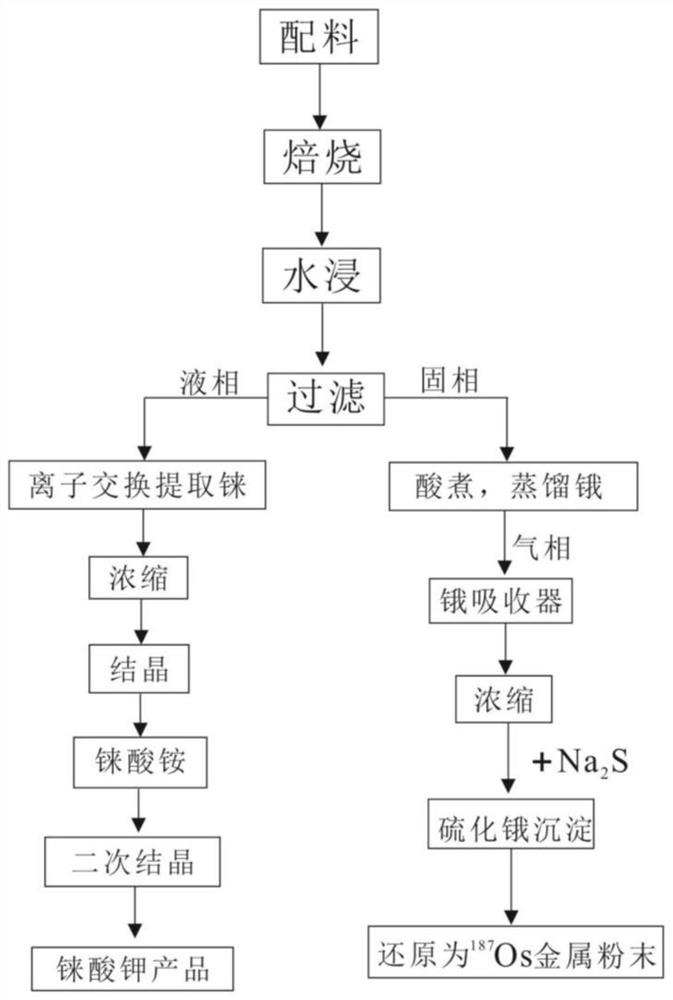

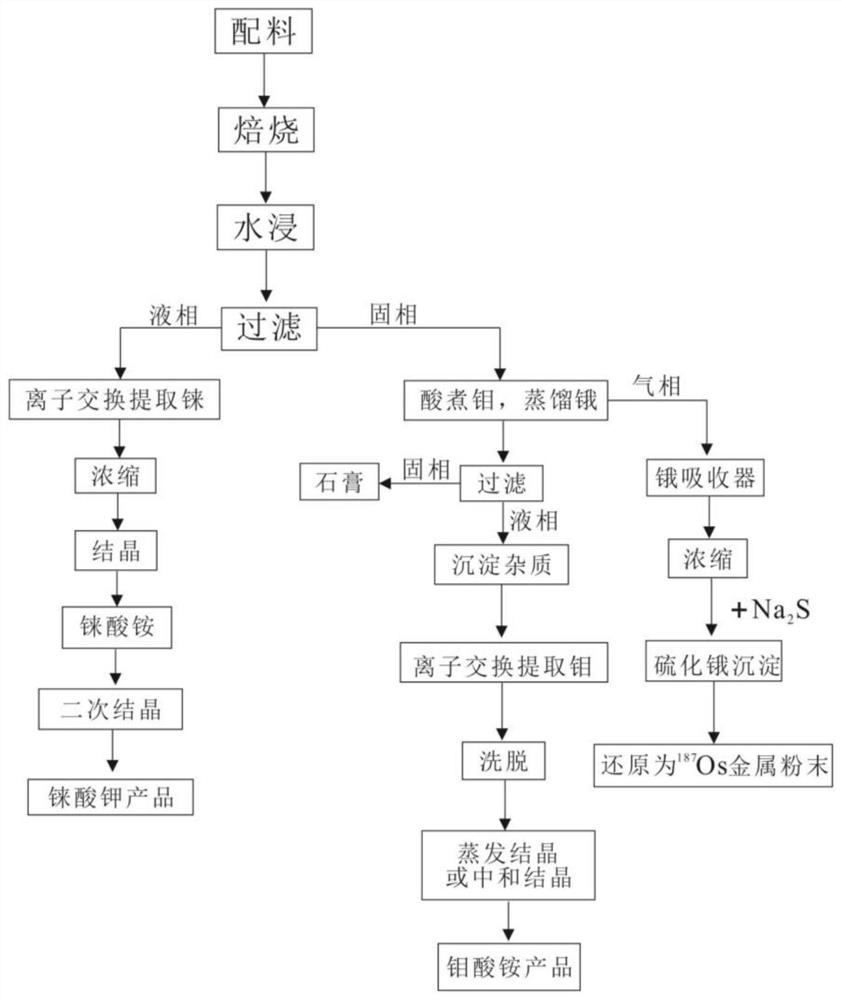

Method for extracting molybdenum, rhenium and radioactive cause 187Os

ActiveCN111876617AHigh yieldEasy to separateRhenium compounds preparationMolybdeum compoundsIon exchangeOsmium tetroxide

The invention discloses a method for extracting molybdenum, rhenium and a radioactive cause 187Os, belongs to the technical field of mineral extraction, and solves the problems that the molybdenum, the rhenium and the radioactive cause 187Os cannot be recovered at the same time and the recovery process seriously pollutes the environment in the prior art. The method for extracting comprises the following steps that burdening, roasting, water leaching and filtering are performed to obtain a first liquid phase and a first solid phase, the first solid phase enters a molybdenum acid boiling and osmium distillation process to obtain volatile osmium tetroxide and slurry, the volatile osmium tetroxide enters a subsequent 187Os extraction process, and the slurry enters a subsequent molybdenum extraction process; and the first liquid phase contains rhenium, and the first liquid phase enters a subsequent rhenium extraction process. The molybdenum extraction process comprises the following steps of filtering, impurity precipitating, molybdenum extracting through ion exchange, eluting and crystallizing, and then ammonium molybdate is obtained. The method realizes simultaneous extraction of themolybdenum, the rhenium and the 187Os by one process.

Owner:NAT RESERACH CENT OF GEOANALYSIS

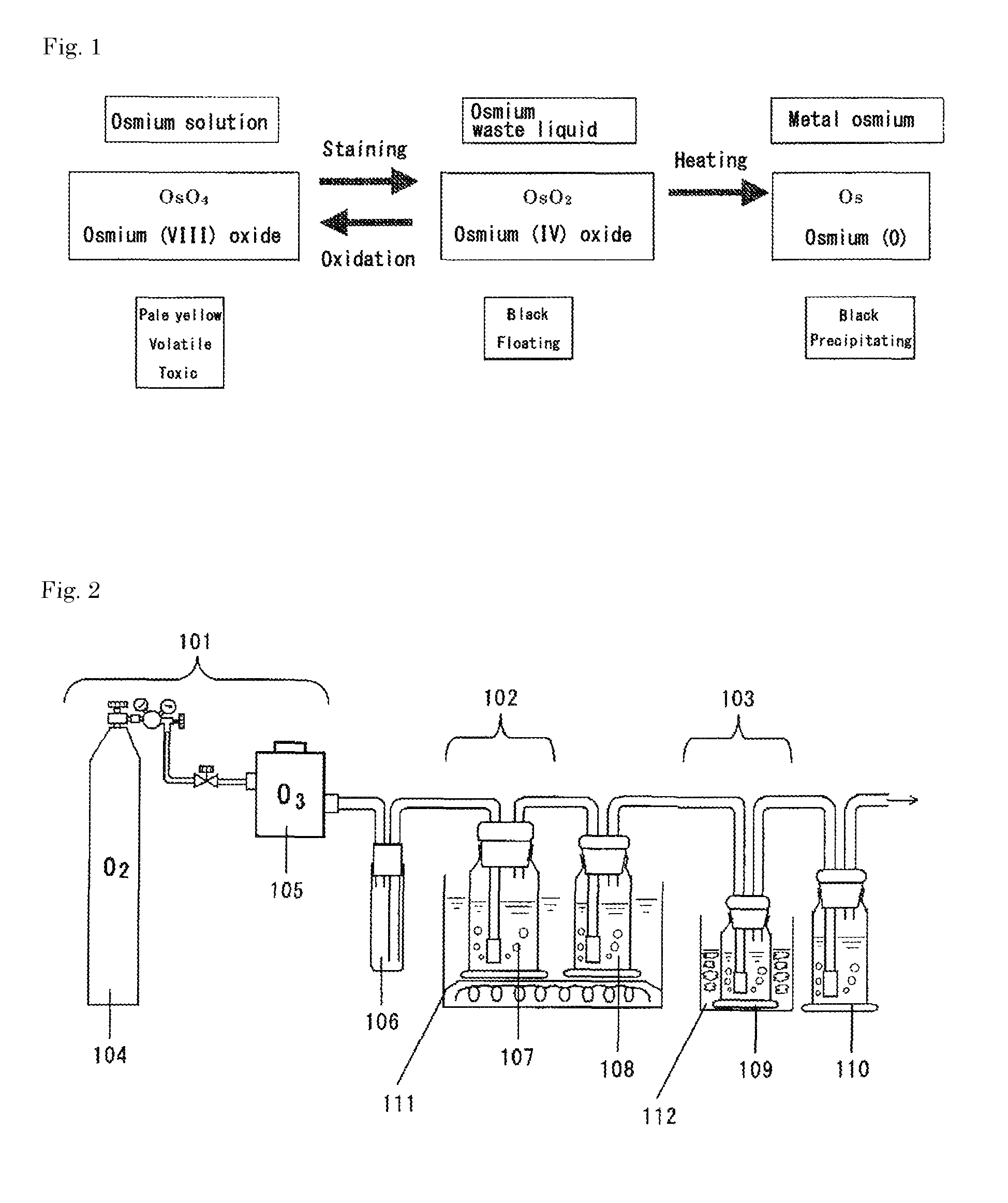

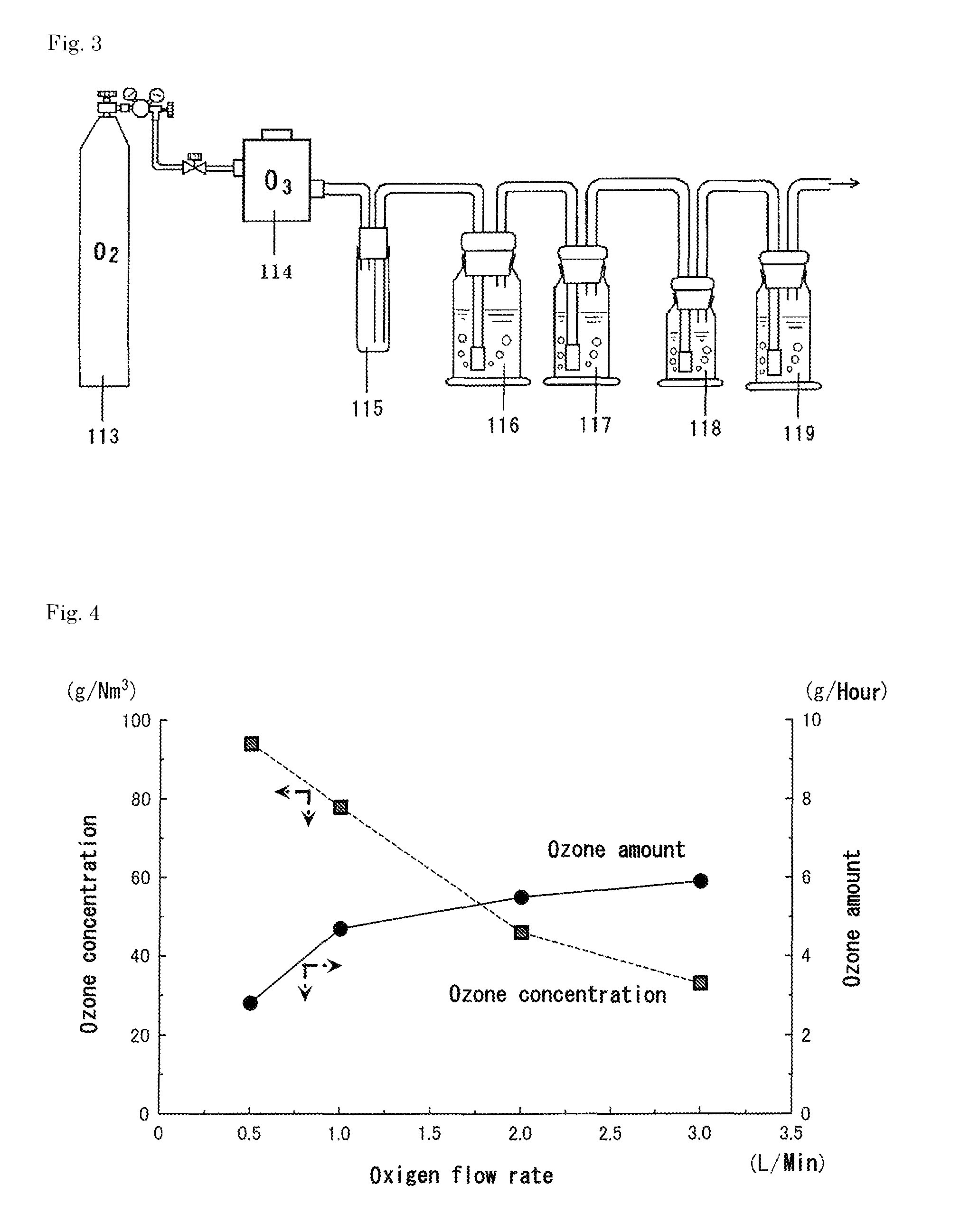

Recovery of reusable osmium tetroxide

InactiveUS9284623B2Ruthenium/rhodium/palladium/osmium/iridium/platinum oxides/hydroxidesWater contaminantsOsmium tetroxideReagent

The present invention enables simple production of osmium tetroxide having comparable performance to that sold in reagents from a solution containing osmium. The present invention relates to a method for producing osmium tetroxide solution, the method comprising a step for using ozone or a similar oxidizing gas to oxidize a solution containing osmium and produce osmium tetroxide gas and a step for introducing the resulting osmium tetroxide gas into a recovery solution; the present invention further relates to a production apparatus therefor.

Owner:HAMAMATSU UNIV SCHOOL OF MEDICINE

High fluorescence quantum yield two-photon Zn<2+> detection fluorescence molecular probe as well as preparation method and application thereof

InactiveCN109761965AImprove resolutionStrong specificityOrganic chemistryFluorescence/phosphorescenceDiseaseOsmium tetroxide

The invention relates to a high fluorescence quantum yield two-photon Zn<2+> detection fluorescence molecular probe as well as a preparation method and application thereof. The molecular probe is specifically synthesized through the following steps: firstly, 2,4-dihydroxy benzaldehyde, amylene diacid diethyl ester and anhydrous piperidine react in ethyl alcohol to obtain a product 1, the product 1reacts with acetic anhydride in anhydrous piperidine to obtain a product 1, the product 2 reacts with osmium tetroxide and sodium periodate in tetrahydrofuran to obtain a product 3, and the product 3reacts with anhydrous potassium carbonate in methyl alcohol to obtain a product 4; and finally, the product 4 is dissolved in ethyl alcohol, 6-hydrazinonicotinic acid and glacial acetic acid are added to flow back, and recrystalization is conducted, so that the high fluorescence quantum yield two-photon Zn<2+> detection fluorescence molecular probe is obtained. The high fluorescence quantum yieldtwo-photon Zn<2+> detection fluorescence molecular probe is suitable for qualitative analysis of Zn<2+> in biological samples such as cells and zebrafish, has the advantages of being low in toxicityand large in penetrating depth, and can be applied to related fields such as analysis chemistry, life organic analysis chemistry, disease prediagnosis and medical clinical detection.

Owner:QUFU NORMAL UNIV

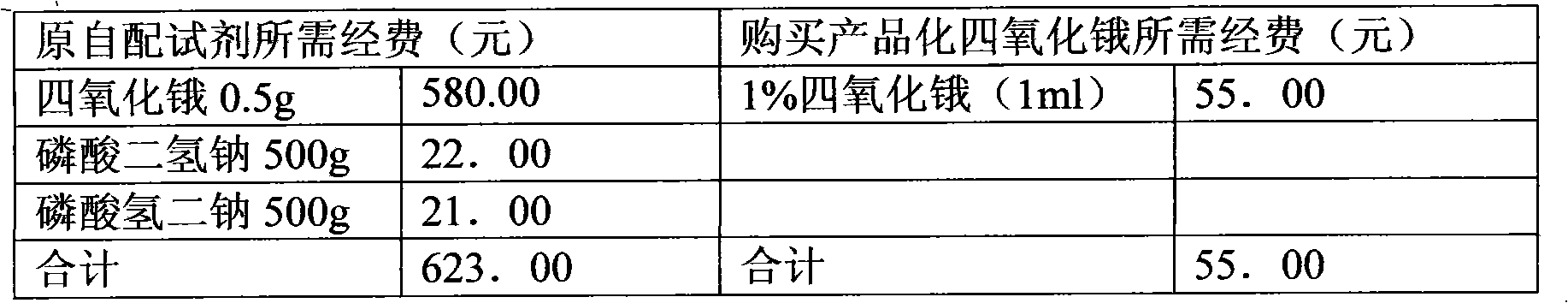

1% osmium tetroxide fixative and preparation method thereof

The invention discloses a 1% osmium tetroxide fixative and a preparation method thereof. The following materials are adopted in the method which comprises the following steps of: (1) preparing a phosphate buffer solution from a disodium hydrogen phosphate solution and a sodium dihydrogen phosphate solution, and carrying out intermediate product inspection after the preparation, wherein the preparation process can be checked by two persons; (2) adding the phosphate buffer solution prepared in the step (1) to osmium tetroxide and distilled water, then purifying and carrying out pH value inspection; and (3) carrying out fused subpackaging on the solution prepared in the step (2) with brown ampoules, carrying out final examination after packaging, and then delivering out of warehouse. The invention has the advantages of high quality, experiment time saving, experiment cost saving, long quality guarantee period and the like, reduces the pollution of outdated reagent to the environment and prevents reagent preparation from doing harm to the health of experimenters.

Owner:SHAOXING UNIVERSITY

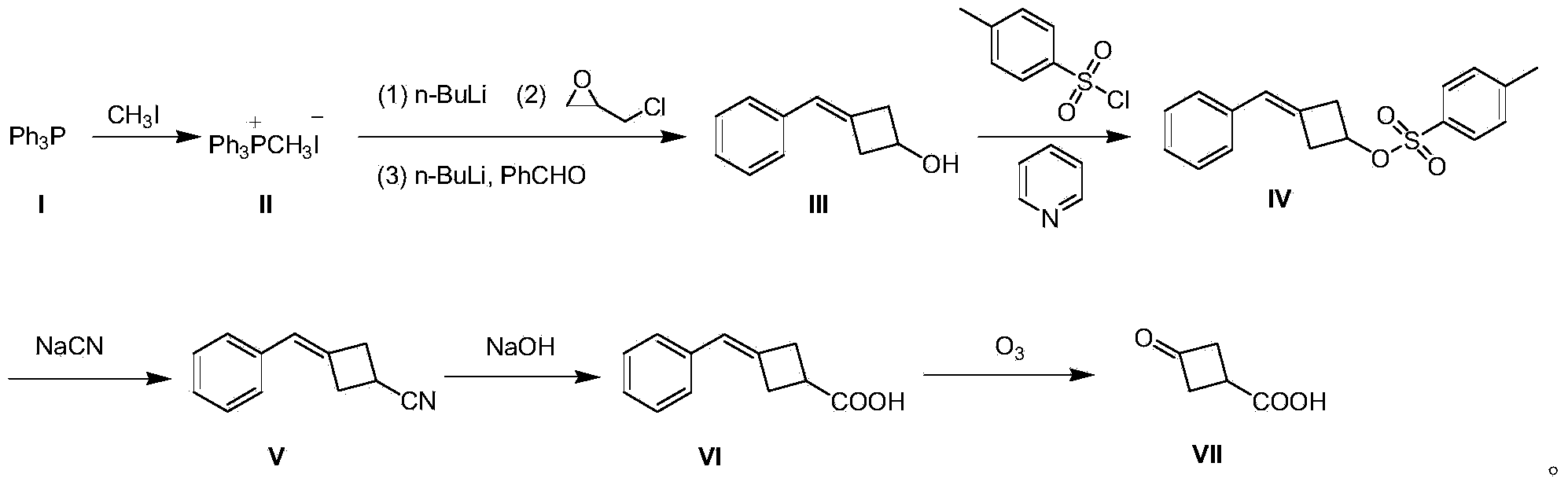

Preparation method of 3-oxocyclobutanecarboxylic acid

InactiveCN103467270AEasy to useLow costOrganic compound preparationCarboxylic compound preparationOsmium tetroxideIodide

The invention discloses a preparation method of 3-oxocyclobutanecarboxylic acid. The preparation method comprises the following steps: (1) preparing methyl triphenylphosphine iodide (II); (2) preparing 3-benzal cyclobutanol (III); (3) preparing methyl-benzenesulfonic acid-3-benzal cyclobutanol ester (IV); (4) preparing 3-benzal cyclobutanecarbonitrile (V); (5) preparing 3-benzal cyclobutylcarboxylic acid (VI); (6) preparing 3-oxocyclobutanecarboxylic acid (VIII). The reaction formula is shown in the description. The preparation method has the advantages that the starting raw materials are low in price; the operation can be done with conventional equipment; ozonation is performed instead of hypertoxic osmium tetroxide oxidation, so that the cost is low, and the technical operation is simple and easy to carry out.

Owner:TIANJIN BORON PHARMATECH CO LTD

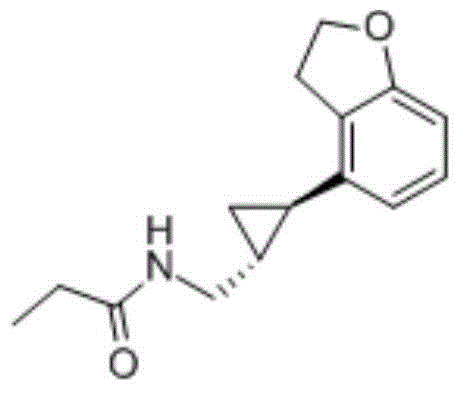

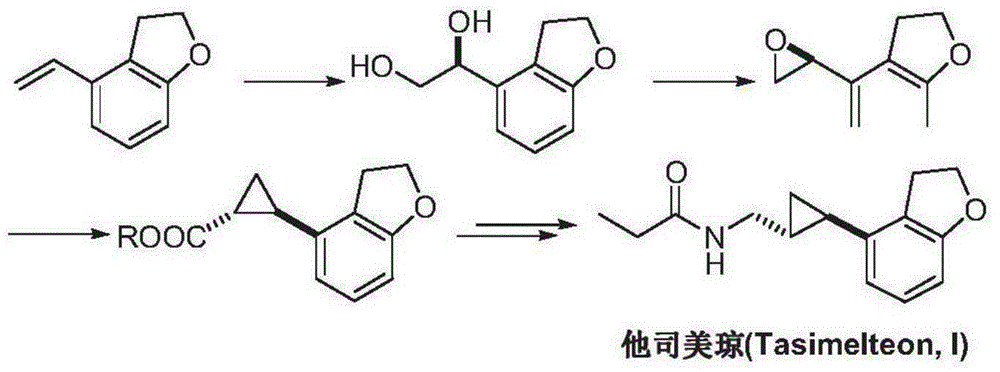

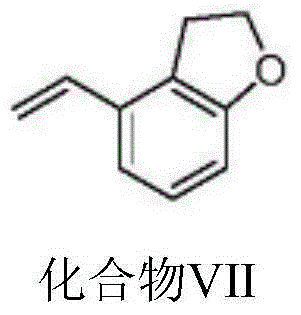

Tasimelteon intermediate and preparation method thereof

ActiveCN106542973AHigh purityShort process routeOrganic compound preparationCarbonyl compound preparationOsmium tetroxideSulfonyl chloride

The invention provides a tasimelteon intermediate and a preparation method thereof. The preparation method comprises the following steps: with a compound a as a raw material, reacting the compound a with benzyl bromide so as to obtain a compound I; then subjecting the compound I to a reaction under the action of a combined catalyst consisting of potassium osmate dihydrate, potassium carbonate, potassium ferricyanide, benzyltriethylammonium chloride and methane sulfonamide or a combined catalyst consisting of osmium tetroxide, potassium carbonate, potassium ferricyanide, benzyltriethylammonium chloride and methane sulfonamide so as to obtain a compound II; subjecting the compound II to an oxidation reaction under the action of sodium periodate or lead tetraacetate so as to obtain an intermediate compound III and carrying out a reduction reaction so as to obtain a compound IV; and subjecting the compound IV to a reduction reaction to remove a benzyl protective group so as to obtain a compound V, then reacting the compound V with p-toluene sulfonyl chloride, carrying out hydroxyl protection and then carrying out cyclization under the action of potassium carbonate so as to obtain the tasimelteon intermediate compound VI. The invention provides a novel process for preparation of the tasimelteon intermediate; and the prepared tasimelteon intermediate has good purity and high quality and is applicable to industrial production.

Owner:NANJING HUAWE MEDICINE TECH DEV

Organic electroluminescent device and preparation method thereof

InactiveCN104576946AEasy to prepareEasy to operateSolid-state devicesSemiconductor/solid-state device manufacturingOsmium tetroxideElectronic transmission

The invention discloses an organic electroluminescent device. The organic electroluminescent device comprises a conductive anode substrate as well as a hole injection layer, a hole transport layer, a light-emitting layer, an electronic transmission layer and a cathode which are stacked on an anode layer of the conductive anode substrate in sequence, wherein the hole injection layer comprises a first hole injection auxiliary layer stacked on the anode layer and a second hole injection auxiliary layer stacked on the first hole injection auxiliary layer; the first hole injection auxiliary material is made from iron trifluoride, ruthenium trichloride, osmium trichloride or osmium tetroxide; the second hole injection auxiliary layer is made from 2,3,6,7,10,11- hexacyano-1,4,5,8,9,12-hexaazatriphenylene. According to the organic electroluminescent device disclosed by the invention, a double-hole injection auxiliary layer is adopted to improve injection capability of the hole, so that the light-emitting efficiency of the organic electroluminescent device is improved. The invention further provides a preparation method for the organic electroluminescent device.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

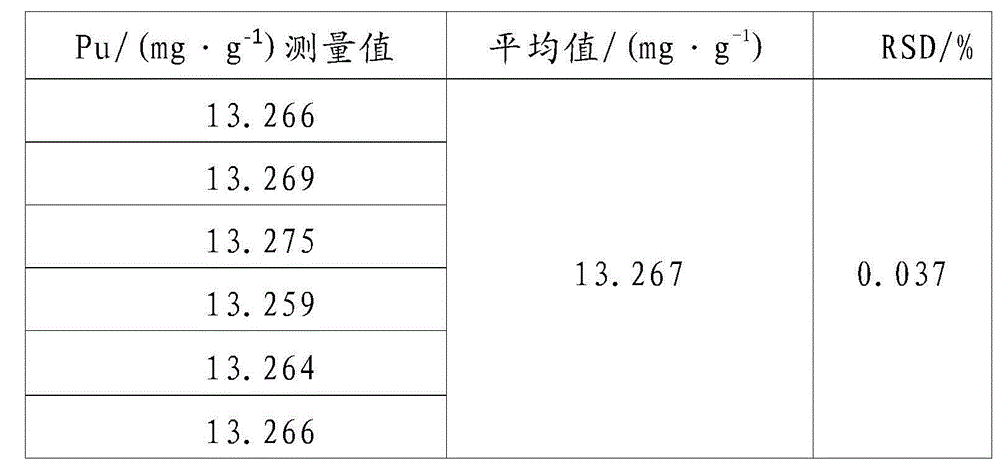

Method for precisely determining plutonium

InactiveCN104597097ASolve the problem of concentration change with laboratory temperatureEliminates the use of osmium tetroxideMaterial electrochemical variablesLiquid wasteOsmium tetroxide

The invention relates to a method for precisely determining plutonium. The method for precisely determining plutonium comprises the following steps: (1) oxidizing plutonium in a plutonium solution into Pu(VI) by adopting excessive AgO, adding acid, and carrying out reaction for removing residual AgO; (2) then adding an excessive Fe(II) solution with known concentration, and reducing Pu(VI) to Pu(IV); (3) titrating residual Fe(II) by adopting a standard potassium dichromate solution with known concentration, and indicating a titration end point by virtue of electric potential; and (4) calculating the plutonium content in a sample according to the mass of potassium dichromate consumed at an equivalent point. The method for precisely determining plutonium has the advantages that the problem that the concentration of the potassium dichromate solution as a titrating solution is changed along with the temperature of a libratory is solved, an operating process is simpler and more convenient, less radioactive liquid waste is produced, the precision degree is high, a measuring result is accurate and reliable, the applicability is strong, and no high-toxicity substance osmium tetroxide is used.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Potassium osmate production process

ActiveCN106698530BRuthenium/rhodium/palladium/osmium/iridium/platinum compoundsOsmium tetroxideDistillation

The invention relates to a new synthetic process of potassium osmate, wherein the synthetic process comprises the steps of fire process, water immersion, neutralization, filtration and washing, distillation, crystallization and the like. A pure osmium powder is used as a raw material, osmium enters a solution by the way of fire-process smelting, and the compound potassium osmate is obtained by oxidation distillation, crystallization and other steps. The potassium osmate is a powder crystal at room temperature, has stable properties and more convenient storage, transport and use compared with osmium tetroxide, and solves the defects of fewer commonly used osmium compounds and troublesome osmium compound collection, packaging, storage and use in the prior art.

Owner:南京东锐铂业有限公司 +1

Preparation method and application of a multifunctional ultrasensitive zn2+ two-photon detection fluorescent molecular probe

ActiveCN108299402BReduce consumptionImaging DiverseOrganic chemistryFluorescence/phosphorescenceOsmium tetroxideAcetic anhydride

The invention relates to a multifunctional ultrasensitive Zn 2+ Preparation method and application of fluorescent molecular probe for two-photon detection. First, product 1 is obtained by reacting 2,4-dihydroxybenzaldehyde, diethyl glutaconate and anhydrous piperidine in ethanol, and product 1 is reacted with acetic anhydride in anhydrous pyridine to obtain product 2, product 2 React with osmium tetroxide and sodium periodate in tetrahydrofuran to obtain product 3, react product 3 with anhydrous potassium carbonate in methanol to obtain product 4; finally, dissolve product 4 in ethanol, add dihydrazine pyridine and glacial acetic acid to reflux, Recrystallization and other steps, that is, the multifunctional ultrasensitive Zn 2+ Fluorescent molecular probes for two-photon detection. Suitable for Zn in biological samples 2+ It can be used in analytical chemistry, life organic analytical chemistry, disease pre-diagnosis and medical clinical testing and other related fields.

Owner:武汉聚成医疗科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com