Laser brazing clearance compensation method

A technology of brazing gap and compensation method, which is applied in the direction of laser welding equipment, welding equipment, welding equipment, etc., can solve the problems of low pass rate, increase of vehicle production cost, and long adjustment time, so as to improve assembly accuracy and facilitate Promote, adjust simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

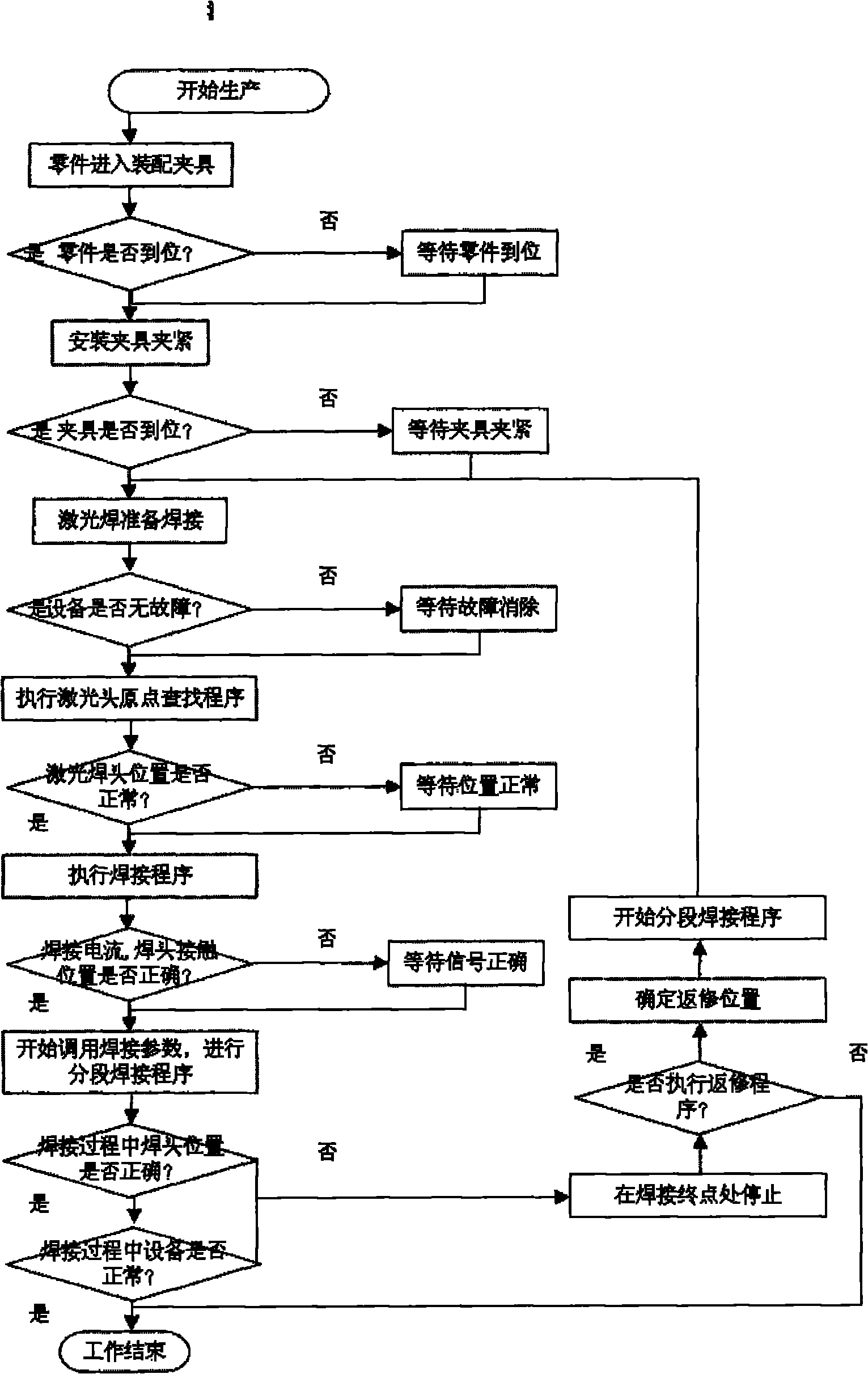

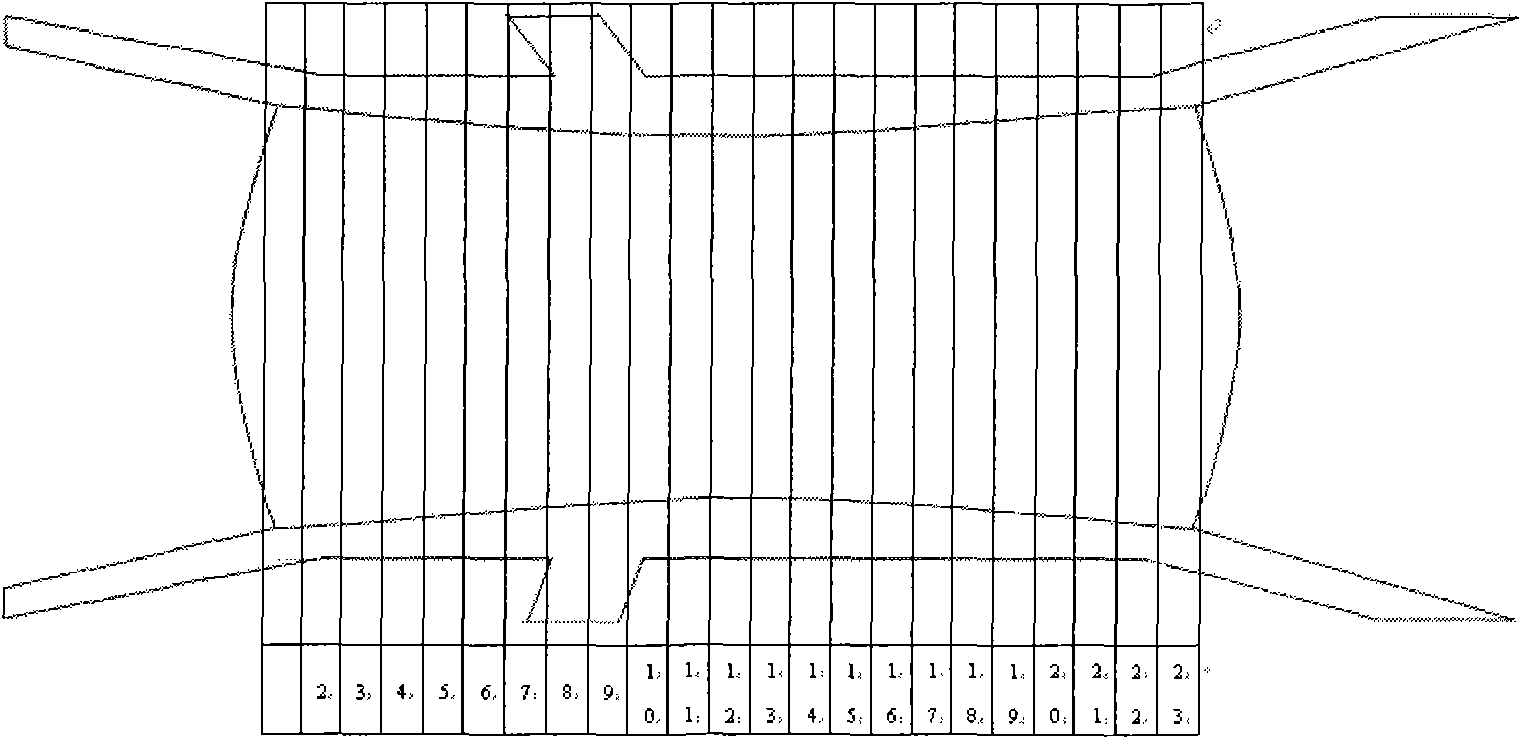

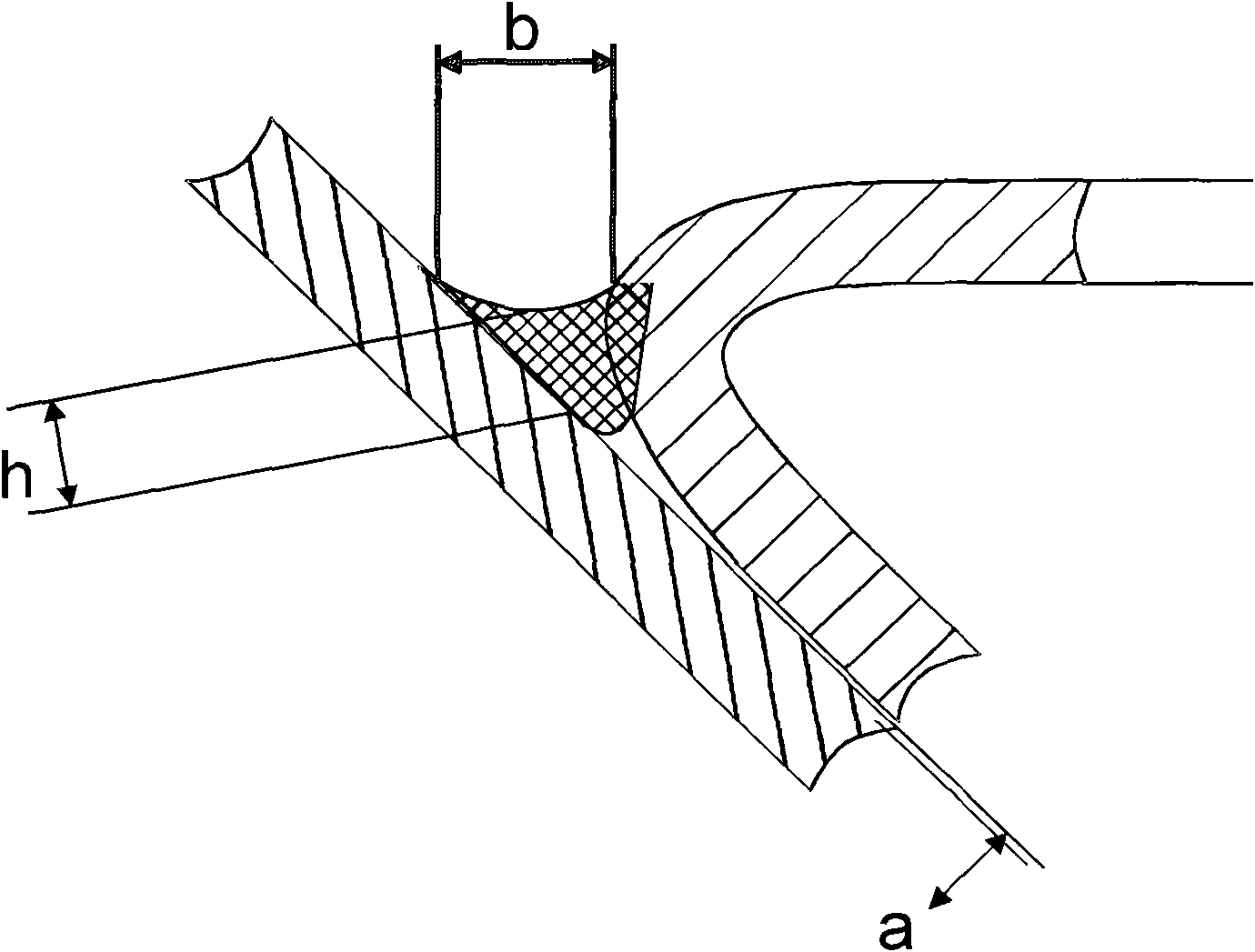

[0015] Such as figure 2 In the assembly area shown, the robot program is decomposed into 23 segments, and segmented control can solve the problem of poor uniformity of the assembly gap. Such as image 3 The shown a is the assembly gap, b is the welding width, and h is the welding penetration depth. By adjusting the robot speed Vb and the wire feeding speed Vs of the hot wire machine, the assembly gap a can be changed to ensure that the welding width b and welding penetration h are stable. . The adjustment range of Vb is less than 2.34 m / min, the adjustment range of Vs is less than 2.88 m / min, the ratio of robot speed Vb to wire feeding speed Vs is (a+b)×k, k is the output loss of the hot wire machine is 0.3525, and the quality requirement of b value is 3mm, by checking such as Figure 4 The table shown to determine the parameters of the robot, such as figure 1 The programmable controller shown in the figure controls the work of the assembly fixture, conveying system, and ...

Embodiment 2

[0019] The programmable controller controls the assembly fixture, conveying system, and robot work, and the robot controls the laser welding machine and laser welding head to work; the parts are transported into the assembly fixture through the conveying system, and the programmable controller detects whether the parts are transported in place and controls the assembly. The fixture is clamped, and the robot controls the laser welding machine to prepare to execute the welding program; execute the laser welding head origin search program to judge whether the position of the laser welding head is correct. If the welding program is performed correctly, if it is not correct, wait for the position to be normal and continue to execute the welding program; after that The system detects whether the welding current and the contact position of the welding head are correct. If the welding parameters are called correctly, the segmental welding is performed; 23 welding procedures are performe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com