Patents

Literature

152 results about "Laser brazing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

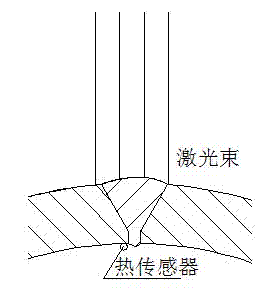

Laser Brazing is a joining process whereby a filler metal or alloy is heated to melting temperatures above and distributed between two or more close-fitting parts, without actually melting the base material.

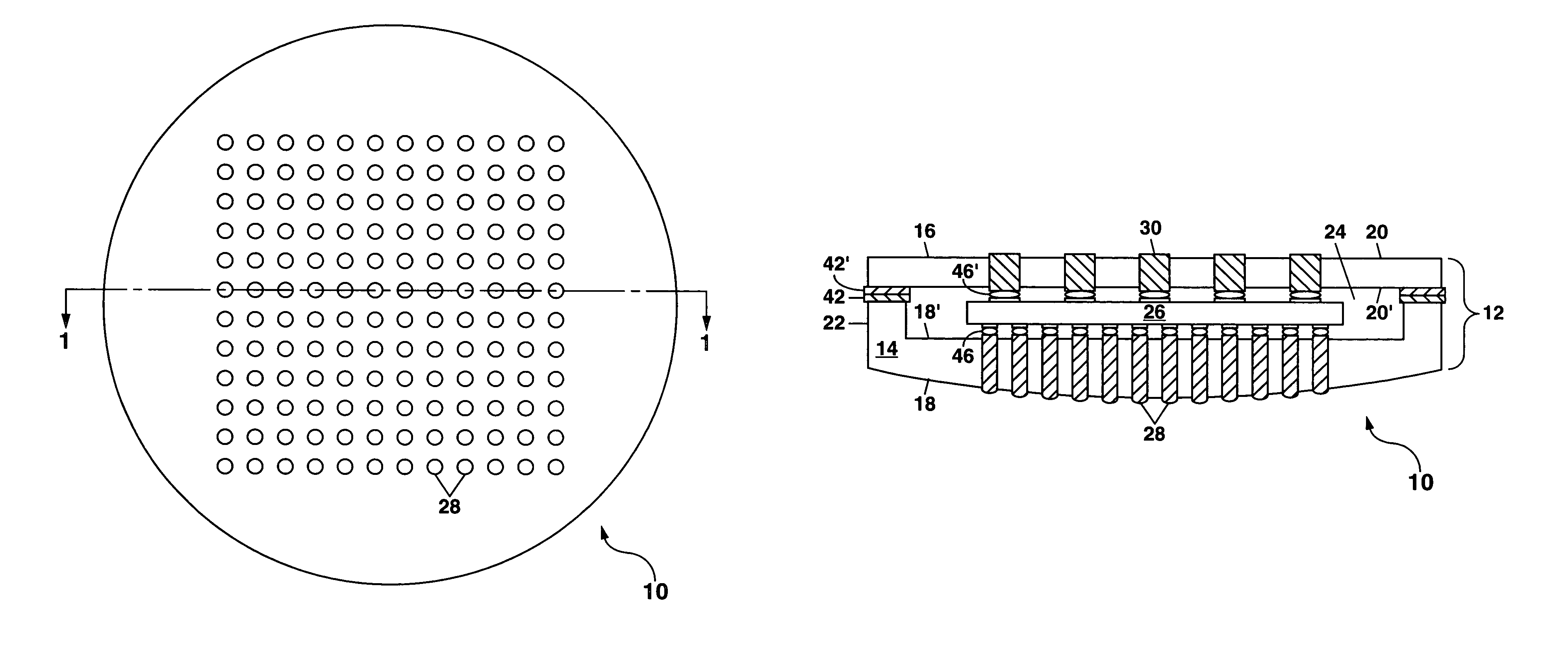

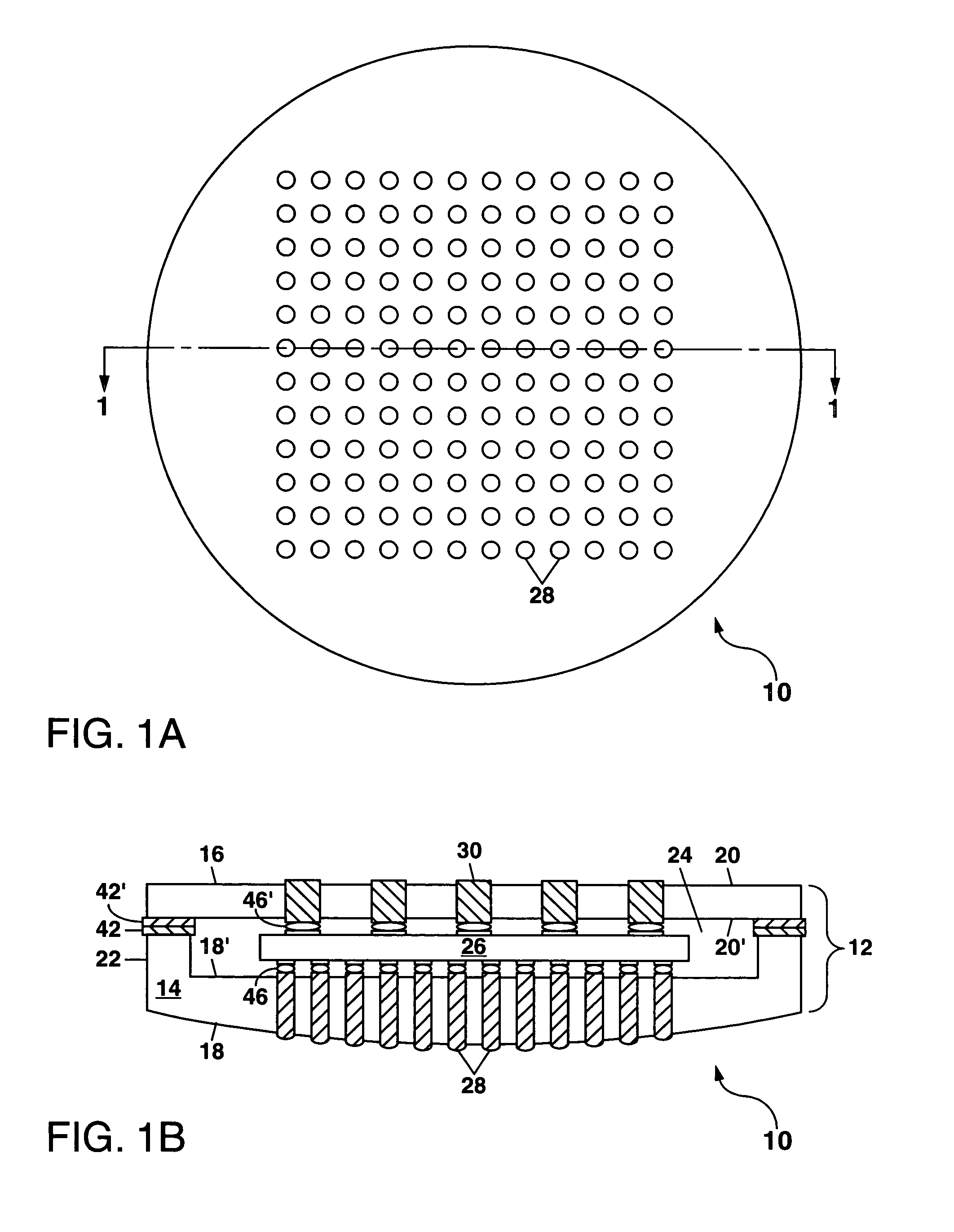

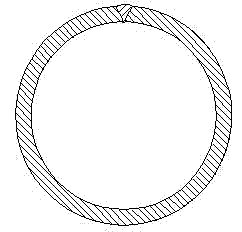

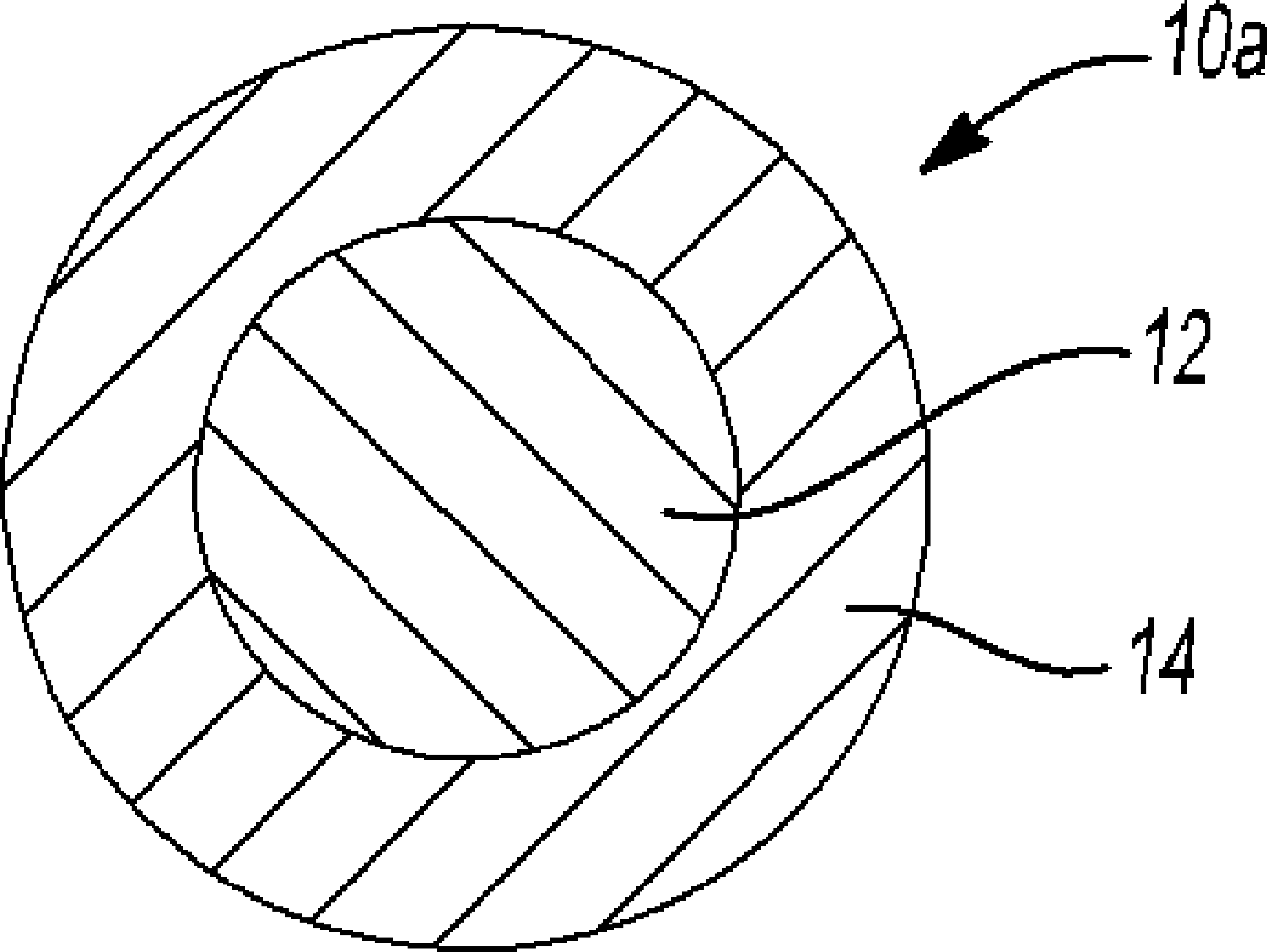

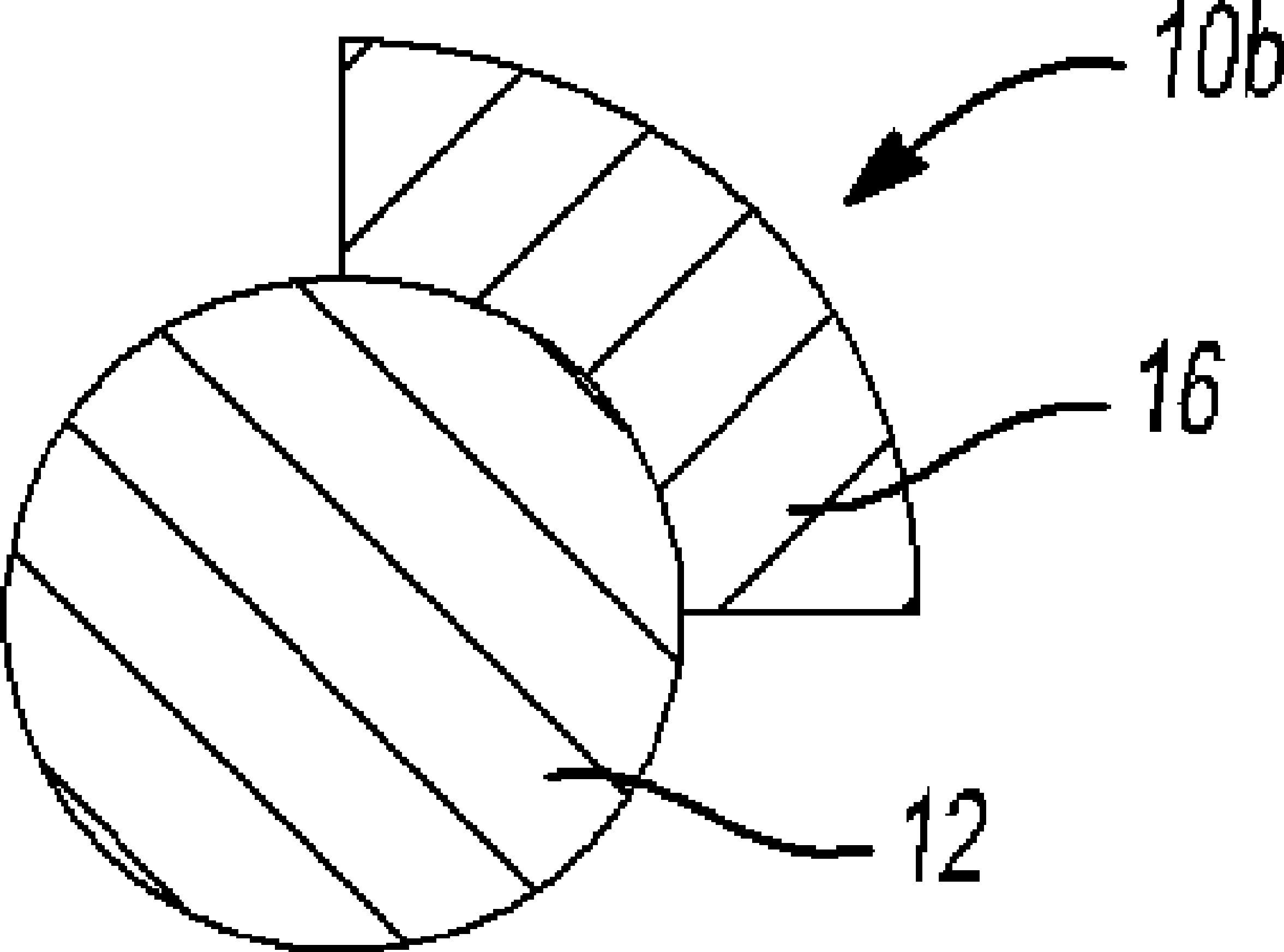

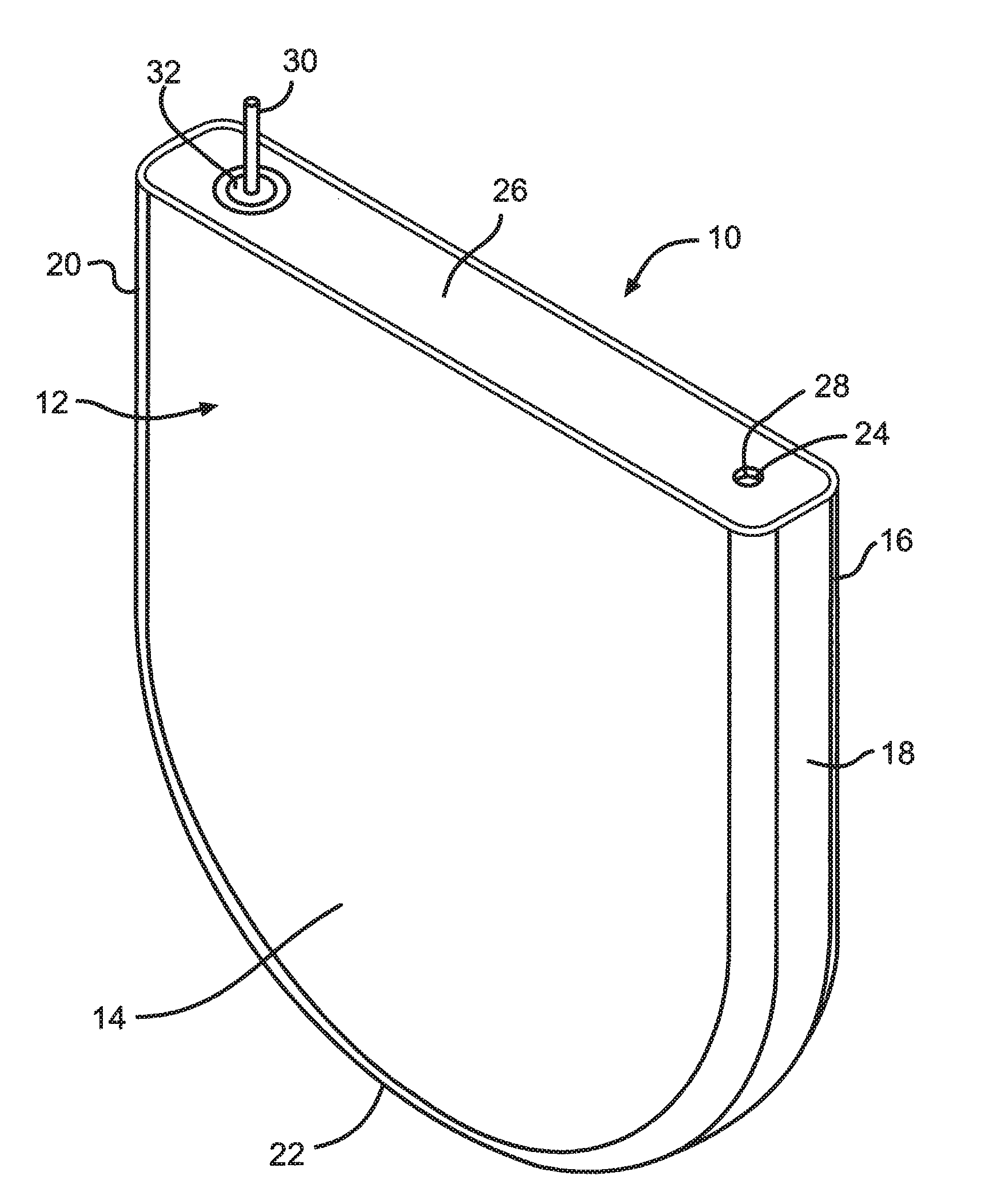

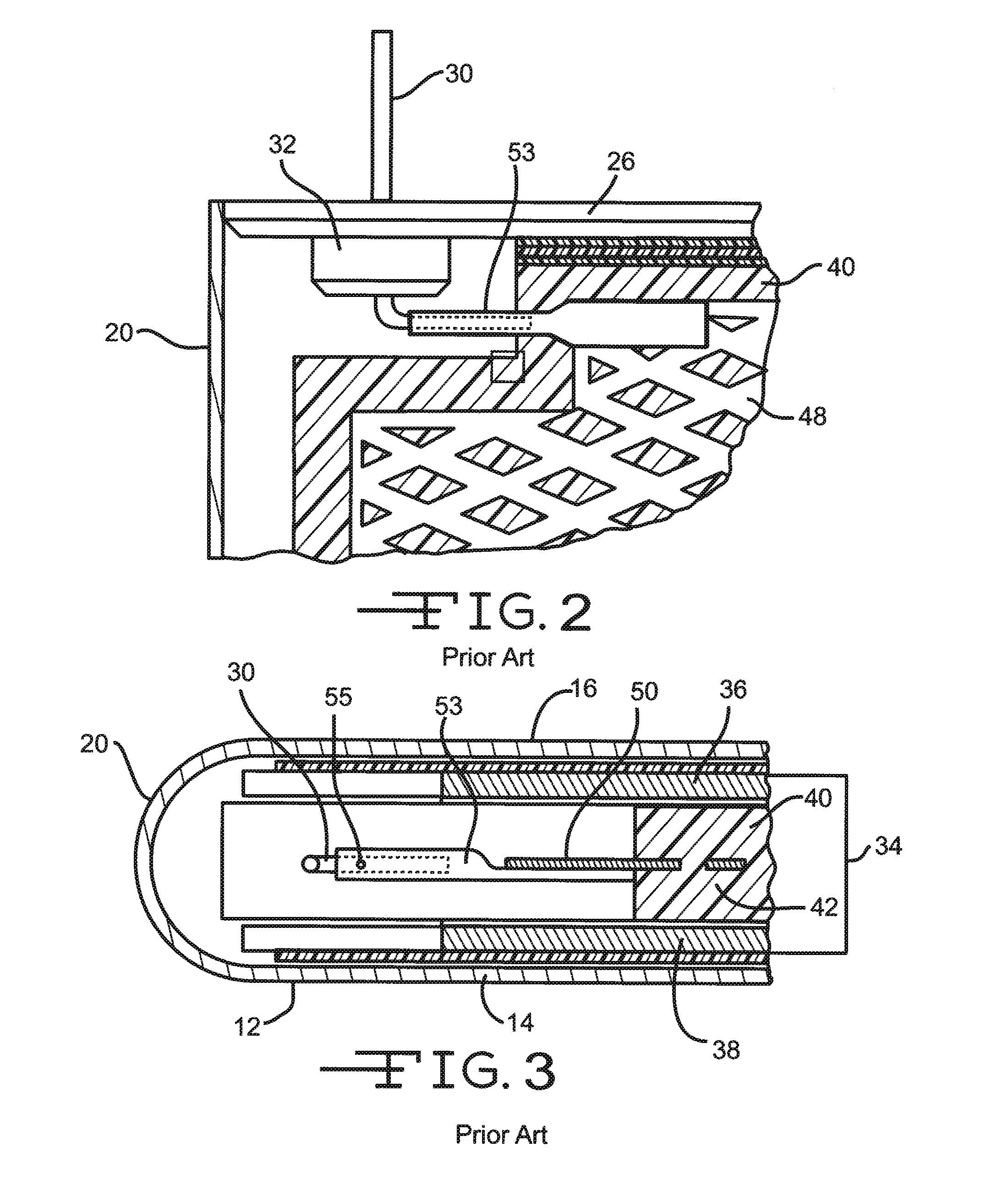

Electrode array for neural stimulation

An electrode array for neural stimulation is disclosed which has particular applications for use in a retinal prosthesis. The electrode array can be formed as a hermetically-sealed two-part ceramic package which includes an electronic circuit such as a demultiplexer circuit encapsulated therein. A relatively large number (up to 1000 or more) of individually-addressable electrodes are provided on a curved surface of a ceramic base portion the electrode array, while a much smaller number of electrical connections are provided on a ceramic lid of the electrode array. The base and lid can be attached using a metal-to-metal seal formed by laser brazing. Electrical connections to the electrode array can be provided by a flexible ribbon cable which can also be used to secure the electrode array in place.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

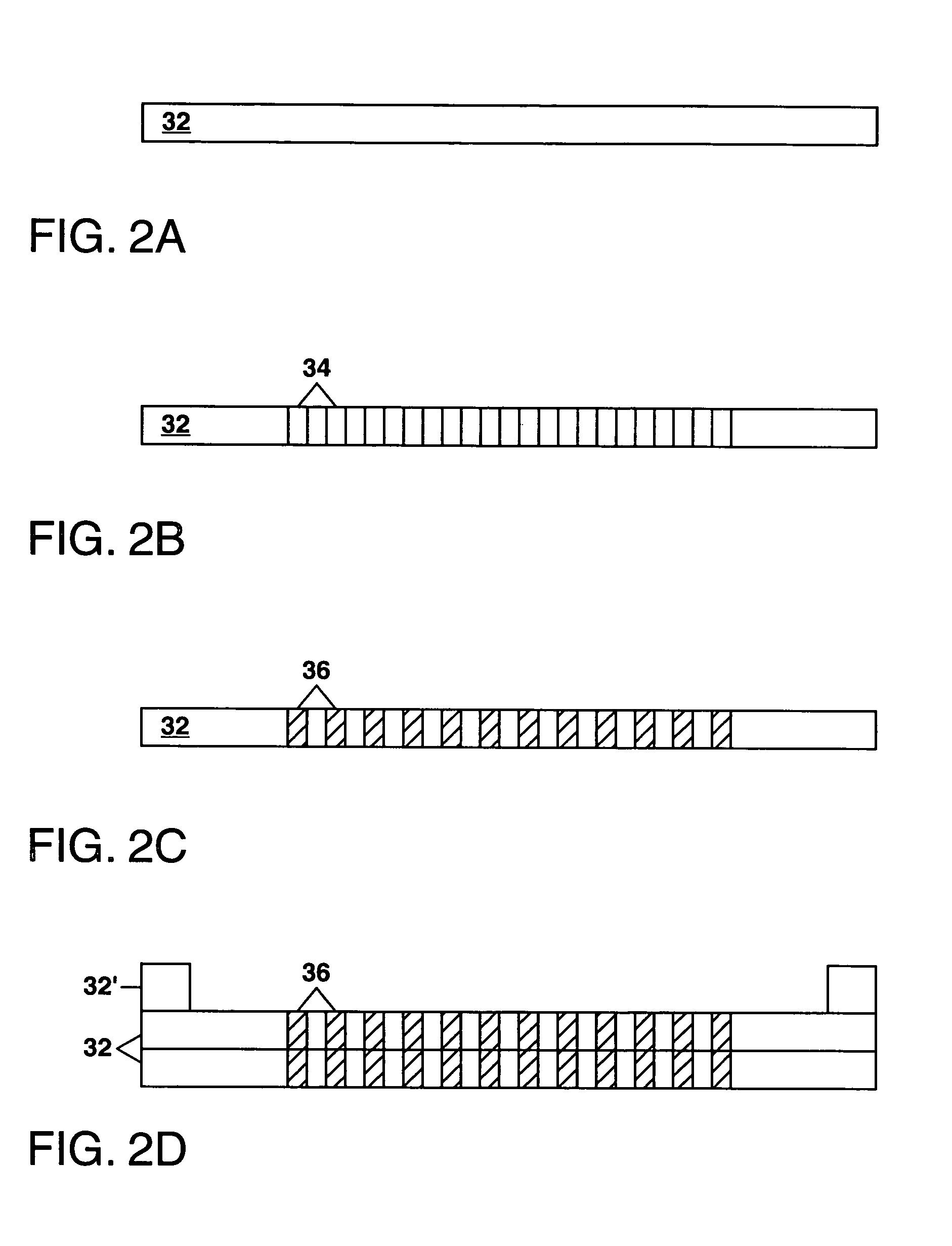

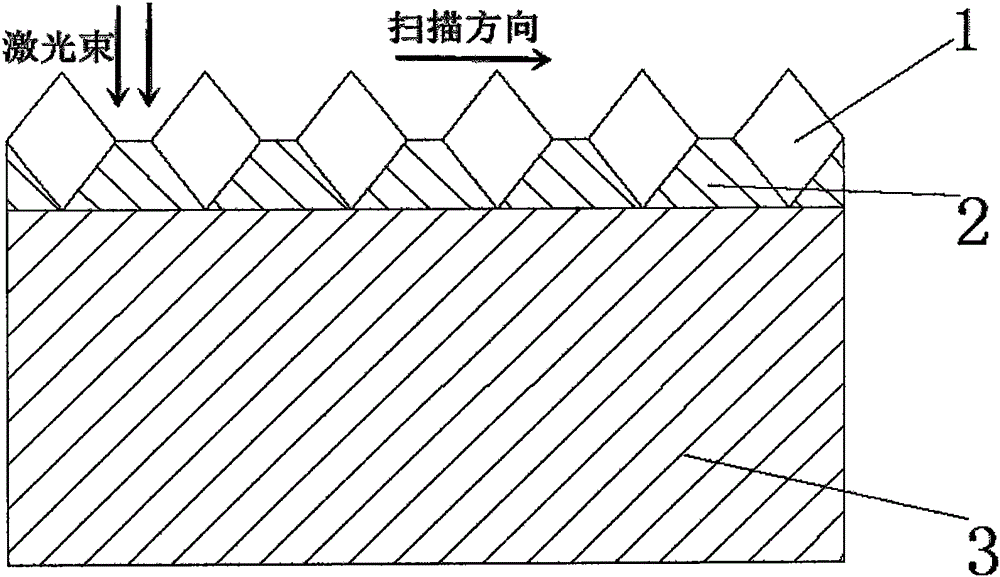

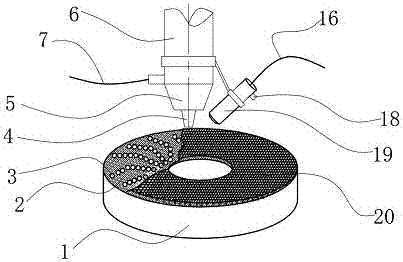

Method for manufacturing nickel base brazing filler metal laser braze welding diamond abrasive grain

ActiveCN101130213ASolve problems such as limited sizeWelding/cutting media/materialsWelding/soldering/cutting articlesFiller metalCo2 laser

The invention discloses a preparing method of nickel-based solder laser brazed diamond abrasive particle in the high temperature brazing technical domain, which comprises the following steps: adopting 45-steel base, nickel base solder and non-coat diamond; placing the manufactured 45-steel base and non-coat diamond in the organic solvent to do ultrasonic wave cleaning; preparing the manufactured sample of three-layered 45-steel base, nickel base solder and non-coat diamond sequently; brazing the sample on the solder equipment with CO2 laser, numeral control machine and gas protective device; heating the nickel-based solder through heating to connect base and diamond strictly. The invention solves some insufficiencies in the high-temperature brazing technique with high manufacturing efficiency, which is easy to control for automation manufacturing.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

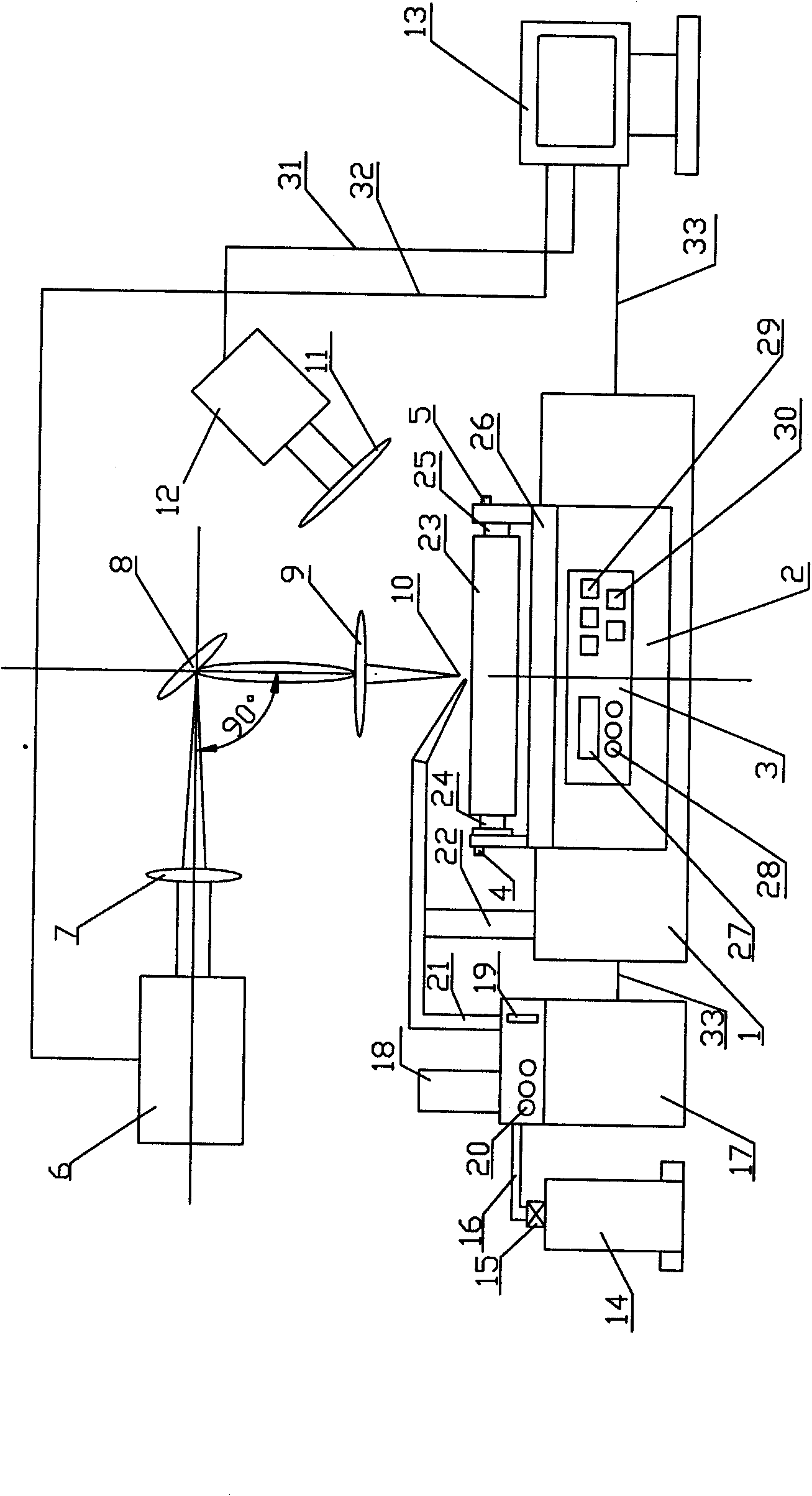

Manufacturing method of copper-based brazing filler metal laser brazing cubic boron nitride grinding particles

ActiveCN105195845AImprove cutting performanceReduce manufacturing costWelding/cutting media/materialsSoldering mediaNumerical controlHeat-affected zone

The invention discloses a manufacturing method of copper-based brazing filler metal laser brazing cubic boron nitride grinding materials. The method particularly comprises the following steps that 1, a 45 steel substrate and CBN grinding particles are put in organic solvent, and deoiling and decontamination treatment are conducted through an ultrasonic cleaning method; 2, copper-based brazing filler metal is laid on the 45 steel substrate, and the CBN grinding particles are orderly distributed on the brazing filler metal; 3, a sample to be added is put on brazing equipment composed of a CO2 laser device, a numerical control machining tool and a gas shielding device, the copper-based brazing filler metal is heated and melted through laser which has certain frequency and is emitted by the CO2 laser device, and the brazing filler metal has good infiltration property on the steel substrate and the CBN grinding particles. According to the manufacturing method of the copper-based brazing filler metal laser brazing cubic boron nitride grinding materials, the manufacturing cost is low, brazing CBN particle grinding is conducted through laser, the energy density is high, the speed of increasing and decreasing the temperature is high, local heating can be achieved, a heat-affected zone is small, and heat damage is not prone to occurrence; laser beams can be transmitted through optical fibers, machining can almost be conducted on any brazing parts, and the flexibility is better.

Owner:HENAN POLYTECHNIC UNIV

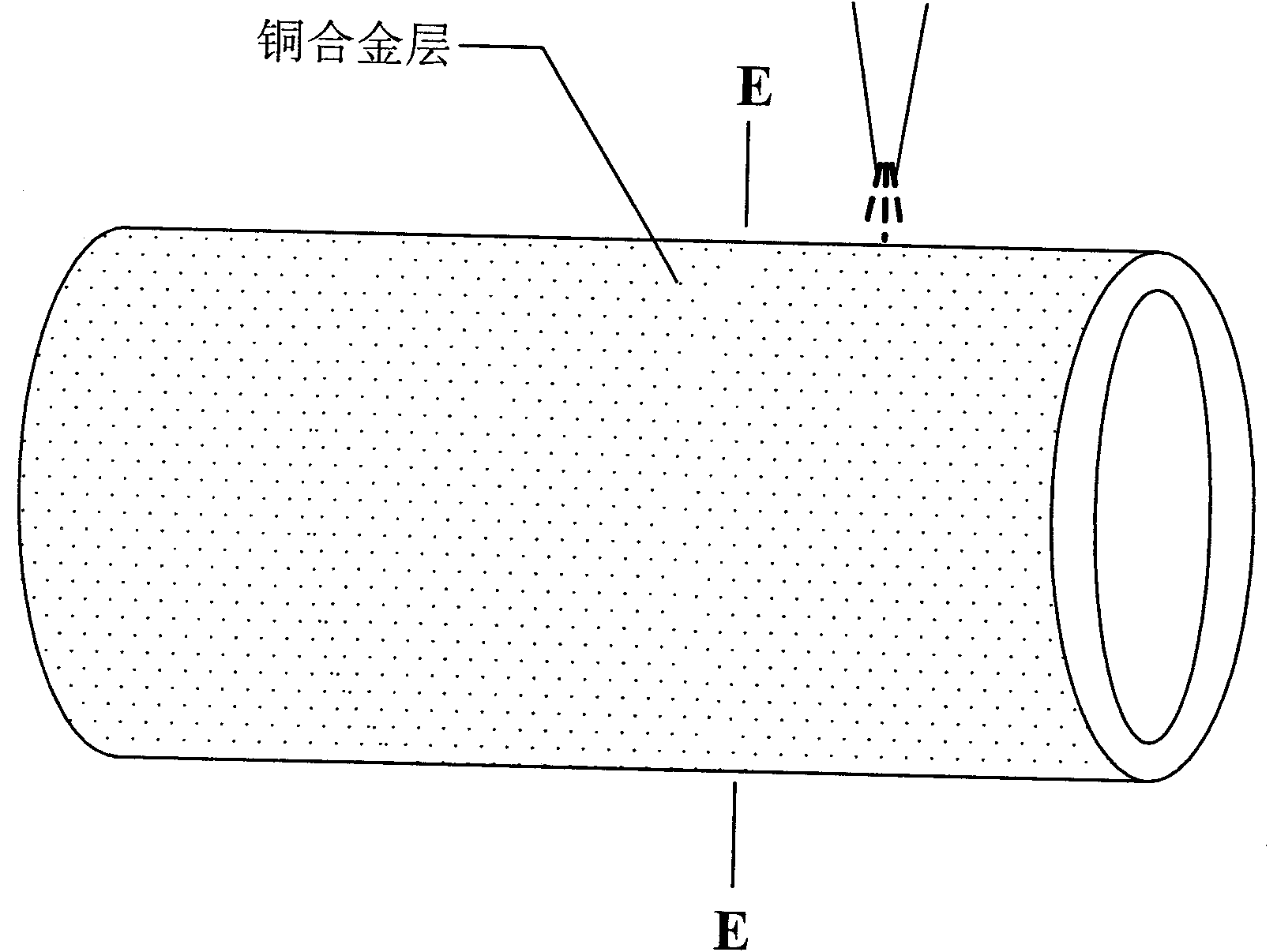

Method for cladding copper alloy layer on surface of steel substrate by laser brazing

InactiveCN101805903ATightly bondedImprove bindingMetallic material coating processesWear resistanceHeat treated

The invention relates to a method for cladding a copper alloy layer on the surface of a steel substrate by laser brazing. A method of feeding powder by argon gas, cladding by laser brazing and vacuum heat treatment is used on a laser machine for cladding a copper alloy layer on the surface of the steel substrate by laser brazing; the laser machine is used for remelting and curing the surface of the steel substrate firstly; and laser beams irradiate in all directions according to the geometric locus of ring steel set by computer programs to enable copper alloy powder and borax powder to be melted and cured on the surface of the steel substrate to form the copper alloy layer. The thickness of the copper alloy layer is 0.5mm; the average microhardness of the copper alloy layer is 375HV0.2 which is 2 times of the average microhardness of the steel substrate; and compared with the steel substrate, the wear resistance of the copper alloy layer is improved by 52.8%, and the corrosion resistance of the copper alloy layer is improved by 45.3%. The method has advanced processes and reasonable parameters; the metallographic structure of the cured and melted layer is compact and firm and can not fall off easily; and the method can be used for cladding alloy layers on the surfaces of steel substrates of various molded surfaces by brazing and can be used for cladding alloy layers on various molded surfaces and special-shaped non-standard molded surfaces, thereby greatly improving the performance of the surfaces of the steel substrates.

Owner:TAIYUAN UNIV OF TECH

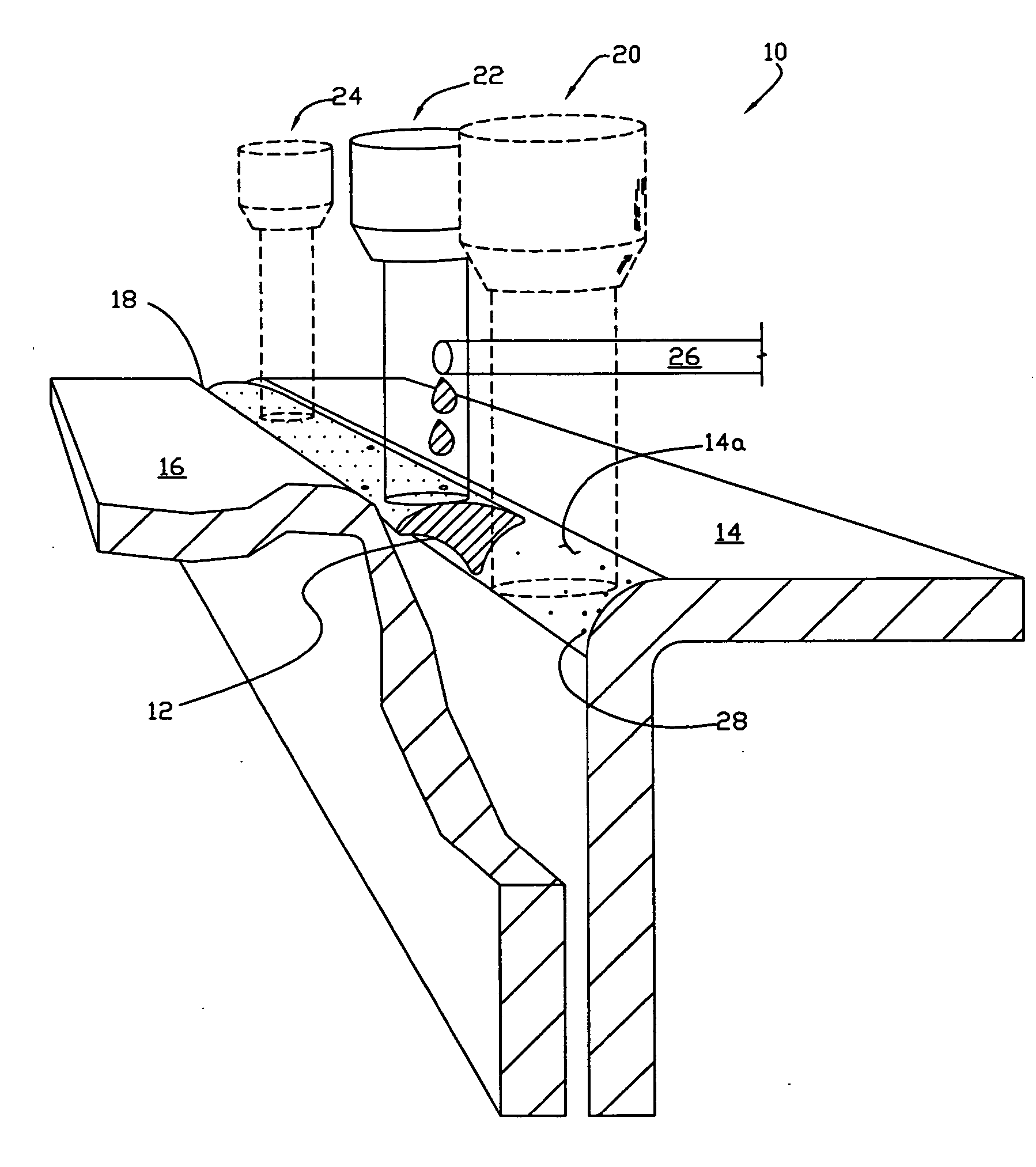

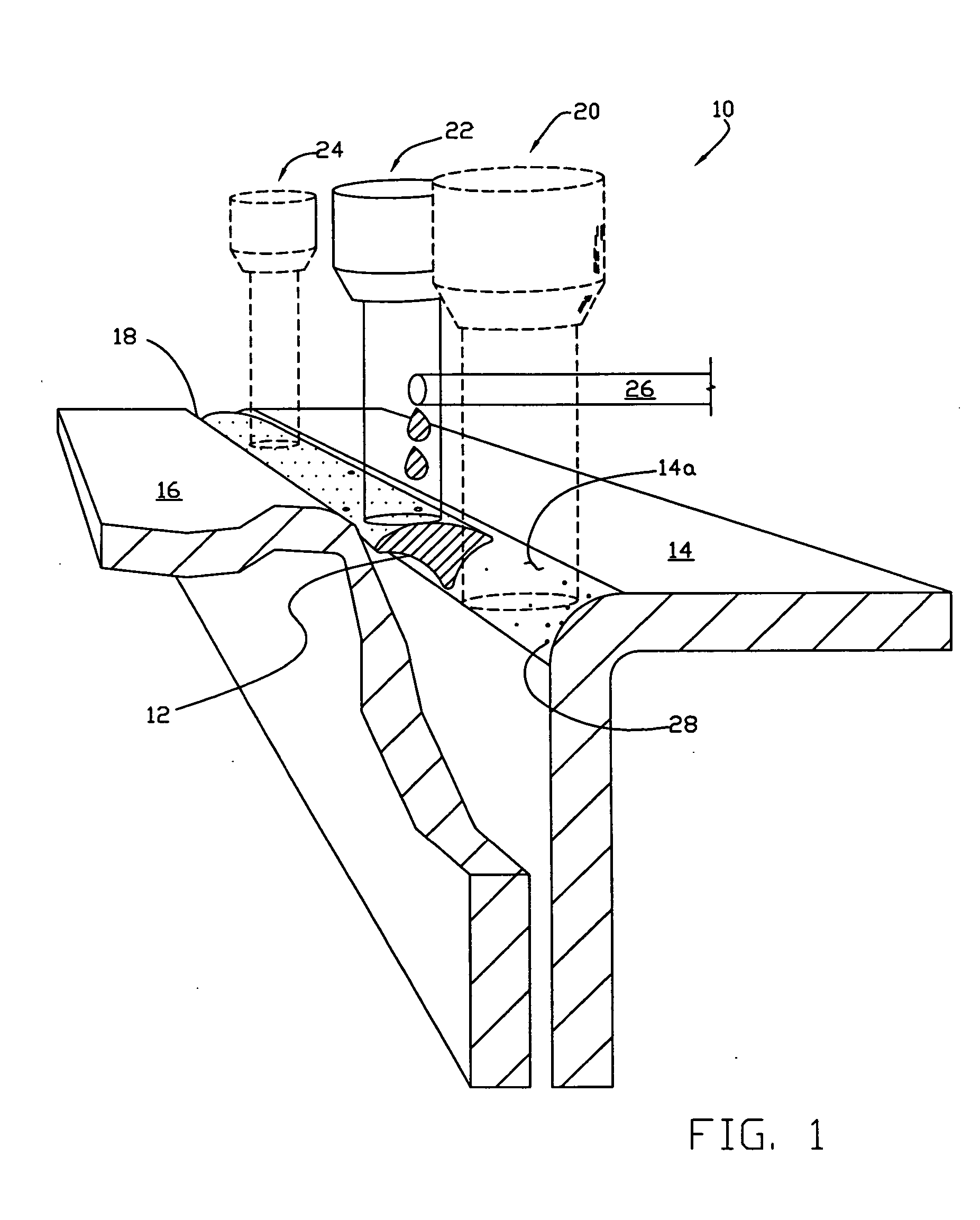

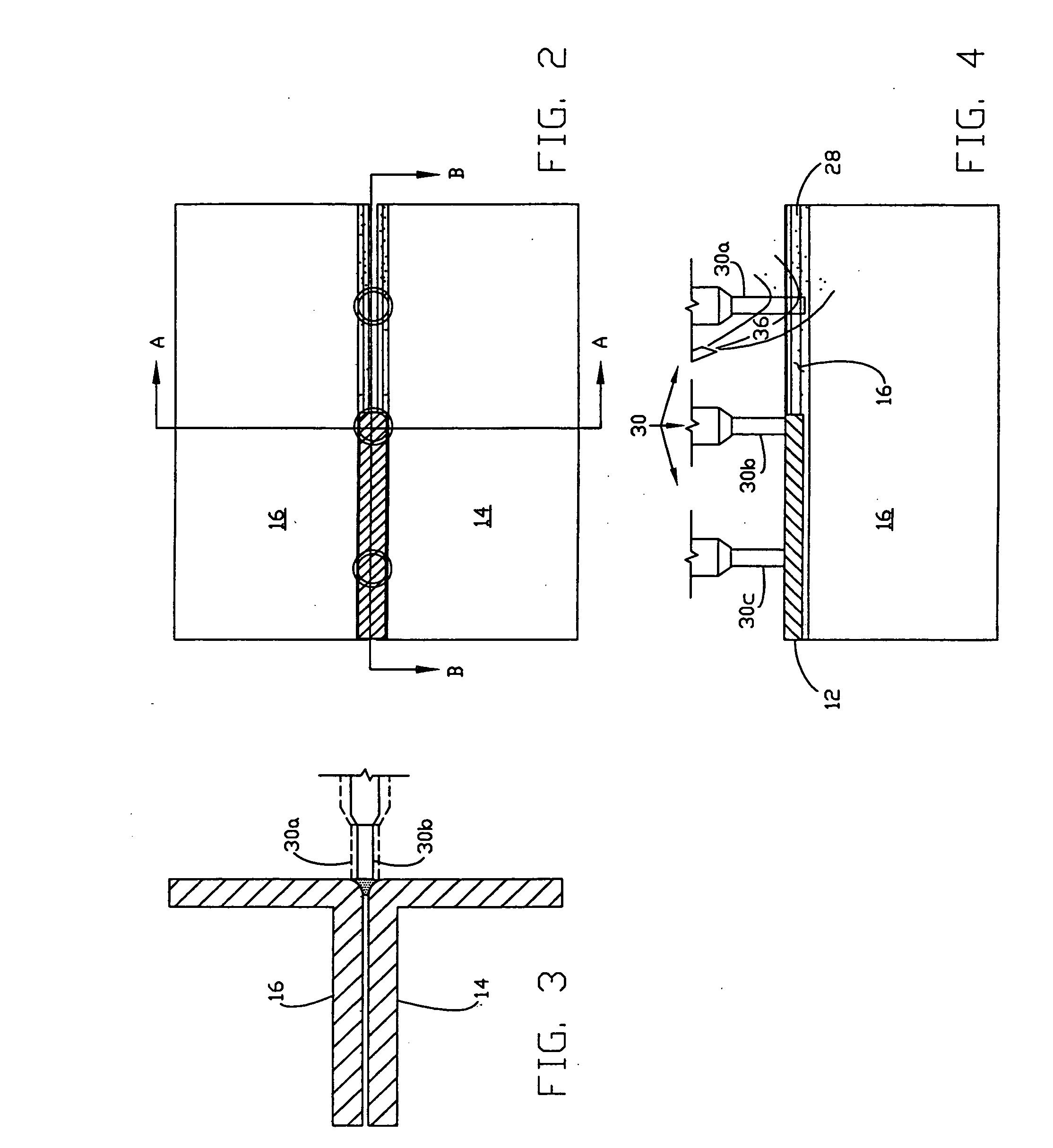

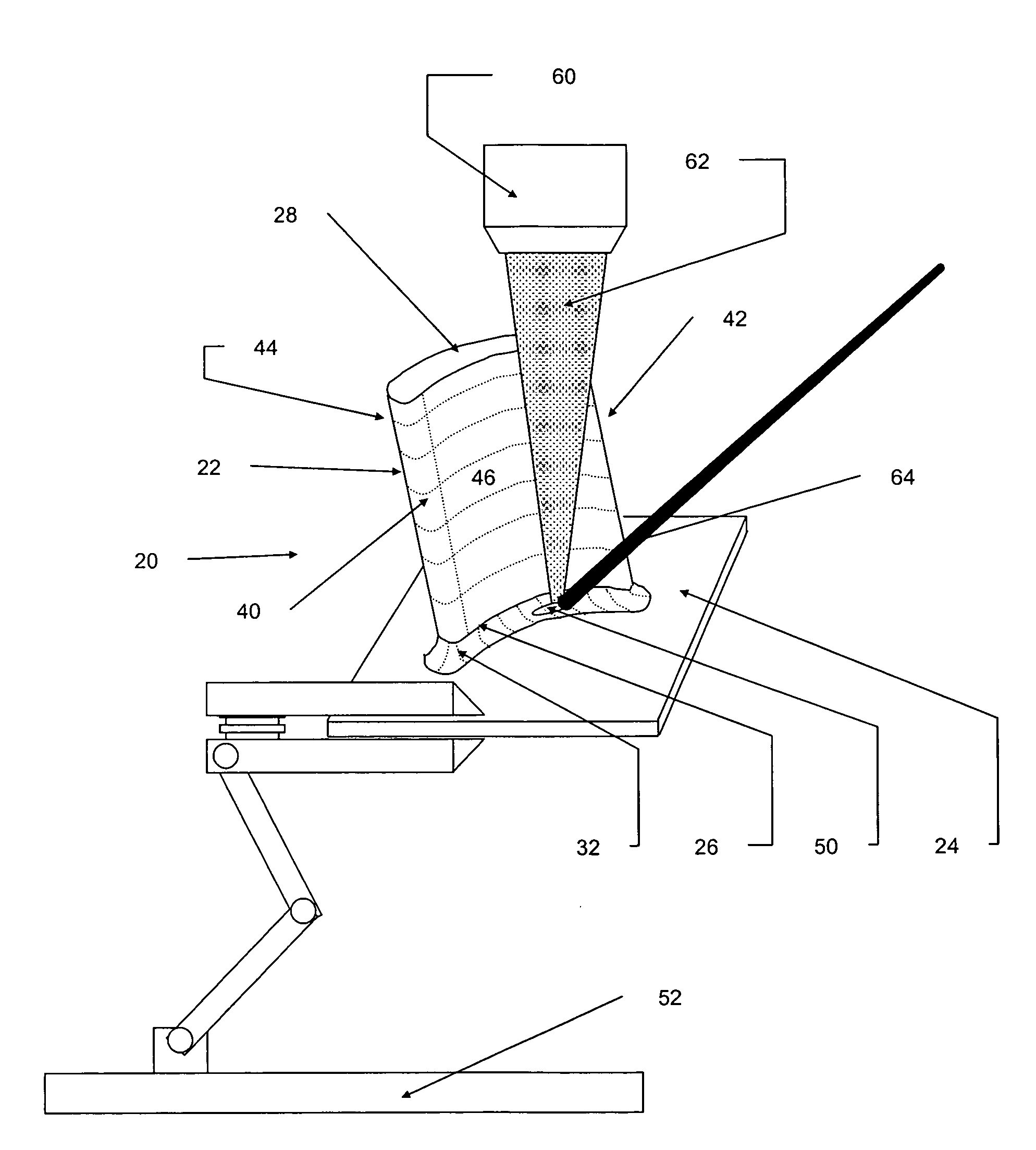

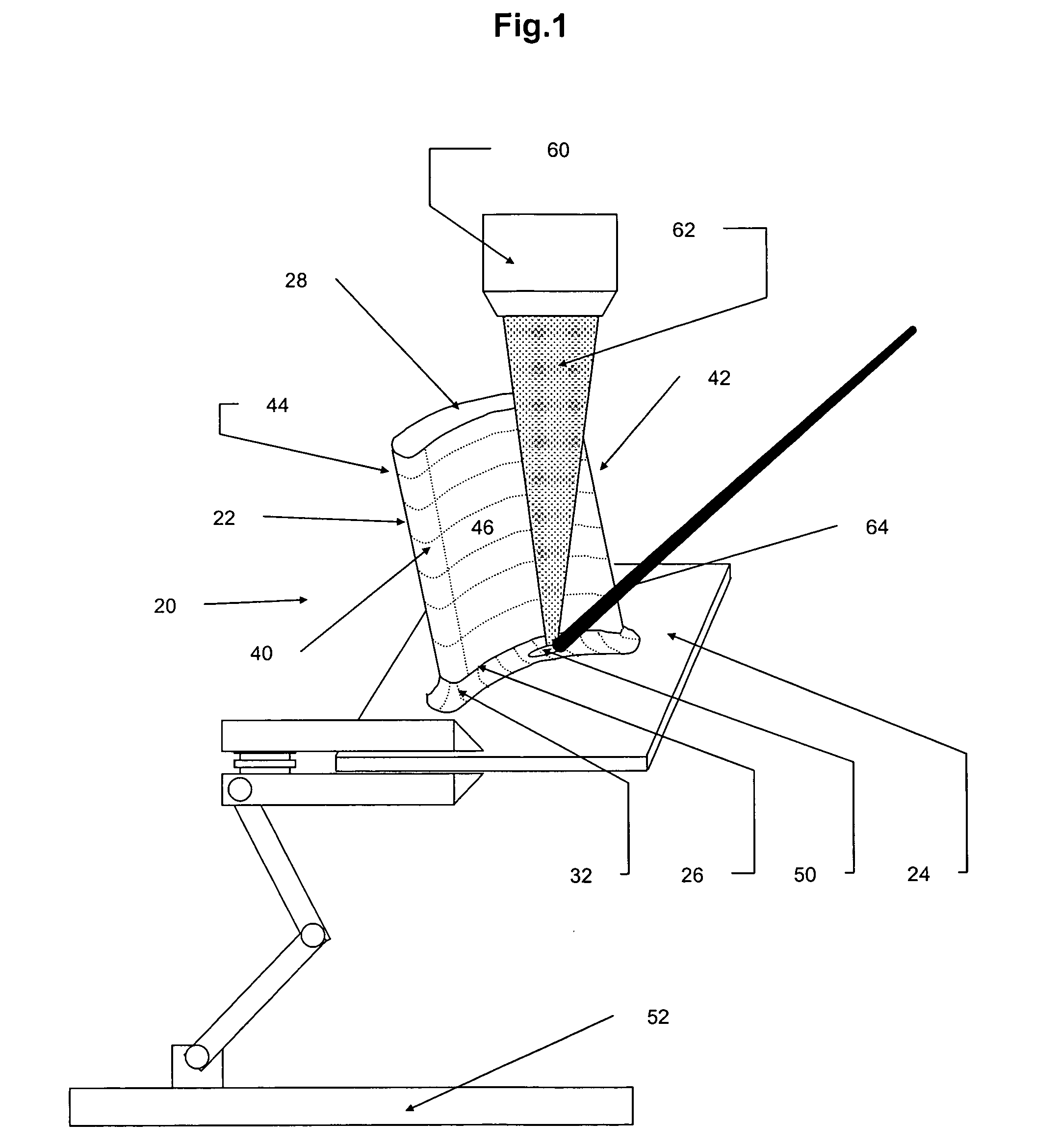

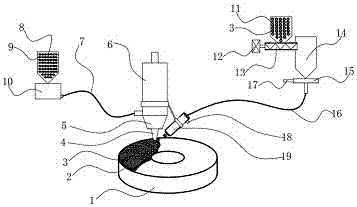

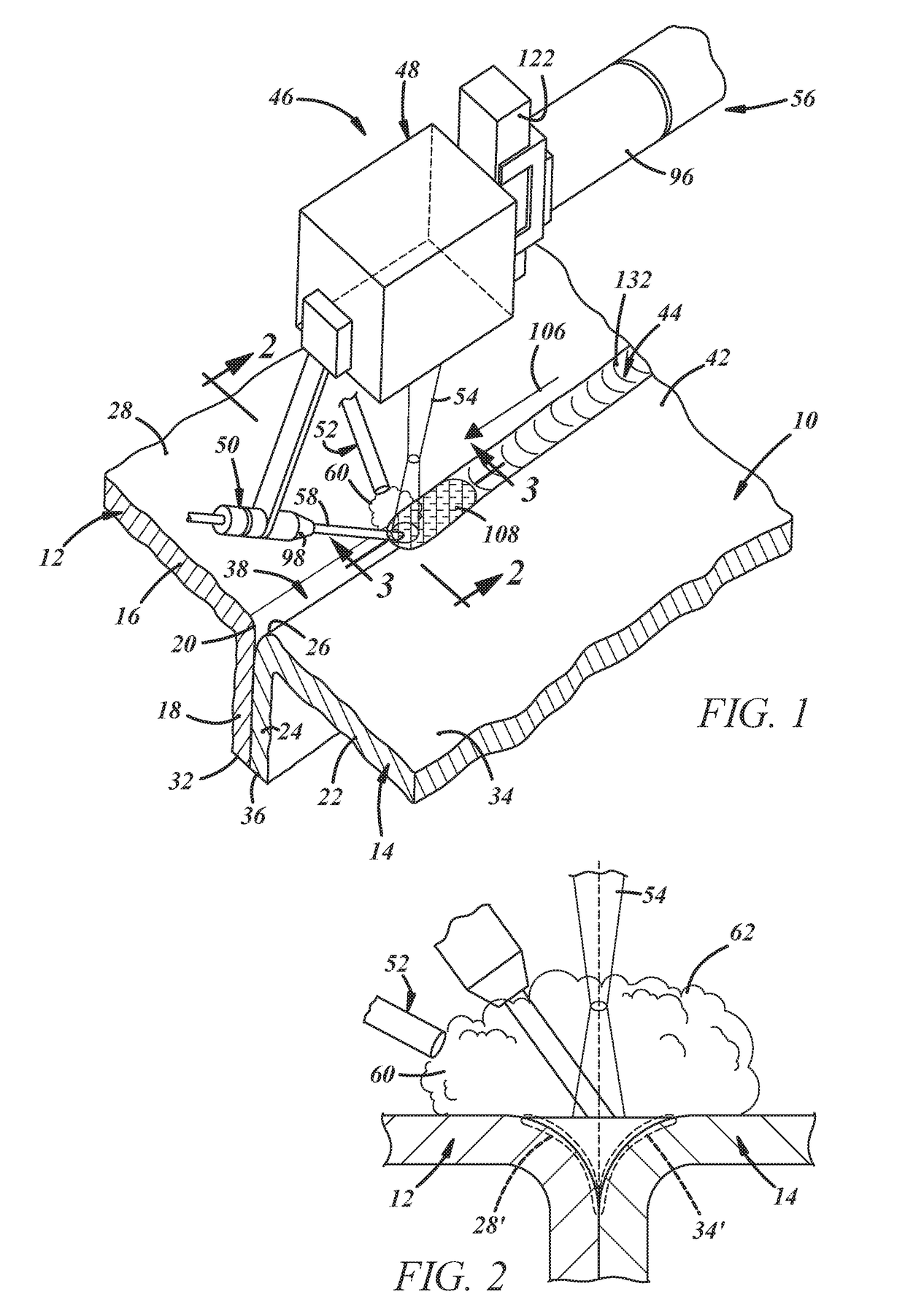

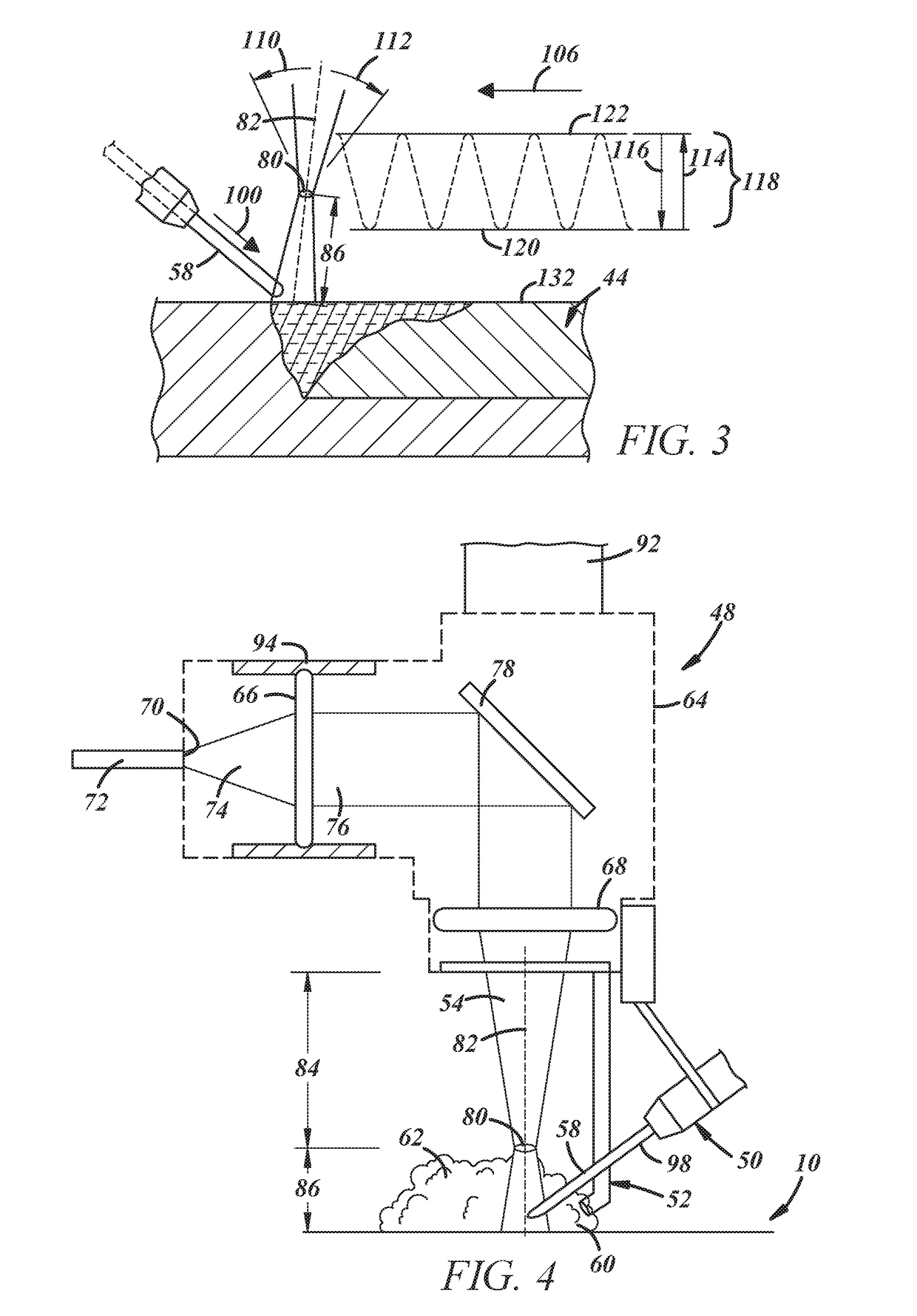

Multi-heat source laser brazing system and method

InactiveUS20060261045A1Reduce the possibilityLow costSoldering apparatusMetal working apparatusPorosityOptoelectronics

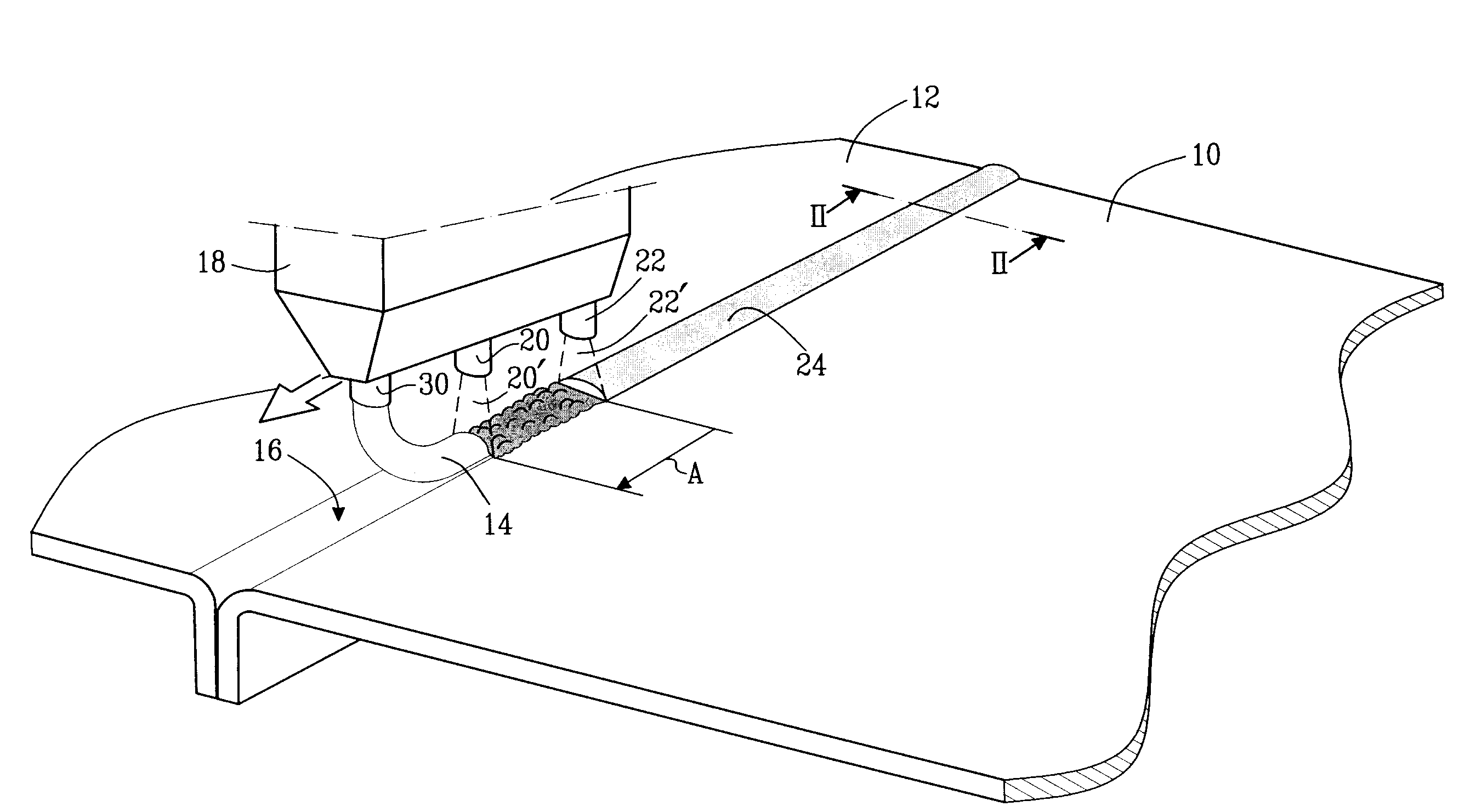

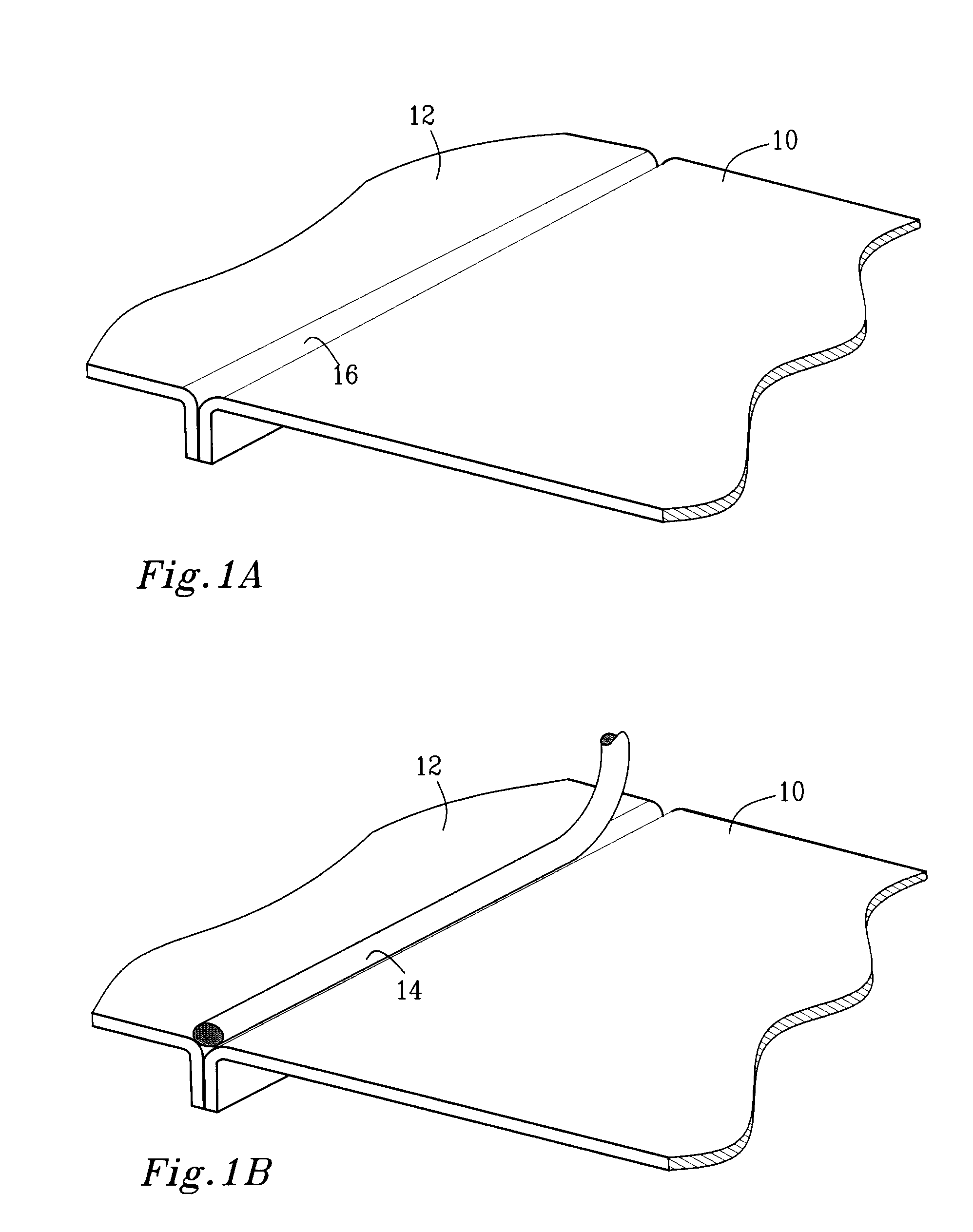

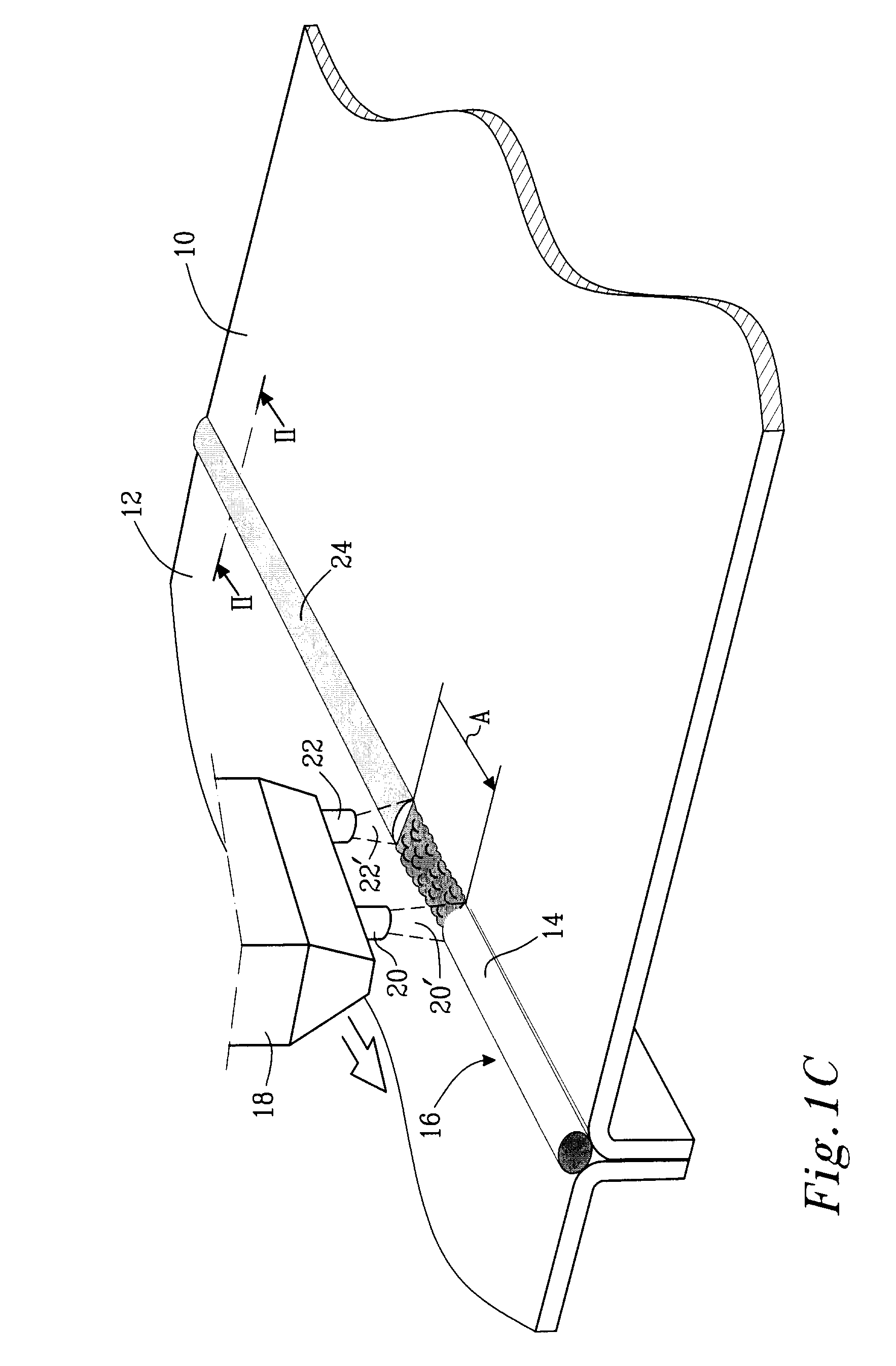

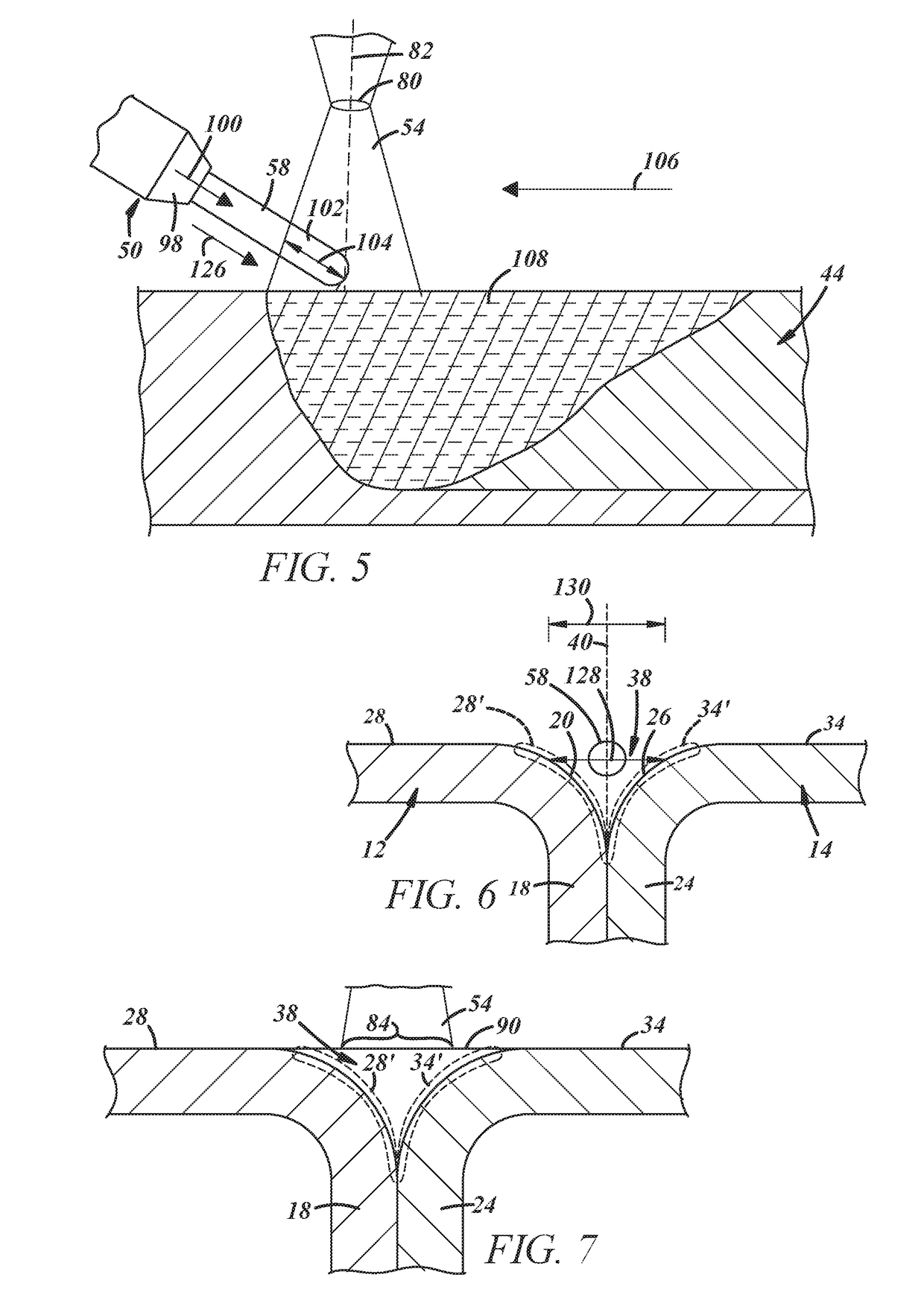

An improved brazing system having a plurality of heat sources is adapted for brazing in tandem a plurality of adjacent workpieces and for reducing porosity in the braze joint. The system preferably includes a first laser beam that engages the workpieces to vaporize surface contaminants thereupon, a second laser beam configured to melt the brazing material, and a third laser beam configured to further heat the material, so as to extend the thermal cycle thereof or re-melt the material.

Owner:GM GLOBAL TECH OPERATIONS LLC

Welding method of laser brazing of X 80 pipeline steel

ActiveCN103192149AAvoid multiple processesUniform preheating effectSoldering apparatusWedge angleEnergy dispersion

The invention relates to a welding method of laser brazing of X 80 pipeline steel and belongs to the advanced manufacturing technology field. High energy laser source is utilized as unified preheating light source and welding light source to perform steps which comprises laser-bounce, transverse beam splitting, energy distribution and inward refocusing are performed on laser through a reflecting mirror, a spectroscope and a focusing mirror, the purpose of laser transverse beam energy distribution is achieved by adjusting the position of the spectroscope, distance between a front laser beam and a rear laser beam is adjusted by adjusting the size of a wedge angle of the spectroscope to form into the front laser beam and the rear laser beam, the front laser beam is served as a preheating light beam, the rear laser beam is served as a welding beam, and energy dispersion of the preheat light beam is performed through a concave lens when the preheating beam is utilized to preheat. The welding method of the laser brazing of the X 80 pipeline steel solves the problem that nonuniform weld microstructure caused by common welding is easy to cause electrochemical corrosion.

Owner:邳州市博睿投资管理有限公司

Brazing repairs

A first component is bulk brazed to a second component. The bulk braze joint is inspected. Responsive to the inspection locating a defect site, the joint is laser brazed at the defect site.

Owner:UNITED TECH CORP

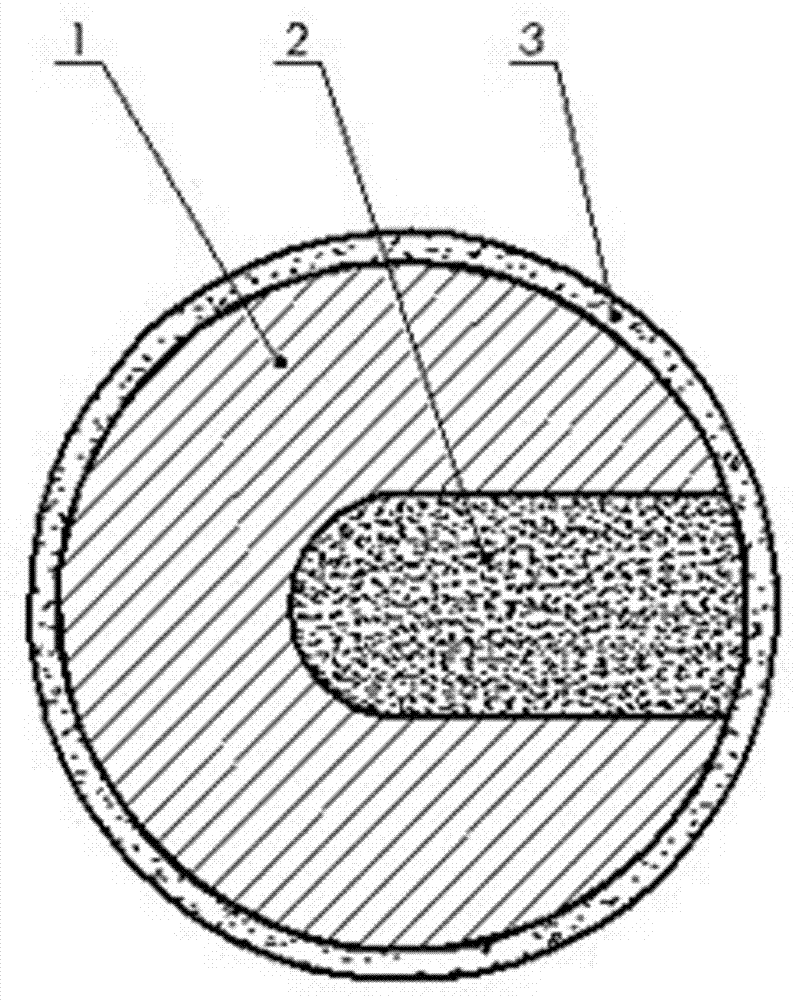

Composite aluminum-base brazing wire for continuously brazing aluminum alloy and method for manufacturing composite aluminum-base brazing wire

InactiveCN103203560AReasonable structureThe joint performance is stable and goodWelding/cutting media/materialsSoldering mediaFiller metalSilicon

The invention discloses a composite aluminum-base brazing wire for continuously brazing aluminum alloy and a method for manufacturing the composite aluminum-base brazing wire. The aluminum-base brazing wire comprises a section of aluminum-base brazing filler metal, non-corrosive brazing fluxes for aluminum and silicon powder coating layers; the section of the aluminum-base brazing filler metal is provided with grooves, the non-corrosive brazing fluxes for the aluminum are composited in the grooves of the section, and the silicon powder coating layers are coated on surfaces of the brazing fluxes; and the section side of the section of the brazing filler metal can be provided with one groove or two grooves or three grooves. The method includes smelting and casting the brazing filler metal of the brazing wire during manufacture and squeezing a blank which is a rod; manufacturing the section of the brazing filler metal of the brazing wire by means of rolling and squeezing; compositing the section of the brazing filler metal with the non-corrosive brazing fluxes for the aluminum; and coating the silicon powder coating layers on the surfaces of the composite brazing fluxes. The composite aluminum-base brazing wire and the method have the advantages that the local composite aluminum-base brazing wire for continuously brazing the aluminum alloy is suitable for intelligent brazing equipment provided with a laser brazing system, so that the intelligent brazing equipment can be used for continuously brazing various medium and large aluminum alloy structural parts with over-burning temperatures higher than 580 DEG C, the quality of brazing seams is stable, and the efficiency is high.

Owner:GUILIN QINGTONG NON FERROUS METAL ARTS & CRAFTS MATERIAL DEV CO LTD

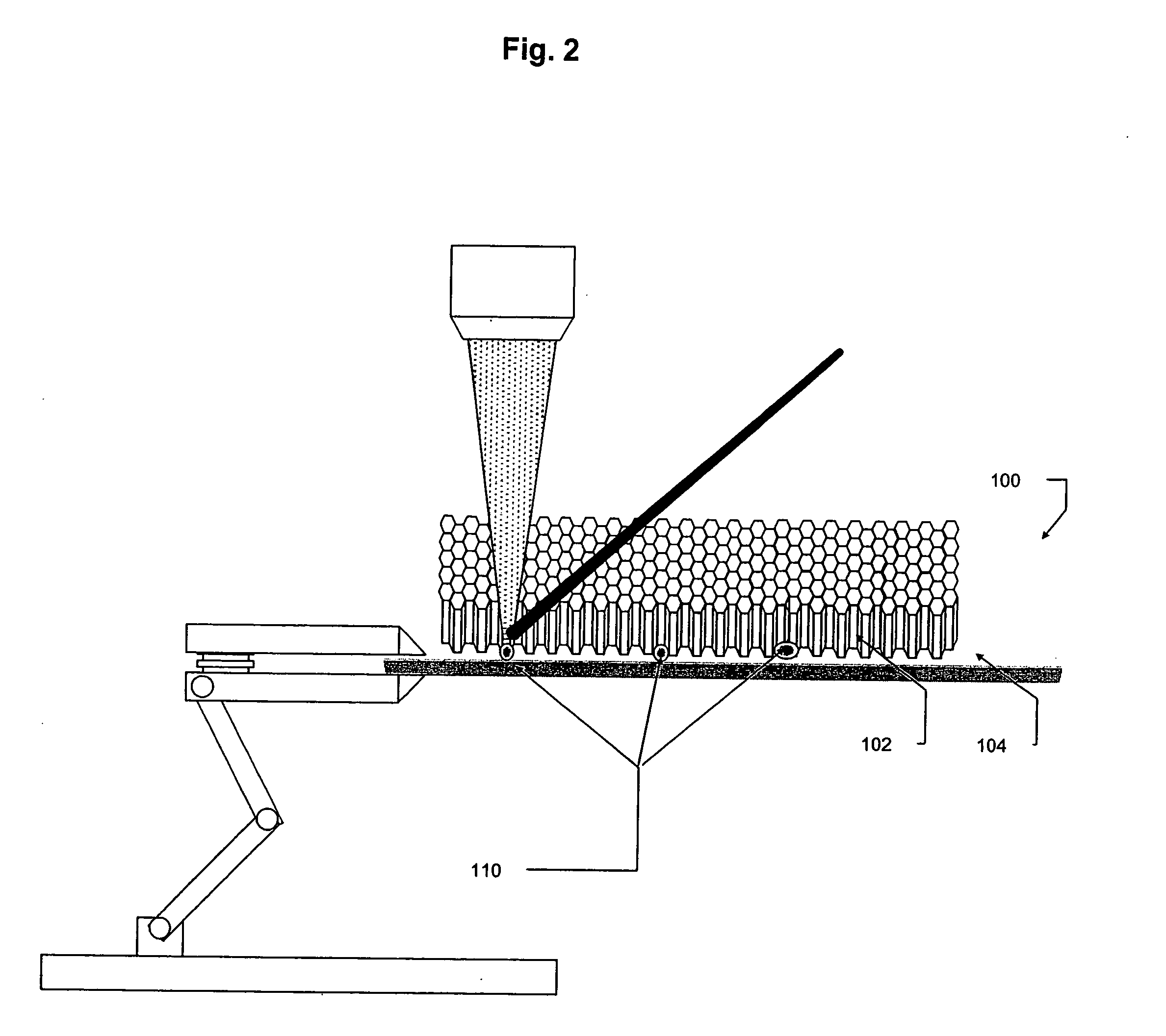

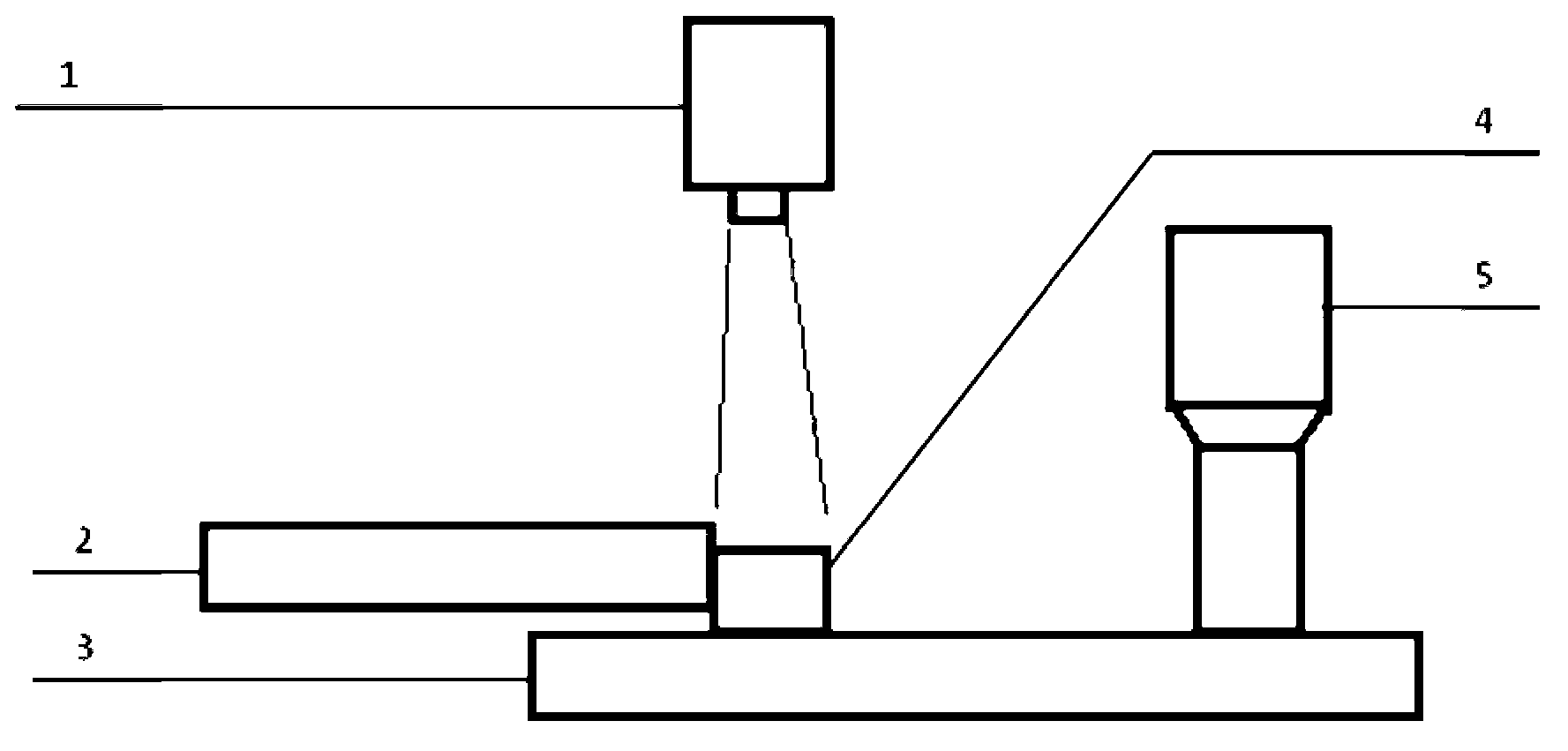

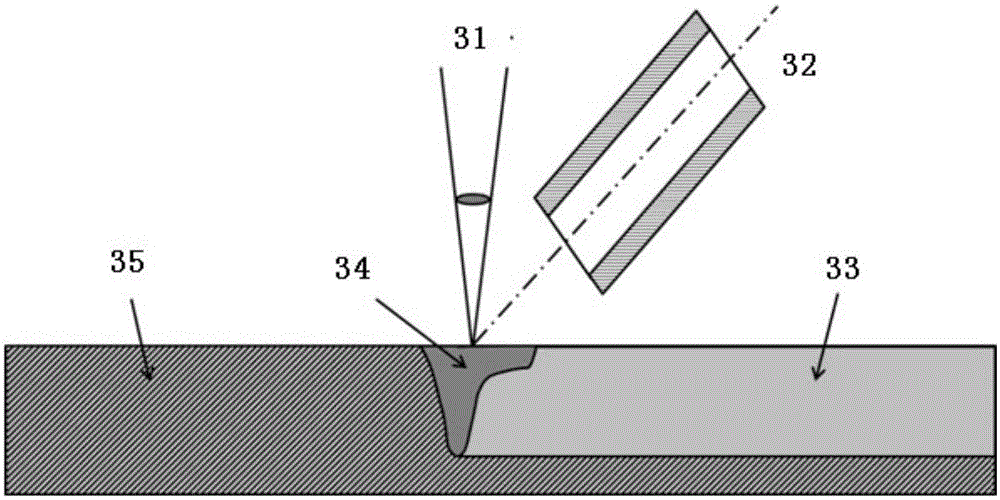

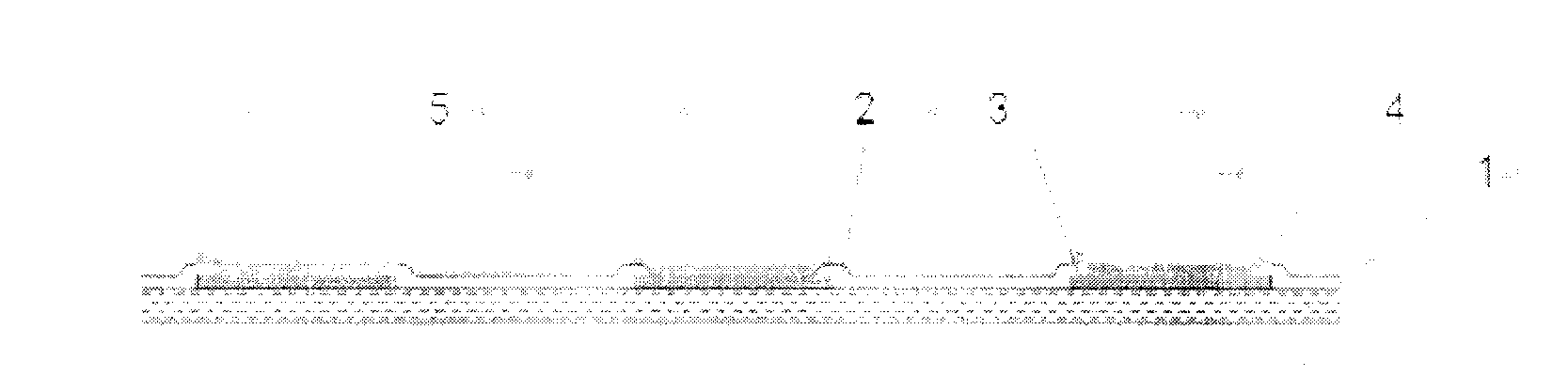

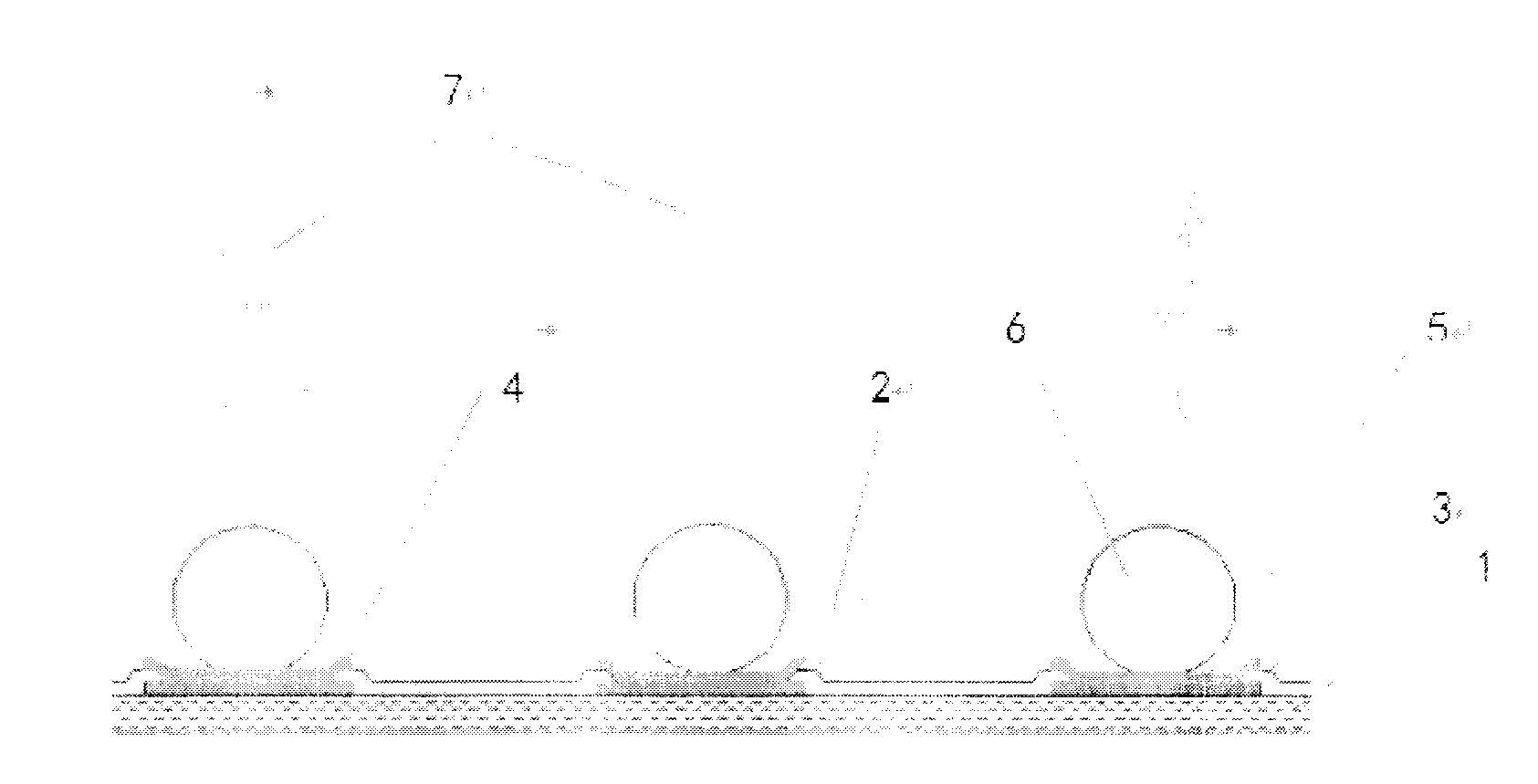

Additive manufacturing method for diamond tool

InactiveCN107150154AAvoid severe burning and oxidationAvoid graphitizationSoldering apparatusMaterials scienceLaser

The invention relates to an additive manufacturing method for a diamond tool. The method includes the steps that a diamond abrasive particle layer is formed at first; then a thin laser brazing layer is formed on the upper surface of the diamond abrasive particle layer, and the step is executed repeatedly until multiple thin laser brazing layers are formed on the upper surface of the diamond abrasive particle layer to cover diamond abrasive particles; the steps are repeated, and accordingly (N-1) laser brazing diamond abrasive particle layers are obtained; and an Nth laser brazing diamond abrasive particle layer is obtained, the laser brazing process is completed, and thus the laser brazing diamond tool with N layers of abrasive particles is prepared. The invention further relates to the diamond tool prepared through the method. According to the additive manufacturing method for the diamond tool, paraxial jet diamond abrasive particles are adopted for conducting multi-layer laser brazing, burning loss oxidation and graphitization of the diamond abrasive particles in the brazing process are avoided, the service life of a laser brazing diamond grinding wheel is prolonged, and orderly distribution and automatic production of the abrasive materials can be realized easily.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

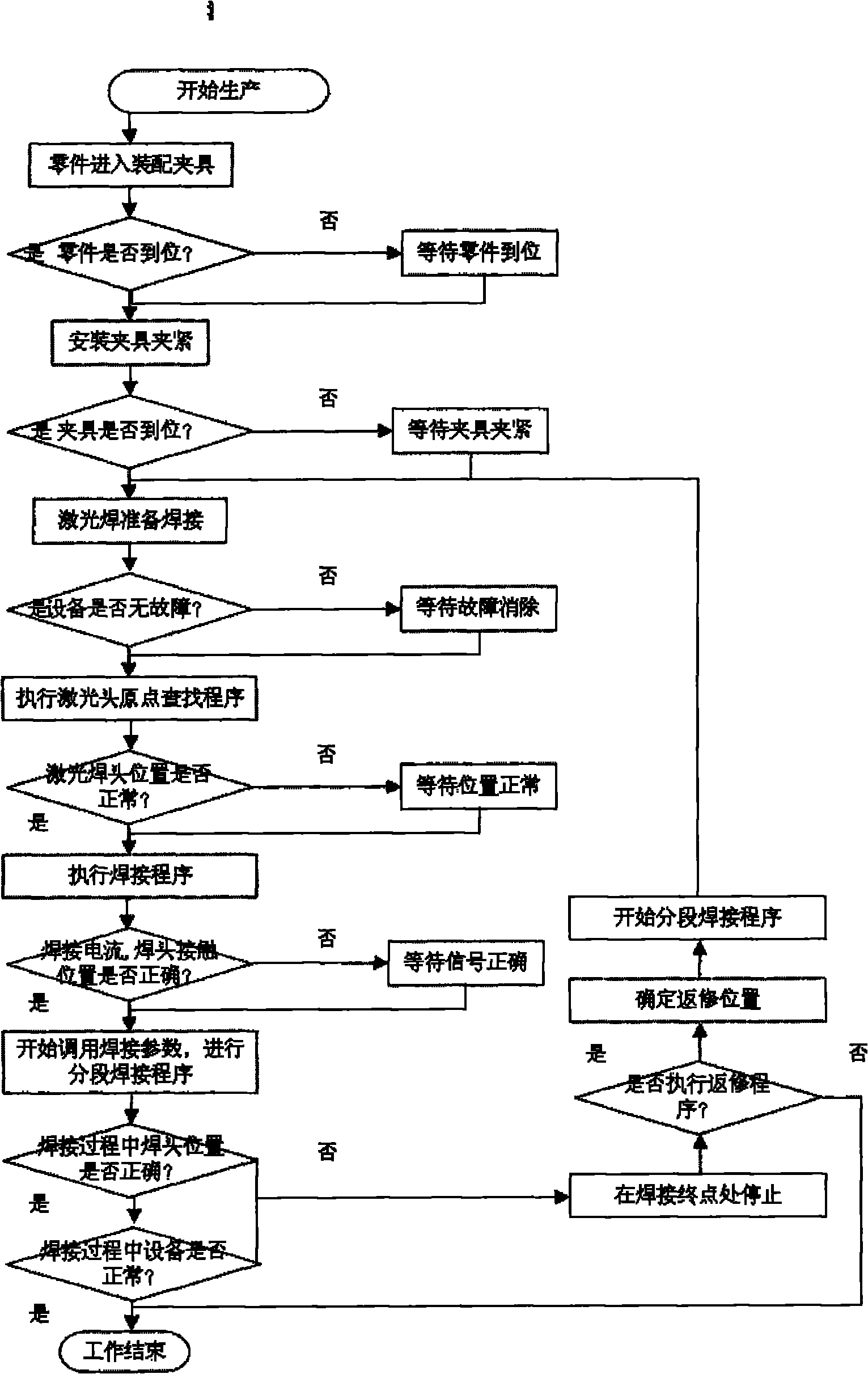

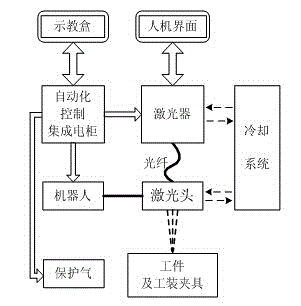

Laser brazing clearance compensation method

InactiveCN101862874AImprove assembly accuracyLow costSoldering apparatusProgramme control in sequence/logic controllersClosed loopQuality control

The invention relates to a laser brazing clearance compensation method. The method is characterized in that: subsection welding program is added into a robot program, twenty three section welding program corresponding is carried out on a welding line with the length of 1.6m, welding parameter is respectively set according to welding condition of each section of the welding line, each section of the welding line is smoothly connected by utilizing the track approaching program of robot, so that the entire three-dimensional arc welding line is smooth in appearance; and a laser welding head origin point search program, a position closed loop control program and a welding line initial point identification program are added into the robot program. The invention requires no modification on mechanical structure, improves assembly accuracy and has low cost; regulating is rapid, thus being applicable to rapid quality control and mass production; and the method is easy to popularize, and adjustment is simple.

Owner:FAW GROUP +1

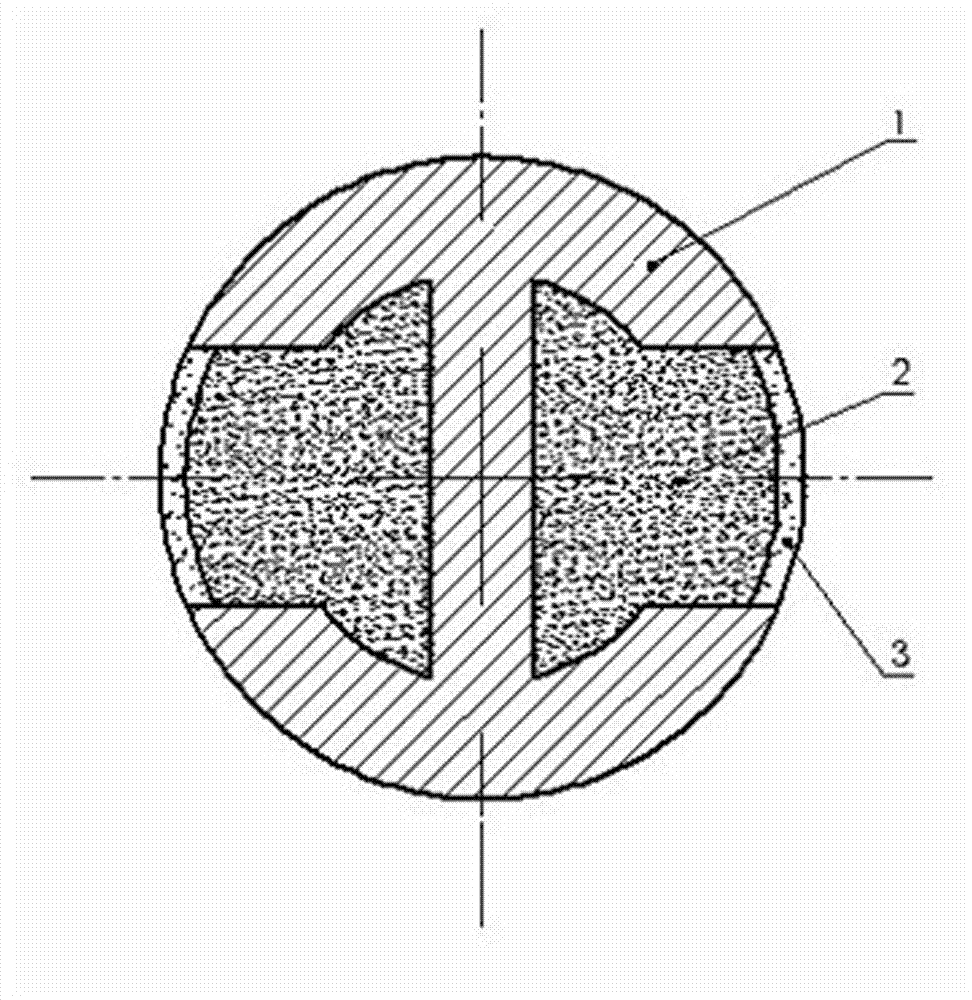

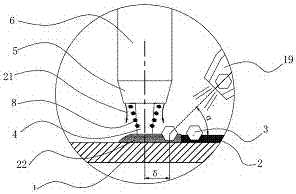

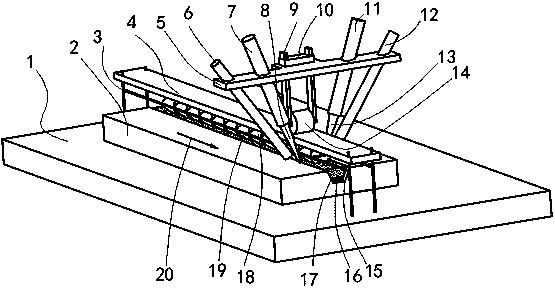

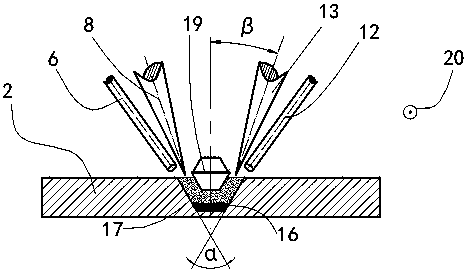

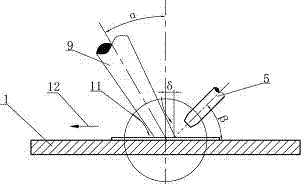

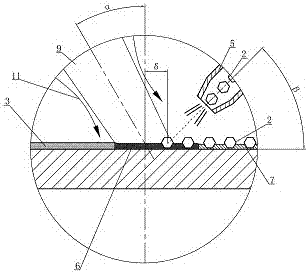

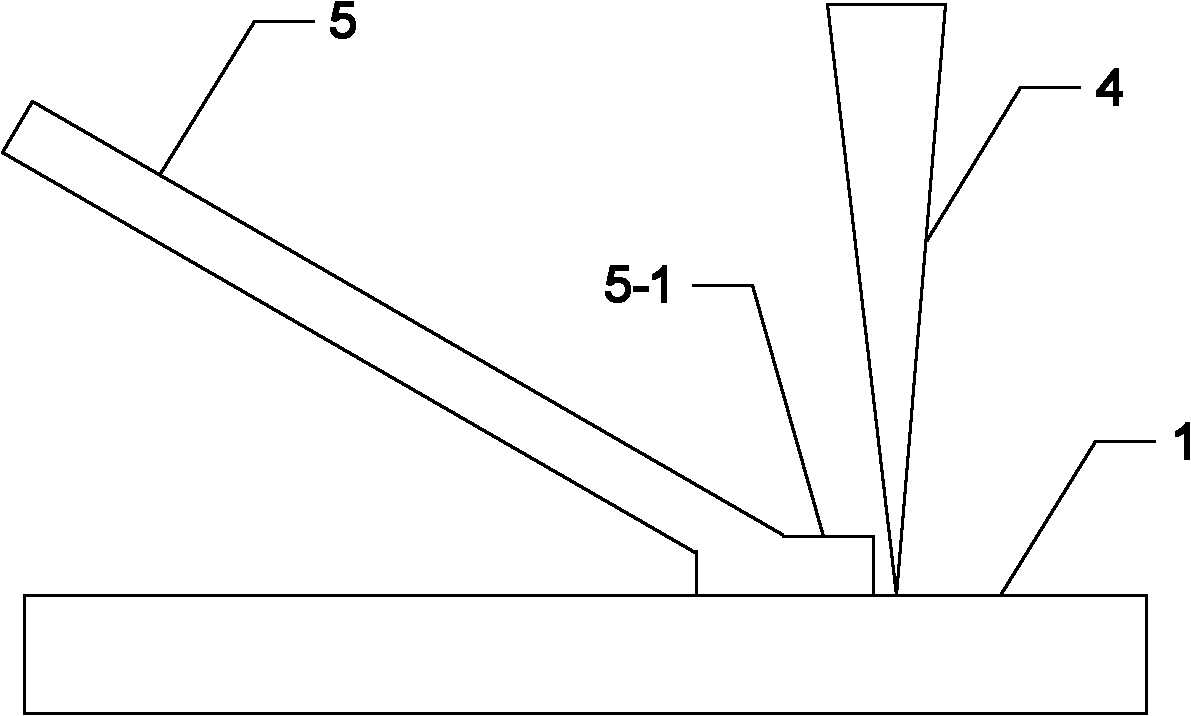

Method and system for performing laser braze welding on diamonds by using double beams

ActiveCN107775193AInhibit aggregationIdeal orderGrinding devicesOther manufacturing equipments/toolsLight beamBonding strength

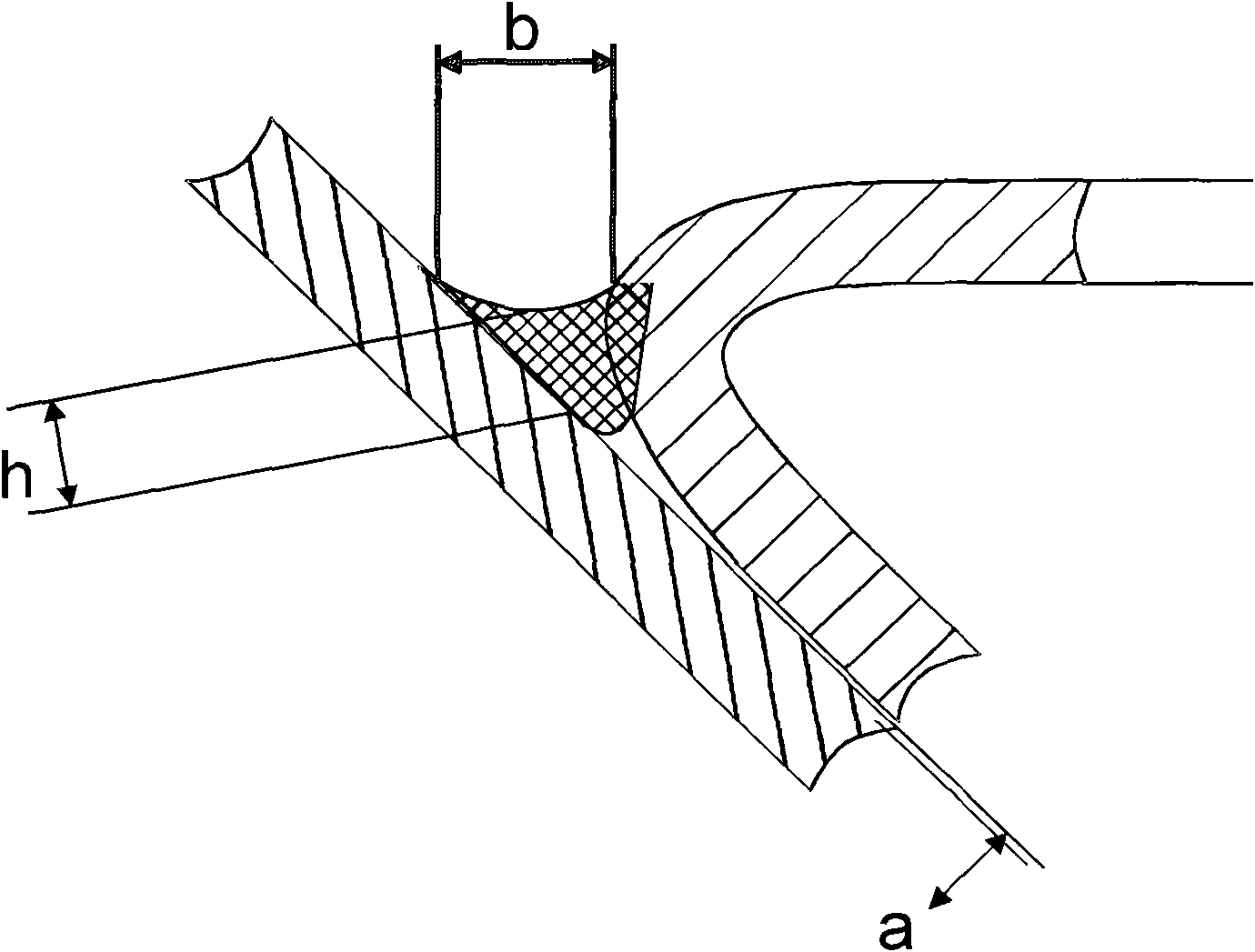

The invention discloses a method for performing laser braze welding on diamonds by using double beams. The method comprises the following steps: providing a matrix for performing braze welding on thediamonds and forming a V-shaped groove in the surface of the matrix; coating a brazing material layer for performing braze welding on the diamonds in the V-shaped groove; providing a wolfram wire mesh, arranging a plurality of grids for putting the diamonds in the wolfram wire mesh; putting the wolfram wire mesh above the brazing material; putting the diamonds into the grids of the wolfram wire mesh to ensure that the diamonds and the brazing material layer have certain contact height; symmetrically abreast arranging two laser heads in the welding direction; starting a laser welding system. Byutilizing the double laser beams, the brazing material layer is aslant input from the two sides of the diamonds, and laser braze welding is carried out. The invention also provides a system for performing laser braze welding on the diamonds by utilizing the double beams. According to the method and the system disclosed by the invention, burning loss oxidation and graphitization of the surfaces ofthe diamonds are reduced, the bonding strength between the brazing material layer and the diamonds is improved, the aggregation phenomenon of the diamonds is avoided, and a desired arrangement sequence of the diamonds can be obtained.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

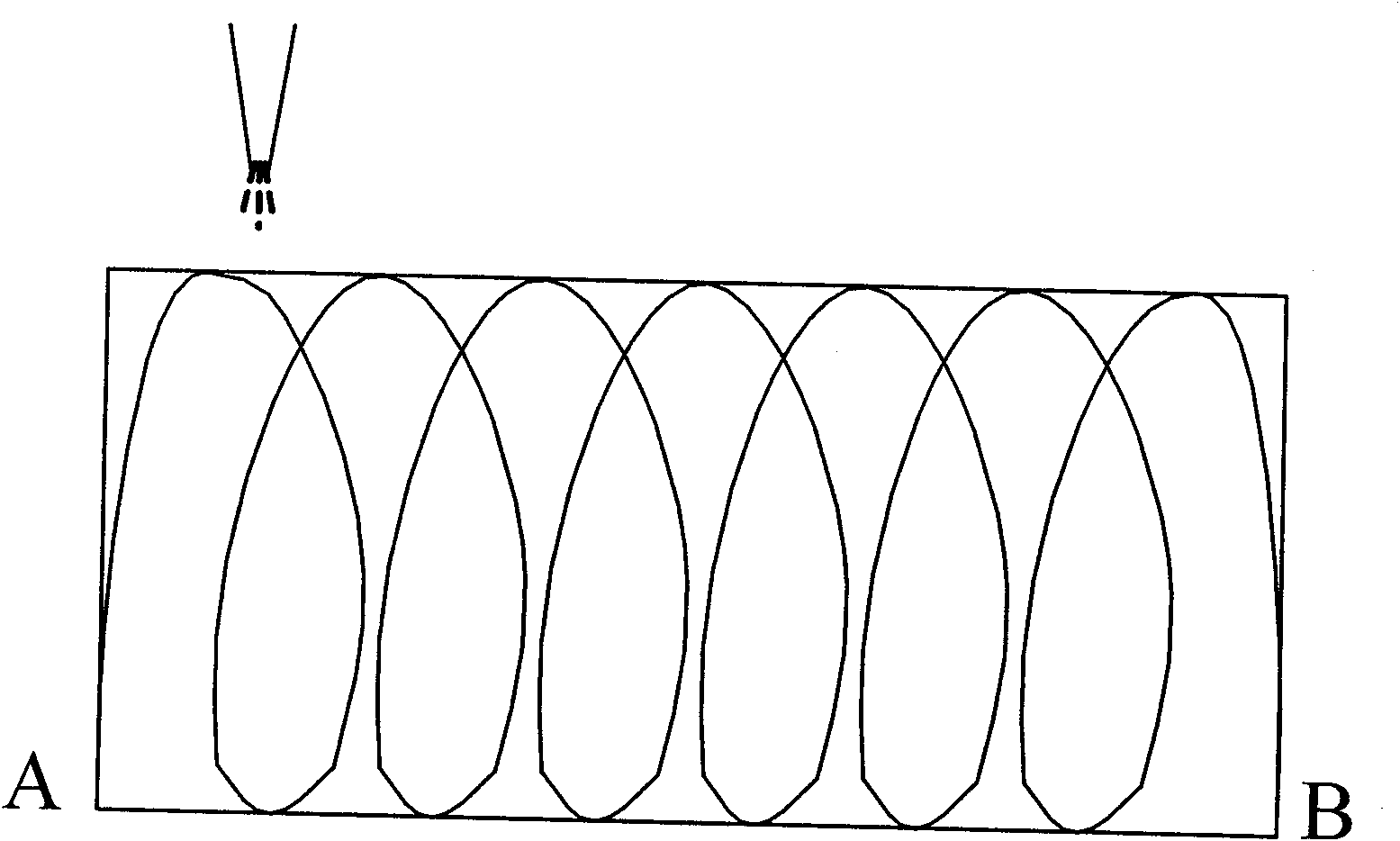

Method for manufacturing abrasive wheels for high-speed railway track slabs by brazing diamonds with laser

ActiveCN101914768AIncrease energy densityFast coolingMetallic material coating processesHeat-affected zoneMaterials science

A method for manufacturing abrasive wheels for high-speed railway track slabs by brazing diamonds with laser comprises the following steps: 1) mixing; 2) coating; 3) spraying; and 4) brazing. The abrasive wheels have the advantages of high grinding efficiency, long life, good grinding quality and the like. Compared with other brazing methods, the method has the following advantages: the energy density of the laser heat source is high, temperature raising and reducing are fast, local heating can be carried out and the heat affected zone is small; the laser beams can be transported by optical fibers, thus machining can be carried out on the parts which are not easy to braze by the conventional methods, the flexibility is good, the workpieces with complex geometrical shapes can be brazed and super-long, super-large, super-thin and super-fine special tools can be manufactured.

Owner:江苏华昌工具制造有限公司

Laser brazing improvement with twinspot

ActiveUS20090114625A1Soldering apparatusLaser beam welding apparatusFilling materialsOptoelectronics

The present invention provides a method for laser brazing a first member to a second member using a laser brazing head. The laser brazing head has means for generating a first laser beam and a second laser beam. The method comprises the steps of: arranging the first member in contact with the second member such that a junction is formed there-between; providing a filler material in the vicinity of said junction, and passing the laser brazing head along the junction such that the first laser beam melts the filler material to at least partially fill said junction to form a brazed joint. The second laser beam then effects a post heat treatment of the brazed joint.

Owner:VOLVO CAR CORP

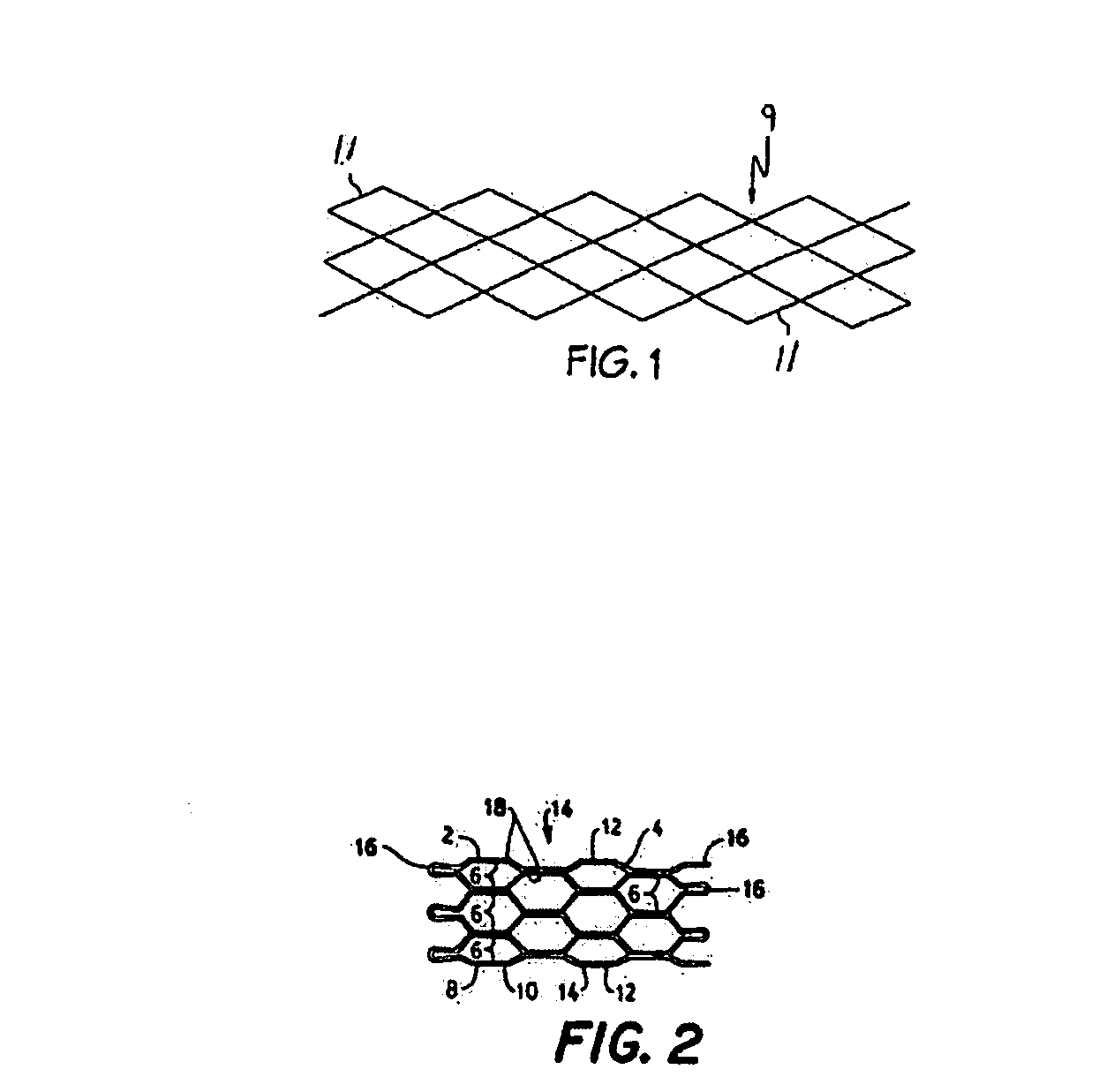

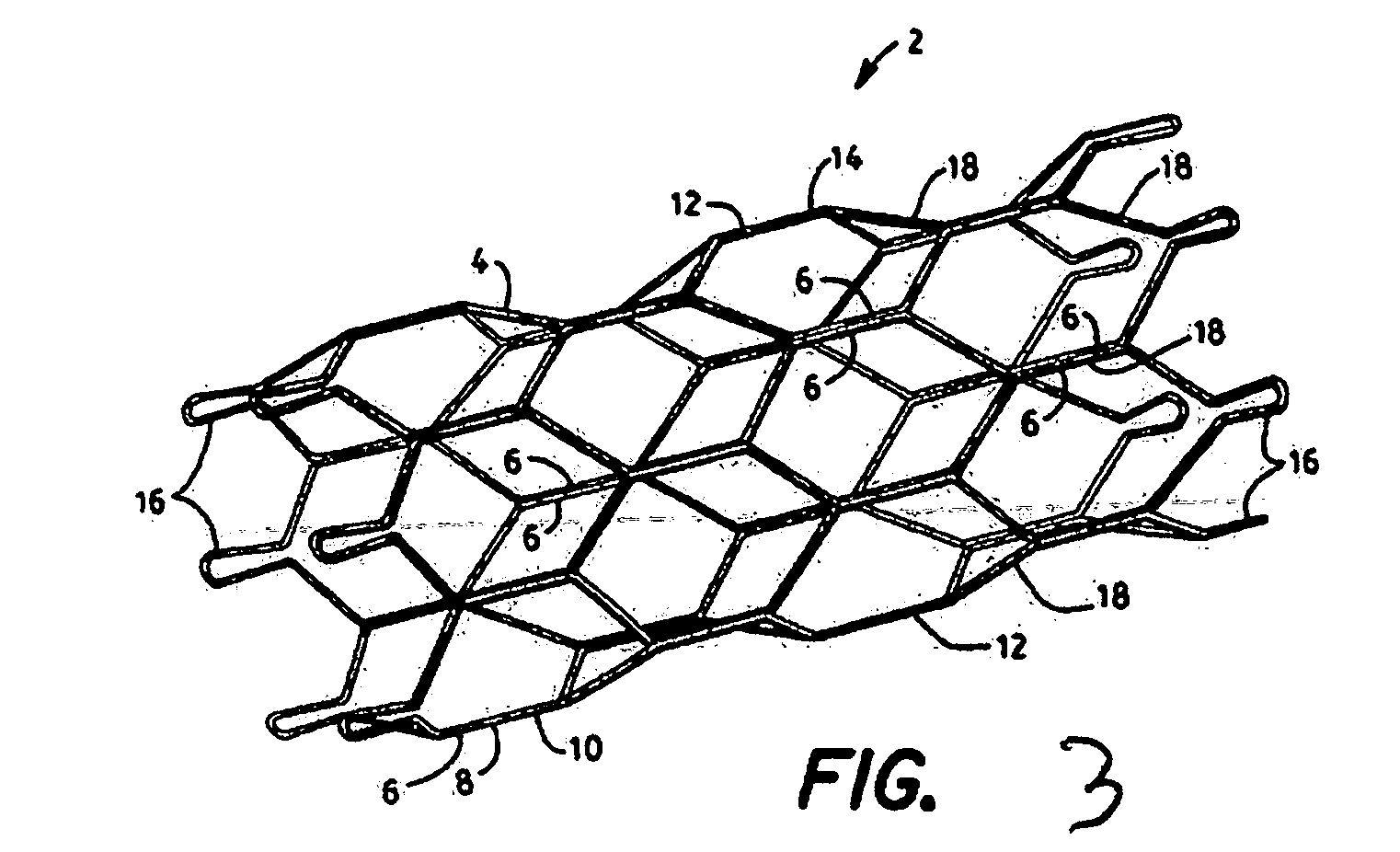

Medical devices having laser brazed joints

A method is provided for forming a brazed joint between first and second elements of a medical device such as a stent. The method begins by forming a joint by positioning the first element with respect to the second element. A filler material is applied to the joint. An electromagnetic beam of energy is applied to the joint to at least partially melt the filler material.

Owner:BOSTON SCI SCIMED INC

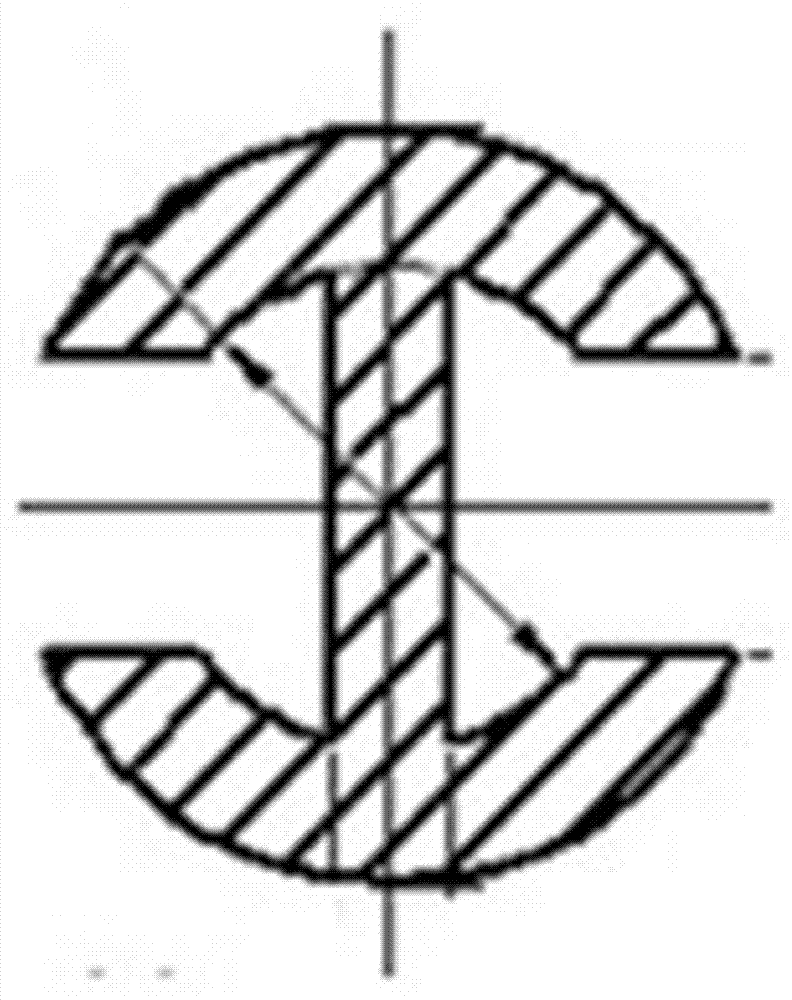

Method for manufacturing single-layer diamond grinding wheel in laser brazing manner

ActiveCN105619272APrevent oxidationImprove wettabilityGrinding devicesWelding/cutting media/materialsSuperhard materialThin layer

The invention relates to a method for brazing single-layer diamond tools, and belongs to the field of manufacturing of superhard material tools. NiCrBSi, CuPSn and TiH2 are mixed to serve as brazing filler metal, TiH2 is decomposed in the laser heating process to generate H2 in real time, and diamond graphitization in the high-temperature brazing process is avoided. Therefore, the single-layer diamond tools are suitable for being brazed with laser beams in air, and high-strength connection between a diamond and a steel substrate can be achieved. A thin layer of carbide is formed on the surface of the diamond after brazing, the hot loss of the Cu-based brazing filler metal on the diamond is small, and the Cu-based brazing filler metal can be used for manufacturing the small-batch and large-size diamond tools. Multiple kinds of alloyed brazing filler metal are mixed, so that the cost of the brazing filler metal is greatly reduced; and ingredient regulation and control are convenient, so that the diamond tools meet the machining requirements of different working conditions and materials.

Owner:启东蓝威金刚石科技有限公司

Method for compositing high-entropy brazing filler metal coating laser brazed ceramic and metal

The invention relates to a method for compositing high-entropy brazing filler metal coating laser brazed ceramic and metal and solves the problem of poor joint performance due to the fact that a largenumber of brittle intermetallic compounds are produced in joints during vacuum brazing of ceramic-metal with traditional brazing filler metal. A composite high-entropy alloy brazing filler metal coating is prepared on a ceramic matrix with a laser cladding or supersonic spray technology, the lower layer is a metal Ni coating, and the upper layer is a high-entropy alloy coating. After the coatingis prepared, the to-be-brazed ceramic matrix and metal are assembled into a lap joint structure after ultrasonic cleaning, and a fiber laser is used as a heat source to braze ceramic and metal under protection of argon. The method is simple to operate, laser is used as the heat source, the welding time is shortened, and the welding efficiency is improved. Meanwhile, brittle intermetallic compoundsdo not exist in brazing seams under the high entropy effect of the high-entropy alloy, and the strength and toughness of the joint are effectively improved.

Owner:BEIJING UNIV OF TECH

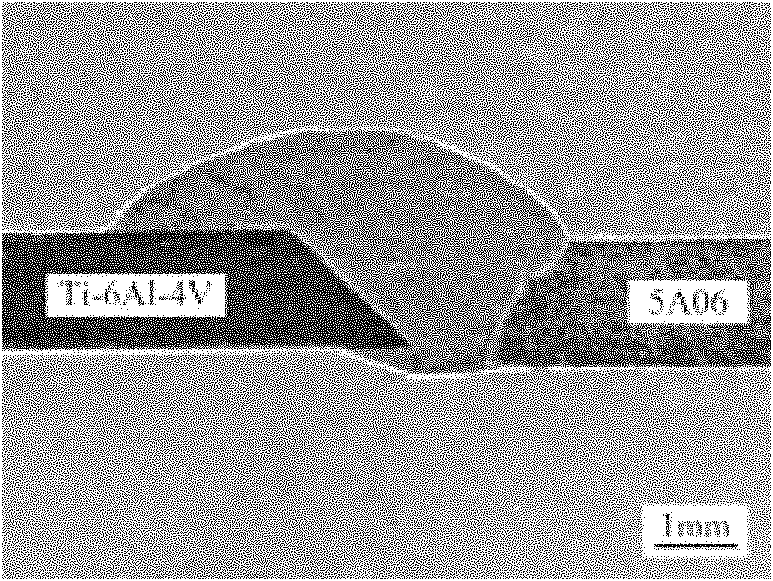

Laser brazing method for TiNi (titanium-nickel) shape memory alloy and dissimilar light metal

ActiveCN103231136ASmall organizationLittle impact on performanceSoldering apparatusShape-memory alloyTitanium

The invention discloses a laser brazing method for a TiNi shape memory alloy and a dissimilar light metal, and belongs to the technical field of dissimilar material connection. To-be-brazed surfaces of the TiNi shape memory alloy and the dissimilar light metal are cleaned and dried after polished and leveled; a lap joint manner is adopted in welding, the dissimilar light metal is taken as an upper plate and is in lap joint onto the TiNi shape memory alloy which is a lower plate, and a brazing filler metal is placed on the TiNi shape memory alloy which is the lower plate and is closely attached to a lap joint end of the dissimilar light metal; the brazing filler metal is heated by lasers, and ultrasonic vibration is loaded on an edge of the TiNi shape memory alloy which is the lower plate after the brazing filler metal comes down and is melted, so that welding seams are filled with the brazing filler metal; and finally a product is taken out after air cooling. According to the method, the brazing joint which is high in strength and has no defects can be obtained.

Owner:TIANJIN BEIBANG COATING MATERIAL

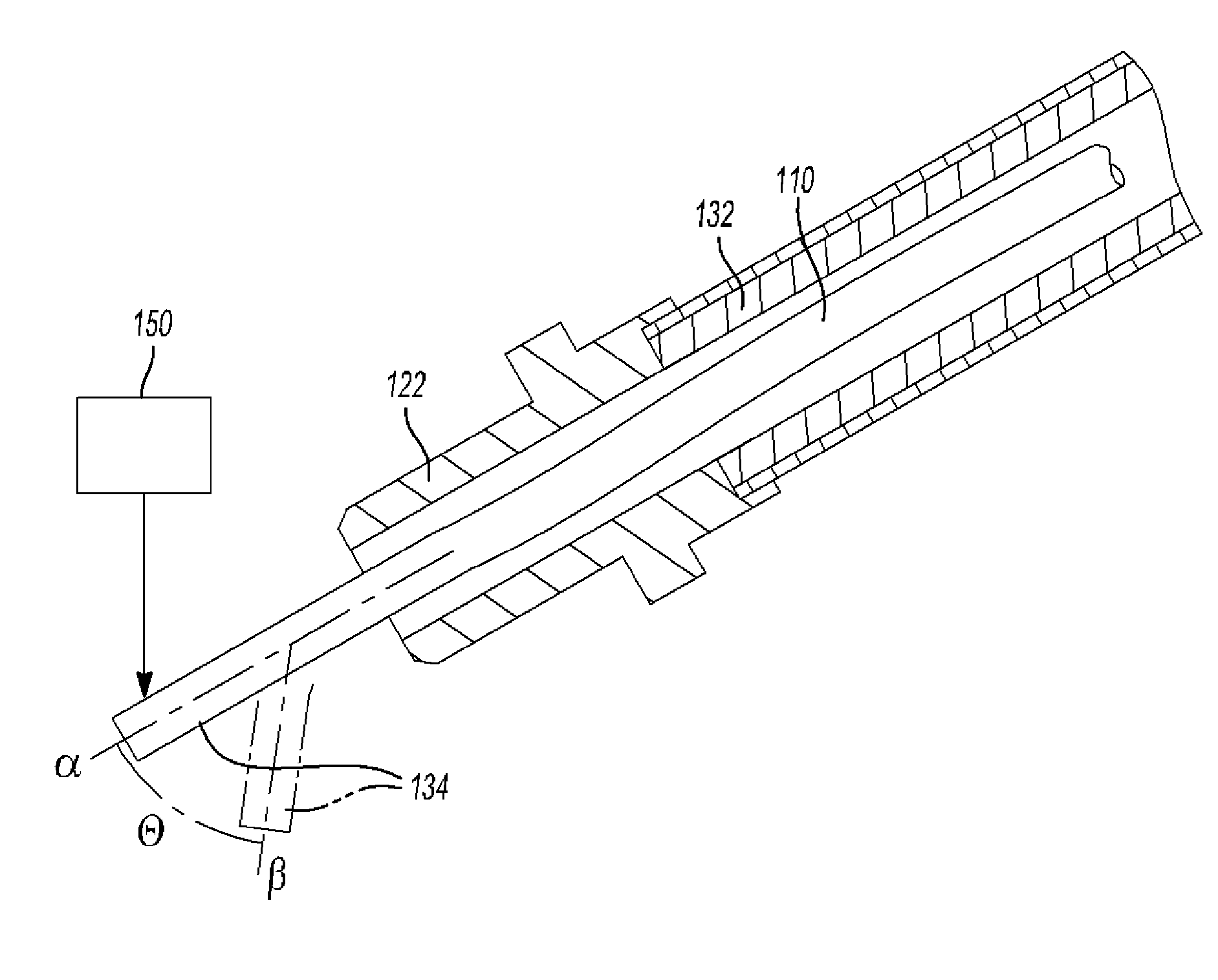

Laser brazing of metal workpieces with relative movement between laser beam and filler wire

InactiveUS20190061053A1Increase and decrease focal distanceImprove the heating effectSoldering apparatusVehicle componentsOptoelectronicsMetal

A method of laser brazing a metal workpiece assembly along a joint seam established between a first metal workpiece and a second metal workpiece involves advancing a laser beam along the joint seam while feeding a filler wire into the laser beam to melt a leading end of the filler wire, which is impinged by the laser beam, to produce and dispense molten filler material within and along the joint seam. The dispensed molten filler material solidifies behind the laser beam into a braze joint. Additionally, as part of the method, a position of a focal point of the laser beam relative to the leading end of the filler wire is repeatedly fluctuated during advancement of the laser beam along at least part of the joint seam.

Owner:GM GLOBAL TECH OPERATIONS LLC

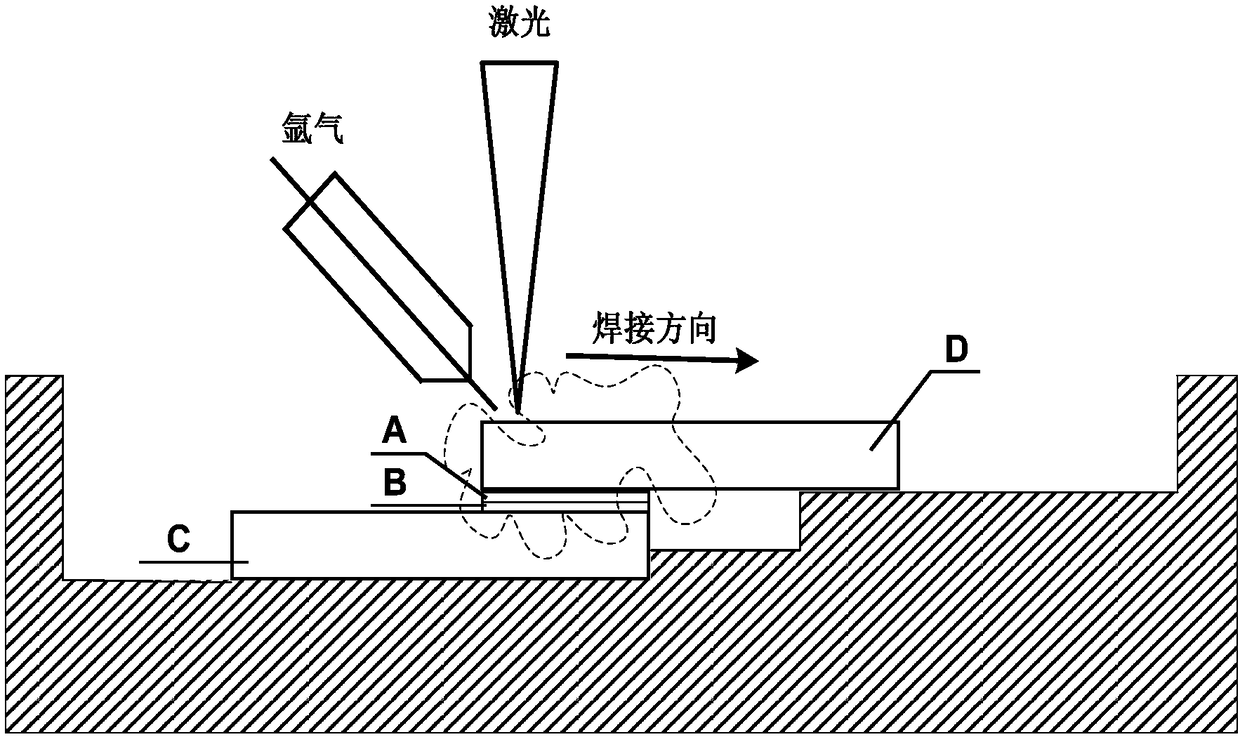

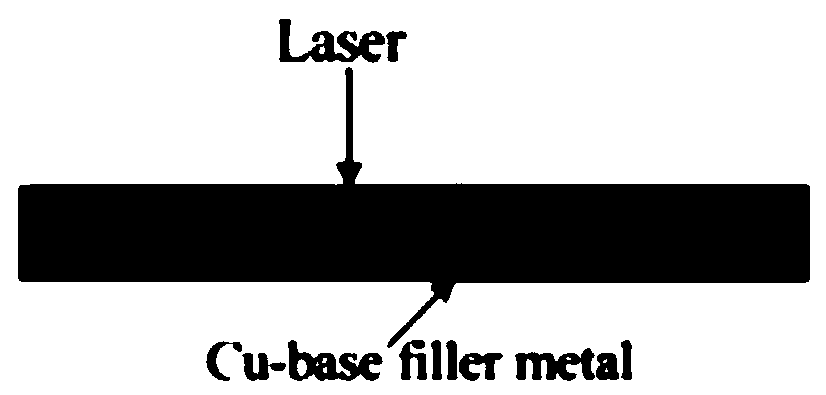

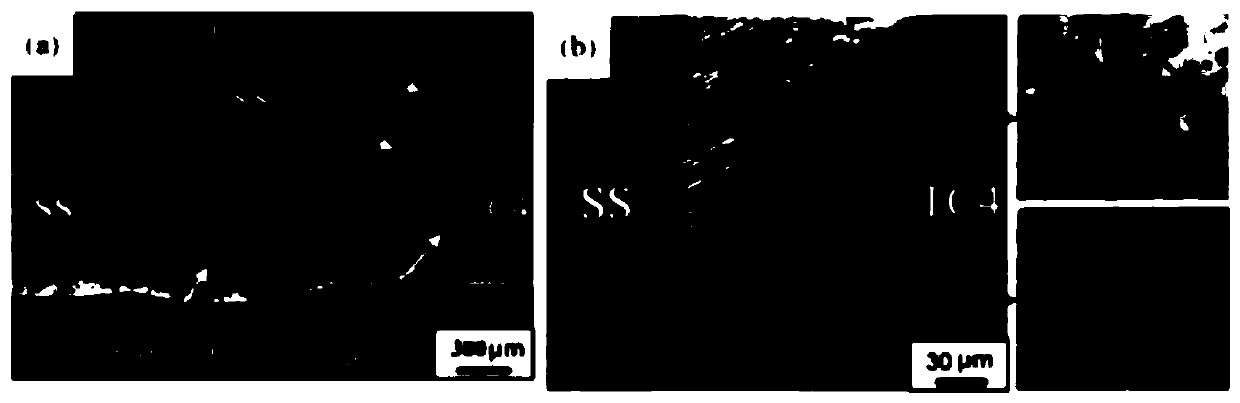

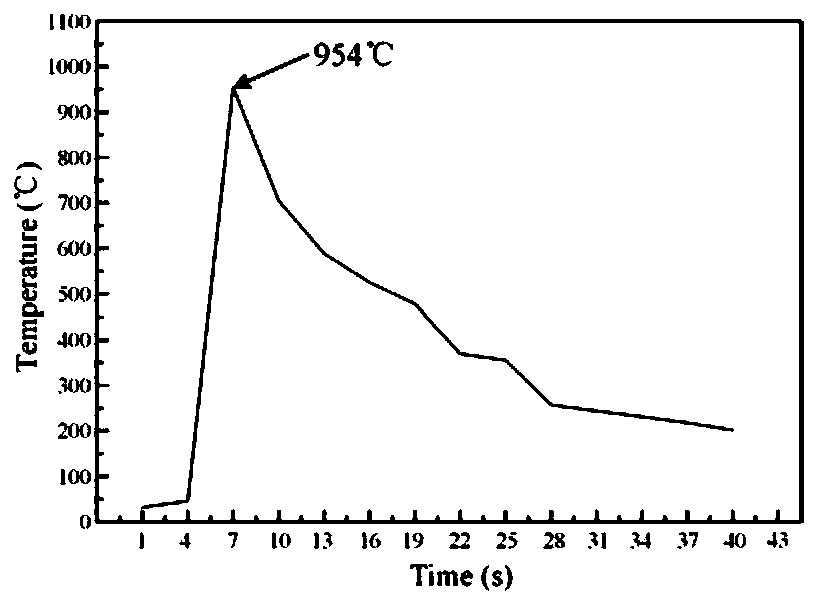

Titanium alloy-stainless steel dissimilar metal laser braze-welding method adopting copper base brazing filler metal

ActiveCN110421223AEasy to shapeAvoid unfusedSoldering apparatusWelding/soldering/cutting articlesLaser lightCopper

The invention relates to a titanium alloy-stainless steel dissimilar metal laser braze-welding method adopting copper base brazing filler metal, and belongs to the technical field of laser gun welding. Aiming at the problem that a brittle Ti-Fe intermetallic compound is produced in the titanium alloy-stainless steel dissimilar metal welding process, a laser light is adopted as a welding heat source, the copper base brazing filler metal is adopted as an interlayer material, and the formation of the Ti-Fe intermetallic compound in the titanium alloy-stainless steel welding process is avoided through laser braze-welding, so that the brittleness of a connector is reduced, and the performance of the connector is improved. By adopting laser single-pass welding, the high-quality and high-efficiency welding connector of dissimilar metal materials containing stainless steel fusion welding seams and unfused stainless steel and braze-welding seams is obtained. The titanium alloy-stainless steel dissimilar metal laser braze-welding method adopting the copper base brazing filler metal comprises the process steps of assembling and clamping a panel, adjusting a pre-tightening force of a stainlesssteel- copper base brazing filler metal-titanium alloy contact surface, focusing a laser beam on a 1.5mm part of a stainless steel plate for welding, and realizing the connection of titanium alloy-stainless steel dissimilar metal.

Owner:XINJIANG UNIVERSITY

Self-adjusting welding wire for welding application

InactiveCN103817455AArc welding apparatusWelding/cutting media/materialsMetal alloyShape-memory alloy

Owner:GM GLOBAL TECH OPERATIONS LLC

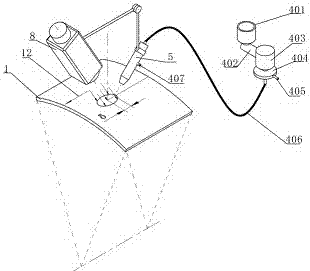

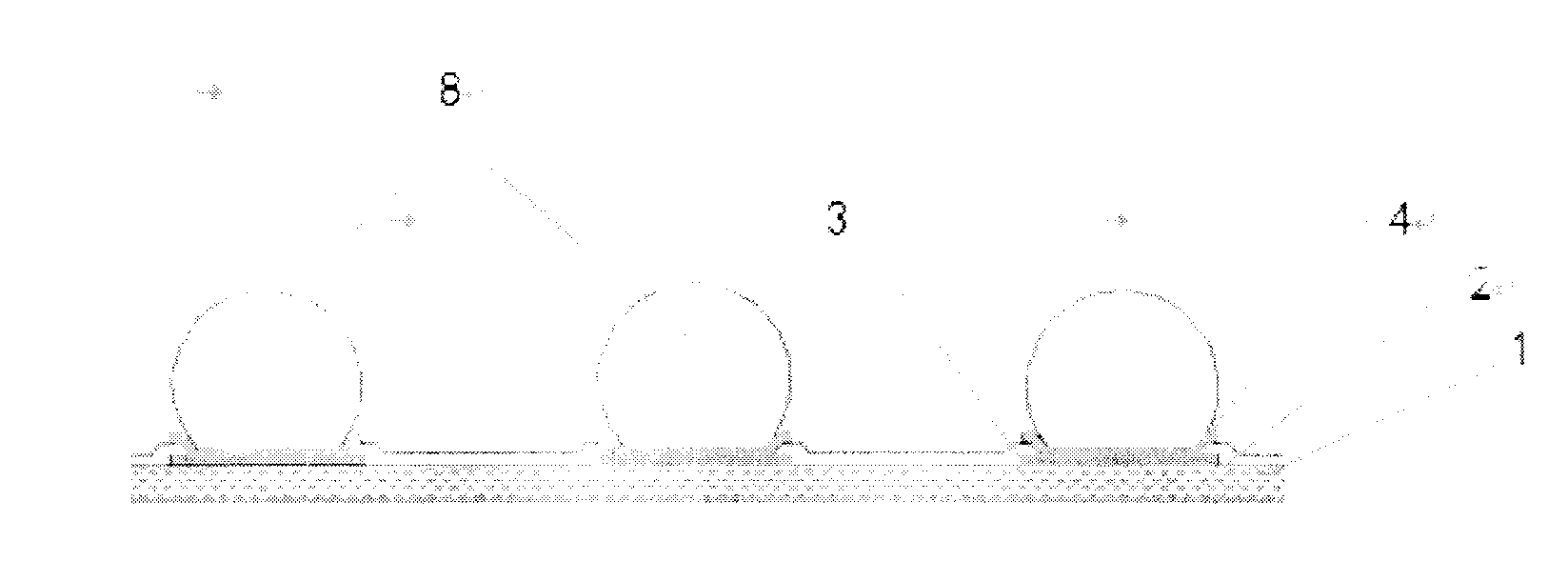

Method of laser brazing tool of monolayer diamond

ActiveCN107096972AAvoid severe burning and oxidationAvoid graphitizationSoldering apparatusLaser beam welding apparatusLaser lightLaser brazing

The invention relates a method for laser brazing tool of monolayer diamond. The method comprises the following steps: providing a basal body of a diamond tool; coating a brazing material on the surface of a diamond tool basal body to prepare a diamond tool blank; providing a jetting system including a hopper and a spray gun connected with the hopper; providing diamond abrasive grains and placing the diamond abrasive grains into the hopper; providing a laser brazing system including a laser generator and a laser brazing working head; aligning the laser brazing working head and the spray gun to a tool blank surface; starting the laser brazing system and the jetting system, and doing synchronous motion of the laser brazing working head and the spray gun to ensure that focused laser beams produced by the laser brazing working head are positioned in front of the working head and are irradiated on the preposed brazing material so as to molten the brazing material; and after laser light spot, the diamond abrasive grains are sprayed by adopting the spray gun into a brazing molten tank. The diamond abrasive grains are jetted by adopting a paraxle to carry out laser brazing, so that burning oxidization and graphitization of the diamond abrasive grains during brazing are avoided.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

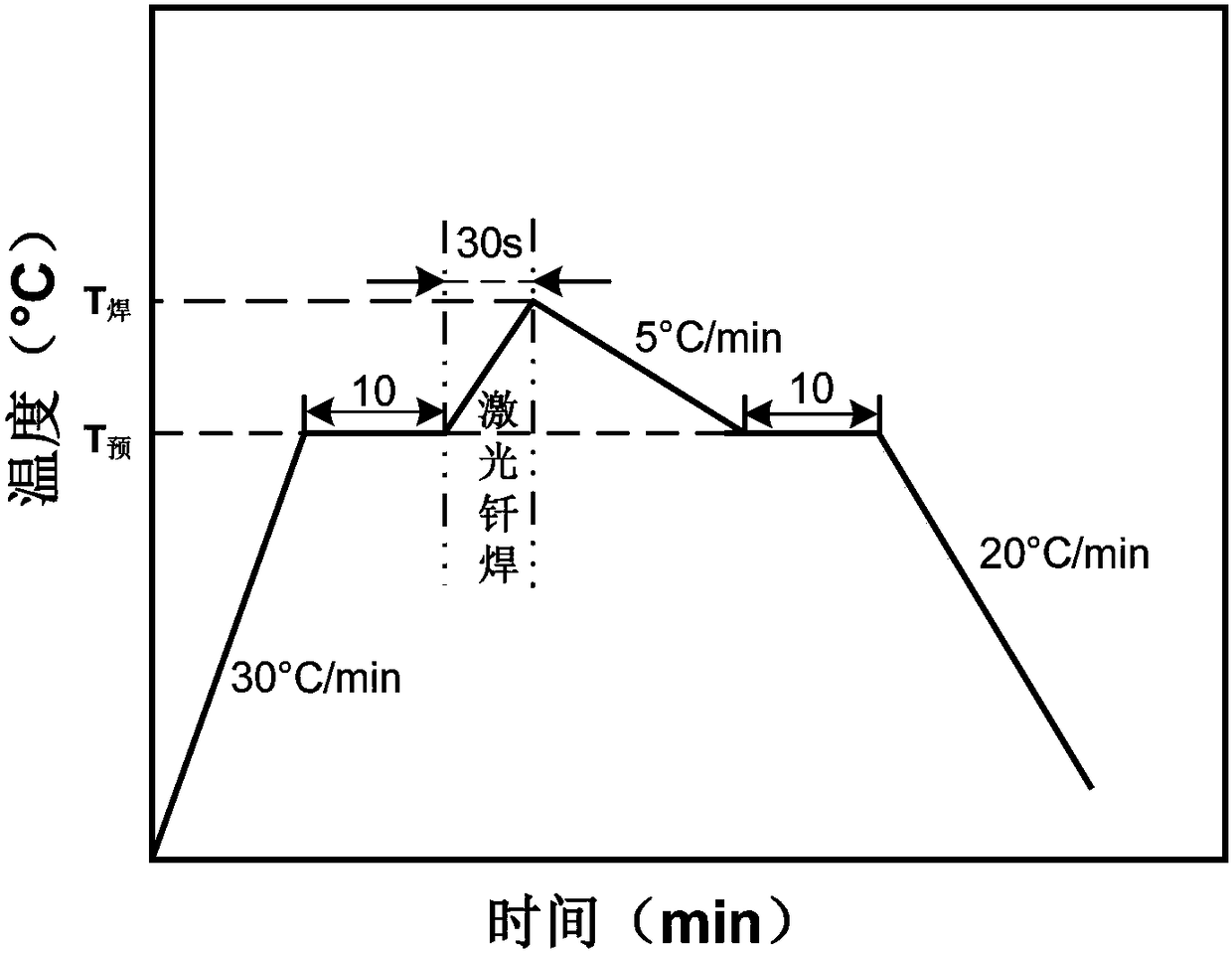

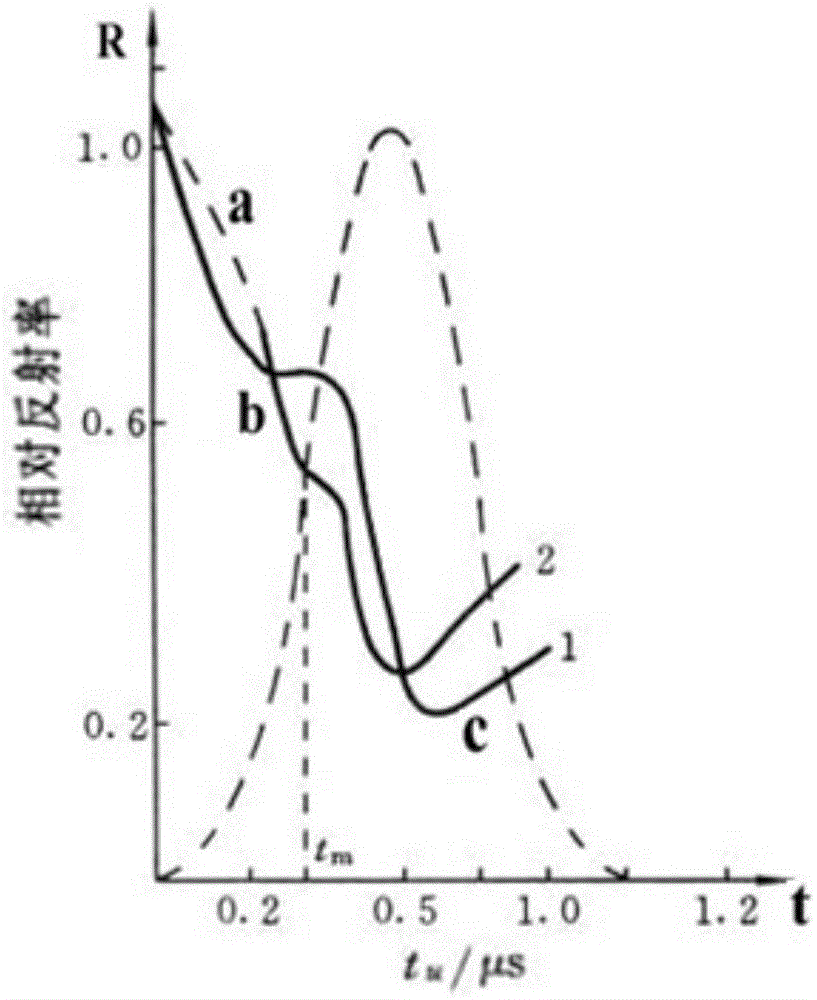

Laser welding technology of automobile power battery aluminum alloy shell

InactiveCN105033385AIncrease temperatureSmall welding heat affected zoneSoldering apparatusPower batteryLaser ranging

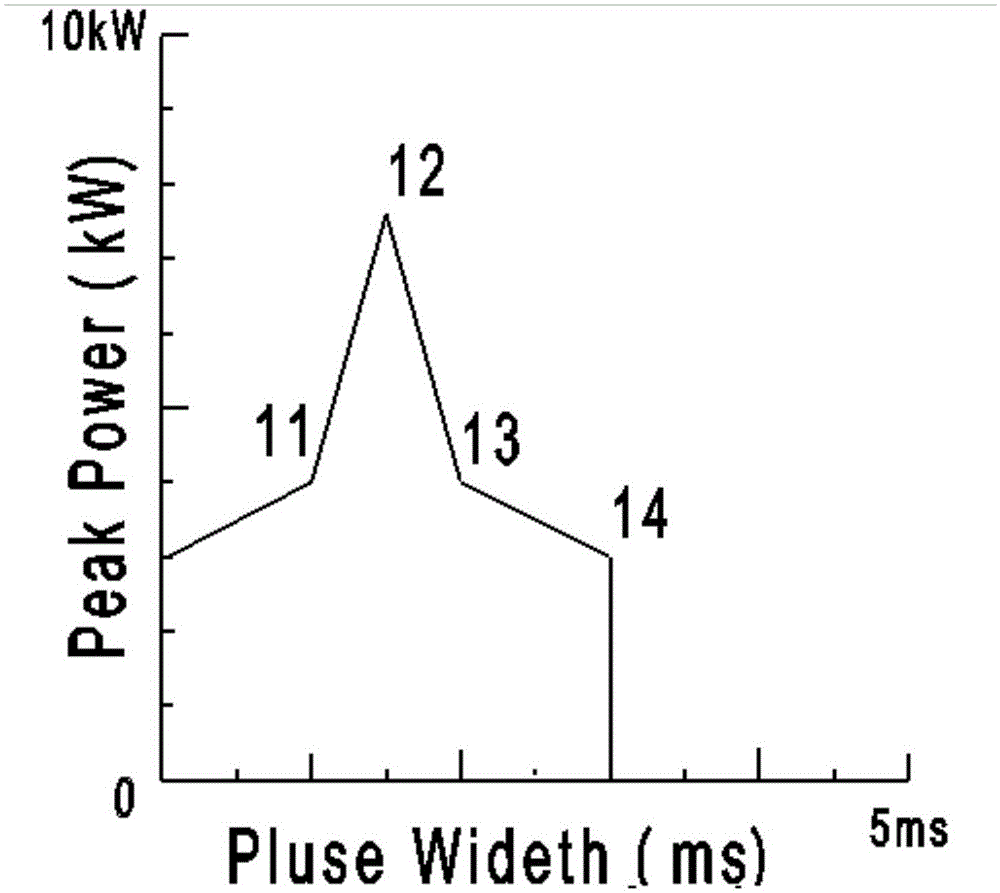

The invention discloses a laser welding technology of an automobile power battery aluminum alloy shell. According to the technology, under the protection of inert gases, a welding line of aluminum alloy is welded in a laser brazing manner. The pulse width of the laser ranges from 3 ms to 7 ms. A preheating stage, a heating stage and an insulating stage are included in the pulse range, wherein the preheating stage is not smaller than 1 ms, the heating stage is not smaller than 1 ms, and the insulating stage is not smaller than 1 ms. The power of the preheating stage and the power of the insulating stage range from 3 kw to 4 kw. The power of the heating stage is increased and then reduced, and the peak power ranges from 6 kw to 8.5 kw. The laser welding technology of the automobile power battery aluminum alloy shell is superior in tensile performance.

Owner:SOUTH CHINA NORMAL UNIVERSITY

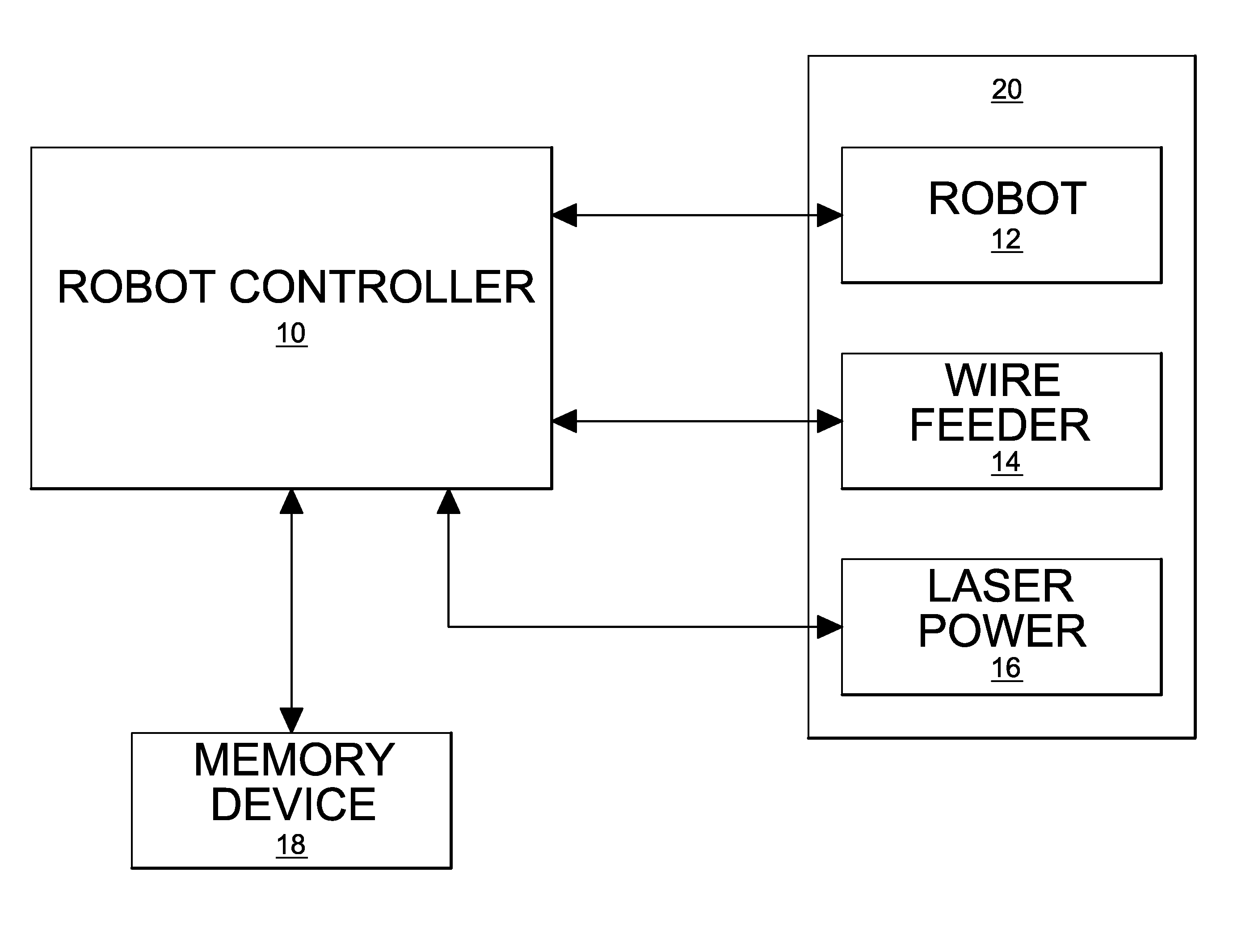

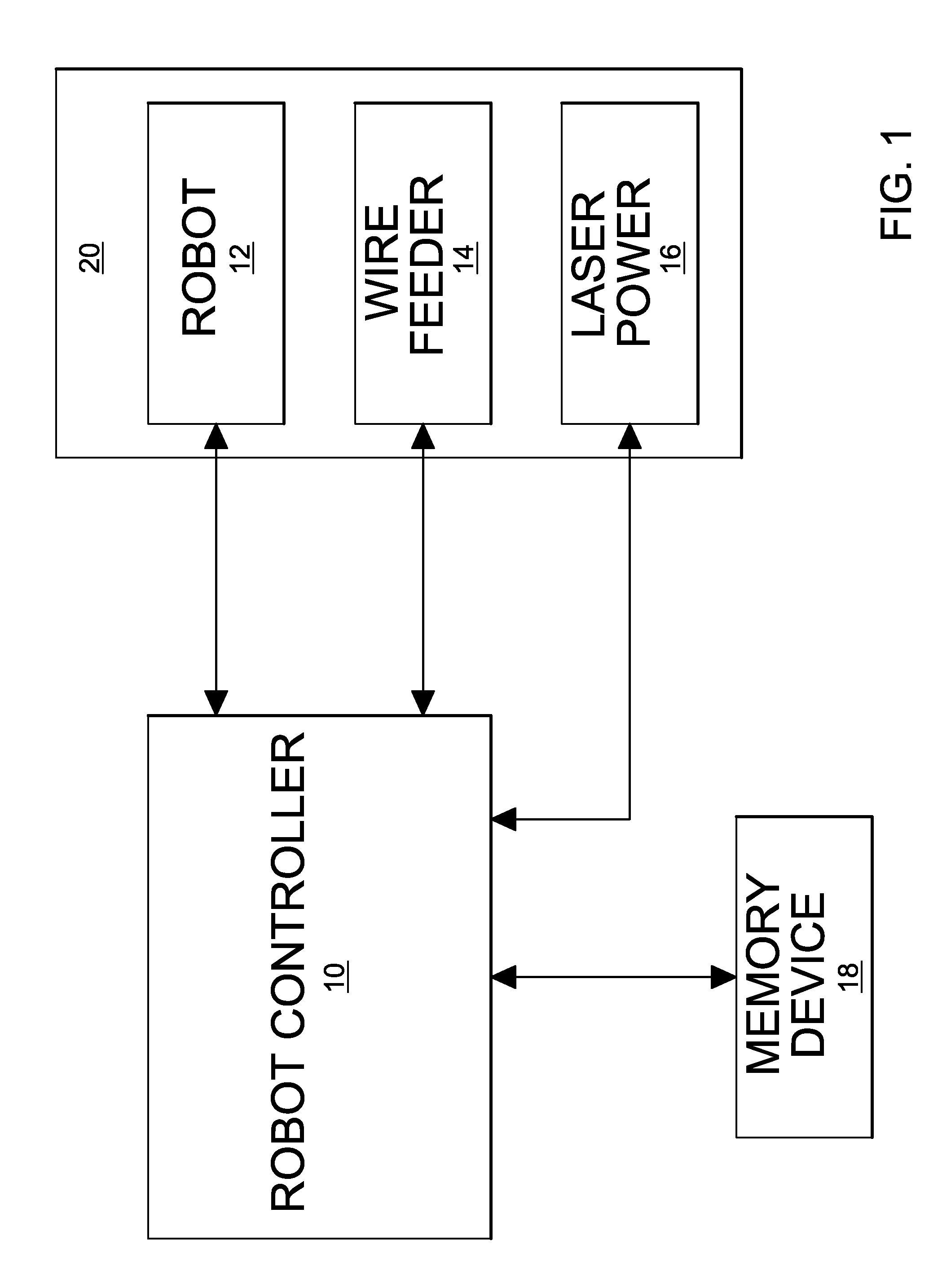

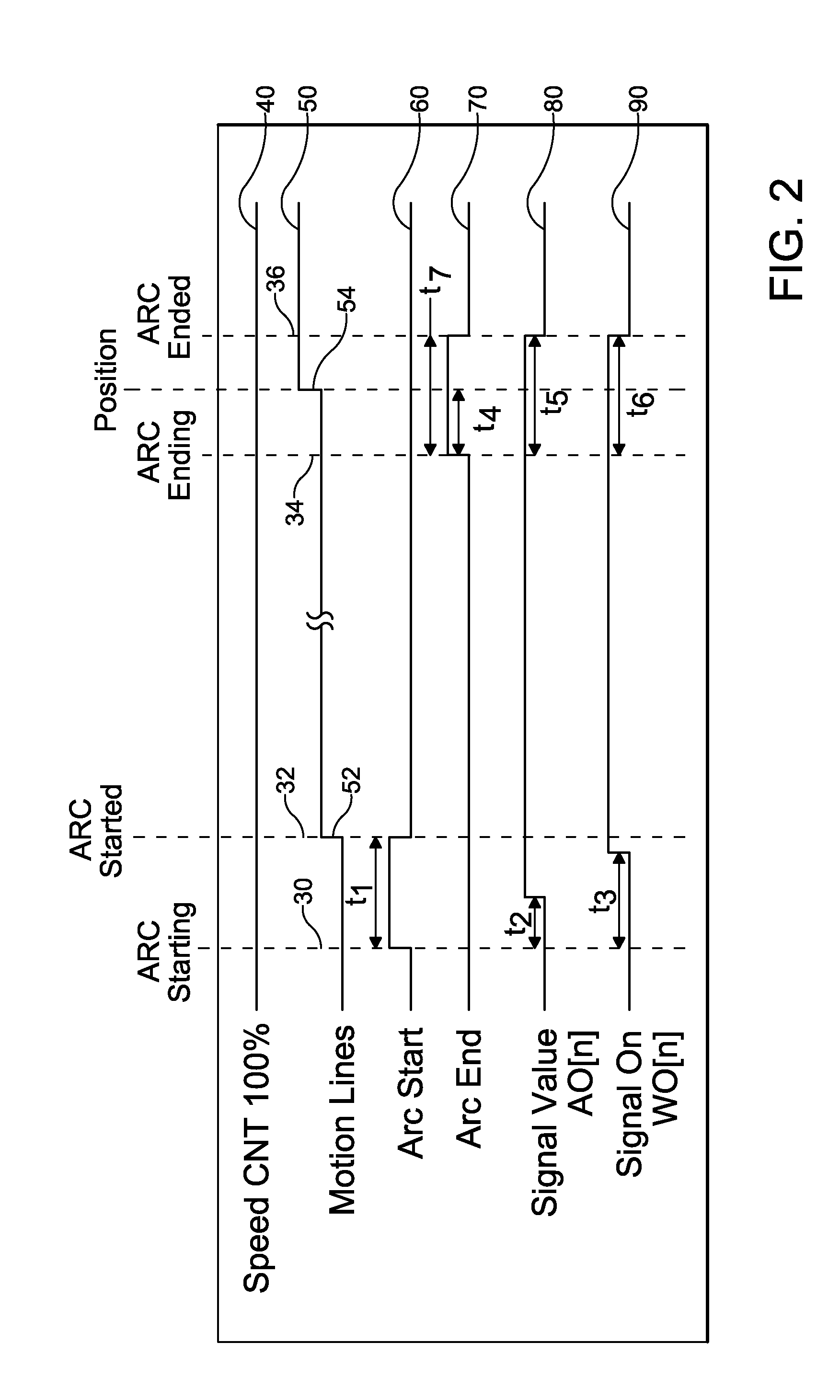

Adaptive control of robotic laser braze/weld operation

A method for adaptive control of a robotic operation of a robot includes providing a software program to generate process signals executable during the robotic operation, including one or more execution commands. A first Signal Value channel is provided to control at least one control process parameter of the robot, where the first Signal Value channel is subject to a first time latency. The execution timing of the first Signal Value channel is synchronized with the one or more execution commands by accounting for the first time latency in relation to the one or more execution commands. The software program is run to generate the process signals and the robot is operated in response to the synchronized execution timing of the execution commands.

Owner:FANUC ROBOTICS NORTH AMERICA

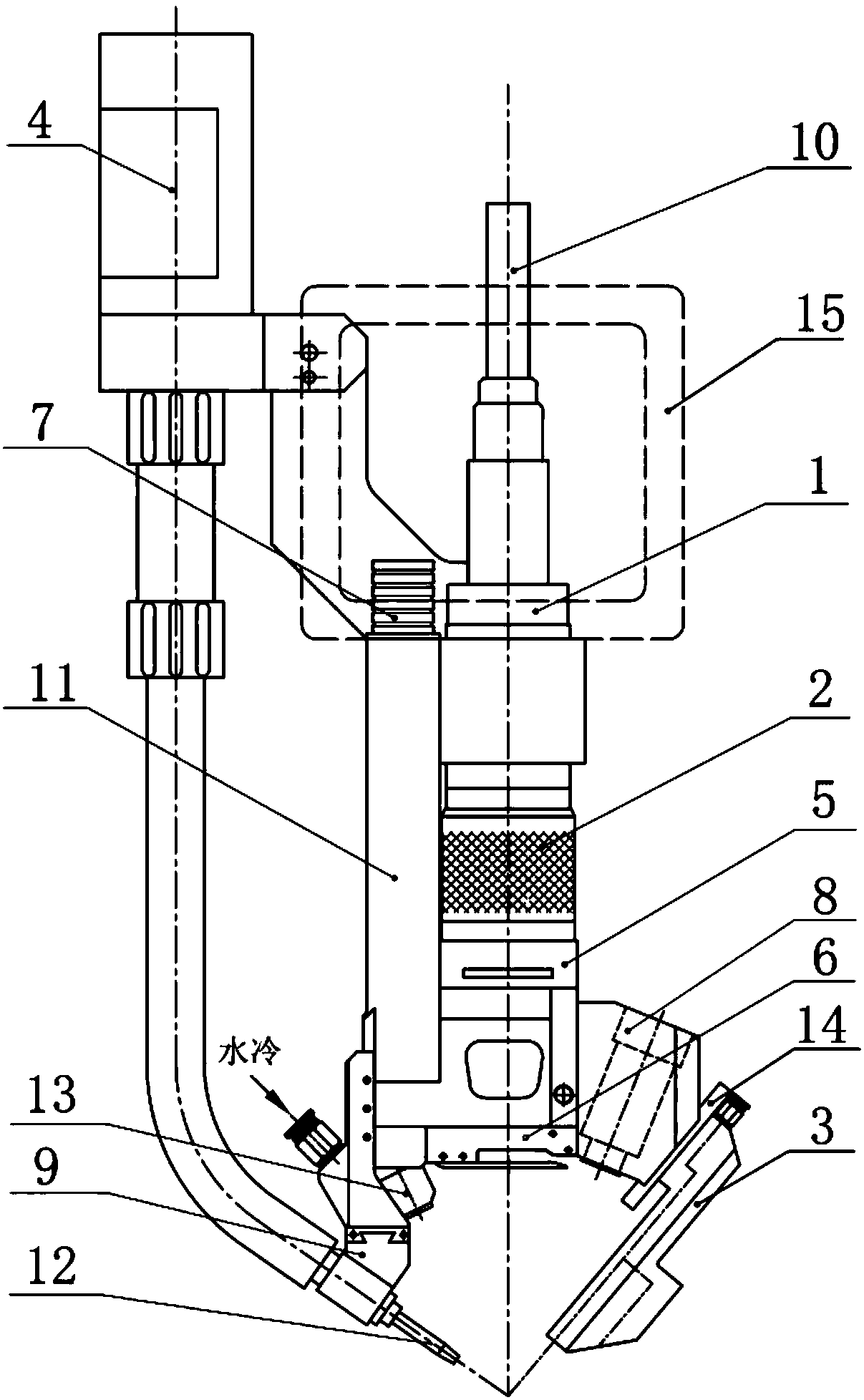

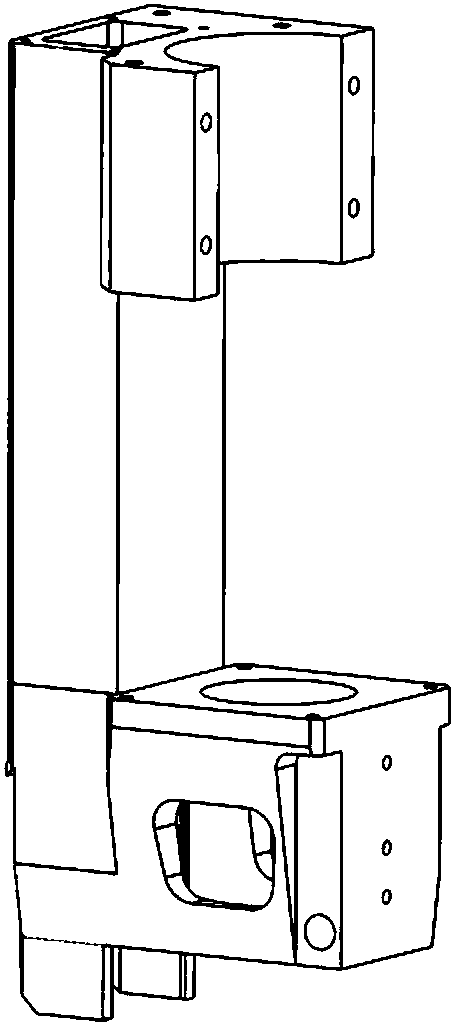

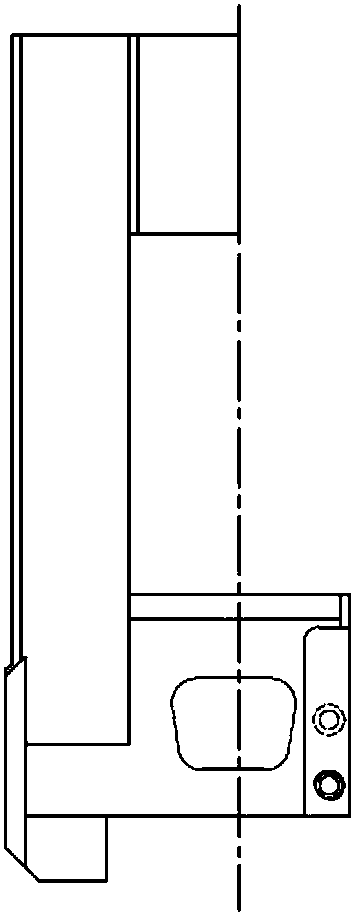

Welding head for laser narrow-gap welding

ActiveCN107717227AImprove protectionAccurate and adjustable medium precisionLaser beam welding apparatusEngineeringCharge couple device

The invention relates to a welding head for laser narrow-gap welding. The welding head can be used for laser narrow-gap multi-layer welding on thick plates and can also be used for laser wire fillingwelding, laser soldering and the like. The structure of the welding head mainly comprises the main parts such as a welding head base body, a laser transmission and focusing module, a welding wire conveying module, a gas protection module, a transverse gas proof curtain and a charge coupled device observation module. During welding, movement mechanisms, such as a mechanical arm, are responsible formoving according to preset routes, the position of optical focal point and the height of the wire feeding drop point can be manually or automatically adjusted only according to the gap depth and width in each layer of welding bead, and the positions of other parts including the welding head base body, a gas protection nozzle and the charge coupled device observation module are not changed; only when the accumulated height of weld joints exceeds a certain value, the heights of the movement mechanisms are required to change, and welding can be completed by repeating the above processes. The welding head adopts a modular design, is compact in structure, and has the characteristics of being high in adaptability, high in welding efficiency and convenient to operate and maintain.

Owner:BEIJING UNIV OF TECH

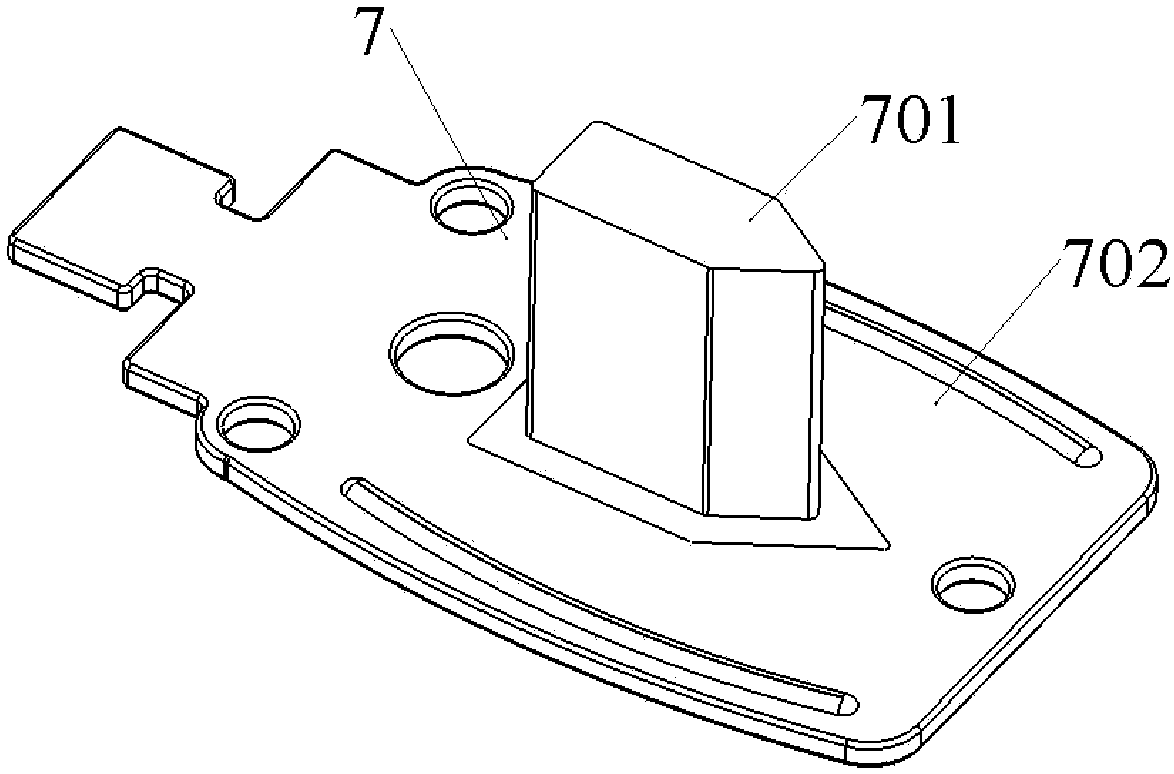

Manufacturing method for flip chip gold bumps

InactiveCN103151275AGuaranteed uniformityEnsure consistencySolid-state devicesSemiconductor/solid-state device manufacturingScreen printingElectricity

The invention belongs to the field of semiconductor package and discloses a manufacturing method for flip chip gold bumps. The method includes the following steps: by utilization of screen printing method, scaling powder with high viscosity is printed on an electrode under bump metal (UBM) plating layer; by utilization of a ball placing device, a matched template is chosen, gold balls are placed on a weld plating layer and the situation that the gold balls are adhered to the chip electrode UBM plating layer is ensured; and by utilization of lasers, the gold balls are re-melted, appropriate irradiation time and power are chosen, and the gold bumps are obtained and meet the shape requirement and requirements of electricity and mechanical performance. By utilization of laser braze, the manufacturing method for the flip chip gold bumps has the unique advantages of being capable of heating locally and quickly, cooling quickly and the like. The laser input power and the laser irradiation time are controlled, the gold bumps with optimal bump shapes, the mechanical performance and the electricity performance are obtained.

Owner:PEKING UNIV SHENZHEN GRADUATE SCHOOL

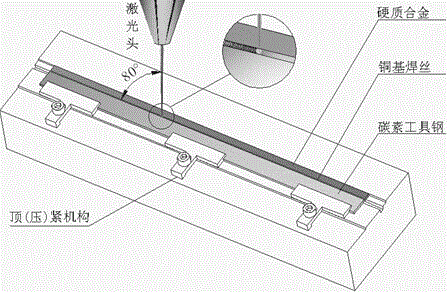

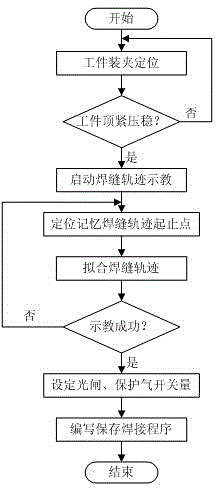

Carbide blade laser brazing method

InactiveCN104588806AFocus spot is smallImprove applicabilityOther manufacturing equipments/toolsWelding/cutting media/materialsLight spotCemented carbide

A carbide blade laser brazing method comprises the following steps of (1) material selecting; (2) tight ejecting and stable pressing; (3) brazing. According to the carbide blade laser brazing method, by means of laser brazing, focusing light spots are small, high-precision flexible positioning can be achieved, and performance is stable; centralized flexible control can be achieved through a robot, the adaptability to workpieces is high, the brazing time can be effectively saved in mass production, and the production cost can be reduced; the effective connection between dissimilar materials is achieved, the brazing quality is high, brazing seams are smooth and attractive, the thermal influence area is small, and the probability of cracking of cemented carbide can be effectively lowered. Copper brazing wires are fully melted, the brazing seams are soaked and are smooth and flat, and the macro defects such as obvious pores and cracks are avoided.

Owner:JIANGSU ZHONGKESIXIANG LASER TECH

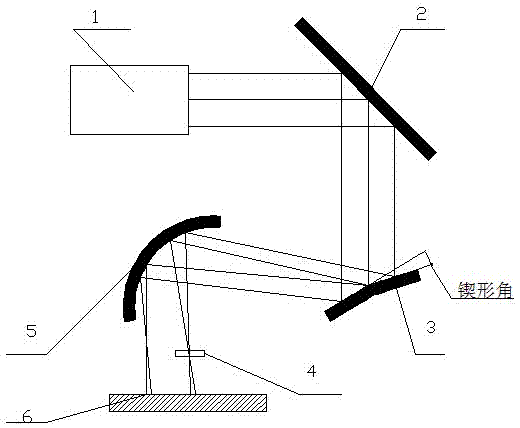

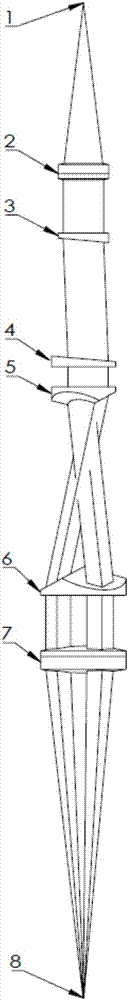

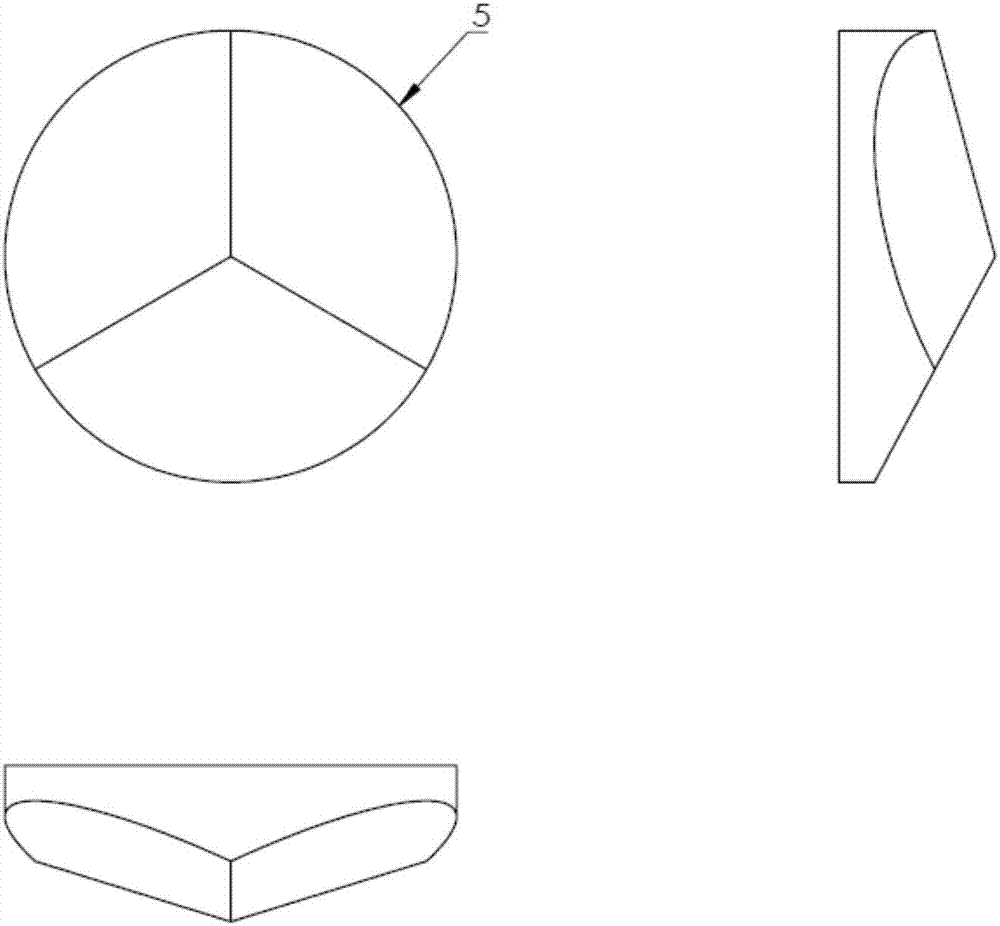

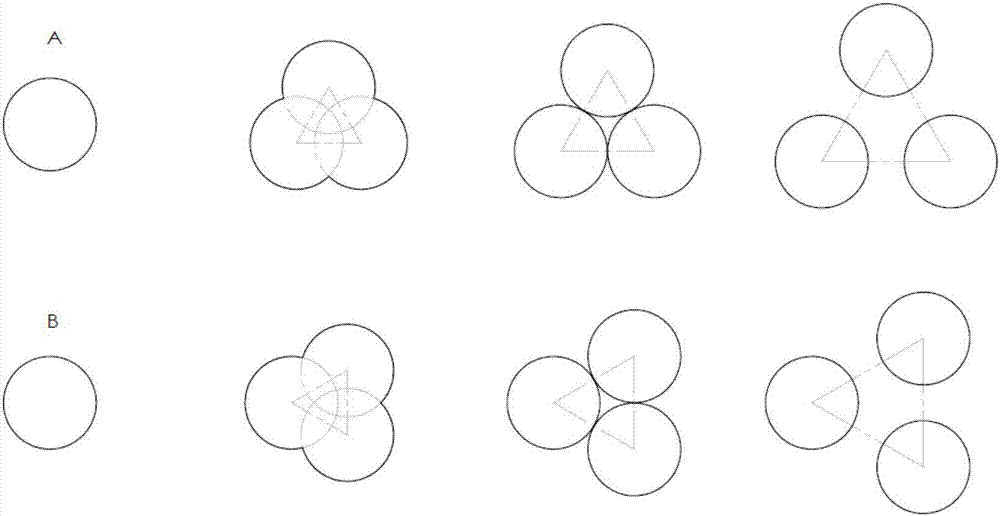

Distance and beam splitting energy adjustable three-light-spot laser welding optical system

InactiveCN107160032AImprove welding qualityNovel structural designLaser beam welding apparatusBeam splittingLight spot

The invention discloses a three-spot laser welding optical system with adjustable spacing and splitting energy. The invention has a novel structural design, and adopts a combination of a circular wedge mirror and a three-beam splitting prism, based on the beam caused by the adjustable spacing of the double circular wedge mirror. Translational characteristics, based on the beam splitting characteristics and edge angle characteristics of the double-chip three-beam splitting prism, and based on the rotation characteristics of the central axis of the circular wedge mirror and the three-beam splitting prism, a focusing three-spot optical system is realized. The three-spot spacing, energy and direction All can be adjusted, suitable for fiber laser laser welding applications with any fiber core diameter, especially helpful to improve the weld seam quality of welded parts in laser brazing.

Owner:SHANGHAI EMPOWER AUTOMATION TECH CO LTD

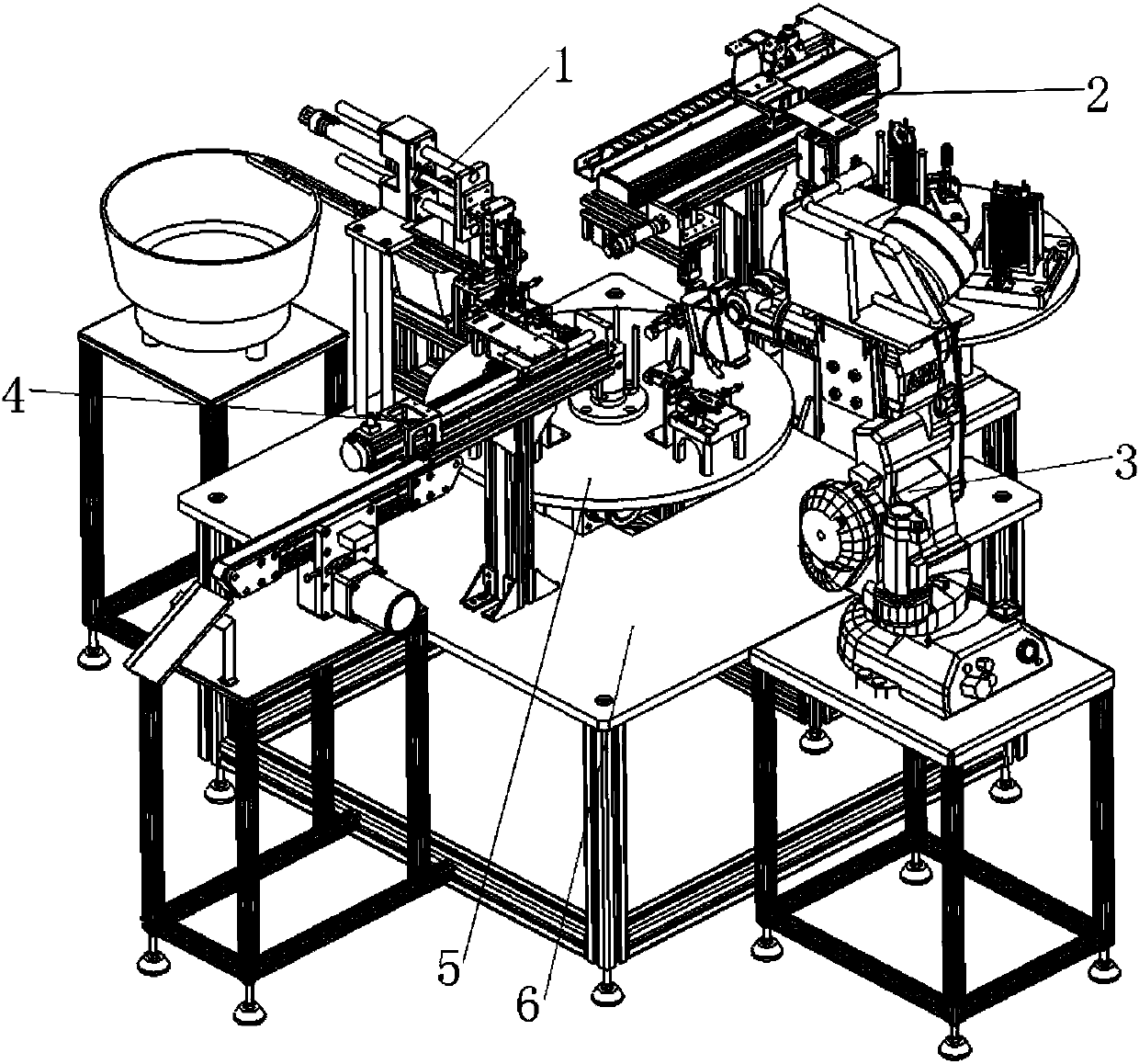

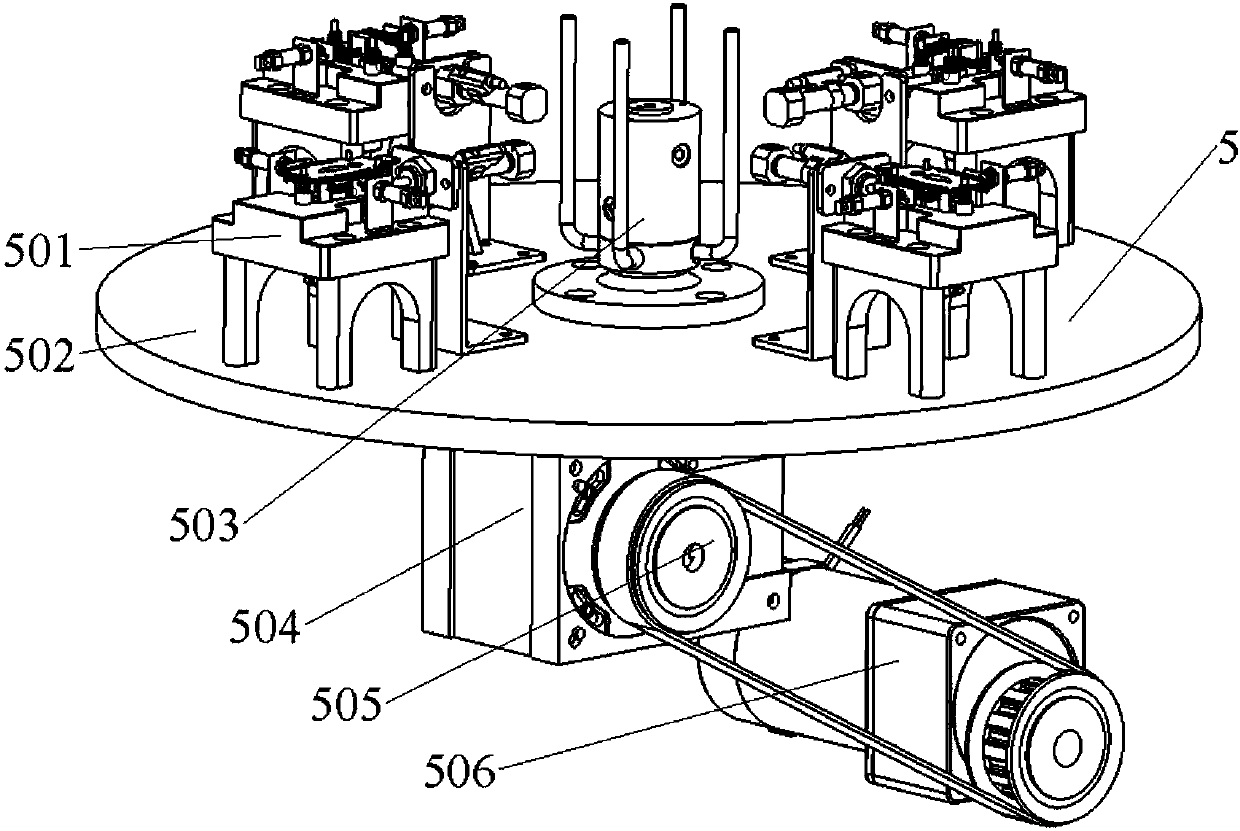

Ultrasound-assisted laser brazing method and device for dissimilar-metal assembly piece

ActiveCN107225327ARealize the welding effectHigh dimensional accuracyWelding/soldering/cutting articlesLaser beam welding apparatusUltrasonic assistedEngineering

The invention provides an ultrasound-assisted laser brazing method for a dissimilar-metal assembly piece. The ultrasound-assisted laser brazing method for the dissimilar-metal assembly piece comprises the steps that (1) a locating die is used for clamping a A-metal stand column; (2) the upper end of the A-metal stand column is heated to be soft; (3) the upper end, which is induction-heated and softened, of the A-metal stand column is inserted into a profiling hole of a B-metal base, and then a dissimilar-metal laser welded preassembly piece is obtained; (4) an ultrasonic vibration source connected with a locating die assembly is started, the laser is emitted out, under the auxiliary action of an ultrasonic vibration composite energy field, a laser-MIG composite welding head conducts melt-brazing along the outline of a connection face of the A-metal stand column and the B-metal base; and (5) the dissimilar-metal laser welded assembly piece is transfers to a conveyer belt and then falls into a material box. By the adoption of the ultrasound-assisted laser brazing method for the dissimilar-metal assembly piece, the large-fusion-depth narrow-weld-joint welding effect can be achieved, and a welded connector better in metallurgical quality is obtained. The invention further provides an ultrasound-assisted laser brazing device for the dissimilar-metal assembly piece.

Owner:山东承坤信息科技有限公司

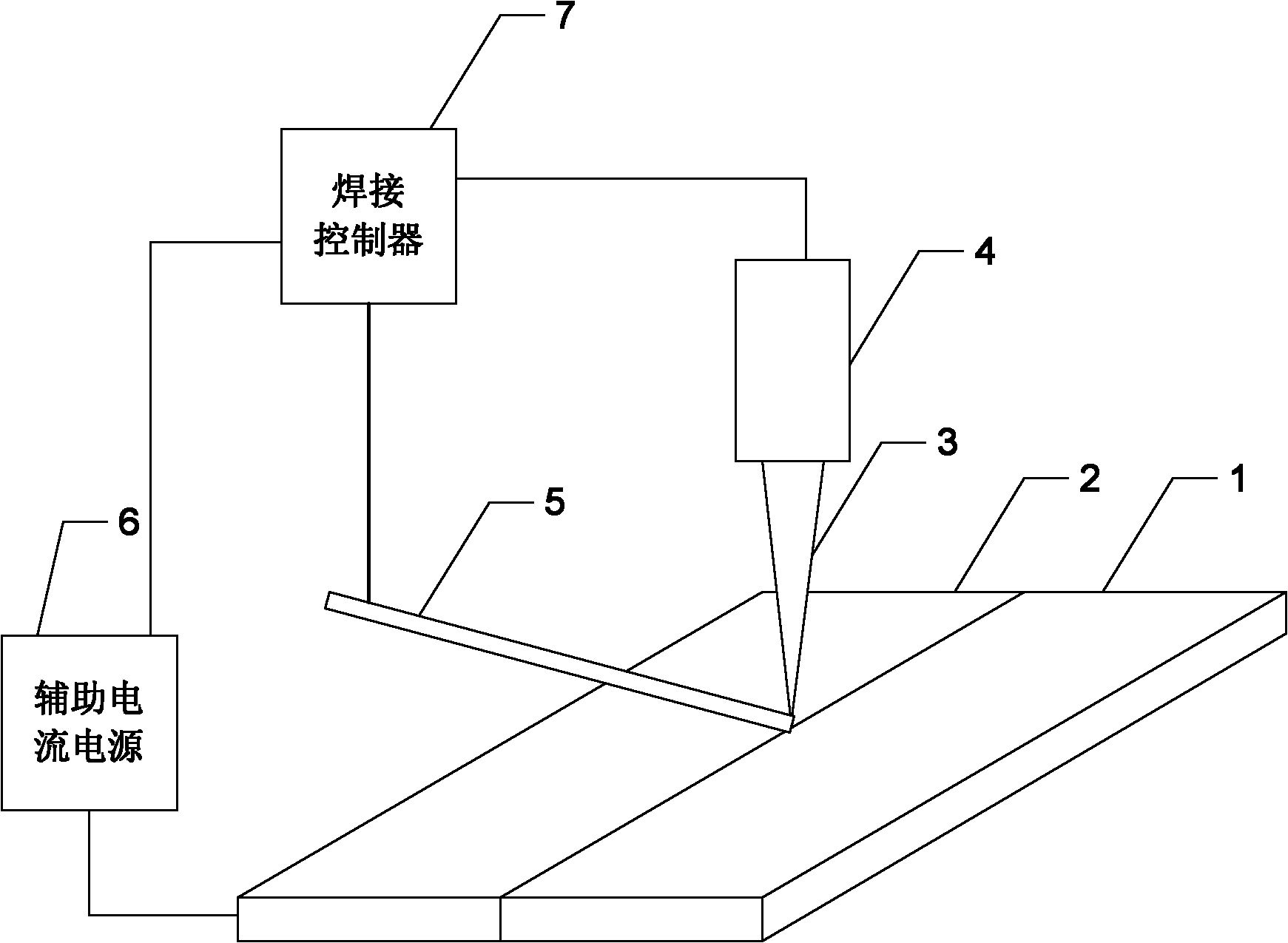

Current-assisted laser brazing method or laser fusion brazing method

The invention relates to a current-assisted laser brazing method or laser fusion brazing method, and belongs to the field of welding. The invention aims to solve the problems of poor moistening and spreading capabilities of brazing materials, and space nonuniformity and low energy utilization efficiency of interface reaction in the traditional laser brazing and laser fusion brazing. In the welding process, two mother metals are connected to one output end of an auxiliary current power supply, the other output end of the auxiliary power supply is connected with a welding wire or a non-fusion electrode through a welding controller, a laser beam is vertically incident to a welding seam, and the welding wire or the non-fusion electrode is added along the front or back side of the welding direction of the laser beam. The method comprises the following steps of: 1. pretreating two mother metals to be welded; 2. fixing the two mother metals to be welded on a worktable, connecting the auxiliary current power supply to the two mother metals; 3. putting the welding wire or the non-fusion electrode at the front or rear side of the welding direction of the laser beam; 4. and starting the laser welding, switching on the auxiliary current power supply, and coordinating and controlling the matching relation between the laser beam and the auxiliary current so as to implement welding.

Owner:HARBIN INST OF TECH

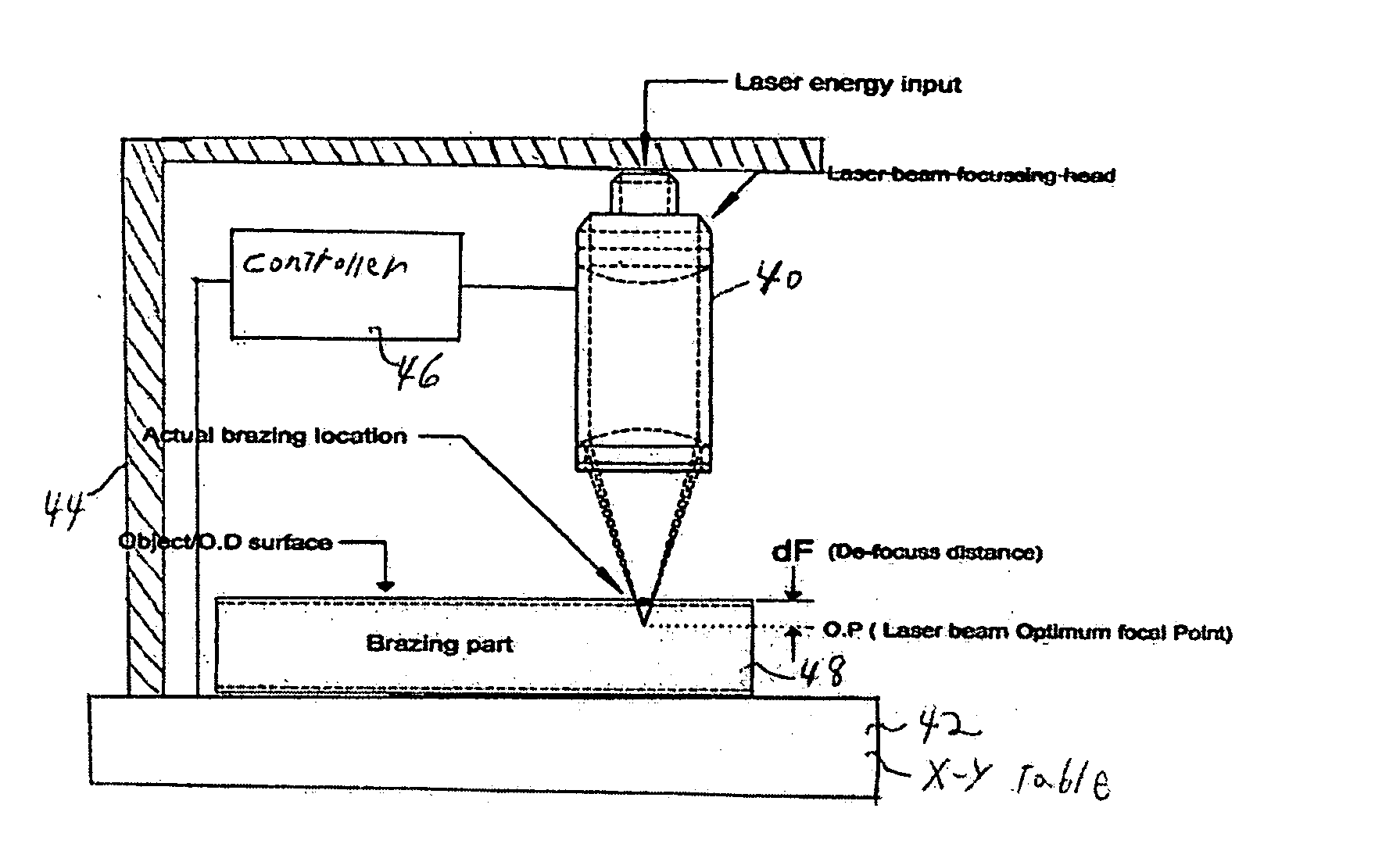

Laser welding-self brazing in medical power manufacturing

InactiveUS20160271728A1Improve bindingEnergy balanceSmall-sized cells cases/jacketsElectrode carriers/collectorsEngineeringElectrochemical cell

A process for creating a laser braze weld joint between a current collector and a terminal pin in the construction of electrochemical cells is described. The laser braze welding process utilizes a laser weld instrument to create a braze-like joint between two work pieces. The weld joint is created by controlling the amount of laser heat and energy imparted to the work pieces through proper control and positioning of the laser beam with respect to the work pieces. Preferably, the method is used to bond the terminal pin to the cathode current collector. This method of attachment is suitable for either primary or secondary cells, particularly those powering implantable biomedical devices.

Owner:WILSON GREATBATCH LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com