Patents

Literature

586 results about "Glyoxylic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

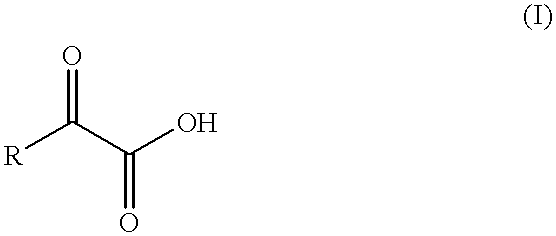

Glyoxylic acid or oxoacetic acid is an organic compound. Together with acetic acid, glycolic acid, and oxalic acid, glyoxylic acid is one of the C₂ carboxylic acids. It is a colourless solid that occurs naturally and is useful industrially.

Novel vehicle alcohols environment-friendly fuel

The preparation of novel vehicle alcohols environment-friendly fuel aims to overcome a plurality of defects caused by replacing alcohols fuel with gasoline. The invention discloses the novel vehicle alcohols environment-friendly fuel which comprises the following components of 50-95 parts of main alcohols fuel, 3-30 parts of low-temperature ignition auxiliary material, 0.1-20 parts of burning value reinforcing agent, 0-15 parts of dispersant, 0-0.05 part of smoke abatement burning agent, 0-5 parts of ignition accelerating agent, 0-0.04 part of antioxidant, 0-0.3 part of emulsification dispersing agent, 0-0.08 part of metal anticorrosion inhibiter, 0-0.8 part of rubber plastic anti-dissolving additive, 0-8 parts of air-resistance regulating agent, 0-6 parts of fuel lubricating agent and 0-0.7 part of glyoxylic acid neutralizer. According to the novel vehicle alcohols environment-friendly fuel, low temperature ignitability is improved, dynamic performance is enhanced, burning is sufficient, discharging is environment-friendly and free form pollution, corrosivity of the alcohols fuel on metal can be controlled, swelling performance of the alcohols fuel on rubber can be controlled and the air resistance phenomenon can be effectively prevented.

Owner:罗浩南 +1

Flavor enhancing methods

InactiveUS6287620B1Improve roundnessEnhances juicy characterMilk preparationDough treatmentKetopinic acidPropanoic acid

alpha-keto acids and certain precursors and derivatives thereof, particularly those selected from the group which consists of glyoxylic acid, 2-oxo-propanoic acid, 2-oxo-butanoic acid, 3-methyl-2-oxo butanoic acid, 3-methyl-2-oxo pentanoic acid, 4-methyl-2-oxo pentanoic acid, 3-hydroxy-2-oxo-propanoic acid, oxalacetic acid, 2-oxo-glutaric acid, 2-oxo-3-phenyl-propanoic acid, 3-(4-hydroxy-phenyl)-2-oxo-propanoic acid, 2-oxo-1H-indole-3-propanoic acid, 2-oxo-1H-imidazole-4-propanoic acid, 4-methylthio-2-oxo-butanoic acid, 3-mercapto-2-oxo-propanoic acid, 3-hydroxy-2-oxo-butanoic acid, 6-amino-2-oxo-hexanoic acid and 5-guanido-2-oxo-pentanoic acid, and precursors and derivatives thereof that are capable of being formed from or releasing said acids in the use medium, are useful as flavouring ingredients. Such ingredients are useful for preparing flavouring compositions and a wide variety of flavoured foodstuffs to which they impart greater creaminess and bulkiness so that they have heightened effect in the mouth and generally an enhanced mouthfeel. They are also useful for enhancing the sweetness of foods sweetened with natural or artificial sweeteners, and giving it a more natural character.

Owner:FIRMENICH SA

Acidic solution for treating surface of magnesium alloy and processing method

InactiveCN101285193AFully activatedHigh activityMetallic material coating processesGlutaric acidBinding force

The invention relates to acid solution used for processing the magnesium alloy surface. The acid solution is water solution which contains acids, inhibitor and wetting agent, wherein, the acids are first acids or mixture of first acids and second acids; the first acids are selected from one type or a plurality of types among citric acids, oxalic acids, tartaric acids, methanoic acids, acetic acids, metacetonic acids, butyric acids, glutaric acids, phenylformic acids, benzene dicarboxylic acids, lactic acids, glycolic acids, glyoxylic acids and amino acids; and the second acids are hydrochloric acids and / or nitric acids. By adoption of the acid solution, the magnesium alloy surface can be fully activated; the membranous layer of a converting film which is formed on the magnesium alloy surface after chemical conversion process is compact, has erosion resistance and good binding force with a paint film. Moreover, the method is a environment-friendly method for processing the magnesium alloy surface.

Owner:BYD CO LTD

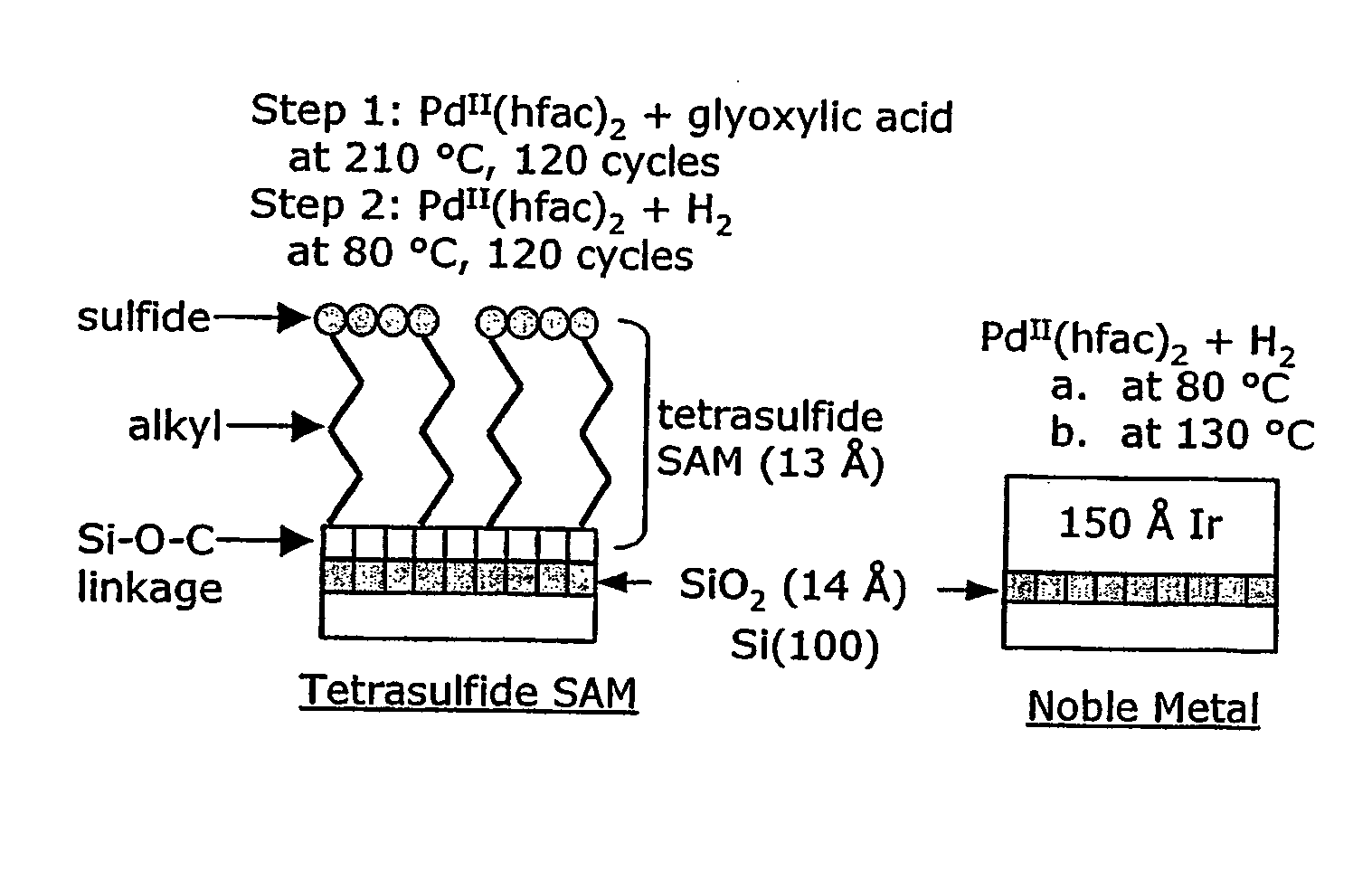

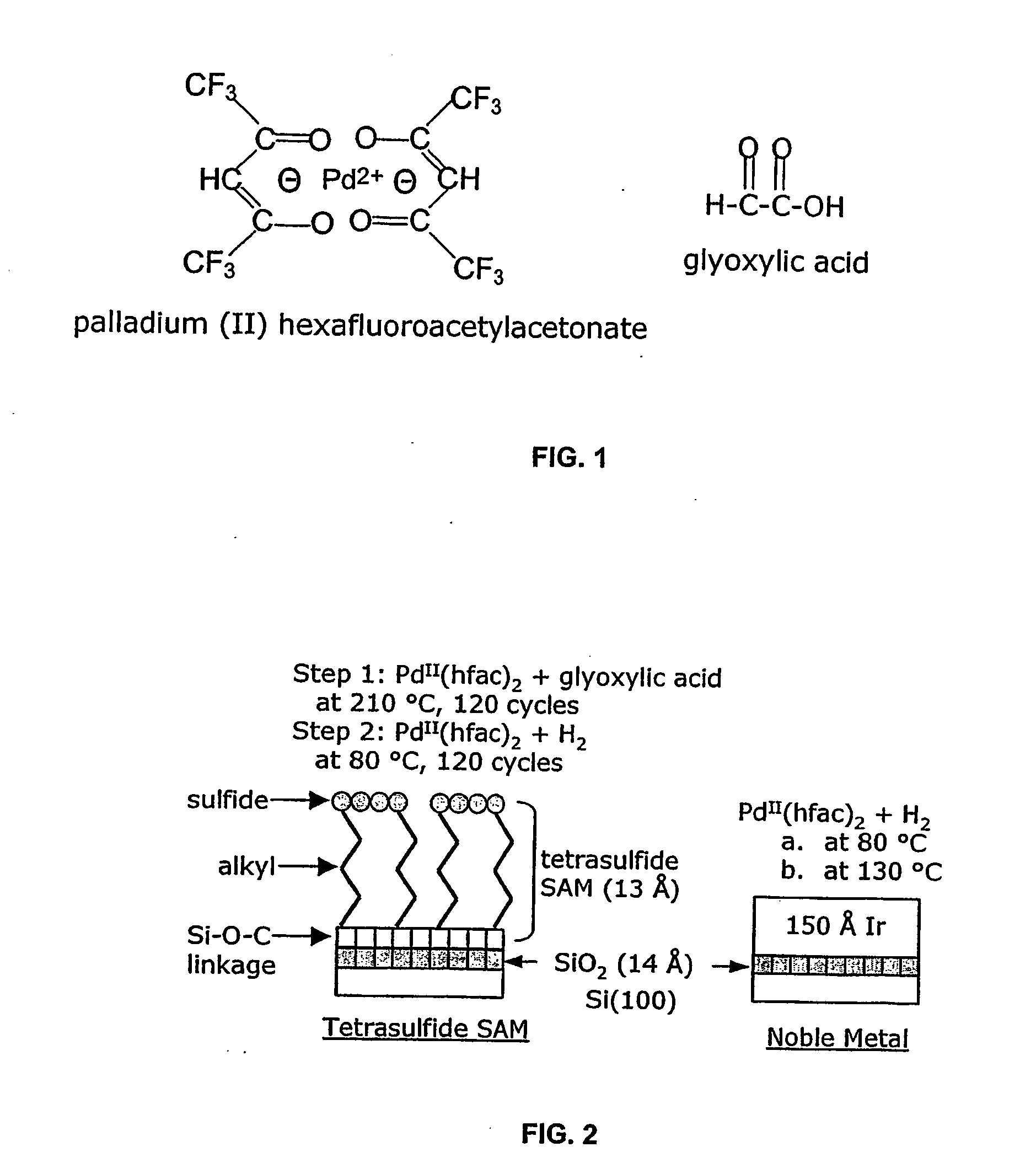

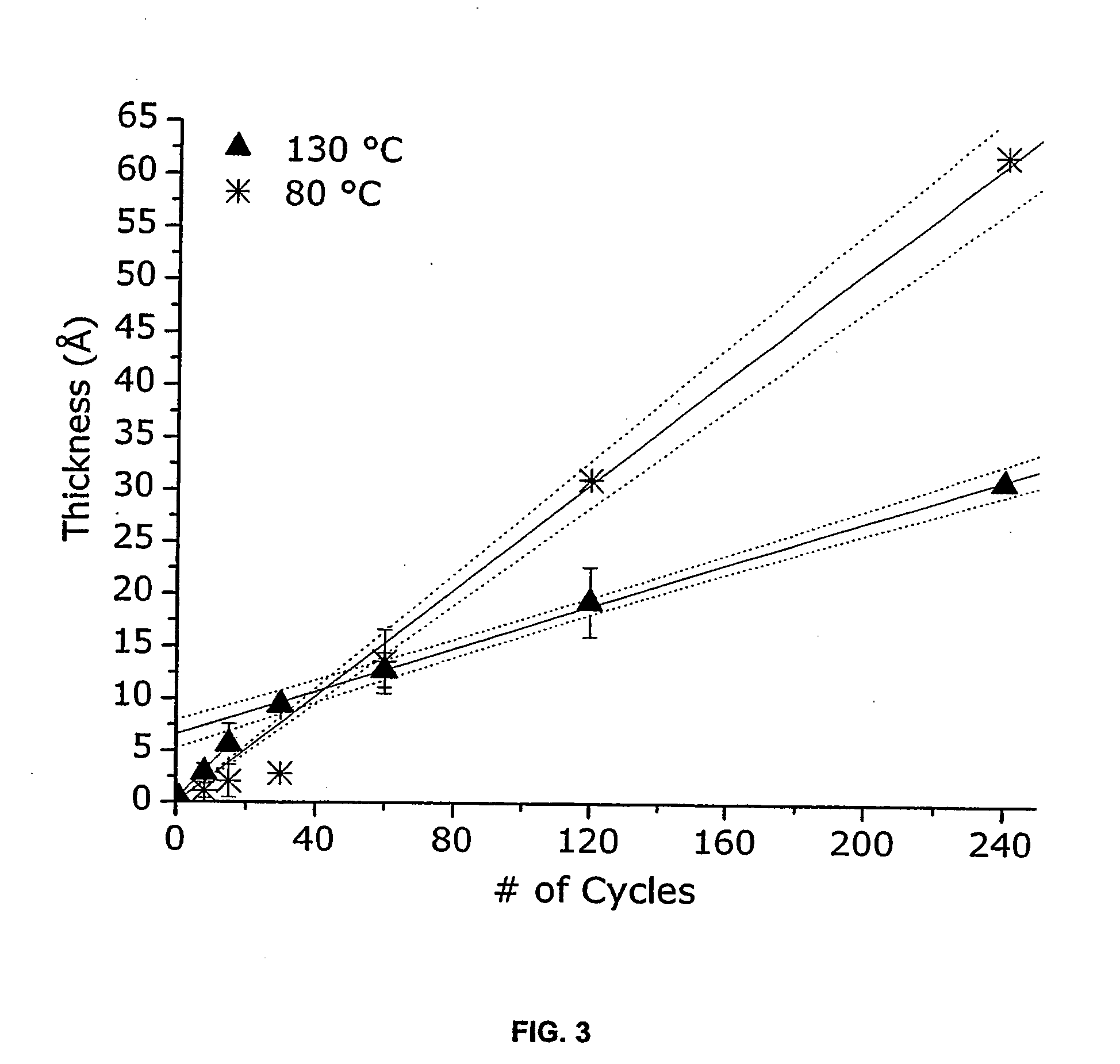

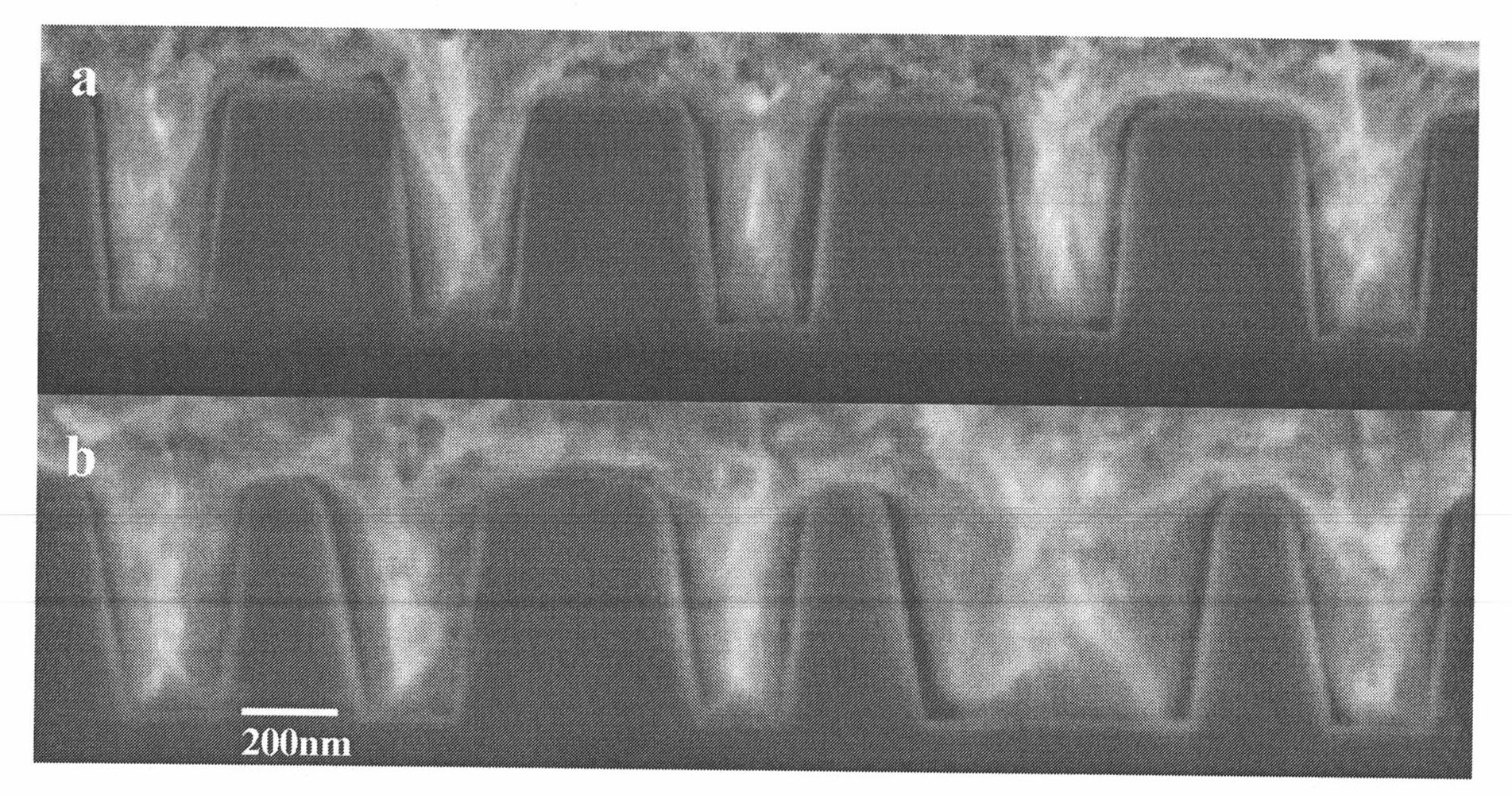

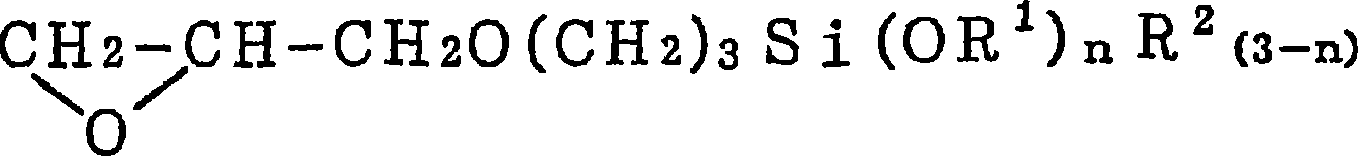

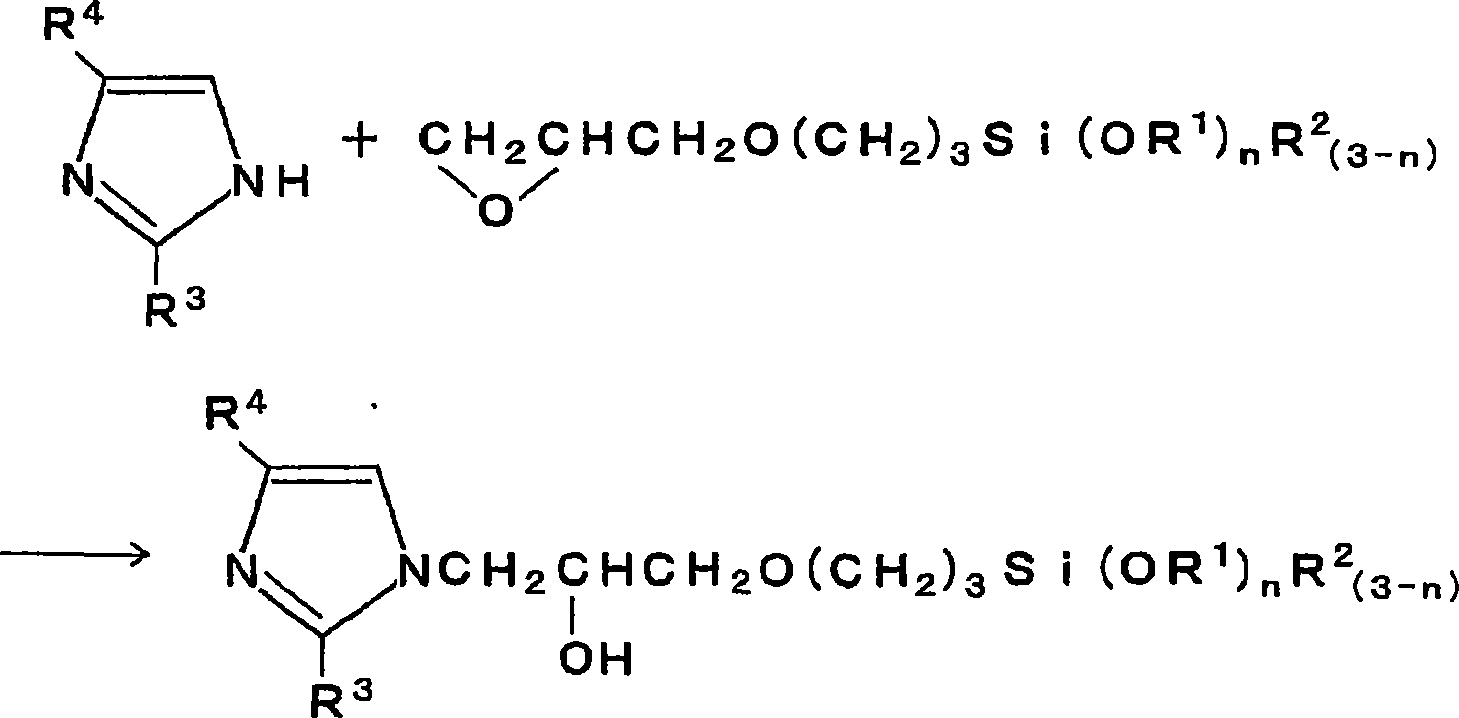

Atomic layer deposition of noble metals

The present invention relates to ALD processes for deposition of a metal selected from Pd, Rh, Ru, Pt and Ir wherein a layer including the metal is formed on a surface composed of a material selected from W, Ta, Cu, Ni, Co, Fe, Mn, Cr, V Nb, tungsten nitride, tantalum nitride, titanium nitride, dielectrics and activated dielectrics at a temperature ranging from >60° C. to <260° C. The layer is formed by sequentially pulsing into a chamber containing the surface a precursor for the metal and a reducing gas selected from hydrogen, glyoxylic acid, oxalic acid, formaldehyde, 2-propanol, imidazole and plasma-activated hydrogen.

Owner:SENKEVICH JOHN JOSEPH +1

Degradable superabsorbent polymers

InactiveUS20130065765A1Increase demandSufficient amountBiocideGlass/slag layered productsGlyoxylic acidFiber

The present disclosure relates to degradable superabsorbent materials based on acetals of glyoxylic acid and derivatives thereof with polyvinyl alcohol, and methods of making the polymers. The polymers are used to make superabsorbent particles, coatings, sheets, and fibers. Formulations and articles including the superabsorbent polymers, particles, coatings, sheets, and fibers are also disclosed.

Owner:RELUCEO

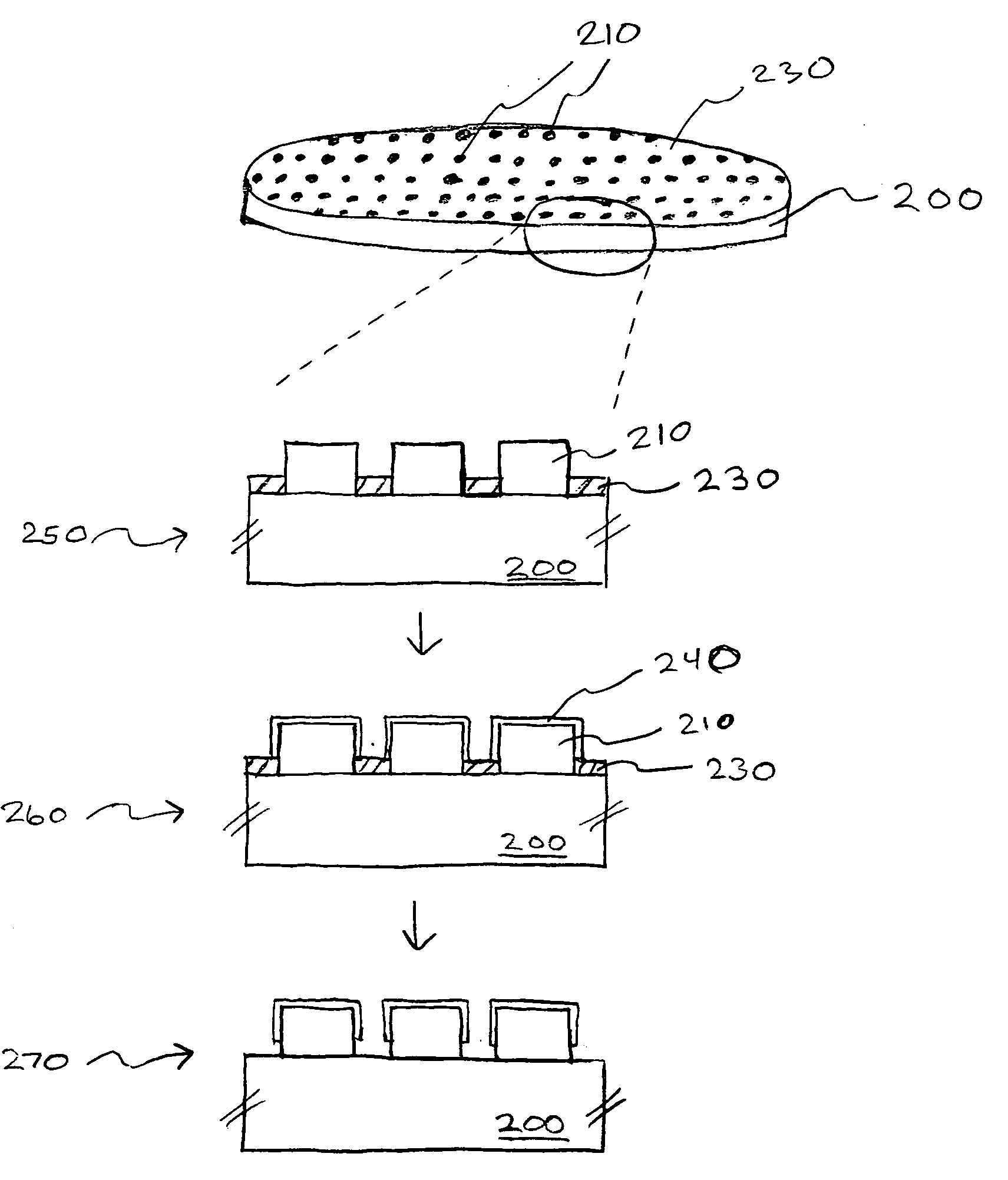

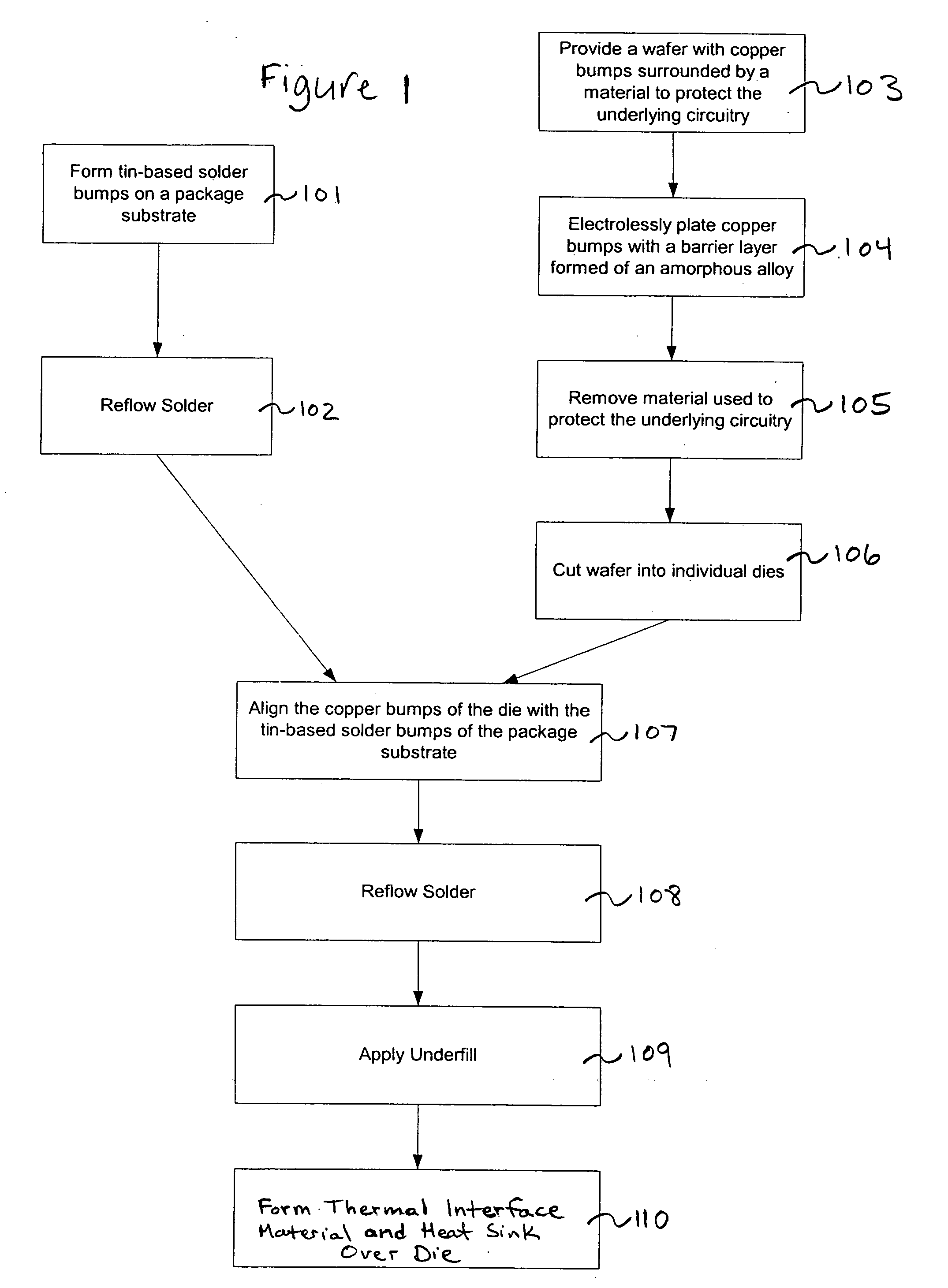

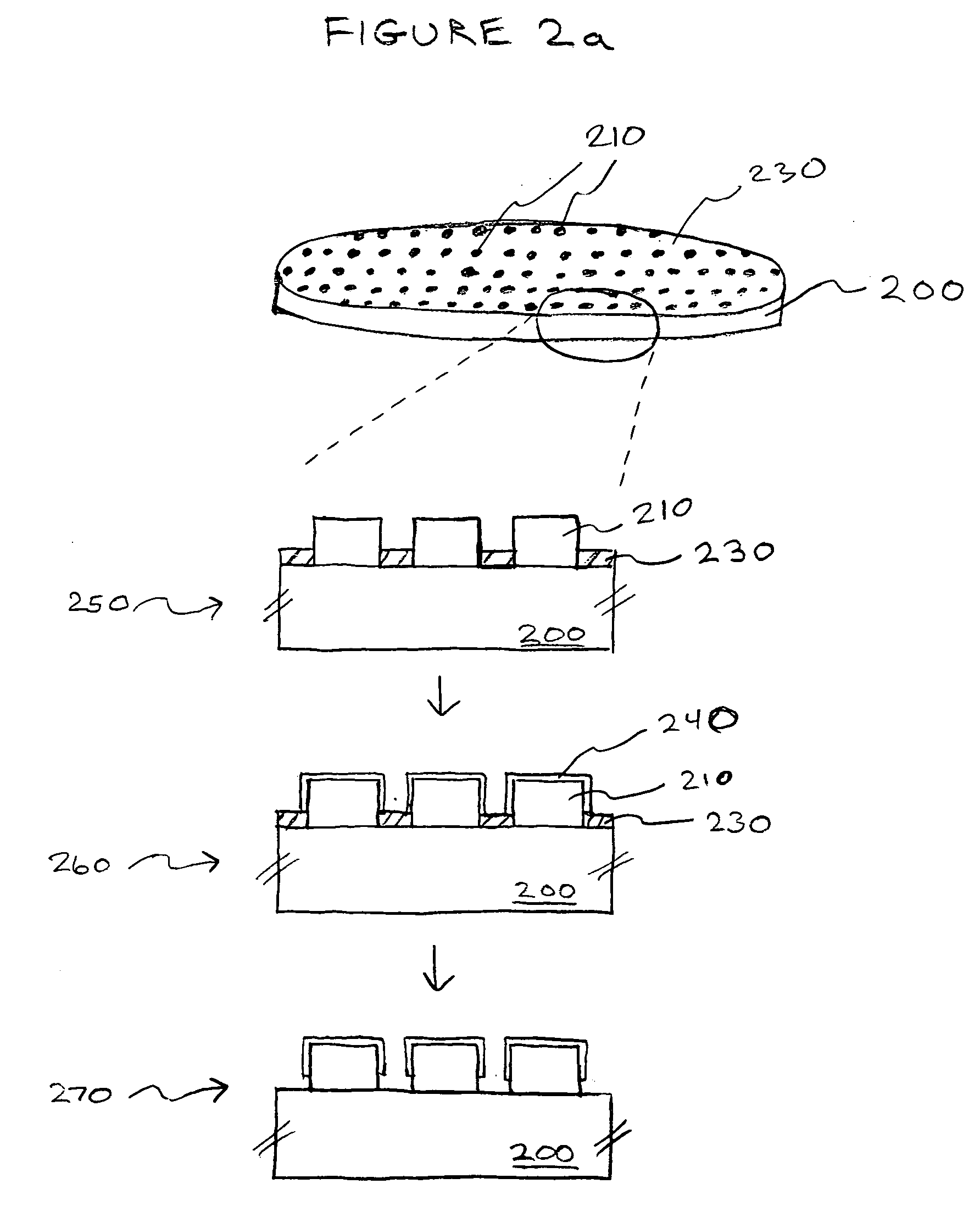

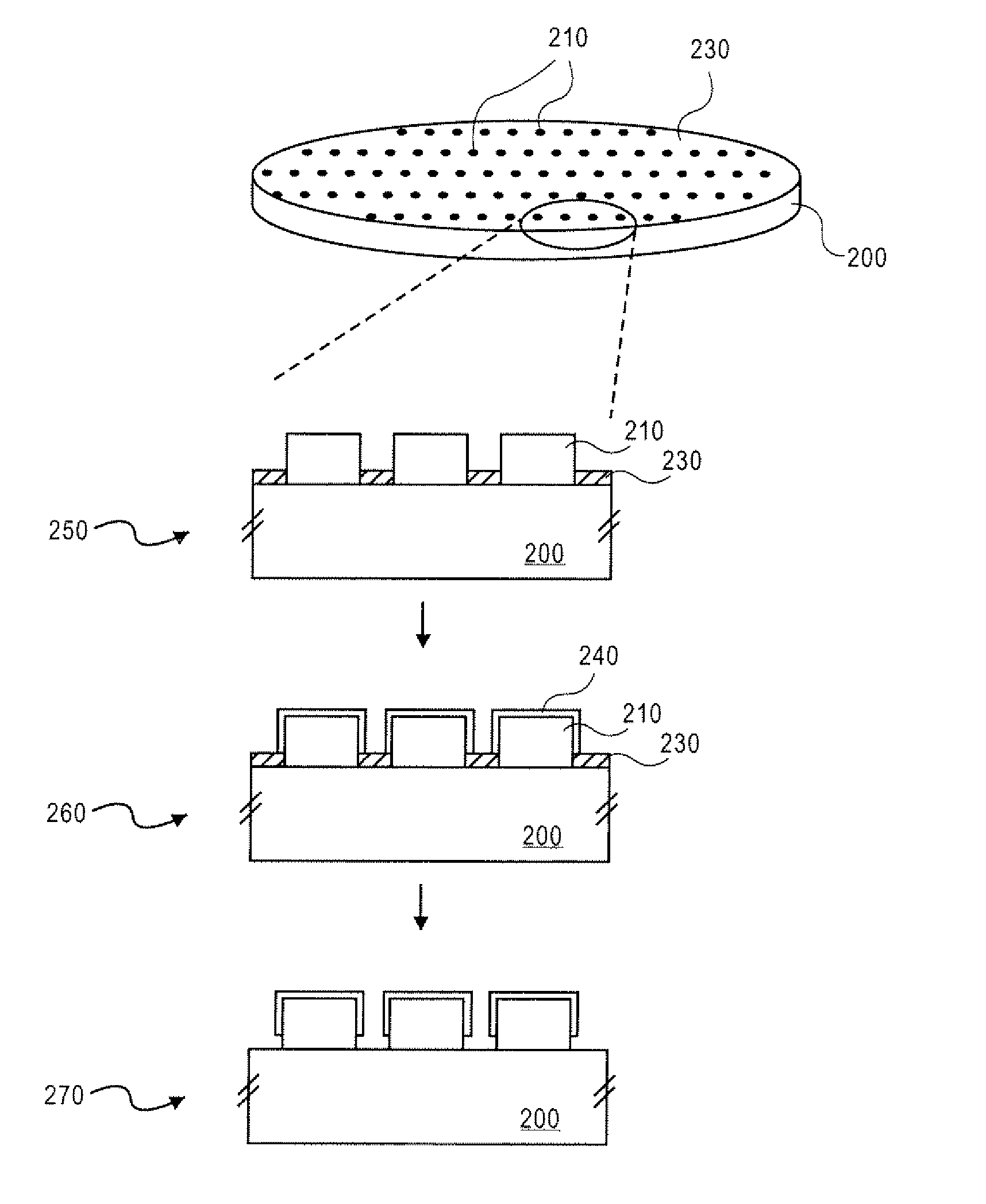

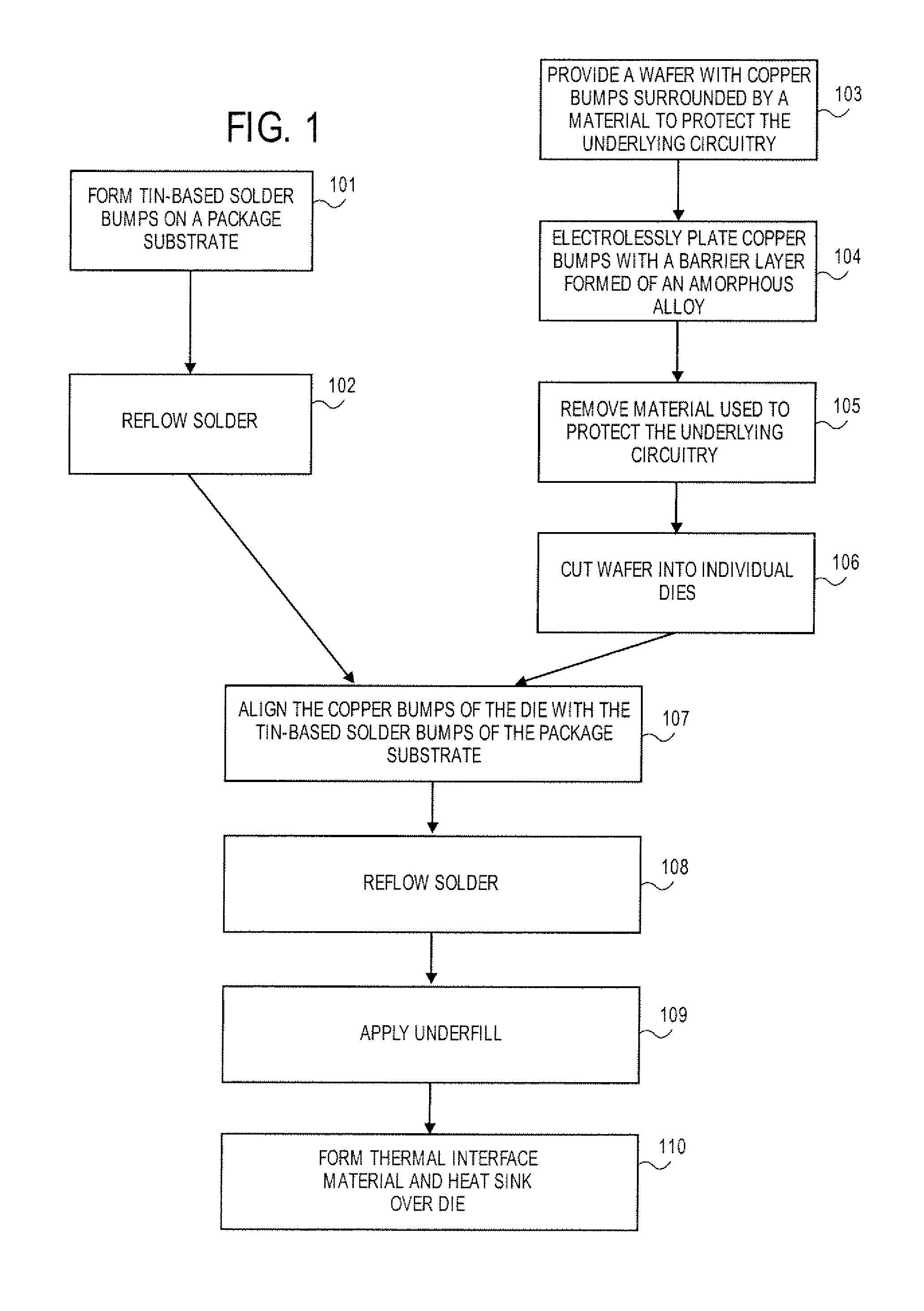

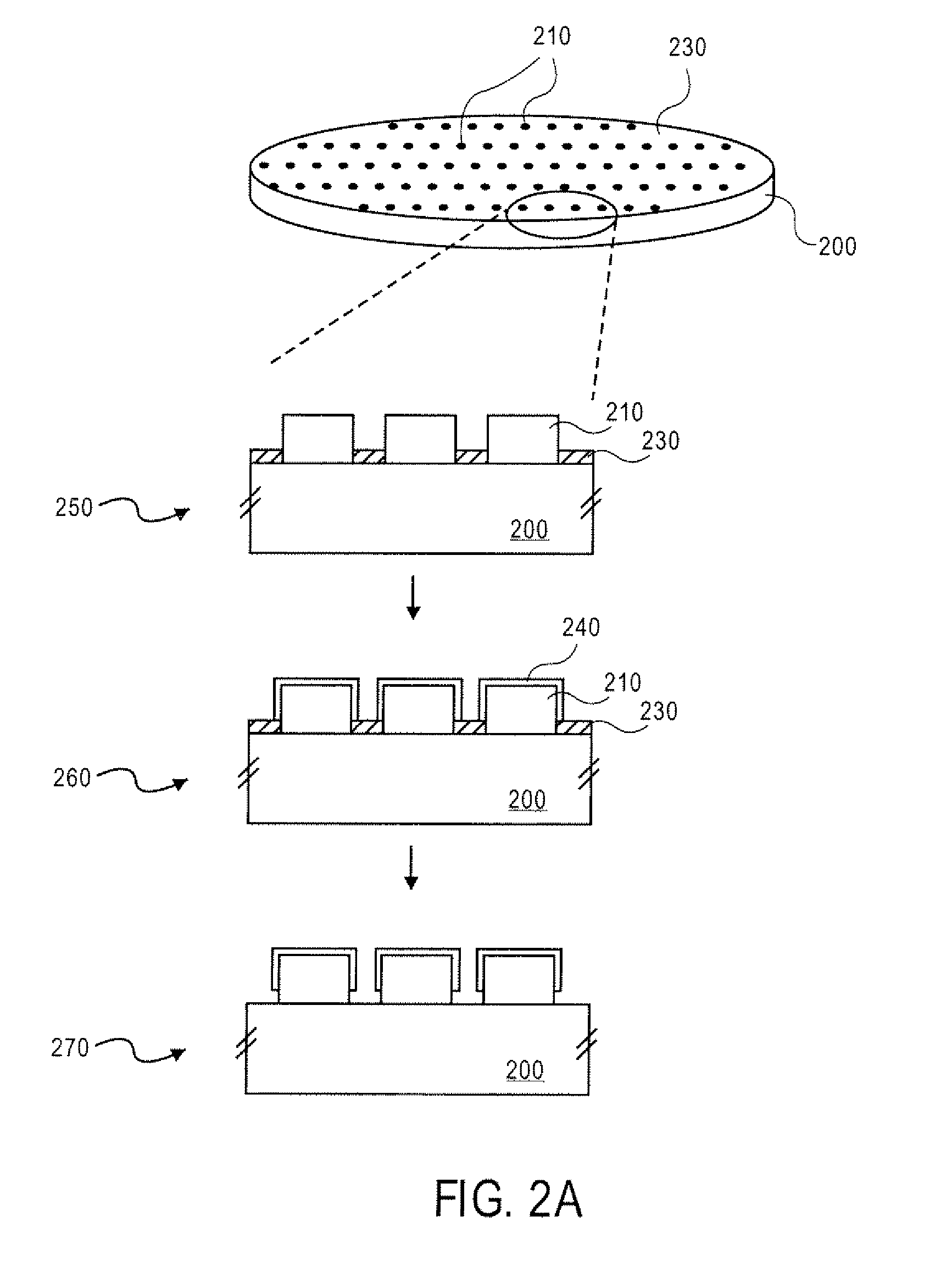

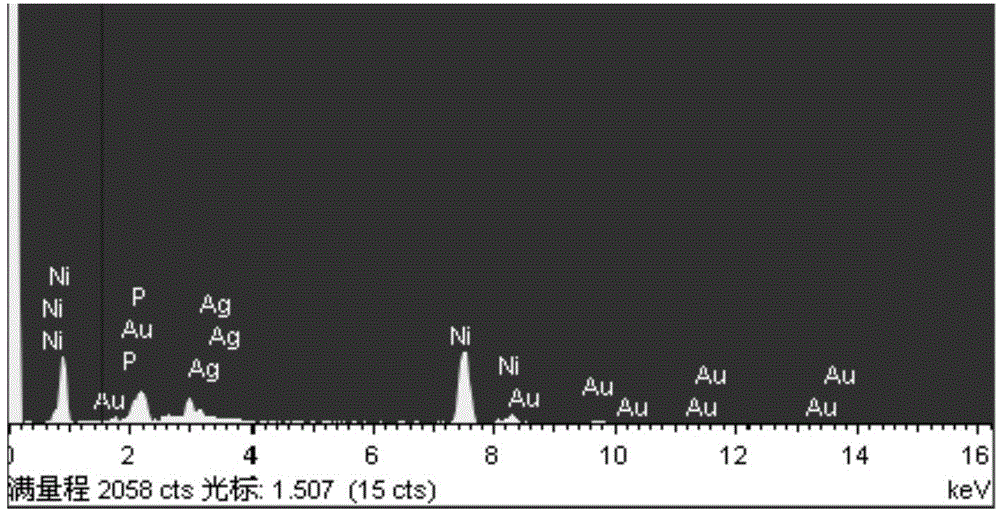

Methods to deposit metal alloy barrier layers

InactiveUS20060071340A1Semiconductor/solid-state device detailsSolid-state devicesGlyoxylic acidCopper interconnect

Metal alloy barrier layers formed of a group VII metal alloyed with boron (B) and / or phosphorous (P) and an at least one element from glyoxylic acid, such as carbon (C), hydrogen (H), or carbon and hydrogen (CH) formed by electoless plating are described. These barrier layers may be used as a barrier layer over copper bumps that are soldered to a tin-based solder in a die package. Such barrier layers may also be used as barrier layer liners within trenches in which copper interconnects or vias are formed and as capping layers over copper interconnects or vias to prevent the electromigration of copper.

Owner:INTEL CORP +1

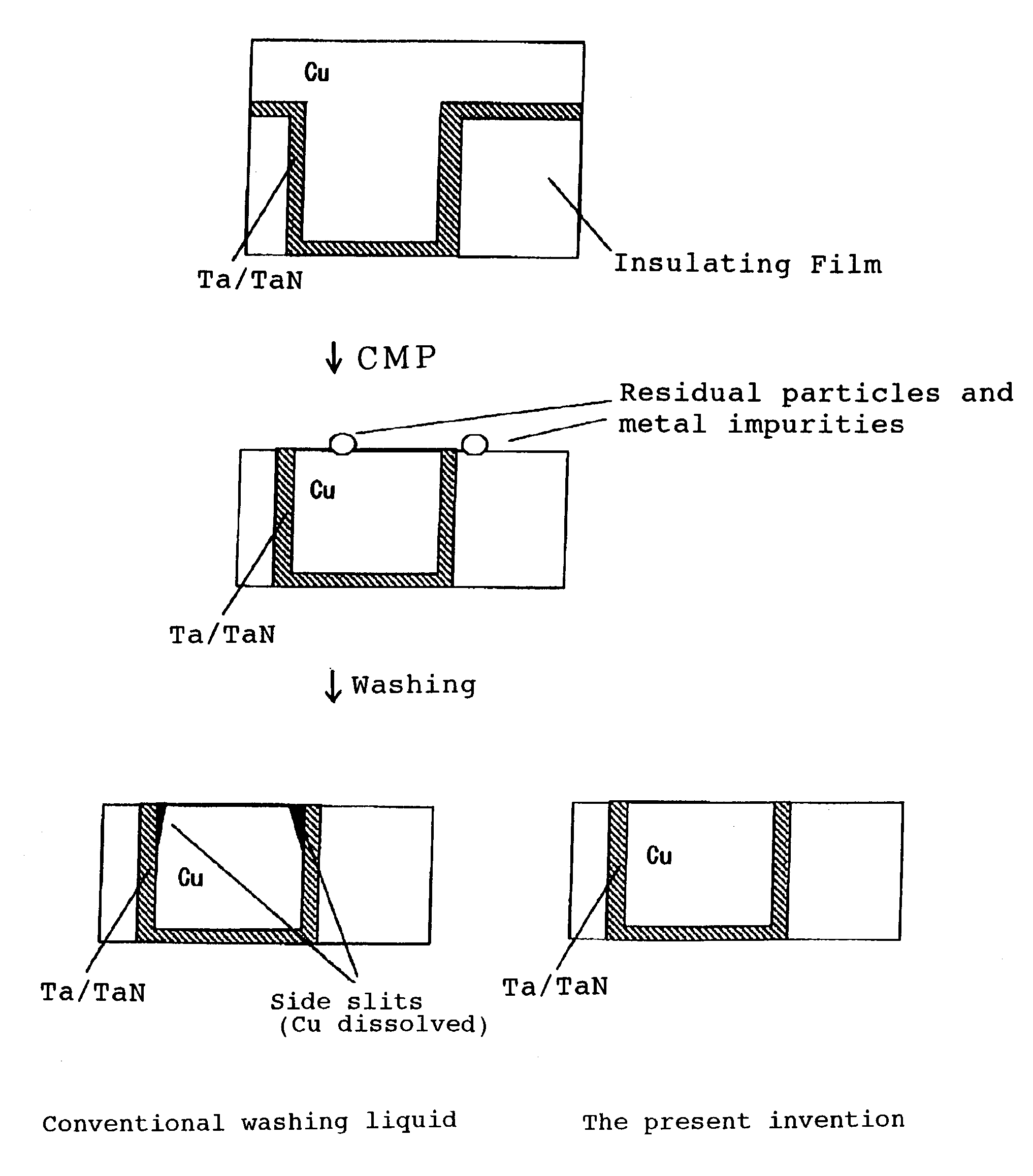

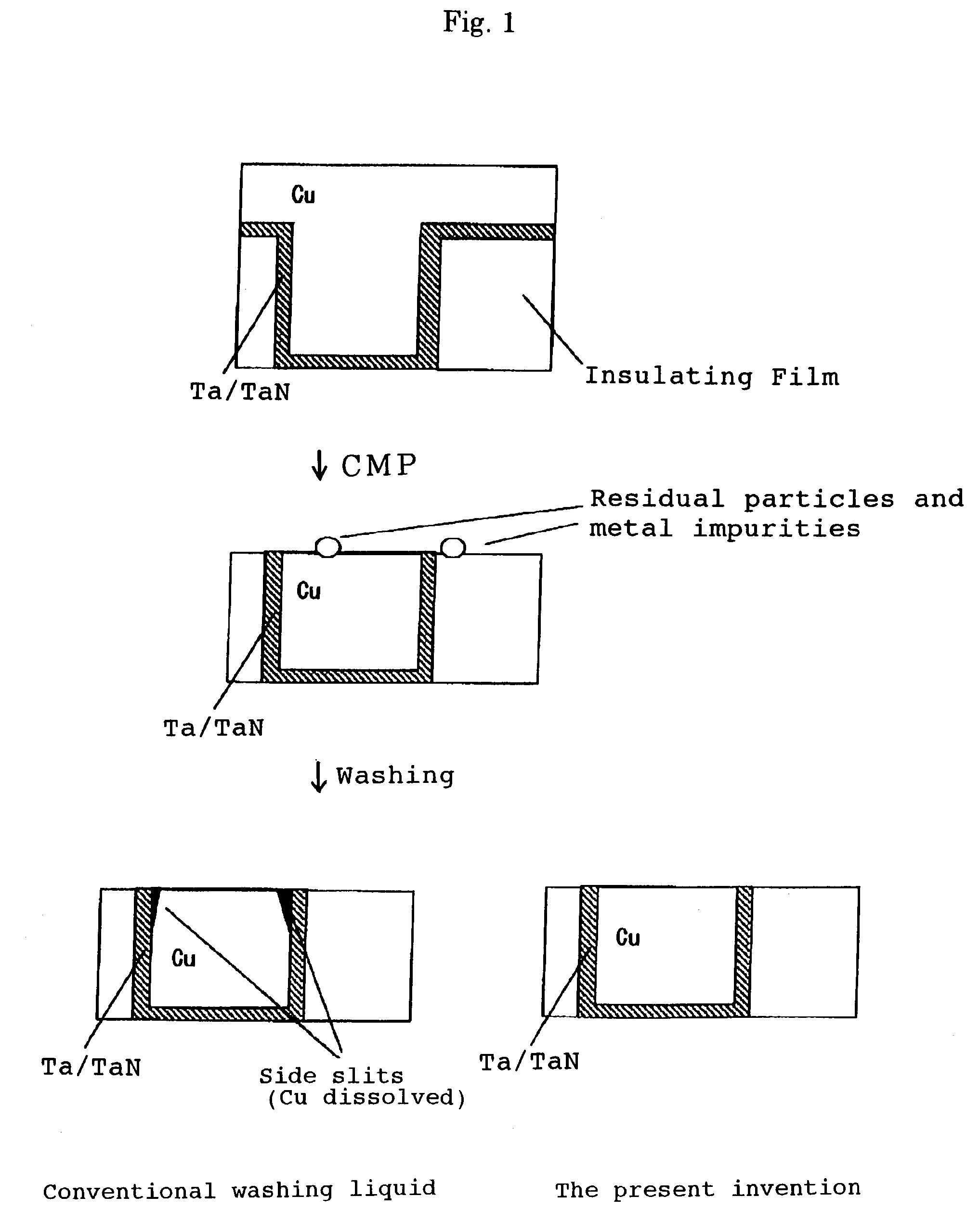

Post-CMP washing liquid composition

InactiveUS7087562B2Improve performanceNot corrodeSurface-active detergent compositionsDetergent mixture composition preparationGlyoxylic acidFructose

A post-CMP washing liquid composition is provided which includes one type or two or more types of aliphatic polycarboxylic acids and one type or two or more types selected from the group consisting of glyoxylic acid, ascorbic acid, glucose, fructose, lactose, and mannose, and which has a pH of less than 3.0. This washing liquid has excellent performance in removing micro particles and metal impurities adhering to the surface of a semiconductor substrate after CMP and does not corrode a metal wiring material.

Owner:KANTO CHEM CO INC +1

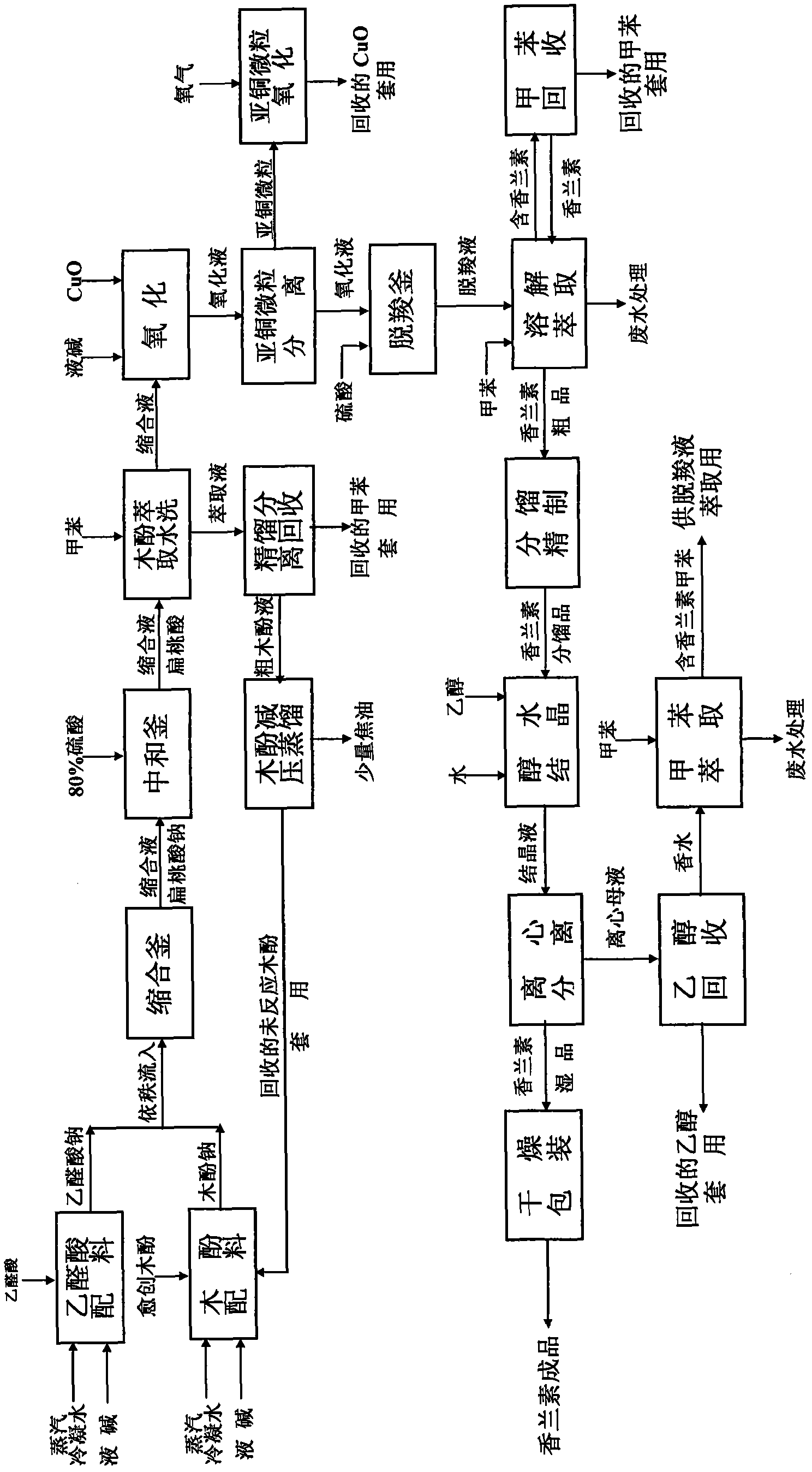

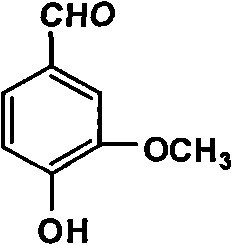

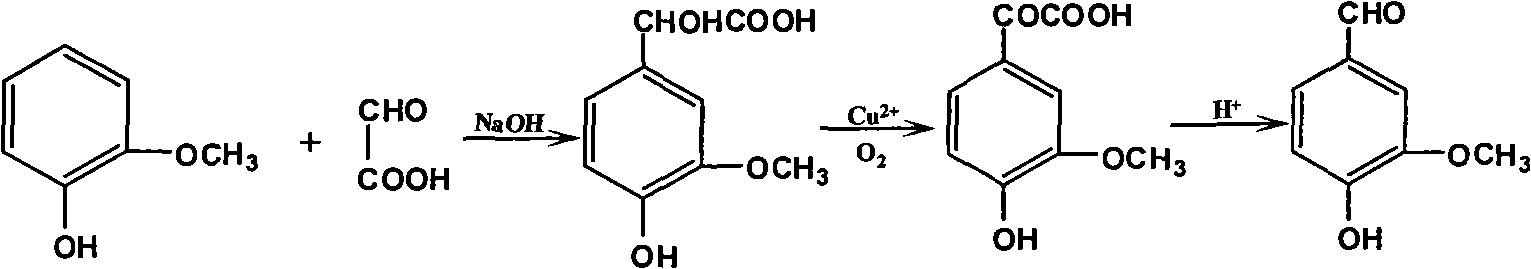

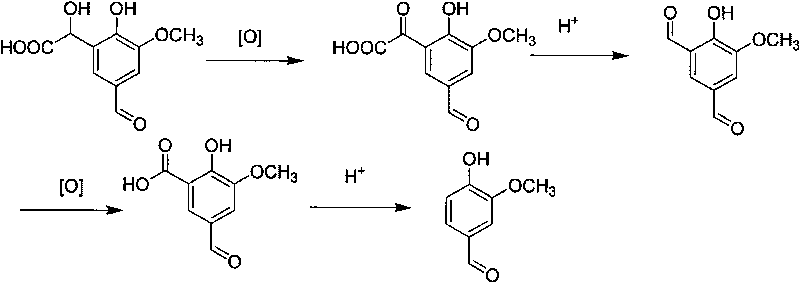

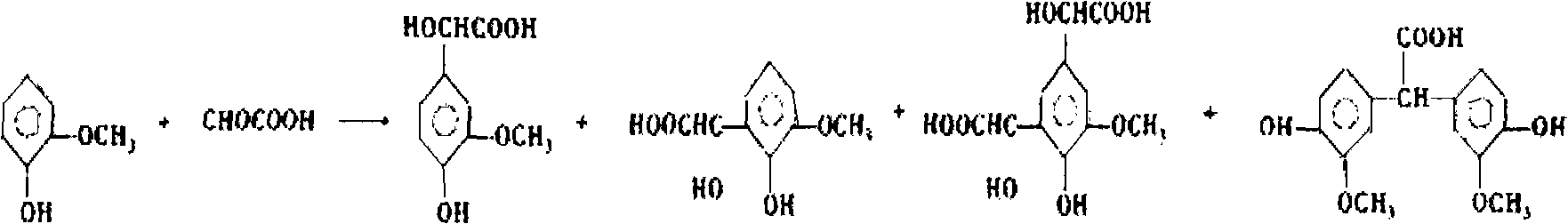

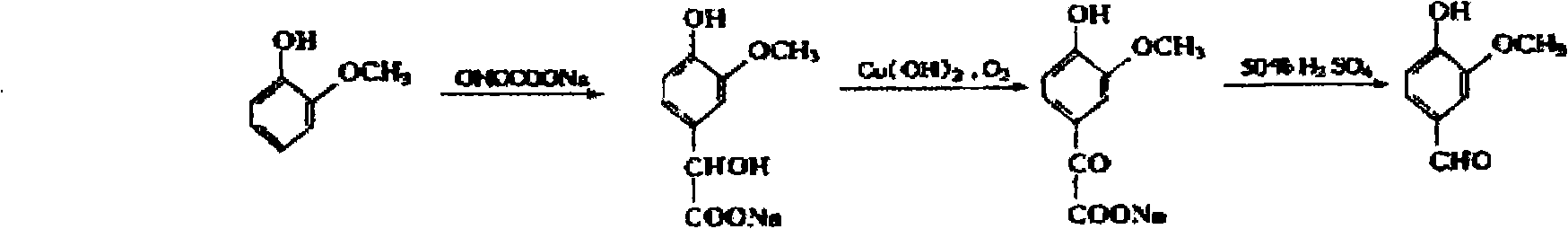

Productive technology of vanlillin by glyoxylic acid method

ActiveCN102010310AReduce organic contentReduce pollution sourcesOrganic compound preparationCarbonyl compound separation/purificationKetonic acidsFractionation

The invention discloses a productive technology of vanlillin by a glyoxylic acid method. The productive technology comprises a synthesis process, a fractionation process and a purification process, wherein the synthesis process comprises condensation treatment, oxidation treatment and decarboxylation treatment of methyl catechol and glyoxylic acid. The productive technology particularly comprisesthe following steps: respectively converting the methyl catechol and the glyoxylic acid into guaiacol sodium and sodium glyoxylate in a sodium hydroxide system; carrying out condensation treatment onthe guaiacol sodium and the sodium glyoxylate; after recovering the unreacted methyl catechol in a condensation liquid, carrying out oxidation treatment, namely carrying out catalytic oxidation on anethanol group in 4-hydroxy-3-methoxybenzene sodium glycolate by using copper oxide in the sodium hydroxide system to form a ketone group, thereby generating a corresponding ketonic acid compound; after separating red copper oxide particles from an oxidation liquid, carrying out decarboxylation treatment, namely using sulfuric acid to acidize the oxidation liquid, and simultaneously converting an acid group in the ketonic acid compound into carbon dioxide so as to generate 4-hydroxy-3- methoxybenzaldehyde; and carrying out the fractionation process and the purification process to obtain the vanlillin.

Owner:喜孚狮王龙香料(宁波)有限公司

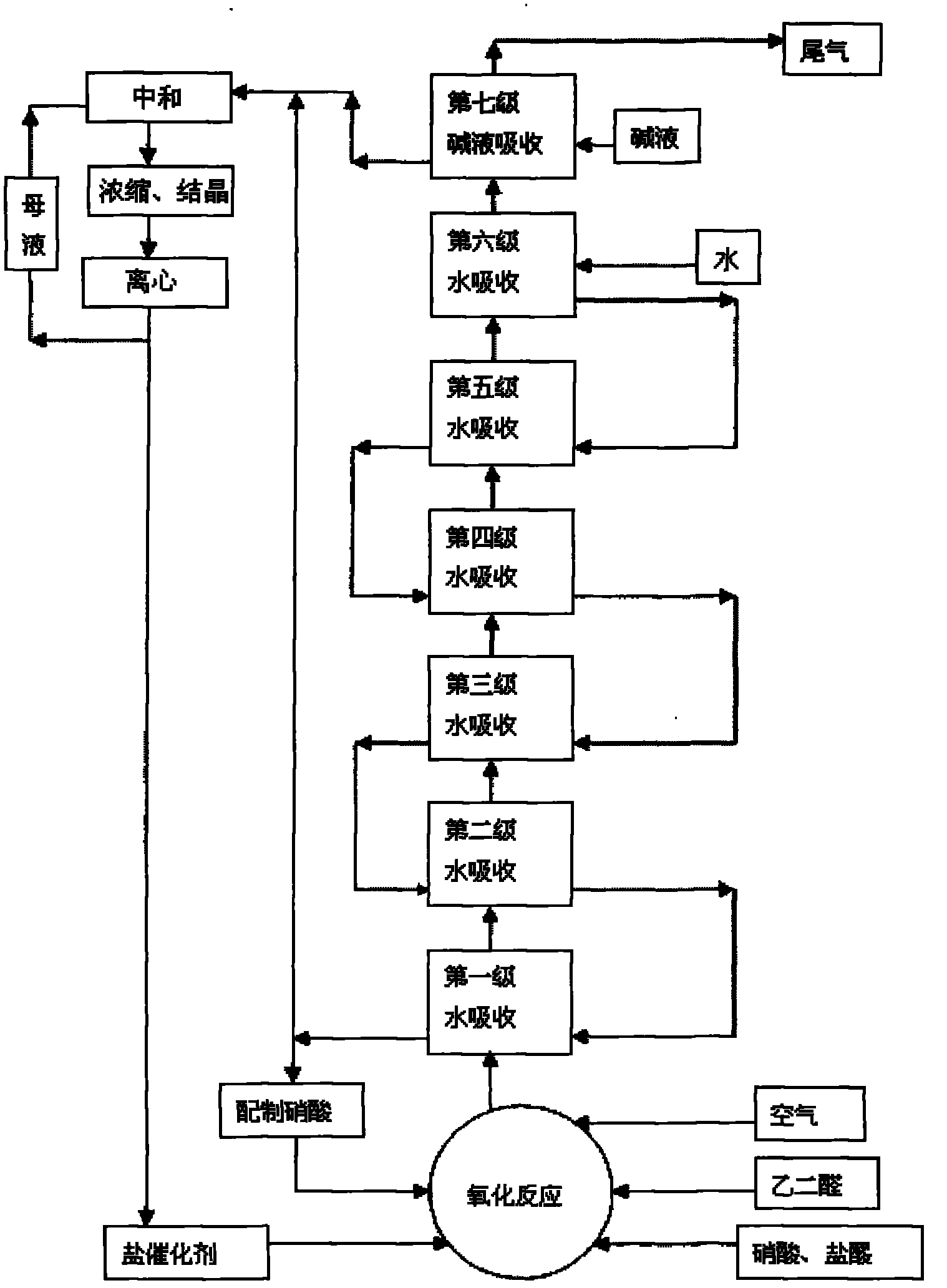

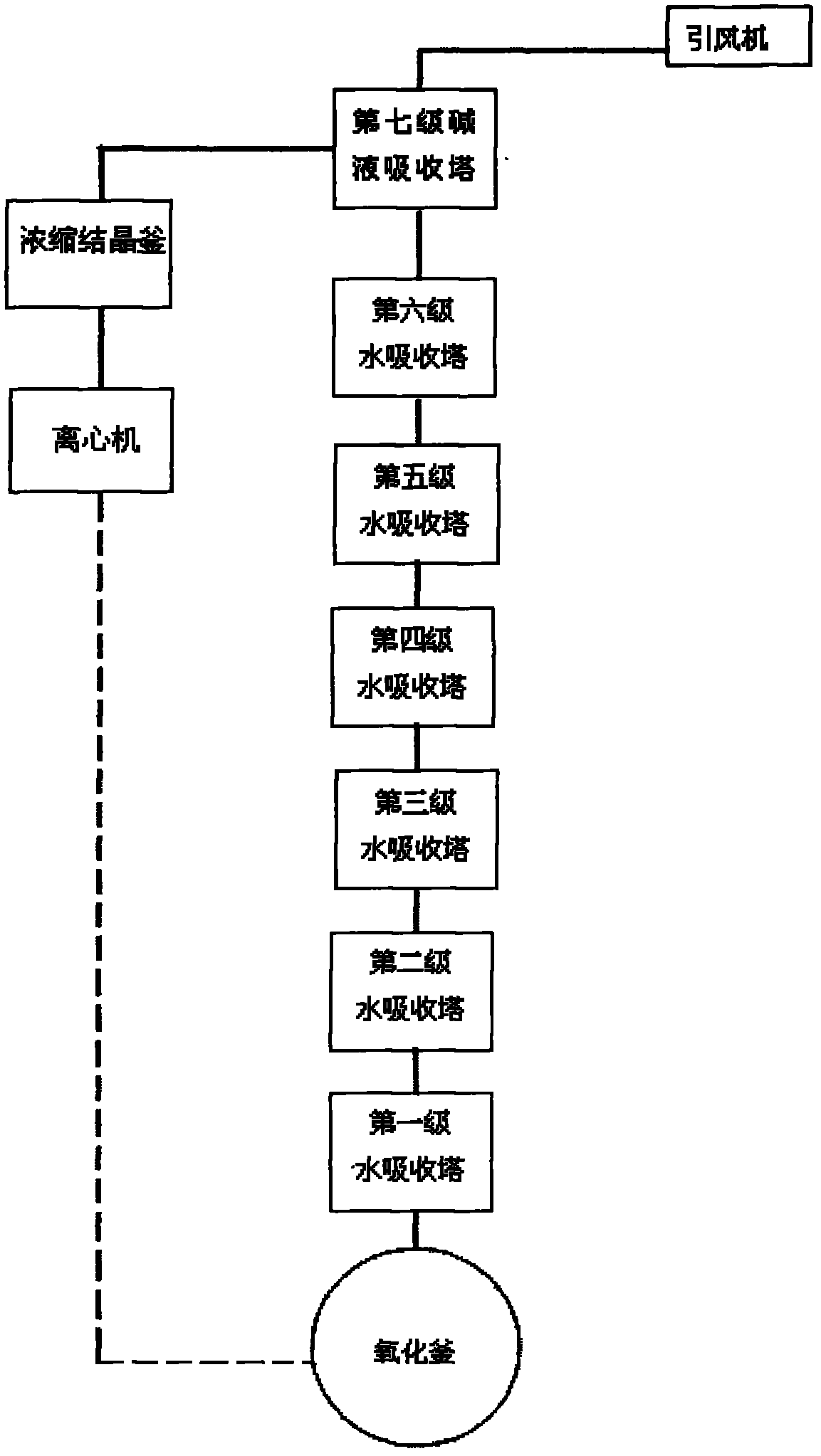

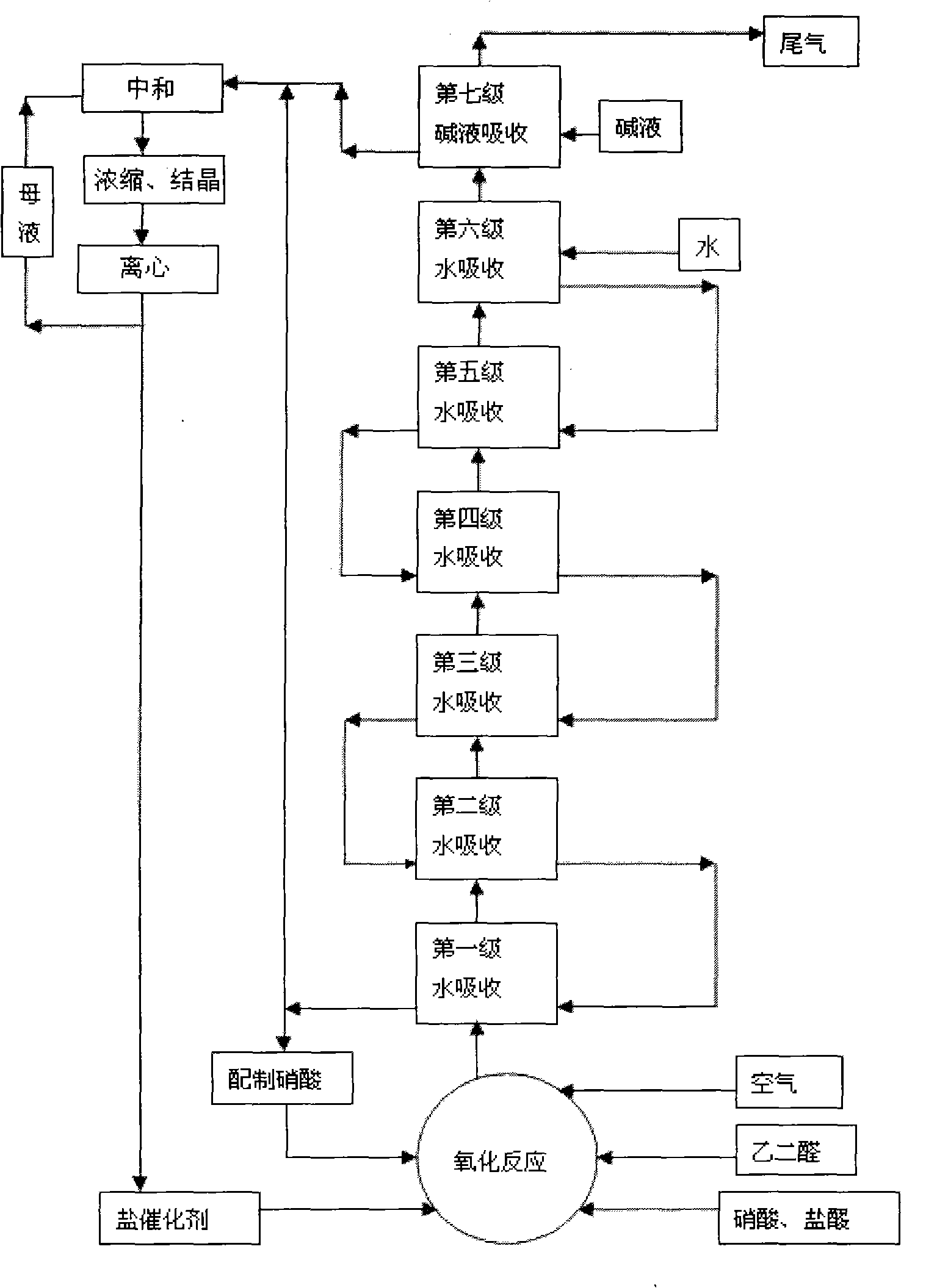

Treatment method and treatment system of tail gas from glyoxylic acid production by nitric acid oxidation of glyoxal

ActiveCN102247748AWill not polluteHigh recovery rateDispersed particle separationAir quality improvementGlyoxylic acidCentrifugation

A treatment method and a treatment system of tail gas from glyoxylic acid production by nitric acid oxidation of glyoxal belong to the fields of environmental protection, energy saving and consumption reduction. The method comprises the following steps: introducing air to oxidize NO in tail gas generated by nitric acid oxidation of glyoxal into NO2; performing six-grade water absorption continuously to absorb gas of NOx and HCl in the tail gas; absorbing the tail gas after six-grade water absorption by a NaOH or Na2CO3 solution to remove residual NO2 and HCl gas and to generate an alkaline solution containing NaNO3, NaNO2, and trace NaCl; discharging the treated tail gas by an induced draft fan; performing neutralization, concentration, crystallization, centrifugation and separation of the generated alkaline solution to obtain a mixed sodium salt containing NaNO3, NaNO2, and trace NaCl, returning the mixed sodium salt to an oxidation vessel to be used as a catalyst for recycle. The treatment system comprises: an oxidation reaction vessel, water absorbing towers from grade one to grade six, a seventh grade alkaline solution absorbing tower, a concentration and crystallization vessel, a centrifuge, and a induced draft fan.

Owner:HUBEI HONGYUAN PHARMA

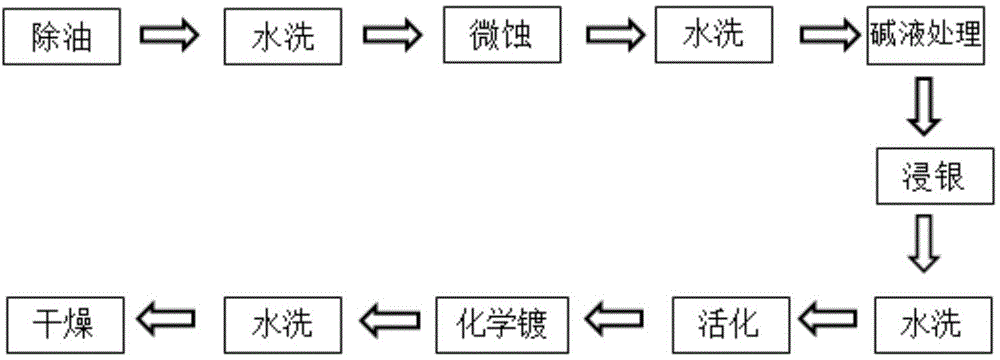

Colloid palladium activation solution, preparation method thereof and non-metal surface activation method

InactiveCN101928937ANon-failure decompositionBreak down evenlyLiquid/solution decomposition chemical coatingActivation methodGlyoxylic acid

The invention provides colloid palladium activation solution which comprises colloid palladium, sodium chloride, glyoxylic acid, hydrochloric acid, stannous chloride and stabilizer for stabilizing the stannous chloride, wherein the glyoxylic acid has strong reducibility and can avoid that divalent tin ions in the activation solution are oxidized, and prolong the service life of the action solution; simultaneously, the glyoxylic acid is adsorbed on the periphery of colloid palladium particles, thereby leading the dispersion of the colloid palladium to be more uniform, avoiding the gel coagulation among the colloid particles and enhancing the activity of the activation solution. The invention provides a preparation method of the colloid palladium, and the process is simple. In addition, the adoption of the colloid palladium activation solution for activating the surface of a non-metal substrate can firstly adsorb the glyoxylic acid in the activation solution on the surface of the non-metal substrate, enhance the bonding force between the colloid palladium particles and the non-metal substrate, leading a plated coating after chemical plating to have uniform thickness and flat surface, and leading the adhesion between the plated coating and the substrate to be very high.

Owner:深圳市新合富力科技有限公司

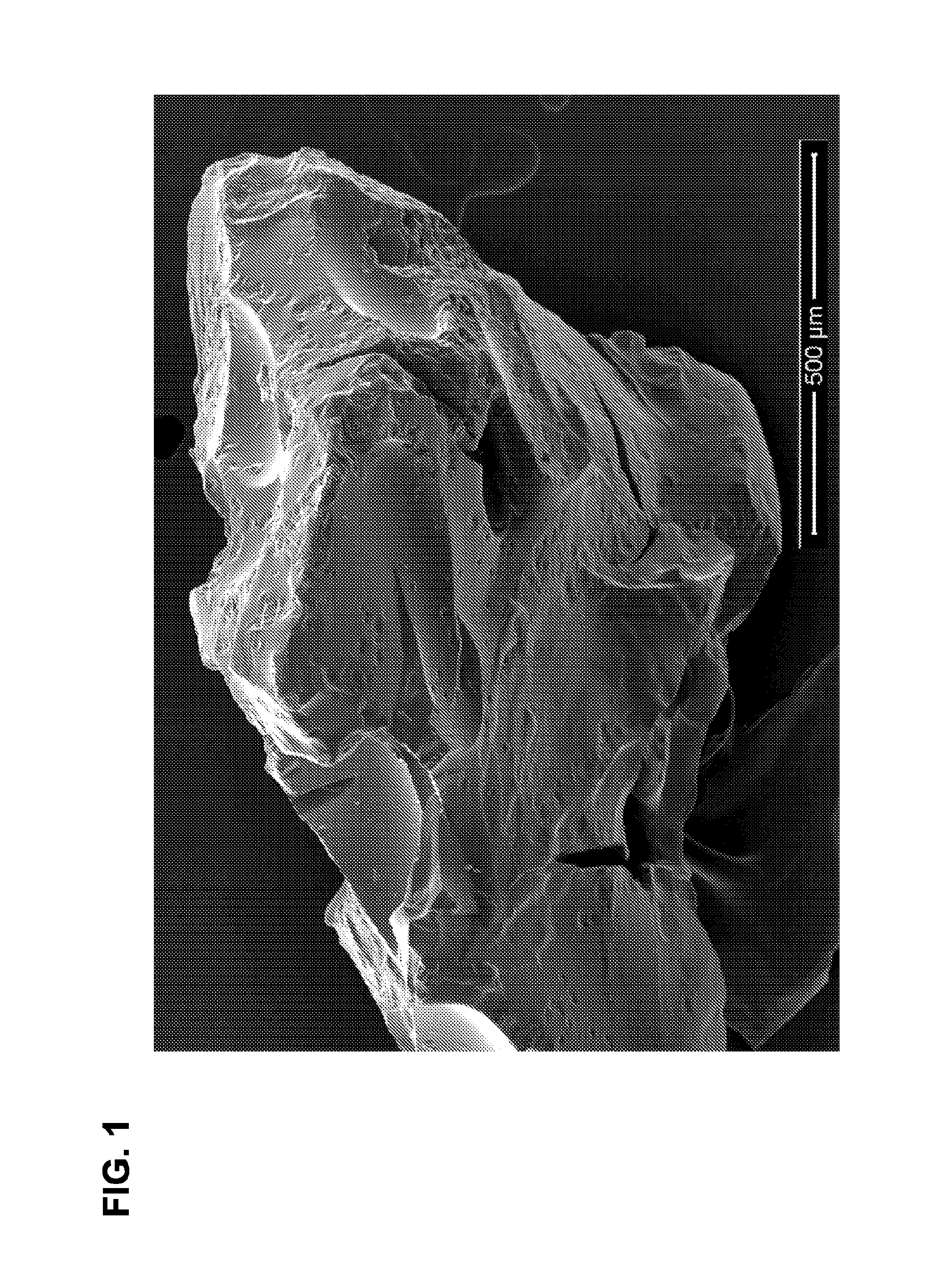

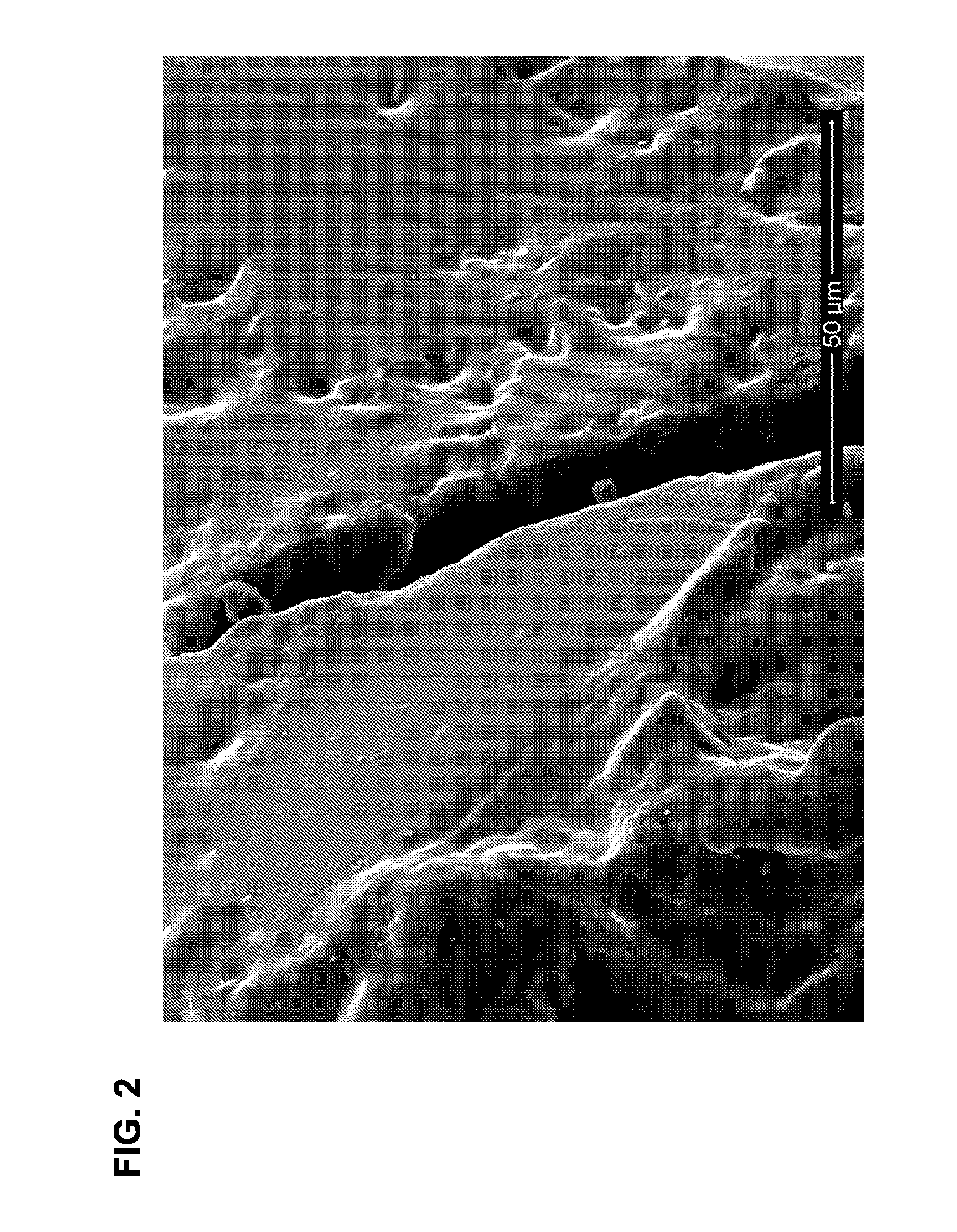

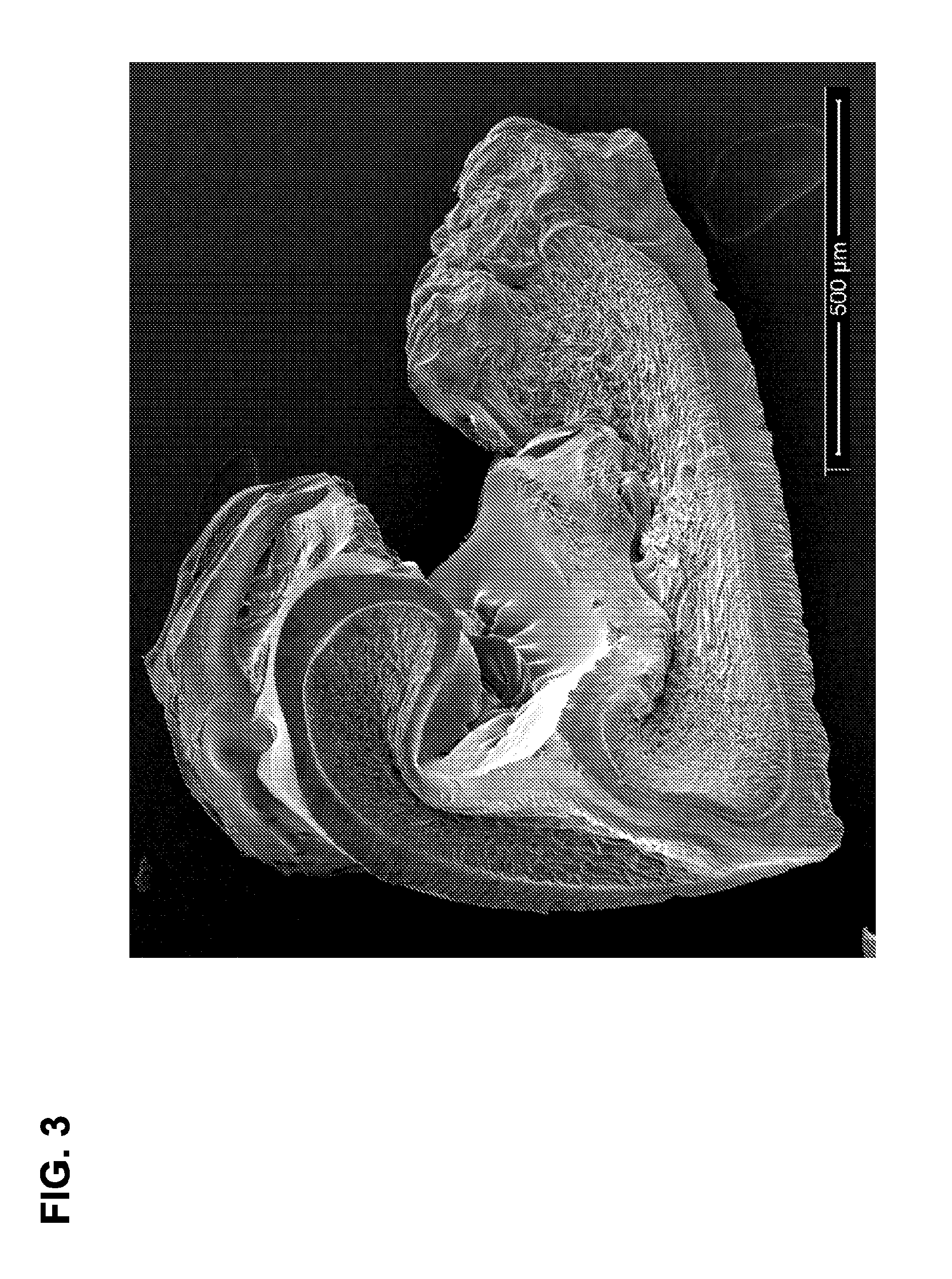

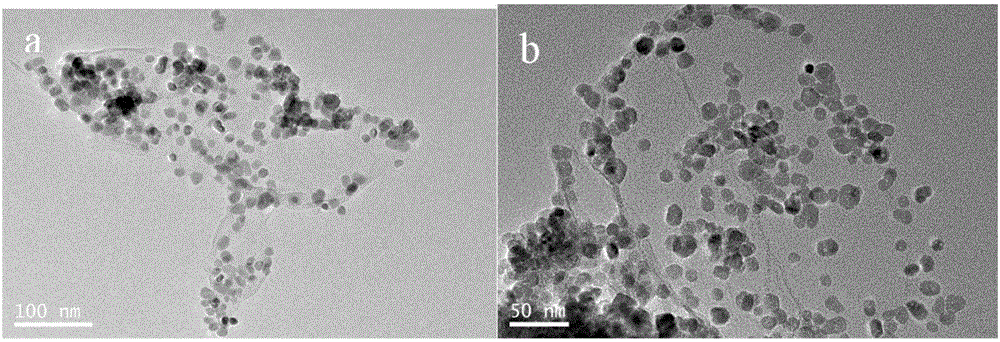

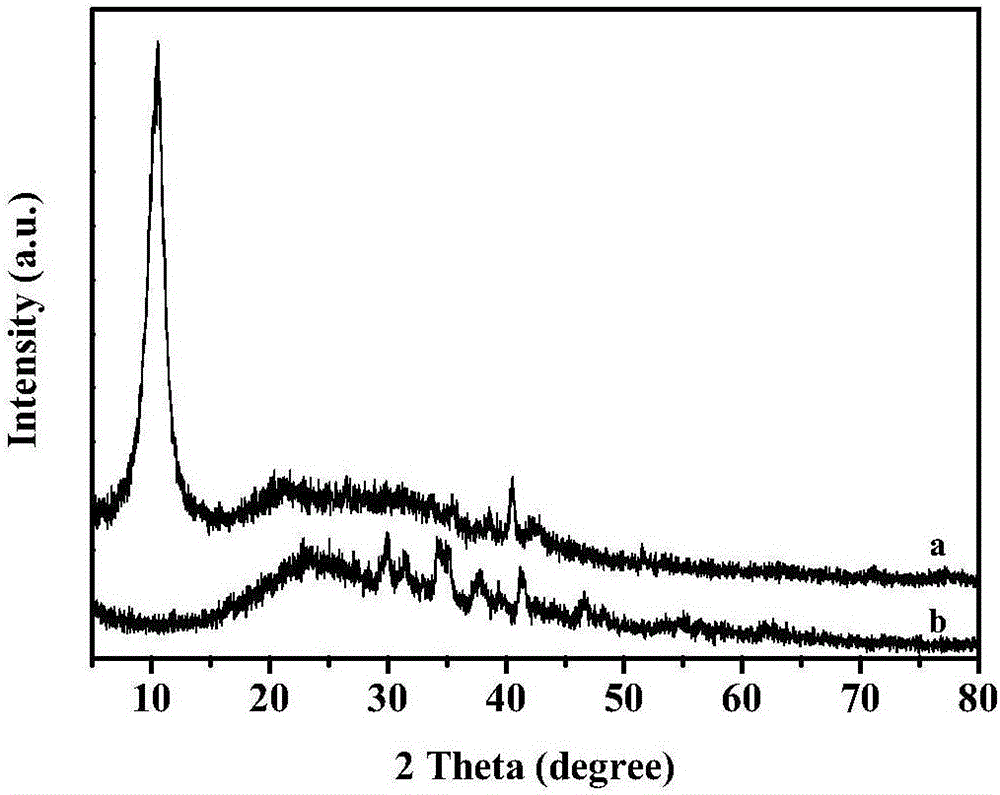

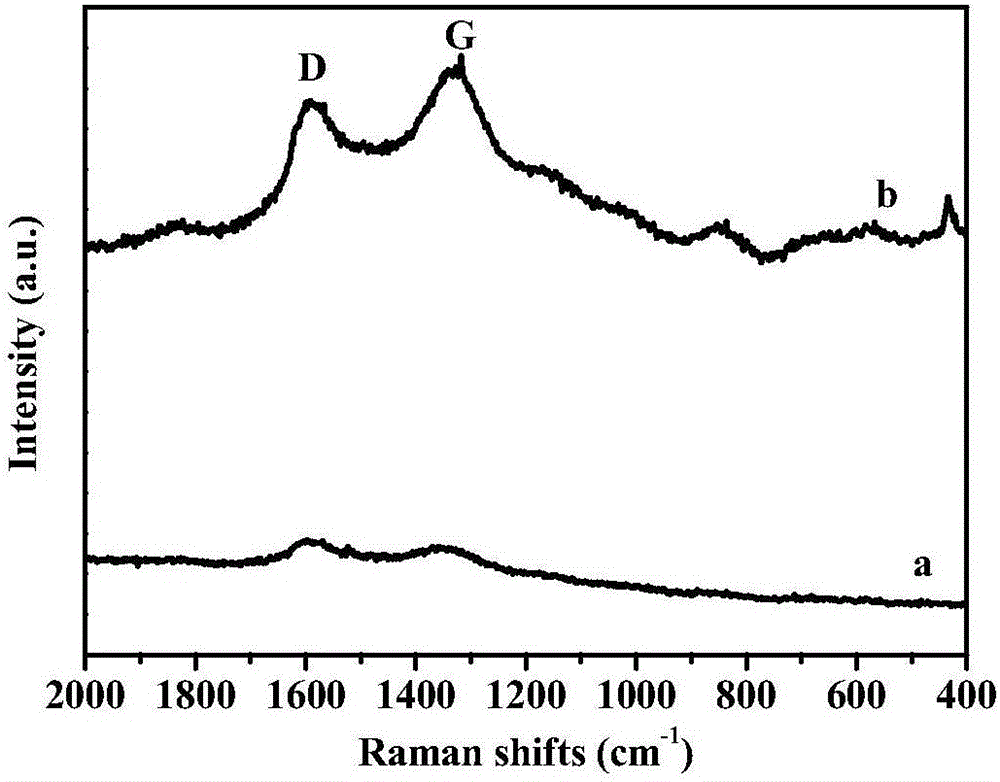

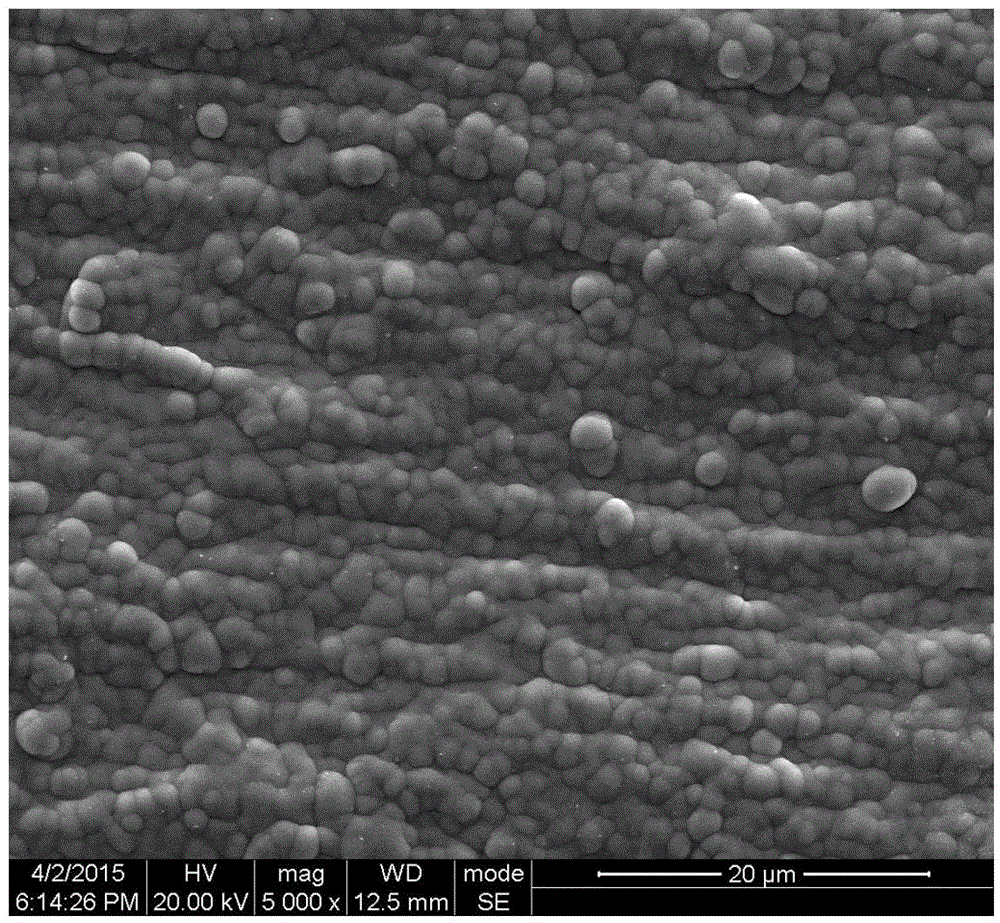

Preparation method for graphene/nano-silver composite antibacterial material

ActiveCN105772739AEasy to prepareMild reaction conditionsMaterial nanotechnologyTransportation and packagingGlyoxylic acidCvd graphene

The invention provides a preparation method for a graphene / nano-silver composite antibacterial material and belongs to the technical field of new materials. The preparation method is characterized in that graphene oxide provided with silver ions in an adsorption manner is put into a reduction agent solution to be heated, the graphene / nano-silver composite material is obtained through centrifugal separation, and a reduction agent is glyoxylic acid. The method has the beneficial effects that reduction of the graphene oxide and the silver ions is sufficient, operation is simple, the process is controllable, and the obtained material has good antibacterial activity on common bacteria.

Owner:湖州因爱伟大卫生用品有限公司

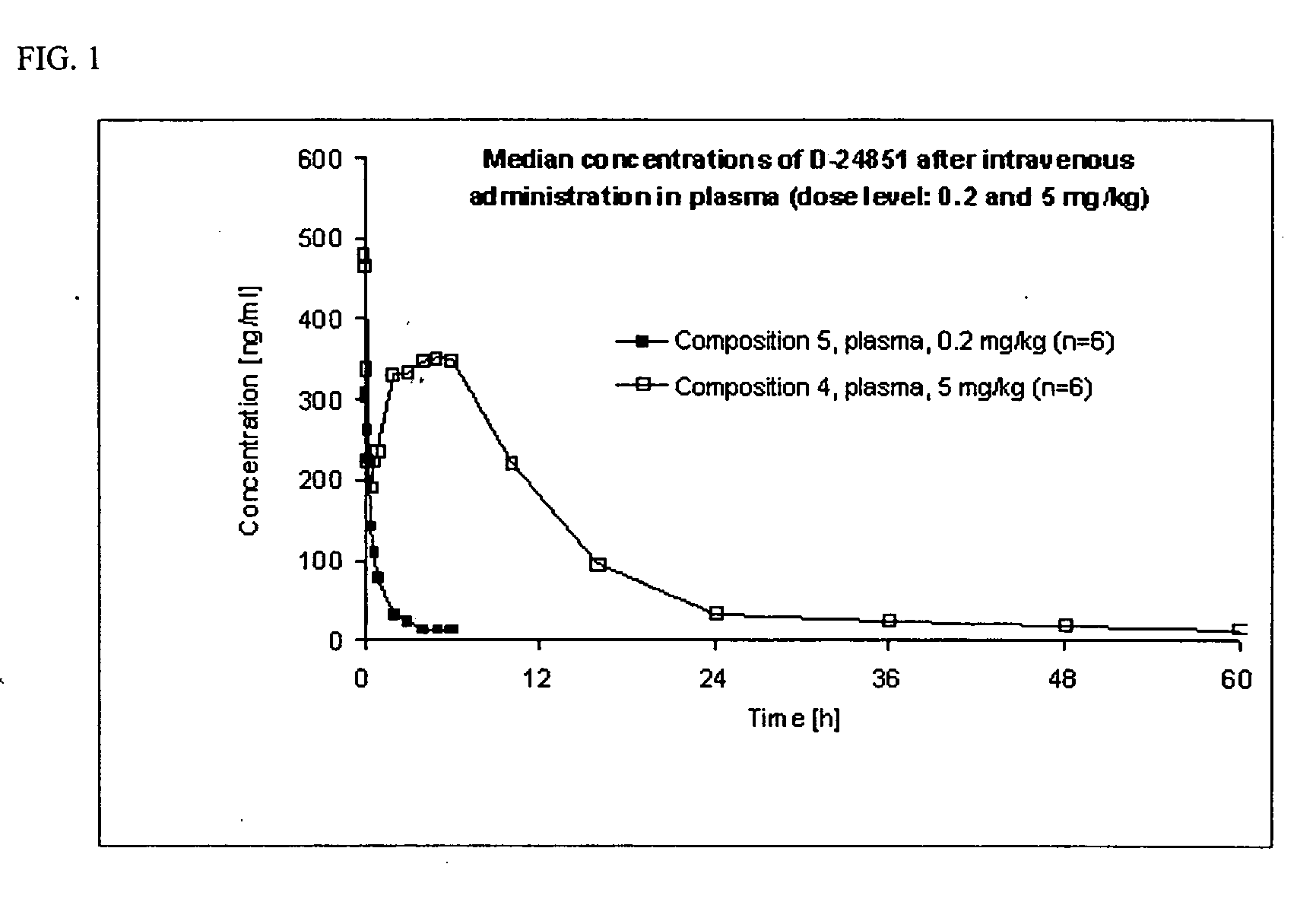

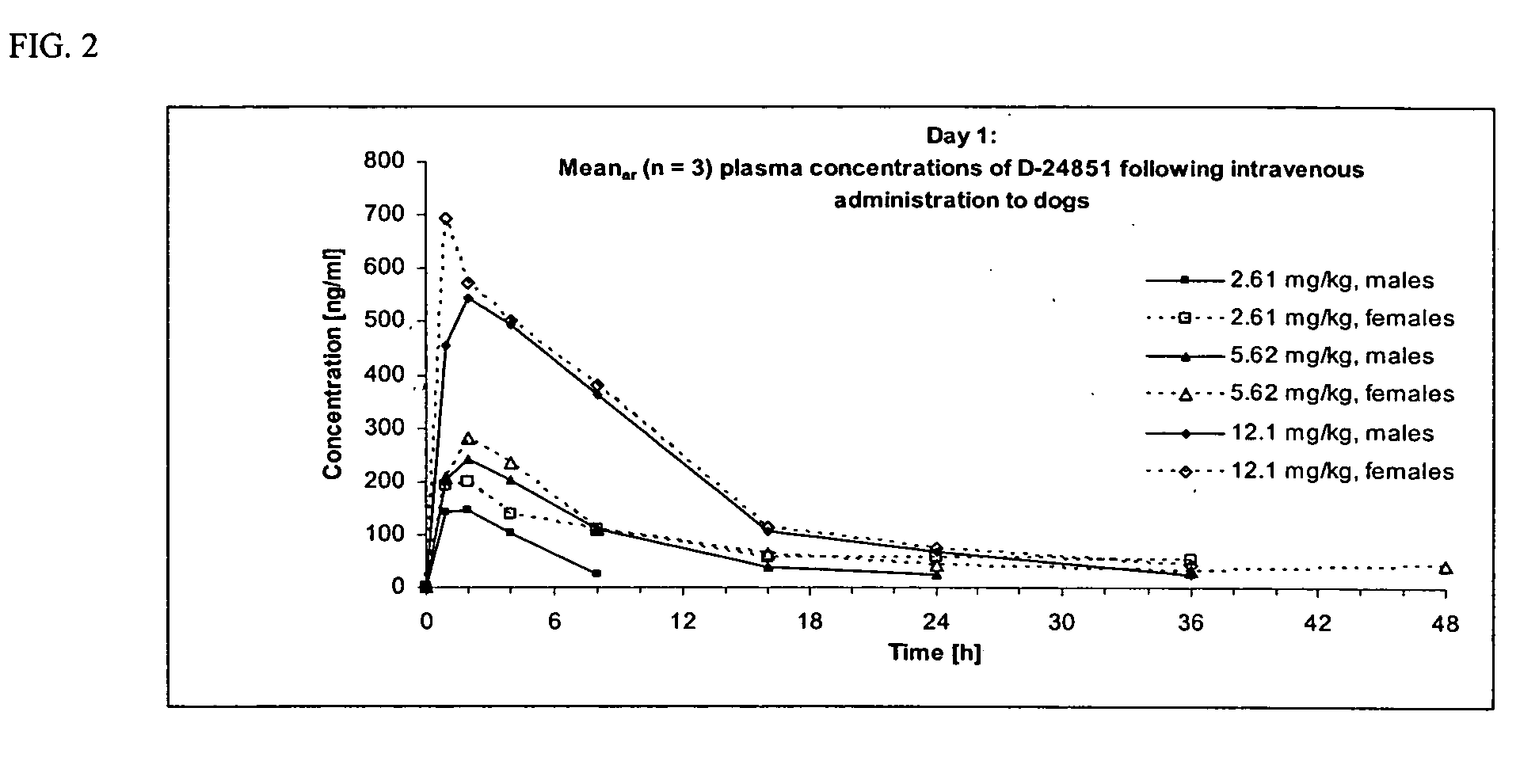

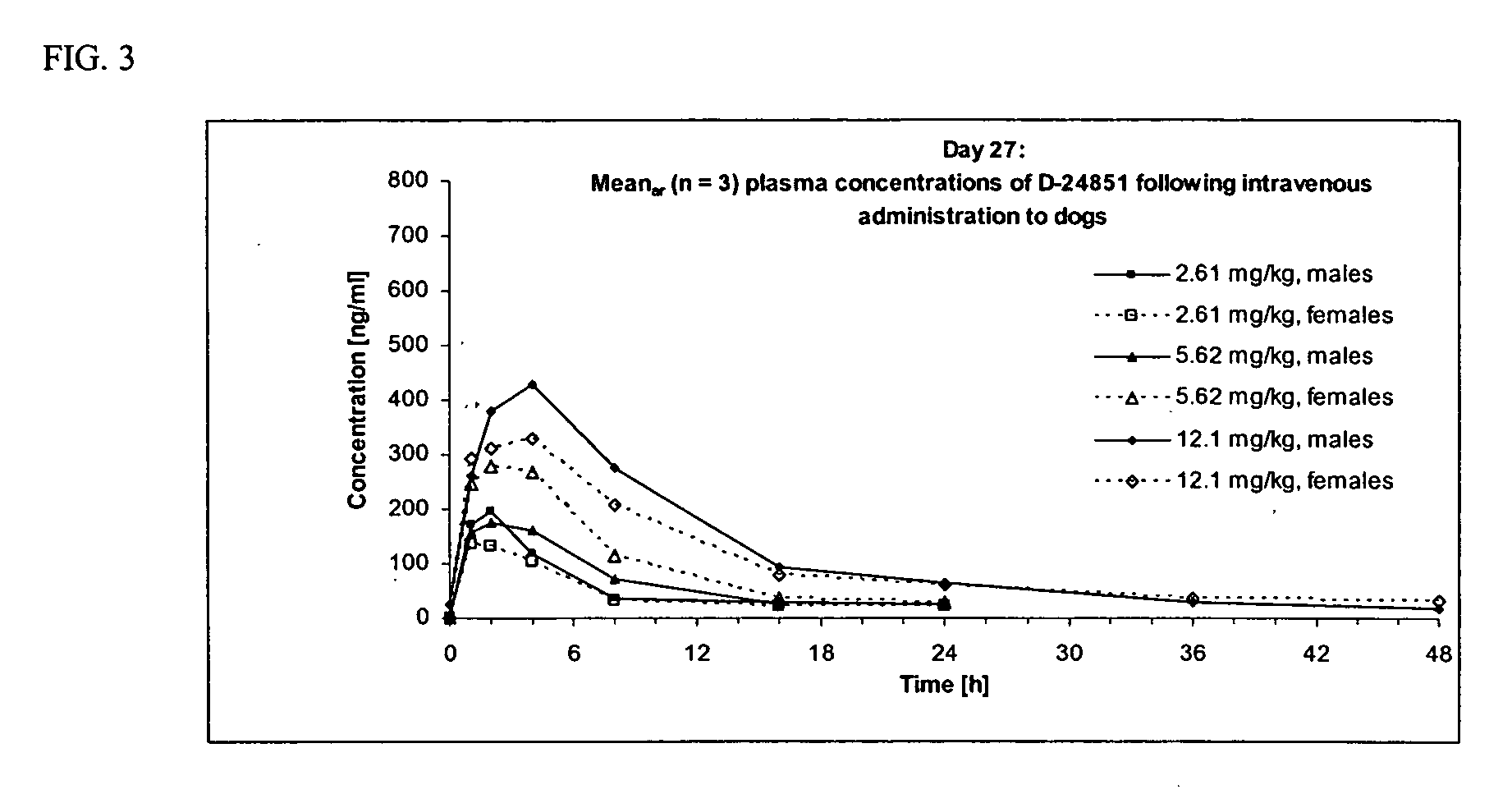

Nanoparticulate compositions of tubulin inhibitor compounds

InactiveUS20060110462A1Low toxicityImprove bioavailabilityAntibacterial agentsBiocideAbnormal tissue growthParticulates

The present invention is directed to novel pharmaceutical compositions comprising nano- and micro-particulate formulations of poorly water soluble tubulin inhibitors of the indole chemical class, preferably N-substituted indol-3-glyoxyamides, and more preferably N-(Pyridin-4-yl)-[1-(4-chlorobenzyl)-indol-3-yl]glyoxylic acid amide (D-24851), also known as “Indibulin,” and methods of making and using such compositions for the treatment of anti-tumor agent resistant cancers and other diseases.

Owner:ZIOPHARM ONCOLOGY INC

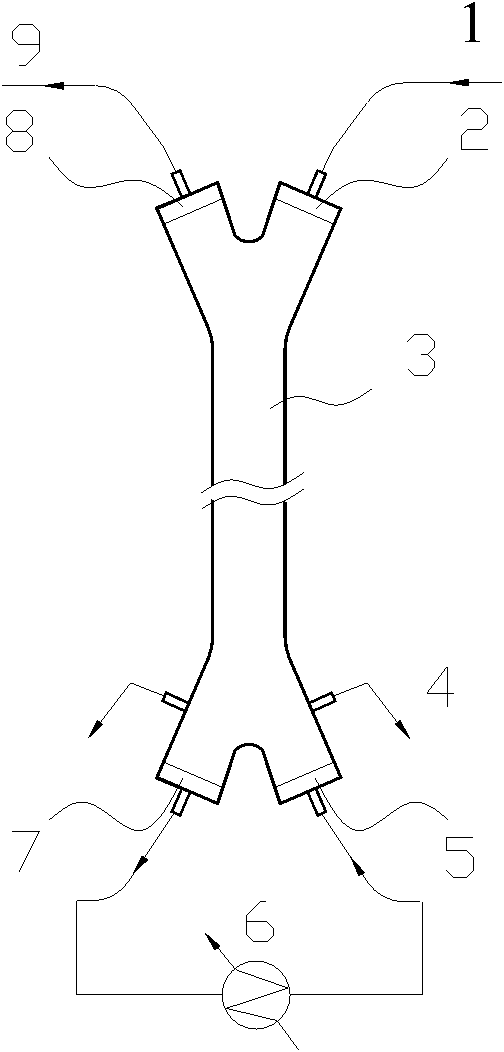

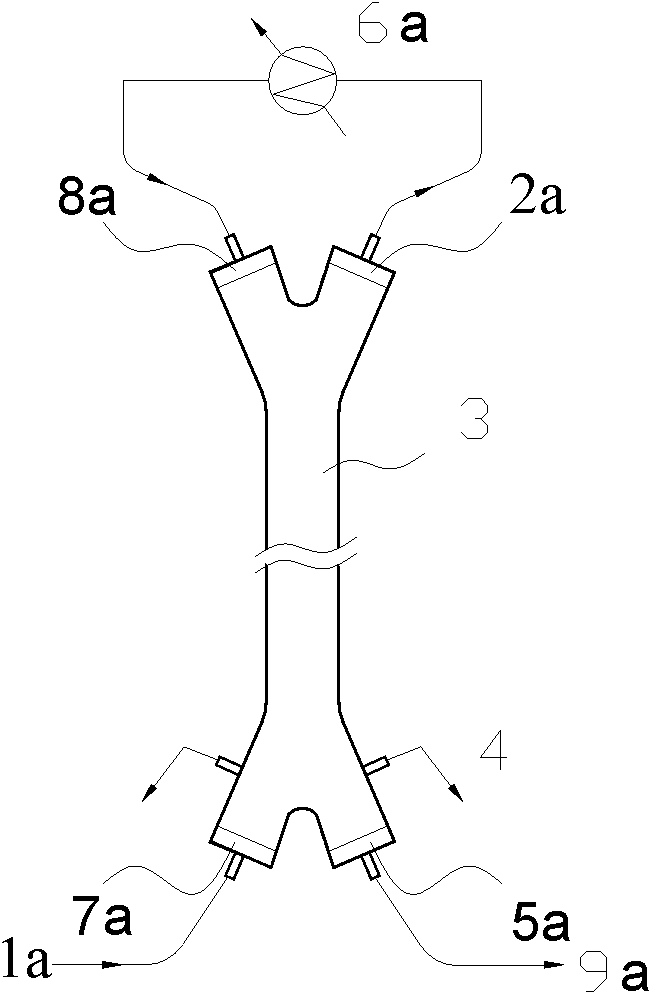

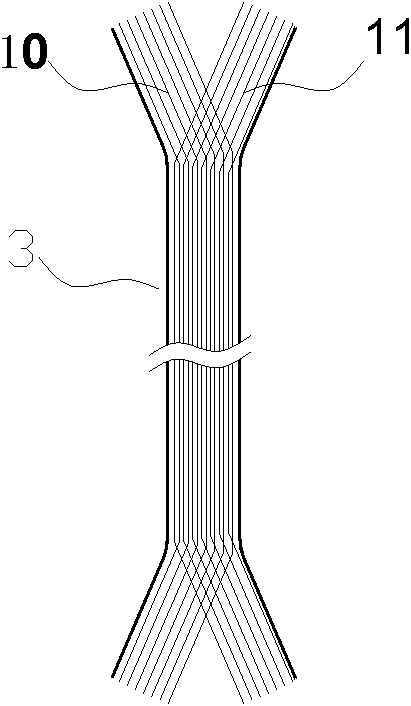

Multi-effect membrane distillation device with efficient internal heat reclamation function and method

ActiveCN102085454AExcellent heat transferExcellent mass transfer effectGeneral water supply conservationEnergy based wastewater treatmentSulfolaneFiber

The invention relates to a multi-effect membrane distillation device with efficient internal heat reclamation function and a method. The middle part of a membrane shell is provided with a cavity, two ends of the membrane shell are provided with an inlet and an outlet respectively, hollow fibrous membranes and hollow fiber pipes arranged uniformly are arranged in the cavity of the membrane shell, joints at two ends of the hollow fibrous membranes and the hollow fiber pipes are connected with the inlet and the outlet respectively, the lower end of the membrane shell is provided with a distillate outlet, and an external heat exchanger is connected in series between the inlet and the outlet of the water return end of a membrane assembly. The device has compact structure, simple and mild operating condition, low energy consumption and high water making rate, and can be used for small-scale dispersed implementation and integrated application; the method can be used in the fields of sea water desalinization, bitter water desalinization, concentration treatment of aqueous solution of nonvolatile or semi-volatile solutes, environmental protection and the like; and particularly when the method is used for concentration of aqueous solution of nonvolatile and semi-volatile solutes such as sodium chloride, ammonium sulfate, ammonium nitrate, sodium nitrate, sodium carbonate, sodium hydroxide, sulfuric acid, hydrochloric acid, glucose, xylitol, urea, glycerol, ethylene glycol, lactic acid, glyoxylic acid, dimethyl sulfoxide, sulfolane and the like, normal pressure steam or hot water is used as a heat source, and the highest water making rate can reach 13.7.

Owner:天津凯铂能膜工程技术有限公司

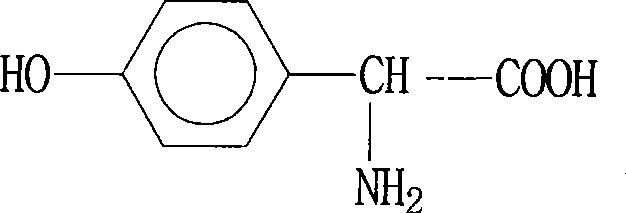

P-hydroxybenzene glycine synthesis technology

InactiveCN101362703AOrganic compound preparationAmino-carboxyl compound preparationSulfite saltHydroxylamine Hydrochloride

The invention belongs to the field of pharmaceutical chemical engineering intermediate production, which relates to a synthesis technology of p-hydroxyphenylglycine (HPG). The purpose of the invention is achieved by the following steps: phenol, glyoxylic acid, water and sulfamic acid carry out the one-pot braise reaction under the action of catalysts such as benzene sulfonic acid, p-toluenesulfonic acid, o-toluenesulfonic acid, and the like; after the reaction is finished, a small amount of reducing substances such as sodium sulfite, sodium bisulfite, hydroxylamine hydrochloride, and the like, are added; finally, the PH value is adjusted by alkali, the mother liquor separation is washed by large amount of water and then washed by organic solvents such as methanol, ethanol, acetone, glacial acetic acid, and the like; the obtained product HPG is white powder, wherein, the content of NPLC is equal to or more than 98.5, which can meet the requirement of splitting. The method has the advantages of low production cost, simple operation, stable quality, etc.

Owner:谢建中

Post-dry etching cleaning liquid composition and process for fabricating semiconductor device

InactiveUS20060019201A1Avoid corrosionReduce the burden onInorganic/elemental detergent compounding agentsSemiconductor/solid-state device detailsDevice materialAmmonium oxalate

A post-dry etching cleaning liquid composition for cleaning a substrate after dry etching is provided, the cleaning liquid composition containing at least one type of fluorine compound, glyoxylic acid, at least one type of organic acid salt, and water. With regard to the fluorine compound, ammonium fluoride may be used. With regard to the organic acid salt, at least one of ammonium oxalate, ammonium tartarate, ammonium citrate, and ammonium acetate may be used.

Owner:SONY CORP +2

Cationic flocculant based on collagen modification and preparation method thereof

ActiveCN102328979AStrong complexing abilityIncrease the amount of complexationWater/sewage treatment by flocculation/precipitationGlyoxylic acidGallic acid ester

The invention relates to a cationic flocculant based on collagen modification and a preparation method thereof. The cationic flocculant is prepared through the following steps of: 1) taking trypsin as hydrolytic agent to hydrolyze industrial gelatine to obtain collagen solution; 2) using glyoxylic acid or gallic acid to modify the obtained collagen solution aiming at increasing the content of carboxyl groups or phenolic hydroxyl groups on collagen molecules to obtain modified collagen solution; and 3) conducting complexation to the obtained modified collagen solution and ferric sulfate or aluminum sulfate according to mass ratio being 1:2 to 1:4 to obtain the cationic flocculant based on the collagen modification. The cationic flocculant can be used for treating waste drilling fluid and solves the problems that the preparation cost of the existing flocculant is high, the synthesized or degraded products are highly toxic and carcinogenic and serious environmental pollution is caused during the current treatment of the waste drilling liquid.

Owner:SHAANXI UNIV OF SCI & TECH

Process for preparing piperonal

A process for preparing piperonal, characterized by comprising the three successive steps: (A) the addition step of reacting 1,2-methylenedioxybenzene with glyoxylic acid in the presence of a strong acid to form 3,4-methylenedioxymandelic acid, (B) the extraction step of adding an organic solvent to the reaction fluid and then neutralizing the resulting fluid with a base to thereby extract 3,4-methylenedioxymandelic acid into the organic solvent and separate the fluid into an organic solvent layer and an aqueous layer, and (C) the oxidation step of removing the aqueous layer, concentrating the organic solvent layer, adding nitric acid to the concentrate, and then making the 3,4-methylenedioxymandelic acid react with the nitric acid to form piperonal.

Owner:UBE IND LTD

Method for converting 2-hydroxyl-3-methoxy-5-aldehyde mandelic acid into vanillin

InactiveCN101712605AAchieve emission standardsOrganic compound preparationWater/sewage treatment by ion-exchangeGlyoxylic acidEconomic benefits

The invention relates to a method for converting 2-hydroxyl-3-methoxy-5-aldehyde mandelic acid into vanillin, which sequentially comprises the steps of adsorbing by macroporous resin, oxidizing, acidizing, reoxidizing, reacidizing, and the like. The method integrates wastewater treatment and reactant recycling and realizes the wastewater treatment by the macroporous resin. Aromatic compounds in the wastewater are recycled by combining an oxidizing and acidizing process to produce a target product-vanillin. The invention realizes the standard discharge of the wastewater, realizes the recycling of the wastewater generated during producing the vanillin by a glyoxylic acid method, and improves economic benefits.

Owner:JIAXING ZHONGHUA CHEM

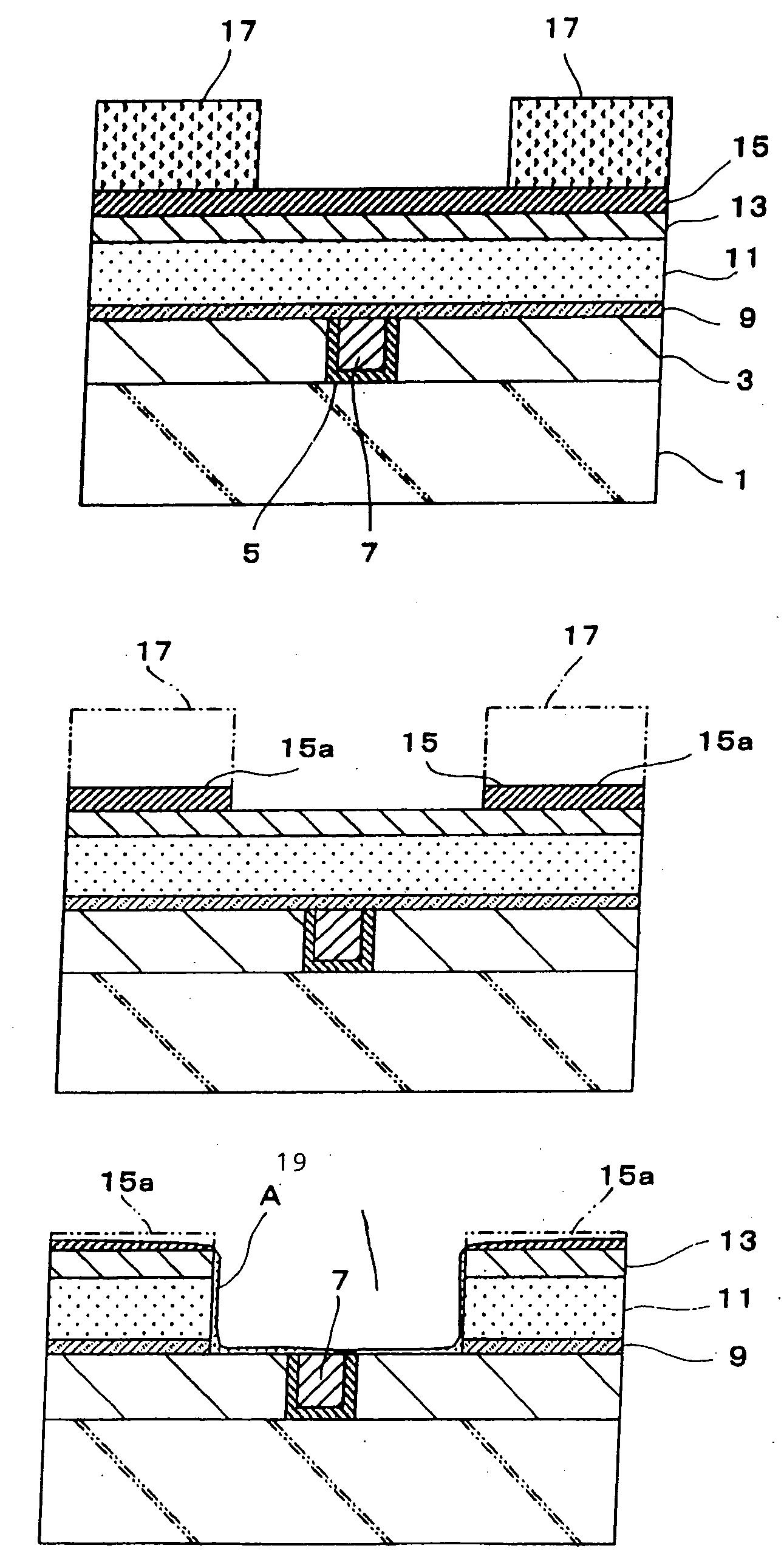

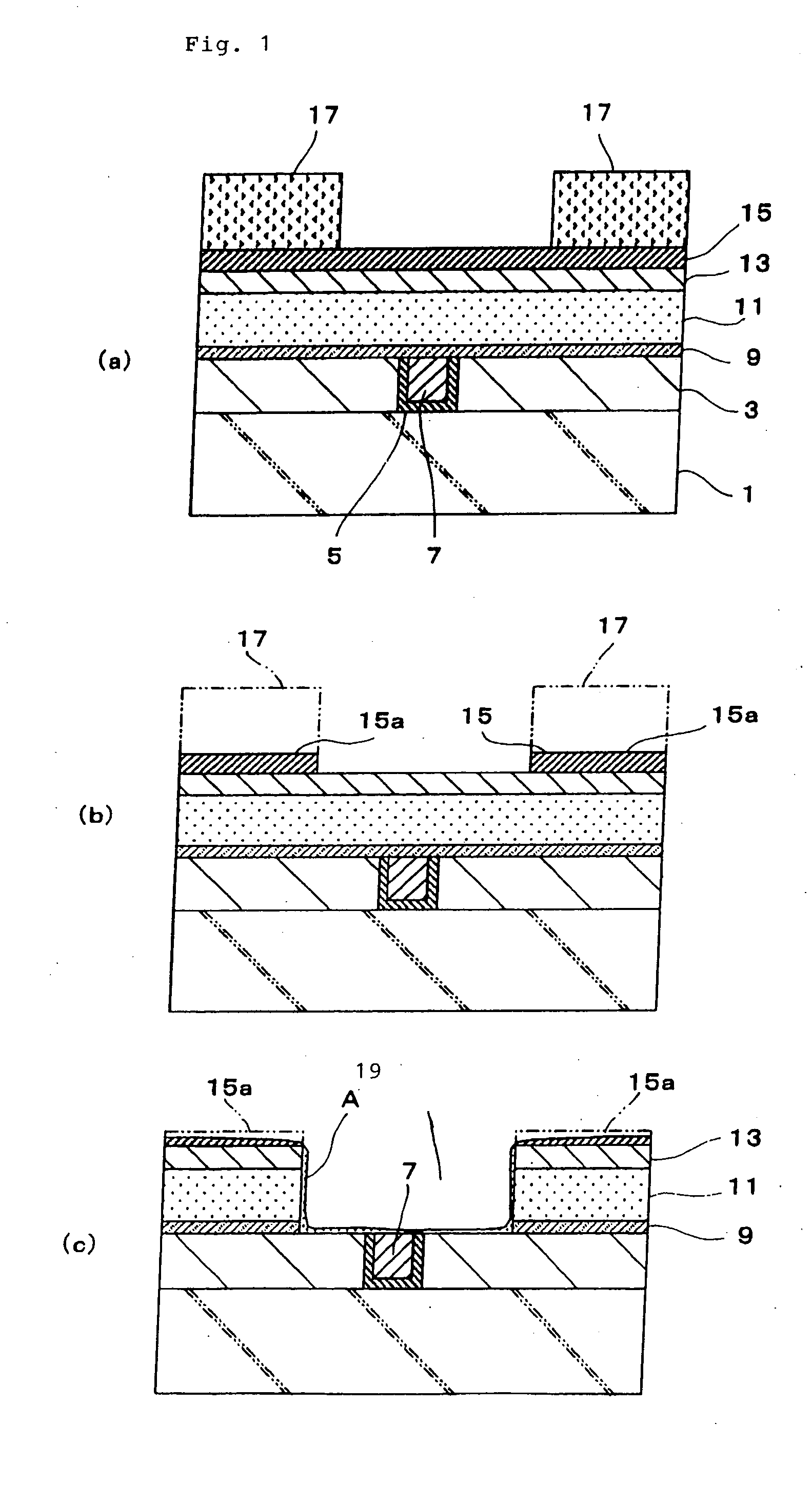

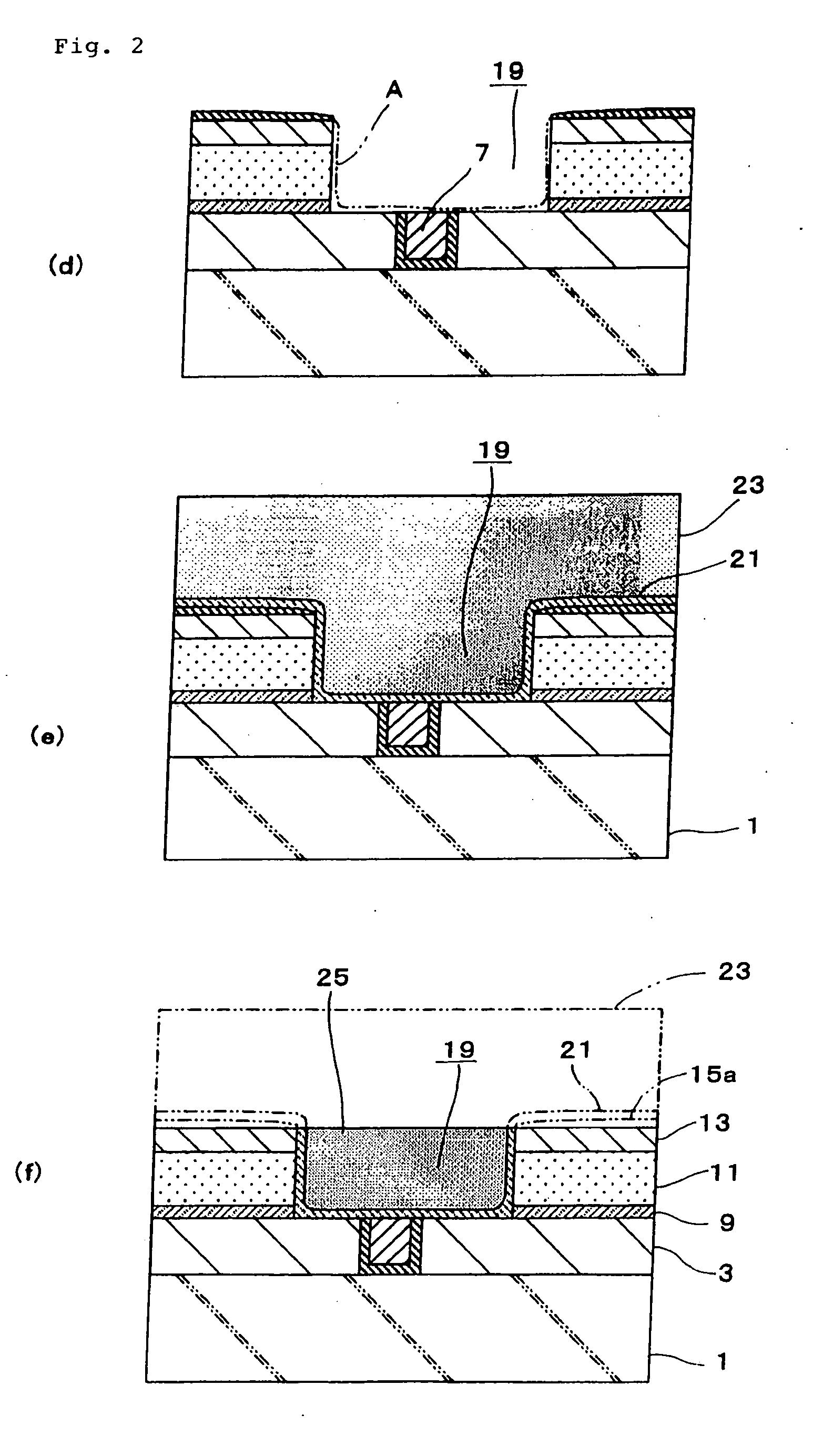

Methods to deposit metal alloy barrier layers

InactiveUS7223695B2Semiconductor/solid-state device detailsSolid-state devicesGlyoxylic acidCopper interconnect

Metal alloy barrier layers formed of a group VIII metal alloyed with boron (B) and / or phosphorous (P) and an at least one element from glyoxylic acid, such as carbon (C), hydrogen (H), or carbon and hydrogen (CH) formed by electoless plating are described. These barrier layers may be used as a barrier layer over copper bumps that are soldered to a tin-based solder in a die package. Such barrier layers may also be used as barrier layer liners within trenches in which copper interconnects or vias are formed and as capping layers over copper interconnects or vias to prevent the electromigration of copper.

Owner:INTEL CORP +1

Electroless copper plating solution and electroless copper plating method

InactiveUS20070071904A1Improve responseEfficient productionLiquid surface applicatorsSemiconductor/solid-state device manufacturingCopper platingThiourea

Owner:JX NIPPON MINING & METALS CO LTD

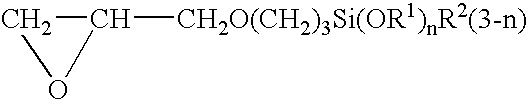

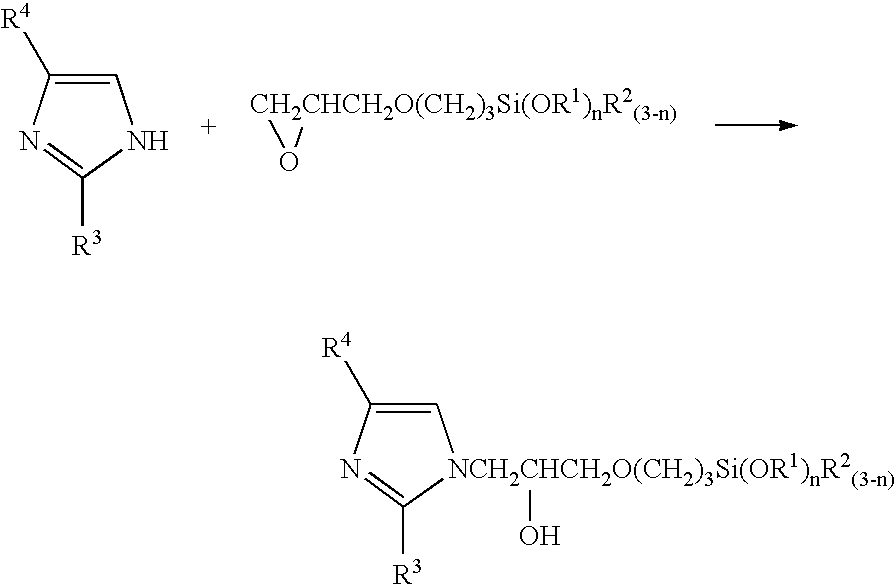

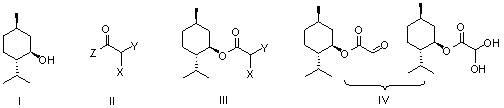

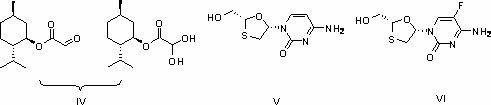

Preparation methods of glyoxylic acid L-menthyl alcohol ester and monohydrate of glyoxylic acid L-menthyl alcohol ester

ActiveCN102516078AEasy to operateMild reaction conditionsPreparation from carboxylic acid halidesFenchyl alcoholL menthol

The invention relates to preparation methods of glyoxylic acid L-menthyl alcohol ester and a monohydrate of the glyoxylic acid L-menthyl alcohol ester, and belongs to the technical field of fine chemical industry. The glyoxylic acid L-menthyl alcohol ester is prepared by the following steps: reacting L-menthol with monohalogen or dihalogen acetyl halide or anhydride to generate monohalogen or dihalogen acetic acid L-menthyl alcohol ester; and reacting in the presence of a pro-oxidant to obtain the glyoxylic acid L-menthyl alcohol ester. The monohydrate of the glyoxylic acid L-menthyl alcohol ester is prepared by the following steps: cooling and diluting a reaction solution using monohalogen acetic acid L-menthyl alcohol ester as a raw material; treating by using a dimethylsulfoxide (DMSO) solution of P2O5 and triethylamine to obtain the glyoxylic acid L-menthyl alcohol ester; washing, extracting and concentrating a reaction solution using dihalogen acetic acid L-menthyl alcohol ester as a raw material to obtain the glyoxylic acid L-menthyl alcohol ester; and treating by using sodium hydrogen sulfite and formaldehyde to obtain the monohydrate of the glyoxylic acid L-menthyl alcohol ester. The total yield of the glyoxylic acid L-menthyl alcohol ester synthesized by the technology can reach over 72 percent; the total yield of the monohydrate of the glyoxylic acid L-menthyl alcohol ester can reach over 80 percent; the purity can reach over 99.5 percent; the technical process is simple and convenient; the raw materials are available; the yield is high; the product purity is high; and the process is suitable for industrial production.

Owner:ZHEJIANG XIANFENG TECH +1

Chemical bronze plating liquid of mixing type non-formaldehyde reducer

ActiveCN1730724ANo pollution in the processGood deposition density (excellent backlight level)Liquid/solution decomposition chemical coatingHybrid typeMethyl aldehyde

The invention relates to a chemical bronze plating liquid of mixing type non-formaldehyde reducer for electronic printing circuit board, wherein the constituents include copper sulfate, EDTA, reducing agent and stabilizing agent, the reducing agent is prepared by mixing two non-formaldehyde reducing agents, which can be hypophosphites, glyoxylic acid and methyl aldehyde addition compound, any two of them can be combined. The advantages of the non-formaldehyde reducing agent include reduced environmental pollution, fast rate of deposition, high copper sedimentary deposit, and good copper deposition compactness.

Owner:GUANGDONG GUANGHUA SCI TECH +1

Catalyst used in catalytic oxidation of glyoxal for preparing glyoxylic acid and preparation method of catalyst

InactiveCN102553628ALow priceHigh selectivityMolecular sieve catalystsOrganic compound preparationOxalateGlyoxylic acid

The invention provides a catalyst used in catalytic oxidation of glyoxal for preparing glyoxylic acid. The catalyst is V2O5 / SBA-15, wherein SBA-15 is used as a carrier to load V2O5. According to the preparation method, the SBA-15 is used as the carrier, oxalic acid solution of ammonium metavanadate is used as impregnation precursor, and the catalyst is prepared by using an equivalent-volume impregnation method. Compared with the noble metal catalyst, the V2O5 / SBA-15 provided by the invention is low in price, the glyoxylic acid can be obtained from the glyoxal under the action of the V2O5 / SBA-15 catalyst without maintaining a certain pH value of a reaction system; only a small amount of oxalic acid is detected from a product; and the catalyst has high glyoxylic acid selectivity and less byproducts.

Owner:TAIYUAN INST OF TECH

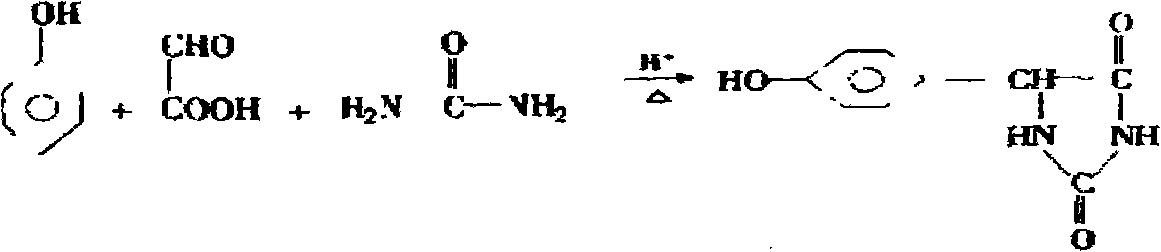

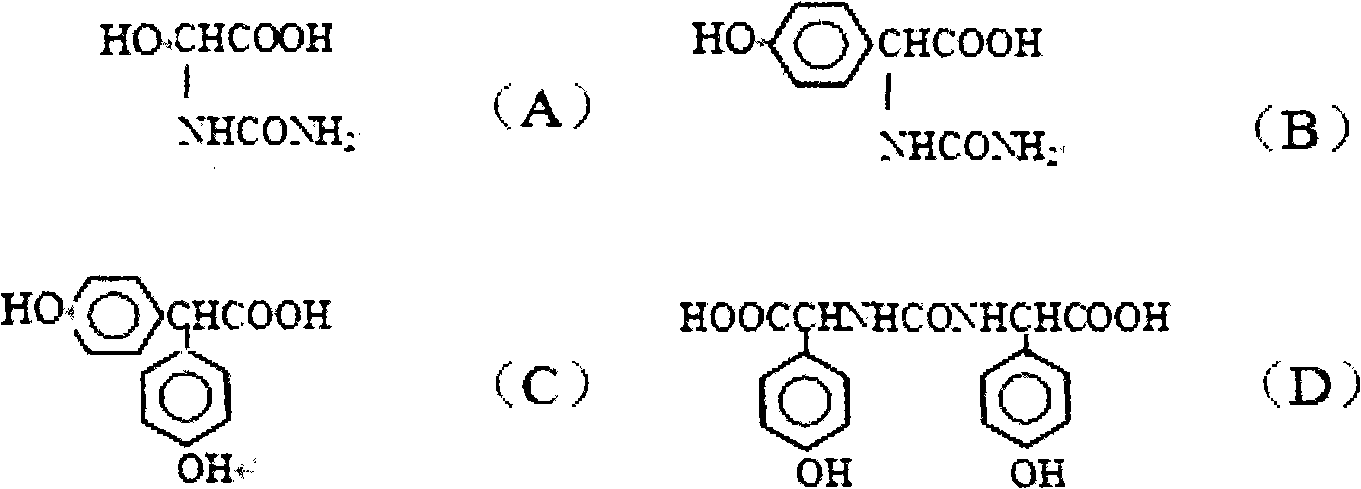

Method for preparing 4-hydroxyphenyl hydantoin

InactiveCN101973941AQuality improvementHigh synthetic yieldOrganic compound preparationAmino-carboxyl compound preparationPhenylacetic acidPhenol

The invention discloses a method for preparing 4-hydroxyphenyl hydantoin from a glyoxylic acid, phenol and urea by condensation under acid condition, which is characterized in that: the 4-hydroxyphenyl hydantoin is prepared in the presence of a sulfamic acid, the production of polymerization impurities is inhibited and simultaneously a phenylglycine byproduct is produced. The mol ratio of the reaction raw materials of the glyoxylic acid to the phenol to the urea to the sulfamic acid is 1:1.0-1.1:1-1.5:0.2-0.5. The method comprises the following steps of: adding dropwise glyoxylic acid solution at the relatively lower temperature of 50 to 60 DEG C to form a 2-ureidobenzeneacetic acid intermediate, preparing the 4-hydroxyphenyl hydantoin at the relatively higher temperature of 80 or 105 DEG C by ring formation and simultaneously producing the p-hydroxyphenylglycine byproduct, wherein reaction solution is subjected to post-treatment to obtain white 4-hydroxyphenyl hydantoin crystals with the purity of 99.6 percent and the yield of 62.7 percent; and mother solution is further treated to obtain white p-hydroxyphenylglycine crystals with the purity of 99.2 percent ad the yield of 10.1 percent. In the method, the main byproduct is p-hydroxyphenylglycine, the utilization rate of the synthesis raw materials is increased and the problems of unstable quality of product and high treatment cost of the mother solution in the prior art are solved.

Owner:TIANJIN VOCATIONAL INST

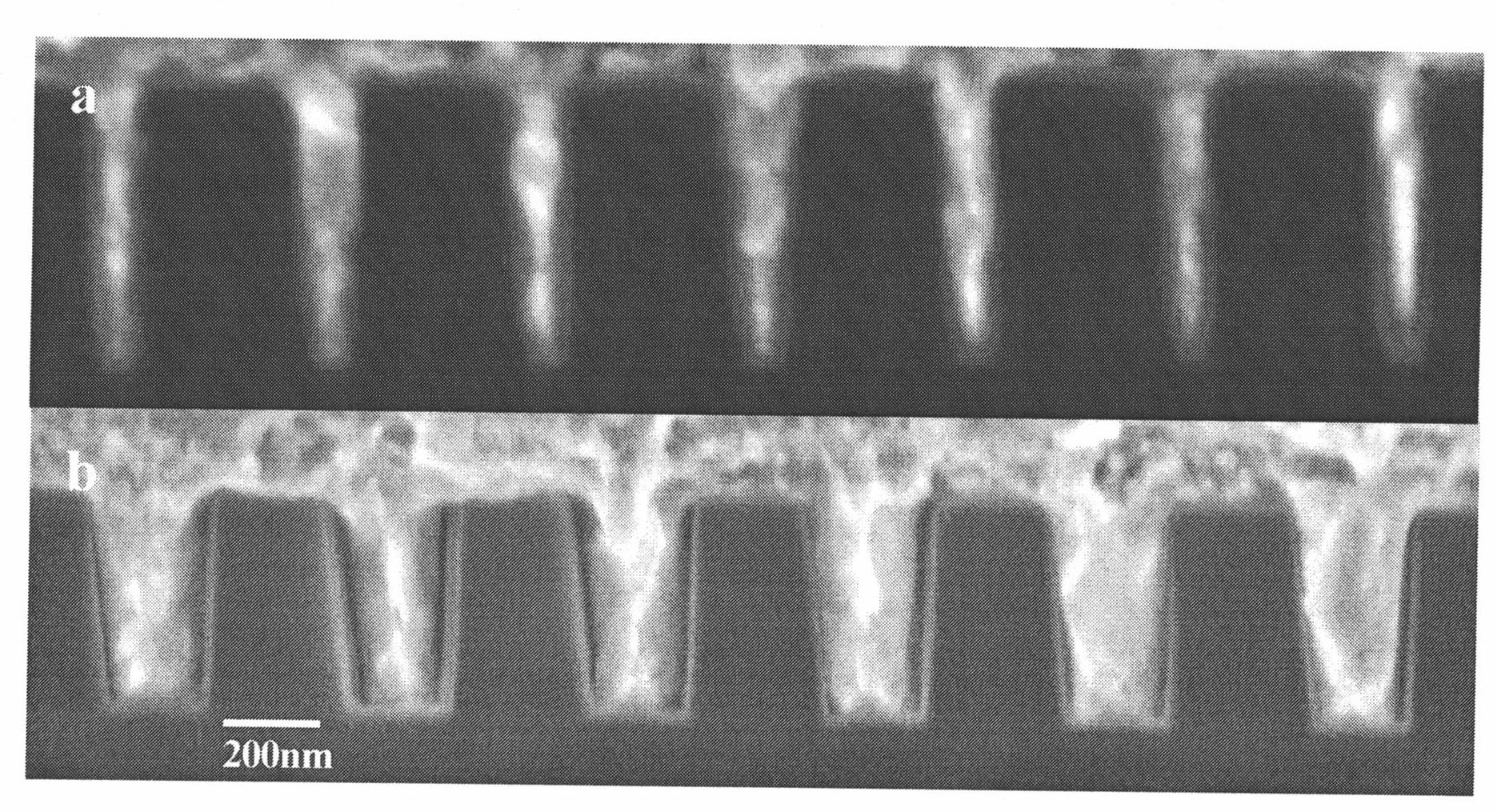

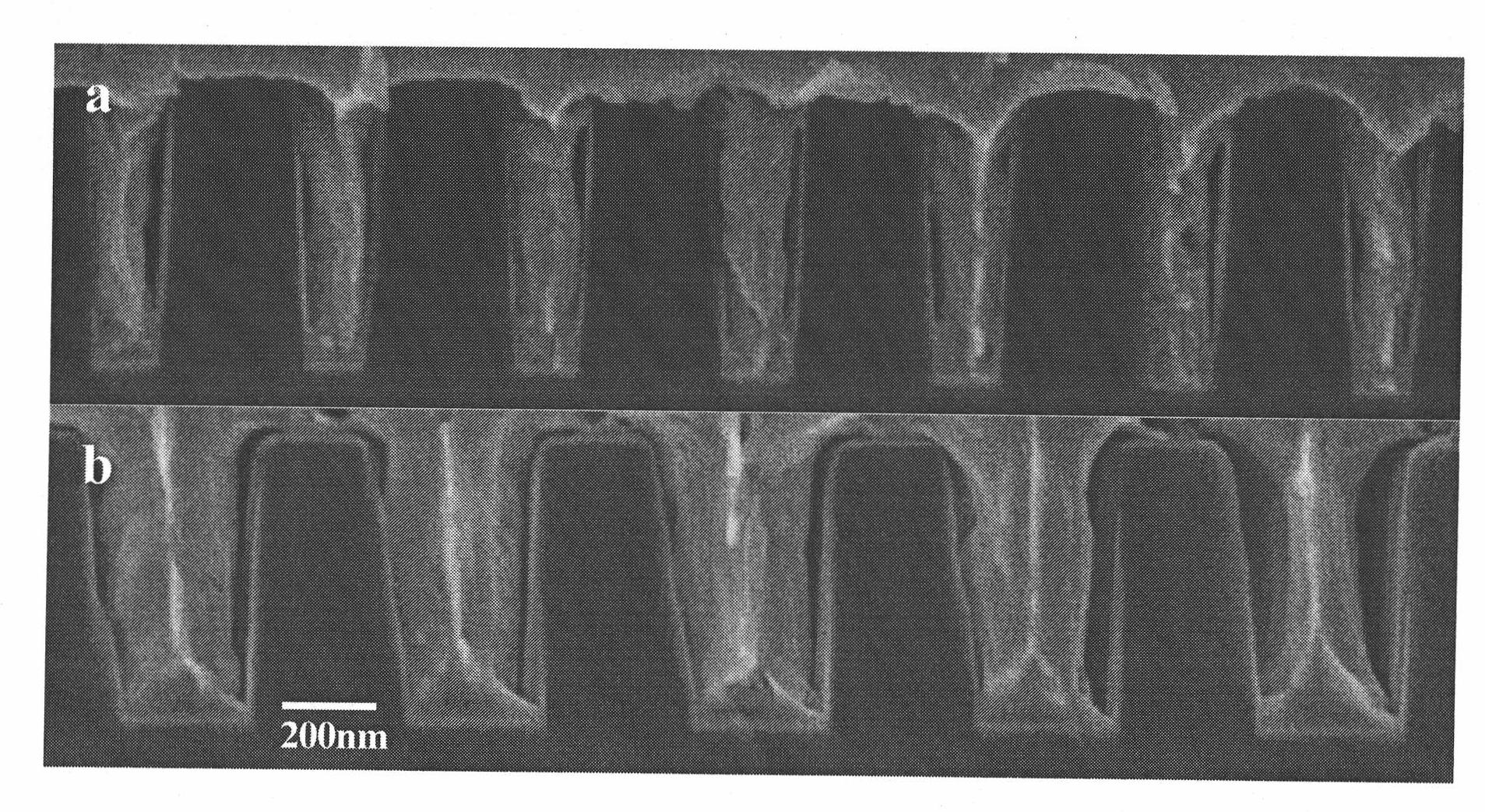

Electroless Copper Plating Solutions for Microvia Filling

InactiveCN102277567ANo holesSeamlessSemiconductor/solid-state device manufacturingLiquid/solution decomposition chemical coatingBenzoxazoleCopper plating

A chemical copper plating solution for micropore filling. 1 L of the chemical copper plating solution comprises 5-20 g of copper sulfate pentahydrate, 10-50 g of disodium ethylene diamine tetraacetate, 1.0-1.5 g of formaldehyde or glyoxylic acid, 0.001-0.02 g of mercapto heterocyclic compounds, 0.02-0.04 g of polyether with an average molecular weight of 3650, 1.5-3.5 g of NaOH, and the balance of distilled water; the mercapto heterocyclic compounds are 2-mercapto benzimidazole, 2- mercapto benzoxazole, 1-phenyl-5-mercapto-tetrazole or 2-mercapto benzothiazole. By simultaneously adding mercapto heterocyclic compounds and polyether with an average molecular weight of 3650 into the chemical copper plating solution, the invention realizes no cavity, no gap of micropores, and perfect chemicalcopper filling; the chemical copper plating solution is stable; and the deposited copper film has good quality.

Owner:SHAANXI NORMAL UNIV

Electroless copper plating solution and method for electroless copper plating

InactiveCN1867697APrevent excessive deposition reactionsUniform platingSemiconductor/solid-state device manufacturingLiquid/solution decomposition chemical coatingCopper platingThiourea

An electroless copper plating solution characterized by using hypophosphorous acid or a hypophosphite salt as a second reducing agent together with a first reducing agent, and simultaneously using a stabilizer for inhibiting copper deposition. The first reducing agent includes formalin and glyoxylic acid, and the hypophosphite includes sodium hypophosphite, potassium hypophosphite, and ammonium hypophosphite. Stabilizers that inhibit copper deposition include 2,2'-bipyridine, imidazole, nicotinic acid, thiourea, 2-mercaptobenzothiazole, sodium cyanide, or thioglycolic acid. When electroless copper is plated on mirror surfaces (such as semiconductor wafers, etc.) where plating reactions are difficult to occur, the electroless copper plating solution can realize uniform plating at a reduced temperature.

Owner:JX NIPPON MINING & METALS CORP

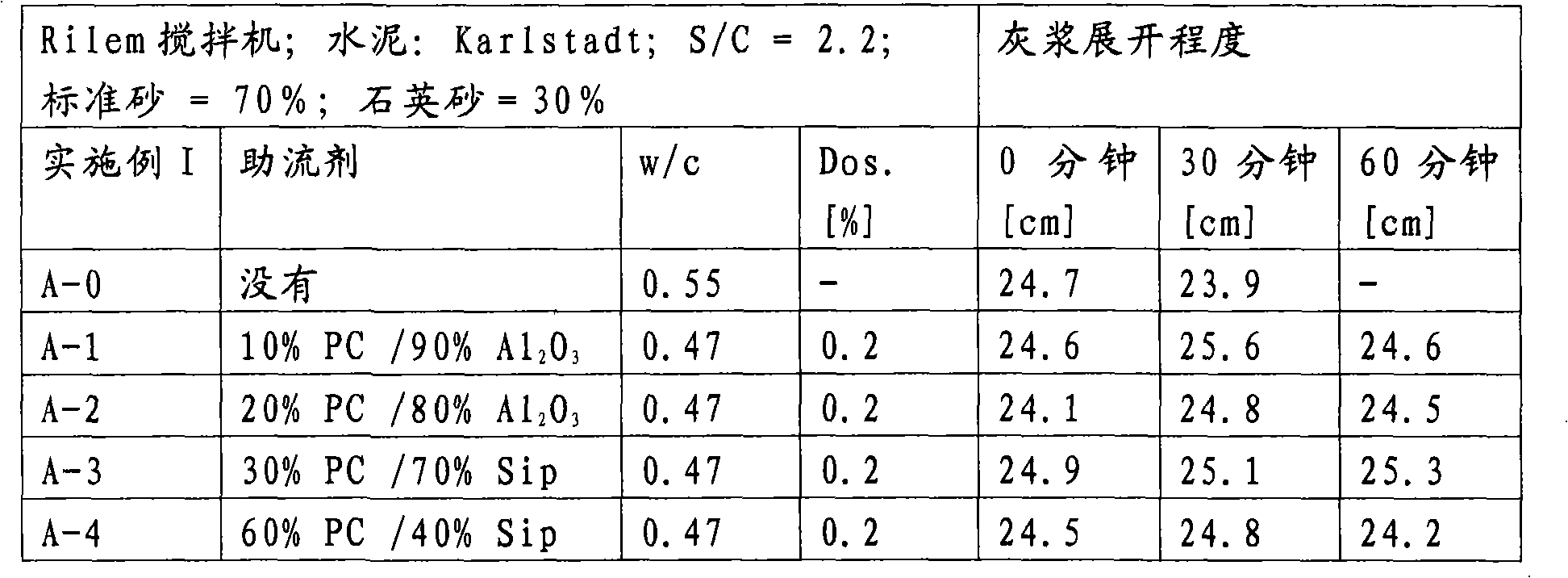

Pulverulent polycondensation products

Pulverulent polycondensation products are described, comprising a) from 5 to 95% by weight of a polycondensation product based on an aromatic or heteroaromatic compound (A) having from 5 to 10 carbon atoms or heteroatoms having at least one oxyethylene or oxypropylene radical and an aldehyde (C) selected from the group of formaldehyde, glyoxylic acid and benzaldehyde or mixtures thereof, and b) from 5 to 95% by weight of a finely divided mineral support material having a specific surface area of from 0.5 to 500 m<2> / g (according to BET to DIN 66 131). The inventive pulverulent polycondensation products are outstandingly suitable in building material mixtures in an amount of from 0.1 to 5% by weight, based on the weight of the building material.; The pulverulent polycondensation products have a number of advantages in this context, for example excellent storage stability, good liquefying action at low dosage and technically simple production.

Owner:CONSTR RES & TECH GMBH

Method for achieving chemical nickel plating by activating surface of PCB

InactiveCN104862677AStrong reductionQuick restoreLiquid/solution decomposition chemical coatingSodium acetateVitamin C

The invention discloses a method for achieving chemical nickel plating by activating the surface of a PCB and belongs to the field of printed circuit board manufacturing. The method comprises the following steps that 1, 0.01-10 g / L soluble silver salt is prepared to serve as a silver soaking solution; 2, activating liquor is prepared from 1-100 g / L pH stabilizer and 10-50 g / L reducing agent, wherein the pH stabilizer is one or more of sodium hydroxide, potassium hydroxide, ammonia water, sodium acetate and the like, and the reducing agent is one or more of formaldehyde, acetaldehyde, glyoxylic acid, methyl alcohol, vitamin C, citric acid and the like; 3, pretreatment of the PCB is conducted; 4, the PCB is soaked in the silver soaking solution for 10-120 seconds after pretreatment, washed and then soaked in the activating liquor for 10-80 seconds; and 5, the PCB obtained in the step 4 is placed in chemical nickel-plating liquor for chemical nickel-plating. According to the method for achieving chemical nickel plating by activating the surface of the PCB, no precious metal palladium is used during activating; the stability of the activating liquor is high; diffusion coating is avoided; and the production cost of the PCB is effectively reduced.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Method for synthesizing vanillin by using glyoxylic acid and guaiacol together

InactiveCN102040495ASimple production processLess investmentMolecular sieve catalystsOrganic compound preparationPtru catalystEthyl group

The invention discloses a method for synthesizing (ethyl) vanillin by using condensation, oxidation and decarboxylation reactions of glyoxylic acid and (ethyl) guaiacol. The method is characterized in that: a Y-shaped molecular sieve is used for loading copper, manganese and cobalt mixed oxide catalysts, and the condensation reaction and the oxidation reaction are simultaneously performed in a reactor. A molar ratio of the glyoxylic acid and the (ethyl) guaiacol serving as raw materials to sodium hydroxide is 1:(1.0-1.2):(2-4); the pH of solution is more than 12 by controlling the dropping speed of alkali solution; and the temperature in the reaction process is controlled to be between 40 and 80 DEG C when the raw materials are dropped, and the temperature in the reaction process is controlled to be between 80 and 100 DEG C after the raw materials are added. The acid concentration of 3-alkoxy-4-hydroxy phenethyl alcohol is below 4 percent all the time during the oxidation reaction. White (ethyl) vanillin crystals are obtained by performing acidification decarboxylation, extraction separation, and vacuum distillation refining on a reaction completing fluid with 50 percent of sulfuric acid, and the yield is 86.3 percent. By the method, an (ethyl) vanillin synthesis process is simplified, the equipment production capacity is improved, and polymerization by-products are restrained, and auxiliary raw material consumption and waste liquid are reduced.

Owner:TIANJIN VOCATIONAL INST

Acidic solution for treating surface of magnesium alloy and processing method

InactiveCN100588743CFully activatedHigh activityMetallic material coating processesGlutaric acidGluconic acid

The invention relates to acid solution used for processing the magnesium alloy surface. The acid solution is water solution which contains acids, inhibitor and wetting agent, wherein, the acids are first acids or mixture of first acids and second acids; the first acids are selected from one type or a plurality of types among citric acids, oxalic acids, tartaric acids, methanoic acids, acetic acids, metacetonic acids, butyric acids, glutaric acids, phenylformic acids, benzene dicarboxylic acids, lactic acids, glycolic acids, glyoxylic acids and amino acids; and the second acids are hydrochloricacids and / or nitric acids. By adoption of the acid solution, the magnesium alloy surface can be fully activated; the membranous layer of a converting film which is formed on the magnesium alloy surface after chemical conversion process is compact, has erosion resistance and good binding force with a paint film. Moreover, the method is a environment-friendly method for processing the magnesium alloy surface.

Owner:BYD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com