Intelligent control system for secondary feeding machine for ladle refining furnace

An intelligent control system, the technology of ladle refining furnace, applied in general control system, control/regulation system, program control and other directions, can solve problems such as multiple auxiliary time, data input error, production rhythm influence, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

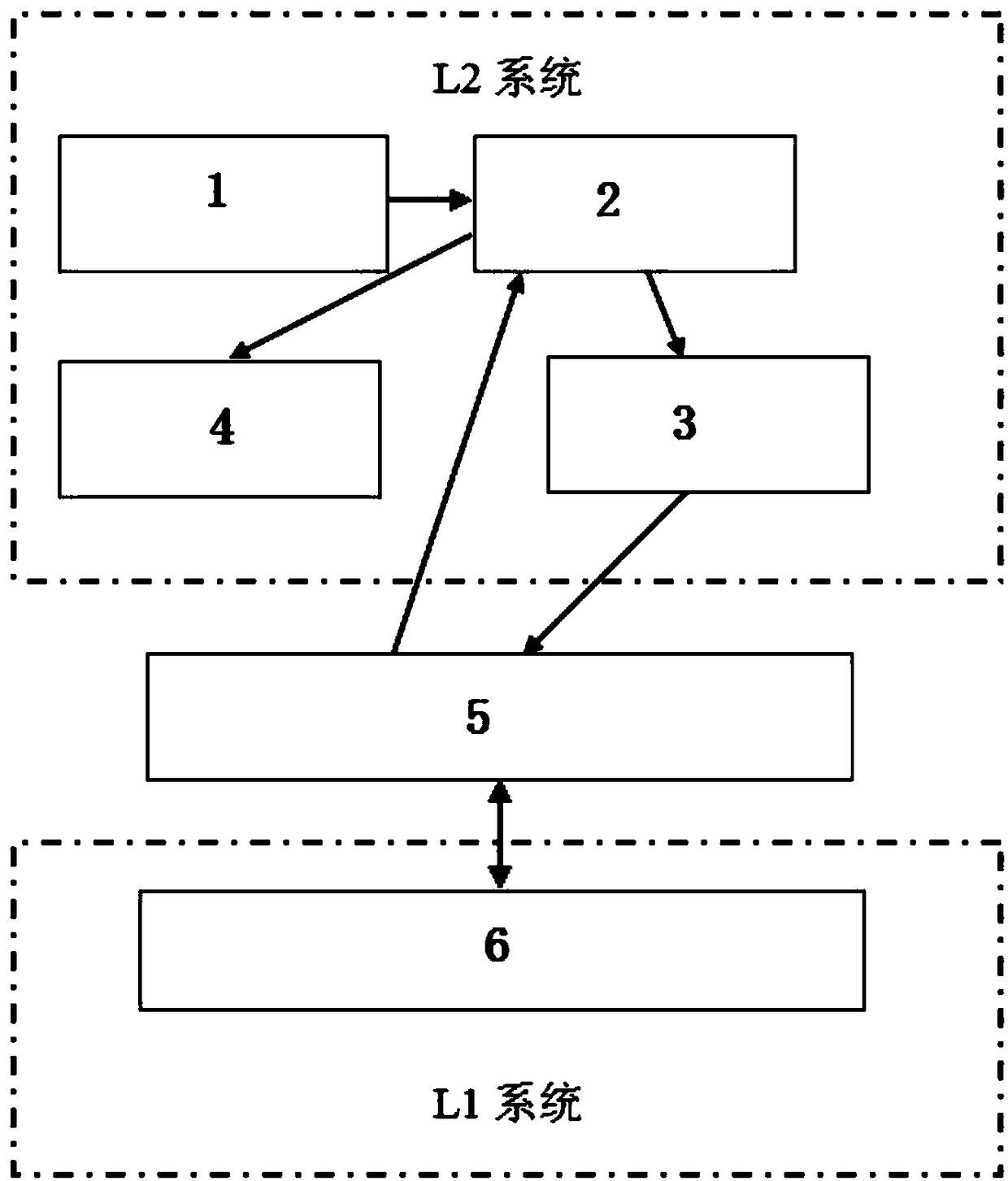

[0149] Embodiment 1: An intelligent control system for the second-stream wire feeder of the ladle refining furnace, including two control systems: the process control system L2 system, which is mainly used for process control, parameter setting, process data collection and storage of production control; basic automation The control system L1 system is mainly used to control the related actions of the equipment through PLC.

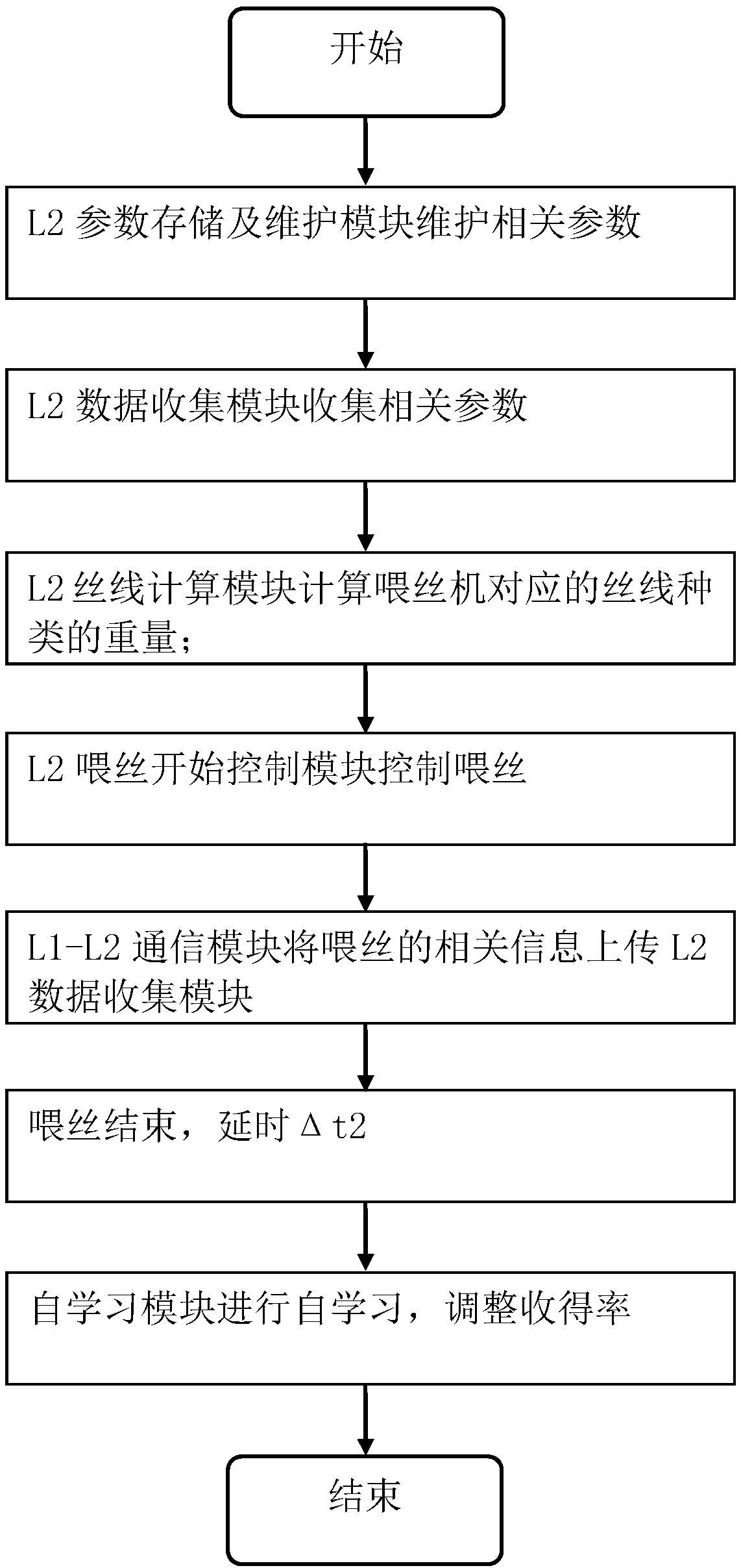

[0150] An intelligent control system for a second-stream wire feeder of a ladle refining furnace, including the following control modules: (1) L2 parameter storage and maintenance module: used for storing and maintaining the types of wires of the wire feeder and related parameters required for calculating the length of the wires; 2) L2 data collection module: used to collect relevant process data of production furnaces; (3) L2 wire calculation module: calculate the required wire feeding amount according to the initial conditions and target requirements of m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com