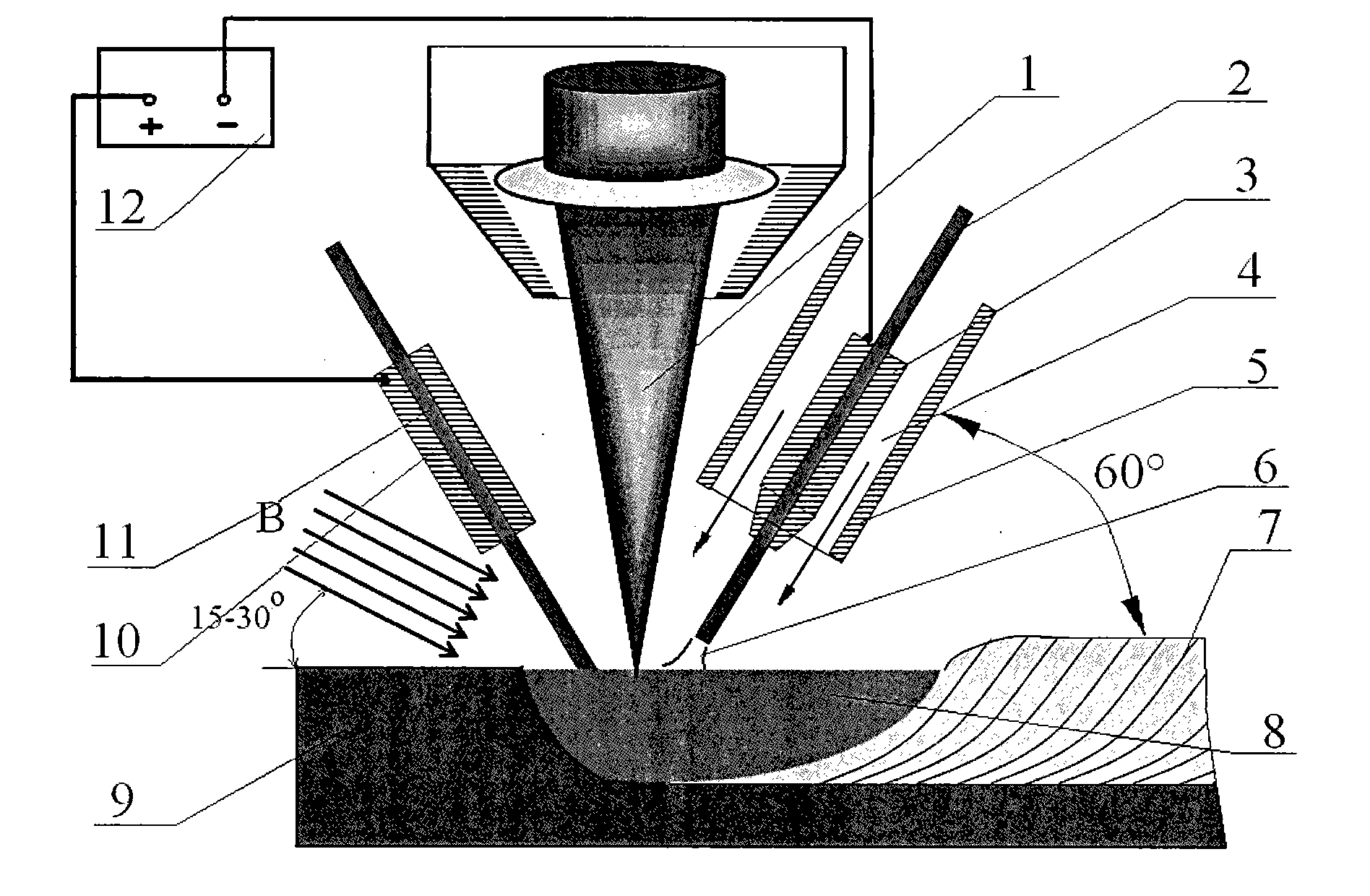

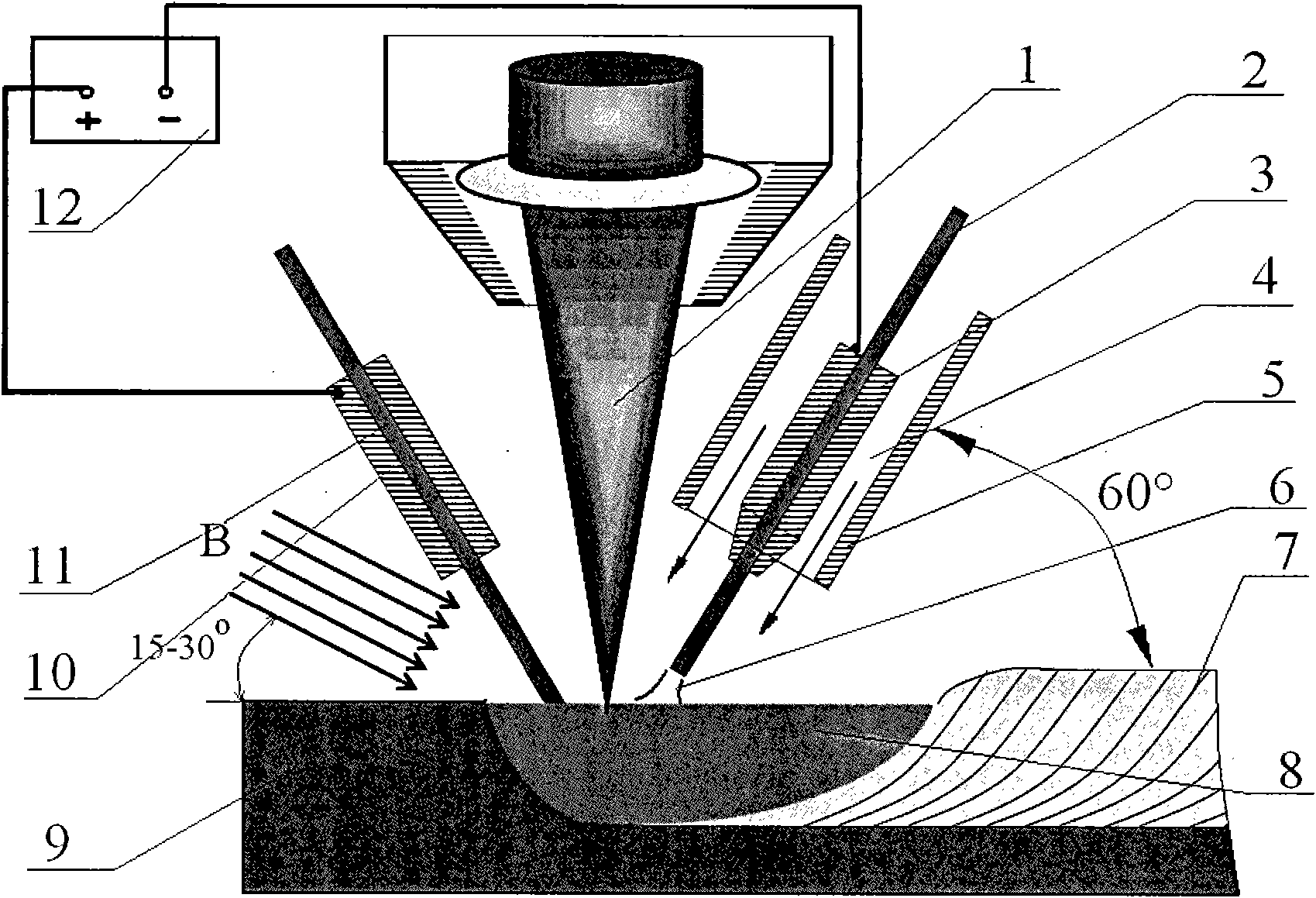

Electromagnetic current coupling field assisted hybrid melting-brazing method for laser-TIG arc and equipment

A current-coupling, field-assisted technology, applied in welding equipment, welding equipment, metal processing equipment, etc., can solve problems such as uniform mixing and full spreading of unfavorable liquid molten pool metal, reducing laser utilization, affecting weld formation, etc. Effectiveness of laser utilization, improved connection quality, increased strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Galvanized steel Q345B and 7075 aluminum alloy materials are assisted by electromagnetic current coupling field laser-TIG arc fusion and brazing, using the external magnetic field assisted laser-DC TIG arc fusion and brazing composite welding method, the thickness of the welding workpiece is 2.8mm, and the butt joint , The brazing process parameters are: DC TIG welding, the workpiece is not connected to the welding power supply, the solder wire is connected to the positive pole, the tungsten pole is connected to the negative pole of the welding power supply, the diameter of the tungsten pole is Φ2.4mm; the welding current is 100-180A; the auxiliary magnetic field strength is 1200-2600Gs; ROFIN-DC030 carbon dioxide laser, power 3500W, spot diameter 0.3mm, welding speed 0.1-2m / min, solder wire diameter Φ1.2mm, through parameter optimization, to achieve the required joint performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com