Removing mechanism for combined saddle-stitching machine

A technology of removing mechanism and saddle stitching, applied in the directions of transportation and packaging, sending objects, thin material processing, etc., can solve the problems of increasing the product scrap rate, not being able to find it in time, and poor accuracy, so as to improve the qualified rate of products and improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

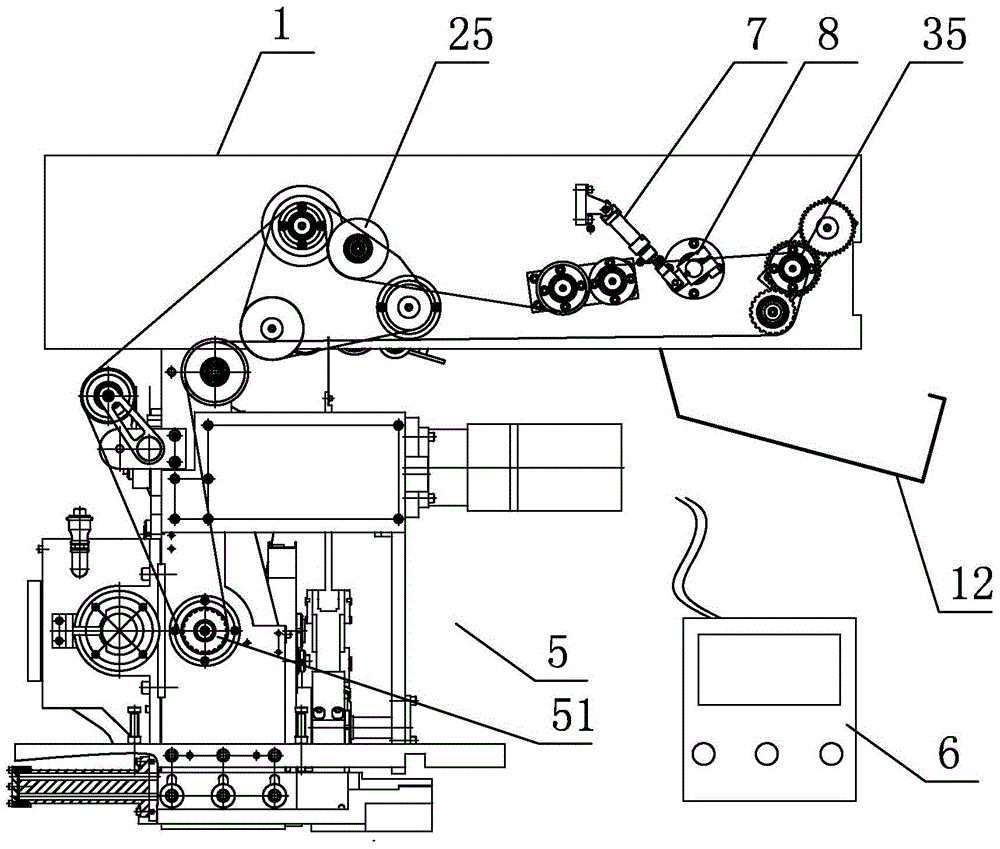

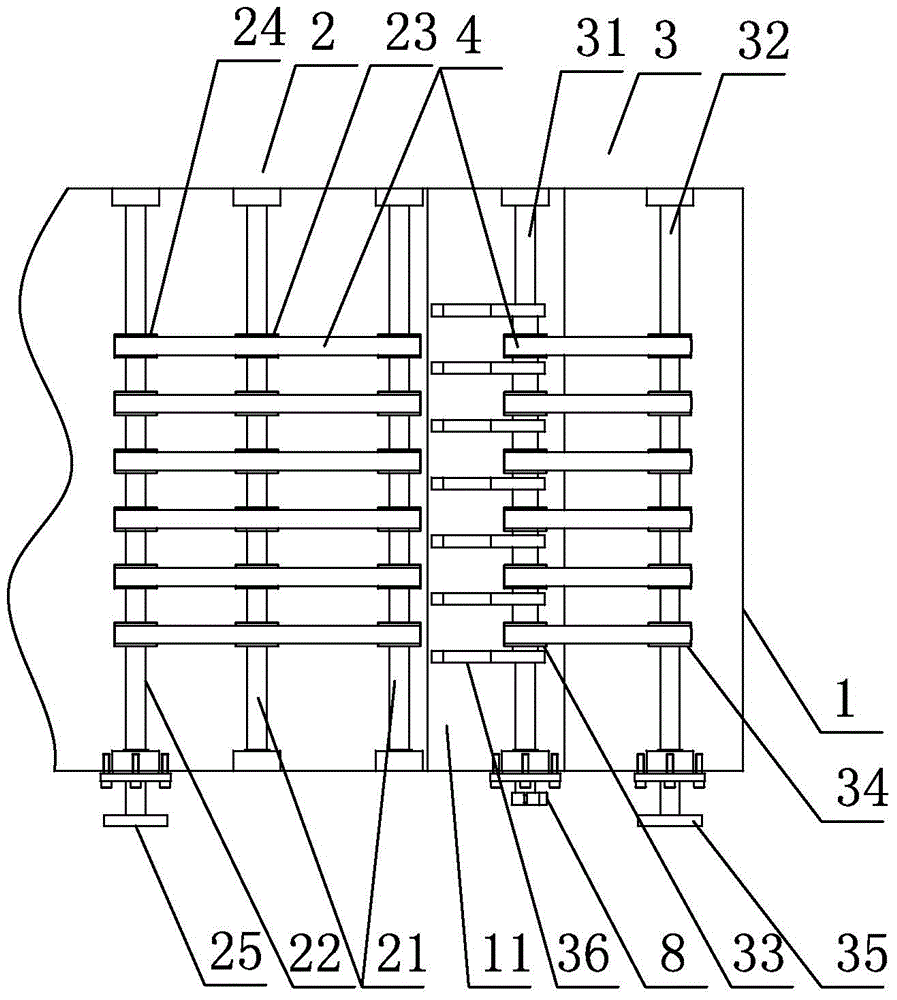

[0018] Such as Figure 1-4 As shown, the rejecting mechanism for the saddle stitching linkage machine of this embodiment includes a frame 1, a conveying device 2 and a rejecting device 3 installed on the frame 1, and the frame 1 is a groove-shaped machine with openings at both ends and a depression in the middle. The shell and the rejecting device 3 are located at the output end of the conveying device 2. The conveying device 2 is used to send the books to the next process, and the rejecting device 3 is used to reject defective products in the conveyed books such as missing orders or pages with wrong pages.

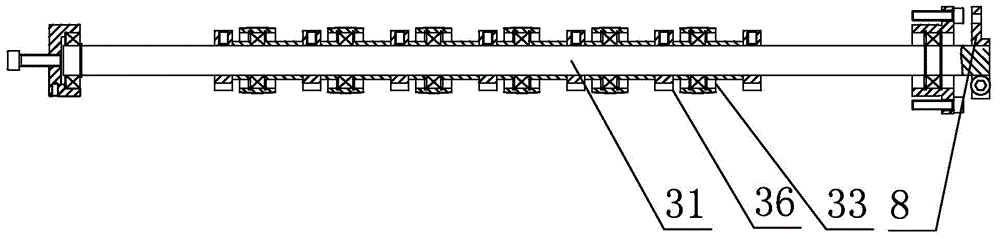

[0019] Such as Figure 1-3 As shown, the transmission device 2 includes a plurality of transmission rods 21 and a drive rod 22, the two ends of the transmission rod 21 and the drive rod 22 are mounted on the frame 1 by means of bearings, and a plurality of rollers 23 are installed on each transmission rod 21 , the roller 23 can rotate around the transmission rod 21, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com