Bullet automatically assembling system based on gravity sieving

An automatic assembly and bullet technology, which is applied in ammunition supply, weapon accessories, offensive equipment, etc., can solve the problems of high labor intensity, low efficiency, and slow speed, and achieve high work efficiency, improved loading efficiency, and wide applicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the drawings and implementation process.

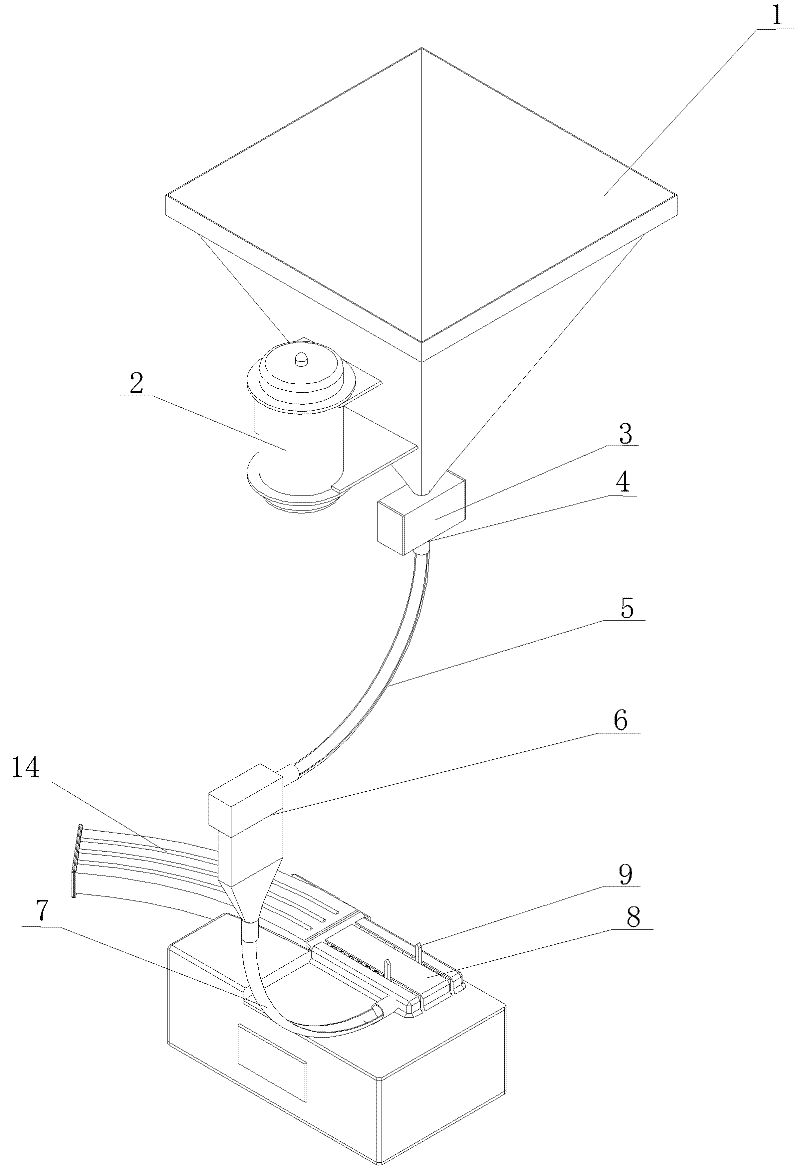

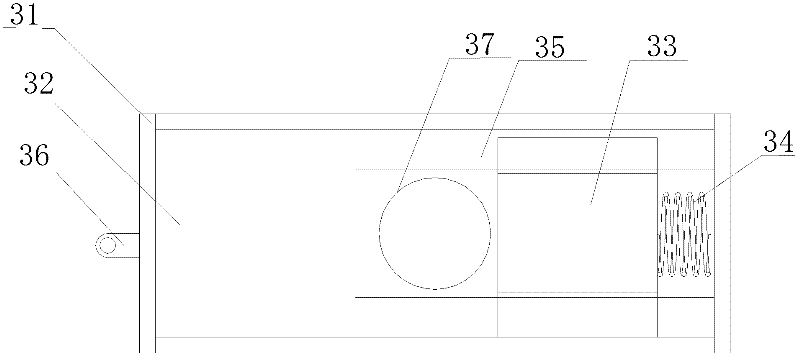

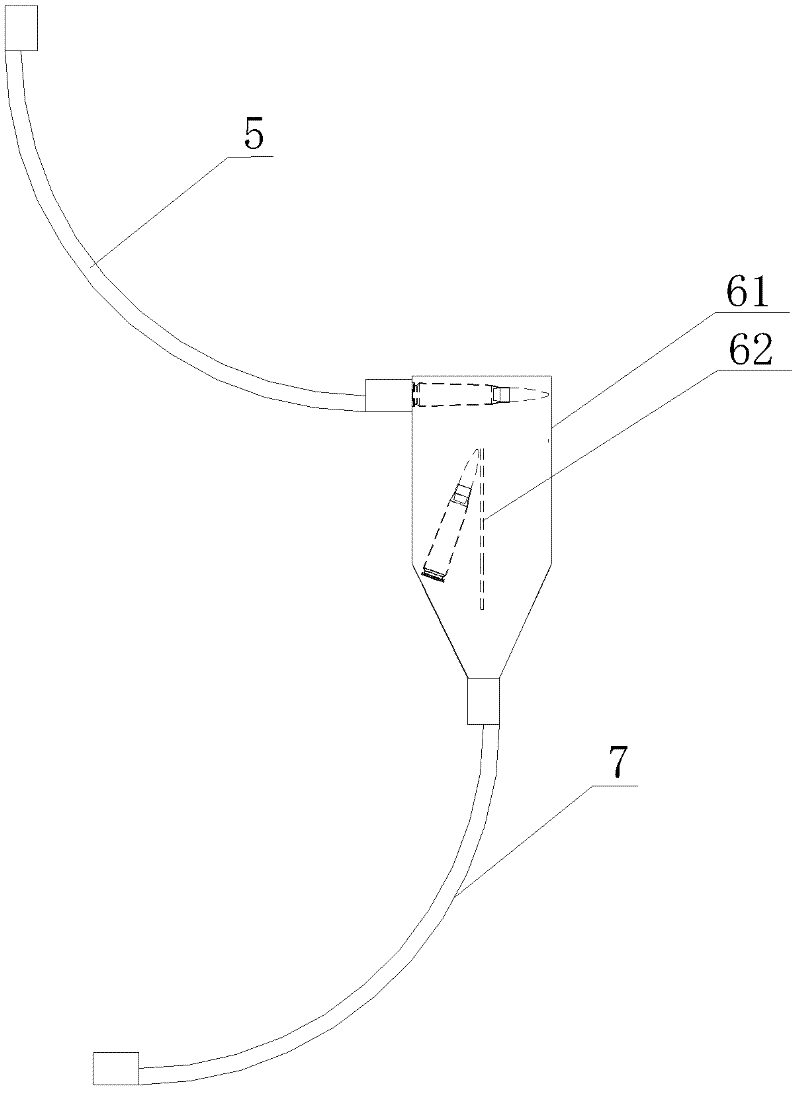

[0028] Such as figure 1 Shown is the bullet automatic assembly system based on gravity screening of the present invention, including a loading funnel 1, an oscillating motor 2, an electromagnet switch 3, a sensor 4 for counting bullets, a first bullet conveying pipe 5, and a bullet for adjusting the number of bullets. The bullet guiding device 6 of direction, the second bullet conveying pipe 7 and the bullet pressing mechanism. The bottom of the loading funnel 1 is provided with a bullet outlet, and the size of the bullet outlet only allows one bullet to pass through. The electromagnet switch 3 and the sensor 4 for counting bullets are installed at the bullet outlet of the loading funnel 1 for driving The oscillating motor 2 that the charging funnel 1 vibrates is installed on the charging funnel 1 side. The bullet output port of loading funnel 1 is comm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com