Patents

Literature

233results about How to "No holes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

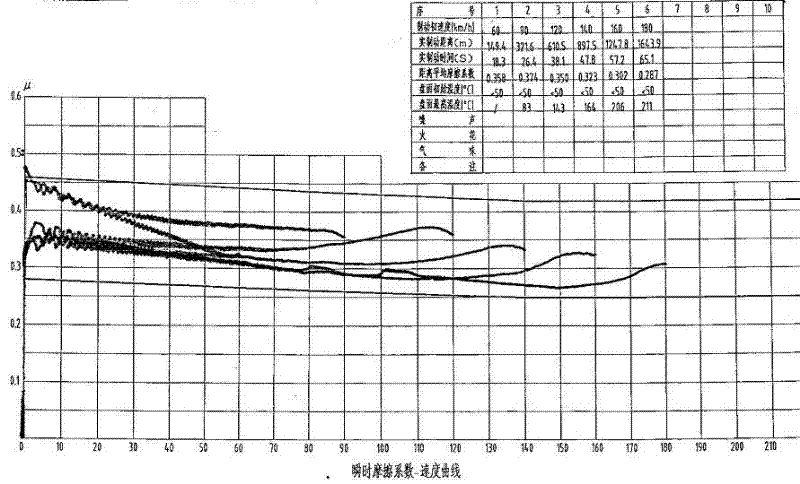

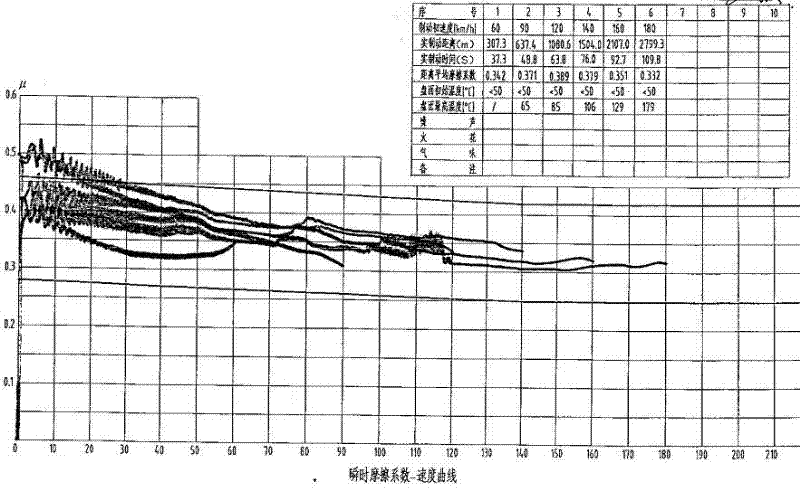

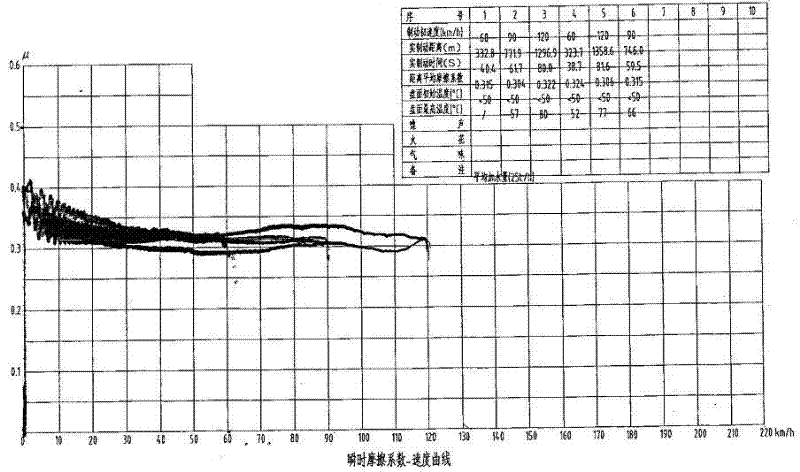

Hybrid fiber reinforced friction material for train braking and preparation method thereof

InactiveCN102191015AImprove toughnessImprove yieldOther chemical processesFriction liningFreight trainsAdhesive

The invention belongs to the technical field of materials, and particularly relates to a hybrid fiber reinforced friction material for train braking and a preparation method thereof. In the invention, a composite modified phenolic resin is used as an adhesive, and hybrid fibers, including carbon fiber, metal fiber, inorganic mineral fiber and the like, are used as the reinforcing fibers. Compared with the prior art, the invention improves the contour machining property of the organic synthetic brake, and the yield of the material is high; the brake has stable frictional property at different braking speeds, does not has obvious degradation of frictional property at high speed, and does not have the phenomena of shedding and cracking on the working surface after the braking test. The friction material provided by the invention can be widely used for manufacturing brake pads, brakes, brake shoes and the like in braking systems of passenger and freight trains, municipal rail transportation, subways and the like.

Owner:FUDAN UNIV

Copper plating solution for PCB (printed circuit board) blind holes, as well as preparation method and plating method of copper plating solution

InactiveCN103572336AReduce internal stressHigh filling ratePrinted element electric connection formationCopper platingPrinted circuit board

The invention relates to the technical field of PCB (printed circuit board) plating, in particular to a copper plating solution for PCB blind holes, as well as a preparation method and a plating method of the copper plating solution. Each liter of the copper plating solution comprises the following components according to contents: 100-300g of copper sulfate pentahydrate, 50-200g of sulfuric acid, 30-100ppm of chlorine ions, 5-50g of brightener, 3-30g of carrier, 2-20g of leveling agent and the balance of deionized water, wherein the concentration ratio of the copper sulfate pentahydrate to the sulfuric acid is (1.5-2): 1. The plating method comprises the following steps: putting a PCB with blind holes into a plating bath with the copper plating solution; plating during air agitation to obtain a copper plating layer. The copper plating layer formed by the plating method has a hole-filling rate as high as 97% above, and is dense, smooth, voidless, seamless, low in surface sediment thickness, relatively good in malleability, good in gloss, high in toughness and low in internal stress.

Owner:东莞市富默克化工有限公司

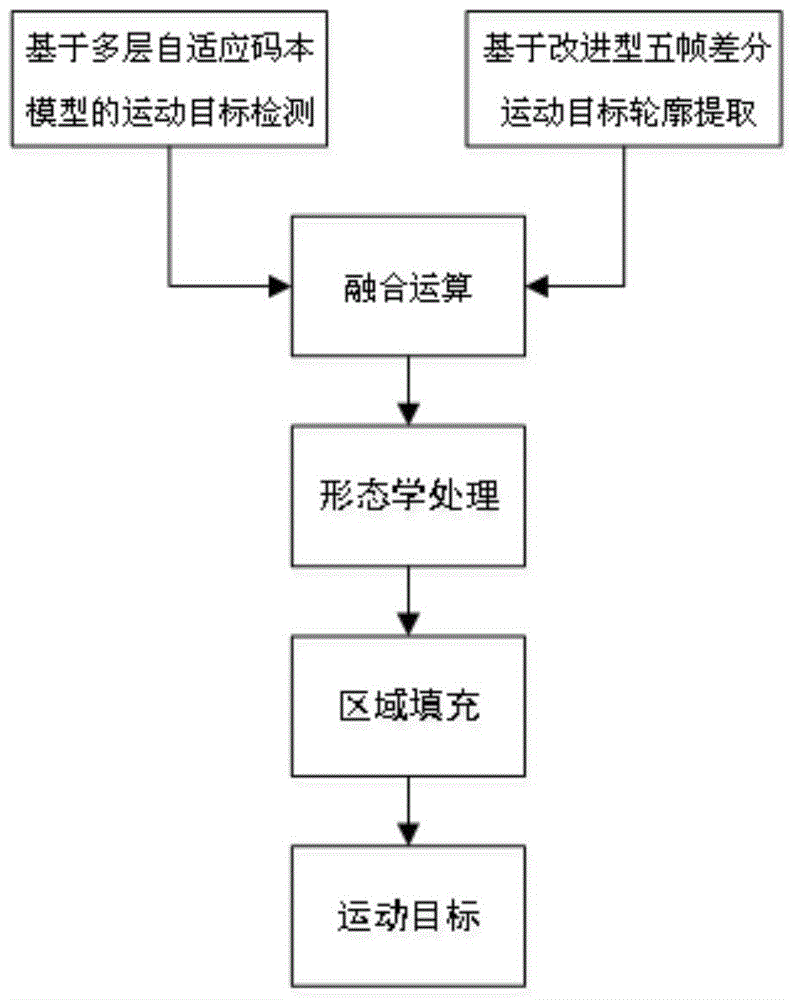

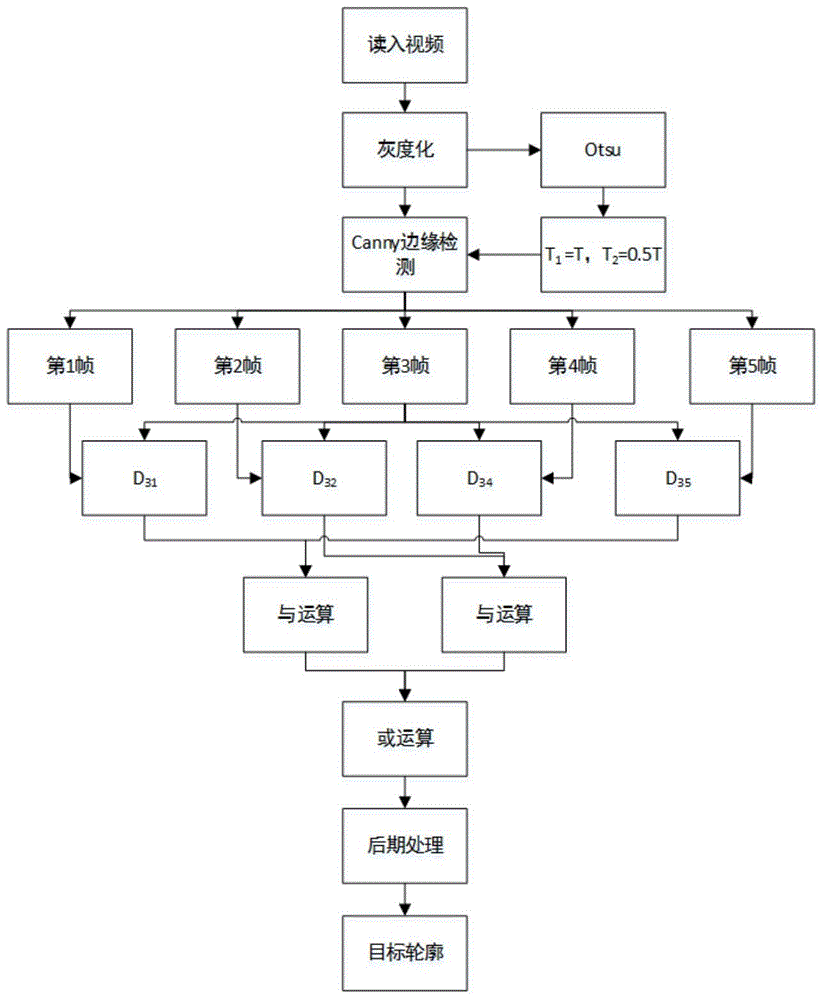

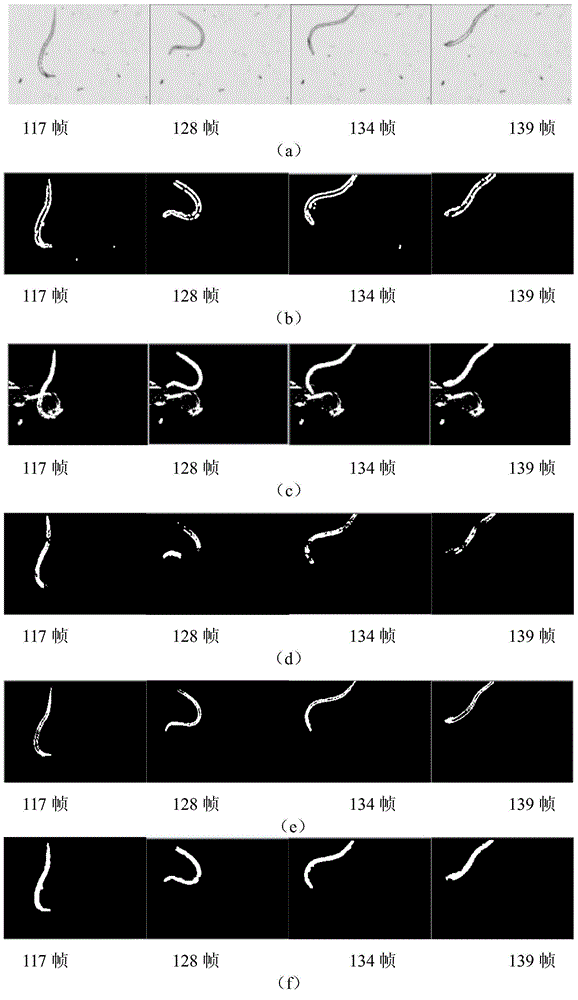

Automatic image detection method for moving microorganisms in sewage

ActiveCN104992447AImprove the accuracy and efficiency of automatic detectionExact numberImage enhancementImage analysisSelf adaptiveSewage

The invention discloses an automatic image detection method for motive microorganisms sewage, and belongs to the technical field of image processing. The method of the invention comprises steps of: step 1. capturing a video image of motion microorganisms in sewage ; step 2. creating a multi-layer adaptive codebook model, and performing moving target detection on the captured image according to the codebook model; step 3. performing target contour extraction on the captured image by using an improved five-frame differential algorithm; step 4. merging or calculating a moving target detection result obtained in step 2 and a moving target contour obtained in step 3; and step 5. performing morphological processing and area filling on an obtained image, so as to obtain a moving target detection result. According to the method of the invention, adaptive complex background modeling and a background updating mechanism are designed, background convergence is accelerated, and in combination with the complete and continuous target contour border extracted by using the improved five-frame differential algorithm, sewage microorganism automatic detection accuracy and efficiency are improved, and the experiment results also prove the effectiveness and real-time property of the method.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Resin sand type casting coating and preparation method thereof

InactiveCN102836952AGood suspensionHigh strengthFoundry mouldsFoundry coresSodium BentoniteFatty alcohol

The invention relates to a resin sand type casting coating and a preparation method thereof, wherein the coating consists of the following components: graphite powder, zircon sand, porzite powder, spodumene powder, sodium bentonite, alkali phenolic resin, silica sol, polyvinyl acetate, carboxymethylcellulose sodium, sodium alkylbenzenesulfonate, fatty alcohol-polyoxyethylene ether and water. The resin sand type casting coating provided by the invention has the advantages of good suspension property, high strength, uniform coating layer and good leveling property. The surface of the dried coating is bright and clean and is free of cavities, bubbles, cracks and the like. After the resin sand type casting coating is used, the cast casting is very high in surface smoothness.

Owner:TAICANG KEBOER PRECISION CASTING

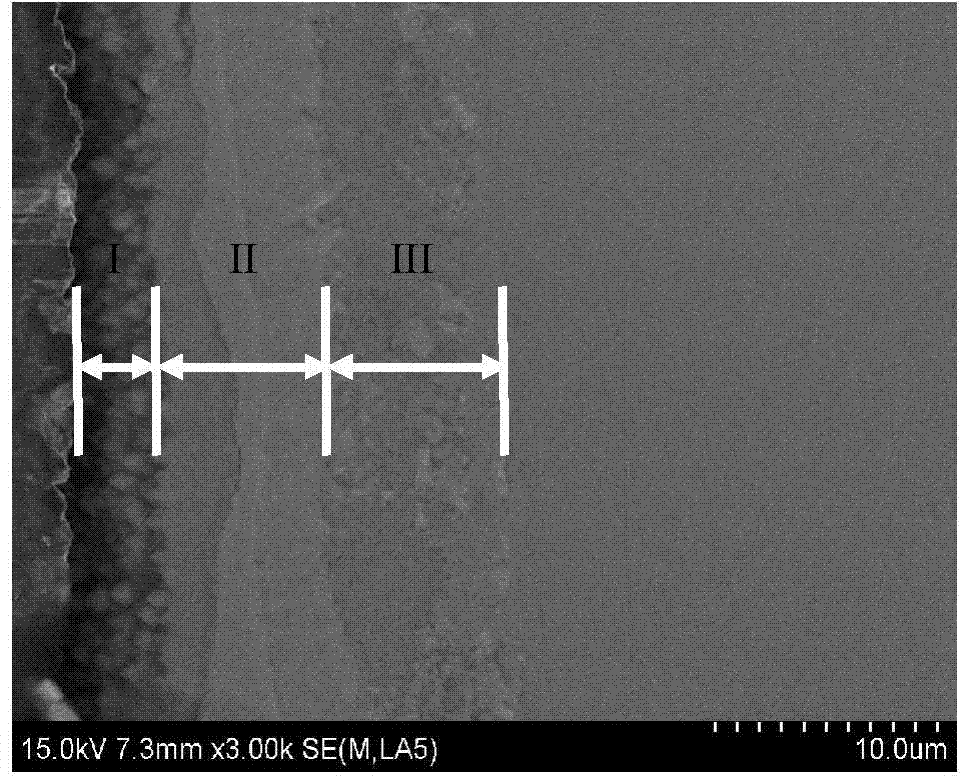

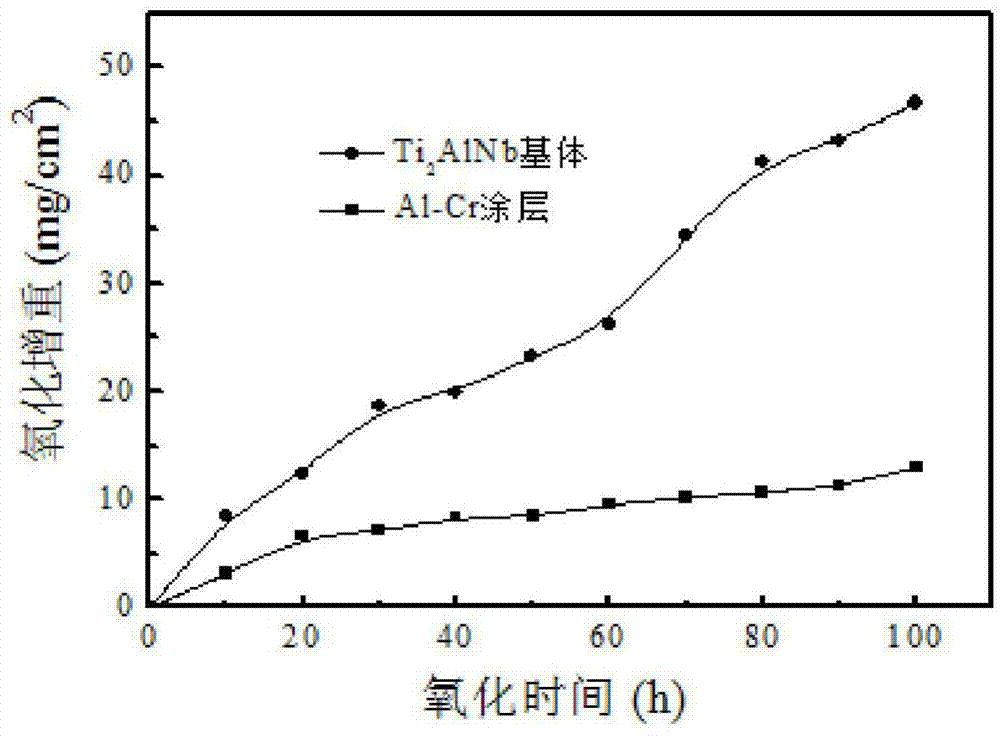

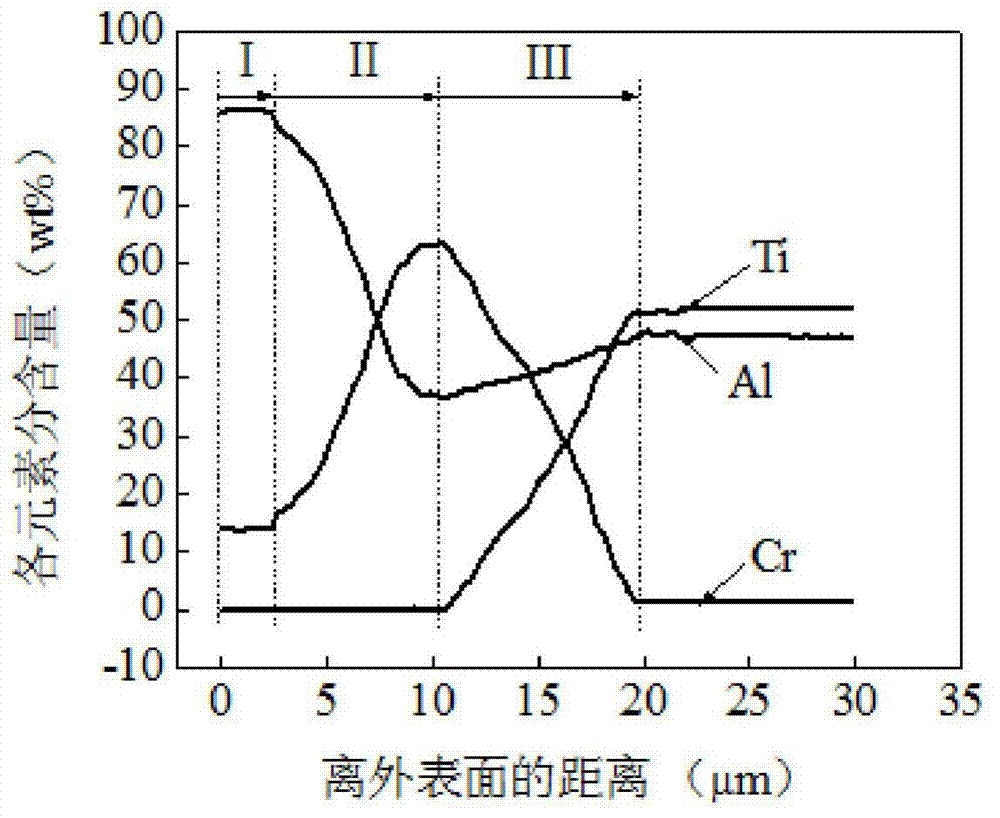

Titanium aluminum alloy surface high temperature oxidation and hot corrosion resistant Al-Cr coating and preparation method thereof

InactiveCN104760349AImprove high temperature oxidation resistanceAccelerated corrosionVacuum evaporation coatingSputtering coatingOxidation resistantThermal shock

The present invention discloses a titanium aluminum alloy surface high temperature oxidation and hot corrosion resistant Al-Cr coating; an Al-rich deposition layer, an Al-Cr alloy layer and a Cr diffusion layer are successively arranged from surface to a titanium aluminum alloy substrate. The content of Al in the Al-rich deposition layer remains the same. The content of Al in the Al-Cr alloy layer gradually reduces outside-to-inside to 70%-100% of the content of Al in the titanium aluminum alloy substrate, and the rest in the Al-Cr alloy layer is Cr. The contents of Cr and Al in the Cr diffusion layer respectively gradually reduces outside-to-inside to same as the contents of Cr and Al in the titanium aluminum alloy substrate, and the rest in the Cr diffusion layer is other elements in the titanium aluminum alloy substrate, and the contents of other elements in the Cr diffusion layer respectively gradually rise to same as the contents of the other elements in the titanium aluminum alloy substrate from zero. The invention also discloses a preparation method of the titanium aluminum alloy surface high temperature oxidation and hot corrosion resistant Al-Cr coating; the titanium aluminum alloy surface high temperature oxidation and hot corrosion resistant Al-Cr coating can give titanium aluminum alloy excellent oxidation resistance and heat resistance corrosion performance under high temperature and long term service conditions, and due to the presence of the diffusion layer of the gradient components, the reliable binding strength and excellent thermal shock resistance can be realized.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

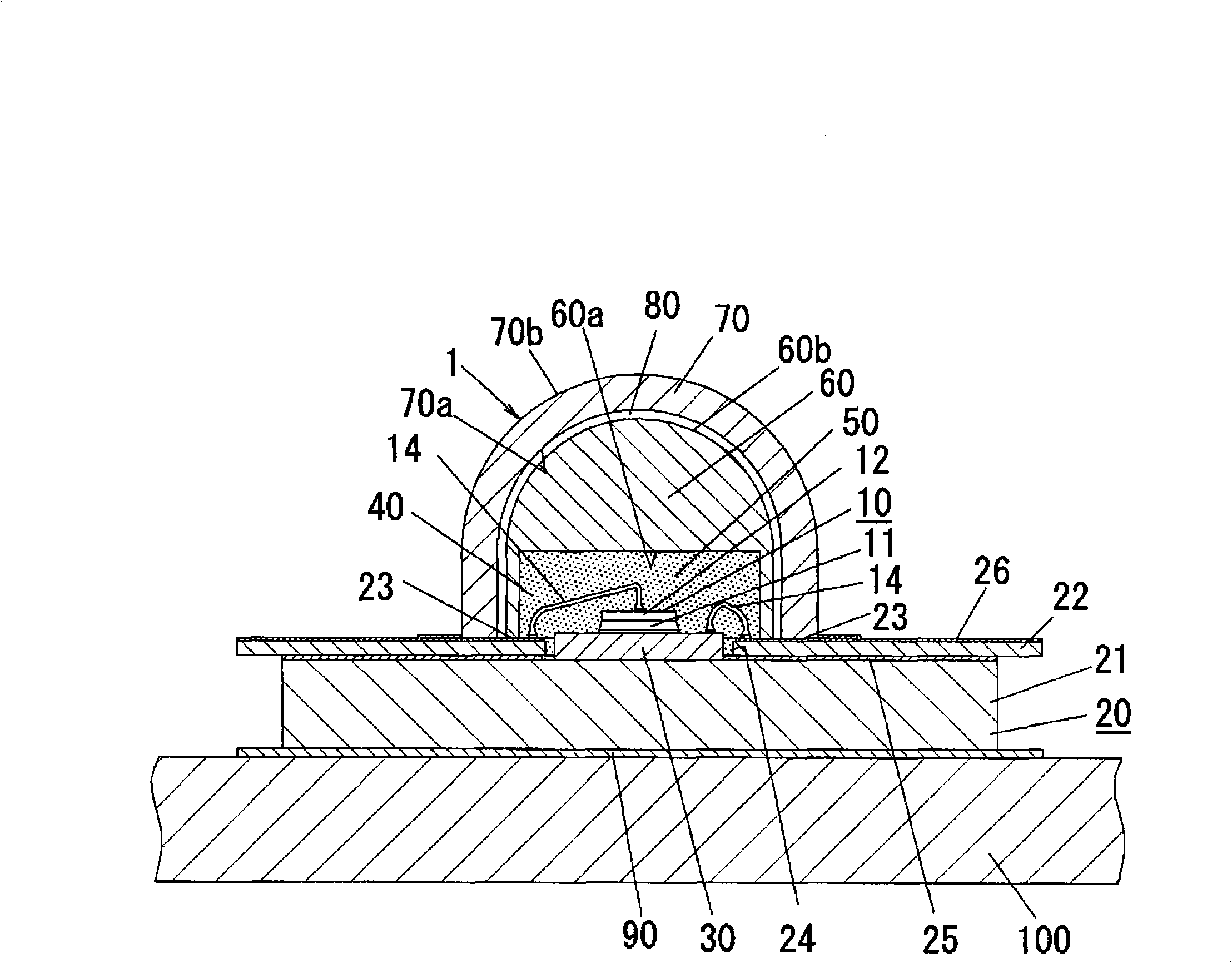

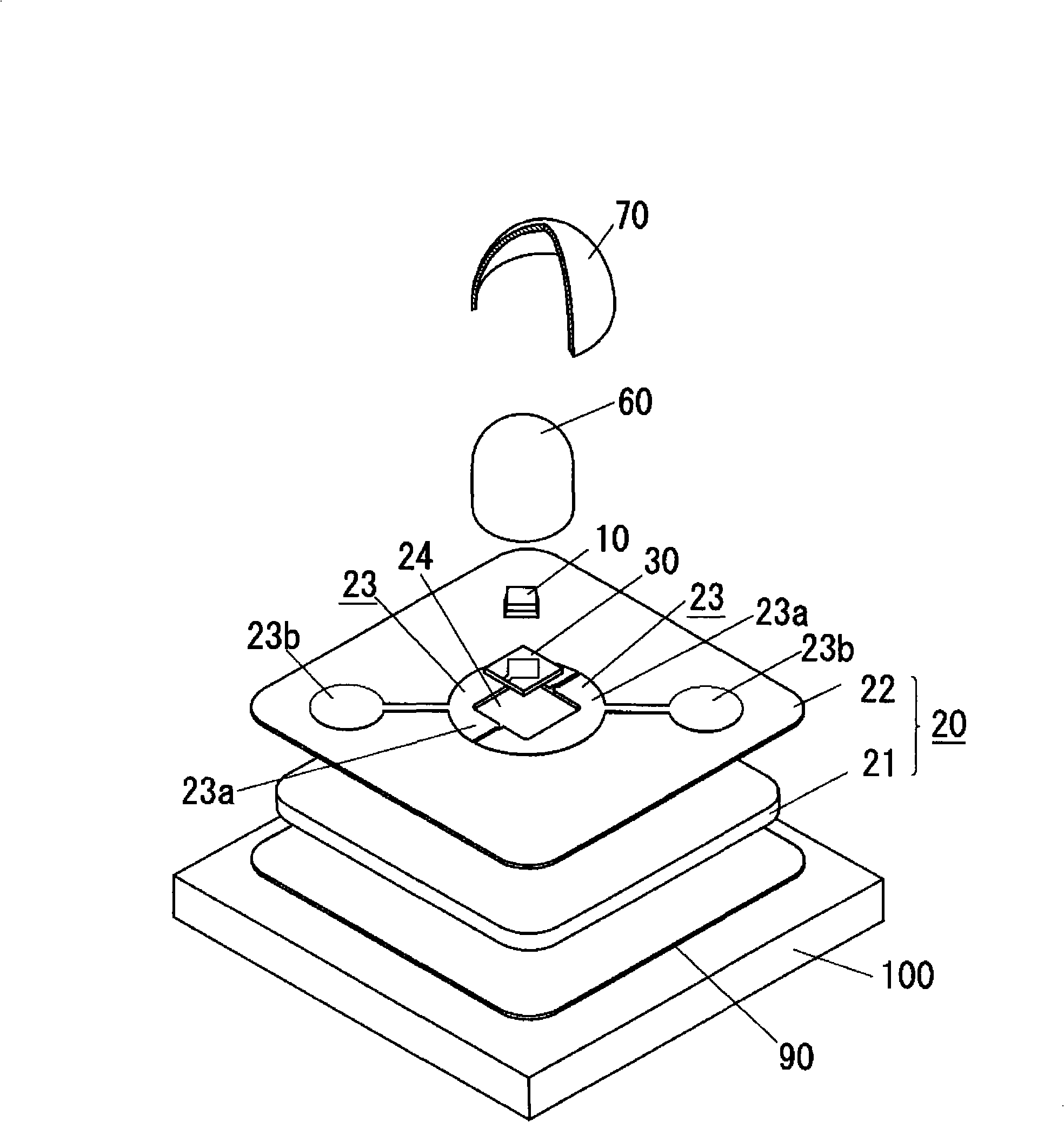

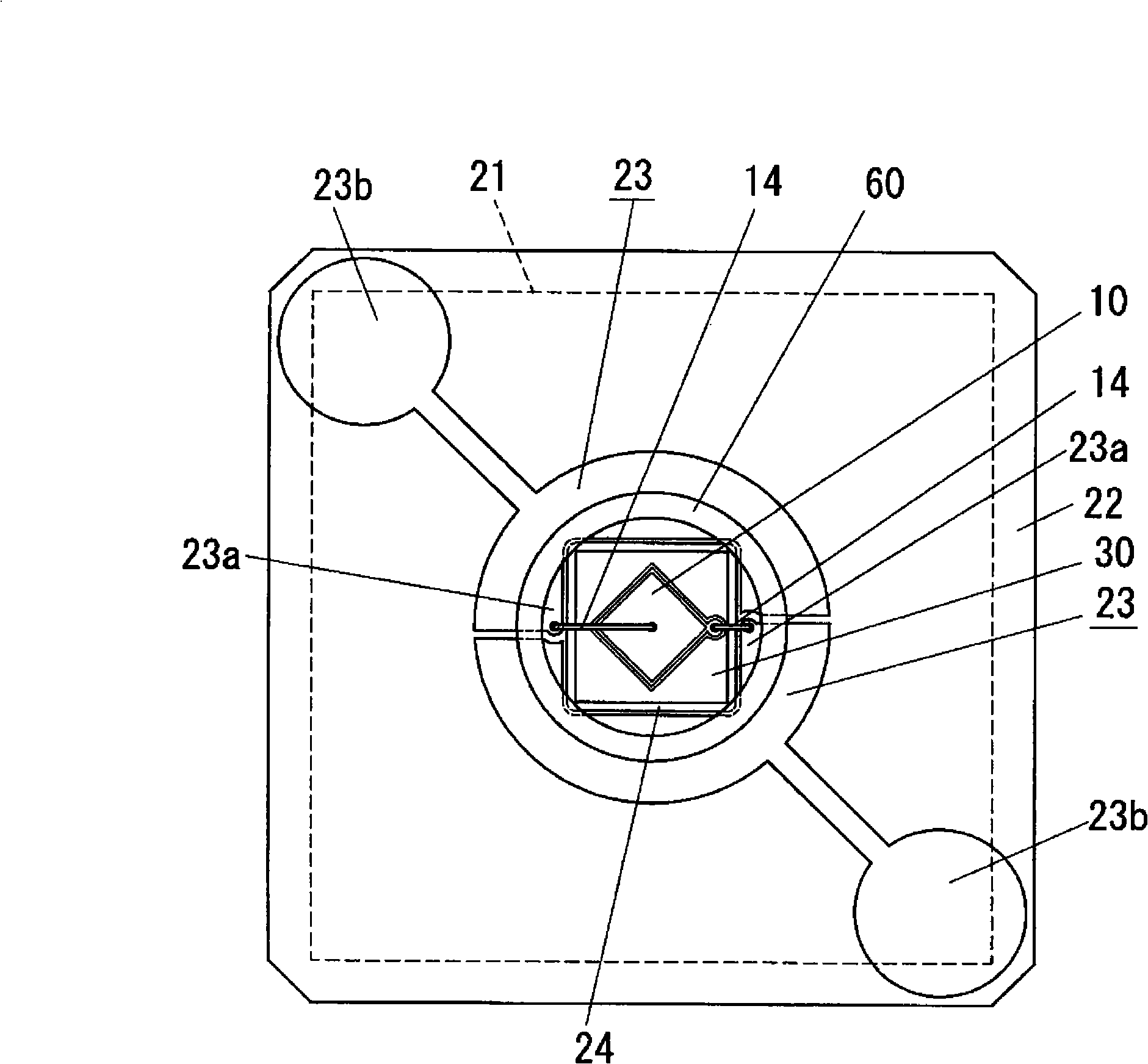

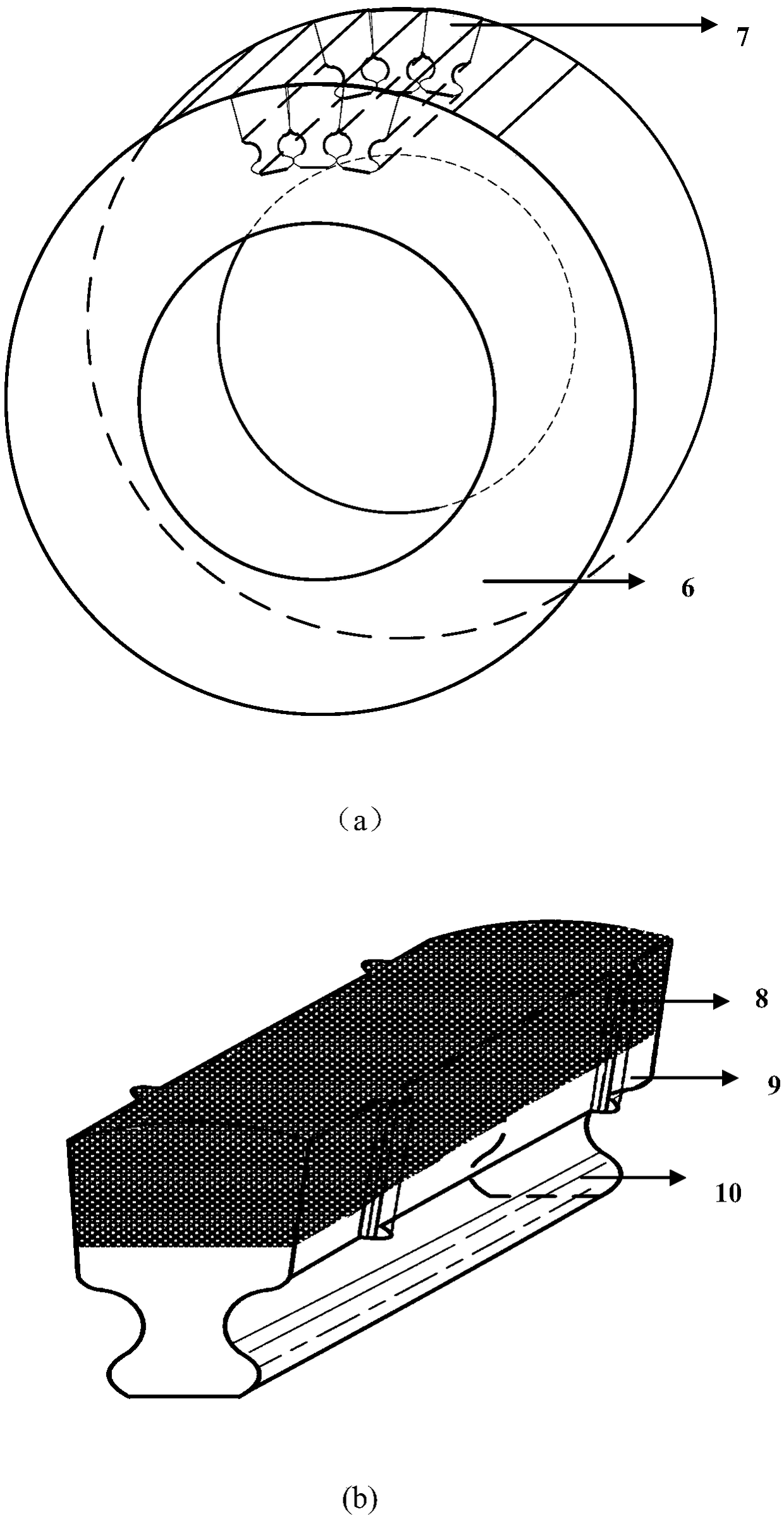

Light-emitting device

InactiveCN101313415ANo holesSolid-state devicesSemiconductor devicesLight emitting deviceLinear expansion coefficient

Disclosed is a light-emitting device (1) comprising an LED chip (10), a mounting board (20) on which the LED chip is mounted, a sealing portion (50) which is composed of a sealing resin material for sealing the LED chip, and a lens (60) made of a transparent resin material. The lens (60) has a recessed portion (40) in the bottom and is fixed to the mounting board (20) in such a manner that the sealing portion (50) is housed in the recessed portion (40). Since the sealing portion is surrounded by the transparent resin lens, the linear expansion coefficient difference between the sealing portion and the surrounding area thereof can be reduced in this light-emitting device. Consequently, there can be suppressed generation of voids in the sealing portion at low temperatures.

Owner:MATSUSHITA DENKO KK

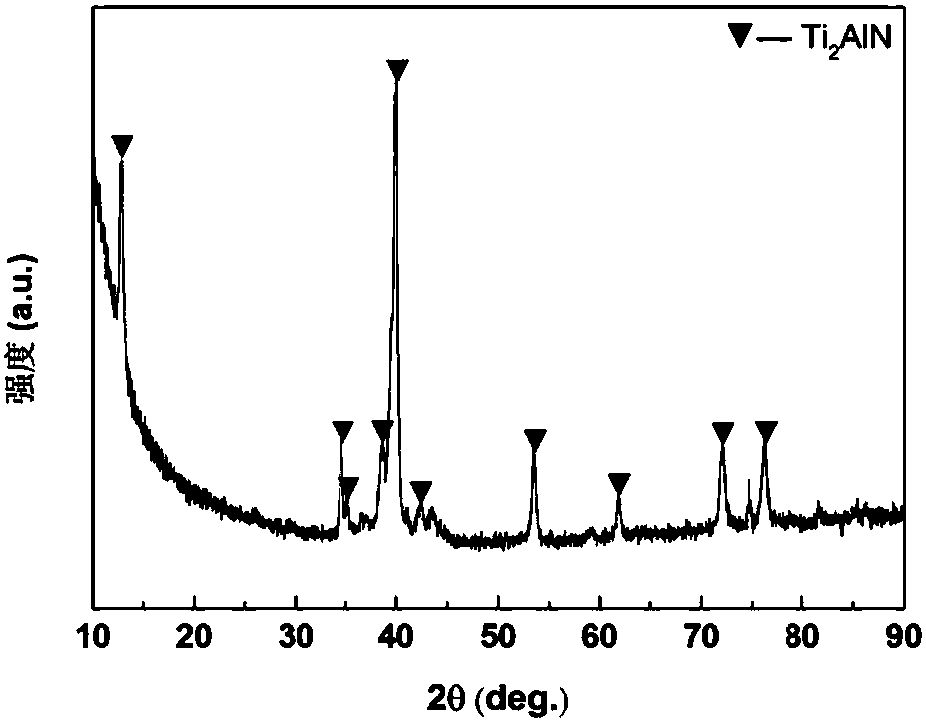

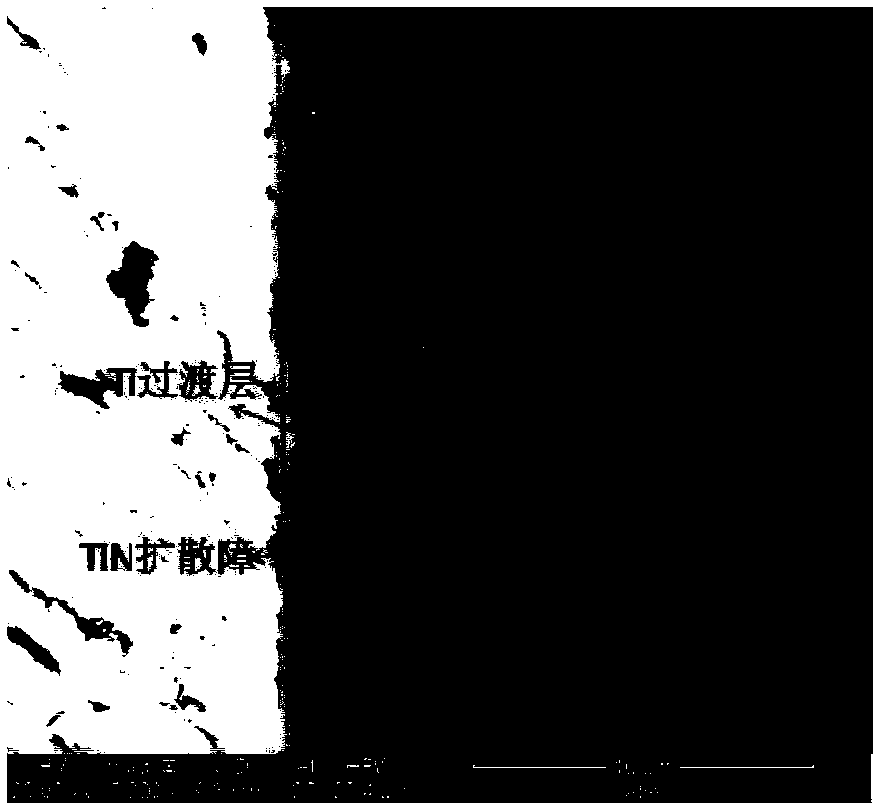

Preparation method for high-purity high-density MAX phase coating

ActiveCN107620033AEasy to controlEasy to homogenize large area depositionVacuum evaporation coatingSputtering coatingHigh densityNitrogen

The invention provides a preparation method for a high-purity high-density MAX phase coating. According to the method, an arc ion plating technology is combined with a magnetron sputtering technology,an M-position element is provided for the arc, an A-position Al element is provided for magnetron, nitrogen or hydrocarbon as reaction gas is introduced for deposition, then thermal treatment is adopted, and the high-purity high-density MAX phase coating is prepared. The prepared MAX phase coating is high in purity, good in compactness, free of a microdefect, high in preparation efficiency, low in cost and capable of overcoming the defects that large particles on the surface of a MAX phase coating prepared through a single arc method are excessive, the density is low, the efficiency is low bymeans of a magnetron sputtering method, and the defects are obvious and has the wide application prospects on the aspects of high-temperature protection, corrosion-resistant application and the like,and the industrial production of the MAX phase coating can be achieved easily.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

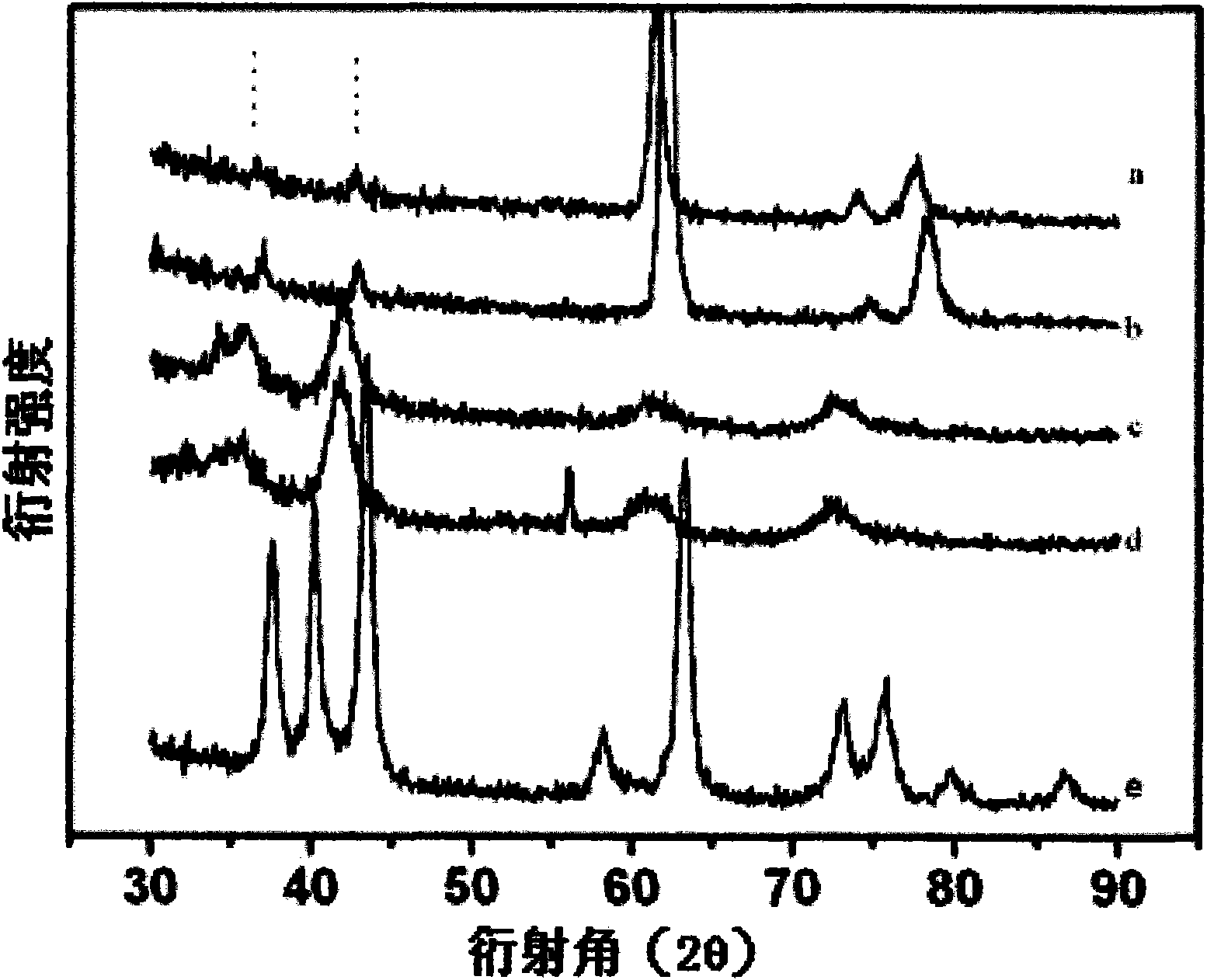

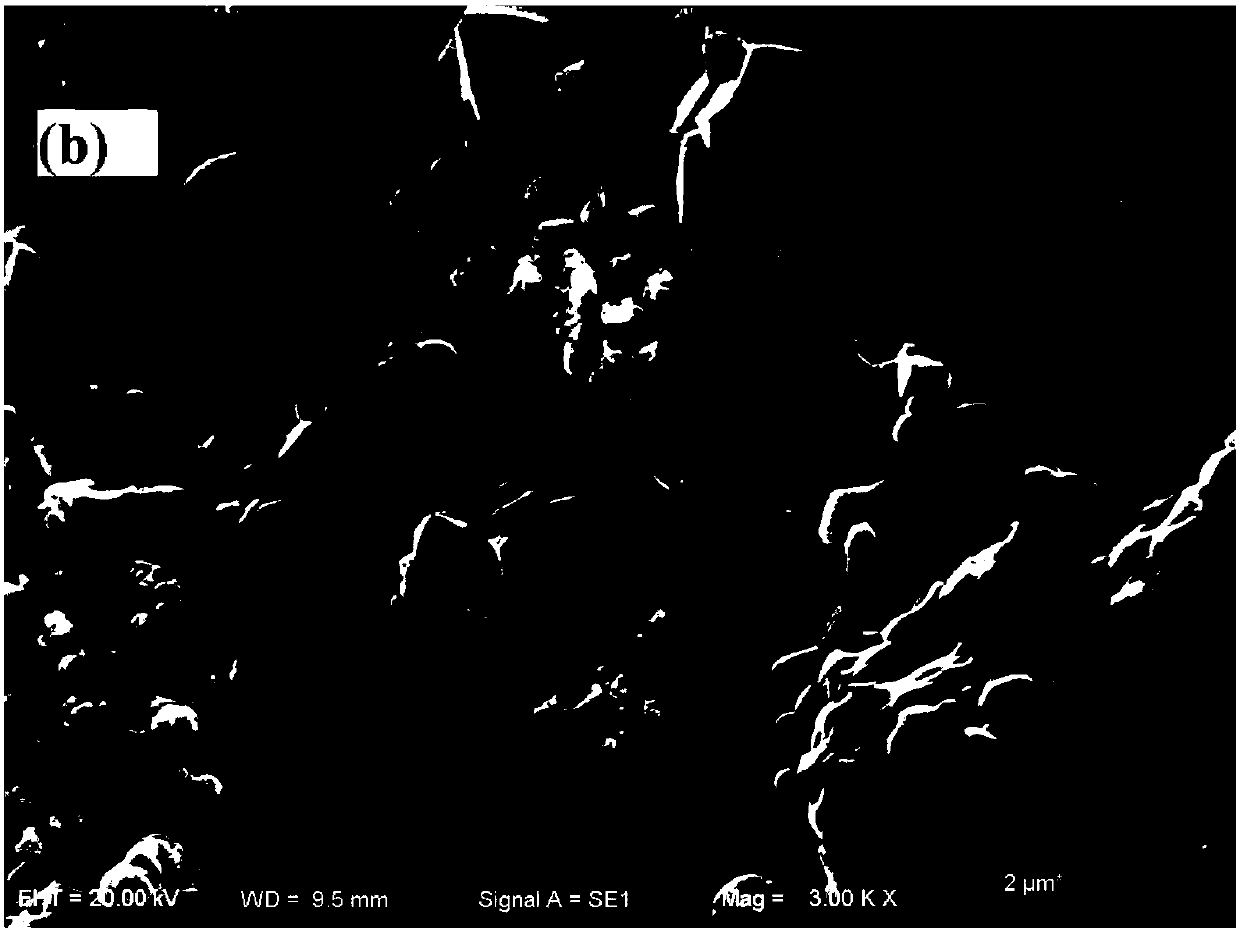

Tungsten nitride based ternary nano composite super-hard film material and preparation method thereof

InactiveCN101624295ANo holesNo crackVacuum evaporation coatingSputtering coatingNitrogenTungsten nitride

The invention discloses a tungsten nitride based ternary nano composite super-hard film material and a preparation method thereof. The material is a nano composite super-hard film which is covered on a substrate and has a chemical formula of WxM1-xN, wherein in the nano composite super-hard film, W represents tungsten metal, M represents metal replacement, N represents nitrogen, and the value range of the x is 0.06 to 0.72; and the film consists of the tungsten metal, nitride solid solution phase of the M metal and tungsten metal phase or consists of tungsten nitride phase, tungsten metal phase and M metal phase, the grain size of the film is 4 to 30 nanometers, and the thickness of the film is 3 to 7mu m. The method comprises the following steps: firstly, placing a composite target consisting of the tungsten metal and the metal replacement and the substrate on a cathode and in a sample stage in a vacuum chamber of magnetron sputtering equipment respectively; after the vacuum degree of the vacuum chamber is less than or equal to 1*10<-3> pa and the temperature of the substrate reaches 350 and 450 DEG C, making the vacuum chamber in argon-nitrogen mixed atmosphere, sputtering the composite target for 60 to 120 minutes to obtain the tungsten nitride based ternary nano composite super-hard film material. The film material and the preparation method can be widely applied in the fields of mechanical manufacture, automobile and textile industry, geologic drilling, die industry and the like.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

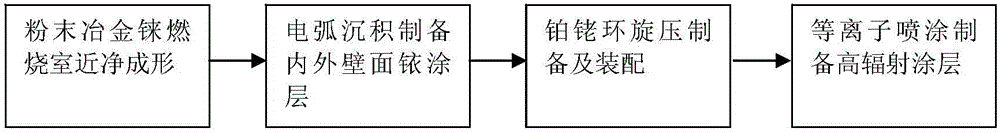

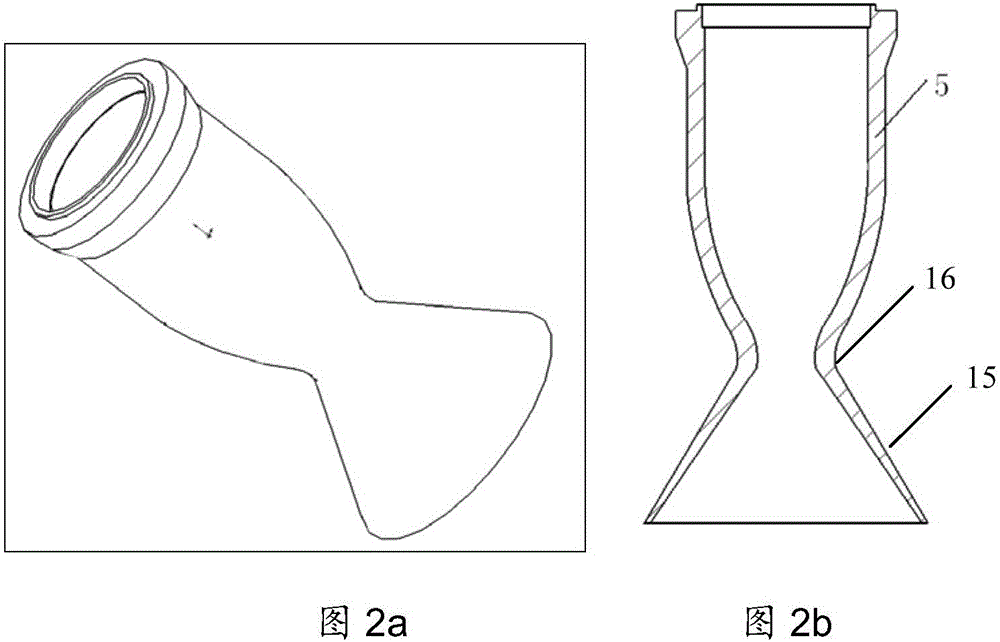

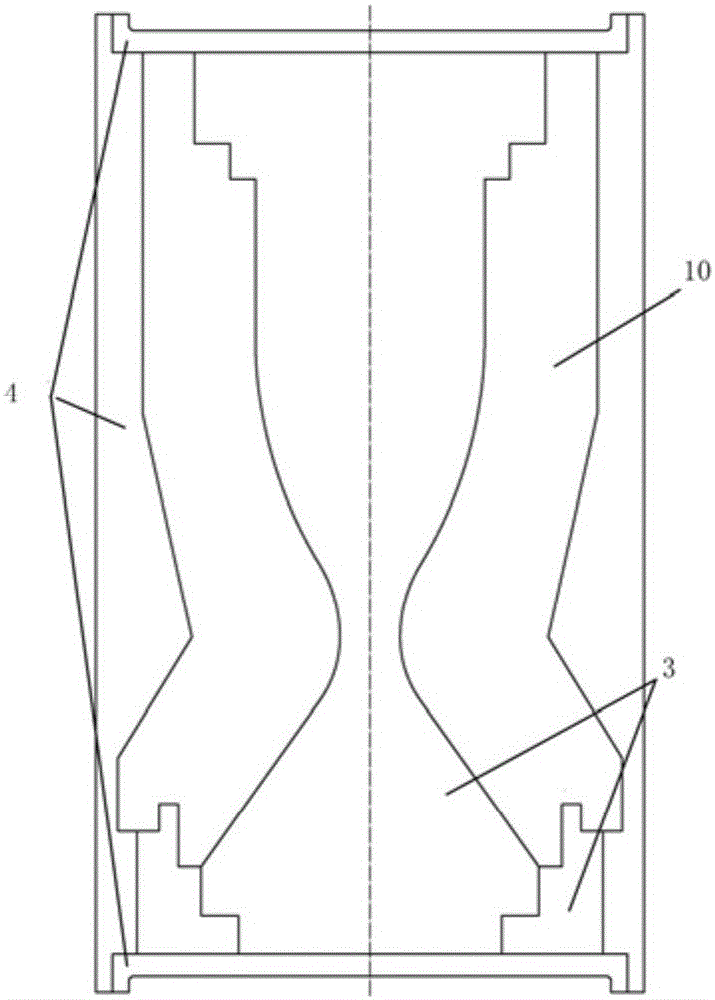

Preparation method for rhenium-iridium combustion chamber

ActiveCN106001554AIncrease the allowable operating temperatureImprove specific impulseShaping toolsMolten spray coatingRheniumIridium

The invention relates to a preparation method for a rhenium-iridium combustion chamber. The preparation method comprises the following steps: preparing a rhenium combustion chamber by adopting a powder metallurgy near-net shape forming technology; preparing iridium coatings at inner and outer surfaces of the rhenium combustion chamber by adopting an electric-arc deposition technology; preparing a platinum-rhodium ring by adopting a spinning technology and assembling the platinum-rhodium ring on the inner wall surface of the combustion chamber; and preparing a metal oxide high-radiation coating on the outer surface of the combustion chamber by adopting a plasma spraying technology. According to the preparation method, by virtue of an optimized design of process methods and process conditions at different stages of a preparation process, the prepared rhenium-iridium combustion chamber is applied to an engine, so that a use and working environment of the engine can be remarkably increased, specific impulse can be improved for the engine, and technical support is provided for prolonging flight life of an aircraft, increasing effective load of the aircraft or increasing range of the aircraft.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

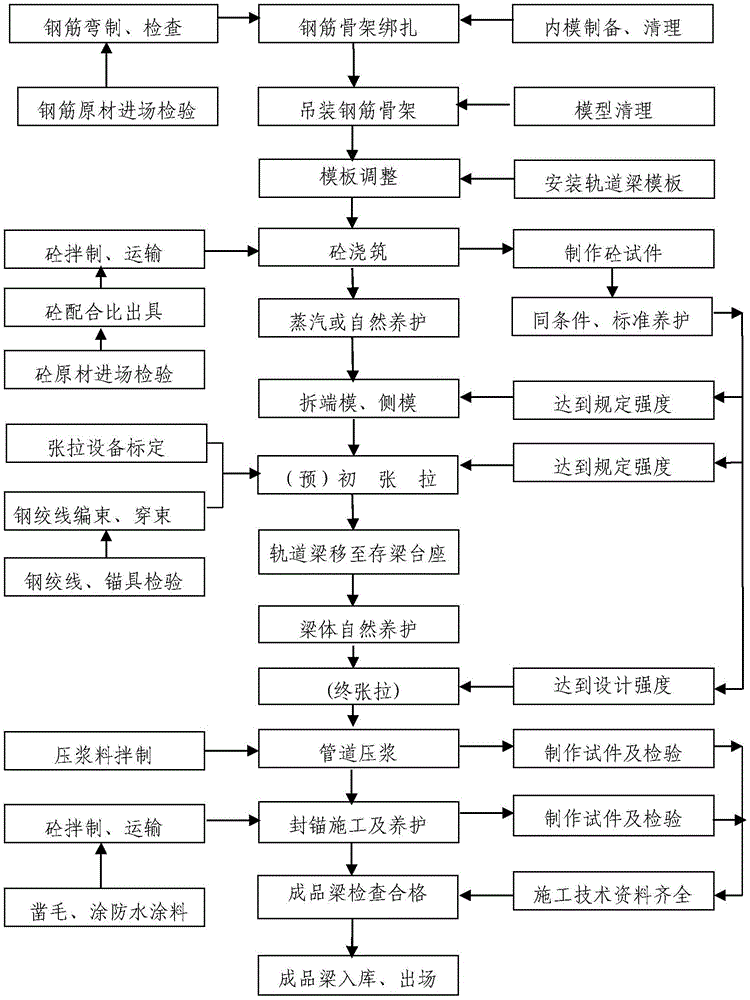

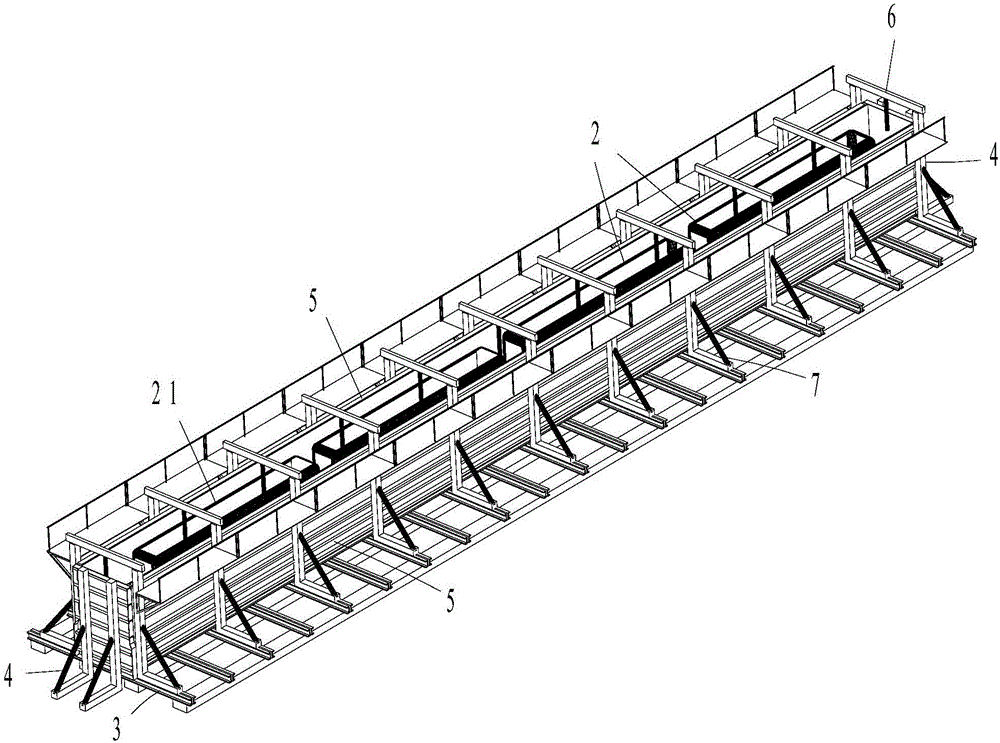

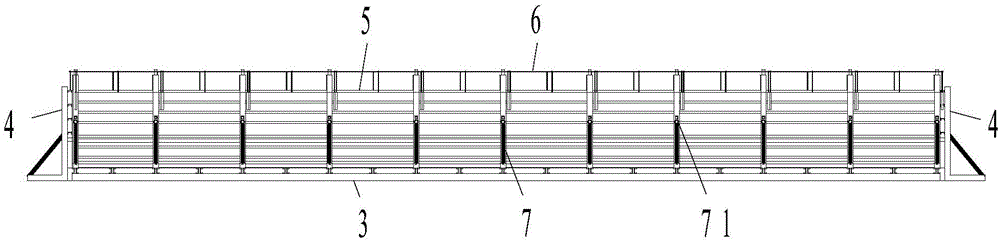

Manufacture method for maglev track beam

ActiveCN105014786AImprove prefabrication efficiencyHigh adjustment accuracyMouldsRailway tracksEngineeringVertical displacement

The invention discloses a manufacture method for a maglev track beam. The manufacture method comprises the following steps: tying a framework of steel reinforcement, manufacturing an internal mold, putting the internal mold in the framework of steel reinforcement, mounting a formwork of track beam, and regulating the formwork of track beam so as to meet the required linearity. The lateral displacement relative to the track beam and the perpendicularity relative to a bottom mold of the side mold of the formwork of track beam can be regulated through a regulating component, and a translating component arranged outside end molds is used for regulating the longitudinal movement relative to the side mold of each end mold. The manufacture method has the advantages of being easy to operate, high in regulating precision and simple to assemble and disassemble the molds. A control component can respectively regulate the transverse displacement, the longitudinal displacement and the vertical displacement of the track beam, the linearity precision can achieve the range of + / -5, and the precast quality of a curved track beam is ensured. The intelligent control can realize high regulating precision, high efficiency and good reliability of a formwork system, and the manufacture method is particularly applicable to precasting of medium-low-speed maglev linear or curved track beams.

Owner:CHINA RAILWAY 23RD CONSTR BUREAU LTD

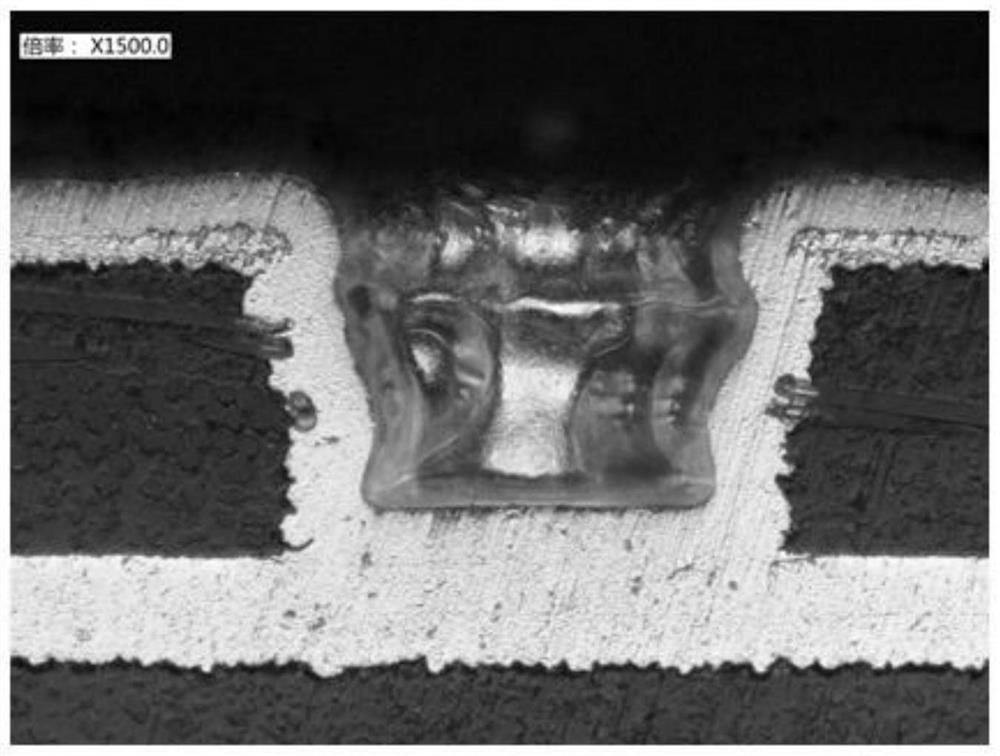

Electroless Copper Plating Solutions for Microvia Filling

InactiveCN102277567ANo holesSeamlessSemiconductor/solid-state device manufacturingLiquid/solution decomposition chemical coatingBenzoxazoleCopper plating

A chemical copper plating solution for micropore filling. 1 L of the chemical copper plating solution comprises 5-20 g of copper sulfate pentahydrate, 10-50 g of disodium ethylene diamine tetraacetate, 1.0-1.5 g of formaldehyde or glyoxylic acid, 0.001-0.02 g of mercapto heterocyclic compounds, 0.02-0.04 g of polyether with an average molecular weight of 3650, 1.5-3.5 g of NaOH, and the balance of distilled water; the mercapto heterocyclic compounds are 2-mercapto benzimidazole, 2- mercapto benzoxazole, 1-phenyl-5-mercapto-tetrazole or 2-mercapto benzothiazole. By simultaneously adding mercapto heterocyclic compounds and polyether with an average molecular weight of 3650 into the chemical copper plating solution, the invention realizes no cavity, no gap of micropores, and perfect chemicalcopper filling; the chemical copper plating solution is stable; and the deposited copper film has good quality.

Owner:SHAANXI NORMAL UNIV

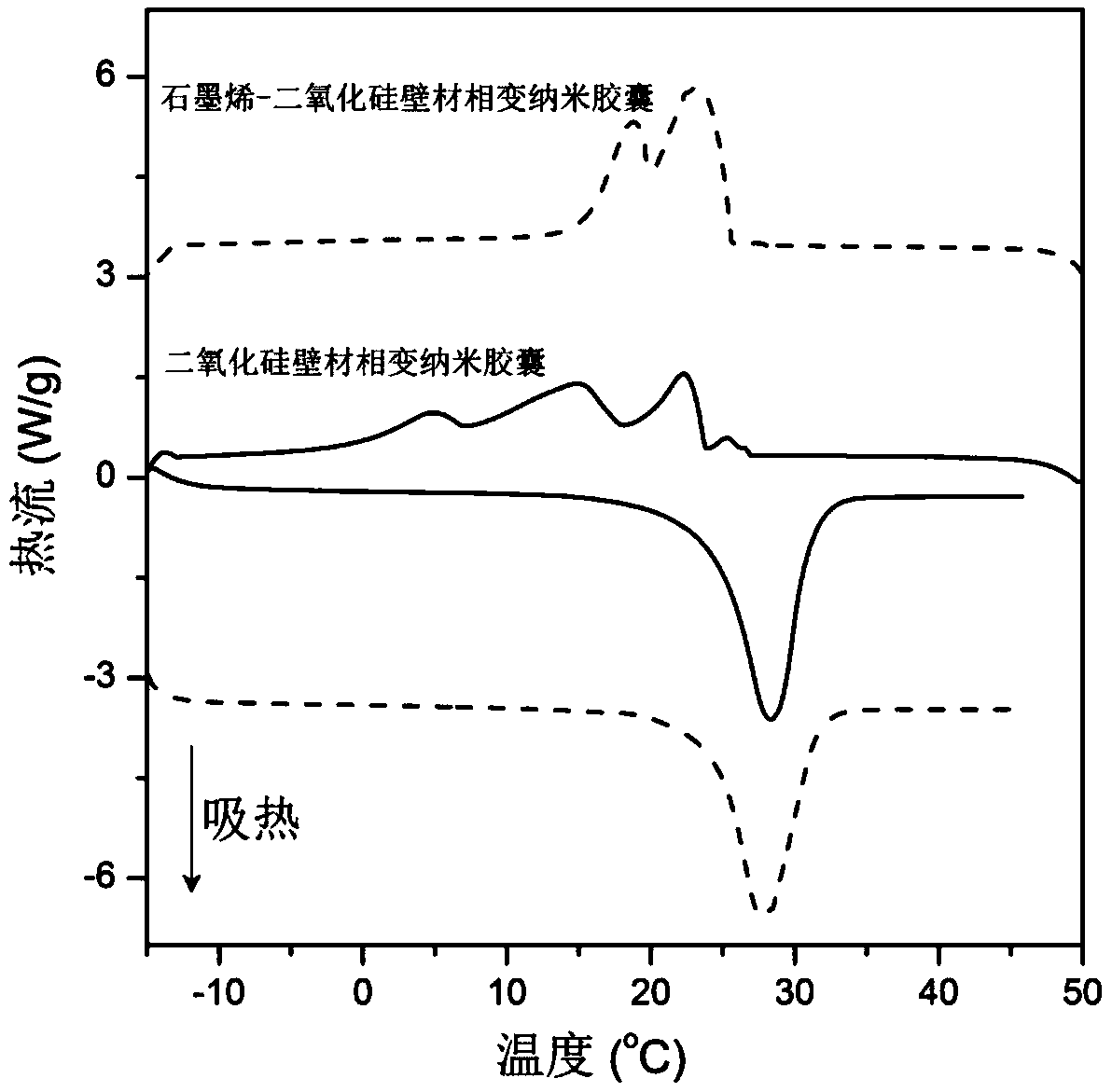

Graphene-silicon dioxide composite wall-material phase-change nanocapsule and preparation method thereof

ActiveCN108774499AEasy to prepareHigh yieldHeat-exchange elementsMicroballoon preparationCvd grapheneSolvent

The invention discloses a graphene-silicon dioxide composite wall-material phase-change nanocapsule and a preparation method thereof. A core material of the phase-change nanocapsule is a paraffin phase-change material, a wall material of the phase-change nanocapsule is a graphene-silicon dioxide composite material, and the particle size of the nanocapsule is nanometer scale. The preparation methodcomprises the following steps: mixing the phase-change material with an alkoxy silane compound so as to obtain an oil phase, adding a cationic surfactant and a water / ethanol mixed solvent, and carrying out high-speed shearing and ultrasonic refining so as to obtain an oil-in-water type fine emulsion; dispersing graphene into deionized water under the assistance of an anionic surfactant so as to form stable graphene dispersion liquid; and dropwise adding the graphene dispersion liquid into the fine emulsion, sequentially adding ethanol and a basic catalyst, heating to react, filtering, washing, and drying, so as to obtain a black powder product. The wall material of the phase-change nanocapsule is the graphene-silicon dioxide composite material, so that a supercooling phenomenon of the phase-change nanocapsule can be eliminated, and meanwhile, the heat conductivity coefficient and heat stability of the phase-change nanocapsule can be increased.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Simplified cultivating method for dry-cure pepper

ActiveCN103493664AEnsure constant temperature and humidityGrowth inhibitionHorticultureFertilizer mixturesSoil temperatureTillage

The invention discloses a simplified cultivating method for dry-cure pepper. The method improves the emergence rate, the planting percent and the strong seedling rate of direct-seeded seeds of pepper by covering and using direct-seeding nutrition balls and direct-seeding nutrition matrix. The method furhter solves the problems that surface layers in field direct seeding is prone to hardening due to the fact that soil temperature and humidity are affected by environment to be large in change to be unfavorable for seed emergence of pepper seeds and growth of seedlings. In addition, the method achieves practicability of pepper direct-seeding techniques and widens popularization and application ranges. By means of black film covering and direct seeding cultivation, the problems of weed growth in fields and serious pepper lodging are effectively solved, minimal tillage or zero tillage in fields are achieved, the use of weed killers is reduced, specific fertilizers are screened through tests to solve the problem of one-time fertilization in pepper production, additional fertilizers are avoided in pepper production on the premise of avoiding output reduction of peppers, and the problem of harvesting dry-cure scatter and fresh peppers at one time in a concentrated mode is solved. Thus, the purposes of achieving low cost production of peppers and improving pepper quality are achieved.

Owner:贵州省辣椒研究所

High alloy matrix metal-ceramic composite and preparation method thereof

The invention discloses a high alloy matrix metal-ceramic composite and a preparation method thereof, and belongs to the field of wear-resistant materials. According to the high alloy matrix metal-ceramic composite, the volume ratio of high alloy matrix materials to metal-ceramic reinforced particles is (1-10):1; the high alloy matrix materials comprise 1-8% of C, main alloying elements, minor additive elements and the balance Fe and unavoidable impurities; the main alloying elements comprise 0-60%of Ni, 0-60% of Mo, 0-40% of Cr, 0-30% of Mn, 0-20% of V, 0-20% of Ti, 0-15% of W and 0-15% of Nb; and the minor additive elements are one or more of B, Si, Zr, Cu, Co, Al and rare earth. The preparation method adopts a programmed temperature-controlled liquid phase sintering method for preparation and can be used directly for wear-resisting materials, or for wear-resisting materials after subsequent heat treatment; and the metallurgical bonding interface between the reinforced phase and thehigh alloy matrix in the composite reaches 40[mu]m-1mm, no cracks occurs after the integral heat treatment, and the service conditions in the wear-resistant material field are met.

Owner:NORTHEASTERN UNIV

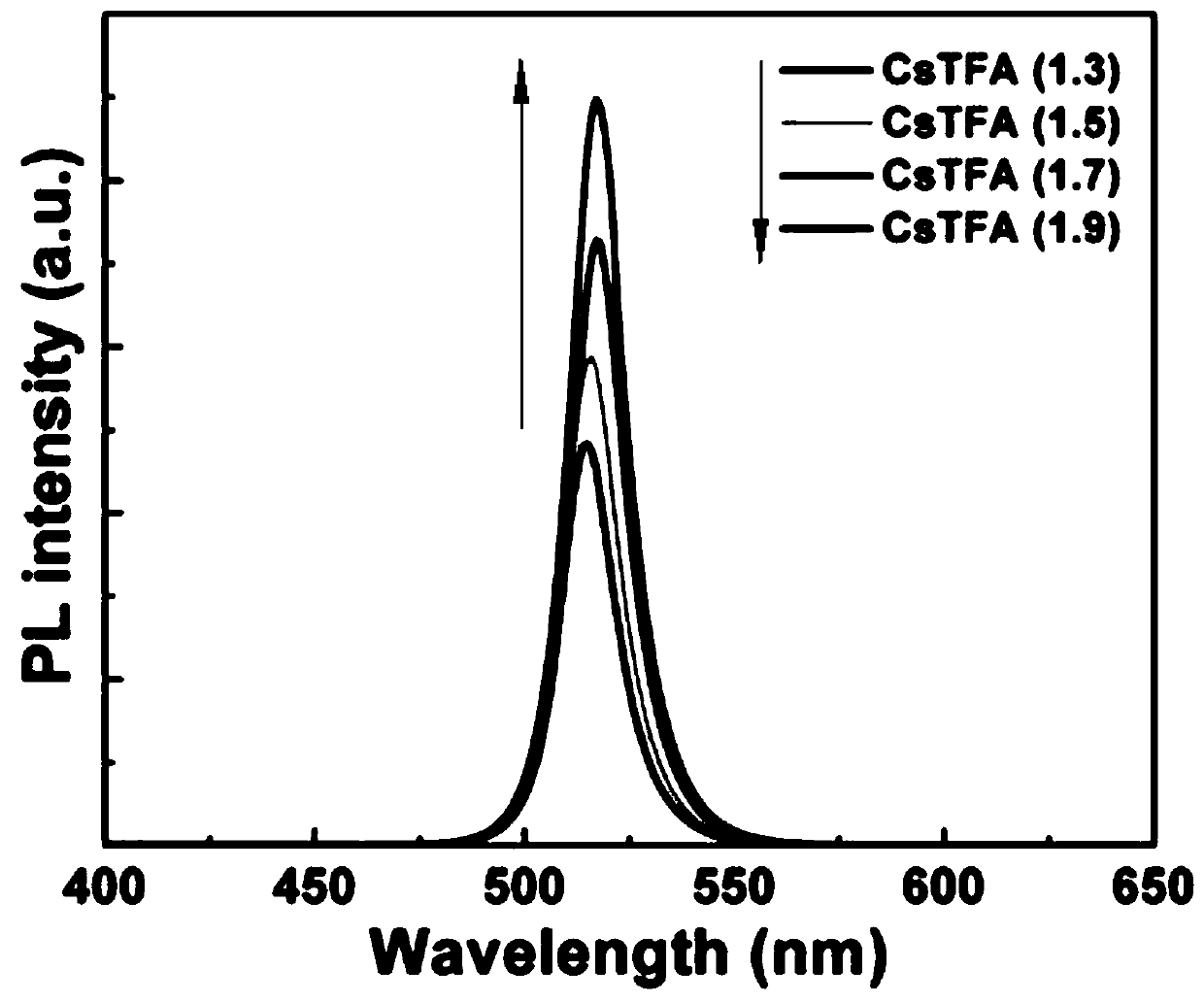

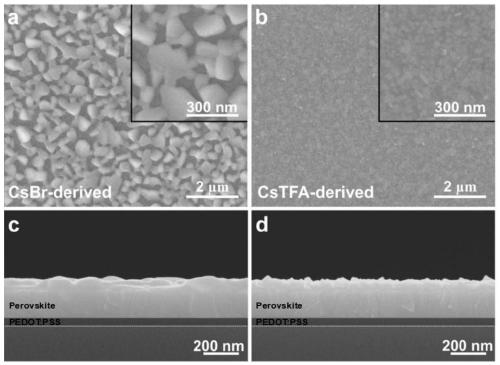

Trifluoroacetate induction based small-grain CsPbX3 perovskite thin film preparation method

InactiveCN110054214ALow costEasy to industrializeSemiconductor/solid-state device manufacturingLead compoundsHalogenTrifluoroacetic acid

The invention discloses a trifluoroacetate induction based small-grain CsPbX3 perovskite thin film preparation method. The method includes steps: firstly, preparing CsPbX3 perovskite precursor solution; secondly, setting the CsPbX3 perovskite precursor solution on a substrate, and performing curing and annealing to form a film. Under irradiation of an ultraviolet lamp, a CsPbX3 perovskite thin film varies in color according to different halogens. According to the method, cesium trifluoroacetate (CsTFA) is adopted as a new cesium source to take the place of cesium bromide (CsBr) which is a traditional cesium source for preparing the CsPbX3 perovskite thin film, and cost of the prepared perovskite thin film is evidently reduced. Compared with a CsPbX3 thin film prepared according to a traditional method, the CsPbX3 thin film prepared according to the method has advantages that stability is evidently improved, the perovskite grain size is evidently reduced, and the preparation process isenvironmentally friendly, green and healthy.

Owner:SHANGHAI UNIV

A coating for lost foam casting cast iron and its manufacturing process

InactiveCN102274924AHigh strengthEasy to operateFoundry mouldsFoundry coresLithiumMaterials processing

The invention discloses a coating for lost foam casting cast iron and production process thereof, belonging to the technical field of the metal material processing and metallurgy. Quartz powder, graphite powder (lead powder), crystalline flake graphite powder, lithium base bentonite, phenolic resin, carboxymethylcellulose, milk-white glue and n-octyl alcohol are taken according to predetermined proportions; next, hot water in a predetermined proportion is taken and then all the materials are blanked and stirred thereto in a predetermined order, thereby obtaining the usable coating. The coating has excellent thixotropism; the coating has no foam or little foam which disappears quickly in the process of stirring and use; and the coating may not craze after being dried.

Owner:SHANDONG XINGHUA MACHINERY

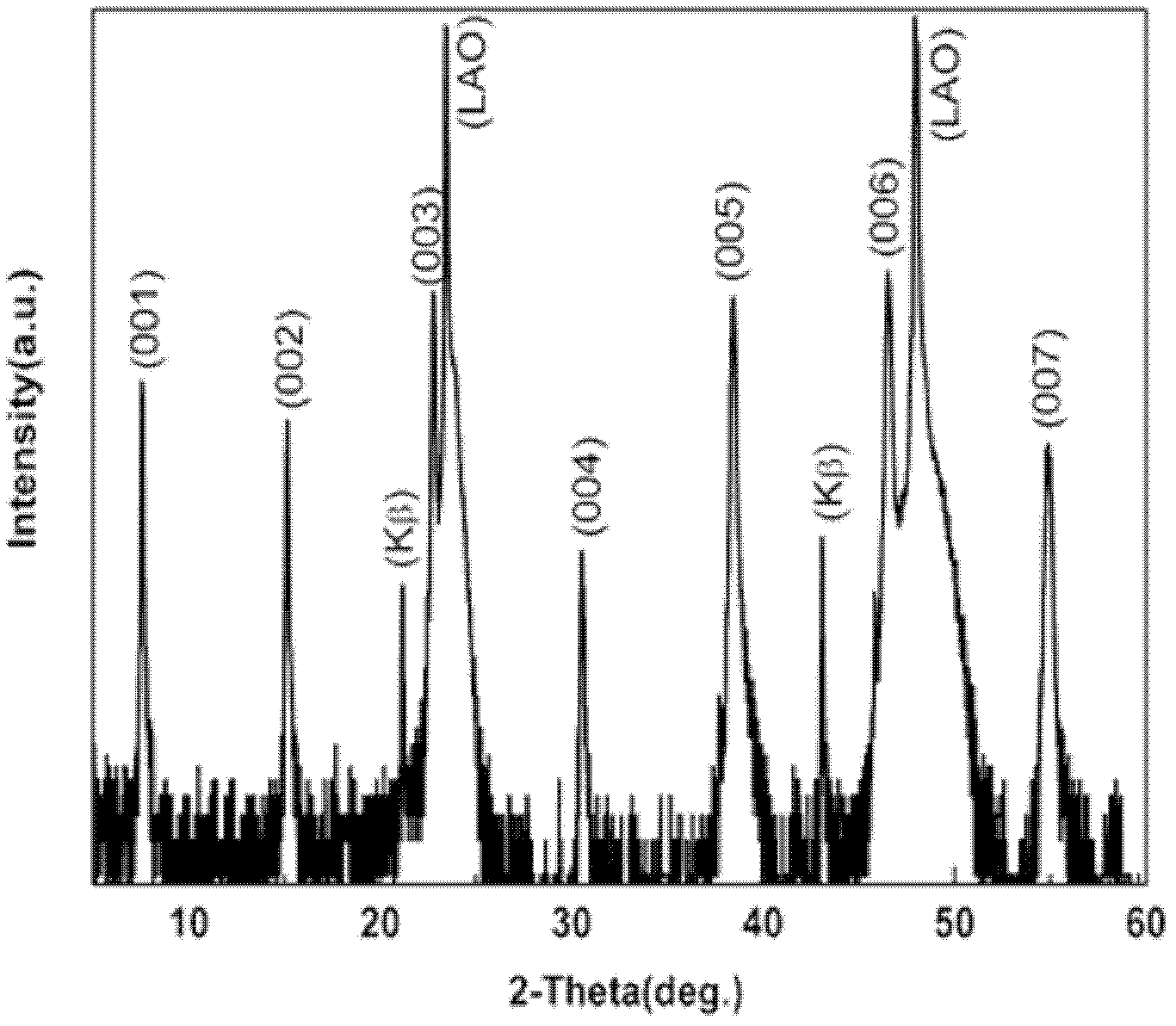

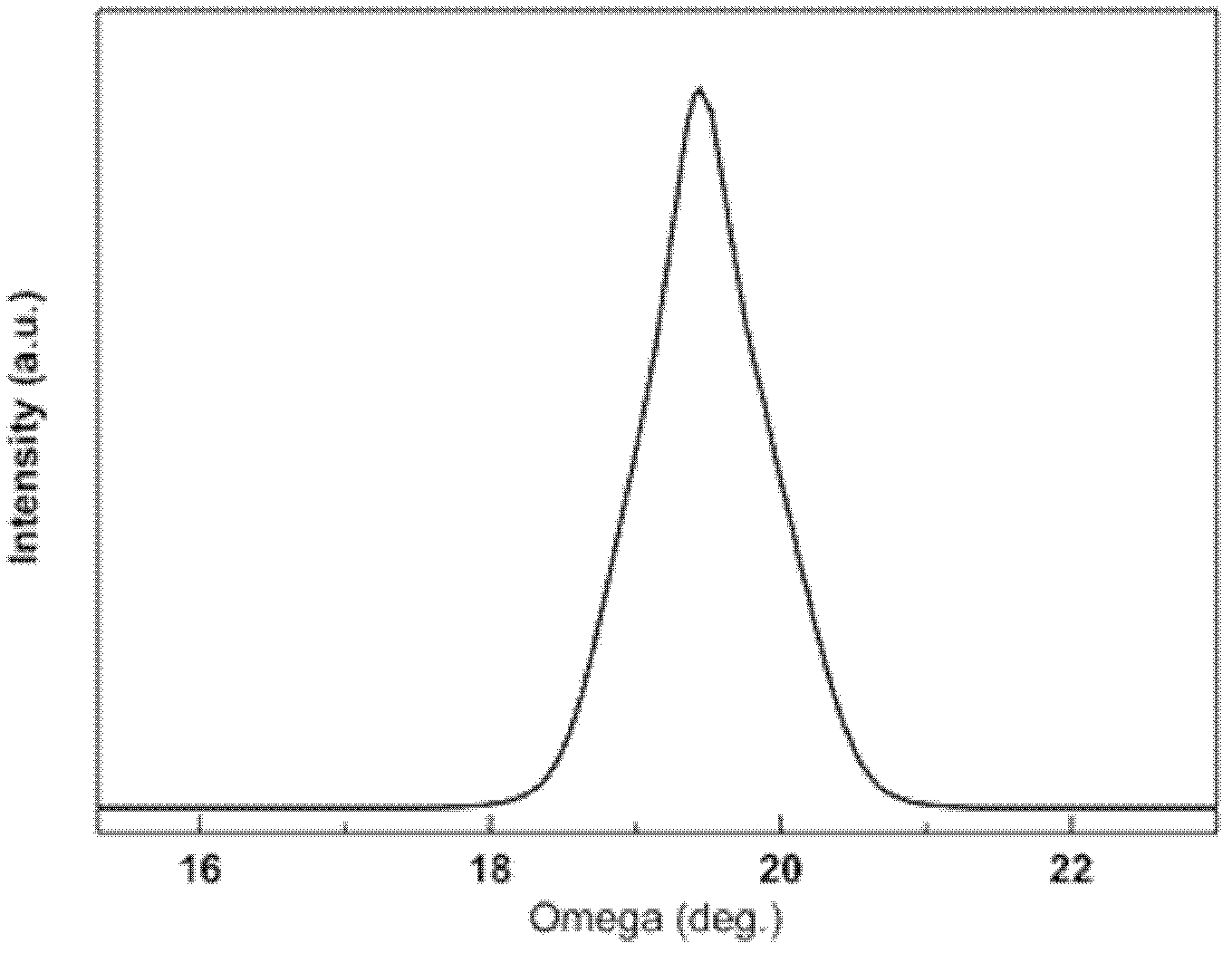

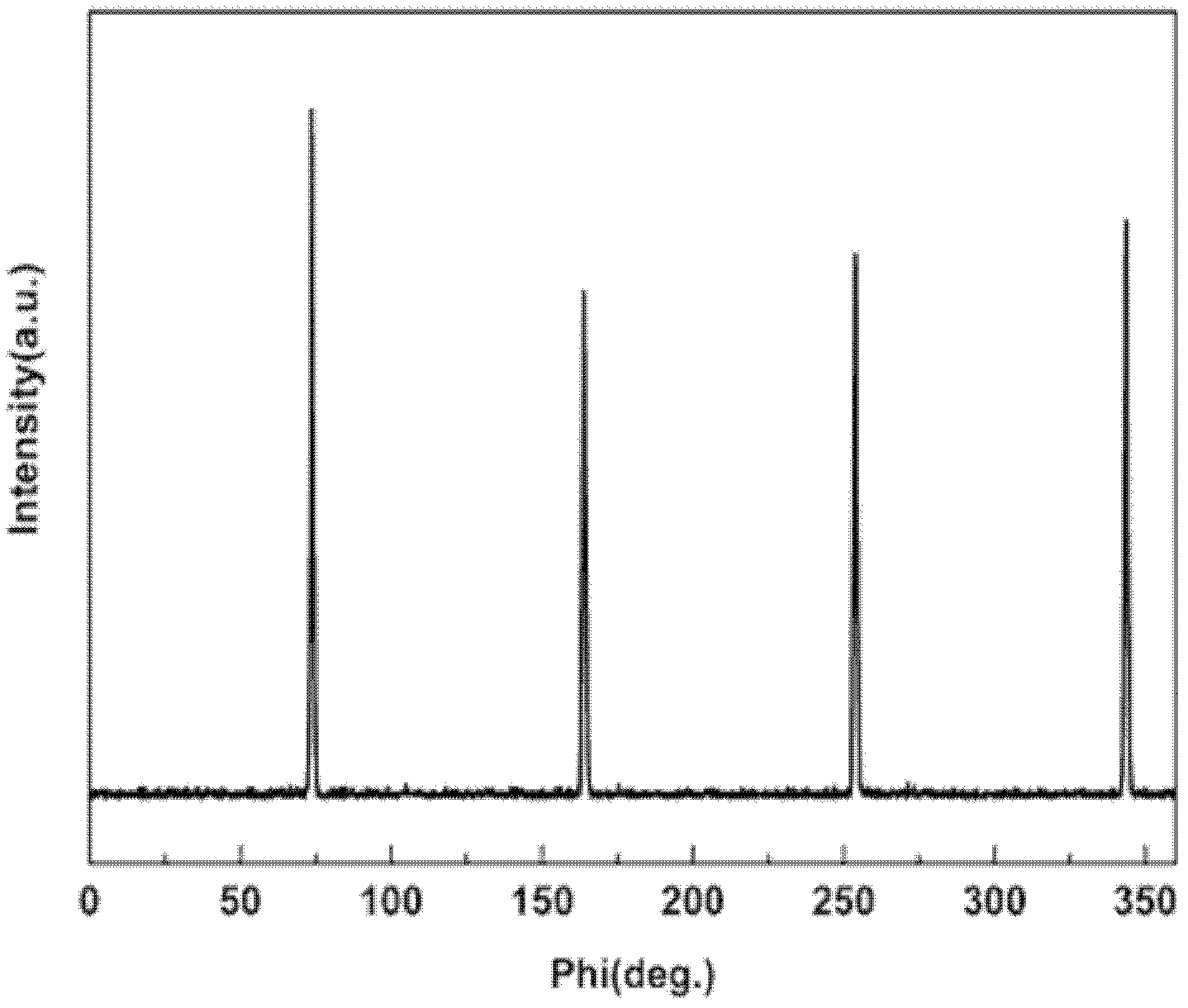

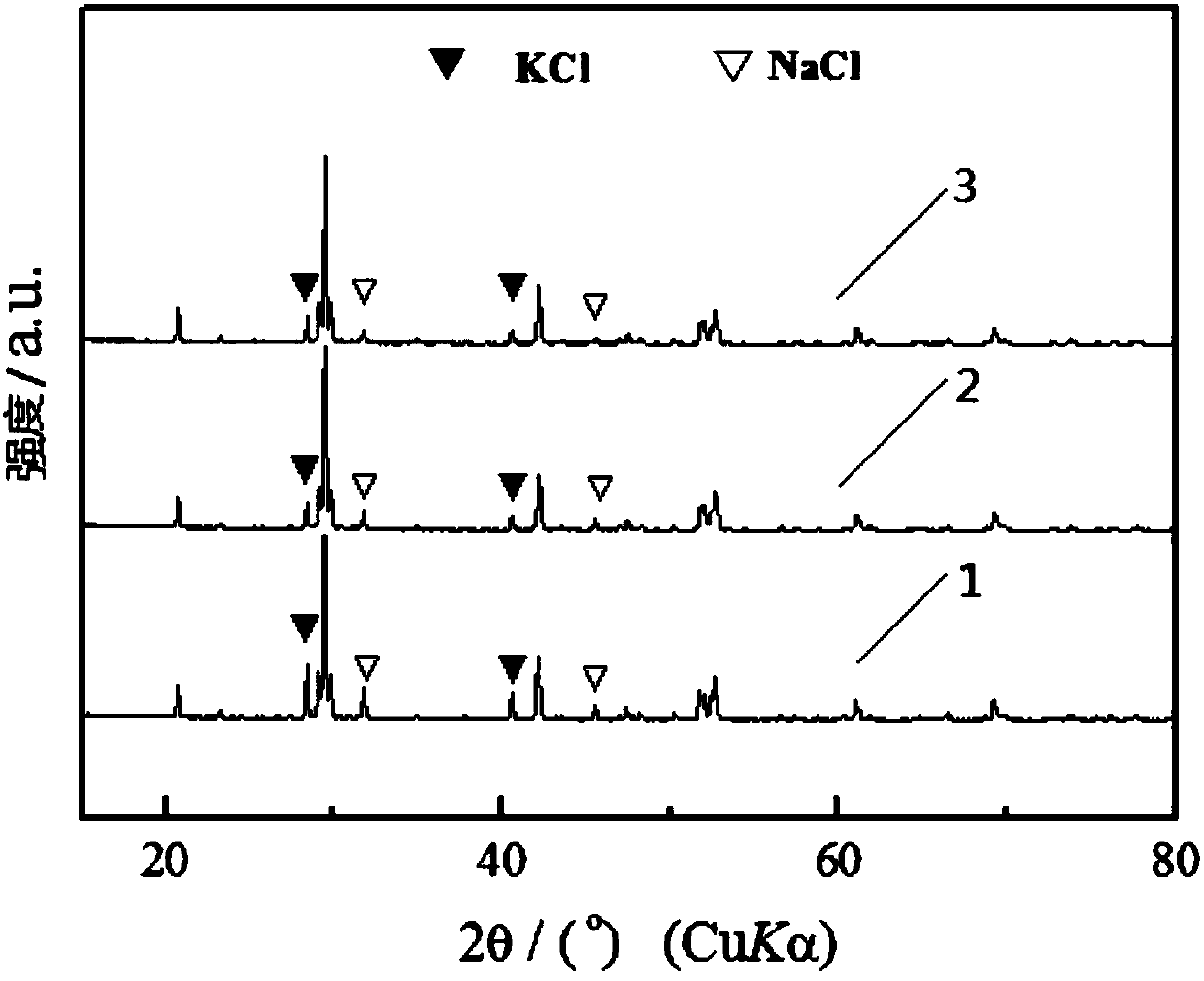

Yttrium barium copper oxide superconducting thin film mixed with samarium and manufacture method thereof

InactiveCN102491740AGood c-axis textureGood in-plane and out-of-plane textureYttrium barium copper oxideChemical composition

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

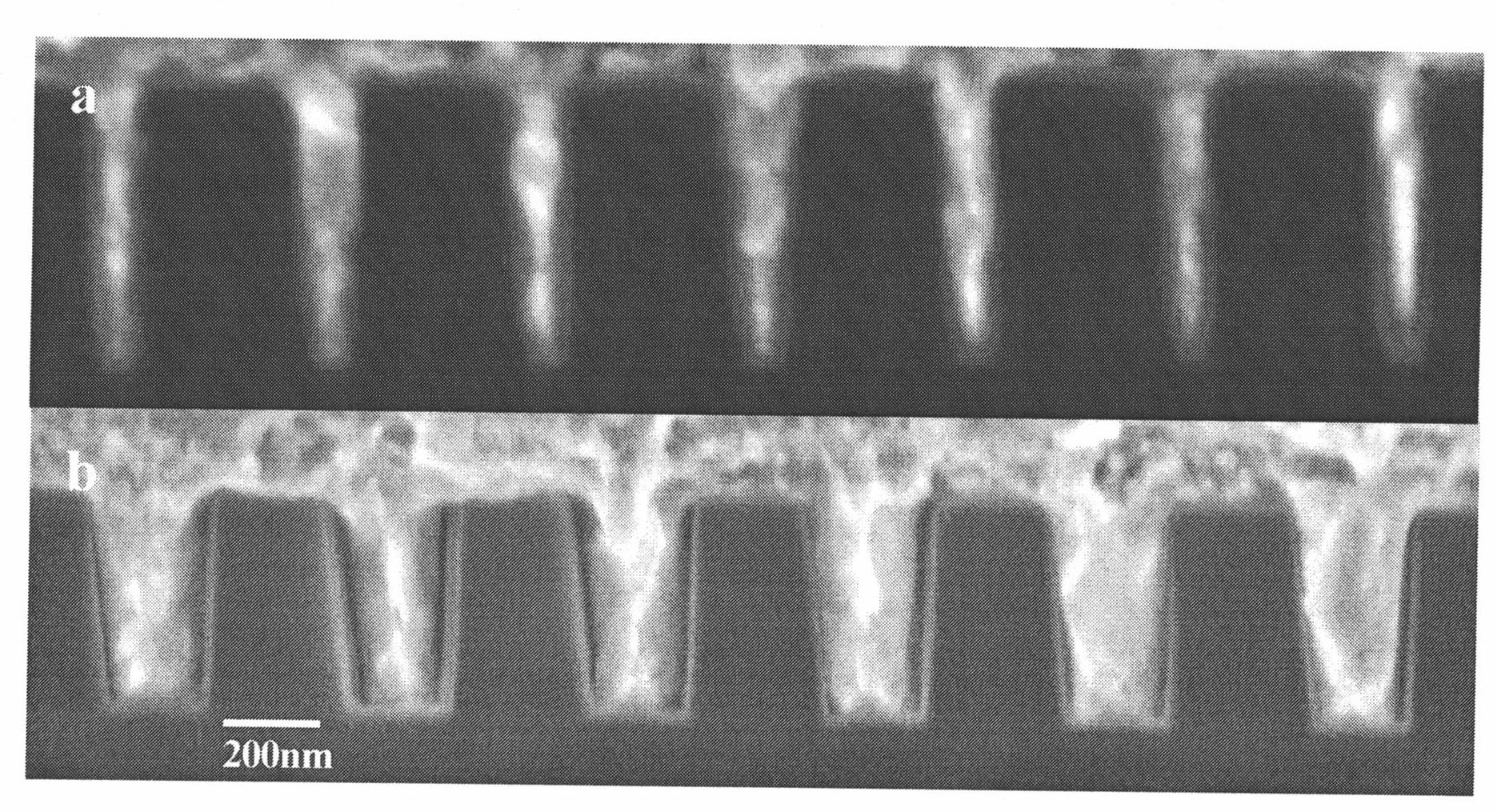

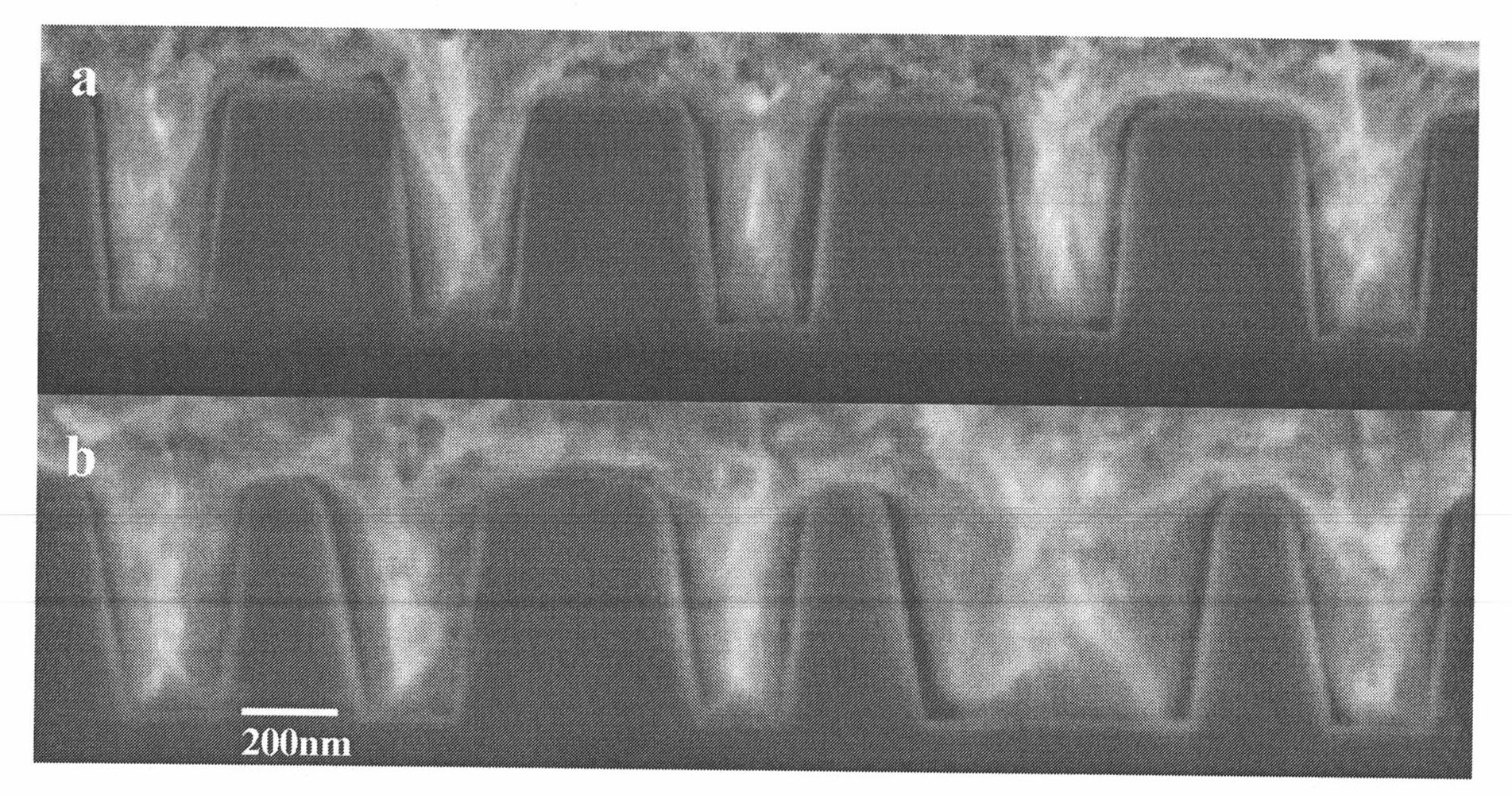

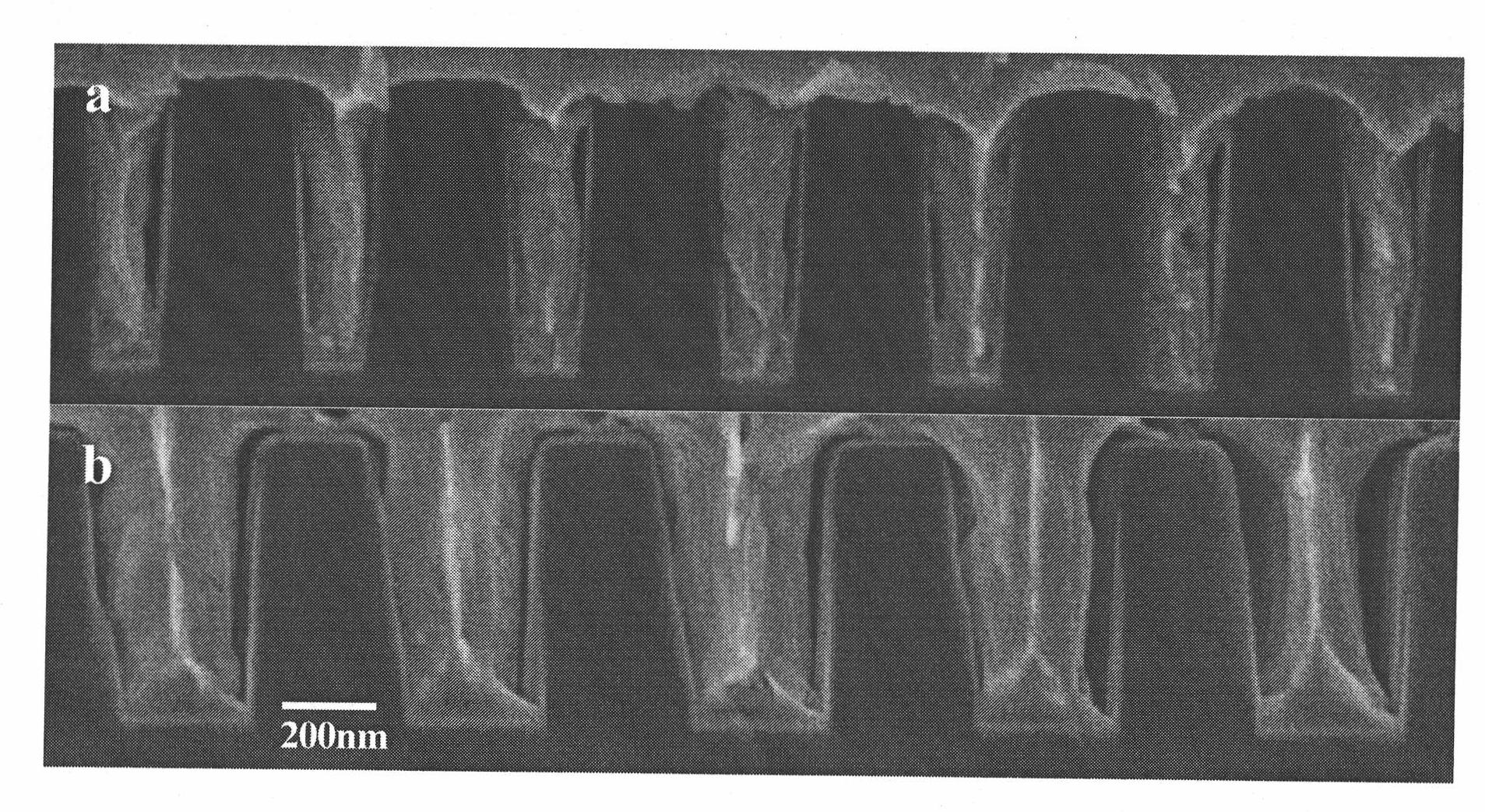

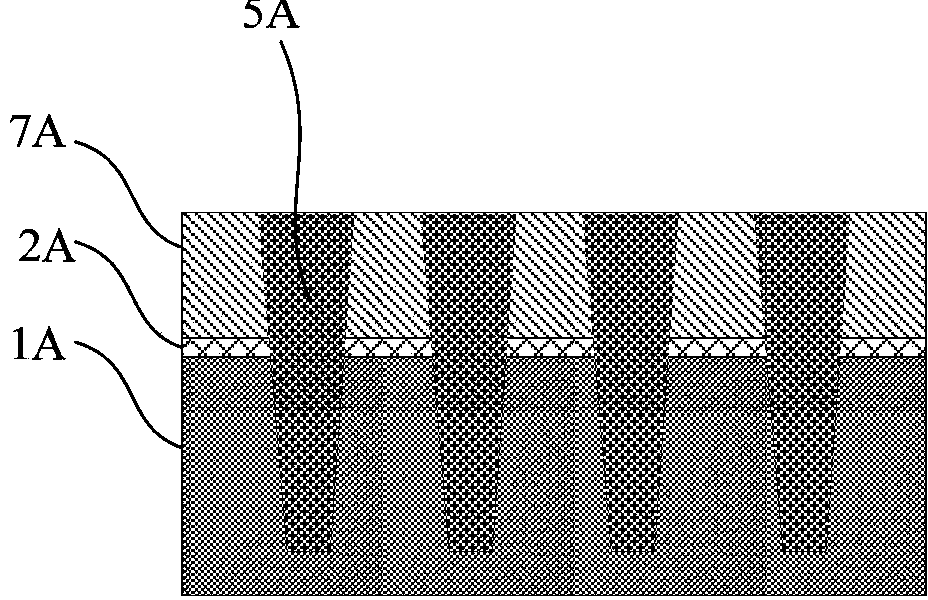

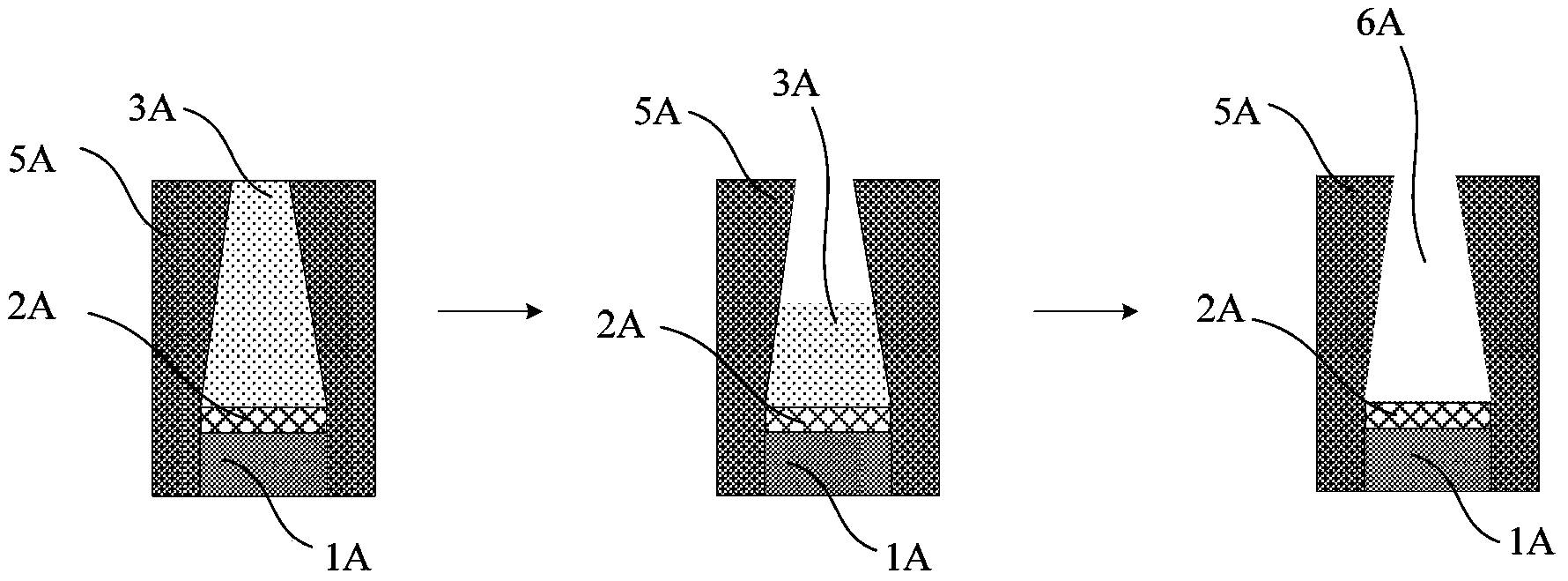

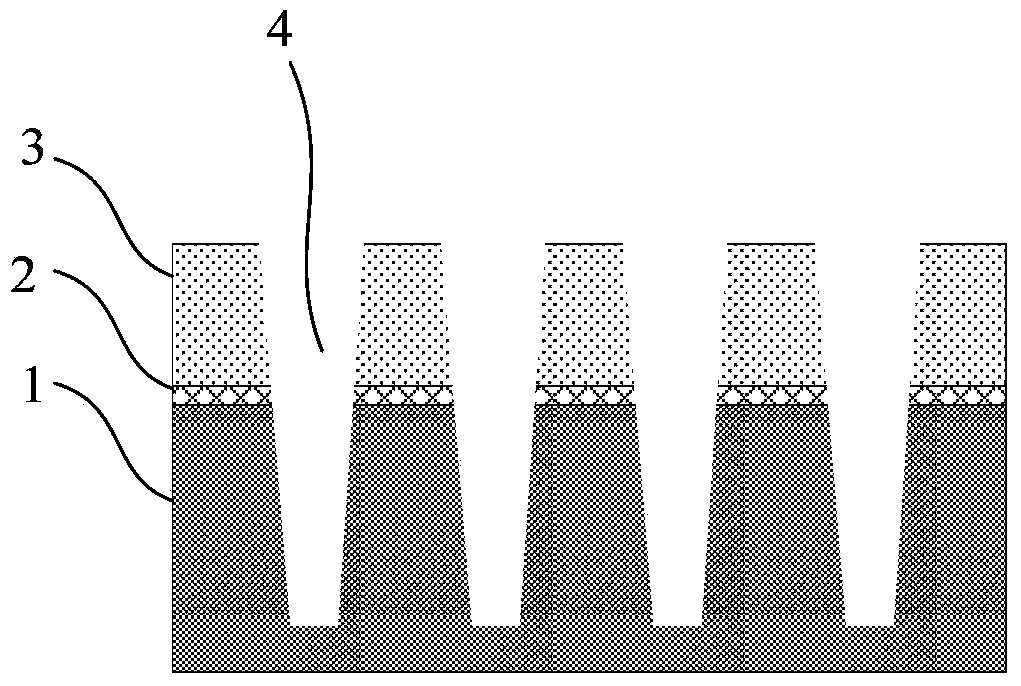

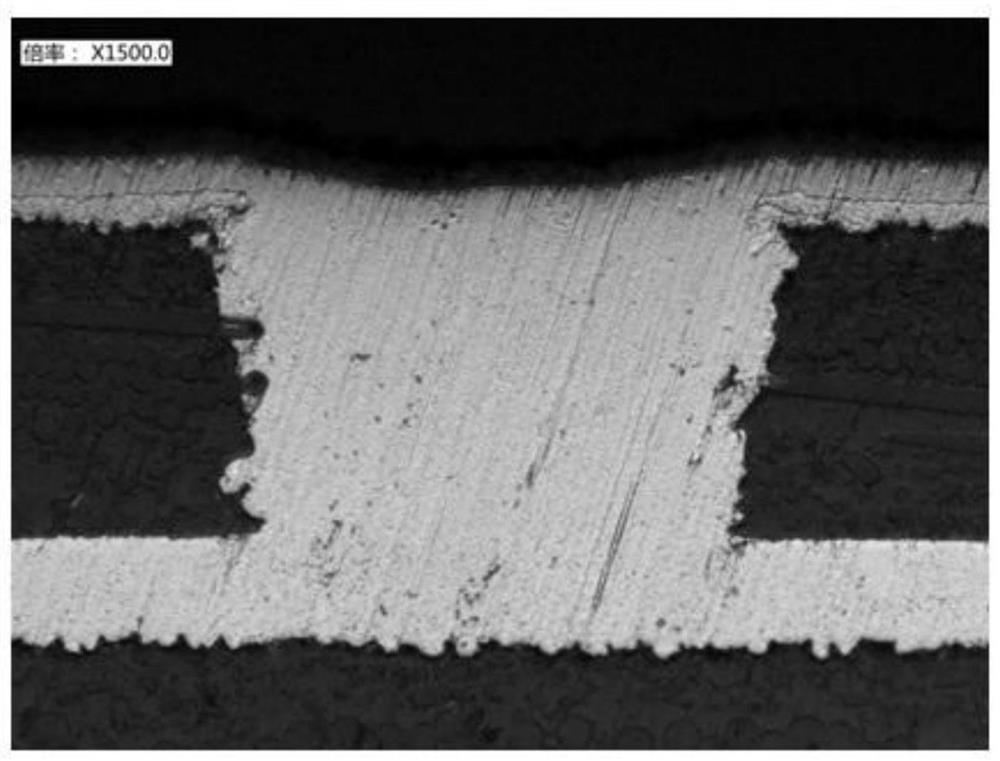

Process method for reducing floating gate holes

InactiveCN104112654AReduce process methodImprove reliabilitySemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductorPhysics

The invention provides a process method for reducing floating gate holes. The process method at least comprises the following steps: at first, a liner oxide layer and a silicon nitride layer are deposited successively on an active region of a semiconductor substrate; secondly, the liner oxide layer, the silicon nitride layer and the active region are etched to form at least two inverted trapezoidal trenches, wherein the trenches do not penetrate through the active region; then, the trenches are filled with an insulating medium material to form shallow trench isolation regions; then, the selective etching process is adopted to etch the silicon nitride layer located between the shallow trench isolation regions, and at the same time, partial shallow trench isolation regions are etched to acquire a rectangular or inverted trapezoidal floating gate preparation region; and finally, a floating gate is prepared and formed in the floating gate preparation prepare. Thus, no hole will occur in the floating gate prepared and formed in the rectangular or inverted trapezoidal floating gate preparation region to avoid the floating gate from being failed, so the device reliability can be enhanced.

Owner:SEMICON MFG INT (SHANGHAI) CORP

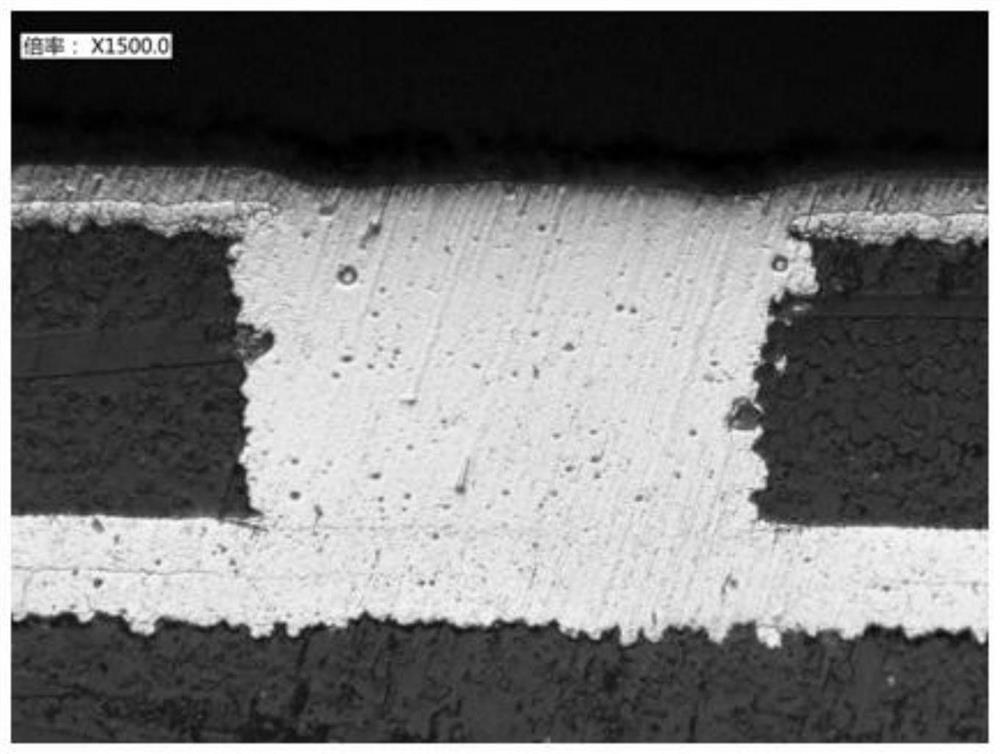

Blind hole filling electrocoppering solution for HDI plate and carrier plate

ActiveCN111945192AImprove plating lifeMaintain fill plating effectJewelleryElectrical resistance and conductanceElectrolysis

The invention discloses a blind hole filling electrocoppering solution for an HDI plate and a carrier plate. An electrocoppering solution comprises the following components of, in concentration, 150-200 g / L of copper sulfate pentahydrate, 40-80 g / L of sulfuric acid (98%), 30-70 mg / L of chloride ions, 0.5-4 mg / L of a brightening agent, 200-500 mg / L of a wetting agent, 5-30 mg / L of a leveling agent,30-100 mg / L of a new additive, and the balance deionized water. The above components are mixed according to the concentration to form the electrocoppering solution, when the electrocoppering solutionis used for electroplating, a Dummy sheet is firstly used for electrolyzing an electroplating bath to 2 AH / L, then electroplating is carried out at a current density of 1-3 A / dm<2 >, a temperature of15-35 DEG C, and a circulation rate of 2-8 TurnOver / H. According to the solution, the stability of a bath solution is improved through the method of adding the new additive, so that a blind hole plating layer is good in deepening plating ability, excellent in hole filling rate, free of voids and cracks, thin in surface copper and bright in surface, the defects of unstable signal transmission, high resistance, excessive power loss and the like caused by blind hole voids or equal-wall growth can be effectively prevented, and the reliability of an electronic product is further improved.

Owner:SHENZHEN CHENGGONG CHEM

Inert multilevel-structure tungsten-aluminum composite material and preparation method thereof

InactiveCN106916984AImprove the phenomenon of diffuse distributionHigh densityTransportation and packagingMetal-working apparatusVacuum pumpingAluminum composites

The invention provides an inert multilevel-structure tungsten-aluminum composite material and a preparation method thereof. The inert multilevel-structure tungsten-aluminum composite material comprises a multilevel-structure tungsten-aluminum composite material and a compact and even tungsten-aluminum metallic compound protecting layer WAl12 or Wal5. The specific preparation method comprises steps as follows: tungsten powder and aluminum powder are mixed and then subjected to ball milling, and aluminum coated tungsten particle cluster composite powder is obtained; the aluminum coated tungsten particle cluster composite powder is mixed with the aluminum powder, a mixture is placed in an aluminum sheath and subjected to compacting, vacuum heating degasification, sealing and hot-isostatic-pressure sintering, the aluminum sheath on the surface is removed, and the multilevel-structure tungsten-aluminum composite material is obtained; the multilevel-structure tungsten-aluminum composite material is put in a high-frequency induction heating furnace, vacuum pumping is performed or inert gas is introduced into the furnace for induction heating, the protecting layer is formed on the surface of the multilevel-structure tungsten-aluminum composite material, and then the inert multilevel-structure tungsten-aluminum composite material is obtained. The inert multilevel-structure tungsten-aluminum composite material prepared with the method is light and high in strength, is provided with the inert protecting layer on the surface, and has good wear resistance and corrosion resistance.

Owner:HUZHOU TEACHERS COLLEGE

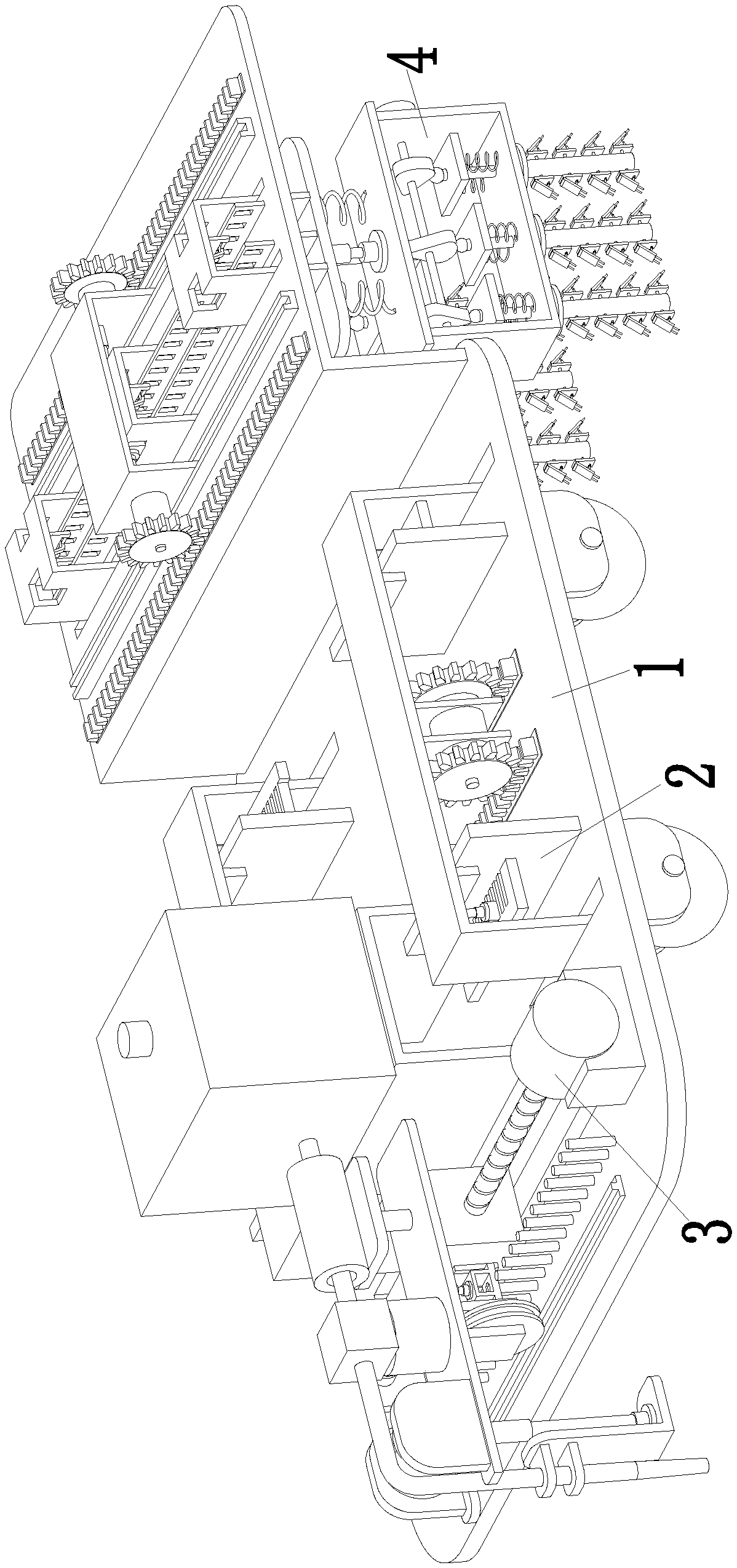

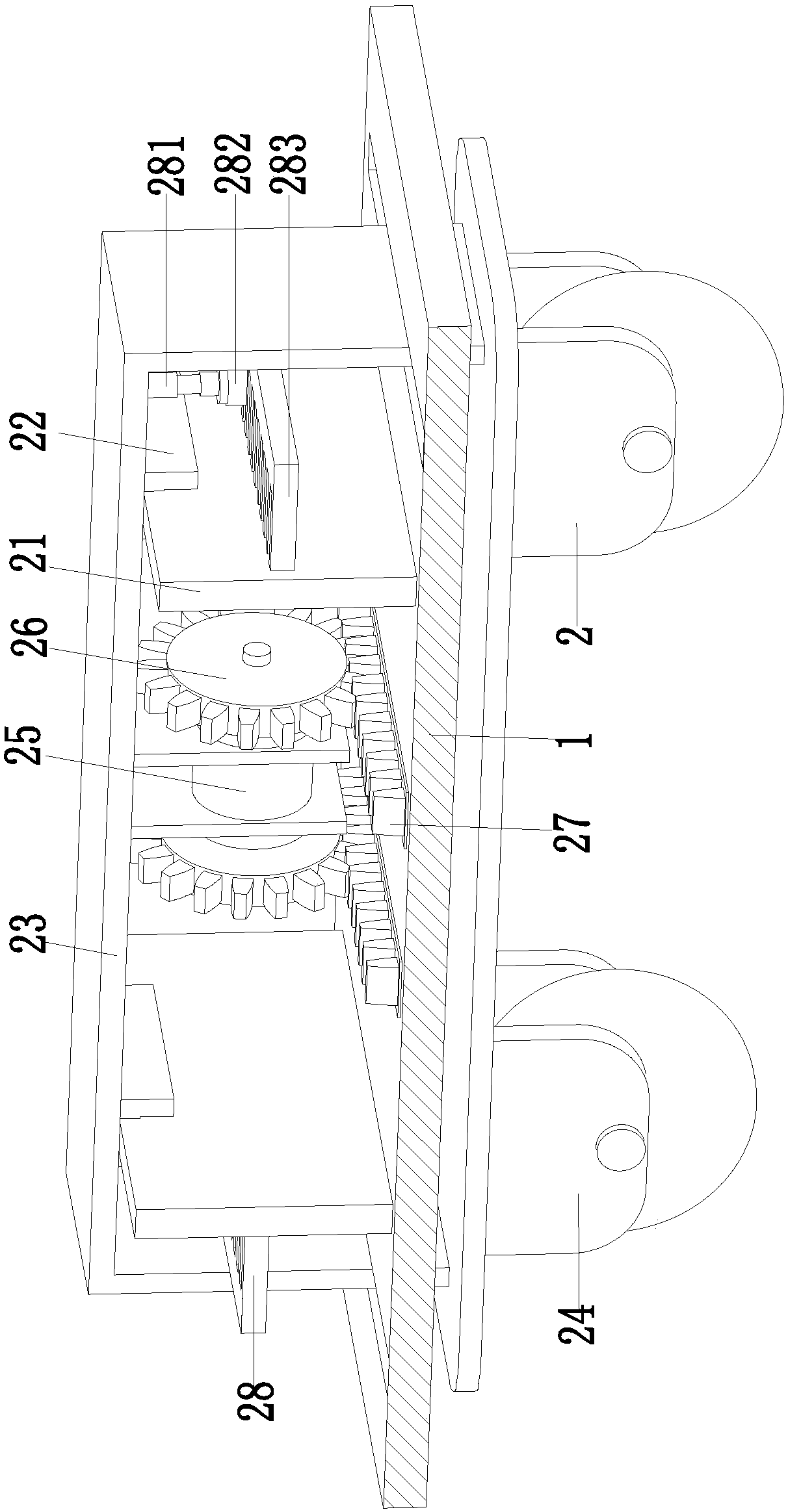

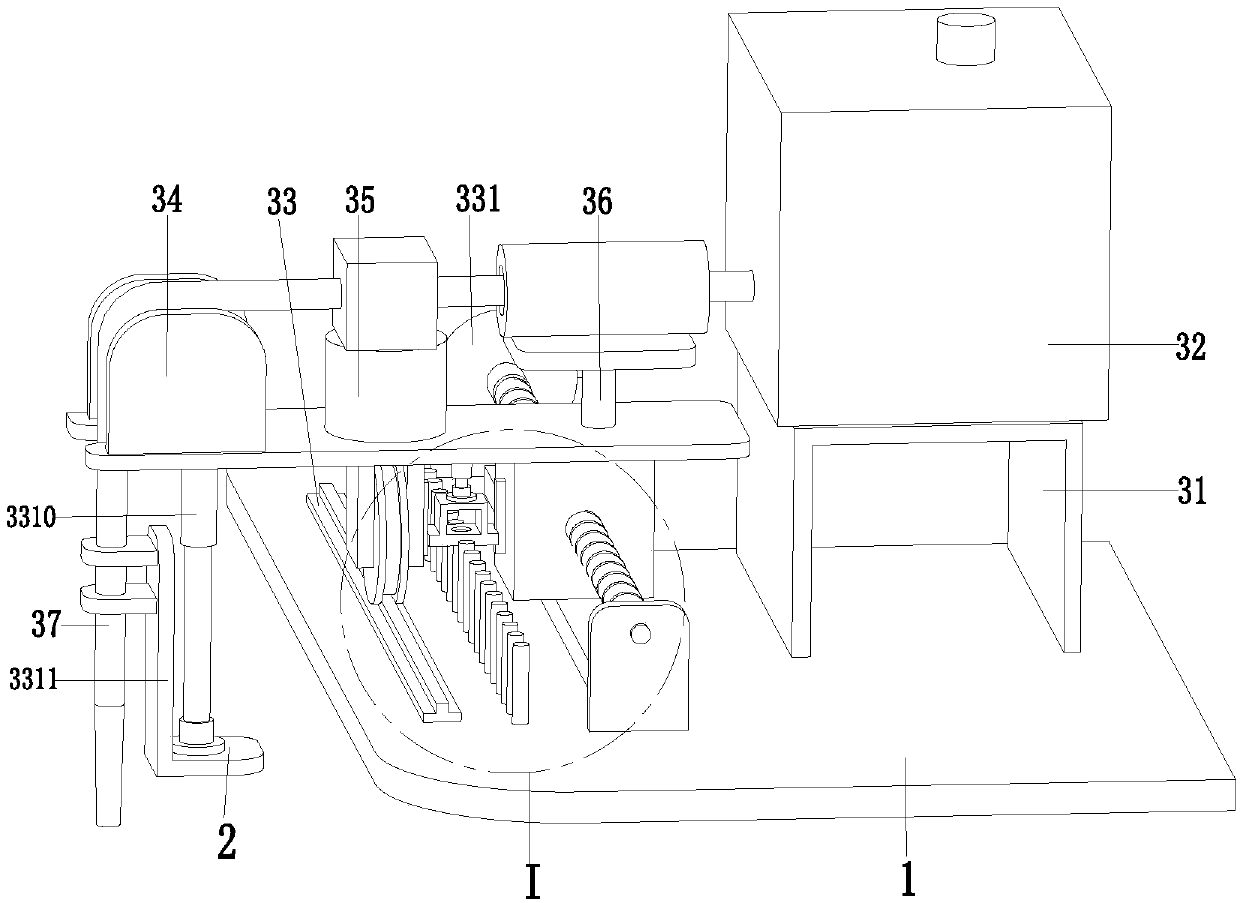

Reinforced concrete bridge cantilever bridge wet joint building and pouring intelligent machine

InactiveCN107815972AStable jobThere is no security riskBridge erection/assemblyBridge materialsReinforced concreteEngineering

The invention relates to a reinforced concrete bridge cantilever bridge wet joint building and pouring intelligent machine. The reinforced concrete bridge cantilever bridge wet joint building and pouring intelligent machine comprises a base plate, wherein two pairs of movable regulating tanks are formed in the base plate, the two pairs of movable regulating tanks are symmetrically formed in the left side and the right side of the base plate, a movable regulating device is arranged in each pair of movable regulating tanks, a perfusion device is arranged at the front end of the base plate, a vibrating and compacting device is arranged at the rear end of the base plate, the perfusion device comprises a perfusion storage tank arranged on the base plate by virtue of a perfusion supporting frame, a discharging hole is formed in the lower side of the front end of the perfusion storage tank, and a perfusion regulating mechanism is arranged at the front end of the base plate. The reinforced concrete bridge cantilever bridge wet joint building and pouring intelligent machine provided by the invention can be used for solving the problems that concrete needs to be manually conveyed by virtue of existing movable equipment in an existing wet joint concrete pouring process, the poured concrete needs to be vibrated and compacted manually by virtue of existing vibrating equipment, a reinforcement cage needs to be avoided in a wet joint concrete pouring and vibrating process and the concrete can not be comprehensively vibrated by virtue of manpower.

Owner:吴秋敏

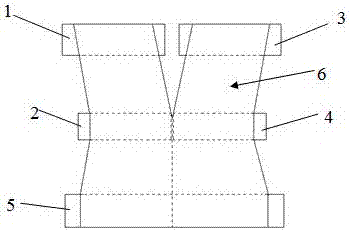

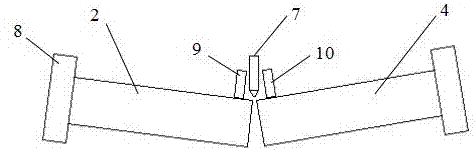

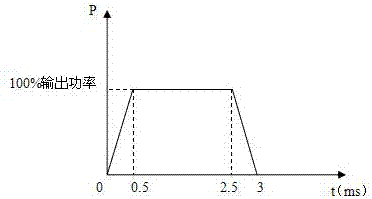

Welding method for stainless steel plates with thickness being smaller than 0.3 mm

ActiveCN106938384AReduce wasteNo missing weldingLaser beam welding apparatusBreaking strengthHeat-affected zone

The invention provides a welding method for stainless steel plates with the thickness being smaller than 0.3 mm. The welding method for the stainless steel plates with the thickness being smaller than 0.3 mm comprises the following steps that the stainless steel plates are cut according to requirements, cut openings are made smooth, and burrs are removed; and the two to-be-welded plates are fixedly mounted on clamps correspondingly, and weld openings of the two to-be-welded plates are aligned; a YAG pulse laser welding machine is adopted, laser beams are kept irradiating the corresponding weld openings of the two plates, and energy is output in the trapezoidal pulse form; and the moving speed of the plates is kept being matched with the frequency and pulse width of laser pulses, so that two adjacent welding spots are made to be in lap joint. By adoption of the welding method for the stainless steel plates with the thickness being smaller than 0.3 mm, small-width stainless steel plates with the same thickness can be combined through laser welding, welding omission, seams, holes, flow and burning damage of a heat affected zone are avoided; the welding spots are continuous, the edges of the welding spots are in lap joint, the overlapping degree of the welding spots is not smaller than half of the diameter of the welding spots, airtightness is guaranteed, and holes are voided; and the strength of welding lines is higher than that of base metal, and high yield strength and tensile breaking strength are achieved.

Owner:天津滨海雷克斯激光科技发展有限公司

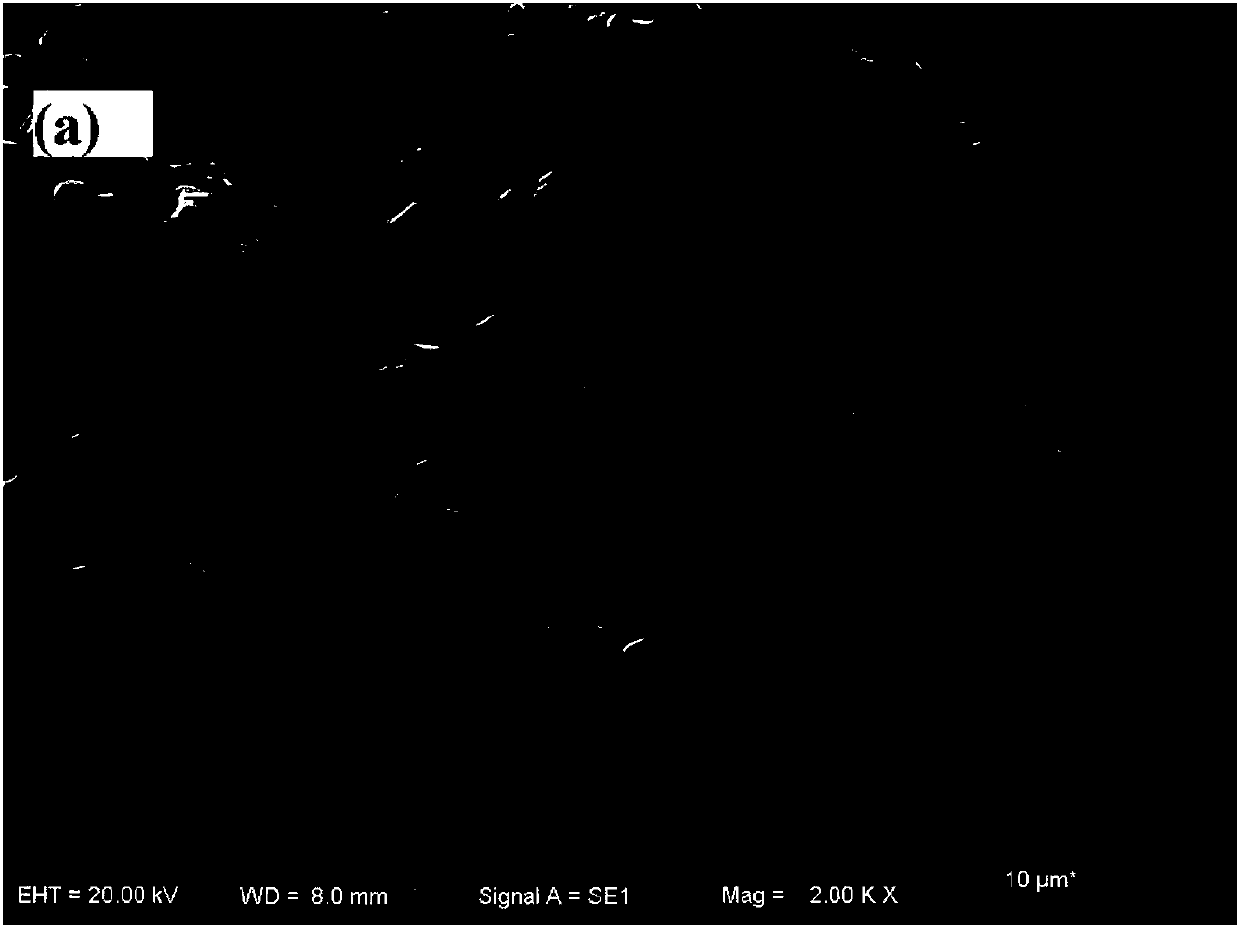

Electronic beam added material manufacturing method of molybdenum base alloy powder

ActiveCN110181048AHigh densityUniform tissueAdditive manufacturing apparatusIncreasing energy efficiencyAlloyAdditive layer manufacturing

The invention discloses an electronic beam added material manufacturing method of molybdenum base alloy powder. The particle size of the used molybdenum base alloy powder is 55-85 microns; and when powder layers are scanned by electronic beams, a twice scanning mode is adopted. The molybdenum base alloy electronic beam added material manufacturing process finds out manufacturing process parametersof added materials with the highest compactness, and adopts the twice scanning mode to solve the nodulizing and powder splashing problems in the manufacturing of the electronic beam added materials to improve the compactness of components to the casting level.

Owner:TSINGHUA UNIV

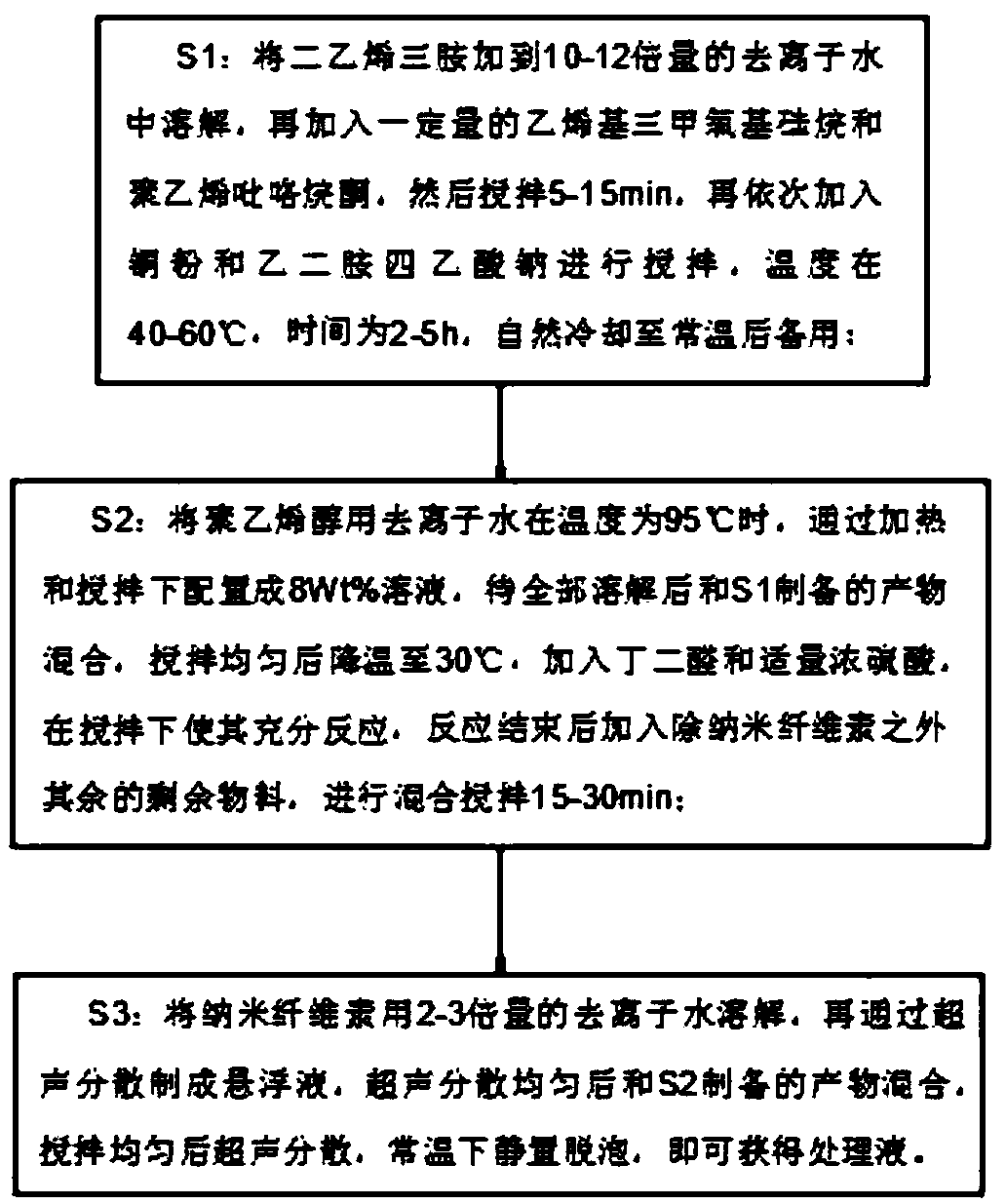

Metal surface silane treating agent containing aqueous nano-zinc oxide and preparation method thereof

ActiveCN103031056AGood corrosion resistanceExtended service lifeAnti-corrosive paintsSodium carboxymethylcelluloseUrea

The invention discloses a metal surface silane treating agent containing aqueous nano-zinc oxide. The metal surface silane treating agent is characterized by being a mixture solution prepared from the following ingredients in parts by weight (gram) in each liter of the mixture: 20-30 parts of propyl trimethoxy silane, 30-40 parts of aminopropyl triethoxy silane, 100-200 parts of aqueous nano-zinc oxide, 2-4 parts of propylene glycol, 2-4 parts of zirconium fluoride, 1-2 parts of ethylene glycol monobutyl ether, 0.8-1 parts of sodium monofluorophosphate, 2-3 parts of ethylene diamine tetramethylene risedremate sodium, 1-2 parts of urea, 0.6-0.8 parts of crylic acid, 0.4-0.6 parts of carboxymethyl cellulose and the balance of water. The metal surface silane treating agent has the advantages that a silane coating layer formed on the surface of a metal after the metal is treated by using the surface silane treating agent provided by the invention has excellent corrosion resistance performance, the service life of the metal is prolonged, and by combining the propyl trimethoxy silane and the aminopropyl triethoxy silane, a compact and solid coating layer is formed on the surface of the metal.

Owner:ANHUI LIUFANG ZHONGLIAN MECHANICAL SHARE

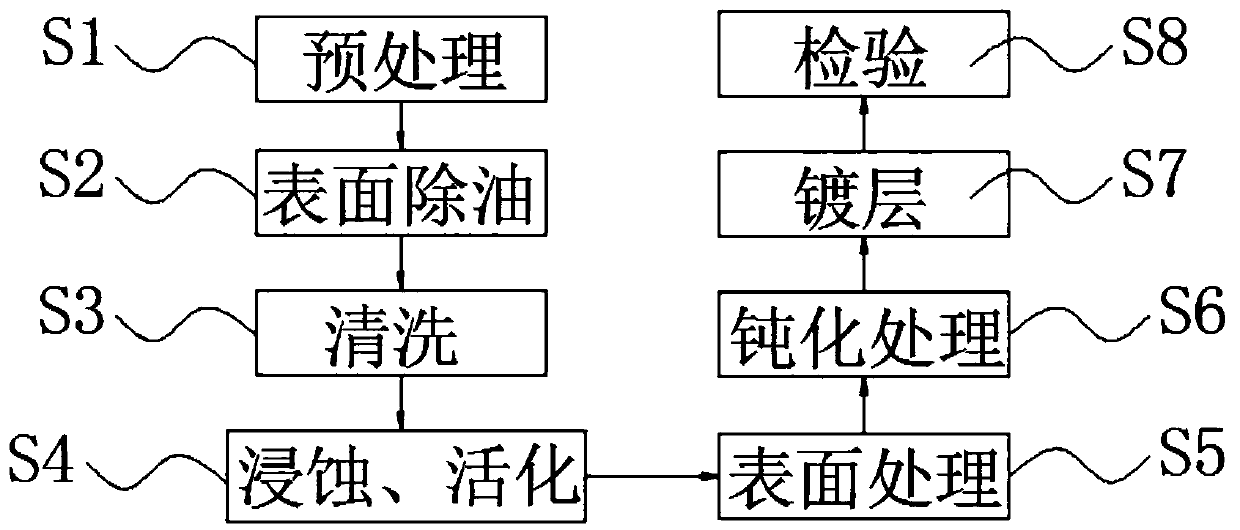

Processing technology of zinc-nickel plating alloy

The invention discloses a processing technology of a zinc-nickel plating alloy. The processing technology comprises the following steps: S1, pretreatment; S2, surface oil removal; S3, cleaning; S4, etching and activation; S5, plating; S6, passivation treatment; S7, surface treatment; and S8, inspection. During actual use, a zinc-nickel alloy coating layer is plated on the surface of a workpiece; the high-strength bonding force with a workpiece can be realized; the zinc-nickel plating alloy plating layer is fine in appearance, free of pinholes and free of blistering; the attractiveness of the workpiece is further improved; meanwhile, after the workpiece plating is finished, the surface is treated by a treatment liquid; the surface of the workpiece can be further protected, so that the workpiece has good thermal stability, corrosion resistance and oxidation resistance, the surface of the workpiece soaked in the treatment liquid is smooth and complete, and holes and redundant parts are avoided; the process is easy to operate, and the corrosion resistance of the plating layer is still superior to that of a pure zinc plating layer after the plating layer is processed.

Owner:TIANJIN DAGANG GALVANIZED FACTORY

A high-temperature self-lubricating wear-resistant powder coating

A high-temperature self-lubricating and wear-resistant powder coating, the raw materials of which are composed of 20-30% of nickel powder, 50-60% of titanium carbide powder or titanium nitride powder, and 10-20% of silver powder according to mass percentage. Use the powder coating of the present invention to spray on the metal substrate after sandblasting and roughening according to the process parameters of laser cladding in the prior art. The material is metallurgically combined and has high bonding strength. The hardness HV is ≥ 1500. The high-temperature self-lubricating wear-resistant coating has excellent anti-friction and wear-resisting properties. The high-temperature friction test temperature is 400-450°C, and its friction coefficient is 0.20- 0.30, with good wear resistance.

Owner:HEFEI UNIV OF TECH

Ytterbium-doped strontium cerate-alkali metal salt co-melt compound and preparation method thereof

InactiveCN107591541ALower working temperatureImprove compactnessCell electrodesSolid electrolyte fuel cellsStrontiumElectrochemistry

The invention provides an ytterbium-doped strontium cerate-alkali metal salt co-melt compound. The ytterbium-doped strontium cerate in the compound is prepared by a solid phase method, a microemulsionmethod or a sol-gel method, and then is composited with the alkali metal salt co-melt at the temperature of 750 DEG C to obtain the compound having good electrochemistry performance, and the operating temperature of a solid fuel cell using the ytterbium-doped strontium cerate as an electrolyte is greatly reduced.

Owner:FUYANG NORMAL UNIVERSITY

Preparation method of nutrition ball and nutrition medium for direct seeding of dry pepper

ActiveCN103483091AFunction increaseGuaranteed normal germinationFertilizer mixturesAdhesiveFermentation

The invention discloses a preparation method of nutrition ball and nutrition medium for direct seeding of dry pepper. The preparation method of the nutrition ball comprises the steps of grinding corn straw, then mixing the corn straw with humus and cow dung, stacking and fermenting the corn straw, the humus and the cow dung, drying or baking and grinding the fermented material after complete fermentation, mixing the material with vermiculite and perlite, adding a water-retaining agent and a binding agent into the material for mixing, adding water into the material to mix the material finally, loading the material into a die, performing pressing forming to the material, taking out the material after the material is dried, and obtaining the nutrition ball for direct seeding. By adopting the nutrition ball and the nutrition medium, the emergence rate, the planting percent and the sound seedling percent for the direct seeding of pepper are improved, the problem that as soil temperature and humidity are easy to be affect by environment and the changes are large, and soil is easy to harden, a surface layer is not beneficial to germination of pepper seeds and seedling growth is solved, the practicality of pepper direct seeding technology is realized, and the extension and application scope of the pepper direct seeding technology is expanded.

Owner:贵州省辣椒研究所

Anti-cracking, wear-resistant and seepage-proof compound mortar and preparation method thereof

The invention discloses anti-cracking, wear-resistant and seepage-proof compound mortar. The anti-cracking, wear-resistant and seepage-proof compound mortar is prepared from raw materials in parts by weight as follows: 20-30 parts of long and short reinforcing fiber, 15-20 parts of a waterproof additive, 10-20 parts of gelatine powder, 10-16 parts of a composite aid, 10-14 parts of glass beads, 65-75 parts of Portland cement, 55-65 parts of fine sand, 35-45 parts of composite filling sand, 1-2 parts of triethanolamine and 1-3 parts of sodium tripolyphosphate. The compound mortar has excellent anti-cracking, wear-resistant and efflorescence preventing properties and has better water resistance, seepage-proof property and adhesion force, relatively excellent impact resistance and thermal insulation and sound insulation effects and a certain pollutant air absorption function; besides, according to the provided preparation method, the material cost is lower, raw materials are easy to obtain, the process is simple, and the compound mortar has higher practical value and excellent application prospects.

Owner:HEFEI GUANGMIN BUILDING MATERIAL CO LTD

Flame-retardant coating fabric high in moisture-penetrability

The invention discloses a flame-retardant coating fabric high in moisture-penetrability. The flame-retardant coating fabric high in moisture-penetrability comprises a first base coating and a second base coating, wherein the first base coating is obtained by drying a sizing agent which is prepared from the following components in parts by mass: 100 parts of polyurethane resin, 38-42 parts of bromoethane, 19-21 parts of diantimony trioxide, 4.5-5.5 parts of zinc borate, 4-5 parts of a bridging agent, 1.6-2 parts of an accelerant, 1.4-1.6 parts of a washable agent and 9-11 parts of phosphate ester flame-retardant oil. The second base coating is obtained by drying a sizing agent which is prepared from the following components in parts by mass: 100 parts of polyurethane resin, 38-42 parts of bromoethane, 19-21 parts of diantimony trioxide, 4.5-5.5 parts of zinc borate, 4-5 parts of the bridging agent, 1.6-2 parts of the accelerant, 1.4-1.6 parts of the washable agent and 9-11 parts of phosphate ester flame-retardant oil. The flame-retardant coating fabric high in moisture-penetrability is small in smoke generation quantity, free of molten drop, high in flame-retardant effect and highly washable; the flame-retardant substance has a small possibility of hydrolyzing.

Owner:KUNSHAN HUAYANG NEW MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com