Automatic detection system for empty glass bottles

An automatic detection and empty bottle technology, which is applied in the direction of automatic packaging control, packaging bottles, conveyor control devices, etc., can solve problems such as equipment failure, blockage, glass empty bottle conveyor belt falling, and achieve the effect of preventing congestion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below through specific embodiments in conjunction with the accompanying drawings. The upper, lower, left, and right mentioned in the present invention are all based on the accompanying drawings.

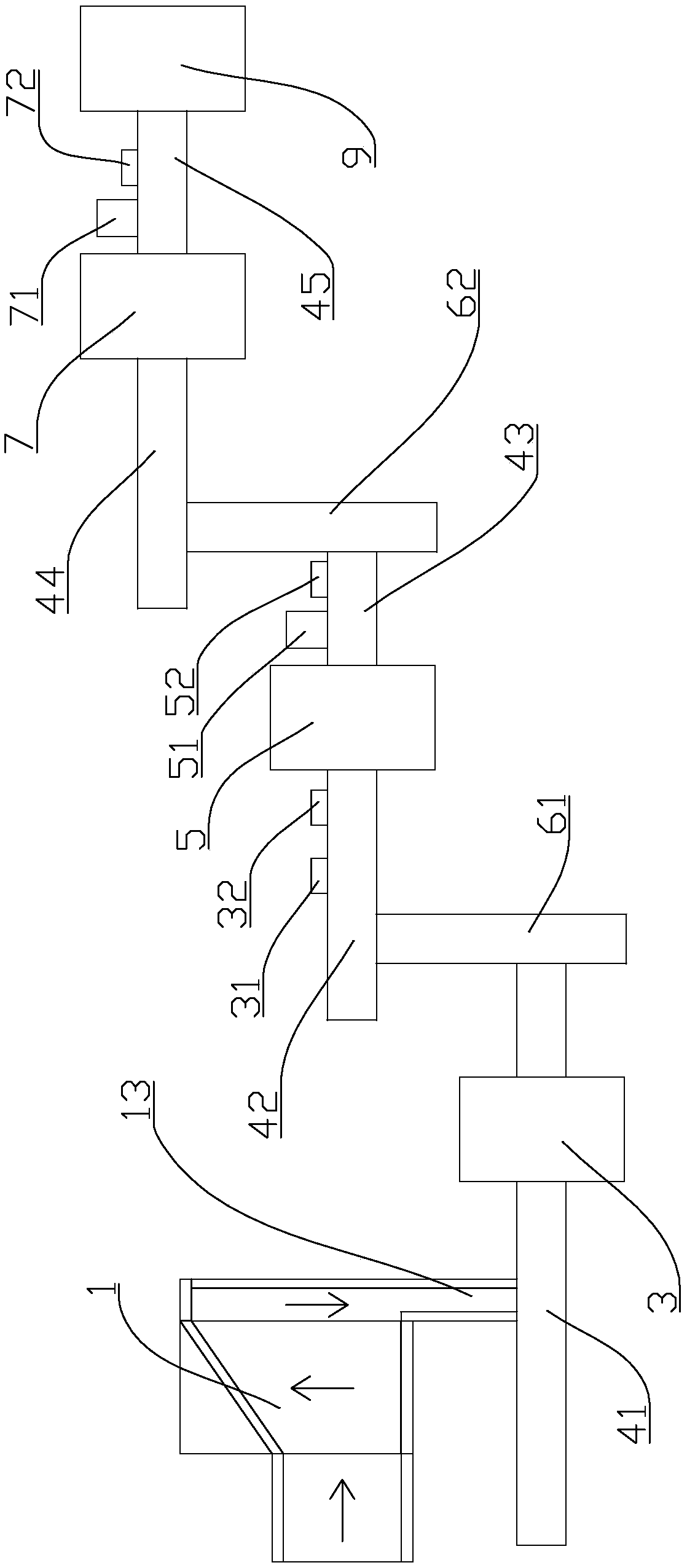

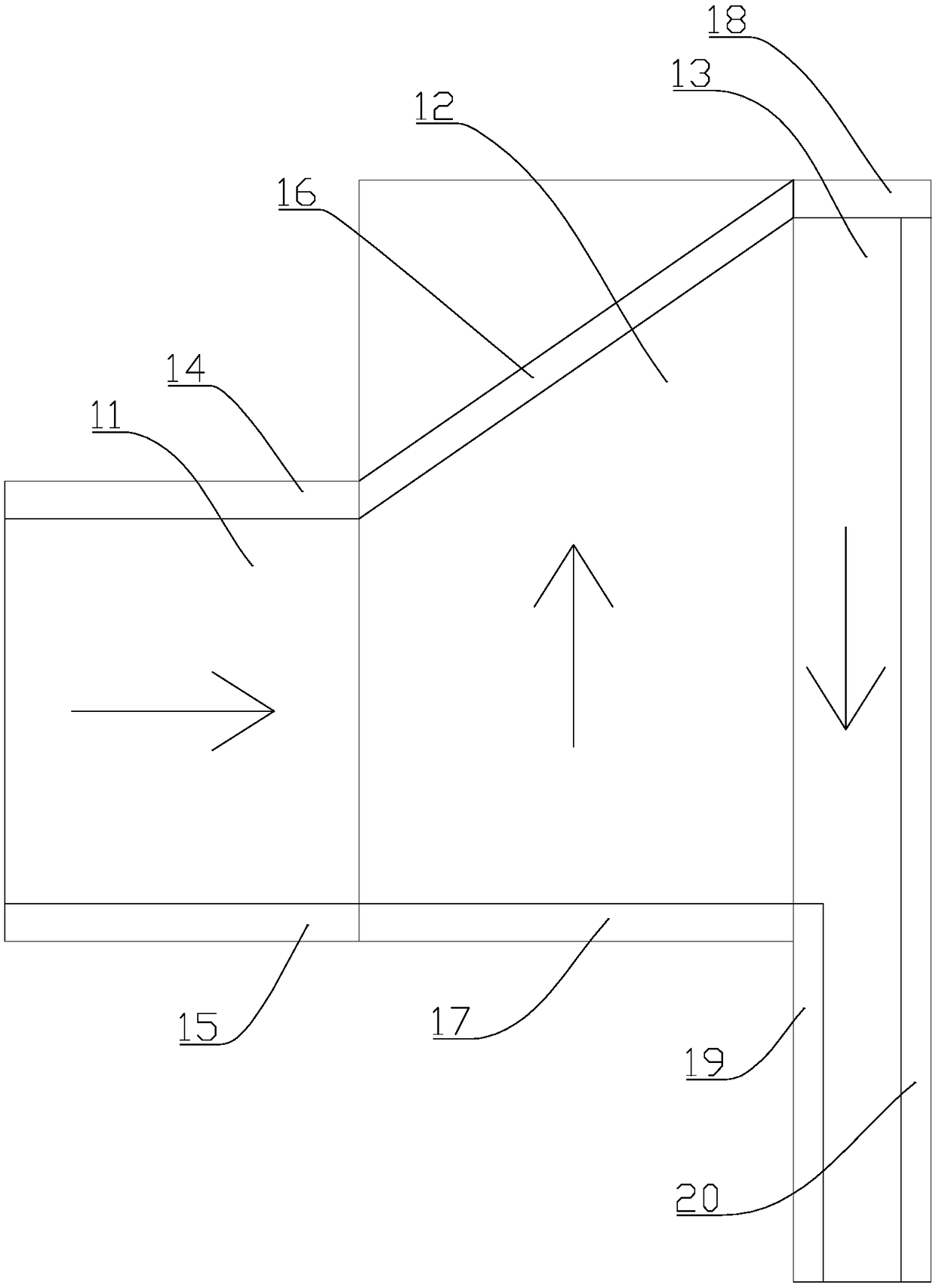

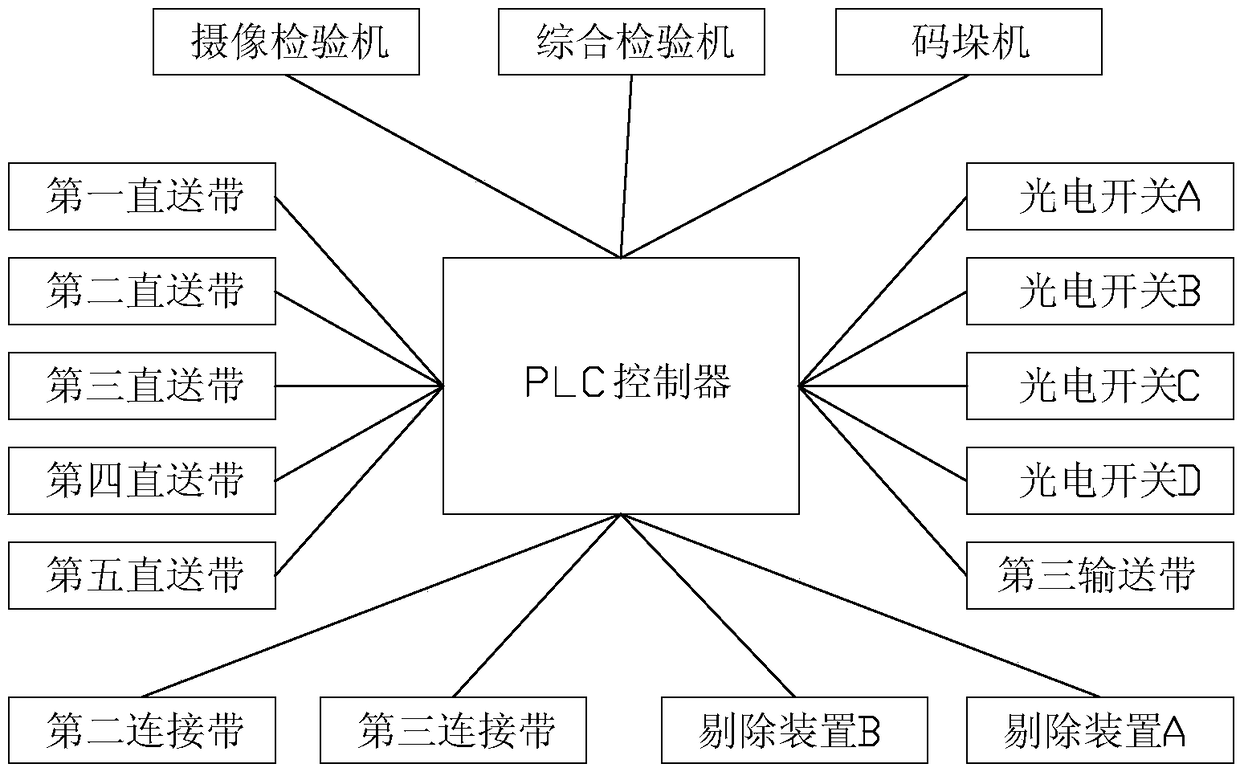

[0019] Such as figure 1 , 2 , a kind of automatic detection system of glass empty bottle shown in 3, comprises the feeding device 1 that is set up successively before and after, lamp inspection table 3, camera inspection machine 5, comprehensive inspection machine 7 and stacker 9, described feeding device The empty glass bottles output from 1 are sent to the light inspection station 3 through the first straight conveyor belt 41, and the empty glass bottles are output from the light inspection station 3, and the glass empty bottles output from the light inspection station 3 pass through the second connecting belt 61 in turn and the second straight-feed belt 42 into the camera inspection machine 5, and the glass empty bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com