Patents

Literature

81results about How to "Realize automatic elimination" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Empty bottle wall defect detection method and device

InactiveCN101819162ARealize automatic eliminationHigh-speed accurate automatic rejectionCharacter and pattern recognitionOptically investigating flaws/contaminationPattern recognitionImaging processing

The invention relates to an empty bottle wall defect detection method, which comprises the following steps: shooting two images by using a camera before and after the same empty bottle is rotated for 90 degrees during advancing, then transmitting the images to a CPU of an industrial personal computer to perform analysis on the images, and judging whether the bottle wall has defect. Image processing comprises the following steps: A, scanning edge point pairs on a bottle neck, positioning the bottle wall, and dividing a detection area of the bottle wall to perform subarea processing; B, pre-processing image data in the positioned area by adopting a grey stretching method; C, partitioning the images by adopting a maximum between-cluster variance method to acquire target information; and D, performing connectivity analysis on the partitioned bottle wall images, extracting characteristic data of each defect, and judging whether each detected connected domain has real defect according to the mass center position, posture ratio and area characteristic of the connected domain. The invention discloses a detection device used for the detection method at the same time. The detection method and the detection device are easily applied in detection equipment of an industrial flow line so as to realize automatic high-speed accurate detection on the empty bottle wall defect.

Owner:SHANDONG UNIV

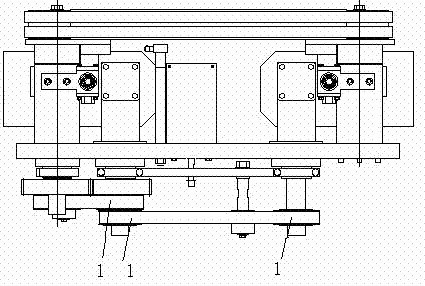

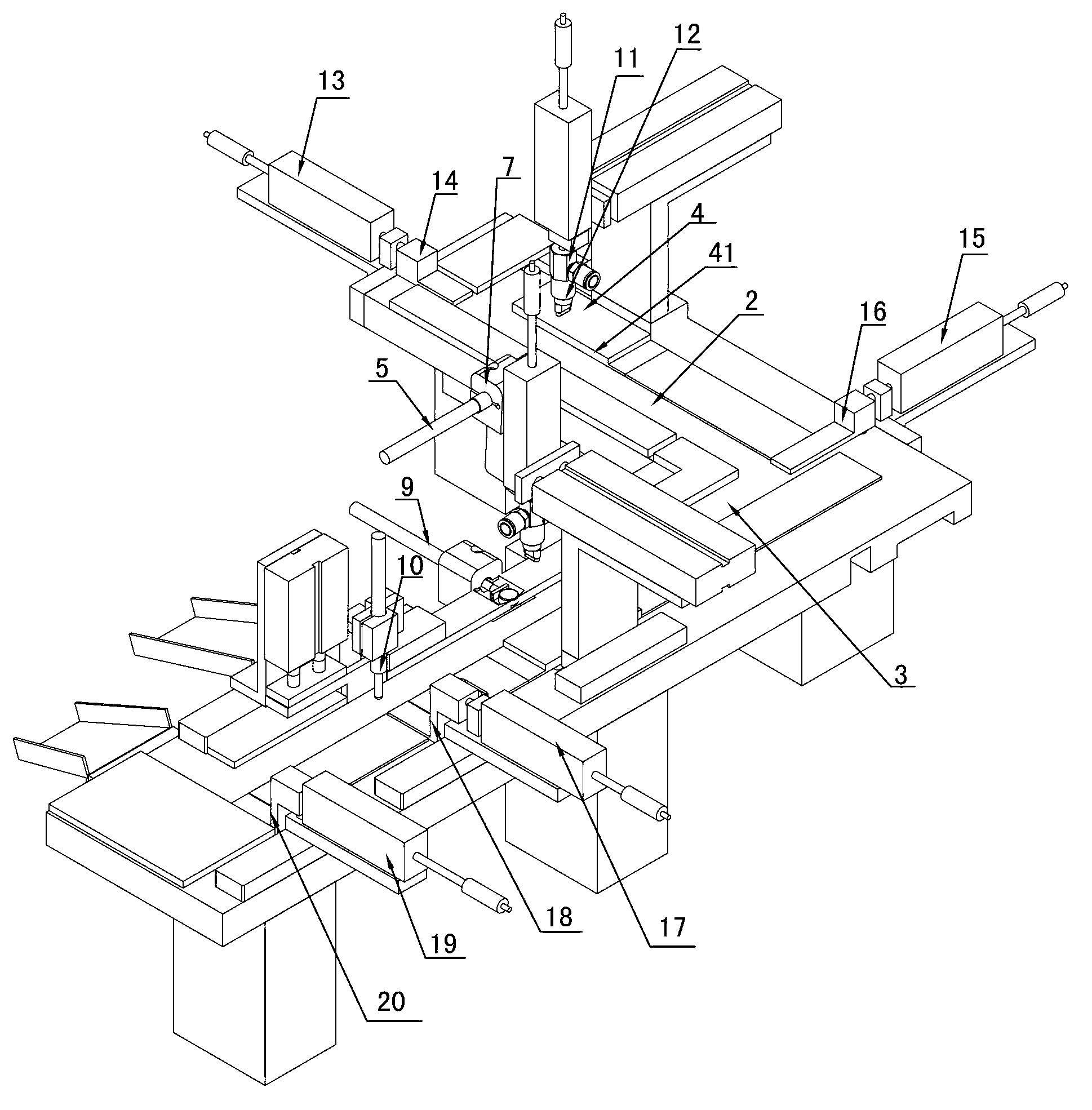

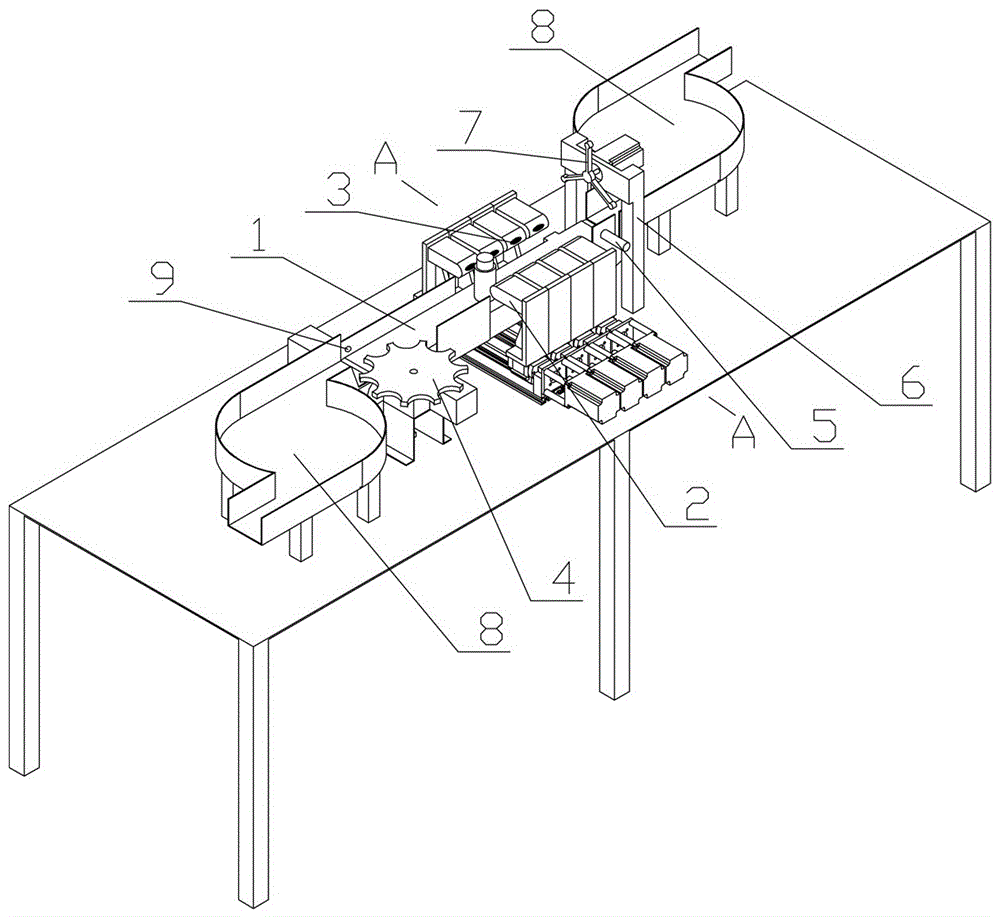

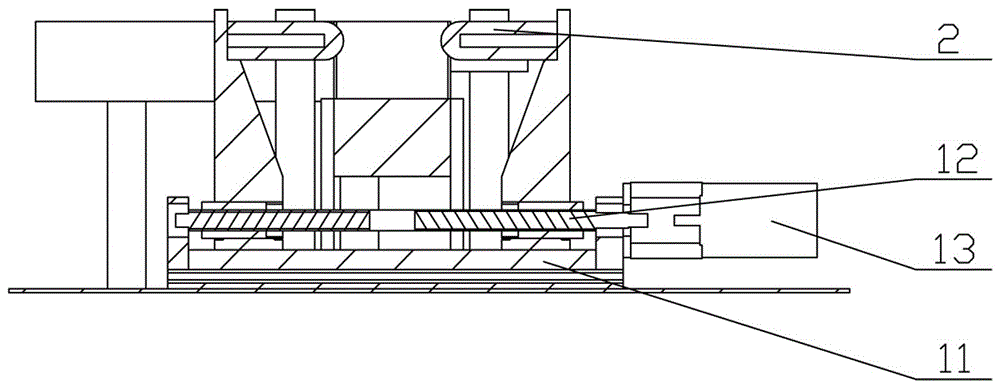

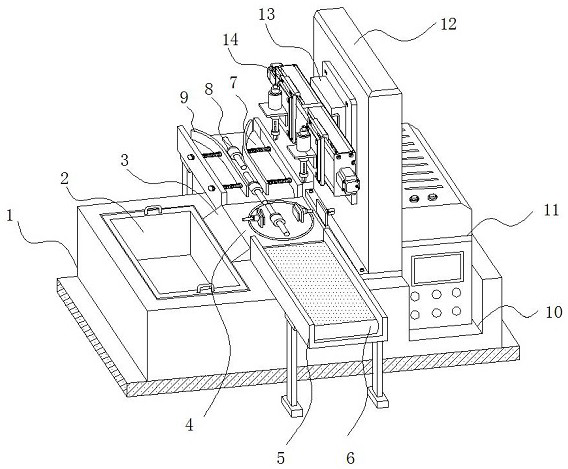

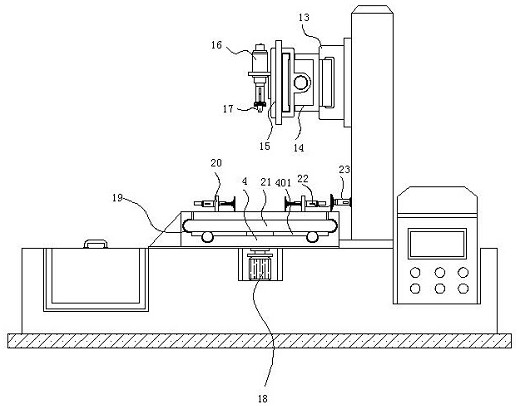

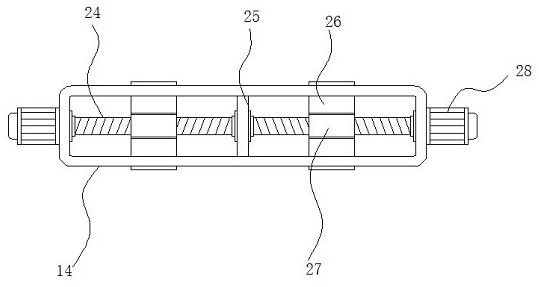

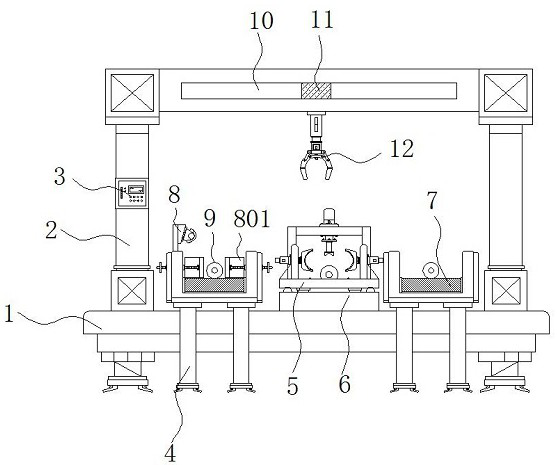

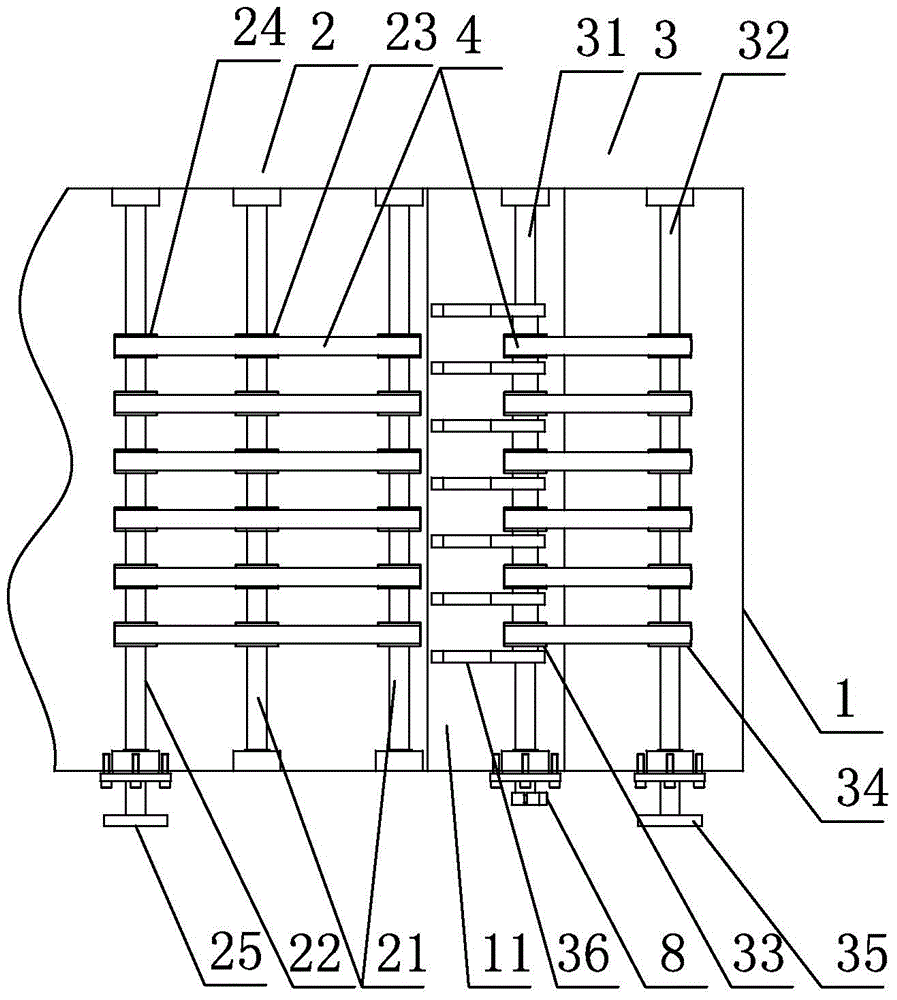

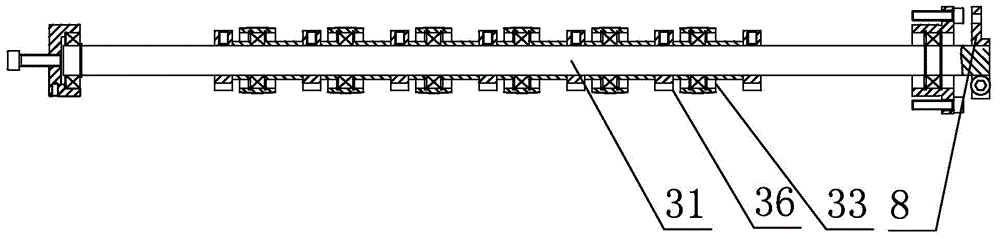

Automatic sorting device for defective products of pole pieces of timers

ActiveCN102601061AImprove accuracy and efficiencyEase of computer processing and managementSortingEngineeringPole piece

The invention discloses an automatic sorting device for defective products of pole pieces of timers. As sorting devices in the prior art are easily affected by inspectors, environment elements and the like, the inspection is instable and the detection efficiency and precision are hard to ensure. According to the invention, a rectangular rack is used as a support, four supporting feet are arranged at the bottom of the rectangular rack, adjusting wheels are arranged on the supporting feet, a material plate is fixed on the rack, eight proximity switches are arranged on the material plate, a movable material clamping plate is arranged on the side surface of the material plate, a material clamping cylinder and a feeding cylinder are connected on the material clamping plate, and a first image acquisition system, a first sorting mechanism, a turn-over mechanism, a second image acquisition system, a second sorting mechanism, a third image acquisition system and a third sorting mechanism are arranged above the material plate from left to right. The automatic sorting device is high in detection precision and large in detection scope and greatly reduces the labor intensity of workers.

Owner:上海同赛水处理科技有限公司

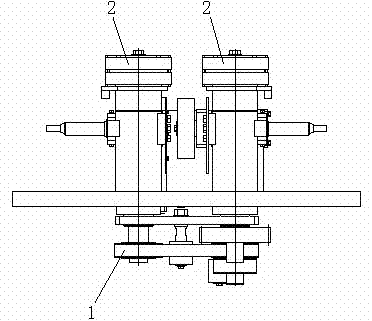

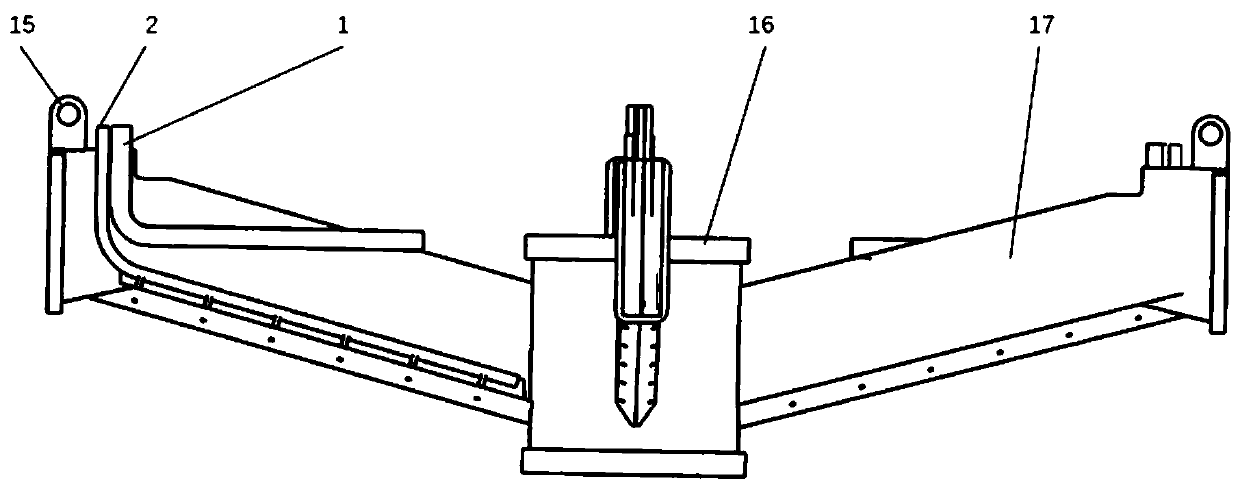

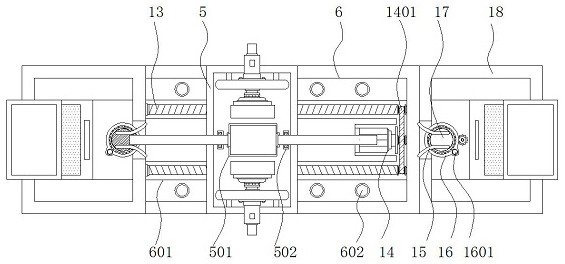

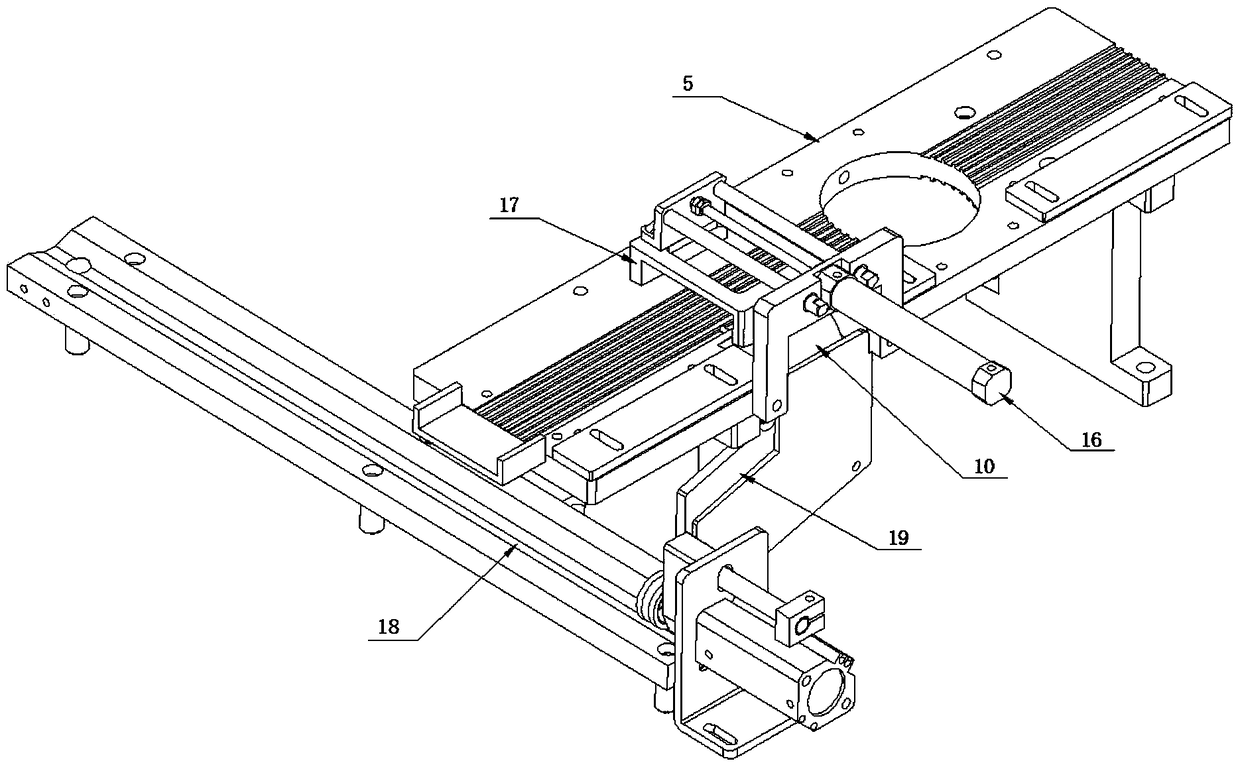

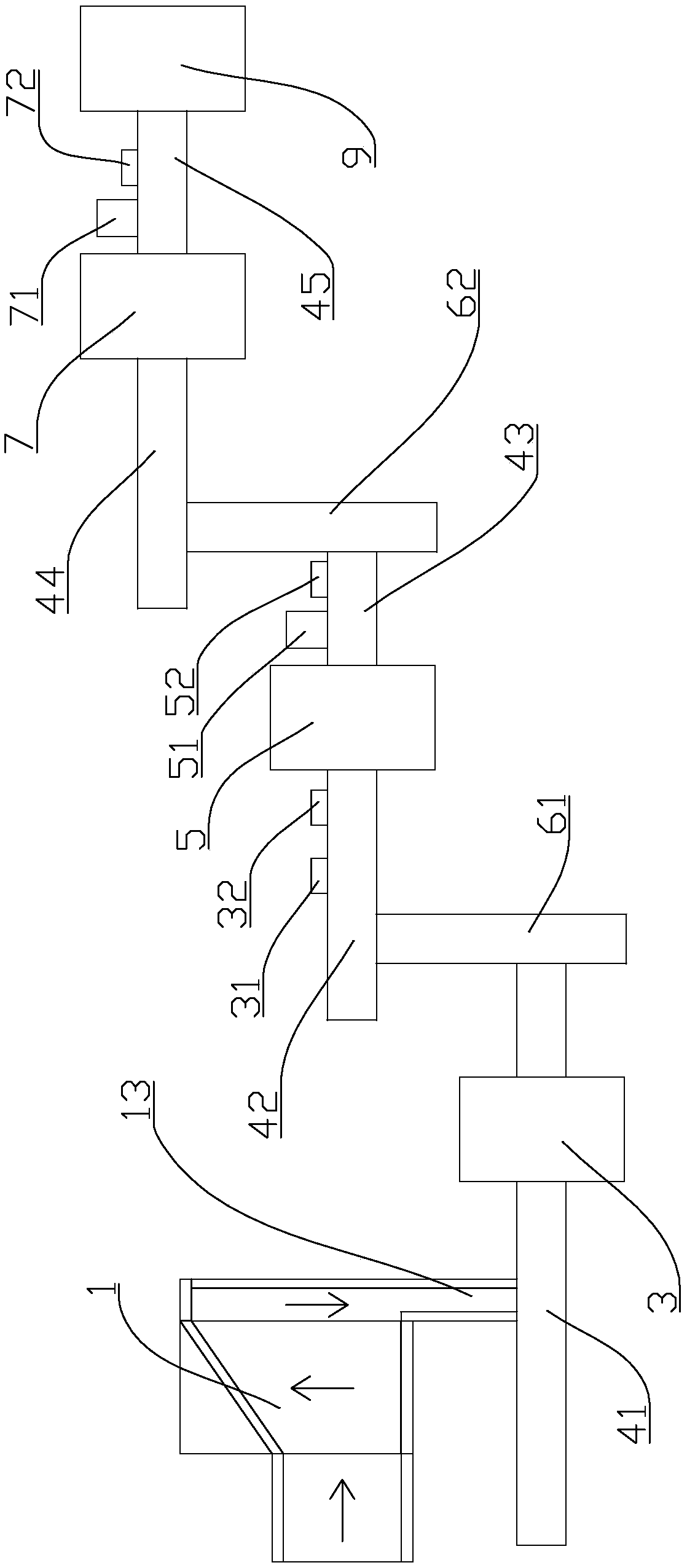

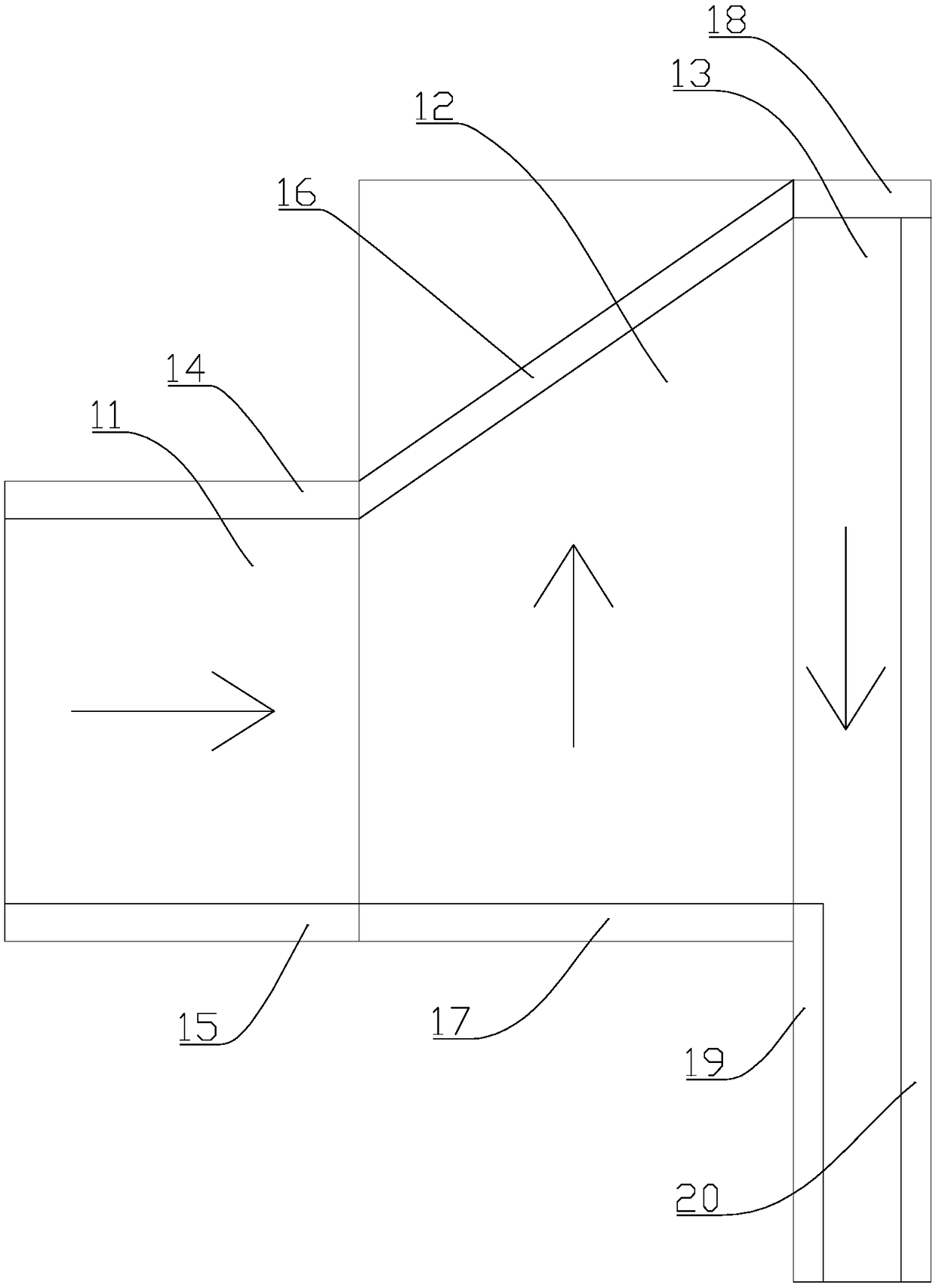

Product three-dimensional dimension automatic selector

ActiveCN103316848AImplement automatic detectionRealize automatic eliminationSortingEngineeringAutomation

The invention discloses a product three-dimensional dimension automatic selector, which comprises a control mechanism, a feeding mechanism, a first transfer passage and a second transfer passage that are horizontal and mutually perpendicular, wherein the inlet of the first transfer passage is provided with a first pneumatic mechanism; the inlet of the second transfer passage is provided with a second pneumatic mechanism; the first transfer passage is provided with a first width sorting mechanism and a first width detection mechanism; the second transfer passage is provided with a second width sorting mechanism and a second width detection mechanism; the first transfer passage or the second transfer passage are provided with a height sorting mechanism and a height detection mechanism; the first width sorting mechanism, the second width sorting mechanism, the height sorting mechanism, the first width detection mechanism, the second width detection mechanism and the height detection mechanism are connected with the control mechanism respectively; the control mechanism is provided with a qualified dimension scope for the first width, the second width and the height of the product. The selector has high automation and work efficiency.

Owner:NINGBO YUNSHENG +5

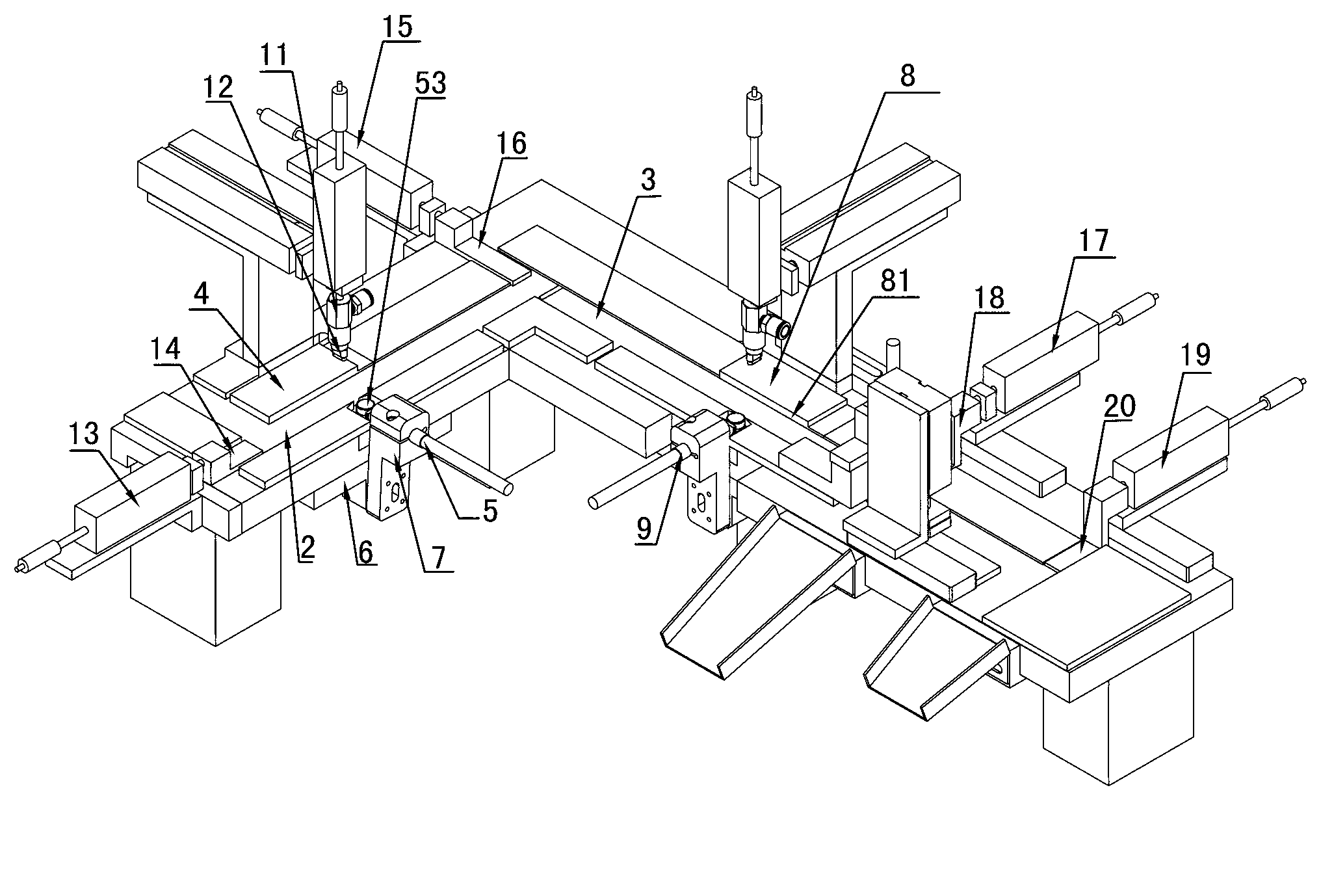

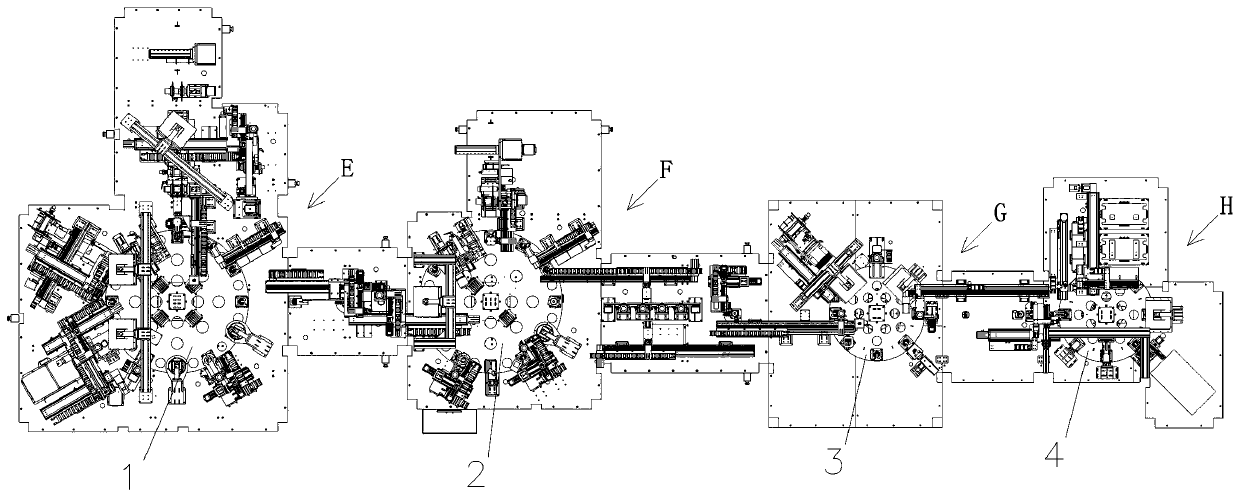

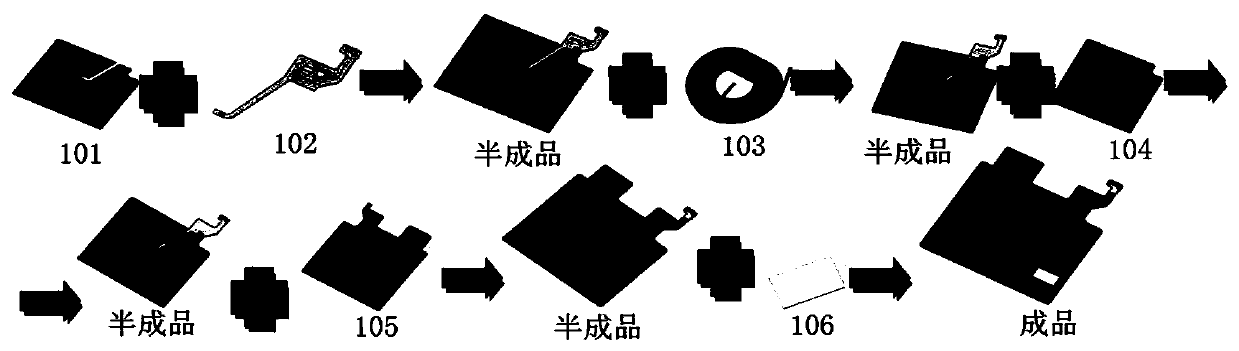

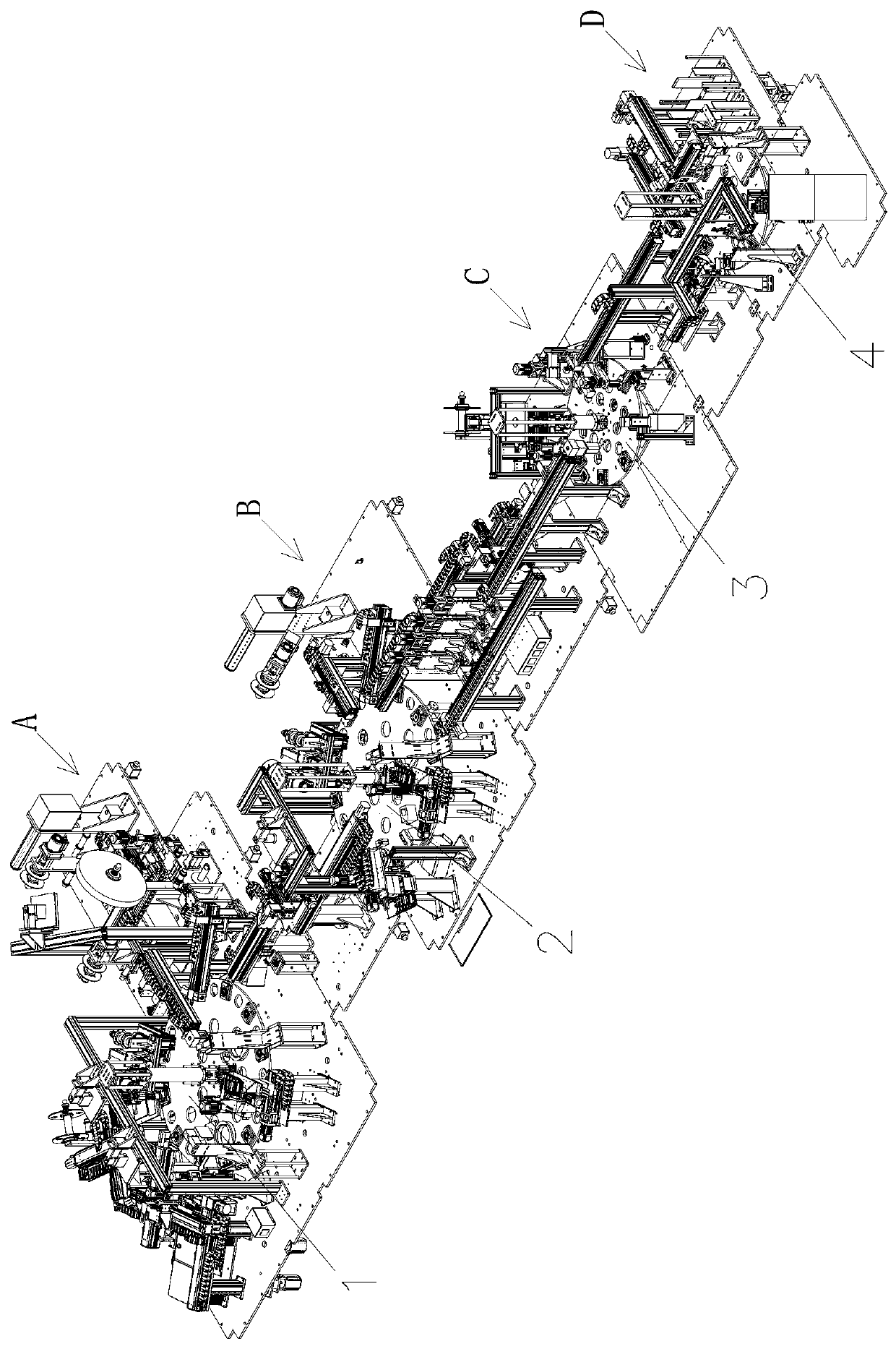

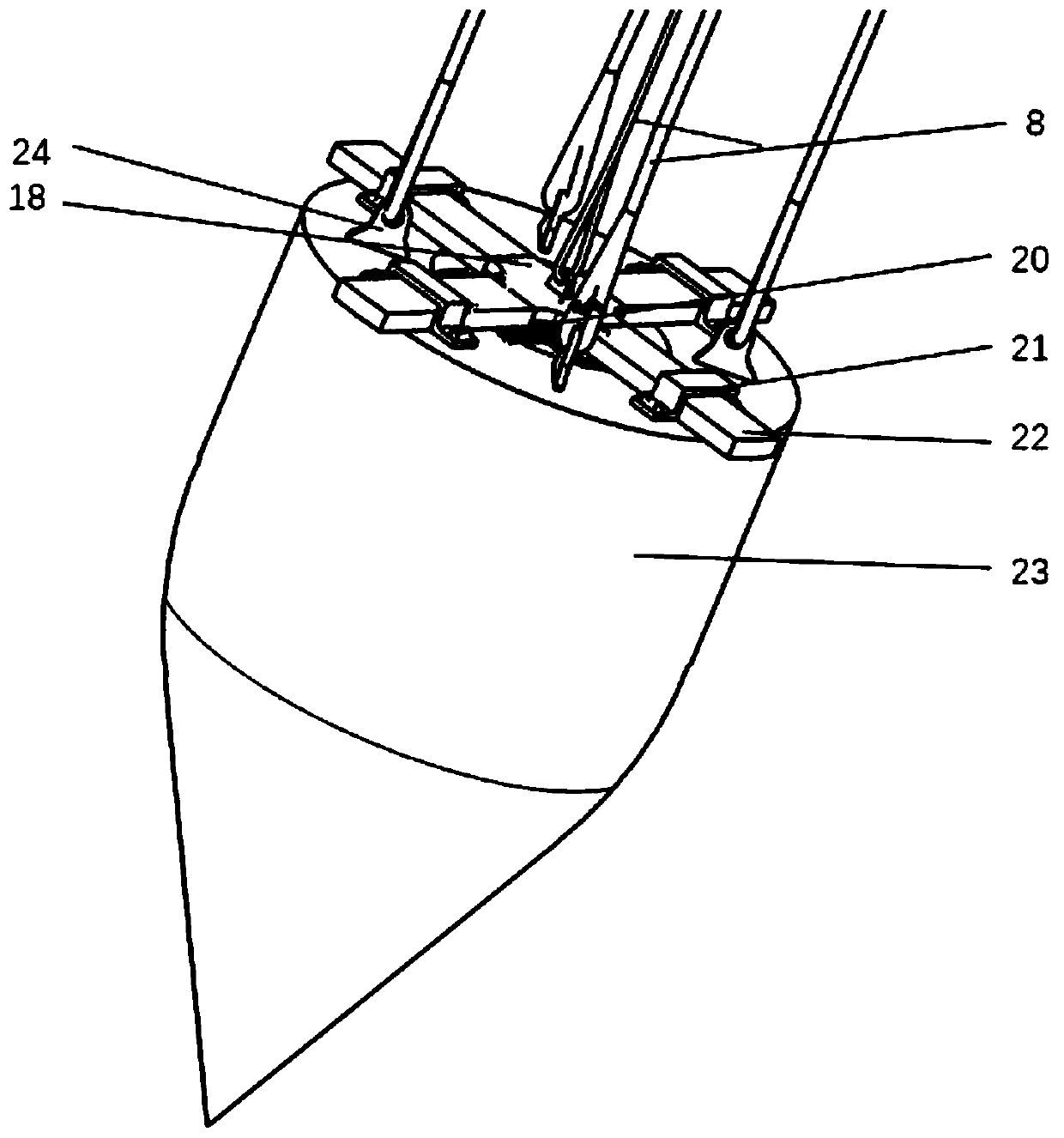

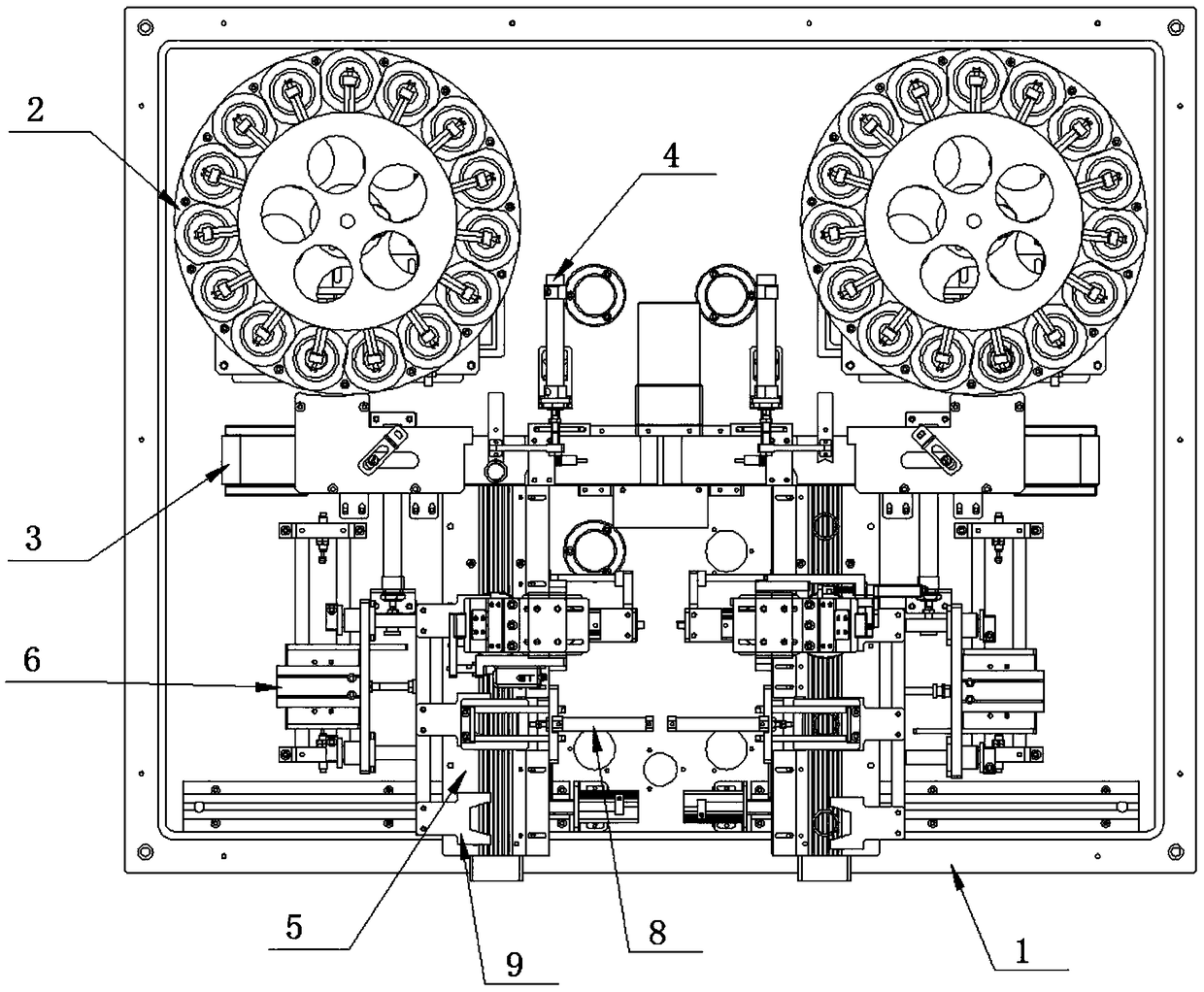

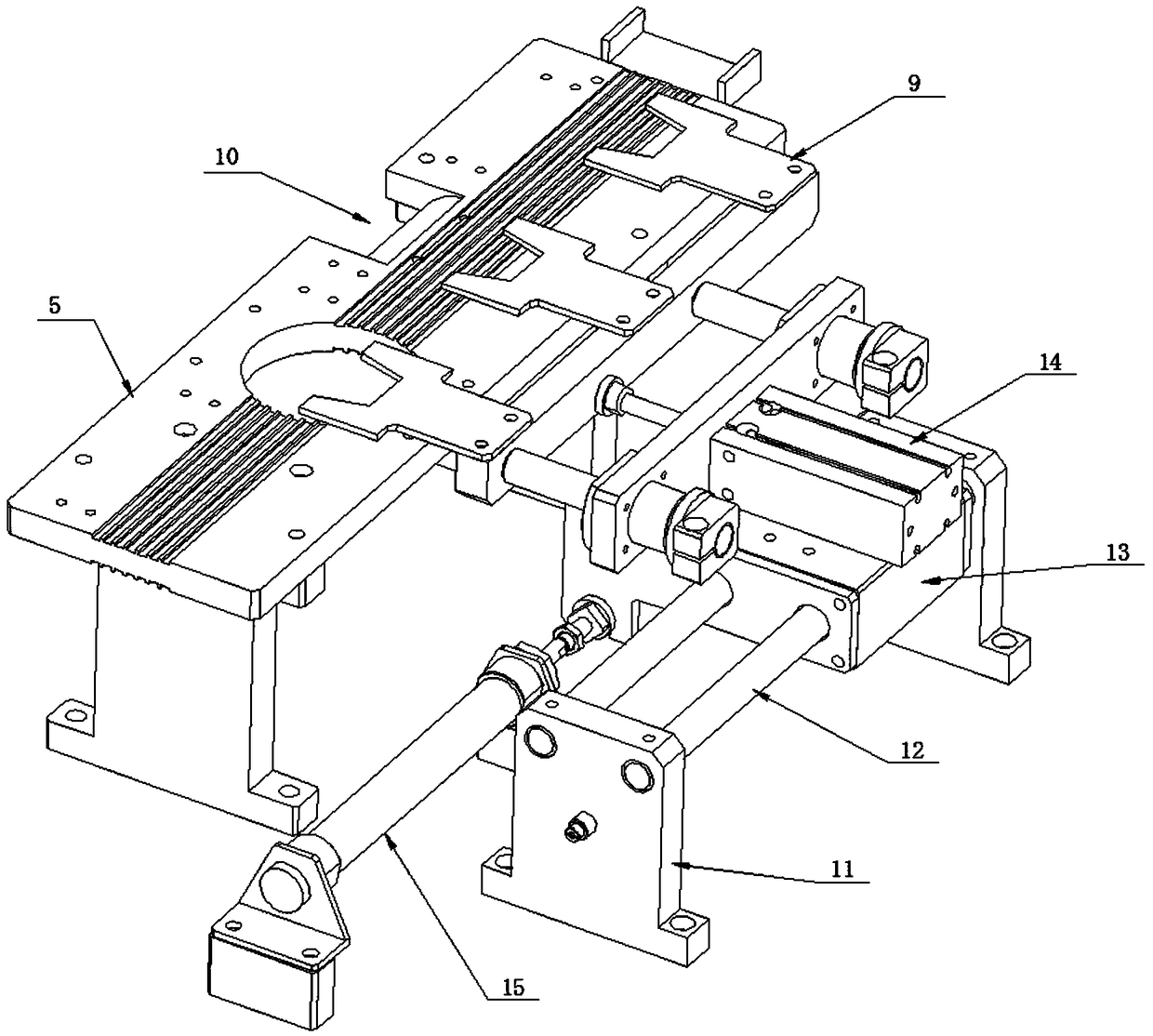

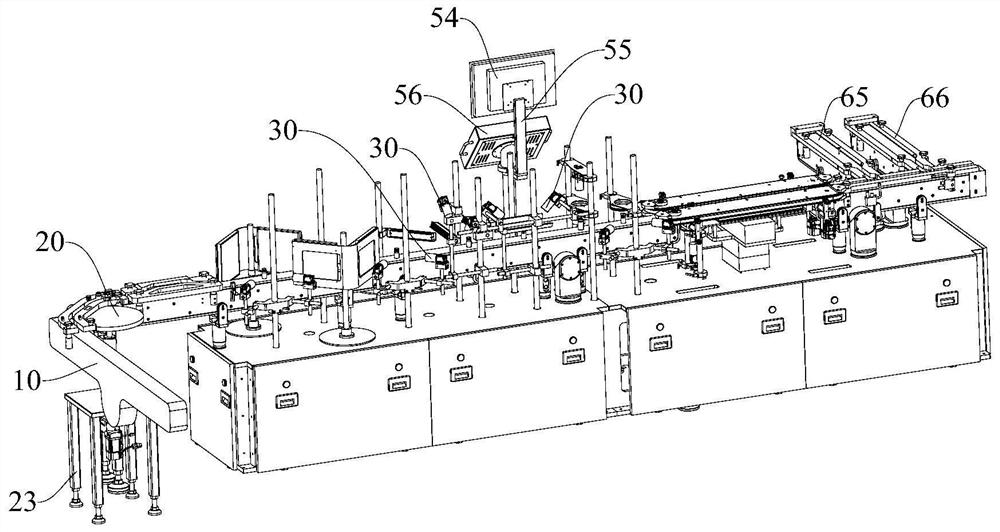

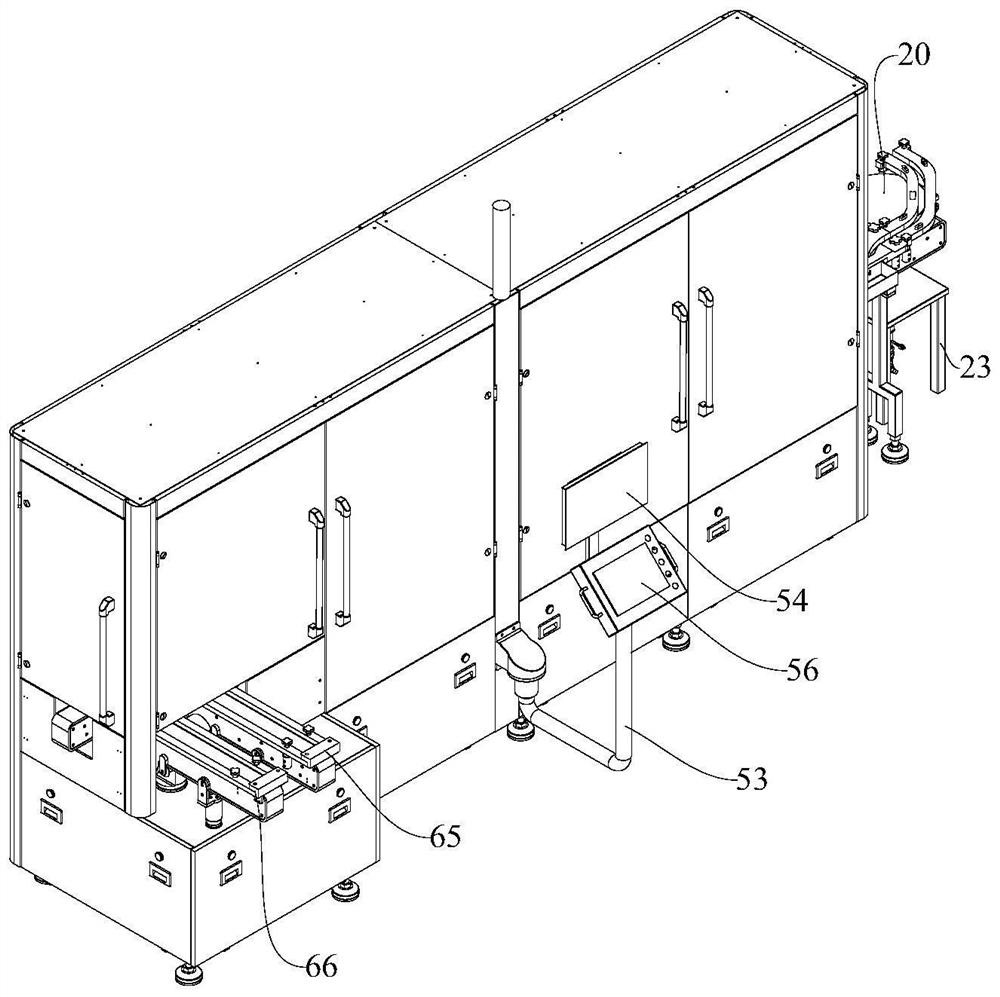

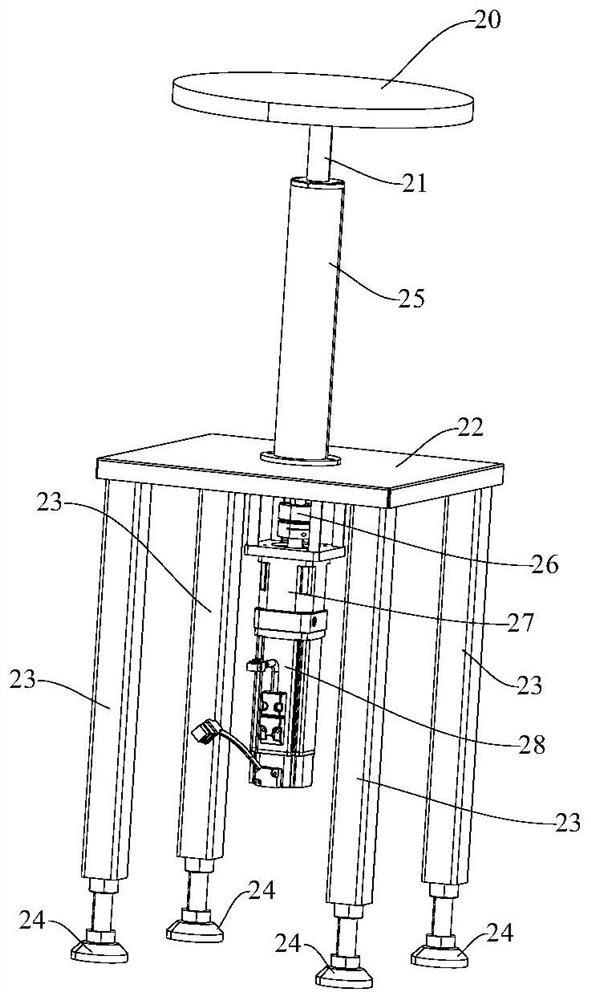

Assembly process of wireless charging module and assembly attaching line

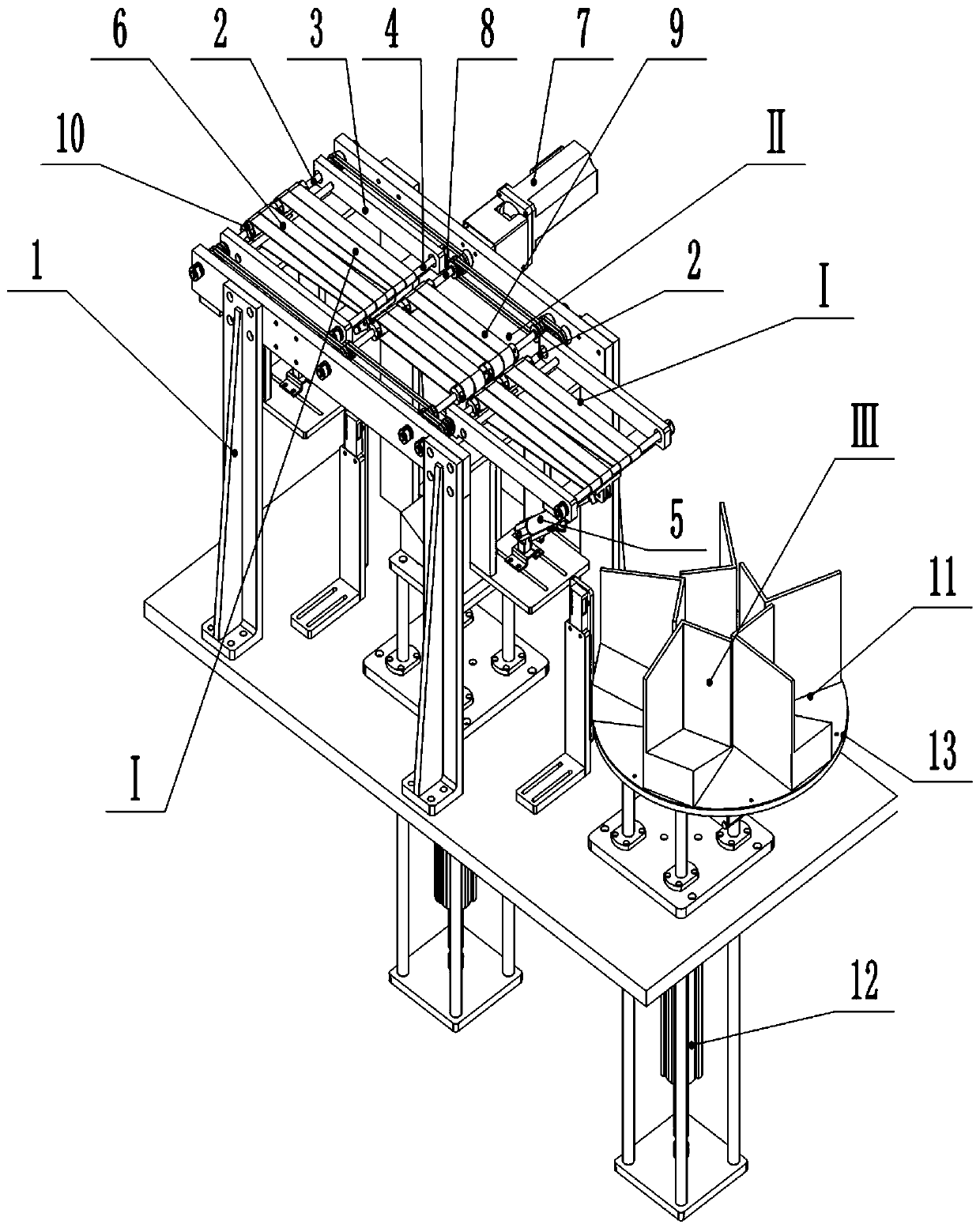

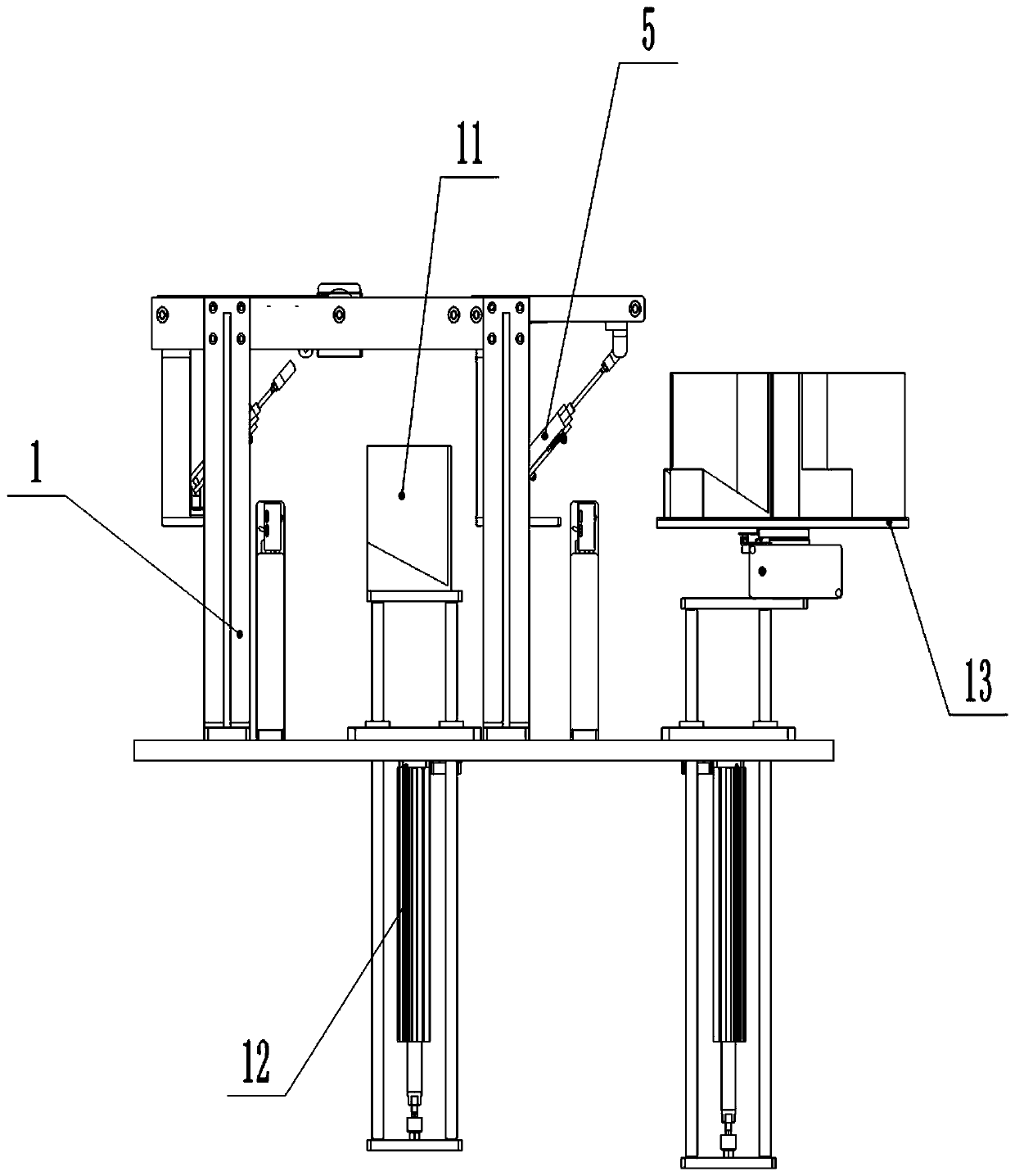

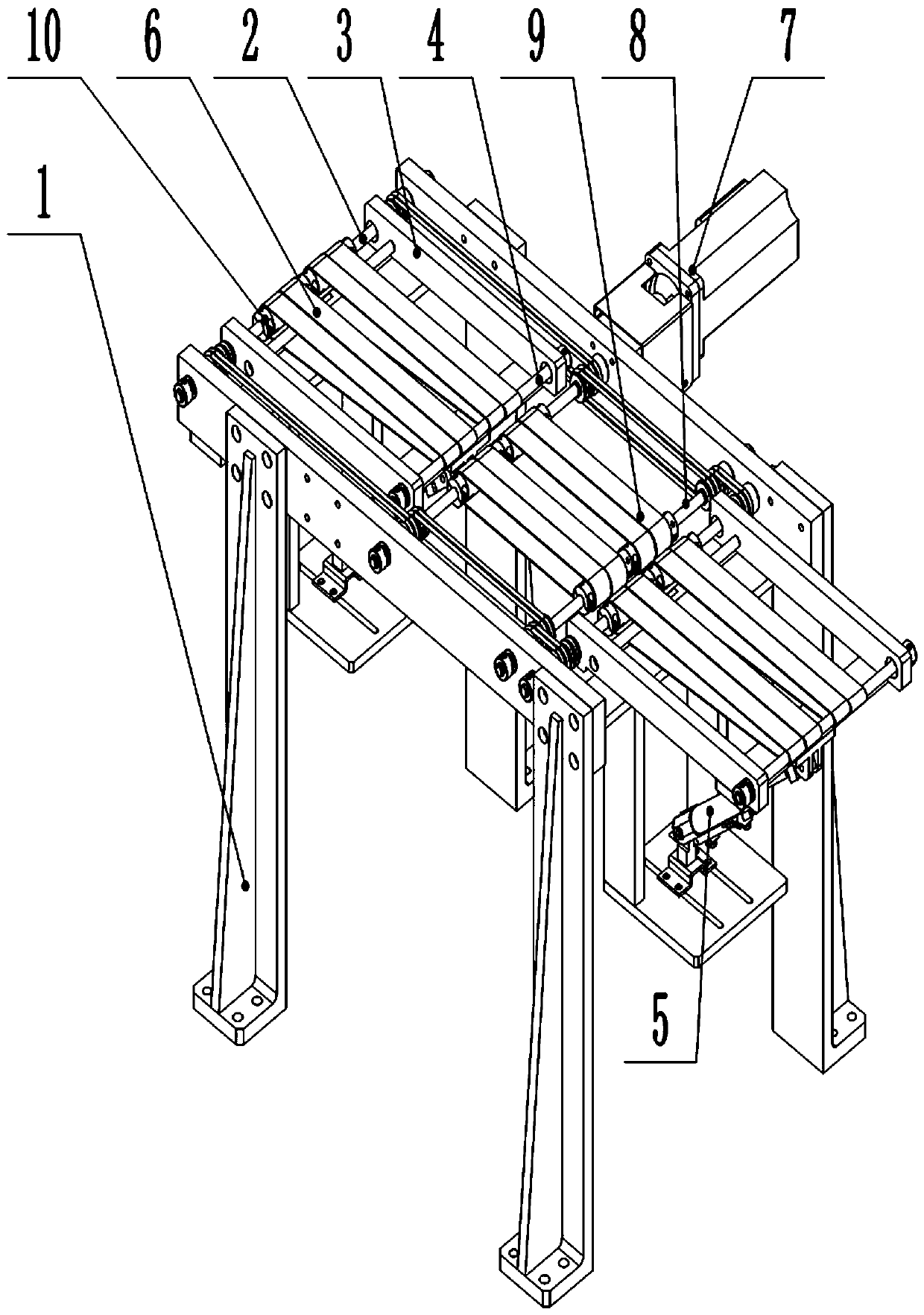

PendingCN109605022ACompact structureRealize automatic eliminationMaterial gluingAssembly machinesEngineeringRotating disc

The invention relates to an assembly process of a wireless charging module and an assembly attaching line. The assembly attaching line comprises a first indexing turntable, a second indexing turntable, a third indexing rotating disc and a fourth indexing rotating disc which are arranged in sequence from front to back, and a plurality of stations are arranged on each of the first indexing rotatingdisc, the second indexing rotating disc, the third indexing rotating disc and the fourth indexing rotating disc. The full-automatic and linear assembly process is adopted, defective products can be assembled fully automatically, detected automatically and removed automatically in large-scale and efficient modes, the four indexing rotating discs are totally arranged, targeted assembly equipment isfurther arranged around each indexing rotating disc, the whole assembly attaching line is compact in structure and is highly modularized, shaping mechanisms are arranged on part of the positions, attaching accuracy is high and can reach + / -0.1 mm, the yield is high, and the production efficiency can reach 1200 pcs / h. The defective products can be removed, finished products can be detected, full-automatic assembly and automatic detection can be achieved, and the defective products can be removed automatically.

Owner:SHENZHEN HADESHENG PRECISION TECH

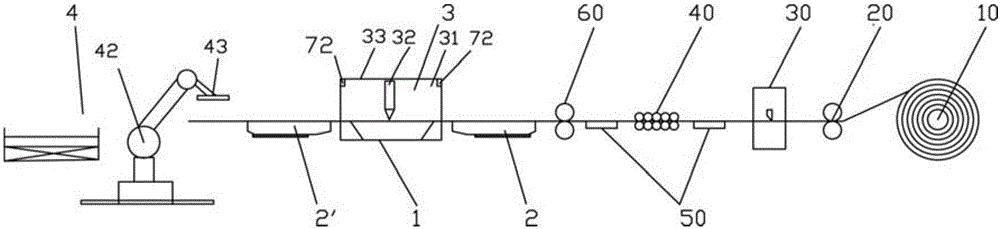

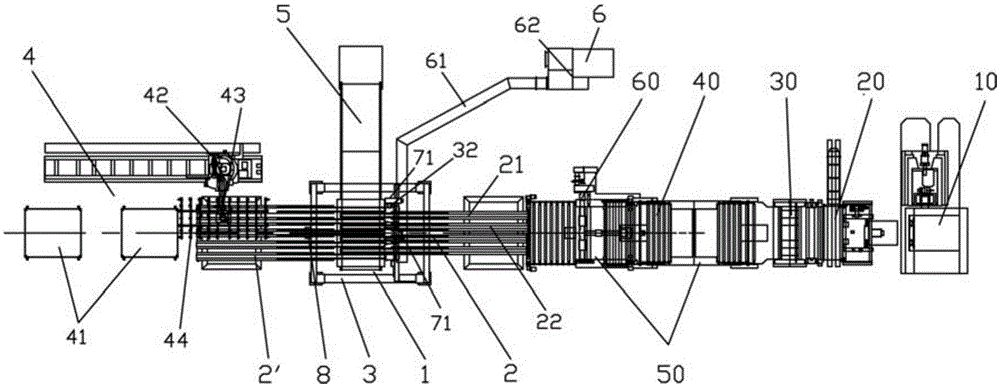

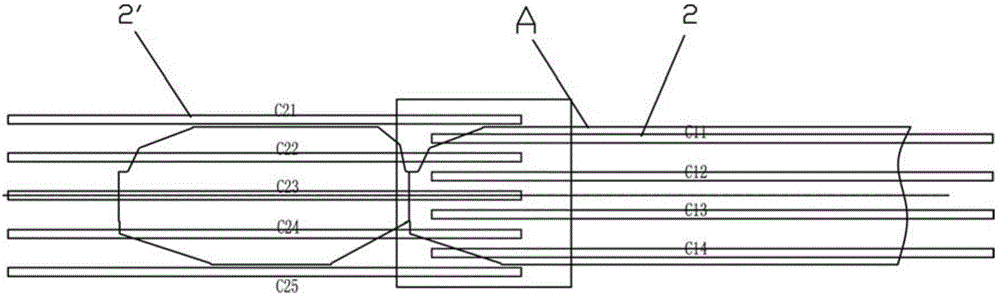

Method and system for laser cutting through dynamic following of synchronous passing plates

ActiveCN105081584ASolve the problem of online automatic dropRealize automatic eliminationWelding/cutting auxillary devicesAuxillary welding devicesControl systemStrip steel

Owner:BAOSHAN IRON & STEEL CO LTD

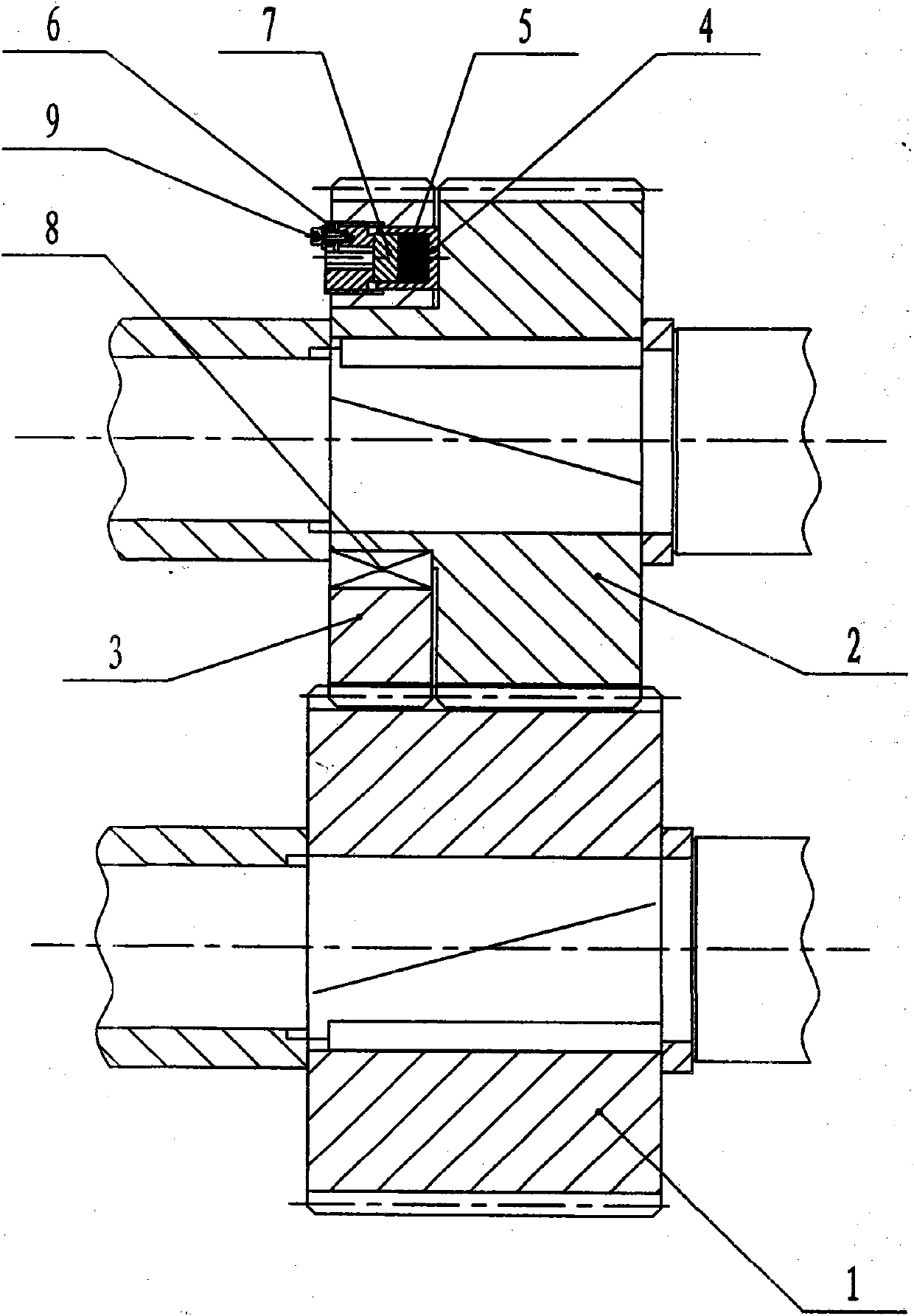

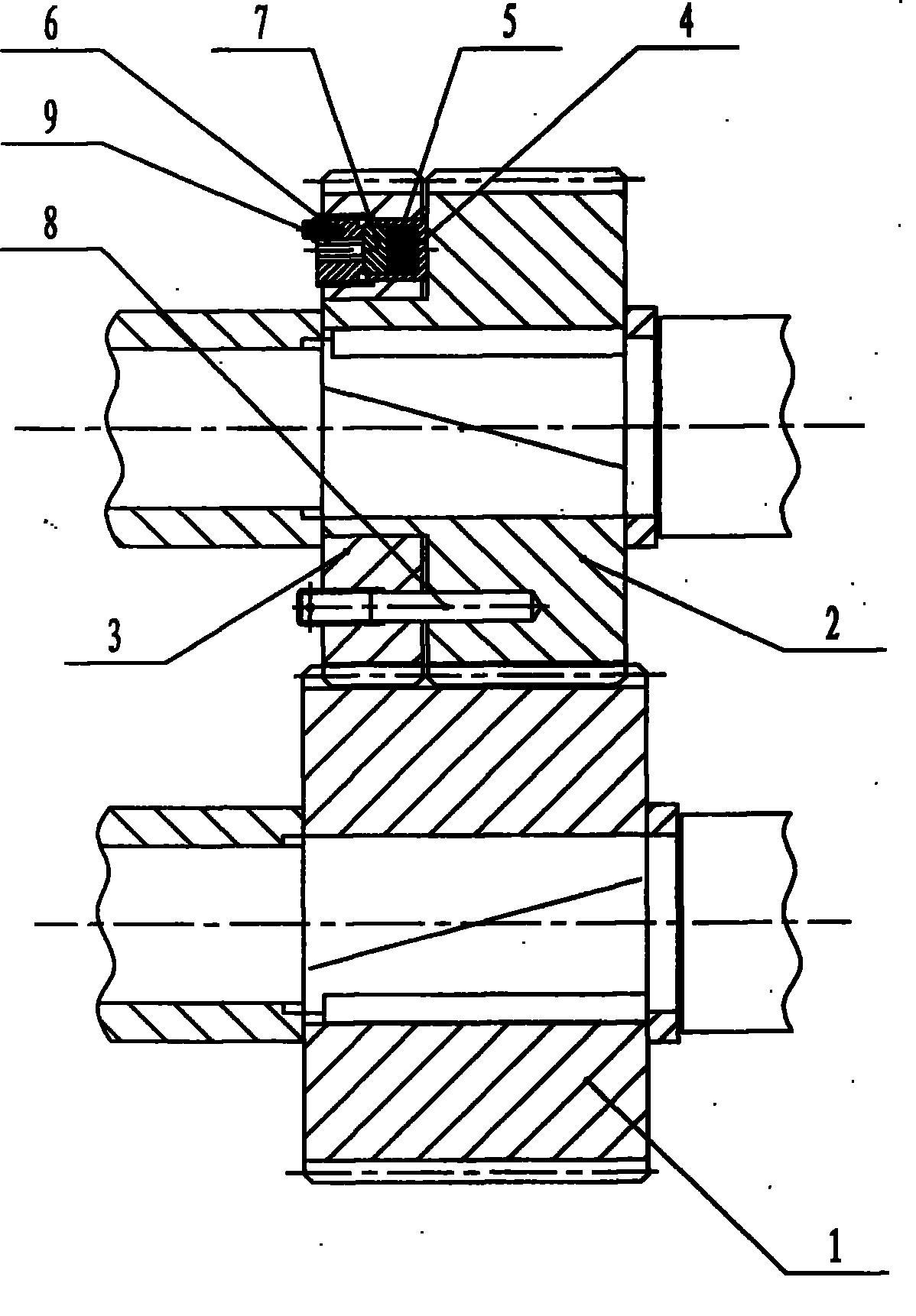

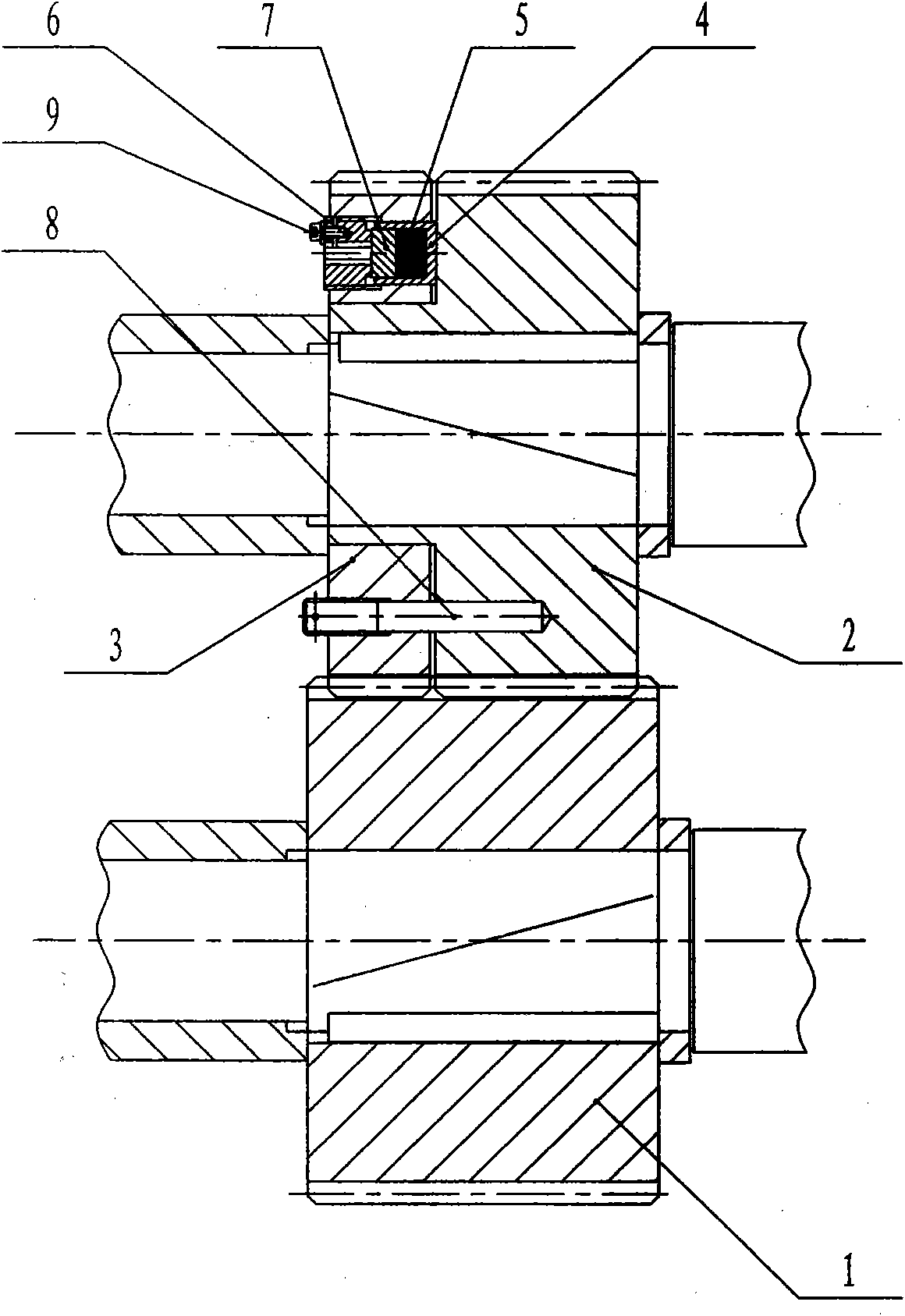

Automatic gear clearance elimination mechanism

InactiveCN101907161AEasy to install and useWork reliablyPortable liftingGearing elementsEngineeringLocknut

The invention discloses an automatic gear clearance elimination mechanism, used for eliminating a clearance of a transmission gear. The transmission gear is meshed with a fixed gear and is connected to a transmission shaft through a connecting piece, a movable gear is fixed on the fixed gear through a pin or a key, a guide sleeve is installed in an end surface hole of the movable gear, a spring is installed in a hole of the guide sleeve, a locking nut presses a press ring to tightly pressing the spring, and the transmission gear, the fixed gear and the movable gear are all helical gears. By turning the locking nut, the movable gear moves along the connecting piece, a clearance generated by abrasion between the transmission gear and the fixed gear is eliminated, and the clearance of the gear is automatically eliminated. In the invention, the transmission gear and the fixed gear in equipment do not needed to be loosened and re-adjusted for eliminating the gear clearance, the gear clearance can disappear automatically under the action of the pre-tightening force of the spring just by turning the locking nut in the process of initial installation to adjust the pre-tightening force of the spring. The invention has the advantages of convenient installation and use, stable and reliable work and free maintenance.

Owner:XIANGYANG BOYA PRECISION IND EQUIP

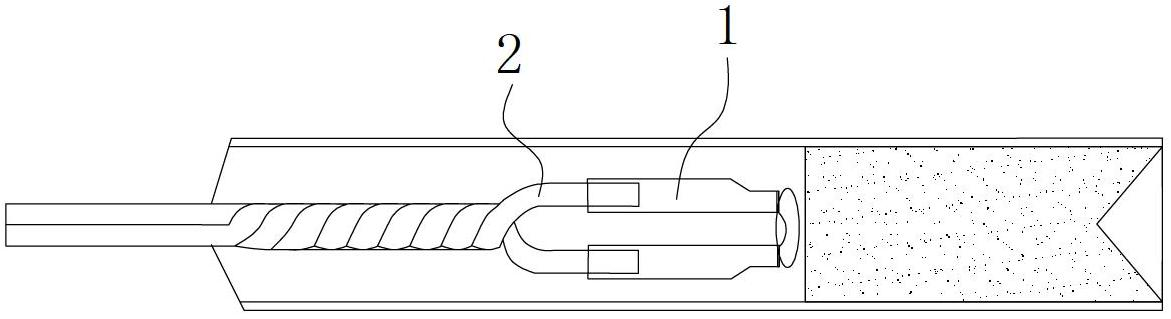

Device and method for detection, rejection and butt connection of rigidity electric ignition powder heads

ActiveCN102679824AIncrease productivitySave human resourcesAmmunition fuzesProgrammable logic controllerElectricity

The invention relates to the manufacture field of rigidity electric ignition powder heads of industrial electric detonators and discloses a device for detection, rejection and butt connection of the rigidity electric ignition powder heads. The device comprises a stepping mechanism, a rigidity electric ignition powder head resistance automatic detection machine, a rejection machine, a hot press welder, a programmable logic controller (PLC) and a computer. The rigidity electric ignition powder head resistance automatic detection machine is provided with a resistance measuring instrument, and a probe is respectively connected with two poles of the resistance measuring instrument. The rejection machine is arranged on the conveying route of the stepping mechanism and located at the back of the rigidity electric ignition powder head resistance automatic detection machine. The hot press welder is arranged on the conveying route of the stepping mechanism and located at the back of the rejection machine. The computer is connected with the rigidity electric ignition powder head resistance automatic detection machine, a rejection cylinder of the rejection machine and the hot press welder through the PLC. The device is high in production efficiency and capable of producing rigidity electric ignition elements with stable resistance and good shockproof capability.

Owner:GUANGDONG HONGDA BLASTING +1

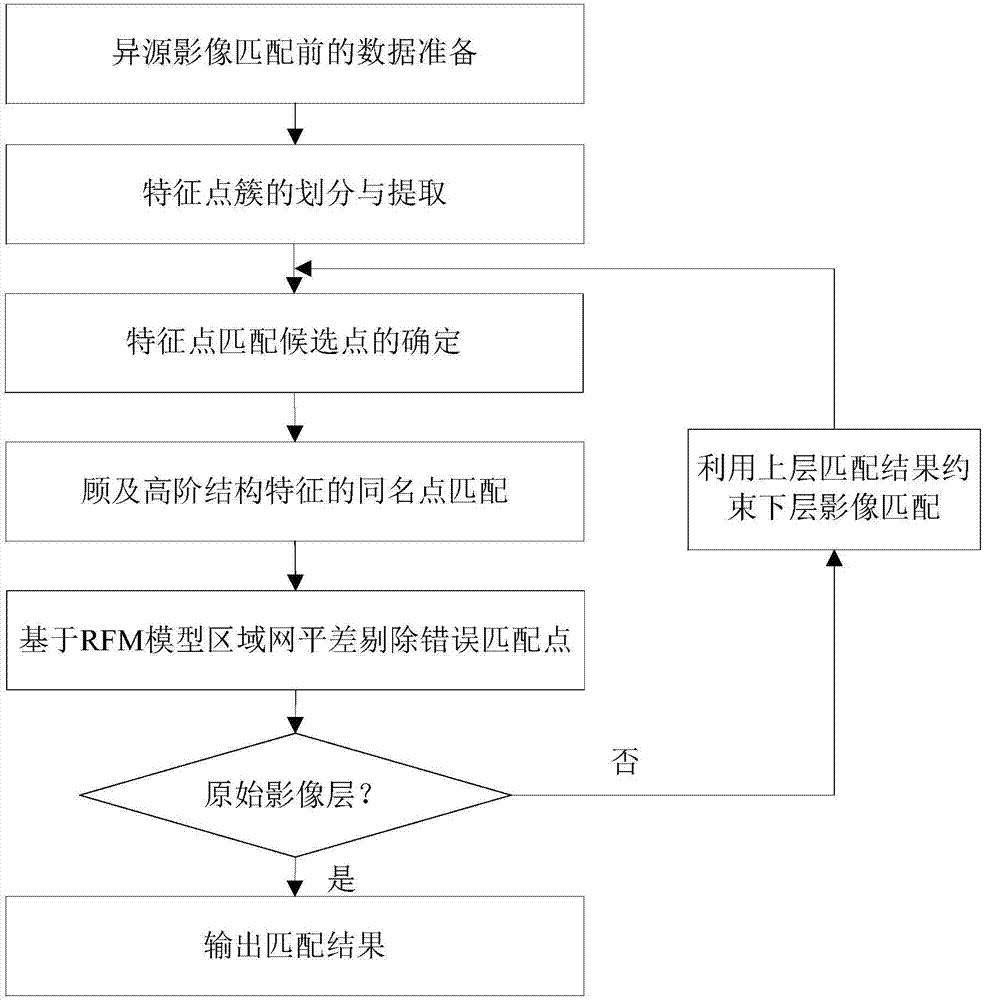

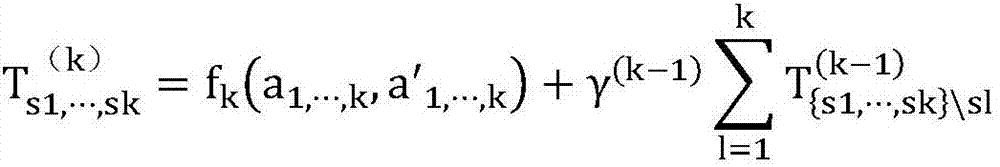

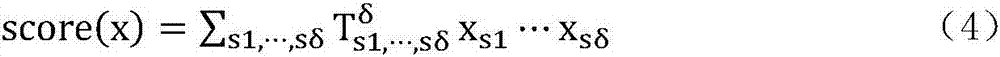

Homonymous point matching method of heterogenous remote sensing images taking high-order structural characteristics into consideration

ActiveCN106886794AAutomatic and reliable matchingAchieve refinementScene recognitionData preparationDependability

The invention provides a homonymous point matching method of heterogenous remote sensing images taking high-order structural characteristics into consideration, and belongs to the field of plotting science and technology. The method comprises that data is prepared before heterogenous images are matched; a characteristic point cluster is divided and extracted; candidate matching points of characteristic points are determined; homonymous points are matched taking the high-order structural characteristics into consideration; a result is matched for each layer of pyramid images, and a local network adjustment based on an RFM model is carried out by utilizing a fusion selecting weight iteration method; and the matching result is refined layer by layer till an original image layer, and the homonymous points of the heterogenous remote sensing images can be matched automatically and reliably. According to the invention, a rational function model and a hypergraph image matching model are used in an integrated manner, geometrical constraint characteristics and the higher-order structural characteristics are introduced to layer-by-layer pyramid image matching, the sparsity of the hypergraph model is ensured, and information loss caused by hyperedge sampling is reduced to the minimum; and the matching reliability and success rate of the heterogenous remote sensing images are improved, and the workload of manual homonymous point measurement is reduced effectively.

Owner:HUBEI UNIV OF TECH

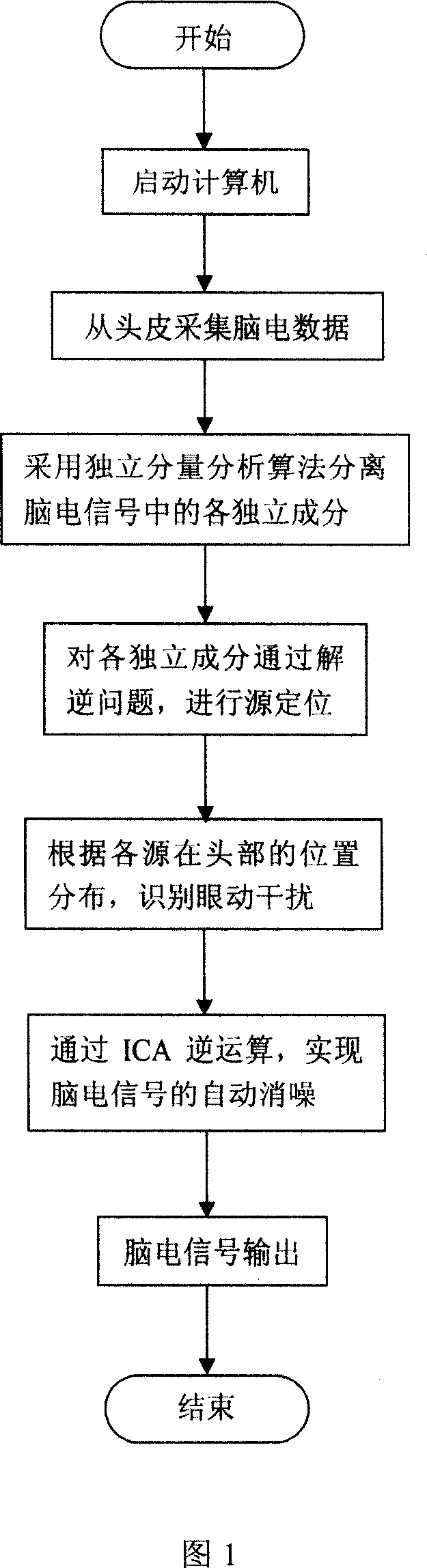

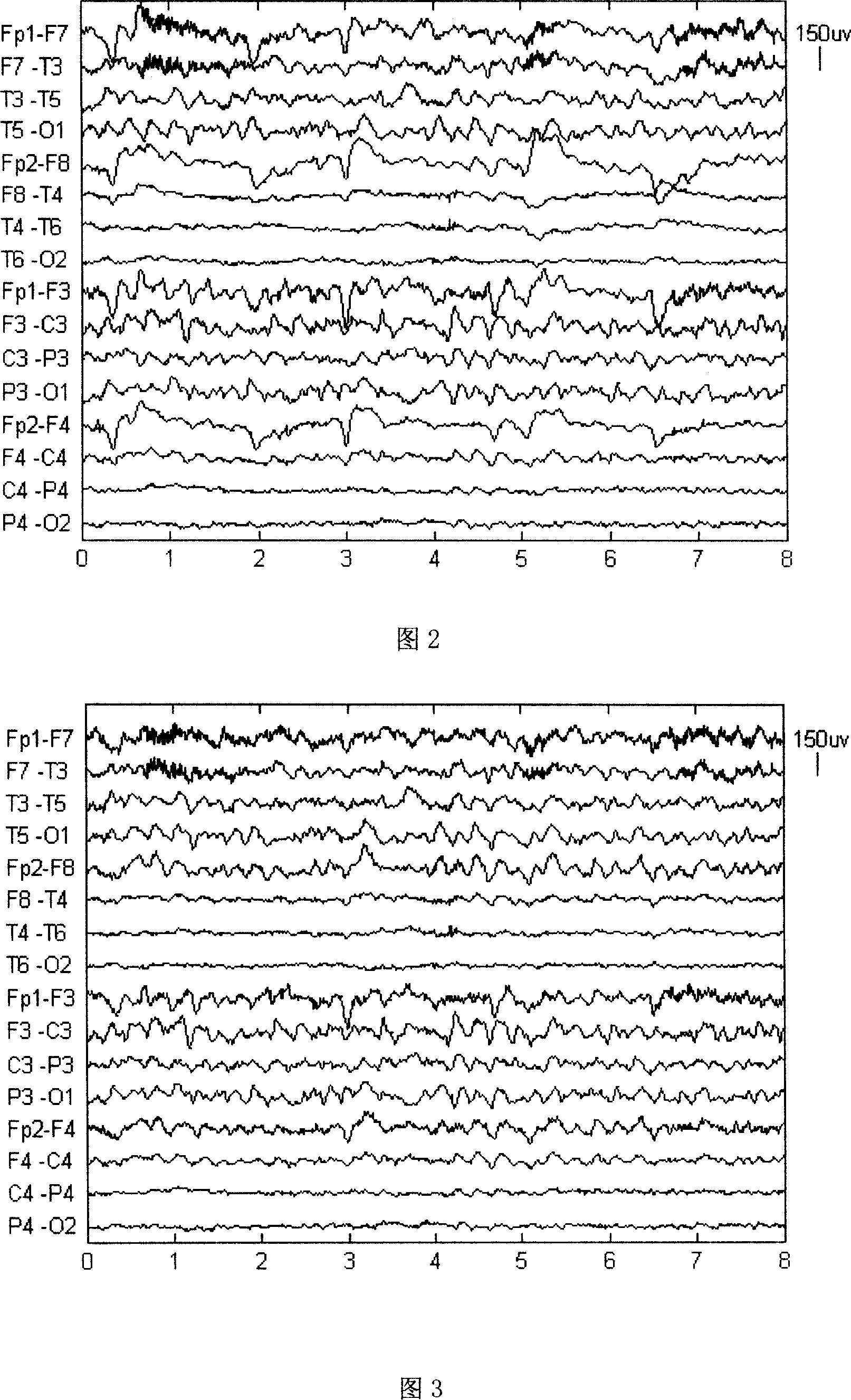

Method for automatically recogniting and eliminating ophthalmogyric interference in electroencephalo-signals

InactiveCN100998503ARealize automatic extractionRealize automatic diagnosisData processing applicationsDiagnostic recording/measuringComputer visionVIT signals

A method for automatically recognizing and eliminating the eye moving interference from electroencephalogram (EEG) includes such steps as extracting the components from EEG by ICA, dipole locating analyzing, creating a bipole position distribution model about eye moving interference, and ICA reverse transformation to automatically eliminate said interference.

Owner:SHANDONG UNIV

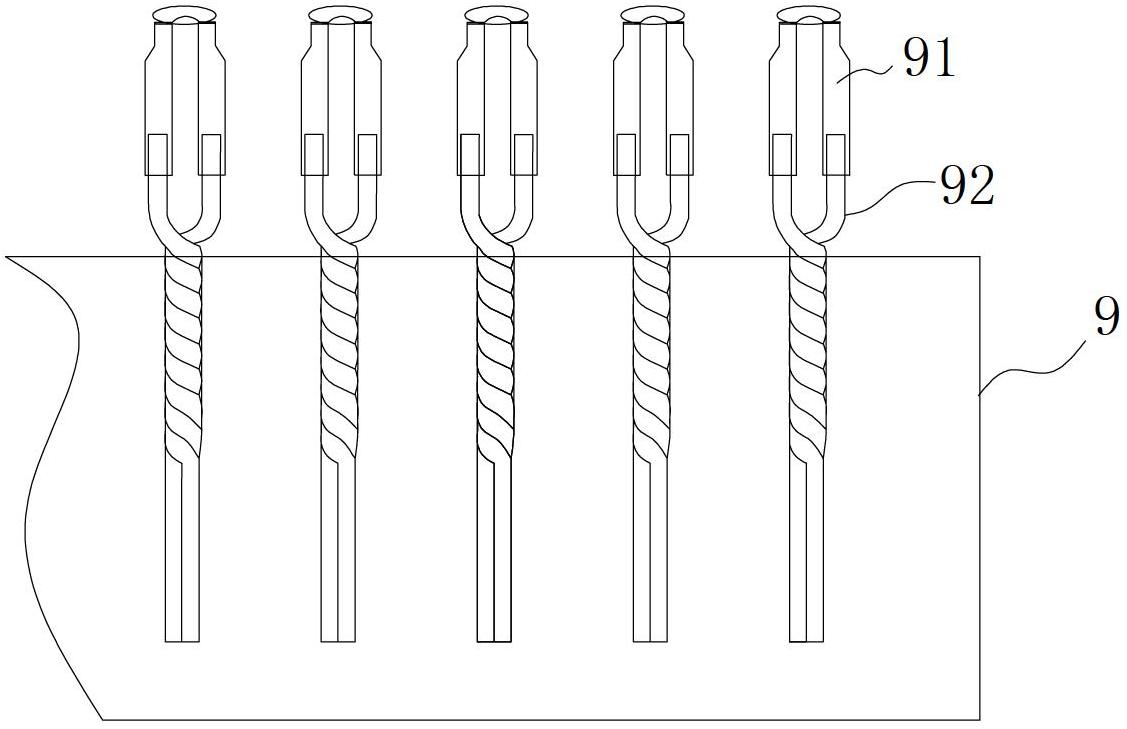

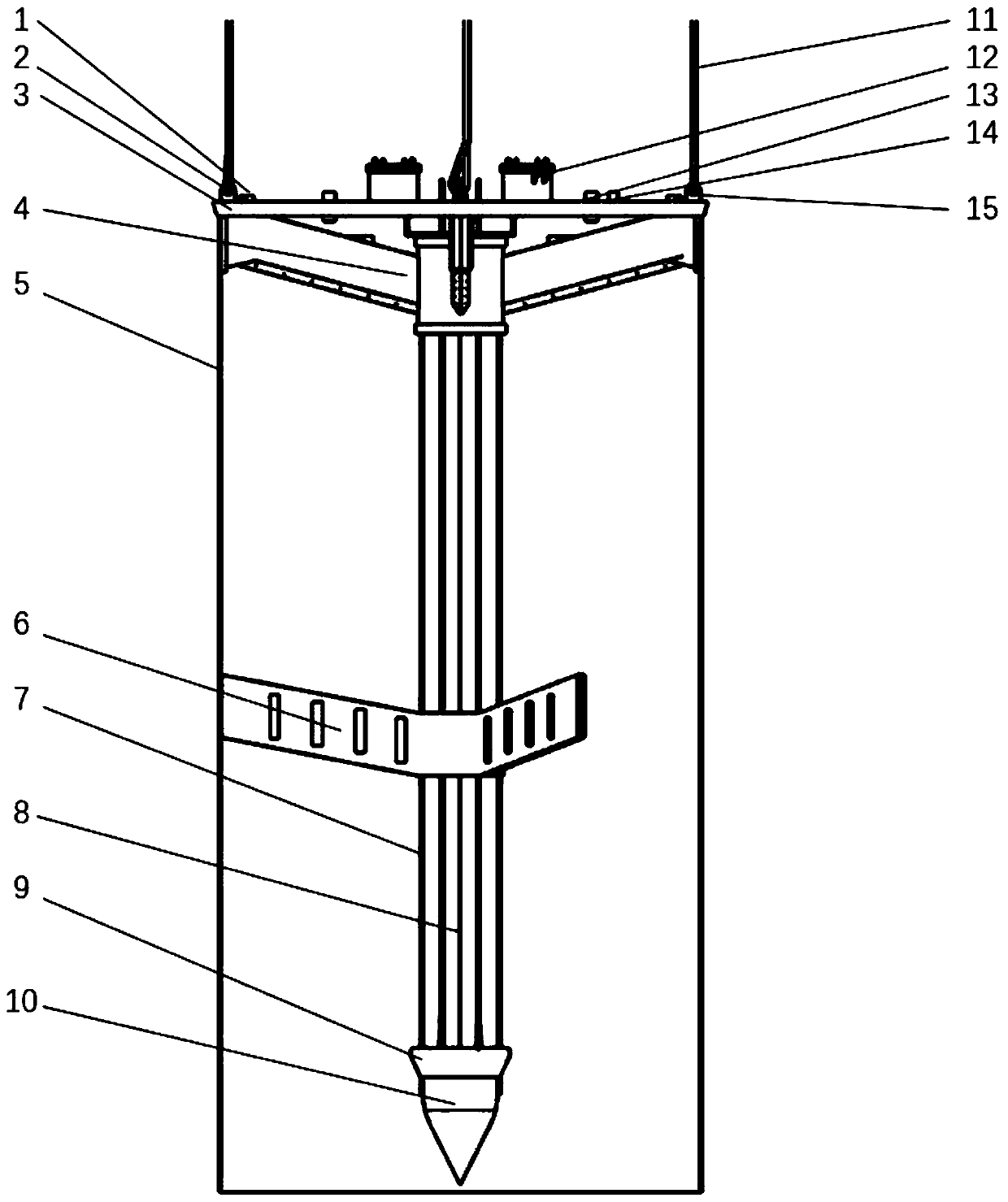

Suction anchor type surface layer well building device suitable for deep water natural gas hydrate exploitation

PendingCN110359843AShallow geological adaptabilityImprove job safetyConstructionsLiquid/gas jet drillingWellheadNatural gas

The invention discloses a suction anchor type surface layer well building device suitable for deep water natural gas hydrate exploitation. The suction anchor type surface layer well building device comprises a suction anchor type guide pipe top cover, a suction anchor outer cylinder, an inner guide pipe, a soil plug prevention functional rib plate, a supporting rib plate and a recoverable conicalguide pipe plug. The suction anchor type guide pipe top cover, the suction anchor outer cylinder and the inner guide pipe are combined to form a suction anchor type guide pipe basic form; the recoverable conical guide pipe plug consists of a conical guide pipe plug and a telescopic fixing device. The suction anchor type surface layer well building technology can be realized by combining the suction anchor installation technology with a guide pipe, the conventional surface layer well construction jetting down-flowing guide pipe technology is replaced, the bearing capacity of a wellhead system is greatly improved, the suction anchor type surface layer well building device is suitable for deep water natural gas hydrate exploitation, meanwhile, the earth plug phenomenon frequently encounteredin suction anchor installation is avoided, and the guide pipe is internally clean and free of mud after installation.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

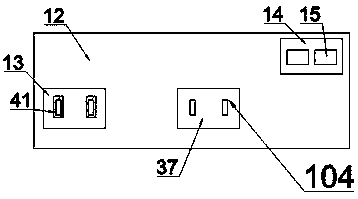

Power plug size and plugging detection device

InactiveCN110788019ARealize automatic eliminationRealize automatic automatic eliminationSortingEngineeringElectric wire

The invention discloses a power plug size and plugging detection device. The power plug size and plugging detection device comprises a detection box; a detection cavity with a rightward opening is formed in the detection box; a conveying device used for conveying power plugs is arranged in the detection cavity, and eight clamping devices used for clamping and fixing the plugs and wires are arranged on the conveying device; a transverse moving device located on the lower side of the conveying device is arranged in the detection cavity; and a detector is arranged on the left inner wall of the detection cavity and used for detecting the pin size of the plugs and performing plugging detection on the plugs. According to the power plug size and plugging detection device, a size detection mechanism can detect the length, width and height of the pin of a plug, and a transverse moving mechanism can connect the plug to a socket and make a wire in contact with contacts on an electric test platform to achieve plugging detection; and plugging detection and size detection are completed in the same period of time, so that the detection time is shortened, and the detection efficiency is improved.Thus, the power plug size and plugging detection device can perform pin size detection and plugging detection of plugs automatically.

Owner:ZHUJI XIANGBO INTELLIGENT HOME TECH CO LTD

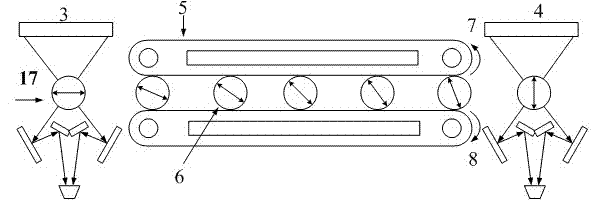

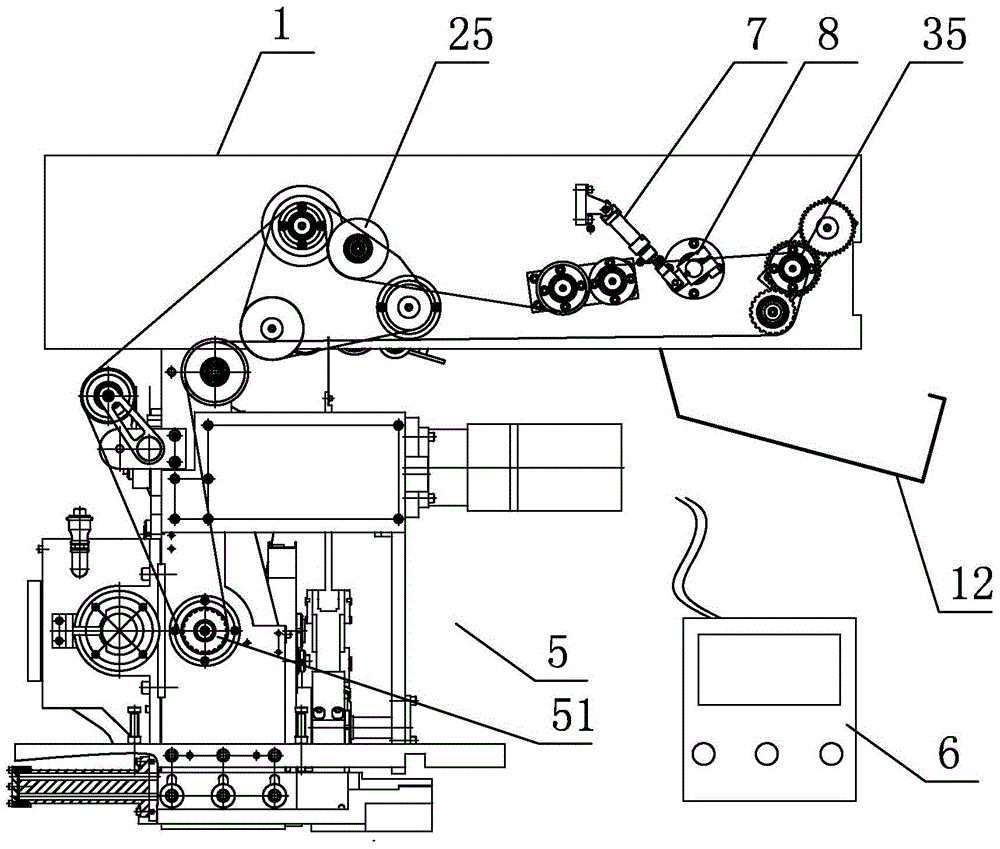

Liquid plastic bottle leak detector for production line and detecting method thereof

InactiveCN106353037ARealize automatic eliminationLabor savingFluid-tightness measurementProduction lineEngineering

The invention relates to a liquid plastic bottle leak detector for production line, several mechanical hands are arranged on both end sides of moving directions of conveyor belt, the mechanical hands are connected with drive device, the clamping part of each mechanical hand is composed of a symmetrical clamping head, a pressure sensor is mounted on each clamping head, the pressure sensor is connected with external PLC control cabinet; a distributor is arranged at the entry end of the conveyor belt, the distributor arranges the distance of bottles entering the conveyor belt; a start detecting sensor is arranged at the entry end of conveyor belt. The bottle leak detector can detect the seal condition of plastic bottles by pressing lightly on the bottles, the device can realize effective identification so that products can be 100% detected, which avoids the problems caused by manual detecting, saves a lot of labor costs and improves the degree of automation of production enterprises.

Owner:阎文

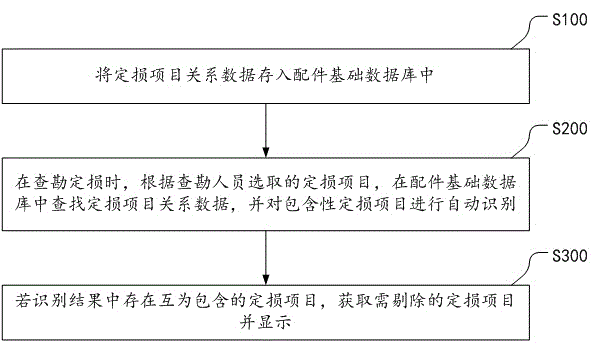

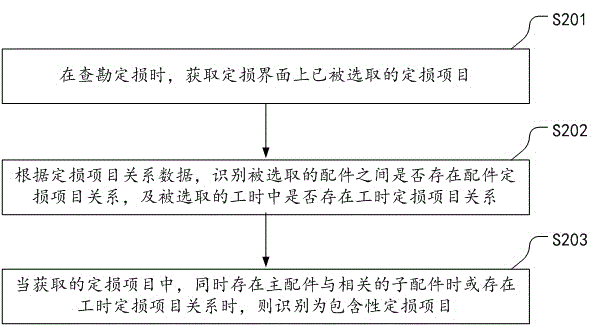

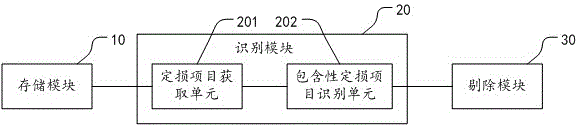

Method and system for deleting mutually inclusive loss assessment project in intelligent loss assessment of car insurance

ActiveCN106600418ARealize automatic eliminationImprove efficiencyFinanceSystems managementComputer science

The invention discloses a method and system for deleting a mutually inclusive loss assessment project in the intelligent loss assessment of the car insurance. The method comprises the steps: storing loss assessment relation data into an accessory basic database; searching the loss assessment relation data in the accessory basic database according to a loss assessment project selected by an investigator during investigation and loss assessment, and carrying out the automatic recognition of an inclusive loss assessment project; obtaining and displaying a to-deleted loss assessment project if the recognition result has the mutually inclusive loss assessment project. According to the invention, the method achieves the automatic deleting of the inclusive loss assessment project through functions of system prompt accessories and work time mutually inclusive project, achieves the automatic deleting of system management and control inclusive leakage, and greatly improves the efficiency and scale of inclusive leakage control.

Owner:CHINA PING AN PROPERTY INSURANCE CO LTD

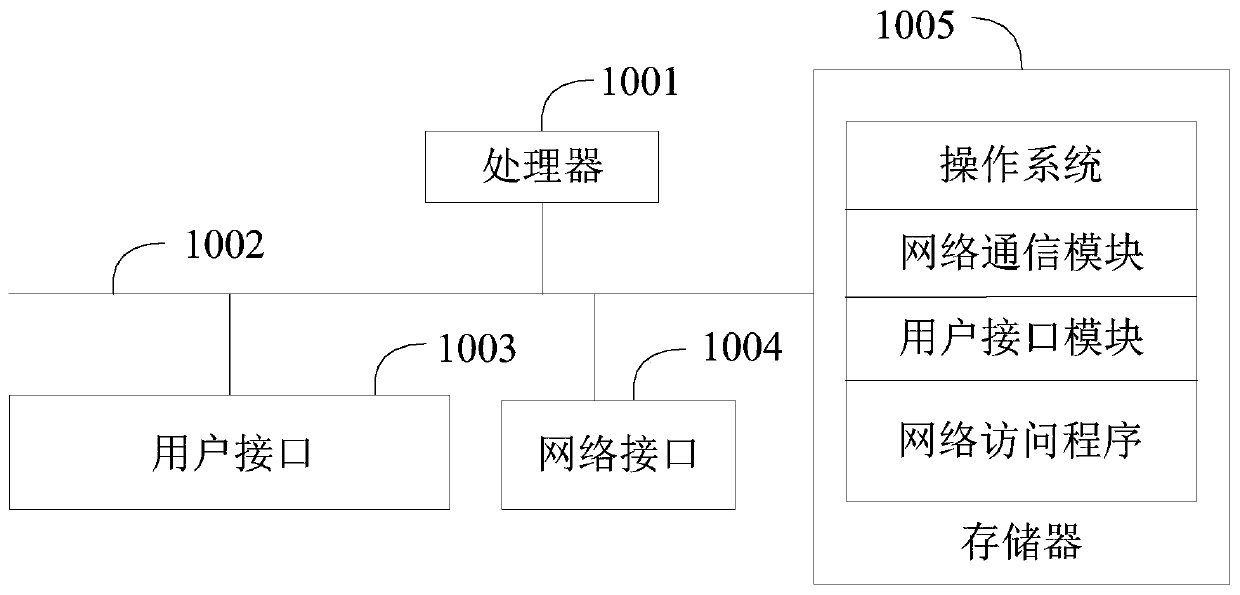

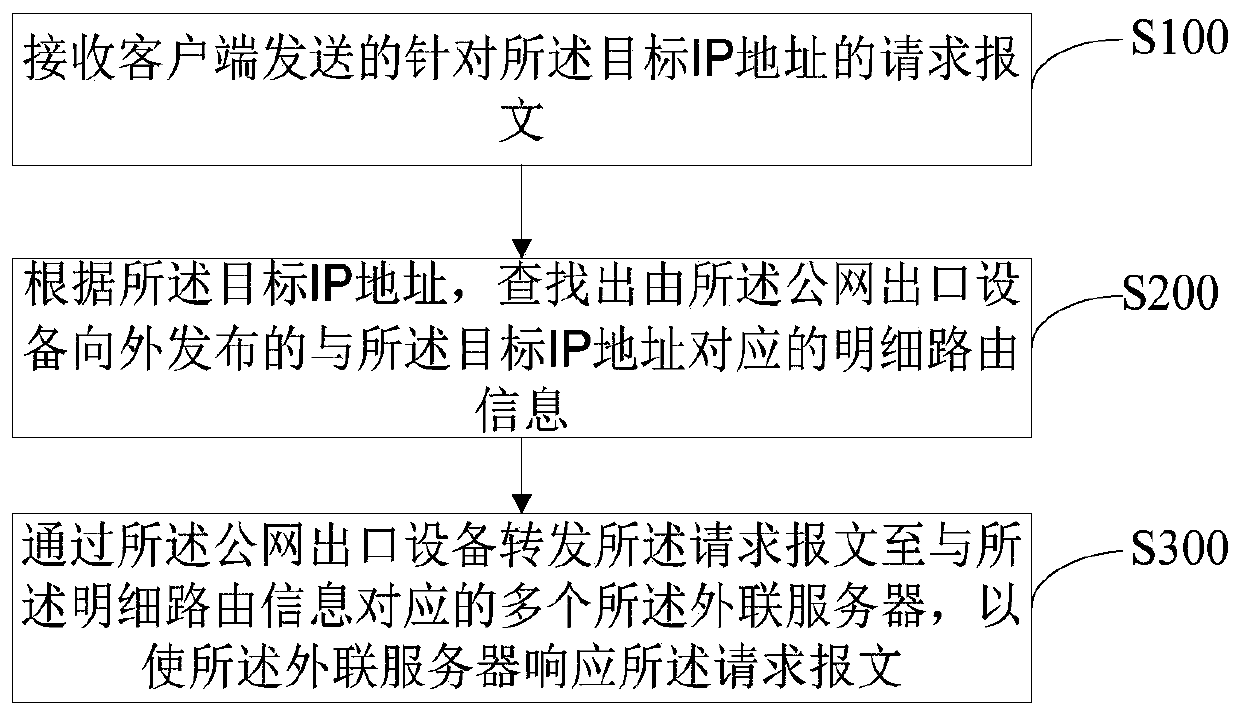

Network access method, system and equipment and computer readable storage medium

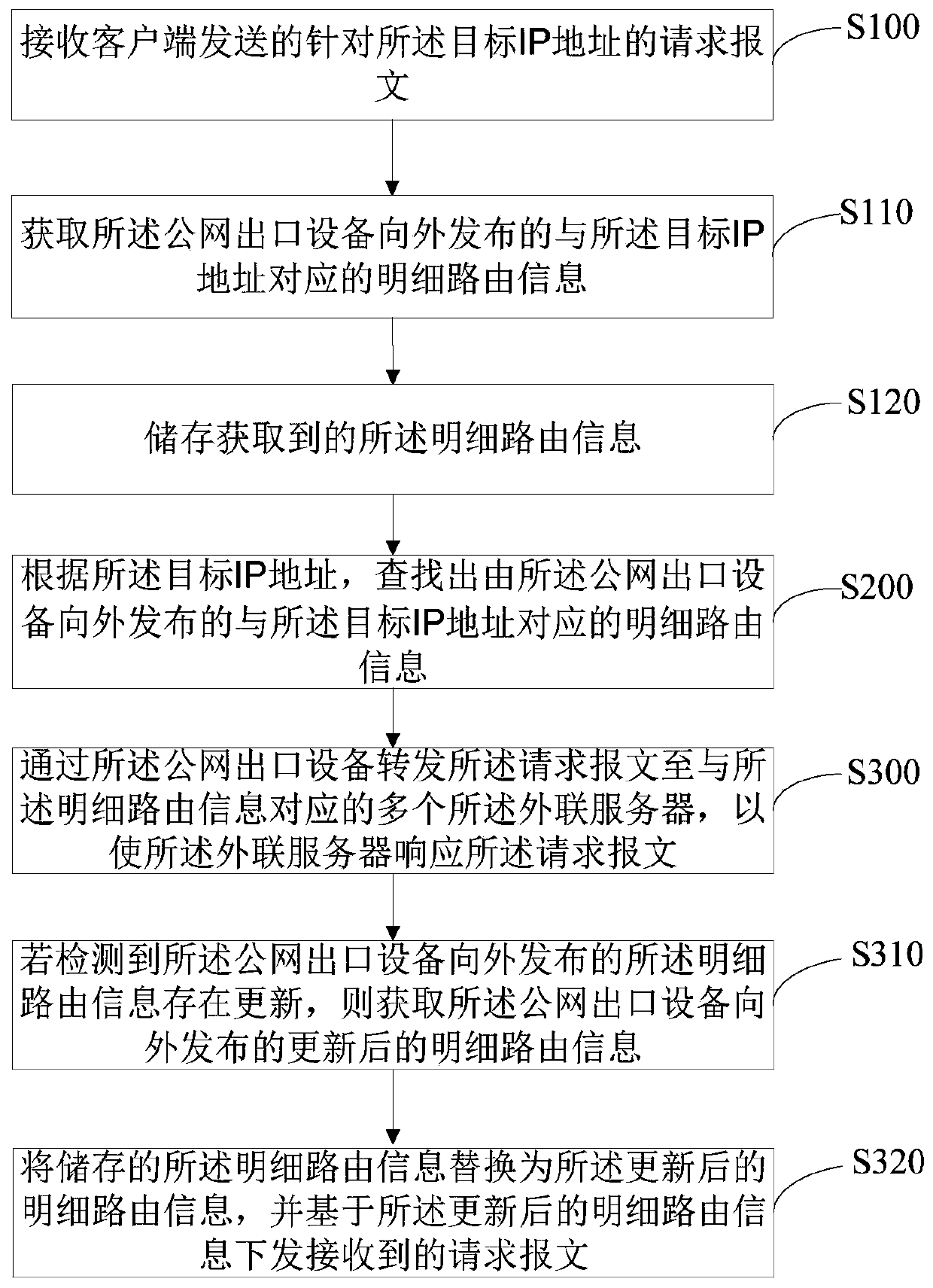

PendingCN109729190AMeet high real-time business requirementsRealize automatic eliminationData switching networksIp addressExternal connection

The invention discloses a network access method, system and equipment and a computer readable storage medium. The method comprises the following steps: receiving a request message for a target IP address sent by a client, Wherein the target IP address is returned to the client by a domain name system DNS server according to a target domain name sent by the client; According to the target IP address, searching detailed routing information which is published outwards by the public network outlet equipment and corresponds to the target IP address, Wherein the detail routing information comprisesaddress routes of a plurality of external connection servers; And forwarding the request message to the plurality of external connection servers corresponding to the detail routing information throughthe public network exit equipment, so that the external connection servers respond to the request message. According to the invention, the problem that the local DNS server is damaged for a long timedue to the fact that the fault of the remote external connection server cannot be perceived in time is solved.

Owner:WEBANK (CHINA)

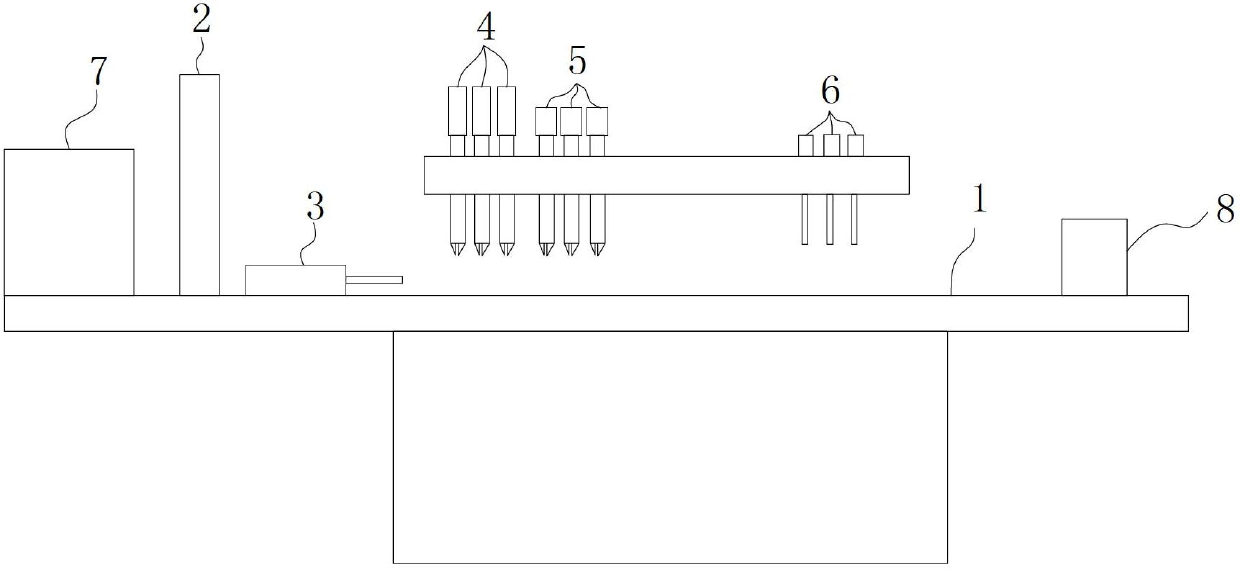

Automatic light emitting diode packaging detection device capable of automatically removing defective products

The invention discloses an automatic light emitting diode packaging detection device capable of automatically removing defective products. The automatic light emitting diode packaging detection devicespecifically comprises a base, a detection table, diodes, a movable guide rail and detection probes, the detection table is mounted in the middle of the top of the base, a waste box is embedded in one side of the top of the base, and a mounting groove is formed in the other side of the top of the base; and a control box is mounted in the mounting groove, a material supply mechanism is mounted atone end of the detection table through a frame body, and a feeding mechanism is fixed to the other end of the detection table through a frame body. The automatic light emitting diode packaging detection device capable of automatically removing the defective products is provided with the movable guide rail, the two detection probes and an infrared locator, so that automatic positioning detection can be achieved, manual operation is not needed, the detection efficiency is higher, assembly line type detection can be conveniently conducted on the diodes, movement between the detection probes doesnot interfere with each other, the diodes of different specifications can be conveniently detected, and the applicability is higher.

Owner:重庆信易源智能科技有限公司

Diode pin bending device capable of conducting surface scratch detection on diode

InactiveCN112091128AImprove processing efficiencyImprove work efficiencySortingStructural engineeringWorkbench

The invention discloses a diode pin bending device capable of conducting surface scratch detection on a diode. The diode pin bending device particularly comprises a base, a workbench, a moving rail and a functional seat; a frame body is mounted at the top end of the base, a control panel is mounted in the middle of one side of the frame body, and an electromagnetic sliding rail is arranged in themiddle of the top end in the frame body; a sliding block is mounted in the electromagnetic sliding rail, and a grabbing mechanism is fixed to the bottom end of the sliding block; and the moving rail is mounted in the middle of the top end of the base, and the workbench is mounted on the moving rail. According to the diode pin bending device capable of conducting surface scratch detection on the diode, by arranging the functional seat, a bending seat and a cutting seat are arranged in the functional seat, a cutting knife on the cutting seat can cut pins of the diode, the bending seat can bend the pins, that is, the diode can be bent and cut off only by fixing the diode once, and the working efficiency is higher.

Owner:广州市金点子机电科技发展有限公司

Removing mechanism for combined saddle-stitching machine

InactiveCN104670963ARealize automatic eliminationImprove work efficiencyArticle deliveryAutomatic controlControl system

The invention discloses a removing mechanism for a combined saddle-stitching machine, relates to a removing device for a bookbinding machine, and aims to achieve rapid, efficient and automatically-controlled removal of inferior-quality products and improve working efficiency. The removing mechanism for the combined saddle-stitching machine comprises a frame, a conveying device and a removing device, wherein the conveying device and the removing device are mounted on the frame. The removing device is positioned at the output end of the conveying device and comprises a transmission shaft, a driving shaft and conveying belts. Two ends of each transmission shaft and the driving shaft are rotationally mounted on the frame. Wheels are mounted on the transmission shaft rotationally. Turning plates are fixed on the transmission shaft which is driven by a driving device. The driving device is controlled by a PLC (programmable logic controller) control system. Driving wheels are fixedly mounted on the driving shaft which is driven by a driving system below the frame. The conveying belts are connected to the wheels and the driving wheels.

Owner:ANHUI PRINTING MECHANICAL & ELECTRICAL

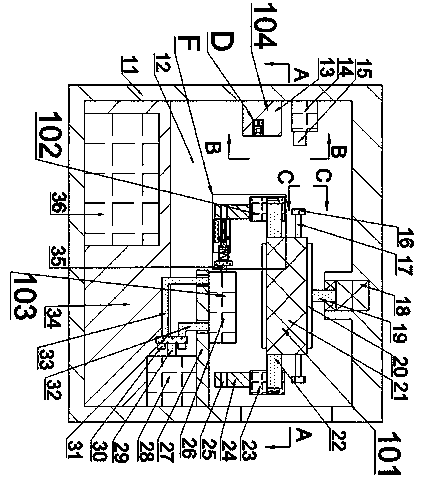

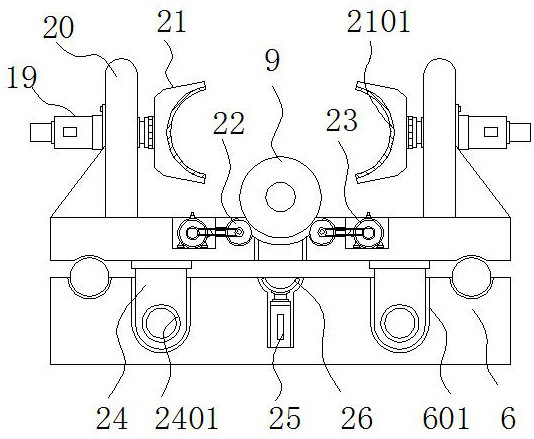

Automatic bearing channel detection device

PendingCN109454017ARealize automatic feeding processRealize automatic eliminationMachine bearings testingSortingMechanical engineeringEngineering

The invention provides an automatic bearing channel detection device. The automatic bearing channel detection device comprises a bottom plate and further comprises rotation storage barrels, a conveying belt, pushing mechanisms, a detection workbench and transverse moving feeding mechanisms, all of which are arranged on the bottom plate. Material barrel air cylinders of the rotation storage barrelspush workpieces to the conveying belt one by one. The detection workbench sequentially comprises a to-be-detected station, a detection station, a transferring station and a to-be-discharged station.The detection station is provided with a detection mechanism, and the transferring station is provided with a waste falling mechanism. The pushing mechanisms are used for pushing the workpieces to theto-be-detected station, and the transverse moving feeding mechanisms are used for sequentially conveying the workpieces to the detection station, the transferring station and the to-be-discharged station. The waste falling mechanism is used for pushing workpieces disqualified through detection into a waste port of the detection workbench. The automatic bearing channel detection device is high indetection degree, the labor cost is reduced, and the detection efficiency is improved.

Owner:浙江科菱智能装备有限公司

Bottle body removing device and bottle body detection equipment

ActiveCN113118050AImprove screening efficiencyRealize automatic eliminationSortingPlastic recyclingImage detectionEngineering

The invention relates to the technical field of quality inspection equipment, and provides a bottle body removing device and bottle body detection equipment. The bottle body removing device comprises a removing conveying belt, a nozzle assembly and a controller, wherein the removing conveying belt is used for driving bottle bodies to move; an air outlet of the nozzle assembly faces the removing conveying belt, and the air flow direction of the air outlet is perpendicular to the moving direction of the removing conveying belt; and the nozzle assembly is electrically connected with the controller, the controller is arranged to control the nozzle assembly to spray air to abnormal bottle bodies, and the abnormal bottle bodies are detected by the controller through bottle body images collected by an image collecting assembly. According to the bottle body removing device and the bottle body detection equipment, the removing conveying belt, the nozzle assembly and the controller are arranged, the controller can control the nozzle assembly to spray air to the removing conveying belt in time, the abnormal bottle bodies can be automatically removed, and the screening efficiency of the bottle bodies can be improved.

Owner:深兰智能科技(上海)有限公司

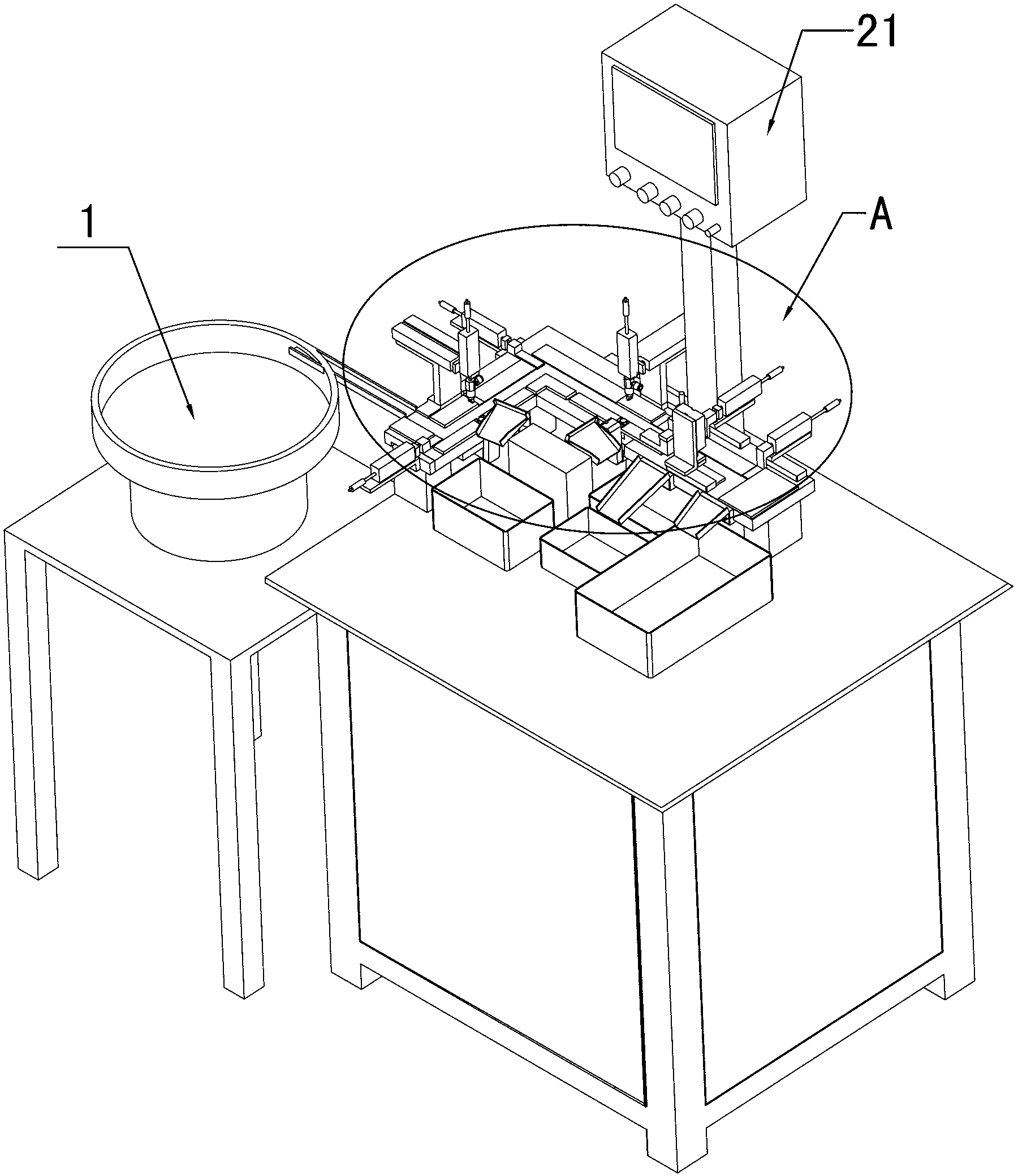

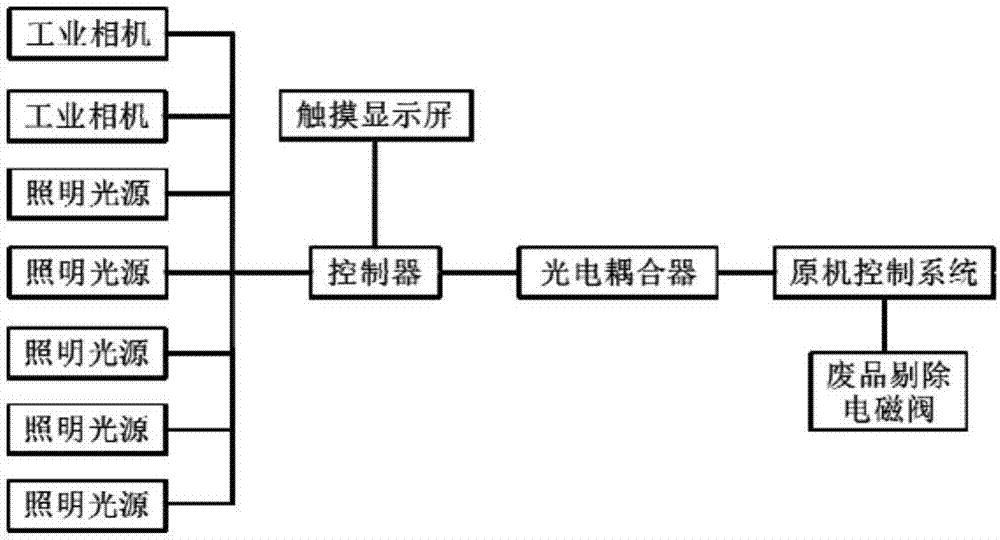

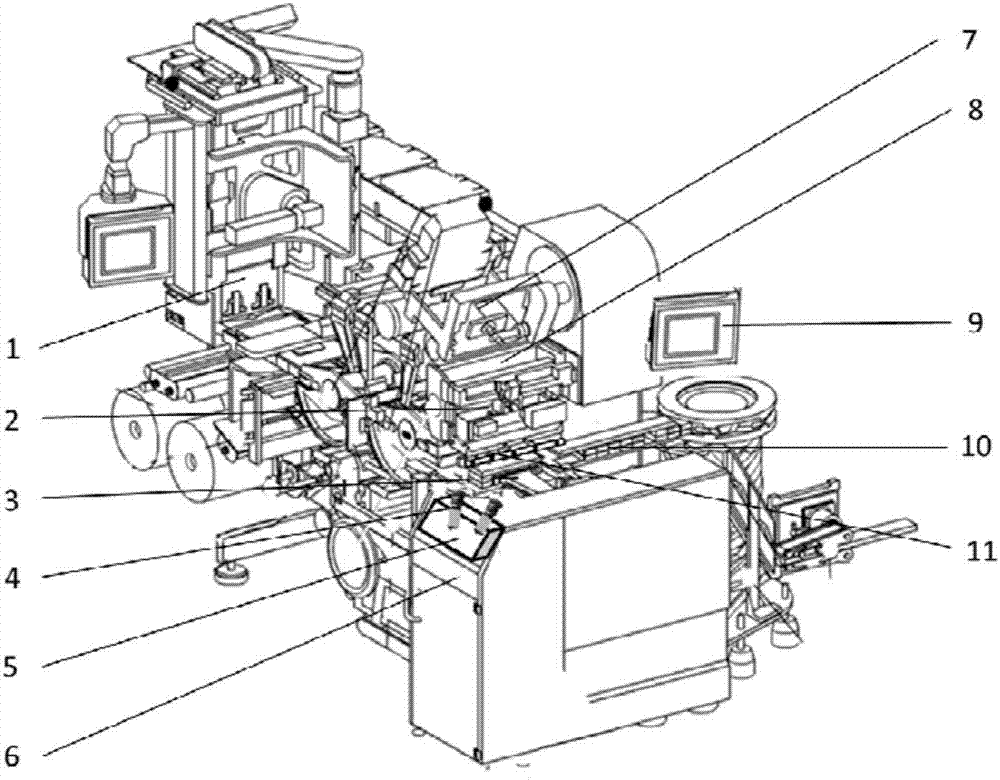

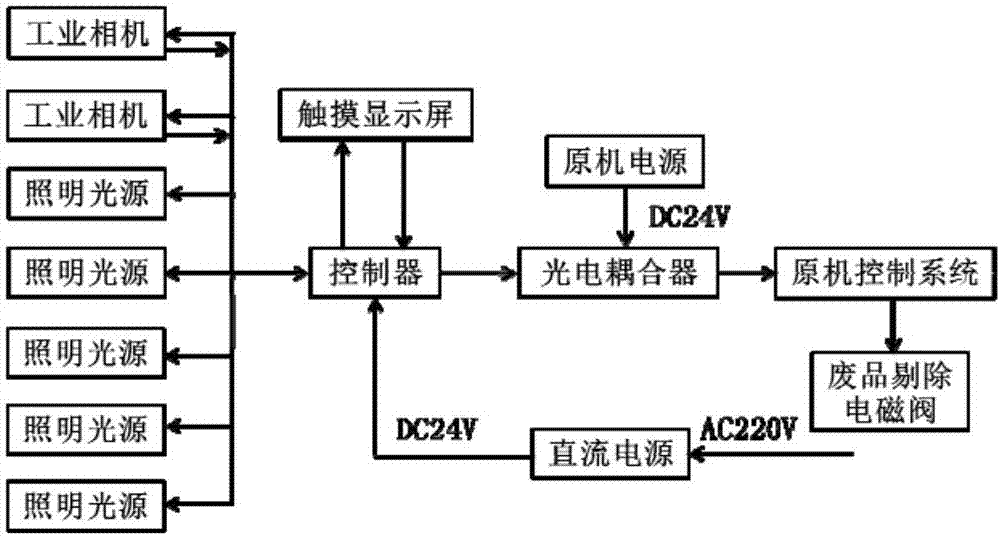

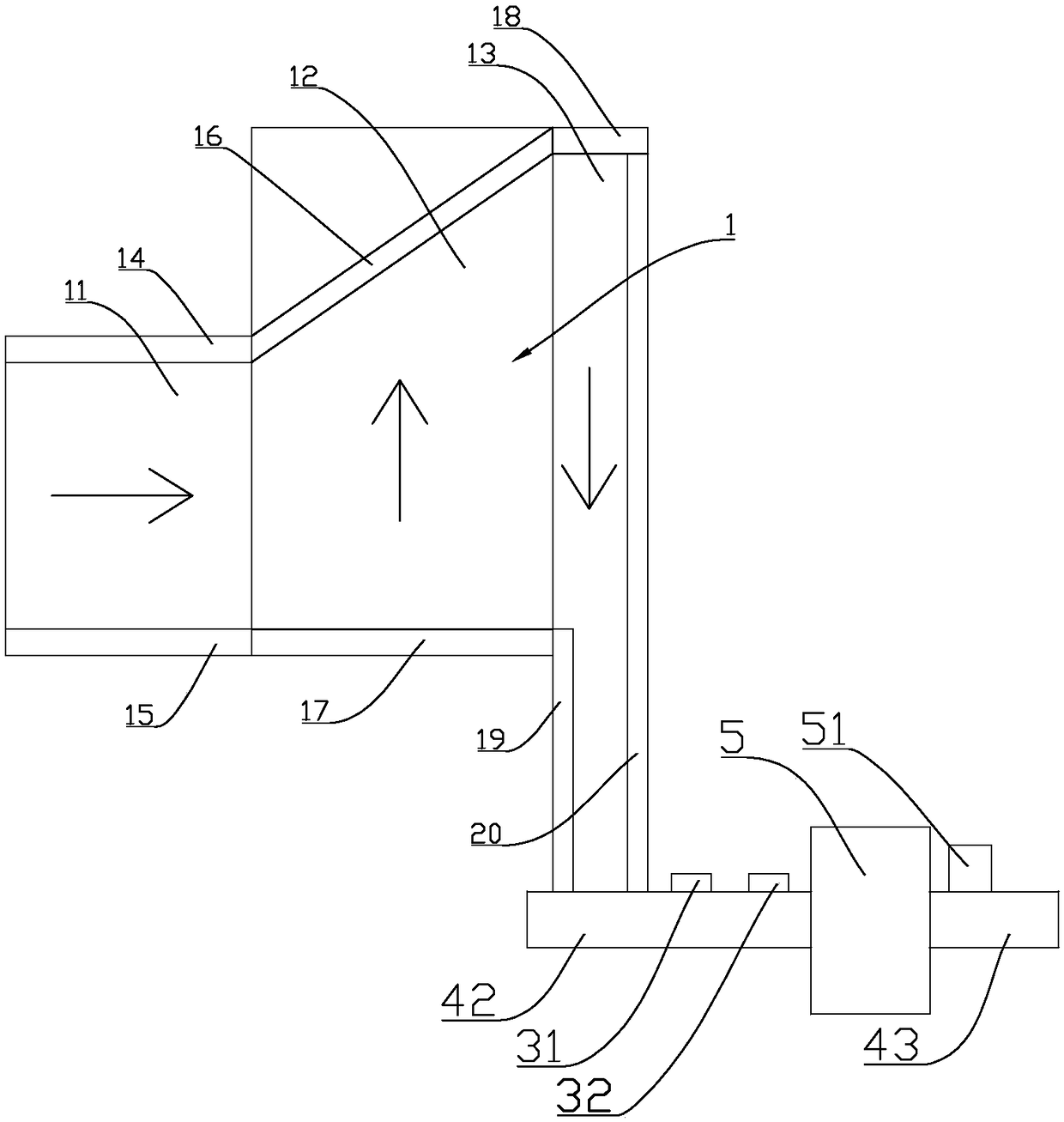

Visual inspection device for glue point of barrel paper of barrel packaging machine

ActiveCN107449783ARealize automatic eliminationPrevent inflowOptically investigating flaws/contaminationMachine controlVisual inspection

The invention discloses a visual inspection device for a glue point of barrel paper of a barrel packaging machine. The device comprises an industrial camera, a mounting bracket, a direct current power supply, an illuminating light source, a touch display, an electric cabinet box body, a photoelectric coupler and a controller, wherein the industrial camera is mounted in a position of a base next to a cigarette pushing plate of a BV high speed barrel box packaging machine; the illuminating light source is mounted in a position of a barrel paper conveying channel through the mounting bracket the touch display and the controller are mounted on the electric cabinet box body; the electric cabinet box body is mounted in a position of a wallboard of the BV high speed barrel box packaging machine; and the industrial camera, the touch display, the illuminating light source and output of the controller are electrically connected to an original machine control plate of the BV high speed barrel box packaging machine. The device can find loss or reduction of glue on the barrel paper in production immediately, can achieve the functions of automatic detection, elimination, statistics and alarming of defective products at the glue point of the barrel paper without interrupting the production flow, so that the detection speed and the operating speed of the equipment are perfectly matched.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

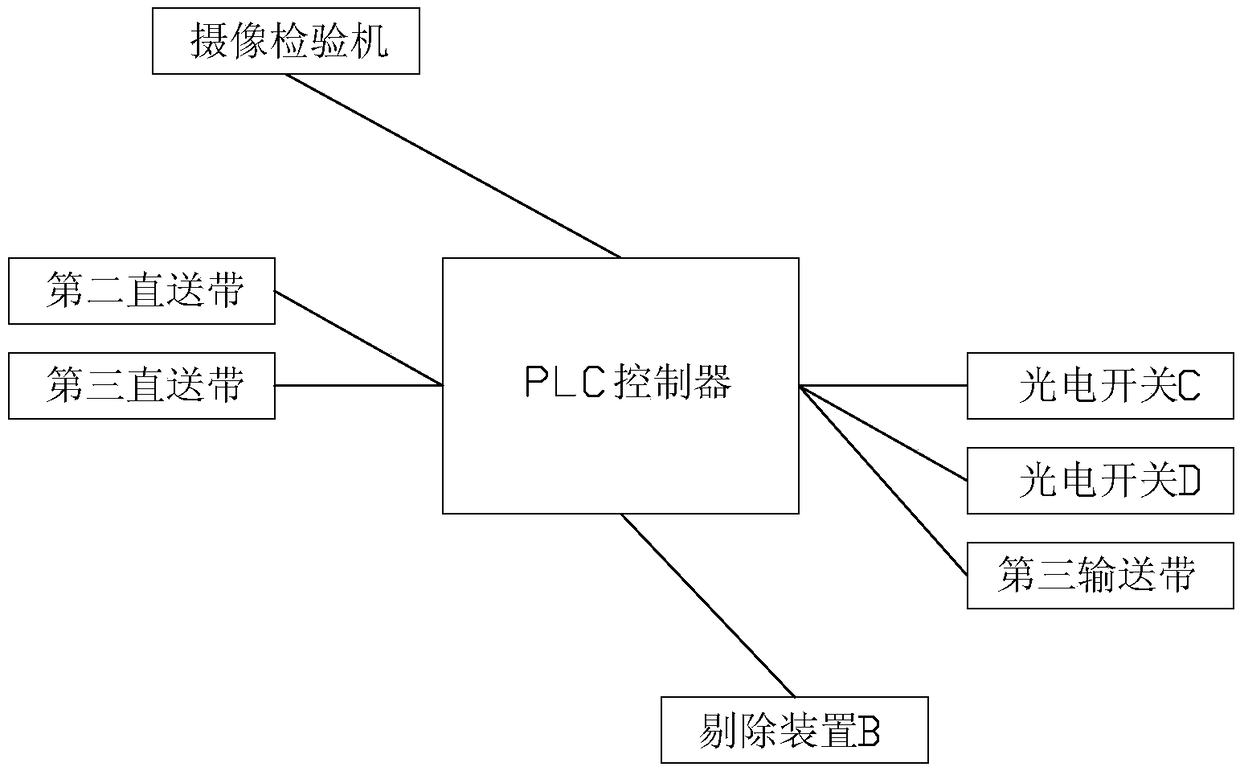

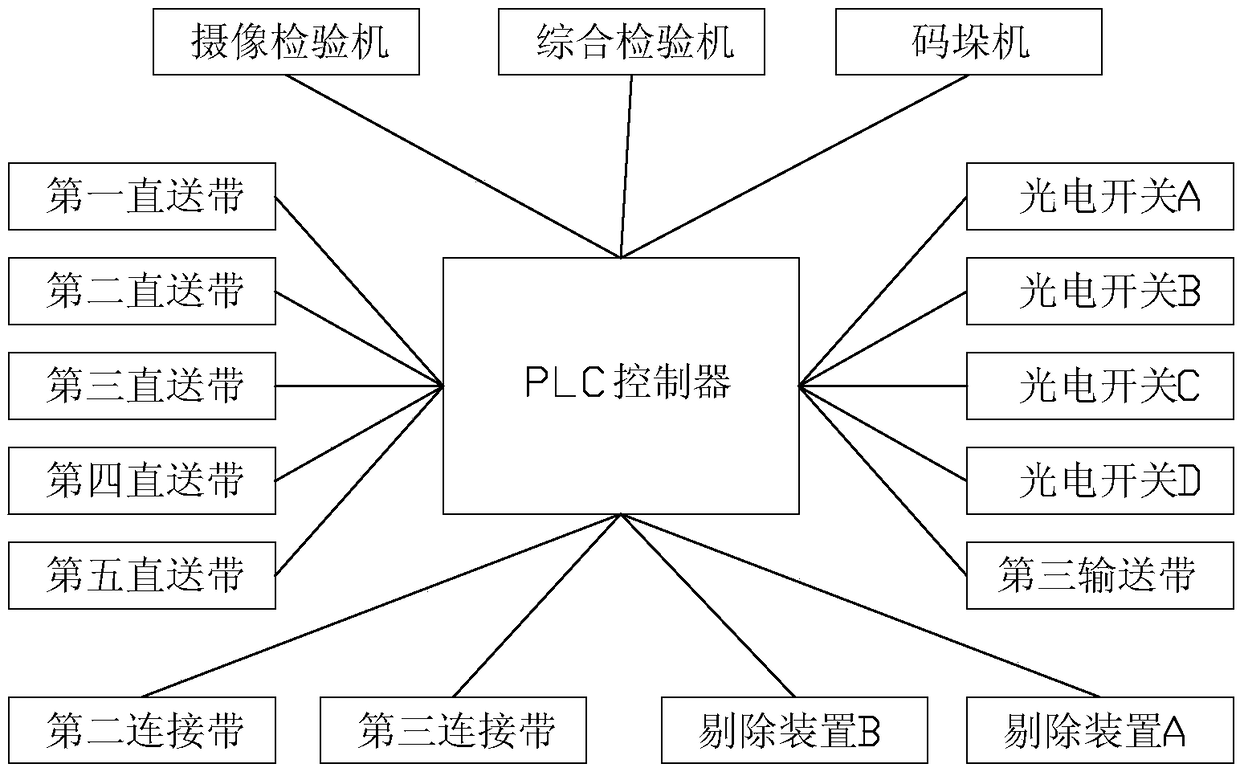

Camera inspection device for empty glass bottles

InactiveCN109279295ARealize automatic eliminationPrevent bottles from being jammed and droppedControl devices for conveyorsPackaging automatic controlEngineeringBottle

The invention discloses a camera inspection device for empty glass bottles. The camera inspection device for the empty glass bottles comprises a feeding device and a camera inspection machine which are sequentially arranged from front to back. The empty glass bottles discharged by the feeding device are conveyed to the camera inspection machine through a second direct conveying belt, and then theempty glass bottles are discharged out of the camera inspection machine through a third direct conveying belt. An optoelectronic switch D and an optoelectronic switch C are arranged on the side portion of the second direct conveying belt in sequence from front to back. A removal device B is arranged on the side portion of the third direct conveying belt. The camera inspection machine, the second direct conveying belt, the third direct conveying belt, the optoelectronic switch C, the optoelectronic switch D and the removal device B are all connected with a PLC. Products incapable of passing inspection of the camera inspection machine can be automatically removed through the removal device B connected with the PLC, the empty glass bottle conveying condition of the direct conveying belts is monitored through the optoelectronic switch C and the optoelectronic switch D connected with the PLC, and therefore, the empty glass bottles are prevented from getting stuck or falling off at any position.

Owner:DEQING CAIFU GLASS

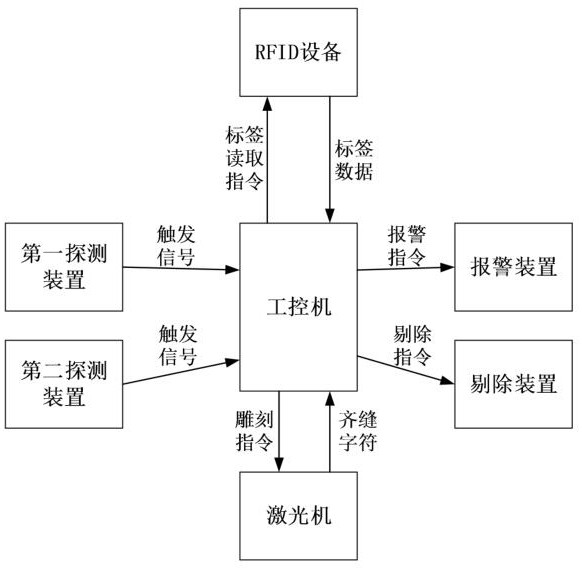

Automatic engraving system and method for seam characters based on RFID

InactiveCN113814573AThere will be no phenomenon of repeated codesThere will be no missing codesMemory record carrier reading problemsLaser beam welding apparatusEngravingSoftware engineering

The invention relates to the technical field of engraving, and specifically relates to an automatic engraving system and method for seam characters based on RFID. The system comprises a first detection device, RFID equipment, a second detection device, an industrial personal computer and a laser machine, the first detection device is used for detecting whether a product with an RFID tag enters an identification area or not; the RFID equipment is used for reading data in the RFID tag and transmitting the data to the industrial personal computer; the second detection device is used for detecting whether the product enters an engraving area or not; the industrial personal computer is used for transmitting the seam characters in the received data to the laser machine and sending an engraving instruction to the laser machine when the product enters the engraving area; and the laser machine is used for executing engraving operation after receiving the engraving instruction. The method comprises the following steps that when the product with the RFID tag enters the identification area, the data in the RFID tag are subjected to reading; when the product enters the engraving area, the engraving instruction is sent to the laser machine; and the laser machine executes the engraving operation after receiving the engraving instruction. According to the automatic engraving system and the method for the seam characters based on the RFID, the problem of repeated engraving can be avoided, and unqualified products can also be removed.

Owner:成都普什信息自动化有限公司

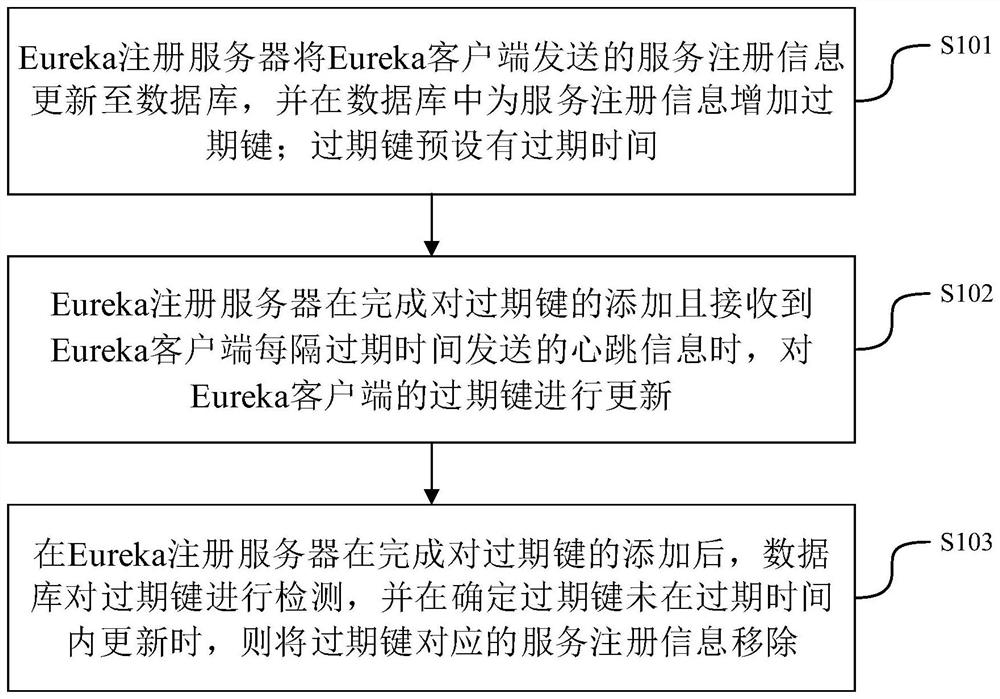

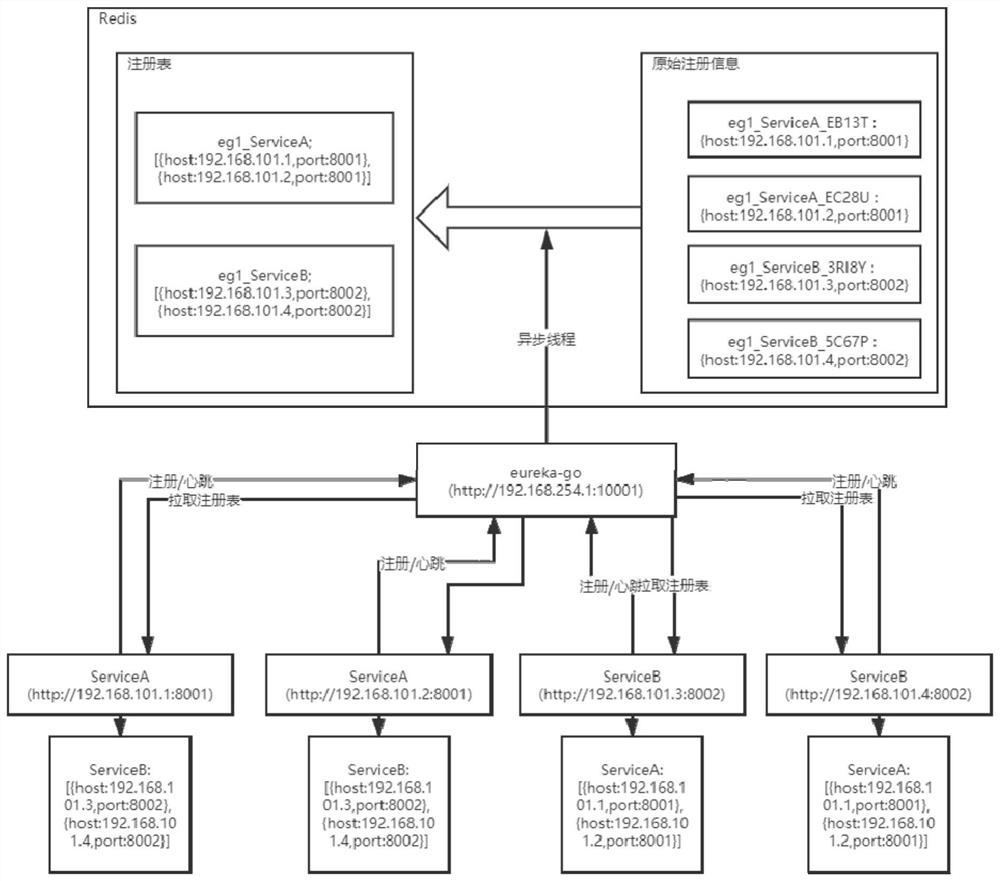

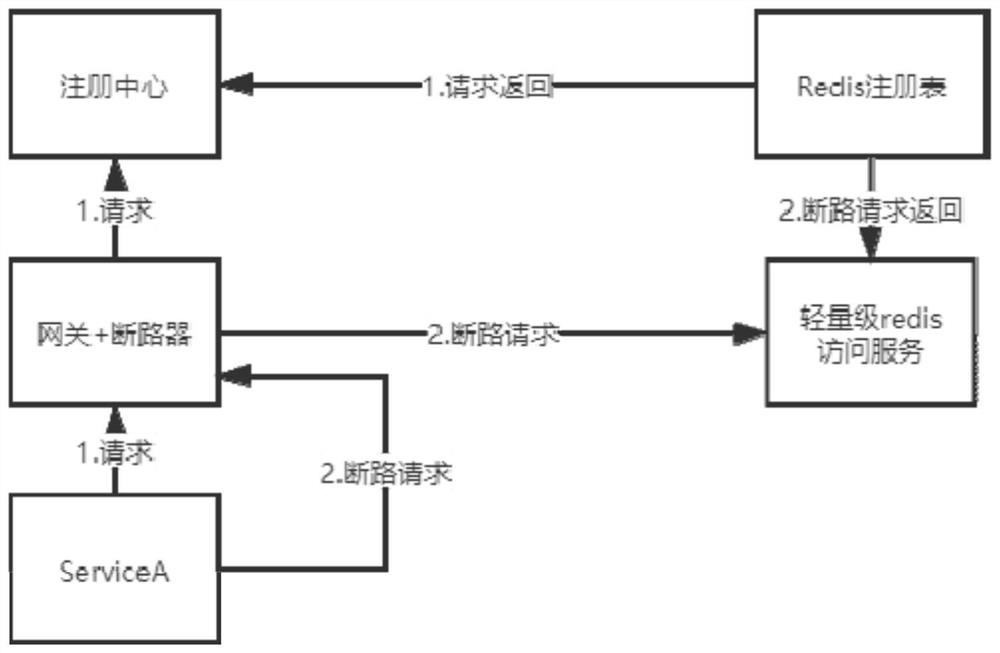

Eureka service management and control method and system and readable storage medium

ActiveCN113190546AReduce storage pressureRealize automatic eliminationDatabase updatingSpecial data processing applicationsExpiration TimeEngineering

The invention discloses an Eureka service management and control method and system and a medium, and the method comprises the steps that an Eureka registration server updates service registration information sent by an Eureka client to a database, and adds an expiration key for the service registration information in the database; expiration time is preset in the expiration key; the Eureka registration server updates the expired key of the Eureka client when completing the addition of the expired key and receiving heartbeat information sent by the Eureka client every expiration time; after the Eureka registration server completes addition of the expired key, the database detects the expired key, and when it is determined that the expired key is not updated within expiration time, service registration information corresponding to the expired key is removed; according to the method, the database can be used for storing the service registration information, and the expiration key is used for realizing automatic elimination of the service registration information, so that the management efficiency of the Eureka registration server can be improved.

Owner:成都新希望金融信息有限公司

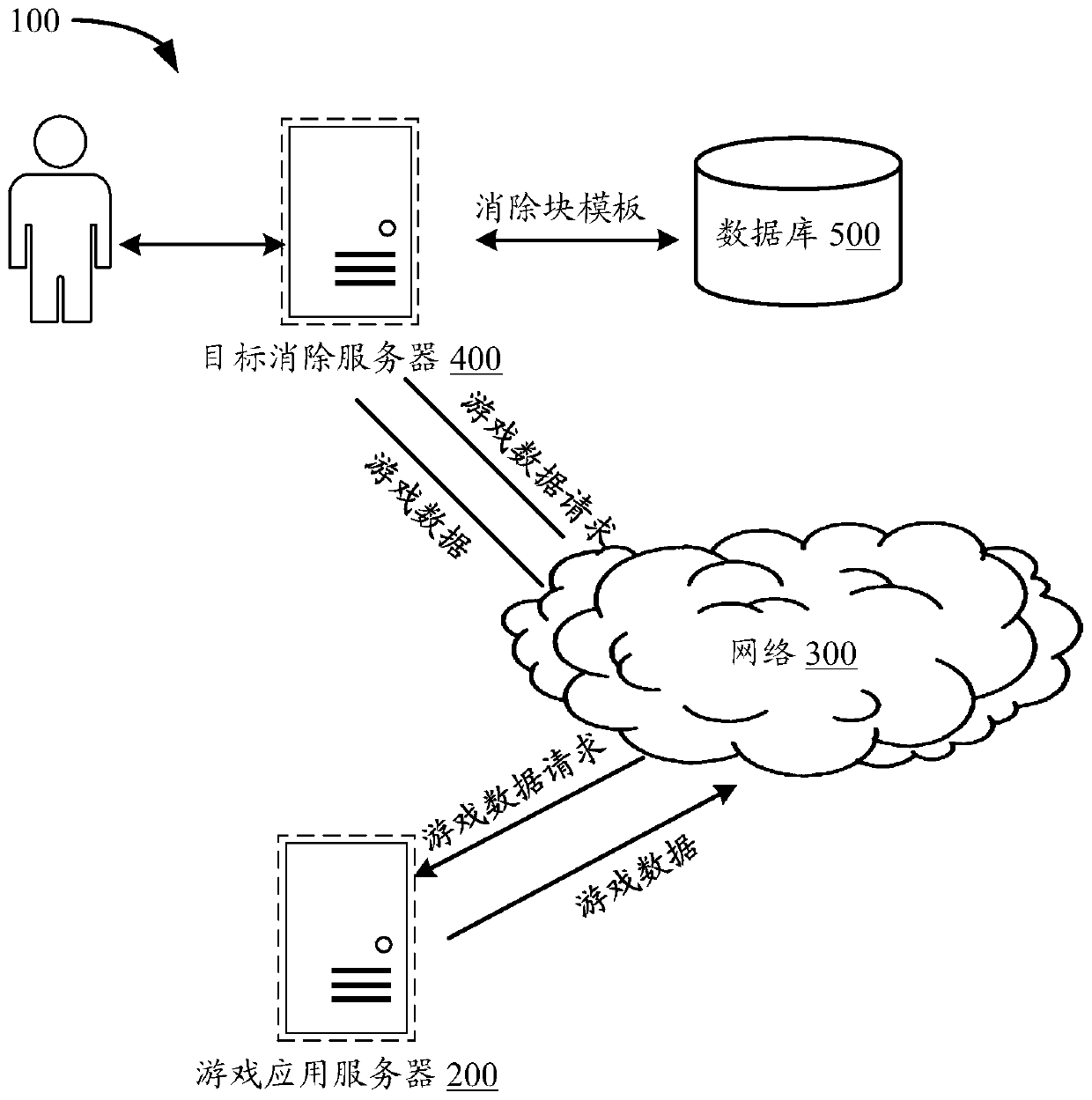

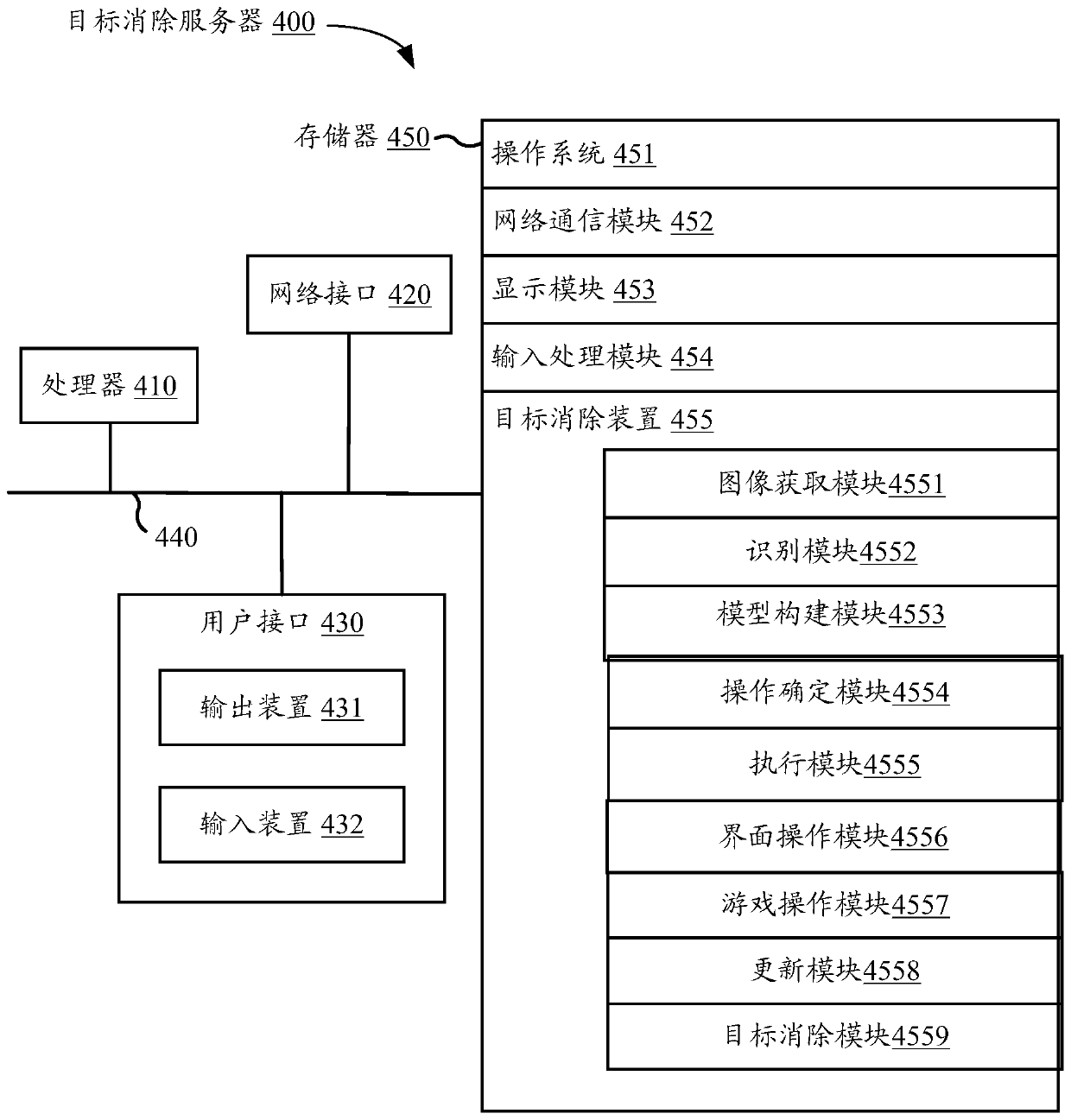

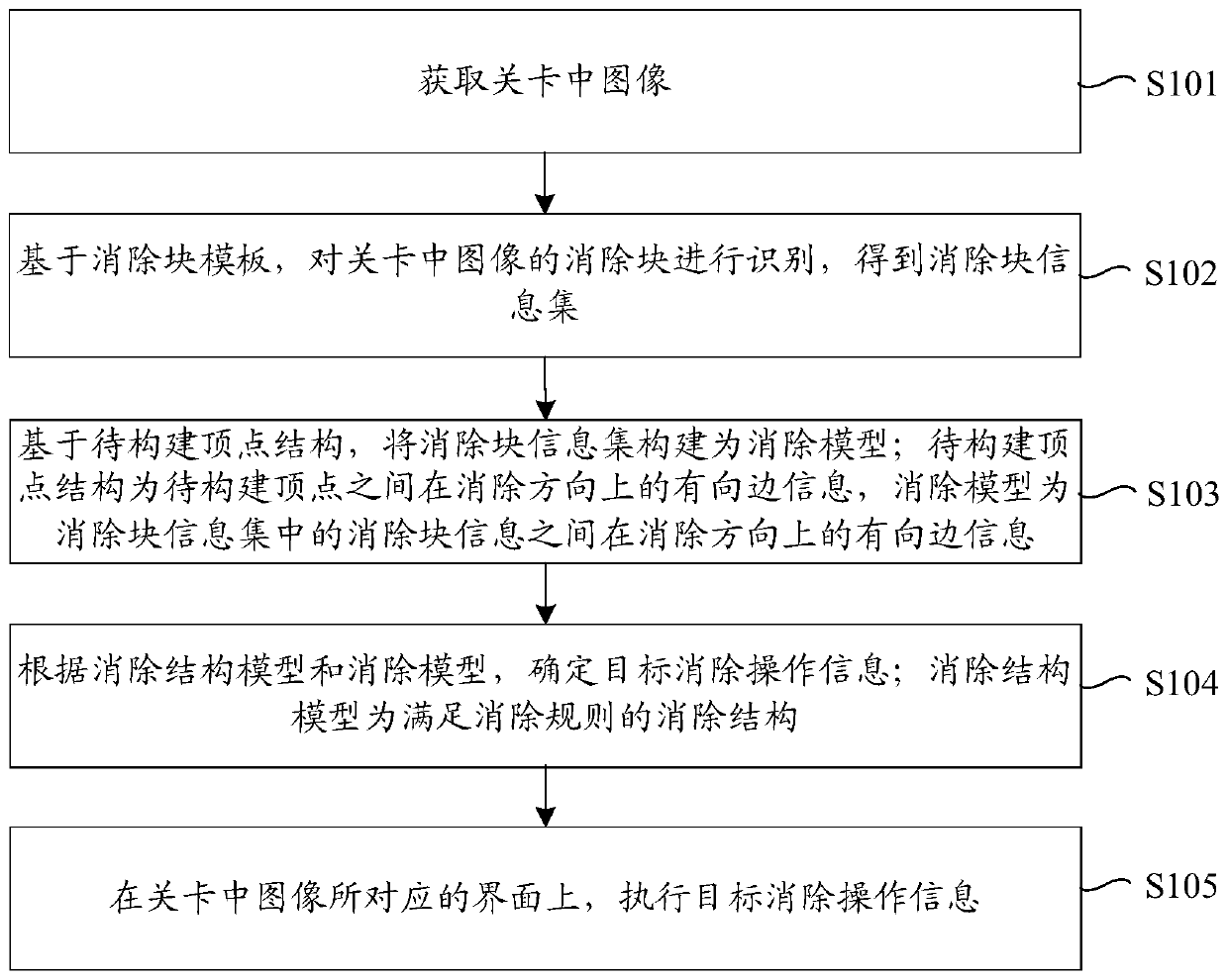

Target elimination method and device

ActiveCN110427241ARealize automatic eliminationImprove intelligenceVideo gamesExecution for user interfacesVertex structureComputer science

The embodiment of the invention provides a target elimination method and device. The target elimination method comprises the following steps: acquiring an image in a checkpoint; based on the elimination block template, identifying elimination blocks of the images in the checkpoint to obtain an elimination block information set; based on the vertex structure to be constructed, constructing the elimination block information set into an elimination model, wherein the to-be-constructed vertex structure is directed edge information between to-be-constructed vertexes in the elimination direction, and the elimination model is directed edge information between elimination block information in the elimination block information set in the elimination direction; determining target elimination operation information according to the elimination structure model and the elimination model, wherein the elimination structure model is an elimination structure meeting an elimination rule; and executing the target elimination operation information on an interface corresponding to the image in the checkpoint. Through the embodiment of the invention, the intelligence of target elimination can be improved.

Owner:TENCENT TECH (SHENZHEN) CO LTD

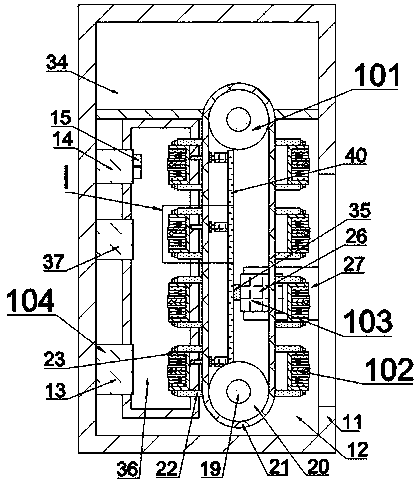

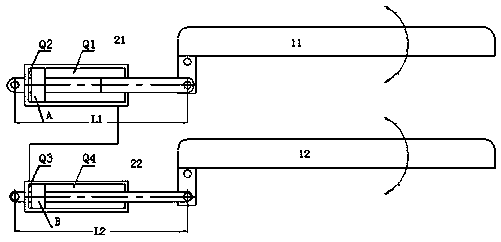

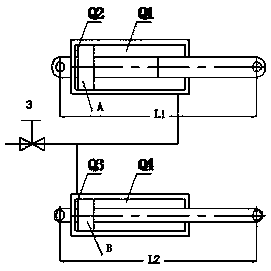

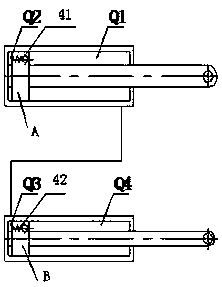

An automatic compensation structure and compensation method for a synchronous hydraulic cylinder of an operating table

ActiveCN104806589BRealize automatic eliminationEliminate height differenceServomotor componentsOperating tablesHydraulic cylinderEngineering

The invention relates to an automatic compensation structure and method of synchronous hydraulic cylinders of an operating table or an operating bed. The automatic compensation structure is applicable to the operating table or the operating bed with longitudinal offset vertical columns, the operating table or the operating bed is provided with a group of synchronous hydraulic cylinders, a first piston and a second piston are arranged in the synchronous hydraulic cylinders respectively and divide the interiors of the synchronous hydraulic cylinders into a first cavity and a third cavity with the same section area, and the first cavity is communicated with the third cavity through a pipeline; a first one-way overflow valve and a second one-way overflow valve are arranged on a piston arranged between the first cavity and a second cavity of the synchronous hydraulic cylinders and on a piston arranged between the third cavity and a fourth cavity of the synchronous hydraulic cylinders respectively; the functions of the first one-way overflow valve and the second one-way overflow valve are preventing hydraulic oil in the second cavity from flowing to the first cavity and preventing hydraulic oil in the third cavity from flowing to the fourth cavity, and enabling the hydraulic oil in the first cavity to flow to the second cavity and the hydraulic oil in the fourth cavity to flow to the third cavity under the set opening pressure of the over-way overflow valves. The automatic compensation structure and method put forward the brand new automatic compensation principle of the synchronous hydraulic cylinders, and achieve automatic elimination of piston position difference by aid of the principle of hydraulic oil pressure difference.

Owner:上海菲曼特医疗器械有限公司

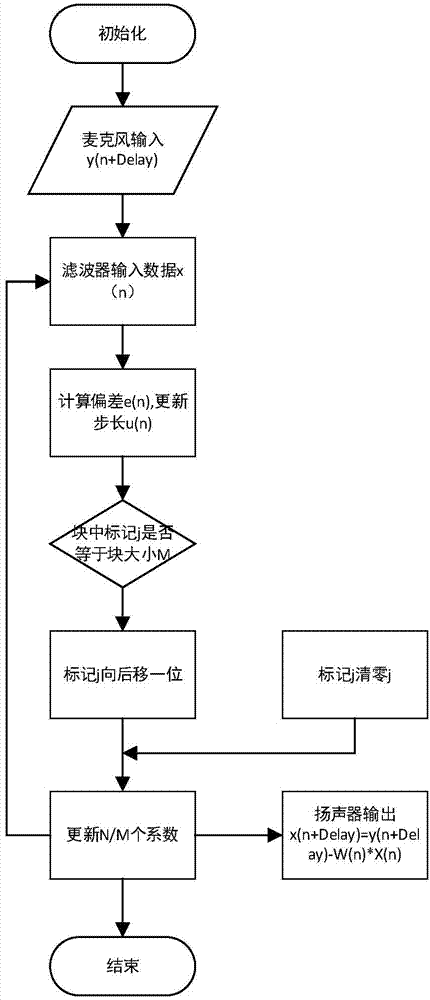

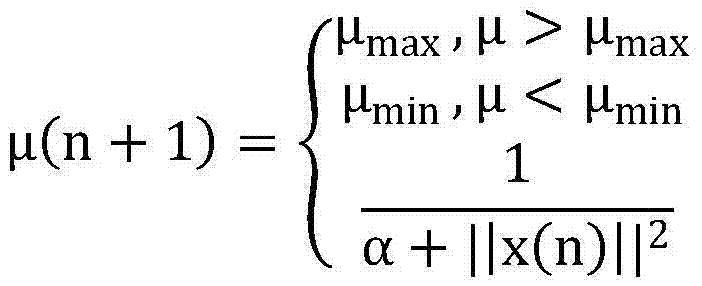

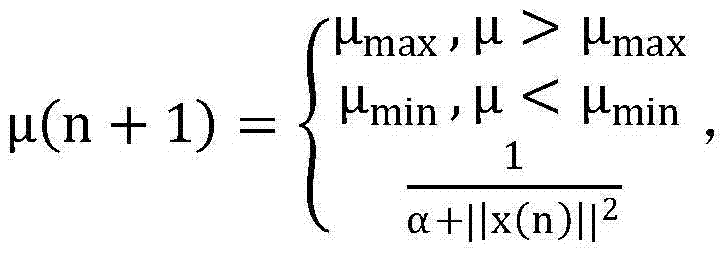

Digital hearing aid echo canceling method based on NLMS algorithm improvement

InactiveCN104754485AMeet real-time requirementsMeet accuracy requirementsDeaf-aid setsLower limitComputation complexity

The invention discloses a digital hearing aid echo canceling method based on NLMS algorithm improvement. The digital hearing aid echo canceling method based on the NLMS algorithm improvement mainly includes that each input data in an M-size block updates N / M coefficients of interval M, after inputting M data, all the coefficients of an adaptive filter are updated. Good convergence rate and steady state error are guaranteed through controlling the upper limit and lower limit of step size normalization. The digital hearing aid echo canceling method based on the NLMS algorithm improvement is capable of realizing the hearing aid echo canceling, lowering the computation complexity of the algorithm, guaranteeing the controllability of the algorithm performance and meeting the timeliness and precision demands of a hearing aid.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

Method for screening facultative anaerobic bacteria producing biosurfactant

ActiveCN111548940AQuick filterEfficient screeningMicroorganism based processesMicroorganism separationBiotechnologyMicrobiology

The invention relates to a method for screening facultative anaerobic bacteria producing biosurfactant, which comprises the following steps: (1) collecting an oil-polluted environment sample, and storing in an environment of 4 DEG C; (2) taking a small amount of samples, adding the samples into an enrichment medium for culture, inoculating the obtained culture solution into a newly prepared enrichment medium for culture, and continuously transferring and culturing for three times; (3) taking the enrichment culture solution transferred for the third time, and coating the enrichment culture solution on an LB plate for culture to obtain a single colony; (4) inoculating the single colony into a fermentation medium for culture, measuring the surface tension of a culture solution, and selectinga strain with the surface tension of the culture solution lower than 30mN / m; and (5) inoculating the selected strain on a crude oil flat plate, and culturing to obtain the strain with an obvious oil discharge ring, namely the anaerobic strain for producing the biosurfactant. Compared with the prior art, the method has the advantage that facultative anaerobic product surfactant strains can be obtained through quick and efficient screening.

Owner:EAST CHINA UNIV OF SCI & TECH

Automatic detection system for empty glass bottles

InactiveCN109279294ARealize automatic eliminationPrevent bottles from being jammed and droppedControl devices for conveyorsPackaging automatic controlAutomatic controlStack machine

The invention discloses an automatic detection system for empty glass bottles. The automatic detection system for the empty glass bottles comprises a feeding device, a light detection table, a camerainspection machine, an integrated inspection machine and a stacking machine, all of which are arranged in sequence from front to back. According to the automatic detection system for the empty glass bottles, the conveying speed and the detection speed can be reasonably and automatically controlled.

Owner:DEQING CAIFU GLASS

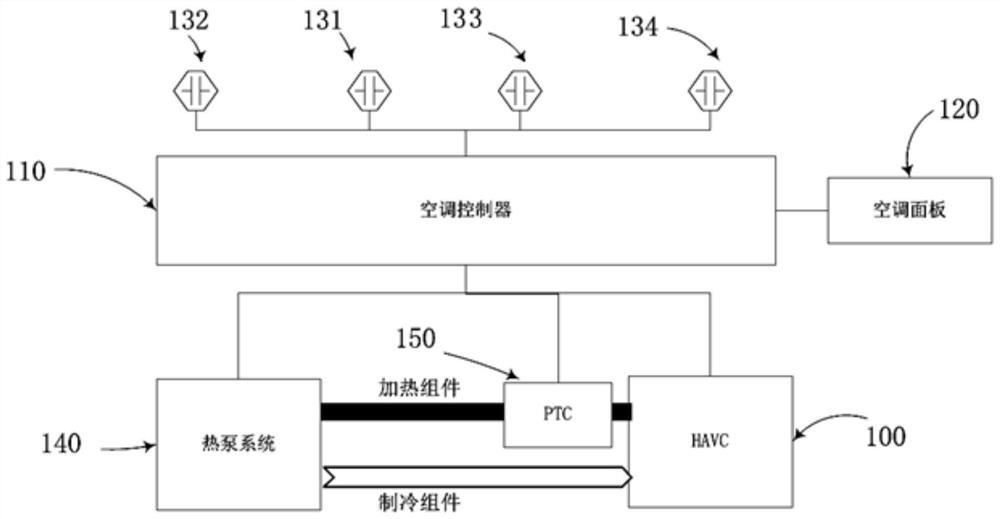

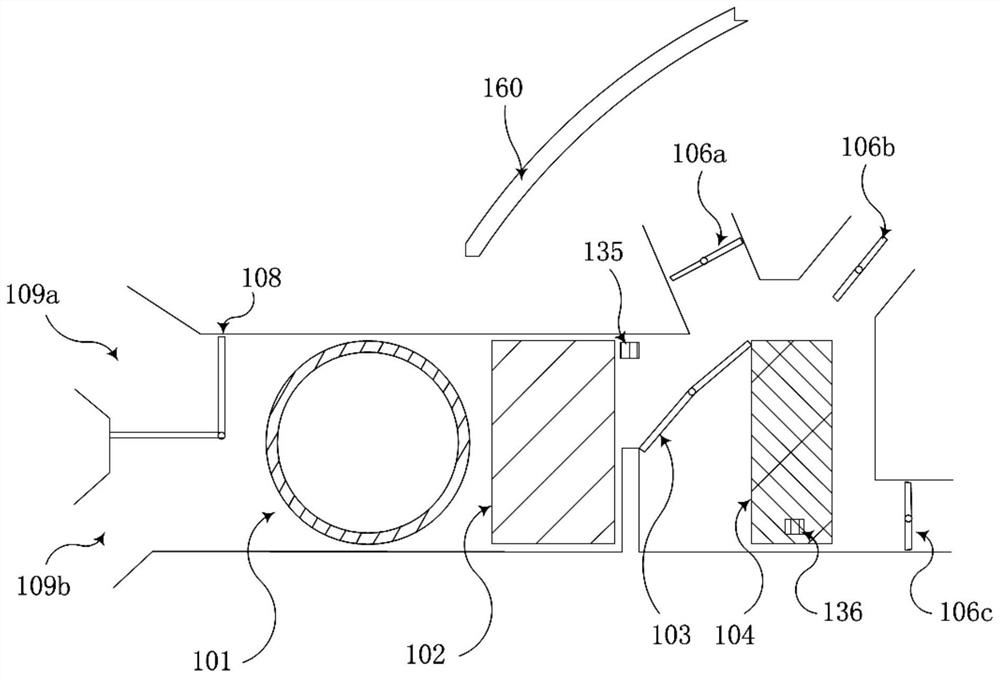

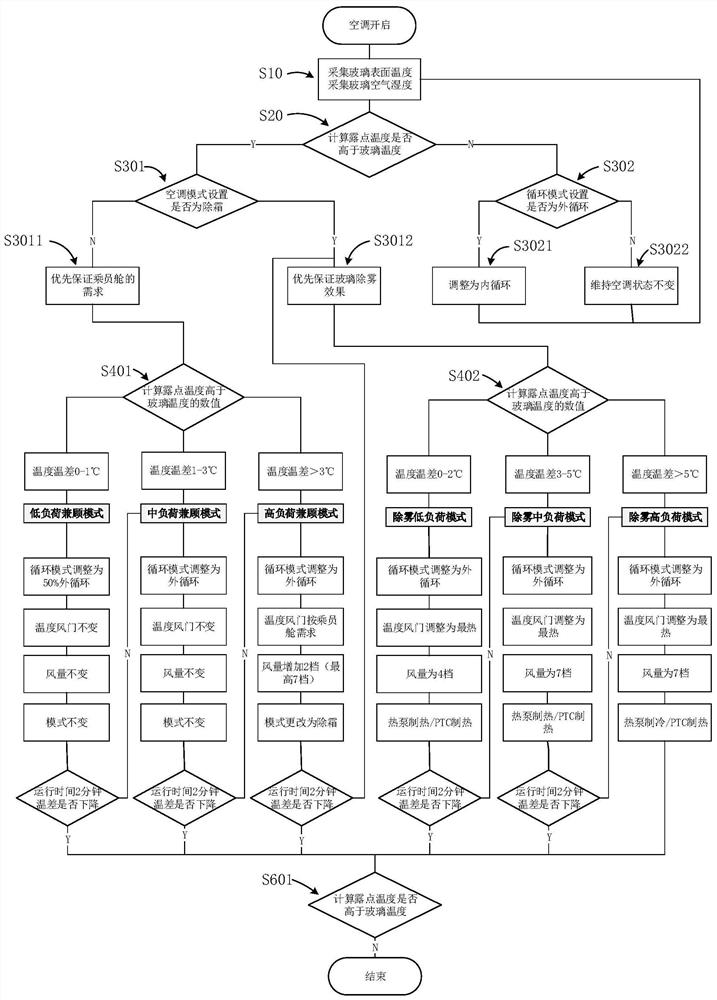

Demisting closed-loop control system for heat pump system of pure electric vehicle and control method thereof

ActiveCN113370746AMeet the needs of defoggingImplement autostartAir-treating devicesVehicle heating/cooling devicesElectric energyLow load

The invention discloses a demisting closed-loop control system for a heat pump system of a pure electric vehicle and a control method thereof. Through a temperature and humidity demisting sensor, the demisting effect of a front windshield is calculated and judged in real time, and different control strategies are formulated corresponding to different fogging working conditions; the modes comprise a low-load consideration mode, a medium-load consideration mode, a high-load consideration mode, a demisting low-load mode, a demisting medium-load mode and a demisting high-load mode. The energy consumption advantage of heat pump heating is utilized to the maximum extent through a graded demisting mode, the matching of the demisting effect and the air conditioner state is achieved through switching of the air conditioner functions, the energy consumption of the demisting function is reduced, meanwhile, the problem that the comfort of a passenger compartment cannot be considered in the demisting mode is solved, electric energy is saved, and the driving range of the electric vehicle in the high-low temperature environment is increased.

Owner:FAW CAR CO LTD

Automatic waste sorting and removing device for belt assembly line

PendingCN110026357ARealize automatic eliminationQuick resetSortingConveyor partsDrive shaftEngineering

The invention relates to the relative technical field of waste removing mechanisms, and specifically discloses an automatic waste sorting and removing device for a belt assembly line. The technical problem that waste of the existing belt assembly line cannot be automatically sorted and removed is solved. The automatic waste sorting and removing device for the belt assembly line includes two or more waste removing conveying sections, waste removing conveying sections include racks, driving shafts, connecting frames, driven shafts and air cylinders, wherein the driving shafts are rotatably mounted on the racks, the connecting frames are rotatably mounted on the driving shafts in a sleeving mode, the driven shafts are rotatably mounted on the connecting frames and are parallel to the drivingshafts, one ends of the air cylinders are hinged to the racks, the driving shafts and the driven shafts are jointly wound with first conveying belts, the driving shafts are connected with motors to drive the driving shafts to rotate, the upper surfaces of the first conveying belts are flush with and connected with the transferring and bearing surface of the belt assembly line to ensure continuousproduct transportation, the air cylinders are located below the connecting frames, the other ends of the air cylinders are hinged to the connecting frames, and through stretching, the air cylinders drives the connecting frames to rotate around the driving shafts to achieve inclining or reset of the first conveying belts.

Owner:TAIYUAN FENGHUA INFORMATION EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com