Catalyst for preparing glyoxylic acid from methyl glycolate, preparation method and application

A technology of methyl glycolate and glyoxylic acid is applied in the preparation of carboxylate, the preparation of carboxylate/lactone, and the preparation of oxygenated compounds, and can solve the problems of harsh reaction conditions, difficult product separation, environmental pollution and the like, To achieve the effects of mild reaction conditions, simple and convenient preparation process and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

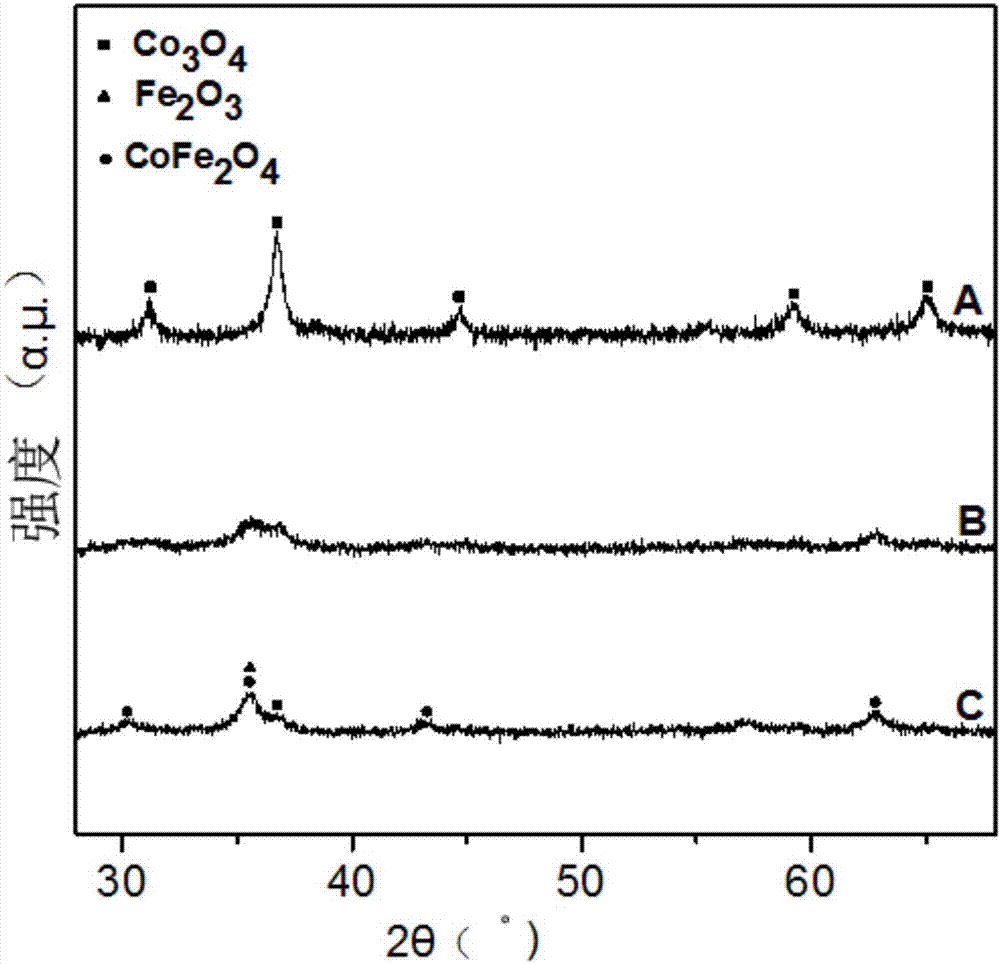

[0022] Weigh 4.65g of cobalt nitrate hexahydrate, 0.81g of ferric nitrate nonahydrate and 2.00g of oxalate dihydrate in a mortar, mix well; add 1mL of ethylene glycol to it, grind for 30min; transfer it to a beaker, Dry in an oven at 110° C. for 12 hours; then bake in a muffle furnace at 300° C. for 4 hours to obtain catalyst A. Its XRD diagram is shown in figure 1 . It includes the composite oxide formed by ferric oxide and tricobalt tetroxide; among them, ferric oxide is amorphous and in an amorphous state.

Embodiment 2

[0024] Weigh 4.65g of cobalt nitrate hexahydrate, 9.70g of ferric nitrate nonahydrate and 2.00g of oxalate dihydrate in a mortar, mix well; add 1mL of ethylene glycol to it, and grind for 30min; Dry in an oven at 110°C for 12h; then bake in a muffle furnace at 300°C for 4h to obtain Catalyst B, whose XRD pattern is shown in figure 1 , in the catalyst, the crystallization effect of ferric oxide and cobalt tetraoxide may not be very good or there are few samples to be tested, so the characteristic peaks are not obvious.

Embodiment 3

[0026] Weigh 4.65g of cobalt nitrate hexahydrate, 12.93g of ferric nitrate nonahydrate and 2.00g of oxalate dihydrate in a mortar, mix well; add 1mL of ethylene glycol to it, grind for 30min; transfer it to a beaker, Dry in an oven at 110°C for 12h; then bake in a muffle furnace at 300°C for 4h to obtain catalyst C, whose XRD pattern is shown in figure 1 , the results show that catalyst C includes ferric oxide and tricobalt oxide composite oxide, and cobalt ferrite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com