Preparation method of radiation-oriented sintered neodymium iron boron magnet ring

A radiation orientation, NdFeB technology, applied in the manufacture of inductors/transformers/magnets, magnetic materials, magnetic objects, etc., can solve the problems of cracking, deformation, uneven shrinkage, etc., to improve fluidity, reduce cracking rate, cracking rate drop effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

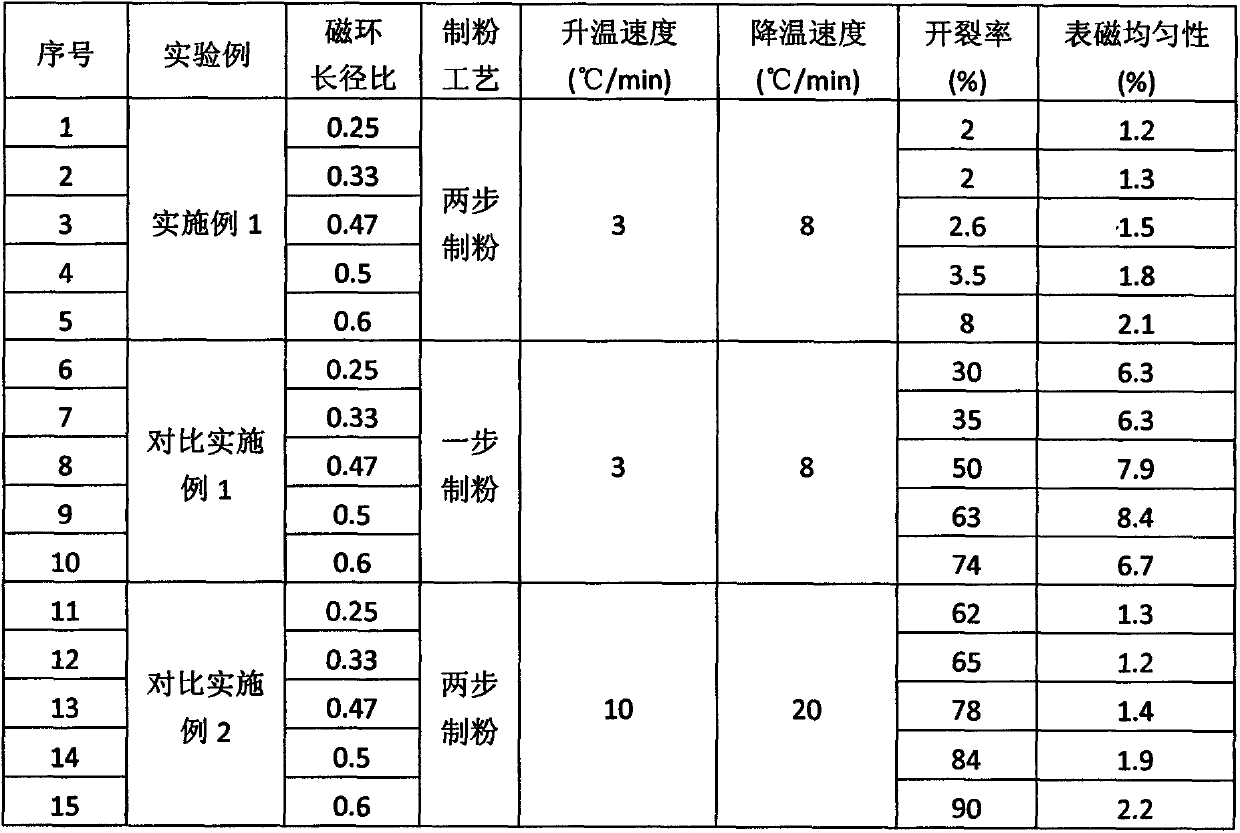

Examples

Embodiment 1

[0019] 1) Place the raw materials prepared in proportion into a vacuum quick-setting furnace for conventional smelting to obtain a cast sheet with a thickness of 0.3mm;

[0020] 2) Absorb the above-mentioned casting sheet at room temperature, and after the hydrogen absorption is saturated, dehydrogenate under vacuum at 550°C, and cool to room temperature after the dehydrogenation is completed, to obtain a coarse powder with a particle size of 300 μm;

[0021] 3) Add 0.15ml of antioxidant and 0.15ml of lubricant per kilogram of powder, dilute the antioxidant and lubricant with gasoline, the volume ratio of agent to gasoline is 1:1, and stir for 100 minutes;

[0022] 4) Put the uniformly stirred coarse powder into the jet mill, and under the protection of nitrogen, obtain a powder with a particle size of 20 μm;

[0023] 5) Add 0.5ml of antioxidant and 0.5ml of lubricant per kilogram of powder, dilute the antioxidant and lubricant with gasoline, the volume ratio of agent to gasol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com