Preparation method of 3-oxocyclobutanecarboxylic acid

A technology of oxocyclobutane carboxylic acid and benzylidene cyclobutanol is applied in the field of preparation of 3-oxocyclobutane carboxylic acid, can solve the problem of high cost, achieve cost economy, technically simple and convenient operation effect used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

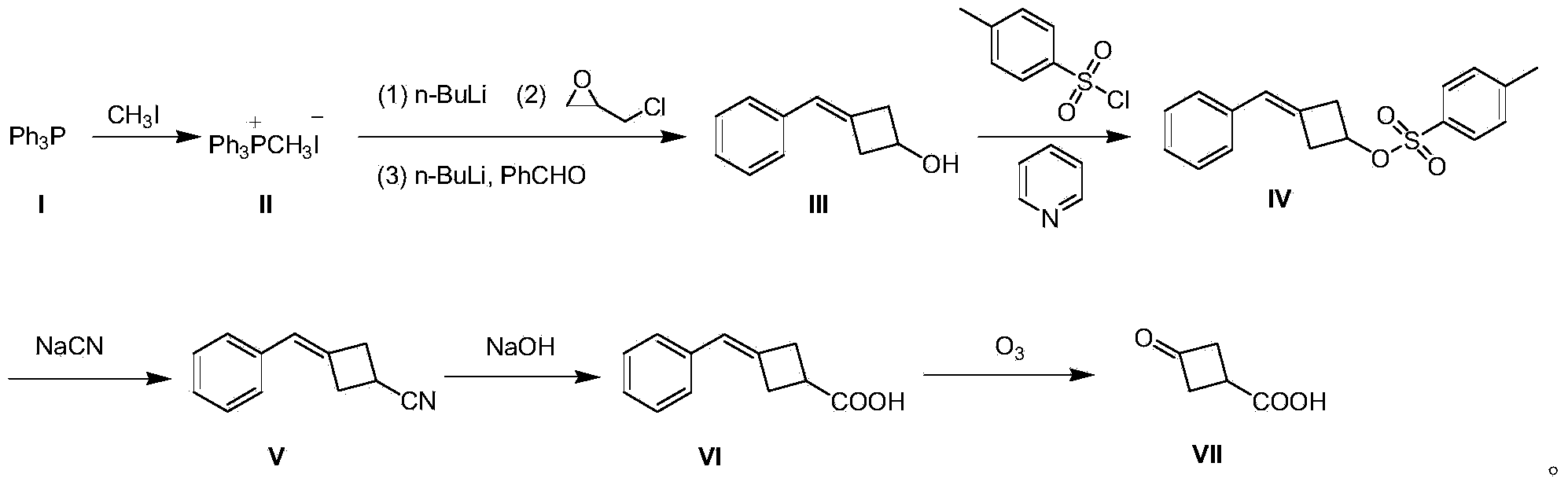

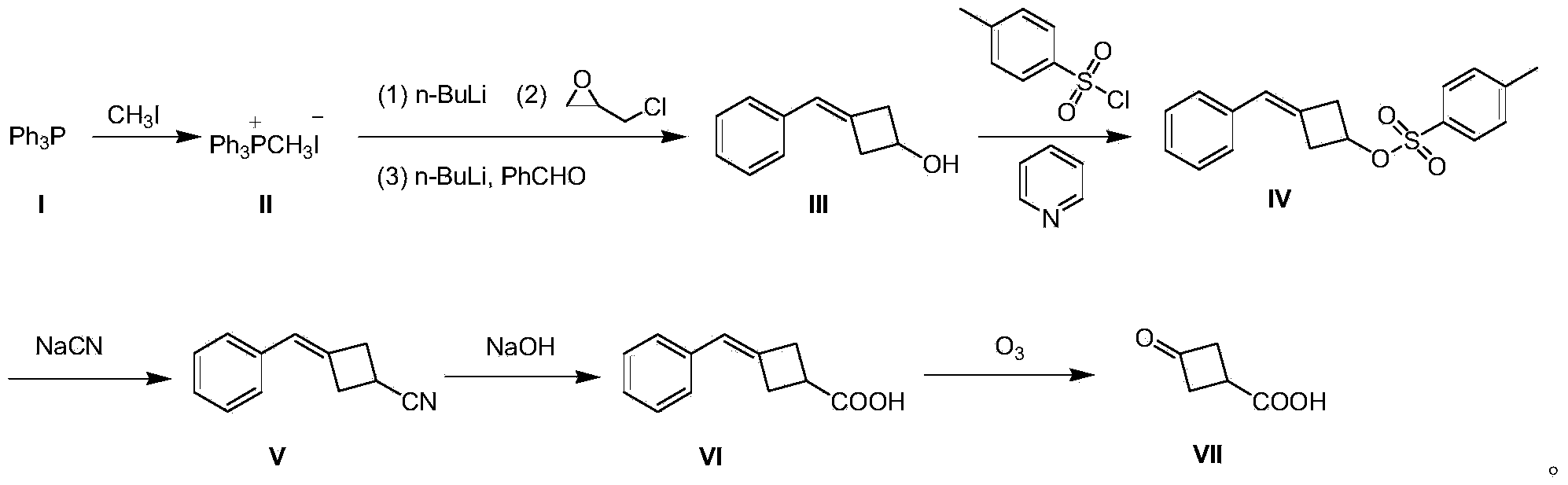

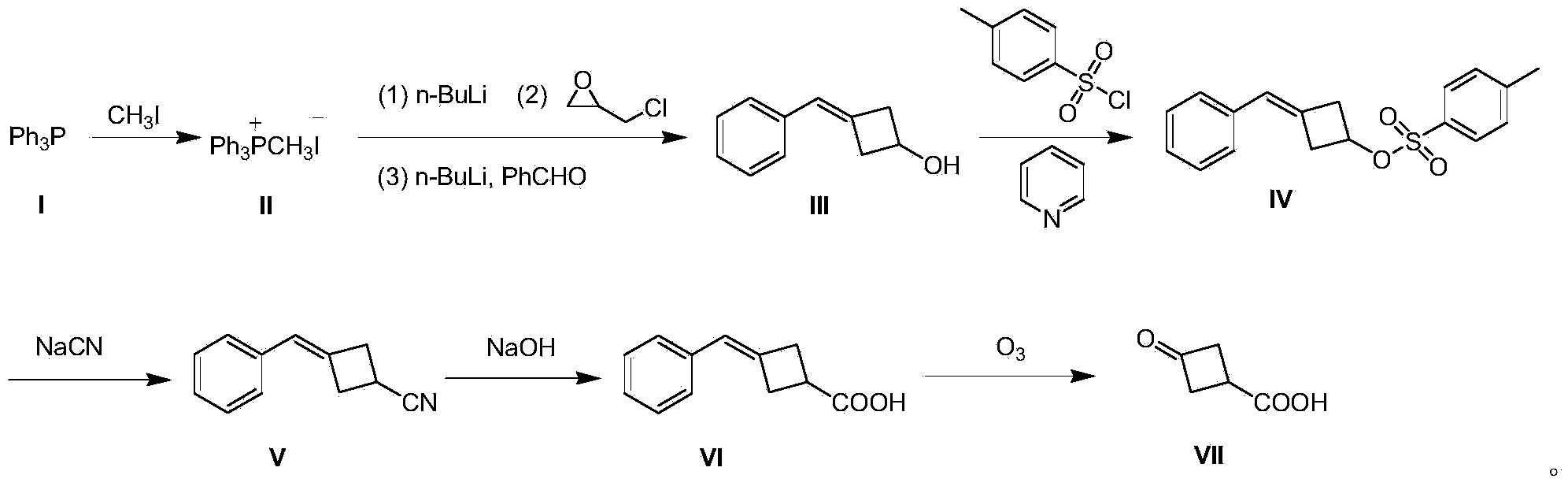

[0020] A preparation method of 3-oxocyclobutane carboxylic acid (VII), comprising the steps:

[0021] (1) Preparation of methyltriphenylphosphine iodide (II)

[0022] 500 g (2.03 mol) of triphenylphosphine (I) was dissolved in 3 L of tetrahydrofuran, 432 g (3.05 mol) of methyl iodide was added dropwise to the system, and the mixture was stirred at room temperature for 12 hours to produce a large amount of white solid, which was filtered to remove excess methyl iodide. And tetrahydrofuran to obtain solid methyl triphenylphosphine iodide (II) 850g, yield 91%;

[0023] (2) Preparation of 3-benzylidenecyclobutanol (III)

[0024] Methyltriphenylphosphine iodide (II) 40.4 g (0.1 mol) was dissolved in 800 mL of toluene, and the temperature was controlled at 0 °C, and 40 mL of n-butyllithium n-hexane solution, 2.5 M (0.1 mol), dripped in 15 minutes; warmed up to room temperature and stirred for 0.5 hours; then cooled to 0 °C, and added 9.2 g (0.1 mol) of epichlorohydrin dropwise at ...

Embodiment 2

[0036] A preparation method of 3-oxocyclobutane carboxylic acid (VII), comprising the steps:

[0037] (1) Preparation of methyltriphenylphosphine iodide (II)

[0038] Dissolve 500 g (2.03 mol) of triphenylphosphine (I) in 3 L of tetrahydrofuran, add 432 g (3.05 mol) of methyl iodide to the system dropwise, and stir at room temperature for 18 hours to produce a large amount of white solids, filter to remove excess methyl iodide And tetrahydrofuran to obtain solid methyl triphenylphosphine iodide (II) 857g, yield 92%;

[0039] (2) Preparation of 3-benzylidenecyclobutanol (III)

[0040]80.8 g (0.2 mol) of methyltriphenylphosphine iodide (II) was dissolved in 1500 mL of toluene, and at -3 °C under temperature control, 96 mL of n-butyllithium in n-hexane solution, 2.5 M ( 0.24mol), dripped in 30 minutes; warmed to room temperature and stirred for 1 hour; then cooled to -3°C, and at this temperature, 18.4g (0.2mol) of epichlorohydrin was added dropwise, and stirred at -3°C for 1 h...

Embodiment 3

[0050] A preparation method of 3-oxocyclobutane carboxylic acid (VII), comprising the steps:

[0051] (1) Preparation of methyltriphenylphosphine iodide (II)

[0052] Dissolve 1000 g (4.06 mol) of triphenylphosphine (I) in 5 L of tetrahydrofuran, add 864 g (6.1 mol) of methyl iodide to the system dropwise, and stir at room temperature for 24 hours to produce a large amount of white solids, filter to remove excess methyl iodide and tetrahydrofuran to obtain solid methyl triphenylphosphine iodide (II) 1775g, yield 95%;

[0053] (2) Preparation of 3-benzylidenecyclobutanol (III)

[0054] Methyltriphenylphosphine iodide (II) 40.4g (0.1mol) was dissolved in 800mL of toluene, and the temperature was controlled at -5°C, 40mL of n-butyllithium in n-hexane solution, 2.5M ( 0.1mol), dripped in 15 minutes; warmed up to room temperature and stirred for 1 hour; then cooled to -5°C, and at this temperature, 9.2g (0.1mol) of epichlorohydrin was added dropwise, stirred at -5°C for 1 hour, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com