Patents

Literature

493results about How to "Implement automatic assembly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

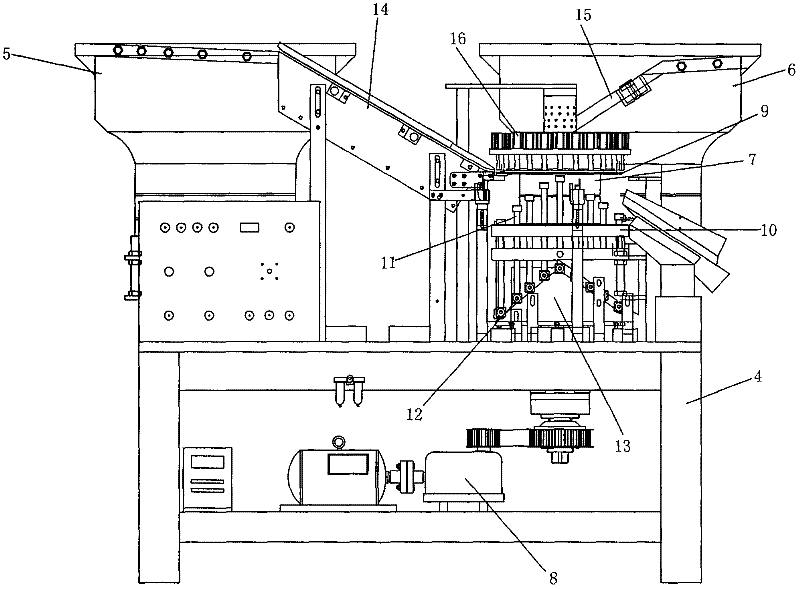

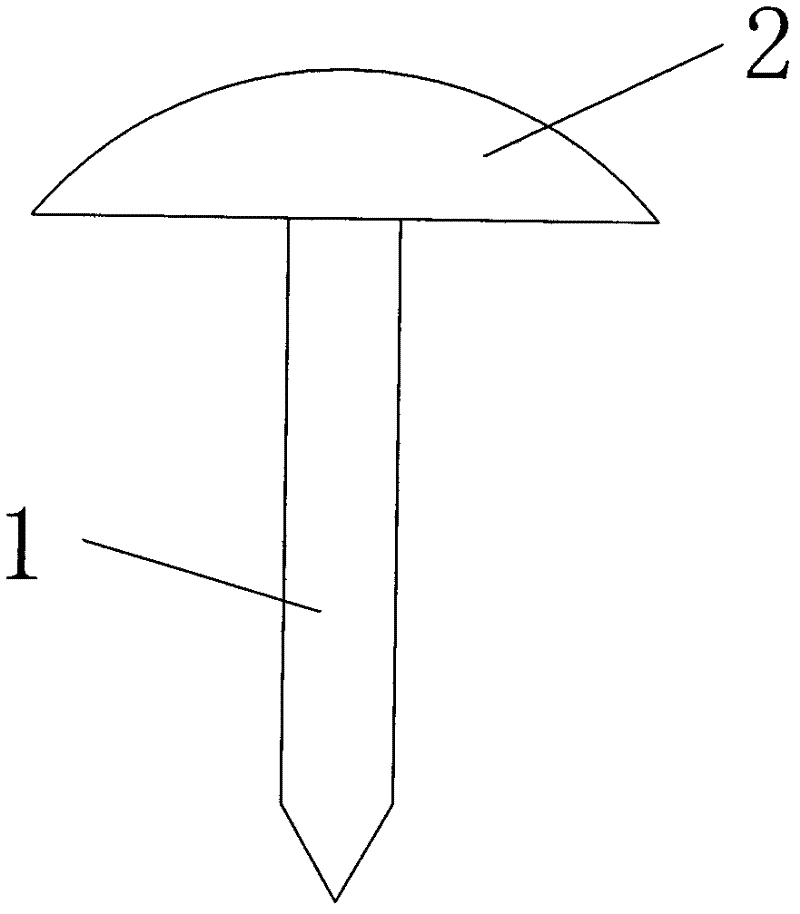

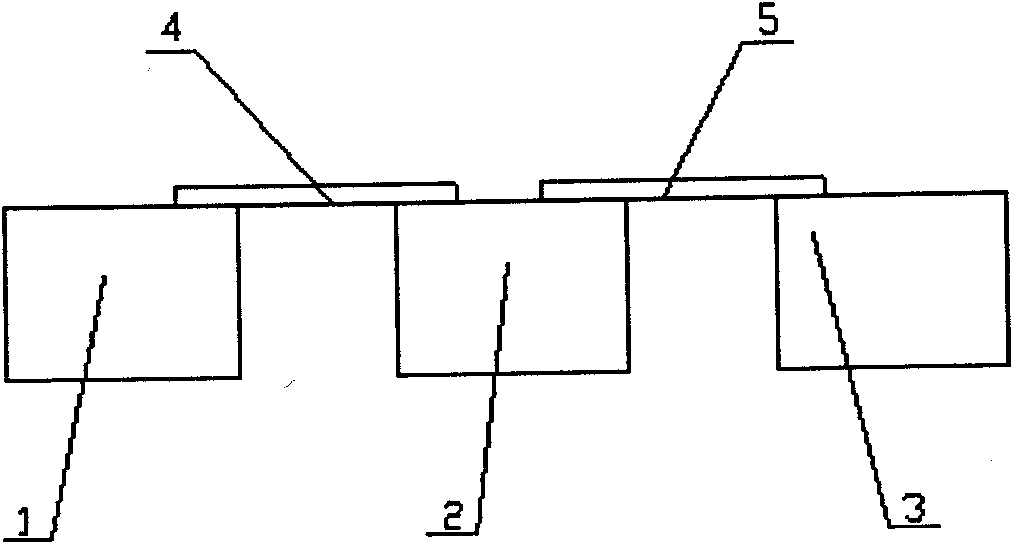

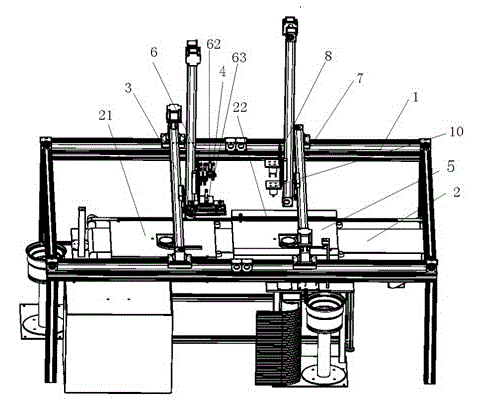

Screw washer assembly machine

InactiveCN102294588AImplement automatic assemblyImprove assembly efficiencyMetal working apparatusDrive motorEngineering

The invention discloses a screw and washer combining machine, which comprises a working platform of a machine frame, a driving motor, a screw conveying rail and a washer conveying rail, wherein a screw vibration plate and a washer vibration plate are arranged on the working platform; a vertical rotating column passes through the working platform; an output shaft of the driving motor is connected with the rotating column; a circle of hanging plate is arranged on the rotating column; hanging and holding notches which are uniformly distributed are formed on the edge of the hanging plate; a plurality of lifting shaft sleeves pass through the rotating column below the hanging plate and correspond to the hanging and holding notches; washer grooves are formed on the upper end faces of the lifting shaft sleeves; lifting bearings are arranged on the tail part of the lifting shaft sleeves; a lifting rail is also sleeved on the lower part of the rotating column partially; the two ends of the screw conveying rail are respectively jointed with the output end of the screw vibration plate and the hanging plate; the input end of the washer conveying rail is jointed with the output end of the washer vibration plate; and the output end of the washer conveying rail is positioned above the hanging plate. The screw and washer combining machine has the advantages that: a screw and a washer are automatically assembled, the assembly efficiency is greatly improved, and a large amount of labour is saved.

Owner:浙江中超工业视镜有限公司

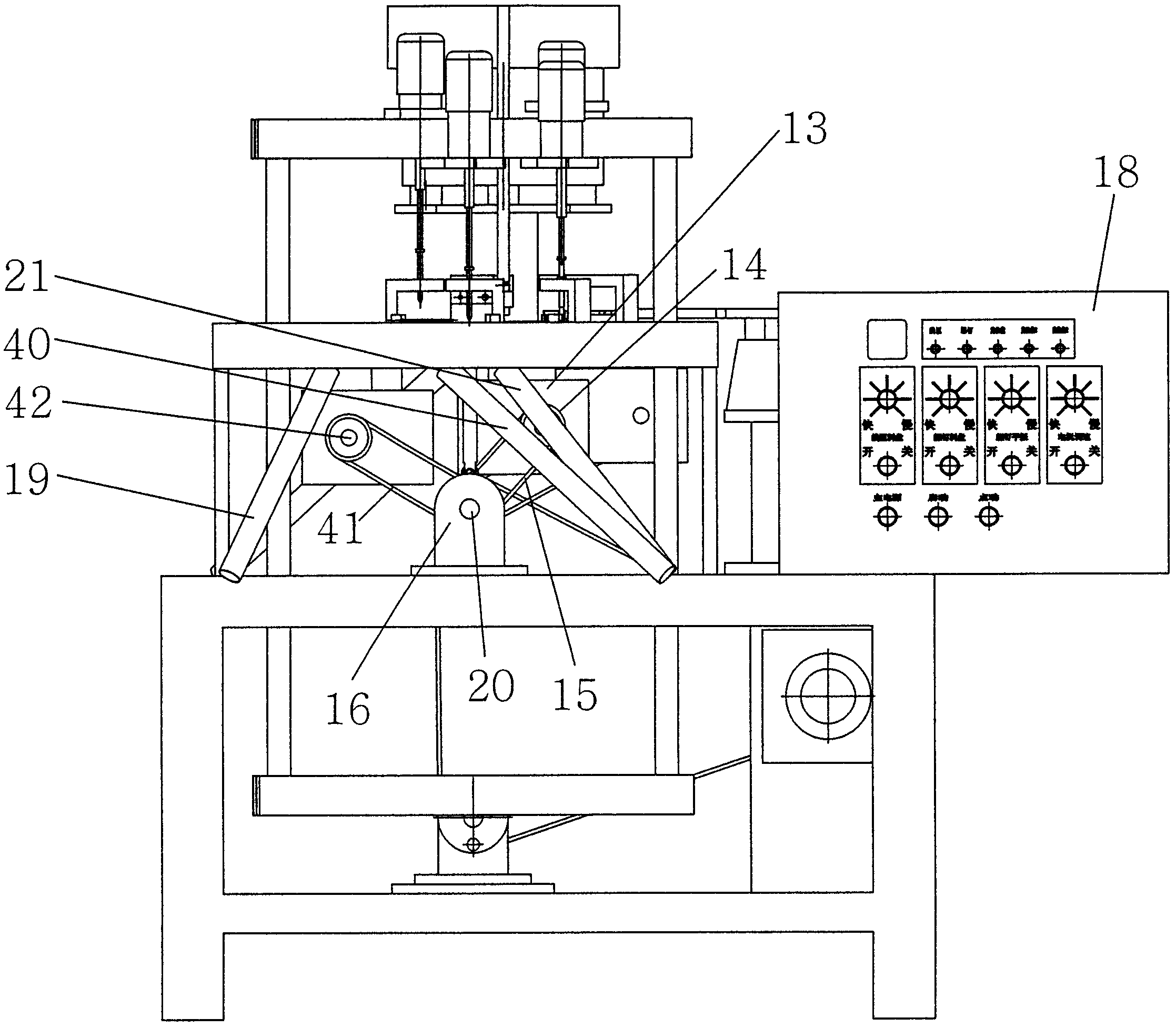

Automatic assembly equipment for spring lock

ActiveCN102248398ANovel structureHigh degree of automationAssembly machinesEngineeringIdentification device

The invention relates to assembly equipment for lockset, in particular to automatic assembly equipment for a spring lock. The automatic assembly equipment comprises a machine frame and a microcomputer controller, wherein a spring feed disc, a mechanical spring feed disc, a spring sealing feed disc, a key bit identification device, a spring swinging device and a mechanical spring sealing installation device are arranged on the machine frame, wherein the key bit identification device, the spring swinging device and the mechanical spring sealing installation device are connected with the microcomputer controller respectively; the spring feed disc is connected with the spring swinging device; and the mechanical spring feed disc and the spring sealing feed disc are connected with the mechanical spring sealing installation device. The automatic assembly equipment for the spring lock has the advantages of novel structure, high automaticity and high assembly efficiency and assembly accuracy.

Owner:JINHUA KETE PRECISION MACHINERY

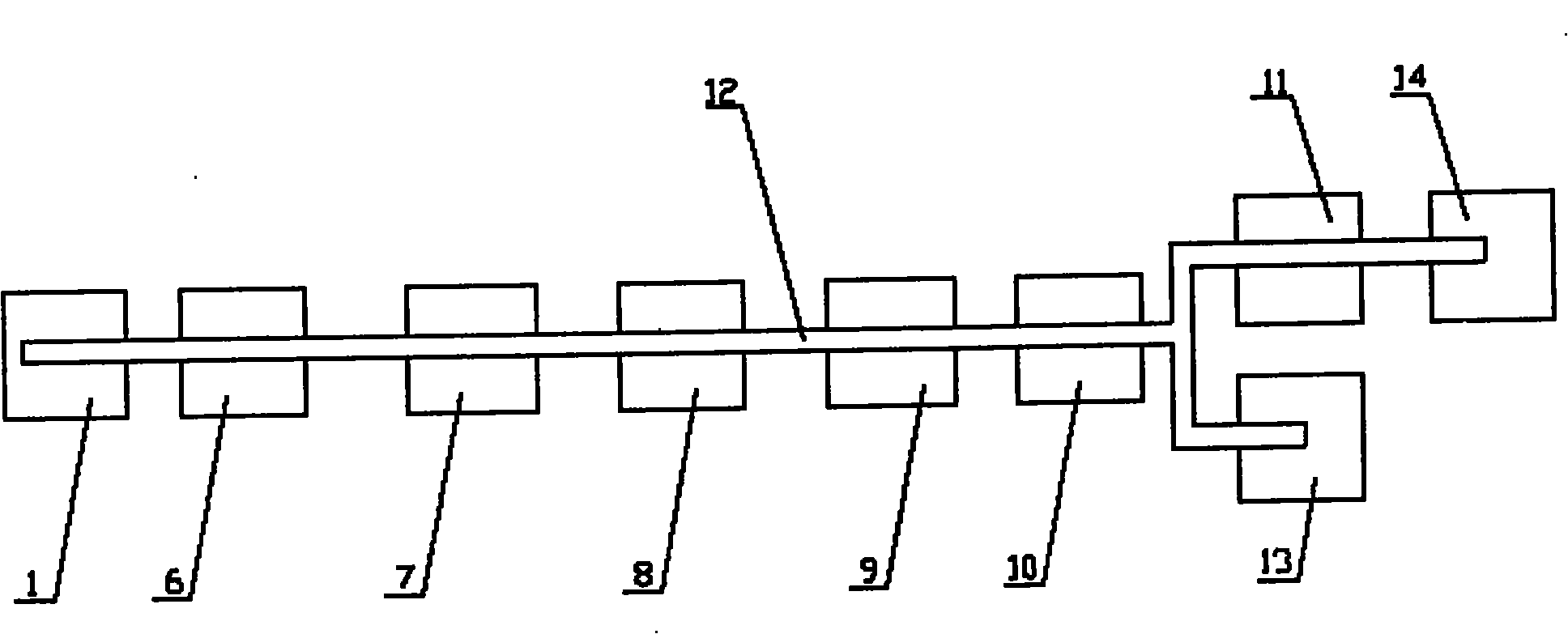

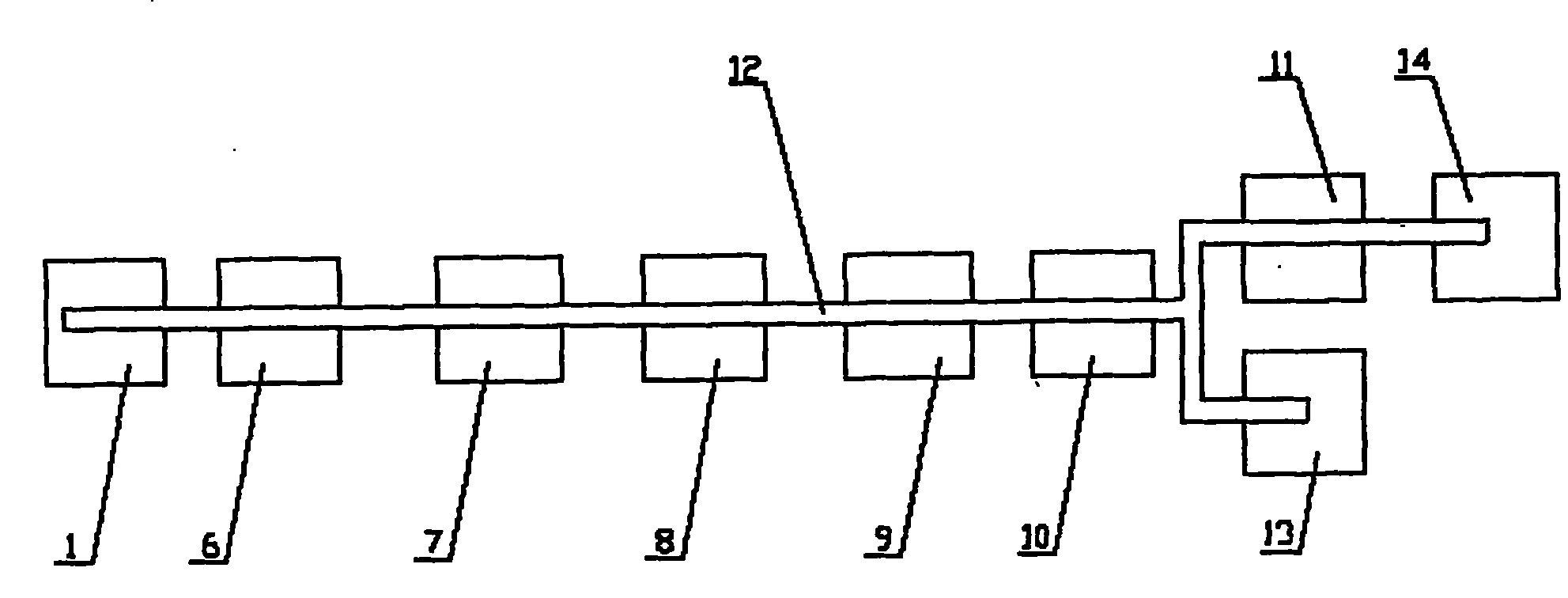

Automatic production line for automobile chains

InactiveCN101786138ARealize the ring riveting head functionImplement automatic assemblyMetal chainsWaste productPre stretching

The invention discloses an automatic production line for automobile chains. The automatic production line is characterized in that: a high speed chain assembling machine, a pre-stretching running-in machine, a disassembling machine, an air distribution piece assembling machine, a riveting machine and a special detection machine are connected in series through a guide rail; and on the one hand, the guide rail is connected in series with a ring joint riveting machine and a finished product box, and on the other hand, the guide rail is also connected in series with a waste product box. Compared with a conventional chain high-speed assembling automatic production line, the automatic production line has the advantages of one-off bulk chain part input and complete finished product production. Automatic assembly of the air distribution pieces for the automobile chains and ring joint riveting and pressing functions of the chains on a working position are realized. A chain guide rail is used for conveying the chains in the automatic production line, and qualified products and waste products of the chain are automatically distinguished. Missing part detection, fragment detection, and close and dead joint detection of the chains are completed on the working position of the single special detection machine.

Owner:南京聚星机械装备股份有限公司

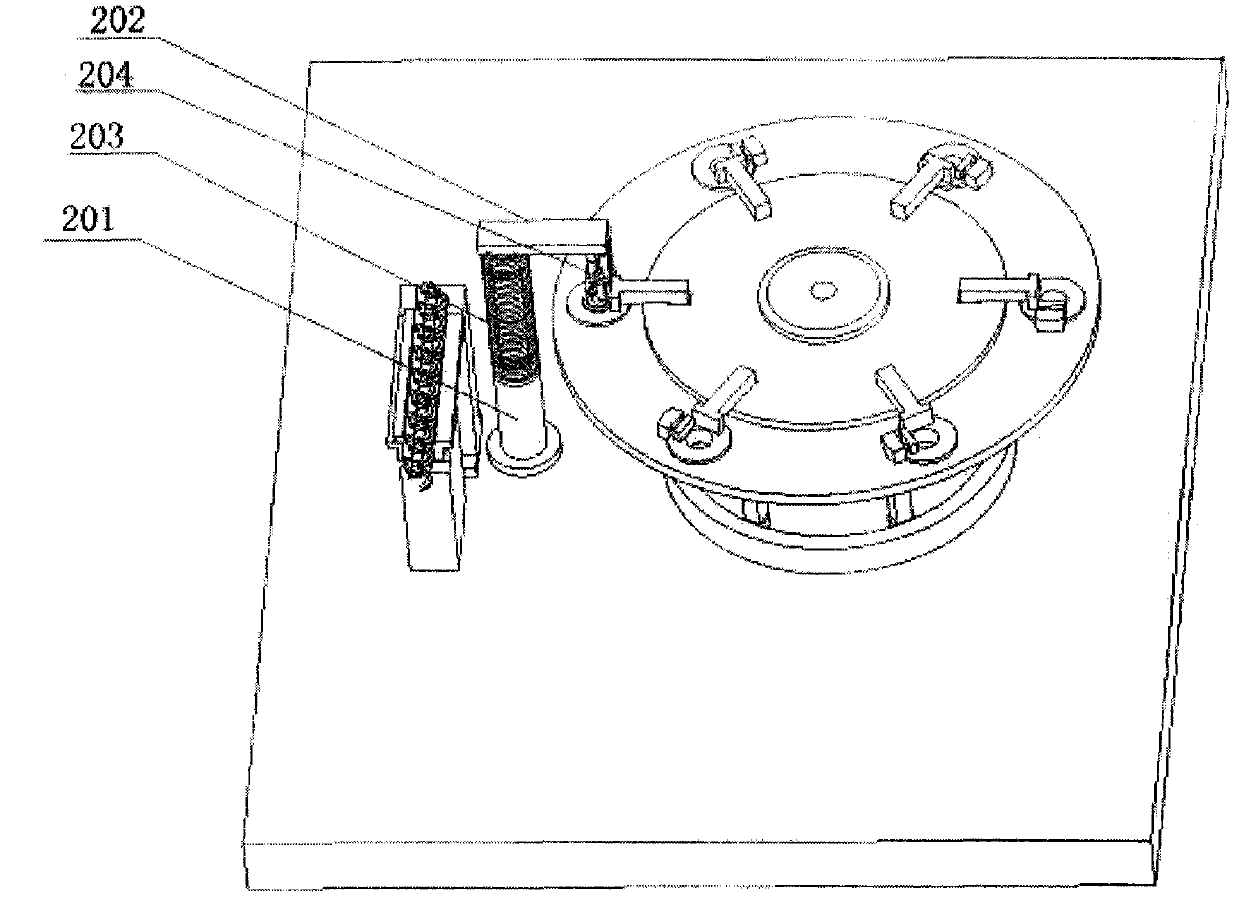

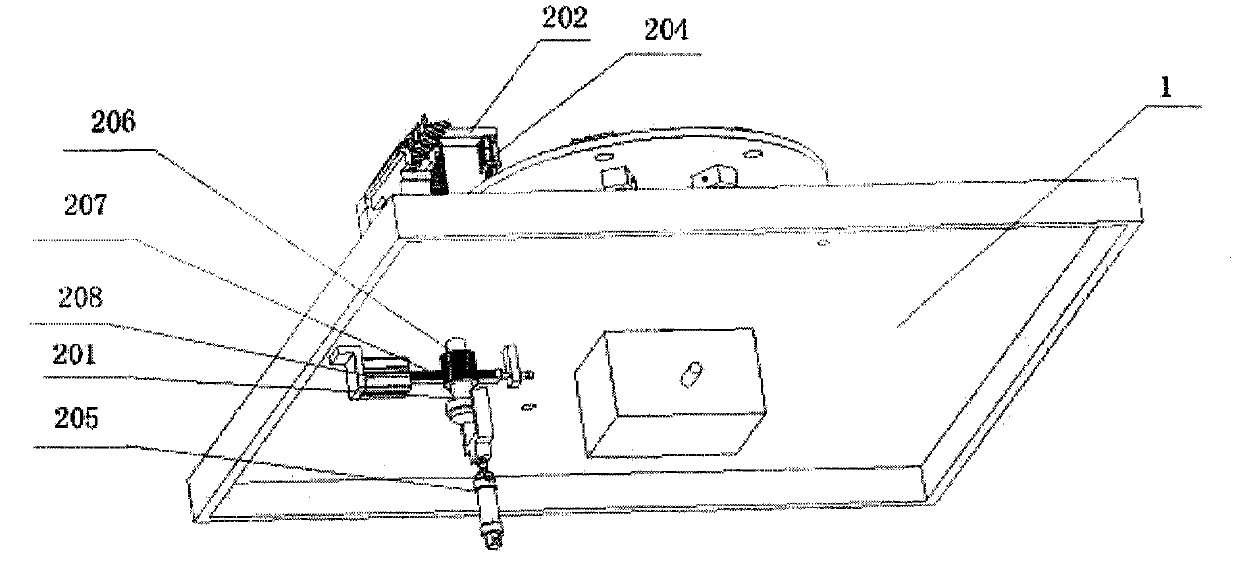

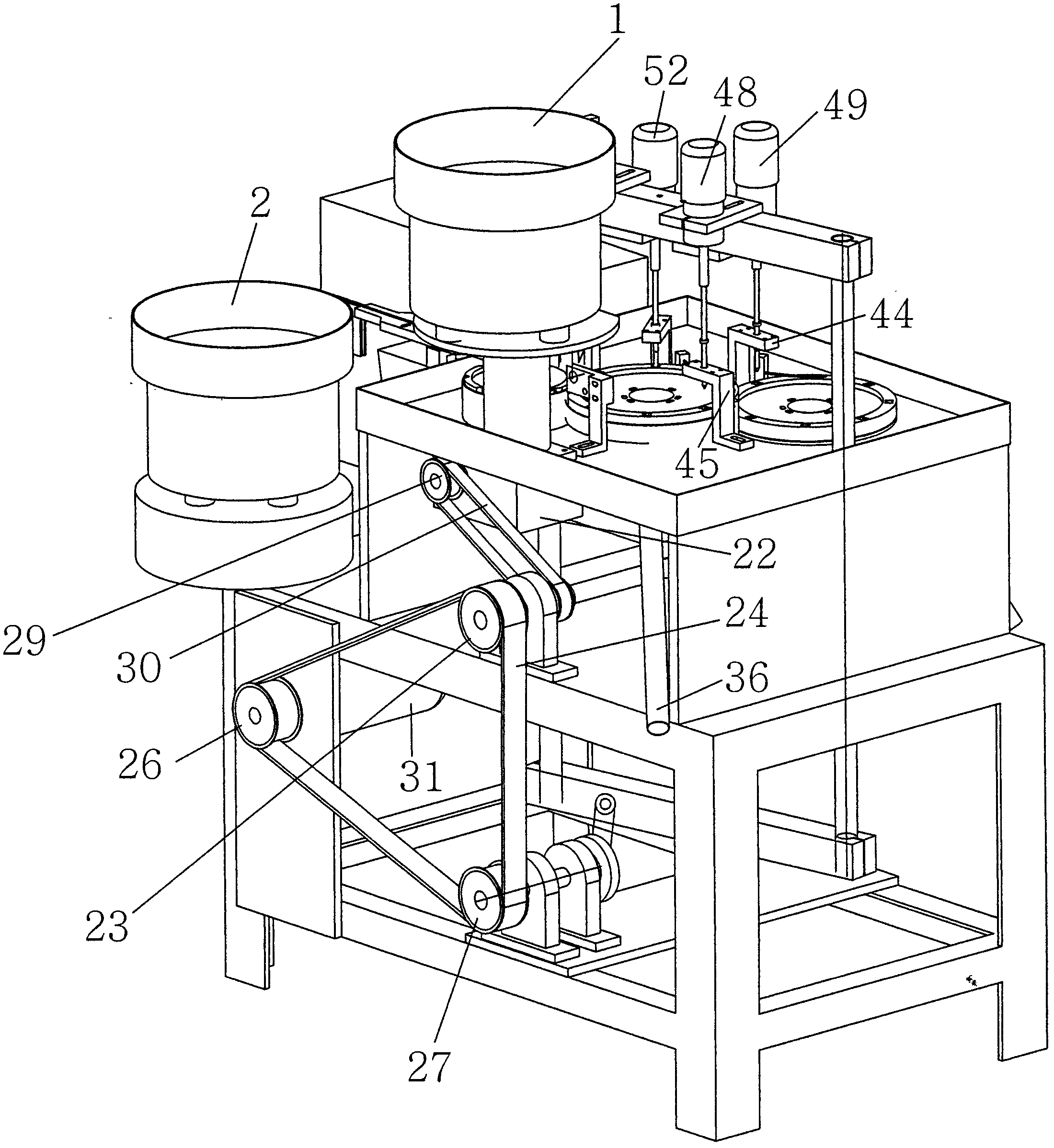

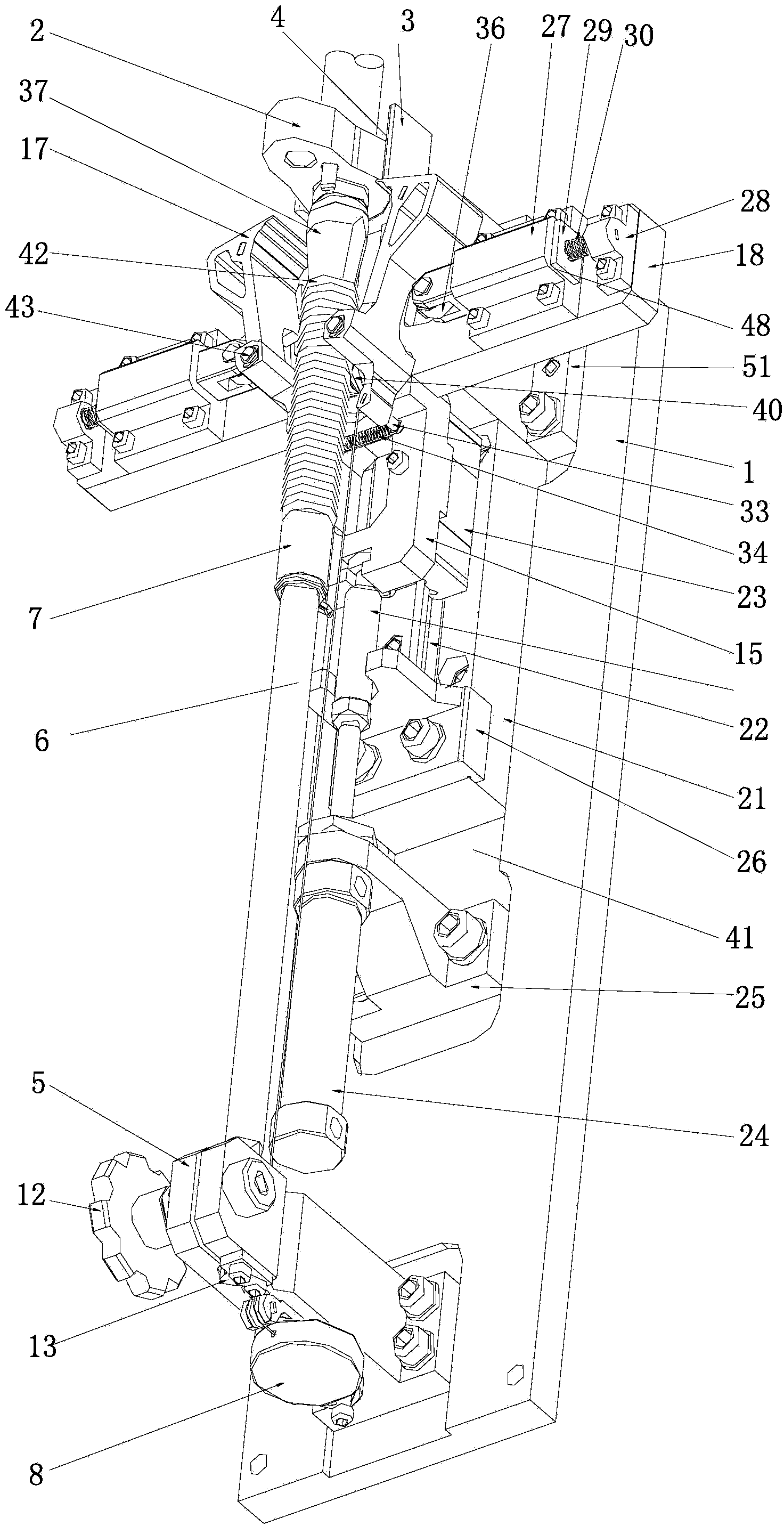

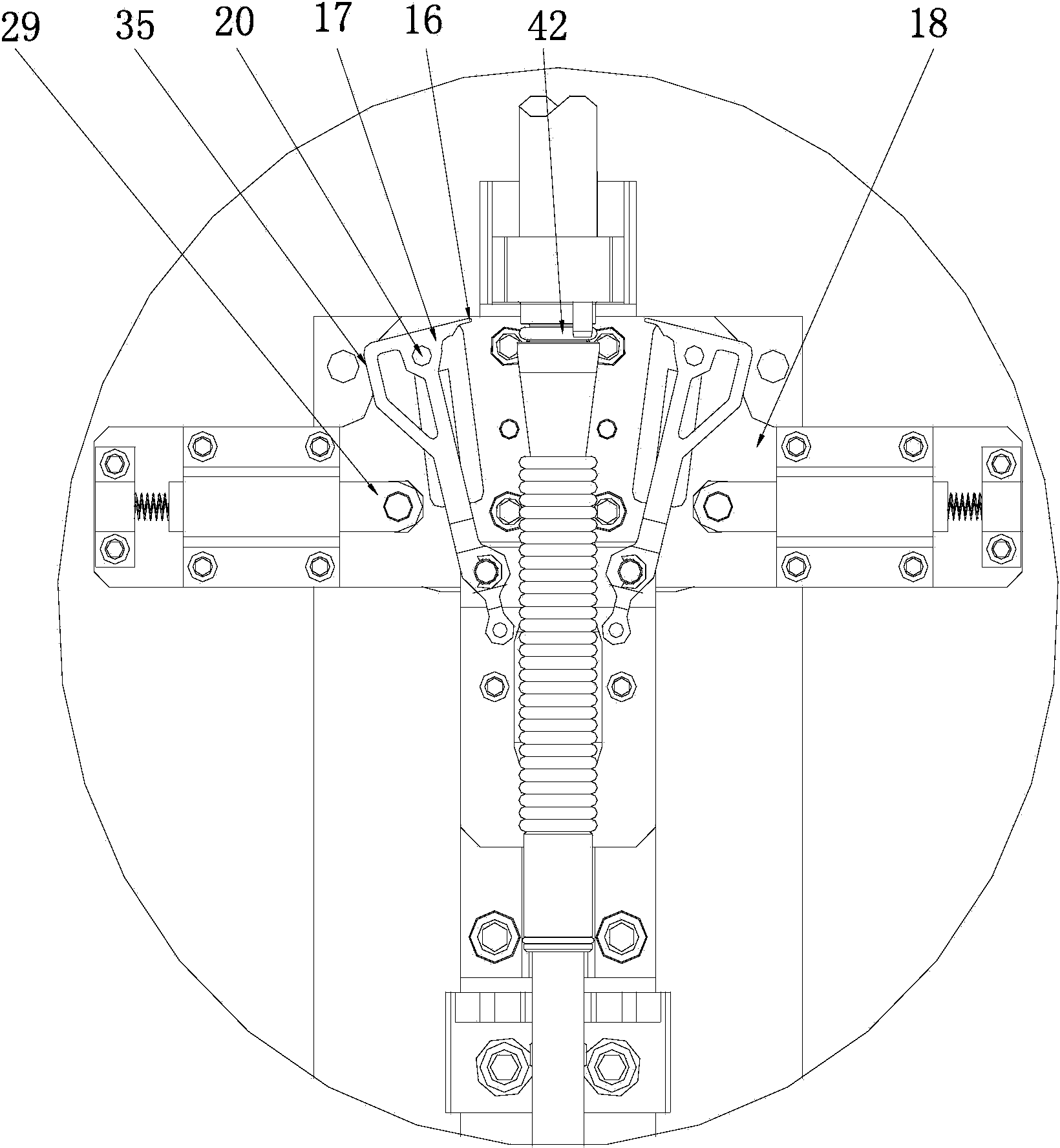

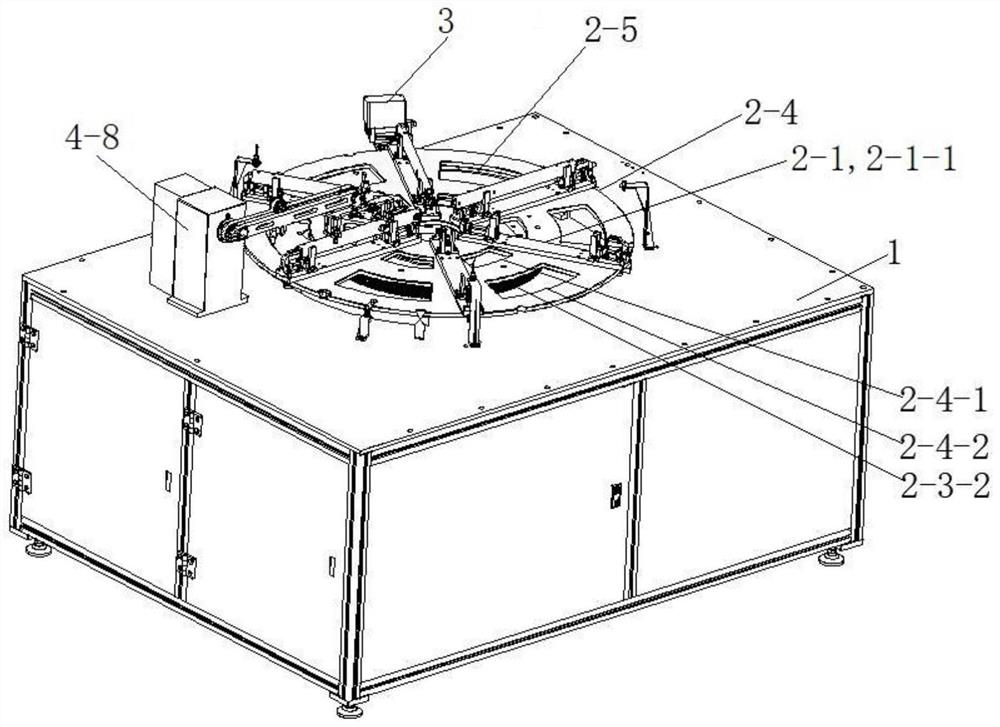

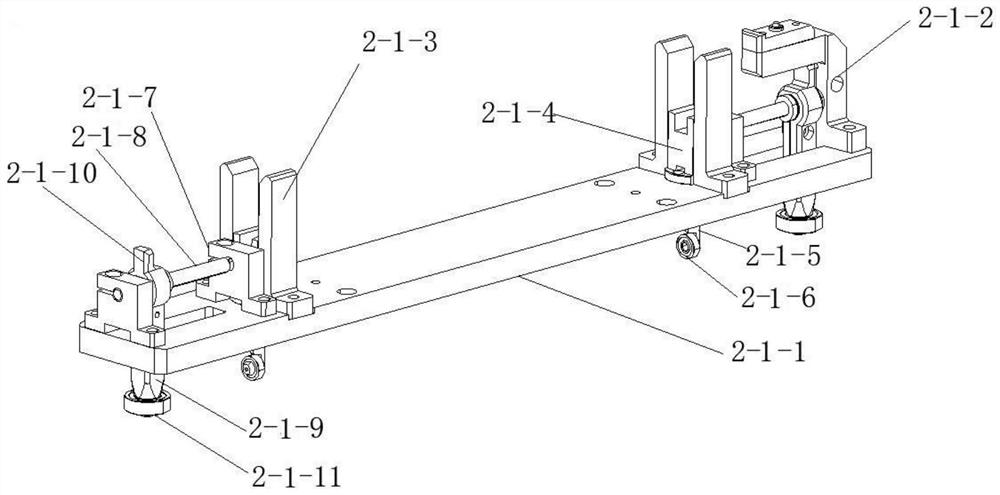

Fire extinguisher head automatic assembling machine

ActiveCN104889727AImplement automatic assemblyIncrease the speed of automatic assemblyAssembly machinesFire extinguisherMechanical equipment

The invention discloses a fire extinguisher head automatic assembling machine, and belongs to the technical field of mechanical equipment manufacturing. The fire extinguisher head automatic assembling machine comprises a rack (1), a rotating disc (2) and a PLC control unit, wherein the rotating disc and the PLC control unit are arranged on the rack (1). A driving mechanism for driving the rotating disc (2) to rotate is arranged on the rack (1), and vibration discs for conveying an extinguisher head element are sequentially arranged on the periphery of the rack (1), and extinguisher head containing holes (3) are sequentially formed in the rotating disc (2) and are evenly formed in the rotating disc in the circumferential direction; an extinguisher head compressing mechanism is arranged on the extinguisher head containing holes (3), and an automatic feeding mechanism, an ejector rod mounting mechanism, a spring and plastic joint mounting mechanism, a lifting handle and pressing handle mounting mechanism, an automatic riveting mechanism and an automatic discharging mechanism are sequentially arranged on the periphery of the rotating disc. The technical problem that in the prior art, fire extinguisher head elements are required to be manually assembled by a worker is solved, and the machine is used for automatically assembling the fire extinguisher head elements; and the production efficiency and the product quality can be improved.

Owner:TAIZHOU LANDUN MACHINERY

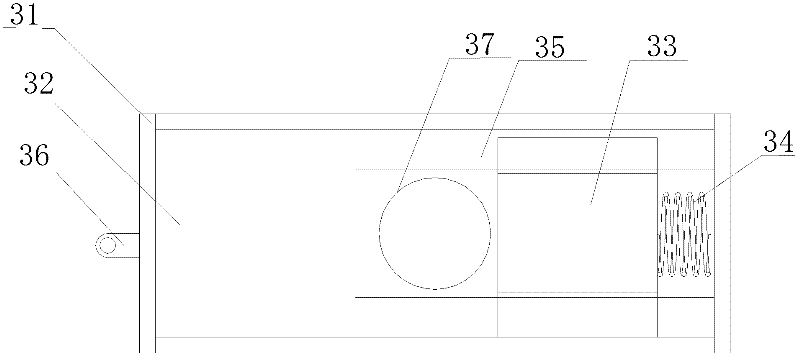

Notebook computer heat radiator assembling device

ActiveCN104914965ASave assembly timeImplement automatic assemblyDigital data processing detailsEngineeringManipulator

The invention discloses a notebook computer heat radiator assembling device. The notebook computer heat radiator assembling device comprises a stand, a conveyance belt assembly, a first triaxial mechanical arm, a template holding mechanical arm and a spacer holding mechanical arm, wherein the conveyance belt assembly is mounted on the stand, and a template placing station and a heat radiator mounting station are arranged on the conveyance belt assembly; a first mechanical arm mounting seat is mounted on the first triaxial mechanical arm mechanism, and the first triaxial mechanical arm mechanism is movably mounted on the stand; the template holding mechanical arm is used for holding a template and is mounted on the first mechanical arm mounting seat, so that the template is arranged on the template placing station under the driving of the first triaxial mechanical arm mechanism after the template holding mechanical arm holds a template; the spacer holding mechanical arm is used for holding a spacer and is also mounted on the first mechanical arm mounting seat, so that a spacer is arranged in a spacer slot of the template of the template placing station under the driving of the first triaxial mechanical arm mechanism after the spacer holding mechanical arm holds the spacer; The device can implement the automatic assembly of a notebook computer heat radiator, so that the assembly time is reduced, and the assembly efficiency is improved.

Owner:JIANGSU UNIV OF TECH

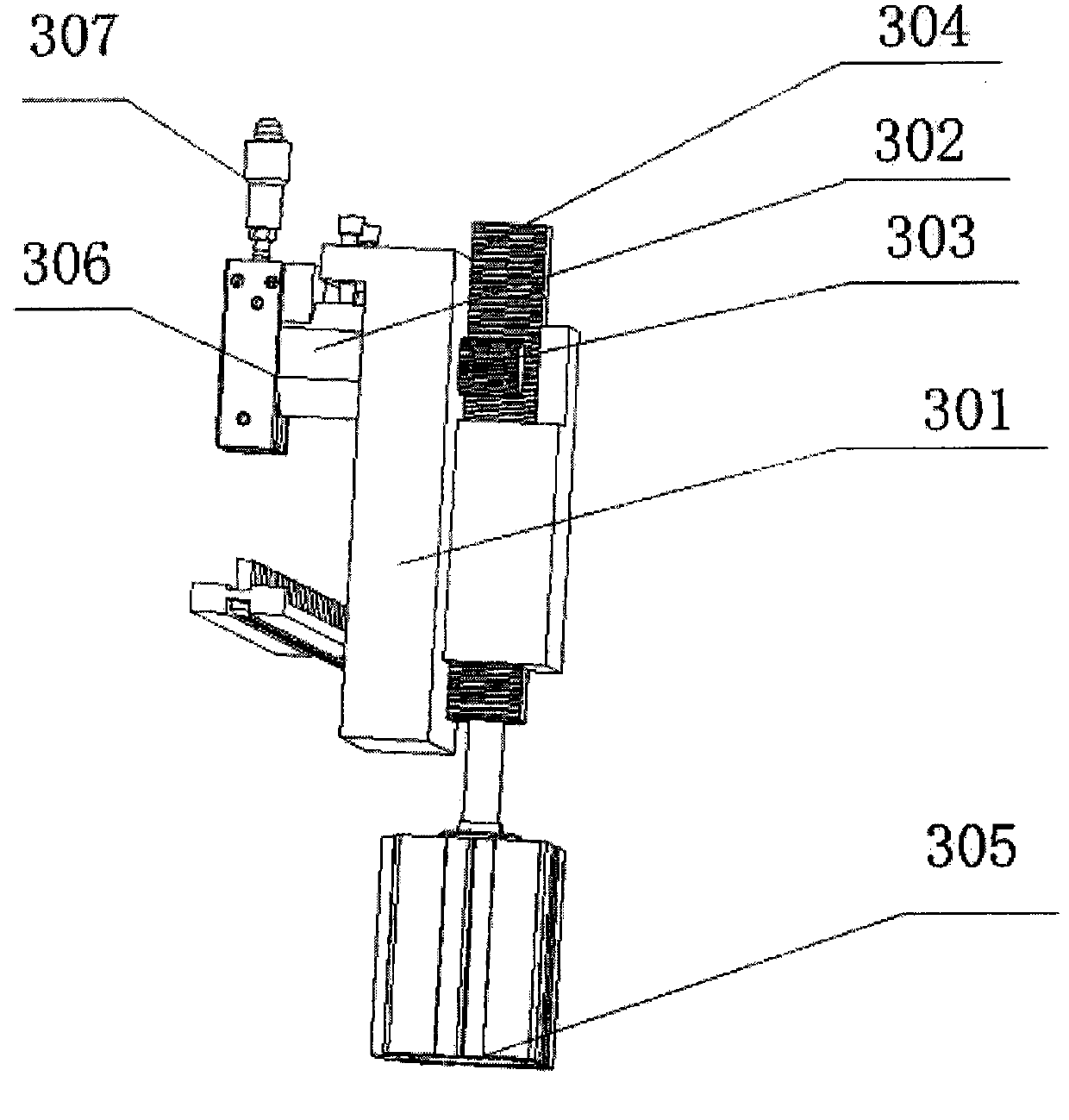

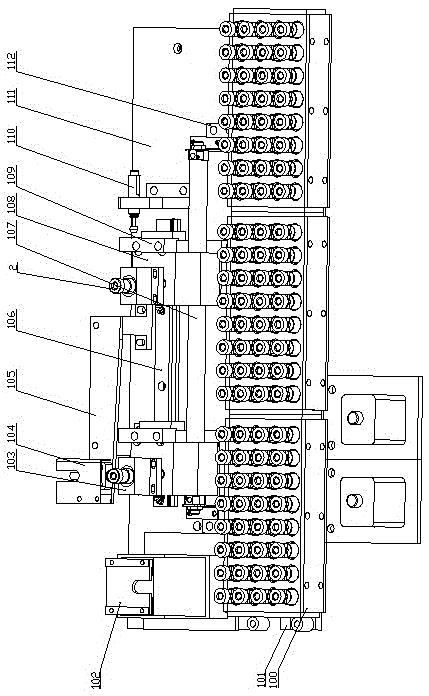

Motor rotor shaft automatic assembling machine

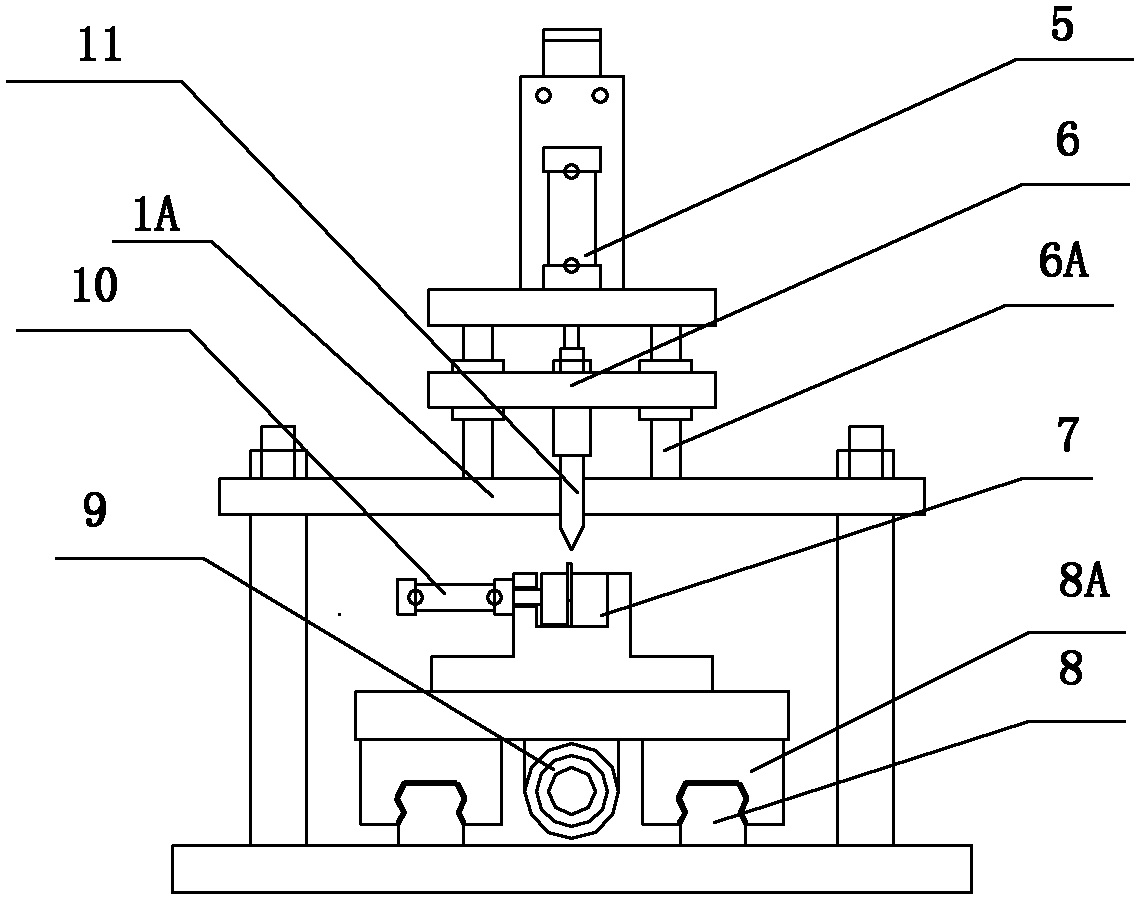

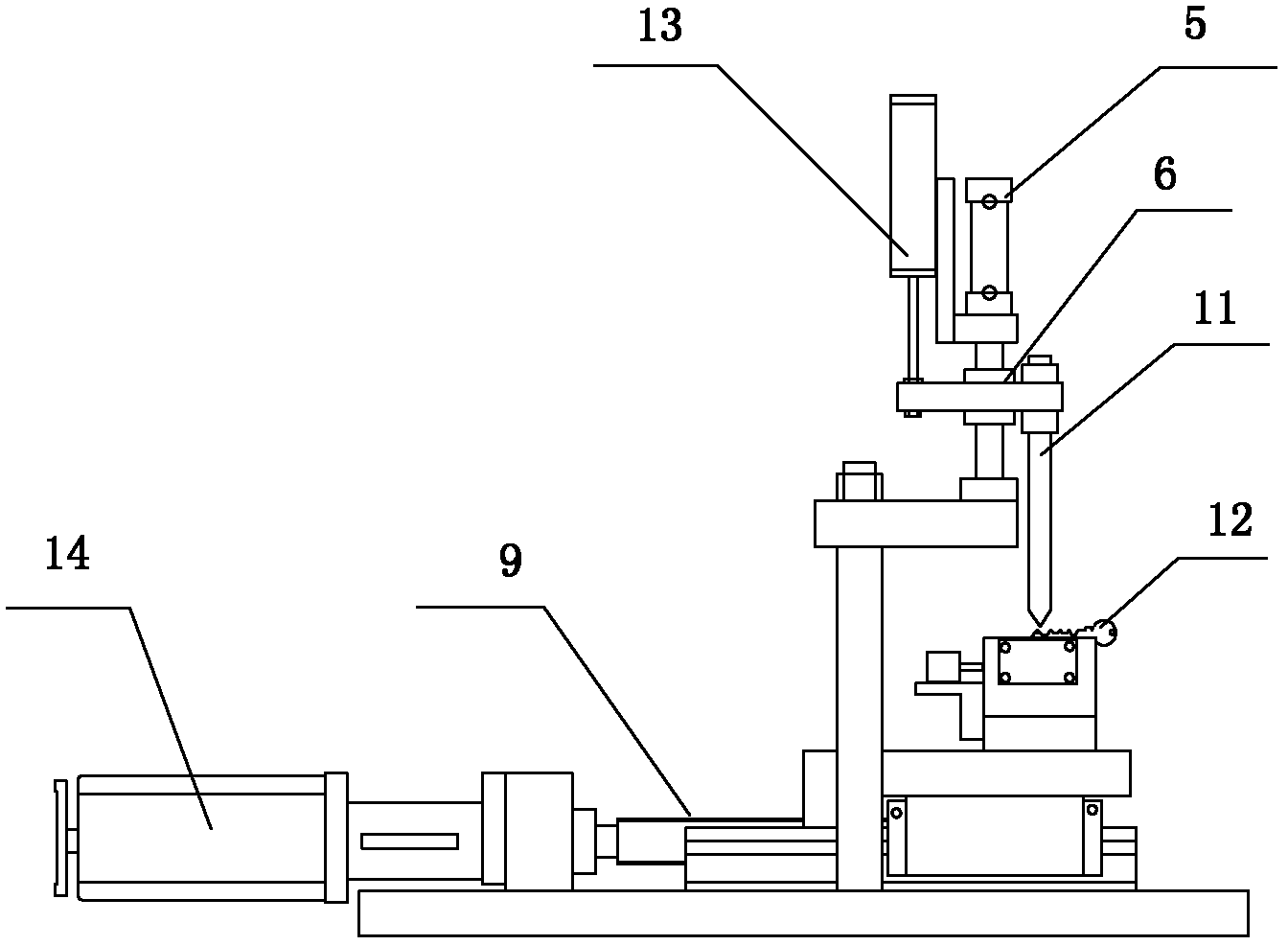

InactiveCN105071608AAvoid damageImplement automatic assemblyManufacturing stator/rotor bodiesOutput deviceEngineering

The invention discloses a motor rotor shaft automatic assembling machine, which comprises a machine frame and an output device, wherein the machine frame is provided with a press-fitting station; a press-fitting mechanism is arranged on the press-fitting station; the machine frame is provided with a pre-assembling station, an iron core automatic supply bin and a rotor shaft automatic supply bin on one side of the press-fitting station, the iron core automatic supply bin is used for conveying horizontally-placed iron cores to the pre-assembling station, and the rotor shaft automatic supply bin is used for conveying horizontally-placed rotor shafts to the pre-assembling station; the pre-assembling station is provided with an inserting and placing drive device and an overturning mechanism, the inserting and placing drive device is used for inserting the rotor shafts into the iron cores horizontally, and the overturning mechanism is used for overturning the iron cores inserted with the rotor shafts to be placed vertically; and an intermediate conveying mechanism which is used for conveying the iron cores inserted with the rotor shafts from the pre-assembling station to the press-fitting station is arranged on the machine frame. The motor rotor shaft automatic assembling machine can achieve the automatic assembly of the rotor shafts and the iron cores, greatly reduces labor intensity of workers, increases production efficiency, can effectively ensure the concentricity between the rotor shafts and the iron cores, prevents the iron cores from being damaged due to tilt rotor shafts because the rotor shafts are not inserted in place, and improves product quality.

Owner:江门市智能装备制造研究院有限公司

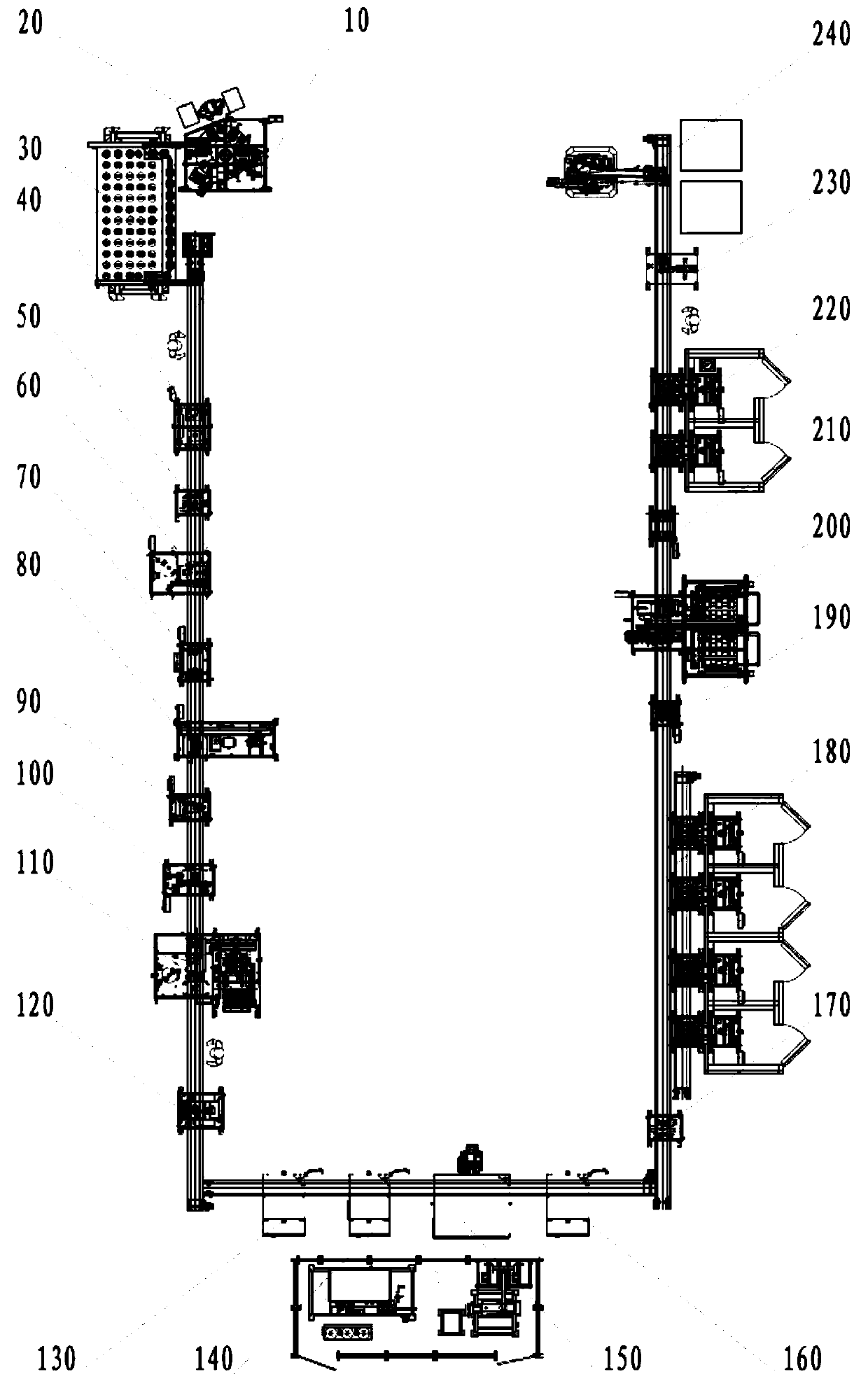

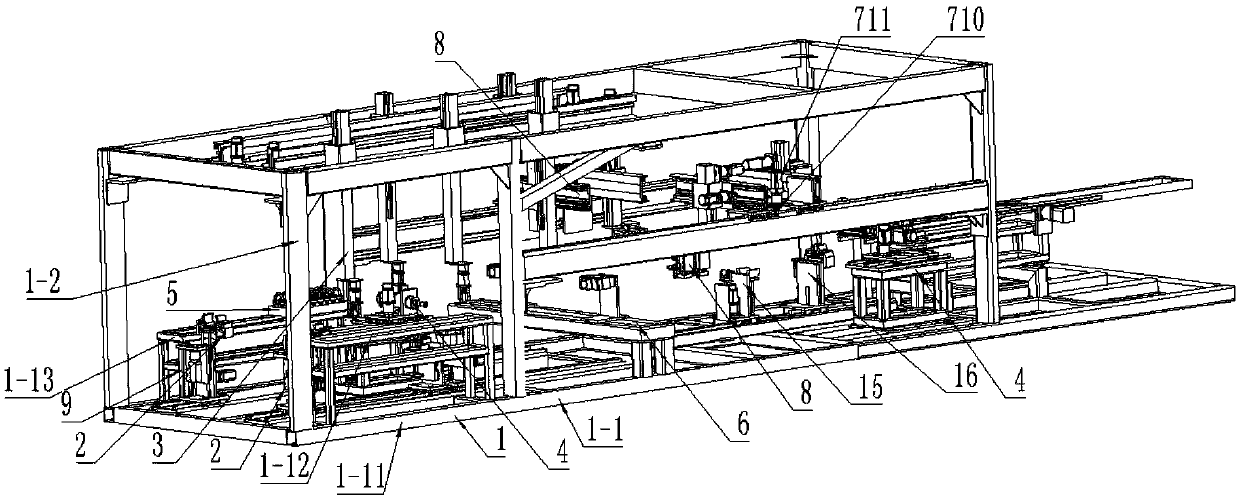

Automatic assembly production line for automobile air conditioner compressors

ActiveCN110587300AReduced manual productivityImplement automatic assemblyAssembly machinesMetal working apparatusProduction lineAutomobile air conditioning

The invention discloses an automatic assembly production line for automobile air conditioner compressors, and belongs to the technical field of automobile air conditioner compressors. The automatic assembly production line comprises a line body and a shell heating press-fitting and coding device, a shell cooling and transferring device, a wiring pole detection device, a shell component overturningdevice I, a lower bearing press-fitting device, a shell component positon detection device, a machine core magnetizing and shell enclosing device, a machine core resistance torque detection device, an abrasion resistant sheet assembly detection device, an eccentric block upper bearing automatic accommodating device, an end cover thread screwing device, nitrogen filling large leakage detection device, vacuuming helium filling device, a helium detection device, a helium recycling device, a shell component overturning device II, a workpiece operation detection device, an automatic heat conduction coating device, a controller assembly device, a controller air-tightness detection device, a comprehensive performance detection device, a vacuuming oil injection nitrogen filling device and a robotoff-line stacking device. By adopting the automatic assembly production line, automatic assembly and detection of the automobile air conditioner compressors are realized; and production efficiency isimproved.

Owner:CSIC PRIDENANJINGINTELLIGENT EQUIP SYST CO LTD

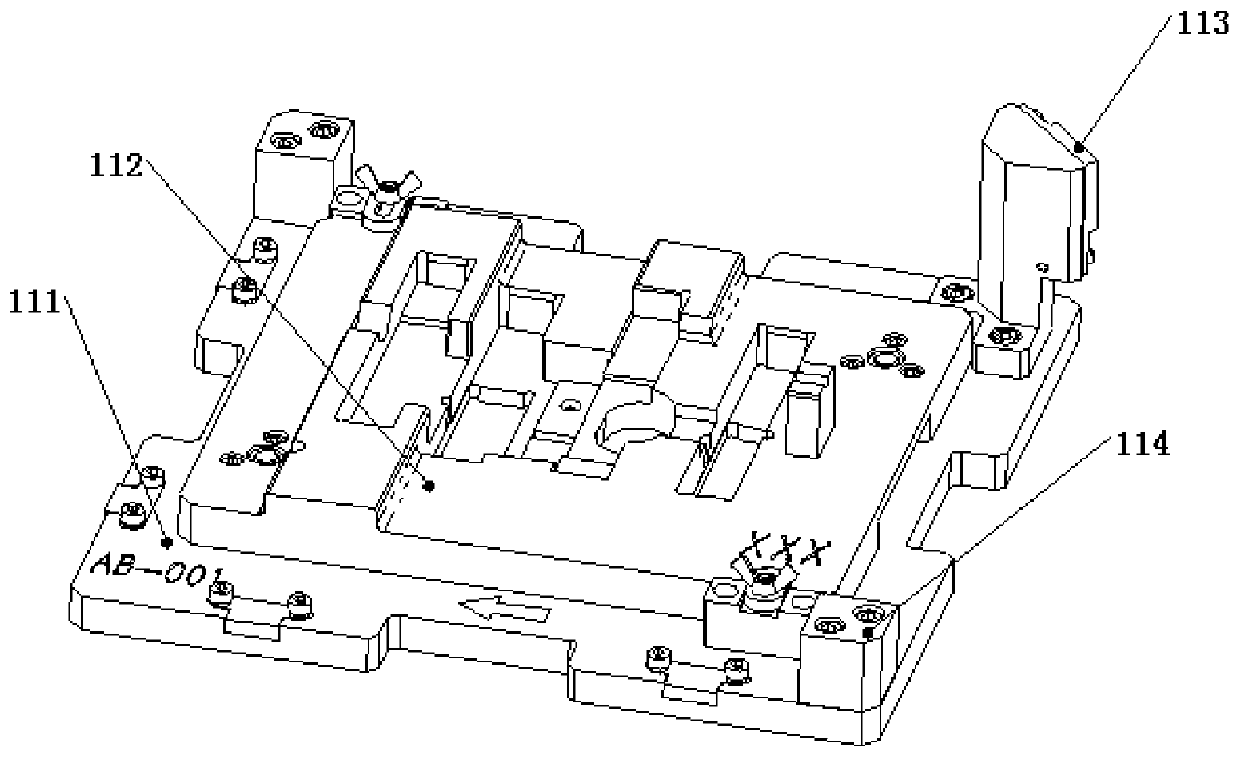

Automatic assembling equipment for brake disc

InactiveCN108723761AWon't rotateImplement automatic assemblyVehicle componentsMetal working apparatusEngineeringSlide plate

The invention relates to the field of assembly of brake discs, in particular to automatic assembling equipment for a brake disc. The automatic assembling equipment comprises a base, a feeding assembly, a material moving assembly, a fixing assembly, a screw locking assembly and a discharge assembly. The feeding assembly, the material moving assembly, the fixing assembly, the screw locking assemblyand the discharge assembly are installed at the top of the base. The material moving assembly comprises a clamping jaw capable of horizontally moving above the fixing assembly. The fixing assembly comprises a machine table, a first sliding board, a first pushing device, a workpiece positioning tool and a workpiece pressing device. The top of the workpiece pressing device is equipped with multiplepositioning columns used for positioning the brake disc. The workpiece pressing device comprises multiple hydraulic rods which are arranged in a tilting manner. The top of the machine table is equipped with a strip-shaped accommodation groove same as the machine table in terms of length. The screw locking assembly comprises an electric screwdriver which can vertically elevate. The discharge assembly comprises a conveyor belt and a material receiving box. Additionally, the feeding assembly is located on one side, departing from the strip-shaped accommodation groove, of the conveyor belt. Production efficiency is increased while production quality is enhanced.

Owner:楚宗美

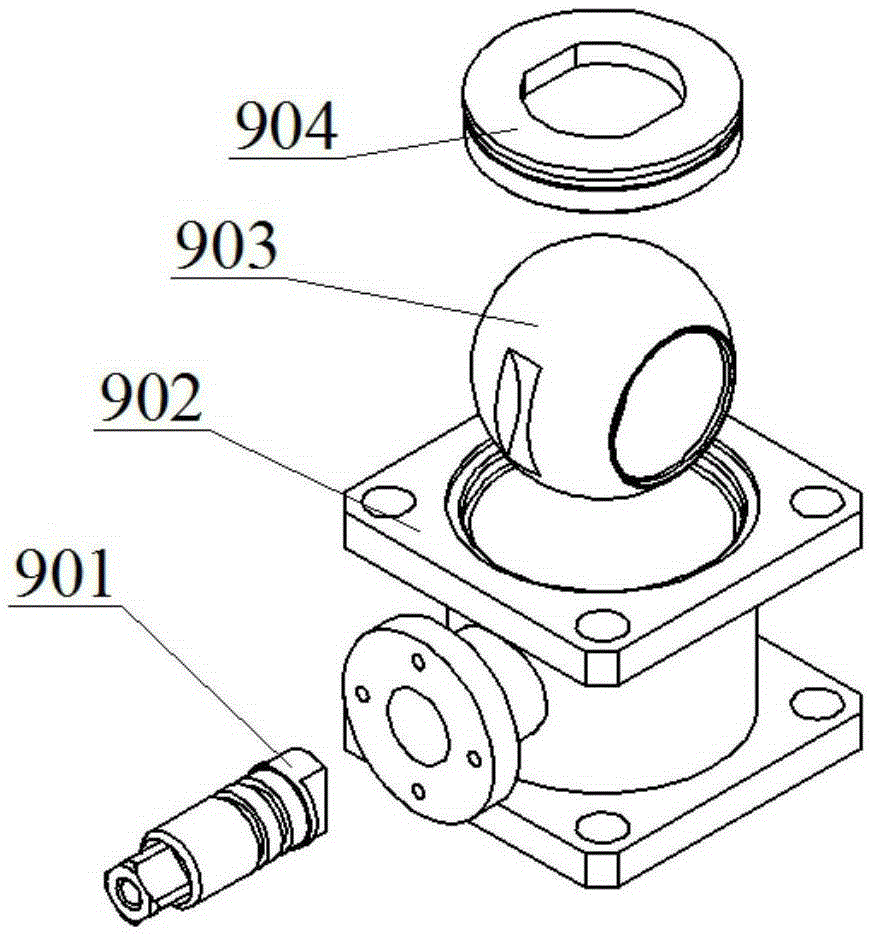

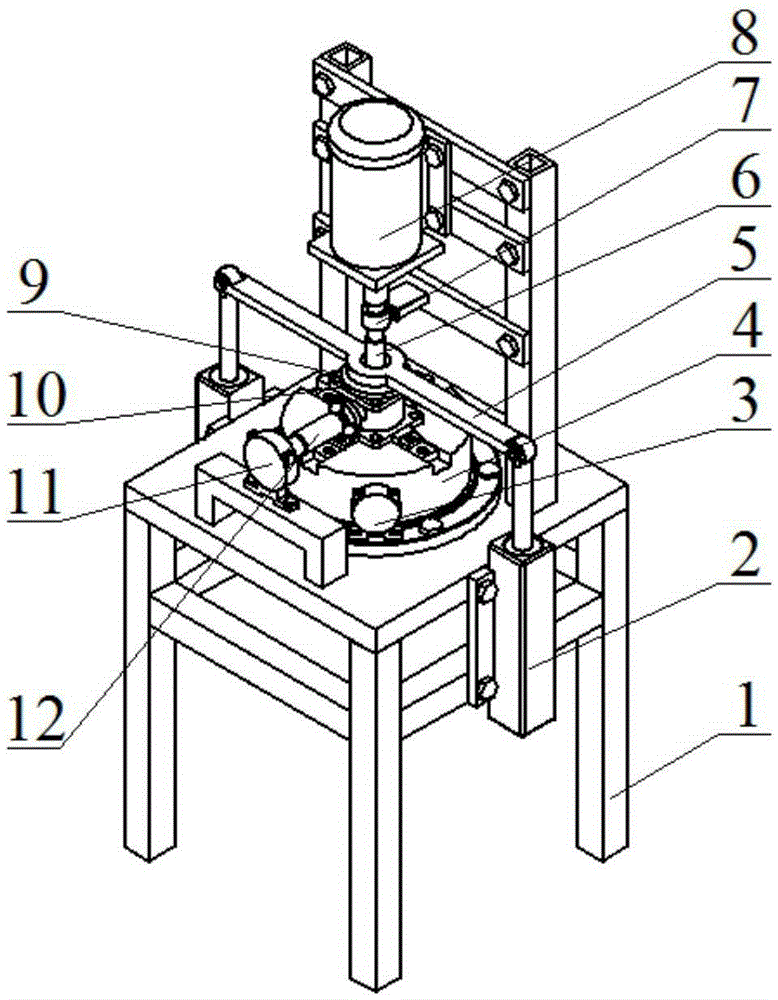

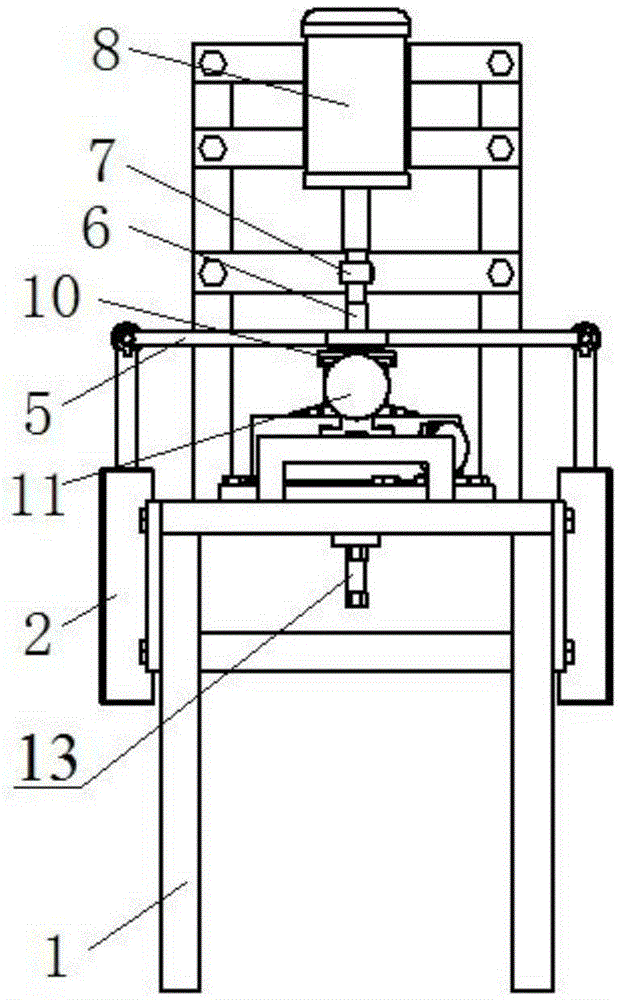

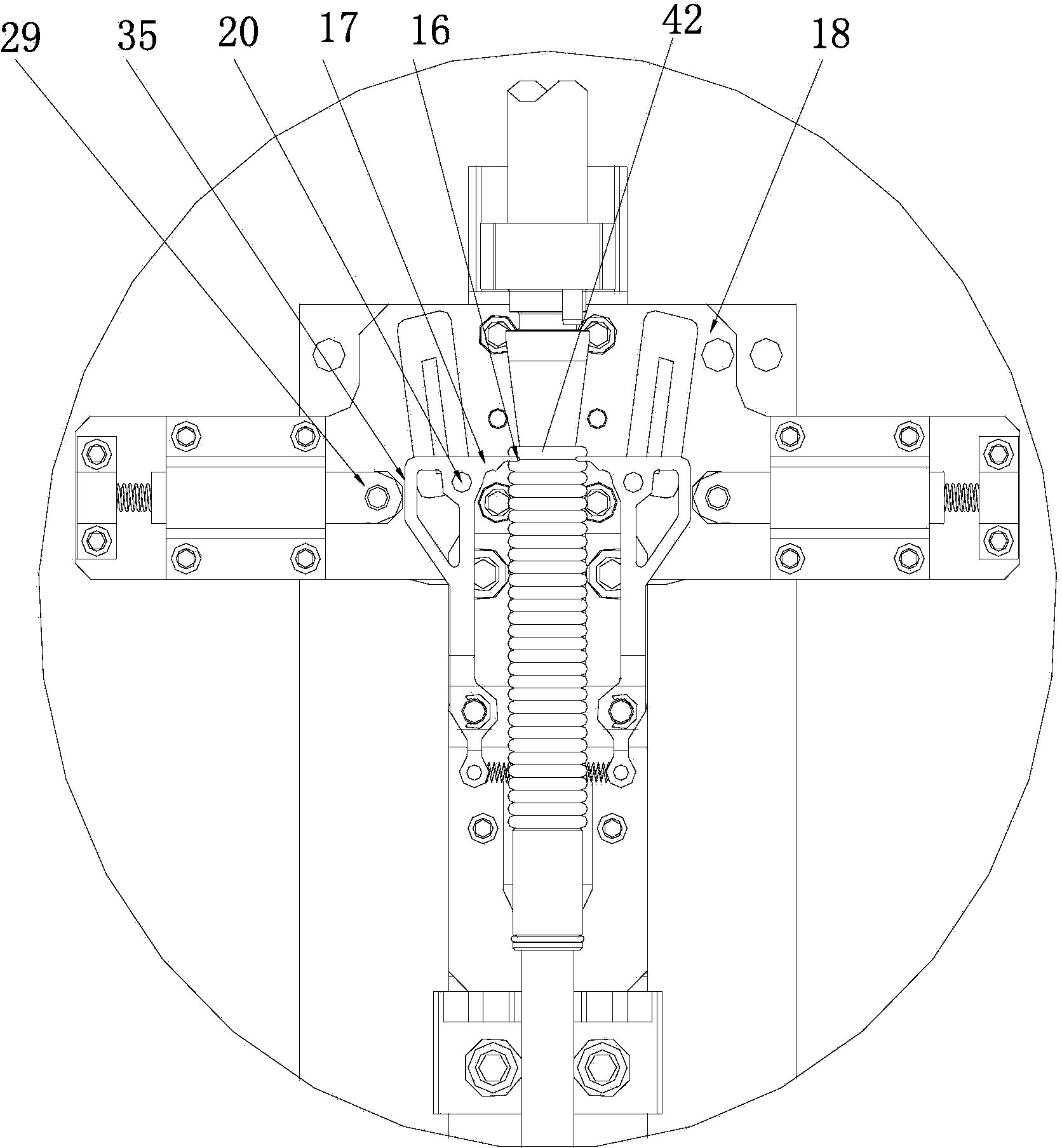

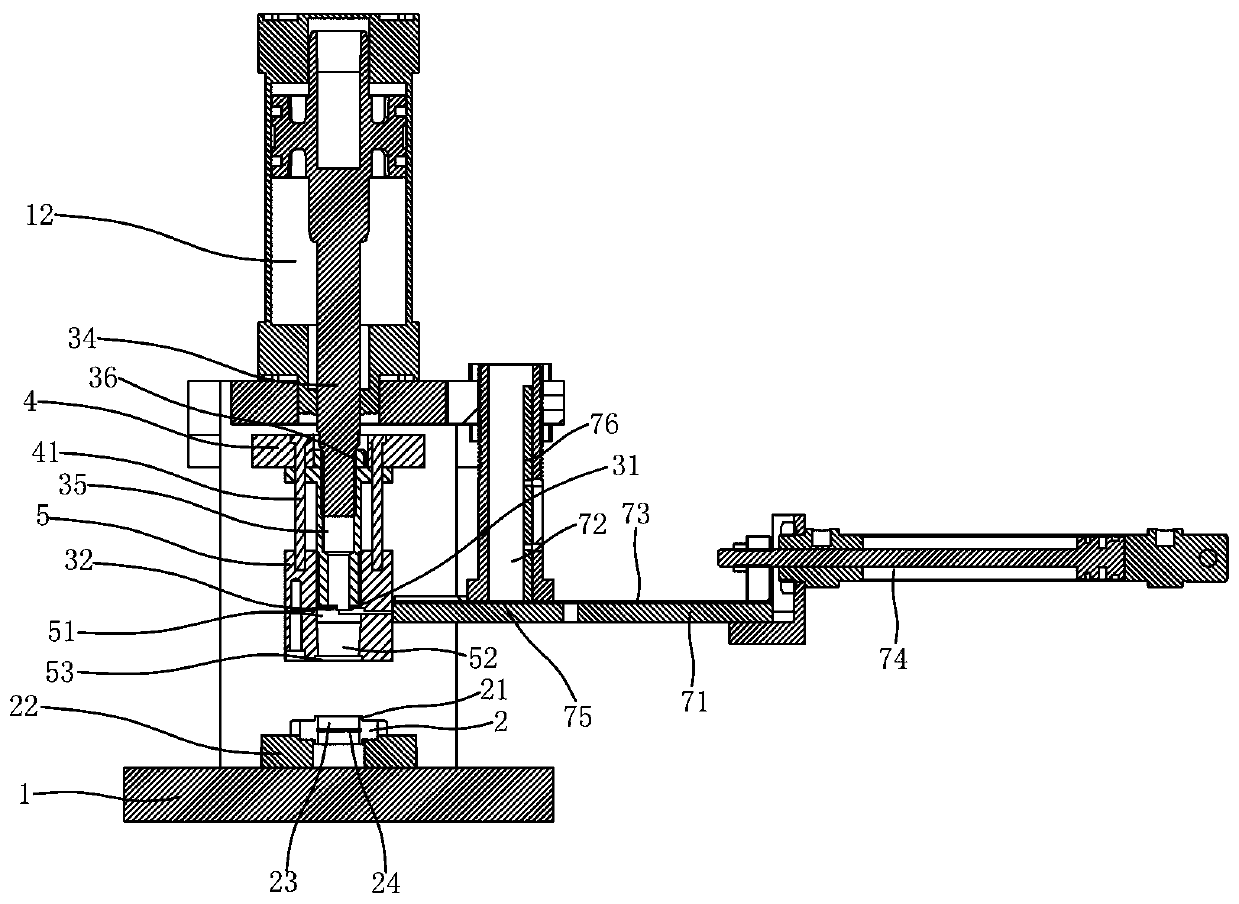

Mechanical device and assembling method for automatic square ball valve assembling system

InactiveCN105312898AImplement automatic assemblySimple processDetection of fluid at leakage pointAssembly machinesElectric machineCoupling

The invention discloses a mechanical device and an assembling method for an automatic square ball valve assembling system. The mechanical device comprises a four-jaw chuck. The four-jaw chuck is connected with a first pneumatic motor, a rubber pad is arranged above the four-jaw chuck, and an air cylinder pressing plate is arranged above the rubber pad; an electric machine is connected with a main transmission connector through a coupling, and the main transmission connector penetrates through the air cylinder pressing plate and is connected with the rubber pad; an air cylinder and a second pneumatic motor are arranged on the side of the four-jaw chuck, the air cylinder is connected with the air cylinder pressing plate, the second pneumatic motor is connected with a transmission sleeve end, and a pneumatic one-way valve is arranged below the four-jaw chuck. The assembling method for the automatic square ball valve assembling system comprises the four steps of valve body clamping, valve cover tightening, valve element inflation and disassembling after assembling is finished. According to the mechanical device and the assembling method for the automatic square ball valve assembling system, integration of the procedures of automatic square ball valve assembling and automatic inflation is achieved, so that the assembling efficiency of a square ball valve and the production quality of a product are improved, and the labor intensity of a worker is reduced.

Owner:CHINA UNIV OF MINING & TECH

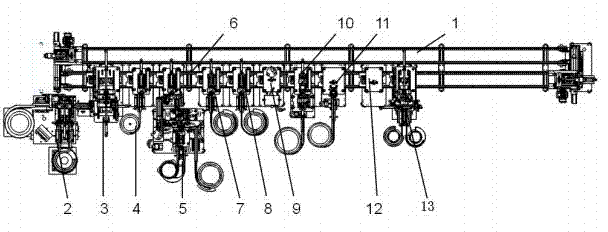

Automatic terminal screw assembling machine with material rejecting function

ActiveCN102303238AImplement automatic assemblySave human effortMetal working apparatusEngineeringMechanical engineering

The invention relates to an automatic terminal screw assembling machine with a material rejecting function, which comprises a terminal vibration disk, a first terminal positioning index plate, a screw vibration disk, a screw positioning index disk, a first electric screw driver, a second terminal positioning index plate and a fourth electric screw driver, wherein the edge of the first terminal positioning index plate is provided with a plurality of first grooves, terminals sent by the terminal vibration disk sequentially fall in the first grooves, the lateral side of the screw positioning index plate is provided with a plurality of notches, screws sent by the screw vibration disk sequentially enter the notches, the first grooves have one first longitudinal coincidence position with the notches, the first electric screw driver is positioned above the first longitudinal coincidence position, the edge of the second terminal positioning index plate is provided with a plurality of second grooves, the first grooves have one second longitudinal coincidence position with the second grooves, and the fourth electric screw driver is positioned above the second groove behind the second longitudinal coincidence position. The automatic terminal screw assembling machine has the advantages of high safety, high production efficiency and stable quality, and has the material rejecting function.

Owner:徐圣宇

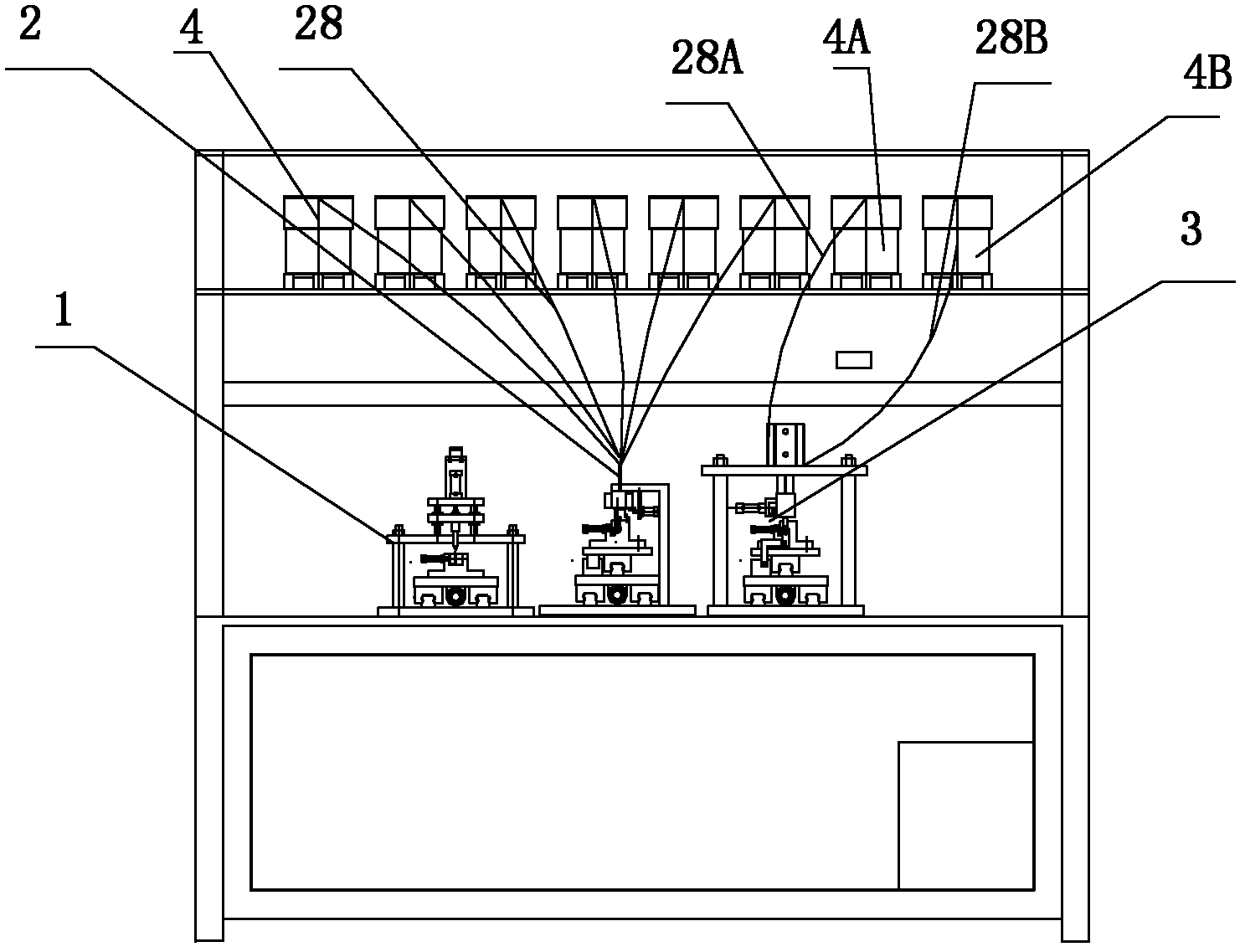

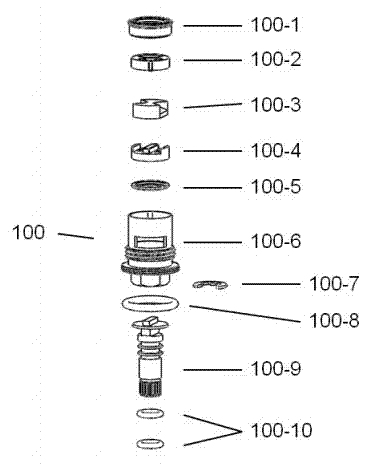

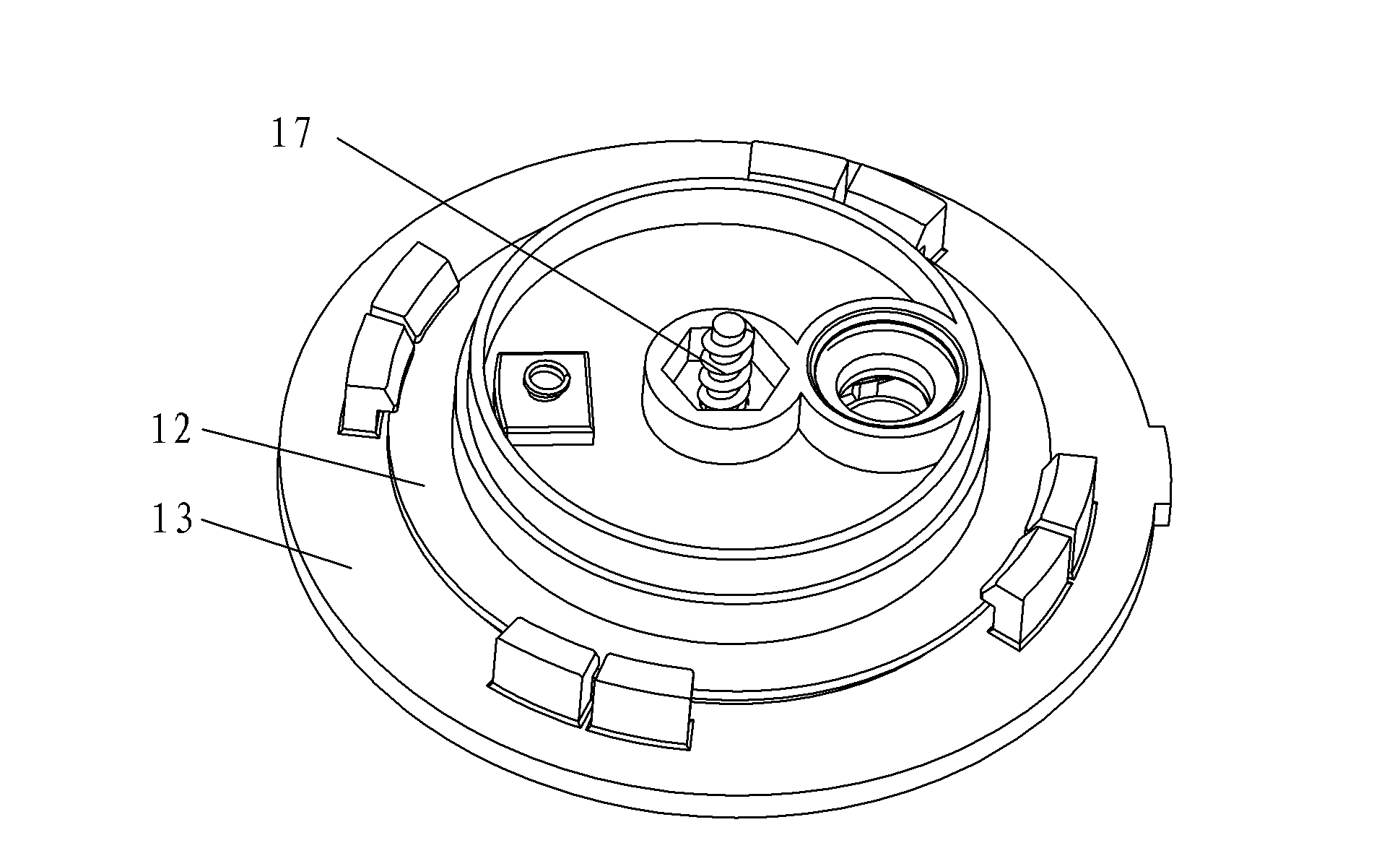

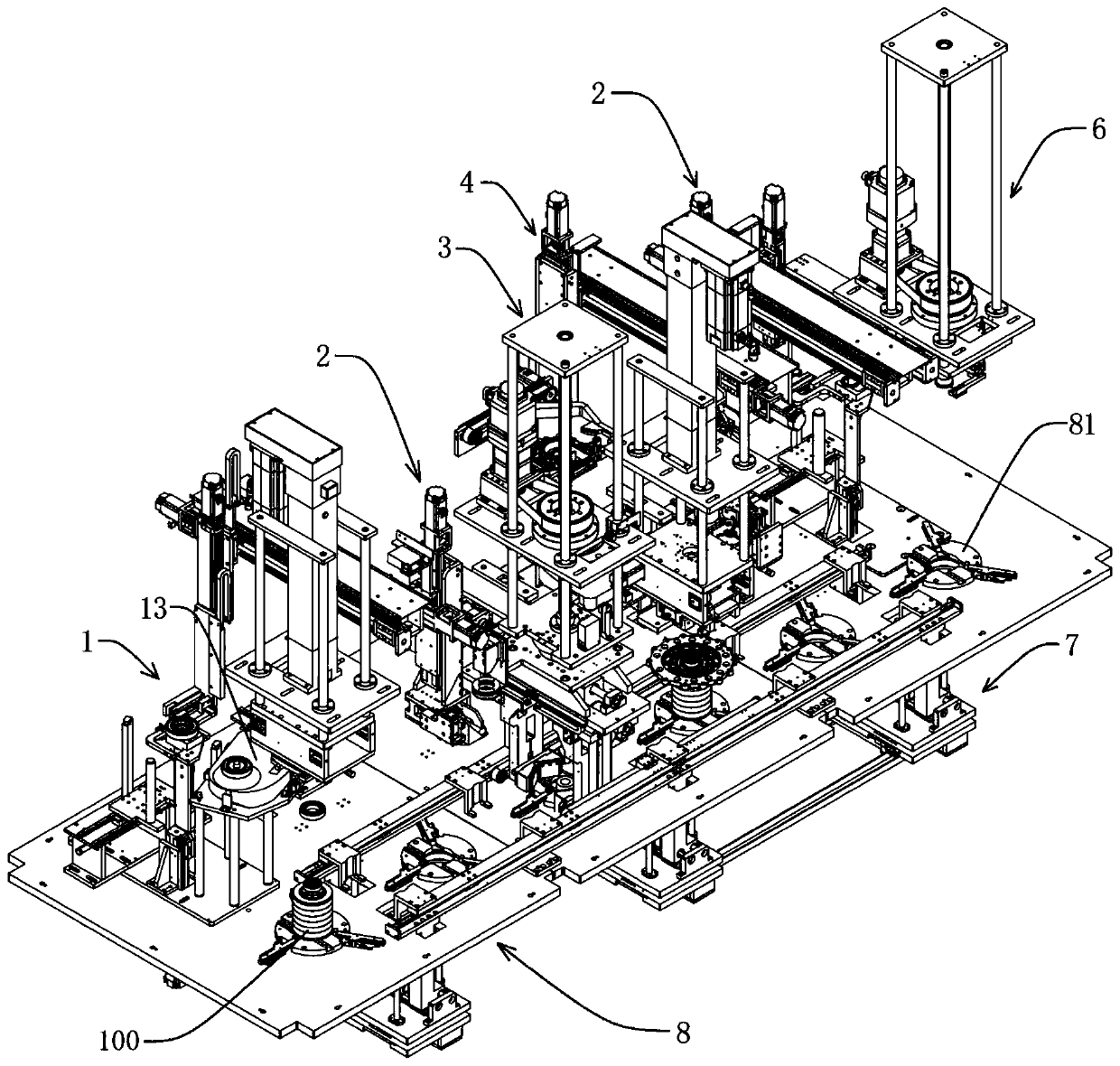

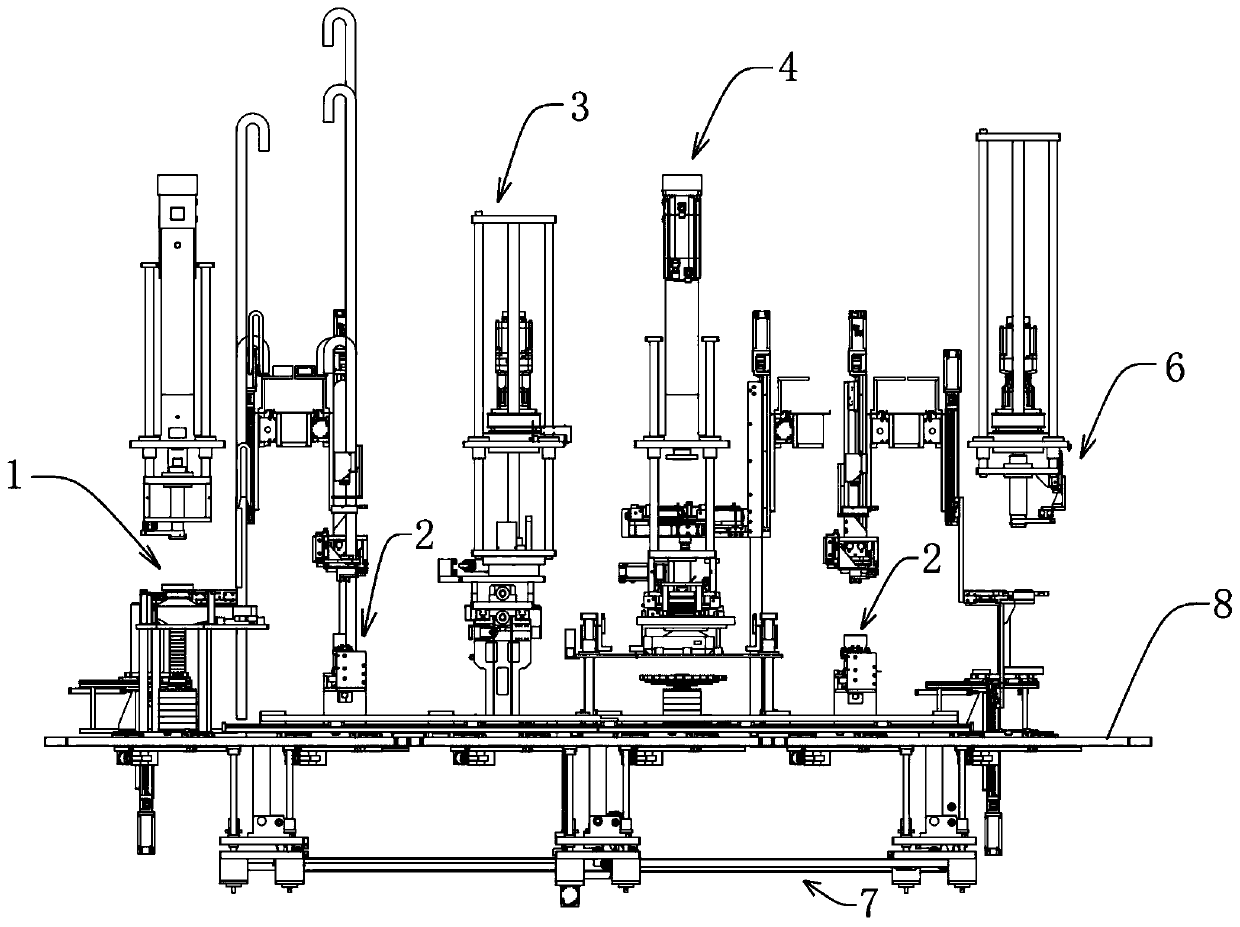

Automatic assembling system for quick-opening ceramic valve element

ActiveCN104708316AImplement automatic assemblyImprove quality stabilityAssembly machinesProduction lineIndustrial engineering

The invention discloses an automatic assembling system for a quick-opening ceramic valve element. The automatic assembling system comprises a general assembling production line. A valve body ferrule work table, a valve body directional feeding work table, a lubricating gasket assembling work table, a valve rod ferrule work table, a valve rod assembling work table, a silencing sheet assembling work table, a movable ceramic sheet assembling work table, an oiling sealing work table, a static ceramic sheet assembling work table, a water pressing ring assembling work table, a pressure supplementing work table and a clamp spring assembling work table are sequentially arranged along the general assembling production line. Corresponding stations are formed through the work tables. The general assembling production line drives a combination clamp to sequentially pass all the stations in the operating process so as to be assembled on all the stations. By the adoption of the automatic assembling system, tens of parts of the ceramic valve element can be automatically assembled, the quality stability of the ceramic valve element is improved, labor cost is low, and production efficiency is improved.

Owner:RES INST OF ZHEJIANG UNIV TAIZHOU

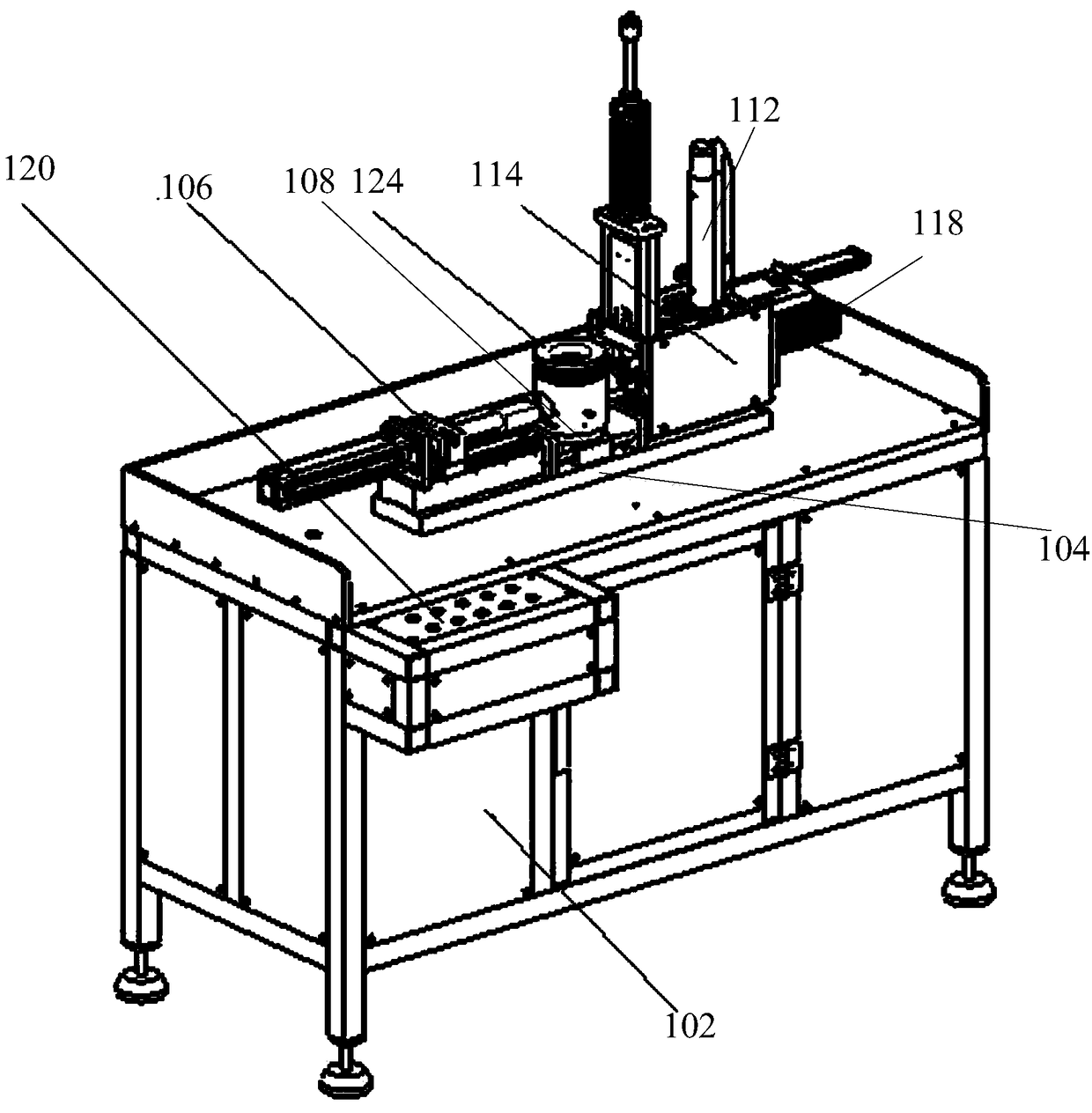

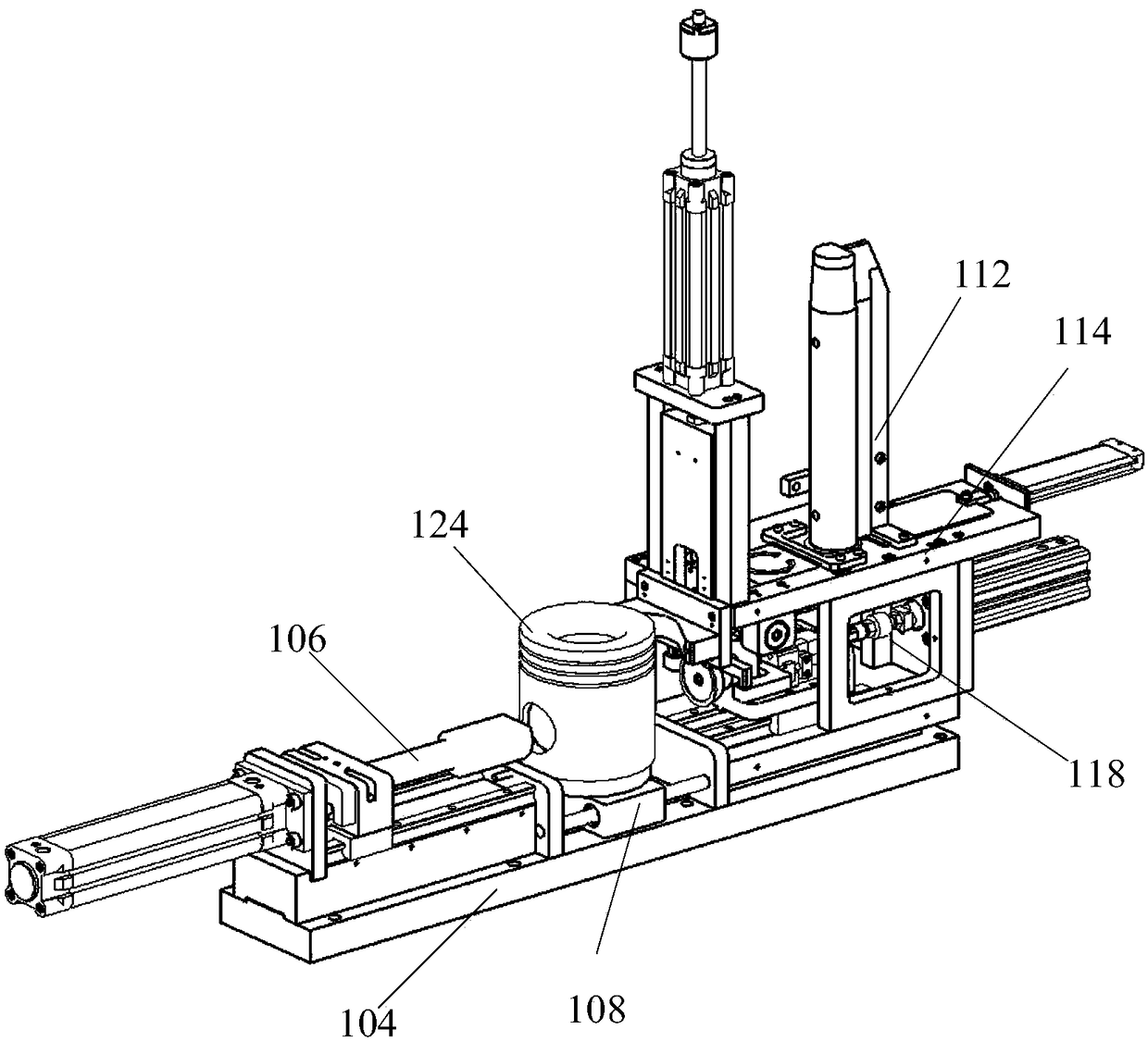

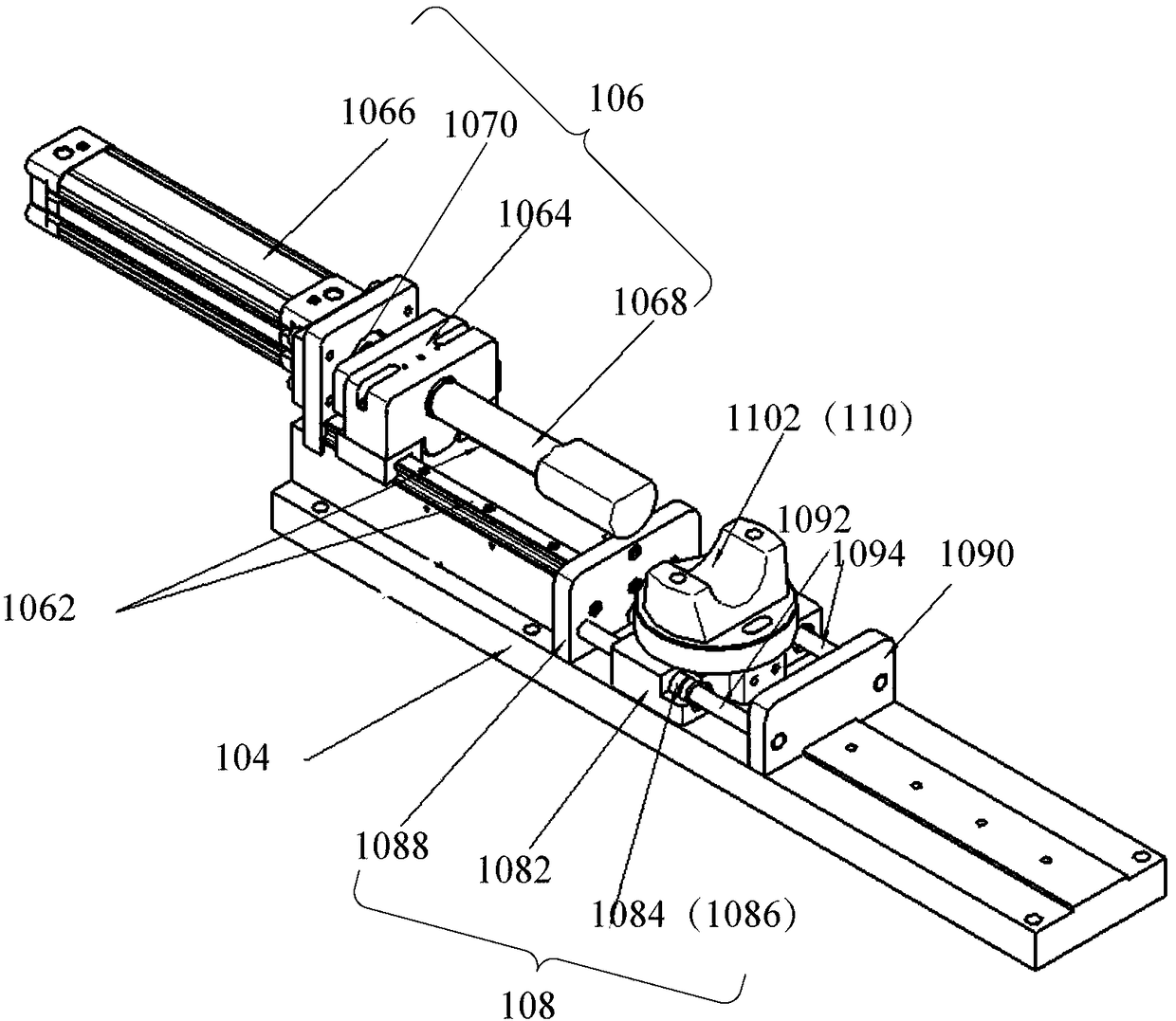

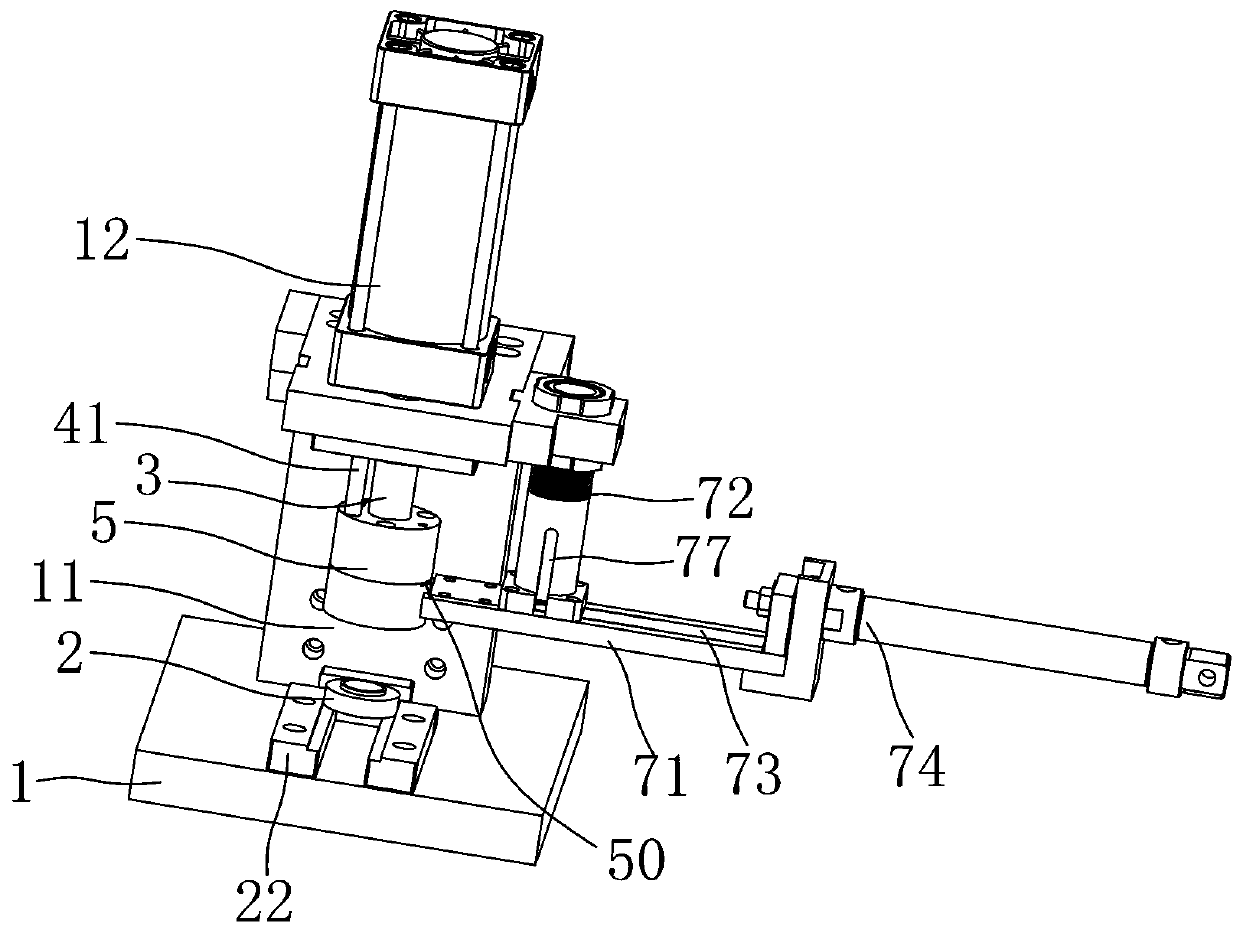

Automatic assembly device and method of piston clamp spring

ActiveCN108544216AImprove continuityImprove the efficiency of automatic assemblyFinal product manufactureMetal working apparatusPiston GuideMaterial storage

The invention provides an automatic assembly device and method of a piston clamp spring. The device comprises a working bed body, a piston locating mechanism, a piston guide mechanism, a piston placement part, a clamp spring material storage part, a clamp spring feeding part, a clamp spring assembly mechanism and a controller. A reference mounting seat is arranged on the working face of the working bed body. The piston locating mechanism is installed on the reference mounting seat. The piston guide mechanism is arranged in cooperation with the piston locating mechanism and installed on the reference mounting seat. The piston placement part is arranged on the reference mounting seat and arranged adjacent to the piston locating mechanism, and the piston placement part is matched with the piston locating mechanism for locating a piston. The clamp spring material storage part and the piston placement part are arranged at intervals for storing and releasing a clamp spring. The clamp springmaterial feeding part is arranged adjacent to the clamp spring material storage part and connected with the piston placement part, and the clamp spring material feeding part comprises a working table,a clamp spring separation mechanism, a clamp spring turnover mechanism and a clamp spring horizontally moving mechanism. The clamp spring assembly mechanism is connected with the clamp spring feedingpart for assembling the clamp spring to the piston. Through the technical scheme, the automatic assembly of the clamp spring on the single side of the piston can be completed, using is convenient, the production efficiency is high, and the assembly quality is stable and reliable.

Owner:BINZHOU BOHAI PISTON CO LTD +1

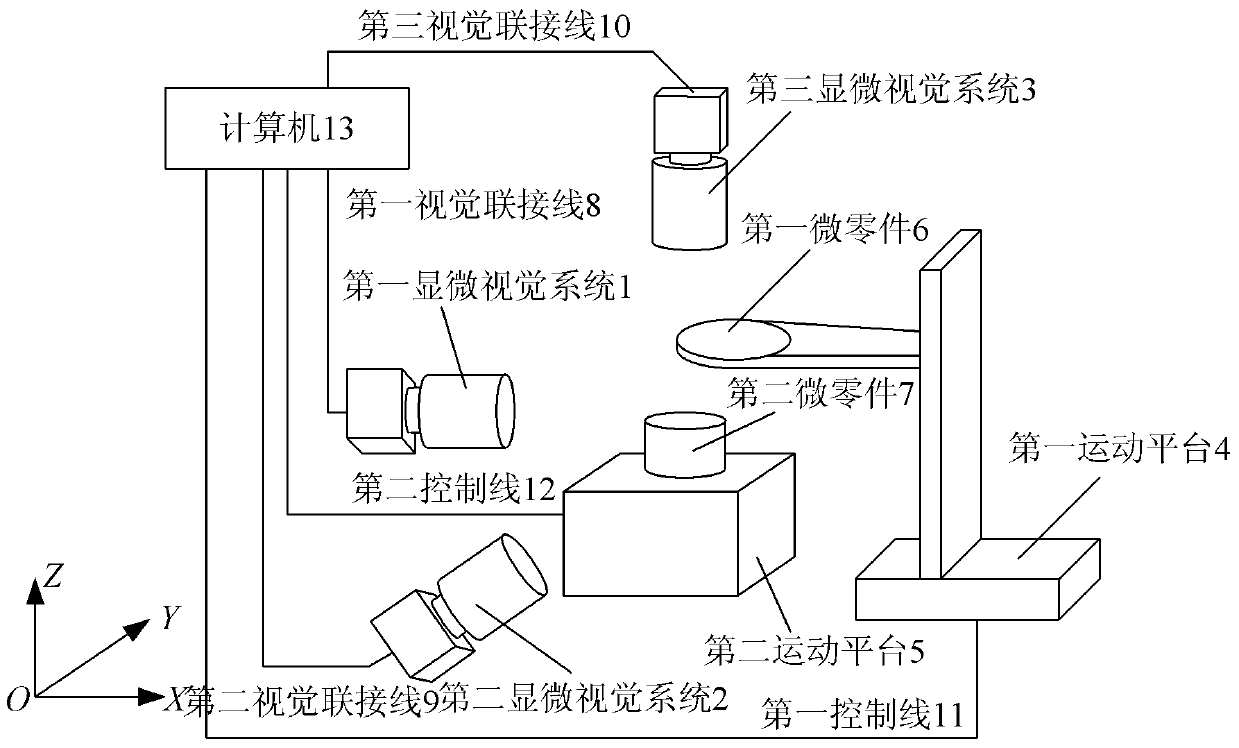

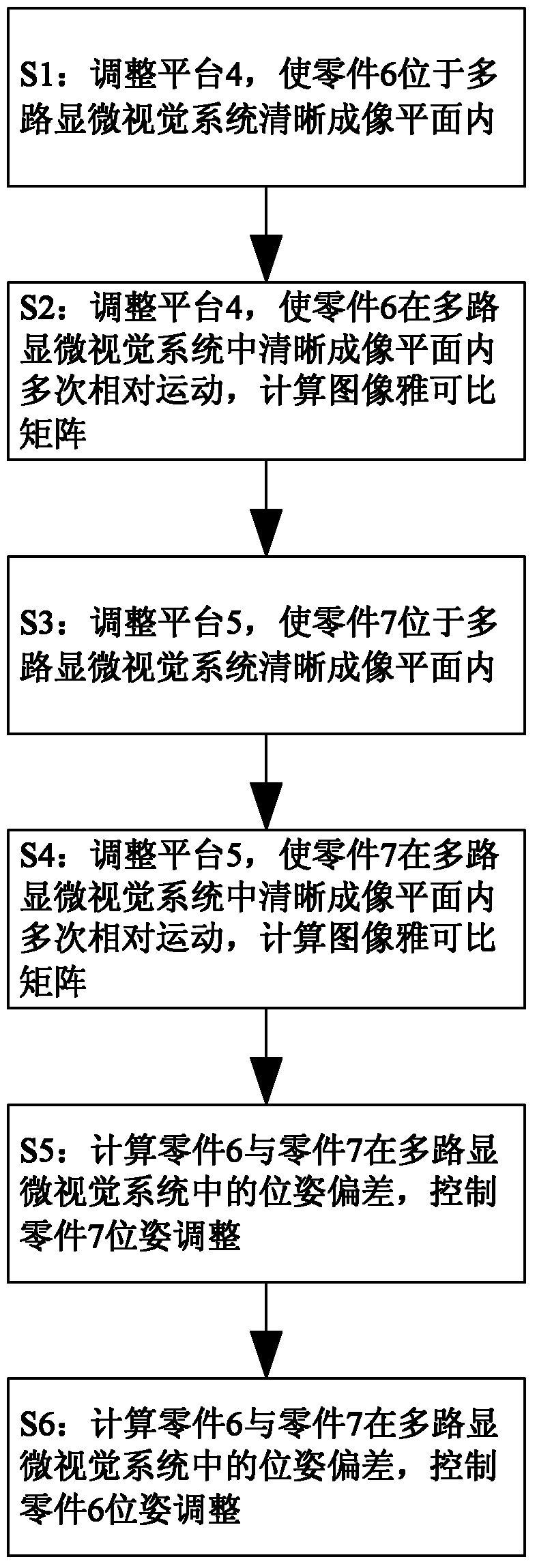

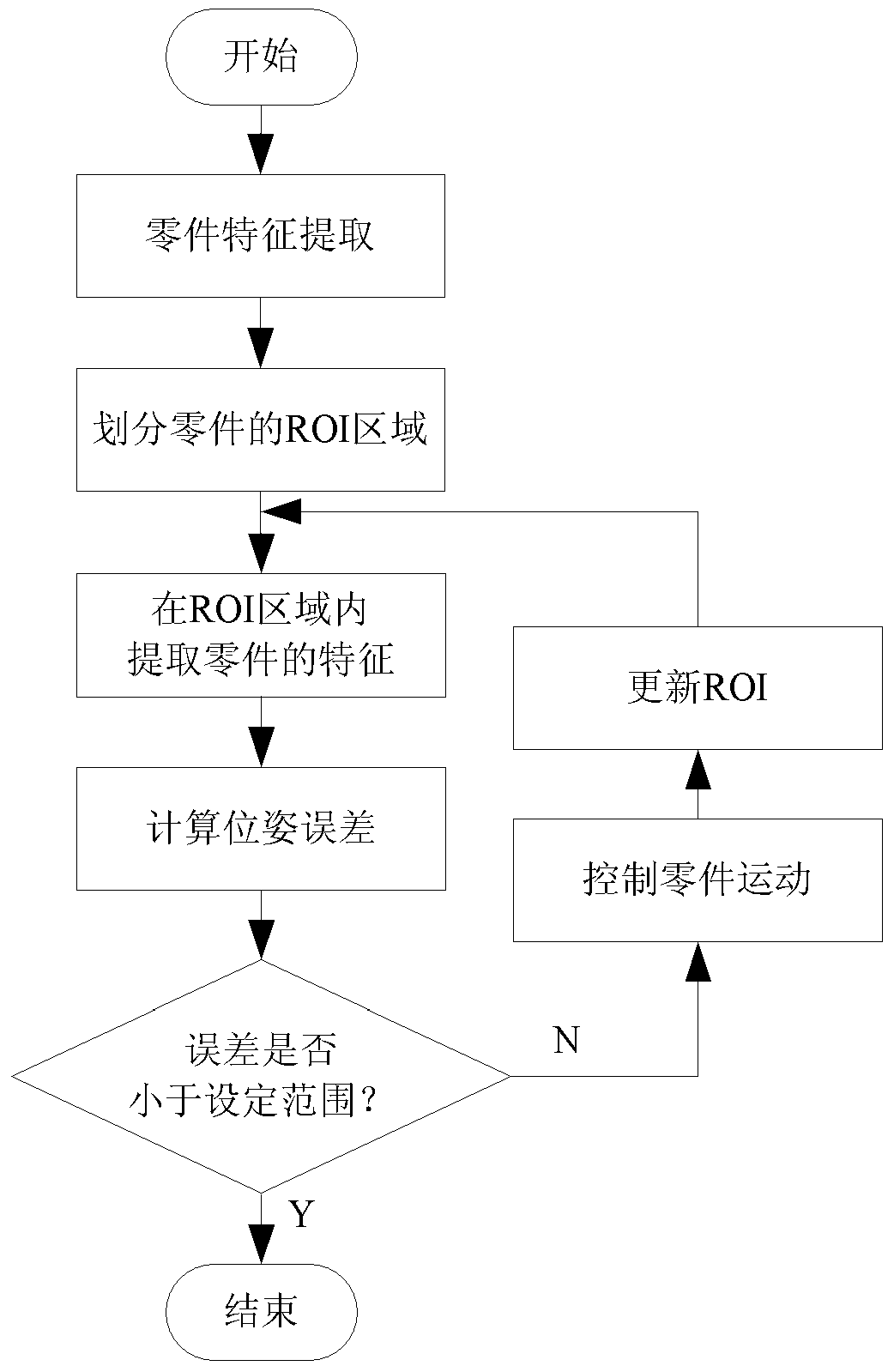

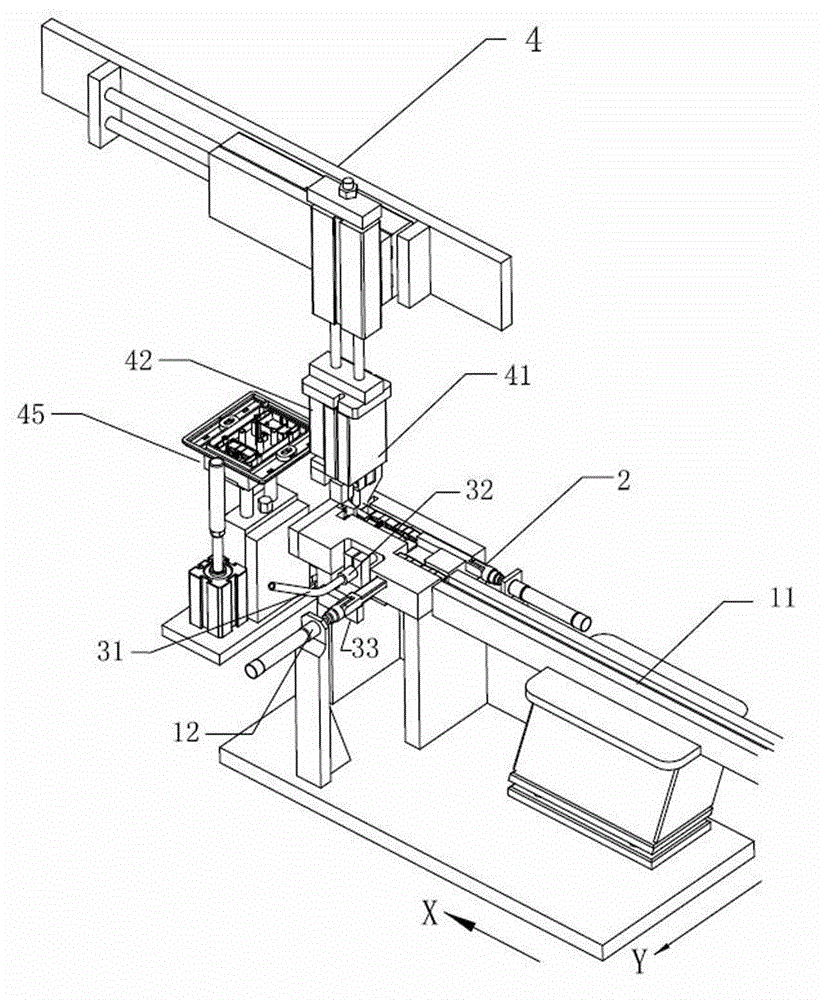

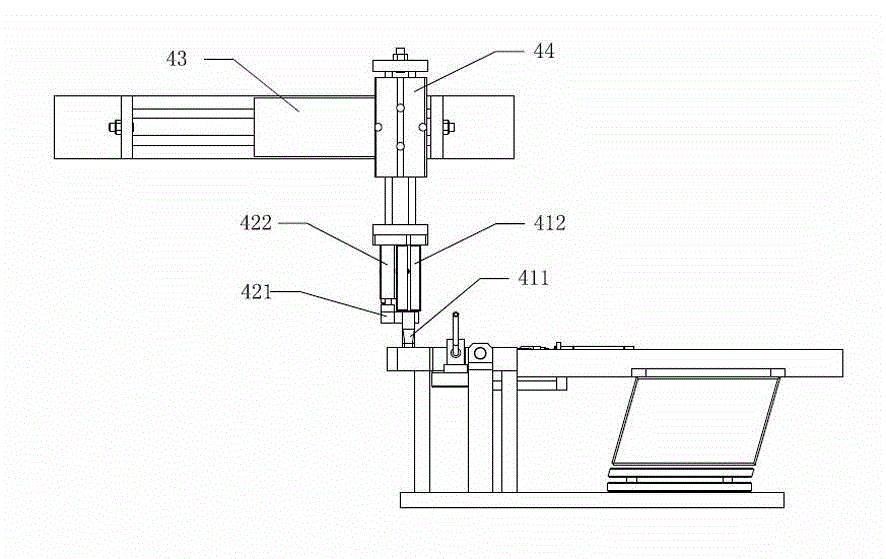

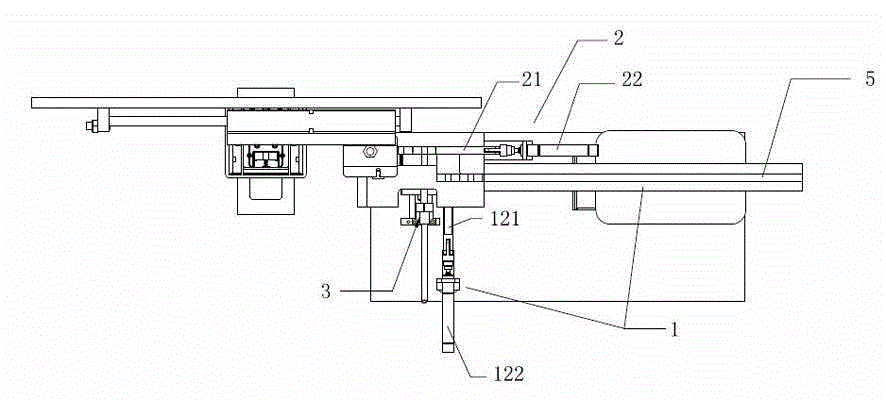

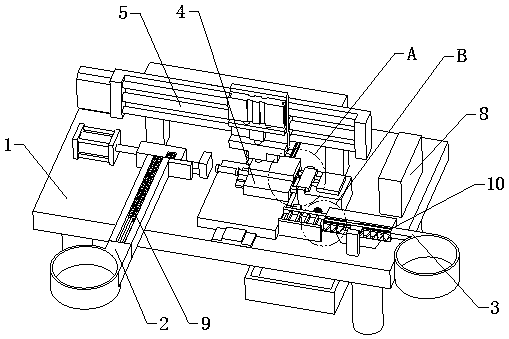

Micro-part automatic aligning device and method based on multipath micro-vision

InactiveCN103273310AImplement automatic assemblyImprove assembly efficiencyMetal working apparatusSimulationEconomic benefits

The invention discloses a micro-part automatic aligning device and method based on multipath micro-vision. The micro-part automatic aligning device comprises a first micro-vision system, a second micro-vision system, a third micro-vision system, a first motion platform, a second motion platform and a computer. The micro-part automatic aligning method includes the following steps that firstly multiple relative motion of first micro-parts in a clear imaging plane is utilized to achieve calibration of the multipath micro-vision systems and the first motion platform, then multiple relative motion of second micro-parts in the clear imaging plane is utilized to achieve calibration of the multipath micro-vision systems and the second motion platform, lastly motion control of the first micro-parts and the second micro-parts is achieved by adopting the PD control law based on a calibrated image jacobian matrix, and therefore pose alignment of the first micro-parts and the second micro-parts is achieved. The micro-part automatic aligning device and the method based on the multipath micro-vision are convenient to operate, short in assembling time and high in assembling accuracy, achieve automatic alignment of millimeter-stage micro-parts of complex structures, and have wide application prospect and considerable social economic benefits.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

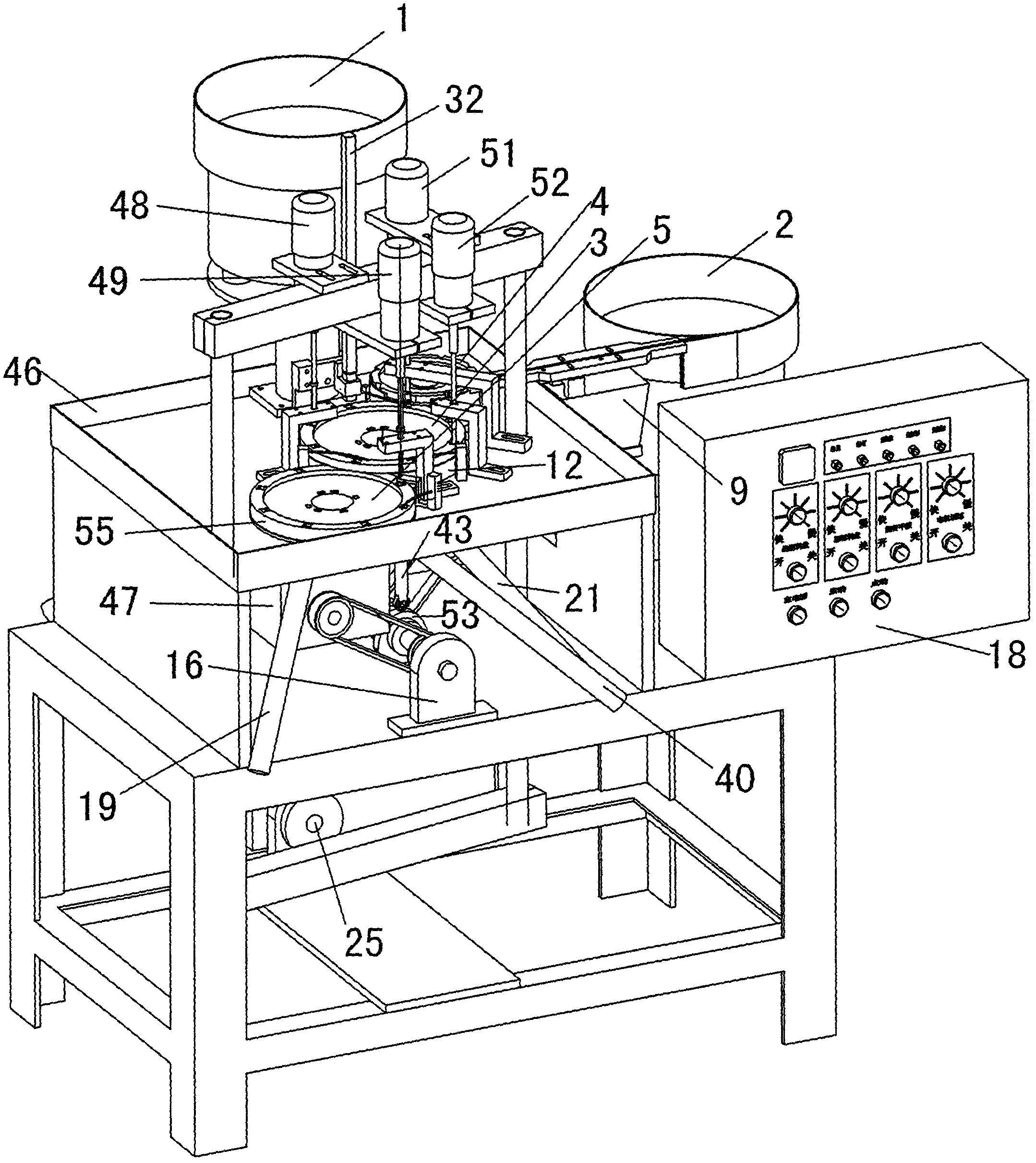

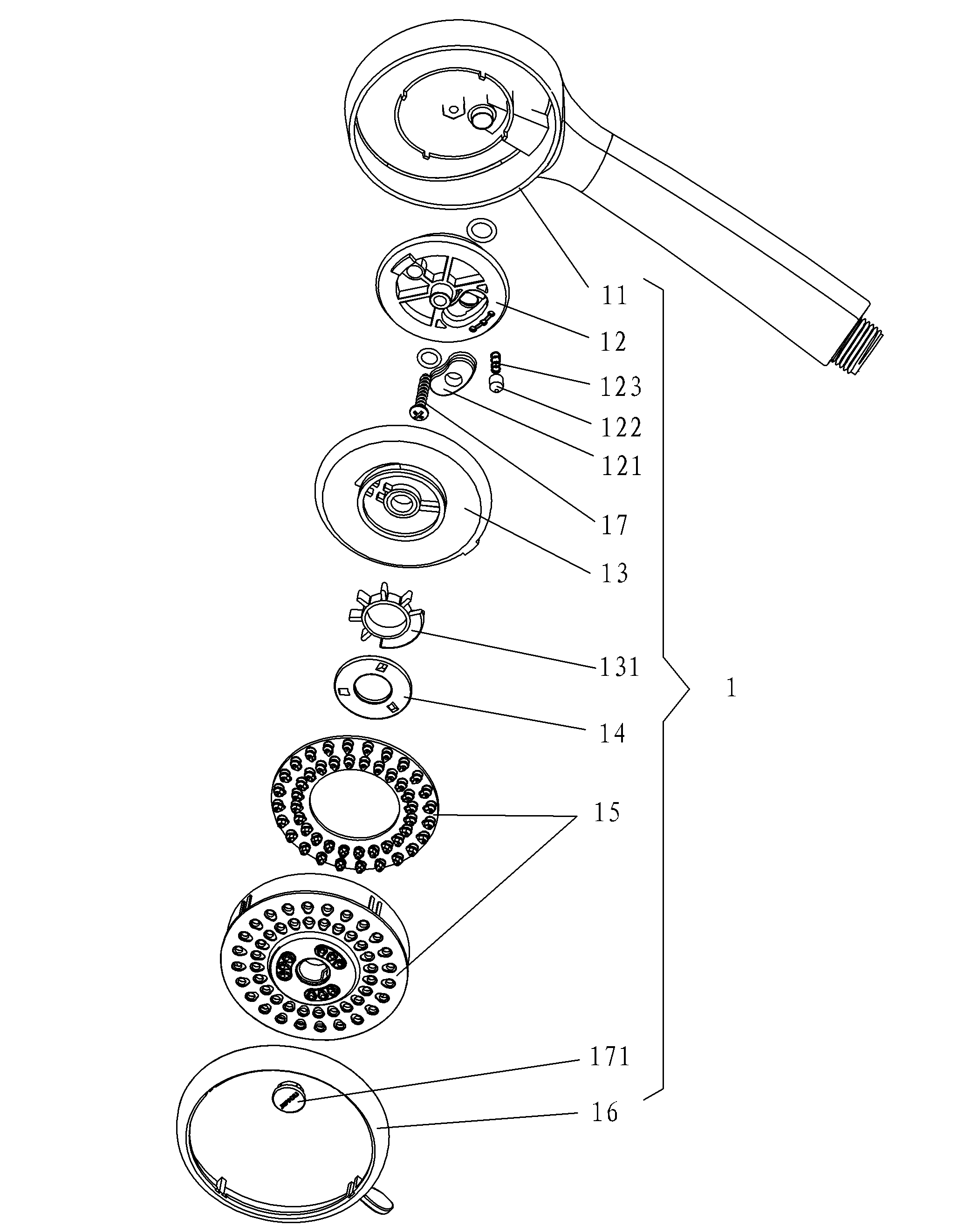

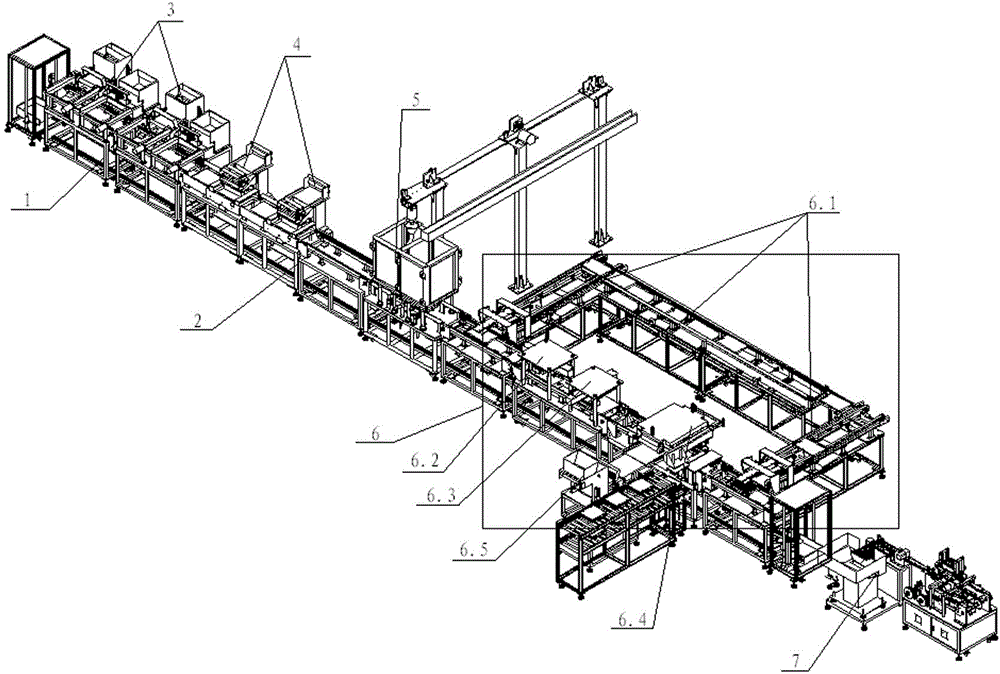

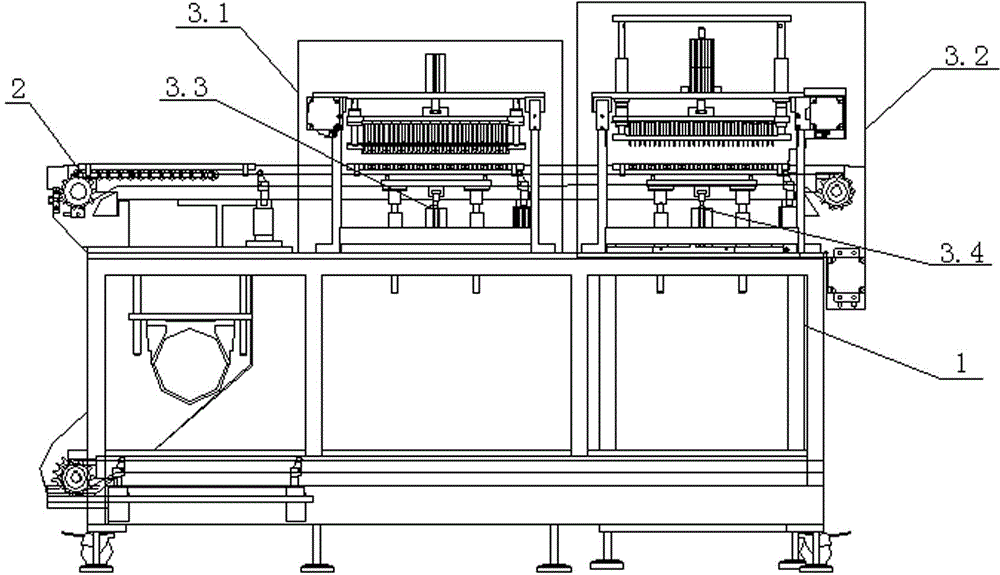

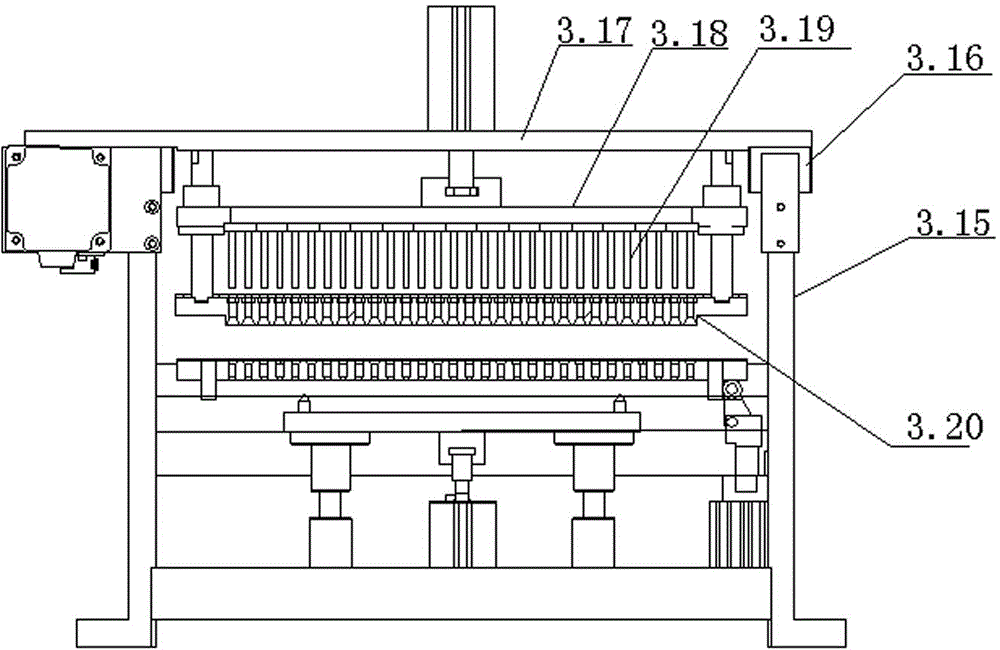

Automatic assembly line for sprinklers

InactiveCN102490005AImplement automatic assemblyHigh degree of automatic assemblyAssembly machinesAssembly lineEngineering

The invention discloses an automatic assembly line for sprinklers, which comprises a first assembling line, a second assembling line, a first conveyor belt, a second conveyer belt and a control cabinet. All output ends of the control cabinet are respectively and correspondingly connected with the corresponding ends of the first assembling, the second assembling line, the first conveyor belt and the second conveyer belt. A tooling plate of a panel group for locating and placing the sprinklers is arranged on the first assembling line, a translation clamp used for moving a sprinkler assembly on the tooling plate to a next work position is correspondingly arranged at the position of the tooling plate, and a first mechanical hand for taking a corresponding sprinkler assembly on the first conveyer belt and assembling the sprinkler assembly on the corresponding tooling plate is correspondingly arranged at the position of the tooling plate. A body table for locating and placing a sprinkler body is arranged on the second assembling ling, and a second mechanical hand for taking a sprinkler assembly on the second conveyer belt and assembling the sprinkler assembly on the corresponding body table is arranged on the second assembling line. The automatic assembly line for sprinklers is high in automatic assembling degree, can efficiently finish assembling the sprinklers in high quality and can greatly reduce labor cost.

Owner:泉州中宇卫浴科技实业有限公司

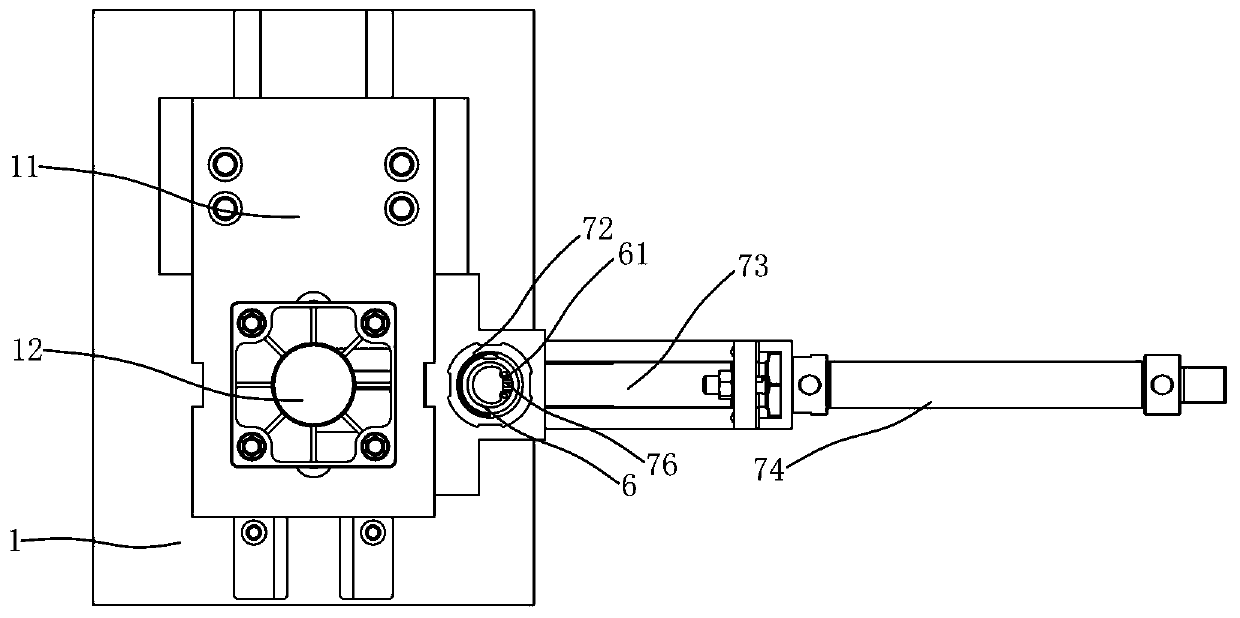

Automatic O-type ring assembling device of automobile pipeline joint

ActiveCN103934658AImplement automatic assemblyMove quicklyMetal working apparatusChinese charactersReciprocating motion

The invention relates to the technical field of automobile pipeline tooling, in particular to an automatic O-type ring assembling device of automobile pipeline joint. The automatic O-type ring assembling device of automobile pipeline joint comprises a baseplate, a limiting block which is arranged on the baseplate and used for limiting the pipeline joint, a feeding mechanism arranged on the baseplate and a material taking and pushing mechanism. The material taking and pushing mechanism comprises a slide carriage which is arranged on the baseplate and can make reciprocating movement in the central spindle axis direction, a clamping jaw which is movably arranged on the slide carriage, moves along with the slide carriage, can move relative to the slide carriage and is provided with clamping teeth, and a driving mechanism which drives the slide carriage and the clamping jaw to make reciprocating movement, a support plate is fixedly arranged on the baseplate below the lamping jaw, a guide groove which is shaped as the Chinese character 'hui' and arranged in an inclined angle with the central spindle axis direction is formed in the support plate, and a guide pin which moves in the guide groove is arranged at the lower end of the clamping jaw. The automatic O-type ring assembling device of automobile pipeline joint has the advantages of being capable of achieving automatic assembling of the pipeline joint O-typed ring, fast in speed, reliable in performance, simple in structure, convenient to operate and capable of replacing manual assembling operation; by means of the device, labor intensity is reduced, and work efficiency is improved.

Owner:常州市盛士达汽车空调有限公司

Automatic assembling mechanism for socket protection door

ActiveCN103331601AImplement automatic assemblyAvoid entanglementMetal working apparatusAutomatic processingManipulator

The invention relates to an automatic assembling mechanism for a socket protection door. The automatic assembling mechanism for the socket protection door comprises a protection door feeding unit, an automatic assembling unit, a pushing unit and a manipulator installation unit. The socket protection door to be assembled is fed through the protection door feeding unit and is pushed to the automatic assembling unit for assembling through the pushing unit. The assembled socket protection door is pushed to the manipulator installation unit through the pushing unit. The protection door feeding unit comprises a protection door linear conveying unit and a protection door separation unit. The socket protection door to be assembled sequentially passes through the protection door linear conveying unit and the protection door separation unit. The protection door separation unit comprises a first pushrod. The automatic assembling unit comprises a spring feeding pipe and a spring sliding rod. The spring sliding rod is movably connected with the spring feeding pipe. The manipulator installation unit comprises an ejection component, a pneumatic clamp component and a manipulator. The ejection component and the pneumatic clamp component are arranged at the lower end of the manipulator. By adopting the structure, the automatic assembling mechanism for the socket protection door has the advantages that the structure is simple, the production efficiency is high and the automatic processing can be realized.

Owner:SIMON ELECTRIC CHINA

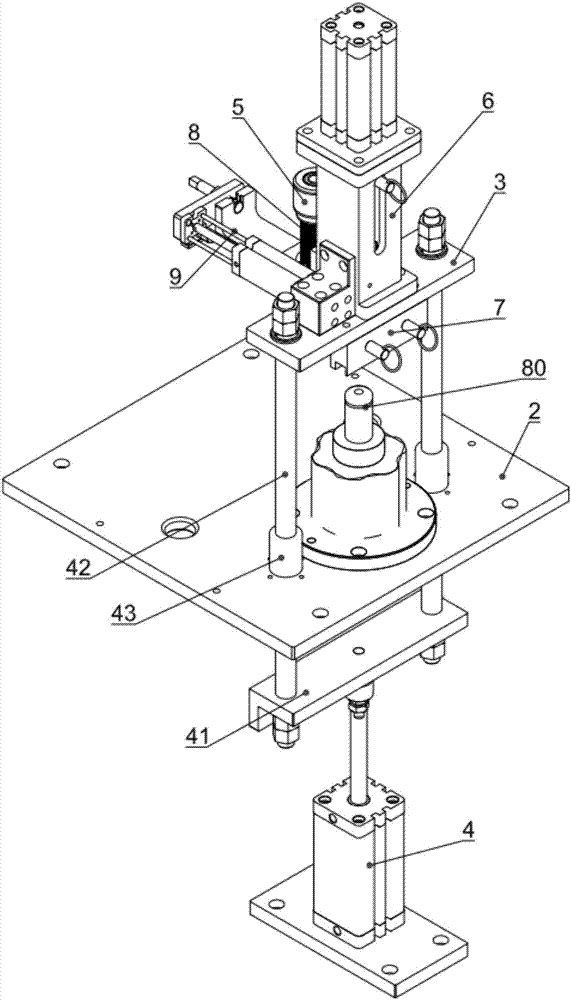

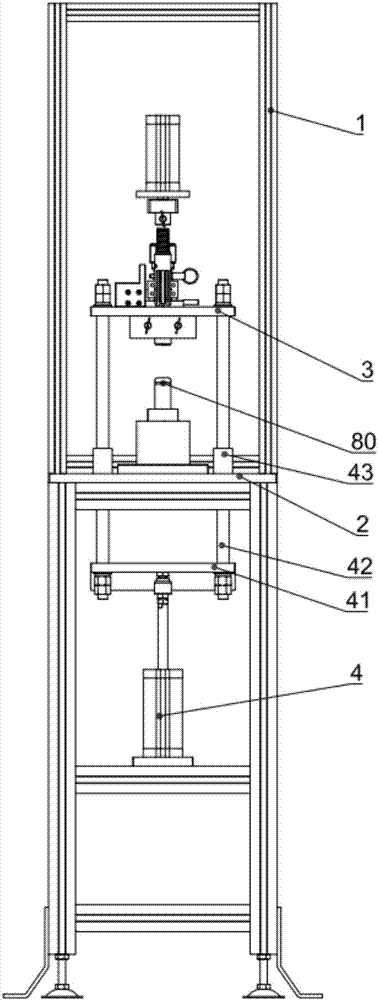

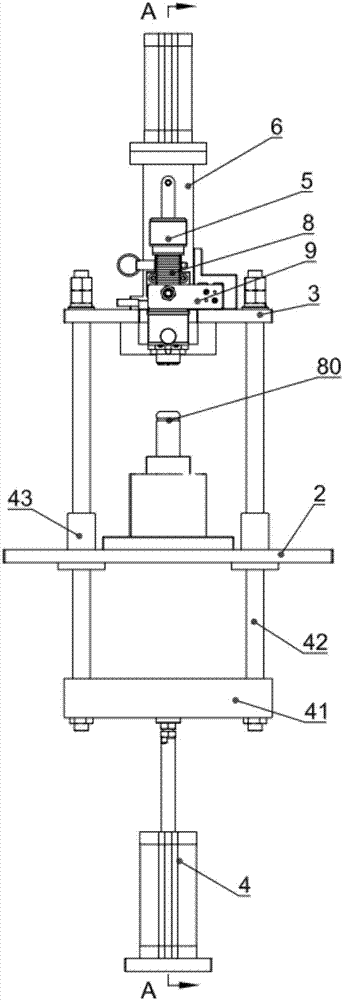

Automatic assembly device of check rings for shafts

PendingCN107443050AImplement automatic assemblyIncrease job securityMetal working apparatusWind energy generationElectricityEngineering

The invention discloses an automatic assembly device of check rings for shafts. The device comprises a rack and further comprises a workbench, a fixing plate, a lifting air cylinder, a material storage unit, a press-mounting unit, a pushing unit and a control unit; the workbench is used for containing parts to be assembled; the fixing plate is arranged above the workbench, and a conveying channel is formed in the fixing plate; the lifting air cylinder is fixed onto the rack, located below the workbench and used for driving the fixing plate and the workbench to move back and forth relatively; the material storage unit is arranged on the fixing plate, and the check rings are arranged on the material storage unit in a sleeving mode; the press-mounting unit is arranged on the fixing plate, and a guide unit and a check ring groove are formed below the press-mounting unit in sequence; the pushing unit is arranged on the fixing plate and pushes the check rings to a guide unit, and the press-mounting unit pushes the check rings of the guide unit into the check ring groove; the control unit, the material storage unit, the pushing unit and the press-mounting unit are all electrically connected to the control unit. According to the automatic assembly device, the problems are solved that in the prior art, manual assembly consumes working hours, the efficiency is low, the labor intensity of personnel is high, the cost is high, and neglected loading exists easily.

Owner:WUHAN LIANHANG ELECTROMECHANICAL

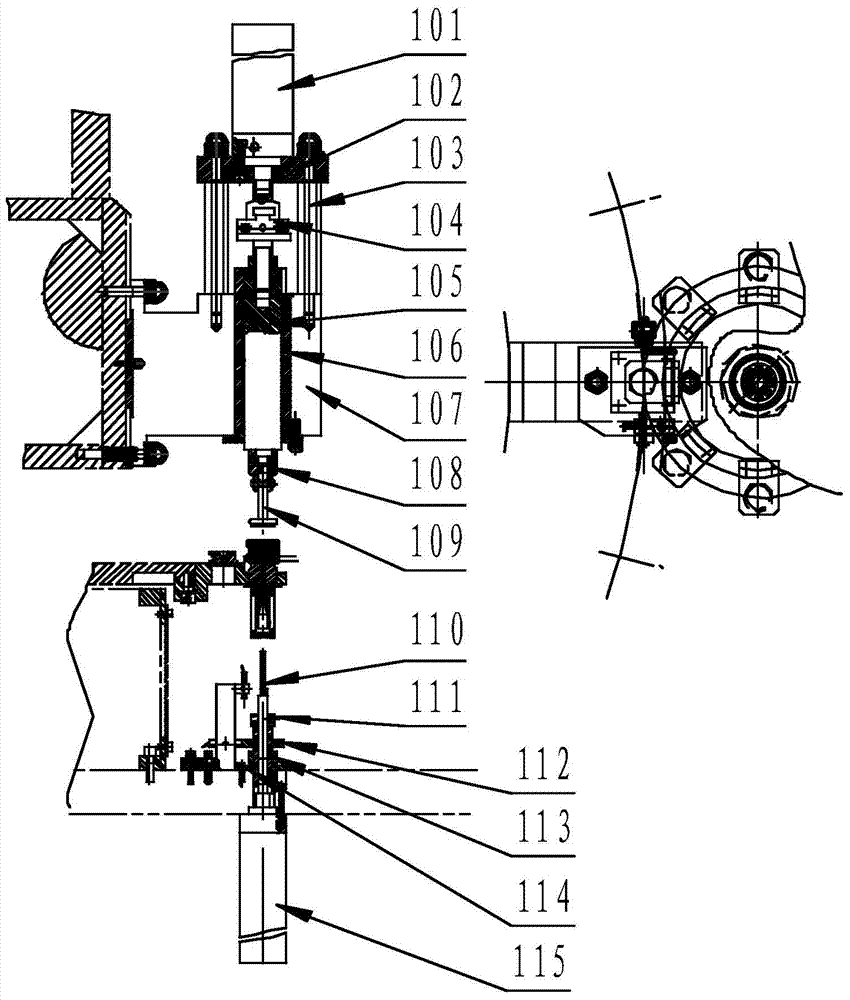

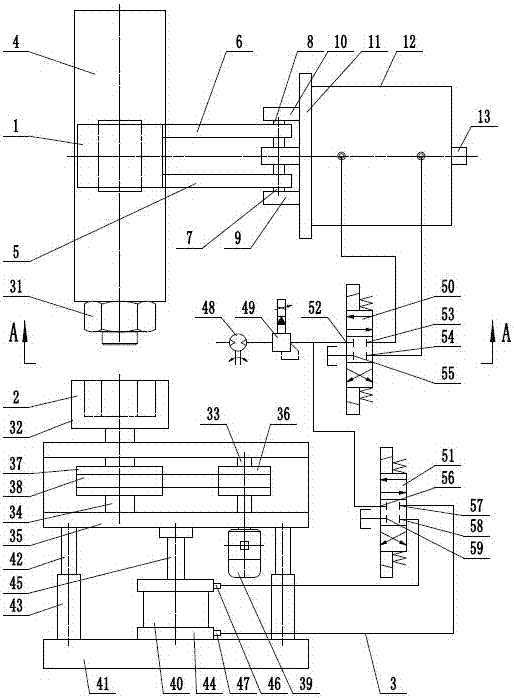

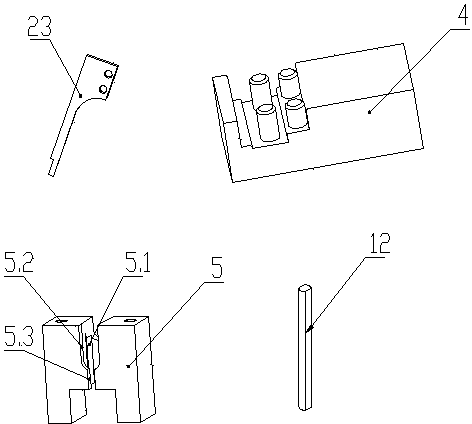

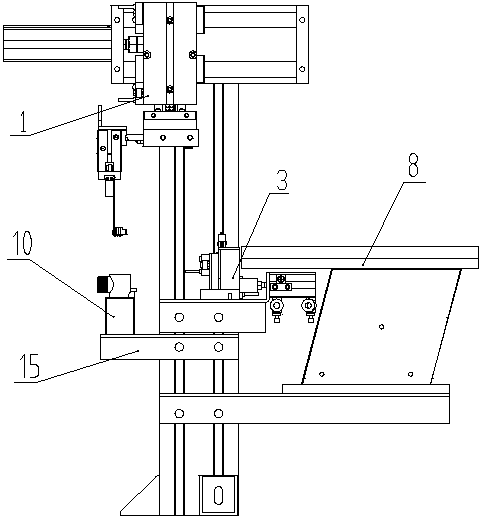

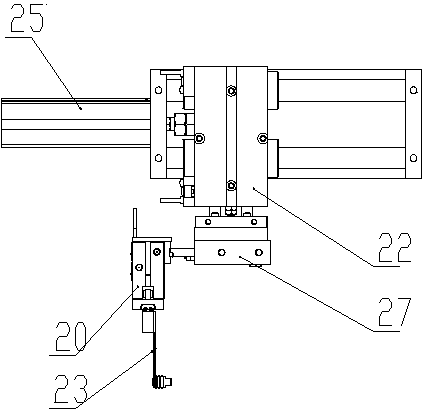

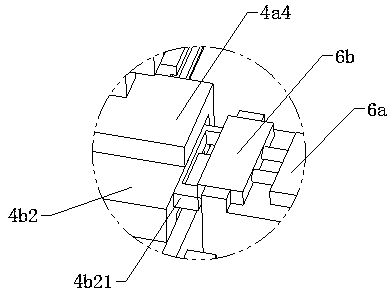

Double-disk detonator automatic assembling machine buckling assembling pressing device

InactiveCN103708987ALow densityReduce manufacturing and management costsDetonatorsManipulatorEngineering

The invention discloses a double-disk detonator automatic assembling machine buckling assembling pressing device. The double-disk detonator automatic assembling machine buckling assembling pressing device is composed of two 24-position disk-type detonator automatic assembling machines and a buckling assembling pressing device. The buckling assembling pressing device is mainly assembled by a charging reinforcement cap ejecting device, a pair of a and b servo central rotating disks, two conveying devices, a overturn grabbing manipulator, three grabbing manipulators, a buckling assembling pressing device and a product turnover die which are joined and matched mutually. The buckling assembling pressing device is used for achieving ejection, grabbing, turnover, overturn and buckling with a discharging shell body of the charging reinforcement cap. The buckling assembling pressing device is arranged between the two 24-position disk-type detonator automatic assembling machines, and used for connection and coordination of product assembling of the two 24-position disk-type detonator automatic assembling machines. The double-disk detonator automatic assembling machine buckling assembling pressing device meets the multifunction requirement, and meets the high reliability requirement of the weapon system development to product assembling.

Owner:北方特种能源集团有限公司西安庆华公司

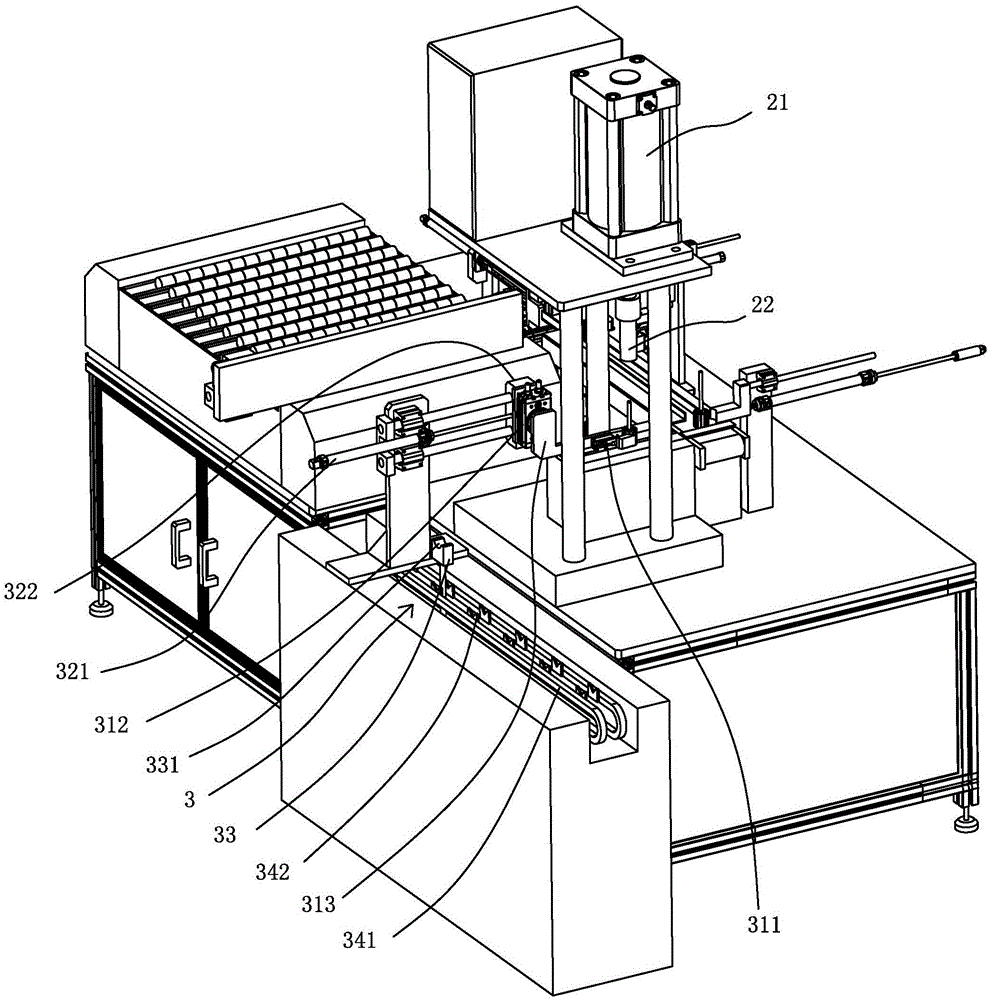

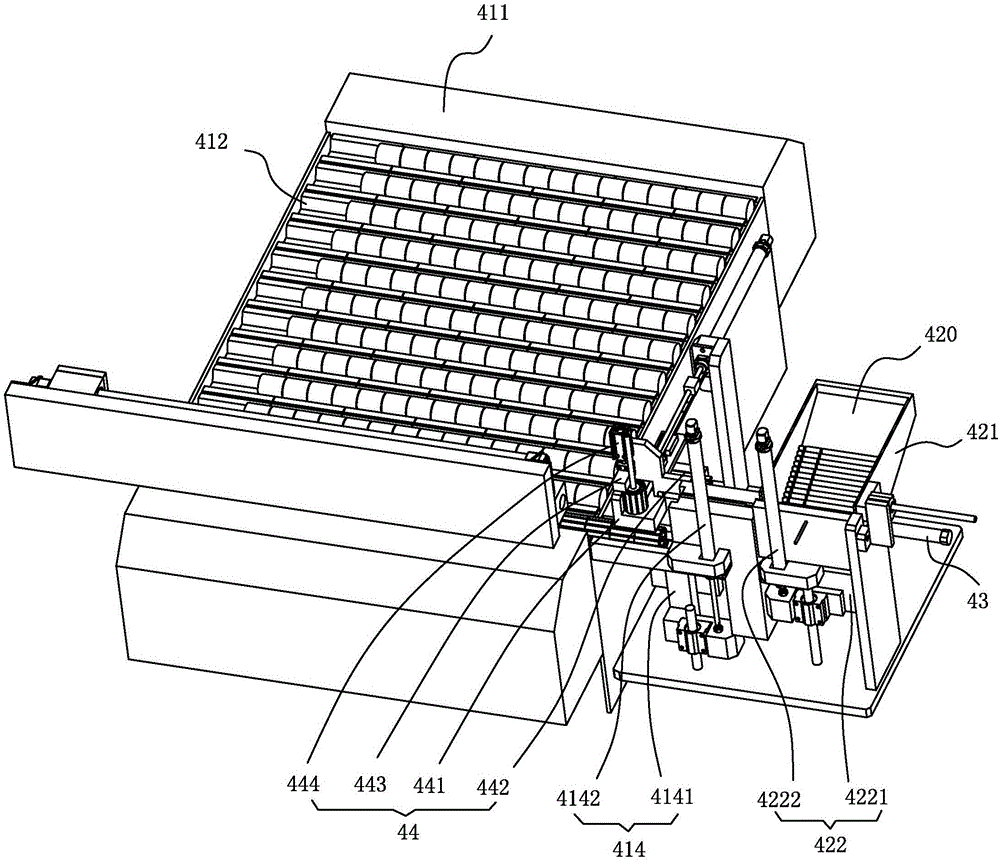

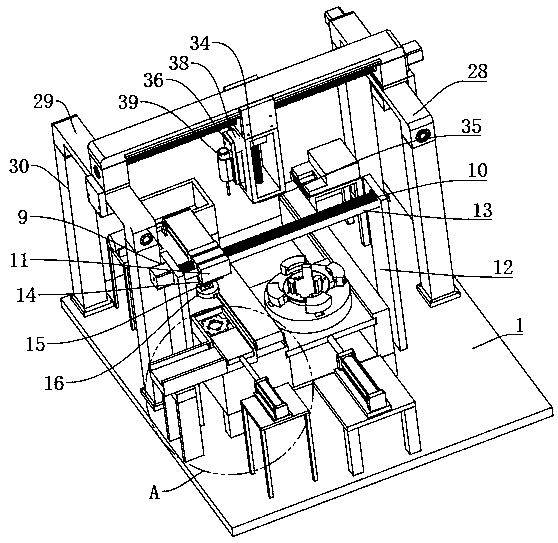

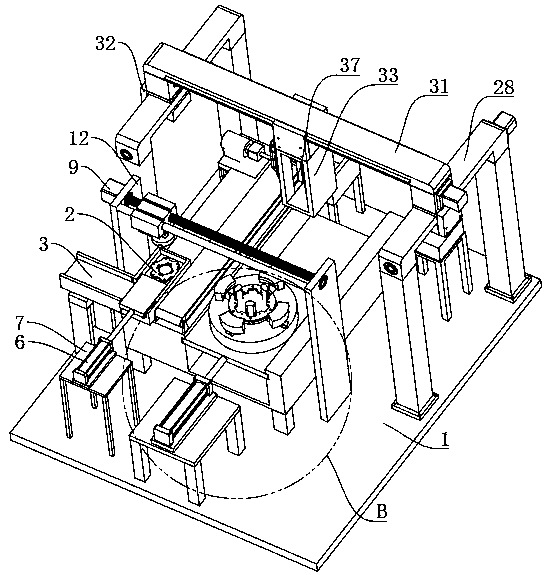

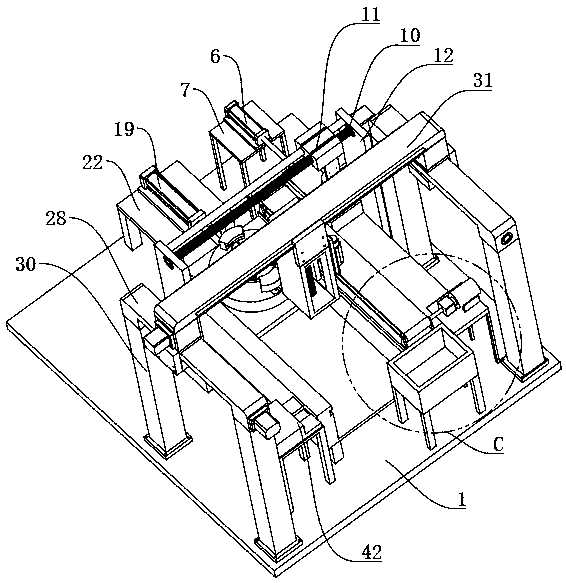

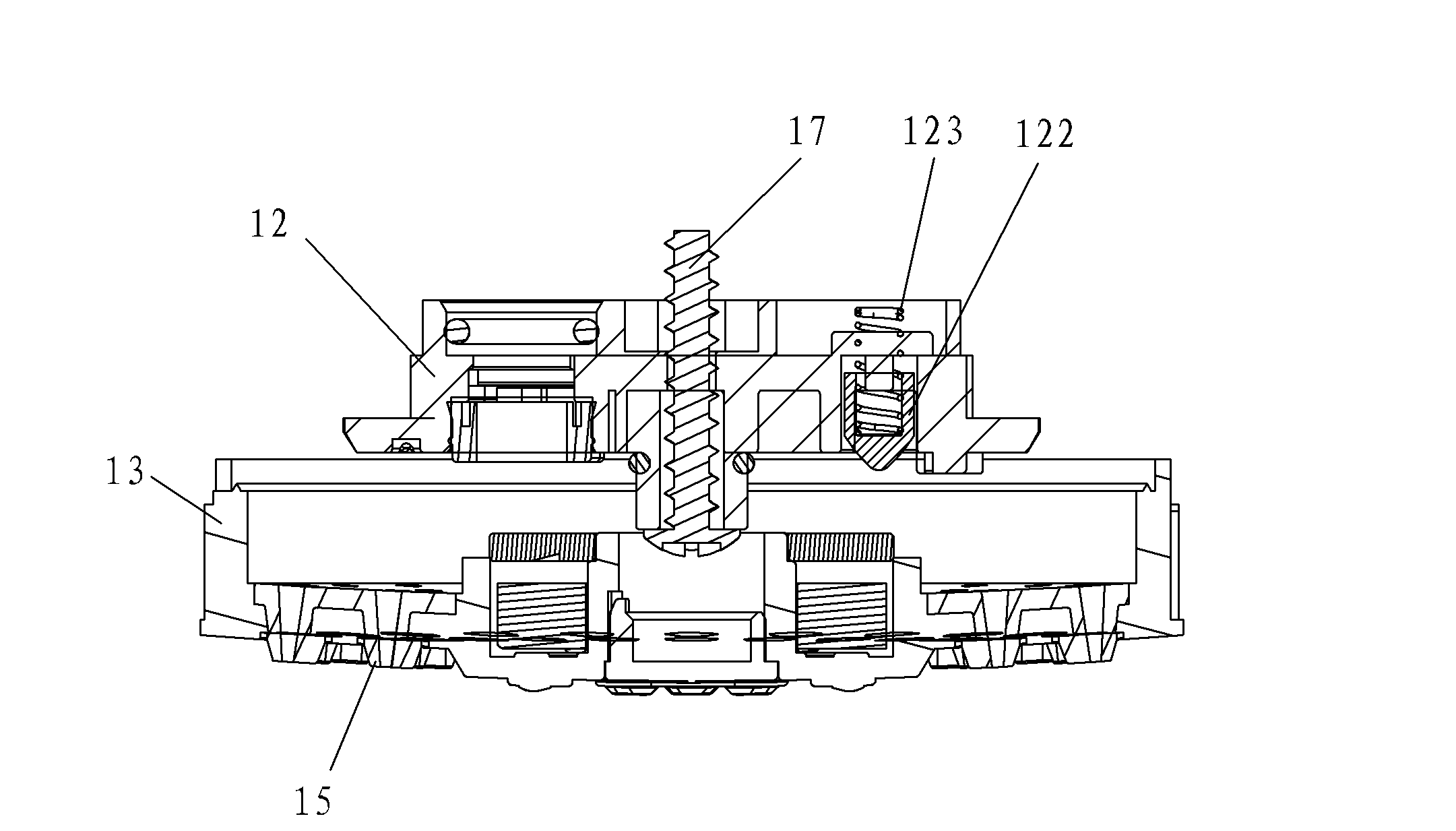

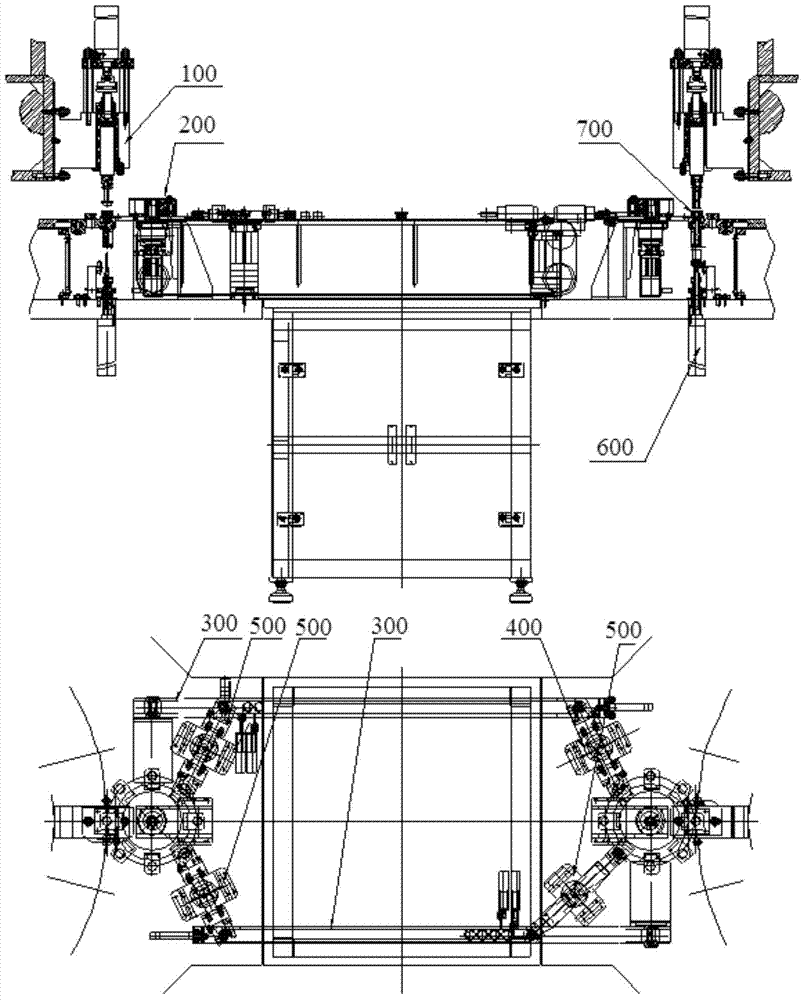

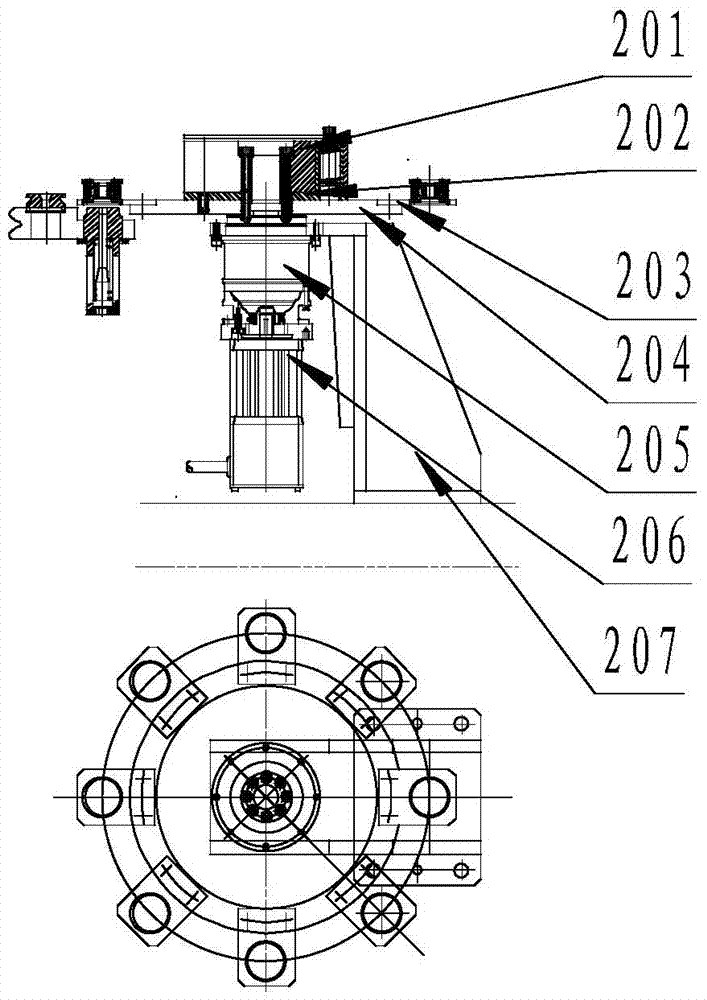

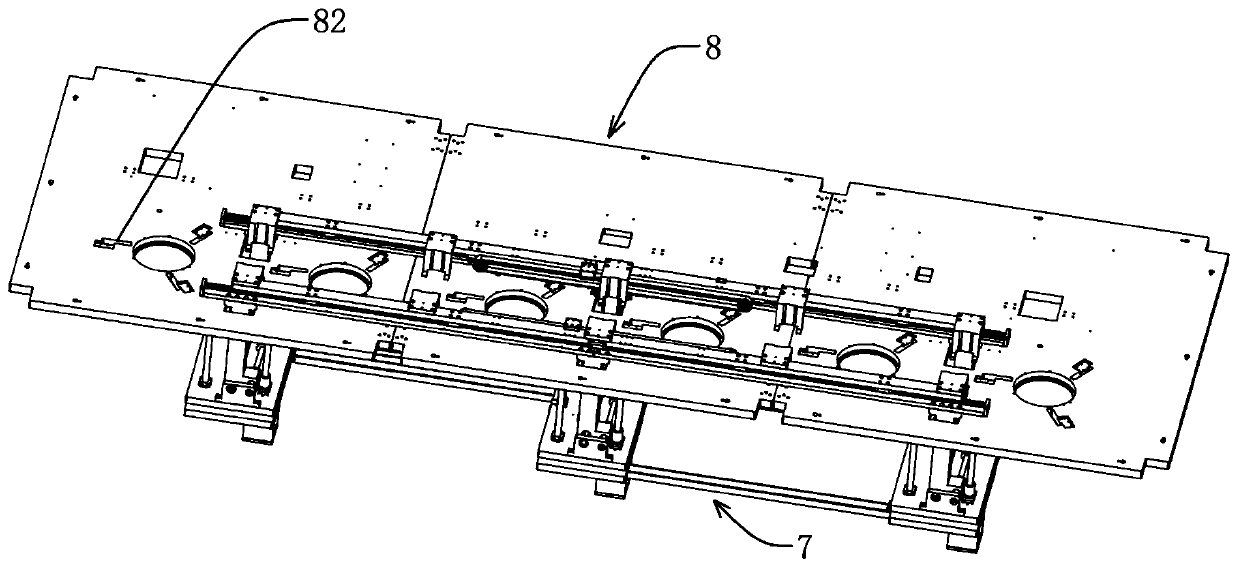

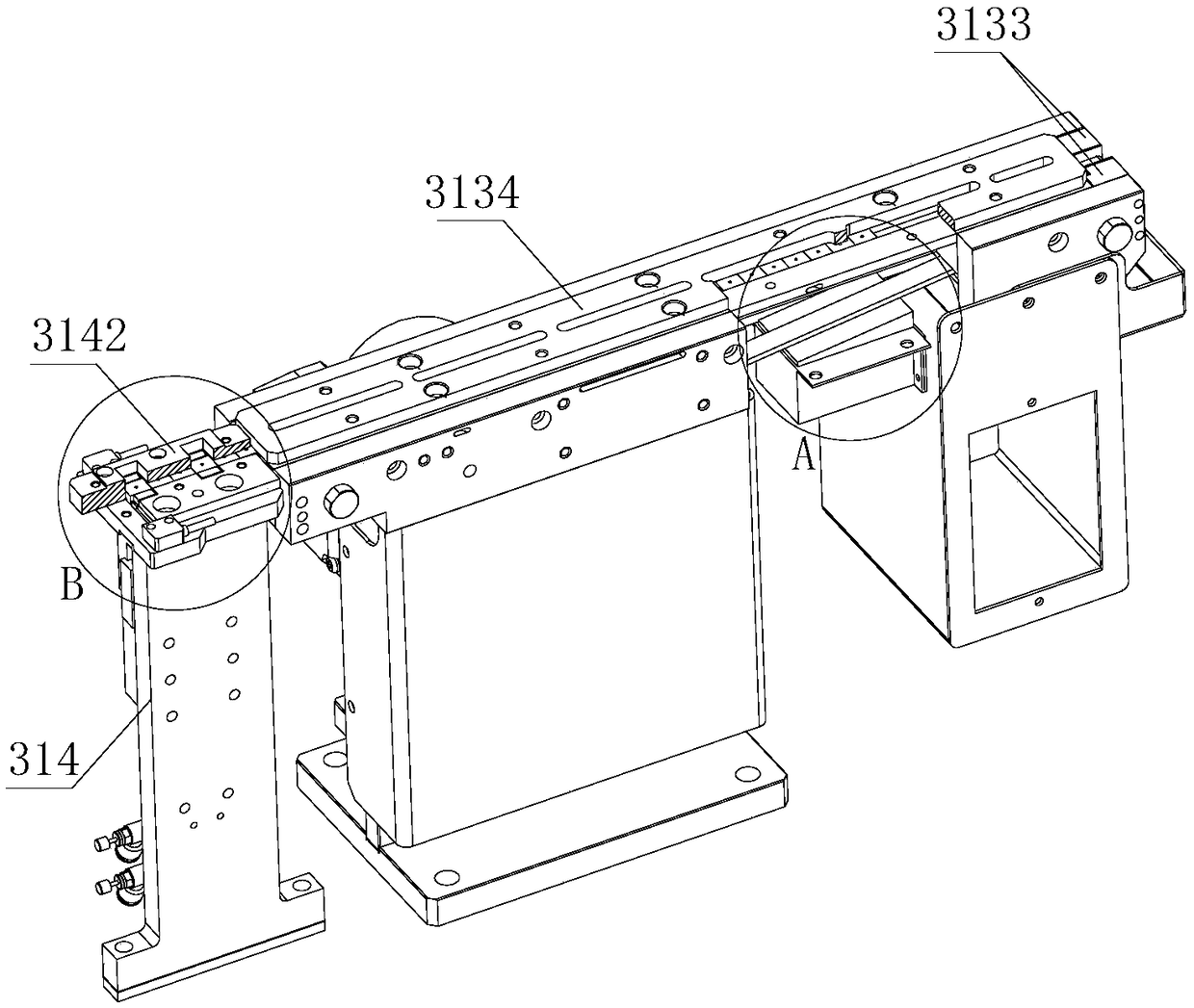

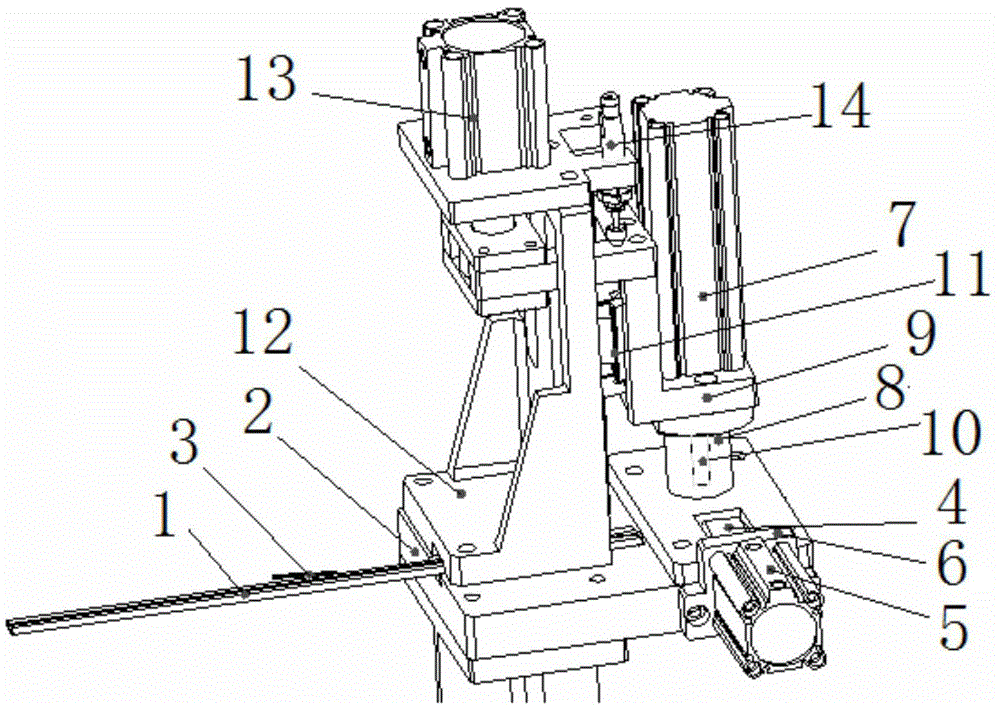

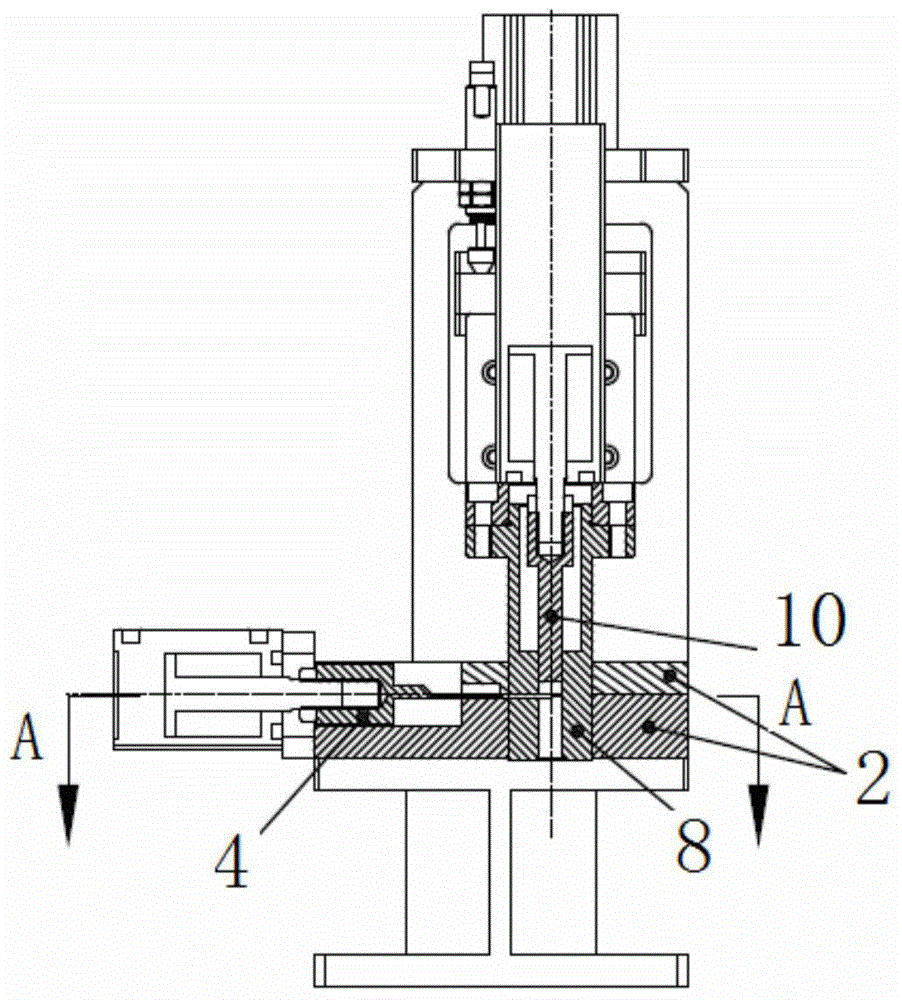

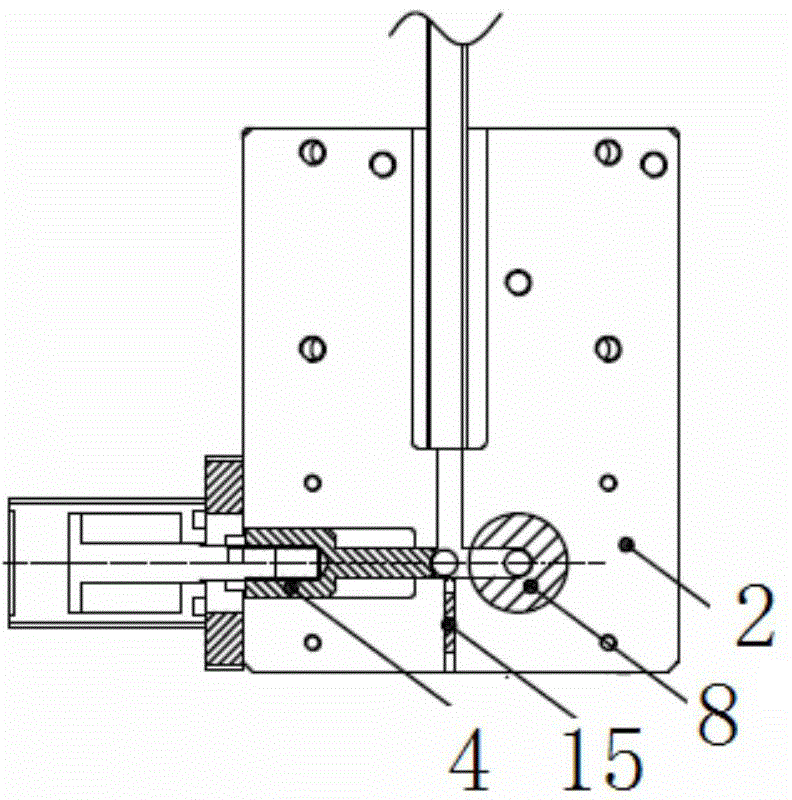

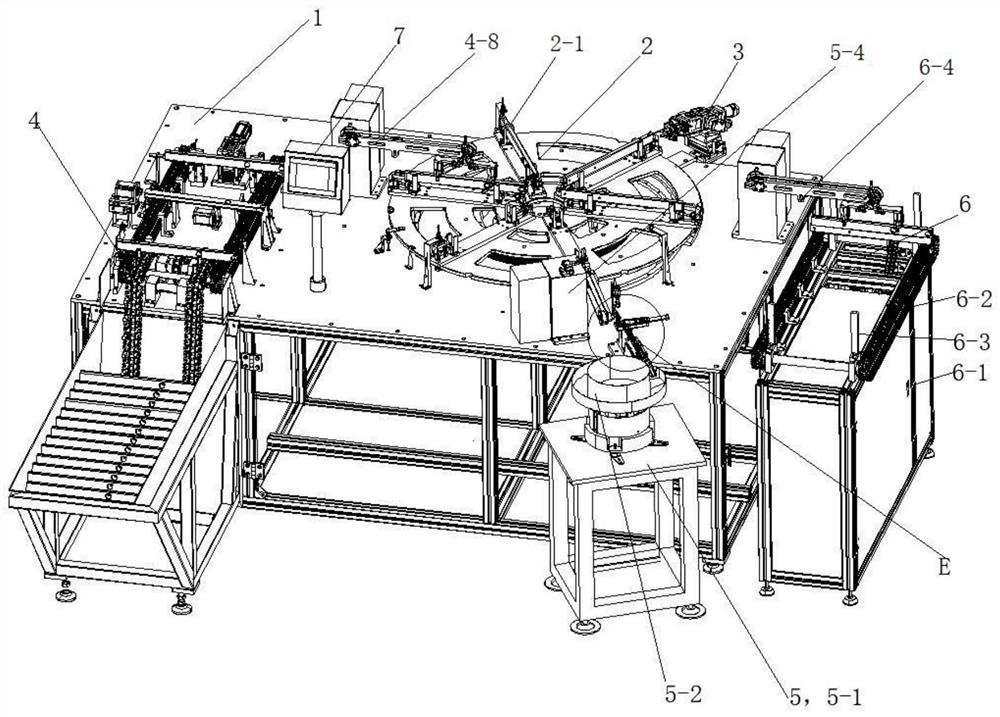

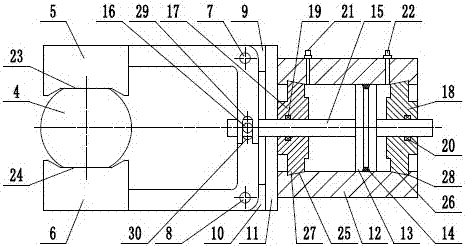

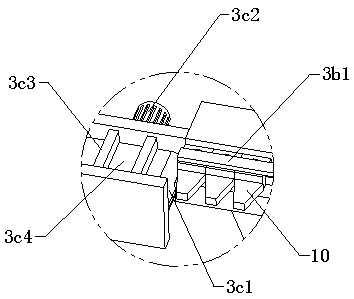

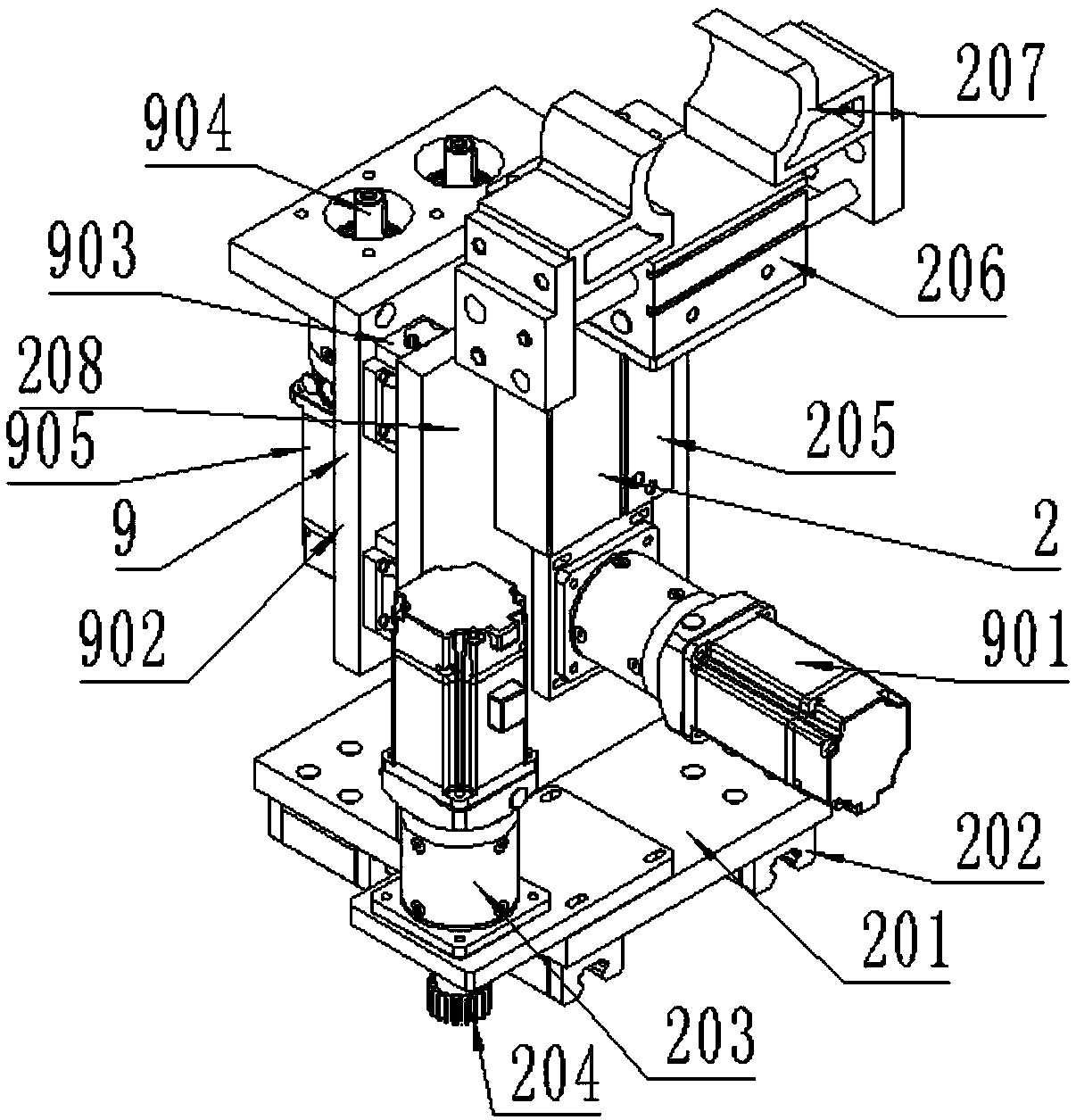

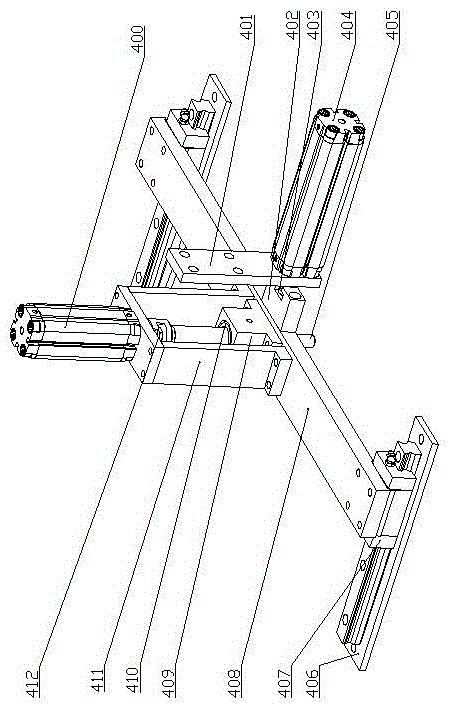

Multi-station transfer mechanism and motor bearing assembly equipment

ActiveCN111300044ASuitable for transferHigh repeatabilityAssembly machinesManufacturing dynamo-electric machinesElectric machineryDrive motor

The invention discloses a multi-station transfer mechanism and motor bearing assembly equipment, and belongs to the technical field of motor assembly. The multi-station transfer mechanism comprises anX-axis transfer assembly, a Y-axis spacing regulating assembly and at least one group of Z-axis lifting assemblies; each Z-axis lifting assembly comprises a rolling ball lead screw and a lifting table which is fixedly connected to a nut in the rolling ball lead screw, wherein the upper end of the lead screw in the rolling ball lead screw is provided with an operation table, the lower end of the lead screw in the rolling ball lead screw is arranged on a support base in a penetrating mode, and the lower end of the lead screw is in transmission connection to a drive motor; the Y-axis spacing regulating assembly comprises two groups of supporting plates which are separately and fixedly connected onto supporting frames in a one-to-one correspondence mode; the supporting frames are arranged ona two-way lead screw in pair, and the two-way lead screw is in transmission connection to a drive motor; and the X-axis transfer assembly comprises transfer plates which axially extend along the X-axis, and are provided with clamping assemblies, and the transfer plates are axially arranged on the supporting plates slidably in the one-to-one correspondence mode. The multi-station transfer mechanismcan quickly take workpieces and switches to different stations, so that operation on each station is convenient.

Owner:BOZHON PRECISION IND TECH CO LTD

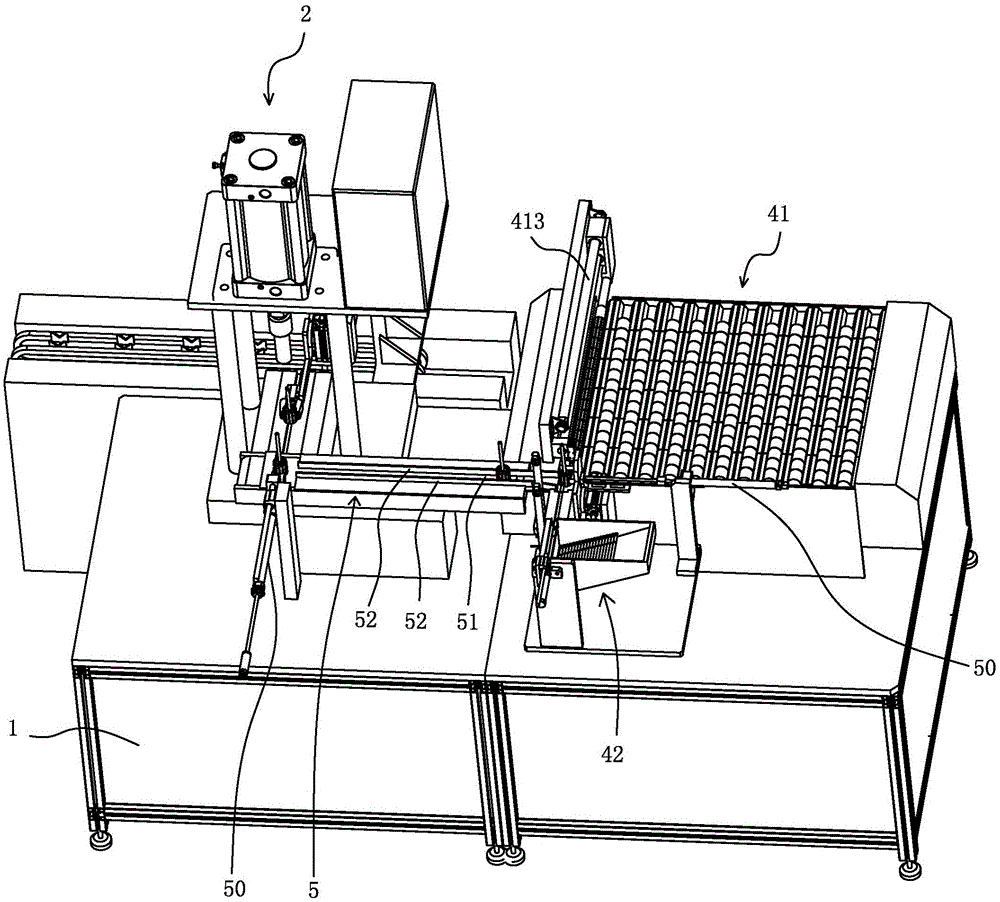

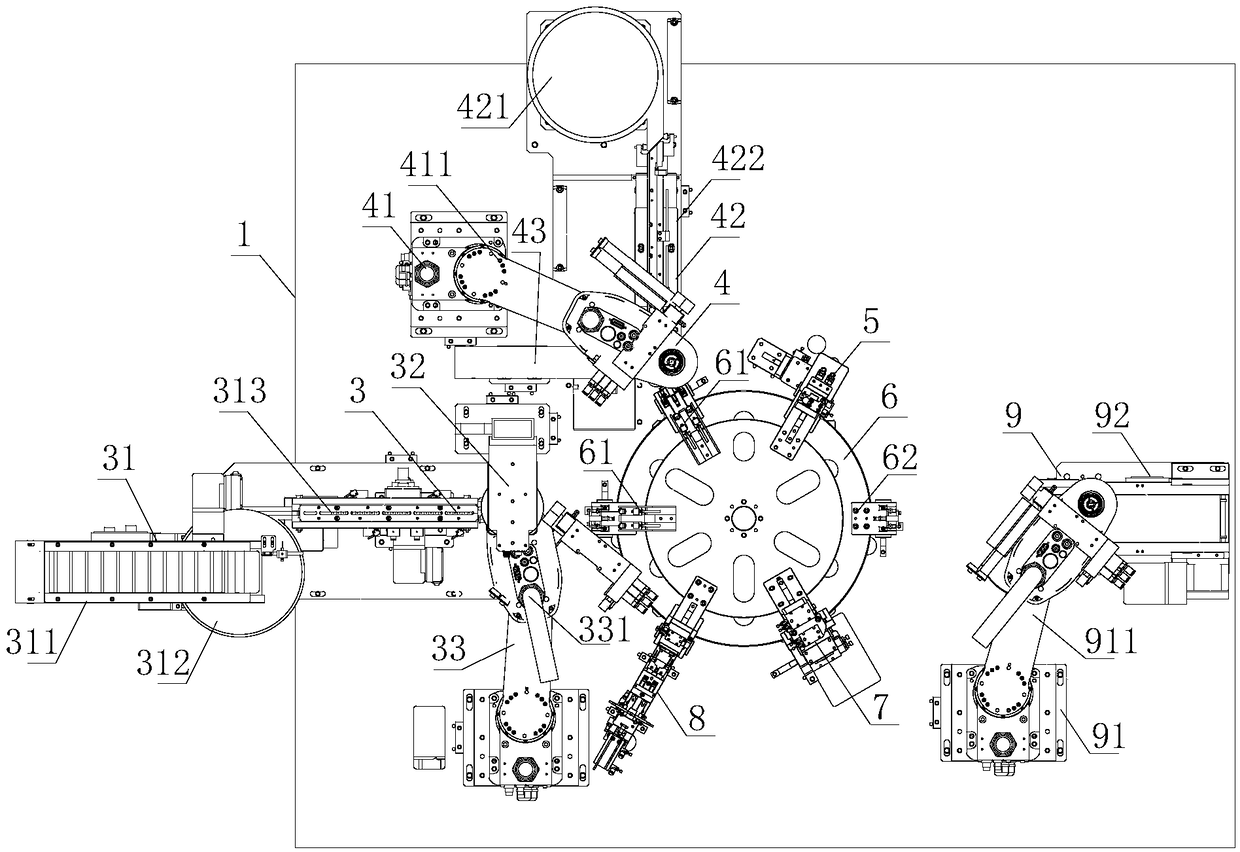

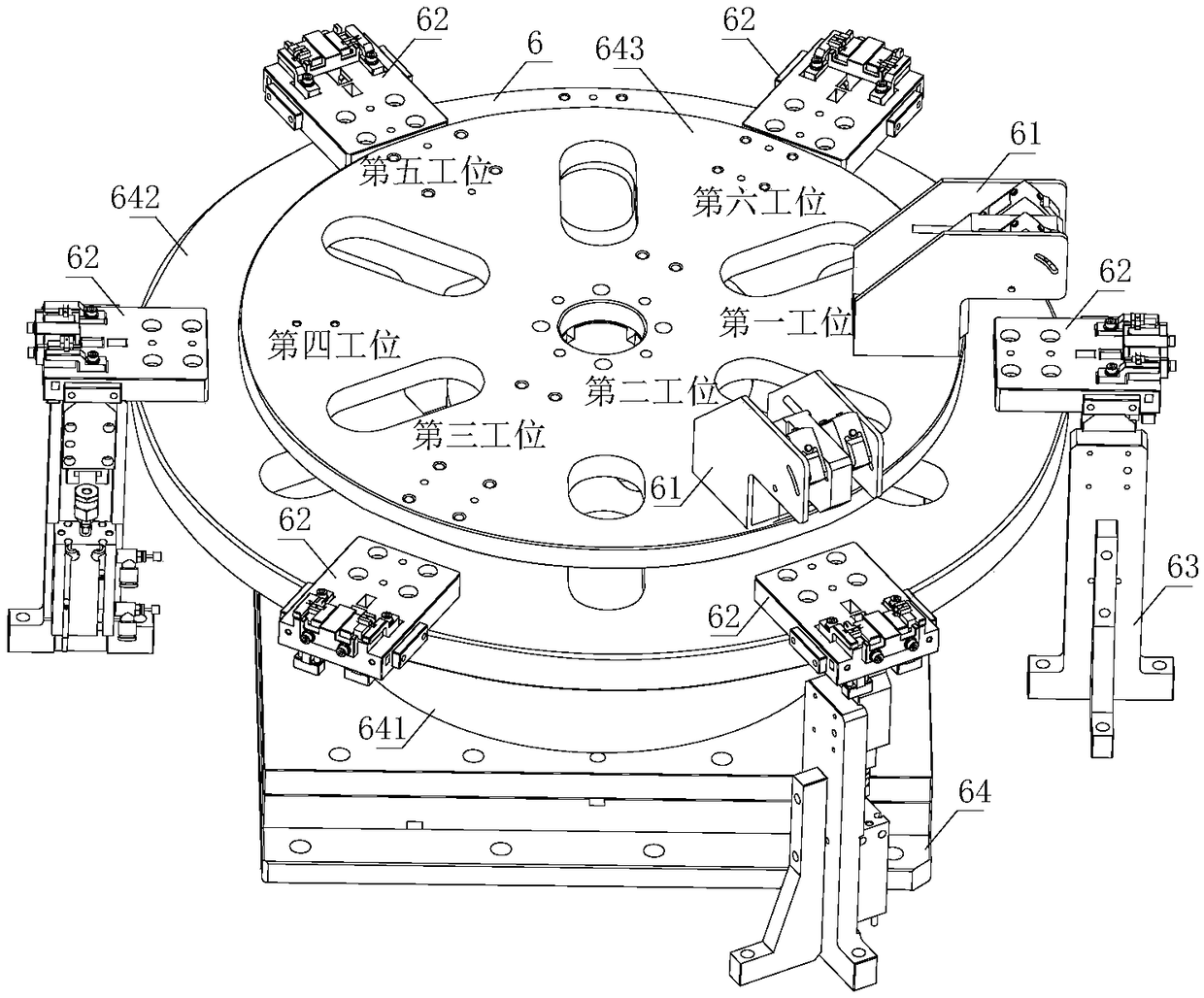

Automatic assembling machine based on mechanical hand and machine vision

ActiveCN108637639AImplement automatic assemblyImprove work efficiencyMetal working apparatusMachine visionEngineering

The invention belongs to the technical field of magnetic core assembling, and discloses an automatic assembling machine based on mechanical hand and machine vision and used for automatically assembling magnetic cores. The automatic assembling machine comprises a rotary disc rotationally arranged along a vertical shaft, the rotary disc is connected with a first driving device driving the rotary disc to rotate, and at least six stations are uniformly distributed in the rotary direction of the rotary disc; each station is provided with a carrying seat, and the carrying seats are fixed to the rotary disc; the first station is provided with a magnetic core body feeding module which is used for placing a magnetic core body into the corresponding carrying seat; the second station is provided witha foot sheet feeding module which is used for placing a foot sheet into the corresponding carrying seat; the third station is provided with a cleaning module which is used for cleaning an assembled magnetic core; the fourth station is provided with a discharging module which is used for transferring the assembled magnetic core to the outside of the automatic assembling machine based on mechanicalhand and machine vision; the fifth station is provided with a riveting module which is used for riveting the foot sheet to the magnetic core body; and the sixth station is provided with a compressingmodule which is used for compressing the foot sheet.

Owner:CHENGDU TIANCHUANG PRECISION MOLD

Automatic inner-hole clamp spring assembling device and method

InactiveCN104889719AImplement automatic assemblyImprove assembly efficiencyMetal working apparatusPre compressionEngineering

The invention discloses an automatic inner-hole clamp spring assembling device and method. The automatic inner-hole clamp spring assembling device comprises a base, a clamp spring feeding plate, a pre-compression cylinder and a clamp spring pushing cylinder, the clamp spring feeding plate is arranged on the base, a clamp spring passage is arranged in the clamp spring feeding plate, a clamp spring positioning barrel is arranged on the clamp spring pushing cylinder, a through hole used for the clamp spring positioning barrel to penetrate is formed in the clamp spring feeding plate, the through hole and the pre-compression cylinder are positioned on two sides of the clamp spring passage correspondingly, a clamp spring pre-compression pushing claw is arranged on the pre-compression cylinder, a notch aligned at the clamp spring pre-compression pushing claw is formed in the clamp spring positioning barrel, and a piston rod of the clamp spring pushing cylinder is connected with a clamp spring pushing finger which is positioned in the clamp spring positioning barrel. By the automatic inner-hole clamp spring assembling device and method, automatic assembling of an inner-hole clamp spring can be realized, assembling efficiency of the inner-hole clamp spring is improved substantially, uniformity and reliability in clamp spring assembling are improved, and automation level of factory assembling is improved.

Owner:芜湖陀曼精机科技有限公司

Automatic welding machine for square pipes and gaskets

PendingCN111958141AReduce human inputImprove welding accuracy andWelding/cutting auxillary devicesAuxillary welding devicesSmall footprintManufacturing engineering

The invention discloses an automatic welding machine for square pipes and gaskets. The welding machine comprises an operating table, a rotary worktable fixedly installed on the operating table, and anautomatic gasket feeding device, an automatic square pipe feeding device, a welding device and an automatic discharging device which are arranged around the rotary worktable sequentially. A welding assembly mechanism is arranged on the rotary worktable; the rotary worktable drives the welding assembly mechanism to circulate and operate among the automatic gasket feeding device, the automatic square pipe feeding device, the welding device and the automatic discharging device; and the welding assembly mechanism receives gaskets at the automatic gasket feeding device and square pipes at the automatic square pipe feeding device, and assembly of the gaskets and the square pipes is completed before movement to the welding device. According to the automatic welding machine, automatic feeding, automatic assembly and welding of the square pipes and the gaskets can be achieved, welded parts are conveyed to a discharging area, manual operation is not needed in the whole process, manpower input is reduced, the welding accuracy and the production safety are improved, the floor area is small, and the production cost is greatly reduced.

Owner:常州三拓焊接设备有限公司

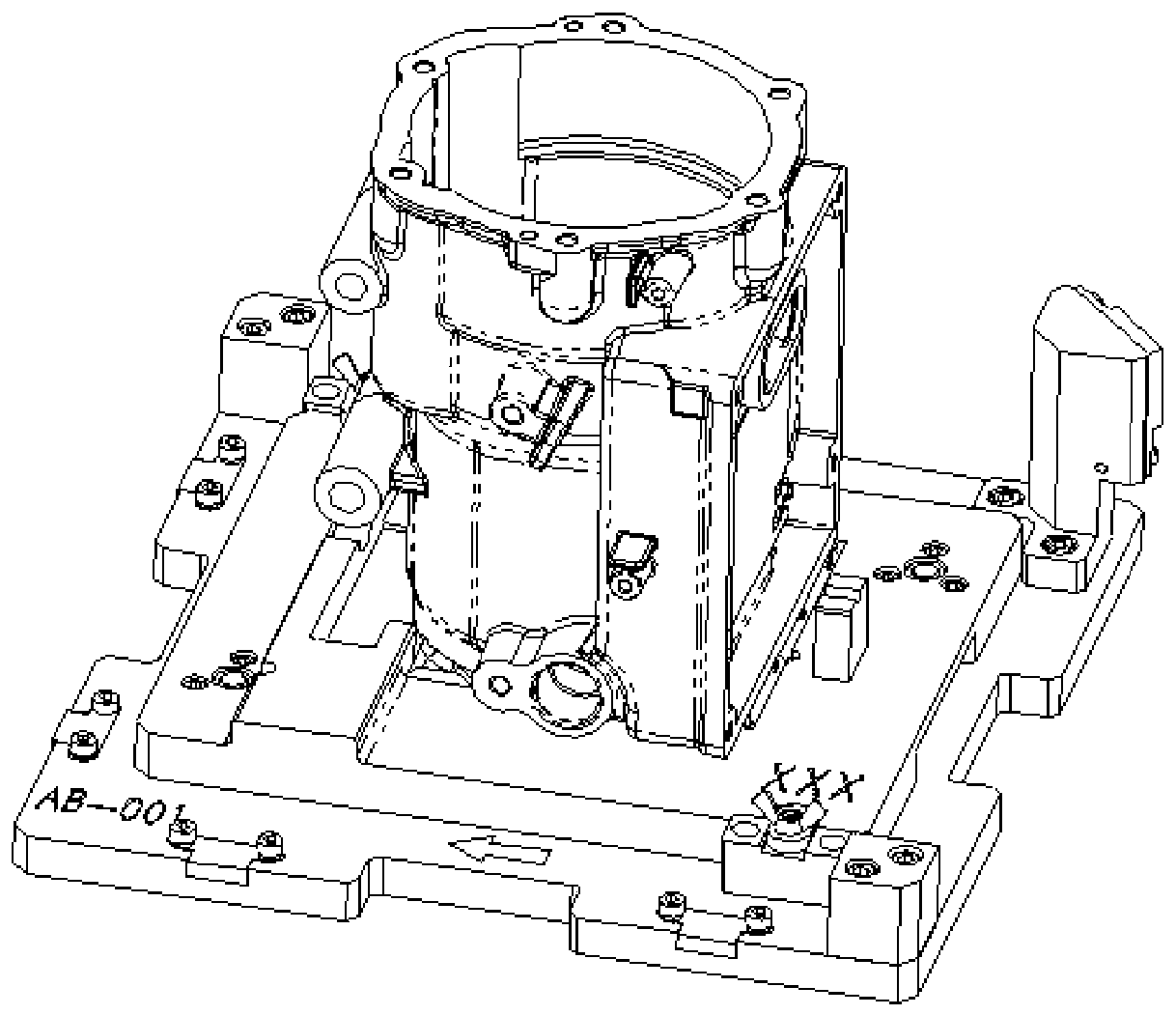

Assembling device for shaft end nuts

InactiveCN107309642AAchieve releaseAvoid moving back and forthMetal working apparatusEngineeringCylinder block

The invention provides an assembly device for a shaft end nut, which belongs to the technical field of shaft workpiece assembly. The piston of the clamping fastening mechanism is slidably arranged in the cylinder body, the driving pin is fixed at one end of the piston rod, the driving pin is inserted into the first open groove and the second open groove, and the guide rod and the guide sleeve of the shaft end nut tightening mechanism are up and down. Slidable connection, the upper end of the tightening piston rod is connected to the tightening support seat, the nut support seat is coaxially installed on the upper end of the second rotating shaft, the air pump of the pneumatic drive mechanism is connected to one end of the pressure regulating valve, and the other end of the pressure regulating valve is connected to the first three The first valve port of the one-position four-way reversing valve and the fifth valve port of the second three-position four-way reversing valve, the second valve port is connected to the first air valve on the cylinder body, and the third valve port is connected to the The second air valve, the sixth valve port is connected to the lower air valve of the tightening cylinder, and the seventh valve port is connected to the upper air valve of the tightening cylinder. The invention quickly realizes the clamping and fastening of the shaft, and realizes the automatic assembly of the nut at the shaft end, and has a reasonable structure.

Owner:TONGXIANG FENGMING TIN MAKING FACTORY

Valve rod assembling method

ActiveCN103465016AImplement automatic assemblyImprove assembly efficiencyMetal working apparatusEngineeringMechanical engineering

Owner:马翔

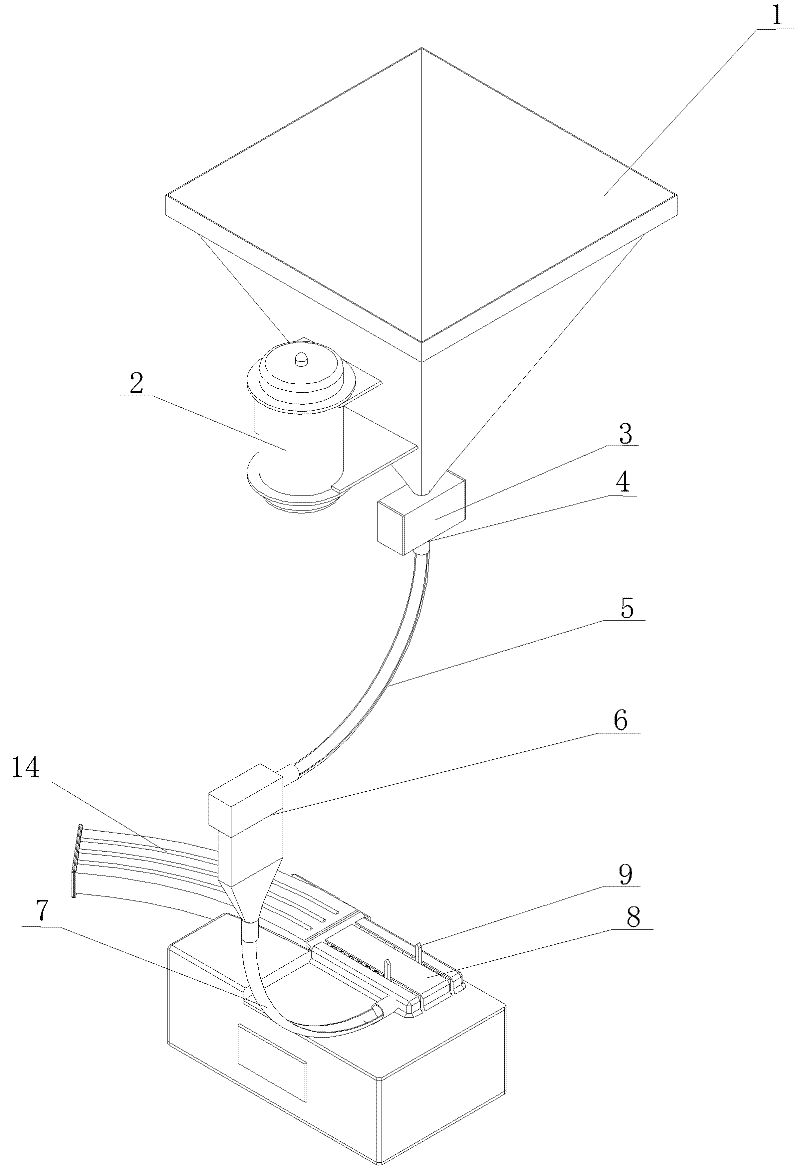

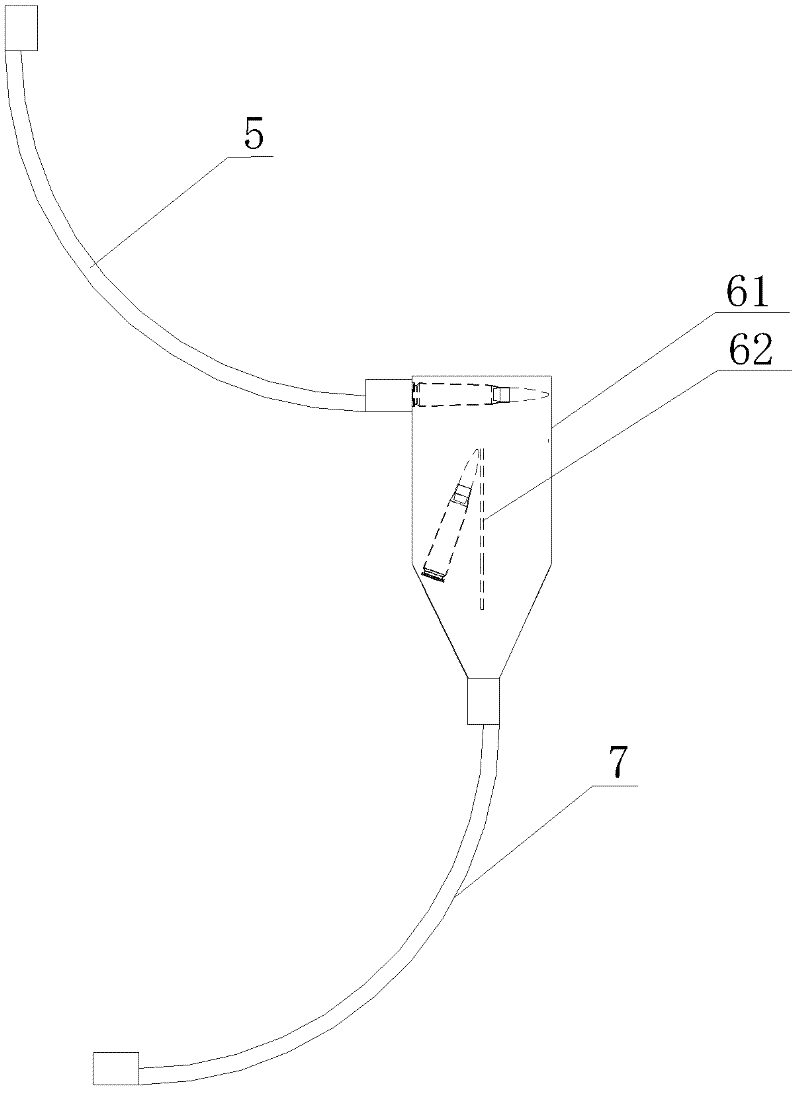

Bullet automatically assembling system based on gravity sieving

InactiveCN102636077AImplement automatic assemblyRealize fully automatic assemblyAmmunition loadingEngineeringMechanical engineering

The invention discloses a bullet automatically assembling system based on gravity sieving, comprising a bullet loading funnel, a vibration motor, a bullet guide device and a bullet pressing mechanism, wherein the bottom of the bullet loading funnel is provided with a bullet output opening; the vibration motor is used for driving the bullet loading funnel to vibrate; the bullet guide device is used for adjusting the direction of a bullet; the inlet of the bullet guide device is communicated with the bullet output opening of the bullet loading funnel through a first bullet conveying pipe; the bullet pressing mechanism is used for pressing the bullet with the adjusted direction into a bullet box; and a bullet inlet of the bullet pressing mechanism is communicated with an outlet of the bullet guide device through a second bullet conveying pipe. According to the invention, the bullets are uniformly sequenced by the gravity sieving through the bullet guide device and the bullets are pressed into the bullet box through the bullet pressing mechanism, so that the full-automatic assembling of the bullets is realized, a manual sequencing link is saved and the bullet loading efficiency is improved; and the automatic bullet assembling system has the advantages of simple structure, strong reliability, wide applicability, high working efficiency and the like.

Owner:ZHEJIANG UNIV

Automatic assembly machine of stationary contact and tension screw stud

InactiveCN108788711AImplement automatic assemblyRealize functions such as countingMetal working apparatusNumerical controlPortal frame

The invention relates to the field of automatic assembly equipment, and particularly relates to an automatic assembly machine of a stationary contact and a tension screw stud. The automatic assembly machine comprises a worktable, a tension screw stud charging device, a stationary contact charging device, a material moving device, an assembly device and a numerical control device, wherein the tension screw stud charging device comprises a first vibrating disc, a tension screw stud guide rail and a first pushing assembly; one end of a stationary contact guide rail is connected with an output end of a second vibrating disc; the other end of the stationary contact guide rail faces a gradual feeding assembly; the material moving device comprises a longitudinal moving material assembly and a transverse material moving assembly; the assembly device comprises a portal frame, a transverse lead screw sliding table, an assembly air cylinder and an assembly motor; an output shaft of the assemblymotor is fixedly connected with a screw lock; and charging is carried out through cooperation of the tension screw stud charging device, the stationary contact charging device and the material movingdevice, and then assembly is carried out by adopting the assembly device, so that the automatic processing is realized. The equipment has the advantages that an operation is flexible, simple and convenient, the labor and production time are greatly reduced, and the high working efficiency is obviously promoted.

Owner:王远志

Safe and environment-friendly firecracker automation assembly production line

InactiveCN104864779AImplement automatic assemblyReduce manual servicesFireworksFirecrackerProduction line

The invention belongs to the technical field of safe and environment-friendly firecracker assembling equipment, and provides a safe and environment-friendly firecracker automation assembly production line for solving the technical problems of safe and environment-friendly firecracker automation production. The safe and environment-friendly firecracker automation assembly production line comprises a main rack, tooling plates and tooling plate conveying mechanisms installed on the left side and the right side of the upper portion of the main rack; the main rack is sequentially provided with an automation metal sleeve solid lead plug assembly machine, an automation fuse inserting machine, an automation powder charging machine, an automation single shell combining machine and an automation firecracker knotting machine from front to back. According to the safe and environment-friendly firecracker automation assembly production line, the automatic assembly of safe and environment-friendly firecrackers is achieved, the manpower service is greatly reduced, the production cost is reduced, and the production efficiency is improved.

Owner:SHENZHEN CHUANGYE TECH

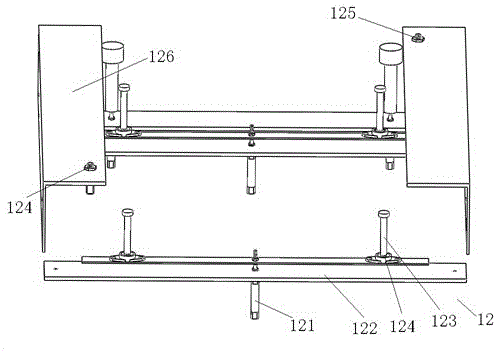

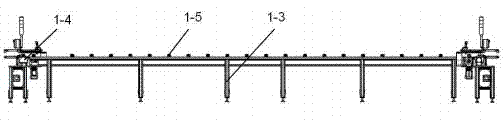

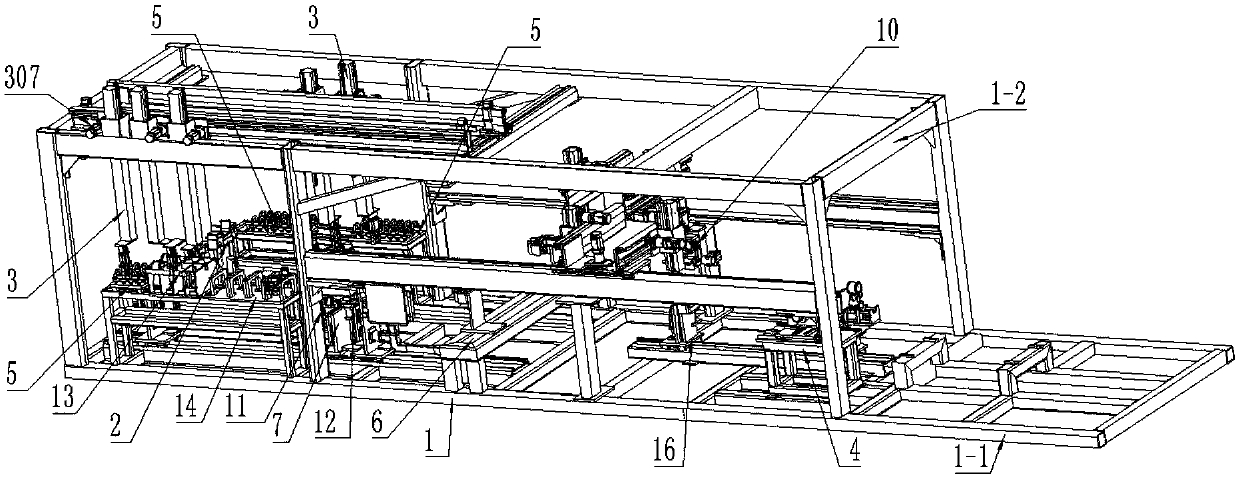

High-speed rail cantilever pre-assembling line

PendingCN109551226ARealize automatic pre-assemblyImprove assembly efficiencyAssembly machinesMetal working apparatusCantileverMechanical engineering

The invention relates to a high-speed rail cantilever pre-assembling line which comprises a rack, a flat cantilever clamping assembly, an inclined cantilever clamping assembly and an assembling mechanism. The flat cantilever clamping assembly, the inclined cantilever clamping assembly and the assembling mechanism are installed on the rack. The flat cantilever clamping assembly and the inclined cantilever clamping assembly are arranged on the left side and the right side of the rack correspondingly. The flat cantilever clamping assembly comprises a flat cantilever clamping moving mechanism anda flat cantilever set clamping mechanism. The inclined cantilever clamping assembly comprises an inclined cantilever clamping moving mechanism and an inclined cantilever set clamping mechanism. The assembling mechanism comprises an assembling moving mechanism and a set screwing mechanism. The assembling moving mechanism comprises an inclined cantilever assembling moving mechanism and a flat cantilever assembling moving mechanism. The flat cantilever assembling moving mechanism can drive a flat cantilever to move transversely and move longitudinally, the inclined cantilever assembling moving mechanism can drive a flat cantilever to move transversely and longitudinally, and the set screwing mechanism can be used for connecting a flat cantilever set with the flat cantilever and connecting aninclined cantilever set with the inclined cantilever. Automatic pre-assembling of a high-speed rail cantilever can be achieved, and the assembling efficiency is high.

Owner:龙口市汇金达智能设备有限公司

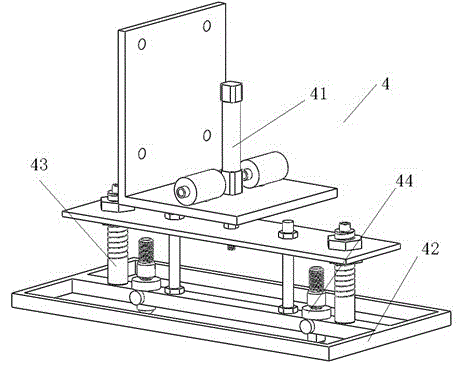

Clamp spring automatic assembly device

PendingCN110153681AImplement automatic assemblyIncrease productivityAssembly machinesMetal working apparatusEngineeringMechanical engineering

The invention aims to provide a clamp spring automatic assembly device which can realize automatic assembly of a clamp spring so as to improve the production efficiency and reduce the labor cost. In order to achieve the aim, the invention adopts the following technical scheme that the clamp spring automatic assembly device comprises a bottom plate, a press is fixed on the bottom plate through a support, and an end cover positioning base is arranged on the bottom plate; the press comprises a press head assembly, the press head assembly comprises a pressing rod, a guide block and a positioning block, wherein the guide block is arranged on the pressing rods in a sleeve mode, a plurality of vertically-penetrating guide holes are formed in the guide block, the lower ends of guide columns penetrate through the guide holes to be fixed with the positioning block, and the positioning block is arranged on the circumferential outer side of the pressing rod in a sleeve mode and is provided with apressing groove which penetrates vertically; and a feeding port allowing the clamp spring to pass is formed in the side face of the positioning block, the feeding port communicates with the pressing groove, the pressing groove comprises an upper pressing groove section and a lower pressing groove section, and the inner diameter of the lower pressing groove section is gradually reduced from top tobottom.

Owner:HENGDIAN GRP INNUOVO ELECTRIC

Automatic assembling device for piston in manual pump

ActiveCN105563082ANovel structureHigh degree of automationMetal working apparatusHand pumpEngineering

The invention relates to an automatic assembling device for a piston in a manual pump, and belongs to the field of mechanical manufacturing. A feeding device is connected with a rodless air cylinder, and the feeding device and the rodless air cylinder are fixed to a mounting plate on the right side of a main frame; the manual pump is initially positioned by a U-shaped limiting block on one side of a manual pump valve body and then is clamped by devices such as a clamping block and a clamping plate which are located on the two sides of the manual pump valve body; and an air cylinder provides power. An opening and closing type pneumatic grabbing part is used for grabbing a piston rod, and the air cylinder located on the upper portion of the opening and closing type pneumatic grabbing part provides power; the air cylinder is mounted on an L-shaped mounting plate, and the L-shaped mounting plate is driven by the rodless air cylinder located on a whole frame, so that pushing work of the piston rod is achieved; and a limiting block connected with the rodless air cylinder positions the precise mounting position of the piston rod. The automatic assembling device has the beneficial effects that the structure is novel, reliability and practicability are achieved, the automation degree is high, and the assembling process is reliable and stable; and the device can be directly applied to an automation assembling production line, and the labor cost is reduced.

Owner:长春宝泽科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com