Patents

Literature

339results about How to "Fully moistened" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fuel Cell and Fuel Cell Use Gas Diffusion Electrode

InactiveUS20070224479A1Increase mechanical strengthIncrease hydrophobicitySolid electrolytesFuel cell auxillariesGas diffusion electrodeRelative humidity

A fuel cell comprised of a proton conductive electrolyte film sandwiched between a pair of catalyst layers, wherein the catalyst layer of at least the cathode is comprised of a mixture including a catalyst ingredient, an electrolytic material, and a carbon material, the carbon material is comprised of a catalyst-carrying carbon material carrying the catalyst ingredient and a gas-diffusing carbon material not carrying the catalyst ingredient, and the catalyst-carrying carbon material has an amount of adsorption of water vapor at 25° C. and a relative humidity of 90% of 50 ml / g or more.

Owner:NIPPON STEEL CORP

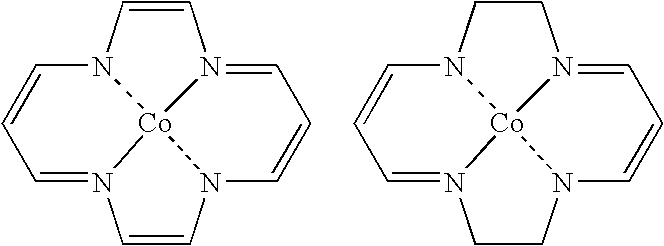

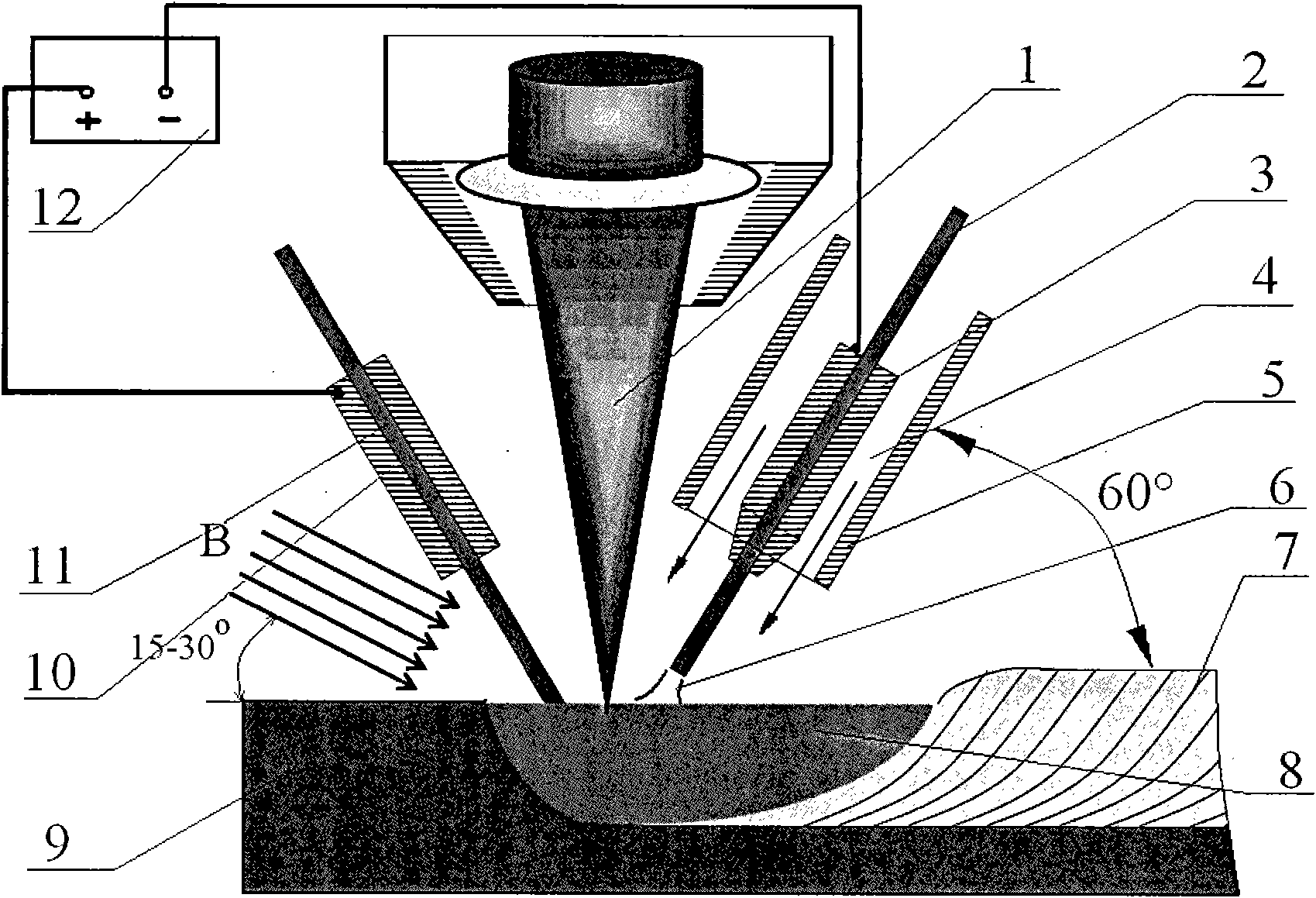

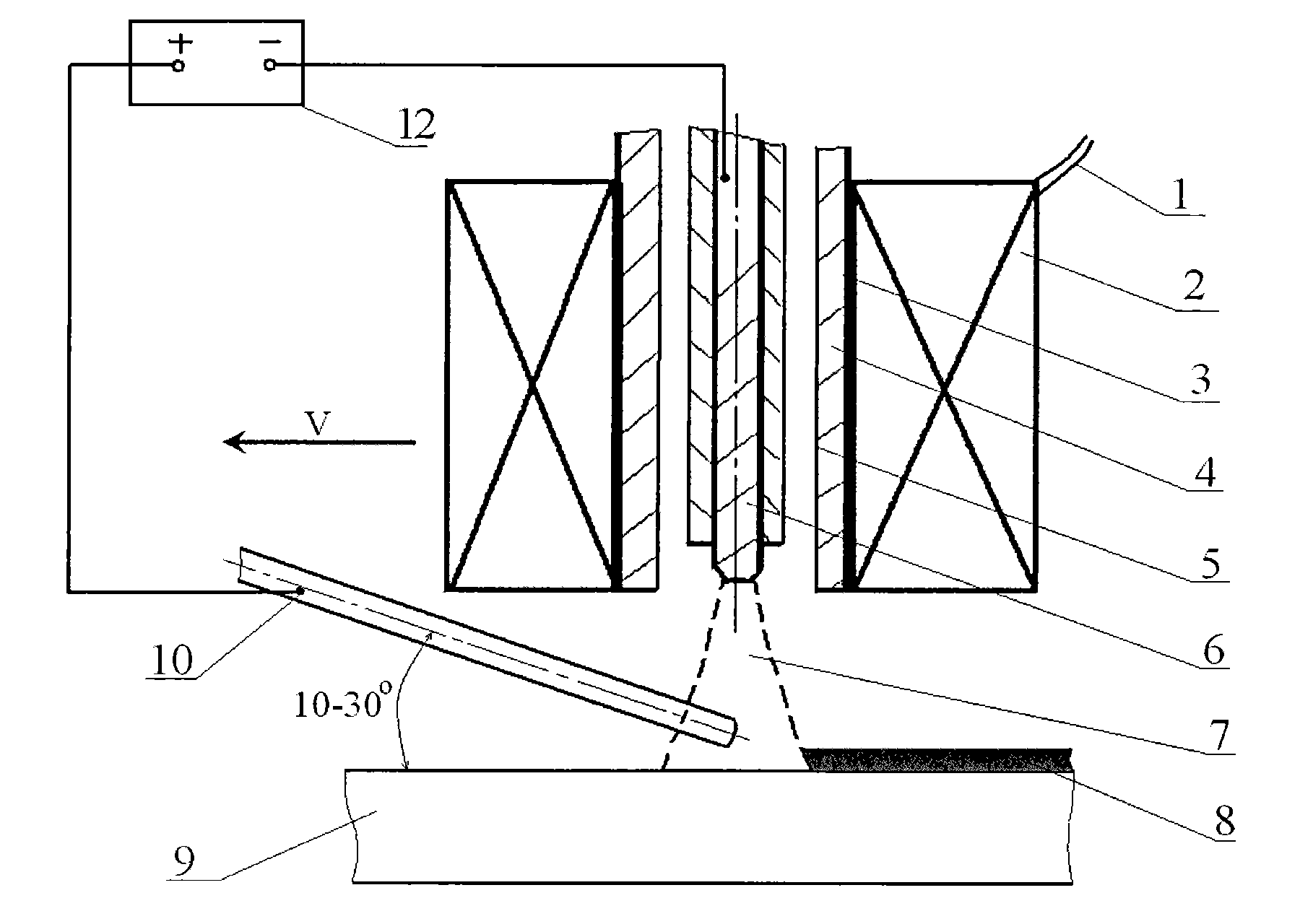

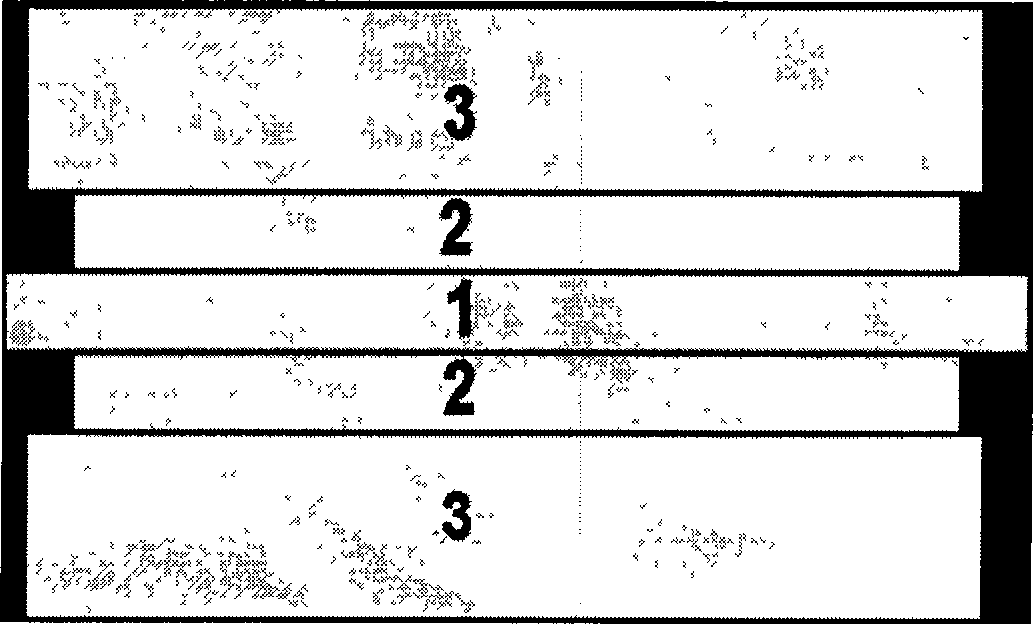

Electromagnetic current coupling field assisted hybrid melting-brazing method for laser-TIG arc and equipment

InactiveCN101862913AImprove connection qualityInhibition formationSoldering apparatusWelding apparatusMetallic materialsWelding defect

The invention discloses an electromagnetic current coupling field assisted hybrid melting-brazing method for a laser-TIG arc and equipment. In addition to the use of the welding zone, an alternating magnetic field is added to control properties of plasma formed through ionization of laser, arc and a raw material metal, thereby improving the laser utilization rate. Under the electric field assisted comprehensive effect, the weld melting depth is increased, and the assistant effect on the melting bath of the liquid-state brazing filler metal for laser-arc melting-brazing is realized through electromagnetic stirring and excitation and enhancement, thereby promoting the orderly flow of the liquid-state brazing filler metal and the rupture, wetting, spreading and proliferation of the liquid-state brazing filler metal on the surface of the high metal material, improving the full mixing of the liquid-state brazing filler metal and the base metal formed by melting the low-melting-point metal material, improving the uniformity of the components of the brazed weld, stabilizing the welding process, reducing welding defects, increasing the welding speed, improving the weld formation, optimizing the structure and performance of the brazed weld, and improving the quality of the brazed joint. Moreover, the equipment has the advantages of simple structure, flexible application, low cost, good effect and easy realization.

Owner:CHONGQING UNIV

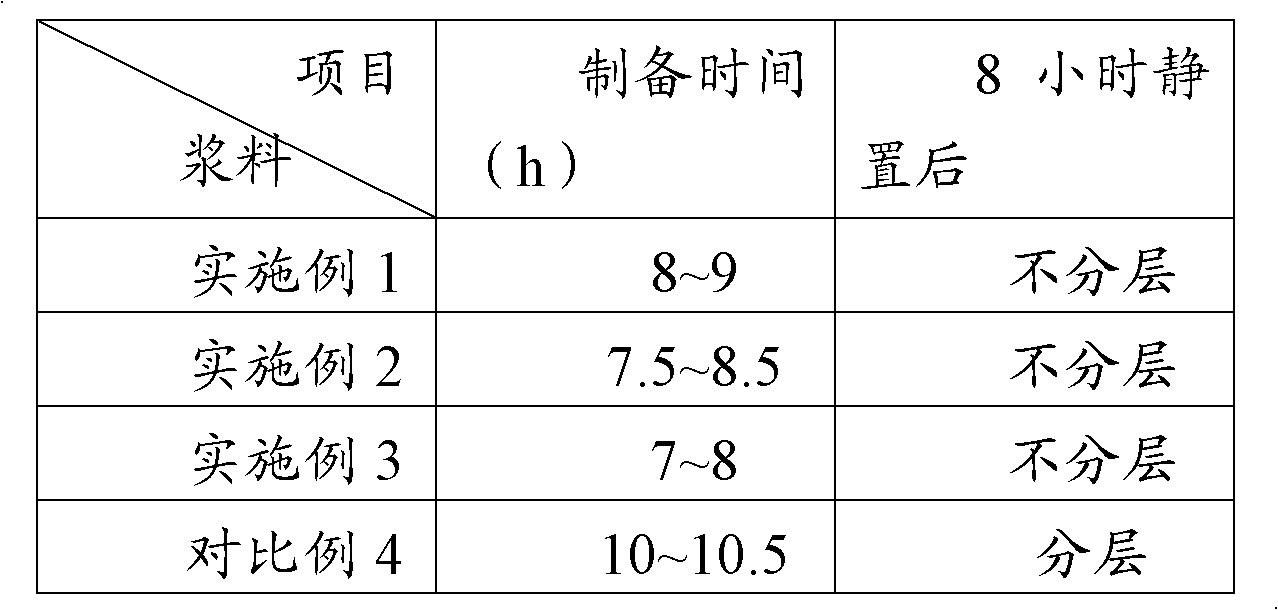

Lithium ion battery, cathode slurry and preparation method thereof

ActiveCN102376940AShort manufacturing timeIncrease productivityCell electrodesSecondary cellsSodium-ion batterySlurry

The invention discloses a lithium ion battery, cathode slurry and a preparation method. The method comprises the following steps: (1) a cathode active substance and a cathode conductive agent are mixed in a stirrer, and then a lubricant is added for uniformly stirring; (2) an additive sodium carboxymethylcellulose CMC is added in the stirrer for stirring; (3) the substance in the stirrer is added in a mixed sizing material which is composed of cathode solvent water and cathode binder, uniformly mixed and stirred to prepare the cathode slurry. The lubricant is alcohol, ketone, or a mixture of alcohol and ketone. The invention employs a combination of a wetting agent, graphite and the conductive agent, thereby the wetting time can be effectively shortened, the preparation time of the slurry is shortened, and the uniformity and stability of the cathode slurry are enhanced.

Owner:SHENZHEN BAK POWER BATTERY CO LTD

AlN ceramic bonded copper substrate and preparation method thereof

The invention provides an AlN ceramic bonded copper substrate which comprises an AlN ceramic substrate and copper foil bonded and connected onto the AlN ceramic substrate and is characterized in that a spinel structure compound modification layer is formed between the AlN ceramic substrate and the copper foil and comprises one or two of CuAlO2, CuAl2O4, Cu2O and CuO. The invention further provides a preparation method of the AlN ceramic bonded copper substrate. The method comprises the steps of spraying nano Cu2O on the surface of the AlN substrate, sintering in inert gas with a micro oxygen content and air sequentially, and then removing a surface oxide by a pickling manner. The prepared modification layer is tightly combined with matrix ceramic, and also has good affinity characteristic with the Cu foil. A uniform oxidation layer can be formed on the surface of the Cu foil by putting the Cu foil in a prepared solution at a certain temperature for specified time and more facilitates an AlN-DBC (direct bonded copper) technology.

Owner:NANJING ZHONGJIANG NEW MATERIAL TECH

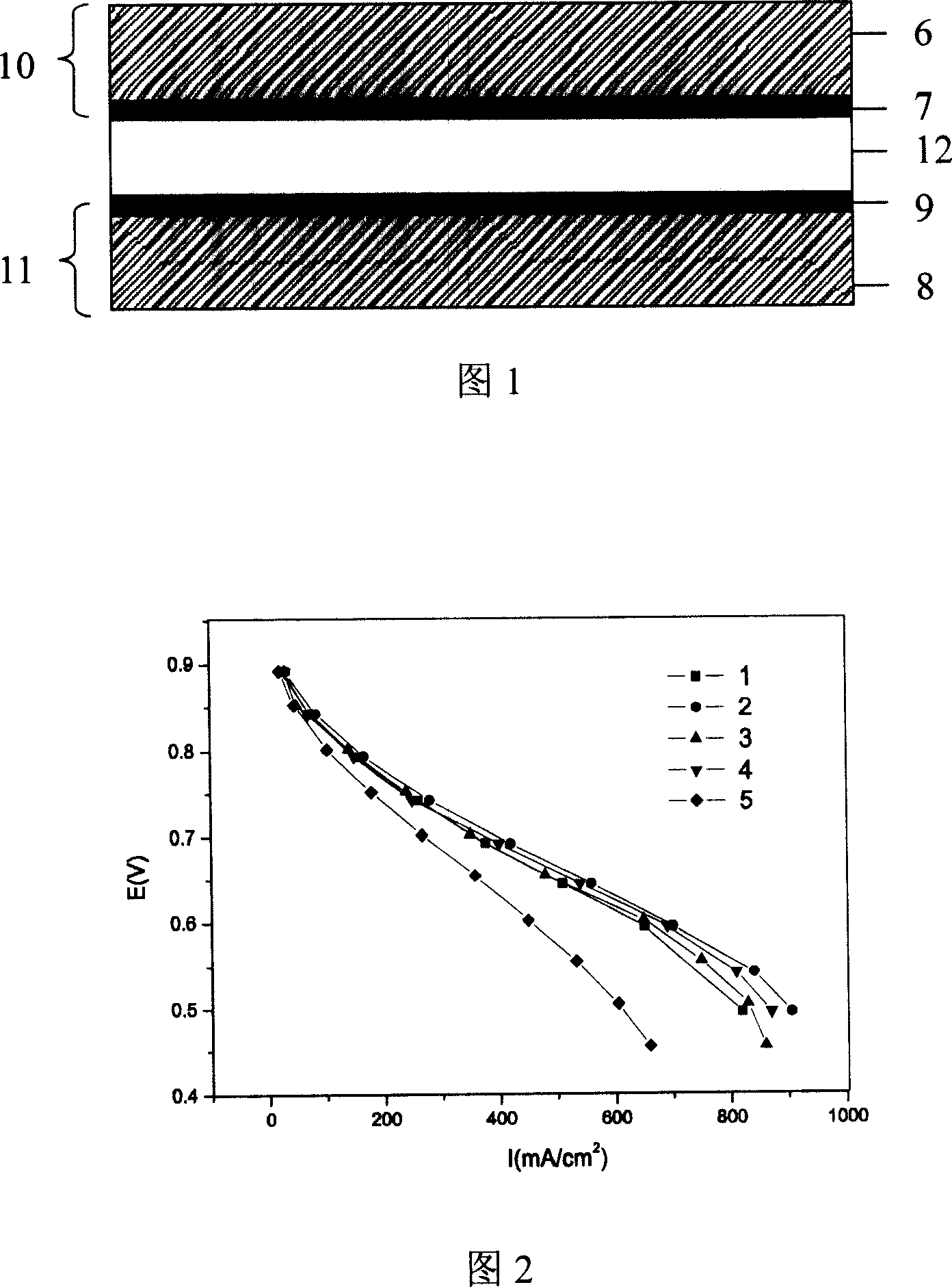

Method for activating membrane electrode of fuel cell

ActiveCN101136477AQuick activationShorten activation timeBatteries circuit arrangementsCell electrodesFuel cellsEngineering

This invention relates to an activating method for membrane electrodes of fuel cells including penetrating an anode fuel and cathode fuel into an anode chamber and a cathode chamber of the fuel battery to let it discharge including multiple discharge periods and at least one time interval among them and the battery discharges in a constant current density in each period.

Owner:BYD CO LTD

Carbon fiber sizing agent

The invention discloses a carbon fiber sizing agent which is prepared from the following materials in parts by weight: 5-25 parts of phenolic resin, 1-5 parts of blend resin, 0.01-5 parts of antistatic agent and 100 parts of solvent, wherein the phenolic resin is thermoplastic phenolic resin or modified phenolic resin, and the blend resin is thermoplastic resin or thermosetting resin. The carbon fiber sizing agent is prepared through the following steps of: firstly, uniformly mixing the phenolic resin and the blend resin, adding a solvent accounting for 10-20% of the total amount of the solvent, enabling the resin to be dissolved in the solvent, and stirring the obtained mixture into a homogeneous solution at room temperature; and then, adding the antistatic agent into the homogeneous solution, stirring the obtained mixture so as to dissolve the antistatic agent, adding the rest of the solvent, and mixing the obtained product so as to obtain an integral solution, thereby obtaining the carbon fiber sizing agent. The carbon fiber sizing agent disclosed by the invention can be compatible with thermoplastic matrix resin better; the matrix resin can fully wet carbon fibers, thereby directly achieving a stress transfer effect on the fibers and the matrix; and compared with an epoxy resin sizing agent, the interlayer shear strength of a composite material of the carbon fiber sizing agent is increased by 15-20%.

Owner:ZHONGFU SHENYING CARBON FIBER

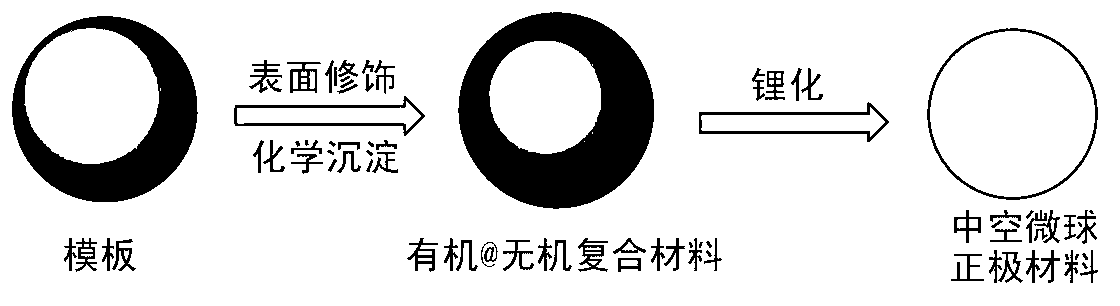

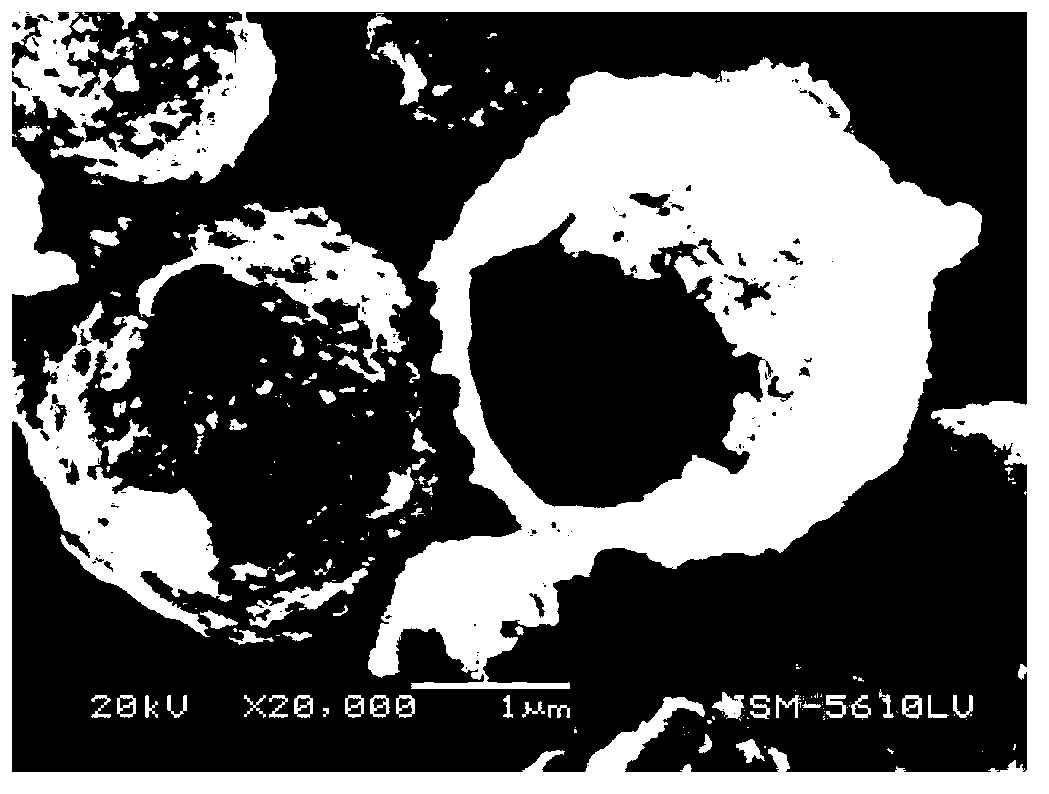

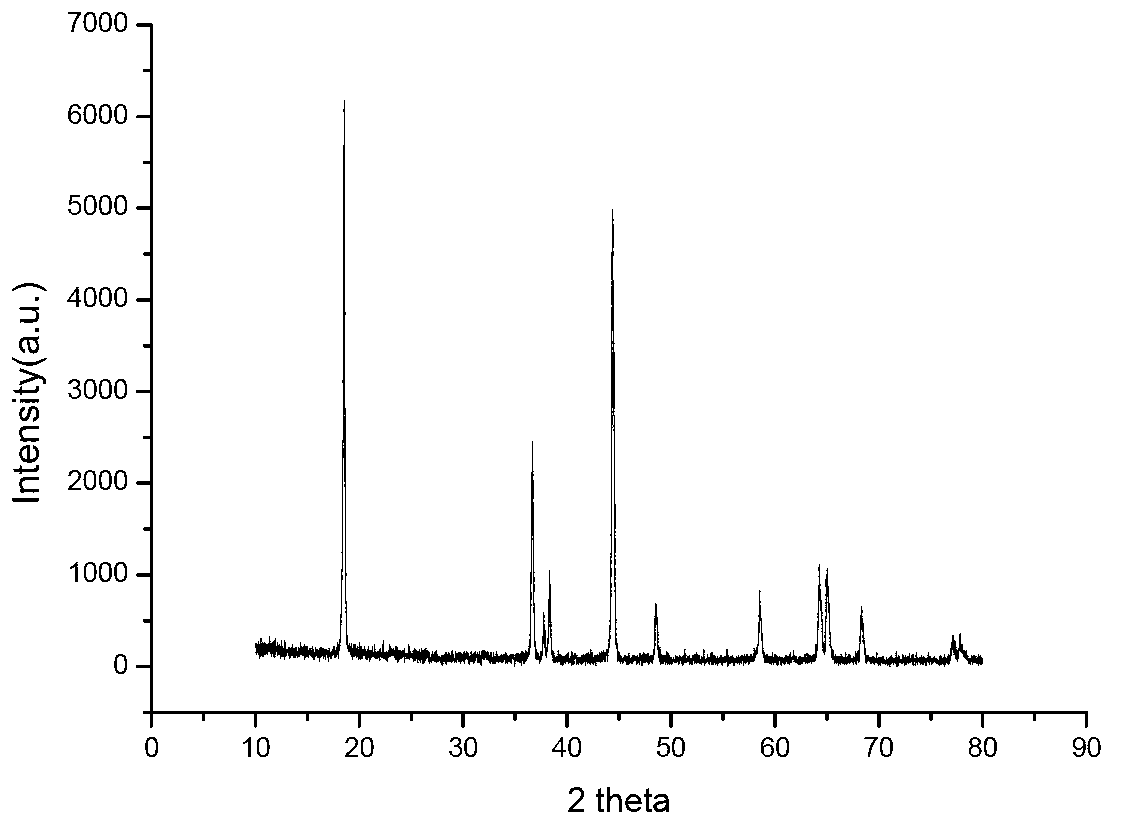

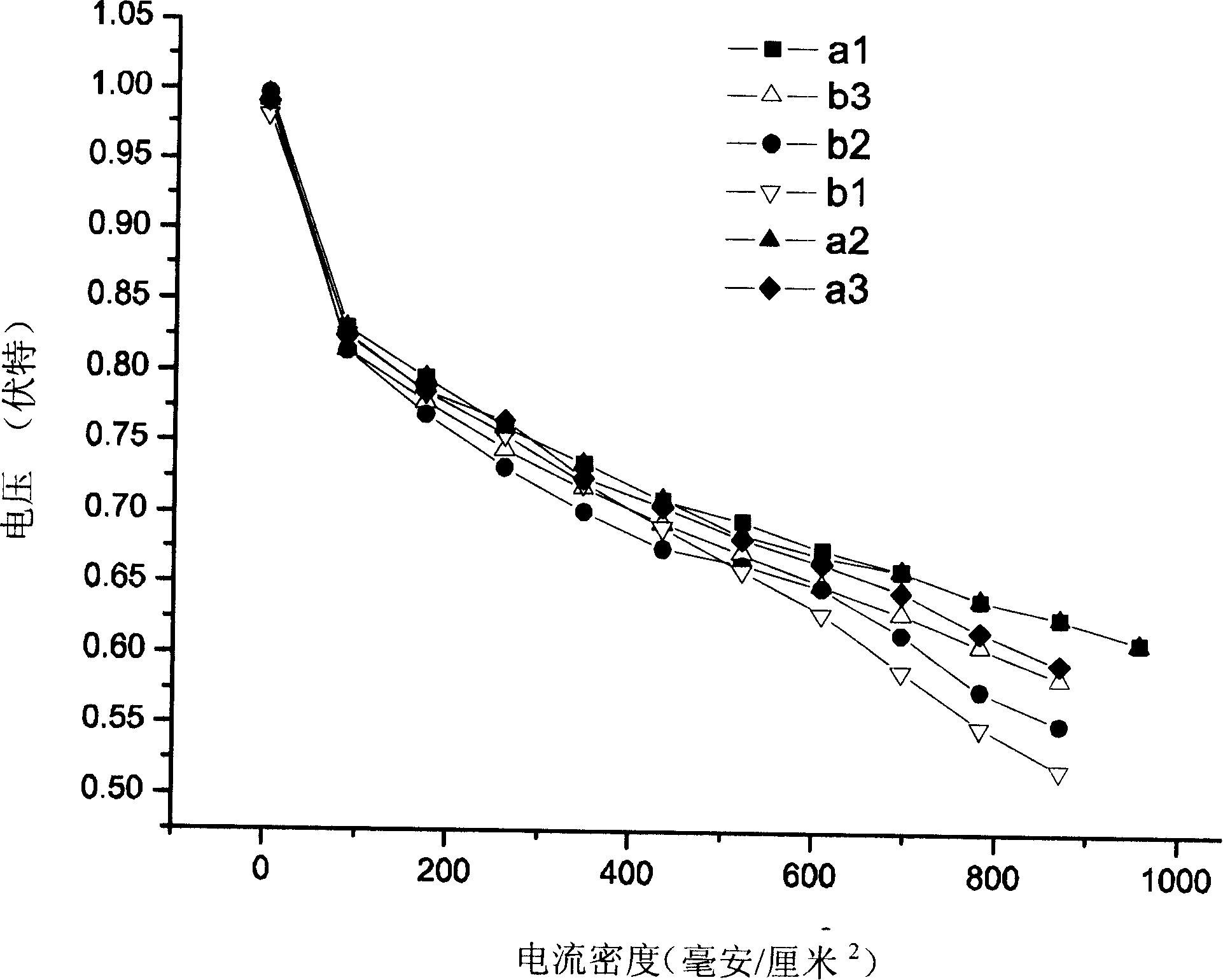

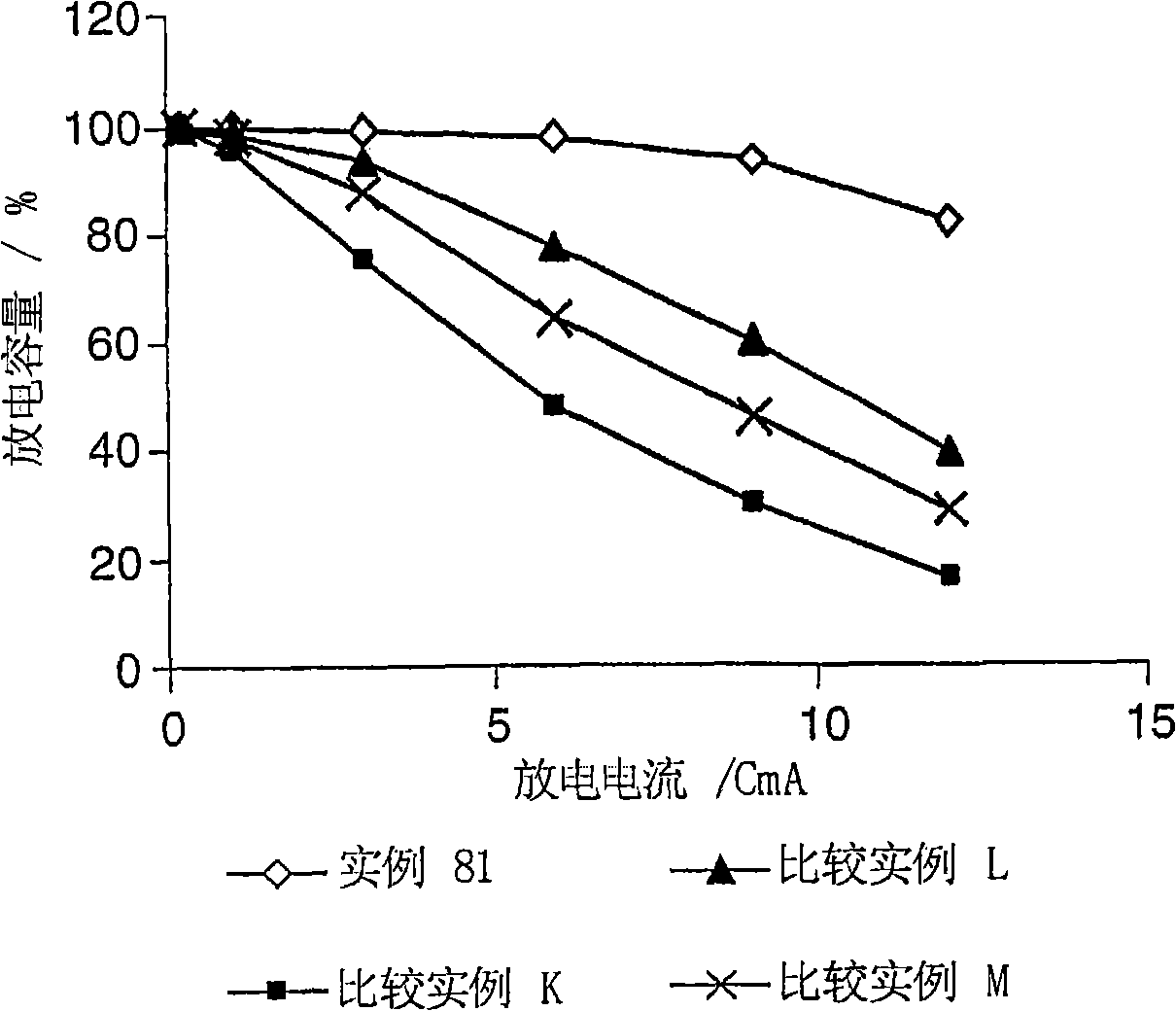

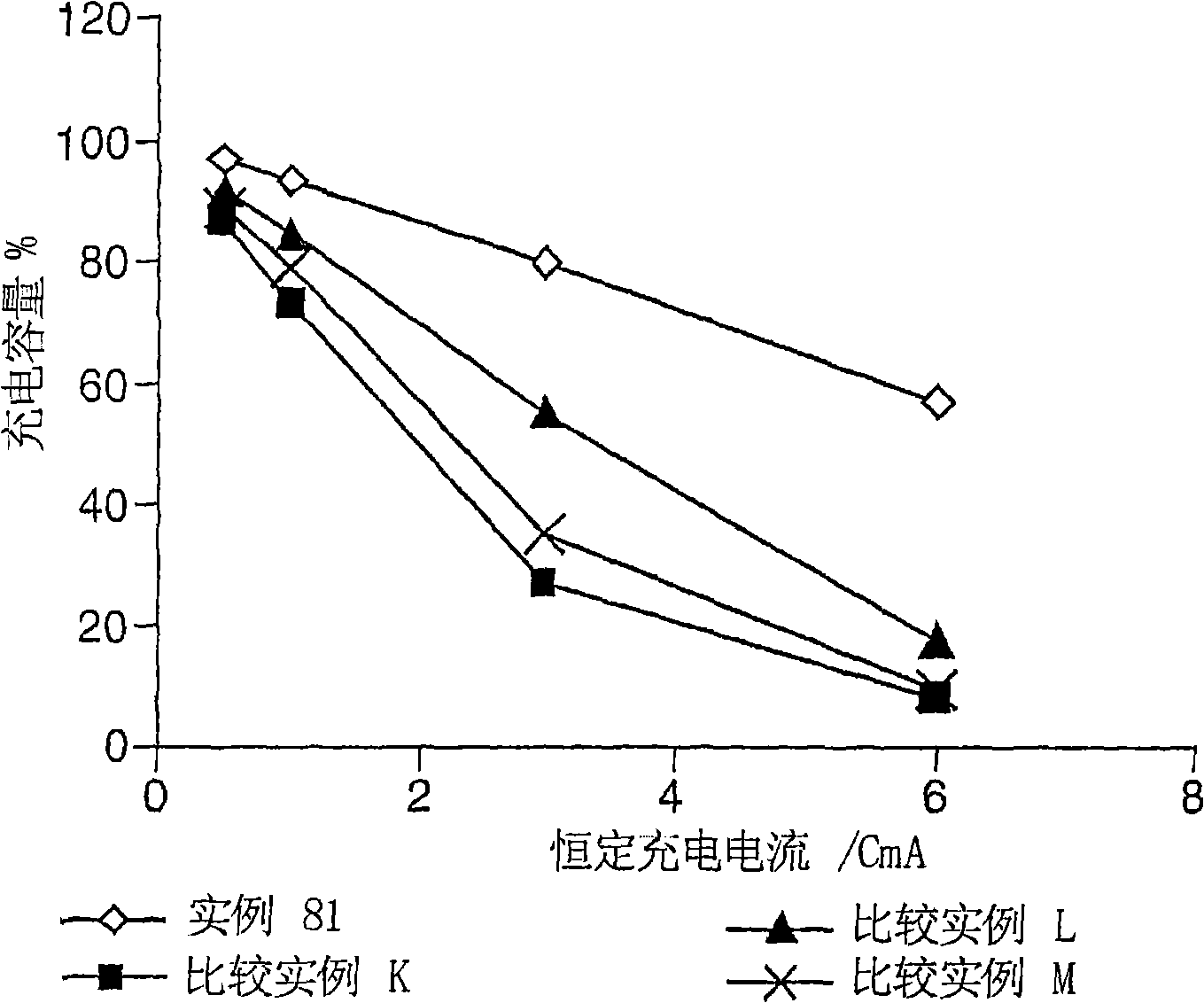

Method for preparing positive material of high-power lithium ion battery

ActiveCN102938459AUniform particle size distributionEasy to processCell electrodesSpherical shapedLithium-ion battery

The invention provides a method for preparing a positive material of a high-power lithium ion battery. The positive material is LiNixCo1-x-yMnyO2 (0<=x, y<=1, and x+y<=1). The method comprises the following steps: choosing a 0.1-10mu m template ball body, performing emulsification dispersing on the template ball body, adding metal salt solution, then adding precipitator, enabling metal ions to evenly deposit on the surface of the template ball body under the effect of the precipitator, performing hot filtering on the template ball body with the metal ions deposited on the surface to obtain an organic-inorganic compound core shell structure material, and performing thermal treatment to obtain the hollow positive material by evenly mixing the organic-inorganic compound core shell structure material with the lithium salt, wherein the metal salt is metal salt of Ni, Co and Mn. The obtained ternary material has regular hollow spherical shape, is even in grain size and grain fineness distribution, can improve the absorbing / releasing capability on non-water electrolyte of active substances, effectively shortens embedding and de-embedding of the lithium ions, accordingly enhances the storage / transmission performance of the lithium ion battery, and provides effective support for large-current high-magnification charging and discharging, and the compounded ternary material can be applied to power battery materials.

Owner:ZHEJIANG NARADA POWER SOURCE CO LTD +1

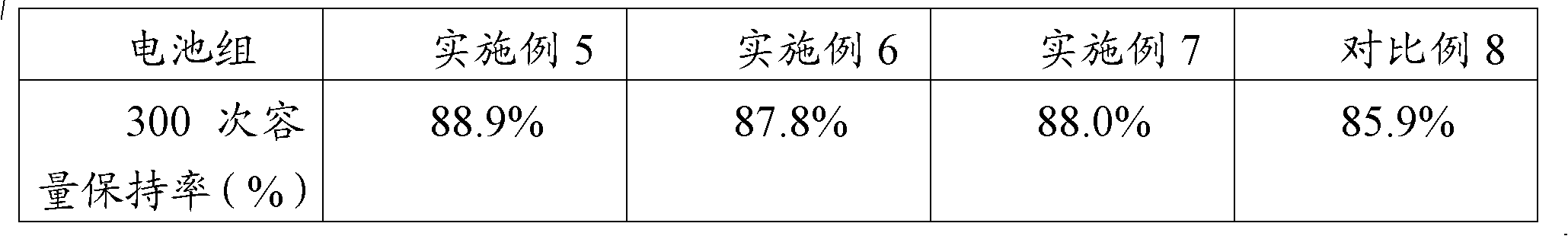

Fuel cell membrane electrode and its preparation method

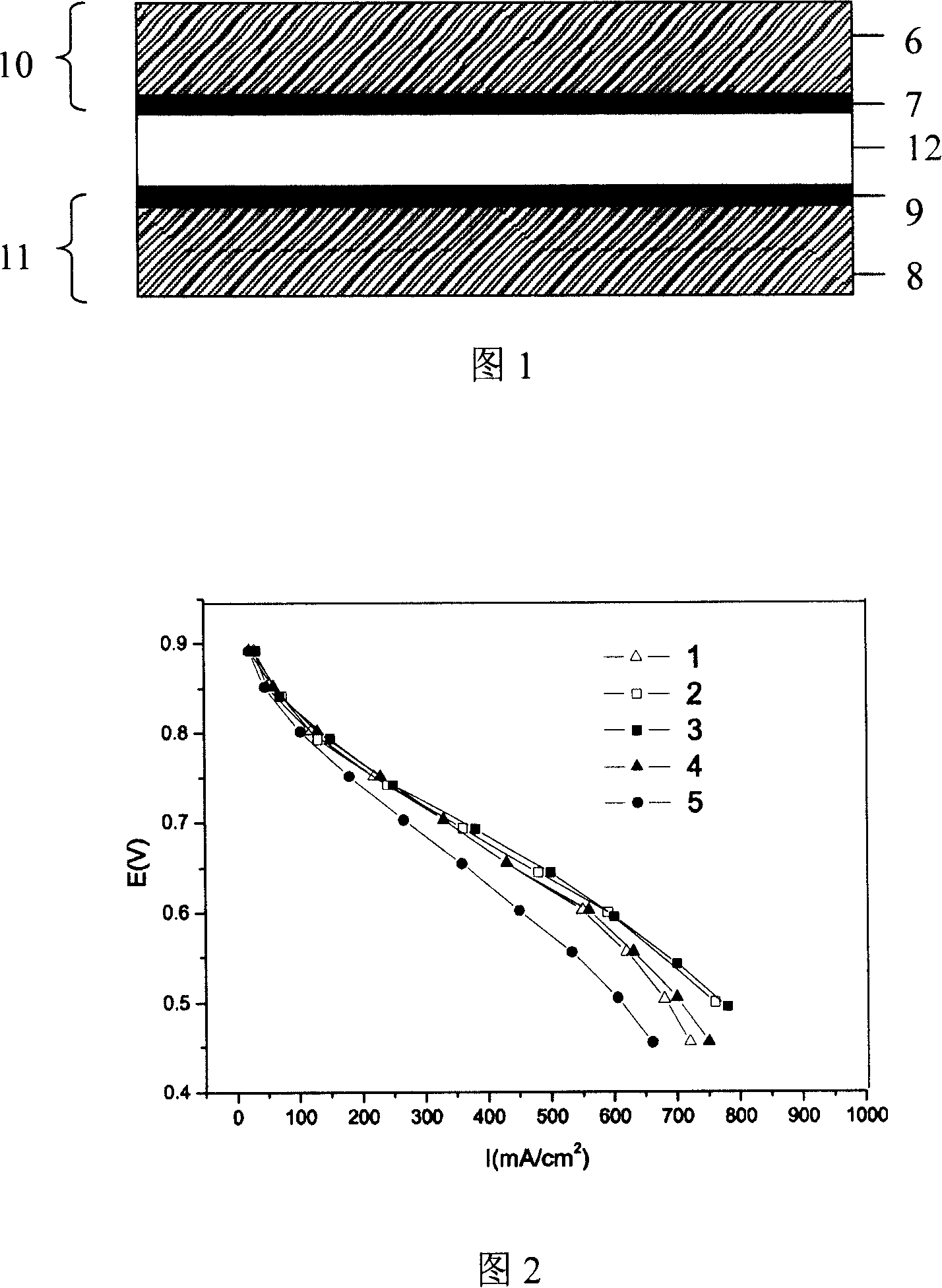

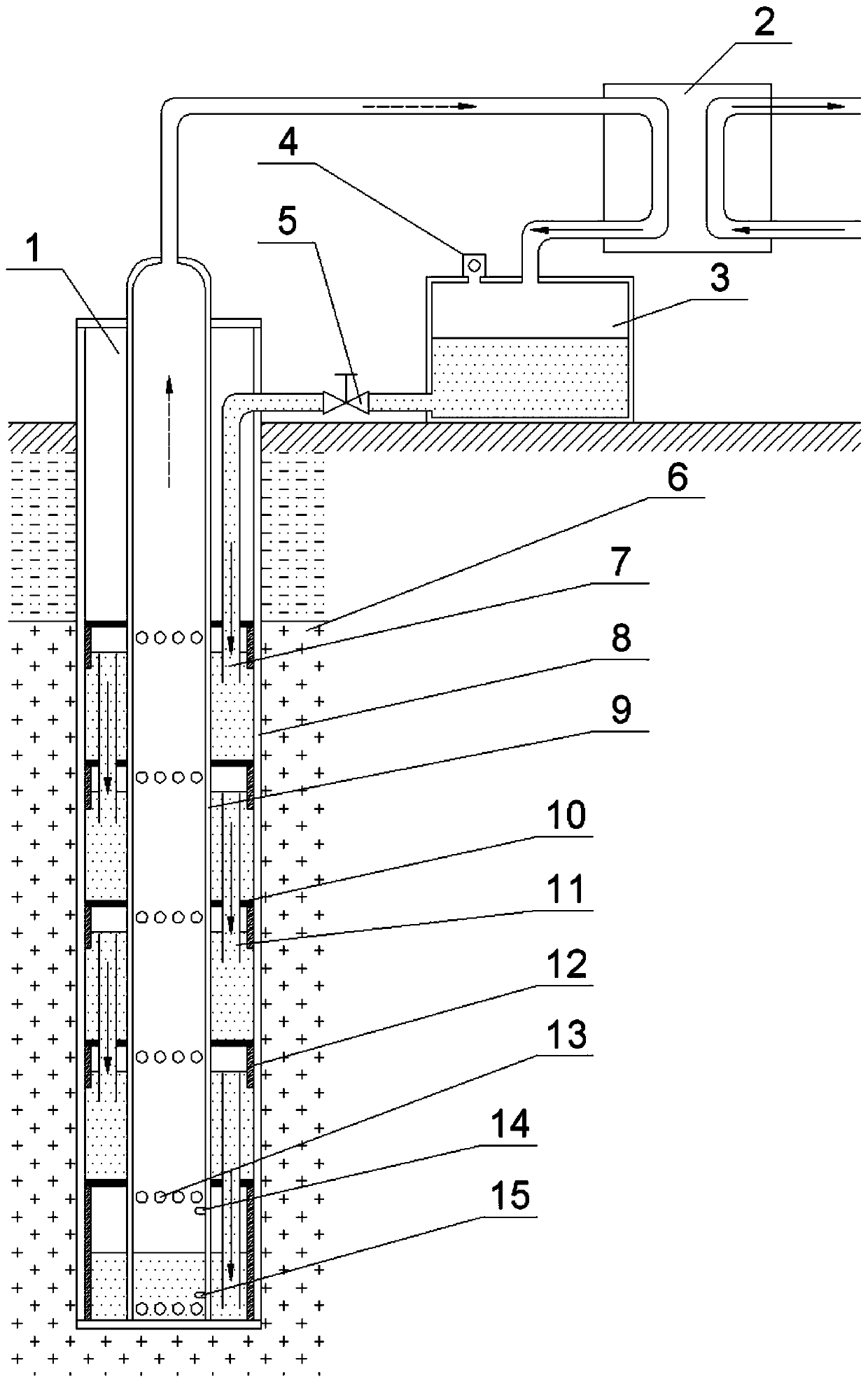

InactiveCN101212054ARealize self-humidificationGood self-humidification performanceCell electrodesFinal product manufactureProtonMembrane configuration

The invention relates to a membrane electrode of a fuel cell, which comprises an anode gas diffusing layer, an anode catalyzing layer, a proton exchange membrane, a cathode catalyzing layer, and a cathode gas diffusing layer. The gas diffusing layers comprise a conductive carrier as well as a conductive agent and a binding agent carried by the conductive carrier, wherein the binding agent in the anode gas diffusing layer is a hydrophilic binding agent. The membrane electrode of the fuel cell provided by the invention has good effect of self-humidifying. When the fuel cell manufactured by adopting the membrane electrode in the invention works in a large current density, the output power of the cell is high.

Owner:BYD CO LTD

Antibacterial mixed liquor, antibacterial paper and production process thereof

The invention relates to antibacterial mixed liquor which takes water as a solvent. The antibacterial mixed liquor comprises prebiotics, an antibacterial agent and a hydrophilic film former. According to the antibacterial mixed liquor, the content of the prebiotics is 1%-15%, the content of the antibacterial agent is 0.1%-5%, and the content of the hydrophilic film former is 0.01%-10%. The invention also relates to antibacterial paper using the antibacterial mixed liquor and a production process of the antibacterial paper. Compared with the prior art, the antibacterial paper using the antibacterial mixed liquor can enable antimicrobial components in the antibacterial paper to be transferred to the surface of the skin of a user so as to further prevent bacteria from continuously reproducing on the skin of the user in the using process.

Owner:GOLD HONG YE PAPER

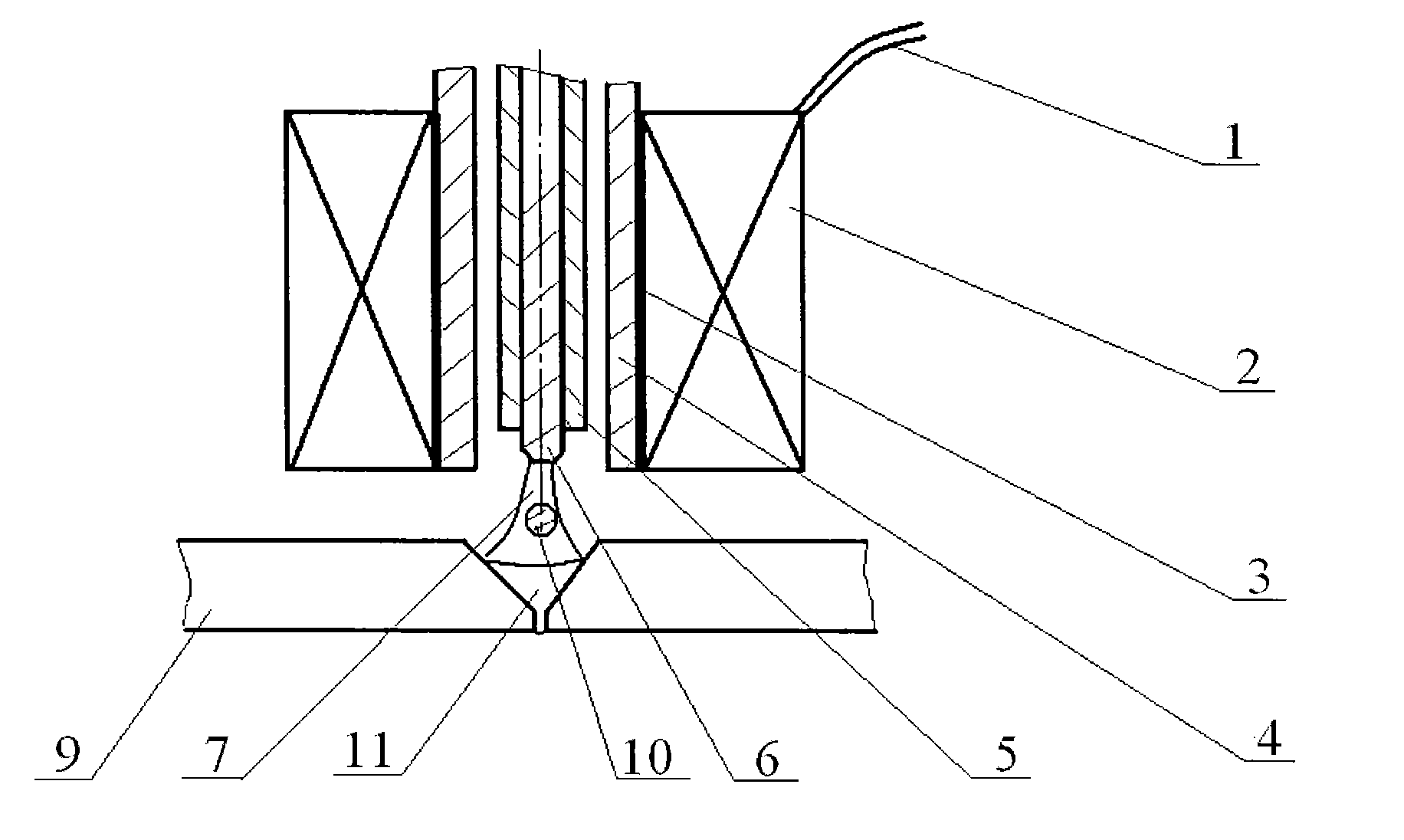

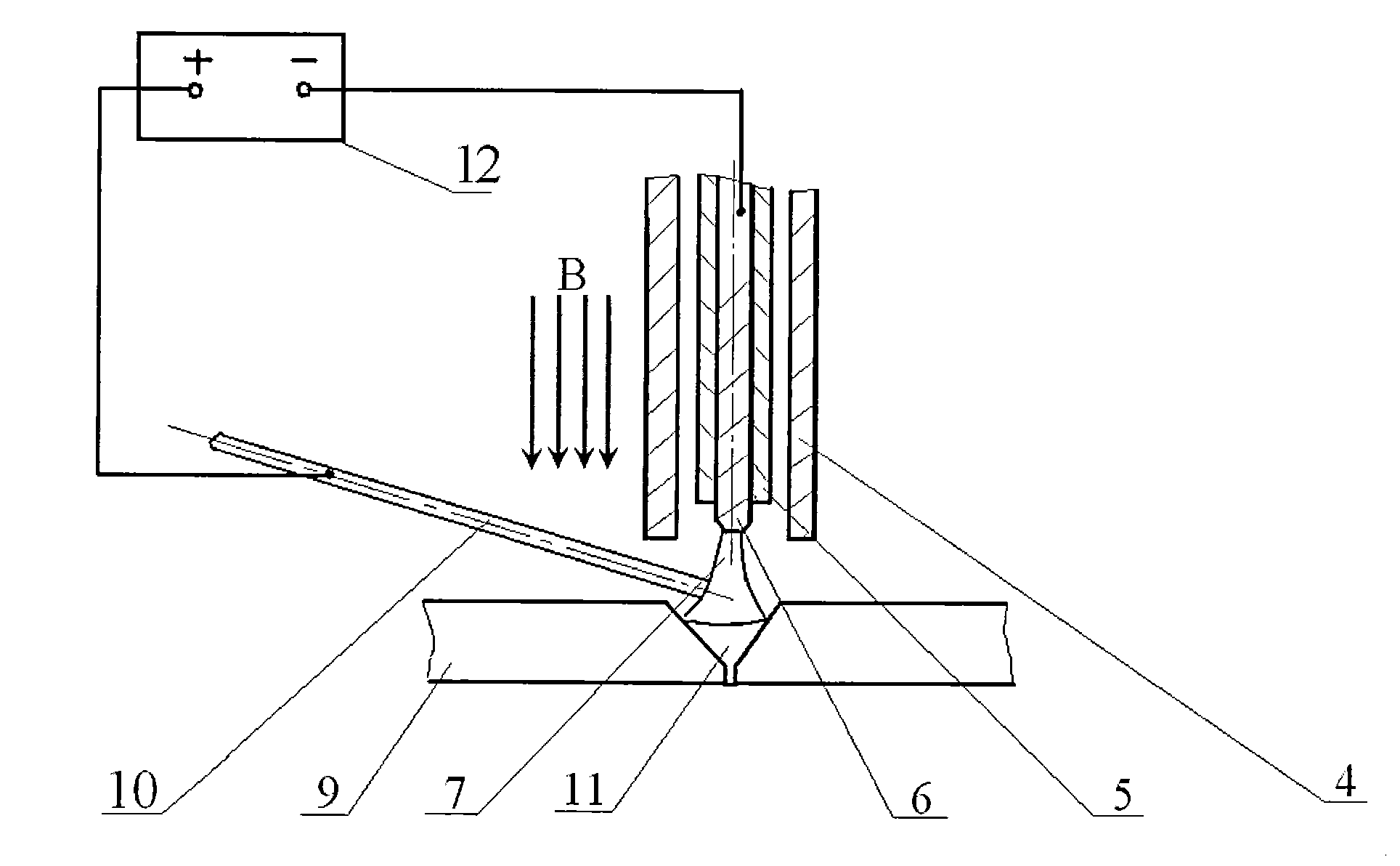

Electromagnetic excited TIG arc melting-brazing hybrid welding method and equipment

InactiveCN101862873AAvoid severe burnsLow heat inputSoldering apparatusMetal working apparatusMetallic materialsWelding defect

The invention discloses an electromagnetic excited TIG arc melting-brazing hybrid welding method and equipment. In addition to the use of the welding zone, an alternating magnetic field is added to control properties of a welding arc, and the assistant effect on the melting bath of the liquid-state brazing filler metal for arc melting-brazing is realized through electromagnetic stirring and excitation and enhancement, thereby promoting the orderly flow of the liquid-state brazing filler metal and the rupture, wetting, spreading and proliferation of the liquid-state brazing filler metal on the surface of the high metal material, improving the full mixing of the liquid-state brazing filler metal and the base metal formed by melting the low-melting-point metal material, improving the uniformity of the components of the brazed weld, reducing welding defects, increasing the welding speed, improving the weld formation, optimizing the structure and performance of the brazed weld, and improving the quality of the brazed joint. Moreover, the equipment has the advantages of simple structure, flexible application, low cost, good effect and easy realization.

Owner:CHONGQING UNIV

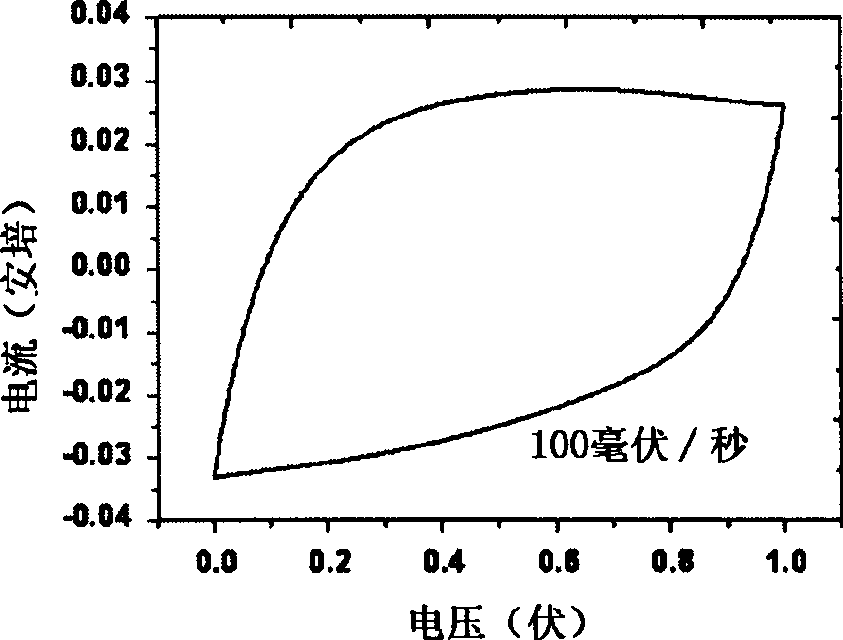

Super capacitor using mono-layer graphite as electrode material

InactiveCN101383231AImprove performanceHigh specific capacitanceElectrolytic capacitorsHybrid capacitor electrodesCapacitanceActivated carbon

The invention relates to a super capacitor which uses a single-layer graphite material as an electrode material. The super capacitor comprises an electrode plate, an electrolyte and a membrane, wherein the electrode plate is prepared by a bubble nickel connecting plate of single-layer graphite which contains active substances, the quality content of the active substance single-layer graphite is 2 to 30wt percent of the quality of a collecting electrode plate, and the single-layer graphite is a soluble single-layer graphite oxide material or an annealed or reductive single-layer graphite material. Compared with the traditional super capacitor which uses active carbon as the electrode material, the super capacitor of the invention saves power resources; compared with the super capacitor which uses a carbon nano tube as the electrode material, the super capacitor of the invention has low cost and good performance and has higher specific capacitance and high energy density (which can reach 50Whkg<-1>), and the specific power of the super capacitor can reach as higher as 40kWkg<-1>.

Owner:TIANJIN PULAN NANO TECH

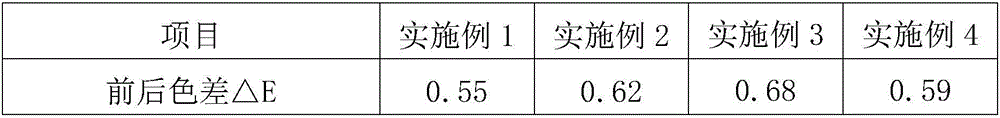

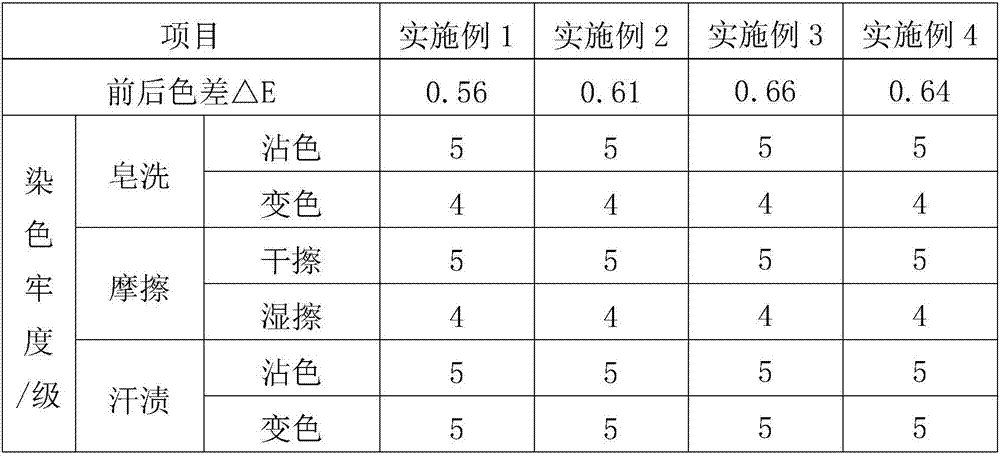

Dyeing and finishing process for polyester blended fiber fabric

ActiveCN106223003ASoft touchImprove water absorptionHeating/cooling textile fabricsHeat resistant fibresDisperse dyeAfter treatment

The invention discloses a dyeing and finishing process for a polyester blended fiber fabric. The process comprises the following steps of 1, pretreatment, wherein the polyester blended fiber fabric is sequentially subjected to scouring, bleaching and enzyme washing; 2, mercerizing and sizing, wherein the fabric is subjected to padding of alkali liquor under the room temperature for pre-sizing; 3, dyeing, wherein the fabric is soaked into dye liquor formed by disperse dyes, dyeing is performed under the temperature of 30-40 DEG C, temperature is increased to 90-110 DEG C at the heating rate being 0.8-1 DEG C / min, washing is performed through warm water, infrared ray pre-heating is performed, and then hot-blast air drying is performed; padding is performed again under the room temperature to reduce the suspended solid dye liquor formed by dyes, a reduction solution is subjected to padding, steam reduction and oxidation are performed, washing is performed through warm water, soaping is performed, and then washing and drying are performed; 4, after-treatment, wherein soft and flame-proof treatment is performed in sequence. According to the dyeing and finishing process for the polyester blended fiber fabric, the touch feeling, elasticity and other properties of the fabric are improved remarkably, dyeing is uniform, the color fastness is high, and the color is full.

Owner:ANHUI YAYUAN PRINTING & DYEING CO LTD

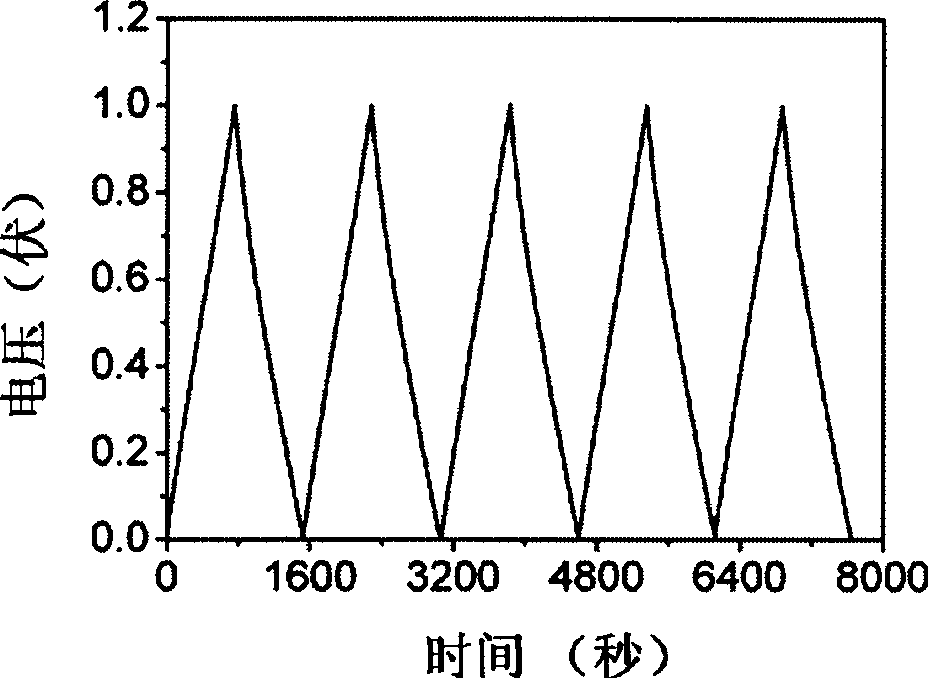

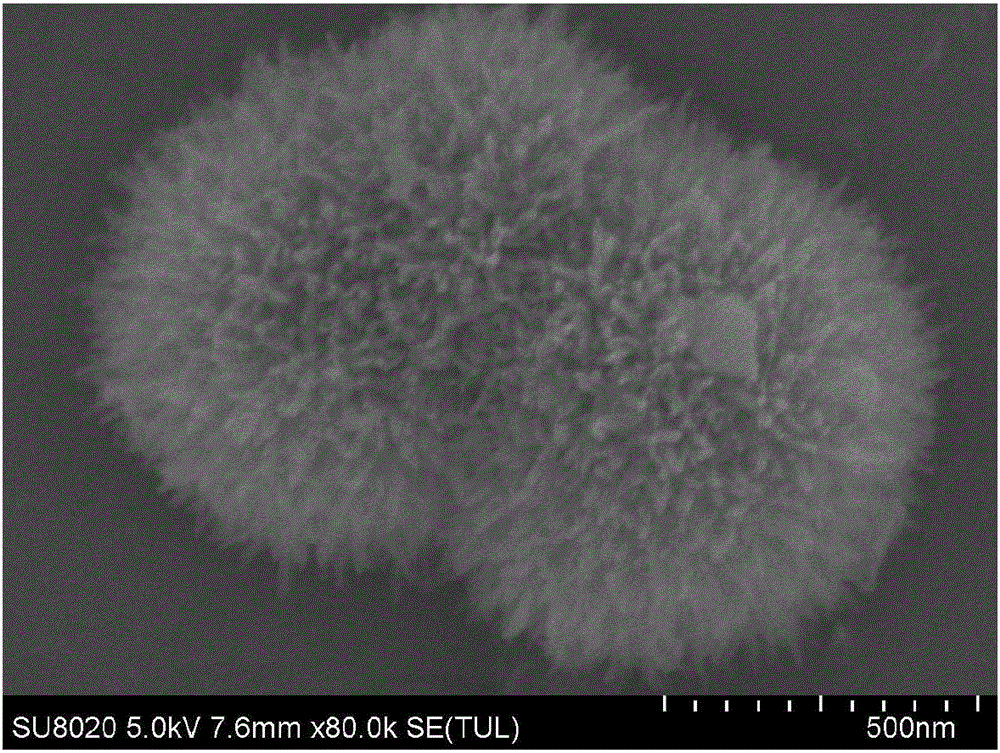

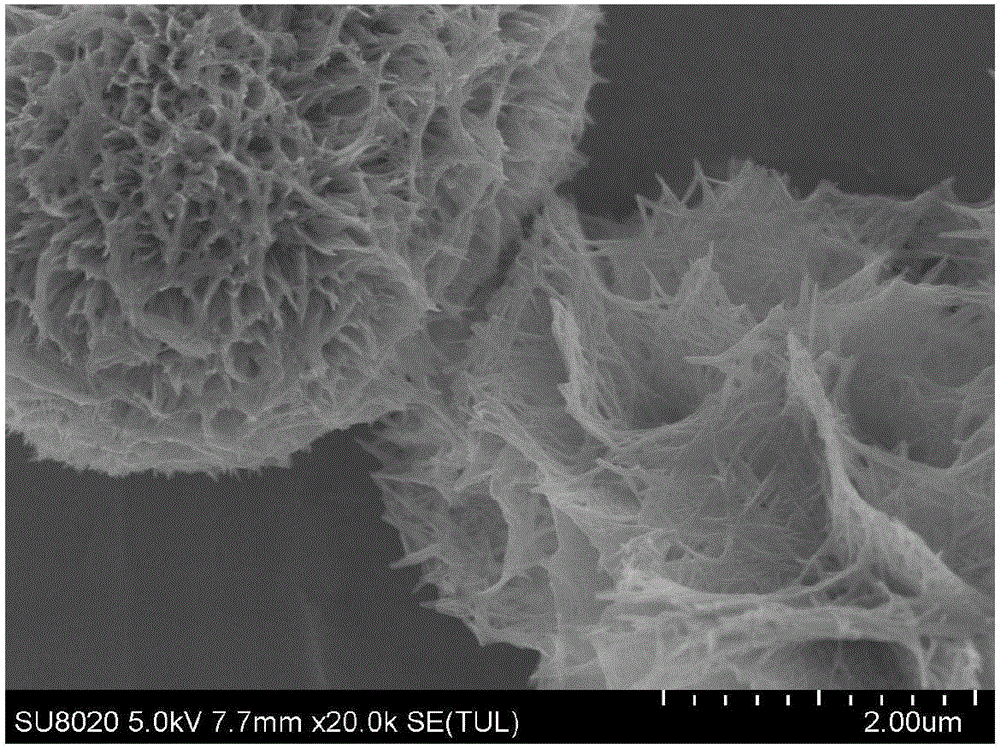

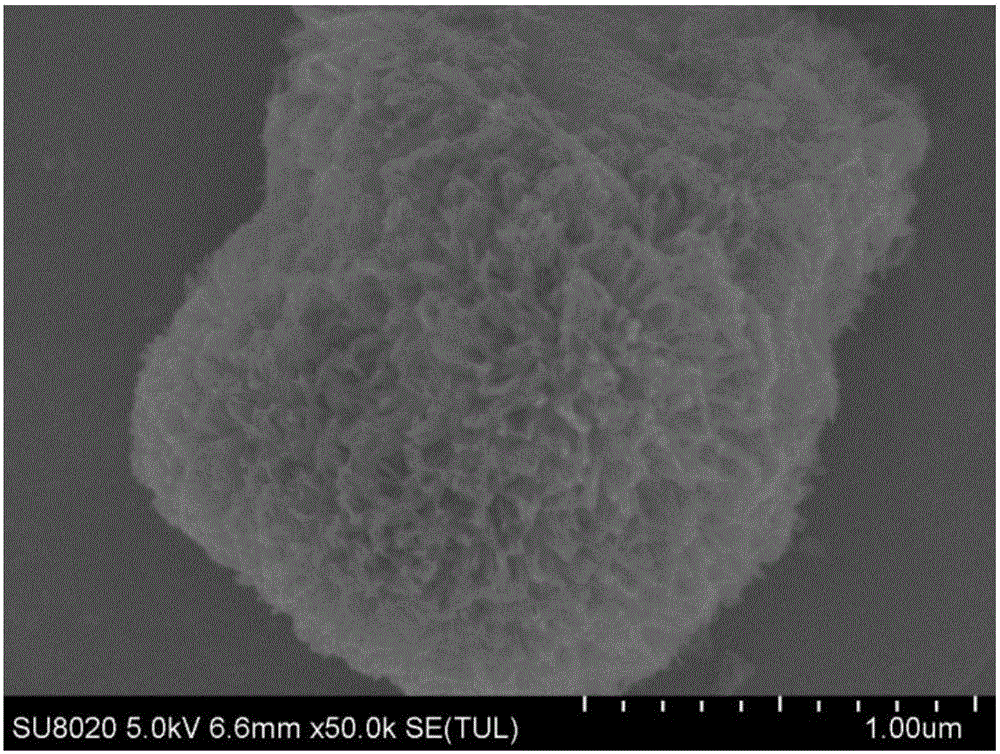

Method for preparing supercapacitor electrode material basic nickel-cobalt carbonate through hydrothermal method

InactiveCN106587171AFully moistenedFull penetrationHybrid capacitor electrodesNickel carbonatesNickel saltHigh pressure

The invention discloses a method for preparing a supercapacitor electrode material basic nickel-cobalt carbonate through a hydrothermal method. The method comprises the following steps that metal nickel salt and / or metal cobalt salt and urea are weighed separately and mixed with deionized water, and stirring is performed so that solids can be dissolved to obtain a mixed solution; the mixed solution is poured into a high-pressure reactor, sealing is performed for performing a reaction for 10-16 h under the temperature of 80-110 DEG C, and a reaction product is obtained; the reaction product is separated, washed and dried to obtain basic nickel-cobalt carbonate. According to the method for preparing the supercapacitor electrode material basic nickel-cobalt carbonate through the hydrothermal method, on the basis of control over raw material compatibility and reaction conditions, the three-dimensional porous structure and morphology can be obtained, sufficient wetting and permeation of an electrolyte are promoted, the superficial area of active substances is sufficiently utilized, and the electrochemical performance is improved.

Owner:BEIJING INSTITUTE OF GRAPHIC COMMUNICATION

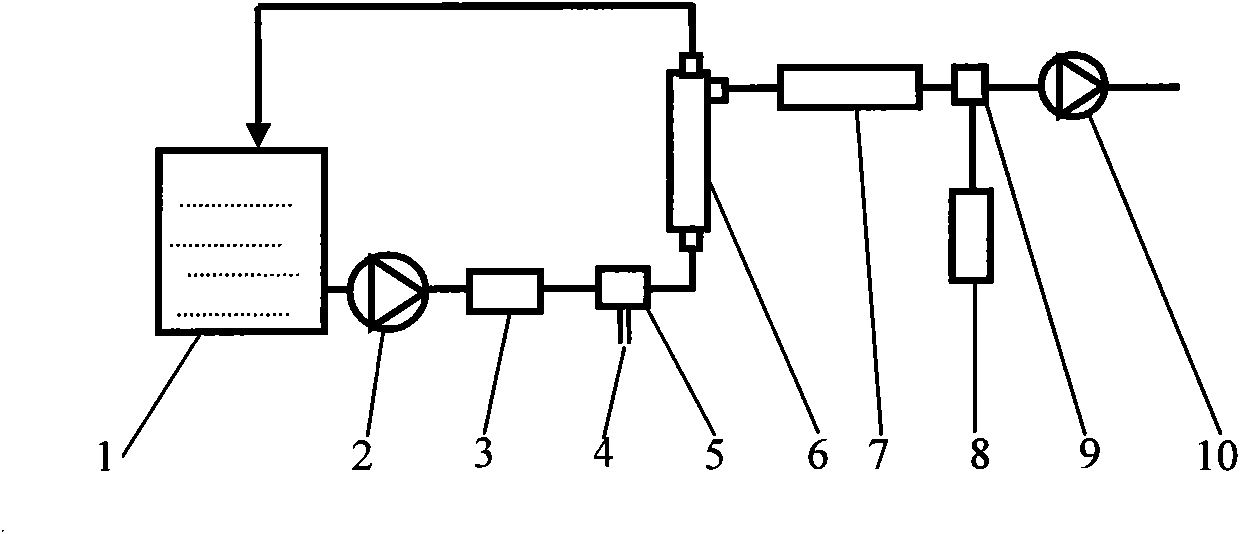

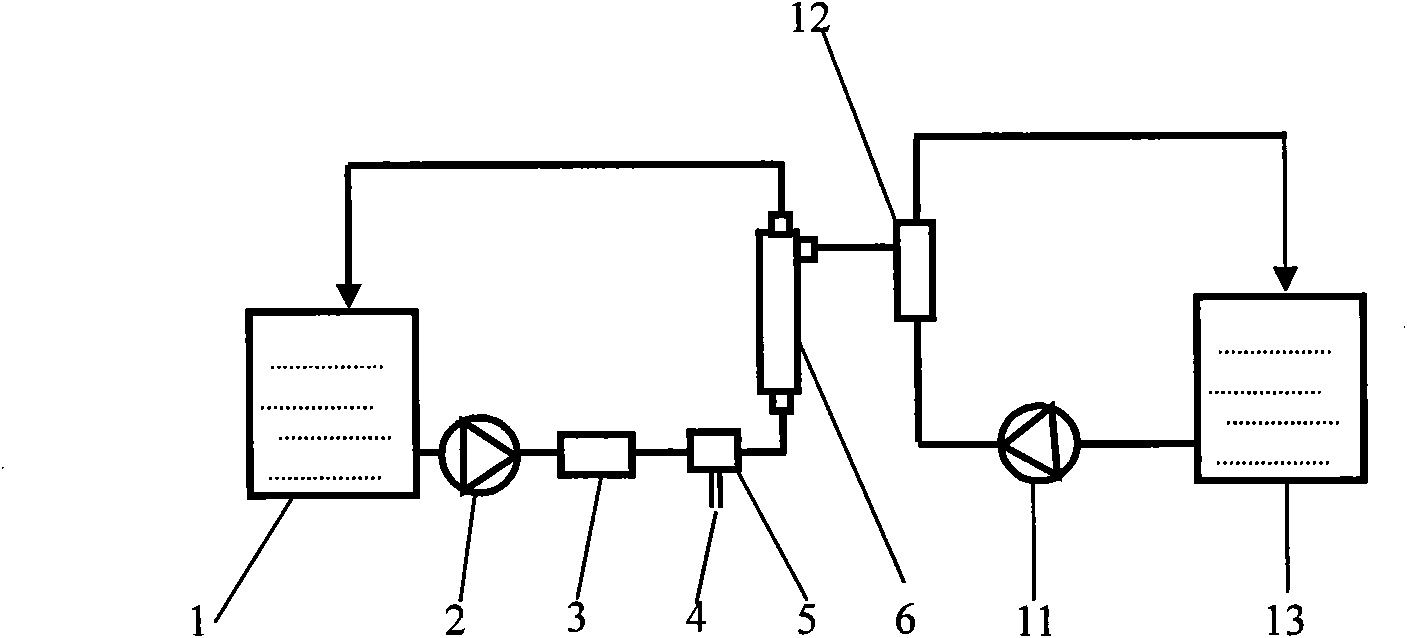

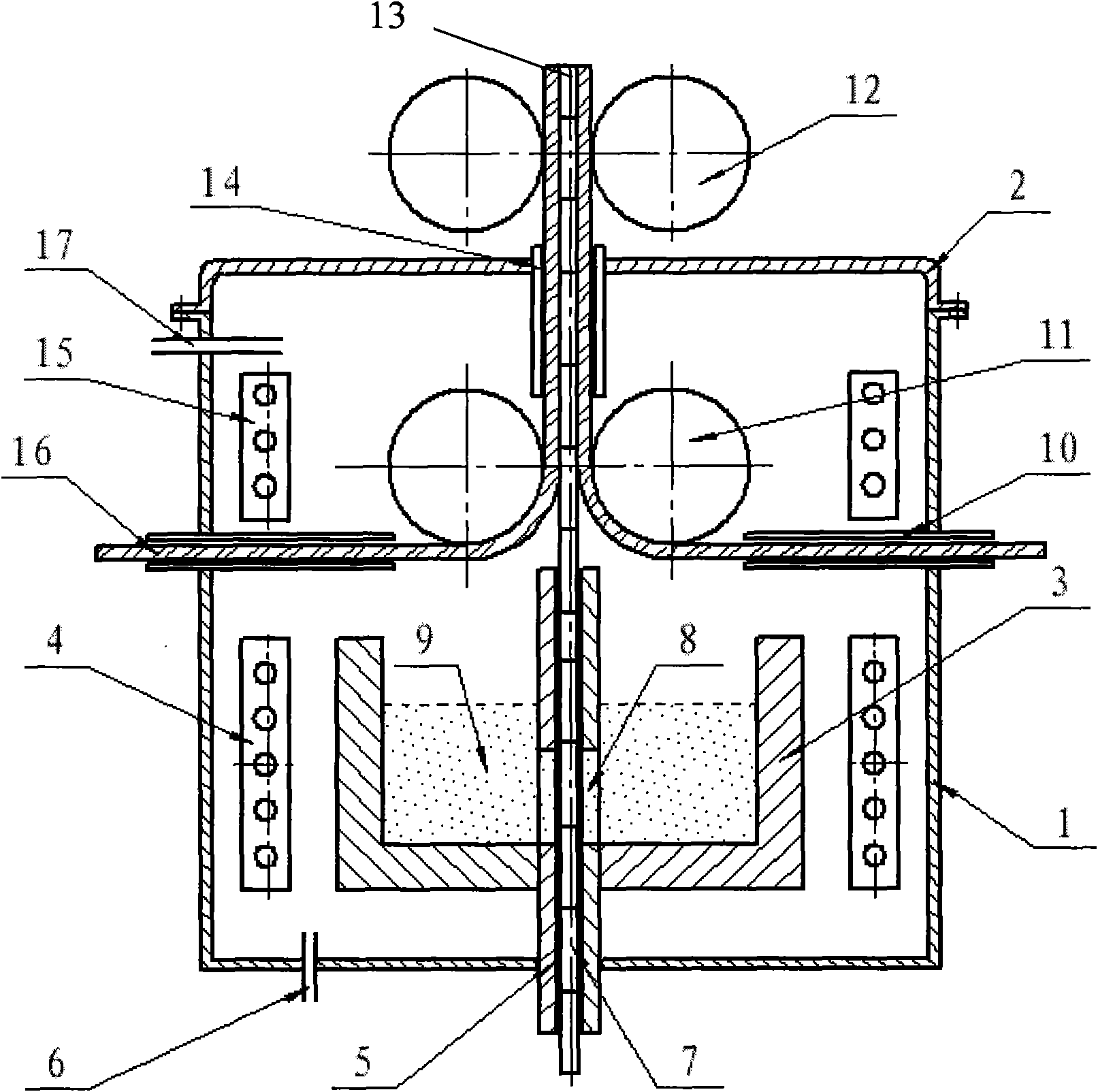

Device and method for air-blowing vacuum membrane distillation

InactiveCN101664642AReduced vacuum requirementsImprove mass transfer efficiencyDistillationForming gasWater vapor

The invention provides a device and a method for air-blowing vacuum membrane distillation. The device for air-blowing vacuum membrane distillation comprises the following sequentially-connected parts:a water tank arranged on the side of raw water; a water pump which is connected with the water tank and is used for pumping the raw water in the water tank; a compressed air inlet which is arranged on the downstream of the water pump and is used for blowing low-pressure compressed air to the raw water; a gas-liquid mixer used for mixing the compressed air and liquid to form gas-liquid mixed fluid; a hydrophobic membrane component used for processing the gas-liquid mixed fluid; and a vacuum generation device arranged on the effluent side of the hydrophobic membrane. In the device and the method, the compressed air is blown into the raw water side of the membrane when vacuum is generated on effluent side of the membrane. Under the suction action of the vacuum, water vapor and part of compressed air passes through the hydrophobic membrane together. As blowing and sweeping actions of the compressed air deliver the water vapor to the other side of the membrane, mass transfer efficiency isimproved. The requirements on the vacuum degree of the effluent side are reduced and equipment cost is reduced. Meanwhile, membrane pollution is effectively relieved.

Owner:TIANJIN POLYTECHNIC UNIV

Air compressing membrane distillation device and method

InactiveCN101564649AImprove mass transfer efficiencyFully moistenedEnergy based wastewater treatmentWater/sewage treatment by heatingWater vaporWater quality

The invention relates to an air compressing membrane distillation device which is characterized by comprising a hot water tank (1) and a condenser (9), wherein the hot water tank (1) comprises two stage hydrophobic membrane assemblies (5, 7) which are respectively used for millipore aeration of compressed air and water-vapor separation; and the condenser (9) is used for cooling the steam. The invention designs a new membrane distillation process, an air compressing membrane distillation system consists of the two stage hydrophobic membrane assemblies, a mass transfer mechanism directly transfers mass by utilizing an air pressure difference but not a steam partial pressure difference, therefore, the mass transfer efficiency is high. Compared with the air swept membrane distillation, compressed air is filtered by a membrane, thereby water is clean and the produced water quality is good; air is wetted completely, and the air consumption is little. Compared with the direct contact membrane distillation, cold fluid and hot fluid are not directly contacted and condensed at two sides of the membrane, and thereby the energy consumption can be obviously reduced. Compared with the vacuum membrane distillation, the energy consumption of an air compressor is lower than that of a vacuum pump, and the utilization efficiency of electric power is high; and meanwhile, the equipment requirement is simple.

Owner:TIANJIN POLYTECHNIC UNIV

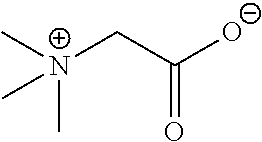

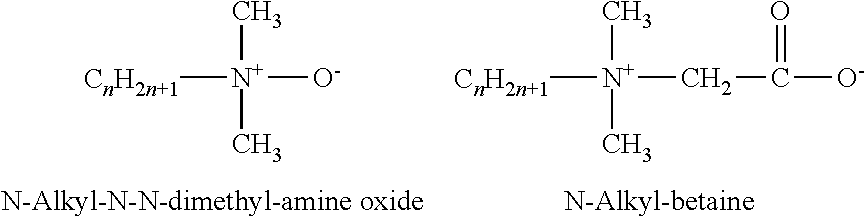

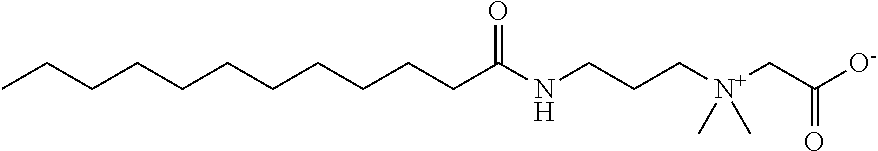

Green Glycine Betaine Derivative Compounds And Compositions Containing Same

InactiveUS20130338227A1Easy to cleanImprove antibacterial propertiesBiocideOrganic compound preparationNatural sourceBetaine

Multifunctional green (eco-friendly) and antimicrobial compositions are described containing cationic glycine betaine esters and / or cationic glycine betaine amides. Particular glycine betaine esters and amides are alkyl(ene) betainate methane sulfonates and betainyl amino alkyl(ene) methane sulfonates. The glycine betaine components are cationic, have a hydrophobic group attached to a carboxylate group through an ester or amide linkage, and are derived from a natural source, such as sugar beets. The glycine betaine esters and amides serve as cationic surfactants which have effective antimicrobial activity. The surfactant compositions are effective as crude mixtures or semi-purified mixtures or purified surfactant compounds of glycine betaine components. The addition of sodium chloride or potassium chloride or magnesium chloride or natural gum or polysaccharide to compositions containing the cationic glycine betaine ester and / or glycine betaine amide derivatives serves to thicken or gel the composition.

Owner:SAINT VICTOR MARIE ESTHER +2

Sapphire wafer polishing solution

ActiveCN104356950AEvenly distributedFully moistenedPolishing compositions with abrasivesReaction rateOrganic base

The invention discloses a sapphire wafer polishing solution which consists of the following components in percentage by weight: 20 to 30 percent of silica sol with solid content of 30 to 40 weight percent, 10 to 20 percent of alumina with a diameter of 80 to 200nm, 0.1 to 0.4 percent of organic base, 0.1 to 3 percent of a dispersing agent, 0.3 to 1 percent of nonylphenol polyethylene ether and the balance of de-ionized water. According to the sapphire wafer polishing solution, the silica sol and the alumina are compounded, so that the polishing speed is ensured, and machining scratches are avoided; furthermore, the nonylphenol polyethylene ether, the dispersing agent and the like are added to form a stable colloidal dispersion system to promote the full wetting of a polished wafer and a polishing pad and the stable and uniform distribution of the polishing solution between the polishing pad and the polishing wafer, so that the reaction rate of each part of the surface of the wafer can be balanced, and the polishing quality is ensured and improved; the sapphire wafer polishing solution can be used for the machining of a sapphire wafer.

Owner:临汾博利士纳米材料有限公司

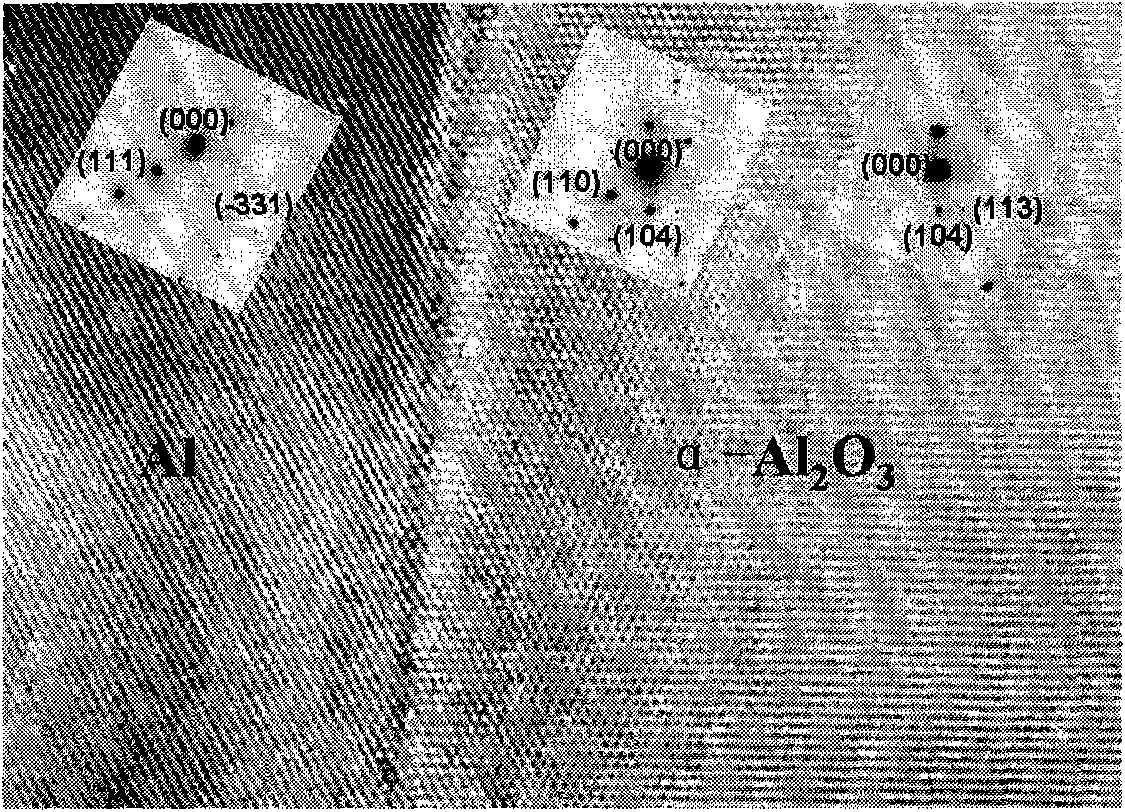

Surface metallization joint method of ceramic and aluminum or aluminum alloy

The invention discloses a surface metallization joint method of ceramic and aluminum or an aluminum alloy, comprising the following steps of: (1) forming a liquid film of an aluminum alloy 1 on a joint surface of the ceramic to obtain the ceramic of which the joint surface is coated with the liquid film of the aluminum alloy 1; and (2) placing the pure aluminum or aluminum alloy 2 on the joint surface of the ceramic of which the joint surface is coated with the liquid film of the aluminum alloy 1, and soldering the ceramic, of which the joint surface is coated with the liquid film of the aluminum alloy 1, with the pure aluminum or an aluminum alloy 2 by taking the liquid film of the aluminum alloy 1 as soldering flux. With the method, an interface formed between the aluminum or the aluminum alloy film and the ceramic is prevented from the inclusion of an oxide from the aluminum surface oxidation film and is very firm and difficult to fall off, the joint strength of the interface between the aluminum or the aluminum alloy and the ceramic is proved to be very firm and exceed the strength of the aluminum per se according to the 90-degree tear strength experiment, and no defects exit on the interface, therefore, the method is suitable for the requirements of industrial production. Therefore, the method has a wide application range in the field of the joint of the ceramic and the aluminum or the aluminum alloy.

Owner:TSINGHUA UNIV

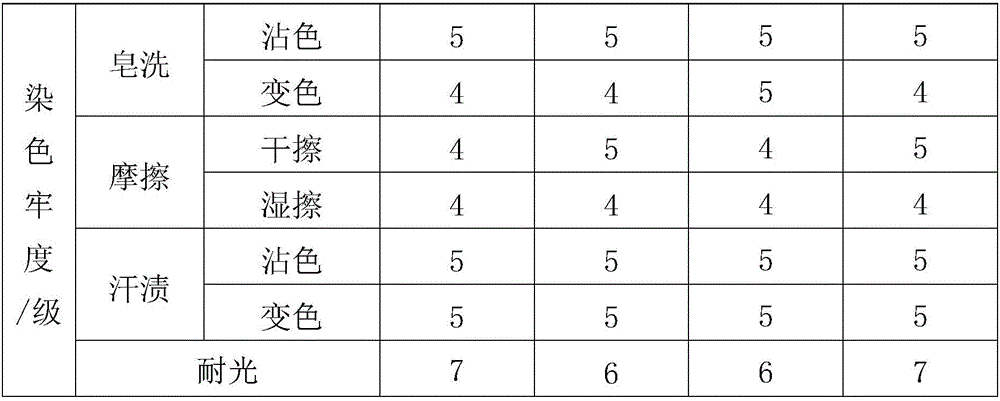

Dyeing and finishing process for polyester interweaved fabric

ActiveCN107059384AGood removal effectHigh whitenessHeat resistant fibresBiochemical treatment with enzymes/microorganismsPhenolsPh buffering

The invention discloses a dyeing and finishing process for polyester interweaved fabric. The dyeing and finishing process comprises the following steps: S1) pre-treating: performing scouring and bleaching and enzyme washing treatment on the polyester interweaved fabric in turn; S2) pre-shaping: performing pre-shaping treatment on the polyester interweaved fabric; S3) dyeing: soaking the polyester interweaved fabric into a dye liquor at a liquor ratio of 1:(10-30), wherein the dye liquor comprises 1-3% of reactive dyes, 2-5% of rare-earth complex micro-encapsulation disperse dyes, 5-15g / L anhydrous sodium sulphate, 1.5-3.5g / L pH buffering agent, 0.1-0.3g / L organic phenol halide and 0.01-0.05g / L organic fluorinated surfactant; and S4) finishing: performing softening and flame-proof treatment on the fabric in turn. The dyeing and finishing process for polyester interweaved fabric, disclosed by the invention, not only can obviously improve the performances, such as, hand feel and elasticity, of the fabric but also can achieve the effects of uniform dyeing, high color fastness and abundant color and luster.

Owner:宣城加特林机械有限公司

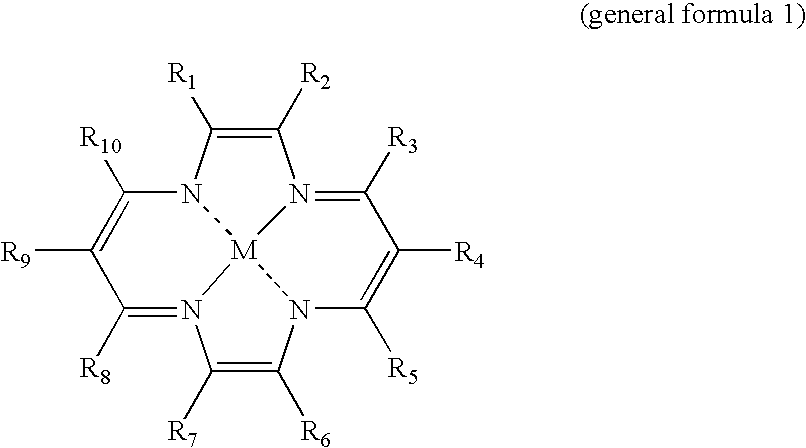

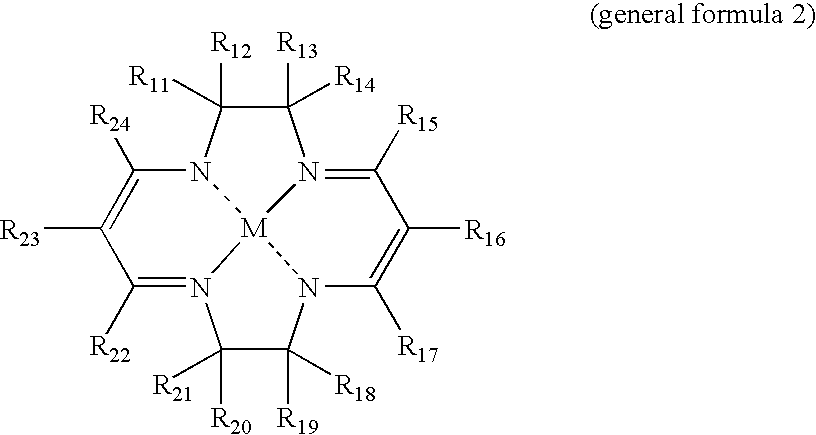

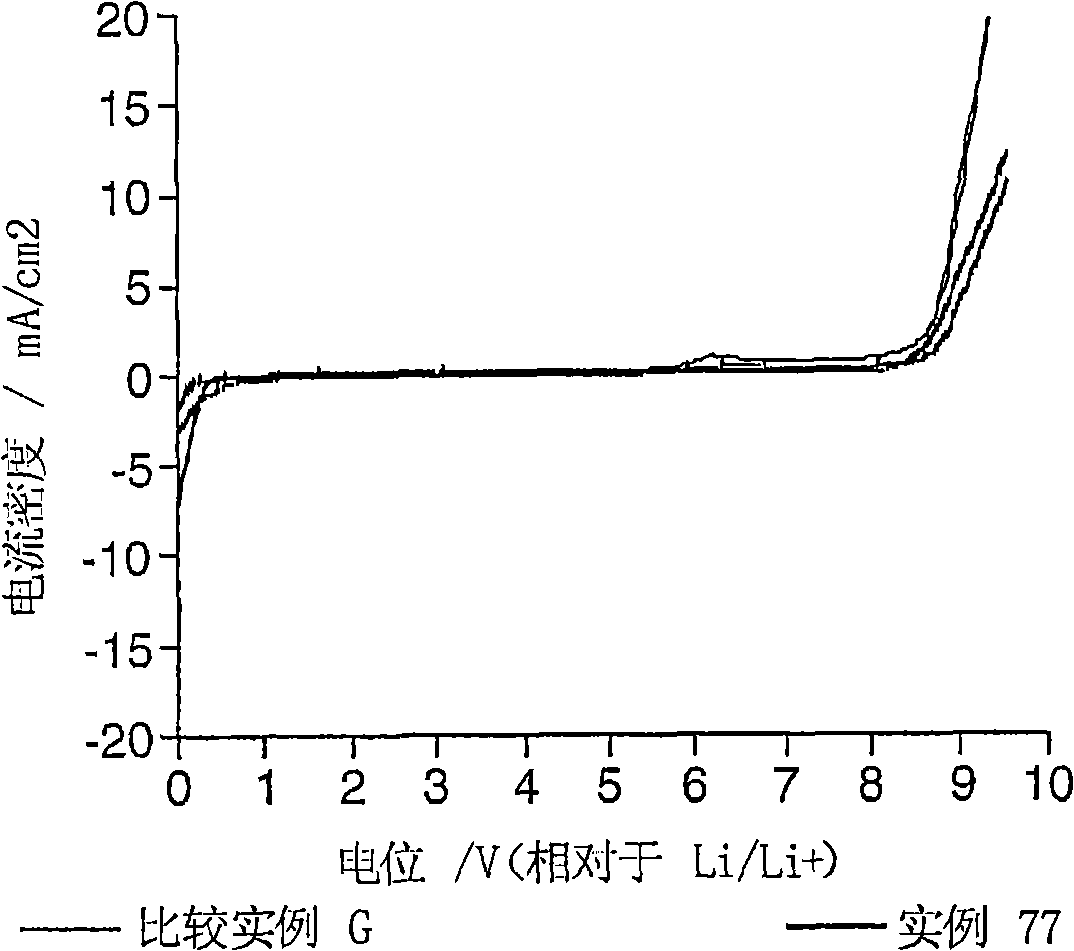

Electrolyte composition

InactiveCN101258637ASufficiently conductiveReduce fireFinal product manufactureActive material electrodesHydrogen atomHeteroatom

An electrolyte composition includes (a) a solvent composition including at least one hydrofluoroether compound, the hydrofluoroether compound including two terminal fluoroalkyl groups and an intervening substituted or unsubstituted oxymethylene group, each of the fluoroalkyl groups including only one hydrogen atom and, optionally, at least one catenated (that is, in-chain) heteroatom, with the proviso that, when the oxymethylene group is unsubstituted, at least one of the terminal fluoroalkyl groups is branched and / or includes at least one catenated heteroatom; and (b) at least one electrolyte salt.

Owner:3M INNOVATIVE PROPERTIES CO

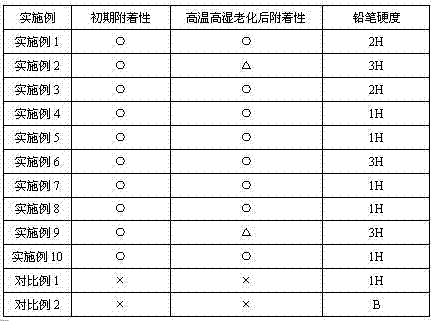

A hard coating composition and hardened film containing the hard coating composition

ActiveCN102268201AReduce internal stressImprove adhesionSynthetic resin layered productsCoatingsIndium tin oxidePet substrate

Provided are a hard coating composition and a hardened membrane containing the same. The hard coating composition comprises, by weight, 30 to 80 parts of hydroxyl-containing acrylate monomers, 1 to 10 parts of an photoinitiator, 20 to 70 parts of a solvent and 0.1 part to 5 parts of a reactive organosilicon surface wetting auxiliary agent, wherein, the hydroxyl-containing acrylate monomers are a mixture of hydroxyl-containing multi-functional acrylate monomers and hydroxyl-containing low functional acrylate monomers mixed according to a weight ratio of 2:8 to 8:2. The composition provided in the invention has excellent adhesion to a PET substrate surface which is never treated and a PET substrate surface which has corona or a failure coating bottom; hardness of the hardened layer of the obtained hardened membrane is greater than 1H, and therefore, the hardened membrane can be used as a hardened membrane of an indium tin oxide (ITO) touch screen, an in-mold label (IML), or the like.

Owner:CHINA LUCKY FILM CORP

Activation method for membrane electrode of fuel cell

ActiveCN101132068AQuick activationShorten activation timeFinal product manufactureCell electrodesActivation methodFuel cells

This invention relates to a method for activating the membrance electrode of fuel cell. The procedures comprise: the positive pole fuel and negative pole fuel are fed into positive pole chamber and negative pole chamber respectively, thus makes the cell discharging, which is multi-stage discharging, including at least one time-interval between the stages, and the discharging being under constant voltage. This invention method makes the activating operation being fulfilled in a short period, and gives higher outpul power.

Owner:BYD CO LTD

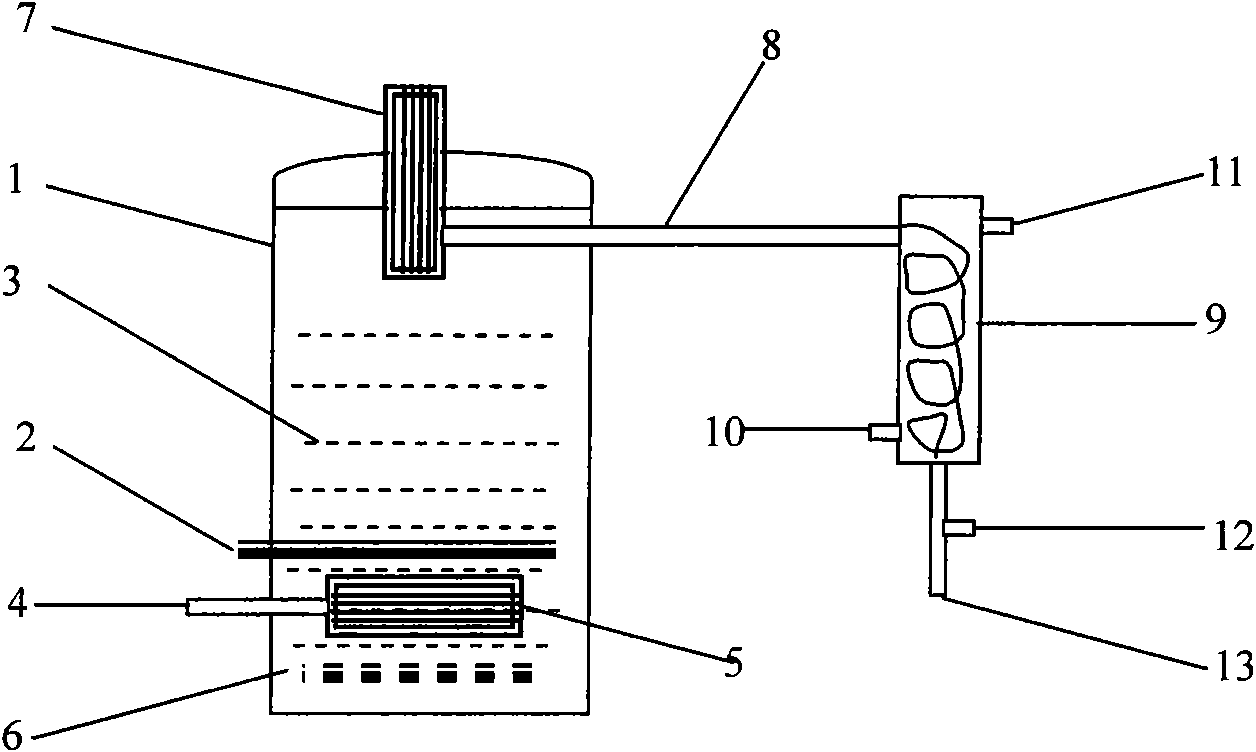

Stepped gravity heat pipe geothermal exploitation system without liquid accumulation effect

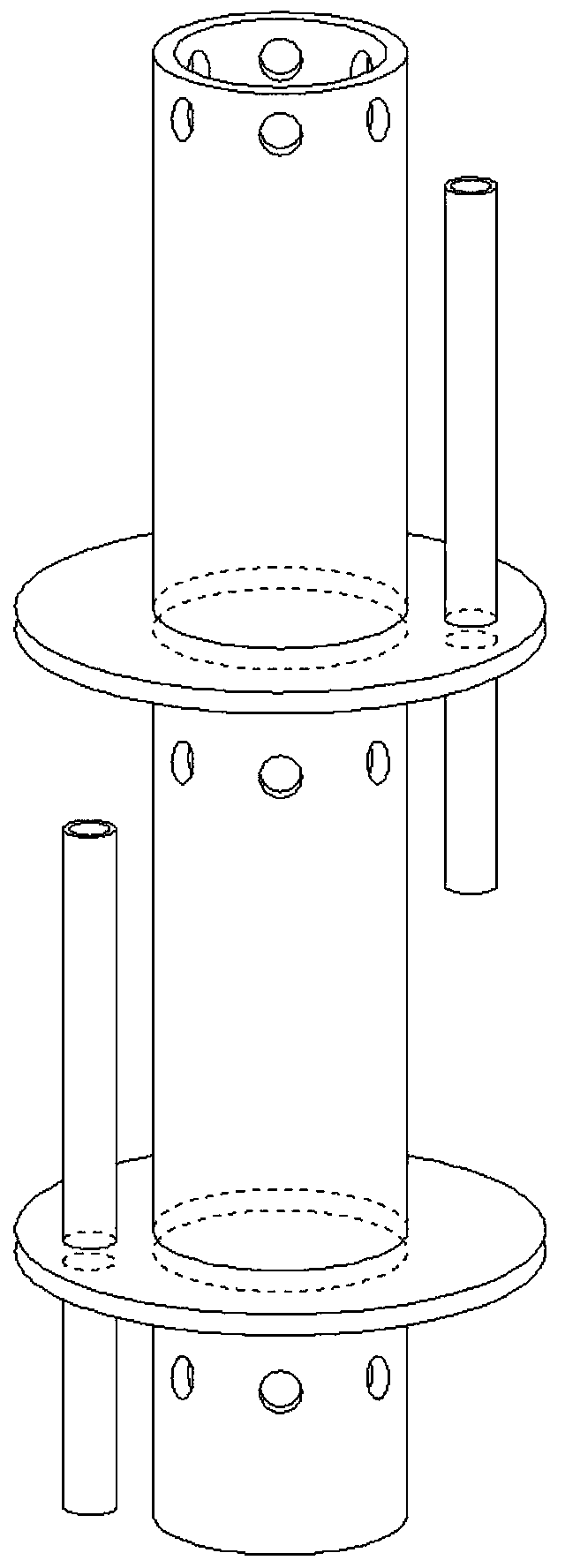

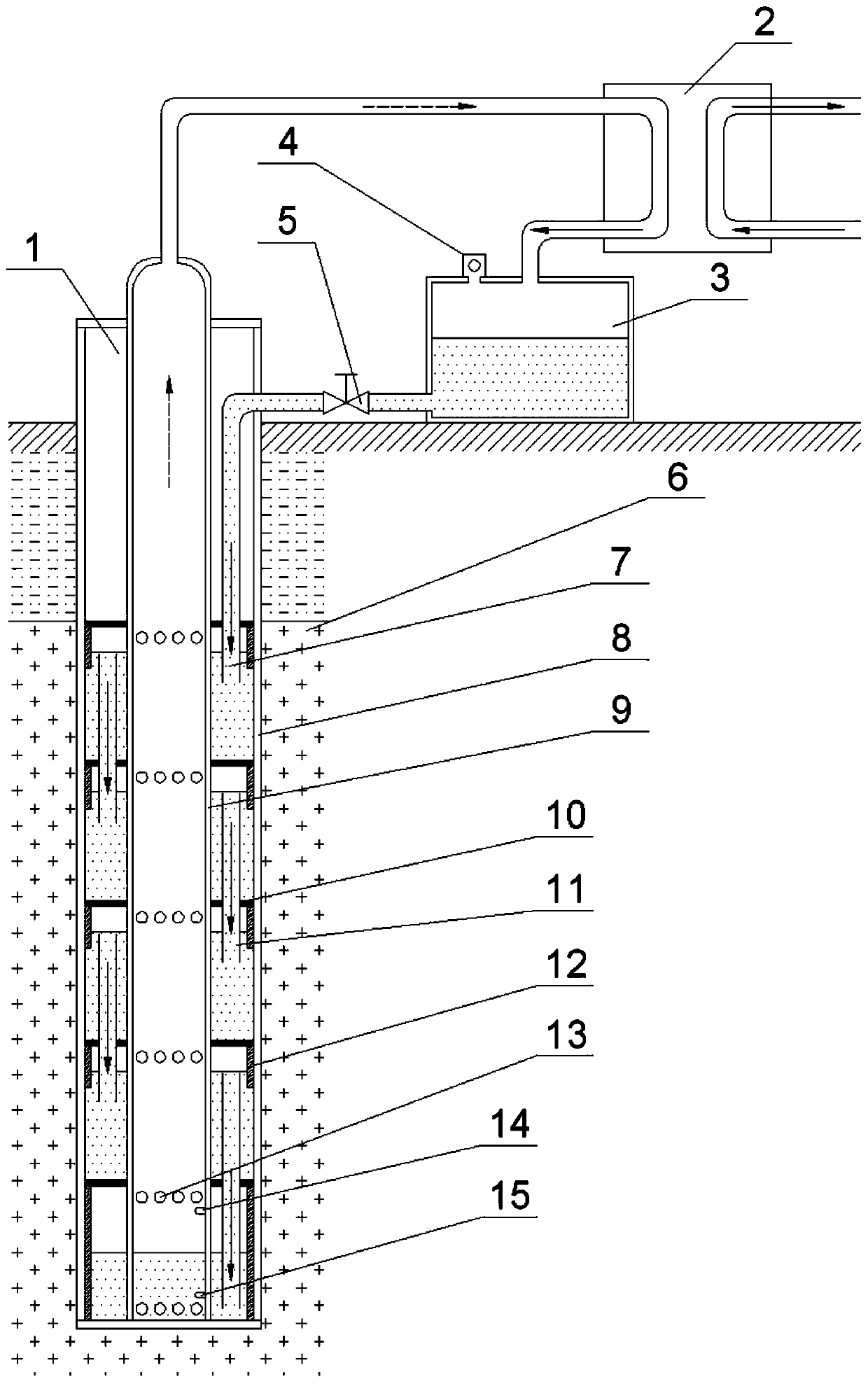

ActiveCN110030746AAchieve miningFully moistenedCollector components/accessoriesGeothermal energy generationLiquid storage tankHeat transfer efficiency

The invention provides a stepped gravity heat pipe geothermal exploitation system without a liquid accumulation effect. The system comprises a gravity heat pipe, a condenser and a liquid storage tank,wherein the gravity heat pipe comprises a liquid return pipe, an outer pipe and an inner pipe, the liquid return pipe is located in a gap between the outer pipe and the inner pipe and is connected with the liquid storage tank, the gap between the outer pipe and the inner pipe adopts a stepped separation structure, a liquid working medium sequentially flows into the separation sections of all stages from the liquid storage tank through the liquid return pipe, and passes through the pipe wall of the outer pipe to absorb heat from high-temperature rock and then is gasified, and after the liquidworking medium becomes a gaseous working medium, then the gaseous working medium enters the inner pipe again and flows into the condenser, and then flows into the liquid storage tank again for circulation after being subjected to heat release condensation. Compared with the prior art, the heat pipe heat absorption section is designed to be of the stepped separation structure, and the liquid levelof each separation section is limited to a certain height through corresponding liquid level control pipe; and the design can solve the problem that the working medium is difficult to evaporate due toexcessively high liquid level while the heat absorption section is fully wetted, so that the heat transfer efficiency when a super-long heat pipe is used for exploiting the geothermal energy is greatly improved.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Antibacterial wear-resistant color masterbatch and preparation method thereof

InactiveCN110003584AImprove antibacterial propertiesImprove wear resistanceWear resistantPolyvinyl chloride

The invention discloses an antibacterial wear-resistant color masterbatch. The color masterbatch comprises the following components: 50 to 80 parts of polyvinyl chloride, 6 to 10 parts of a calcium zinc heat stabilizer, 20 to 30 parts of filler calcium carbonate, 20 to 30 parts of chlorinated polyethylene, 2 to 5 parts of a colorant, 1 to 3 parts of a lubricant, 1 to 2 parts of antioxidant phosphite ester, 1 to 2 parts of polyethylene wax, 20 to 30 parts of an environment-friendly plasticizer, 1 to 2 part of an ultraviolet absorber, 15 to 20 parts of an antibacterial agent, and 5 to 10 parts of a wear-resistant agent. A preparation method of the antibacterial wear-resistant color masterbatch comprises the following steps: (1), adding the polyvinyl chloride and the chlorinated polyethyleneinto a high-speed mixer according to certain mass parts, so as to perform high-speed mixing; (2), reducing the temperature to room temperature after the plasticizer is sufficiently absorbed by the polyvinyl chloride and the chlorinated polyethylene; (3), adding the blended materials into a double-screw extruder. The formed antibacterial wear-resistant color masterbatch can improve the antibacterial and wear-resistant effect of a polyvinyl chloride product, and has the advantages of stable performance, high coloring power, good dispersibility, high safety in use, high environmental protection property and high nontoxicity.

Owner:ANHUI JIHONG MATERIAL TECH

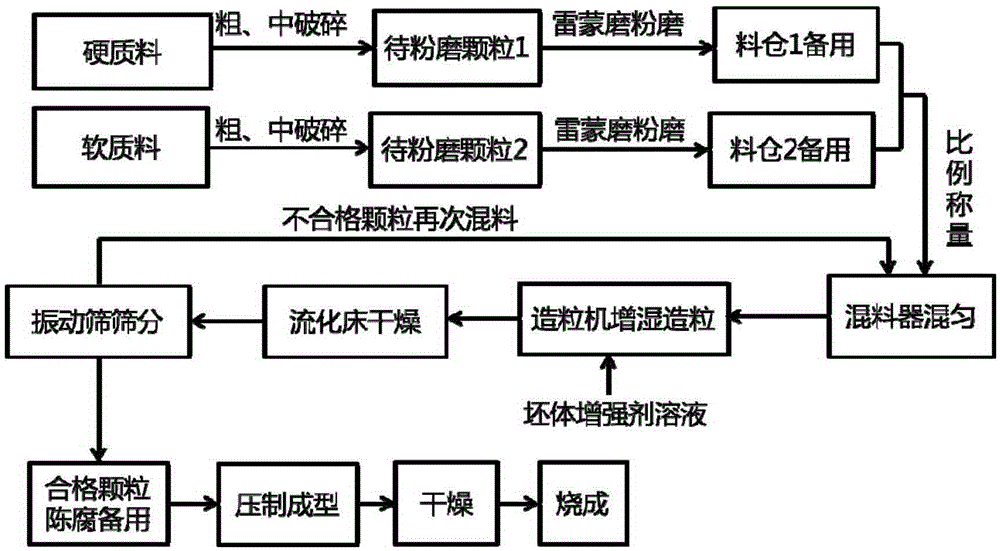

Ceramic tile blank and preparation method

The invention relates to a ceramic tile blank and a preparation method. CMC (Carboxymethylcellulose), PVA (Polyvinyl Acetate), sodium polyacrylate and sodium alginate of which the mass ratio is (2 to 3):(0.5 to 0.8):(15 to 20):(0.01 to 0.03) are mixed, and then water is added, so as to obtain a body enhancer solution of which the mass fraction is 5 to 8%; hard materials and soft materials are uniformly mixed to be added to a granulator, the body enhancer solution is added to the granulator, powder granulated by the granulator is dried until the moisture content is 5 to 8%, and then screening is performed, so as to obtain the ceramic tile blank. All components of the ceramic tile blank are suitable for a dry pulverizing process, compared with a general dry granulating technique, the ceramic tile blank has the advantages of stable quality and good granule fluidity, after a ceramic tile sample is fired, the average breaking strength reaches 38 to 55 MPa, and the water absorption is less than or equal to 0.5%.

Owner:湖北亚细亚陶瓷有限公司 +1

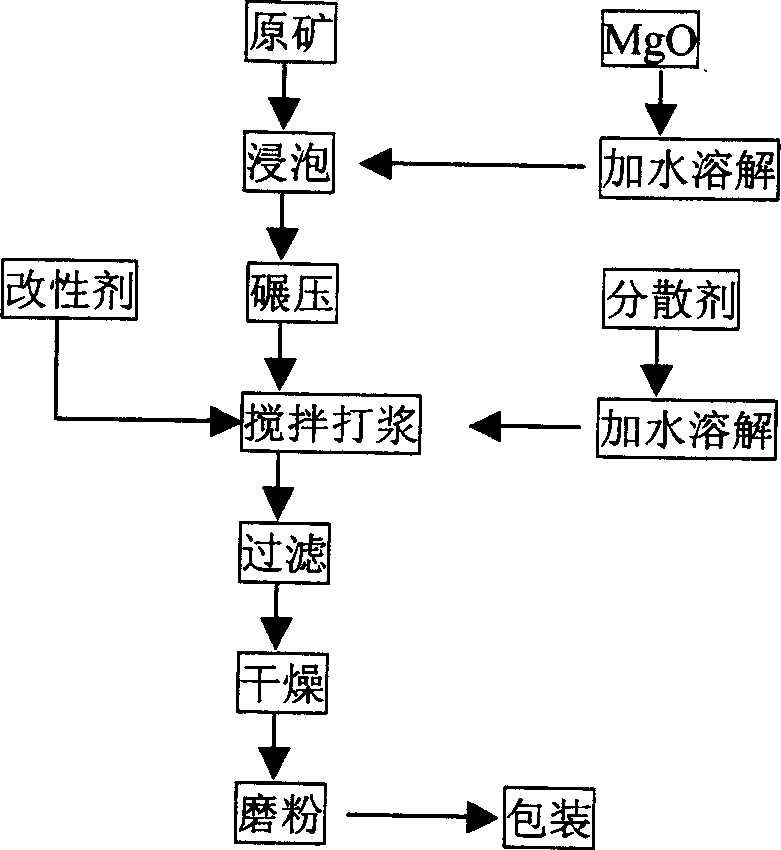

Production method of attapulgite gelatin for coating thickener

This invention discloses a method for producing attapulgite gel used in paint thickening agent, comprising: first, soak the attapulgite ore concentrate with water and additive for 5-7d, wherein the additive MgO is 2-4% of the ore concentrate weight, and the ratio of the ore concentrate and water is 1:9; then roll the mixture at pressure of 50-70 kilogram / cm2 to be wet material with 40-55% water content, soak the wet material for another 2-3 days, and continuously roll 2-3 more times to obtain the finished wet material; second, filtrate the wet material, and dry it at below 120Deg C to obtain the dry material with 8-12% water content; finally, grind the dry material to 500 order to obtain the attapulgite gel. This invented attapulgite thickening agent used in water paint and solvent paint is characterized of high viscosity coefficient and thixotropy index, thorough dispersion, and no agglomeration.

Owner:JIANGSU PROVINCE HUAIYUAN MINING

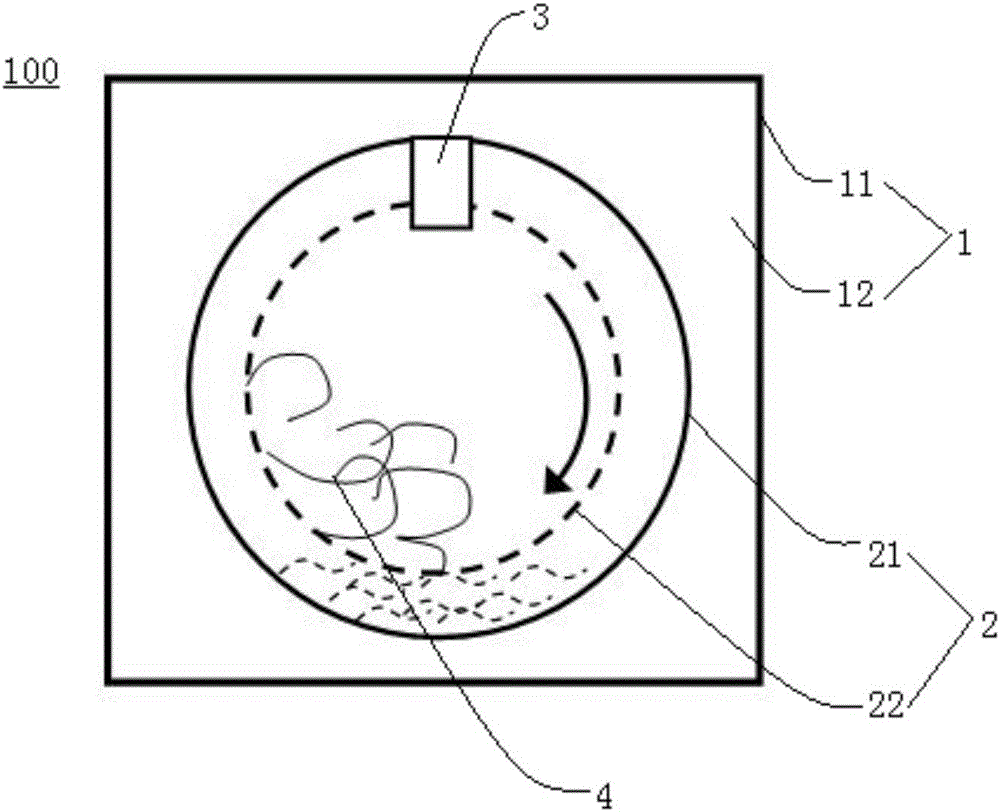

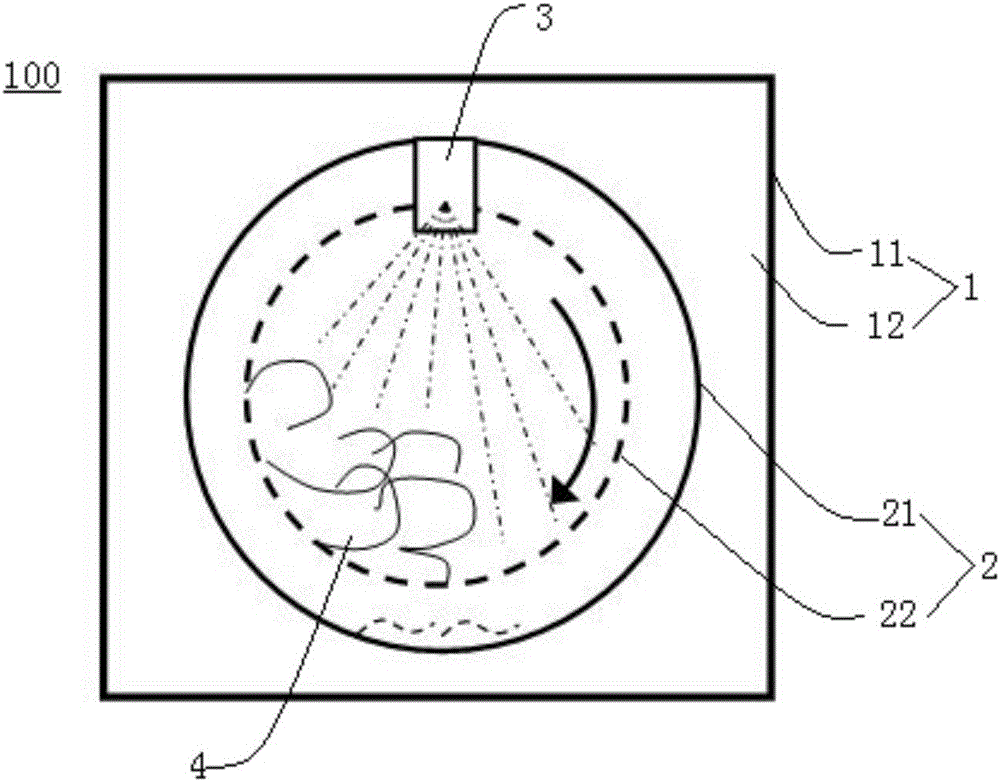

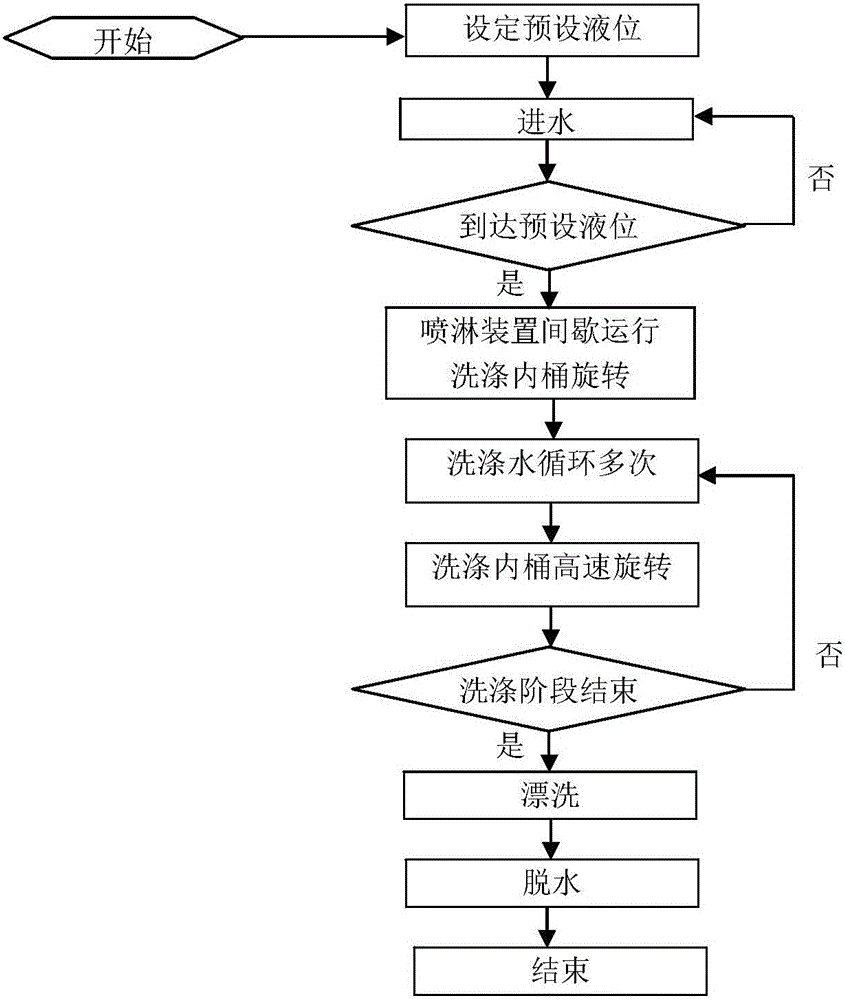

Washing equipment and washing method thereof

ActiveCN105862310AExpand the spraying areaFully moistenedOther washing machinesControl devices for washing apparatusProcess engineeringEnergy conservation

The invention discloses washing equipment and a washing method thereof. The washing equipment comprises a washing body, a washing barrel component and a spraying device, wherein the washing barrel component is arranged in the washing body; the spraying device is arranged on at least one of the washing body and the washing barrel component; the spraying device is positioned at the upper part of the washing barrel component and used for pumping the liquid in the washing barrel component and spraying the liquid towards to-be-washed objects in the washing barrel component. According to the washing equipment, the spraying device is arranged on the upper part of the washing barrel component, and the spraying area of the spraying device is enlarged, so that the to-be-washed objects can be fully wetted, the usage amount of the washing water can be reduced, and the energy conservation and environmental friendliness are achieved.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

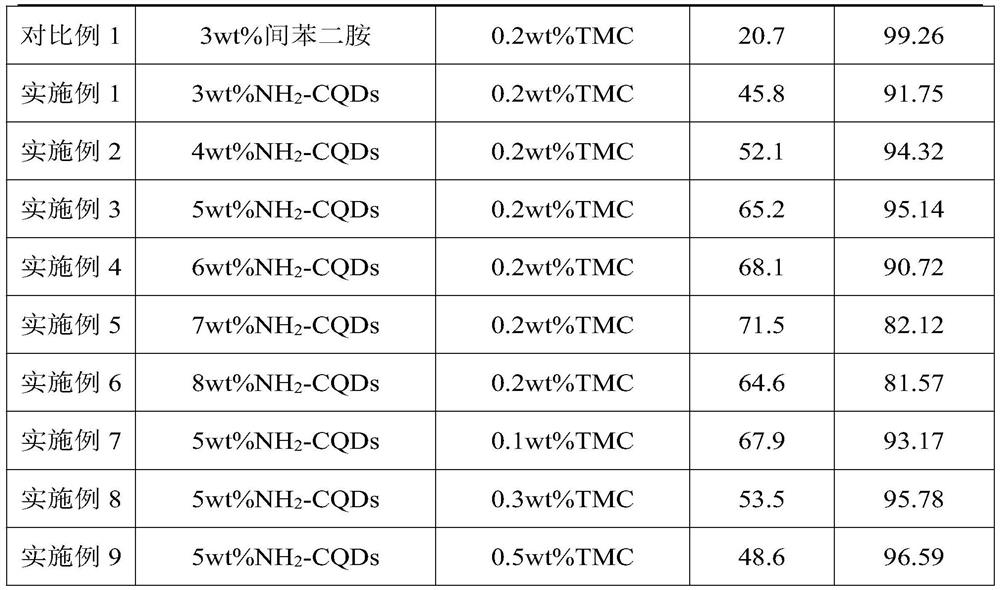

Polyamide reverse osmosis membrane and preparation method thereof

ActiveCN111992049AIncrease water fluxIncrease water channelMembranesGeneral water supply conservationPolymer scienceActive agent

The invention provides a polyamide reverse osmosis membrane and a preparation method thereof. The membrane comprises a porous support membrane and a carbon quantum dot-containing polyamide layer growing on the surface of the porous support membrane, and the carbon quantum dot-containing polyamide layer comprises the following raw material components: aminated carbon quantum dots, an oil-phase reaction monomer, an oil-phase solvent, an acid acceptor, a pH regulator and a surfactant; the preparation method comprises the following steps: 1, preparing aminated carbon quantum dots; and 2, preparingthe polyamide reverse osmosis membrane. According to the polyamide reverse osmosis membrane disclosed by the invention, the aminated carbon quantum dots are used as a novel water-phase reaction monomer, and a polyamide layer structure containing the carbon quantum dots is formed on the polysulfone porous support membrane by directly carrying out a cross-linking reaction on amino groups on the aminated carbon quantum dots and trimesoyl chloride, so that the water flux can be improved from multiple aspects.

Owner:HUNAN OVAY TECH CO LTD

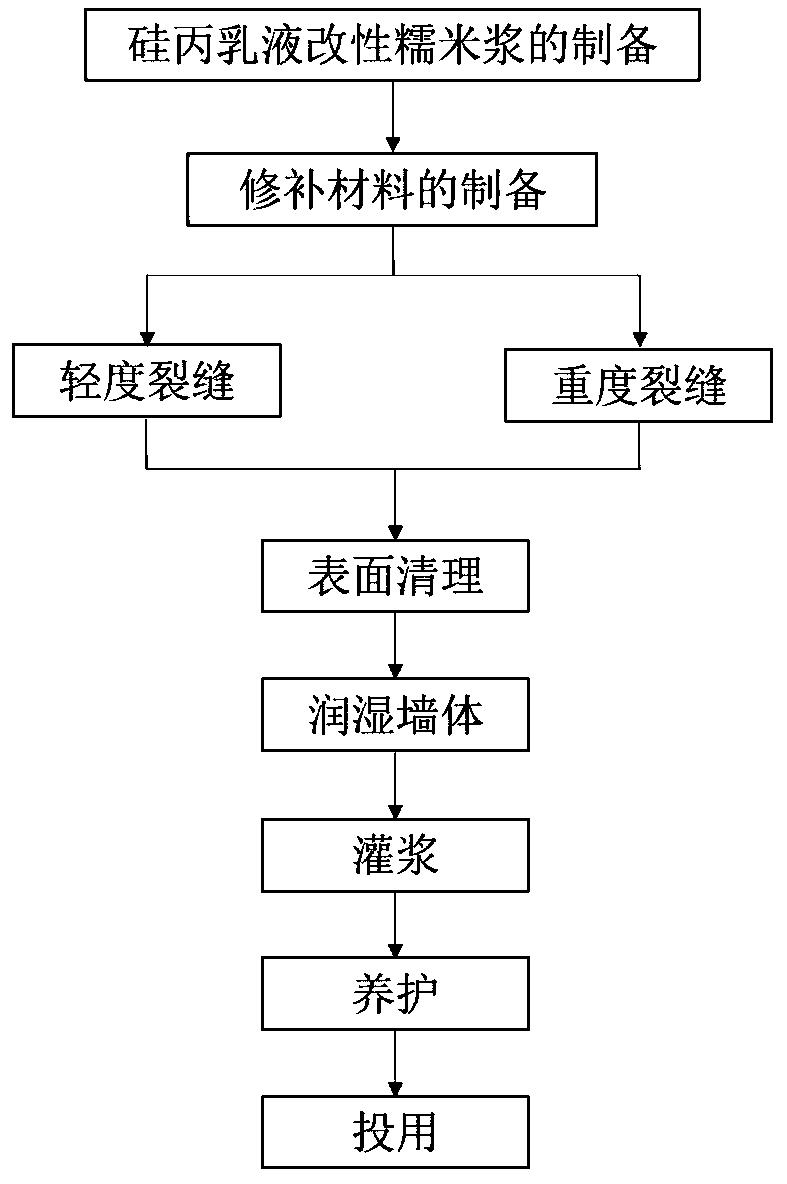

Repairing material for ancient building black brick wall cracks and construction process

The invention discloses a repairing material for ancient building black brick wall cracks and a construction process, and belongs to the field of ancient building repairing. Quicklime, slaked lime, black brick ash, quartz sand, 107 building glue powder, hydroxypropyl methyl cellulose, starch ether, a water reducing agent and an antifoaming agent are fully mixed according to a mass ratio, and thenprepared silicone acrylic emulsion modified glutinous rice slurry is added and fully stirred to obtain the product. The repairing material meets the requirements of cultural relic protection and repair, has good flowability, is beneficial to grouting operation and full filling of gaps, and has good compressive strength and bonding strength, good toughness, small shrinkage rate, good water resistance and strong ageing resistance after being cured. The repairing material has good adhesive force with black bricks, the appearance color is close to that of a black brick wall, the repairing materialhas good compatibility with the black brick wall, the cost is low, and the economic practicability is high. The repair material construction process is elaborated in detail, construction is convenient and fast, and the rework period can be effectively shortened.

Owner:厦门翰林苑建设工程有限公司

Sintered preparation method of iron-based metal ceramic material with high TiC content

The invention discloses a method for preparing an iron-based titanium carbide metal ceramic with high ceramic content through sintering. The component formulation comprises 45-80 % of TiC and 20-55 % of iron-based binder phase in percentage by weight, wherein the optimal components of the iron-based binder phase are 65-80% of Fe (Ferrum), 1-5 % of Mo (Molybdenum), 2-10 % of Ni (Nickel), 0-10 % ofMn (Manganese), 10-22 % of Cr (Chromium), 0-2.5 % of Ti (Titanium) and 0-2.5 % of Si (Silicon) in percentage by weight. The method comprises the following steps of: after uniformly mixing the powder prepared according to the formulation, pressing the powder into a 10*10*2 cm blank; and then putting the blank into a vacuum furnace and vacuumizing the furnace; next, heating up to 200 DEG C at a speed of 10 DEG C / min; preserving the heat for 10 minutes; and then heating up to 400 DEG C at a speed of 10 DEG C / min; preserving the heat for 10 minutes again; heating up at a speed of 10 DEG C / min in the same way; preserving the heat for 10 minutes every 200 DEG C until the sintering temperature is 1450 DEG C; and after sintering the blank for 4 hours, cooling the blank along with the furnace to the room temperature. According to the invention, the wettability between the iron-based binder phase and the titanium carbide ceramic phase can be largely improved so that the iron-based binder phase and the titanium carbide ceramic can be sufficiently wetted while being sintered at high temperature, thus the completely compact iron-based metal ceramic can be obtained.

Owner:王华彬

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com