Automatic assembly equipment for spring lock

An automatic assembly and pin lock technology, applied in metal processing equipment, assembly machines, manufacturing tools, etc., can solve the problems of high error rate, low assembly efficiency and assembly accuracy, and low assembly accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

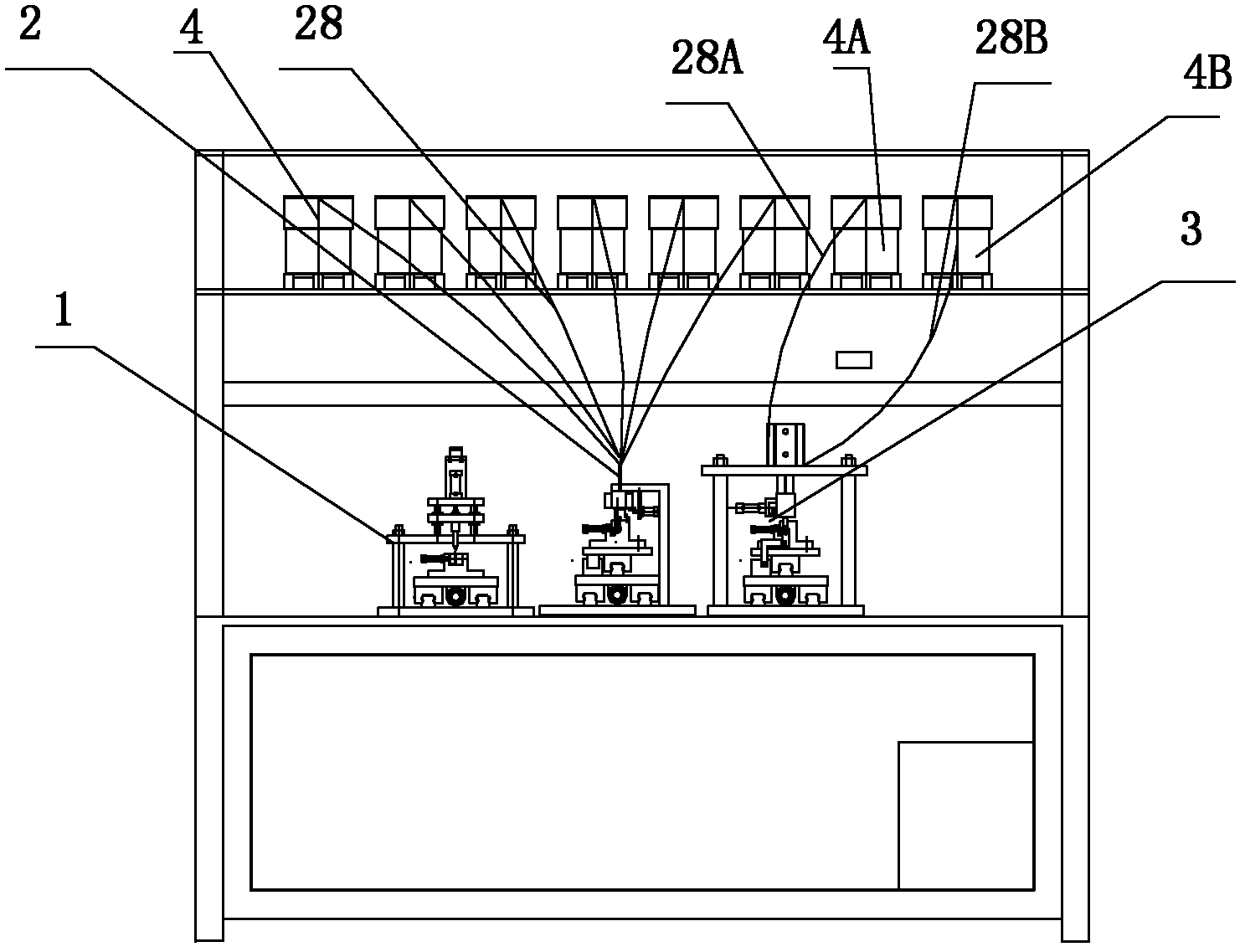

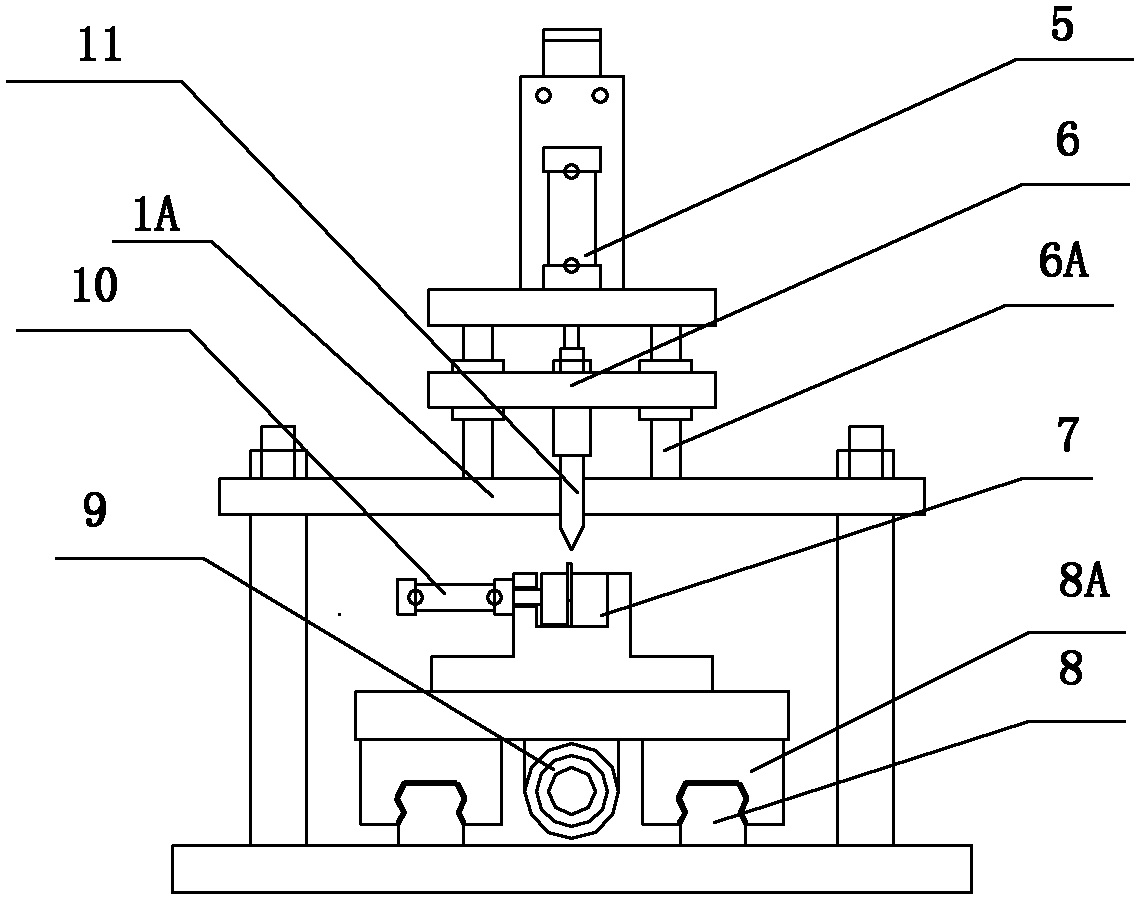

[0037] like Figure 1-12 The shown automatic assembly equipment for tumbler locks includes a frame, a pneumatic control assembly and a microcomputer controller. A pin feeding tray 4, a spring feeding tray 4A, a sealing bullet feeding tray 4B, and a key chip recognition device are installed on the frame. 1. The pin swing device 2 and the spring cover installation device 3, the key tooth pattern identification device 1, the pin swing device 2 and the spring cover installation device 3 are respectively connected with the microcomputer controller, and the pin feed tray 4 is connected with the pin swing device 2 are connected, the spring feeding tray 4A and the bullet feeding tray 4B are both connected with the spring sealing installation device 3, the microcomputer controller controls the pneumatic control assembly, the key tooth pattern identification device 1, the pin swing device 2 and the spring sealing installation device 3 actions.

[0038] The key chip identification devic...

Embodiment 2

[0053] The pin lock with double lock cylinder has two rows of pins before and after, such as the double unlocking cylinder of the door lock. During the production and processing of the pin lock with double lock cylinder, various reasons may cause the margins on both sides of the lock body to be unequal, and the error is still very random.

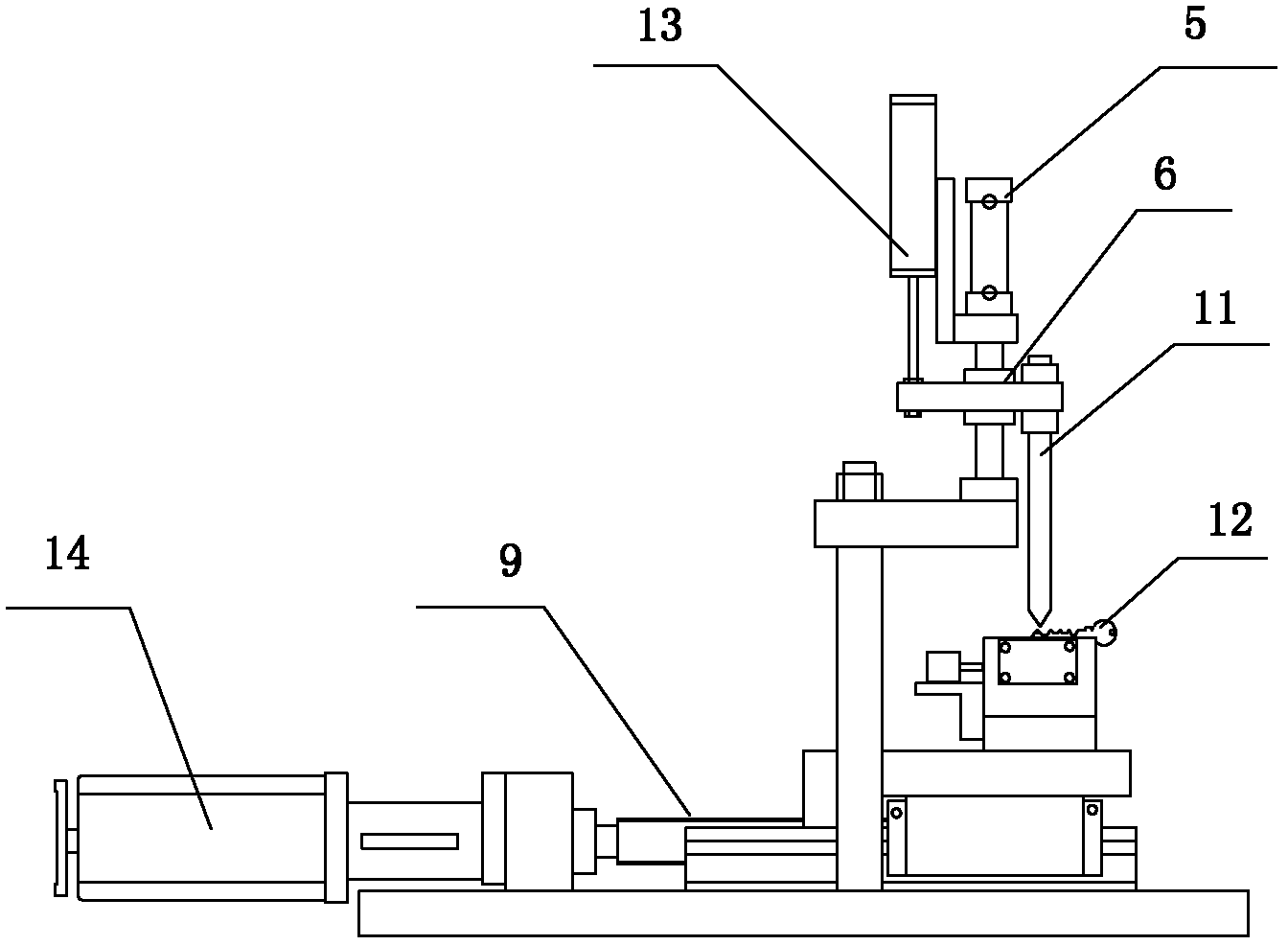

[0054] like figure 1 , figure 2 , image 3 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 and Figure 16 The shown automatic assembly equipment for tumbler locks is mainly suitable for tumbler locks with double lock cylinders. The other structures are the same as those in Embodiment 1. The structures of the pin swing device 2 and the spring cover installation device 3 are different from those in Embodiment 1.

[0055] like Figure 13 and Figure 14 The pin swing device 2 shown includes all the structures of Embodiment 1, and the pin swing device 2 also includes the second ...

Embodiment 3

[0060] like figure 1 , figure 2 , image 3 , Figure 17 , Figure 18 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 and Figure 12 The shown automatic assembly equipment for tumbler locks has the same other structure as that of embodiment 1, and the pin swing device 2 is different from that of embodiment 1, and is also mainly suitable for tumbler locks with double lock cylinders.

[0061] The pin swing device 2 also includes the second moving assembly 24 of the lock body, the second moving assembly cylinder 30, the middle positioning block 22, the front positioning block 29 and the rear positioning block 23, and the second moving assembly 24 of the lock body is fixed on the lock body fixture to move. In mechanism, the lock body fixture 18 is fixed on the lock body second moving assembly 24, the second moving assembly cylinder 30 is connected to the lock body second moving assembly 24, the middle positioning block 22 is installed on the lock...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com