Patents

Literature

35results about How to "No intertwining" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

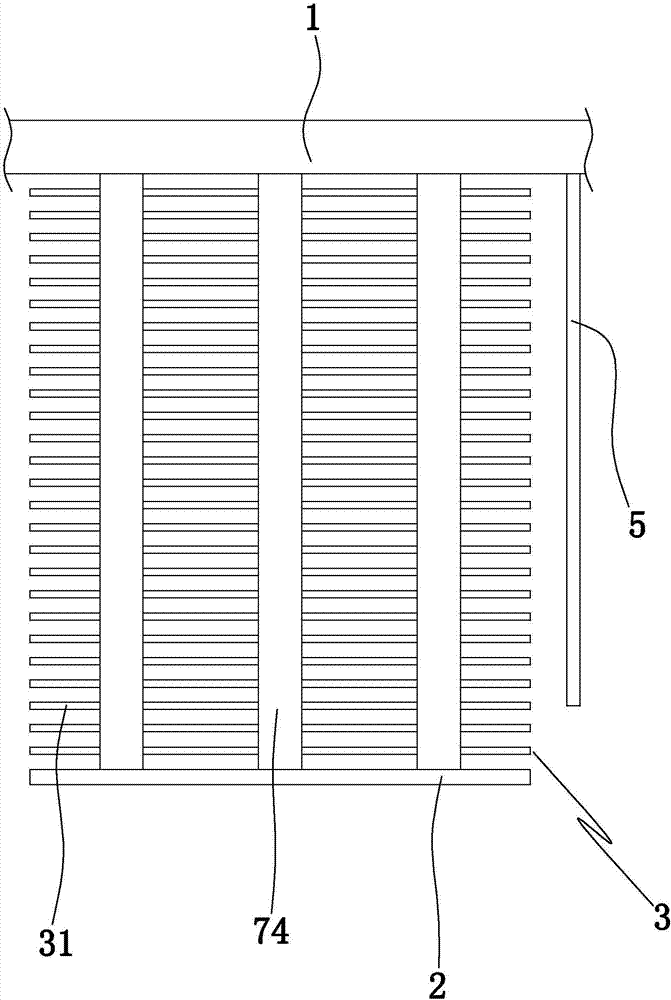

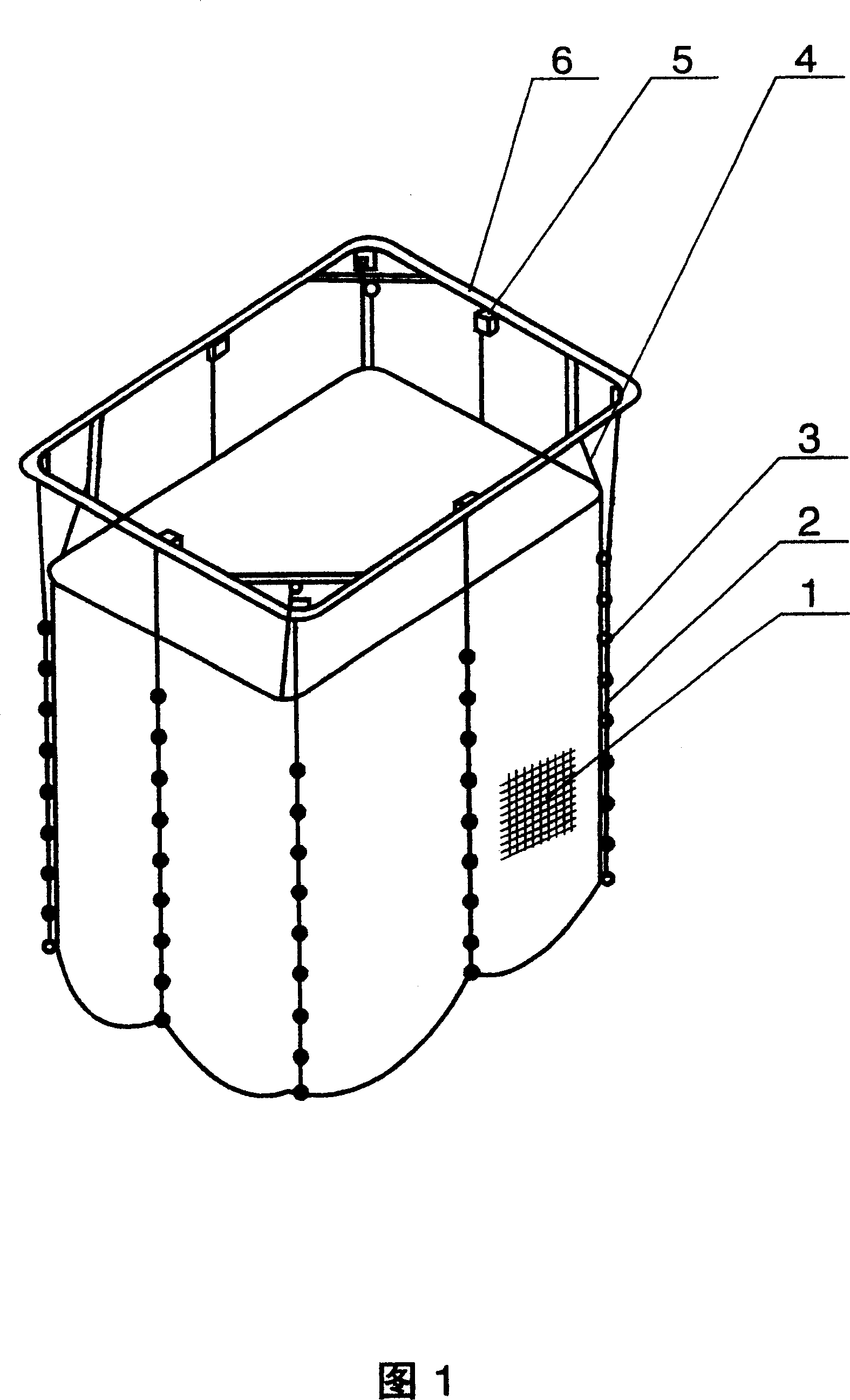

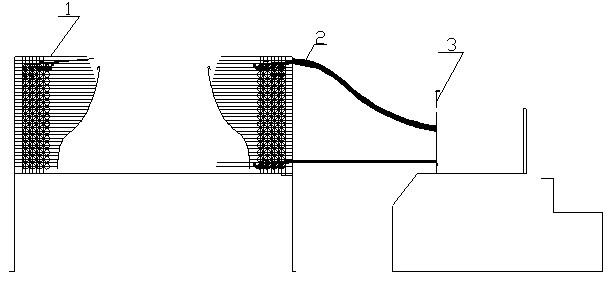

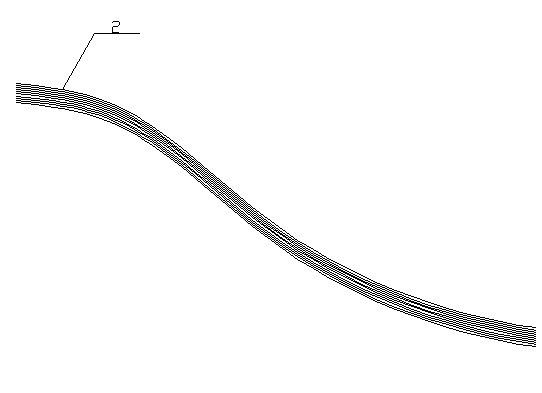

Anti-twisting type sectional warping machine

The invention discloses an anti-twisting type sectional warping machine. The anti-twisting type sectional warping machine comprises a bobbin creel, a yarn fixing rack, a yarn distributing device and a drum, wherein the bobbin creel comprises a rack, yarn guiders, a flexible cover and yarn cone shafts; yarn cones are placed on the yarn cone shafts; the yarn cone shafts are fixed on the rack; each yarn cone shaft is provided with the corresponding yarn guider; and the flexible cover is fixed on the rack and covers the yarn cones. The anti-twisting type sectional warping machine is simple in structure; the circumstance that warp yarns are twisted together and are knotted in a warping process is avoided effectively; and the warping efficiency is improved.

Owner:佛山市三水三强塑胶有限公司

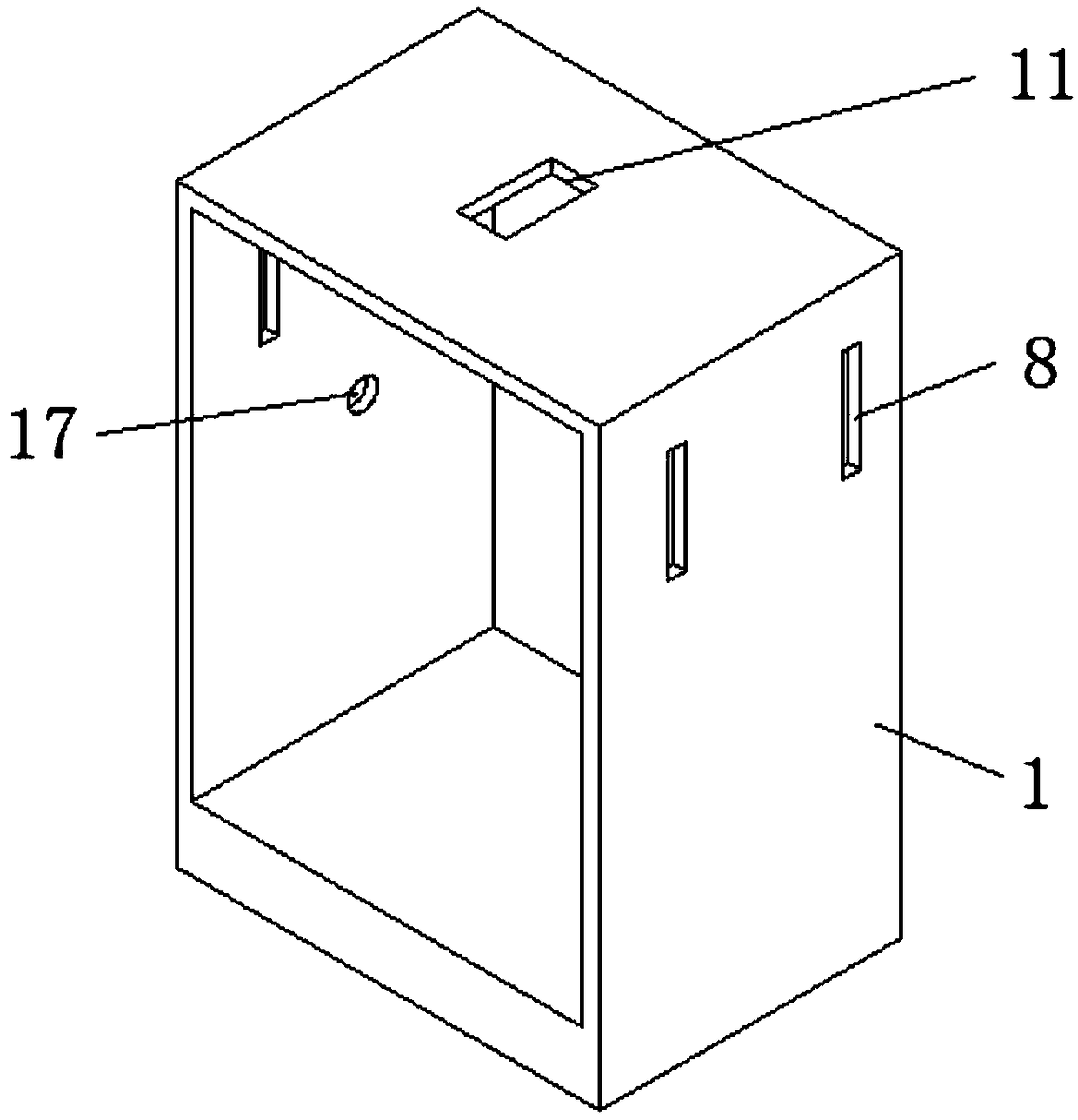

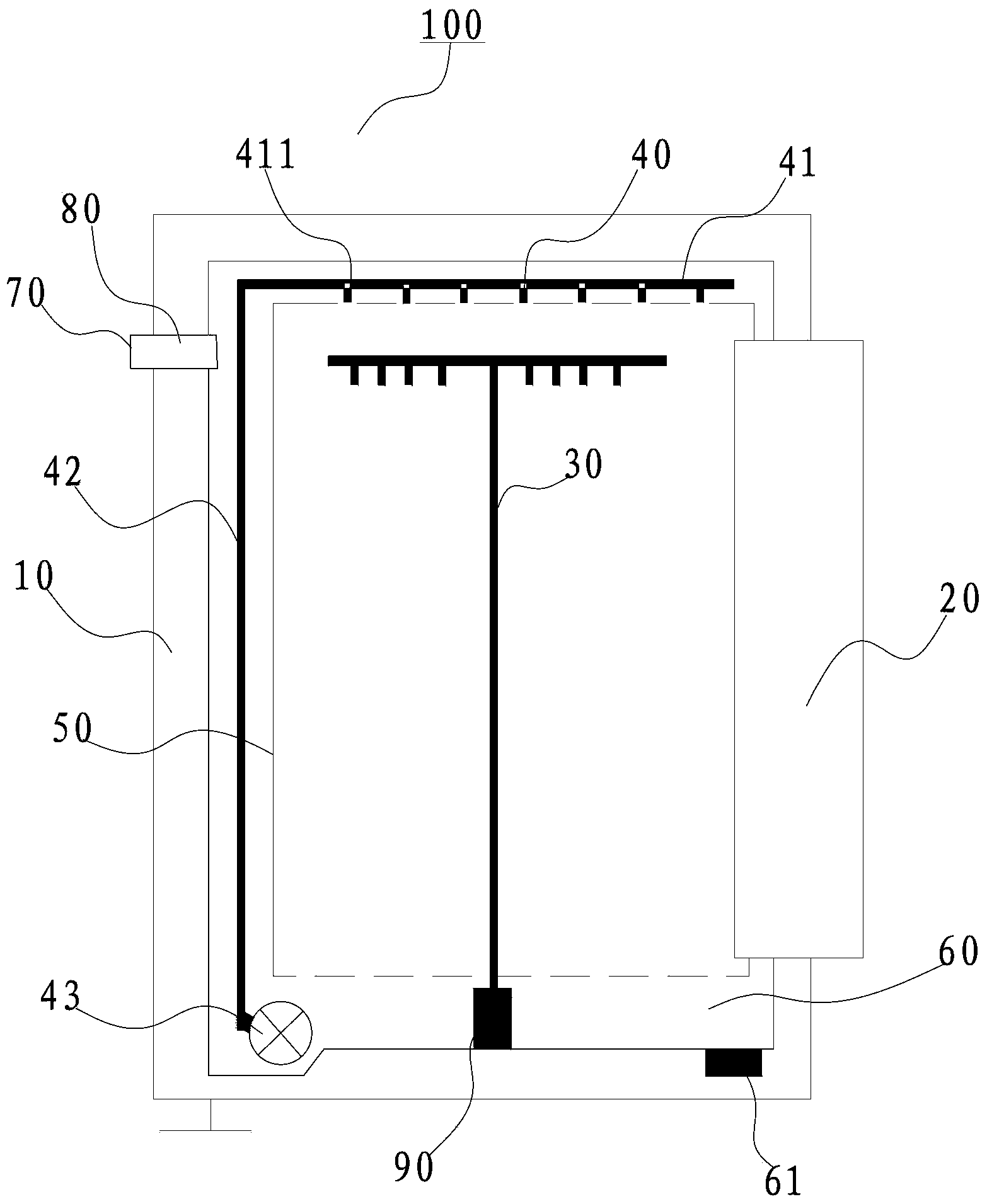

Energy storage charging pile with temperature lowering and heat dissipating functions

PendingCN108773288AAvoid shakingFlexible switchingCooling/ventilation/heating modificationsElectric propulsionConductor CoilEnergy storage

The invention belongs to the technical field of charging piles, and particularly relates to an energy storage charging pile with the temperature lowering and heat dissipating functions to solve the problems in the prior art that application is not convenient enough, wires are liable to twine together, and protection effect is low. The energy storage charging pile comprises a protection cabinet; apartition plate is fixedly connected into the protection cabinet in a horizontal mode; a plurality of ventilation holes are vertically formed in the partition plate; a pile body is fixedly connected with the bottom of the inner wall of the protection cabinet; a charging wire is fixedly connected with the top on one side of the pile body; one end of the charging wire is fixedly connected with a plug; a machinery room is fixedly connected with one side of the protection cabinet; a motor is fixed connected into the machinery room; a through hole matched with an output shaft of the motor is horizontally formed in the protection cabinet; and the output shaft of the motor penetrates through the through hole and is fixedly connected with a wire wrapping disc in the protection cabinet. Applicationis convenient, cross winding of the charging wire does not occur, heat dissipation effect is high, security is high, and internal parts are not liable to fall off and damage.

Owner:南京微晟电源科技有限公司

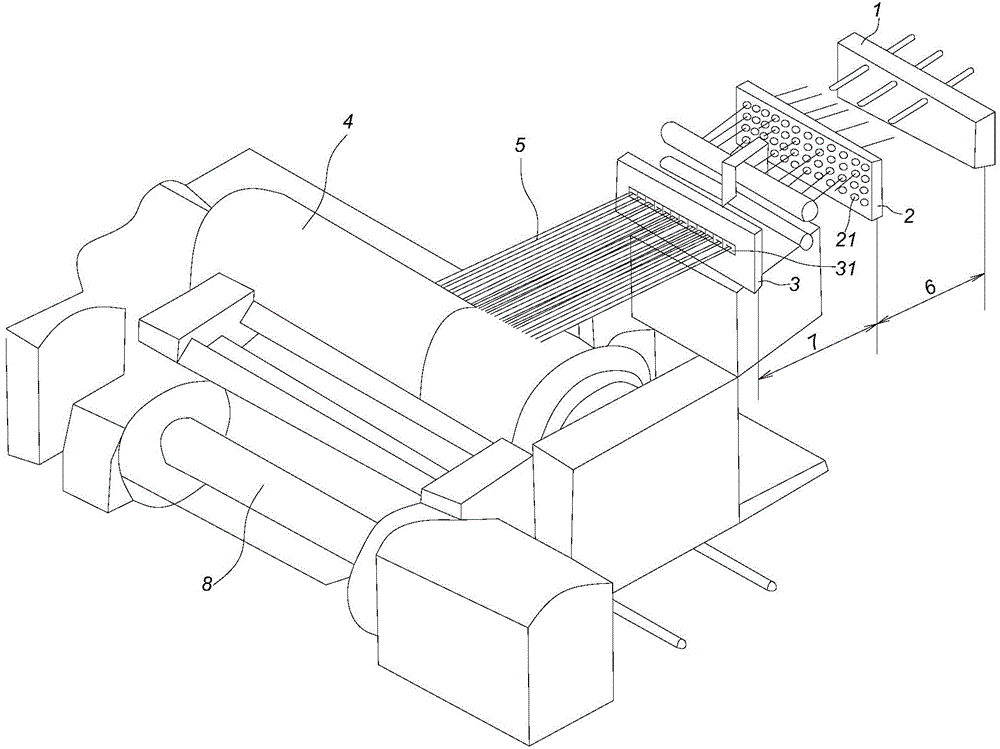

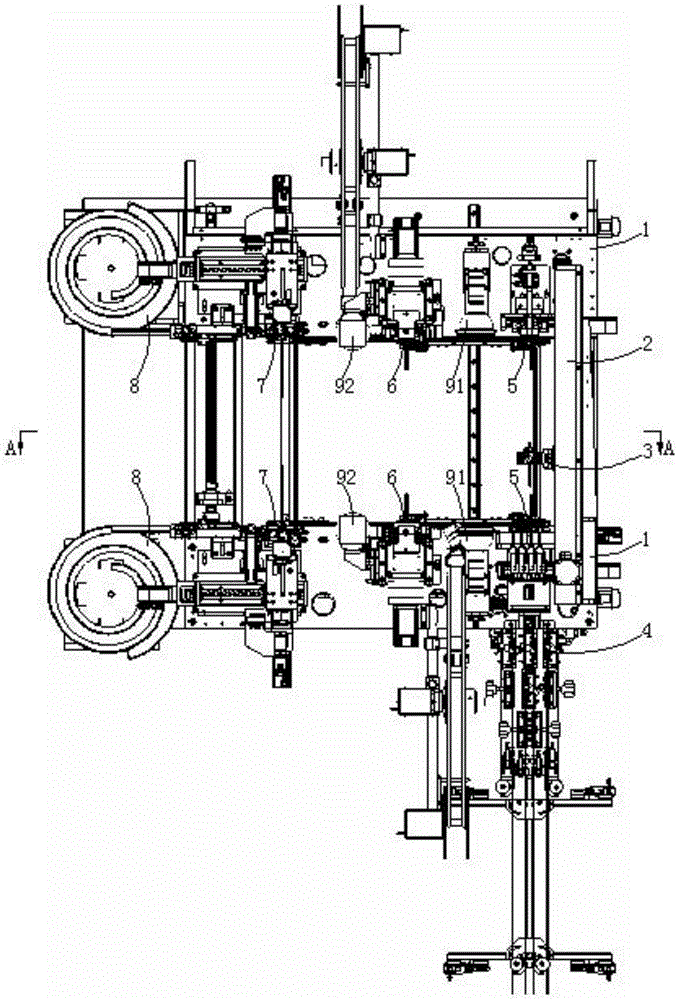

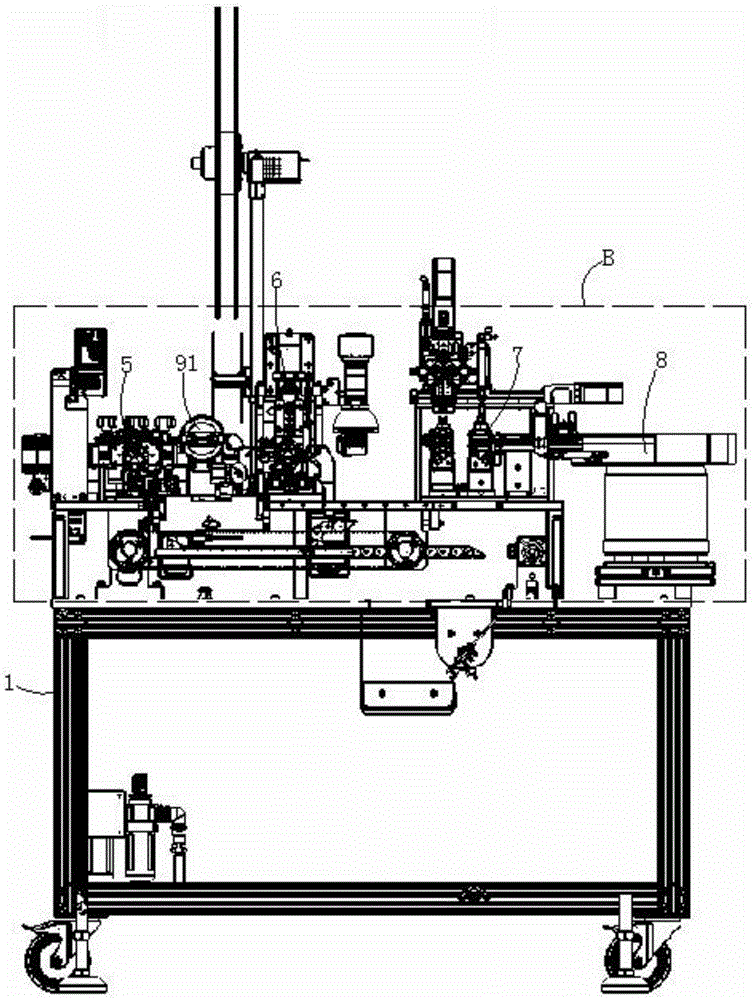

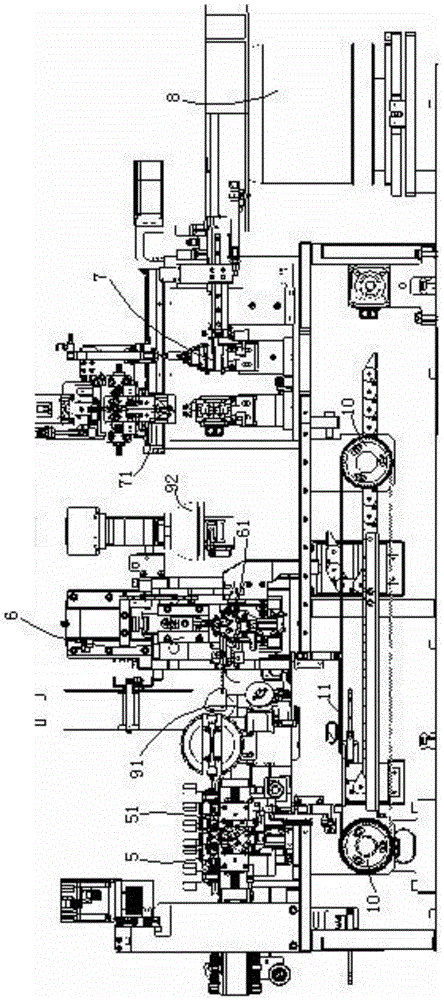

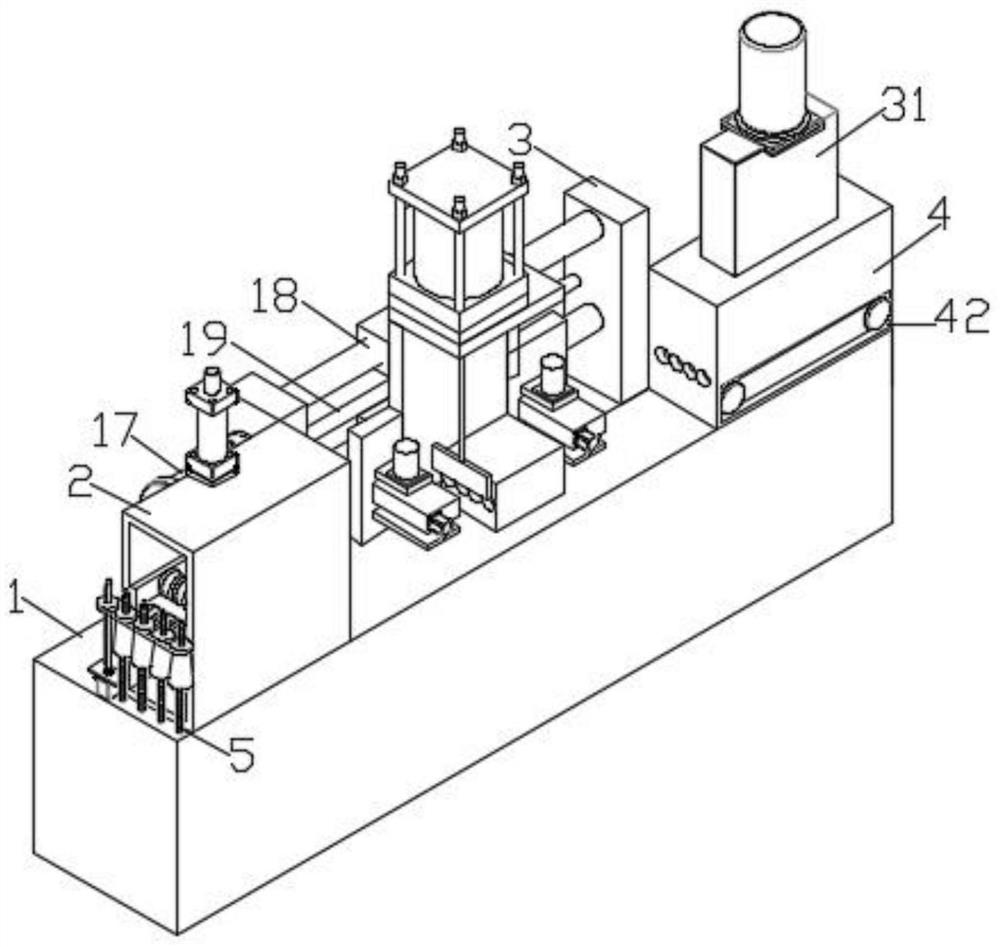

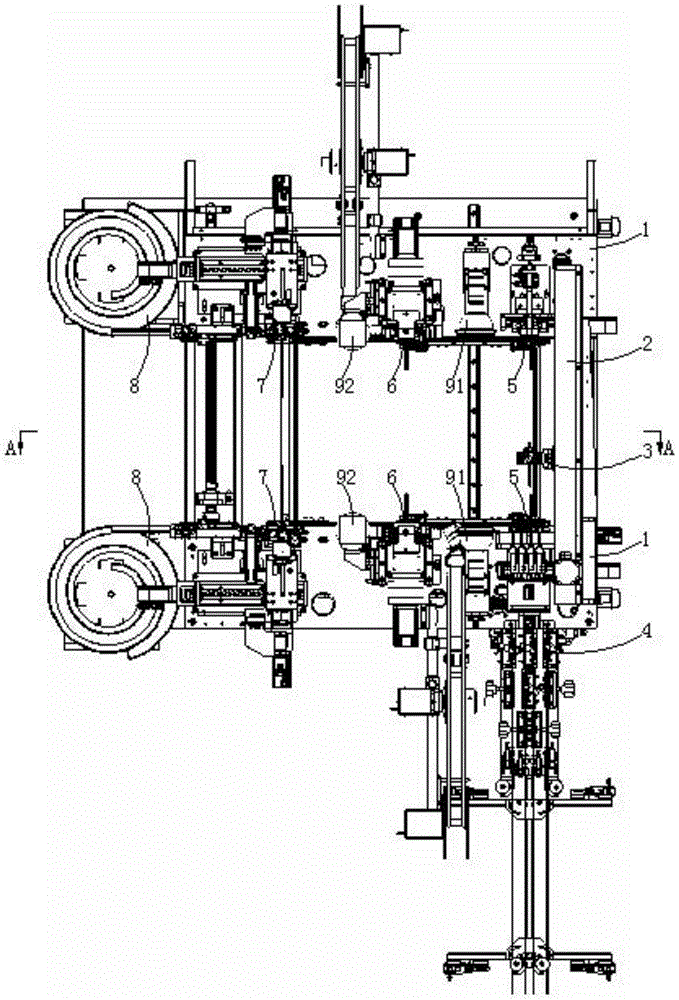

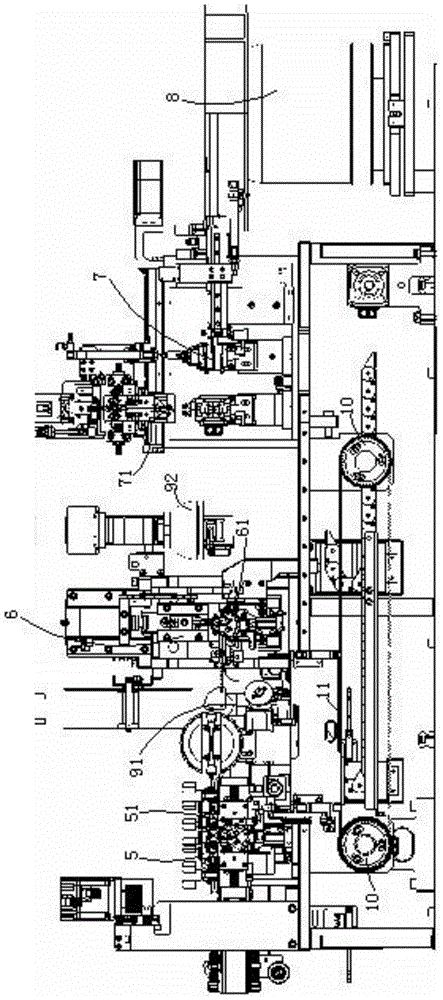

Automatic wire harness making system

ActiveCN104867625AImprove automationOrderly rowsManufacturing wire harnessesVideo monitoringAutomatic control

The invention belongs to the wire harness terminal making and glue cover penetrating technical field, and specifically provides an automatic wire harness making system mainly comprising a frame, a peeling cutting mechanism, a wire terminal making mechanism, and a glue cover plugging mechanism connected in sequence; pulling clamps and convey clamps allow the wires to be fast conveyed and transferred between the mechanisms; the technical effects are that the automatic wire harness making system saves labor, is convenient for automatic control, and high in production efficiency; finished products are tidily arranged, thus preventing wire mutual winding problems caused by free scattering; in addition, a first and a second video monitoring systems can control the terminal plugging quality in a making process, and a monitoring detection result is more objective, accurate and reliable.

Owner:杨志强

Method for improving carbon nano tube parallel array density

ActiveCN103964413ARaise Parallel ArrayOvercoming the problem of not being able to slide directly on the substrateMaterial nanotechnologyCarbon compoundsPolyesterHigh density

The invention discloses a method for improving the density in the process of carbon nano tube transfer. The method comprises the following steps: firstly, transferring the carbon nano tube parallel array growing on a substrate to a retractable membrane capable of shrinking in a single direction, such as the retractable materials of silicone rubber, polyester, a shape memory alloy and the like; secondly, shrinking the membrane in the direction perpendicular to the extension direction of the carbon nano tube to improve the density of the carbon nano tube parallel array; finally, transferring the carbon nano tube parallel array to a target substrate through the adoption of chemical methods. According to the method provided by the invention, the efficiency is high, the cost is low, the high-quality high-density carbon nano tube parallel array can be obtained, and the difficulty of transferring the conventional carbon nano tube can be solved successfully.

Owner:PEKING UNIV

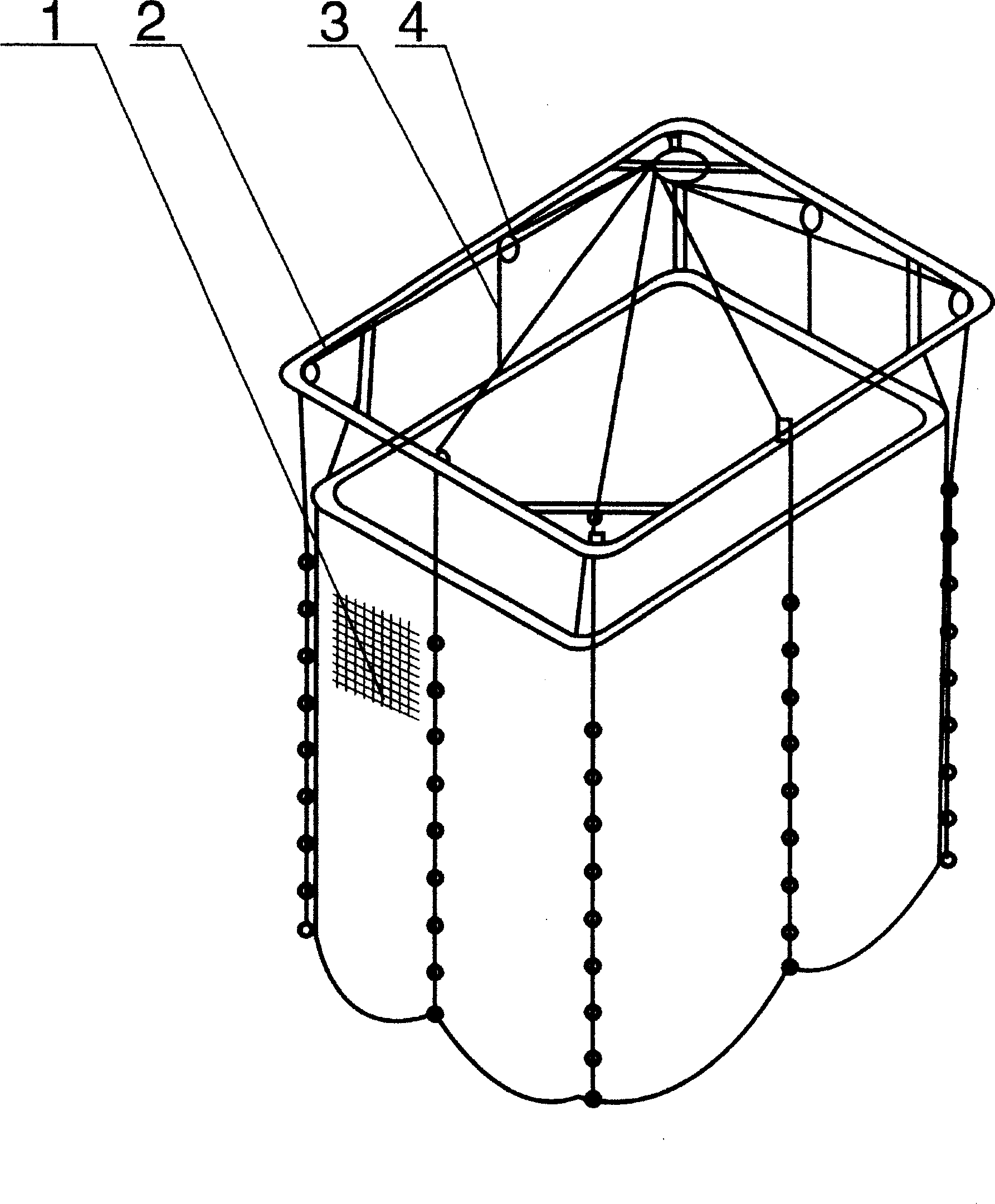

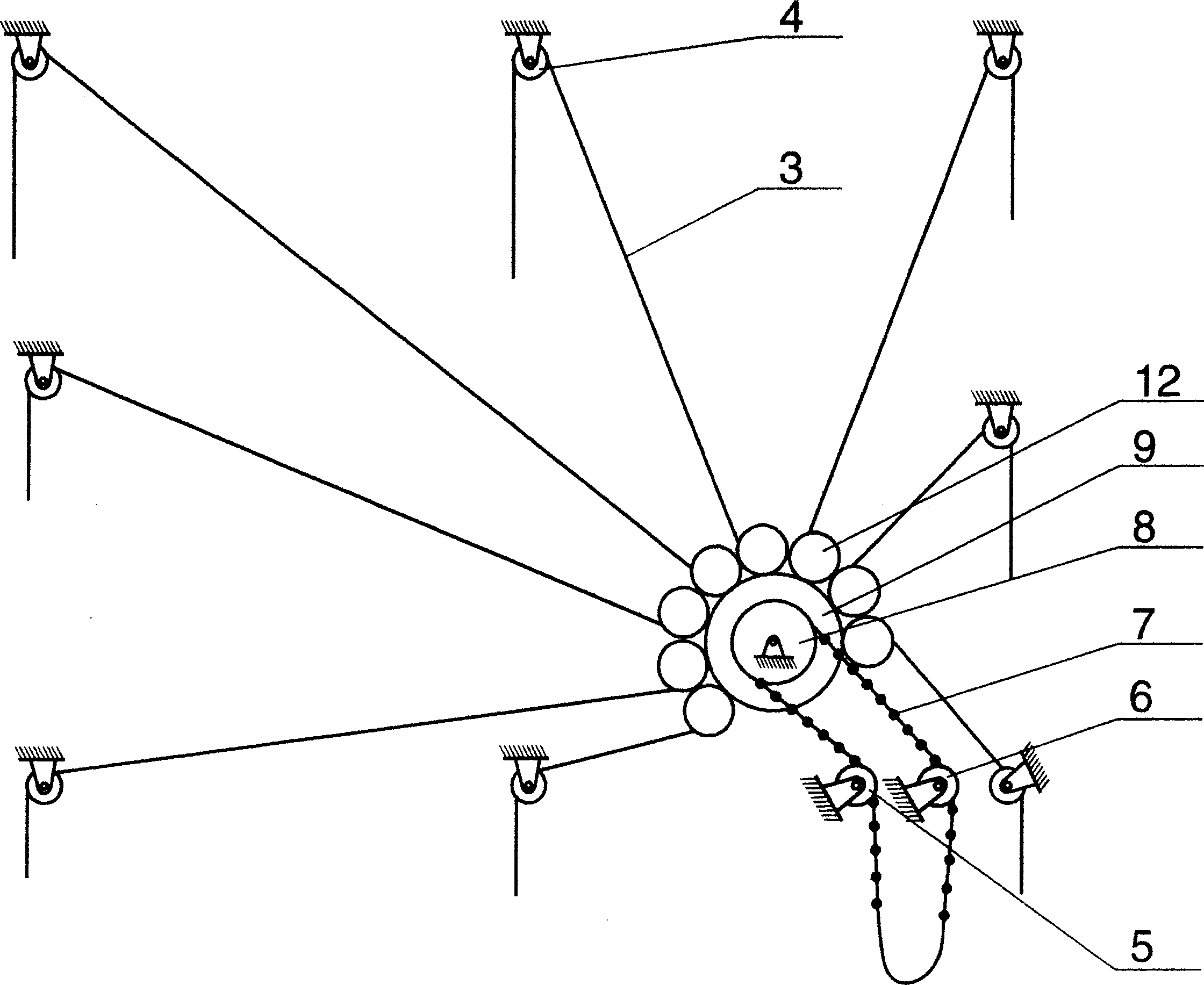

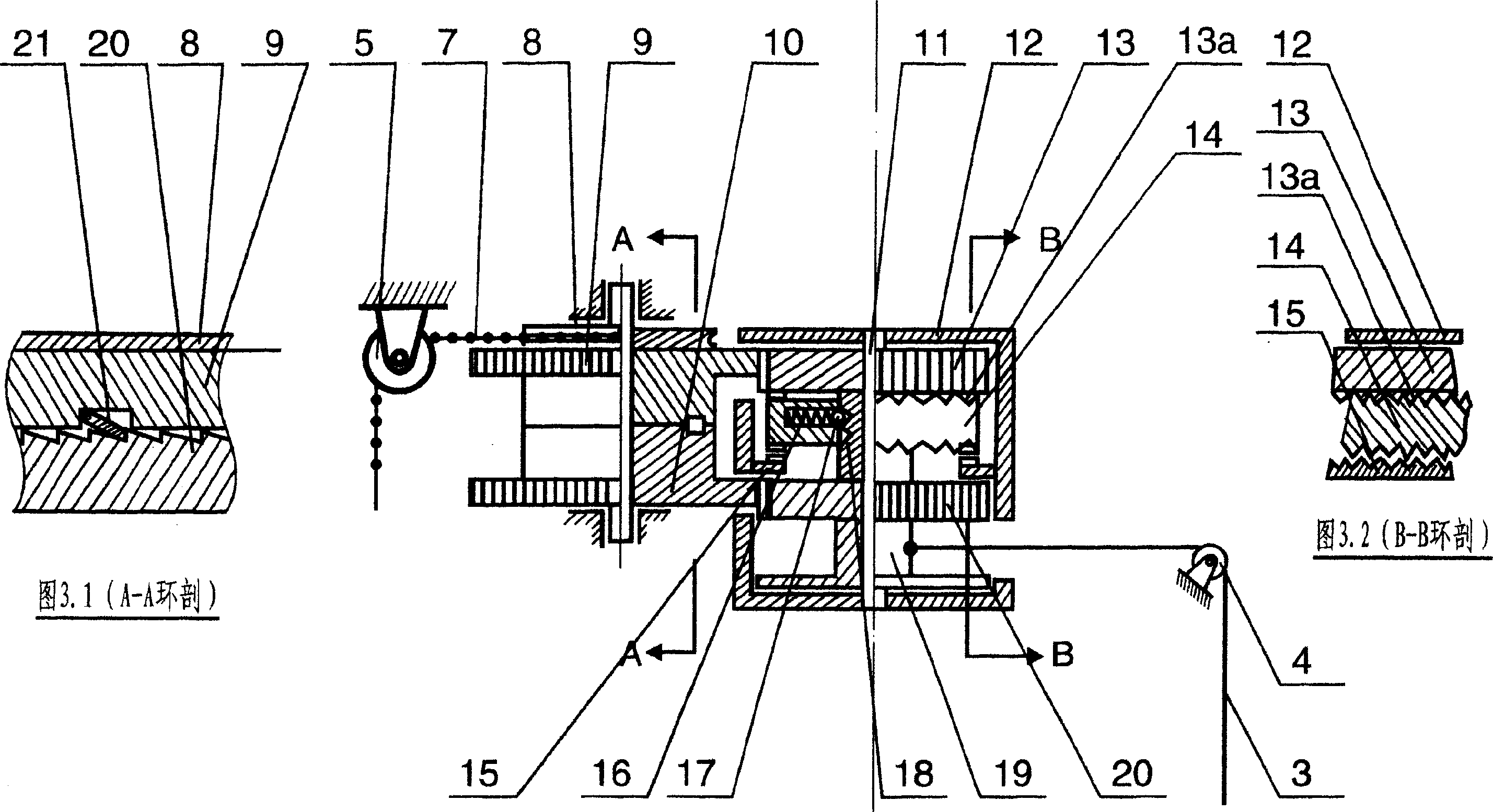

Mosquito net elevator

The mosquito net elevator includes a driver, a driving gear and elevating pulleys in the same number as the drawing points. It features that around the driving gear there are drawing units in the same number as the drawing points. Each drawing unit consists of one casing, one middle shaft, one driven gear, one reel and one piece of elevating rope. It also features that between the driven gear and the reel in each drawing unit there is an overload separator and one brake. The elevator is superior in that each drawing unit is used to draw a piece of rope and thus there is no twisting failure and that the elevator elevates the net in balanced and regular mode.

Owner:邱林

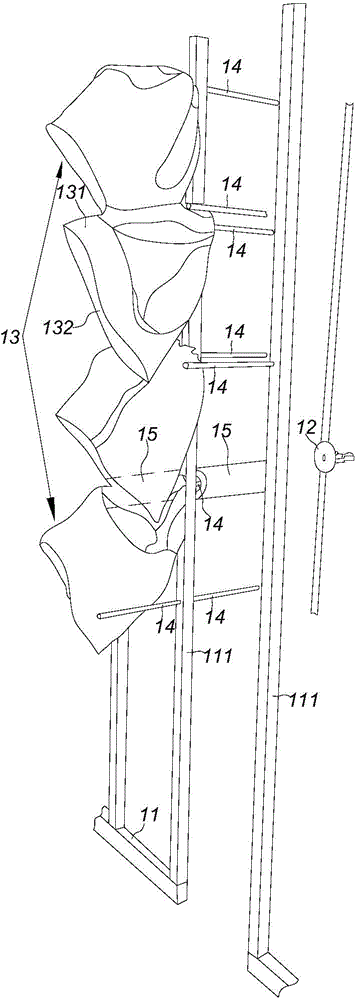

Circular pulling rope type blind

InactiveCN106968583AOpen efficientlyNo intertwiningLight protection screensAgricultural engineeringRolling shutter

Owner:HANGZHOU YOUPU PLASTIC NEW MATERIAL CO LTD

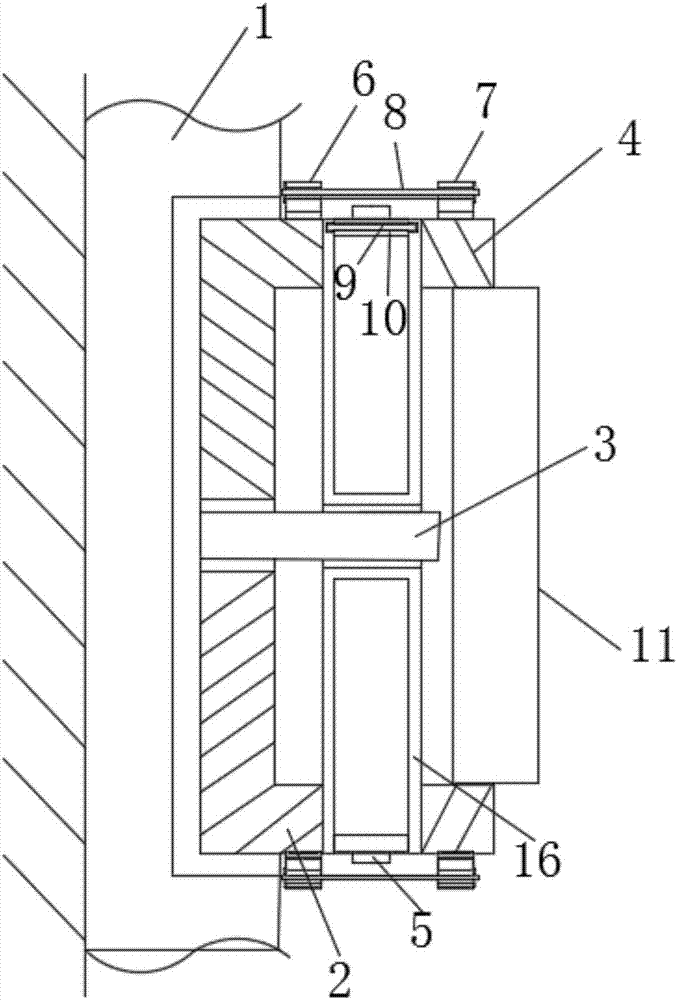

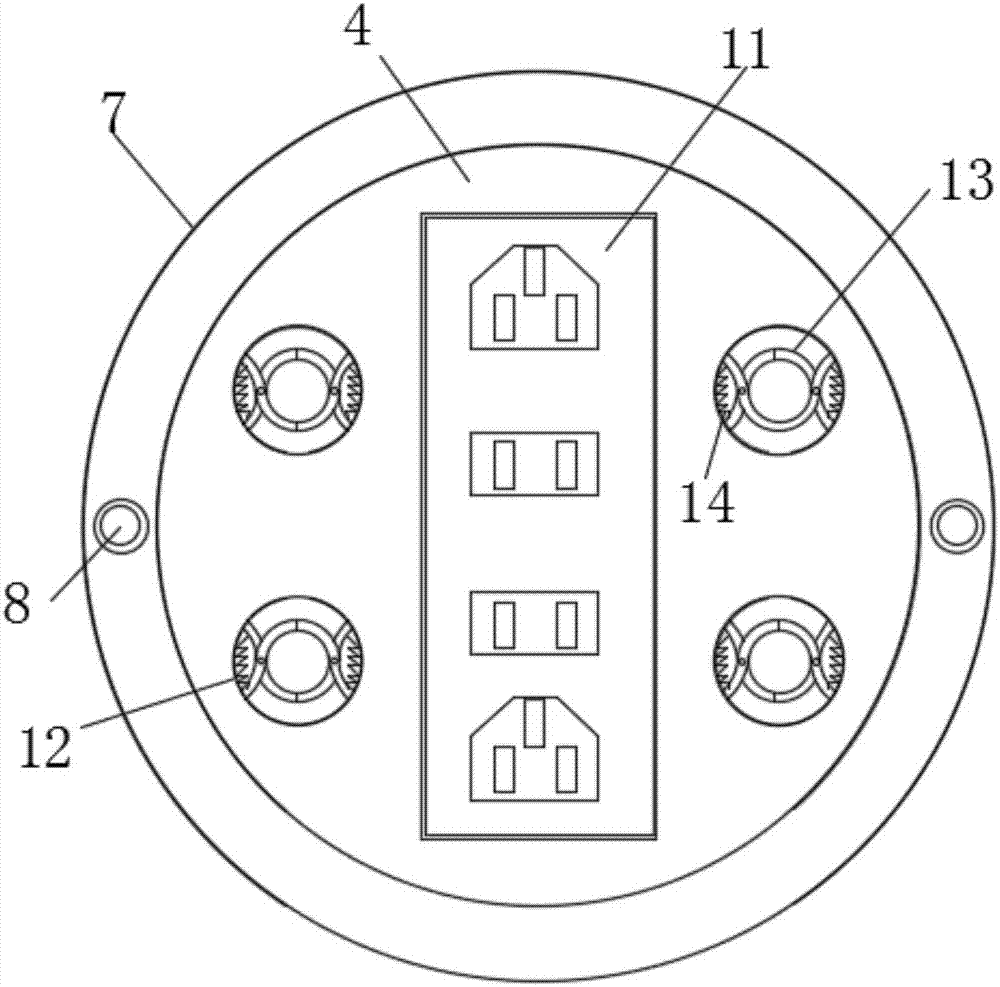

Wall-inserting type patch board with wire end arranging function

InactiveCN107492743AWill not affect the useConvenient ArrangementCouplings bases/casesFlexible lead accommodationEngineering

The invention discloses a wall plug-in type plug-in board capable of arranging thread ends, which includes a wall body, a first groove is arranged on the wall body, and a first mounting seat is plugged into the first groove body, and the first mounting seat is plugged into the first groove body. A first set of disks is fixedly sleeved on a mounting base, and the first set of disks is fixed on the wall through fixing pins. The bottom side of the inner cavity of the first mounting base is fixedly inserted with an insertion shaft, and the insertion shaft is fixed A storage box is sleeved, and the storage box is composed of two chassis and two concentric rings of different sizes. The outer ring of the small ring is provided with a partition groove, and the partition groove is detachably inserted with a partition. The number of partitions is not less than 4. In the present invention, by fixing the plug-in board on the installation board inserted into the wall, under the pulling and moving of many connecting ends, the position will not be moved indiscriminately, and the use of the plug-in board will not be affected; The limit port is convenient for arranging and arranging many connecting ends along the two sides and the top in order, and various connecting lines will not be intertwined.

Owner:刘悦

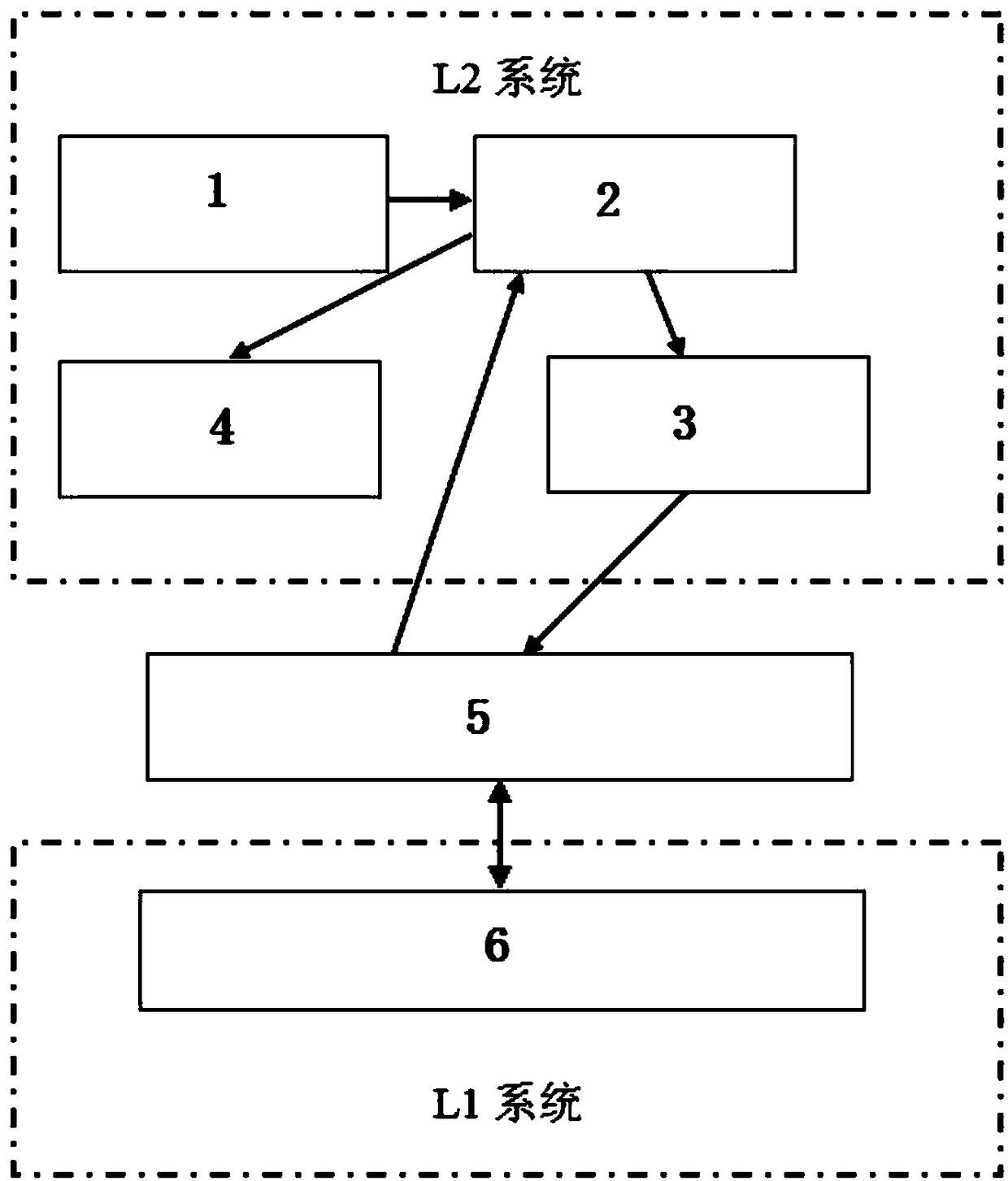

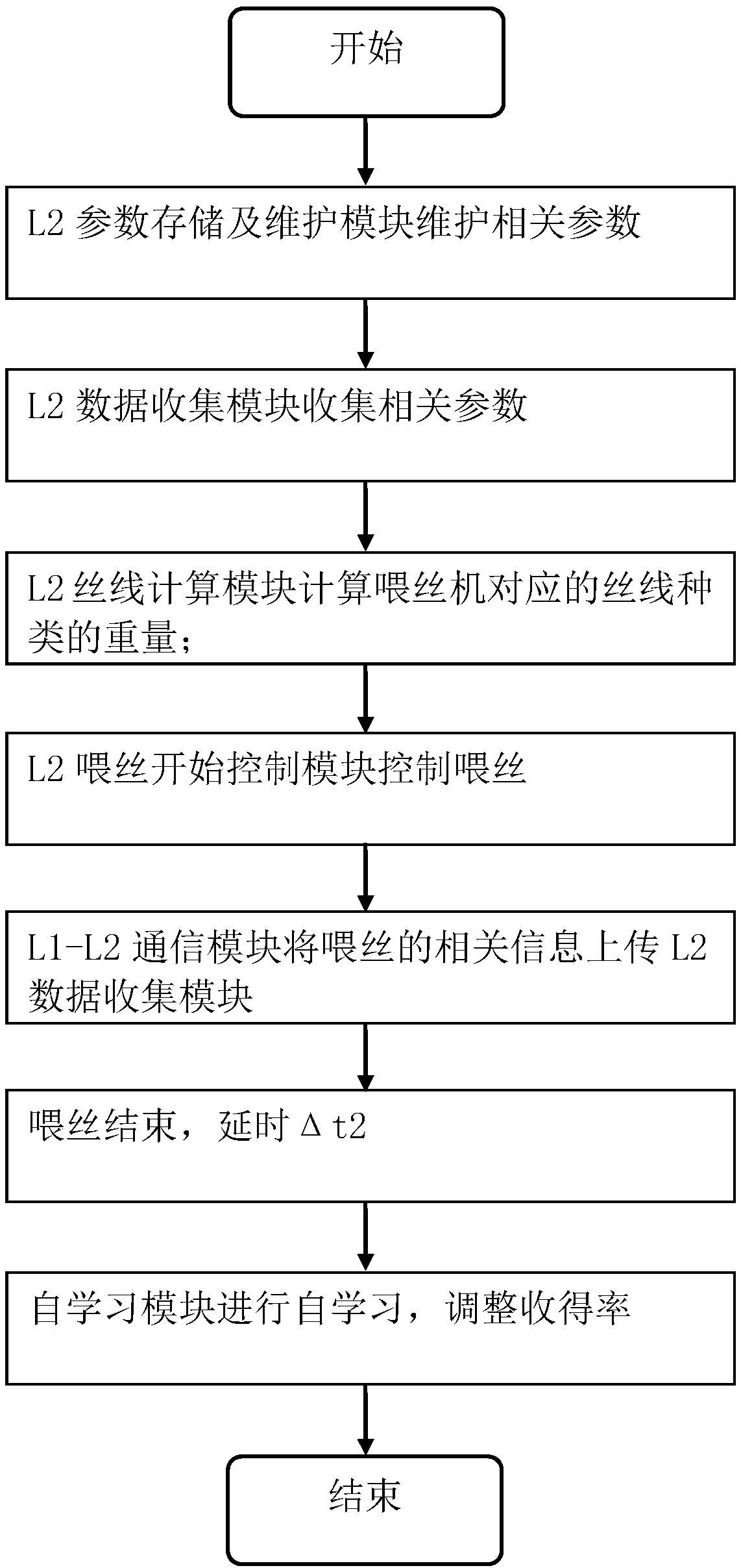

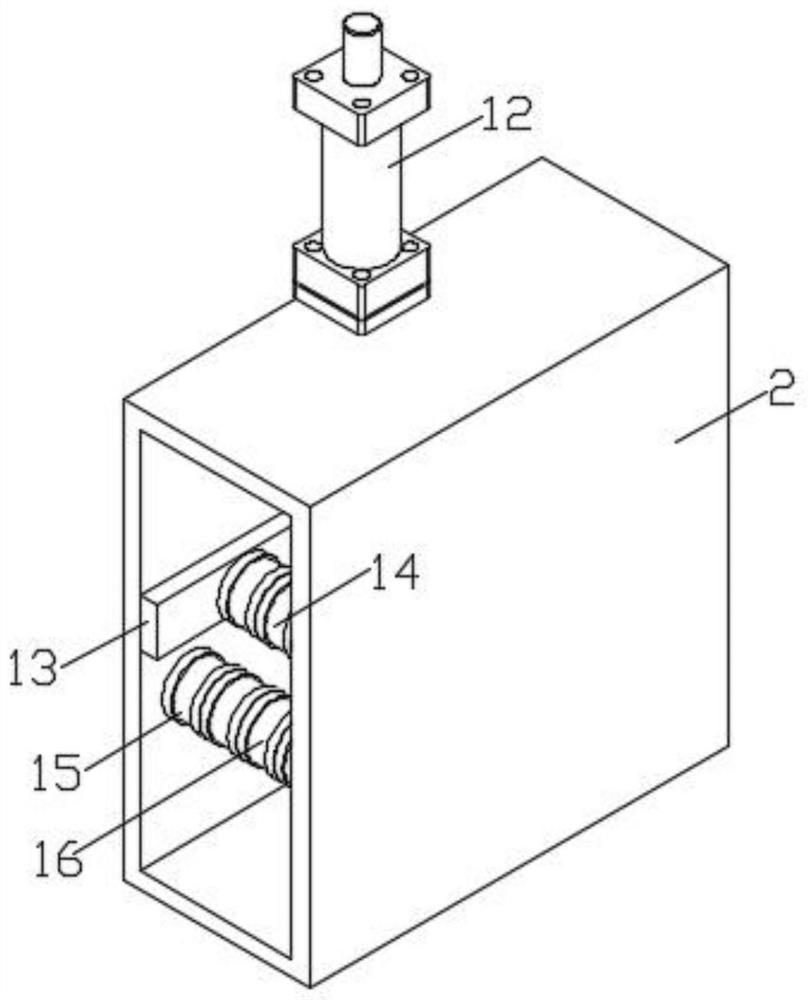

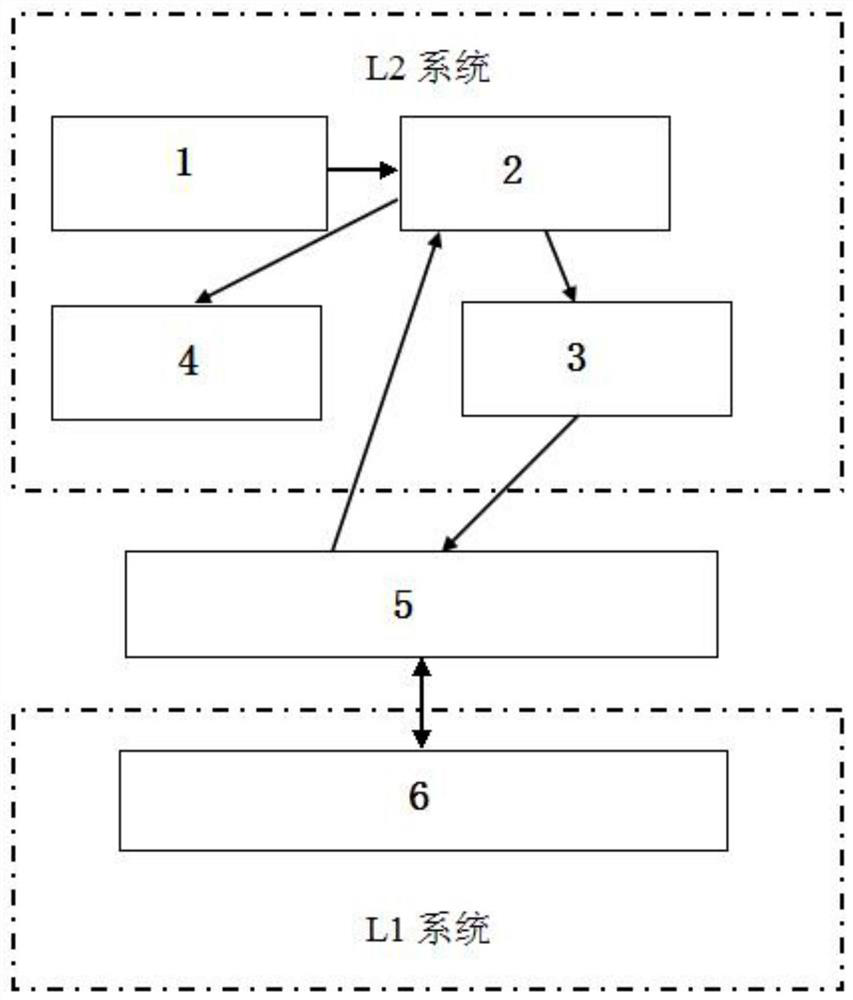

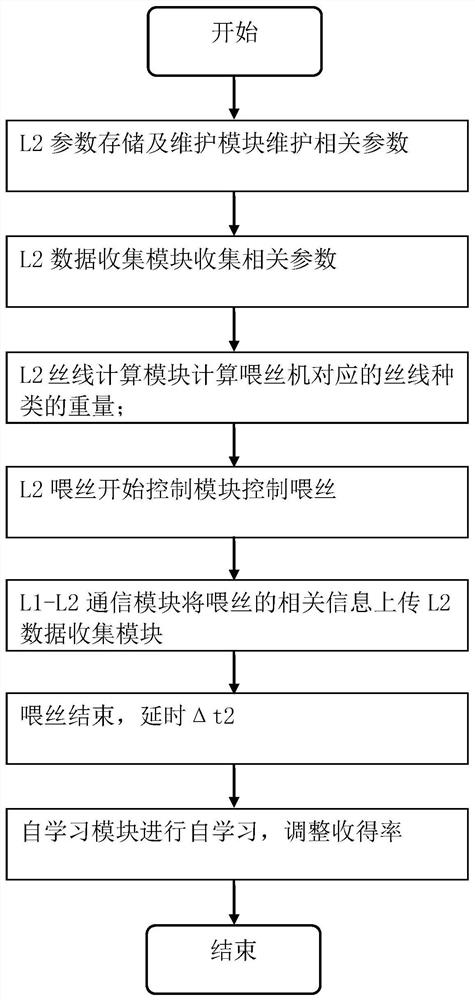

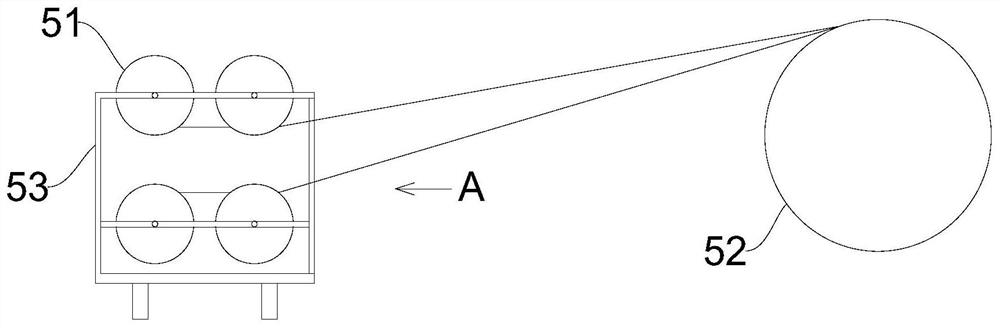

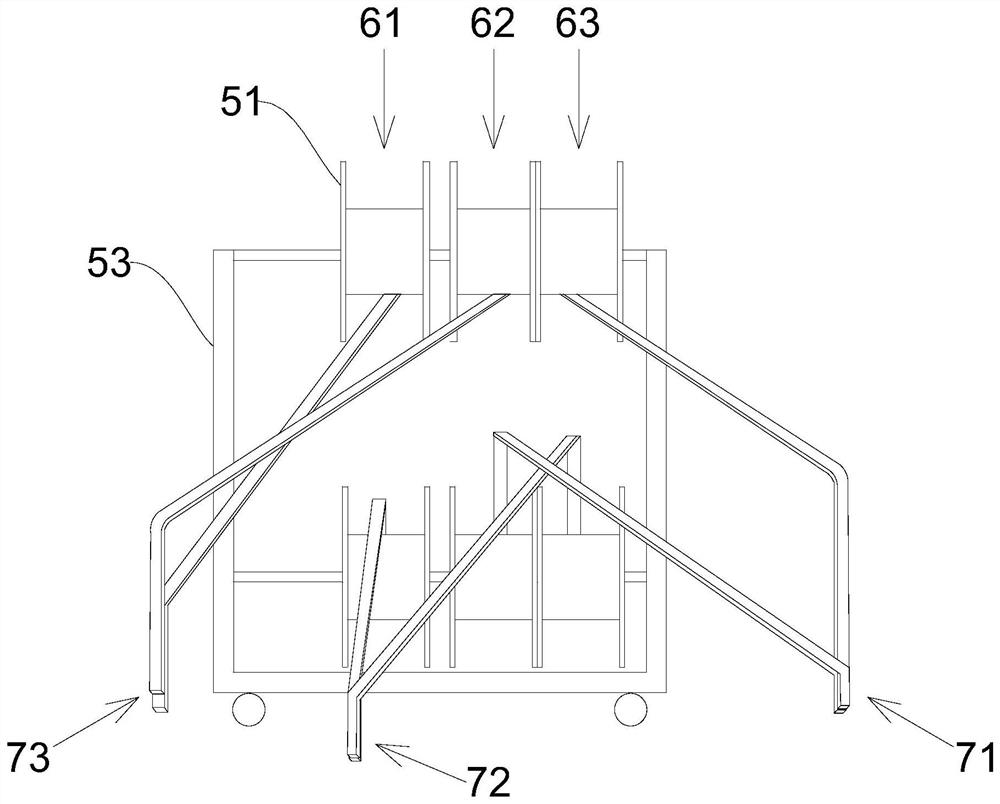

Intelligent control system for secondary feeding machine for ladle refining furnace

ActiveCN109283881ANo intertwiningAffect qualityIncreasing energy efficiencyProgramme control in sequence/logic controllersComputer moduleMolten steel

The invention relates to an intelligent control system for a secondary feeding machine for a ladle refining furnace. The intelligent control system comprises an L2 parameter storage and maintenance module, an L2 data collection module, an L2 thread yield self-learning module, an L2 thread calculation module, an L1-L2 communication module and an L1 PLC control module. According to the invention, the technique of automatically calculating thread types and lengths is employed. On the basis of the initial composition and target composition requirements of molten steel, the needed thread types andlengths are calculated automatically, so that the error caused by manual calculation is avoided and thus the control precision is improved. Moreover, no manual computation is needed, so that the manual labor intensity is reduced.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

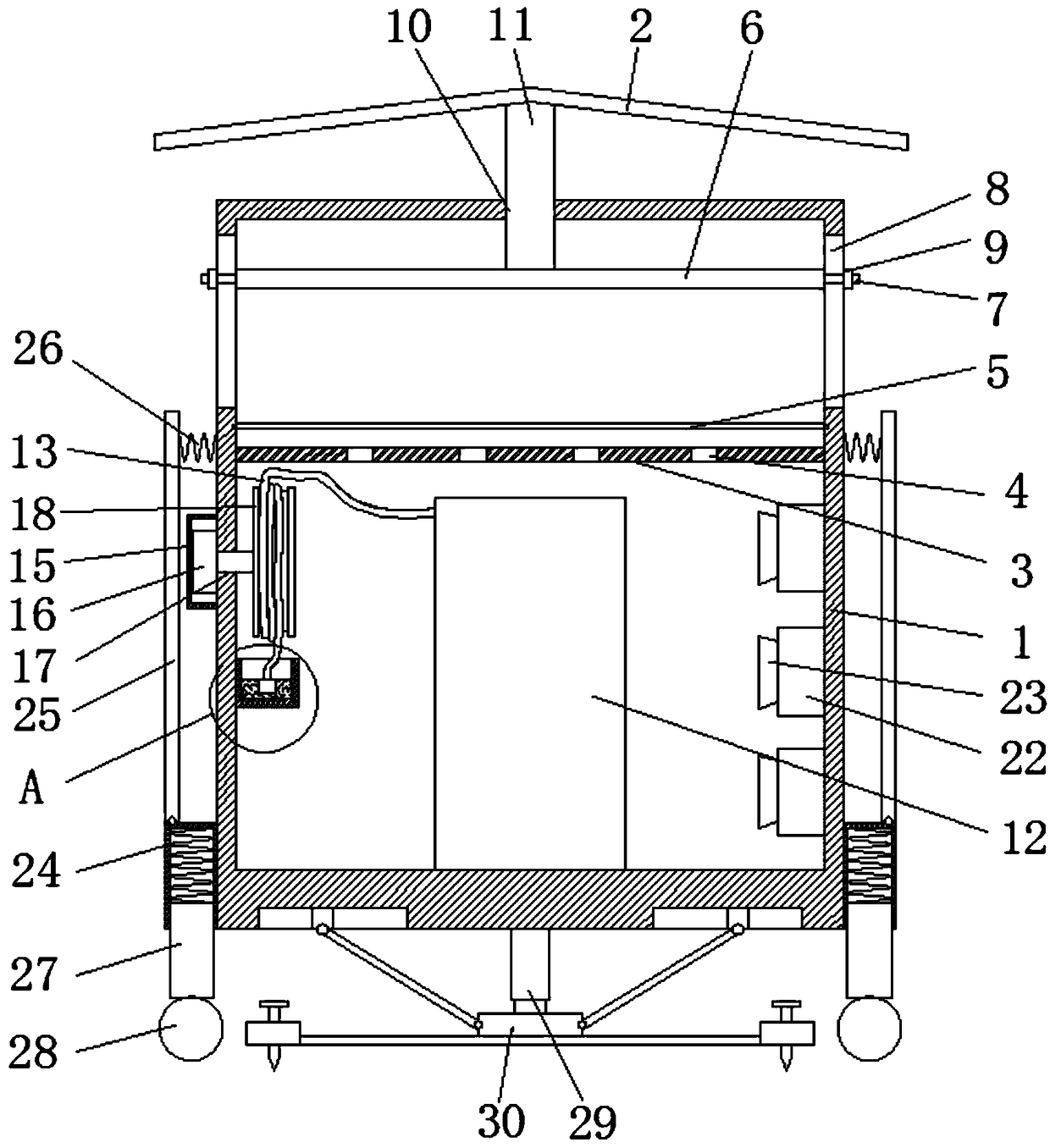

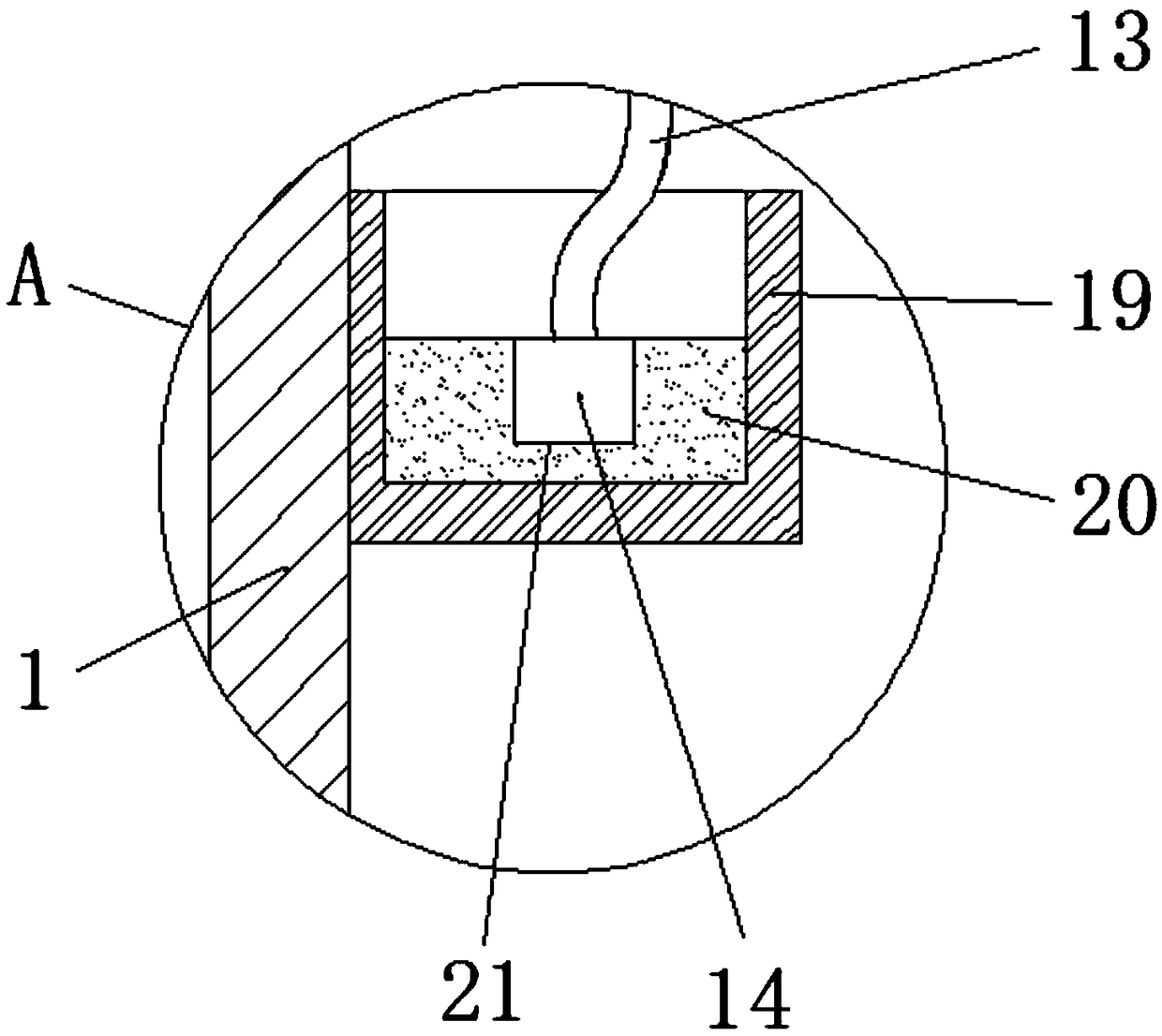

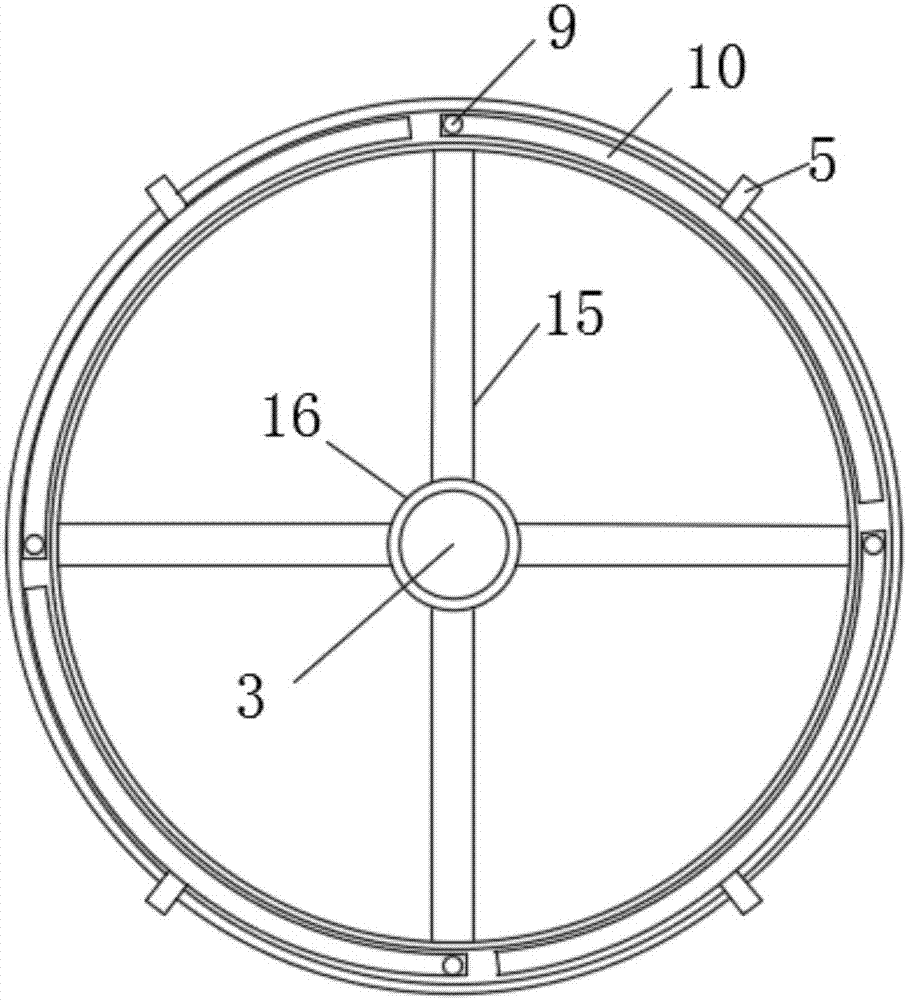

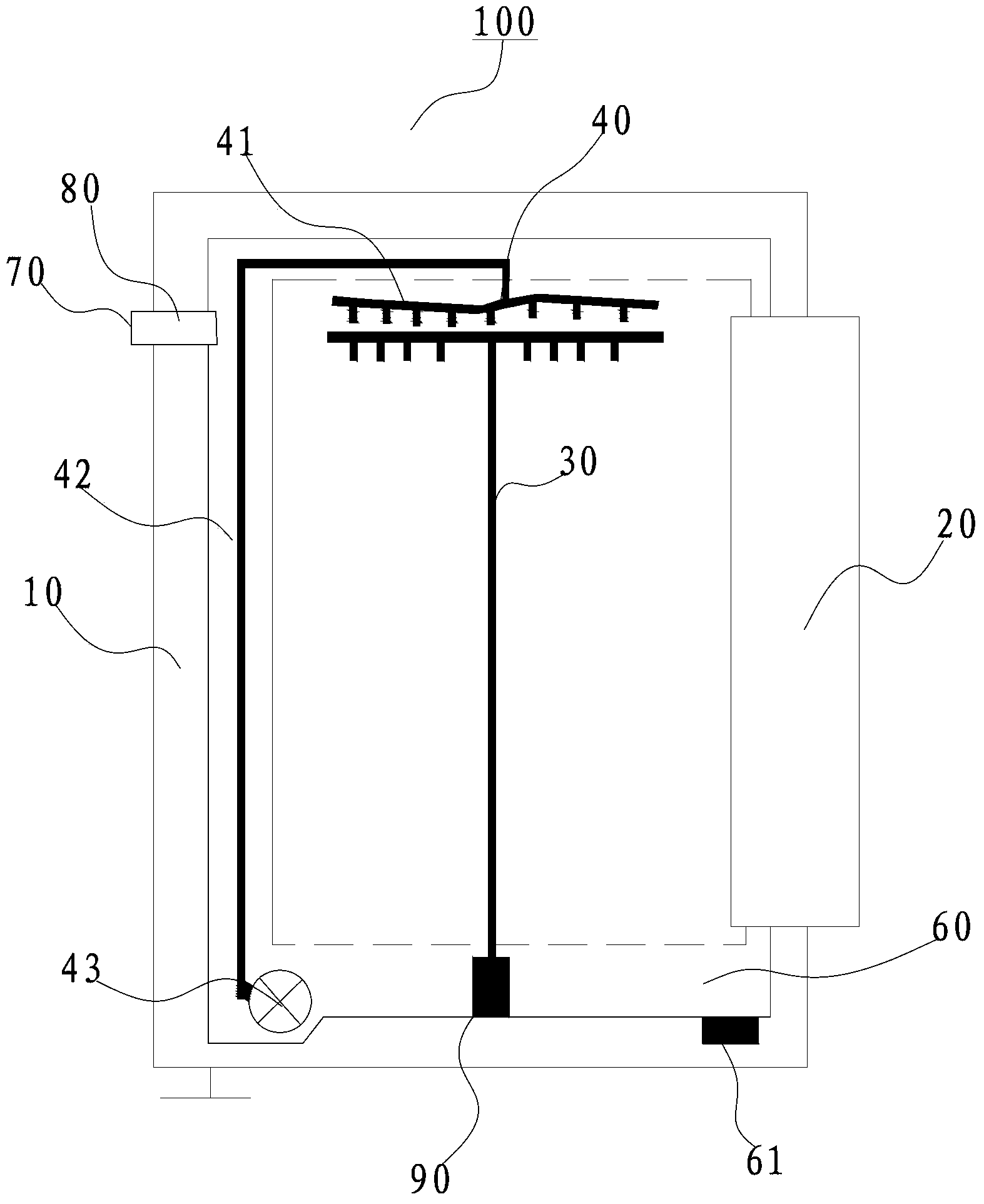

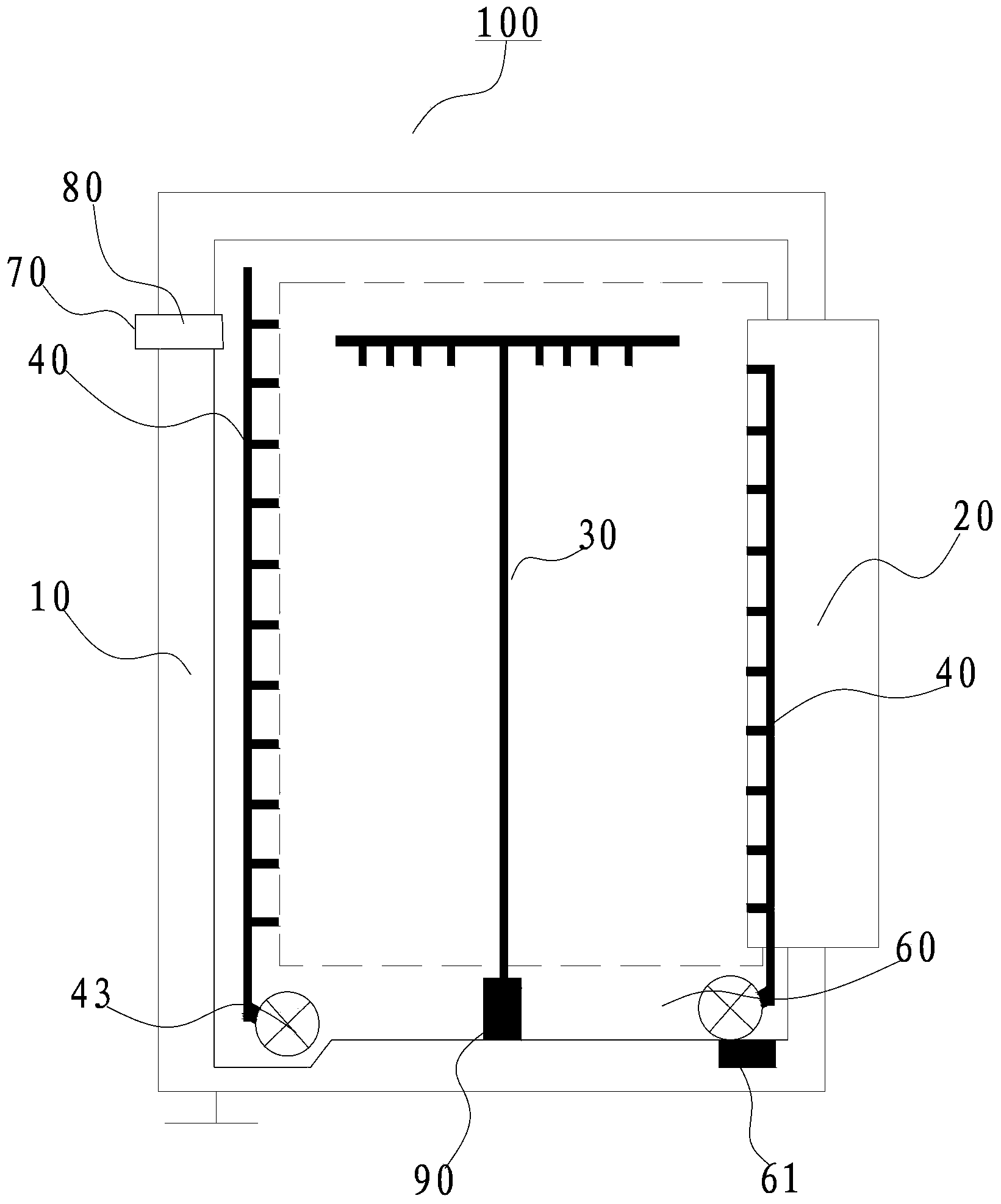

Washing machine

InactiveCN103485115AReduce wearNo intertwiningWashing machine with receptaclesTextiles and paperLaundry washing machineEngineering

The invention discloses a washing machine, comprising a box body, a door body, a clothes placing device and a sprinkling device, wherein the box body is provided with an inner cavity, the door body is connected with the box body for opening or closing the inner cavity, the clothes placing device is arranged in the box body, clothes are arranged on the clothes placing device in a relative rest manner, the sprinkling device is used for absorbing water stored in the box body and sprinkling the clothes placing device with the absorbed water, and the sprinkled water is absorbed by the sprinkling device again, so that the water stored in the box body can be used for cyclically sprinkling. According to the washing machine disclosed by the invention, the clothes in the clothes placing device are washed in a high-speed sprinkling manner, the phenomena of involvement and rubbing generated in the washing process of the washed clothes are avoided, and the wear to the clothes in the clothes washing process can be reduced.

Owner:WUXI LITTLE SWAN CO LTD

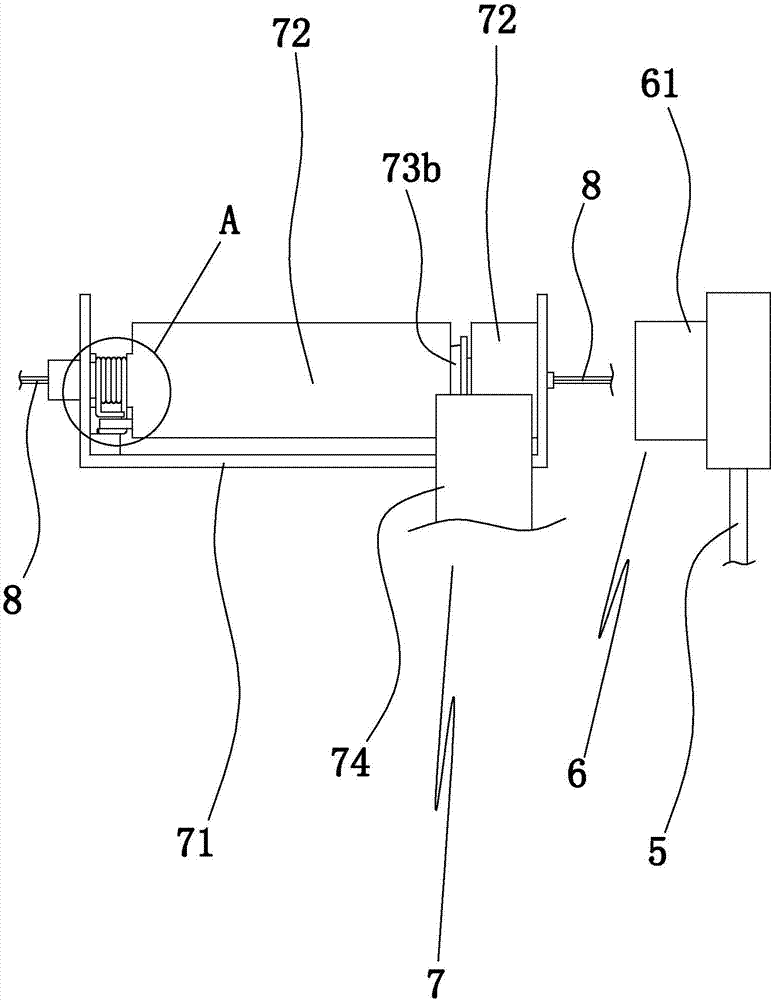

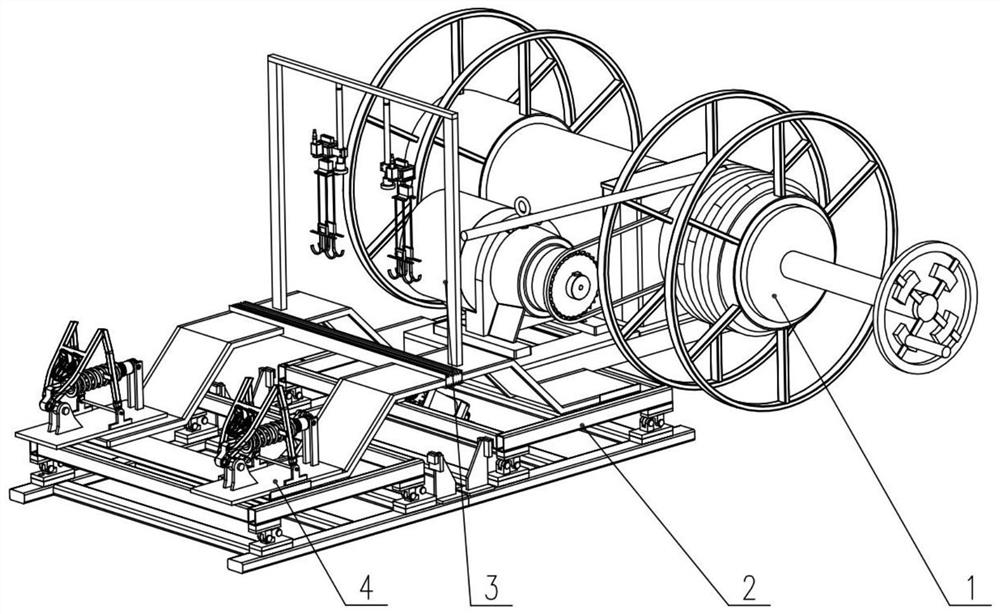

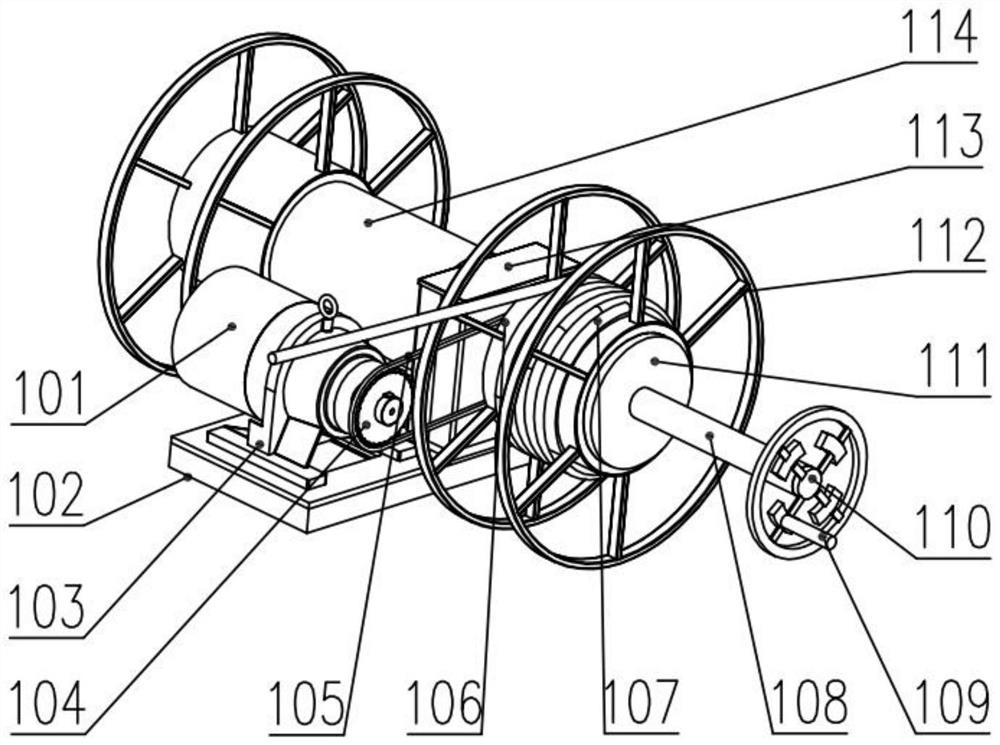

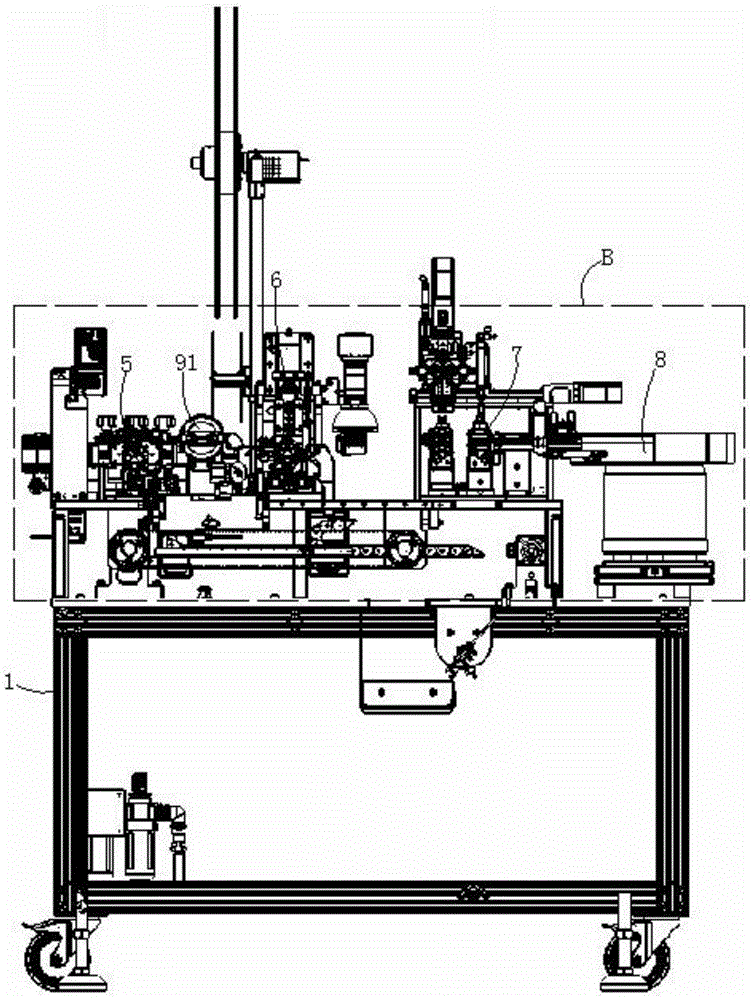

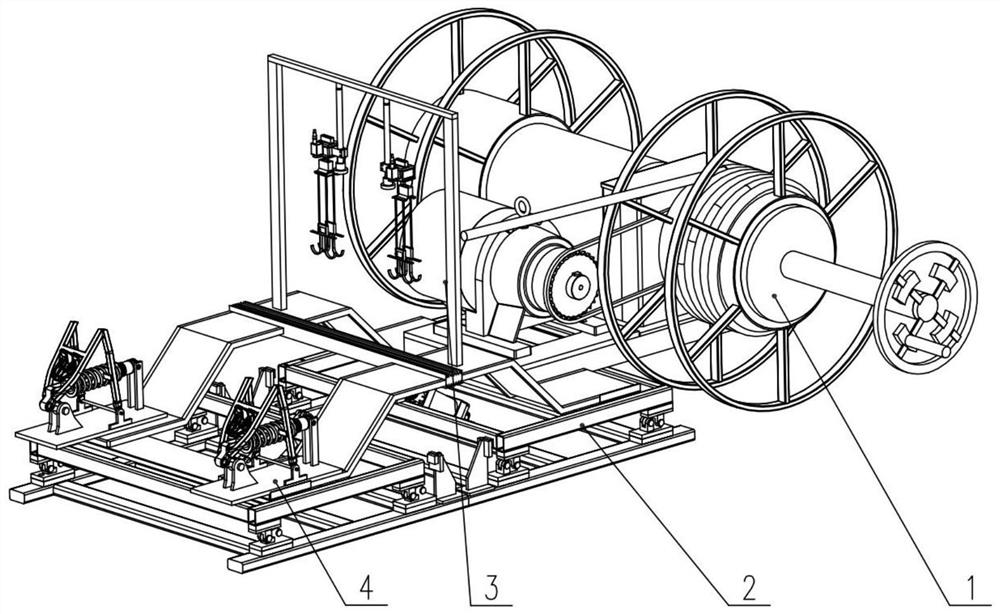

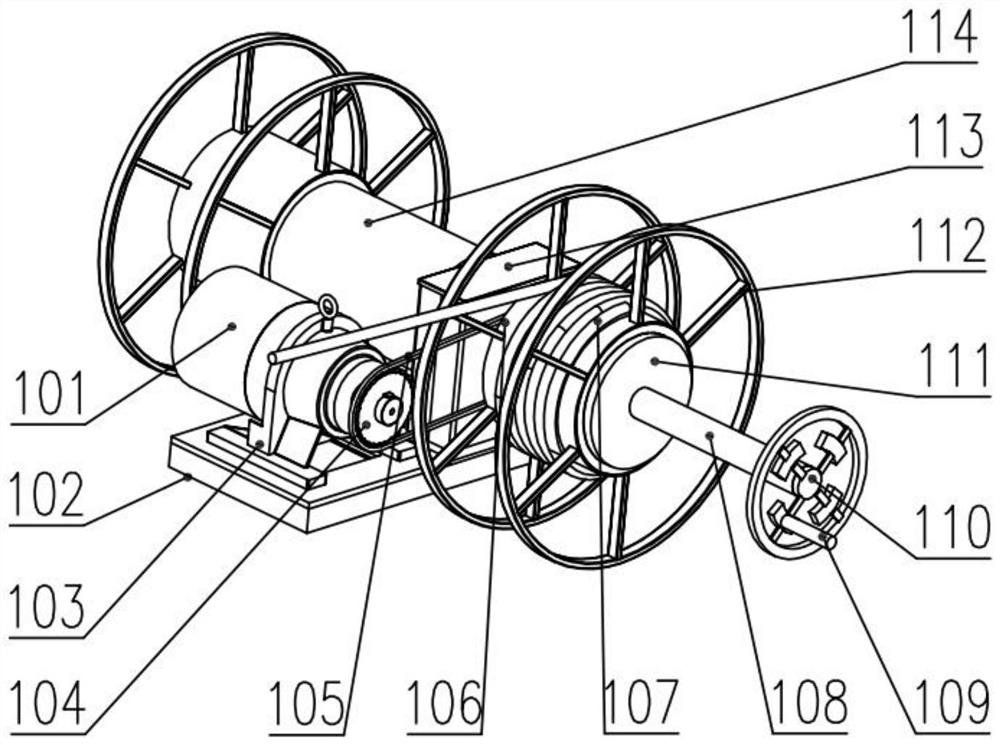

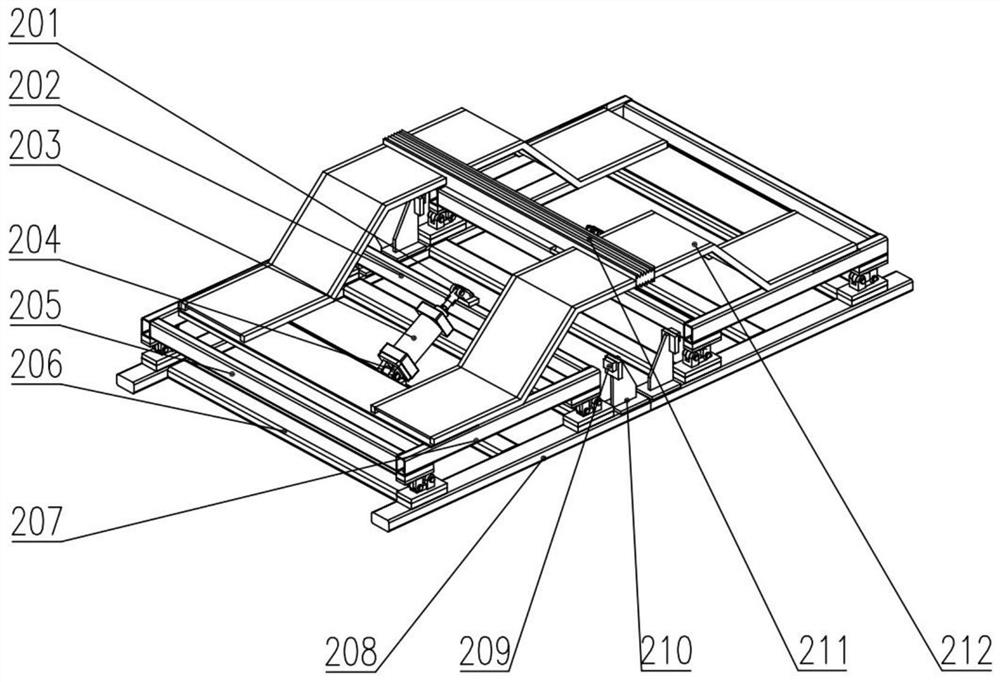

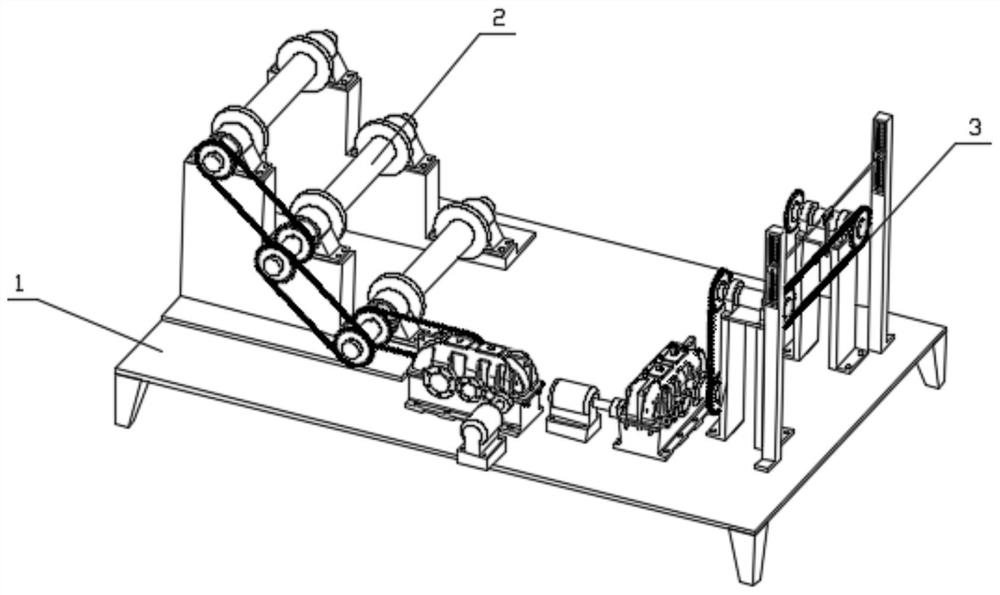

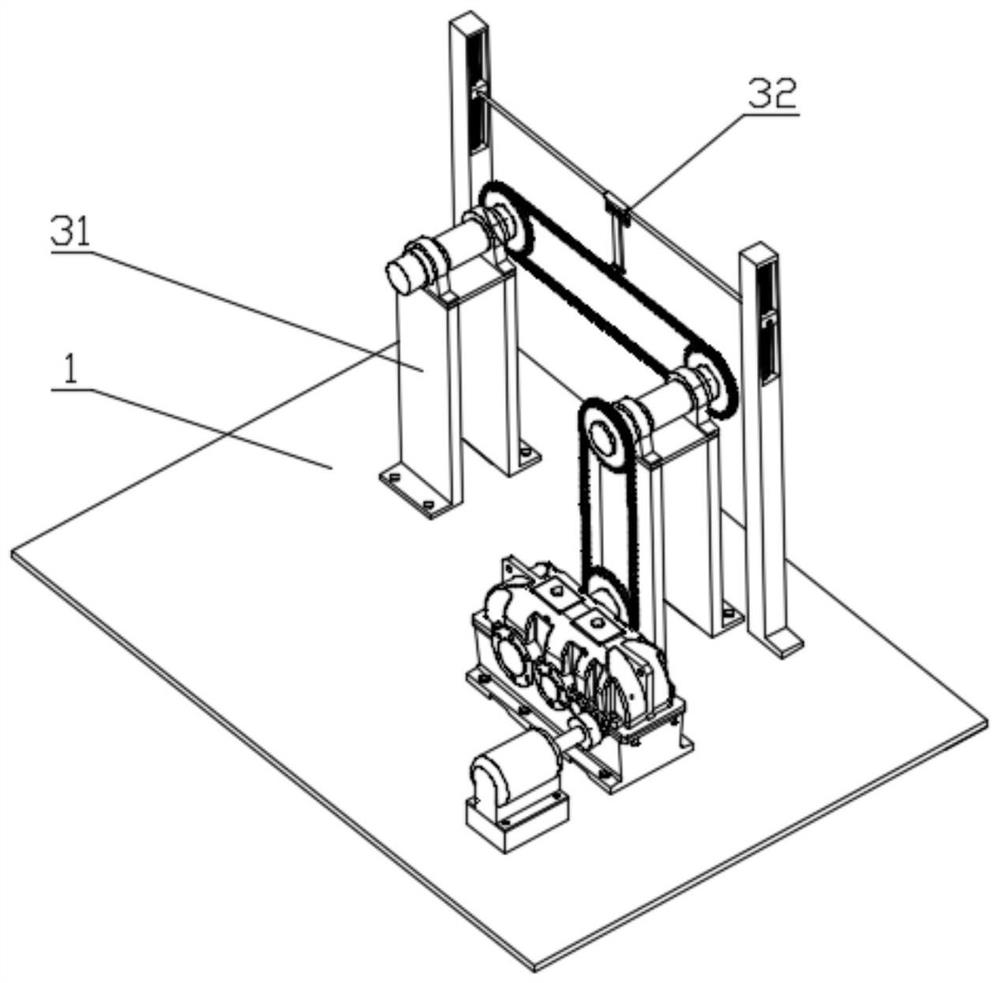

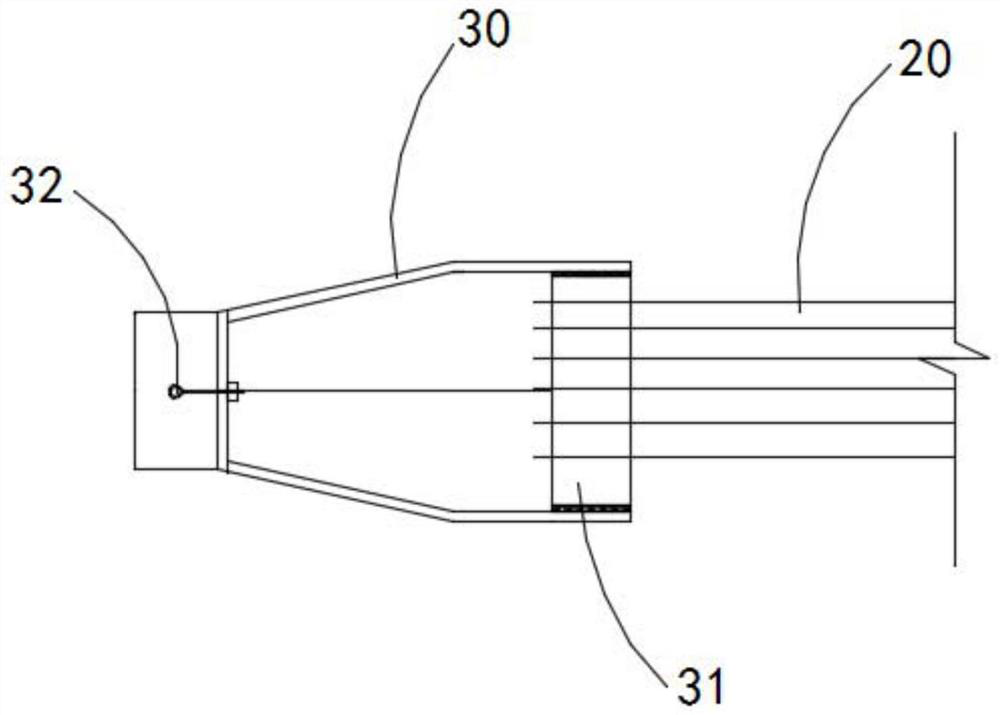

Auxiliary cable mounting equipment for power transmission network

ActiveCN113422321APay-off installation is normalScientific and reasonable designVibration suppression adjustmentsApparatus for overhead lines/cablesCrankElectric machinery

The invention discloses auxiliary cable mounting equipment for a power transmission network, which relates to the field of engineering machinery. The equipment comprises a winding device, adjusting underframes, a branching device and a caliper device. The small belt wheel, the belt and the large belt wheel are driven by the motor on the winding device to carry out transmission, the winding wheel is driven to rotate, cable take-up and pay-off work is performed, and if a circuit breaks down, the operation can be achieved by manually rotating the hand wheel. When the cable is tightened too tightly, the oil cylinders on the two symmetrically-installed adjusting underframes drive the two underframes to adjust the relative positions around the cranks, and organ damping is used for guaranteeing the stability of the structure. The left position and the right position are judged through the positioning sensor on the branching device, the signal receiver is used for receiving signals, and the cable can be divided into four paths to be separated from different supporting hooks so that winding is avoided. The cable is locked and loosened through calipers on the caliper device, and a hydro-pneumatic spring is mainly used for reducing vibration to equipment when the cable is tightened and rebounds.

Owner:兴化市永安电力工具有限公司

Cutting device for steel strand machining and working method thereof

PendingCN112589010AConsistent pay-off heightPrevent large drop in pay-off heightScrew threadMachining

The invention discloses a cutting device for steel strand machining and a working method thereof. The cutting device for steel strand machining comprises a machining table, a guide chamber and a leading-out chamber are installed on the machining table, two side columns are arranged between the guide chamber and the leading-out chamber, a plurality of fixing screws are arranged on one side of the guide chamber, the fixing screws are sleeved with pulleys II in a threaded mode, winding drums are installed on the pulleys II, the winding drums are used for winding steel strands. A plurality of steel strands can be unreeled at the same time, meanwhile, the winding drums can automatically ascend while unreeling is conducted, due to the fact that the steel strands are wound on the winding drums, it is guaranteed that the pay-off height of the winding drums can be kept consistent with that of a lower limiting rod, and the situation that the drop between the pay-off height of the winding drums and the pay-off height of the lower limiting rod is large is prevented; and through the design of two limiting belts, the situation that the steel strands rebound when cut off can be prevented, and meanwhile, the steel strands can be continuously conveyed after being cut off.

Owner:AOSHENG MAANSHAN STEEL WIRE & WIRE ROPE

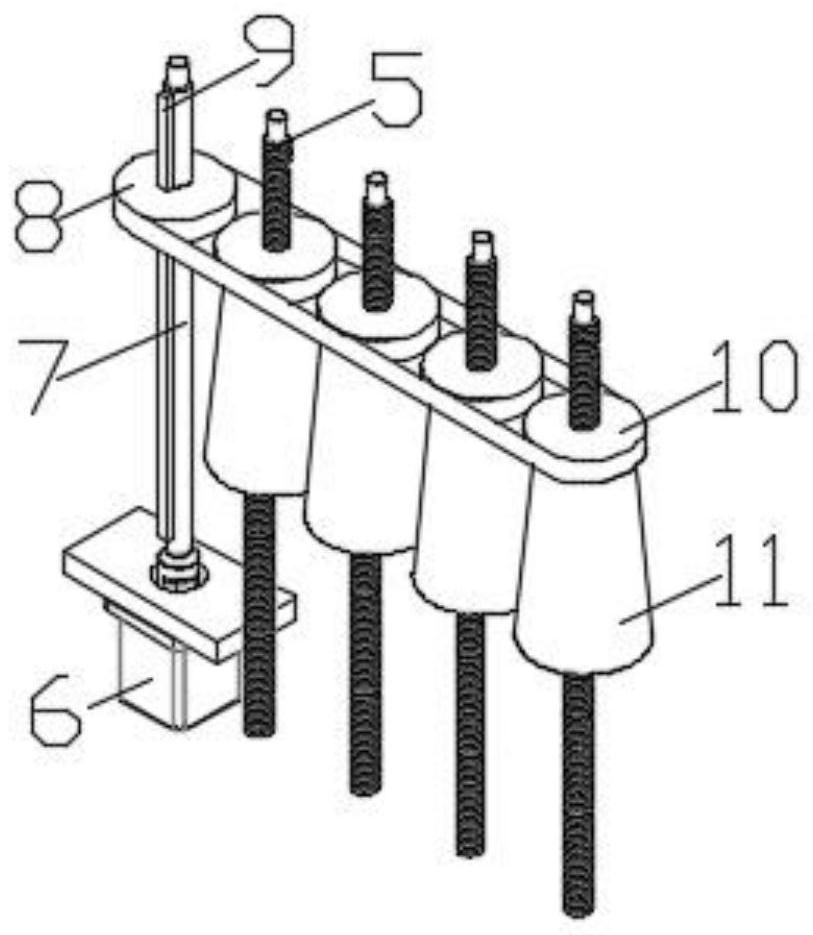

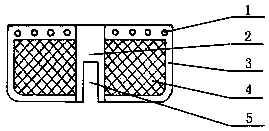

Yarn guiding device

The invention relates to textile machinery components, particularly to a yarn guiding device, which comprises an upper fixed plate and a lower fixed plate arranged in parallel, wherein center holes are both formed in the centers of the upper fixed plate and the lower fixed plate; more than three upper edge holes and lower edge holes are formed on the upper fixed plate and the lower fixed plate; a distance from the upper center hole to the upper edge holes on the upper fixed plate is larger than that from the lower center hole to the lower edge holes on the lower fixed plate; and yarn guides are arranged in the upper and lower center holes and the upper and lower edge holes. The yarn guiding device has the advantages that the structure is simple, silk yarns can be threaded conveniently, and compound yarn ballooning check twisting points can be directly formed on silk outlets of thermotropic silk and multistrand sewing threads. The yarn guiding device can precisely cover thermotropic silk quilt covers among the multistrand sewing threads, and therefore, the yarn guiding device solves the technical problems that in the prior art, the thermotropic silk quilt covers can not be covered among the ultistrand sewing threads precisely, the silk outlets can not directly form the compound yarn ballooning check twisting points, assembled structures are complex, the operation is difficult, and raw material and labor force are wasted, so that finished products of the yarns have poor quality.

Owner:单水甫

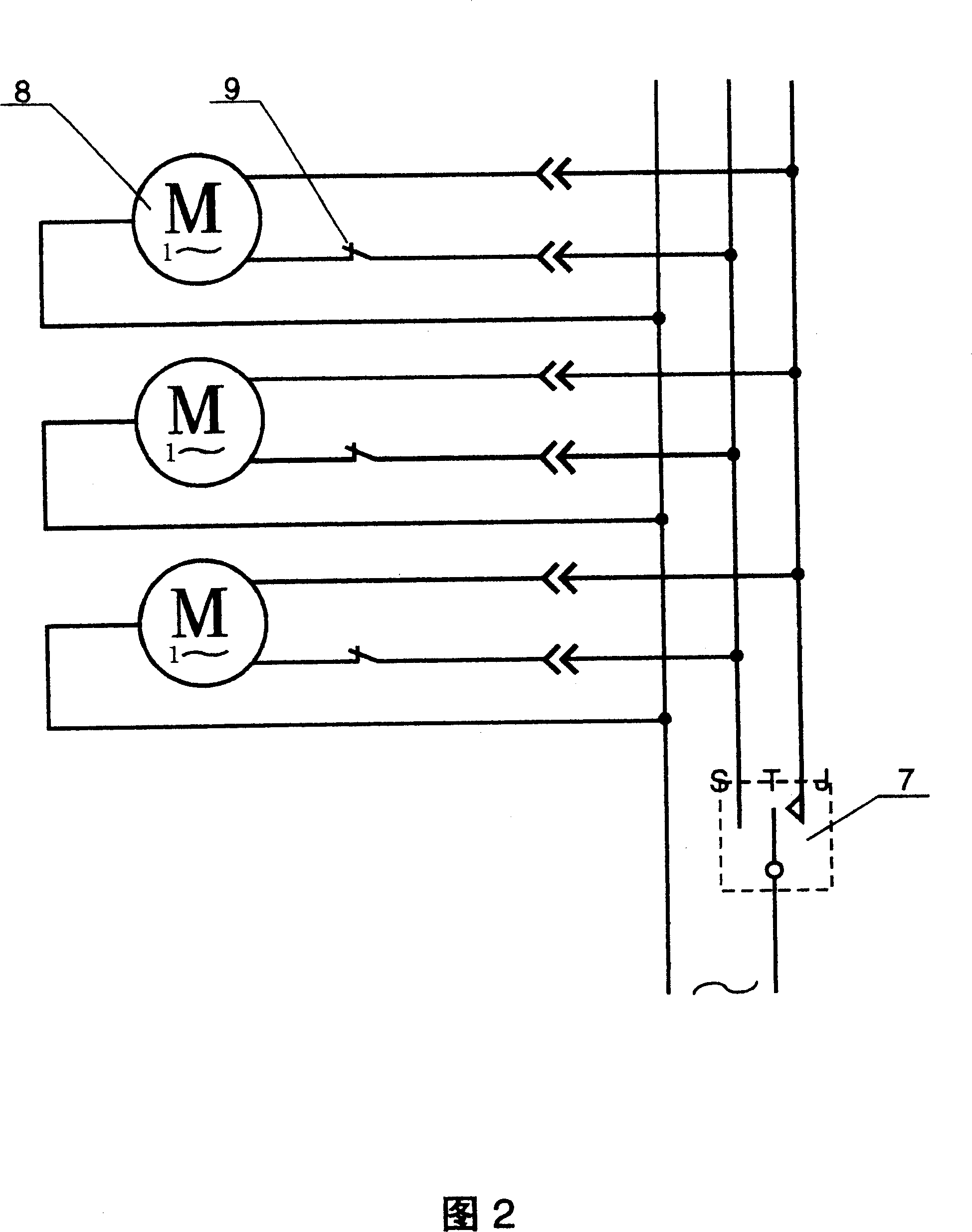

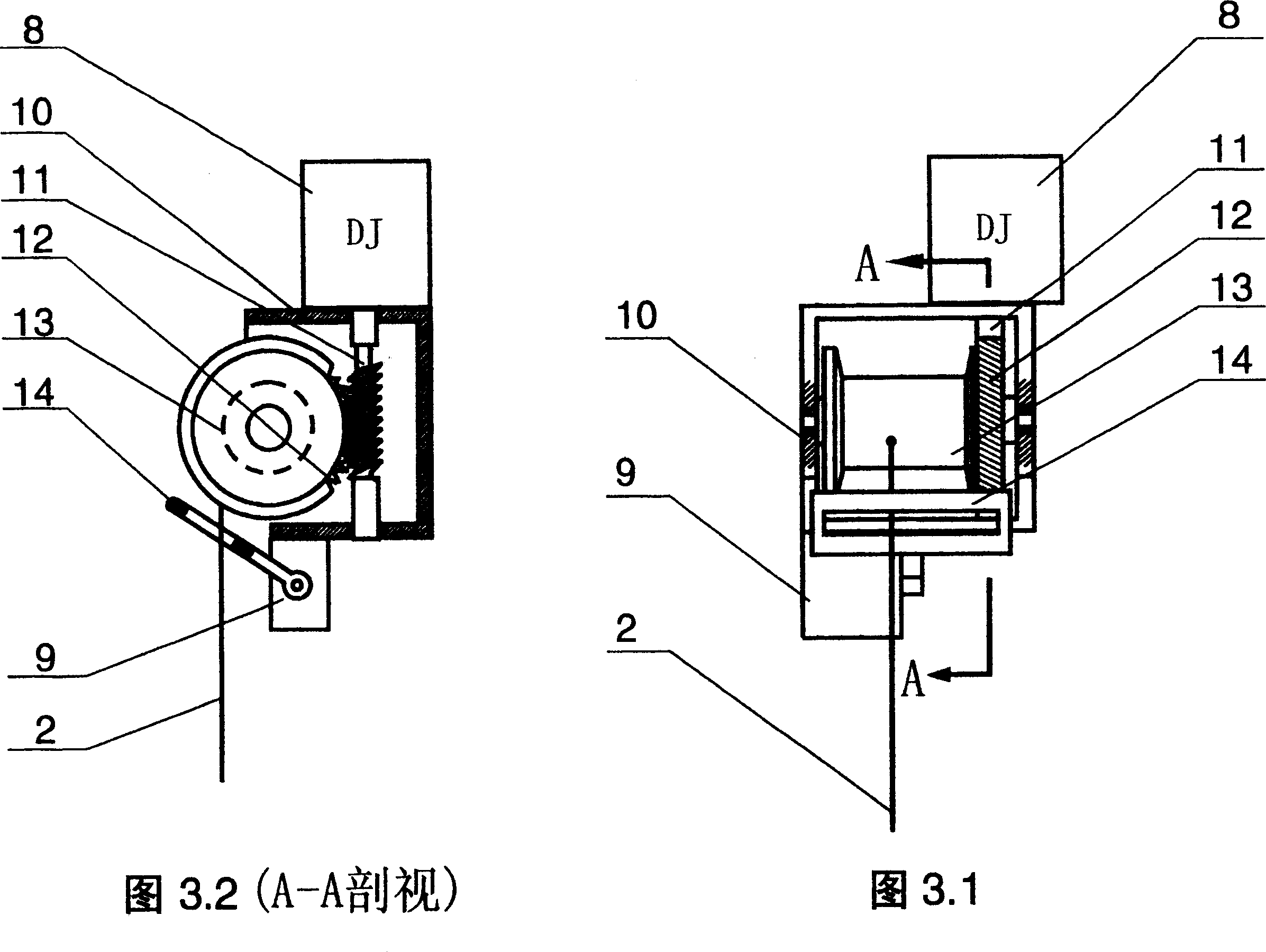

Electric mosquito net elevating mechanism

InactiveCN1321877CNo intertwiningAvoiding "Rope Rope" FailuresWinding mechanismsInsect netsEngineeringArresting gear

The electric mosquito net elevating mechanism includes at least two electric elevators and each of the electric elevators includes a motor, a casing, a reel, a piece of elevating rope and a brake to prevent the reel from rotating inversely. The reel is connected to the brake, the the elevating rope has a end connected to the reel and the other end connected to the lower edge of the net via a string of rings. Each electric elevator draws only one elevating rope, and this can prevent twisting of rope and ensure the levelness of the elevated net.

Owner:邱林

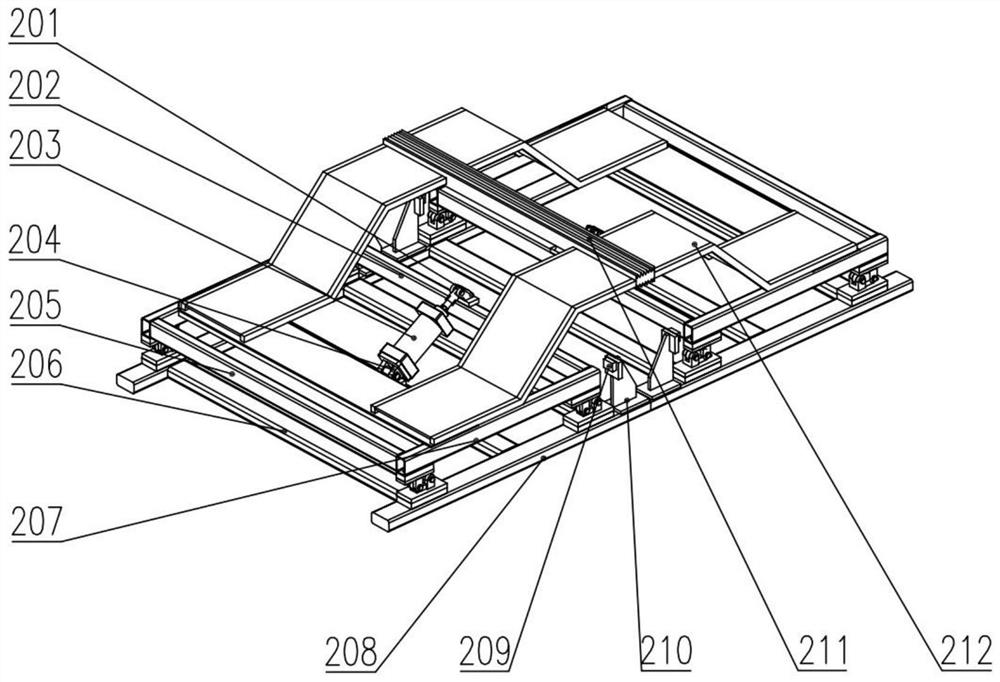

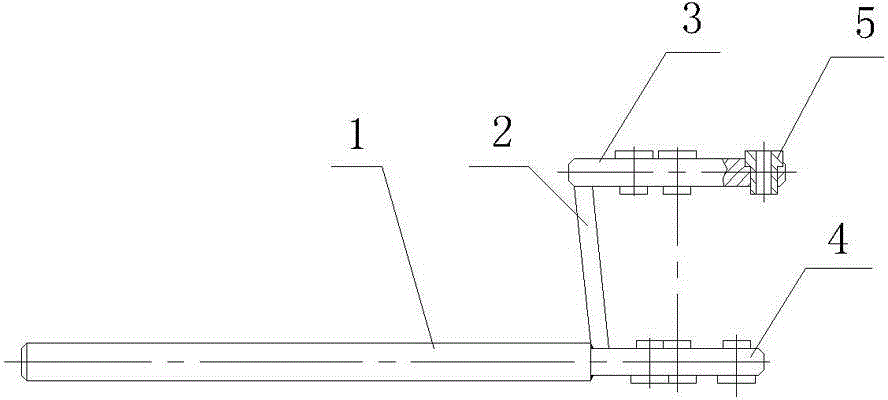

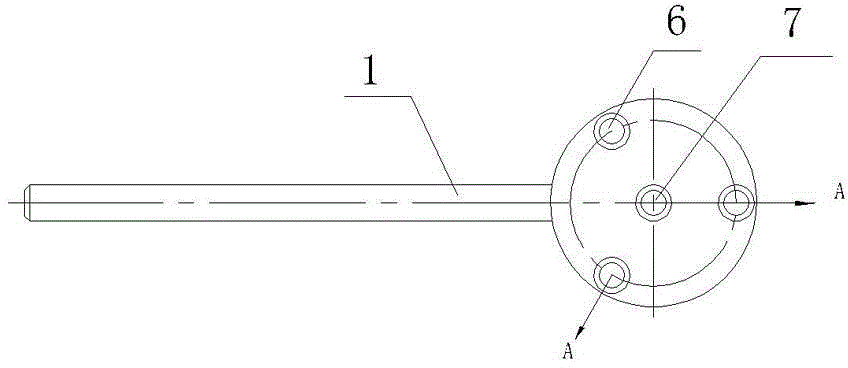

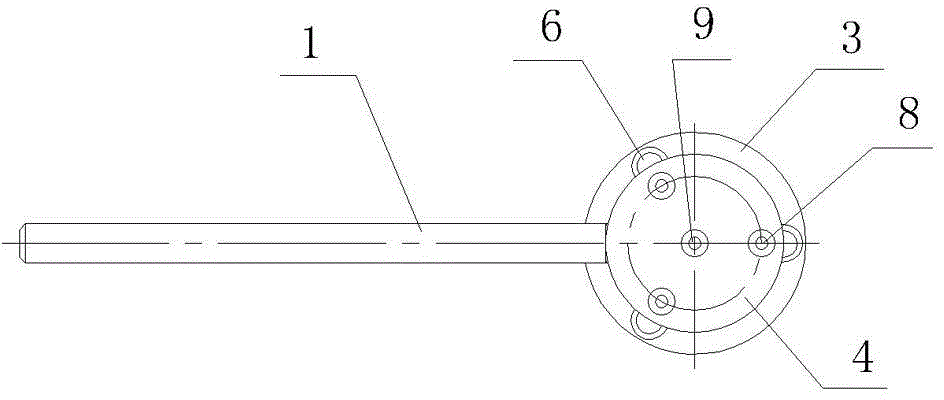

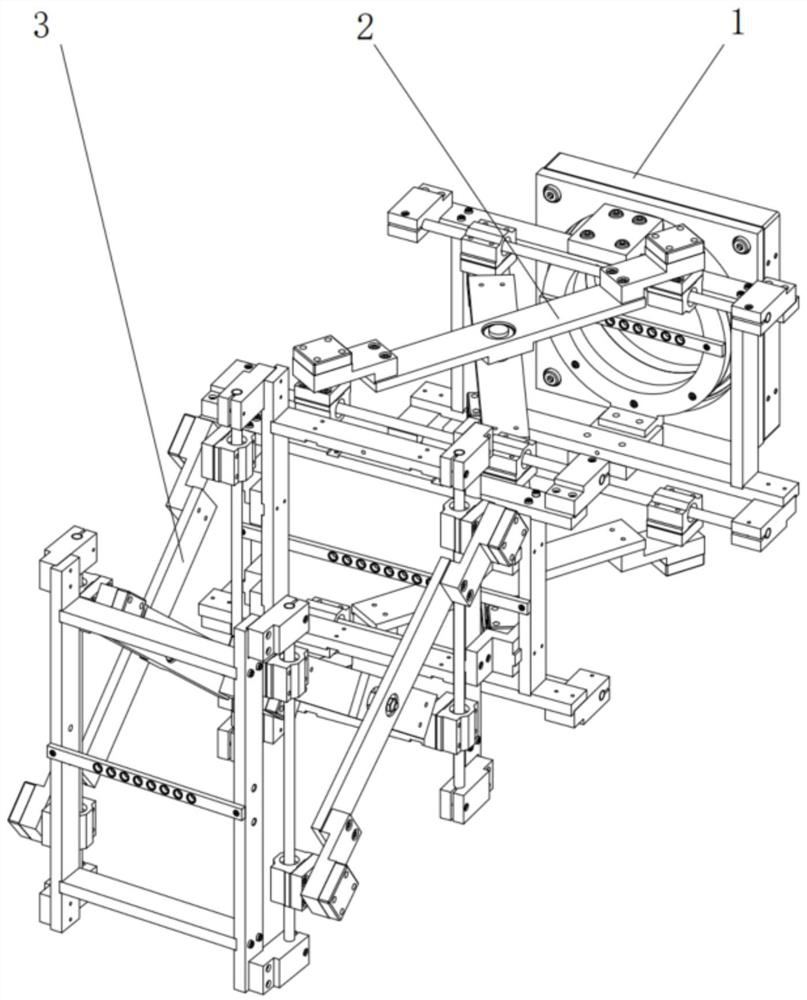

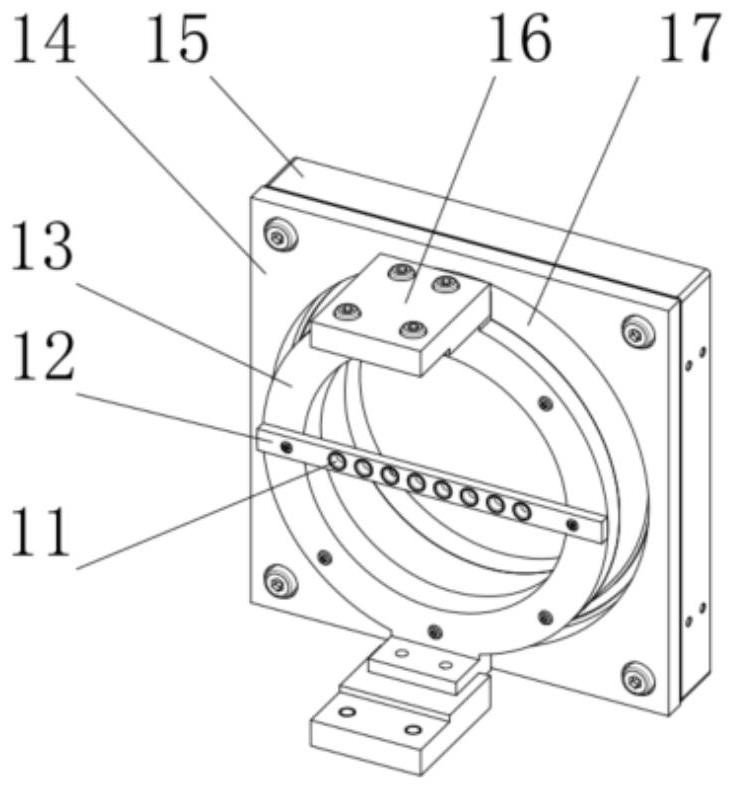

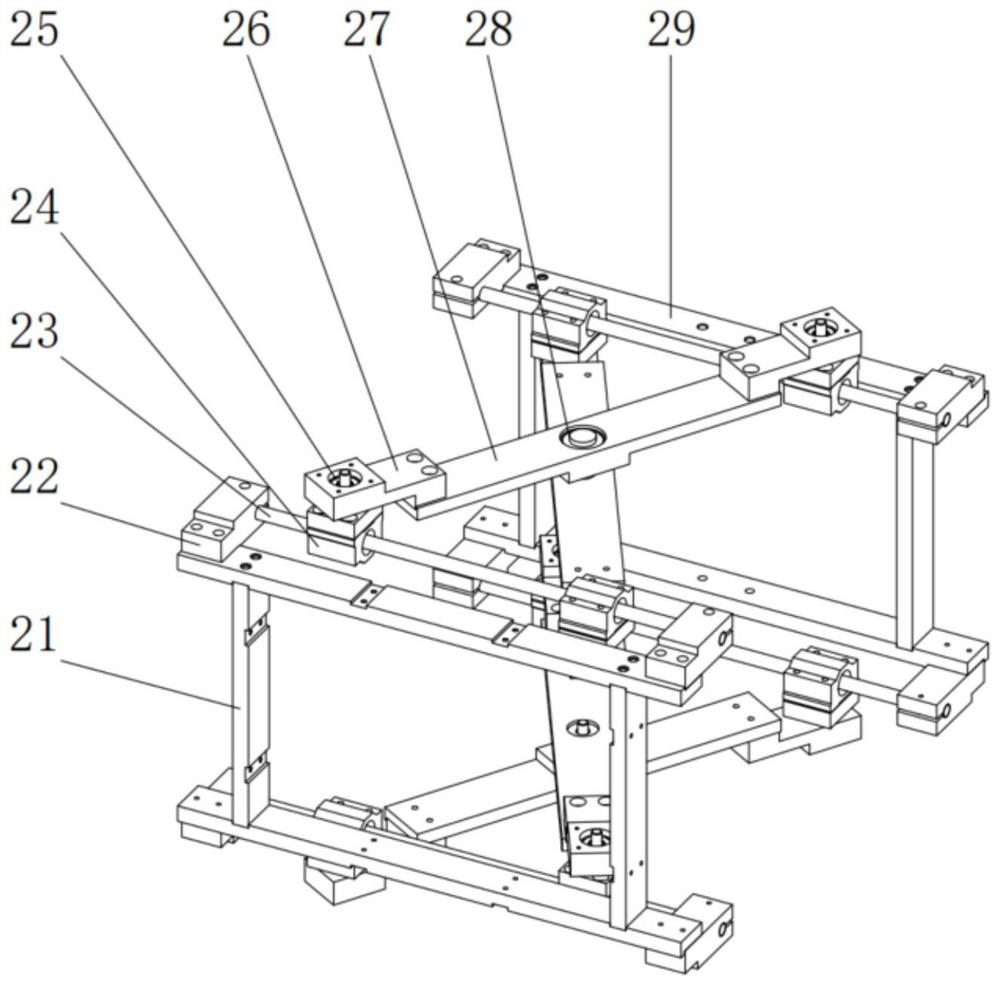

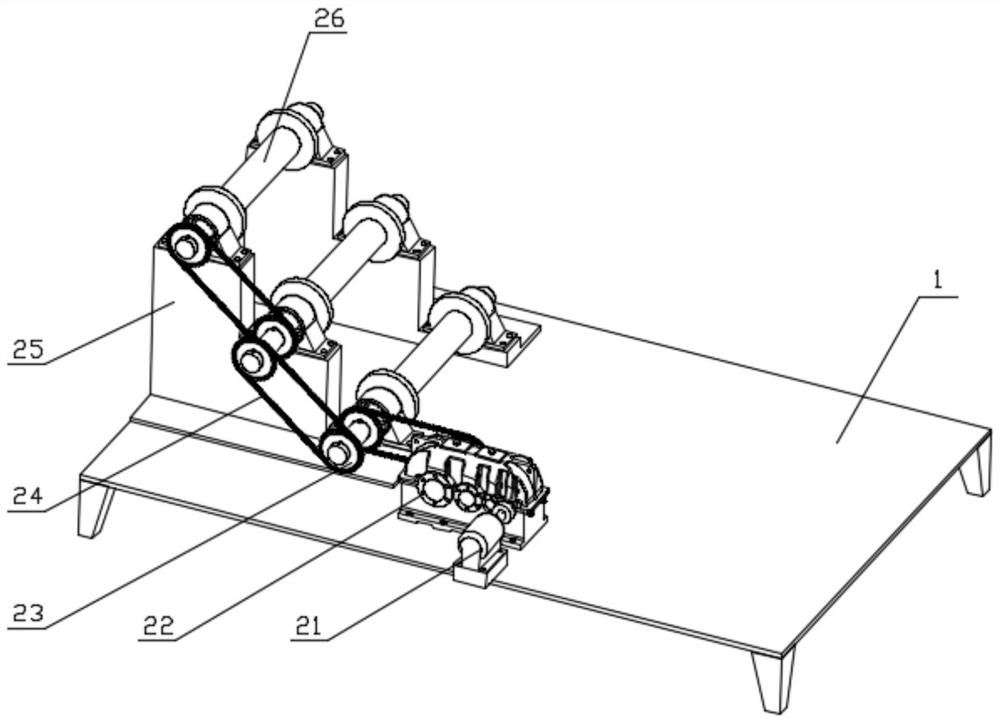

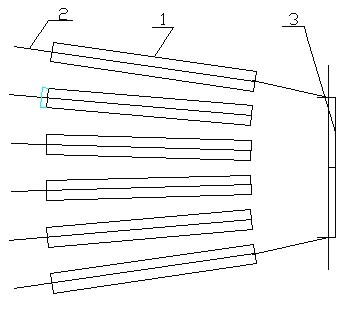

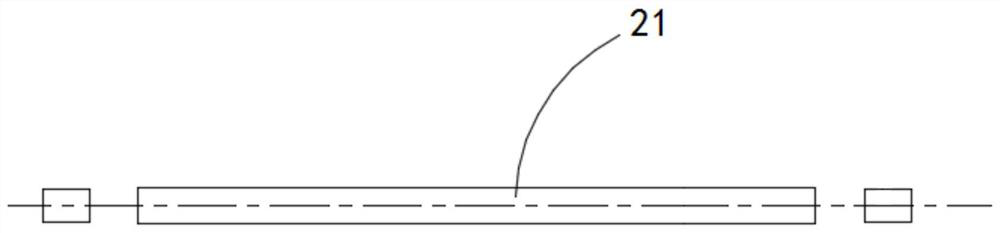

Yarn guide device for fiber laying

The invention relates to a yarn guide structure of fibers, in particular to a yarn guide device for fiber laying, and aims to solve the problems that a traditional floor type creel yarn guide mechanism limits the degree of freedom of motion of a robot, needs to use a multi-degree-of-freedom mold rotary table to increase the size of winding equipment and is high in equipment cost. The fixed end of the rotating mechanism is fixedly connected with the yarn guide frame, the rotating end of the rotating mechanism is connected with the fixed end of the pitching mechanism, the movable end of the pitching mechanism is connected with the fixed end of the swing mechanism, the movable end of the swing mechanism is connected with the yarn guide frame, and a fiber tow sequentially penetrates through the pitching mechanism and the swing mechanism from the rotating mechanism. The invention belongs to the processing field of fiber laying.

Owner:HARBIN INST OF TECH

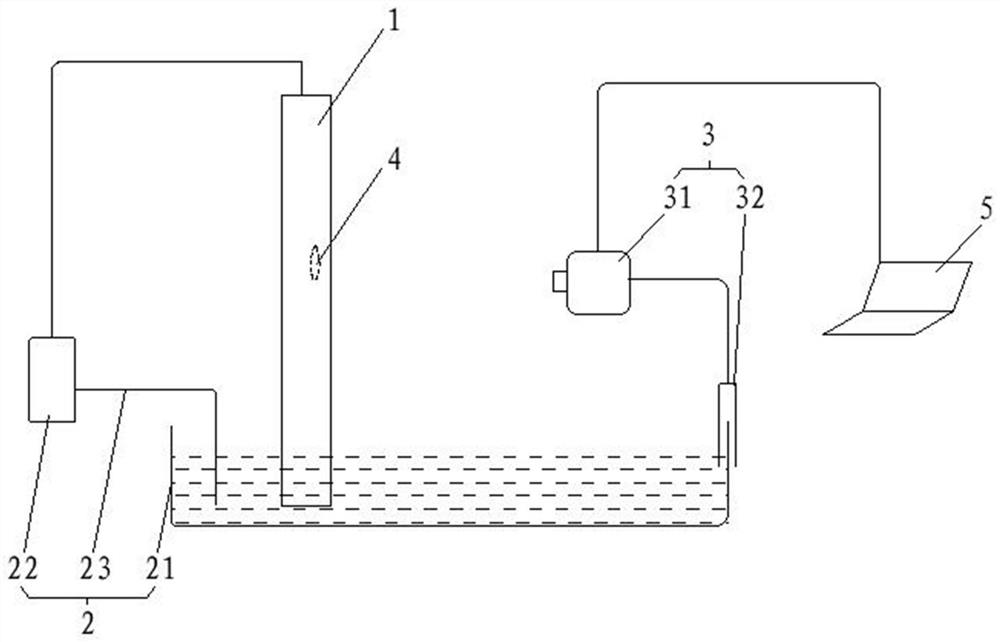

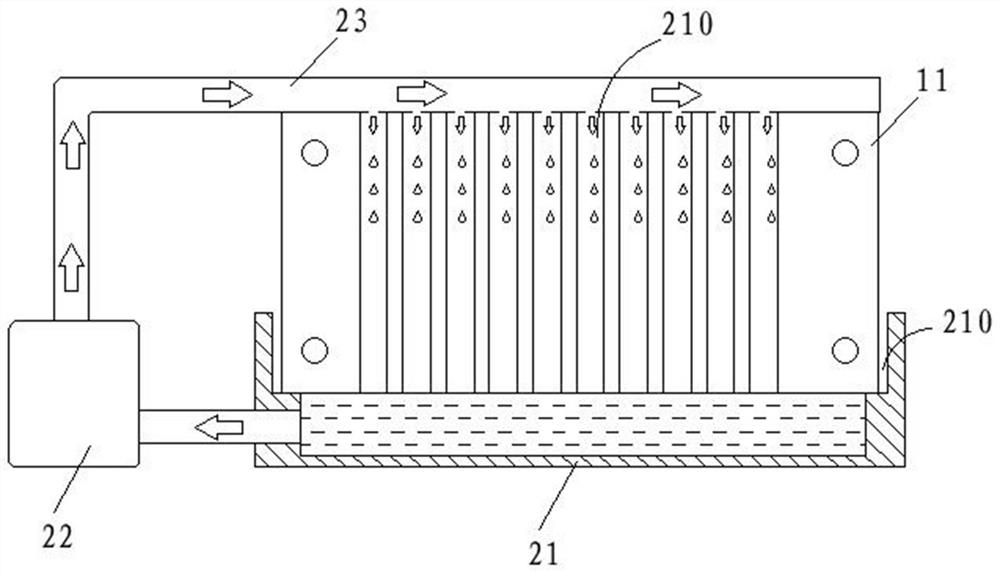

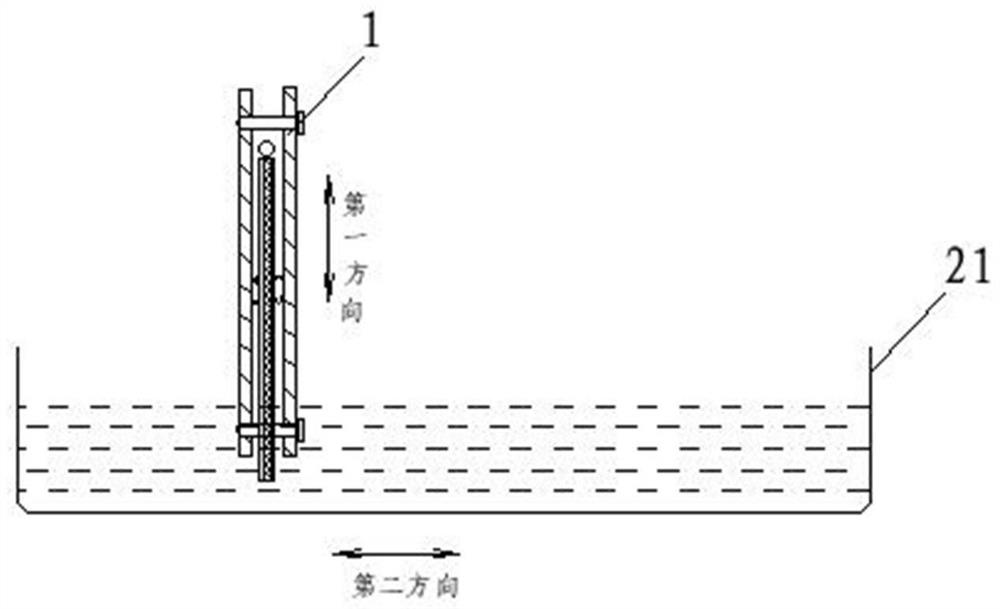

Seed vigor detection device and method

PendingCN112881396ARealize online detectionEasy to get directlyInvestigation of vegetal materialGerminating apparatusImaging processingAgricultural engineering

The invention provides a seed vigor detection device and method. The seed vigor detection device comprises a germination device, a water supply device and an image acquisition module, wherein the germination device comprises a seed metering plate and a water absorption layer, the seed metering plate is transparent and is provided with a first surface, a seed groove is formed in the first surface and extends in the first direction, and the water absorption layer is attached to the first surface; the water supply device is connected with the water absorption layer; and a lens of the image acquisition module extends to the second surface of the seed metering plate, the second surface is opposite to the first surface, and the image acquisition module is connected with the image processing module. According to the seed vigor detection device, on-line detection of the vitality of the to-be-detected seed is realized, and the detection efficiency and accuracy rate are ensured.

Owner:BEIJING RES CENT FOR INFORMATION TECH & AGRI

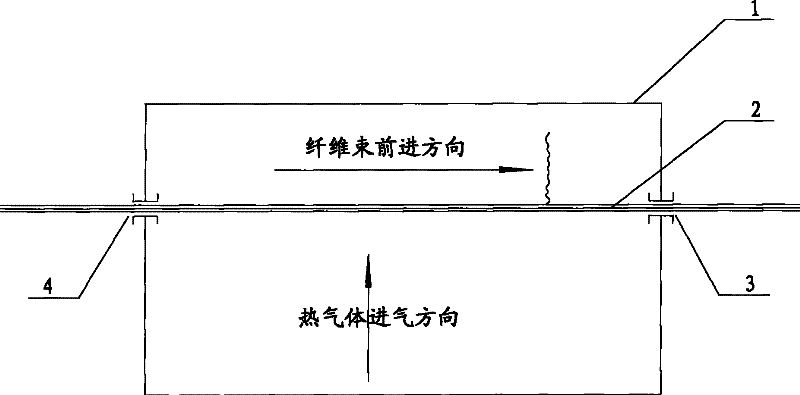

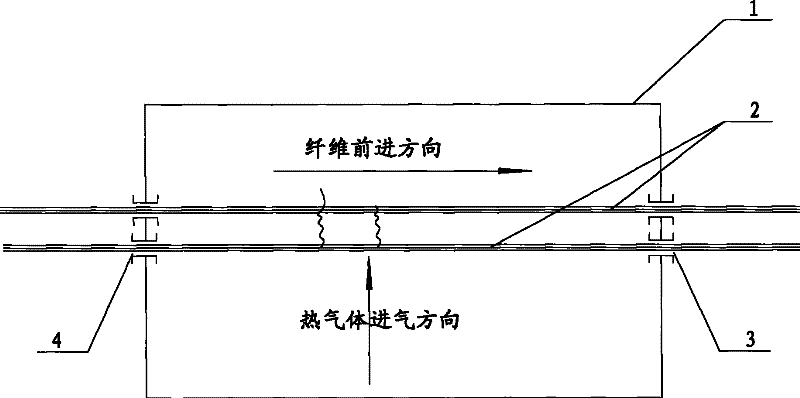

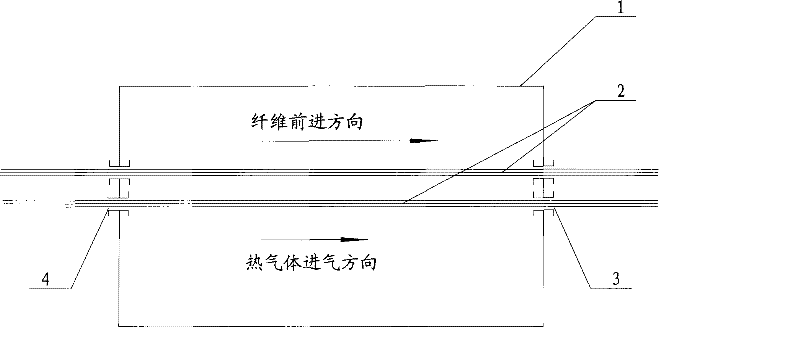

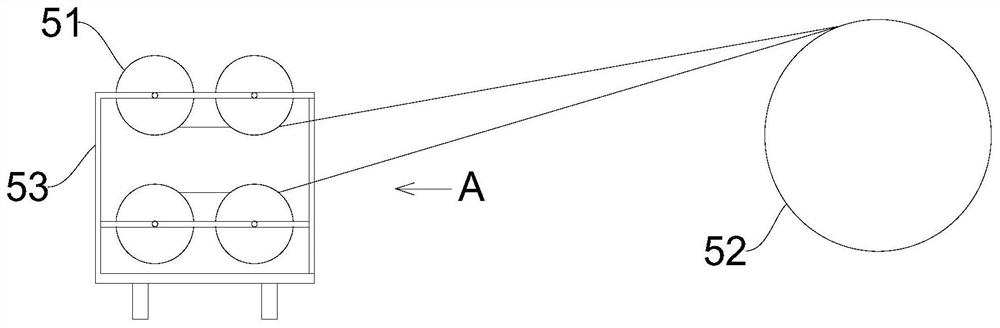

Heating method of polyethylene fibre bundle

InactiveCN101684574BNo intertwiningGuaranteed smooth productionArtificial filament heat treatmentStretch-spinning methodsPolymer scienceFiber bundle

The invention discloses a heating method of a polyethylene fibre bundle. In the process that the polyethylene fibre bundle passes through a heating box, hot gases are blown towards the polyethylene fibre bundle, and the gas inlet direction of the hot gases is same with the advance direction of the polyethylene fibre bundle. Compared with the prior art, the gas inlet direction of the hot gases forheating the polyethylene fibre bundle is parallel to the advance direction of the polyethylene fibre bundle , if a certain breakage occurs during the advance of the polyethylene fibre bundle, the broken polyethylene fibre can be always approximately parallel to the movement direction of the polyethylene fibre bundle under the blowing of the hot gases, a plurality of fiber bundles can not be mutually entwisted during the fiber bundles coexist, thereby being beneficial to the polyethylene fibre bundle entering or exiting the polyethylene fibre bundle outlet of the heating box and the smooth production of the polyethylene fibre bundle. The invention also provides a polyethylene fibre bundle prepared by the heating method of the polyethylene fibre bundle.

Owner:杨珍芬

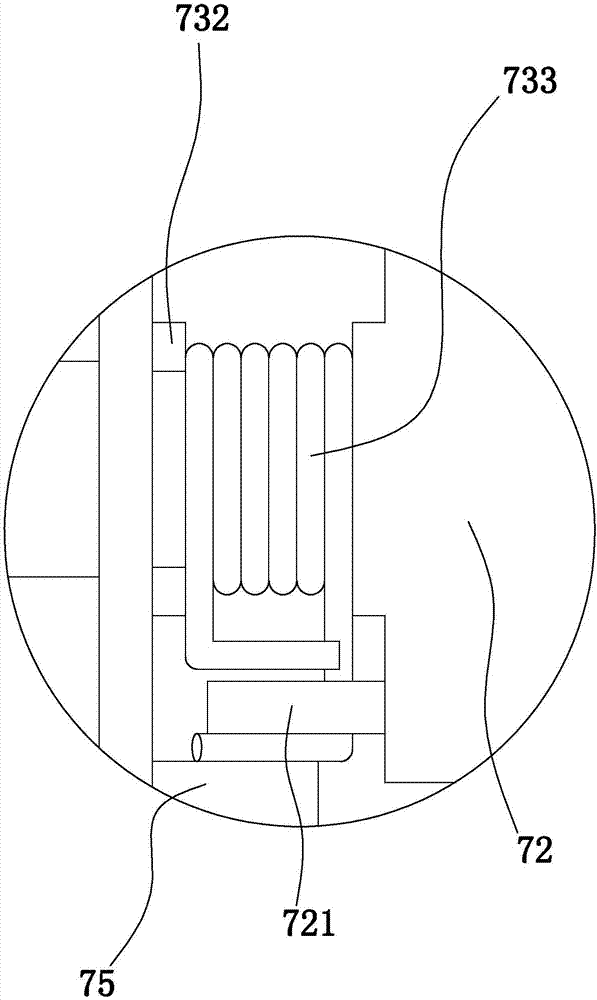

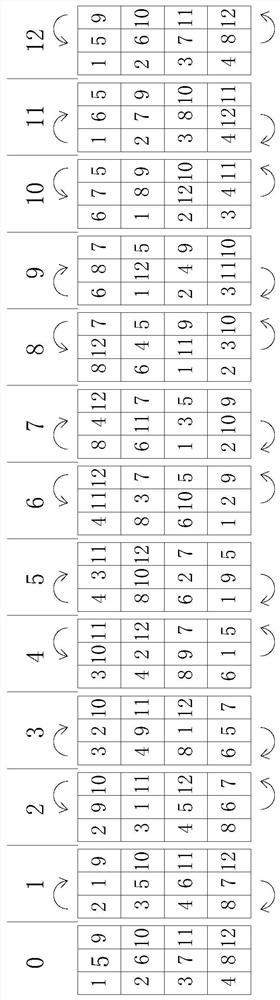

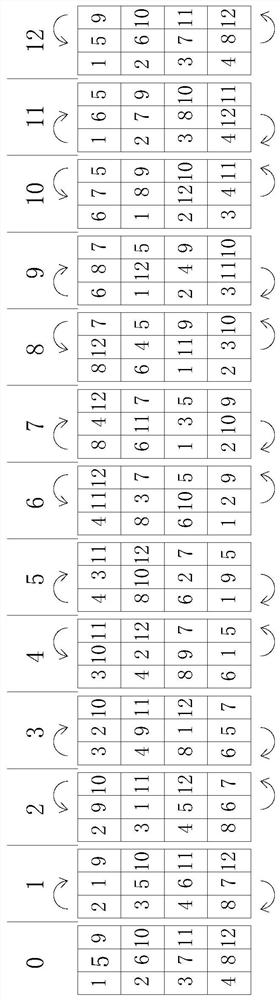

Conducting wire arrangement method, three-spiral coil winding method and transformer

ActiveCN112599350AWind evenlyNo intertwiningTransformers/inductances coils/windings/connectionsCoils manufactureTransformerMechanical engineering

The invention provides a conducting wire arrangement method, a three-spiral coil winding method and a transformer, and belongs to the technical field of transformer manufacturing. The conducting wirearrangement method comprises the steps: carrying out reasonable arrangement and reverse twisting of a to-be-wound conducting wire before winding to obtain a first conducting wire column, a second conducting wire column and a third conducting wire column. According to the conducting wire arrangement method, the three-spiral coil winding method and the transformer, the problem of conducting wire winding in the three-spiral coil winding process can be solved.

Owner:BAODING TIANWEI GROUP TEBIAN ELECTRIC

An automatic wire harness production system

ActiveCN104867625BImprove automationOrderly rowsManufacturing wire harnessesVideo monitoringAutomatic control

The invention belongs to the wire harness terminal making and glue cover penetrating technical field, and specifically provides an automatic wire harness making system mainly comprising a frame, a peeling cutting mechanism, a wire terminal making mechanism, and a glue cover plugging mechanism connected in sequence; pulling clamps and convey clamps allow the wires to be fast conveyed and transferred between the mechanisms; the technical effects are that the automatic wire harness making system saves labor, is convenient for automatic control, and high in production efficiency; finished products are tidily arranged, thus preventing wire mutual winding problems caused by free scattering; in addition, a first and a second video monitoring systems can control the terminal plugging quality in a making process, and a monitoring detection result is more objective, accurate and reliable.

Owner:杨志强

Cable auxiliary installation equipment for transmission network

ActiveCN113422321BPay-off installation is normalScientific and reasonable designVibration suppression adjustmentsApparatus for overhead lines/cablesEngineeringControl theory

The invention discloses auxiliary cable installation equipment for a power transmission network, relates to the field of engineering machinery, and includes a hoisting device, an adjusting chassis, a branching device, and a caliper device. The motor on the hoisting device drives the small pulley, the belt and the big pulley to drive, and drives the hoisting wheel to rotate to perform the cable take-up and release work. If the circuit fails, it can also be realized by manually turning the handwheel. When the cable is too tight, the oil cylinders on the two symmetrically installed bottom frames drive the two bottom frames to adjust their relative positions around the crank, and the organ damping is used to ensure the stability of the structure. The determination of the left and right positions is realized through the positioning sensor on the branching device. The signal receiver is used to receive the signal. The cable can be divided into four ways and separated from different hooks to avoid entanglement. The cable is locked and released by the caliper on the caliper device, and the oil-pneumatic spring is mainly used to reduce the vibration caused to the equipment when the cable is tight and rebounds.

Owner:兴化市永安电力工具有限公司

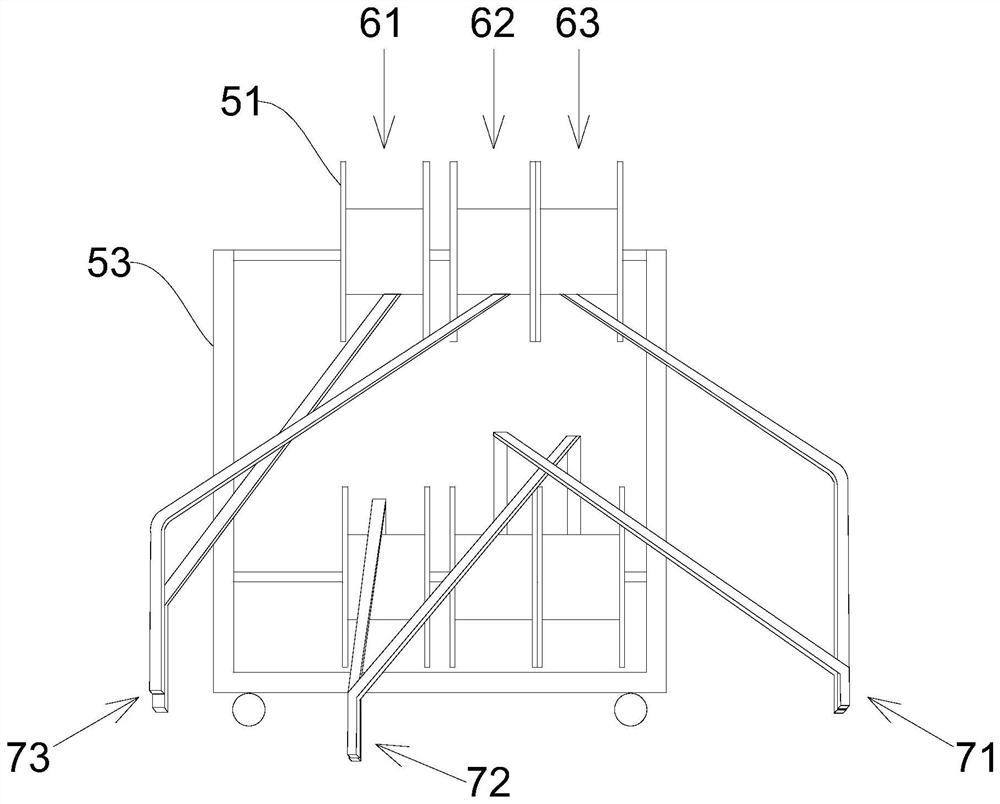

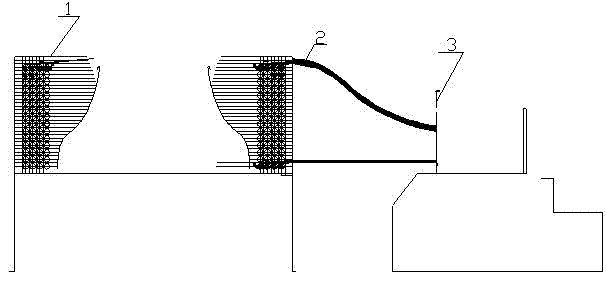

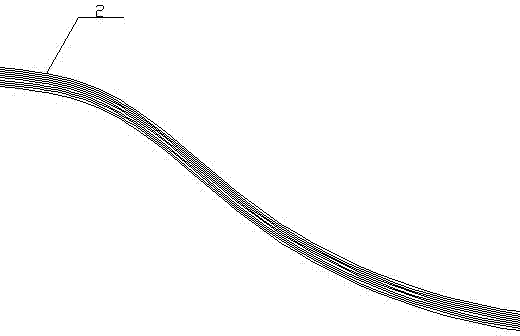

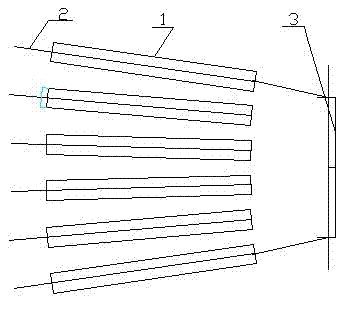

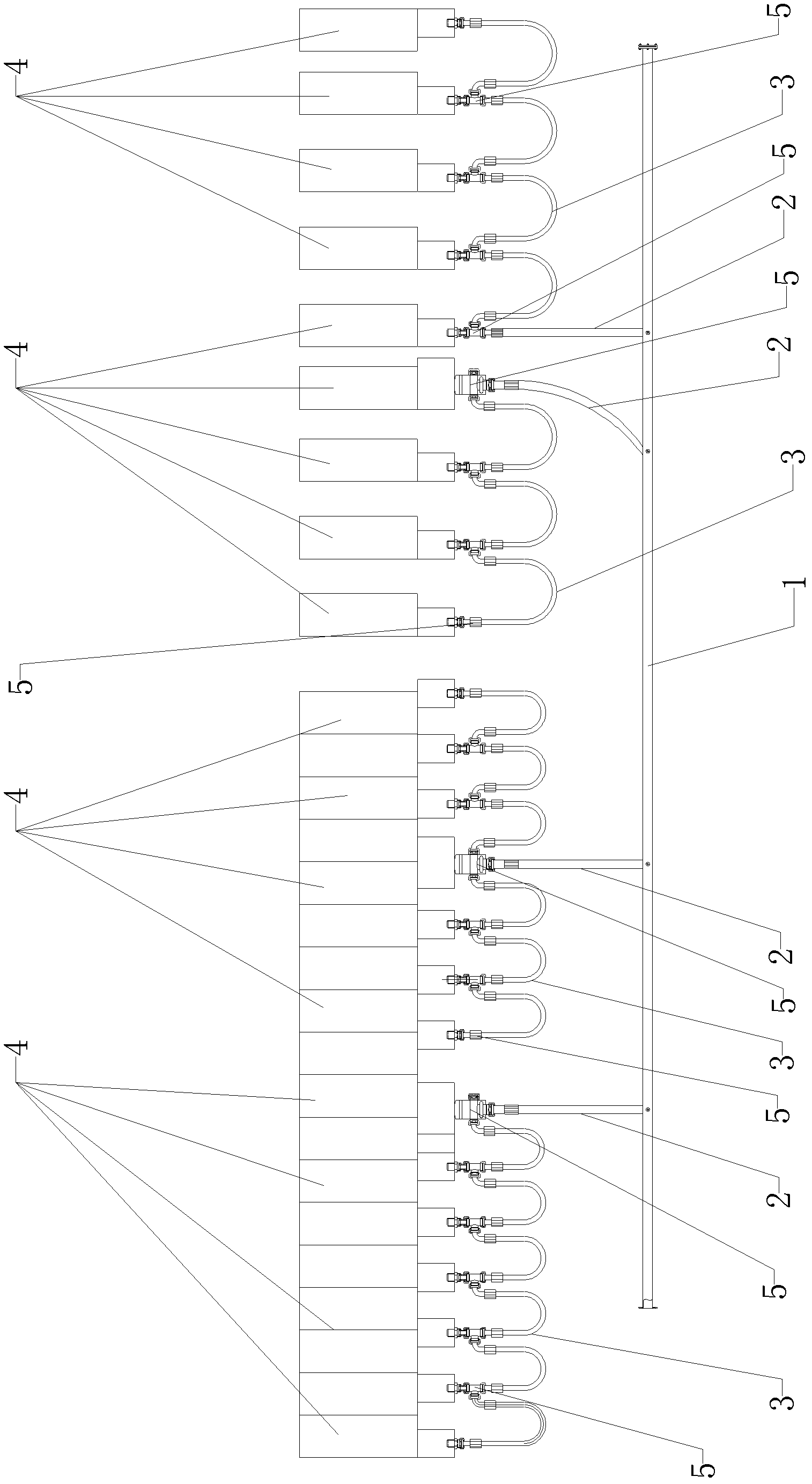

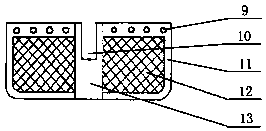

Carpet loom bobbin creel

The invention relates to a carpet loom bobbin creel capable of making yarns inside the carpet loom bobbin creel pass through a yarn guide tube to a yarn guide plate and ensure that the yarns are not twisted and knotted. The carpet loom bobbin creel comprises a carpet loom bobbin creel; yarns are suspended on two sides of each group of bobbin creels in the carpet loom bobbin creel; and the suspended yarns pass through the yarn guide tube to the yarn guide plate respectively. The carpet loom bobbin creel has the advantages of: 1, fundamentally solving the problem that a lot of yarns on the bobbin creel are influenced by respective tension rate in the process of weaving the carpet so as to cause the phenomenon that the yarns are twisted and knotted and cannot be weaved; 2, ensuring the smooth operation of the yarns in the guide tube due to horizontal arrangement and feed between the yarn guide tube and yarn inlet and outlet or due to a design of horizontal arrangement and arc-shaped feed; and 3, novel, unique, simple and practical structure, and unexpected technical effects and economic benefit.

Owner:ZHEJIANG ARTISTIC CARPETAB MFG

Multi-cable traverse unit

ActiveCN112573288ANo intertwiningSimple structureFilament handlingReciprocating motionControl theory

The invention discloses a multi-cable traverse unit which comprises a winding component used for synchronously winding multiple cables on corresponding winding reels, and a traverse component used forenabling the cables to reciprocate in the horizontal direction so as to arrange the cables smoothly and uniformly, and the winding component can be provided with the winding reels and enable the winding reels to rotate synchronously. Through the traverse component, the multiple cables can horizontally reciprocate simultaneously to be uniformly wound on the winding reels. The multi-cable traverseunit is simple in structure and can be adjusted according to actual requirements, the components are convenient to mount and dismount, cable arranging is uniform, the quality is high, the cables are not intertwined, and the working quality and efficiency are guaranteed.

Owner:合肥龙智机电科技有限公司

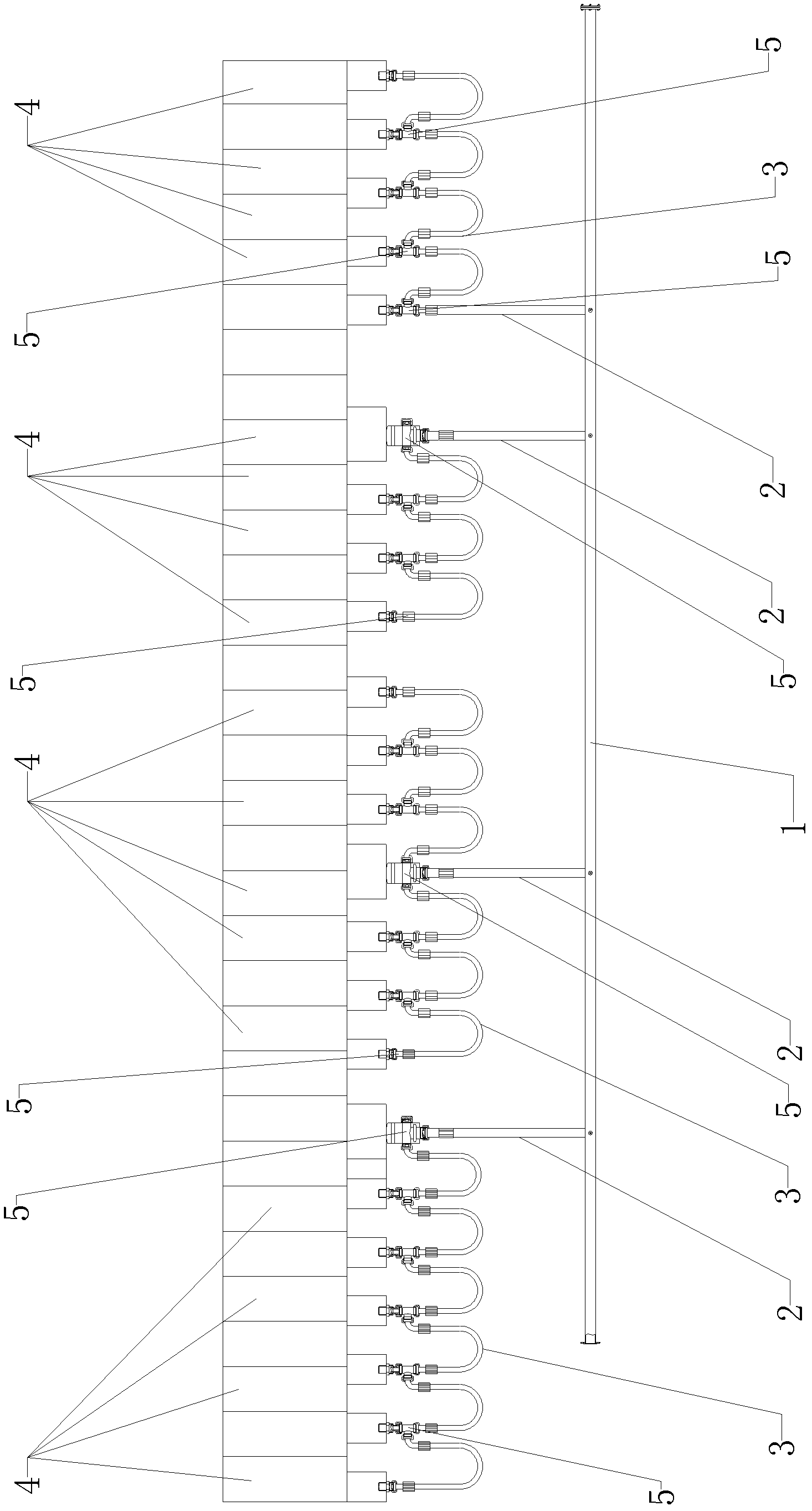

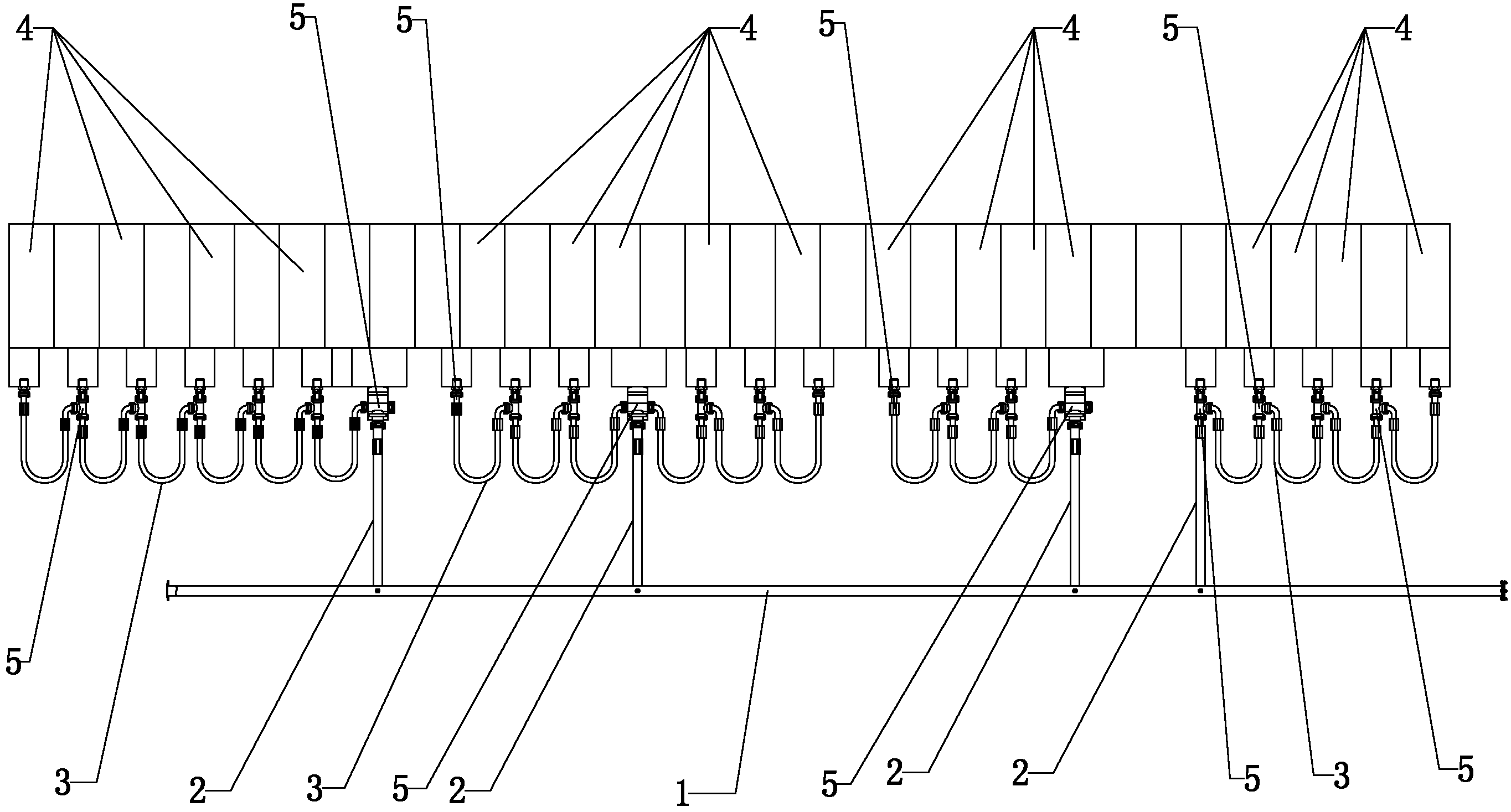

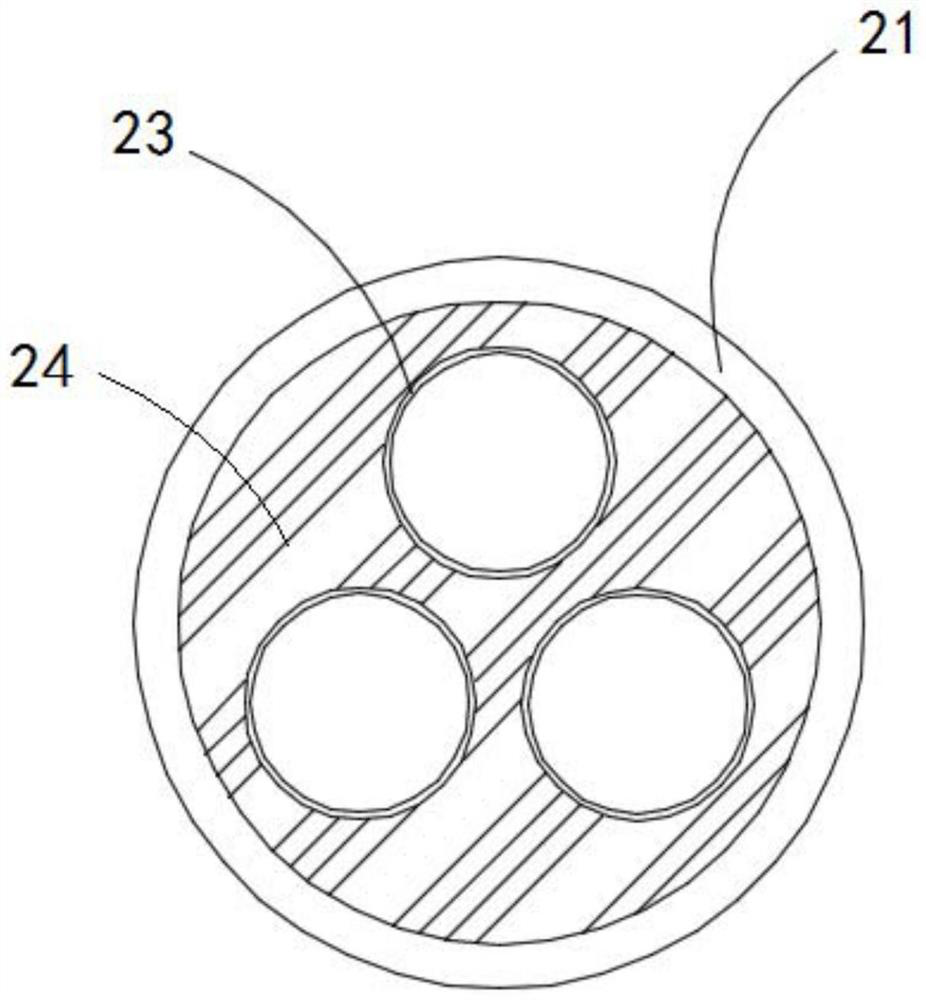

Dendriform water in-out system of filter press filter plate

InactiveCN102397716ASimple structureAvoid safety accidentsFiltration separationFilter pressWater pipe

The invention relates to a dendriform water in-out system of a filter press filter plate, which comprises a trunk header pipe, a plurality of principal branch header pipes and branch pipes, wherein the principal branch header pipes and the branch pipes form a pipe bundle; the pipe bundle and the trunk header pipe form the dendriform water in-out system; one end of the dendriform water in-out system is communicated with the filter press filter plate; and the other end of the water in-out system is connected with external water supplies and water drainage. The dendriform water in-out system of the filter press filter plate has the beneficial effect that the water in-out system of the filter press filter plate is optimized on the premise of guaranteeing a water in-out function; the water inlet pipe and the water outlet pipe of the filter press filter plate are changed into the mode of a pipe bundle combined by long pipes and short pipes from the mode of being directly connected with the header pipe; the long pipes are directly connected with the header pipe, and the short pipes are connected with the header pipe in series; the long pipes are distributed at intervals, and the original small gap is changed into a big gap; and when the filter plate group is pulled open and combined, water pipes are free from mutually coiling to prevent the long water pipes from being extruded into the filter plate. In the dendriform water in-out system, the pipe bundle plays a constraining role when the pipeline is collapsed to fall and fail, and therefore safety accidents can be avoided.

Owner:北京中水长固液分离技术有限公司

Winding-reducing and partial load-reducing device for washing machine with adjustable diameter and buoyancy for easy storage

ActiveCN107287824BNo intertwiningAvoid collisionOther washing machinesWashing machine with receptaclesEngineeringBias effect

The invention discloses a winding-reducing and partial load-reducing device for a washing machine with adjustable diameter and buoyancy, which is convenient for storing, and comprises an upper insertion piece and a lower insertion piece; Set the left and right mesh nylon, set the upper insert slot opening downward on the upper insert frame between the left and right mesh nylon, and set a row of upper insert adjustment for fixing and adjusting the separator on the upper edge of the upper insert The positioning hole of the separator, the middle part of the upper insert frame is a hollow expansion part, the hollow inner cavity is a water injection cavity, and the top of the water injection cavity is provided with a water injection port, which can adjust the buoyancy by injecting water and reduce the friction with the water leaves of the washing machine; the upper and lower The inserts are connected to each other through the slots of the upper and lower inserts to form a cross-shaped assembly. The invention has the advantages of reasonable structure, good anti-eccentric load effect, convenient storage, adjustable diameter and buoyancy.

Owner:临沭县独沭一帜富华商贸有限公司

Carpet loom bobbin creel

The invention relates to a carpet loom bobbin creel capable of making yarns inside the carpet loom bobbin creel pass through a yarn guide tube to a yarn guide plate and ensure that the yarns are not twisted and knotted. The carpet loom bobbin creel comprises a carpet loom bobbin creel; yarns are suspended on two sides of each group of bobbin creels in the carpet loom bobbin creel; and the suspended yarns pass through the yarn guide tube to the yarn guide plate respectively. The carpet loom bobbin creel has the advantages of: 1, fundamentally solving the problem that a lot of yarns on the bobbin creel are influenced by respective tension rate in the process of weaving the carpet so as to cause the phenomenon that the yarns are twisted and knotted and cannot be weaved; 2, ensuring the smooth operation of the yarns in the guide tube due to horizontal arrangement and feed between the yarn guide tube and yarn inlet and outlet or due to a design of horizontal arrangement and arc-shaped feed; and 3, novel, unique, simple and practical structure, and unexpected technical effects and economic benefit.

Owner:ZHEJIANG ARTISTIC CARPETAB MFG

Steel strand ground pipe penetrating system in large-span steel truss and pipe penetrating construction method

InactiveCN112282376ANo damageNo intertwiningBuilding material handlingArchitectural engineeringLong span

The invention discloses a steel strand ground pipe penetrating system in a large-span steel truss, which is used for enabling steel strands to penetrate into a lower chord pipe. A plurality of casingpipes are arranged in the lower chord pipe. The pipe penetrating system comprises a platform arranged on the ground, a winch which is arranged on one side of the platform, and a supporting frame whichis arranged on the platform and is close to the winch, wherein a traction rope is wound on the winch, the traction rope extends into the casing pipes from one ends of the casing pipes and extends outof the casing pipes from the other ends of the casing pipes, and the end, extending out of the casing pipes, of the traction rope is connected with the steel strands; and pulleys capable of rotatingfreely are arranged on the supporting frame, the traction rope winds around the corresponding pulley and then penetrates into the corresponding casing pipe, and the traction rope is made to be far away from the inner walls of the casing pipes through the arrangement of the pulleys. The winch is switched on to drive the traction rope to pull the steel strands, the steel strands are made to correspondingly penetrate into the casing pipes, and ground pipe penetrating is achieved.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

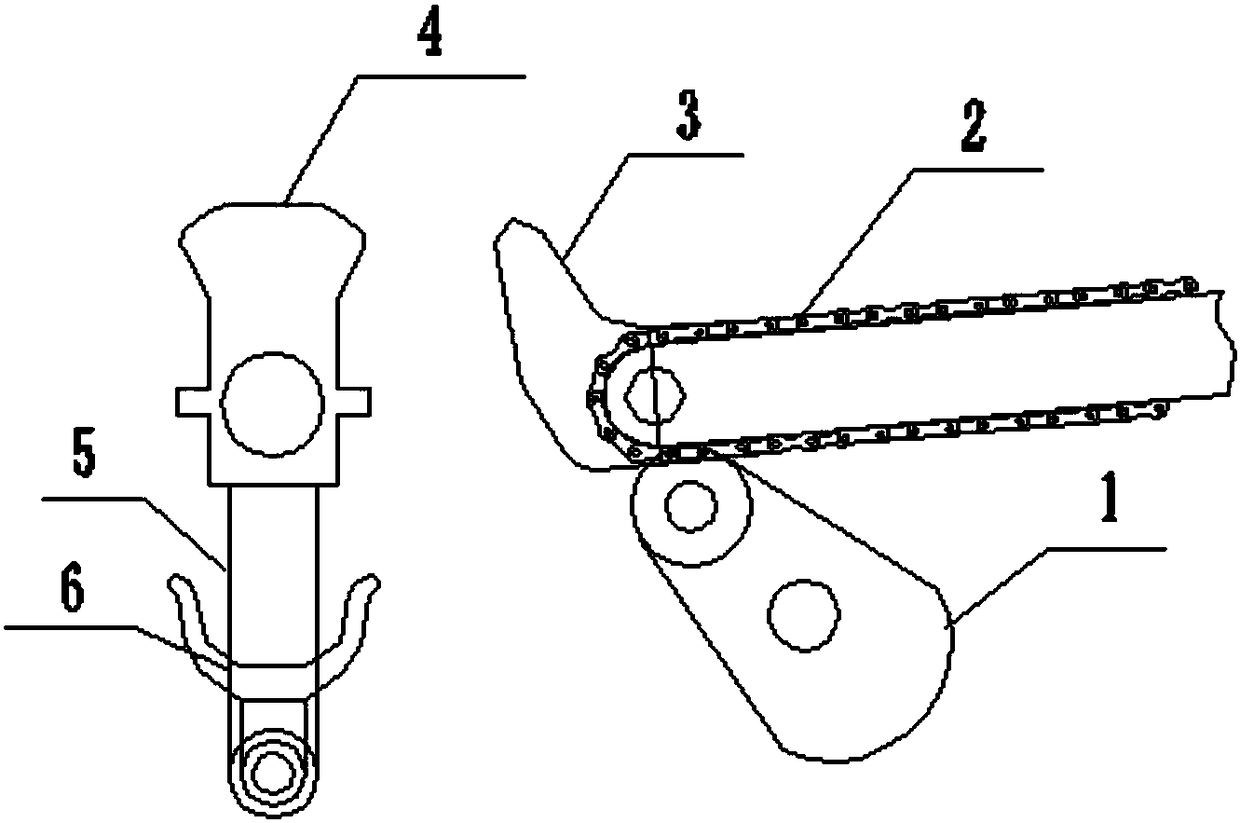

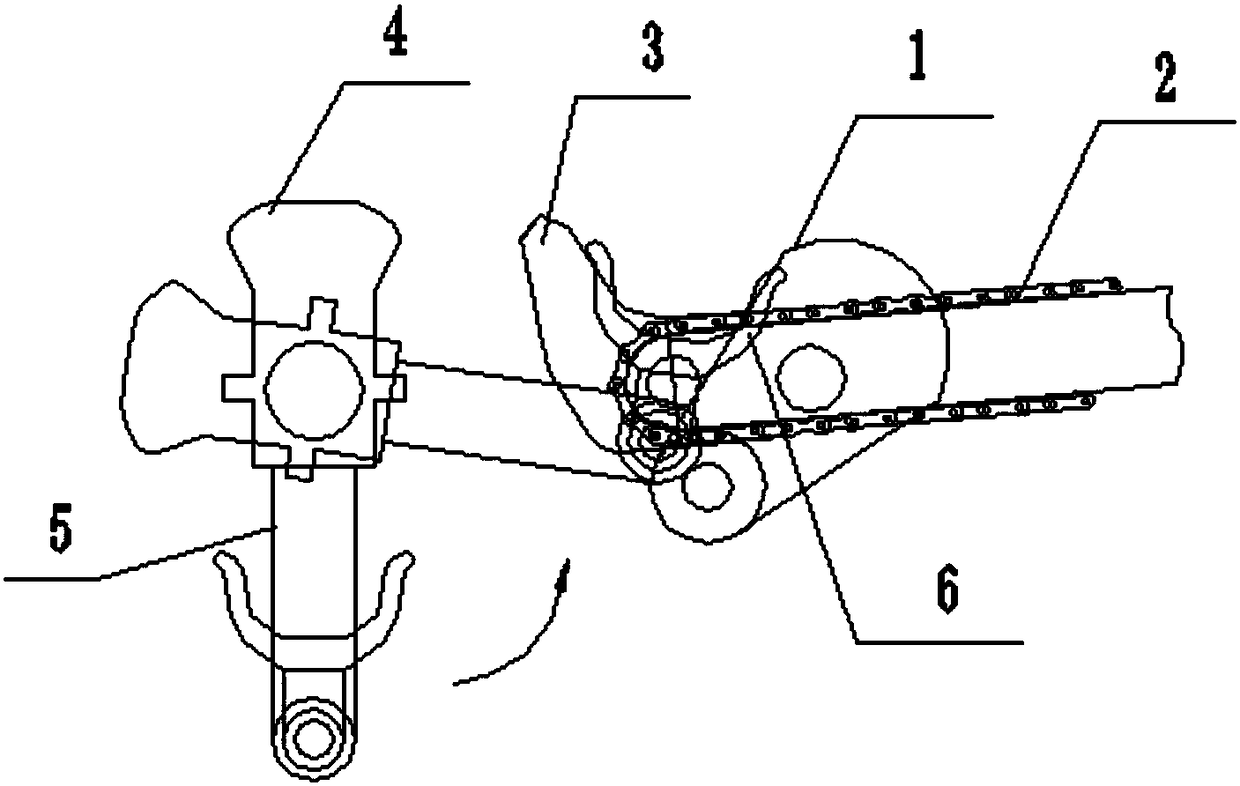

Bar collecting device

InactiveCN108502524ANo intertwiningWill not cause sheddingConveyor partsEngineeringMechanical engineering

The invention relates to the field of rolling equipment, in particular to a bar collecting device which comprises a chain conveying mechanism, a push plate and a collecting mechanism. Two baffle plates are fixedly arranged at the tail end of the chain conveying mechanism; the push plate is hinged under the chain conveying mechanism; and the collecting mechanism is arranged in front of the chain conveying mechanism, and comprises an oscillating bar, a counter weight fixedly arranged on the upper part of the oscillating bar, and a support plate fixedly arranged on the lower part of the oscillating bar. The device provided by the invention is simple in structure and convenient to operate, prevents products from intercross enwinding and prevents a surface oxide layer protection peel from falling off.

Owner:盐城市联鑫钢铁有限公司

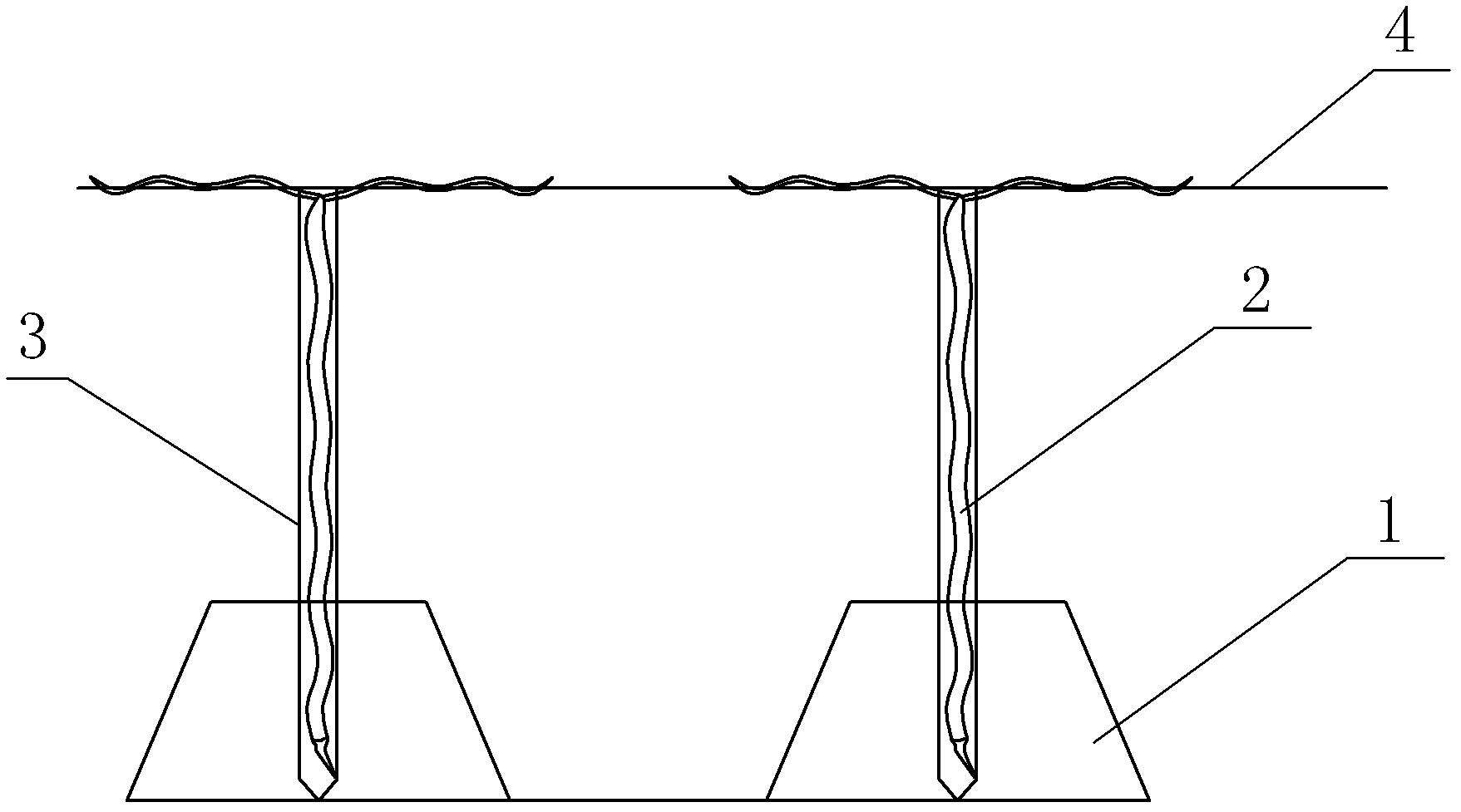

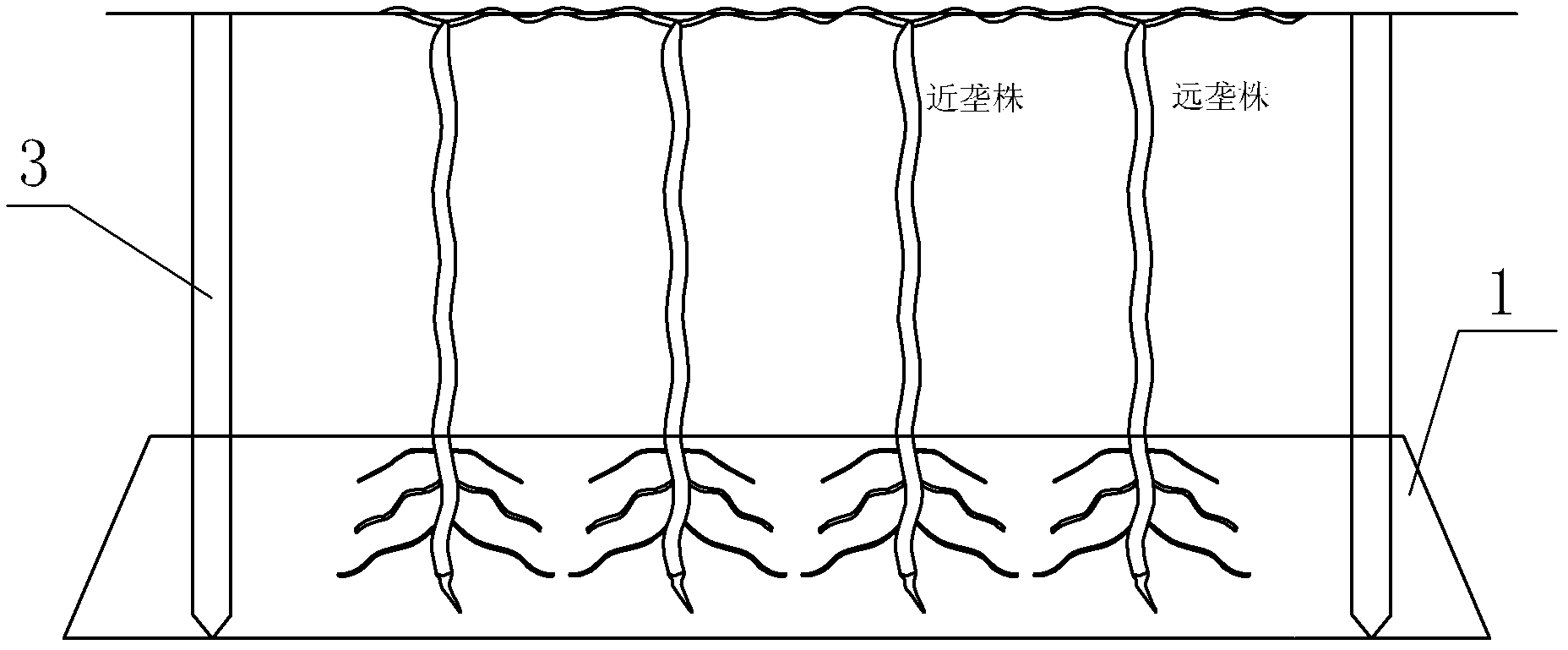

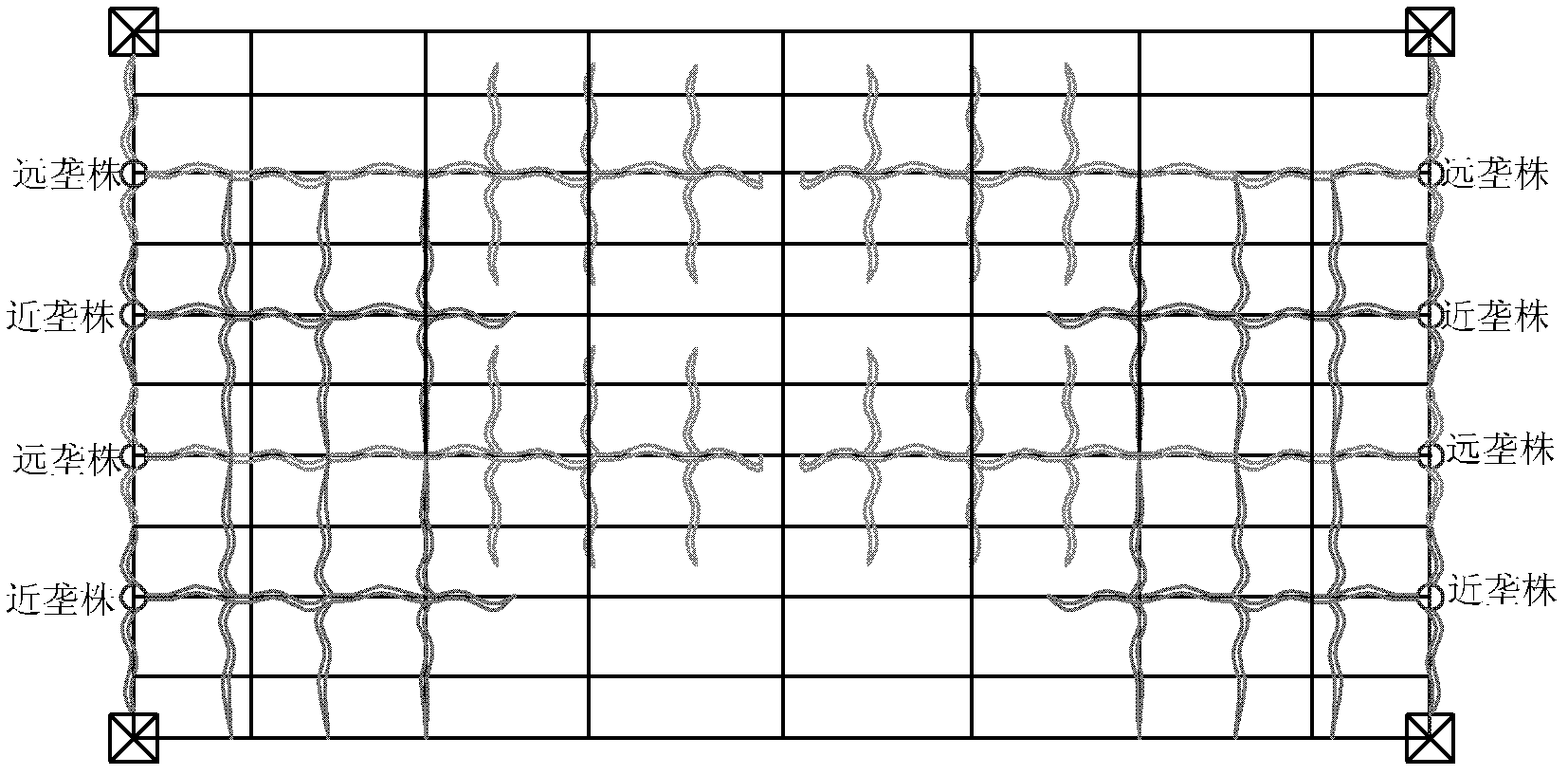

Pruning method for kiwifruit in elevated wide-spacing close-planting cultivation

The invention discloses a pruning method for kiwifruit in elevated wide-spacing close-planting cultivation, which includes the steps: preparing a land and ridging; planting single kiwifruit seedlings at intervals of one meter; setting uprights on each ridge at intervals of 4 meters, and setting up a grid shed with steel wire ropes; performing pinching when each kiwifruit seedling grows 2.0-2.5m long; after the top of each seedling sprouts, reversing two buds and removing other buds; allowing the two buds to grow in opposite directions perpendicular to the ridges along the steel wire ropes andgrow into main vines; dividing adjacent kiwifruit plants on the ridges into near plants and far pants, and pruning the near plants and the far plants respectively; when the main vine of each near plant grows about 3.0m long, controlling the main vine not to grow forward, and allowing fruiting branches to grow on the main vine at intervals of 30-40cm; when the main vine of each far plant grows about 4m long, controlling the main vine not to grow forward, and removing all growing branch buds in an area 2.5m from the end of each branch on the corresponding ridge to the main vine; and allowing fruiting branches to grow on the main vine from the 2.5m position to the tail end of the main vine. By the method, reasonable distribution of kiwifruit vines can be promoted, and good ventilation and sunlight are guaranteed.

Owner:张有连

Intelligent Control System of Secondary Wire Feeder in Ladle Refining Furnace

ActiveCN109283881BNo intertwiningAffect qualityIncreasing energy efficiencyProgramme control in sequence/logic controllersControl engineeringProcess engineering

The invention relates to an intelligent control system for a second-stream wire feeder of a ladle refining furnace, characterized in that the control system includes an L2 parameter storage and maintenance module, an L2 data collection module, an L2 wire yield self-learning module, and an L2 wire calculation module , L1‑L2 communication module and L1 PLC control module. This solution automatically calculates the type and length of the wire, and automatically calculates the type and length of the wire according to the initial composition and target composition requirements of the molten steel, avoiding manual calculations. The error makes the control accuracy higher, and does not require manual calculation, reducing the labor intensity of manual work.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Conductor arrangement method, triple helical coil winding method and transformer

ActiveCN112599350BWind evenlyNo intertwiningTransformers/inductances coils/windings/connectionsCoils manufactureTransformerHelical coil

The invention provides a wire arrangement method, a triple helical coil winding method and a transformer, which belong to the technical field of transformer manufacturing. The above wire arrangement method performs reasonable arrangement and reverse twisting on the wires to be wound before winding, The first wire row, the second wire row and the third wire row are obtained; the wire arrangement method, the triple helical coil winding method and the transformer provided by the present invention can solve the wire winding problem in the triple helical coil winding process.

Owner:BAODING TIANWEI GROUP TEBIAN ELECTRIC

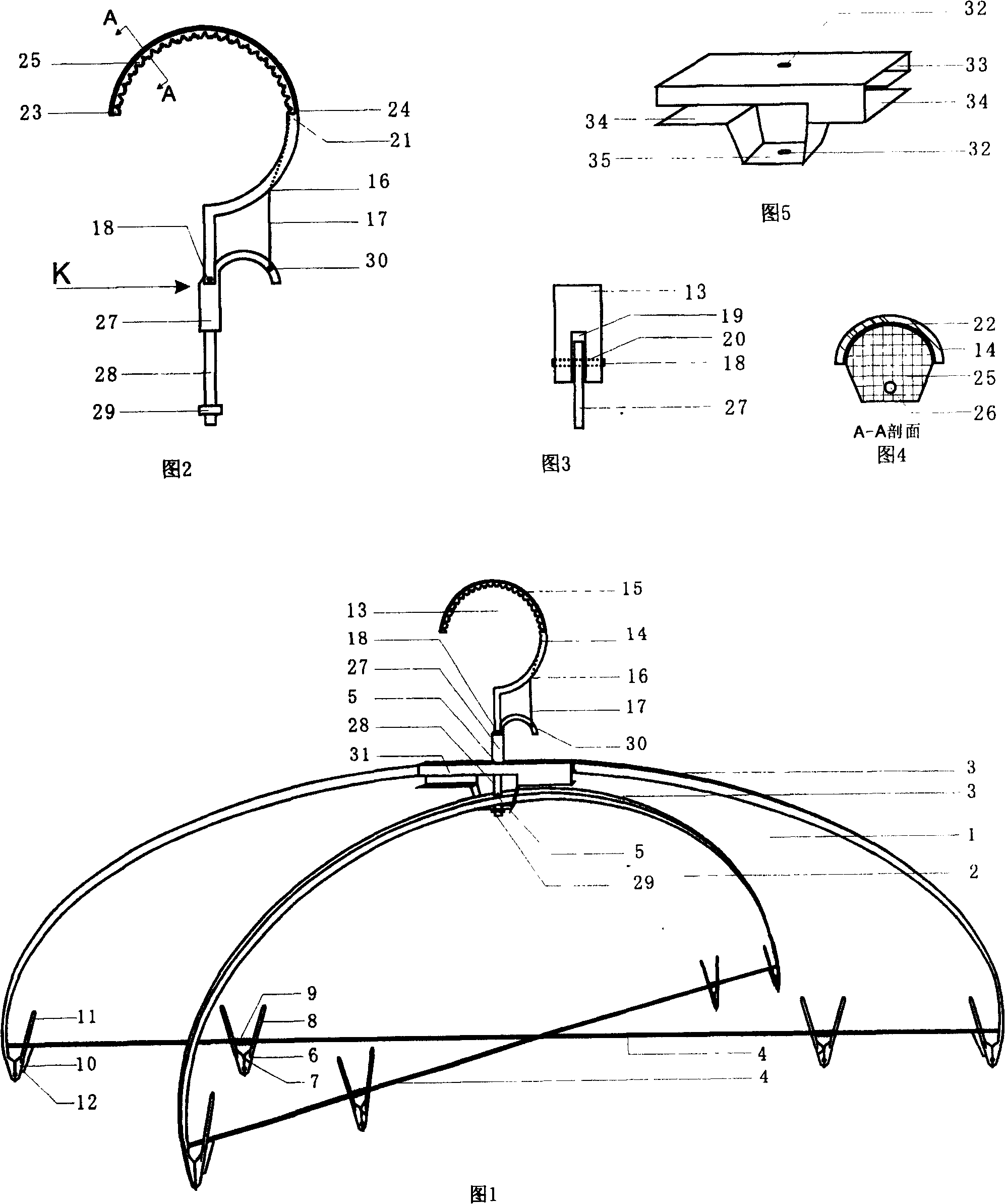

Clotheshorse

A clothes hanger suitable for both clothes and trousers is composed of a big and a small bow-shaped units consisting of a curved supporting bar and a linking bar with clamps, a hook, and a bow-shaped locator for making the small bow-shaped unit is coincident with or perpendicular to the big one.

Owner:饶建明

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com