Patents

Literature

649results about How to "Seamless" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

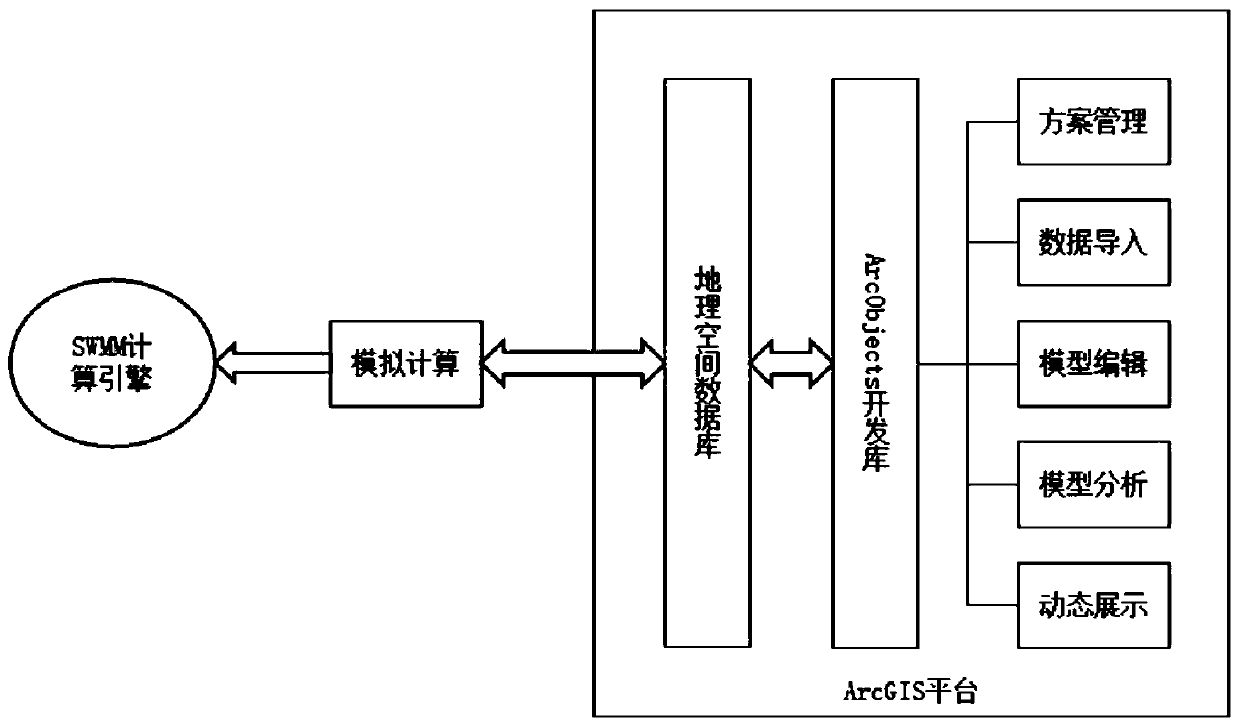

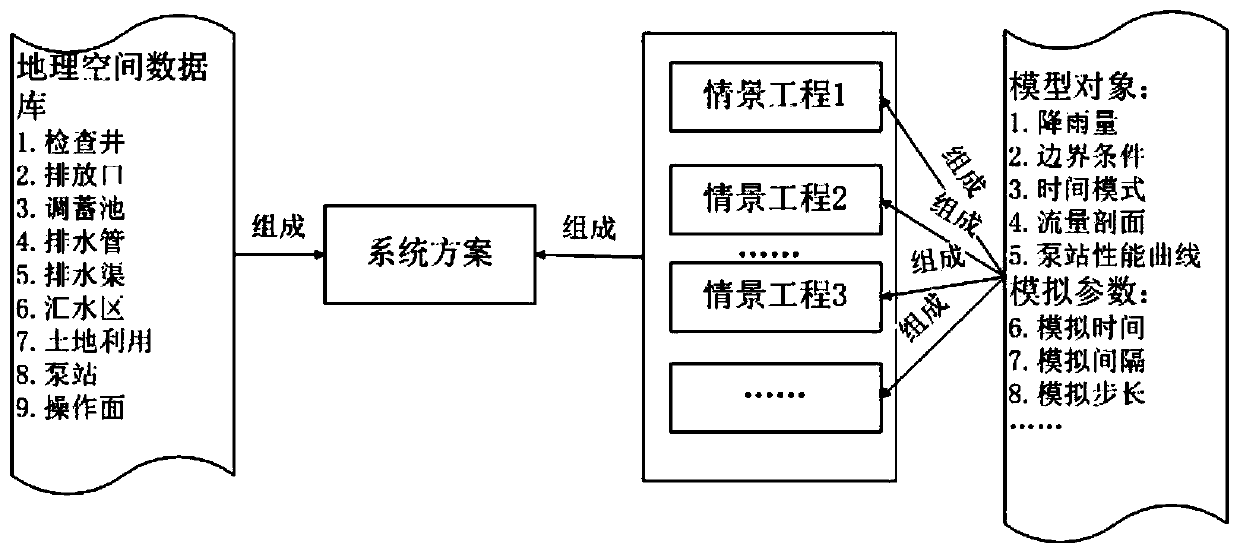

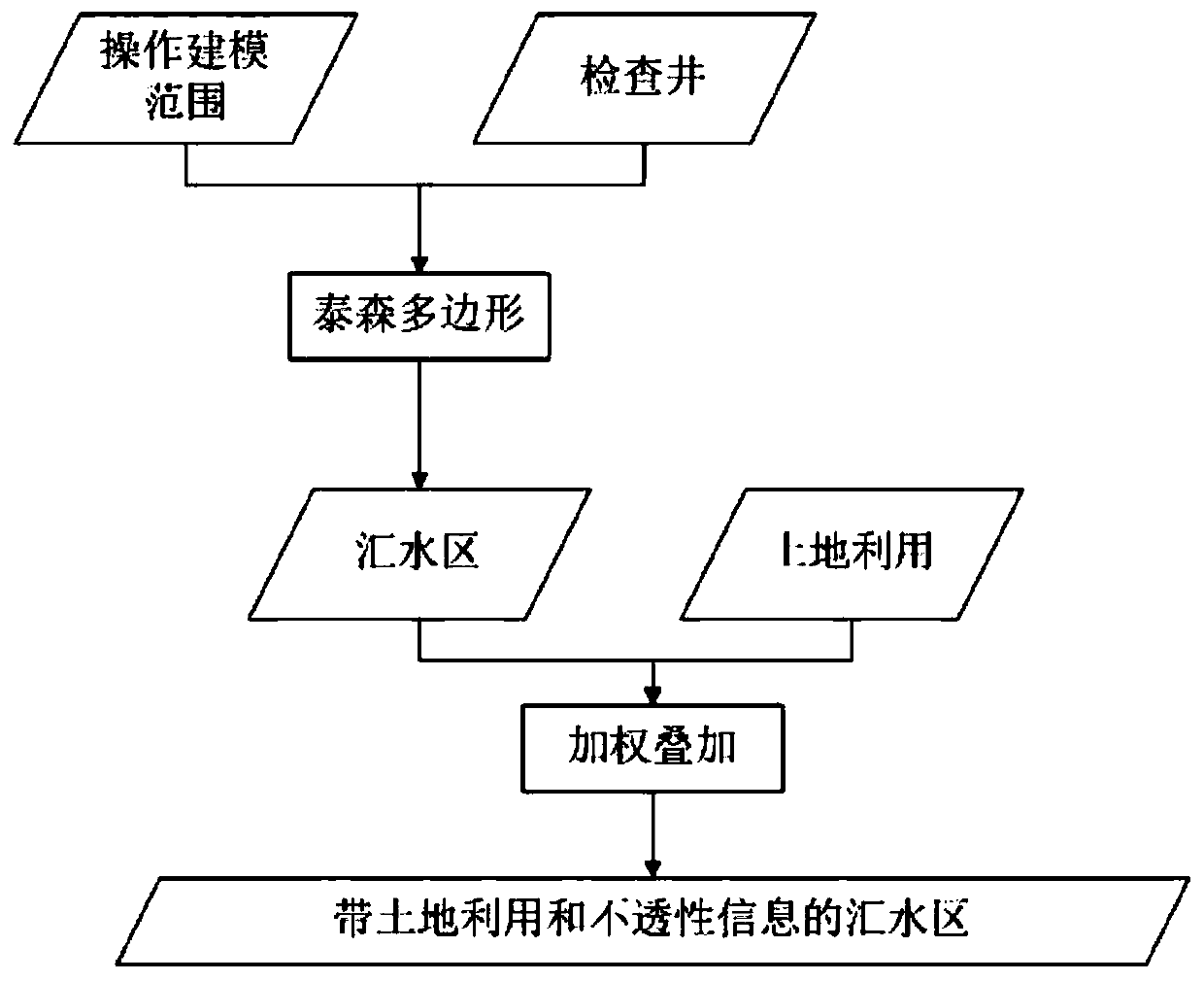

Urban inland inundation intelligent modeling and analysis method based on GIS and SWMM

ActiveCN110298076AHigh degree of construction automationThe analysis results are accurate and highClimate change adaptationDesign optimisation/simulationRisk levelCoupling

The invention relates to an urban inland inundation intelligent modeling and analysis method based on a GIS and an SWMM. The method comprises the following steps: constructing a simulation system based on the GIS and the SWMM; carrying out automatic preprocessing on the model data and automatically identifying topology errors; calculating a hydrological-hydrodynamic coupling model based on the SWMM by combining rainfall, calculating the amount of rainwater converged into a drainage pipe network system, simulating to obtain actual condition information in the drainage pipe network, and obtaining pipe point overflow data; performing surface water inundation analysis according to the pipe point overflow data, simulating the surface water to obtain the depth of the surface water, and distributing the surface water flow based on a window method; performing early warning analysis on waterlogging of surface water, comprehensively considering prediction of the surface water, automatically dividing waterlogging risk levels of different areas according to a calculation result of a hydrological-hydrodynamic coupling model and a result of surface water inundation analysis, and providing an early warning scheme for drainage waterlogging prevention emergency. The method has the advantages of being low in construction cost, high in model construction automation degree and accurate in analysisresult.

Owner:GUANGZHOU AOGE INTELLIGENT TECH CO LTD

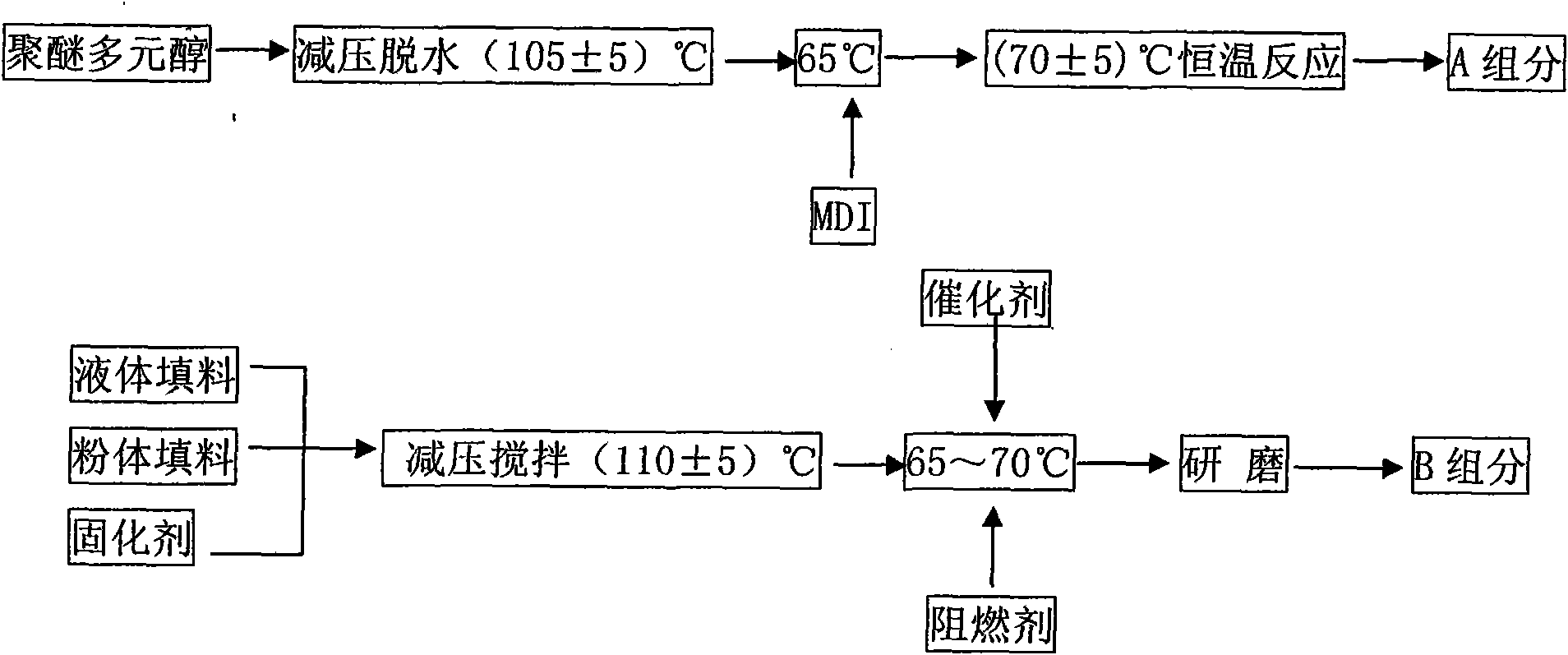

High-iron special flame-resistant polyurethane waterproof coating and preparation method thereof

InactiveCN101619193ALow volatilityLow vapor pressureFireproof paintsPolyurea/polyurethane coatingsPrepolymerHigh intensity

The invention discloses a high-iron special flame-resistant polyurethane waterproof coating and a preparation method thereof. The high-iron special flame-resistant polyurethane waterproof coating comprises an A component of an isocyanate group terminated polyurethane prepolymer and a B component of a dense cure-crosslinking agent. The prepared double-component high-strength flame-resistant polyurethane waterproof coating has tensile strength of 3.5-10MPa, at-break elongation of 450-600 percent and concrete interface boning strength greater than 2.5MPa and is used by uniformly mixing the A component and the B component according to a certain proportion and coating the mixture on a concrete waterproof plane to solidify into an integral waterproof coating with elasticity, firmness and durability. The coating is suitable for concrete ballast bridge floors and non-ballast bridge floors of high-iron passenger special line bridges and railway bridge culvert waterproof engineering and is suitable for the waterproofness of other buildings and constructions with higher requirements on waterproof performance.

Owner:天津市耀新科技发展有限公司

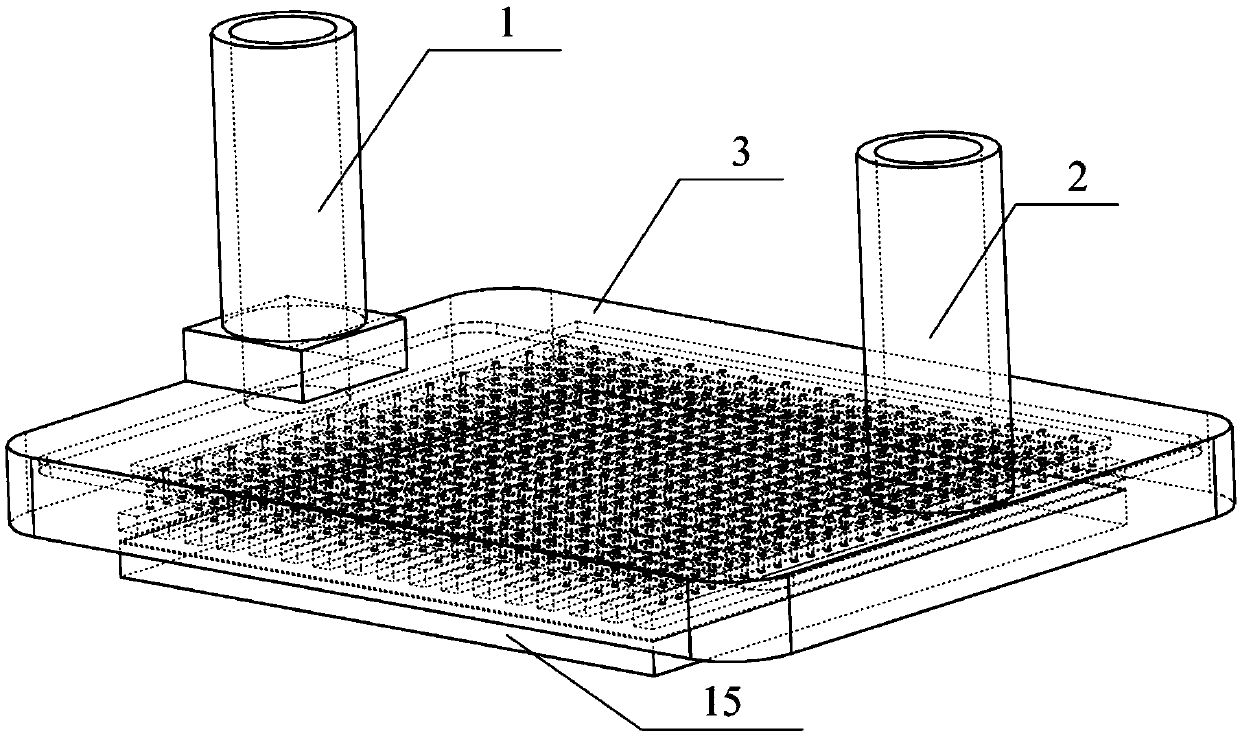

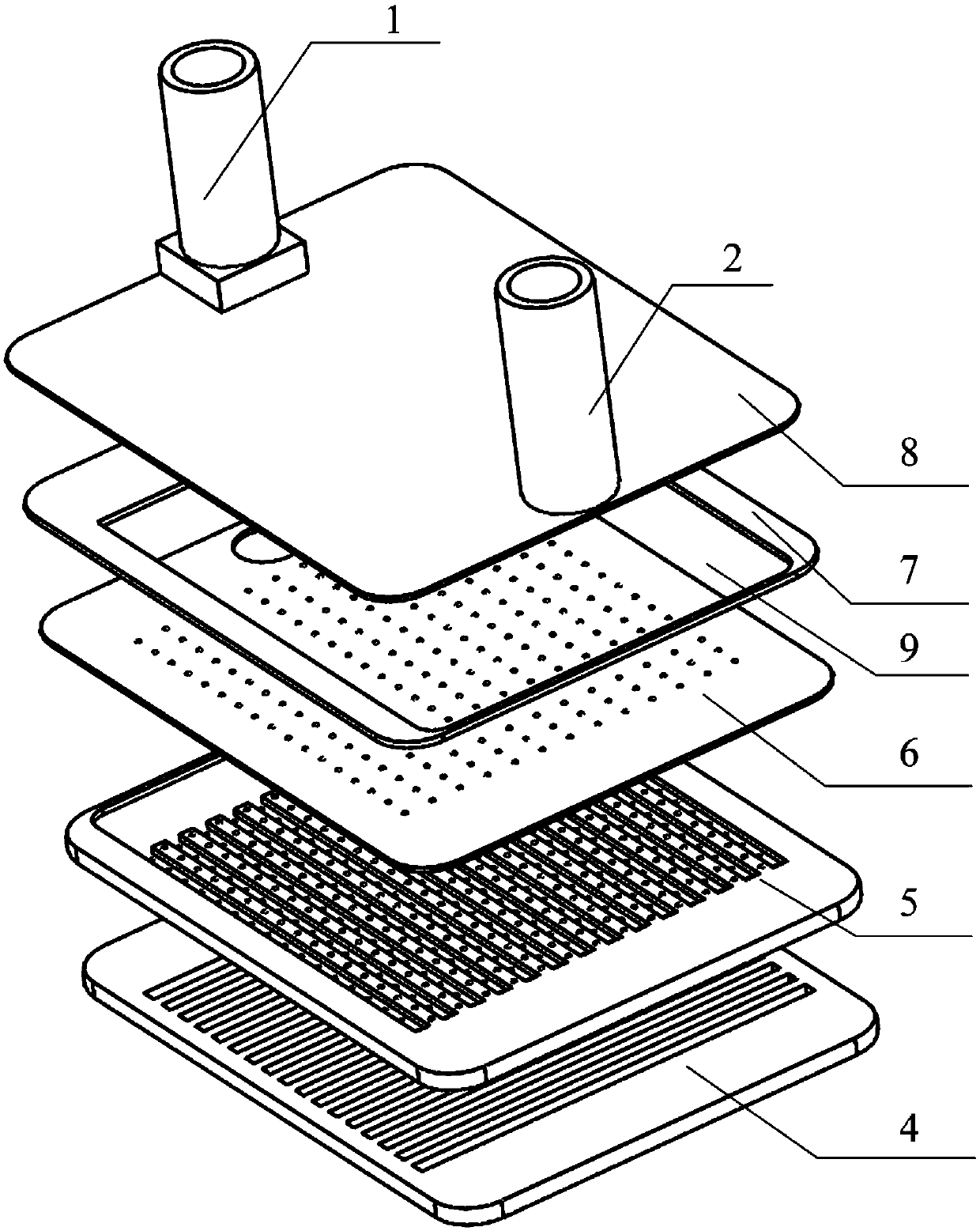

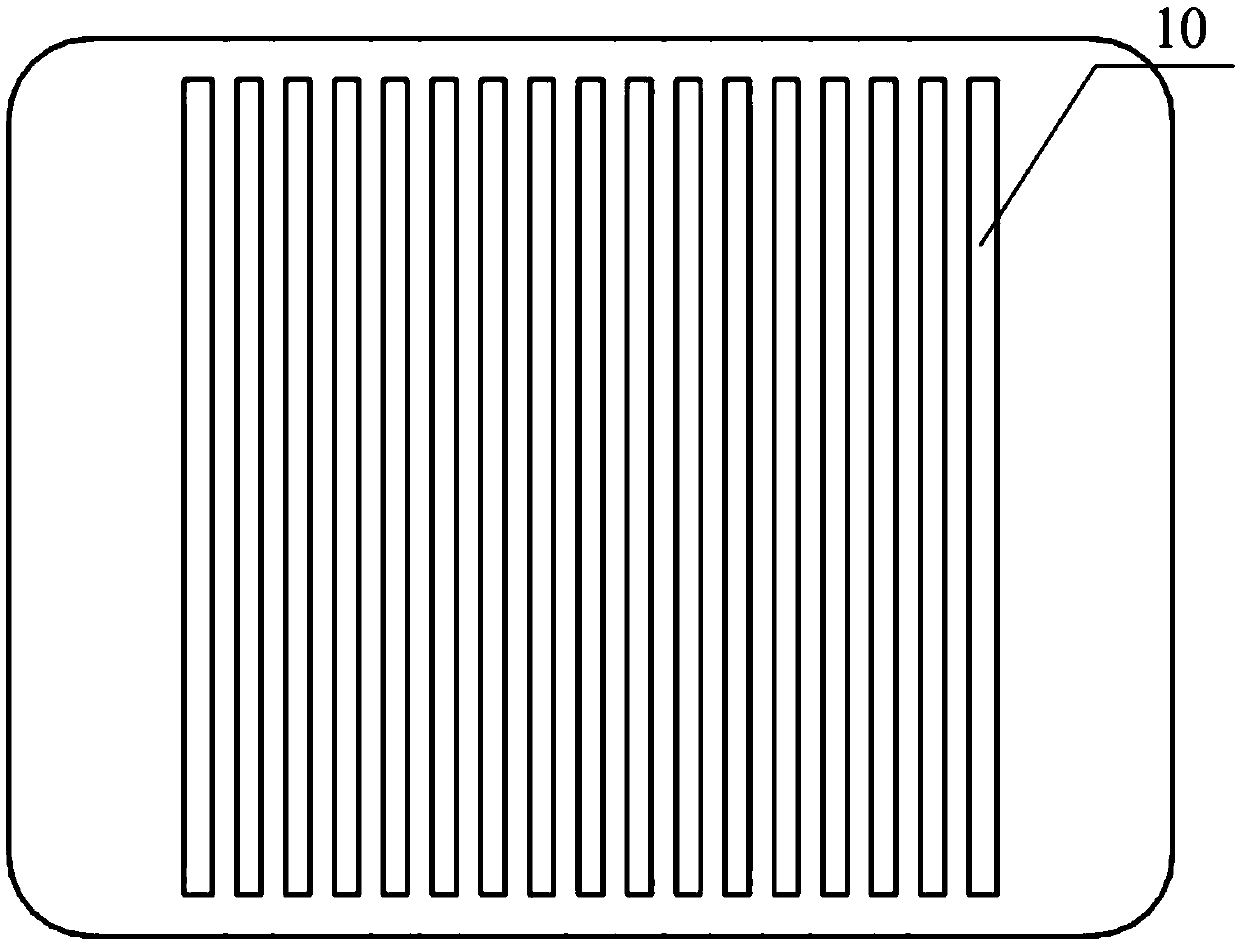

Multi-branch jet flow microchannel chip liquid cooling and heat radiating device

ActiveCN109524376AImprove cooling effectIncrease the heat exchange areaSemiconductor/solid-state device detailsSolid-state devicesWhole bodyCooling fluid

The invention belongs to the field of the heat dissipation of electronic devices and specifically discloses a multi-branch jet flow microchannel chip liquid cooling and heat radiating device which comprises a cooling liquid inlet pipe, a cooling liquid outlet pipe and a multi-branch jet flow microchannel cavity. The cooling liquid inlet pipe and the cooling liquid outlet pipe are installed on themulti-branch jet flow microchannel cavity which is a compact whole body formed by stacking and bonding an inlet and outlet layer, a recovery layer, a recovery hole layer, a jet nozzle layer and a microchannel layer in order, the cooling liquid inlet pipe is arranged on the inlet and outlet layer and communicates with the jet nozzle layer, cooling liquid enters into the microchannel layer via the jet nozzle layer, the cooling liquid outlet pipe is arranged on the inlet and outlet layer and communicates with the recovery layer, and the heat-absorbing cooling liquid is discharged out of the cooling liquid outlet pipe from the microchannel layer via the jet nozzle layer, the recovery hole layer and the recovery layer. According to the multi-branch jet flow microchannel chip liquid cooling andheat radiating device, the uniformity of the temperature of a chip can be improved, the heat dissipation performance is improved, and the heat dissipation problems of a high heat flux density chip anda heat generating electronic device can be solved.

Owner:HUAZHONG UNIV OF SCI & TECH

Copper plating solution for PCB (printed circuit board) blind holes, as well as preparation method and plating method of copper plating solution

InactiveCN103572336AReduce internal stressHigh filling ratePrinted element electric connection formationCopper platingPrinted circuit board

The invention relates to the technical field of PCB (printed circuit board) plating, in particular to a copper plating solution for PCB blind holes, as well as a preparation method and a plating method of the copper plating solution. Each liter of the copper plating solution comprises the following components according to contents: 100-300g of copper sulfate pentahydrate, 50-200g of sulfuric acid, 30-100ppm of chlorine ions, 5-50g of brightener, 3-30g of carrier, 2-20g of leveling agent and the balance of deionized water, wherein the concentration ratio of the copper sulfate pentahydrate to the sulfuric acid is (1.5-2): 1. The plating method comprises the following steps: putting a PCB with blind holes into a plating bath with the copper plating solution; plating during air agitation to obtain a copper plating layer. The copper plating layer formed by the plating method has a hole-filling rate as high as 97% above, and is dense, smooth, voidless, seamless, low in surface sediment thickness, relatively good in malleability, good in gloss, high in toughness and low in internal stress.

Owner:东莞市富默克化工有限公司

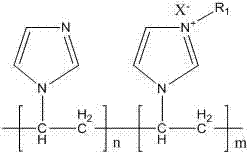

Preparation method for iron-based amorphous magnetic powder core with ultrahigh magnetic conductivity

ActiveCN103730224ASolving Press Molding ProblemsImprove permeabilityInorganic material magnetismCouplingLarge particle

The invention belongs to the technical field of alloyed soft magnetic powder core and particularly relates to a preparation method for an iron-based amorphous magnetic powder core with ultrahigh magnetic conductivity. The preparation method includes the steps of 1), subjecting an iron-based amorphous thin belt to heat treatment; 2), smashing the iron-based amorphous thin belt to obtain iron-based amorphous powder; 3), subjecting the iron-based amorphous powder to screening and matching, and then mixing the same to mixed powder containing coarse powder and fine powder; 4), subjecting the mixed powder to passivating, coupling, insulation coating and lubricating treatment in sequence by adopting passivator, coupling agents, insulating compounds, binding agents and lubricating agents, and then pressing for forming; 5), subjected the formed magnetic powder to annealing treatment and spraying insulation treatment in sequence. By the method of mixing and coupling treatment upon the coarse powder and the fine powder, the problem about pressing large-particle amorphous powder for forming can be effectively solved, and the iron-based amorphous magnetic powder core with the ultrahigh magnetic conductivity more than 200 can be prepared.

Owner:QINGDAO YUNLU ADVANCED MATERIALS TECH CO LTD

Geopolymer dry powder regenerated polystyrene heat preservation and heat insulating mortar

InactiveCN1762884ANo pollution in the processHigh affinitySolid waste managementHigh resistancePolymer science

The heat insulating mortar consists of earth polymer powder 48-54 wt%, regenerated polystyrene grain 5-8 wt%, flyash 28-30 wt%, latex powder 8-10 wt%, polypropylene fiber 0.20-0.35 wt%, and functional additive 3-4 wt%. The present invention adopts earth polymer powder to replace Portland cement as inorganic cementing material, and the heat insulating mortar has high strength, low shrinkage, high resistance to acid and alkali corrosion, environment friendship and other advantages.

Owner:严素玲

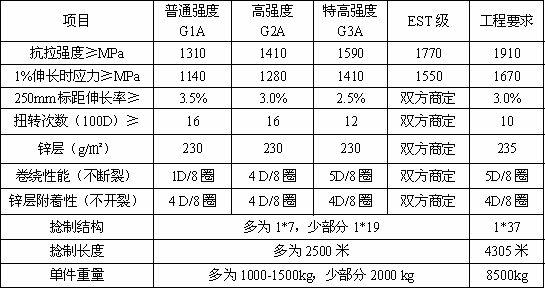

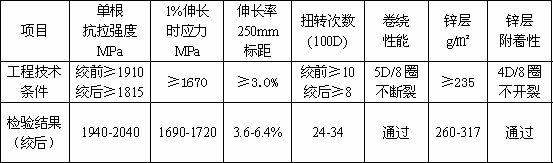

Production process of extra-high strength steel stranded wire for long-span transmission wire

ActiveCN102688906AEasy to implementMeet the technical requirements of large-scale engineeringExtrusion cleaning devicesWire rodHigh carbon

The invention relates to a production process of steel stranded wires, and in particular relates to a production process of an extra-high strength steel stranded wire for a long-span transmission wire. A raw material with a diameter of theta9.0mm and a steel grade of 82B is utilized to produce a 37-strand hot galvanizing steel stranded wire with a total diameter of 20.16mm and a single-wire diameter of 2.88mm for the long-span transmission wire. The production process comprises the following steps of: (1) coiling the raw material, carrying out surface treatment, and drawing a high carbon steel wire rod of theta9.0mm to theta8.5mm; (2) carrying out heat treatment, acid-washing, phosphating, and surface treatment on a wire rod; (3) drawing a finished product: carrying out 13-pass drawing processing by using a high-power and multi-pass LT-11 / 650 type water tank wire-drawing machine, wherein a compression ratio is 12-18.6%; (4) inspecting, putting online, hot galvanizing, and winding by using a spool; and (5) inspecting, and twisting. The production process of the steel stranded wire is simple in realization mode, and all indexes of the produced extra-high strength hot galvanizing steel stranded wire meet the technical requirements of long-span projects.

Owner:巩义市恒星金属制品有限公司

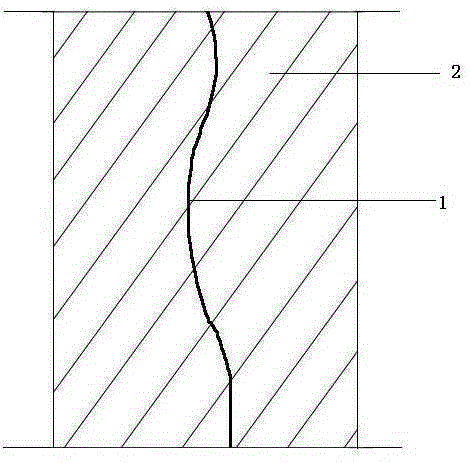

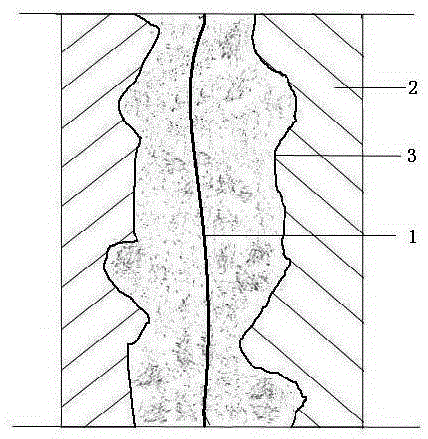

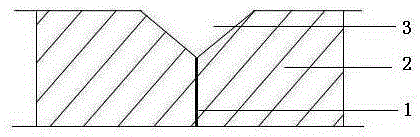

Construction process for plugging and consolidating concrete crack through chemical grouting

InactiveCN105239789ACrack works wellUniform thicknessBuilding repairsFoundation repairChemical groutingMaterials science

The invention relates to a construction process for plugging and consolidating a concrete crack through chemical grouting, which belongs to the technical field of concrete consolidation engineering and in particular relates to a concrete crack plugging and consolidating method. The construction process for plugging and consolidating the concrete crack through the chemical grouting comprises the following steps of the first step, opening a V-shaped groove, which is 20 mm wide at the upper part and at least 20mm deep, along the concrete crack; the second step, flushing the V-shaped groove; the third step, plugging the V-shaped groove; the fourth step, drilling a grouting hole; the fifth step, mounting a grouting head; the sixth step, performing grouting; and the seventh step, removing the grouting head. The construction process for plugging and consolidating the concrete crack through the chemical grouting, provided by the invention, is advantaged in that the grouting process is simple and convenient, the operation of the process is convenient, the crack is closely plugged without a gap, the plugged concrete crack is durable and fatigue-proof and not prone to crack again, the concrete crack plugging effect is good, the concrete surface is completely dry, leakage and moist are avoided, the thickness of a plugging and finishing coating on the surface of the crack is uniform, no missed brushing, no base exposure, no peeling, no swelling and no crack are achieved. And moreover, the process causes no pollution to the environment.

Owner:赵涛

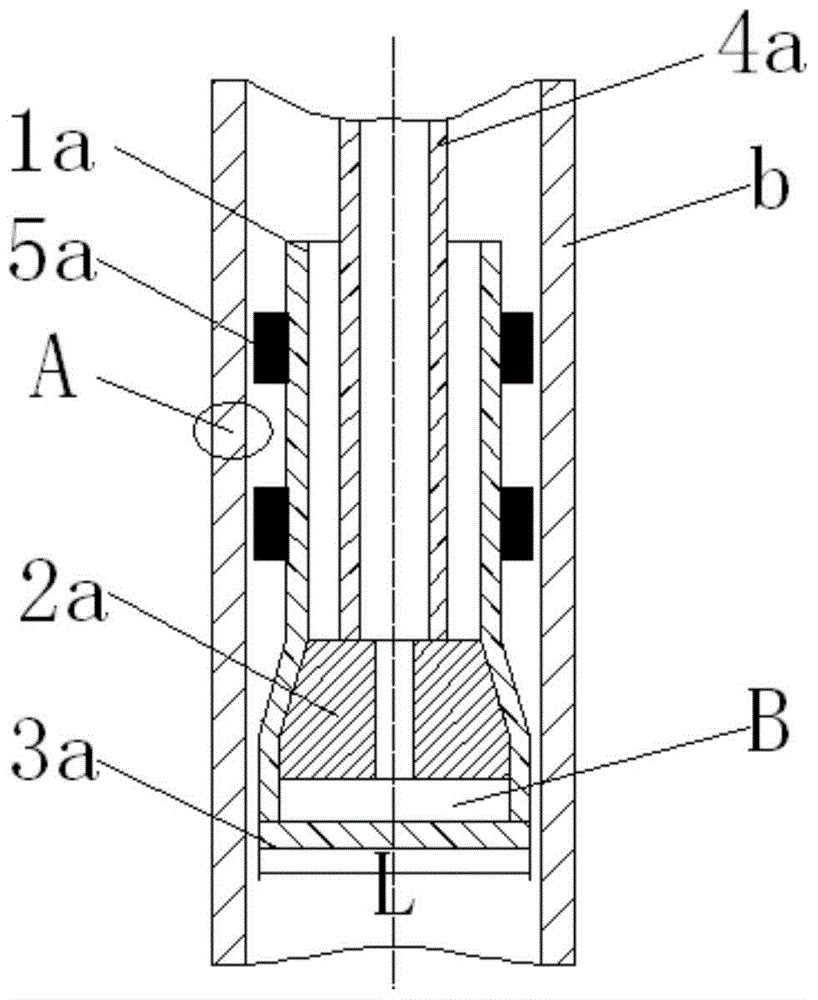

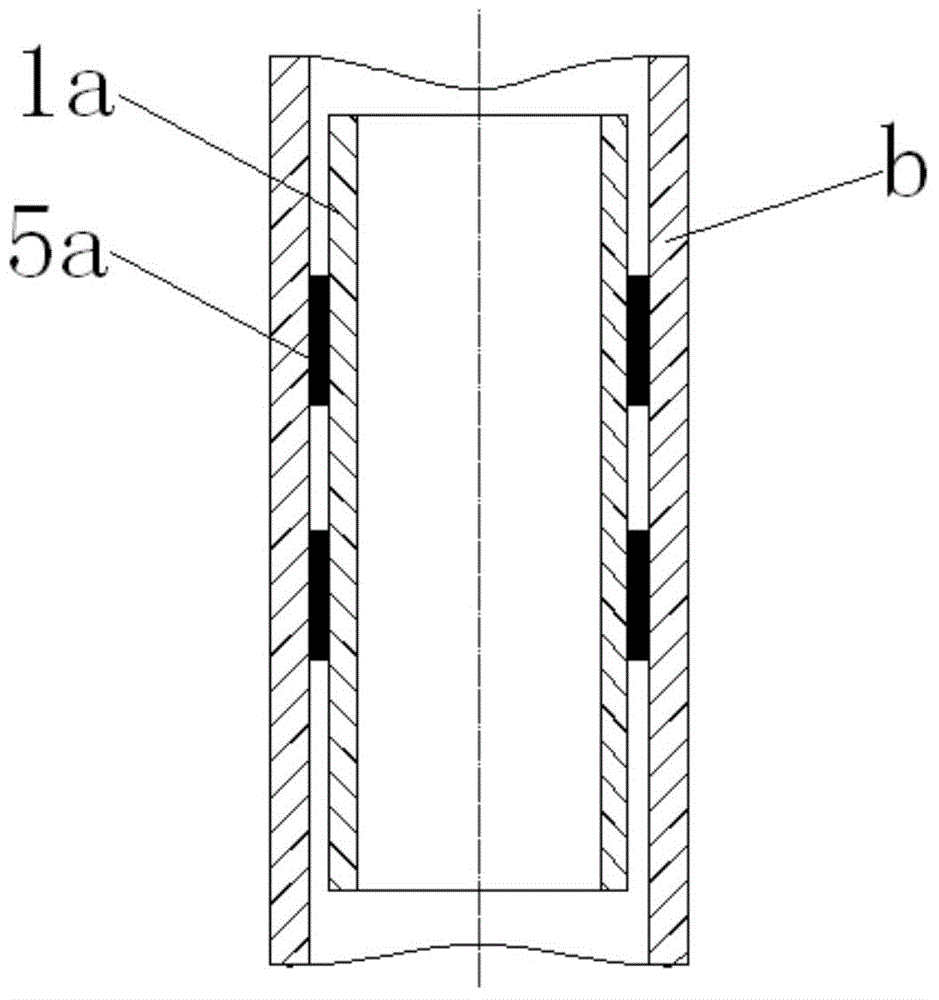

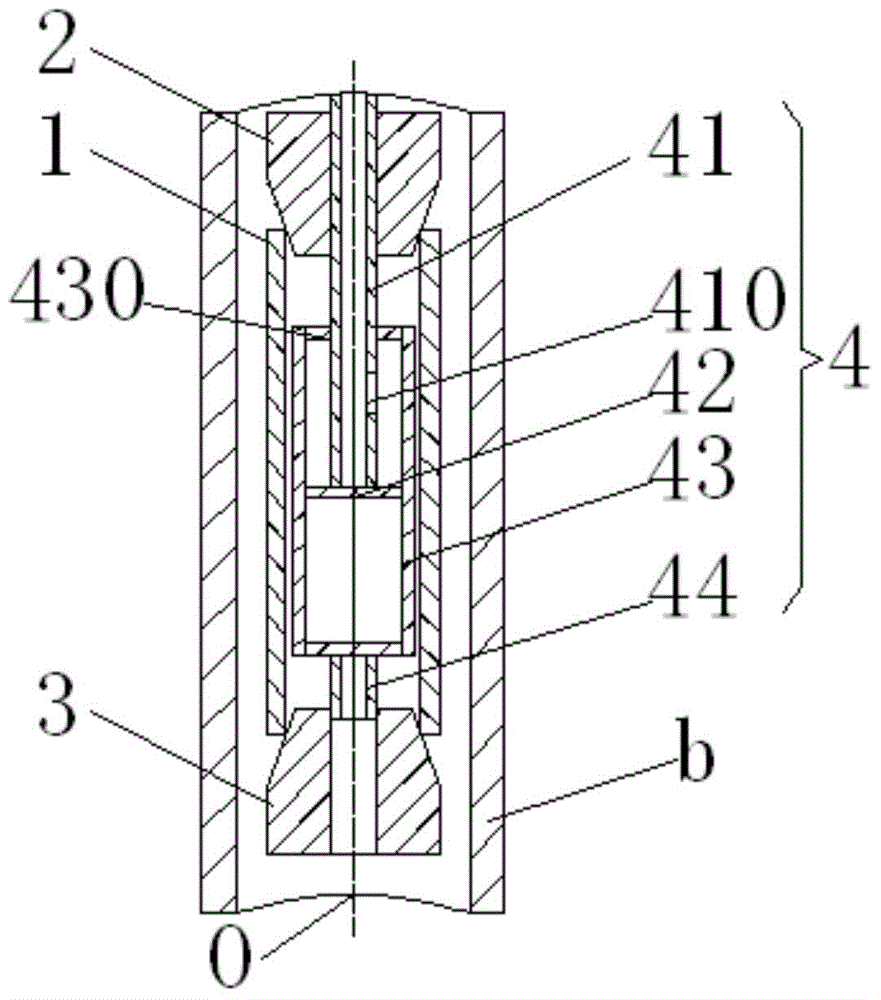

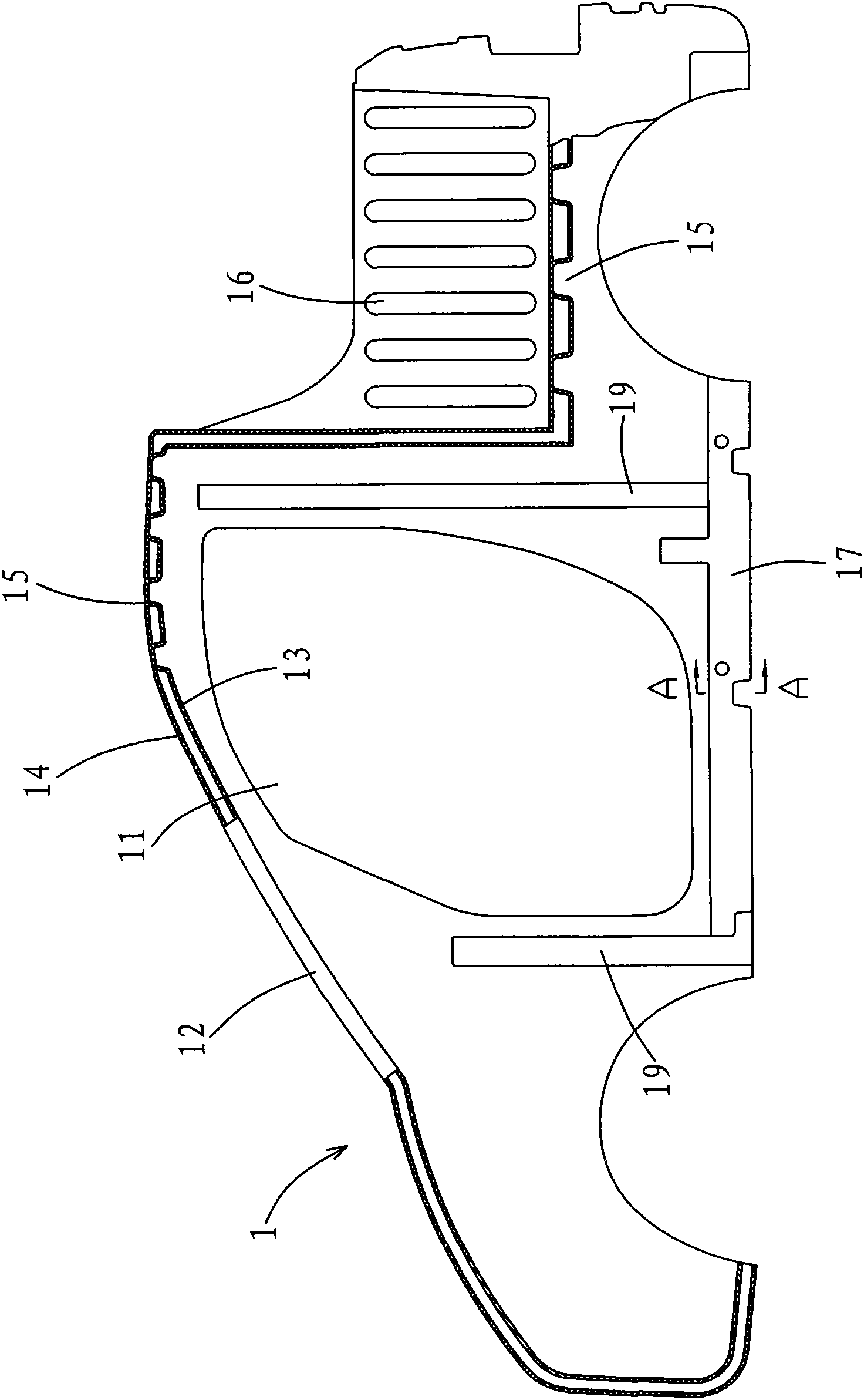

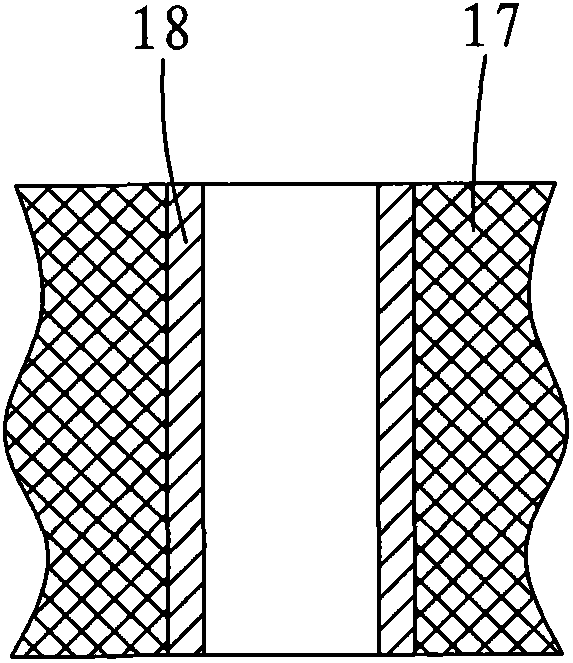

Expansion pipe repairing device

InactiveCN104153735AImprove efficiencyImprove passabilityBorehole/well accessoriesEngineeringConical surface

The invention discloses an expansion pipe repairing device which comprises an expansion pipe, an upper expansion cone, a lower expansion cone and a force applying component. The expansion pipe is a hollow pipe column extending along an axis. The pipe column is provided with a first port and a second port which are opposite. Each of the upper expansion cone and the lower expansion cone is provided with a conical surface. The conical surface of the upper expansion cone and the conical surface of the lower expansion cone are respectively clamped to the first port and the second port of the expansion pipe. The force applying component can drive the upper expansion cone and the lower expansion cone to move towards each other long the axis of the expansion pipe. By the expansion pipe repairing device, primary and secondary repairing of a casing damage well can be performed efficiently.

Owner:PETROCHINA CO LTD

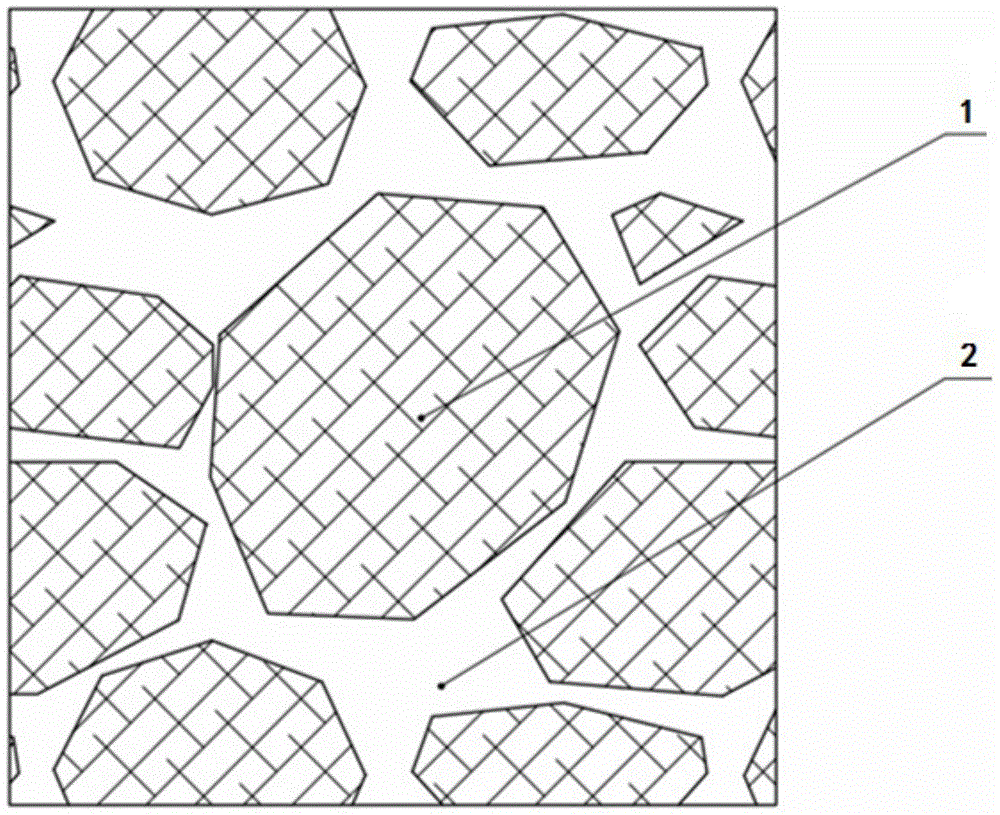

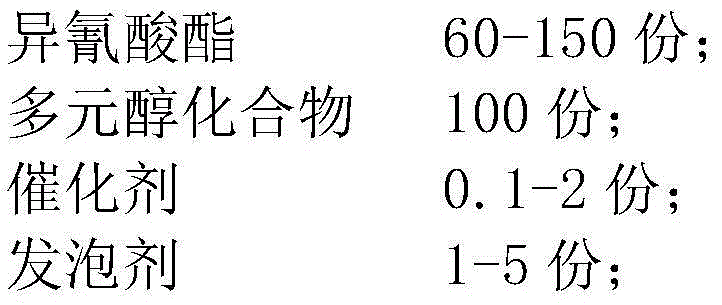

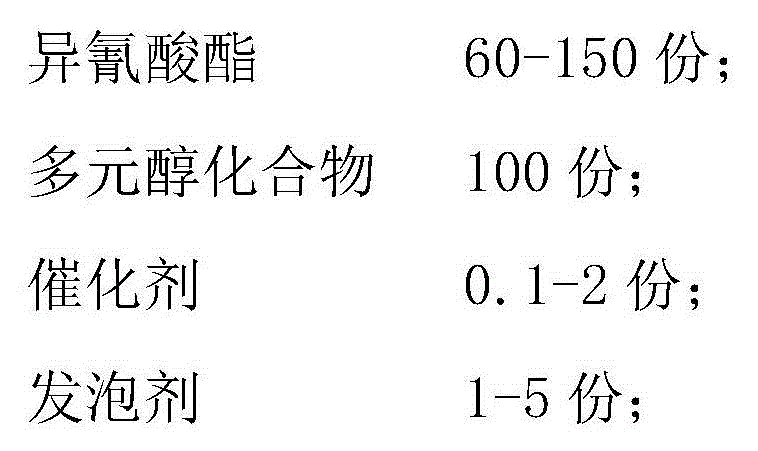

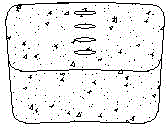

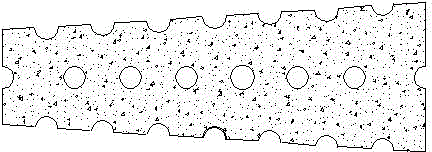

Composite polyurethane foam sheet produced by using hard foam wastes, and preparation method thereof

The invention provides a composite polyurethane foam sheet produced by using hard foam wastes. The sheet is prepared from, by weight, 60-150 parts of isocyanate, 100 parts of a polyol compound, 0.1-2 parts of a catalyst, 1-5 parts of a foaming agent, and hard foam wastes accounting for 60-90% of the total mass of raw materials. The sheet has the advantages of high utilization rate of the hard foam wastes, low energy consumption in the production process, provision of a new way for repeated utilization of the hard foam wastes, energy and material saving, and no influences on environment.

Owner:TIANJIN DALIN NEW MATERIAL TECH

Production method of ultrahigh magnetic permeability of iron-based nanocrystalline magnetic powder core

InactiveCN103745791ASolving Press Molding ProblemsEasy to press and formInorganic material magnetismMechanical crushingCoupling

The invention belongs to the technical field of alloy soft magnetic powder cores and particularly relates to a production method of an ultrahigh magnetic permeability of iron-based nanocrystalline magnetic powder core. The production method comprises step 1, performing mechanical crushing treatment on an iron-based nanocrystalline thin belt so as to obtain iron-based nanocrystalline powder; step 2, screening and matching the iron-based nanocrystalline powder and mixing into mixed powder which is formed by coarse powder and fine powder; step 3, performing passivation, coupling and insulation coating treatment on the mixed powder in turn through a passivation agent, a coupling agent, an insulating agent and a binding agent and performing compression forming; step 4, performing annealing treatment and spraying insulation treatment on the formed magnetic powder core in turn. According to the production method of the ultrahigh magnetic permeability of iron-based nanocrystalline magnetic powder core, the coarse powder and fine powder mixing and coupling treatment is adopted and accordingly the problem of the compression forming of large particle nanocrystalline powder can be effectively solved and the ultrahigh magnetic permeability of iron-based nanocrystalline magnetic powder core can be produced, wherein the magnetic permeability can reach more than 200.

Owner:QINGDAO YUNLU ADVANCED MATERIALS TECH CO LTD

Polymer dry mixed mortar

The dry mixed polymer mortar consists of quartzite 60-65 wt%, cement 20-25 wt%, limestone powder 8-12 wt%, amylase 3-3.5 wt%, thixotropic bentonite lubricant 1-3 wt%, organic silicon compound 1.5-2.0wt%, hydrophobic agent 0.15-0.20 wt%, methyl cellulose 0.20-0.30 wt% and cellulose fiber 0.30-0.60 wt%. It is one kind of green furnishing and decorating material and has the features of light weight, high strength, high adhesion, being fireproof, etc.

Owner:王胜怀

Preparation method for wear-resisting metal ceramic composite material

The invention discloses a preparation method for a wear-resisting metal ceramic composite material. The preparation method comprises the steps of uniformly mixing ceramic particles or ceramic particles being subjected to surface preprocessing with self-fluxing alloy powder by polyvinyl alcohol to obtain a mixture; filling a mould cavity of a pressing machine with the mixture, wherein a 2-10mm common steel gasket is arranged at the bottom of the cavity in advance, and the mixture bears 50-70MPa from the pressing machine; after molding and demolding, putting both a biscuit and the gasket into a drying box of 150 DEG C to be drying for 2 hours; putting the dried biscuit and the gasket into a vacuum furnace to be sintered for 30-90 minutes, wherein the temperature of the vacuum furnace is 1000-1300 DEG C, and the vacuum degree is 0.1-1.0Pa; and cooling down and taking out of the furnace to obtain the wear-resisting metal ceramic composite material. The composite material is prepared by pressing and has the relatively high compactness after being sintered; if being compounded on the surface of a wear-resisting part, the wear-resisting part has the relatively long friction durability; the mixture does not contain an adhesive agent, so that the composite material does not generate slag inclusion and pores after being sintered.

Owner:NANTONG GAOXIN ANTIWEAR MATERIALS TECH CO LTD

Low-carbon water granite paint

The invention relates to a low-carbon water granite paint which comprises 30-60 parts of composition A, 10-30 parts of composition B, 15-30 parts of composition C and 0.2-1.2 parts of thickener D. Compared with natural stone, the low-carbon water granite paint has the following advantages: 1. light dead weight: the low-carbon water granite paint can not increase the load to buildings, can be applied to the basal plane of the external wall without the risk of shedding, and is very suitable for external thermal insulation; 2. strong simulation sensation: the low-carbon water granite paint can be compounded to simulate various types of granite without color difference; 3. the low-carbon water granite paint is free from the restrictions of the complex basal plane, can be easily used for construction, and can completely cover the wall without seams; 4. the pointing construction can sufficiently display the tactile sensation of the decoration design of the dry-hanging stone; and 5. the surface of the coating can be treated to enhance the pollution resistance and weather resistance, thereby reducing the maintenance. Compared with the traditional real stone paint, the low-carbon water granite paint has the following advantages: 1. material saving and light dead weight as compared with the real stone paint simulated granite; 2. simple construction: the low-carbon water granite paint can be sprayed by only a single gun, but the real stone paint simulated granite needs to be sprayed by multiple guns; 3. the effect of the low-carbon water granite paint is more similar to the natural stone than the real stone paint simulated granite; and 4. when the low-carbon water granite paint is used for large-area construction, people can not feel color difference of uneven color dots caused by using the real stone paint simulated granite.

Owner:ZHONGSHAN TAILAI PAINT CHEM

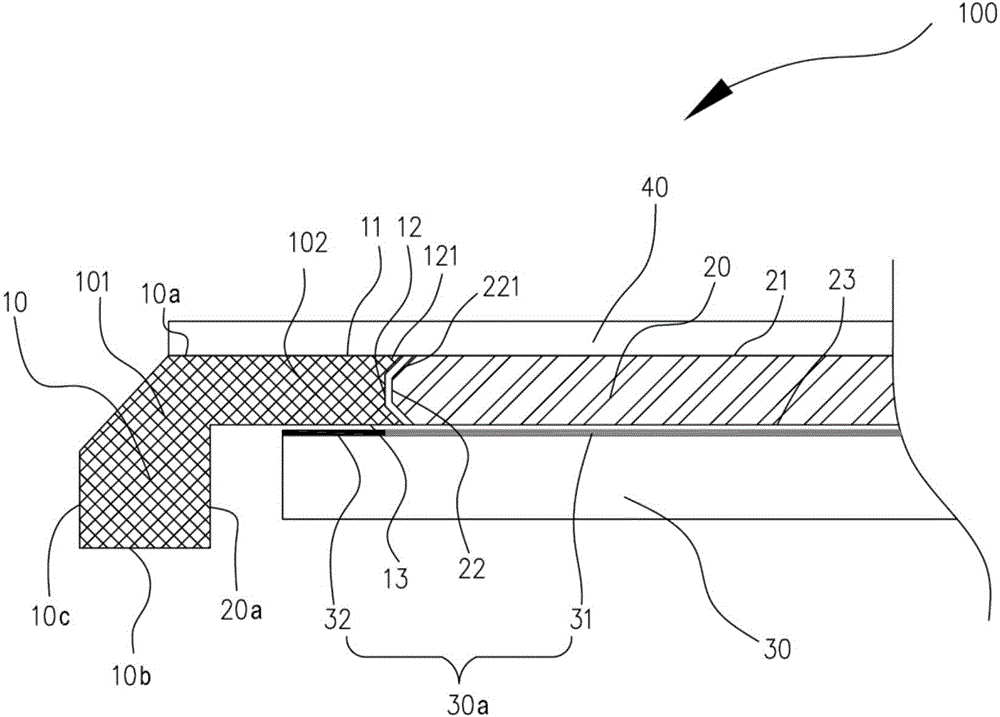

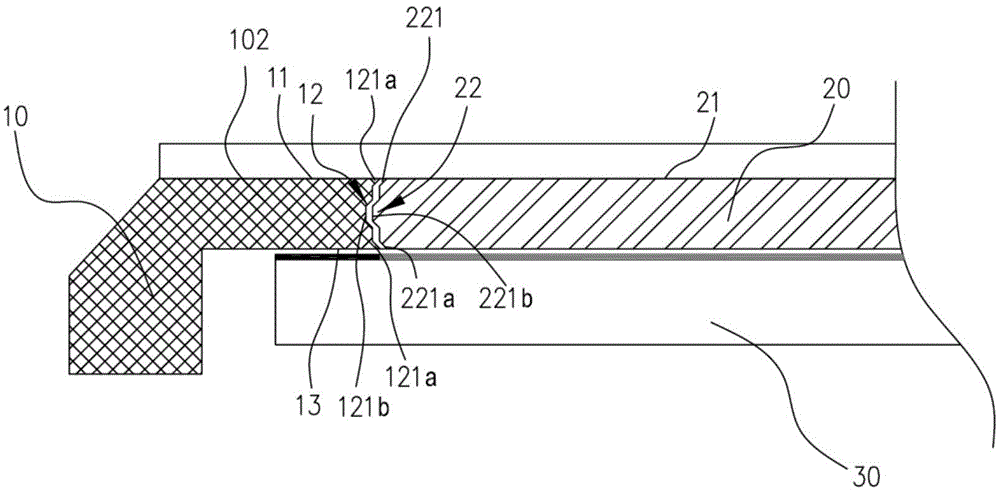

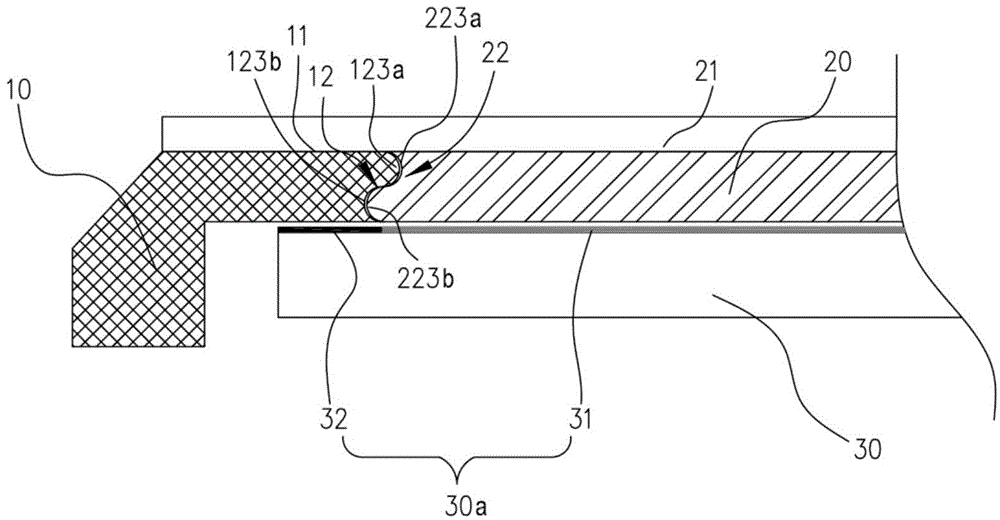

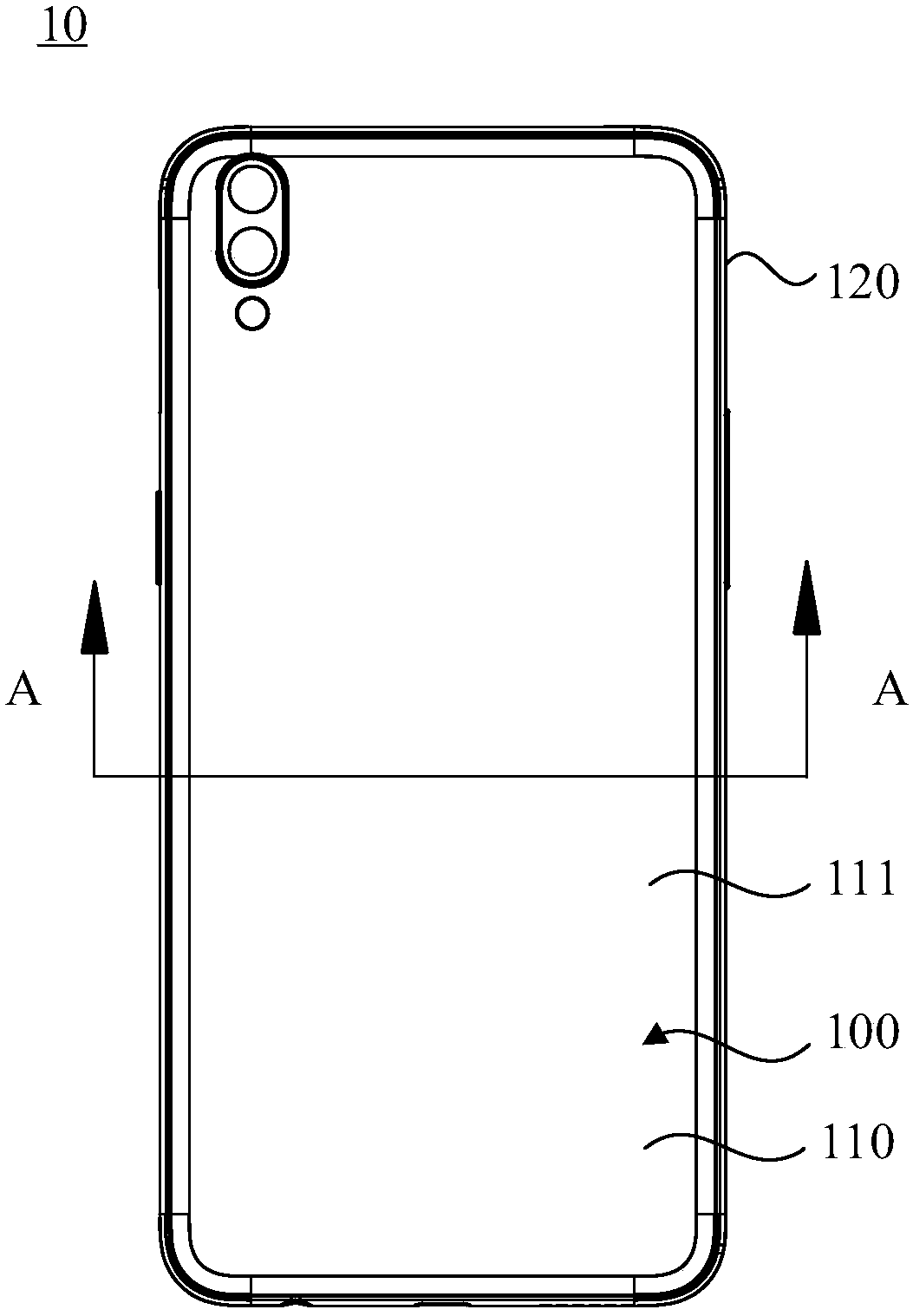

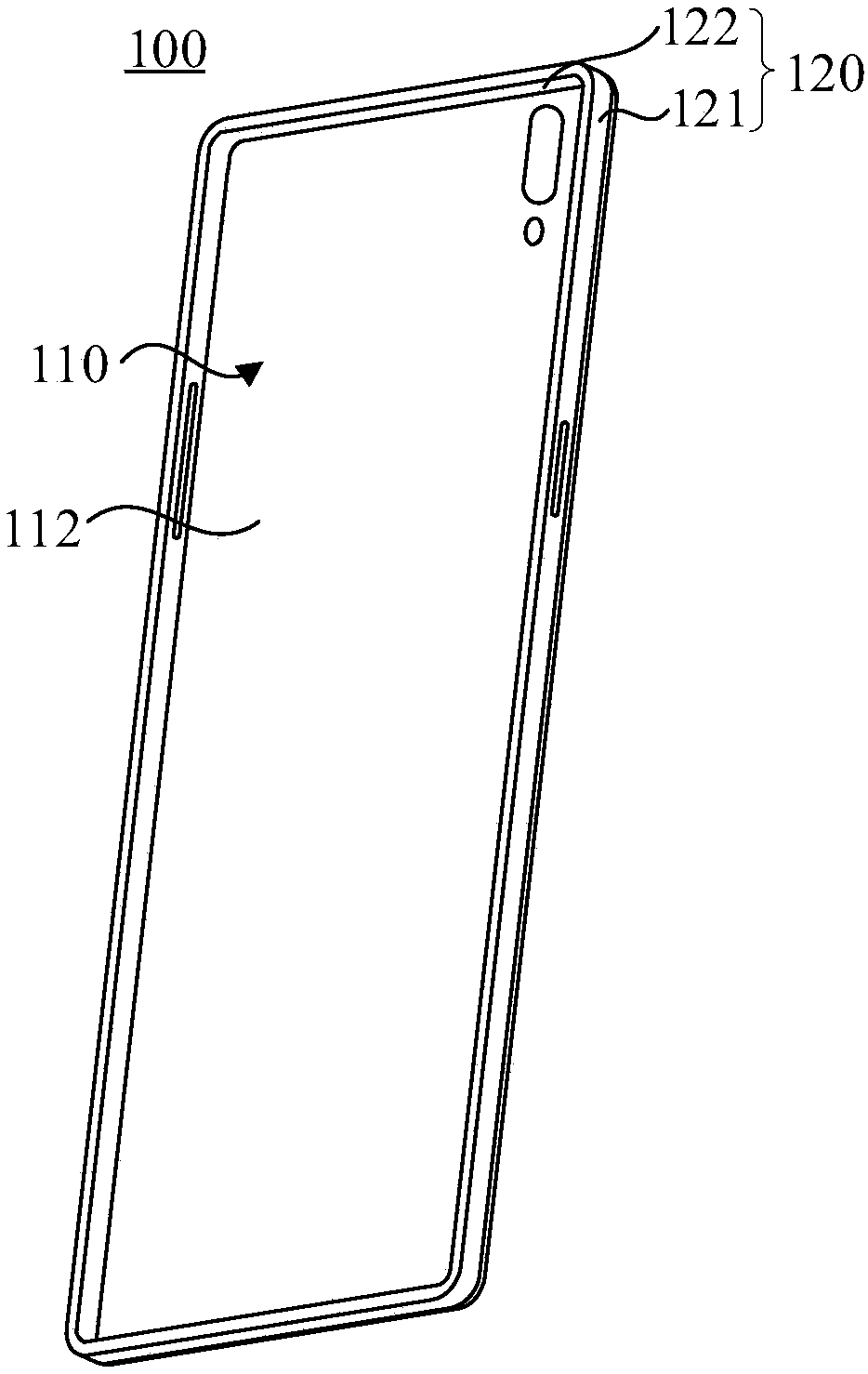

Terminal front cover and terminal

ActiveCN104866018AGood lookingImprove ergonomicsDigital data processing detailsTelephone set constructionsGlass sheetComputer engineering

The invention discloses a terminal front cover and a terminal. The terminal front cover includes a frame, a glass plate and a display screen, wherein the display screen includes a display surface; the display surface includes a display area and a non-display area; the non-display area surrounds the display area; the frame is fixed on the display surface and includes a visual surface and a first inner connecting surface connected to the visual surface; the glass plate comprises an upper surface and a second inner connecting surface connected to the upper surface; the first inner connecting surface is arranged on the inner side of the frame; the second inner connecting surface is arranged on the periphery of the glass plate; the frame is integrally formed on the glass plate; the first inner connecting surface of the frame is fitted with the second inner connecting surface of the glass plate; the visual surface and the upper surface are smoothly connected with each other to form a seamless smooth outer surface; the visual surface correspondingly shields the non-display area.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Automatic precipitation sampler

The invention aims to provide an automatic precipitation sampler which comprises a sampling bottle, a sampling bottle sensor, a pressure sensor, a detection funnel, a rain collection funnel, a cover, a rotary motor, a lifting rod, a lifting rod motor and a water injection mechanism, wherein the lifting rod is mounted below the cover; the lifting rod motor drives the lifting rod so that the cover moves up and down; the rotary motor is connected with the cover and drives the cover to rotate; the cover covers the rain collection funnel; the rain collection funnel is communicated with the water injection mechanism; the sampling bottle is arranged by corresponding to the water injection mechanism; the sampling bottle sensor is mounted on the water injection mechanism to detect whether the sampling bottle is full of water or not; the detection funnel is arranged beside the rain collection funnel; a pipeline blocking rainwater is connected below the detection funnel; a bypass pipe is mounted on the pipeline; and the pressure sensor is mounted on the bypass pipe. The automatic precipitation sampler provided by the invention can automatically collect rainwater in precipitation and automatically stop sampling after the rain stops; and after the collection, the precipitation automatic sampler can store the sample perfectly and record the precipitation-related data.

Owner:HARBIN ENG UNIV

Method of applying breadth textile wall paper

The present invention discloses a novel broad textile wall paper applying method, it includes the wall surface treatment step, applying basic cloth step and / or surface textile wall paper step. Among that, said surface textile wall paper is broad textile wall paper, the breadth is larger than 1. 2 m and less than 6. 5 meters. Said applying surface textile wall paper step is: cutting surface textile wall paper which size is same with the wall surface which needs to be constructed, the surface textile wall paper can be pre-coated with hot-melt binder or no binder, than applying the surface textile wall paper and the basic cloth under the conditions of heating up and pressurizing. The basic cloth applying uses the traditional glue stickup technology. The method in the invention can bond the broad textile wall paper on walls easily, and it has no joints and bubbles, the applying is smooth and beautiful; if the refitting is needed, it can be again composed one layer or several layers directly.

Owner:绍兴市新丝路布业有限公司

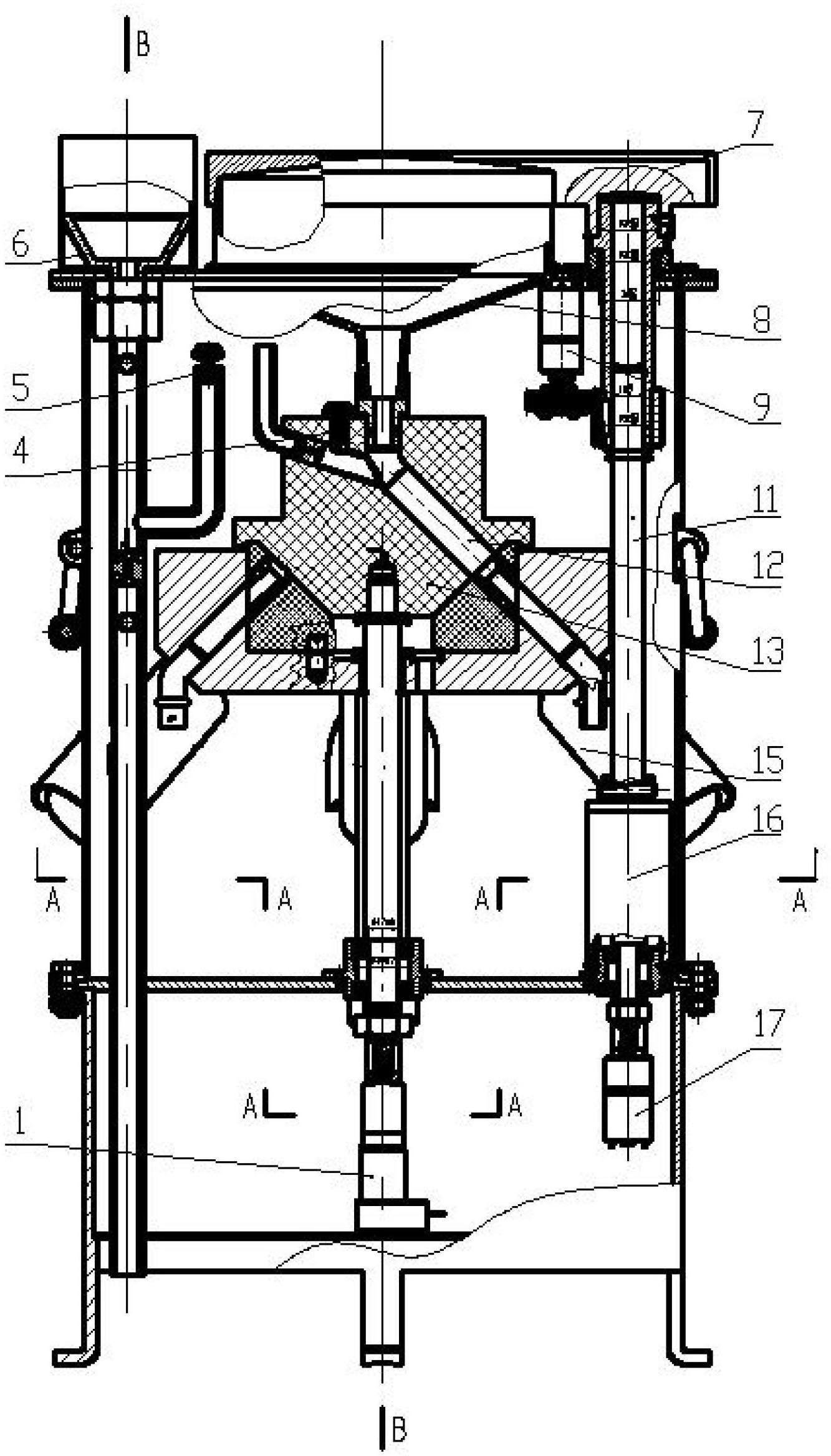

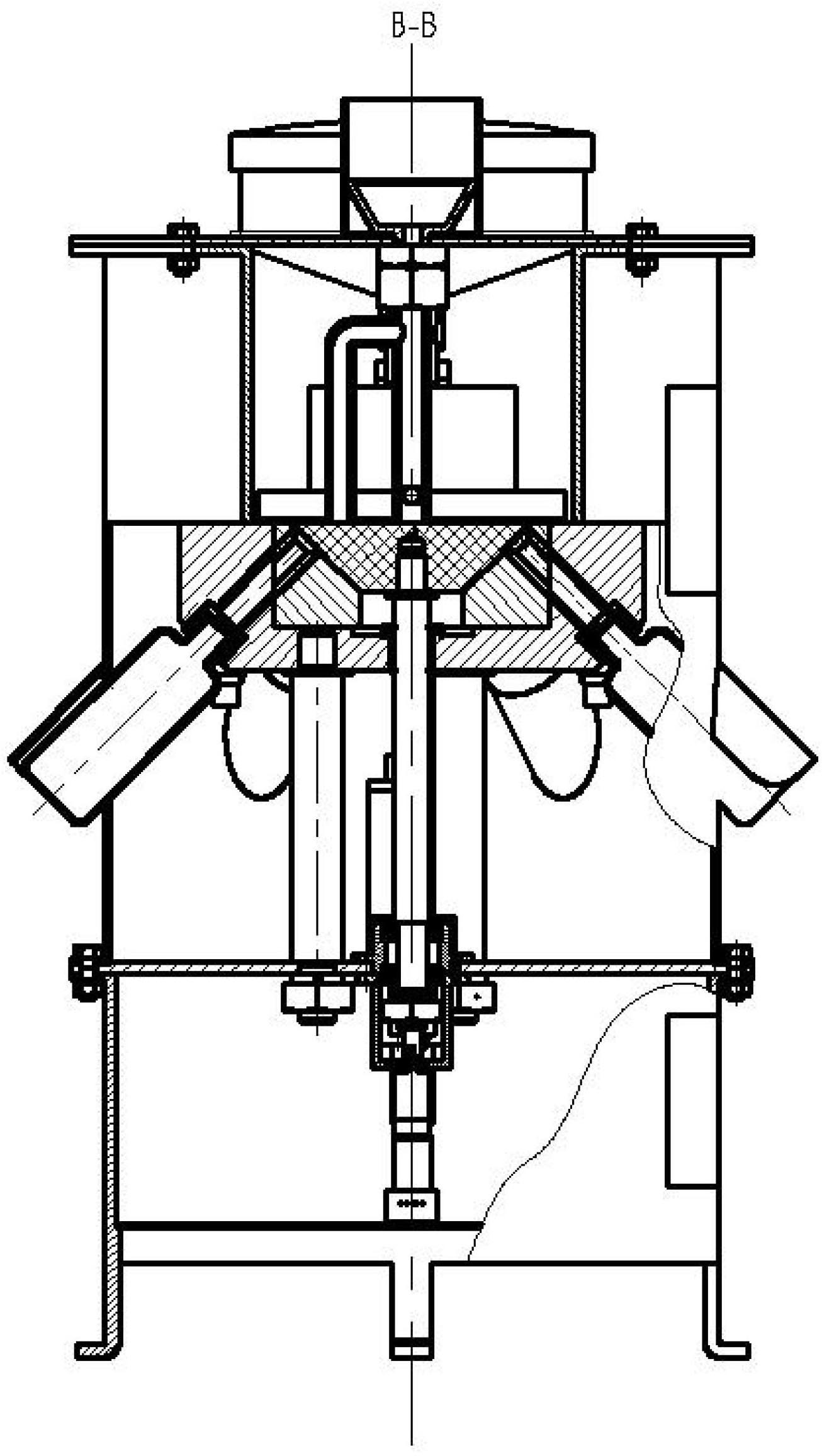

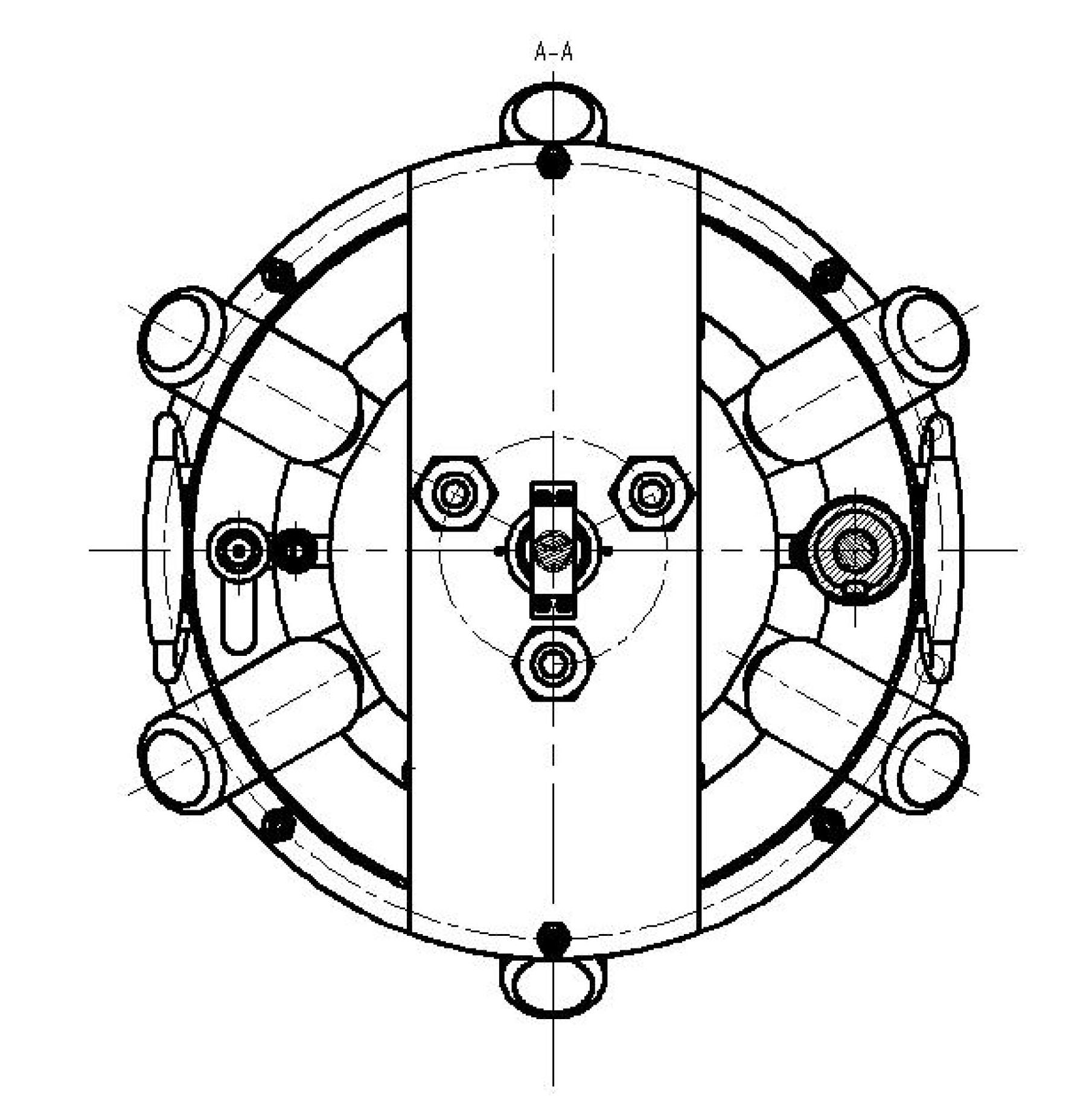

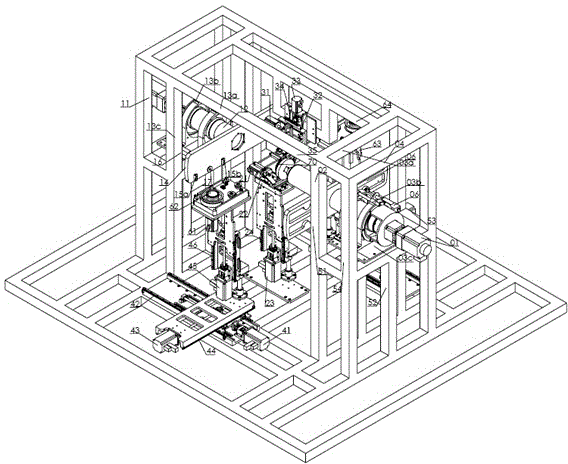

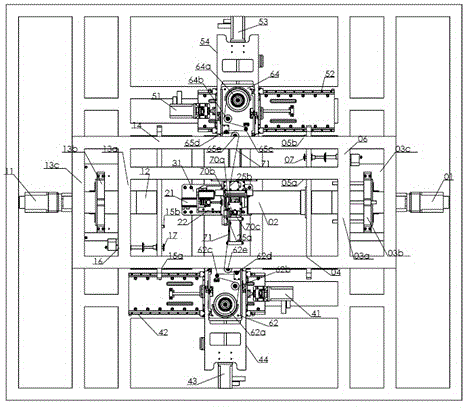

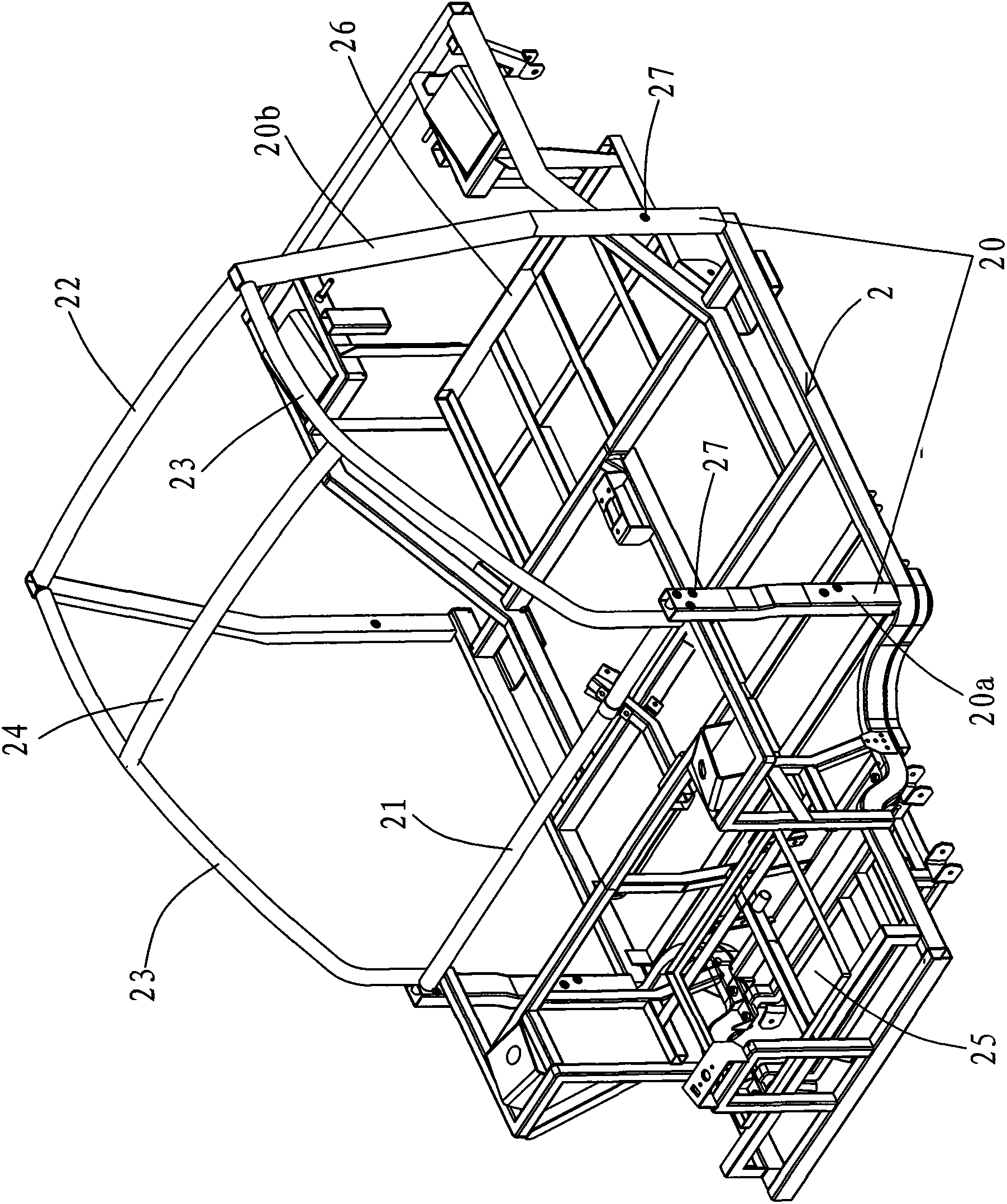

Automatic optical fiber gyroscope winding machine and optical fiber winding method

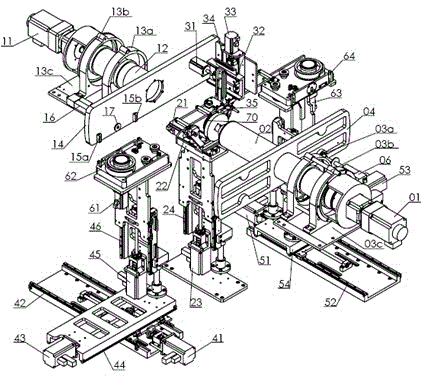

ActiveCN104792338AEvenly linedImprove work efficiencyMeasurement devicesWinding machineConductor Coil

The invention relates to an automatic optical fiber gyroscope winding machine and an optical fiber winding method. The optical fiber gyroscope winding machine comprises a rack, a take-up tray, a spindle system, a sub-spindle system, a foot pressing system, a guiding system, a forward moving base, a backward moving base, a front pay-off tray base and a rear pay-off tray base. The optical fiber winding method comprises the processes of preparing, hanging a rear pay-off tray, removing the rear pay-off tray, hanging a front pay-off tray, removing the front pay-off tray, winding and arranging optical fibers. According to the technical scheme, the winding machine and the winding method can eliminate the drawbacks in the prior art, achieves automatic optical fiber winding, has the characteristics of uniform winding arrangement, no gap and the like, and can greatly improve the operation efficiency.

Owner:合肥正阳光电科技有限责任公司

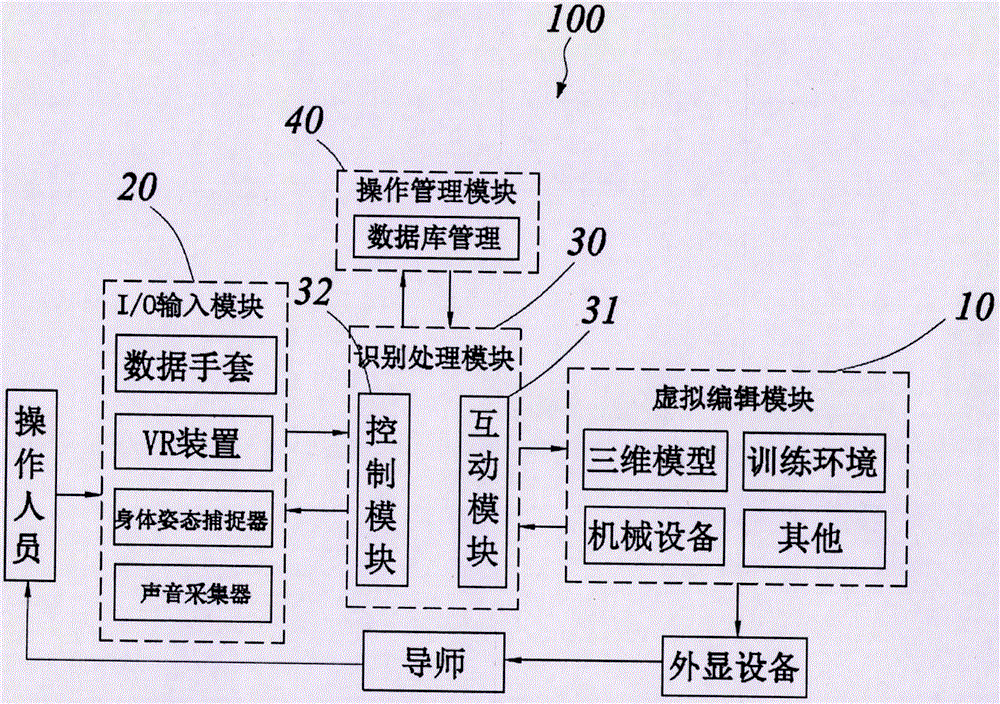

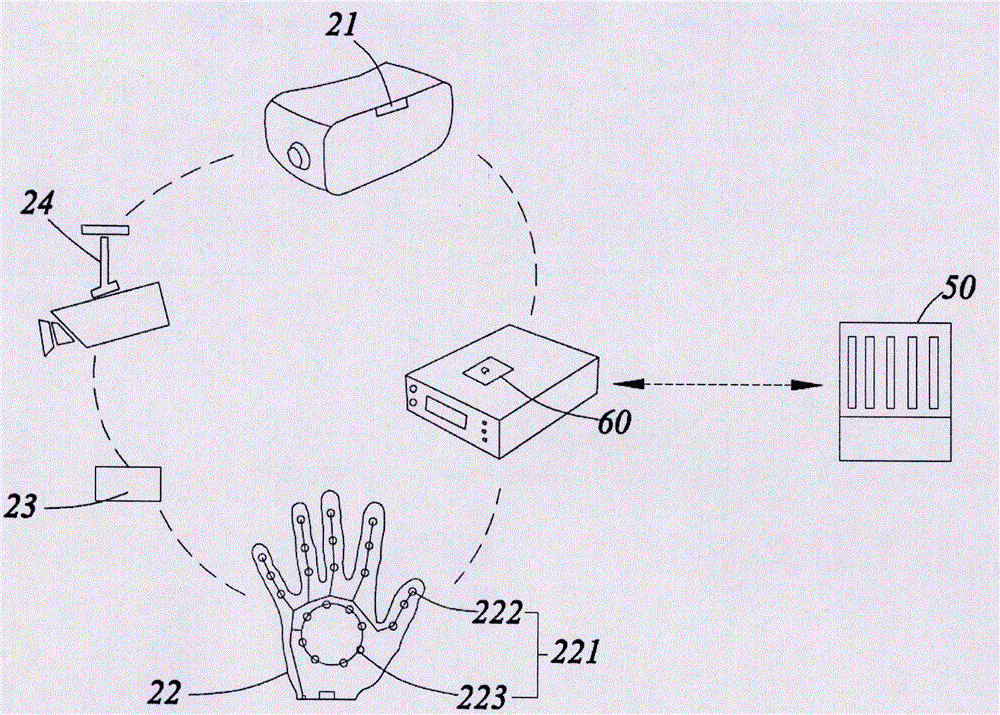

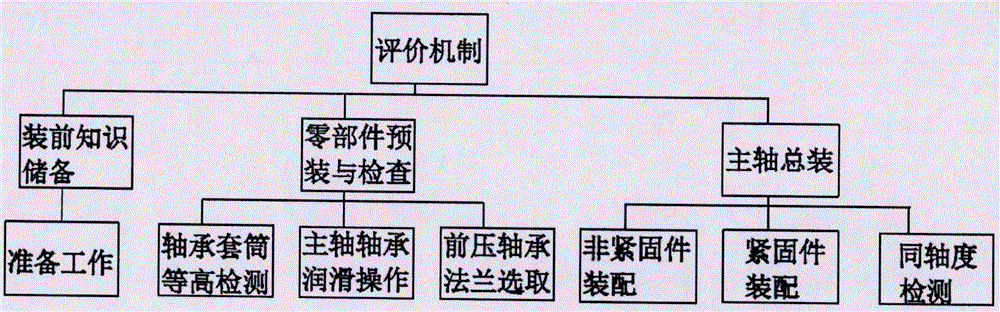

Virtual practice training system and method of mechanical equipment

InactiveCN106782013AReduce the cost of trainingQuick Master RepairEducational modelsData informationDisplay device

The invention provides a virtual practice training system of mechanical equipment. The virtual practice training system comprises a virtual editing module, an I / O (Input / Output) input module, a recognition processing module and an operation management module, wherein the virtual editing module is used for editing the content of a virtual scene; the I / O input module comprises a VR (Virtual Reality) display device, a data glove, a sound acquisition device and a movement capturing device, and is used for feeding back operation data of people to be trained; the recognition processing module is used for acquiring data information, fed back through the I / O input module, of the people to be trained, and analyzing and processing the data information to obtain a score conclusion; and the operation management module is used for establishing an operation database aiming at the people to be trained by the formed data content. The invention further provides a method for carrying out practice training by utilizing the virtual practice training system of the mechanical equipment. By adopting the virtual practice training system and method, provided by the invention, the teaching difficulty of traditional practice training can be broken through, the investment cost can be reduced, and the practice training activity of the people to be trained is improved.

Owner:HUNAN UNIV

Automobile with one-time formed plastic shell

InactiveCN102328702ASimple manufacturing processIncrease productivitySuperstructure subunitsSuperstructure connectionsEngineeringBody weight

The invention relates to an automobile with a one-time formed plastic shell. The automobile comprises an automobile body and a chassis, wherein the automobile body is a hollow double-layer plastic shell which is integrally formed at one time by a rotational molding process and is provided with an automobile door installation hole and an automobile window installation hole in advance; a plurality of contact reinforcing ribs are formed between an inner-layer wall body and an outer-layer wall body of the hollow double-layer plastic shell; a plurality of convex reinforcing ribs are formed on the external surface of the outer-layer wall body or the inner-layer wall body of the hollow double-layer plastic shell; a chassis embedding groove is formed at the lower end of the external surface of the inner-layer wall body of the hollow double-layer plastic shell; a plurality of threaded sleeves are embedded into the chassis embedding groove; the chassis is embedded into and in threaded connection with the chassis embedding groove; the external surface of the inner-layer wall body of the hollow double-layer plastic shell is provided with door post embedding grooves on two sides of the automobile door installation hole; and the upper end of the chassis is fixedly provided with door posts inserted into the door post embedding grooves. The automobile has the advantages of high strength and surface performance, light body weight, low cost and the like, and is easy to manufacture and convenient to assemble.

Owner:应革

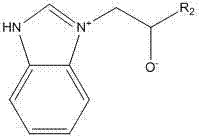

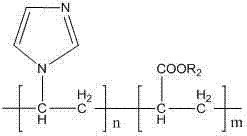

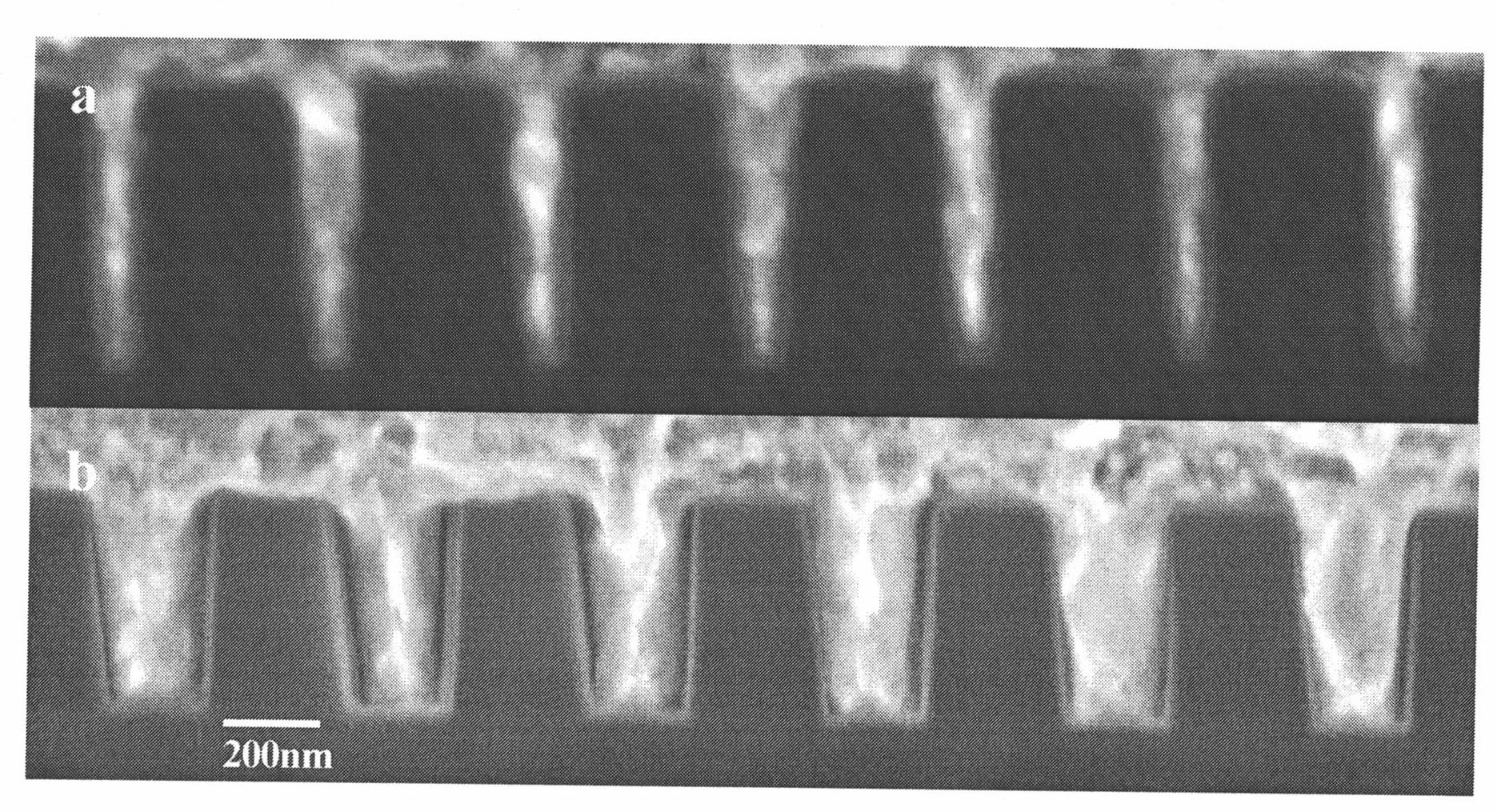

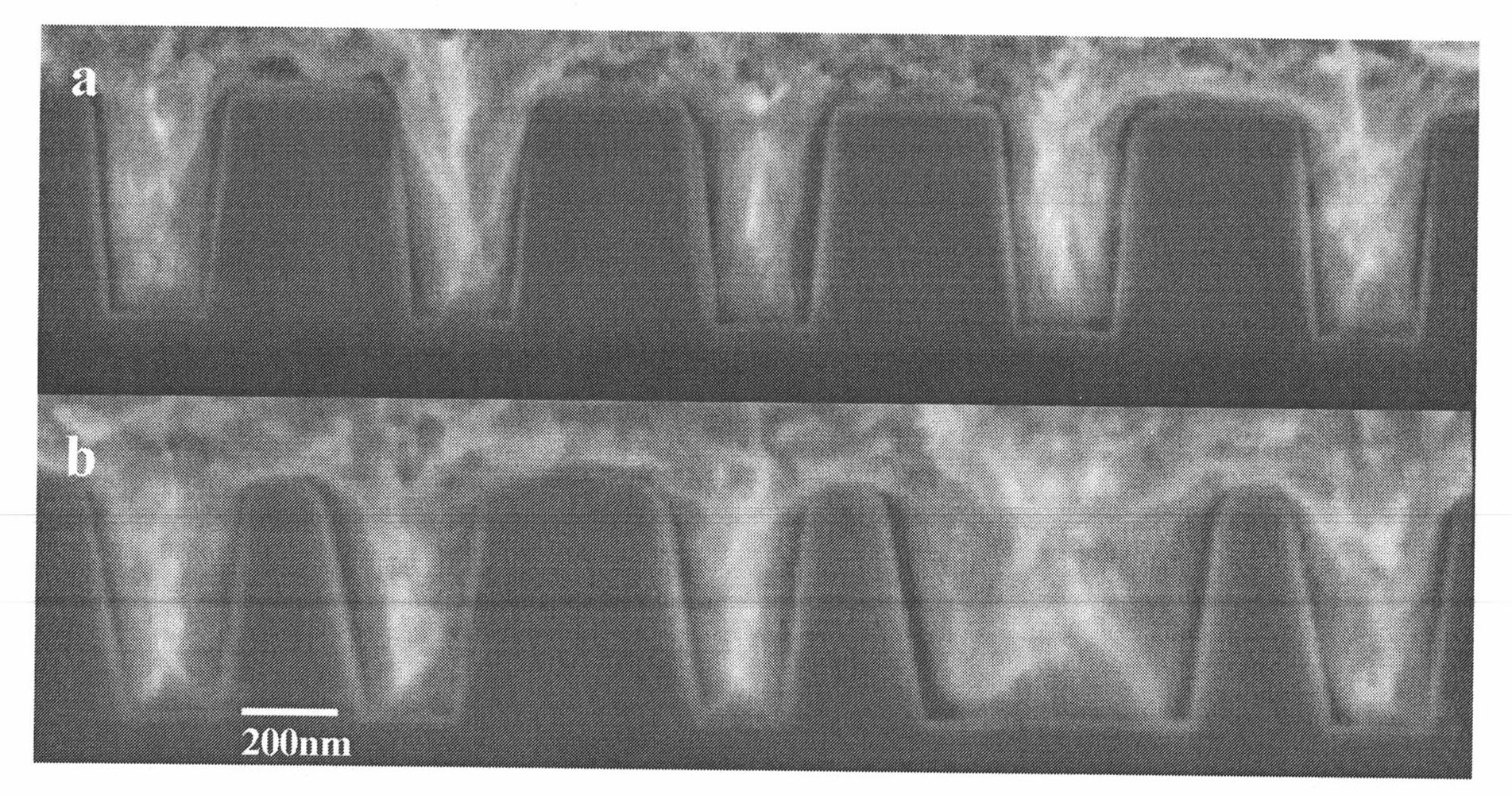

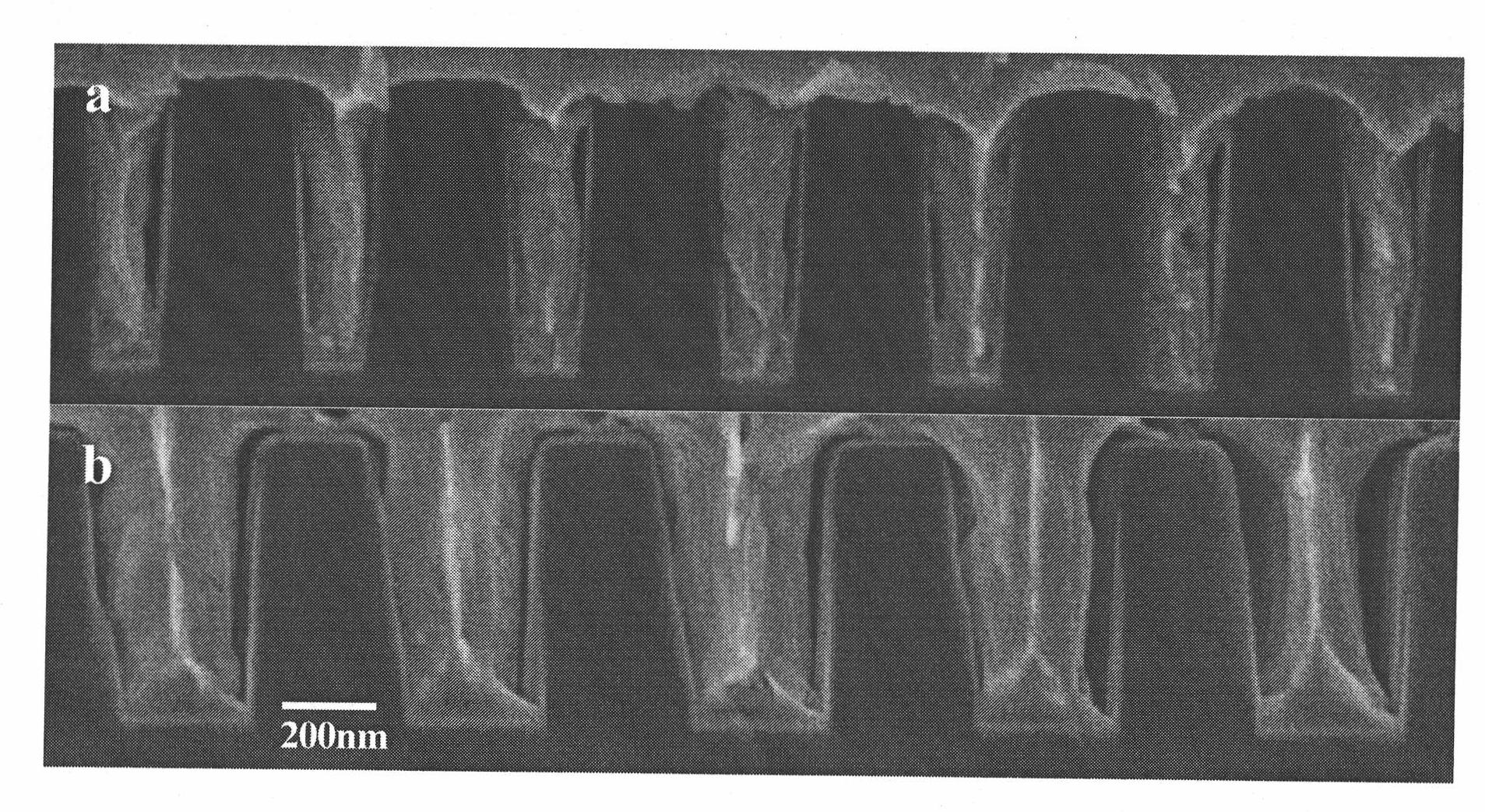

Electroless Copper Plating Solutions for Microvia Filling

InactiveCN102277567ANo holesSeamlessSemiconductor/solid-state device manufacturingLiquid/solution decomposition chemical coatingBenzoxazoleCopper plating

A chemical copper plating solution for micropore filling. 1 L of the chemical copper plating solution comprises 5-20 g of copper sulfate pentahydrate, 10-50 g of disodium ethylene diamine tetraacetate, 1.0-1.5 g of formaldehyde or glyoxylic acid, 0.001-0.02 g of mercapto heterocyclic compounds, 0.02-0.04 g of polyether with an average molecular weight of 3650, 1.5-3.5 g of NaOH, and the balance of distilled water; the mercapto heterocyclic compounds are 2-mercapto benzimidazole, 2- mercapto benzoxazole, 1-phenyl-5-mercapto-tetrazole or 2-mercapto benzothiazole. By simultaneously adding mercapto heterocyclic compounds and polyether with an average molecular weight of 3650 into the chemical copper plating solution, the invention realizes no cavity, no gap of micropores, and perfect chemicalcopper filling; the chemical copper plating solution is stable; and the deposited copper film has good quality.

Owner:SHAANXI NORMAL UNIV

Shell, electronic device and production method for shell

InactiveCN108401049AImprove the three-dimensional effectCrystal clear appearanceGlass reforming apparatusTelephone set constructionsFlat glassSurface processing

The invention relates to a shell, an electronic device and a production method for the shell. The production method for the shell comprises the following steps of a, providing plate glass and carryingout hot bending on each edge of the plate glass, thereby obtaining a glass body comprising a plate part and bended edges; b, carrying out thinning processing on the plate part at the side wherein anouter surface of the plate part of the glass body is; and c, carrying out surface processing on the outer surface of the glass body, thereby obtaining the shell comprising a main body and a side wallpart, wherein the side wall part is thicker than the main body. According to the production method for the shell, the hot bending is carried out to obtain the glass body and the thinning processing iscarried out on the plate part of the glass body to obtain the shell of which side wall part is thicker than the main body, so the operation is simple, and the production cost is reduced. The shell isan integrated structure and is seamless. The appearance of the shell is glittering and translucent, and a visual effect is good. The side wall part is thicker than the main body, namely, the thickness difference exists between the side wall part and the main body, so the stereoscopic impression of the shell is high, and the aesthetic feeling and hand feeling of the shell are improved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

High mesh size print cylinder mould production method

ActiveCN101284438AUniform thicknessExtended service lifePrinting pre-treatmentForme preparationPrinting inkEngineering

Owner:山东同大镍网有限公司

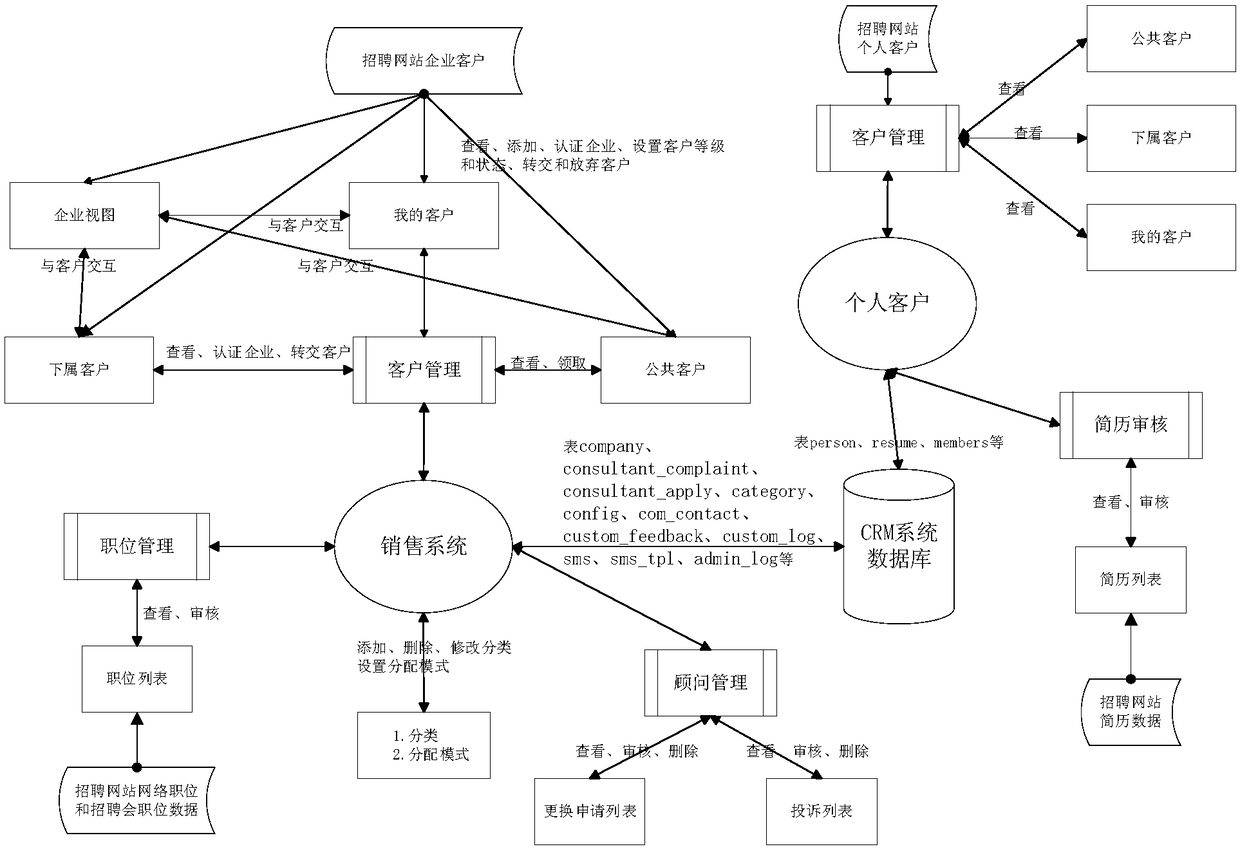

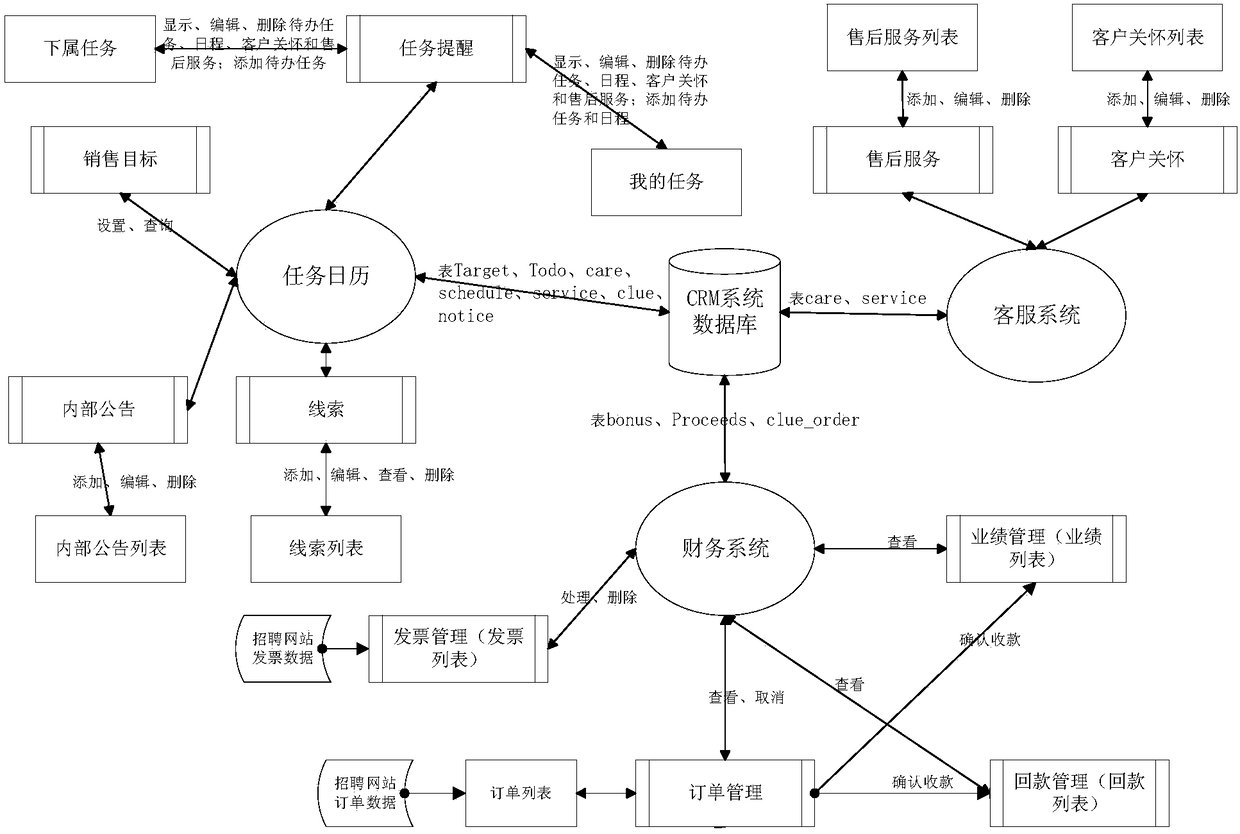

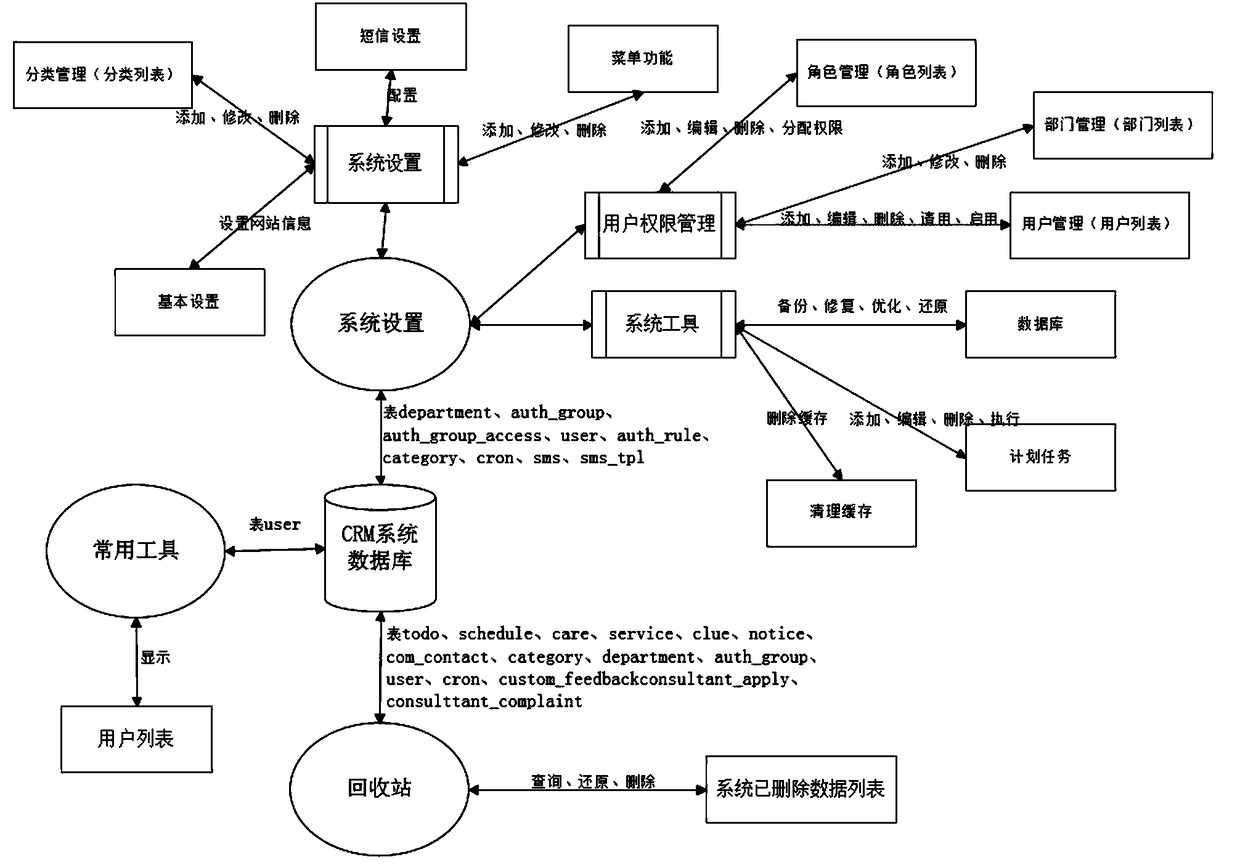

Sales management system for network

InactiveCN108564273AIncrease authenticityNo redundant functionsCustomer relationshipResourcesTablet computerThird party

The invention belongs to the technical field of networks and discloses a sales management system for a network. Nine modules of home page, task calendar, sales system, personal customer, customer service system, financial system, common tools, system management and recycling station are set. Customer data has wide sources and high authenticity. System data mainly comes from a recruitment website,a user can register for the recruitment website by himself or herself through a mobile phone, a tablet computer, a PC and the like to be a system customer and also can become the system customer through the participation in a job fair, the manual entry by a salesperson and the like. The data obtained by the recruitment website and the job fair is more authentic. The system can view the informationof an enterprise customer from a third party through an interface, and the authenticity of the data is improved. The system has no redundant function and is seamlessly connected to the recruitment website. The system is specially developed for the recruitment website and has no other redundant function, and at the same time, the functions of consultant management, job management and the like which do not exist in a similar system are added.

Owner:江苏艾克斯信息科技有限公司

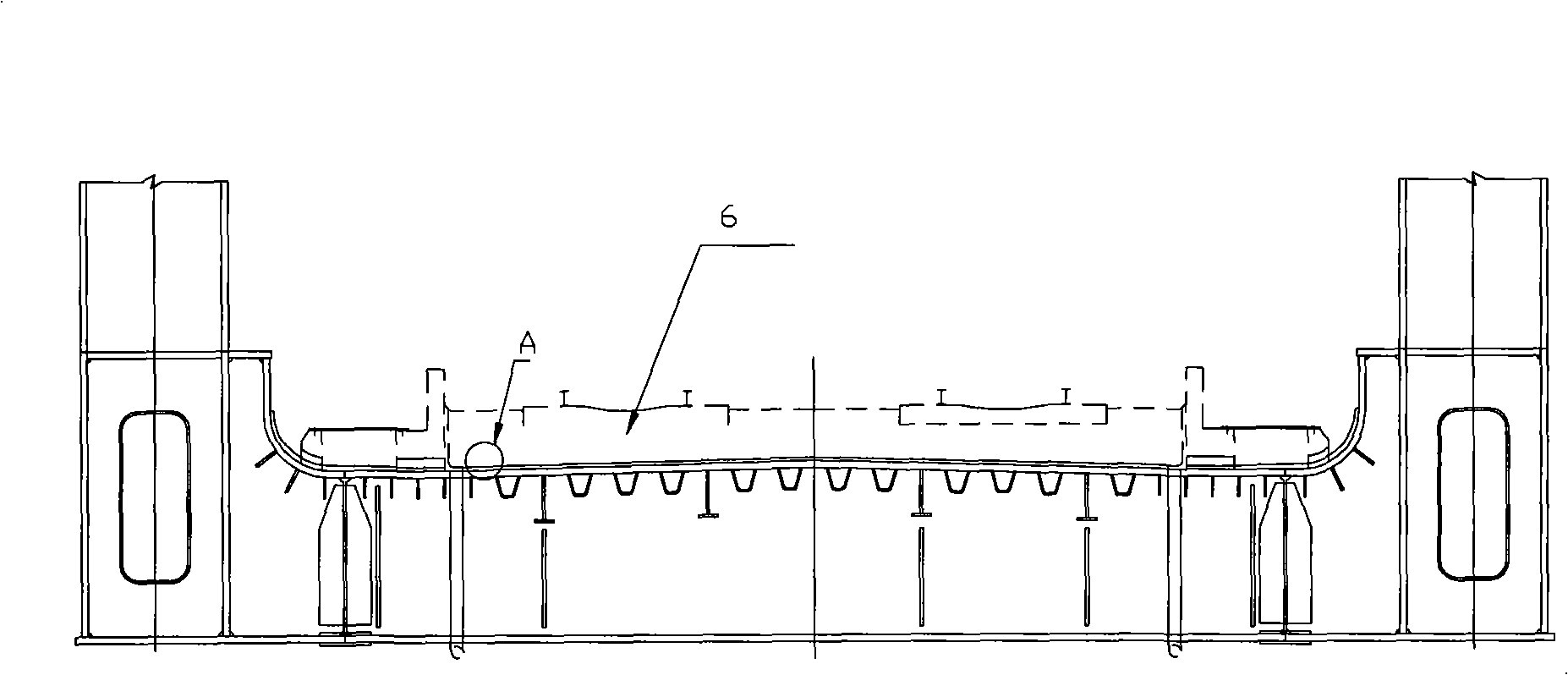

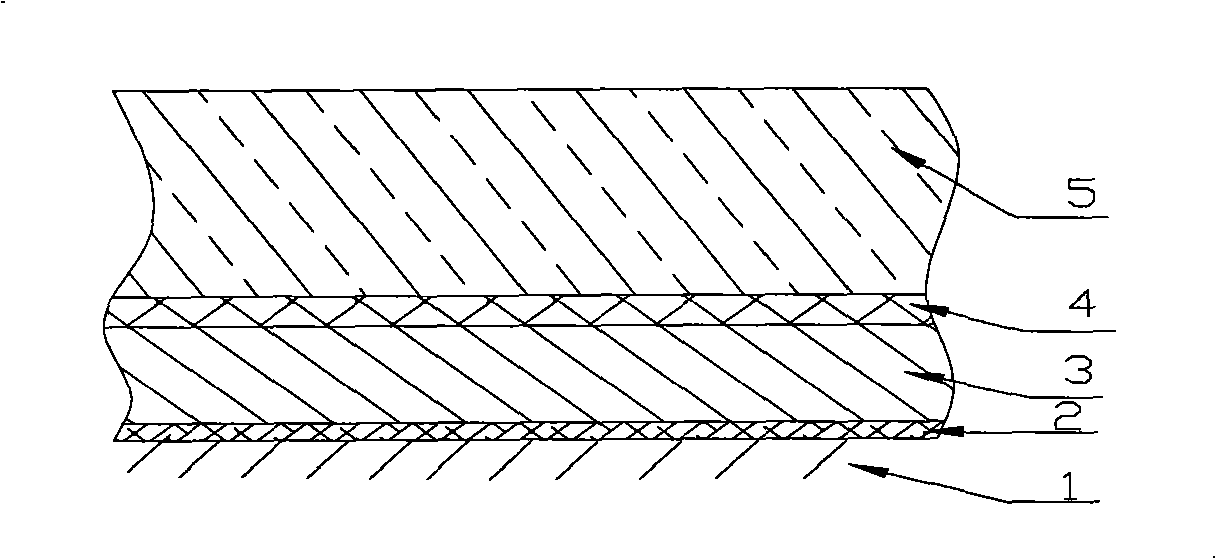

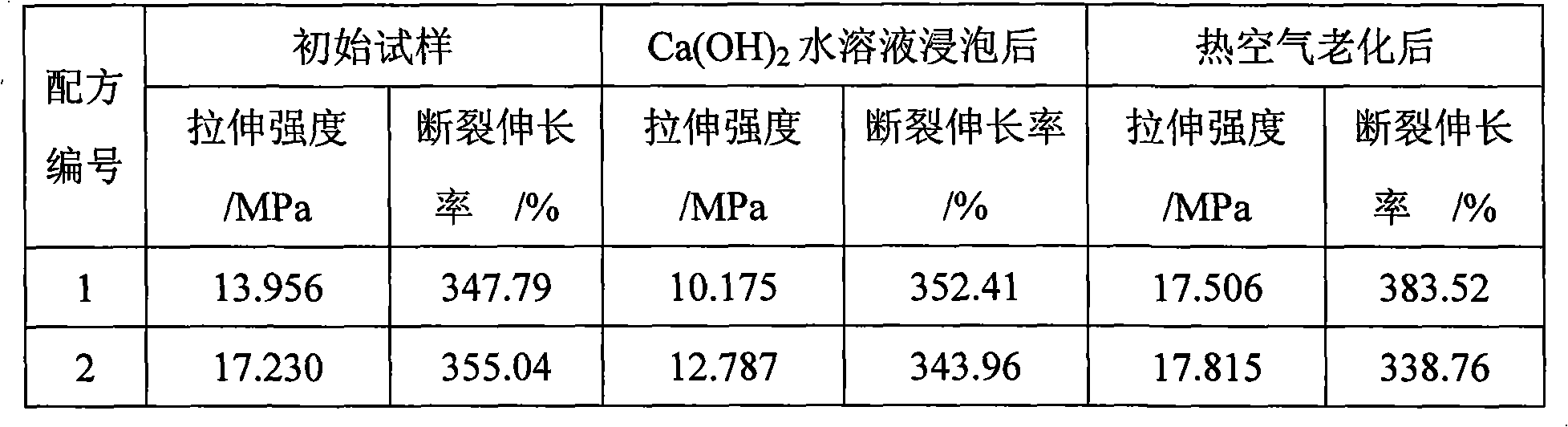

Guarding system for railway steel bridge deck and construction process thereof

InactiveCN101307450ASeamlessImprove waterproof performancePolyurea/polyurethane coatingsElastomerEpoxy

The invention relates to a railway steel bridge surface protective system, which comprises an epoxy zinc-enriched erosion resistant coating, a polyurea elastomer waterproof layer, a connecting layer and a concrete protective layer, wherein, epoxy zinc-enriched materials comprise a composition A and a composition B; the composition A comprises epoxy resin, organic bentonite, zinc powder, additives, inhibitive pigment A, inhibitive pigment B and solvent; the composition B is 115 curing agent, 650 curing agent and solvent; a polyurea elastomer comprises a material A and a material B, wherein, the material A is semi-prepolymer and thinner, and the material B is amine-terminated polyether, amine chain extender, color paste and thinner. The invention also relates to a construction technique for the railway steel bridge surface protective system. By adoption of the construction technique, the antirust property is superior; waterproof coating has superior physicochemical mechanical property; the waterproof layer has no seam; no dead angle exists during the construction process; the construction technique is simple and convenient, and the construction efficiency is high; the anticorrosive and waterproof problems of a steel bridge surface are solved; the durability of a bridge is improved; and the maintenance period and the service life of the steel bridge surface are prolonged.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

Manufacturing method of printing rotary screen with high mesh number and high aperture ratio

The invention relates to a manufacturing method of a printing rotary screen with high mesh number and high aperture ratio. The manufacturing method comprises the following steps: (1) first, manufacturing a 125-405-mesh mould and compressing hole patterns; (2) placing the manufactured mould in a plating bath filled with a plating liquid, and preparing a primary plating single net on the surface tendon line of the mould by using nickel as the anode and the mould as the cathode; (3) placing the single net in the plating bath filled with the plating liquid by taking nickel as the anode and the single net as the cathode, adding an additive consisting of butynediol diexthoxyl ether, propynol propoxyl ether, pyridinium propyl sulfobetaine and pyridinium hydroxy propyl sulfobetaine, and thickening the single net so as to secondarily plate; and (4) taking out the secondarily plated single net, washing and drying. The additive added controls the longitudinal and transverse growth ratios of the single net tendon line, and the 125-405-mesh printing rotary screen with high mesh number and high aperture ratio is obtained. The manufacturing method overcomes the deficiencies of high manufacturing cost, environmental pollution and the like in the prior art.

Owner:江苏东方镍网有限公司

Method for producing finished product or semi-finished product technological board by using waste materials

InactiveCN102139502ALow costSave wood resourcesFlat articlesDomestic articlesWater contentProcess engineering

The invention relates to a method for producing a finished product or semi-finished product technological board by using waste materials. The method comprises the following technological steps of: preparing materials; collecting the waste materials; cutting and crushing or breaking the collected waste materials; screening crushed materials with qualified size by using a screening machine; heating and softening the crushed materials; allowing the materials to enter a defibrator and performing hot grinding to form fibriform pulp; performing gluing by using an environment-friendly adhesive, wherein the applying quantity is 30 to 40 percent; drying, wherein the drying degree is that the water content is equal to or less than 5 percent; prepressing to form blank boards; performing hot moulding by using a hot press; and performing postprocessing to form the finished product. By the method, various technological boards can be manufactured by using the waste materials such as offcut of various materials, wood shavings, sawed bran, branches, straws, rice straws and the like. The method has the advantages of forming at a time and discarding the traditional process of sawing, planing and chiseling during production so as to improve production efficiency along with simple process, low cost and environmental friendliness.

Owner:王小华

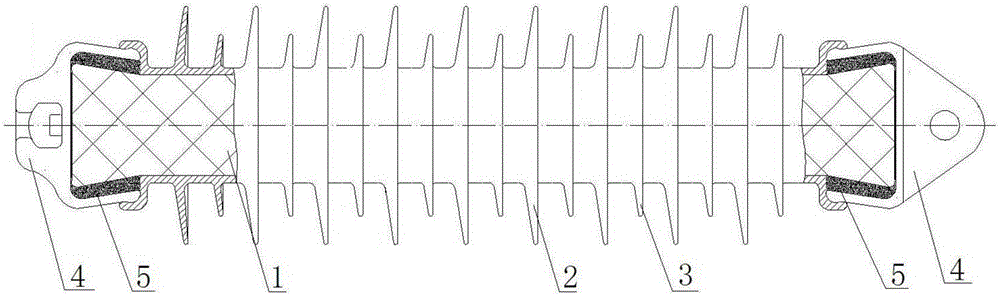

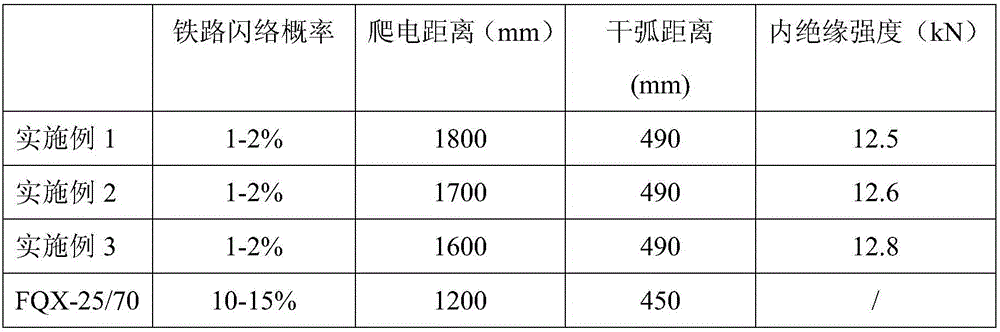

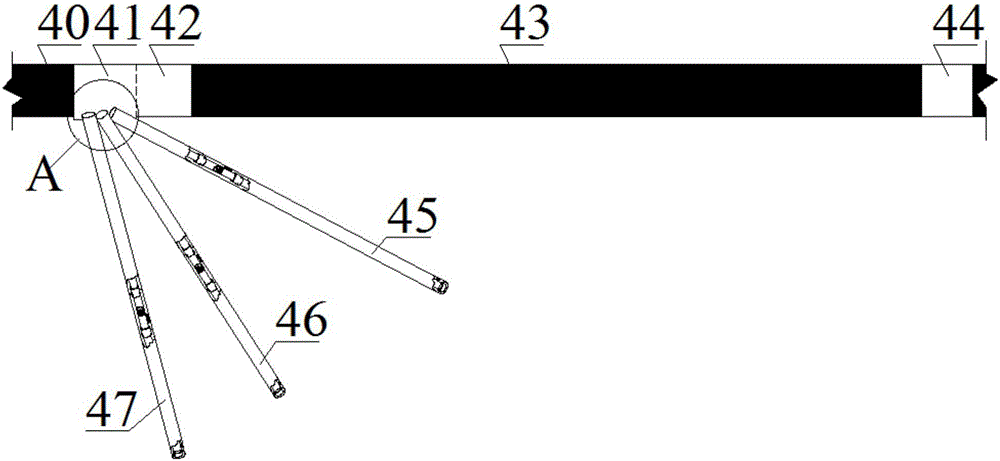

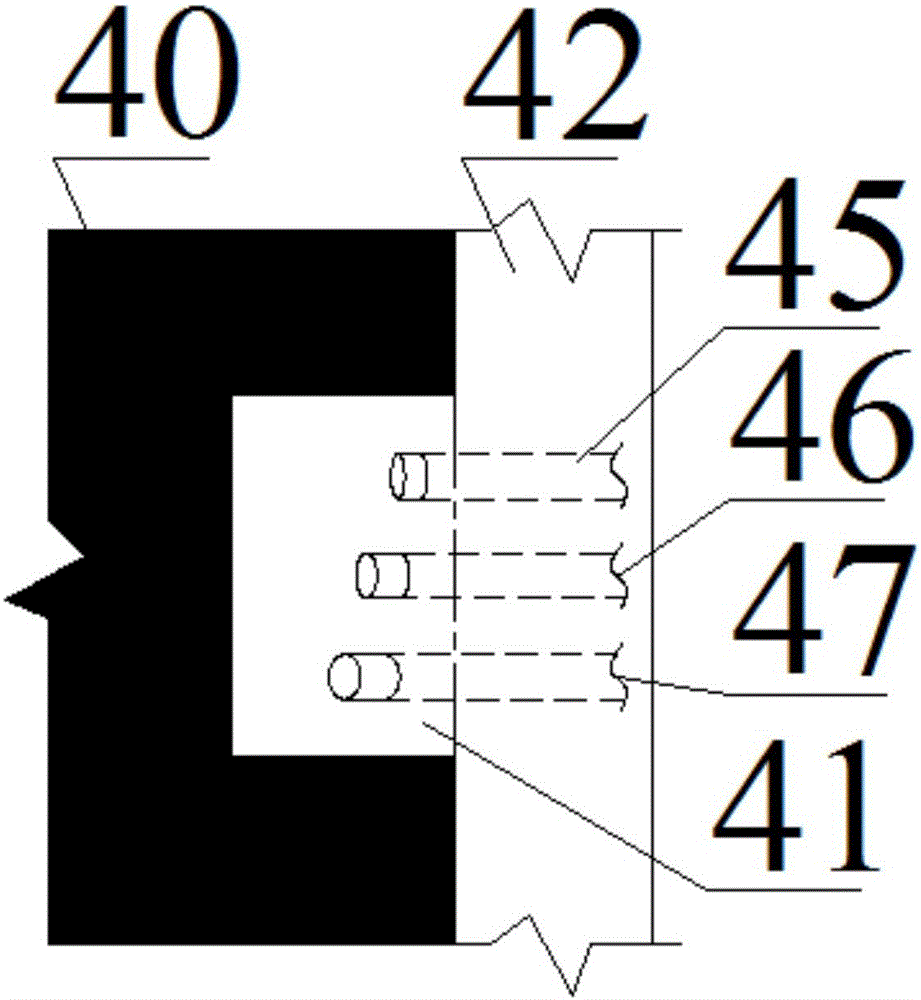

Rod-shaped suspension type composite insulator for railway and fabrication method of composite insulator

ActiveCN105845286AReduce flashover accidentsIncrease creepage distanceSuspension/strain insulatorsComposite insulatorsAdhesive

The invention discloses a rod-shaped suspension type composite insulator for railway. The rod-shaped suspension type composite insulator comprises a ceramic rod insulator body, fitting accessories and an external insulation umbrella skin sheath, wherein the fitting accessories are arranged at the two ends of the insulator body by adhesives, the external insulation umbrella skin sheath sleeves the ceramic rod insulator body and is overlapped with the fitting accessories, and the external insulation umbrella skin sheath comprises large umbrellas and small umbrellas and is formed according to a sequence that the large umbrella is arranged and then the small umbrella is arranged from top to bottom. The rod-shaped suspension type composite insulator has the advantages that the creep distance and the dry arcing distance are increased, the creep distance is increased by around 50%, the dry arcing distance is increased, the pollution flashover frequency is reduced, and the probability of a flashover accident occurring in the railway is reduced; an integral injection molding production process is used for production, an umbrella sleeve is attractive in appearance and is few in interface, a core rod and the sheath are bonded firmly without a gap, the rod-shaped suspension type composite insulator is high in internal insulation performance, and a phenomenon of interface breakdown is prevented.

Owner:JIANGSU SOUTH PORCELAIN INSULATOR CO LTD

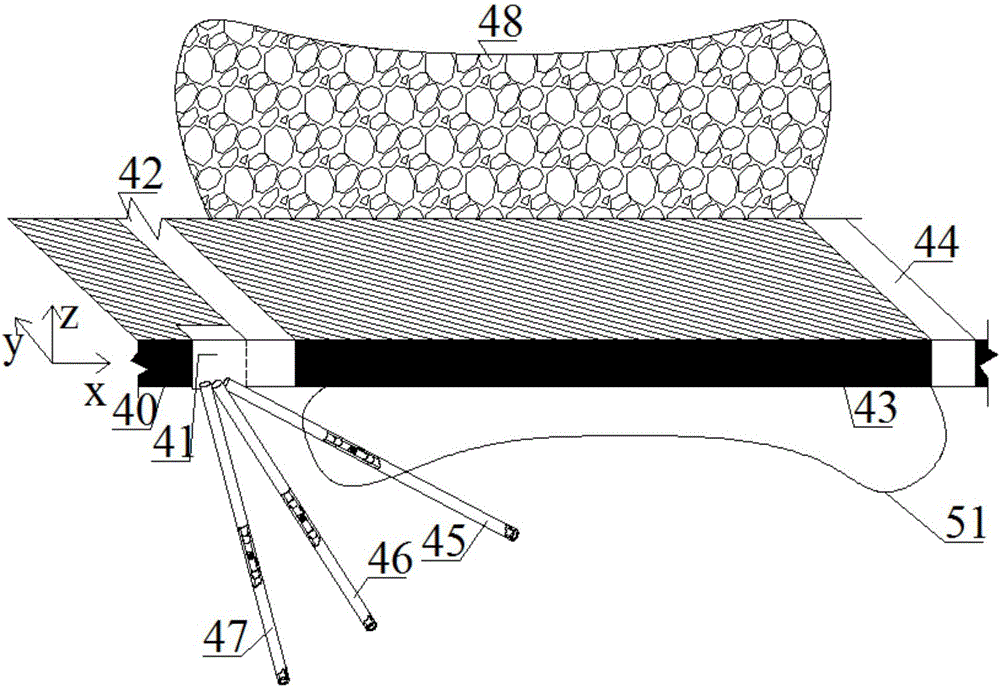

Detection system and method for monitoring fracture development of coal pillar-free gob-side entry retaining floor

ActiveCN106285628AReasonable structural designSafe and stable drillingSurveyConstructionsEngineeringCoal pillar

The invention relates to a detection system and a method for monitoring fracture development of a coal pillar-free gob-side entry retaining floor. The method comprises the following steps of chiseling a floor drilling field at one side of the coal pillar-free gob-side entry retaining, drilling in a floor rock layer according to different angles, gradually butting transparent hollow pipe sections by a butting sealing system, and sending into each drilling hole; grouting and anchoring a gap between each drilling hole and the corresponding transparent hollow pipe, enabling a detection positioning assembly to record the fracture of the drilling surrounding rock according to different scales of a measuring tape, performing monitoring tasks on evolution of floor mining failure rule for multiple times in different mining phases until the data is stable, and then finishing the observation. The method has the advantages that the floor small-angle drilling hole, the floor medium-angle drilling hole, and the floor large-angle drilling hole extend from the drilling field to the floor of a to-be-mined coal layer and are distributed in parallel in a stereo way; by observing the fracture condition of adjacent drilling holes in the same time and the fracture condition of the same drilling hole in different coal mining phases, the development state of the plastic failure area of the floor and the development state of the failure area of the floor after the coal bed is mined are determined, so as to provide reliable data reference for safety construction.

Owner:XIAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com