Double-station shoe sole laser cutting machine and method

A laser cutting machine and laser cutting technology, used in laser welding equipment, manufacturing tools, metal processing equipment, etc., can solve problems such as low efficiency, high rejection rate, and burrs, and achieve convenient operation, simplified structure, and reliable positioning. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

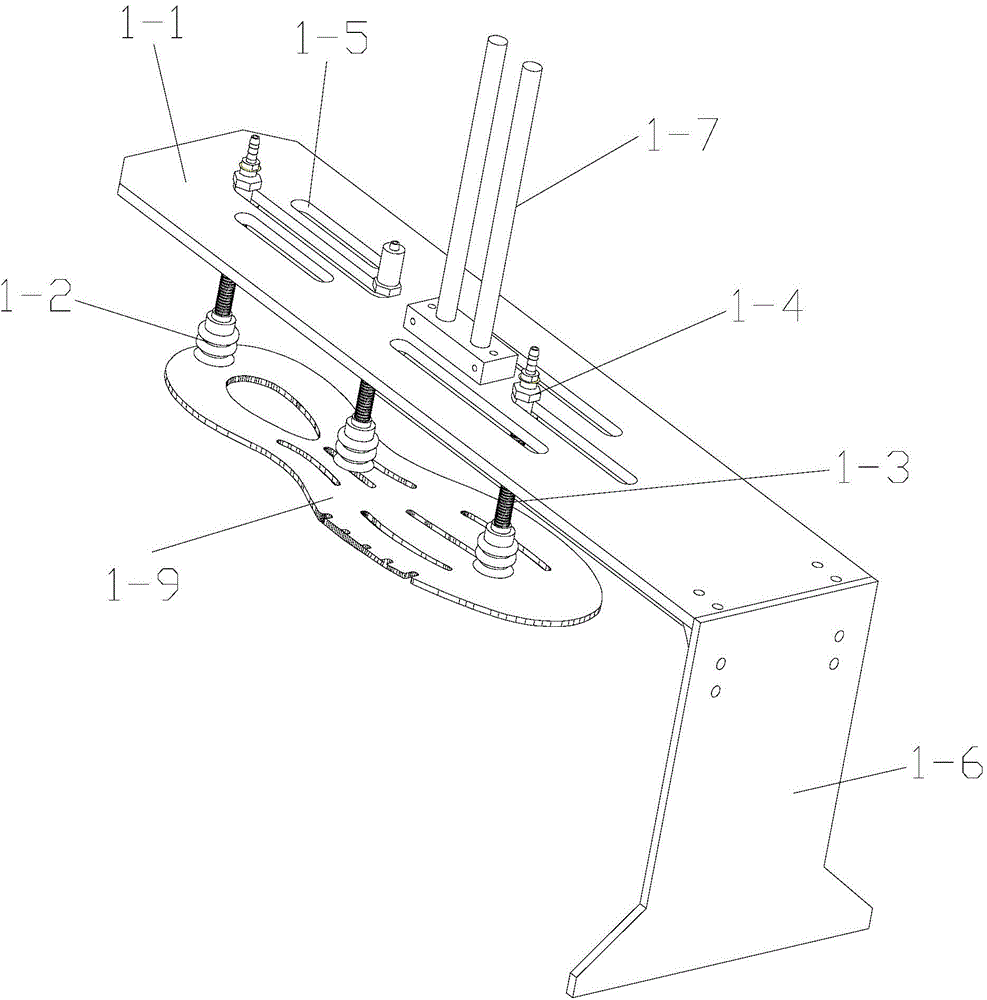

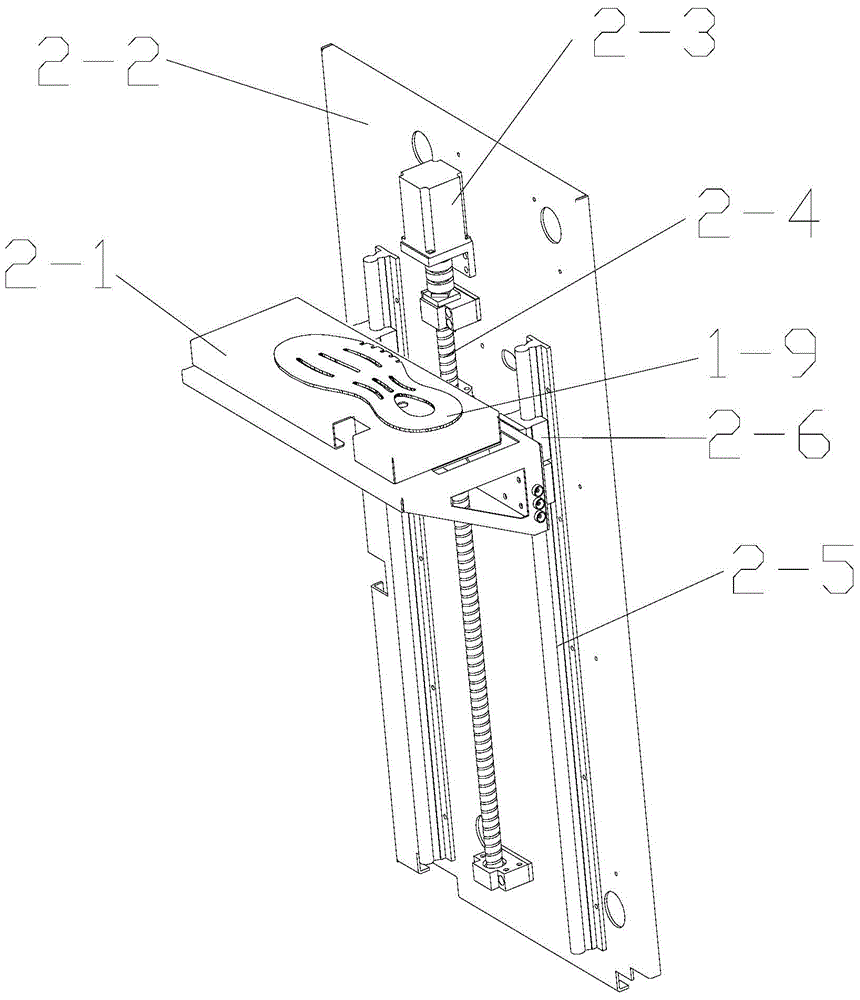

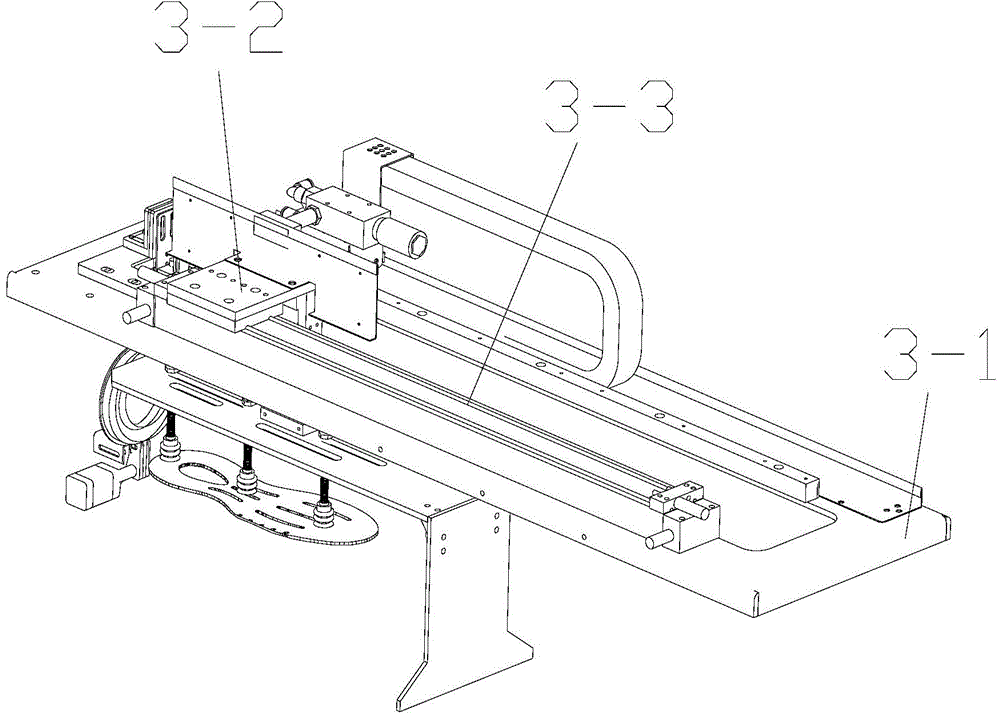

[0044]A dual-station shoe sole laser cutting machine includes: a frame, a processing table, a feeding mechanism, a laser processing mechanism, and a casing.

[0045] The structure of each part will be explained separately below.

[0046] 1. Rack.

[0047] The frame adopts a frame structure for the installation of the processing table, feeding mechanism, laser processing mechanism and shell. The lower end of the frame adopts fixed feet, and universal wheels can also be installed.

[0048] Second, the processing table.

[0049] The processing table includes: two cutting tables with the same structure, a modeling table, and a double-station translation mechanism. A cutting table, a modeling table, and another cutting table are sequentially connected from left to right to form a whole, and the whole is translated left and right at the front end of the frame through a double-station translation mechanism.

[0050] The cutting table is a cube-shaped sealed box structure, and a p...

Embodiment 2

[0099] In this embodiment, the processing table includes two cutting tables with the same structure, which are connected by a flat part in the middle, and the modeling table, modeling camera and modeling system are not used. The modeling process is completed by another modeling device, and it only needs to import the modeling data into the laser cutting control system.

[0100] The parts not mentioned in this embodiment are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com