Patents

Literature

117results about How to "Realize fully automatic assembly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

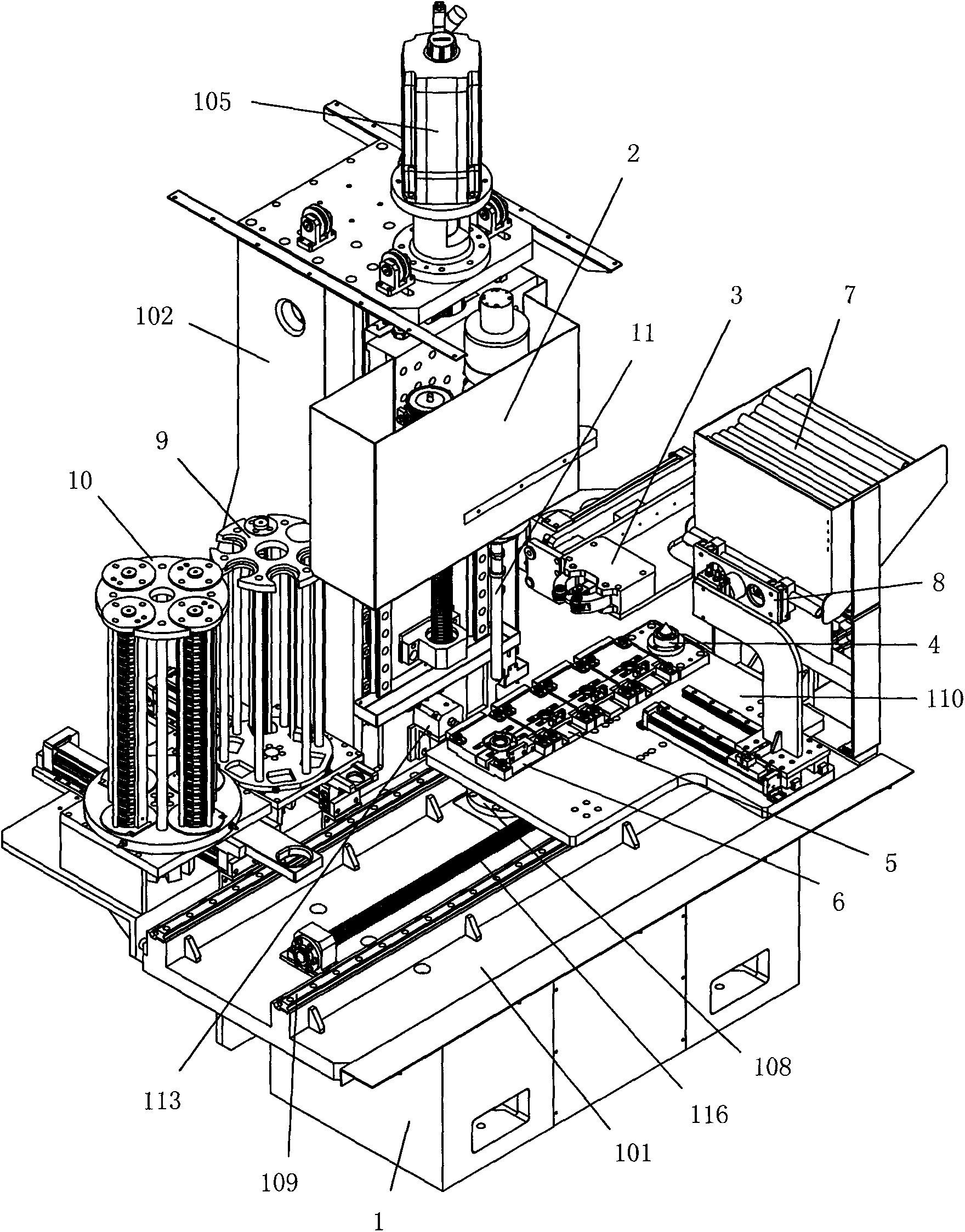

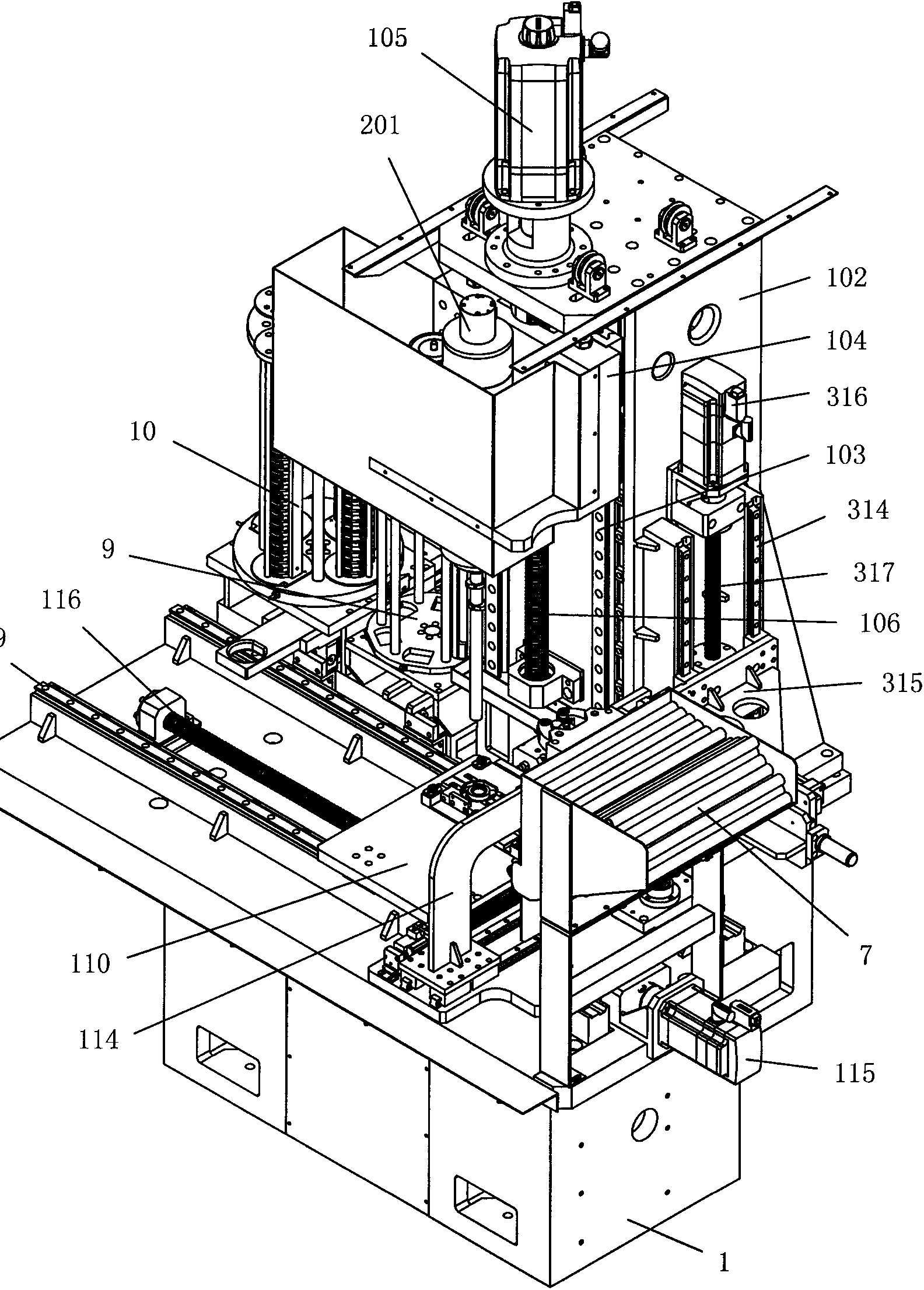

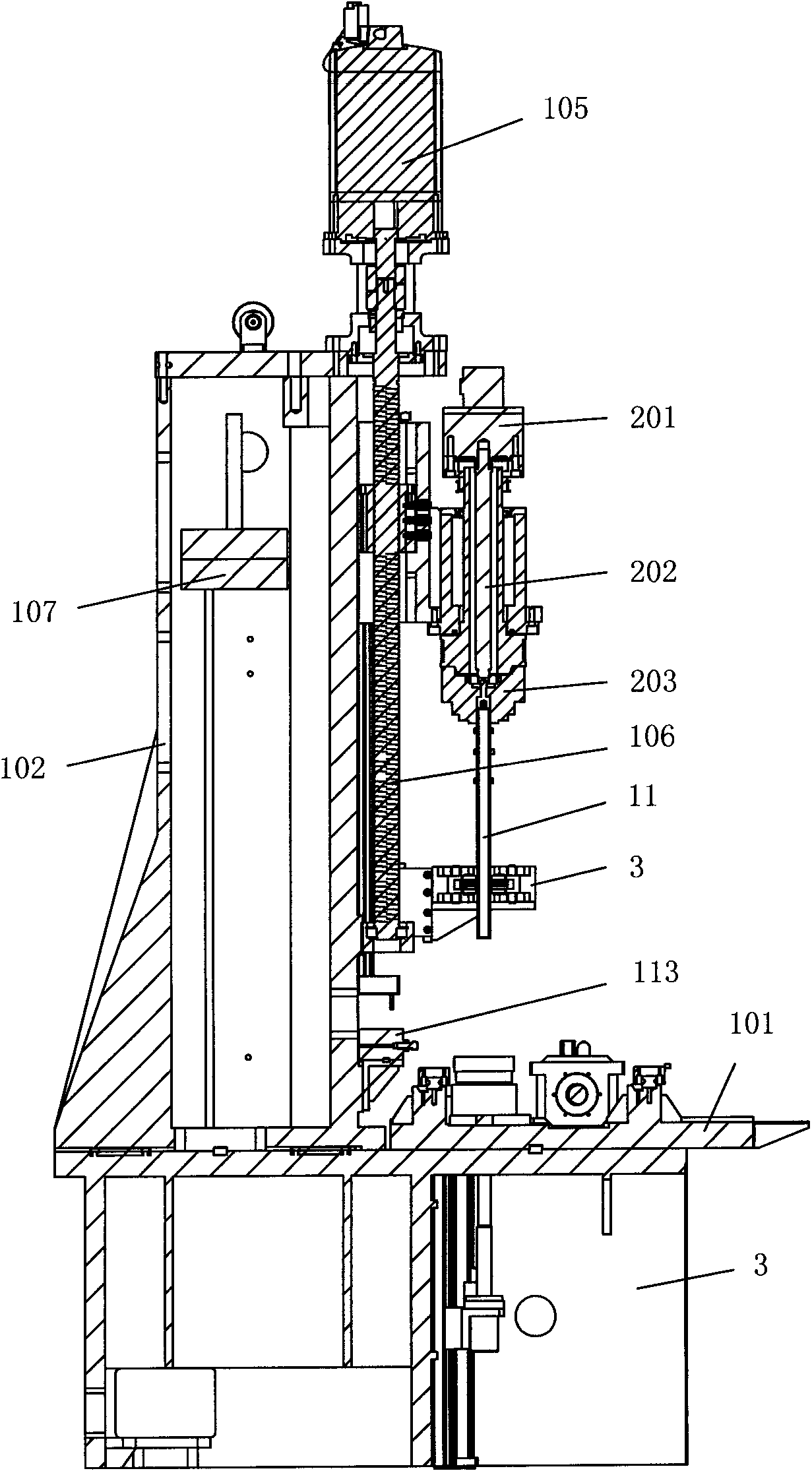

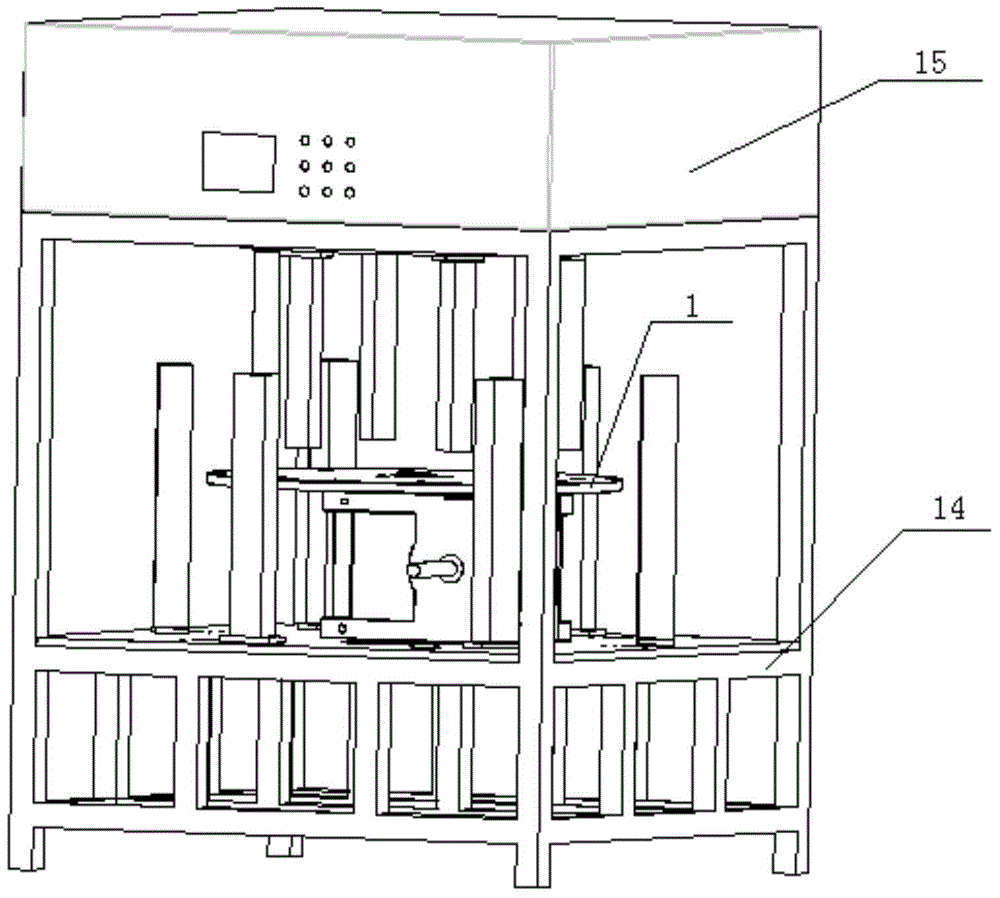

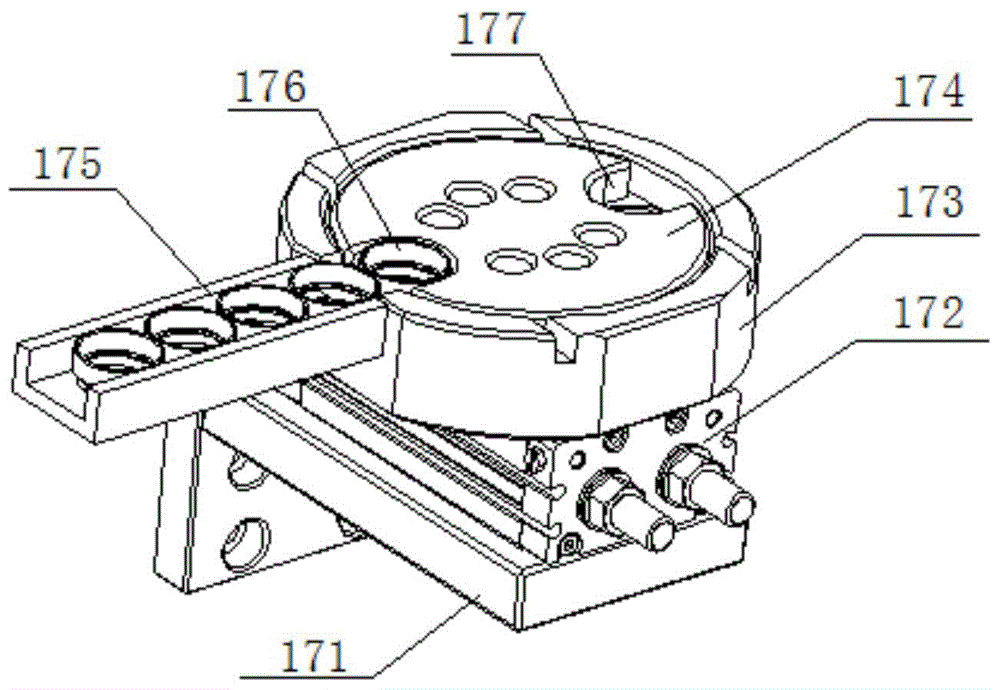

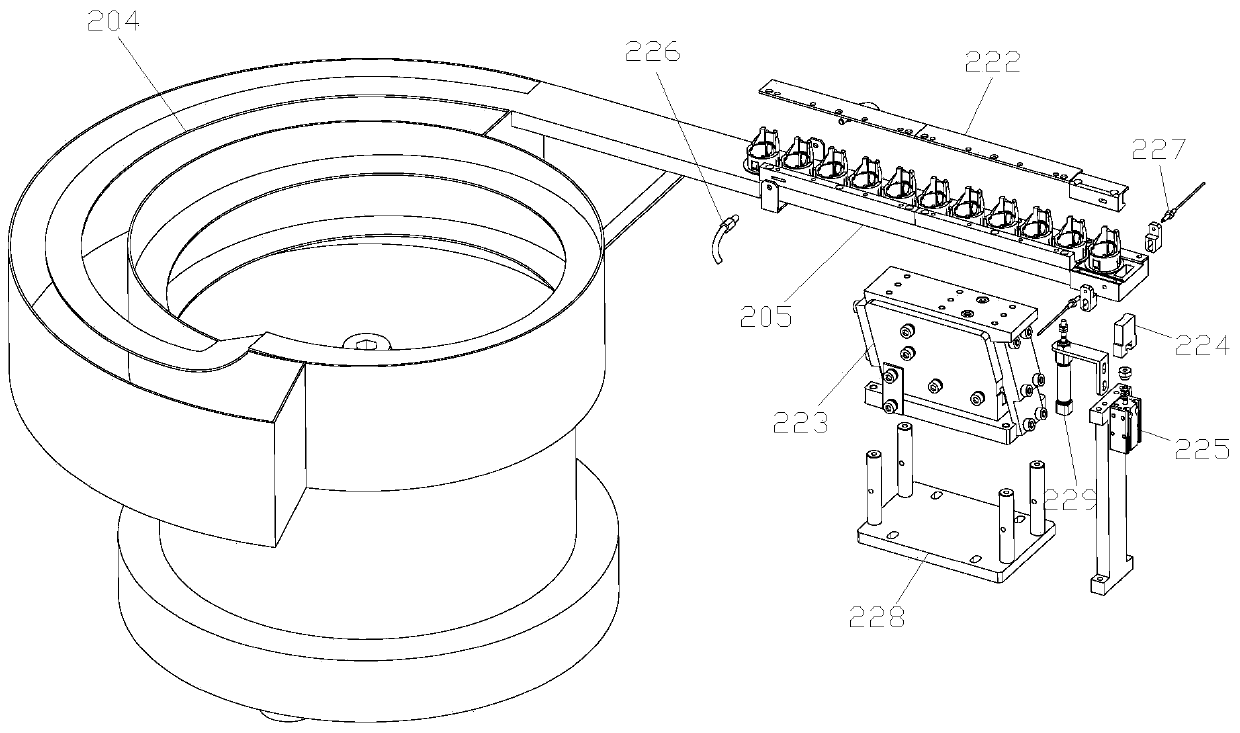

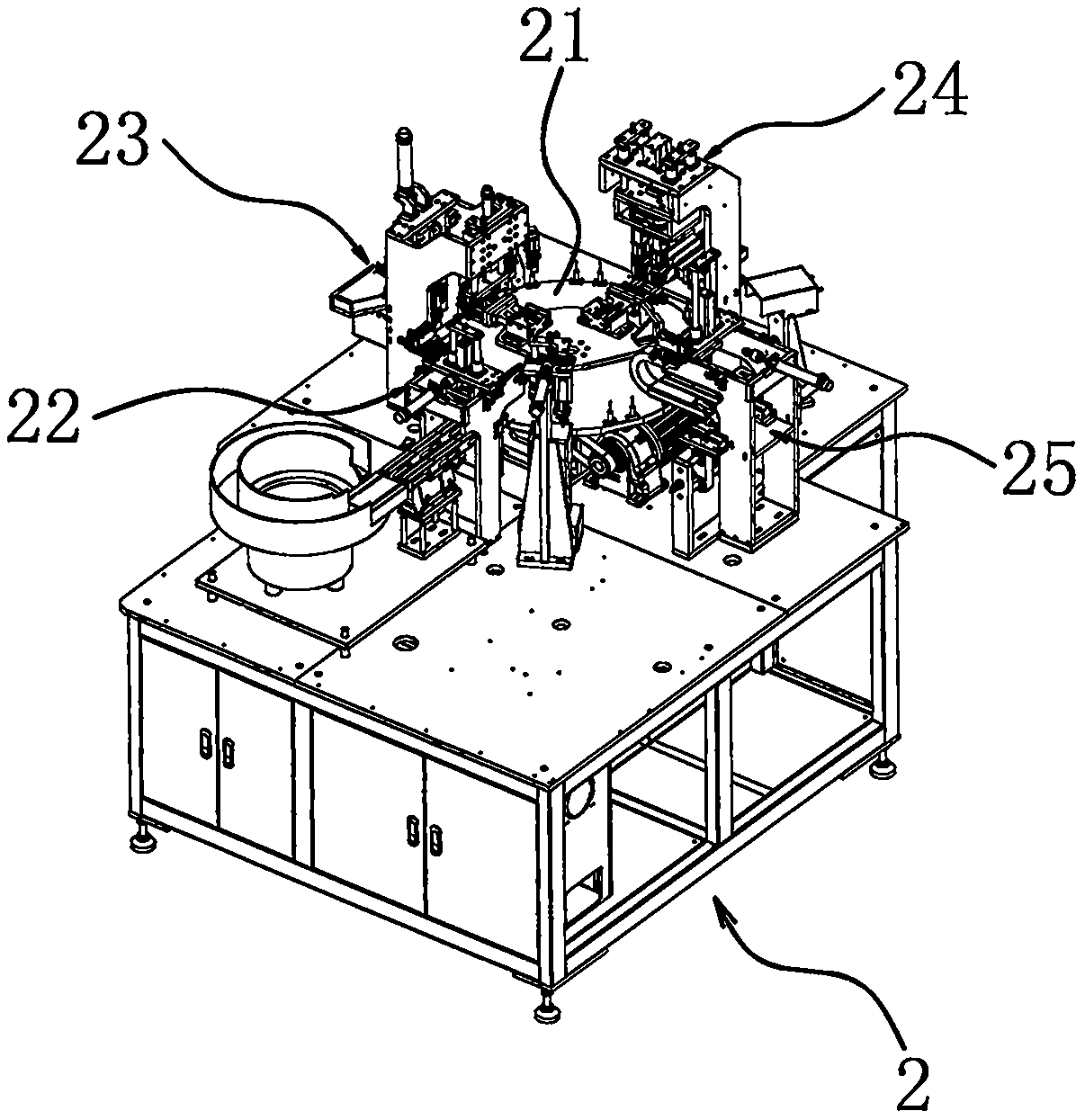

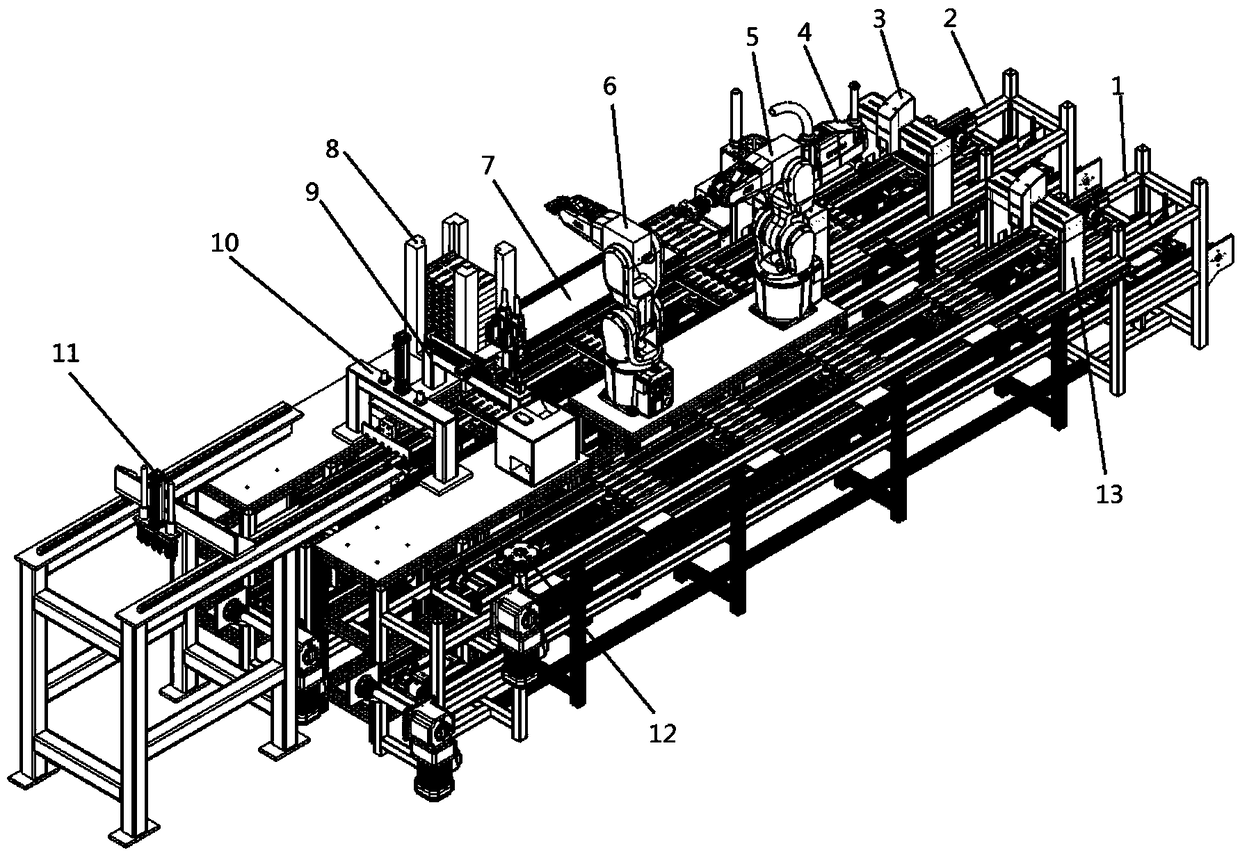

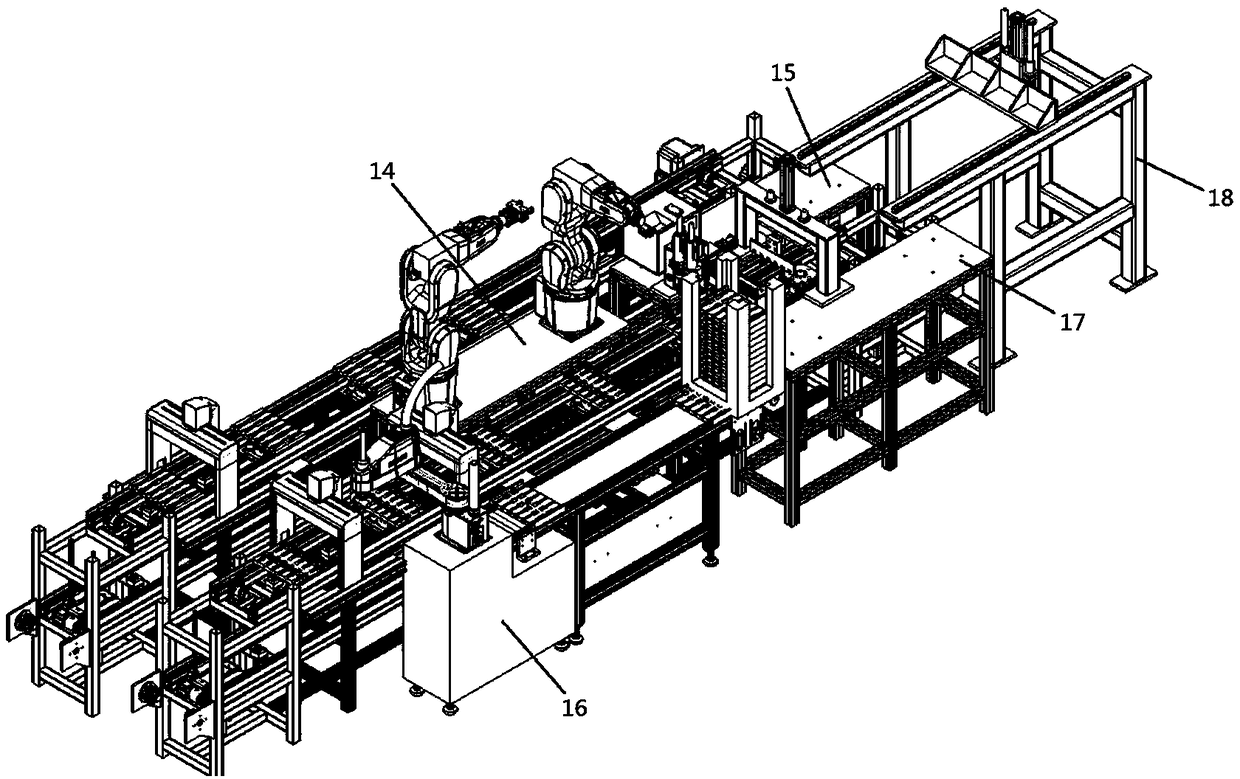

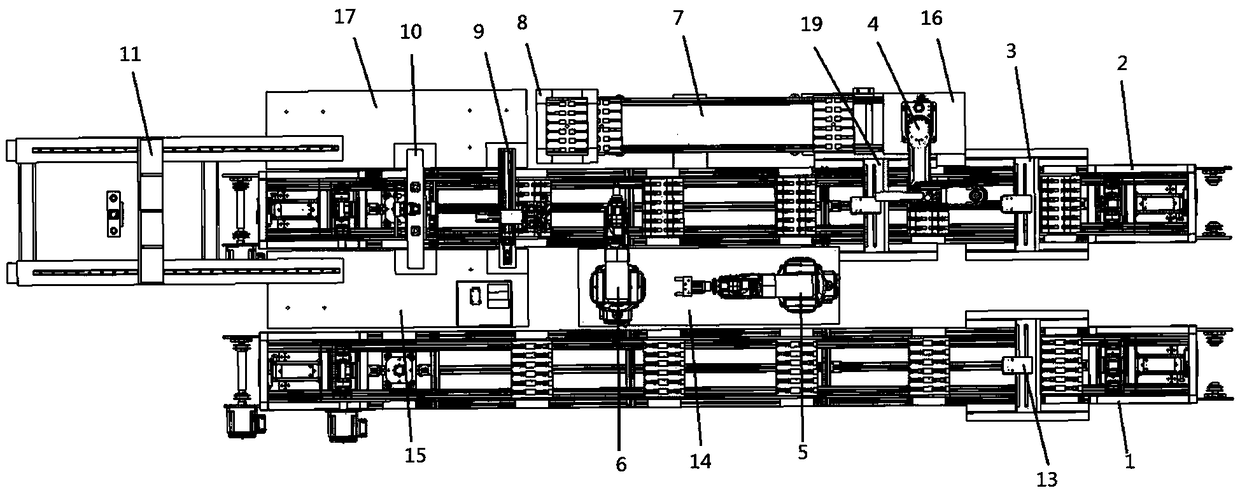

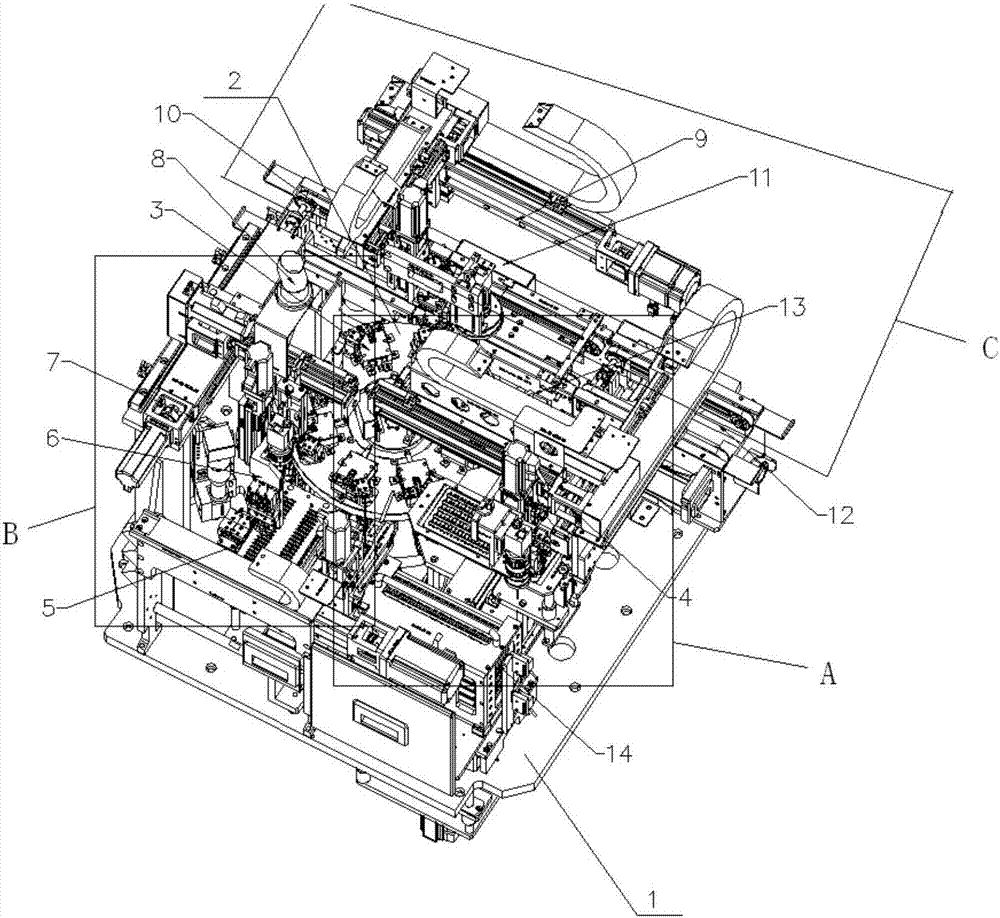

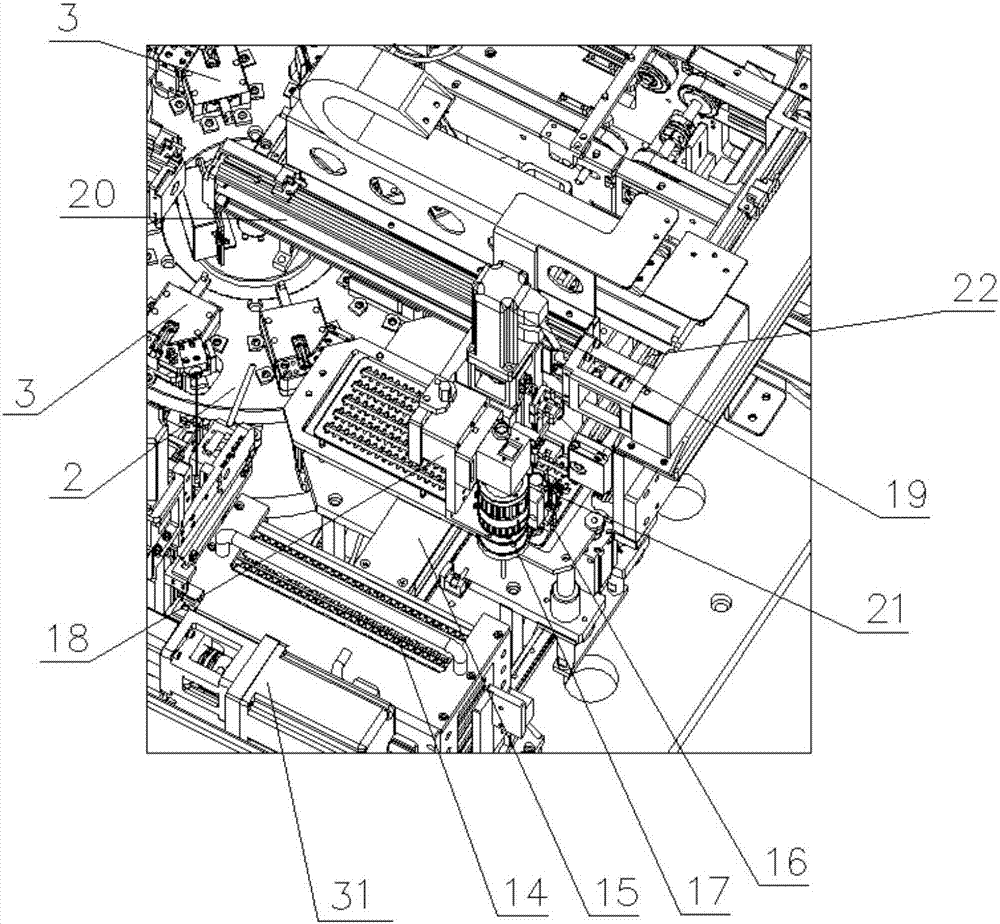

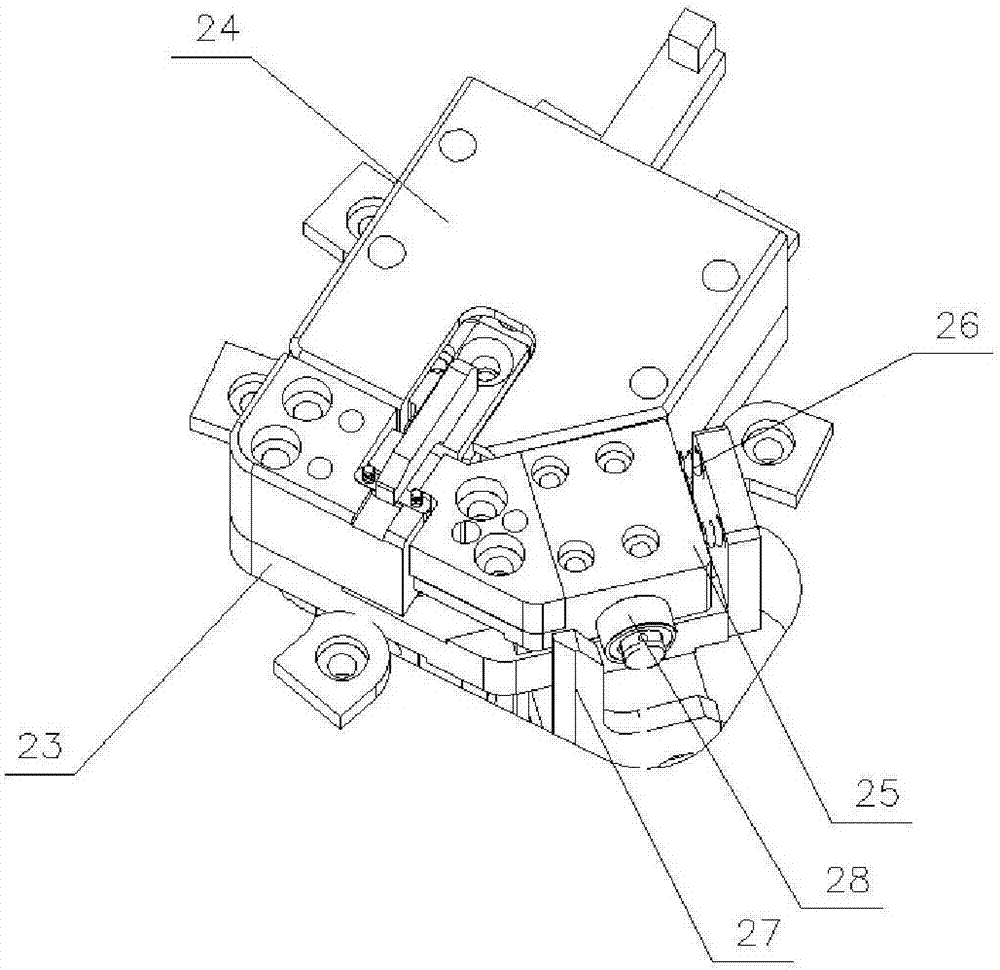

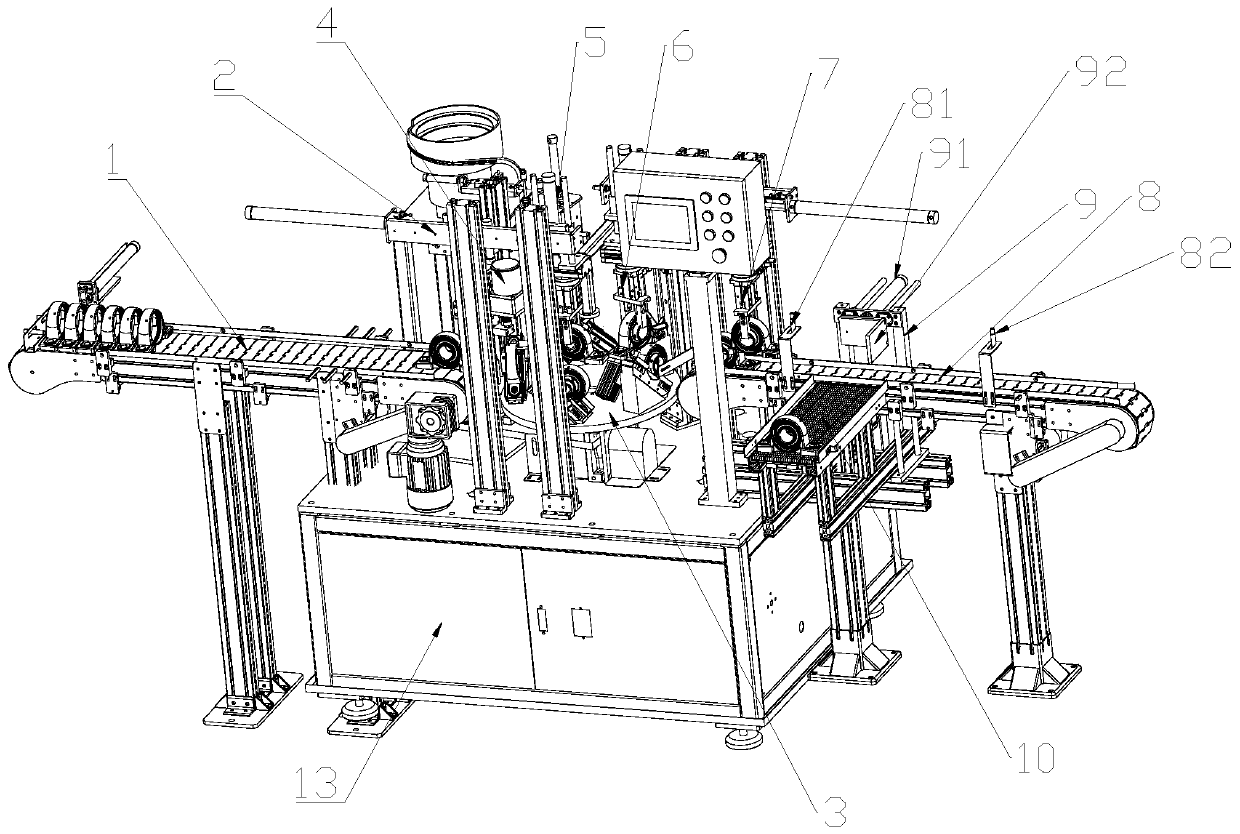

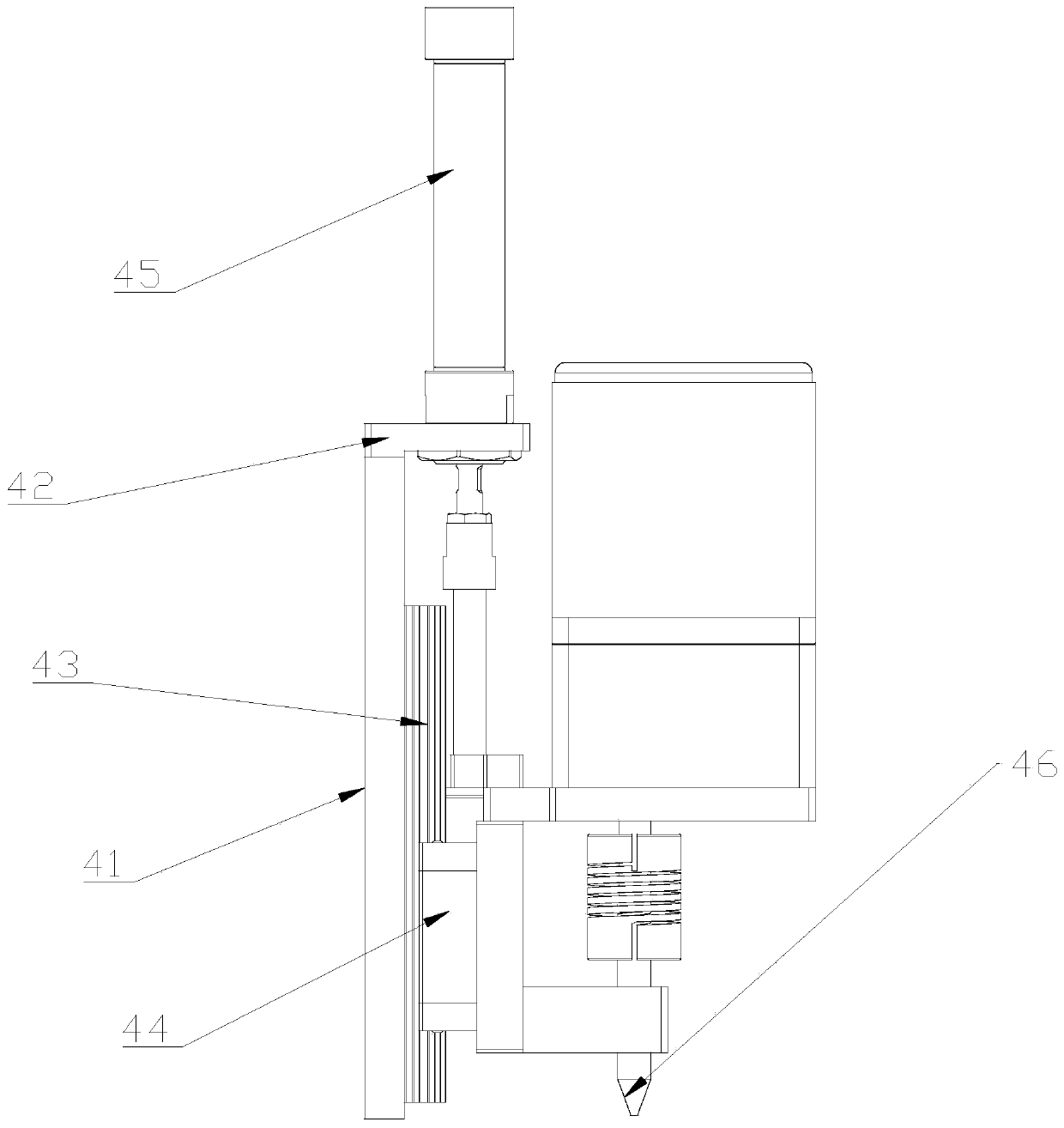

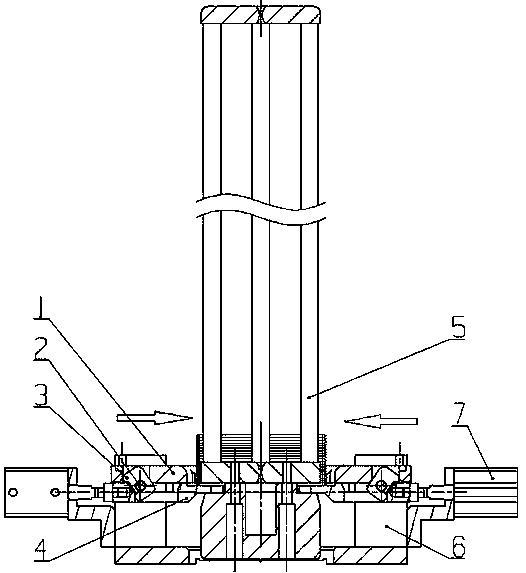

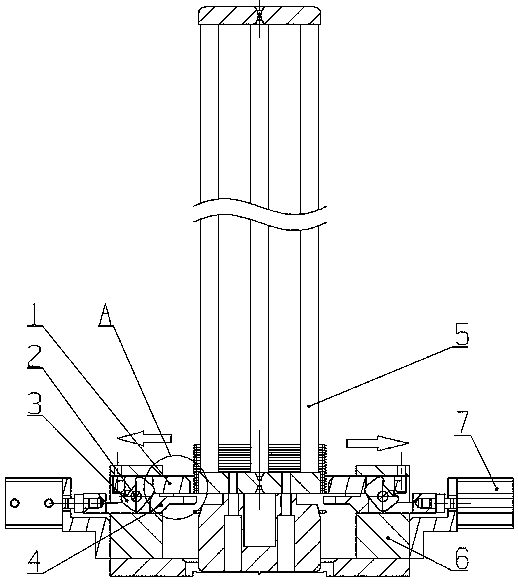

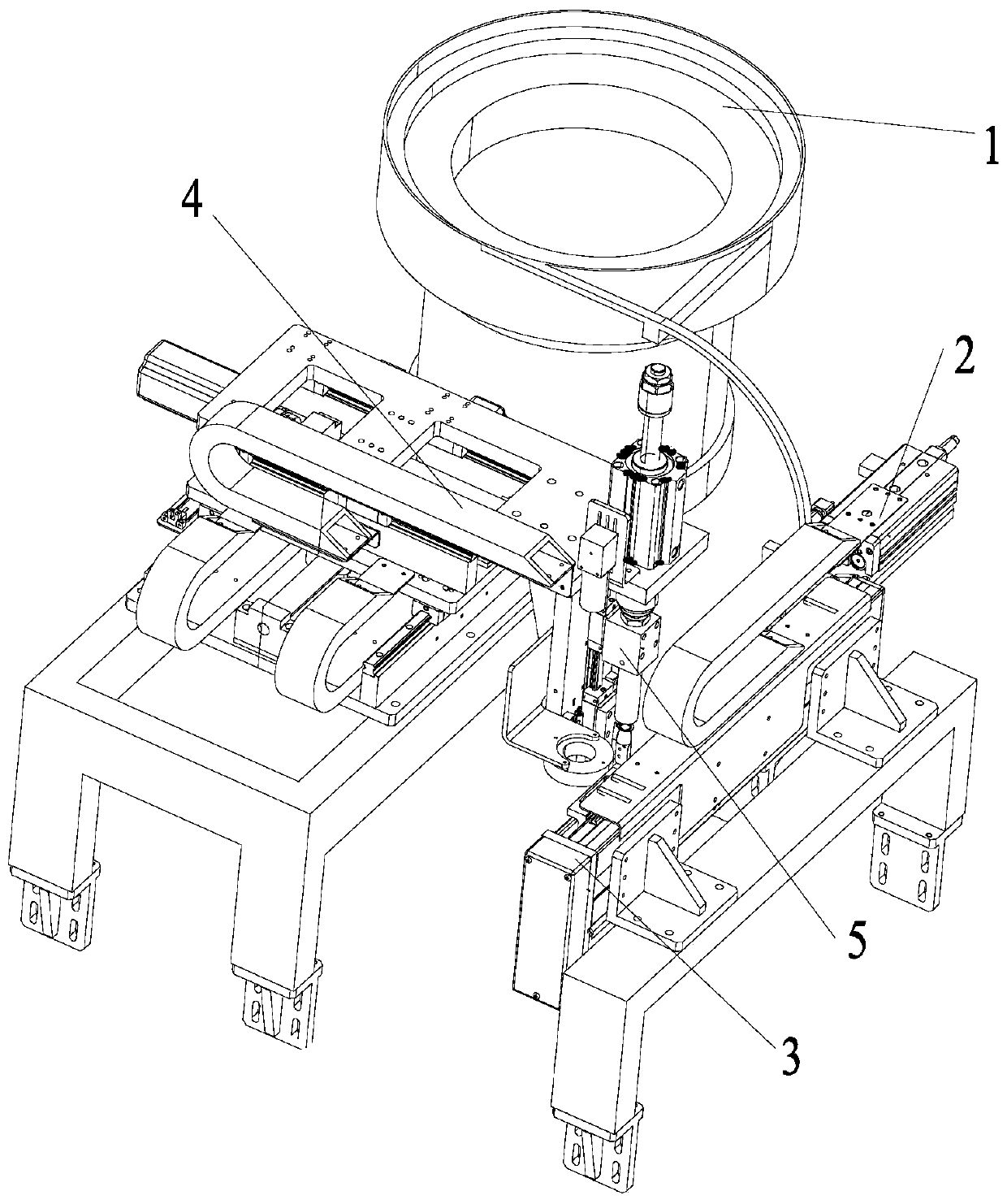

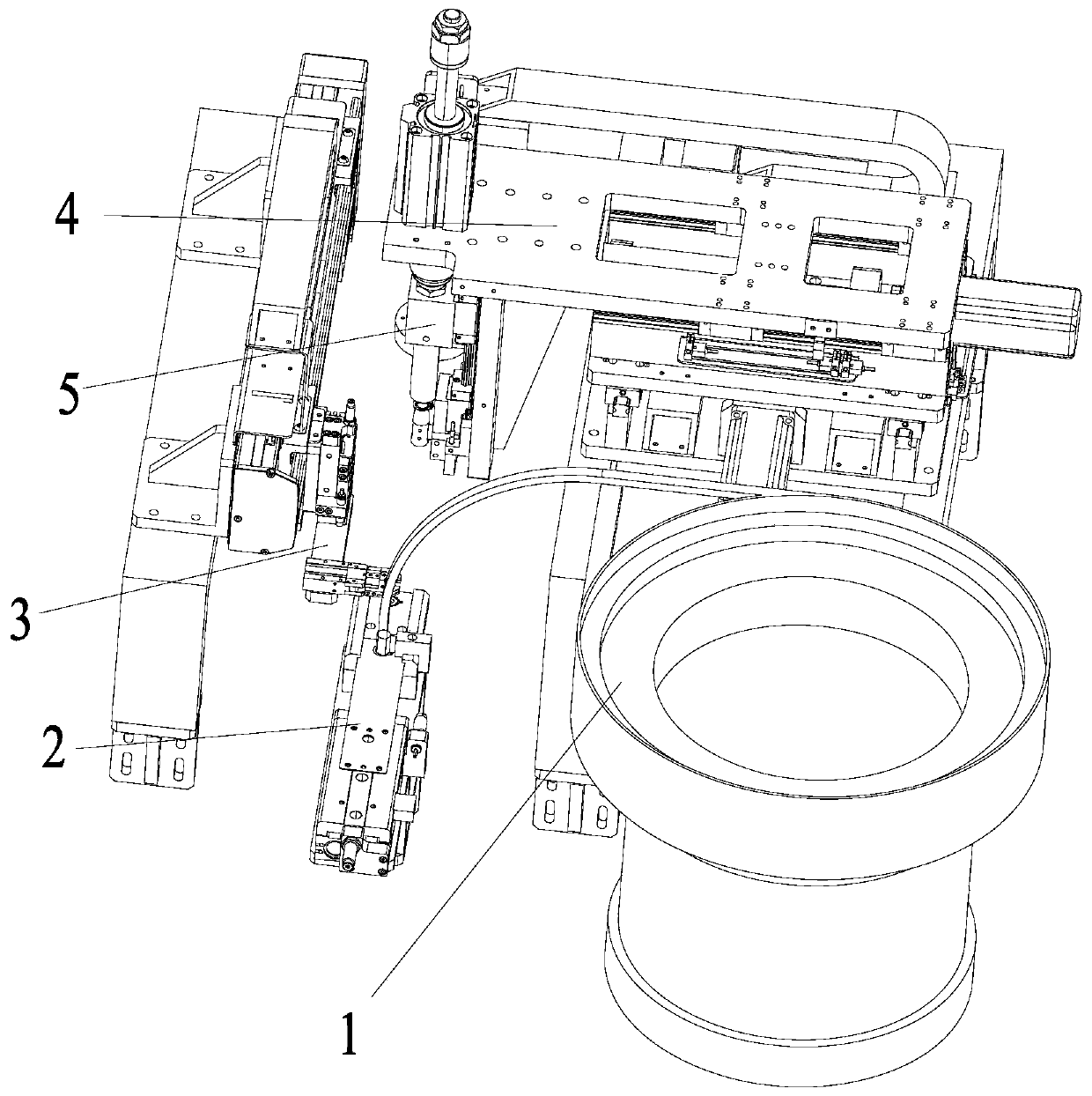

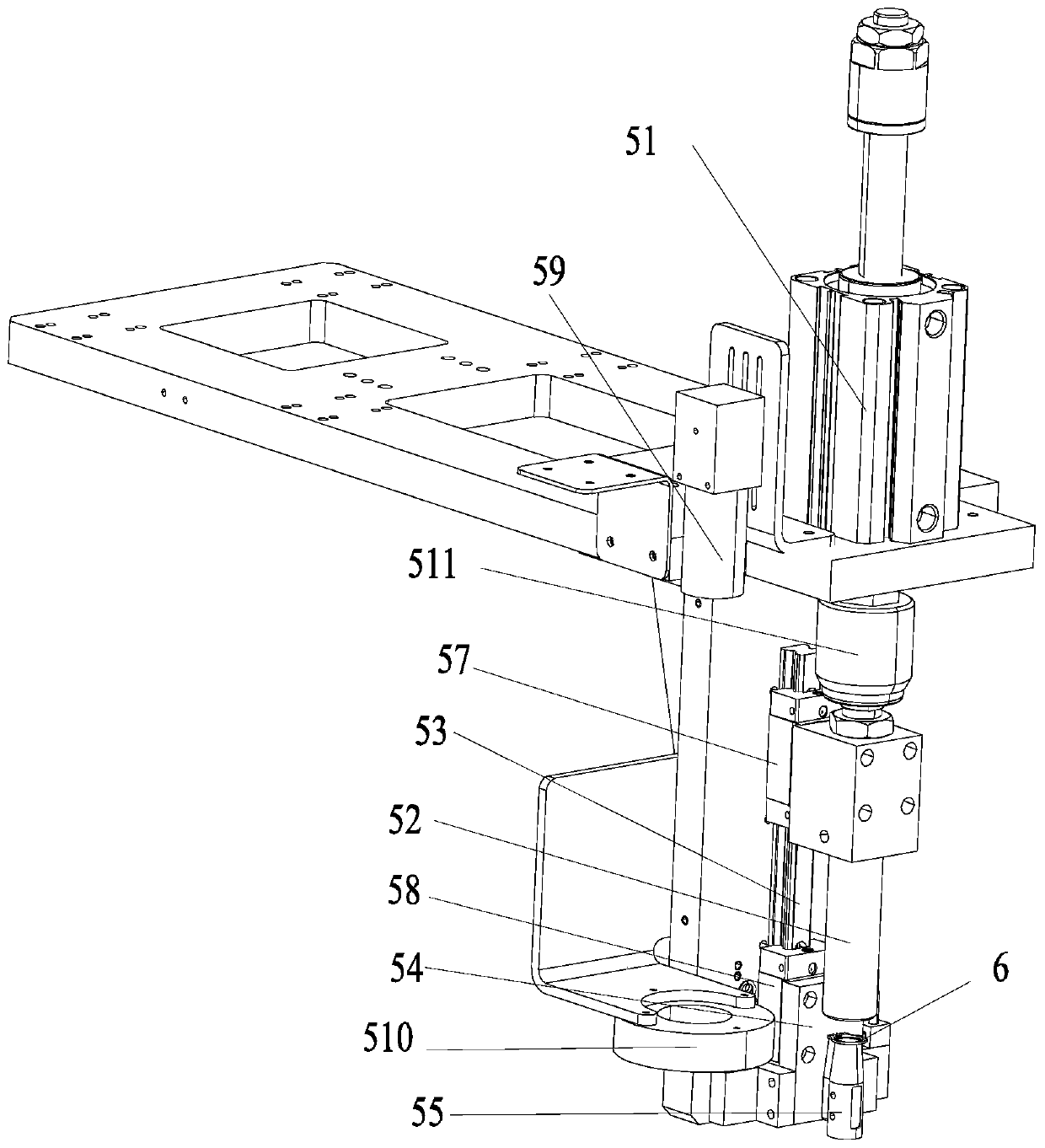

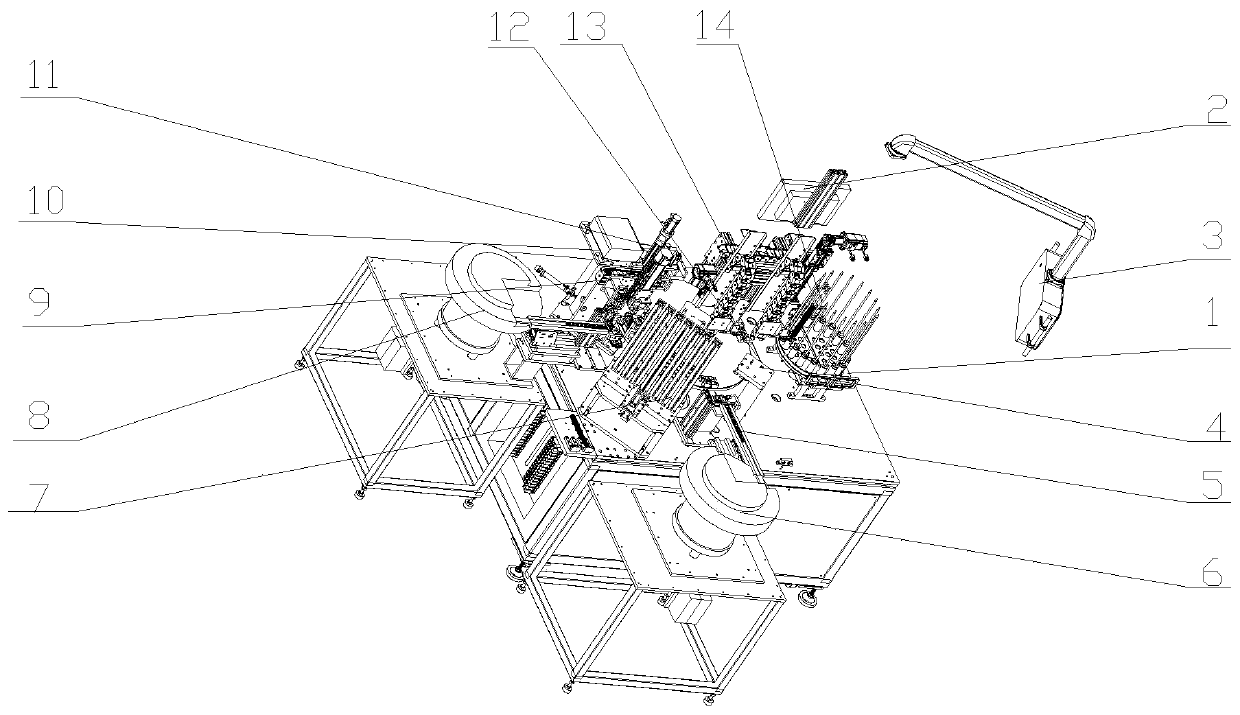

Automatic camshaft assembling machine

ActiveCN103406758ARealize fully automatic assemblyIncrease productivityAssembly machinesManipulatorEngineering

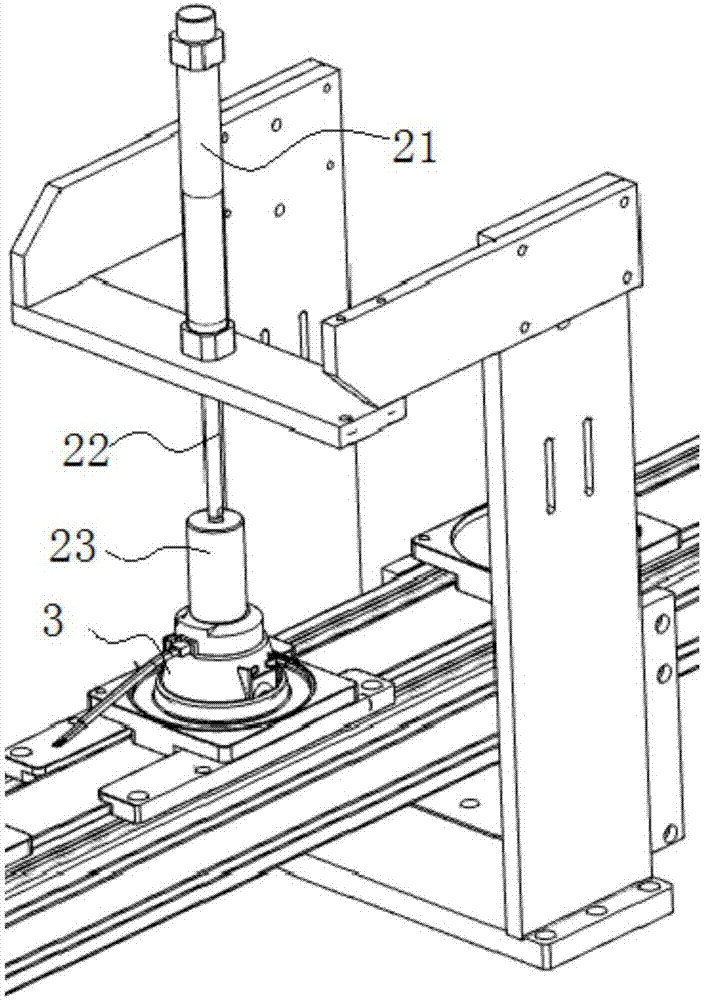

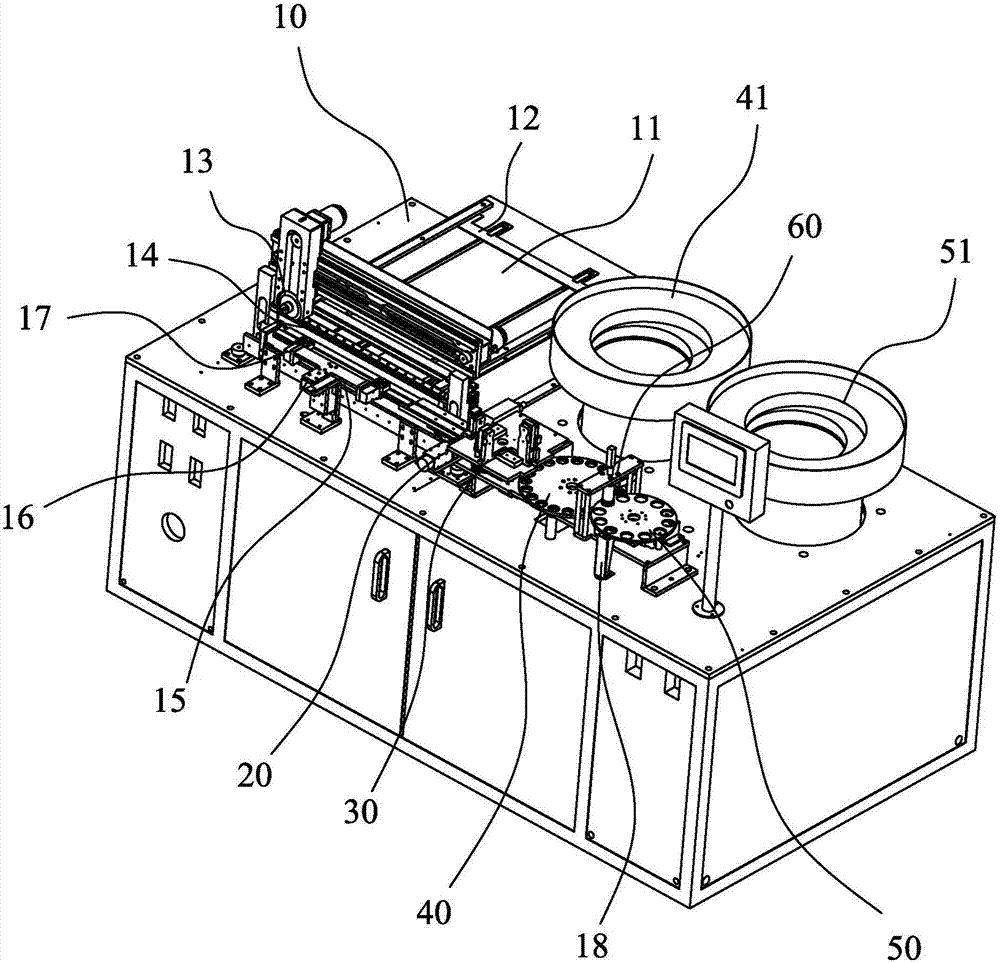

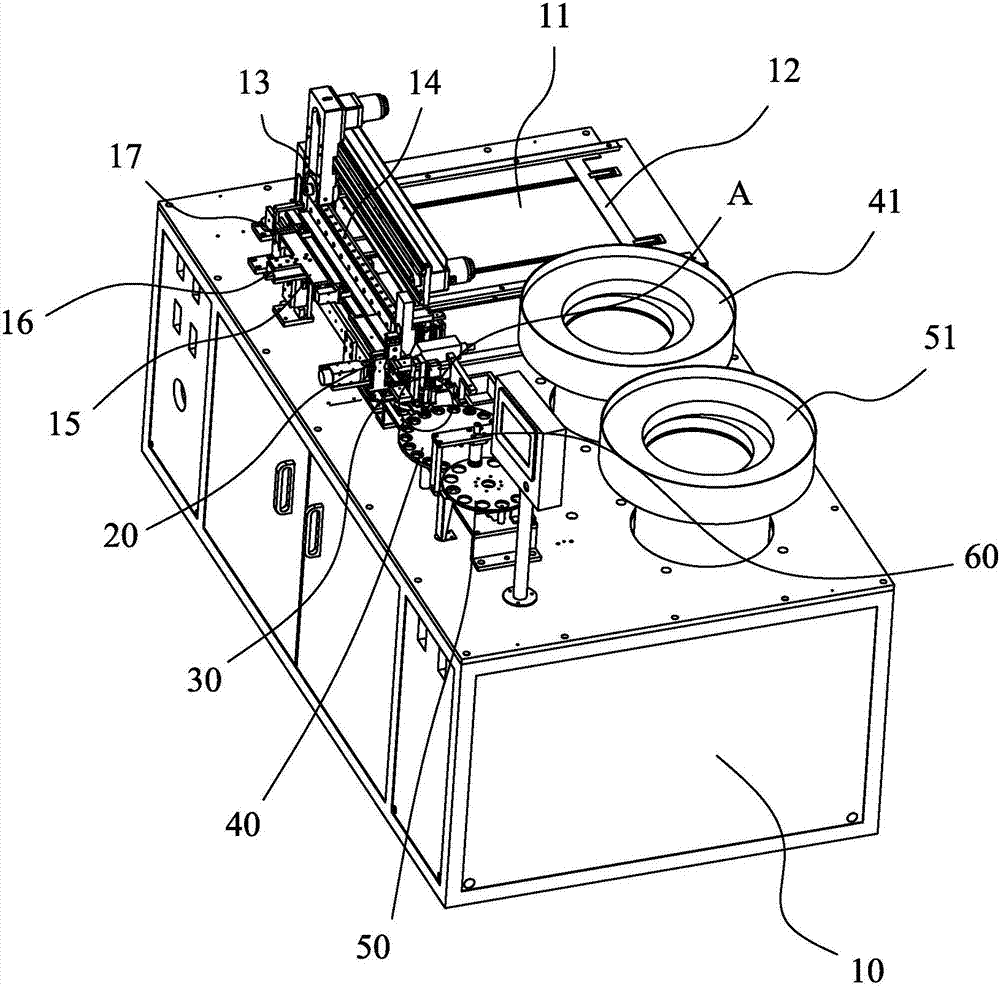

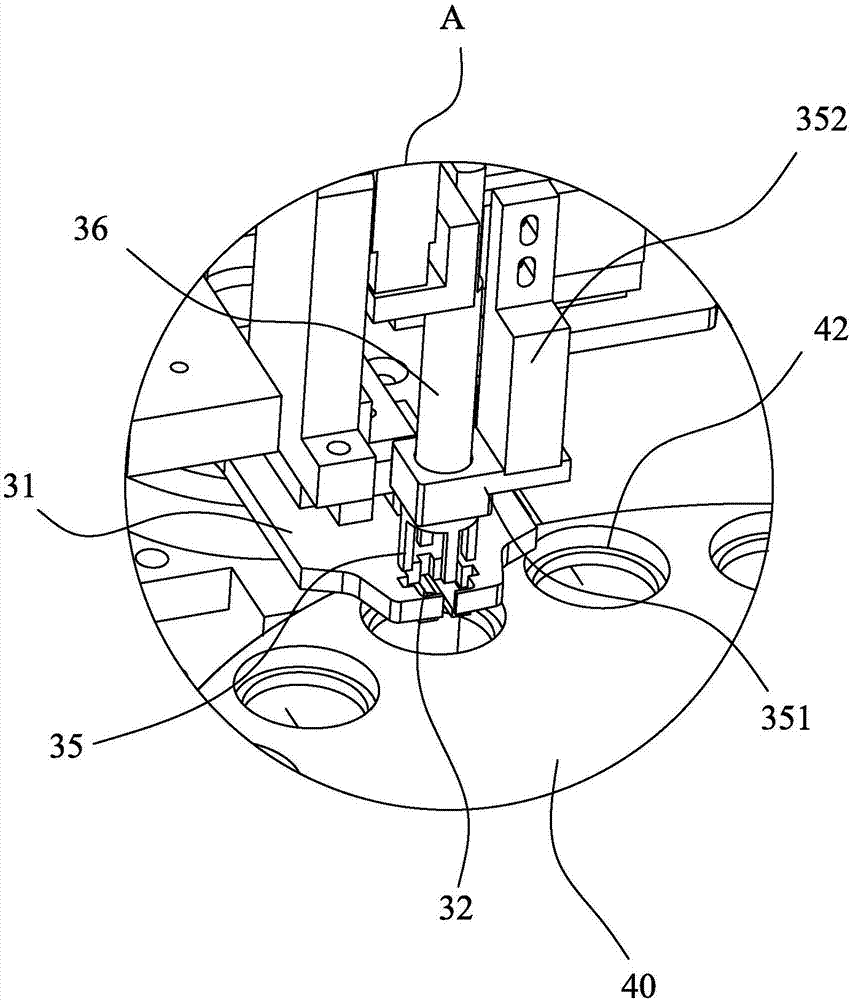

An automatic camshaft assembling machine comprises a frame, a worktable and a stand column. A clamping and rotating mechanism for clamping a pipe and driving the pipe to rotate is vertically and slidably arranged on the stand column. A knurling mechanism capable of moving to the position just below the clamping and rotating mechanism is arranged on one side of the clamping and rotating mechanism. A sliding table is transversely and slidably arranged in the front of the clamping and rotating mechanism. A pipe positioning clamp, cam clamping tools and a flange clamping tool are sequentially and parallelly mounted on the rear portion of the sliding table. A pipe storing mechanism for storing the pipes is arranged in the front of the knurling mechanism. A mechanical arm for conveying the pipes is longitudinally and slidably arranged on the rear portion of the sliding table. A cam storing mechanism for storing cams and a cam pushing mechanism for pushing the cams are arranged on the other side of the clamping and rotating mechanism. A flange storing mechanism for storing flanges and a flange pushing mechanism for pushing the flanges are arranged on the outer side of the cam storing mechanism. By the aid of the structure, full-automatic assembling of camshafts can be realized, production efficiency is greatly improved, and labor intensity is lowered.

Owner:宁波江宸智能装备股份有限公司

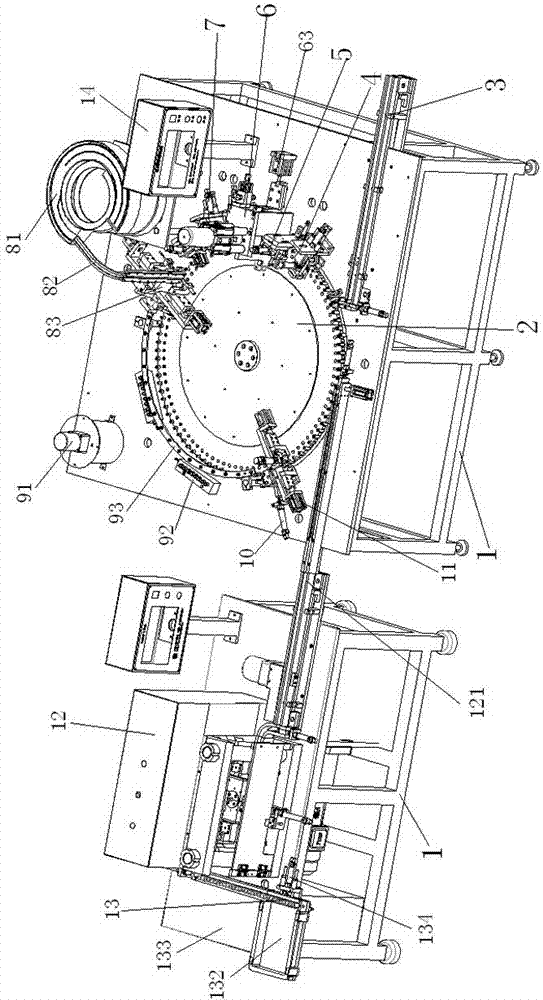

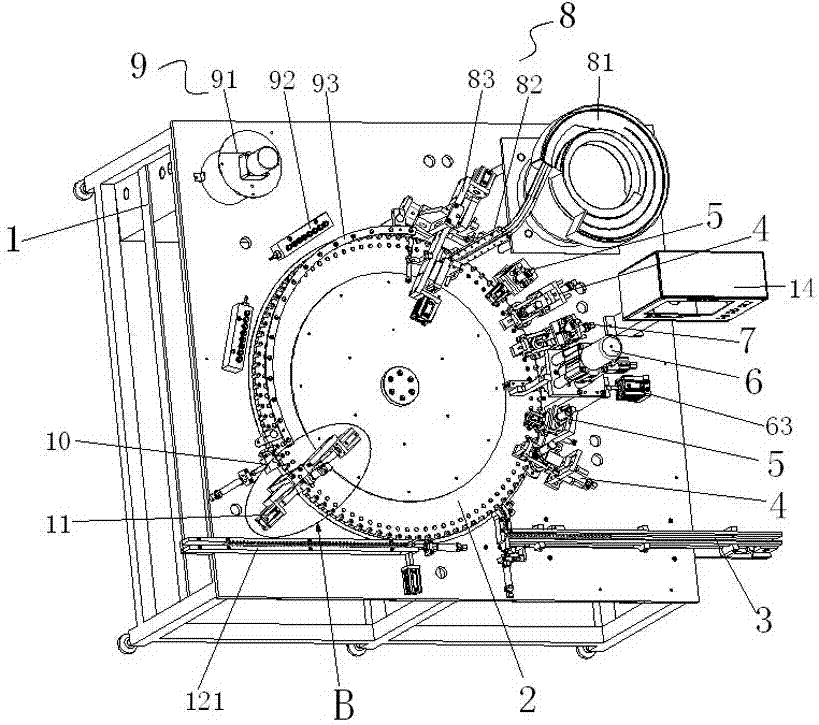

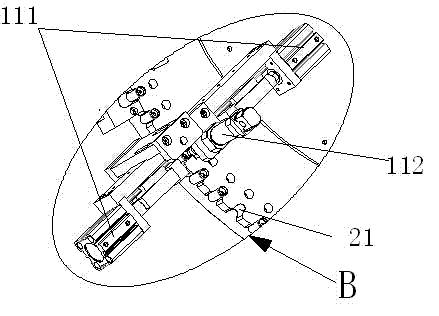

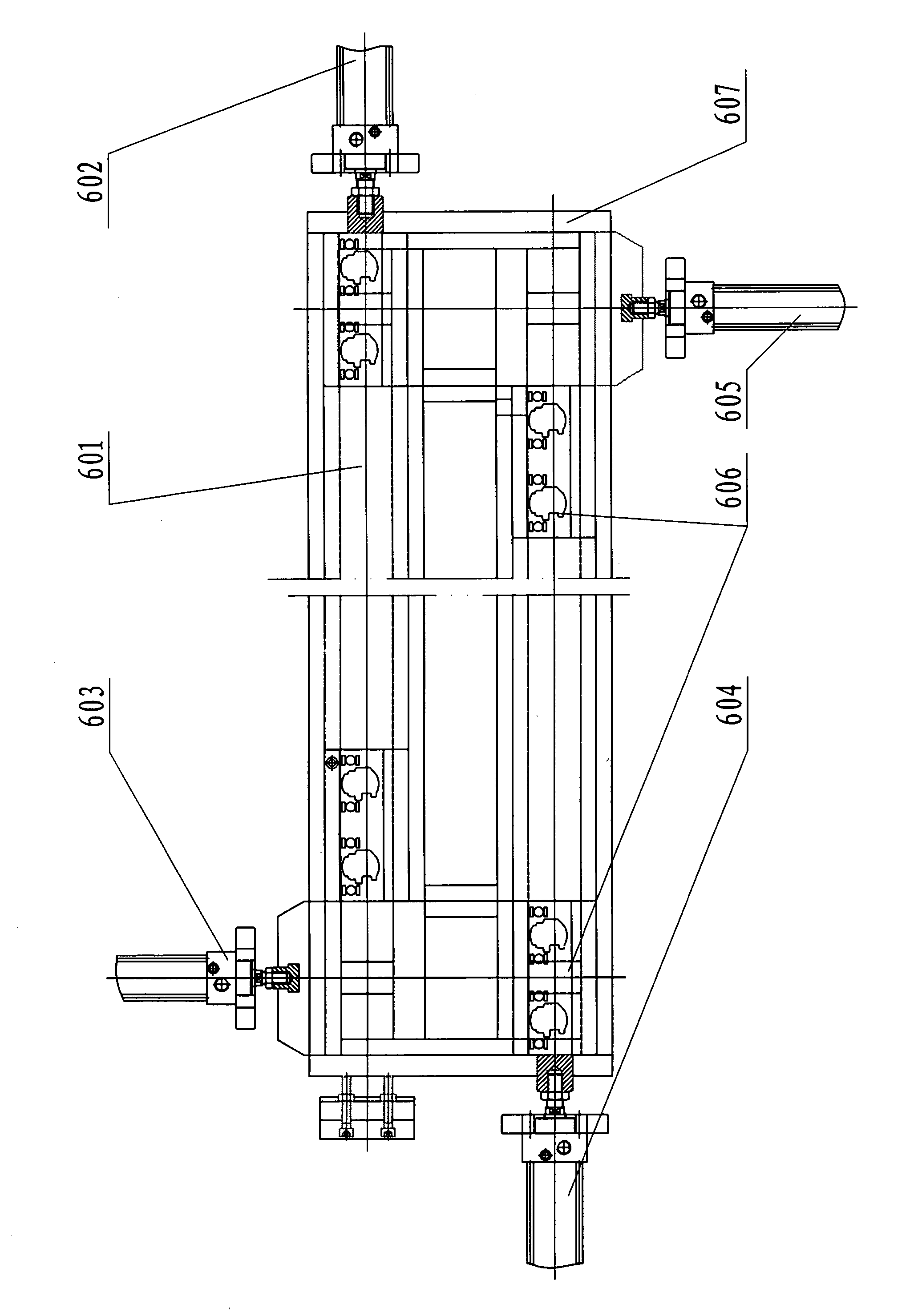

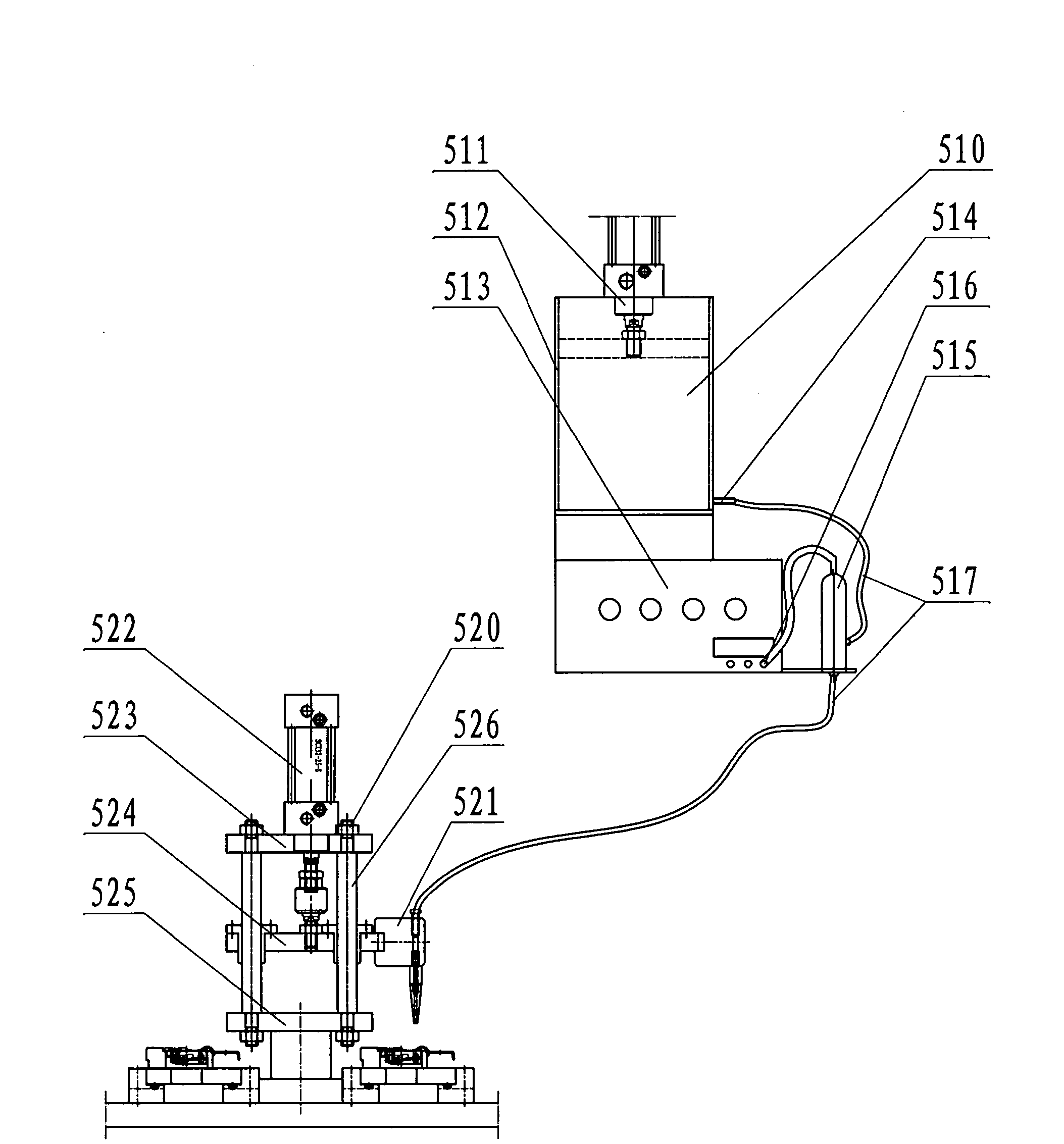

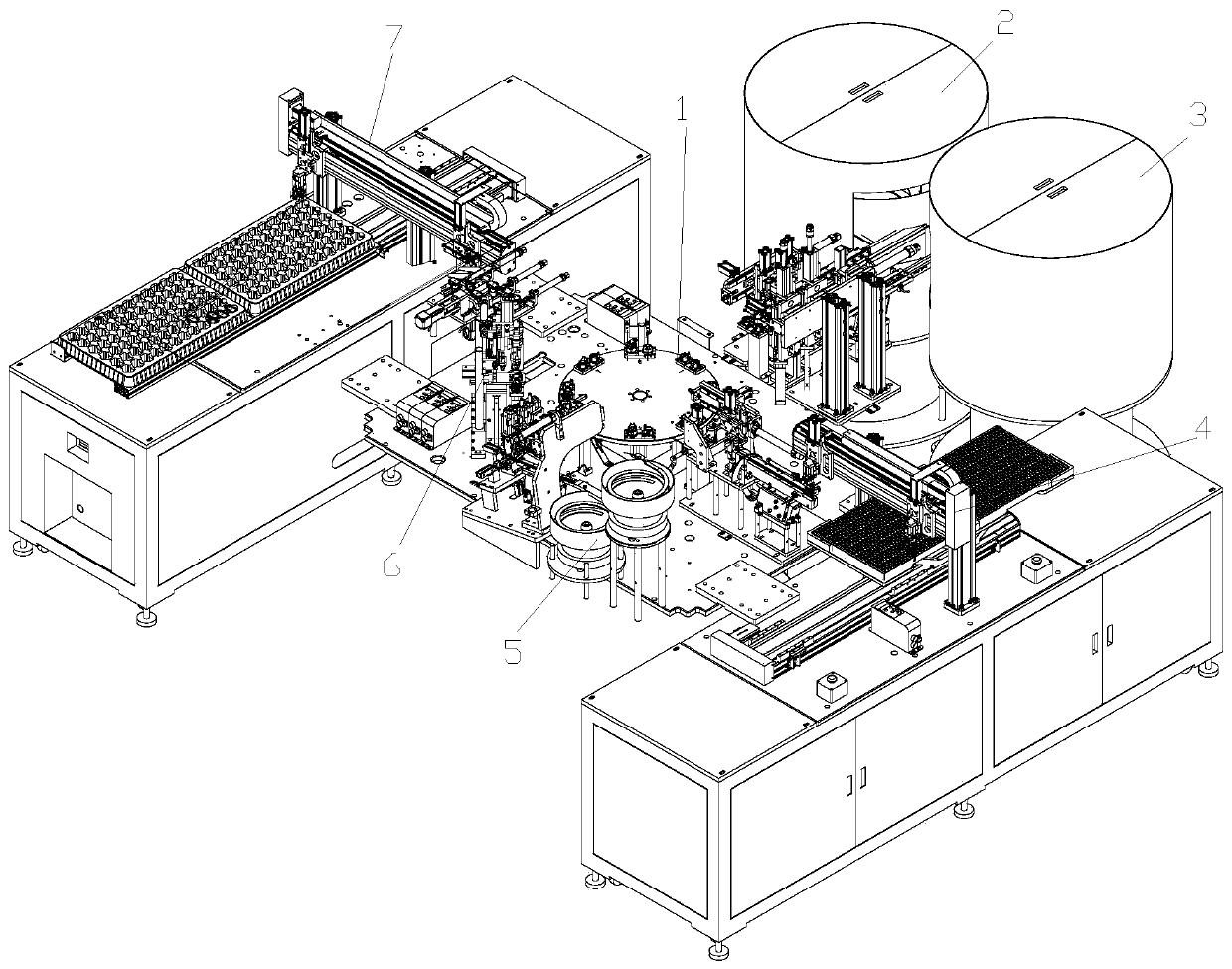

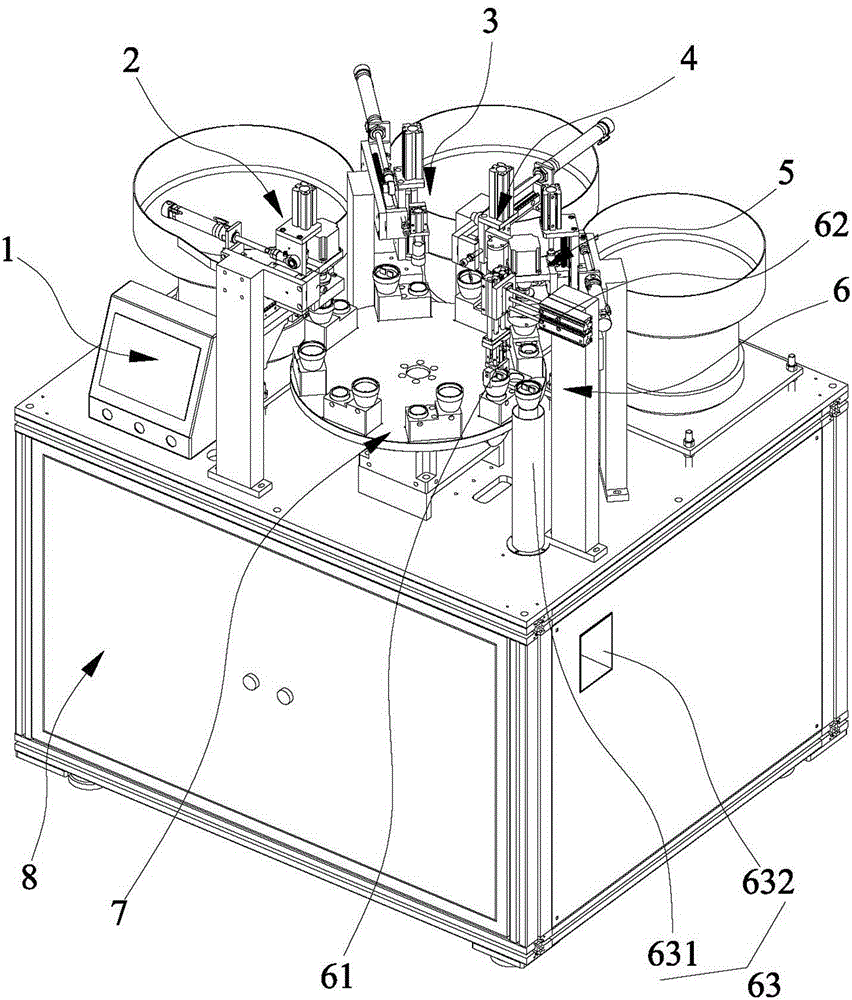

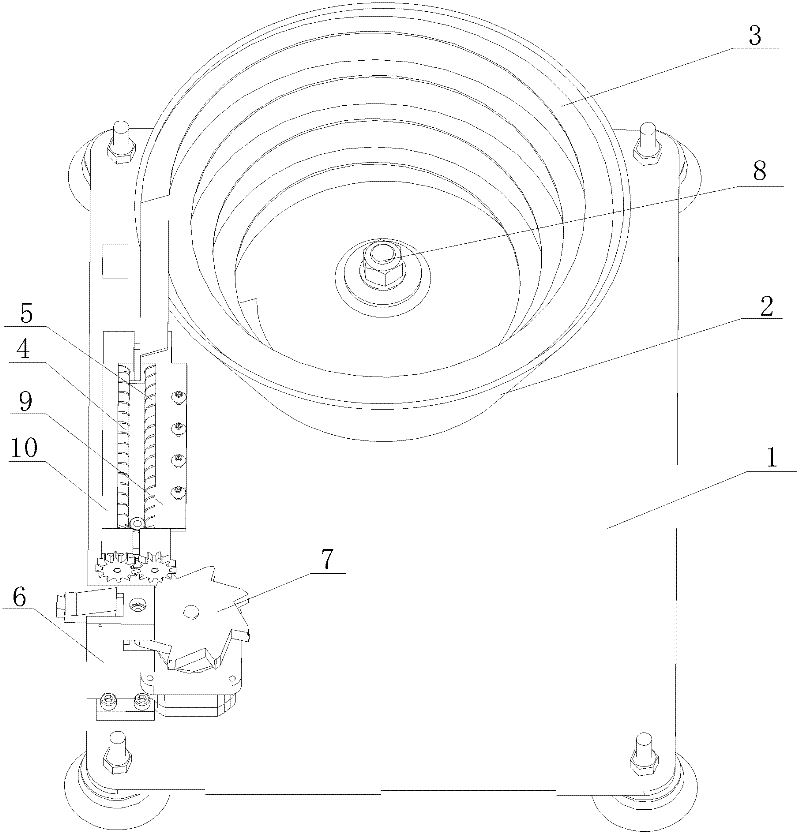

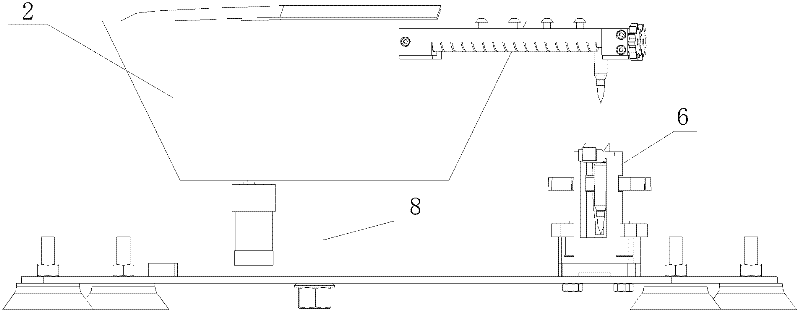

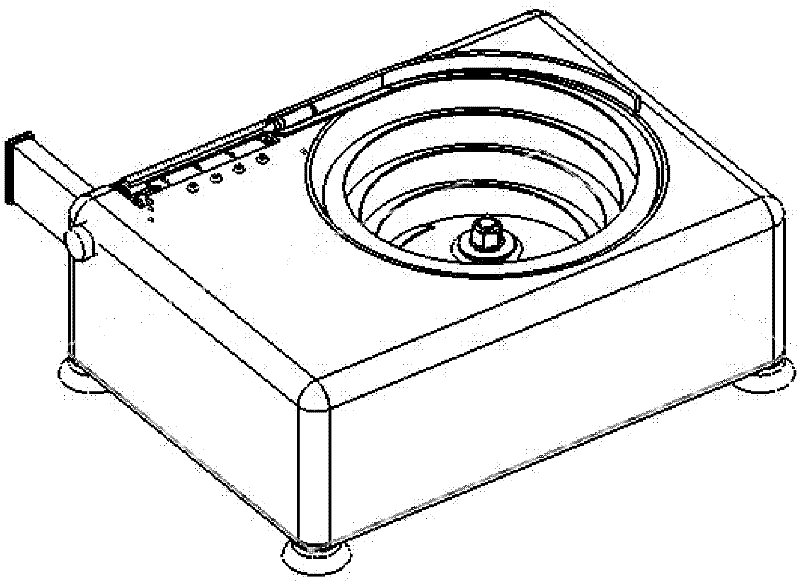

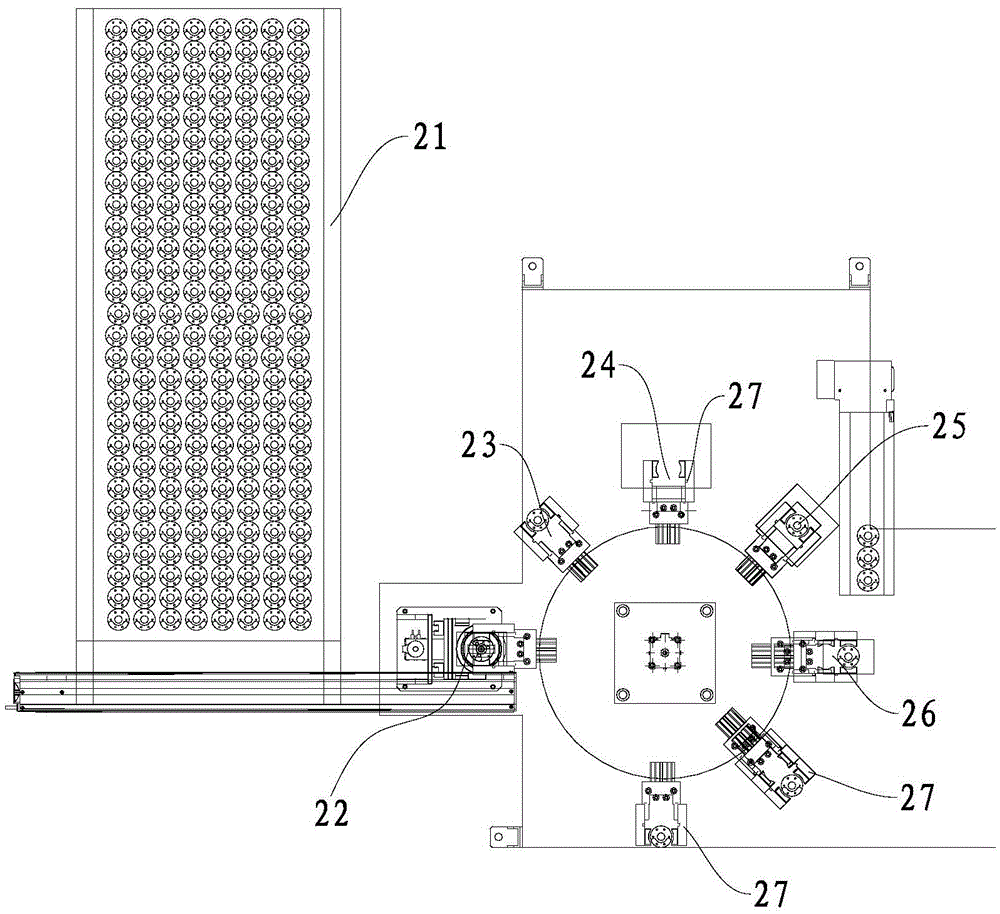

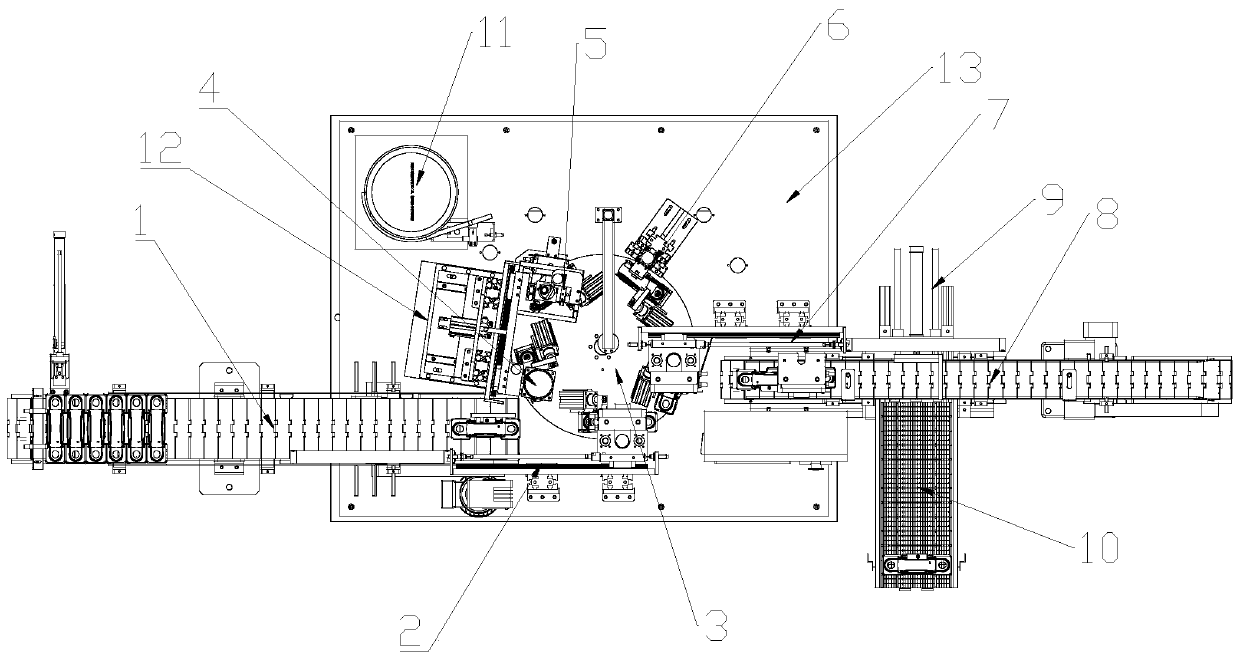

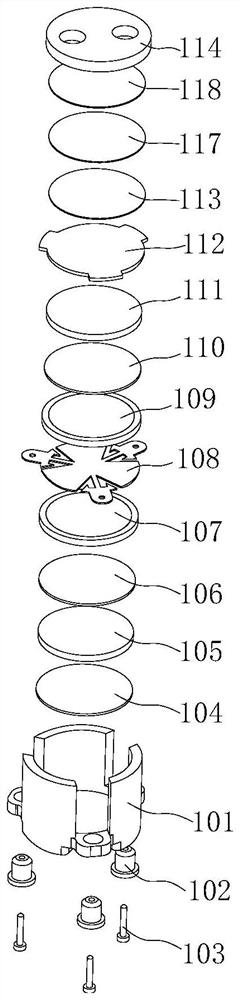

Automatic cylindrical battery assembling machine

ActiveCN104505531ARealize fully automatic assemblyShorten the timePrimary cell manufactureAssembling battery machinesEngineeringAutomatic testing

The invention provides an automatic cylindrical battery assembling machine. The automatic cylindrical battery assembling machine comprises a rack and an indexing plate arranged on the rack and driven to rotate by a divider controlled by a stepping motor, wherein a clamping groove for adsorbing a cylindrical battery to be assembled is arranged on the circumference of the indexing plate according to the dividing angle of the divider; and the automatic cylindrical battery assembling machine also comprises a feeding chute, a tab locating device, a tab shaping device, a groove rolling device, a gluing device, a cap welding device, a liquid injection device, an unqualified product discharging device, a cap pressing device, an automatic sealing machine and a finished product discharging device which are arranged around the indexing plate and sequentially work cooperatively. According to the automatic cylindrical battery assembling machine, the working procedures such as feeding, tab locating, tab shaping, groove rolling, gluing, cap welding, liquid injection, discharging of unqualified products, cap pressing, and automatic sealing and discharging of finished products in the assembling procedures of the cylindrical battery are integrated, the cylindrical battery can be assembled in a full-automatic manner, the whole machine only is required to be monitored by one person, the cost and the time are saved, and the production efficiency is greatly improved.

Owner:惠州亿恒特自动化科技有限公司

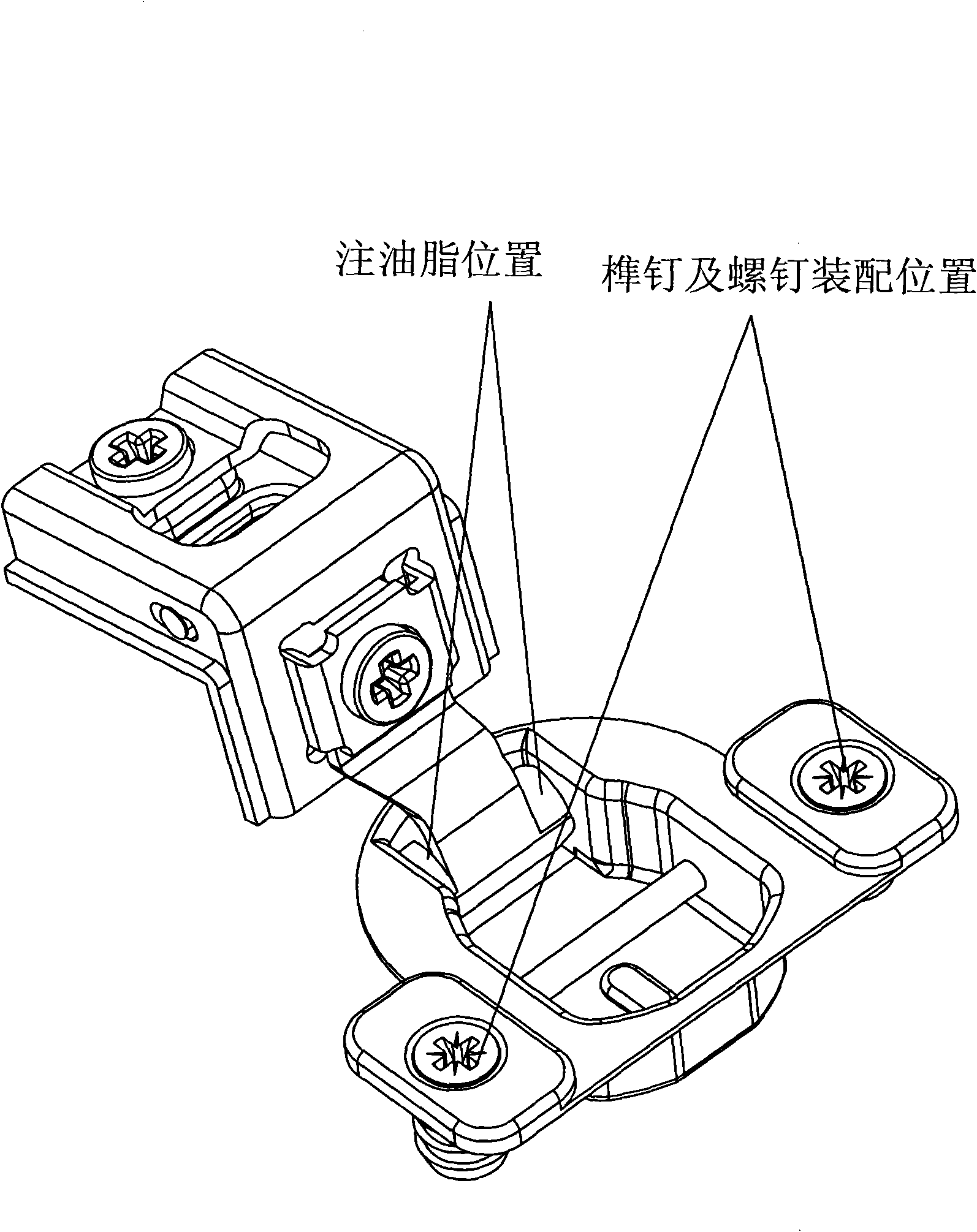

Automatic assembly equipment for hinge pre-installed tenon and oil injection process

InactiveCN102267047ARealize fully automatic assemblyImprove assembly productivityProportioning devicesLubricating pumpsSequence controlQuality assurance

The invention adopts the dowel pressing process, presses the metal screw into the center hole of the plastic dowel, the outer diameter of the screw is slightly larger than the diameter of the center hole of the dowel, and utilizes the elastic deformation and plastic deformation of the plastic dowel to make the screw and the dowel Tightly combined, so that it is firmly fixed on the fixed pocket of the hinge, and at the same time, the quantitative oil injection process is adopted to automatically inject the lubricating grease into the lubricating point quantitatively. The automatic assembly equipment of the present invention includes a dowel grasping mechanism, a dowel vibrating feeding mechanism, a dowel pre-installing mechanism, a screw vibrating feeding mechanism, a grease injection mechanism, a movable clamp cycle stepping and carrying mechanism and a microcomputer control system. Action sequence is controlled by microcomputer control system. The invention realizes the fully automatic assembly of dowel pre-installation and oil injection process, improves the assembly production efficiency and ensures the assembly quality.

Owner:GUANGDONG SACA PRECISION MFG CO LTD

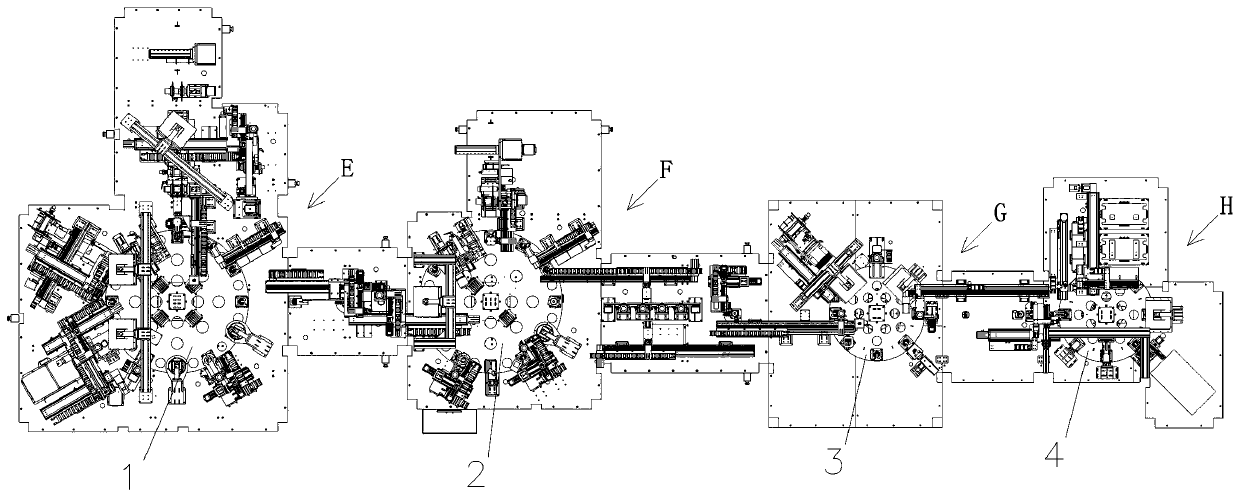

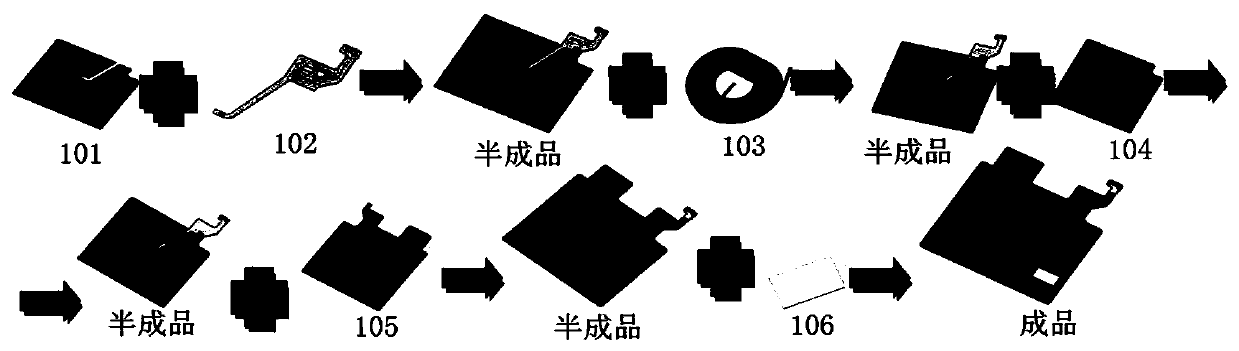

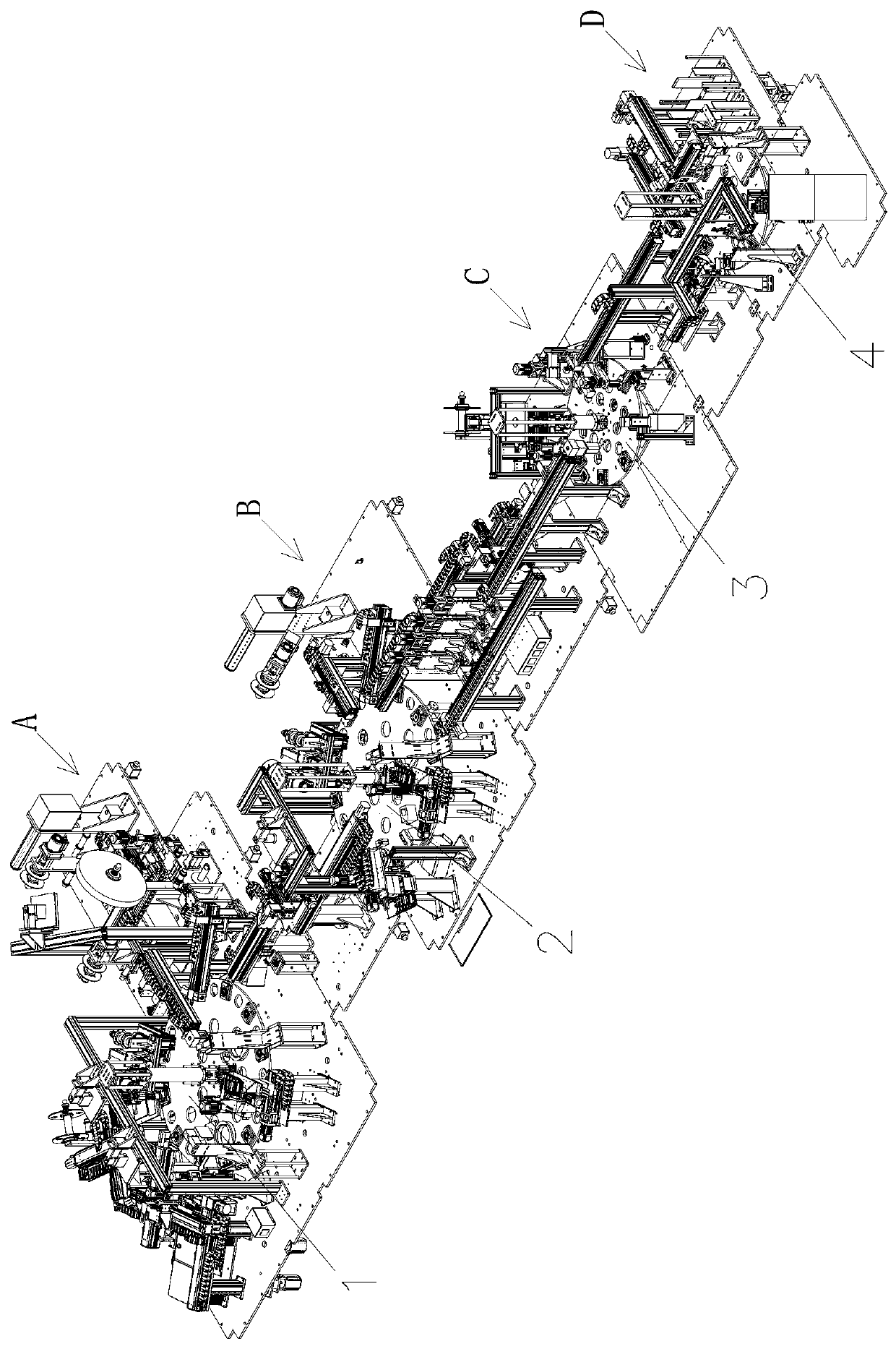

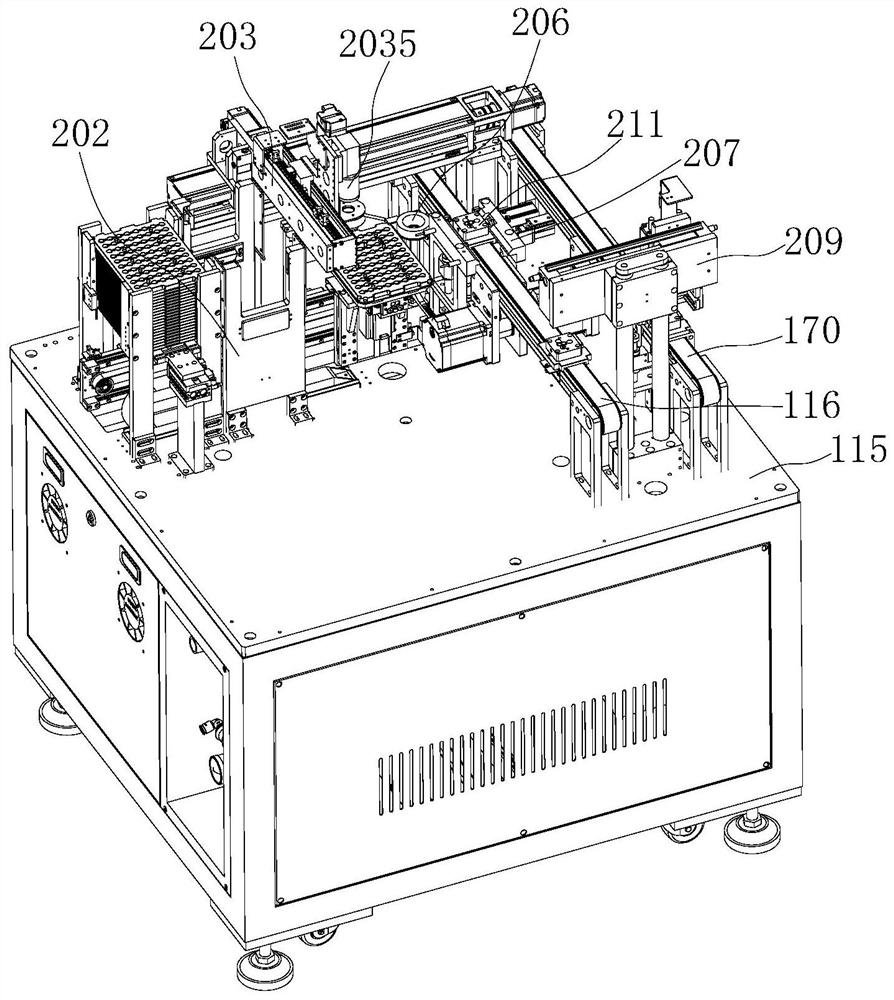

Assembly process of wireless charging module and assembly attaching line

PendingCN109605022ACompact structureRealize automatic eliminationMaterial gluingAssembly machinesEngineeringRotating disc

The invention relates to an assembly process of a wireless charging module and an assembly attaching line. The assembly attaching line comprises a first indexing turntable, a second indexing turntable, a third indexing rotating disc and a fourth indexing rotating disc which are arranged in sequence from front to back, and a plurality of stations are arranged on each of the first indexing rotatingdisc, the second indexing rotating disc, the third indexing rotating disc and the fourth indexing rotating disc. The full-automatic and linear assembly process is adopted, defective products can be assembled fully automatically, detected automatically and removed automatically in large-scale and efficient modes, the four indexing rotating discs are totally arranged, targeted assembly equipment isfurther arranged around each indexing rotating disc, the whole assembly attaching line is compact in structure and is highly modularized, shaping mechanisms are arranged on part of the positions, attaching accuracy is high and can reach + / -0.1 mm, the yield is high, and the production efficiency can reach 1200 pcs / h. The defective products can be removed, finished products can be detected, full-automatic assembly and automatic detection can be achieved, and the defective products can be removed automatically.

Owner:SHENZHEN HADESHENG PRECISION TECH

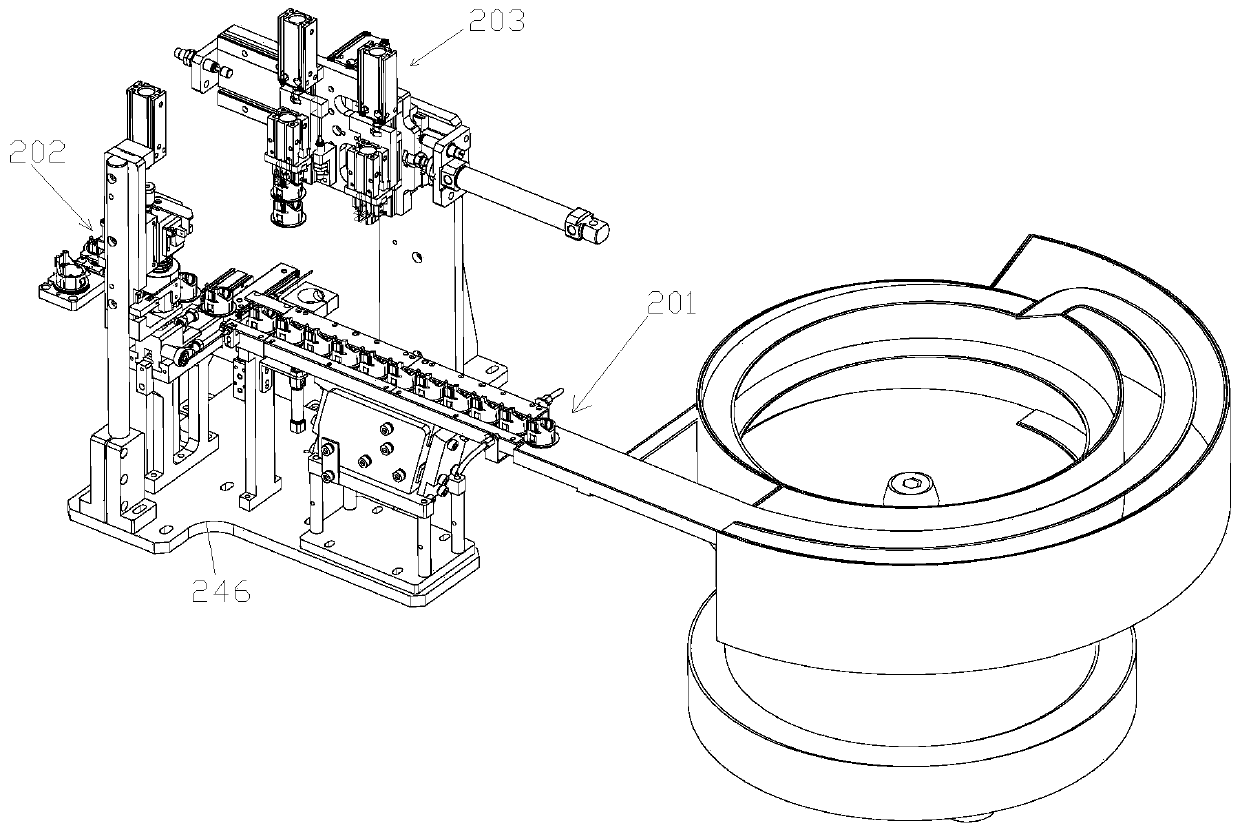

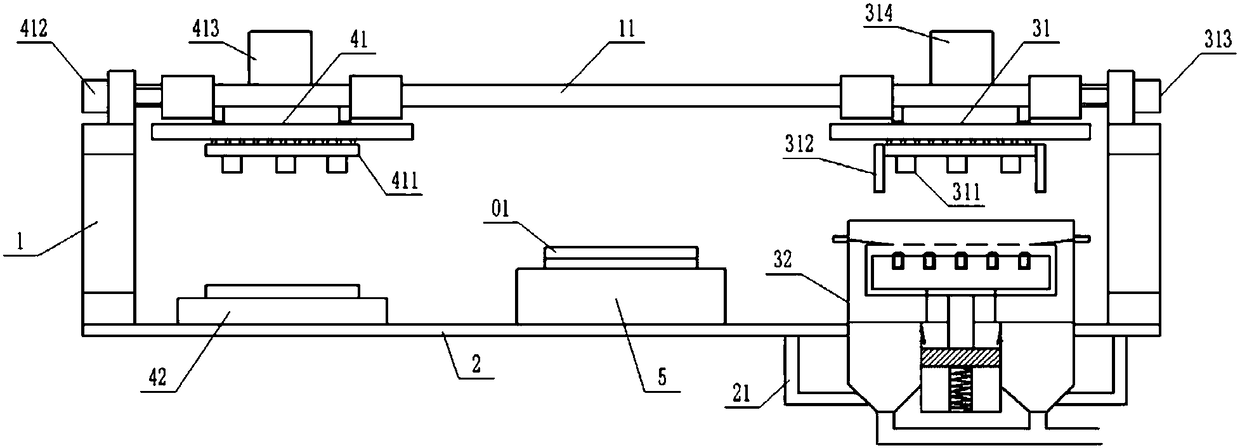

Three-way valve assembly machine and assembly method thereof

PendingCN107263092AEliminate Hygiene ProblemsRealize fully automatic assemblyAssembly machinesPhysicsEngineering

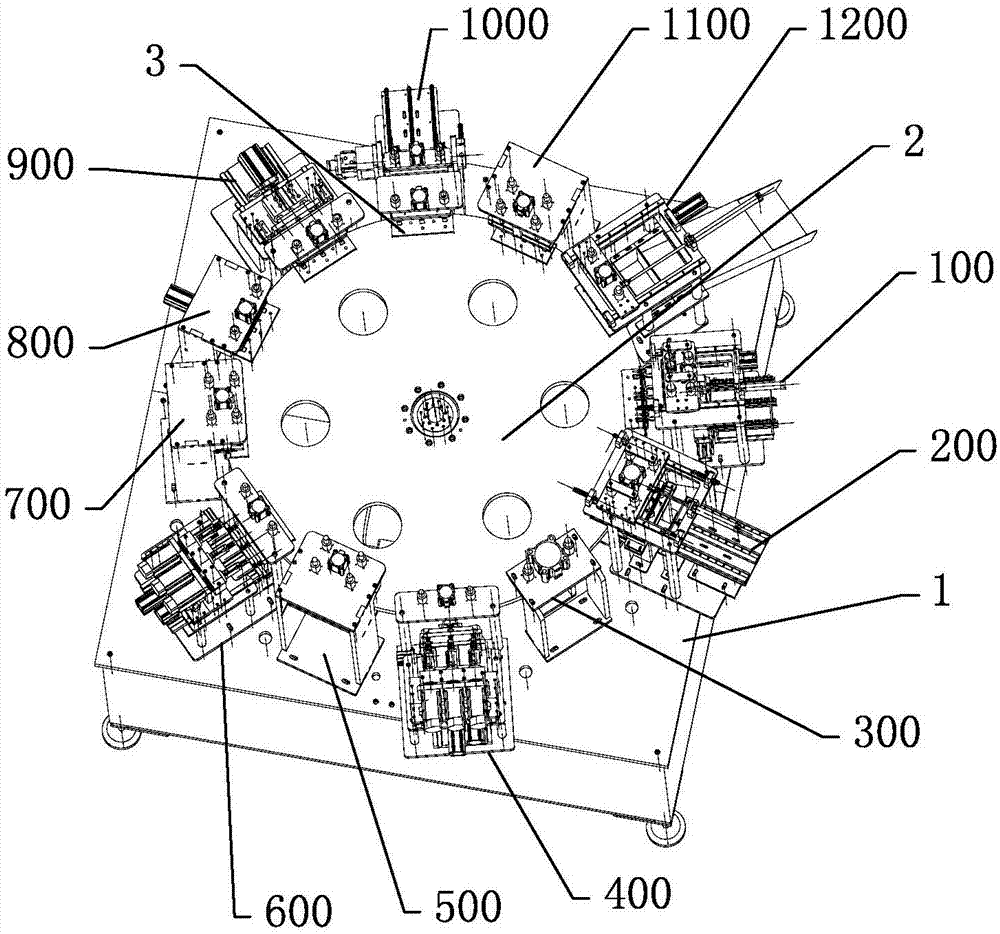

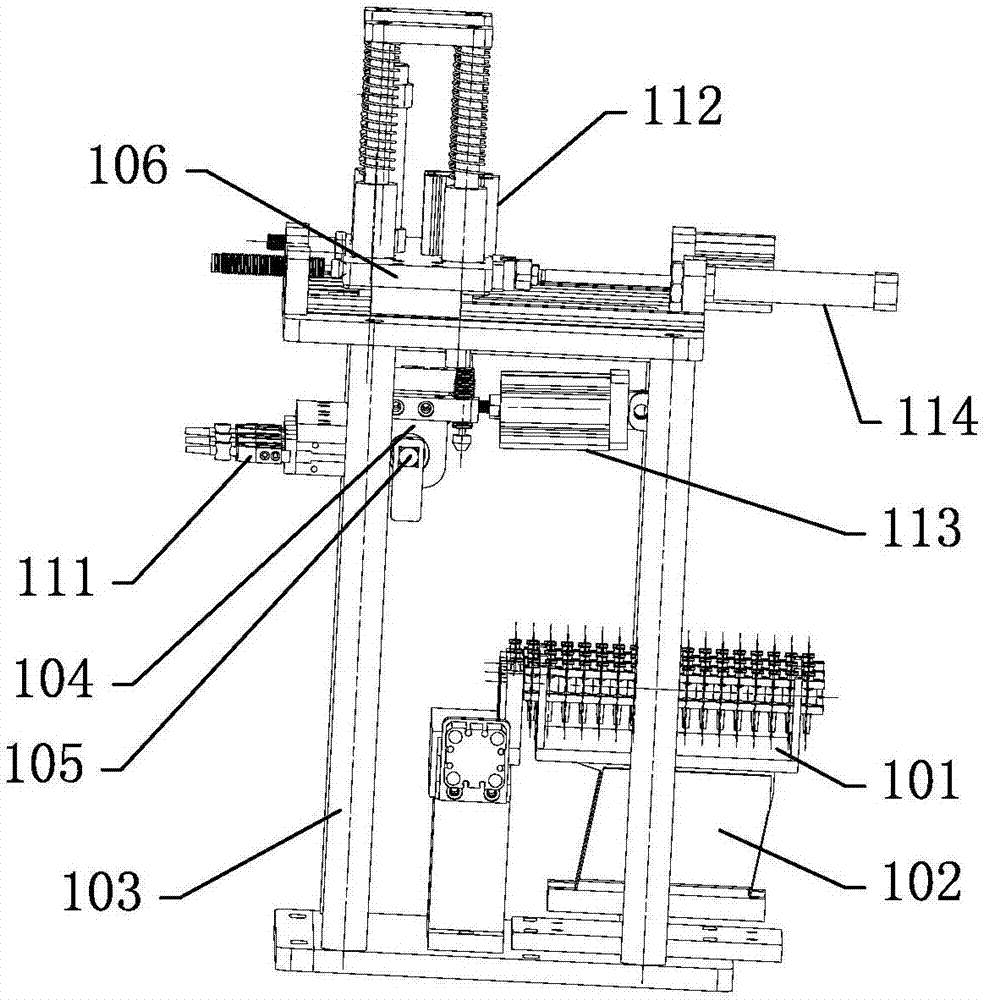

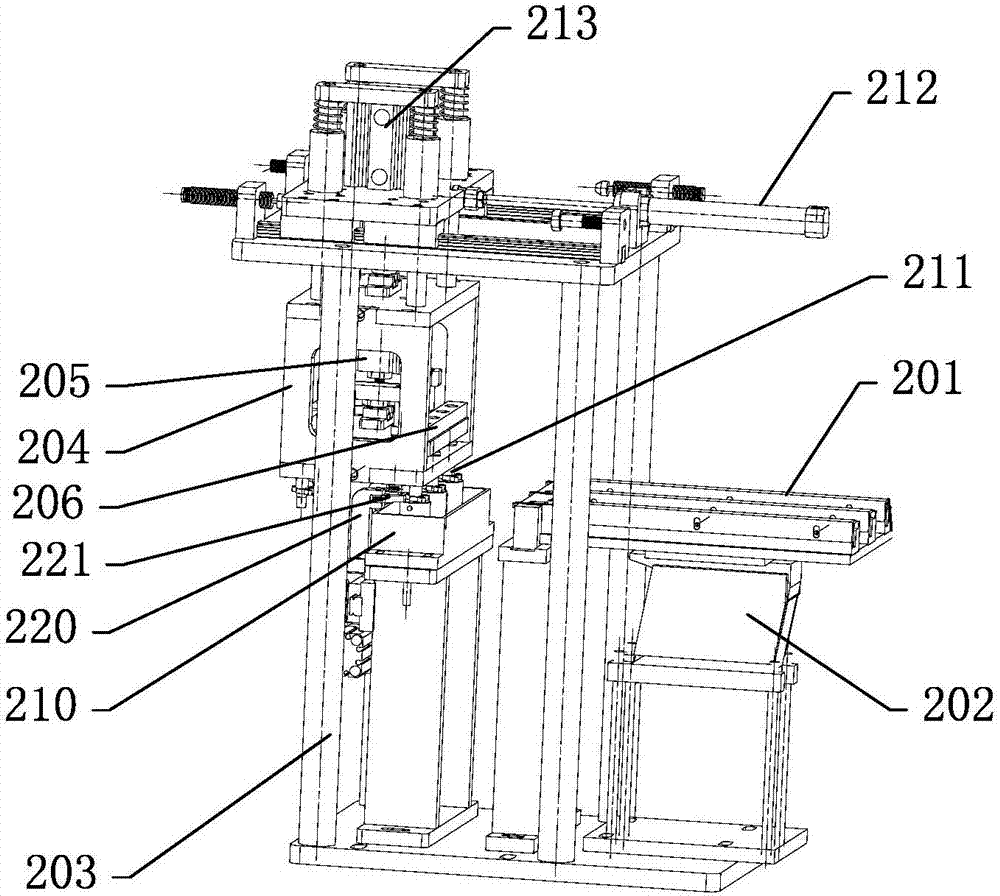

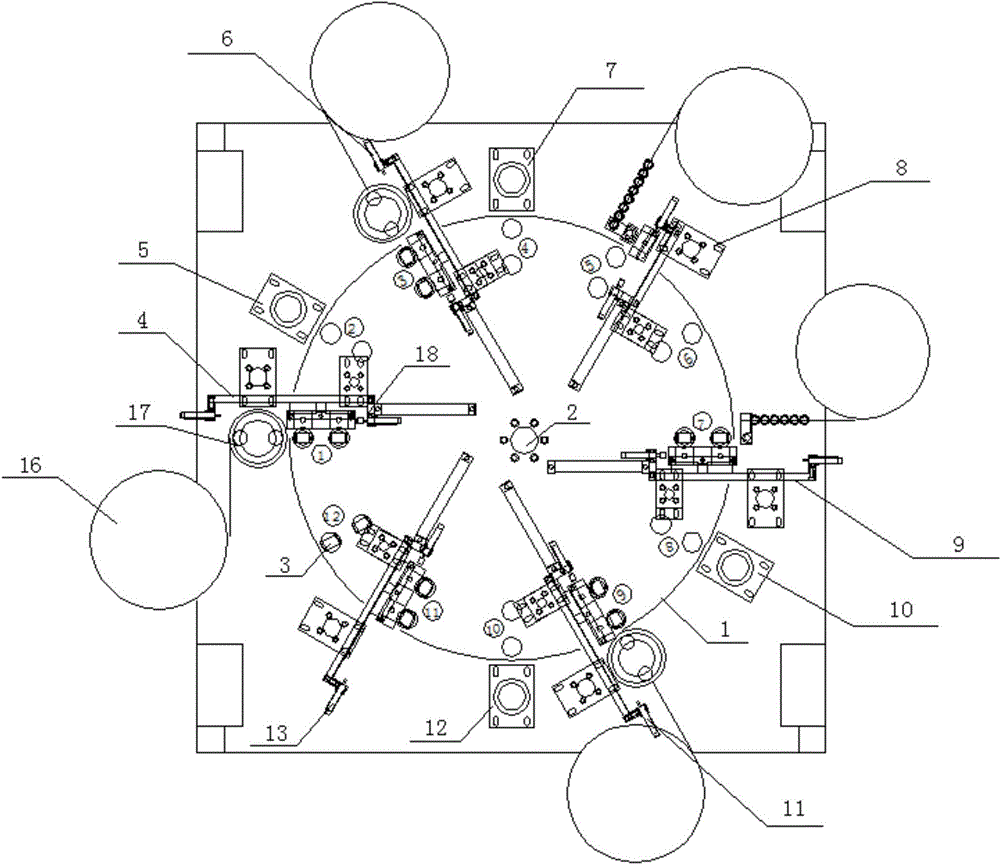

The invention discloses a three-way valve assembly machine and an assembly method thereof, and aims to provide the high-efficiency and high high-precision three-way valve assembly machine and the assembly method thereof. According to the technical scheme, the three-way valve assembly machine comprises a machine frame (1); a multi-station rotary workbench (2) is arranged on the machine frame (1); a plurality of clamps (3) are arranged on the machine frame (1); and aiming at the clamps and movable paths of all the clamps, a valve body feeding station (100), a valve element mounting station (200), a valve element compressing station (300), a first screw top mounting station (400), a first valve body rotating station (500), a second screw top mounting station (600), a second valve body rotating station (700), a gas tightness detection station (800), a spiral head mounting station (900), a sheath mounting station (1000), a valve element rotating station (1100) and a discharging station (1200) are sequentially arranged on the machine frame (1). The three-way valve assembly machine and the assembly method thereof are applicable to the field of assembly.

Owner:WENLING DEGUANG AUTOMATION EQUIP

Full-automatic 1/2 quick-connect assembly assembling machine tool

ActiveCN104625729ARealize fully automatic assemblyImprove assembly efficiencyAssembly machinesMetal working apparatusCamMachine tool

The invention relates to a full-automatic 1 / 2 quick-connect assembly assembling machine tool which comprises a circular working table, a transmission device and a driving device. Twelve product positioning clamps are arranged on the circular working table circumferentially at equal intervals. Each product positioning clamp comprises two positioning clamp bodies which are the same. A plastic cover put-in device, a plastic cover pressing device, a plastic sleeve put-in device, a plastic sleeve pressing device, a first snap spring put-in device, a second snap spring put-in device, a snap spring pressing device, a plastic gasket put-in device, a plastic gasket pressing device and a finished product discharge device are sequentially arranged at the position, corresponding to the positioning clamp bodies, of the circumference of the outer side of the circular working table. The circular working table and the transmission device are concentrically installed on a machine tool bottom plate. Twelve cam intermittent dividers are arranged on the transmission device at equal intervals. The driving device drives the transmission device to rotate so as to drive the circular working table to rotate intermittently anticlockwise by 30 degrees each time. Full-automatic assembling of 1 / 2 quick-connect assemblies can be achieved, the number of operators is small, the assembling efficiency is high, and the product quality is stable.

Owner:JIAXING IDC PLUMBING & HEATING TECH

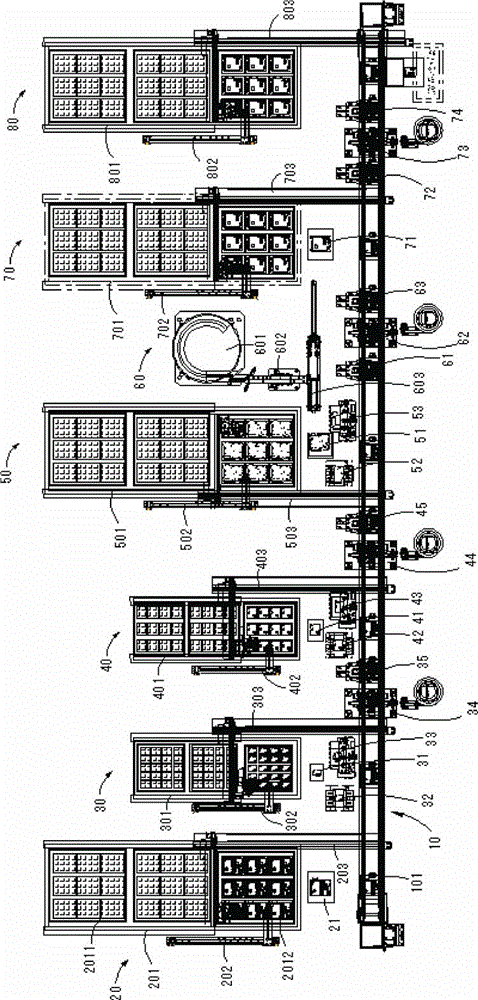

Automatic assembling machine for automobile cigar lighter

PendingCN110842554ARealize fully automatic assemblyQuality improvementAssembly machinesEngineeringStructural engineering

The invention provides an automatic assembling machine for an automobile cigar lighter. The automatic assembling machine comprises turning plate jigs which are distributed in annular arrays; a clamping sleeve assembling mechanism, a clamping sleeve ring assembling mechanism, a clamping sleeve cover assembling mechanism, a torsional spring and shaft assembling mechanism, an integrated assembling mechanism and a finished product discharging mechanism are arranged in a manner of surrounding the outer side of the turning plate jigs; the clamping sleeve assembling mechanism comprises a clamping sleeve feeding device, a clamping sleeve detecting device and a clamping sleeve manipulator; the clamping sleeve ring assembling mechanism comprises a clamping sleeve ring feeding device, a transfer station jig and a transfer assembling manipulator; the clamping sleeve cover assembling mechanism comprises a clamping sleeve cover feeding device and a transfer assembling device; the torsional spring and shaft assembling mechanism comprises a torsional spring and shaft feeding device, a torsional spring and shaft manipulator and a torsional spring and shaft press-mounting device; and the integratedassembling mechanism comprises a total assembly manipulator and a torsional shaping device. The automatic assembling machine can realize full-automatic assembly of a cigar lighter, is high in assemblyefficiency, also has a detection function and realizes high quality of an assembled finished product.

Owner:沈阳益川科技有限公司

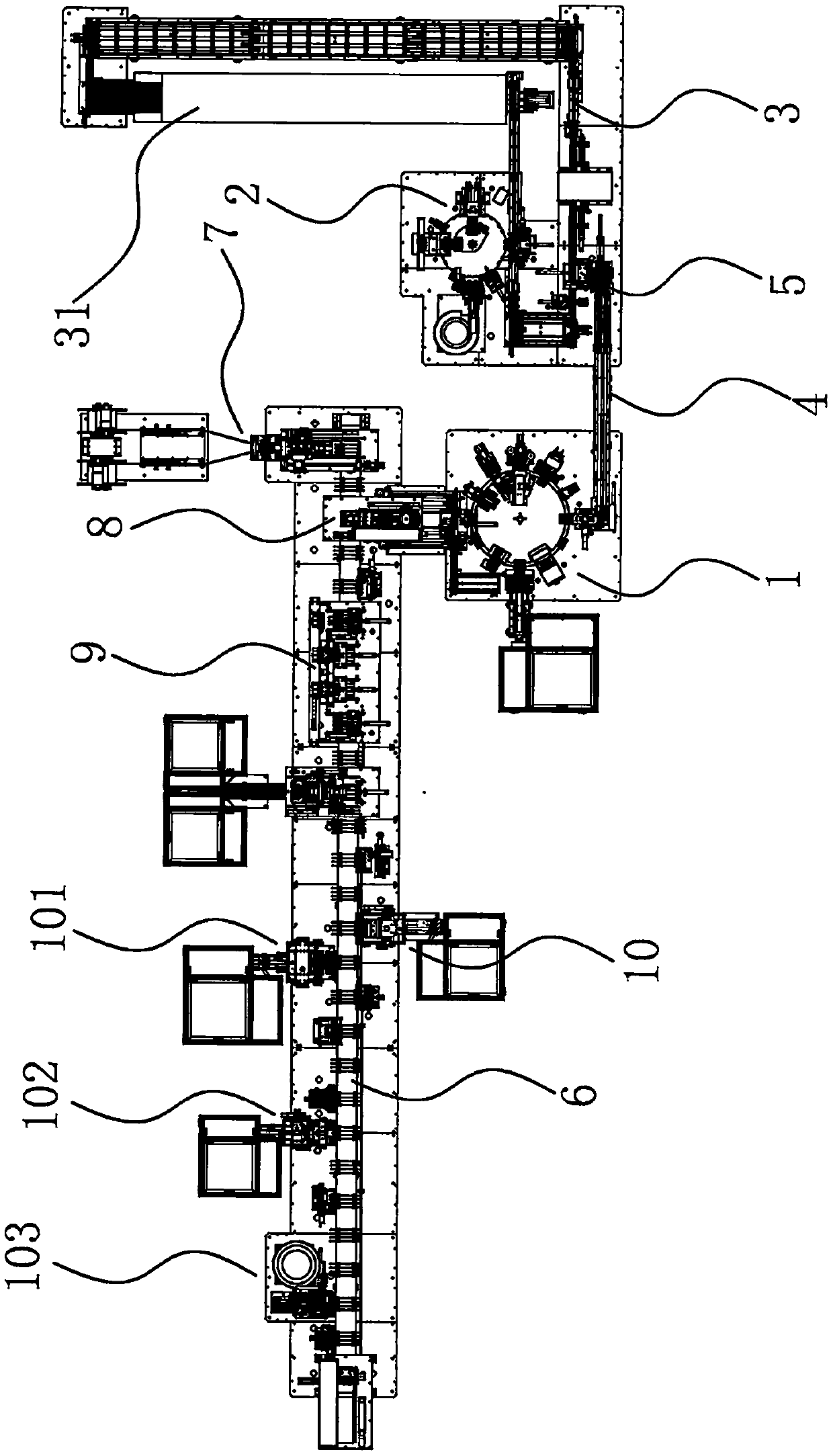

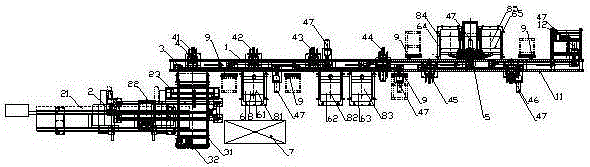

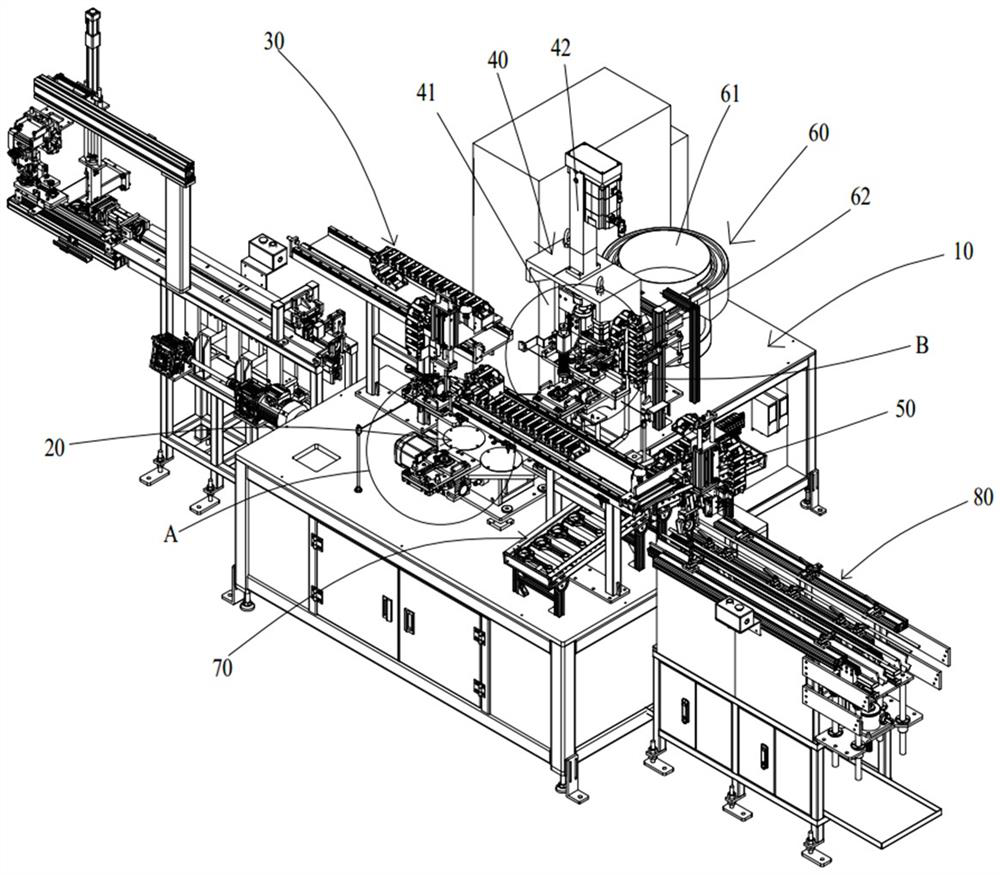

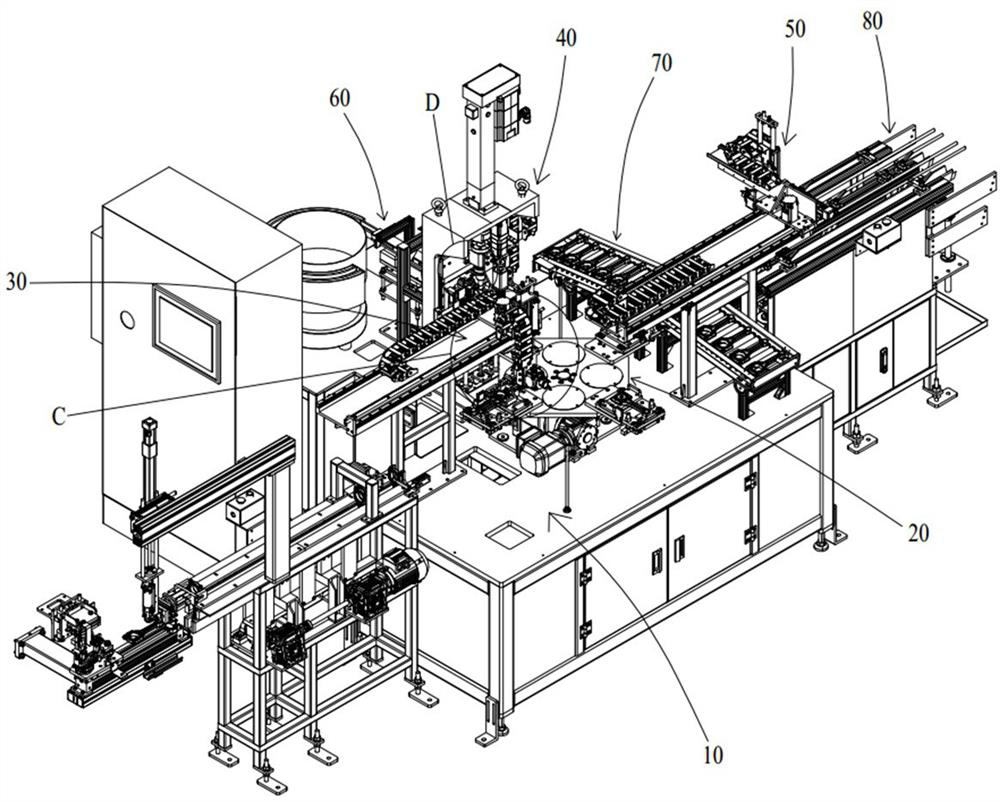

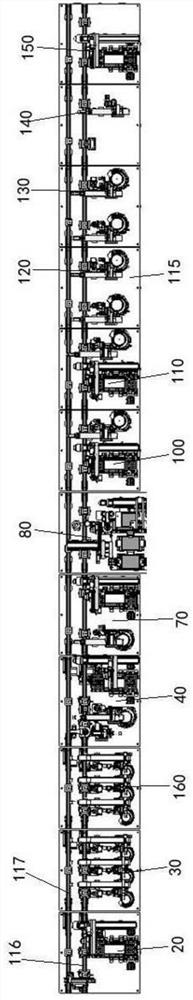

ACU automatic assembly production line

InactiveCN104647031ARealize fully automatic assemblyImprove work efficiencyAssembly machinesMetal working apparatusProduction lineAgricultural engineering

The invention discloses an ACU automatic assembly production line. The ACU automatic assembly production line comprises a speed-multiplier chain assembly line, a middle frame charge mechanism, an adapter plate mounting mechanism, a first screw charge mechanism, a core plate mounting mechanism, a second screw charge mechanism, a main board mounting mechanism, a protective plate mounting mechanism, a third screw charge mechanism, a top cover plate mounting mechanism, a fourth screw charge mechanism, a finished product discharge mechanism, and the like. The ACU automatic assembly production line provided by the invention can automatically assemble a middle frame, an adapter plate, a core plate, a main board, a protective plat and a top plate in sequence, so that the full-automatic assembly is realized, the working efficiency is high and the cost is low.

Owner:GUANGDONG LYRIC ROBOT INTELLIGENT AUTOMATION CO LTD

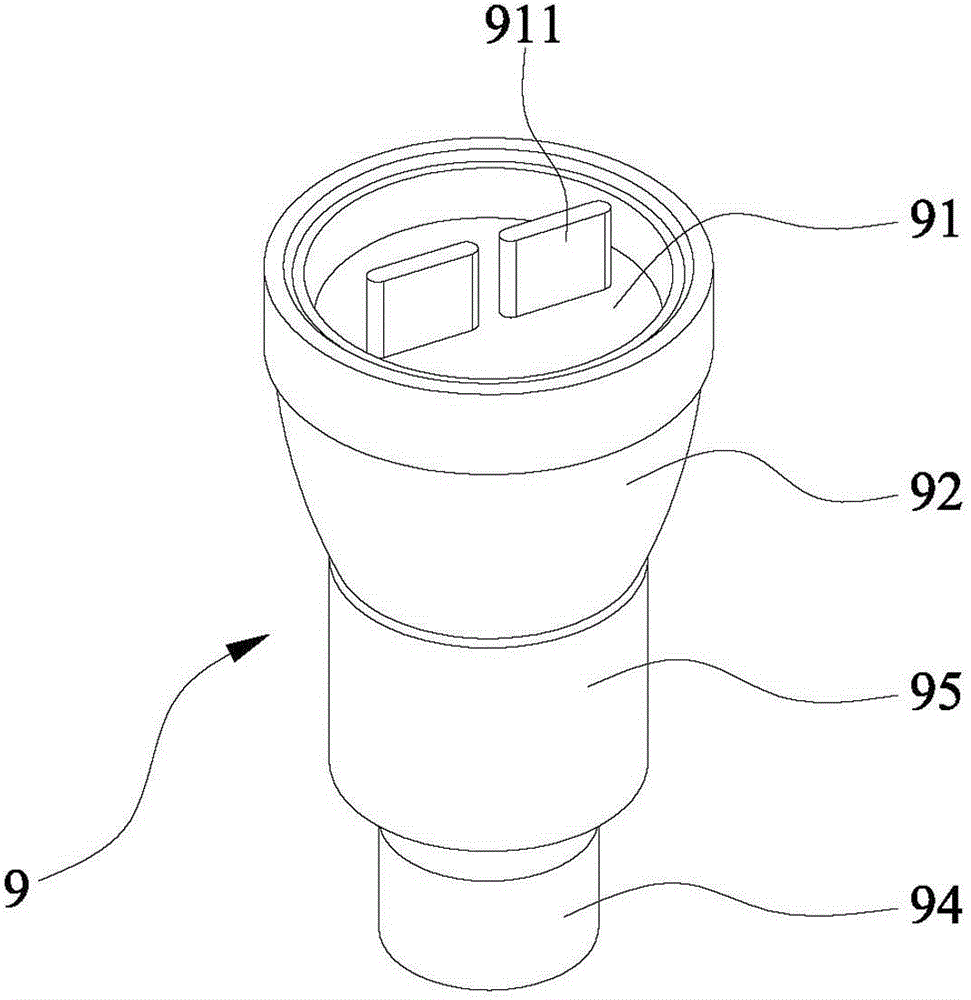

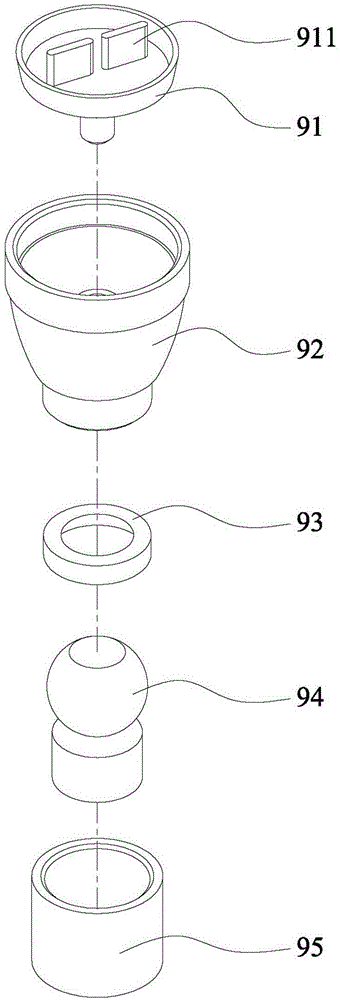

Automatic shower nozzle assembly machine

ActiveCN104924071ARealize fully automatic assemblyImprove assembly efficiencyAssembly machinesUniversal jointEngineering

The invention discloses an automatic shower nozzle assembly machine. The shower nozzle is formed by assembling a surface cover, a body, a rubber cushion, a universal joint and a nut; the assembly machine comprises a control mechanism, a surface cover and body assembly mechanism, a universal joint assembly mechanism, a rubber cushion assembly mechanism, a body and nut assembly mechanism, a multi-station splitting mechanism and a rack, and the control mechanism controls all the mechanisms to act. The assembly machine is designed for all assembly procedures of an existing simple shower nozzle, the shower nozzle can be assembled automatically, accordingly, the assembly efficiency can be improved greatly, and the assembly cost and the assembly reject ratio are reduced.

Owner:XIAMEN UNIV OF TECH

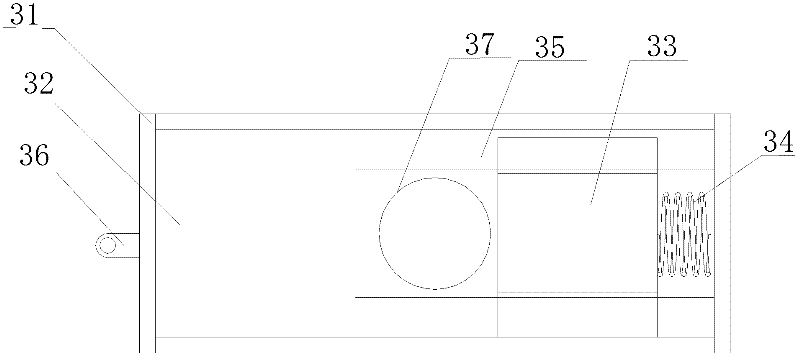

Automatic bullet loading system based on friction conveying and screw conveying

InactiveCN102645129ARealize fully automatic assemblyEasy to installAmmunition loadingEngineeringMechanical engineering

The invention discloses an automatic bullet loading system based on friction conveying and screw conveying. The system comprises a base, a roller, a screw conveying belt, two screw rods parallel to each other, a magazine combining seat and a bullet push mechanism, wherein the roller rotates relative to the base; the screw conveying belt is fixedly connected with the base and is close to the inner wall of the roller; an input end of the screw conveying belt is located at the bottom of the roller; a bullet conveying channel is formed between the two screw rods; an inlet of the bullet conveying channel is connected with an output end of the screw conveying belt; the magazine combining seat is provided with a bullet receiving groove; a top opening of the bullet receiving groove is connected with an outlet of the bullet conveying channel; a first opening and a second opening are arranged in the two opposite side walls of the bullet receiving groove respectively; the first opening is communicated with an inlet of the magazine; and the bullet push mechanism is mounted at the second opening. Through the invention, the whole process of loading the disordered bullets into the magazine is automatically finished, the manual sorting link is saved, the bullet loading efficiency is improved, and the repair and maintenance are more convenient.

Owner:ZHEJIANG UNIV

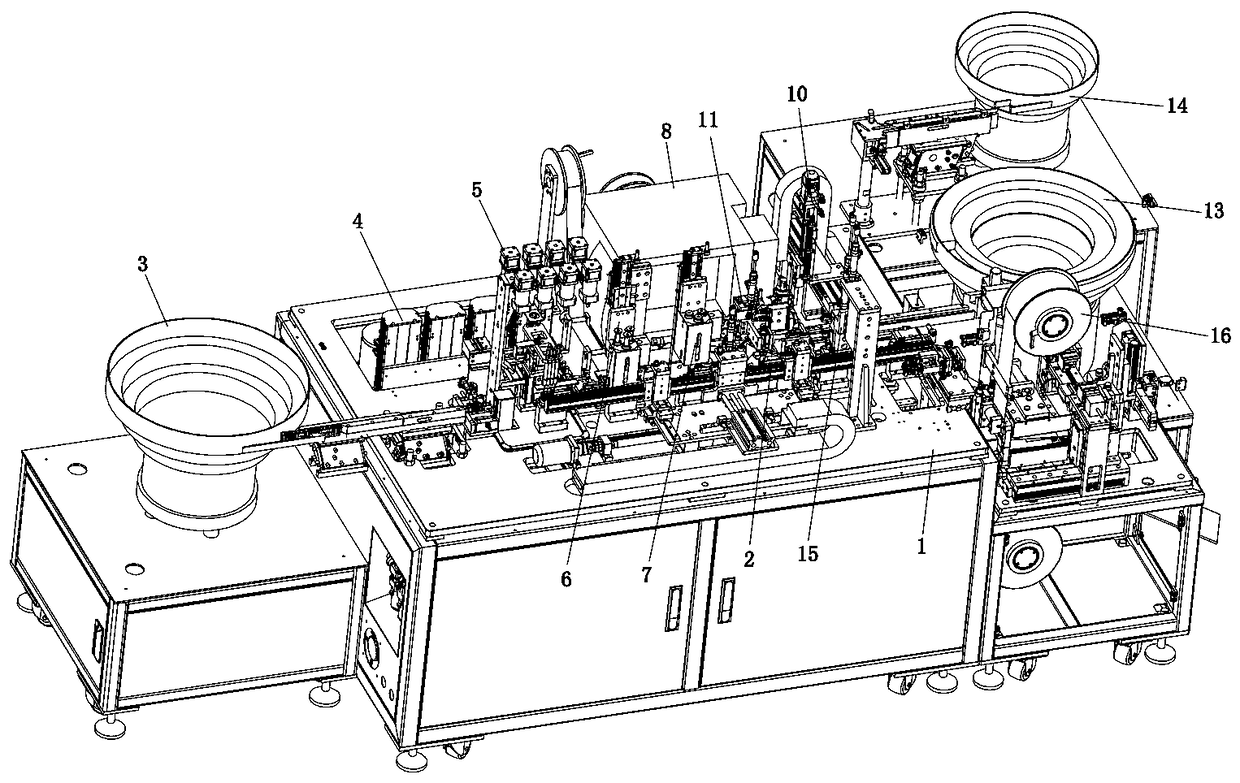

Automatic assembly method of decorative light production line

ActiveCN103862278ARealize fully automatic assemblyGuaranteed normal operationAssembly machinesConveyor partsProduction lineFully automatic

The invention provides an automatic assembly method of a decorative light production line. The automatic assembly method of the decorative light production line can solves the problems of poor precision, low production efficiency and the like in existing decorative light production and comprises a vibrating tray, a vibrator, a feeding rail, a conveying rail, a blending rail, a positioning mechanism, a filament clamping mechanism, a forking mechanism, a testing mechanism, a discharging mechanism, a holder assembling mechanism and a filament bending mechanism. The automatic assembly method comprises the following steps of 1) material feeding; 2) vibrating arrangement; 3) horizontal conveying; 4) torsional transition conveying; 5) vertical conveying; 6) inter-insertion positioning; 7) filament clamping; 8) forking; 9) testing; 10) discharging; 11) holder assembling; 12) filament bending; 13) finish product collection. The automatic assembly method of the decorative light production line achieves mechanical fully-automatic assembly through the cooperation of an automatic feeding device and an automatic assembly device and has the advantages of improving the production efficiency, ensuring the percentage of pass, reducing the production cost and the like.

Owner:平湖市博宏塑料制品厂

Kit full-automatic filling and sealing production line and production technology thereof

PendingCN109080895ARealize fully automatic assemblyIncrease production capacityLiquid materialIndividual articlesProduction lineLiquid injection

The invention discloses a kit full-automatic filling and sealing production line and a production technology of the production line. The production line comprises a machine frame, a conveying mechanism, a box body feeding mechanism, a liquid storage mechanism, a liquid injection mechanism, a presealing and film cutting mechanism, a liquid sealing mechanism, an online printing mechanism, a label removal mechanism, a label suction mechanism, a cover sealing mechanism, a box cover feeding mechanism, a needle head feeding mechanism and a needle head installing mechanism. The technological steps such as box body staggered feeding, liquid injection, film cutting and presealing, hot sealing, label printing, label removal and suction, box cover staggered feeding, labeling machine rotation, cover sealing, needle head feeding and needle head installation are integrated, kit full-automatic assembly and filling sealing are achieved, the production capacity is effectively improved, the production cost is reduced, and the product quality is improved.

Owner:SHENZHEN XING GRAIN AUTOMATION CO LTD

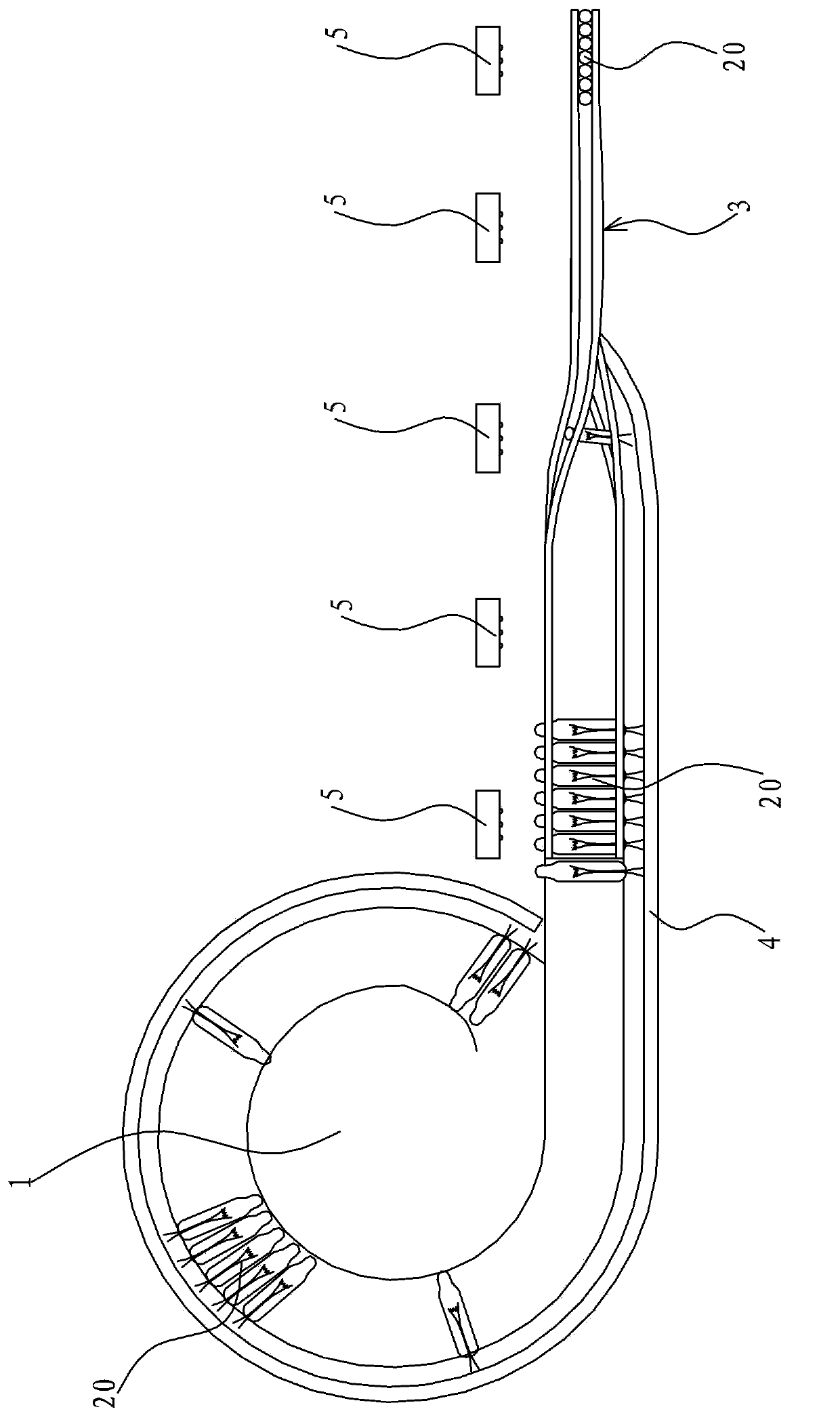

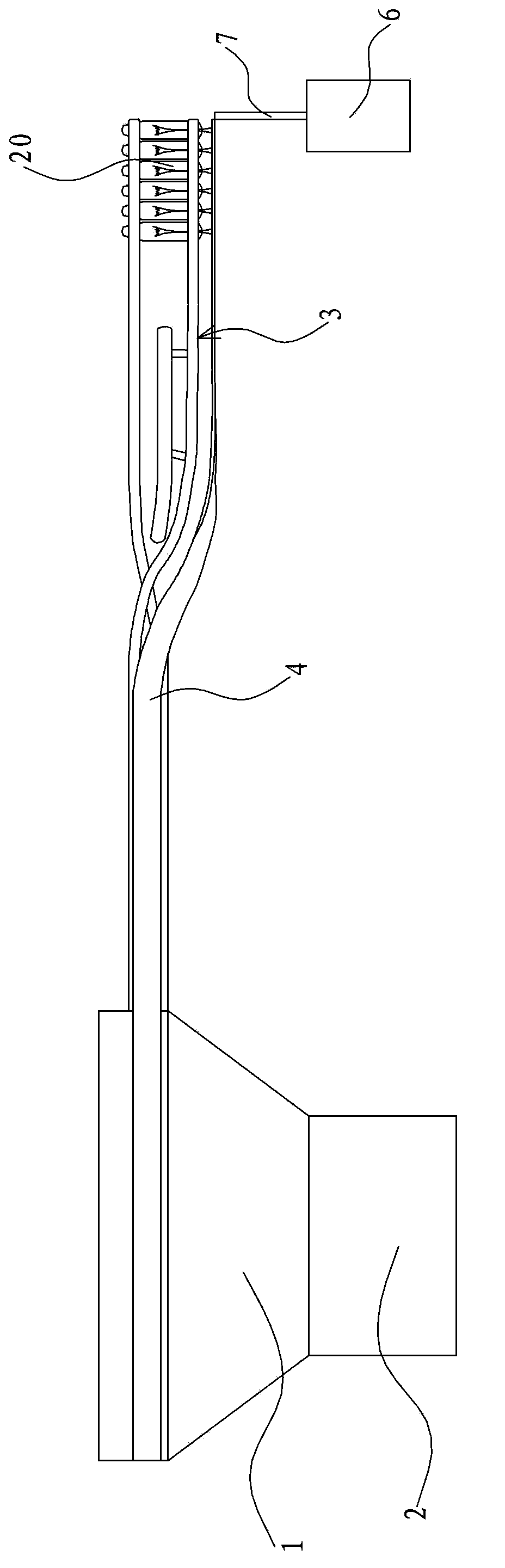

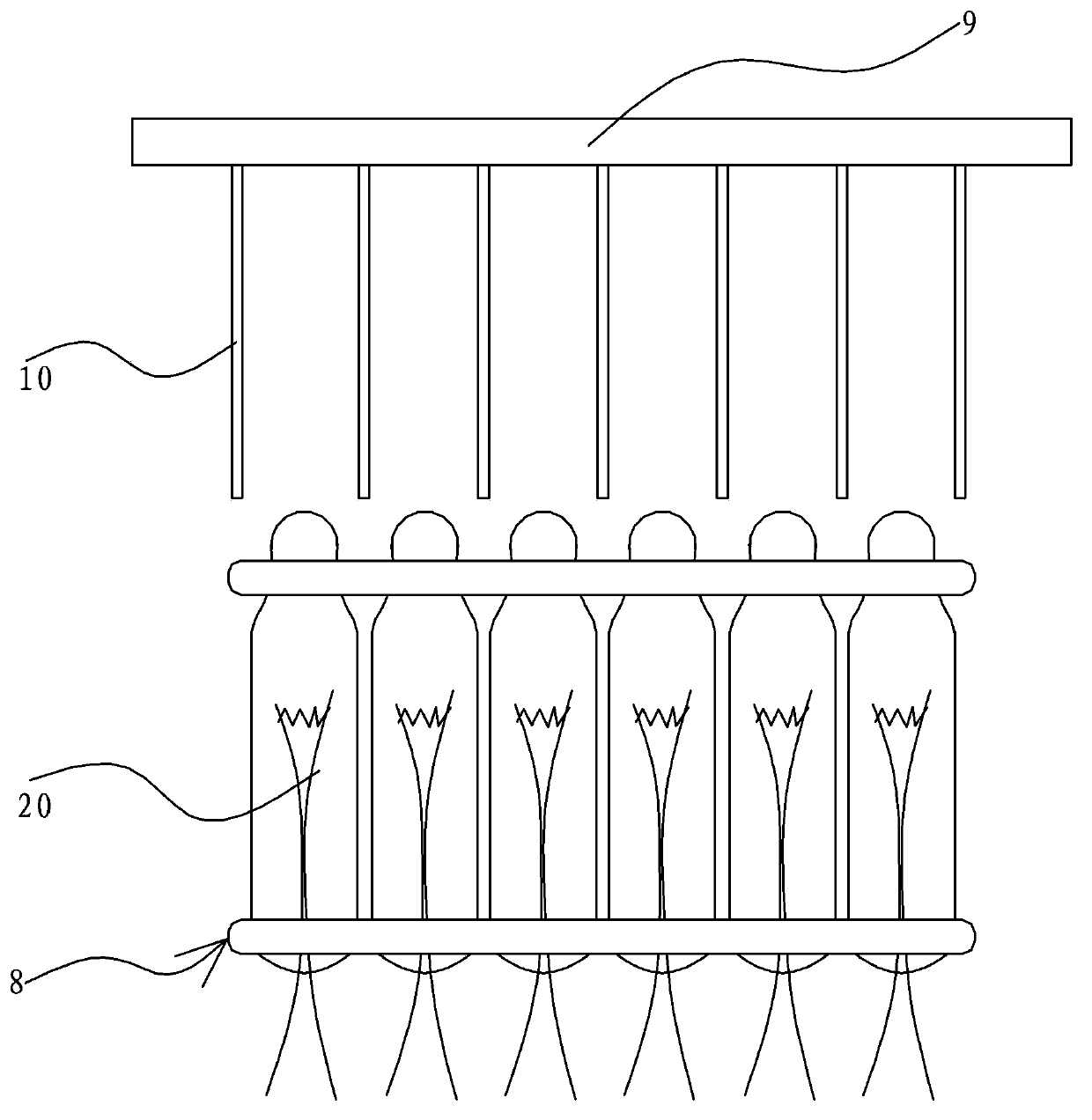

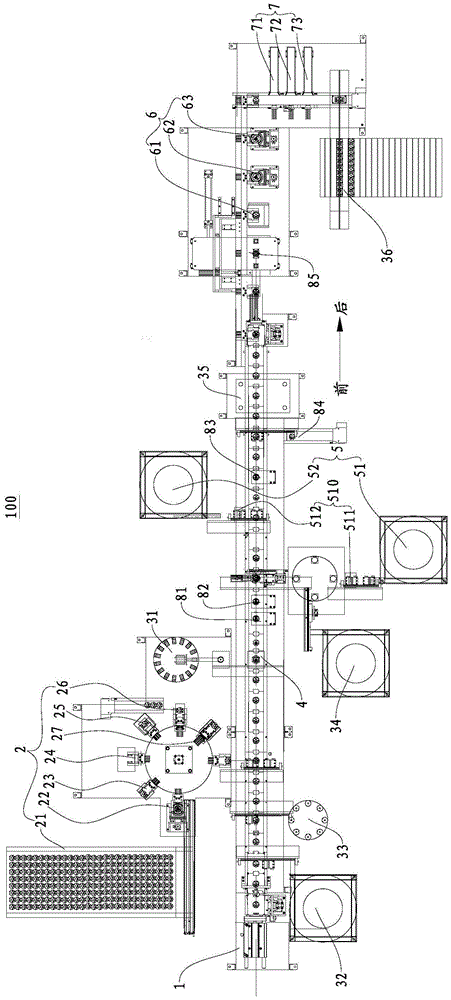

Puncture needle assembly machine

PendingCN109514251AImprove separation efficiencyStable and continuous feedingAssembly machinesMetal working apparatusEpoxyAssembly line

The invention provides a puncture needle assembly machine and belongs to the technical field of medical equipment. The puncture needle assembly machine solves the problem that the degree of automationof an existing puncture needle assembly machine is low. The puncture needle assembly machine comprises a circulation conveying line I, a circulation conveying line II and a needle tube component transfer mechanism, wherein a needle tube component assembly mechanism is located on one side of the circulation conveying line I and comprises a turntable I, a needle seat feeding component, an upper epoxy resin component and a blanking component; and a butterfly wing assembly mechanism comprises a turntable II, a surrounding butterfly wing feeding component, a butterfly wing surface fixing component, an assembly component, a needle surface positioning component, a spraying point component and a glue dispensing component. With adoption of the puncture needle assembly machine, the butterfly wing and the needle tube component are assembled together through the butterfly wing assembly mechanism, the needle tube, the needle seat and the butterfly wing realize assembly line type full automatic assembly and the assembling efficiency of the puncture needle is greatly improved.

Owner:昕迪智能装备(东莞)有限公司

Automatic rotor assembling system

ActiveCN105490473ARealize fully automatic assemblyImprove assembly efficiencyManufacturing stator/rotor bodiesEngineeringRivet

The invention discloses an automatic rotor assembling system which comprises the components of a main conveying line; a rotor core conveying device which is used for storing and conveying rotor cores; a magnet conveying device which is used for storing and conveying magnets; a lower balancing block conveying device which is used for storing and conveying lower balancing blocks; an end plate conveying device which is used for storing and conveying end plates; a magnet mounting device which is mounted in the main conveying line and is used for mounting the magnet that is conveyed by the magnet conveying device into a rotor core in the main conveying line; an upper balancing block conveying device which is used for storing and conveying upper balancing blocks; a rivet conveying device which is used for storing and mounting rivets, wherein the rivet conveying device is provided with a rivet perpendicularity detecting device which is used for detecting the perpendicularity of each rivet; a riveting device which is used for riveting and fixing the rivet; a quality detecting device; a defective product removing device; and a finished product storing device. The automatic rotor assembling system can realize full automatic assembling of the rotor and furthermore improves assembling efficiency and qualified rate.

Owner:ANHUI MEIZHI PRECISION MFG

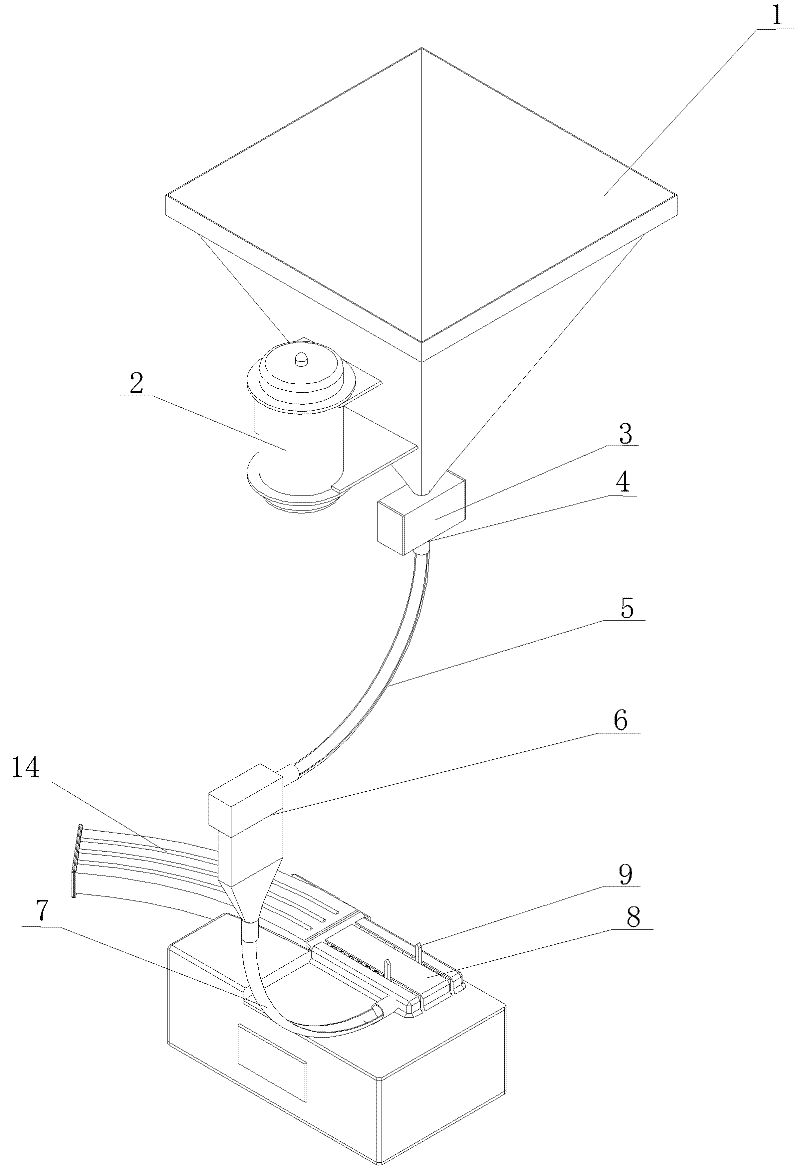

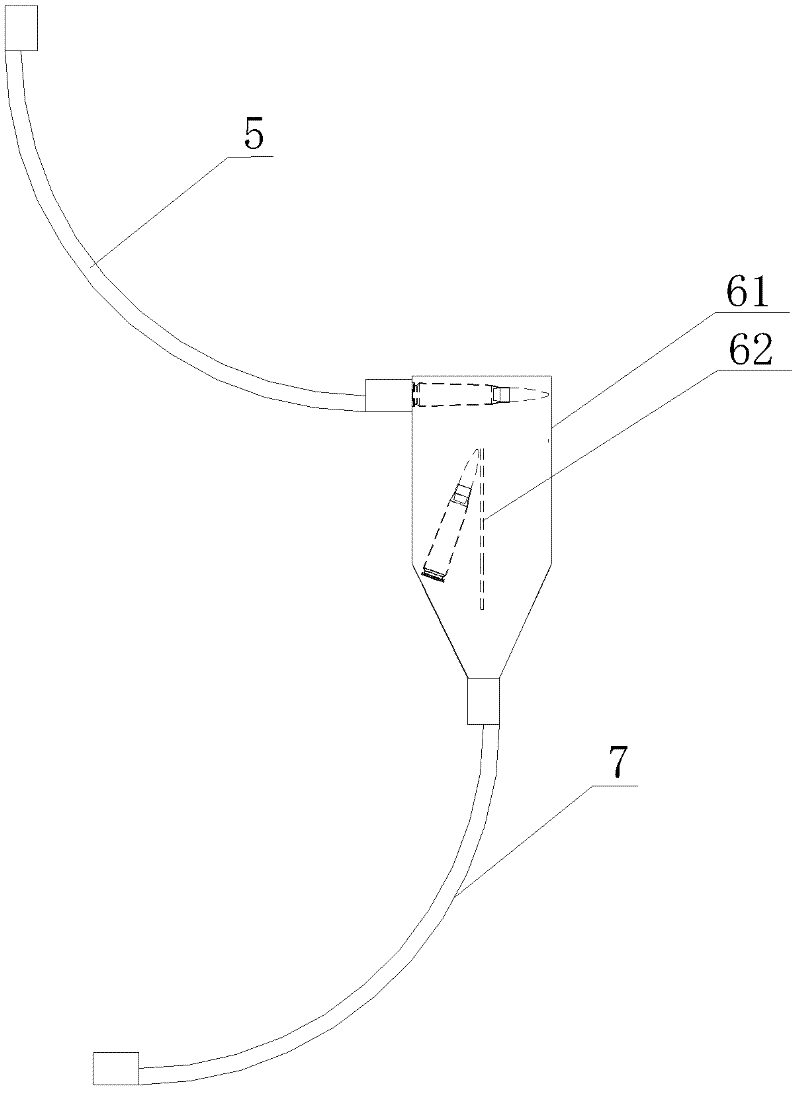

Bullet automatically assembling system based on gravity sieving

InactiveCN102636077AImplement automatic assemblyRealize fully automatic assemblyAmmunition loadingEngineeringMechanical engineering

The invention discloses a bullet automatically assembling system based on gravity sieving, comprising a bullet loading funnel, a vibration motor, a bullet guide device and a bullet pressing mechanism, wherein the bottom of the bullet loading funnel is provided with a bullet output opening; the vibration motor is used for driving the bullet loading funnel to vibrate; the bullet guide device is used for adjusting the direction of a bullet; the inlet of the bullet guide device is communicated with the bullet output opening of the bullet loading funnel through a first bullet conveying pipe; the bullet pressing mechanism is used for pressing the bullet with the adjusted direction into a bullet box; and a bullet inlet of the bullet pressing mechanism is communicated with an outlet of the bullet guide device through a second bullet conveying pipe. According to the invention, the bullets are uniformly sequenced by the gravity sieving through the bullet guide device and the bullets are pressed into the bullet box through the bullet pressing mechanism, so that the full-automatic assembling of the bullets is realized, a manual sequencing link is saved and the bullet loading efficiency is improved; and the automatic bullet assembling system has the advantages of simple structure, strong reliability, wide applicability, high working efficiency and the like.

Owner:ZHEJIANG UNIV

LED car lamp assembling device

ActiveCN108723770ARealize fully automatic assemblyIncrease productivityAssembly machinesEngineeringRejection rate

The invention provides an LED car lamp assembling device which comprises a first dual-layer double chain conveyor line, a second dual-layer double chain conveyor line, a first three-axis dispenser, asecond three-axis dispenser, a first workpiece feeding robot, a second workpiece feeding robot, a third workpiece feeding robot, a single-layer conveyor line, an automatic plate discharging mechanism,an automatic screw machine, a testing device, a discharging and carrying device and a locating mechanism, wherein the discharging and carrying device comprises X-axis guide rails, Y-axis guide rails,first cylinders and a second cylinder; and the locating mechanism comprises photoelectric sensors, locating baffles, locating columns, trays and locating dowels. The LED car lamp assembling device achieves full-automatic assembling of an LED car lamp, the assembling precision is hugely improved, the production efficiency of the LED car lamp is improved, and the rejection rate of a product is reduced.

Owner:FOSHAN NANHAI GUANGDONG TECH UNIV CNC EQUIP COOP INNOVATION INST +1

Full-automatic solar frame production robot

InactiveCN105215690ARealize fully automatic assemblyRealize feeding transmissionOther manufacturing equipments/toolsAutomatic controlDrive motor

The invention discloses a full-automatic solar frame production robot which comprises a rack, a cutting mechanism, a conveying mechanism, a mechanical arm, an automatic corner brace installing machine, a punch mechanism and a master control box. The cutting mechanism, the conveying mechanism, the mechanical arm, the automatic corner brace installing machine and the punch mechanism are all arranged on the rack. The conveying mechanism comprises a conveying belt and a conveying drive motor. The rack is provided with a high-speed linear guide rail. The full-automatic solar frame production robot has the beneficial effects that the robot can achieve feeding and conveying, positioning and machining in all processes, full-automatic assembling of corner braces and full-automatic control according to standard technological process design, the robot can replace traditional manual operation and achieve automatic process production, scratches of products are reduced, positioning is more accurate, and efficiency is higher.

Owner:SHENZHEN HONGYIBAO AUTOMATION EQUIP CO LTD

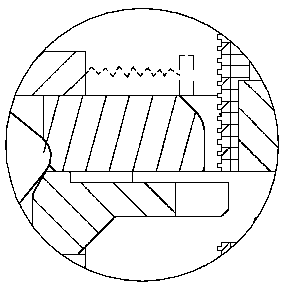

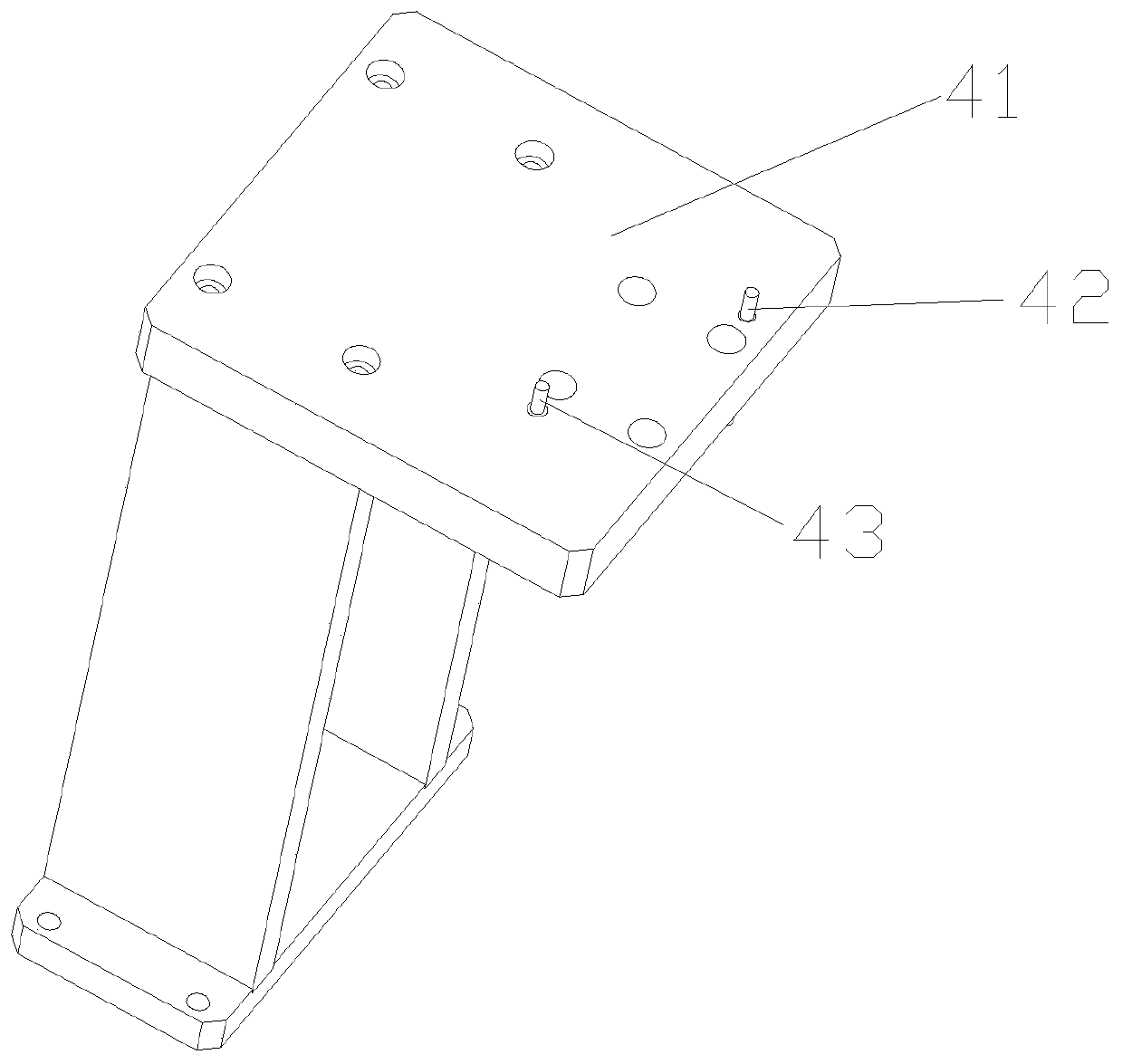

Clutch disc assembly assembling mechanical hand

The invention relates to the technical field of clutch production and particularly discloses a clutch disc assembly assembling mechanical hand which comprises a rack and a base. The base is arranged at the lower end of the rack. A guide rail is arranged at the upper end of the rack. The base is provided with an assembling table used for assembling a clutch disc assembly. A rivet taking and placingunit and a wave-shaped piece taking and placing unit are arranged on the two sides of the assembling table correspondingly. The clutch disc assembly assembling mechanical hand can achieve fully automation assembling of a clutch disc assembly, and is low in operation cost, high in assembling speed and high in efficiency.

Owner:安徽光生电缆有限公司

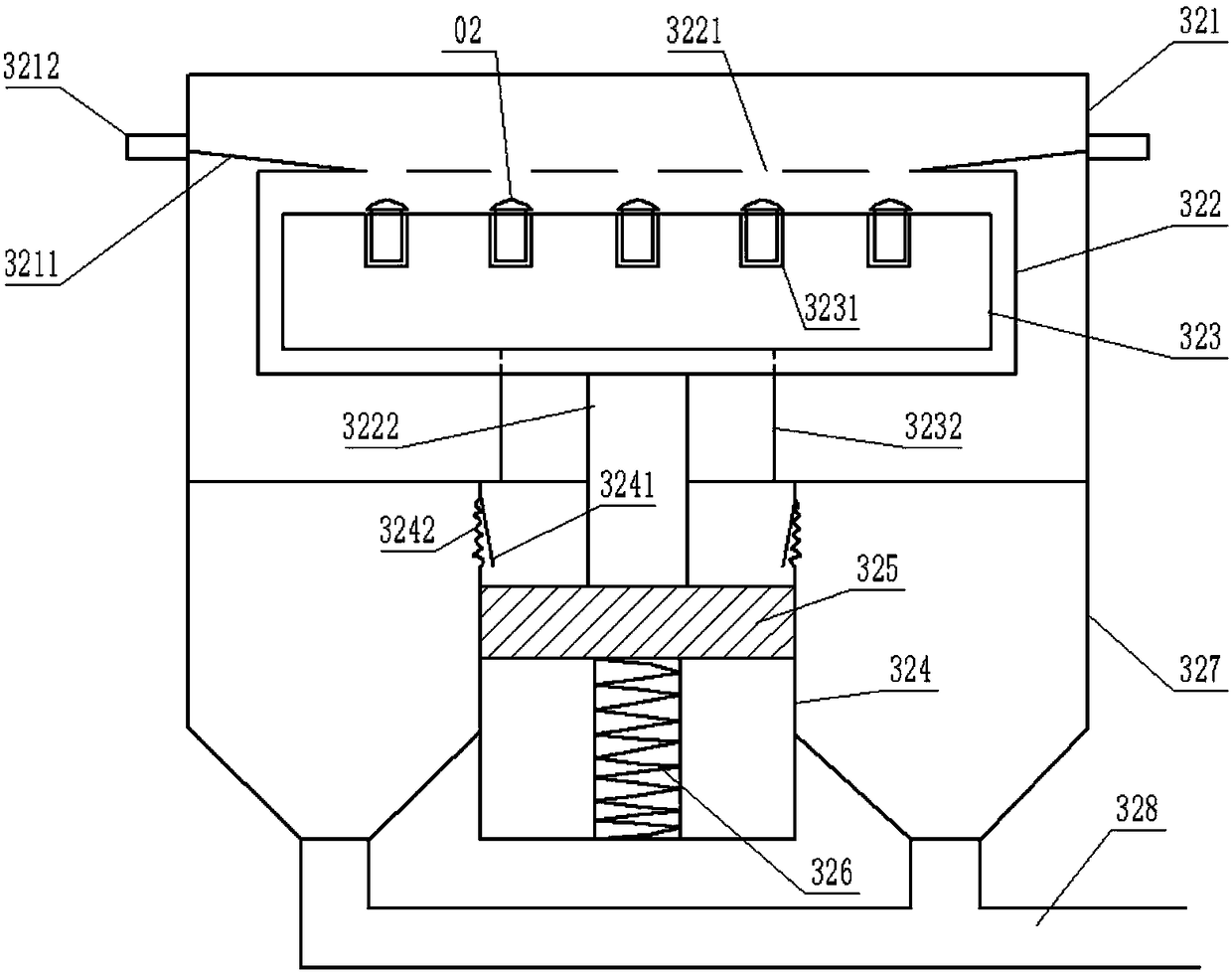

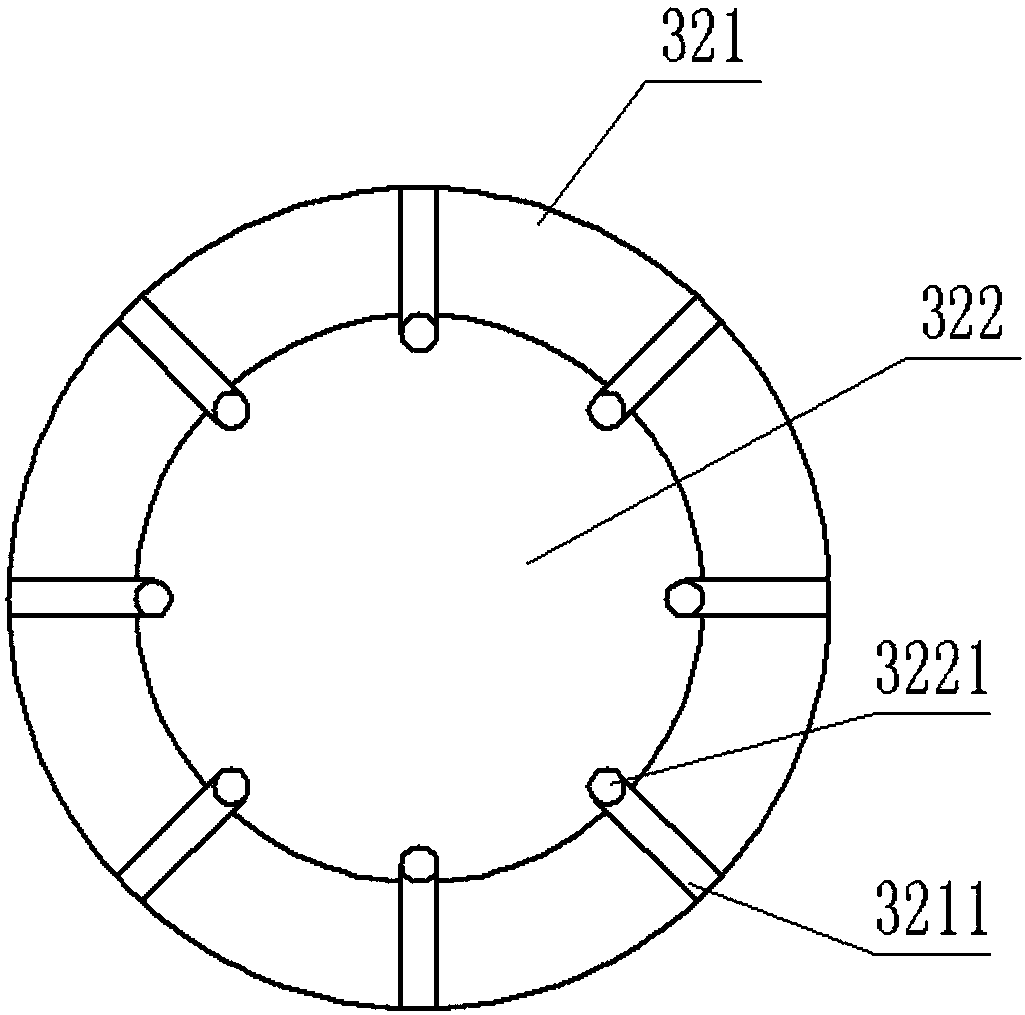

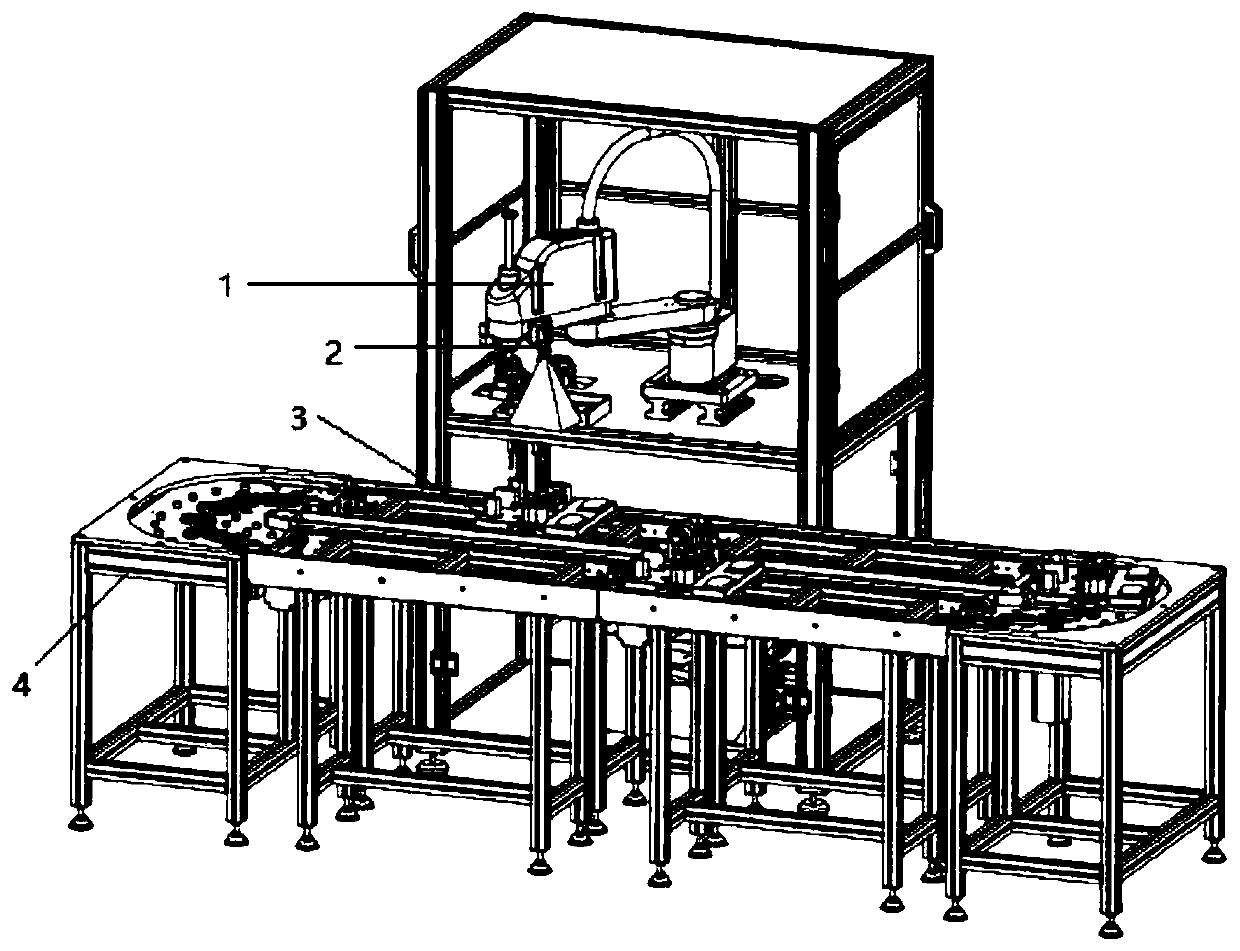

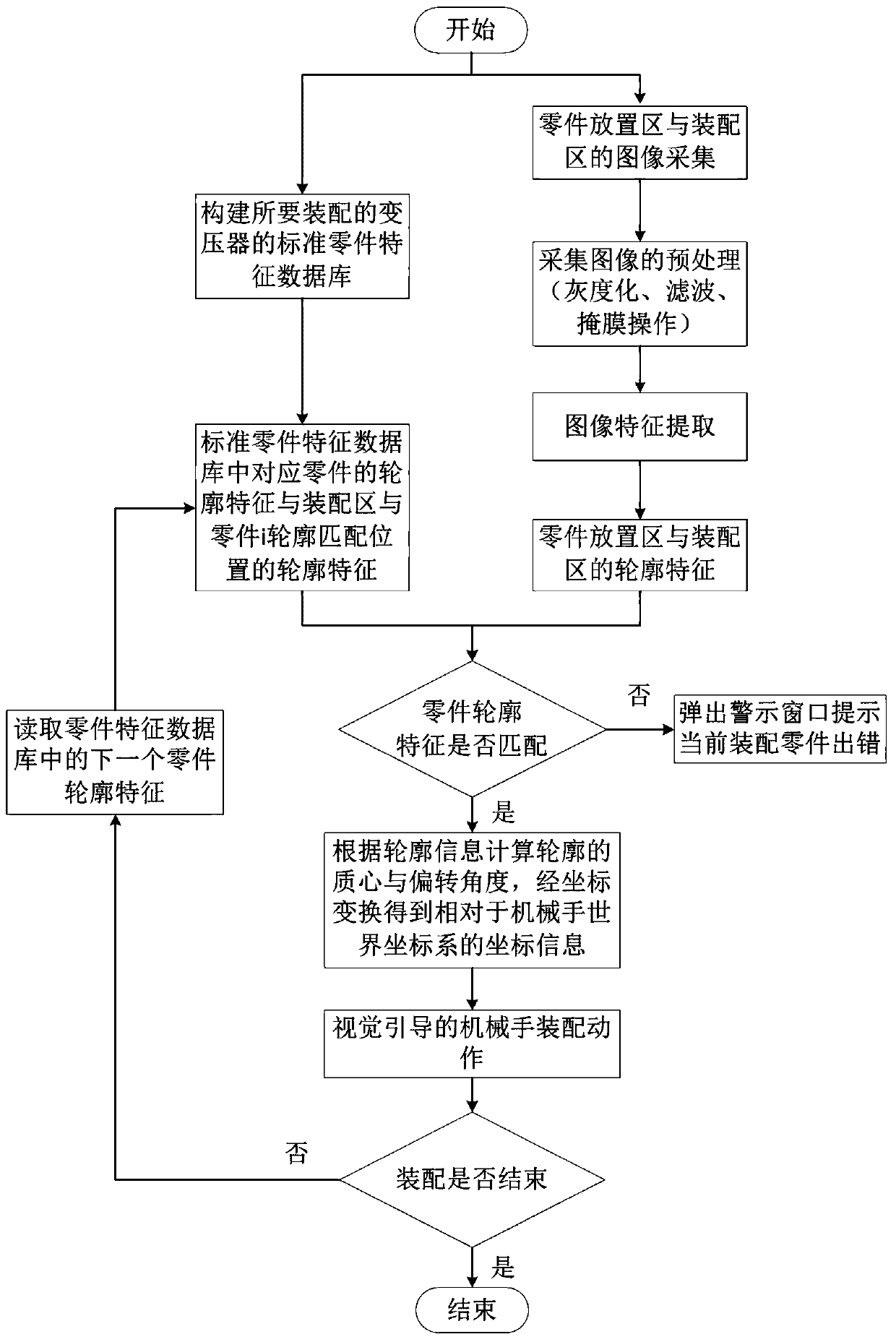

Automatic transformer assembly method based on machine vision

ActiveCN109926817ARealize fully automatic assemblyAvoid misuseProgramme-controlled manipulatorAssembly machinesFeature extractionMachine vision

The invention provides an automatic transformer assembly method based on machine vision. The method comprises the steps of a standard part feature database of a to-be-assembled transformer is established; images of a part placement area and an assembly area are collected; image features are extracted; parts are matched; a manipulator assembly path is acquired; and assembling is conducted. A camerais adopted for replacing human eyes for measuring the assembly position, the assembly precision of products is improved, meanwhile, the labor consumption is reduced, the assembly method is stable inoperation, the production efficiency and the production automation level are greatly improved, and the method is suitable for the large-batch transformer production assembly process.

Owner:NANJING UNIV OF SCI & TECH

O-shaped ring assembling equipment

The invention discloses O-shaped ring assembling equipment. By means of a button feeding module, buttons on trays in a button tray containing area are placed in various product positioning carriers on the surface of a rotary disc to be positioned one by one, and the buttons rotate along with the rotary disc; by means of an O-shaped ring mylar positioning device, after O-shaped ring mylars are fixed and positioned, an O-shaped ring picking and assembling mechanism takes the O-shaped rings one by one and rotate and assemble the O-shaped rings into annular inner grooves in the button circumferential outer side at the assigned positions; finished products are subjected to main viewing and overlooking detection through a horizontal detection mechanism and a vertical detection mechanism; meanwhile, an empty tray conveying mechanism conveys empty trays to an empty tray positioning mechanism to be positioned, a controller controls a discharging module to take products detected to be qualified from positioning in the product positioning carriers and place the products detected to be qualified into the empty trays on the empty tray positioning mechanism; and disqualified products are placed in a waste product recycling box, and the trays which are fully loaded with the products finally are conveyed out through a finished product conveying mechanism. According to the O-shaped ring assembling equipment, full-automatic assembling on the O-shaped rings on the buttons is achieved, the production efficiency is high, the yield is high, and the production cost is low.

Owner:JIANGSU JUSTECH PRECISION IND CO LTD

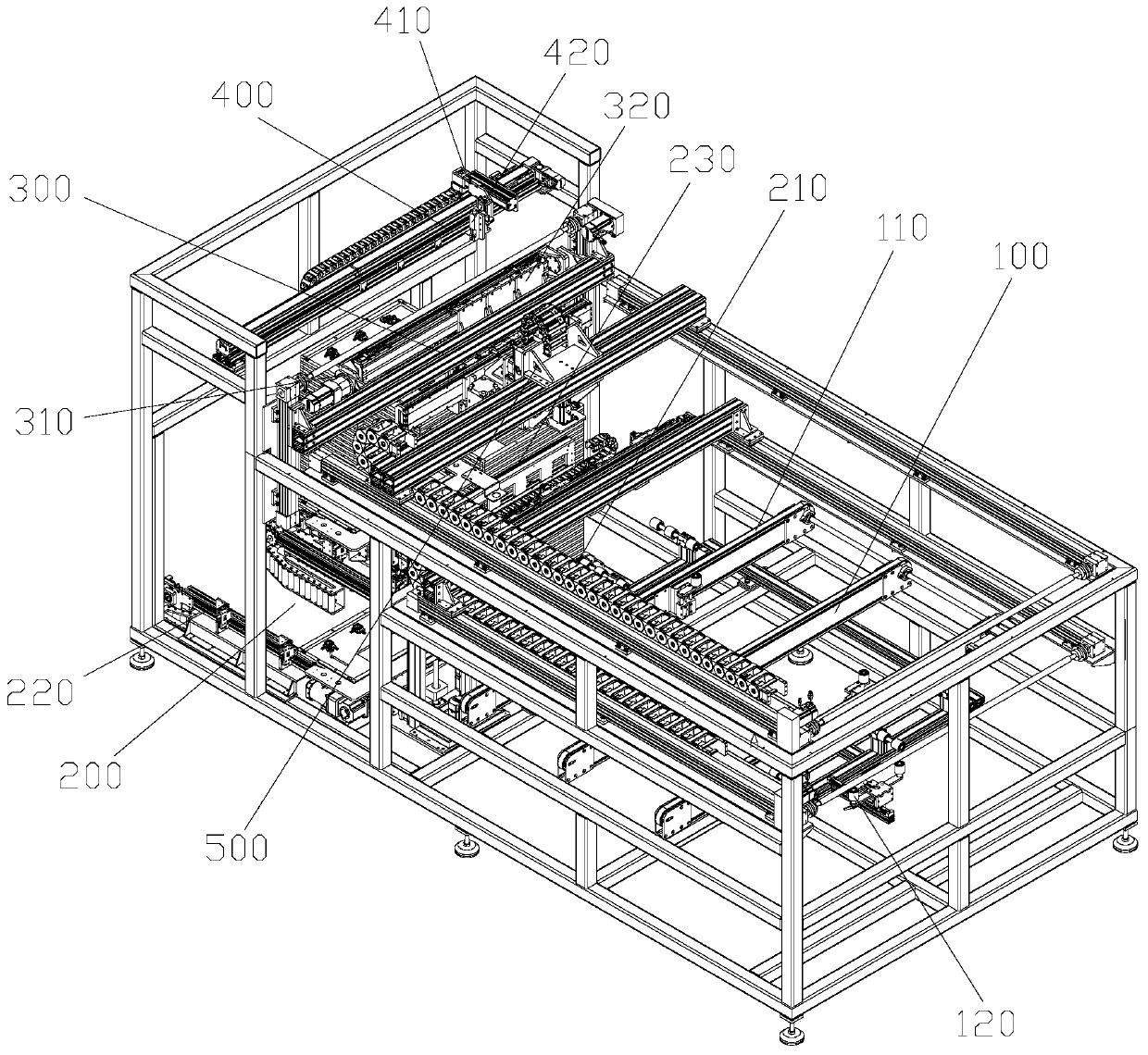

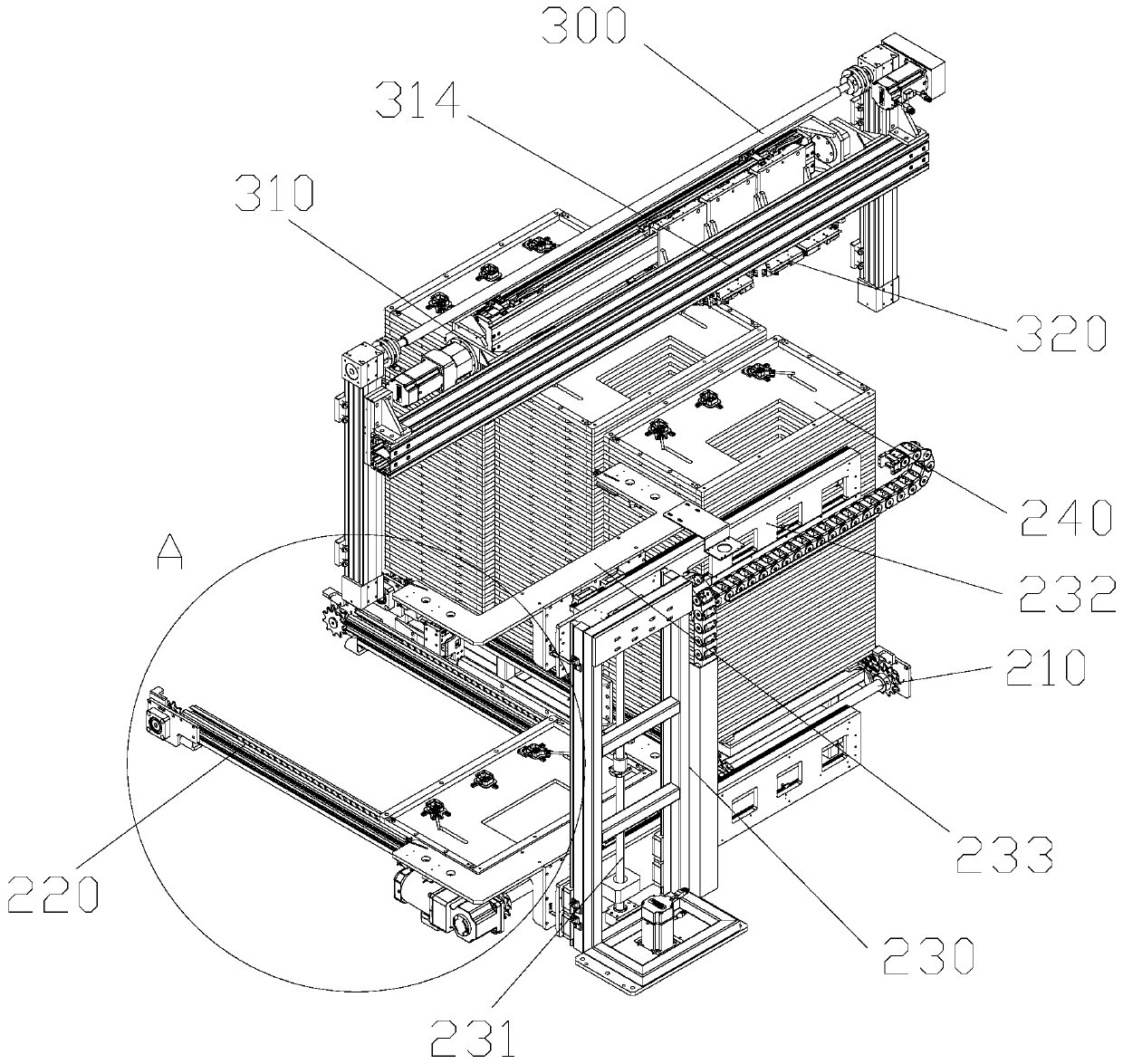

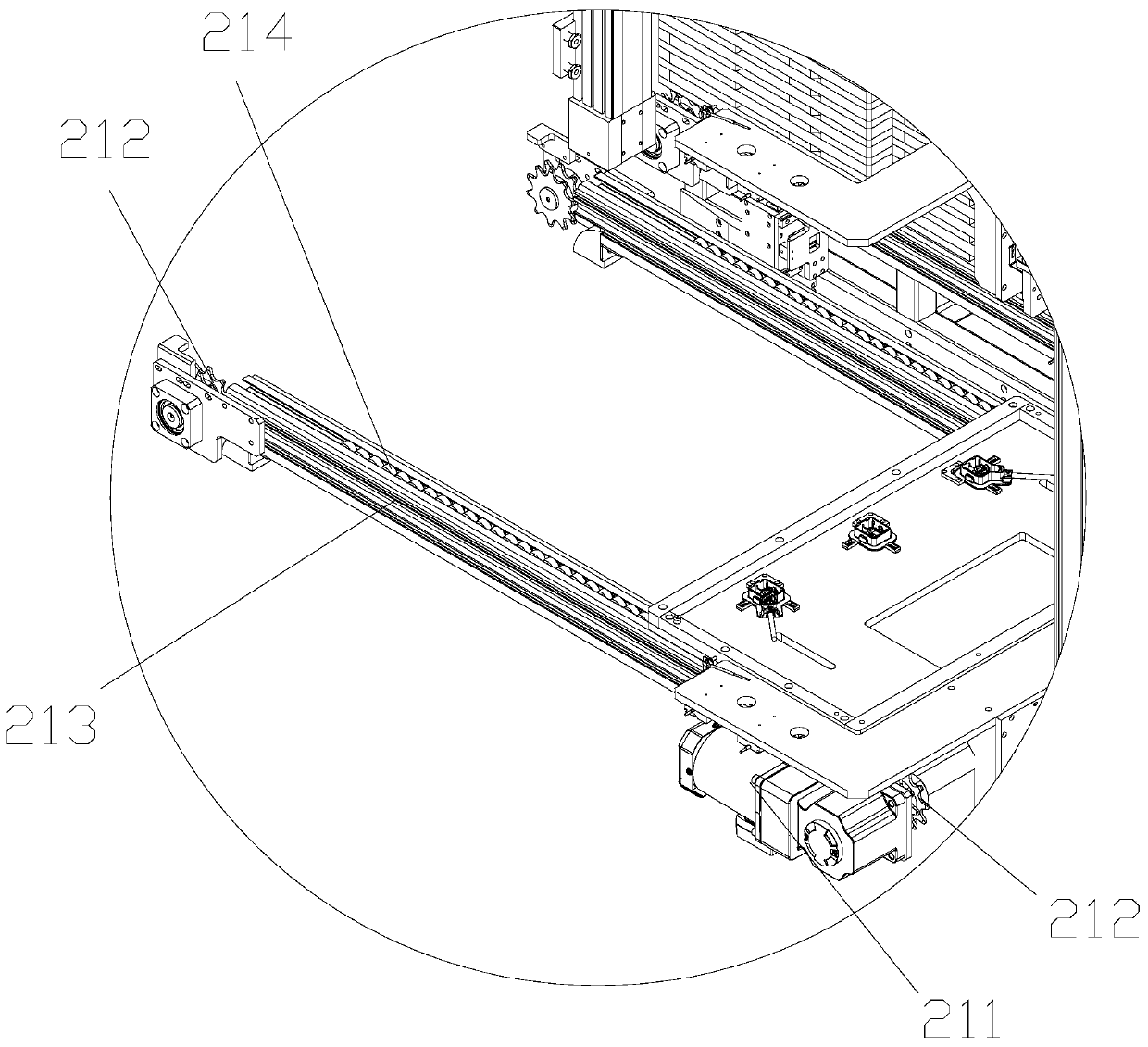

Shaping and assembling equipment of junction boxes

PendingCN111299075ARealize fully automatic assemblyReduce labor costsLiquid surface applicatorsMaterial gluingEngineering physicsMaterials science

The invention relates to the technical field of automation equipment, and discloses shaping and assembling equipment of junction boxes. The equipment comprises a conveying portion, a feeding portion,a switching portion, a dispensing portion and an assembling portion. The conveying portion conveys photovoltaic modules to the positions of the to-be-mounted junction boxes, the feeding portion continuously conveys the to-be-mounted junction boxes, the switching portion picks up the junction boxes and cooperates with the feeding portion, the dispensing portion and the assembling portion, the junction boxes are transferred, the assembling portion picks up the junction boxes conveyed by the switching portion and carries out shaping and detecting on pins on the photovoltaic modules, it is guaranteed that the pins can penetrate through the junction boxes, and then the junction boxes are pressed on the photovoltaic modules. Full-automatic assembly of the junction boxes is achieved, manpower issaved, and the working efficiency is greatly improved.

Owner:SUZHOU HORDA NEW ENERGY EQUIP

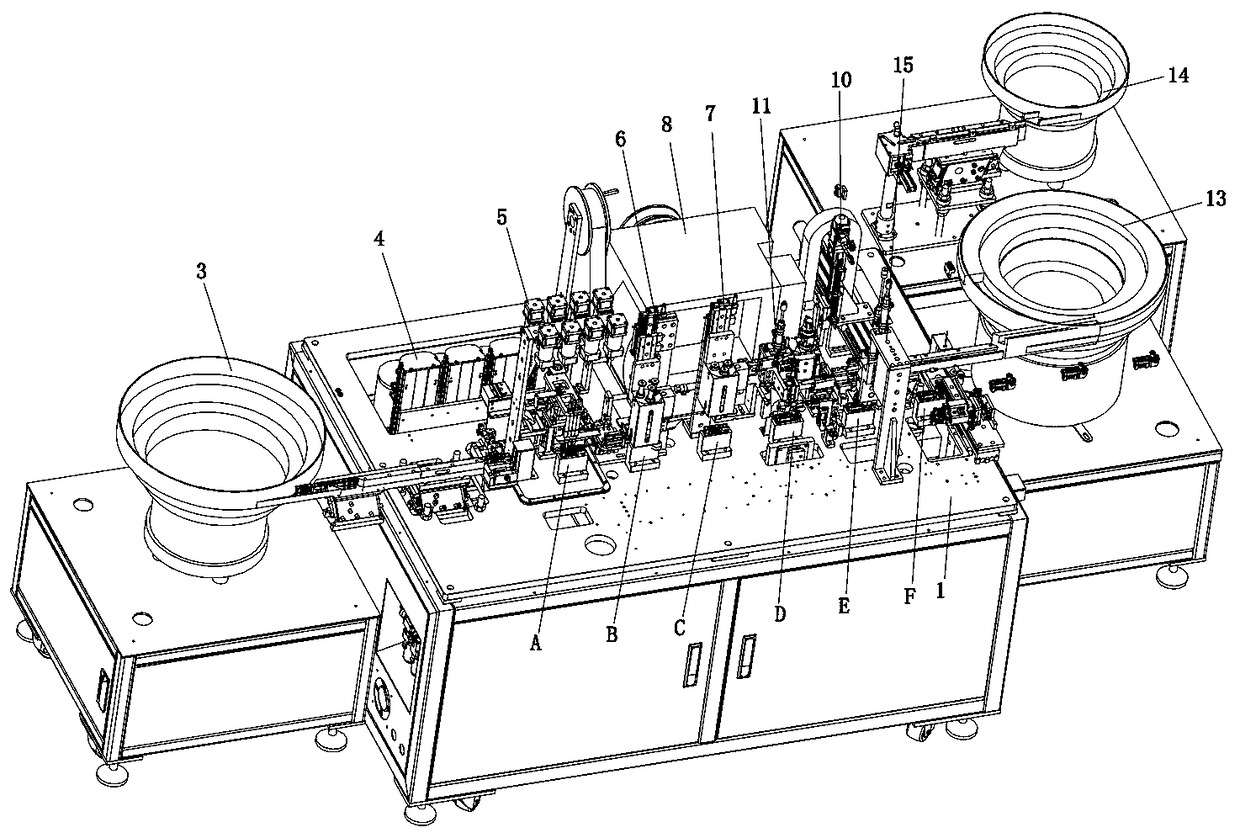

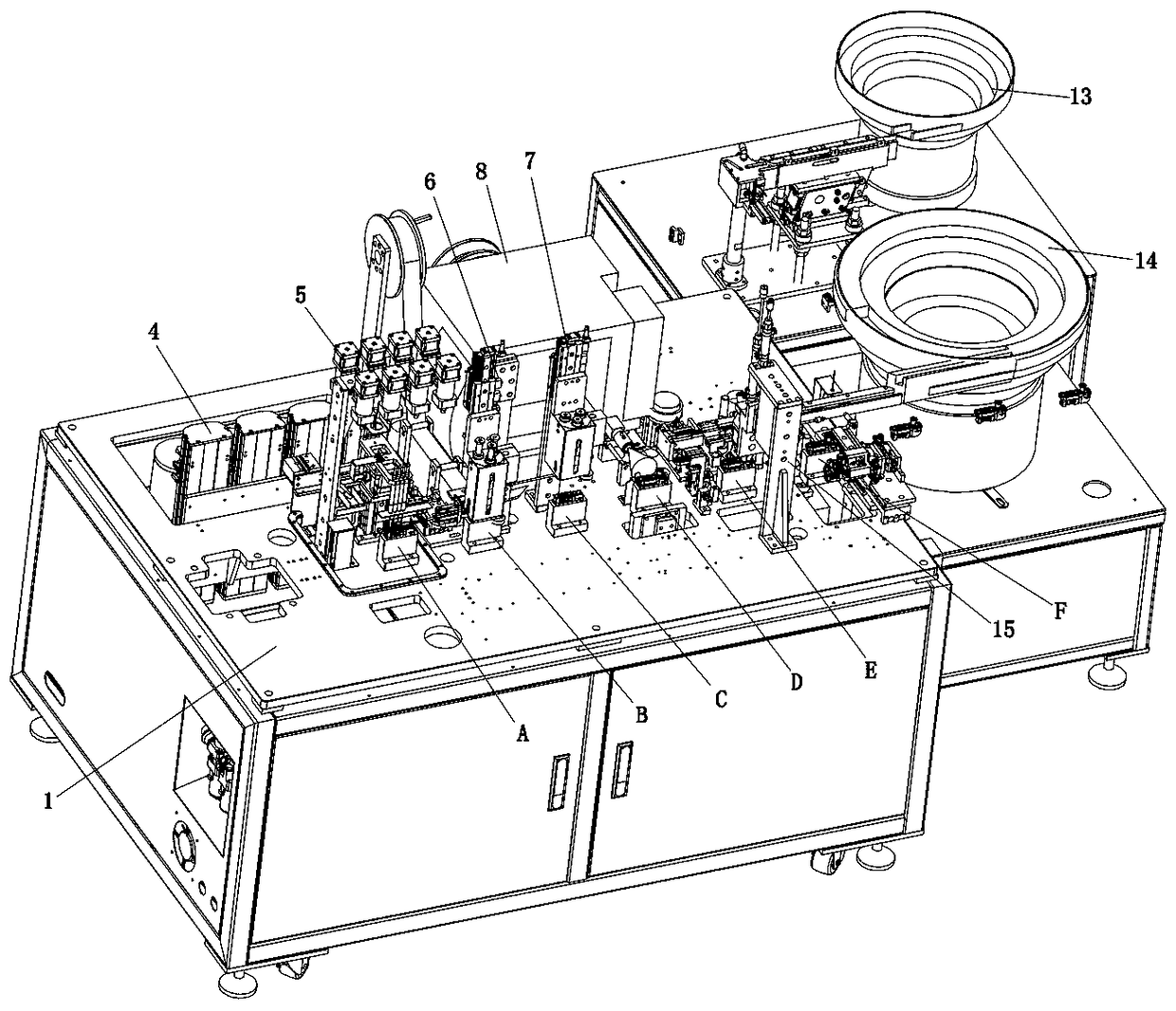

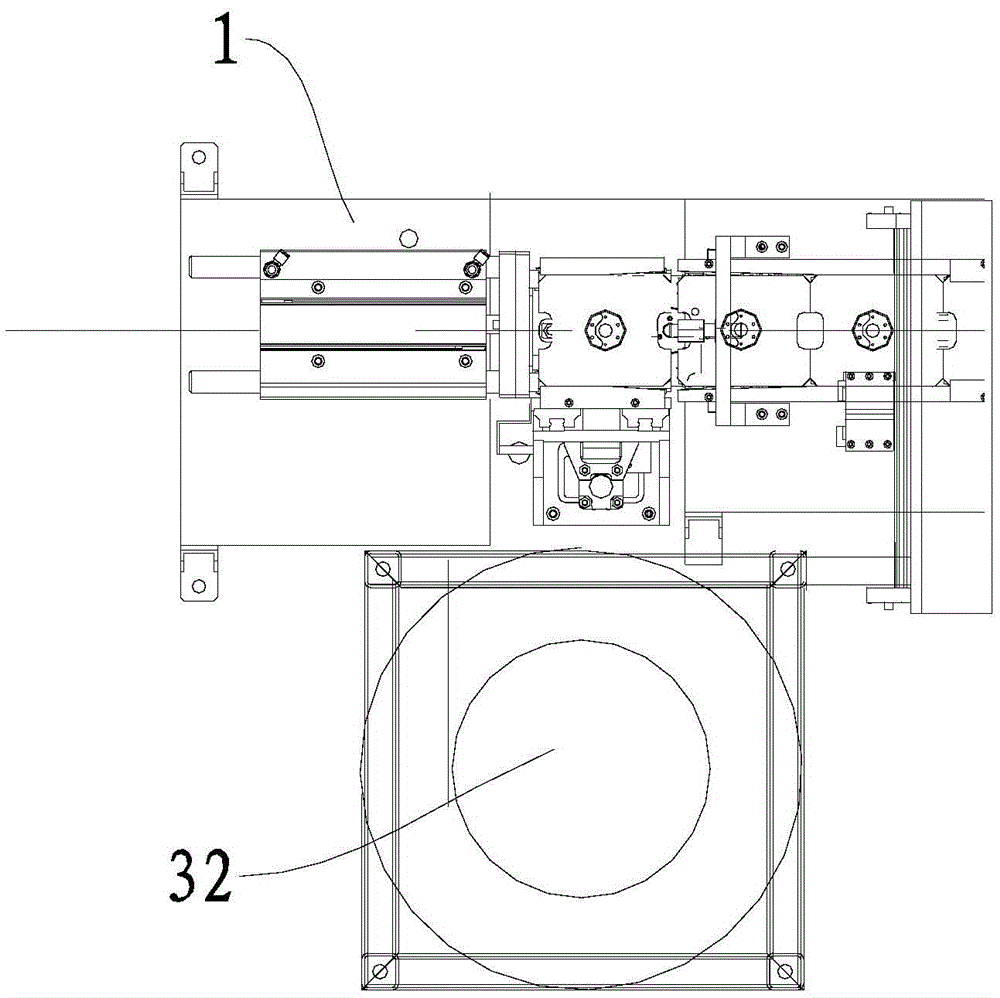

Full-automatic plummer block housing insert bearing oil nozzle assembly machine

ActiveCN111590307ARealize fully automatic assemblyImprove work efficiencyMetal working apparatusProcess engineeringTransfer mechanism

The invention provides a full-automatic plummer block housing insert bearing oil nozzle assembly machine. A feeding conveying belt drives a plummer block to move towards the direction of a feed clamping and transferring mechanism, the feed clamping and transferring mechanism clamps and places the plummer block into a seat body locating mechanism to achieve locating, a rotating disc assembly drivesthe plummer block to sequentially pass through an oil nozzle locating mechanism, an oil nozzle vibration feeding and spinning mechanism and an oil nozzle detection mechanism to be treated, and a discharge clamping and transferring mechanism clamps the treated plummer block to a discharge conveying belt. In the whole process, an oil nozzle can be assembled in an oil nozzle hole fully automatically, compared with manual machining in the traditional technology, the work efficiency can be greatly improved, and compared with the traditional technology, the work precision of the full-automatic assembly manner can also be greatly improved.

Owner:广州顺大智能装备有限公司

Automatic separation equipment used for engine piston combined type oil ring bushing rings

ActiveCN108058006ARealize automatic separationRealize fully automatic assemblyMetal working apparatusAutomatic test equipmentPiston ring

The invention belongs to the technical field of gasoline engines and particularly relates to automatic separation equipment used for engine piston combined type oil ring bushing rings. The automatic separation equipment used for engine piston combined type oil ring bushing rings comprises a bushing ring stock bin and air cylinder propelling mechanisms. The lower end of the bushing ring stock bin is connected with the air cylinder propelling mechanisms. Each air cylinder propelling mechanism comprises an air cylinder, a shifting block, an upper sliding plate, a lower sliding plate and a support, wherein the shifting block is installed on the support through a rotating pin in a swing mode, the upper sliding plate and the lower sliding plate are placed in a support sliding rail, the lower sliding plate is connected with the displacement end of the air cylinder, the lower sliding plate reciprocates under the action of the air cylinder so as to touch the lower movable end point of the shifting block, the upper movable end point of the shifting block moves to touch the upper sliding plate in a swing mode, and a return spring connected to the support is installed on the upper sliding plate. The automatic separation equipment used for engine piston combined type oil ring bushing rings has the beneficial effects that one-by-one separation of combined oil ring bushing rings can be guaranteed, one bushing ring is separated and fed at each time, and thus full-automatic assembling of piston rings is realized, assembling efficiency is improved, and the labor intensity of workers is relieved.

Owner:BINZHOU BOHAI PRECISION MACHINERY +1

Device and method for assembling clamp spring for shaft

PendingCN110394632ARealize fully automatic assemblyEasy to replaceMetal working apparatusEngineeringManipulator

The invention belongs to the technical field of intelligent assembly, and particularly relates to a device and a method for assembling a clamp spring for a shaft. The device comprises a clamp spring feeding vibration plate, a clamp spring distributing mechanism, a clamp spring grabbing mechanical arm, an XY plane servo moving platform and a clamp spring press-fitting mechanism; the clamp spring press-fitting mechanism comprises a press-fitting air cylinder, a clamp spring press head, a press-fitting guide rail, an expansion head installation base, a clamp spring expansion head and a reset spring, the expansion head installation base is in sliding connection with the press-fitting guide rail through the second slide block; the clamp spring press head is slidably connected with the press-fitting guide rail through the first slide block; one end of the reset spring is connected to the XY plane servo movable platform, and the other end of the reset spring is connected with the expansion head installation base; the clamp spring grabbing mechanical arm is used for taking down the clamp spring from the clamp spring distribution mechanism and then placing the clamp spring on the clamp spring expansion head. According to the device and the method, the automatic assembling of the clamp springs can be realized, the assembling of the clamp springs of various specifications can be met, andthe equipment universality is high.

Owner:宁波易拓智谱机器人有限公司

Automatic press-in device for connecting rod copper sleeve

PendingCN111805205ARealize fully automatic assemblyIncrease productivityMetal working apparatusStructural engineeringMachine

The invention relates to an automatic press-in device for a connecting rod copper sleeve. The automatic press-in device comprises a machine table, a rotary disc transportation mechanism, a first loading mechanism, a press-in mechanism, an unloading mechanism and a second loading mechanism, wherein the rotary disc transportation mechanism is arranged on the machine table; the first loading mechanism, the press-in mechanism and the unloading mechanism are sequentially wound on the rotary disc transportation mechanism; and the second loading mechanism is arranged at one side of the press-in mechanism. The first loading mechanism and the second loading mechanism separately realize automatic loading for a connecting rod and a copper sleeve, automatically presses the copper sleeve into a small end hole of the connecting rod through the rotary disc transportation mechanism and the press-in mechanism, realizes fully-automatic assembly between the copper sleeve and the connecting rod, is high in production efficiency, is good in assembly effect, and improves product integral quality.

Owner:东风本田汽车零部件有限公司

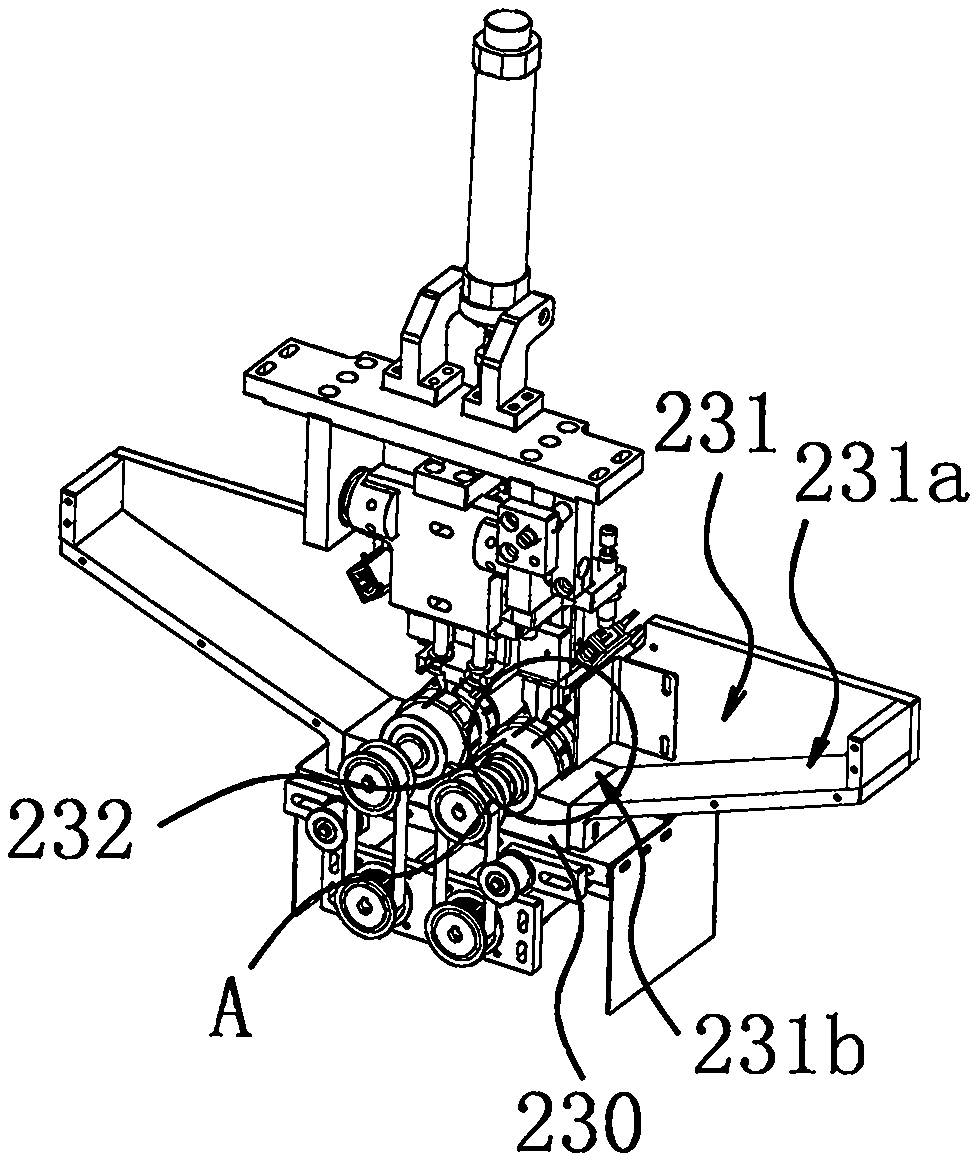

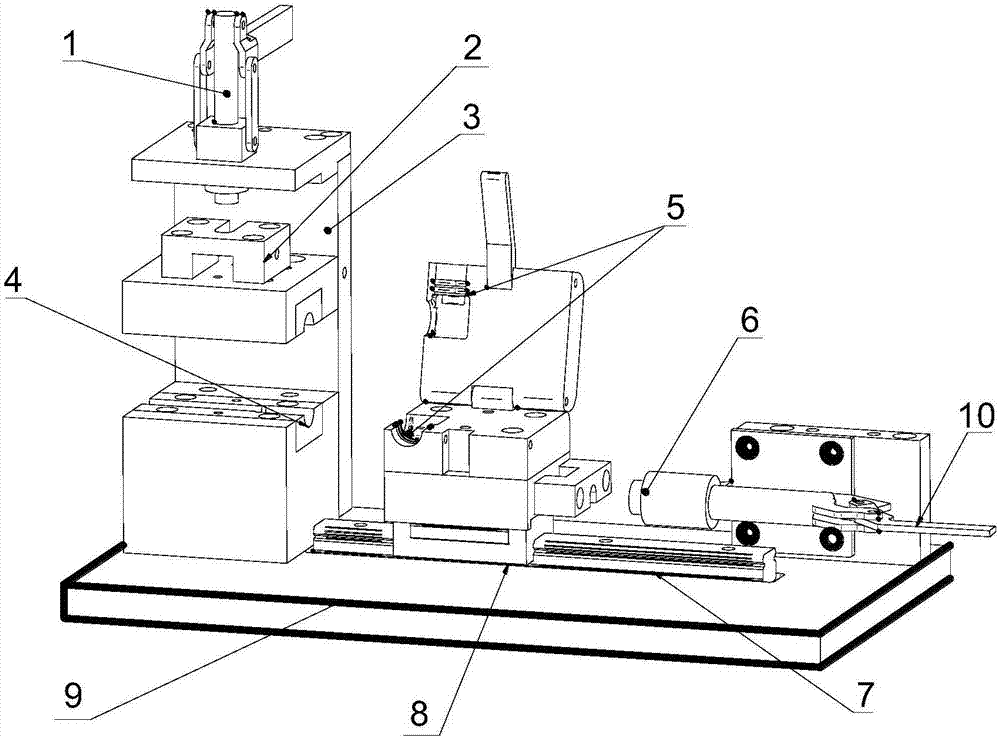

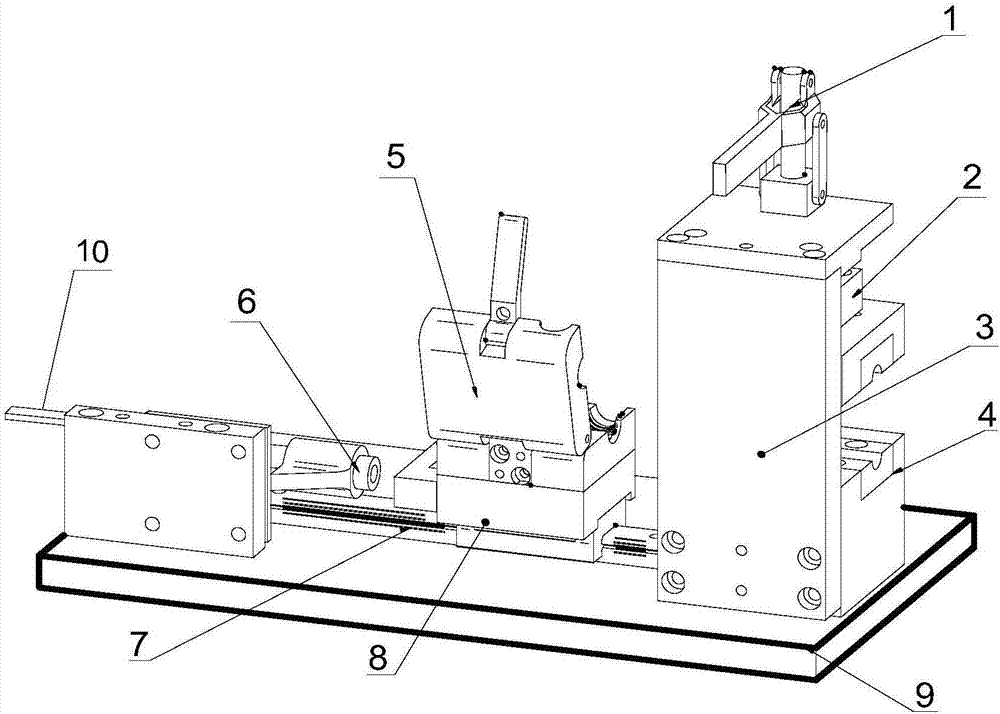

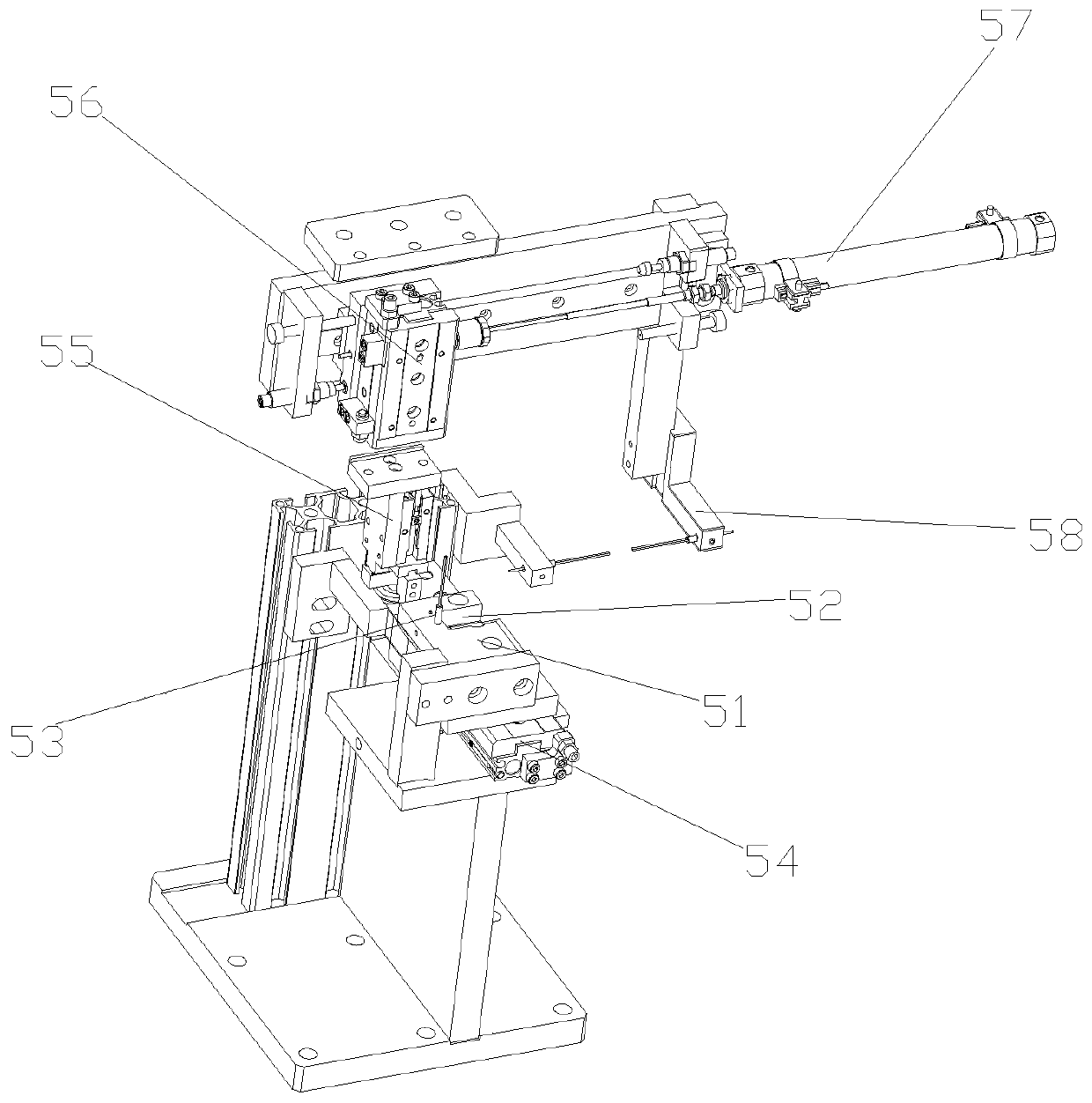

Nylon pipe joint assembly mechanism

PendingCN107160149AImprove assembly qualityImprove efficiencyMetal working apparatusButt jointMaterials science

The invention discloses a nylon pipe joint assembly mechanism. The nylon pipe joint assembly mechanism comprises a guide rail base, and a pipe clamping mold and a joint clamping mold mounted on the guide rail base; the pipe clamping mold is fixed at the most right end of the guide rail base without moving; a slide guide rail is arranged on the upper end surface of the guide rail base from middle to left end; the joint clamping mold is transitionally joined on the slide guide rail through a slide block for moving; the joint clamping mold is positioned in middle of the guide rail base; and a limiting rod is arranged at the left end of the joint clamping mold. The limiting rod and the slide rail are matched through the pipe clamping mold and the joint clamping mold; the slide block and the joint clamping mold move in the slide guide rail; and a joint of the joint clamping mold is pressed into a nylon pipe to finish butt joint of the nylon pipe and the joint. The nylon pipe joint assembly mechanism solves the problems of low speed and low efficiency in manual assembly of joint clamping rings, has the advantages of good assembly quality and high efficiency, saves the cost, realizes full-automatic assembly, greatly saves the space, and improves the efficiency.

Owner:HEFEI JIANGHUAI AUTOMOBILE PIPE

Microwave annular device assembly equipment

ActiveCN111644830ARealize fully automatic assemblyImprove assembly efficiencyMetal working apparatusMagnetEngineering

The invention discloses microwave annular device assembly equipment, and relates to the technical field of annular device production equipment. The microwave annular device assembly equipment comprises a working platform, a jig assembly line arranged on the working platform, a cavity body feeding mechanism, an insulating ring assembly mechanism, an inner conductor assembly mechanism, a grounding sheet and permanent magnet assembly mechanism, a grounding sheet and microwave substrate assembly mechanism, a central conductor assembly mechanism, a permanent magnet and anti-rotation sheet assemblymechanism and a temperature compensation sheet and rotary cover assembly mechanism, and the cavity body feeding mechanism, the insulating ring assembly mechanism, the inner conductor assembly mechanism, the grounding sheet and permanent magnet assembly mechanism, the grounding sheet and microwave substrate assembly mechanism, the central conductor assembly mechanism, the permanent magnet and anti-rotation sheet assembly mechanism and the temperature compensation sheet and rotary cover assembly mechanism are arranged sequentially on the working platform and located on one side of the jig assembly line. The microwave annular device assembly equipment has the beneficial effects that the automatic assembly of a microwave annular device can be realized, the assembly efficiency and the rate of good products are improved, and the labor intensity is reduced.

Owner:深圳市罗博威视科技有限公司

Automatic assembly detection machine for yarn tensioning wheel

PendingCN110977457ARealize fully automatic assemblySave human effortMeasurement devicesAssembly machinesYarnStructural engineering

The invention discloses an automatic assembly detection machine for a yarn tensioning wheel. The automatic assembly detection machine comprises a rack. The rack is provided with a rotation disc and arotation driving mechanism driving the rotation disc to rotate. The rotation disc is provided with multiple carriers in the circumference direction, and the outer side of the rotation disc is providedwith a plastic ring vibration disc feeding mechanism, a magnet clip feeding mechanism, a stainless steel ring vibration disc feeding mechanism, a stainless steel ring pressure maintaining assembly mechanism, a stainless steel ring planeness detection mechanism, a defective product collection mechanism and a good product collection rotation disc in sequence in the circumference direction. The automatic assembly detection machine further comprises a plastic ring carrying feeding mechanism arranged between the rotation disc and the plastic ring vibration disc feeding mechanism and used for carrying plastic rings to the carriers, a stainless ring carrying feeding mechanism arranged between the rotation disc and the stainless steel ring vibration disc feeding mechanism and used for stainless steel rings to the carriers, and a product carrying mechanism for carrying good products or defective products to the defective product collection mechanism and the good product collection rotation disc respectively. The automatic assembly detection machine can fully automatically assemble the plastic rings, magnets and stainless steel rings. The labor is saved, and the production capacity is improved.

Owner:KUNSHAN HUAYU AUTOMATION TECH

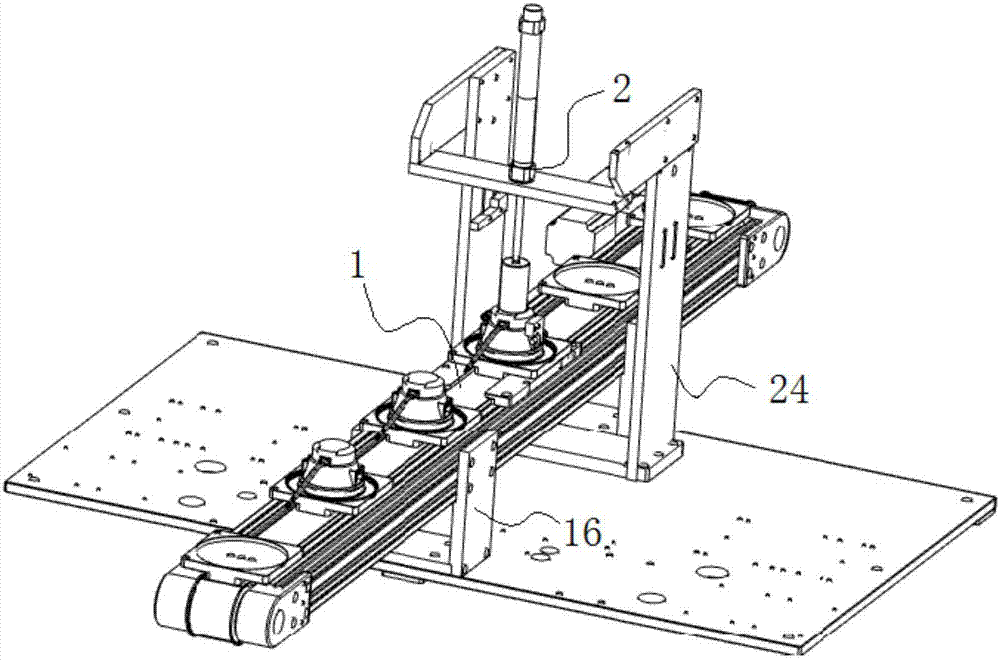

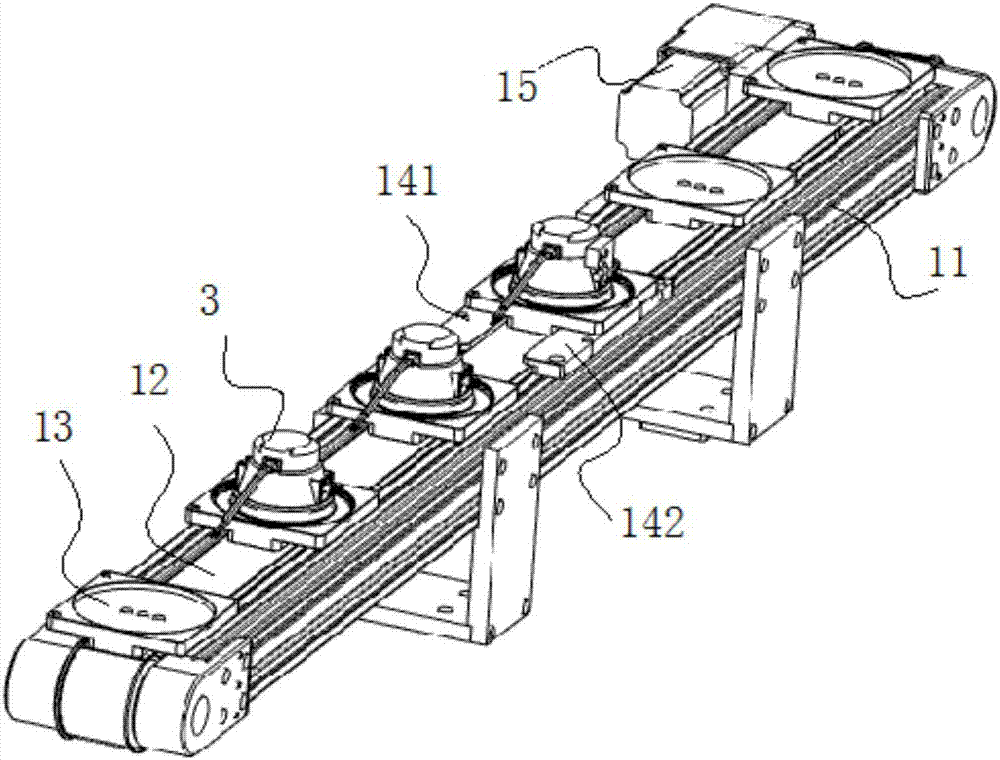

Automatic down lamp conveying, locating and clamping device

PendingCN107310900ALabor savingLow costConveyorsControl devices for conveyorsElectrical and Electronics engineeringMechanical engineering

The invention discloses an automatic down lamp conveying, locating and clamping device. The automatic down lamp conveying, locating and clamping device comprises an automatic down lamp conveying mechanism and an automatic down lamp locating and clamping mechanism, wherein the automatic down lamp locating and clamping mechanism is located above the automatic down lamp conveying mechanism; the automatic down lamp conveying mechanism comprises driving wheels, a support frame, a driving belt, a plurality of carriers and a group of locating and clamping plates, the carriers are all connected to the surface of the driving belt and move along with the driving belt; the locating and clamping plates are fixed on the support frame and located under the automatic down lamp locating and clamping mechanism; a cylinder of the automatic down lamp locating and clamping mechanism drives a pushing rod to press one down lamp and clamp a groove of the corresponding carrier with the locating and clamping plates, and location fixing of the down lamp is realized; the automatic down lamp conveying mechanism further comprises a down lamp in-place sensor. With adoption of an automatic operation mode, down lamps are conveyed to preset mounting locations and fixed in an automatic conveying, locating and clamping manner, connection with an upstream spring feeding device and the like is facilitated, next automatic assembly operation is also facilitated, all that is needed is to place the down lamps on the carriers manually, and labor is saved.

Owner:KUNSHAN TUOYU AUTOMATION TECH CO LTD

Full-automatic kit assembler

ActiveCN106891573ARealize fully automatic assemblyIncrease productivityEnvelopes/bags making machineryPaper-makingAgricultural engineering

The invention discloses a full-automatic kit assembler. The full-automatic kit assembler comprises a frame, a film plate cutting mechanism, a film bar taking mechanism, a lower shell vibration disc, an upper shell vibration disc, a film bar tailoring mechanism, a film block feeding mechanism, a lower shell turntable, an upper shell turntable and a pressing shell mechanism; the frame is fixedly provided with the film plate cutting mechanism; the film bar taking mechanism is mounted in a port of the film plate cutting mechanism; the film bar tailoring mechanism is arranged on one side of the film bar taking mechanism; one side of the film bar tailoring mechanism is connected with a film block feeding mechanism; the lower shell turntable is mounted on one side of the film block feeding mechanism; the upper shell turntable is mounted on one side of the lower shell turntable; the pressing shell mechanism is arranged in the overlapped place of the upper shell turntable and the lower shell turntable; the lower shell turntable is connected with the lower shell vibration disc; the upper shell turntable is connected with the upper shell vibration disc; and multiple through grooves are uniformly distributed in the edges of the lower shell turntable and the upper shell turntable. The full-automatic kit assembler is compact in structure and convenient to use, and can quickly and effectively realize full-automatic kit assembly.

Owner:DONGGUAN RONGAN ELECTROMECHANICAL EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com