Soft tissue packing machine

A packaging machine and soft pumping technology, which is applied in packaging, transportation packaging, paper product packaging, etc., can solve the problems of low packaging rate, affecting production efficiency, and broken bags of packaging bags, so as to ensure uniformity, improve packaging speed and Effect, the effect of saving labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

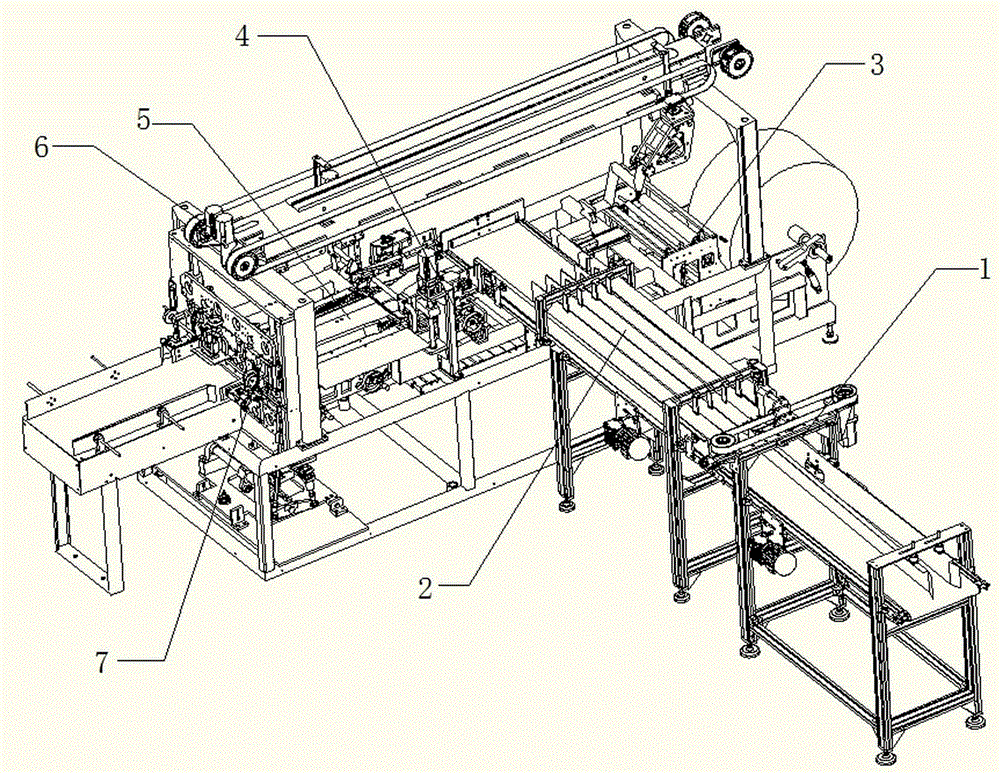

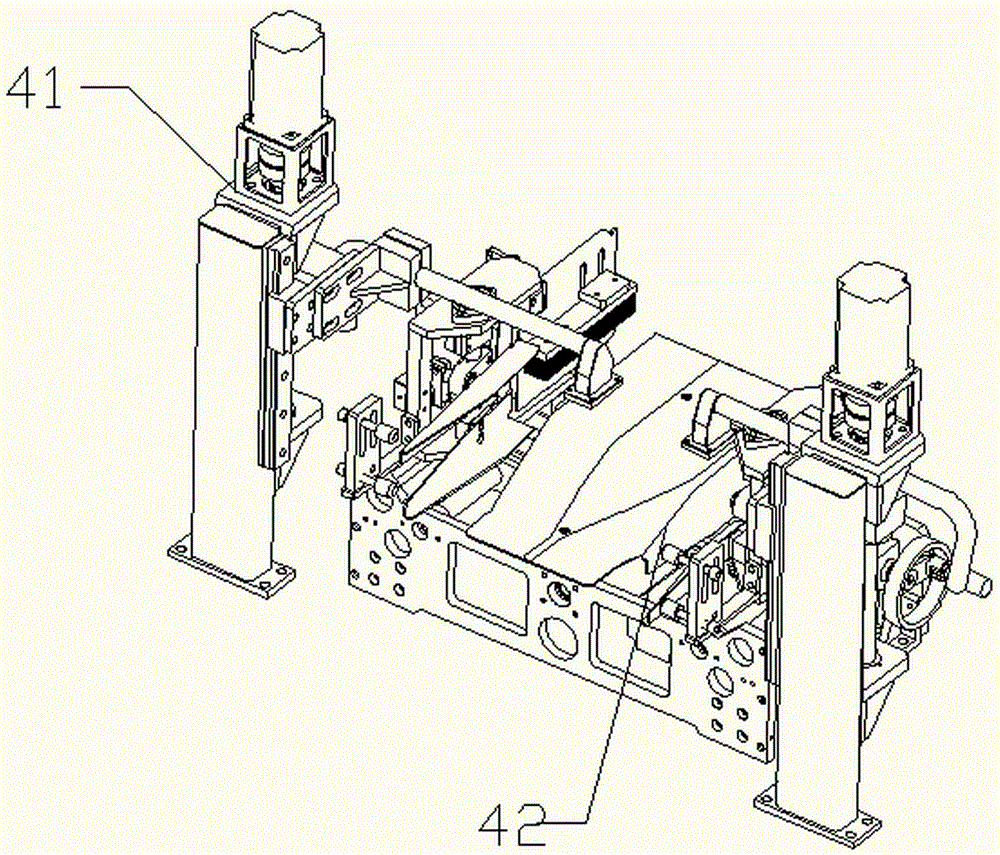

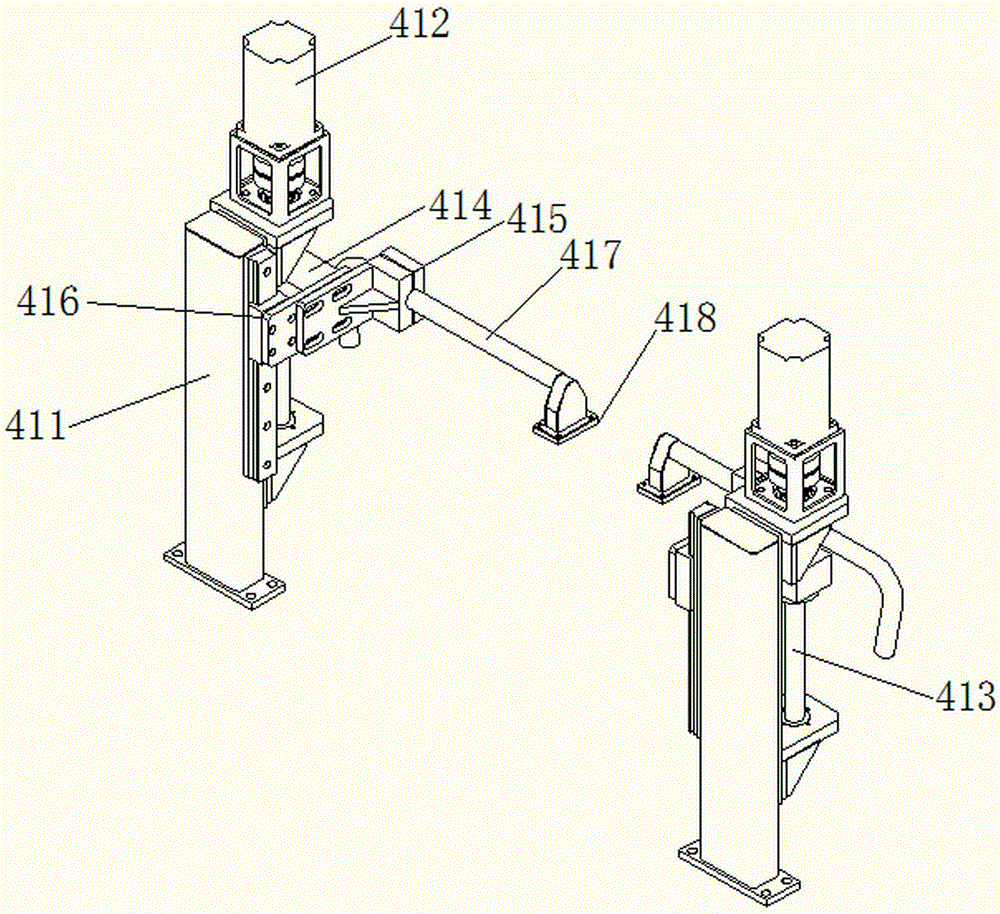

[0041] As a preferred embodiment of the present invention, with reference to the attached figure 1 and 2 , the present invention includes a lane-separating conveying part 1, a sorting and conveying part 2, a supporting film feeding part 3, a bag opening part 4, a negative pressure conveying part 5, a bag pushing part 6, a knife sealing part 7, the bag opening The bag opening device 4 includes a propulsion translation device, 41 bag opening devices and 42 bag opening devices. The 41 bag opening devices include a group of left and right symmetrical supports 411 and driving devices 412; the described bag opening device 42 includes two left and right symmetrical Set the opening claw 421, the opening claw 421 includes a fixed bracket 4211, an upper opening claw 4212 and a lower opening claw 4213; The outside of the fixed bracket 4211 is also provided with an adjustment bracket 423, the fixed bracket 4211 is slidably connected to the adjustment bracket 423, and one end of the adjus...

Embodiment 2

[0047] As another preferred embodiment of the present invention, with reference to the attached figure 1 , 2 And 3, the present invention comprises lane-splitting conveying part 1, material arrangement conveying part 2, supporting film sending film part 3, bag opening part 4, negative pressure conveying part 5, push bag part 6, knife sealing part 7, described The bag opening and opening device 4 includes a propulsion translation device, 41 bag opening devices and 42 bag opening devices. The 41 bag opening devices include a group of left and right symmetrical supports 411 and driving devices 412; the described bag opening device 42 includes left and right symmetrical Two sets of claws 421, the claws 421 include a fixed bracket 4211, an upper claw 4212 and a lower claw 4213; the end of the fixed bracket 4211 is provided with a limiting plate 422, and the limiting plate 422 is correspondingly arranged on The outer side of the claw 421; the fixed bracket 4211 is also provided wit...

Embodiment 3

[0055] As another preferred embodiment of the present invention, with reference to the attached figure 1 , 2 , 3 and 4, the present invention includes lane-separating conveying part 1, material sorting and conveying part 2, supporting film feeding part 3, bag opening and opening bag part 4, negative pressure conveying part 5, pushing bag part 6, knife sealing part 7, The bag opening and opening device 4 includes a propulsion and translation device, 41 bag opening devices and 42 bag opening devices, and the 41 bag opening devices include a group of left and right symmetrical brackets 411 and driving devices 412; the bag opening device 42 includes Two sets of opening claws 421 that are left and right symmetrical, the opening claws 421 include a fixed bracket 4211, an upper opening claw 4212 and a lower opening claw 4213; On the outside of the opening claw 421; an adjustment bracket 423 is also provided under the fixed bracket 4211, and the fixed bracket 4211 is slidably connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com