Automatic separation equipment used for engine piston combined type oil ring bushing rings

An automatic separation and combination technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problem of inseparable, combined oil ring liner separation and automatic feeding process difficult to achieve, unable to achieve full automatic piston ring Assembly and other problems to achieve the effect of reducing labor intensity of workers and improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

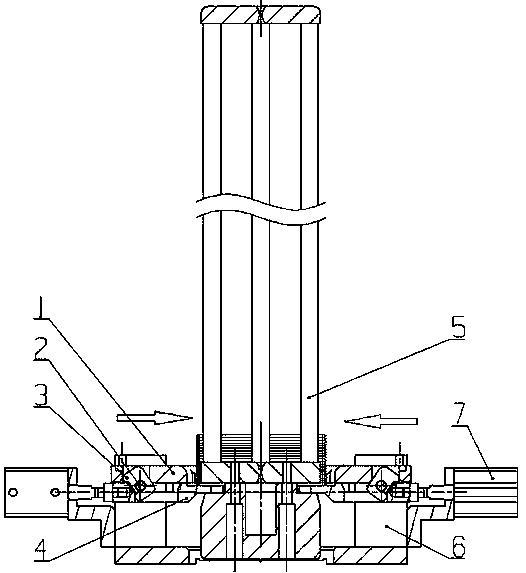

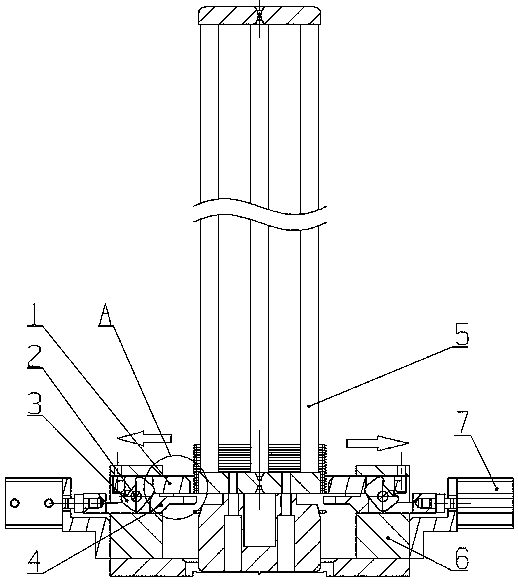

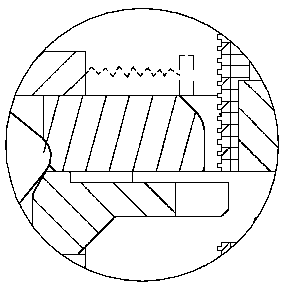

[0017] Accompanying drawing is a kind of specific embodiment of the present invention.

[0018] The automatic separation equipment for engine piston combined oil ring backing rings of the present invention includes a backing ring storage bin 5 and a cylinder propulsion mechanism, the backing ring storage bin 5 is a vertical frame structure of a rectangular frame or a cylindrical frame body, and the superimposed The lining ring is movable over the stand structure, and the lower end of the lining ring bin is connected with a cylinder propulsion mechanism, which is symmetrically installed on the left and right sides of the lining bin 5; the cylinder propulsion mechanism includes a cylinder 7, a dial block 3, and an upper slide plate 1. The lower plate 4 and the support 6, the displacement end of the cylinder 7 are movably connected to the shifting block 3, and the shifting block 3 is installed on the support 6 through the rotating pin 2; the displacement of the cylinder 7 drives t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com