Visual inspection device for glue point of barrel paper of barrel packaging machine

A technology of visual inspection device and machine box, which is applied in measurement devices, optical testing of flaws/defects, material analysis by optical means, etc., can solve problems such as loss, poor glue spraying, discontinuity, etc. Easy to maintain effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

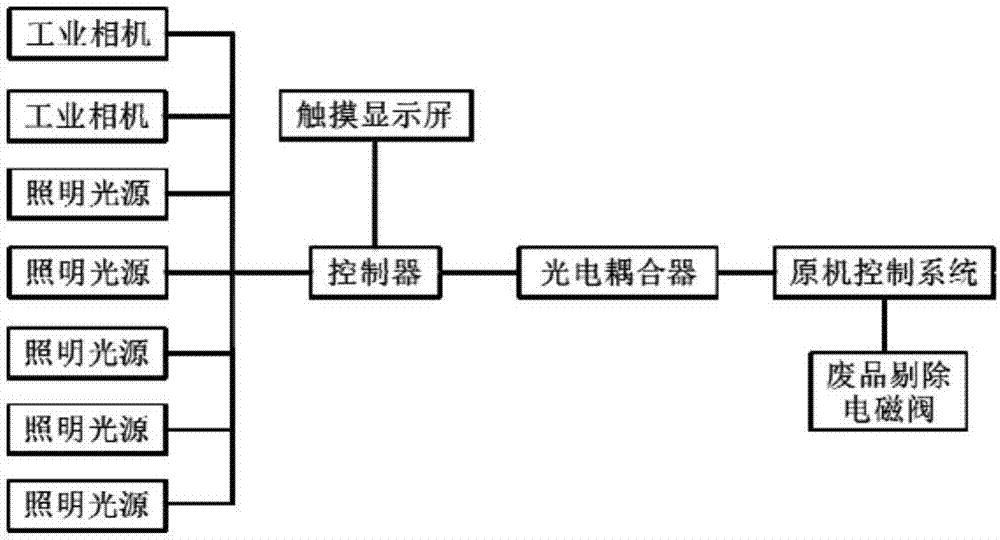

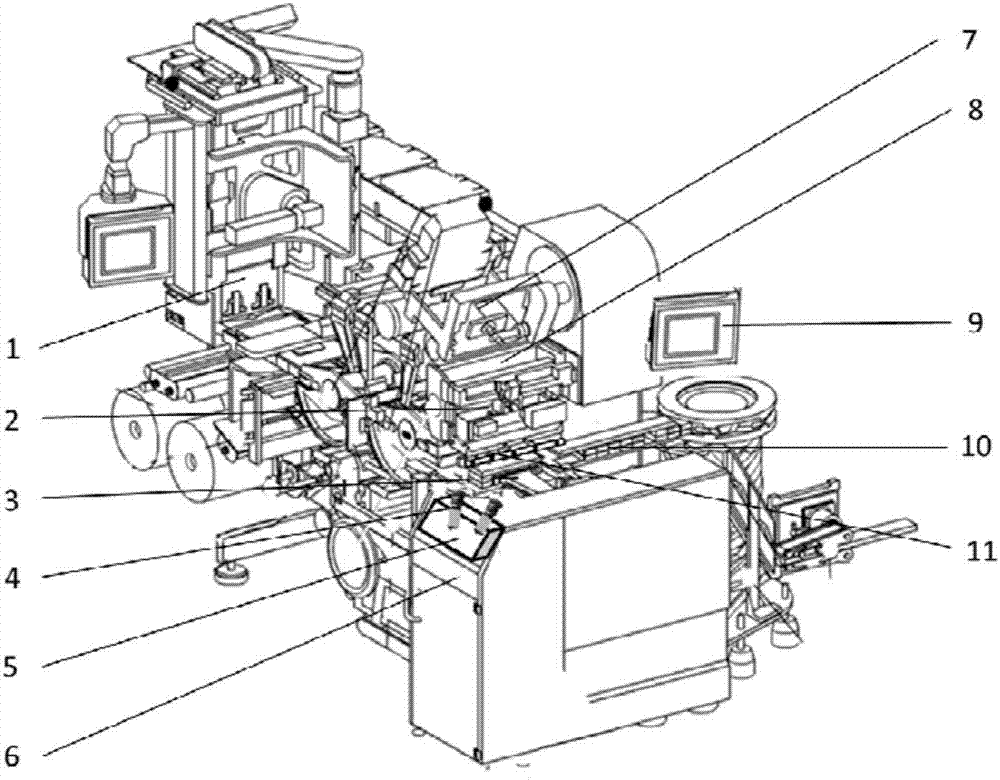

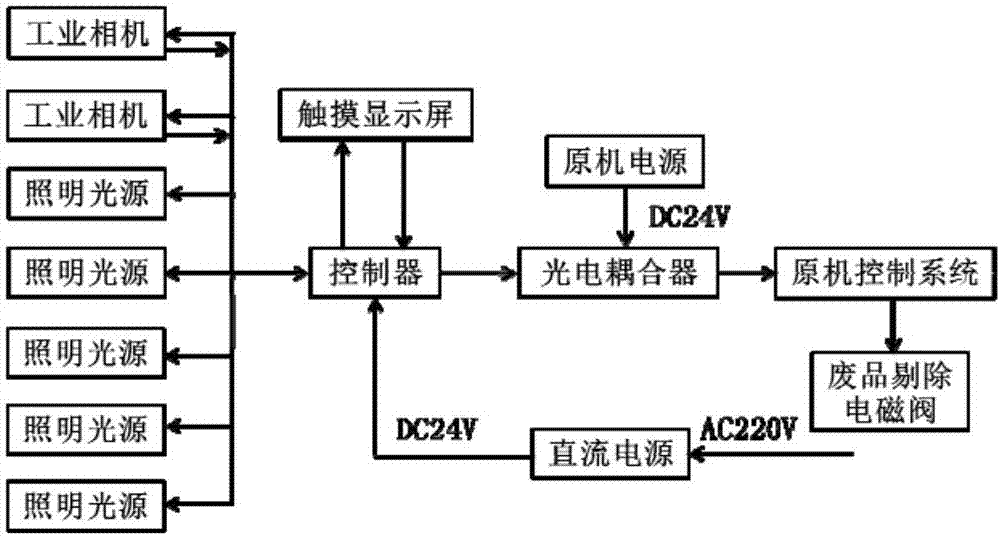

[0019] Such as figure 1 As shown, a BV high-speed packaging machine carton paper glue point visual detection device, its basic composition includes: industrial camera, lighting source, controller, touch display, photocoupler, DC power supply, etc., industrial camera, lighting source, control The device is connected to the electric control system of the original machine through a photocoupler, and the user can modify the camera image position, detection sensitivity parameters, detection reference voltage value, and shift parameters on the touch display without interrupting the production process. Automatically detect and reject products with defective glue spots on carton paper. In this embodiment, the model is as follows: industrial camera specification model: COGNEX ISM1400-C01 (lens LENS 3.5mm); controller model: IPC627C (6ES7647-6CB050AX0); touch display screen: FPM-3120G-RAM; photocoupler: TRS24VDC 1C0; lighting source: LED24VDC; DC power supply: SDR-120-24.

[0020] Suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com