Automatic shower nozzle assembly machine

A technology for assembly machines and assembly mechanisms, applied in assembly machines, metal processing equipment, manufacturing tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

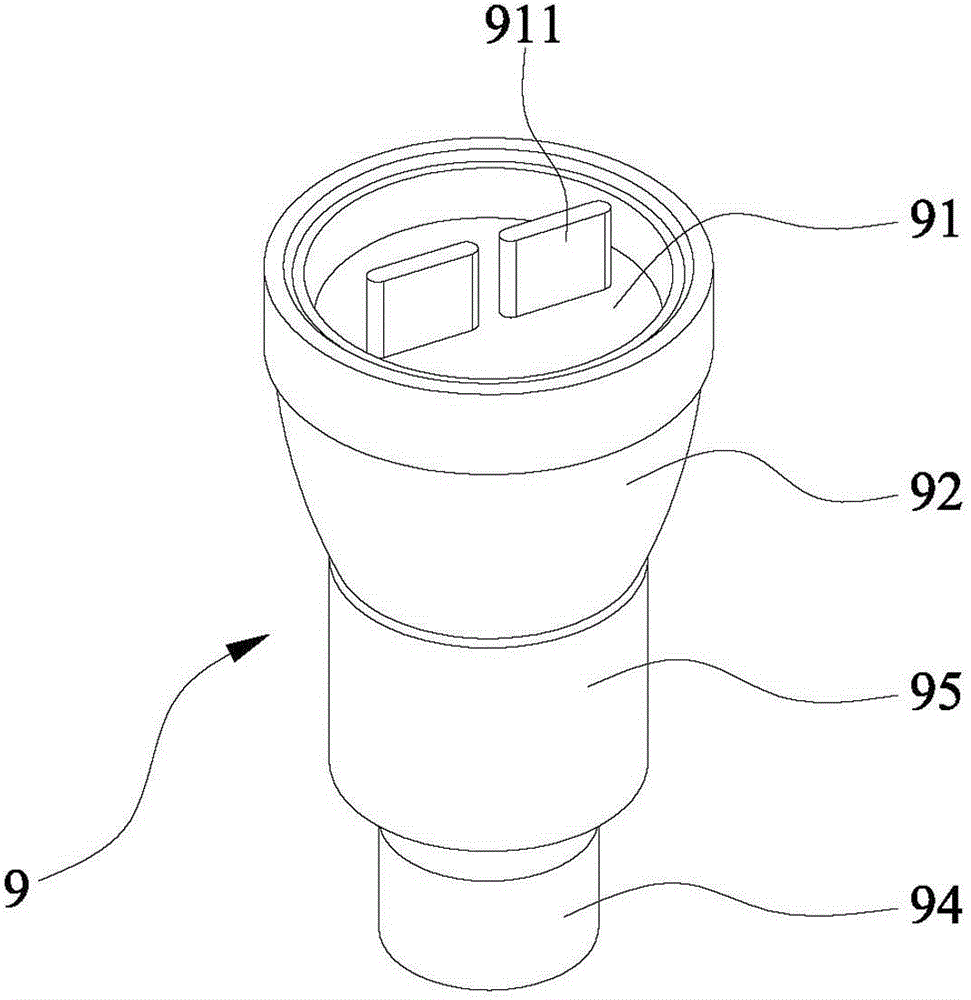

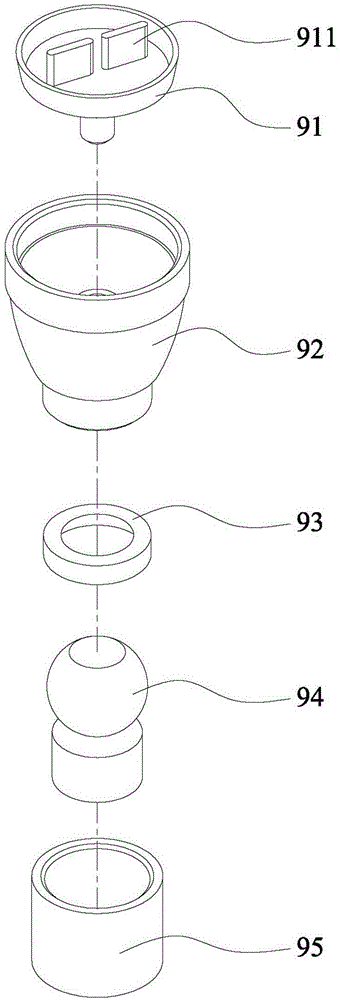

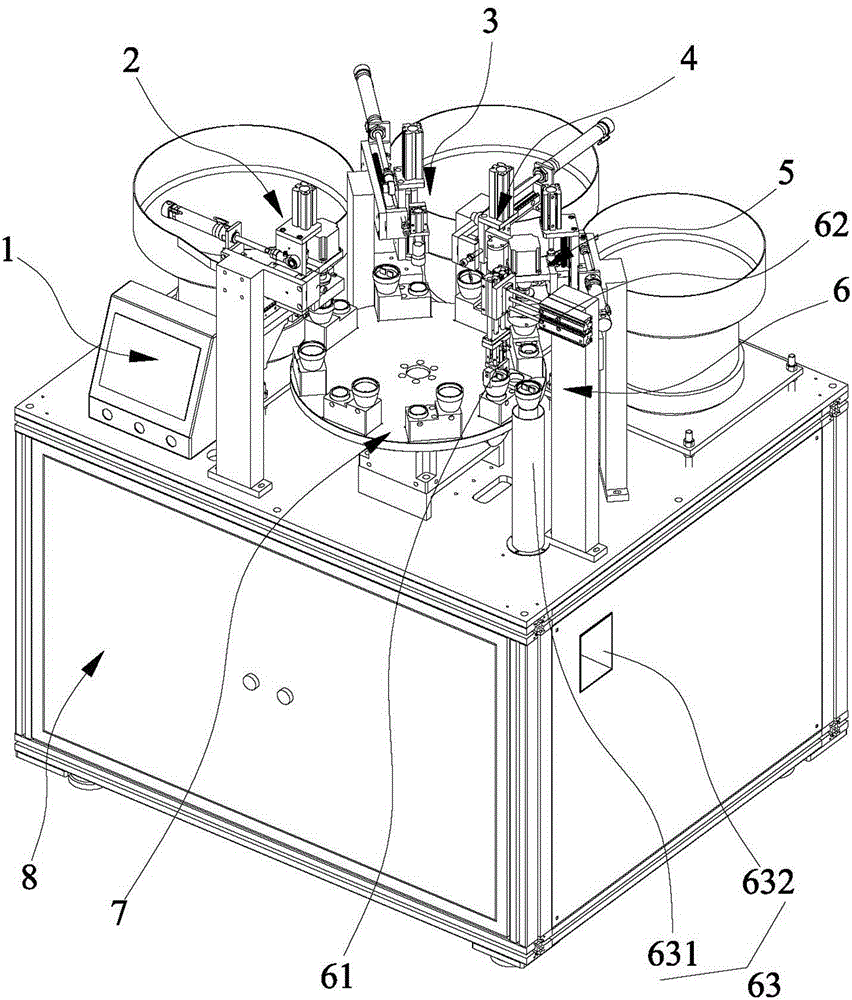

[0033] What the present invention discloses is a kind of nozzle automatic assembly machine, such as Figure 3 to Figure 7 Shown is a preferred embodiment of the present invention. The nozzle automatic assembly machine is specially designed for figure 1 and figure 2 Shown is the assembly machine of the shower head. The automatic assembly machine of the shower head includes a control mechanism 1, a cover and body assembly mechanism 2, a universal head assembly mechanism 3, a rubber pad assembly mechanism 4, a body and nut assembly mechanism 5, and a multi-station The dividing mechanism 7 and the frame 8 may further include a finished product unloading mechanism 6 . in:

[0034] The control mechanism 1 is used for the unified control of subsequent mechanisms, which can be controlled by PLC and can be configured with a touch screen. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com