Automatic assembling mechanism for socket protection door

A socket protection door, automatic assembly technology, applied in metal processing, metal processing equipment, manufacturing tools and other directions, can solve the problems of cumbersome assembly process, low production efficiency, small spring volume, etc., to achieve simple assembly process, improve production efficiency, Assemble the effect quickly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to understand the technical content of the present invention more clearly, the following examples are given in detail.

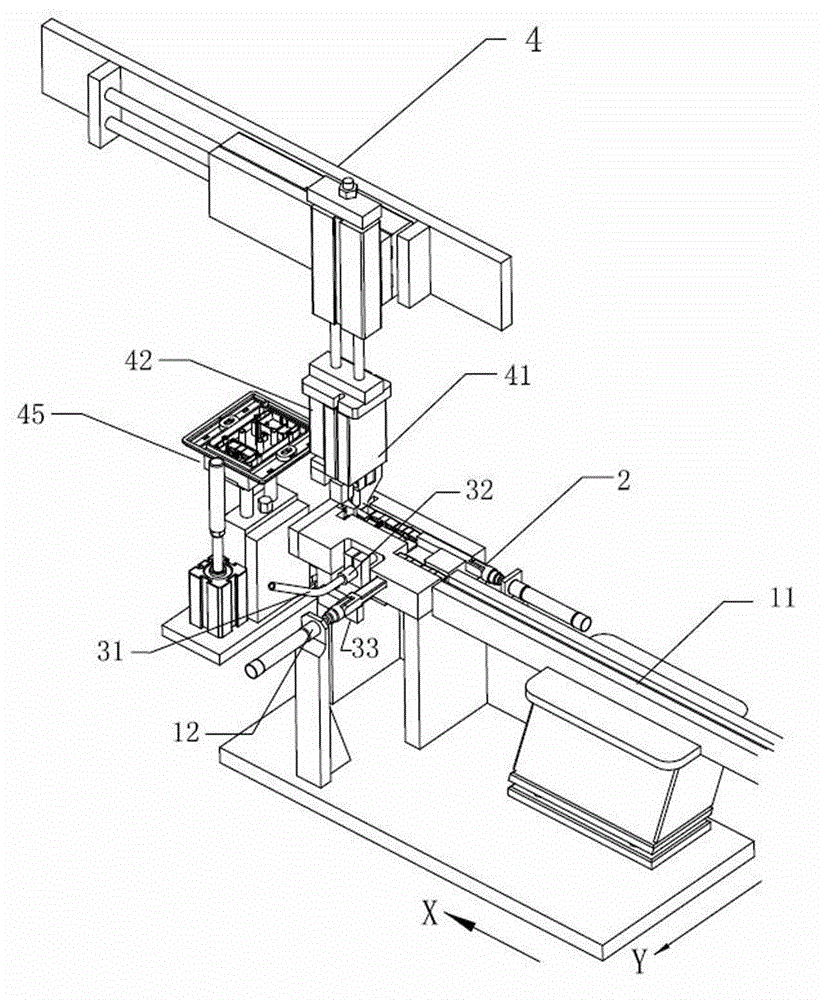

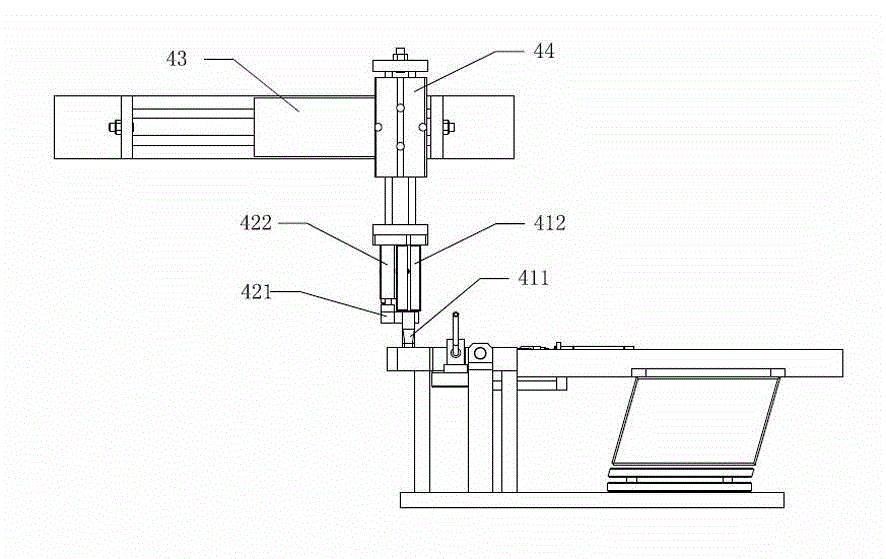

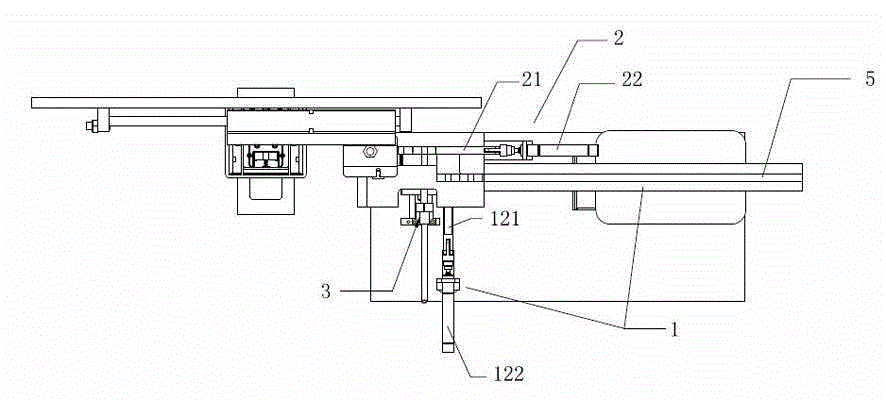

[0045] see figure 1 , figure 2 , image 3 and Figure 4 , figure 1 It is a structural schematic diagram of the present invention, figure 2 It is the front view of the present invention, image 3 It is a top view of the present invention, Figure 4 It is a schematic diagram of the assembled socket protection door of the present invention. The present invention includes a protective door feeding unit 1, an automatic assembly unit 3, a material pushing unit 2 and a manipulator installation unit 4. The socket protective door to be assembled first enters the protective door feeding unit 1 along the track 5, and then is pushed by the pushing unit 2 To the automatic assembly unit 3, when the spring is installed in the hole of the protective door, the pushing unit 2 pushes the assembled socket protective door to the manipulator installation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com