Method for extracting molybdenum, rhenium and radioactive cause 187Os

A technology of radioactivity and origin, applied in chemical instruments and methods, preparation of rhenium compounds, rhenium compounds, etc., can solve the problems of simultaneous recovery of molybdenum, rhenium and radioactive origin, environmental pollution, etc., achieve high yield, simple equipment, The effect of less investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

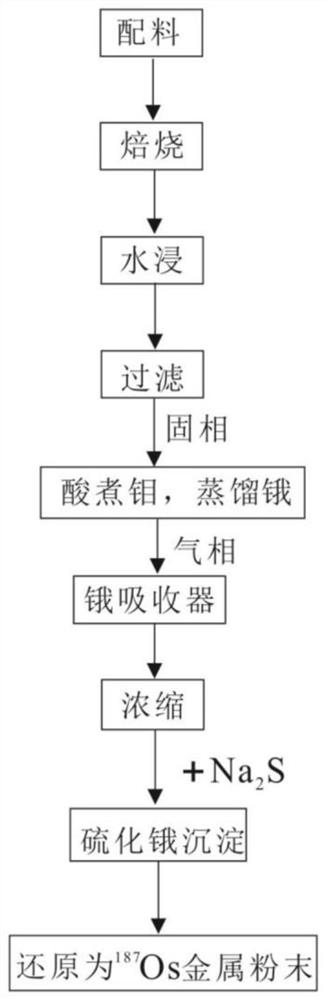

[0065] A specific embodiment of the present invention provides a radiogenic 187 The extraction method of Os, such as figure 1 As shown, the extracted raw material is molybdenum concentrate, specifically molybdenite, because the reducing ore-forming fluid (such as positive hexavalent Mo and positive heptavalent Mo is reduced to positive four valence Mo), positive tetravalent Os can also be reduced to positive trivalent Os or even zero valent Os. The lower the valence state of the ion, the larger the ionic radius, and the reduction of Os in the positive tetravalent state will not only generate a larger Os ion, but also cause a charge imbalance, making it impossible to replace Mo with the same quality. In the formation environment of molybdenite, positive tetravalent Os is reduced to low-valent Os ions with a larger ionic radius, which is the main reason why molybdenite does not contain ordinary Os.

[0066] The crystal lattice of Re is similar to that of Mo. When molybdenite c...

Embodiment 2

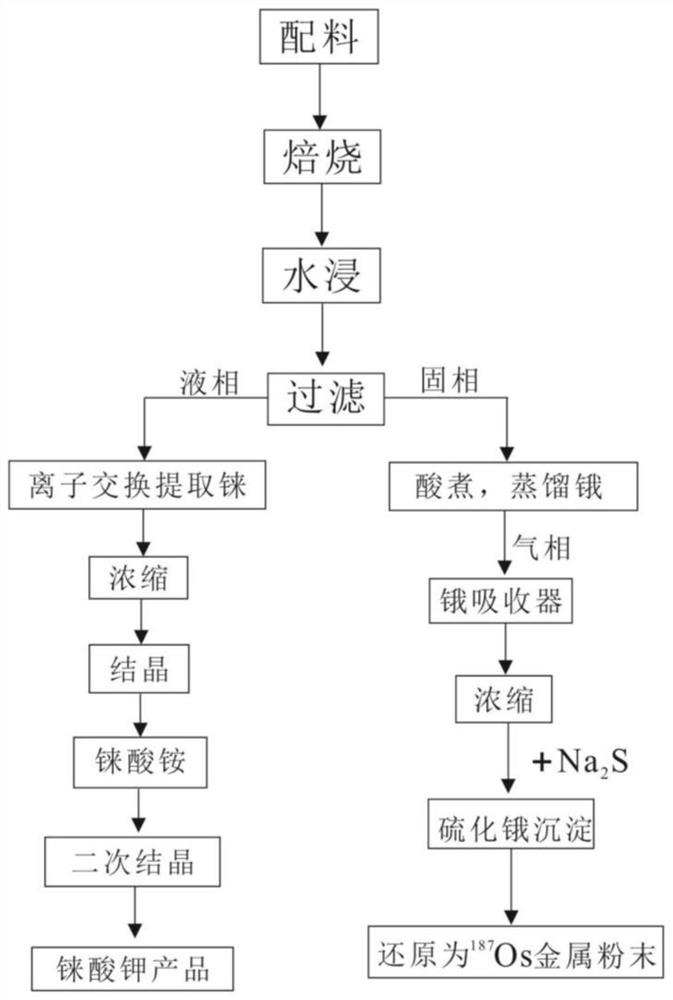

[0151] Such as figure 2 Shown, the extraction rhenium process of embodiment one more specifically comprises the following steps:

[0152] Step a: extracting rhenium by ion exchange to obtain an eluent containing rhenium.

[0153] The rhenium-containing immersion solution treated by water immersion flows through the ion exchange column at a flow rate of 500 ml / min, the rhenium in the immersion solution remains on the column, and impurities such as calcium and molybdenum flow out with the effluent. When rhenium can be detected in the effluent, it indicates that the capacity of the column is full, and the loading of the column is stopped. The effluent can be returned to the rhenium leaching process for continued use. Wash the column with 50 liters of 10% NaOH solution (to remove molybdenum), and then wash it with deionized water until neutral. with 9% NH 4 The SCN solution eluted rhenium from the column. The flow rate of the eluent should be as slow as possible, and the spe...

Embodiment 3

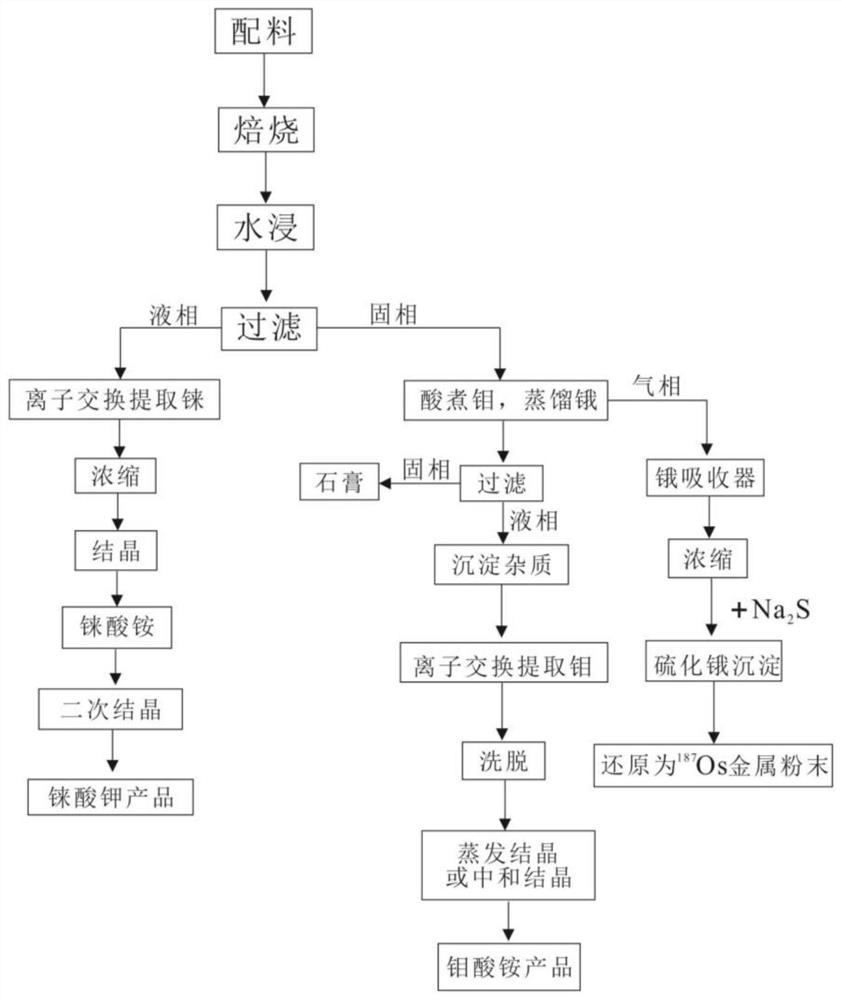

[0159] Such as image 3 Shown, the extraction molybdenum process of embodiment one more specifically comprises the steps:

[0160] Step i: Separating the slurry from solid to liquid, the main component of the solid phase is CaSO 4 (gypsum), the liquid phase is adjusted to neutrality (pH about 7) with calcium carbonate, filtered, and the filtrate is subjected to subsequent molybdenum extraction process.

[0161] It should be noted that after the liquid phase is adjusted to neutral, it must be filtered within four hours, otherwise the dissolved molybdenum will precipitate in the form of calcium molybdate, reducing the recovery rate of molybdenum.

[0162] After the reaction is over, put all the thick slurry in the kettle into a receiving tank with a volume of 1000 liters, and introduce it into a centrifuge in stages for solid-liquid separation, and collect the liquid phase. Wash the filter residue twice with a small amount of water, and (the degree of washing directly affects ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com