Automatic waste sorting and removing device for belt assembly line

A technology of automatic sorting and rejection device, applied in the direction of sorting, transportation and packaging, conveyor objects, etc., can solve the problem that belt assembly line waste cannot be automatically sorted and rejected, and achieve the effect of saving manpower, ensuring continuity and facilitating promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

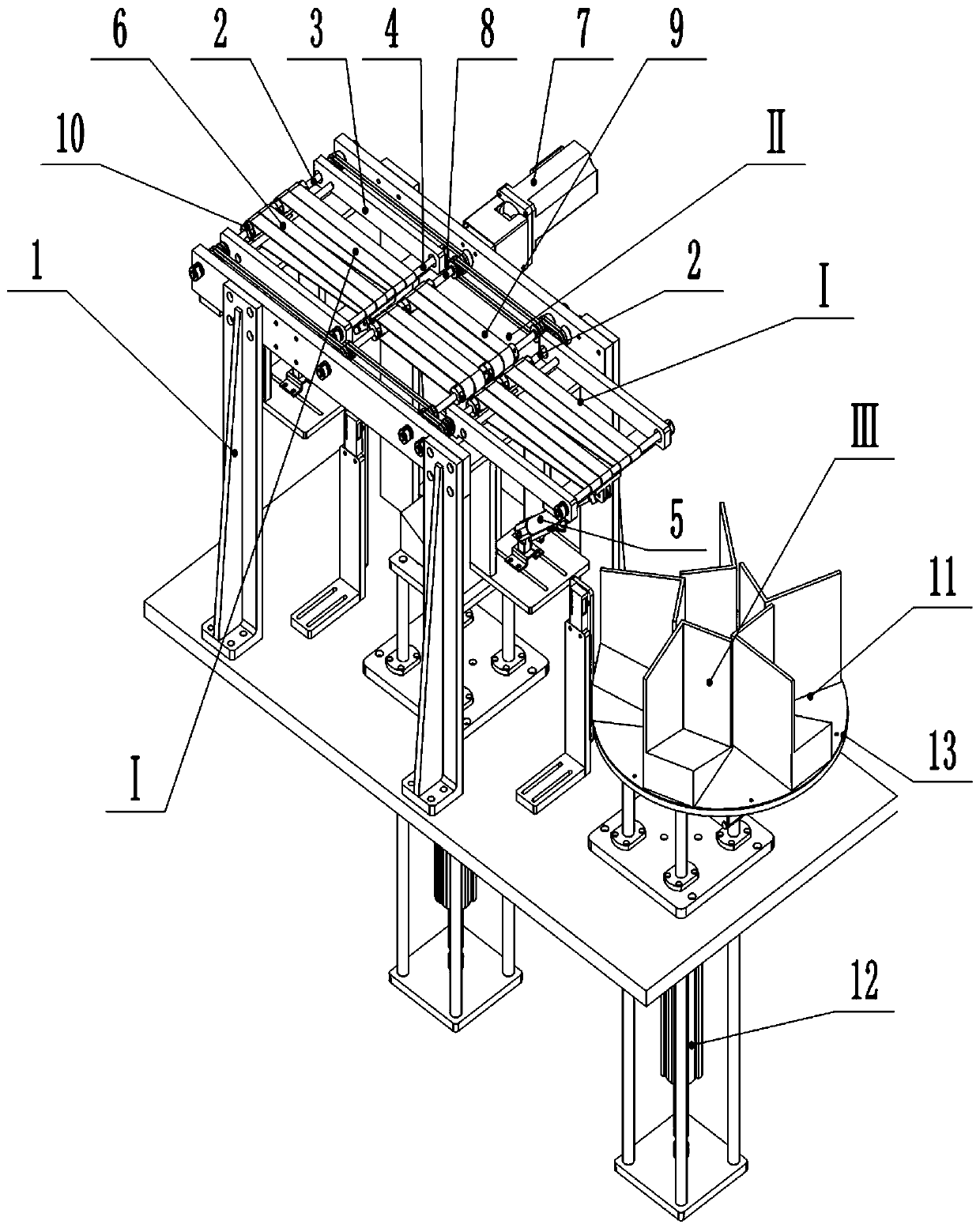

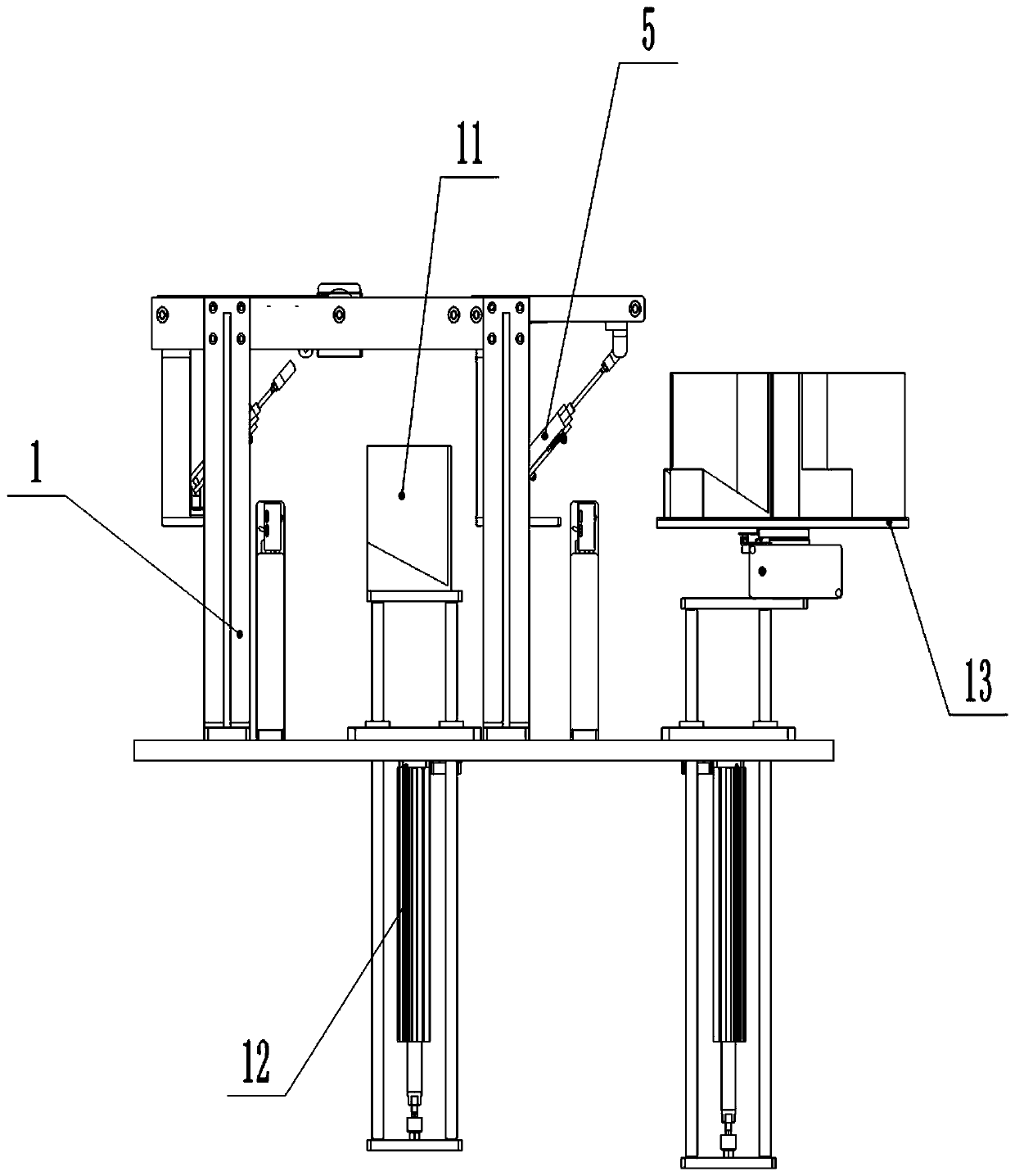

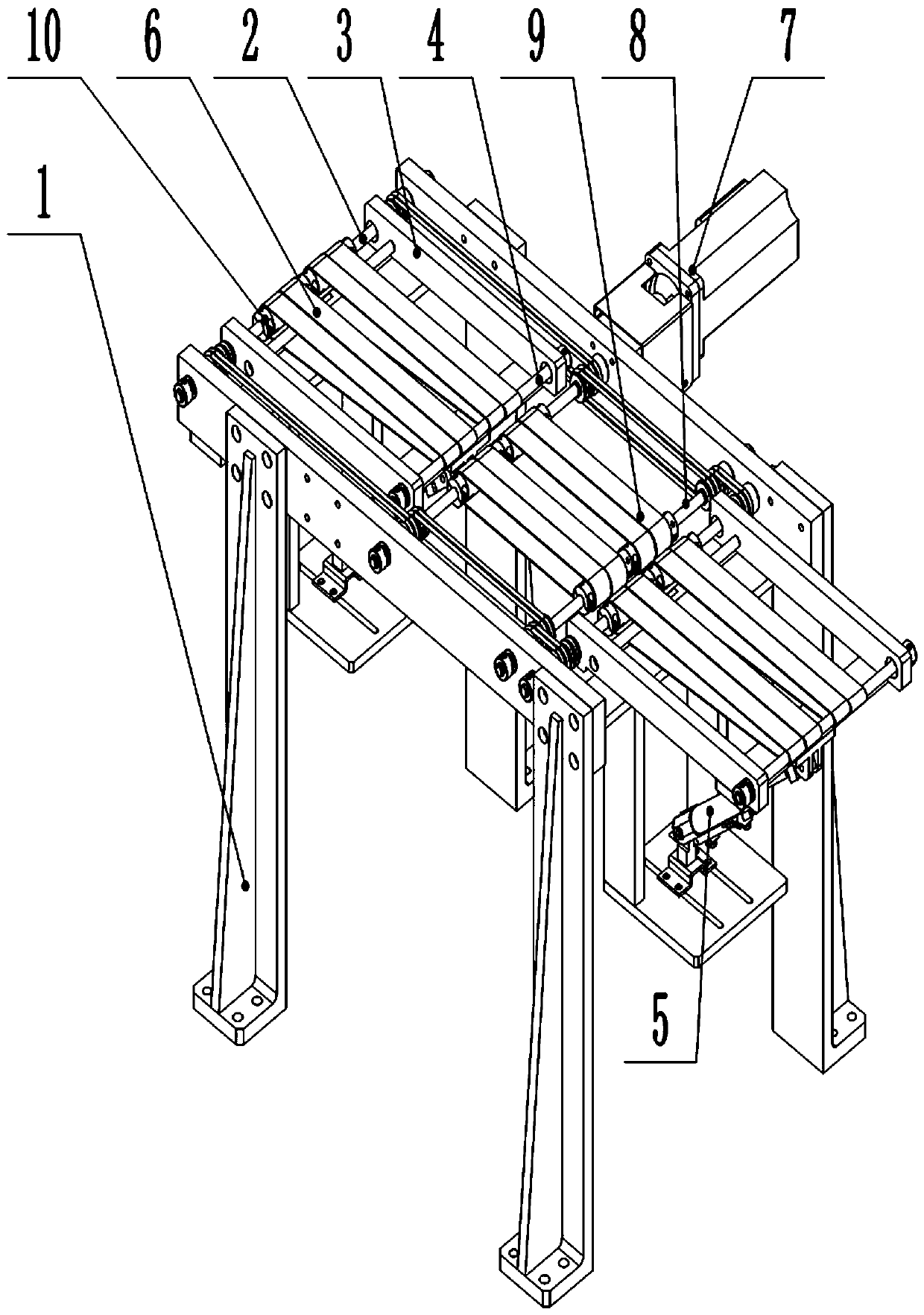

[0012] refer to Figure 1-Figure 4 , an automatic sorting and removing device for waste materials on a belt assembly line, including a detection sensor for detecting product quality, and at least two waste material removal conveying sections I, each of which waste material rejecting conveying sections I are independently plugged in The middle part of the assembly line or independently connected to the end of the assembly line and located behind the detection sensor, the waste removal conveying section I includes a frame 1, a drive shaft 2 rotatably mounted on the frame 1, and a connection sleeve rotatably mounted on the drive shaft 2 Frame 3, a driven shaft 4 that is rotatably mounted on the connecting frame 3 and parallel to the driving shaft 2, and a cylinder 5 with one end hinged on the frame 1, the driving shaft 2 and the driven shaft 4 are jointly wound with a first conveyor belt 6. The driving shaft 2 is connected with a motor 7 that drives its rotation. The upper surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com