Safe and environment-friendly firecracker automation assembly production line

An assembly line, safety and environmental protection technology, applied in the direction of weapon types, pyrotechnics, offensive equipment, etc., can solve problems such as difficult to complete by hand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

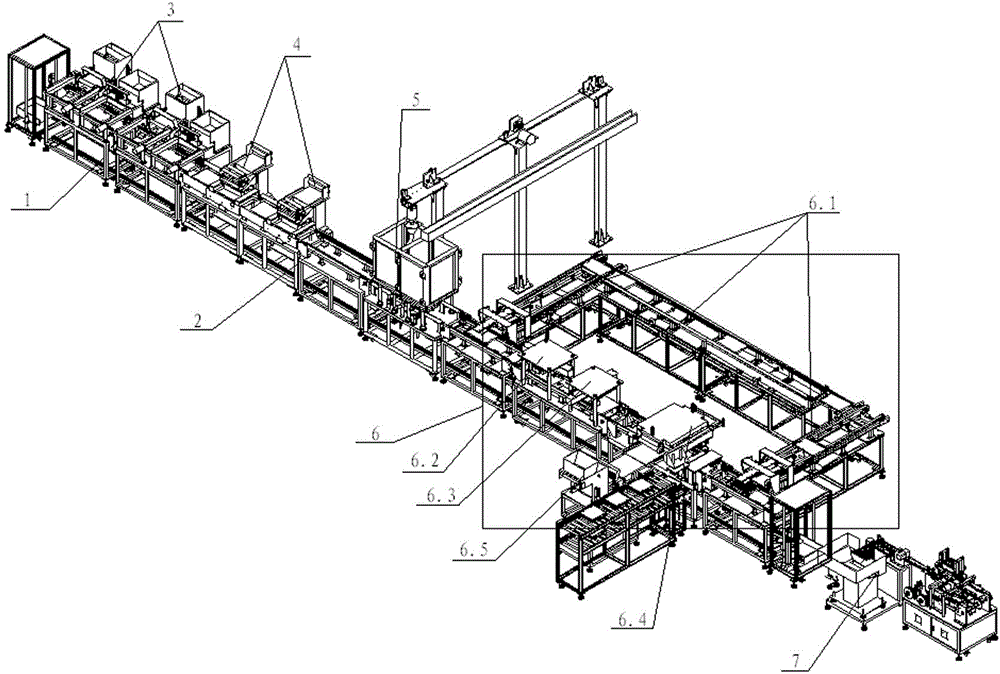

[0018] Such as figure 1 As shown, a safe and environment-friendly firecracker automatic assembly production line includes a main frame 1, a tooling tray 8 and a tooling tray conveying mechanism 2 installed on the left and right sides of the upper part of the main frame 1, and the main frame 1 is sequentially provided with automatic Metal sleeve fixing plug assembly machine 3, automatic insertion machine 4, automatic powder filling machine 5, automatic single shell assembly machine 6 and automatic whip tying machine 7.

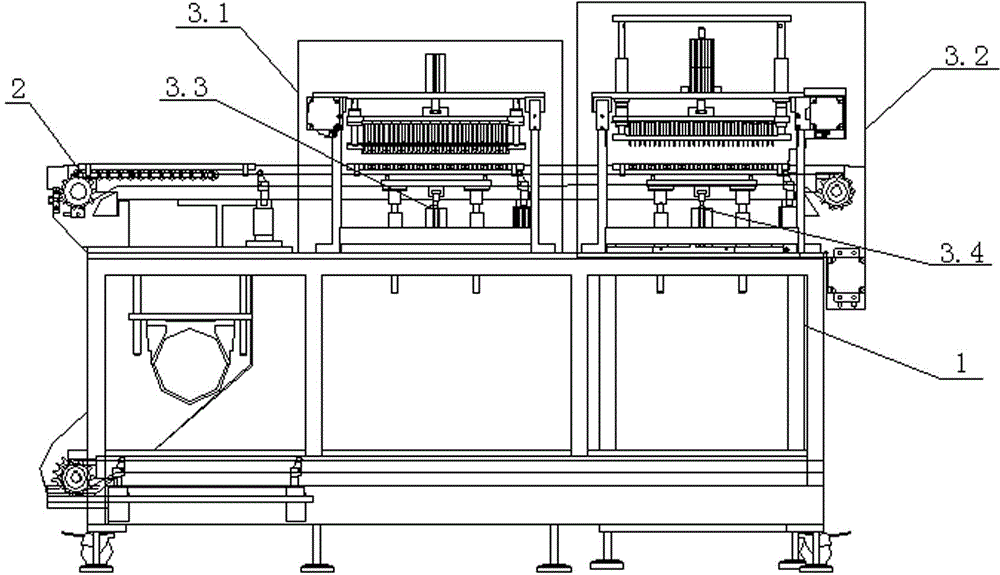

[0019] Such as figure 2 As shown, the automatic metal sleeve fixed plug assembly machine 3 includes a metal sleeve feeding mechanism 3.1, a fixed plug feeding mechanism 3.2, a jacking positioning mechanism I3.3 and a jacking positioning mechanism II3.4, and the metal sleeve The feeding mechanism 3.1 and the fixed plug feeding mechanism 3.2 are located on the upper part of the main frame 1, the jacking positioning mechanism I3.3 is located at the lower part of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com