Patents

Literature

229results about How to "Easy to press and form" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nickel-cobalt-manganese multi-doped lithium ion battery cathode material and preparation method thereof

InactiveCN101621125AIncrease compaction densityLow hygroscopicityElectrode manufacturing processesSecondary cellsChemical synthesisPolyvinyl alcohol

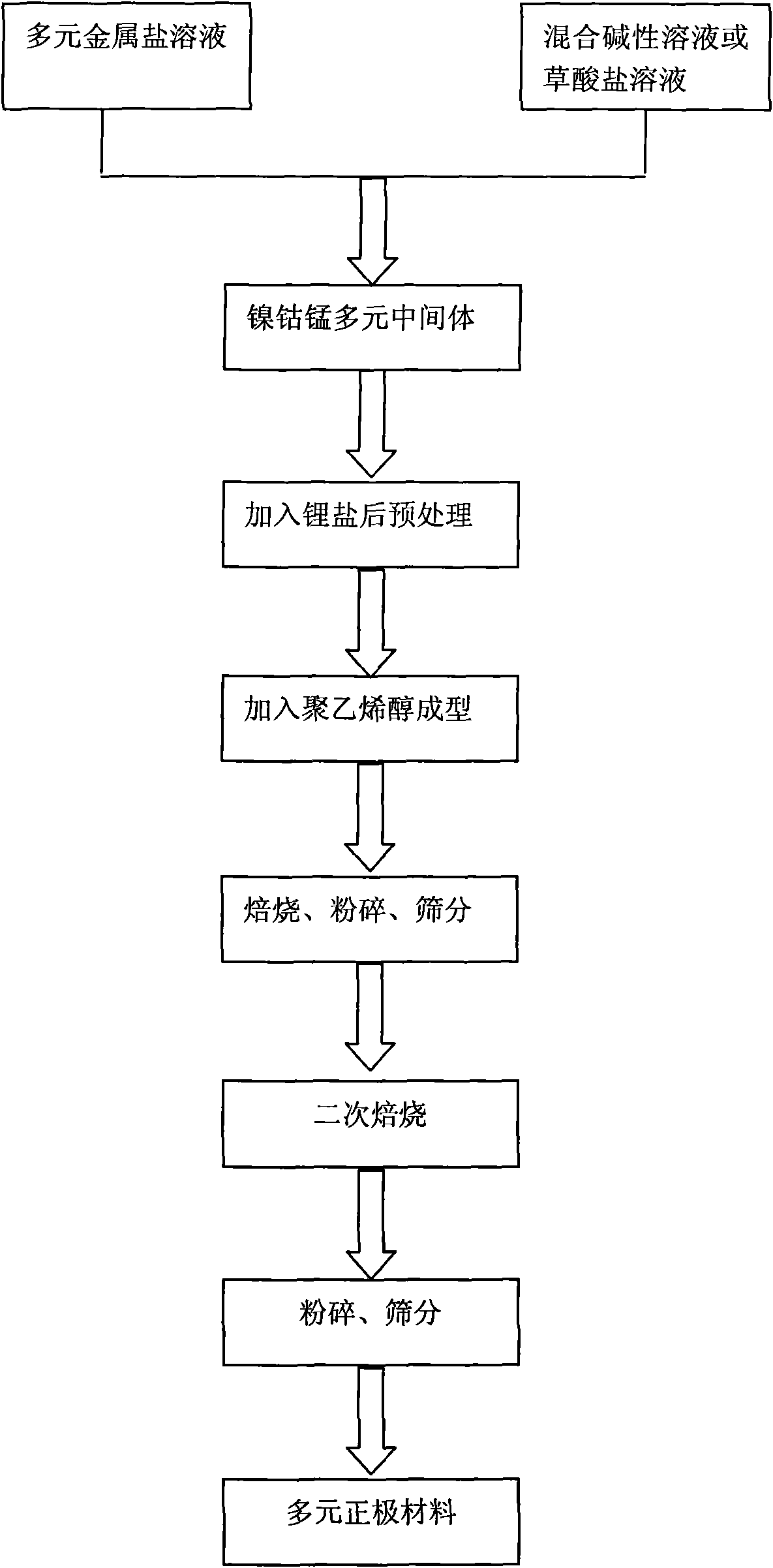

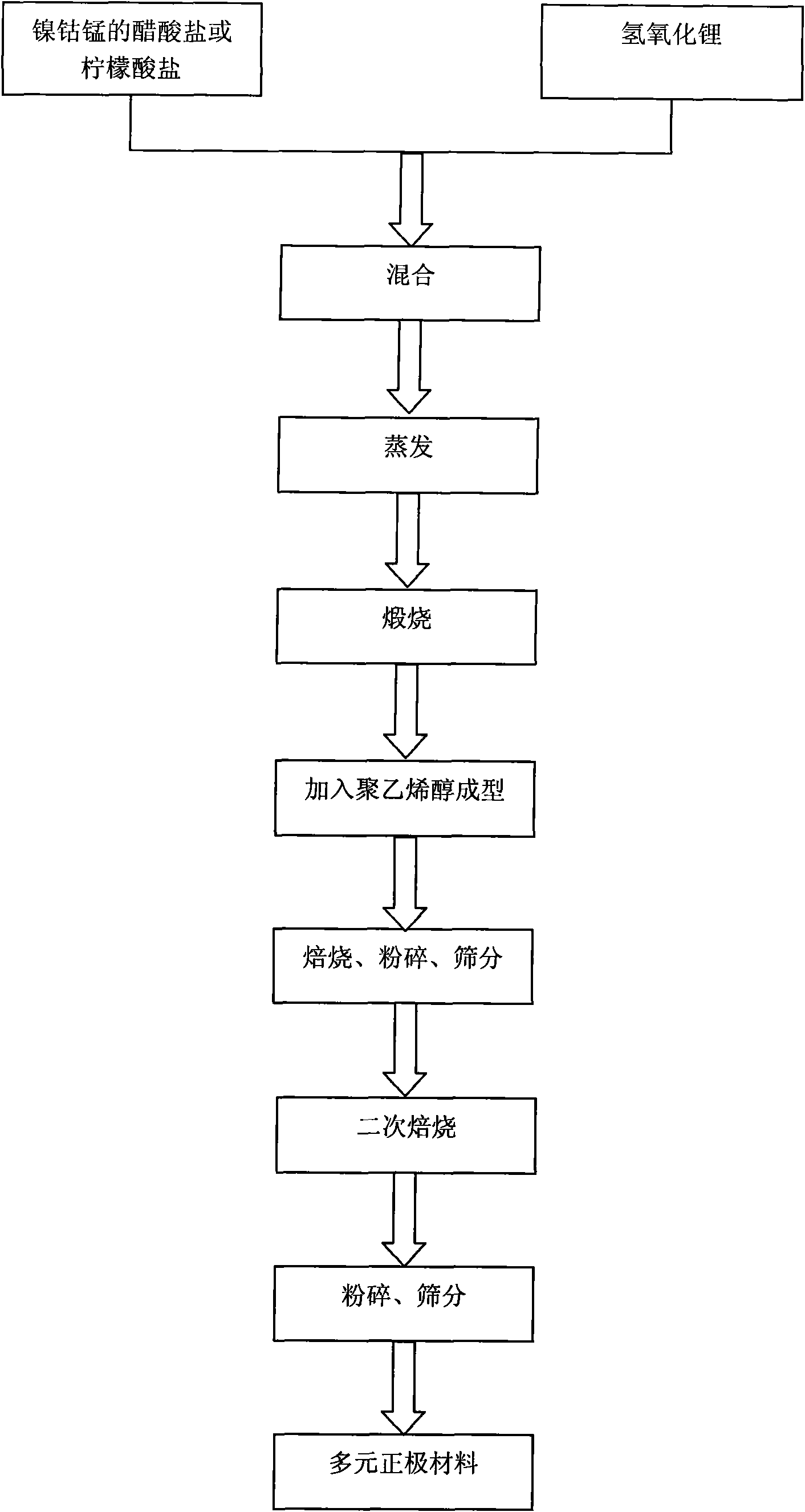

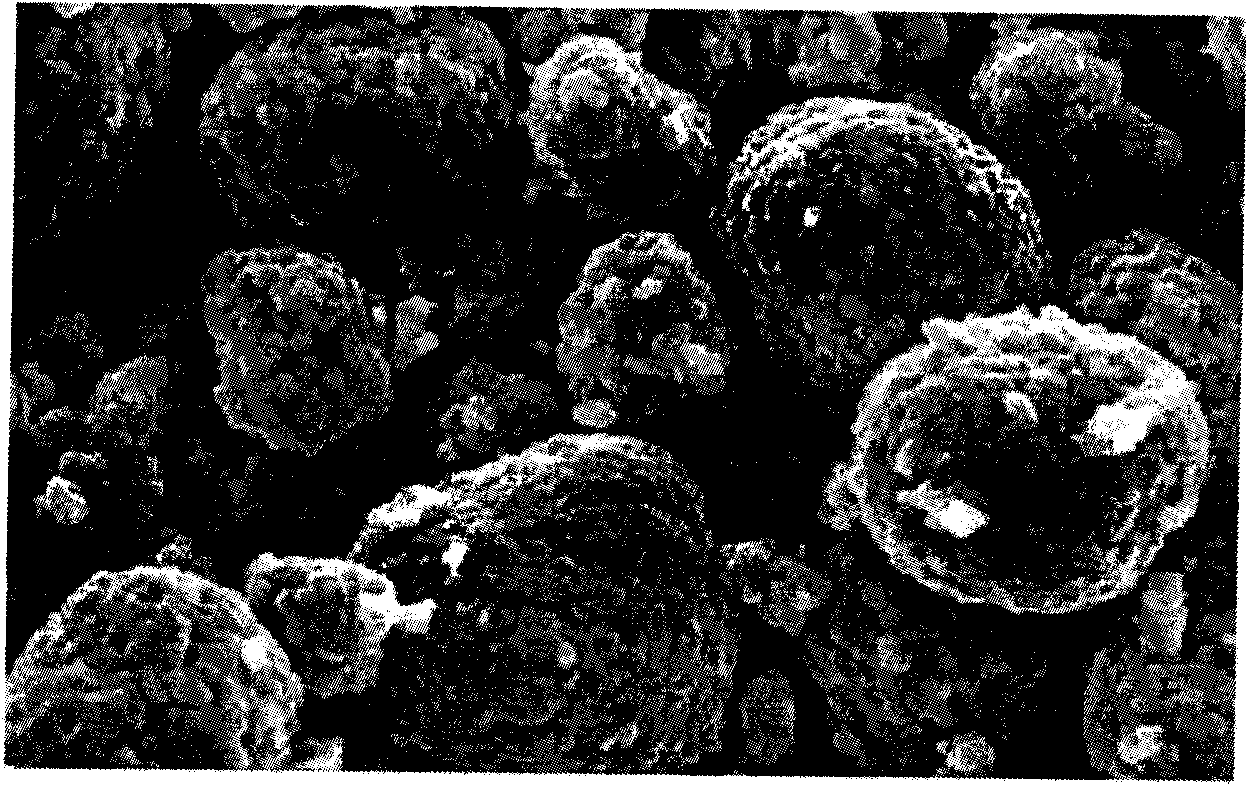

The invention discloses a nickel-cobalt-manganese multi-doped lithium ion battery cathode material with high compacted density and a preparation method thereof, belonging to the technical field of energy materials. The preparation method of the battery cathode material comprises the following steps: preparing a nickel-cobalt-manganese multi-doped intermediate by a coprecipitation method or a chemical synthesis method; mixing the multi-doped intermediate with lithium salts; after pretreatment, adding polyvinyl alcohol to the obtained mixture; uniformly mixing the polyvinyl alcohol and the mixture and then pressing the mixture into a cake; roasting the cake at 800-950 DEG C; taking the roasted cake out and carrying out cooling, pulverization and 400 meshes of sieving on the cake; then roasting obtained powder at 700-800 DEG C, taking the powder out and carrying out cooling, pulverization and sieving on the powder to obtain the battery cathode material. Granules of the battery cathode material are non-agglomerated single-crystal grains with a grain diameter of 0.6-30 microns, a chemical formula of LiNixCoyMnzM[(1-x-y-z)]O2, a degree of compaction of 3.5-3.7g / cm<3> and a primary discharge capacity of 150-165mAh / g, thus the battery cathode material has good cycle performance and higher safety performance.

Owner:CHENGDU JINGYUAN NEW MATERIALS TECH

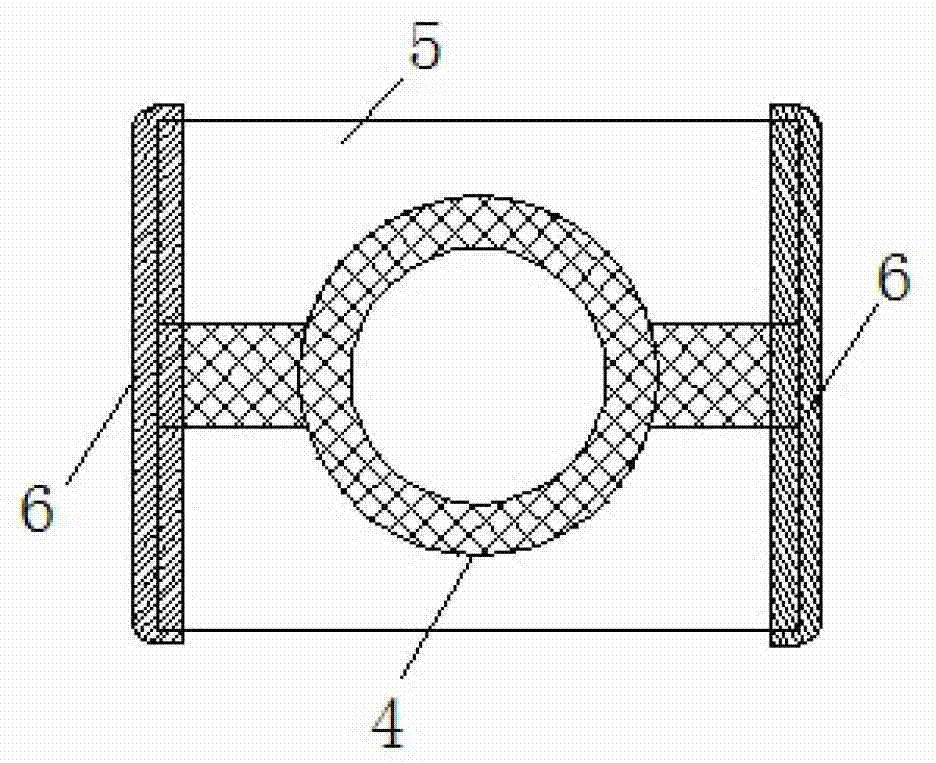

Coil and magnetic powder integrated inductor and manufacturing method thereof

InactiveCN102737802AReduce lossHigh densityTransformers/inductances coils/windings/connectionsInorganic material magnetismCompression moldingSputtering

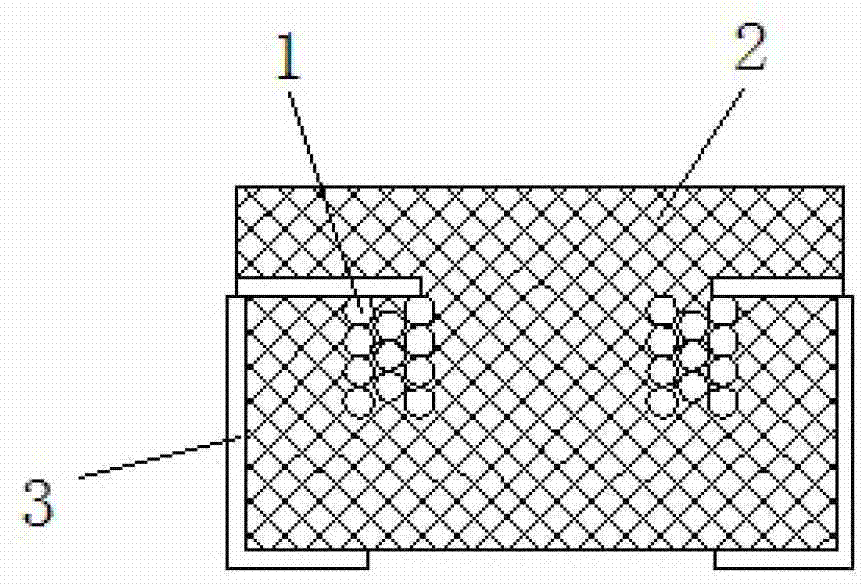

The invention provides a coil and magnetic powder integrated inductor. The coil and magnetic powder integrated inductor comprises a cubic magnetic material block (5) which is internally provided with an embedded coil (4), wherein an end electrode (6) is arranged on each of two opposite sides, each of the end electrodes is connected with one end of the coil, the magnetic material block consists of more than two kinds of magnetic powder in different average particle sizes and insulation resin, and the general formula of the compositions of the magnetic powder is Fe100-x-y-z SixCryBz. A manufacturing method comprises the following steps: (I) uniformly mixing the magnetic powder in different particle sizes; (II) mixing the magnetic powder and the insulation resin into a compound magnetic material group; (III) manufacturing the hollow coil; (IV) heating a forming mold and a lower punch, filling the compound magnetic material group and the hollow coil, molding in compression, preserving heat till the resin is solidified, and then demolding; (V) polishing the two end faces; and (VI) performing vacuum sputtering to prepare the electrode. The compression molding operation can be carried out with relatively low pressure, and the magnetic particle and the coil are barely damaged in the compressing process.

Owner:ZHEJIANG JIAKANG ELECTRONICS CO LTD

Production method of aluminum strip for cosmetic bottle cap

The invention discloses a production method of an aluminum strip for a cosmetic bottle cap. The production method comprises the steps of: (1) preparation of an ingot and adoption of a new alloy, wherein the ingot comprises the following elements in percentage by weight: not more than 0.08% of Si, not more than 0.1% of Fe, not more than 0.03% of Cu, not more than 0.02% of Mn, not more than 0.02% of Mg, not more than 0.02% and not less than 0.01% of Ti, and the balance of Al; (2) surface milling; (3) uniform heating; (4) hot rolling; (5) cold rough rolling; (6) cleaning; (7) intermediate annealing; (8) cold finish rolling; (9) stretching, bending, straightening and cleaning of trimmings; and (10) checking. The aluminum strip has such excellent characteristics as smooth and bright surface, stable mechanical performance, precise dimensional tolerance, easy punch forming, low earing ratio after punching of the bottle cap and good anodizing effect, and is suitable for producing top-grade cosmetic bottle cap.

Owner:DALISHEN ALUMINUM

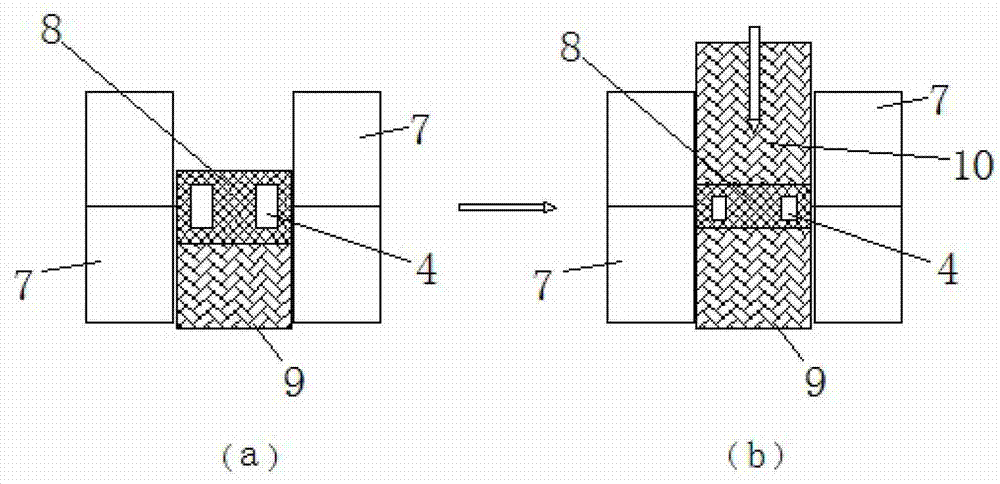

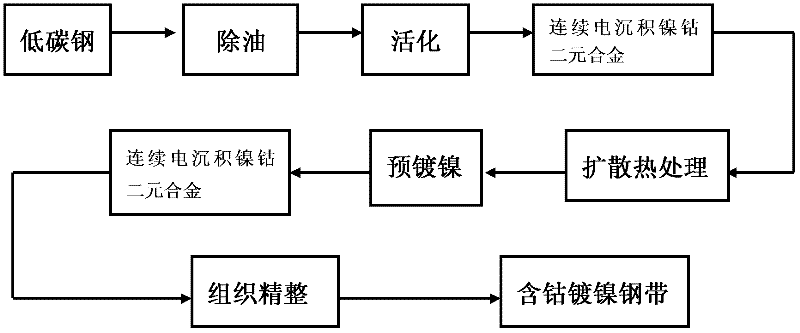

Cobalt-containing nickel plated steel strip serving as lithium battery shell material and preparation method thereof

InactiveCN102230200AImprove performanceTimely supplementCell component detailsElectrical batteryNitrogen

The invention discloses a cobalt-containing nickel plated steel strip serving as a lithium battery shell material and a preparation method thereof. The preparation method comprises the following procedures of: (1) pretreating a base material; (2) continuously electrodepositing a nickel-cobalt alloy plating layer on the pre-treated base material; (3) carrying out diffusion annealing treatment on the nickel-cobalt alloy plating layer under a protective atmosphere like high-purity nitrogen; (4) plating a nickel-cobalt alloy plating layer on the metal subjected to the diffusion annealing treatment again; and (5) rolling the plated nickel-cobalt alloy plating layer in a cold manner. The cobalt containing nickel plated steel strip disclosed by the invention is prepared by a special process of tightly combining the nickel-cobalt alloy plating layer and a low-carbon steel strip and then electroplating the nickel-cobalt alloy plating layer and the low-carbon steel strip, shows better corrosion resistance and can be used for shell materials of primary batteries, secondary batteries and lithium ion power cells such as 18650, 26650 and the like.

Owner:XIANGTAN UNIV

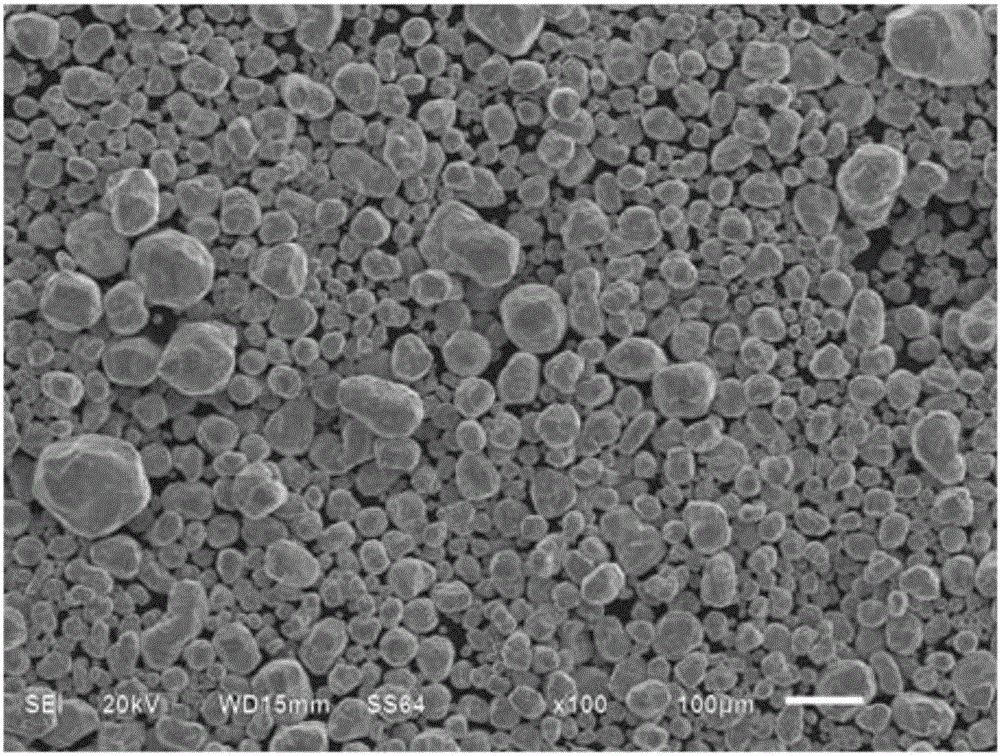

Preparing method for ball-like metal magnetically soft alloy powder

ActiveCN105710378ALow impurity contentGood formability and magnetic propertiesTransportation and packagingMetal-working apparatusForming processesSingle crystal

The invention relates to a preparing method for ball-like metal magnetically soft alloy powder, and belongs to the technical field of powder preparing. The method comprises the steps that raw materials of a metal magnetically soft alloy are weighed and mixed according to the weight ratio, intermediate-frequency induction smelting is adopted, and the molten alloy is prepared into an alloy casting strip through a thin-strip continuous casting technology; the alloy casting strip is placed into a crushing device, and the alloy casting strip is crushed into particle powder under the inert gas shielding condition; the crushed powder is placed into a shaping treatment device to be shaped, ball-like powder with the regular shape is obtained, the powder is subjected to annealing heat treatment, and fine powder is prepared through screening and collecting. According to the method, the uniformity of alloy powder components can be obviously improved, meanwhile, the powder wrapping insulating and pressing forming are facilitated through the prepared ball-like single-crystal particle powder, the uniformity degree of a soft magnetism powder core pressing insulating layer and the mechanical strength obtained after pressing forming can be obviously improved, the probability of damage of the insulating layer in the powder pressing forming process is greatly reduced, and accordingly the application field of the soft magnetism powder core is greatly enlarged.

Owner:有研增材技术有限公司

Production method of ultrahigh magnetic permeability of iron-based nanocrystalline magnetic powder core

InactiveCN103745791ASolving Press Molding ProblemsEasy to press and formInorganic material magnetismMechanical crushingCoupling

The invention belongs to the technical field of alloy soft magnetic powder cores and particularly relates to a production method of an ultrahigh magnetic permeability of iron-based nanocrystalline magnetic powder core. The production method comprises step 1, performing mechanical crushing treatment on an iron-based nanocrystalline thin belt so as to obtain iron-based nanocrystalline powder; step 2, screening and matching the iron-based nanocrystalline powder and mixing into mixed powder which is formed by coarse powder and fine powder; step 3, performing passivation, coupling and insulation coating treatment on the mixed powder in turn through a passivation agent, a coupling agent, an insulating agent and a binding agent and performing compression forming; step 4, performing annealing treatment and spraying insulation treatment on the formed magnetic powder core in turn. According to the production method of the ultrahigh magnetic permeability of iron-based nanocrystalline magnetic powder core, the coarse powder and fine powder mixing and coupling treatment is adopted and accordingly the problem of the compression forming of large particle nanocrystalline powder can be effectively solved and the ultrahigh magnetic permeability of iron-based nanocrystalline magnetic powder core can be produced, wherein the magnetic permeability can reach more than 200.

Owner:QINGDAO YUNLU ADVANCED MATERIALS TECH CO LTD

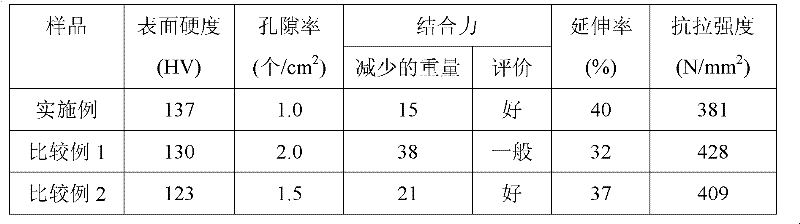

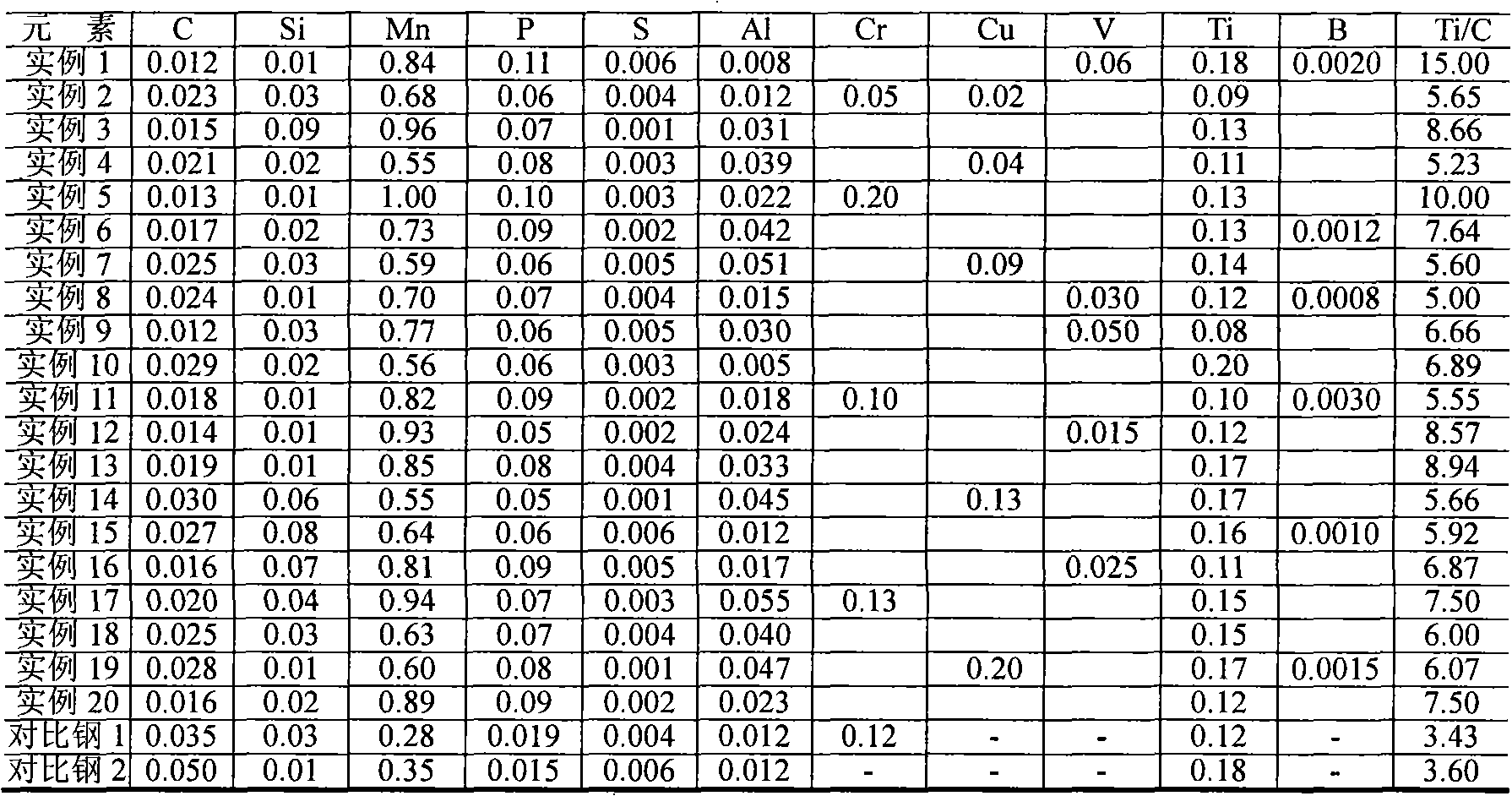

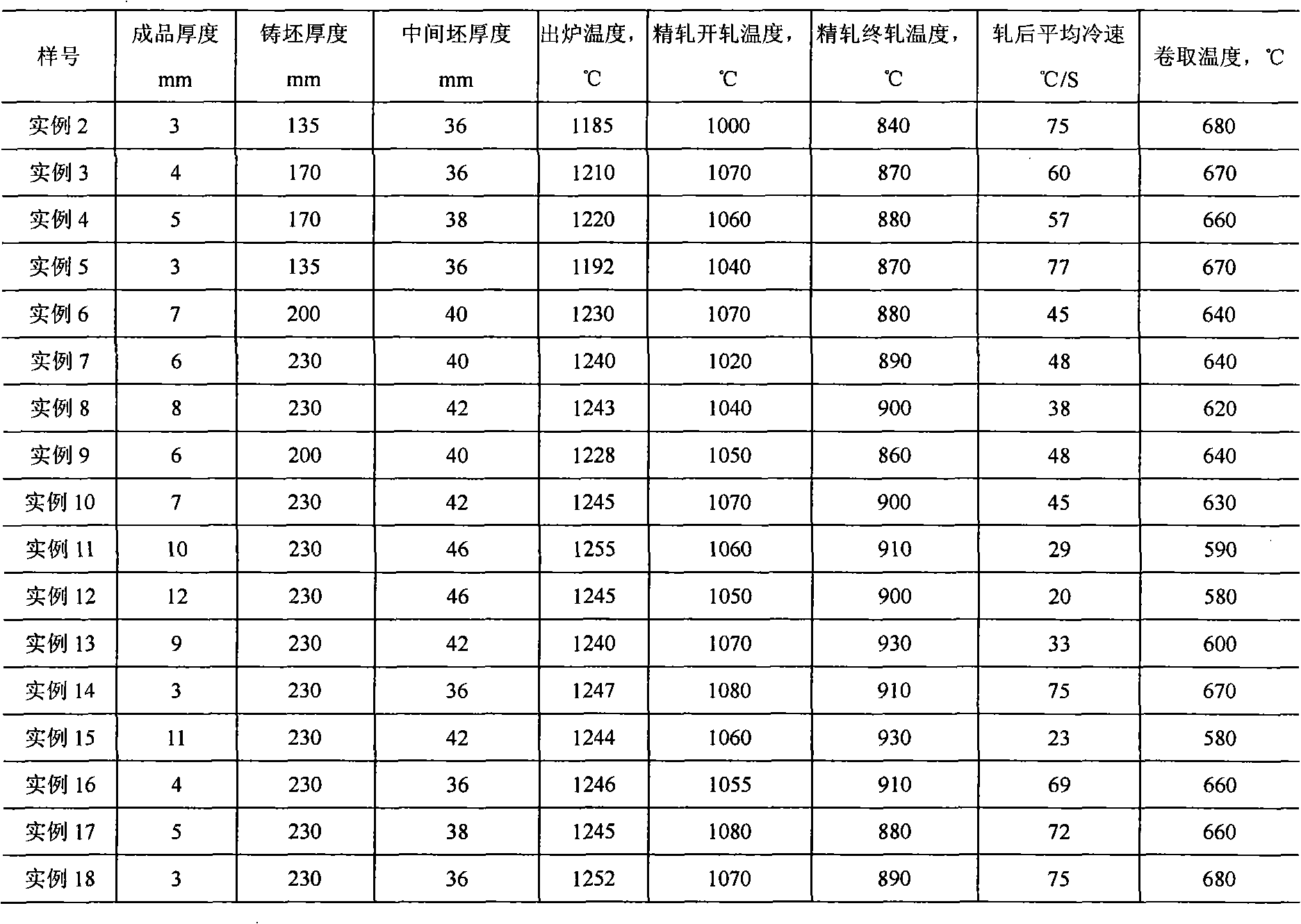

High-strength hot rolled steel plate for counter enameling and manufacturing method thereof

The invention relates to a high-strength hot rolled steel plate for counter enameling and a manufacturing method thereof. The high-strength hot rolled steel plate for counter enameling comprises the following smelting components in weight percent: 0.012-0.03 percent of carbon (C), not greater than 0.10 percent of silicon (Si), 0.55-1.0 percent of manganese (Mn), 0.05-0.11 percent of phosphorus (P), not greater than 0.006 percent of sulfur (S), not greater than 0.005 percent of nitrogen (N), 0.08-0.20 percent of titanium (Ti), 0.005-0.055 percent of aluminum sulfide (Als), 5-15 percent of Ti / C and the balance of ferrum and inevitable impurities, wherein more than one or two of vanadium, boron (B), copper (Cu) and chromium (Cr) is selectively added. The manufacturing method comprises the following steps: producing a plate blank through continuous casting; evenly heating the plate blank to 1180-1260 DEG C; then, removing phosphorous with high-pressure water and carrying out rough rolling to prepare an intermediate blank; carrying out 5-7-pass finish rolling to target thickness; carrying out laminar flow cooling to 570-680 DEG C and coiling. The high-strength hot rolled steel plate for the counter enameling has no phosphorus explosion; the yield strength is higher than 280MPa after the high-strength hot rolled steel plate for the counter enameling is enameled under the conditions that the temperature is 800-920 DEG C and the thickness is greater than 8mm. The high-strength hot rolled steel plate for the counter enameling is suitable for roll forming, bend forming and simple punch forming and is a reliable special steel plate material for a counter enameling assembly structure.

Owner:ANGANG STEEL CO LTD

Method for producing ultra-coarse grain cemented carbide through utilizing high energy stirring and ball-milling technology

The invention relates to a method for producing ultra-coarse grain cemented carbide through utilizing a high energy stirring and ball-milling technology. Preparation raw materials comprise WC, Co and a small amount of NbC or / and TaC which is served as an additive, wherein the particle granularity of the WC is not less than 15 micrometers, and the WC accounts for 82.0-95.5wt%, the Co accounts for 4.5-18wt%, and the additive accounts for 0.0-0.5wt%. The preparation method comprises the following steps: (1) a high energy stirring and ball milling process, namely, filling all the preparation raw materials, i.e. the WC, cobalt powder and the additive into a high energy stirring ball mill, and adding a plasticizer and a ball-milling addition agent for ball milling; (2) a vacuum drying and granulating process; and (3) conventionally pressing a mixture for forming, and carrying out vacuum sintering or pressure sintering within a scope of 1400 DEG C-1480 DEG C. By utilizing the technology, the milling effect of the powder can be greatly improved, the ball milling time is obviously shortened, the production efficiency is improved, the energy consumption is reduced, and alloy crystal grains are uniformly distributed.

Owner:ZIGONG JINDUN CEMENTED CARBIDE

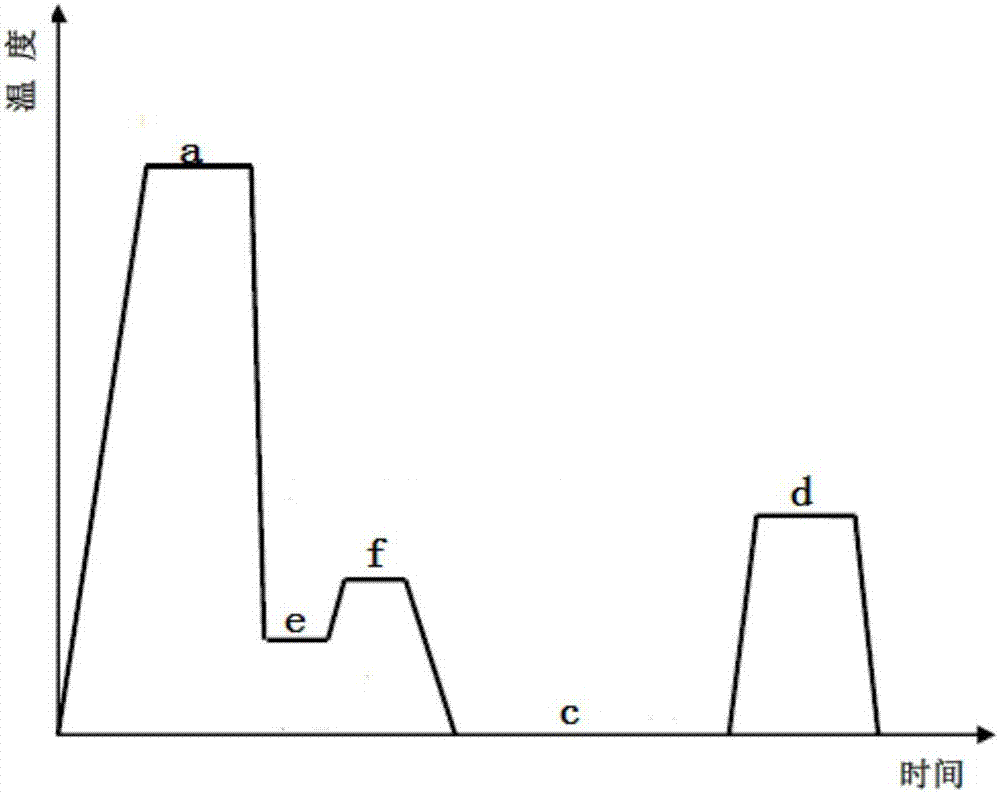

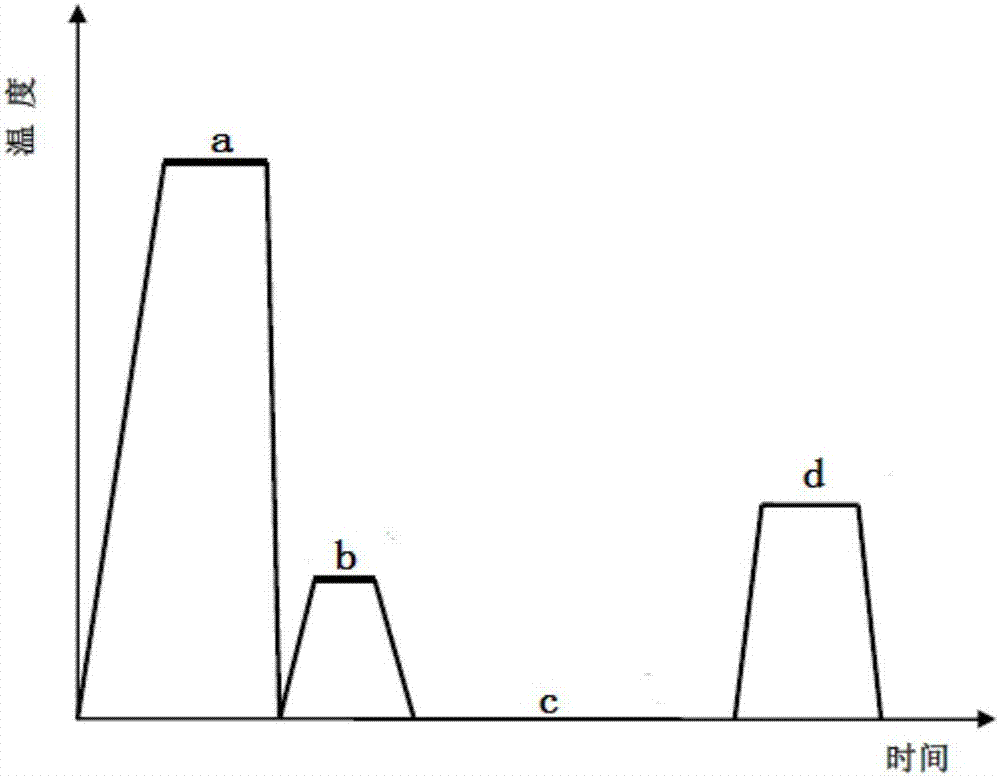

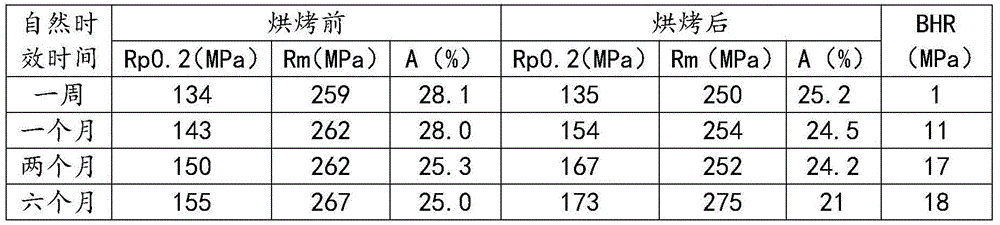

Heat treatment method capable of improving natural aging stability of 6000-series aluminum alloy and aluminum alloy plate

The invention discloses a heat treatment method capable of improving natural aging stability of 6000-series aluminum alloy and an aluminum alloy plate, and relates to the technical field of aluminum alloy heat treatment. The heat treatment method comprises the following steps that a 6000-series aluminum alloy plate is subjected to solid solution treatment and quenched to 40-60 DEG C, heat is preserved for 5-20 min, then the temperature is quickly increased to 100-120 DEG C, heat is preserved for 2-5 min, and then the plate is cooled to the room temperature. By means of the method, the problems that a traditional solid solution pre-aging treatment method is poor in natural aging stability and short in bake hardening performance maintaining time are relieved. By adoption of the heat treatment method, the stability in the room temperature stagnating process can be better regulated and controlled, and thus adverse influences of natural aging are restrained; and not only can the aluminum alloy keep a good forming property for a long time, but also the paint-bake hardenability of the aluminum alloy is obviously improved, after paint baking, the strength and hardness of the obtained aluminum alloy plate are obviously improved, the yield strength is greater than 200 MPa, and the hardness is greater than 95 HB.

Owner:SHANDONG NANSHAN ALUMINUM +1

Inner-mould ornamental plastic member capable of being completed by ordinary injection die and its production method

InactiveCN1807087AImprove rigidityAvoid scourDecorative surface effectsLaminationProduction rateEngineering

The invention provides a mold decoration plastic made by common injection mold. It comprises plastic base, sheet metal compounded with plastic base, and decoration flexible layer containing patterns and words compounded with sheet metal. The thickness of sheet metal is 0.1-1.2mm, the rigidity is good, and the cost is low. The invention also provides the manufacturing method. The production rate and rate of finished products are high.

Owner:CHENGDU ZHONG JI GUO YE NEW MATERIAL

Machine-made charcoal and preparation method thereof

The invention discloses machine-made charcoal. The machine-made charcoal is prepared from the following components in parts by weight: 40-50 parts of Chinese herbal medicine residues, 2-5 parts of a combustion improver, 35-52 parts of biomass waste and 6-10 parts of a binder, wherein the Chinese herbal medicine residues consist of 60-65 parts of wormwood, 10-15 parts of lavender platycodon grandiflorum, 4-6 parts of dried tangerine or orange peel, 2-4 parts of lotus leaves, and 10-24 parts of momordica grosvenori and a branch-leaf mixture thereof. The machine-made charcoal disclosed by the invention takes waste Chinese herbal medicine residues as raw materials, so that the waste is changed into things of value; the properties of the residual medicines are utilized, so that the machine-made charcoal not only has no irritant small, but also has fresh scent; more importantly, the machine-made charcoal has a health effect and a certain action on cough, sphagitis and bronchial asthma, and does not cause a dryness-heat feeling.

Owner:FUJIAN ZHONGMEI CHEM ENVIRONMENTAL PROTECTION TECH CO LTD

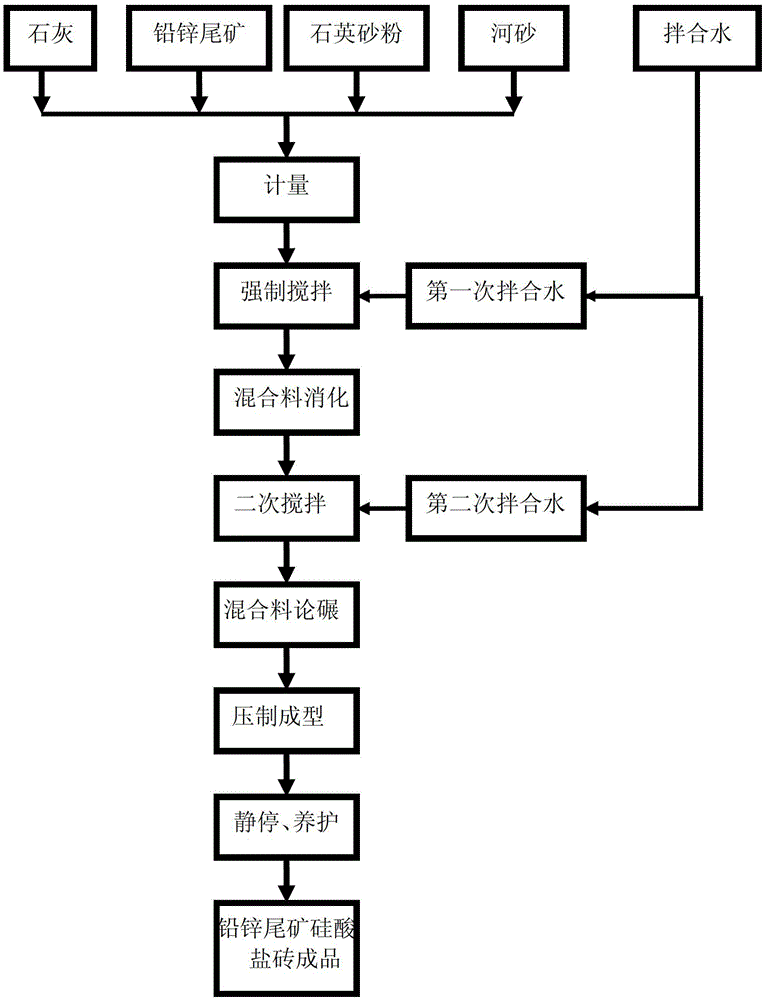

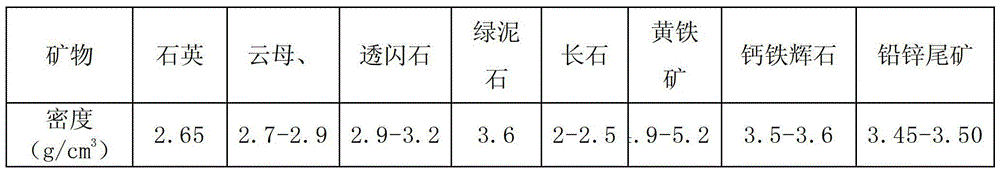

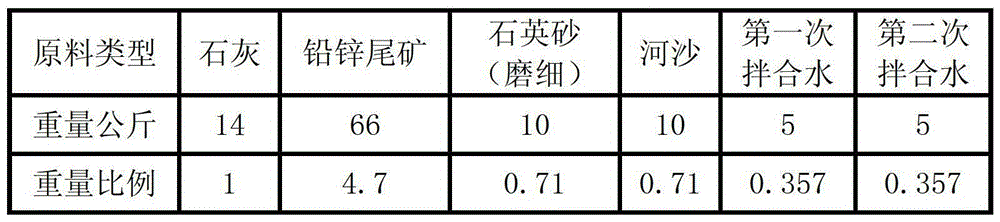

Method of manufacturing silicate bricks with lead-and-zinc tailings

InactiveCN103058618AHigh strengthIncrease the defect of insufficient silica contentSolid waste managementBrickPrill

The invention aims at features to the lead-and-zinc tailings and provides a method of manufacturing steaming-and-pressing silicate wall materials, wherein the features include low content of silica, large density, coarse granules and the like. The method of manufacturing silicate bricks with lead-and-zinc tailings has the advantages that the lead-and-zinc tailings with high true density, containing a certain number of coarse granules and high bulk density is used and can be used for aggregates of the silicate bricks with good effects of moulding pressure transition and beneficial for compression moulding. High compression moulding density can be obtained. The defect that the content of the silica in the lead-and-zinc tailings is not enough can be overcome through adulteration partial ground fine quartz sands. The method of manufacturing silicate bricks with the lead-and-zinc tailings is a processing method of the lead-and-zinc tailings that the technology is simple and the cost is low.

Owner:JIANGSU EAST CHINA MINE TAILINGS MANAGEMENT ENG +1

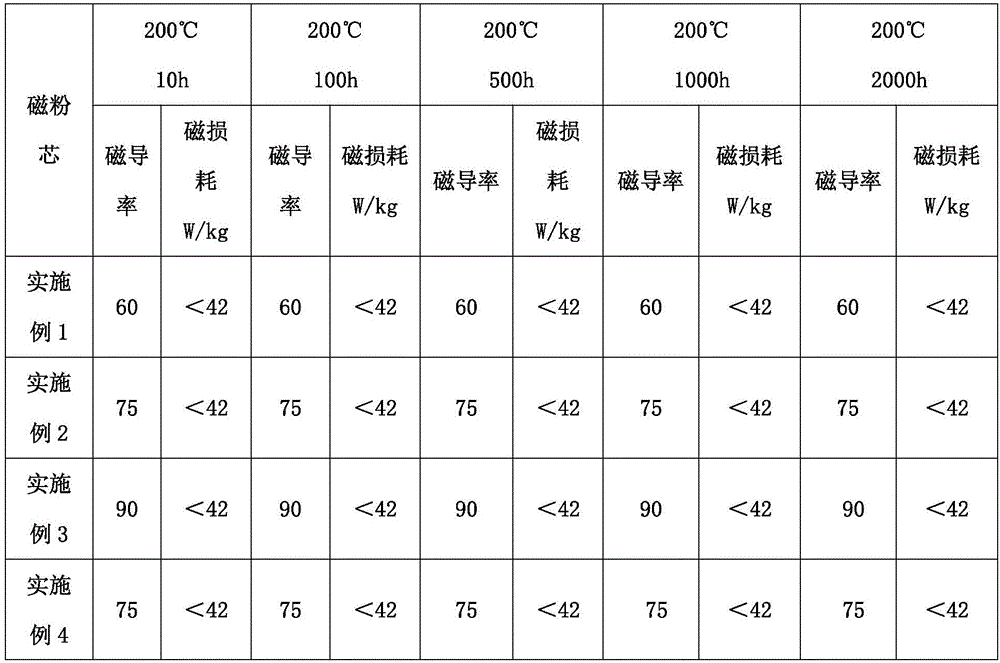

Amorphous soft magnetic composite magnetic powder core and preparation method thereof

ActiveCN106205935AGood calenderabilityExcellent magnetic propertiesTransportation and packagingMetal-working apparatusMagnetic powderPrecursor polymer

The invention belongs to the field of a metal-based soft magnetic composite material. A preparation method comprises the following steps of preparing amorphous alloy powder from an amorphous alloy thin strip; screening and compounding the amorphous alloy powder to obtain a first product; performing passivation and coupling processing on the first product to obtain a second product; mixing and stirring the second product and a ceramic precursor polymer solution to obtain composite amorphous powder; and performing formation, thermal processing and insulation layer coating on the composite amorphous powder to obtain amorphous soft magnetic composite magnetic powder. By adopting a ceramic precursor polymer as an insulation binding agent, the step of adding insulation agent powder is omitted, the problems of unstable magnetic conductivity and poor thermal stability during traditional preparation of the magnetic powder core by crashing the amorphous thin strip are solved, the production cost is reduced, and the amorphous soft magnetic composite magnetic powder can be applied to a certain electronic device with application requirements for high frequency and low loss.

Owner:张听

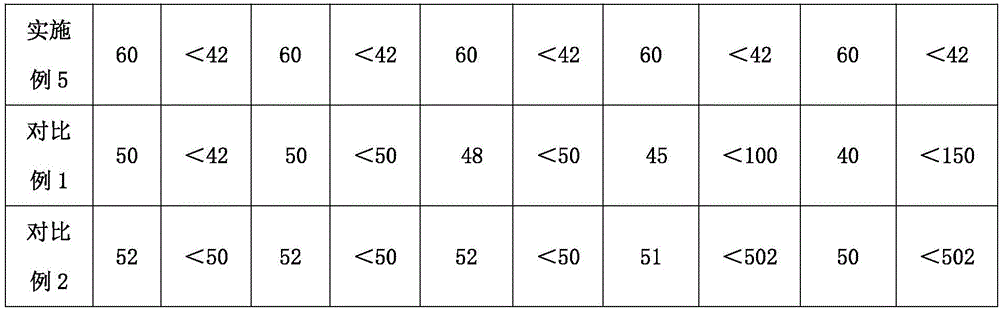

Preparation method of pure rhenium product

The invention discloses a preparation method of a pure rhenium product. The method comprises the processes of rhenium powder pretreating, pressing and forming, dewaxing, pre-sintering, sleeve wrapping, hot isostatic pressing, wrapped sleeve removal, high-temperature sintering process and the like. According to the preparation method of the pure rhenium product, large-size pure rhenium rods, pure rhenium blocks and other products are prepared, and the advantages of being controllable in shape and size and high in density are achieved.

Owner:ATTL (BEIJING) ADVANCED MATERIALS CO LTD +2

Raw material mixing method and preparation technology for molybdenum copper alloy for heat sinking, and product

ActiveCN108913927AImprove uniformitySolve the problem of uniformity of distributionHeat sinkLarge size

The invention provides a raw material mixing method for a molybdenum copper alloy for heat sinking. Raw materials of an alloy material for heat sinking comprise copper powder and molybdenum powder. The method is characterized in that the loose specific weight of the molybdenum powder is adjusted firstly, a difference value of the loose specific weight of the molybdenum powder and the loose specific weight of the copper powder is smaller than 0.5 g / cm<3>, and then according to the need of the mixing proportion, the copper powder and the molybdenum powder are mixed uniformly. According to the method, the problems that due to copper powder aggregating in the mixture of the molybdenum powder and the copper powder, in the copper infiltration and sintering process, the copper powder is fused, acopper pool with the large size is formed, and the copper distribution uniformity in the alloy material is influenced are effectively solved, the mixing uniformity of the mixture of the molybdenum andthe copper is improved, and thus the uniformity of the physical performance of the molybdenum copper alloy is improved. The invention further provides a preparation technology for the molybdenum copper alloy for heat sinking, and a product.

Owner:ZHUZHOU JIABANG REFRACTORY METAL

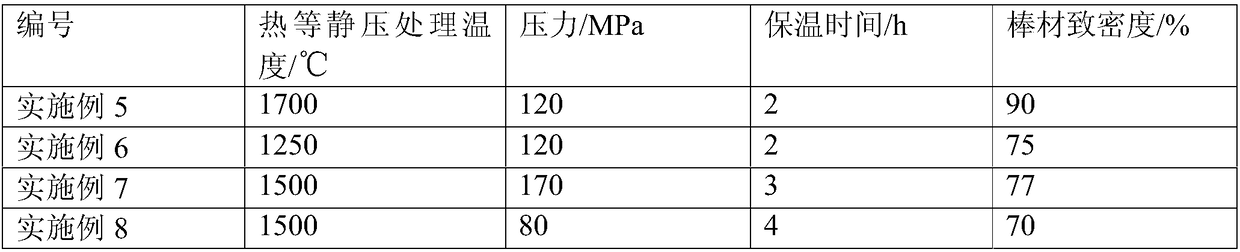

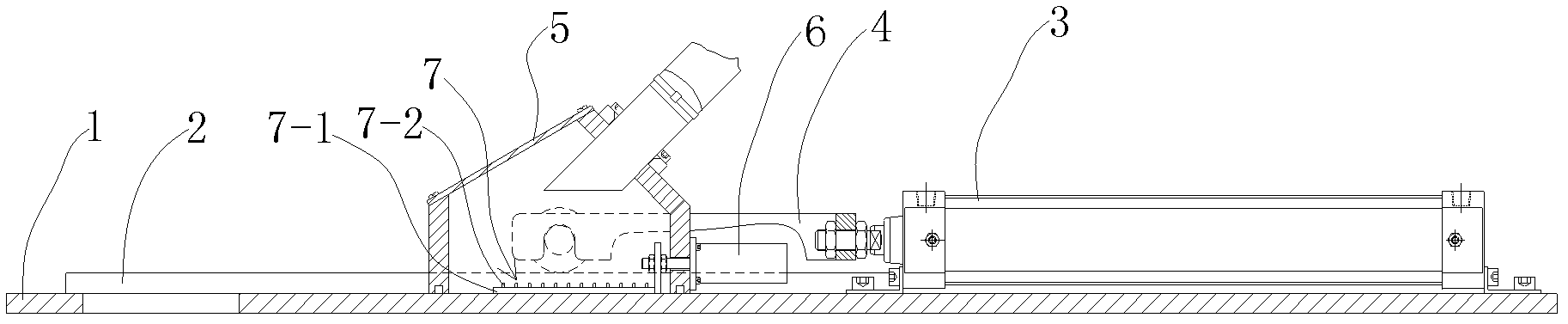

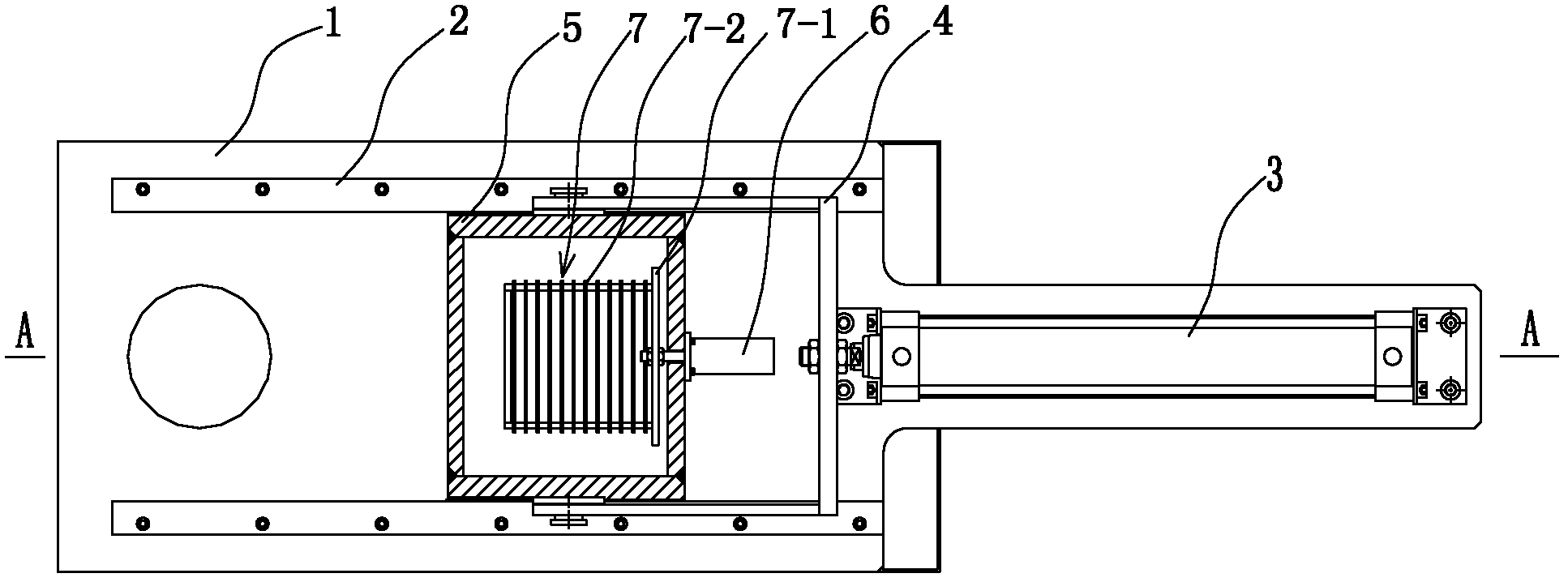

Powder feeding device for powder hydraulic press

InactiveCN102275334AGuaranteed uniformityEnhanced inhibitory effectPressesEngineeringMechanical engineering

The invention relates to a powder feeding device of a powder hydraulic press, comprising a guide rail fixed on a product support plate and a feeding cylinder, a feeding bracket slidably installed on the guide rail, a feeding box fixed on the feeding bracket, the feeding bracket and the feeding cylinder The push rod end is fixedly connected, and it is characterized in that: the vibration cylinder is fixed on the side wall of the feed box perpendicular to the guide rail, and the push rod end of the vibration cylinder is fixedly connected with a vibration grid, and the vibration grid is located in the feed box. The invention adopts a vibrating cylinder and a vibrating grid. During the process of filling the powder raw material into the cavity of the mold, the vibrating cylinder pushes the grid to reciprocate and vibrate, so that the powder raw material evenly falls into the cavity, ensuring the uniformity of powder raw material filling and facilitating subsequent pressing. forming.

Owner:TIANJIN TIANDUAN PRESS CO LTD

Sol-bonded sagger for sintering of a lithium battery cathode material and preparation method thereof

The invention relates to a sol-bonded sagger for sintering of a lithium battery cathode material and a preparation method thereof. According to a technical scheme, 20-25wt% of corundum particles are adopted as aggregate, 12-20wt% of corundum fine powder, 20-25wt% of cordierite, 20-25wt% of magnesia-alumina spinel, 2-10wt% of silica powder and 5-10wt% of clay are adopted as the matrix, and the aggregate and the matrix are called raw materials. The preparation method includes: carrying out ball milling on the matrix for 1-3h to obtain a premix; stirring the aggregate and a mullite sol accountingfor 2-5wt% of the raw materials uniformly to obtain premixed aggregate; and then adding the premixed aggregate into the premix, adding a mullite sol accounting for 2-5wt% of the raw materials, conducting stirring, mechanical pressing molding and drying, and carrying out heat preservation at 1300DEG C-1400DEG C for 2-4h to obtain the sol-bonded sagger for sintering of the lithium battery cathode material. The preparation method has simple in process and short production period, and the prepared product has good sintering performance, large volume density, high compressive strength, excellent thermal shock resistance and good erosion resistance.

Owner:WUHAN UNIV OF SCI & TECH

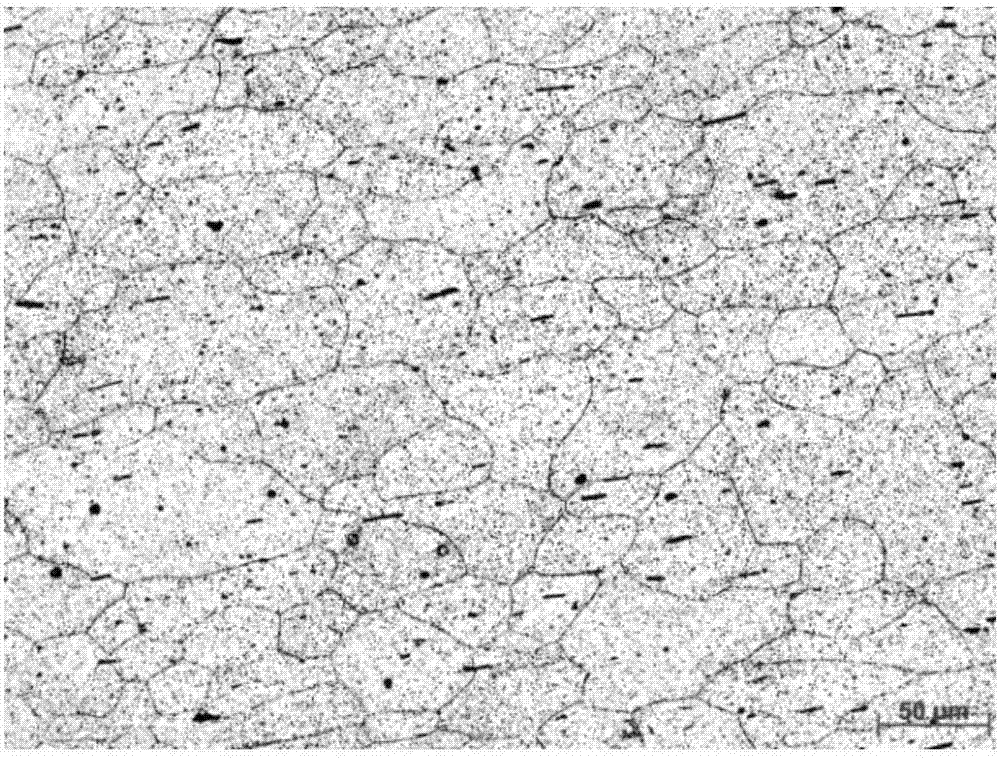

Manufacturing method of aluminum alloy cartridge shell and cartridge shell

InactiveCN109158604AFast coolingFine and uniform grainAnodisationCartridge ammunitionAnodic oxidationCopper

The invention provides an aluminum alloy cartridge shell and a manufacturing method of the aluminum alloy cartridge shell. The manufacturing method of the aluminum alloy cartridge shell includes the following steps that S1, an aluminum alloy raw material is prepared, and an aluminum alloy solution is smelted; S2, an aluminum alloy cartridge shell blank is prepared; S3, forming treatment is conducted; and S4, surface treatment is conducted. According to the structural features and the use environments of the cartridge shell, alloy components are designed scientifically and reasonably, the aluminum alloy cartridge shell is manufactured after a 3D jet molding fast solidifying technology, multi-pass die stamping forming treatment and hard anodizing surface treatment, the whole set of technological process is complete, operability is high, and the purpose of replacing traditional copper and steel cartridge shells can be achieved.

Owner:HUNAN UNIV OF TECH

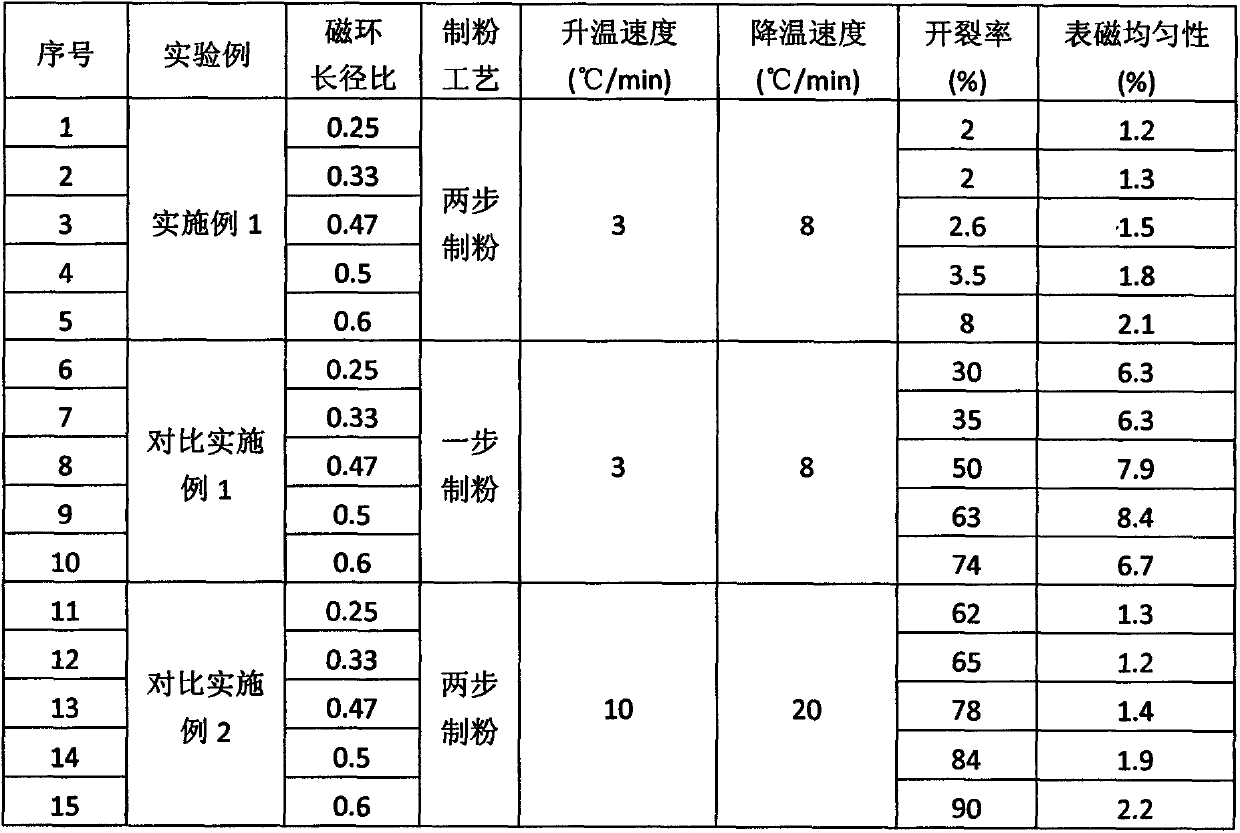

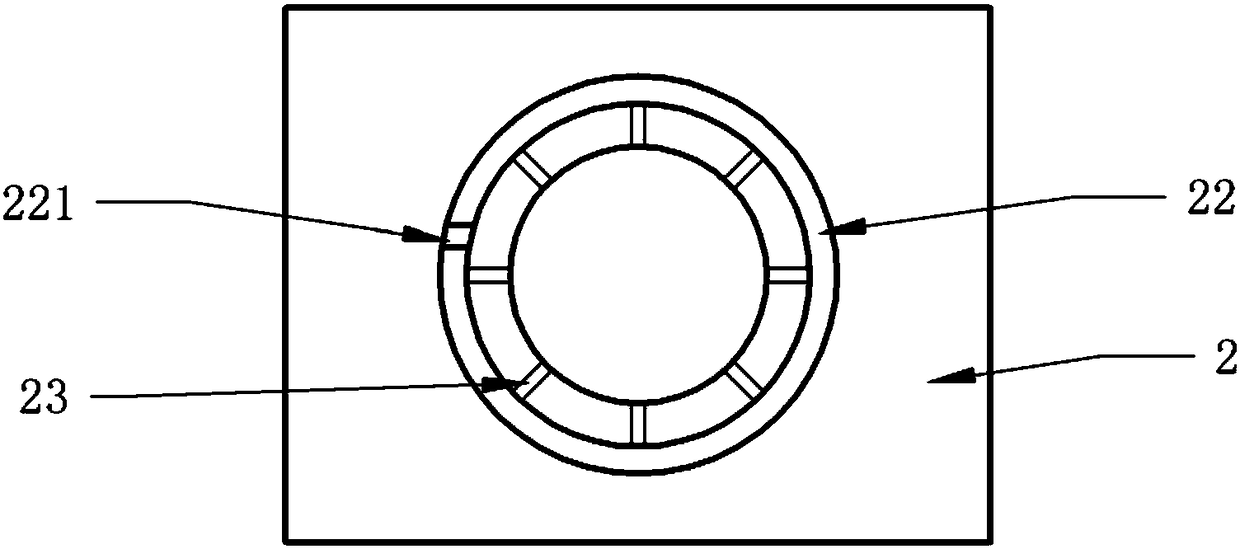

Preparation method of radiation-oriented sintered neodymium iron boron magnet ring

InactiveCN107768062AImprove roundnessImprove uniformityInorganic material magnetismInductances/transformers/magnets manufactureHydrogenSlow cooling

The invention provides a method for preparing a radiation orientation sintered NdFeB magnetic ring, which specifically includes smelting, hydrogen crushing, jet milling, radiation orientation molding and sintering. During the powder making process, through two jet mills and two additions of lubricants, the fluidity of the powder is improved, the powder is fully oriented along the radial direction in the magnetic field, and the density of the green compact becomes uniform in the axial and radial directions , greatly improve the roundness of the magnetic ring and the uniformity of the magnetic surface, and at the same time, the method of slow heating and cooling is adopted during the sintering process to reduce the internal stress caused by uneven cooling or heating, and the cracking rate of the magnetic ring sintering is greatly reduced.

Owner:NINGBO KETIAN MAGNET

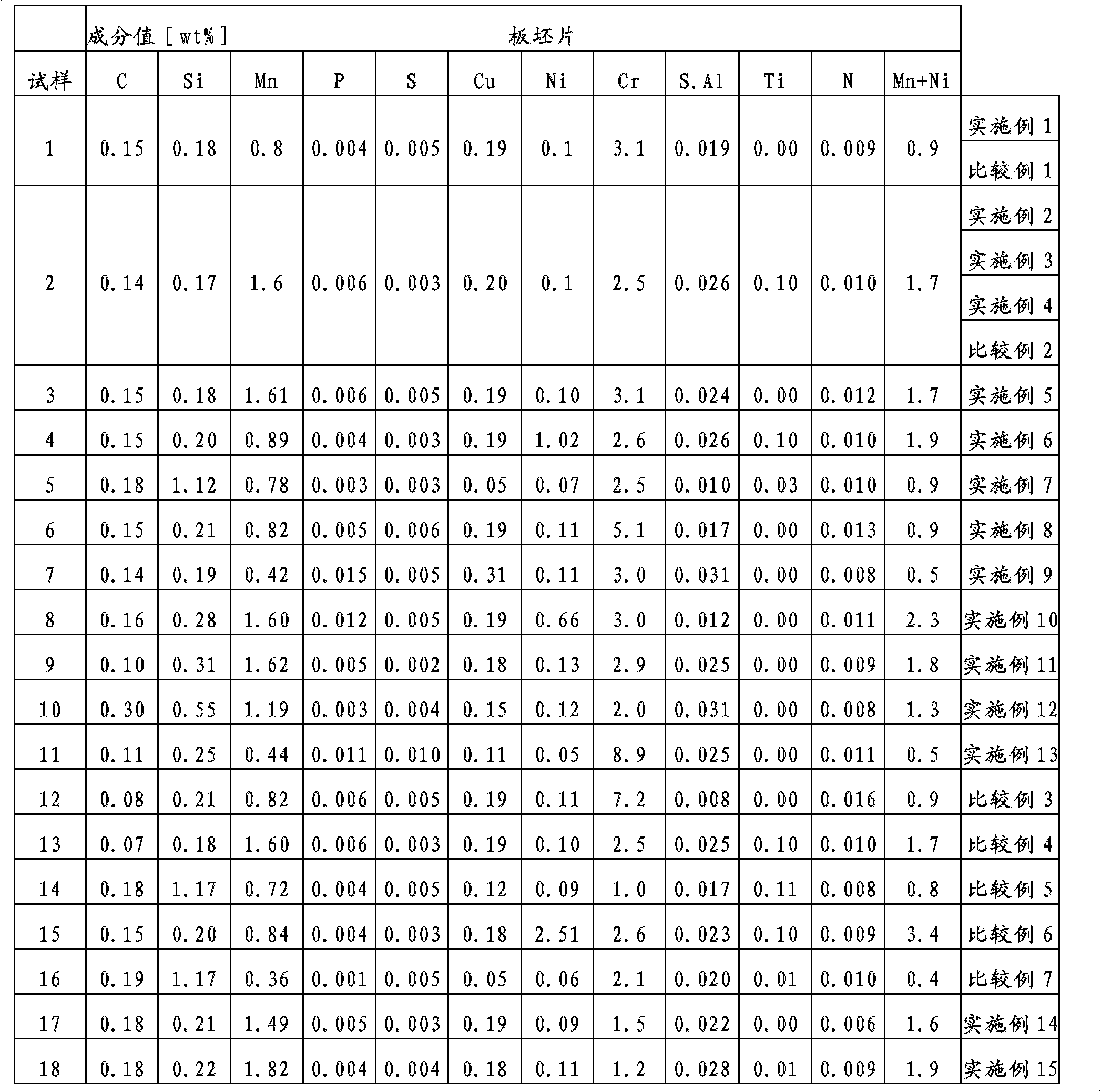

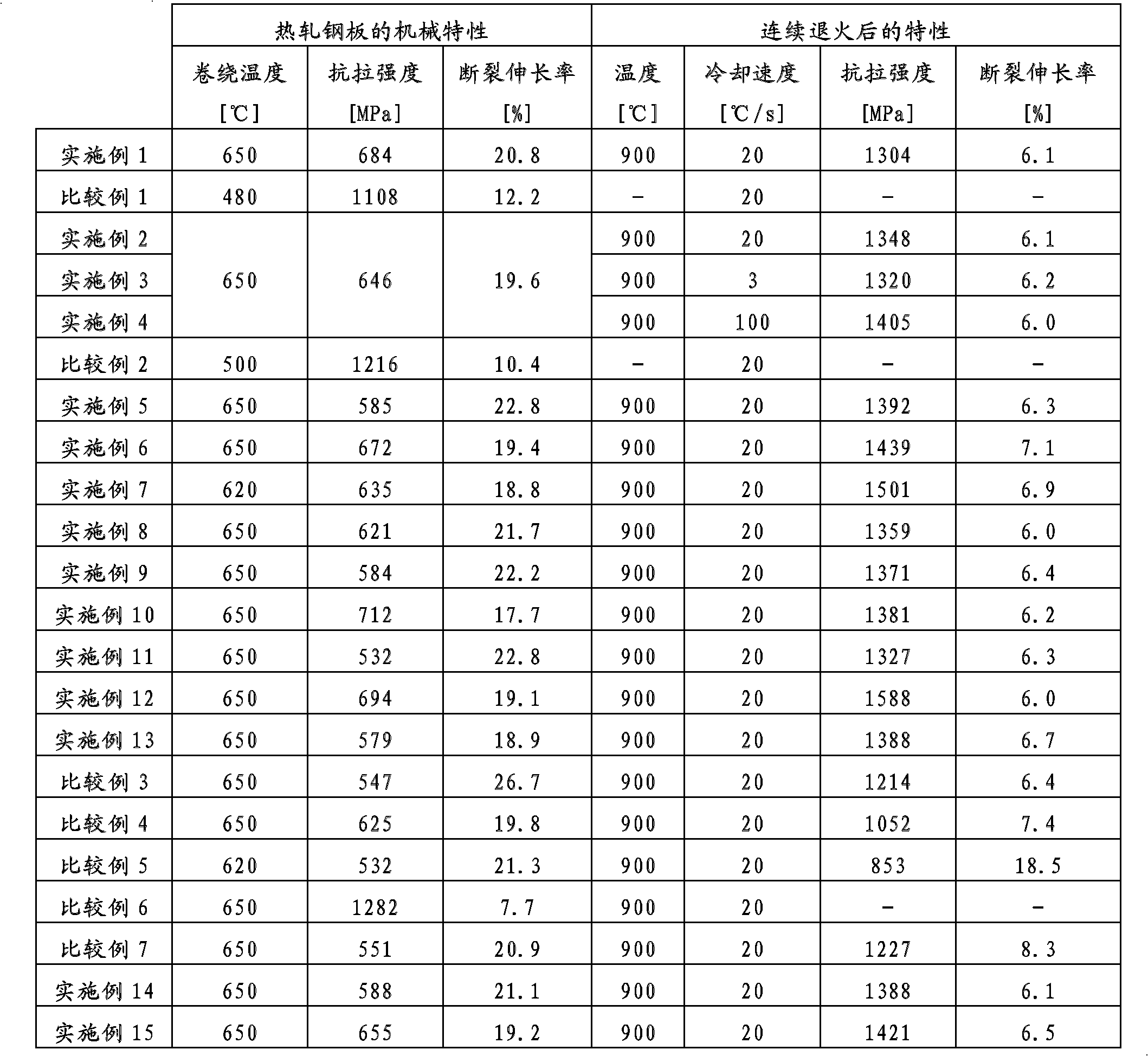

Process for production of cold-rolled steel sheet having excellent press moldability, and cold-rolled steel sheet

ActiveCN102471821AReduce loadHigh strengthRotary drum furnacesHeat treatment furnacesHot rolledMaterials science

Disclosed are: a cold-rolled steel sheet which undergoes less load during cold rolling and has excellent press moldability and high strength; and a process for producing the cold-rolled steel sheet. A hot-rolled steel sheet comprising 0.10 to 0.30 mass% of C, 0.2 mass% or more of Mn, 0.01 mass% or more of Ni (wherein the sum total of Mn and Ni is 0.5 to 2.5 mass%), and 1.2 to 9.0 mass% of Cr, with the remainder being iron and unavoidable impurities, and having a tensile strength of 1000 MPa or less is washed with an acid, and is subjected to cold rolling at a total rolling ratio of 60% or more, thereby producing a cold-rolled steel sheet. The cold-rolled steel sheet is subjected to the final continuous annealing treatment at a homogenizing temperature of 750 DEG C or higher and a cooling rate of 3 to 100 DEG C / s. In this manner, a cold-rolled steel sheet having a tensile strength of 1280 MPa or more, a breaking elongation of 3% or more, and a thickness of 0.05 to 0.60 mm.

Owner:TOYO KOHAN CO LTD +1

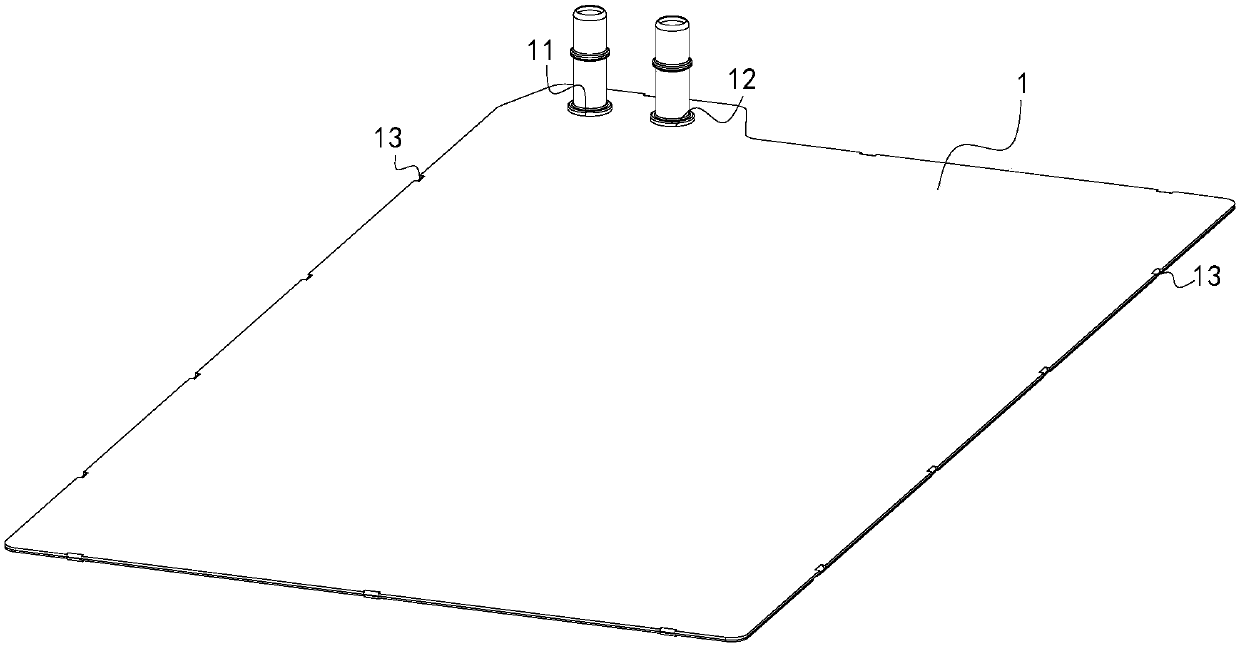

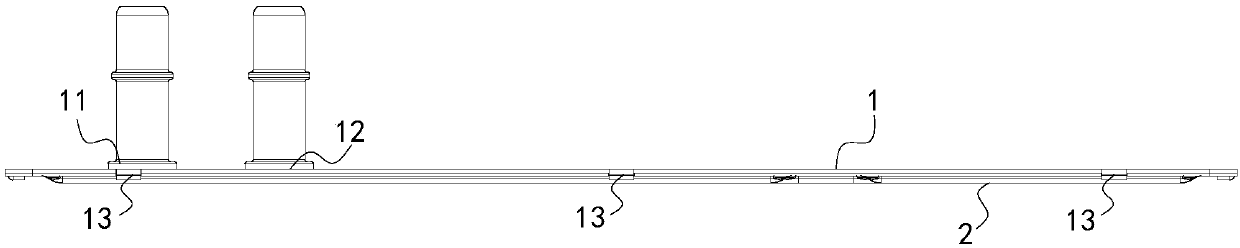

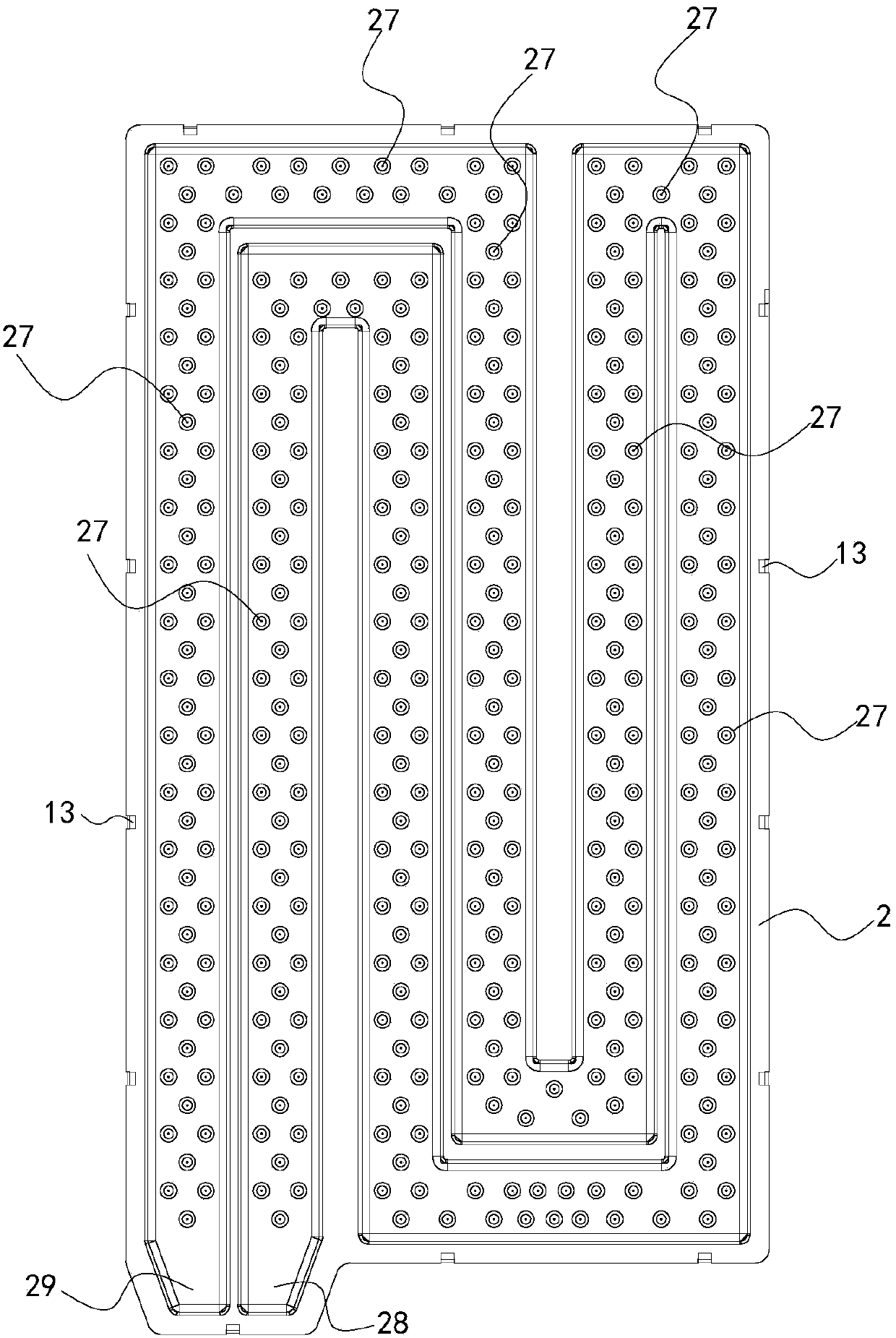

Power battery water-cooling plate for brazing

InactiveCN107863587ASimple structureImprove pressure resistanceSecondary cellsBatteriesPower batteryEngineering

The invention relates to a power battery water-cooling plate for brazing. The power battery water-cooling plate comprises an upper plate and a lower plate, wherein the upper plate is buckled with thelower plate, the upper plate and the lower plate are fixed by brazing, a runner is formed between the upper plate and the lower plate and is used for a cooling liquid to flow, the runner comprises a liquid inlet runner and a liquid return runner which are arranged in parallel, an inlet and an outlet of the runner are arranged in parallel, a liquid inlet is formed in a position, corresponding to the inlet, of the upper plate, and a liquid outlet is formed in a position, corresponding to the outlet, of the upper plate. The power battery water-cooling plate is formed by only combining the upper plate and the lower plate, is simple in structure, good in pressure resistance, light in weight and high in heat exchange efficiency and is difficult to leak; by arranging the liquid inlet runner and the liquid outlet runner in parallel, the thermal equalization performance of a battery module is greatly improved; and the upper plate and the lower plate are fixed by brazing, the production efficiency is high, the weight of a battery module water-cooling system is reduced, the heat exchange capability of the water-cooling plate is improved, good temperature uniformity is achieved, and the powerbattery water-cooling plate is suitable for rapid production on a large scale.

Owner:BEIJING PRIDE NEW ENERGY BATTERY

Method for preparing hard alloy mixture by attritor milling process

The invention relates to a method for preparing a hard alloy mixture, in particular to a method for preparing a hard alloy mixture by an attritor milling process. |By adopting attritor milling and adding a certain amount of dispersing agent, adhesive and the like, a superfine hard alloy mixture is obtained. The method for preparing the hard alloy mixture by the attritor milling process has the characteristics of high milling efficiency, low energy consumption, suitability for mass production and the like, and can be widely applied to preparation of the superfine hard alloy mixture.

Owner:浙江东钨实业有限公司

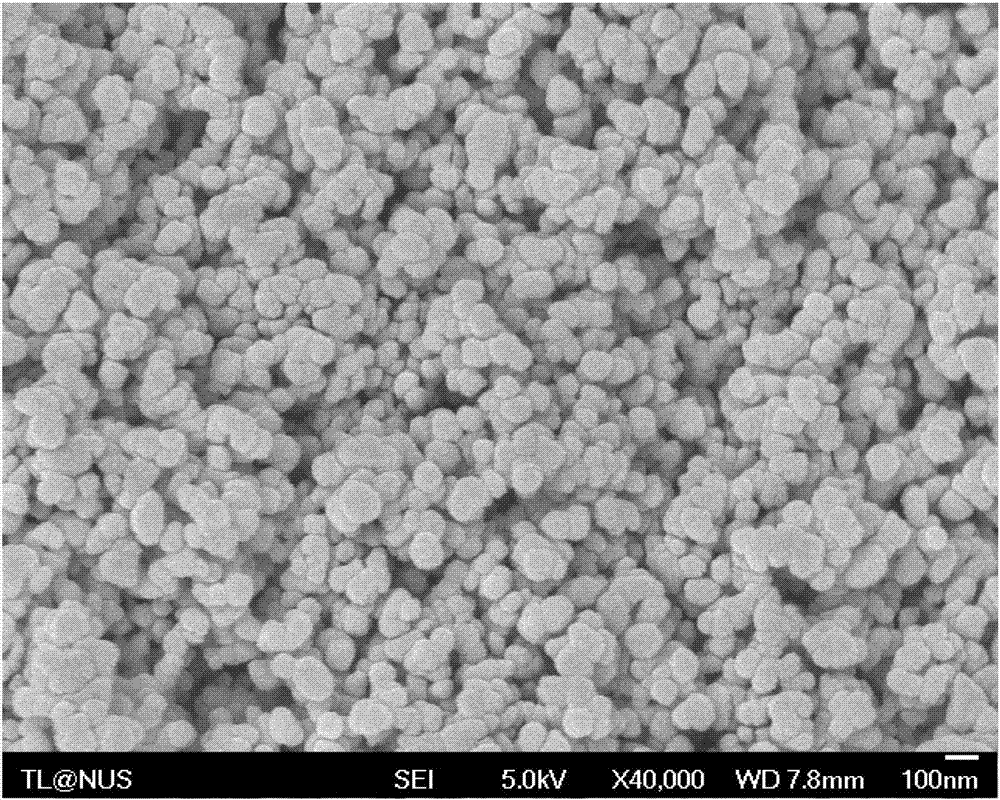

Preparation method of indium tin oxide composite powder

ActiveCN106882835AReduce agglomerationReduce hard agglomeratesMaterial nanotechnologyGallium/indium/thallium compoundsIndiumIndium tin oxide

The invention discloses a preparation method of indium tin oxide composite powder, belonging to the technical field of preparation of indium tin oxide composite powder. The method comprises the following steps: preparation of mixed salt liquid: putting an InCl3 liquid and an SnCl4 liquid into a reaction kettle according to the In2O3:SnO2 weight ratio of 9:1, and uniformly mixing; addition of dispersing agents: adding polyvinylpyrrolidone, beta-alanine and ethanediol according to the weight ratio of 2:1:3, and adding more than 20% excessive of urea; coprecipitation reaction: gradually heating to 60-90 DEG C, keeping the temperature while continuously stirring until the In<3+> in the reaction solution is completely precipitated, carrying out ultrasonic treatment for 1 hour, continuing stirring, and aging to obtain an indium tin precipitate; and washing, drying, grinding, screening and carrying out high-temperature calcination to obtain the high-sintering-activity nano indium tin oxide composite powder. The indium tin oxide composite powder prepared by the method has the advantages of less hard aggregation and favorable flowability, and is easy for pressure molding.

Owner:ANHUI TUOJITAI NOVEL CERAMIC TECH

1xxx/5xxx aluminum alloy composite and preparing method thereof

InactiveCN109763041AMeet stampingFulfil requirementsTemperature control deviceMetal rolling arrangementsPunchingAlloy composite

The invention relates to a preparing method of an aluminum alloy composite, in particular to a preparing method of the 1xxx / 5xxx aluminum alloy composite. According to the preparing method of the 1xxx / 5xxx aluminum alloy composite, an aluminum alloy composite finished product is finished through steps of core layer alloy and coating layer alloy board preparing, surface treatment, welding fixing, preheating, hot rolling, cold rolling and annealing; 1xxx series aluminum alloy and 5xxx series aluminum alloy are rolled to prepare the 1xxx / 5xxx aluminum alloy composite product in a composite manner, and advantage characteristics of the 1xxx series and 5xxx series aluminum alloy materials can be sufficiently combined; compared with an existing single 5xxx series aluminum alloy, the welding property of the prepared product can be obviously improved, meanwhile, good structural strength and corrosion resistance performance are achieved, punching molding is easy, and the requirement of a car wheel fender for punching molding and welding performance can be completely met.

Owner:广西南南铝加工有限公司

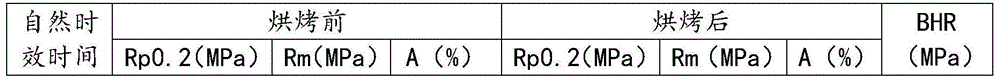

Thermal treatment method for improving bake-hardening performance and natural aging stability of 6xxx-series aluminum alloys

The invention discloses a thermal treatment method for improving bake-hardening performance and natural aging stability of 6xxx-series aluminum alloy, and belongs to the technical field of aluminum alloy processing. The thermal treatment method comprises the following steps: within 20 minutes after performing solution treatment on 6xxx-series aluminum alloy plates and quenching to the room temperature, entering a furnace at 50-150 DEG C, and cooling to be lower than 40 DEG C at the cooling rate of 3-20 DEG C / h within 20 minutes after keeping the temperature. The thermal treatment method disclosed by the invention is simple in process, high in production efficiency, and capable of effectively improving the natural ageing stability and the bake-hardening performance of the 6xxx-series aluminum alloy car plates, so that the 6xxx-series aluminum alloy car plates can be applicable to automotive body aluminum alloy plates.

Owner:广西南南铝加工有限公司

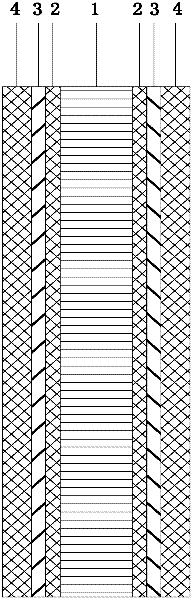

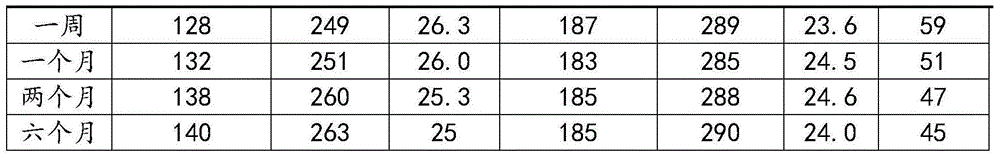

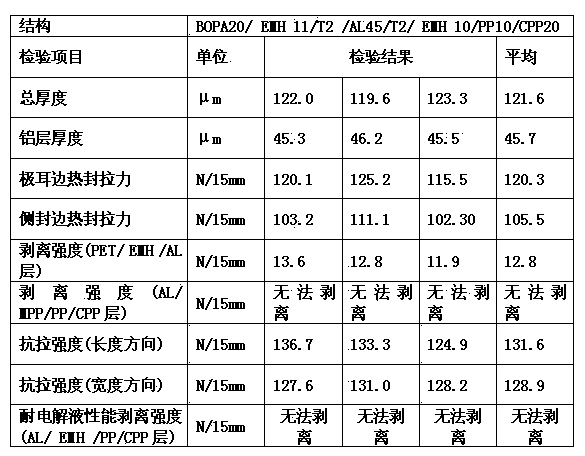

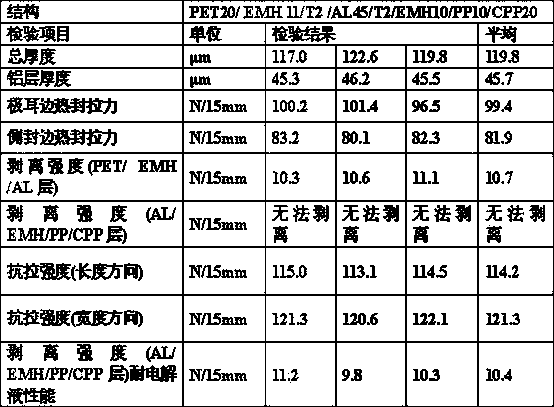

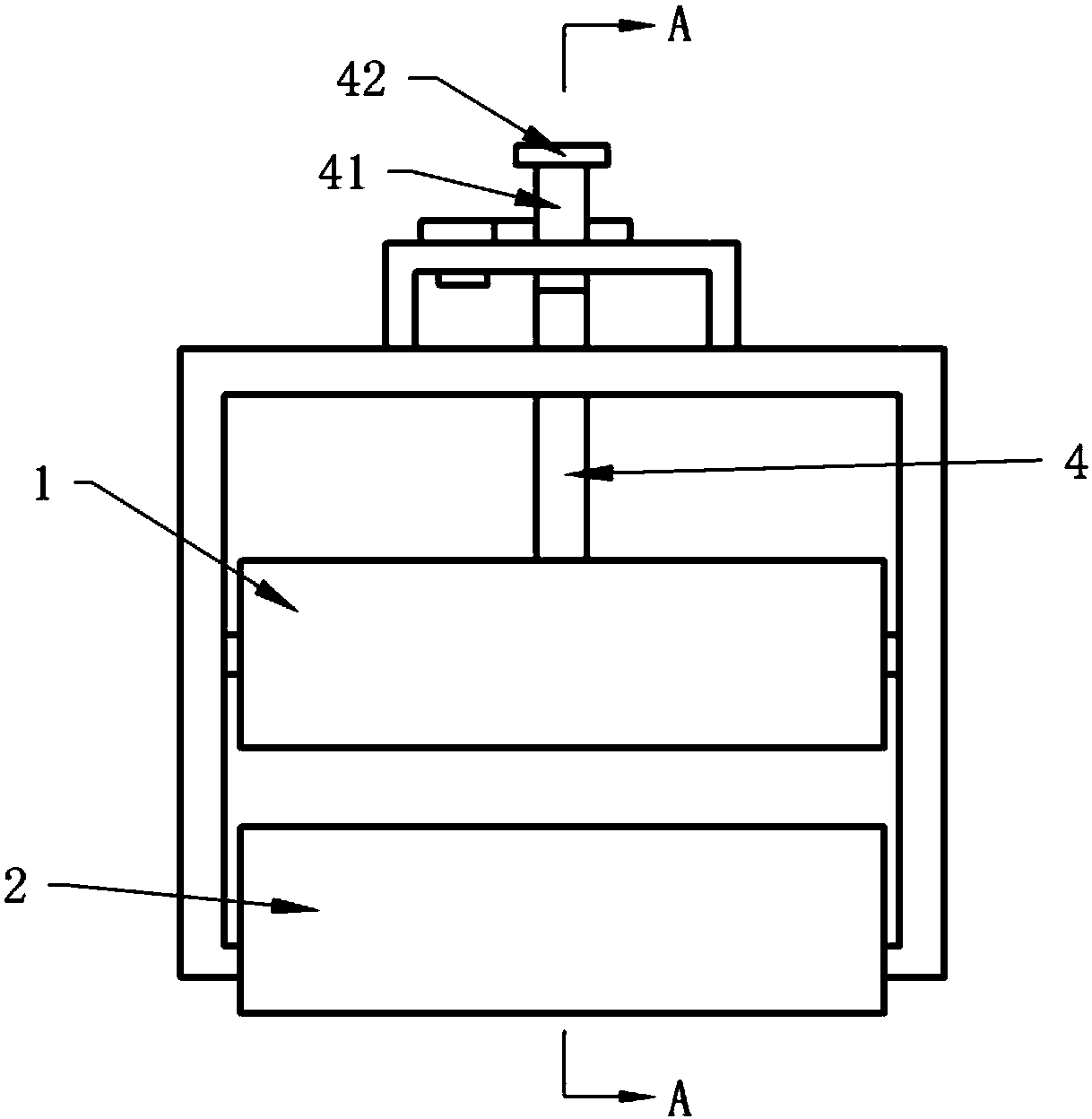

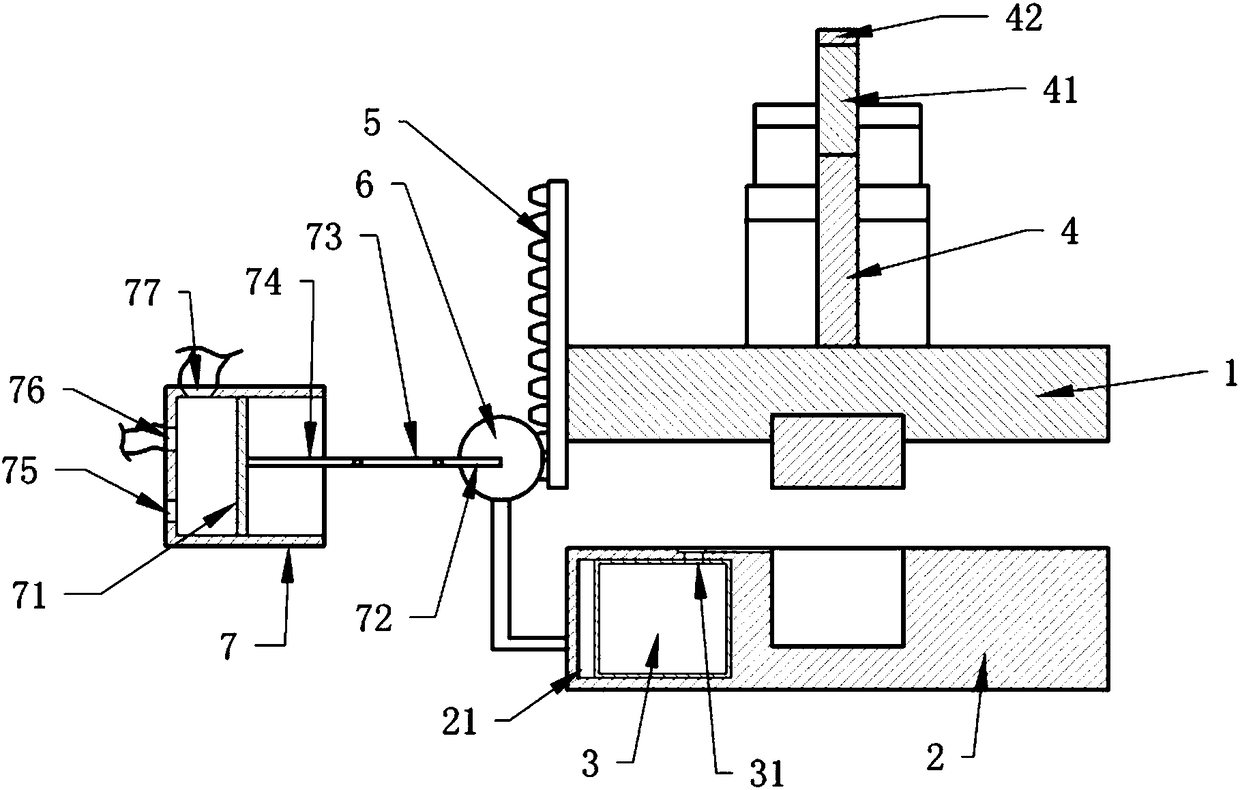

Aluminum-plastic extrusion composite film of lithium ion battery and preparation method of composite film

ActiveCN103400951AImprove electrolyte resistanceHigh tensile strengthSynthetic resin layered productsLaminationComposite filmProtection layer

The invention discloses an aluminum-plastic extrusion composite film of a lithium ion battery. The aluminum-plastic extrusion composite film sequentially consists of a protection layer, a first extrusion layer, a first coating layer, an aluminum foil layer, a second coating layer, a second extrusion layer, a homo-polymerizing layer and a heat-sealing layer from outside to inside, wherein the first coating layer and the second coating layer are sprayed on the upper surface and the lower surface of the aluminum foil layer respectively; the protection layer is adhered to the first coating layer through the first extrusion layer; the second coating layer is adhered to the heat-sealing layer by co-extrusion and compositing of the second extrusion layer and the homo-polymerizing layer (7). The invention also discloses a preparation method of the aluminum-plastic extrusion composite film of the lithium ion battery. In order to alleviate oxidation layering of a packaging film caused by corrosion of a battery electrolyte under the high temperature condition, the corrosion resistance and insulating performance of an inner layer of the composite film are improved, and the electrolyte resistance of the composite film is improved; the tension strength, tensile strength and breaking elongation of the whole composite film are improved, and thus punch forming of the composite film is facilitated. The composite film is applicable to packaging of the lithium ion battery, a capacitor and an electrolyte.

Owner:江苏共巨锂电材料有限公司

Die for automobile part

The invention belongs to the technical field of automobile part machining and discloses a die for an automobile part. The die comprises an upper convex die and a lower concave die. The lower concave die is internally provided with a feeding bin, the feeding bin is internally provided with a material storage air bag, and the material storage air bag is provided with a material outlet and a feedingopening. The lower concave die is provided with a feeding slot and material guide slots. The die further comprises an inverted-U-shaped bracket, the bracket comprises a transverse rod and a vertical plate, and the upper surface of the upper concave die is rotatably connected with a screw rod penetrating through the transverse rod. The die further comprises a drive piece, and the drive piece comprises a first gear and a rack. One side of the lower concave die is provided with a supporting frame, the supporting frame is provided with a rotating shaft, the first gear is fixed to one end of the rotating shaft, and the other end of the rotating shaft is provided with a rotary table. One side of the lower concave die is provided with a gas storage barrel, and the gas storage barrel is internallyand slidably connected with a piston. The die further comprises a first connection rod, a second connection rod and a third connection rod, wherein the first connection rod, the second connection rodand the third connection rod are hinged in sequence. By means of the die for the automobile part, the problem that in the prior art, a stamped and formed automobile part is in close fit with the lower die so that the formed automobile part is not prone to be taken out is solved.

Owner:CHONGQING YINSHENG MOLD

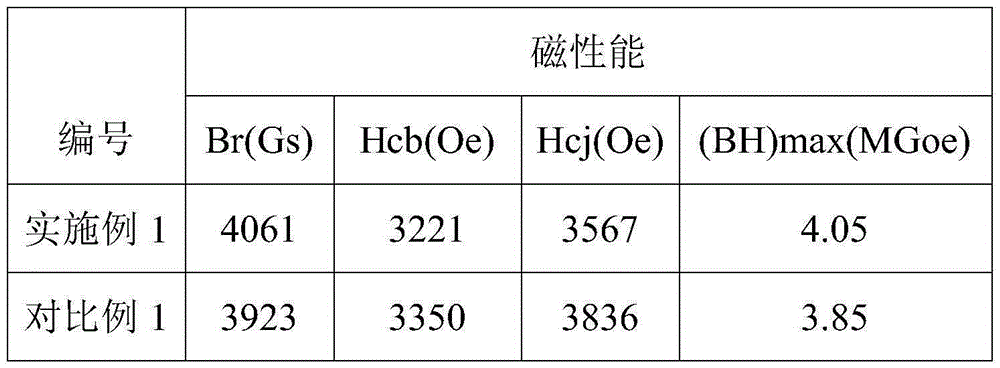

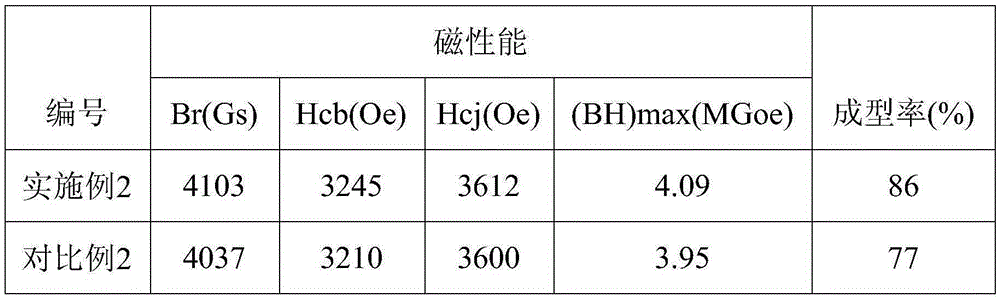

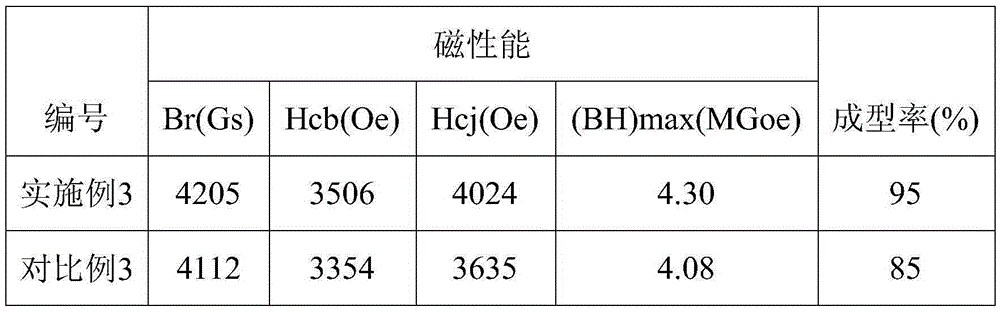

Method for manufacturing dry press permanent magnetic ferrite

ActiveCN105384434AOptimization of particle size and morphology of magnetic powderImprove orientationMagnetic powderMass ratio

The invention discloses a method for manufacturing dry press permanent magnetic ferrite. The method comprises the following specific operating steps: selecting a pre-sintering material, adding multiple needed additives according to a mass ratio, and performing ball milling; storing the slurry subjected to ball milling until the slurry is dried; drying the magnetic powder, adding 0-0.6 percent of calcium stearate, 0.8-1.2 percent of an alcohol camphor solution and 0-0.4 percent of talcum powder, and dispersing the material by using a high-speed dispersion machine after the materials are uniformly mixed and stirred; tempering the magnetic powder at the temperature of 60-90 DEG C; molding in a magnetic field of 8000Oe or more, thereby obtaining a formed body with the height of 1.2-2cm; maintaining the temperature of the green body at the temperature of 350-400 DEG C for 1-3 hours, and maintaining the temperature at the temperature of 1150-1350 DEG C for 0.1-3 hours; and grinding, cleaning and detecting. The method disclosed by the invention has the beneficial effects that on one hand, technology improvement is performed, and a low-temperature tempering process is increased, so that the particle size and shape of the magnetic powder can be optimized, the degree of orientation is improved, and the magnetic performance is further improved; on the other hand, due to improvement of additives in the granulation process, compression molding is promoted, and the yield is further improved.

Owner:武穴东磁磁材有限公司

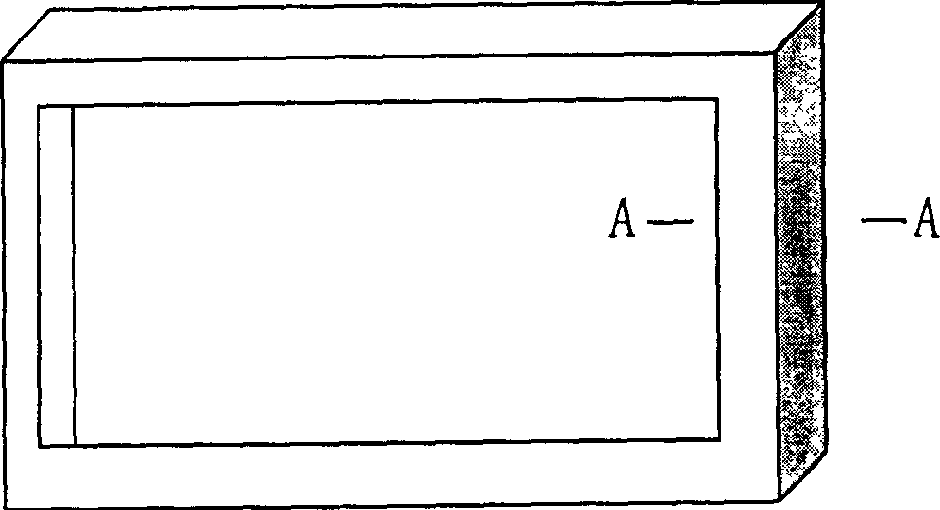

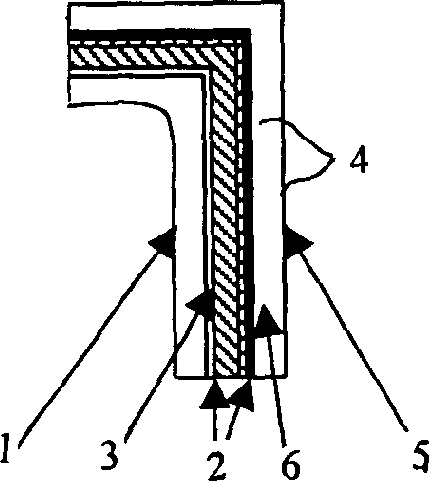

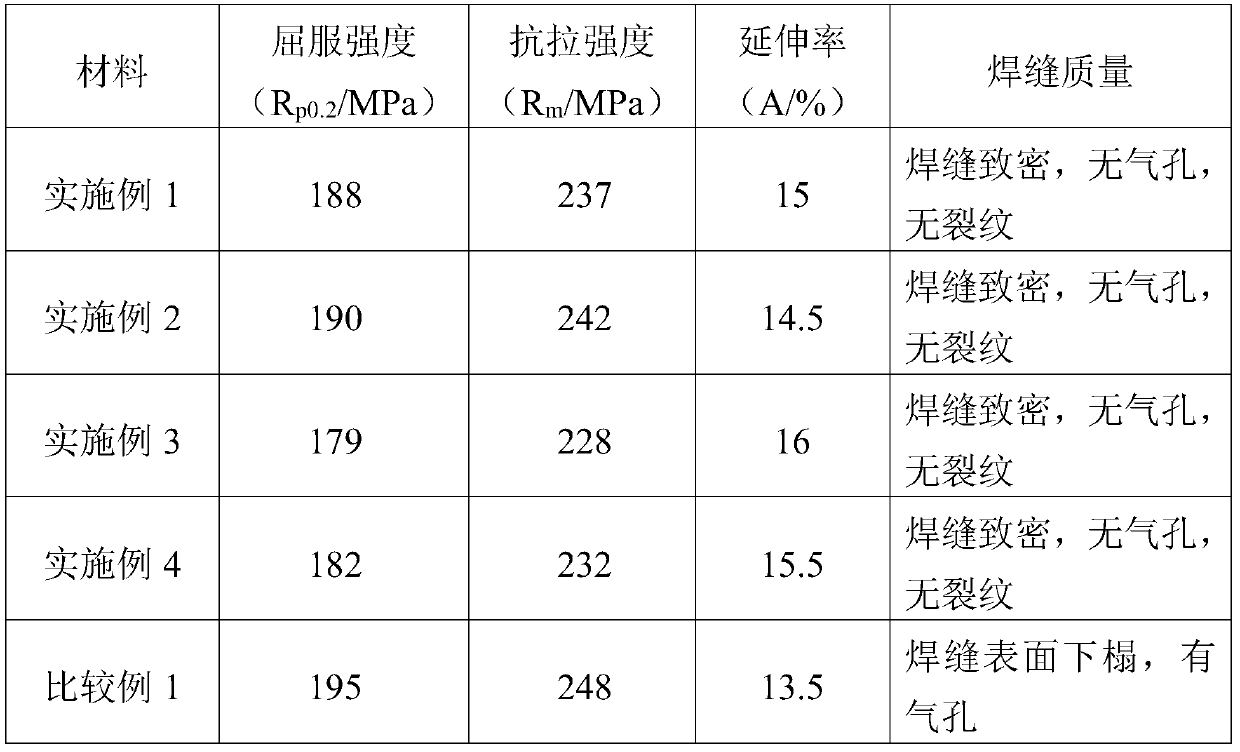

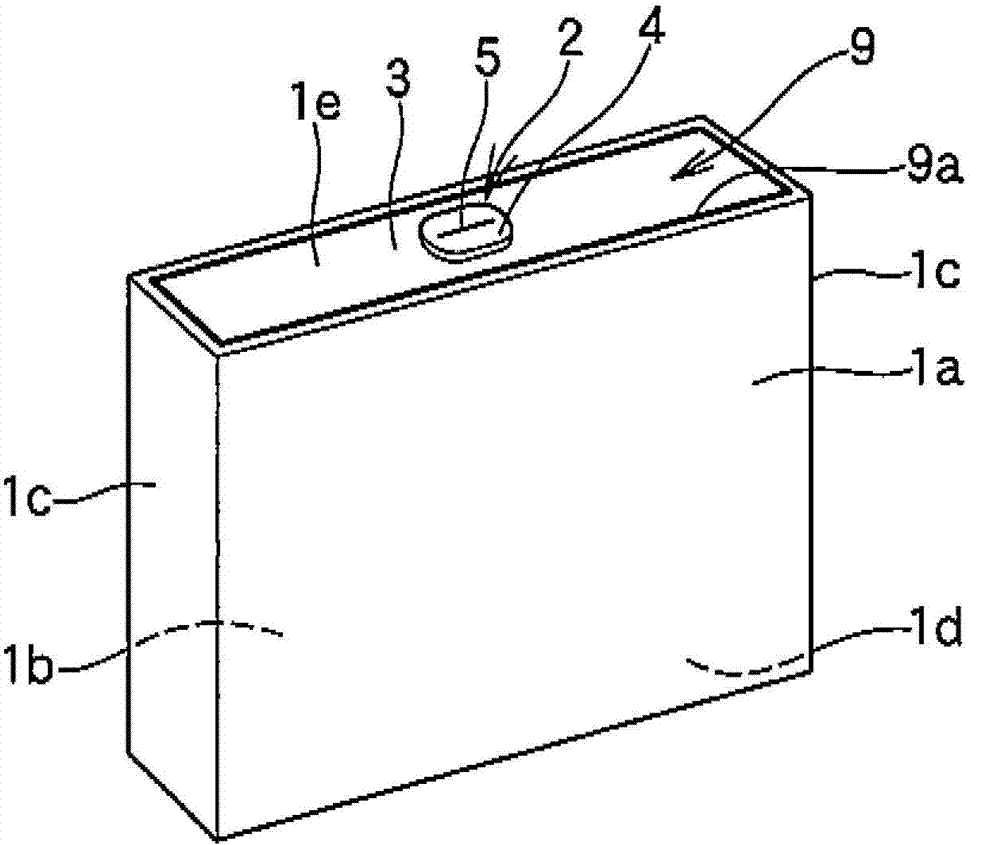

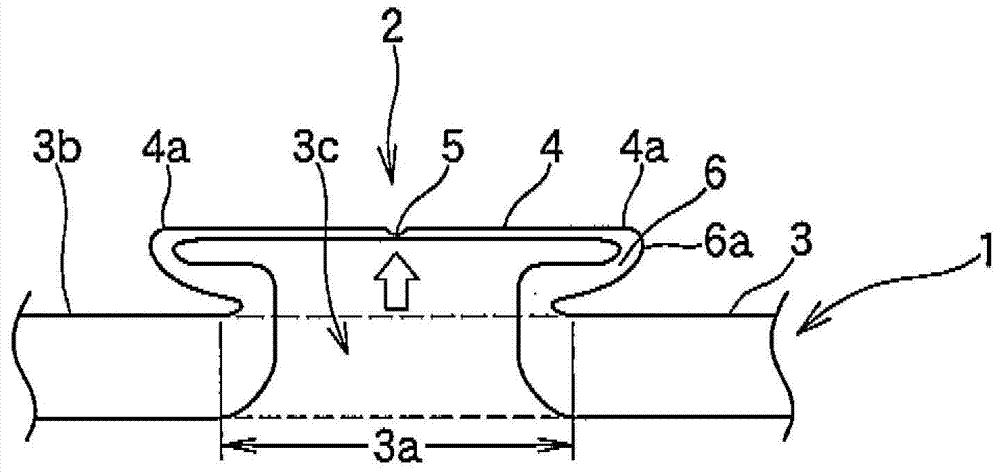

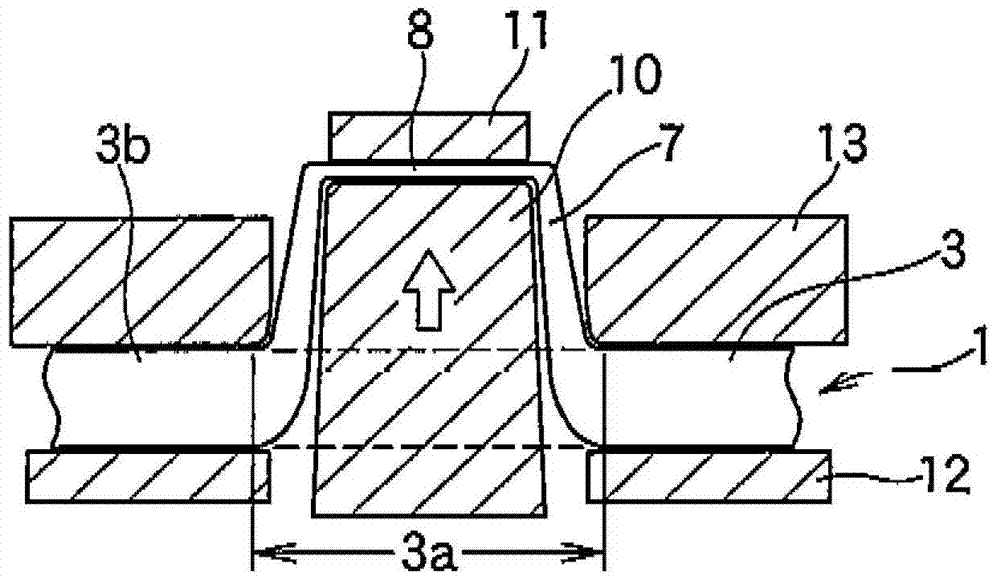

Battery casing and battery casing safety valve forming method

ActiveCN104282850AEasy to press and formReliable splitSmall-sized cells cases/jacketsLarge-sized cells cases/jacketsElectrical batteryEngineering

The invention provides a forming method for the safety valve of an aluminum alloy lithium-ion battery casing. The method utilizes punching to form in shape with high precision and working efficiency. As a safety valve (2), one part (3a) of the battery casing (1) wall (3) is punched to form a cup shaped protruding part which protrudes externally. The top of the safety valve (2) is a flat thin film (4). The circumferential part (4a) of the thin film top (4) crosses the side wall (6) of the protruding part facing the thin film top and is integrated to the battery casing (1) wall (3) as a whole unit.

Owner:KOBE STEEL LTD

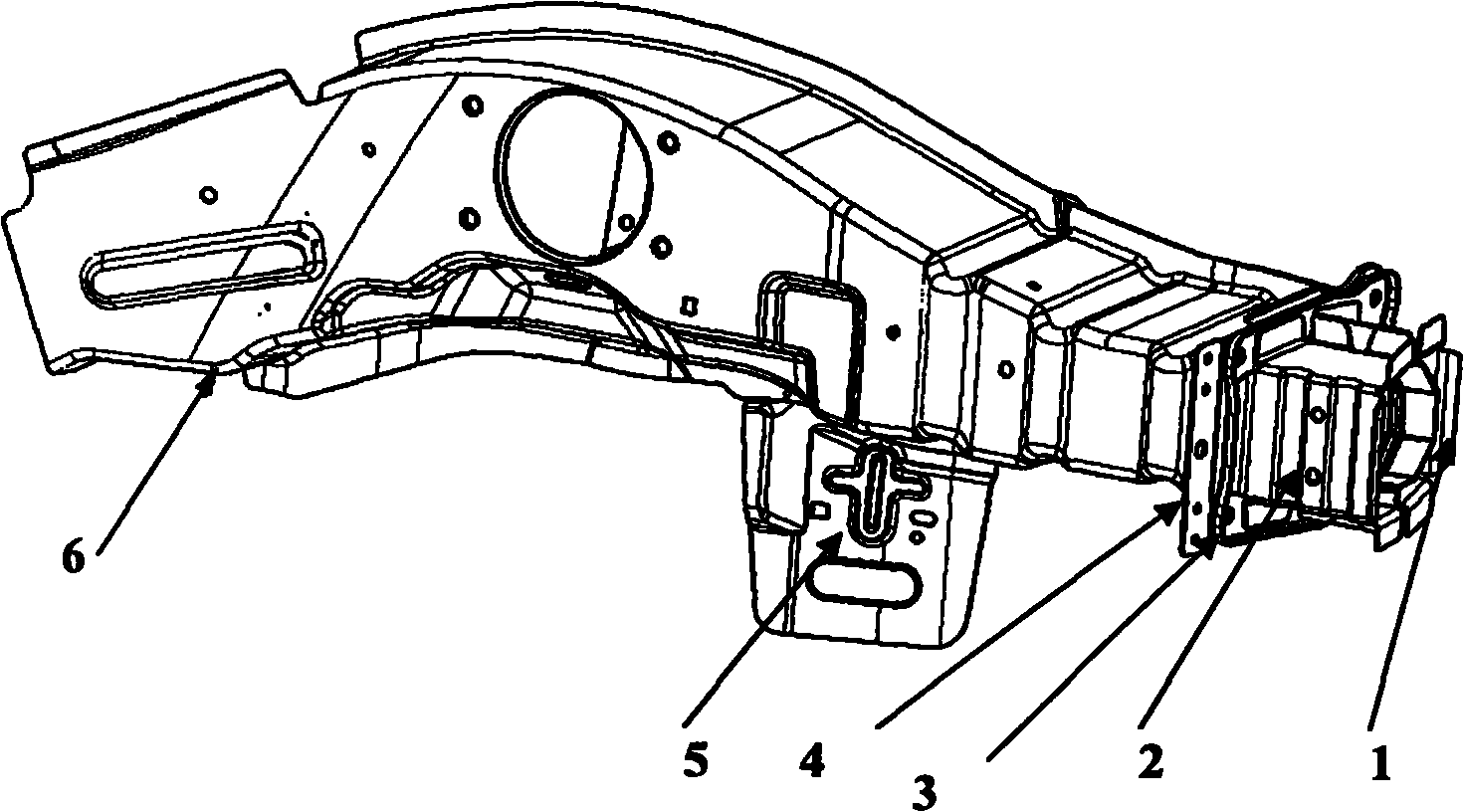

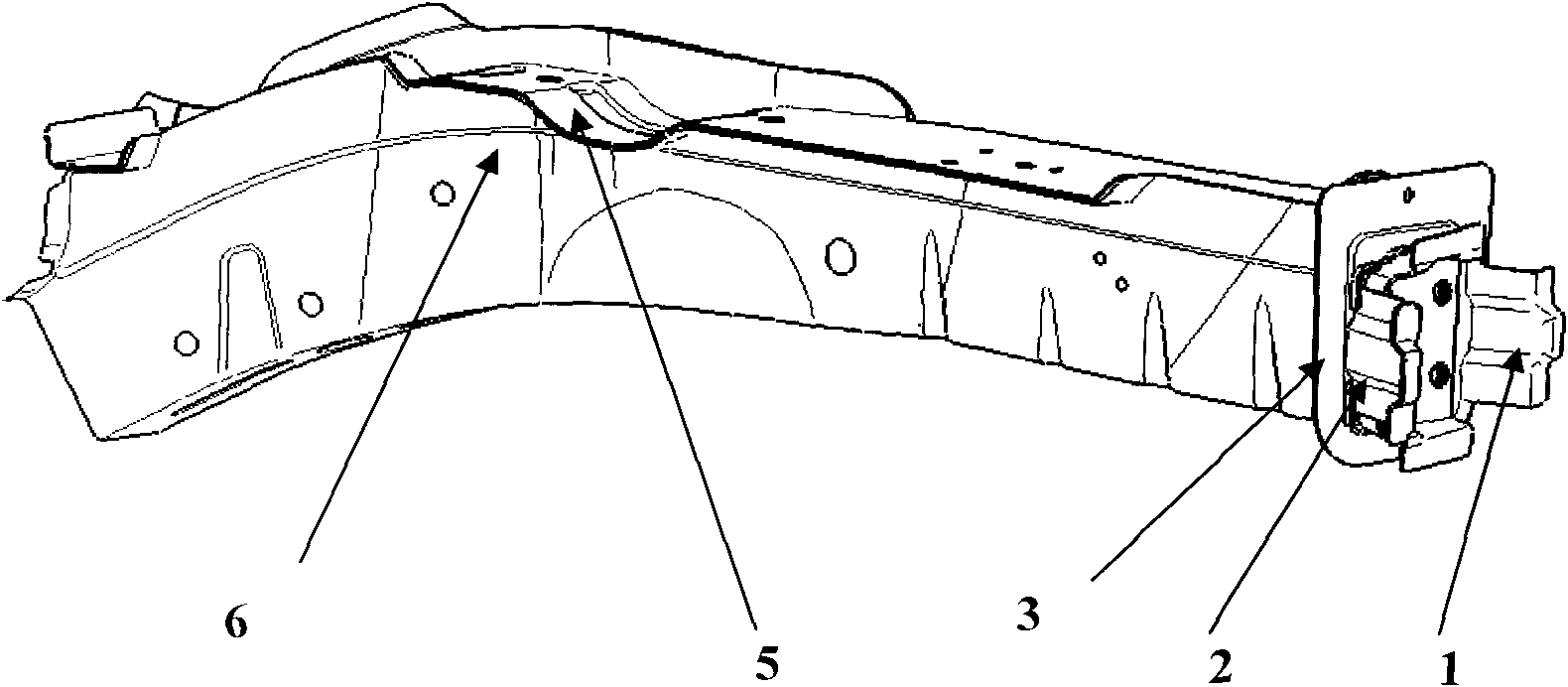

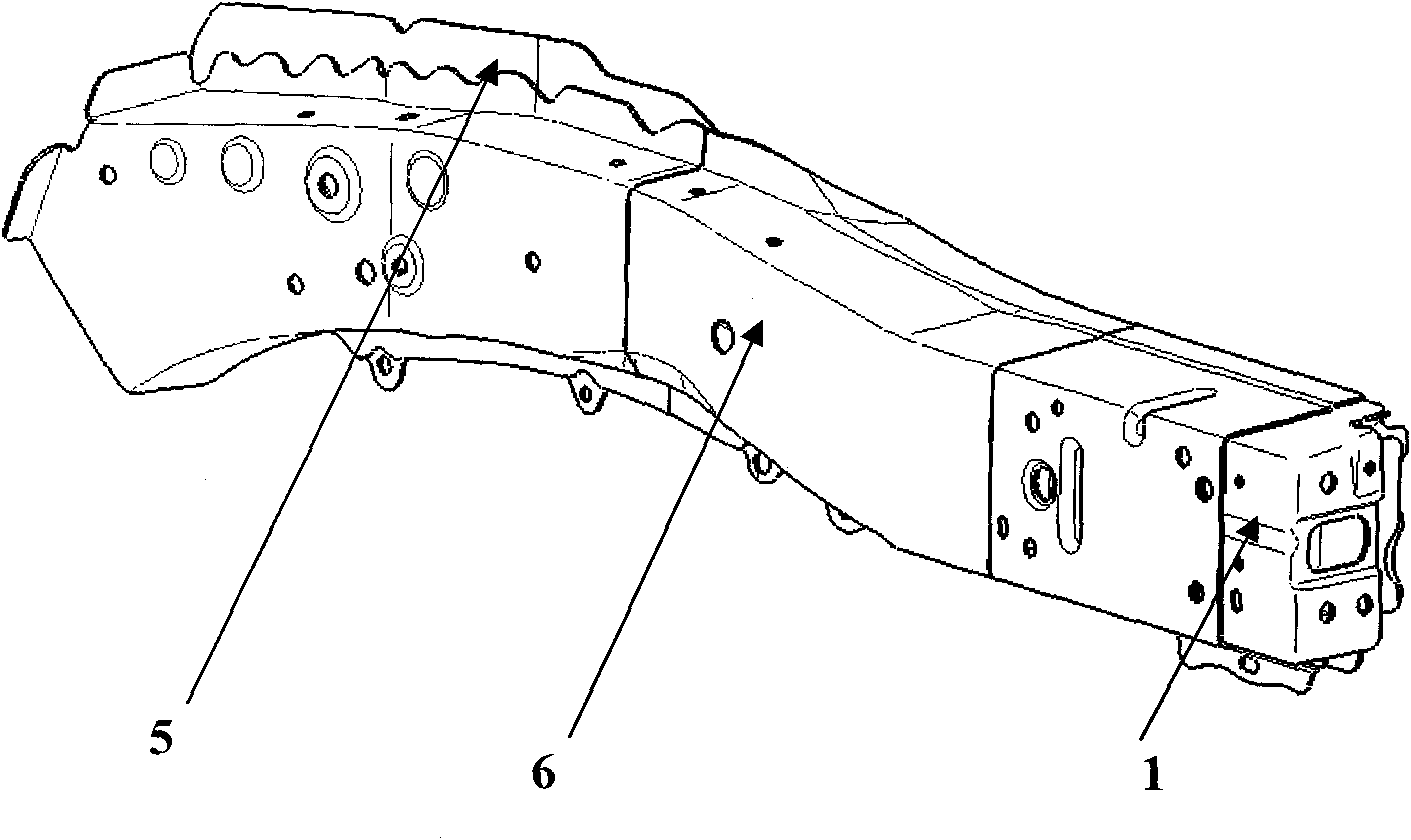

Automobile engine nacelle curb girder front part with reinforced energy absorbing structure

The invention discloses an automobile engine nacelle curb girder front part with a reinforced energy absorbing structure. The front part comprises a body, a foreplate of an external closing plate, a front lock plate, and a support of a front crush box, which is connected on the front lock plate. The invention is characterized in that one end of the front internal crush box and one end of the front external crush box are respectively connected with the support of the front crush box; the front internal crush box and the front external crush box are oppositely locked with each other and the front internal crush box is arranged inside the front external crush box; a first half reinforced cylinder and a second half reinforced cylinder are arranged inside the front internal crush box and are oppositely connected into a cylinder; and one end of the cylinder is connected with the support of the front crush box. Adopting a unique structure with the front internal crush box inside the front external crush box guarantees the complete absorption of energy during offset collision; the partitioning is reliable and punch forming is easy, thereby guaranteeing that an automobile can be successfully repaired when colliding at low speed; and the invention completely reaches the high-star score E-NCAP and C-NCAP according to the analysis of CAE.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com