Automatic bearing channel detection device

An automatic detection and bearing groove technology, applied in mechanical bearing testing, sorting, etc., can solve problems such as low work efficiency, achieve the effects of reducing labor costs, high intelligence, and improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

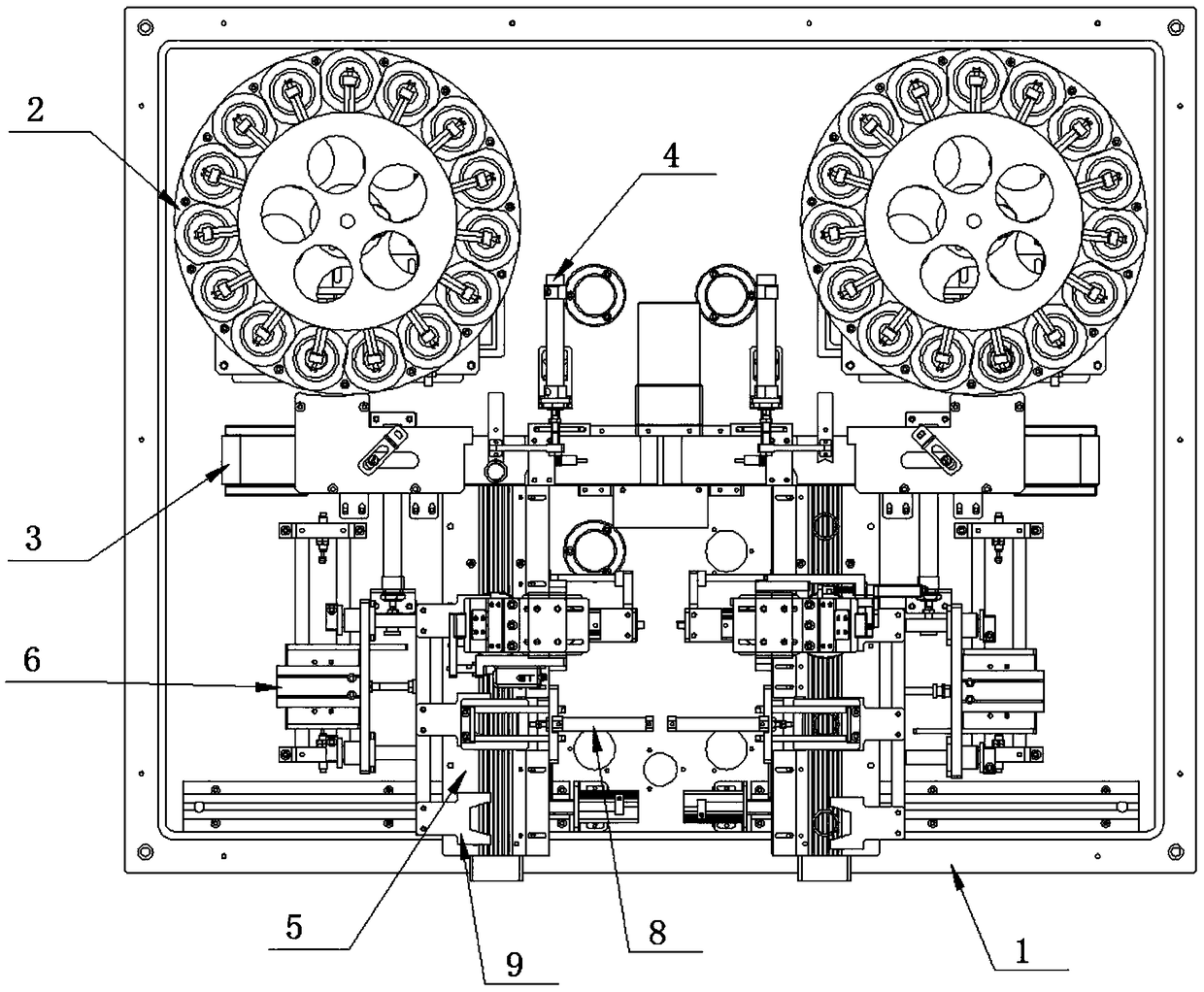

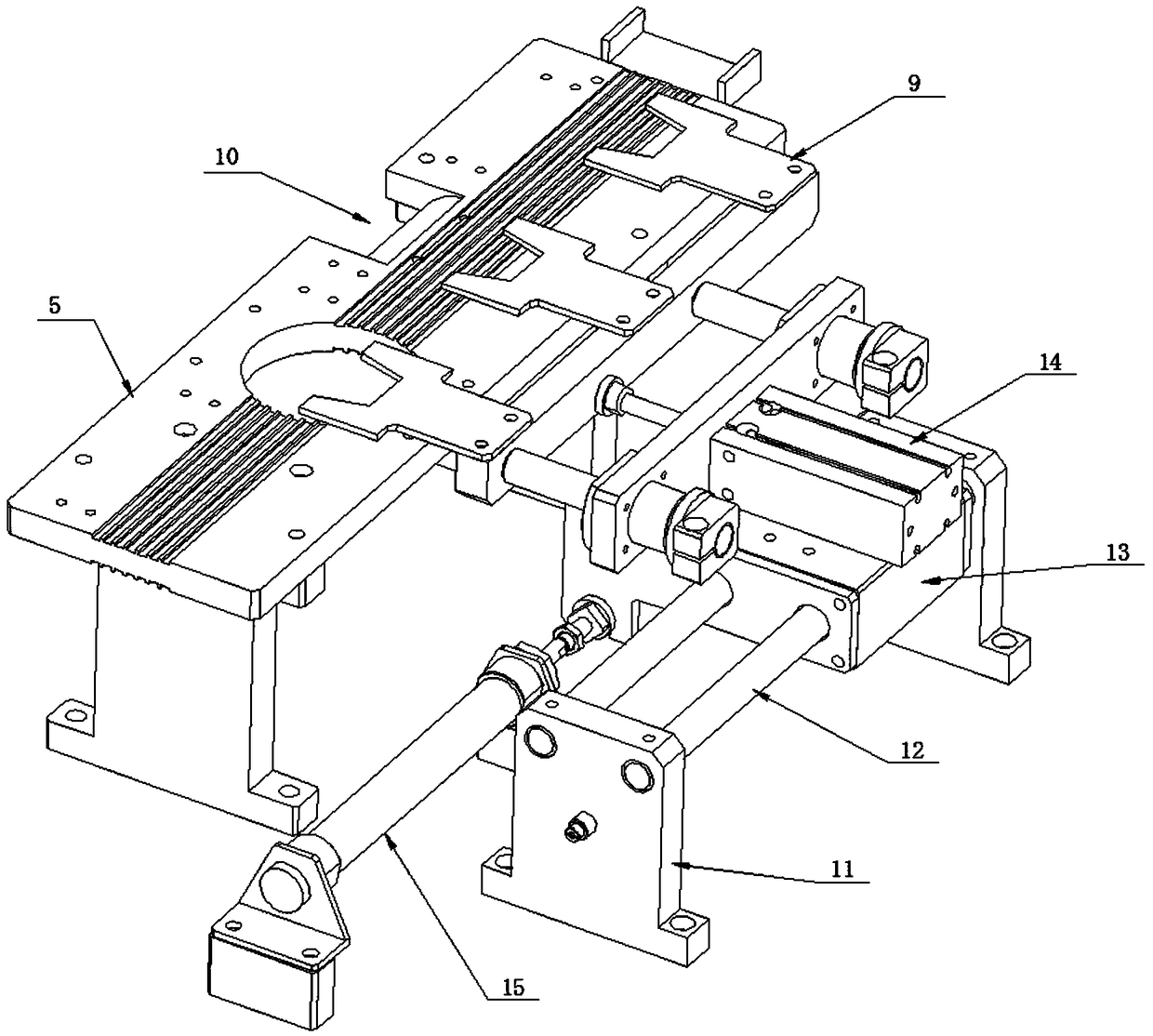

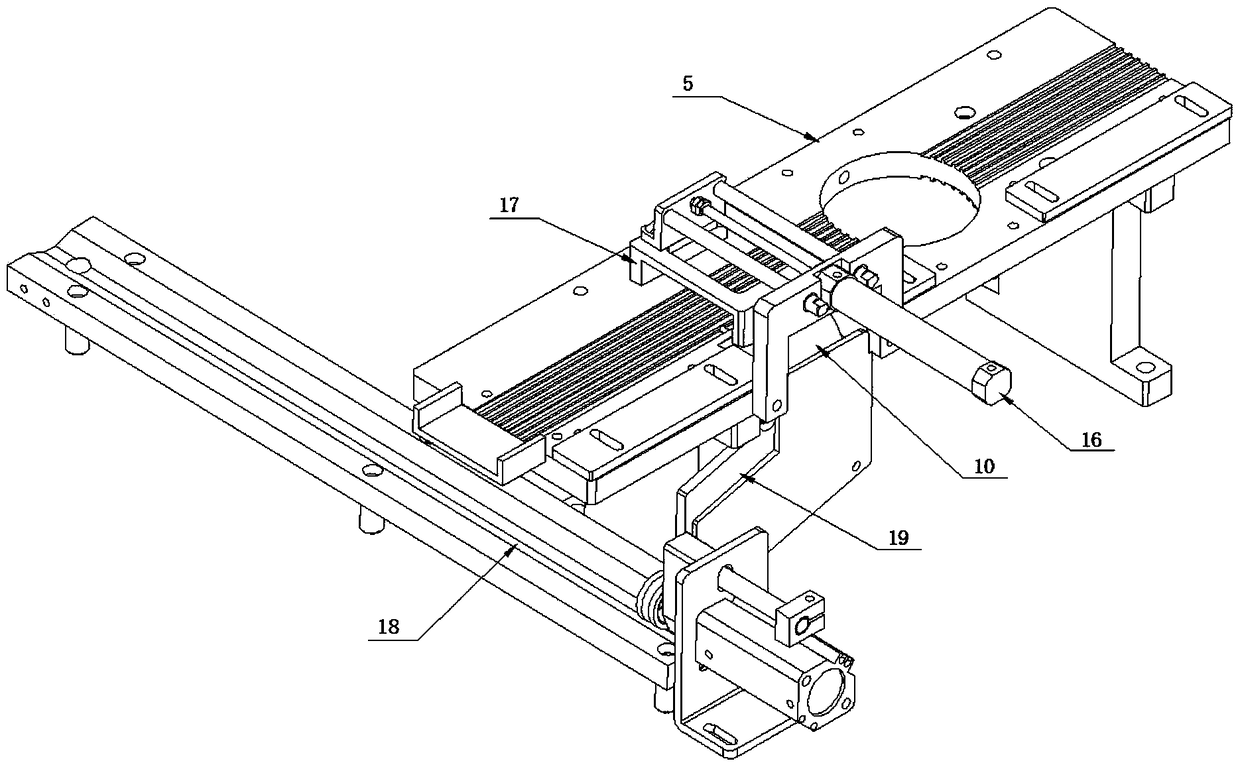

[0030] refer to Figure 1 to Figure 7 , the present invention provides an automatic detection device for a bearing channel, comprising: a base plate 1 and a rotating storage tank 2 installed on the base plate 1, a conveyor belt 3, a material pushing mechanism 4, a detection table 5 and a traverse feeding mechanism 6; The barrel cylinder 7 of the rotating storage barrel 2 pushes the workpieces to the conveyor belt 3 one by one. The detection workbench 5 includes the station to be inspected, the station to be inspected, the station to be transferred and the station to be unloaded in sequence. There is a detection mechanism for detecting the workpiece channel, and a waste material blanking mechanism 8 is installed on the transfer station; The shifting lever 9 is used to transfer the workpieces on the station to be inspected to the inspection station, the transfer station and the station to be unloaded sequentially; the waste material dropping mechanism 8 is used to push the unqua...

Embodiment 2

[0040] refer to Figure 8 and Figure 9 , the difference between the present embodiment and the first embodiment is that: the rotating storage cylinder 2 stores the bearing outer ring workpiece 41; the detection mechanism includes an outer ring detection machine 42 for detecting the bearing outer ring workpiece 41; the outer ring detection machine 42 It includes an outer ring support 43, an outer ring detection bracket 44, an outer ring detection cylinder 45 installed on the outer ring support 43, and an outer ring lifting cylinder 46; between the outer ring detection bracket 44 and the outer ring support 43, a plurality of outer The ring spring piece 47 is connected, the outer ring support 43 is equipped with an outer ring fixed detection block 48, the outer ring detection bracket 44 is equipped with an outer ring movable detection head 49; the outer ring rising cylinder 46 is connected with an outer ring pushing seat 50 , the outer ring detection cylinder 45 is connected wi...

Embodiment 3

[0044] refer to Figure 1 to Figure 10 , the present embodiment provides an automatic detection device for bearing grooves, including a bottom plate 1, and the left and right sides of the bottom plate 1 are respectively provided with a rotating storage tank 2 with the same structure, a conveyor belt 3, a pushing mechanism 4, a detection workbench 5 and Traversing feeding mechanism 6; bearing inner ring workpiece 29 is installed in the rotary storage tank 2 on the left side, and bearing outer ring workpiece 41 is installed in the rotation storage tank 2 on the right side; The barrel cylinder 7 is used to push the bearing inner ring workpieces 29 to the left conveyor belt 3 one by one, and the barrel cylinder 7 of the right rotary storage barrel 2 is used to push the bearing outer ring workpieces 41 to the right conveying one by one. On the belt 3; the detection workbench 5 comprises successively the station to be detected, the detection station, the transfer station and the sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com