Potassium osmate production process

A kind of technology of potassium osmate and its production method, applied in the direction of ruthenium/rhodium/palladium/osmium/iridium/platinum compound, inorganic chemistry, chemical instrument and method, etc., can solve the problem of collection, packaging, storage and use, and inconvenient use and other issues, to achieve the effect of convenient transportation and use, and stable properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with specific examples.

[0021] (1) pyrometallurgy

[0022] 1. Fire method: fully stir the pure osmium powder and sodium peroxide at a ratio of 1:3, and put it in an iron pot. Usually spread a layer of sodium peroxide on the bottom of the pot first, pour part of the osmium powder, add some sodium peroxide, and stir well; then pour the osmium powder, add sodium peroxide, and stir well until all the osmium powder is added, set aside Sodium peroxide partially covers the surface.

[0023] Put the iron pot in the fire method furnace, cover the furnace lid, and gradually heat up to 650-680 degrees. Keep the temperature constant for 2 to 3 hours, stirring several times in the middle. Lift out the iron pan, let it cool slightly, transfer the material into an iron box while it is still hot, smash it into small pieces, and let it cool down. Related responses:

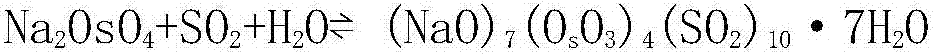

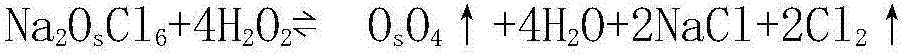

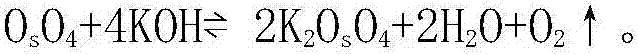

[0024] Os+Na 2 o 2 →Na 2 OSo 4 +Na 2 O+O...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com