Patents

Literature

3810results about How to "Adjustable spacing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

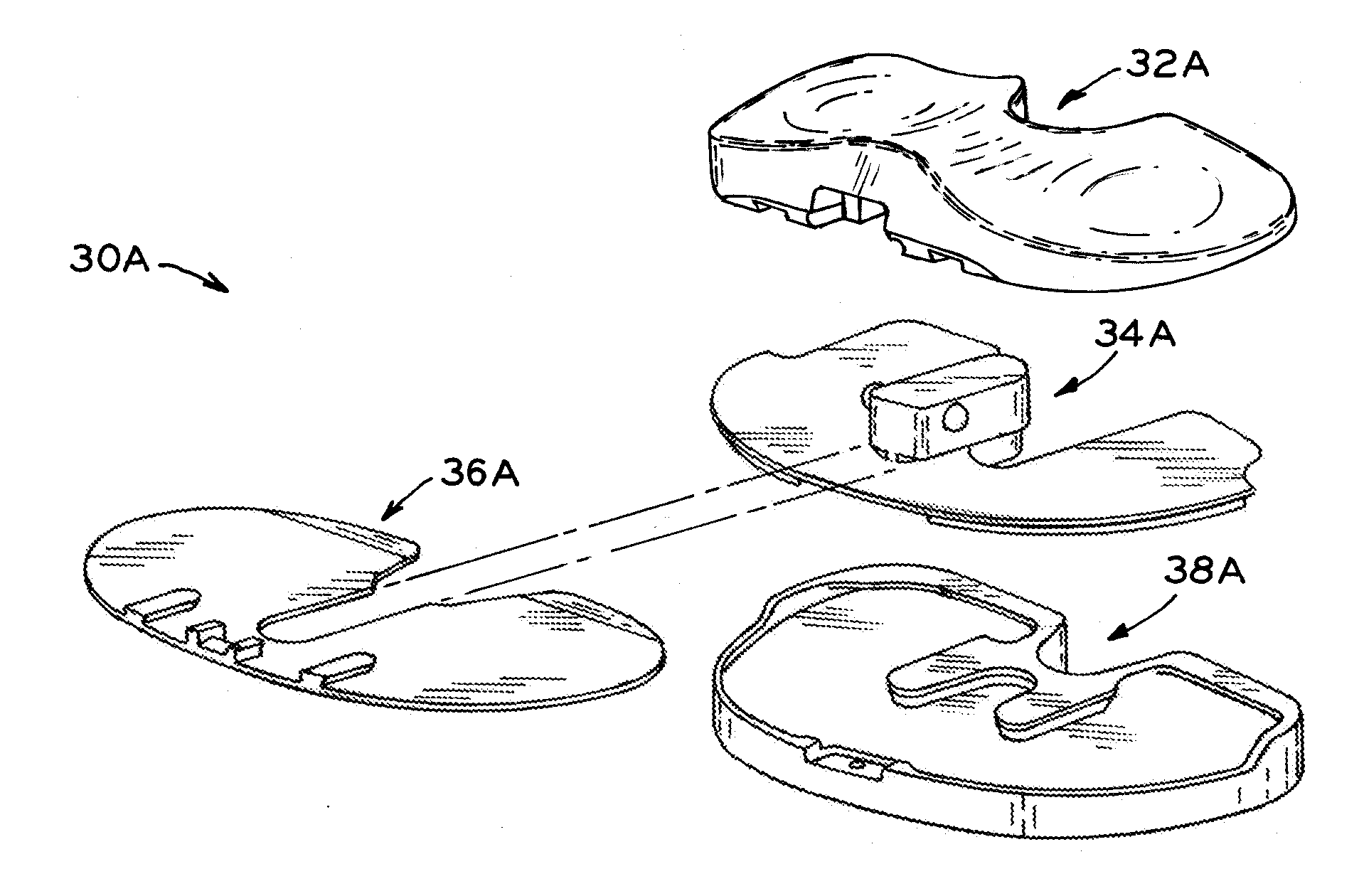

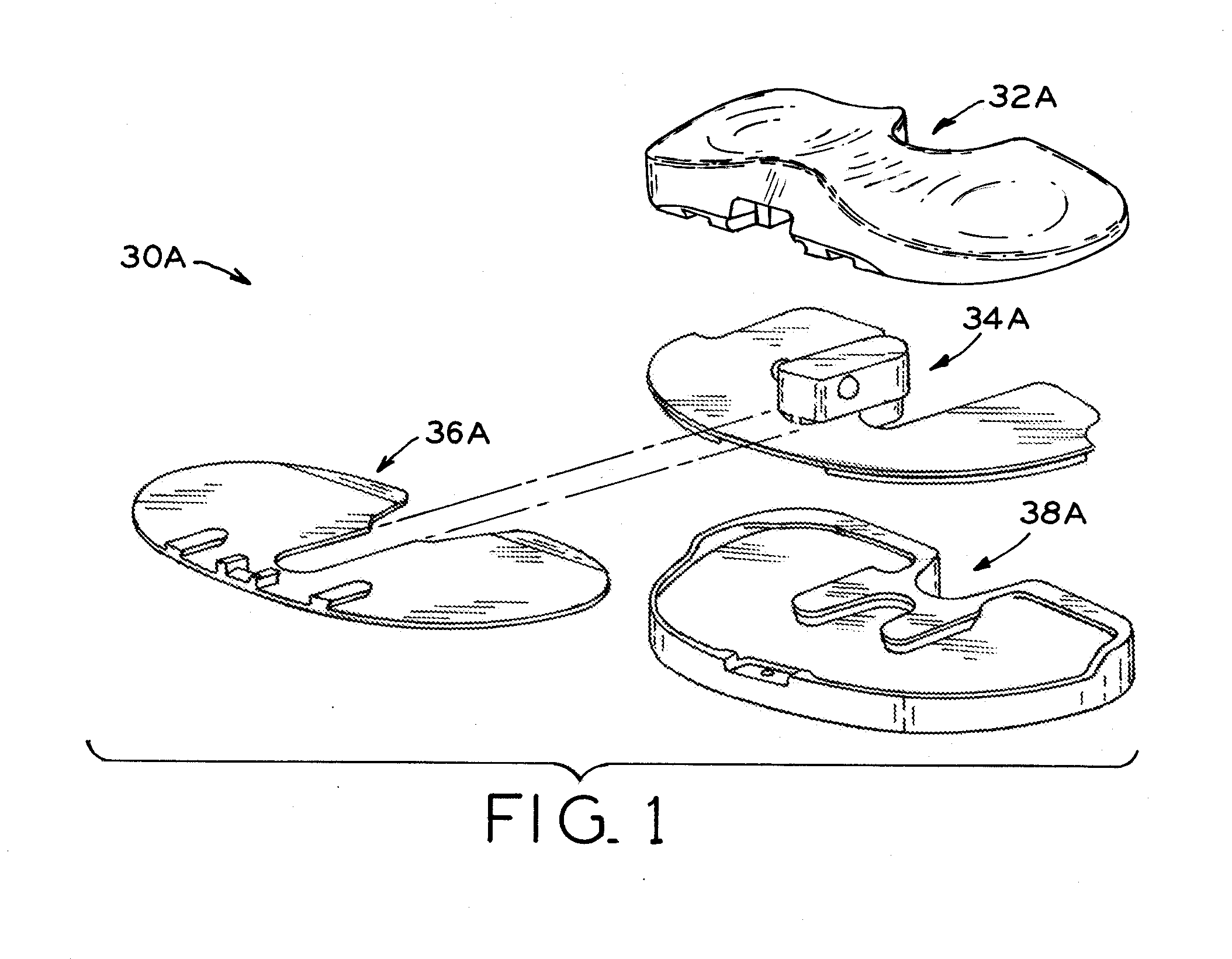

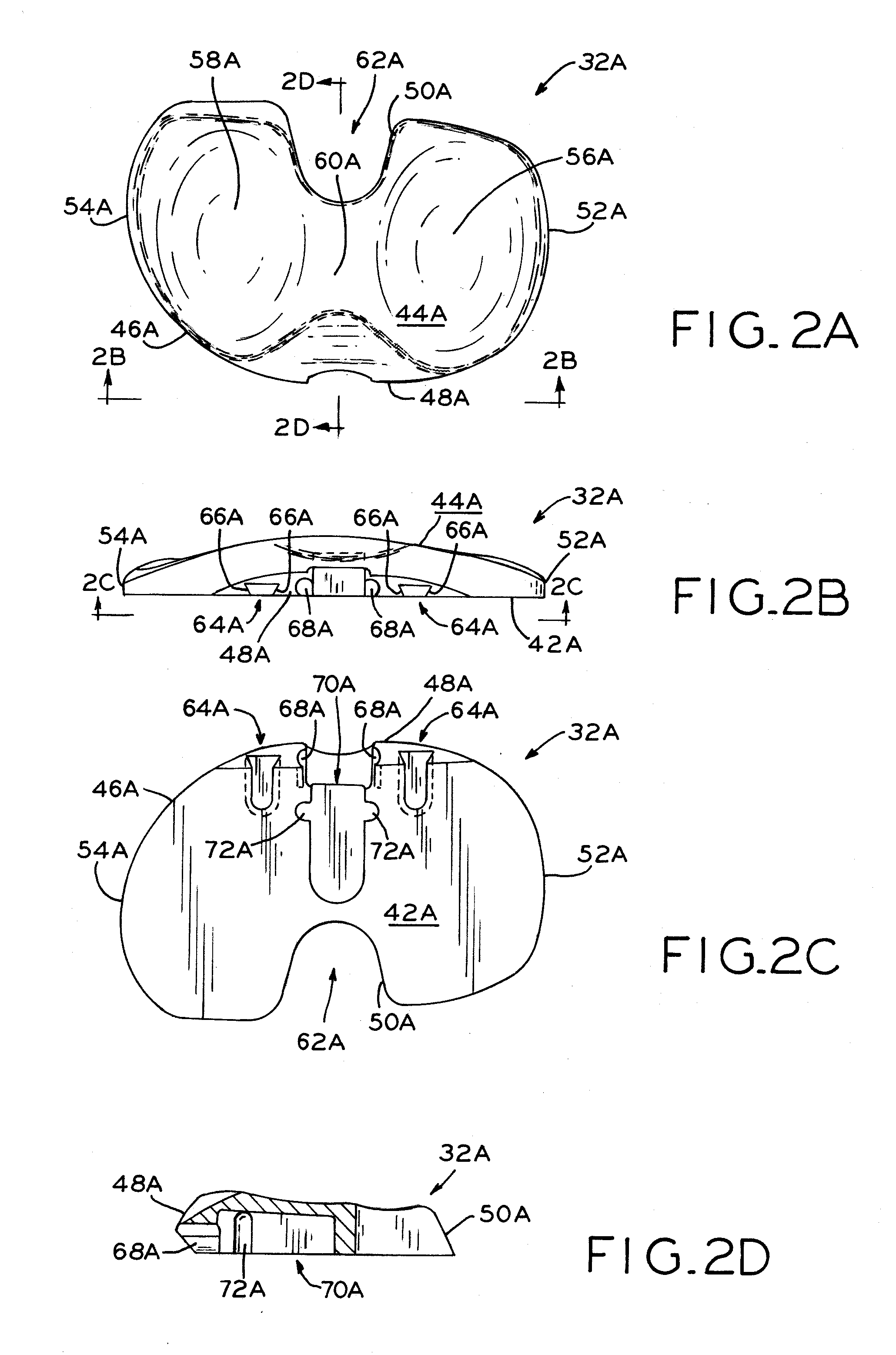

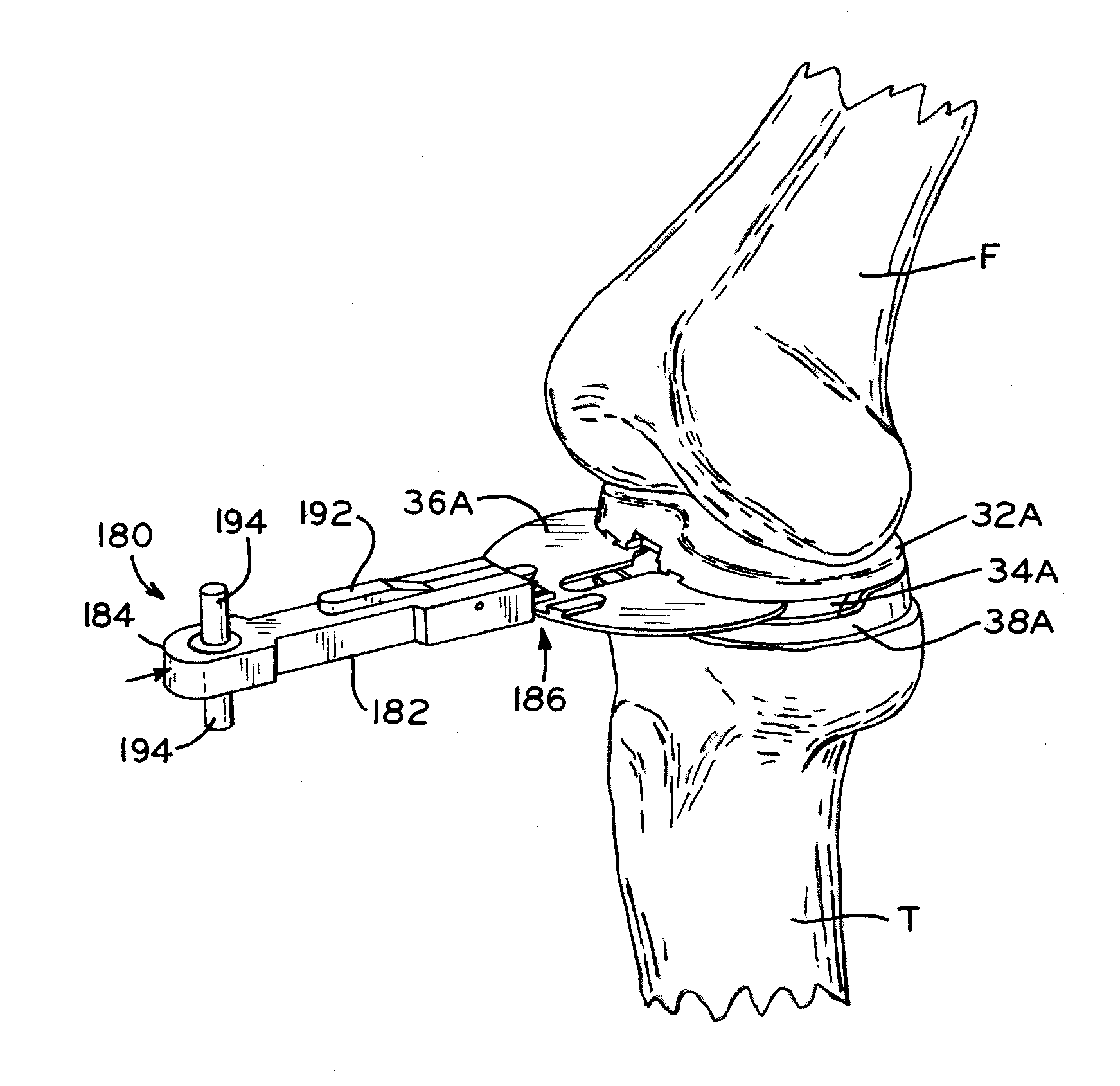

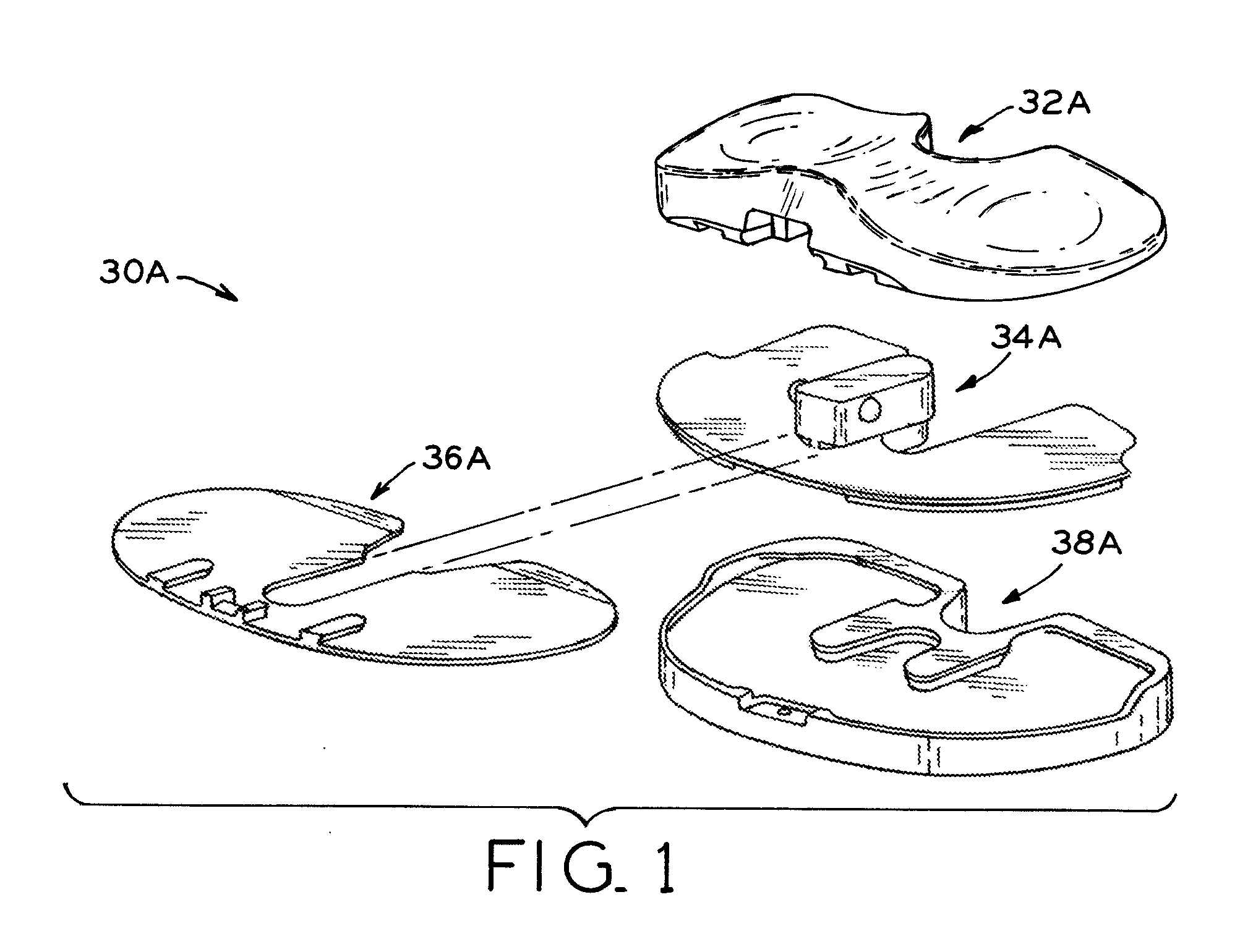

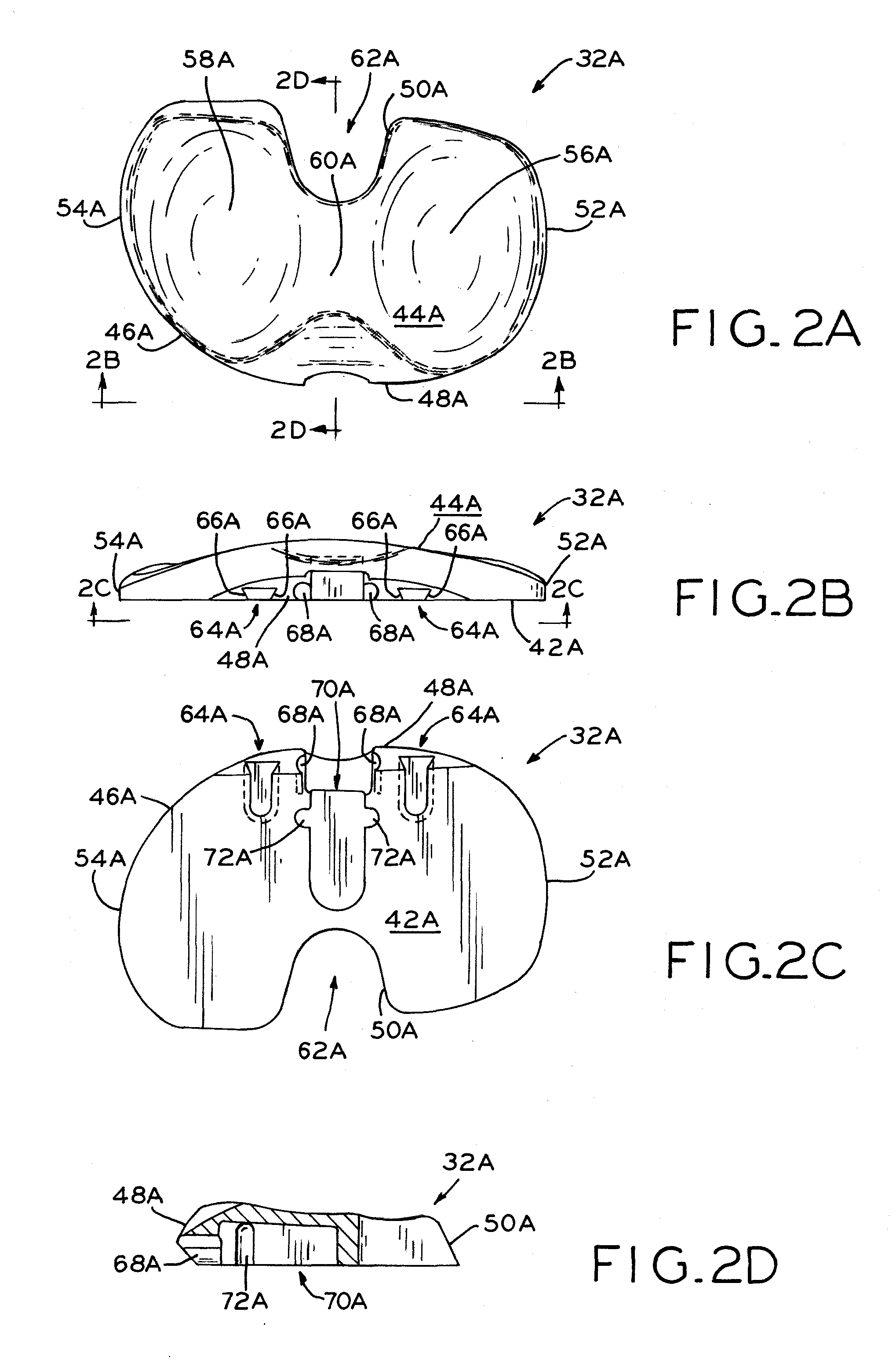

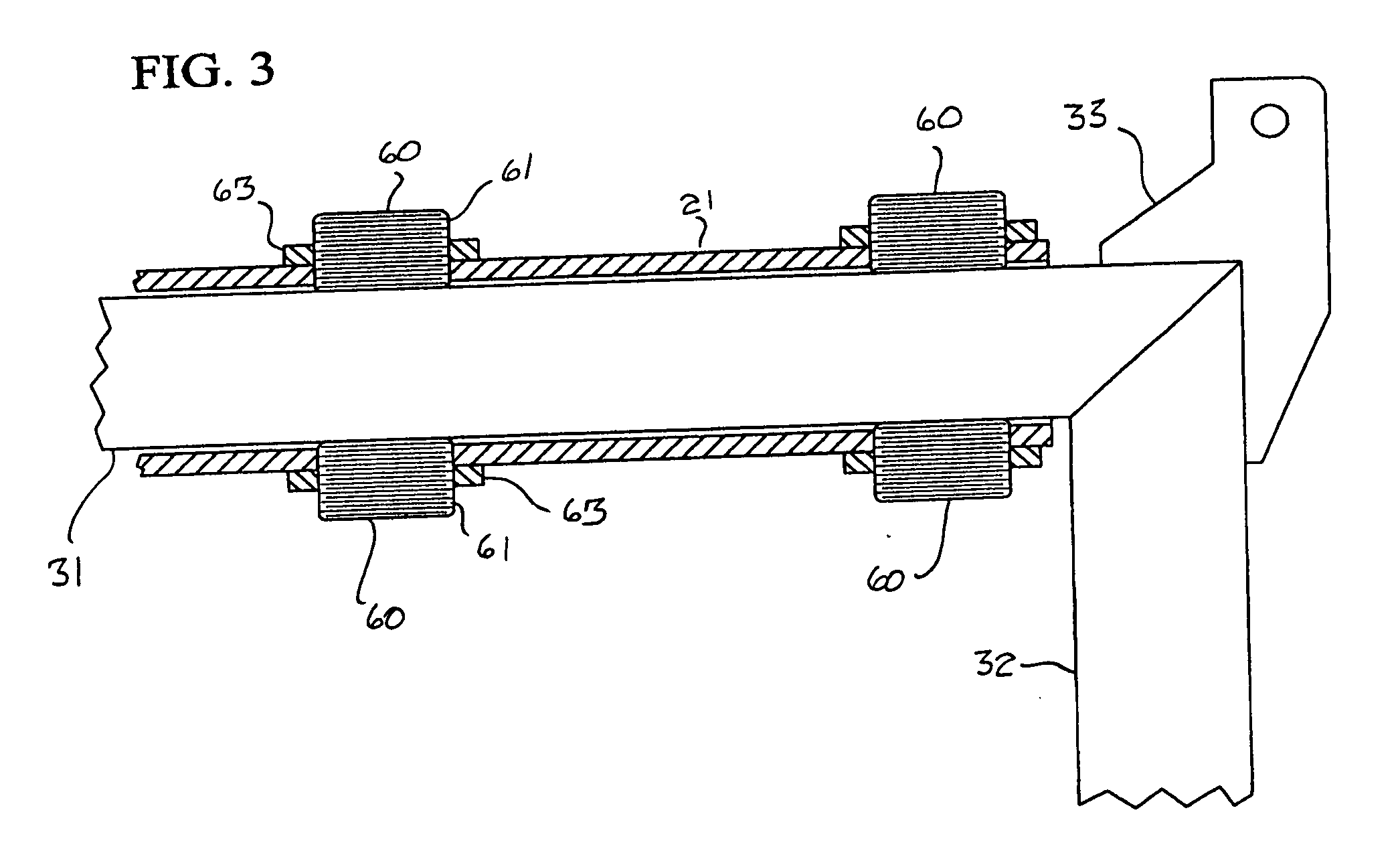

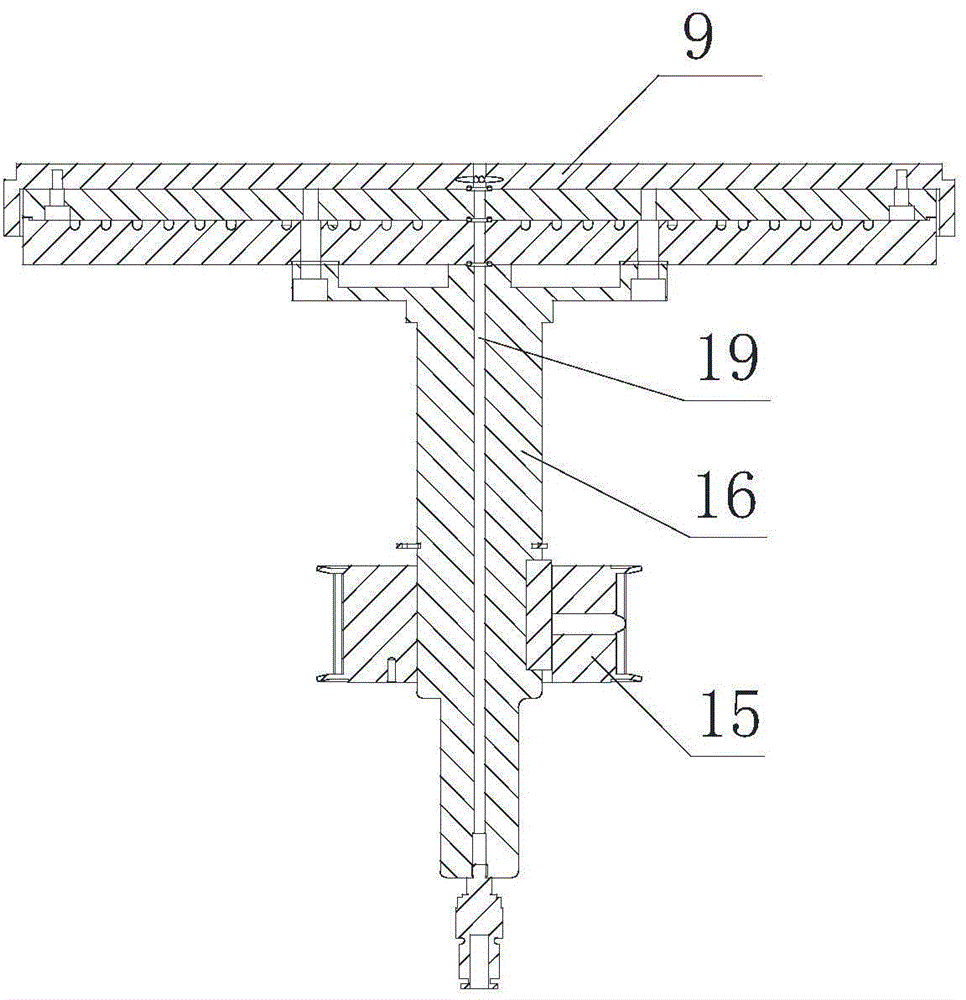

Provisional tibial prosthesis system

ActiveUS20120158152A1Reduce in quantityAdjustable spacingJoint implantsDiagnostic recording/measuringTibiaKnee surgery

The present disclosure provides a provisional tibial prosthesis system for a set of prosthetic knee joints for implantation in a natural knee, the provisional tibial prosthesis system including a bearing component and a bearing support, the spacing of the bearing component from the bearing support is adjustable to allow for representation of a variety of different sized final tibial prostheses. In this system, only one provisional bearing component corresponding to each level of constraint is needed and shims are used to adjust the spacing of the bearing component from the bearing support. The shims are slidably insertable between the bearing component and the bearing support in an anterior / posterior direction to allow for adjustment of the spacing of the bearing component from the bearing support. The number of provisional components needed during knee surgery is reduced and adjustment of the system only requires the knee joint to be distracted by a distance equal to the height of a particular shim.

Owner:ZIMMER INC

Provisional tibial prosthesis system

ActiveUS8603101B2Reduce in quantityAdjustable spacingJoint implantsDiagnostic recording/measuringKnee surgeryTibia

The present disclosure provides a provisional tibial prosthesis system for a set of prosthetic knee joints for implantation in a natural knee, the provisional tibial prosthesis system including a bearing component and a bearing support, the spacing of the bearing component from the bearing support is adjustable to allow for representation of a variety of different sized final tibial prostheses. In this system, only one provisional bearing component corresponding to each level of constraint is needed and shims are used to adjust the spacing of the bearing component from the bearing support. The shims are slidably insertable between the bearing component and the bearing support in an anterior / posterior direction to allow for adjustment of the spacing of the bearing component from the bearing support. The number of provisional components needed during knee surgery is reduced and adjustment of the system only requires the knee joint to be distracted by a distance equal to the height of a particular shim.

Owner:ZIMMER INC

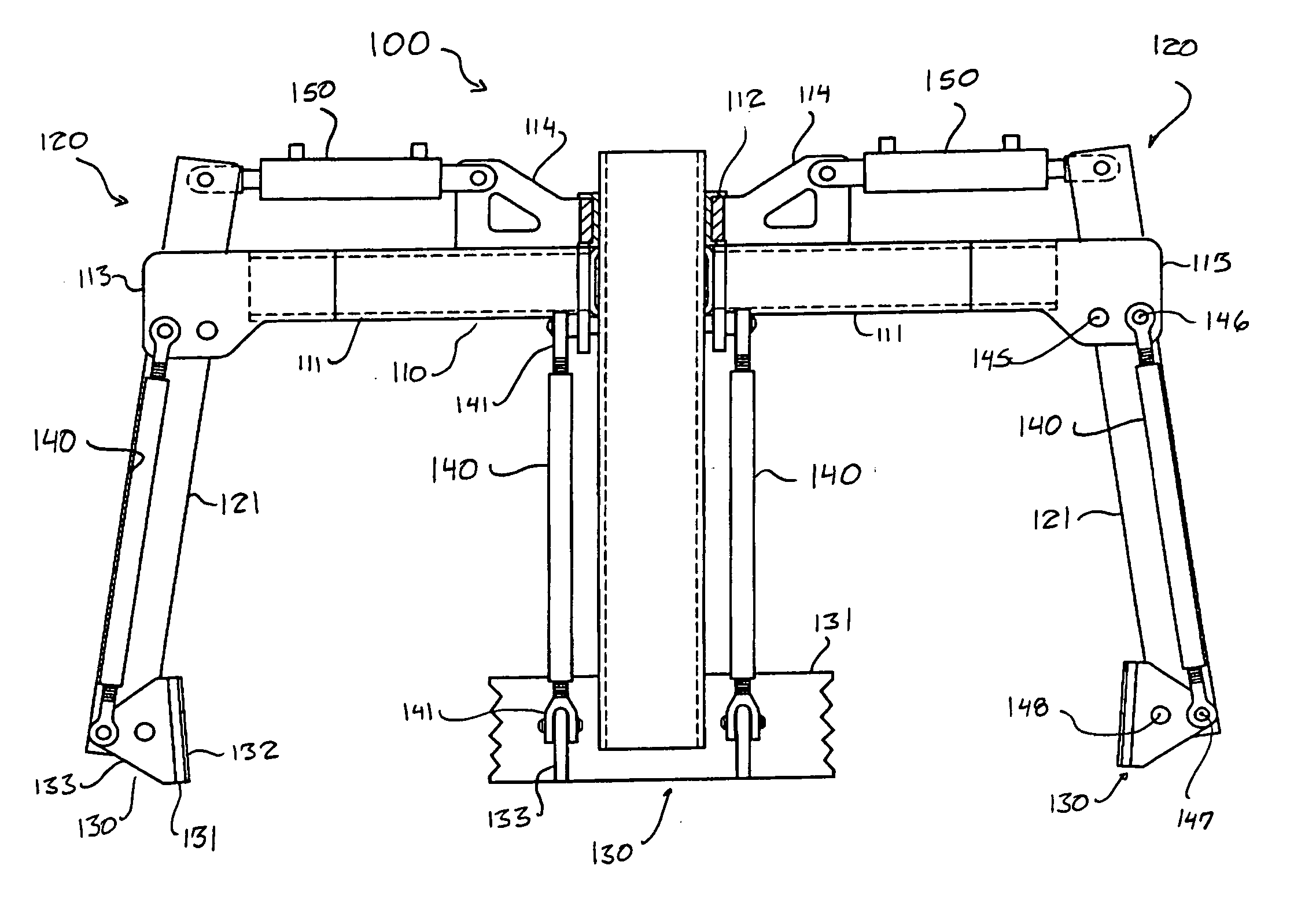

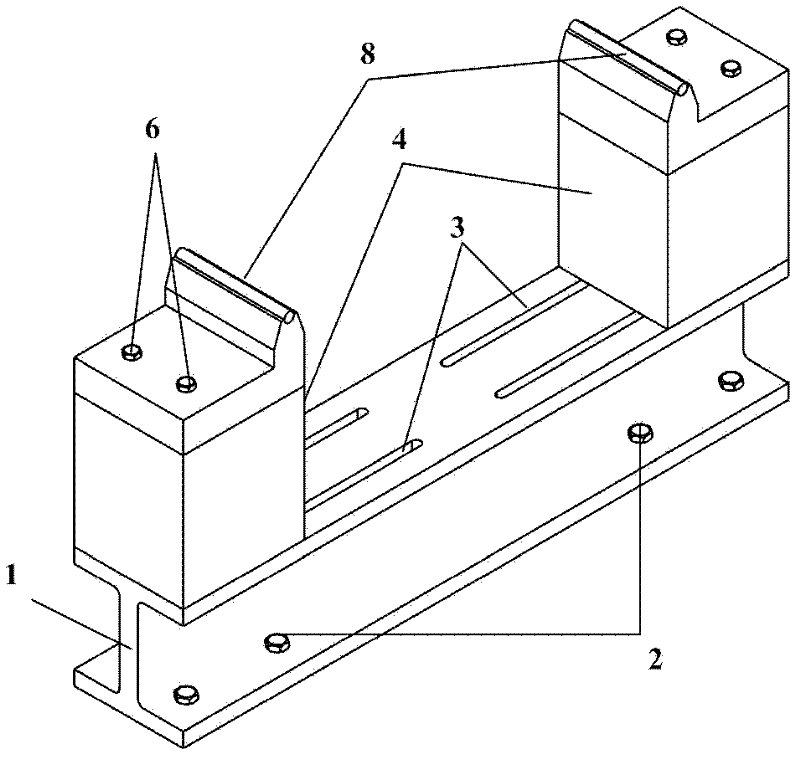

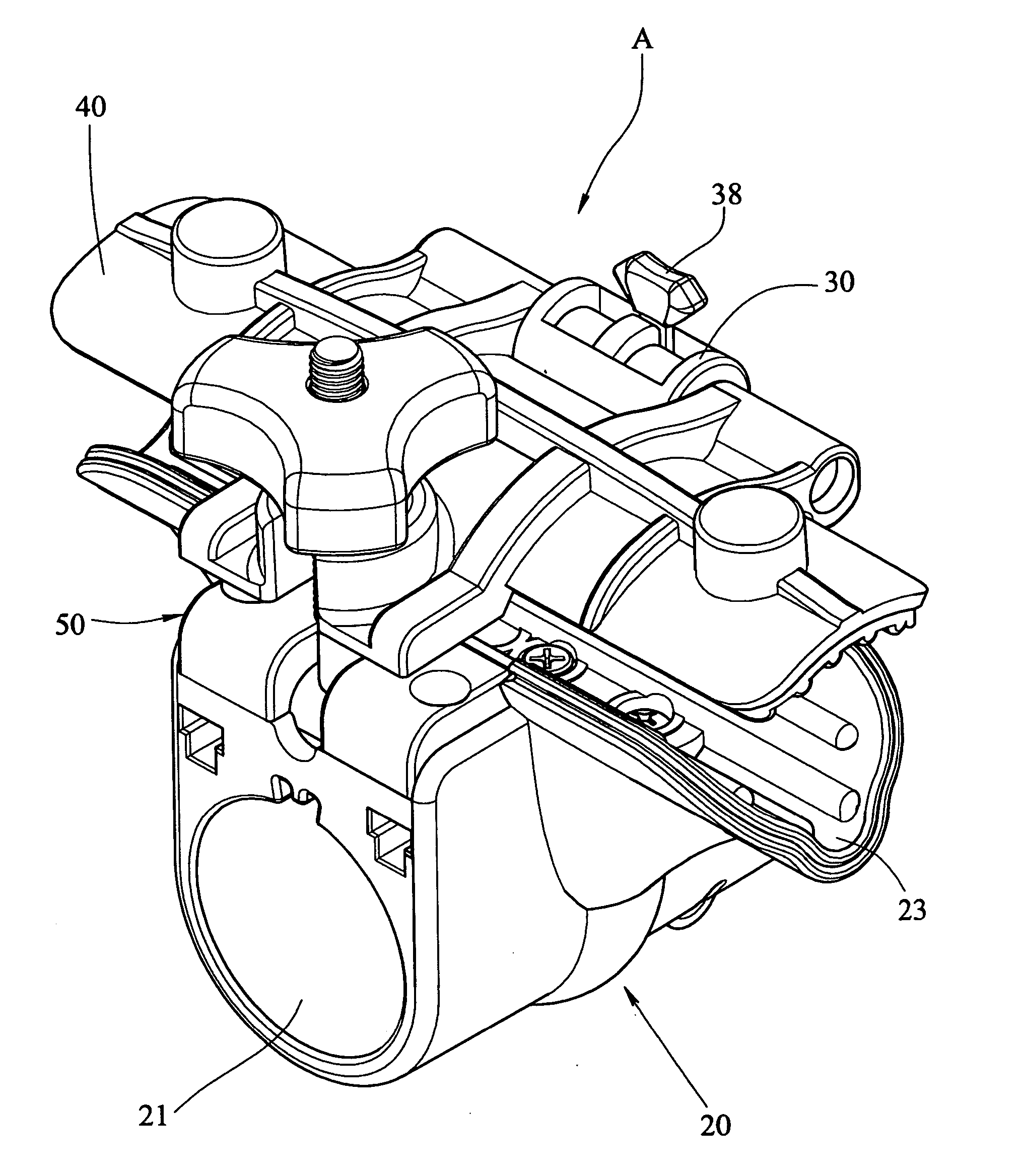

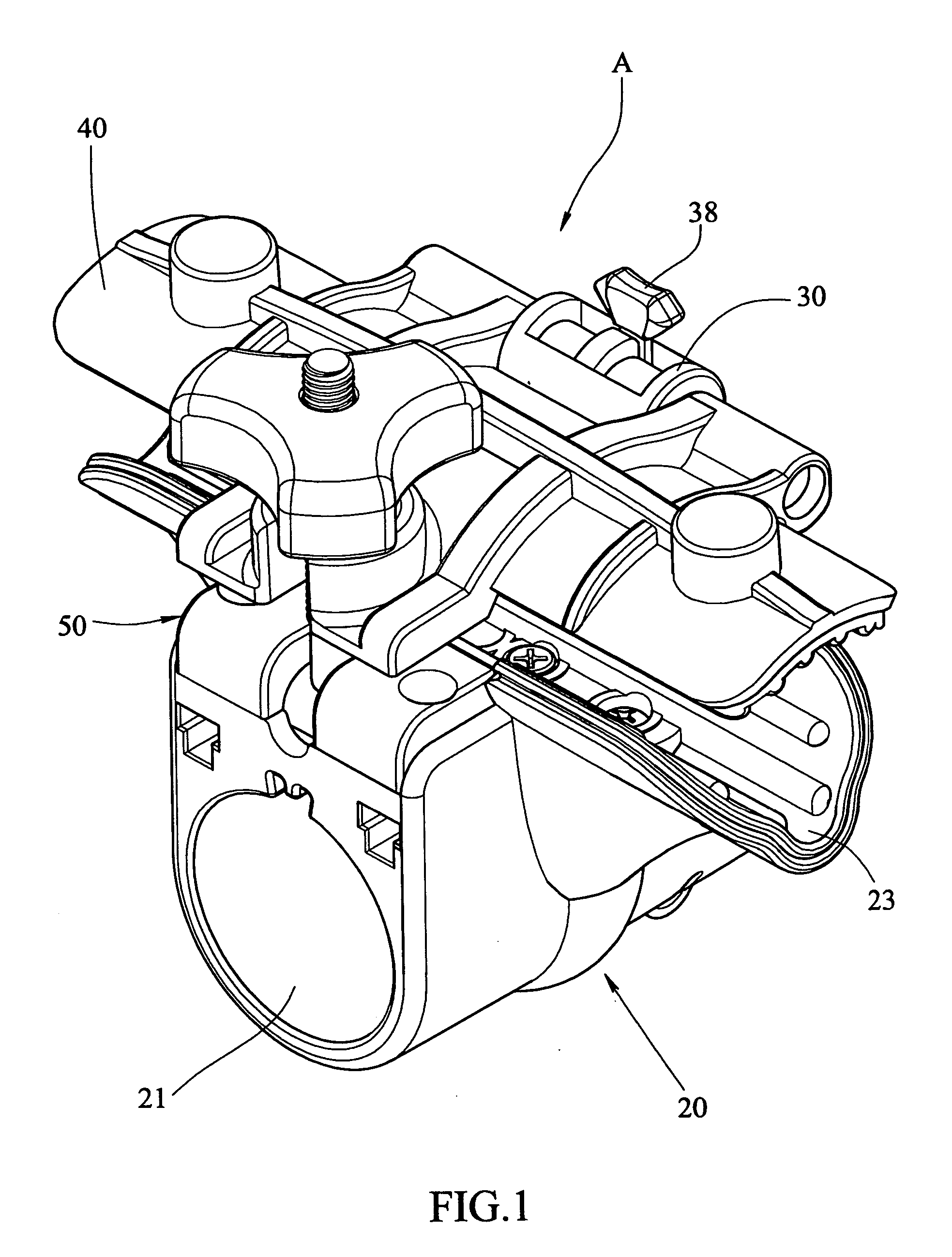

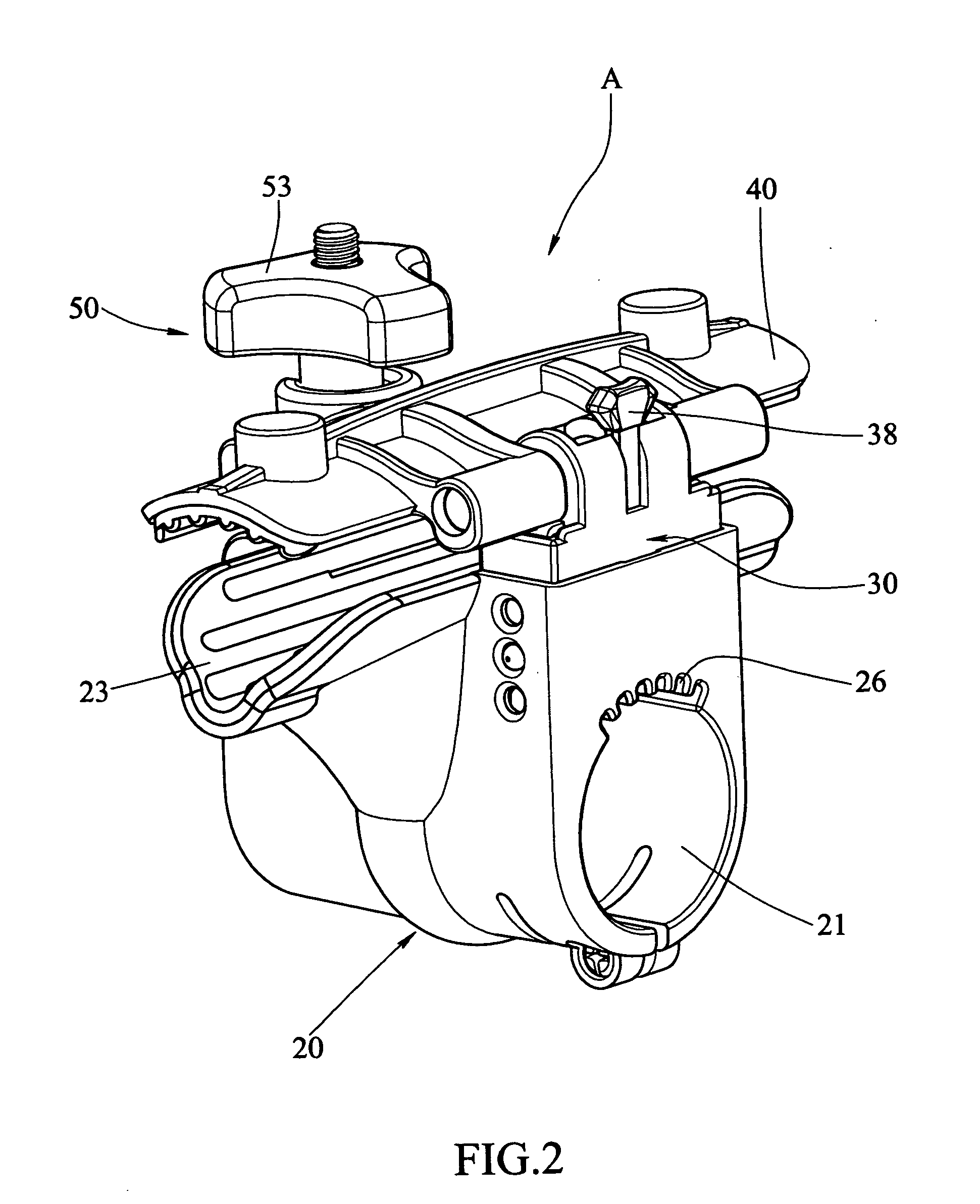

Clamping apparatus

A clamping apparatus includes a frame and a pair of opposing clamping arms mounted on the frame for movement towards and away from each other to grasp or release a load. In one embodiment, each clamping arm is guided for movement with respect to the frame by an adjustable bushing which can be rotated to adjust the position of the bushing with respect to the clamping arm. In another embodiment, each clamping arm defines a four-bar linkage which controls the angle with respect to the vertical of a contact portion of the clamping arm. The clamping apparatus may be mounted on a lift truck or other support member by a connector which permits the angle of the clamping apparatus with respect to the horizontal to be adjusted and which enables the clamping apparatus to pivot about an axis between a position in which it is disposed outboard of the axis and a position in which is it disposed forward of the axis.

Owner:TYGARD MACHINE & MFG

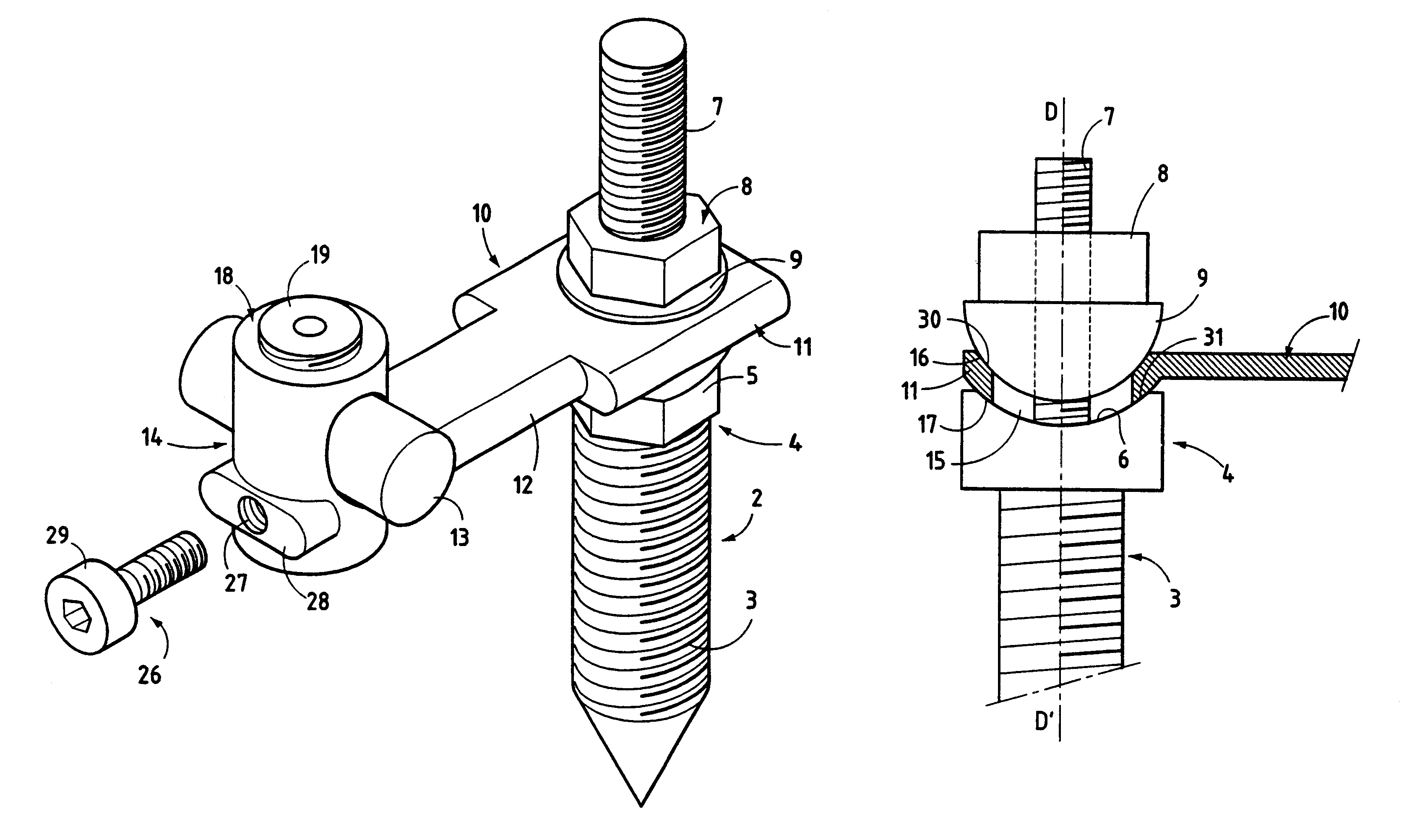

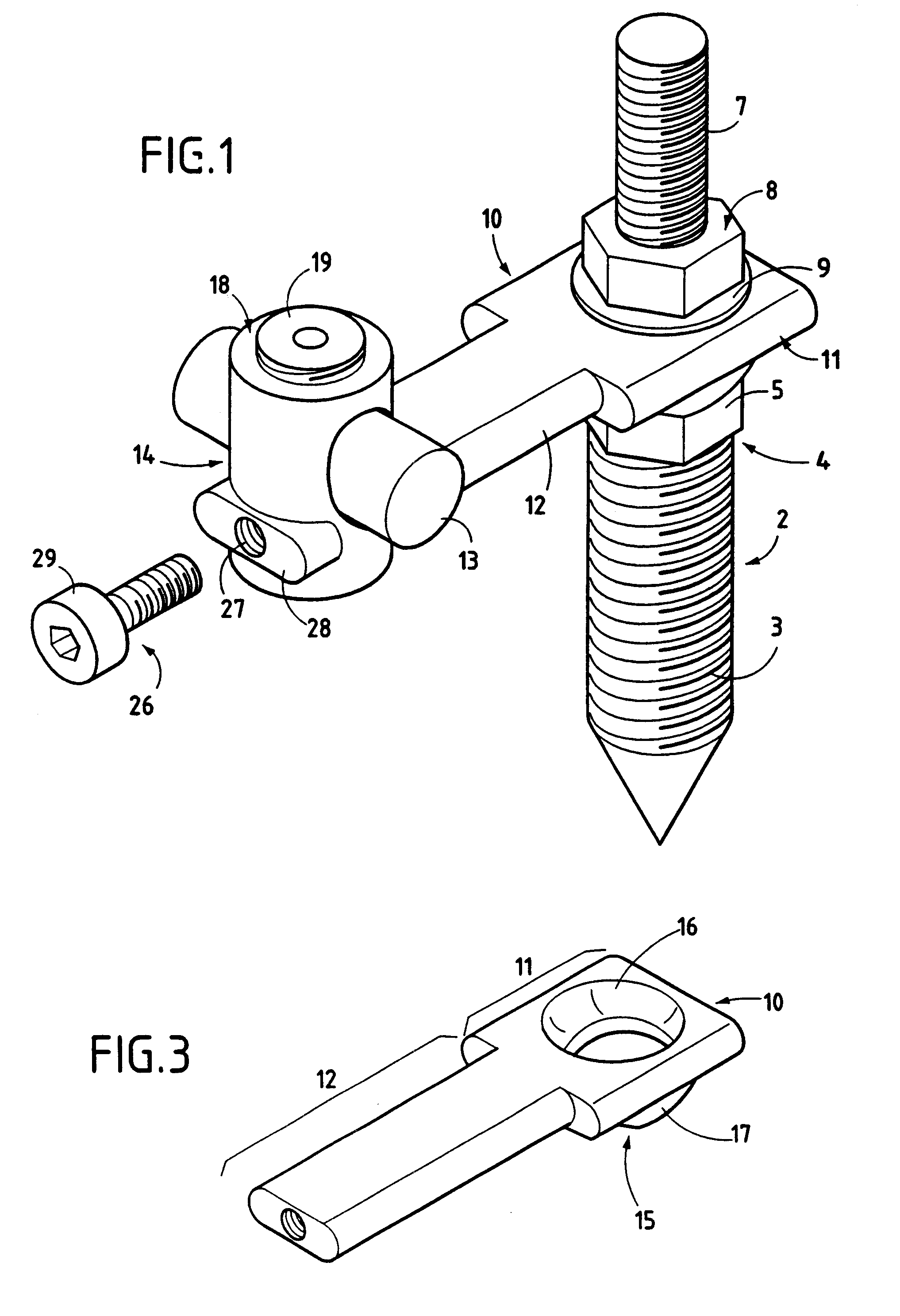

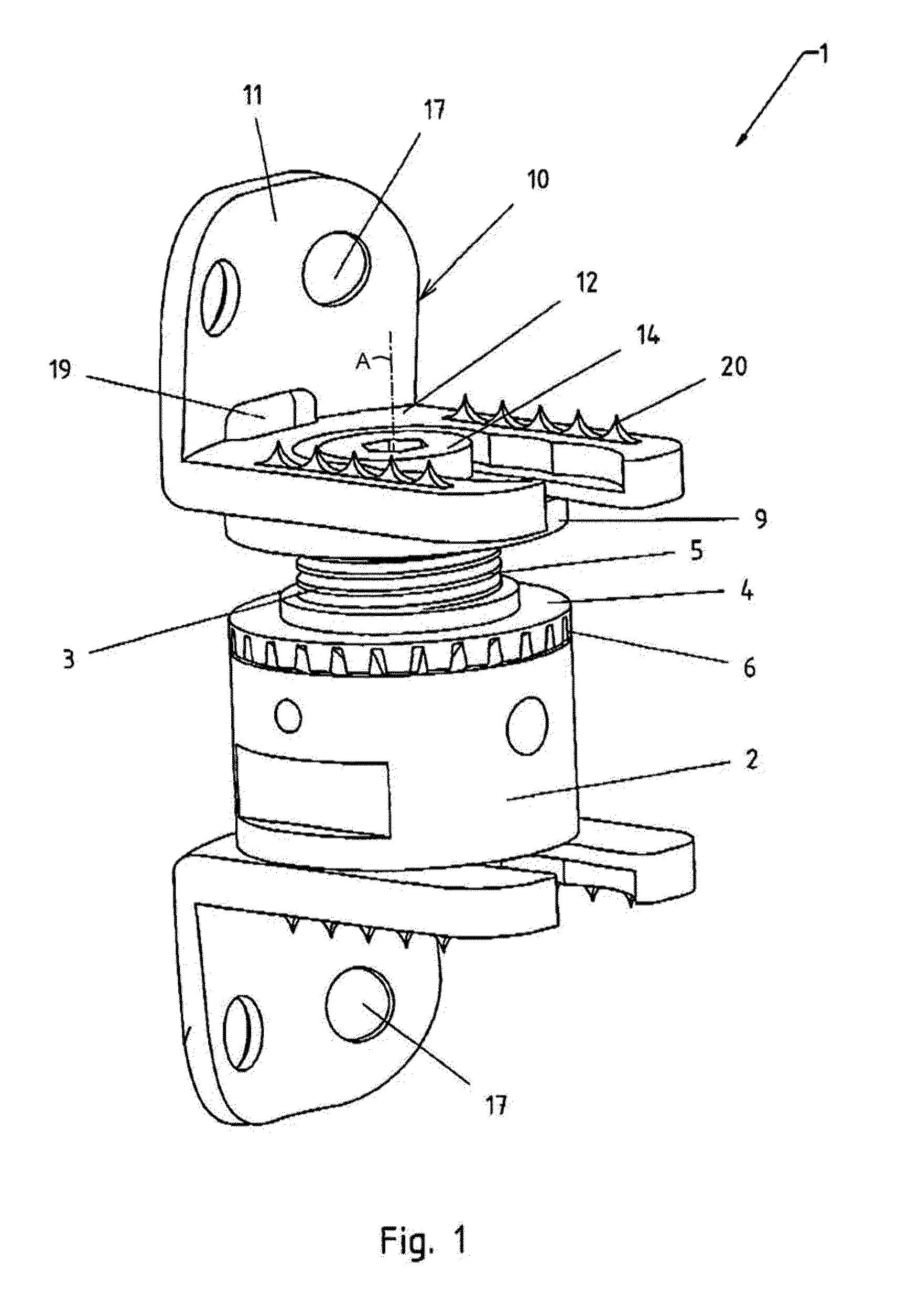

Connection device for osteosynthesis

InactiveUS6432109B1Easy to adjustAdjustable spacingInternal osteosythesisDiagnosticsScrew threadOsteosynthesis

The ostheosynthesis connection device of the invention is designed to connect a screw for implanting in the spine to a vertebral support rod. The screw is constituted by a bottom first threaded portion, a head having flats and a curved base, and a top second threaded portion in line with the first. A nut having a curved base is suitable for co-operating with the second threaded portion. For connection with the screw, a connection piece has a hole of inside diameter that is greater than the outside diameter of the second threaded portion of the screw, and around said hole it has curved top and bottom bearing faces such that the connection piece is locked in position relative to the screw once the nut has been tightened by the curved base of the nut bearing against the top bearing face thereof and by the bottom bearing face being clamped against the curved base of the head of the screw.

Owner:SOCIETE DE GENIE MEDICAL SGM

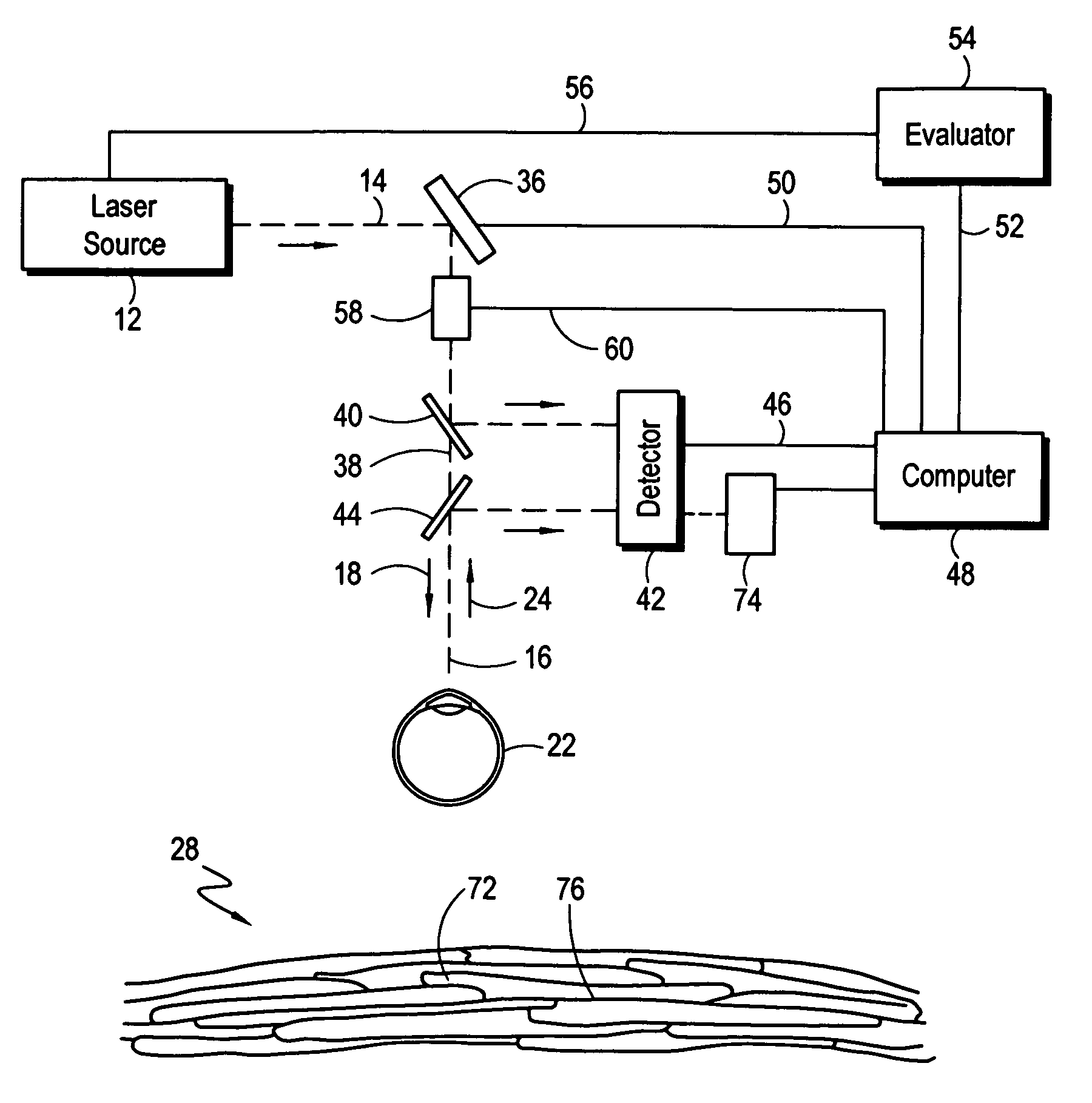

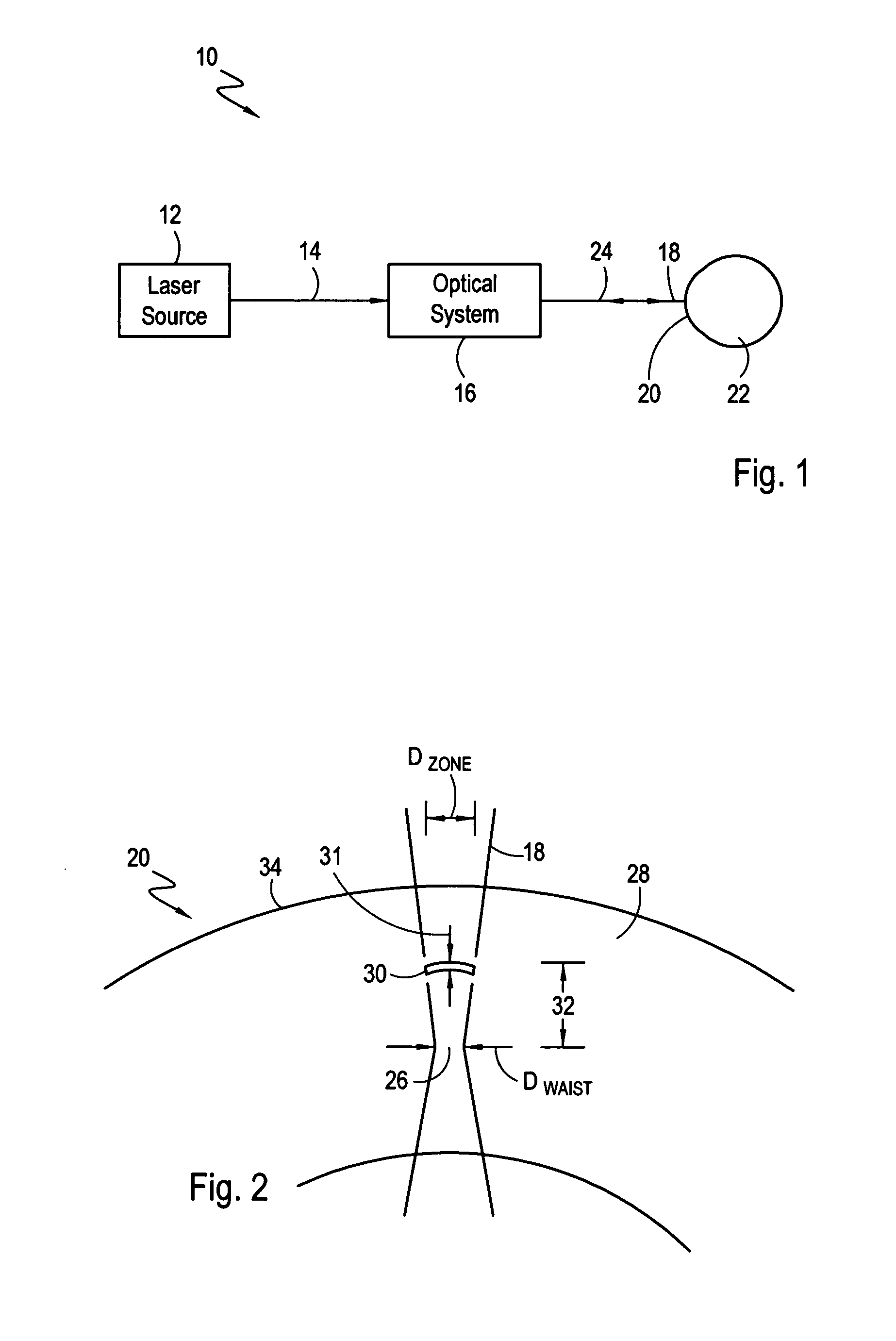

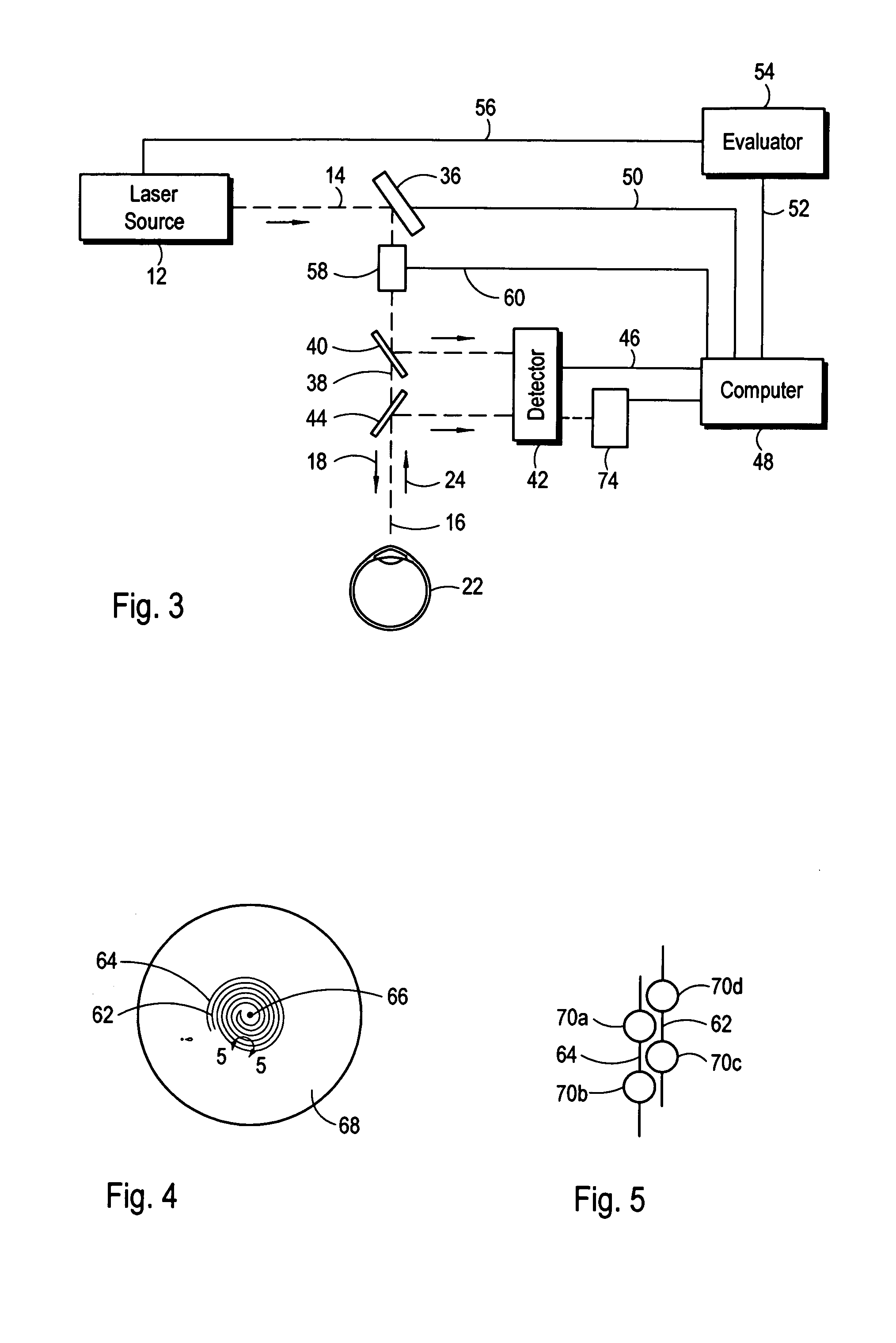

Method and apparatus for intrastromal refractive surgery

InactiveUS7101364B2Minimize heat damageFast ablationLaser surgerySurgical instrument detailsKeratorefractive surgeryPulse energy

A method and apparatus for intrastromal refractive surgery is disclosed wherein tissue at selected locations within the stroma of the cornea is photoablated using a pulsed laser beam. The apparatus includes an optical system for forming a shaped laser beam having a waist at a predetermined distance from the optical system. The pulse duration and pulse energy of the laser beam are selected to cause ablation to occur in front of the waist (i.e. between the waist and the optical system). To achieve this, a pulse energy is used that exceeds the minimum pulse energy required for ablation at the waist. By ablating in front of the waist, a relatively large ablation zone (per pulse) is created (compared to ablation at the waist). Furthermore, while the laser is scanned through the cornea to effectuate a refractive change, the optical system maintains a uniform waist for the laser beam.

Owner:TECHNOLAS PERFECT VISION

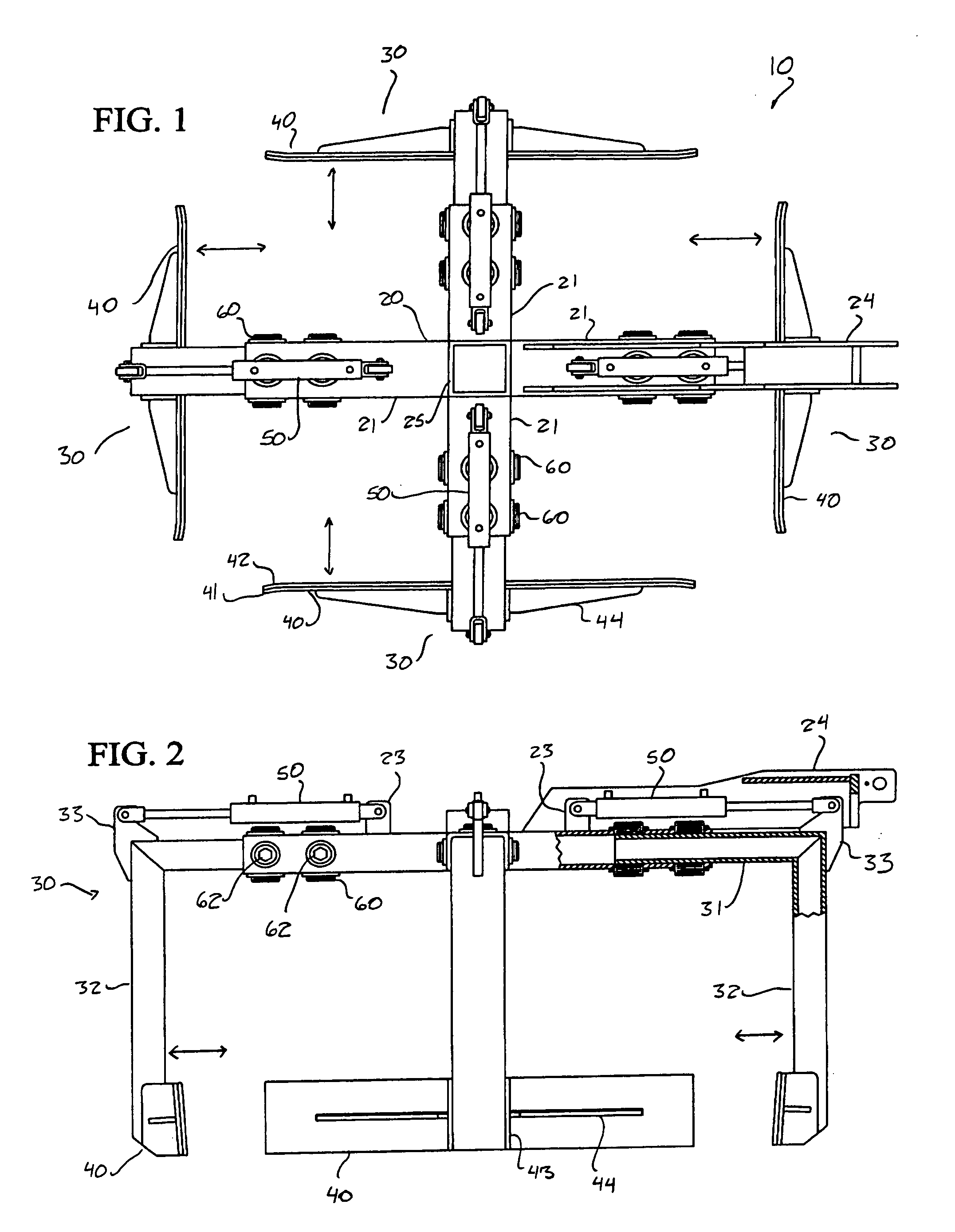

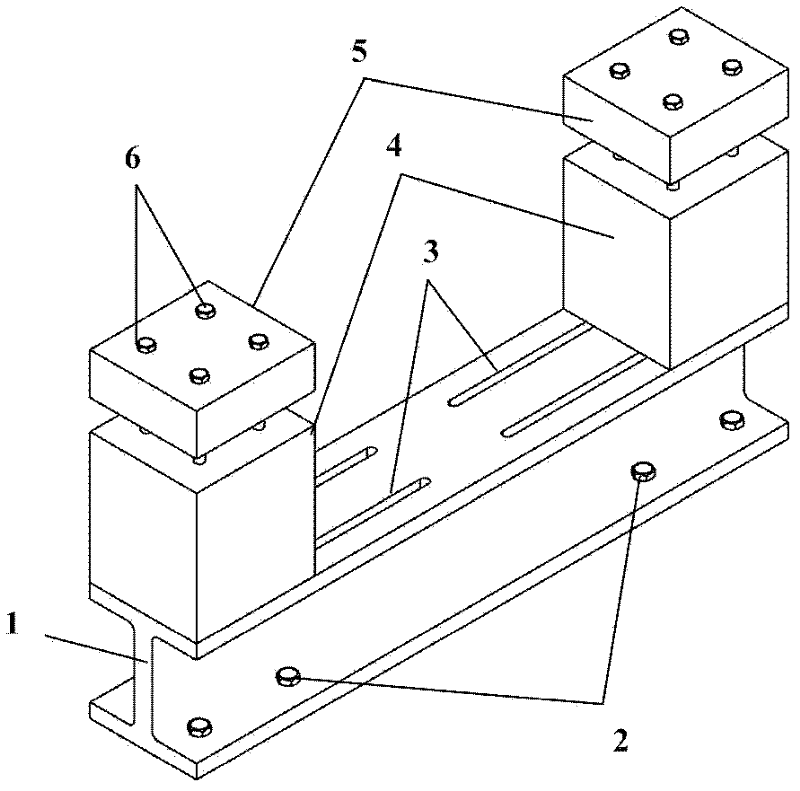

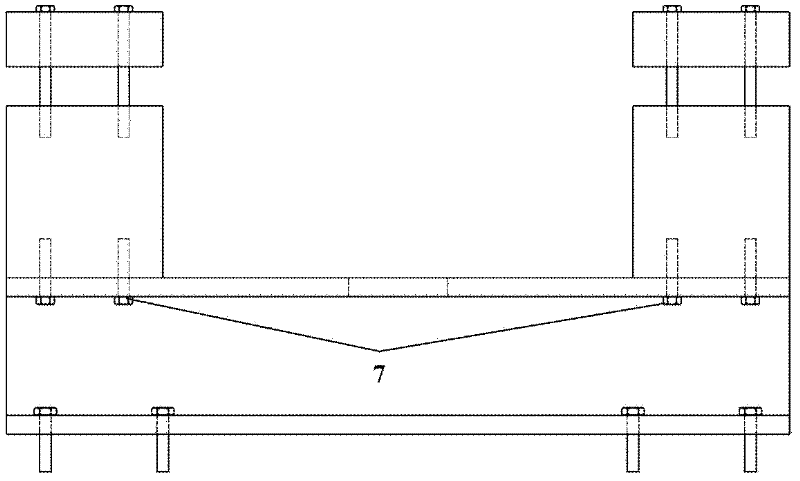

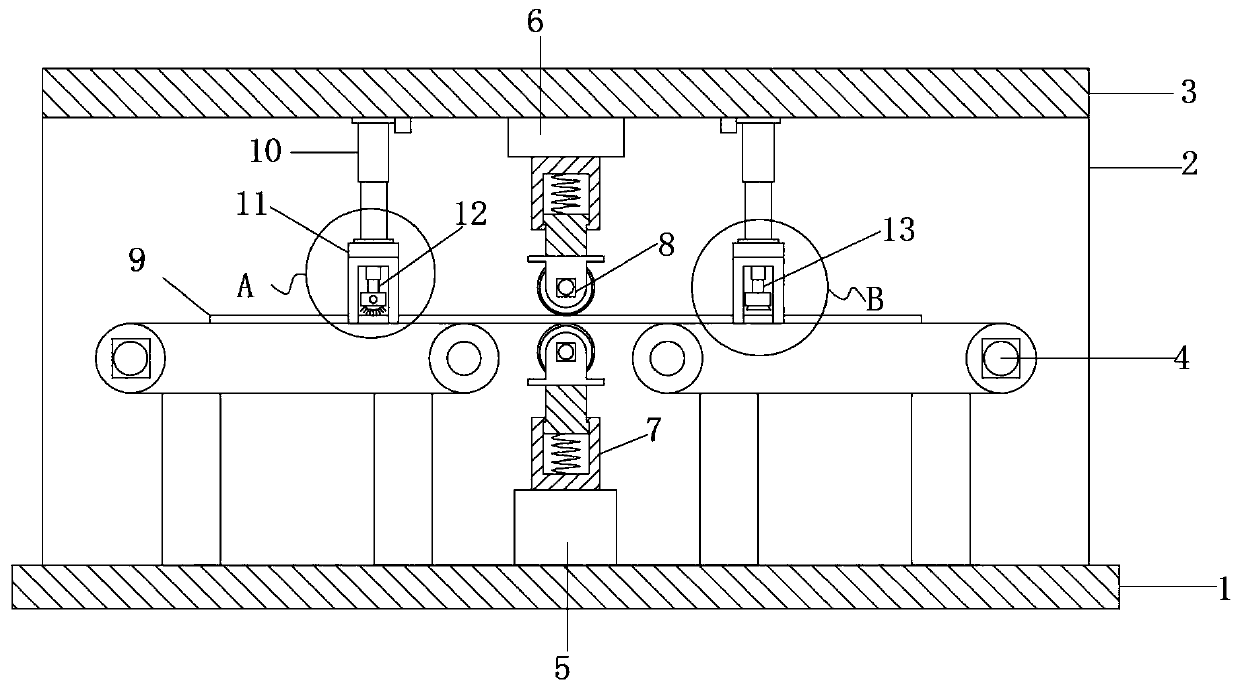

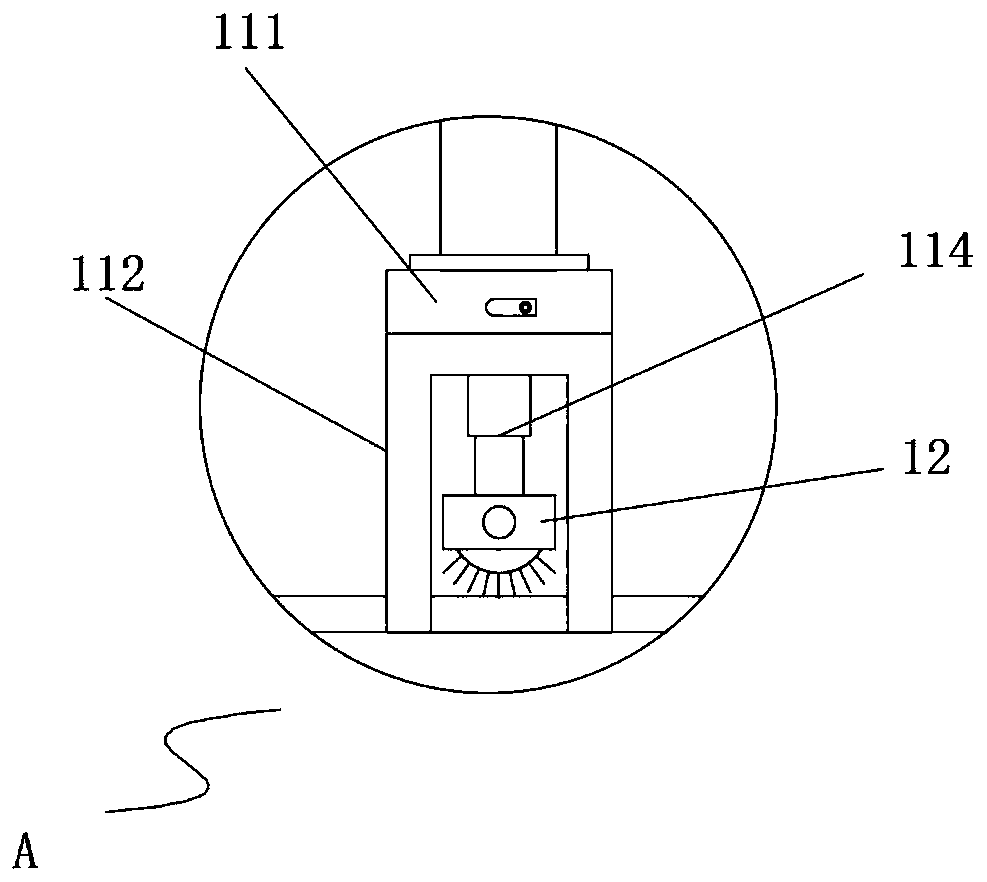

Adjustable test fixture

InactiveCN102494943AReasonable structural designAdjustable spacingShock testingStrength propertiesEngineeringTest fixture

The invention discloses an adjustable test fixture device, which comprises an H beam base, two support bases arranged on the H beam base and clamped pressure sheets arranged on the tops of the support bases; two pairs of support base guide grooves are arranged on an upper wing plate of the H beam base; and one support base is movably connected to each pair of support base guide grooves. The device disclosed by the invention is simple for operation and high in precision; the positions of the support bases can be adjusted through the guide grooves on the upper wing plate of an H beam, so that the distance between the support bases can be adjusted, thus, the purpose of applying to test pieces with different geometrical sizes can be achieved; different boundary types can be realized by replacing the types of the support bases on the upper wing plate of the H beam; and the H beam base can move, thus, the adjustable test fixture is convenient to experiment and test in different places and has a certain portability.

Owner:XI AN JIAOTONG UNIV

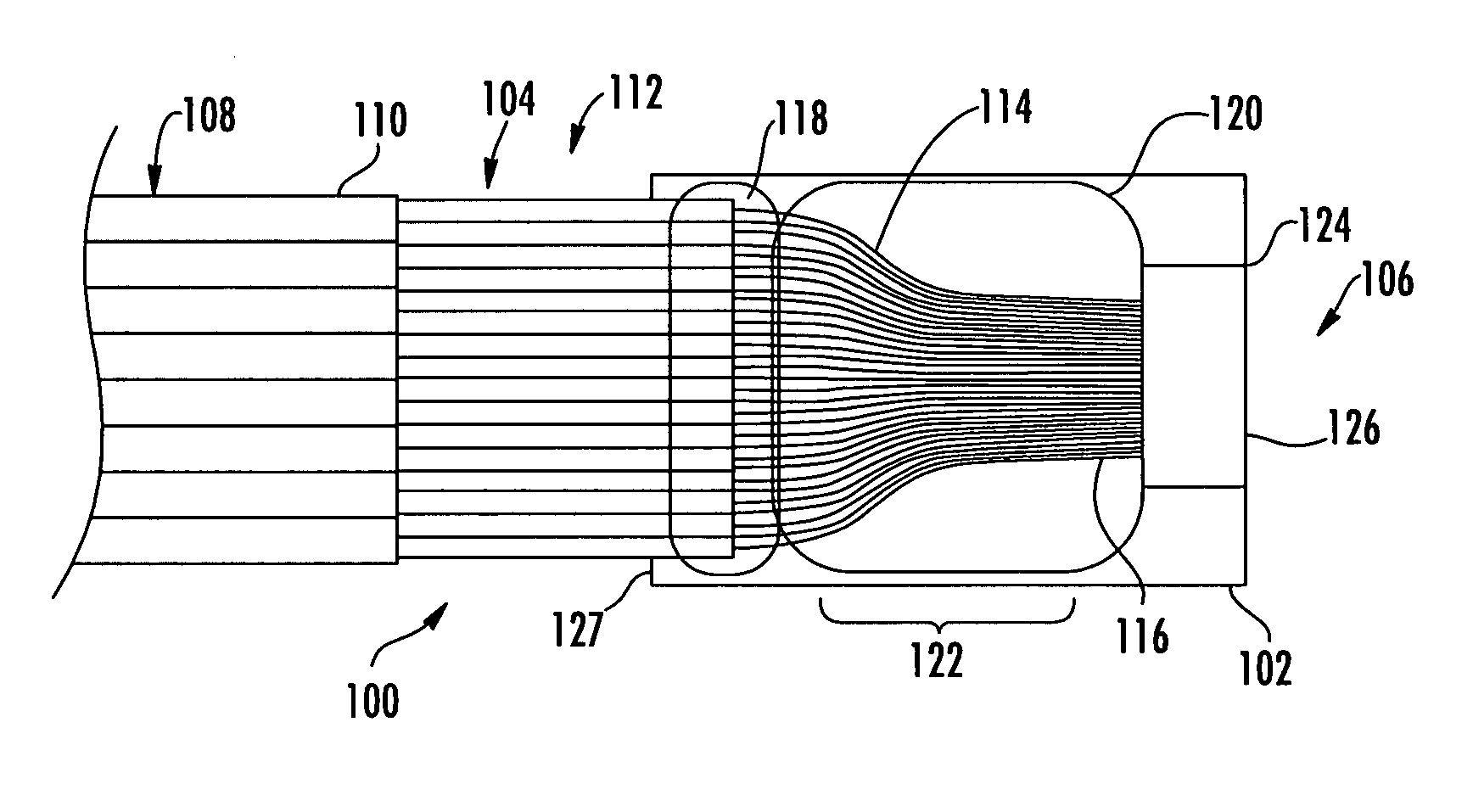

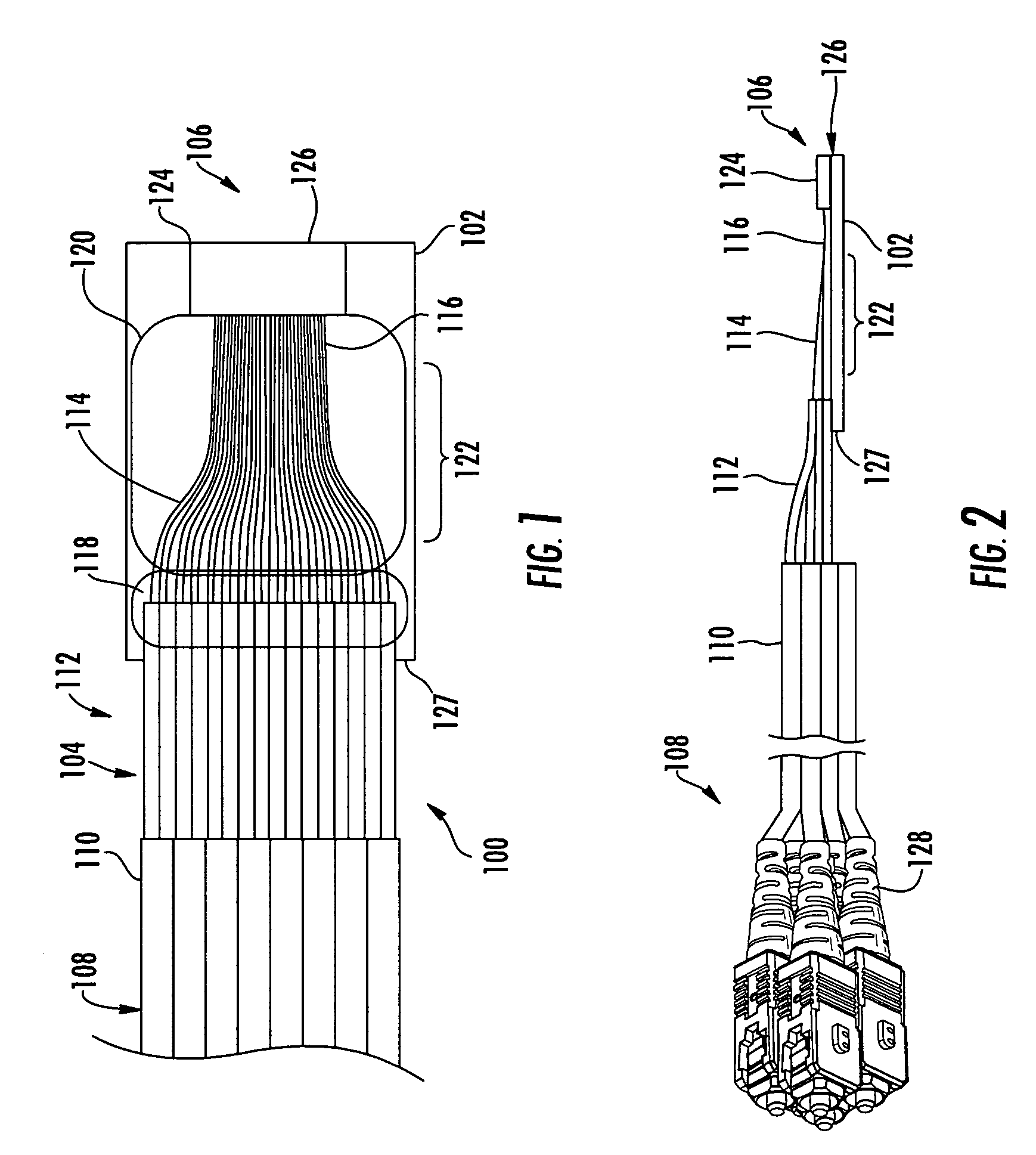

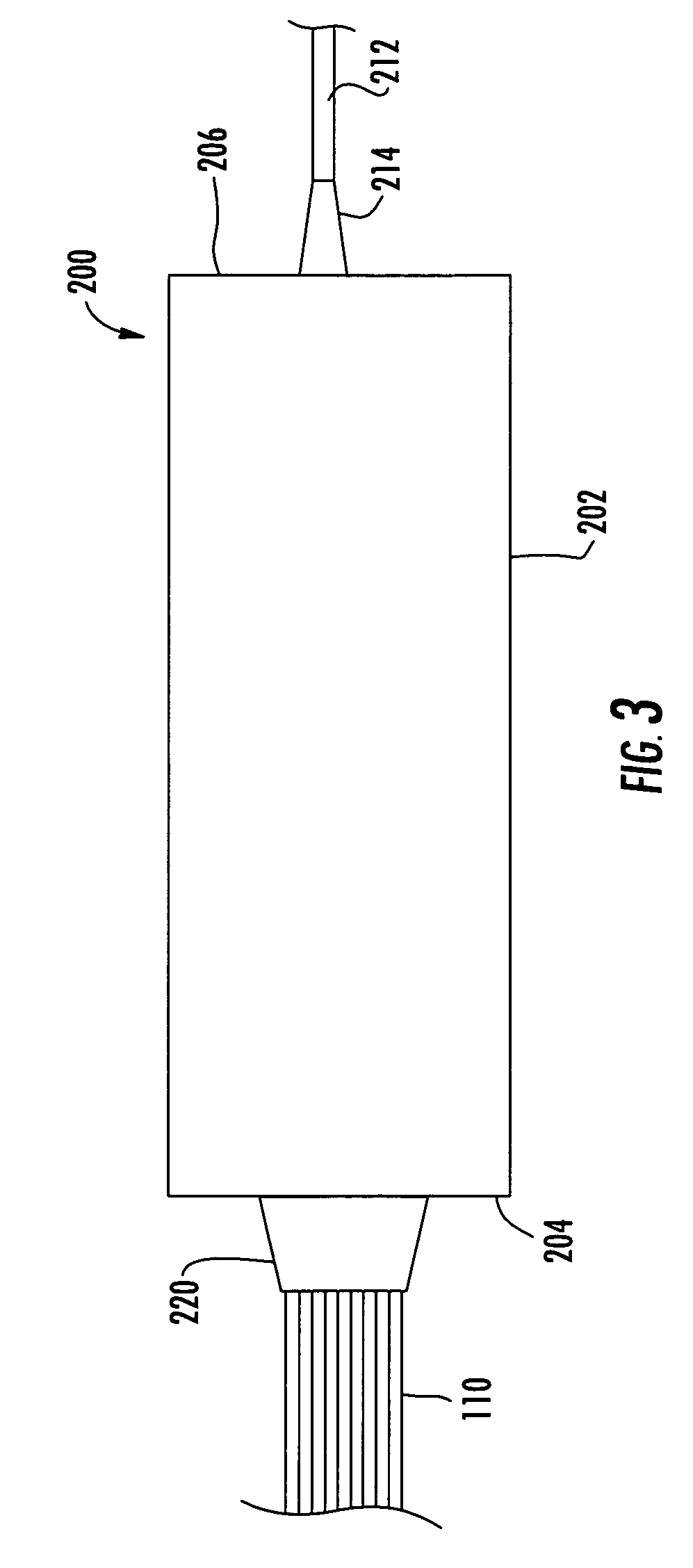

Optical fiber splitter module and fiber optic array therefor

An optical fiber splitter has a higher density fiber optic array that allows for smaller packaging. The optical fibers that extend from the optical fiber splitter have one end connectorized and their spacin at the other end reduced, thereby eliminating components that were heretofore required. A method of making the fiber optic array includes interleaving the optical fibers to reduce the overall dimensions of the fiber optic array and the fiber optic splitter. A tool is used to reduce the spacing of the optical fibers in the fiber optic array.

Owner:CORNING OPTICAL COMM LLC

Adjustable bicycle racks

InactiveUS20060249466A1Adjustable spacingLocks for portable objectsCycle standsVehicle frameEngineering

Owner:WANG CHIU KUEI

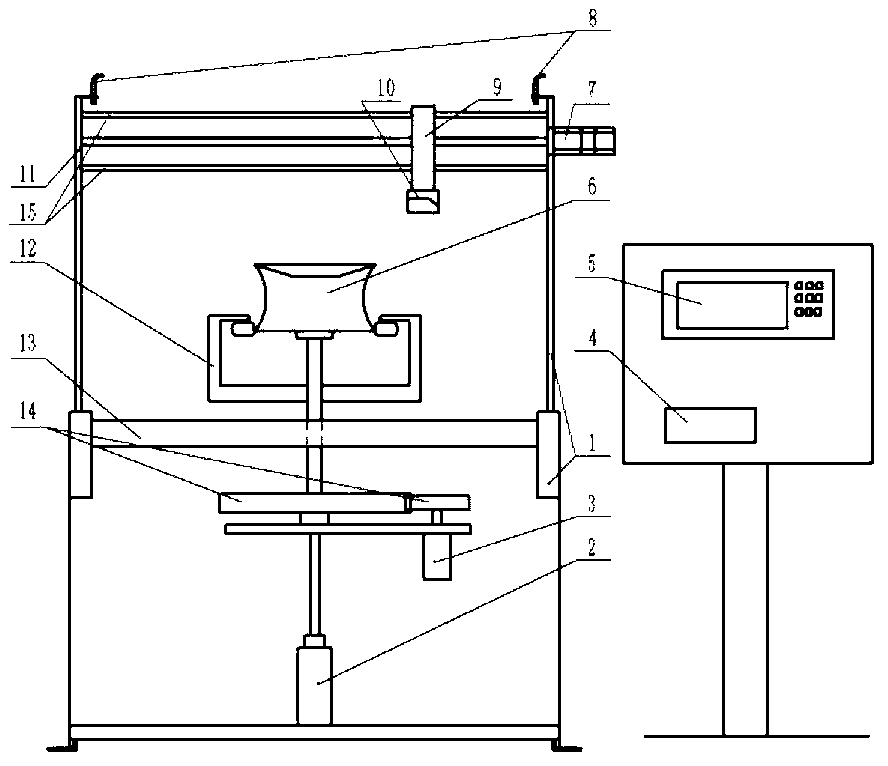

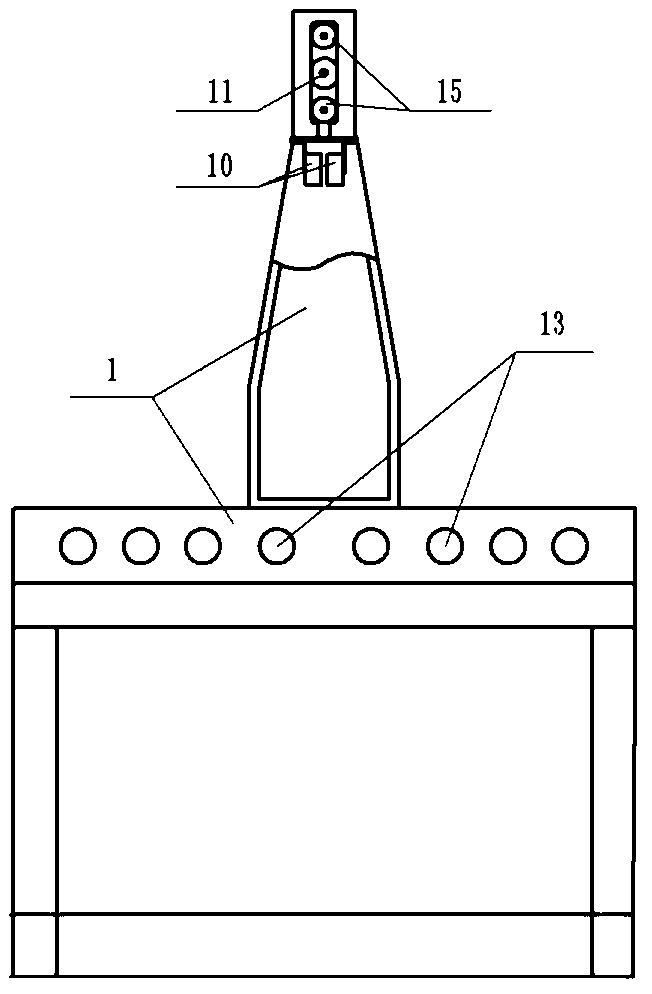

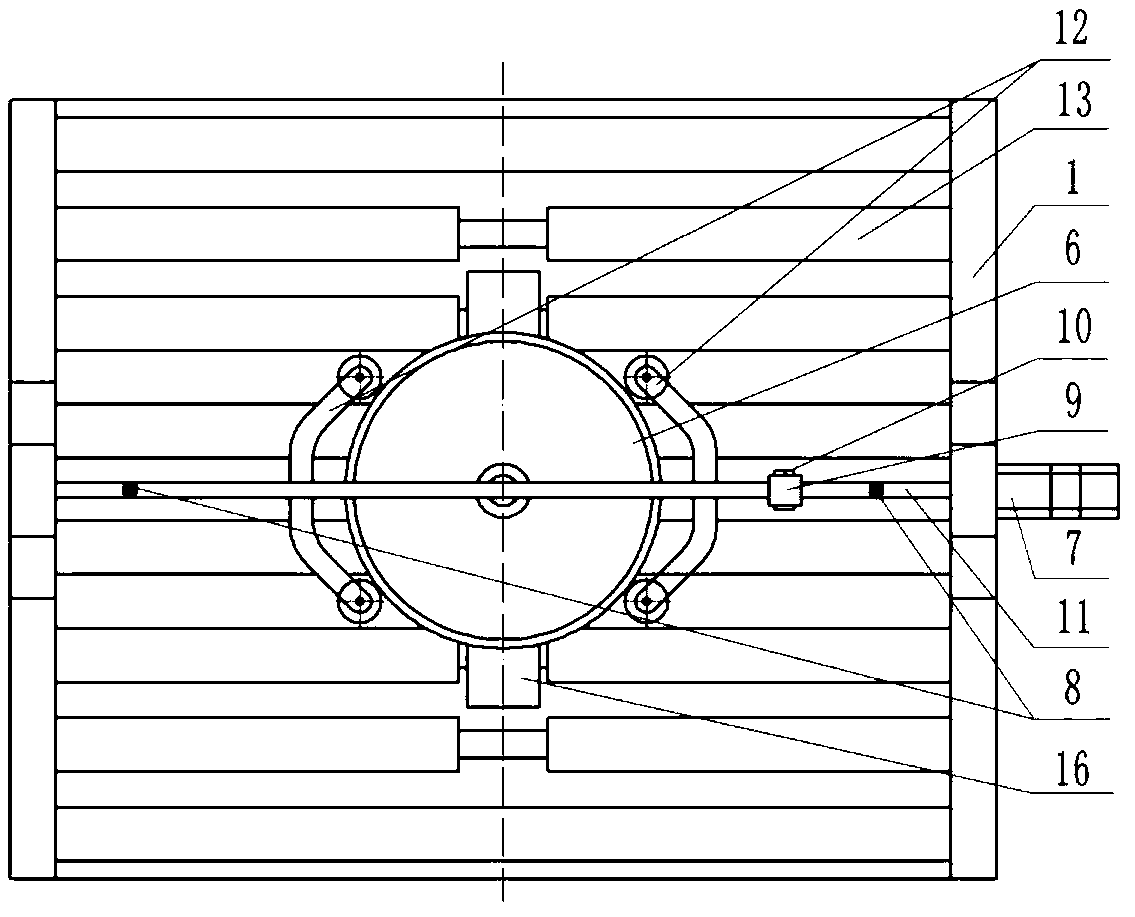

On-line automobile aluminium alloy hub blank deformation measurement method and measurement device

The invention discloses an on-line automobile aluminium alloy hub blank deformation measurement method and a measurement device which relate to the field of automated measurement. The measurement device comprises a test table, a pneumatic clamping mechanism, an air cylinder lifting mechanism, a hub-rotating mechanism, two laser sensors, a motion control module, an industrial personal computer for storing and processing data, and data processing software. By scanning a hub blank in all directions, the measurement device can simultaneously measure the wheel rim deformation and the center axial deformation of the hub blank, thus achieving the effects of high measurement accuracy, more measurement points, high speed and high reliability, automatically measuring the hub blank on line, and increasing the production efficiency of enterprises. The process of measurement is automatic, measurement can be adapted to harsh environments, and cannot be affected by vibration, smoke or humidity, the total measurement time is 30 seconds, the measurement precision is 0.02mm, and the actual demand on measurement can be satisfied.

Owner:BEIJING ORIENT

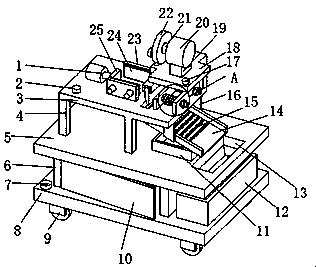

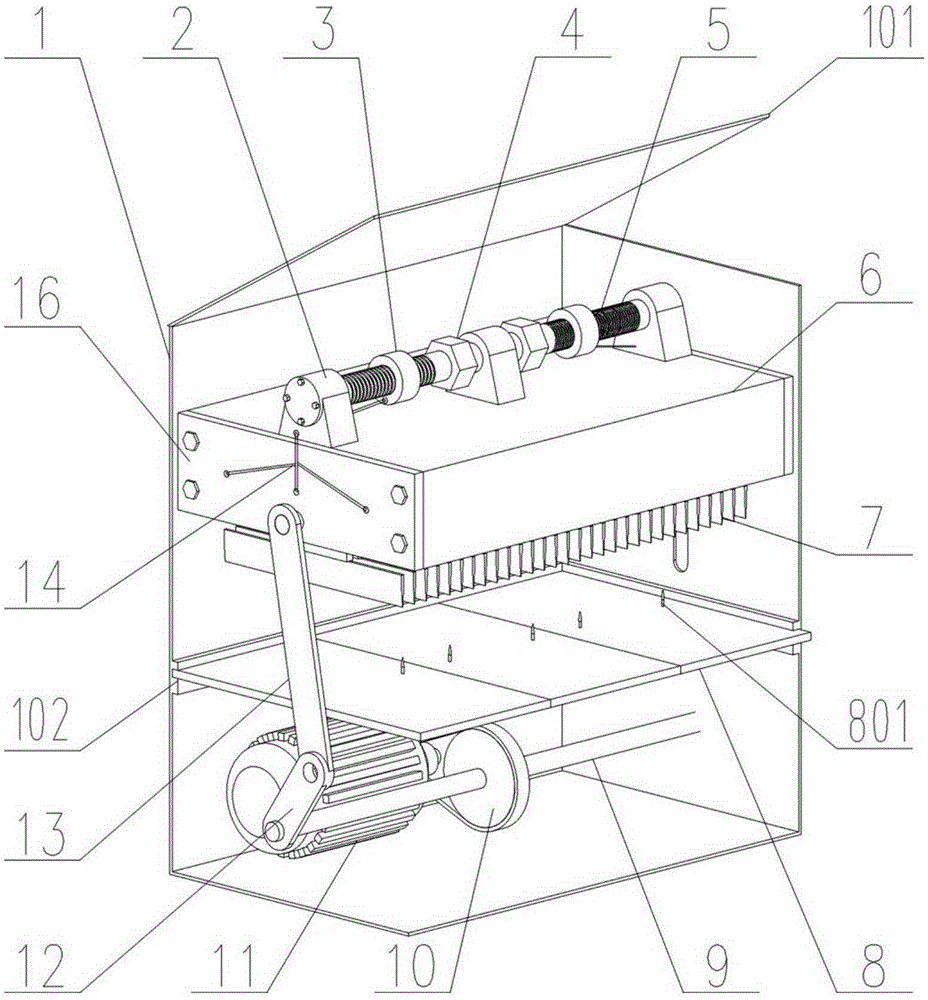

Efficient slicing machine special for preparation of traditional Chinese medicine decoction pieces

InactiveCN108789581AAvoid uneven slice thicknessEasy to replaceMetal working apparatusHeating arrangementSlice thicknessEngineering

The invention discloses an efficient slicing machine special for preparation of traditional Chinese medicine decoction pieces. The efficient slicing machine comprises a machine seat. A drying box is arranged on the left side of the upper surface of the machine seat. A collecting box is arranged on the right side of the upper surface of the machine seat. A base is arranged on the upper surface of the drying box. A discharging port is formed in the right side of the upper surface of the base. Supporting columns are arranged on the left side of the upper surface of the base. A workbench is arranged at the upper ends of the four supporting columns. A slice thickness adjusting mechanism is arranged on the right side of the upper surface of the workbench. A pushing mechanism is arranged on the left side of the upper surface of the workbench. A first positioning clamp plate is arranged on one side of the middle of the upper surface of the workbench. A second positioning clamp plate is arranged on the other side of the middle of the upper surface of the workbench. Adjustable bolts are connected with threads of threaded holes in the side surface of the second positioning clamp plate. A clamping plate is arranged at the ends of the adjustable bolts. According to the efficient slicing machine special for preparation of the traditional Chinese medicine decoction pieces, moving is convenient, traditional Chinese medicine is convenient to clamp, it is guaranteed that slice thickness is uniform, the slice thickness can be adjusted, and chippings and slices are collected in a classified mode.

Owner:亳州市合七医药科技有限公司

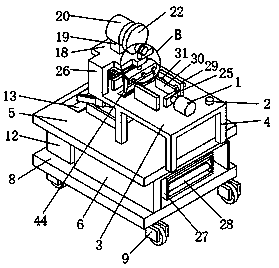

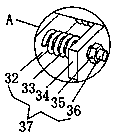

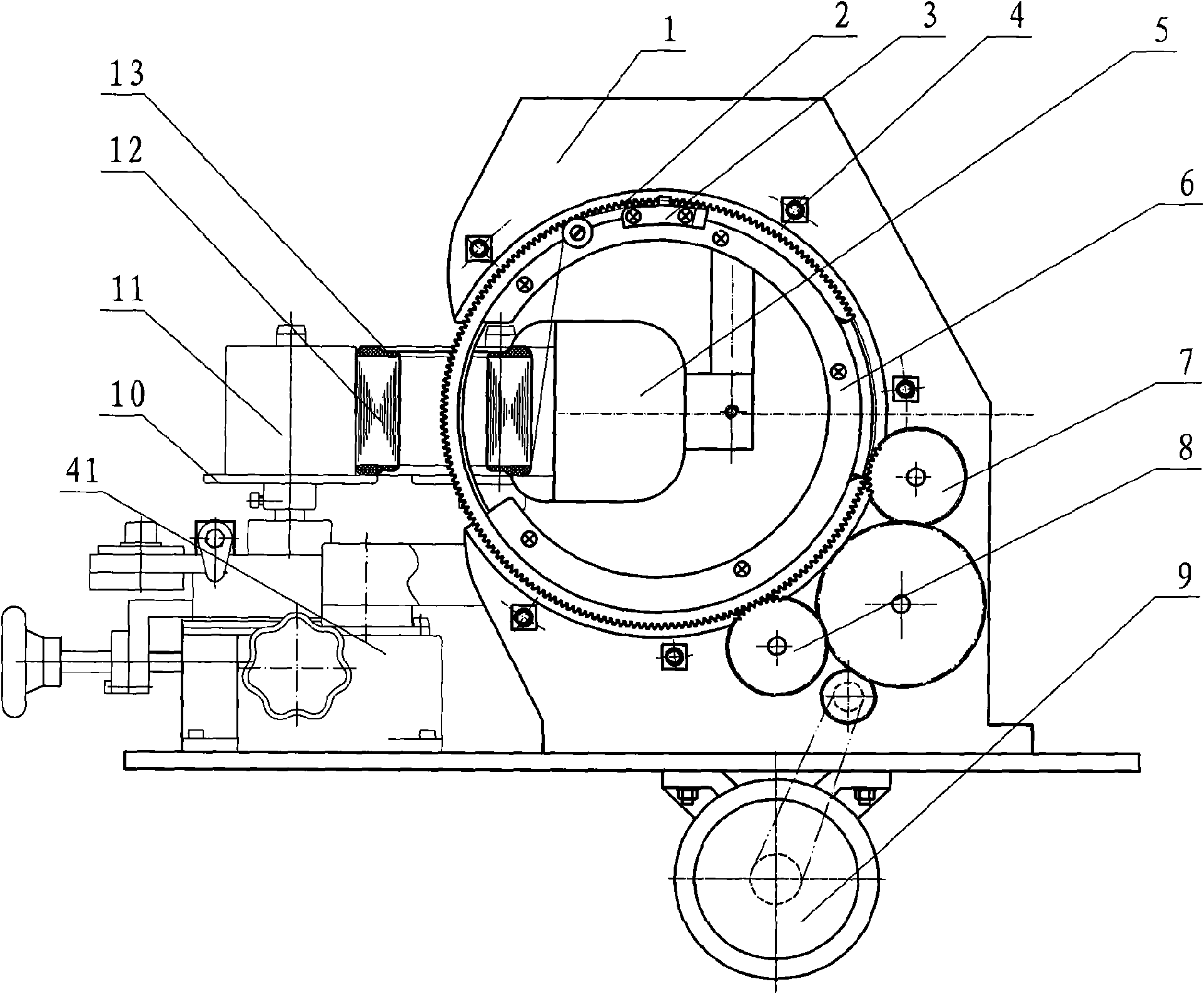

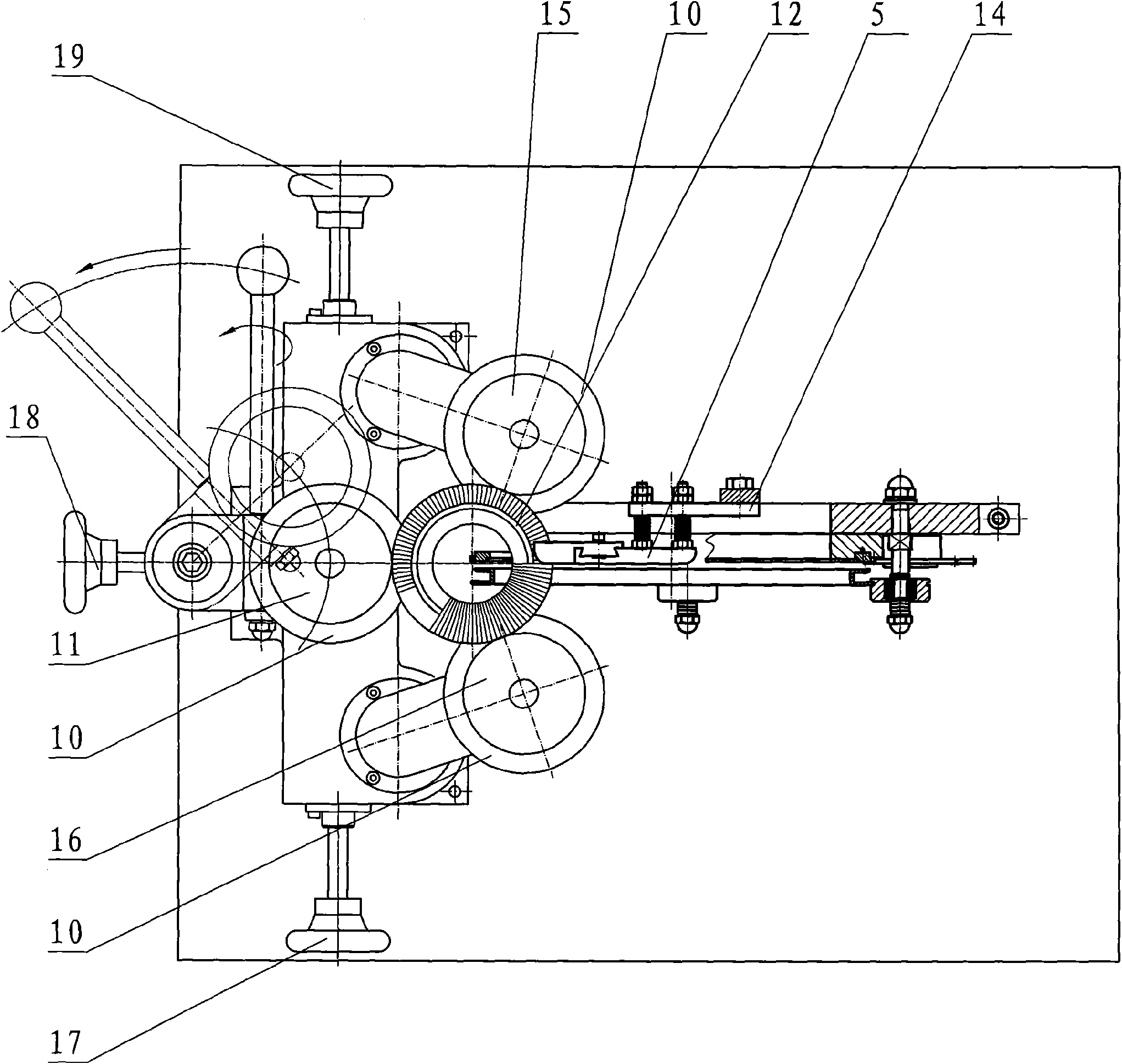

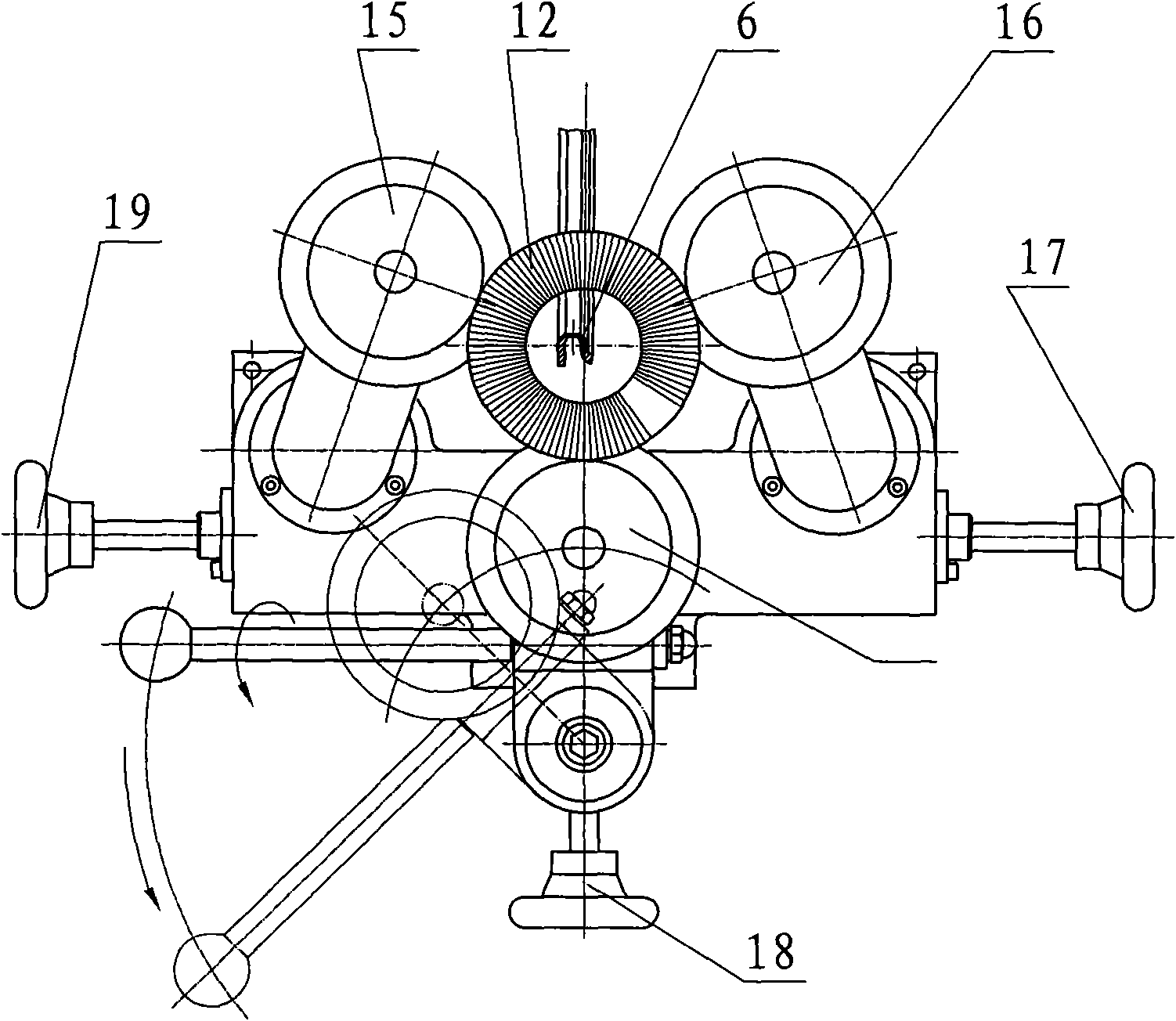

Ring-shaped winding machine

The invention discloses a ring-shaped winding machine which comprises an open-type machine head, an electric cabinet, a transmission mechanism, a wire storage mechanism, a winding mechanism and a wire arranging mechanism, wherein the wire arranging mechanism comprises a mounting seat, a driving rubber wheel provided with a tray and a driven rubber wheel, and the driving rubber wheel provided with the tray is connected with a second transmission mechanism in a transmission way; the wire storage mechanism is provided with a wire storage ring, the winding mechanism is provided with a gear provided with an opening, and the gear provided with the opening is connected with a first transmission mechanism in a transmission way and connected with the wire storage ring when rotating clockwise. The ring-shaped winding machine is characterized in that the second transmission mechanism is driven by a stepper motor, the electric cabinet is internally provided with a singlechip control system, a wire distance amending button is arranged on the electric cabinet, the stepper motor is controlled by a singlechip, and the wire distance amending button is electrically connected with the singlechip. The ring-shaped winding machine can increase or reduce the number of wire distance pulse by the control of the wire distance amending button and the singlechip, so that enamelled wires can be accurately wound into a wire groove all the time, and the phenomenon of wire jumping or overlapping can be stopped.

Owner:温州市南方机械制造有限公司

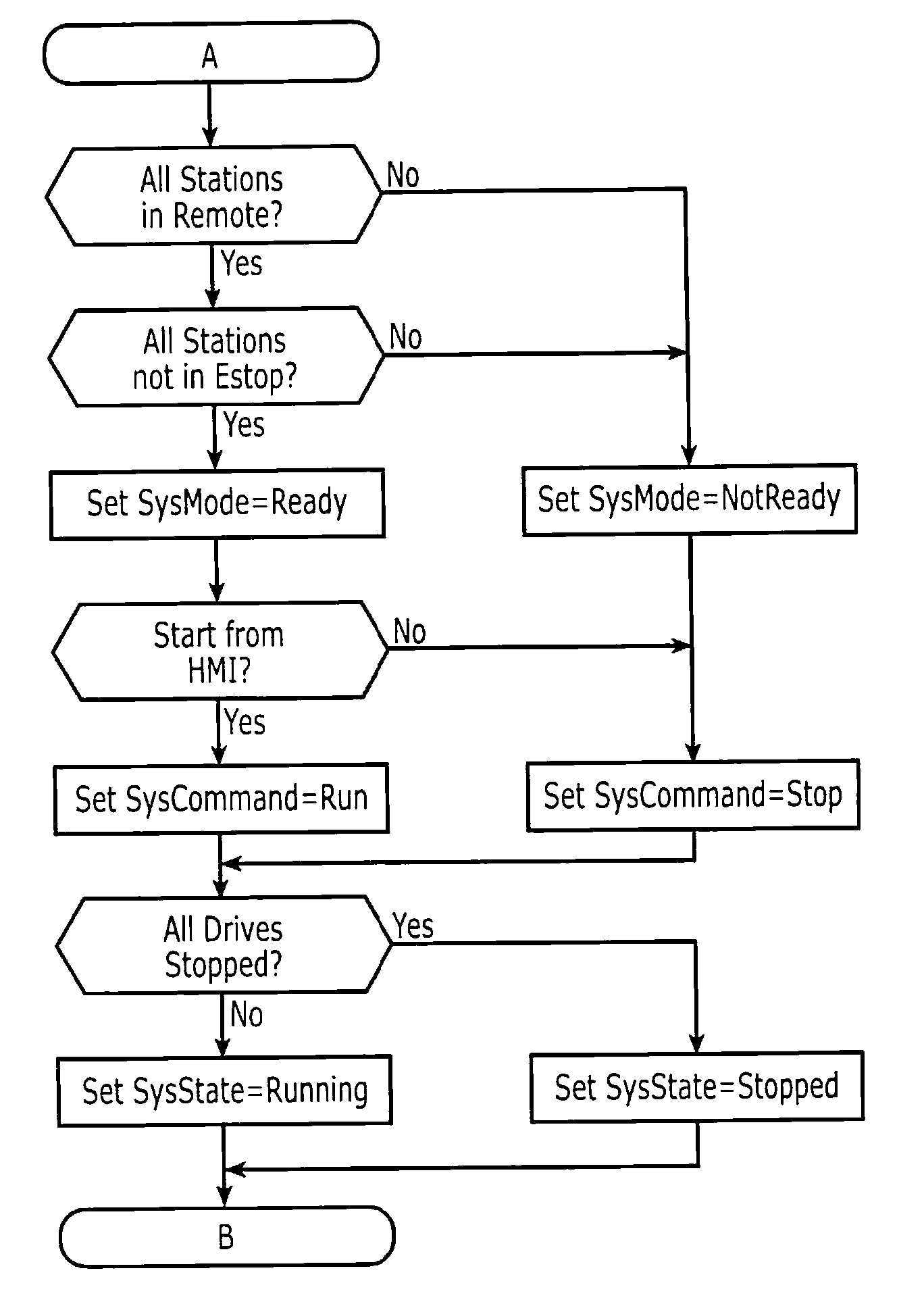

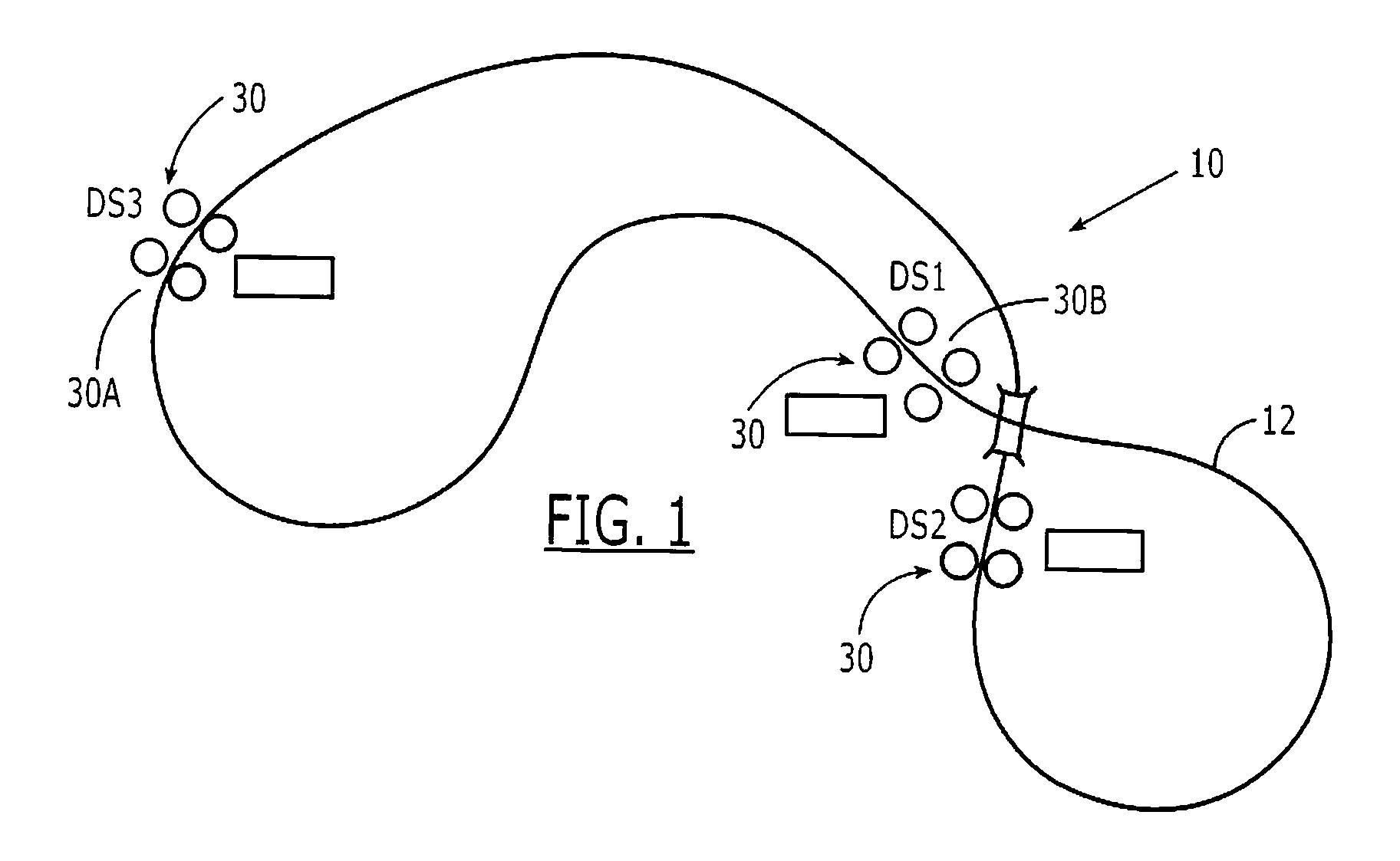

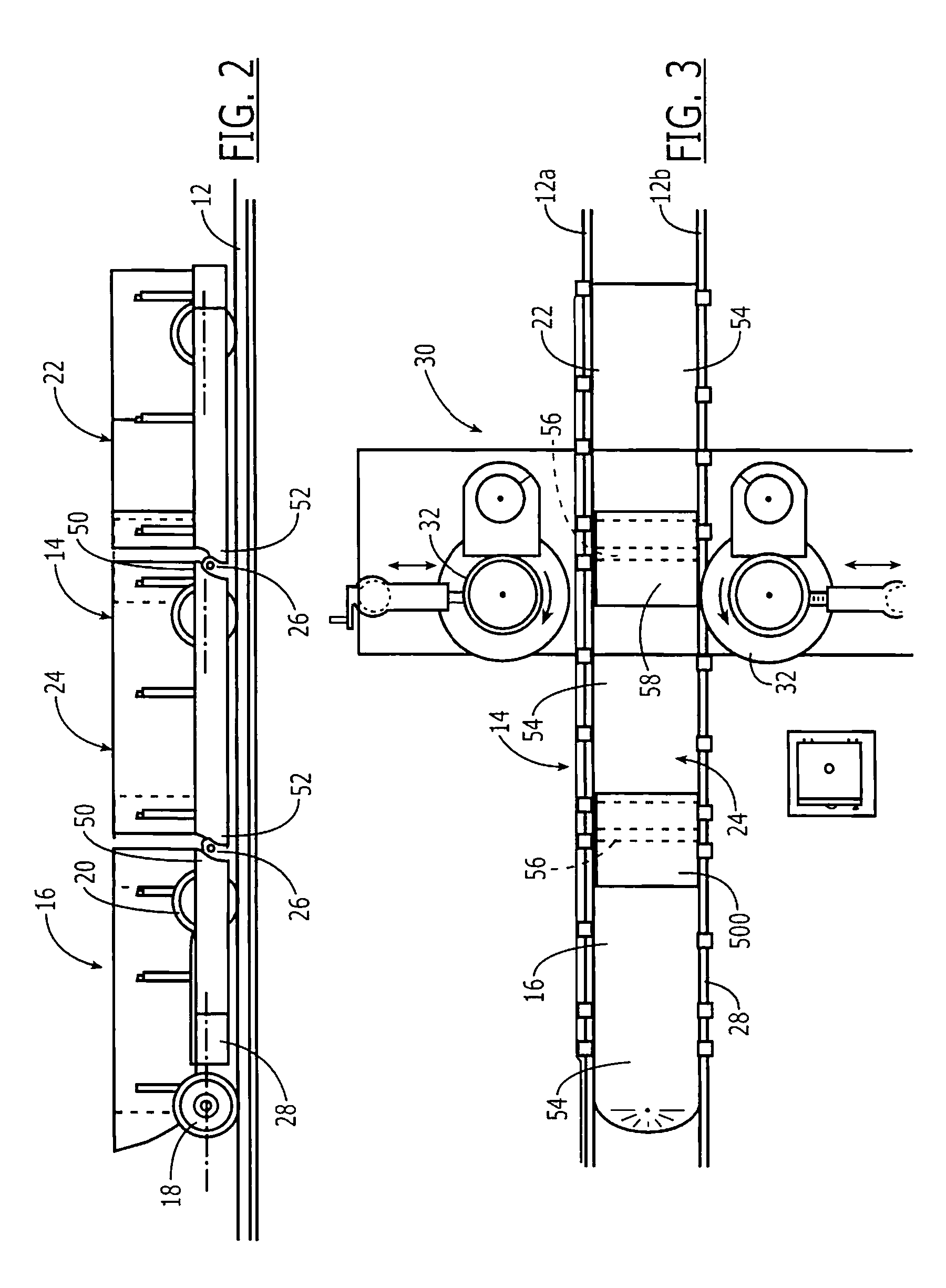

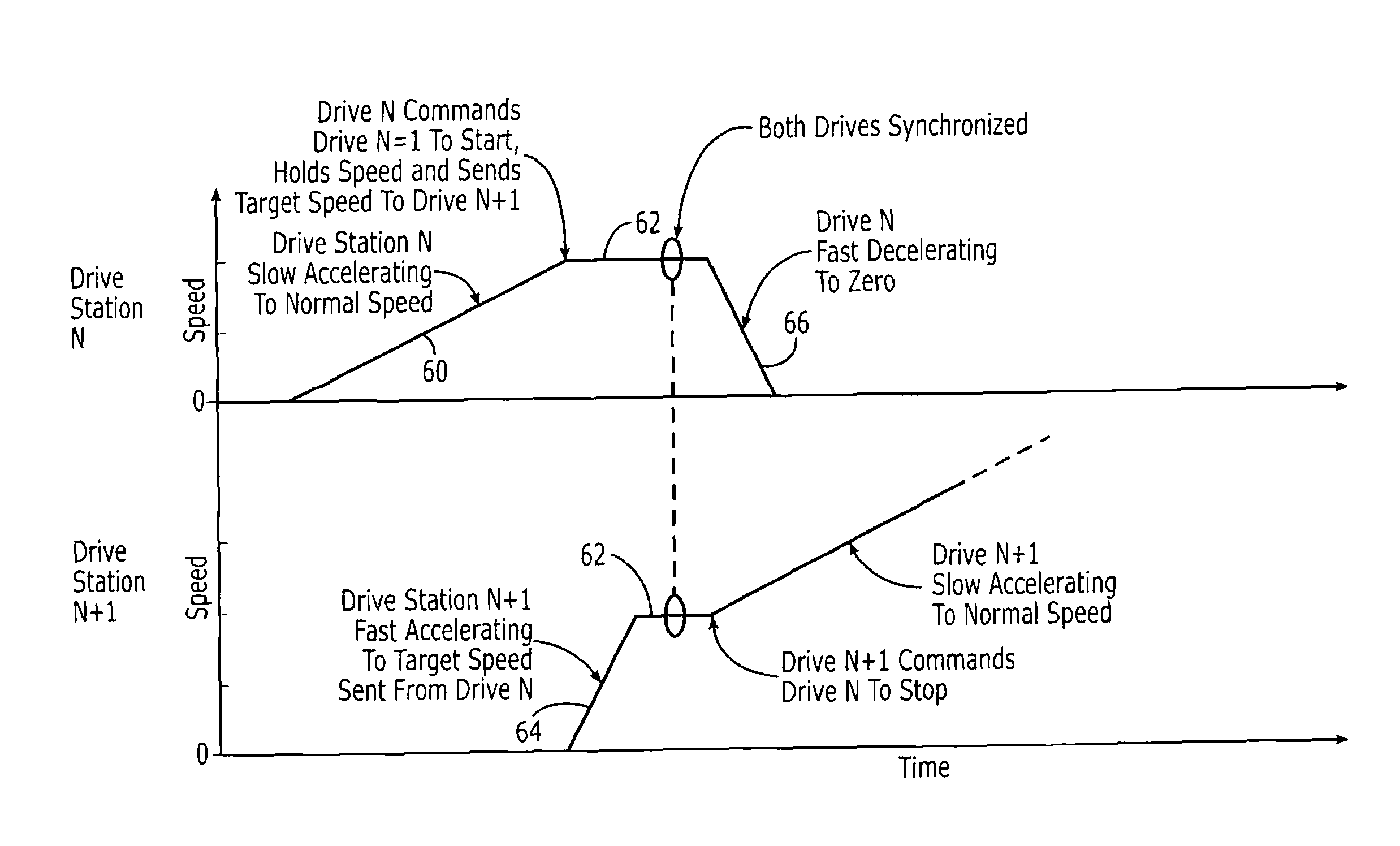

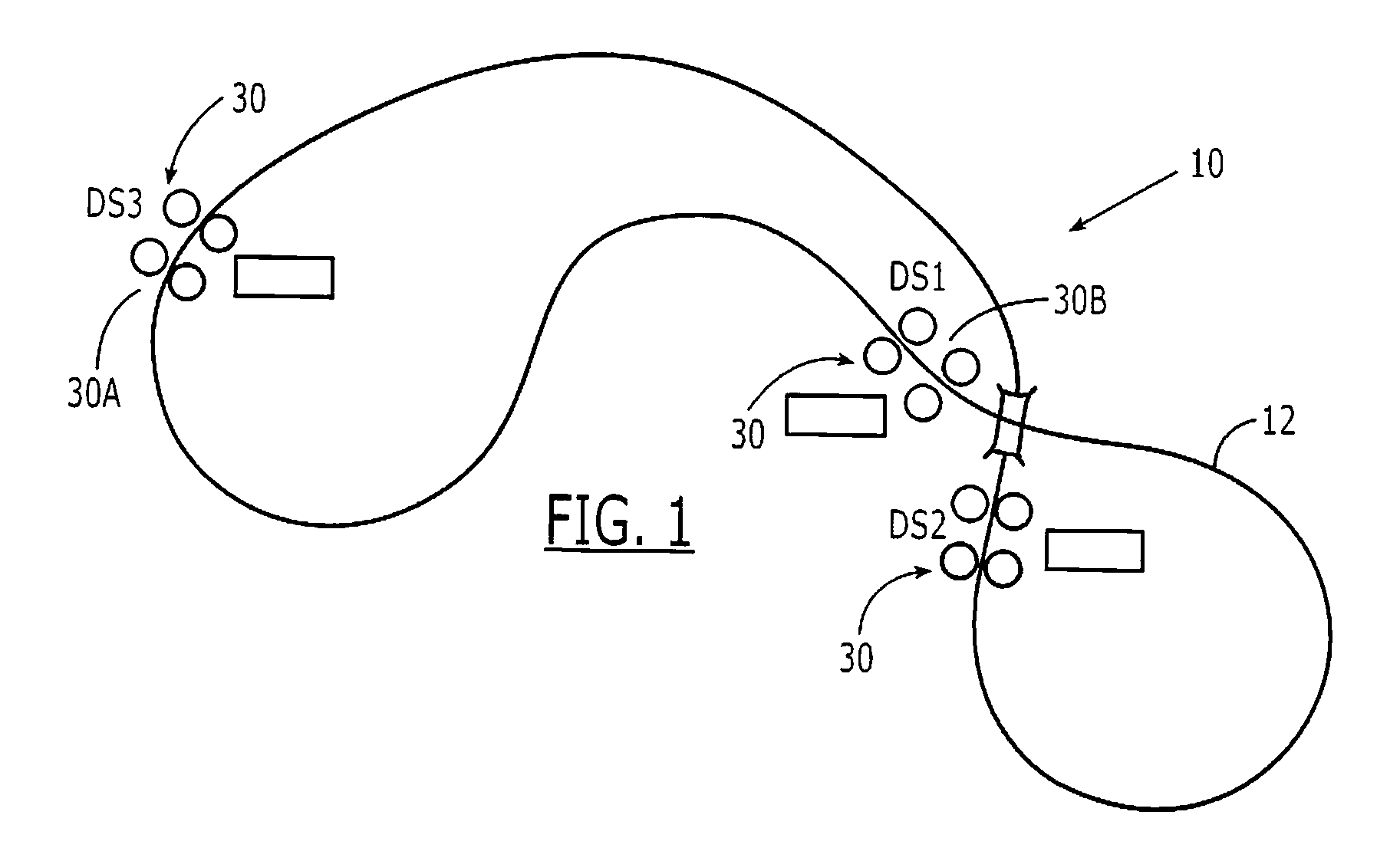

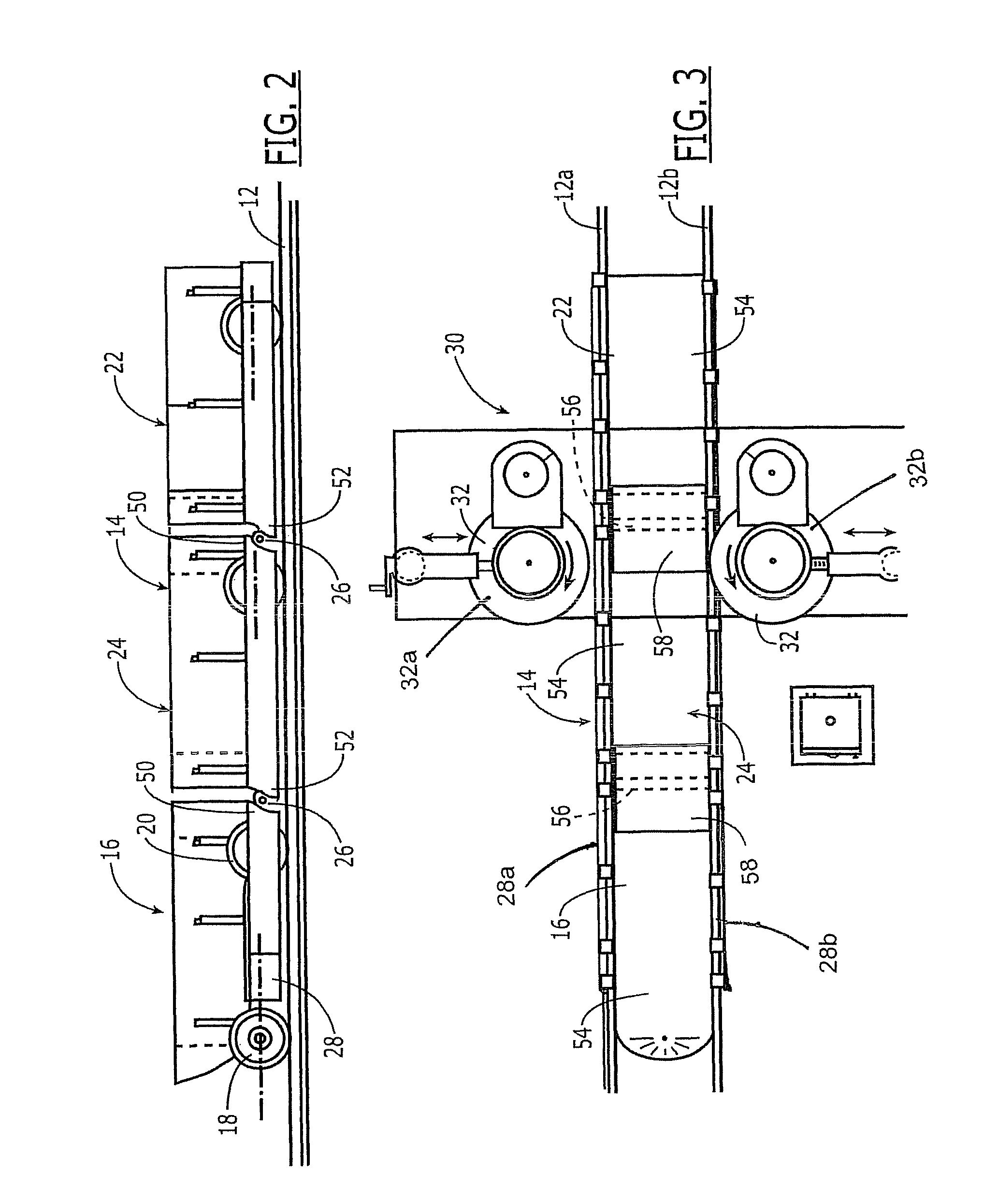

Method of Controlling a Rail Transport System for Conveying Bulk Materials

ActiveUS20080154451A1Reliably determinedIncrease speedDigital data processing detailsRailway componentsTransport systemEngineering

A train is driven by drive stations positioned along a track for frictionally contacting side plates on the train. The drive speed is controlled in response to sensors located at each drive station sensing a position of a wheel and a side plate for confirming a presence of the train. A start command is transmitted from the drive station driving the train to a second drive station downstream when a lead car is within a preselected distance from the second drive station. The drive station at the second drive station is quickly accelerated to a target speed for synchronizing the first drive station with the second drive station. After receiving the train, the second drive station then transmits a stop command to the first drive station for fast decelerating the drive station to a stop.

Owner:RAIL VEYOR TECH GLOBAL

Preparation method and application of graphene oxide composite membrane

InactiveCN105727758AAdjustable spacingImprove performanceSemi-permeable membranesDispersed particle separationGas separationHummers' method

The invention discloses a preparation method and application of a graphene oxide composite membrane, and belongs to the technical field of gas separation membranes.The preparation method of the graphene oxide composite membrane comprises the steps that an aqueous dispersion liquid of graphene oxide is prepared through a Hummer method, and ultrasonic dispersion is conducted; metal salt or oxysalt is added, and heating and mixing are conducted; the surface of a micro-filtration membrane is covered with the prepared dispersion liquid through a vacuum filtration method; the membrane is put into a drying oven to be dried.The preparation method of the graphene oxide composite membrane has the advantages that the preparation method is simple, the thickness of the obtained membrane is smaller than 10 nm, the space between graphene sheet layers is adjustable, the obtained composite membrane is used for gas separation and has excellent comprehensive performance.Particularly, the graphene oxide composite membrane prepared from sodium tetraborate has high CO2 permeation flux and CO2 / CH4 and CO2 / N2 selectivity, and it is obtained through mixed gas tests under the humidifying condition that the CO2 permeation flux can reach 650 GPU, CO2 / CH4 selectivity is 75, and CO2 / N2 selectivity is 58.

Owner:TIANJIN UNIV

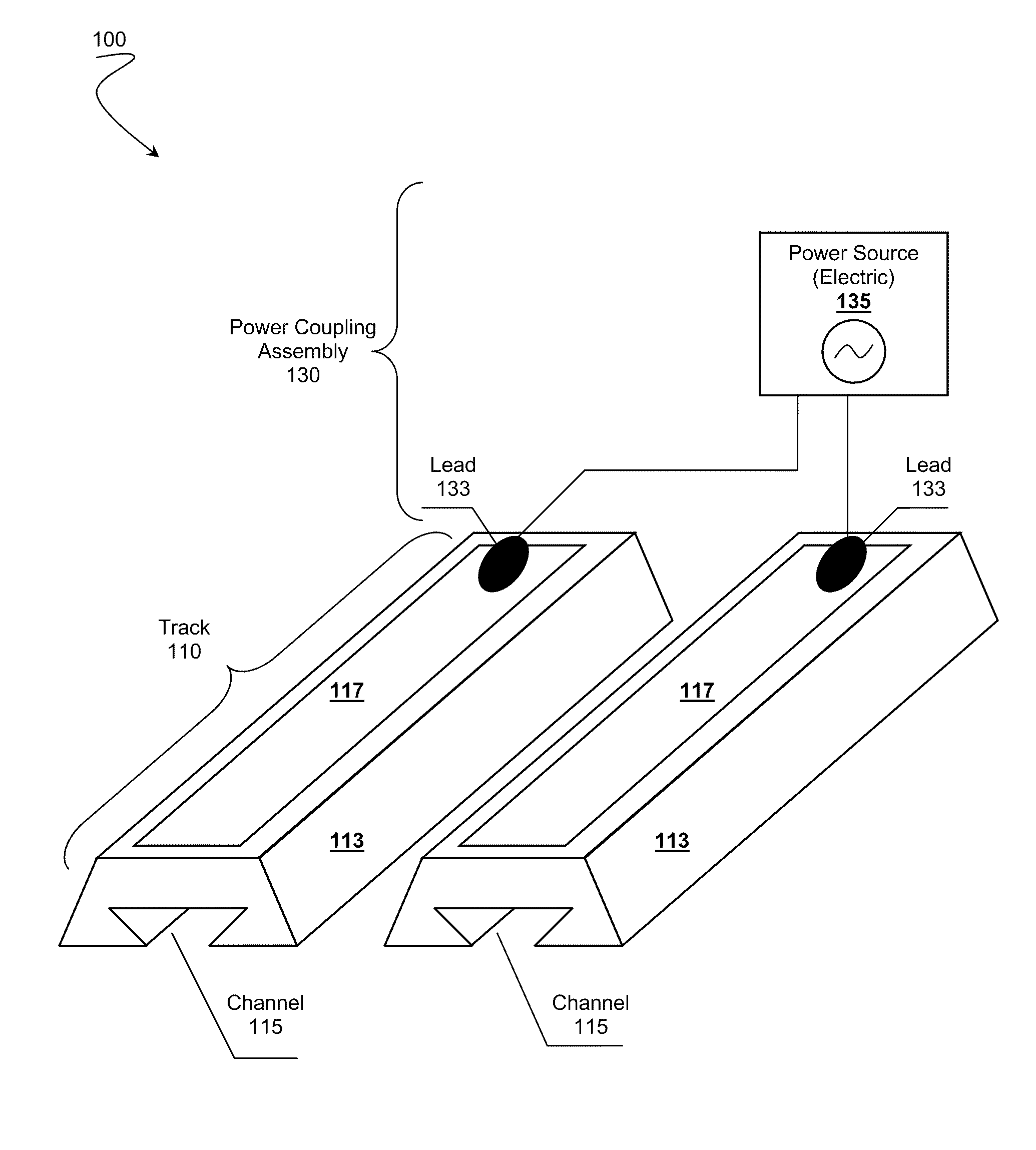

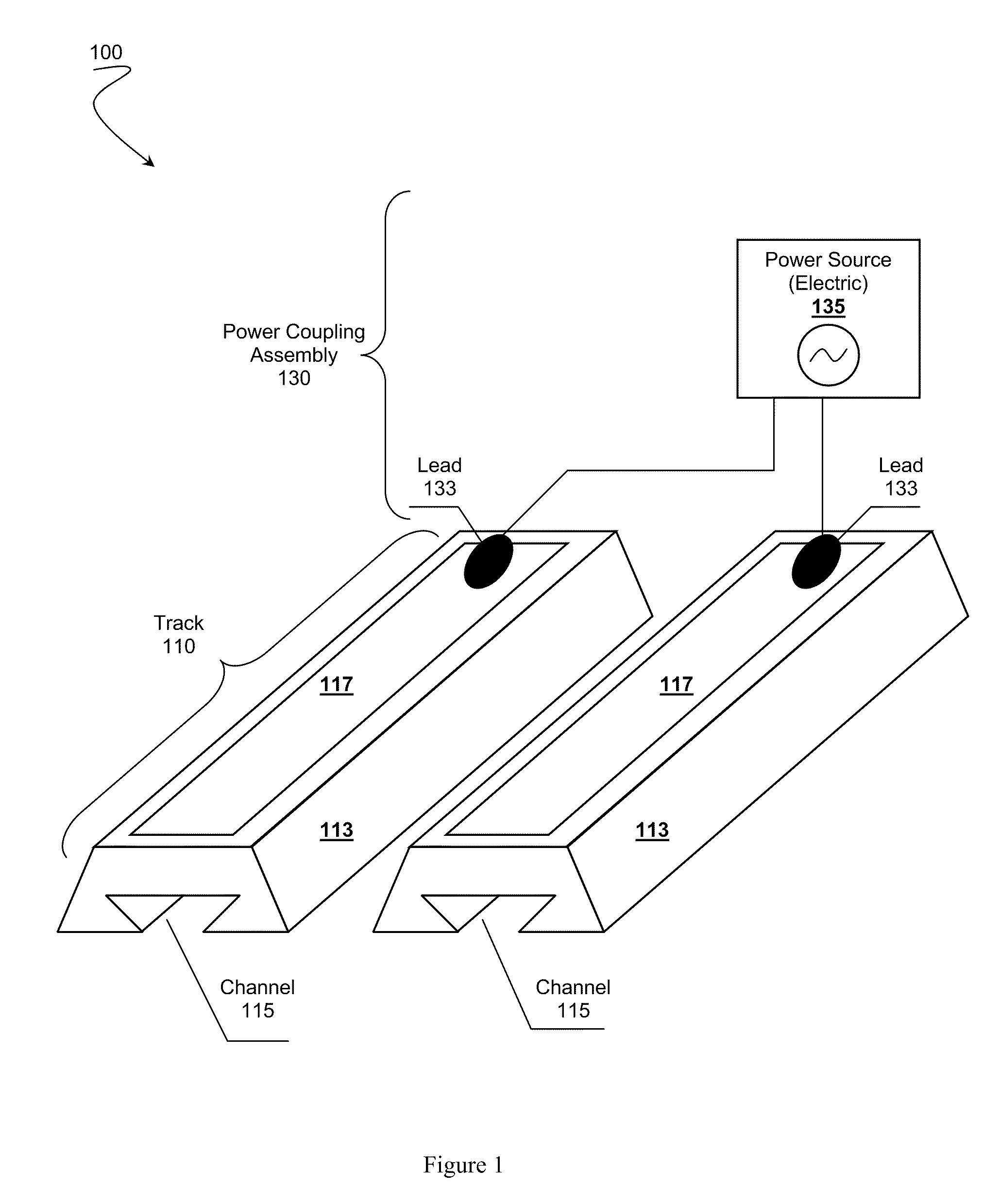

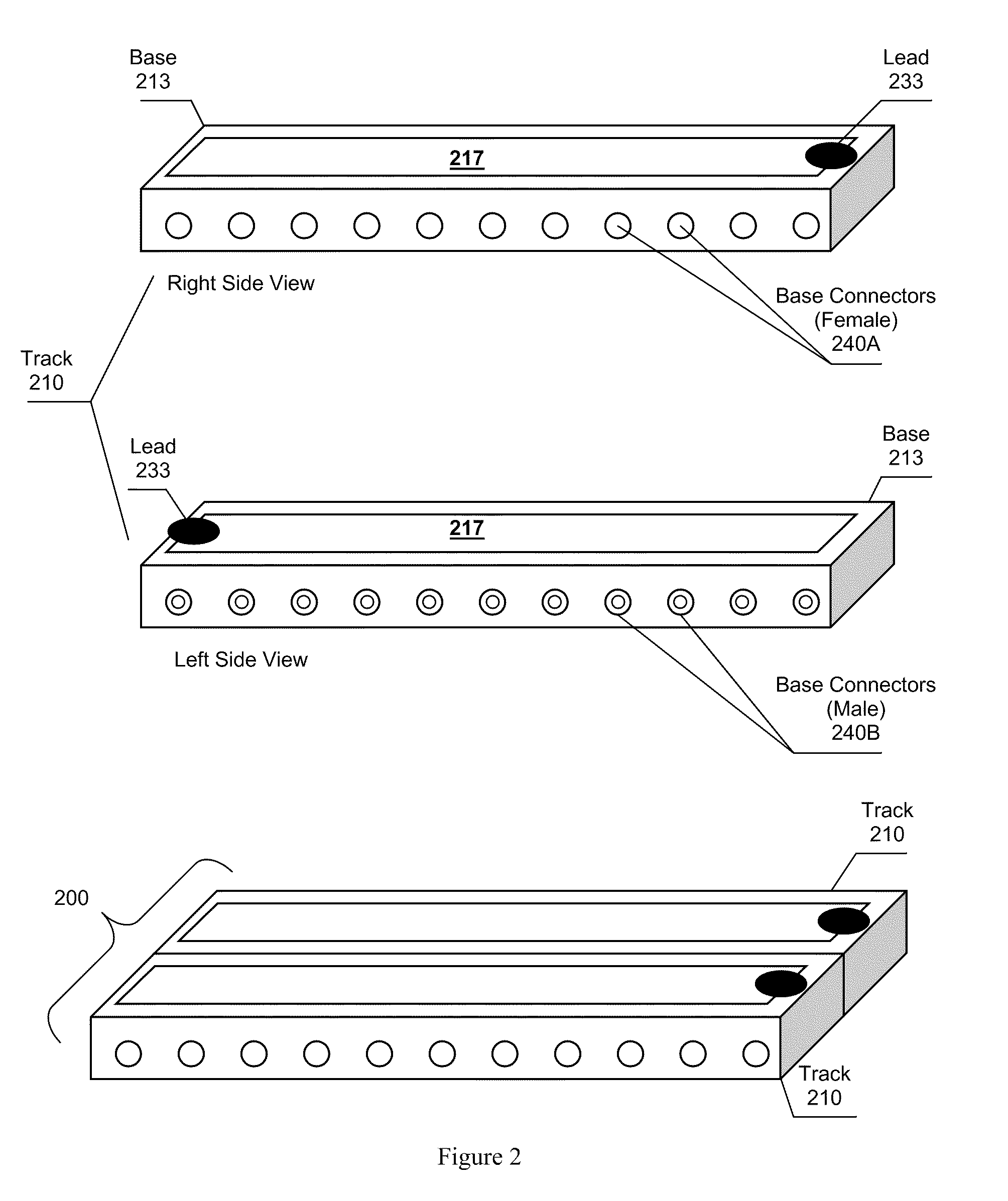

Electric Pest Deterrent Tracks and Systems

InactiveUS20110214339A1Accurate spacingAdjustable spacingElectric shock equipmentsPasturing equipmentElectrical conductorEngineering

Electrical deterrent systems are presented. A deterrent system can include electrical deterrent tracks comprising an insulator base and a conducting strip affixed to a top surface of the track. The bases can include one or more base connectors that allow tracks to be joined together in various configurations including area covering arrays. The conducting strips can be woven, non-woven, meshes, or other types of conductors.

Owner:BIRD B GONE

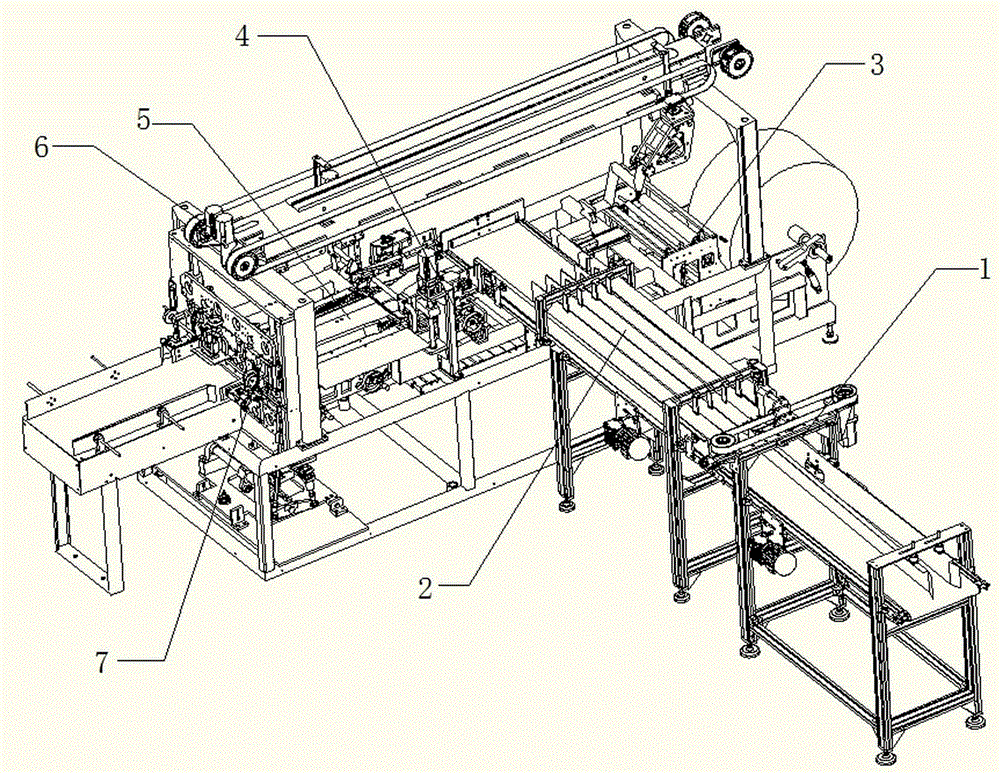

Soft tissue packing machine

ActiveCN103950590AGuaranteed uniformityReduce labor costsPaper article packagingWrapping material feeding apparatusEngineeringSoft tissue

The invention discloses a soft tissue packing machine, and relates to the technical field of tissue packing machinery. The soft tissue packing machine comprises a path division conveying component, a material sorting conveying component, a membrane supporting and conveying component, a bag opening and strutting component, a negative pressure conveying component, a bag pushing component and a cutter seal component. The soft tissue packing machine disclosed by the invention has the advantages that the bag opening and strutting component, a membrane conveying mechanism and a membrane conveying mechanism are improved, according to the soft tissue packing machine, the bag opening size of packing bags can be regulated, the soft tissue packing machine is suitable for the package of products in any specifications, the soft tissue packing machine adopts integral operation, the efficiency is improved, the cost is reduced, and the packing quality can also be unified.

Owner:上海松川峰冠包装自动化有限公司

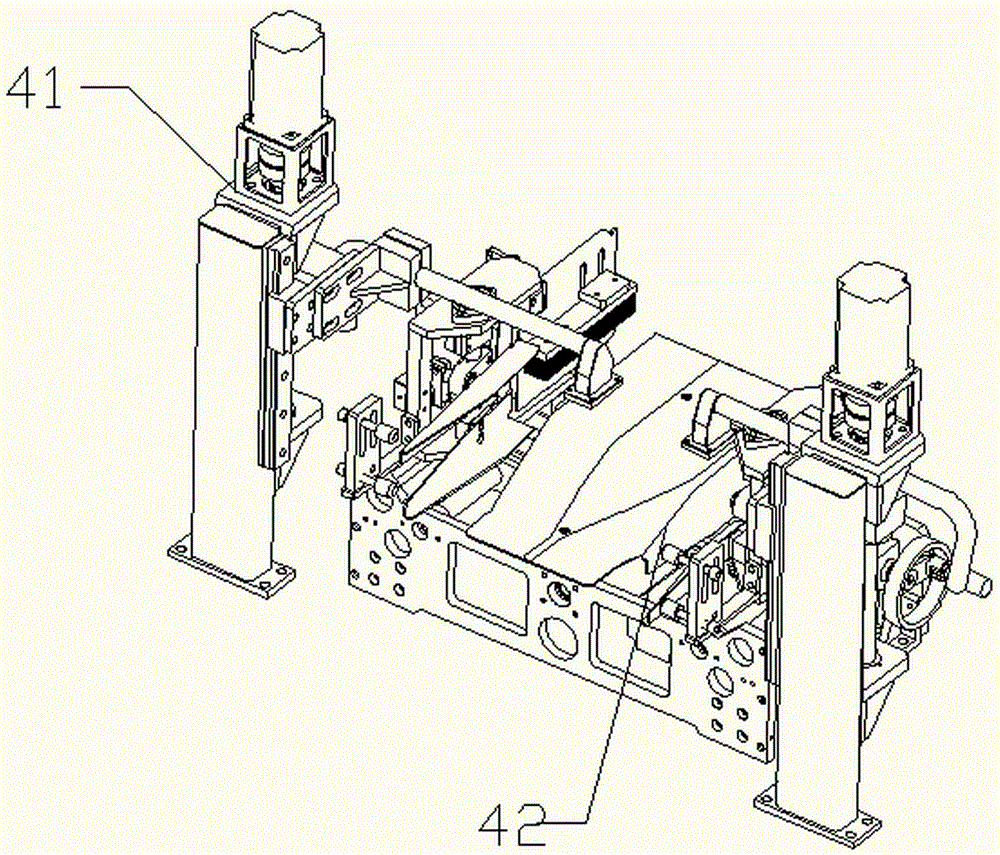

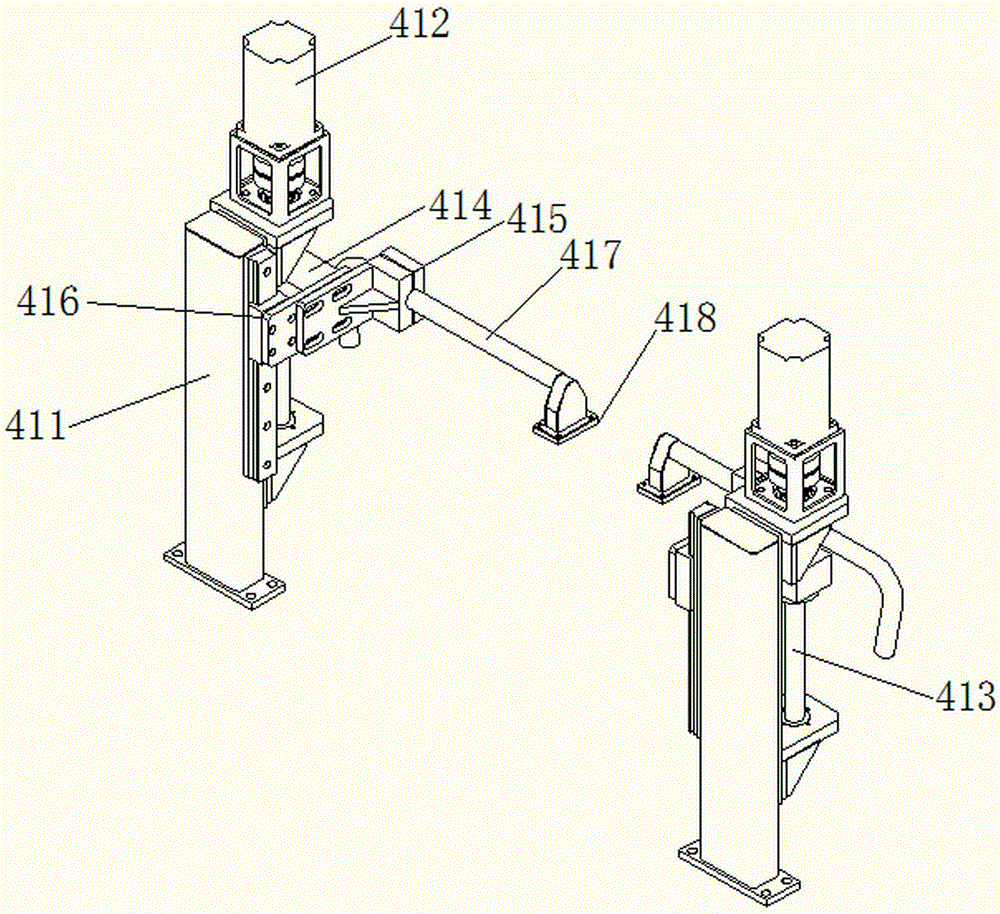

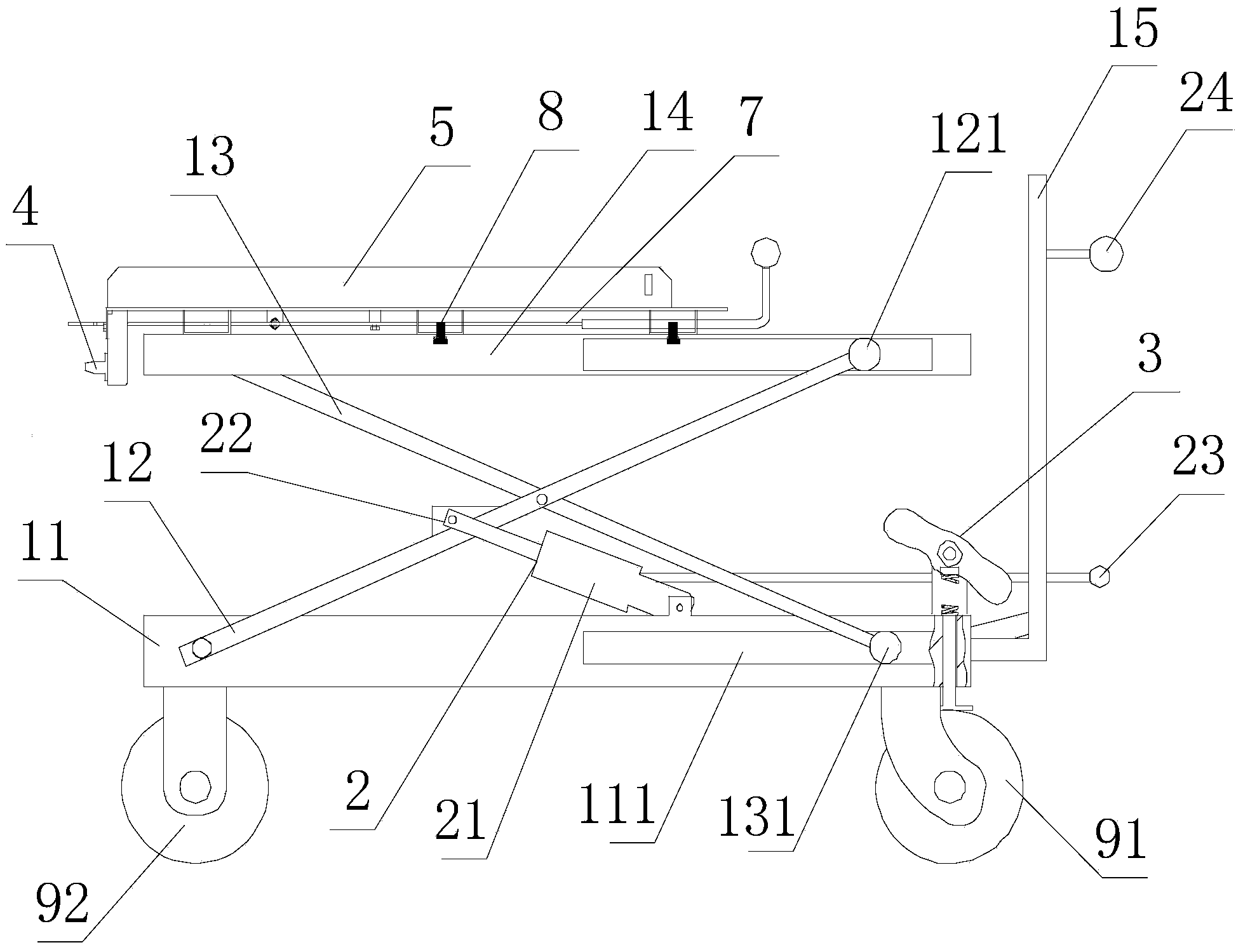

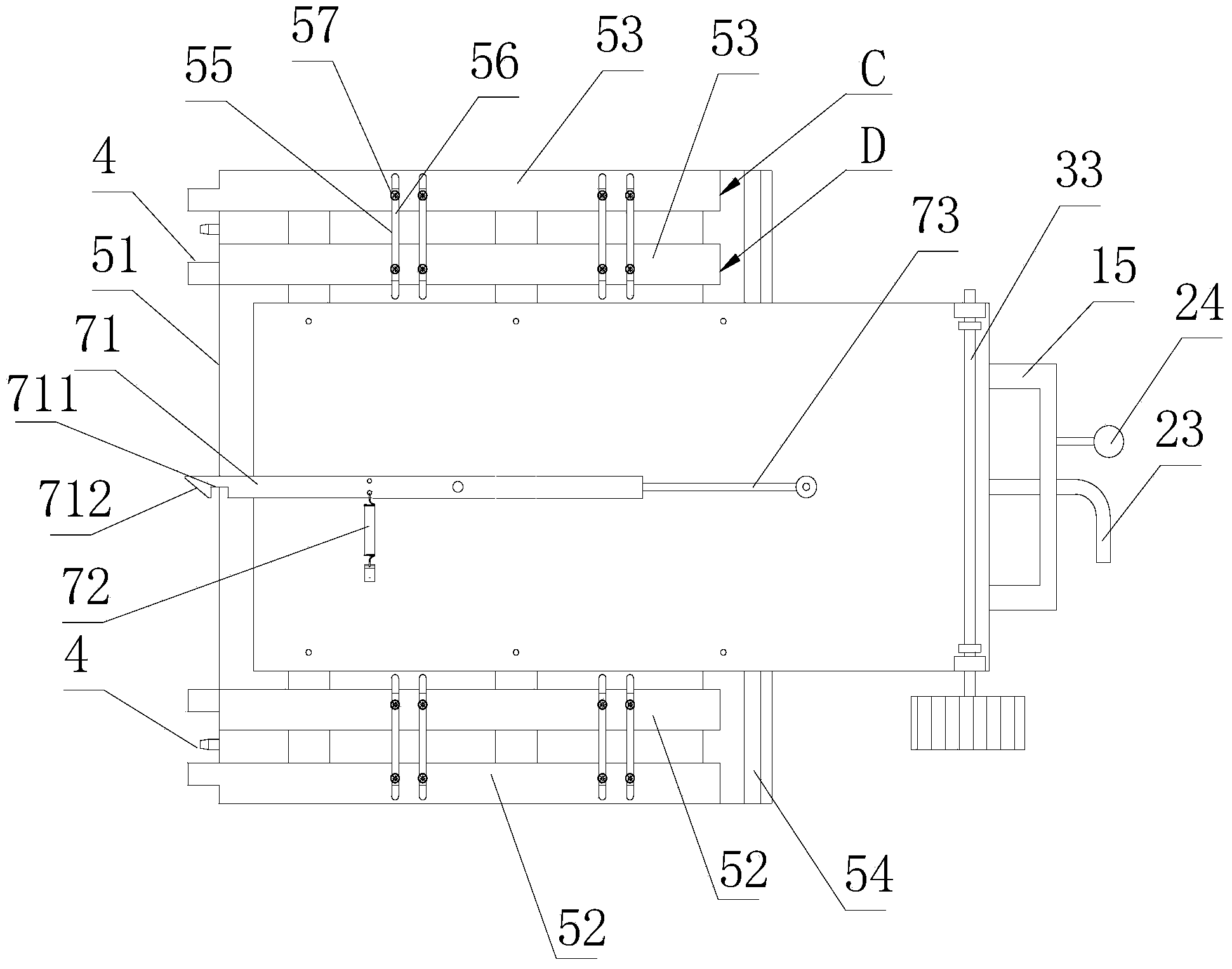

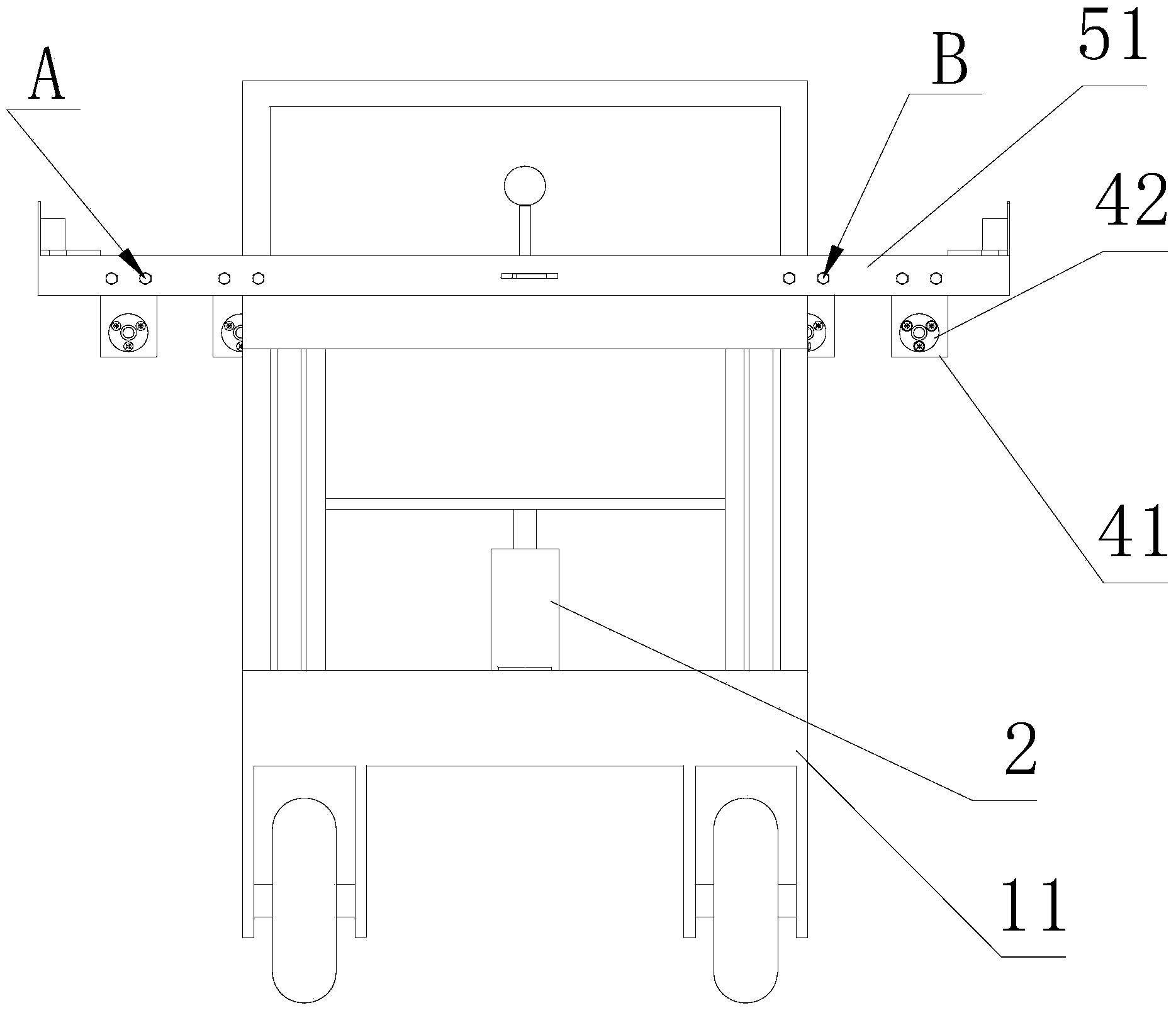

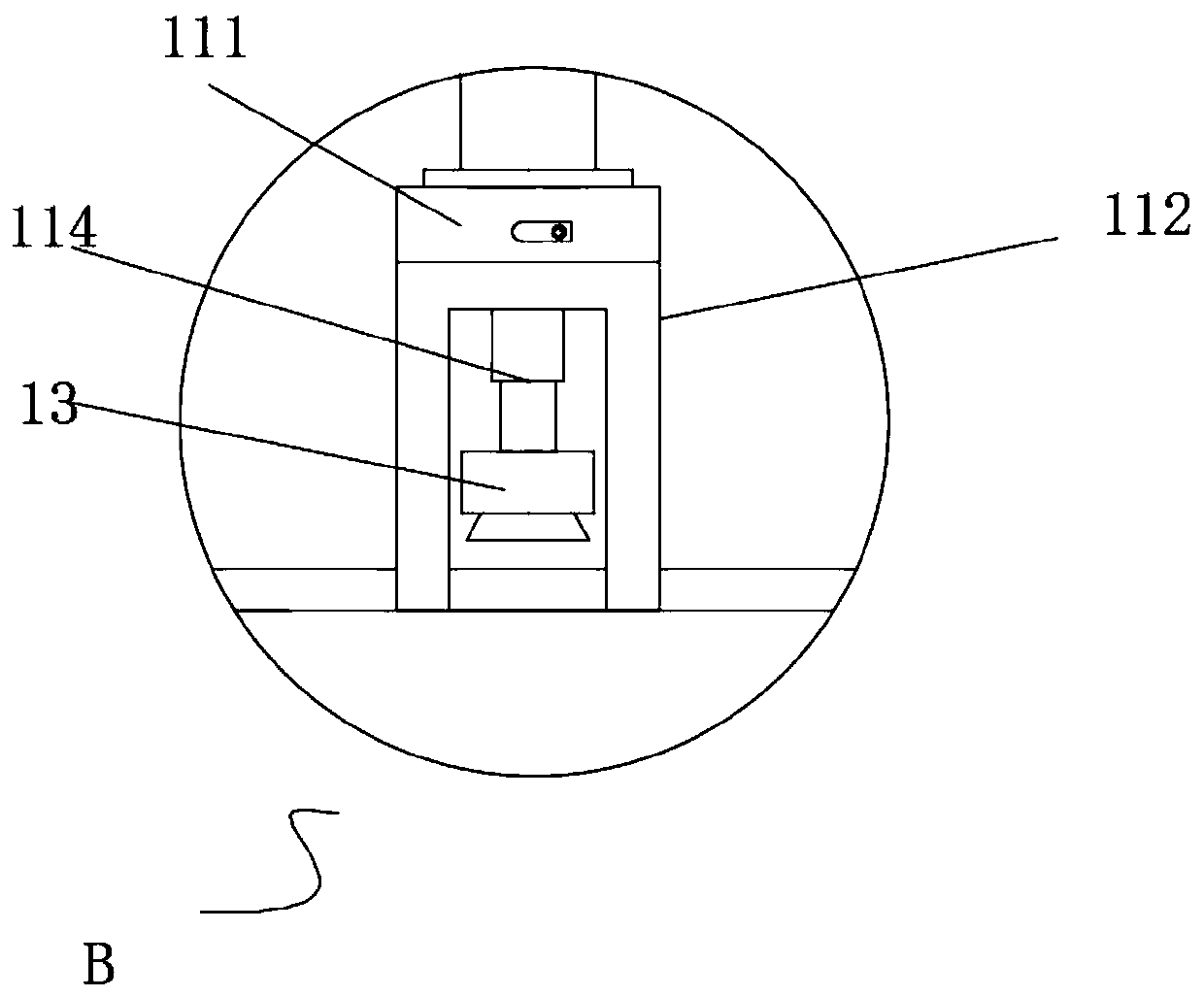

Vacuum circuit breaker transfer vehicle with adjustable width and height

ActiveCN103746308ALower center of gravityStrong general performanceSwitchgearHand carts with multiple axesEngineeringElectrical and Electronics engineering

The invention relates to a vacuum circuit breaker transfer vehicle with adjustable width and height. The vacuum circuit breaker transfer vehicle comprises a body provided with a mobile device at the bottom and a hydraulic lifting assembly, wherein the body is movably connected with a brake assembly and is provided with at least one set of positioning assemblies and guide assemblies with an adjustable gap, and a locking assembly for locking a vacuum circuit breaker on the body is arranged on the guide assemblies. The vacuum circuit breaker transfer vehicle has the advantages that the reliable locking between the body and the vacuum circuit breaker as well as between the body and a cabinet body is guaranteed and the center of gravity of the body is effectively lowered as the cabinet body provided with the vacuum circuit breaker is fixedly arranged on the body through the positioning assemblies and the vacuum circuit breaker is fixedly locked on the body through the locking assembly, as the gap between the positioning assemblies is adjustable and the height adjustment is performed by the control of the hydraulic lifting assembly, the body can be adaptive to different models effectively, the universality is strong, the work efficiency is greatly improved, and the use effect is good.

Owner:JINHUA POWER SWITCH +2

Preparation and application of functionalized graphene oxide composite membrane

InactiveCN106064023AAdjustable spacingImprove performanceSemi-permeable membranesDispersed particle separationFiltration membranePolyethylene glycol

Belonging to the technical field of gas separation membranes, the invention discloses a preparation method and application of a functionalized graphene oxide composite membrane. The preparation process includes: preparing an aqueous dispersion of graphene oxide by Hummer method and conducting ultrasonic dispersion; adding polyethylene glycol diamine, and carrying out heating stirring; covering a micro-filtration membrane surface with the prepared dispersion by vacuum pumping filtration; and placing the membrane into a drying oven to perform drying. The preparation method provided by the invention is simple, the prepared membrane has a thickness of less than 10nm, and the graphene interlamellar spacing is adjustable, the prepared composite membrane can be used for gas separation, and has excellent comprehensive performance. In particular, the graphene oxide composite membrane prepared from polyethylene glycol diamine with a molecular weight of 1000 has high CO2 permeation flux and CO2 / CH4, CO2 / N2 selectivity, mixed gas test under a dry condition finds that the CO2 permeation flux can reach 220GPU, the CO2 / CH4 selectivity is 42, and the CO2 / N2 selectivity is 55.

Owner:TIANJIN UNIV

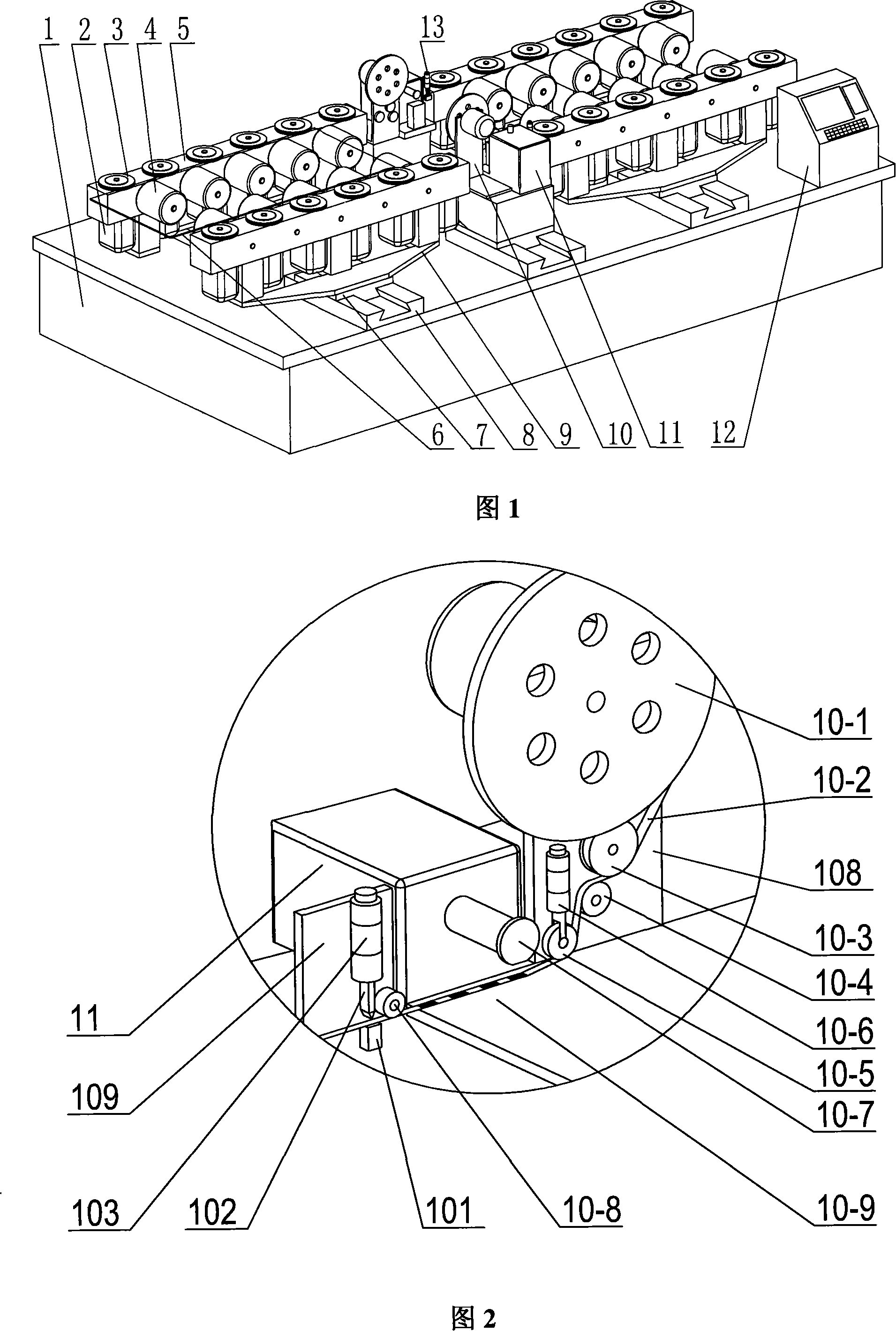

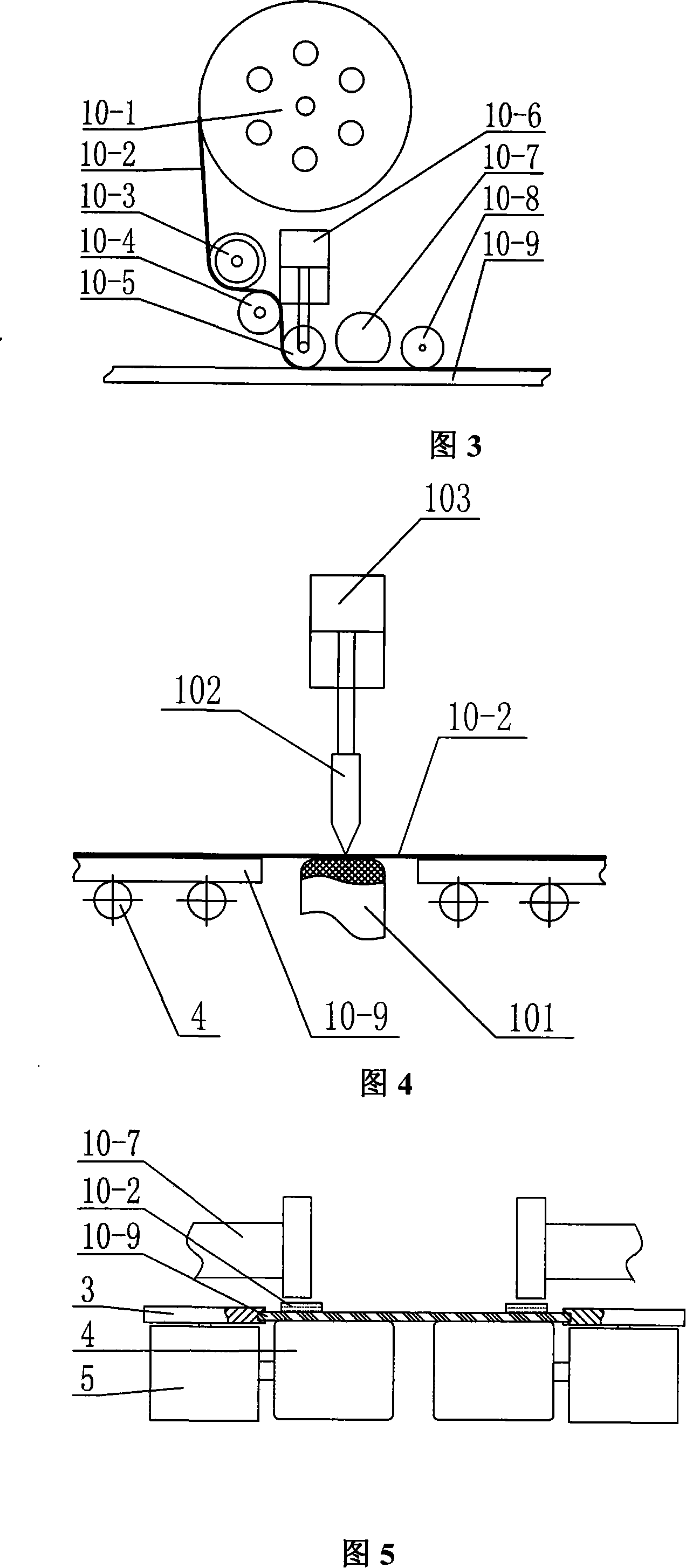

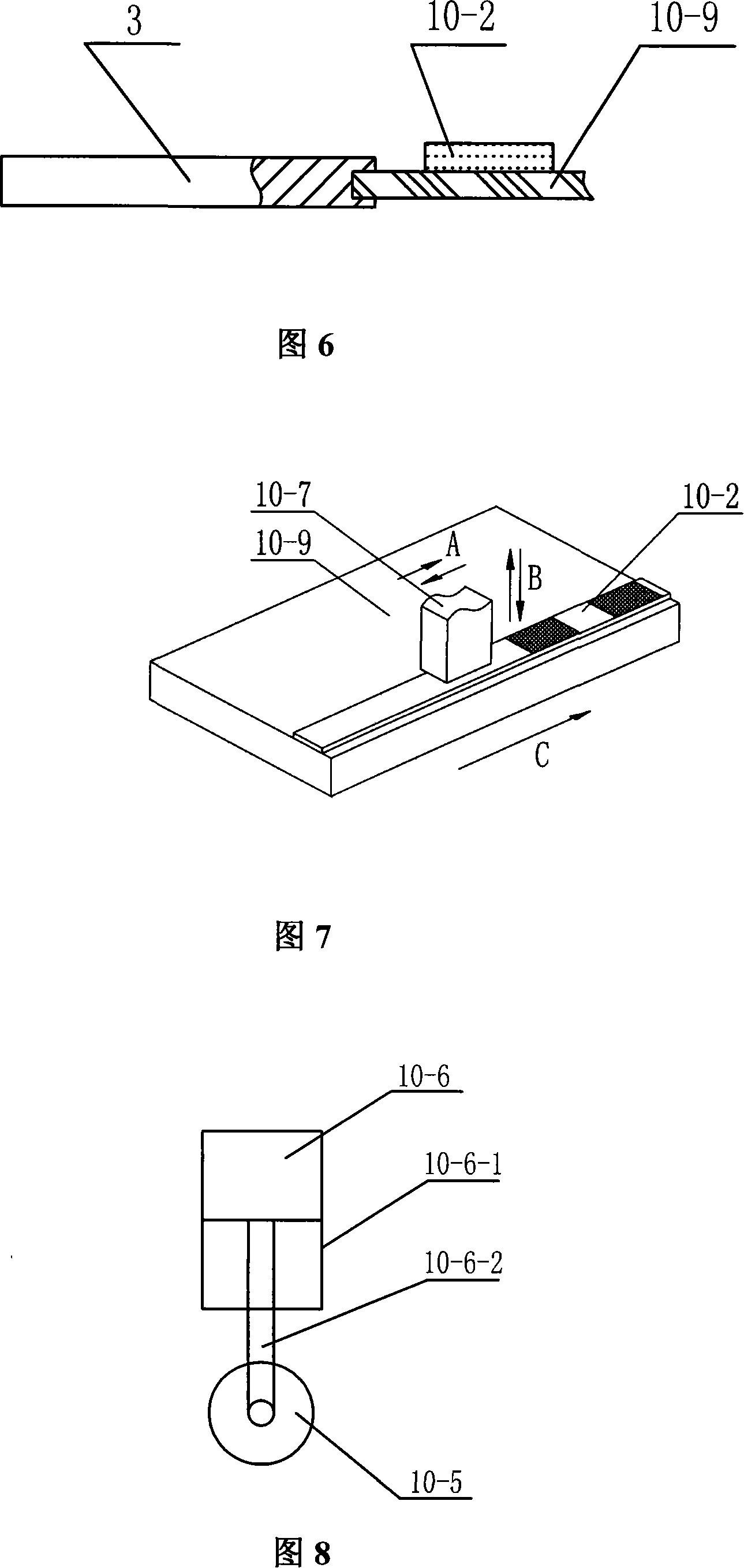

Ultrasonic soldering equipment for solar cell electrode

InactiveCN101110458ASatisfy the pressure line requirementsImprove efficiencyFinal product manufactureSemiconductor devicesElectrical batteryEngineering

The present invention discloses an automatic ultrasonic wave welding equipment for welding amorphous silicon solar cell electrode, which aims to improve current ultrasonic wave metal spot welding machine and add a mechanical wire pressing and take-up device and method to replace manual wire pressing and laying and is technically characterized in that a working table is composed of a feeding zone, a welding zone and a discharging zone. An electrode wire 10-2 is coiled on an uncoiling wheel 10-1 of the electrode wire pressing device 10. A guide wheel 10-3 and an extension-resistant tightening pulley 10-4 are arranged on a front slab bracket 108 below the uncoiling wheel 10-1. A corresponding ultrasonic wave welding head 10-7 is mounted between a coiling wheel 10-5 and a flattening wheel 10-8. The present invention is suitable for automatic welding of thin film solar cell electrode with glass or flexible material as substrate, thus ensuring high precision, nice appearance and equal distance between welding spots, improving welding efficiency and eliminating rosin joint.

Owner:李毅

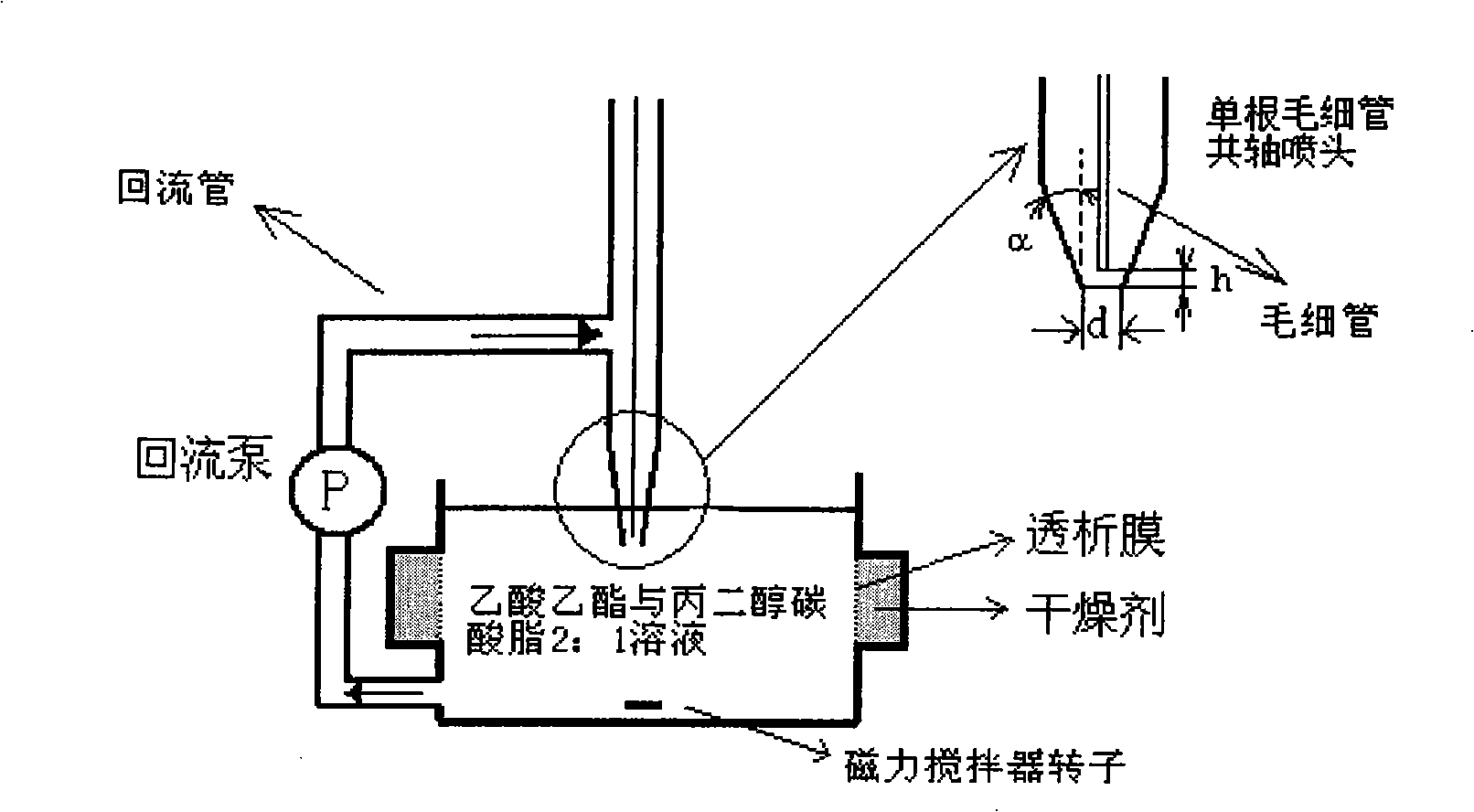

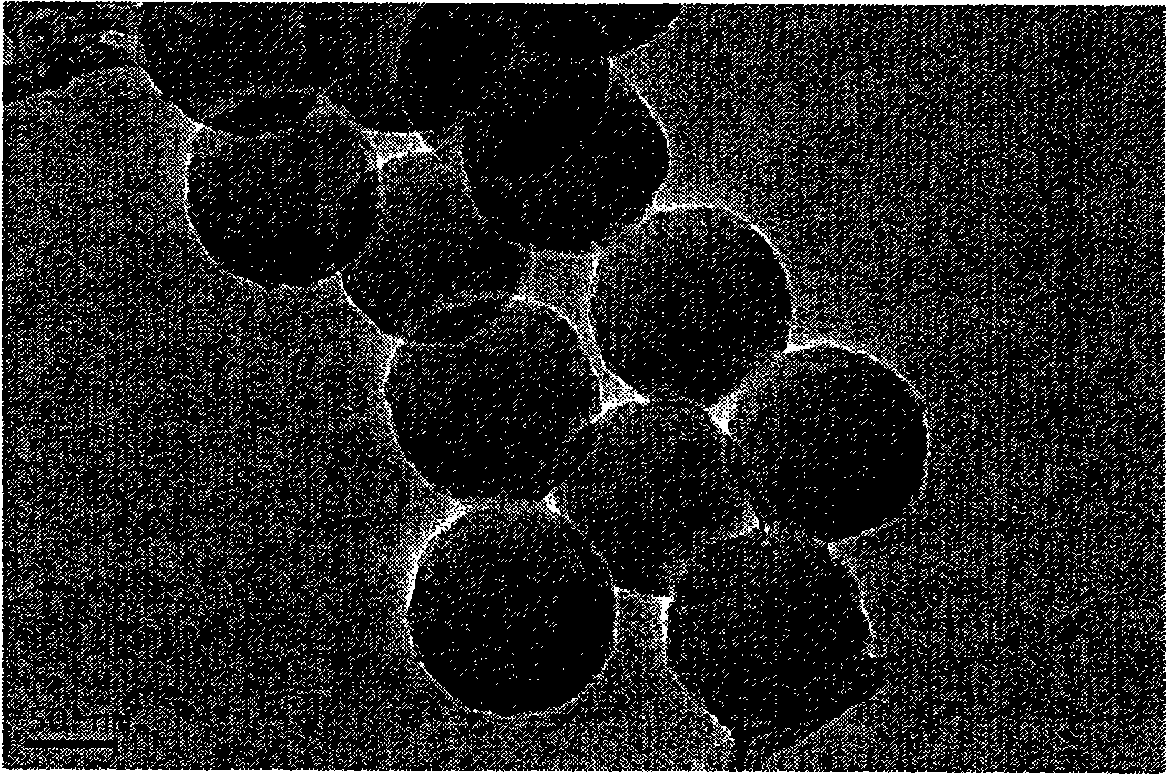

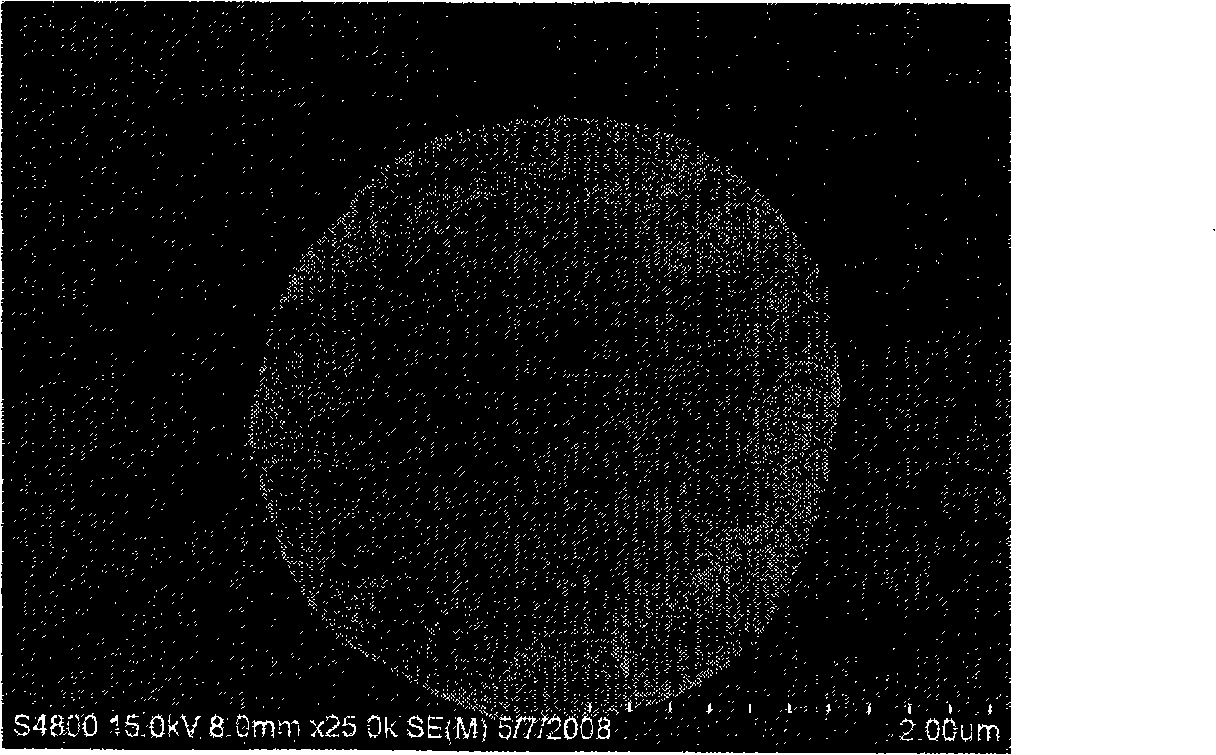

Preparation method for one-size nano-particle fluorescence microsphere

InactiveCN101342472AAvoid adsorptionImprove uniformityMicroballoon preparationLuminescent compositionsSolubilityOil phase

The present invention provides a preparation method of an uniform-size nanoparticle fluorescent microsphere. The density of fluorescent nanoparticle colloidal aqueous solution of the microsphere is adjusted to the micro-mol level so as to obtain the colloidal solution evenly scattered in the aqueous solution; the evenly scattered colloidal solution in the aqueous solution is injected into oil-phase solvent through capillary at the speed of 0.5 to 1.25 percent Vs / min so as to form droplets and Vs is the volume of the oil-phase solvent; the oil-phase solvent adopts bi- or multi-mixture with the solubility between 2 to 10 percent and the density equal to the density of water; containers and reflux pipes adopt the hydrophobic material; the water in droplets is absorbed by the oil phase and the nanoparticles form a dense sphere; an absorbent continuously absorbs the water dissolved in the oil phase, so that the water content in the oil phase is far lower than the saturation; the nanoparticle polymer with the size from dozens of nano to hundreds of nano, the spherical height higher than 5 percent and the size error less than 10 percent is obtained through regulating the density of the quantum pot colloidal solution and the velocity of the reflux pipe.

Owner:SOUTHEAST UNIV

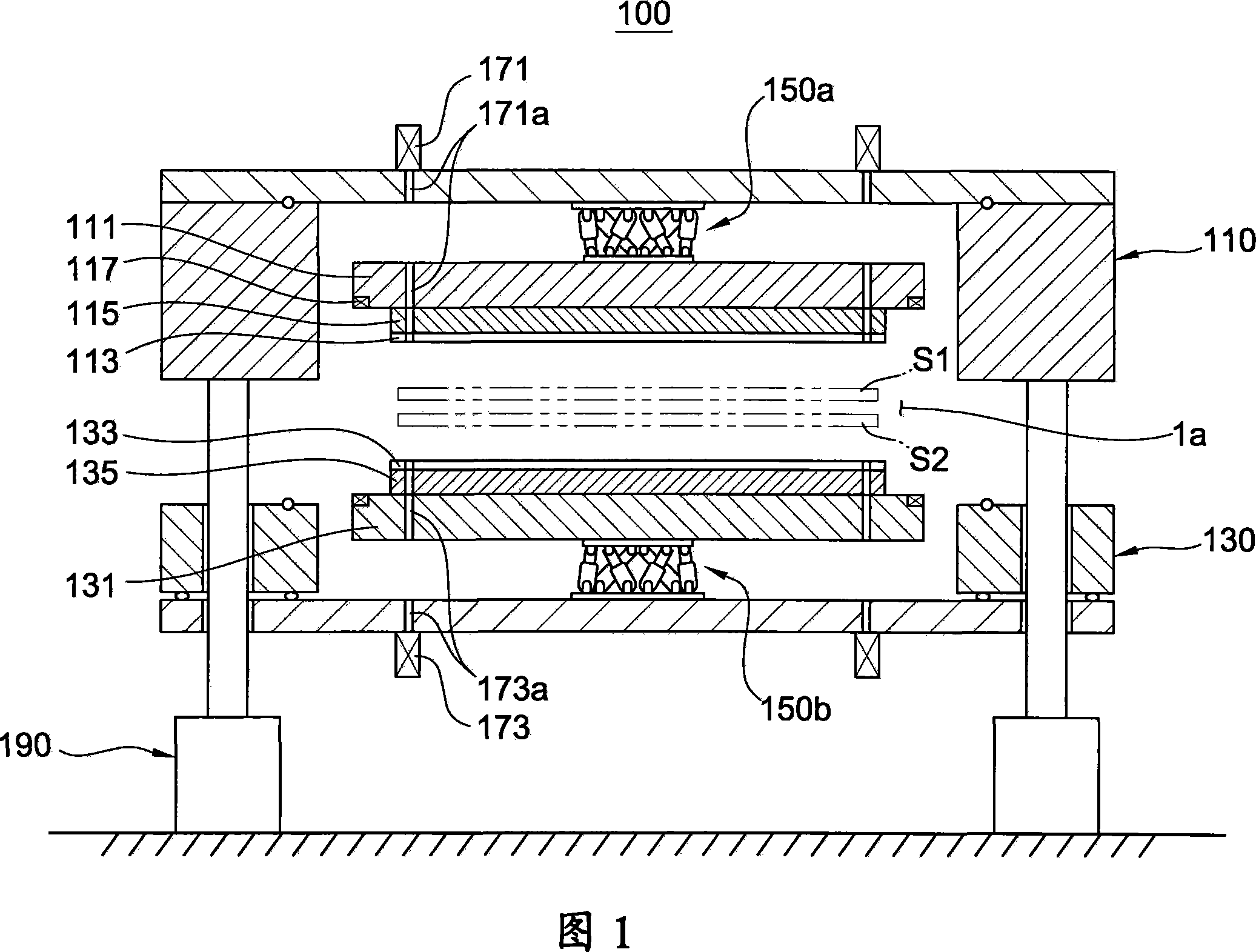

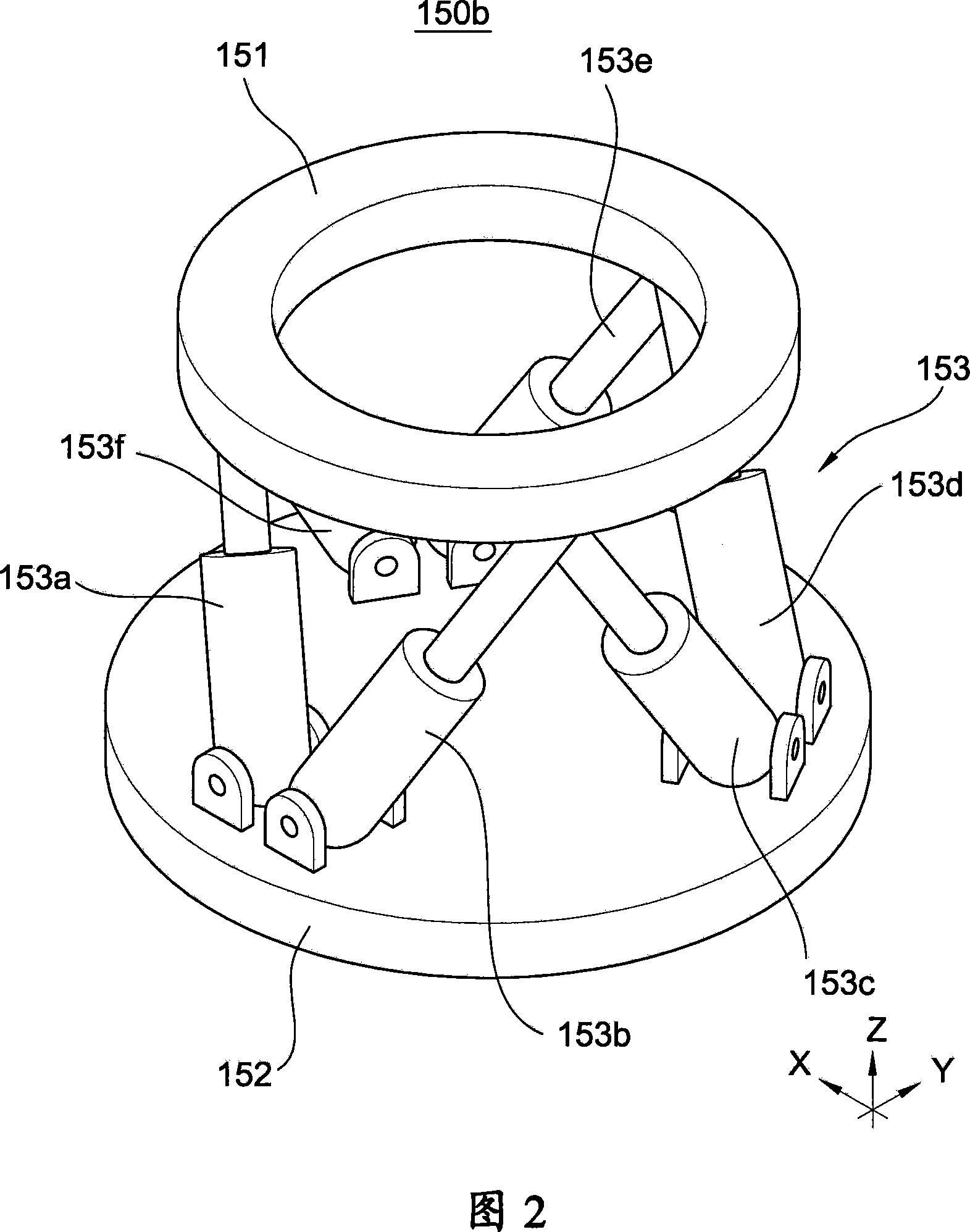

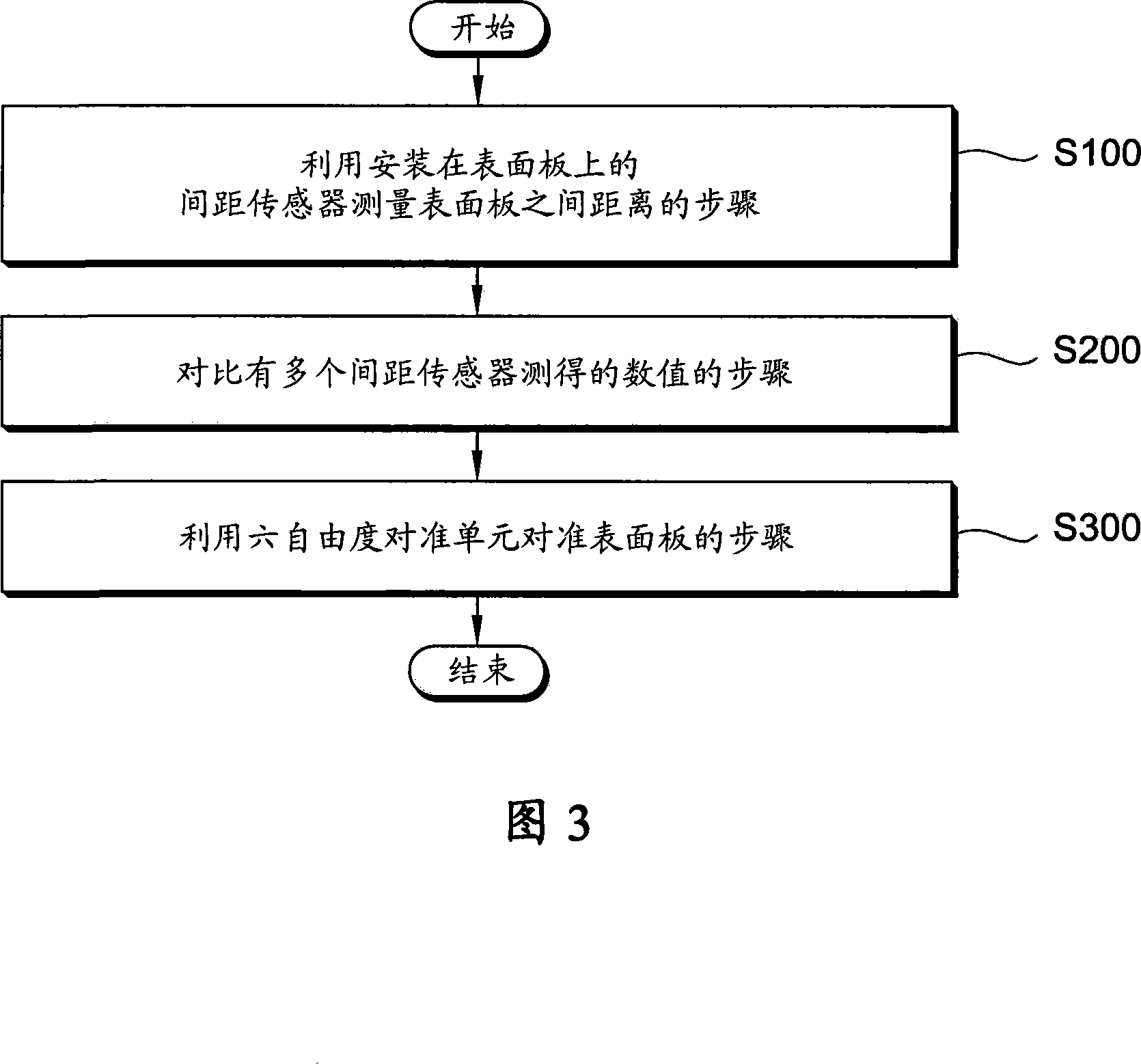

Substrate bonding apparatus having alignment unit and method of aligning substrates using the same

InactiveCN101144926AImprove alignment efficiencyHigh yieldLamination ancillary operationsLaminationEngineeringSix degrees of freedom

A substrate bonding apparatus includes a first chamber having a first surface plate where a first substrate is placed. A second chamber is disposed opposite to the first chamber. The second chamber has a second surface plate where a second substrate is placed. The second substrate is to be bonded to the first substrate. An alignment unit is installed in at least one of the first and second chambers. The alignment unit is capable of carrying out a six-degrees-of-freedom alignment between the first and second substrates. Thus, the substrates can be maintained parallel to each other, a spacing between the substrates can be automatically adjusted, and the substrates can be aligned in the X and Y axis directions.

Owner:ADVANCED DISPLAY PROCESS ENG CO LTD

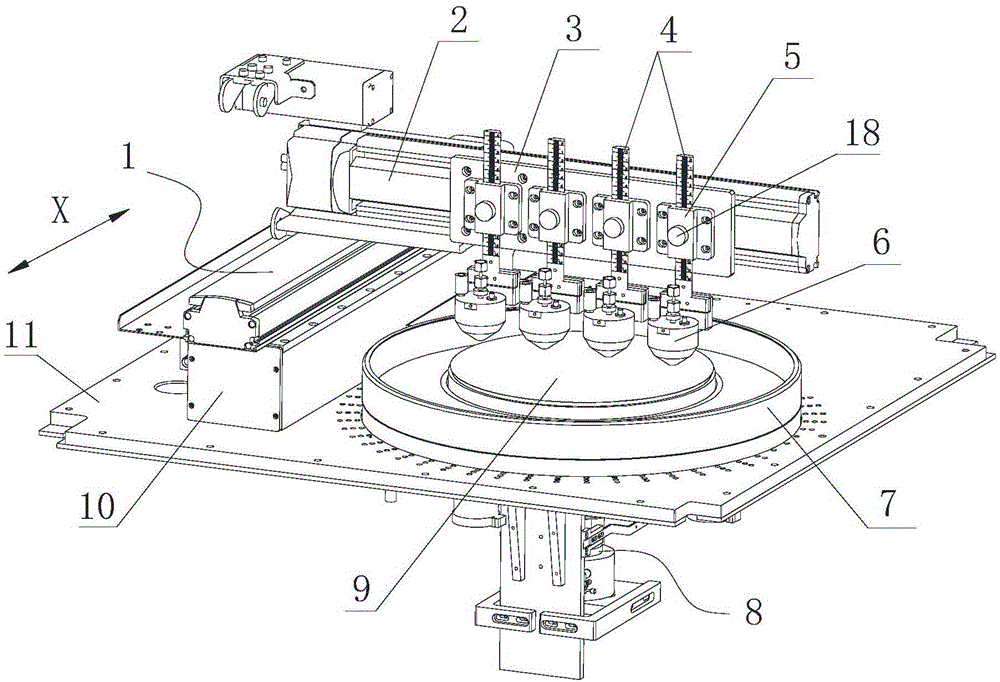

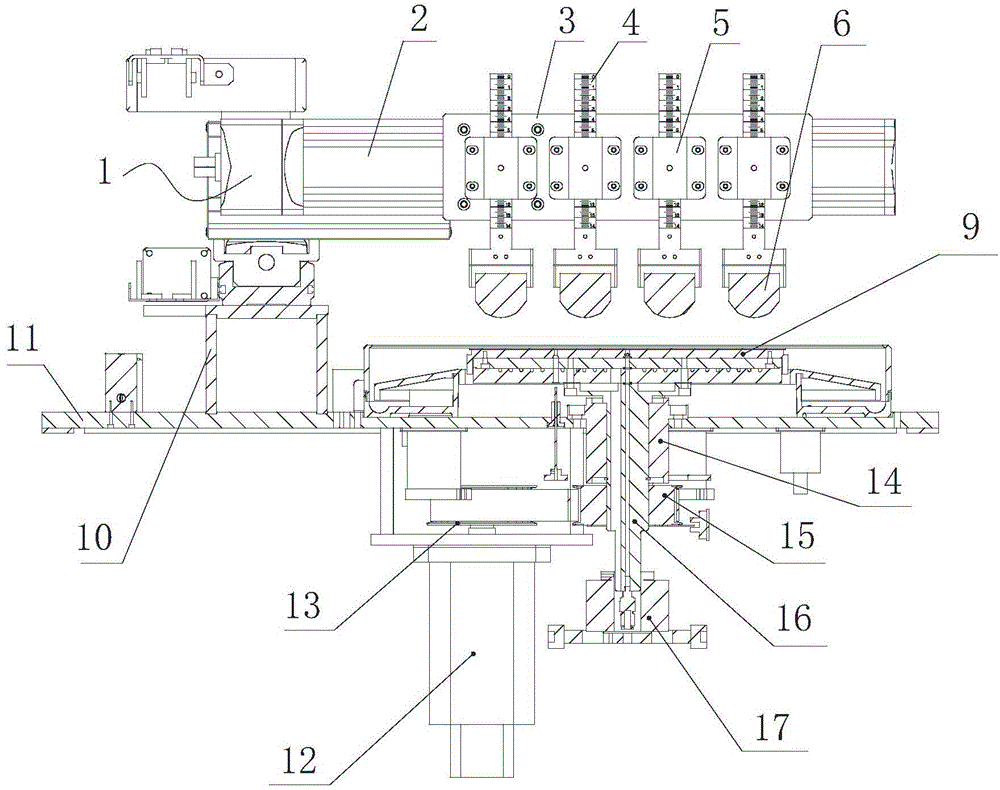

Semiconductor made thick photoresist film coating device and application method thereof

ActiveCN105772323AUniform film thicknessAvoid bumpingLiquid surface applicatorsSpraying apparatusEngineeringFilm-coated tablet

The invention relates to the field of semiconductor processing, in particular to a semiconductor made thick photoresist film coating device and an application method thereof. The semiconductor made thick photoresist film coating device comprises an electric cylinder, spraying heads, a photoresist cup assembly, a rotary adsorption mechanism and a base plate. The electric cylinder and the photoresist cup assembly are both arranged on the base plate. A movable beam is arranged on the electric cylinder. The spraying heads spraying heads of which the intervals and the height can be all adjusted are arranged on the movable beam. The rotary adsorption mechanism is provided with a rotary adsorption disk used for adsorbing a wafer. The adsorption disk is arranged in the middle of the photoresist cup assembly. During photoresist film coating, the spraying heads are driven by the movable beam of the electric cylinder to move horizontally above the adsorption disk. The to-be-processed wafer is put on the adsorption disk. The multiple spraying heads are driven by the electric cylinder to move synchronously and horizontally and spraying photoresist, and then the wafer is fixedly adsorbed by the adsorption disk. The multiple spraying heads are driven by the electric cylinder to move synchronously and horizontally and spray the atomized photoresist. According to the semiconductor made thick photoresist film coating device and the application method thereof, even spraying is ensured, the film thickness of the whole wafer is made to be uniform, and edge protrusions of the wafer is avoided completely.

Owner:SHENYANG KINGSEMI CO LTD

Anti-twisting type sectional warping machine

The invention discloses an anti-twisting type sectional warping machine. The anti-twisting type sectional warping machine comprises a bobbin creel, a yarn fixing rack, a yarn distributing device and a drum, wherein the bobbin creel comprises a rack, yarn guiders, a flexible cover and yarn cone shafts; yarn cones are placed on the yarn cone shafts; the yarn cone shafts are fixed on the rack; each yarn cone shaft is provided with the corresponding yarn guider; and the flexible cover is fixed on the rack and covers the yarn cones. The anti-twisting type sectional warping machine is simple in structure; the circumstance that warp yarns are twisted together and are knotted in a warping process is avoided effectively; and the warping efficiency is improved.

Owner:佛山市三水三强塑胶有限公司

Method of controlling a rail transport system for conveying bulk materials

ActiveUS8140202B2Reliably determinedIncrease speedDigital data processing detailsAutomatic initiationsTransport systemRail transportation

A train is driven by drive stations positioned along a track for frictionally contacting side plates on the train. The drive speed is controlled in response to sensors located at each drive station sensing a position of a wheel and a side plate for confirming a presence of the train. A start command is transmitted from the drive station driving the train to a second drive station downstream when a lead car is within a preselected distance from the second drive station. The drive station at the second drive station is quickly accelerated to a target speed for synchronizing the first drive station with the second drive station. After receiving the train, the second drive station then transmits a stop command to the first drive station for fast decelerating the drive station to a stop.

Owner:RAIL VEYOR TECH GLOBAL

Paperboard film laminating device for paperboard processing

ActiveCN110202907ASave lamination timeImprove production efficiencyLamination ancillary operationsLaminationPaperboardEngineering

The invention discloses a paperboard film laminating device for paperboard processing in the technical field of paperboard processing. The device includes a base. Vertical beams are arranged on the top end of the base. A crossbeam is arranged on the top ends of the vertical beams. The device can carry out film laminating on the upper and lower surfaces of a paperboard at the same time through double film laminating roller structures which are arranged upper-lower symmetric, which saves the film laminating time of the paperboard. The design of elastic connectors makes a film and the paperboardtighter after rolling. The limit mechanism arranged on the two sides of film laminating mechanisms can limit a movement track of the paperboard so as to avoid the problem of inaccurate alignment of the film and the paperboard during film laminating. The spacing of the limit mechanisms is adjustable, which can carry out limiting and righting of paperboards with different width. A roller brush cleaning mechanism can clean dust on the exposed surface of the paperboard before the film laminating, which improves the adhesion effect between the film and the paperboard. An arranged hot-air drying mechanism can carry out hot air heating on the film paper after the film laminating to make the adhesion effect better.

Owner:ZHEJIANG JUDING PACKAGING

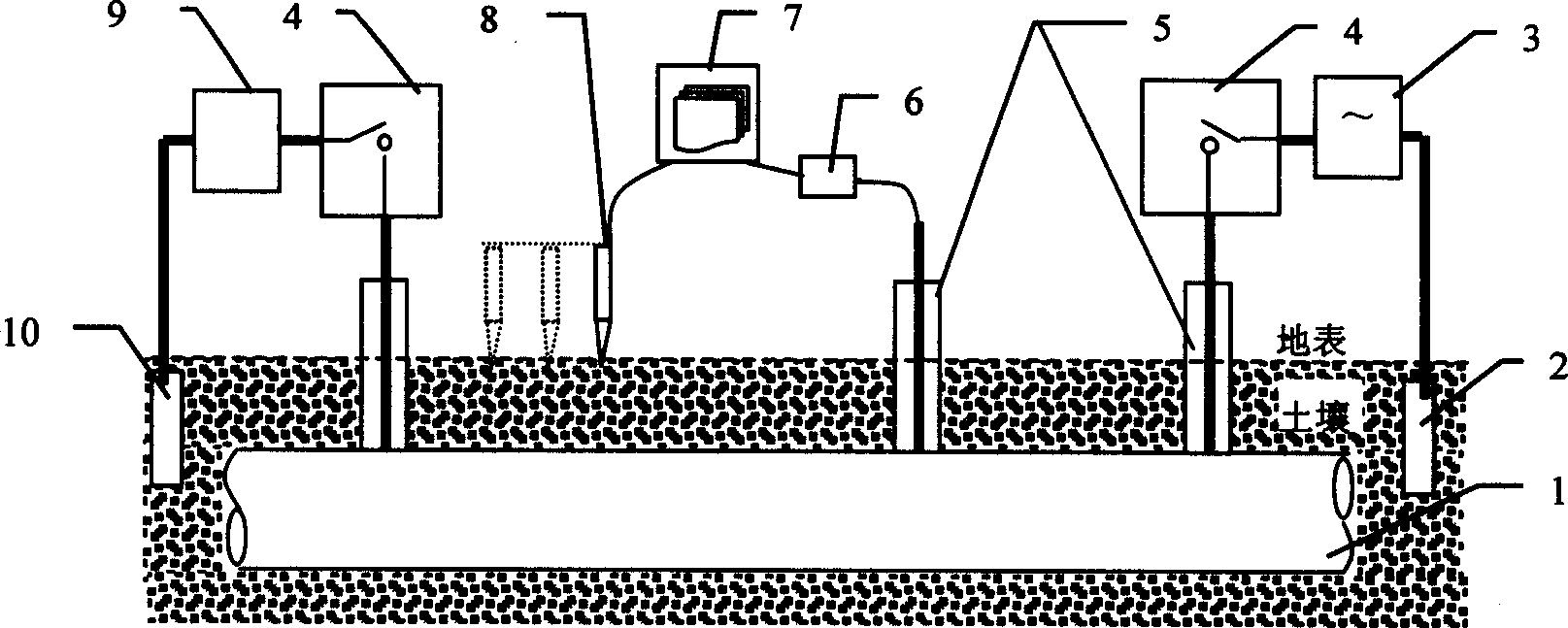

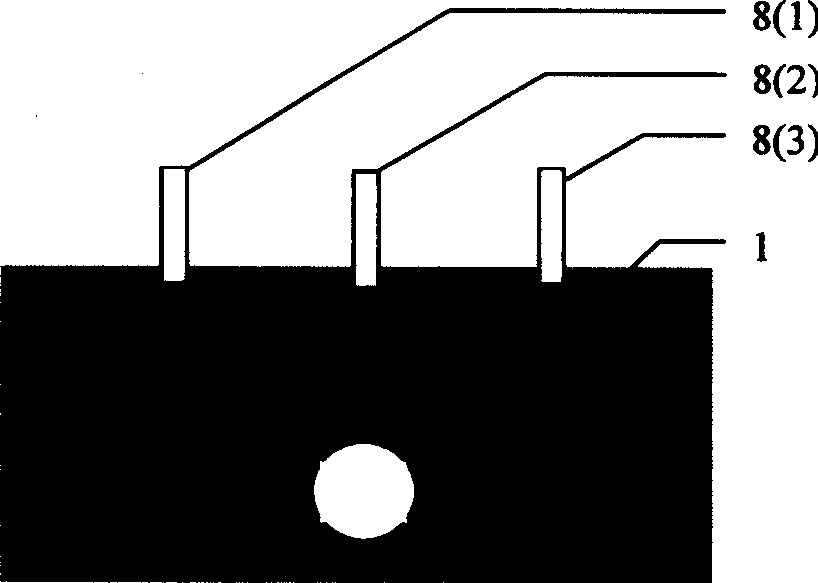

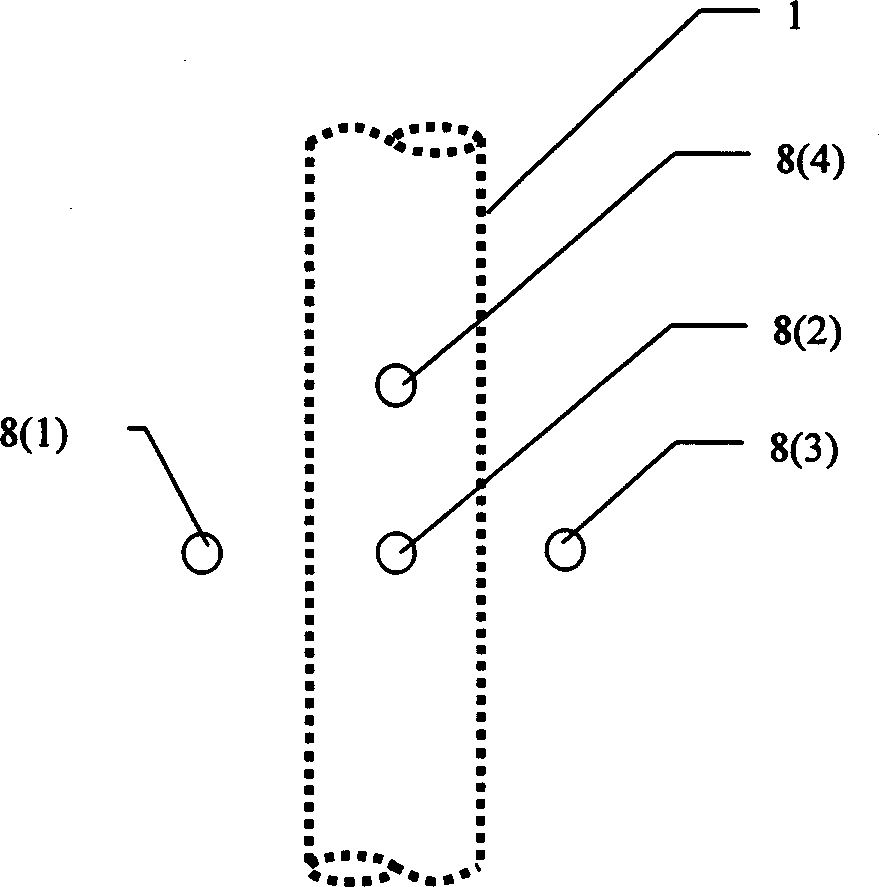

Comprehensively measuring method and device for electric potentials of pipe earth and ground surface for cathodic pipeline pretection

InactiveCN1456879AImprove detection efficiencyEliminate measurement effectsWeather/light/corrosion resistanceMaterial resistanceMicrocomputerData acquisition

The method uses at least each reference electrode to carry out measurement for pipe located position potential and for ground surface potential separately at the same time and instant interruption current method or additional applied eciting current signal method is applied to eliminate IP drop in the measuring course. The testing data collected by recorder is analysed by the microcomputer to confirm the true pipe located position potential and ground surface potential. The device to realize the method consists of reference electrode set, data collector recording device, signal generating device, current interrupt appliance, distance measurer and microcomputer analysis system, of which the signal generating device, current interrupt appliance and data collection recording device are set in synchronization with GPS.

Owner:TIANJIN UNIV

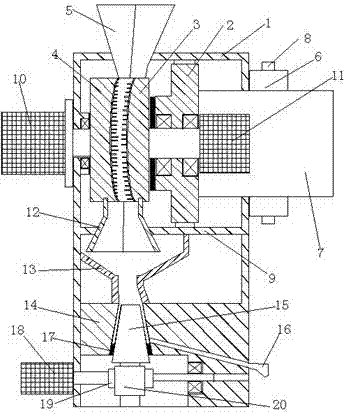

Multistage type traditional Chinese medicine smashing machine

InactiveCN107309057AGuaranteed crushing effectPracticalCocoaGrain treatmentsPulverizerChinese herbology

The invention discloses a multi-stage traditional Chinese medicine pulverizer. The invention adopts two stages of crushing. Firstly, a convex roller and a concave roller are used for primary crushing, and then a millstone is used to grind it to a required particle size. The method can make the Chinese medicine will not be subjected to excessive extrusion force every time it is crushed, so as to ensure that the molecular structure of the Chinese medicine is not damaged, and the efficacy of the Chinese medicine is guaranteed. In addition, the present invention is set as the center of the feeding port of the primary crushing component. The axial direction is perpendicular to the central rotation axis direction of the primary convex roller, and the central axis direction of the feed port of the secondary crushing assembly is parallel to the central axis of the secondary rotating grinding disc of the secondary crushing assembly, which can make the medicine from different Feeding at an angle ensures the crushing effect of the medicine. The distance between the first-stage crushing components of the present invention is adjustable, which can adapt to the crushing of different traditional Chinese medicines and has strong practicability.

Owner:王建梅

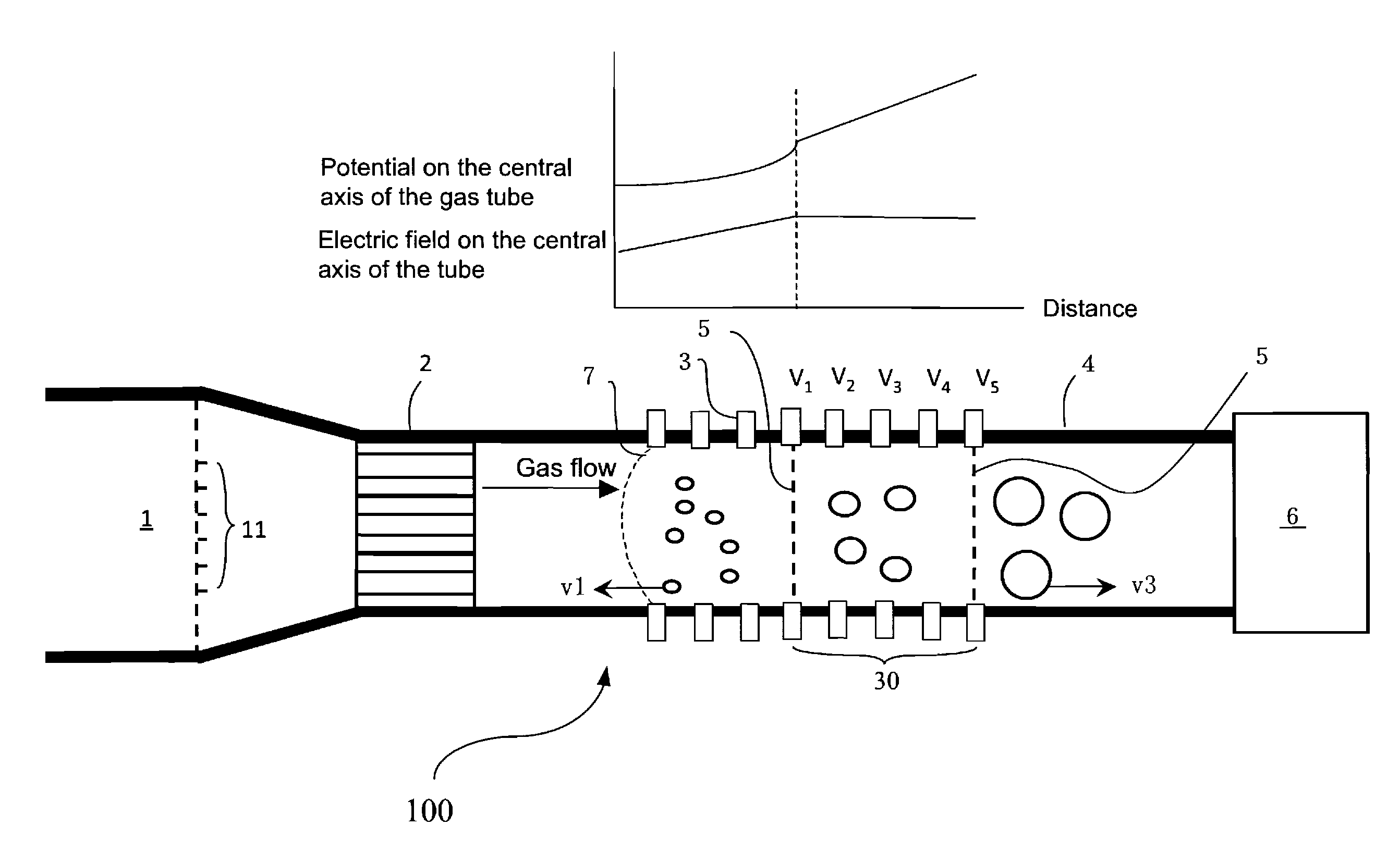

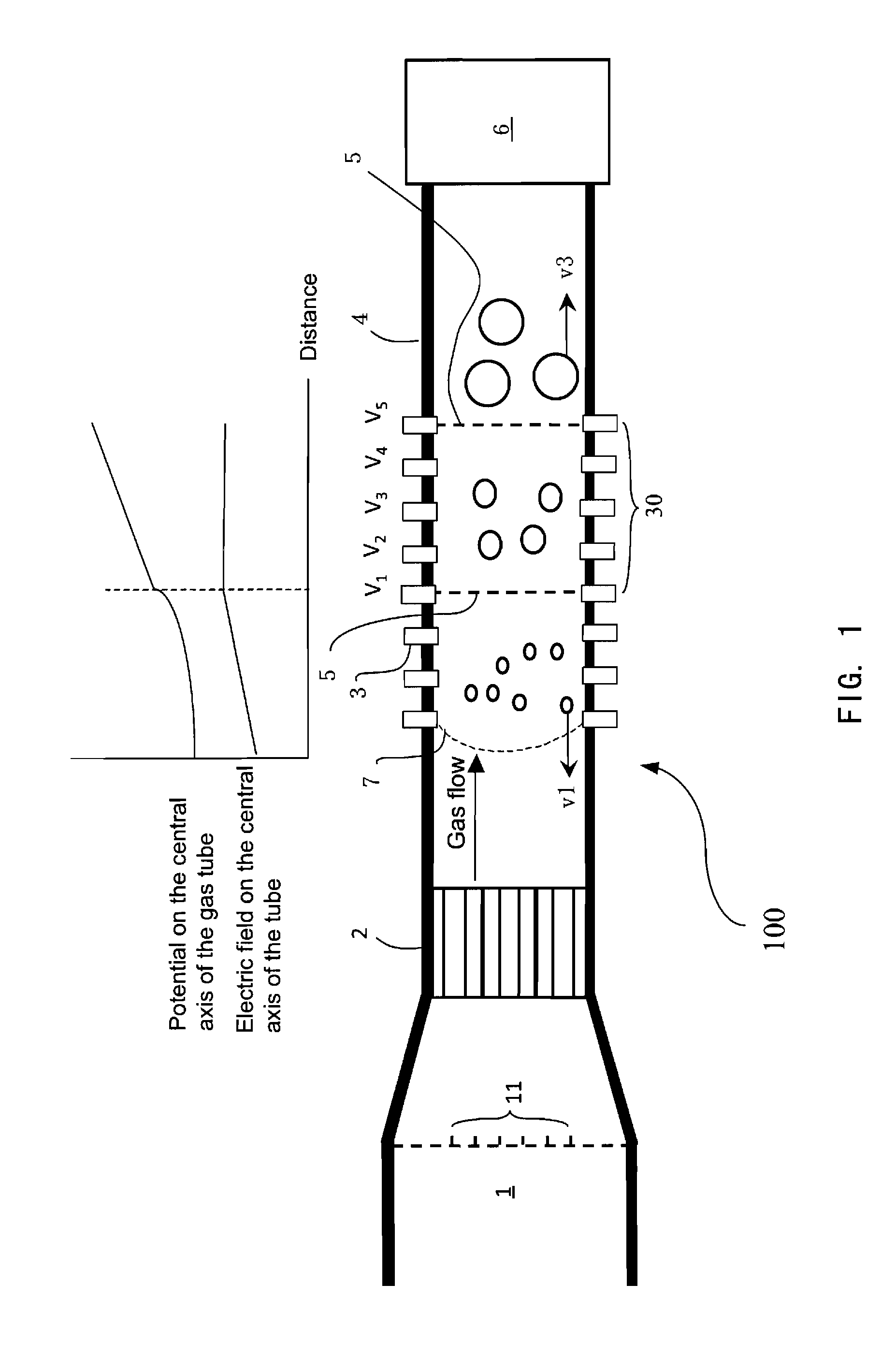

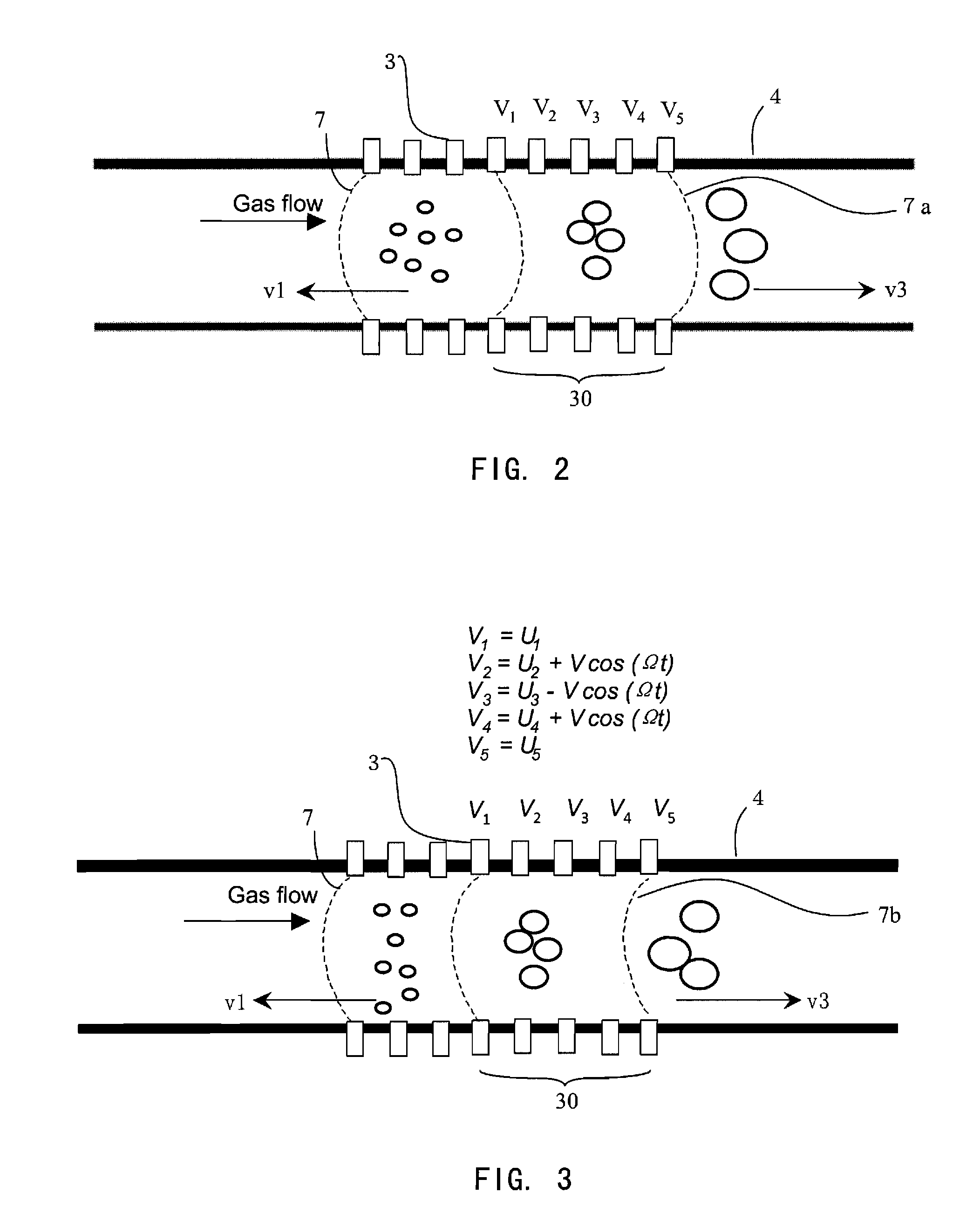

Device for separating, enriching and detecting ions

ActiveUS20110220790A1Increase ion enrichment timeImprove detection efficiencyTime-of-flight spectrometersMaterial analysis by electric/magnetic meansDynamic balanceMass analyzer

A device for separating, enriching and detecting ions comprises: a gas tube, in which a carrier gas flows at a uniform rate; an ion source; multiple electrodes provided in the gas tube and applied with electric voltages respectively, so that at least an electric field is produced along the axis of the gas tube; an ion detector; and an ion extraction channel, by which specific enriched ions will be guided across the side wall of the gas tube toward the ion detector and be analyzed. The device enriches ions utilizing the following characteristic: compound ions with specific ion mobility maintain a dynamic balance for a period of time in a flow field under the combination of a carrier gas and a suitable electrical field against the direction of the carrier gas. Simultaneously, multiple compound particles with different ion motilities can be separated and enriched at positions with different electrical field intensities in a flow field in the same manner. The device also comprises synchronously export latitudinally enriched ions at different positions in a flow field, and performs later mass analysis using a mass spectrometer.

Owner:SHIMADZU RES LAB SHANGHAI

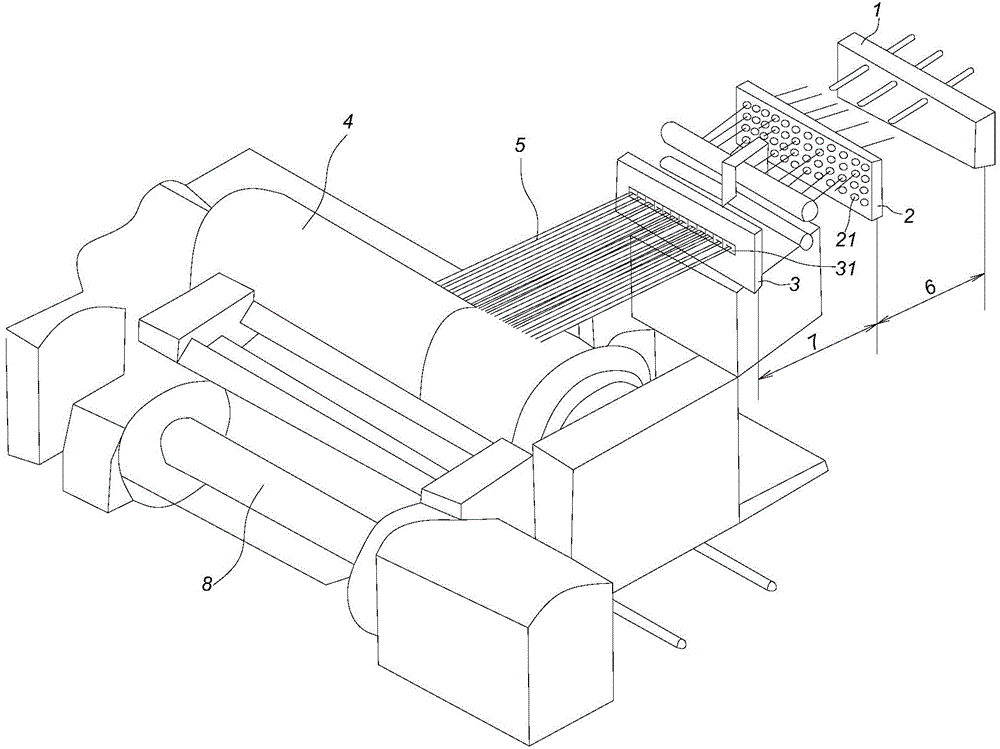

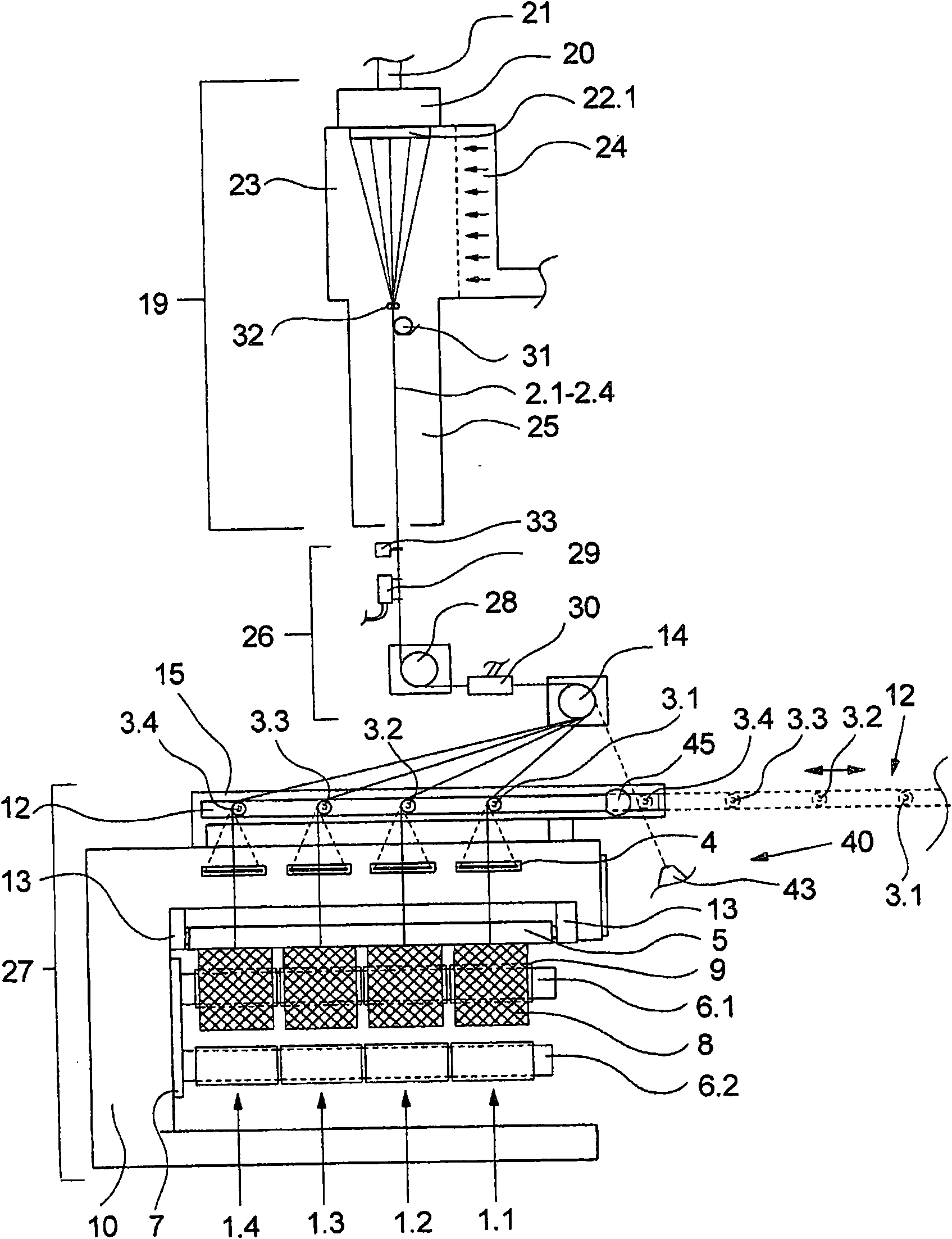

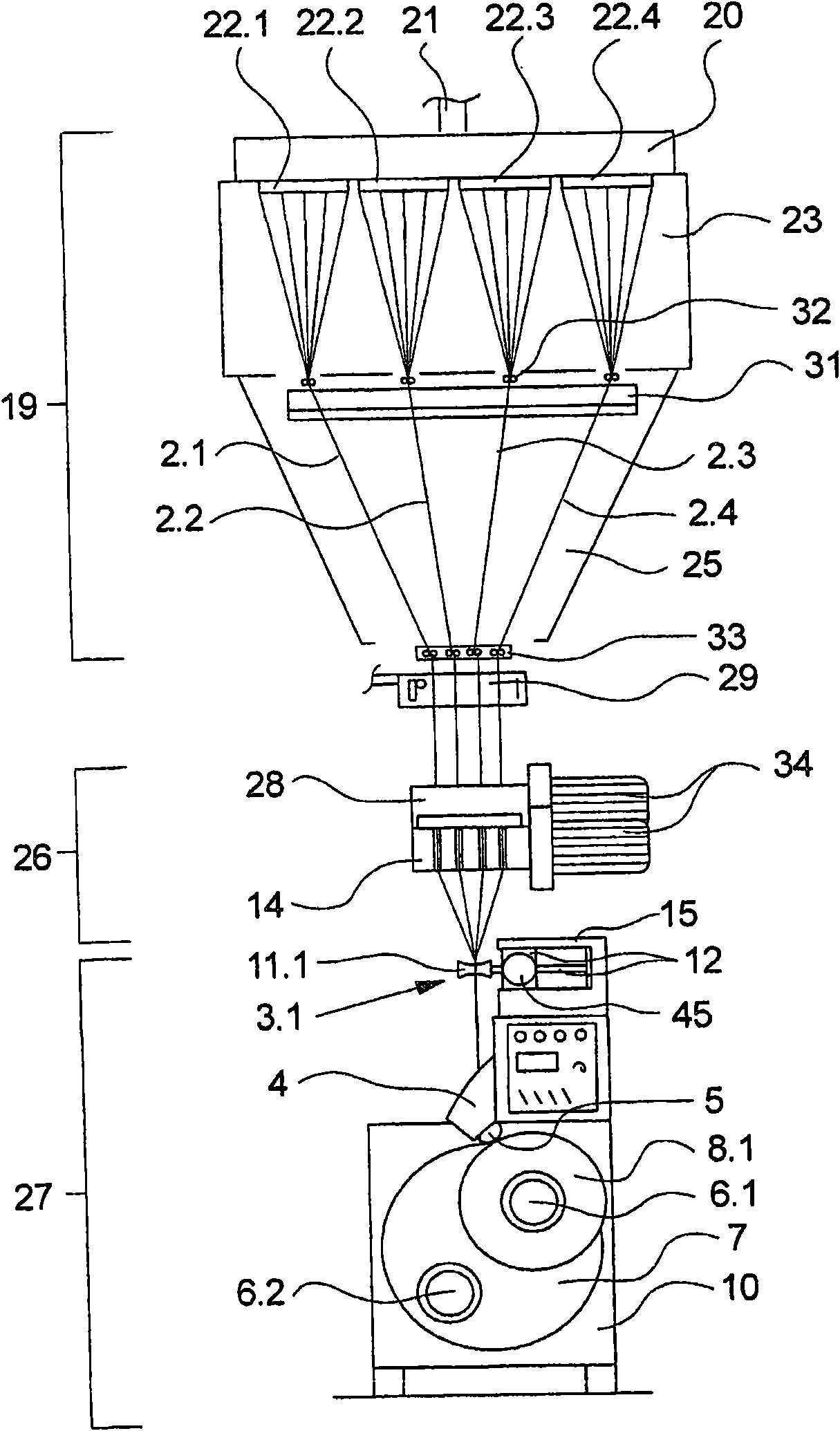

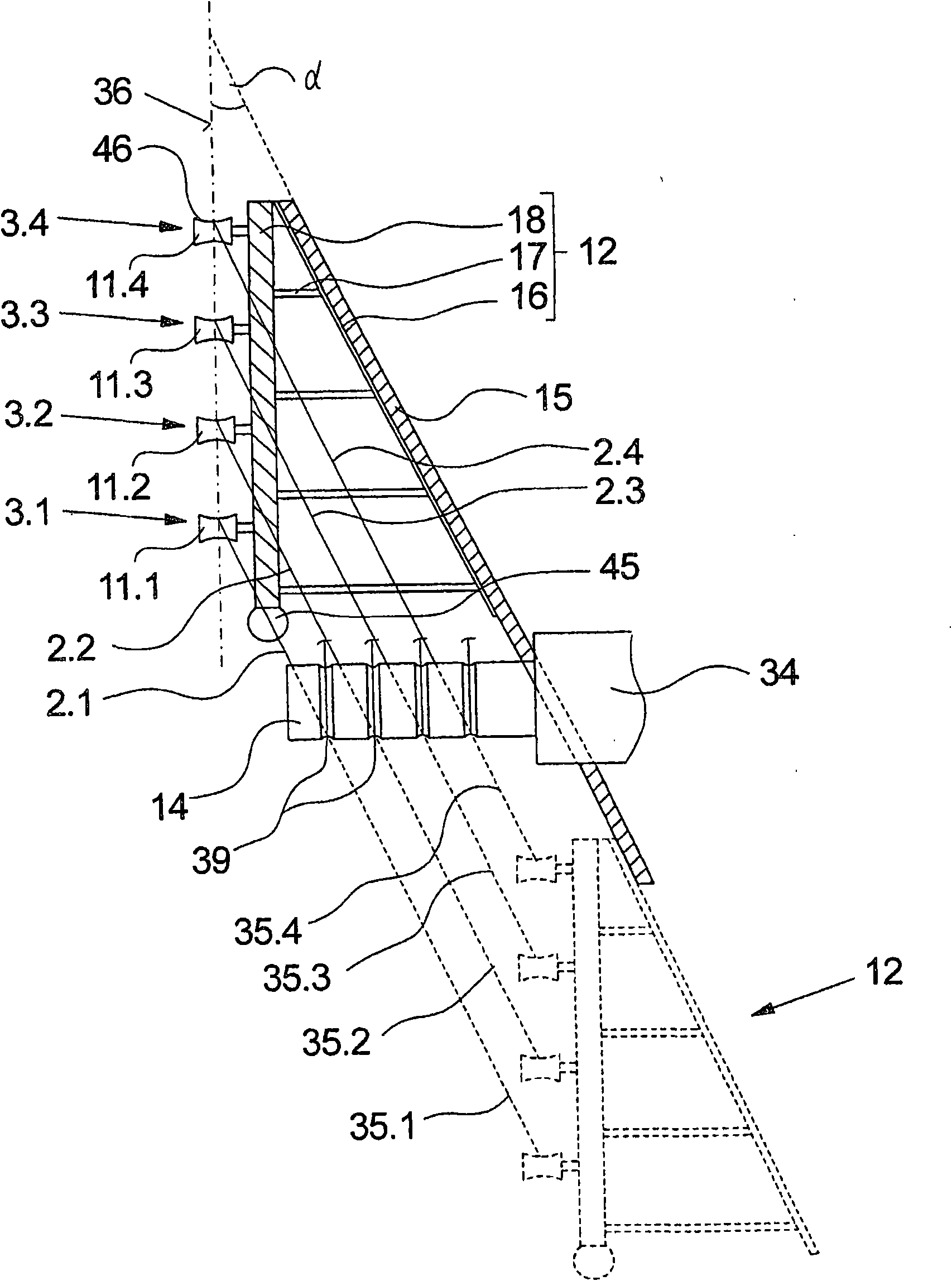

Device for melt-spinning and winding synthetic threads

ActiveCN101680119AFully automatedCompact structureNew-spun product collectionArtificial thread manufacturing machinesWinding machineEngineering

The invention relates to a device for melt-spinning and winding synthetic threads, comprising a spinning device, a treatment device and a winding machine. The treatment device is provided with a take-off godet for guiding the threads before the threads are fed and distributing the threads to a plurality of winding points in the winding machine. The take-off godet is disposed above the winding machine and guides the threads on the circumference such that the threads run parallel next to each other. The take-off godet is arranged transversely to a winding spindle, above the winding machine. Thewinding machine is equipped with a plurality of top thread guides, which are mounted upstream of the winding points and are located in a feeding plane. In order to improve the application process regarding the distribution of the filaments on the individual winding points when starting the process or pausing the process, the take-off godet and the group of the top thread guides for applying the threads into the winding points of the winding machine are designed to be moveable relative to each other according to the invention.

Owner:OERLIKON TEXTILE GMBH & CO KG

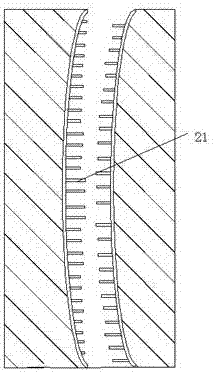

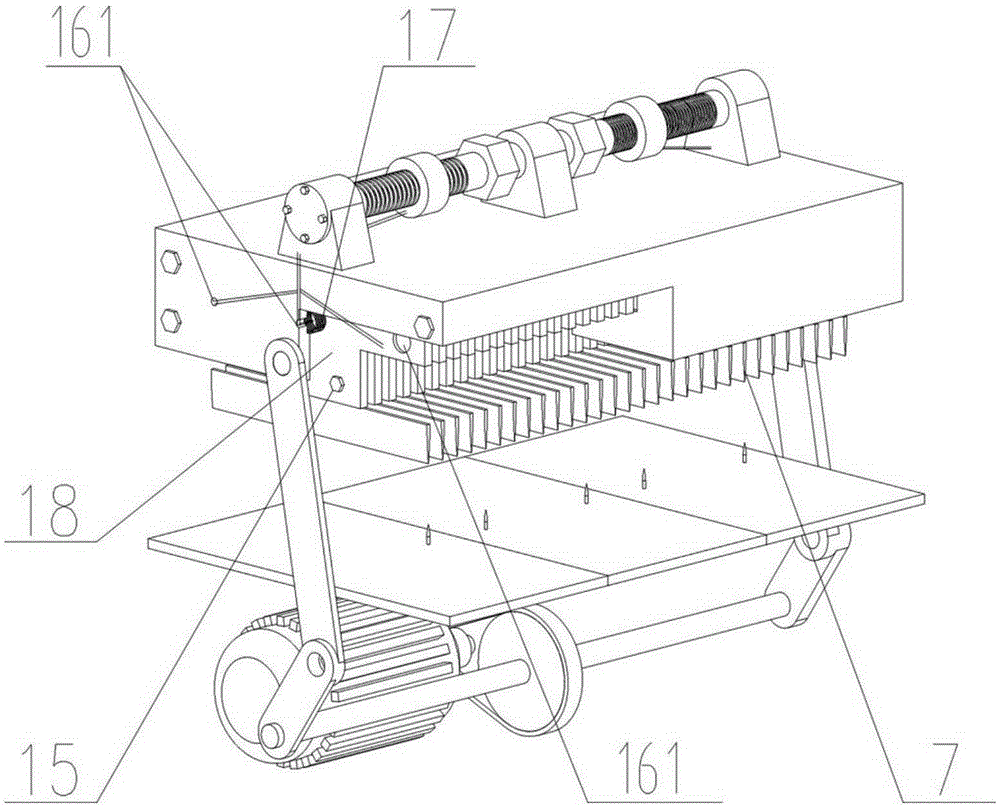

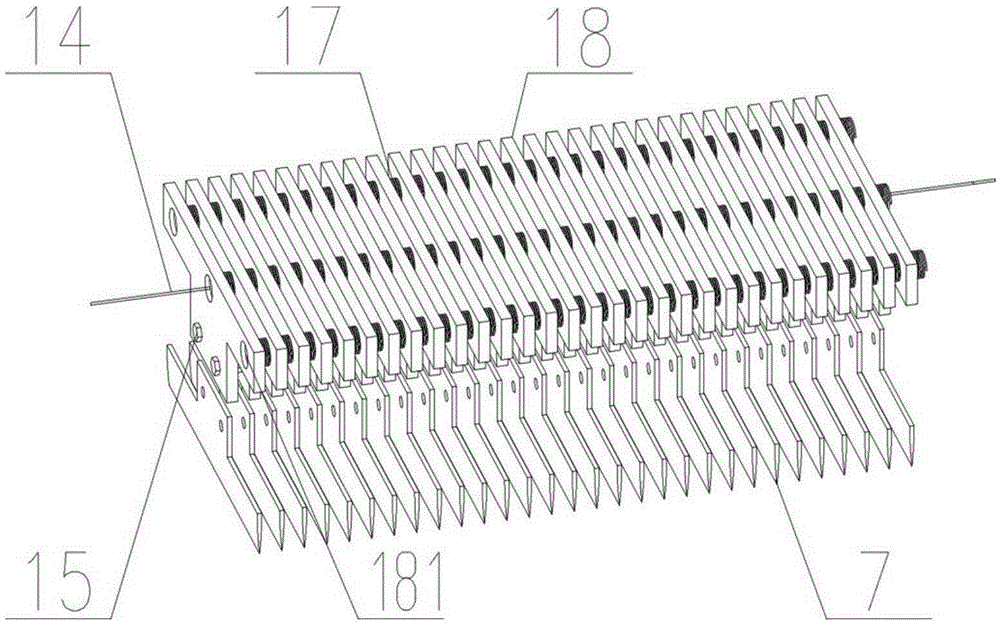

Slicing device capable of adjusting thickness

InactiveCN105345856AAdjustable thicknessAdjustable spacingMetal working apparatusElectric machineryKnife blades

The invention discloses a slicing device capable of adjusting the thickness. Spring sets are arranged among a plurality of cutter bases. The cutter bases located at the two ends are connected with a thickness adjusting device through pull ropes. The cutter bases are fixedly provided with blades through connecting screws, and the cutter bases are further connected with a reciprocating lifting driving device. Material base plates are arranged at the positions opposite to the blades. In the thickness adjusting device, lead screws are borne on bearing bases fixedly arranged on an adjusting base, nuts are in threaded connection with the lead screws, and the nuts are fixedly connected with the pull ropes. The lead screws are provided with adjusting heads or motors used for driving the lead screws to rotate. According to the slicing device capable of adjusting the thickness, the distance among the blades can be conveniently adjusted by arranging the thickness adjusting device, and therefore the thickness of cut materials can be adjusted.

Owner:XI AN JIAOTONG UNIV

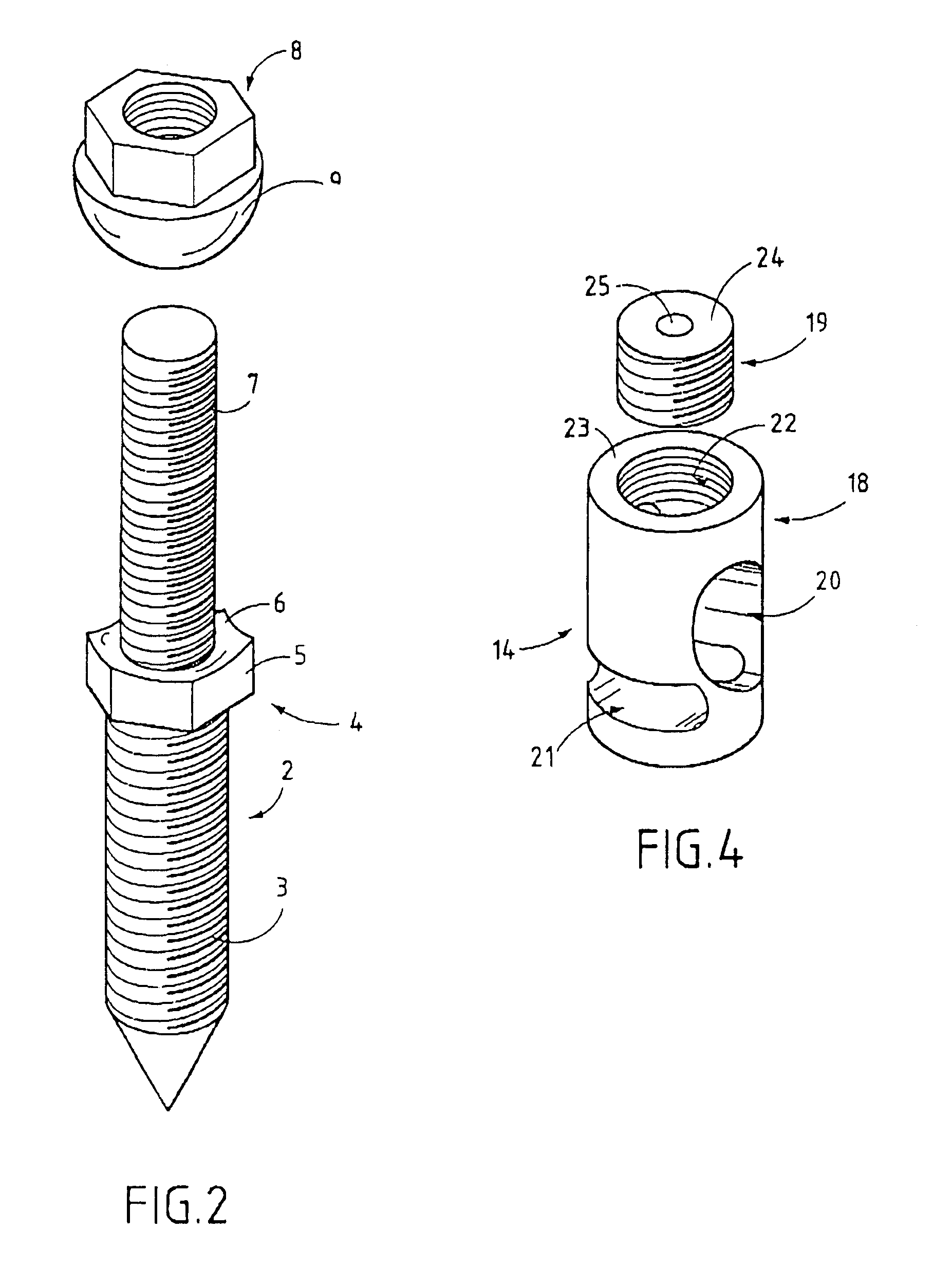

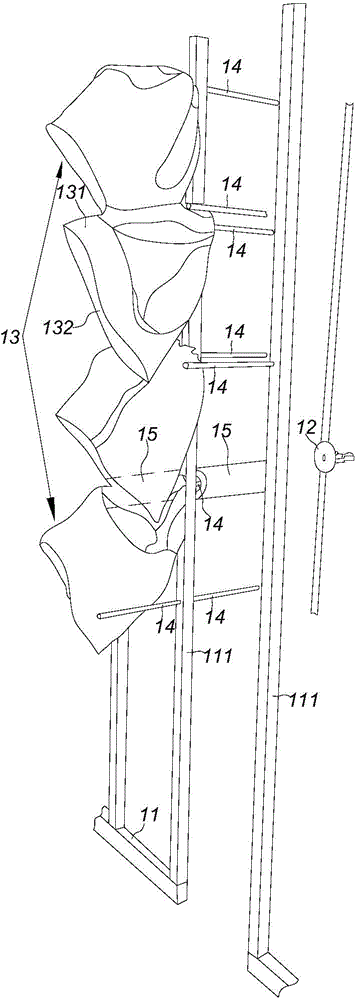

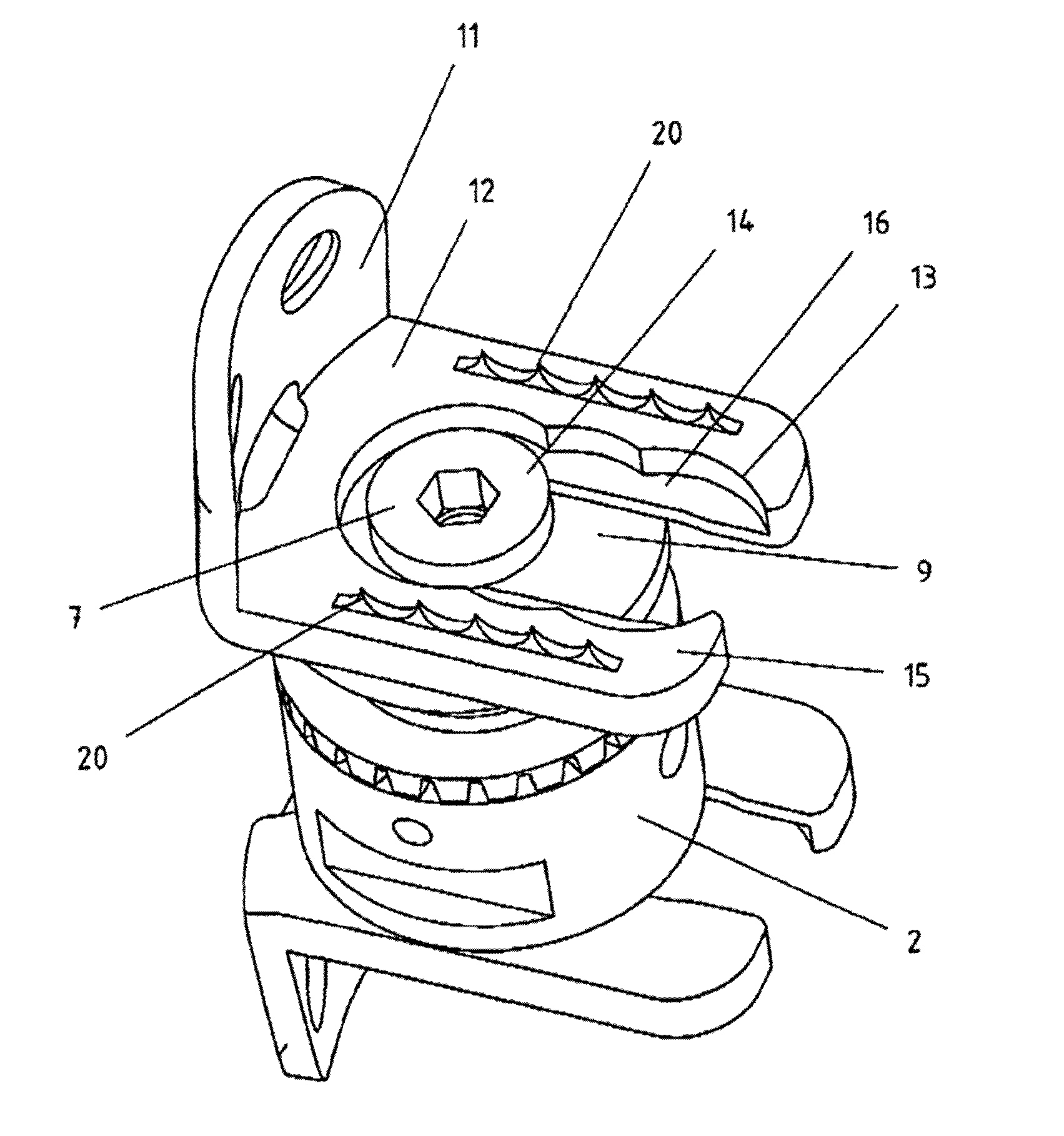

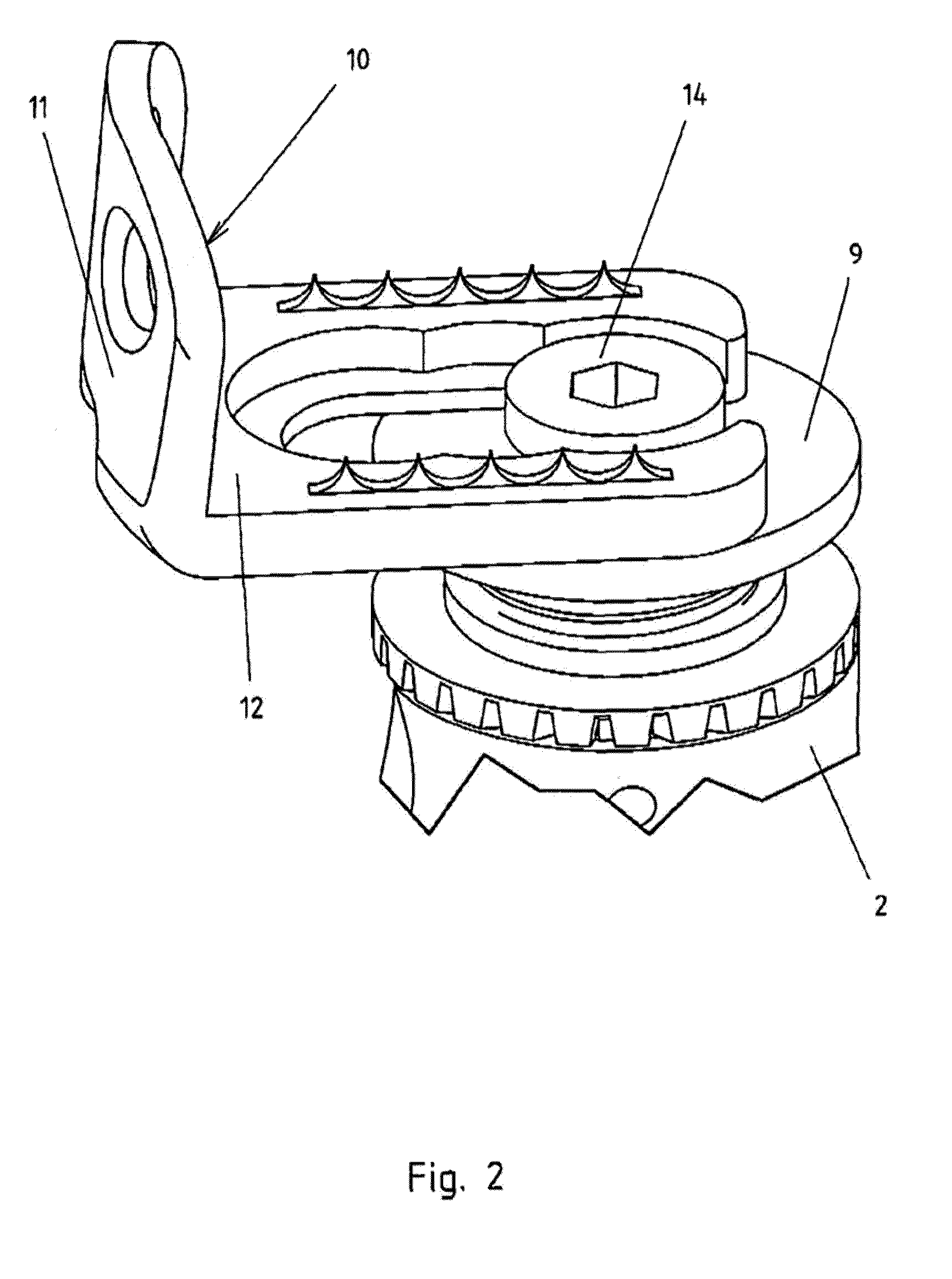

Implant for use between spiral vertebrae

InactiveUS8128701B2Minimally invasive procedureDifferent placementSuture equipmentsLigamentsBiomedical engineeringLumbar vertebral column

The invention relates to an implant for use between the vertebrae (8) of the spine as a placeholder for vertebrae or vertebrae parts removed from the spine, having a first implant part (2) and a second implant part (3), which can be adjusted against each other in the direction of the coaxial longitudinal axis thereof for changing the length of the implant (1), and having at least one mounting bracket (10) that can be attached to one of the implant parts (2 and 3), and which faces the adjacent vertebra, and partially overlaps the same. The mounting bracket (10) is formed by a vertebra attachment plate (11) and by a base plate (12) comprising a guide rail (13), protruding from the vertebra attachment plate, and serving for the radial adjustment of the mounting bracket (11) as opposed to the one implant part (2 and 3), is wherein a means is associated with the one implant part (2 and 3) for the radial fixation of the base plate (12).

Owner:ULRIKH GMBKH & KO KG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com