Automatic down lamp conveying, locating and clamping device

A positioning clamping and automatic positioning technology, which is applied in the direction of conveyor control devices, conveyors, conveyor objects, etc., can solve the problems that cannot meet the development trend of high efficiency, high quality and low cost, difficult choice between processing output and processing cost, and no operation Model automation equipment and other issues to achieve the effect of streamlined structure, labor saving, and high speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

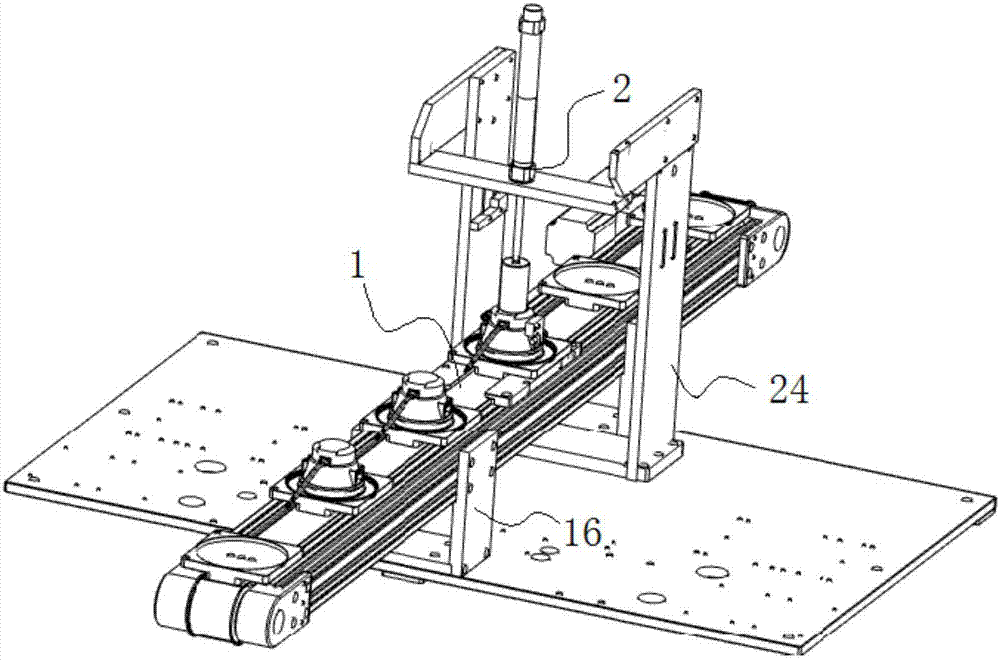

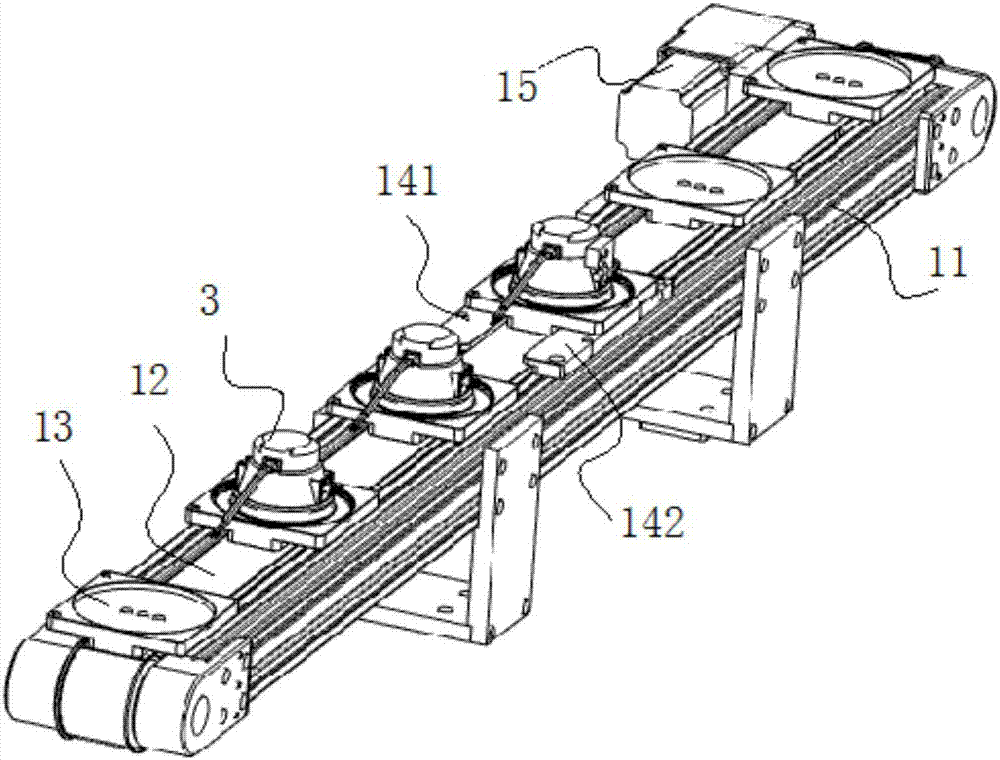

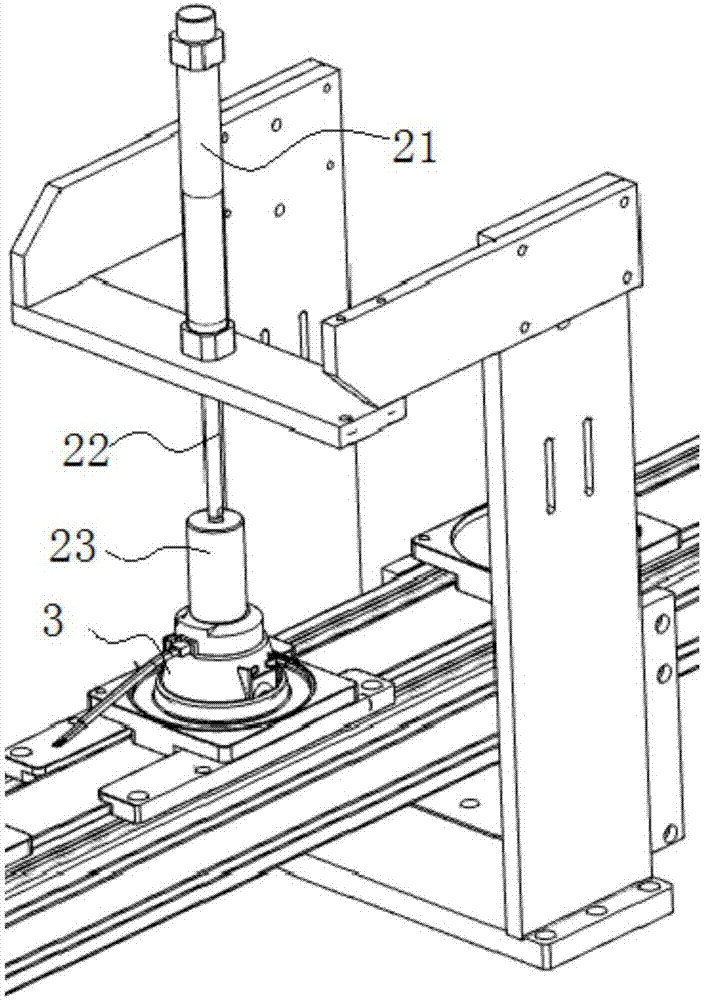

[0035] Embodiment: a downlight automatic transmission and positioning clamping device, such as Figure 1 to Figure 5 As shown, taking the automatic transmission direction of the downlight as the front, it includes the automatic transmission mechanism 1 for the downlight and the automatic positioning and clamping mechanism 2 for the downlight, and the automatic positioning and clamping mechanism for the downlight is located above the automatic transmission mechanism for the downlight;

[0036] The downlight automatic transmission mechanism 1 includes a transmission wheel (not shown in the figure), a supporting frame 11, a transmission belt 12, a plurality of carriers 13 and a set of positioning splints. Circular movement, all the carriers are connected to the surface of the transmission belt and move with the transmission belt, the downlight 3 is placed on the carrier, the positioning splint is fixed on the support frame and is located in the automatic positioning of the downlig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com