Welding method for stainless steel plates with thickness being smaller than 0.3 mm

A technology of stainless steel plate and welding method, applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve the problems of waste of raw materials, increase of product production cost, non-destructive welding, etc., achieve reduction of production cost, reduction of waste of raw materials, good Effect of Yield Strength and Tensile Break Strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment one: the plate to be welded is a 304 stainless steel plate with a thickness of 0.3mm, and the welding may include the following steps:

[0031] A. Material cutting, cutting the stainless steel plate according to the requirements, making the incision smooth and removing the burrs;

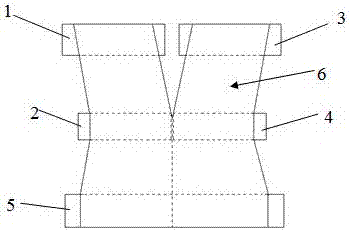

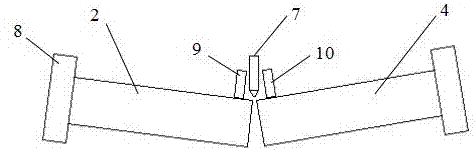

[0032] B. Install and fix the two parts of the plates to be welded on the fixture respectively, align the welding ports of the two plates to be welded, and the gap between the weld ports is 0.06mm;

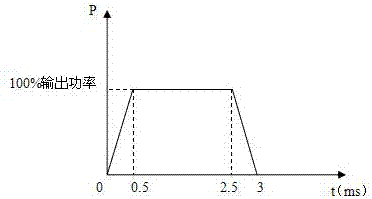

[0033] C. Use YAG pulse laser welding machine, and use inert gas as the shielding gas during welding. When welding, ensure that the air in the welding part is excluded, so that the laser welding pool is covered by the shielding gas; keep the laser beam irradiated on the two plates. Corresponding to the position of the welding port, the power of the laser beam is 50W, the energy is 2J, the positive defocus is 1mm, the spot diameter on the workpiece is 0.3mm, the frequency is 50HZ, and t...

Embodiment 2

[0036] Embodiment two: the plate to be welded is a 301 stainless steel plate with a thickness of 0.2mm, and the welding may include the following steps:

[0037] A. Material cutting, cutting the stainless steel plate according to the requirements, making the incision smooth and removing the burrs;

[0038] B. Install and fix the two parts of the plates to be welded on the fixture respectively, align the welding ports of the two plates to be welded, and the gap between the weld ports is 0.03mm;

[0039] C. Use YAG pulse laser welding machine, and use inert gas as the shielding gas during welding. When welding, ensure that the air in the welding part is excluded, so that the laser welding pool is covered by the shielding gas; keep the laser beam irradiated on the two plates. Corresponding to the position of the welding port, the power of the laser beam is 60W, the energy is 2J, the positive defocus is 1mm, the spot diameter on the workpiece is 0.5mm, the frequency is 55HZ, and t...

Embodiment 3

[0042] Embodiment three: the plate to be welded is a 316 stainless steel plate with a thickness of 0.1mm, and the welding may include the following steps:

[0043] A. Material cutting, cutting the stainless steel plate according to the requirements, making the incision smooth and removing the burrs;

[0044] B. Install and fix the two parts of the plates to be welded on the fixture respectively, align the welding ports of the two plates to be welded, and the gap between the weld ports is 0.015mm;

[0045] C. Use YAG pulse laser welding machine, and use inert gas as the shielding gas during welding. When welding, ensure that the air in the welding part is excluded, so that the laser welding pool is covered by the shielding gas; keep the laser beam irradiated on the two plates. Corresponding to the position of the welding port, the power of the laser beam is 55W, the energy is 2J, the positive defocus is 1mm, the spot diameter on the workpiece is 0.4mm, the frequency is 55HZ, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com